Patents

Literature

48results about How to "Low specific gravity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

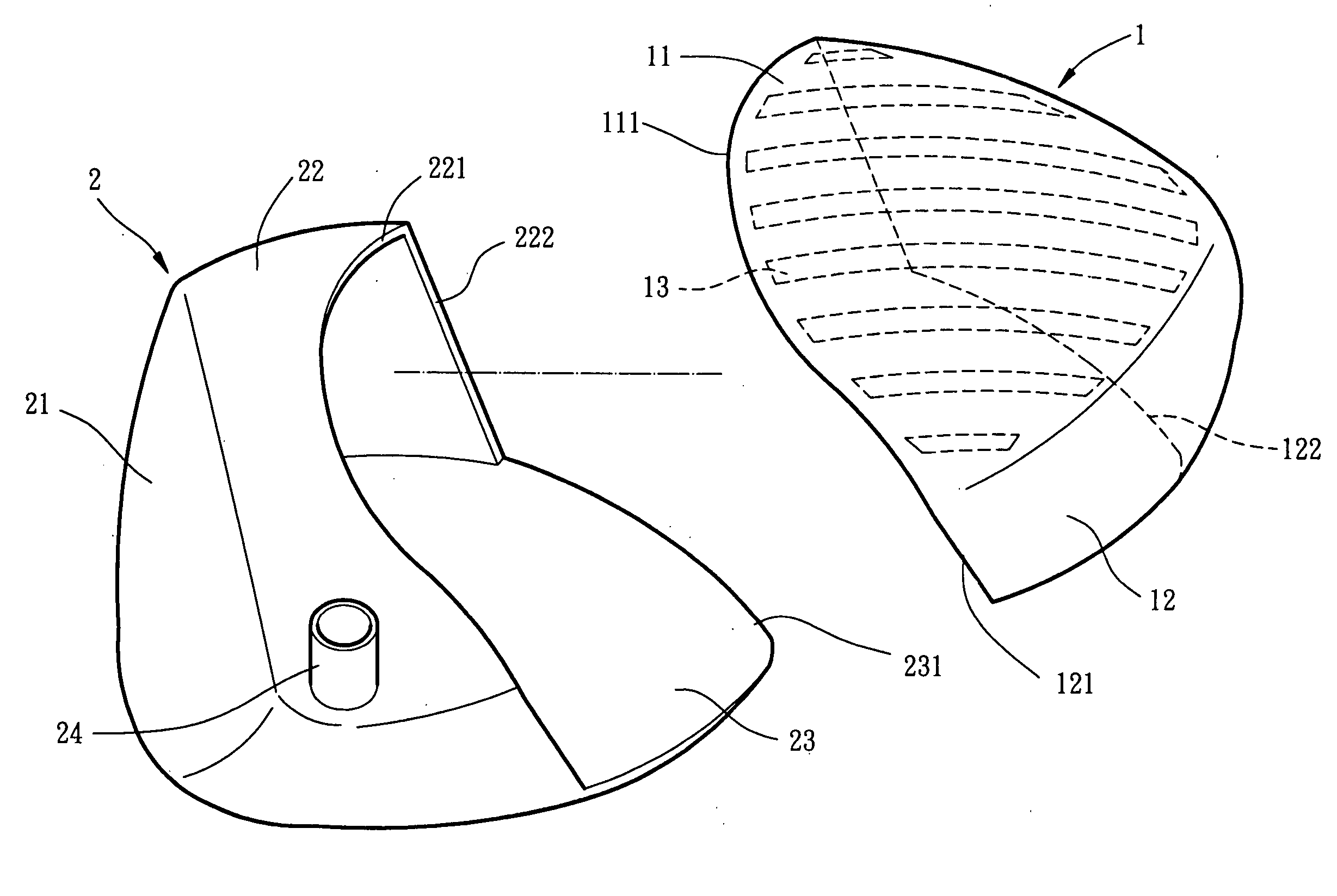

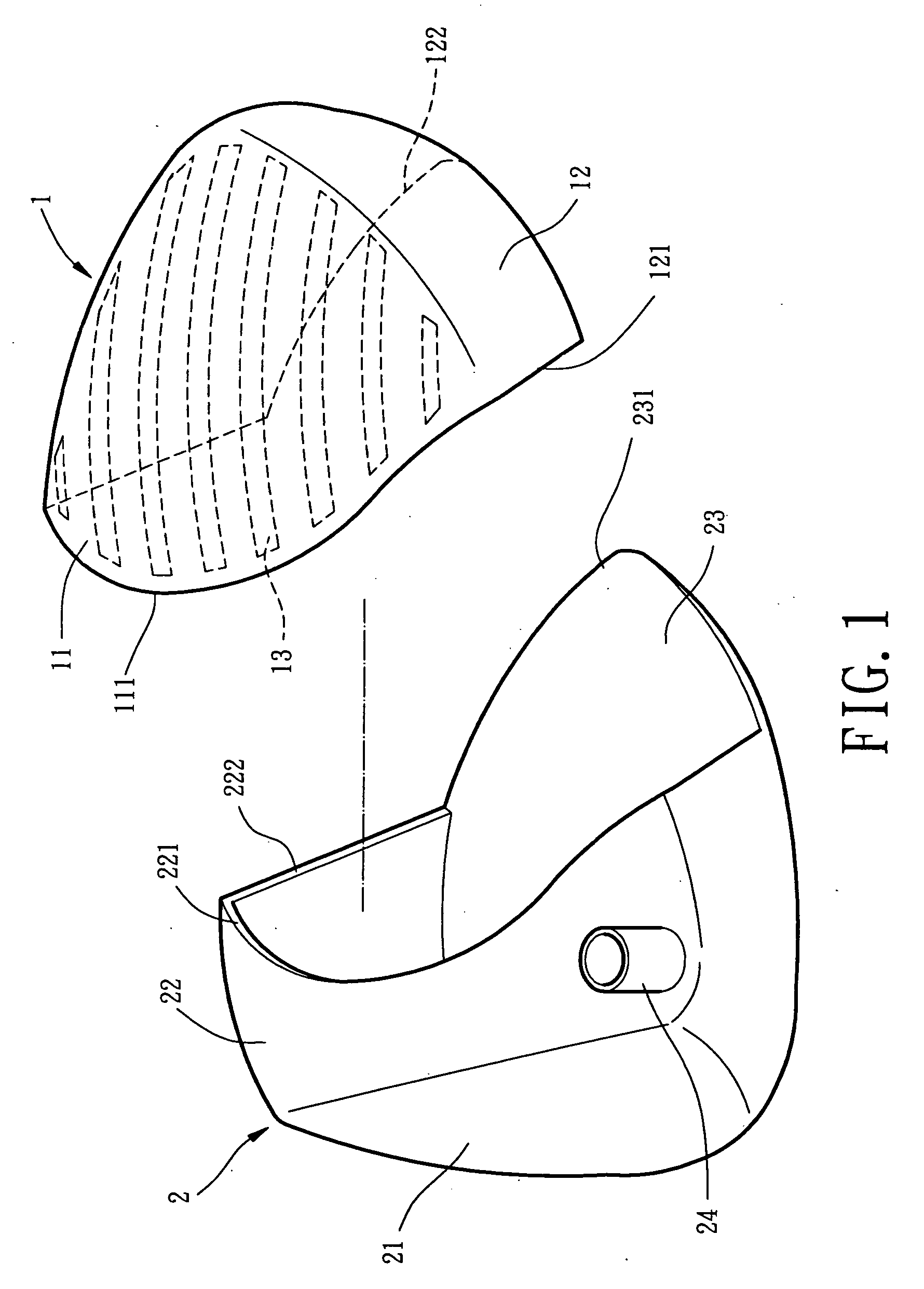

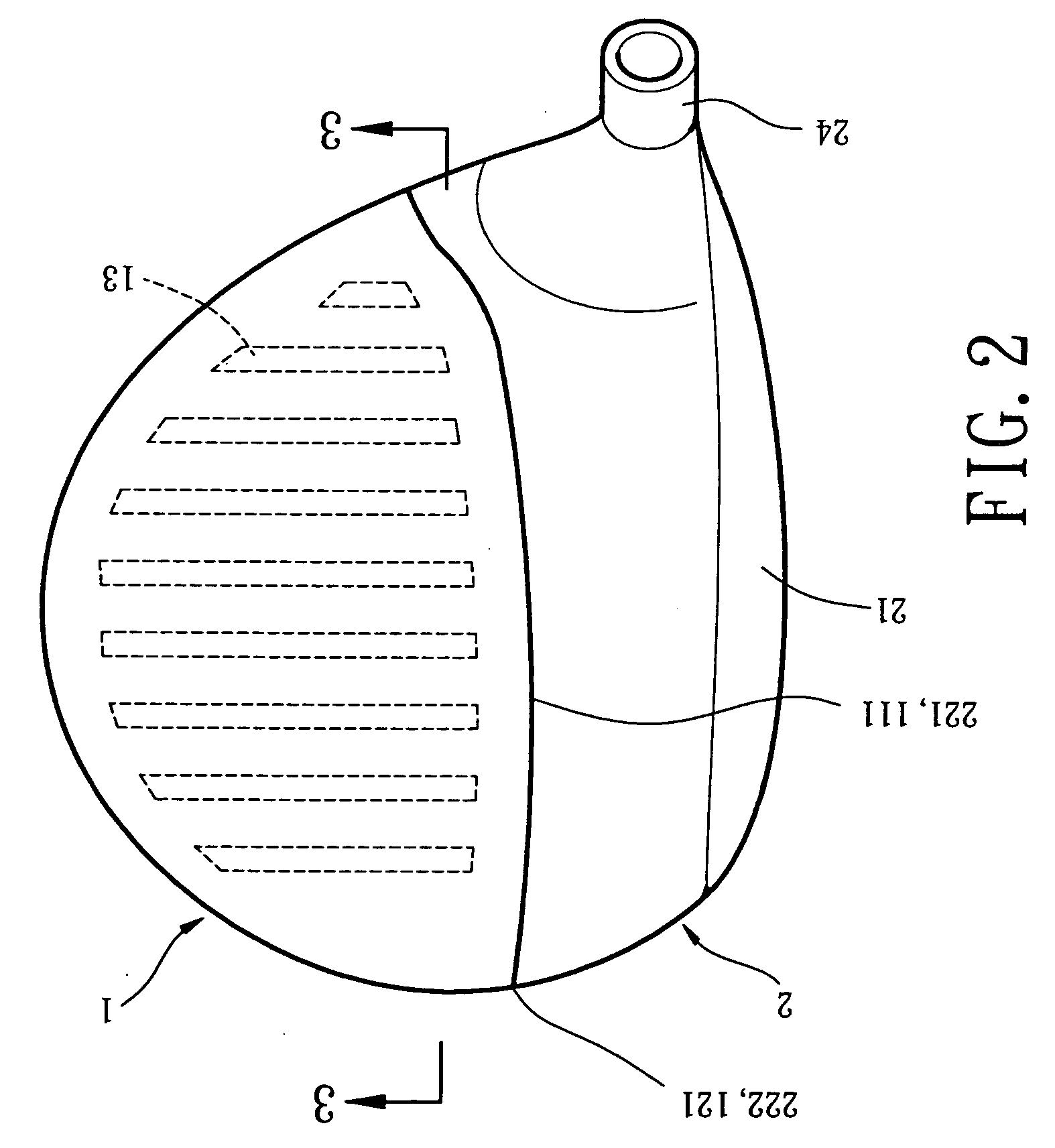

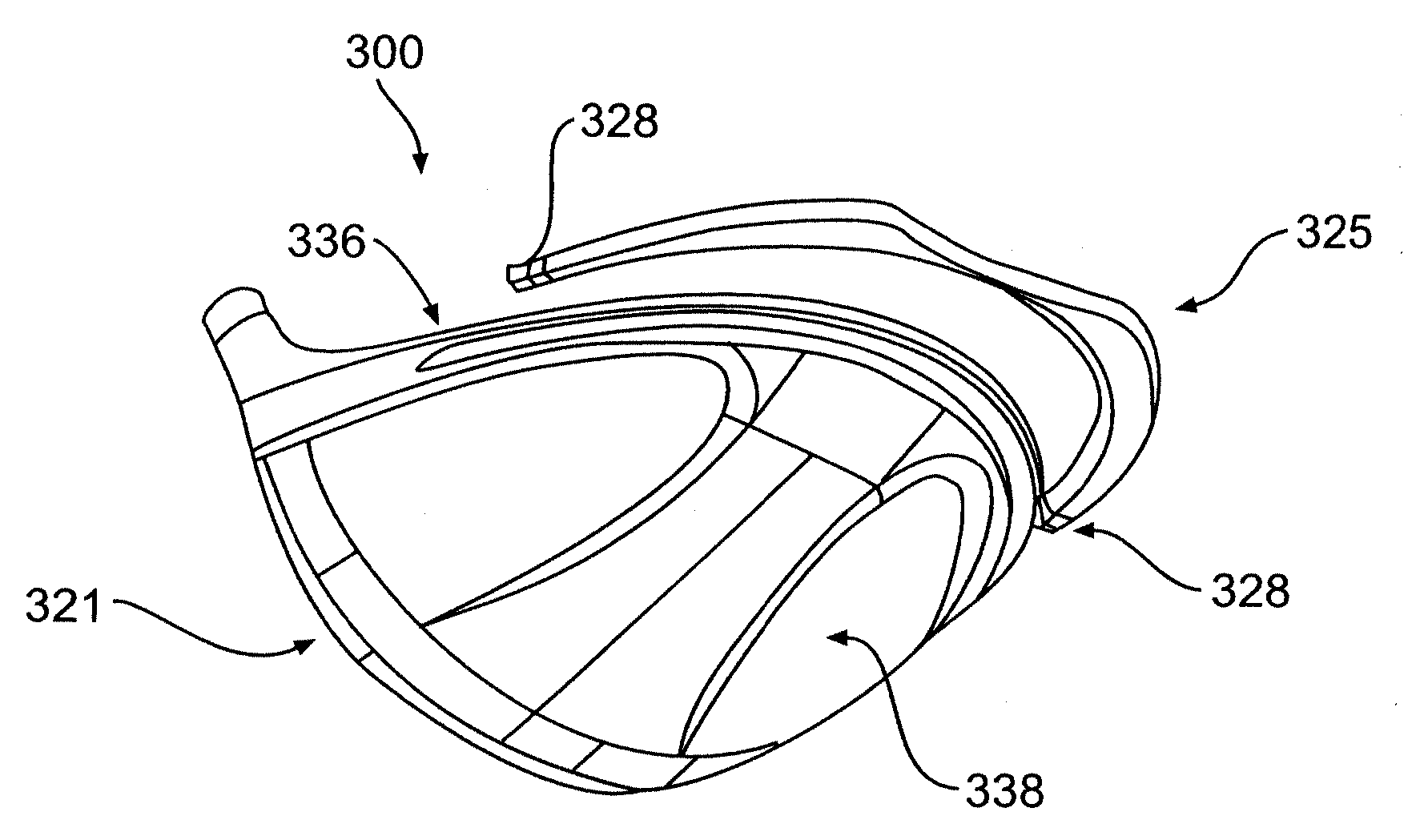

Weight-adjustable golf club head provided with rear lightweight covering

InactiveUS20080070721A1Thin thicknessLower center of gravityGolf clubsRacket sportsEngineeringGolf Ball

A weight-adjustable golf club head includes a rear lightweight covering and a golf club head body combined therewith. The rear lightweight covering has a rear crown portion and a rear wall portion extended therefrom. The golf club head body is combined with the rear lightweight covering which is designed to have a striking face, a front crown portion and a sole portion. The rear lightweight covering is made from a low specific gravity metal, and is designed to have a thickness less than 0.6 mm. The rear lightweight covering has an inner surface formed with a plurality of reinforcing ribs.

Owner:FUSHENG IND CO LTD

Resin composition for foam and use thereof

InactiveUS20060154998A1Less decrease in hardnessLow specific gravitySolesSynthetic resin layered productsSpecific gravityCompression set

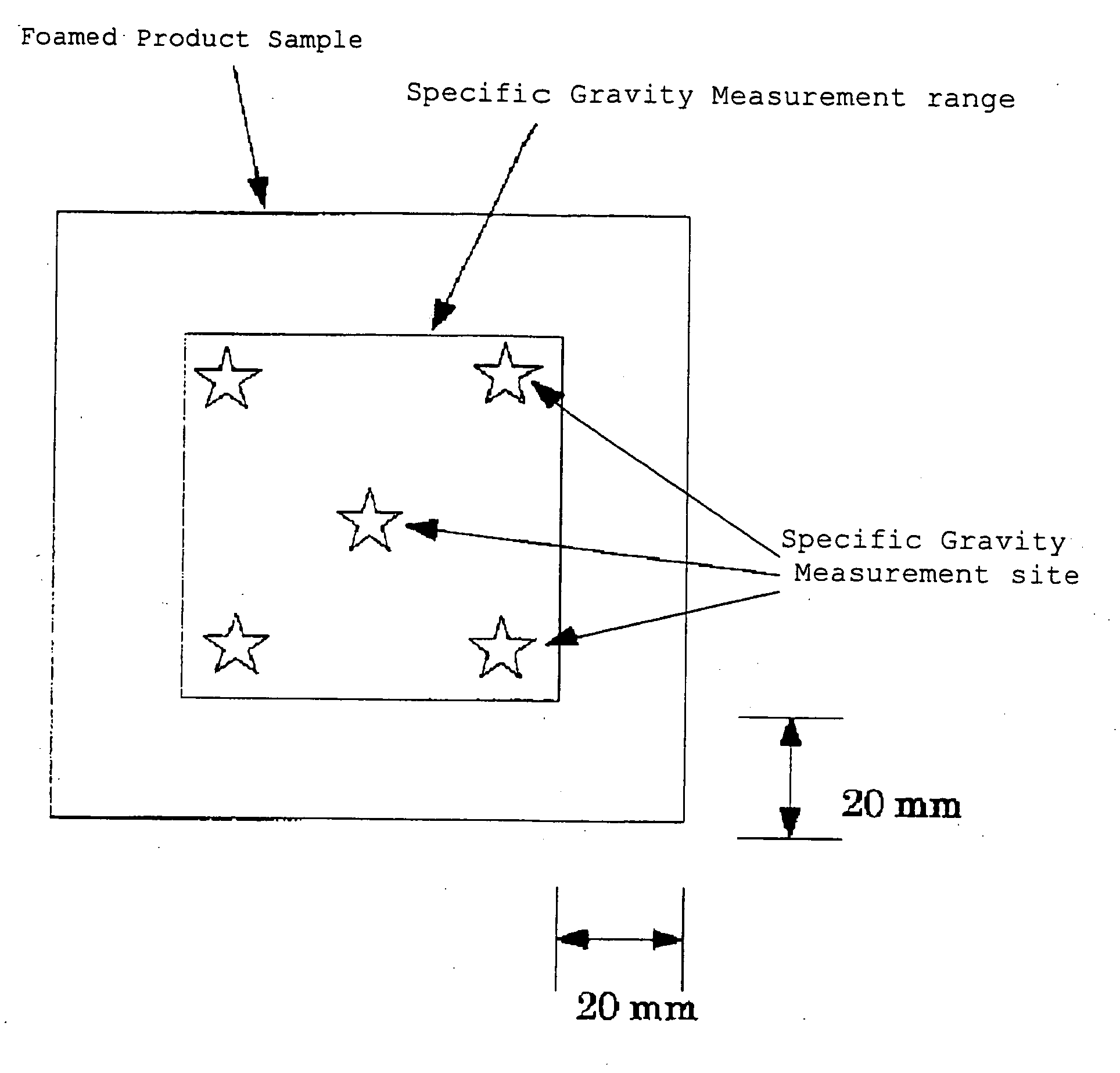

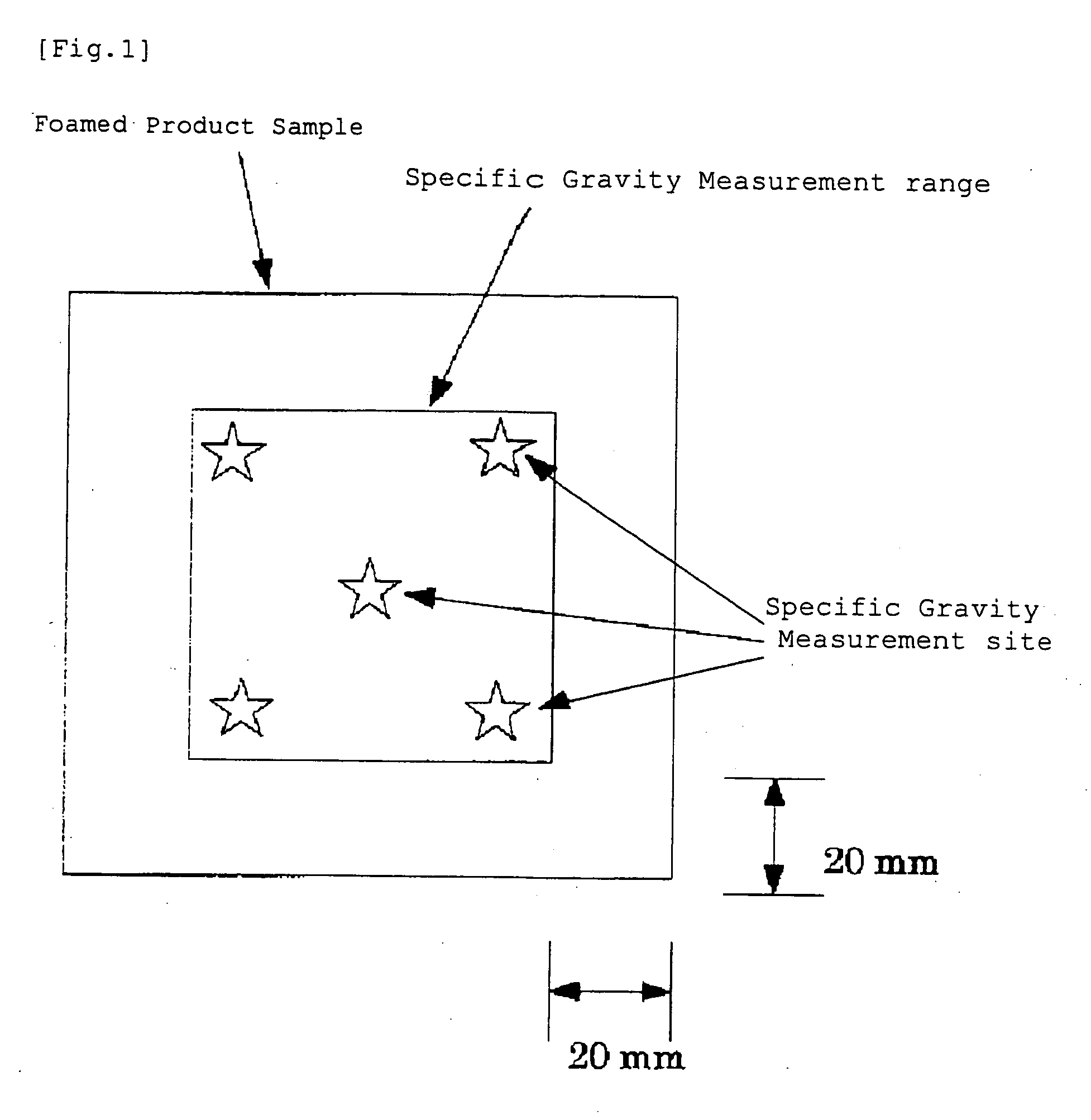

A composition which can provide a foamed product (non-crosslinked or crosslinked foamed product) having low specific gravity and low compression set (CS), excelling in the tensile strength properties and the tear strength properties, as well as in impact resilience, and exhibiting a less decrease in hardness at high temperatures; a foamed product produced therefrom; and a laminate produced using the foamed product are provided. A resin composition for a foamed product comprising 5 to 95 pars by weight of an ethylene / α-olefin copolymer (A1), 5 to 95 parts by weight of a styrene block copolymer (B), and based on 100 parts by weight of the total of components (A1) and (B), 0 to 1900 parts by weight of an ethylene / polar monomer copolymer (A2).

