Patents

Literature

2142results about How to "Low dielectric loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing high dielectric constant polymer-based nano composite material

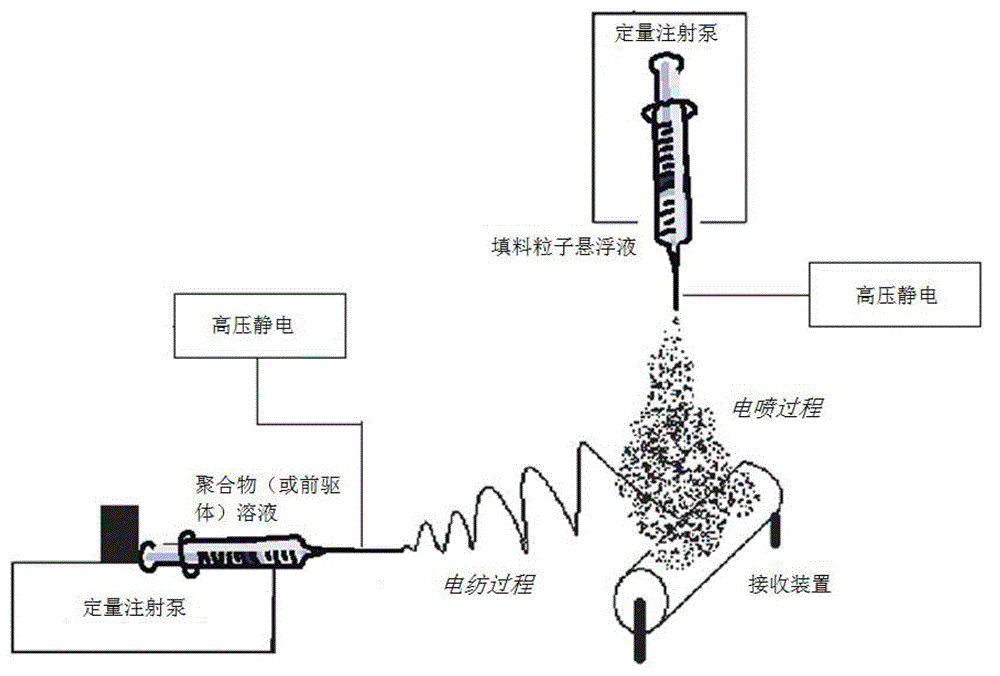

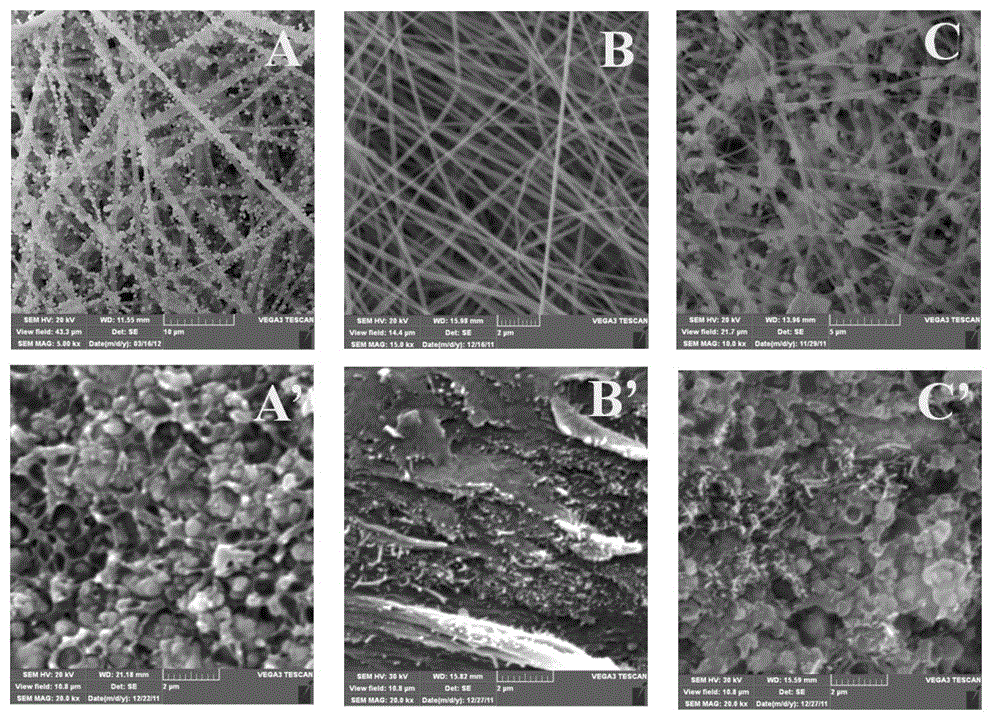

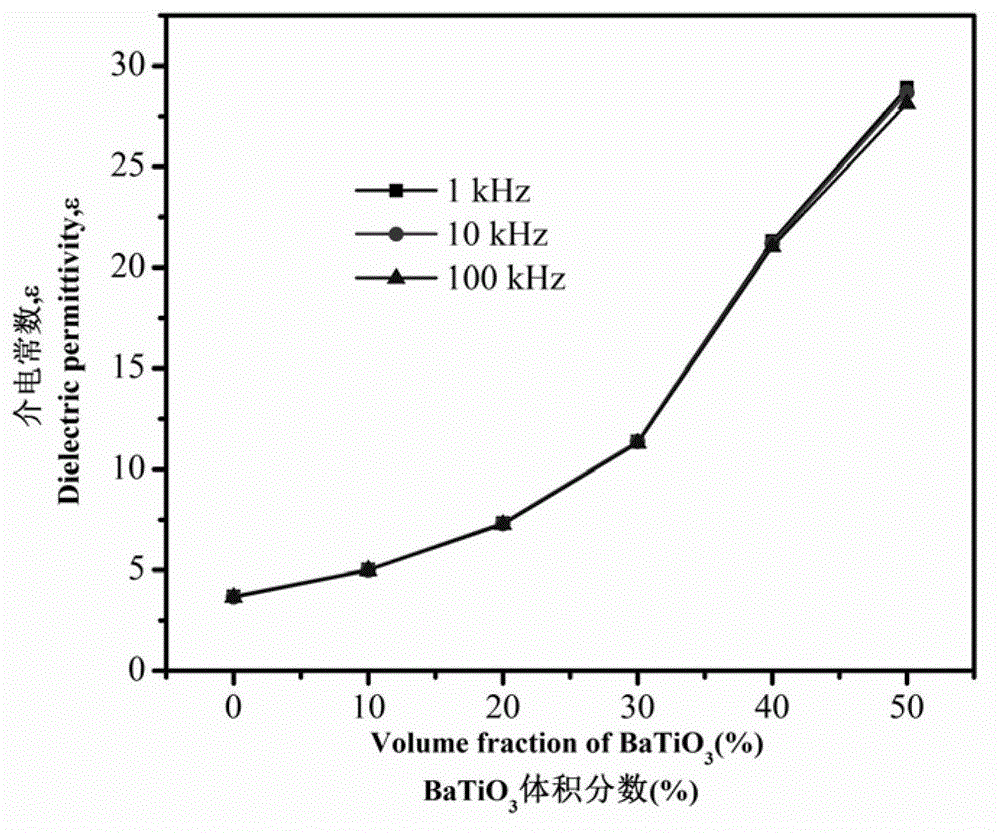

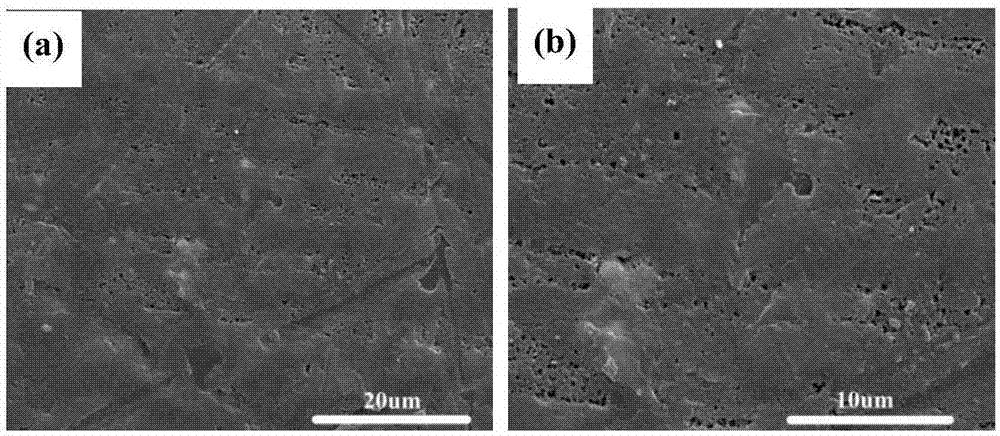

InactiveCN103147226AHigh dielectric constantControllable dielectric constantNon-woven fabricsFiberMatrix solution

The invention provides a method for preparing high dielectric constant polymer-based nano composite material. The method comprises the following steps: performing electrostatic spinning on a polymer matrix solution and simultaneously performing electrostatic spraying on a filler particle suspension; simultaneously receiving the products of the electrostatic spinning and the electrostatic spraying through a common receiving device to obtain a composite fiber membrane; and finally obtaining the high dielectric constant polymer-based nano composite material with filler particles uniformly dispersed after the composite fiber membrane is processed through a hot-pressing processing technique. The composite material prepared by the invention has the characteristics of high dielectric constant, low dielectric loss and the like; and at the same time the dielectric constant of the composite material can be adjusted through adjusting the content of the filler particles in the polymer matrix. The invention has the advantages of simple process, convenient operation and little environment pollution, can well solve the problem that the filler particles is uniformly dispersed in the polymer matrix, and is expected to the microelectronic industry as dielectric material and the like for preparing embedded capacitors.

Owner:JIANGXI NORMAL UNIV

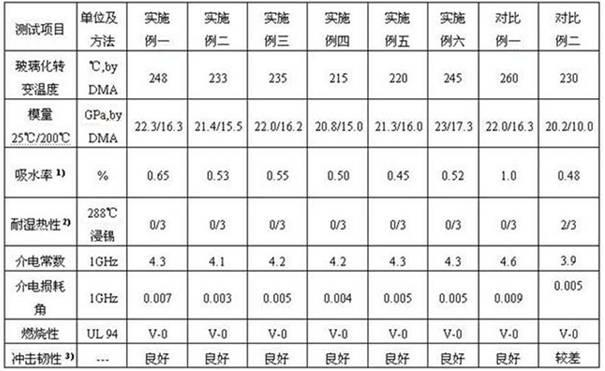

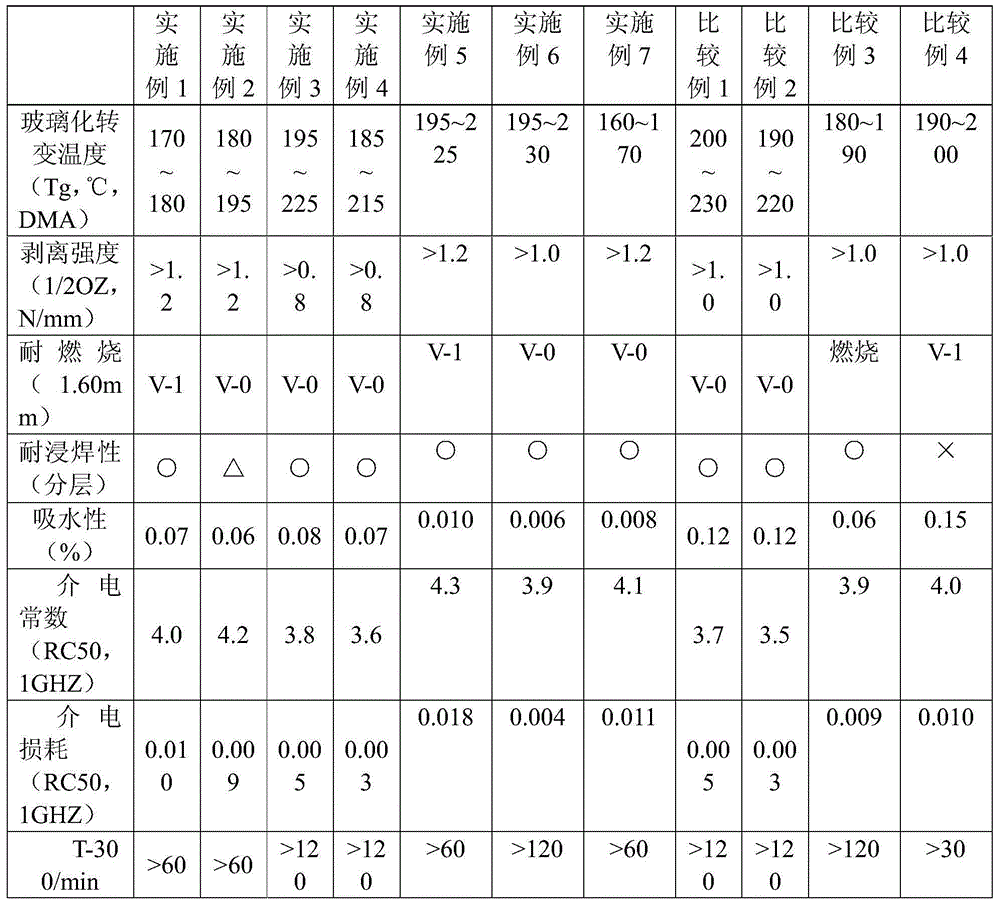

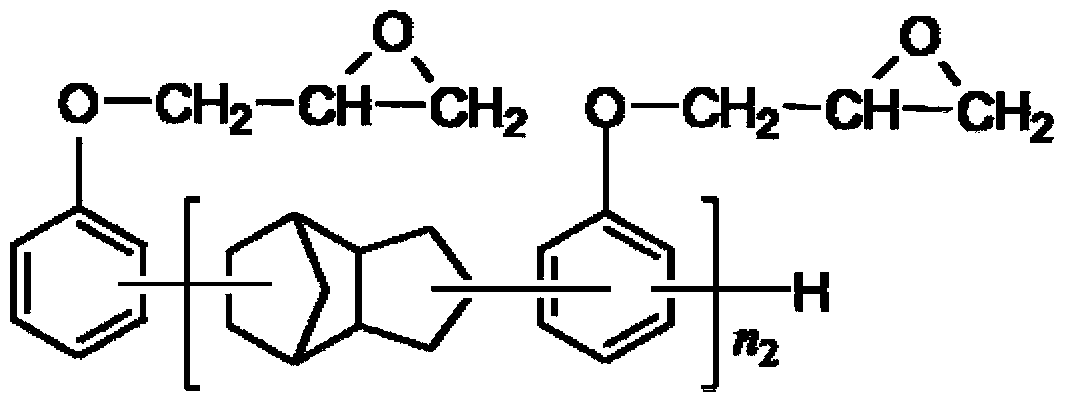

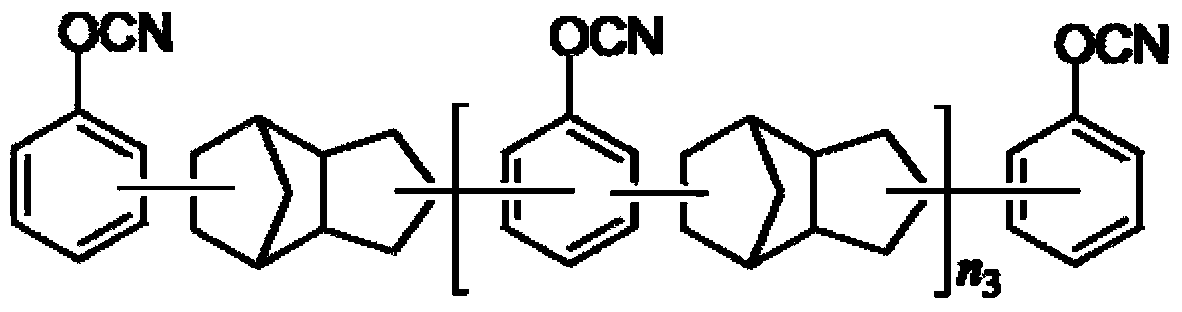

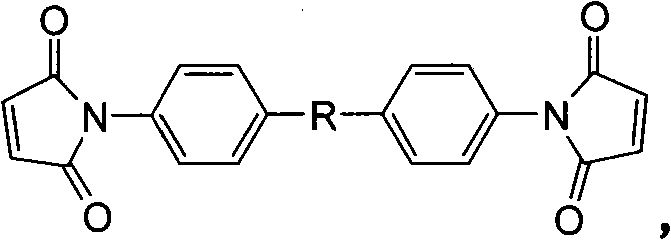

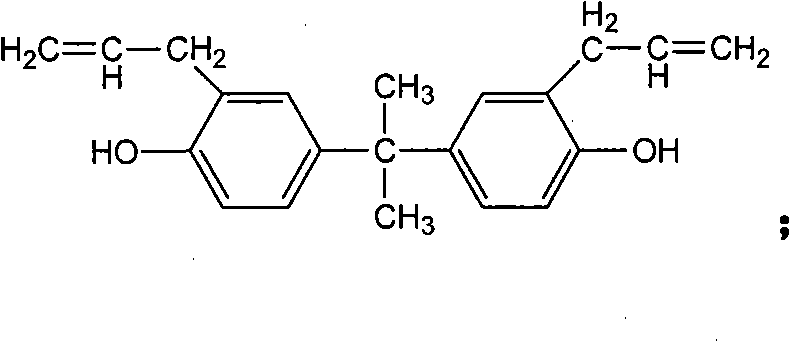

Thermosetting resin composition, prepreg and laminated board

ActiveCN102115600AExcellent heat and humidity resistanceImprove heat resistanceGlass/slag layered productsMetal layered productsEpoxyDielectric loss

The invention discloses a thermosetting resin composition, which is characterized by comprising the following components in part by weight: 8 to 80 parts of allyl modified bismaleimide resin prepolymer, 15 to 60 parts of cyanate resin and 5 to 40 parts of halogen-free epoxy resin, wherein the allyl modified bismaleimide resin prepolymer is prepared by reacting bismaleimide resin with an allylcompound at the temperature of between 110 and 160DEG C for 20 to 100 minutes, and a weight ratio of the bismaleimide resin to the allylcompound is 100:(30-120). The composition can be used for preparing a prepreg and a laminated board. The composition and the laminated board have excellent humidity resistance, high heat resistance, low water absorption rate, high modulus, lower dielectric constant and dielectric loss, and good processing toughness, and can realize halogen-free flame retardancy.

Owner:SHENGYI TECH SUZHOU

High electric energy density polymeric compositions, methods of the manufacture therefor, and articles comprising the same

