Patents

Literature

114results about How to "Improve crush resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

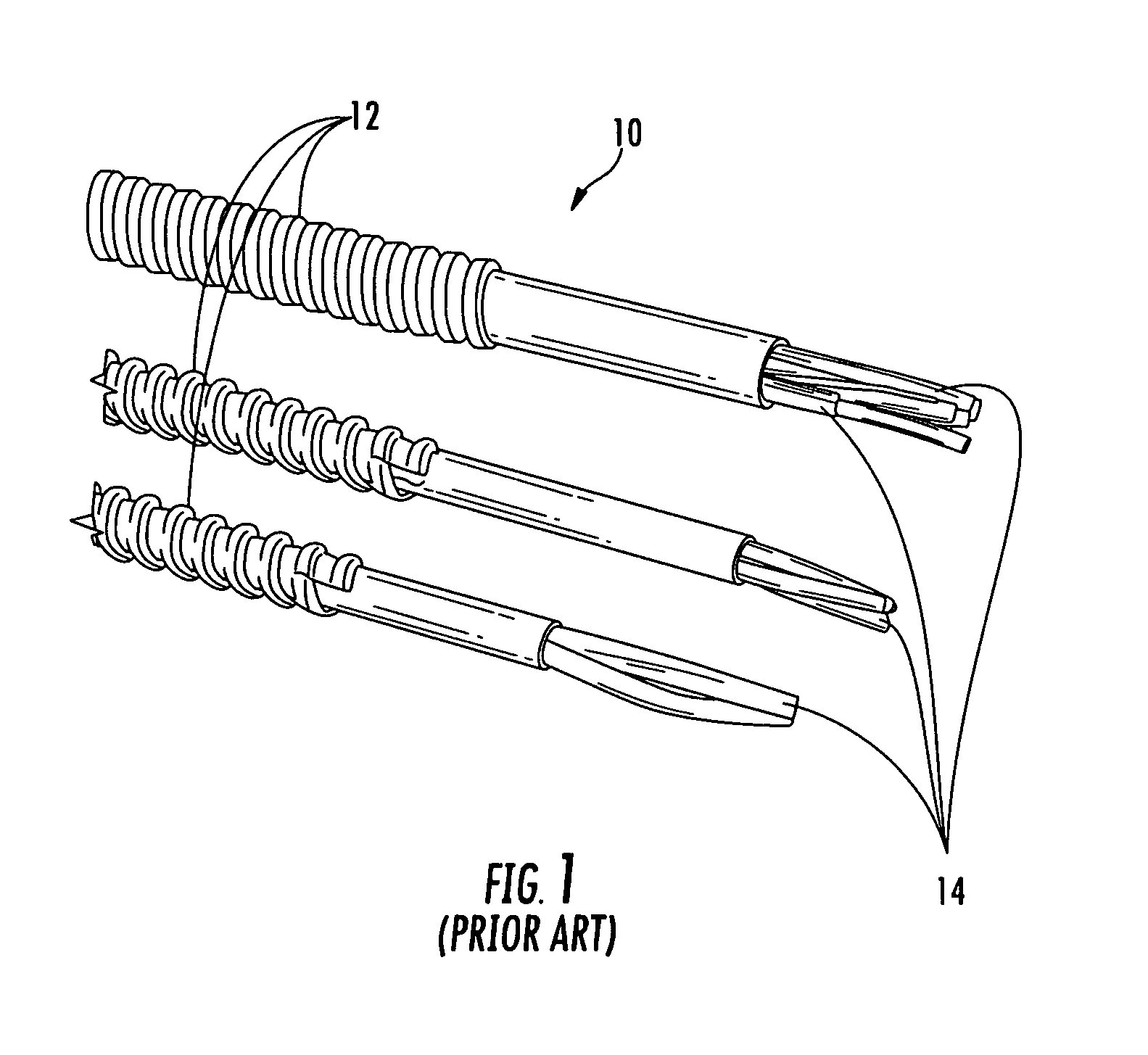

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coated and cured proppants

ActiveUS20130065800A1Improve crush resistanceGood fracture conductivityPretreated surfacesFluid removalAlcoholFirming agent