Owner:MITSUI CHEM INC

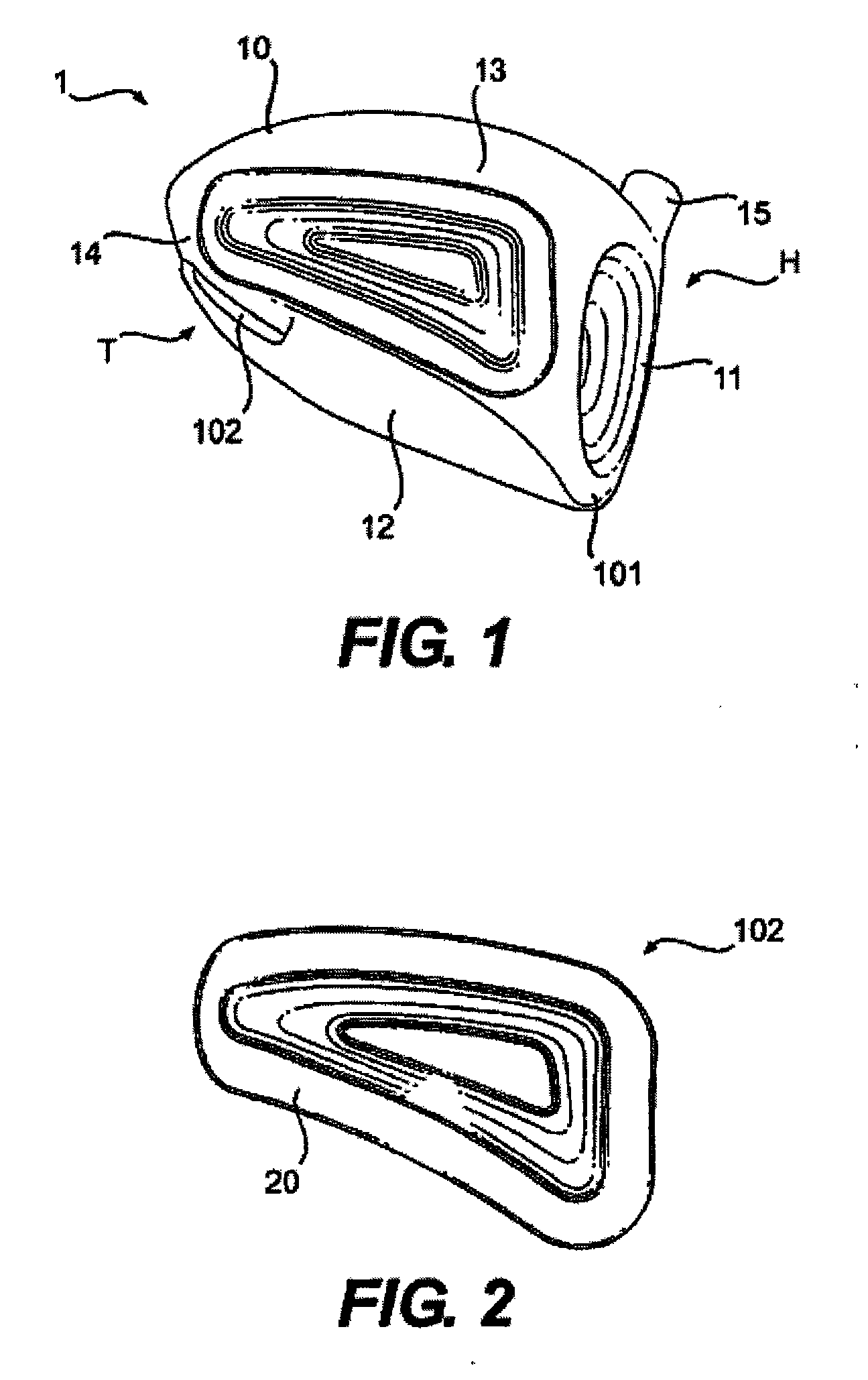

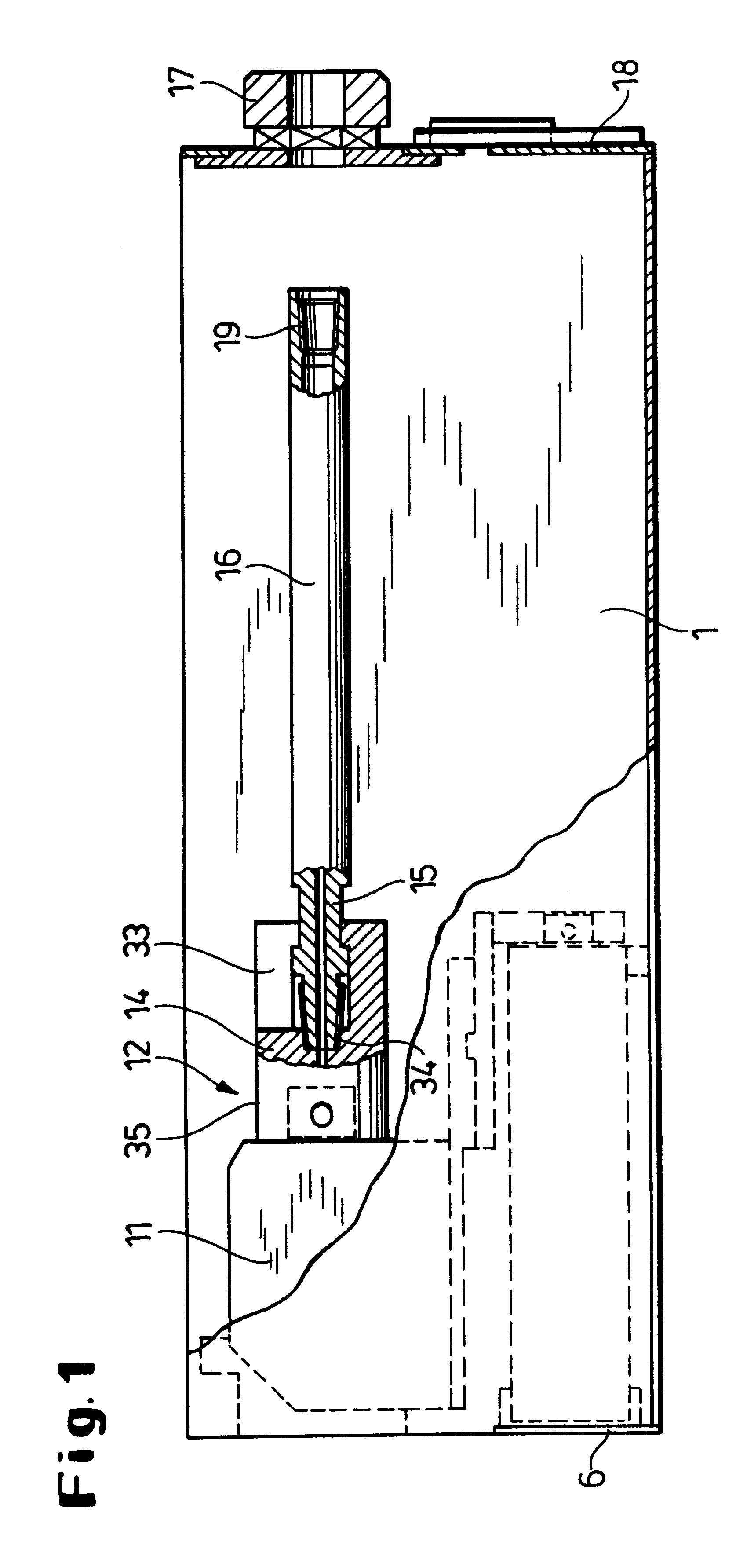

Golf club head with moveable insert

InactiveUS20100105499A1Low specific gravityReduced specific gravitySpace saving gamesGolf clubsLocking mechanismGolf Ball

The present invention is directed toward a golf club head with an adjustable insert. The insert is moveable in a face to back direction, and may be locked into place by one or more locking mechanisms. The insert may be adjustable so that the overall distance from the face to the back approaches the distance from the heel to the toe.

Owner:COBRA GOLF

Magnetic particle tagged reagents and techniques

ActiveUS20070172899A1Eliminate needLow specific gravityBiological testingMagnetic immunoreagent carriersSpecific gravityChemical synthesis

Methods for separating, in a continuous, multizone fluid medium, cells, particles, or other molecules of interest (MOI) from associated or contaminating unwanted materials not of interest (MNOI). The invention involves forced movement of MOI into certain zones having properties which deter the entry of unwanted materials. Differential movement of MOI and MNOI occurs by active counterforces that move MNOI but not MOI. MOI are tagged with magnetic particles and moved with a magnetic field through a fluid, or zones, of higher specific gravity that prevents, by flotation counterforce, unwanted less dense materials from entering. Surfaces specifically coated with reactants are reactive with the MOI in the tagged magnetic particle complex and of buoyant or other forces are used to remove any unbound material from the surface before reading. Readable labels, in addition to the magnetic particle tagged complex itself, such as enzymes, fluorophors, chemiluminescent materials, radioactive isotopes, chromogenic and fluorogenic substrates and other labels may be used. In most embodiments, materials of interest are delivered to a special final zone for reading or harvesting. The invention applies to many assays, diagnostic tests, separative procedures and chemical syntheses.