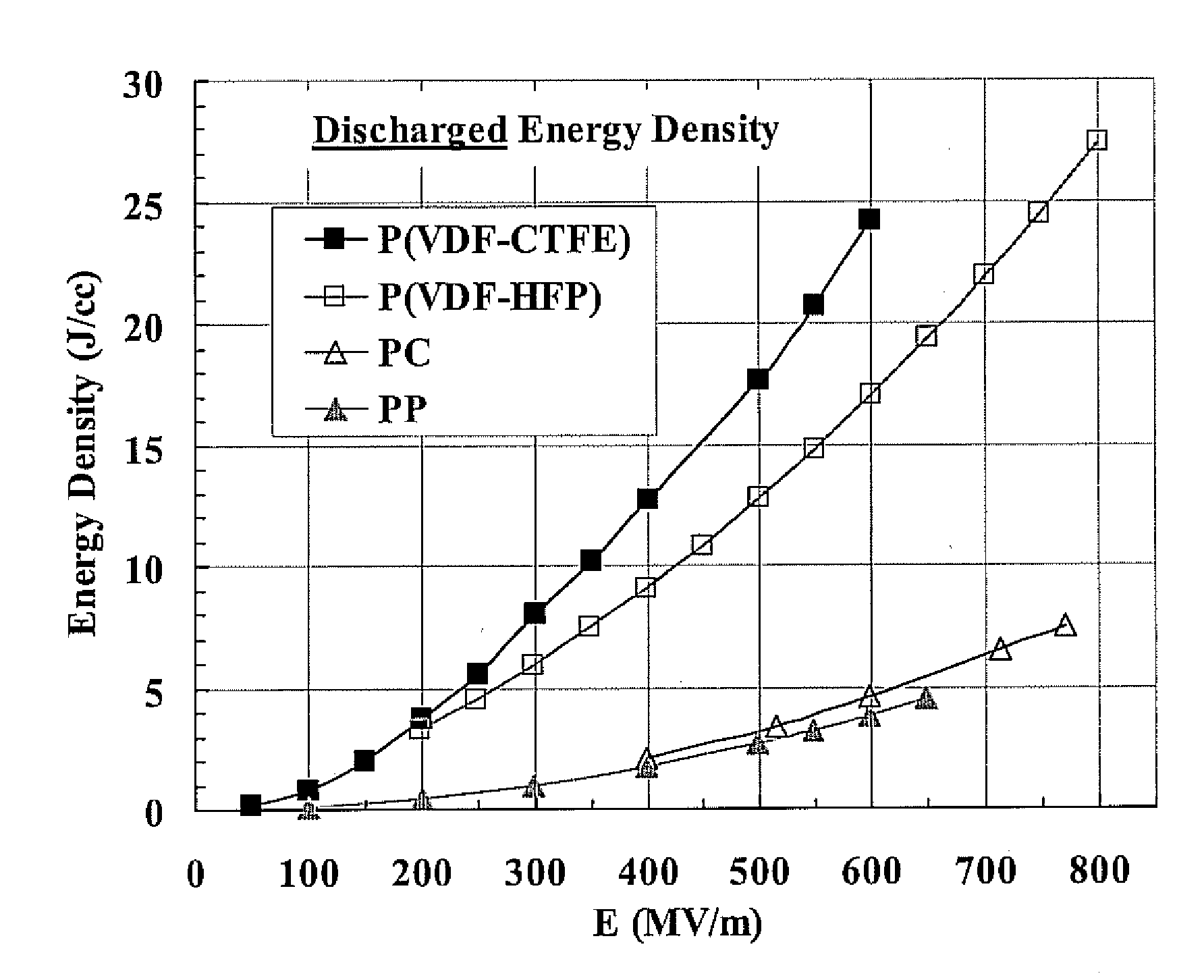

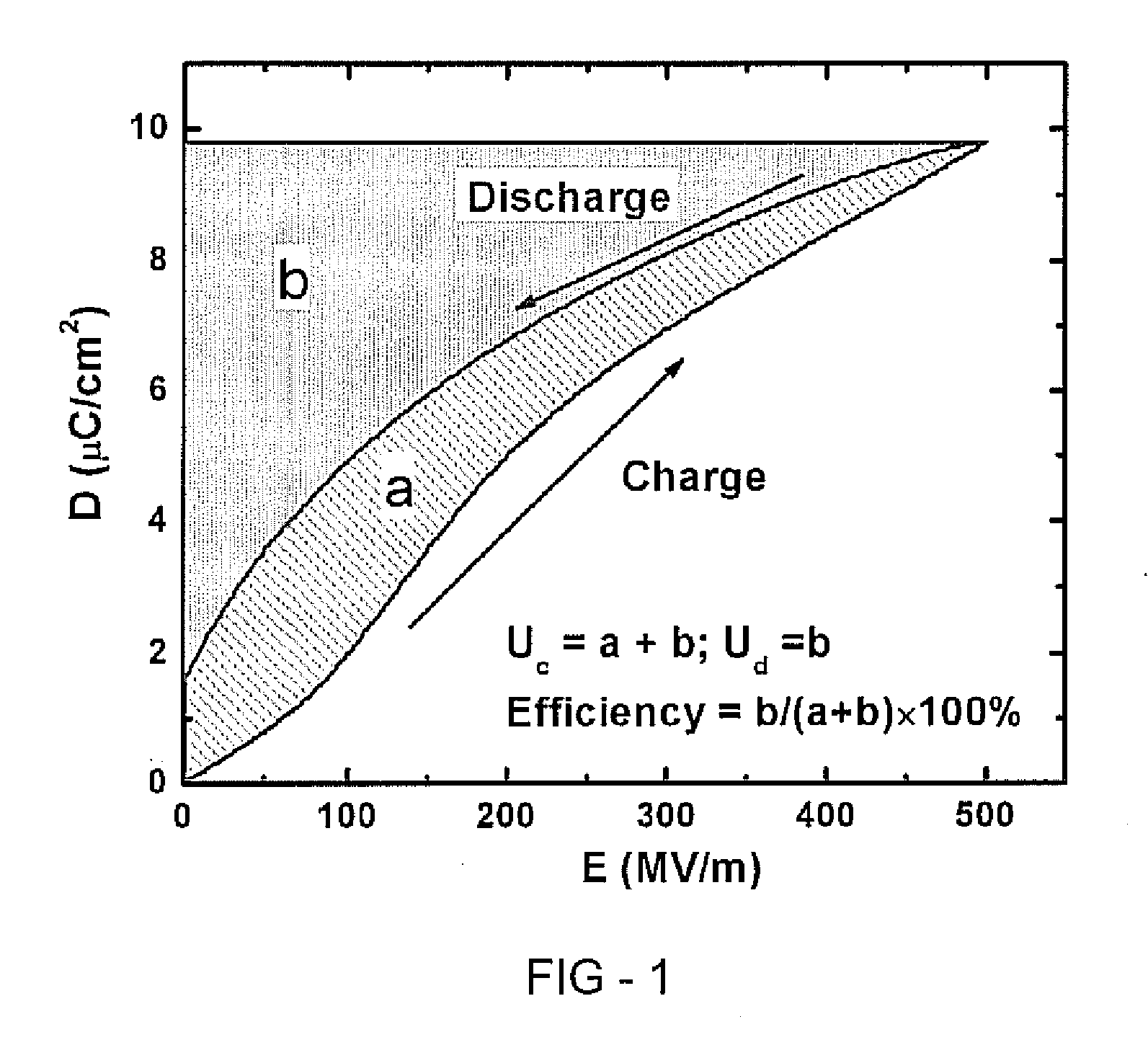

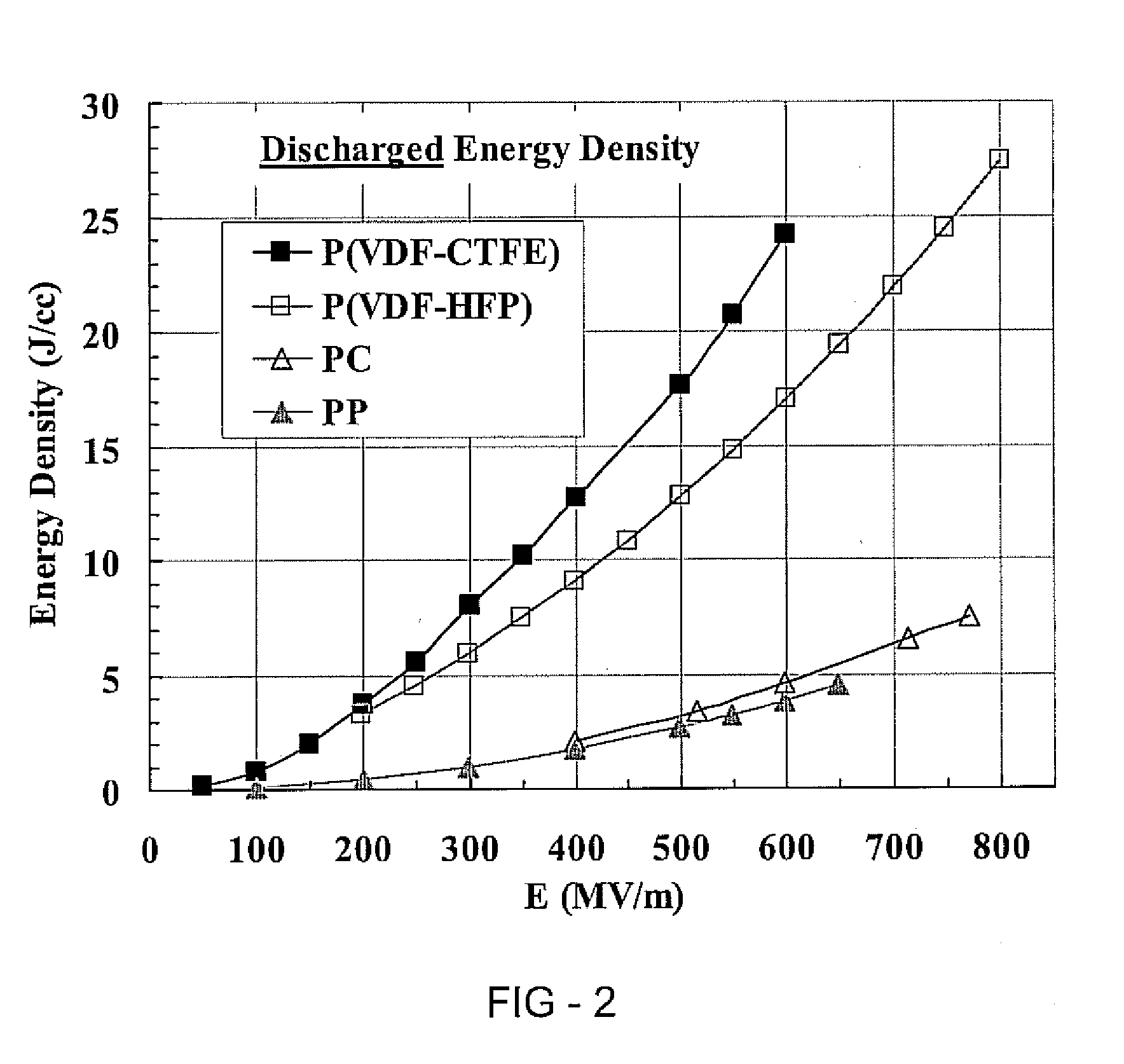

InactiveUS20100067172A1Improve efficiencyFast dischargeFixed capacitor dielectricVehicular energy storagePolymer capacitorPolymer science

Examples of the present invention relate generally to high electric energy density polymer film capacitors with high charge-discharge efficiency and fast discharge speed. For example, a high energy density polymer capacitor may be fabricated using a polymer blend comprising one or more high dielectric constant PVDF-based polymers (including homopolymers, copolymers and / or terpolymers) and one or more other polymer with low dielectric loss and high volume resistivity compared to the one or more PVDF-based polymers. An example film capacitor may comprise a high temperature fluoropolymer with dielectric loss lower than 0.2% and good film manufacturability. Polymer films can be stretched and orientated at least in one direction to make thinner films with improved performance. Film capacitors can be made by winding metallized films, plain films with metal foils, or using a hybrid construction where the dielectric films comprise the new compositions. Capacitors can also have a multilayer construction where the films are metallized.

Owner:NOVASENTIS

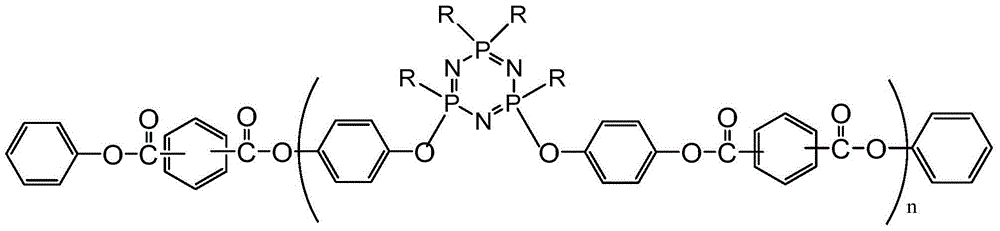

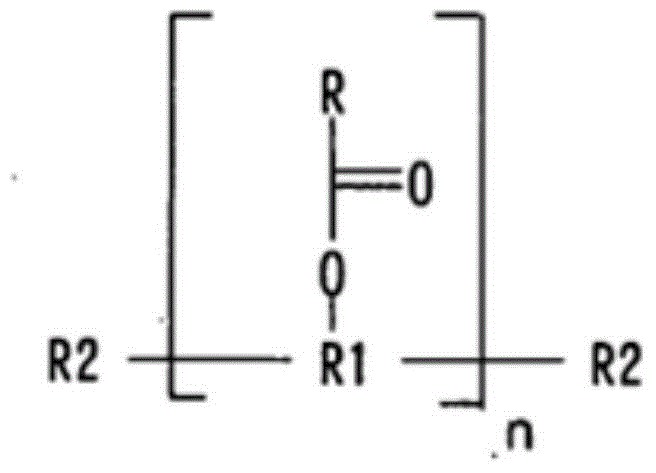

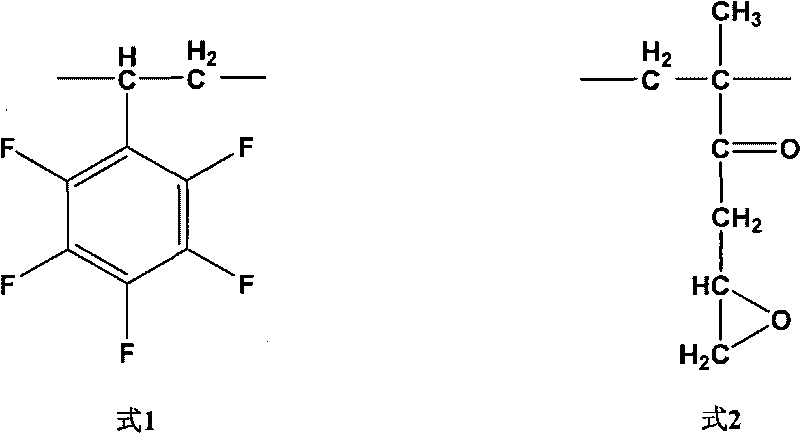

Phenoxy cyclotriphosphazene active ester, halogen free resin composition and application thereof

InactiveCN105153234AHalogenatedHalogen Free HalogenatedGroup 5/15 element organic compoundsEpoxyHigh Frequency Waves

The invention discloses phenoxy cyclotriphosphazene active ester, halogen free resin composition and application thereof. The phenoxy cyclotriphosphazene active ester contains the substance having the following structure shown in the description in mol ratio of at least 65%. The halogen free resin composition comprises, by weight, 5 to 50 parts of phenoxy cyclotriphosphazene active ester, 15 to 85 pars of thermosetting resin, 1 to 35 parts of curing agent, 0 to 5 parts of curing accelerator and 0 to 100 parts of inorganic filling material. The phenoxy cyclotriphosphazene active ester, halogen free resin composition and application thereof, by generating no hydroxy in the reaction between active ester and thermosetting resin such as epoxy resin and so on through introducing phenoxy cyclotriphosphazene active ester into thermosetting resin, can meet requirements of halogen free and flame retardation, improve the electrical property of the system (reduce and stabilize Dk and Df), and enable the substrate material with high frequency and high speed to be halogen free.

Owner:GUANGDONG SHENGYI SCI TECH

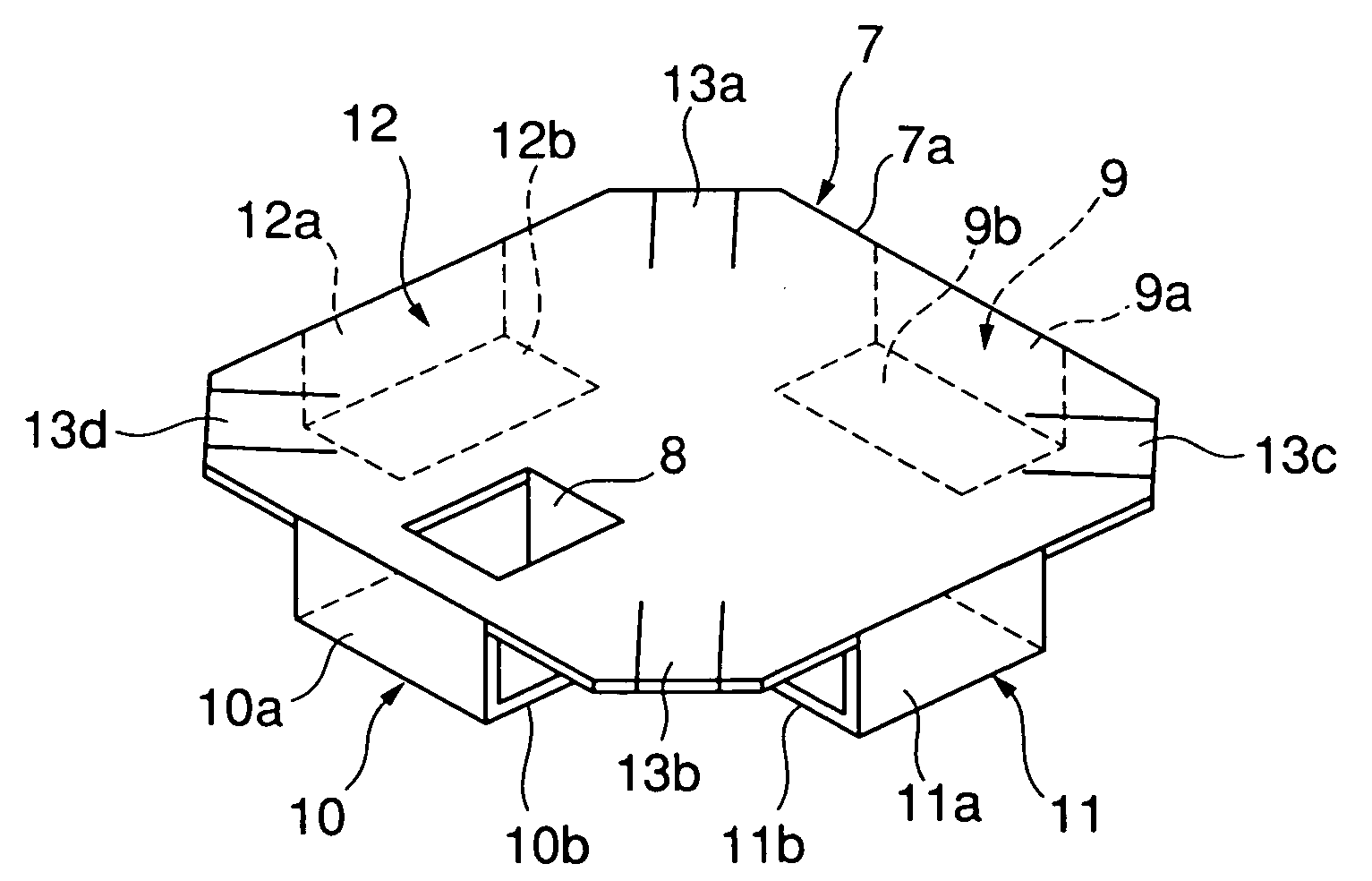

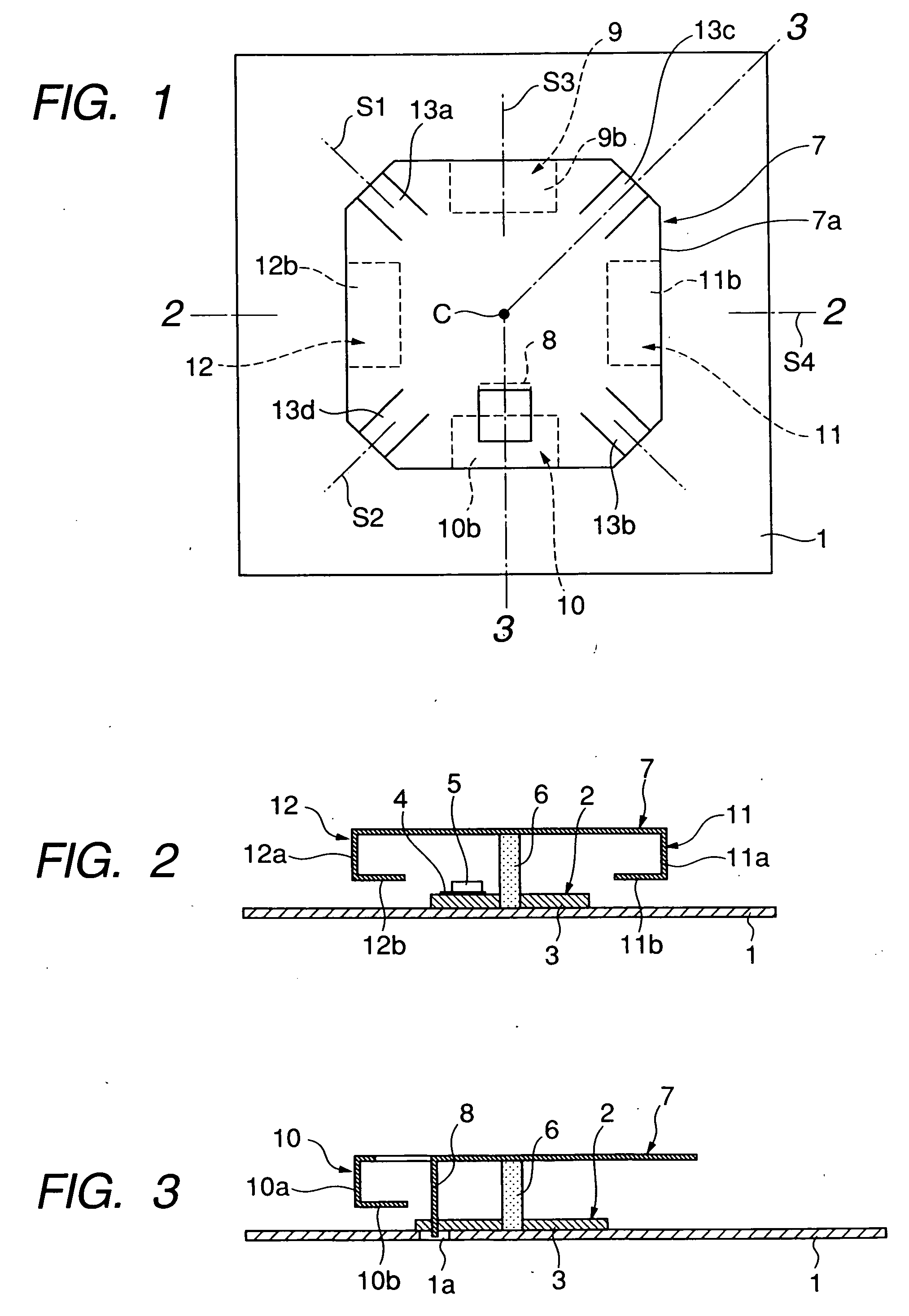

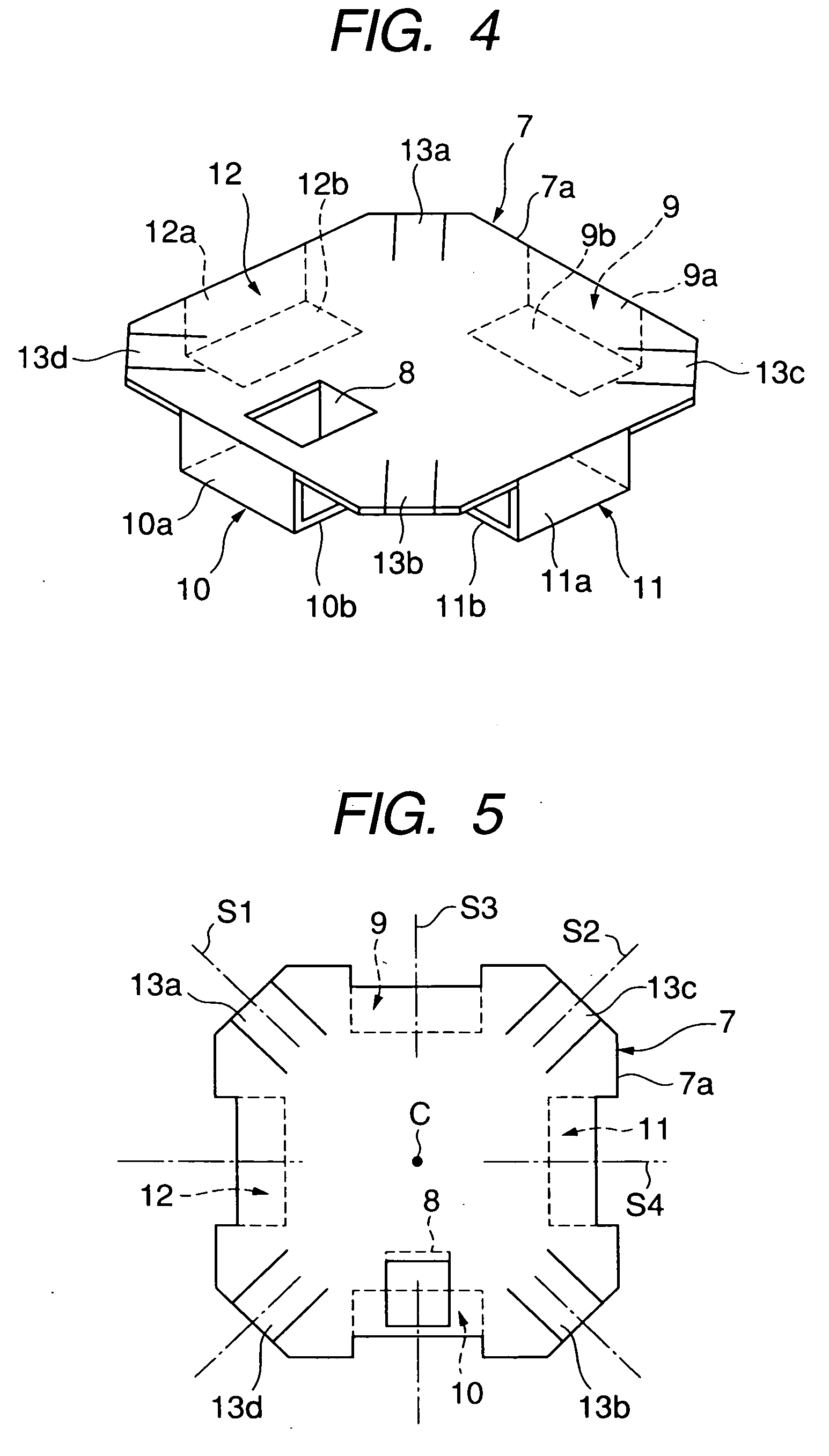

Antenna device suitable for miniaturization

InactiveUS20050116875A1Increase capacitanceReduce resonance frequencySimultaneous aerial operationsAntenna supports/mountingsCapacitanceMiniaturization

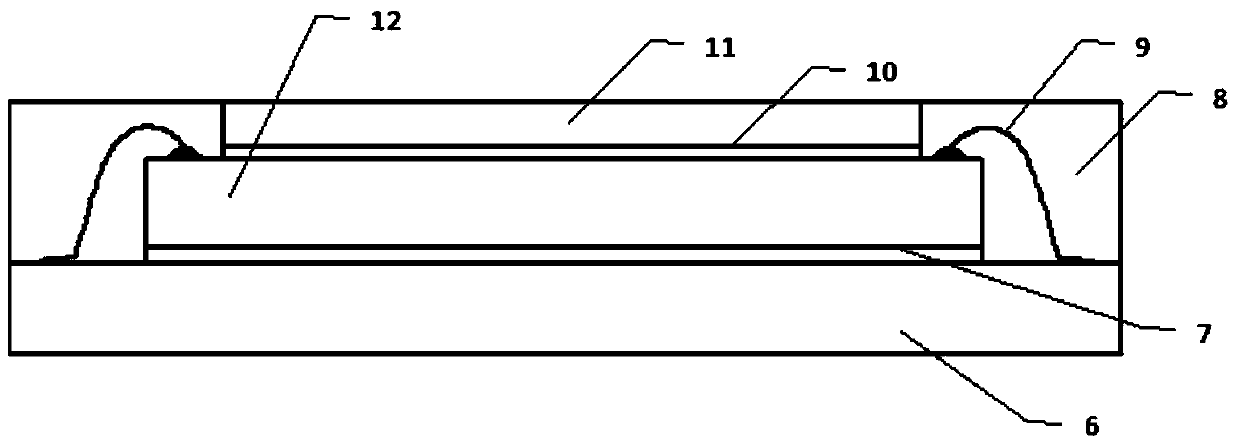

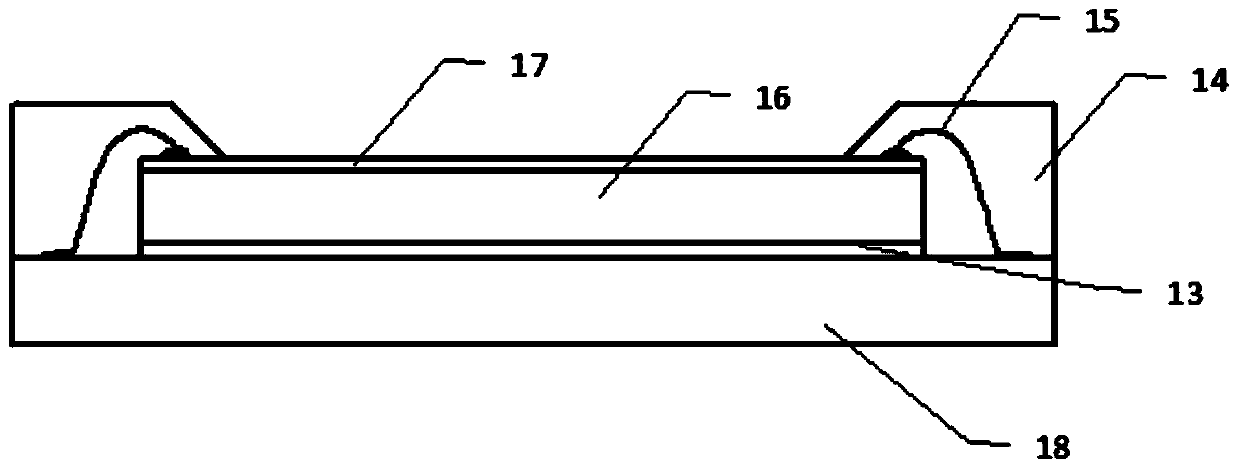

An antenna device includes a ground conductor plate composed of a metal plate and a radiating conductor plate composed of a metal plate and arranged at a predetermined gap from the ground conductor plate. First extending portions are provided in the radiating conductor plate to extend toward the ground conductor plate, and / or second extending portions are provided in the ground conductor plate to extend toward the radiating conductor plate. Capacitance is formed between the first extending portions and the ground conductor plate, between the second extending portions and the radiating conductor plate, or the first extending portions and the second extending portions respectively.

Owner:ALPS ALPINE CO LTD

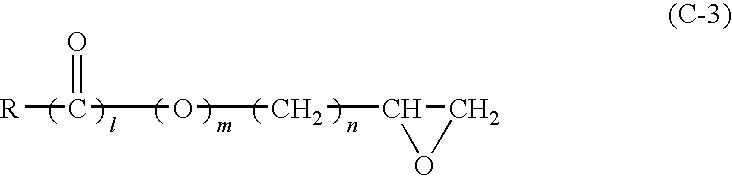

Coating composition

ActiveUS20090281224A1Low dielectric lossExcellent in winding property (flexibility)Thin/thick film capacitorFixed capacitor dielectricDielectric lossSolvent

There is provided a coating composition comprising (A) a thermoplastic non-fluorine-containing polymer, (B) inorganic ferroelectric particles, (C) an affinity-improving agent comprising at least one of a coupling agent, a surfactant and an epoxy group-containing compound, and (D) a solvent, and there is provided a film formed using the coating composition which has highly dielectric property and low dielectric loss, can be made thin, is excellent in winding property (flexibility) and is suitable as a highly dielectric film for a film capacitor.

