Patents

Literature

1149results about "Gas discharge vessels/containers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glass plate for display devices

ActiveUS20090298669A1Low environmental loadQuality improvementGas discharge vessels/containersThin material handlingDisplay deviceGlass sheet

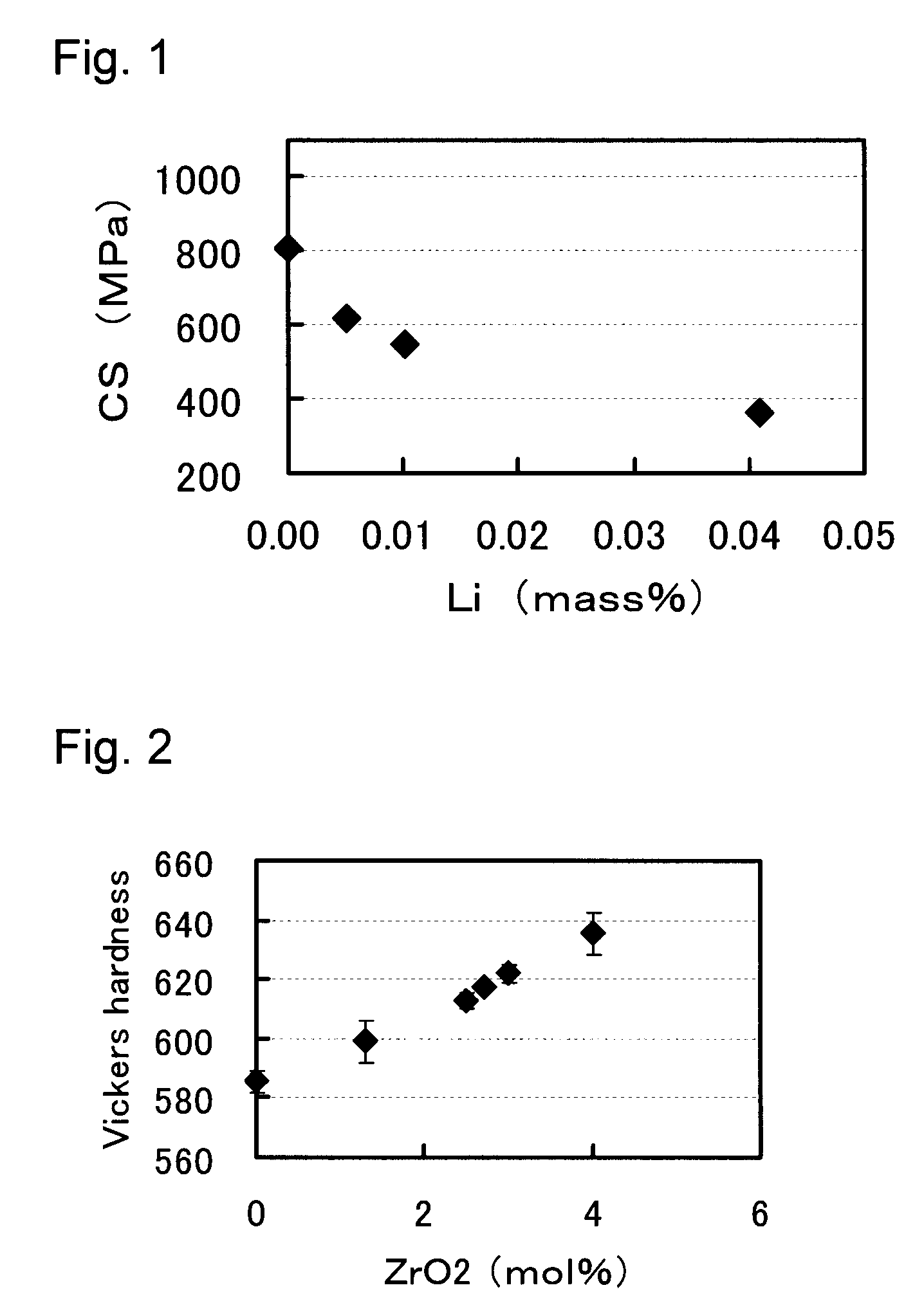

To provide a glass plate for display devices wherein without carrying out a post treatment, the depth of a compression stress layer is increased, while the surface compression stress is prevented from being excess only by chemical tempering.A glass plate for display devices, which is obtained by chemically tempering a glass plate comprising, as represented by mol % based on the following oxides, from 50 to 74% of SiO2, from 1 to 10% of Al2O3, from 6 to 14% of Na2O, from 3 to 15% of K2O, from 2 to 15% of MgO, from 0 to 10% of CaO and from 0 to 5% of ZrO2, wherein the total content of SiO2 and Al2O3 is at most 75%, the total content of Na2O and K2O, i.e. Na2O+K2O, is from 12 to 25%, and the total content of MgO and CaO, i.e. MgO+CaO, is from 7 to 15%.

Owner:ASAHI GLASS CO LTD

Heat sink of plasma display apparatus

InactiveUS20070267174A1Easy to processImprove productivityGas discharge vessels/containersSolid cathode detailsProduction rateEngineering

As to a heat sink manufacturing method of a plasma display apparatus according to the present invention and the manufacturing device, a widthwise direction air channel and a lengthwise direction air channel are formed through a extrusion and a rolling processing to facilitate a processing with a continuous extrusion and rolling processing. Accordingly, the productivity is notably improved.

Owner:LG ELECTRONICS INC

Heat spreader for display device

InactiveUS7306847B2Temperature differenceGraphiteGas discharge vessels/containersLiquid-crystal displayDisplay device

A heat spreader for a display device, such as a plasma display panel, a light emitting diode or a liquid crystal display, which includes at least one sheet of compressed particles of exfoliated graphite having two major surfaces.

Owner:NEOGRAF SOLUTIONS LLC

Gas dischargeable panel

InactiveUS20040032215A1Illumination efficiency is highImprove reflectivityAddress electrodesSustain/scan electrodesElectrode pairElectrical and Electronics engineering

A gas discharge panel includes a first substrate and a second substrate. A plurality of display electrode pairs which are each made up of a sustain electrode and a scan electrode are formed on the first substrate, and the first substrate and the second substrate are set facing each other with a plurality of barrier ribs in between so as to form a plurality of cells. In this gas discharge panel, at least one of the sustain electrode and the scan electrode includes: a plurality of line parts; and a discharge developing part which makes a gap between adjacent line parts smaller in areas corresponding to channels between adjacent barrier ribs than in areas corresponding to the barrier ribs.