Owner:CHROME RED TECH

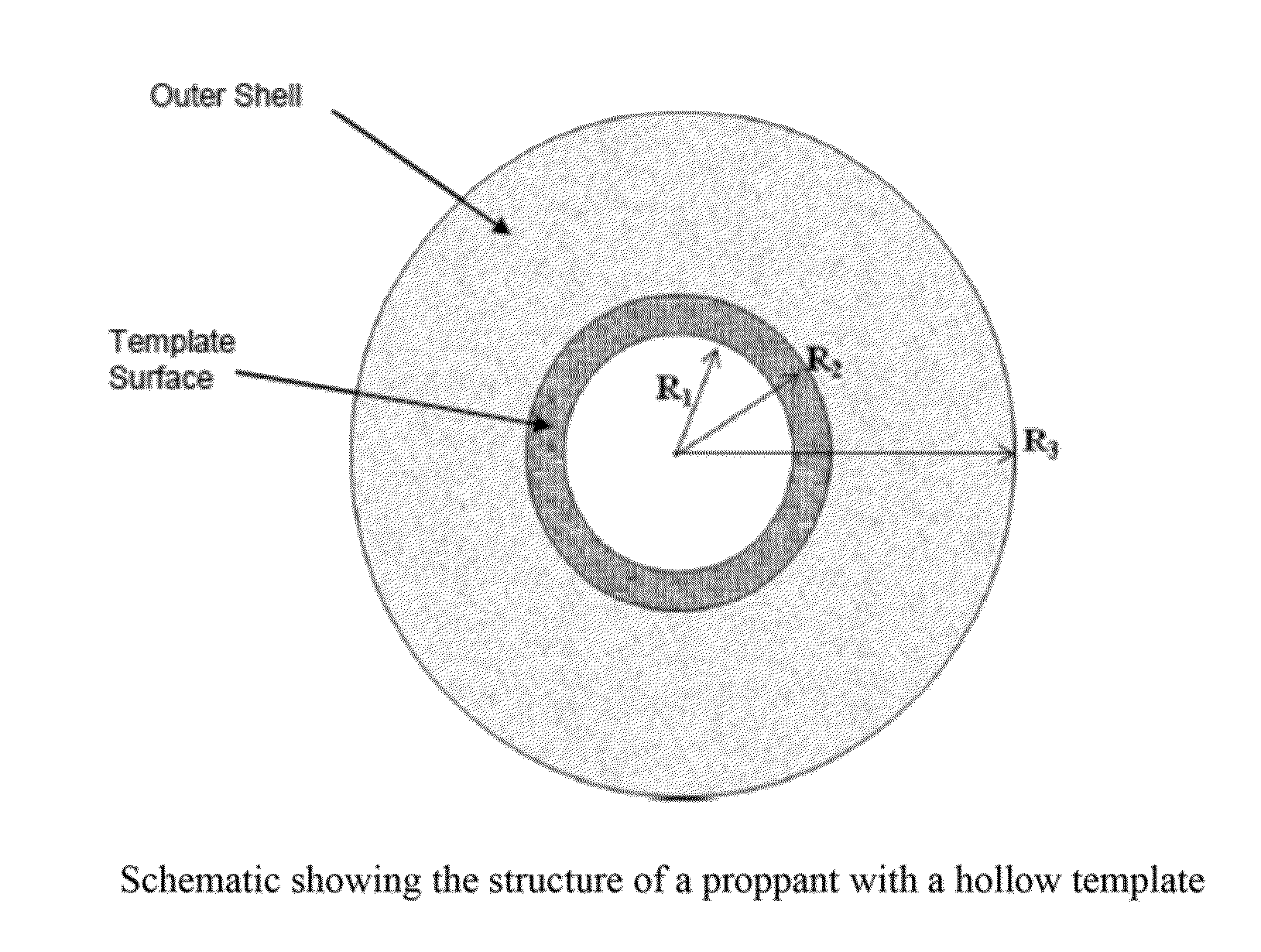

Light Weight Proppant With Improved Strength And Methods Of Making Same

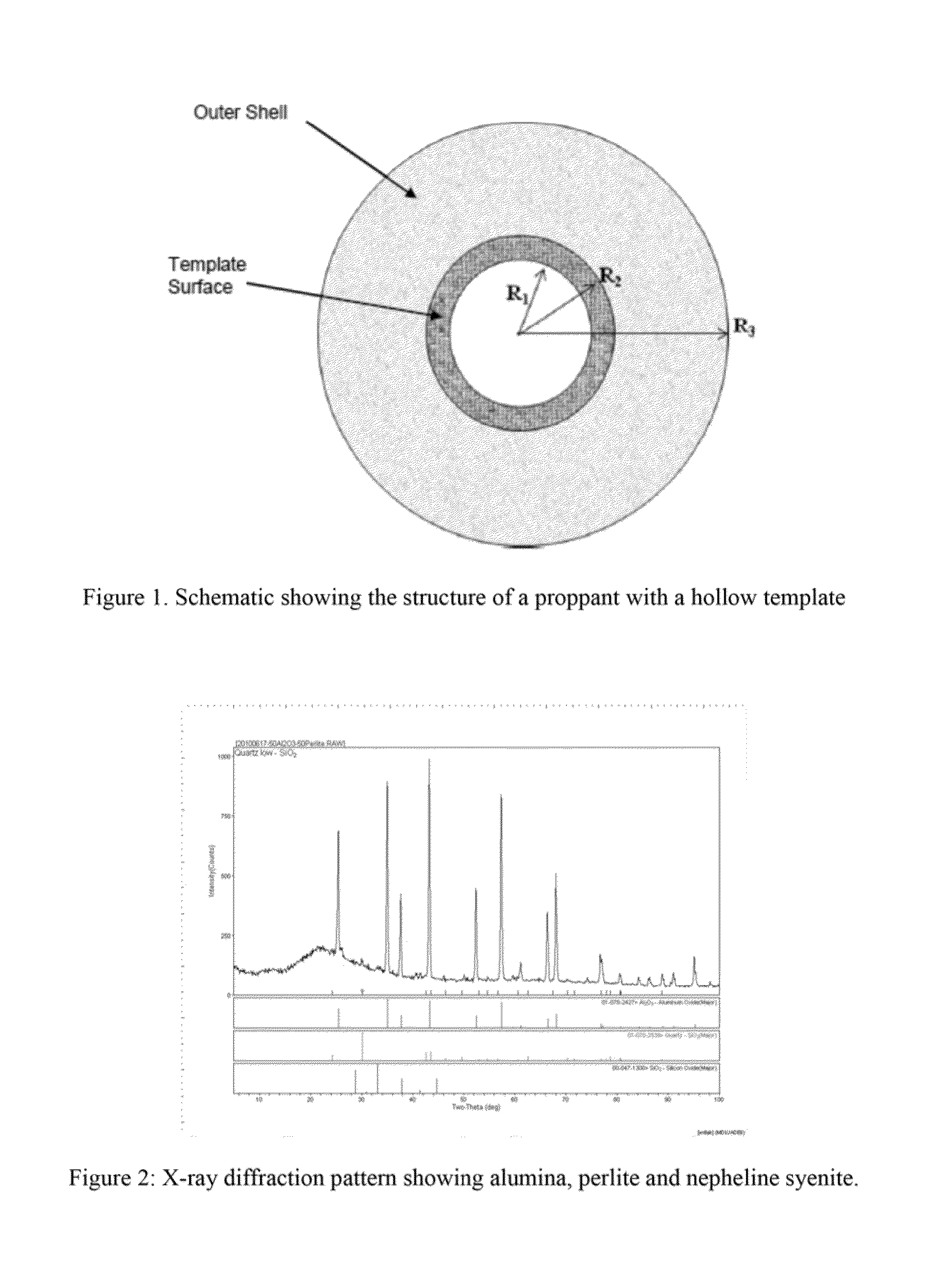

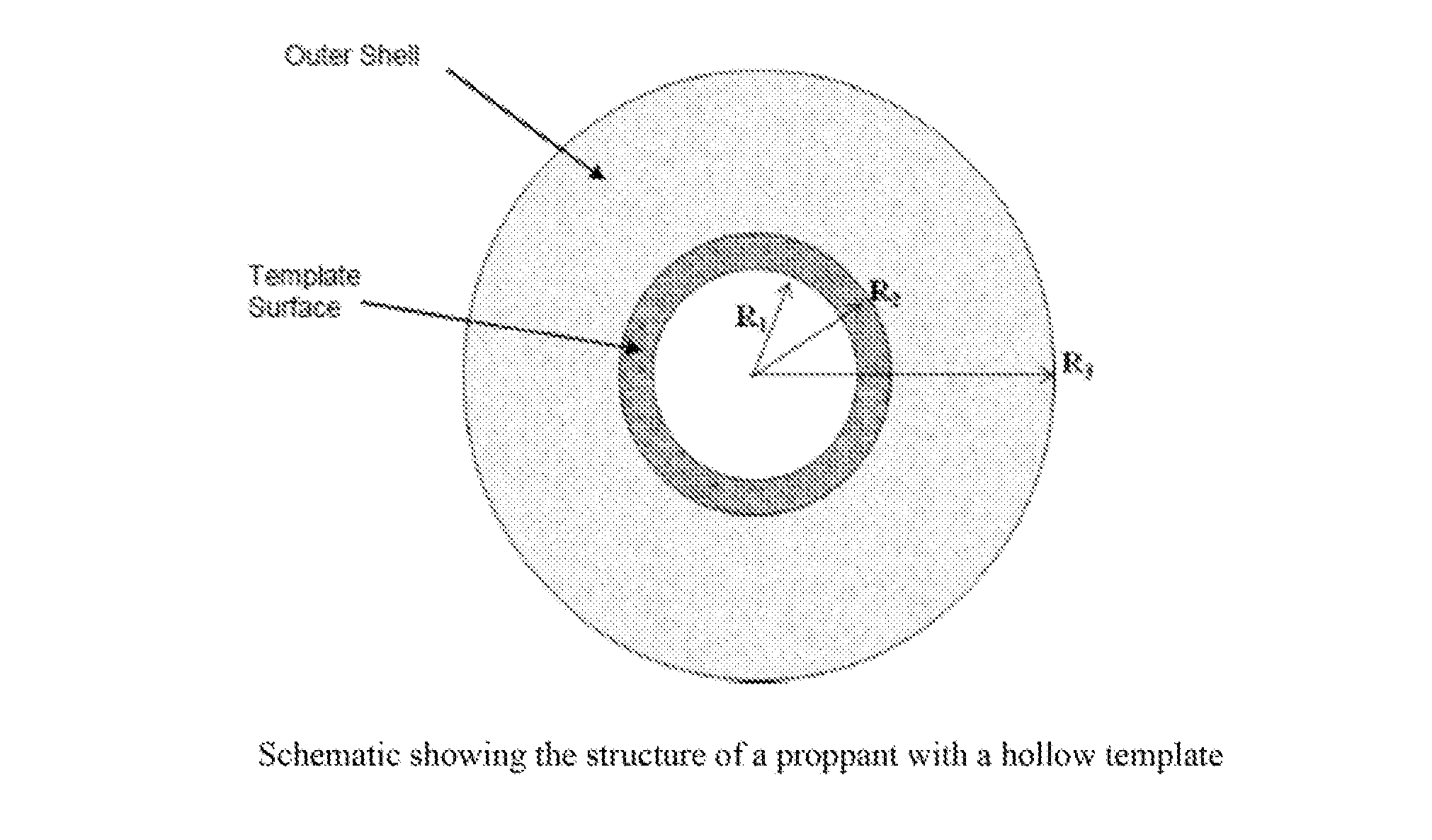

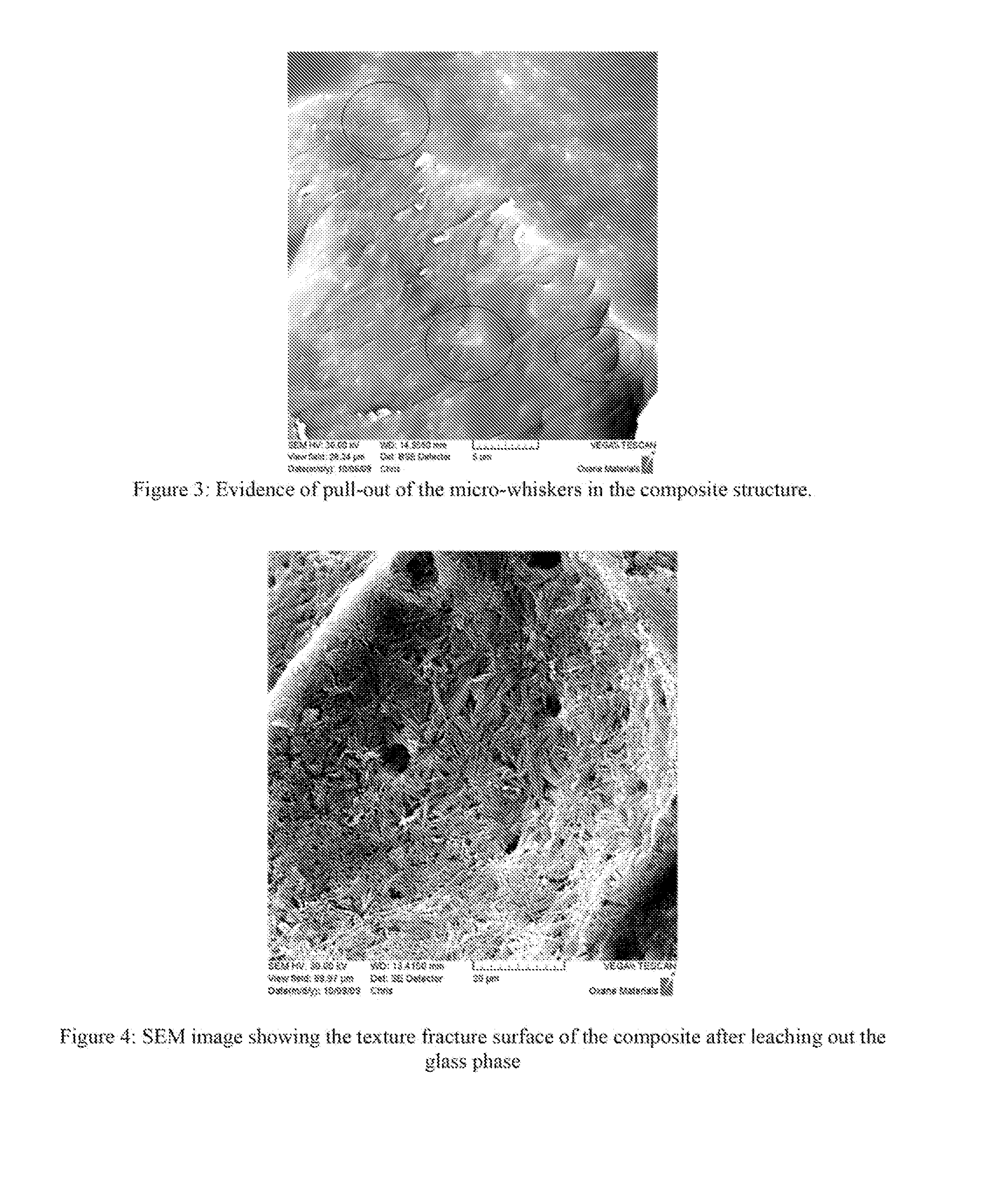

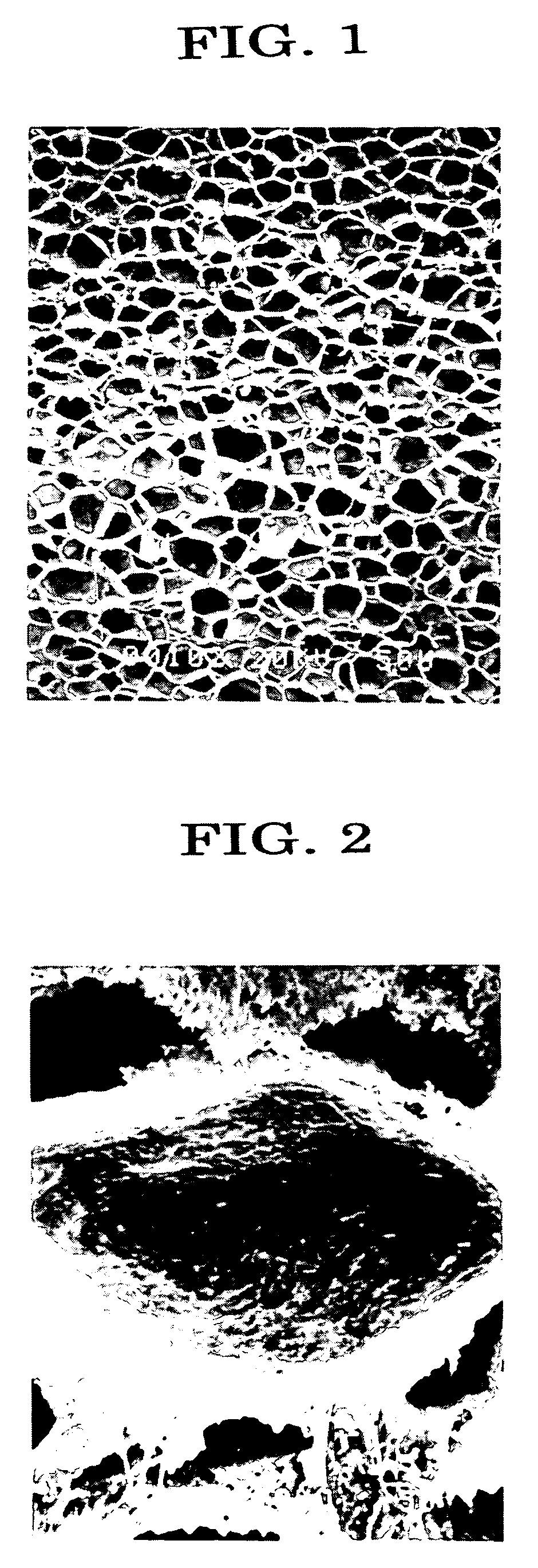

ActiveUS20130206408A1Low densityHigh strengthFluid removalCeramic shaping apparatusCeramic compositeAmorphous phase

Methods are described to make strong, tough, and / or lightweight glass-ceramic composites having a crystalline phase and an amorphous phase generated by viscous reaction sintering of a complex mixture of oxides and other materials. The present invention further relates to strong, tough, and lightweight glass-ceramic composites that can be used as proppants and for other uses.

Owner:HALLIBURTON ENERGY SERVICES INC

Light Weight Proppant With Improved Strength And Methods Of Making Same

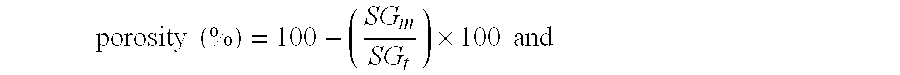

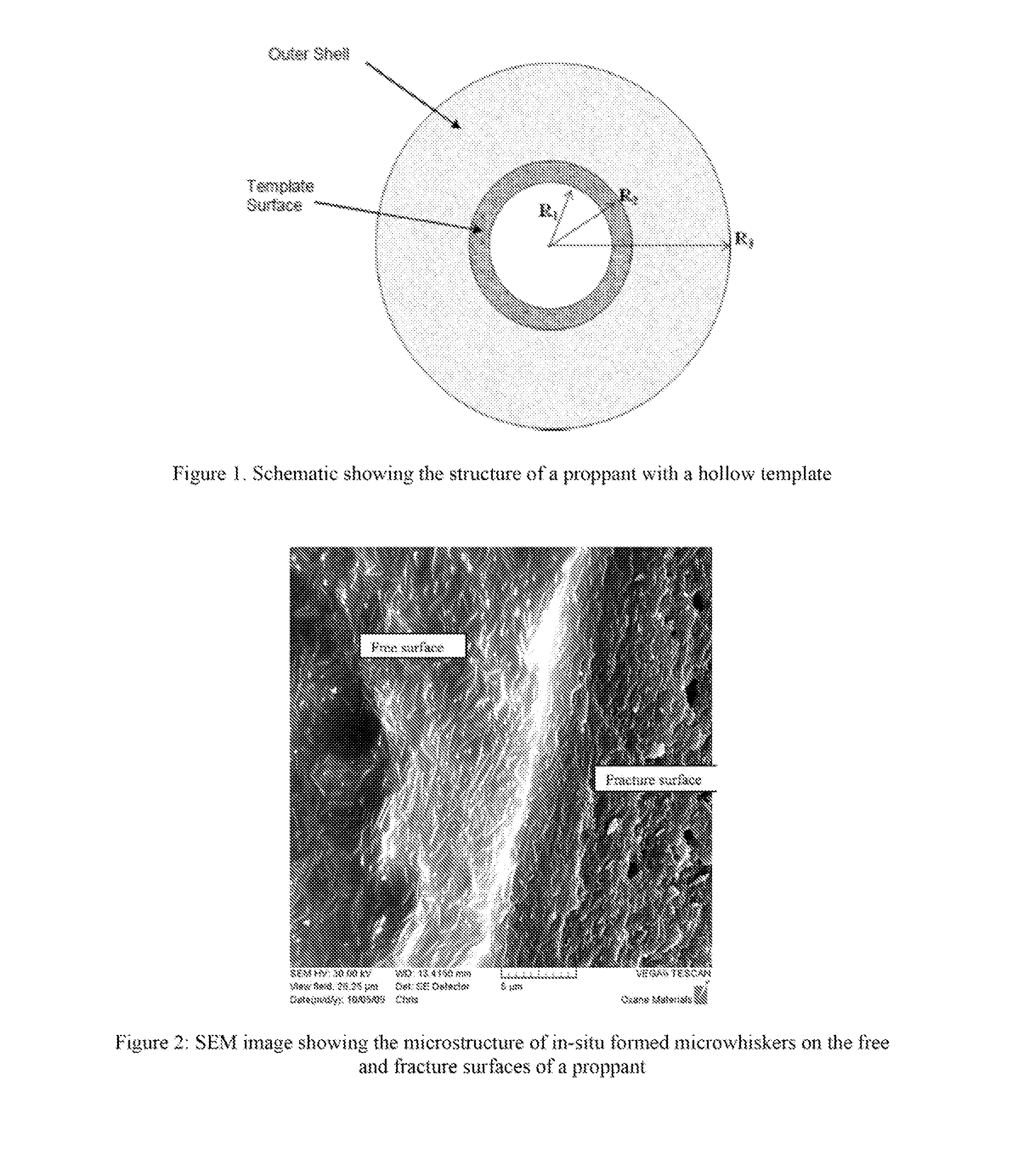

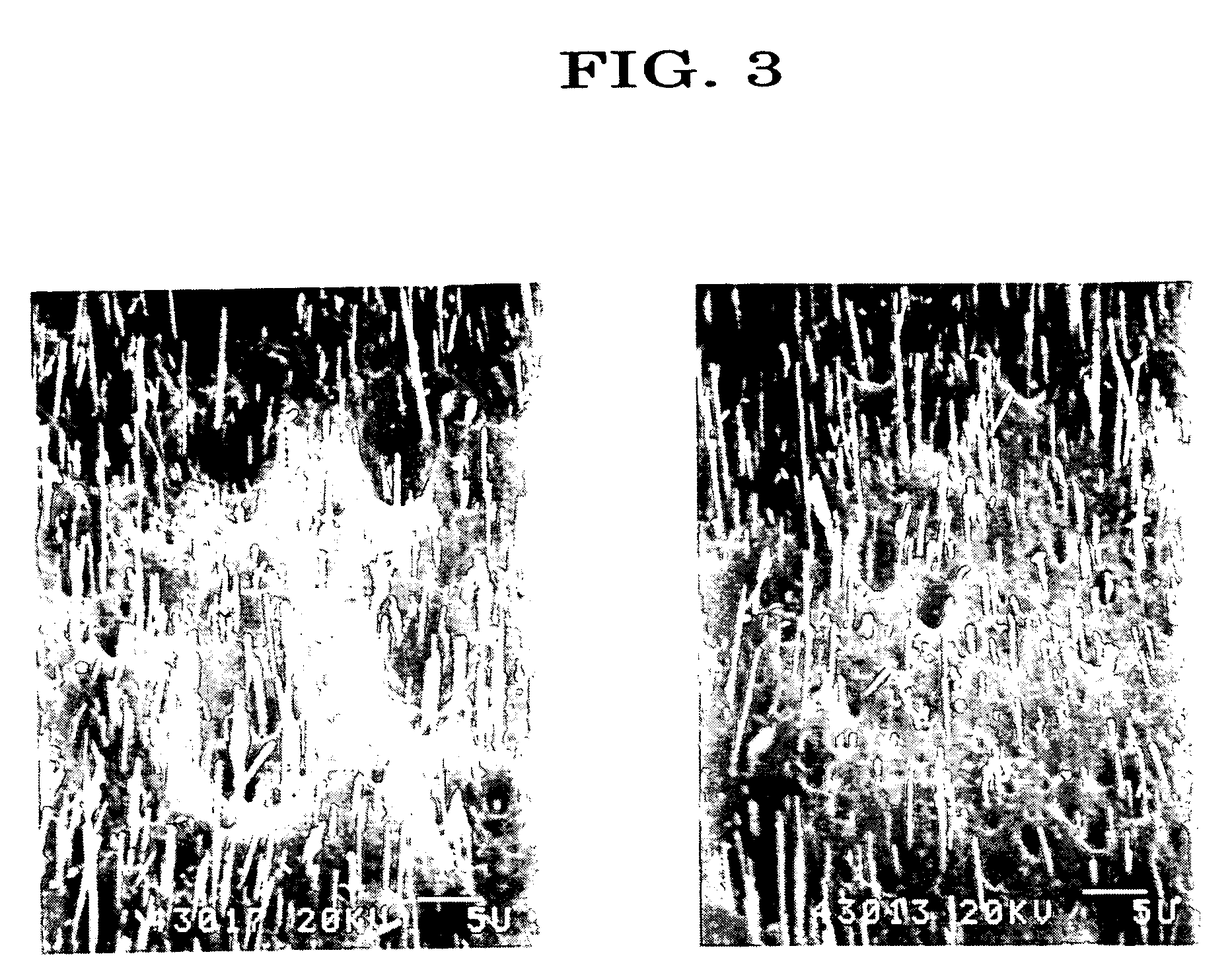

InactiveUS20130244914A1Reduce densityLow specific gravityFluid removalCeramic shaping apparatusOxideWhiskers

Methods are described to make strong, tough, and lightweight whisker-reinforced glass-ceramic composites through a self-toughening structure generated by viscous reaction sintering of a complex mixture of oxides. The invention further relates to strong, tough, and lightweight glass-ceramic composites that can be used as proppants and for other uses.

Owner:HALLIBURTON ENERGY SERVICES INC

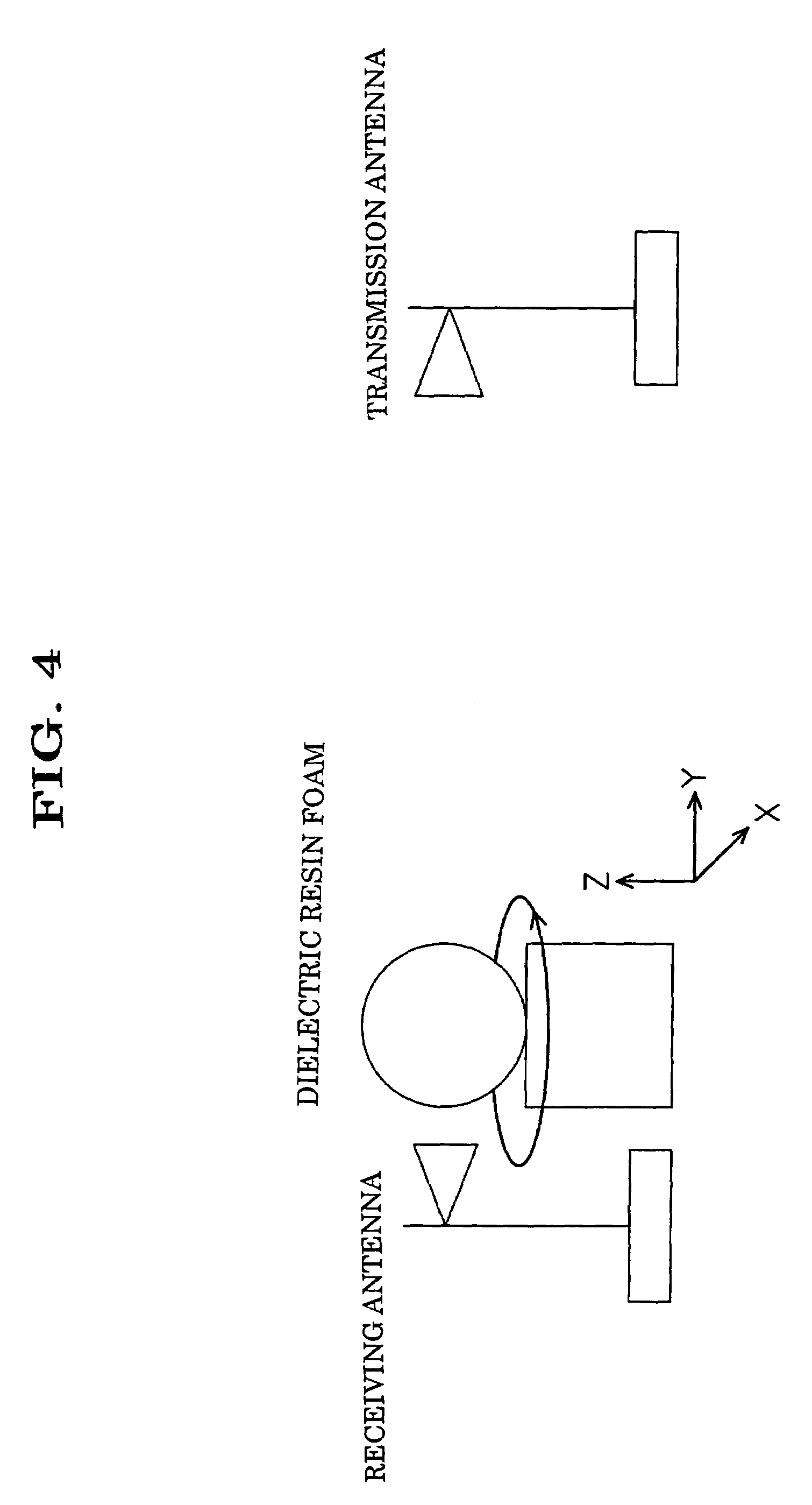

Dielectric resin foam and lens for radio waves using the same

InactiveUS7179844B2Excellent dielectric propertiesLow specific gravityPlastic/resin/waxes insulatorsCircuit susbtrate materialsDielectricSynthetic resin

It is an object of the present invention to provide a dielectric resin foam which has high and uniform dielectric properties and is preferable for use as various dielectric materials. A dielectric resin foam obtained by expanding a resin composition comprising a synthetic resin and a fibrous and / or plate-like dielectric inorganic filler is provided.

Owner:OTSUKA CHEM CO LTD +1

Metallic Pigment Composition and Uv Metallic Ink Composition or Uv Metallic Coating Composition Using the Same

InactiveUS20080216706A1Readily apparentExcellent in metal lusterInksPigment treatment with macromolecular organic compoundsNitrocelluloseUV curing

The invention provides a metallic pigment composition capable of preventing gelation of a UV metallic ink or a UV metallic coating material containing an ultraviolet-curable resin and providing good metallic effect and the stability with lapse of time and a UV metallic ink composition and a UV metallic coating material composition using it. The metallic pigment composition contains metal flakes and a nitrocellulose as essential components and the nitrocellulose is contained at a ratio in a range of 0.1 to 12 parts by mass to the metal flakes 100 parts by mass. The UV metallic ink and a UV metallic coating material are provided by adding the metallic pigment composition. The surfaces of the metal flakes are preferable to be coated with a phosphorus compound.

Owner:TOYO ALUMINIUM KK

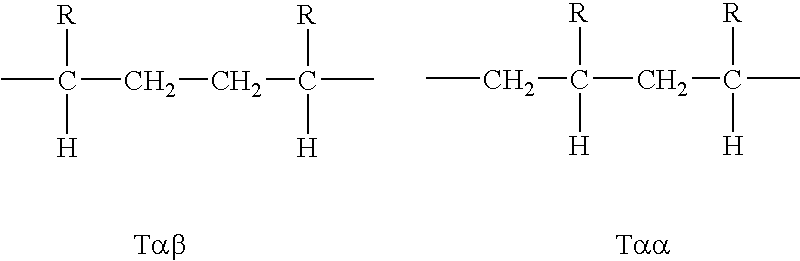

Ethylenic copolymer, compostion containing the copolymer and use thereof

ActiveUS20090249645A1High contentLow specific gravityPlastic/resin/waxes insulatorsDomestic footwearSpecific gravityWeather resistance

An object of the present invention is to provide a novel ethylene-α-olefin copolymer excellent in crosslinking properties; a foamed molded article having a low specific gravity and a low compression set (CS) and a composition capable of producing the foamed molded article, footwear parts composed of a foamed molded article; an ethylenic copolymer composition excellent in balance between weather resistance and mechanical strength, and an electric wire coating material and an electric wire sheath using the ethylenic copolymer composition; and a thermoplastic elastomer capable of producing a molded article excellent in balance between mechanical strength and toughness. The ethylenic copolymer (A) of the present invention is a copolymer composed of only ethylene and an α-olefin having 3 to 20 carbon atoms, and is characterized in that vinyl-group content (a) per 1000 carbon atoms as measured by infrared absorption spectroscopy, MFR10 / MFR2.16 (b), and the specific gravity (c) are within a specific range.

Owner:MITSUI CHEM INC

Shrink film and cylindrical shrink label

InactiveUS20100279133A1Low specific gravityEasy to separateSynthetic resin layered productsLabelsPolyester resinPolypropylene

[Object] To provide a multilayer shrink film which is composed of different polymers, i.e., a polypropylene resin and an aromatic polyester resin and which does not suffer from delamination even in a center-sealed portion during shrinking process; and a cylindrical shrink label using the shrink film.[Solving Means] The shrink film has a multilayer structure including layers A, B, and C in the order of (layer A) / (layer B) / (layer C) without the interposition of any other layer, in which the layer A is a resin layer mainly containing a modified aromatic polyester resin; the layer B is an intermediate layer mainly containing an ethylene-vinyl acetate resin and having a vinyl acetate component content of 20 to 30 percent by weight; and the layer C is a resin layer mainly containing a polypropylene resin.

Owner:FUJI SEAL INTERNATIONAL INC

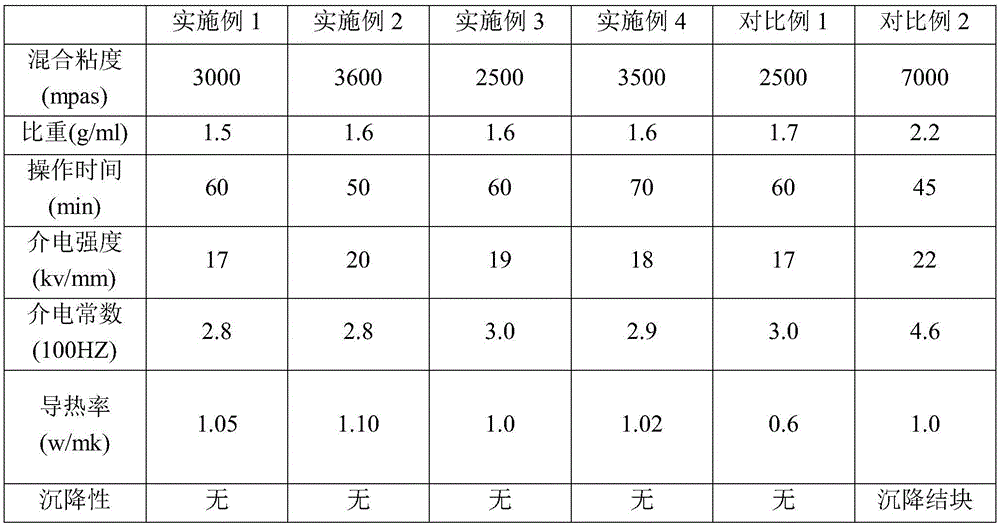

Preparation method of high-thermal-conductivity low-specific-gravity flame-retardant organic silicon pouring sealant

InactiveCN107892898ALow conductivityImprove sexual functionNon-macromolecular adhesive additivesHeat conductingSealant

The invention provides a preparation method of a composite graphene high-thermal-conductivity low-specific-gravity flame-retardant organic silicon pouring sealant. A mixture is formed by mixing a component A and a component B in the weight ratio of 1:(1-2), the mixture is poured into equipment when the fluidity of the mixture remains, and then room-temperature curing molding or heating curing molding is conducted. The component A comprises, by weight, 47.4-61.6% of vinyl silicone oil, 3-12% of modified heat-conducting micro-powder, 0.4-0.6% of catalyst and 35-40% of flame-retardant agent. Thecomponent B comprises, by weight, 41.99-57.992% of vinyl silicone oil, 3-12% of graphene composite heat-conducting filler, 4-6% of hydrogen-containing silicone oil, 0.005-0.008% of inhibitor and 35-40% of flame-retardant agent. By means of surface treatment and compounding of different kinds of heat-conducting filler, the graphene composite heat-conducting filler is prepared, and the dispersion problem of the heat-conducting filler and organic silicon rubber is improved; the graphene composite heat-conducting filler can improve the heat-conducting performance of the organic pouring sealant; bysimulating different particle sizes and using compounds obtained according to different particle sizes, the organic silicon pouring sealant is high in thermal conductivity and low in specific gravity.