Owner:DAIKIN IND LTD

Dielectric composite material for fingerprint sensor induction layer and preparation method thereof

ActiveCN104194271AImprove convenienceImprove securitySolid-state devicesPrint image acquisitionEpoxyFire retardant

The invention discloses a dielectric composite material for a fingerprint sensor induction layer and a preparation method thereof. The dielectric composite material is prepared from an epoxy resin, a phenol aldehyde resin, a first dielectric inorganic filler, a second dielectric inorganic filler, a curing agent, an adhesion accelerator, a releasing agent and a flame retardant. The dielectric composite material has the advantages of high dielectric constant, small dielectric loss, stable dielectric properties (can not greatly change along with test frequency), non-transparency and high hardness; and the prepared fingerprint sensor induction layer satisfies the requirements for reliability and stability on the premise of achieving the thickness requirement, and can be used in various portable electronic products. The dielectric composite material is free of heavy metal lead, and thus, is green and environment-friendly. The dielectric composite material is convenient and safe; and thus, the terminal not only can be substituted for the existing digital-input cryptographic identification system, and can also be used on any electronic component in need of privacy.

Owner:TECORE SYNCHEM

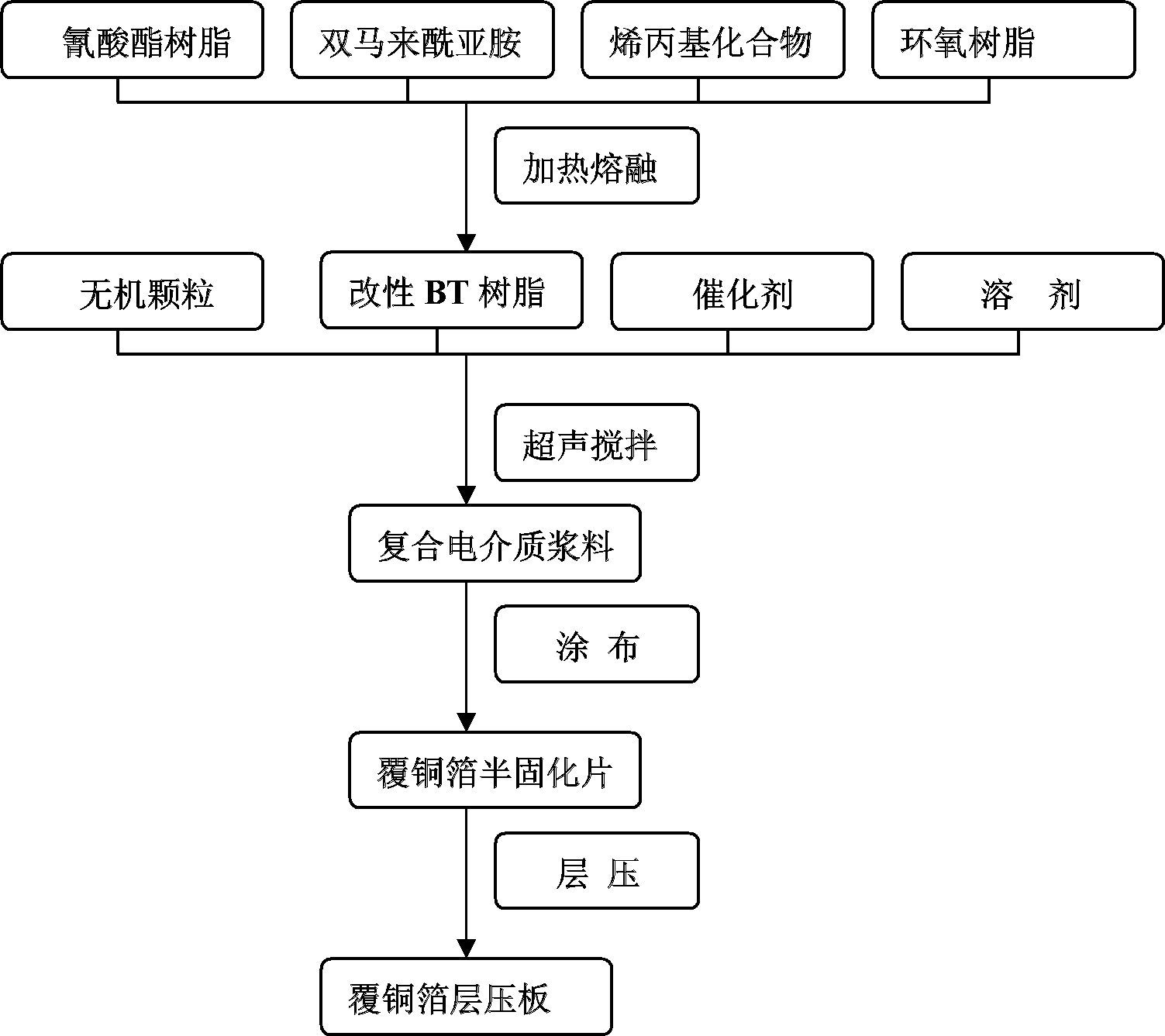

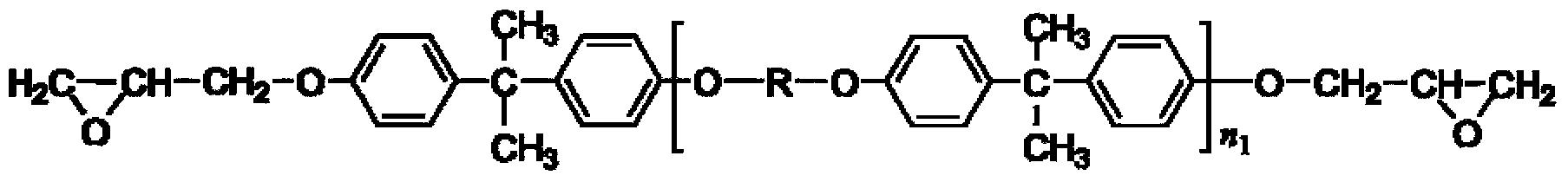

Composite dielectric material, copper-clad foil prepreg manufactured and copper-clad foil laminated board by using composite dielectric material

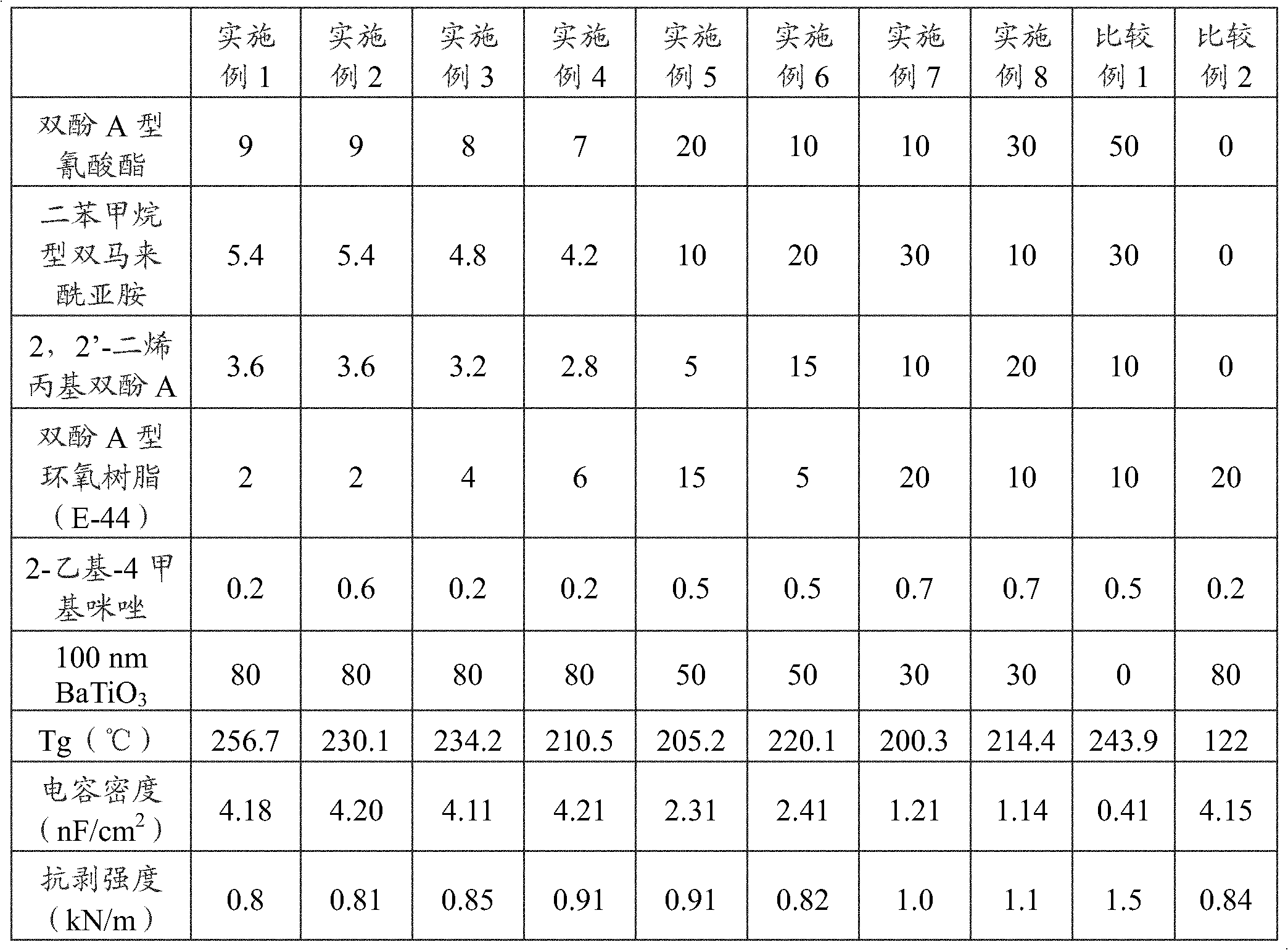

ActiveCN102643543AHigh dielectric constantLow dielectric lossSynthetic resin layered productsMetal layered productsCopper foilCyanate ester

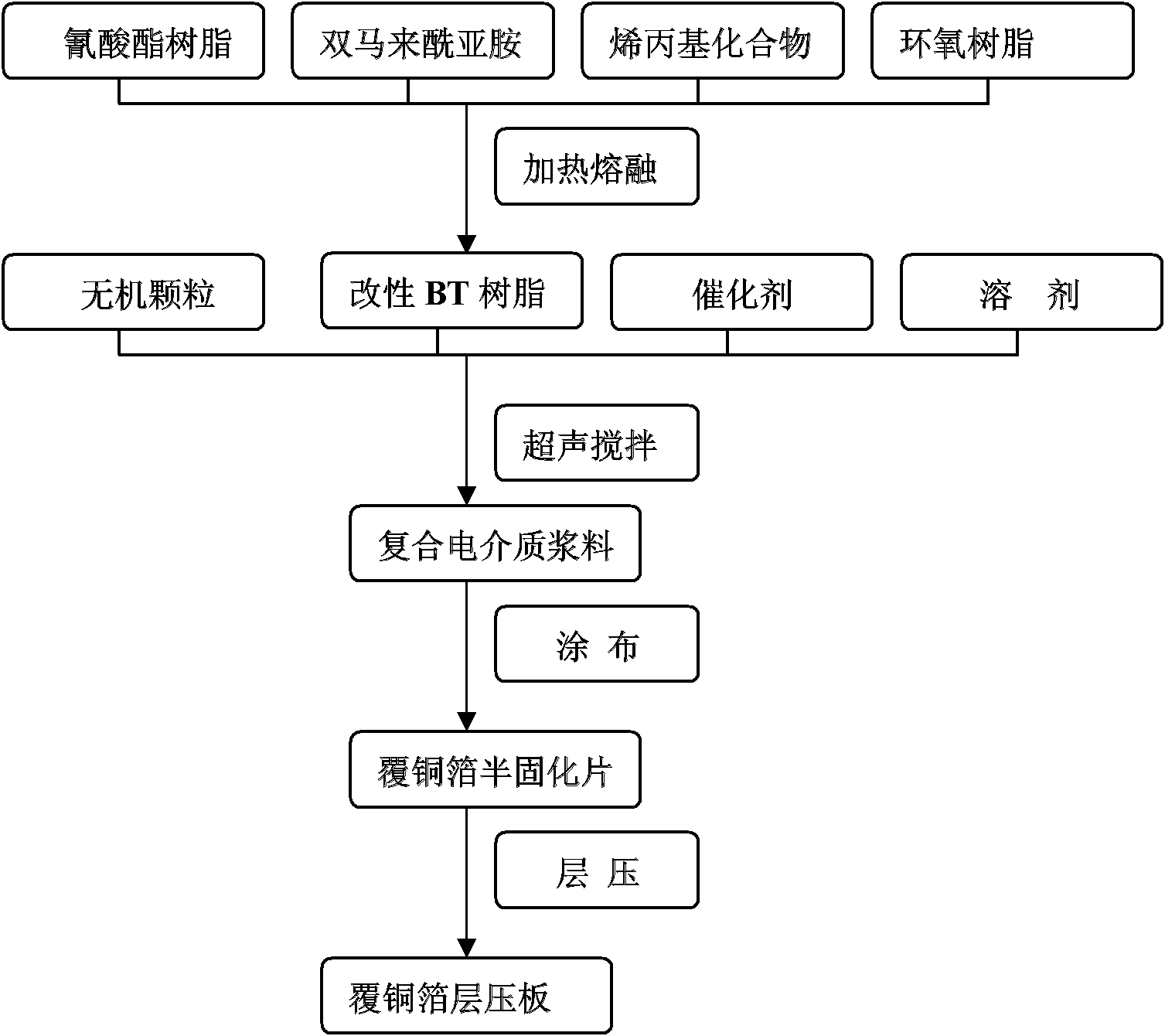

The invention discloses a composite dielectric material, a prepreg manufactured and a copper-clad foil laminated board by using the composite dielectric material, wherein the composite dielectric material comprises the components by mass percent: 4-30% of bismaleimide compound, 7-30% of cyanate ester monomer, 2-20% of epoxy resin, 2-20% of allylphenol compound, 0.5-5% of catalyst and 30-80% of inorganic filler, wherein the inorganic filler is high-dielectric oxide and / or conductive particles, and can be evenly dispersed in organic matrix by surface grafting or surface coating modification; the prepreg manufactured by the composite dielectric material can be obtained by coating the composite dielectric material on the surface of copper foil and carrying out heat treatment at 80-100 DEG C. The copper-clad foil laminated board is obtained by laminating the prepreg at the temperature of 120-200 DEG C. The copper-clad foil laminated board has the excellent characteristics of high glass transition temperature, high dielectric constant, low dielectric loss, high peel strength and the like, thus being used for manufacturing a high-temperature resistant embedded capacitor printed circuit board (PCB).

