Patents

Literature

1152 results about "Chemical activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for synthesis of carbon-coated redox materials with controlled size

ActiveUS20040033360A1Low costReduce the numberMaterial nanotechnologyHybrid capacitorsCross-linkRedox

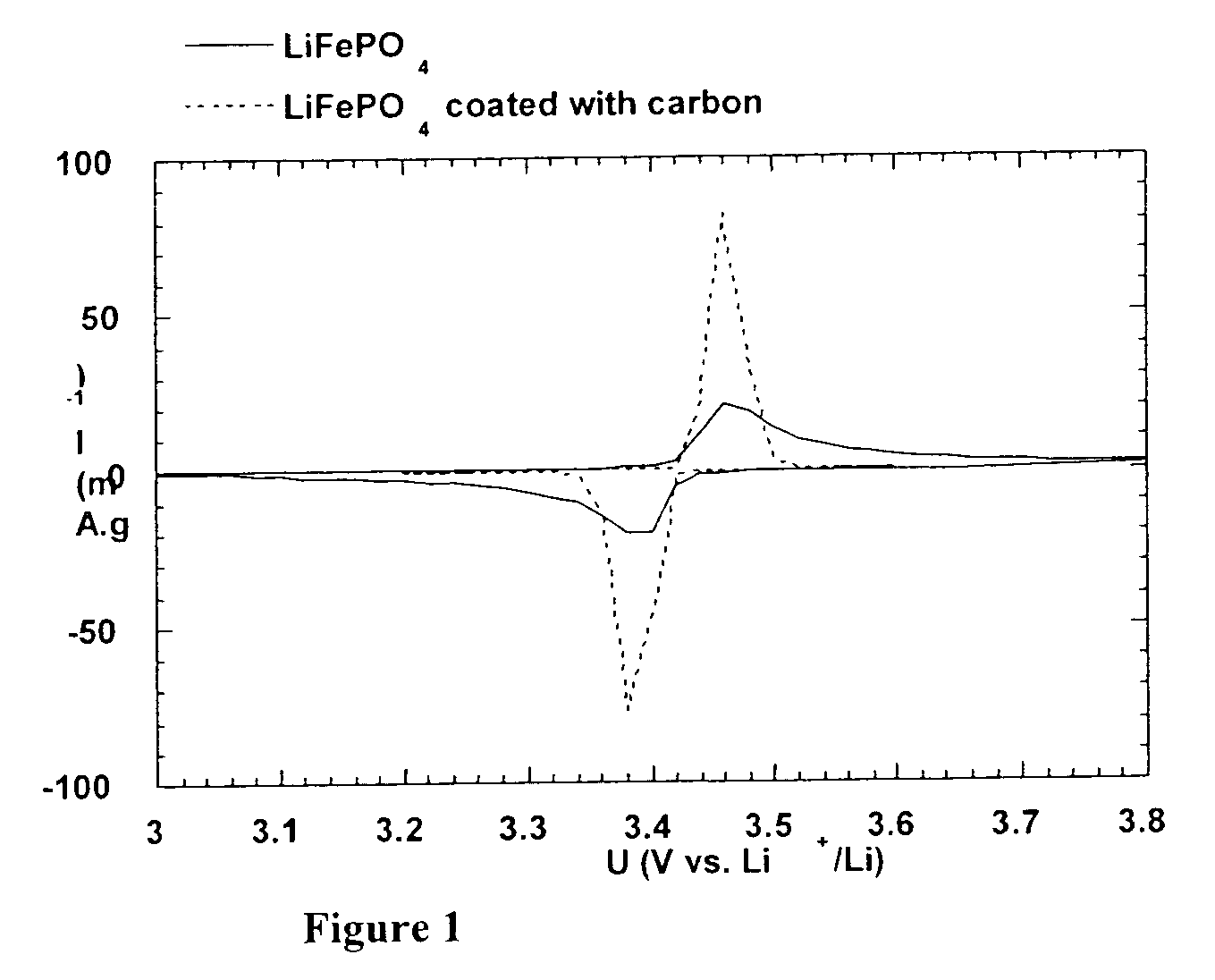

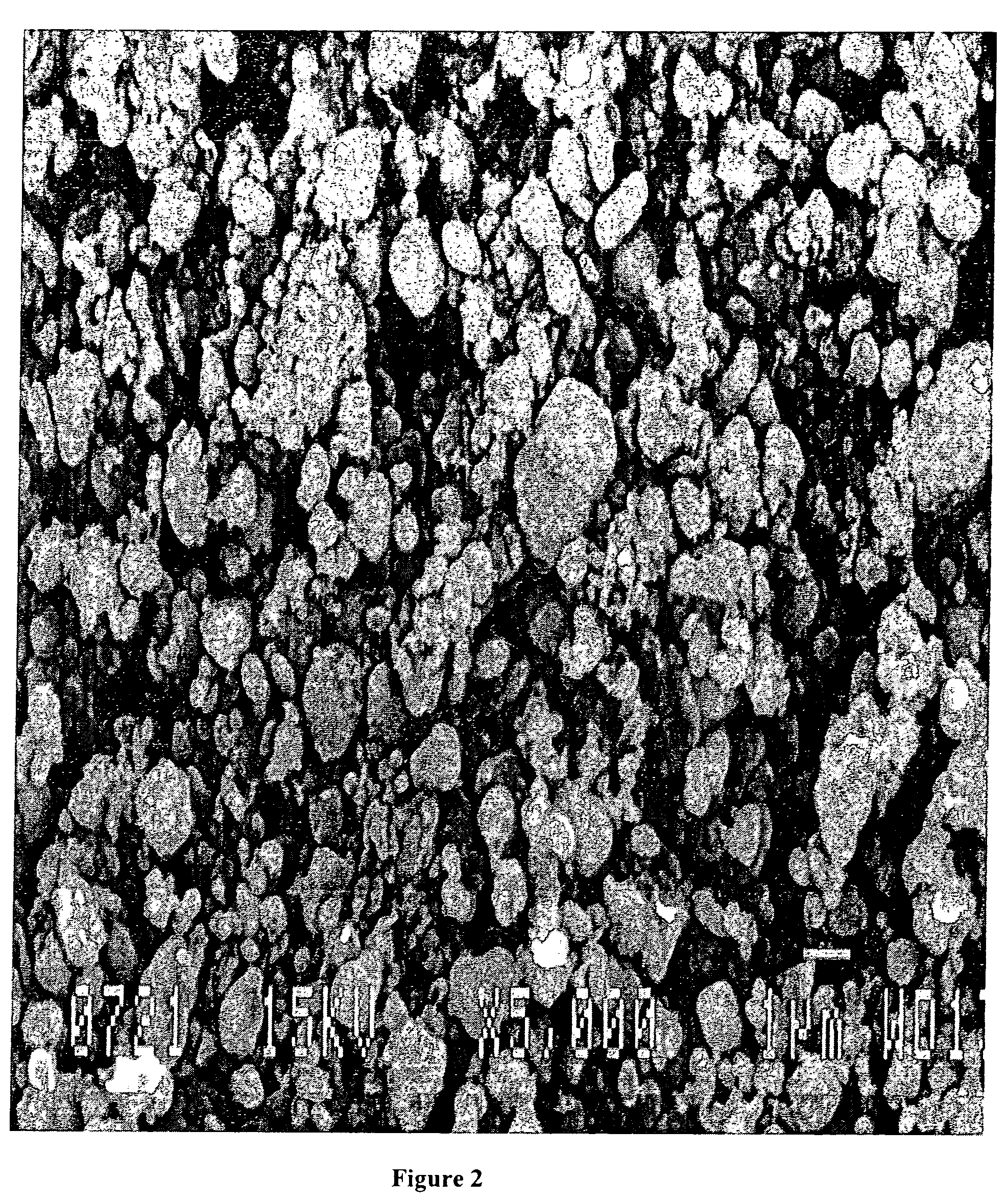

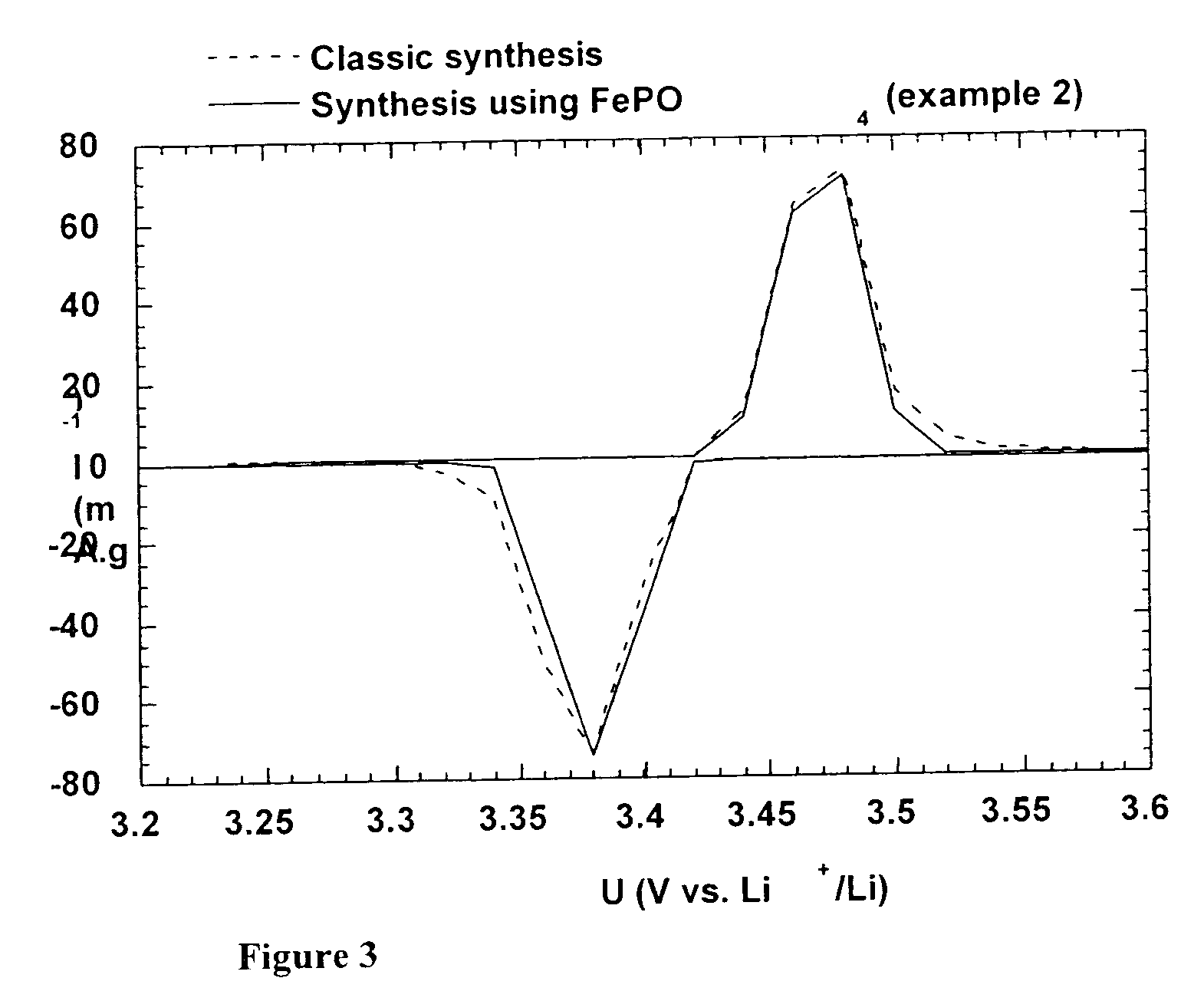

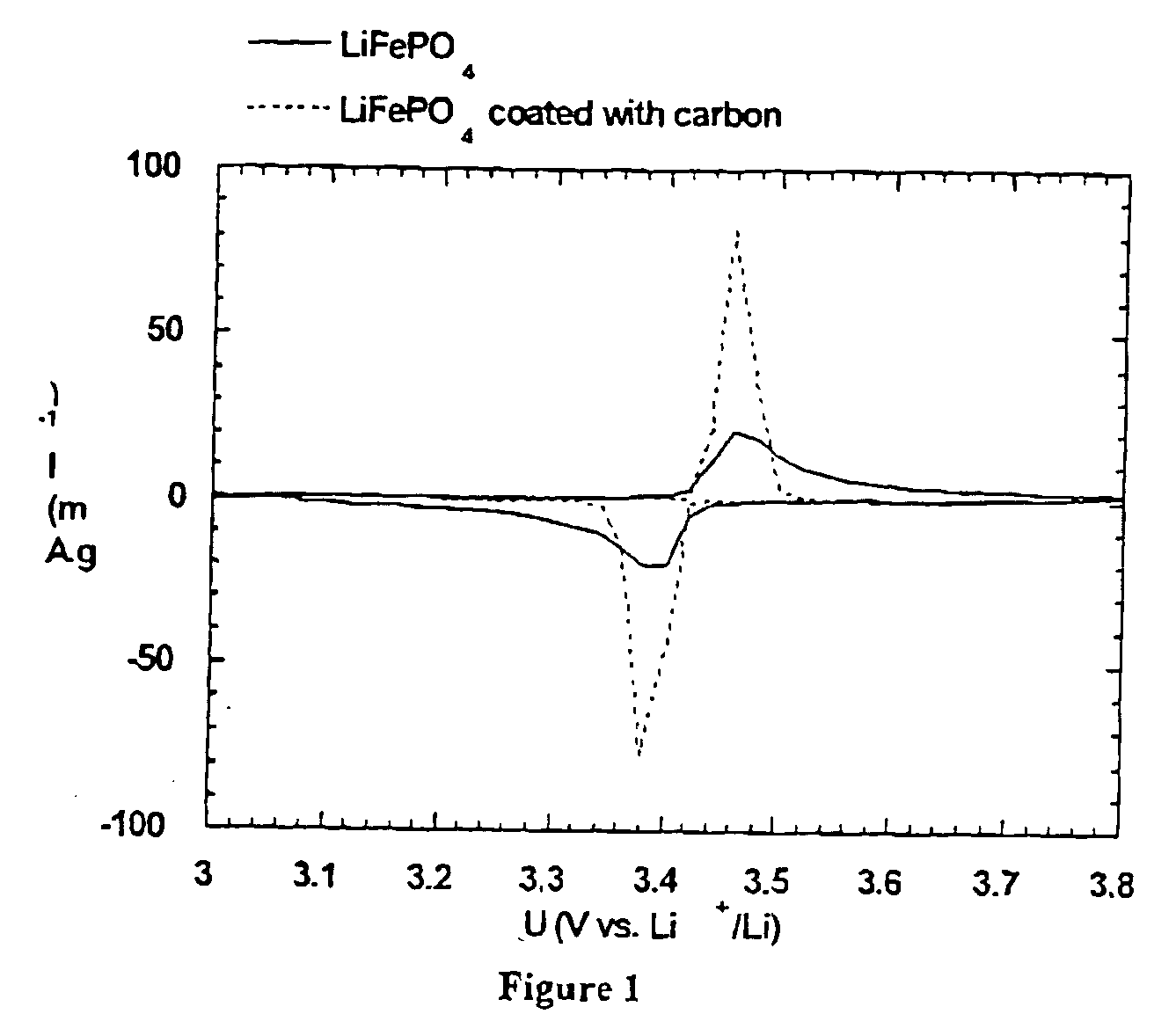

A method for the synthesis of compounds of the formula C-LixM1-yM'y(XO4)n, where C represents carbon cross-linked with the compound LixM1-yM'y(XO4)n, in which x, y and n are numbers such as 0<=x<=2, 0<=y<=0.6, and 1<=n<=1.5, M is a transition metal or a mixture of transition metals from the first period of the periodic table, M' is an element with fixed valency selected among Mg<2+>, Ca<2+>, Al<3+>, Zn<2+> or a combination of these same elements and X is chosen among S, P and Si, by bringing into equilibrium, in the required proportions, the mixture of precursors, with a gaseous atmosphere, the synthesis taking place by reaction and bringing into equilibrium, in the required proportions, the mixture of the precursors, the procedure comprising at least one pyrolysis step of the carbon source compound in such a way as to obtain a compound in which the electronic conductivity measured on a sample of powder compressed at a pressure of 3750 Kg.cm<-2 >is greater than 10<-8 >S.cm<-1>. The materials obtained have excellent electrical conductivity, as well a very improved chemical activity.

Owner:CENT NAT DE LA RECHERCHE SCI +2

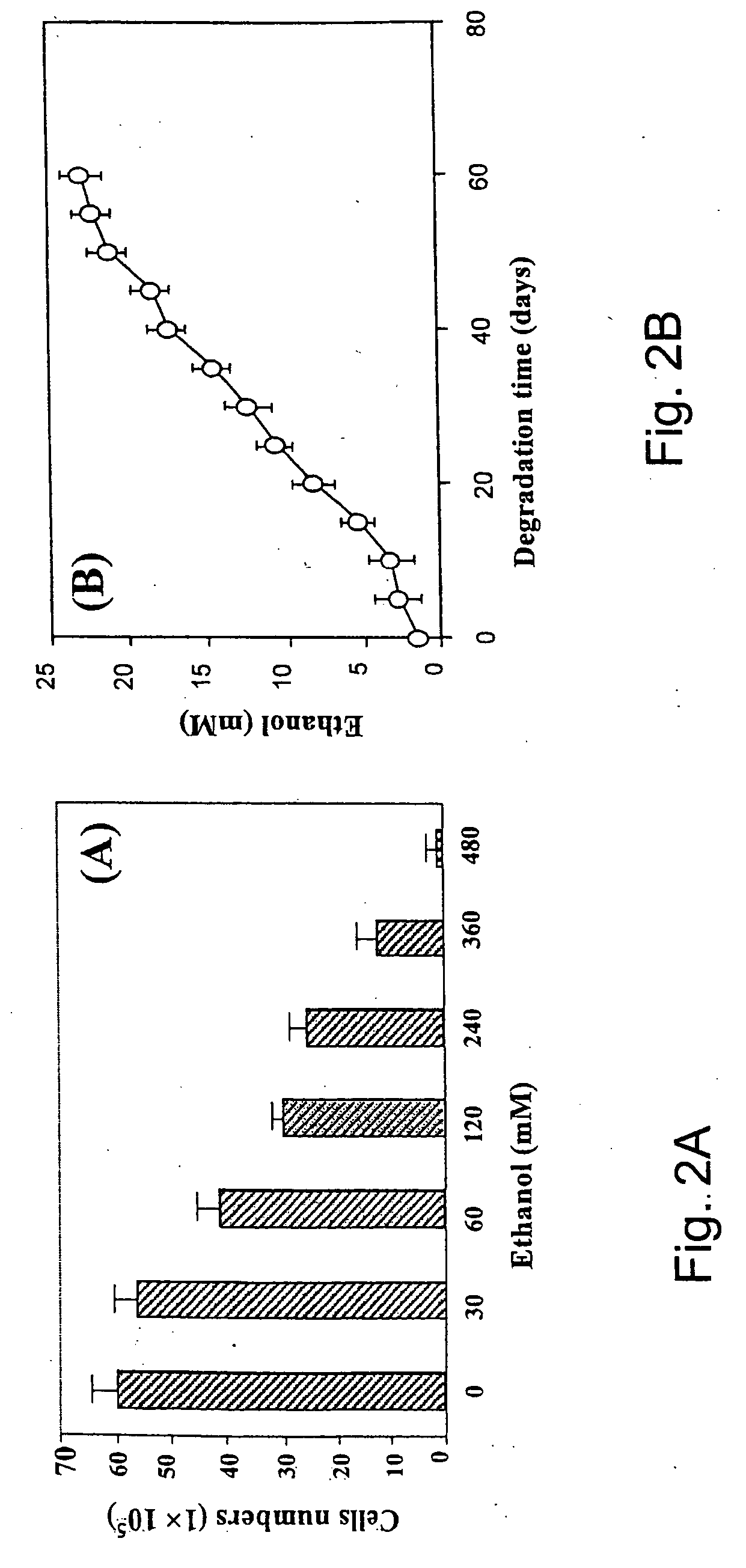

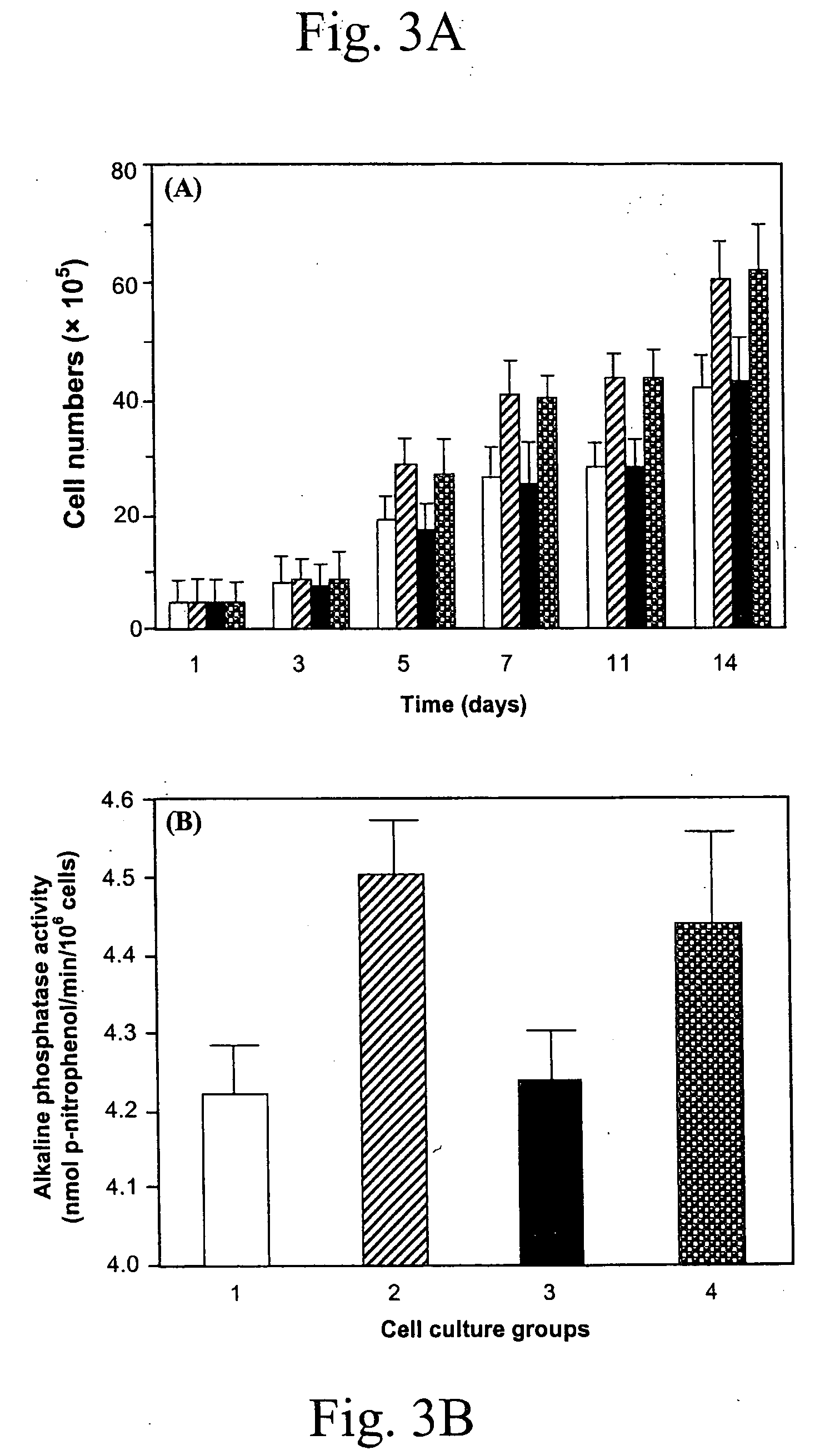

Biodegradable polyurethanes and use thereof

InactiveUS20050013793A1Improve responseIncrease ratingsCell culture supports/coatingSkeletal/connective tissue cellsPolymer scienceDrug biological activity

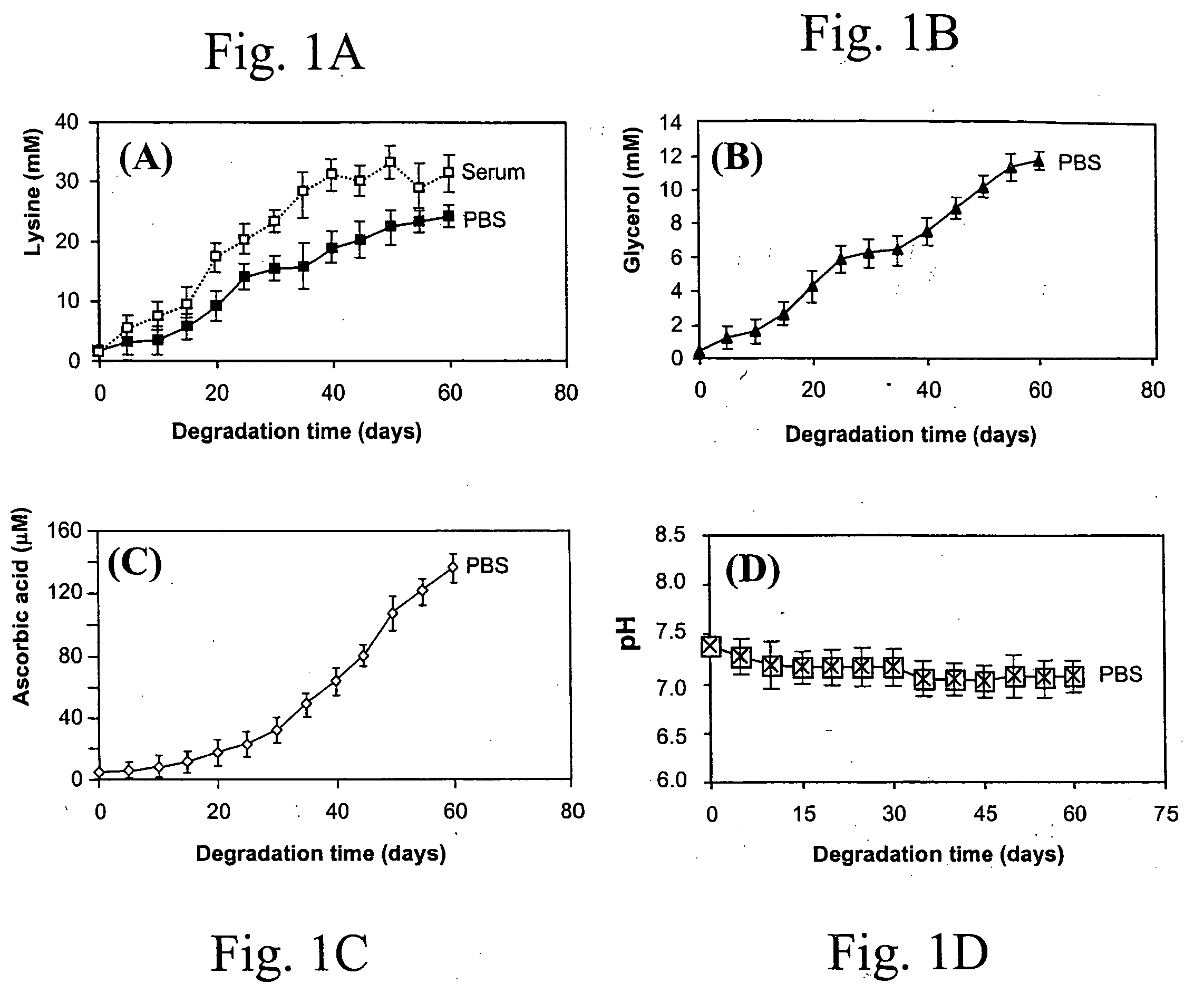

A biodegradable and biocompatible polyurethane composition synthesized by reacting isocyanate groups of at least one multifunctional isocyanate compound with at least one bioactive agent having at least one reactive group —X which is a hydroxyl group (—OH) or an amine group (—NH2). The polyurethane composition is biodegradable within a living organism to biocompatible degradation products including the bioactive agent. Preferably, the released bioactive agent affects at least one of biological activity or chemical activity in the host organism. A biodegradable polyurethane composition includes hard segments and soft segments. Each of the hard segments is preferably derived from a diurea diol or a diester diol and is preferably biodegradable into biomolecule degradation products or into biomolecule degradation products and a biocompatible diol. Another biodegradable polyurethane composition includes hard segments and soft segments. Each of the hard segments is derived from a diurethane diol and is biodegradable into biomolecule degradation products.