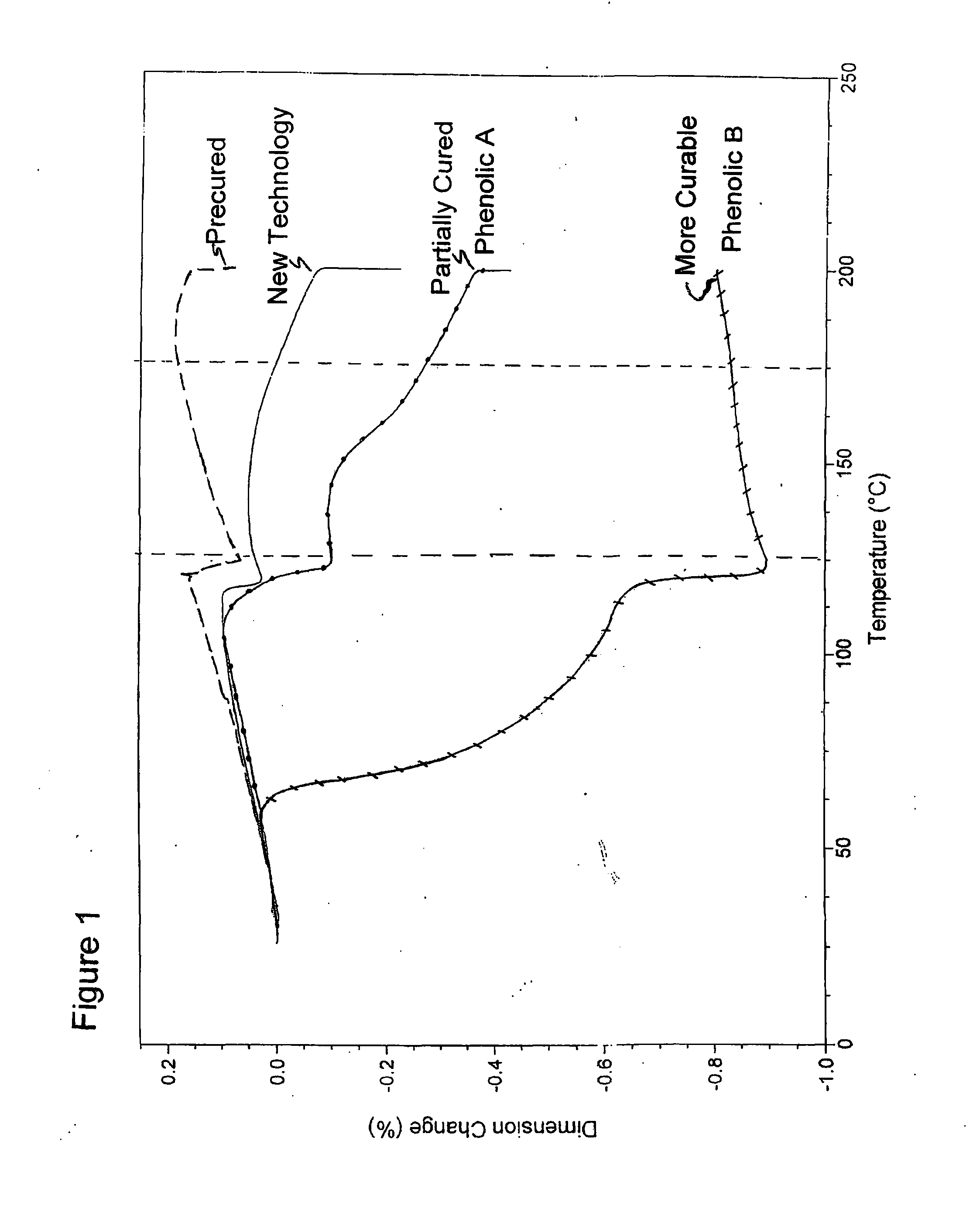

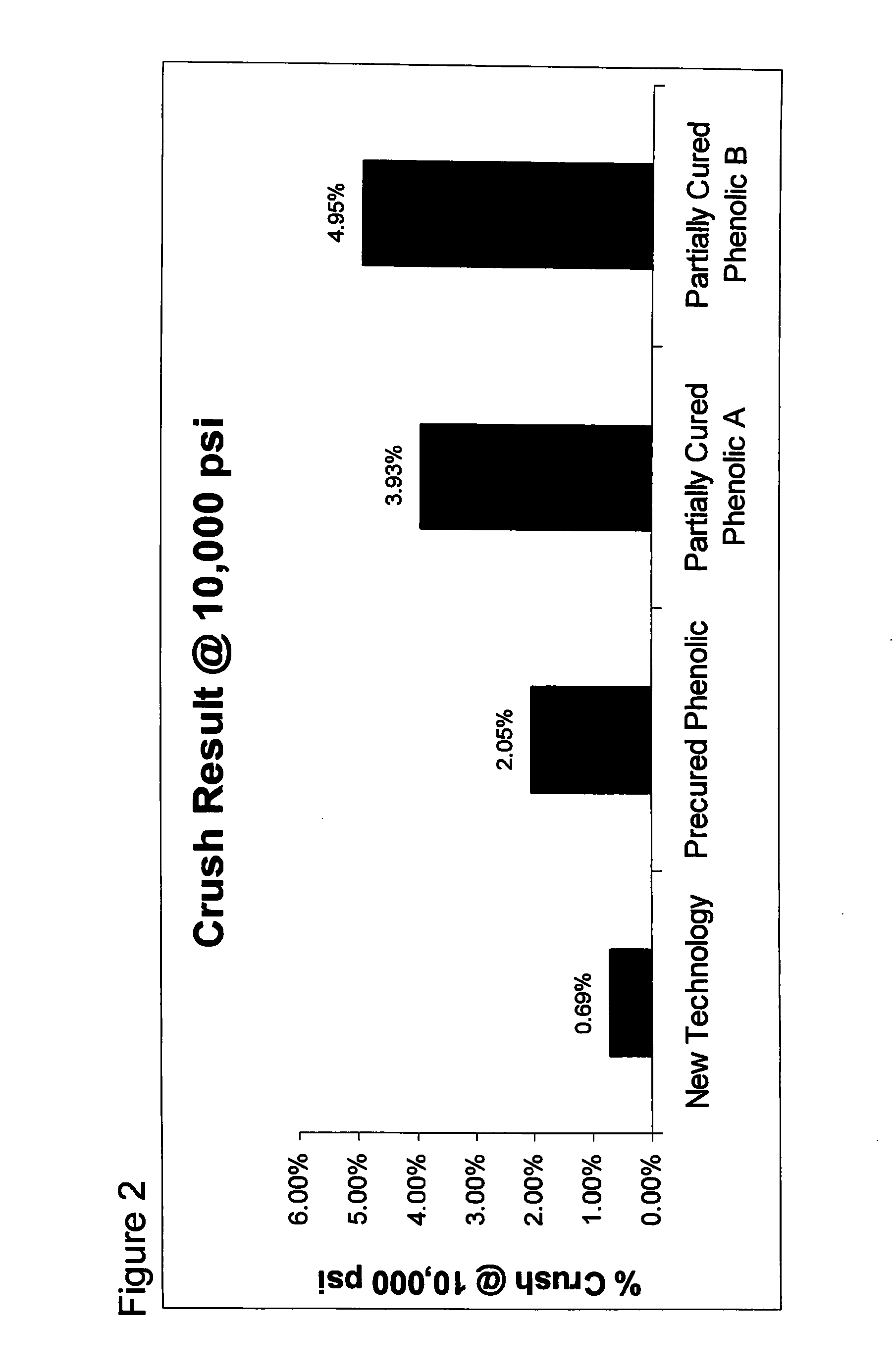

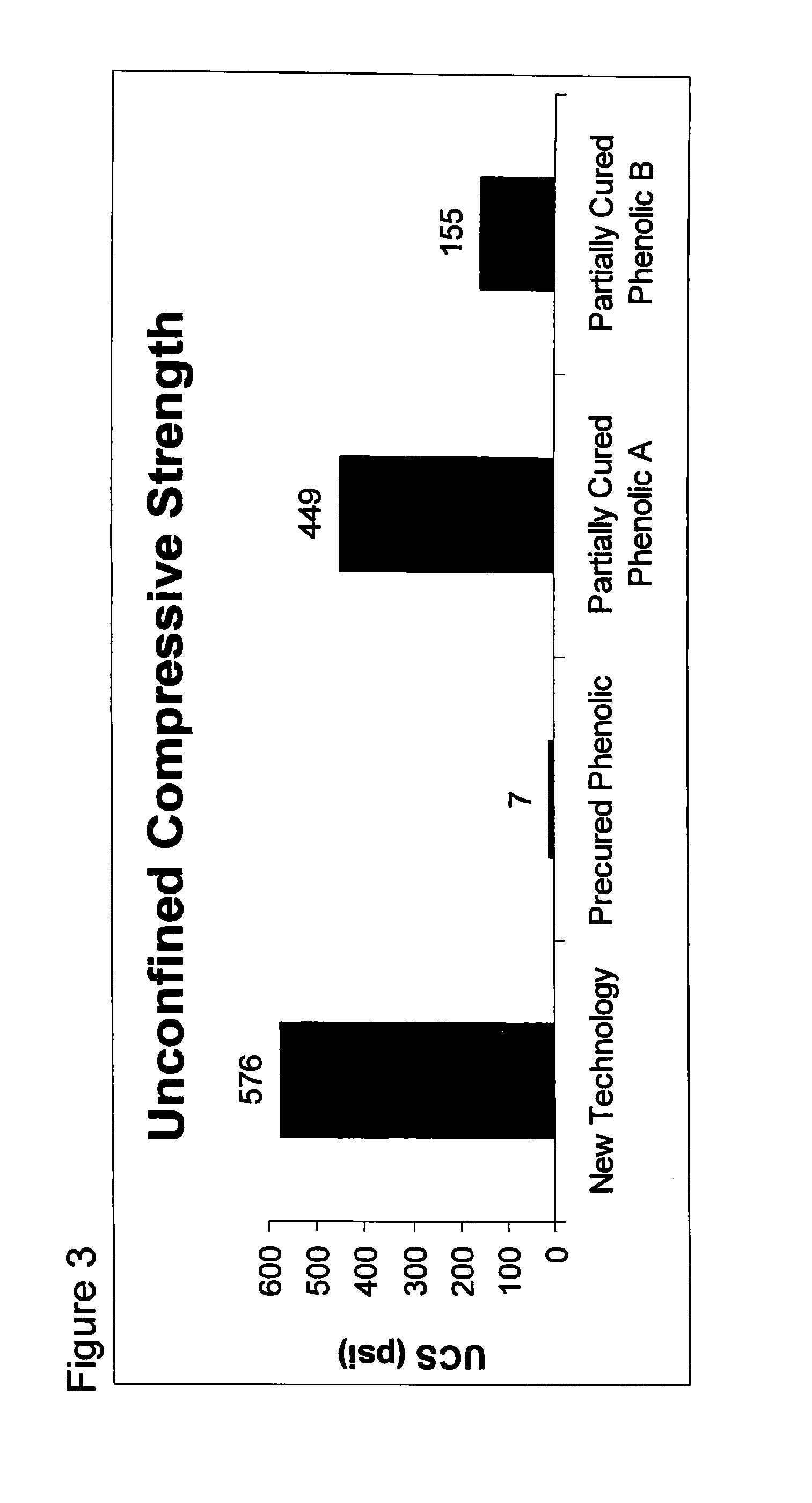

Solid proppants are coated with a coating that exhibits the handling characteristics of a pre-cured coating while also exhibiting the ability to form particle-to-particle bonds at the elevated temperatures and pressures within a wellbore. The coating includes a substantially homogeneous mixture of (i) at least one isocyanate component having at least 2 isocyanate groups, and (ii) a curing agent comprising a monofunctional alcohol, amine or amide. The coating process can be performed with short cycle times, e.g., less than about 4 minutes, and still produce a dry, free-flowing, coated proppant that exhibits low dust characteristics during pneumatic handling but also proppant consolidation downhole for reduced washout and good conductivity. Such proppants also form good unconfined compressive strength without use of an bond activator, are substantially unaffected in bond formation characteristics under downhole conditions despite prior heat exposure, and are resistant to leaching with hot water.

Owner:PREFERRED TECH

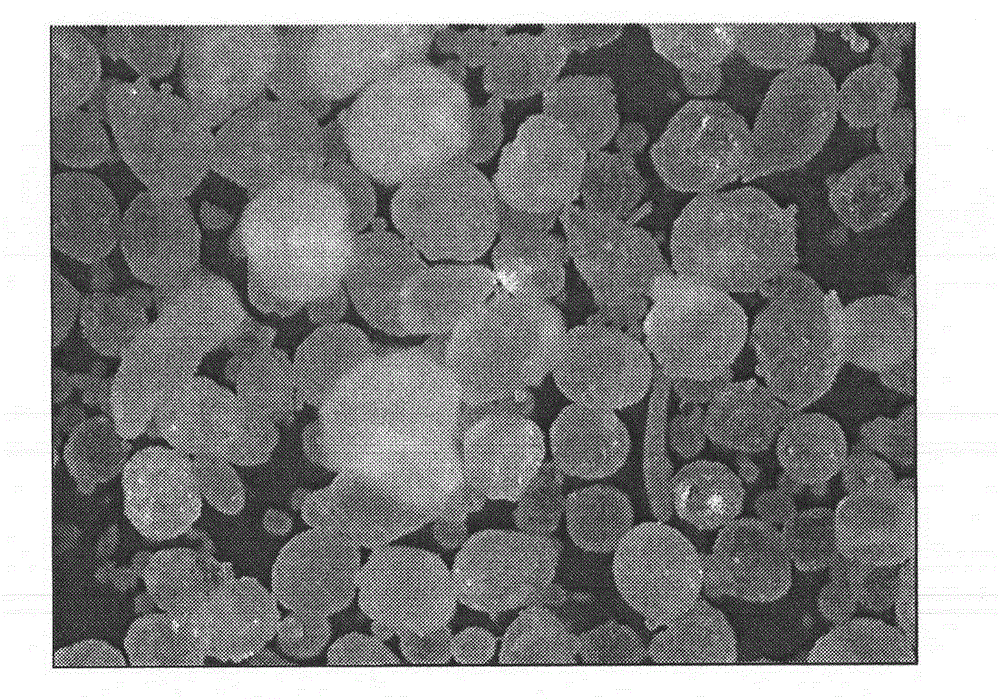

Functional resin tectorial membrane proppant and preparation method thereof

ActiveCN101531893AThrough highPrevent passageFluid removalDrilling compositionTectorial membraneSide chain

