Patents

Literature

233 results about "Cupric nitrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper(II) nitrate, also known as cupric nitrate, is a chemical compound. Its chemical formula is Cu(NO3)2. It contains copper in its +2 oxidation state. It also contains nitrate ions.

Micron-order Fenton-like catalyst, and preparation method and application thereof

InactiveCN103285862AEasy to makeRaw materials are cheap and easy to getIron compoundsColor/spectral properties measurementsOrganic solventPeroxidase

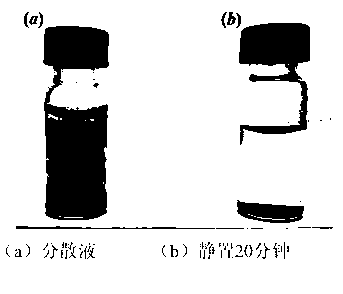

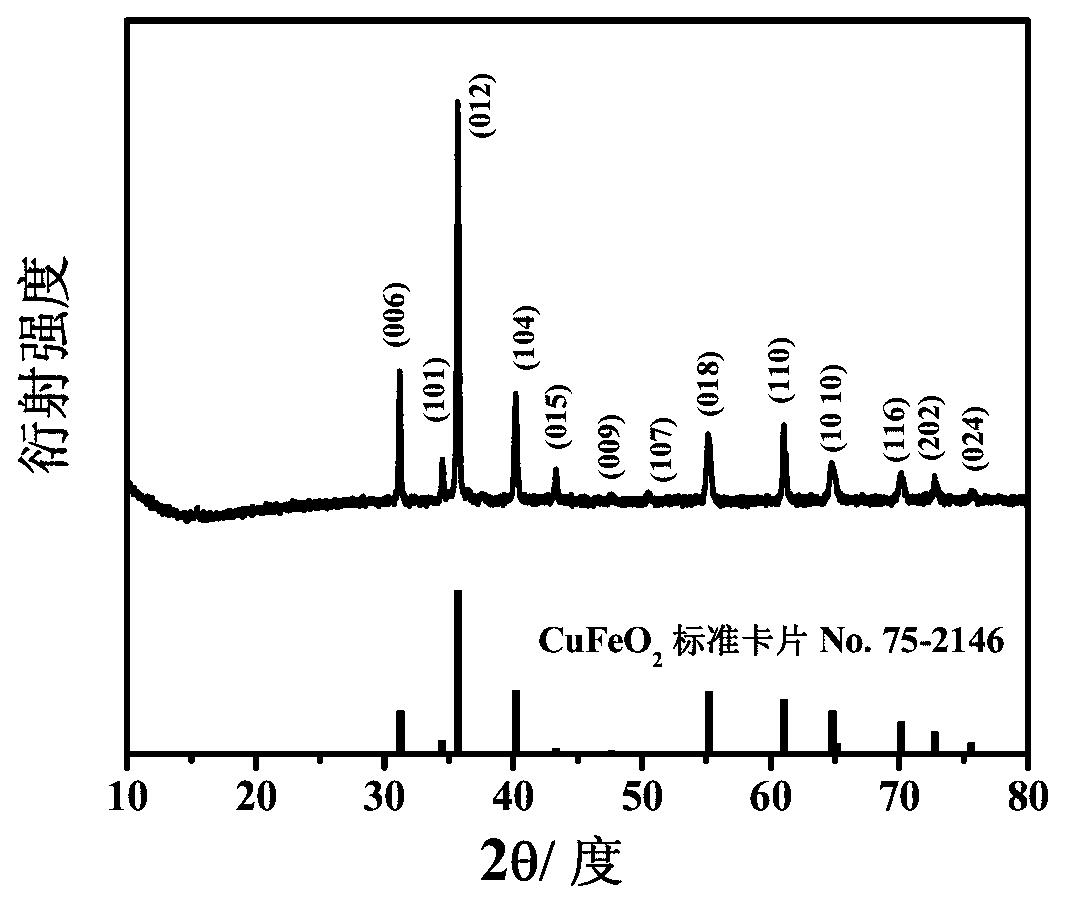

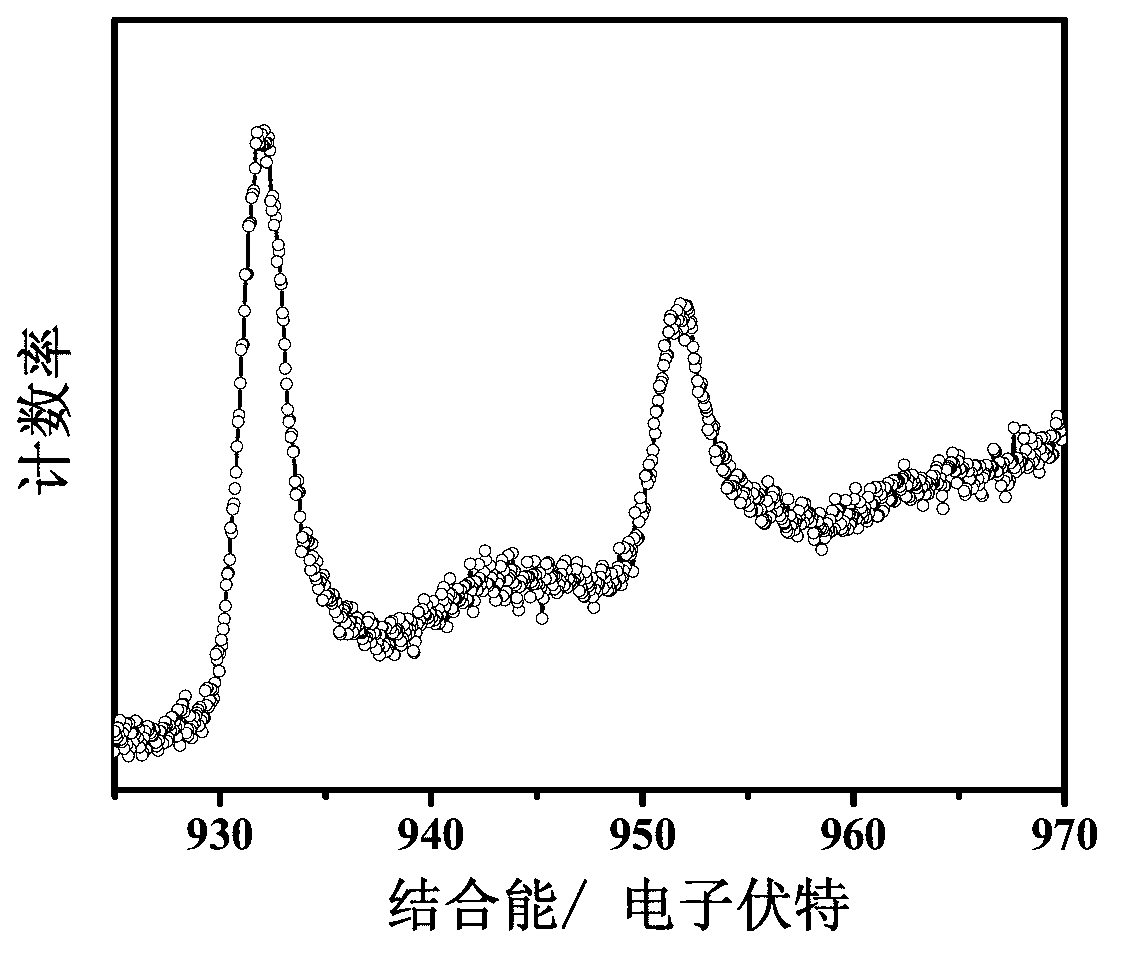

The invention provides a Fenton-like catalyst which is chalcopyrite CuFeO2. A preparation method for the Fenton-like catalyst comprises the following steps: dissolving the raw materials ferric nitrate and cupric nitrate in water; adding alkali and a weak reducing agent to prepare a sol; and subjecting the sol to a hydro-thermal reaction so as to prepare the CuFeO2 Fenton-like catalyst. The Fenton-like catalyst provided by the invention has the advantages of simple preparation process, low cost, no organic solvent, environment-friendliness and stable chemical activity; since the particle of the Fenton-like catalyst is micron order, the Fenton-like catalyst can rapidly settle, and thus, the Fenton-like catalyst can be easily recovered and be repeatedly used many times. The Fenton-like catalyst can be used as a natural peroxidase substitute and used for detection and analysis of H2O2 content in food, biological and environmental samples and for degradation and mineralization of organic pollutants.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES +1

Preparation method of metal-organic framework material for adsorbing separation of carbon dioxide/ methane

ActiveCN102728331ARelieve pressureReduce energy consumptionOther chemical processesDispersed particle separationMetal-organic frameworkCupric nitrate

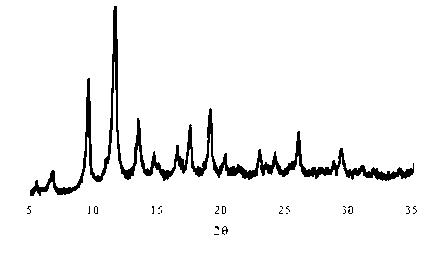

The invention discloses a preparation method of a metal-organic framework material for adsorbing separation of carbon dioxide / methane. The preparation method comprises the following steps of: (1) mixing 0.46-1.16mol / L cupric nitrate water solution and 0.23-0.58mol / L trimesic acid ethanol solution, fully stirring, then adding into a stainless steel reaction kettle provided with a polytetrafluoroethylene inner liner for sealing, and carrying out solvent thermal reaction while controlling the crystallization temperature to be 60-150 DEG C and the crystallization time at 12-24h; (2) opening the stainless steel reaction kettle, filtering, sequentially washing by methyl alcohol and deionized water, and drying at the temperature of 80-105 DEG C to obtain blue crystal; and (3) vacuumizing the blue crystal at the temperature of 150-200 DEG C to obtain the Cu-containing metal-organic framework material.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Sponge composite metallic organic framework material for adsorption separation

ActiveCN110038540AStrong loadHigh load rateGas treatmentOther chemical processesFragilityMetal-organic framework

The invention relates to a sponge composite metallic organic framework material for adsorption separation and belongs to the technical field of materials. According to the invention, a two-step in-situ growth method is adopted for loading MOFs (metallic organic framework material) into a duct in a sponge carrier. The MOFs is synthesized from following organic ligands and metal salts, wherein the organic ligands include pyrazine, trimesic acid, terephthalic acid, 2,5-dihydroxyterephthalic acid, and the metal salts include cupric fluosilicate, magnesium nitrate, zirconium chloride, cupric nitrate, chromic nitrate, ferric nitrate, aluminum nitrate and hydrates thereof. According to a preparation method provided by the invention, a large amount of MOFs loaded in the duct in the sponge carriercan be realized; MOFs load rate is high; load is stable; the defects of fragility and easiness in loss of MOFs powder can be overcome; a breakthrough experiment proves that the material provided by the invention has the characteristics of high CO2-absorbing capacity, high adsorption separation selectivity, stable adsorption separation property, and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

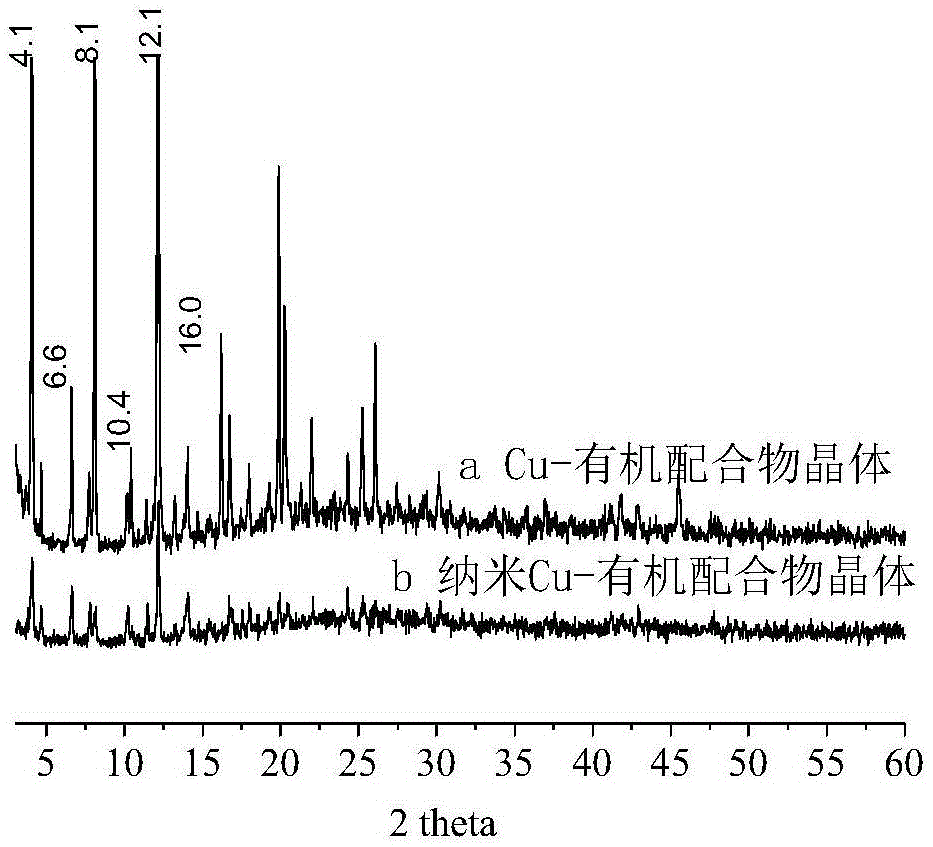

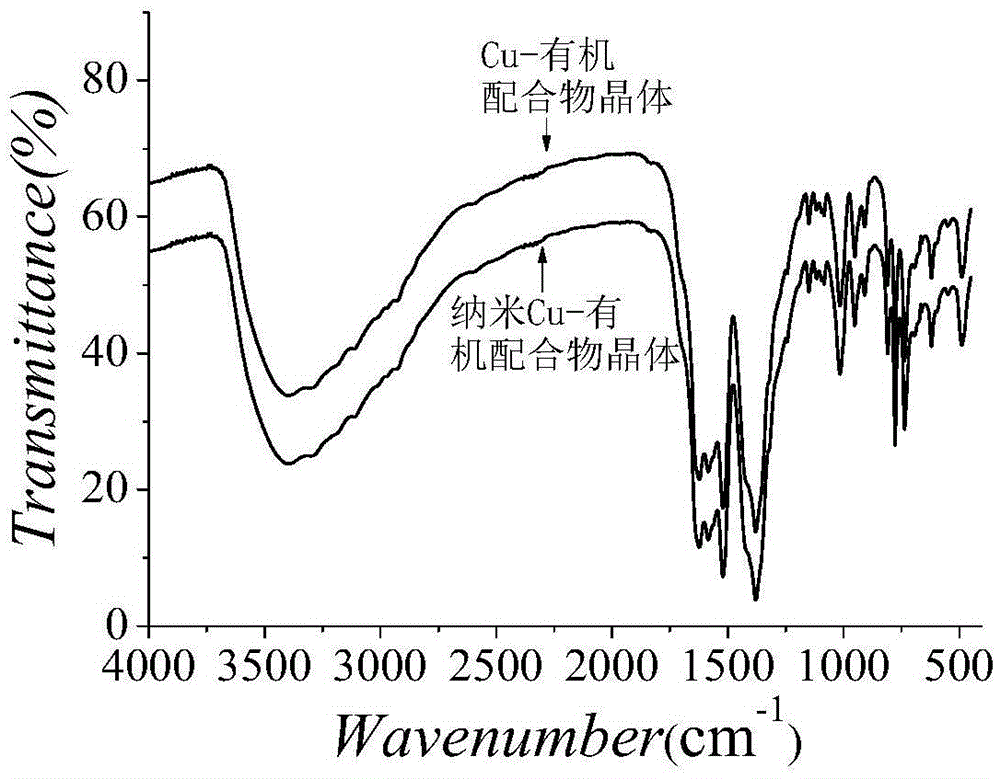

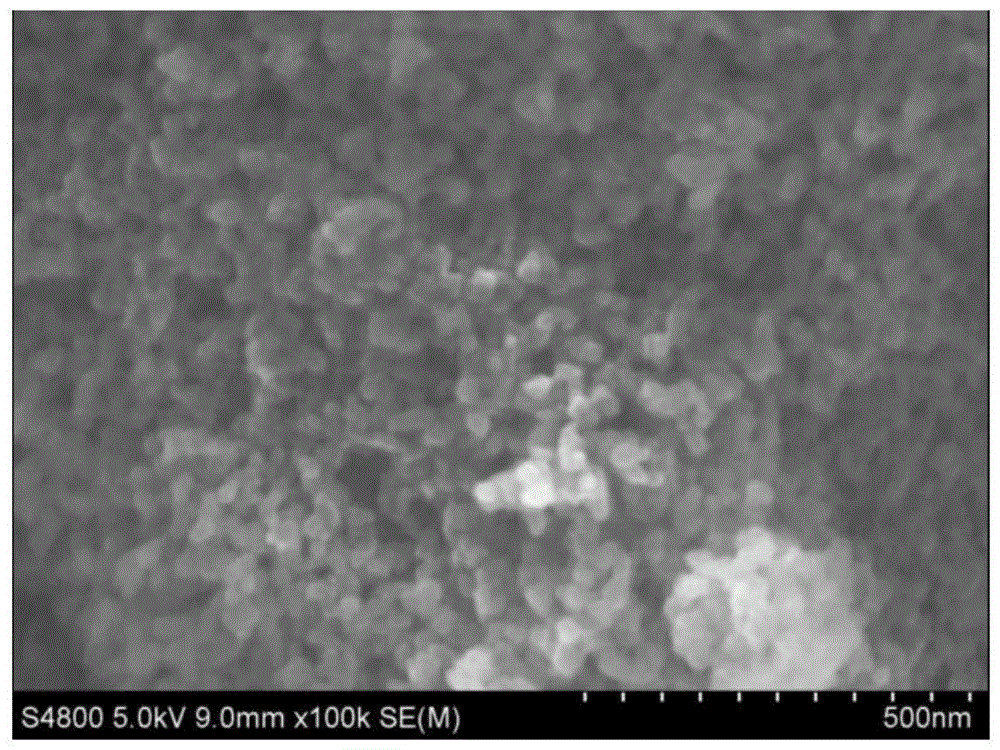

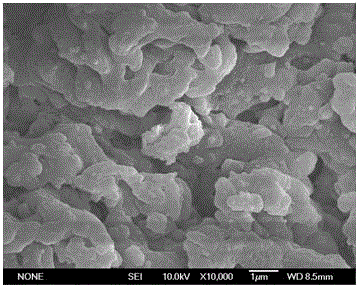

Preparation method and application of nanometer Cu-organic complex crystal

InactiveCN105524007ASimple methodSmall sizeOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsChemical industryM-aminophenol

The invention relates to a preparation method and application of a nanometer Cu-organic complex crystal, belonging to the technical fields of metal organic complexes, material science, nano-materials, chemical industry, catalysis and the like. According to the invention, cupric nitrate and 5-aminoisophthalic acid are used as main raw materials, and a metal organic complex gel method is employed to prepare the nanometer Cu-organic complex crystal. The preparation method has the advantages of low cost for raw materials, easy process and operation and low energy consumption. The nanometer Cu-organic complex crystal can realize high-efficiency catalytic reduction of 4-nitrophenol into 4-aminophenol and has good application prospect in heterogeneous catalytic reduction.