Owner:CARNEGIE MELLON UNIV +1

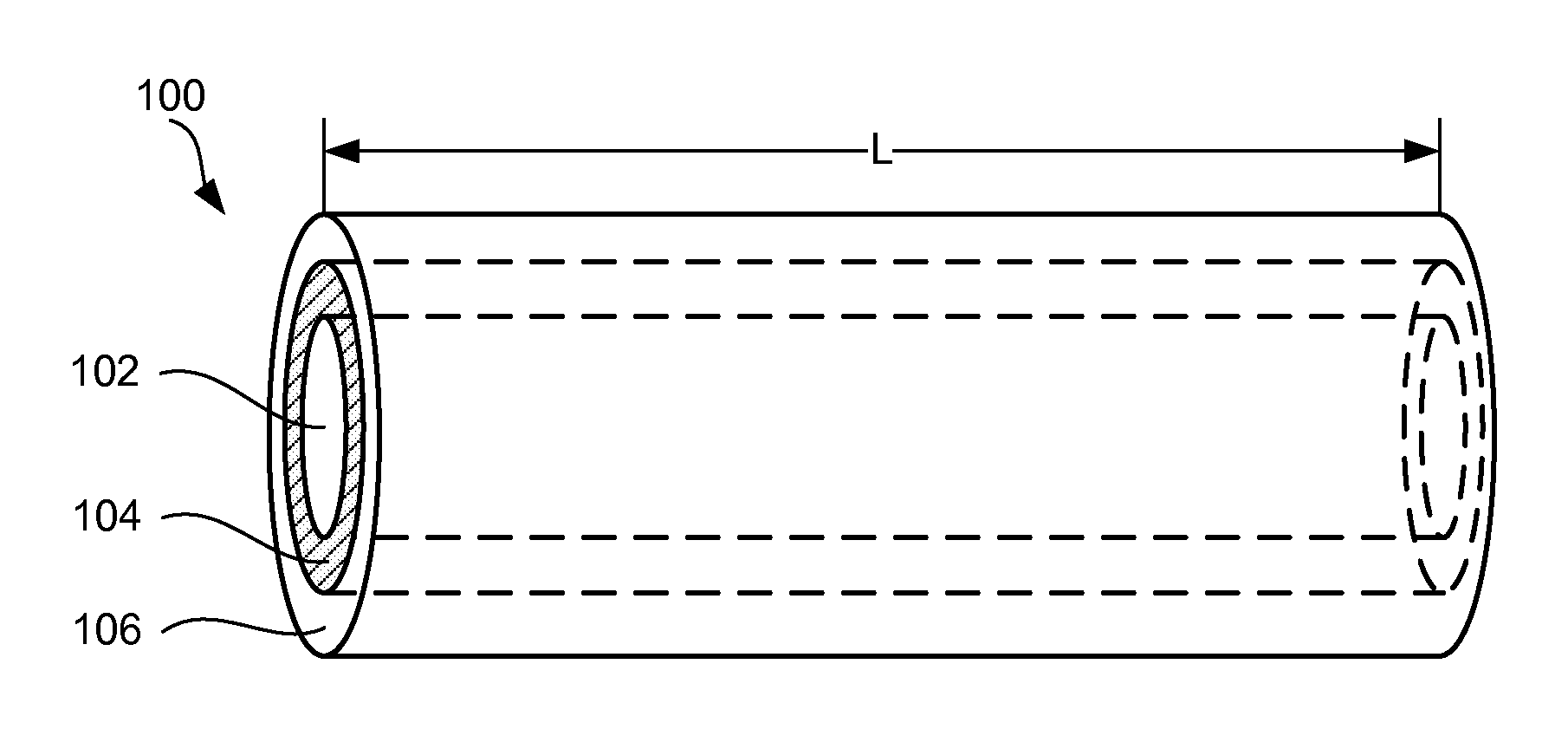

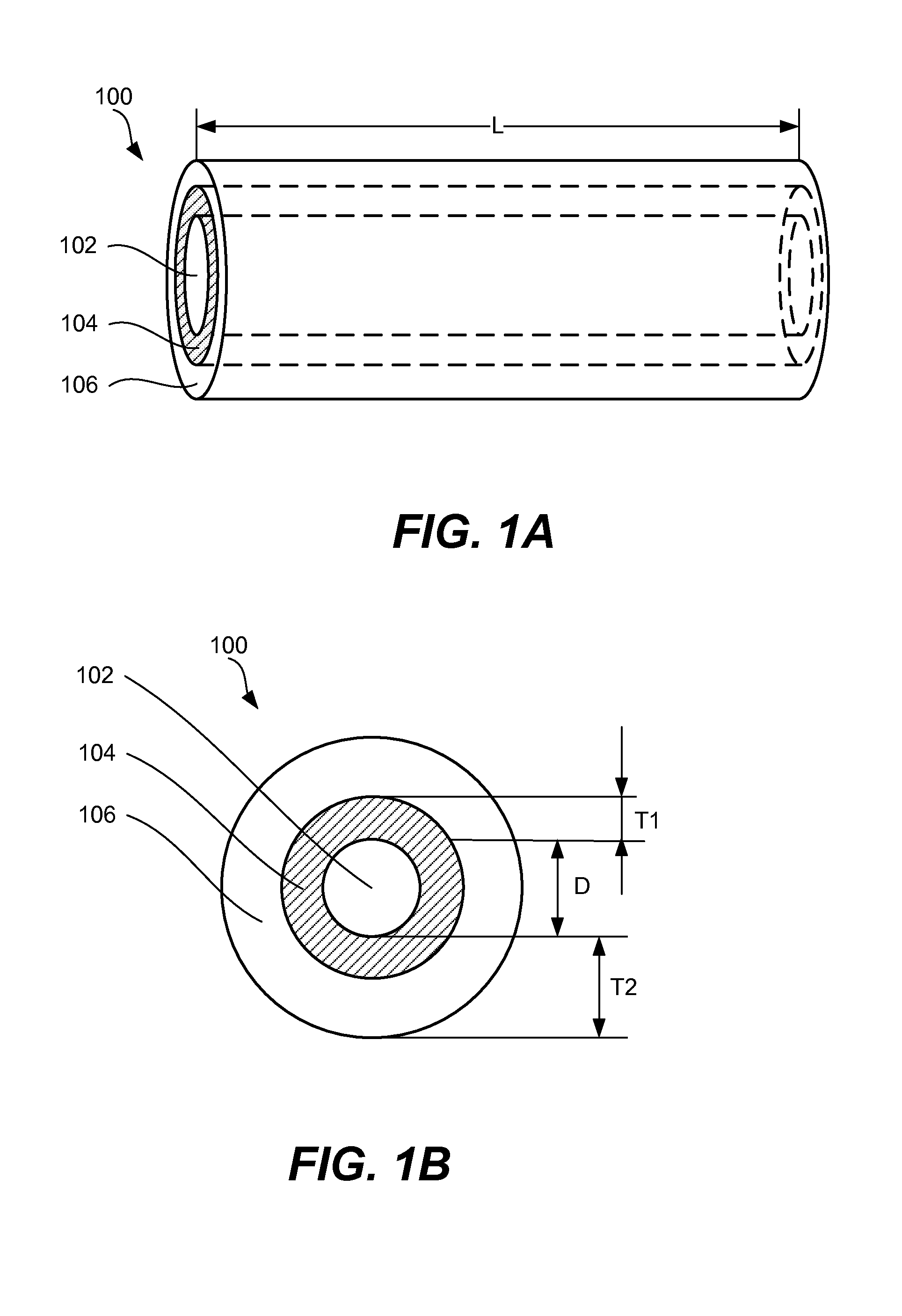

Core-shell high capacity nanowires for battery electrodes

InactiveUS20100330421A1Large capacityInhibition formationMaterial nanotechnologyNanostructure manufactureNanowireElectrochemistry

Provided are nanostructures containing electrochemically active materials, battery electrodes containing these nanostructures for use in electrochemical batteries, such as lithium ion batteries, and methods of forming the nanostructures and battery electrodes. The nanostructures include conductive cores, inner shells containing active materials, and outer shells partially coating the inner shells. The high capacity active materials having a stable capacity of at least about 1000 mAh / g can be used. Some examples include silicon, tin, and / or germanium. The outer shells may be configured to substantially prevent formation of Solid Electrolyte lnterphase (SEI) layers directly on the inner shells. The conductive cores and / or outer shells may include carbon containing materials. The nanostructures are used to form battery electrodes, in which the nanostructures that are in electronic communication with conductive substrates of the electrodes.

Owner:AMPRIUS INC

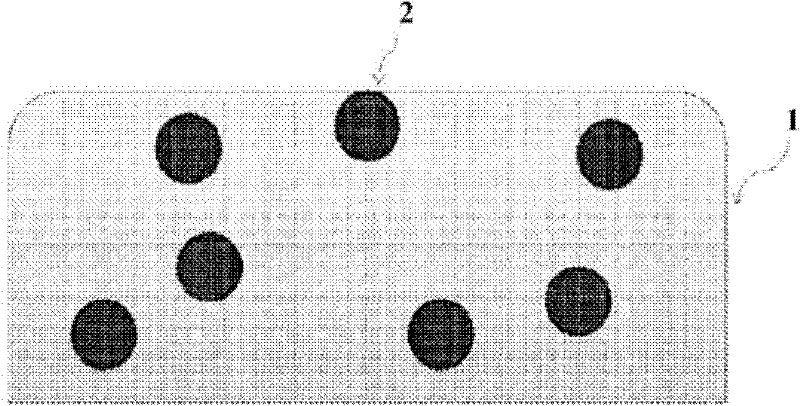

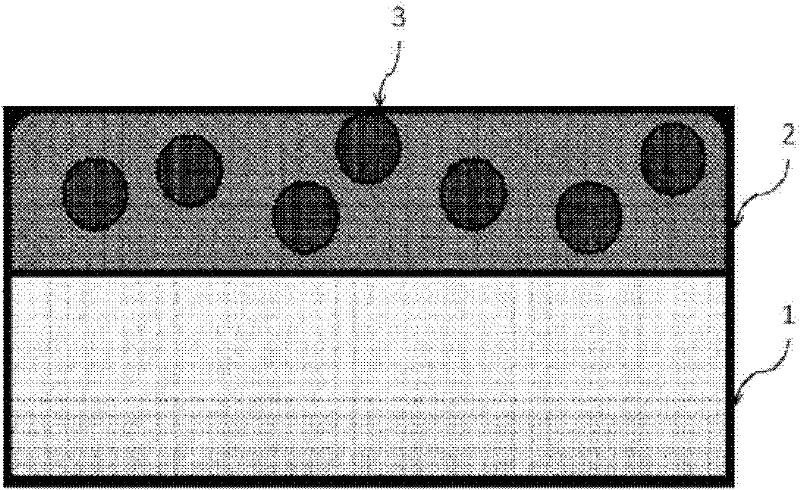

Enhanced surfaces, coatings, and related methods

Disclosed are methods for incorporating additives, such as chemically active particles, into the surfaces of articles or into coatings disposed atop articles. The disclosed methods are also applicable to conventional molding techniques, and can be performed in batch or continuous fashion.

Owner:TPK HLDG

Synthesis method for carbon material based on lixm1-ym'(xo4)n

InactiveUS20040086445A1Improve performanceLow costHybrid capacitorsElectrolytic capacitorsElectrical conductorSynthesis methods

Method of synthesis for a material made of particles having a core and a coating and / or being connected to each other by carbon cross-linking, the core of these particles containing at least one compound of formula LixM1-yM'y(XO4)n, in which x,y and n are numbers such as 0<=x<=2, 0<=y<=0.6 and 1<=n<=1.5, M is a transition metal, M' is an element with fixed valency, and the synthesis is carried out by reaction and bringing into equilibrium the mixture of precursors, with a reducing gaseous atmosphere, in such a way as to bring the transition metal or metals to the desired valency level, the synthesis being carried out in the presence of a source of carbon called carbon conductor, which is subjected to pyrolysis. The materials obtained have excellent electrical conductivity as well as very improved chemical activity.

Owner:CENT NAT DE LA RECHERCHE SCI +2

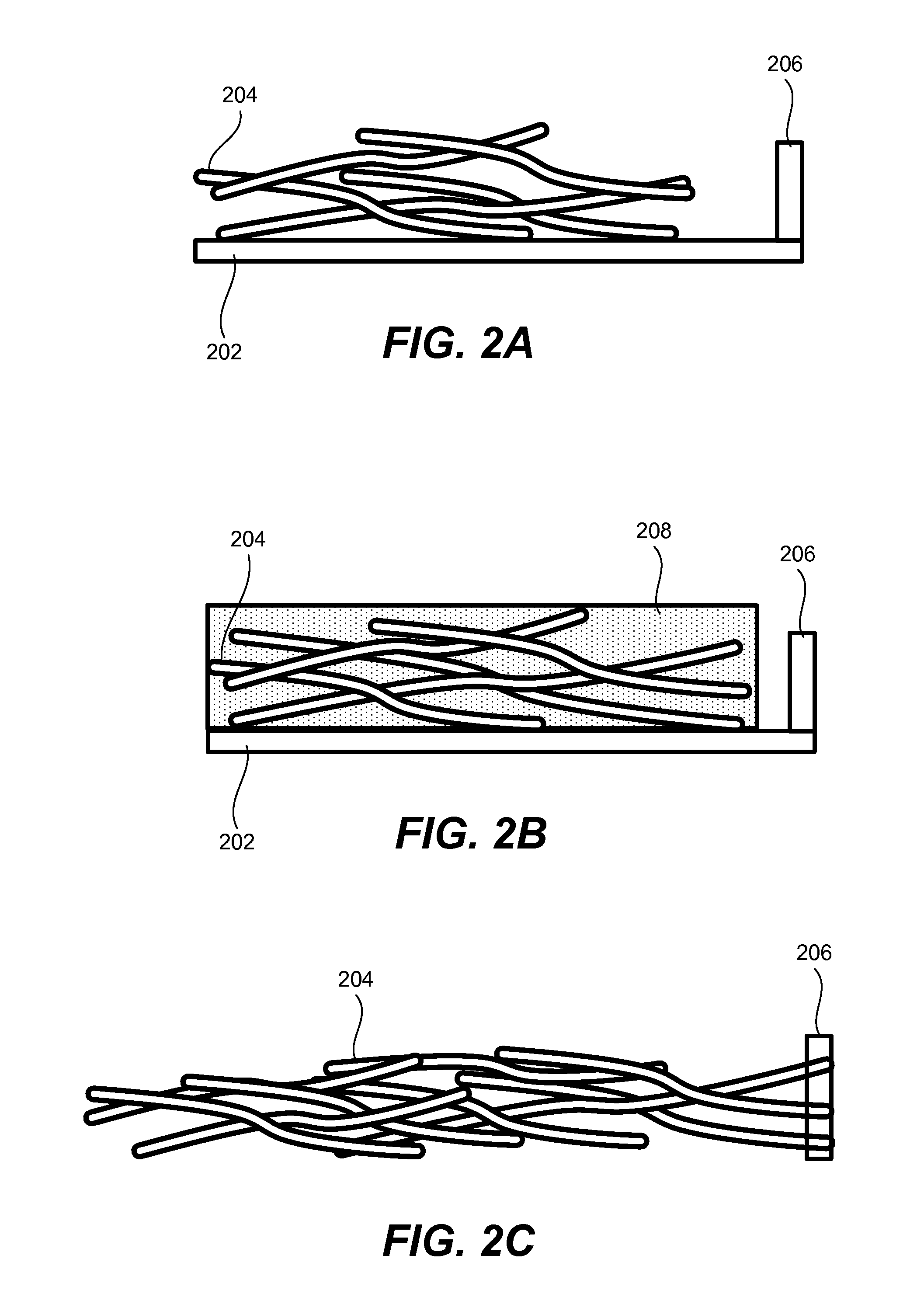

Battery including carbon foam current collectors

InactiveUS6979513B2Electrode manufacturing processesSemi-lead accumulatorsElectrical batteryNanotechnology