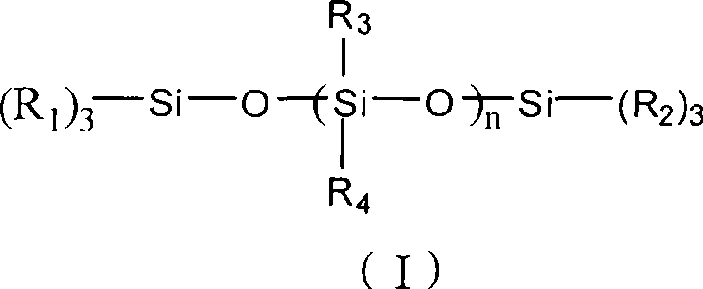

The invention relates to a functional resin tectorial membrane proppant and a preparation method thereof, and belongs to the technical field of oil-gas field development. The functional resin tectorial membrane proppant comprises aggregate and a resin film coated on the aggregate. Said resin film comprises organic silicon compounds of one or more active groups of amino, hydroxyl, carboxyl, alkoxyl and hydrosulphonyl. The side chain of the organic silicon compound is a hydrophobic group. The cured resin film has different wetting qualities for oil and water. The functional resin tectorial membrane proppant of the invention has a function of allowing the smooth permeation of oil gas and preventing water from penetrating through the proppant. Such a function improves the separation effect ofoil gas and water and reduces the oil production cost. The excellent hydrophobicity of the resin film facilitates the proppant to have excellent water resisting property and improves the crushing resistance of the proppant, so that the stream guidance effect is good for a long time.