Owner:青岛科孚纳米技术有限公司

Shrink Film

InactiveUS20090061245A1Improve shrinkageAdequate shrinking speedSynthetic resin layered productsThin material handlingPolymer scienceGlycidyl methacrylate

Disclosed is a shrink film which includes a core layer; two plies of intermediate layer respectively arranged on both sides of the core layer; and two plies of surface layer respectively arranged on both outer sides of the intermediate layers, and which has a five-layered multilayer structure composed of three types of layers [(surface layer) / (intermediate layer) / (core layer) / (intermediate layer) / (surface layer)]. The core layer is a resinous layer mainly containing a polyolefin resin, the surface layer is a resinous layer mainly containing a polyester resin, and the intermediate layer is a resinous layer mainly containing a polyethylene resin containing a glycidyl methacrylate (GMA) component. The shrink film has a low specific gravity, shows excellent shrink properties, has a high interlayer strength between film layers, and is tough, excellent shrink film. It is particularly useful as a shrink label for PET bottles.

Owner:FUJI SEAL INTERNATIONAL INC

Irregular shaped ferrite carrier and electrophotographic developer using the ferrite carrier

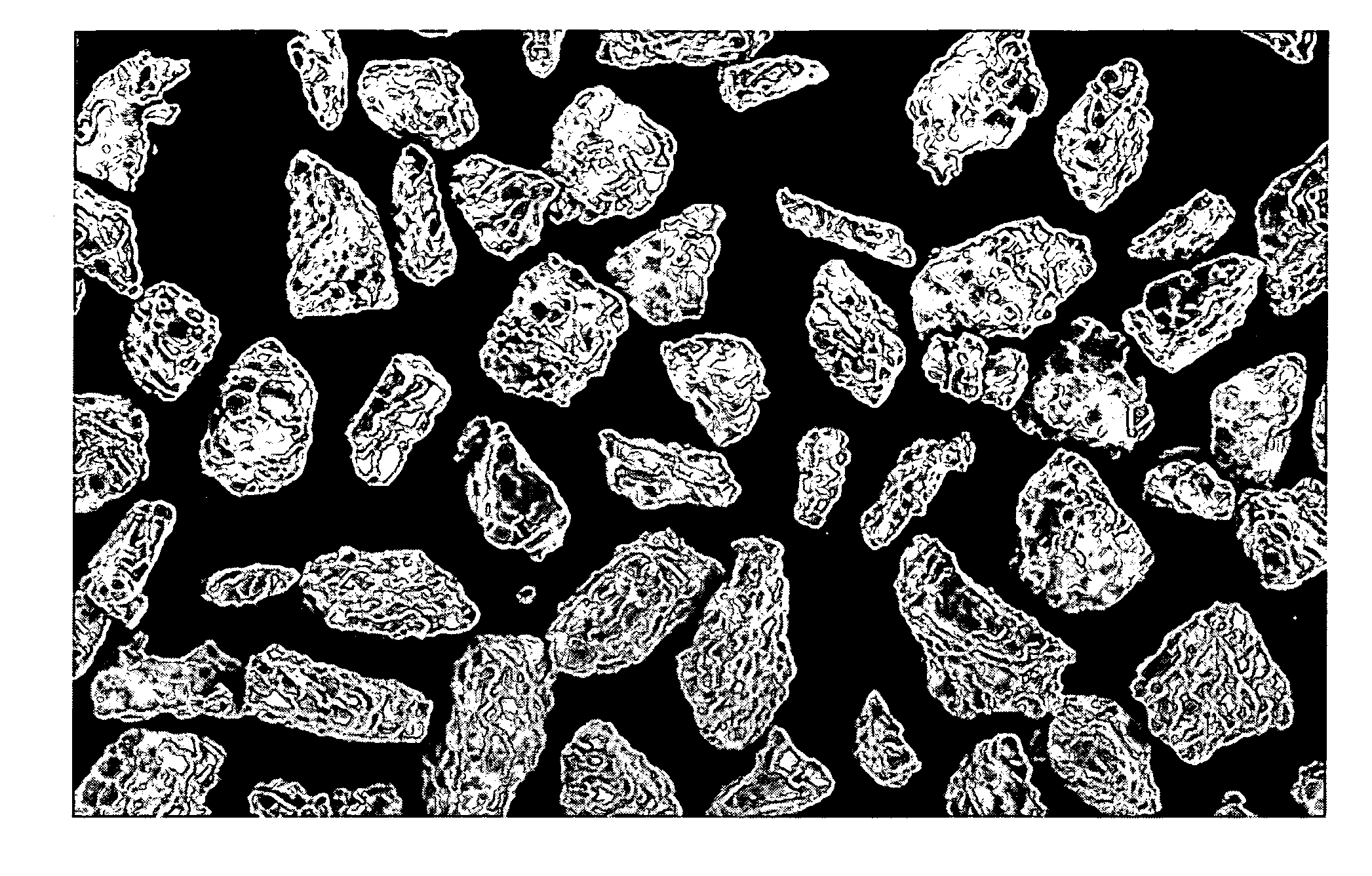

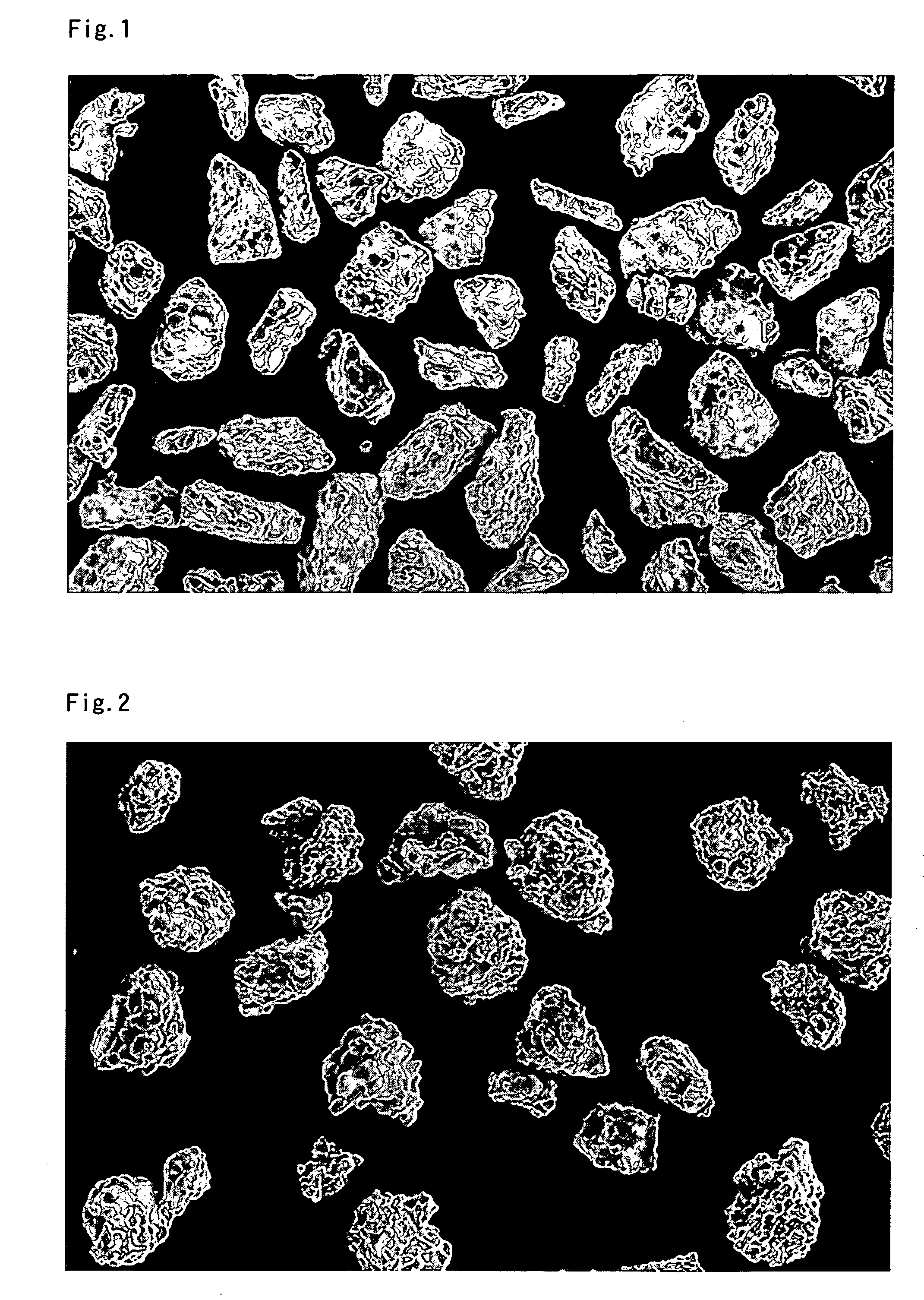

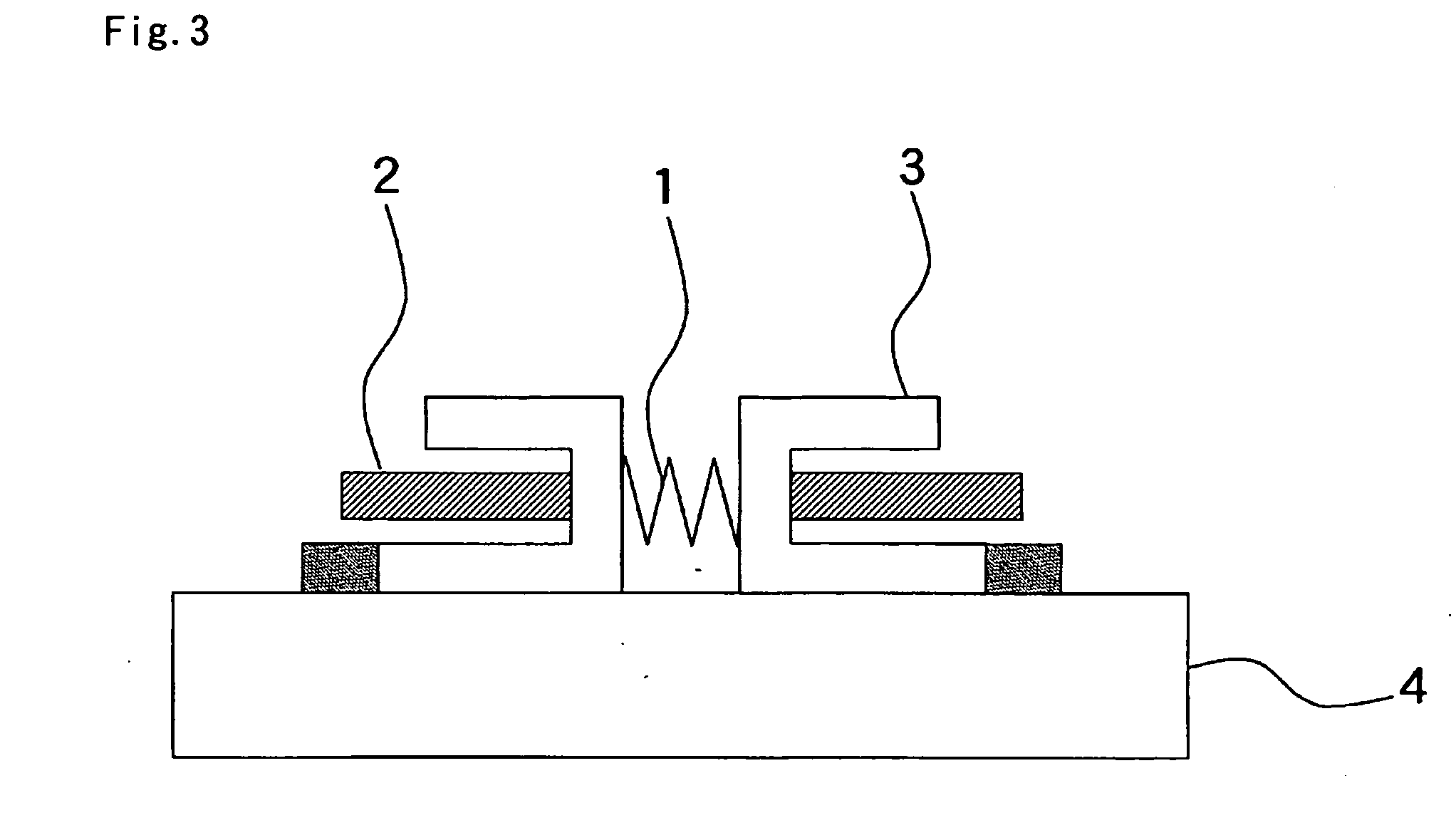

InactiveUS20060194137A1Lower resistanceIncreased operating lifeDevelopersElectrical resistance and conductanceProject area

It is contemplated to provide irregular shaped ferrite carrier which has a lower resistance, a high specific surface area, a low specific gravity and a longer operational life, and an electrophotographic developer comprising the ferrite carrier which prevents the toner scattering, has a high image density, and is responsive to high-speed and color imaging. The irregular shaped ferrite carrier is characterized in that the carrier particles are irregular shaped, and 40 percent by number or more of the particles have a rock candy sugar shape and / or an oyster shell shape, and that the shape factor (SF-1=R2 / S×π / 4×100, wherein R is a maximum length and S is a projected area.) is 140 to 250, and the distribution width (δ) is 60 or less.

Owner:POWDERTECH

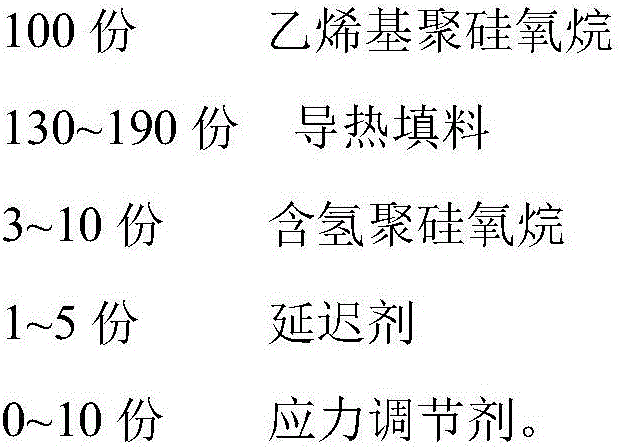

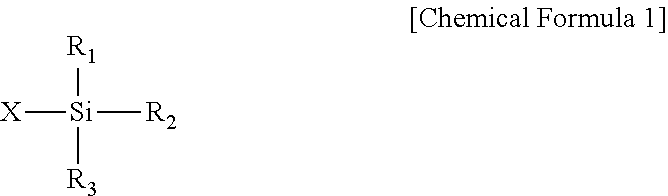

New energy organosilicone pouring sealant with high thermal conductivity and low specific gravity

PendingCN106833510ALow specific gravityEasy to operateNon-macromolecular adhesive additivesHeat-exchange elementsFiberNew energy

The invention discloses a new energy organosilicone pouring sealant with high thermal conductivity and low specific gravity. The new energy organosilicone pouring sealant comprises (A) linear or branched chain polysiloxane of at least two vinyl bonded silicon atoms or mixture thereof; (B) at least two silicon-hydrogen bonded polysiloxane, at least one epoxy group and at least one alkoxy; (C) an addition reaction catalyst; and (D) a thermal-conducting filler treated through a special process, specifically, a compound filler of graphene, a short carbon fiber, silica powder, aluminium hydroxide, a spherical magnesium oxide and spherical boron nitride. The thermal conductivity is greater than or equal to 0.95W / m.K and the specific gravity is smaller than or equal to 1.6g / ml.

Owner:宁波聚力新材料科技有限公司

Non-alkali glass substrate

The present invention relates to a non-alkali glass substrate, having a strain point of 685° C. or higher and 750° C. or lower, an average thermal expansion coefficient at 50 to 350° C. of from 35×10−7 to 43×10−7 / ° C., a specific gravity of from 2.50 to 2.80, a photoelastic constant of 25 nm / MPa / cm or more and less than 29 nm / MPa / cm, and a temperature (T4) at which viscosity reaches 104 dPa·s of 1,250° C. or higher and lower than 1,350° C., and having a prescribed composition.

Owner:ASAHI GLASS CO LTD

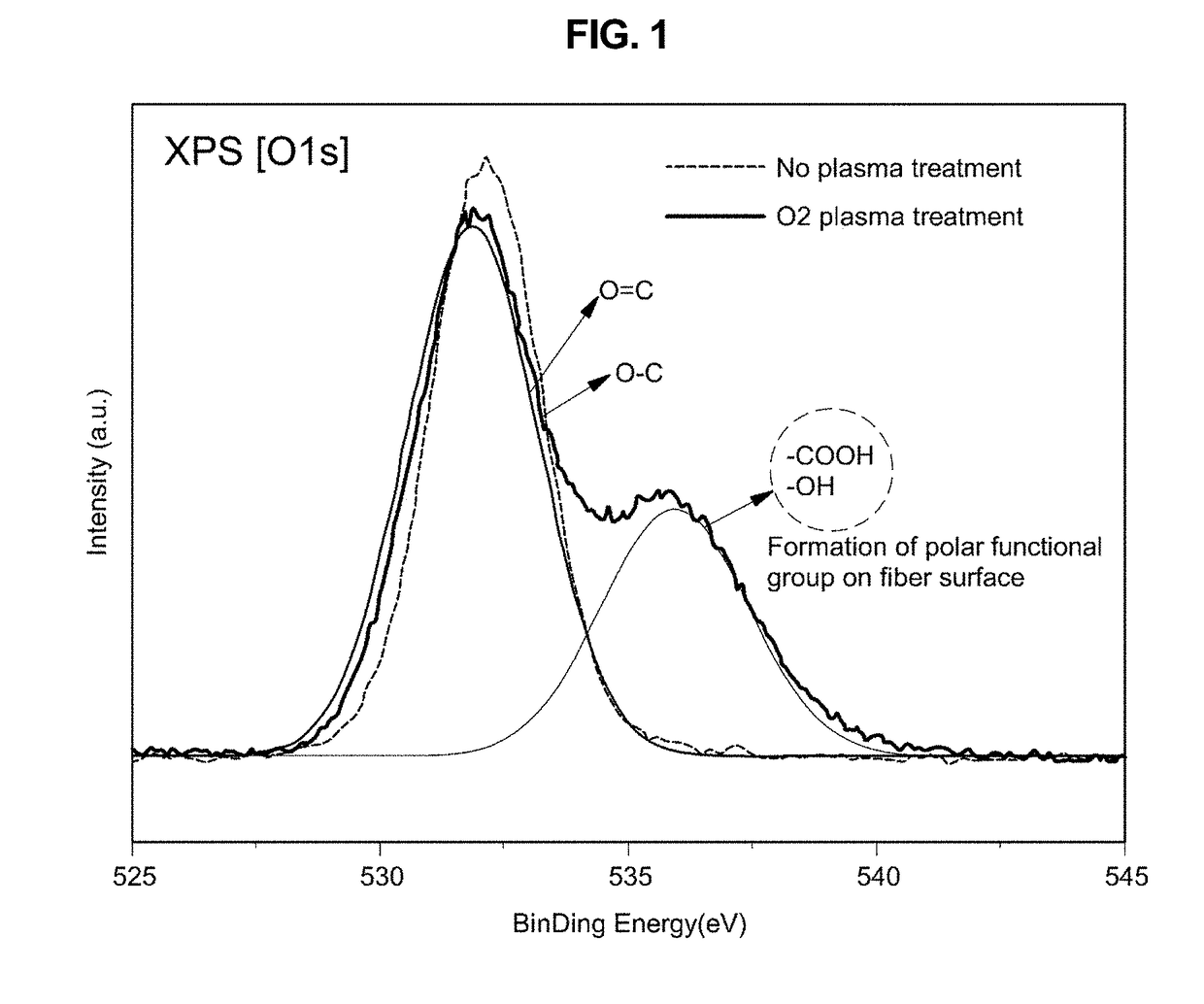

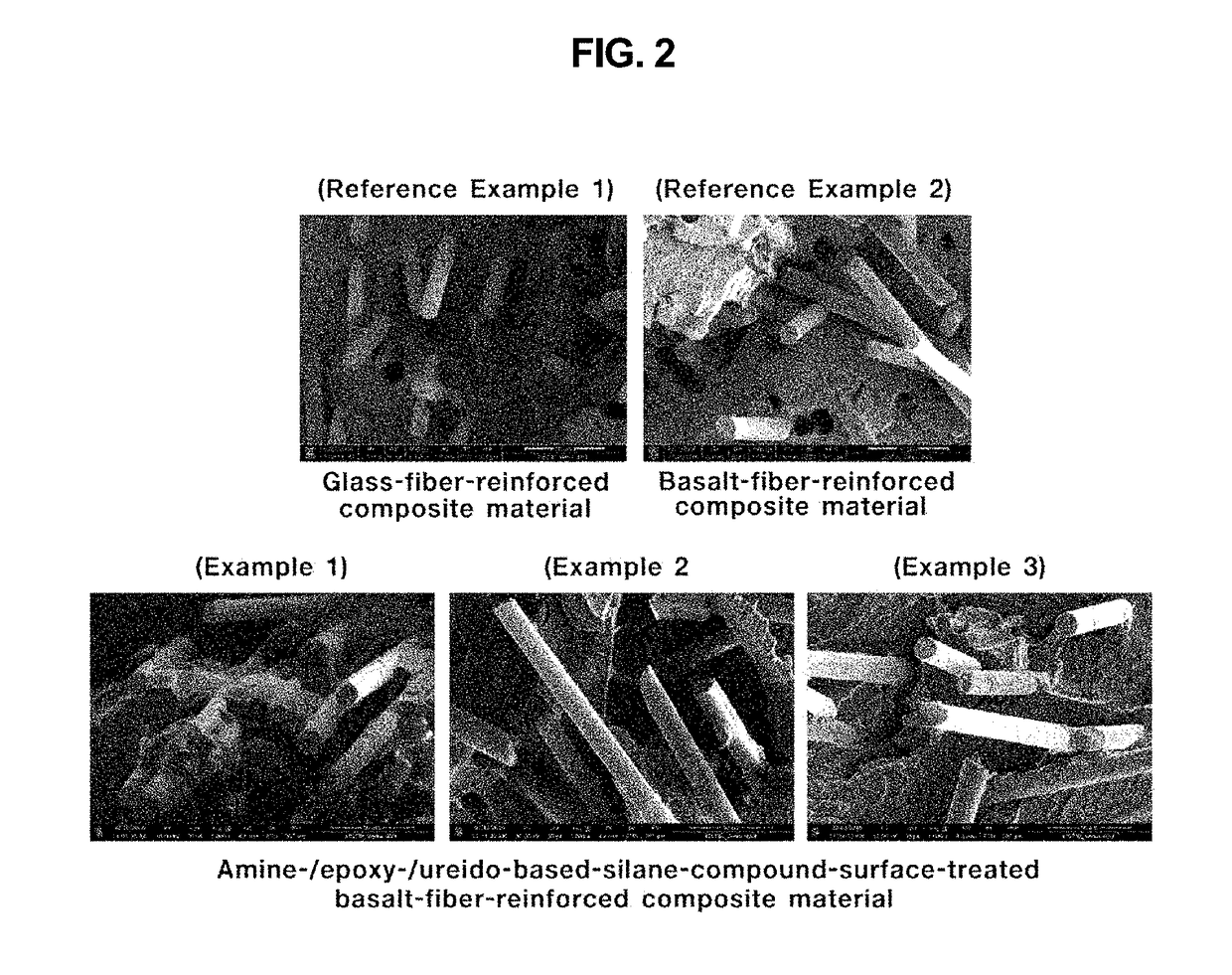

Basalt-fiber-reinforced thermoplastic composite material and method of manufacturing the same