Owner:SHANDONG NORMAL UNIV

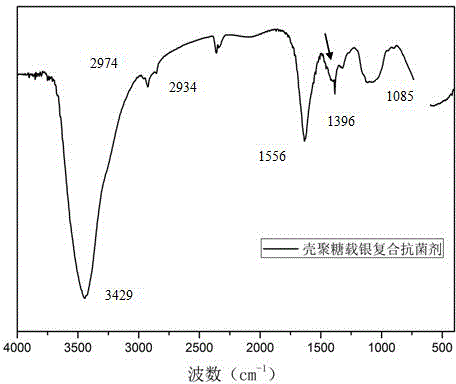

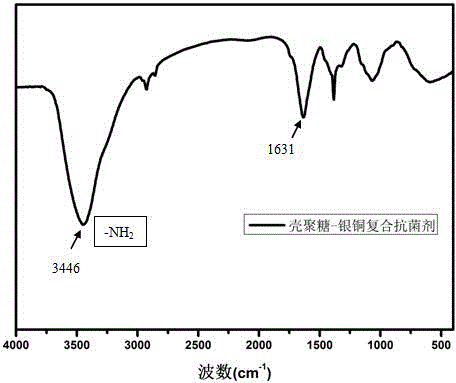

Method for preparing complex antimicrobial agent by blending chitosan and silver copper

InactiveCN104145993AReduce usageImprove antibacterial propertiesAntibacterial agentsOrganic active ingredientsEscherichia coliEnvironmental resistance

The invention relates to a method for preparing a complex antimicrobial agent by blending chitosan and silver copper. The method comprises the following steps: silver nitrate and cupric nitrate are blended according to the concentration ratio of 1:30 to 1:80, and then are blended with chitosan. Therefore, a light blue antibacterial agent powder is prepared. According to the method provided by the invention, the usage amount of silver is reduced, the chitosan is also used as a reducing agent, chemical reagents are no longer added, and the toxicity of an antibacterial agent is reduced. Due to the change of technological conditions, the oxidation-reduction reaction of the chitosan and the cupric nitrate can be performed sufficiently, an aldehyde group (-CHO) is generated in the reaction, Ag<+> is enabled to be completely reduced to elemental silver, Cu<2+> is hibernated in a chitosan basal body, so as to play a synergistic antibacterial effect, a remarkable inhibiting effect on escherichia coli and staphylococcus aureus is detected through an inhibition ring test, an inhibition ring which is equal to or greater than 10 mm is formed under a culture condition of 37 DEG C, a remarkable bacteriostatic effect is played, materials used cause no harm to human body, the price is low, and the novel complex antimicrobial agent is green and environment-friendly.

Owner:TAIYUAN UNIV OF TECH +1

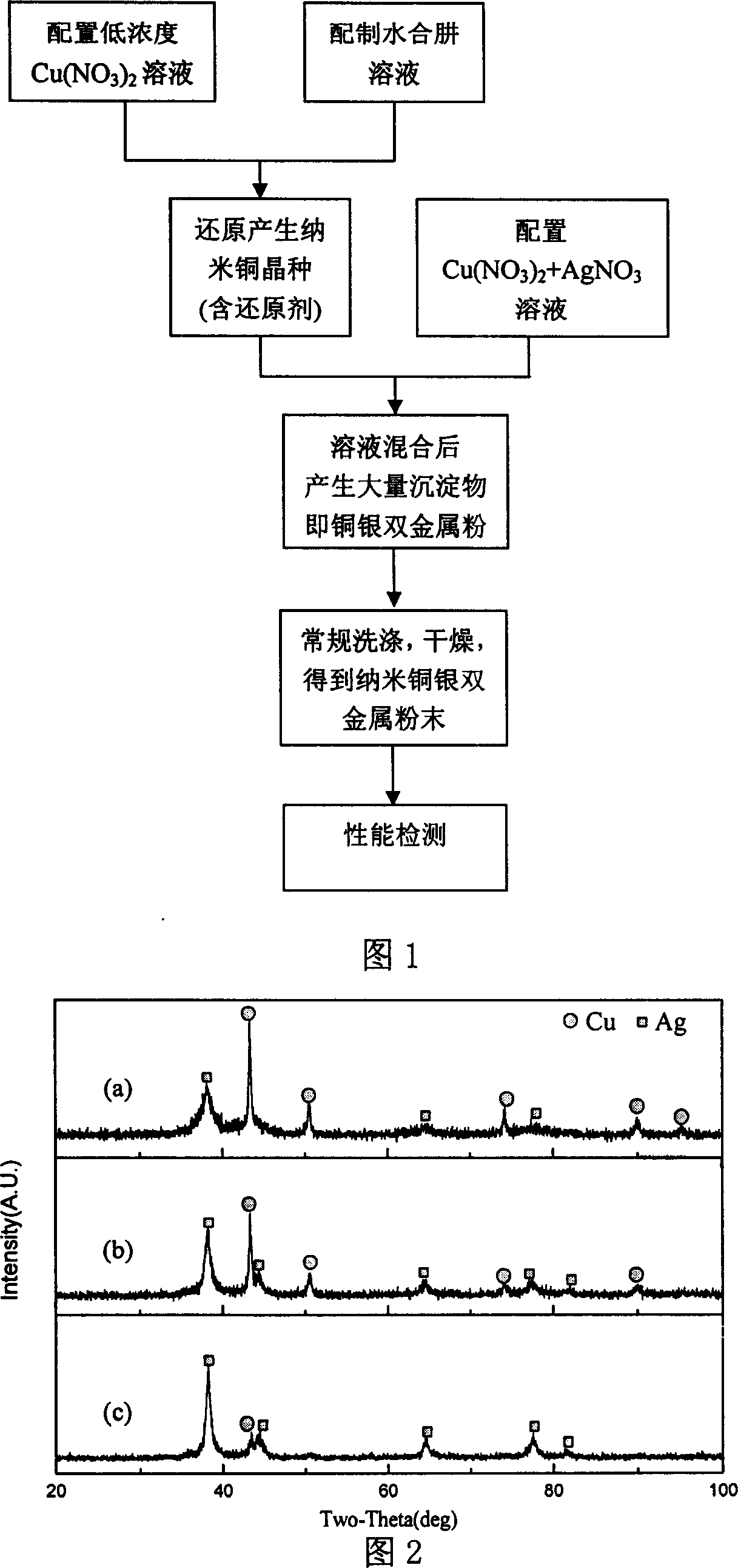

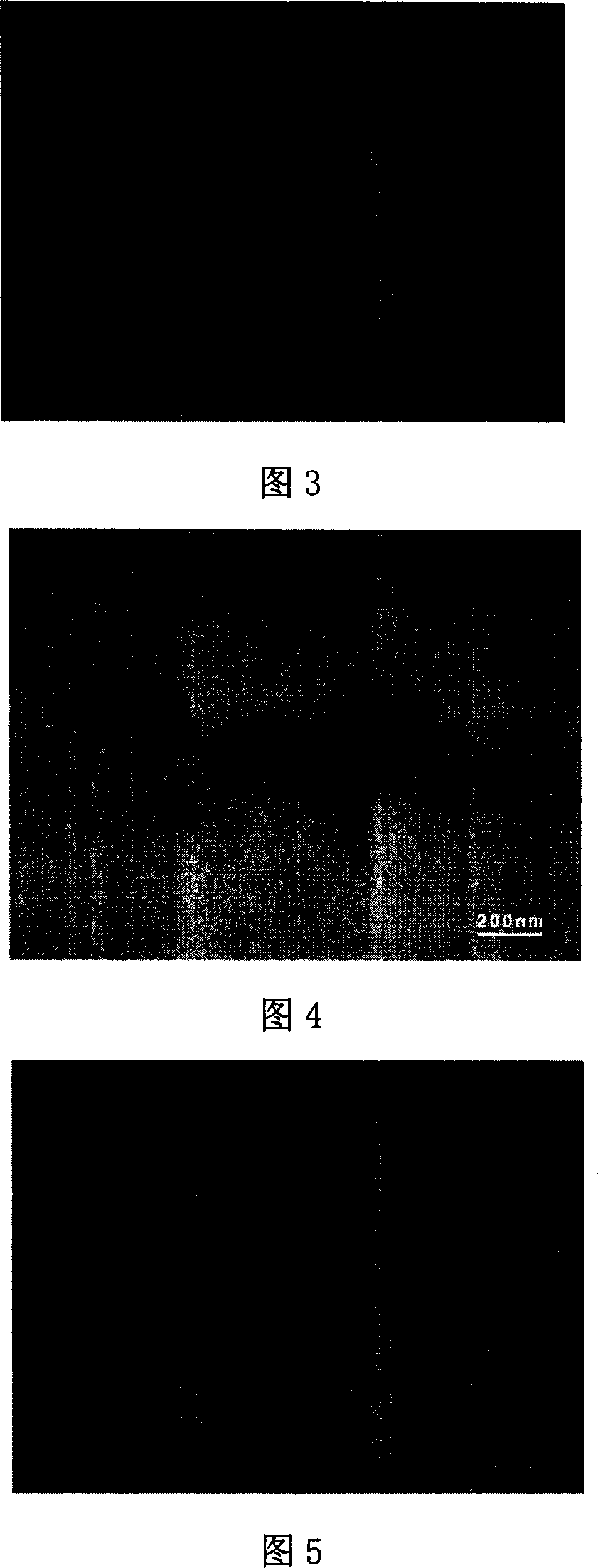

Preparation method of nanometer copper-silver bimetallic composite powder

The invention provides a nano-copper-silver double metal powder preparation method--crystal nucleon growth method. The method prepares nano-copper seed crystal using chemical reduction copper ions, makes the copper and silver generate on nano-copper seed crystal to preparing copper silver double metal powder. The process is: first dissolving a small amount of copper ion salts cupric nitrate into water, preparing cup ammonium solution with ammonia complication, then deacidizing it into sol containing nano-copper seed crystal in the water solution of hydrazine hydrate, then making the silver nitrate and cupric nitrate grow on the nano-copper seed crystal in the deacidized process to forming copper-silver double metal particles, preparing final product after washing and drying. The method solves the shortcomings of big waste of copper and silver and non-uniform product quality in prior art. The particle size of prepared nano-copper-silver double metal powder is less than 100 nm, and it has good dispersion and good oxidation resistance property.

Owner:BEIJING UNIV OF CHEM TECH

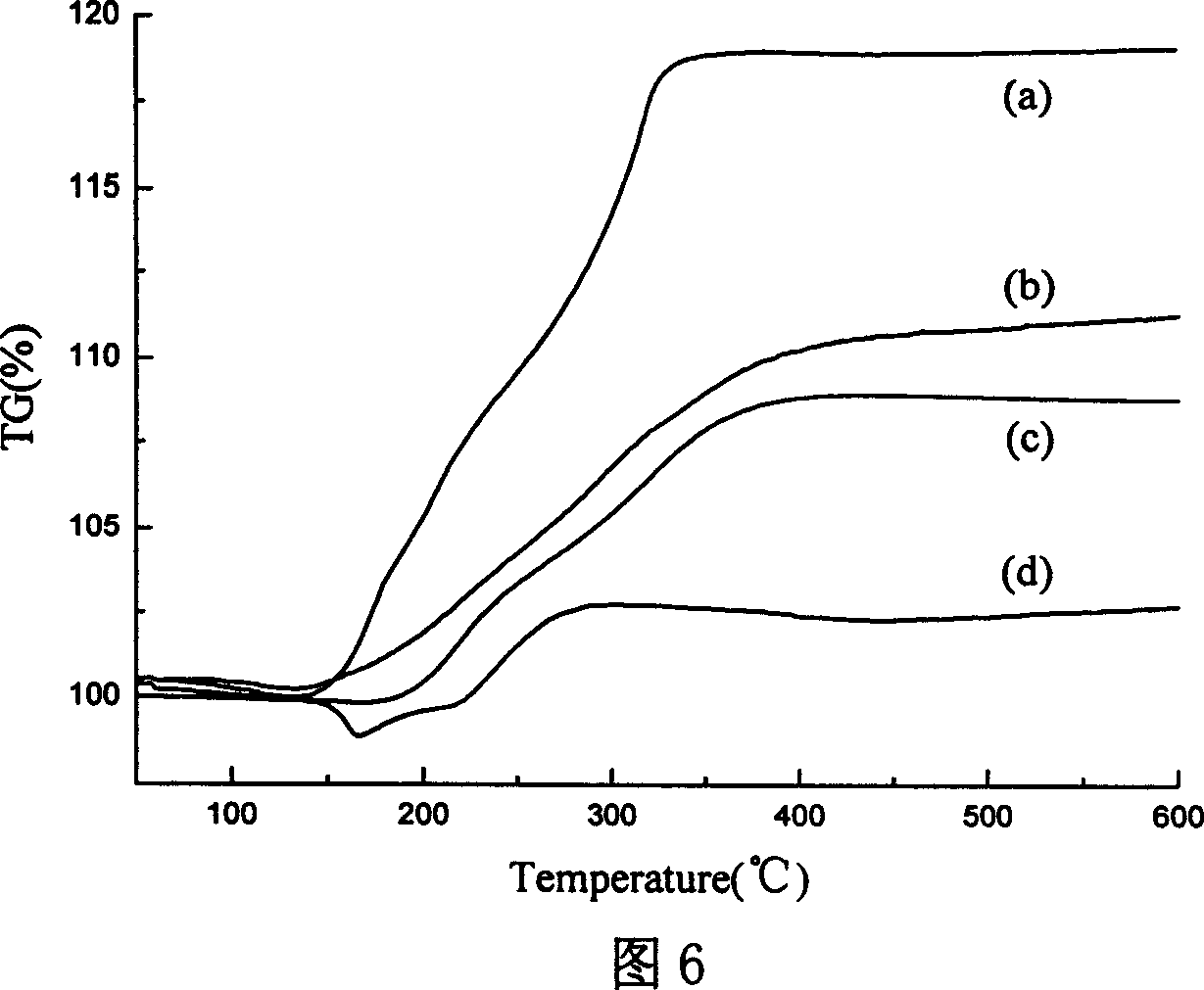

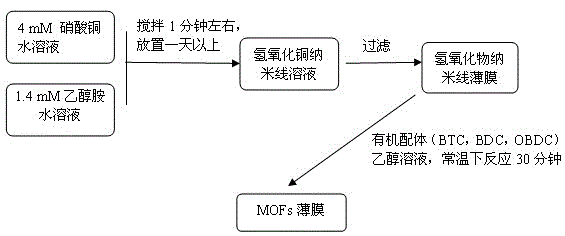

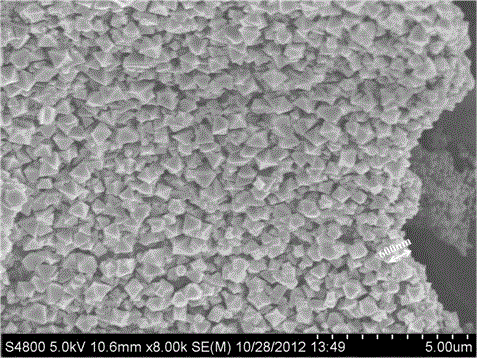

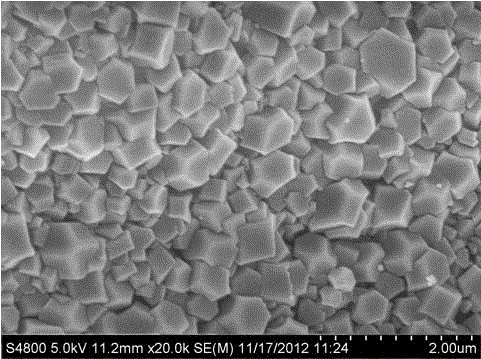

Method of rapidly preparing metal organic framework material thin-film from hydroxide nanowires and organic ligands under normal temperature

The invention discloses a method of rapidly preparing a metal organic framework material thin-film from hydroxide nanowires and organic ligands under a normal temperature. The method comprises (1) adding an ethanolamine aqueous solution into cupric nitrate, zinc nitrate or cadmium nitrate aqueous solution of a same volume under magnetic stirring, slowing down a stirring speed to obtain corresponding copper hydroxide, zinc hydroxide or cadmium hydroxide nanowire solution, and directly filtering the nanowire solution through a porous alumina film to form a nanowire layer; (2) adding the nanowire layer into an organic ligand solution with ethanol, octanol or N,N-dimethyl formamide as a solvent, and reacting for 30 minutes under the normal temperature to obtain the metal organic framework material thin-film. The method provided by the invention can directly prepare large-area compact thin-film on a porous substrate under the normal temperature, and the method is simple in operation steps, low in cost, and environmental-protective. Reaction residues can be easily recovered. The prepared thin-film can stably exist. The method expands an application range of the metal organic framework material thin-film.

