Micron-order Fenton-like catalyst, and preparation method and application thereof

A catalyst, a type of technology, applied in the field of catalysis, can solve problems such as instability, difficult recovery, and low catalyst activity, and achieve the effects of easy recovery, simple preparation process, and wide application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh 2.416g Cu(NO 3 ) 2 ·3H 2 O with 4.04g Fe(NO 3 ) 3 9H 2 O was dissolved in 60mL of water and stirred at 25°C for 2h. With stirring, 15 mL of a solution containing 8 g of NaOH was added dropwise. Stir for another 30 min, add 1 mL of n-propionaldehyde, and continue stirring for 10 min to obtain a dark brown sol. Finally, the obtained 75mL dark brown sol was transferred to a 10mL polytetrafluoroethylene reactor and kept at 180°C for 48h to obtain micron-sized CuFeO 2 Fenton-like catalyst.

Embodiment 2

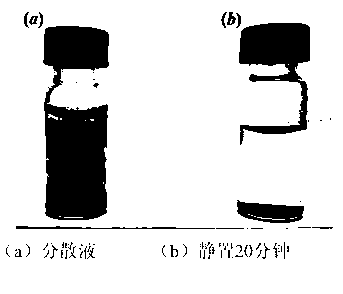

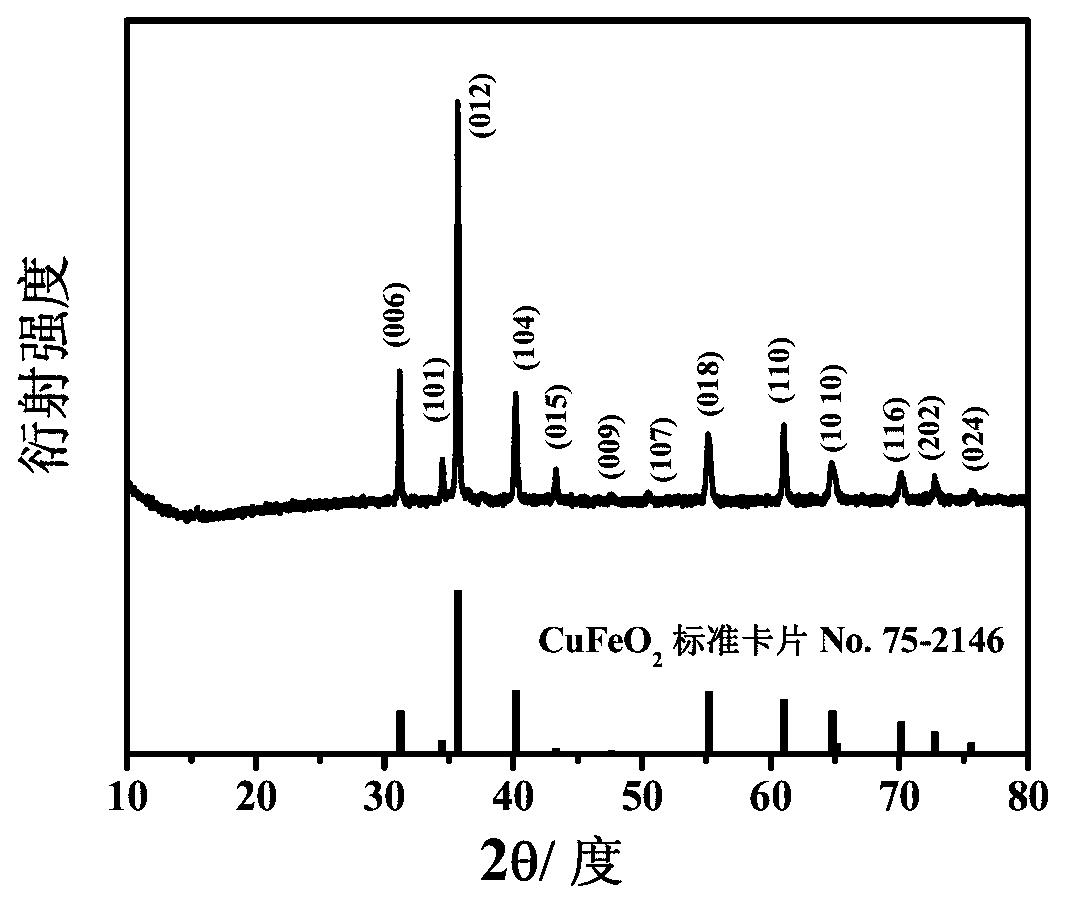

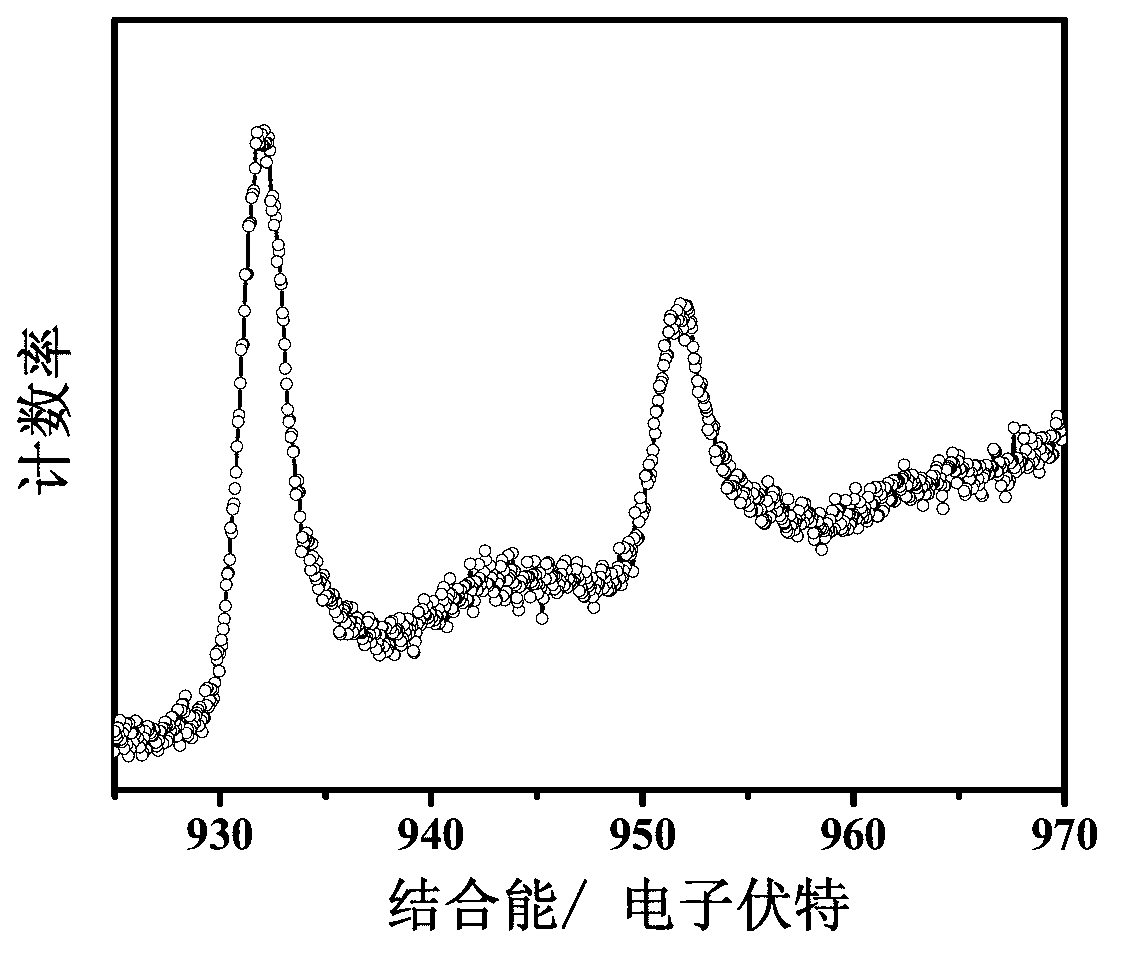

[0035] The XRD collection of illustrative plates of the granular product prepared by the inventive method and chalcopyrite CuFeO 2 Standard XRD card (No.75-2146) compares, finds that the product that the inventive method makes has typical chalcopyrite structure, does not have the generation of impurity phases such as iron oxide, cupric oxide and cuprous oxide, and its result and CuFeO 2 Standard XRD spectrogram (JCPDS File No.75-2146) is consistent, proves that the product prepared by the present invention