Owner:HYUNDAI MOTOR CO LTD +2

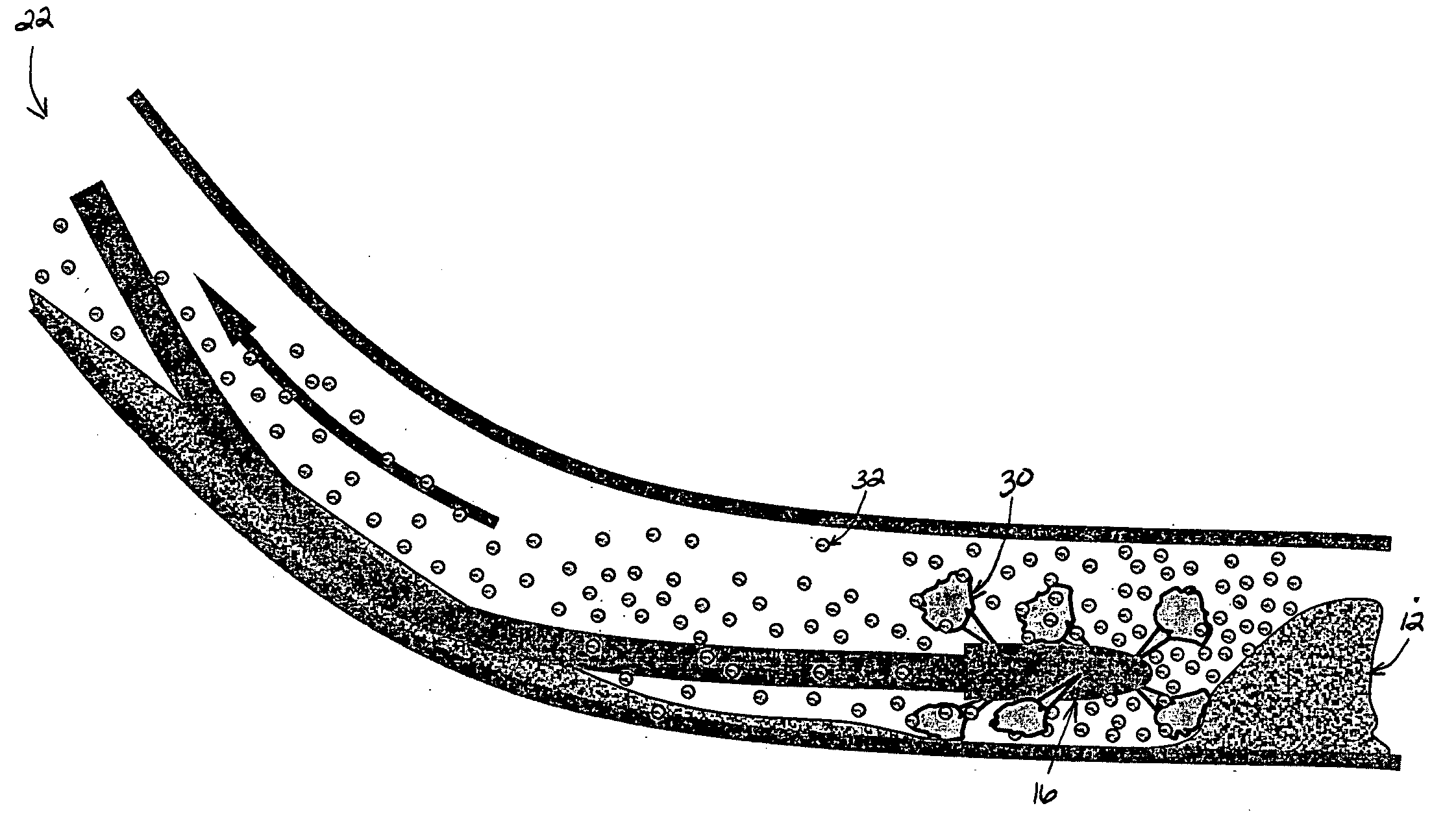

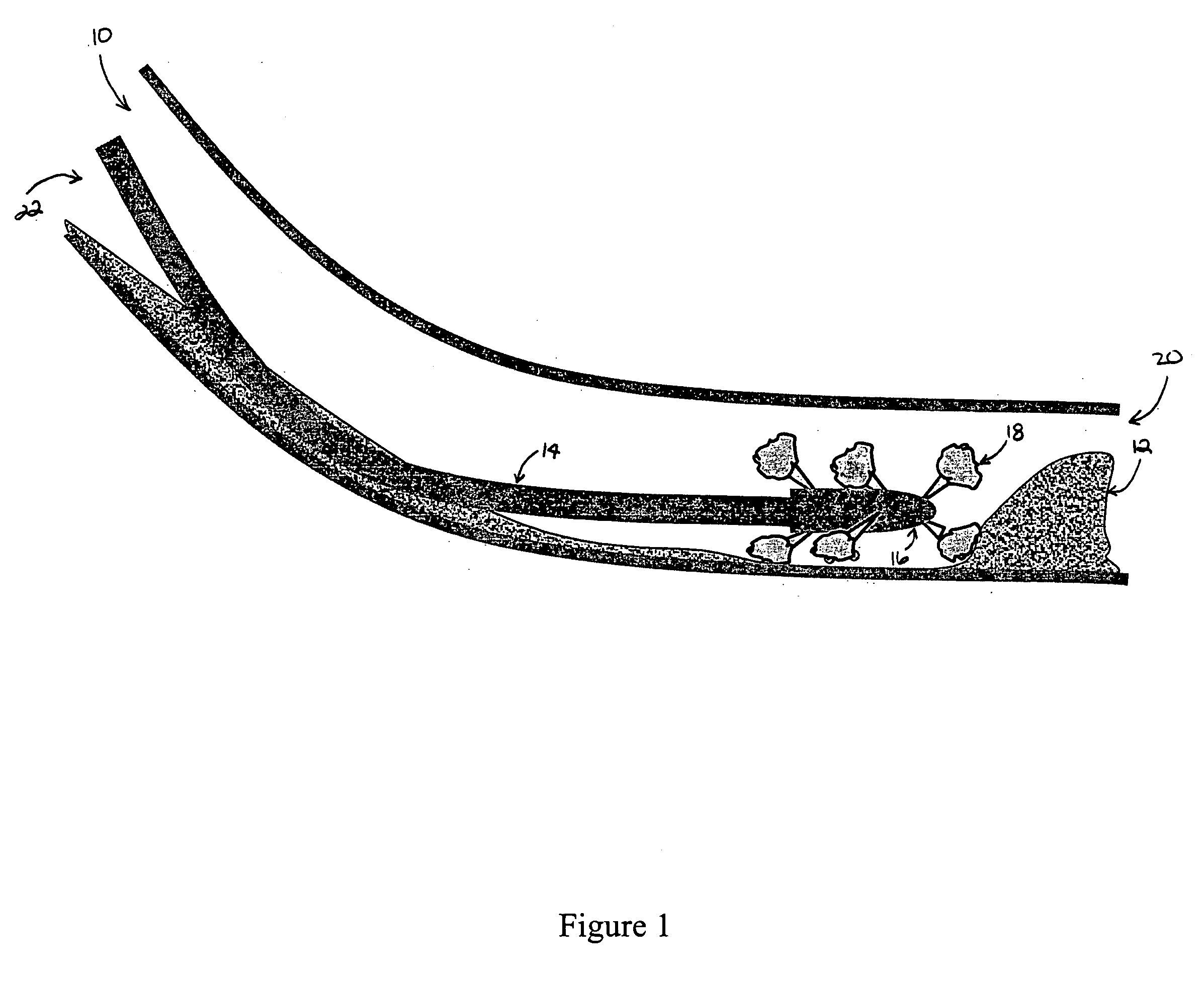

Gel capsules for solids entrainment

The present invention is a method for treating a subterranean wellbore. More specifically, the invention is a method for removing wellbore solids. A first, polymer containing fluid is placed in the solids bed. A second, viscosifying fluid is then placed into the solids bed thereby agitating the solids in the bed and causing the formation of a gel capsules when mixed with the biopolymer fluid. These gel capsules are capable of trapping or entraining the agitated solids. The gel capsules typically have a relatively high volume and a relatively low density, thereby making their removal from the wellbore easier.

Owner:SCHLUMBERGER TECH CORP

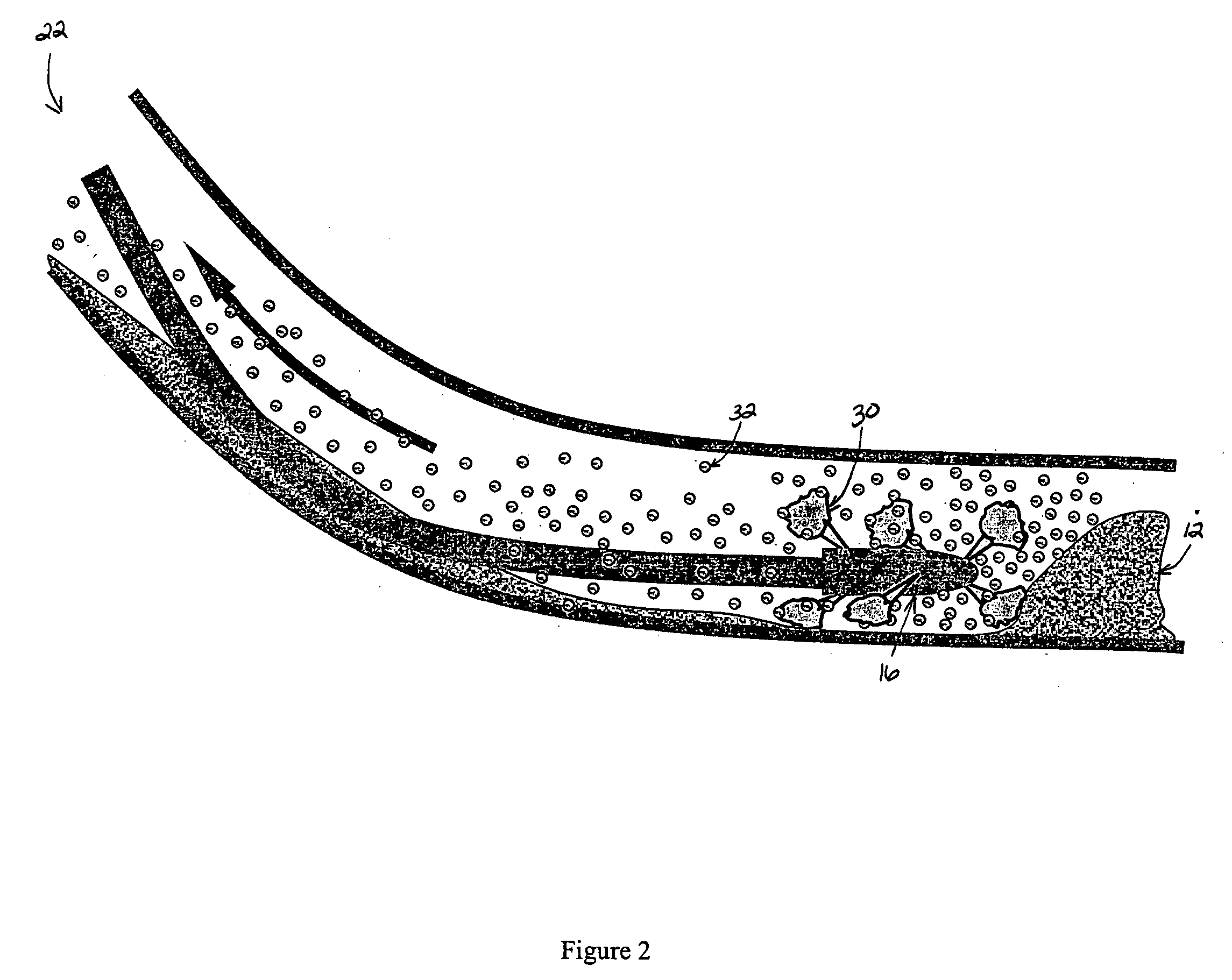

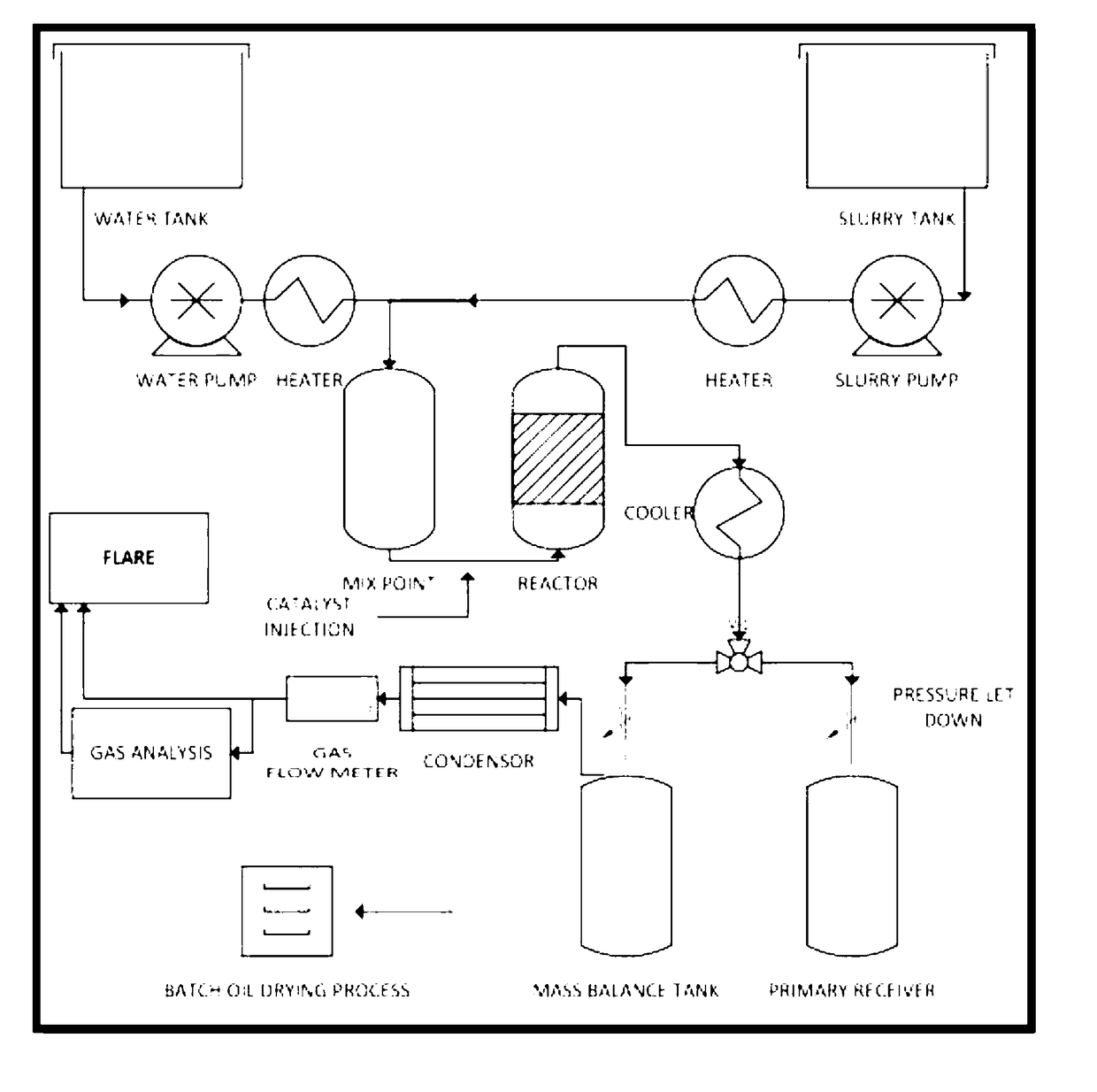

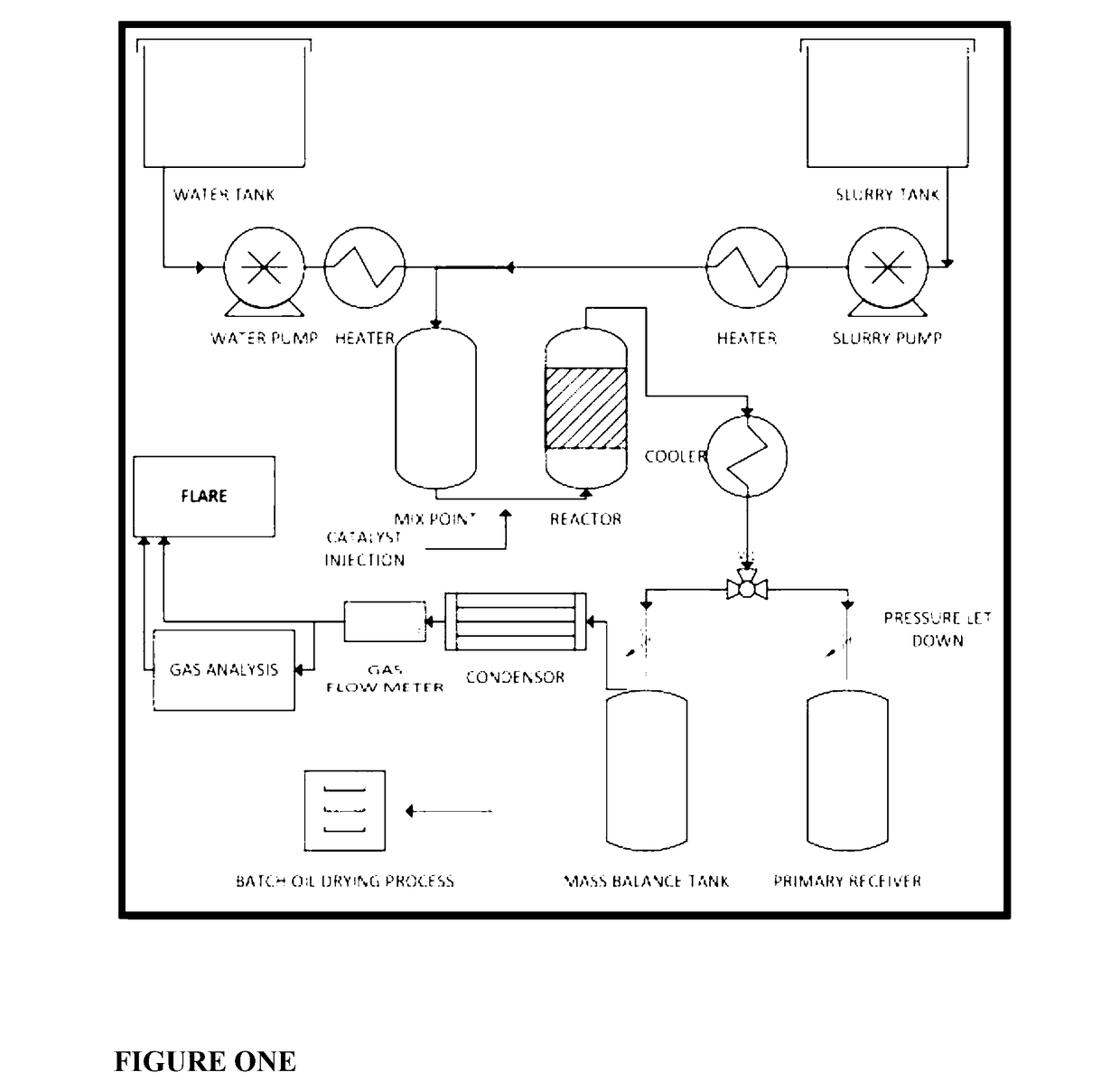

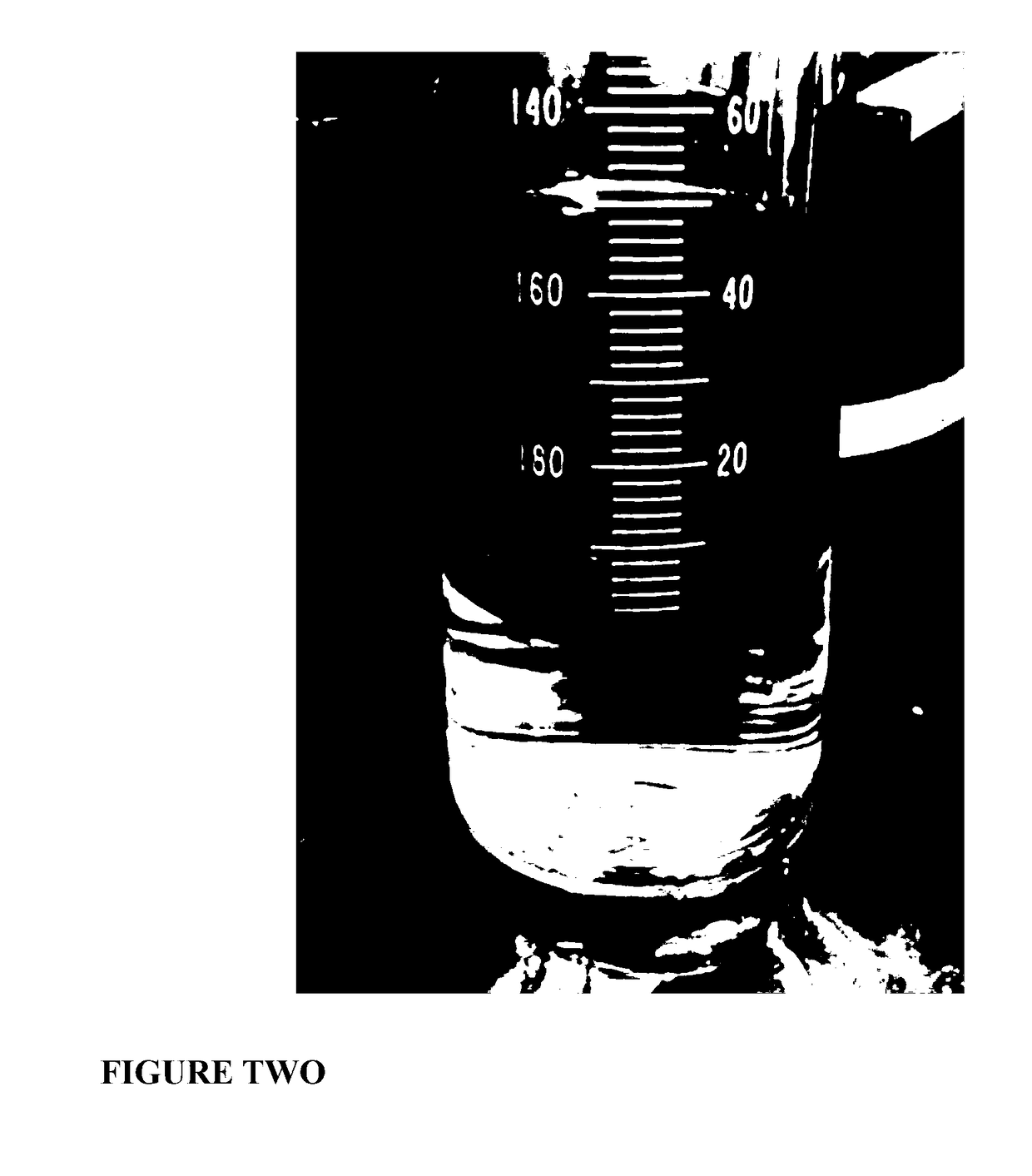

Upgrading residues, heavy oils and plastics

InactiveUS20180245001A1Reduce viscosityLow specific gravityThermal non-catalytic crackingTreatment with plural serial stages onlySolventChemistry

The present invention relates to upgrading heavy petroleum oils, their residues, and / or polymeric materials. More specifically the present invention relates to a method for upgrading heavy petroleum oils, their residues, and / or polymeric materials by hydrothermal treatment with an aqueous solvent.