Owner:PANASONIC CORP

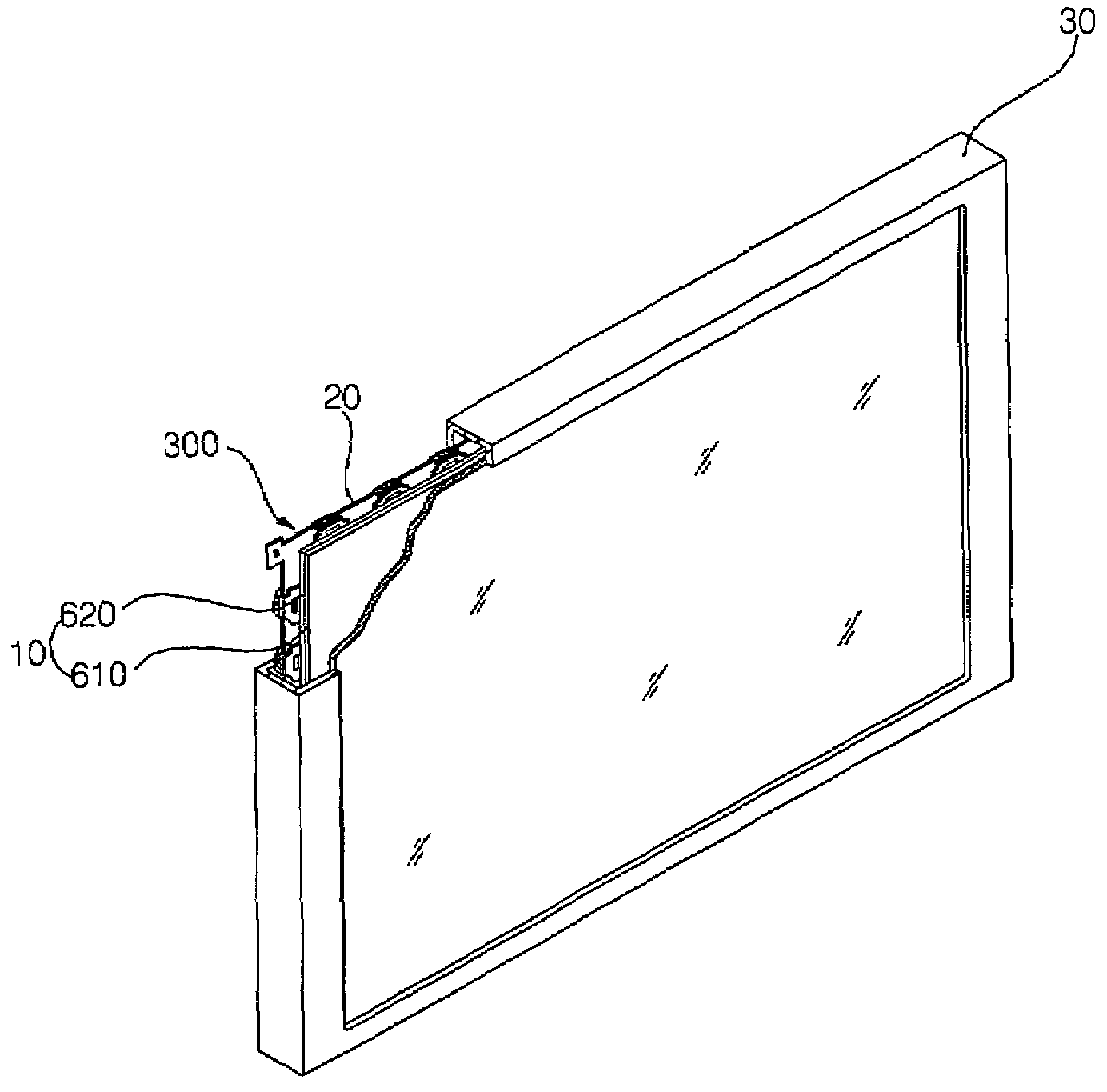

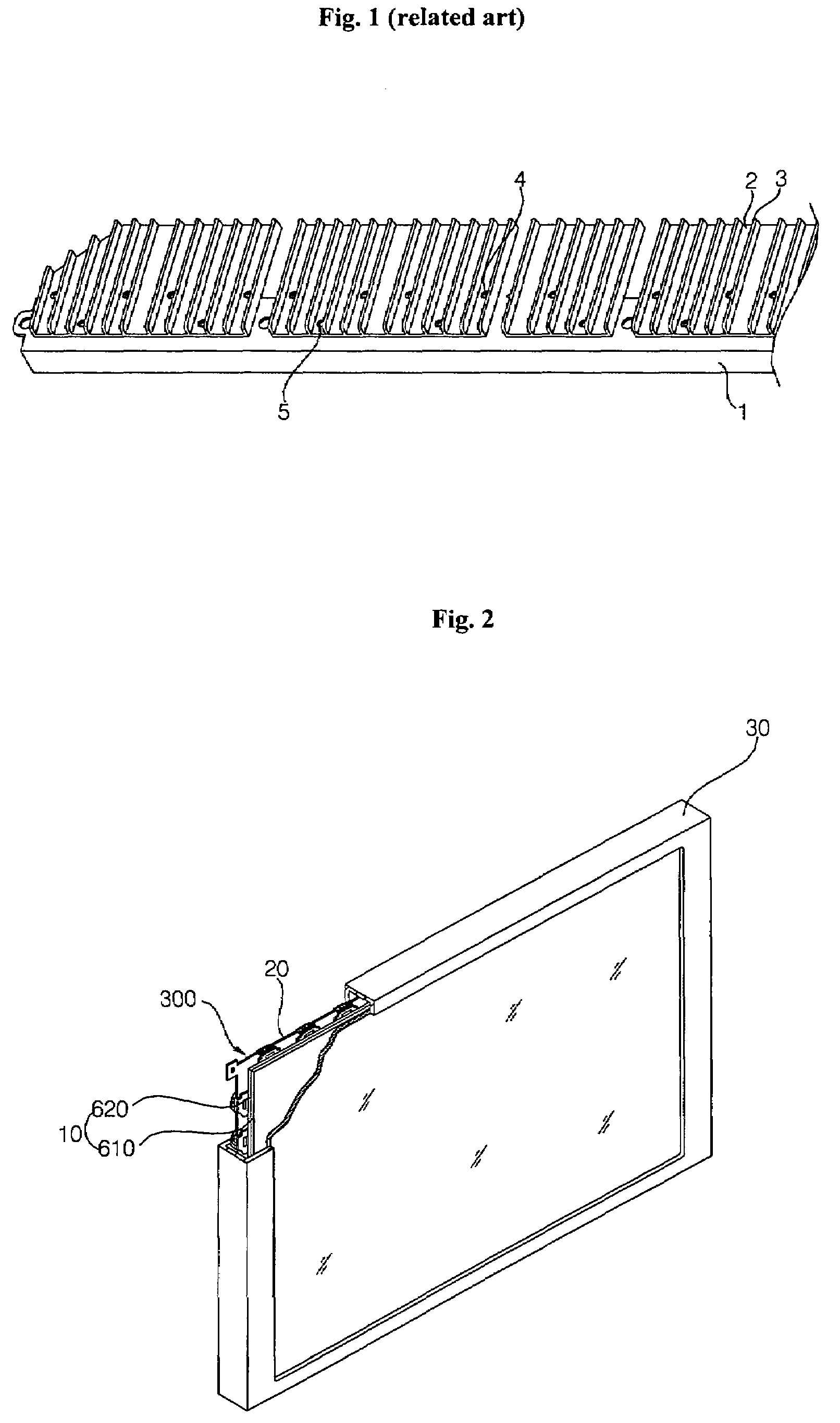

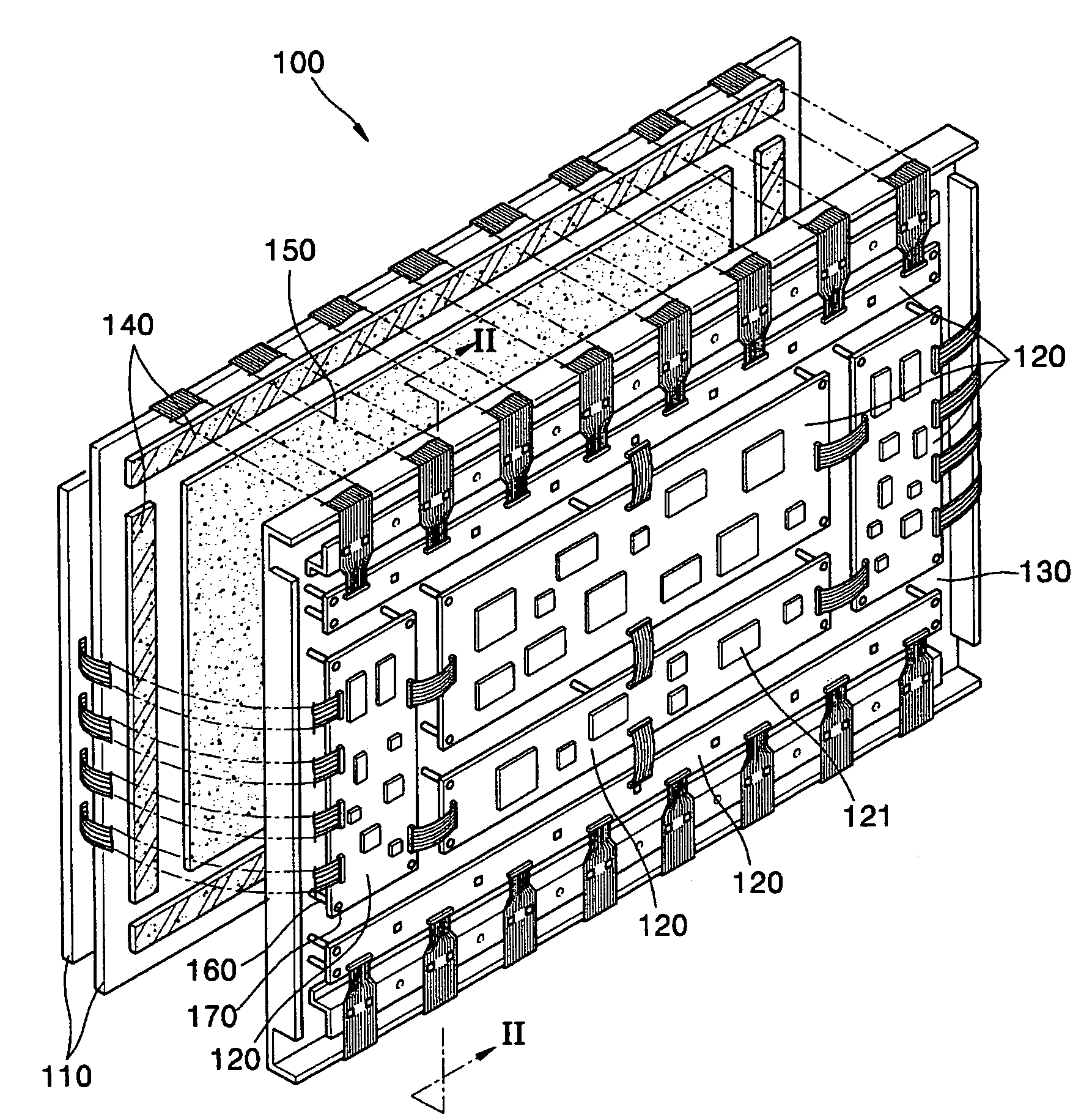

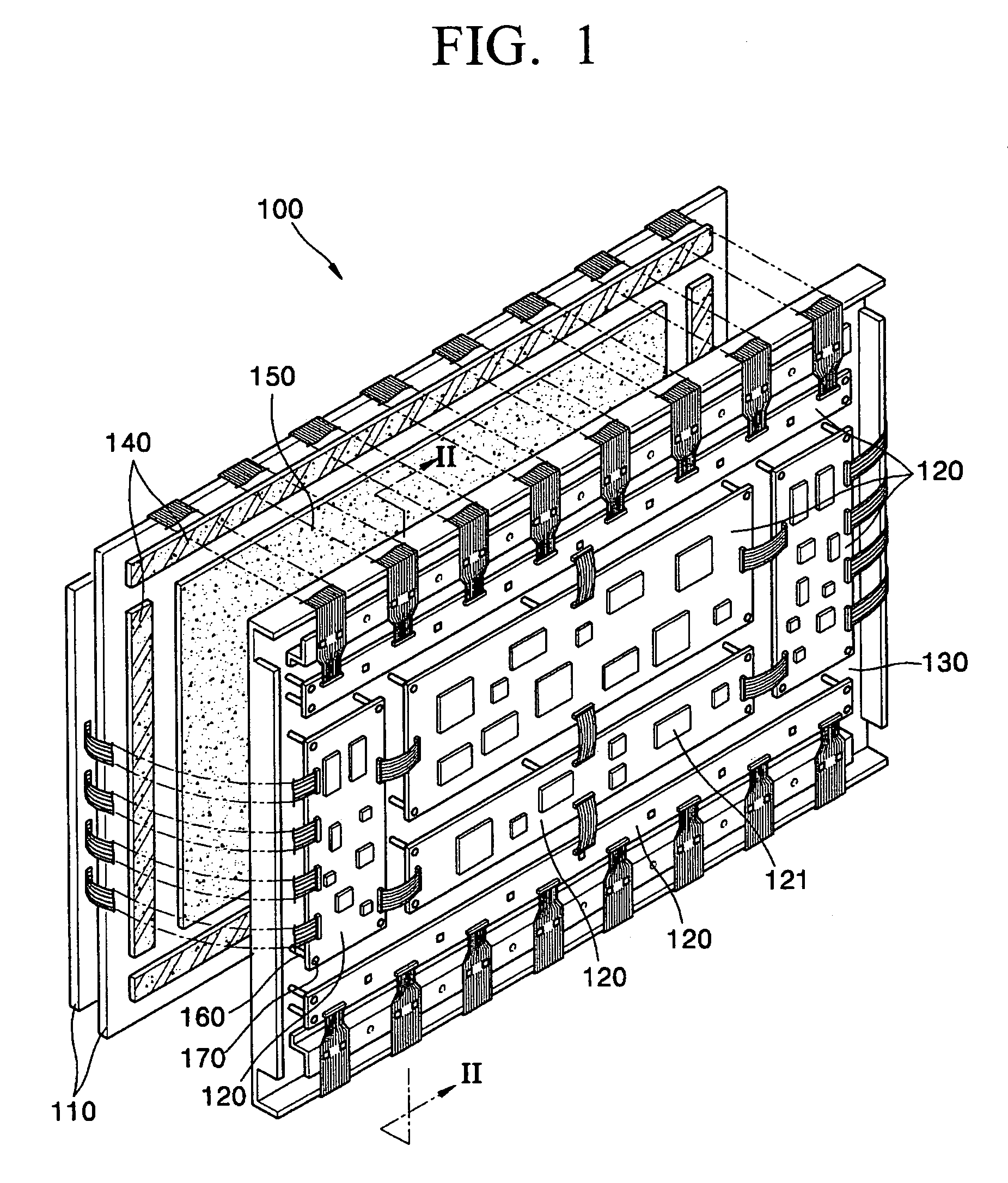

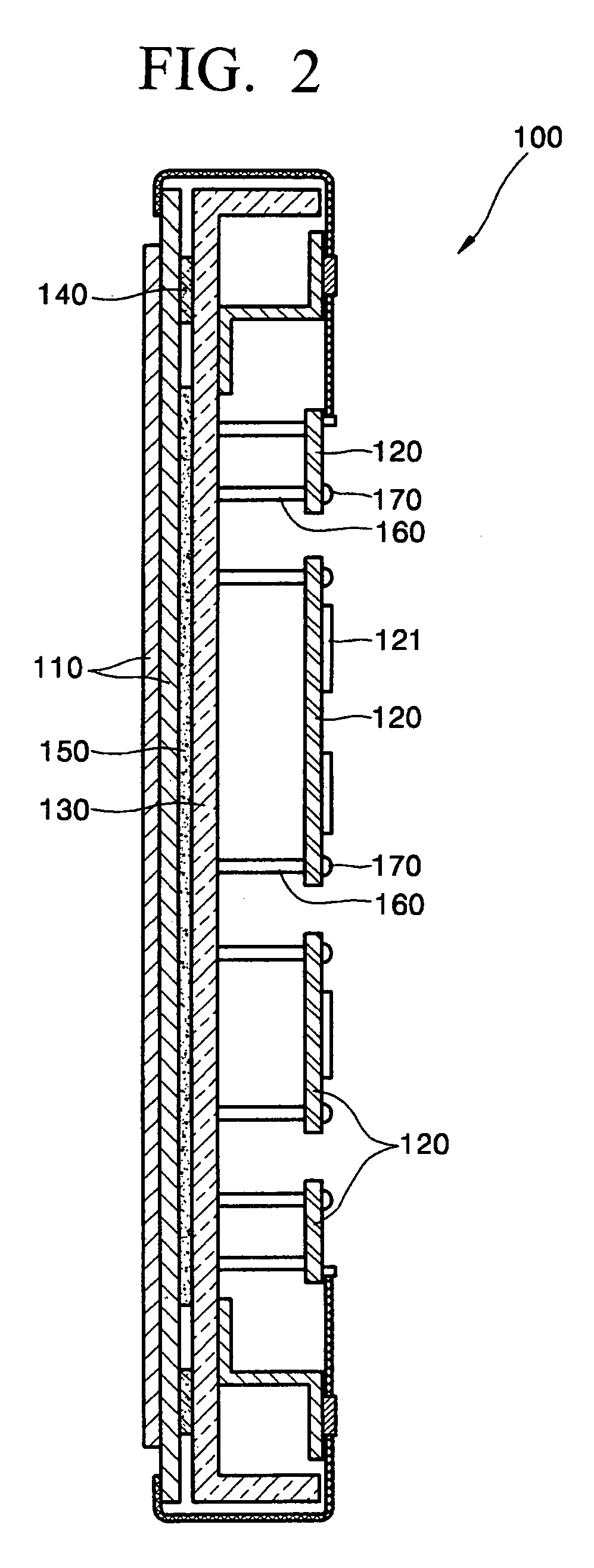

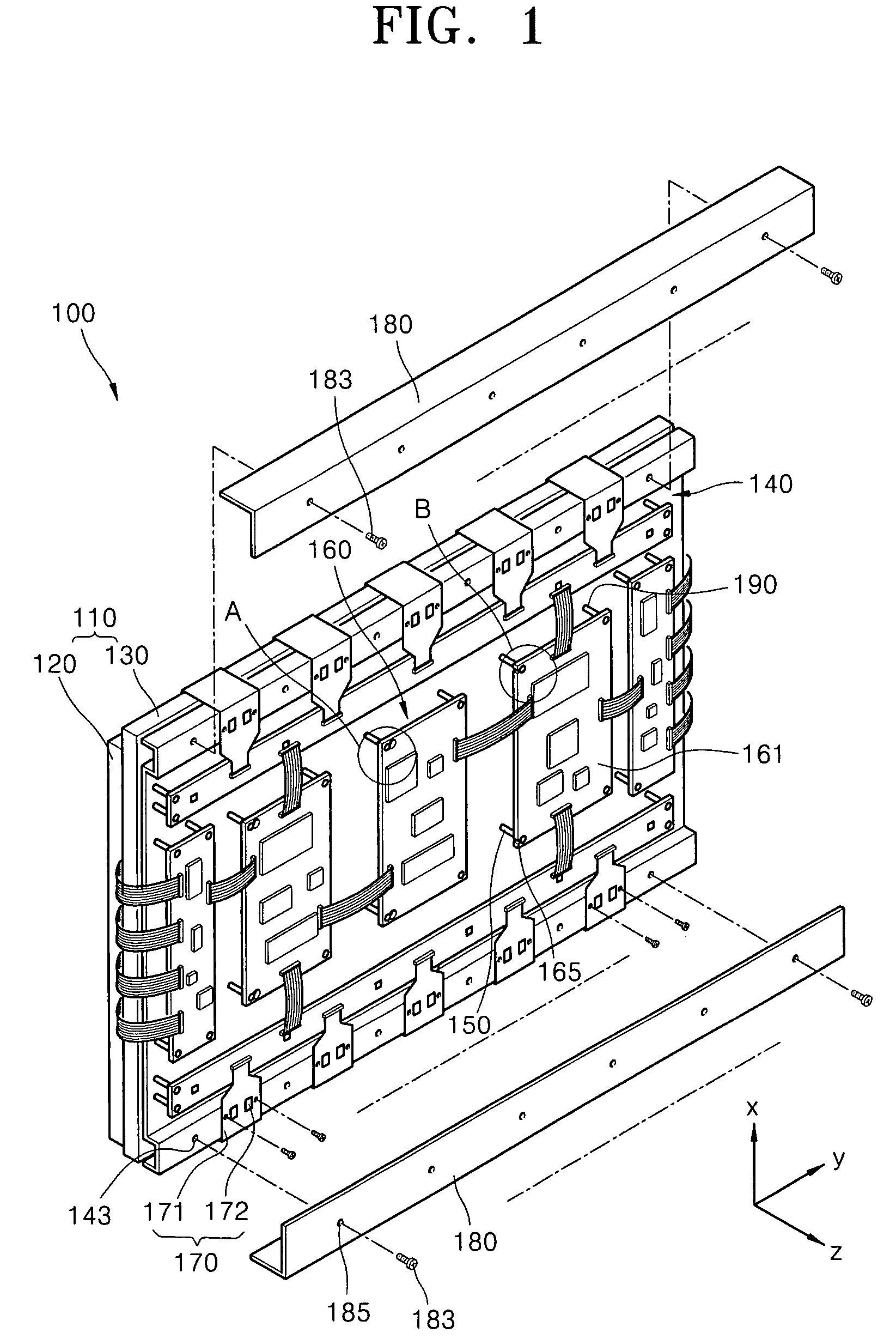

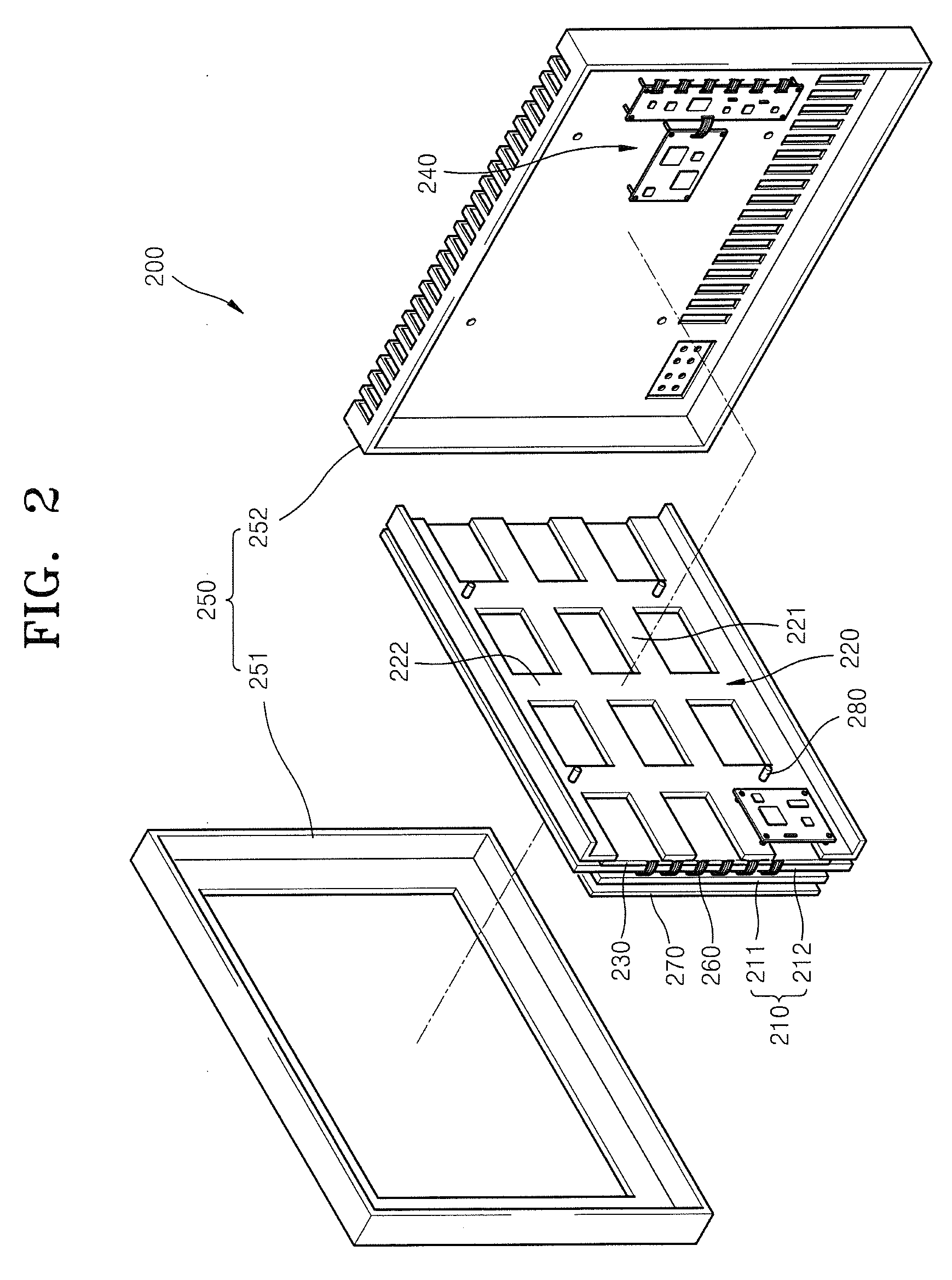

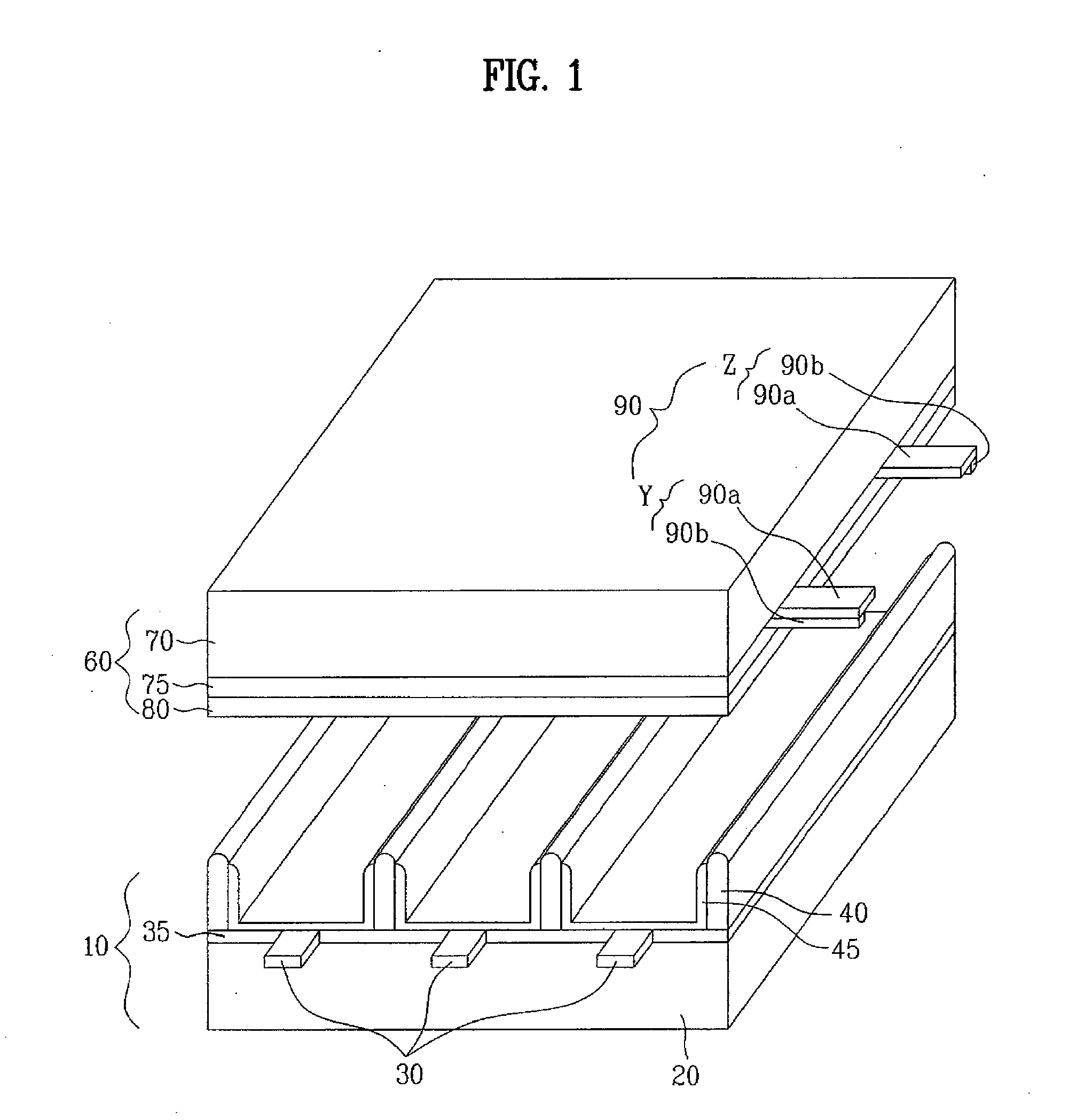

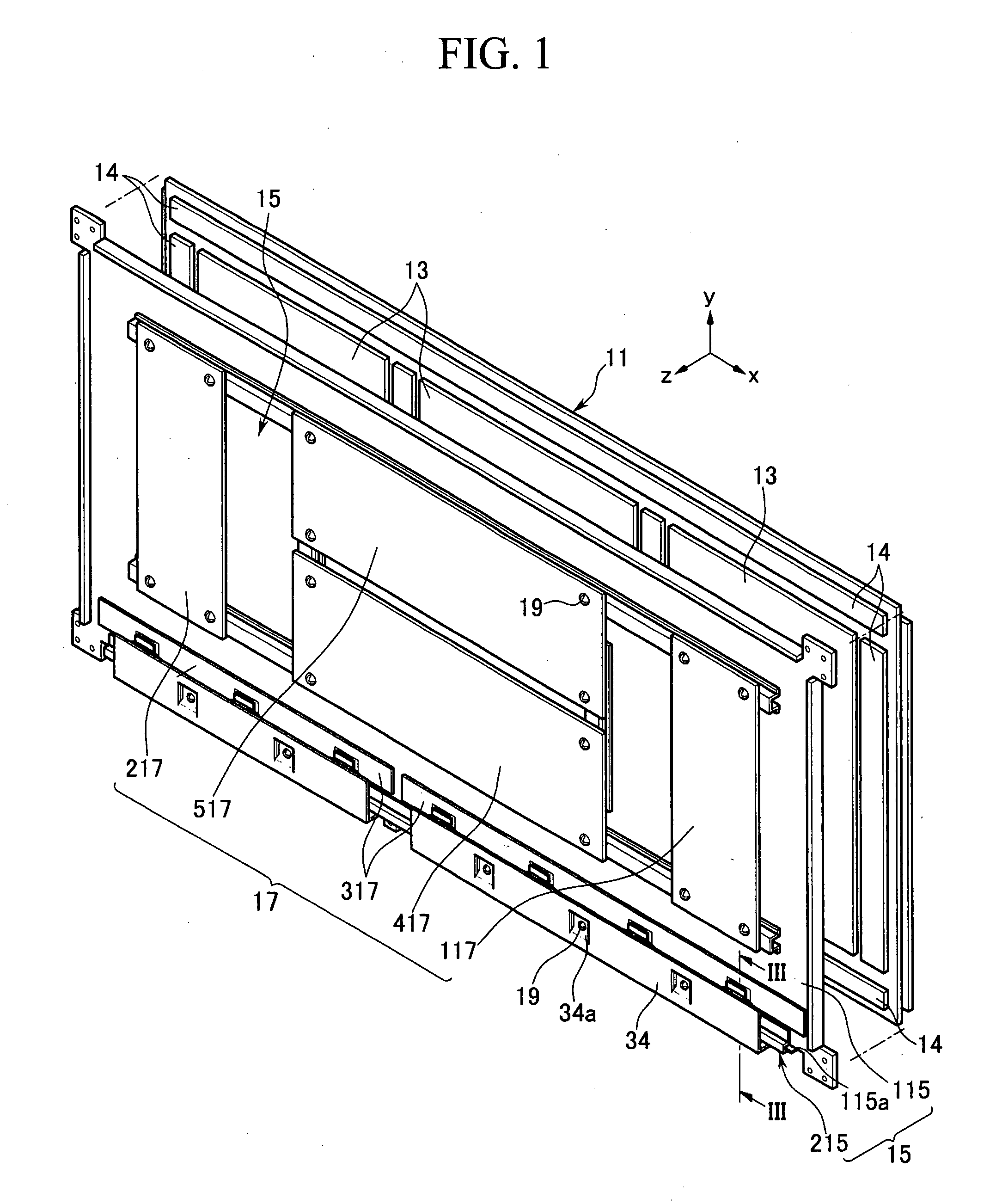

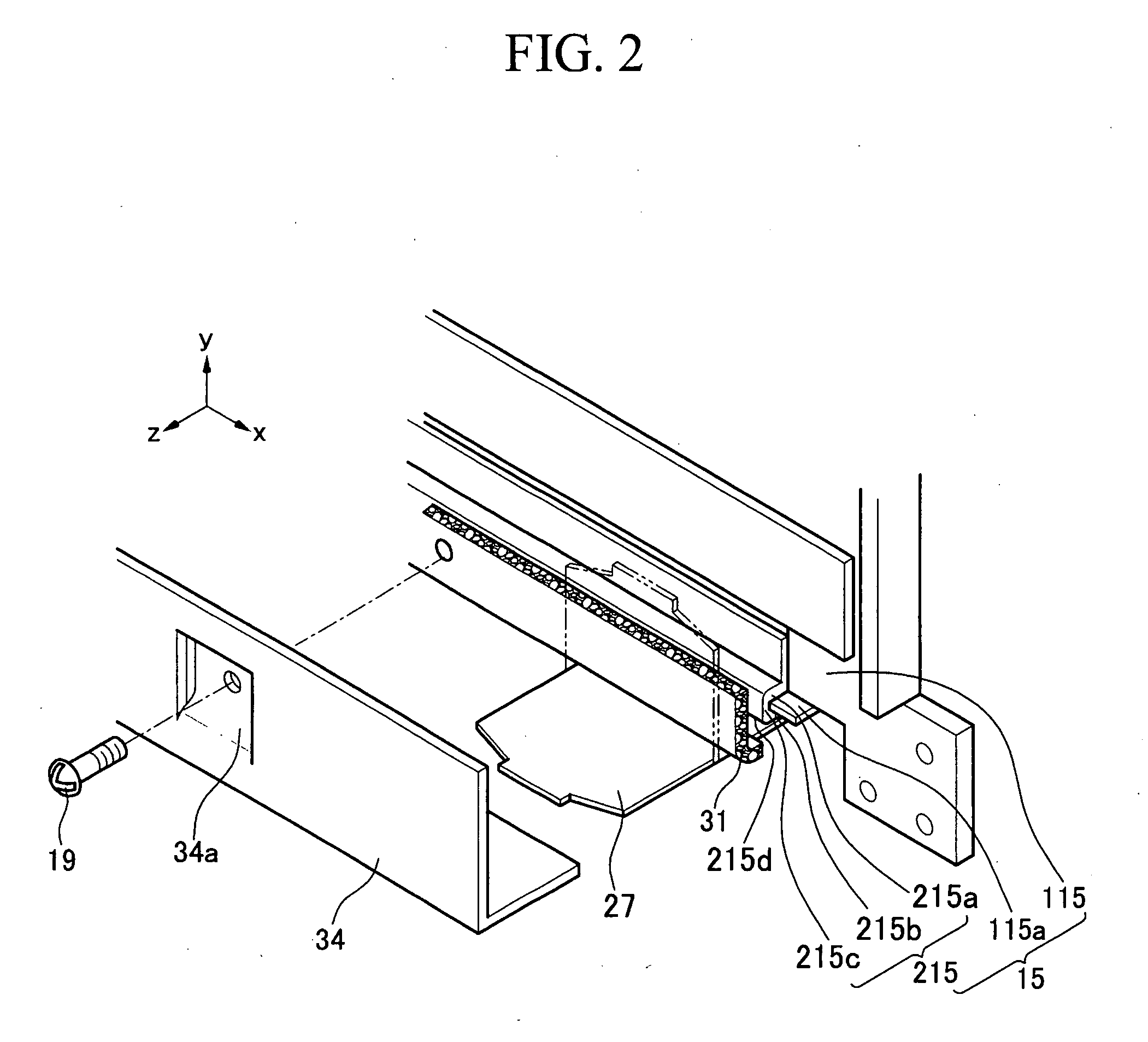

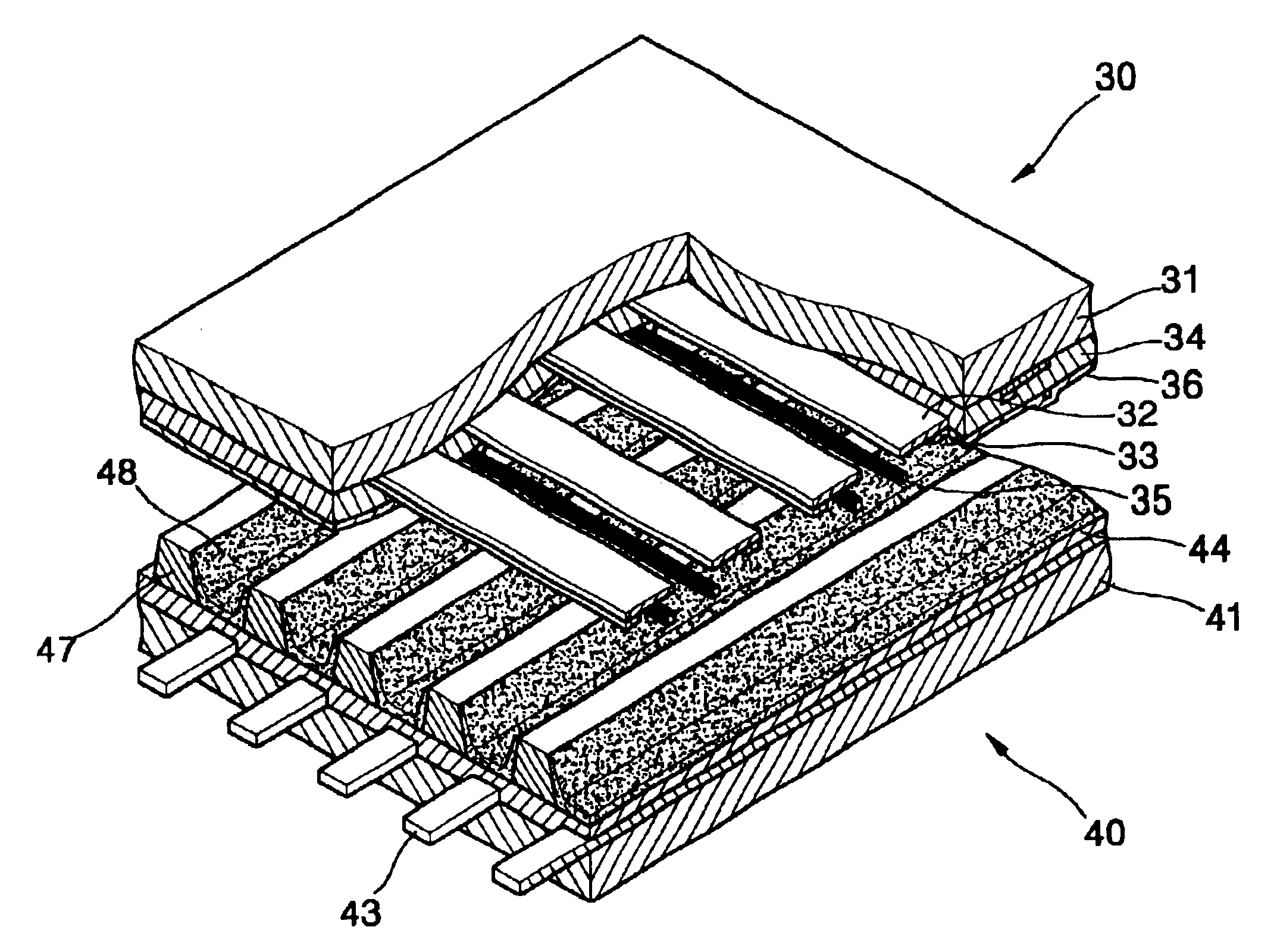

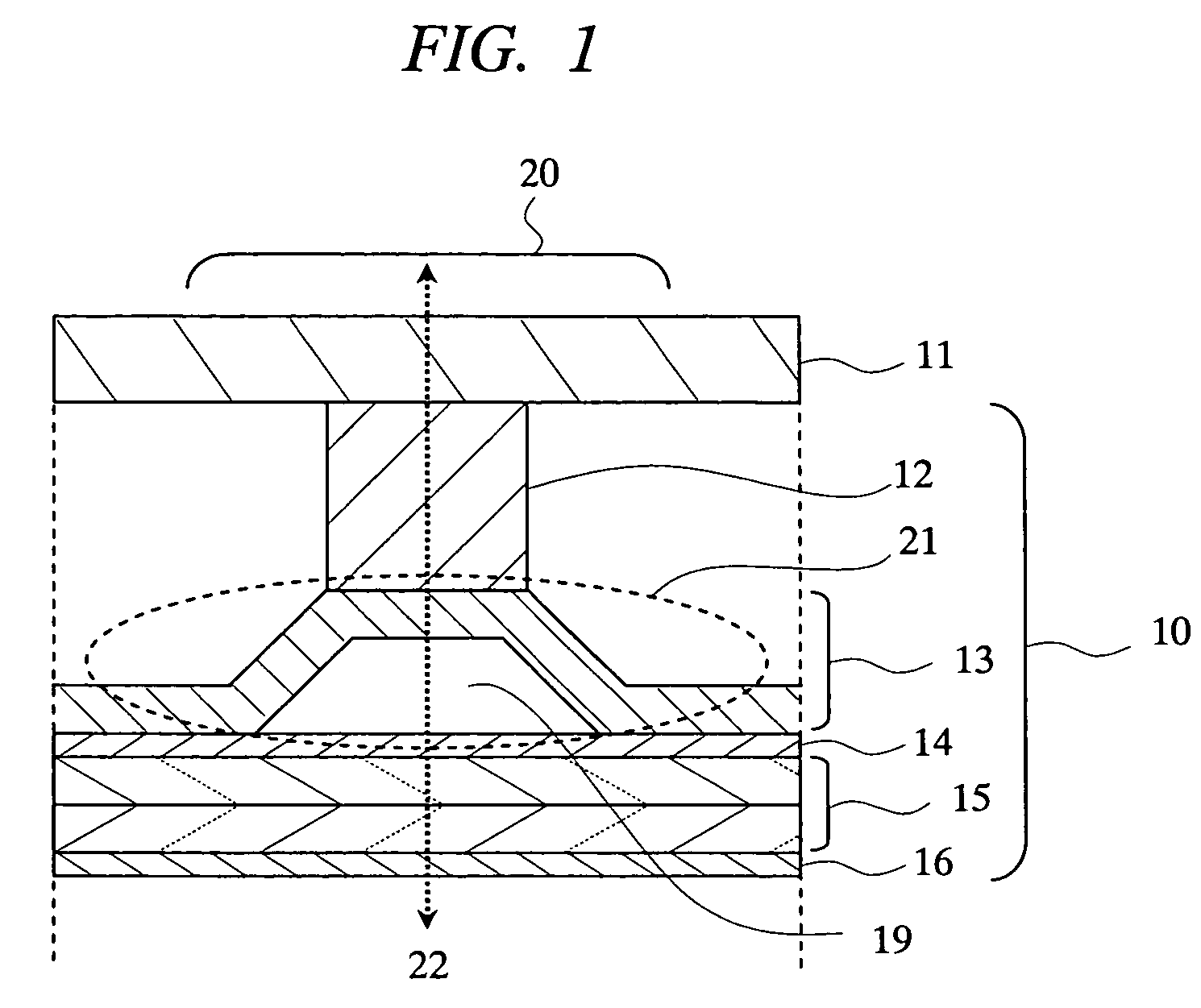

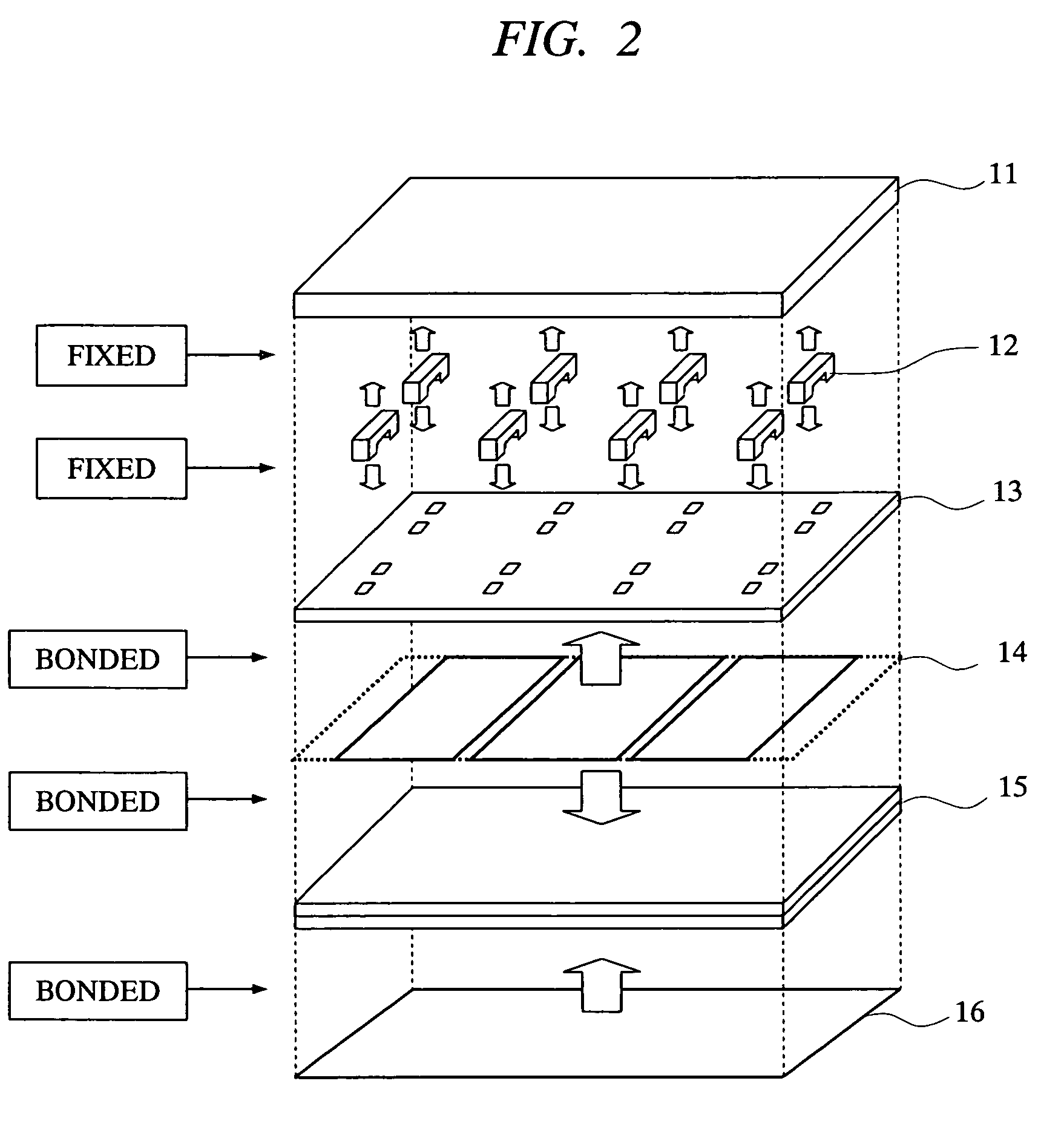

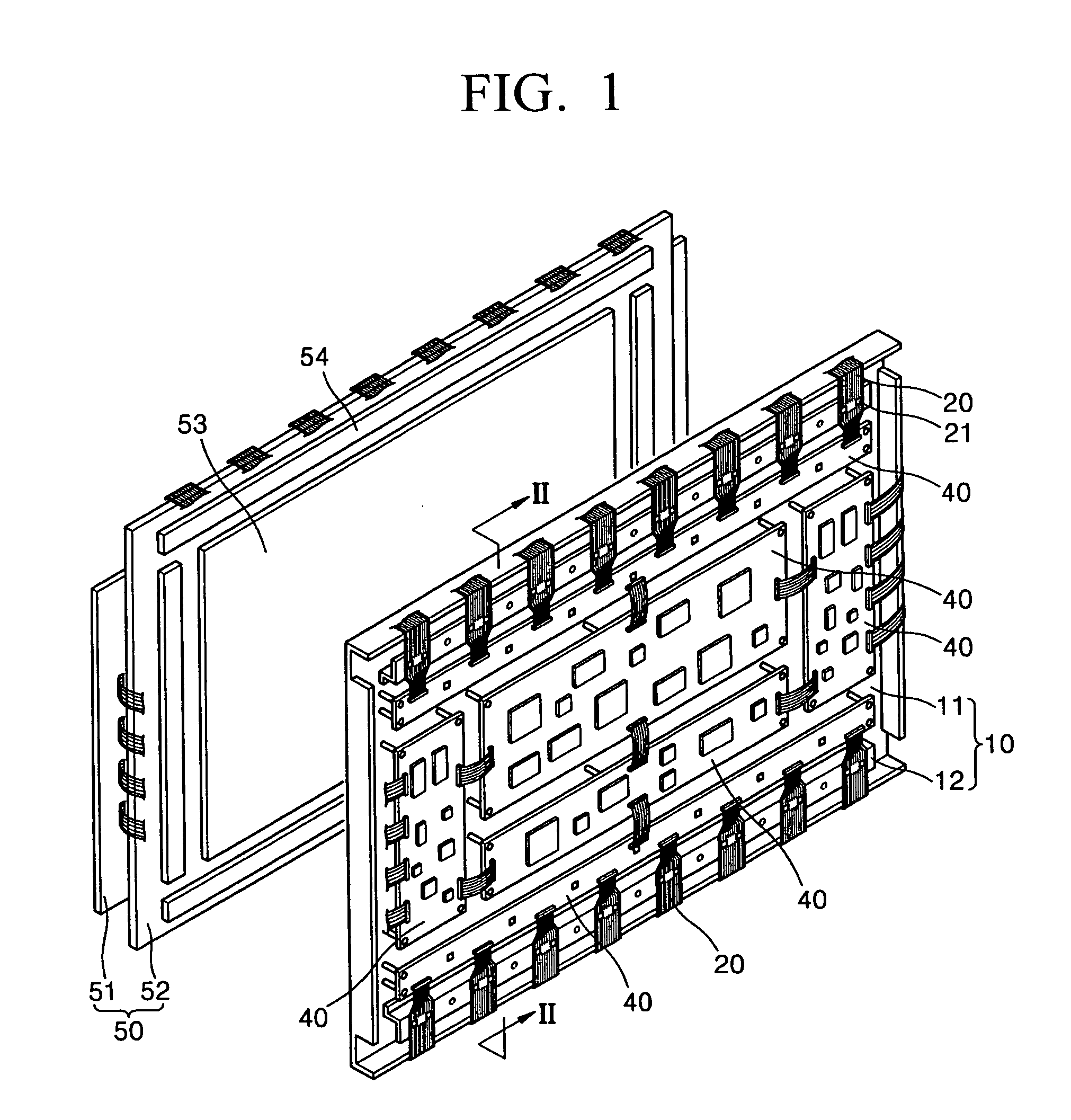

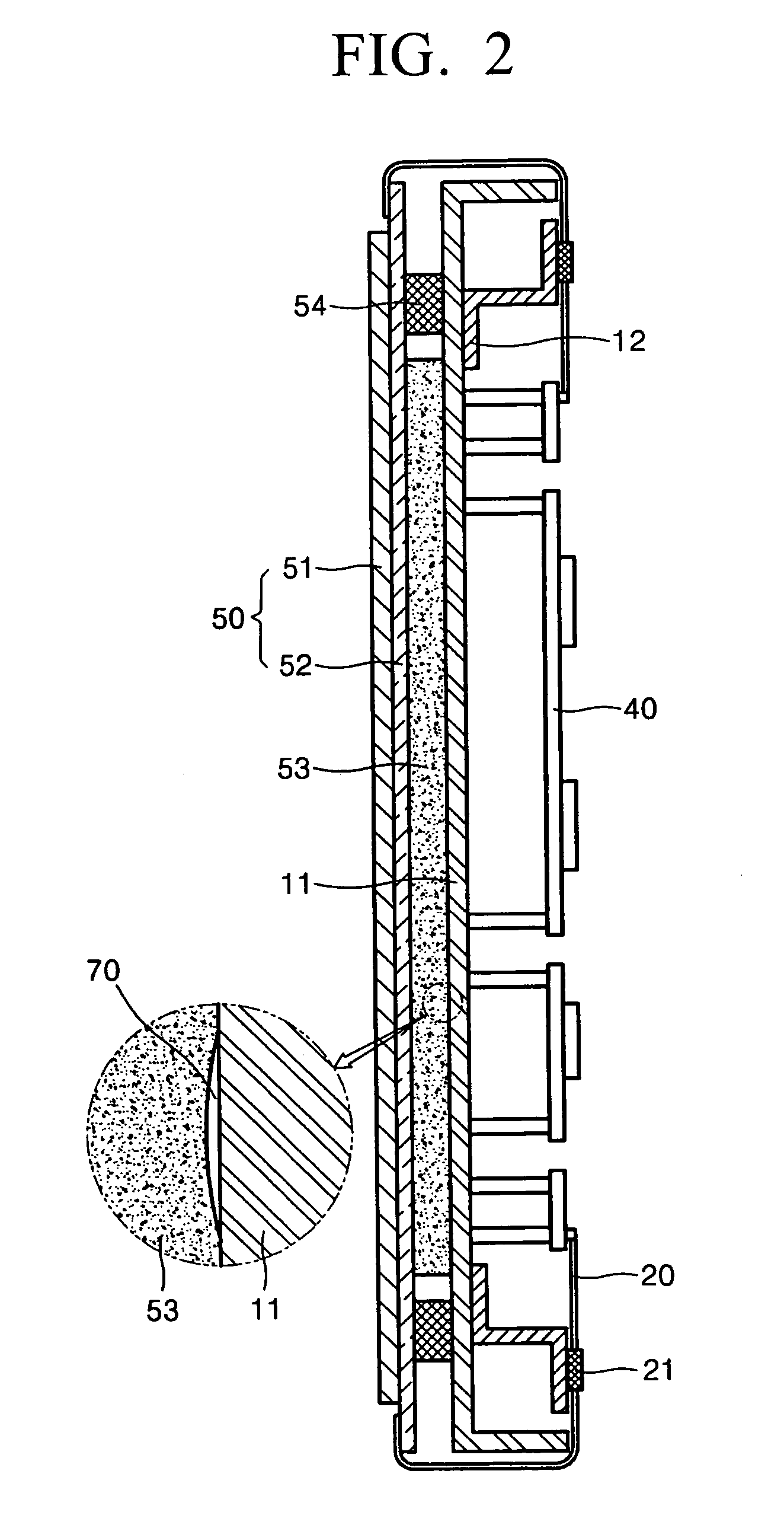

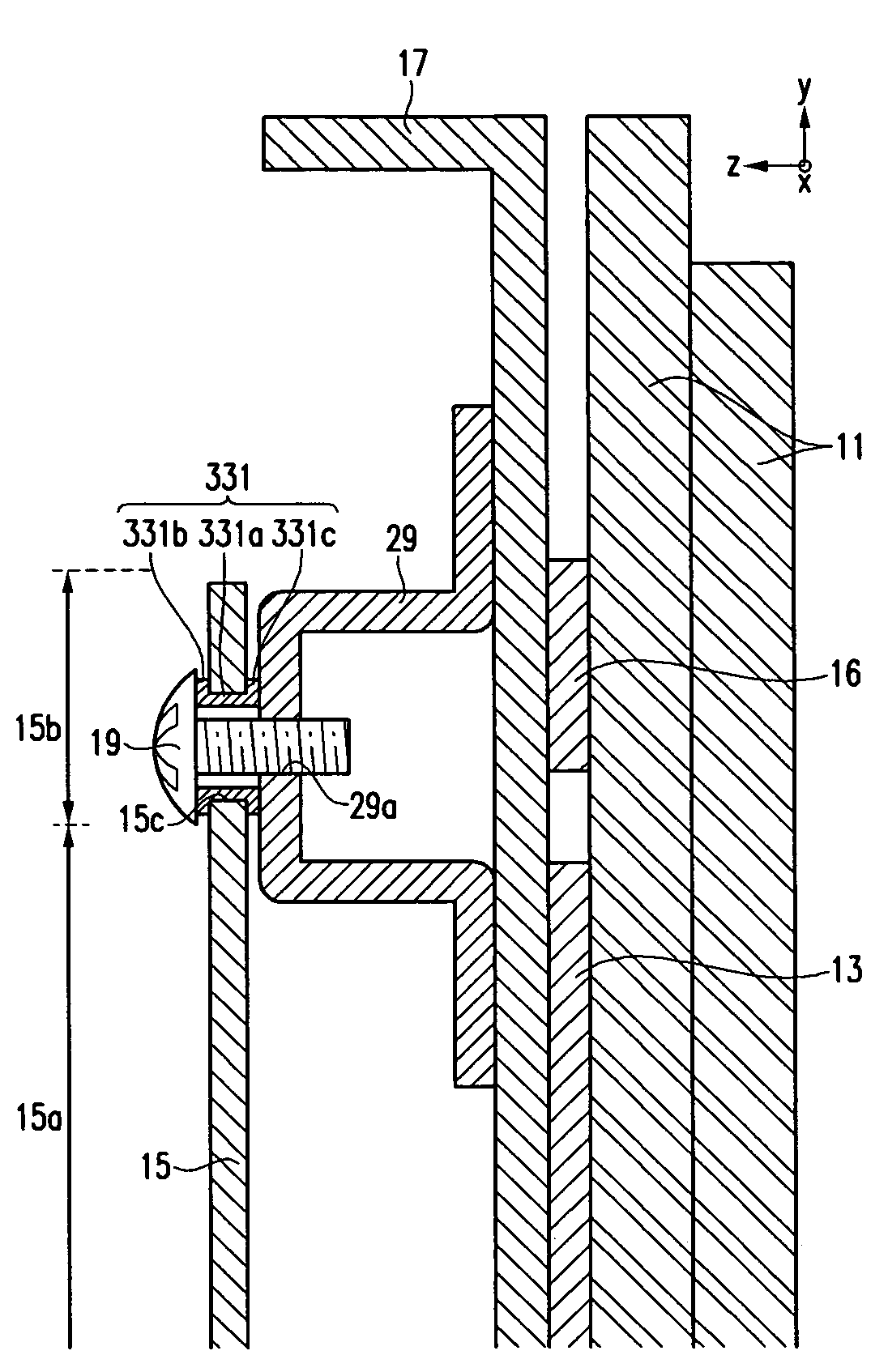

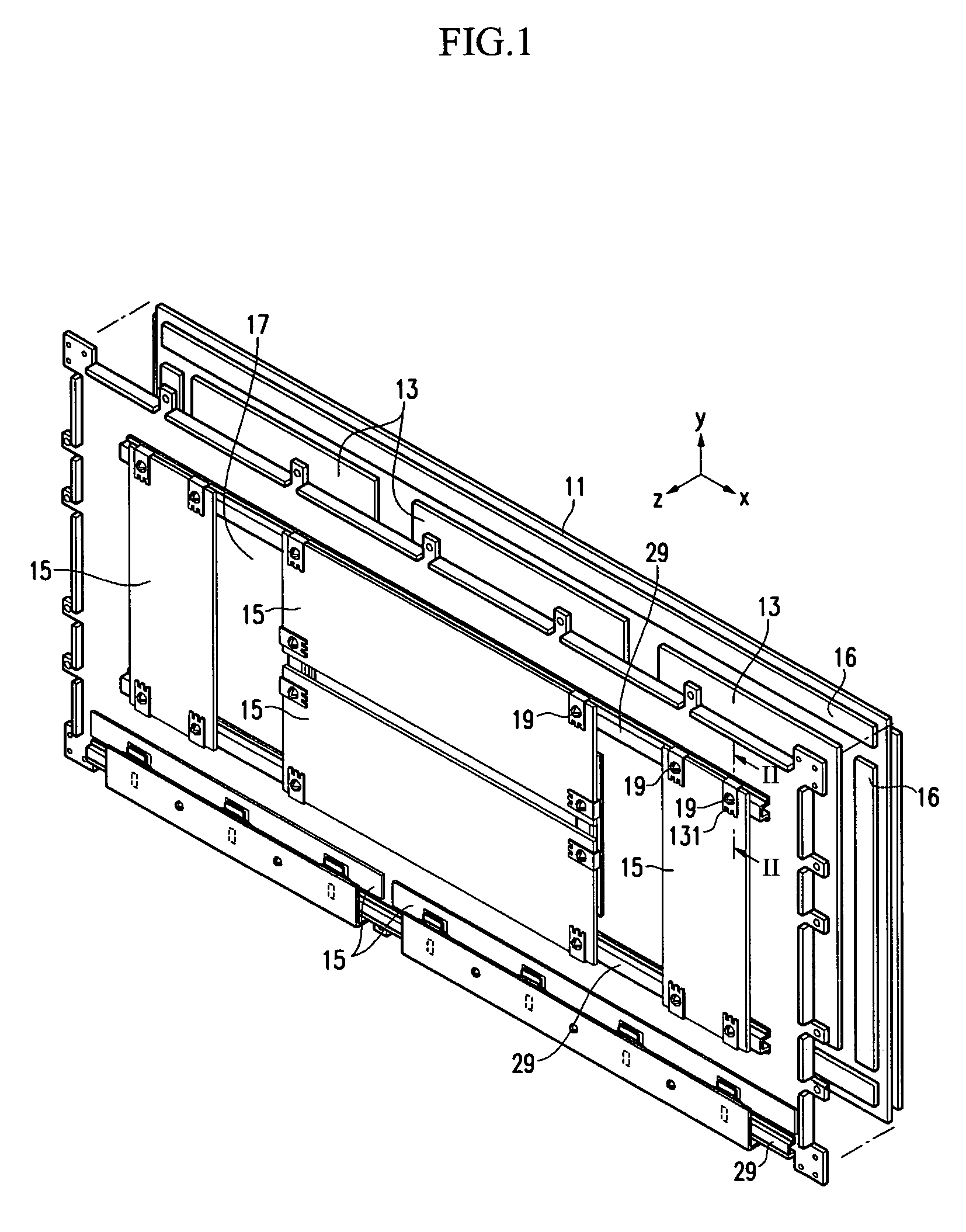

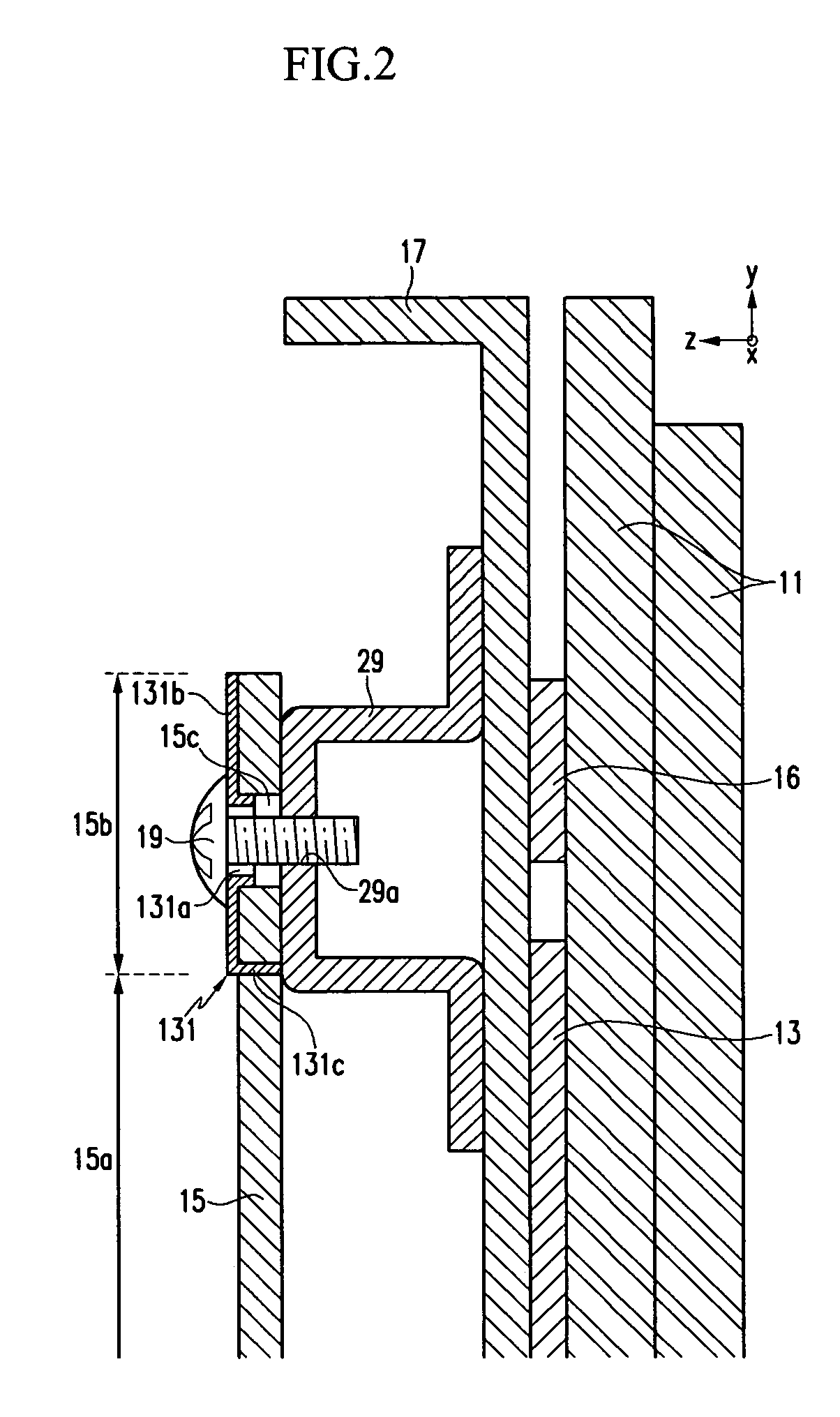

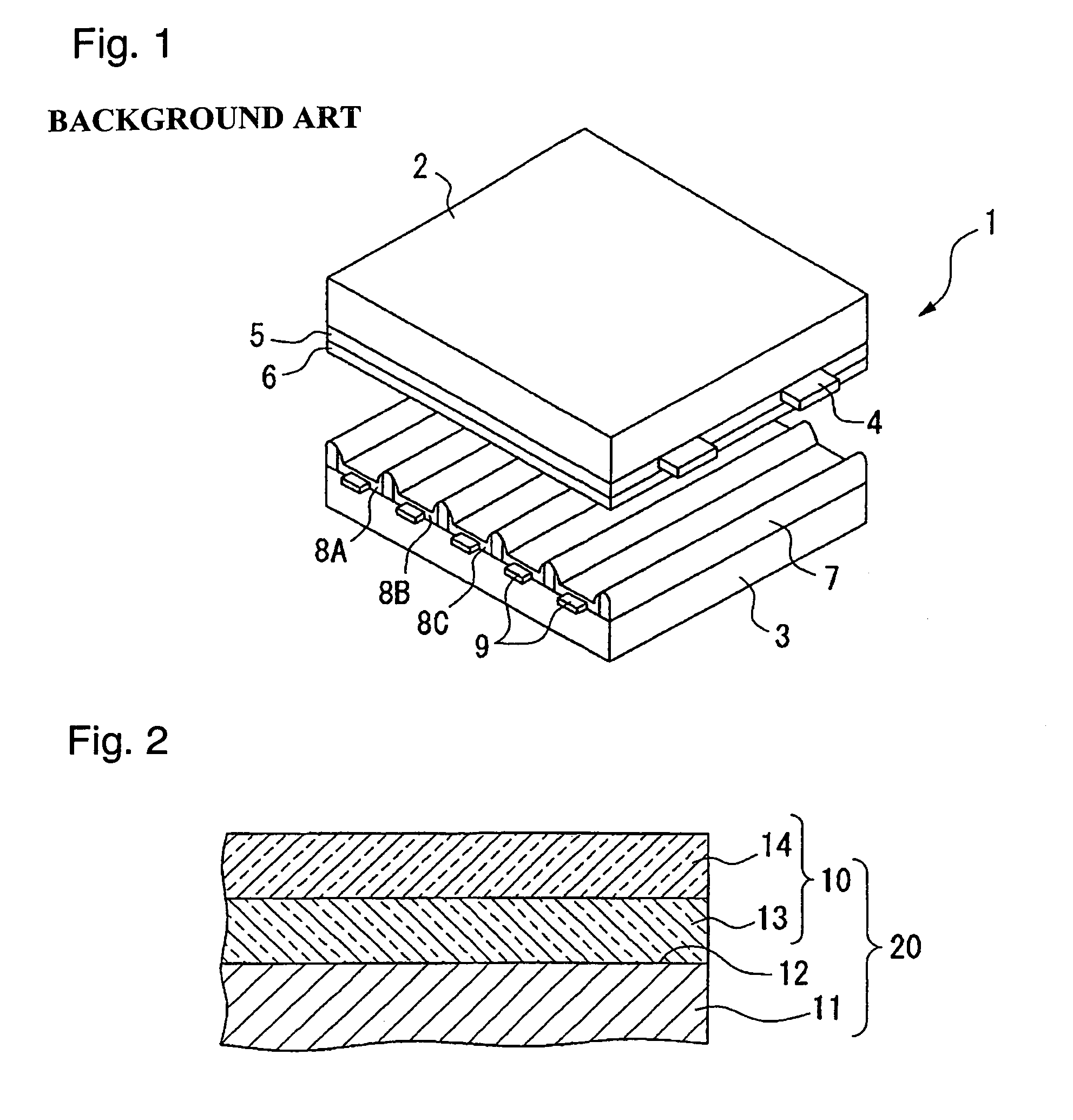

Chassis structure for plasma display module and plasma display module including the chassis structure

InactiveUS7342792B2Efficiently dissipatedEasy to assembleDigital data processing detailsAlternating current plasma display panelsPlasma displayBackplane

A chassis structure for a plasma display module, and a plasma display module including the chassis structure effectively dissipate heat generated by a plasma display panel and improve assembly of the plasma display module. The chassis base includes: a front plate; a back plate separated from the front plate; and a heat dissipation member disposed between the front plate and the back plate, and having a bent cross-section arranged so that some surfaces of the heat dissipation member contact the front plate and some surfaces of the heat dissipation member contact the back plate to allow air flow between the front and back plate.