Owner:ZHEJIANG UNIV

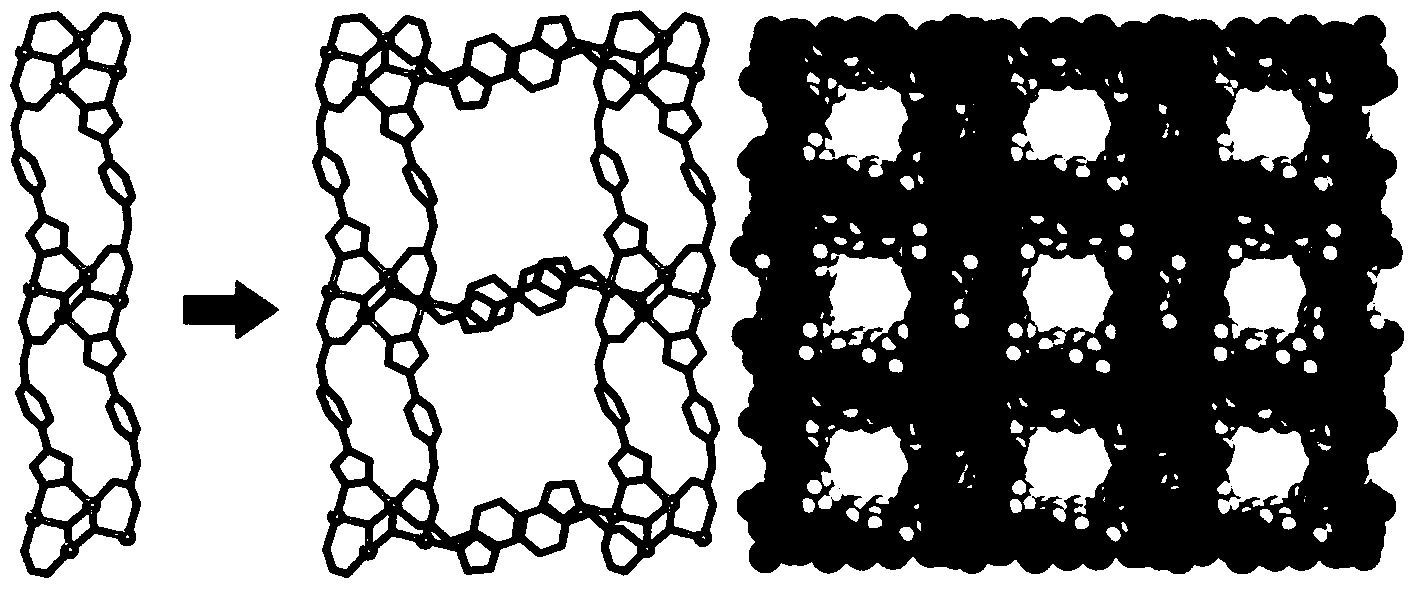

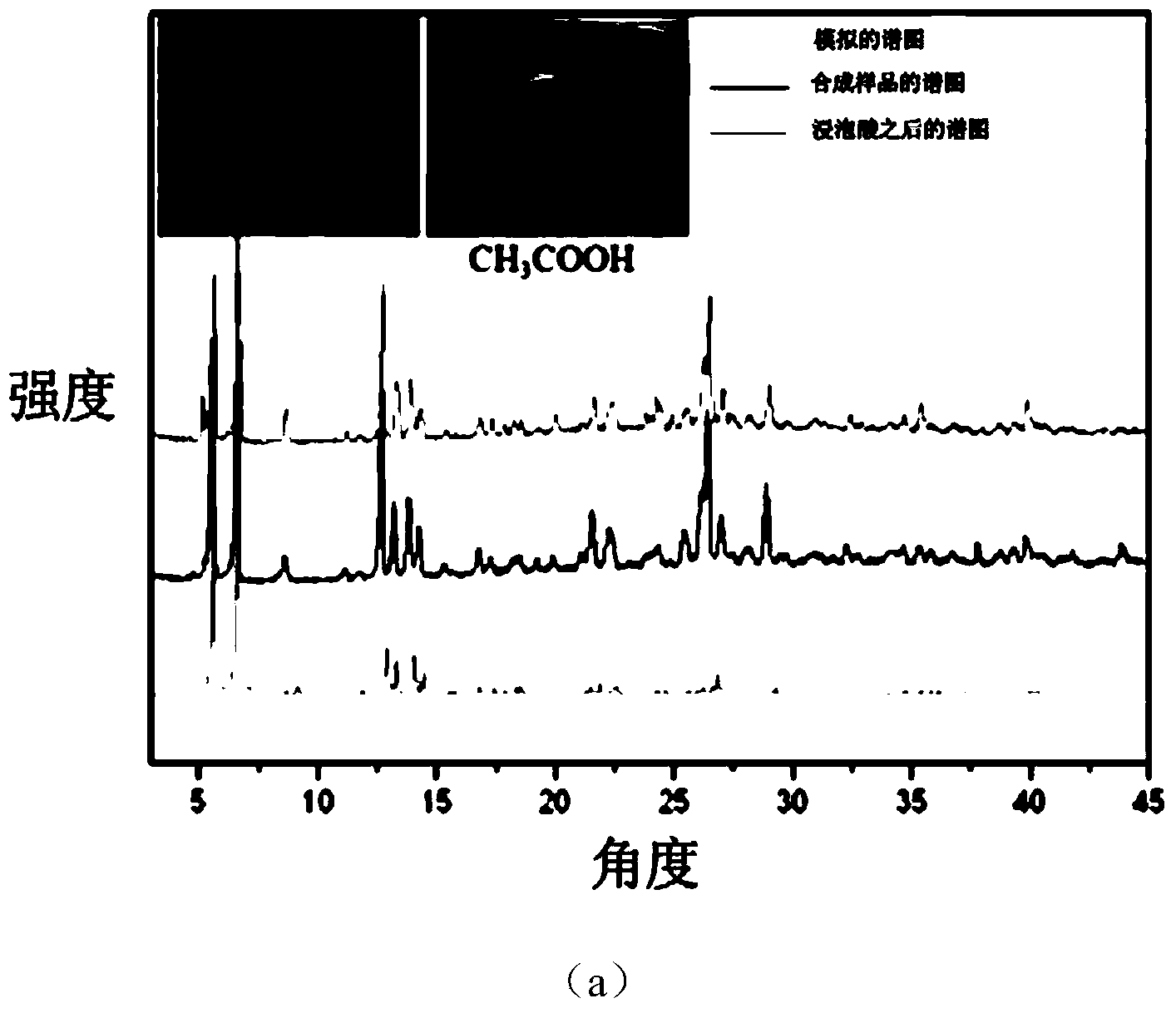

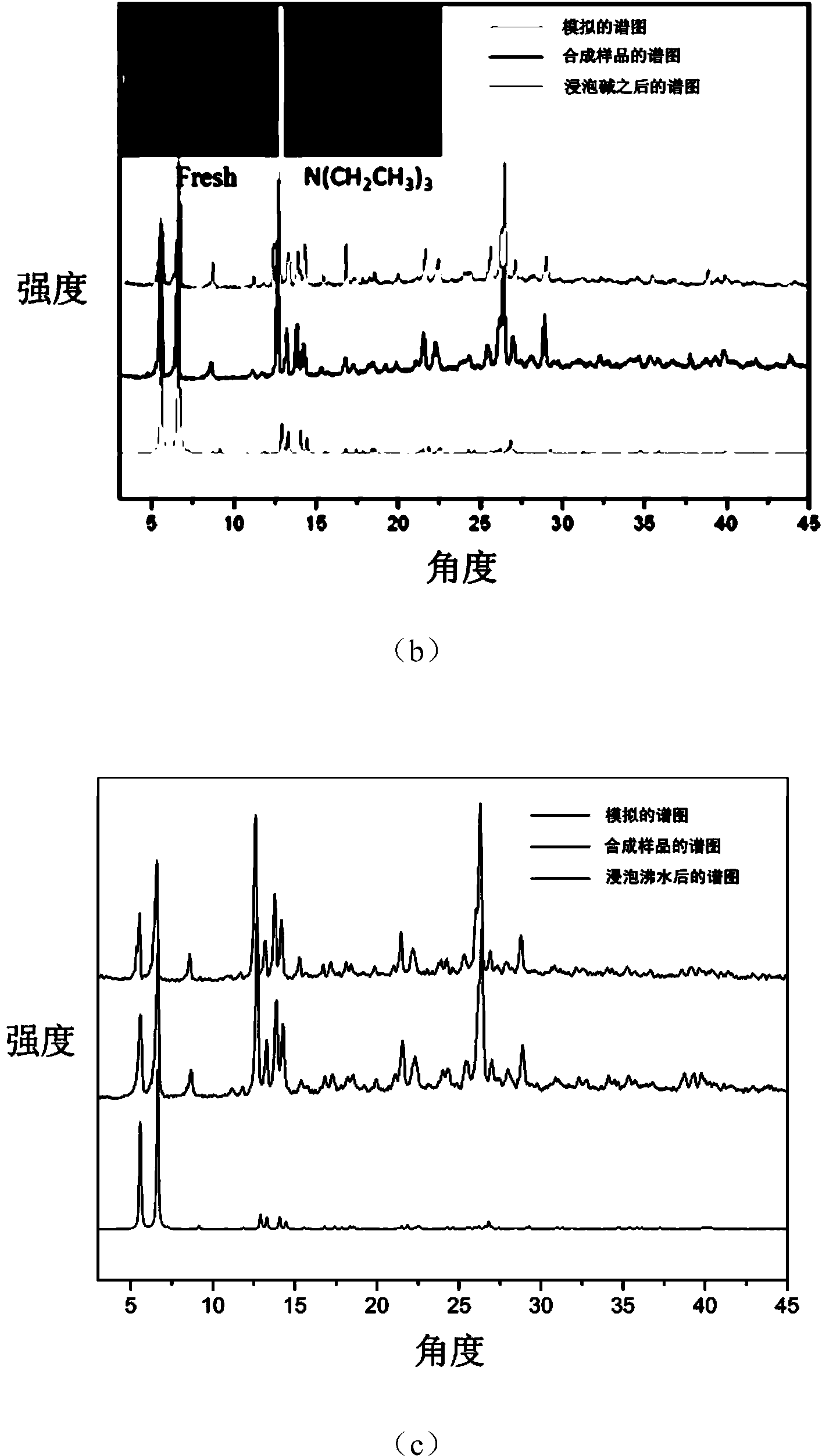

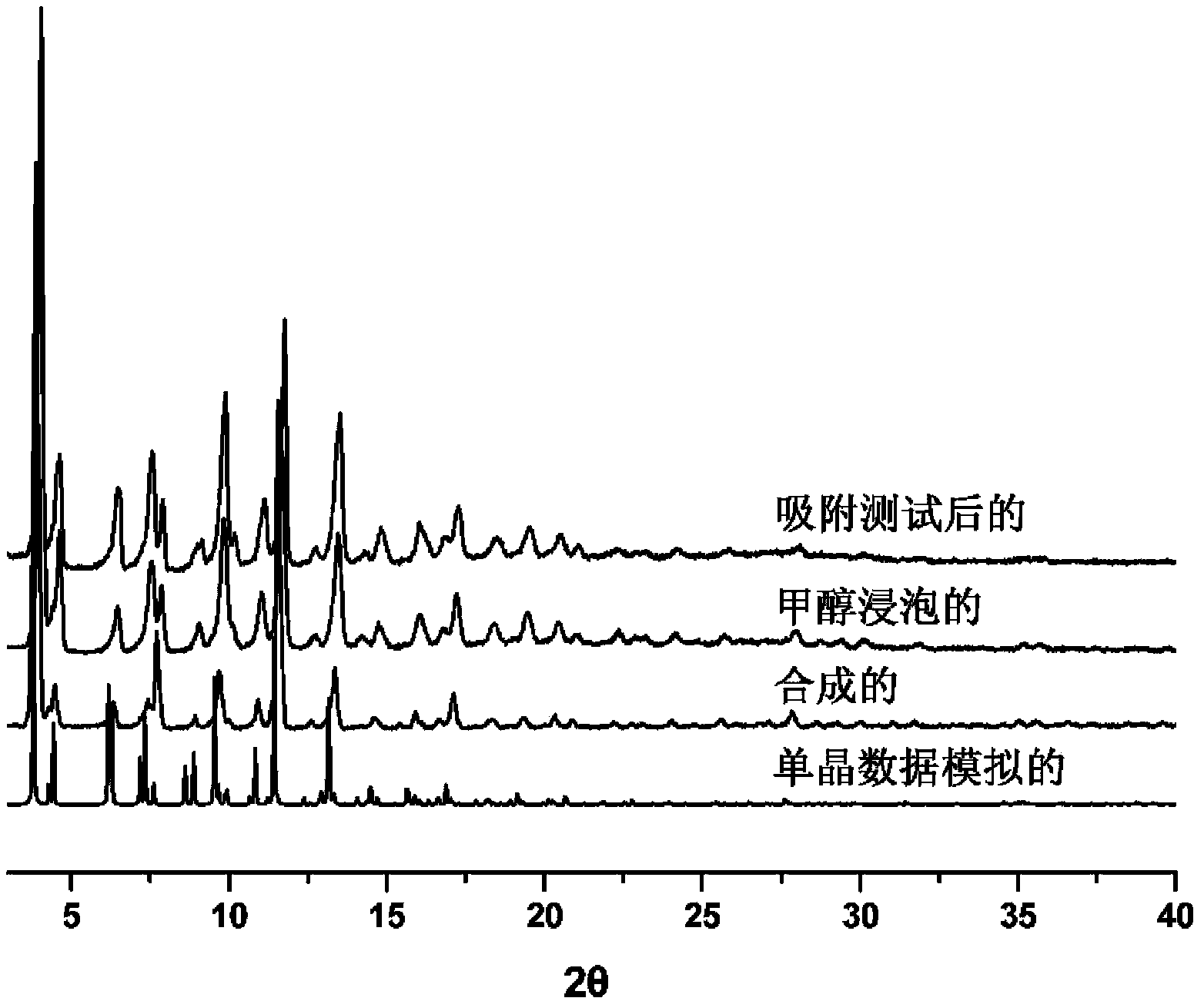

Porous metal-organic framework hybrid material as well as preparation method and application thereof

InactiveCN103665006AMild conditionsEasy to prepare in large batchesOther chemical processesCopper organic compoundsAbsorption capacityCupric nitrate

The invention discloses a porous metal-organic framework hybrid material. A chemical formula of the porous metal-organic framework hybrid material is (Cu4O2(tpa)2)*2NO3*DMA, wherein Htpa adopts 4-(4-benzene acetoxy)-1, 2, 4-triazole, and DMA adopts N, N-dimethylacetamide; and the hybrid material is synthesized by cupric nitrate tetrahydrate serving as metal salt and 4-(4-benzene acetoxy)-1, 2, 4-triazole serving as an organic ligand. The porous metal-organic framework hybrid material has the advantages as follows: 1), raw materials for synthesis are cheap and easy to obtain, the condition is mild, large-scale preparation of the hybrid materials is easy to realize, and the crystal form can be maintained in the large-scale synthetic process; 2), the product has excellent acid resistance and alkaline resistance, and the structure can be maintained in a boiled water environment; and 3), the absorption capacity of the product on CO2 at the temperature of 273K can reach 52 cm<3>g<-1> while the absorption capacity of the product on N2 is only 3.4 cm<3>g<-1>, so that the porous metal-organic framework hybrid material has a good potential application value in the aspect of CO2 preferential absorption.