Owner:IGNITE ENERGY RESOURCES LTD

Automotive lamp extension molding

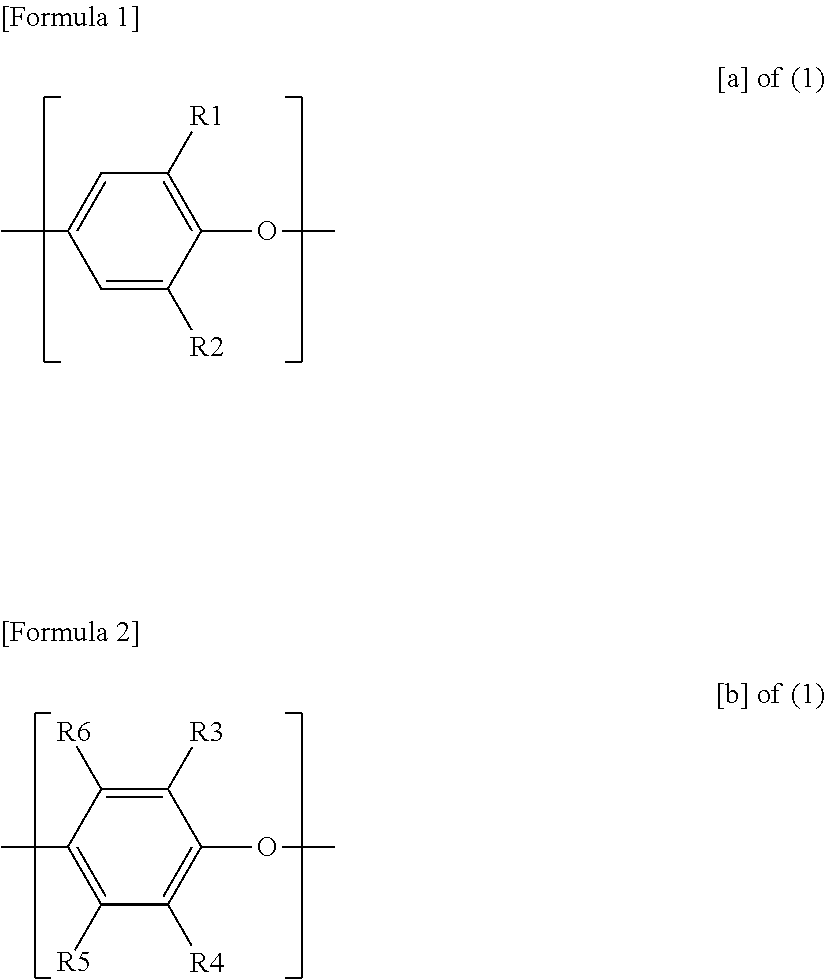

ActiveUS20130267641A1Low specific gravityGood balance of heat resistance and fluidityVehicle headlampsLighting and heating apparatusSpecific gravitySolvent

[Problem to be Solved] The present invention has an object to provide an automotive lamp extension molding comprising a resin composition having a low specific gravity, being excellent in the balance of heat resistance and fluidity, and being excellent in gloss and brightness feeling of the surface of the molded article.[Solution] The automotive lamp extension molding according to the present invention comprises a resin composition comprising 50 to 95 mass % of a polyphenylene ether (A), and having a specific gravity in the range of 1.00 to 1.12. The reduced viscosity (measured at 30° C. using a chloroform solvent) of the (A) component is preferably 0.25 to 0.45 dl / g, and more preferably 0.25 to 0.38 dl / g.

Owner:ASAHI KASEI CHEM CORP

Cement blend

InactiveUS20090283017A1Desirable and improved and strengthBroaden applicationDrilling compositionSealing/packingSilicon dioxideMaterials science

A cement blend includes a cement mixture and a permeable, micro-cluster silica material present in an amount from about 10 percent to about 30 percent by weight of the cement mixture. The cement blend may be used in casing a borehole when appropriate fluid loss agents are included in the cement blend. Additionally, a cement additive is added to a cement mixture to provide the cement blend. This cement additive can be formulated in a kit form.

Owner:CATALYST PARTNERS

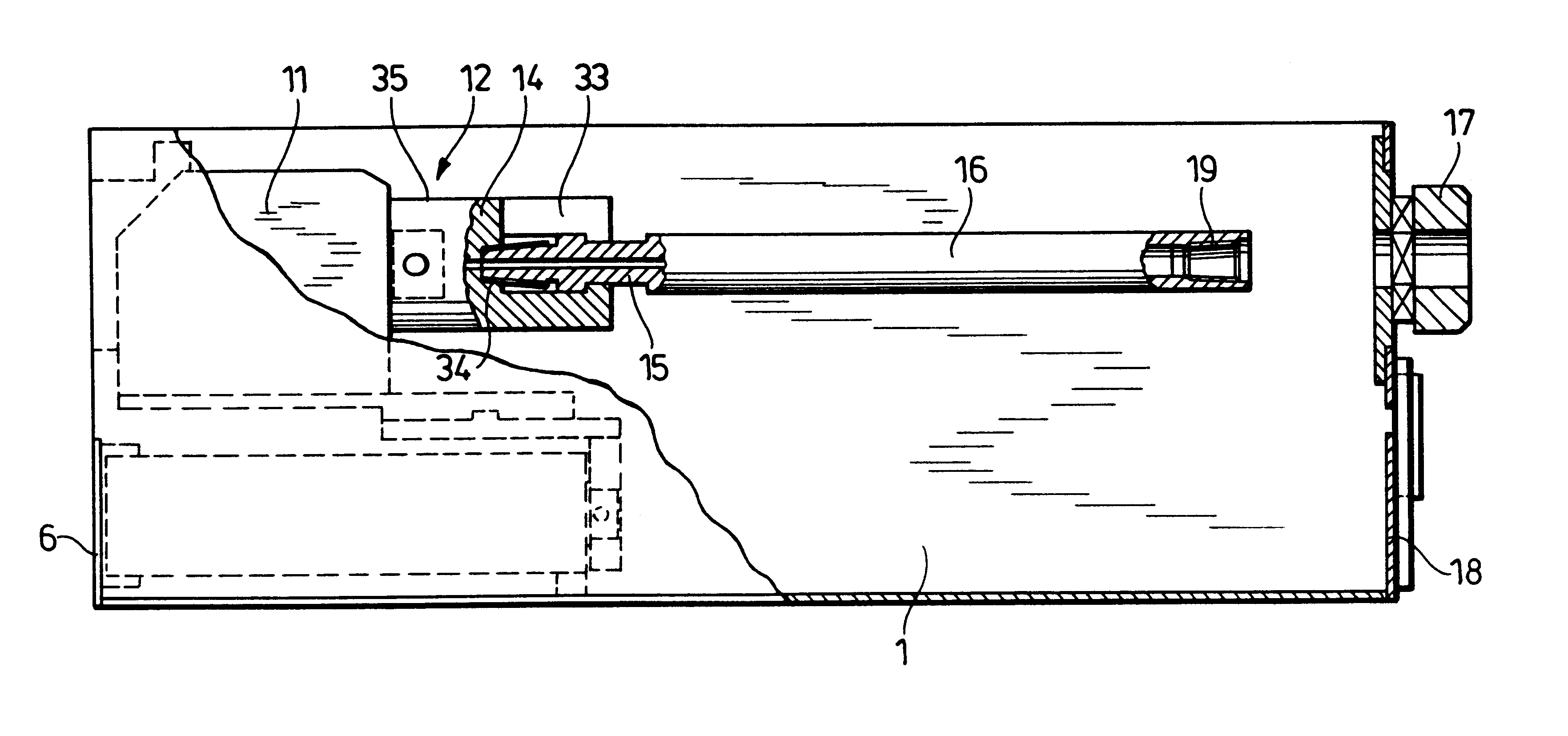

Boring apparatus with coupling for rapid connection of drill string segments

InactiveUS6267187B1Reduced cross sectionLow specific gravityDrilling rodsConstructionsCouplingFeed drive

In apparatus for producing and expanding earth boreholes and for destroying and replacing underground pipelines or for driving in pipes, a feed drive and a rotary drive having a plug-in coupling comprising a chuck and a locking portion at the end of a string is located in a frame. The string comprises a plurality of sections or lengths having an internal screw thread at one end and an external screw thread on the locking portion at the other end, which at the same time is provided with a key face to hold fast said string section while it is screwed together with the next following string section.

Owner:TRACTO TECHN PAUL SCHMIDT SPEZIALMASCHEN

Glass substrate and its production process

InactiveUS20110251044A1Low specific gravityImprove productivityCathode-ray/electron-beam tube vessels/containersGas discharge vessels/containersProduction rateThermal expansion

To provide a glass substrate which has a high glass transition temperature, which has a thermal expansion coefficient close to that of soda lime glass, which has a low specific gravity, which will hardly undergo yellowing, and which further has good melting characters and is thereby produced with high productivity.A glass substrate which has a composition comprising, as represented by mass percentage based on oxides,SiO2 55 to 65%, Al2 O3 4 to 8%, MgO 6 to 9%, CaO 0.1 to 5%, SrO 0.5 to 6%, BaO 0 to 2%, MgO + CaO + SrO + BaO 6.6 to 19%, Na2 O 0 to 5%, K2 O 9.5 to 21%, Na2 O + K2 O 10 to 22%, ZrO2 0.5 to 5%, Fe2 O30.06 to 0.15%,which has a specific gravity of at most 2.7, which has an average thermal expansion coefficient from 50 to 350° C. of from 80×10−7 / ° C. to 90×107 / ° C., which has a glass transition temperature of at least 640° C., and wherein when the viscosity is η, the temperature at which log η=2 is satisfied is at most 1,550° C., and the yellow coloring b* on the glass surface is at most 8.