Owner:FIREFLY ENERGY INC

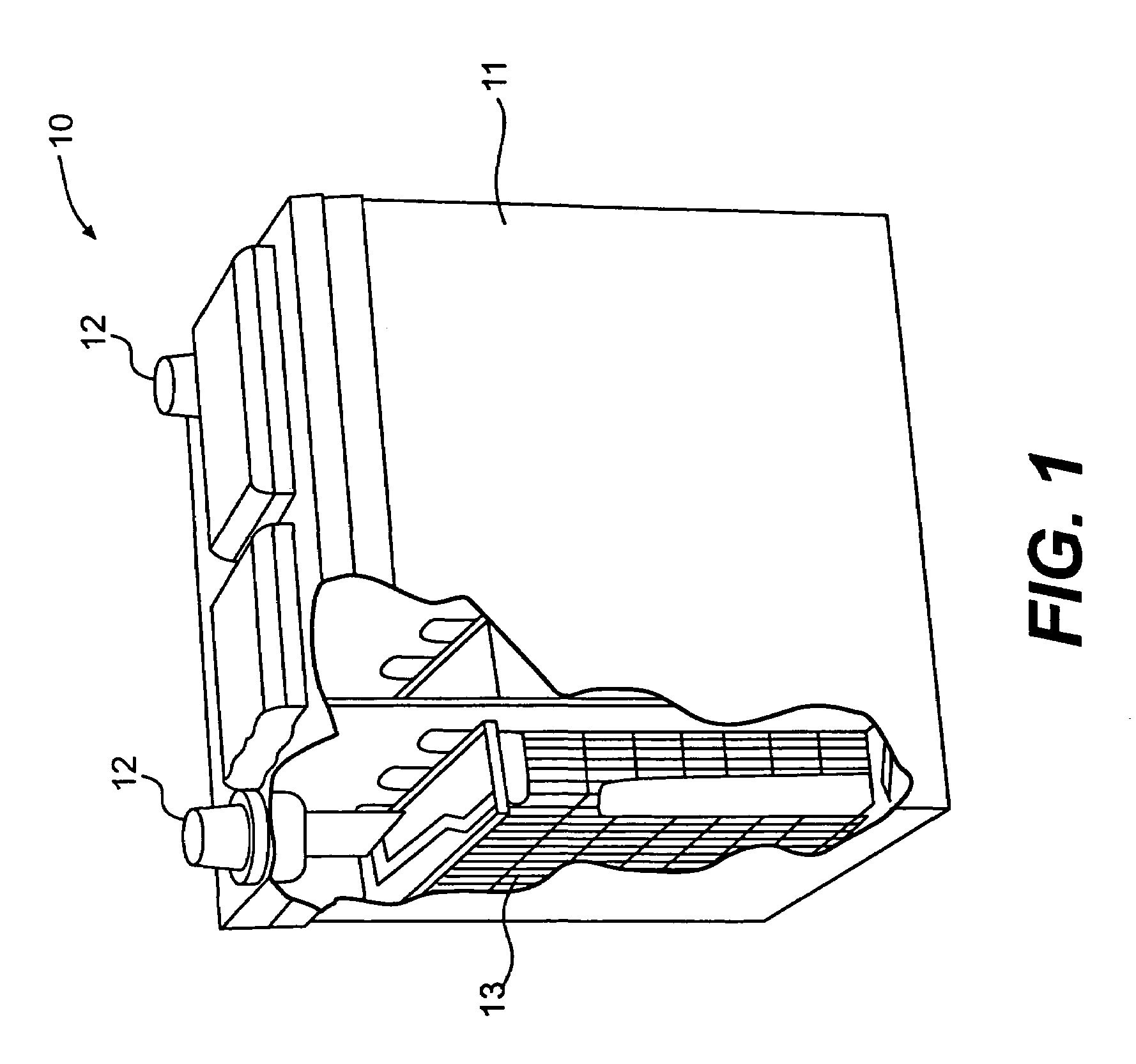

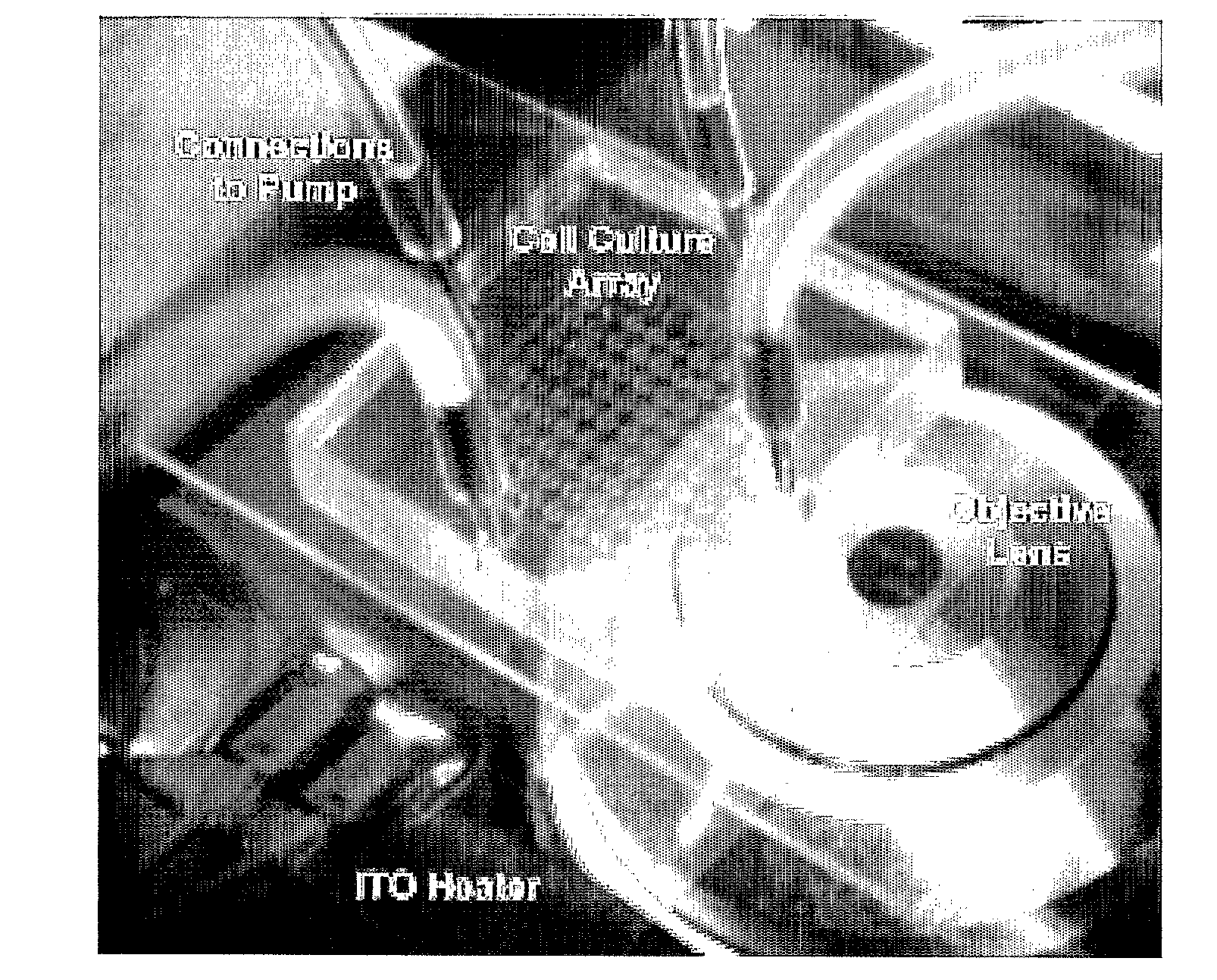

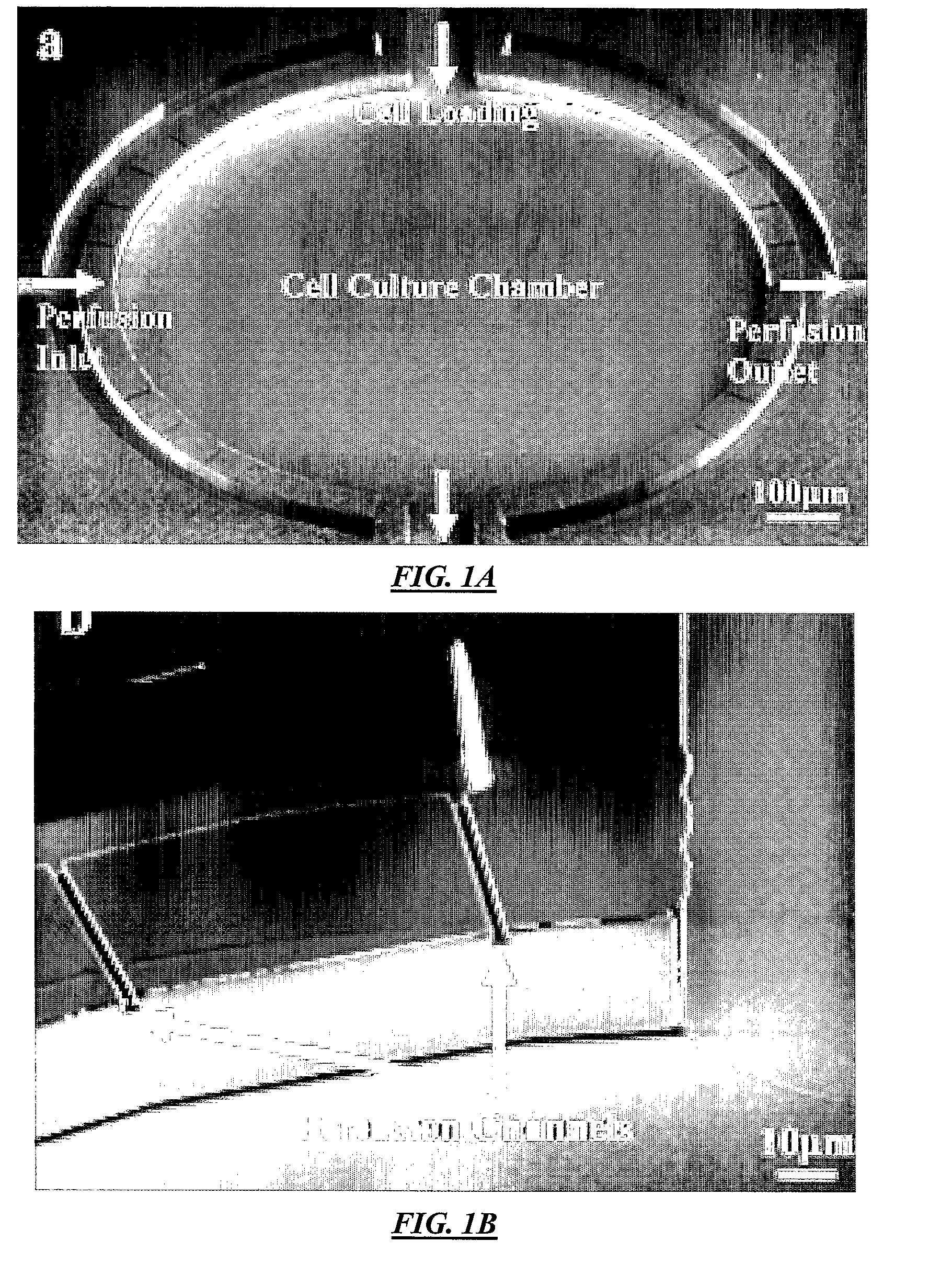

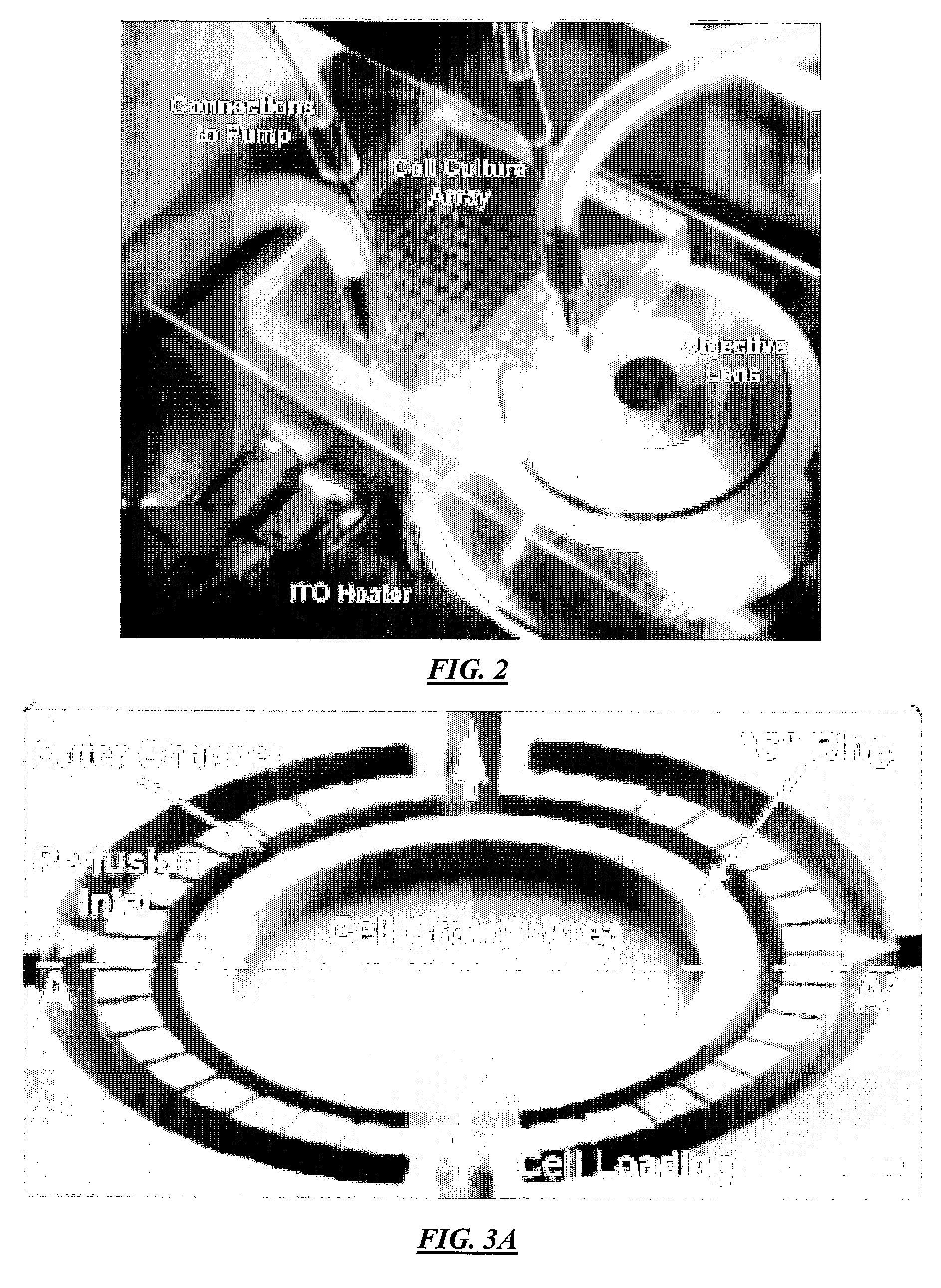

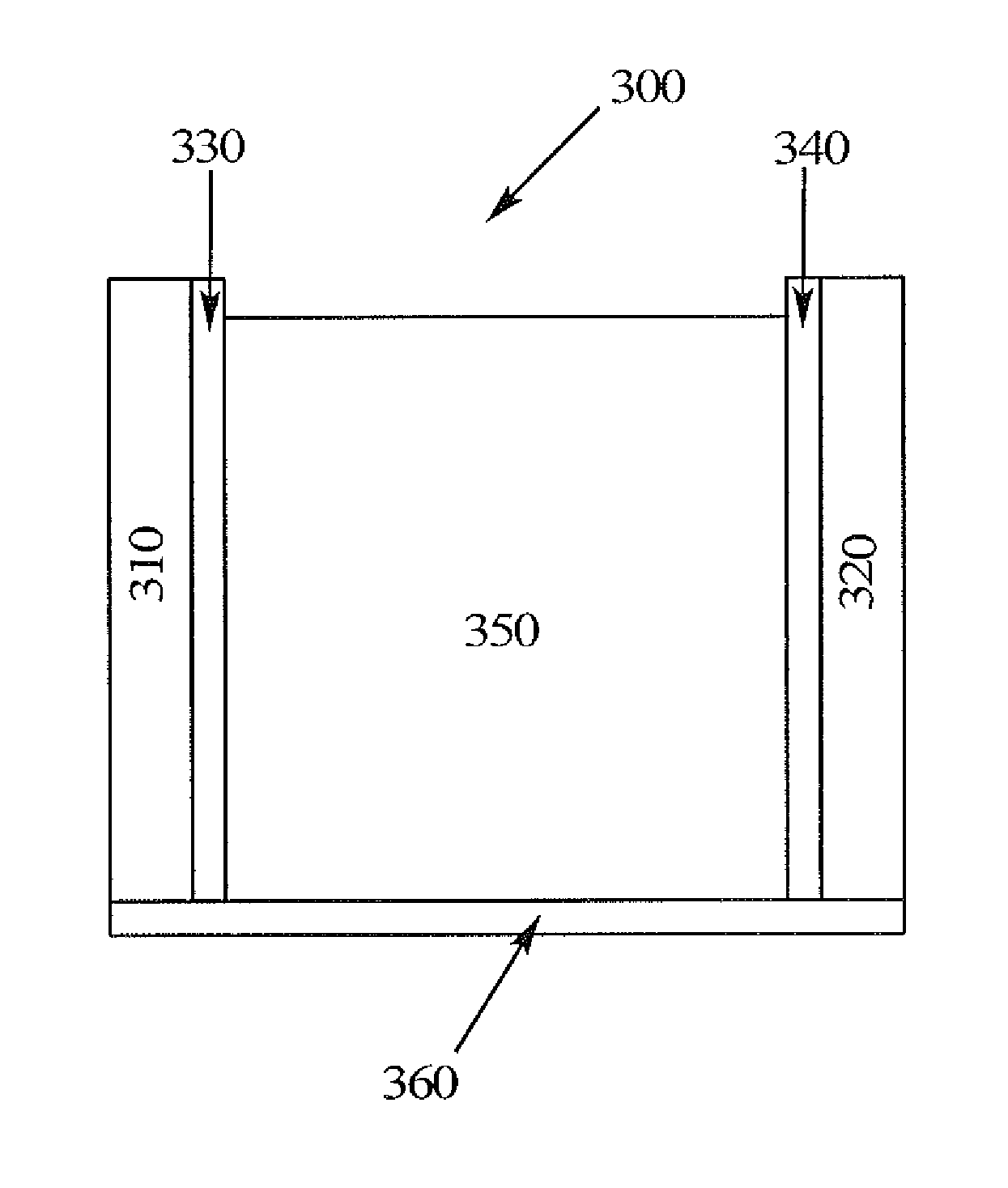

Methods and apparatus for cell culture array

ActiveUS20090023608A1Easy to manufactureIncrease fluid resistanceVertebrate cellsLaboratory glasswaresBiochemistryChemical activity

Owner:RGT UNIV OF CALIFORNIA

Photoalignment materials having improved adhesion

The present disclosure provides for new photoalignment (co)polymer materials which demonstrate improved adhesion to a substrate. The (co)polymeric structure includes at least one photochemically active chromophore and at least one adhesion promoter group. Articles of manufacture, optical elements, ophthalmic elements and liquid crystal cells which include at least one photoalignment layer made from the photoalignment (co)polymer materials and methods for formation are also disclosed.

Owner:TRANSITIONS OPTICAL INC

Method of synthesizing electrochemically active materials from a slurry of precursors

InactiveUS6913855B2Quality improvementHigh-quality materialPhosphatesElectrode thermal treatmentCompound (substance)Slurry

A method for making an active material comprises the steps of forming a slurry, spray drying the slurry to form a powdered precursor composition, and heating the powdered precursor composition at a temperature and for a time sufficient to form a reaction product. The slurry has a liquid phase and a solid phase, and contains at least an alkali metal compound and a transition metal compound. Preferably the liquid phase contains dissolved alkali metal compound, and the solid phase contains an insoluble transition metal compound, an insoluble carbonaceous material compound, or both. Electrodes and batteries are provided that contain the active materials.

Owner:RIL USA INC +1

Assay tools and methods of use

InactiveUS20120129248A1Bioreactor/fermenter combinationsBiological substance pretreatmentsAnalysis toolsImproved method

The present invention provides assay tools for the detection of biological or chemical activity in a sample. The assay tools of the invention provide direct detection using a positive signal generated on a surface of the assay tool. These assay tools provide improved methods for detection and / or identification of multiple agents (e.g., enzymes) in a sample, analysis of substrate specificity of such agents, and binding affinities and specificities of such agents. Upon activity a component is released from a first immobilised construct and then captured by a capture surface. At least two different immobilised constructs are used.

Owner:PROGNOSYS BIOSCI

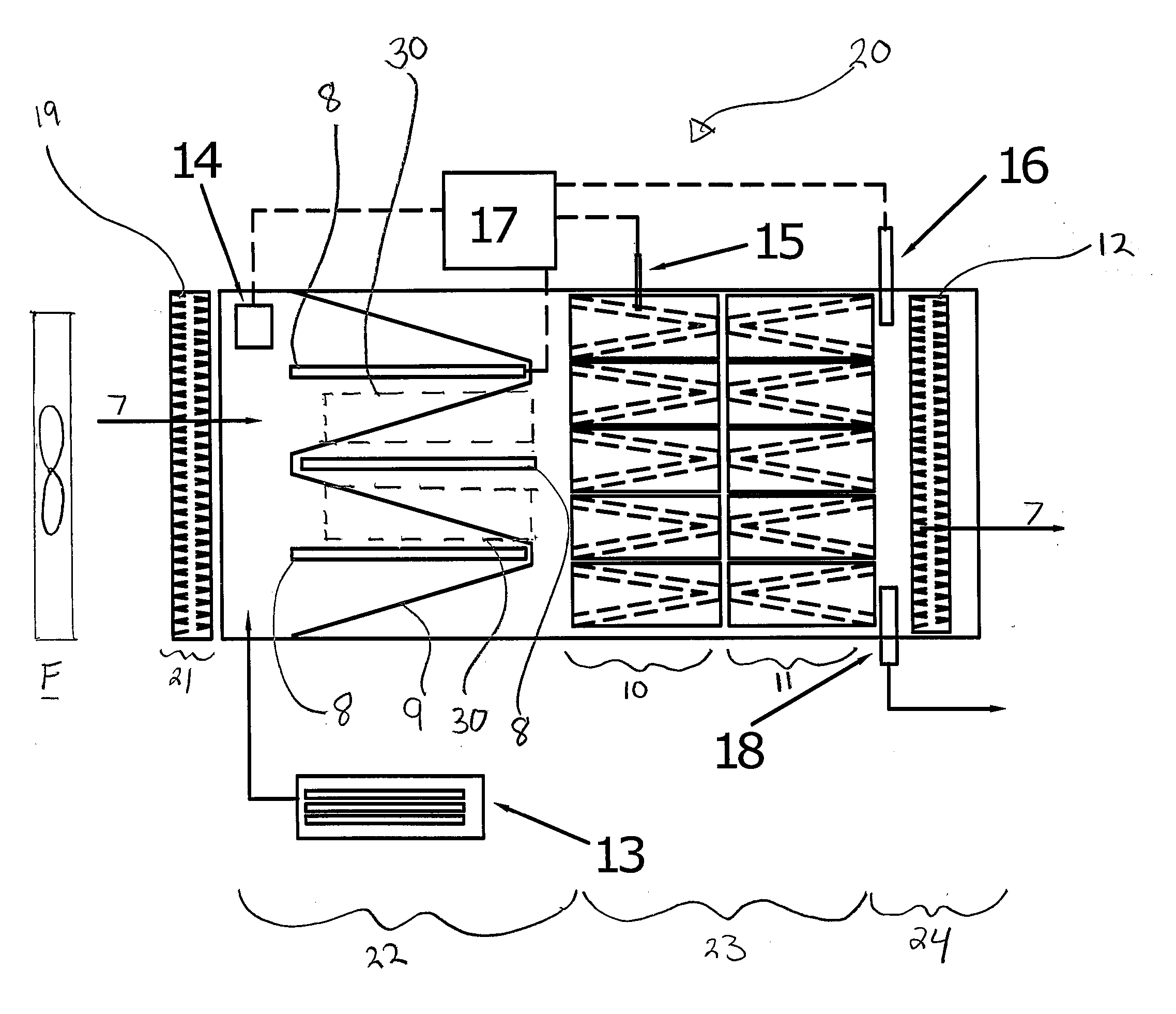

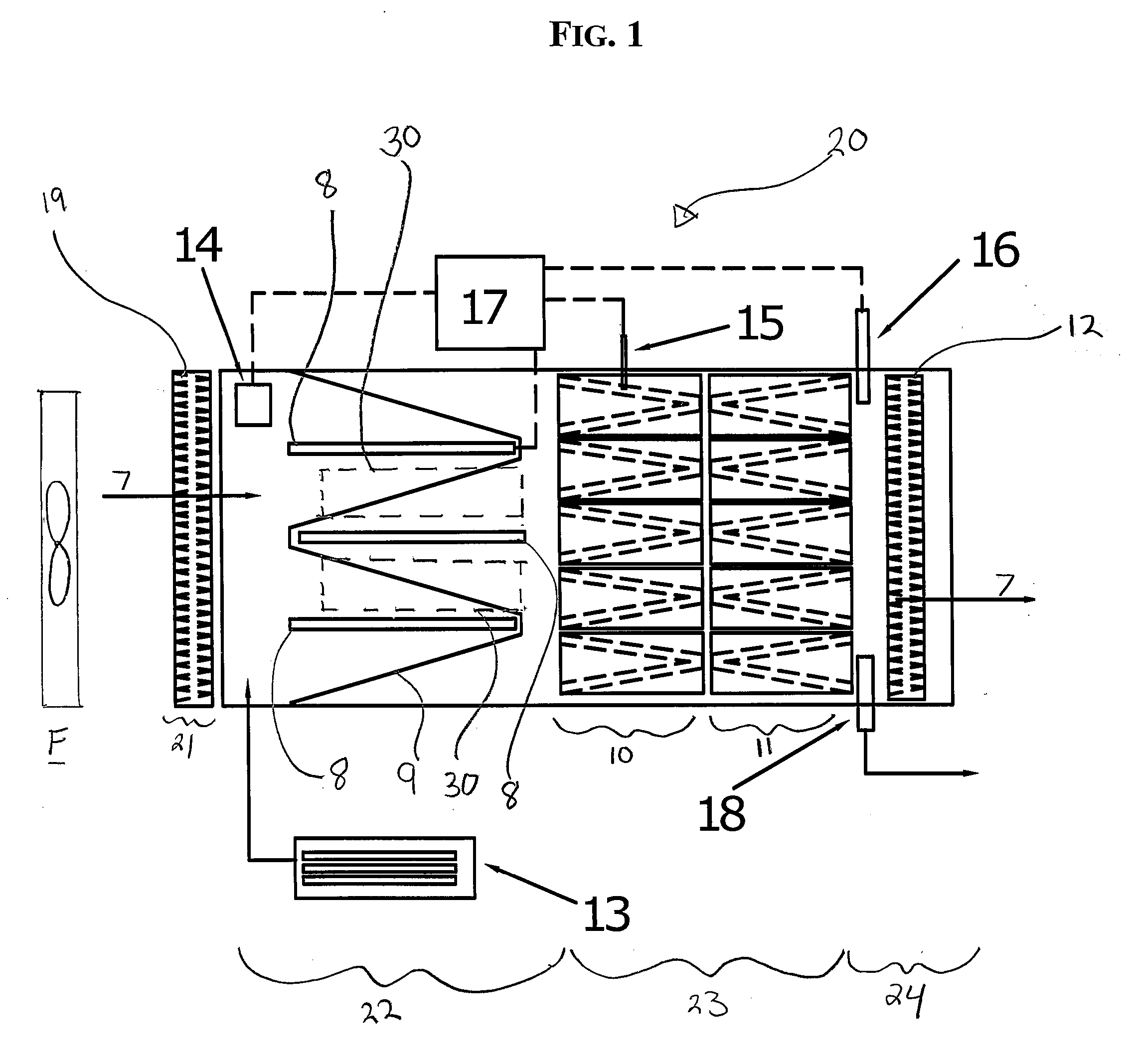

Onsite chemistry air filtration system

ActiveUS20070041882A1Reducing airborne bio-matterLower capability requirementsCombination devicesAuxillary pretreatmentAir filtrationGas phase

An onsite chemistry air filtration system to remove gaseous contaminants from air is disclosed. The onsite chemistry air filtration system of the present invention comprises: a conventional particulate filtration section, a photochemical filtration section, a static gas phase filtration section and a catalytic filtration section. The conventional particulate filtration section captures solids and condensables. In the photochemical filtration section, UV lamps generate bio-destruction and surface photochemical activity on a semiconductor catalyst material, provide a radiation source to irradiate airborne contaminant molecules and to energize their states to promote reactions and generate airborne ozone and radicals. In the static gas phase filtration section, gas phase filtration media is used to capture contaminants, concentrate them in a relatively confined space and allow airborne generated chemistries to concentrate and react in-situ, thereby creating a regeneration effect on the media. In the catalytic filtration section, catalytic media scavenges and converts airborne radicals and ozone to harmless by-products.

Owner:ROSEBERRY JEFFREY L

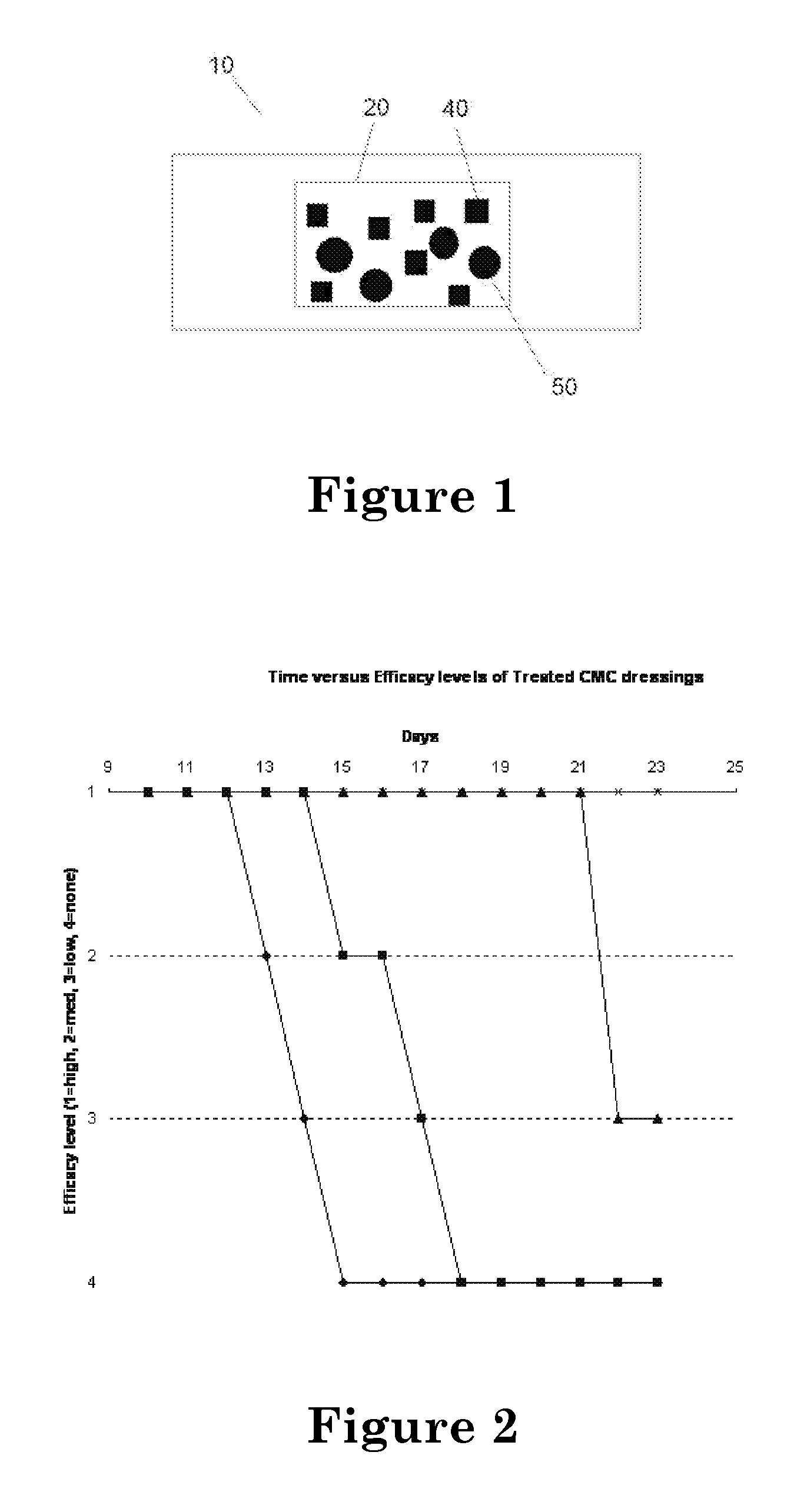

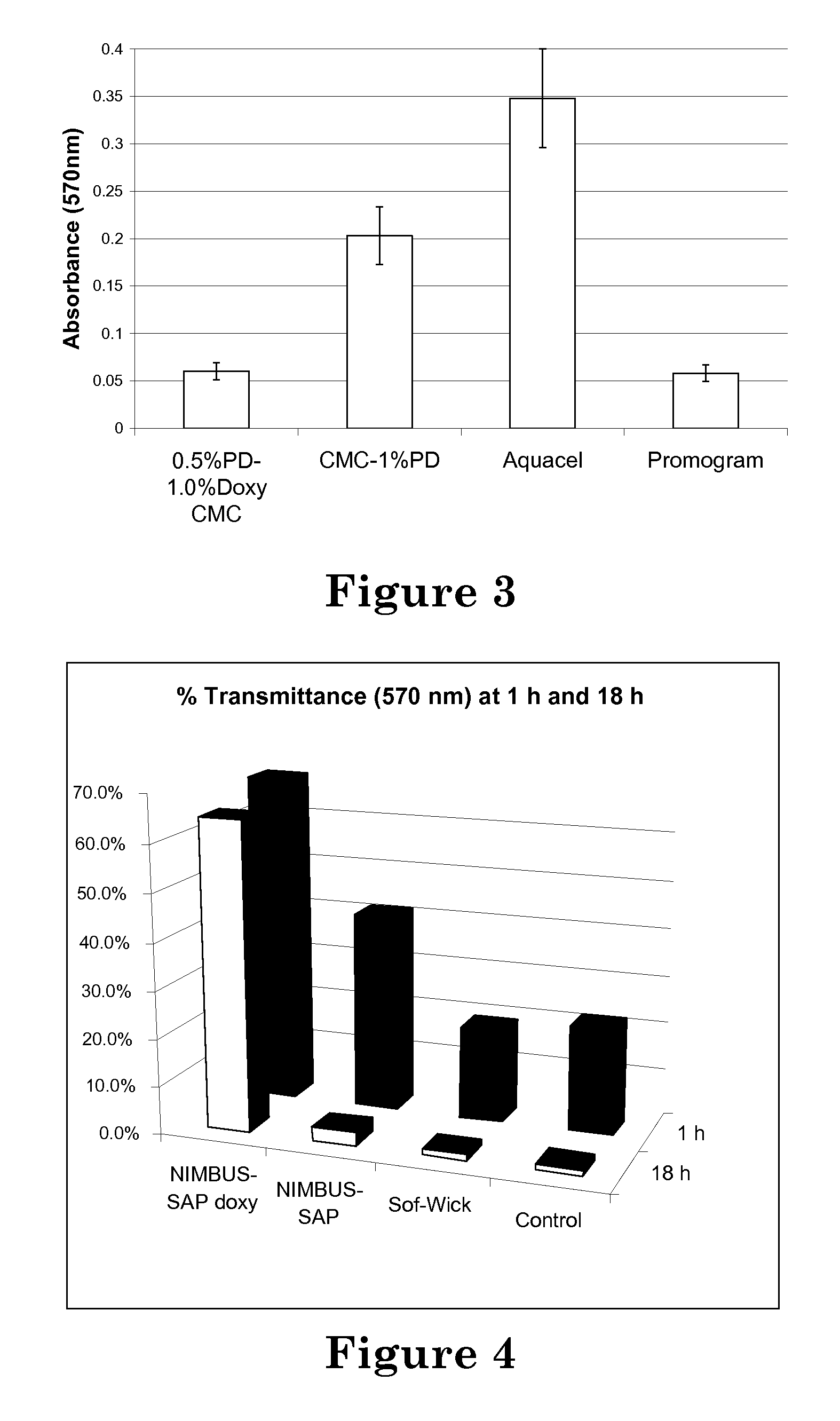

Absorbent substrate with a non-leaching antimicrobial activity and a controlled-release bioactive agent.

This invention relates to antimicrobial wound dressings having a non-leaching antimicrobial activity, releasable antimicrobial and antiprotease agents, and a controlled-release bioactive agent such as doxycycline. The Wound dressing material is absorbent and acts as a substrate for antimicrobial and antiprotease agents as well as bioactive agents. More generally, this invention relates to methods and compositions for materials having a non-leaching coating that has antimicrobial properties. The coating is applied to substrates such as gauze-type wound dressings, powders and other substrates. Covalent, non-leaching, non-hydrolyzable bonds are formed between the substrate and the polymer molecules that form the coating. A high concentration of anti-microbial groups on multi-length polymeric molecules and relatively long average chain lengths, contribute to an absorbent or superabsorbent surface with a high level antimicrobial efficacy. Utilization of non-leaching coatings having a plurality of anionic or cationic sites is used according to this invention to bind a plurality of oppositely charged biologically or chemically active compounds, and to release the bound oppositely charged biologically or chemically active compounds from said substrate over a period of time to achieve desired objectives as diverse as improved wound healing to reduction in body odor.

