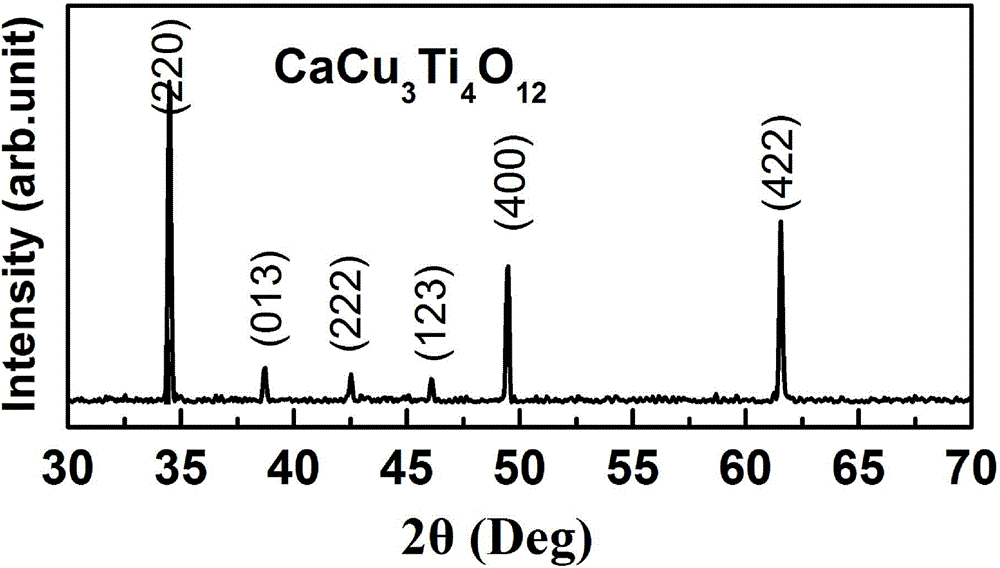

Method for manufacturing low dielectric loss CaCu3Ti4O12 ceramic

A low dielectric and ceramic technology, applied in the field of preparation of low dielectric loss CaCu3Ti4O12 ceramics, can solve the problems of high dielectric loss of products, high density of ceramic sheets, and imbalanced composition ratio, and achieve low raw material cost and low dielectric constant. High, uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Weigh 8.349 g of calcium nitrate, 25.624 g of copper nitrate and 64.876 g of citric acid, and use absolute ethanol as the solvent to completely dissolve the three raw materials, then use nitric acid to adjust the pH value to 2-3, and finally get blue Transparent mixed solution A;

[0030] (2) Measure 48.376 mL of butyl titanate, add an equal volume of absolute ethanol, stir until completely mixed, and obtain a light yellow mixed solution B;

[0031] (3) Put solution A in a magnetic stirrer and keep stirring, then slowly add solution B into solution A (to prevent hydrolysis of butyl titanate) until a transparent mixed solution is formed, then add 2 g of polyethylene glycol to promote into glue;

[0032] (4) Place the mixed solution finally obtained in the above step (3) in a water bath, adjust the temperature to 80°C, and stir at 200 rpm until a blue xerogel is formed;

[0033] (5) Put the obtained blue xerogel in an evaporating dish, adjust the ...