Owner:NANKAI UNIV

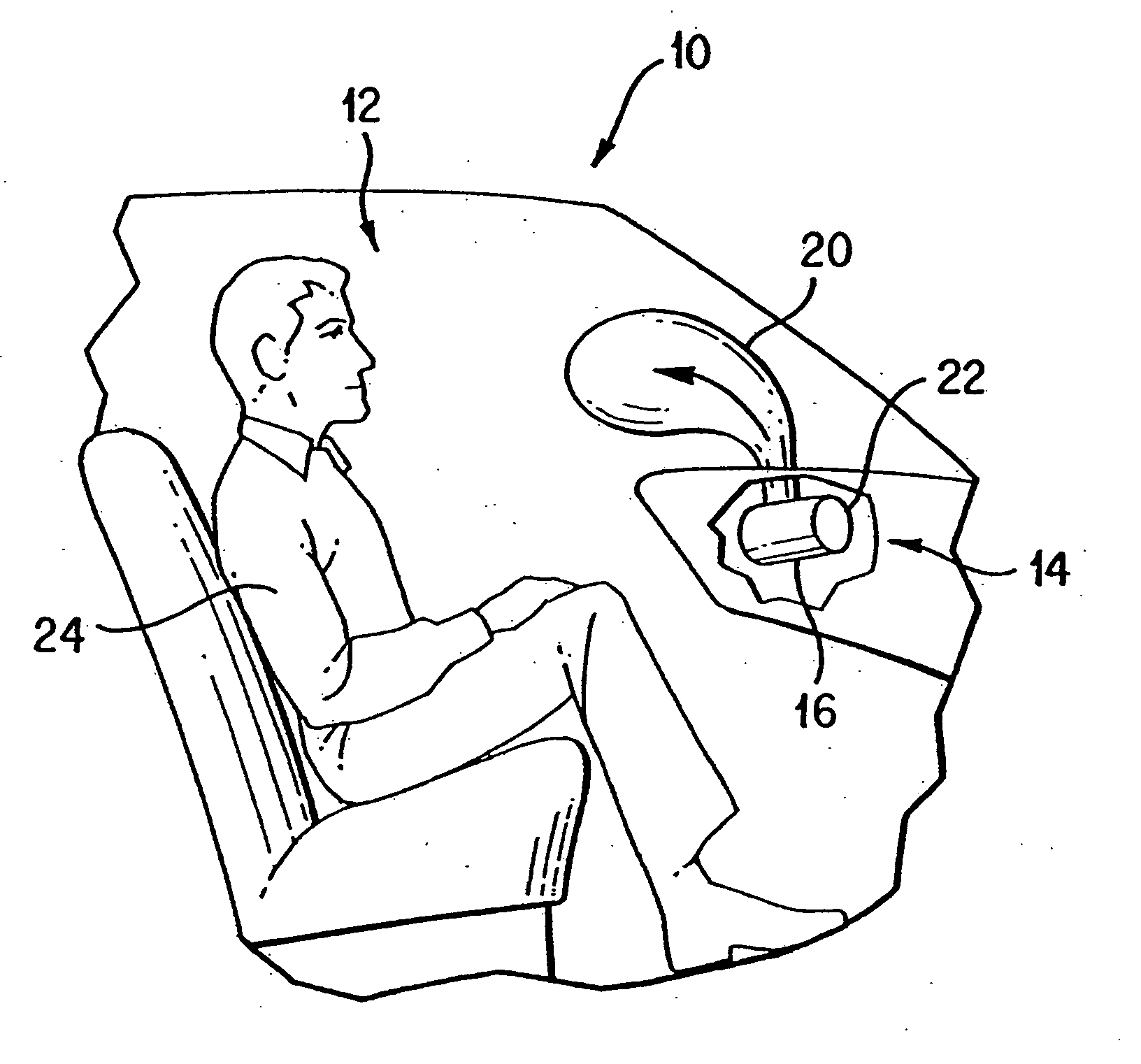

Ammonium perchlorate-containing gas generants

ActiveUS20050067076A1Non-explosive/non-thermic compositionsAmmonium perchlorate explosive compositionsScavengerCopper nitrate

Ammonium perchlorate-containing gas generant compositions which, upon combustion, produce or result in an improved effluent and related methods for generating an inflation gas for use in an inflatable restraint system are provided. Such ammonium perchlorate-containing gas generant compositions include ammonium perchlorate present with a mean particle size in excess of 100 microns. Such ammonium perchlorate-containing gas generant compositions also include or contain a chlorine scavenger present in an amount effective to result in a gaseous effluent that is substantially free of hydrogen chloride when the gas generant is combusted, wherein at least about 98 weight percent of the chlorine scavenger is a copper-containing compound. Suitable copper-containing chlorine scavenger compounds include basic copper nitrate, cupric oxide, copper diammine dinitrate-ammonium nitrate mixture wherein ammonium nitrate is present in the mixture in a range of about 3 to about 90 weight percent, copper diammine bitetrazole, a copper-nitrate complex resulting from reaction of 5-aminotetrazole with basic copper nitrate and combinations thereof.

Owner:AUTOLIV ASP INC

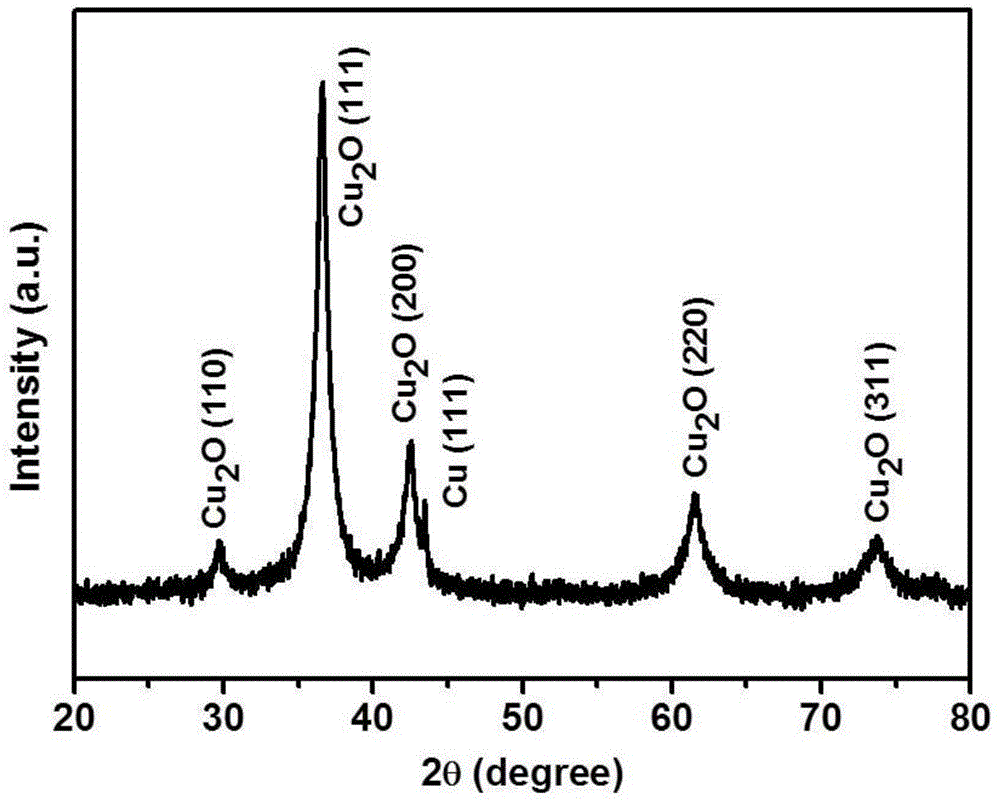

Preparation method for copper/cuprous oxide/cyclized polyacrylonitrile visible-light-driven photocatalyst

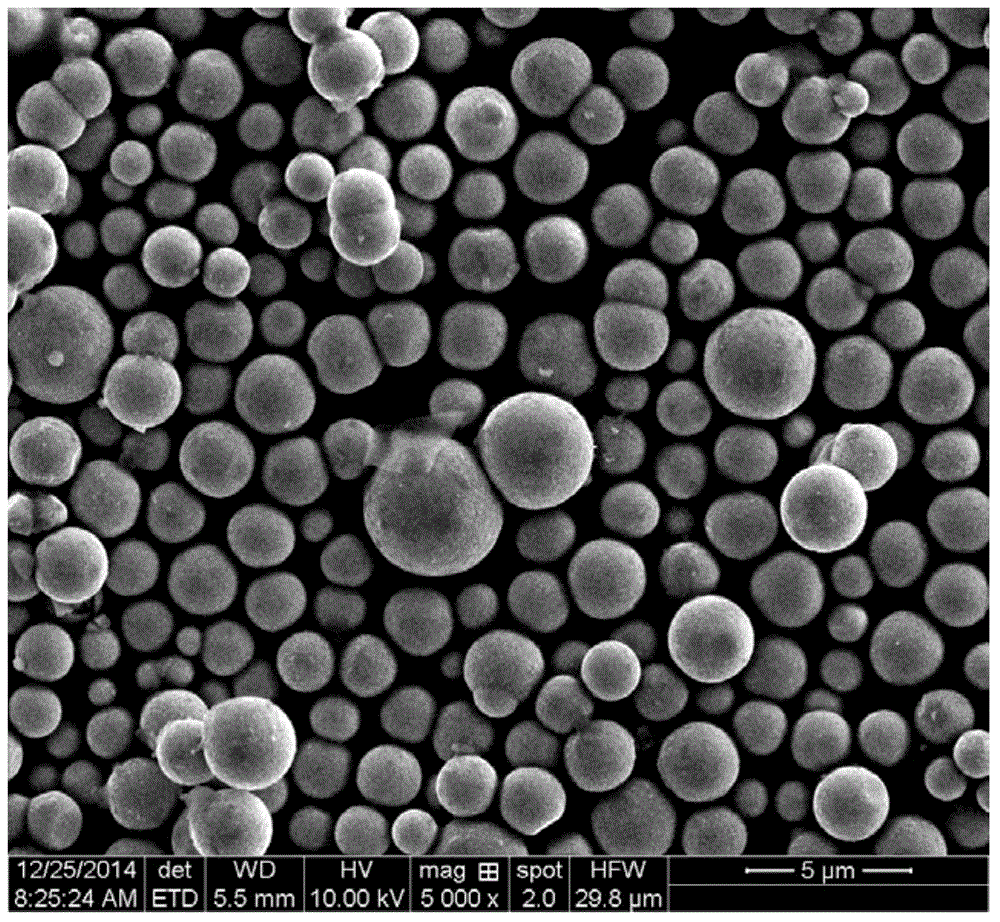

InactiveCN105126917ASmall particle sizeEvenly dispersedOrganic-compounds/hydrides/coordination-complexes catalystsDehydrogenationIon exchange

The invention discloses a preparation method for a copper / cuprous oxide / cyclized polyacrylonitrile visible-light-driven photocatalyst, and belongs to the technical field of environmental cleaning photocatalyst new materials. The preparation method includes the steps of firstly, preparing a nanometer copper hydroxide / photocatalyst compound by synchronously conducting solvent conversion and in-situ ion exchange reaction with photocatalyst, cupric nitrate and sodium hydroxide as raw materials; secondly, reducing copper hydroxide into cuprous oxide in situ through ascorbic acid; thirdly, conducting thermal treatment under the nitrogen atmosphere, reducing a small amount of cuprous oxide into elementary substance copper while cyclization and dehydrogenation are conducted on polyacrylonitrile to form a conjugated structure, and obtaining the copper / cuprous oxide / cyclized polyacrylonitrile visible-light-driven photocatalyst. The raw materials are wide in source, cost is low, the preparation method is simple and suitable for large-scale production, cyclized polyacrylonitrile can improve the separation efficiency of photoproduction electron holes and absorption of the visible light areas and can have a protection and optical corrosion reduction effect on copper / cuprous oxide, and the obtained catalyst is remarkable in adsorption and photocatalytic effect.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

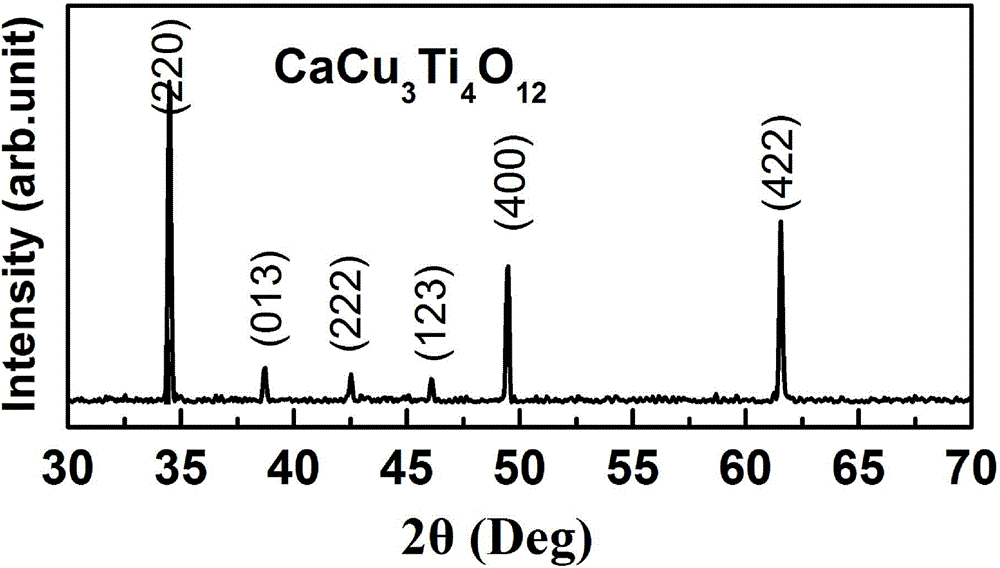

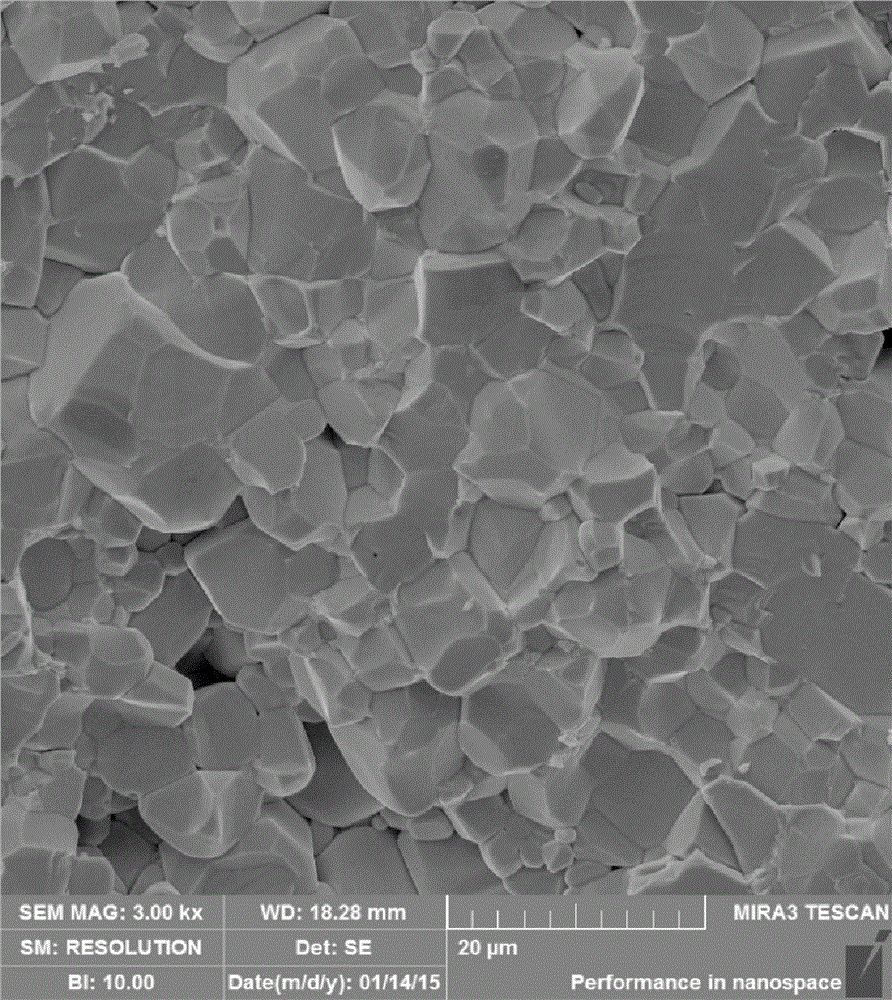

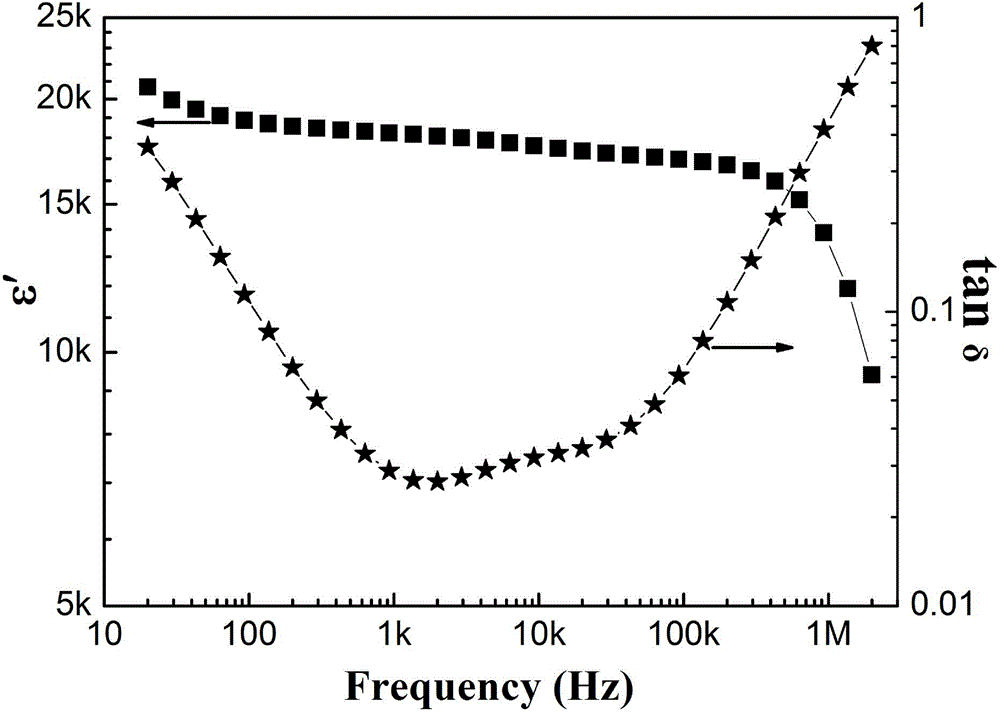

Method for manufacturing low dielectric loss CaCu3Ti4O12 ceramic

The invention discloses a method for manufacturing low dielectric loss CaCu3Ti4O12 ceramic materials by using a sol-gel method and belongs to the technical field of dielectric substances. The method specifically includes the following steps: adopting the sol-gel method, utilizing calcium nitrate, cupric nitrate and butyl titanate as raw materials, utilizing absolute ethyl alcohol as a solvent, utilizing nitric acid to adjust the pH value of the solution, weighing the raw materials according to the proportion to form the sol, then placing the sol into a water bath at the temperature of 80 DEG C, stirring continuously till xerogel is formed, utilizing an electric furnace and a muffle furnace to remove organics, burning and breaking obtained precursor powder, then adding adhesive to conduct grinding and pelleting to obtain a ceramic blank 1 mm in thickness and 12 mm in diameter, placing the blank into a sintering furnace to conduct sintering and keep the temperature, and finally acquiring CaCu3Ti4O12 ceramic samples with high dielectric constant and low dielectric loss. The method is simple in process and easy to operate. The manufactured ceramic samples are compact, uniform, stable in dielectric constant and low in dielectric loss.