Owner:ASAHI GLASS CO LTD

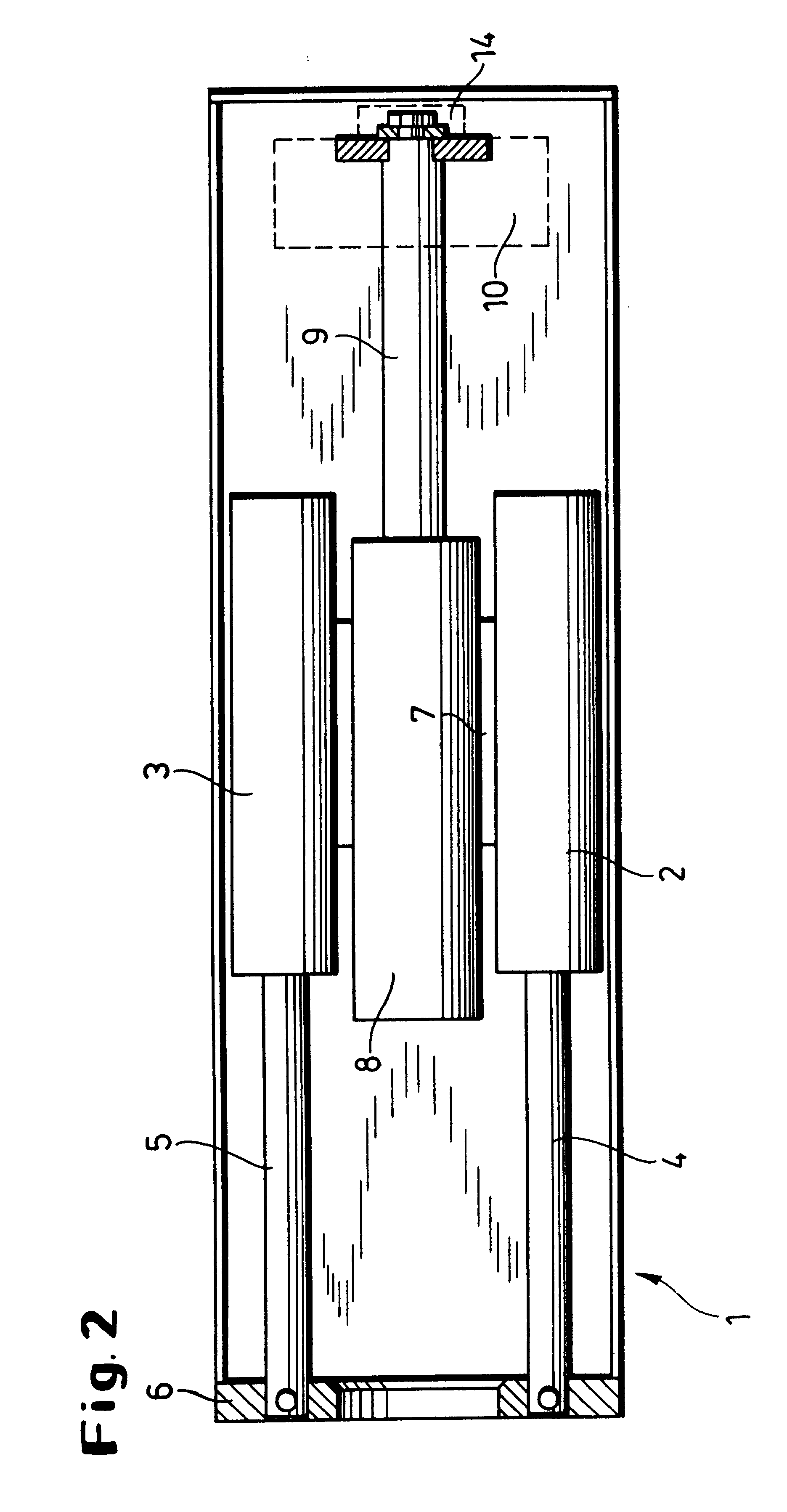

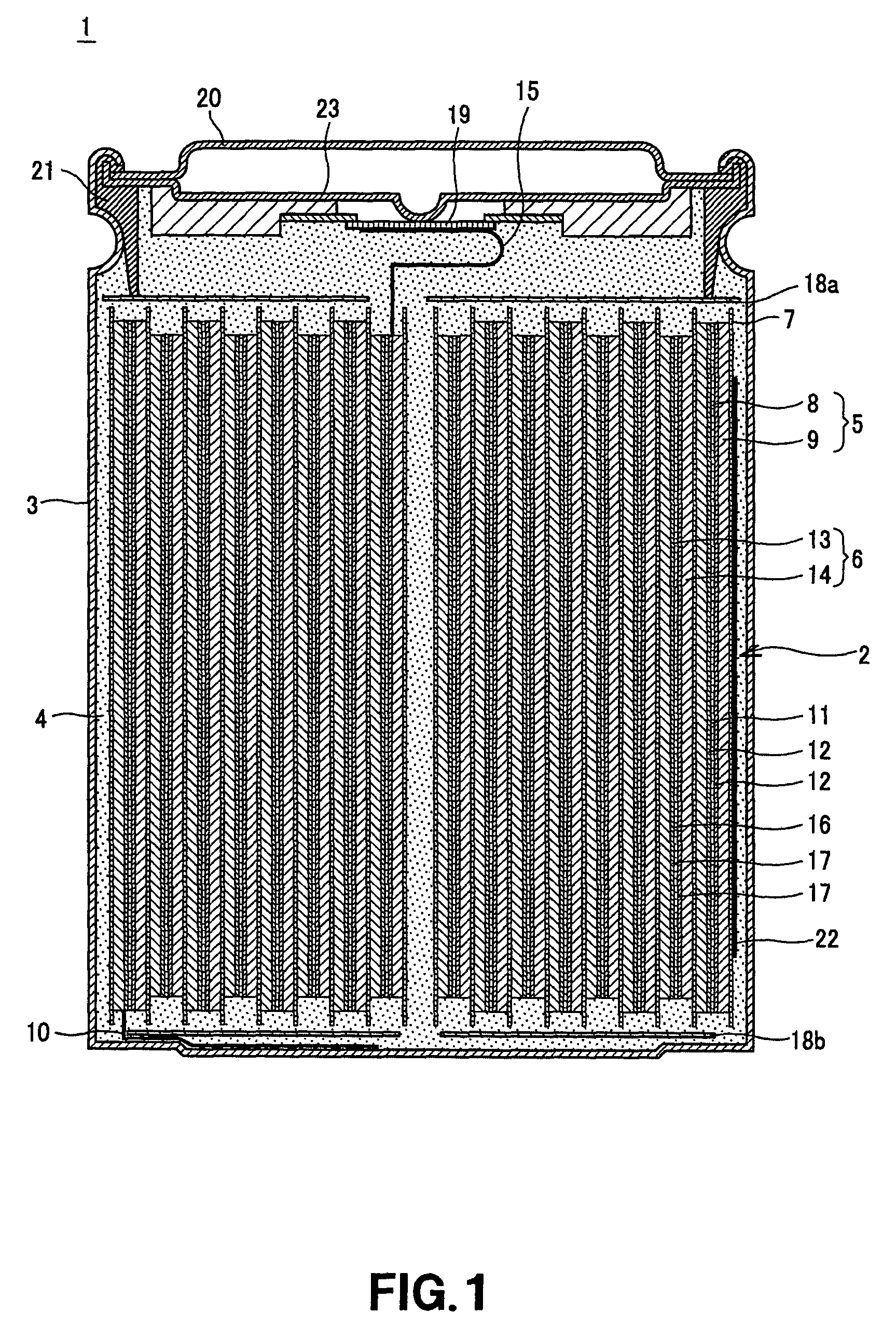

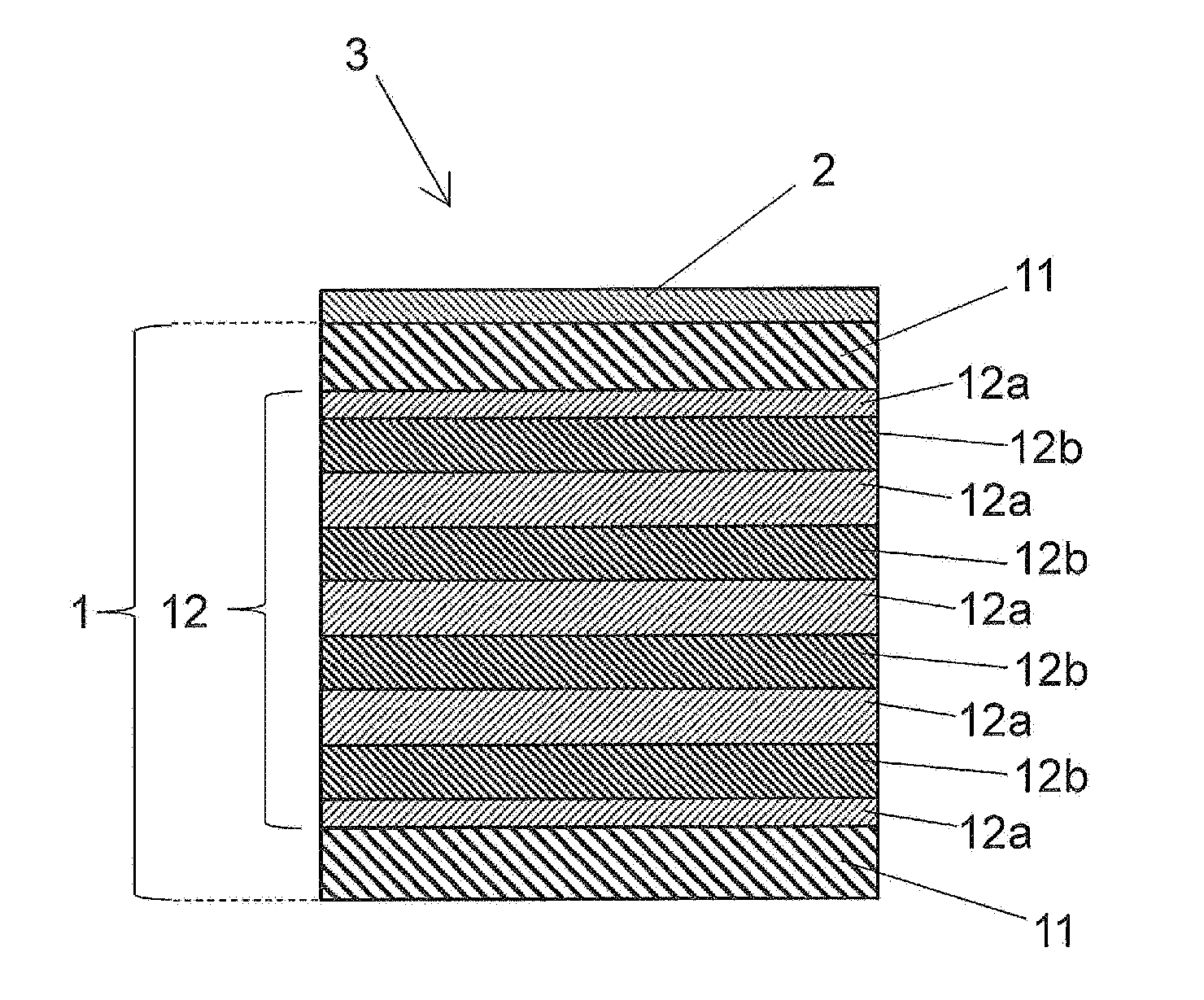

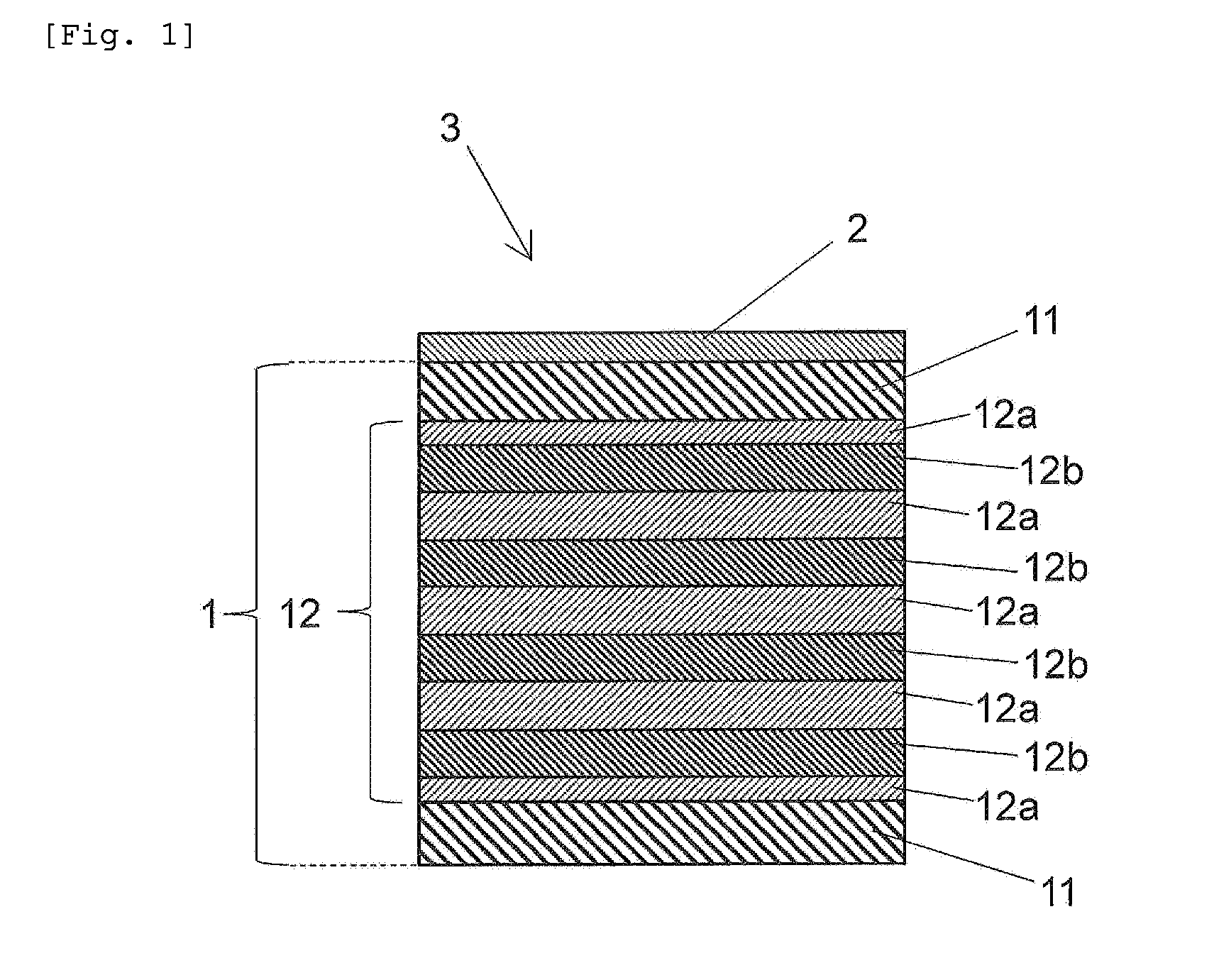

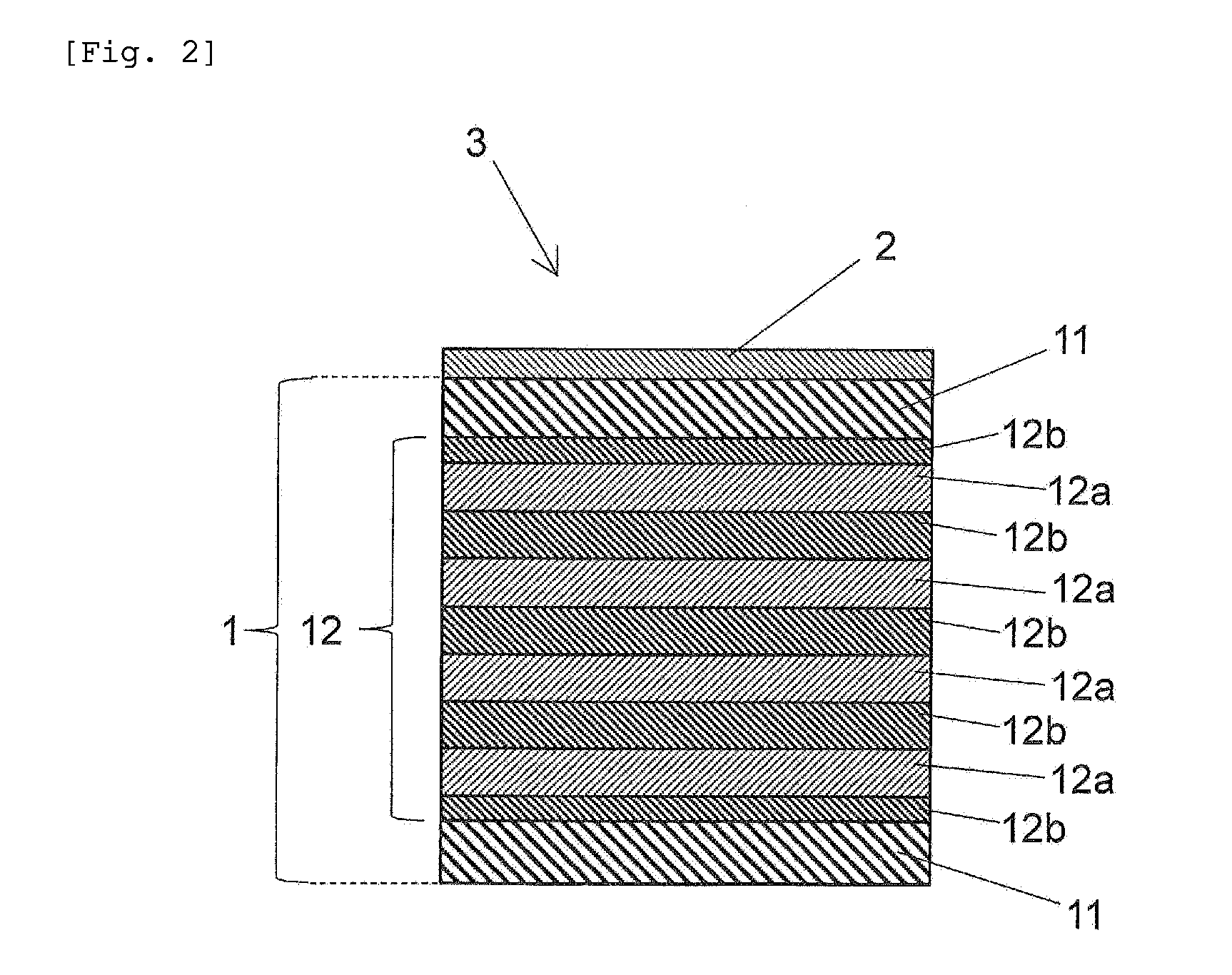

Battery

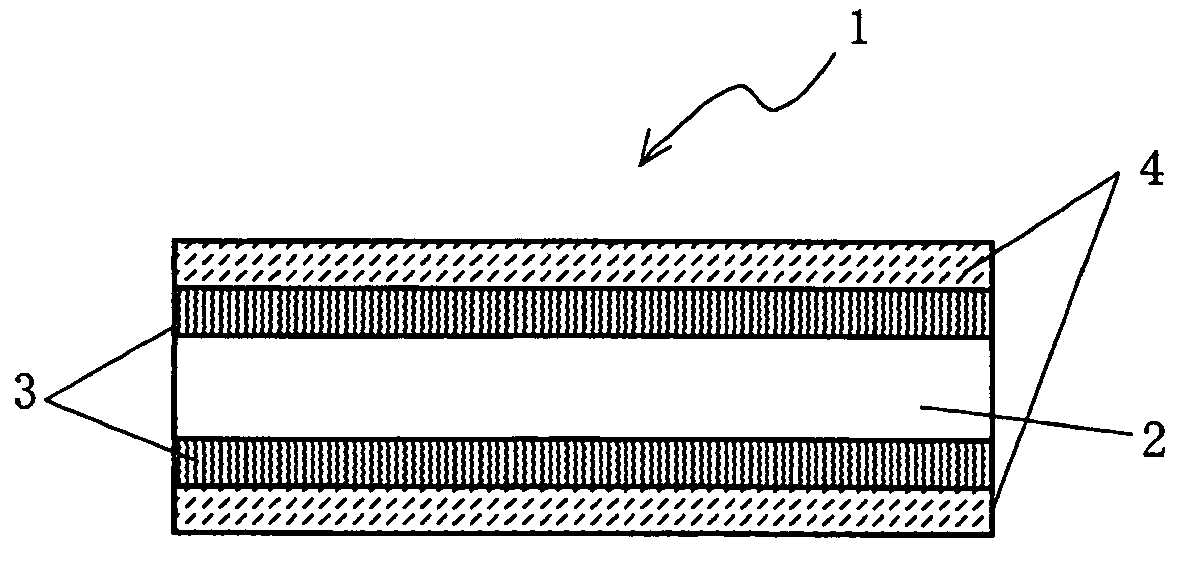

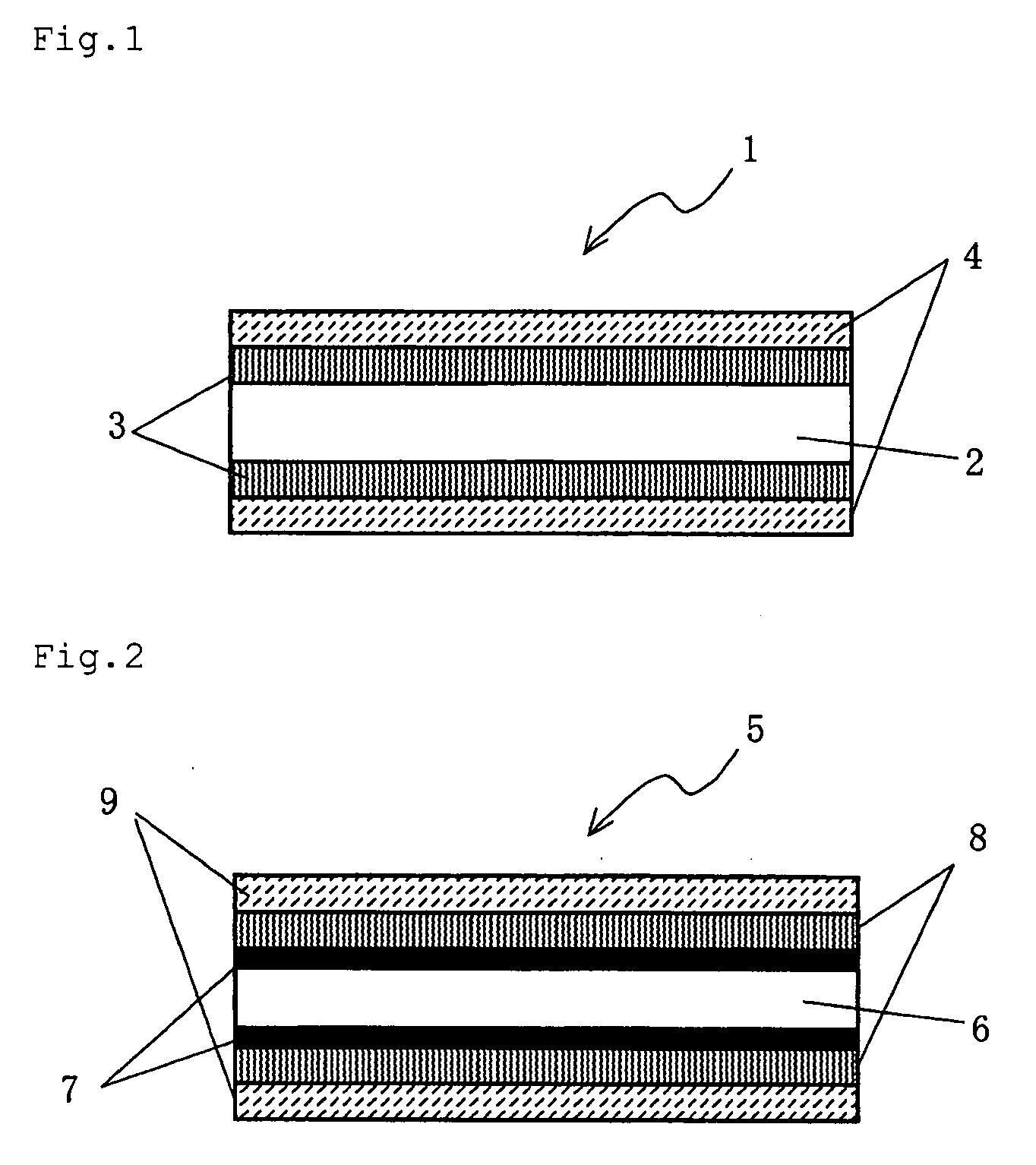

InactiveUS7217476B2Reduce weightAccurate specific gravityNon-aqueous electrolyte accumulatorsFinal product manufactureHigh energyElectron

Disclosed is a battery with a light weight and a high energy density. The battery includes a anode 5, having a layer of an anode active material 9 formed on an anode substrate 8, a cathode 6, including a layer of a cathode active material 14 formed on a cathode substrate 13, and a non-aqueous liquid electrolyte 4. The anode substrate 8 includes an anode resin film 11 containing a polymer and an anode metal layer 12 containing an electrically conductive metal. Since the anode resin film 11 reduces the weight of the anode substrate 8 and the anode metal layer 12 imparts electron conductivity to the anode substrate 8, the battery may be reduced in weight without detracting from battery characteristics to increase the energy density.

Owner:SONY CORP

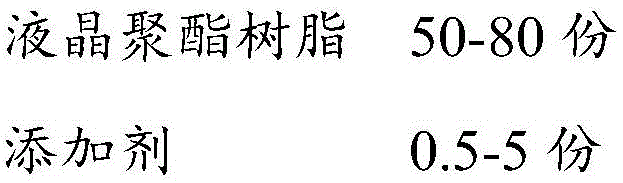

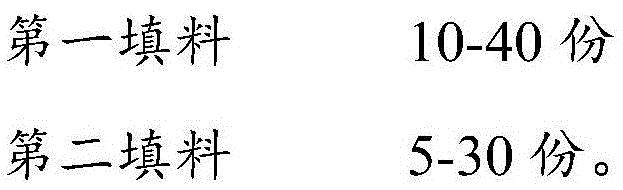

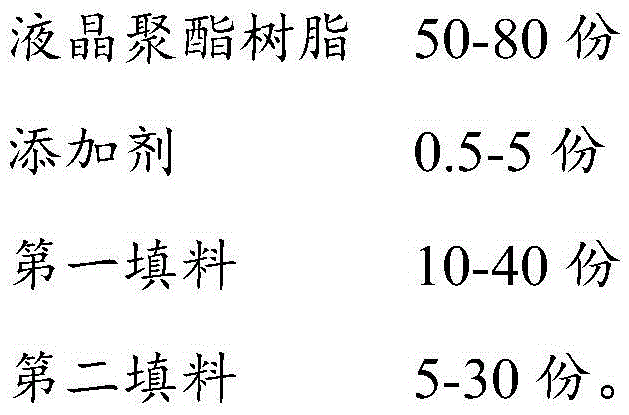

Light liquid crystal polyester resin compound and preparation method thereof

The invention discloses a liquid crystal polyester resin compound and a preparation methodthereof. The liquid crystal polyester resin compound disclosed by the invention is prepared from the following components in parts by weight: 50 to 80 parts of liquid crystal polyester resin, 0.5 to 5 parts of additive, 10 to 40 parts of a first filler, and 5 to 30 parts of a second filler. The liquid crystal polyester resin compound disclosed by the invention is low in specific weight, and excellent in mechanical property, heat resisting property and machinability. The preparation method comprises the steps of firstly mixing the liquid crystal polyester resin, the additive, the first filler and the second filler, and secondly performing fusion and extrusion treatments. The preparation method can effectively ensure the property stability of the prepared liquid crystal polyester resin compound; meanwhile, the preparation method is mature in process, simple and controllable, and easy to realize industrialization.

Owner:JIANGSU WATER SPECIAL MATERIAL MFG CO LTD

Glass substrate and its production process

This invention relates to a glass substrate having a high glass transition temperature, a thermal expansion coefficient near that of soda-lime glass, and a low specific gravity, which is not prone to yellowing, and which also has good solubility and high productivity. The glass substrate has a composition in mass % in terms of oxide amount which is SiO2: 55-65%, Al2O3: 4-8%, MgO: 6-9%, CaO: 0.1-5%, SrO: 0.5-6%, BaO: 0-2%, MgO+CaO+SrO+BaO: 6.6-19%, Na2O: 0-5%, K2O: 9.5-21%, Na2O+K2O: 10-22%, ZrO2: 0.5-5%, and Fe2O3: 0.06-0.15%, has a specific gravity of 2.7 or less, an average thermal expansion coefficient at 50-350° C. of 80×10−7 / ° C. to 90×10−7 / ° C., and a glass transition temperature of at least 640° C., wherein, defining η as viscosity, the temperature satisfying log η=2 is at most 1550° C., and the yellow coloring b* of the glass surface is at most 8.

Owner:ASAHI GLASS CO LTD

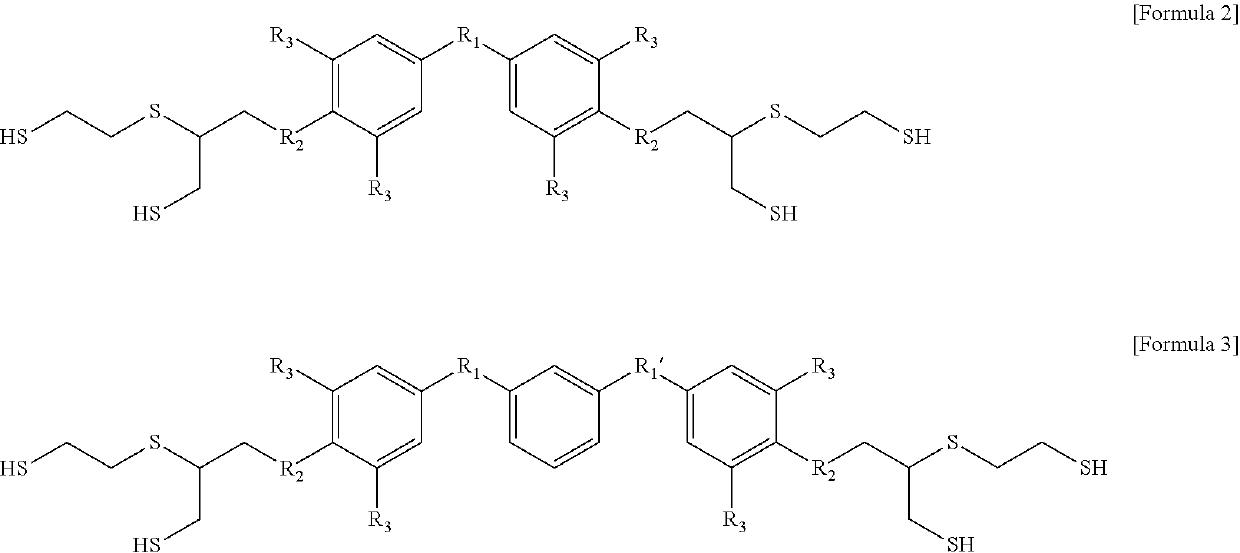

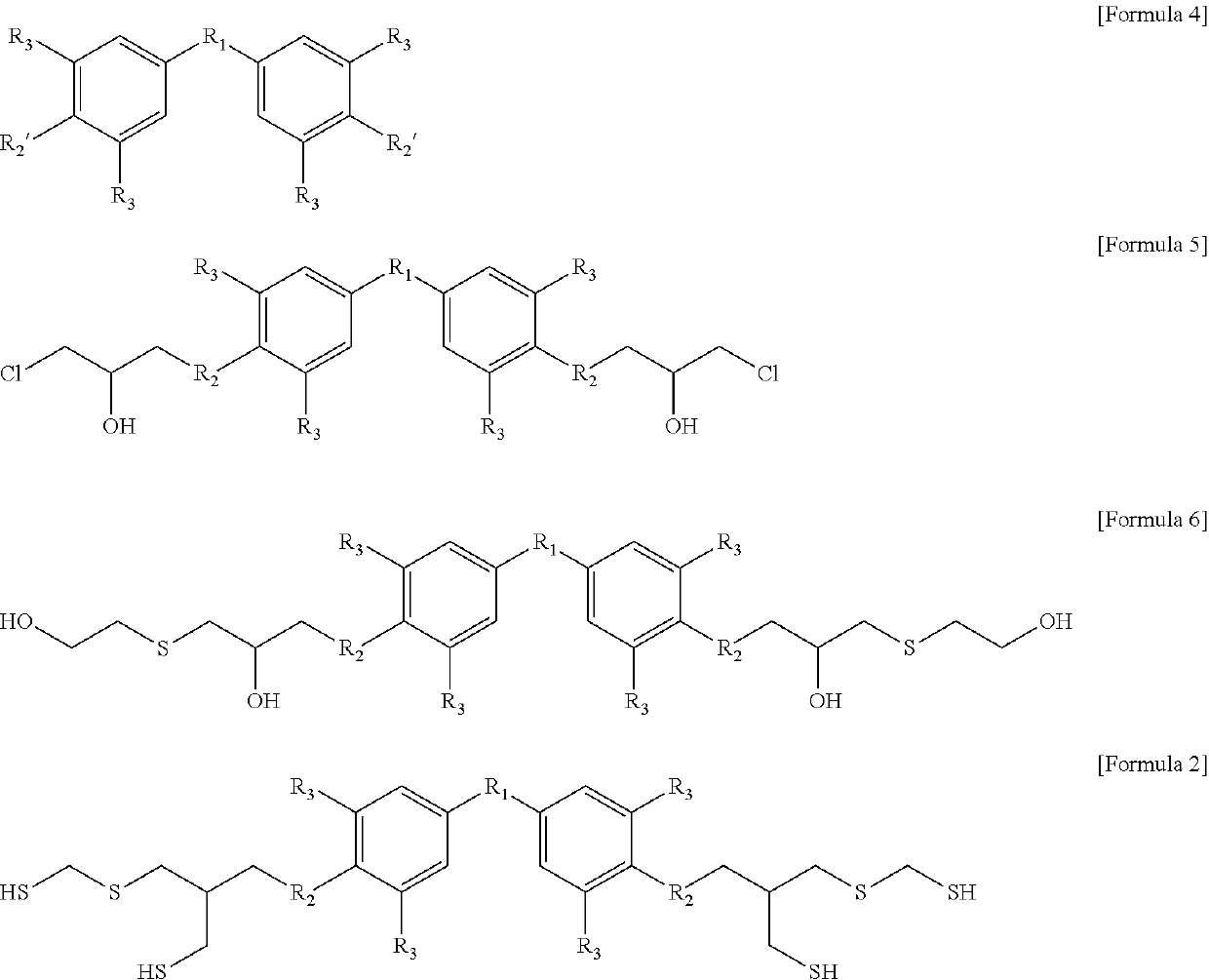

Aromatic polythiol compound for optical material

ActiveUS20190292144A1Improve mechanical propertiesHigh refractive indexThiol preparationProjector focusing arrangementOptical propertyEyeglass lenses

An embodiment relates to an aromatic polythiol compound for optical materials, and the aromatic polythiol compound according to the embodiment contains a phenyl group and a large number of sulfur atoms in its polythiol structure so that a polymerizable composition and an optical material obtained therefrom have excellent optical properties such as high refractive index and low specific gravity, as well as excellent mechanical properties such as low cure shrinkage; thus, they can be advantageously used for producing various plastic optical lenses such as eyeglass lenses and camera lenses.