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

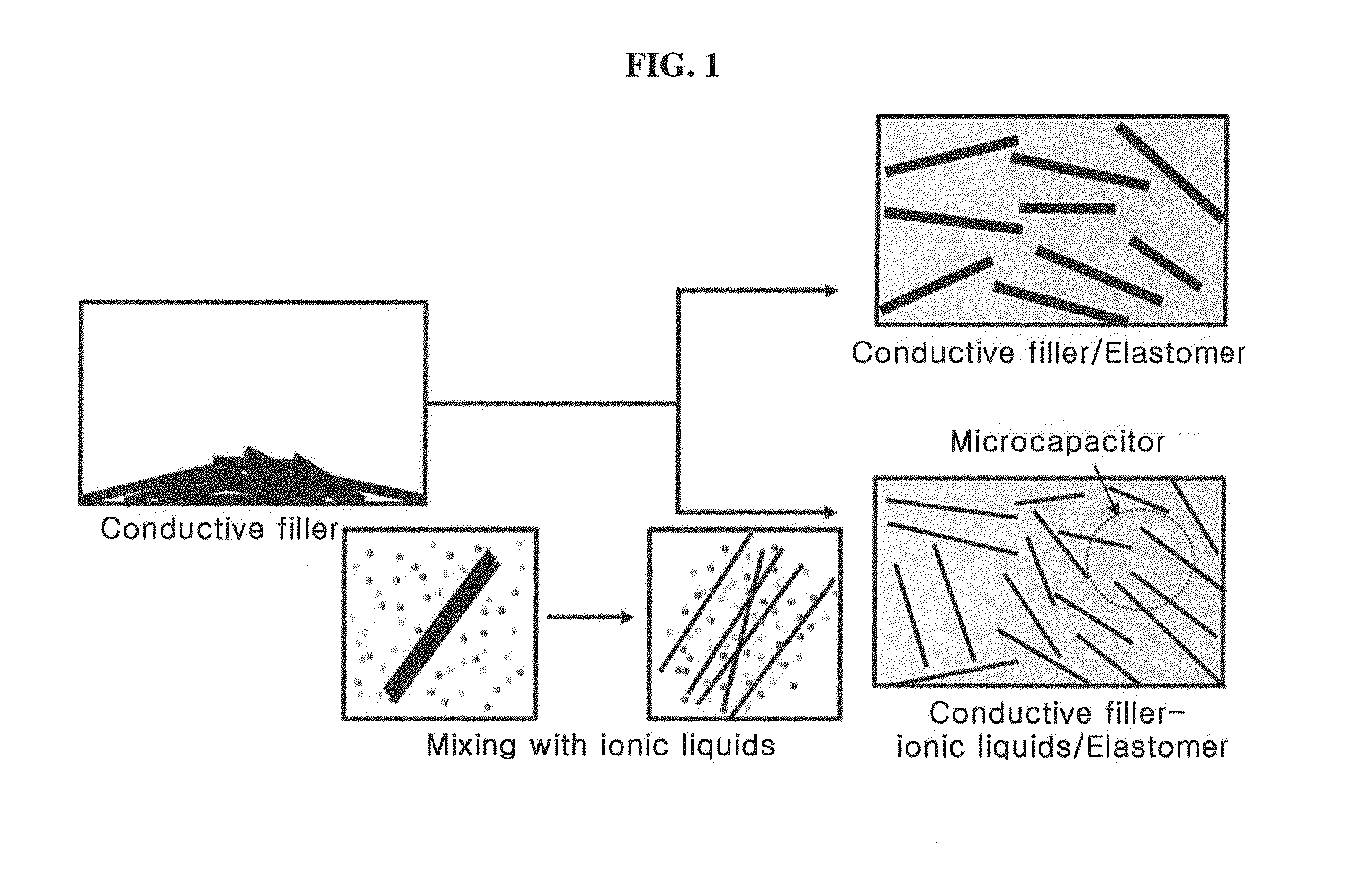

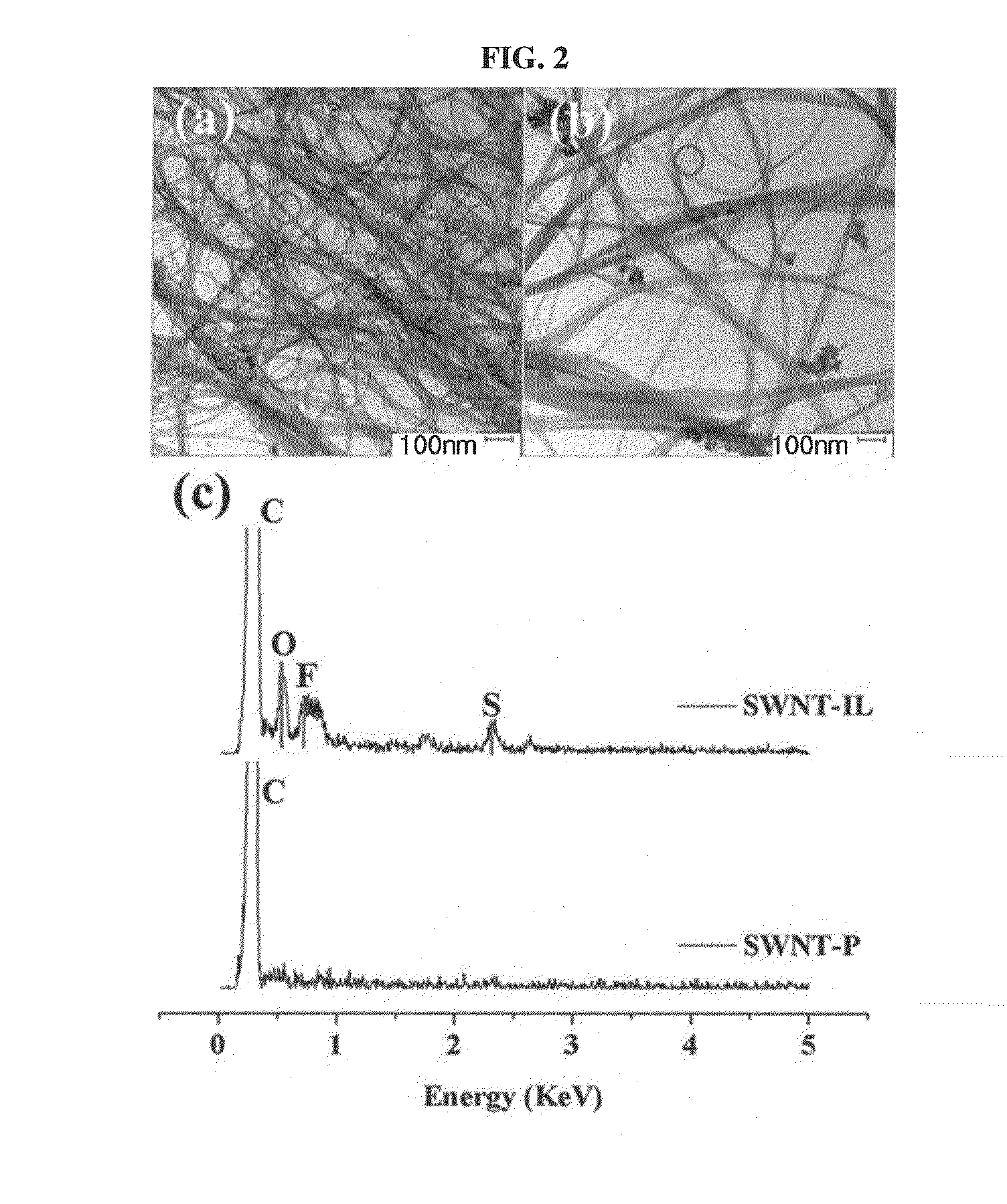

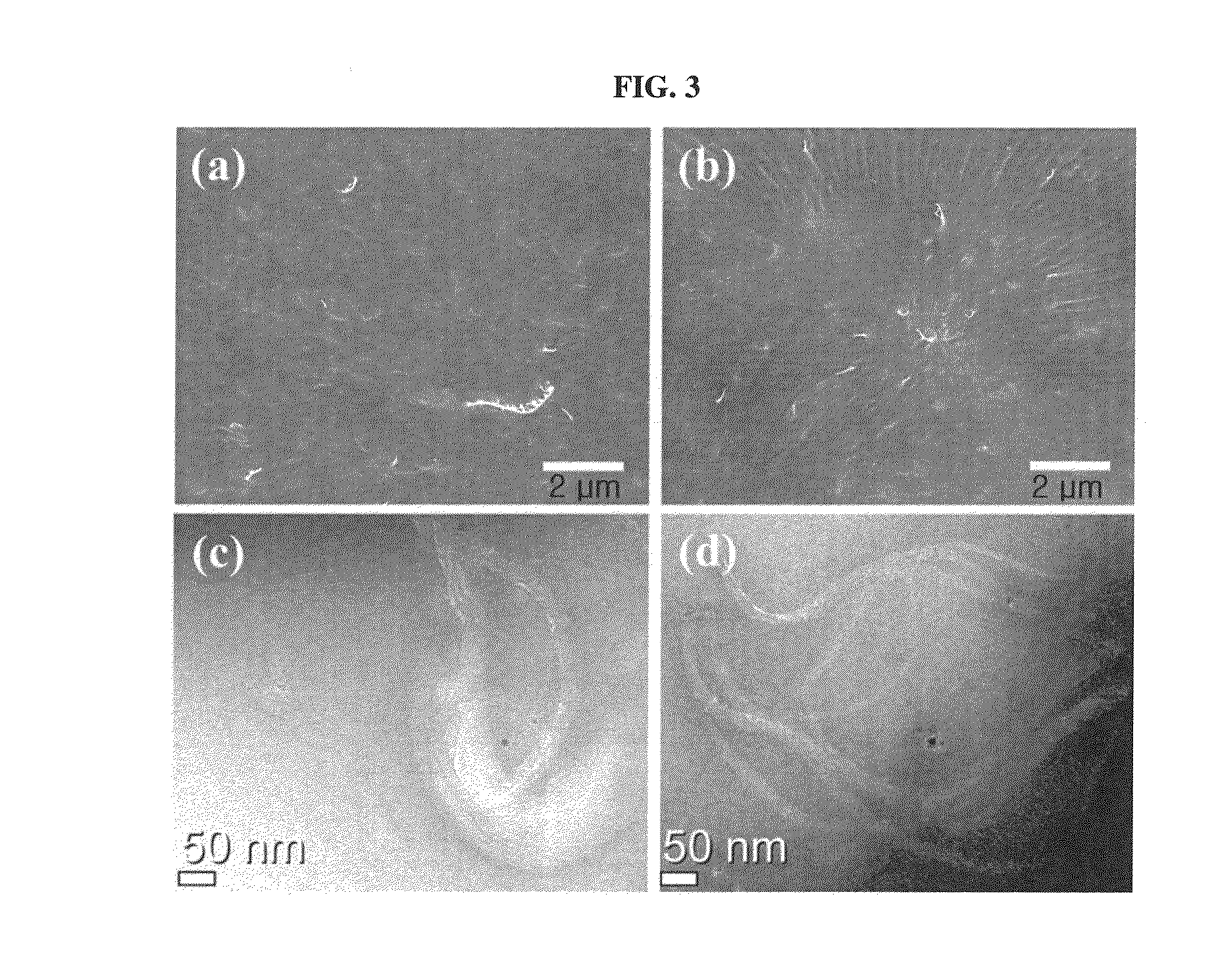

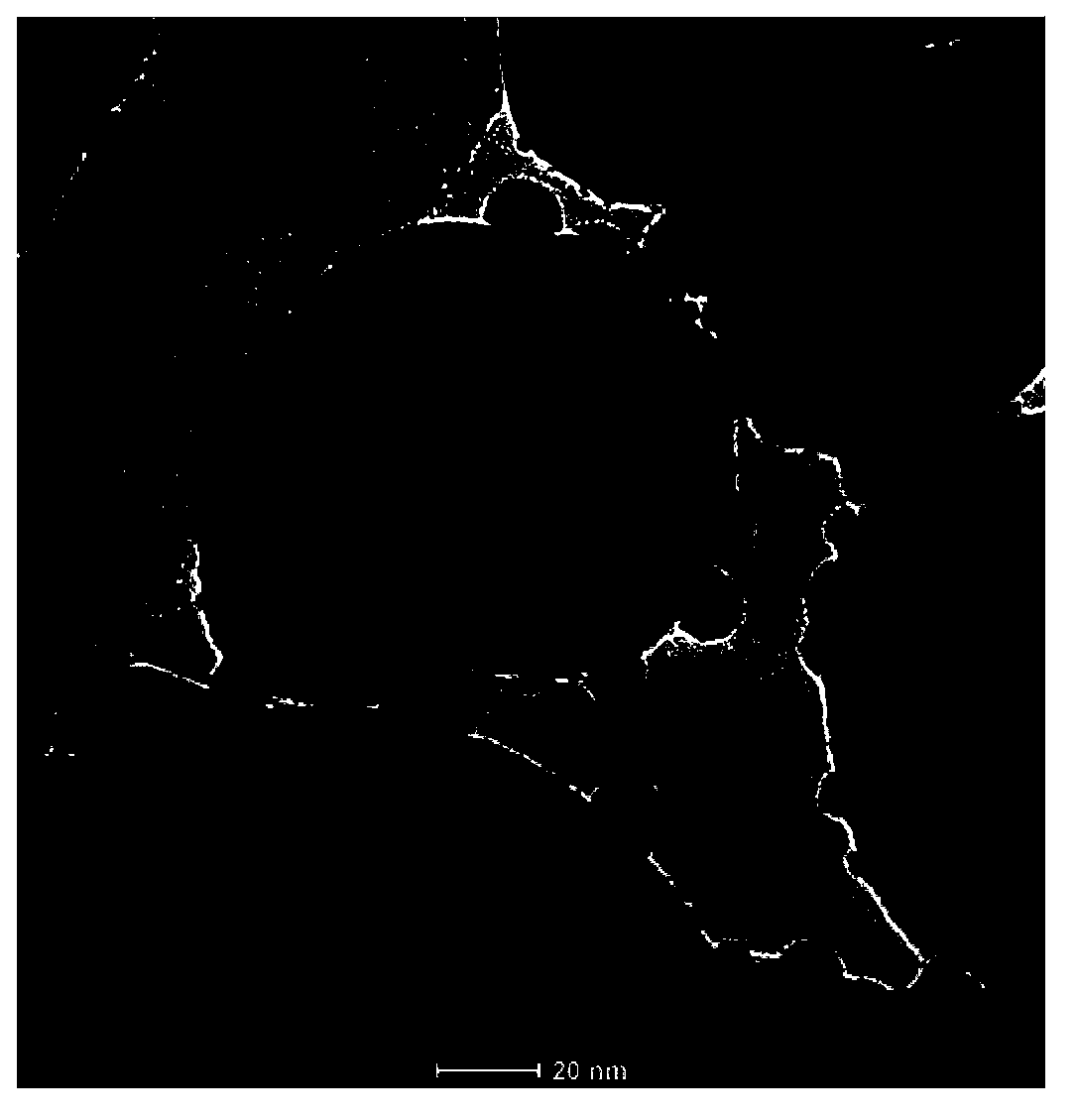

Elastomer composite with improved dielectric properties and production method thereof

ActiveUS20130310495A1Good dispersionHigh dielectric constantMaterial nanotechnologyInorganic insulatorsElastomer compositesConductive polymer

Disclosed is an elastomer-conductive filler composite with improved dielectric properties. The composite includes conductive fillers and an ionic liquid dispersing the conductive fillers. The ionic liquid is used as a dispersant to effectively enhance the dispersion of the conductive fillers, achieving a high dielectric constant and a low dielectric loss of the composite without deteriorating the physical properties of the conductive fillers. The use of the ionic liquid can reduce the number of processing steps and the presence of the conductive fillers at a low concentration in the composite can minimize deterioration of the physical properties of the elastomer. Further disclosed is a method for producing the composite.

Owner:KOREA INST OF SCI & TECH

Nano doping dielectric material for preparing base-metal inner-electrode multi-layer ceramic sheet type capacitor

ActiveCN101182201AImprove performanceMeet performance requirementsFixed capacitor dielectricStacked capacitorsBarium titanateCeramic capacitor

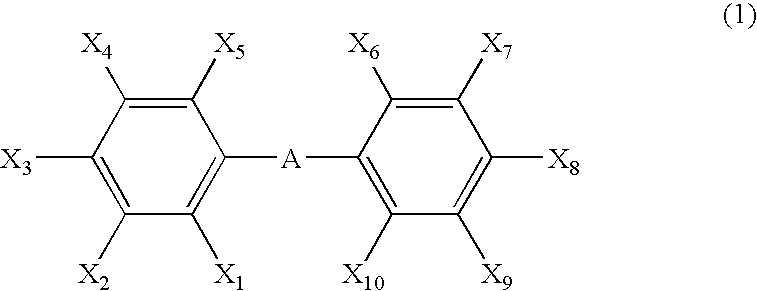

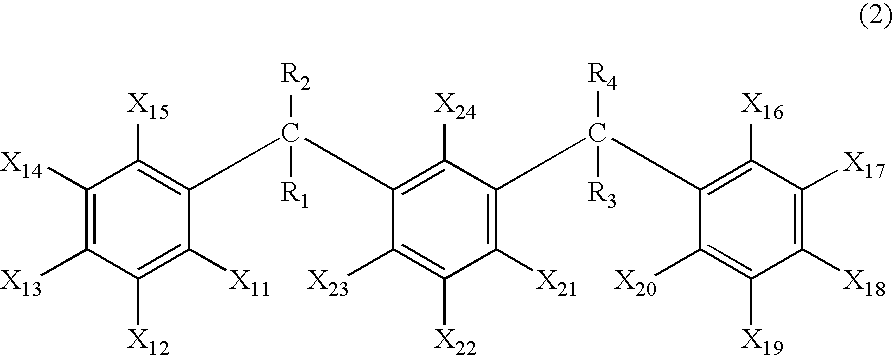

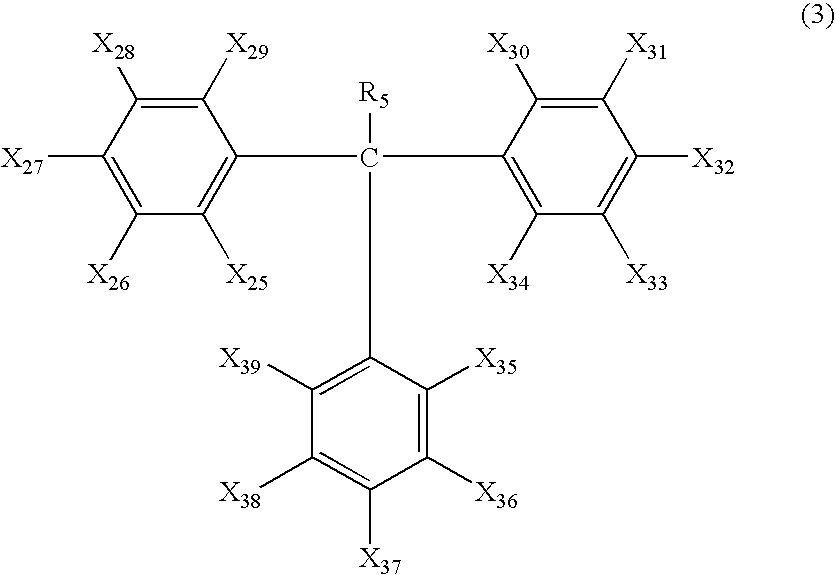

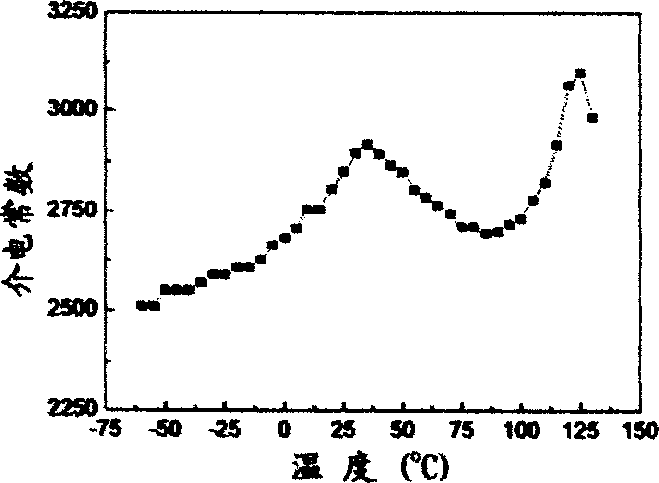

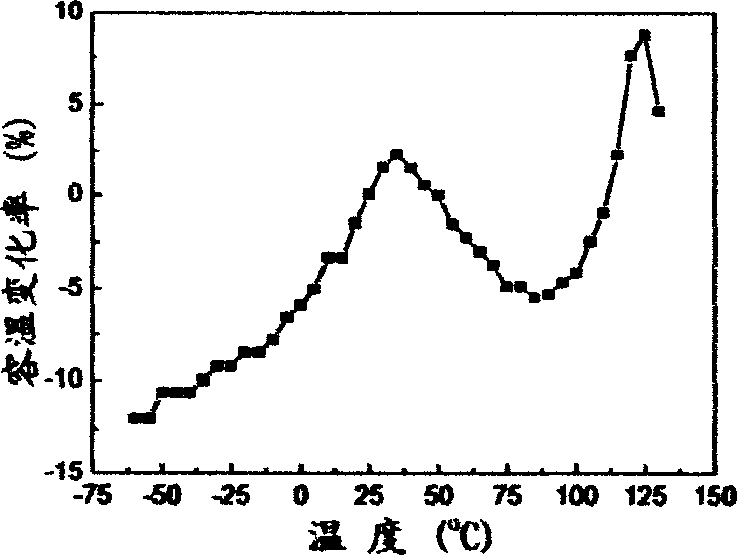

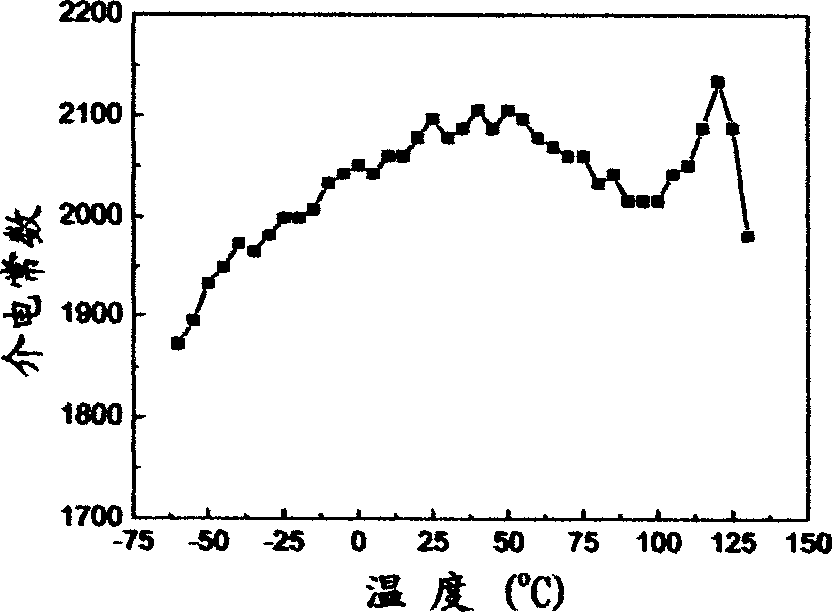

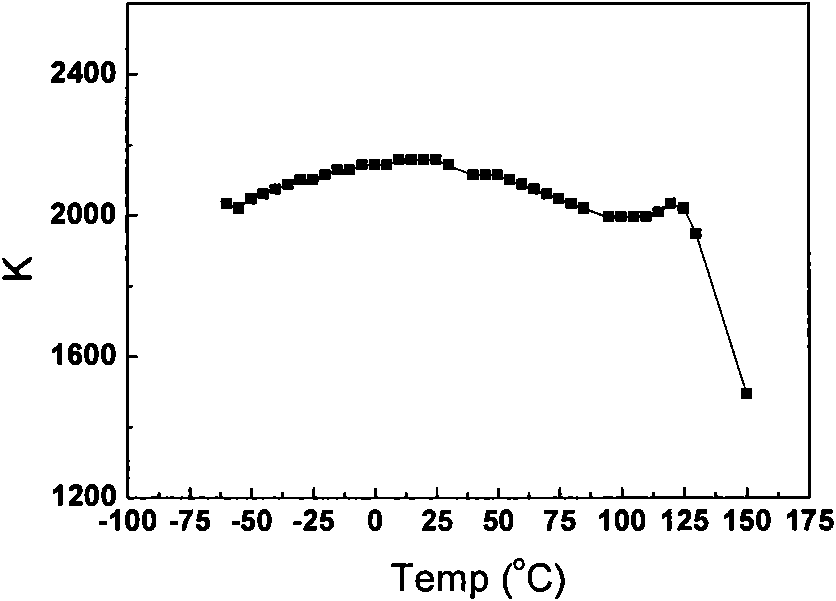

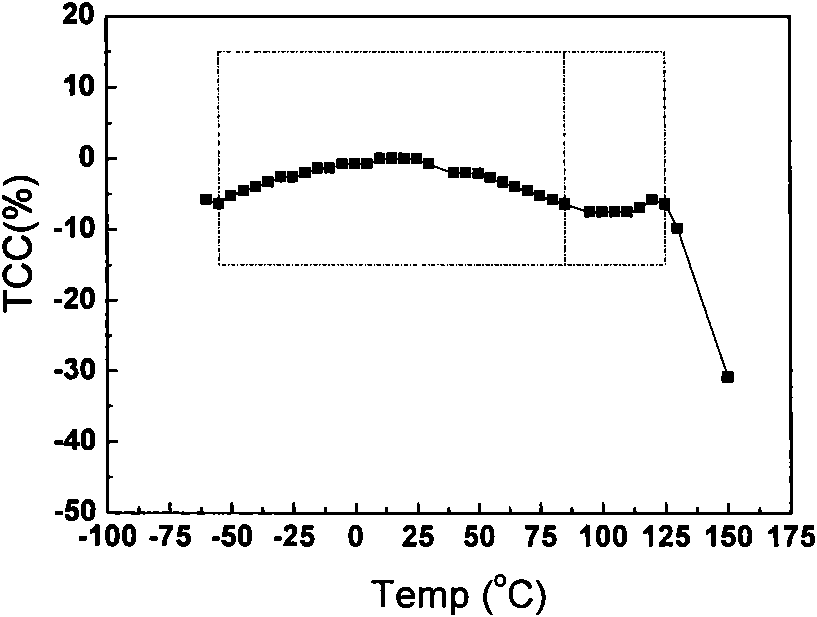

The invention discloses a base metal internal electrode multilayer ceramic chip capacitor dielectric material prepared by nano-doping, which belongs to the technical scope of capacitor material preparation. The ceramic material is composed of barium titanate BaTiO3 as the main material with a mole fraction of 90-98 mol% in the formula and nano dopant accounting for 2-10 mol% of the total material. In a reducing atmosphere, "two-stage" sintering or conventional sintering at a temperature range of 950 ° C to 1250 ° C can obtain X7R / X5R type MLCC materials with excellent performance. The room temperature dielectric constant of the material (wafer sample) can be Controlled at 2000-2600, capacity temperature change rate ≤ ± 15%, dielectric loss at room temperature ≤ 1.5%, ceramic grain size can be controlled at 100-200nm, good uniformity, suitable for production of large capacity, dielectric layer thickness less than Multilayer ceramic capacitors with an ultra-thin dielectric layer of 3 μm, high insulation resistivity, and stable performance.

Owner:TSINGHUA UNIV

Composition for forming photosensitive dielectric material, and transfer film, dielectric material and electronic parts using the same

InactiveUS20040094752A1High dielectric constantHigh dimensionalLiquid organic insulatorsSemiconductor/solid-state device manufacturingInorganic particleDielectric loss

A photosensitive composition for forming a dielectric of the present invention comprising inorganic particles, an alkali developable resin and additives, wherein the additives comprise a compound having a quinonediazido group (C1), a compound containing at least two alkyletherified amino groups in the molecule (C2) and a thermal acid generator (C3), or wherein the inorganic particles comprise inorganic superfine particles (A-I) having a mean particle diameter of less than 0.05 mum and inorganic fine particles (A-II) having a mean particle diameter of not less than 0.05 mum. The composition can be calcined at low temperatures to form a dielectric layer with high dimensional precision, said layer having a high dielectric constant and a low dielectric loss. Also provided are a dielectric and an electronic part prepared from the composition.

Owner:JSR CORPORATIOON

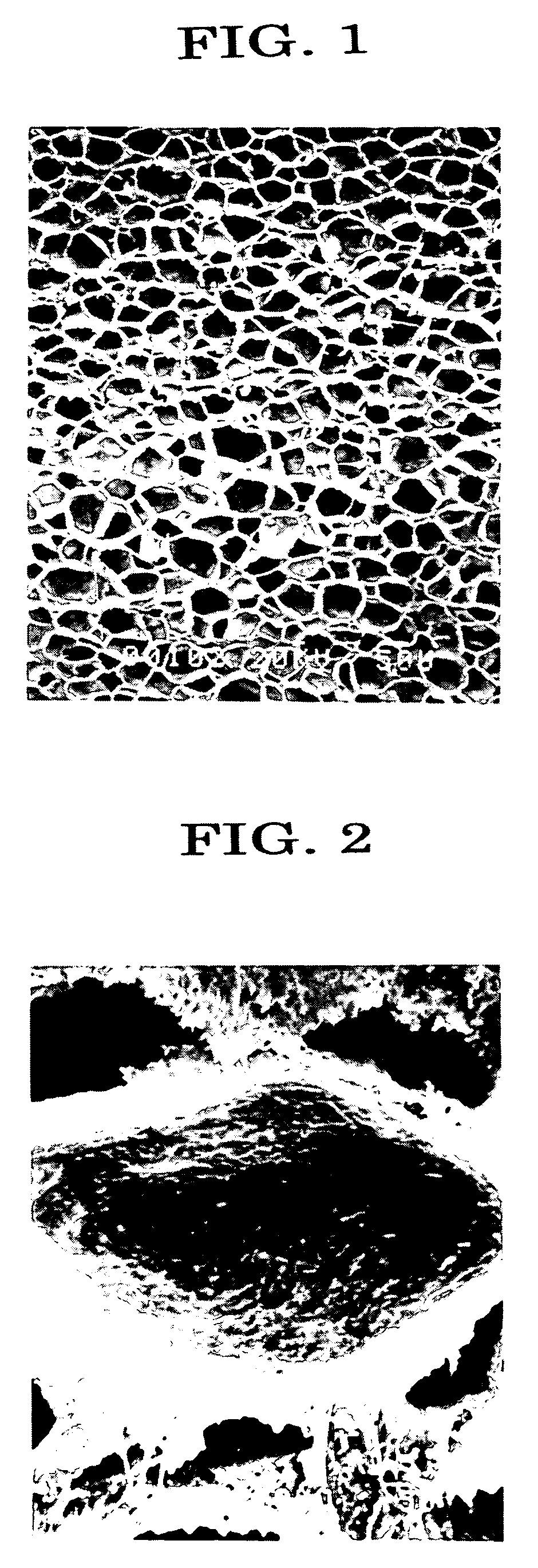

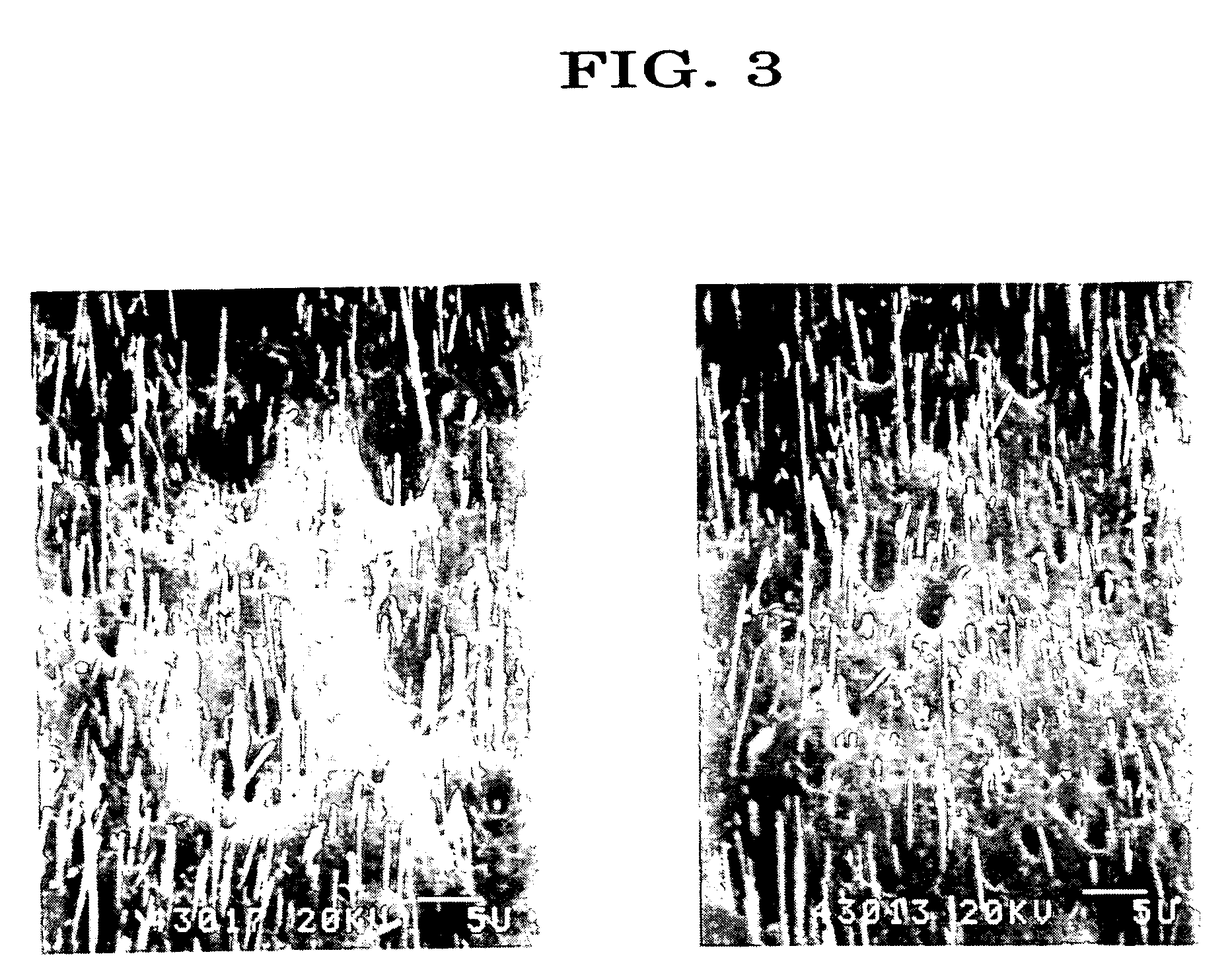

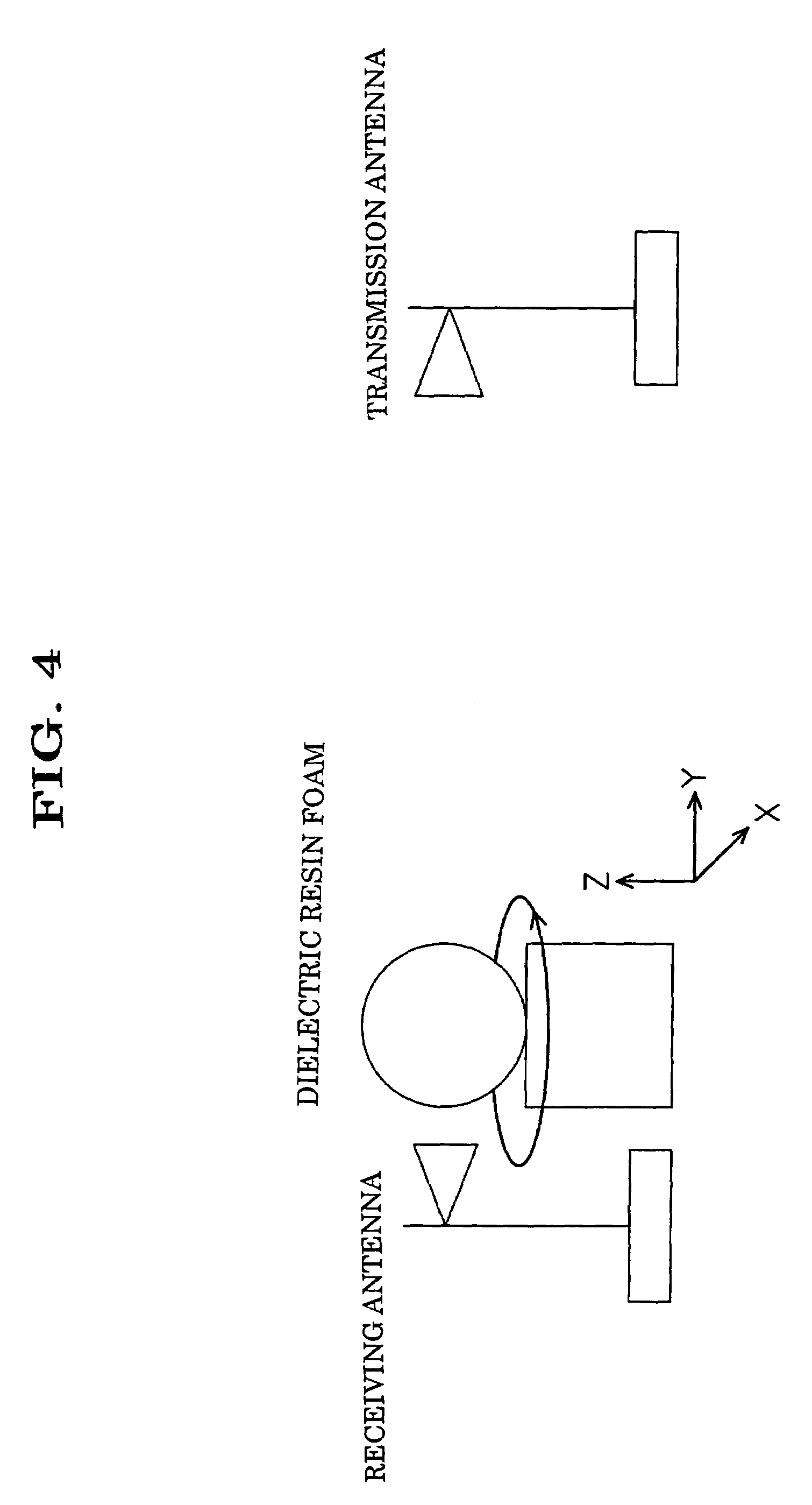

Dielectric resin foam and lens for radio waves using the same

InactiveUS7179844B2Excellent dielectric propertiesLow specific gravityPlastic/resin/waxes insulatorsCircuit susbtrate materialsDielectricSynthetic resin

It is an object of the present invention to provide a dielectric resin foam which has high and uniform dielectric properties and is preferable for use as various dielectric materials. A dielectric resin foam obtained by expanding a resin composition comprising a synthetic resin and a fibrous and / or plate-like dielectric inorganic filler is provided.