Owner:SAMSUNG SDI CO LTD

Display device

InactiveUS20060012962A1Low costSmall massMagnetic/electric field screeningStatic indicating devicesDisplay deviceEngineering

A display device, particularly a plasma display device, low in cost and small in mass, having a display panel capable of being prevented from deforming even upon application of an external force to the front panel. A plasma display device includes an exterior housing by the provision of a frame-formed front panel and a back cover, to provide a PDP within the same. A module plate and a heat sink are provided in a back of the PDP and fixed to the PDP. The heat sink is in a squared-U form that one plate is bent perpendicular twice, having a portion fixed to the PDP and another portion abutting against a backside of the front panel. A gap is provided between a functional film put on a front-side substrate of the PDP and the front panel.

Owner:PIONEER CORP

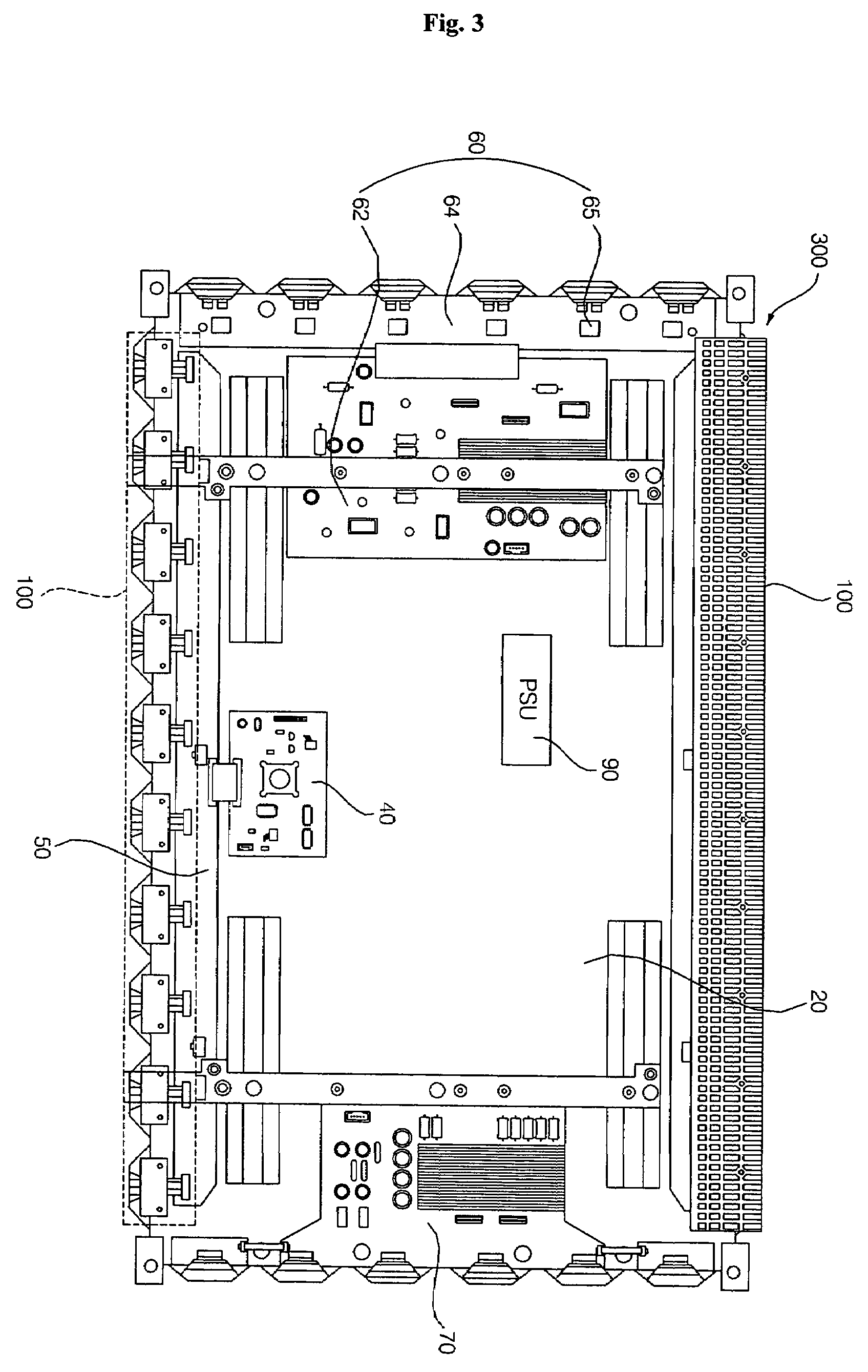

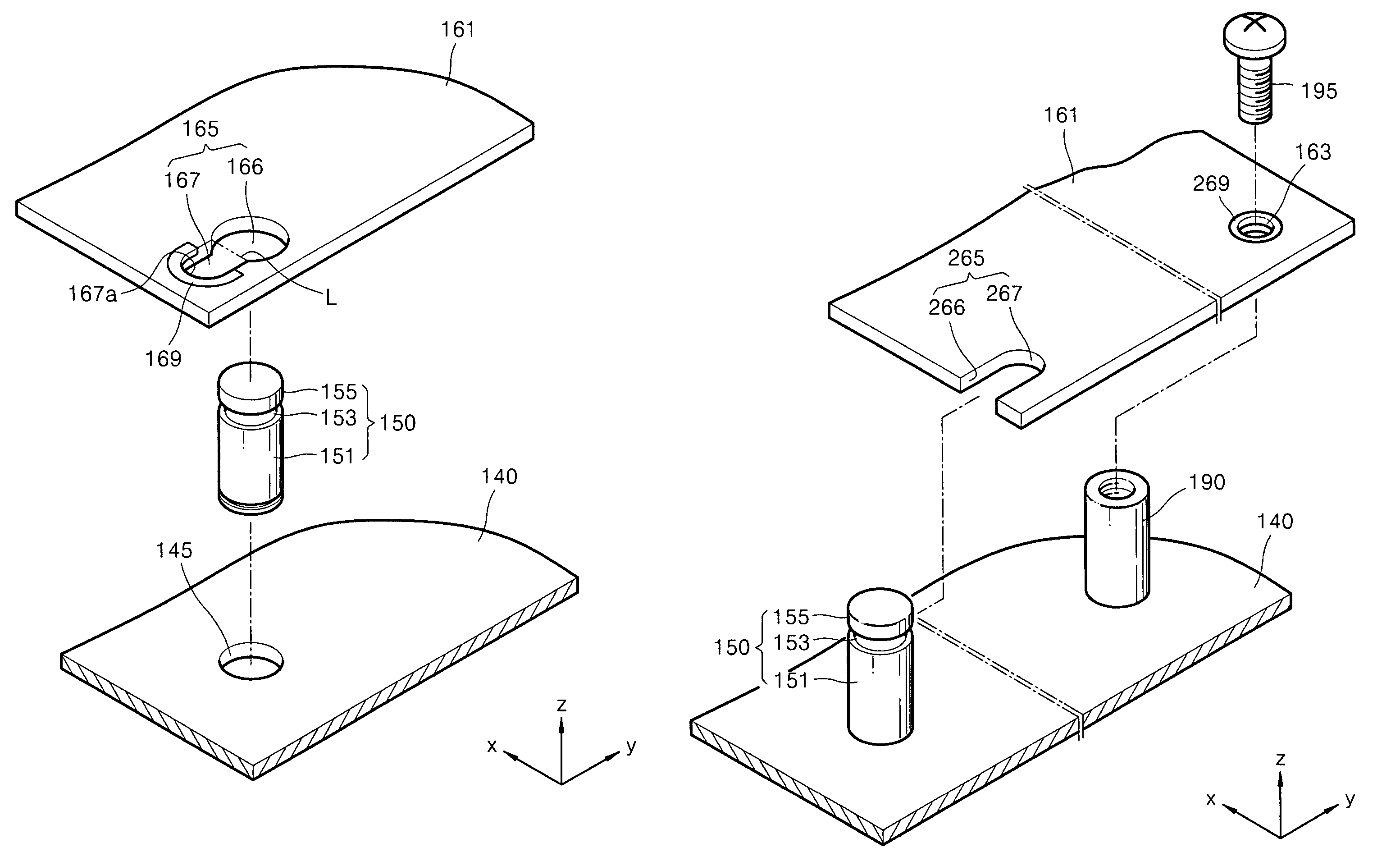

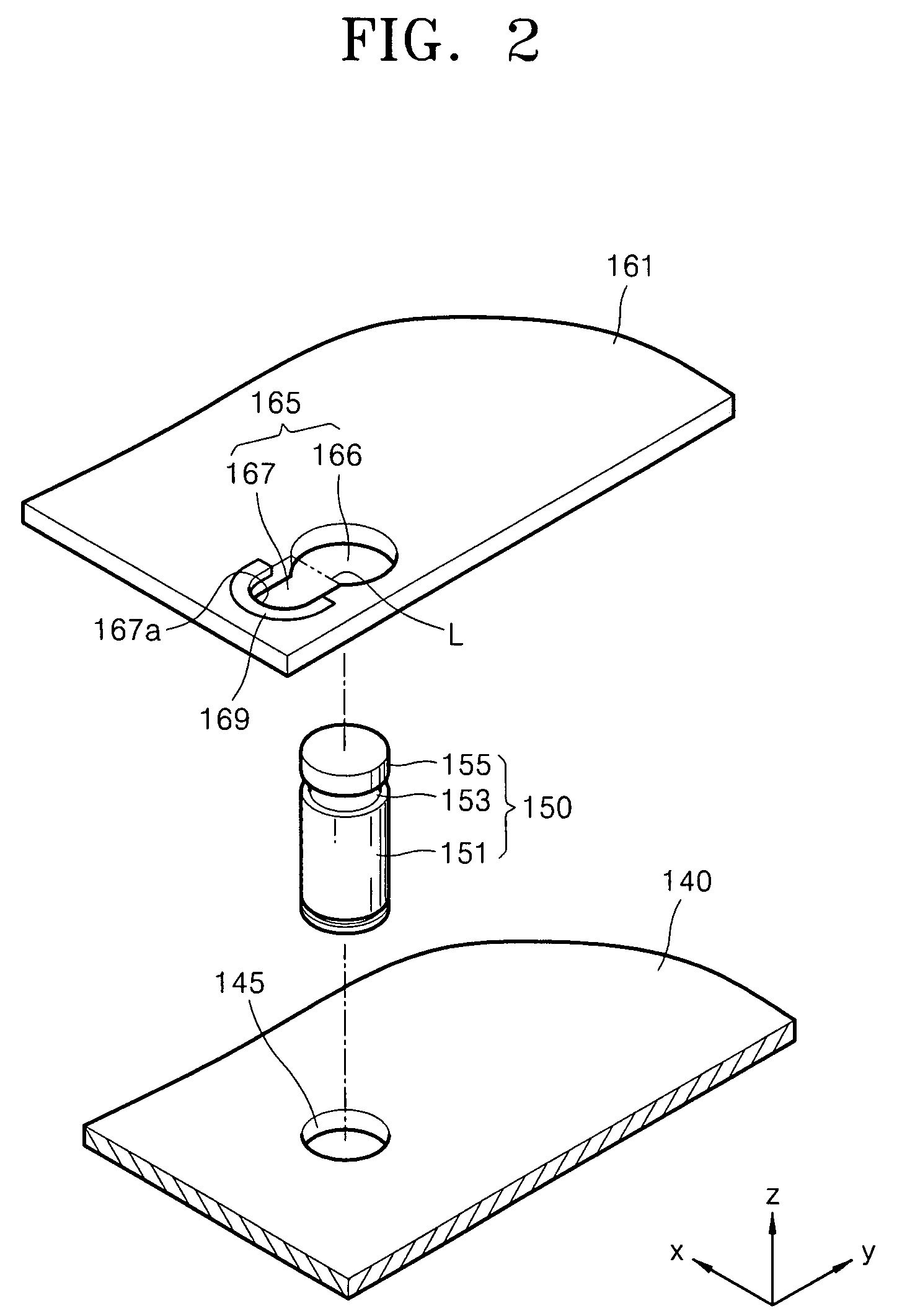

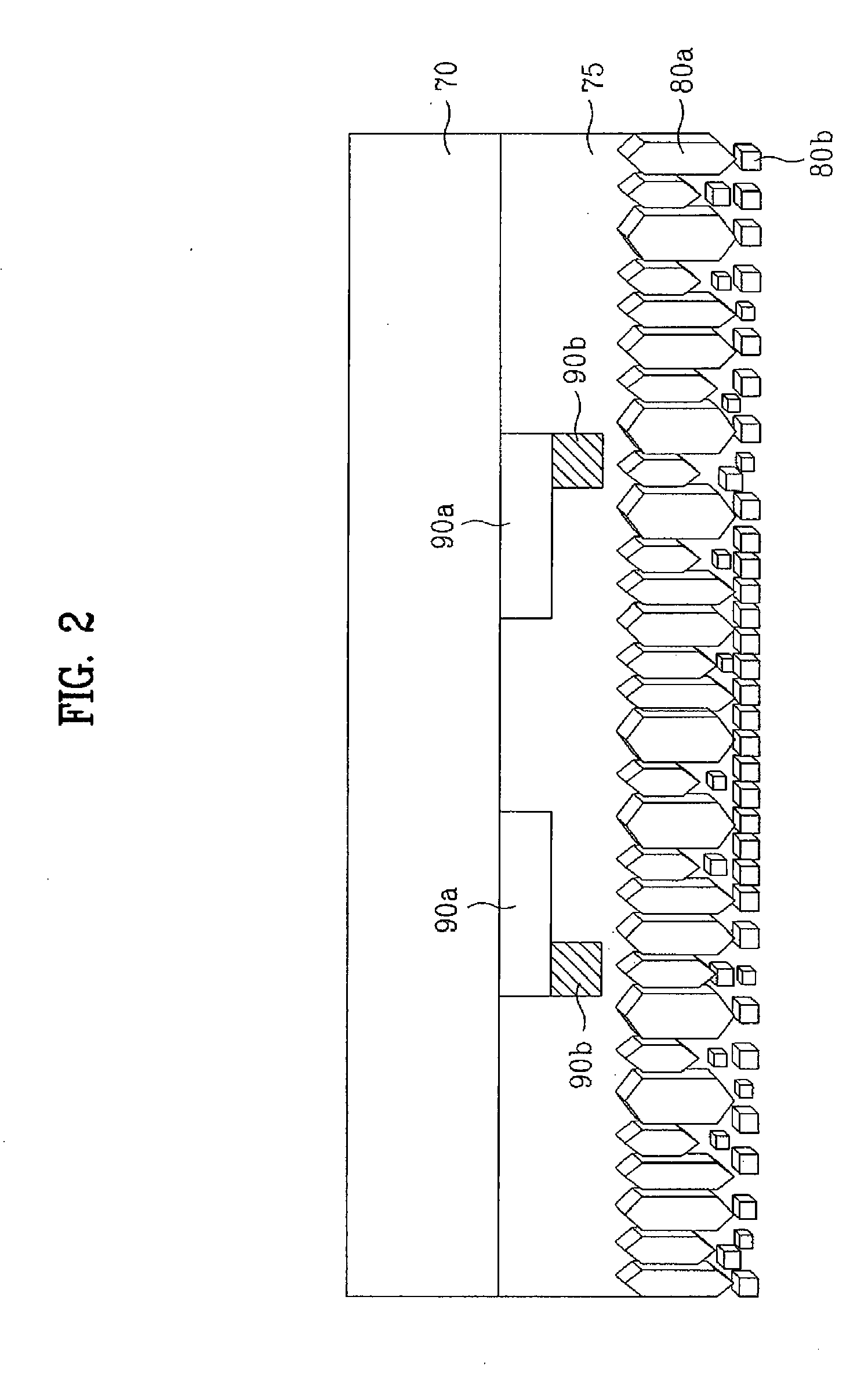

Fixing structure of circuit board and display module comprising the same

InactiveUS7364442B2Effective alignmentEfficiently securingSubstation/switching arrangement detailsPrinted circuit groundingElectrical and Electronics engineeringEngineering

A fixing structure for a circuit board includes at least one board mounting hole in the circuit board, the board mounting hole having a guide hole and an insertion hole, and at least one board mounting member inserted through the board mounting hole, the board mounting member having a main body, a cover, and an insertion portion therebetween, wherein the insertion portion has a cross-sectional area smaller than either of the main body or the cover and is capable of fitting in the insertion hole of the board mounting hole.

Owner:SAMSUNG SDI CO LTD

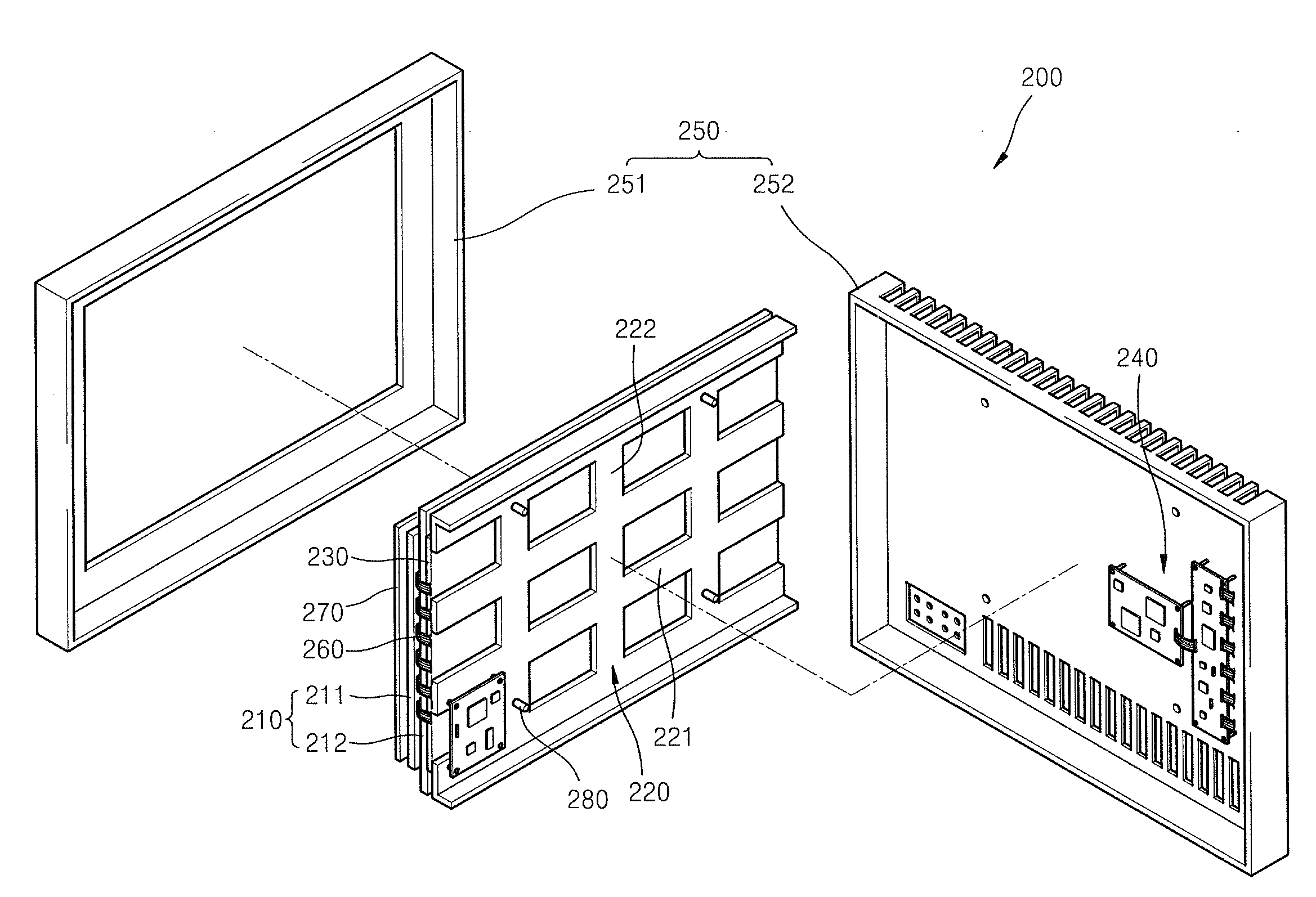

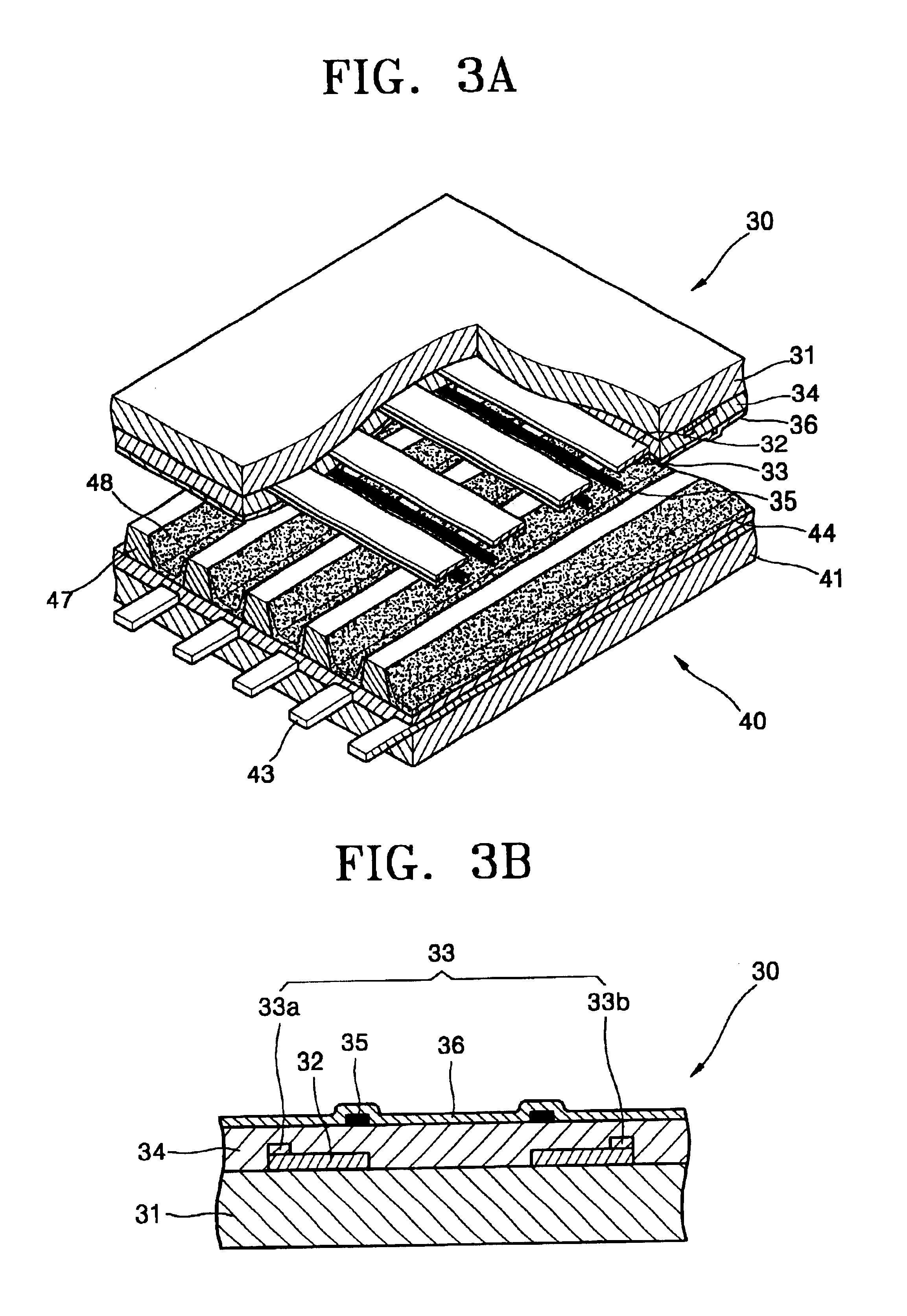

Plasma display panel device

InactiveUS20070258199A1Improve discharge performanceGood electrical functionalitySubstation/switching arrangement detailsGas discharge vessels/containersThin metalEngineering

A plasma display panel device including a panel to display an image, a chassis base coupled to a rear surface of the panel, a thin metal plate interposed between the panel and the chassis base, a plurality of driving boards applying an electrical signal to discharge electrodes patterned within the panel, and a case to house the panel, the chassis base, the thin metal plate, and the driving boards. The chassis base is in the shape of a frame, so that the manufacturing costs of the chassis base are drastically reduced.

Owner:SAMSUNG SDI CO LTD

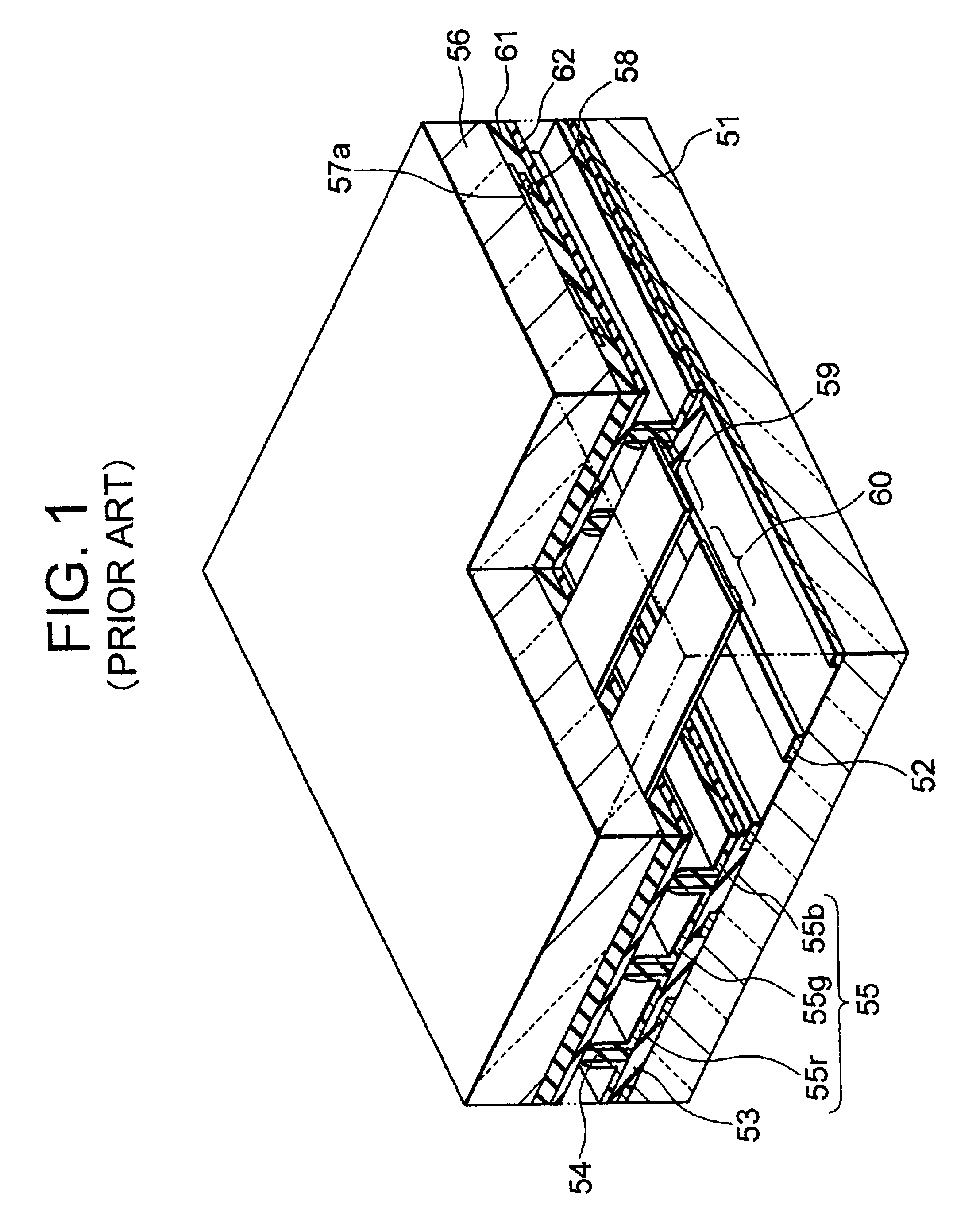

Plasma display panel having an improved plane electrode structure

InactiveUS6819046B2Wide operation marginReduce power consumption rateAddress electrodesSustain/scan electrodesPlanar electrodeFixed ratio

The PDP disclosed herein has a plurality of thin wire electrodes extending in the row direction, which are laid out in such a way as to widen the interval at a fixed ratio (2 times) from the discharge gap section toward the non-discharge gap section as well as to shorten the lengths of those row direction thin wire electrodes in steps with a fixed difference (approximately 20 mumxleft / right) from the cell's vertical center axis toward the partition walls. They are connected by thin wire electrodes that extend in the column direction to form antenna-shaped plane electrodes and the thin wire electrodes that extend in the column direction from the center of the antenna-shaped plane electrodes and the bus electrodes that extend in the row direction are connected to form a sustaining electrode pair (scan electrode and common electrode).