Owner:QUICK MED TECH +1

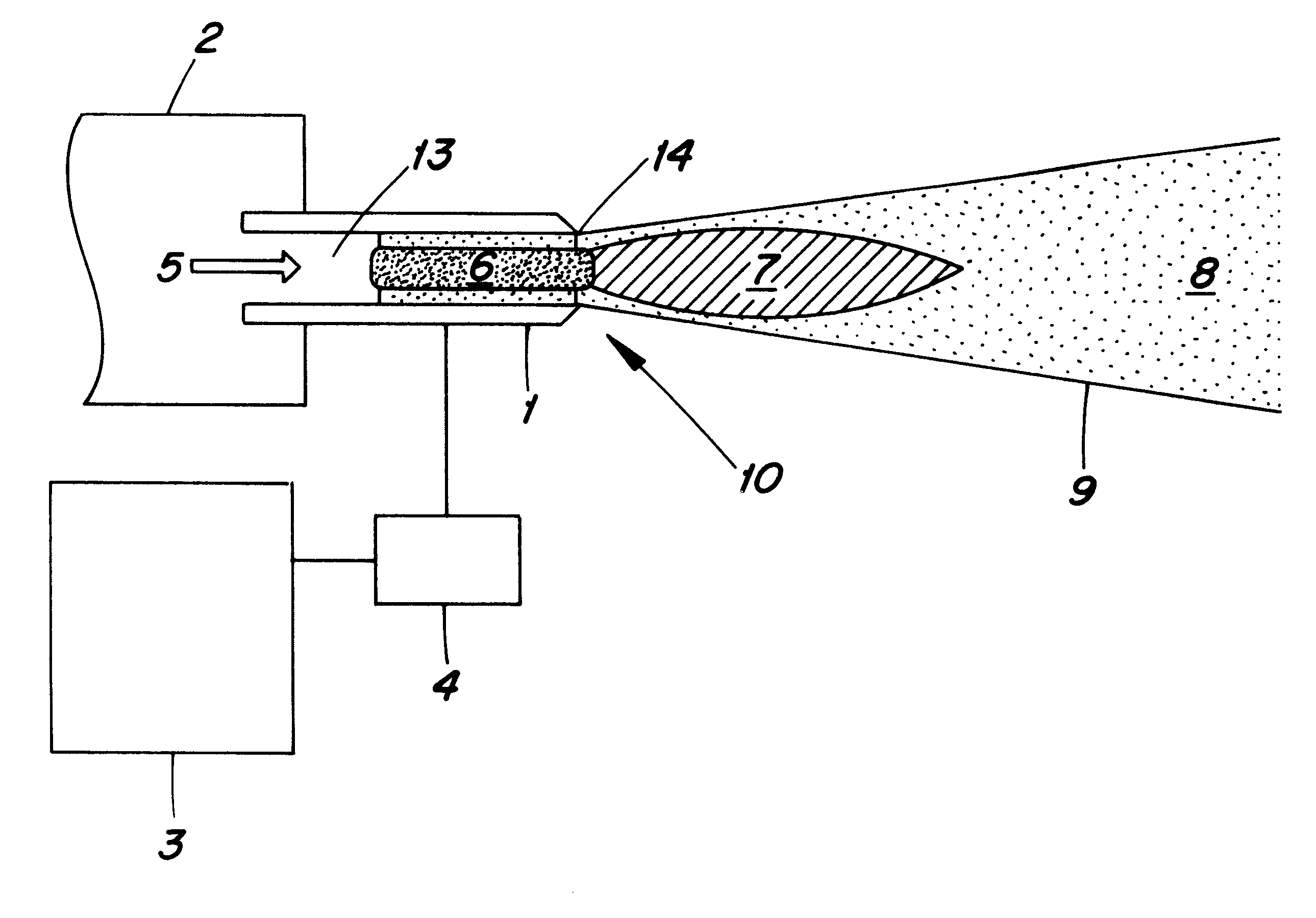

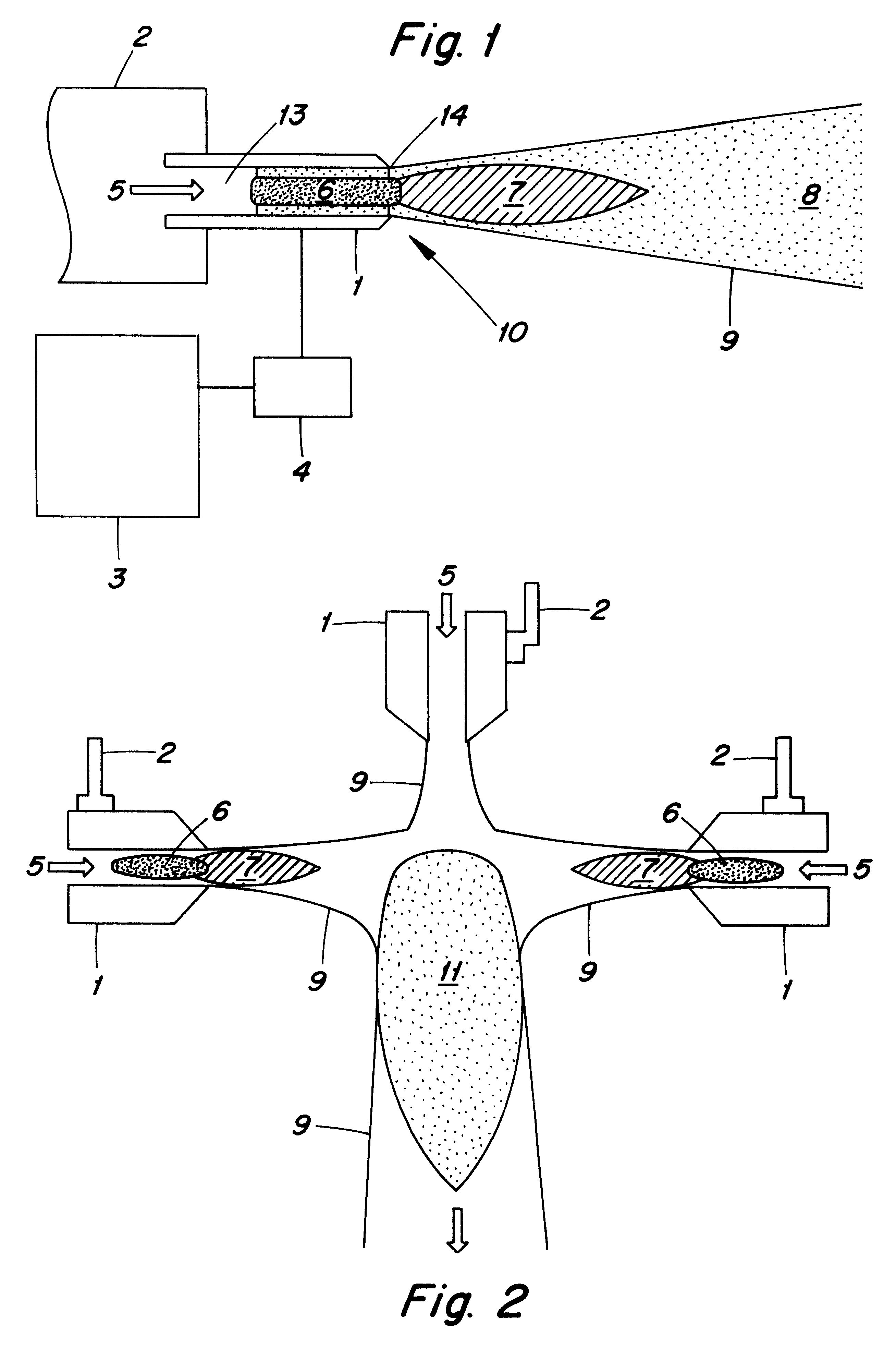

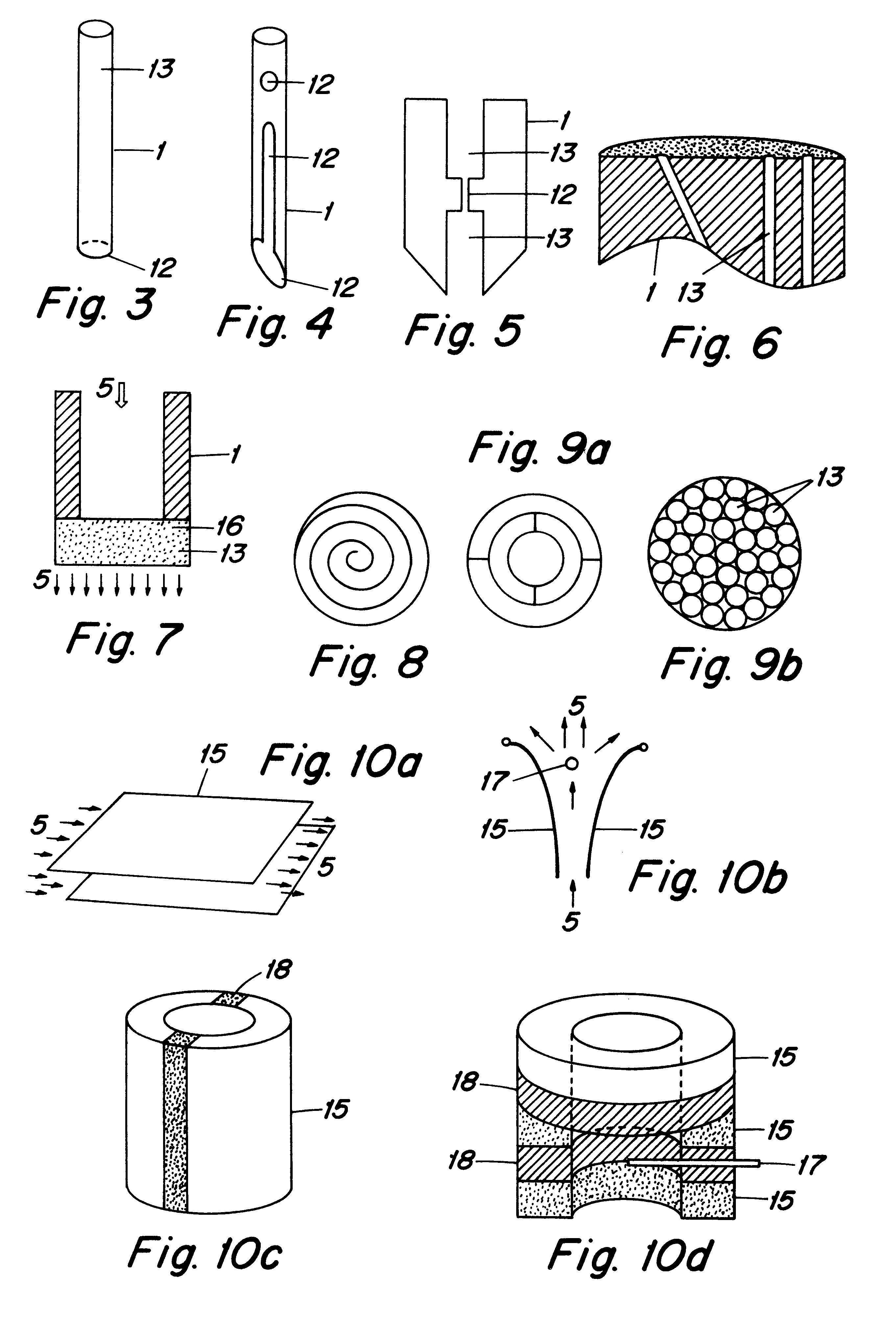

Method of making a physically and chemically active environment by means of a plasma jet and the related plasma jet

The method consists in the fact that from at least one external source (3) electromagnetic energy is conducted to at least one hollow electrode (1) with elements (14) locally increasing the density of electromagnetic energy, by which, inside the cavities of the electrode (1) and / or at its orifice and in the external environment an intensive discharge is generated. The plasma jet consists of at least one hollow electrode (1) of conductive or conductive and dielectric material with at least one element (14) locally increasing the density of electromagnetic energy inside the hollow electrode (1) and / or at its orifice and / or outside, which consists of a design element (12) and / or a physical element (17) acting in the transversal and / or the longitudinal direction with respect to the streaming working medium (5) and is further constituted by at least one source (3) or electromagnetic energy attached via the impedance adapting member (4) consisting of a system of regulatory transformation and transfer elements, onto the conductive part of the hollow electrode (1).

Owner:MASARYK UNIVERSITY

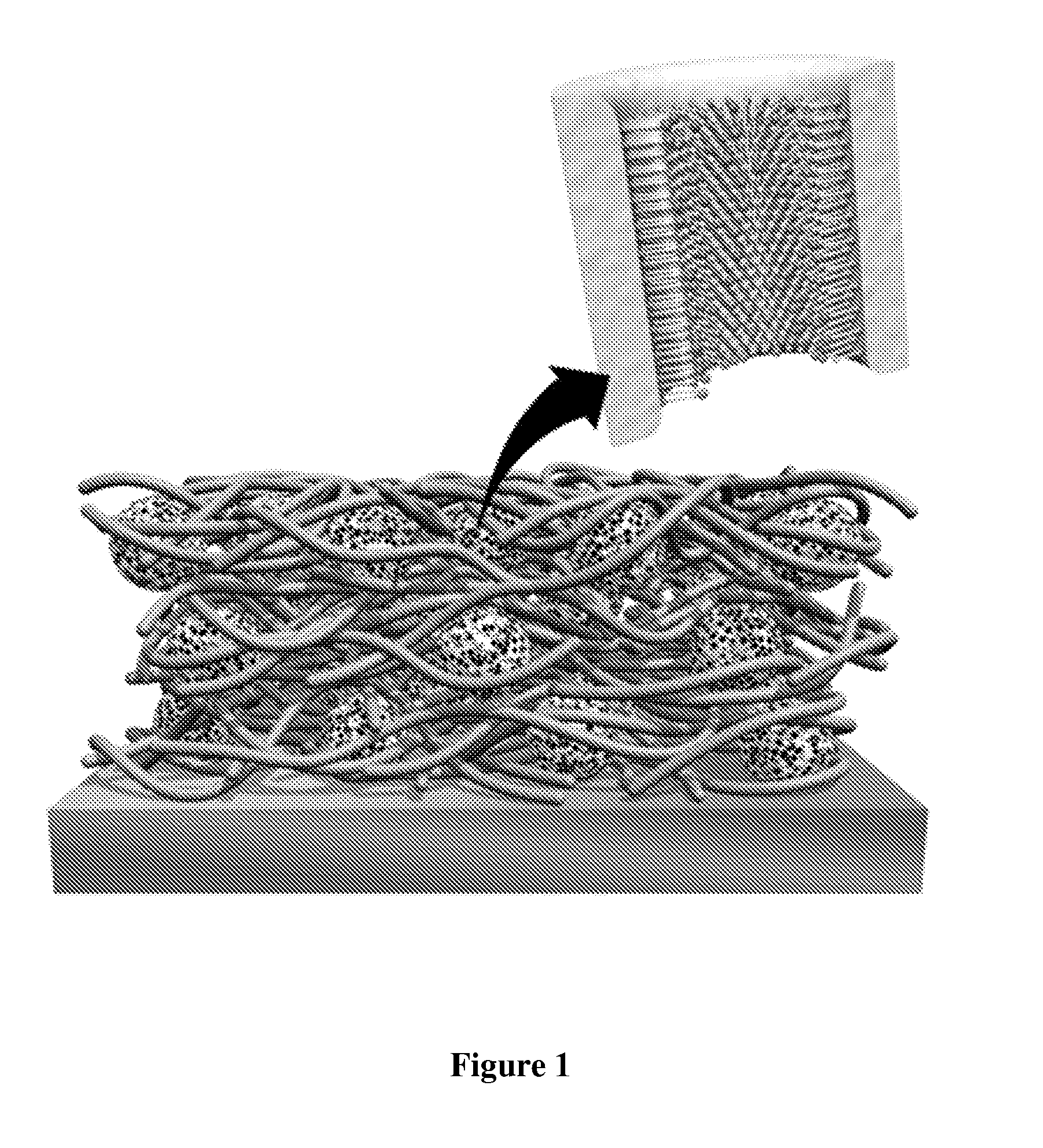

Porous multi-component material for the capture and separation of species of interest

A method and porous multi-component material for the capture, separation or chemical reaction of a species of interest is disclosed. The porous multi-component material includes a substrate and a composite thin film. The composite thin film is formed by combining a porous polymer with a nanostructured material. The nanostructured material may include a surface chemistry for the capture of chemicals or particles. The composite thin film is coupled to the support or device surface. The method and material provides a simple, fast, and chemically and physically benign way to integrate nanostructured materials into devices while preserving their chemical activity.