Owner:TAIYUAN UNIV OF TECH

Method for electrochemical detection of acephate by aid of molecularly imprinted polymer film supported on surface of metal-organic framework material

InactiveCN106198701ALarge specific surface areaMass transfer speedMaterial electrochemical variablesMetal-organic frameworkDifferential pulse voltammetry

The invention relates to a method for electrochemical detection of acephate by the aid of a molecularly imprinted polymer film supported on the surface of a metal-organic framework material. The metal-organic framework material formed by cupric nitrate and 4,4'-biphenyldicarboxylic acid is taken as a support body, acephate is taken as a template molecule, methacrylic acid is taken as a function monomer, ethylene glycol dimethacrylate is taken as a crosslinking agent, azodiisobutyronitrile is taken as an initiator, the molecularly imprinted polymer film supported on the surface of the metal-organic framework material is synthesized and ultrasonically dispersed in a nafion solution for spin-coating of the surface of an electrode, and acephate is detected with a differential pulse voltammetry method. A molecularly imprinted polymer with large specific surface area and high mass transfer speed is obtained and is used for detecting acephate. The method has good stability and high sensitivity.

Owner:UNIV OF JINAN

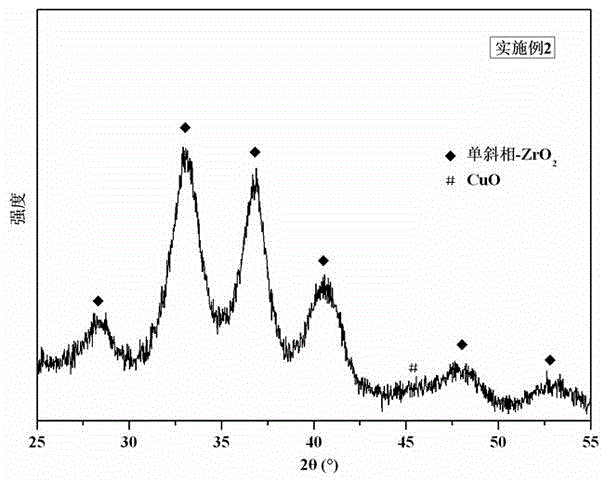

Al assistant-modified CUO-ZrO2 water gas shift catalyst and preparation method thereof

InactiveCN103599780AAvoid the phenomenon of hard agglomerationHigh catalytic activityHydrogenMetal/metal-oxides/metal-hydroxide catalystsPotassium hydroxideHigh activity

The invention discloses an Al assistant-modified CUO-ZrO2 water gas shit catalyst and a preparation method thereof, and belongs to the technical filed of water gas shift processes and catalysts. According to the preparation method, an Al assistant-modified CUO-ZrO2 carrier is obtained by dissolving an aluminum salt, a zircon salt and urea in water to form a mixed solution, performing hydrothermal treatment on the mixed solution, and washing, drying and roasting hydrothermal products; the Al assistant-modified CUO-ZrO2 carrier is dispersed into a cupric nitrate aqueous solution; the CuO-ZrO2-Al2O3 water gas shift catalyst is prepared by depositing and precipitating by using potassium hydroxide, washing, drying and roasting. The Al assistant-modified CUO-ZrO2 water gas shift catalyst prepared by the preparation method has the advantages of low activation temperature, high activity, wide activity temperature area, high selectivity and high thermal stability, and is especially suitable for the operation environment with hydrogen-rich reaction gas and low steam-to-gas ratio. The activity of the Al assistant-modified CUO-ZrO2 water gas shit catalyst is better than that of the commercial CuO-ZnO-Al2O3 low-temperature water gas shift catalyst.

Owner:FUZHOU UNIV

Catalyst for eliminating ozone and nitrogen oxide and its prepn. process

InactiveCN1375348ALarge specific surface areaImprove decomposition efficiencyDispersed particle separationCatalyst activation/preparationDecompositionManganese

The preparation method of catalyst for removing ozone and nitrogen oxide includes the following steps: using manganese nitrate, cupric nitrate, nickel nitrate and silver nitrate to prepare nitrate solution, soaking catalyst carrier into nitrate solution, taking out and drying, heating in nitrogen gas, then heating the catalyst carrier in nitrogen and hydrogen mixed gas and cooling to room temp. so as to obtain the invented catalyst. Said catalyst is high in efficiency for ozone decomposition and possess higher reduction efficiency for nitrogen oxide, and its specific area is large, it can be fully contacted with air and can be used for removing harmful gas produced in discharge air-cleaning and sterilizing device and negative ion generator.

Owner:XI AN JIAOTONG UNIV

Chiral MOF-graphene hybrid material, and preparation method and application thereof

InactiveCN107490610ASimple processEasy to industrializeMaterial electrochemical variablesEnantiomerHybrid material

The invention discloses a chiral MOF-graphene hybrid material, a preparation method thereof, and the application of the chiral MOF-graphene hybrid material to the detection of chiral drug enantiomers, and belongs to the technical fields of nanometer composite materials, macromolecule-based composite materials, graphene-based composite materials and chiral sensing detection. The method comprises the following main steps: blending an alkaline aqueous solution of L-aspartic acid and an aqueous solution of cupric nitrate-graphene oxide, adding an ethanol solution of 4, 4'-bipyridine, leaving the mixture to stand over a night, performing centrifugal separation, washing and drying, so as to obtain the chiral MOF-graphene hybrid material. A chiral MOF-graphene hybrid material sensor constructed through the hybrid material is applied to the sensitive detection of the contents of R-2-amino-3-phenylpropionic acid and S-2-amino-3-phenylpropionic acid enantiomers.

Owner:UNIV OF JINAN

Preparation of ash-cleaning and coke-removing agent for city domestic refuse incinerator

InactiveCN101338237AImprove dust accumulation and slaggingImprove efficiencyFuel additivesIncinerator apparatusSlagCupric nitrate

The invention discloses an ash and burnt removal agent composition for rural domestic waste incinerator. The ash and burnt removal agent comprises the components with the following weight portions of 50-70 percent of nitrates, 5-10 percent of loosening agent, 10-15 percent of sodium chloride, 5-15 percent of activator, 5-10 percent of vermiculite and 1-2 percent of cupric oxychloride. The nitrates are cupric nitrate and sodium nitrate. The loosening agent refers to borax. The activator refers to ammonium nitrate, carbon powder and sulfur powder. The ash and burnt removal agent is applied in ash and burnt removal field of the rural domestic waste incinerator, which has good effect for improving the ash and slag in the waste incinerator.

Owner:XI AN JIAOTONG UNIV

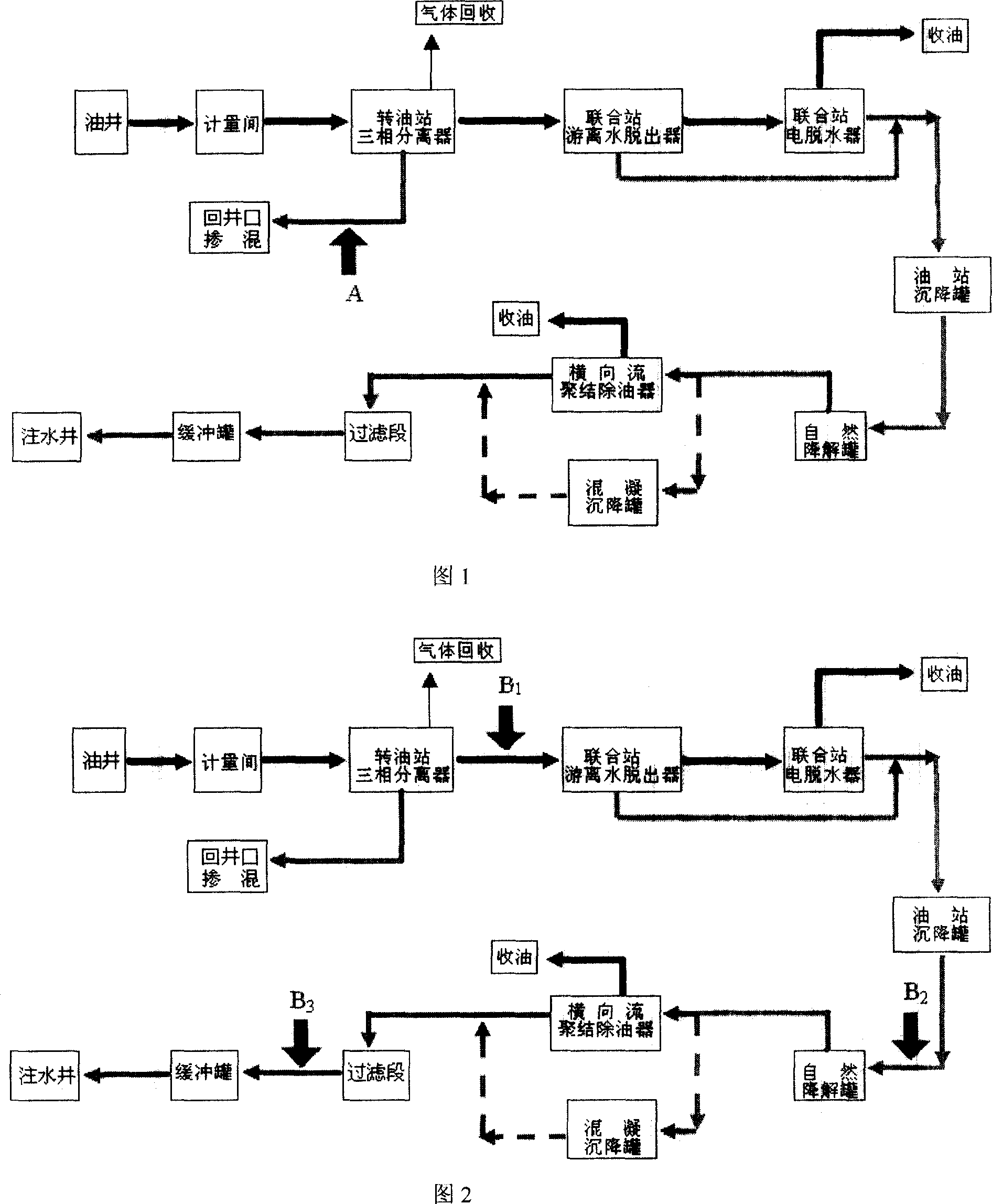

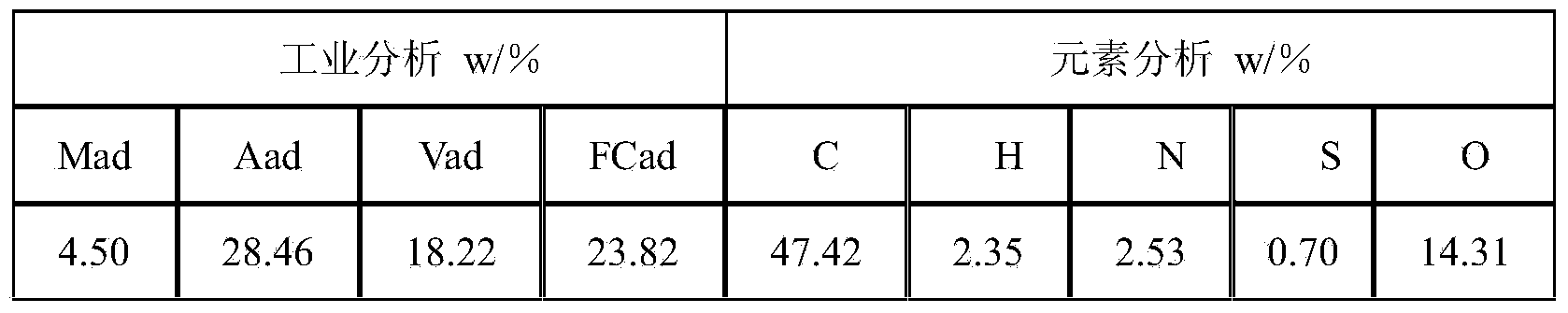

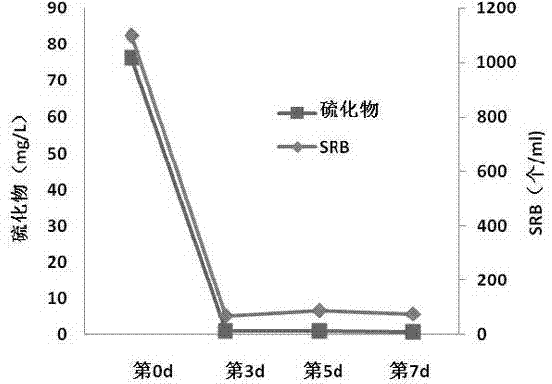

Method for inhibiting activity of sulfate reducing bacteria in oil field surface water and agent used thereof

ActiveCN101011066AInhibitory activityInhibition of reducing bacteria activityBiocideAnimal repellantsPresent methodSulfate-reducing bacteria

The invention relates to a method for restraining the activity of reduction bacterial in the ground water of oil field, and relative drugs. The invention can resolve the problems of present method as low SRB disinfect ratio, high chemical toxicity, serious pollution or the like. The invention comprises 100 deals of sodium nitrate, 2-20 deals of erinitrit, 0.2-0.6 deals of cobalt nitrate, 0.2-0.6 deals of nickel nitrate, 0.2-0.6 deals of cupric nitrate, and 0.2-0.6 deals of sodium molybdate. And the restraining method comprises that 1, preparing the mother solution of restraining agent; 2, measuring the content of SO42-; 3, adding the mother solution of restraining agent. The inventive restraining agent can improve the activity of anti-nitrated microbe, without toxicity, pollution and the drug-fast generation. The invention uses the environment and nourishment competitions to restrain the activity of SRB in the ground water of oil field, to reduce more than 85% of S2 density.