Owner:PIONEER CORP

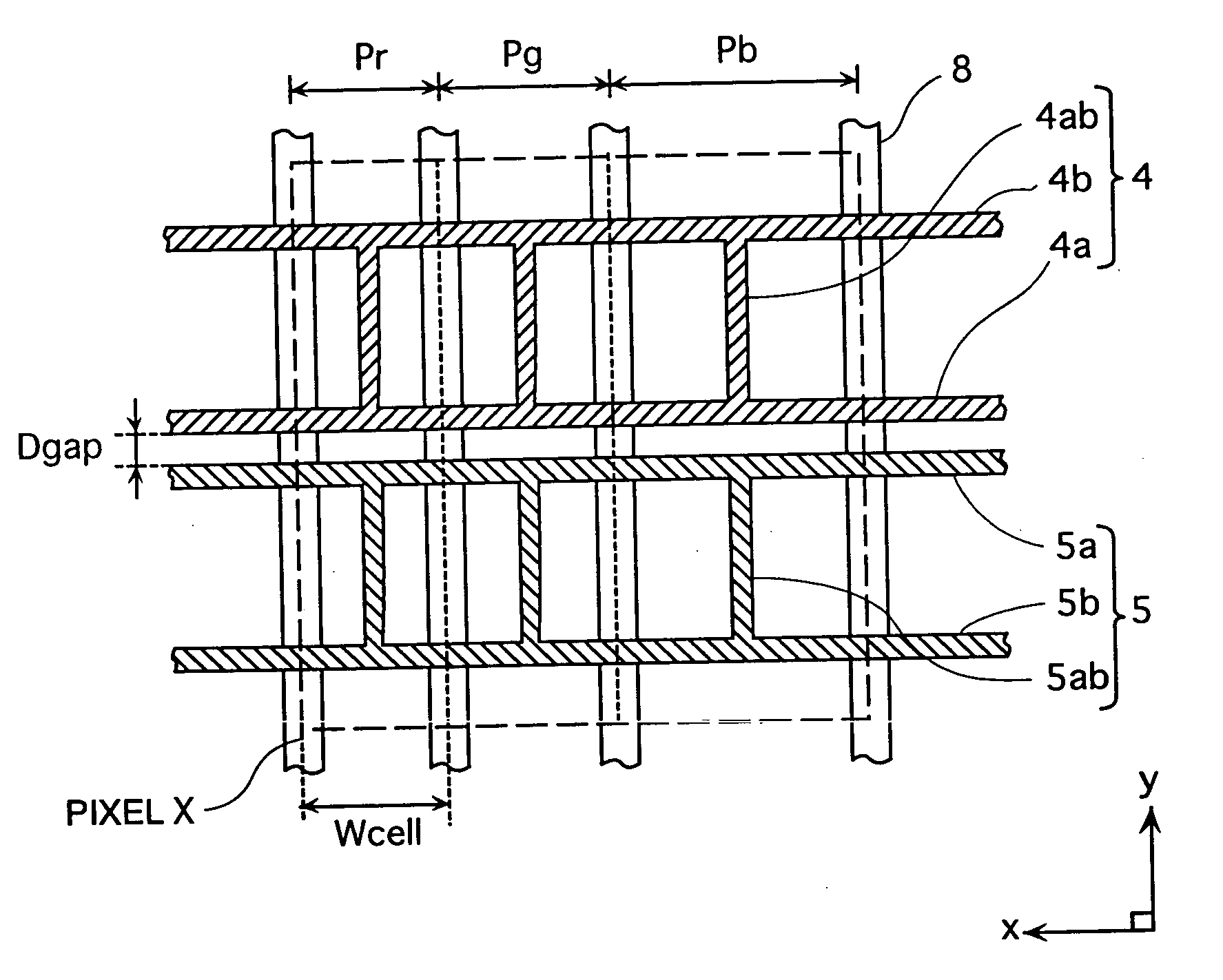

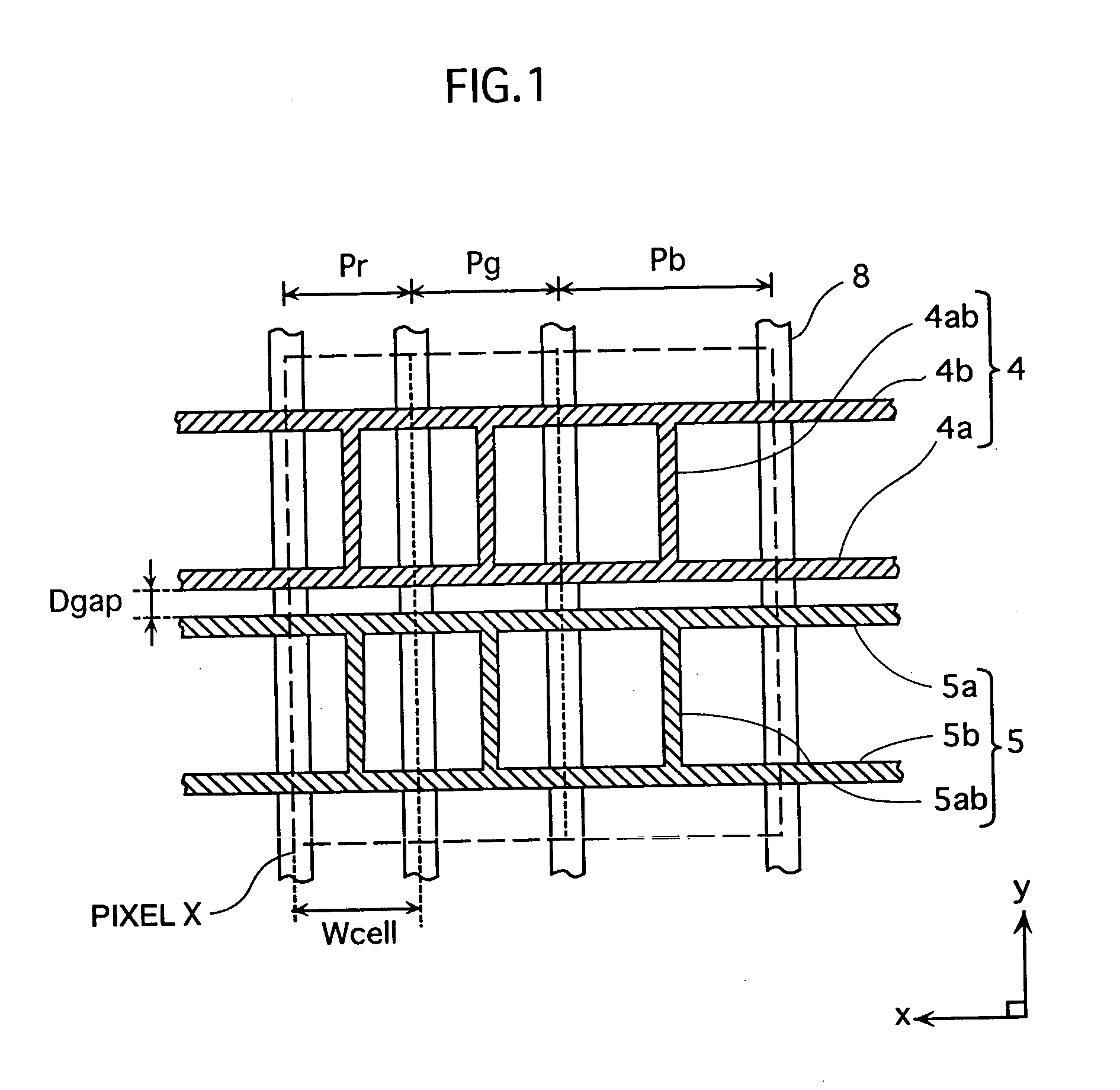

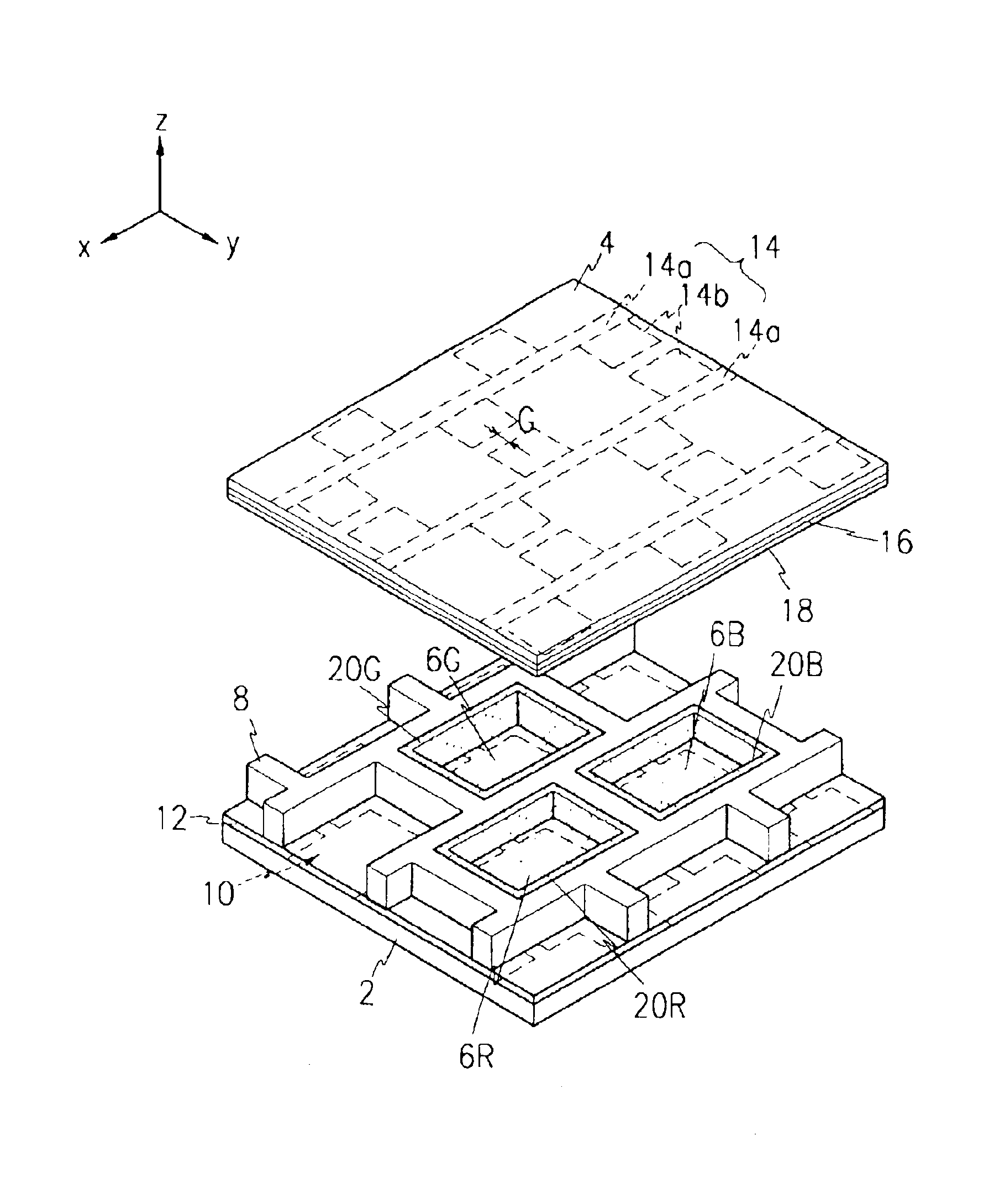

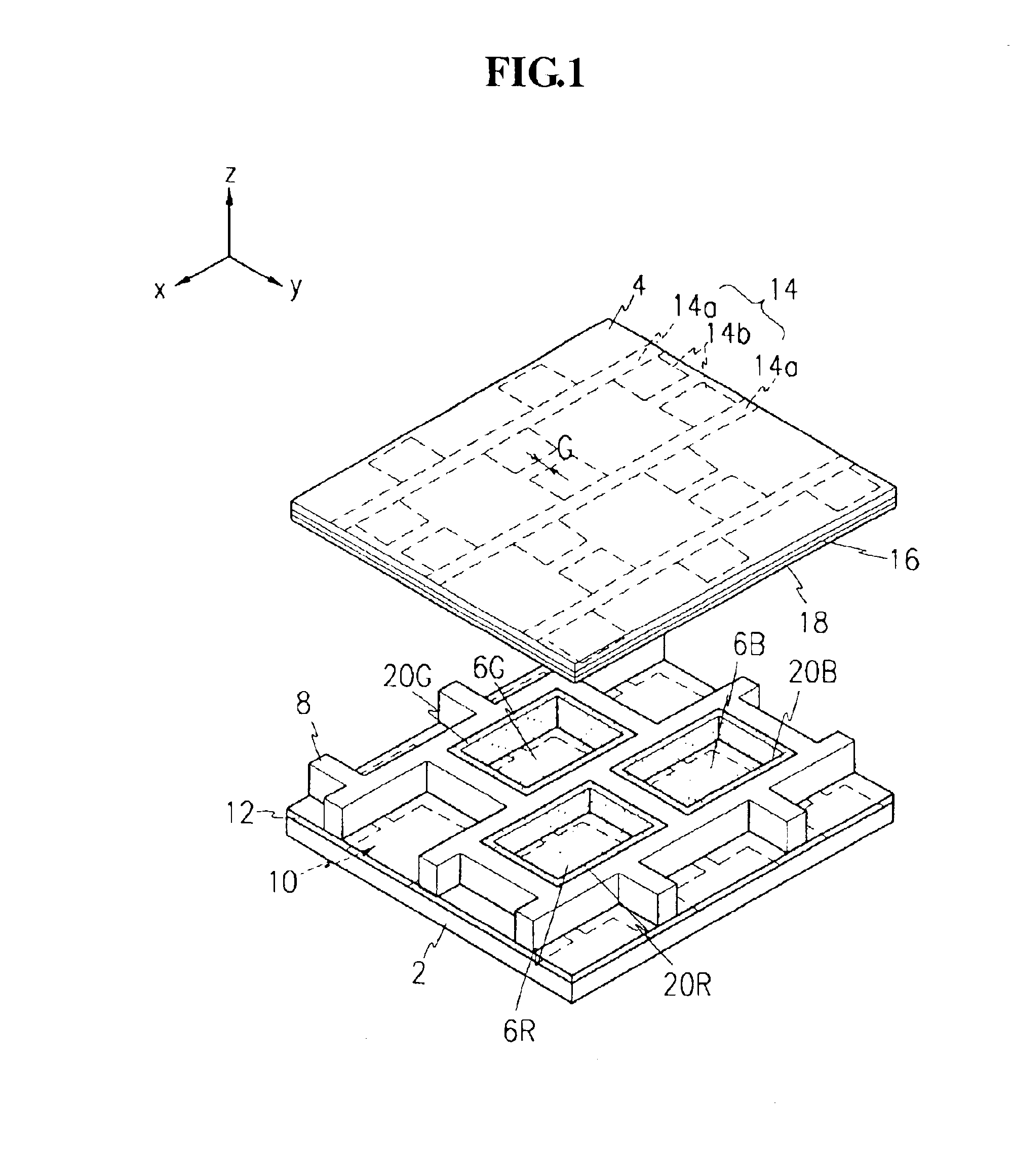

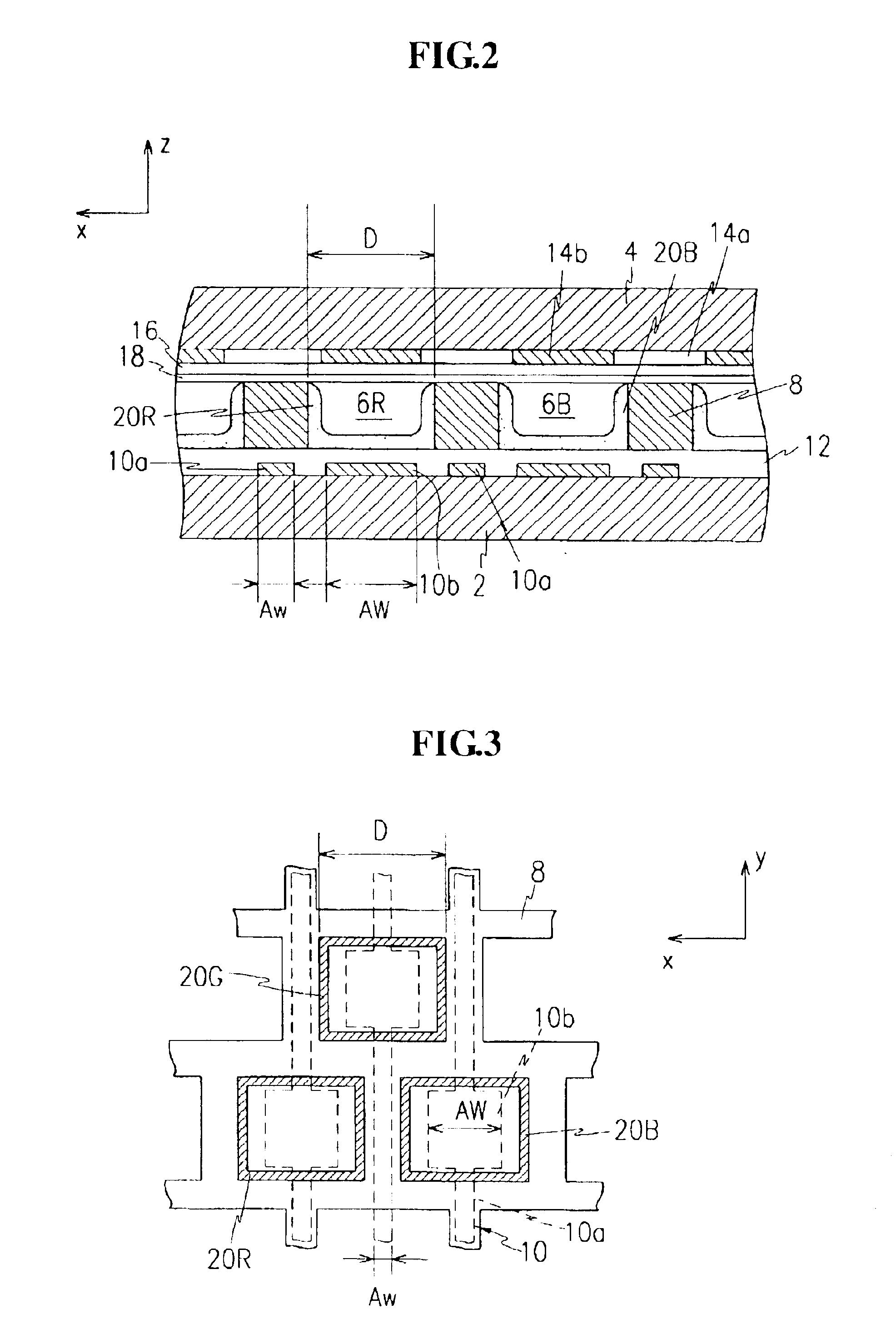

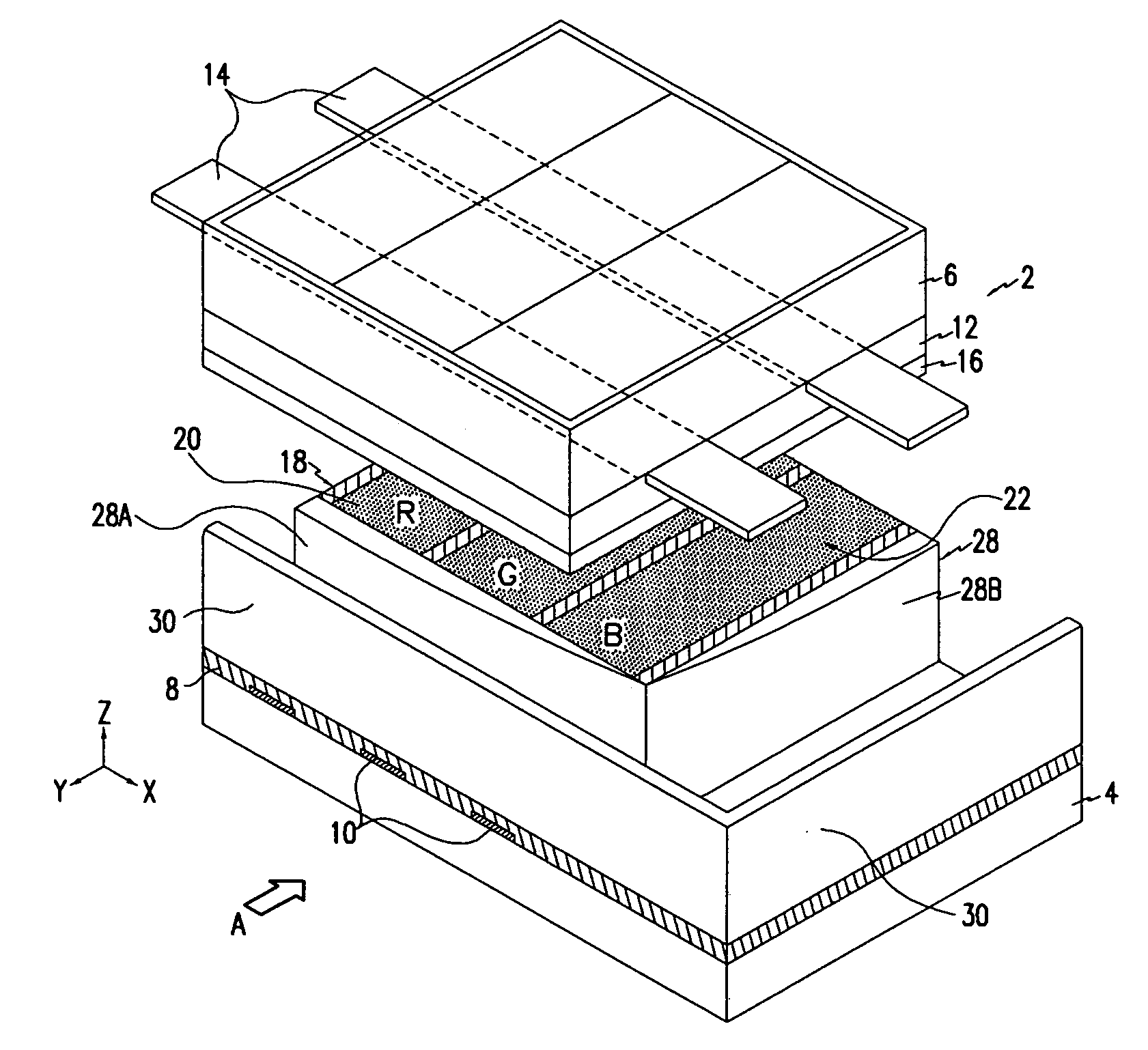

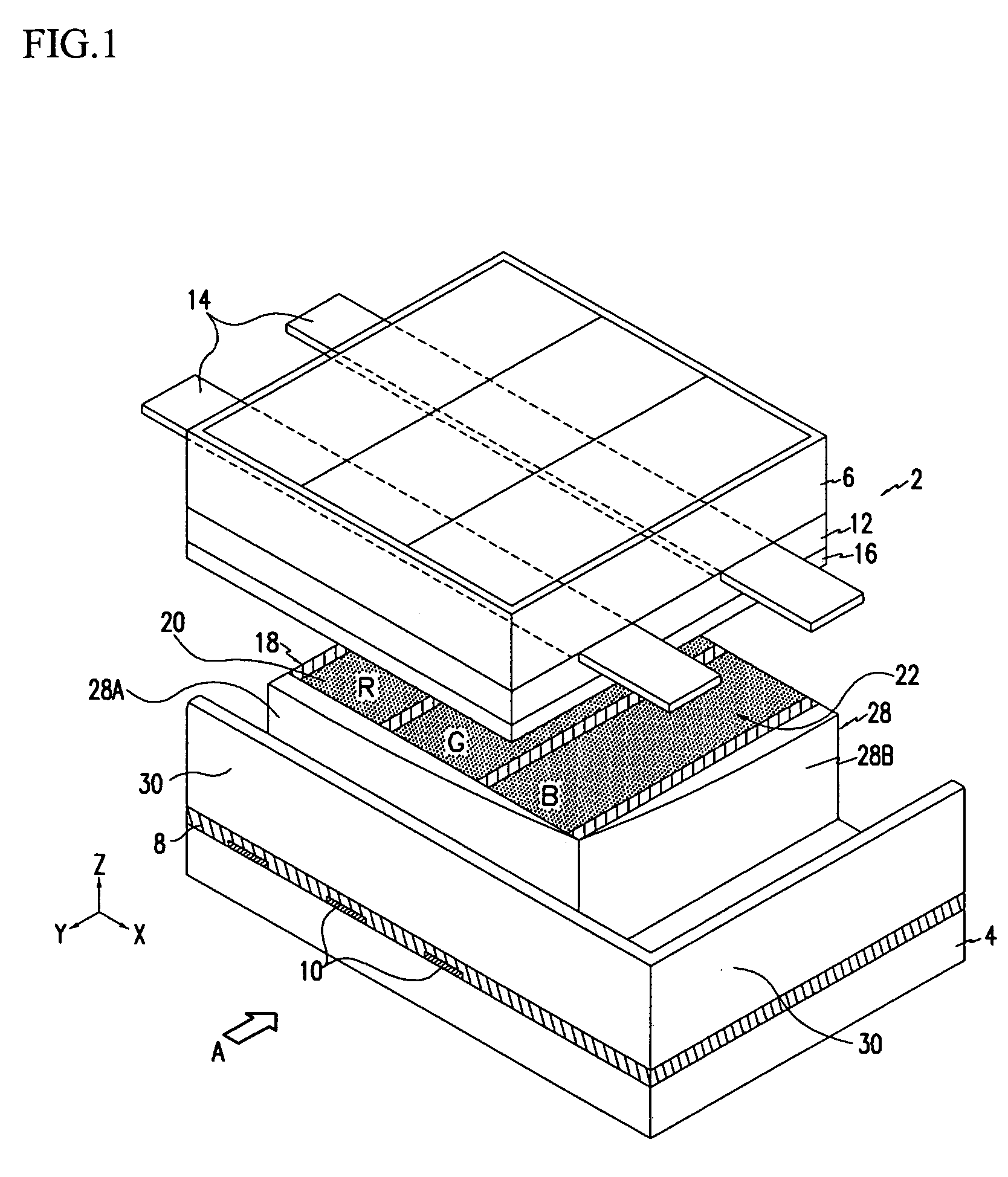

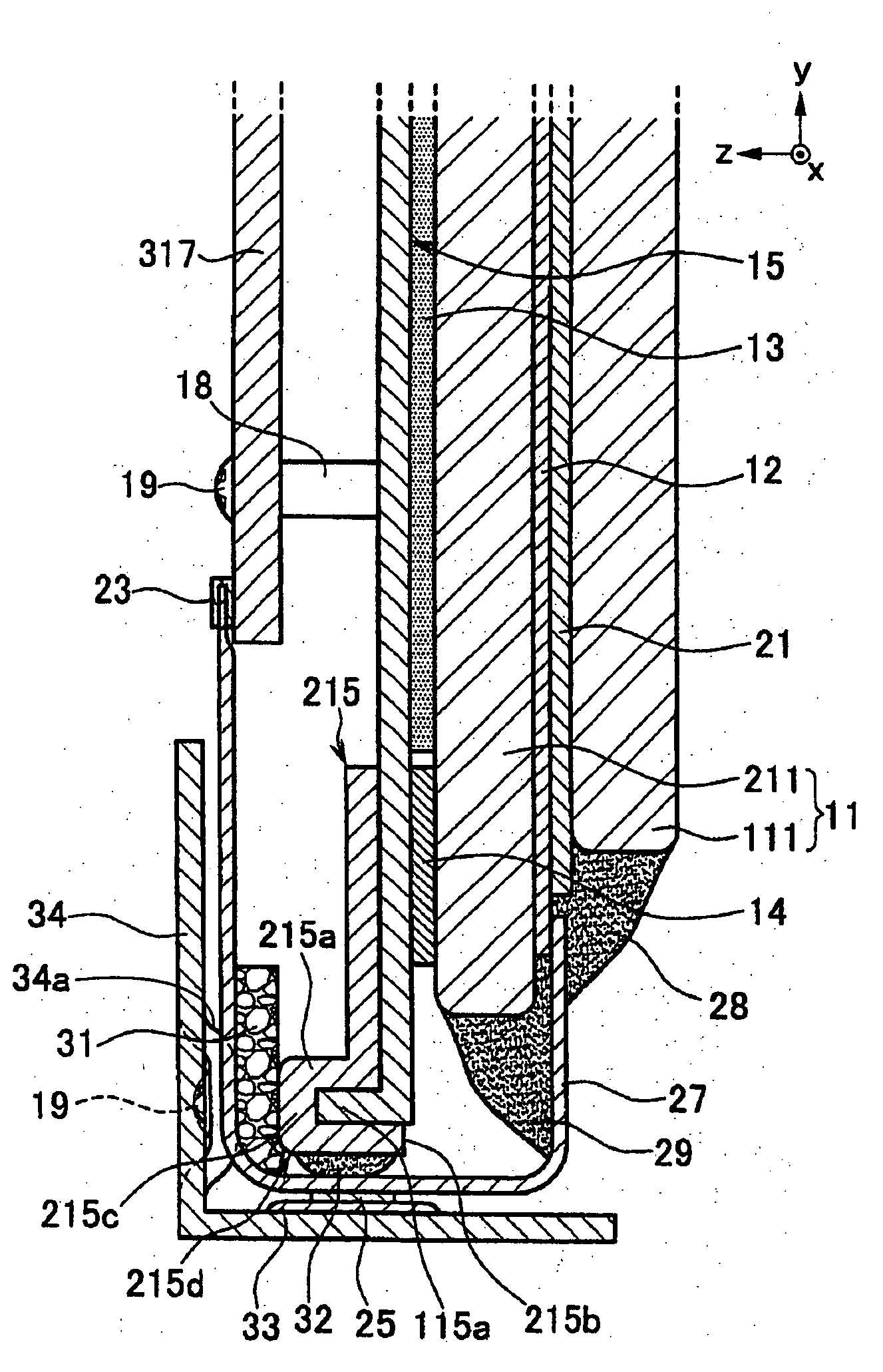

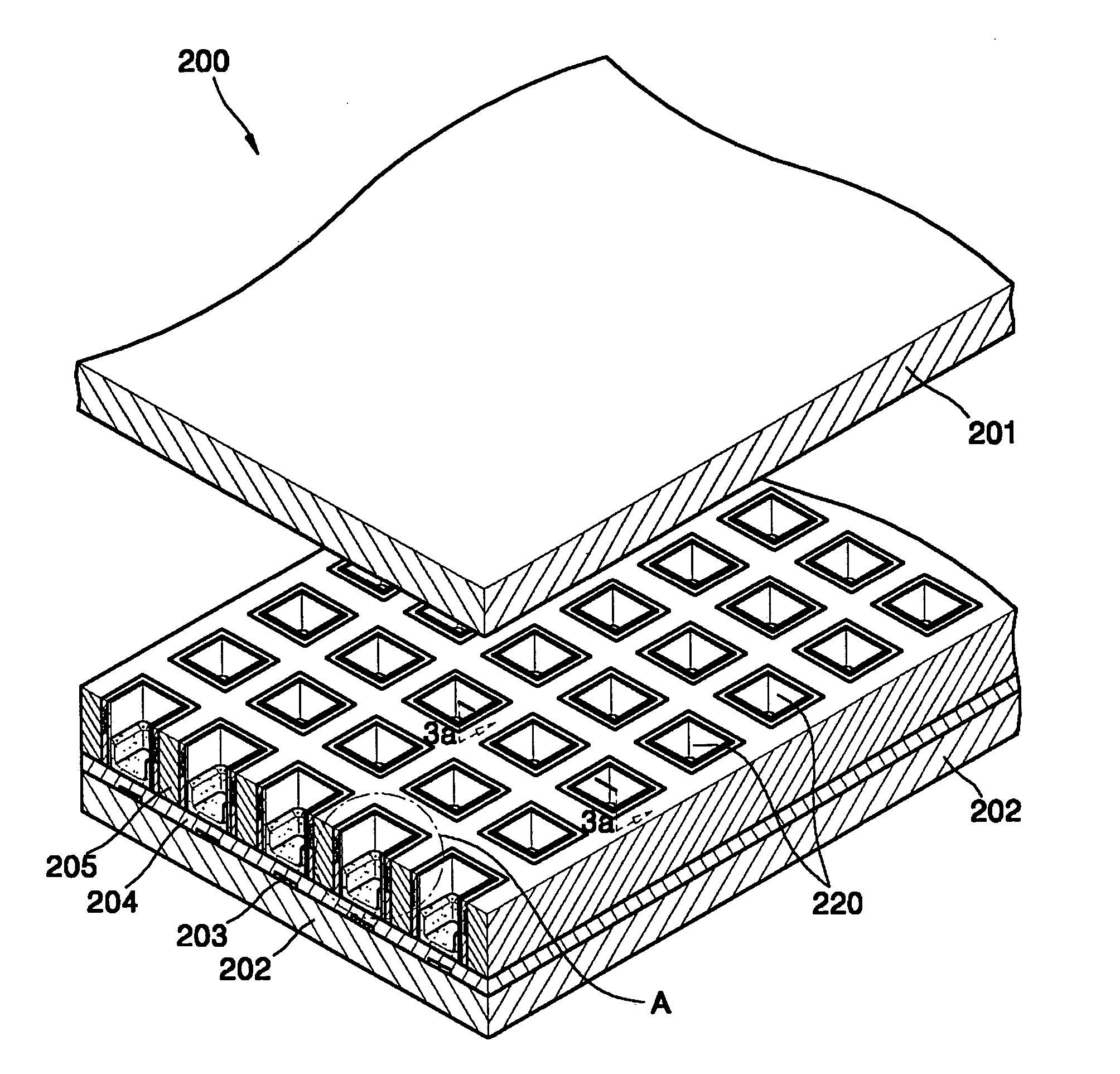

Plasma display panel having delta discharge cell arrangement

InactiveUS6853136B2Stable addressingImproving address voltage marginAddress electrodesGas discharge vessels/containersEngineeringPlasma display

A plasma display panel includes a first substrate and a second substrate, the first substrate and the second substrate being provided with a predetermined gap therebetween. Barrier ribs are formed in a non-striped pattern between the first substrate and the second substrate, the barrier ribs defining a plurality of discharge spaces. A plurality of address electrodes are formed on the first substrate along a direction (y), the address electrodes being formed within and outside discharge spaces. A plurality of sustain electrodes are formed on the second substrate along a direction (x), the sustain electrodes being formed within and outside discharge spaces. The address electrodes include large electrode portions provided within discharge spaces and small electrode portions provided outside the discharge spaces. If a width of large electrode portions is AW, a width of small electrode portions is Aw, and a distance between barrier ribs along direction (x) is D, AW is larger than Aw, and AW is 40-75% of D.

Owner:SAMSUNG SDI CO LTD

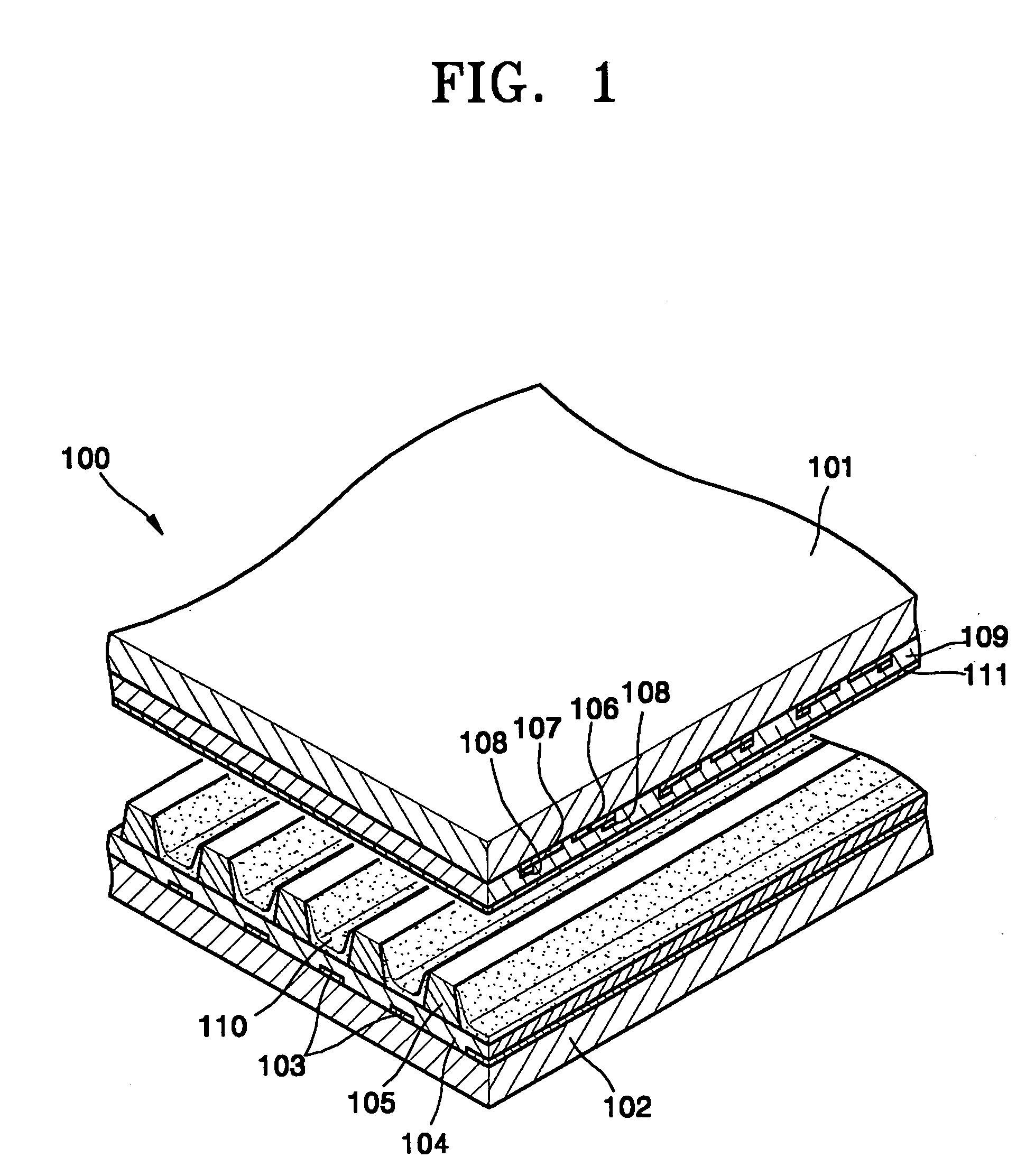

Plasma display panel

InactiveUS20070126361A1Reduce voltageImproves contrast and jitter characteristicSustain/scan electrodesGas discharge vessels/containersTectorial membraneEngineering

Disclosed is a plasma display panel with improved discharge characteristics. The plasma display panel comprises an upper panel and a lower panel integrally joined to the upper panel through barrier ribs wherein the upper panel includes a dielectric layer, a first protective film formed on one surface of the dielectric layer and composed of columnar magnesium oxide crystal particles, and a second protective film formed on the first protective film and composed of hexahedral magnesium oxide crystal particles.

Owner:LG ELECTRONICS INC

Plasma display panel

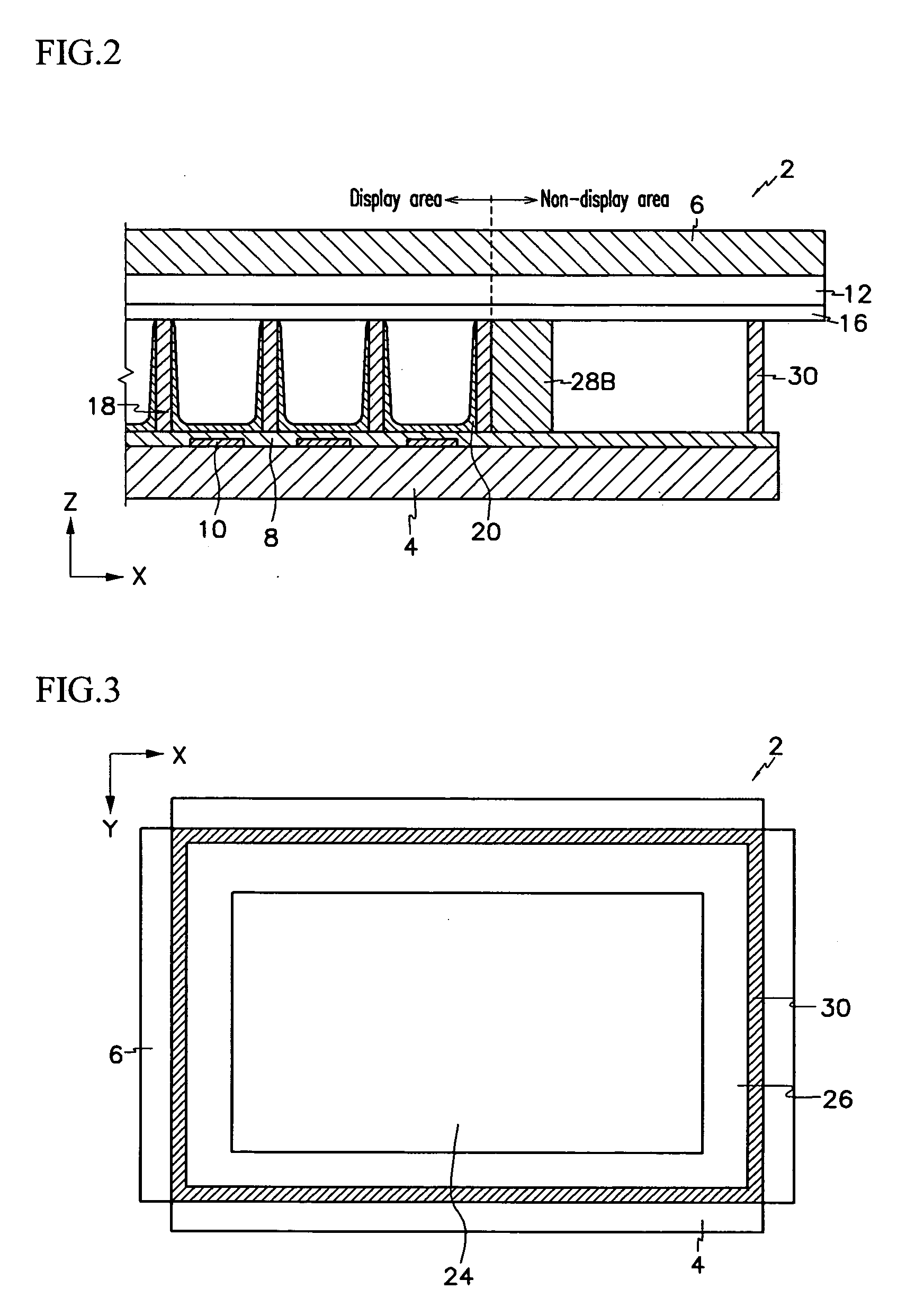

InactiveUS20040201351A1Improve structural strengthMinimize damageAddress electrodesSustain/scan electrodesPhosphorEngineering

A plasma display panel includes first and second substrates spaced apart from each other at a distance while proceeding substantially parallel to each other. The first and the second substrates have a display area and a non-display area. A plurality of address electrodes are formed on the first substrate, and covered by a dielectric layer. Main barrier ribs are arranged between the substrates to form discharge cells. Phosphor layer is formed with the discharge cells. A plurality of discharge sustain electrodes are formed on the surface of the second substrate facing the first substrate, and covered by a dielectric layer. Reinforcing barrier ribs are arranged at the non-display area while surrounding the display area, and connected to the main barrier ribs with an outer structure curved toward the outside of the substrates.