Owner:BATTELLE MEMORIAL INST

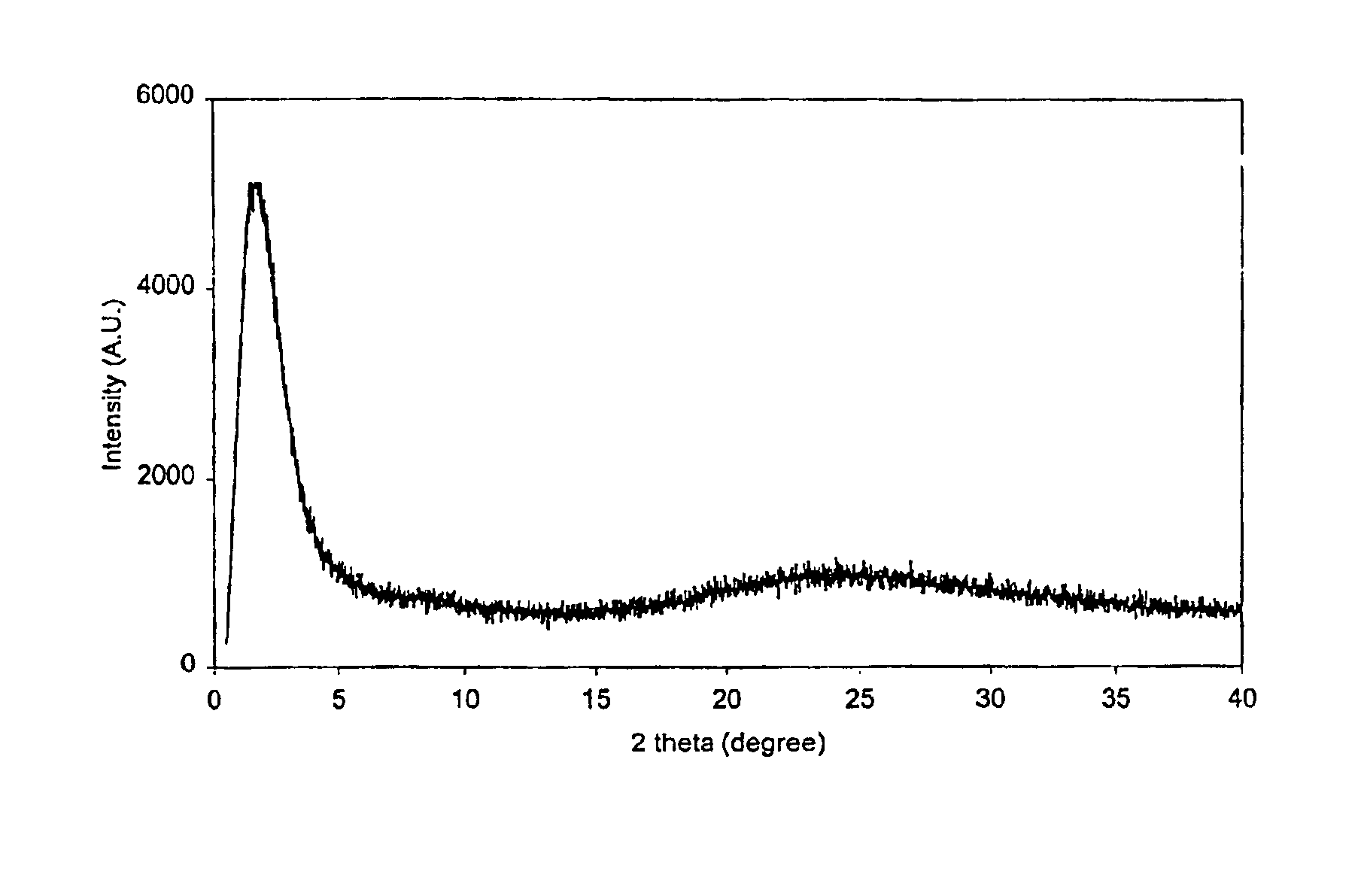

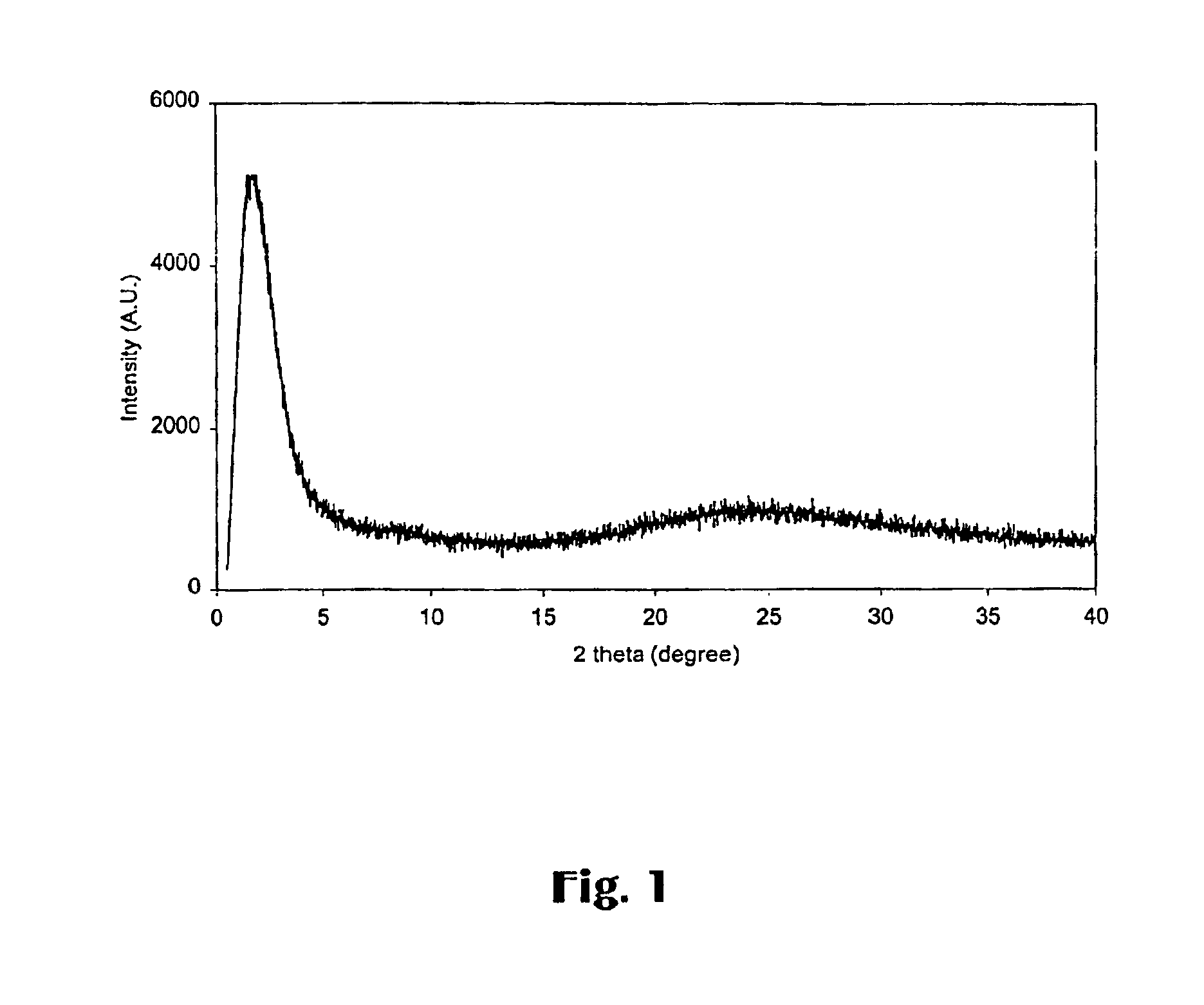

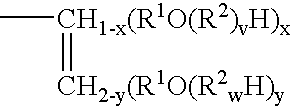

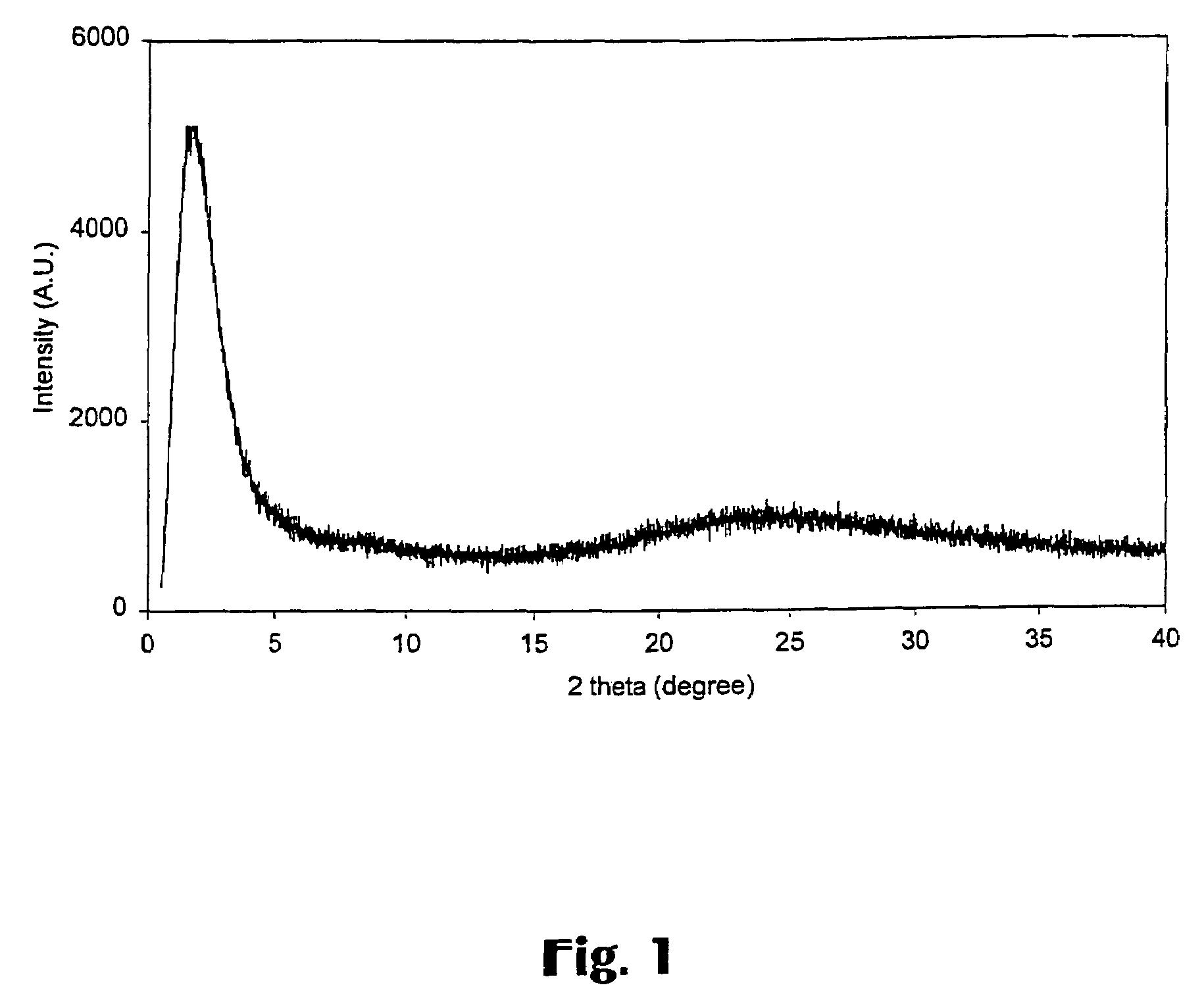

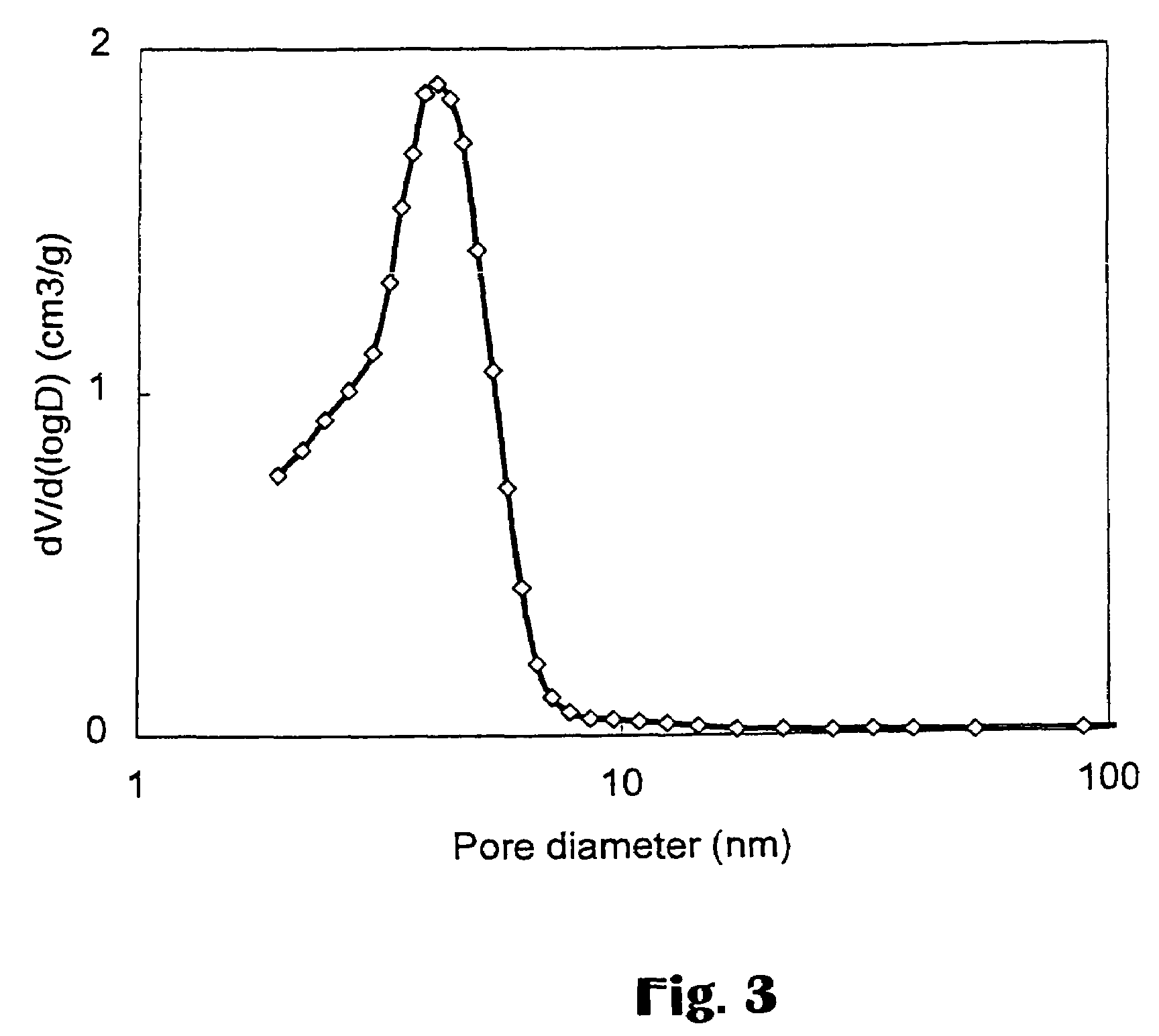

Mesoporous material with active metals

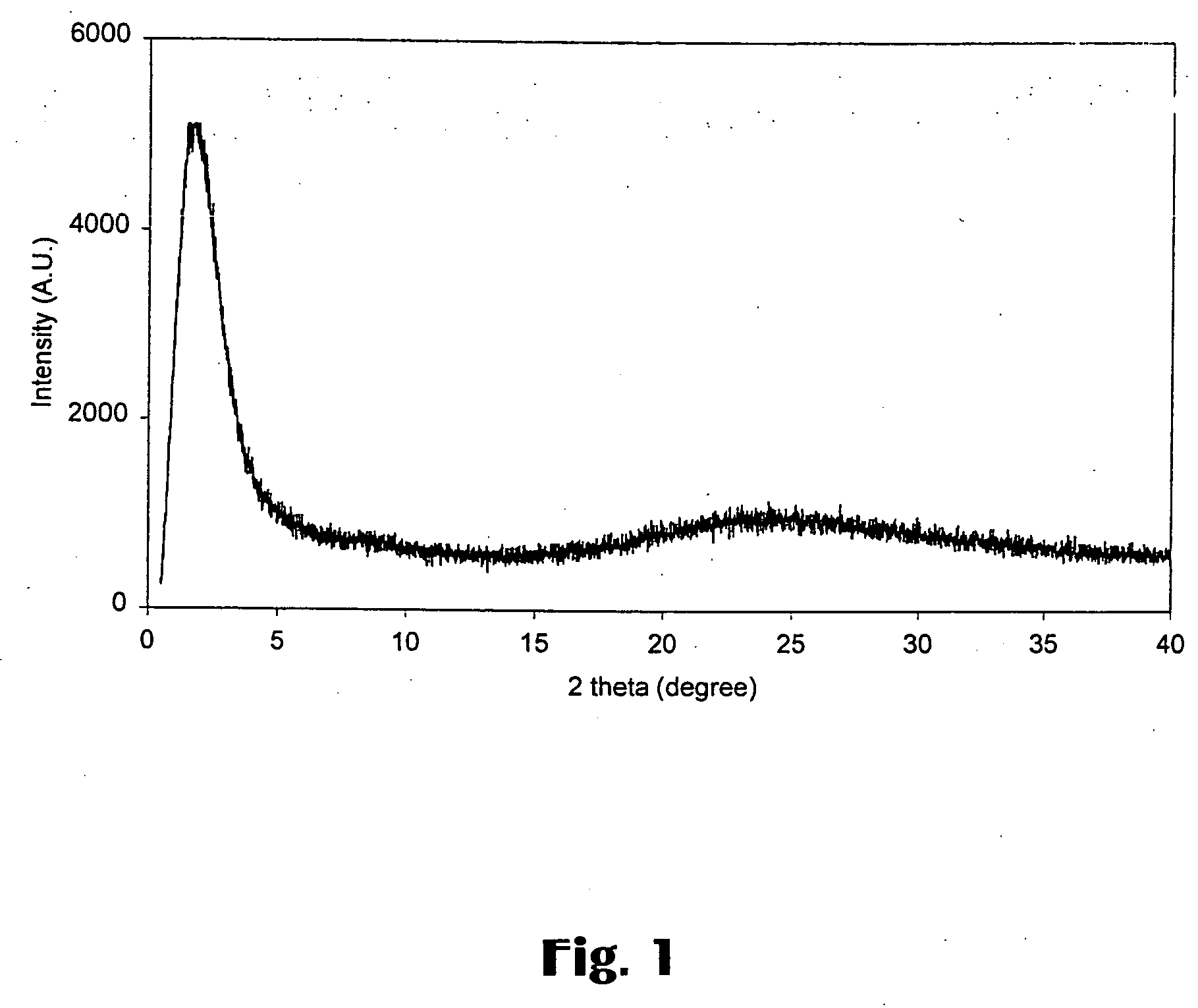

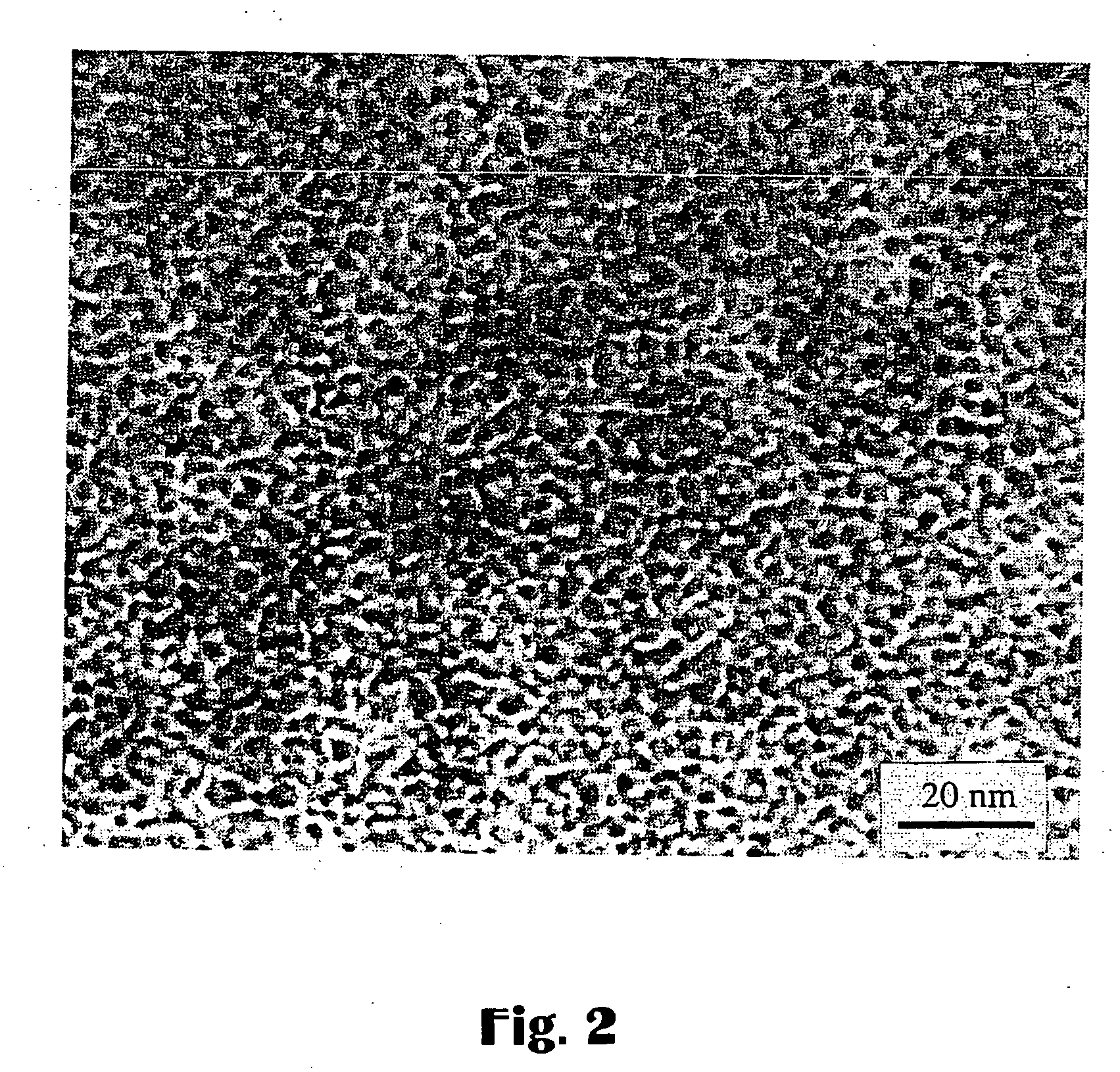

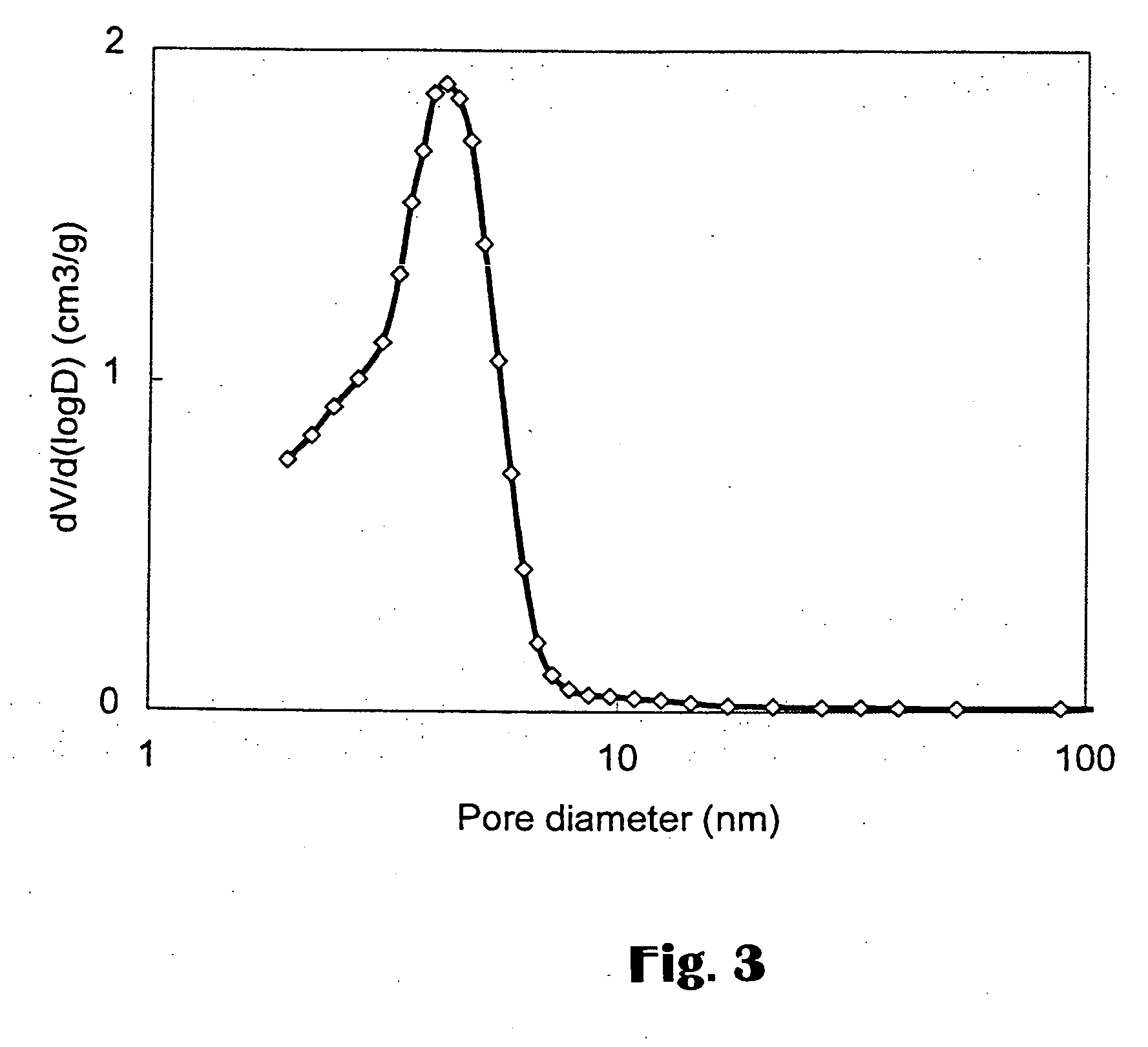

A process for treating organic compounds includes providing a composition which includes a substantially mesoporous structure of silica containing at least 97% by volume of pores having a pore size ranging from about 15 Å to about 30 Å and having a micropore volume of at least about 0.01 cc / g, wherein the mesoporous structure has incorporated therewith at least about 0.02% by weight of at least one catalytically and / or chemically active heteroatom selected from the group consisting of Al, Ti, V, Cr, Zn, Fe, Sn, Mo, Ga, Ni, Co, In, Zr, Mn, Cu, Mg, Pd, Pt and W, and the catalyst has an X-ray diffraction pattern with one peak at 0.3° to about 3.5° at 2θ. The catalyst is contacted with an organic feed under reaction conditions wherein the treating process is selected from alkylation, acylation, oligomerization, selective oxidation, hydrotreating, isomerization, demetalation, catalytic dewaxing, hydroxylation, hydrogenation, ammoximation, isomerization, dehydrogenation, cracking and adsorption.

Owner:ABB LUMMUS GLOBAL INC

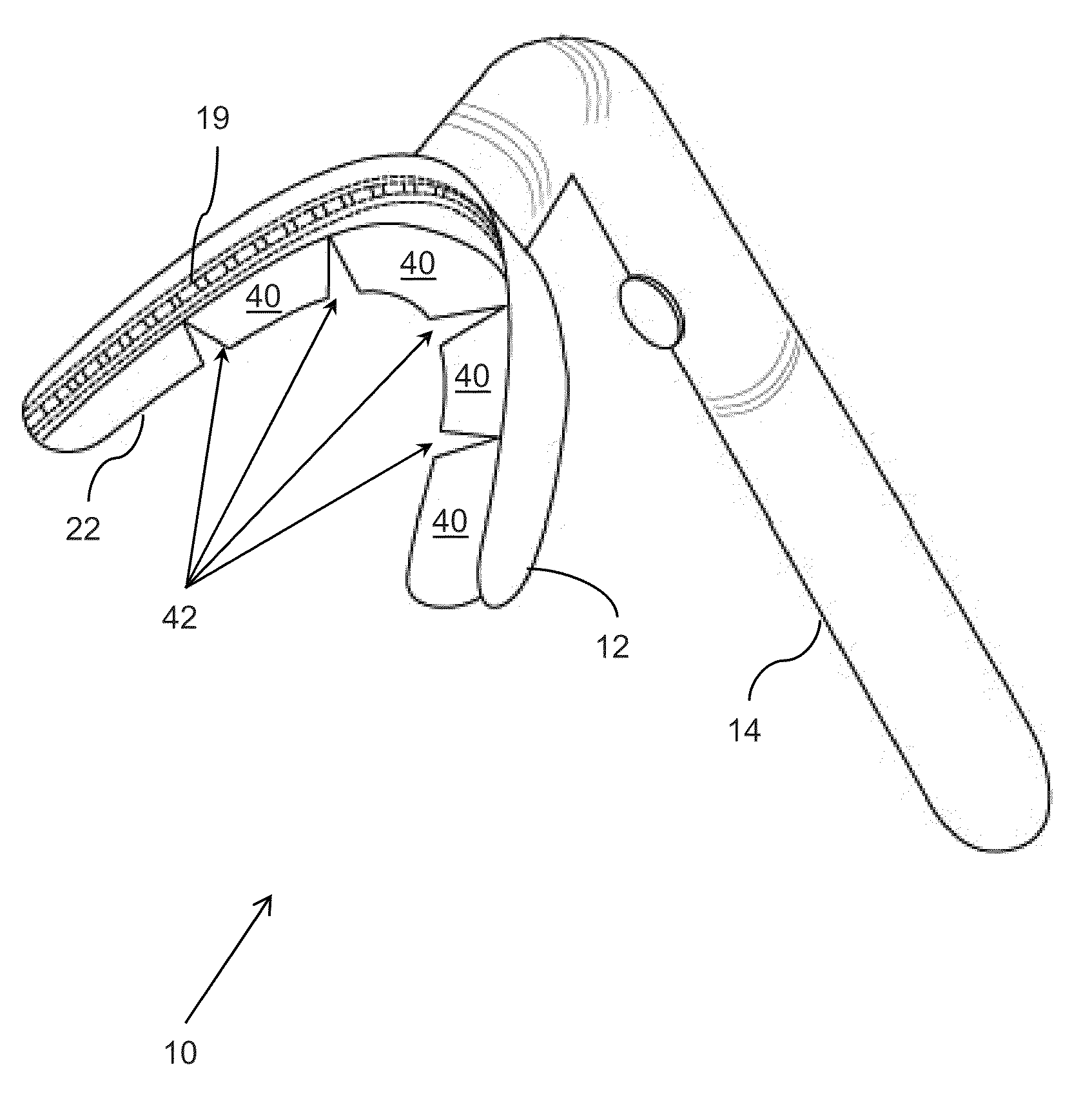

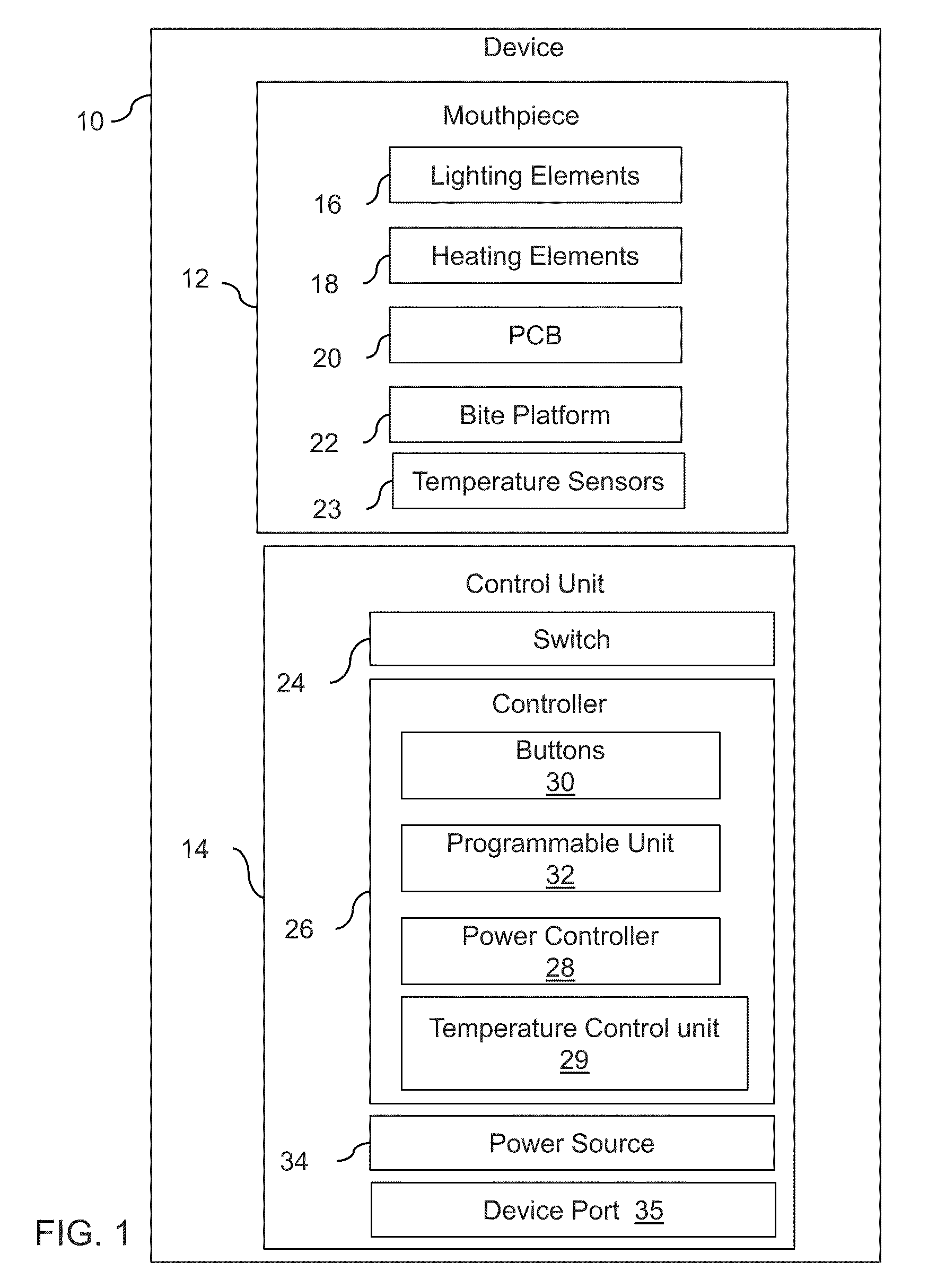

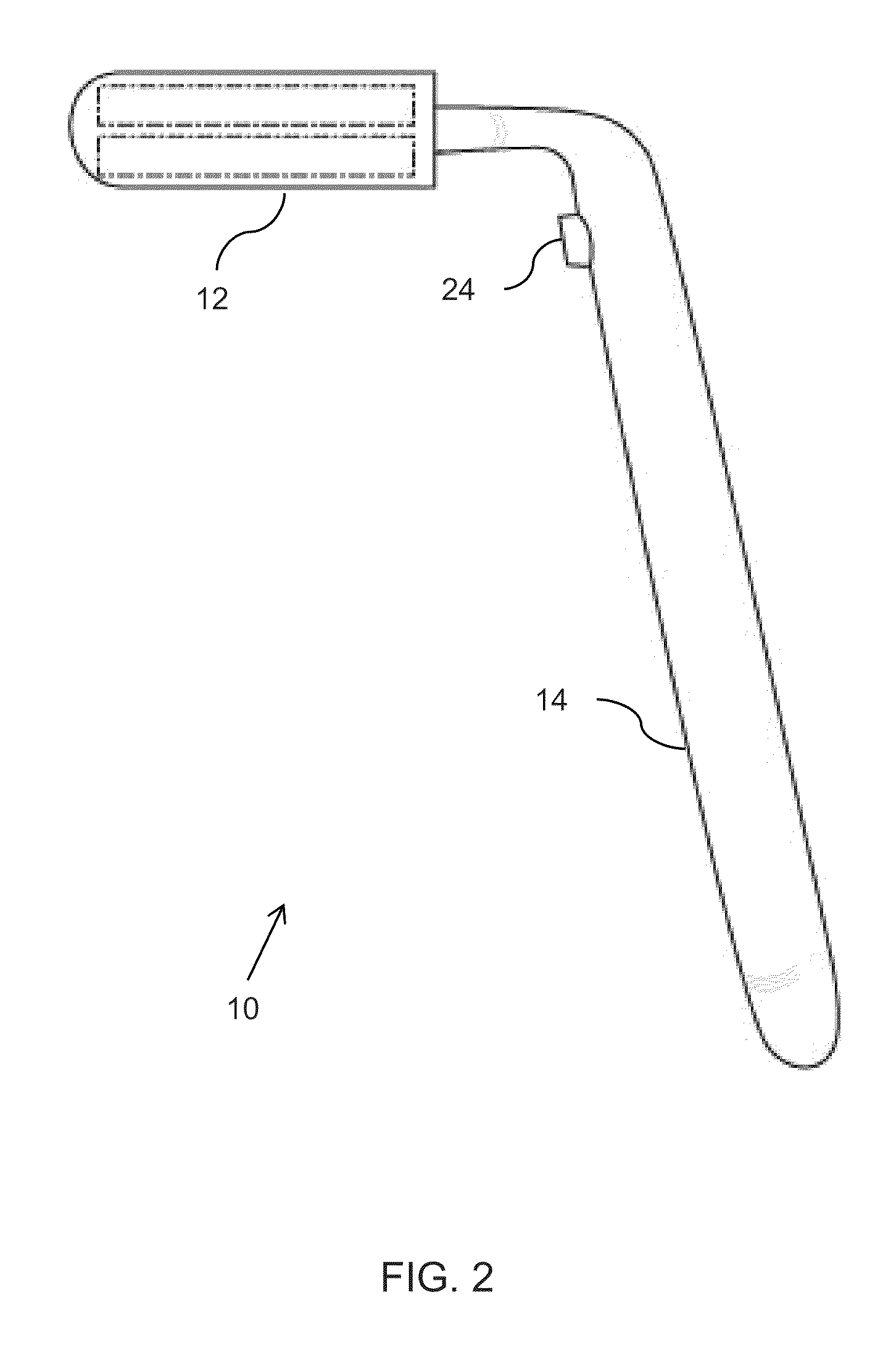

Device and method for dental whitening

Embodiments of the invention provide a portable dental whitening device. The device comprises a flexible mouthpiece including a bite platform having a horseshoe shape adapted to receive a plurality of mouth shapes. The mouthpiece comprising at least one lighting element for generating light, at least one heating element for generating heat, a flexible printed circuit board, and at least one temperature sensor for detecting the temperature of the heat generated by the at least one heating elements. Further, the device comprises a control unit for selectively powering said lighting element and said heating element. The dental whitening is achieved by applying simultaneously the light and the heat and the chemical activity delivered by a whitening agent provided in the mouthpiece.

Owner:WOLFF ANDY +1

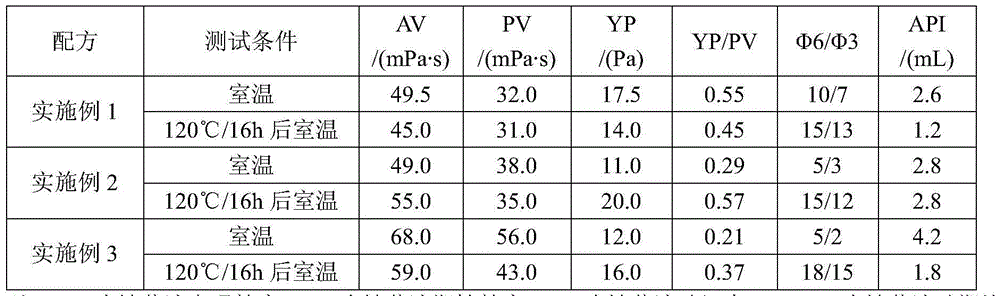

Water-based drilling fluid of shale gas horizontal well reinforced well wall and application thereof

ActiveCN104694092AImprove stabilityGood dispersionDrilling compositionBorehole/well accessoriesMicro nanoWater based

The invention relates to a water-based drilling fluid of a shale gas horizontal well reinforced well wall and an application thereof. The water-based drilling fluid comprises, by weight, 100 parts of water, 0-5 parts of clay, 0.5-3 parts of micro-nano particle blocking agents, 0.5-3 parts of chemical blocking agents, 0.1-2 parts of tackifier, 1-5 parts offiltrate reducer, 0.05-2 parts of encapsulating inhibiting agents, 0.1-3 parts of polyamine inhibiting agents, 1-5 parts of lubricant, 0.1-1 part of alkalinity regulator, 2-25 parts of inorganic salt, and 0-200 parts of weighting agents. The micro-nano particle blocking agents and the chemical blocking agents in the water-based drilling fluid of the shale gas horizontal well reinforced well wall have the effect of reinforcing the well wall in a cooperative mode, can effectively block micropore seams of shale to hinder pressure transmission, can further obviously improve the membrane efficiency of the shale, and facilitates the balance anti-collapse function of chemical activity.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

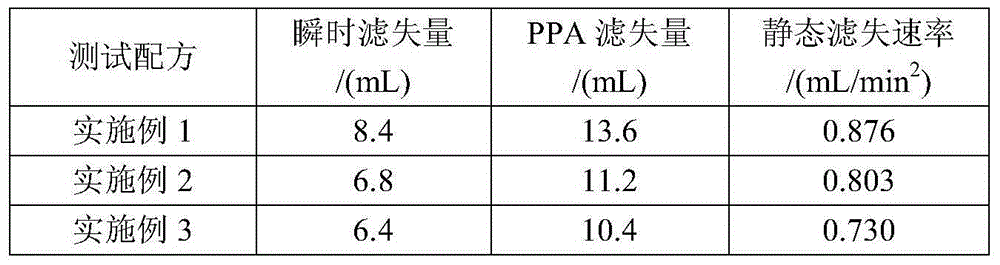

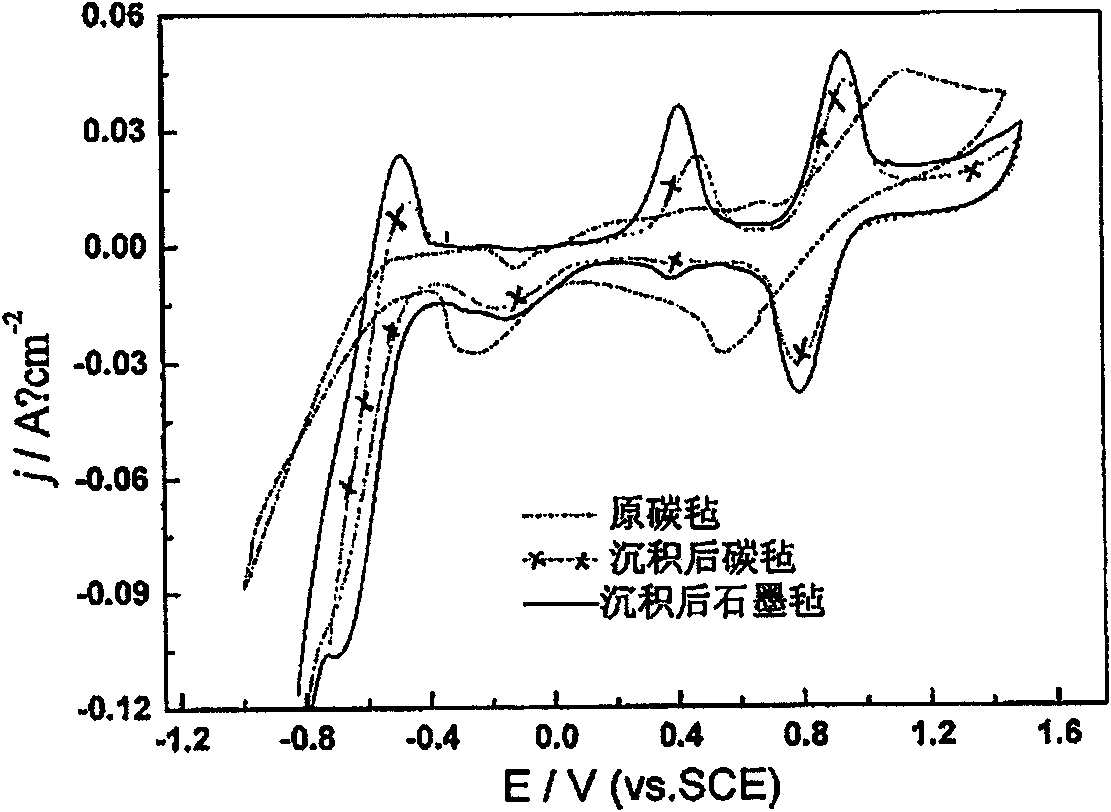

Electrode materials and all-vanadium redox flow battery containing electrode materials

InactiveCN101651201AReduce dosageLow costElectrode manufacturing processesRegenerative fuel cellsCarbon nanotubeRedox

The invention provides an electrode for a vanadium battery, comprising a carbon basal body and a carbon nano-tube layer formed on the surface of the basal body, wherein the carbon basal body is selected from a graphite felt, a carbon felt, a carbon paper and carbon cloth. The invention also provides an all-vanadium redox flow battery containing the electrode. The electrode has improved electrochemical activity and reliable mechanical strength.