Owner:DAQING OILFIELD CO LTD +2

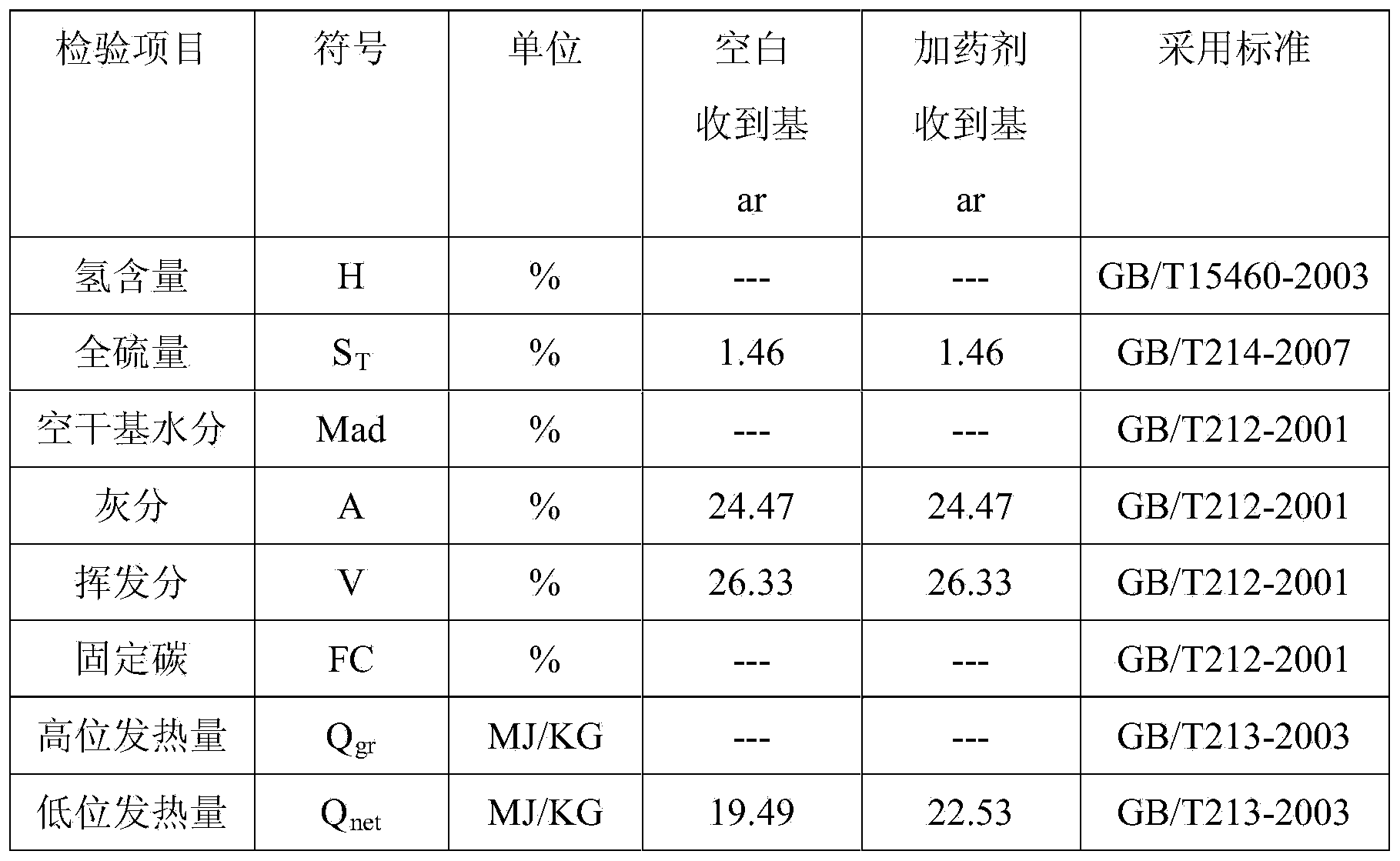

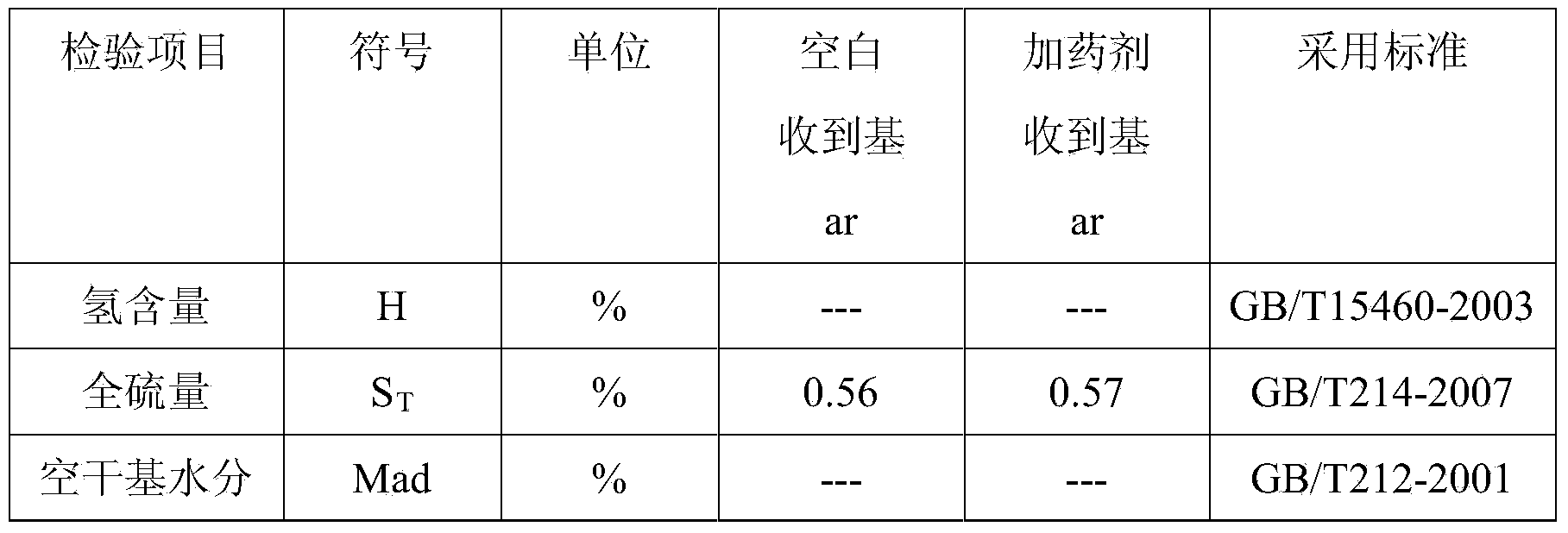

Coal combustion composite catalyst

ActiveCN104028306AEasy to useLow ignition temperatureOrganic-compounds/hydrides/coordination-complexes catalystsFuel additivesNitrationPhytic acid

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Catalyst used for producing promoter N-t-butyl benzothiazole sulfonamide and its preparation method

InactiveCN102309986AEasy to prepareEasy to industrializeOrganic chemistryMolecular sieve catalystsMANGANESE ACETATECerium nitrate

The invention relates to a catalyst used for producing promoter N-t-butyl benzothiazole sulfonamide and its preparation method, the catalyst is one or more metal salt of copper acetate, copper sulphate, cupric nitrate, cobaltous acetate, rose vitriol, oleic acid cobalt, cobalt nitrate, acetic acid cerium, sulfuric acid cerium, cerium nitrate, manganese acetate, manganese sulfate, manganous nitrate and the like. A carrier of the catalyst is one or more of SiO2, Al2O3, TiO2, medium-pore material molecular sieve, microporous material molecular sieve and the like. The prepared catalyst is used for synthesizing TBBS by using an oxygen oxidation process, the reaction is used for characterizing the performance of the catalyst. The catalyst amount accounts for 0.02-0.1% of weight of the reactant. The invention has the advantages that the catalyst formula is reasonable, an active ingredient and the carrier are contained, the amount is small and the catalysis effect is good, and the catalyst is capable of increasing the disperse area of the active ingredient to increase the contact area of the active ingredient and the reactant, raising the reaction speed and simultaneously reducing the catalyst amount. The catalyst enables more than 97% of yield of TBBS by optimizing the reaction condition.

Owner:KEMAI CHEM

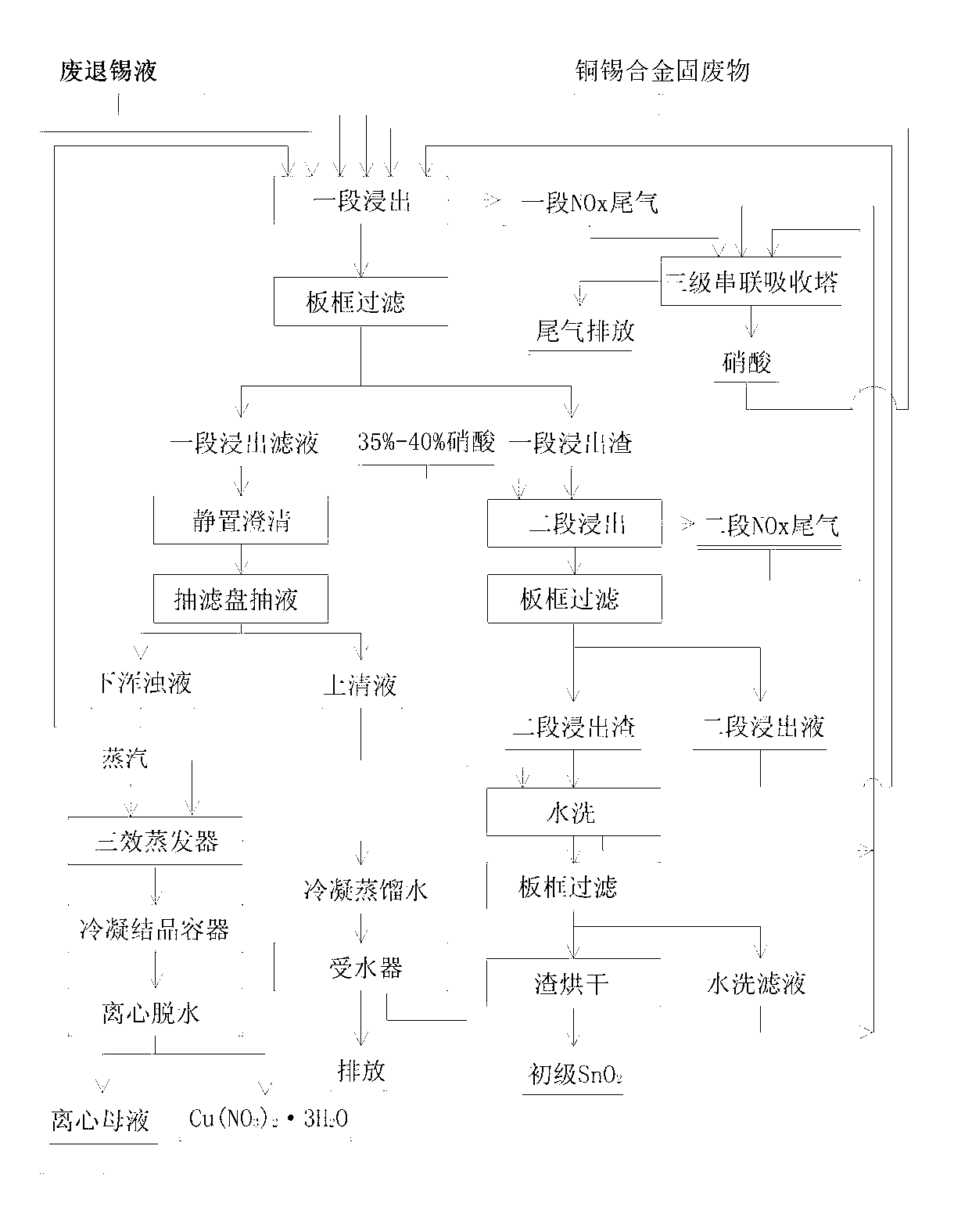

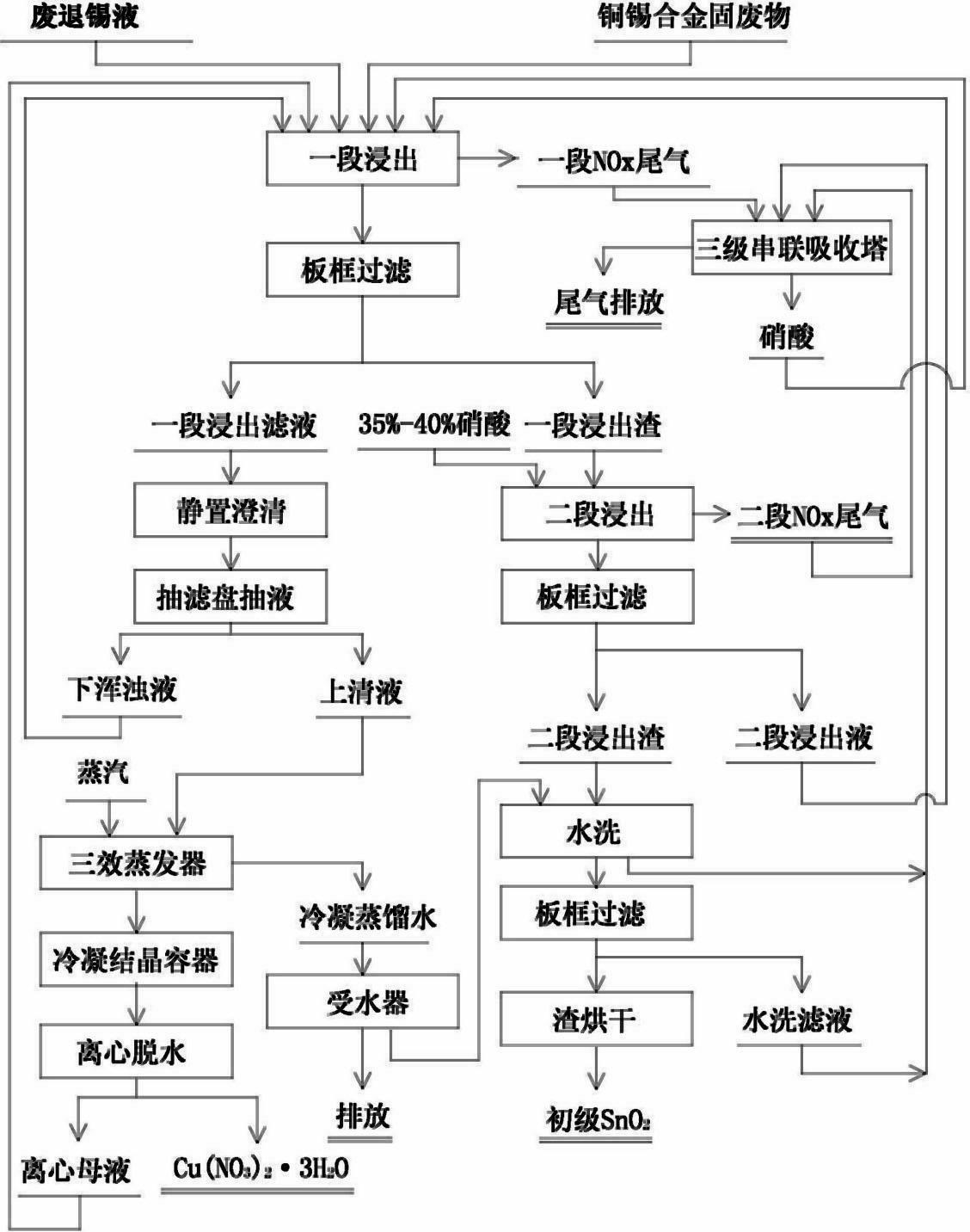

Process for comprehensively utilizing waste tin-stripping solution

InactiveCN102703905AAchieve reuseSolve the problem of total nitrogen emission standardsWater contaminantsWaste water treatment from metallurgical processAlloyCupric nitrate

The invention relates to a process for comprehensively utilizing a waste tin-stripping solution. According to the process, the waste tin-stripping solution and electronic copper tin alloy solid wastes are used as process raw materials; a two-section leaching step, a parallel flow triple-effect evaporation, concentration and crystallization step, and a step for preparing acid by absorption of tail gas are combined; synchronous treatment is performed; all components in raw materials react with each other; copper and tin are efficiently leached out and separated; after being absorbed by water, the tail gas can be used for preparing acid; the absorption rate can be more than 95 percent; and primary SnO2, industrial cupric nitrate crystals and nitric acid products are obtained finally. The wastewater produced in the whole process and the discharge of the tail gas can meet the national requirement of environment friendliness, the environment is effectively protected from being polluted, and the treatment cost of the wastewater can be reduced greatly.

Owner:方亚飞

Hydrocatalyst for preparing fuel by hydrodealkylation of coal-tar pitch and preparation thereof

InactiveCN101302439AImprove qualityVersatilityRefining to eliminate hetero atomsHydrodealkylationBiological activation

The invention relates to hydrosenation catalyst for producing oil by converting heavy coal tar pitch into light coal tar pitch, which is characterized in that: 100 portions of macroporous alumina is immersed into 100 portions of solution which consists of 3.5 to 20.5 weight percent of nickel nitrate and 3.0 to 25.0 weight percent of molybdenum nitrate for 2 hours at a temperature of between 50 and 60 DEG C; the mixture stands and supernatant is poured out, and then the mixture is dried for 4 hours at a temperature of 120 DEG C, activated for 5 hours at a temperature of 480 DEG C, and then immersed into cupric nitrate solution, cobalt nitrate solution, silver nitrate solution, ferric nitrate solution or bismuth nitrate solution with a concentration between 1.1 and 12.0 weight percent; and the catalyst is prepared through immersion, drying and activation which are the same as the above. The content of the nickel oxide and the molybdenum oxide in the catalyst is respectively 1.2 to 11.2 weight percent and 1.1 to 15.4 weight percent of the weight of carrier, and the content of cupric oxide, cobalt oxide, silver oxide, ferric oxide or bismuth oxide is 1.1 to 7.8 weight percent of the weight of the carrier. The hydrogenation catalyst has good adaptability to various coal tar pitch raw materials, high hydrogenation degree, strong controllability, low operating cost, and high yield of the oil produced by converting the heavy coal tar pitch into the light coal tar pitch; and the overall oil yield of fuel can reach over 75 percent.