Owner:SAMSUNG SDI CO LTD

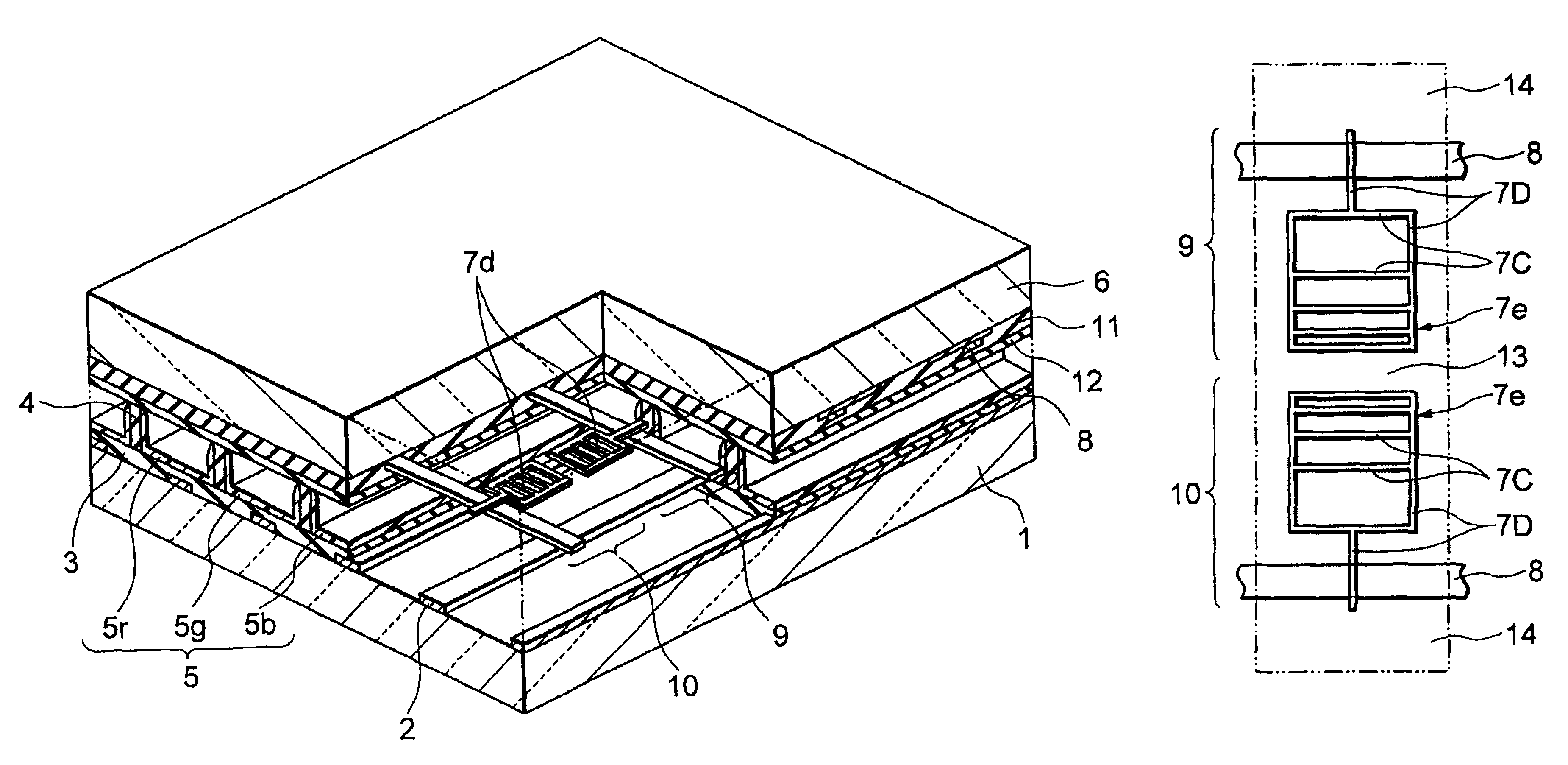

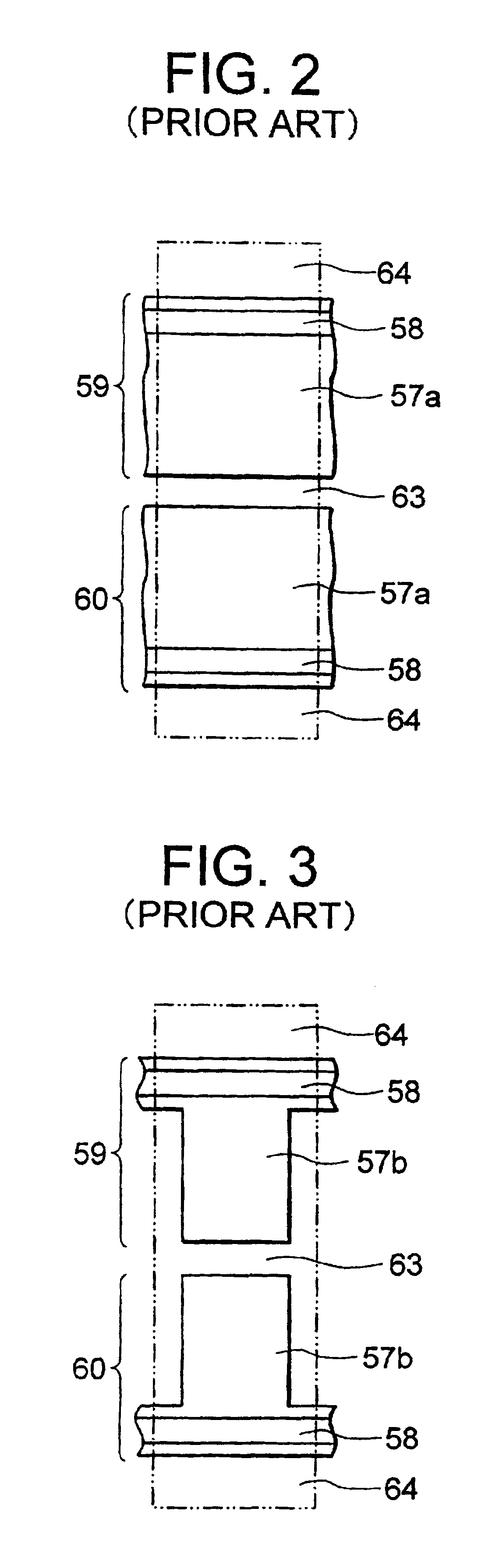

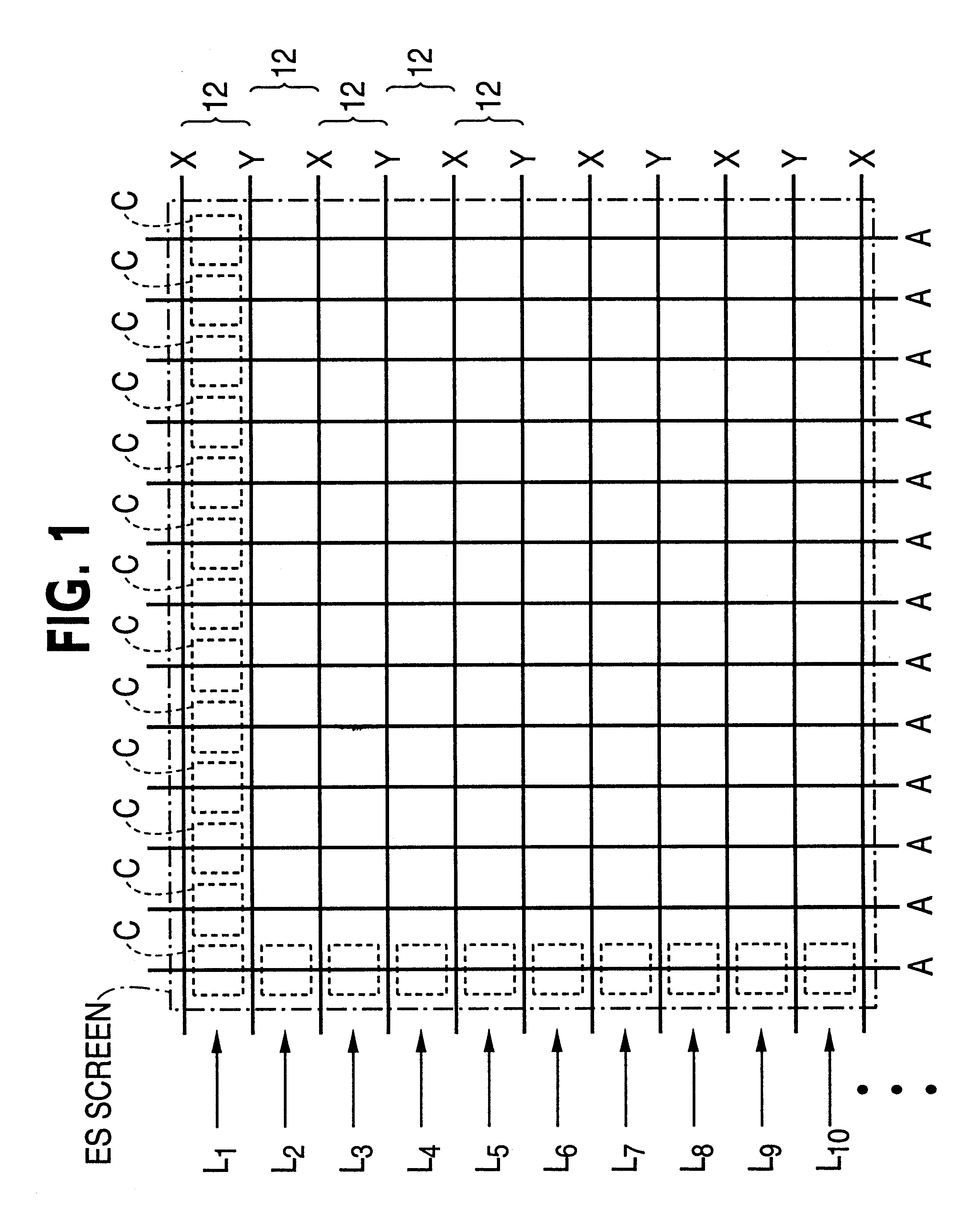

Plasma display panel with various electrode projection configurations

InactiveUS6495957B2Reduce the burden onPrevented from expandingAddress electrodesSustain/scan electrodesEngineeringElectrode pair

A plasma display panel includes a plurality of row electrodes defining rows of a screen. The row electrodes are arranged at intervals so that adjacent row electrodes are capable of serving as an electrode pair for generating a surface discharge. Each of the row electrodes includes a belt-shaped base extending along the full length of the screen in a direction of the rows and protrusions extending from the base toward an adjacent row electrode in every column.

Owner:HITACHI PLASMA PATENT LICENSING

Heat spreader for display device

InactiveUS20060171124A1Temperature differenceGraphiteGas discharge vessels/containersLiquid-crystal displayDisplay device

A heat spreader for a display device, such as a plasma display panel, a light emitting diode or a liquid crystal display, which includes at least one sheet of compressed particles of exfoliated graphite having two major surfaces.

Owner:NEOGRAF SOLUTIONS LLC

Plasma display device

InactiveUS20080186662A1Reduce noise transferAvoid problemsMagnetic/electric field screeningGas discharge vessels/containersDisplay devicePrinted circuit board

A design for a plasma display device that attenuates noise generated in a flexible printed circuit (FPC) so that the noise does not reach the chassis base, the FPC connecting a printed circuit board assembly to electrodes within the plasma display panel. The plasma display device includes a spacer made out of non woven fabric and located between the FPC and the chassis.

Owner:SAMSUNG SDI CO LTD

Plasma display panel

InactiveUS20050093444A1Increased aperture percentageImprove transmittanceAddress electrodesSustain/scan electrodesOptoelectronicsPlasma display

A plasma display panel includes a pair of substrates spaced apart from each other and facing each other, a visible light generator arranged between the pair of substrates, and an electrode layer adapted to apply the same potential to a plane arranged between the pair of substrates at a predetermined angle with respect to a direction perpendicular to the pair of substrates.

Owner:SAMSUNG SDI CO LTD

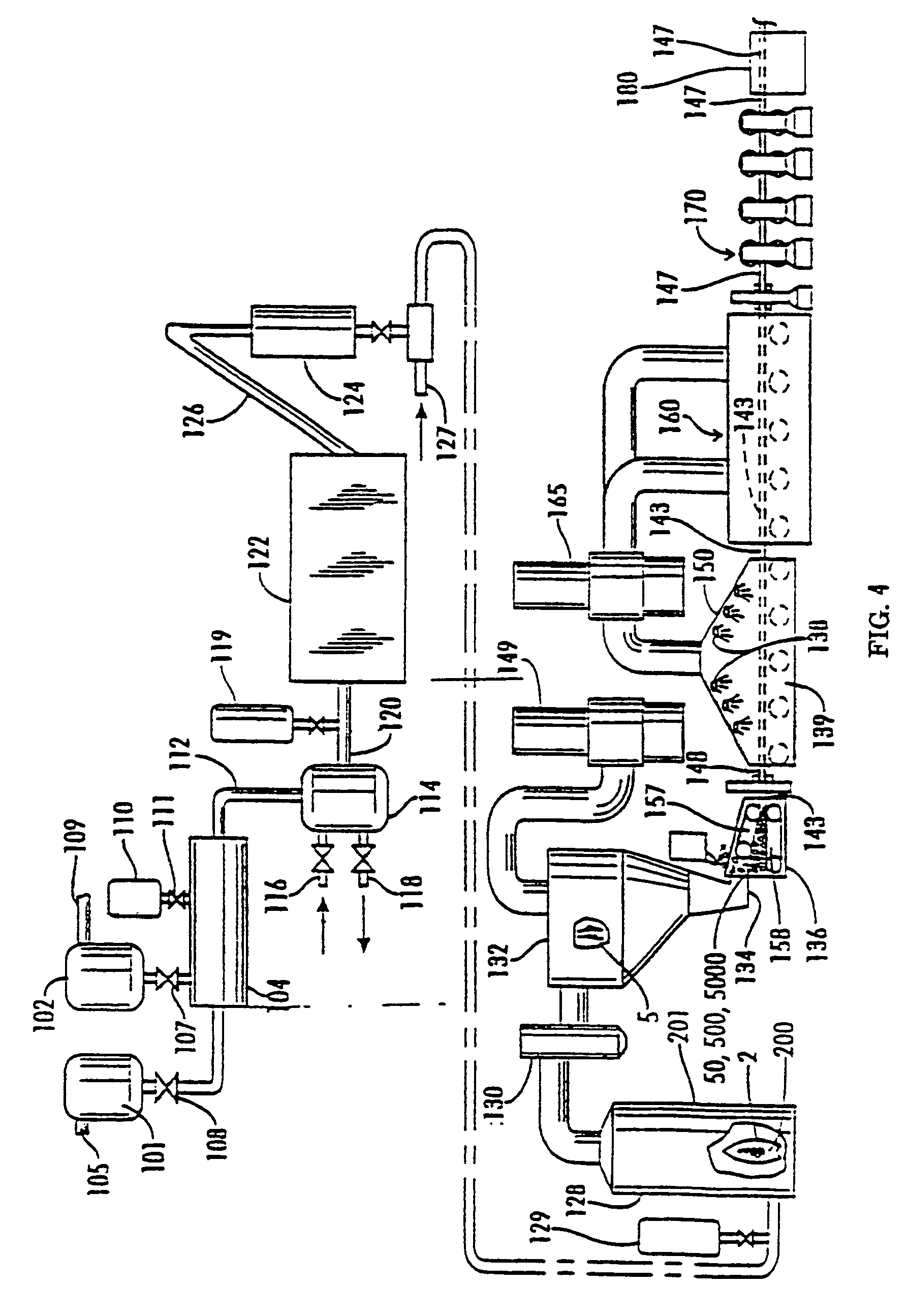

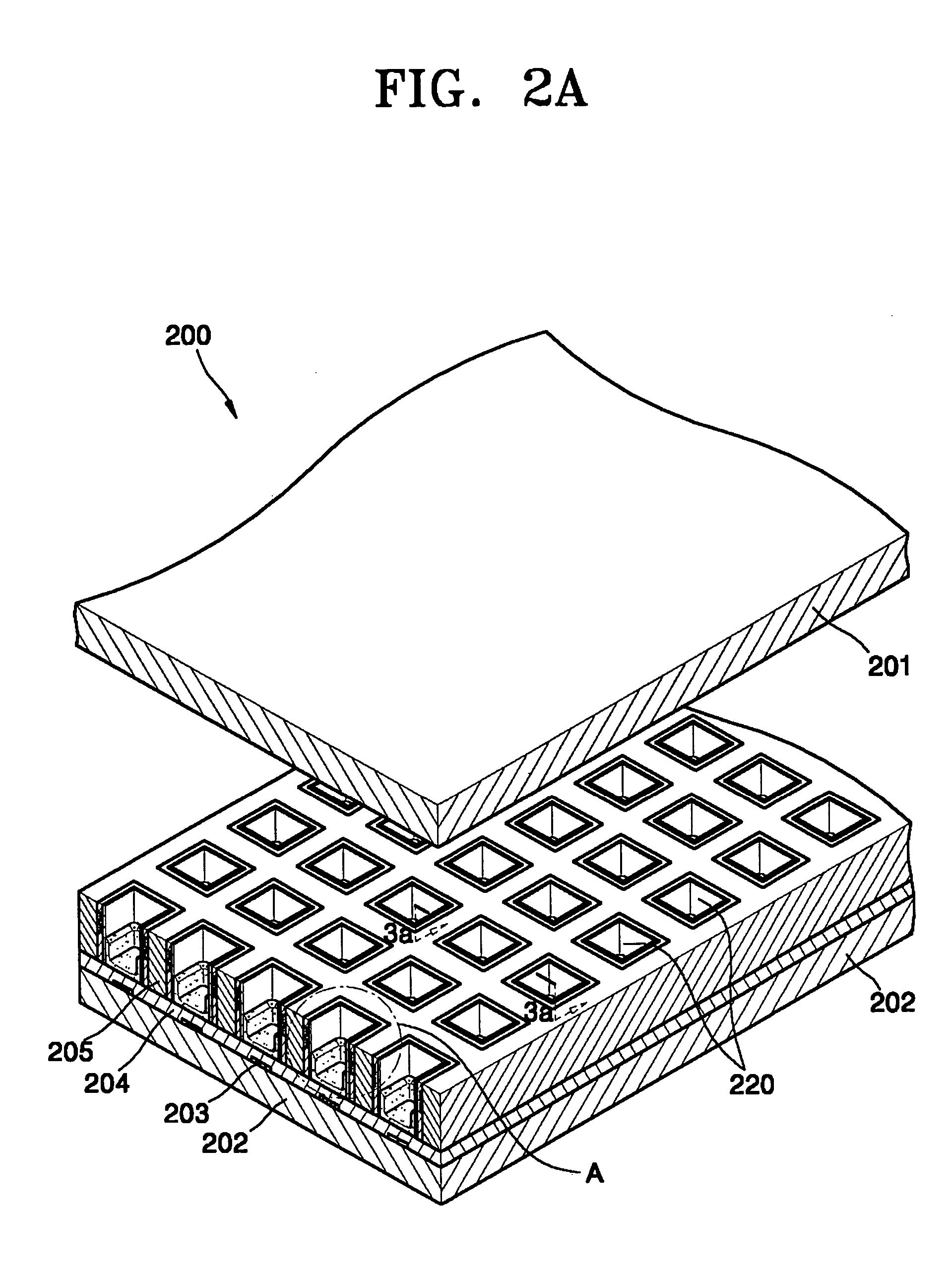

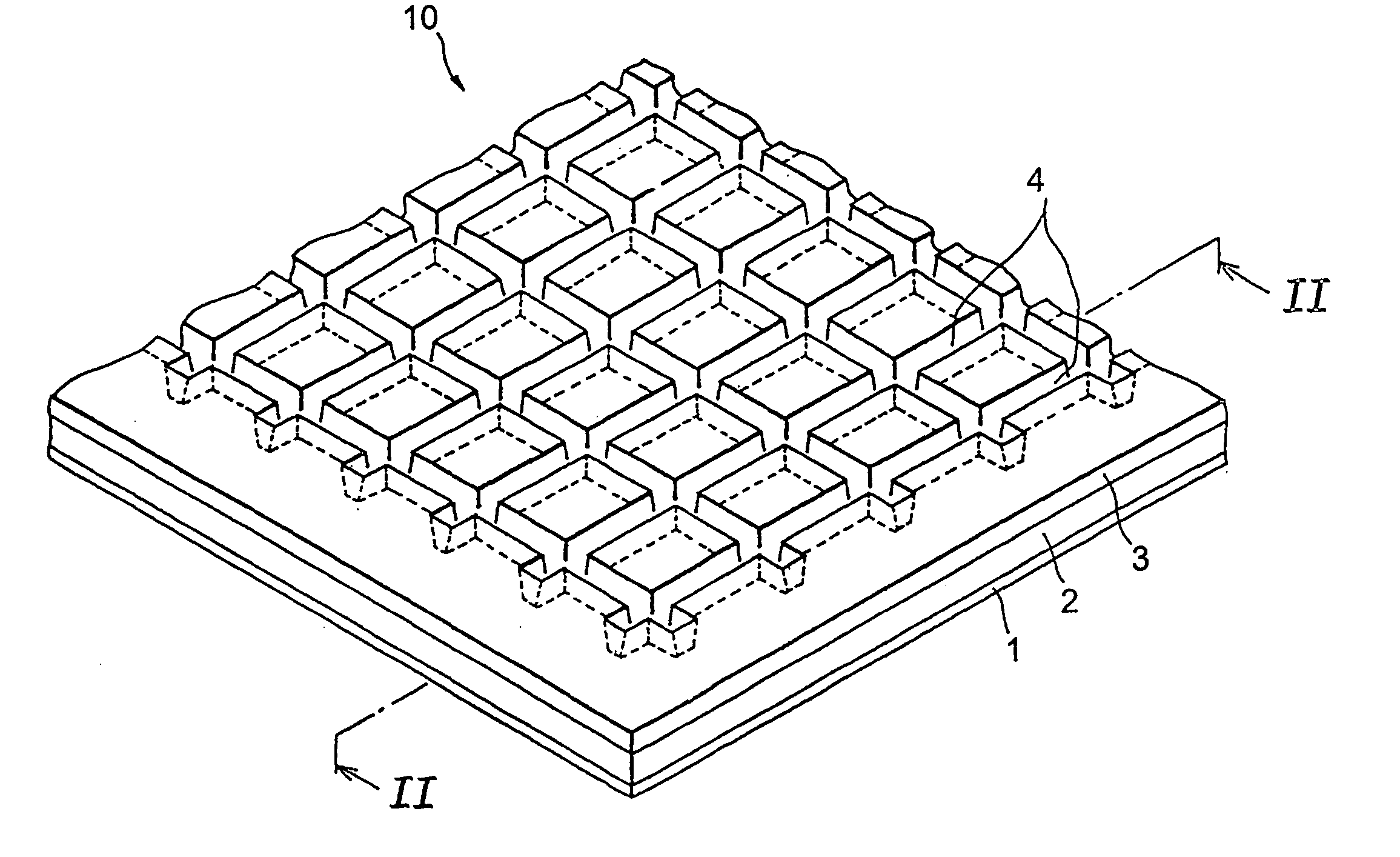

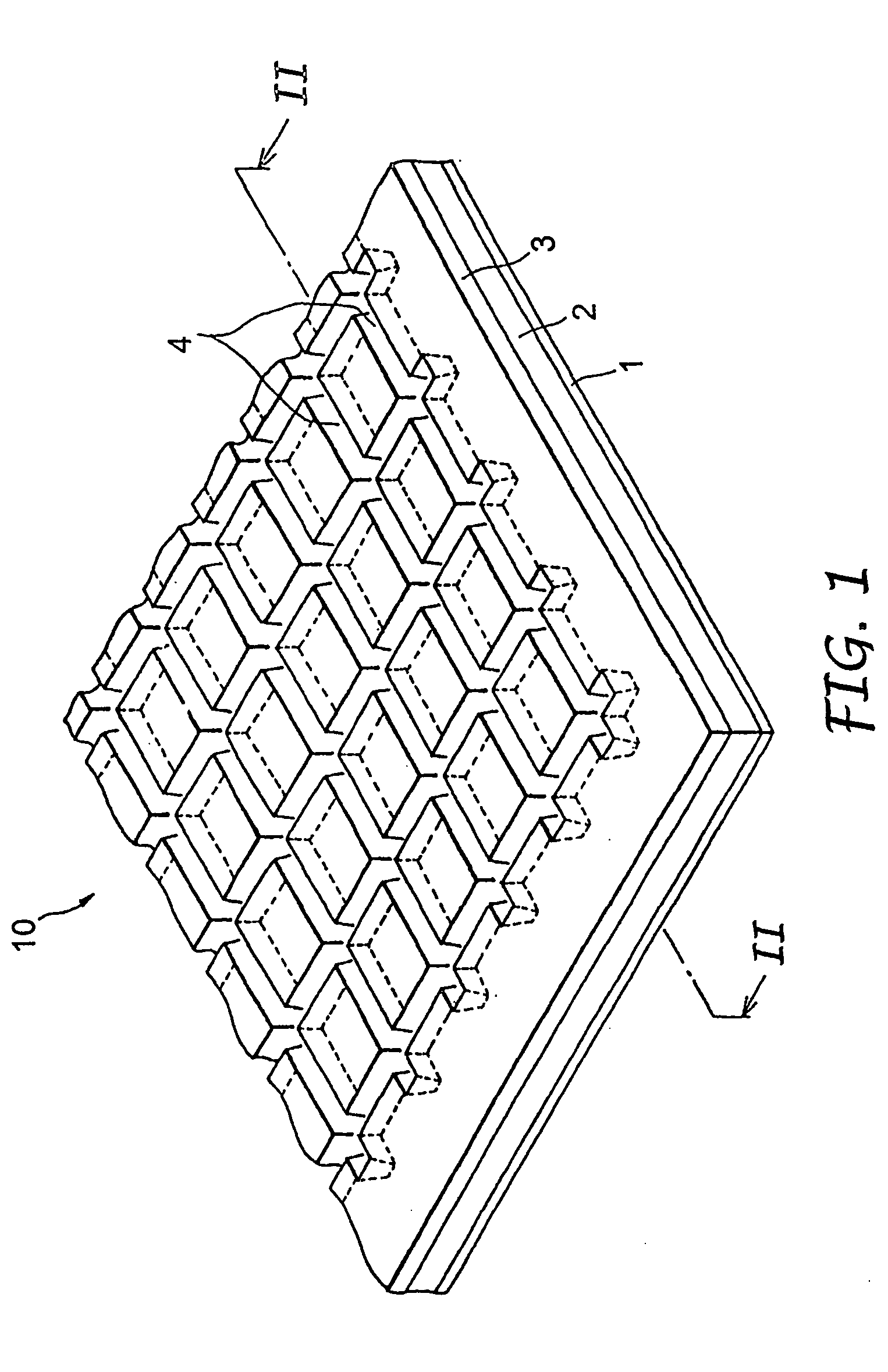

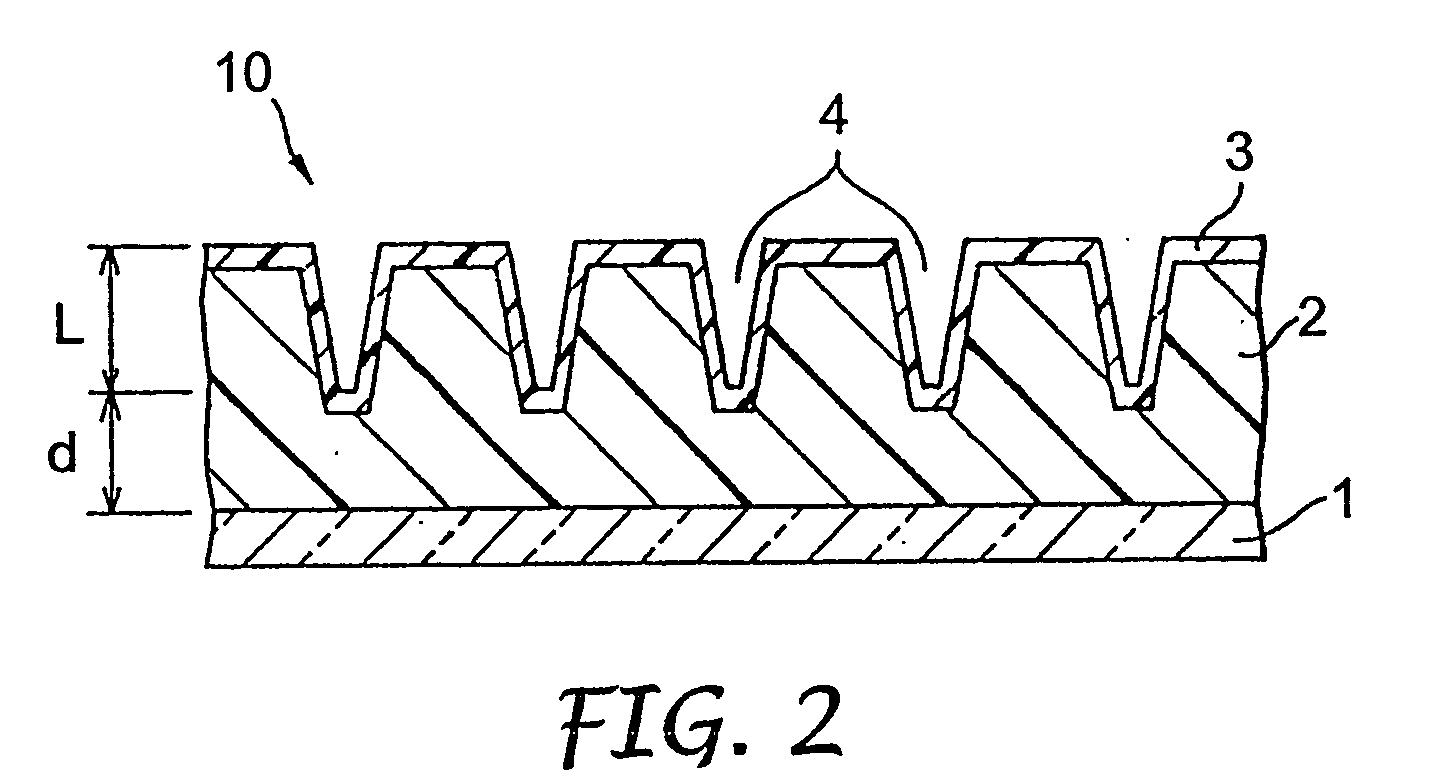

Flexible mold and method of manufacturing microstructure using the same

InactiveUS20050253290A1Simple structureLighting and heating apparatusGas discharge electrodesViscosityPolymer chemistry

To provide a flexible mold (10) useful for manufacturing a PDP rib having a lattice pattern and other microstructures, and capable of highly precisely manufacturing the microstructures without involving defects such as occurrence of bubbles and pattern deformation. A flexible mold (10) comprises a base layer (2) made of a first curable material having a viscosity of 3,000 to 100,000 cps at 10 to 80° C. and a coating layer (3) coating a surface of the base layer (2) and made of a second curable material having a viscosity of 200 cps or below at 10 to 80° C.

Owner:3M INNOVATIVE PROPERTIES CO

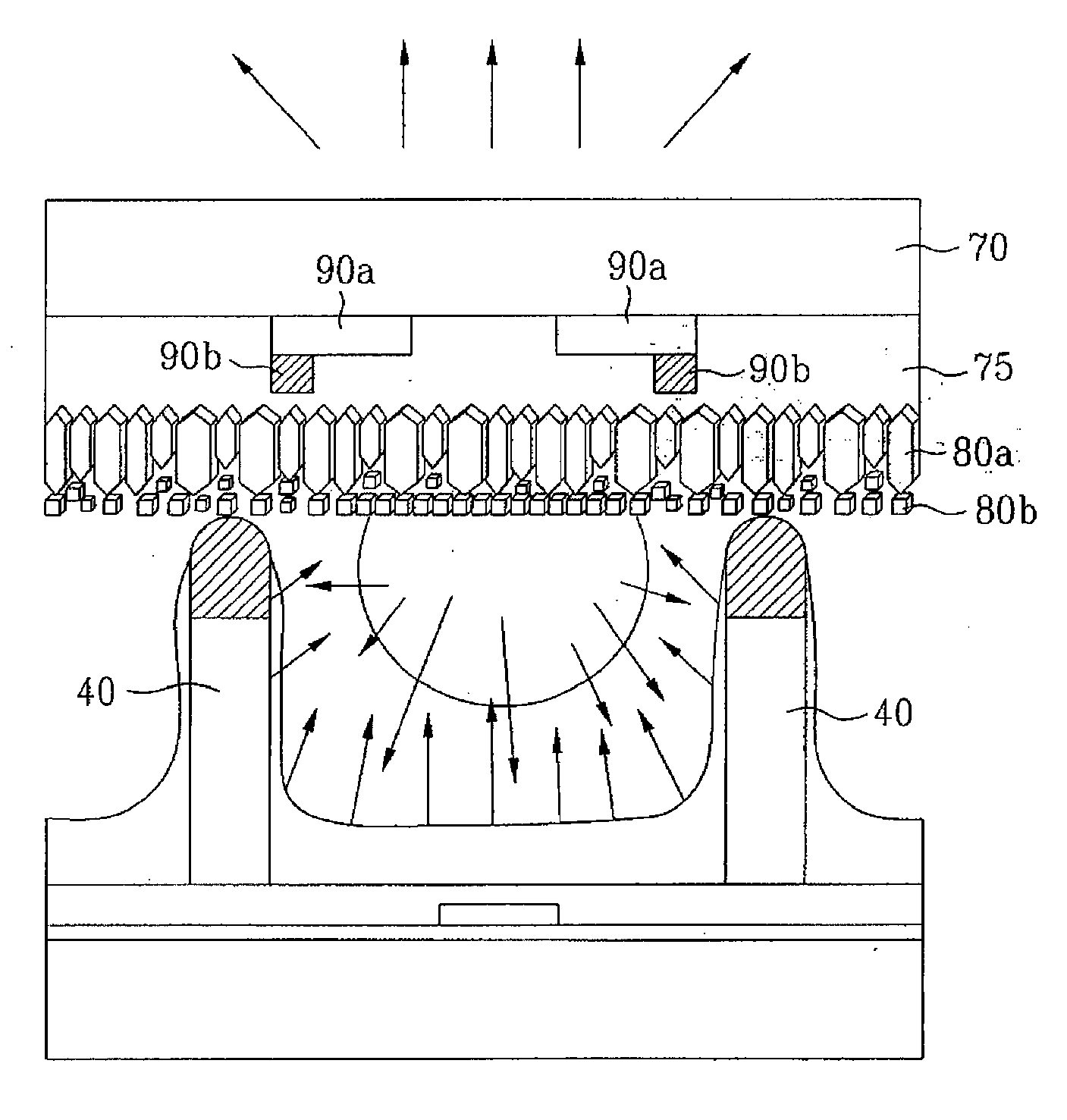

Plasma display panel utilizing carbon nanotubes and method of manufacturing the front panel of the plasma display panel

InactiveUS6933674B2Improve luminous efficiencyIncrease contrastAddress electrodesSustain/scan electrodesCarbon nanotubeSecondary electrons

A plasma display panel using carbon nanotubes is provided. In the front panel of the plasma display panel, transparent electrodes are formed as strips on the glass substrate. Bus electrodes are each formed as strips along the outer edge on the upper surface of each of the transparent electrodes and in parallel to the transparent electrodes. A dielectric layer is formed on part of the glass substrate, parts of the transparent electrodes, and the bus electrodes. Carbon nanotube strips are aligned on the dielectric layer such that the carbon nanotube strips face the transparent electrodes. A protective layer is formed on part of the dielectric layer and the carbon nanotube strips. Accordingly, the secondary electron emission characteristic is improved, resulting in a high-quality display screen having a high luminous efficiency and a high contrast ratio.