Owner:BIG PAWER ELECTRICAL TECH XIANGYANG +1

Controlled release of biologically active substances from select substrates

InactiveUS20050033251A1Reducing and eliminating numberImprove the level ofBiocideBaby linensHigh concentrationWound dressing

This invention relates to methods and compositions for materials having a non-leaching coating that has antimicrobial properties. The coating is applied to substrates such as gauze-type wound dressings, powders and other substrates. Covalent, non-leaching, non-hydrolyzable bonds are formed between the substrate and the polymer molecules that form the coating. A high concentration of anti-microbial groups on multi-length polymer chains and relatively long average chain lengths, contribute to an absorbent or superabsorbent surface with a high level antimicrobial efficacy. Utilization of non-leaching coatings having a plurality of anionic or cationic sites is used according to this invention to bind a plurality of oppositely charged biologically or chemically active compounds, and to release the bound oppositely charged biologically or chemically active compounds from said substrate over a period of time to achieve desired objectives as diverse as improved wound healing to reduction in body odor.

Owner:QUICK MED TECH

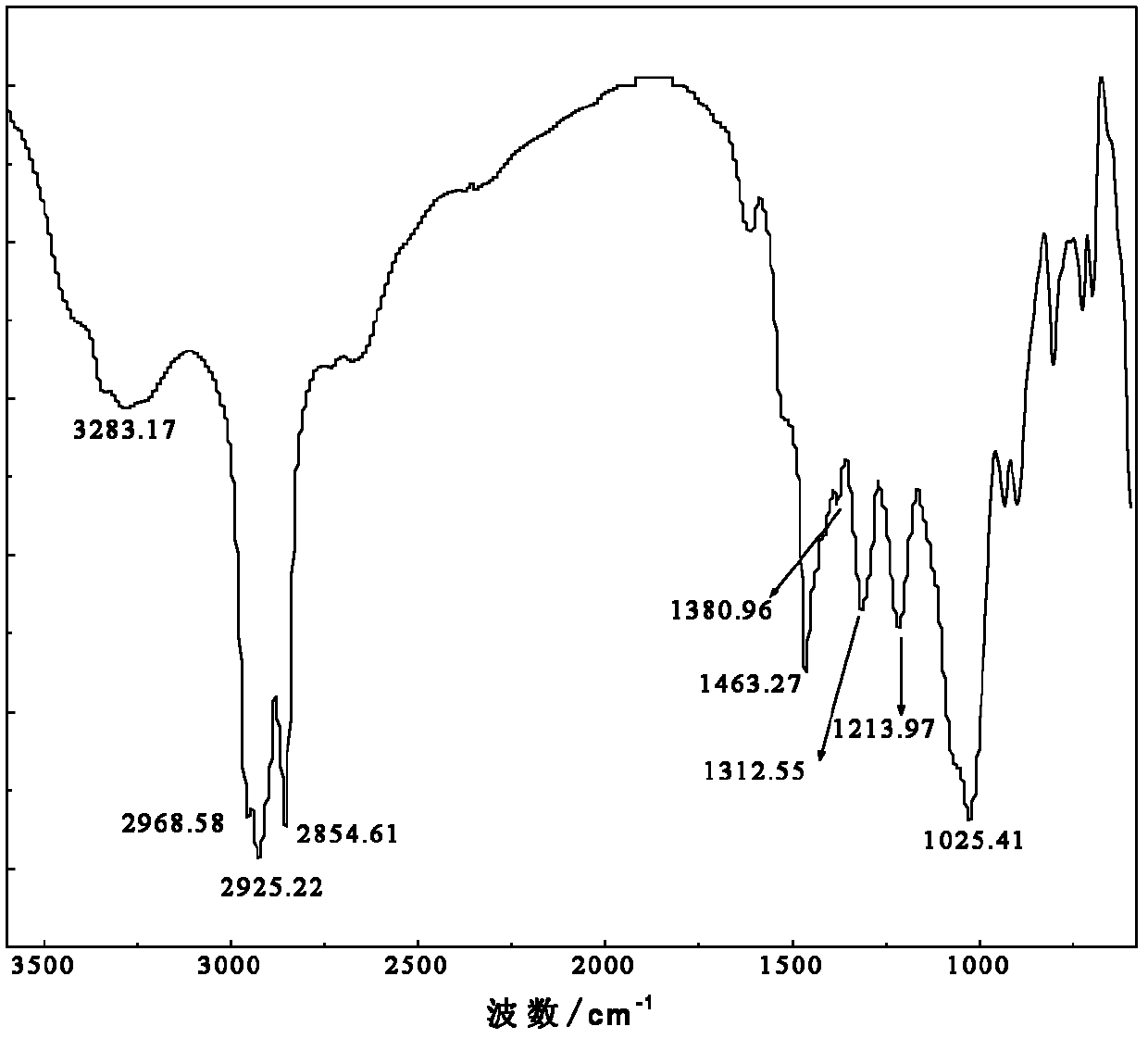

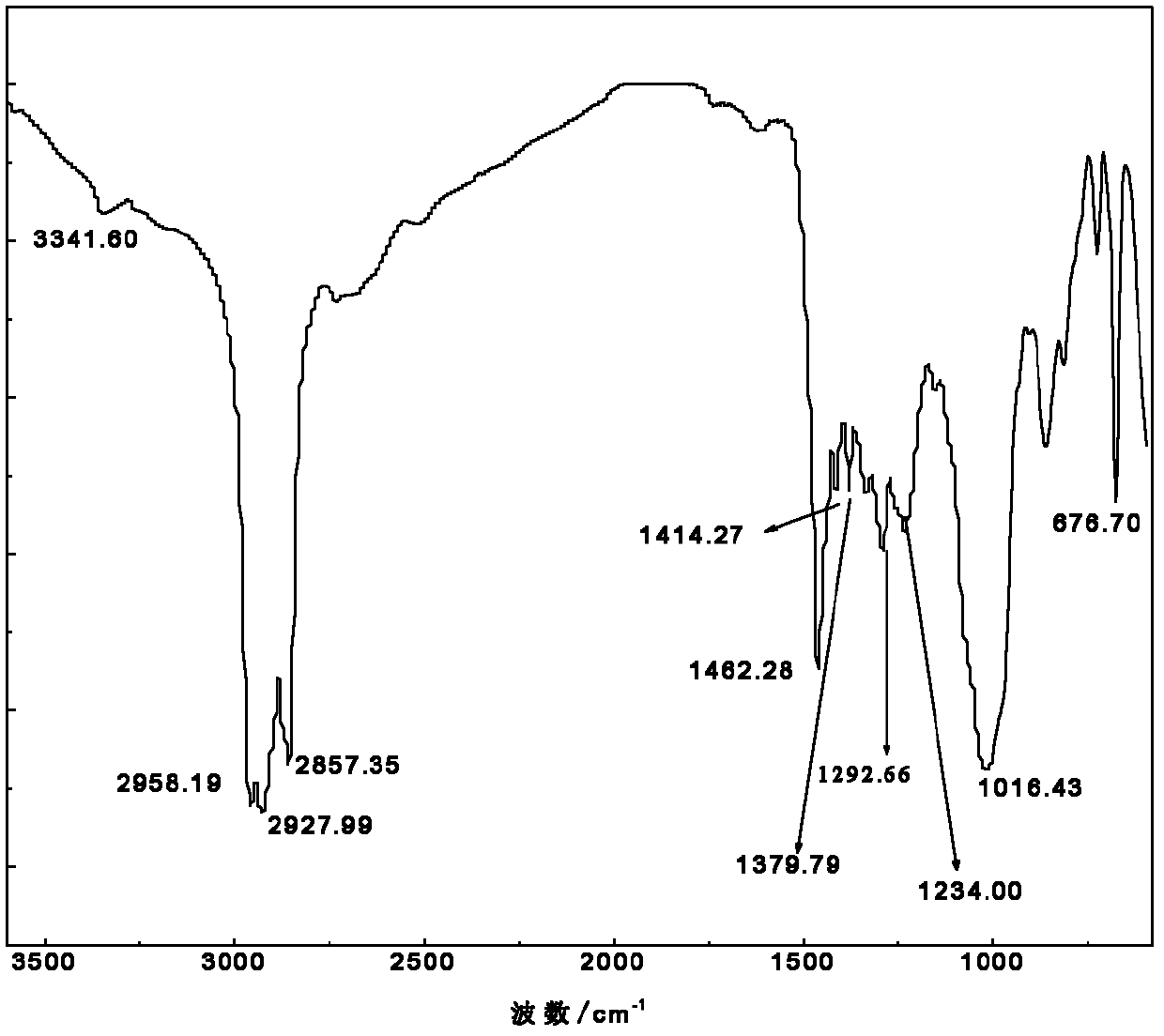

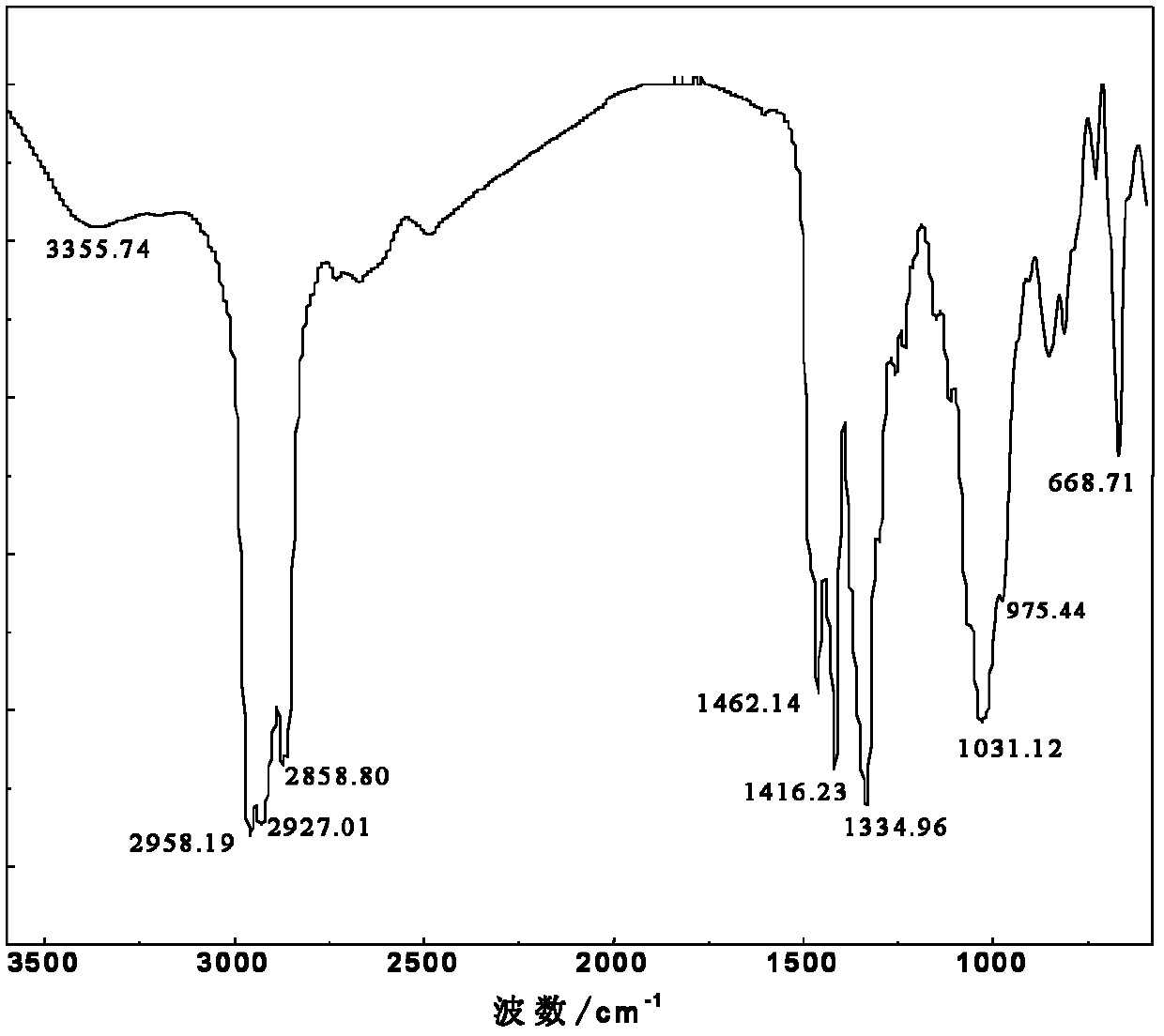

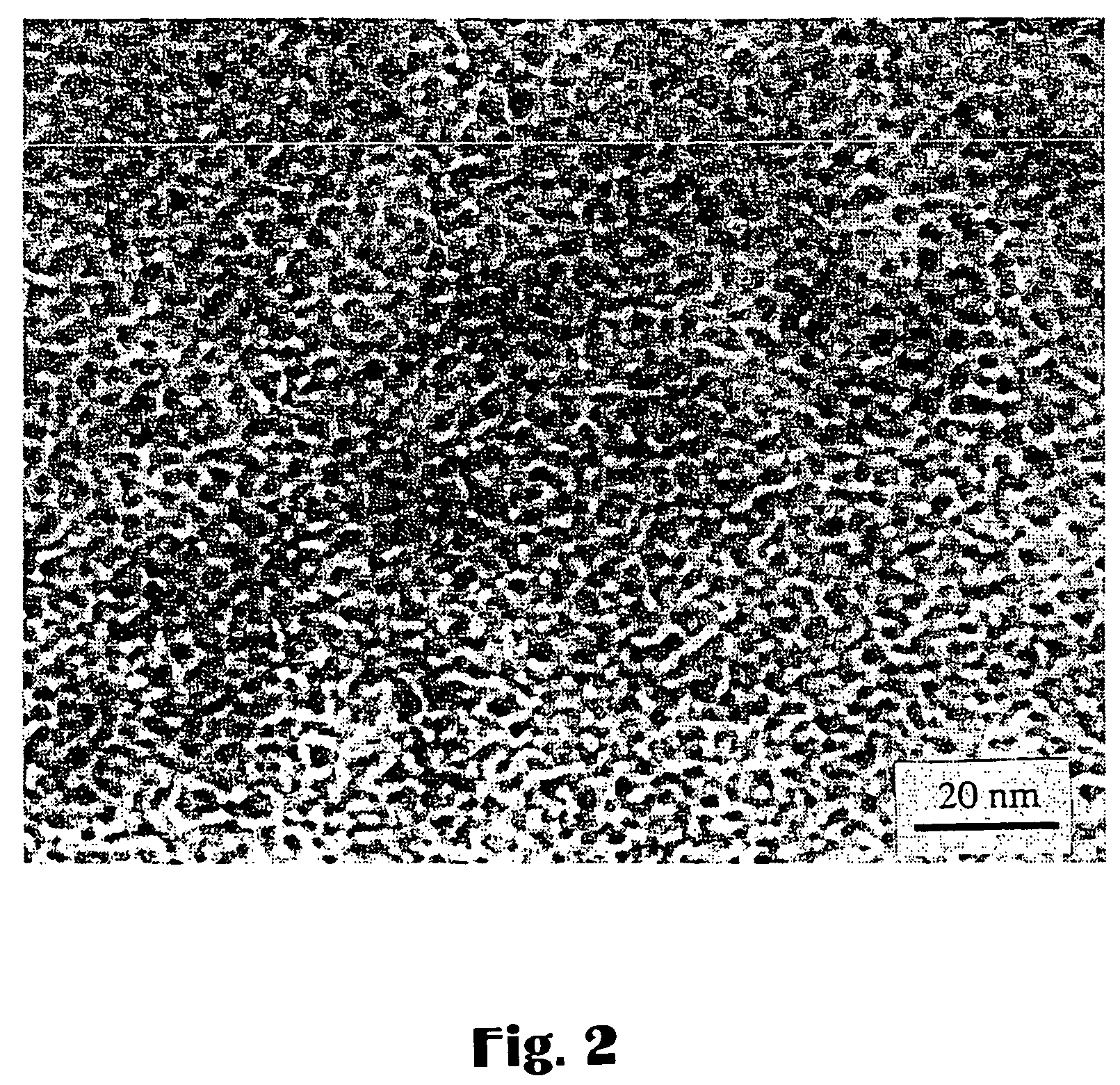

Extreme pressure antiwear additive and preparation method and application thereof

InactiveCN102504913AModerate chemical activityGood oil solubilityGroup 5/15 element organic compoundsAdditivesSolubilityOil sludge

The invention provides an extreme pressure antiwear additive and a preparation method and application thereof; the extreme pressure antiwear additive has a general formula structure as shown in the specification, wherein R1, R2 and R3 in the formula is respectively alkyl groups, aryl groups or aralkyl of a C4-C20 linear chain or branched chain. The extreme pressure antiwear additive provided by the invention is formed by reacting phosphorus oxychloride, C1-C20 alcohols, organic amine and benzotriazole. The extreme pressure antiwear additive provided by the invention can be applied to lubrication oil and lubricating grease with 0.1-2.0wt% of recommended dosage. The extreme pressure antiwear additive provided by the invention has moderate chemical activity, good oil solubility, very good compatibility with other addition agents, no peculiar smell and good thermal oxidation stability, and can effectively reduce the abrasion of devices and oil sedimentation as well as generation of oil sludge. After applied to gear oil, the extreme pressure antiwear additive has excellent antiwear performance and thermal oxidation stability; and simultaneously the extreme pressure antiwear additive can be applied to a lubricating grease and automatic transmission liquid and hydraulic oil of automobiles.

Owner:天津市金岛润滑科技股份有限公司

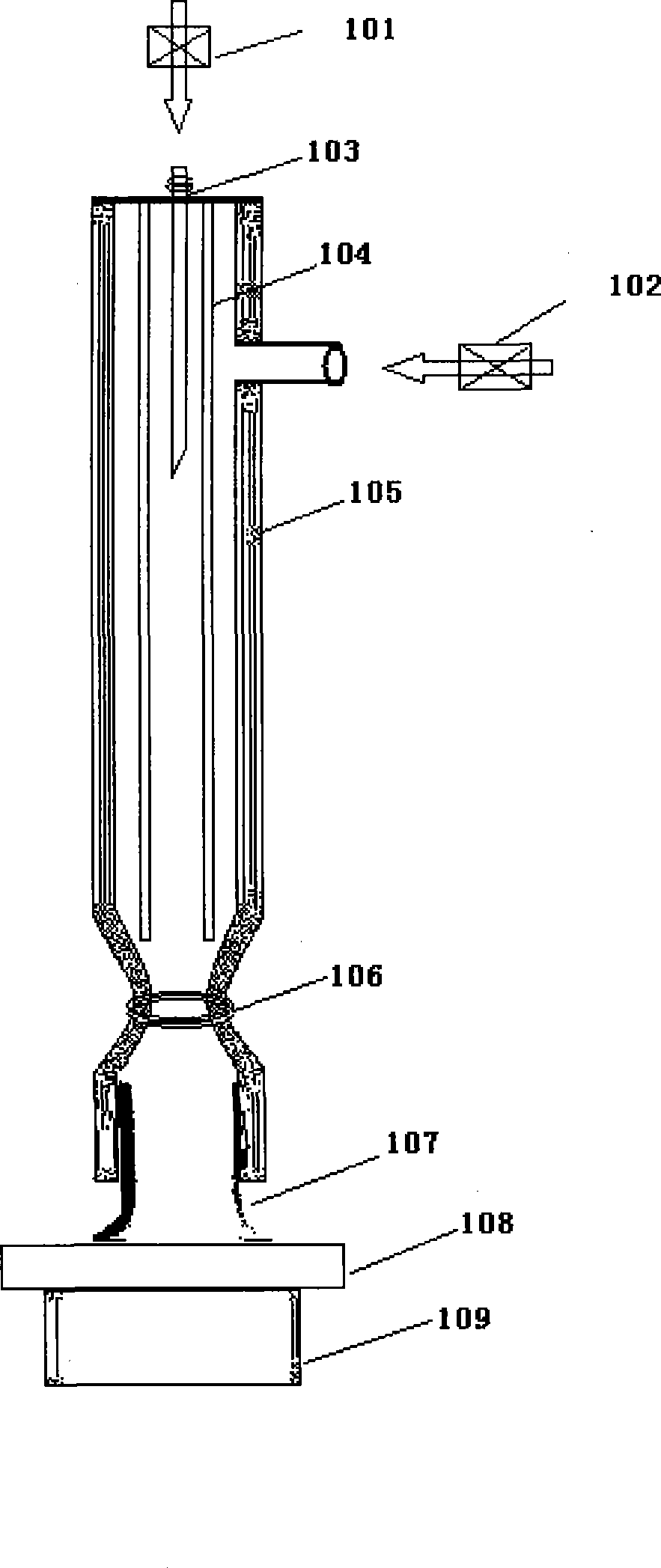

Preionization atmos low-temperature plasma jet generator

InactiveCN101466194AReduce breakdownIncrease discharge powerElectric discharge tubesPlasma techniquePlasma jetHigh concentration

The invention relates to an atmospheric pressure low-temperature plasma jet reactor with preionization structure, which belongs to plasma discharge reactor technical field, and the reactor is characterized in that: the device main body is a millimeter magnitude main silica tube with one open end; a part is arranged above the open end at the lower part with 15 to 25mm, and the part becomes the thinnest at 20mm part, and a ring-shaped electrode is wound on the part; a thin silica tube is connected at the closed end arranged in the inner part thereof through the closed end arranged at the upper part of the silica tube; and a needle electrode is arranged in the thin silica tube. An earthing electrode is arranged below the open end of the main silica tube; and the argon gas is filled into the needle electrode, and the oxygen gas is filled into the main silica tube. The needle electrode and the ring-shaped electrode can be exerted with the same high voltage; the needle electrode discharge can supply the seed electrons for the ring-shaped electrode discharge, and a stable glowing discharge plasma jet is arranged between the ring-shaped electrode and the earthing electrode. The reactor has the beneficial effects that the obtained plasma jet can generate high-concentration chemical activity species, and the reactor has practical value.