Owner:TONGJI UNIV

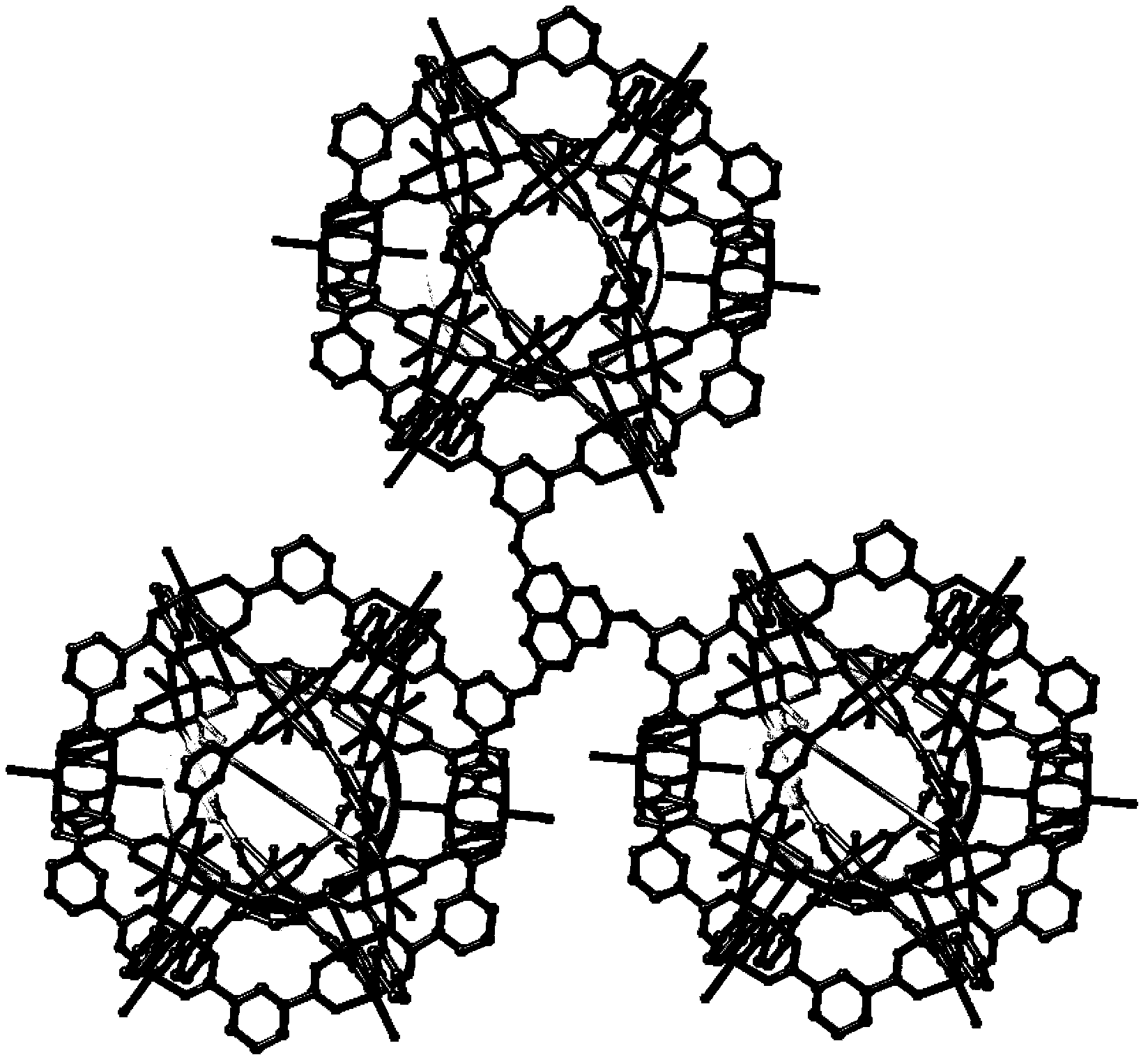

Porous copper organic framework material for CO2 adsorption and separation and preparation method of porous copper organic framework material

InactiveCN103435620AImprove thermal stabilityLarge specific surface areaProductsOrganic chemistrySeparation technologyCo2 storage

The invention relates to a novel porous metal organic framework material for CO2 adsorption and separation and a preparation method of the porous metal organic framework material, and belongs to the cross field of inorganic chemistry, organic chemistry and material chemistry. The method comprises the steps of taking 2,5,8-tri-(3,5-dicarboxyl aniline)-s-heptazine as a ligand to perform solvothermal reaction with cupric nitrate or copper perchlorate in a mixed solvent formed by an organic solvent and water, washing, drying, and obtaining the novel porous metal organic framework material. The porous metal organic framework material prepared by the method has a regular crystal structure, uniform pore size distribution, excellent CO2 selective adsorption ability, and an important significance in the technical field of CO2 storage and separation.

Owner:JILIN UNIV

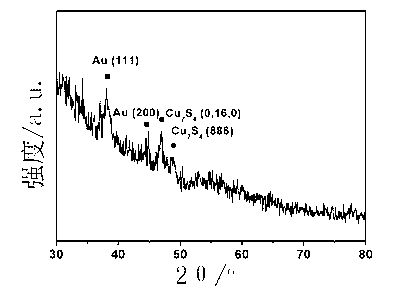

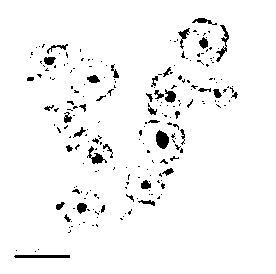

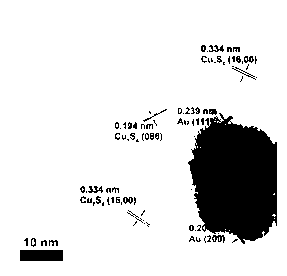

Nanometer composite material having gold/tetra-sulfide hepta-copper core-shell structure and preparation method thereof

InactiveCN103251949AEasy to prepareMild conditionsEnergy modified materialsInorganic non-active ingredientsHyperthermia TreatmentCupric nitrate

The invention discloses a nanometer composite material having a gold / tetra-sulfide hepta-copper core-shell structure and a preparation method of the nanometer composite material. The method comprises the following steps of: reducing chloroauric acid under a boiling condition to obtain a gold nano-particle sol solution; cleaning and concentrating the solution; dispersing into a cupric nitrate solution to ensure that the volume ratio of the gold nano-particle sol solution and the cupric nitrate solution is 0.05-0.5; reducing by using hydrazine hydrate to obtain gold / cuprous oxide core-shell structure particles; and finally, reacting gold / cuprous oxide particles with excessive amount of sodium sulfide in ethyl alcohol to obtain the nanometer composite material having the gold / tetra-sulfide hepta-copper core-shell structure. The preparation method of the composite material is simple and mild in condition; and in the preparation process, the particle dispersibility is good, the size is accurately controlled, the aim of medicinal-thermal co-therapy (medicine chemotherapy and laser-induced thermotherapy) against cancers is fulfilled, and the significance to the development of a cancer treatment method is realized.

Owner:TIANJIN UNIV

Method of producing green fluorescent powder

InactiveCN101130689AImprove luminous performanceSmall particle size distributionCathode ray tubes/electron beam tubesLuminescent compositionsSolventCupric nitrate

The invention relates to a making method of green fluorescent powder, which comprises the following steps: mixing zinc blend as host material, cupric nitrate as activating agent, aluminum fluoride as coactivator, chlorauric acid, barium iodide as auxiliary solvent and sulfur in the blending machine to produce phosphor powder burning material; putting the phosphor powder firing material into the quartz container with the sulfur and active carbon to burn in the tunnel with protecting gas of N2; removing non-luminous or luminous abnormal powder and impurity from the phosphor powder under ultraviolet lamp to obtain the green emitting phosphor. The invention uses a fluxing agent material of the barium iodide and a new coactivator material of the aluminum fluoride, which improves luminous property of the phosphor powder with reducing particle size distribution and reduces usage of the coactivator of chlorauric acid at the same time.

Owner:CAIHONG GRP ELECTRONICS CO LTD

Preparation method of tin-doped cuprous oxide

InactiveCN104874400AAbundant raw materialsLow costMetal/metal-oxides/metal-hydroxide catalystsHigh pressureSolvent

The invention belongs to the technical field of photocatalysts, in particular to a preparation method of tin-doped cuprous oxide. The preparation method provided by the technical scheme of the invention comprises the following steps: adding ethanediol to cupric nitrate and stannous chloride to be prepared into a solution; stirring the solution fiercely and transferring into a high-pressure autoclave, reacting for 10 hours at 140 DEG C to obtain the precipitate; cleaning the precipitate and placing the cleaned precipitate into a vacuum drying oven for drying for 12 hours at 60 DEG C to obtain the end product. The preparation method of tin-doped cuprous oxide, provided by the invention, is simple in process, simple in equipment, and a solvothermal method is adopted, so that the solution is directly mixed to be placed in the high-pressure autoclave for reaction at 140 DEG C to obtain the end product, the yield is high, and the raw materials adopted by the method are abundant and non-toxic.

Owner:UNIV OF JINAN

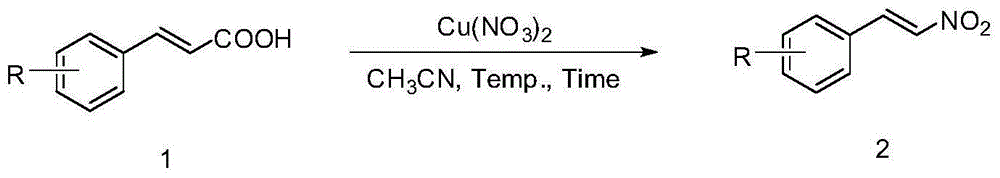

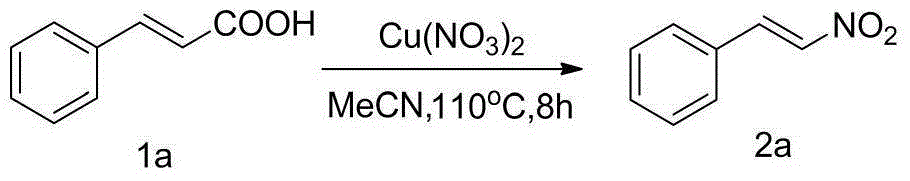

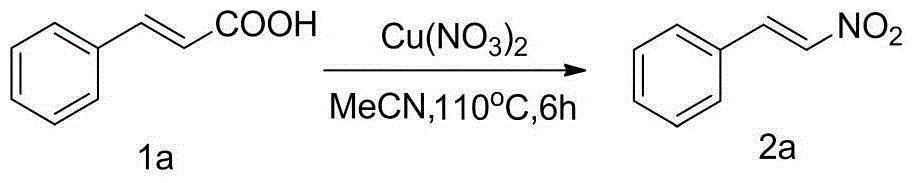

Method for preparing beta-nitrostyrolene compound

InactiveCN105152935AHigh yieldMild reaction conditionsOrganic chemistryOrganic compound preparationNitrostyrolMicrowave

The invention discloses a method for preparing beta-nitrostyrolene compounds. The method uses cinnamic acid compounds and cupric nitrate as raw materials, the raw materials are heated in acetonitrile and finally the beta-nitrostyrolene compounds are obtained through decarboxylation coupling. The cupric nitrate not only is used as a reactant, but also is used as transition metal catalyst. The reaction does not need the participation of ligands, acid, alkali, oxidant and the like, and does not need microwave heating, either. The preparation method has the advantages that the raw materials are low-cost and easy to obtain, the reaction system is mild, the operation is simple, the yield is high and the industrialization prospect is good.

Owner:ANHUI UNIV OF SCI & TECH

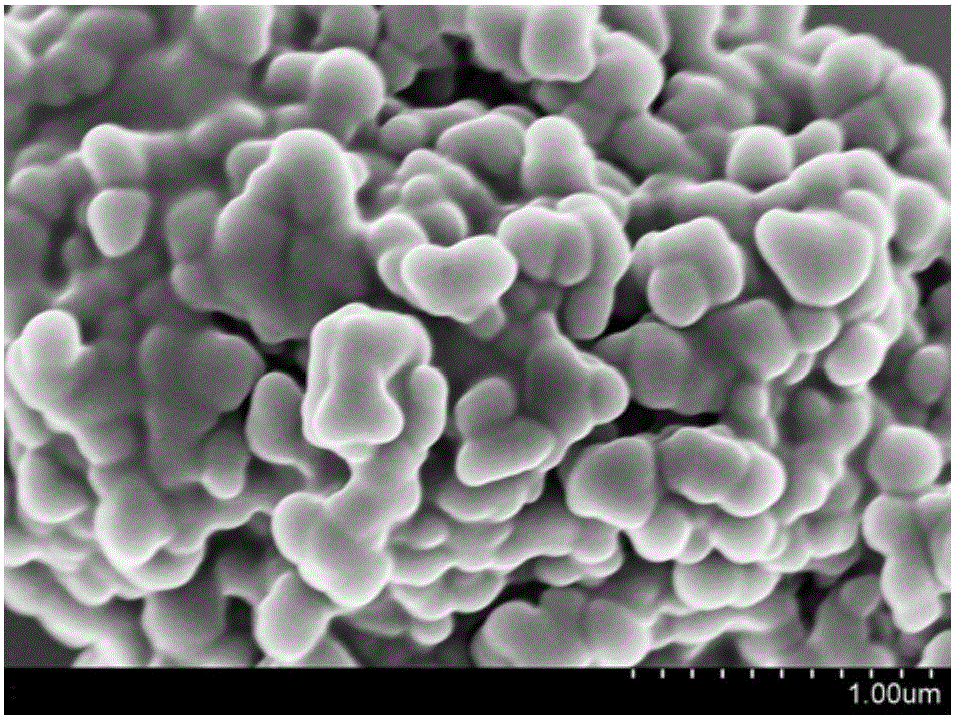

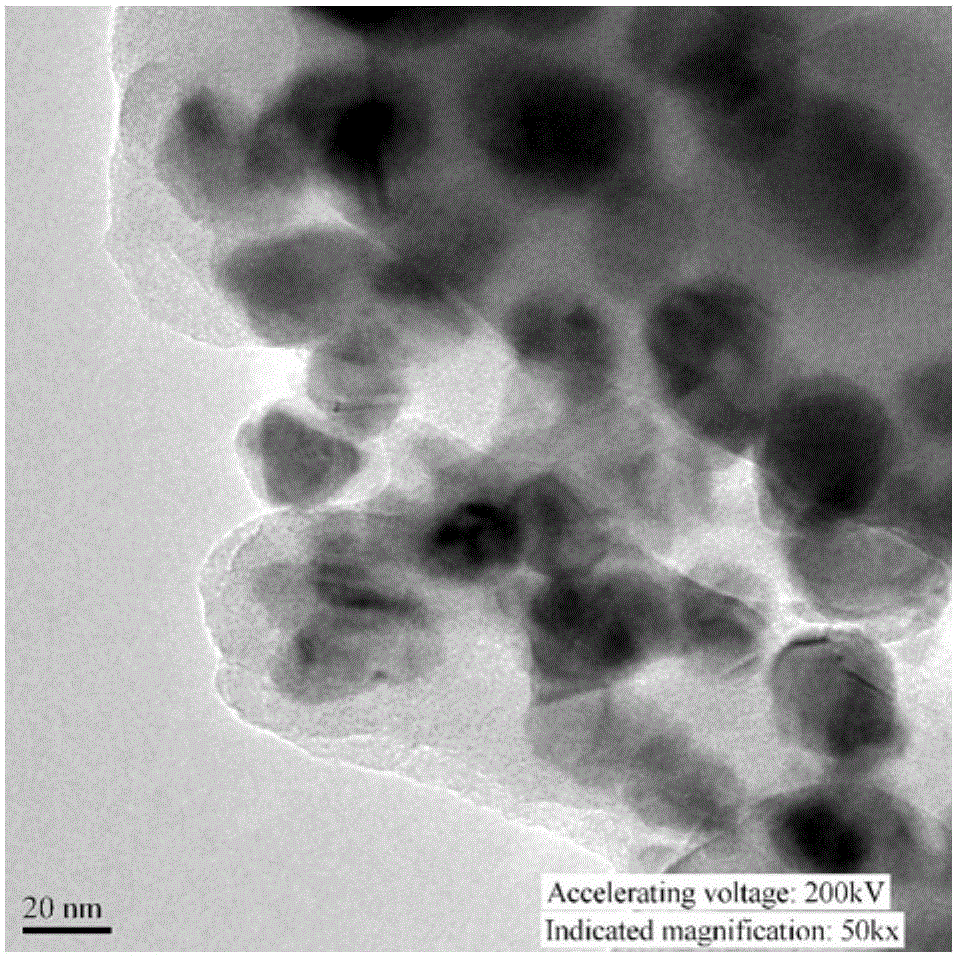

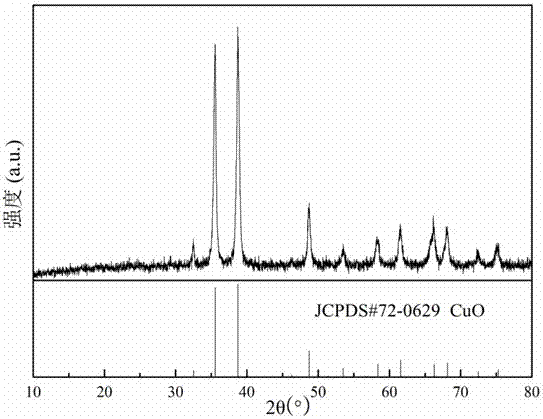

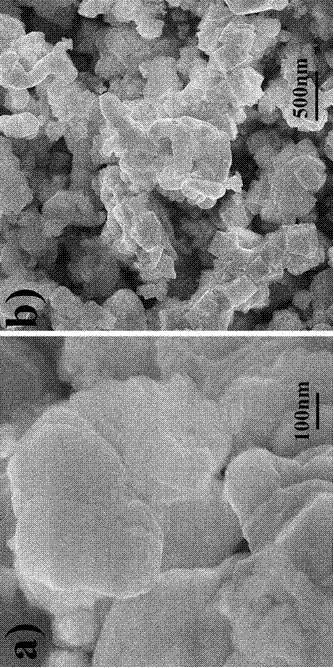

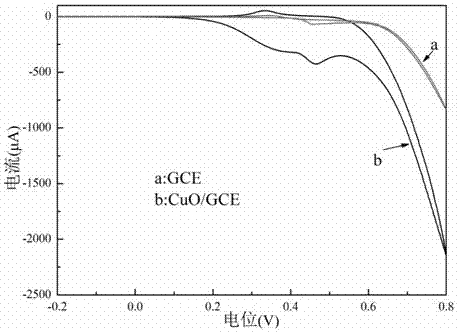

Copper oxide nonenzymatic glucose electrochemical sensor

ActiveCN107991371AAccurate detectionEfficient detectionMaterial electrochemical variablesGlucose sensorsCopper oxide

A copper oxide nonenzymatic glucose electrochemical sensor belongs to the technical field of detection. The invention aims synthesizing a transtition metal oxides CuO nano material by a convenient preparation method in order to build the copper oxide nonenzymatic glucose electrochemical sensor with high sensitivity, wide detection range and low cost. The raspberry-shaped CuO provided by the invention is prepared from the following raw materials of cupric nitrate, ethyl alcohol, P123, HMT and ethylene glycol. The black copper oxide solid is prepared by comprising the steps: dropwise covering black copper oxide solid dispersing solution onto the surface of glassy carbon electrode subjected to pretreatment for later use to serve as a working electrode of the nonenzymatic glucose sensor, forming a three electrode system by combing a saturated calomel electrode serving as a reference electrode and a platinum wire electrode serving as a counter electrode. The accurate glucose detection can be realized, basic data and theoretical support are applied to the industrialization applications of the nonenzymatic glucose sensor. A CuO / GCE electrode has the advantages that selectivity is good, isnot disturbed by crylic acid, ascorbic acid and the like, is not influenced by chloridion in the solution. Therefore, the CuO / GCE electrode has the excellent performance in glucose detection.