Embodiment 2

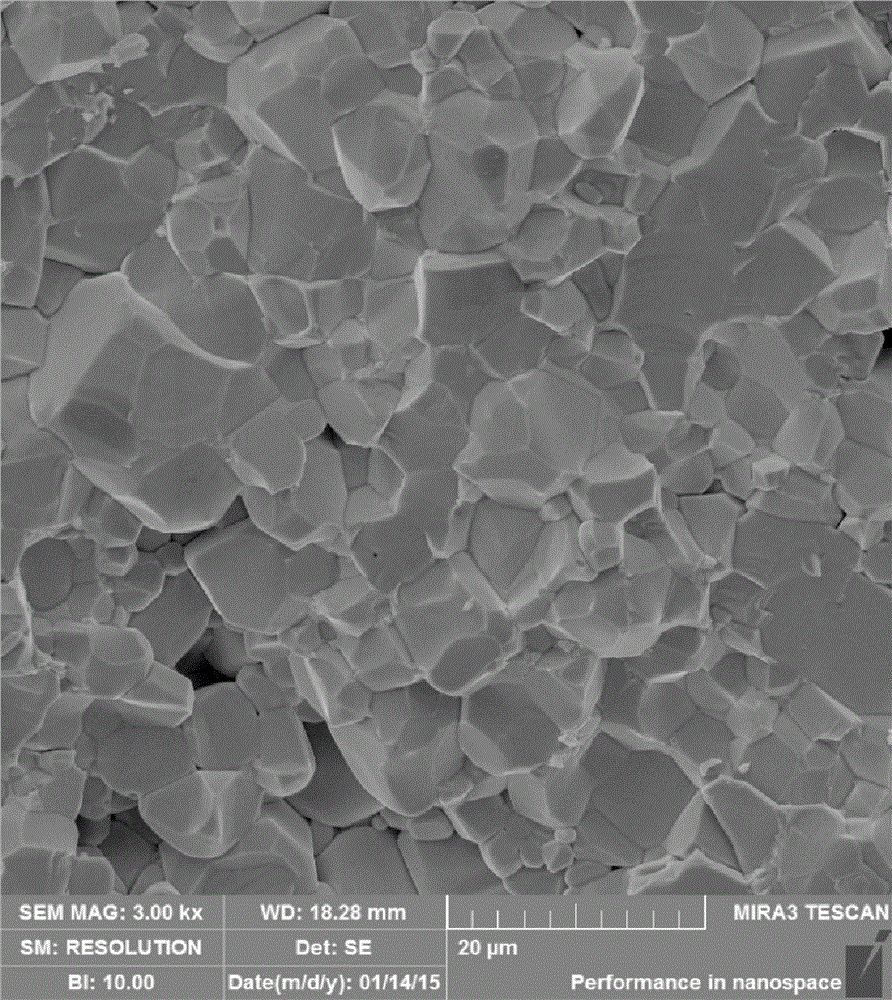

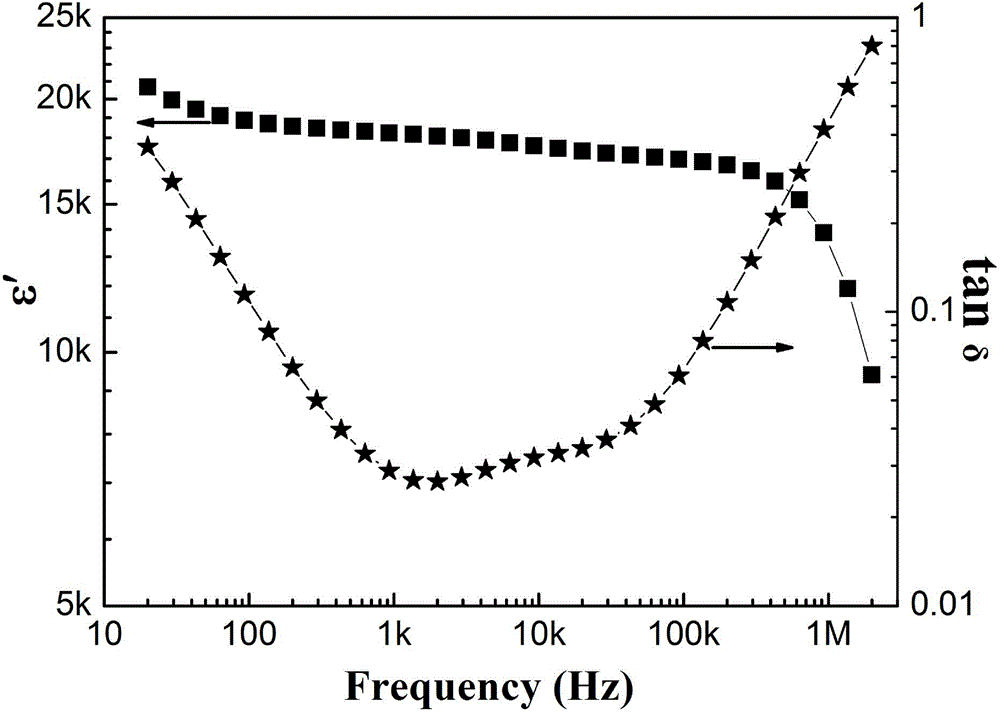

[0039] The difference between this example and Example 1 is that the sintering temperature in step (8) is 1080 °C, and the holding time is still 8 h. The grain size of the CCTO ceramic sample obtained in this example is 3-12 μm, and the relative density is 89.2% About; at 1 kHz, tanδ can be reduced to 0.038, and ε' is greatly improved compared with the sample of Example 1.

Embodiment 3

[0041] The difference between this example and Example 1 is that the sintering temperature in step (8) is 1100 °C, and the holding time is still 8 h. The grain size of the CCTO ceramic sample obtained in this example is 4-15 μm, and the relative density is about 90.1%; at 1 kHz, tanδ can be reduced to 0.029, and ε' is slightly improved compared with the sample in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com