Owner:OTSUKA CHEM CO LTD +1

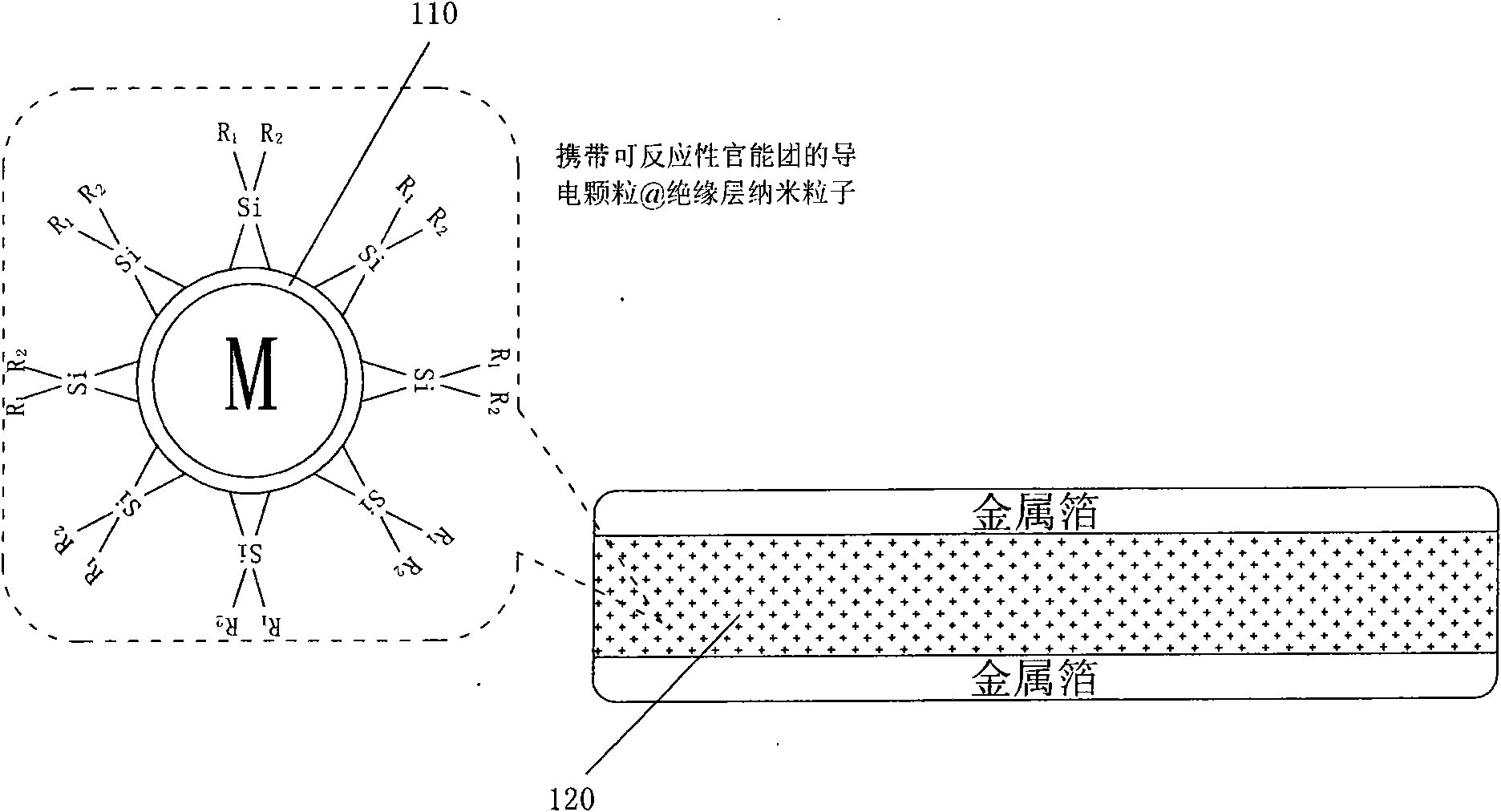

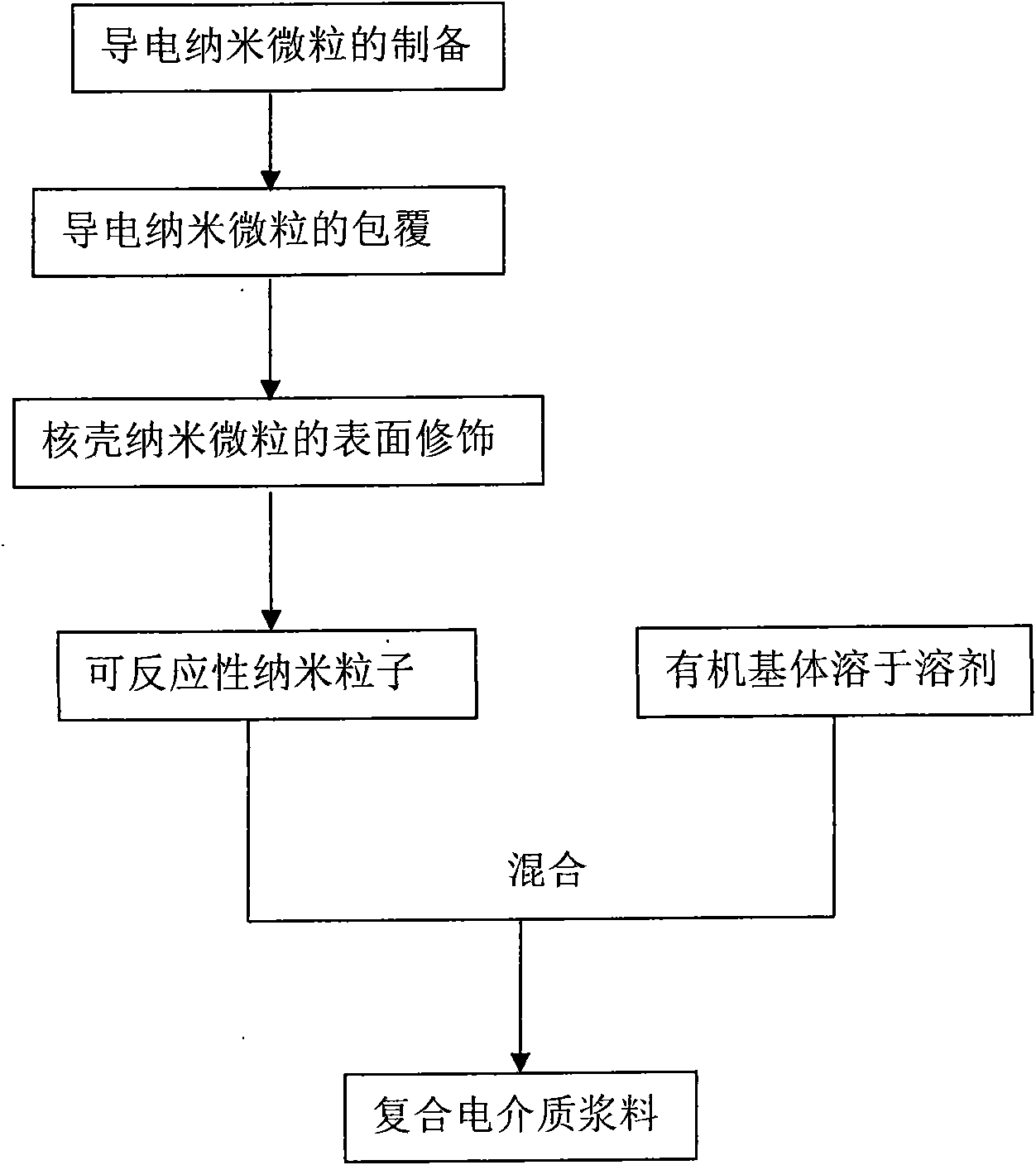

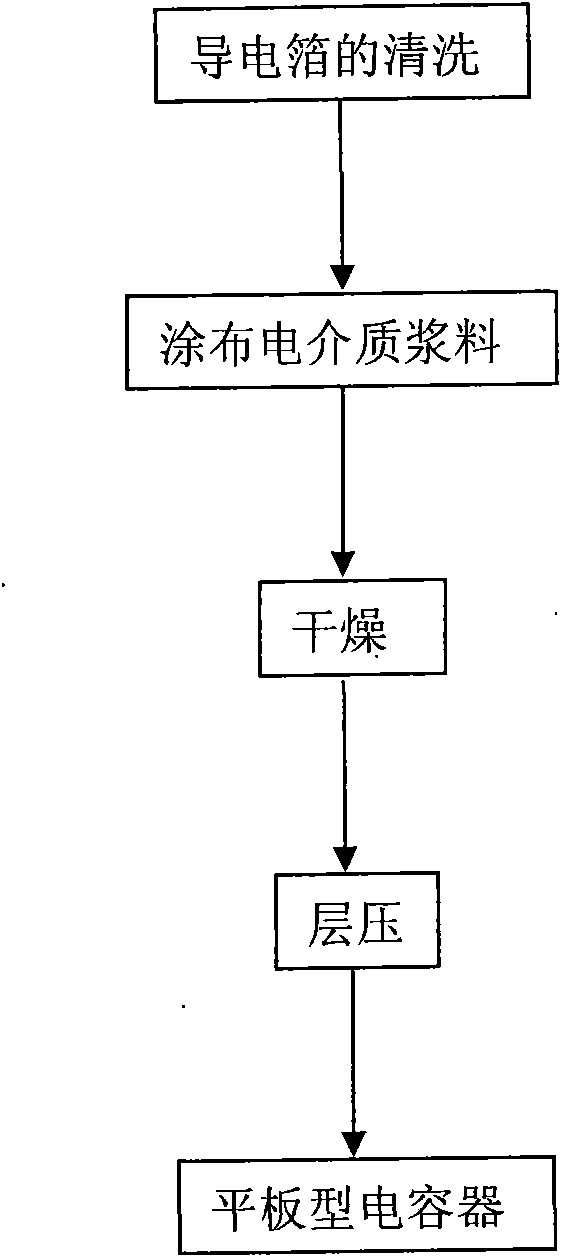

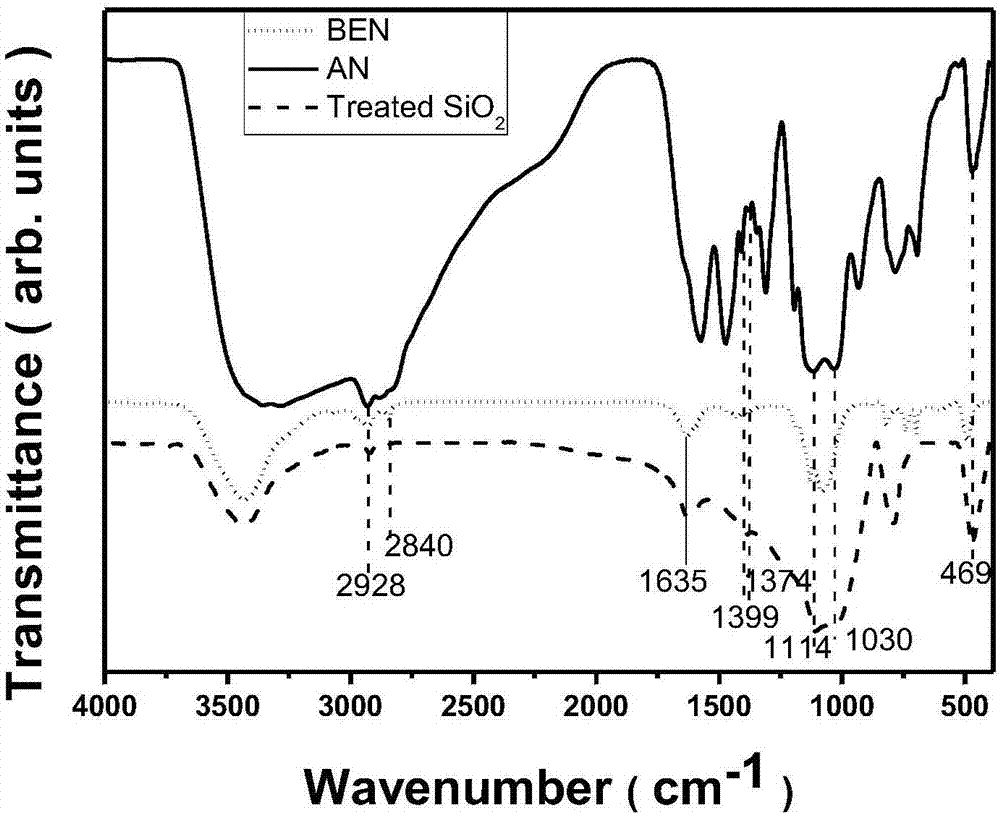

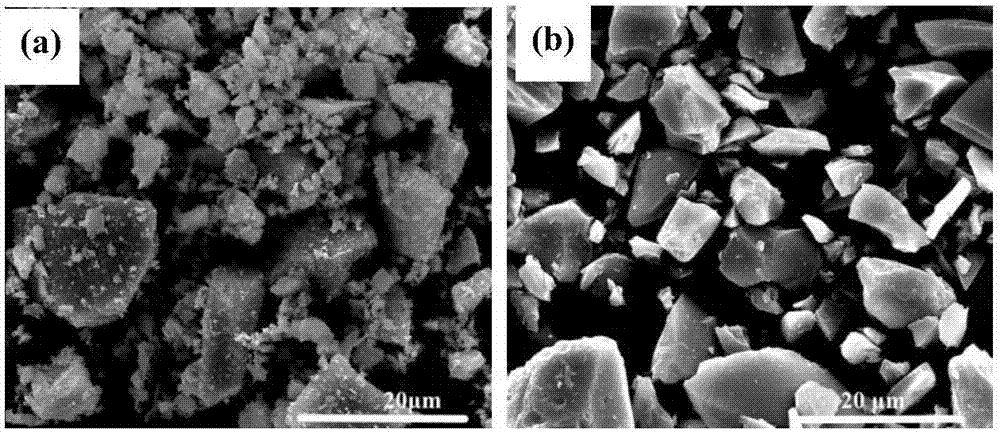

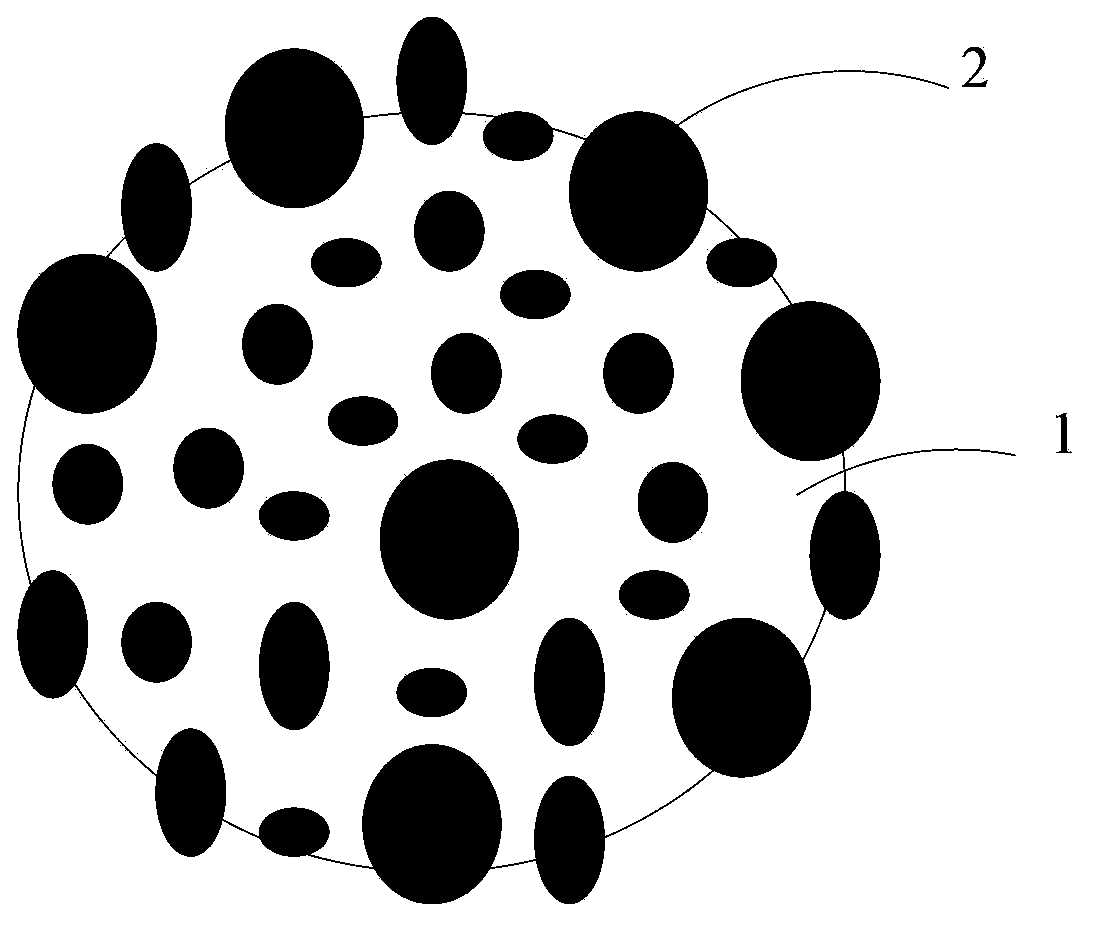

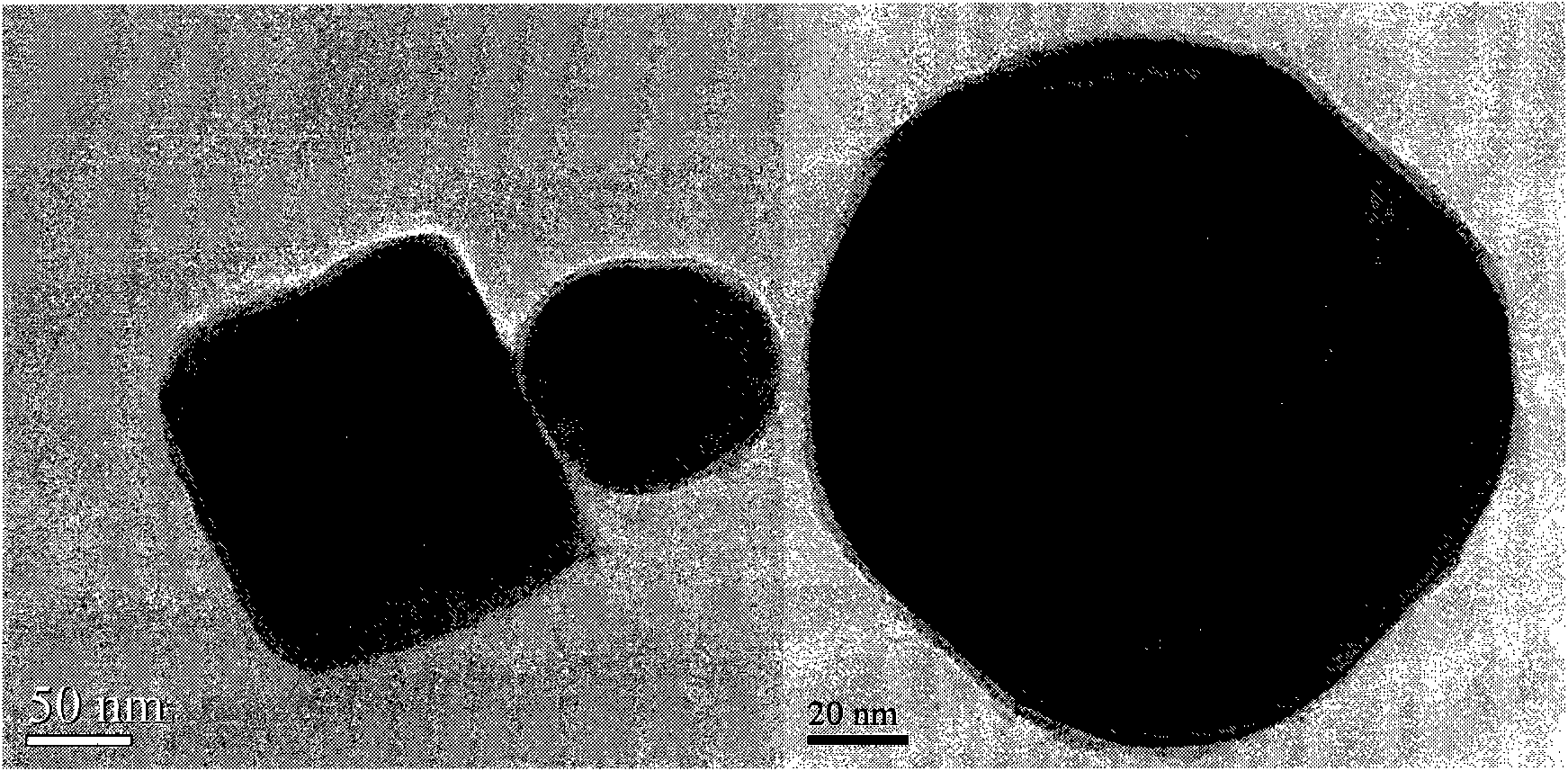

Polymer-matrix composite dielectric material and plate capacitor

ActiveCN101677033AIncrease capacitance densityHigh dielectric constantPlastic/resin/waxes insulatorsFixed capacitor electrodesElectronic componentCore shell

The invention discloses a plate capacitor and polymer-matrix composite dielectric material which can be filled with reactive nano particles, belonging to the technical field of the electronic materialand the electronic component. The reactive nano particles are conductive nano particles in core shell structures, the surface of each conductive nano particle is coated with a layer of insulating coating, and the surface of the insulating coating can carry reactive functional groups. The nano particles can be organically combined with polymer through the reactive functional groups and can be evenly dispersed in the matrix of the polymer. The polymer-matrix composite dielectric material which can be filled with the conductive nano particles can be used as the dielectric layer and flexible foilsheets can be used the upper electrode and the lower electrode of the plate capacitor.