Owner:DALIAN UNIV OF TECH

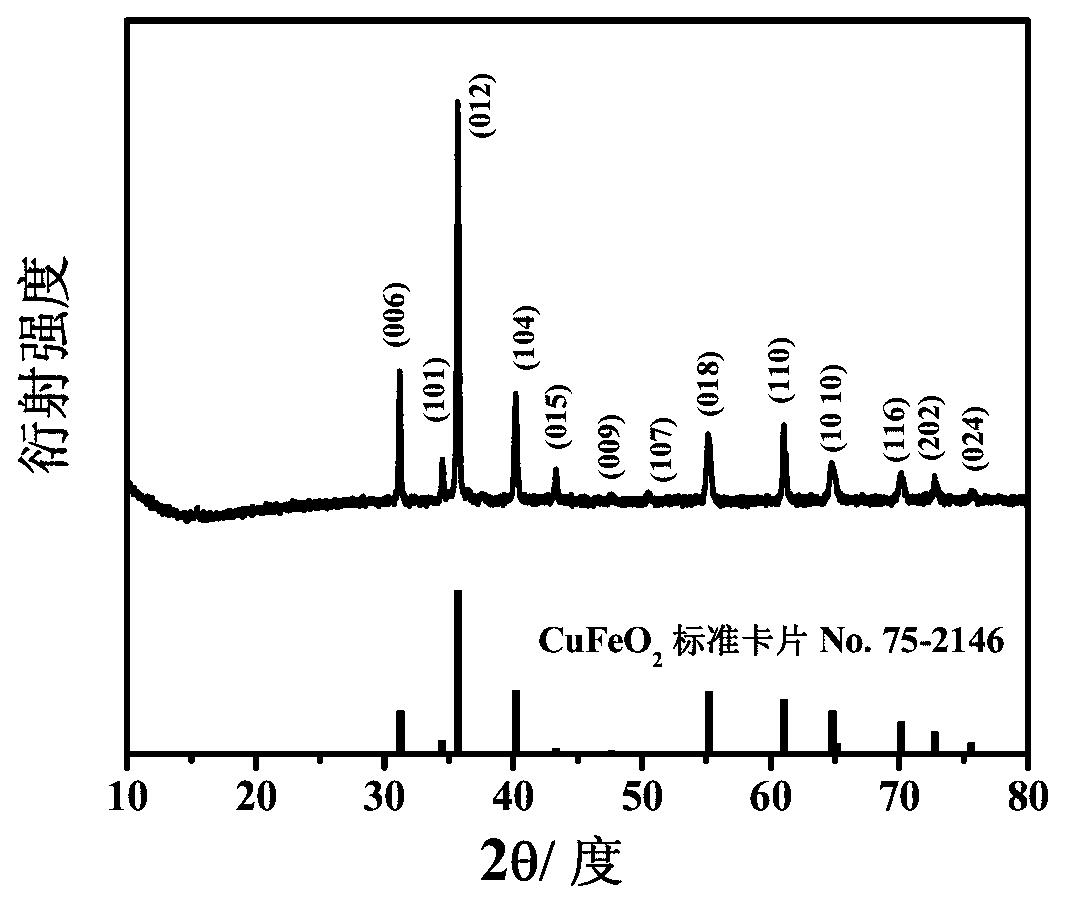

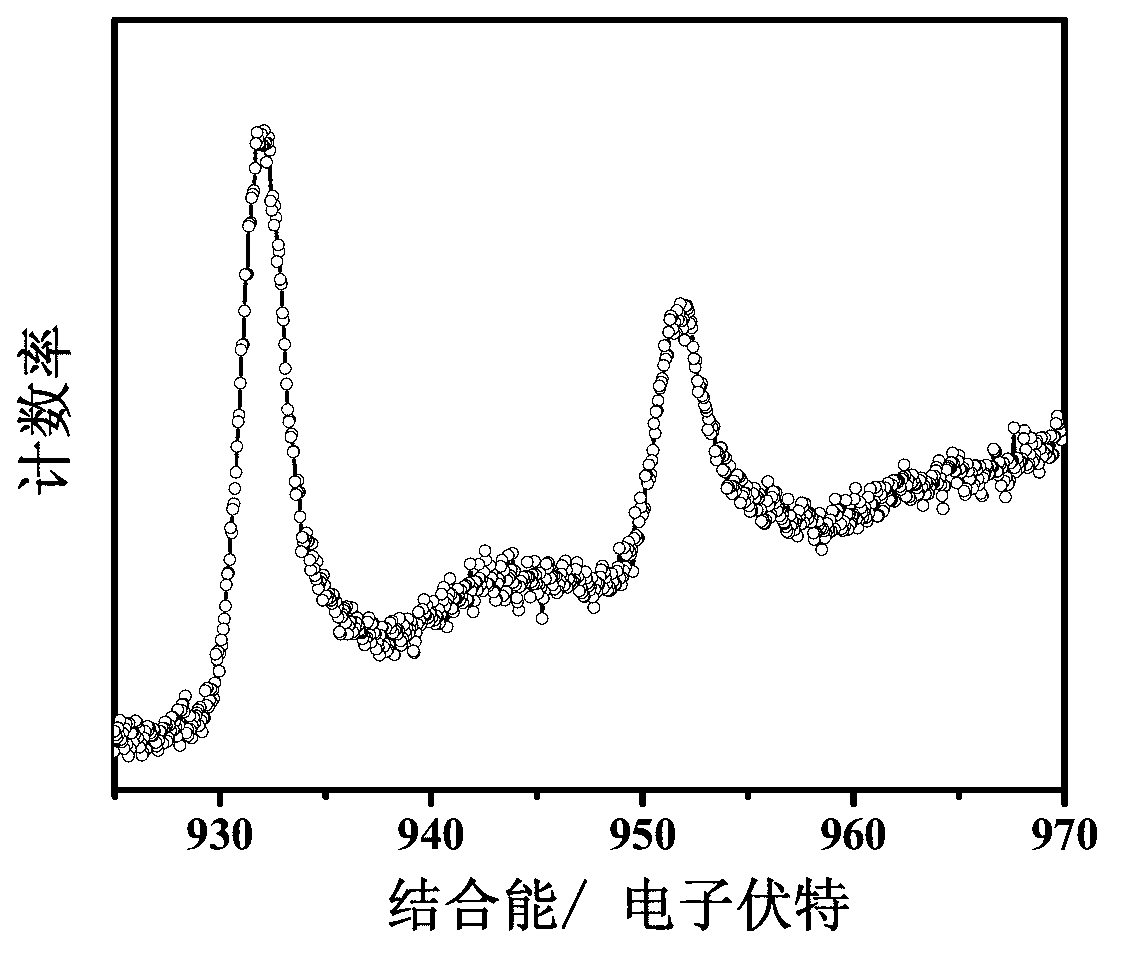

Micron-order Fenton-like catalyst, and preparation method and application thereof

InactiveCN103285862AEasy to makeRaw materials are cheap and easy to getIron compoundsColor/spectral properties measurementsOrganic solventPeroxidase

The invention provides a Fenton-like catalyst which is chalcopyrite CuFeO2. A preparation method for the Fenton-like catalyst comprises the following steps: dissolving the raw materials ferric nitrate and cupric nitrate in water; adding alkali and a weak reducing agent to prepare a sol; and subjecting the sol to a hydro-thermal reaction so as to prepare the CuFeO2 Fenton-like catalyst. The Fenton-like catalyst provided by the invention has the advantages of simple preparation process, low cost, no organic solvent, environment-friendliness and stable chemical activity; since the particle of the Fenton-like catalyst is micron order, the Fenton-like catalyst can rapidly settle, and thus, the Fenton-like catalyst can be easily recovered and be repeatedly used many times. The Fenton-like catalyst can be used as a natural peroxidase substitute and used for detection and analysis of H2O2 content in food, biological and environmental samples and for degradation and mineralization of organic pollutants.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES +1

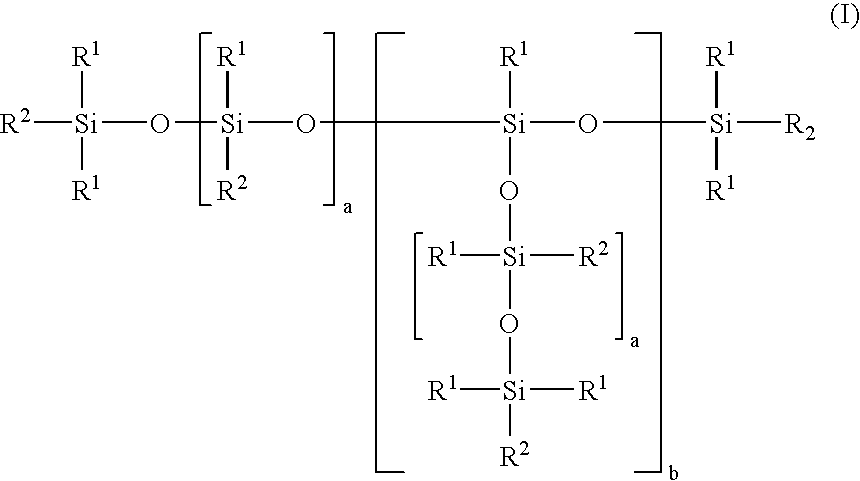

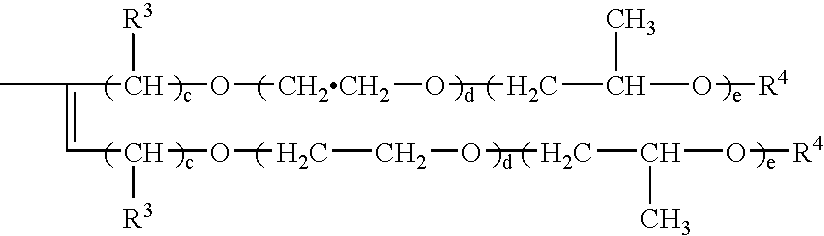

Agrochemical compositions comprising alkylenediol-modified polysiloxanes

InactiveUS20070213226A1Good curative effectImprove performanceBiocideAnimal repellantsCarboxyl radicalHydrogen

Described are agrochemical compositions which comprise of one or more one agrochemical active ingredient(s) and alkylenediol-modified polysiloxanes of the general formula (I): wherein R1 are alkyl radicals having 1 to 4 carbon atoms or aryl radicals, wherein at least 80% of the radicals R1 are methyl radicals , R2 in the molecule are identical or different and can have the following definitions: a) in which R3 is a hydrogen or alkyl radical, R4 is a hydrogen, alkyl or carboxyl radical, c is a number from 1 to 20, d is a number from 0 to 50, e is a number from 0 to 50 or b) correspond to R1, with the provisio that in the average molecule at least one radical R2 has the definition (a), a is a number from 1 to 200; b is a number from 0 to 10; and optionally one or more other agrochemically acceptable ingredients. The agrochemical compositions of the invention have enhanced efficacy, enhanced hydrolytic stability and / or decreased foaming properties.

Owner:EVONIK GOLDSCHMIDT GMBH

Mesoporous material with active metals

A process for treating organic compounds includes providing a composition which includes a substantially mesoporous structure of refractory oxide containing at least 97% by volume of pores having a pore size ranging from about 15 Å to about 30 Å and having a micropore volume of at least about 0.01 cc / g, wherein the mesoporous structure has incorporated therewith at least about 0.02% by weight of at least one catalytically and / or chemically active heteroatom selected from the group consisting of Al, Ti, V, Cr, Zn, Fe, Sn, Mo, Ga, Ni, Co, In, Zr, Mn, Cu, Mg, Pd, Pt and W, and the catalyst has an X-ray diffraction pattern with one peak at 0.3° to about 3.5° at 2 theta (θ). The catalyst is contacted with an organic feed under reaction conditions wherein the treating process is selected from alkylation, acylation, oligomerization, selective oxidation, hydrotreating, isomerization, demetalation, catalytic dewaxing, hydroxylation, hydrogenation, ammoximation, isomerization, dehydrogenation, cracking and adsorption.

Owner:LUMMUS TECH INC

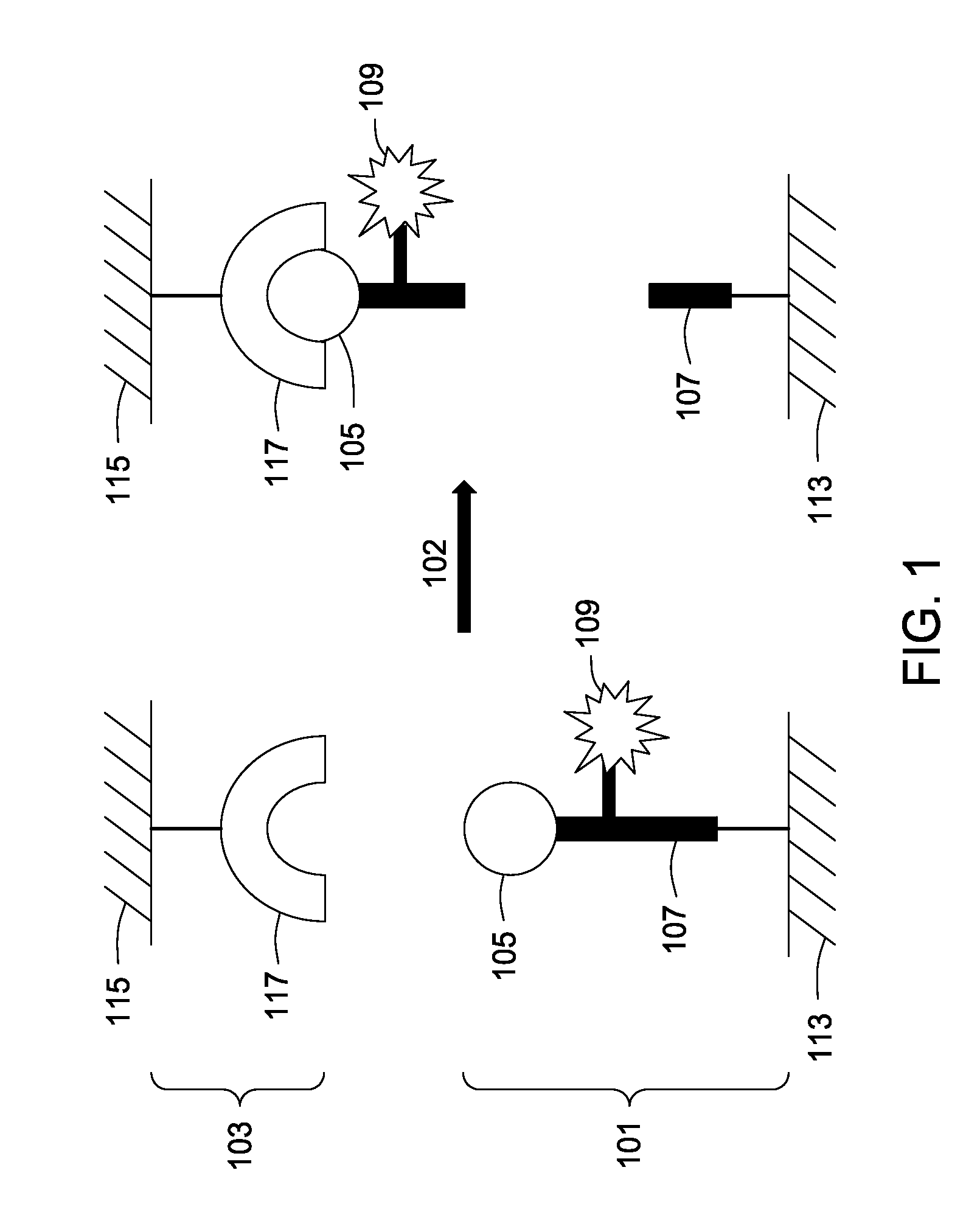

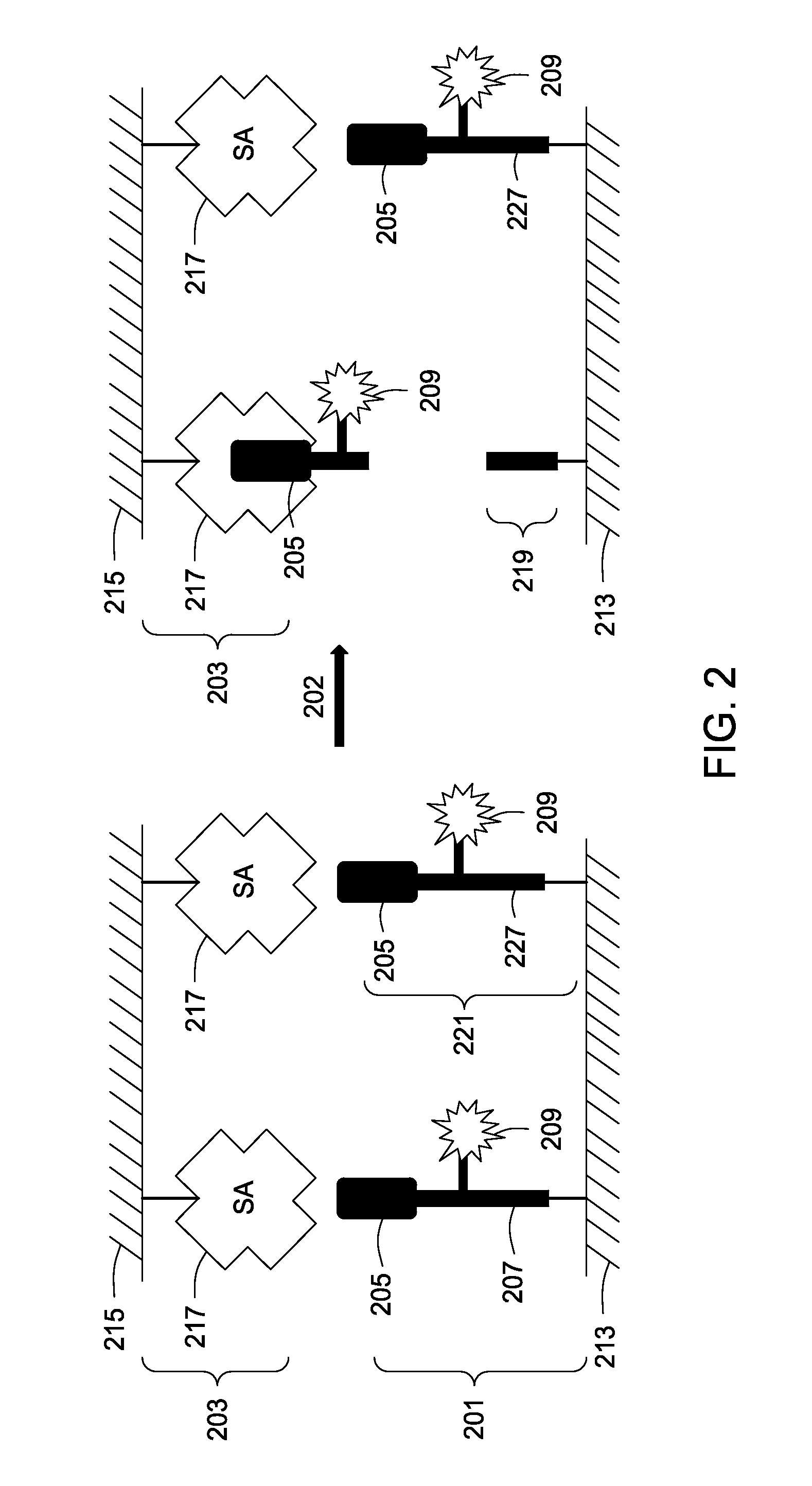

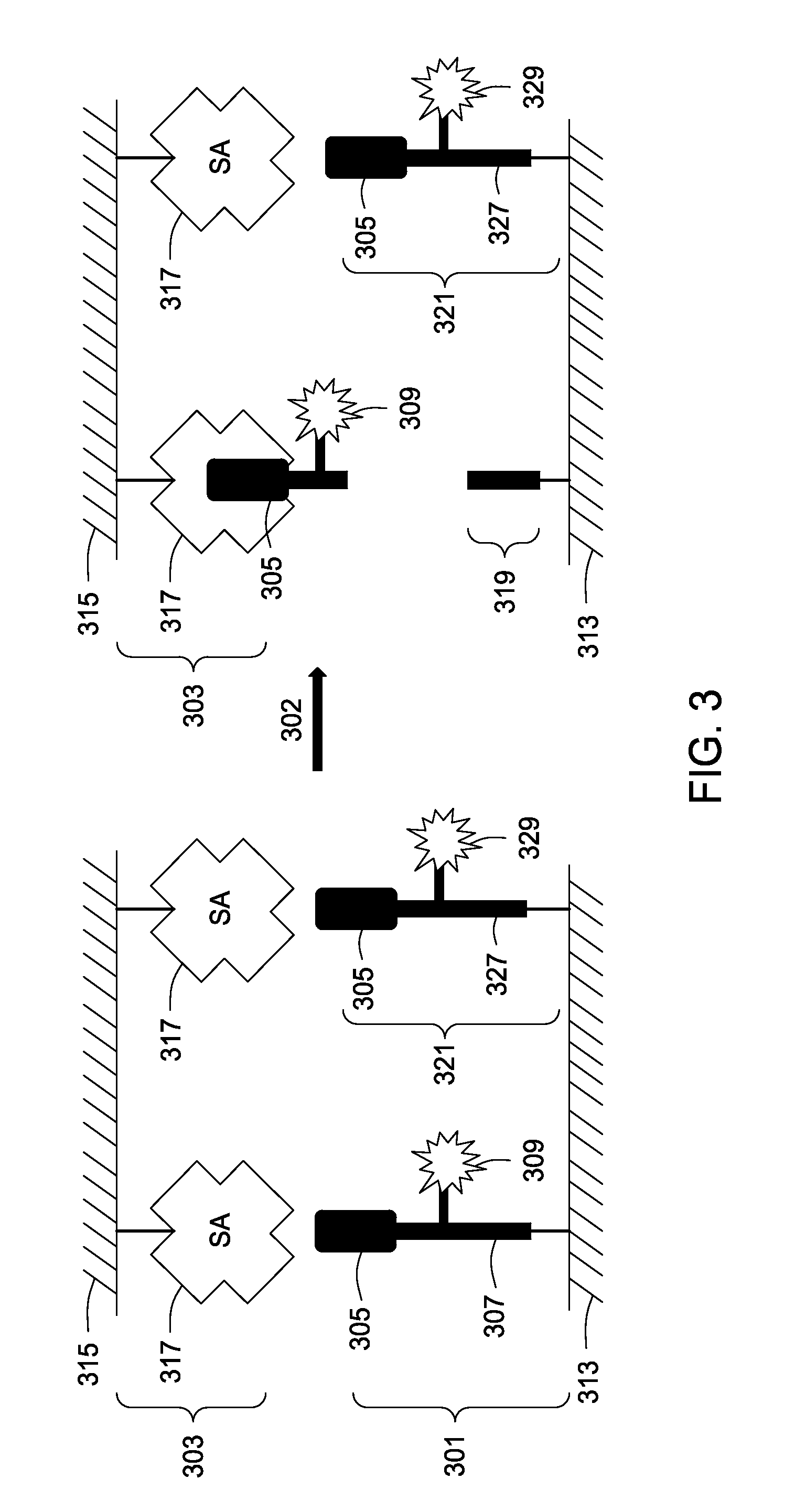

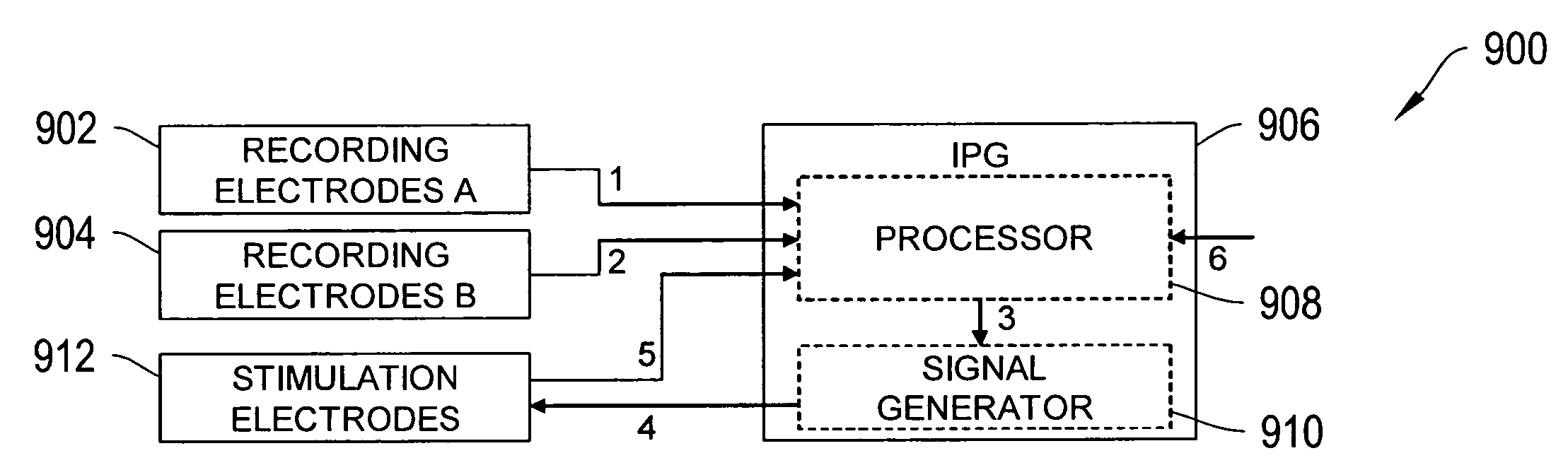

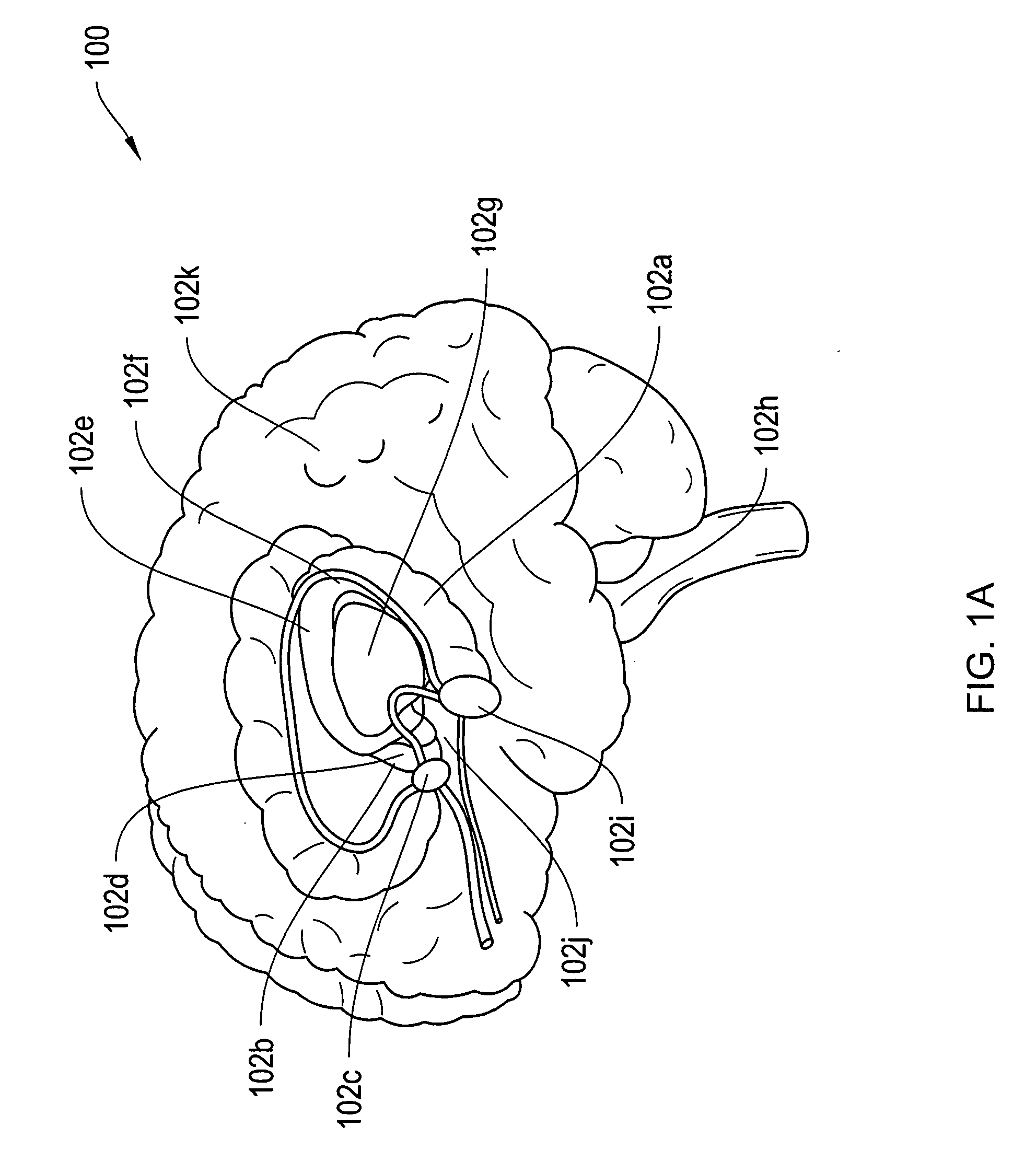

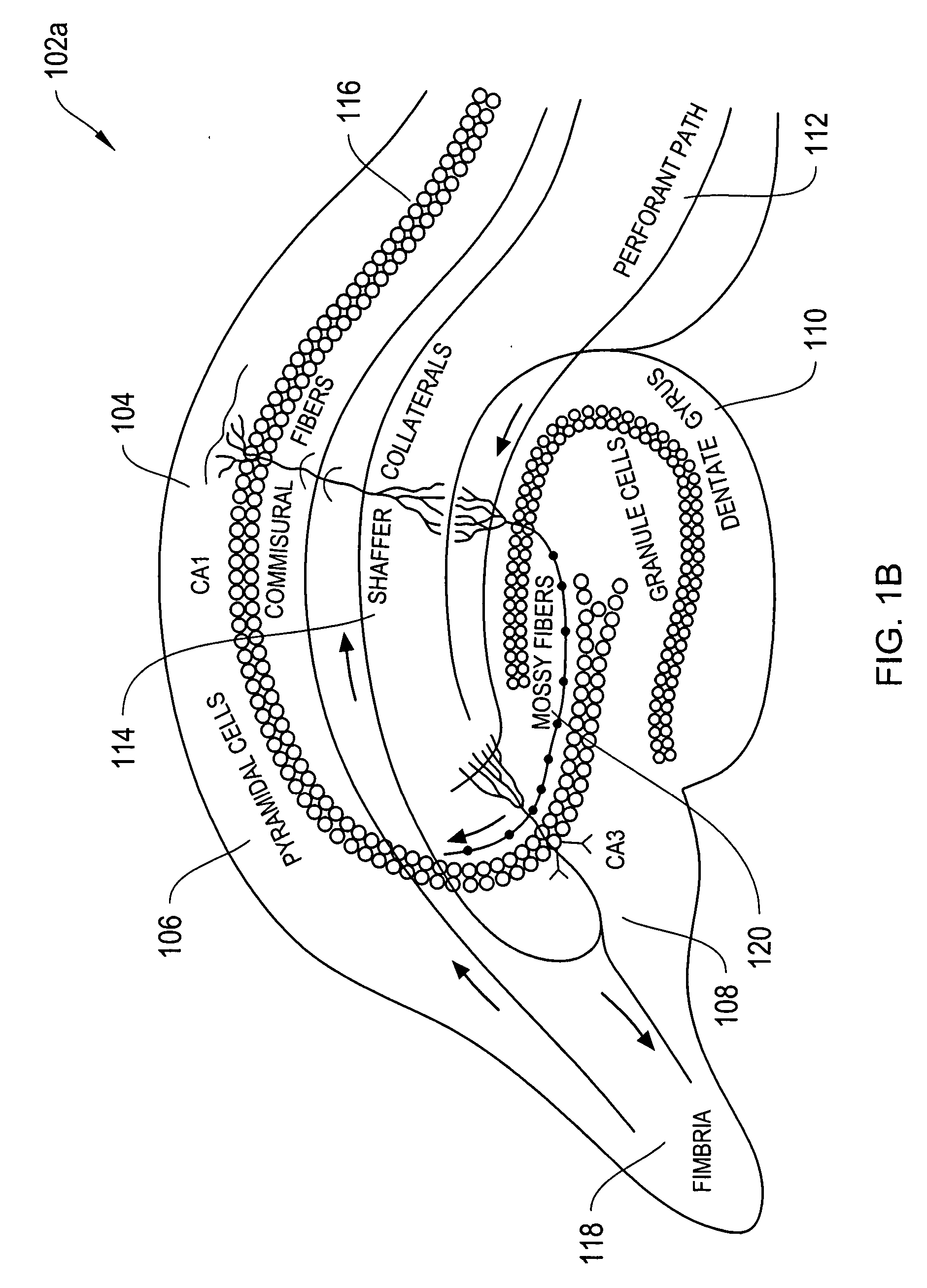

Systems and methods for improving a cognitive function

In many aspects, the invention relates to systems and methods for providing cognitive therapy through stimulation of activating and inhibiting neurons in the brain, thereby modulating neural firing rhythms. The stimulation of neurons is controlled through a feedback process whereby neuron firing rhythms are altered based on naturally occurring electrical and chemical activity in the brain. Neurons in specific regions of the brain may be targeted in order to establish neural signaling pathways and establish communication between these regions.