is indeed chalcopyrite CuFeO 2 ,See figure 1 . The binding energy of the product surface Cu2p3 / 2 and Cu2p1 / 2 that the inventive method makes is respectively 932.1eV and 951.8eV, proves that the valence state of Cu on the product surface that the inventive method makes is monovalent, see figure 2 . The granular product prepared by the method of the invention is a rhombohedral hexahedron, and the particle diameter is about 2-3 μm. See image 3 . After the dispersion liq...

Embodiment 3

[0037] Micron CuFeO of the present invention 2 The Fenton-like catalyst was dispersed in 3mL distilled water, ultrasonically dispersed, and an equal volume of 1mmol L -1 3,3,5,5-Tetramethylbenzidine aqueous solution mixed, then add H 2 o 2 (final concentration is 5.0×10 -7 ~2.0×10 -4 mol L -1 ). At this time, the substrate 3,3,5,5-tetramethylbenzidine will be catalyzed and oxidized to generate a blue product with a maximum absorption wavelength of 650nm. After reacting for 15 minutes, quickly take 2 mL of the reaction solution and centrifuge it, and measure its absorbance at 650 nm on a UV-Vis spectrophotometer. The change value of the absorbance A of this kind of enzyme catalytic system at 650nm and H 2 o 2 Concentration at 5.0×10 -7 ~2.0×10 -4 mol L -1 There is a good linear relationship in the range. Utilizing the excellent performance of this kind of enzyme catalytic system, it can be conveniently used in low concentration H in actual samples such as food, envi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com