Owner:围场满族蒙古族自治县津通铸造材料有限公司

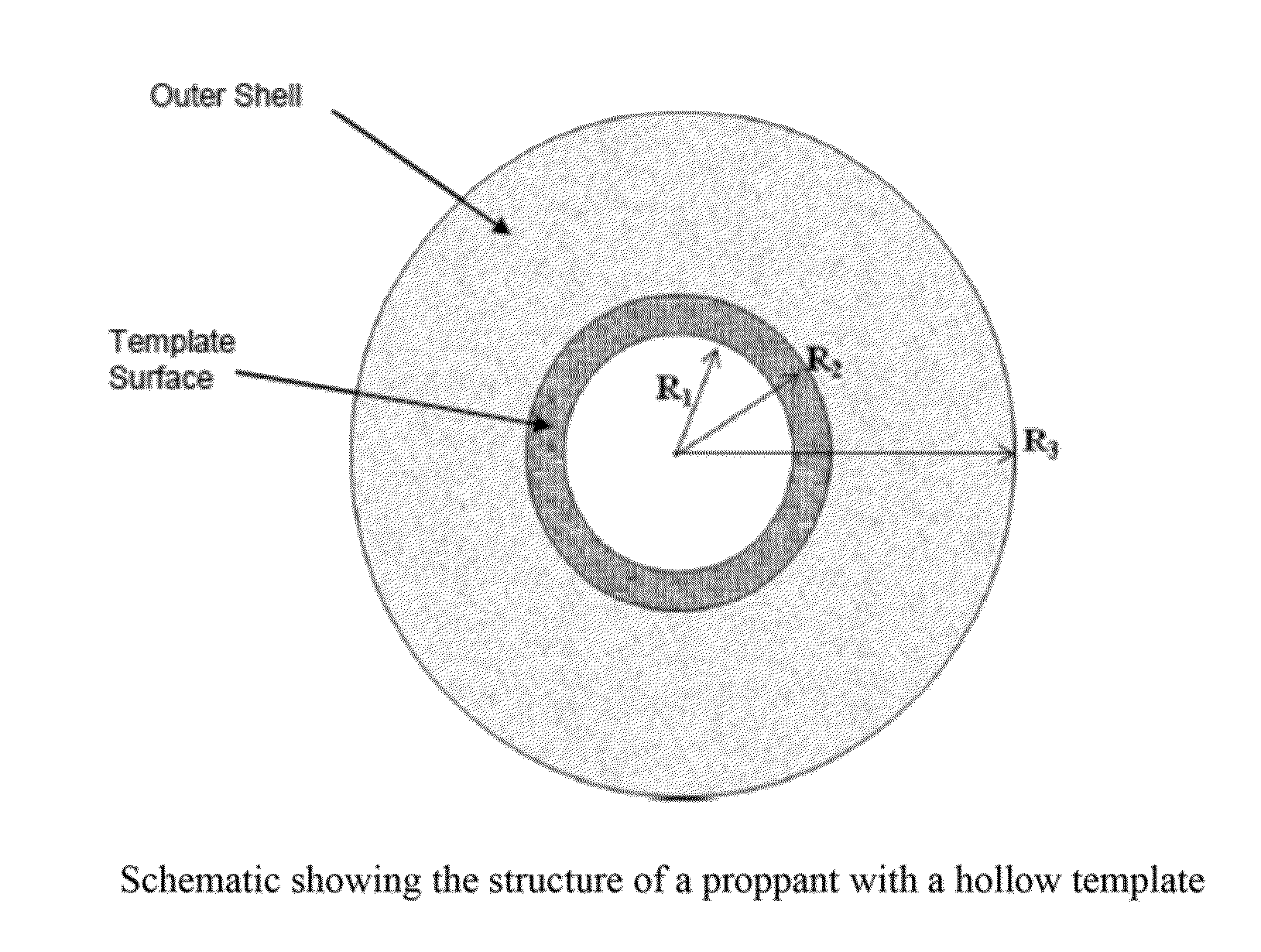

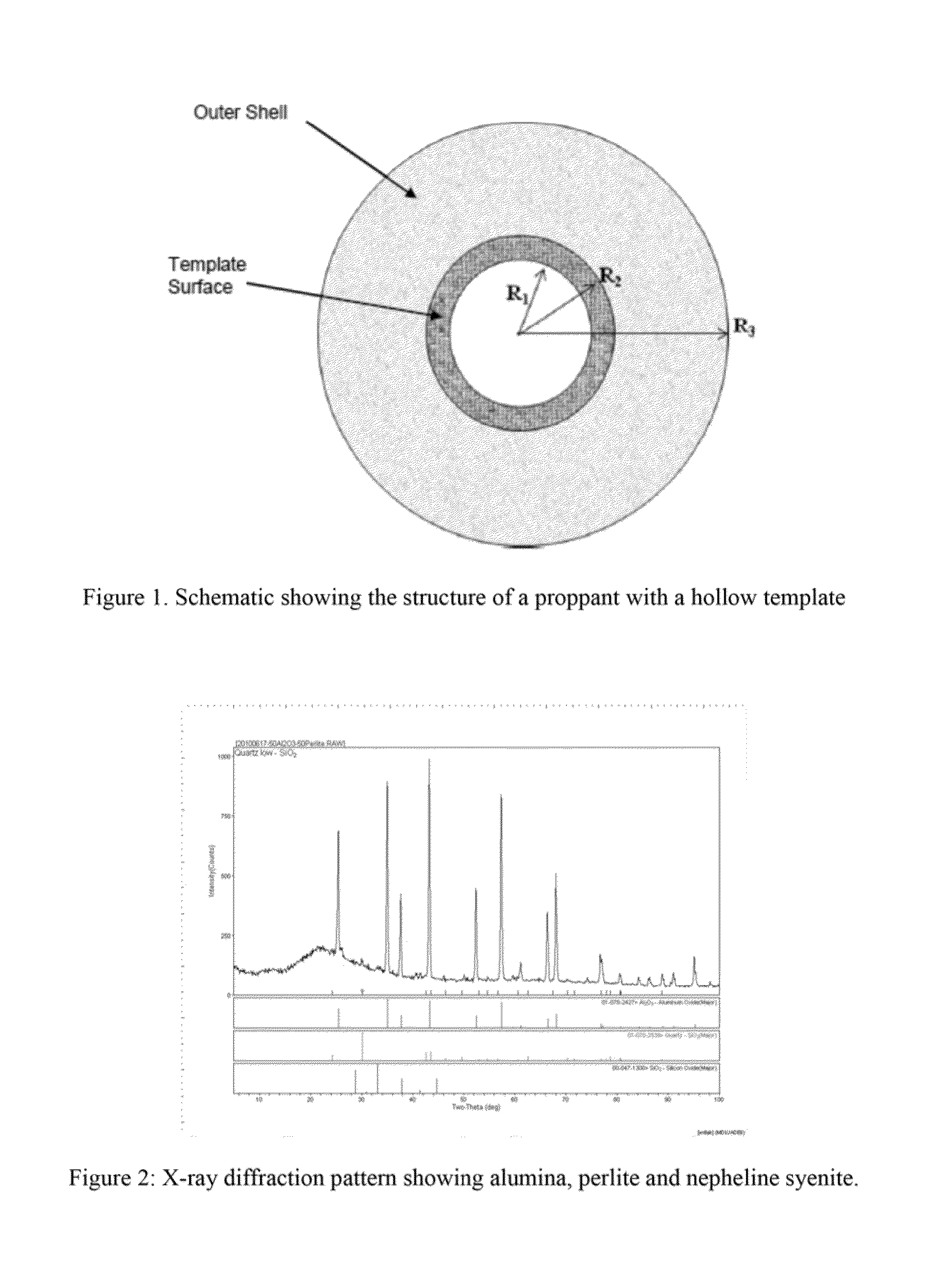

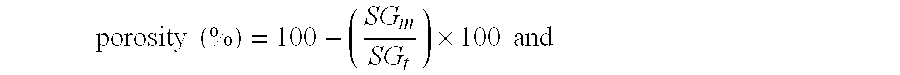

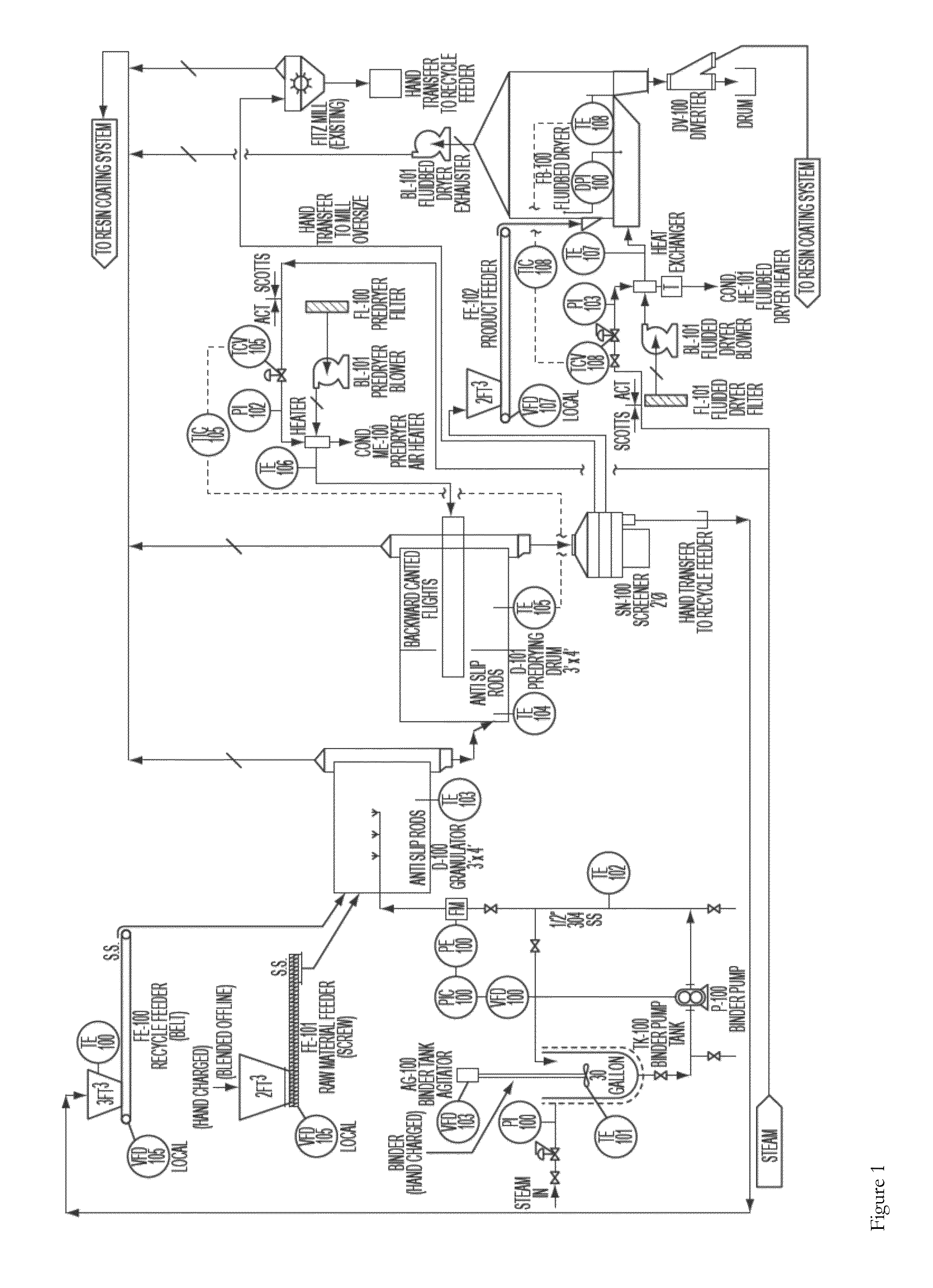

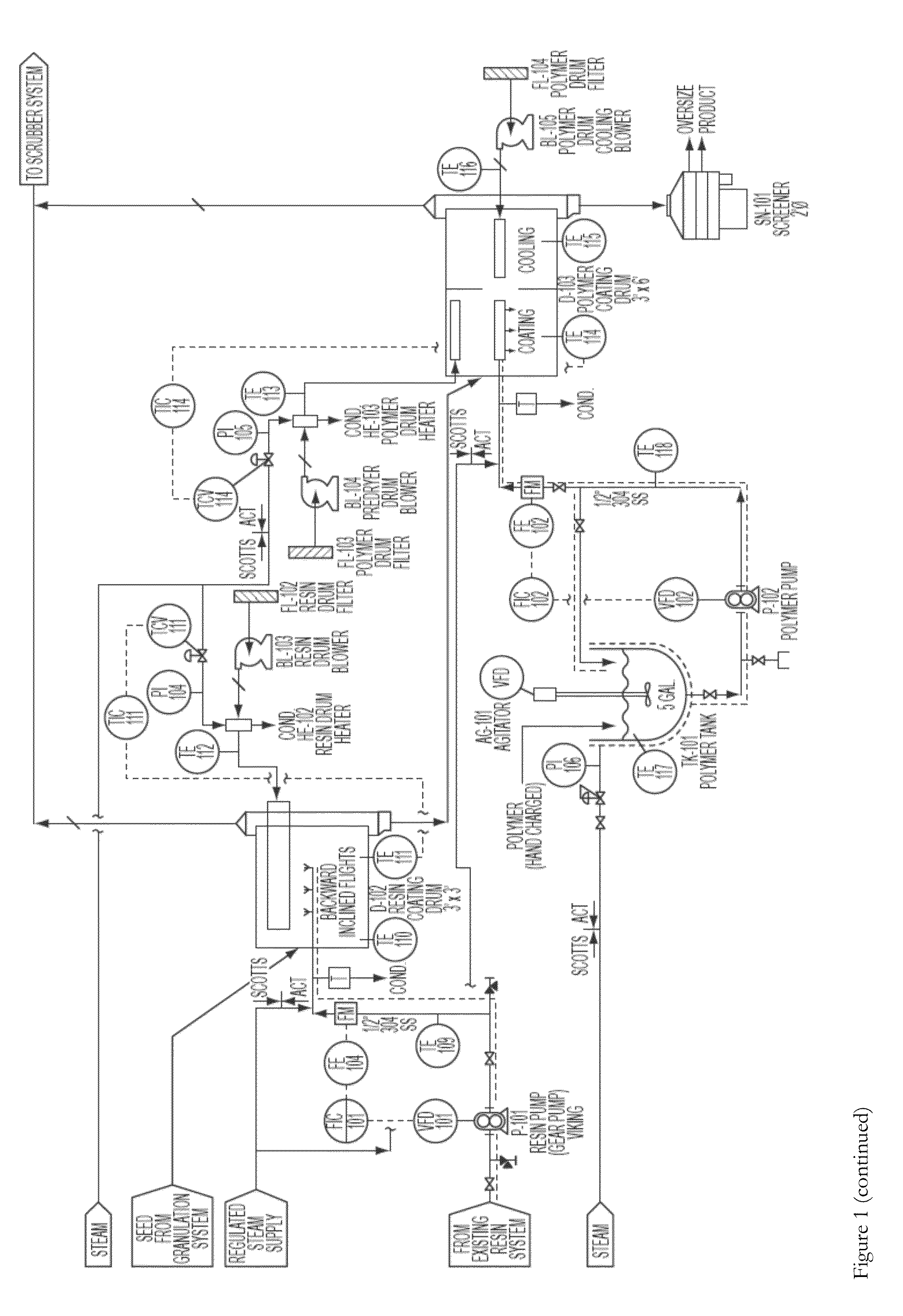

Light Weight Proppant With Improved Strength And Methods Of Making Same

ActiveUS20130206408A1Low densityHigh strengthFluid removalCeramic shaping apparatusCeramic compositeAmorphous phase

Methods are described to make strong, tough, and / or lightweight glass-ceramic composites having a crystalline phase and an amorphous phase generated by viscous reaction sintering of a complex mixture of oxides and other materials. The present invention further relates to strong, tough, and lightweight glass-ceramic composites that can be used as proppants and for other uses.