Owner:MEDTRODE

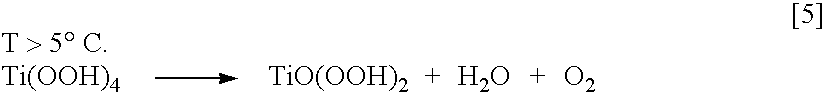

Method for preparing titanium dioxide product for high-specific surface area denitrating catalyst

InactiveCN101318697AImprove performanceWill not polluteCatalyst carriersDispersed particle separationFiltrationHigh surface

The invention relates to a method for preparing titania raw materials with high specific surface area used by denitration catalyst, which relates to the chemical product preparation technical field. The method comprises the following steps that: a metatitanic acid produced by adoption of the sulfuric acid method is processed by an organic surfactant and then modified so as to reduce the viscosity of the metatitanic acid; and loose titania products with high specific surface area and high surface chemical activity used by the denitration catalyst are prepared through filtration and calcination of the processed metatitanic acid. The method has a simple technique for processing the metatitanic acid and has low cost; and added organic substances are fully decomposed during the calcining stage, thereby impurities can not be brought into the final products and the environmental pollution can not be caused.

Owner:四川华铁钒钛科技股份有限公司

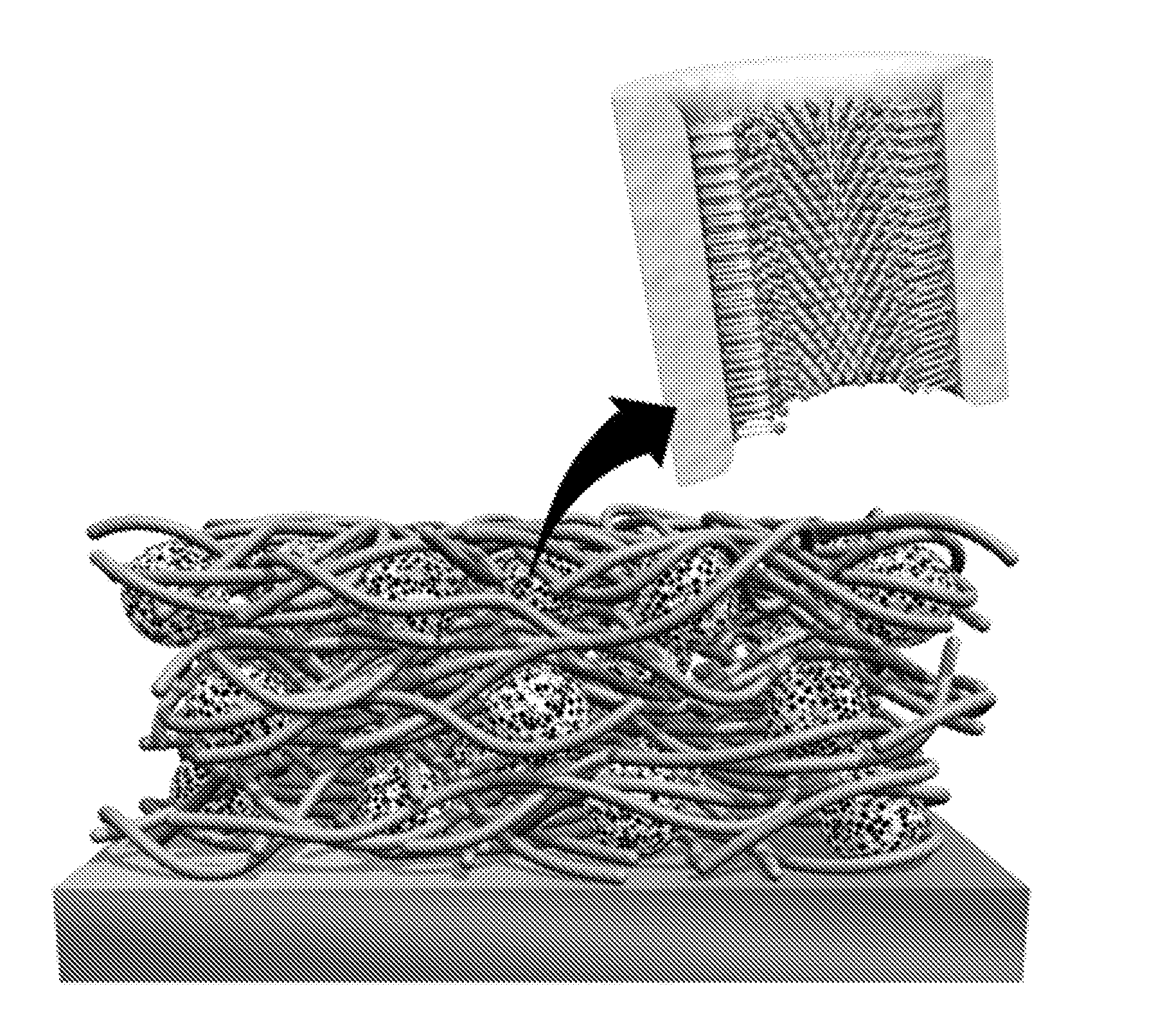

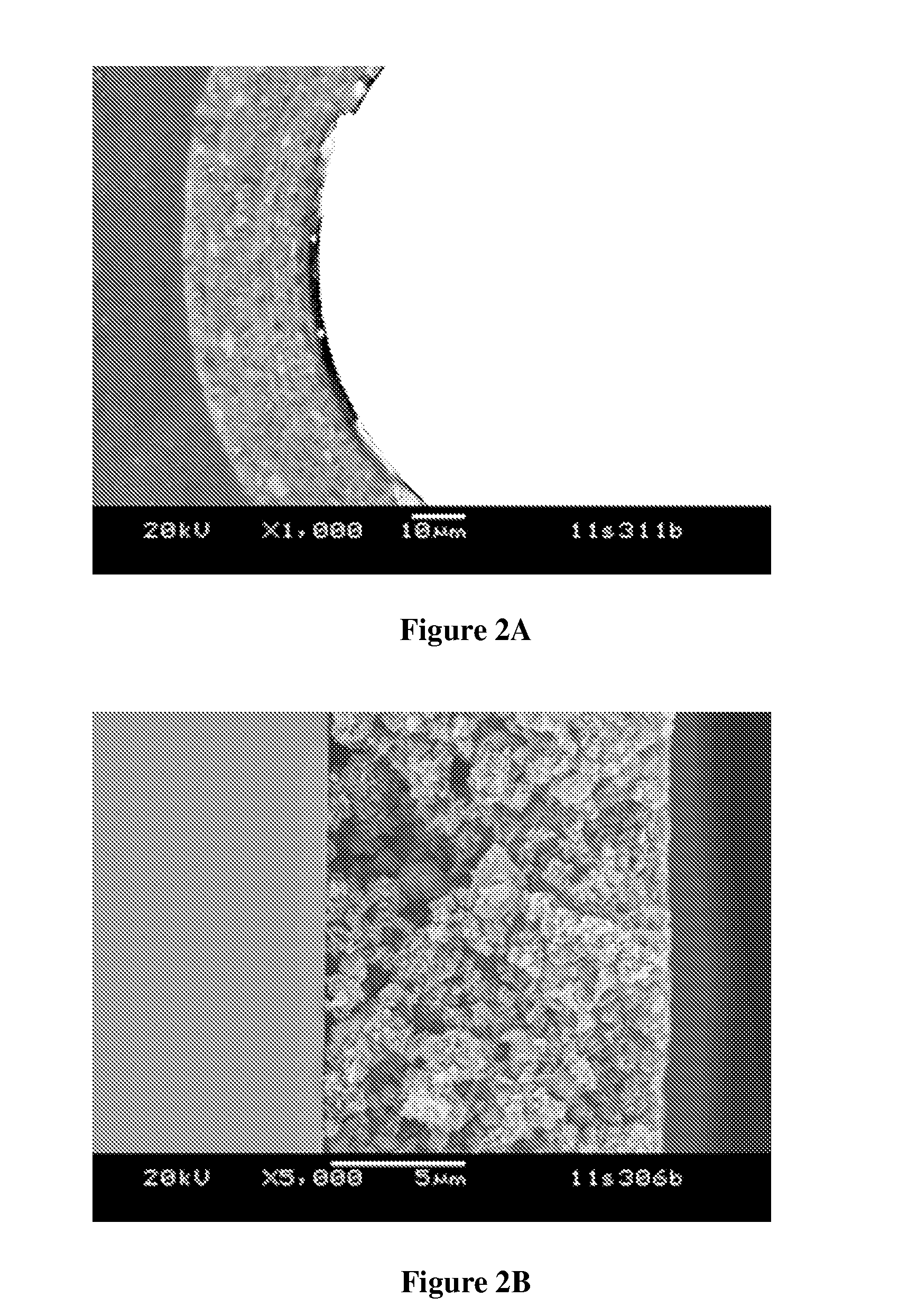

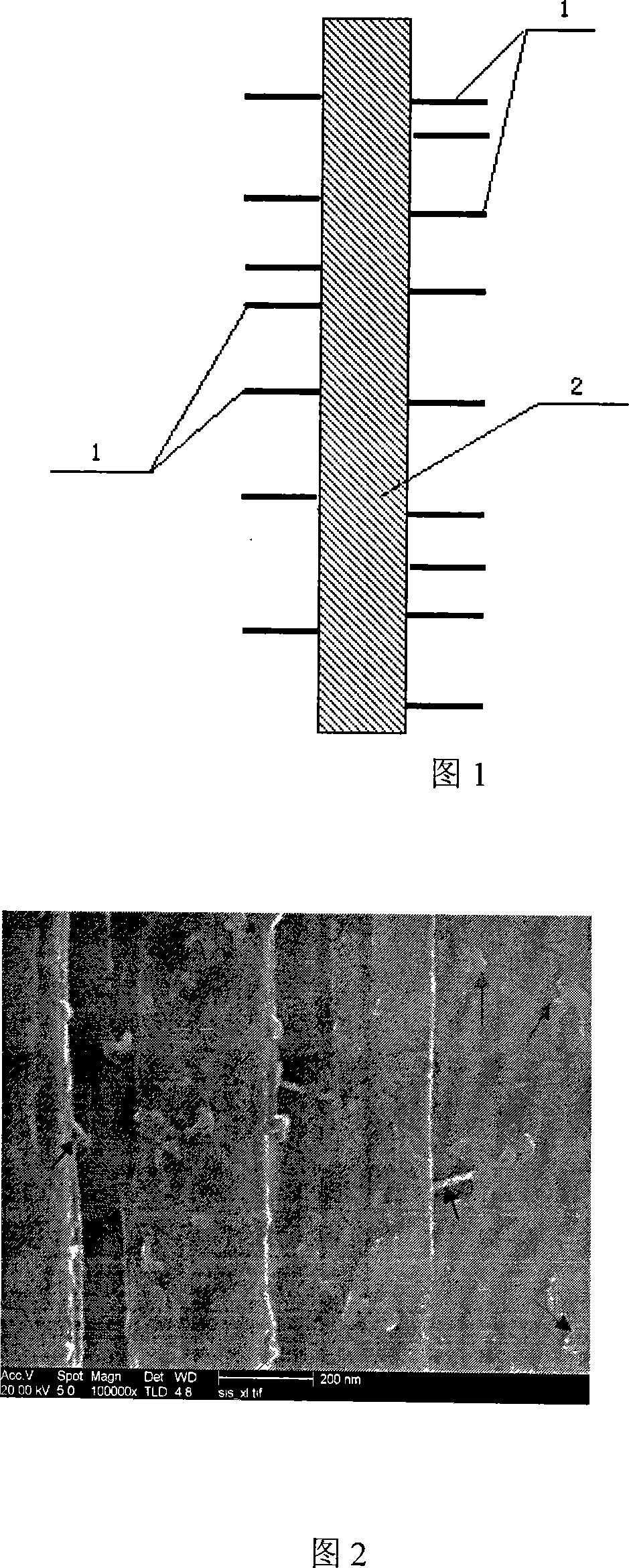

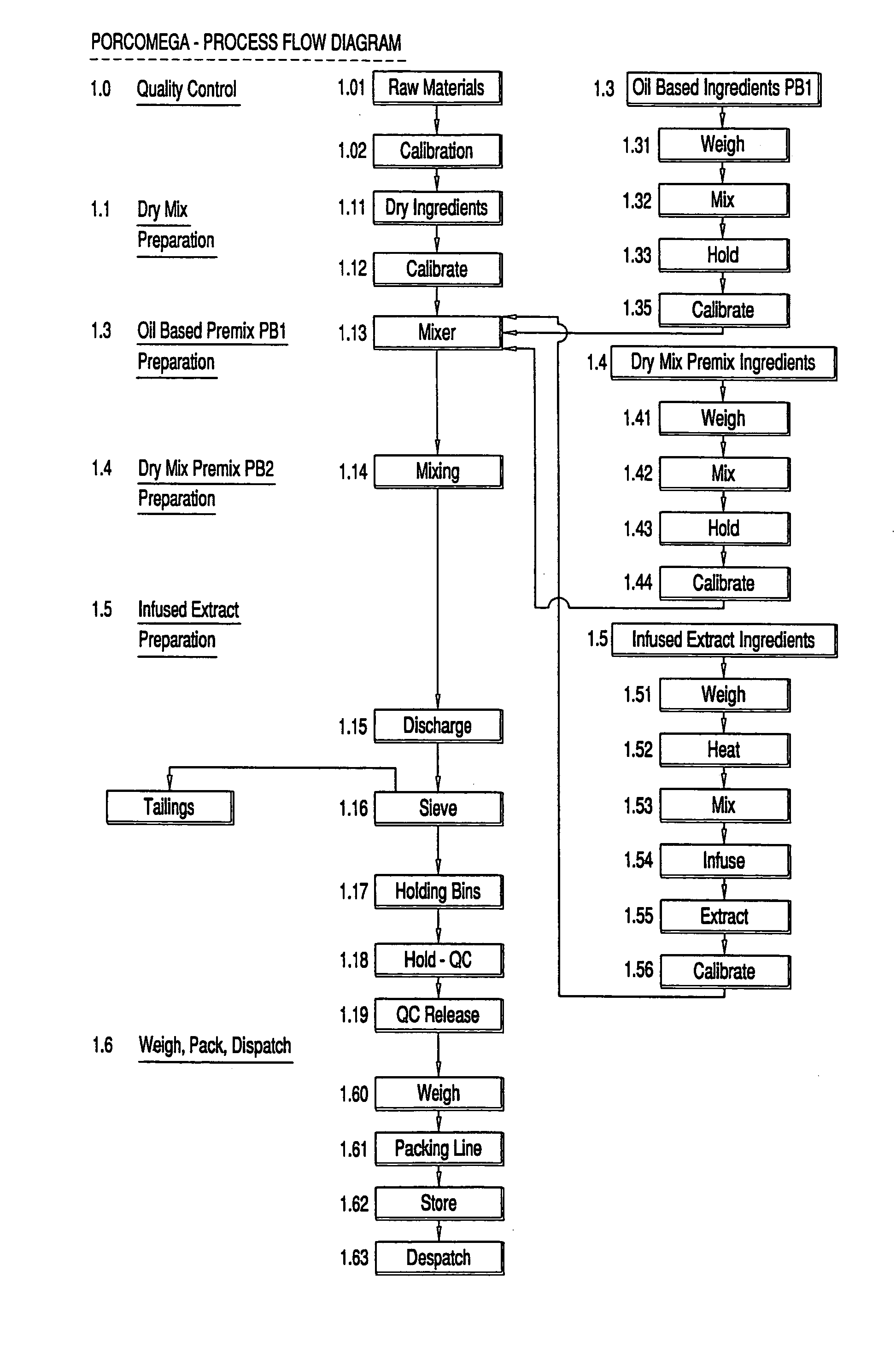

Carbon nano-tube connecting carbon fiber multi-scale reinforcing body and method for producing the same

InactiveCN101173386ATake full advantage of mechanical propertiesRealize chemical bond connectionFibre treatmentArtificial filament chemical after-treatmentFiberCarbon fibers

The invention discloses a multi-scale reinforcement body that carbon nano-tube is connected with carbon fiber and a preparation method aiming at solving the drawbacks of increasing rigidity at the interface, lowering toughness of material and not improving performance of resin base between the fibers and between carbon fiber plywoods after prior carbon fiber treatment is made. The multi-scale reinforcement body of carbon nano-tube connecting carbon fiber is made through combining between a carbon nano-tube decorated by 1, 6 hexamethylenediamine and carbon fiber with acyl chloride functional group on the surface. The preparation method comprises: the carbon nano-tube decorated by 1, 6 hexamethylenediamine and the carbon fiber with acyl chloride functional group on the surface are prepared before put into N,N-dimethylformamide for reaction, thereby getting the multi-scale reinforcement body of carbon nano-tube connecting carbon fiber. The invention has the advantages of big activity on the surface, a plurality of chemical activated functional groups, strong reactive activity, good cohesiveness with the base, improving shearing intensity at the interface for composite material by 127.5% to 144.7% and improving toughness for the base by 34.43% to 48.67%.

Owner:HARBIN INST OF TECH

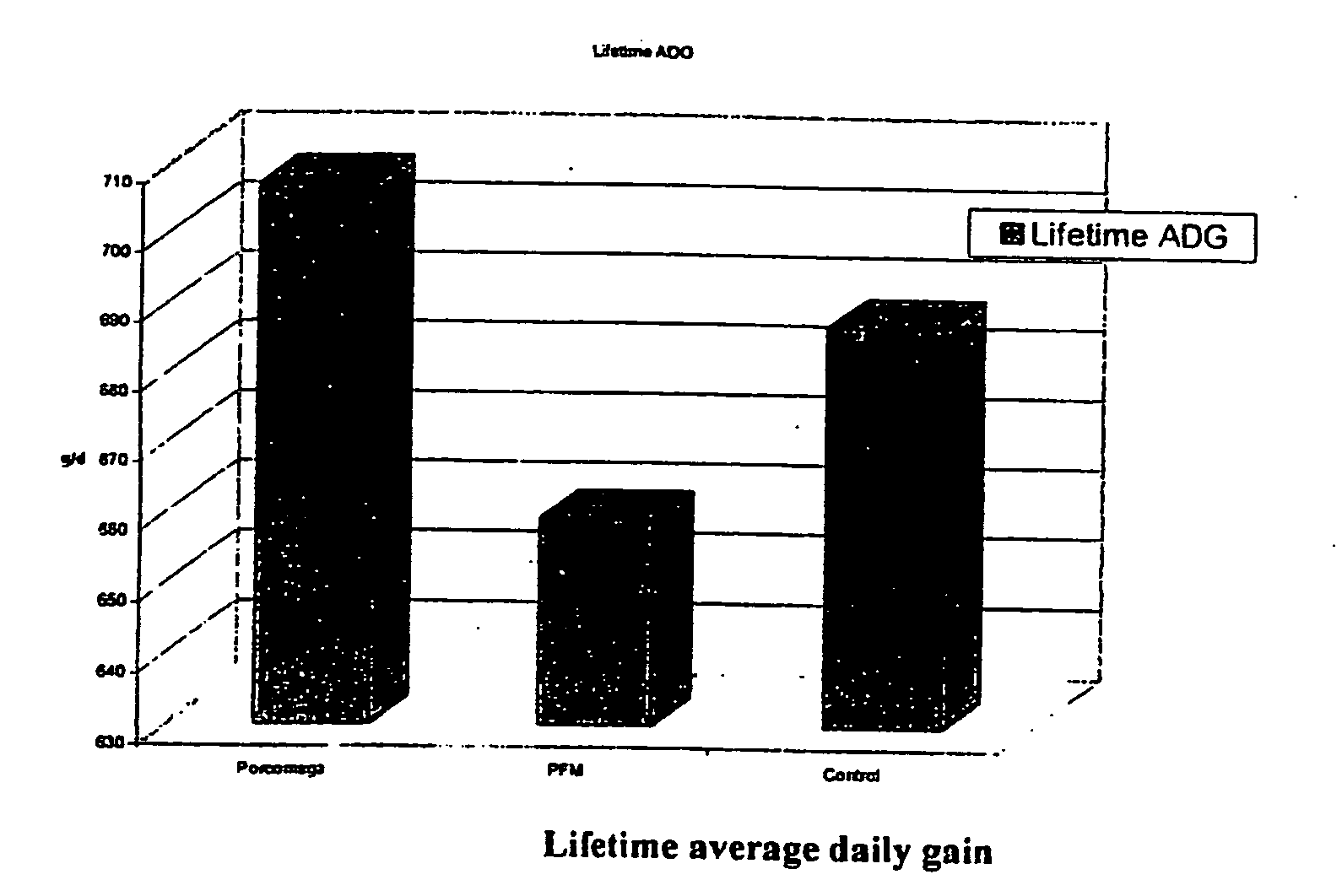

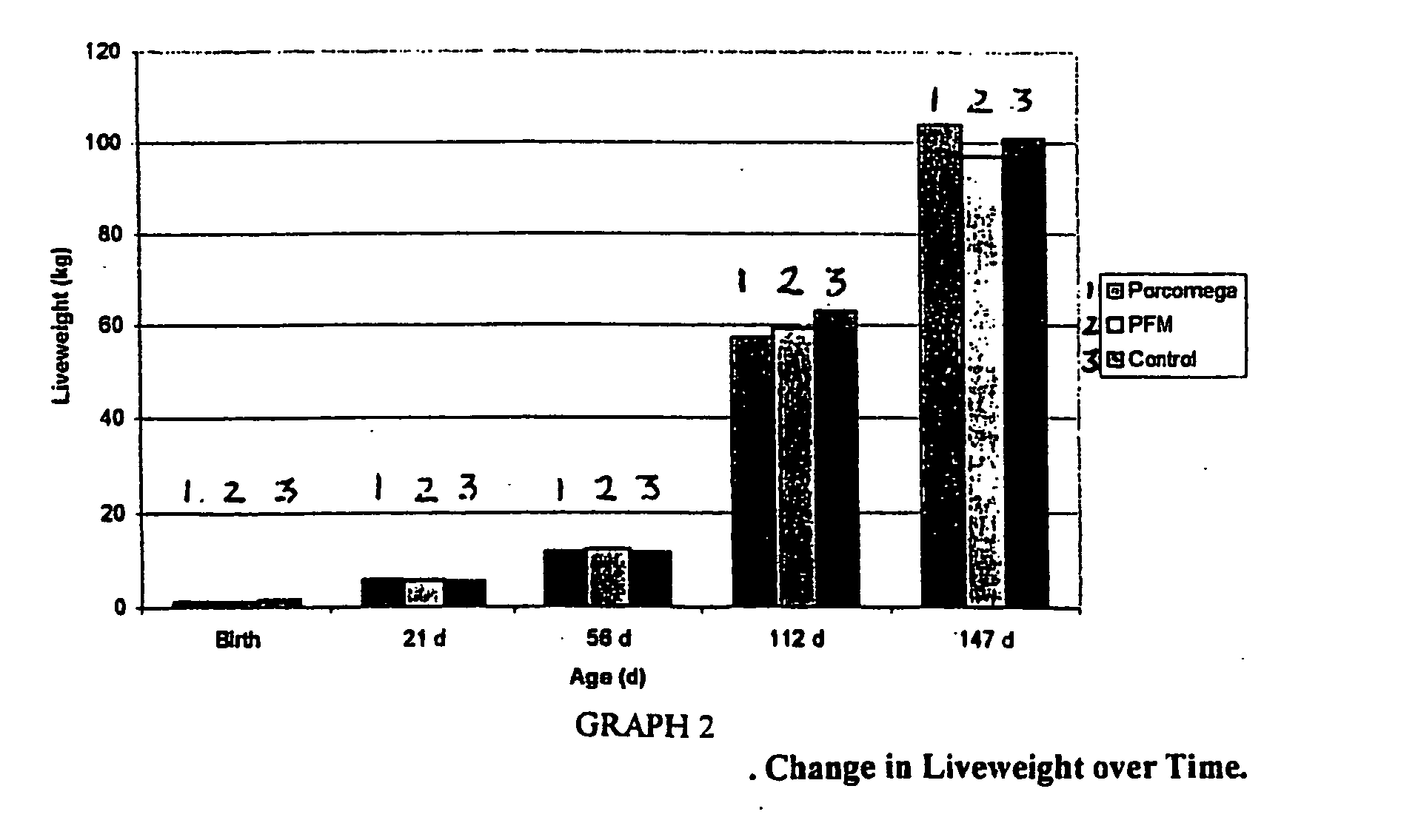

Animal feed supplement for the nutritional enrichment of animal produce

InactiveUS20050266052A1Easy to useMaximises nutritional value of produceBiocideClimate change adaptationAntioxidantAnti fungal

An animal feed supplement includes fish meal as a source of omega 3 long chain fatty acids for inclusion in the diet of an animal. The animal feed supplement also includes at least one naturally-occurring antioxidant; at least one synthetic antioxidant; an antibacterial agent; an anti-mold / anti-fungal agent; and an anti-chemical activity agent. The omega 3 long chain fatty acids are provided at a level which maximises the nutritional value of food produce from the animal, but without taint of the food produce. The feed supplement is greater than 5% of the total dietary intake of the animal.

Owner:BARTLETT GRAIN

Mesoporous material with active metals

A process for treating organic compounds includes providing a composition which includes a substantially mesoporous structure of silica containing at least 97% by volume of pores having a pore size ranging from about 15 Å to about 30 Å and having a micropore volume of at least about 0.01 cc / g, wherein the mesoporous structure has incorporated therewith at least about 0.02% by weight of at least one catalytically and / or chemically active heteroatom selected from the group consisting of Al, Ti, V, Cr, Zn, Fe, Sn, Mo, Ga, Ni, Co, In, Zr, Mn, Cu, Mg, Pd, Pt and W, and the catalyst has an X-ray diffraction pattern with one peak at 0.3° to about 3.5° at 2θ. The catalyst is contacted with an organic feed under reaction conditions wherein the treating process is selected from alkylation, acylation, oligomerization, selective oxidation, hydrotreating, isomerization, demetalation, catalytic dewaxing, hydroxylation, hydrogenation, ammoximation, isomerization, dehydrogenation, cracking and adsorption.

Owner:SHAN ZHIPING +5

Metal peroxide films

ActiveUS20050234178A1Efficient use ofImprove wettabilityNanotechZirconium compoundsParticulatesNanoparticle

Disclosed are adhesive coating compositions containing a metal peroxide for producing clear colorless adhesive coatings on substrates, particularly micro particulate substrates. In one preferred embodiment the nanoparticle coatings are chemically active and function at a high level of efficiency due to the high total surface area of the micro particulate substrate. Also disclosed are coated substrates and compositions having nanoparticles bound to a substrate by the coating compositions.

Owner:PURETI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com