Owner:SAMSUNG SDI CO LTD

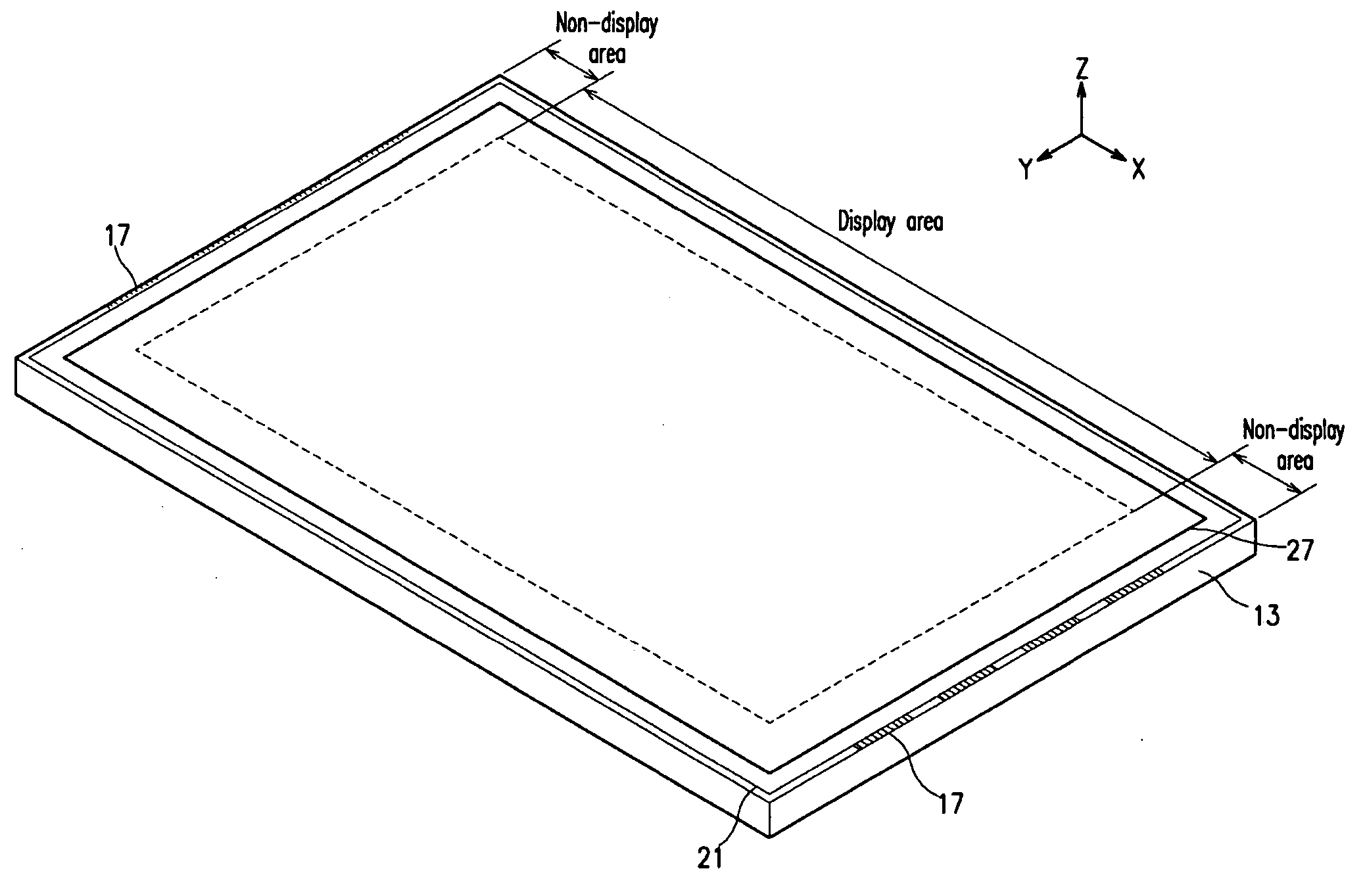

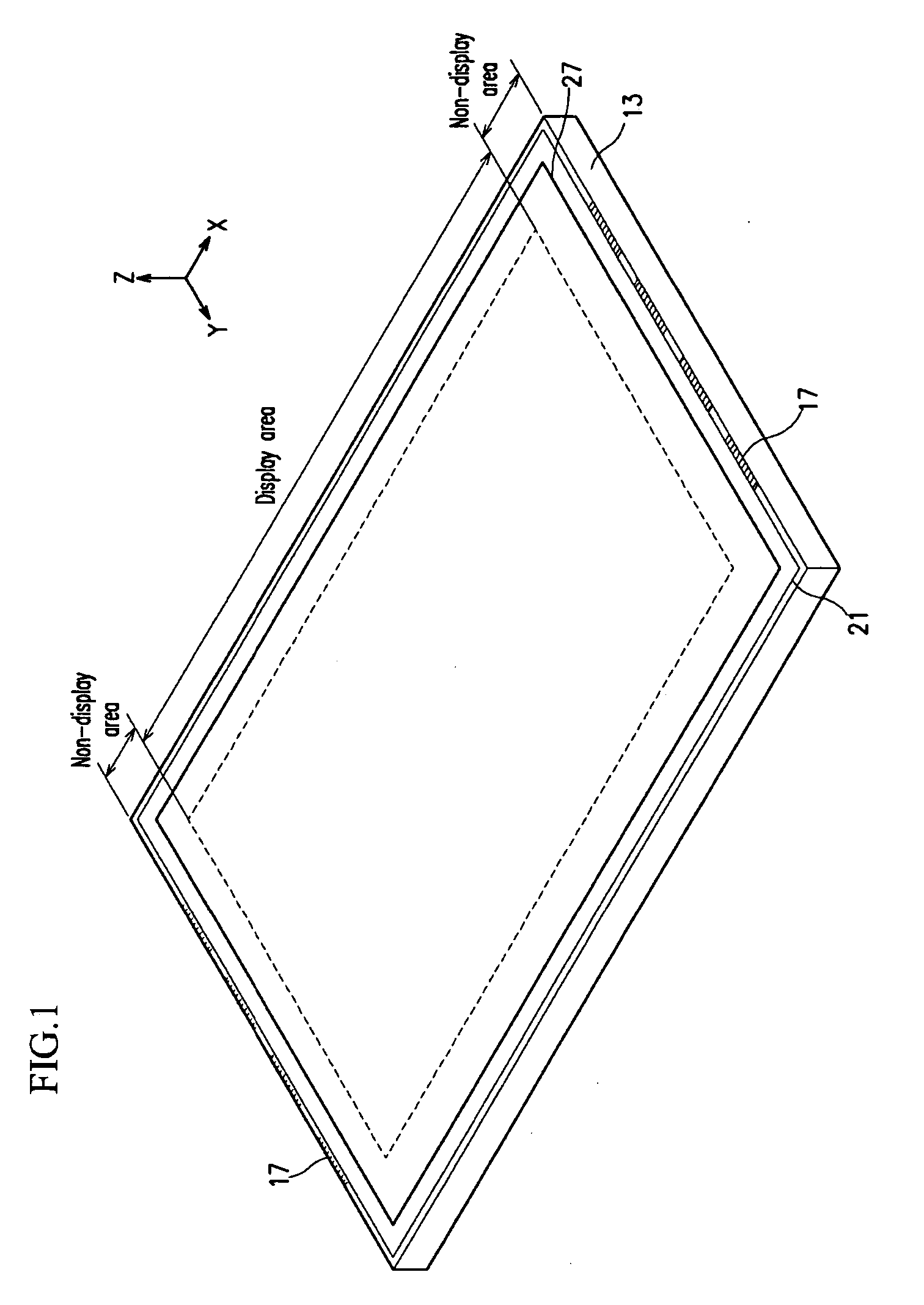

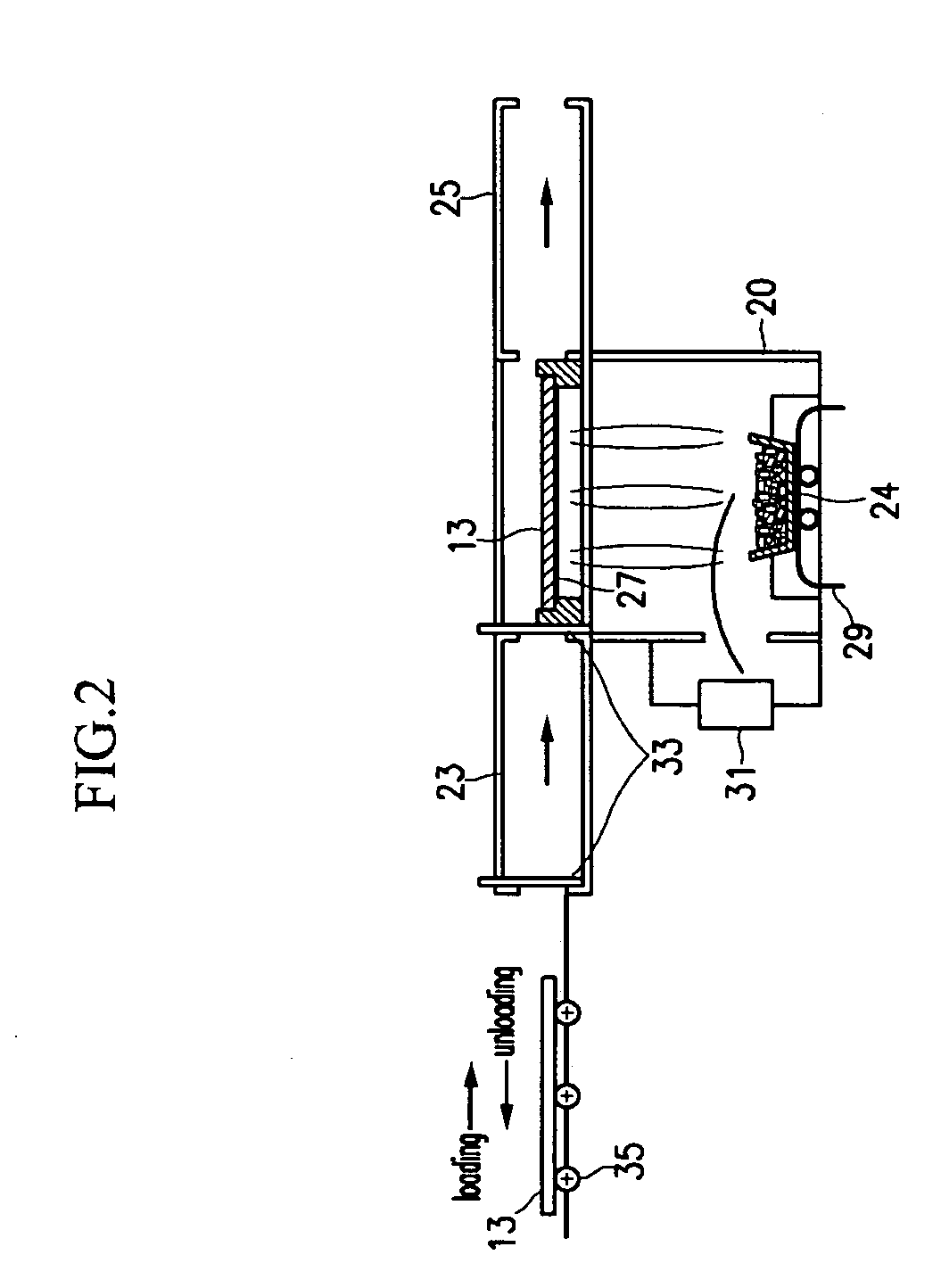

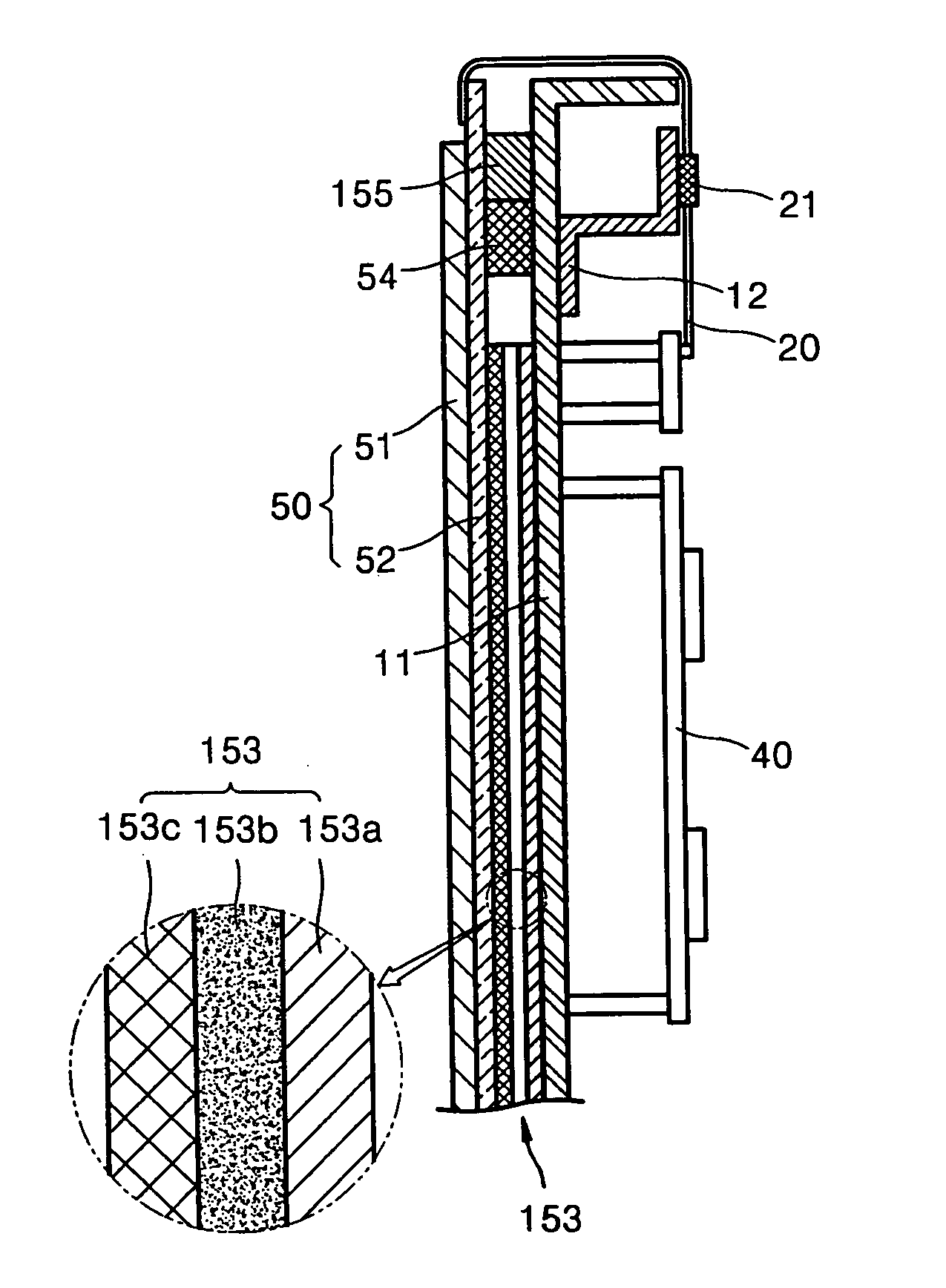

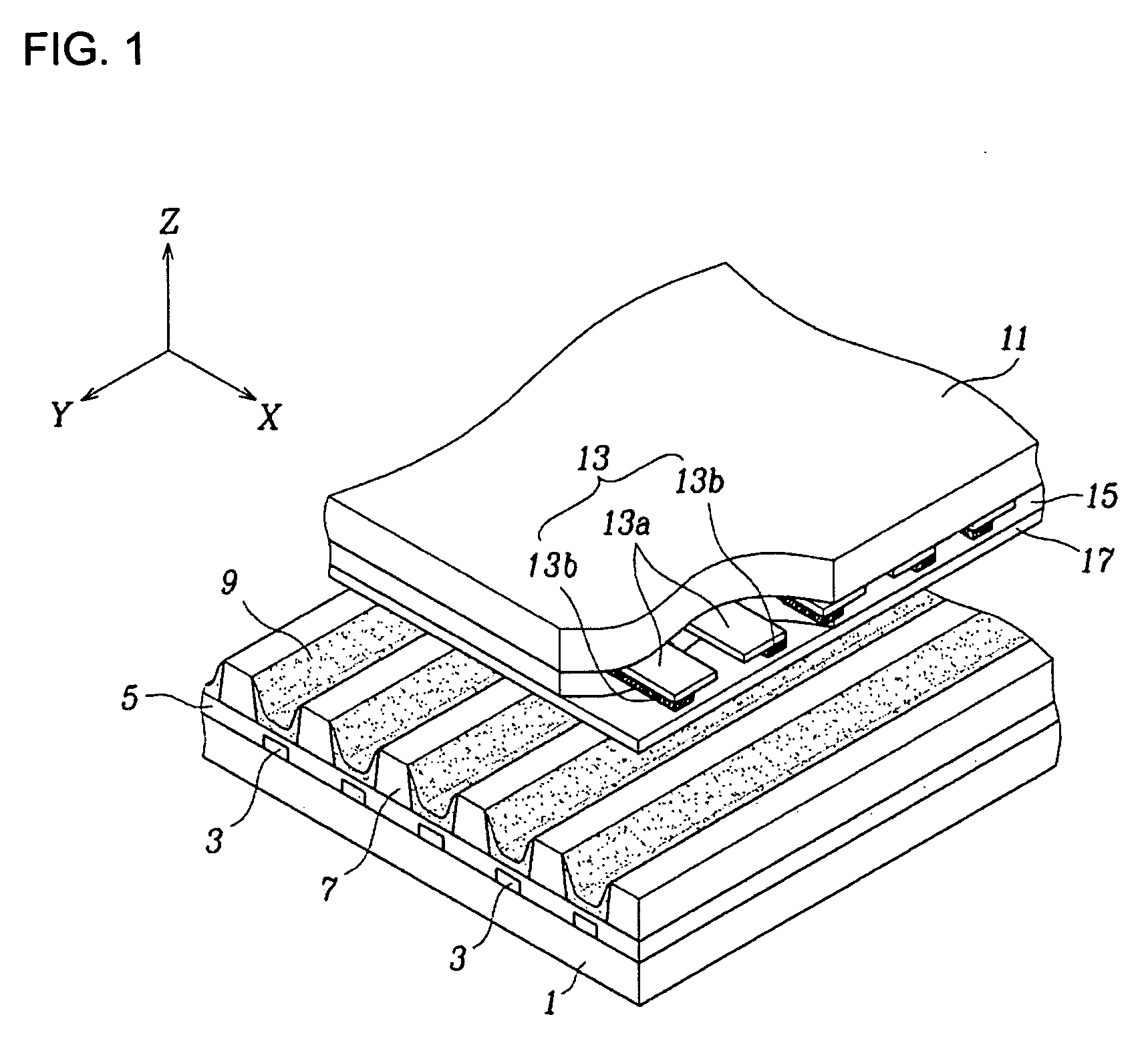

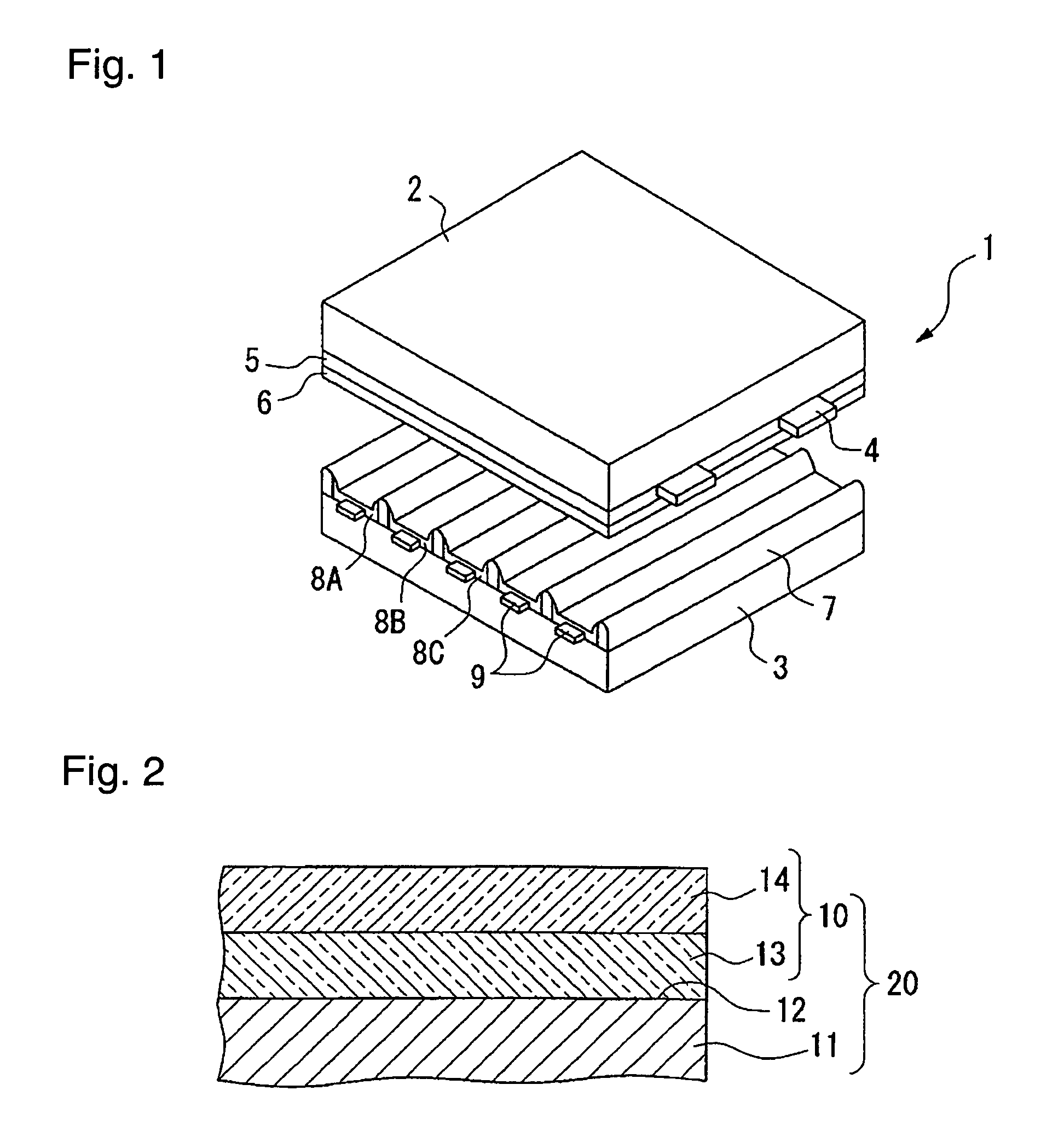

Flat display panel module and flat display apparatus

InactiveUS7554798B2Improve performanceEffectively buffering, absorbing, or distributing a forceGas discharge vessels/containersDigital data processing detailsAdhesive beltShock resistance

Owner:MAXELL HLDG LTD

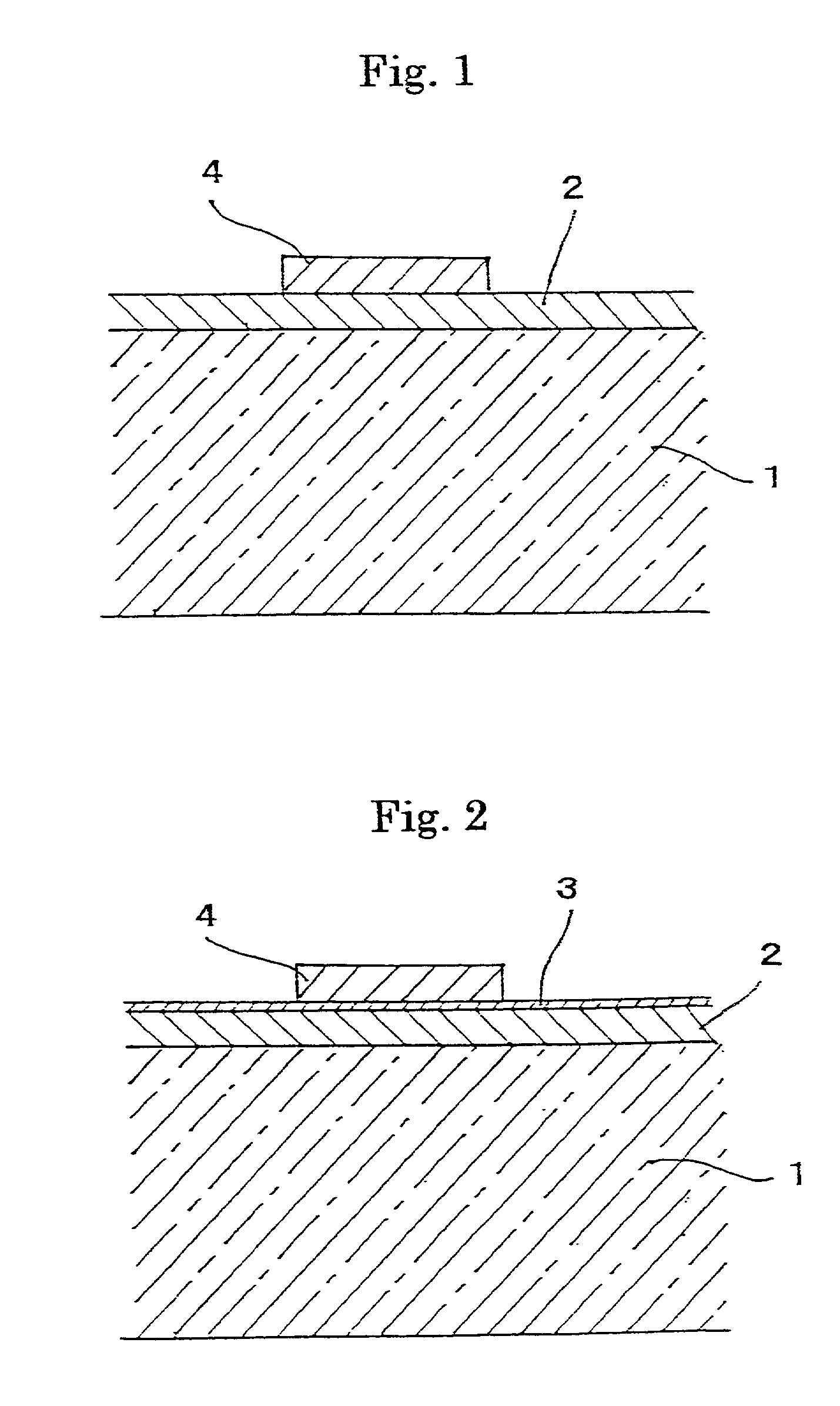

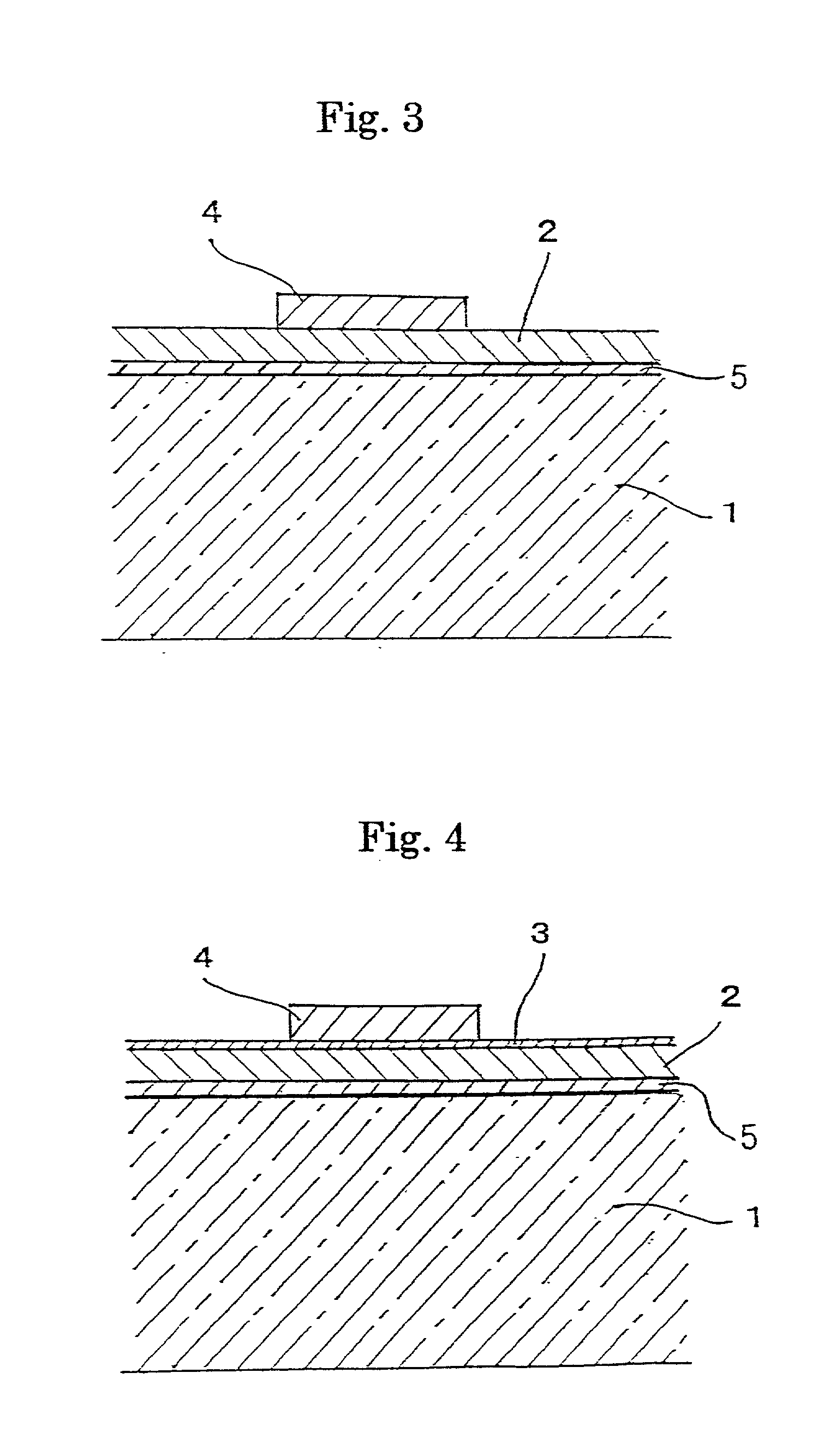

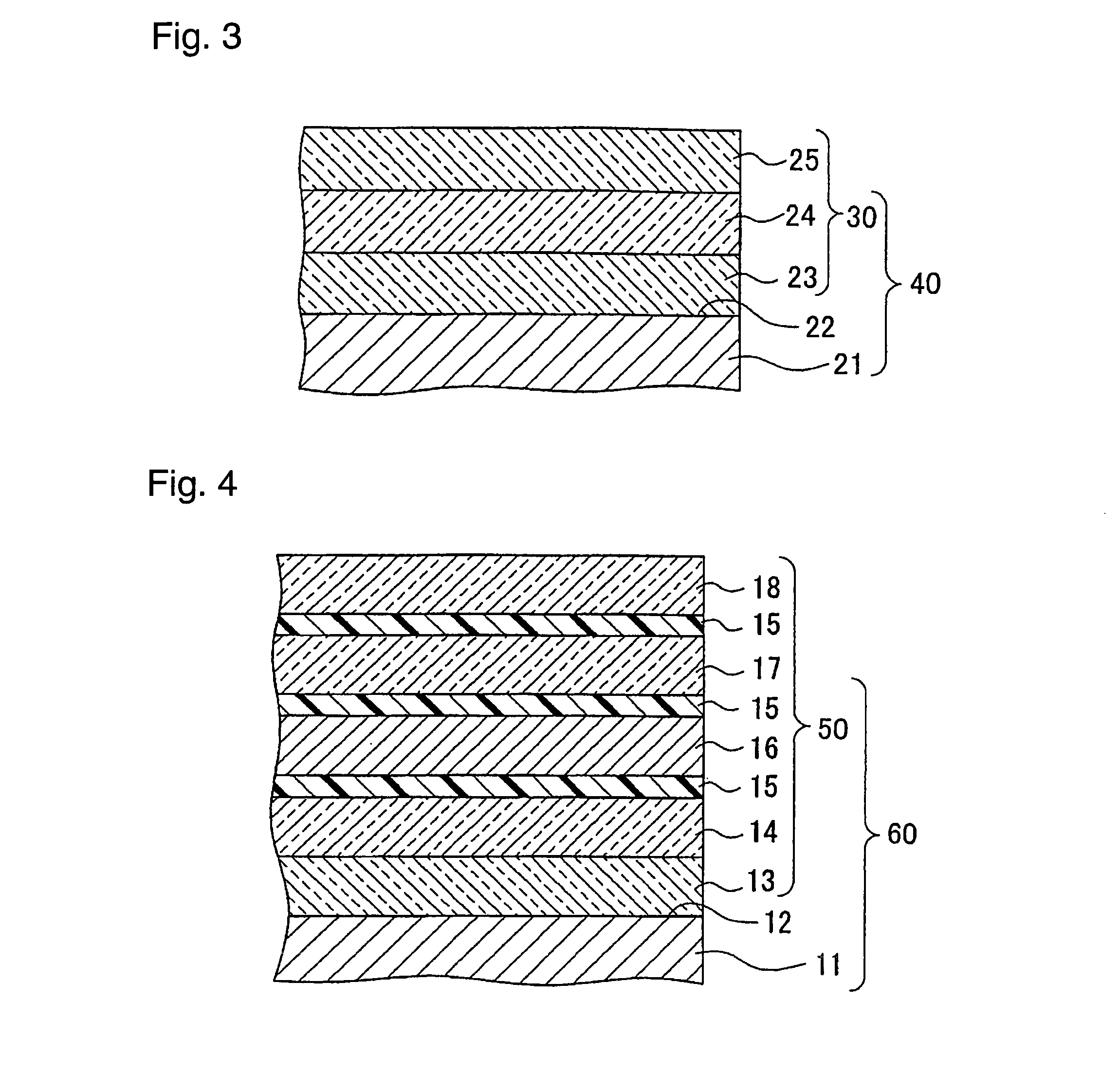

Glass article and glass substrate for display panel

InactiveUS20010016253A1Excellent efficiency of preventing diffusion of metal ionInhibited DiffusionGas discharge vessels/containersLayered productsAlkali ionsElectrical resistance and conductance

A glass article having no problem of stain due to metal colloids because of its excellent efficiency of preventing the diffusion of metal ions, and a glass substrate for a high-quality display comprising the aforementioned glass article are provided. The glass article comprises an alkali-containing glass substrate 1, and a barrier film 2 formed on a surface of the alkali-containing glass substrate 1. The metal ion diffusion barrier film 2 mainly contains indium oxide and / or tin oxide. A glass substrate for a display comprises: an alkali-containing glass substrate 1; an alkali ion diffusion barrier film 5 formed on a surface of said alkali-containing glass substrate 1; a barrier film 2 mainly containing indium oxide and / or tin oxide; an insulating film 3; and an electrode film 4. The surface electrical resistance of the insulating film is kept in a range from 1.0x106 OMEGA / square to 1.0x1016 OMEGA / square even after heating process at 550° C. for 1 hour.

Owner:NIPPON SHEET GLASS CO LTD

Plasma display panel provided with an improved protective layer

InactiveUS20050088095A1Improve material propertiesImproved operating characteristicAddress electrodesSustain/scan electrodesLong axisEngineering

A plasma display panel (PDP) includes a first substrate and a second substrate opposing one another with a predetermined gap therebetween. The PDP also includes first electrodes formed on a surface of the first substrate opposing the second substrate, and second electrodes formed on a surface of the second substrate opposing the first substrate. Long axes of the first electrodes intersect those of the second electrodes. Also included in the PDP are dielectric layers. One dielectric layer is formed covering the first electrodes on the first substrate, and another dielectric layer is formed covering the second electrodes on the second substrate. There is further included an MgO protection layer that is formed covering the dielectric layer on the first substrate. A crystalline orientation planes of the MgO protection layer are produced by mixing (111) planes and (110) planes, and a mixing ratio of the (111) planes and the (110) planes is settled according to a grain size of the MgO protection layer.

Owner:SAMSUNG SDI CO LTD

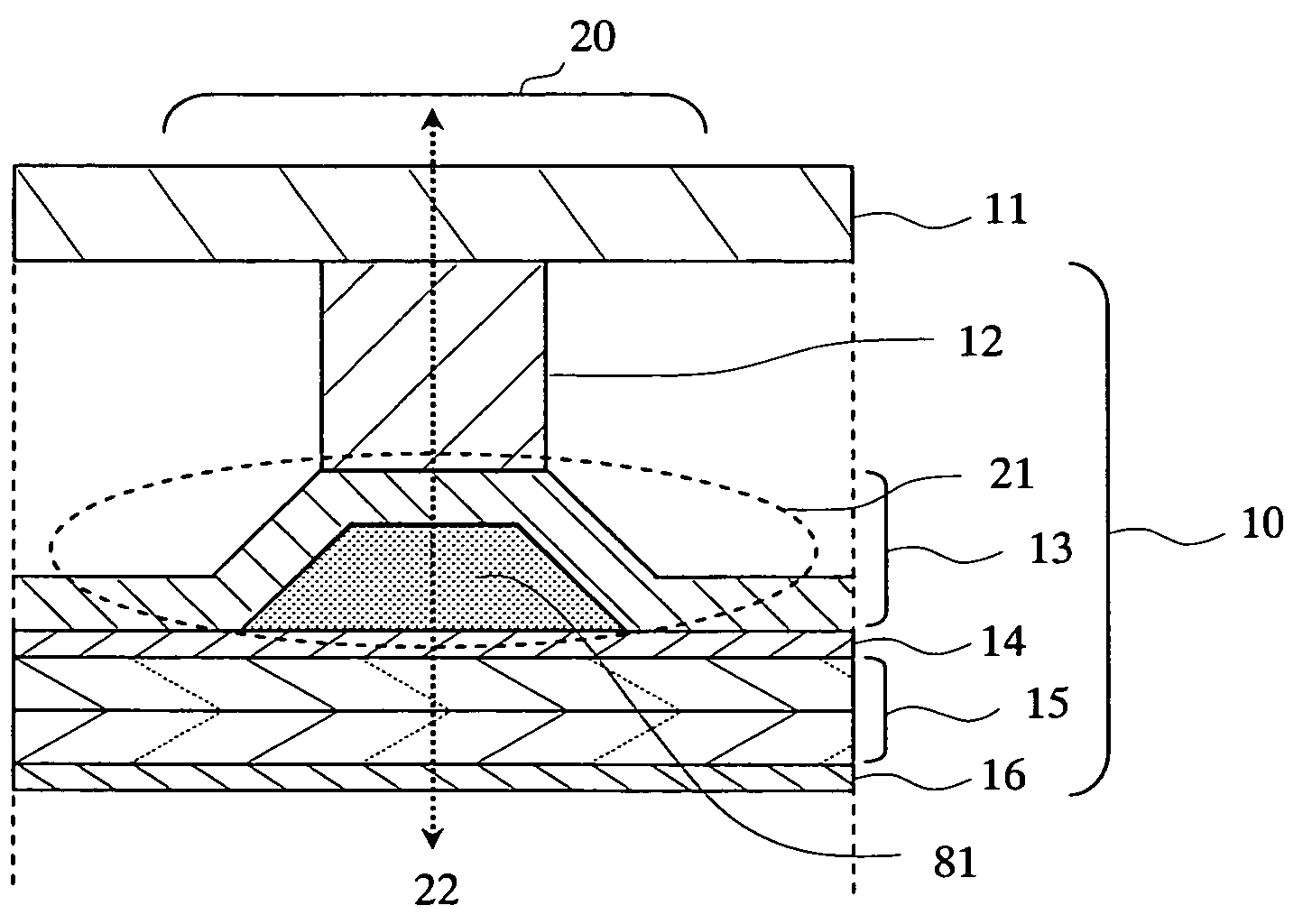

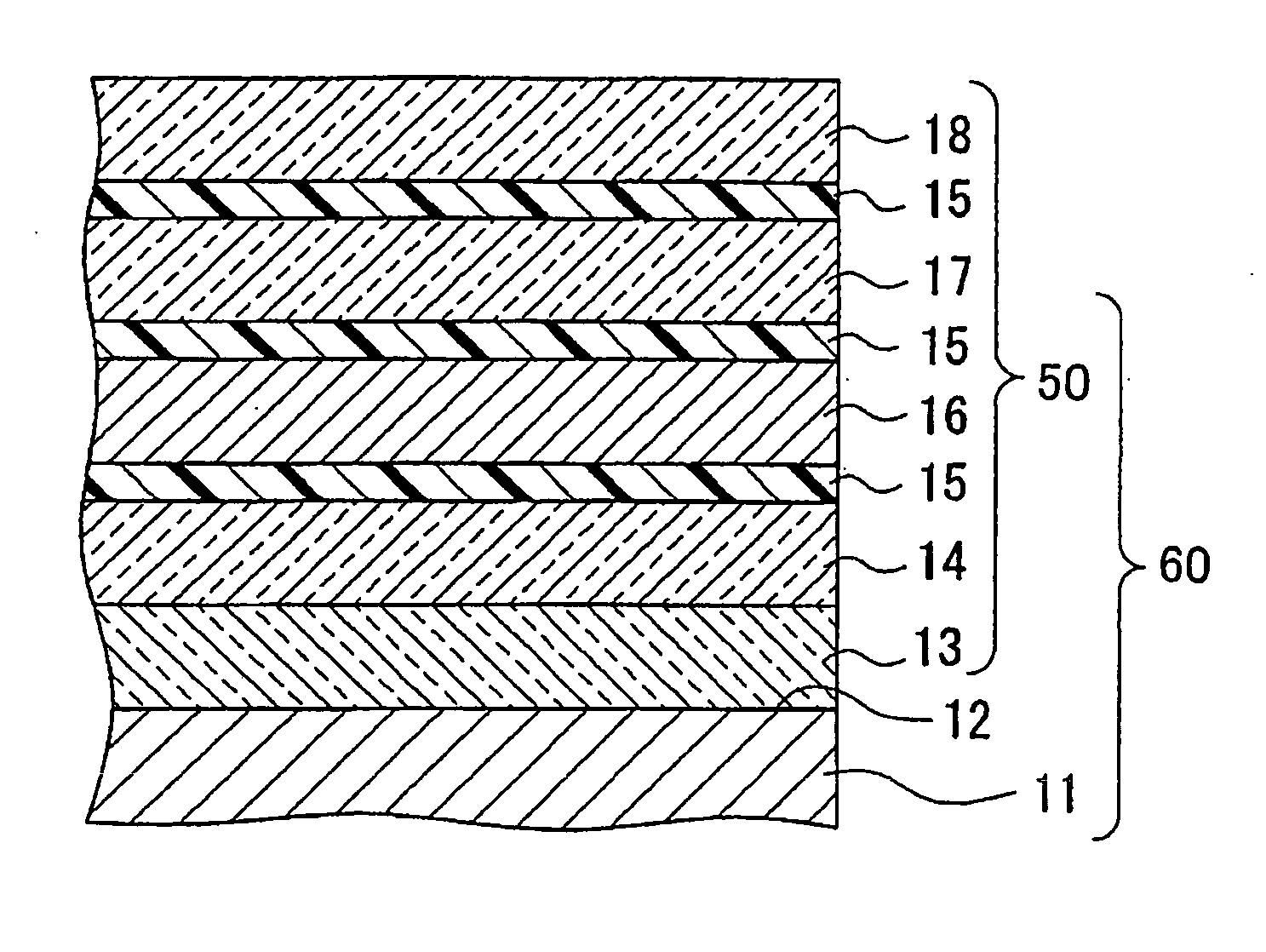

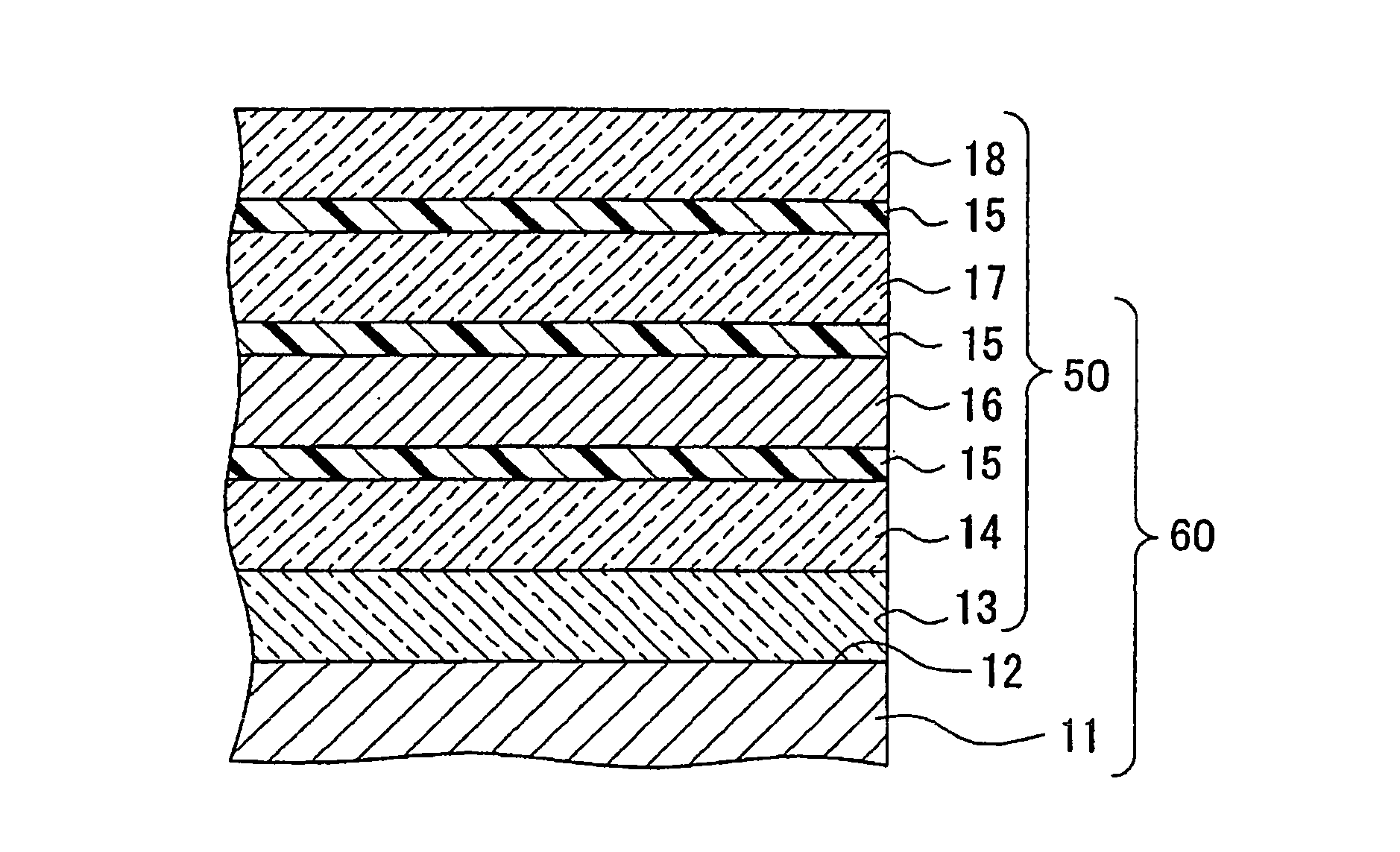

Heat dissipation structure for display panel and display module equipped with the structure

InactiveUS20060098412A1Efficiently dissipatedStatic indicating devicesLayered productsEngineeringMetal sheet

A heat dissipation structure for a display panel efficiently dissipates heat generated during operation of the display panel, and a display module including the heat dissipation structure is also so characterized. The heat dissipation structure is capable of preventing electromagnetic waves generated during the operation of the display panel operation from adversely influencing a driving circuit. The heat dissipation structure comprises: a display panel; a heat dissipating sheet contacting a rear surface of the display panel; and a chassis base disposed on a rear side of the heat dissipating sheet and connected to the display panel via a double-sided adhesive element. The heat dissipating sheet includes two heat dissipating layers and a metal sheet layer interposed between the two heat dissipating layers.