Owner:HALLIBURTON ENERGY SERVICES INC

Multi-purpose lignin-carbohydrate binding system

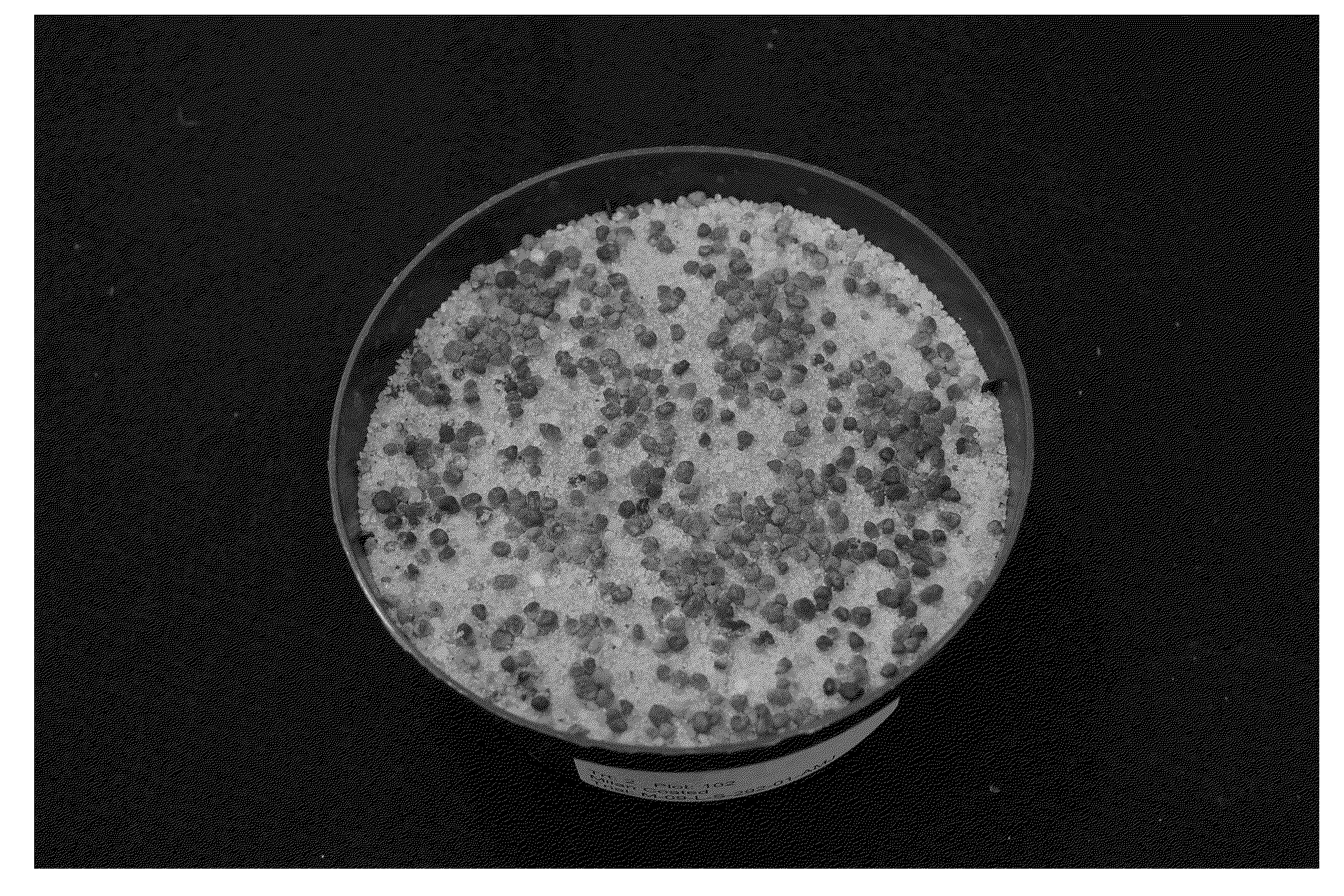

InactiveUS20140235438A1Improve crush resistanceHigh hardnessCalcareous fertilisersBiocideDual purposeGermination

The present invention relates to a novel, dual purpose binder formulation or system. The invention also relates to a process of agglomerating dispersed particles or fines into substantially spherical and crush resistant granules. The invention further relates to a method of covering a seed and binding the seed with a material mixture beneficial for seed germination. The invention also relates to an all-in-one seed agglomerated by the dual purpose binder formulation.