Owner:SKC CO LTD

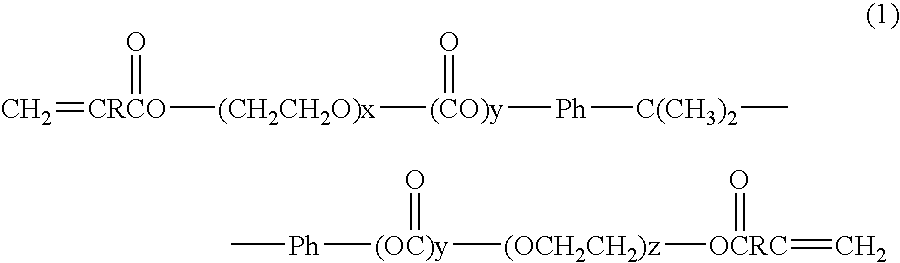

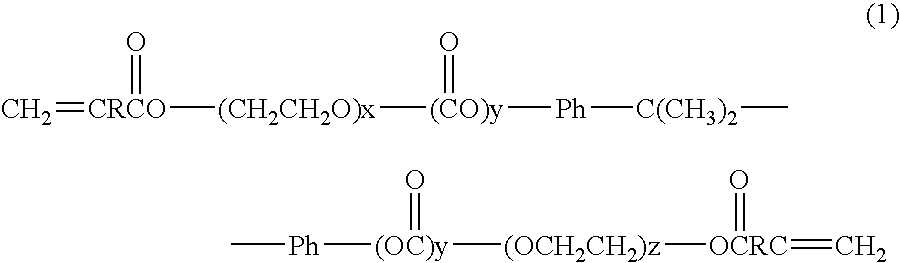

Composition for optical material, optical material and lenses

InactiveUS6852780B2Effective absorptionLow specific gravityOrganic dyesSpectral modifiersMeth-Heat resistance

Disclosed are optical materials which effectively absorb UV light up to the long wavelength band, have low specific gravity, and have balanced properties including impact and heat resistances; lenses; and optical material compositions as their starting materials. The composition contains a polymerizable monomer material consisting of at least one di(meth)acrylate of formula (1): (R: CH3 etc., Ph: a phenylene group; x, z: an integer of 1 to 5; y: 0 or 1) and at least one monomer (M) having at least one vinyl group in one molecule other than monomers of formula (1), and an additive selected from component (A1), (A2), or (B), or mixtures thereof, provided that components (A1) and / or (B) is contained, and when component (B) is contained, components (A1) and / or (A2) is also contained:(A1): a chlorinated benzotriazole UV absorber; (A2): a chlorine-free benzotriazole UV absorber; (B): a coloring agent having absorption maximum in 520-650 nm.

Owner:NOF CORP

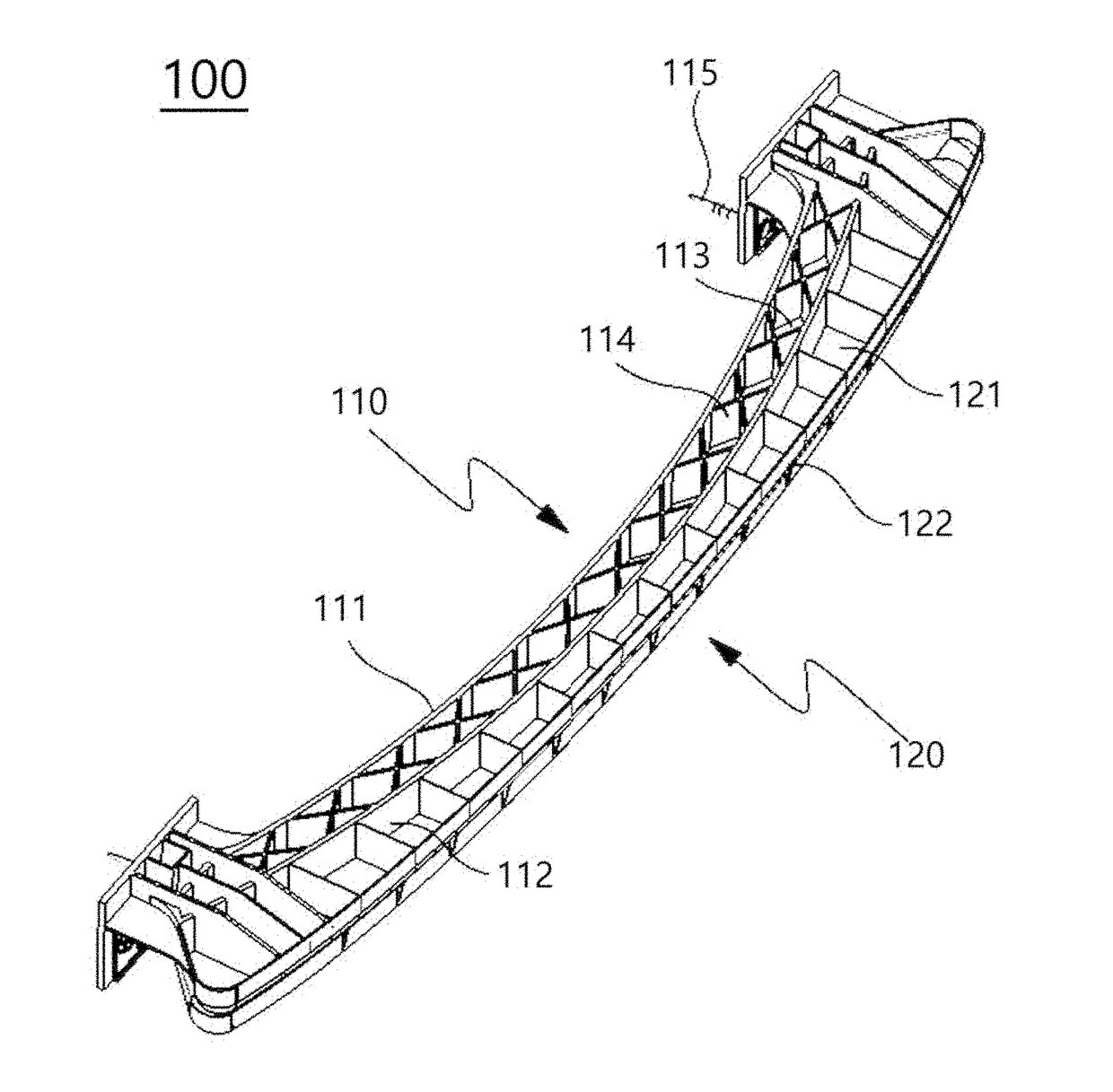

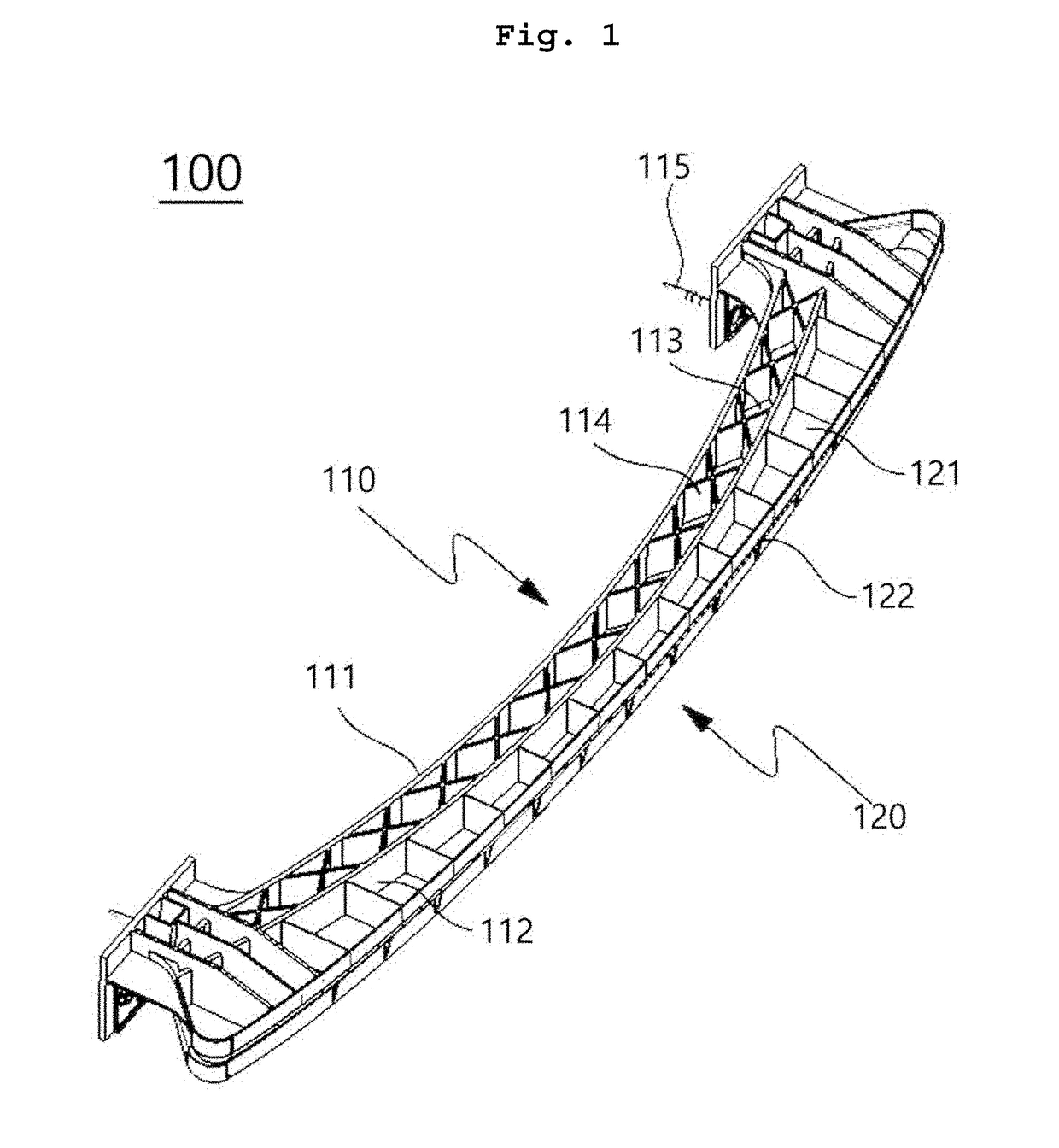

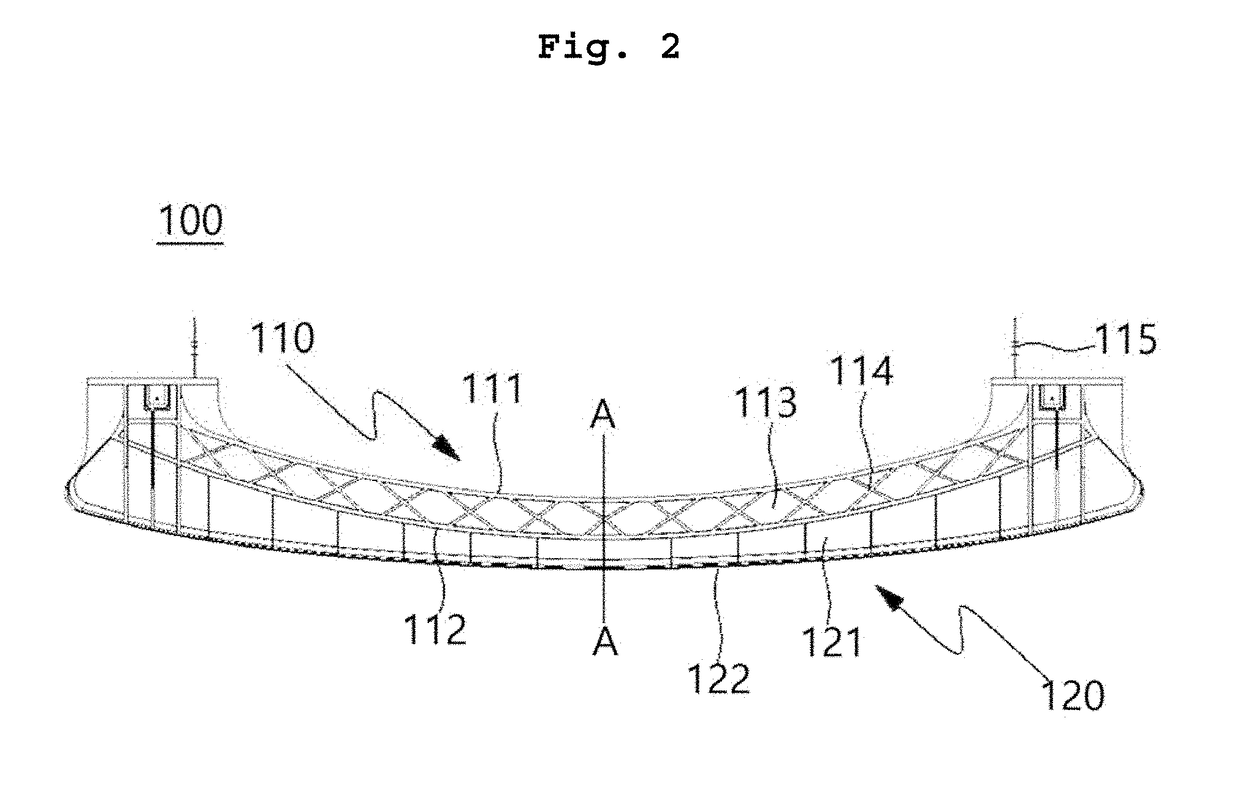

Polyolefin resin, preparation method therefor, and vehicle rear bumper beam using same

Disclosed is a polyolefin resin, a method for preparing the same, and a vehicle rear bumper beam using the same. The polyolefin resin is characterized by being composed of a thermoplastic resin composite including a polymer base including a polypropylene homopolymer, which has a molecular weight distribution of 2 to 10, and a colorant; and a fiber reinforcing material that is impregnated into the polymer base and has a length of 5 to 20 mm, wherein 10 to 50 wt % of the fiber reinforcing material is included with respect to the polyolefin resin. The method is characterized in that a thermoplastic resin composite is formed by impregnating a molten mixture including a polypropylene homopolymer, which has a molecular weight distribution of 2 to 10, and a colorant with a fiber reinforcing material having a length of 5 to 20 mm.

Owner:LOTTE CHEM CORP +1

Shrink label

InactiveUS20160368251A1Increase stiffnessResists natural contractionStampsSynthetic resin layered productsSurface layerPolyolefin

To provide an olefinic shrink label that includes an olefinic shrink film having excellent stretchability. The shrink label offers stiffness, transparency, and heat shrinkability at excellent levels and has a low specific gravity. A shrink label according to the present invention includes a shrink film. The shrink film includes a base layer part, and two surface layers disposed on or over both sides of the base layer part. The surface layers each contain an amorphous cycloolefin polymer in a content of equal to or more than 50 percent by weight. The base layer part includes 5 to 65 layers. The layers constituting the base layer part include at least one layer (resin layer (A)) that contains a polyolefin resin in a content of equal to or more than 50 percent by weight.

Owner:FUJI SEAL INTERNATIONAL INC

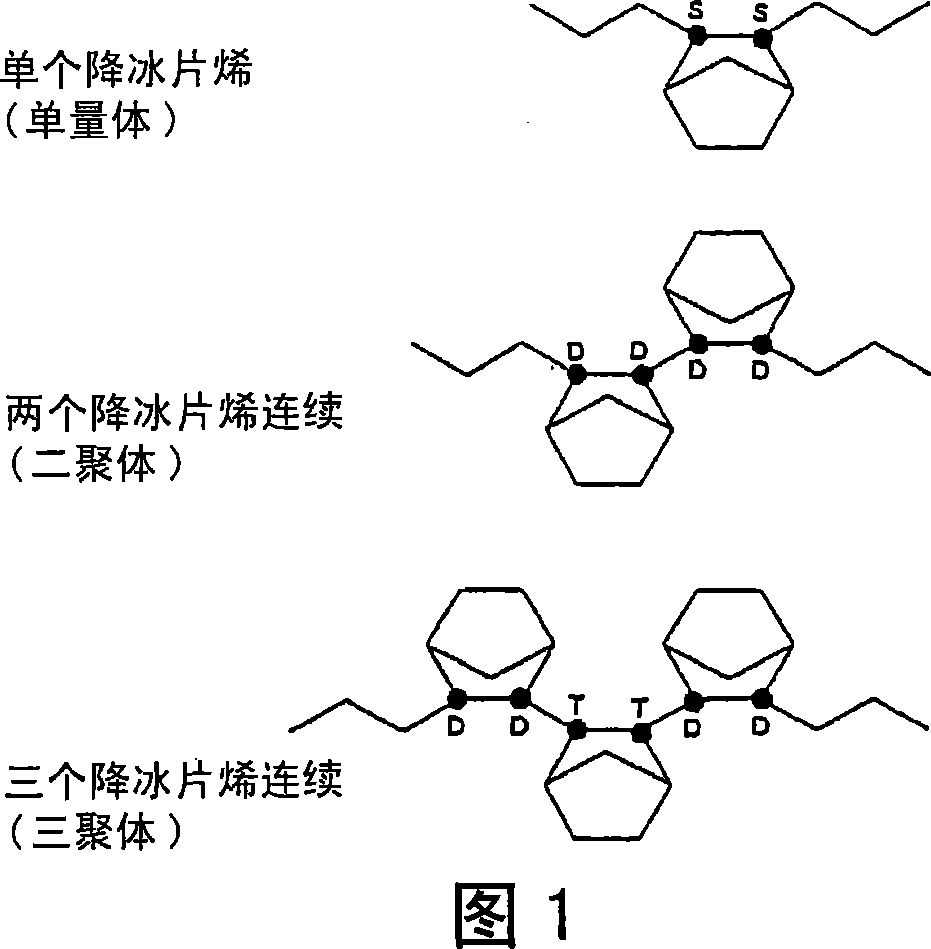

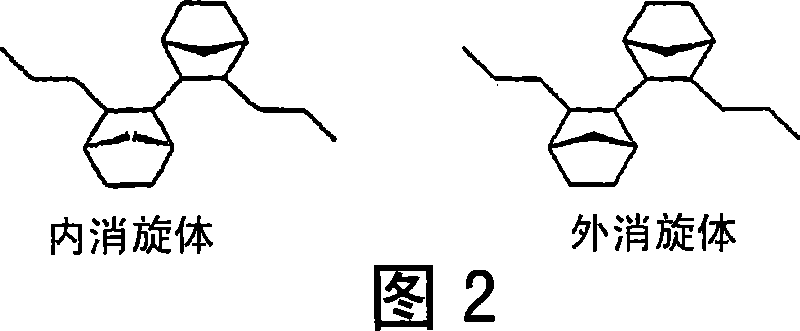

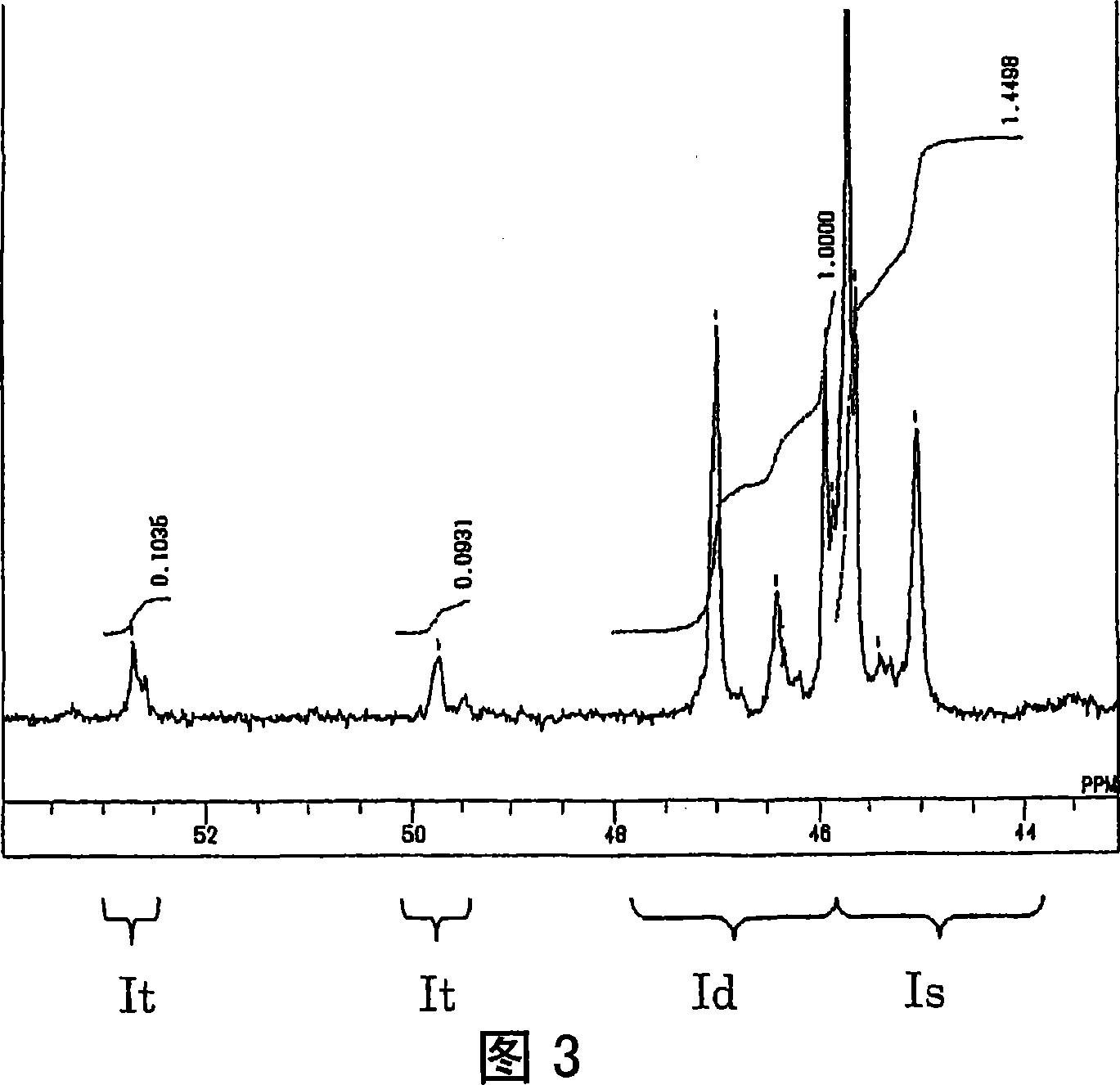

Retardation film

InactiveCN101065691ALow photoelasticityLow wavelength dispersionPolarising elementsIn planeDynamic viscoelasticity

It is excellent in heat resistance and significantly reduced in specific gravity, birefringence, photoelasticity, and wavelength dispersion. It further has the high ability to compensate for retardation. The retardation film comprises a norbornene copolymer composition containing a norbornene copolymer comprising 40-60 mol% repeating units derived from at least one norbornene monomer selected from the group consisting of a monomer represented by the general formula (I), a monomer represented by the general formula (II), a monomer represented by the general formula (III), a monomer represented by the general formula (IV), and a monomer represented by the general formula (V) and 60-40 mol% repeating units derived from an acyclic olefin monomer. When the norbornene copolymer composition is formed into a film and then stretched in a stretch ratio of 2 while being heated at the glass transition temperature determined from dynamic viscoelasticity, then the stretched film has an in-plane birefringence defined by the following equation of 0.0033 or larger.

Owner:SEKISUI CHEM CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com