Owner:NORTHEAST DIANLI UNIVERSITY

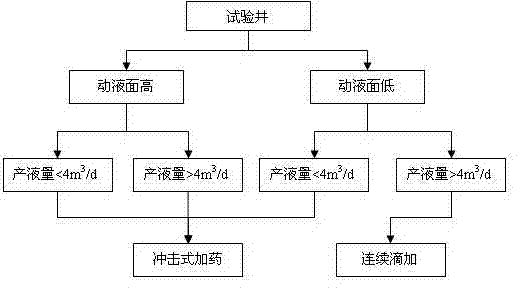

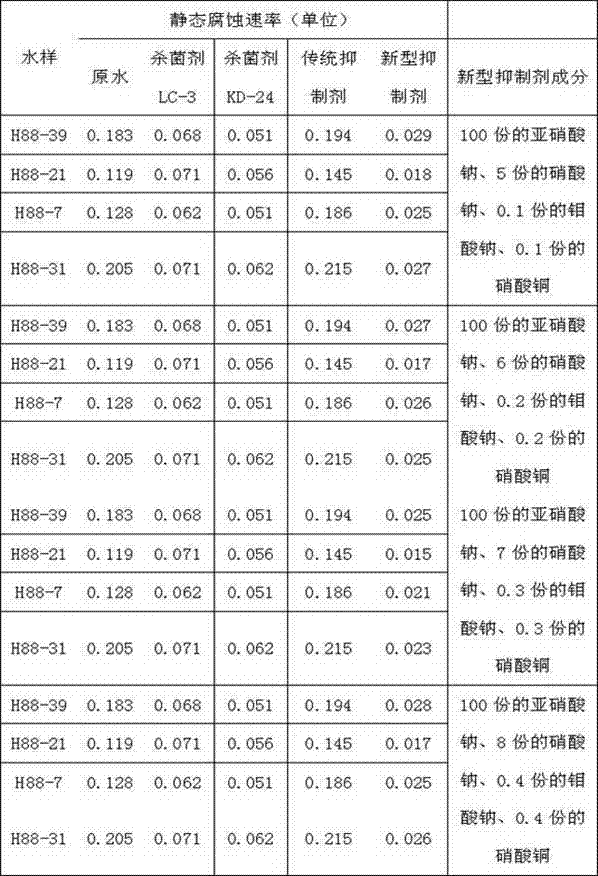

Novel biological inhibitor for inhibiting activity of sulfate reducing bacteria in oil well and use method thereof

ActiveCN103113866AGrowth inhibitionInhibition of reducing bacteria activityBorehole/well accessoriesSulfate-reducing bacteriaCupric nitrate

The invention discloses a novel biological inhibitor for inhibiting activity of sulfate reducing bacteria in an oil well and a use method thereof in the field of production of an oil field. The inhibitor comprises the following components in parts by weight: 100 parts of sodium nitrite, 5-10 parts of sodium nitrate, 0.1-0.5 parts of sodium molybdate and 0.1-0.5 parts of cupric nitrate. The use method comprises the following steps of: (1) determining the concentration contents of SO4<2-> and S<2-> in produced water of the oil field; (2) converting dosage of the inhibitor; (3) preparing an inhibitor mother liquid described in claim 1 according to the dosage of sodium nitrite; and (4) adding the inhibitor mother liquid obtained in the step (3) into the shaft through a sleeve in an adding mode by the sleeve of the oil field. The corrosion rate of the produced water is lowered by using the inhibitor, and the production cost is reduced. Growth of source denitrifying bacteria in the well is activated, so that fast grow of SRB (Sulfate Reducing Bacteria) is effectively inhibited. The inhibitor can be used for inhibiting the activity of sulfate reducing bacteria in the oil well.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing cupric sulphate by using cupric nitrate exhausted liquid

InactiveCN101113014ADoes not increase procurement costsAvoid destructionCopper sulfatesEconomic productionCupric nitrate

The invention relates to a method of preparation of copper sulfate with cupric nitrate waste solution, aiming at recycling cupric nitrate waste solution from manufacturing process of PCB and making the cupric nitrate waste solution as raw materials of solid copper sulfate. Concentrated sulfuric acid is first added into the cupric nitrate waste solution and forms a mixed solution of the sulfuric acid and the cupric nitrate and the sulfuric acid and the cupric nitrate react to each other chemically therein; then the mixed solution of the sulfuric acid and the cupric nitrate is heated to vaporize and separate HNO3 and the other solution is cooled then to generate copper sulfate crystal containing water or moisture; finally solid copper sulfate powder in a gain shape can be obtained after the crystal is dehydrated. The invention not only can completely recycle cupric nitrate solution and avoid secondary pollution, but also can directly get cheap or free raw material for preparing copper sulfate, thereby reducing economic production cost.

Owner:谢政龙

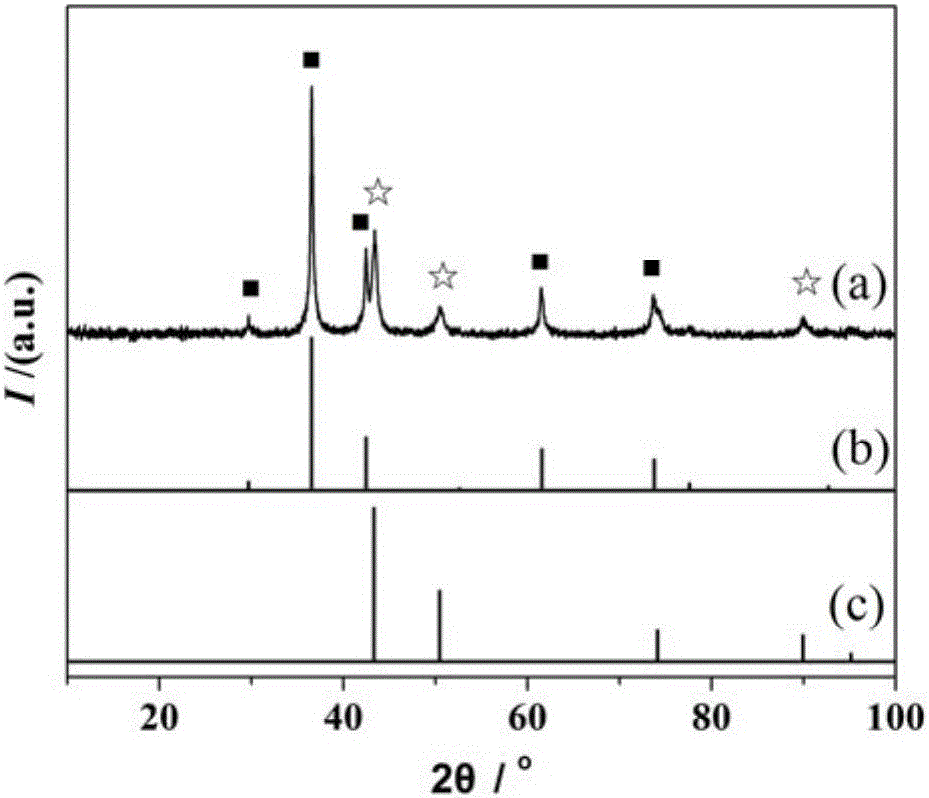

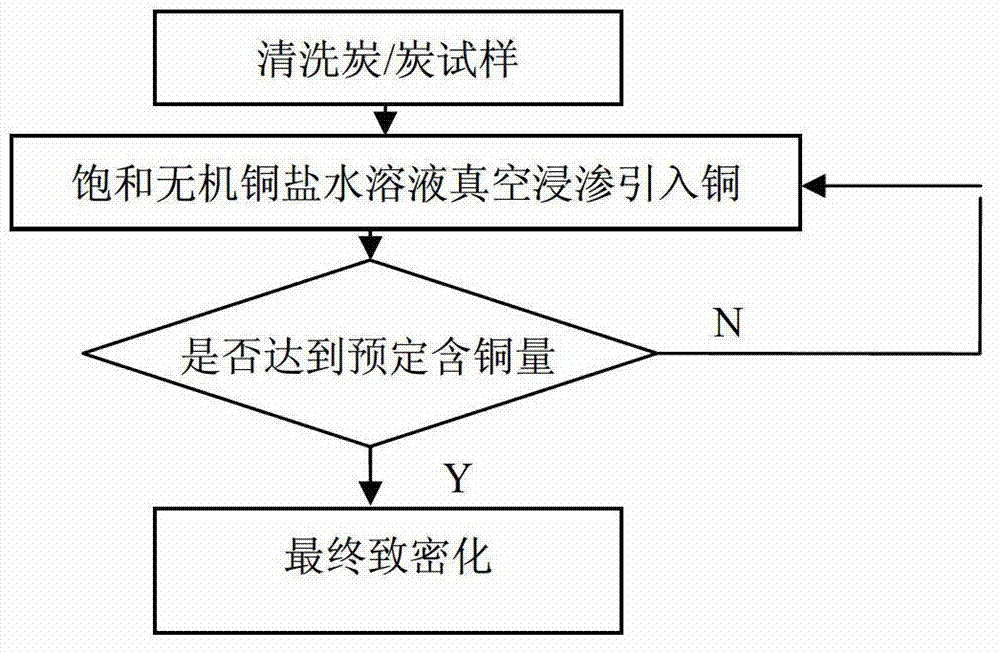

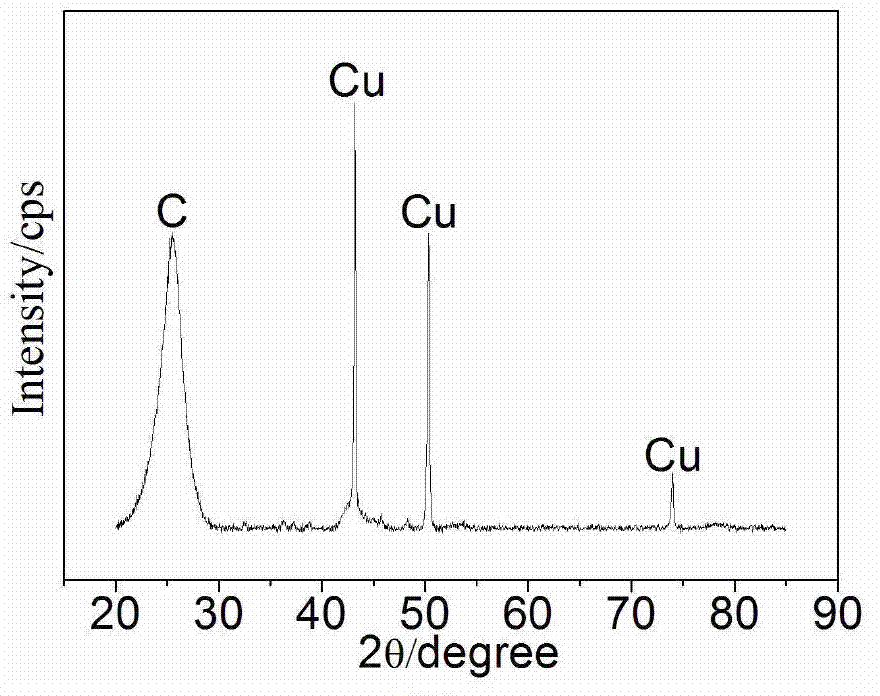

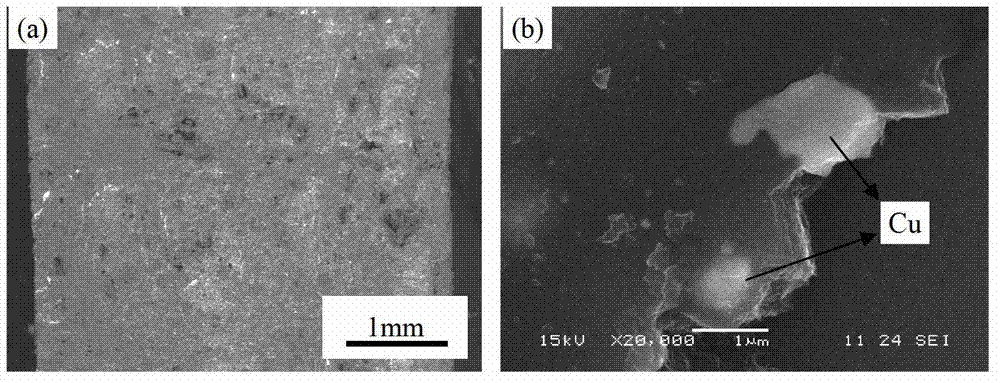

Preparation method of carbon/carbon-copper composite material

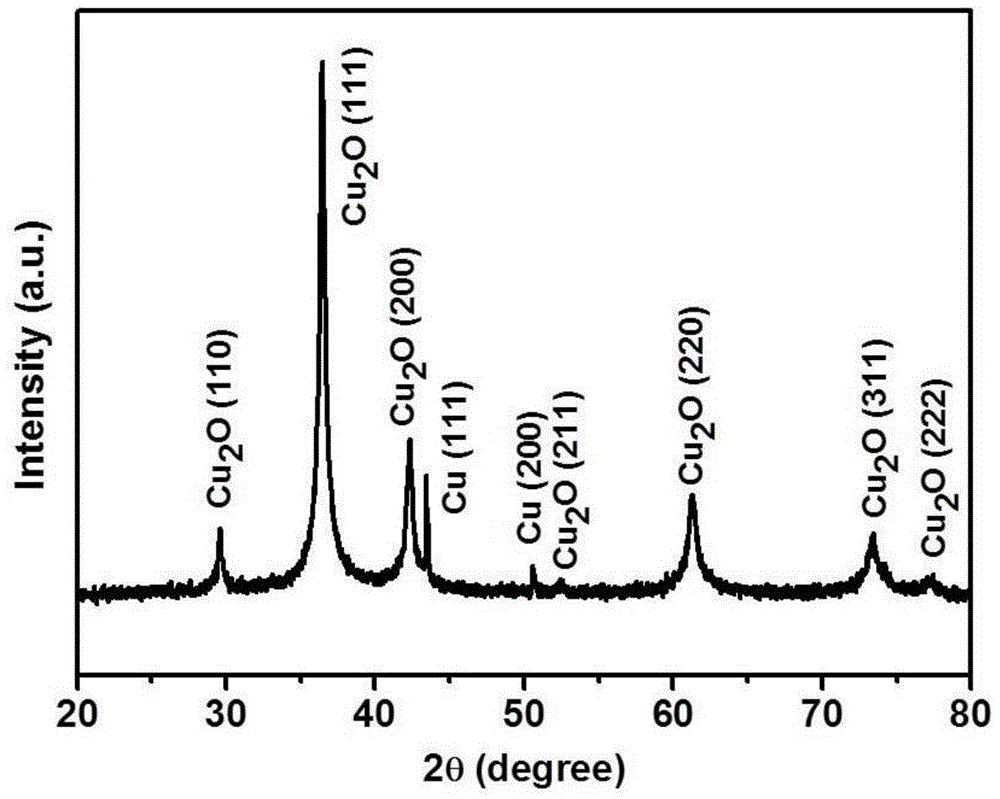

ActiveCN102776404AImprove permeabilityDiffraction peaks are narrow and sharpCarbon compositesAqueous solution

The invention discloses a preparation method of carbon / carbon-copper composite material. The preparation method is to introduce copper into carbon / carbon composite material via a reaction method of vacuum dipping of inorganic copper salt aqueous solution-decomposing of inorganic copper salt at high temperature-in-situ carbon thermal reduction. The preparation method comprises the steps of cleaning and parching a graphited carbon / carbon composite material sample with density of 0.6 to 1.40g / cm<3> for standby; preparing inorganic copper salt aqueous solution with a certain concentration, and heating, and then feeding the heated saturated solution into the carbon / carbon composite material sample under a vacuum condition so as to introduce the copper source, and then parching and thermally processing at high temperature to obtain the copper-contained carbon / carbon composite material sample; finally densifying the prepared copper-contained carbon / carbon composite material sample to obtain the carbon / carbon-copper composite material sample. The prepared carbon / carbon-copper composite material has two phases of carbon and copper, and has no impurities; and the coppers are uniformly distributed in the composite material, and combined with the carbon well. The inorganic copper salt is copper sulfate or cupric nitrate.

Owner:无锡博智复合材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com