Owner:OMS INVESTMENTS INC

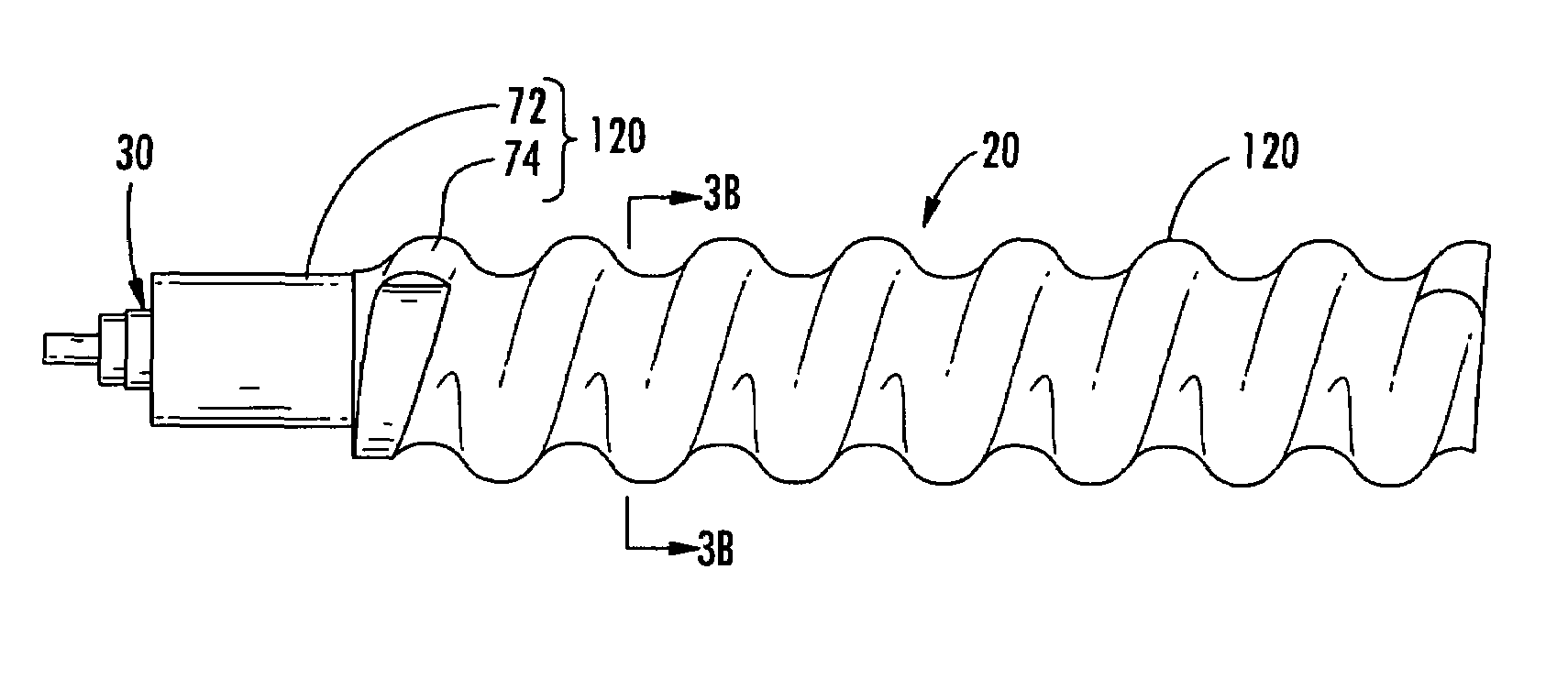

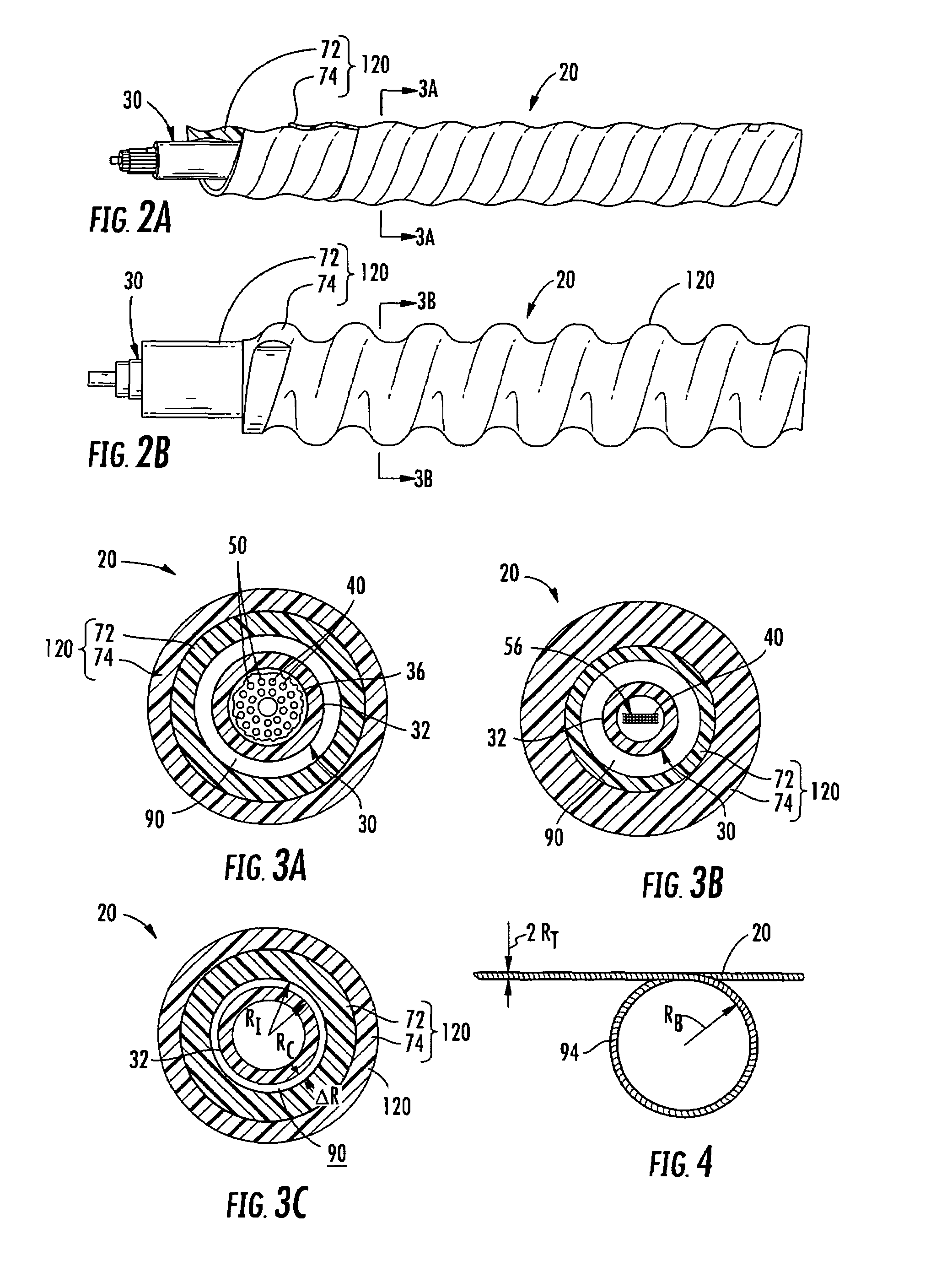

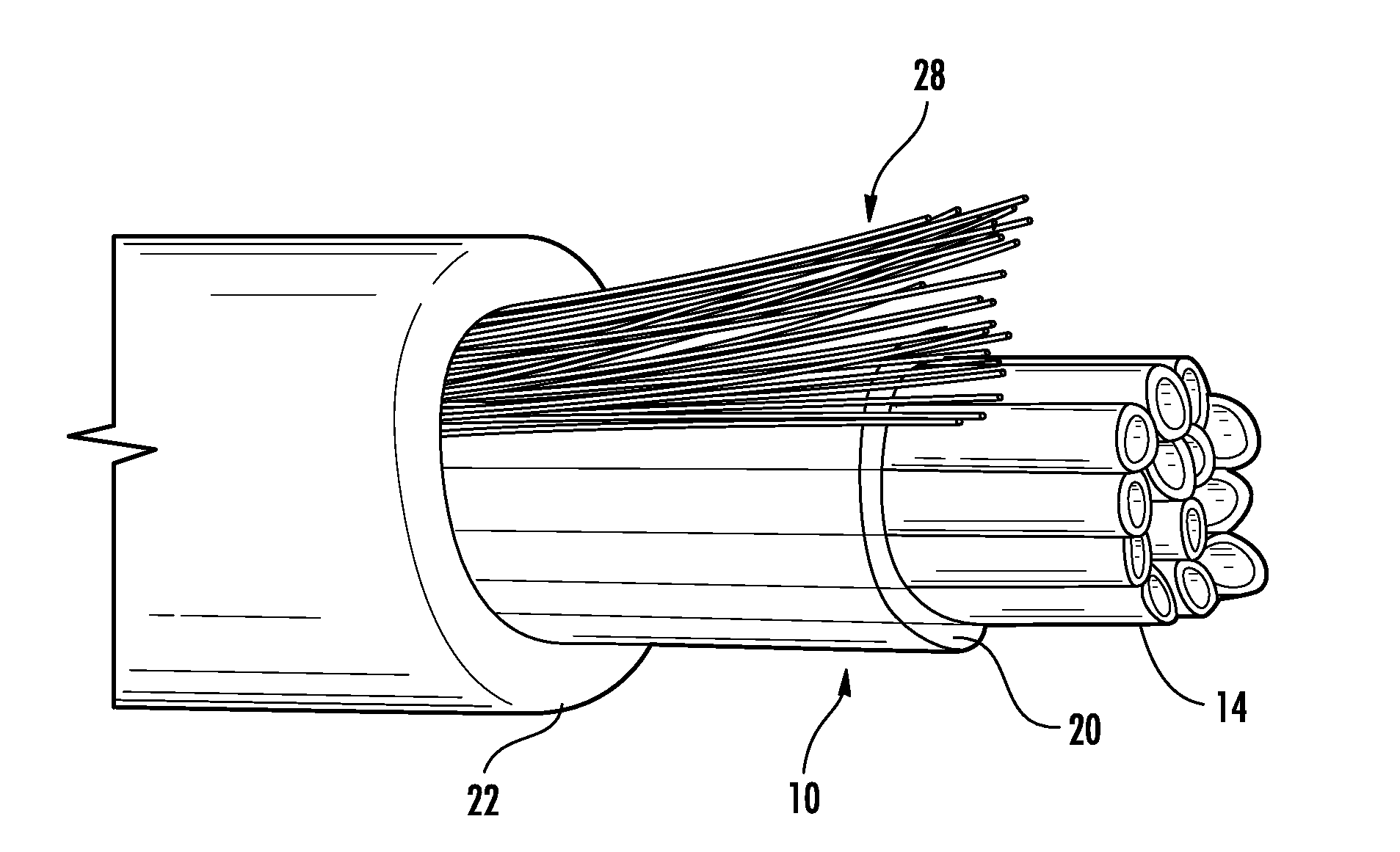

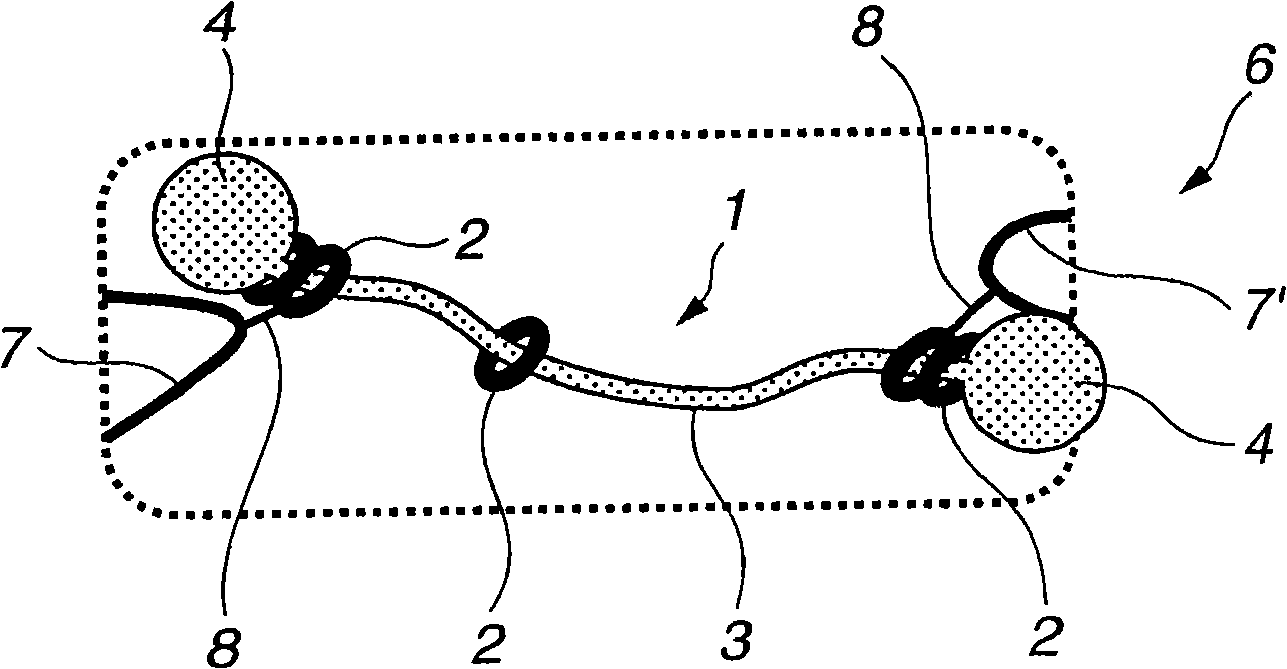

Armored fiber optic assemblies and methods of making the same

ActiveUS7702203B1Improve crush resistanceImprove impact resistanceFibre mechanical structuresElectricityFiber

Armored fiber optic assemblies are disclosed that include a dielectric armor along with methods for manufacturing the same. The dielectric armor has an armor profile, thereby resembling conventional metal armored cable to the craft. The dielectric armor provides additional crush and impact resistance and the like for the optical fibers and / or fiber optic assembly therein. The dielectric armor is advantageous to the craft since it provides the desired mechanical performance without requiring the time and expense of grounding like conventional metal armored cables. Additionally, the armored fiber optic assemblies can have any suitable flame and / or smoke rating for meeting the requirements of the intended space.