Owner:SAMSUNG SDI CO LTD

Pb-free glass composition for barrier ribs of plasma display panel, and plasma display panel comprising the Pb-free glass barrier ribs prepared therefrom

InactiveUS20060019814A1Fast etch rateHigh densityGas discharge electrodesGas discharge vessels/containersCopper oxidePolymer chemistry

Disclosed is a Pb-free glass composition for barrier ribs of a PDP, which includes from 20 to 70 wt % of ZnO; from 10 to 50 wt % of BaO; from 10 to 40 wt % of B2O3; from 0 to 20 wt % of P2O5; from 0 to 20 Wt % of SiO2; from 0 to 20 wt % of Bi2O3; from 0 to 30 wt % of V2O5; from 0 to 10 wt % of one or more oxides selected from the group consisting of Na2O, Li2O, and K2O; from 0 to 10 wt % of CaO; from 0 to 10 wt % of MgO; from 0 to 30 wt % of SrO; from 0 to 20 wt % of MoO3; from 0 to 10 wt % of Al2O3; from 0 to 10 wt % of one or more oxides selected from the group consisting of Sb2O3, CuO, Cr2O3, As2O3, CoO, and NiO; and from 0 to 10 wt % of TiO2, and a plasma display panel comprising the Pb-free glass barrier ribs prepared therefrom.

Owner:SAMSUNG SDI CO LTD +1

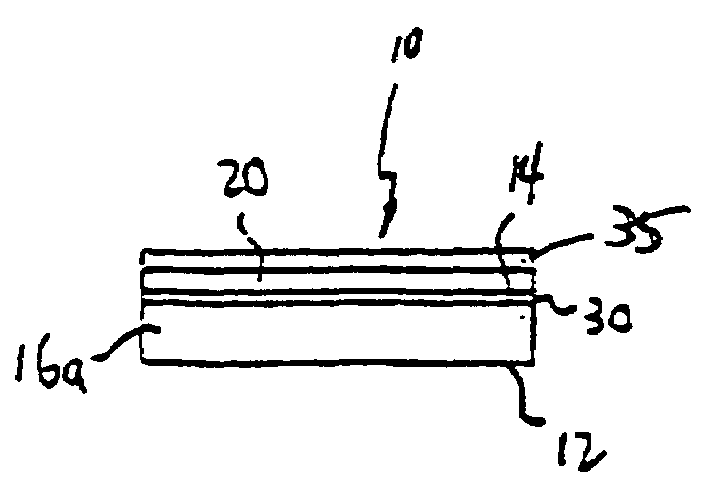

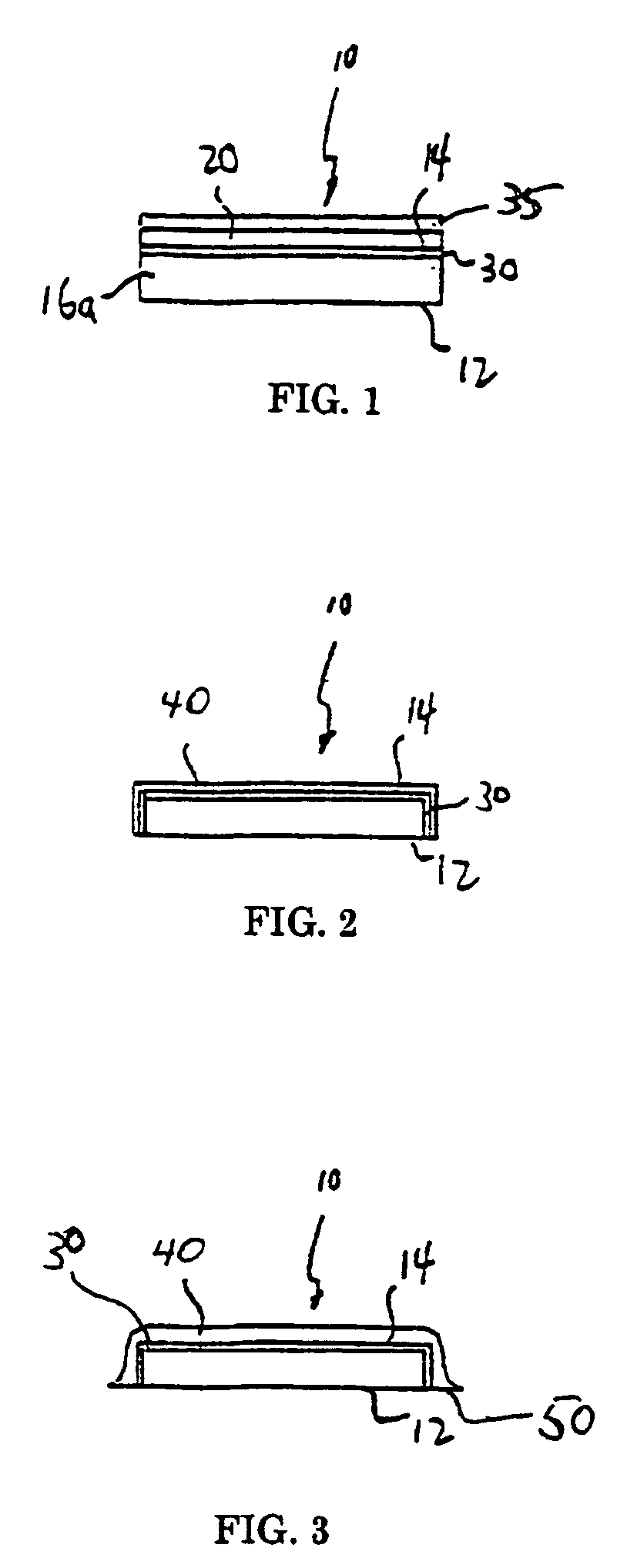

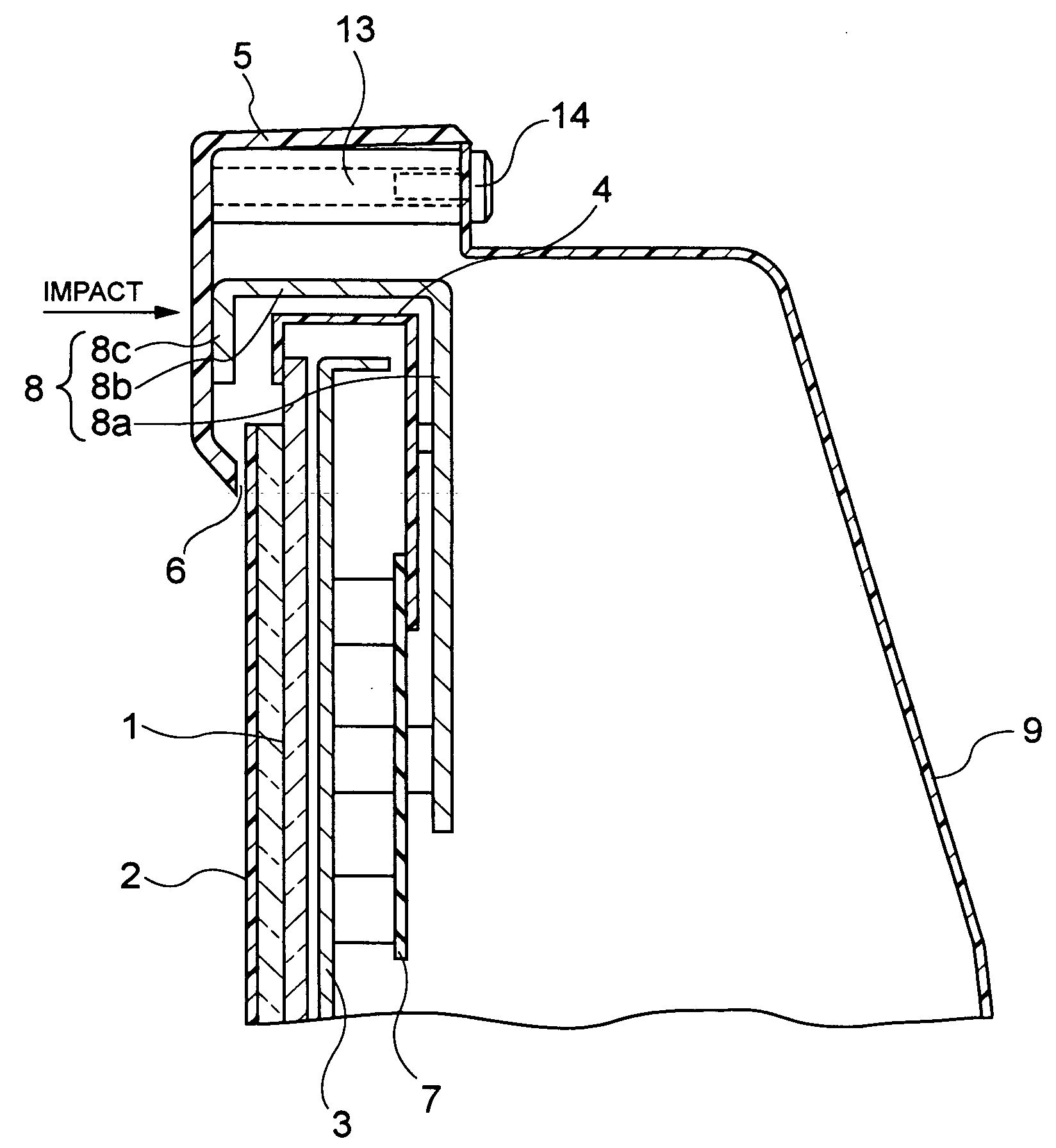

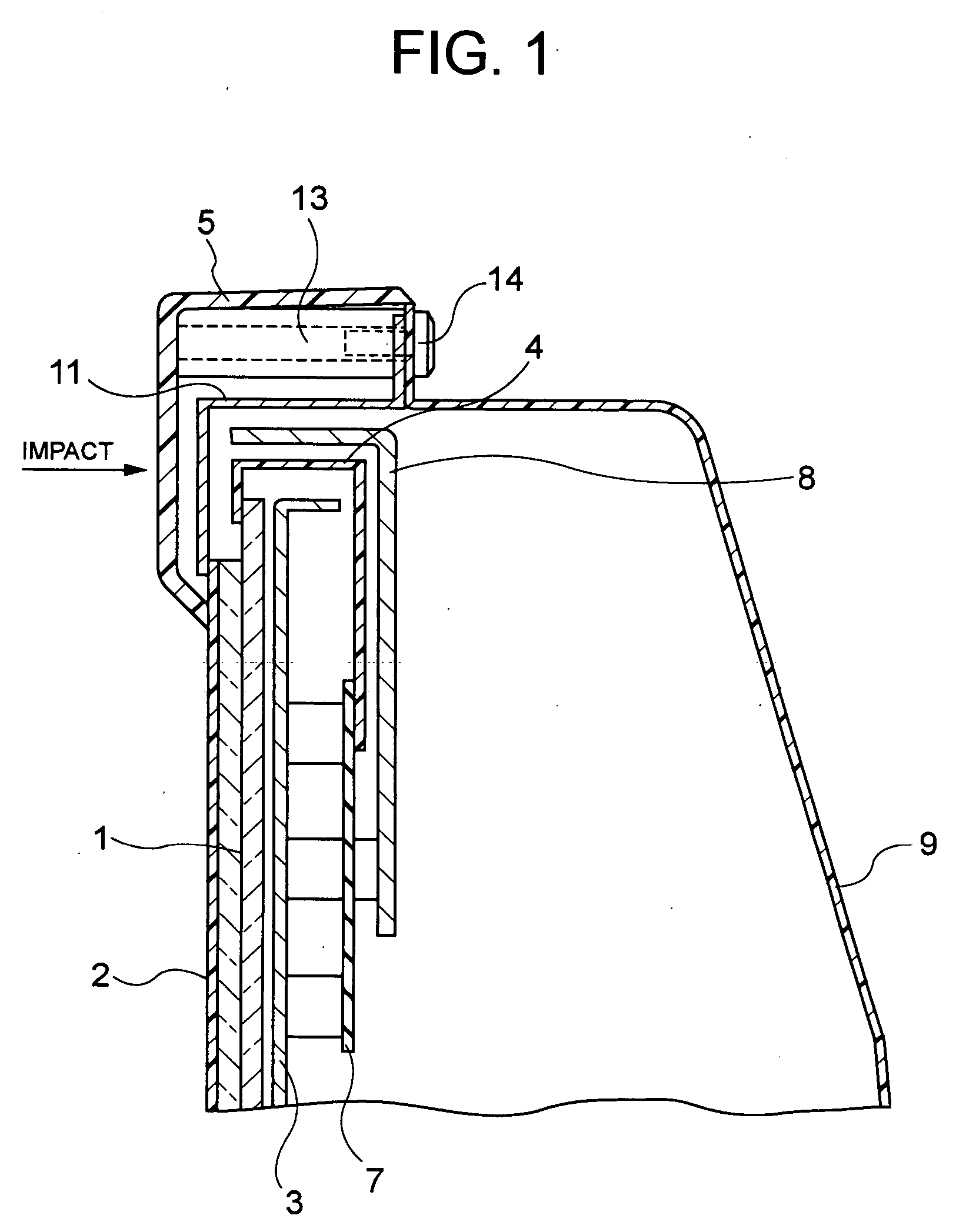

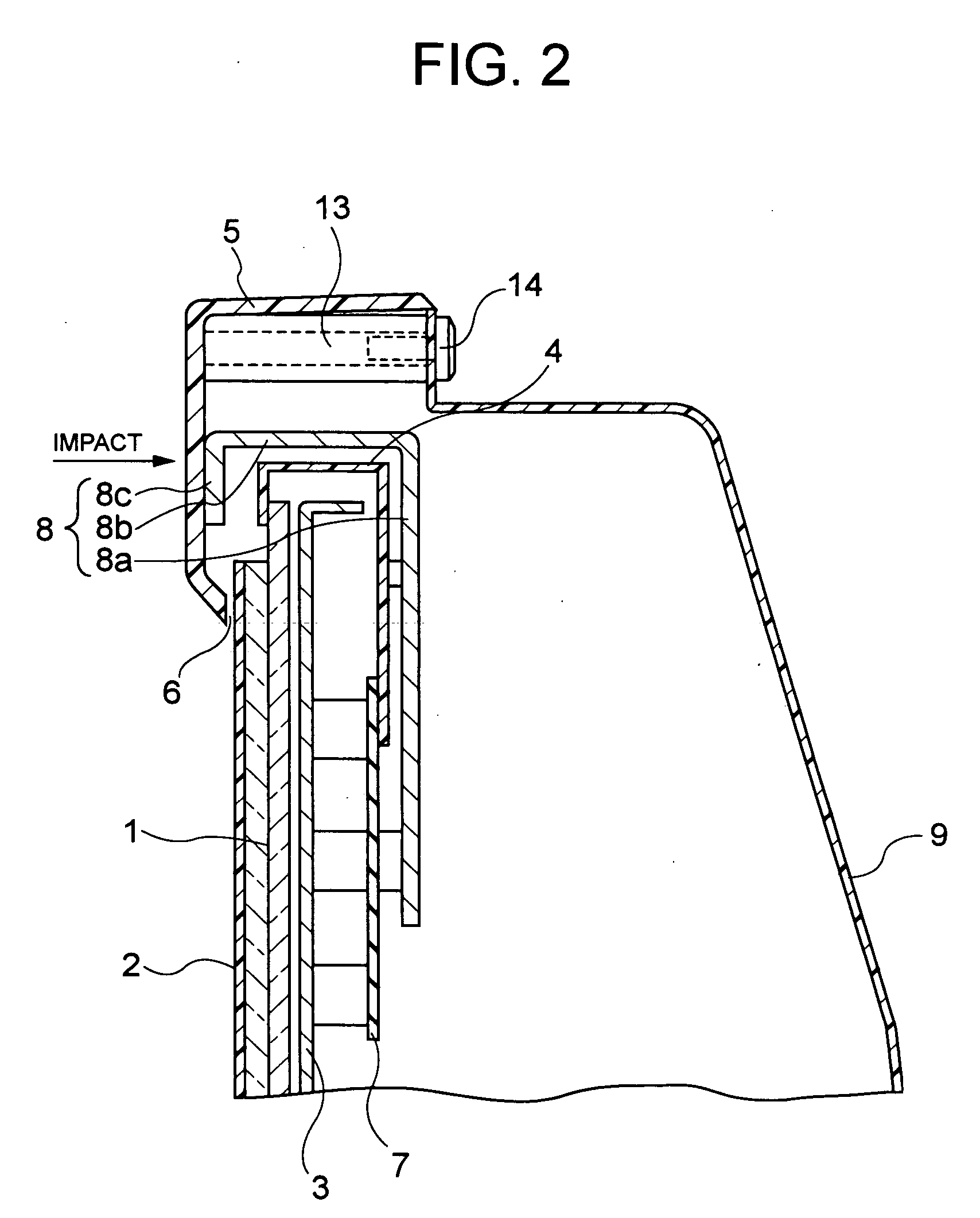

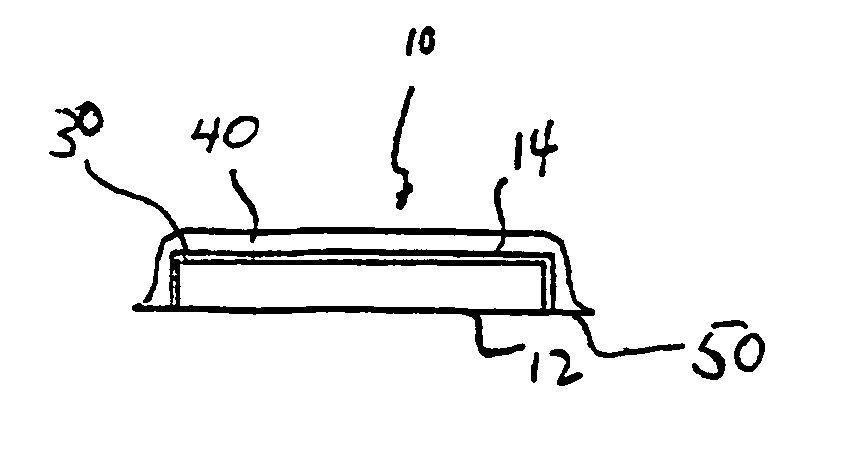

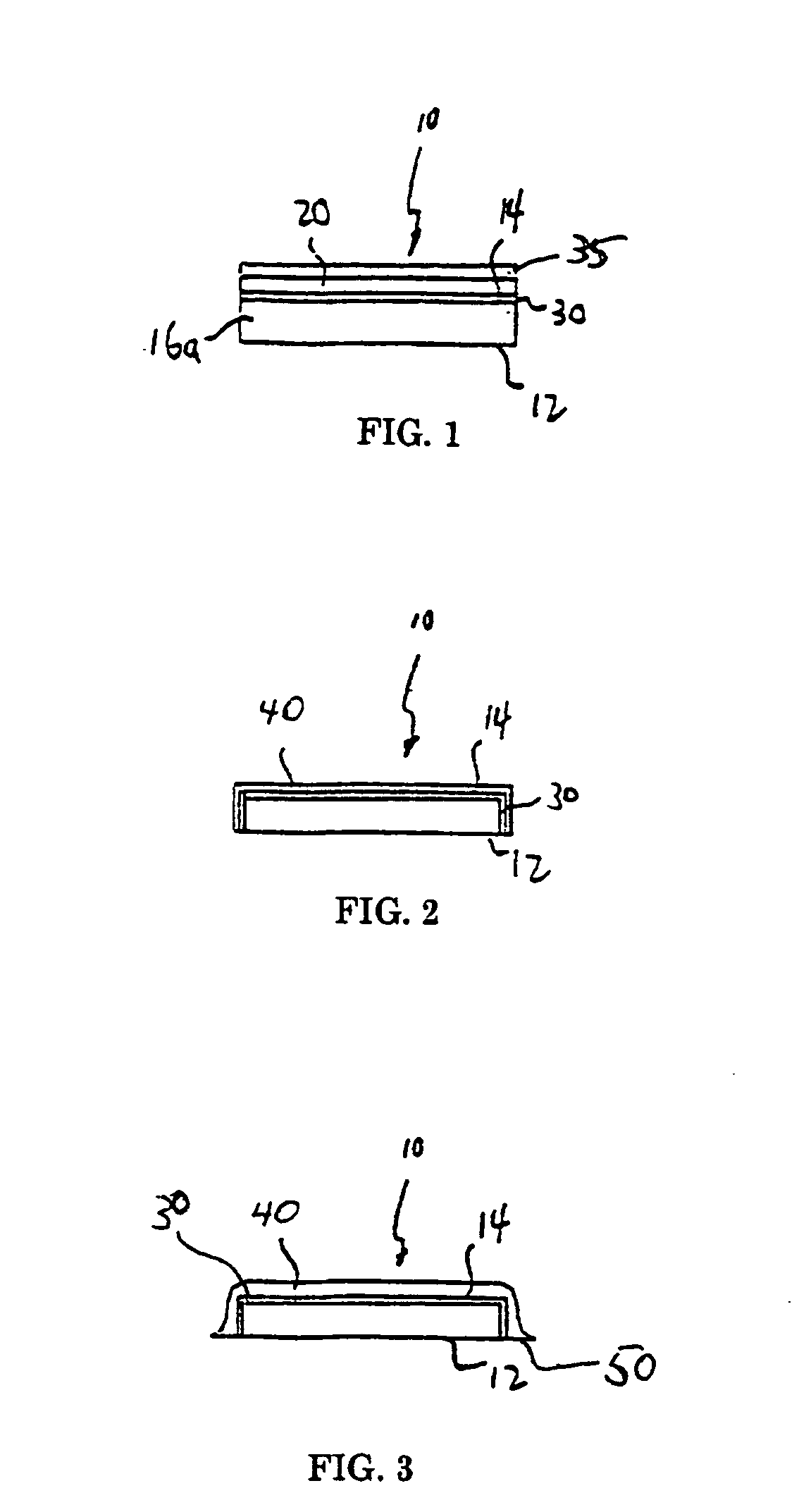

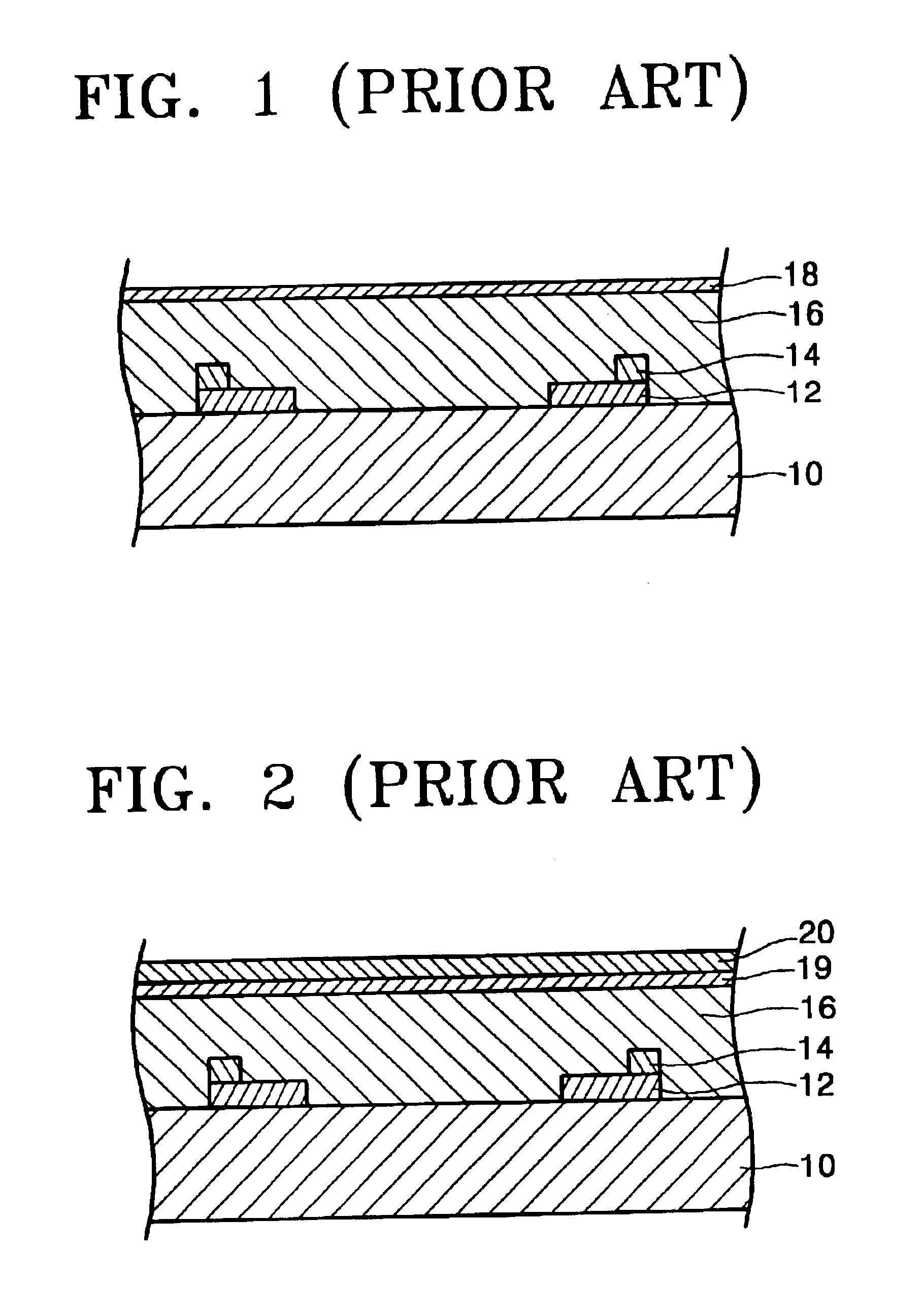

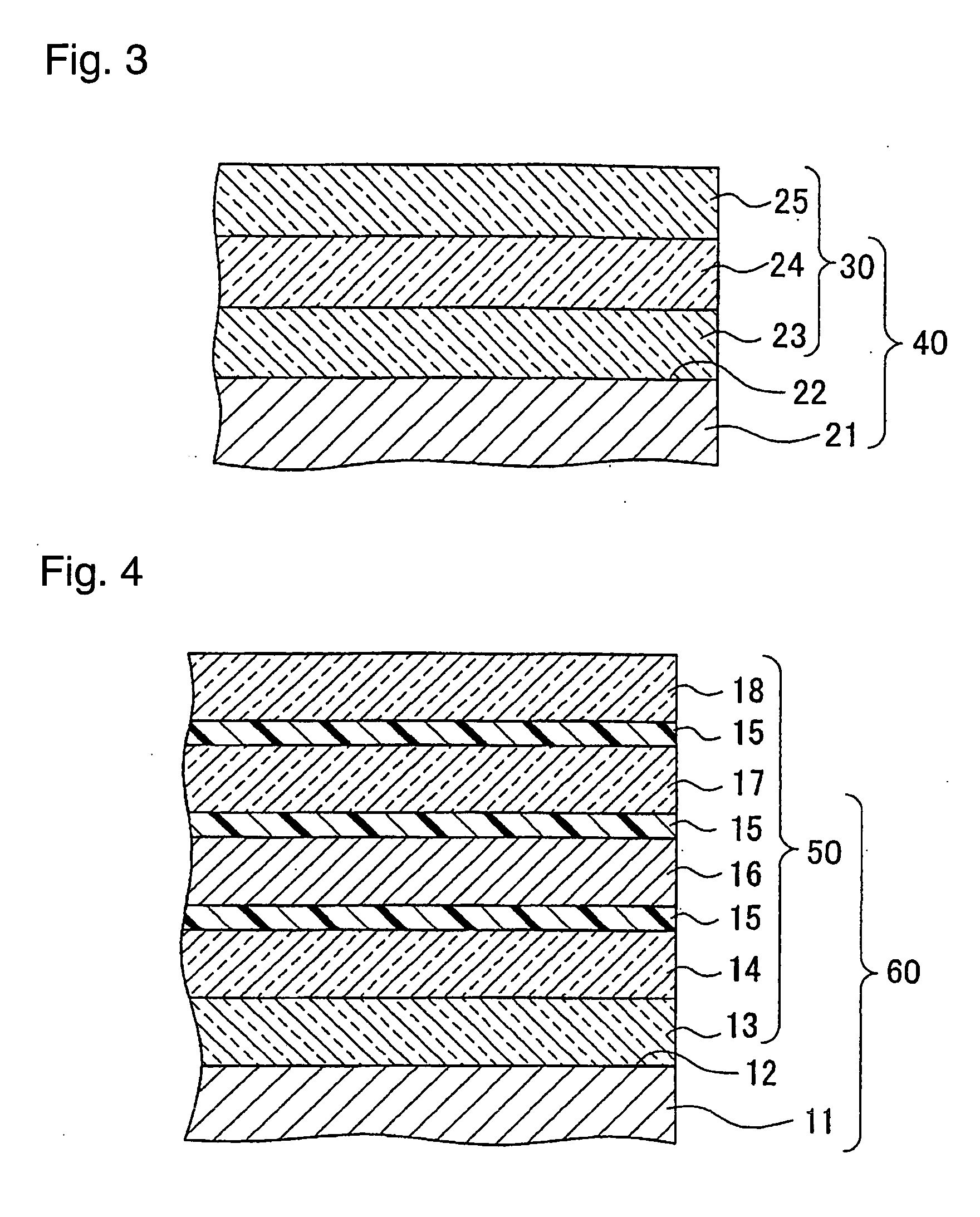

Impact-resistant film for flat display panel, and flat display panel

InactiveUS20050077826A1Avoid breakingAvoid scatterGas discharge vessels/containersSynthetic resin layered productsShear modulusDisplay device

An impact-resistance film for a flat display panel which is to prevent breakage and scattering of glass of the panel when panel receives an impact and which at the same time makes the weight reduction and thickness reduction possible, is presented. An impact-resistant film 30 for a flat display panel, which is an impact-resistant film to be bonded to a front glass 22 of a flat display panel main body 21 and which comprises a first layer 23 on the front glass side of the flat display panel, made of a transparent synthetic resin having a shear modulus of from 1×103 Pa to 1×106 Pa, a second layer 24 on the viewer's side of the first layer, made of a transparent synthetic resin having a shear modulus of at least 1×108 Pa, and a third layer 25 on the viewer's side of the second layer, made of a transparent synthetic resin having a shear modulus of at least 1×106 Pa and less than 1×108 Pa.

Owner:ASAHI GLASS CO LTD +1

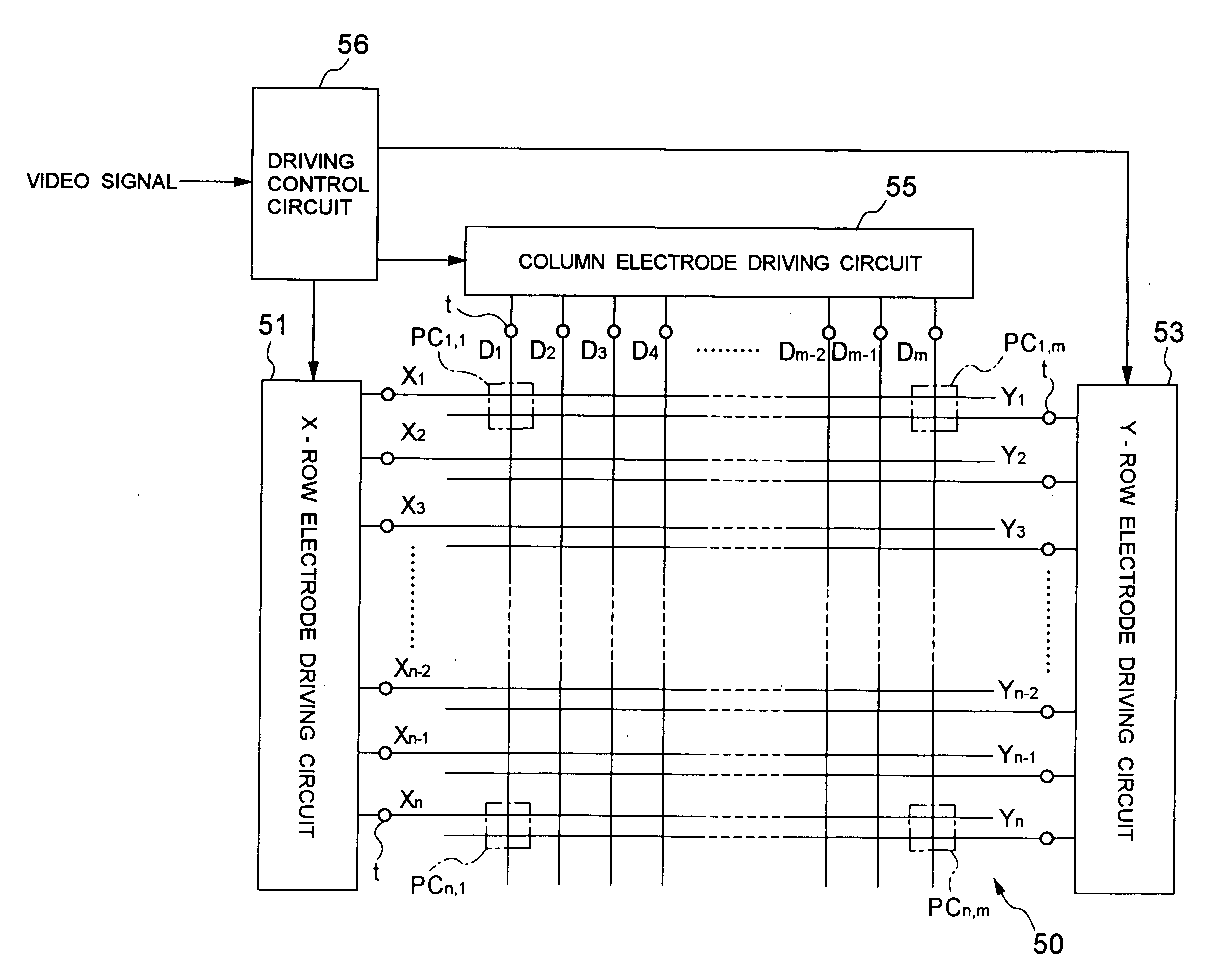

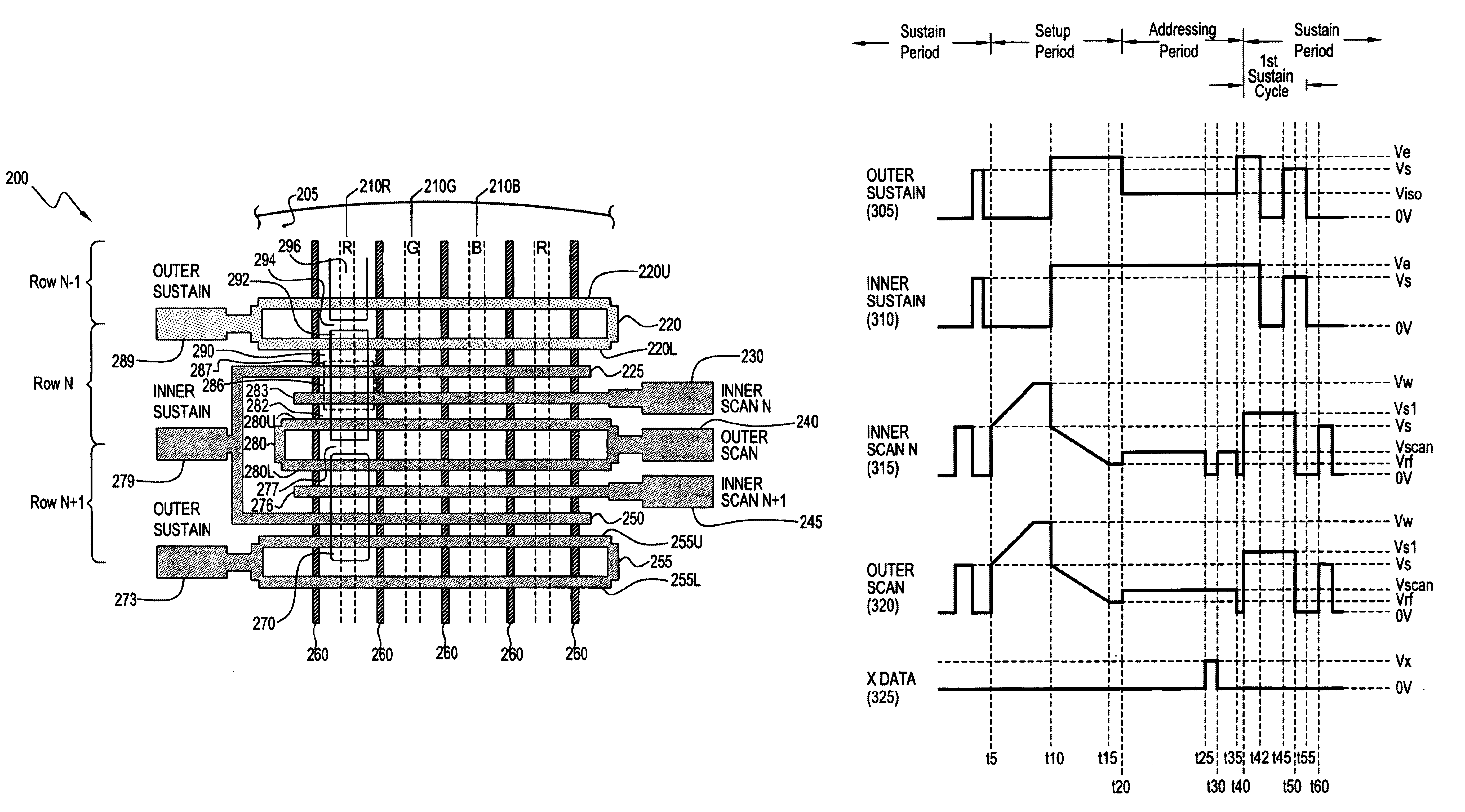

Plasma display device

InactiveUS20050264487A1Speeding up address scanning without damaging the stability of the address scanningSustain/scan electrodesStatic indicating devicesElectrode pairLuminescence

A plasma display device having a plasma display panel in which, each display cell contains a magnesium oxide layer including magnesium oxide crystals that are excited by an electron beam to emit cathode luminescence light having a peak in a wavelength range of 200 to 300 nm. In an addressing period, a row electrode driving circuit applies a scanning pulse to one row electrodes of row electrode pairs in turn, while a column electrode driving circuit supplies column electrodes with data pulses corresponding to one row electrode which is applied with the scanning pulse.