Owner:SHENZHEN INST OF ADVANCED TECH

A preparing method of a ceramic-filled polytetrafluoroethylene microwave composite-medium substrate

A preparing method of a ceramic-filled polytetrafluoroethylene microwave composite-medium substrate is disclosed. The method includes 1) adding silicon dioxide ceramic powder into a liquid mixture of hydrogen peroxide and concentrated hydrochloric acid after the silicon dioxide ceramic powder is dried, and heating the mixture to 50-70 DEG C to obtain a suspension; 2) subjecting the suspension to suction filtration and drying a product in a vacuum environment; 3) adding the silicon dioxide ceramic powder obtained in the step 2) into a solution mixture of deionized water and absolute alcohol, adjusting the pH value to be 3-5, weighing a coupling agent the weight of which is 1.0-2.5% of the weight of the silicon dioxide ceramic powder, performing ball milling, and fully mixing the mixture to obtain a material mixture; 4) filtering and drying the material mixture to obtain modified silicon dioxide ceramic powder; 5) ball-milling and mixing the modified silicon dioxide powder, chopped glass fibers and polytetrafluoroethylene, and then performing demulsification to obtain dough; and 6) subjecting the dough to molding and hot-pressed sintering. The ceramic-filled material prepared by the method has a low dielectric constant (with epsilon being equal to 2.94), ultralow dielectric loss (with tg[delta] being less than 0.0008, 10 GHz), low water absorption (less than 0.02%) and a small thermal expansion coefficient (less than 20 ppm / DEG C).

Owner:汕头超声覆铜板科技有限公司

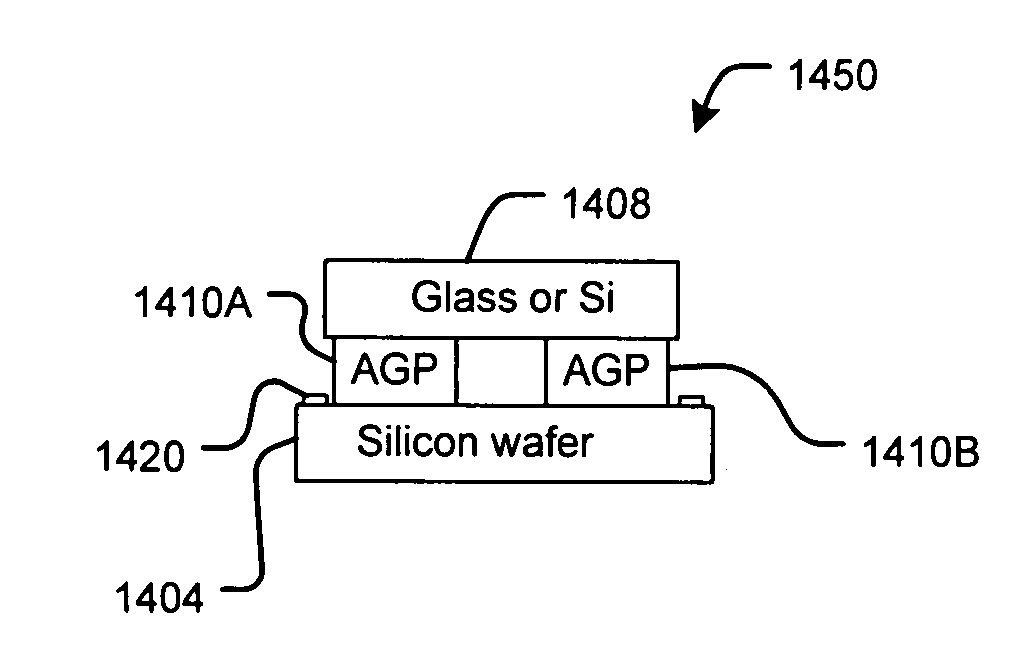

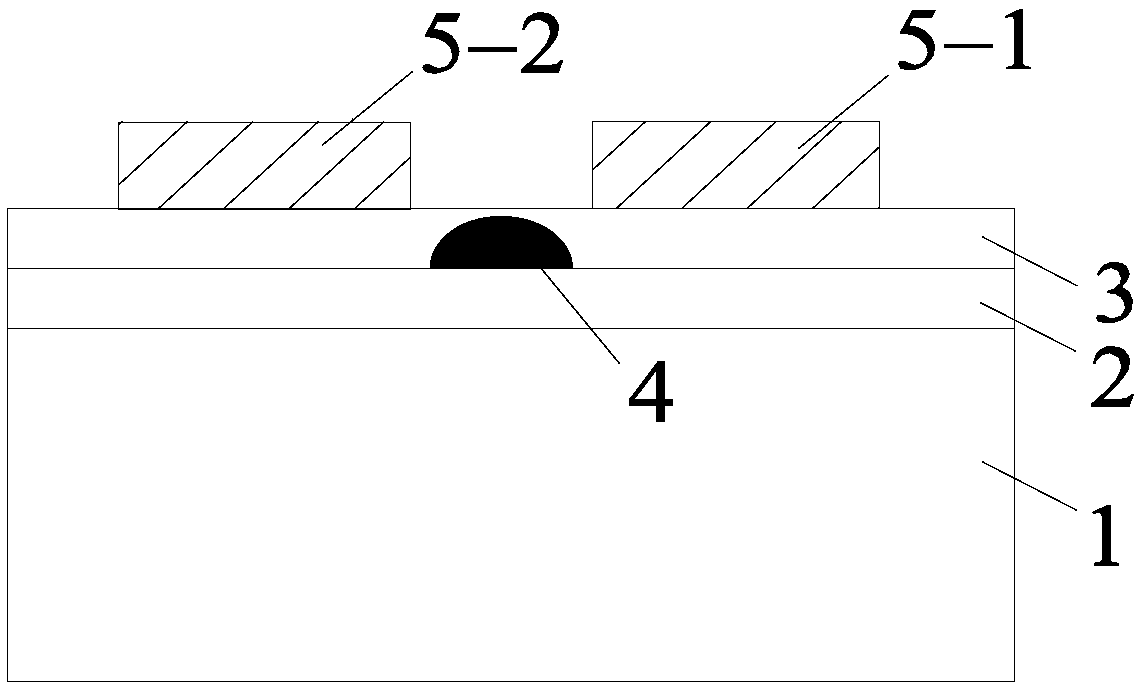

Integrated circuit including silicon wafer with annealed glass paste

InactiveUS20060113639A1Low dielectric lossPulse automatic controlSemiconductor/solid-state device detailsEngineeringConductive materials

An integrated circuit (IC) package comprises an IC wafer and an annealed glass paste (AGP) layer that is arranged adjacent to the IC wafer. A molding material encapsulates at least part of the IC wafer and the AGP layer. The AGP layer is arranged on at least one side of the IC wafer. The AGP layer is arranged on a plurality of disjoint areas on at least one side of the IC wafer. A layer of a conductive material is arranged on a portion of the AGP layer.

Owner:MARVELL WORLD TRADE LTD

Dielectric material for thermostable laminated ceramic capacitor with basic-metal inner electrode

InactiveCN1404080AImprove uniformityImprove performanceFixed capacitor dielectricCeramicsDielectric lossCeramic capacitor

The present invention is material for laminated ceramic capacitor with high temperature stability and basic material inner electrodes. The inner electrode is made of low cost metal, such as Ni, Cu and their alloy. The dielectric material comprises BaTiO3 as main component, and additives in cludes CaO, CaTiO3, BaO, SiO2, SrO2, MnO2, MgO, Co2O3, Co3O4, Fe2O3 and Y2O3 as well as one or more RE oxide and salt in certain proportion and is prepared through mixing, sintering in reducing atmosphere of mixed nitrogen and hydrogen. The dielectric has excellent performance, including room temperature dielectric constant of 2000-3000, etc. The material of the present invention is suitable for producing great capacity superthin laminated ceramic capacity with high insulating resistivity and stable performance.

Owner:TSINGHUA UNIV

High-dielectric-constant resin composition and application thereof

InactiveCN103351581ALow dielectric lossExcellent dielectric propertiesSynthetic resin layered productsMetal layered productsGlass fiberDielectric loss

The invention relates to a high-dielectric-constant resin composition, as well as a prepreg and a copper-clad laminate (CCL) which are manufactured thereby. The prepreg manufactured by the high-dielectric-constant resin composition comprises high-dielectric-constant glass fiber fabric and a high-dielectric-constant resin composition subjected to impregnation drying and then attached to the high-dielectric-constant glass fiber fabric. The CCL manufactured by the high-dielectric-constant resin composition comprises at least one overlapped prepreg and copper foils pressed and coated on both sides of the overlapped prepregs. The CCL manufactured by the high-dielectric-constant resin composition has the performances of high dielectric constant, low dielectric loss, high glass transition temperature, high peel strength and the like and can meet the performance requirement of the high-dielectric-constant antenna substrate.

Owner:GUANGDONG SHENGYI SCI TECH

Molybdenum-based ultralow-temperature sintering microwave medium ceramic materials and preparation method thereof

The invention discloses molybdenum-based ultralow-temperature sintering microwave medium ceramic materials and a preparation method thereof. Based on a general structural formula of A4B3O12, a series of ceramic materials, which can be sintered at a temperature lower than 7,000 DEG C and have excellent microwave dielectrical properties ( a dielectric constant of 8.5 to 11.1 and a quality factor Qfof between 36,000 and 108,000GHz), can be obtained by using low-valence cation (such as Li<+>, Zn<2+>, Ca<2+>, Cu<2+>, Mg<2+>, Al<3+>, In<3+>, Cr<3+> and Ga<3+>) composite at a position A and a high-valence cation Mo<6+> at a position B and by using the conventional solid-phase reaction sintering method. The concrete structural expression of the ceramic material comprises Li2M<2+>2(MoO4)3(M<2+> may be Zn<2+>, Ca<2+>, Cu<2+> and Mg<2+>) and Li3M<3+>(MoO4)3(M<3+> may be Al<3+>, In<3+>, Cr<3+> and Ga<3+>).

Owner:XI AN JIAOTONG UNIV

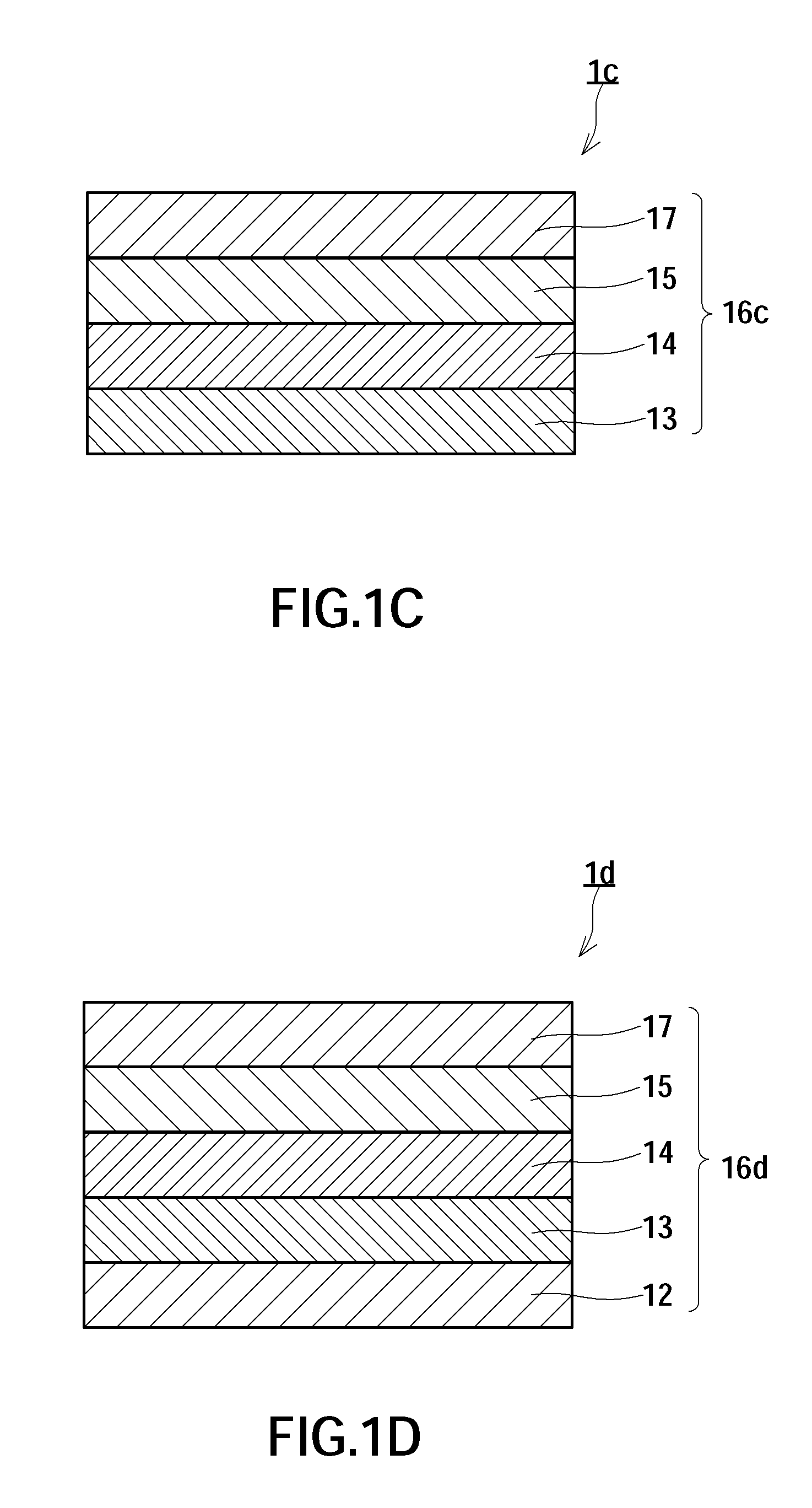

Piezoelectric thin film and method of manufacturing the same, ink jet head, method of forming image with the ink jet head, angular velocity sensor, method of measuring angular velocity with the angular velocity sensor, piezoelectric generating element, and method of generating electric power with the piezoelectric generating element

ActiveUS20110143146A1Low dielectric lossImprove piezoelectric performanceAcceleration measurement using interia forcesPiezoelectric/electrostriction/magnetostriction machinesLead zirconate titanateAngular velocity

Provided are a piezoelectric thin film including a lead-free ferroelectric material and exhibiting high piezoelectric performance comparable to that of lead zirconate titanate (PZT), and a method of manufacturing the piezoelectric thin film. The piezoelectric thin film of the present invention comprises: a LaNiO3 film having a (001) orientation; a NaNbO3 film having a (001) orientation; and a (Bi, Na, Ba) TiO3 film having a (001) orientation. The LaNiO3 film, the NaNbO3 film, and the (Bi, Na, Ba)TiO3 film are laminated in this order.

Owner:PANASONIC CORP

Hybridized particle, polymer-based composite material, their preparation methods and use of polymer-based composite material

The invention discloses hybridized particles, a polymer-based composite material, their preparation methods and a use of the polymer-based composite material. The hybridized particles comprise insulating ceramic particles and conductive microparticles loaded on the surfaces of the insulating ceramic particles. The conductive microparticles are granularly and discretely distributed on the surfaces of the insulating ceramic particles. The preparation method of the hybridized particles adopts an in-situ chemical-reduction technology, a sol-gel technology, an in-situ polymerization technology, a high-temperature heat treatment technology or a mechanical milling technology. The polymer-based composite material comprises the hybridized particles and a polymer filled with the hybridized particles. The polymer-based composite material comprises 20-80wt% of the hybridized particles. The hybridized particles have stable structures and stable performances. The polymer-based composite material has the excellent performances such as high dielectric constant, low dielectric loss and stable performances. The preparation methods of the hybridized particle and the polymer-based composite material have the advantages of simple process, easy control of conditions, high production efficiency and industrial production applicability.

Owner:SHENZHEN INST OF ADVANCED TECH

Super low-loss and small-line width microwave ferrite material and preparation method for microwave ferrite material

The invention relates to a super low-loss and small-line width microwave ferrite material and a preparation method for the microwave ferrite material and belongs to the field of microwave communication and magnetic materials. The main phase of the material is of a johnstonotite structure, and the chemical formula of the material is Y3-2x-yCa2x+yFe5-x-y-zVxZryAlzO12, wherein x is not less than 0.02 but is not more than 0.25, y is not less than 0.05 but is not more than 0.25, and z is not less than 0.01 but is not more than 0.25. The preparation method comprises the following steps of: calculating according to chemometry and weighing a raw material, vibratory milling, presintering, vibratory grinding and coarse crushing, sanding fine crushing, spray granulation, compression moulding and sintering. Proved by testing, the ferromagnetic resonance line width deltaH of the obtained material is not more than 1.27KA / m, the dielectric loss tgdeltae is not more than 0.5*10-4, and the insertion loss of an assembled microwave device is not more than 0.21dB, and thereby, the stability and the reliability of the obtained material are greatly enhanced, and the application range is broadened. The manufactured microwave ferrite device has the advantages of wide working band and low insertion loss.

Owner:TDG HLDG CO LTD

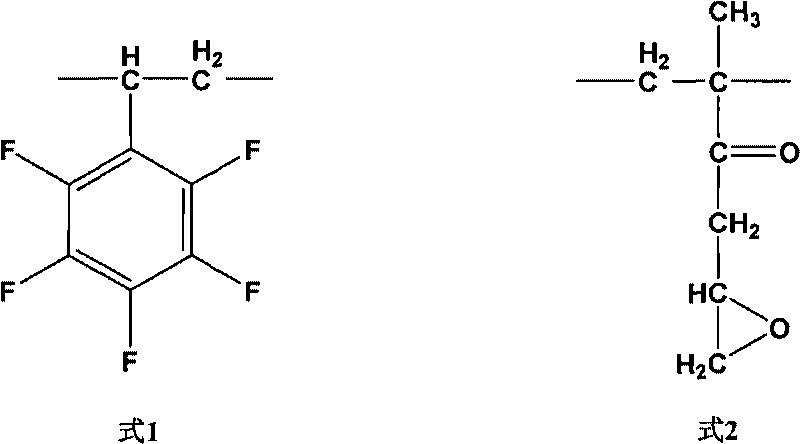

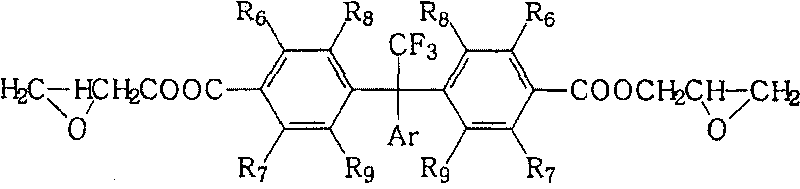

Adhesive combination, covering film and flexible circuit board

ActiveCN101747854AGood high temperature resistanceLow dielectric lossEpoxynovolac adhesivesNon-metallic protective coating applicationChemistryFirming agent

The invention provides an adhesive combination. The adhesive combination contains thermoplastic resin, thermosetting resin and a firming agent, wherein the thermosetting resin contains polyphenyl ether with epoxy functional groups at the end, perfluor styrene-methacrylic acid epoxy propyl ester copolymer, bisphenol A epoxy resin and phenolic aldehyde epoxy resin. The invention further provides a flexible circuit board and a covering film which comprises the adhesive combination. The peeling strength of the provided flexible circuit board is from 12 to 16N / cm, the dielectric constant is from 1.4 to 1.8, the dielectric loss is from 0.0013 to 0.0017, the rotating speed is 300 r / m under the working environment (50 DEG C), the flexibility is 180 DEG, the flexible circuit board can be bent more than 12 million number of times, the flame retardance reaches UL to 94V0, and the GTT (glass-transition temperature) of an adhesive is from 200 to 220 DEG C.