Owner:PANASONIC CORP

Gas dischargeable panel

InactiveUS7009587B2Improve the display effectIncrease the driving voltageAddress electrodesSustain/scan electrodesEngineeringElectrode pair

A gas discharge panel includes a first substrate and a second substrate. A plurality of display electrode pairs which are each made up of a sustain electrode and a scan electrode are formed on the first substrate, and the first substrate and the second substrate are set facing each other with a plurality of barrier ribs in between so as to form a plurality of cells. In this gas discharge panel, at least one of the sustain electrode and the scan electrode includes: a plurality of line parts; and a discharge developing part which makes a gap between adjacent line parts smaller in areas corresponding to channels between adjacent barrier ribs than in areas corresponding to the barrier ribs.

Owner:PANASONIC CORP

Plasma display device with grounding module

InactiveUS7357645B2Simplified chassis base structureEasy to GrindMagnetic/electric field screeningGas discharge vessels/containersComputer moduleDisplay device

A plasma display device includes a plasma display panel mounted on a first side of a chassis base, a mount on a second side of the chassis base, the mount being electrically connected to the chassis base, a printed circuit board including an electrical grounding section and having an opening in the electrical grounding section, the printed circuit board mounted on the mount by an electrically conductive fastener passing through the opening in the electrical grounding section, and a grounding module positioned in the opening so as to be between the electrical grounding section and the electrically conductive fastener and electrically connecting the electrical grounding section to the mount.

Owner:SAMSUNG SDI CO LTD

Impact-resistant film for flat display panel, and flat display panel

InactiveUS7005794B2Prevent breakage and scatteringReduce weightDischarge tube luminescnet screensGas discharge vessels/containersShear modulusDisplay device

An impact-resistance film which is bondable to a front glass of a flat display panel main body that includes a first layer on the front glass side of the flat display panel that is made of a transparent synthetic resin having a shear modulus of from 1×103 Pa to 1×106 Pa. The film includes a second layer on the viewer's side of the first layer that is made of a transparent synthetic resin having a shear modulus of at least 1×108 Pa and includes a third layer on the viewer's side of the second layer that is made of a transparent synthetic resin having a shear modulus of at least 1×106 Pa and less than 1×108 Pa.

Owner:ASAHI GLASS CO LTD +1

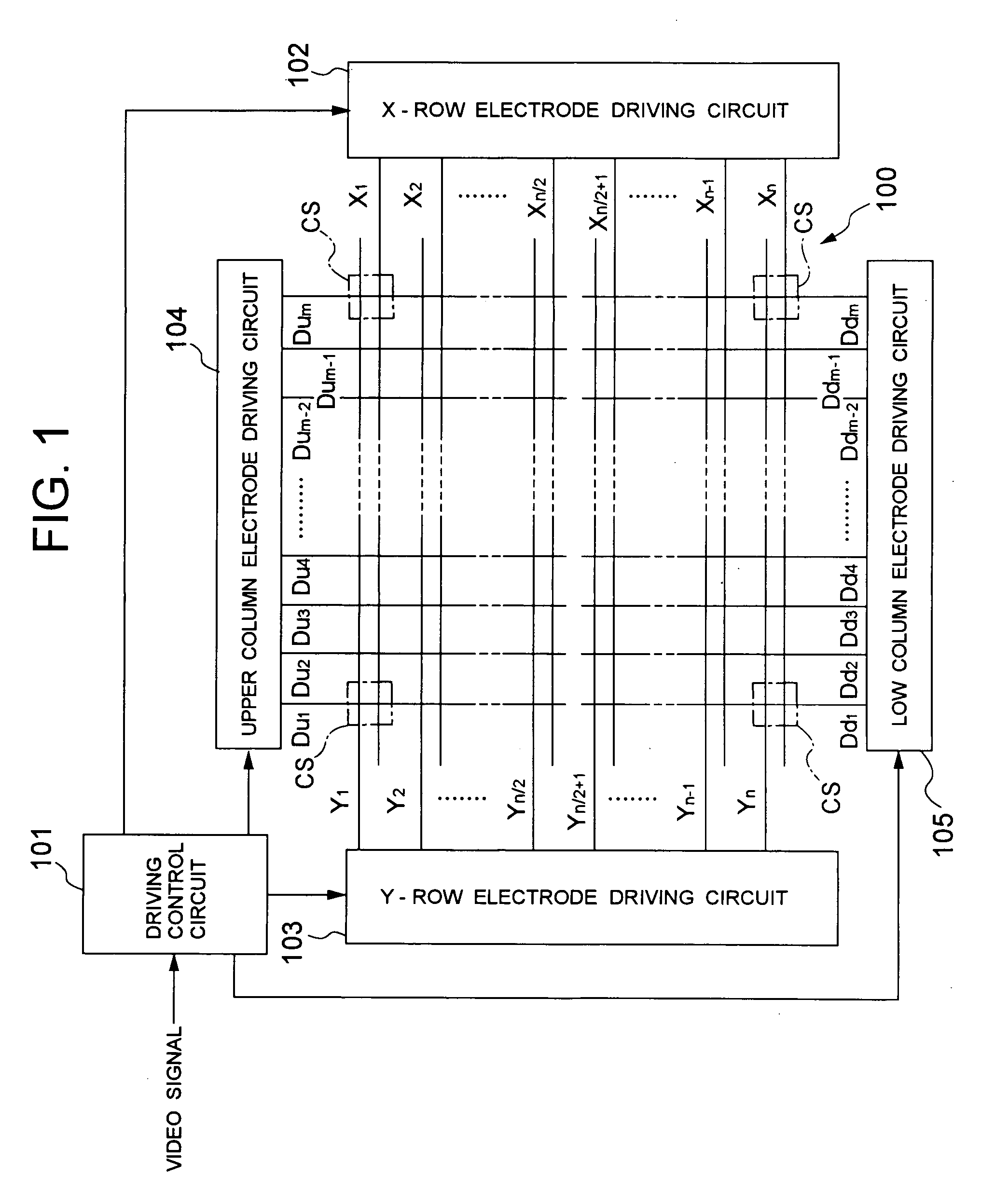

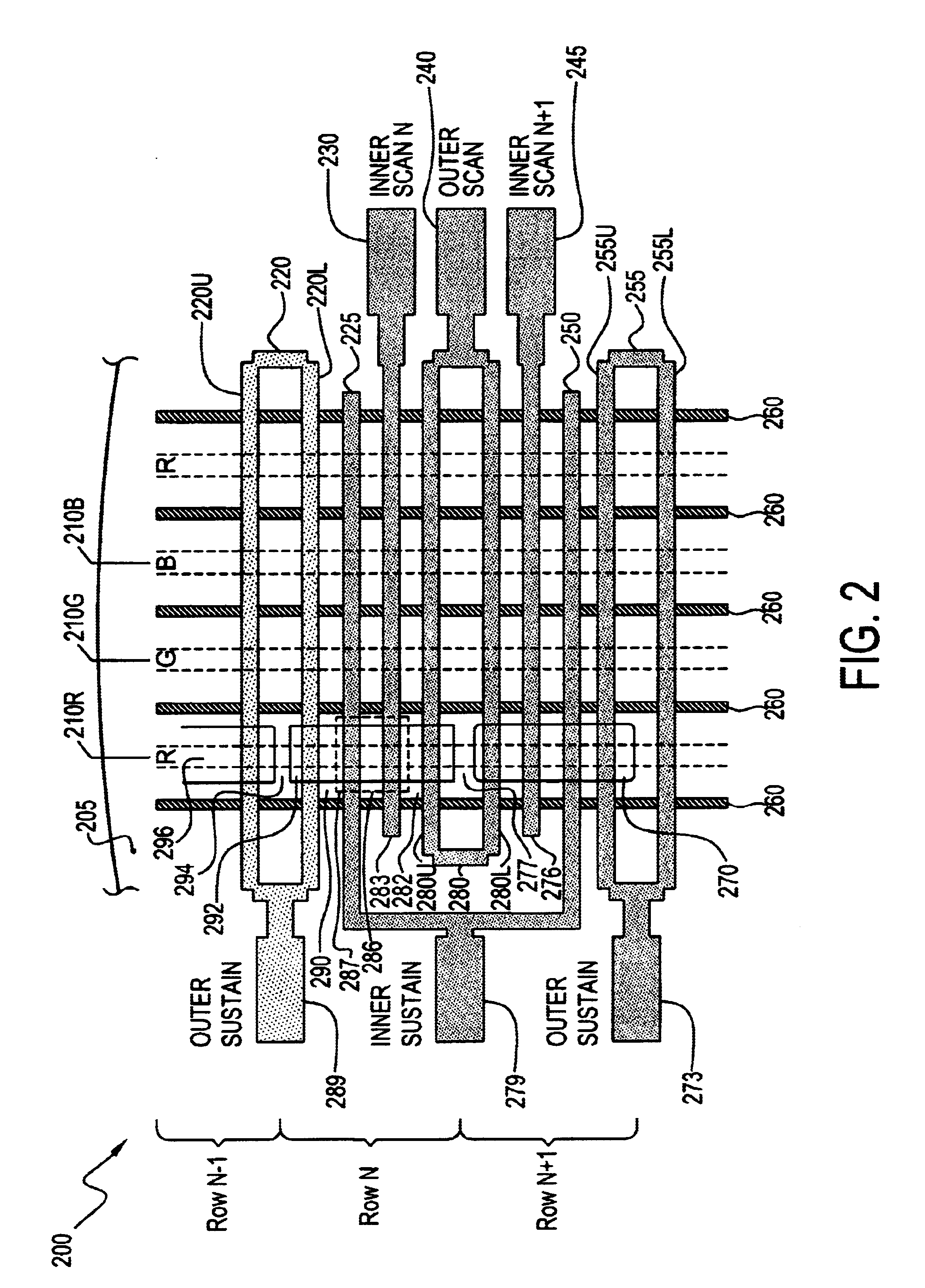

Plasma display with split electrodes

InactiveUS6853144B2Minimize vertical crosstalkIncrease brightnessAddress electrodesSustain/scan electrodesDisplay deviceEngineering

Owner:PANASONIC CORP

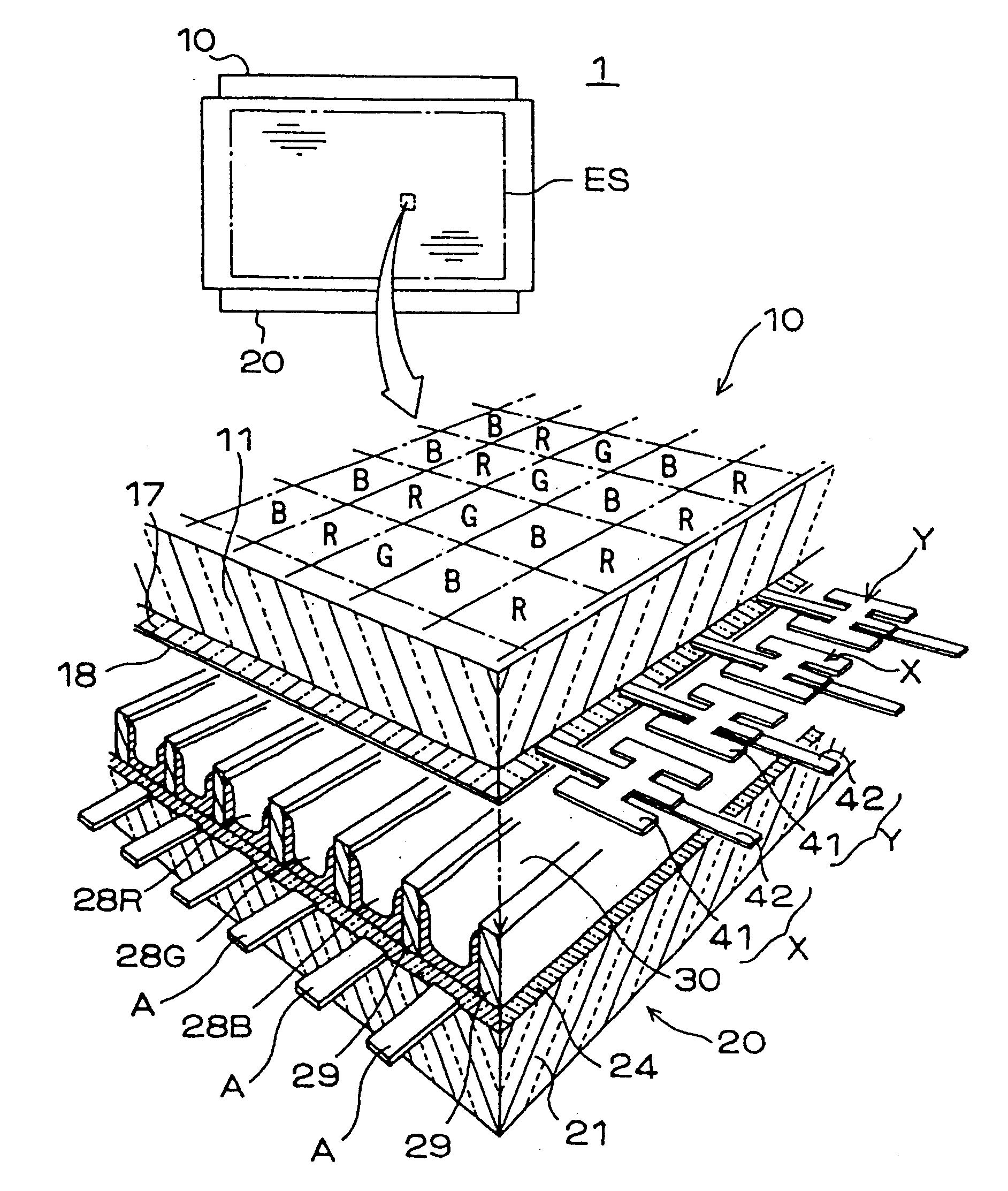

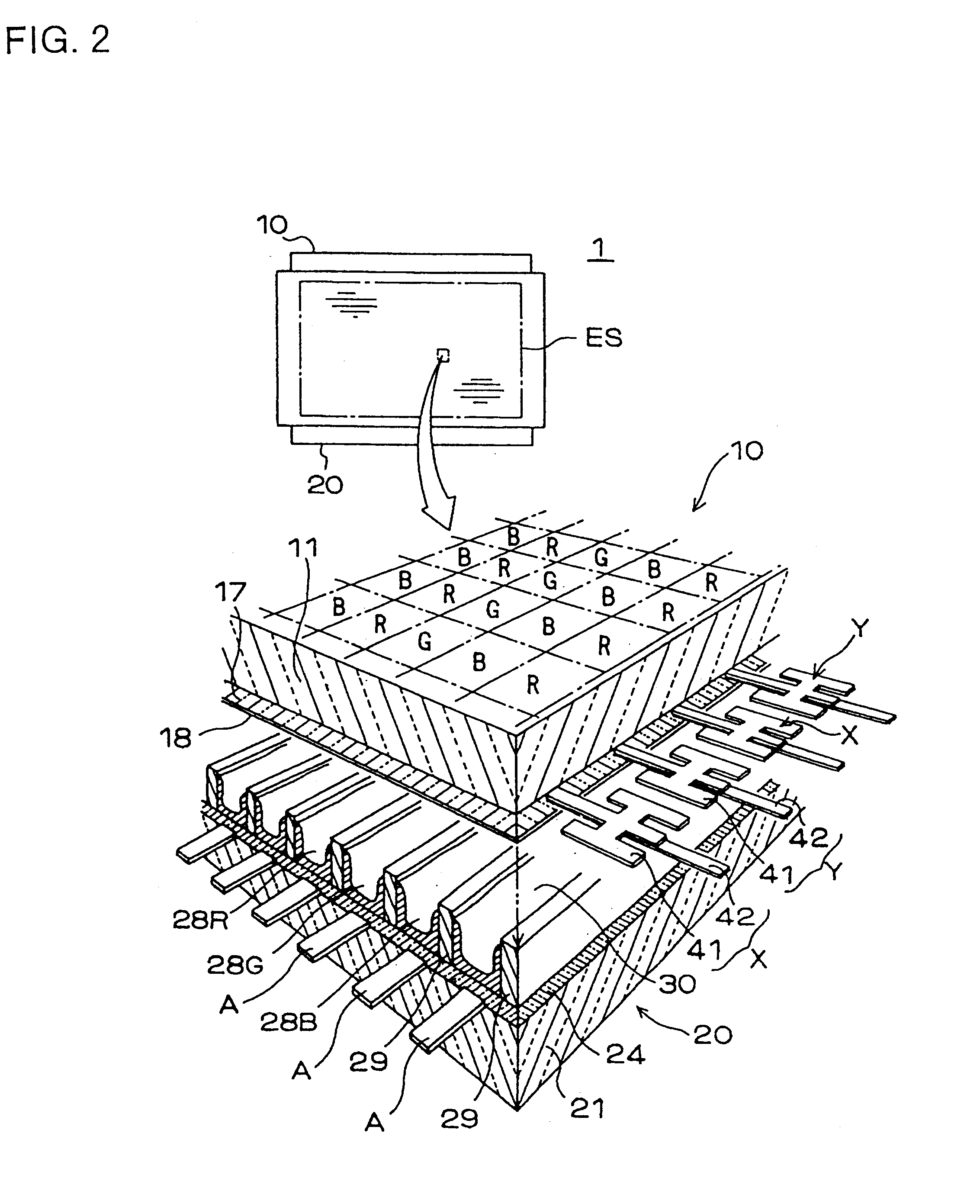

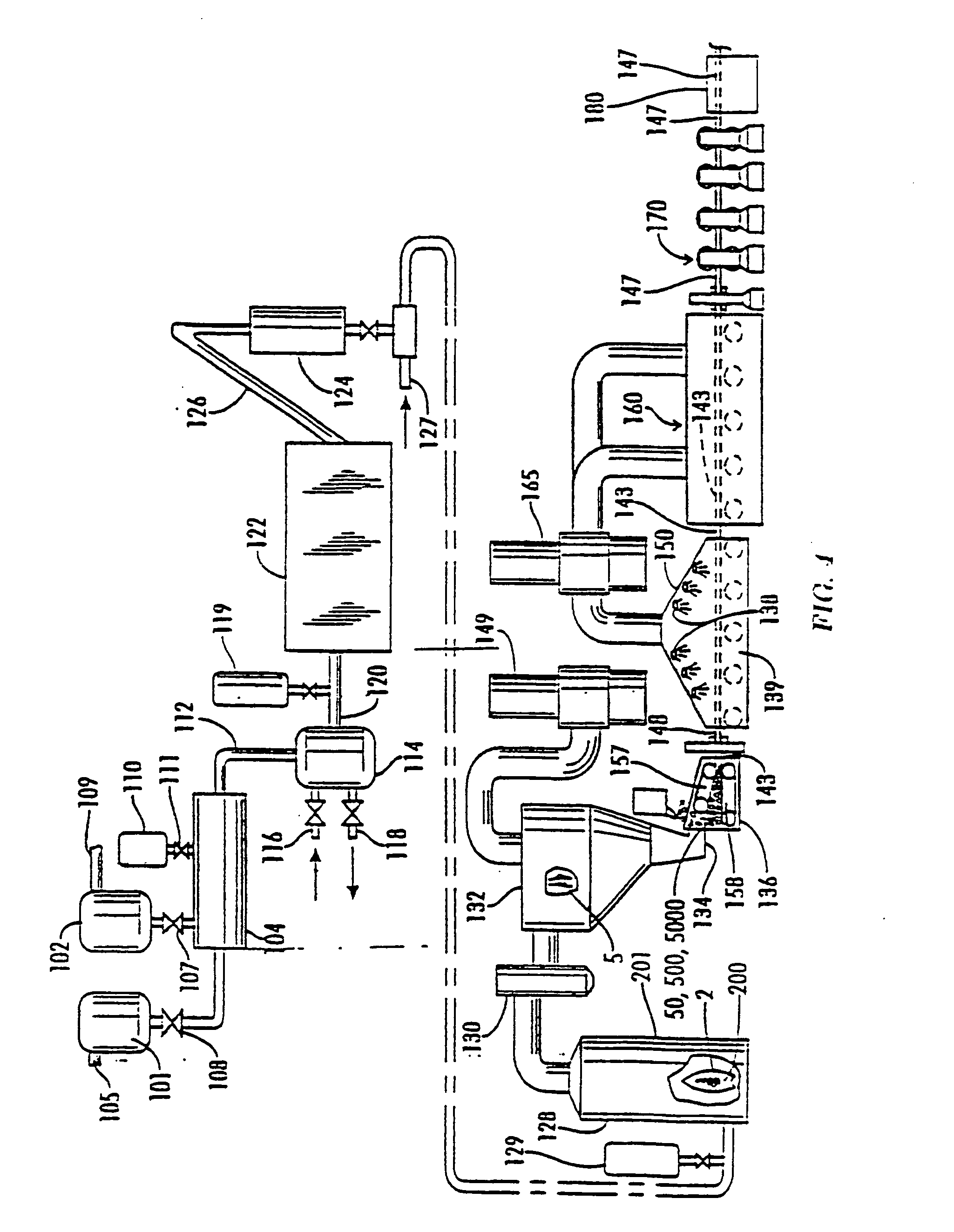

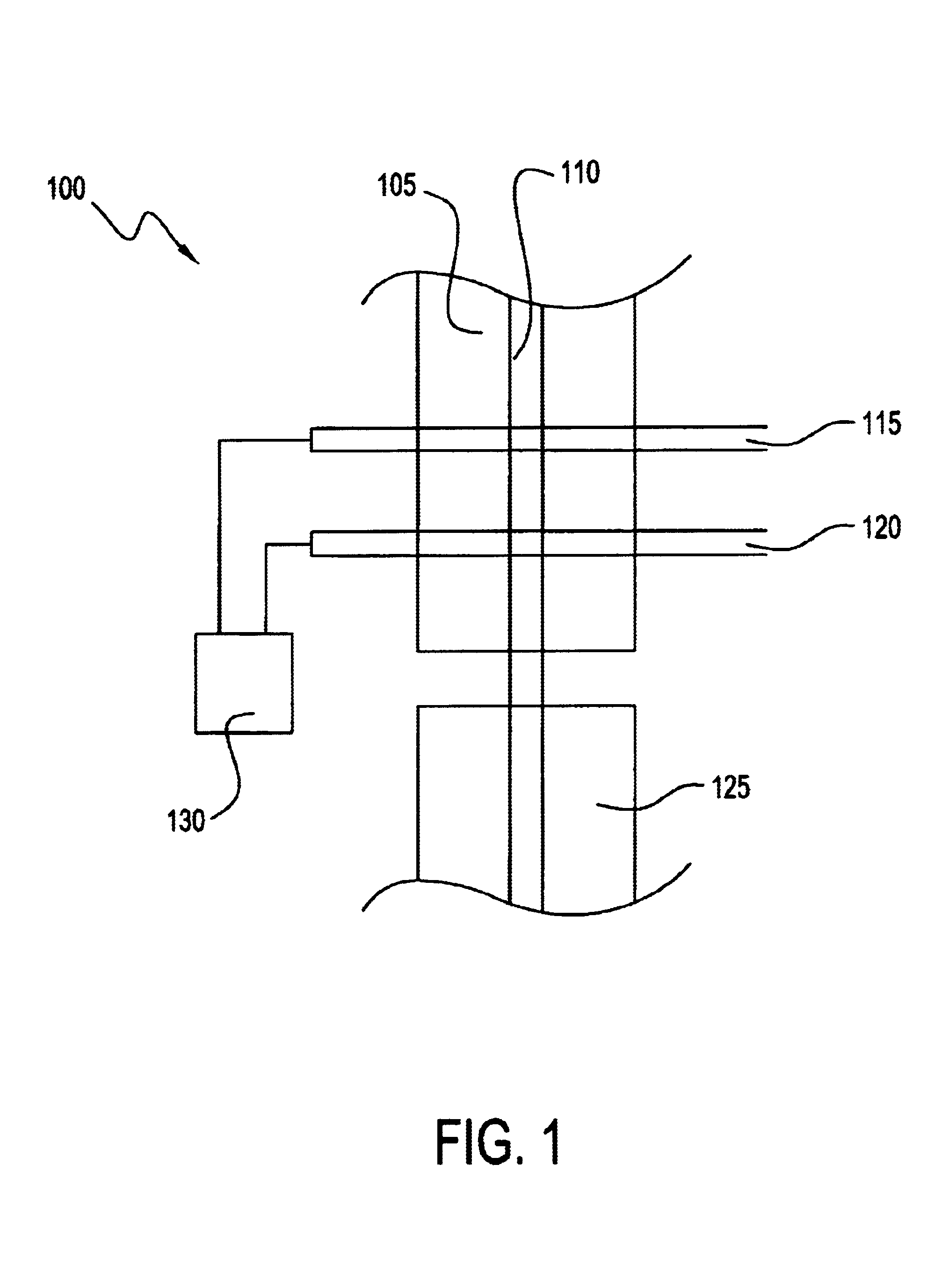

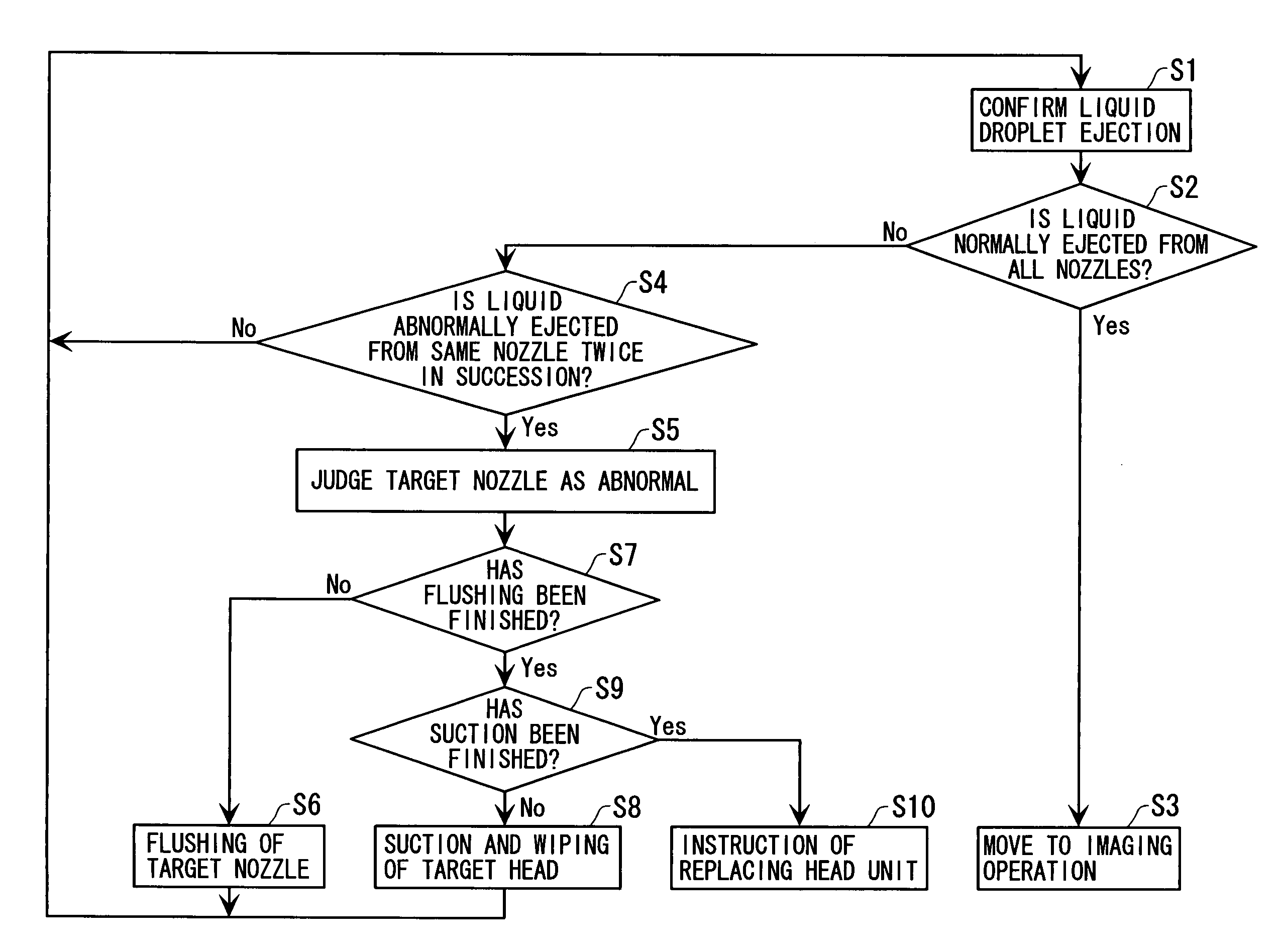

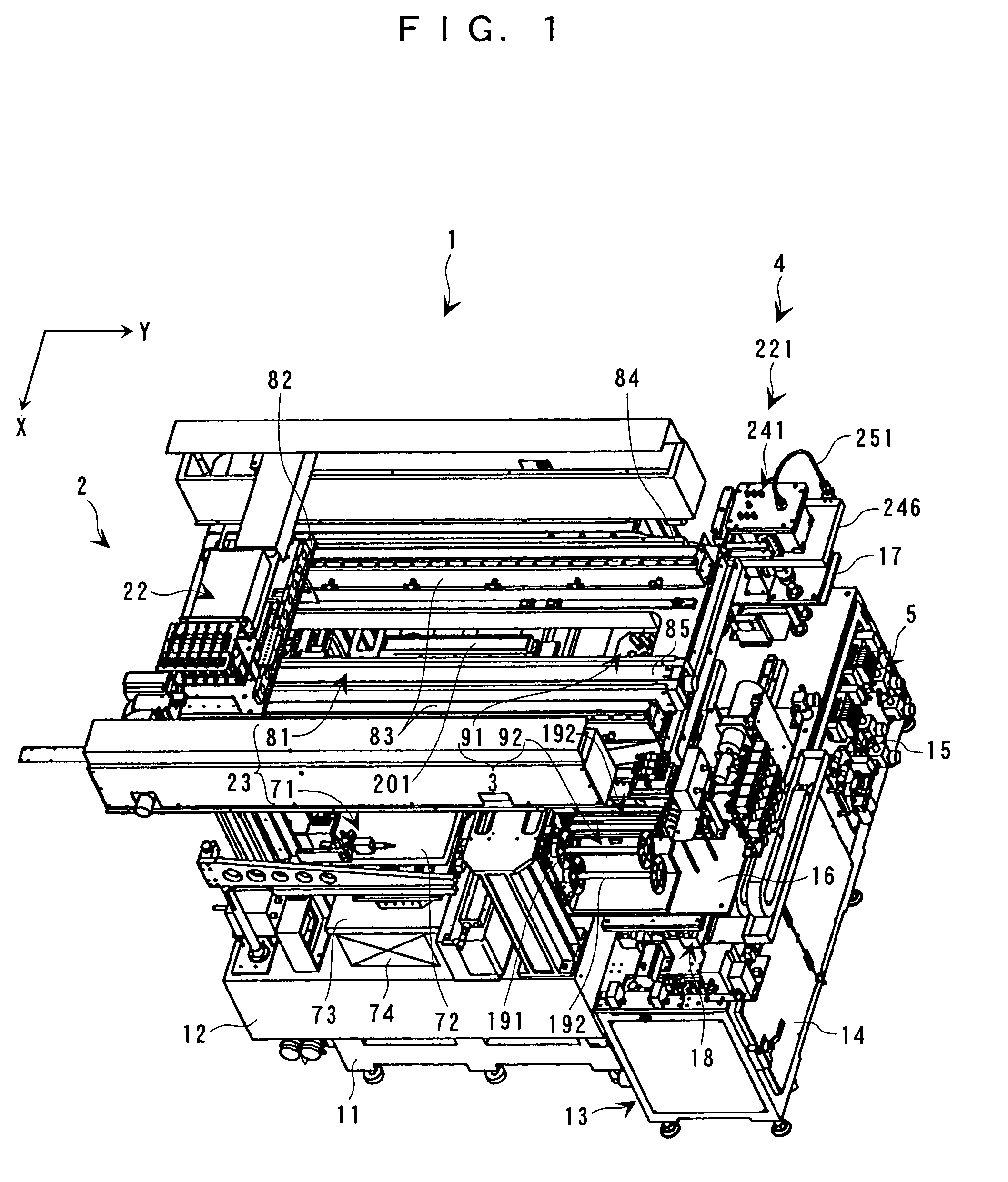

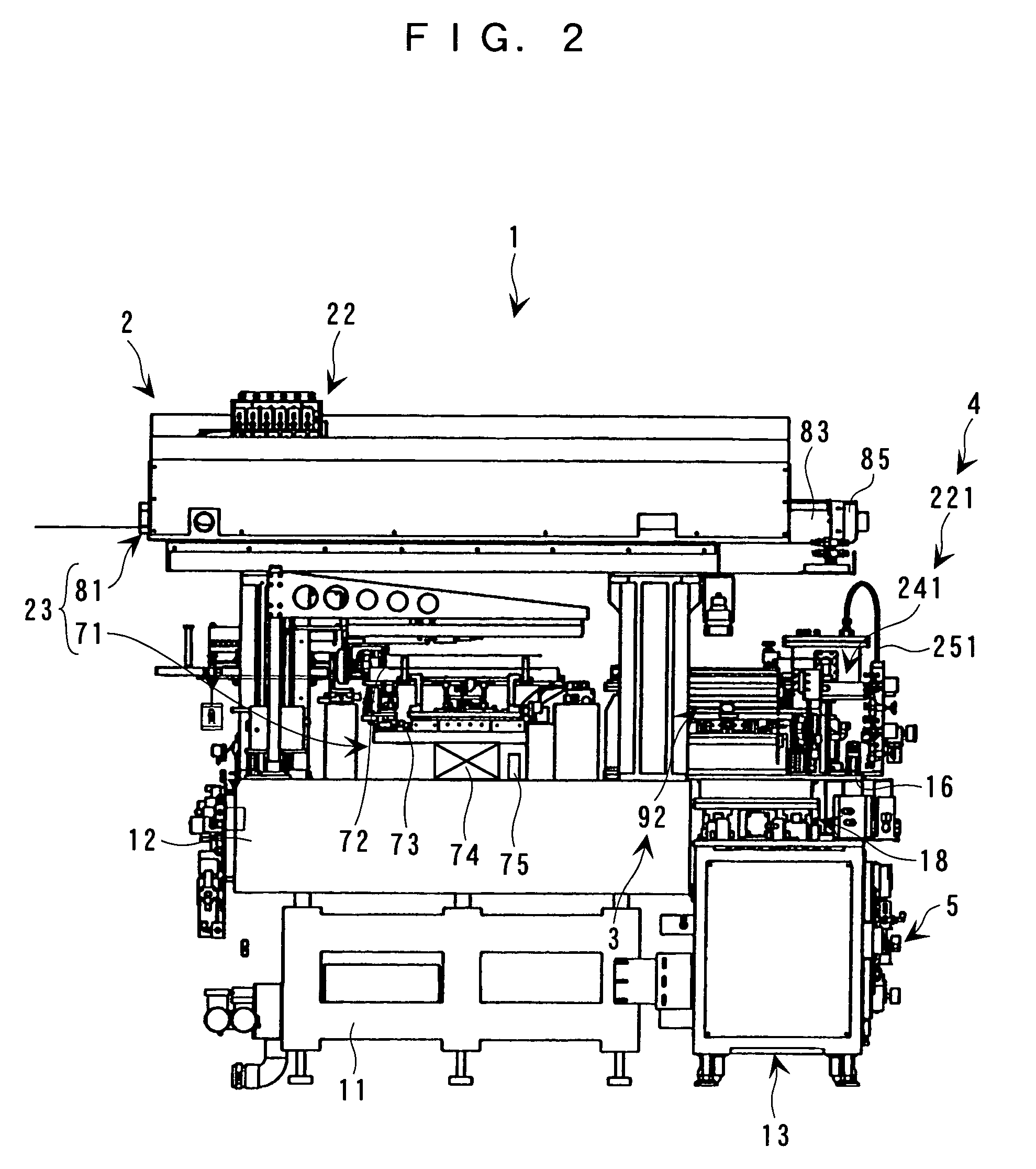

Method of determining abnormality of nozzles in imaging apparatus; imaging apparatus; electrooptic device; method of manufacturing electrooptic device; and electronic equipment

ActiveUS7101013B2Avoid misjudgmentEasy to operateInking apparatusGas discharge electrodesEngineeringImaging equipment

In an imaging apparatus having a head unit mounting thereon liquid droplet ejection heads with a plurality of ejection nozzles, a confirmation is made before starting an imaging operation as to whether or not liquid droplets are normally ejected from the respective ejection nozzles. This confirmation is made by using optical liquid droplet detectors having a light emitting element and a light receiving element. When ejection of liquid droplets from any of the ejection nozzles of liquid droplet ejection heads is determined to be abnormal in an ejection confirming operation, the ejection confirming operation is performed again. When the ejection of the liquid droplets from the same ejection nozzle is determined to be abnormal also in this ejection confirming operation, this ejection nozzle is judged to be abnormal.

Owner:KATEEVA

Popular searches

Heat exchange apparatus Cooling/ventilation/heating modifications Identification means Casings/cabinets/drawers details Vessels or leading-in conductors manufacture Electrical apparatus contructional details Cold-cathode tubes Electrode disposition Discharge tube main electrodes Indirect heat exchangers

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com