Owner:BYD CO LTD

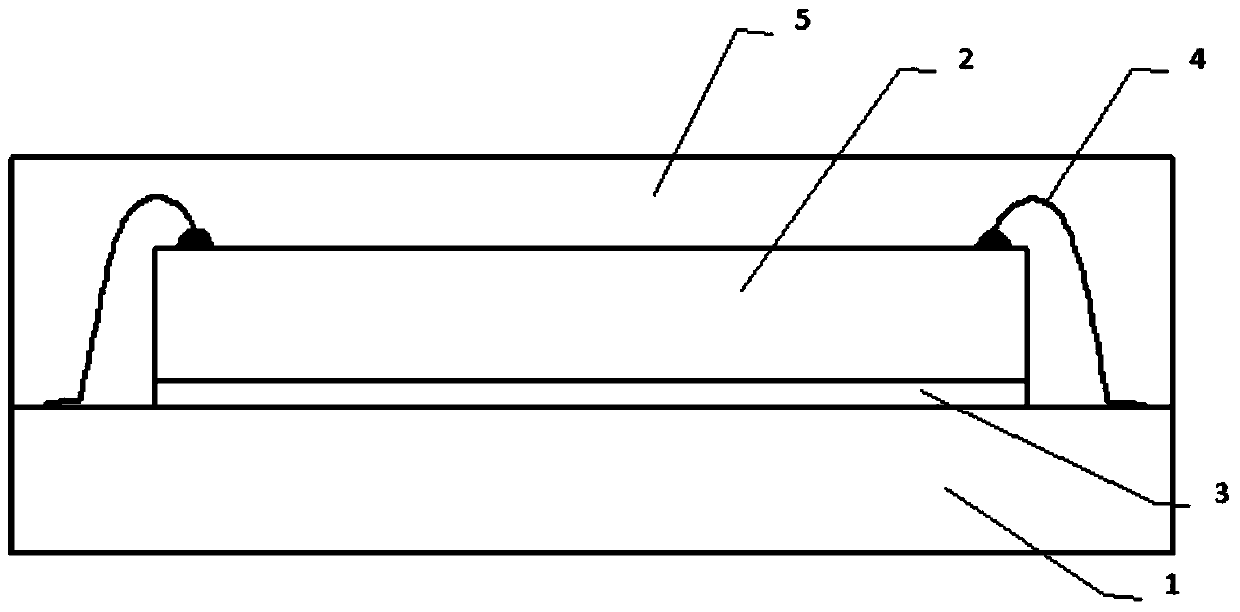

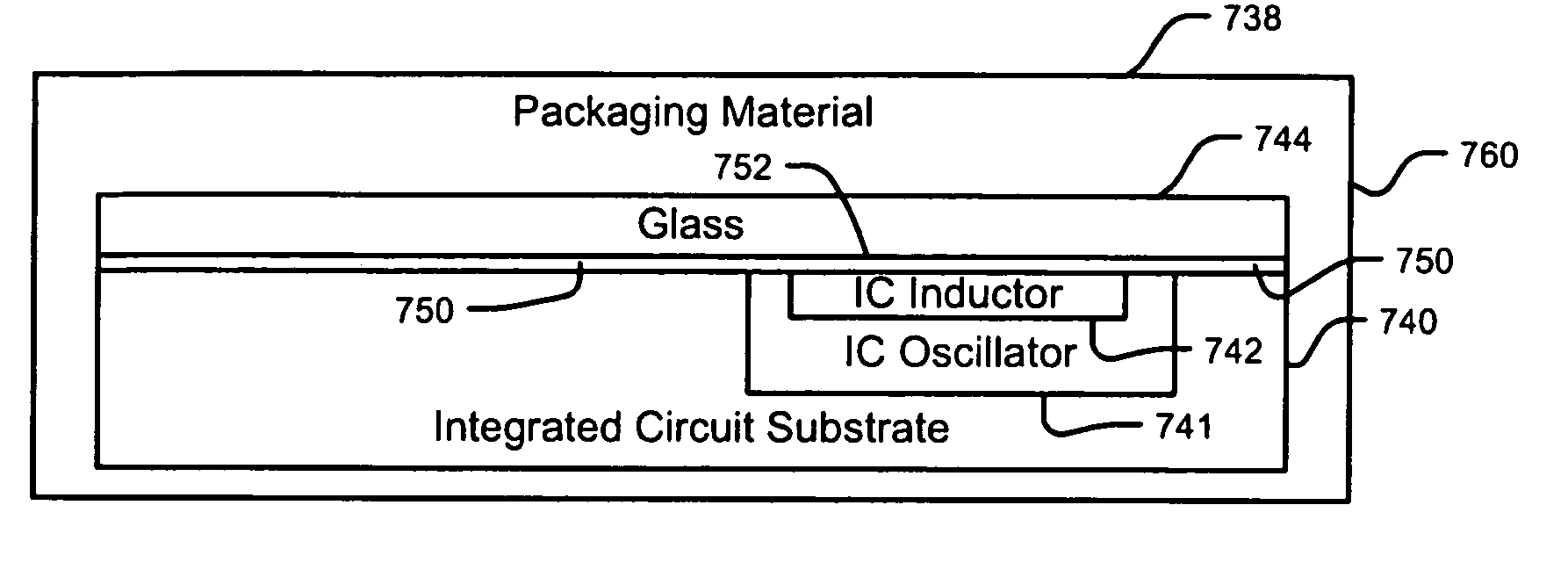

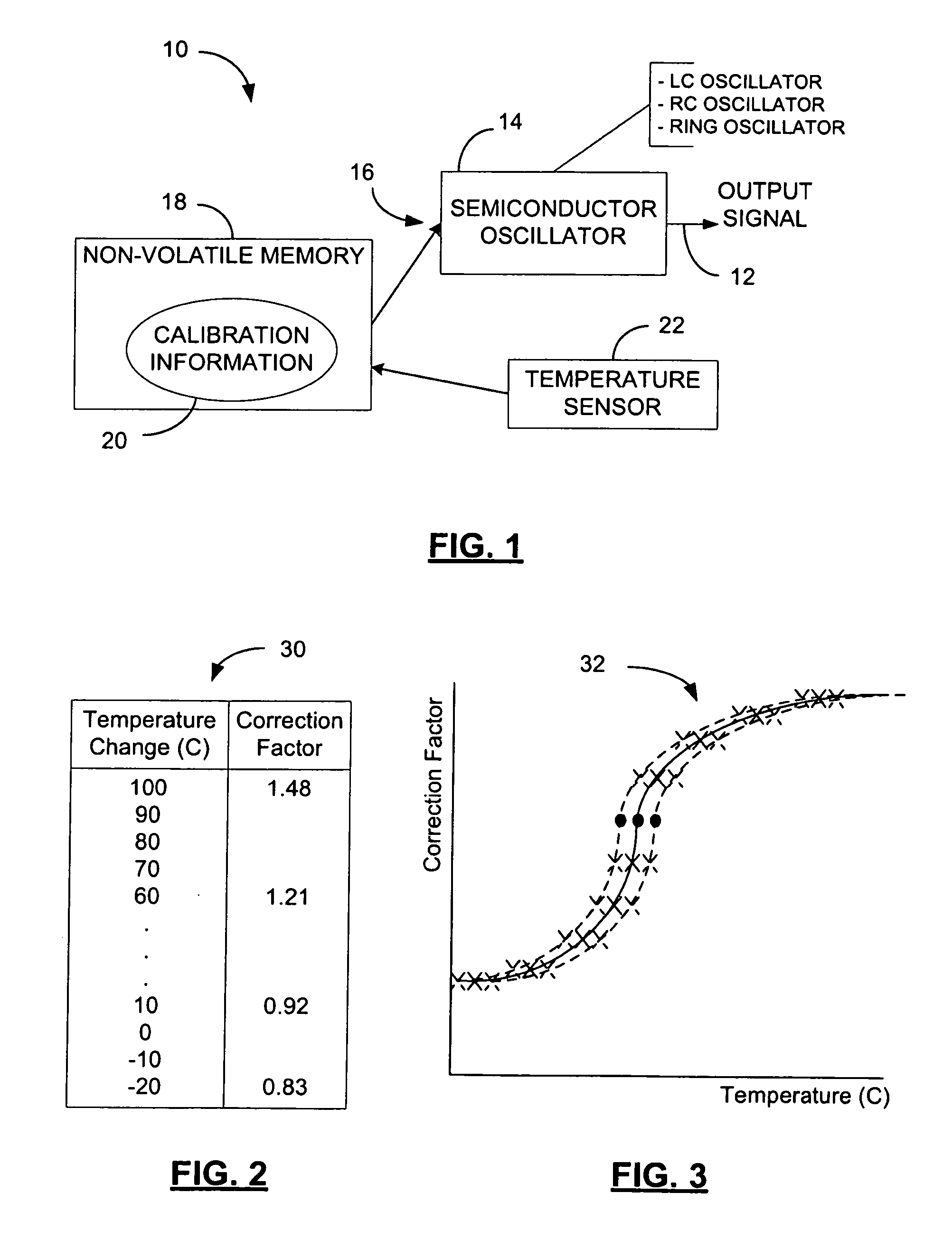

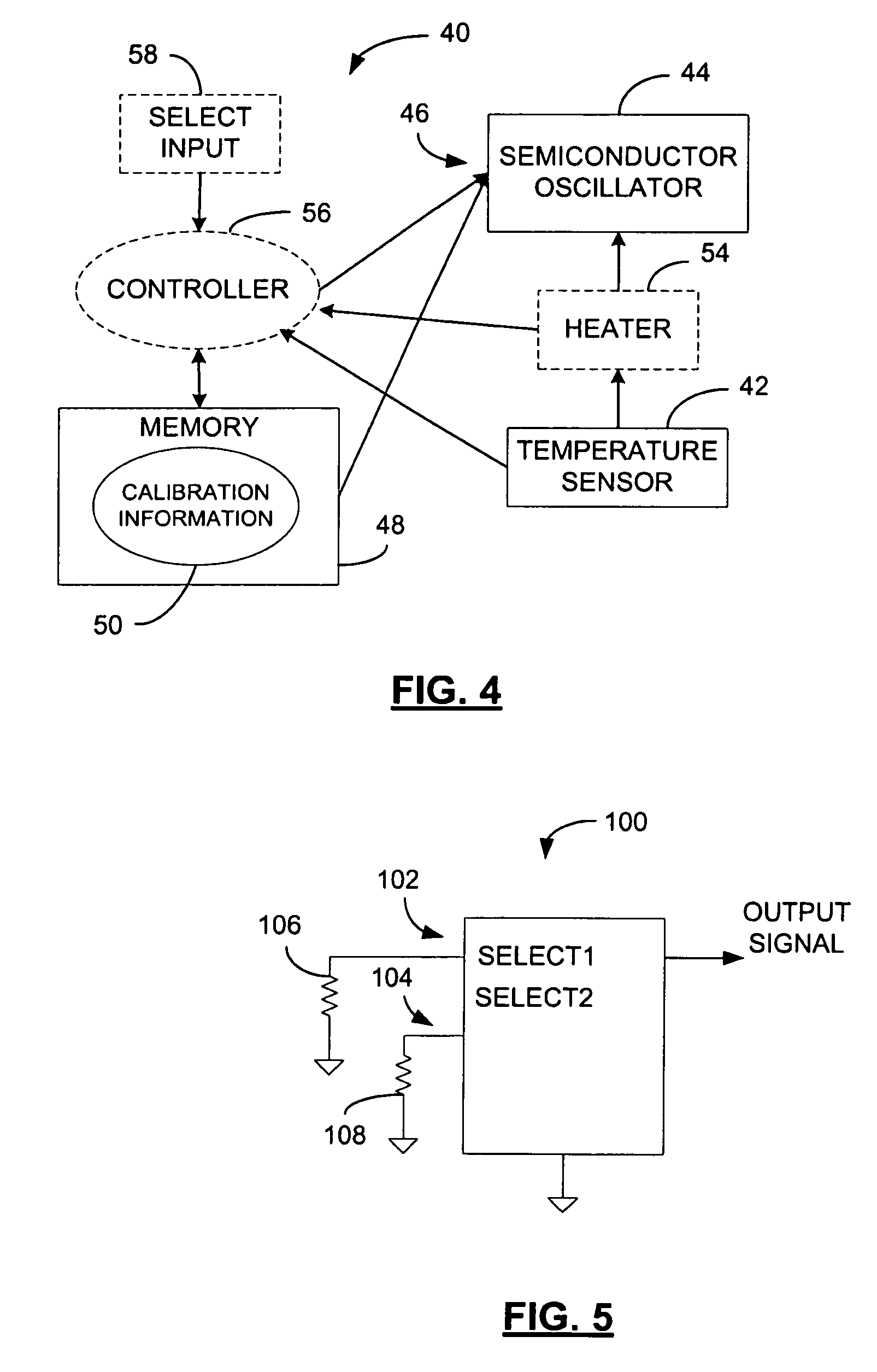

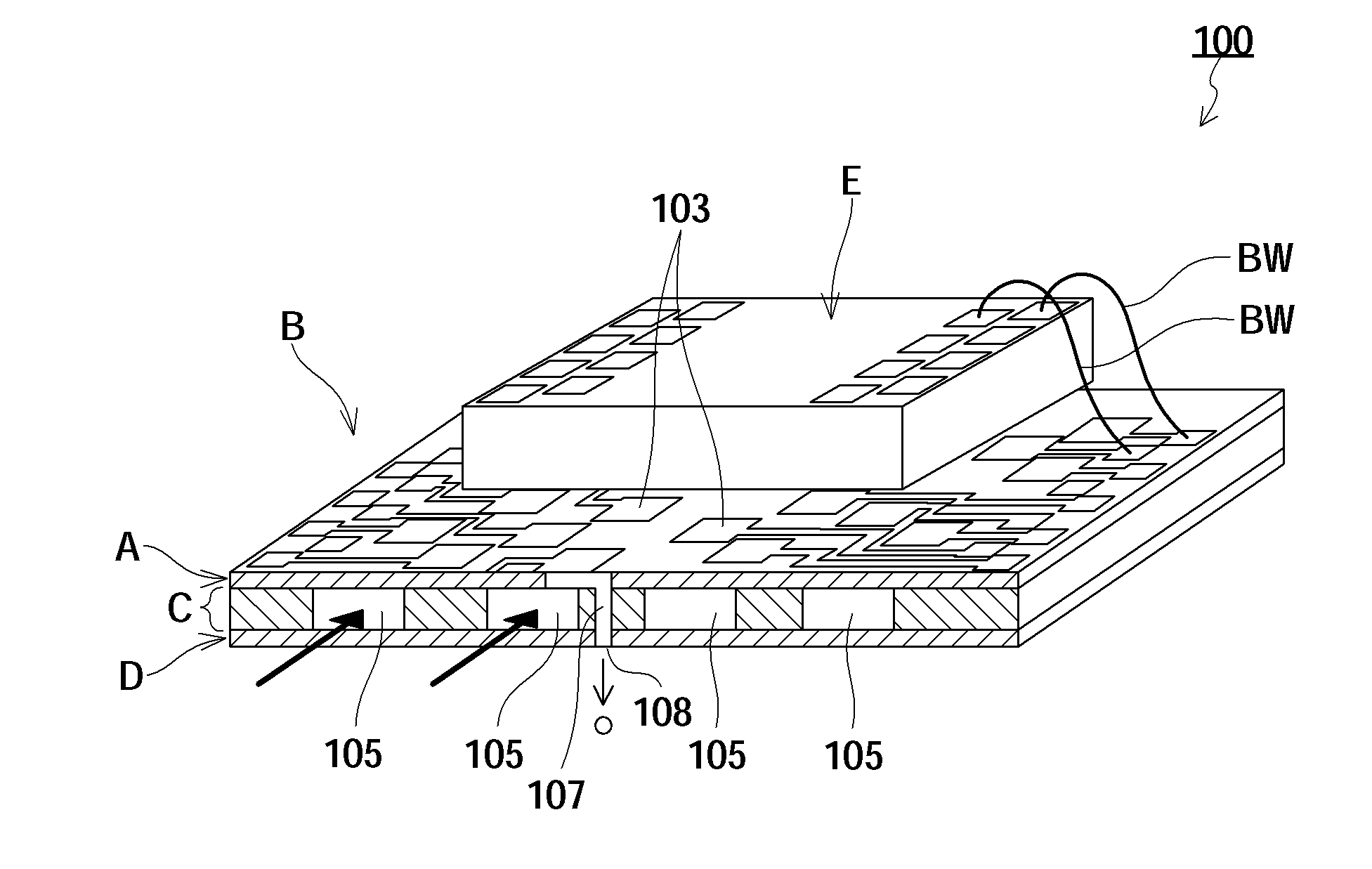

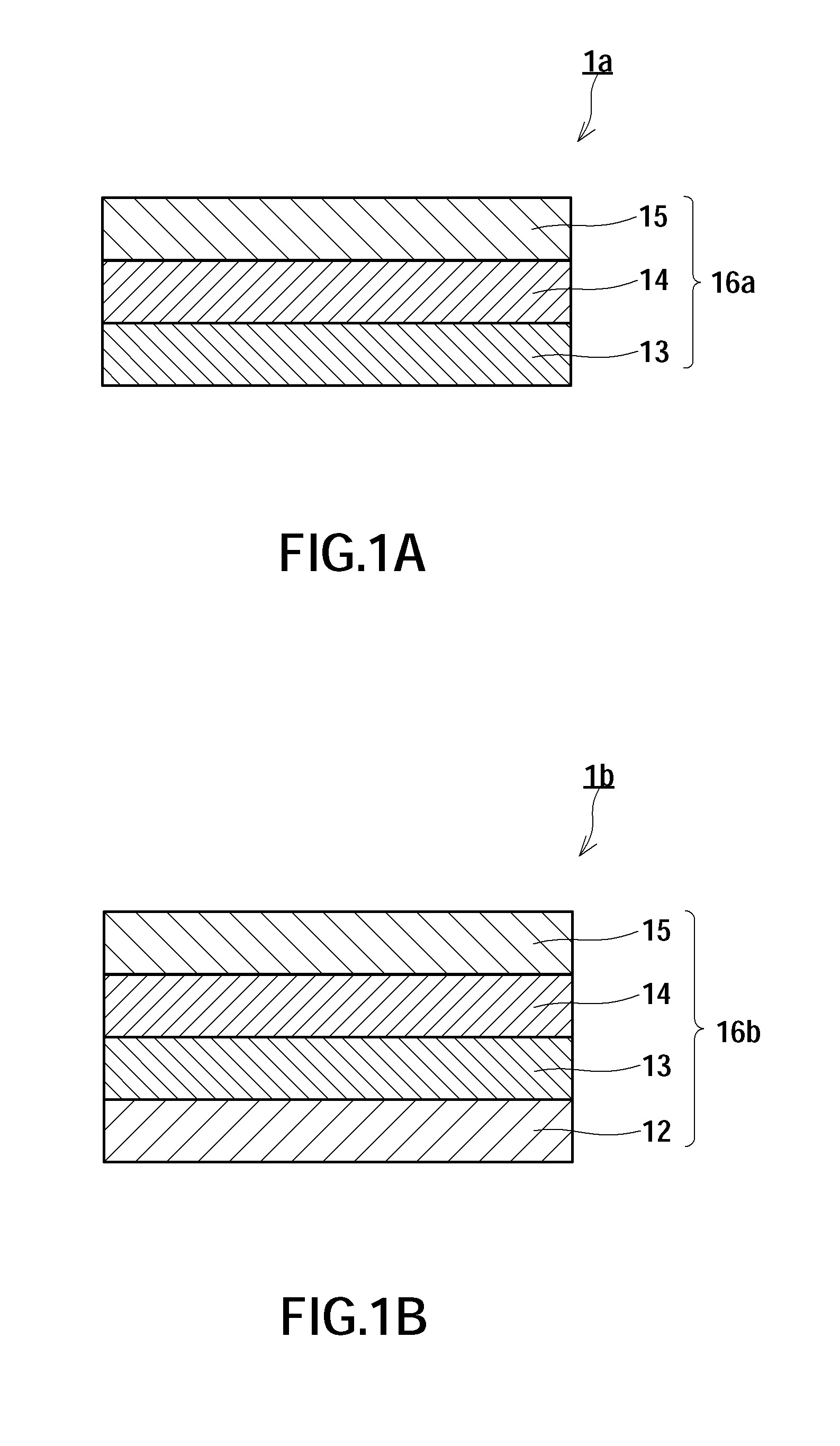

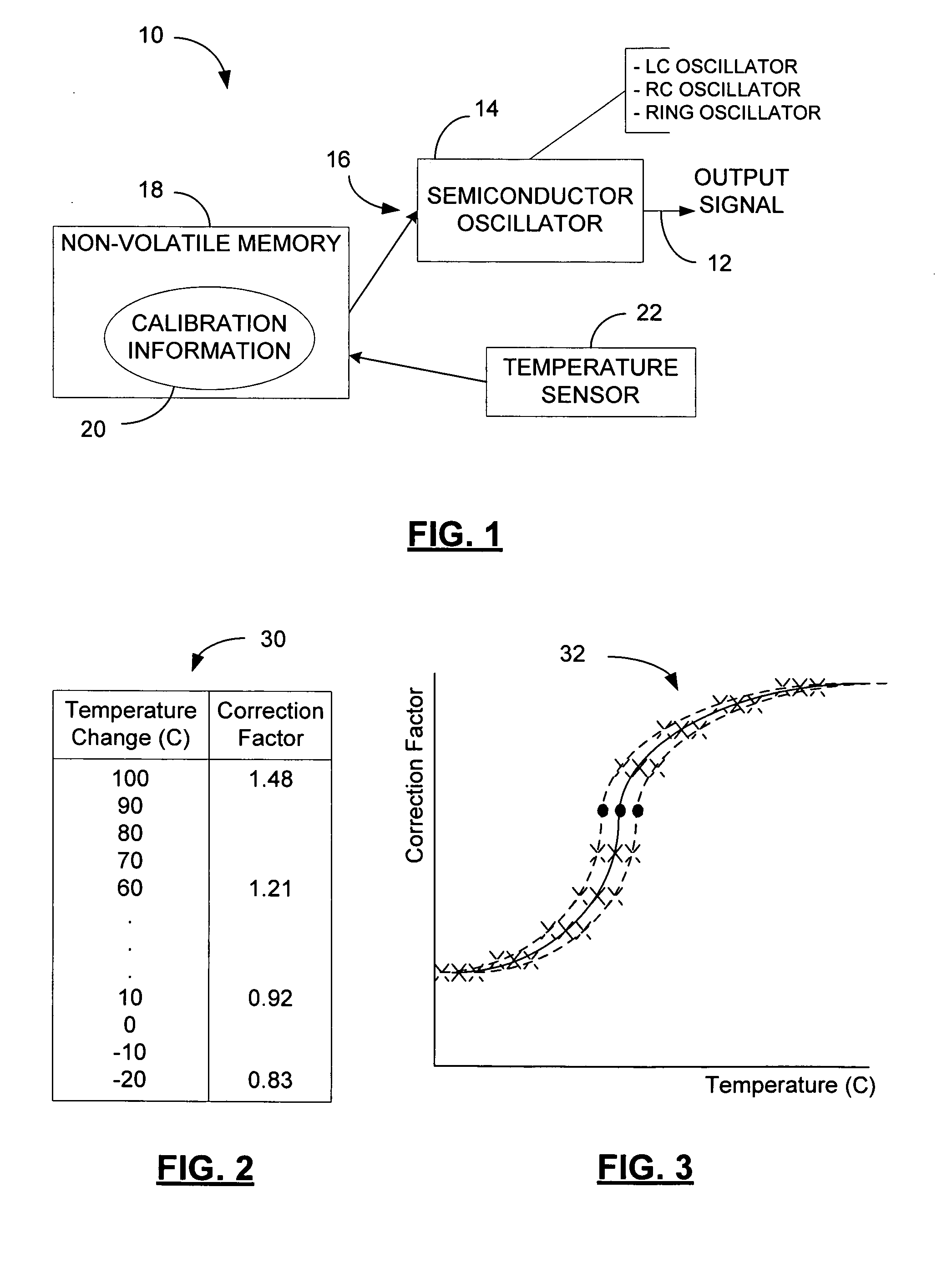

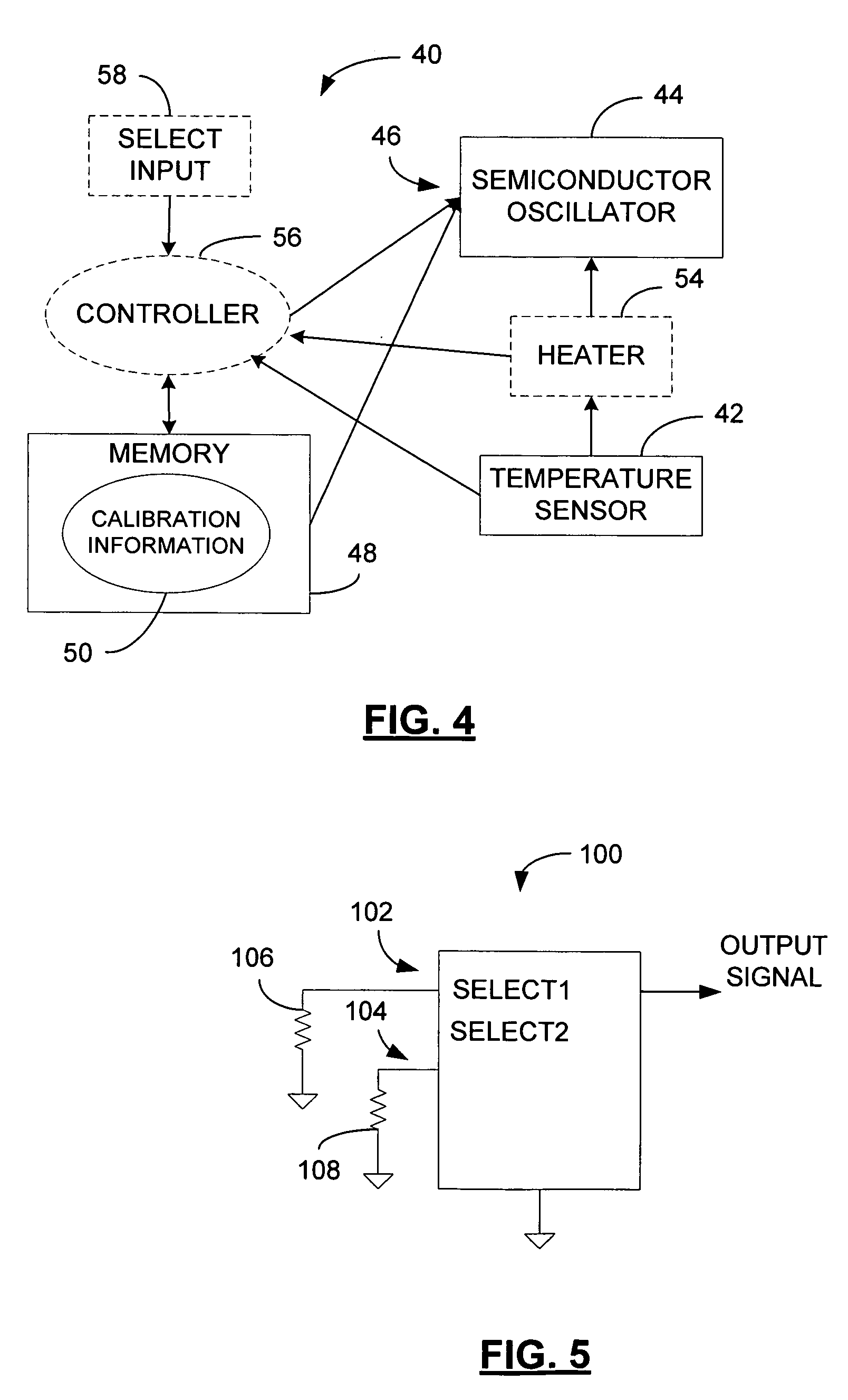

Integrated circuit with low dielectric loss packaging material

InactiveUS20060249840A1Low dielectric lossTemperatue controlSemiconductor/solid-state device detailsDielectric lossEngineering

An integrated circuit package comprises an integrated circuit that comprises a temperature sensor that senses a temperature of the integrated circuit. A memory module stores data relating to oscillator calibrations and selects one of the oscillator calibrations as a function of the sensed temperature. An oscillator module generates a reference signal having a frequency that is based on the selected one of the oscillator calibrations. A packaging material encases at least part of the integrated circuit and has a low dielectric loss.

Owner:MARVELL ASIA PTE LTD

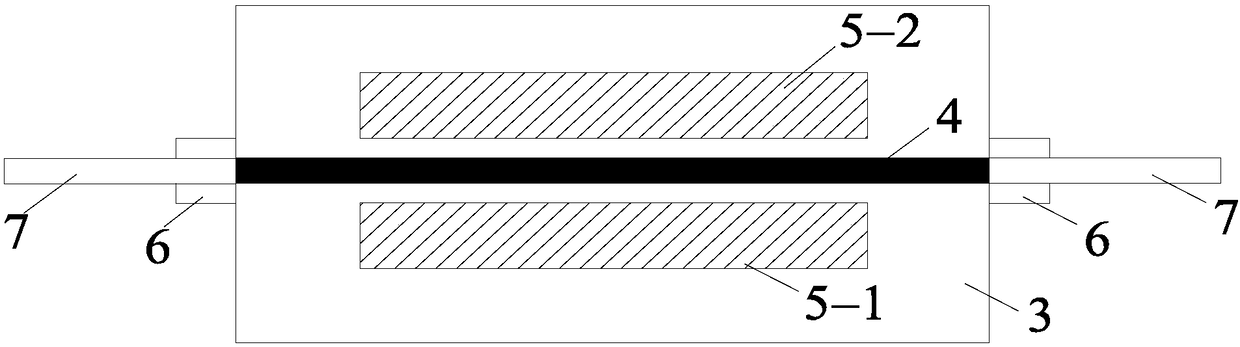

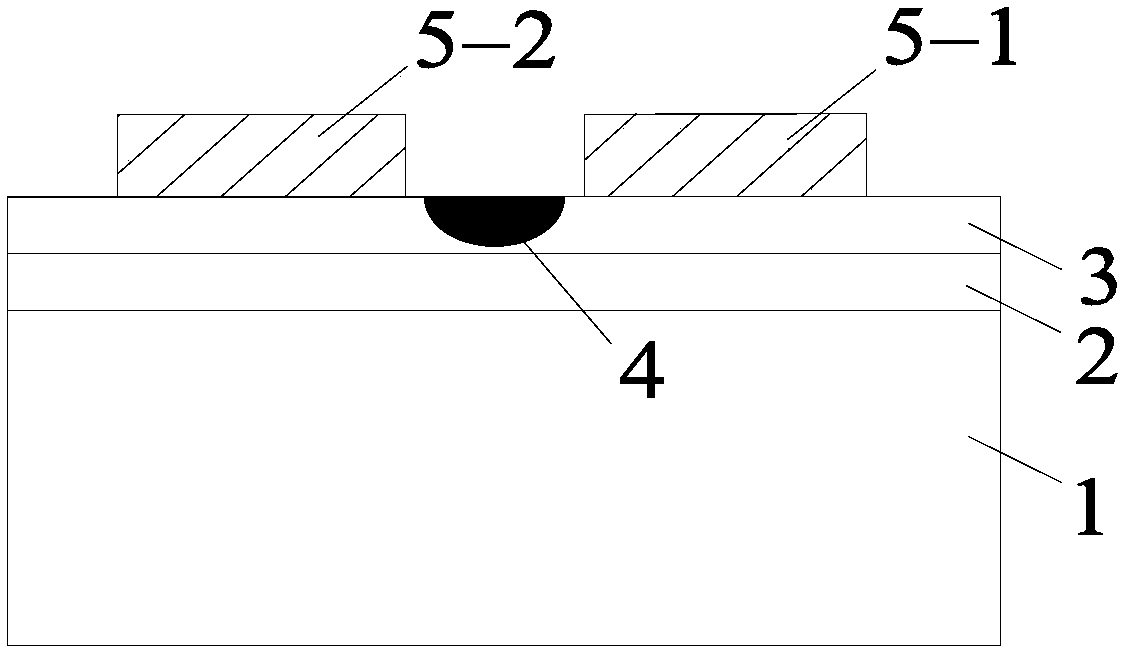

Silicon-based lithium niobate high-speed light modulator and preparation method thereof

InactiveCN108732795ARealize heterogeneous integrationReduce lossNon-linear opticsModulation bandwidthSingle crystal

The invention discloses a silicon-based lithium niobate high-speed light modulator and a preparation method thereof. The modulator comprises a silicon substrate wafer, a lower silicon dioxide cladding, lithium niobate film, an optical waveguide, a metal electrode, a silicon V-shaped groove and a coupling optical fiber, wherein the lower silicon dioxide cladding is located on the upper surface of the silicon substrate wafer, and the lithium niobate film is located on the lower silicon dioxide cladding. The silicon-based lithium niobate high-speed light modulator has the advantages that heterogeneous integration of a lithium niobate single crystal body and a silicon single crystal body is achieved; by utilizing the thin-film lithium niobate wafer and the characteristics such as low dielectric constant and low dielectric loss of the lower silicon dioxide cladding, improvement of modulation rate (or modulation bandwidth) of the lithium niobate light modulator can be achieved; by utilizingthe thin-film lithium niobate wafer and the high insulativity of the lower silicon dioxide cladding, intensity increase of microwave electromagnetic fields distributed in the lithium niobate film canbe achieved, the modulation efficiency of electric fields to light fields is improved, and the driving voltage of the modulator is reduced.

Owner:天津领芯科技发展有限公司

Preparation method of copper clad plate

ActiveCN101652026AGuaranteed performanceGuaranteed flame retardant performanceLaminationLamination apparatusEpoxyCopper foil

The invention discloses a preparation method of copper clad plate and the method comprises the following steps: (1) adopting bismaleimide resin and allyl compound in a weight ratio of 100:40-100 to react at 110-160 DEG C for 10-120min and obtain prepolymer, cooling to room temperature after finishing the reaction, using acetone to prepare prepolymer solution; (2) adding 15-150 parts of epoxy resinwith phosphorous, 10-100 parts of compound curing agent and 0-5 parts of curing accelerator in the solution obtained in the step 1, stirring evenly to obtain a glue solution, selecting a flat E-glassfibic cloth, coating the glue solution evenly on the glassfibic cloth, then roasting to prepare B-stage prepreg; (3) cutting the B-stage prepreg to proper size according to the size of a pressing machine, overlying five prepregs while placing two high impact copper foils with the same size separately on the top and bottom of the prepregs, placing the prepregs with copper foils in a vacuum hot pressing machine to press and obtaining the copper clad plate. The obtained copper clad plate can meet the demand for halogen-free and flame resistance, the heat resistance and humidity resistance are excellent, and the low dielectric loss and pressing toughness are good.

Owner:SHENGYI TECH SUZHOU

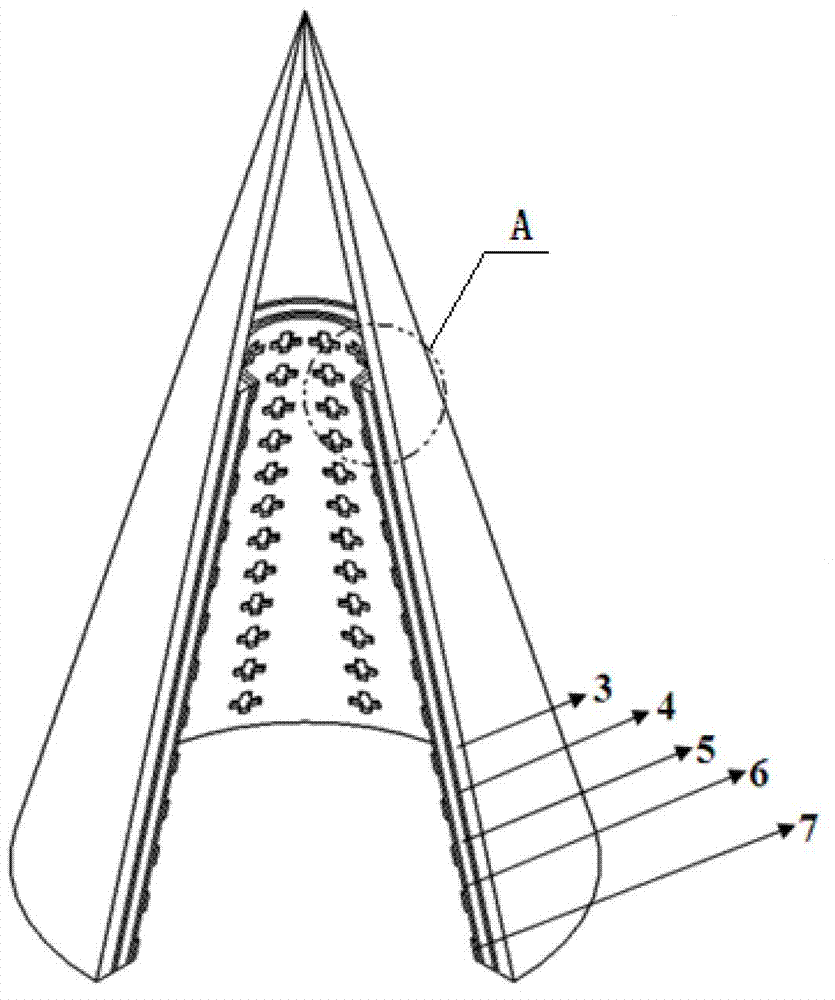

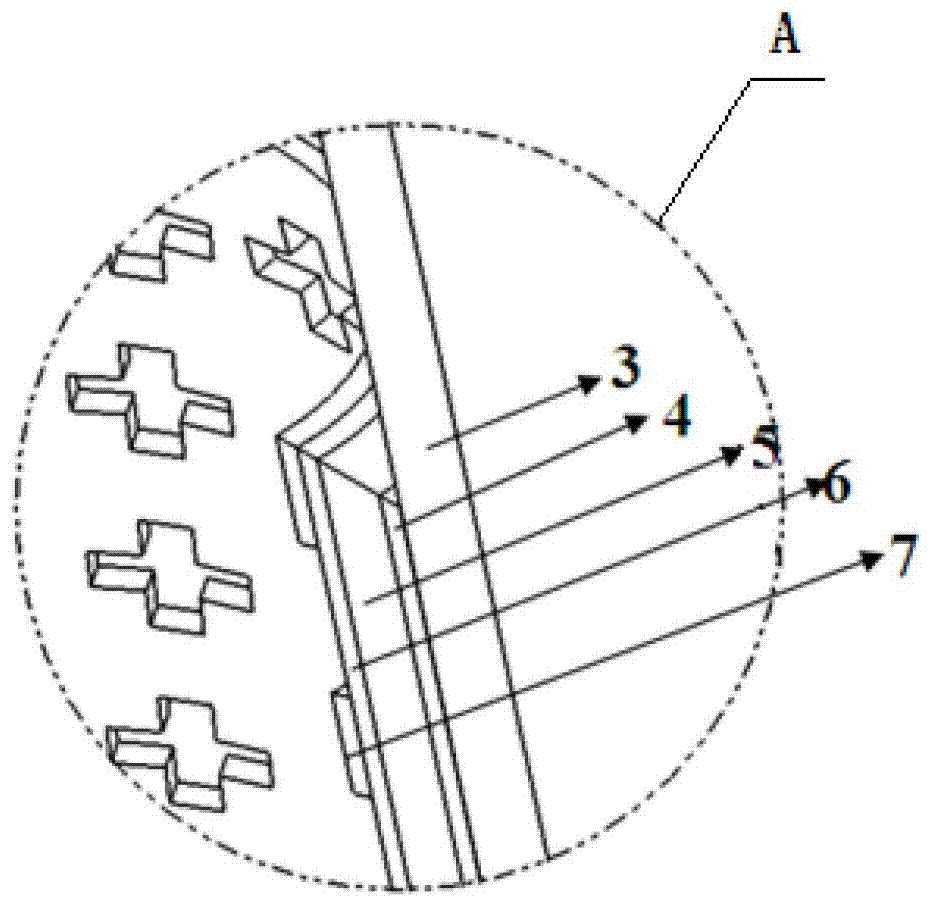

High-performance frequency selection radar cover

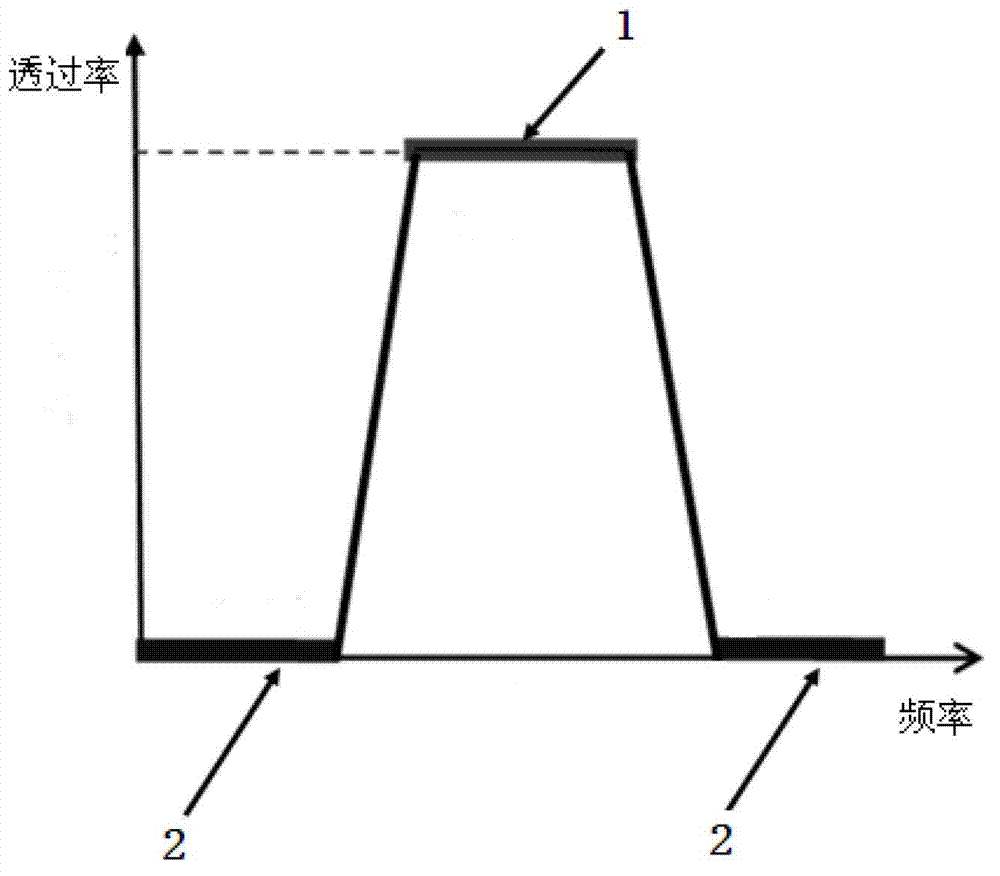

ActiveCN102868021ALow dielectric lossPassband insertion loss is smallAntenna adaptation in movable bodiesRadiating element housingsLow-k dielectricEnvironmental geology

The invention belongs to the technical field of stealth and provides a high-performance frequency selection radar cover used for stealth of flight weapons in order to overcome the shortages of single-screen FSS (frequency selective surface) structural design in the prior art, and difficulty in achieving FSS engineering by bilateral dielectric load FSS and double-screen FSS due to complex structure and high processing difficulty. The radar cover comprises an original radar cover, a first splice dielectric layer, an ultralow dielectric constant dielectric layer, a second splice dielectric layer and a soft FSS film layer. The first splice dielectric layer, the ultralow dielectric constant dielectric layer, the second splice dielectric layer and the soft FSS film layer are molded and combined into an FSS lining from an outer layer to an inner layer, and an FSS lining layer is attached on an inner surface of the original radar cover. Due to the fact that selected cellular and foam media both belong to ultralight materials, weight of the frequency selection radar cover is not increased. The high-performance frequency selection radar cover is relatively simple in structure, process tolerance is large since design margin is large, and difficulty, cycle and cost of process are lowered.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

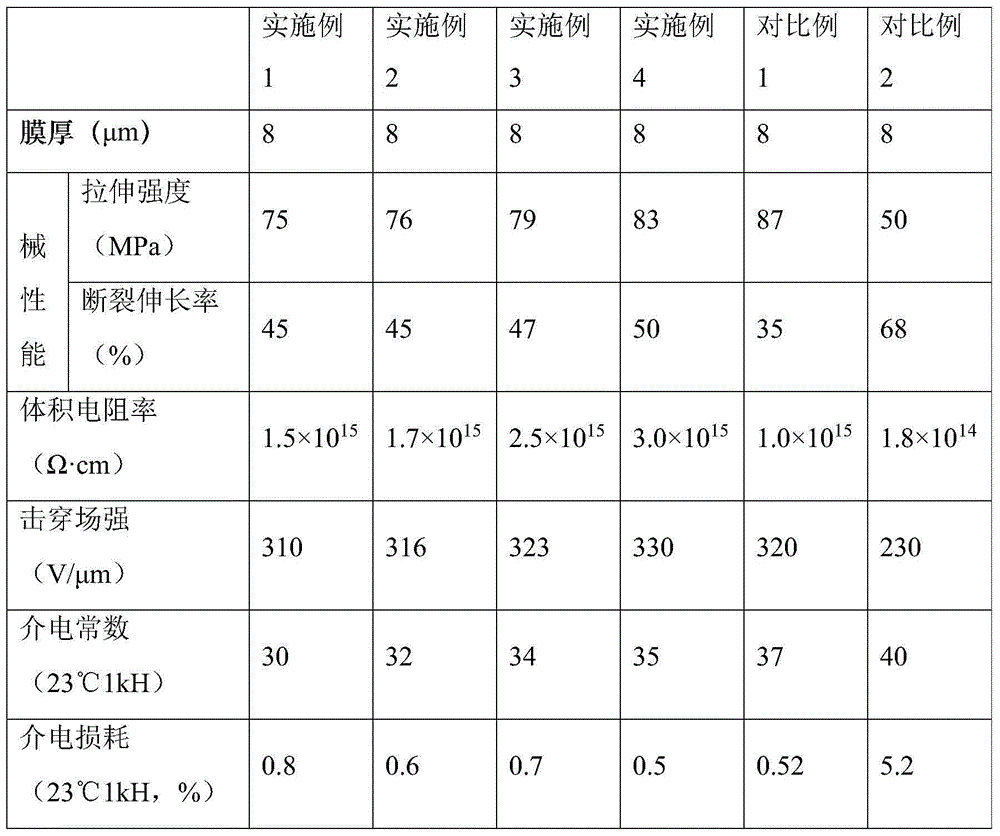

Polyvinylidene fluoride/polypropylene composite film for film capacitor and preparation method

ActiveCN104479161AHigh dielectric constantLow dielectric lossThin/thick film capacitorStacked capacitorsPolypropylene compositesBarium titanate

The invention provides a polyvinylidene fluoride / polypropylene composite film for a film capacitor. A base film of the polyvinylidene fluoride / polypropylene composite film is a polypropylene dielectric film; the upper surface and the lower surface of the base film are respectively coated with polyvinylidene-fluoride-based coatings with same thickness; the polyvinylidene-fluoride-based coatings comprise the following components in volume fraction: 0-20% of metal conductive powder, 20%-60% of barium titanate, 0-20% of rubber particles and the balance of polyvinylidene fluoride. The prepared polyvinylidene fluoride / polypropylene composite film is high in dielectric property, low in dielectric loss and good in mechanical property and processability. The invention further provides a preparation method of the polyvinylidene fluoride / polypropylene composite film for the film capacitor. The preparation method is simple, feasible and applicable to industrial production.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

Glass ceramics for use as a dielectric for gigahertz applications

InactiveUS20130120193A1High dielectric constantLow dielectric lossSimultaneous aerial operationsRadiating elements structural formsFrequency filteringLanthanide

A glass-ceramic which is particularly suitable as dielectric for use in the high-frequency range, in particular as dielectric resonator, as electronic frequency filter element or as antenna element is disclosed. The glass-ceramic has at least the following constituents (in mol % on an oxide basis): 5-50% of SiO2, 0-20% of Al2O3, 0-25% of B2O3, 0-25% of BaO, 10-60% of TiO2, 5-35% of Re2O3, where Ba can be partly replaced by Sr, Ca, Mg, where Re is a lanthanide or yttrium and where Ti can be partly replaced by Zr, Hf, Y, Nb, V, Ta.

Owner:SCHOTT AG

Base metal inner electrode multi-layer ceramic wafer type capacitor medium material prepared by chemical coating of water system

ActiveCN101880167ASmall temperature change rateLow dielectric lossFixed capacitor dielectricStacked capacitorsComposite oxideNitrogen gas

The invention discloses a ceramic powder body which can be taken as a base metal inner electrode multi-layer ceramic wafer type capacitor medium material and a preparation method thereof. Doped elements are evenly coated on the surfaces of barium titanate grains by means of chemical coprecipitation; the main material of the barium titanate BaTiO3 is 90-97mol% of the ceramic powder material; and the use amount of the composite oxide of a nanometer coating later is 3-10mol% of the gross amount of the ceramic powder material. The ceramic powder material is sintered in the reducing atmosphere which is controlled by a nitrogen and hydrogen-mixed humidifying gas within the temperature range of 950-1250 DEG C to obtain an X7R / X5R type MLCC material, wherein the room temperature dielectric constant of the material is 2000-3000, the vessel temperature change rate is less than or equal to + / -15%, the vessel temperature dielectric loss is less than or equal to 2%, the crystalline grain of the ceramic is less than 2000nm, the dielectric loss is small, the evenness of the material is good, and the material is applied to manufacturing a multi-layer ceramic capacitor with large capacity and ultrathin dielectric layer (the depth of the dielectric layer is less than 3mu m).

Owner:TSINGHUA UNIV +1

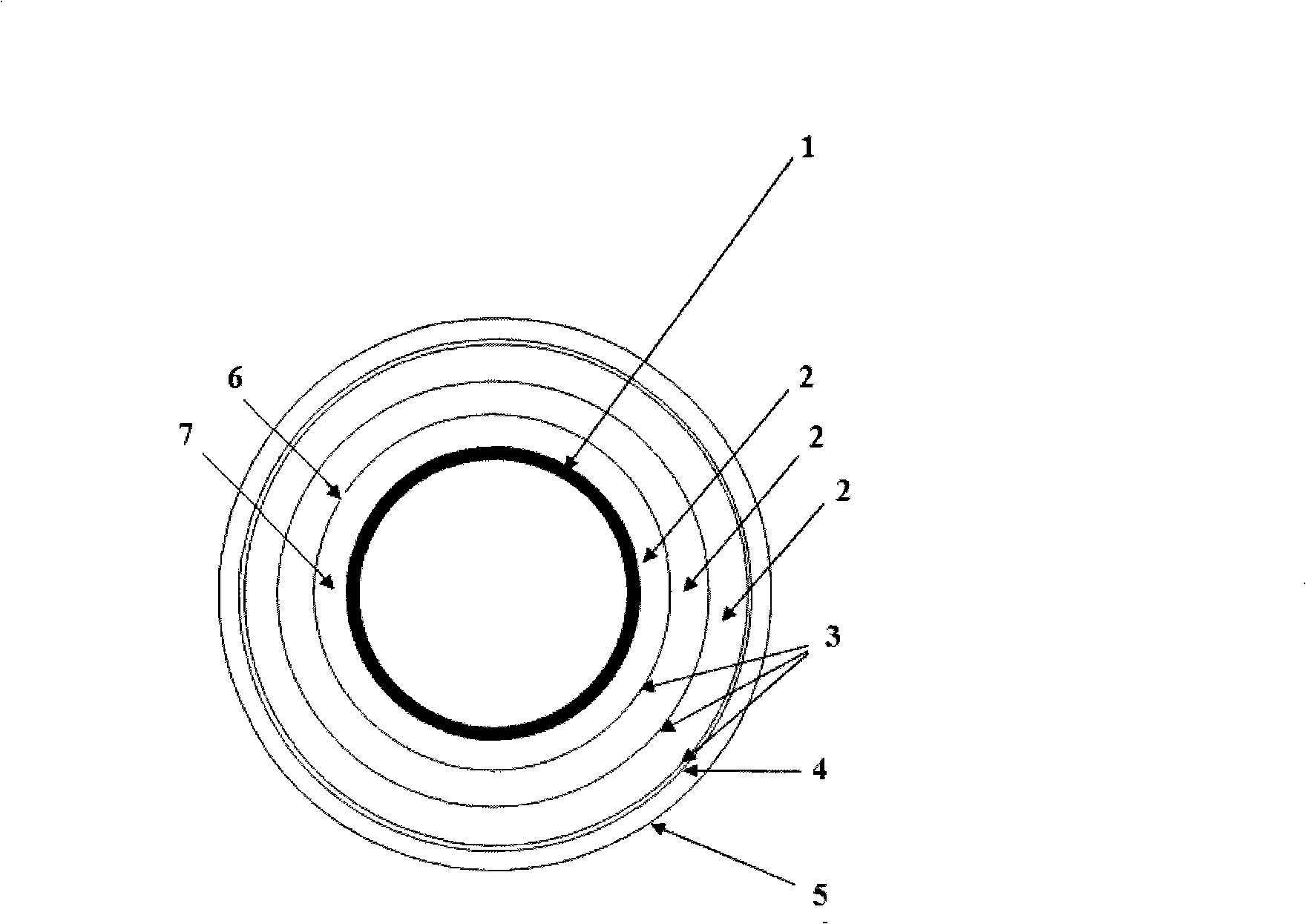

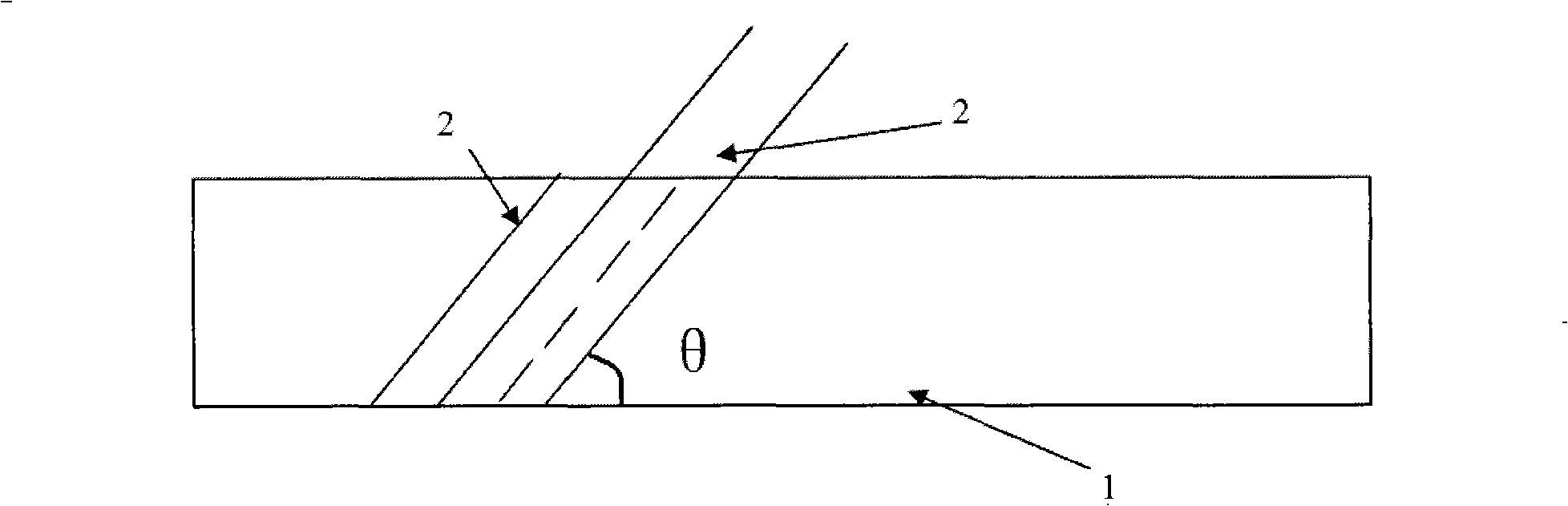

Composite insulating tube type bus and method for preparing the same

ActiveCN101339824AImprove insulation performanceImprove securityRigid-tube cablesManufacturing rigid-tube cablesState of artElectrical conductor

The invention discloses a compound insulating tube busbar and a preparation method thereof in the technical field of high voltage insulated conduction. The compound insulating tube busbar comprises a conductor tube, a compound insulating layer, a semiconductor electric strip layer, a shielding layer and a sleeve, wherein, the conductor tube is positioned on the innermost layer; a plurality of the compound insulating layers and the semiconductor electric strip layers are crosswise arranged at the external part of the semiconductor tube; a copper foil layer is arranged at the external part of the semiconductor electric strip layer and the sleeve is arranged at the external part of the copper foil layer. The preparation method of the invention adopts different properties of a solid buddle-free insulating film strip and insulating liquid to enwind and solidify the shaped insulating tube busbar on the surface of the tubular conductor, which causes the production procedure to be simple and the maintenance to be simple and convenient; compared with the prior art, the compound insulating tube busbar has better insulating property and longer service life, and can be applied to bitter environments.

Owner:SHANGHAI XIBANG ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com