Owner:CORNING OPTICAL COMM LLC

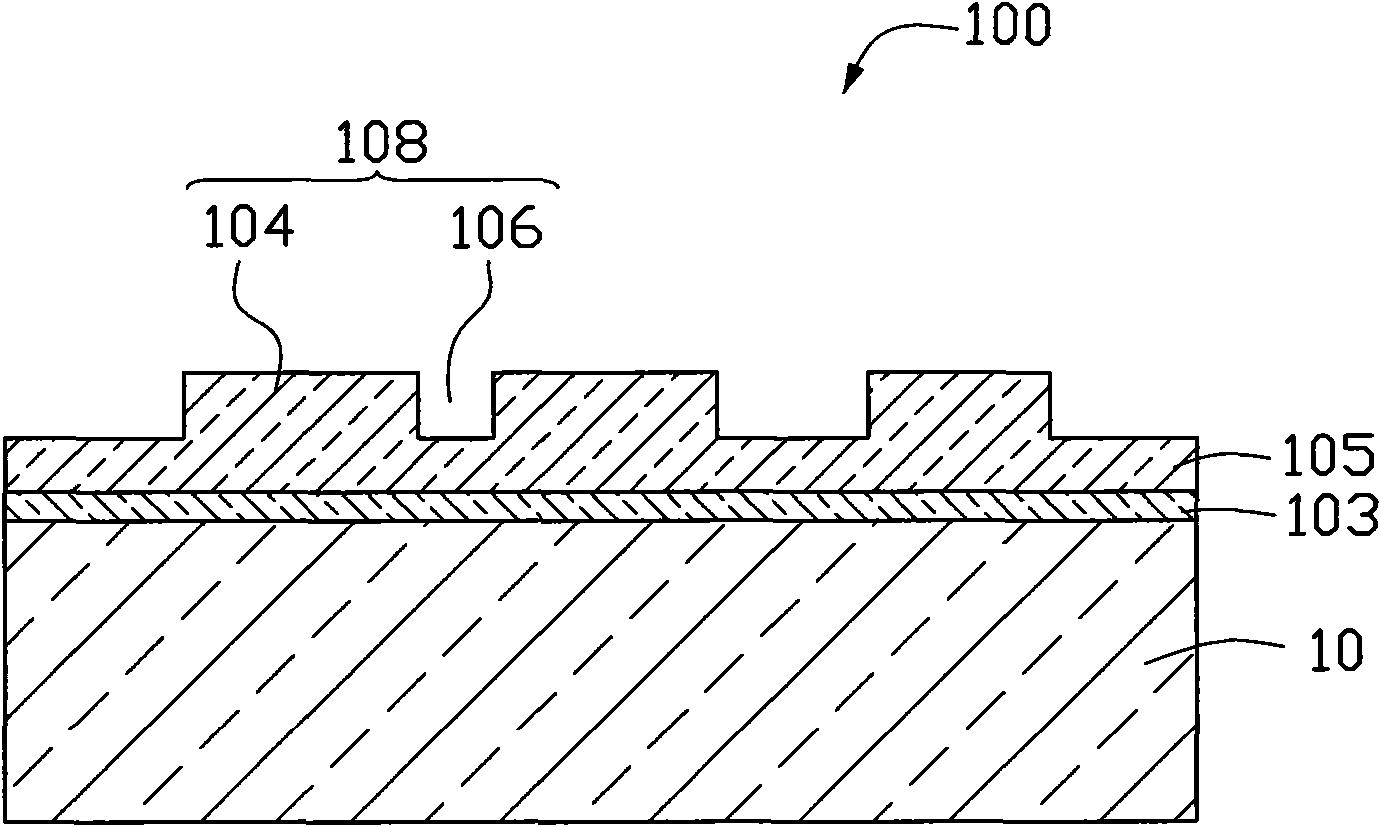

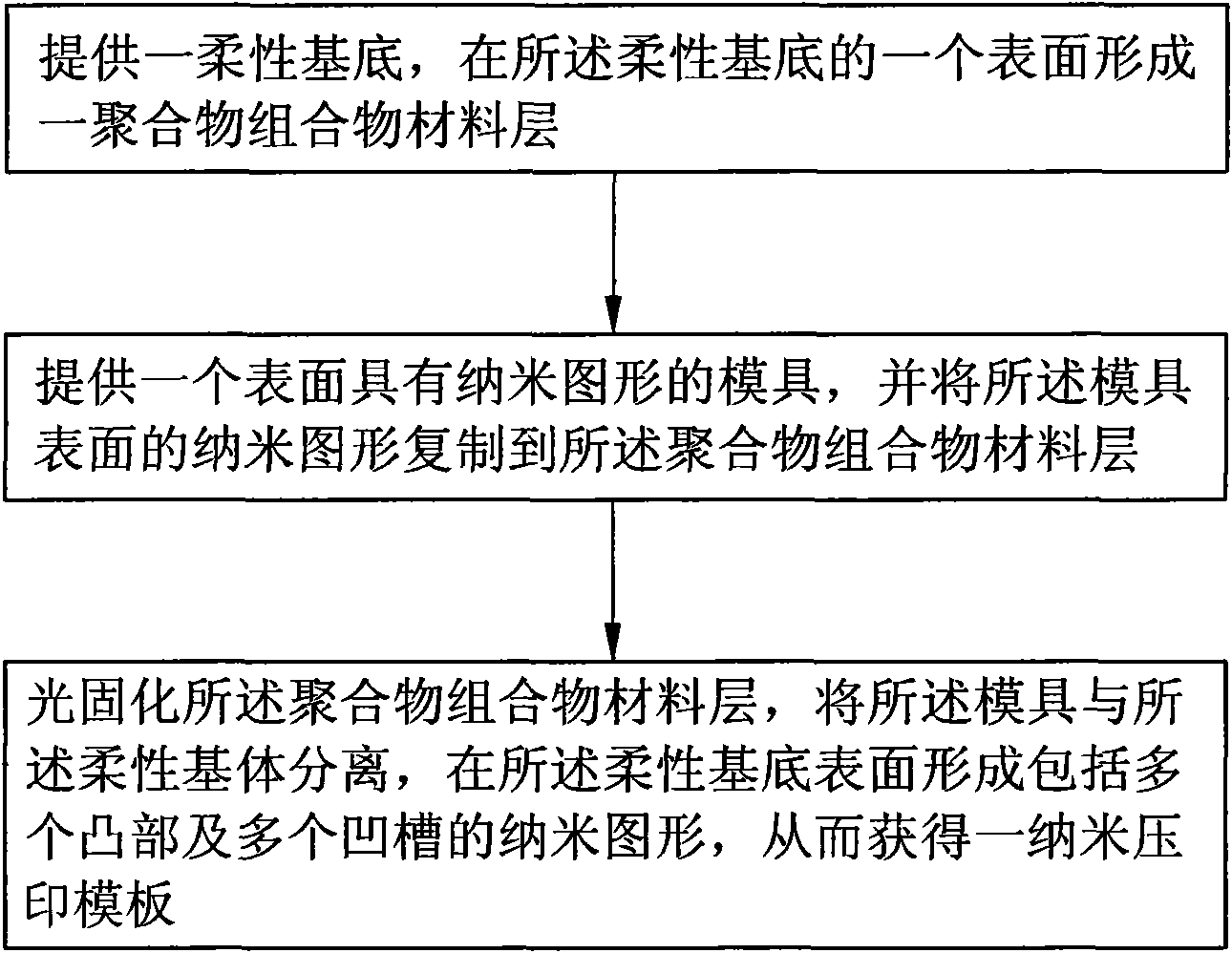

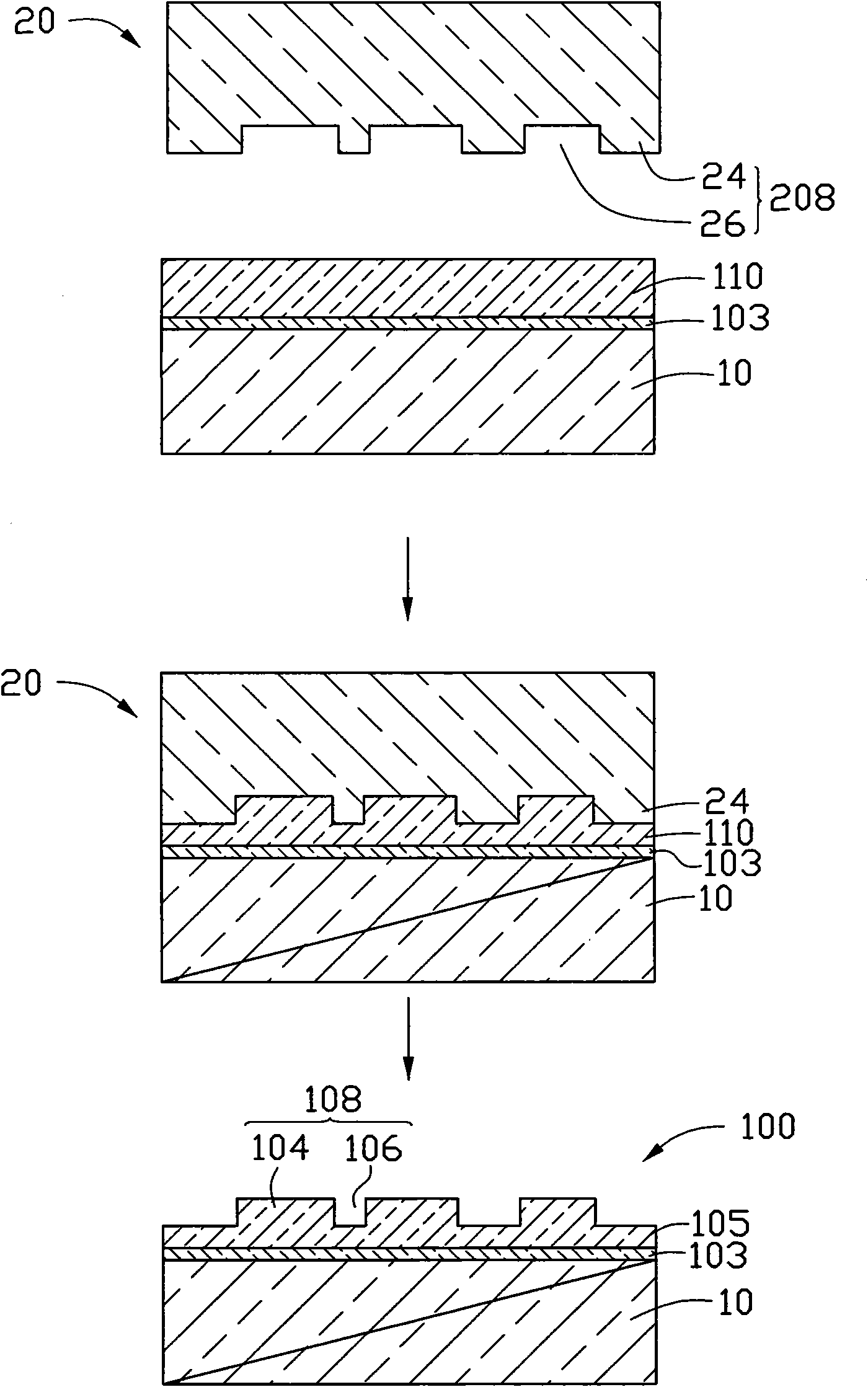

Nano-imprint template and preparation method thereof

ActiveCN101923279AFlexibleGood crush resistancePhotomechanical apparatusOriginals for photomechanical treatmentCross-linkDiluent

The invention provides a nano-imprint template which comprises a flexible substrate and a polymer layer formed on a surface of the flexible substrate, wherein, a nano-graph is formed on a surface of the polymer layer away from the flexible substrate; and the polymer layer is a solidified cross-linked substance composed of a hyperbranched lower polymer, perfluoro polyether, methyl methacrylate and an organic diluent. The invention further provides a preparation method of the nano-imprint template.

Owner:TSINGHUA UNIV +1

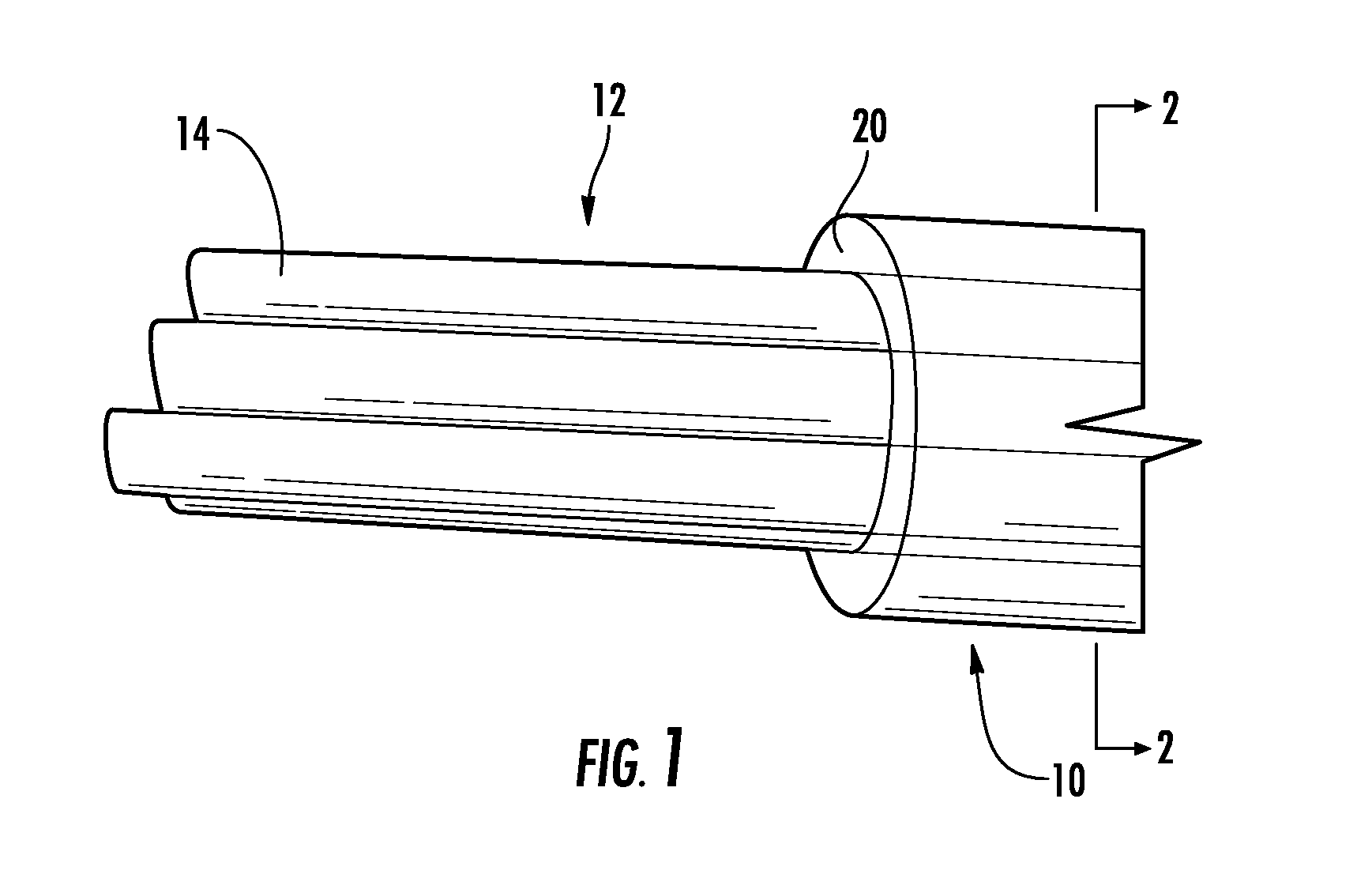

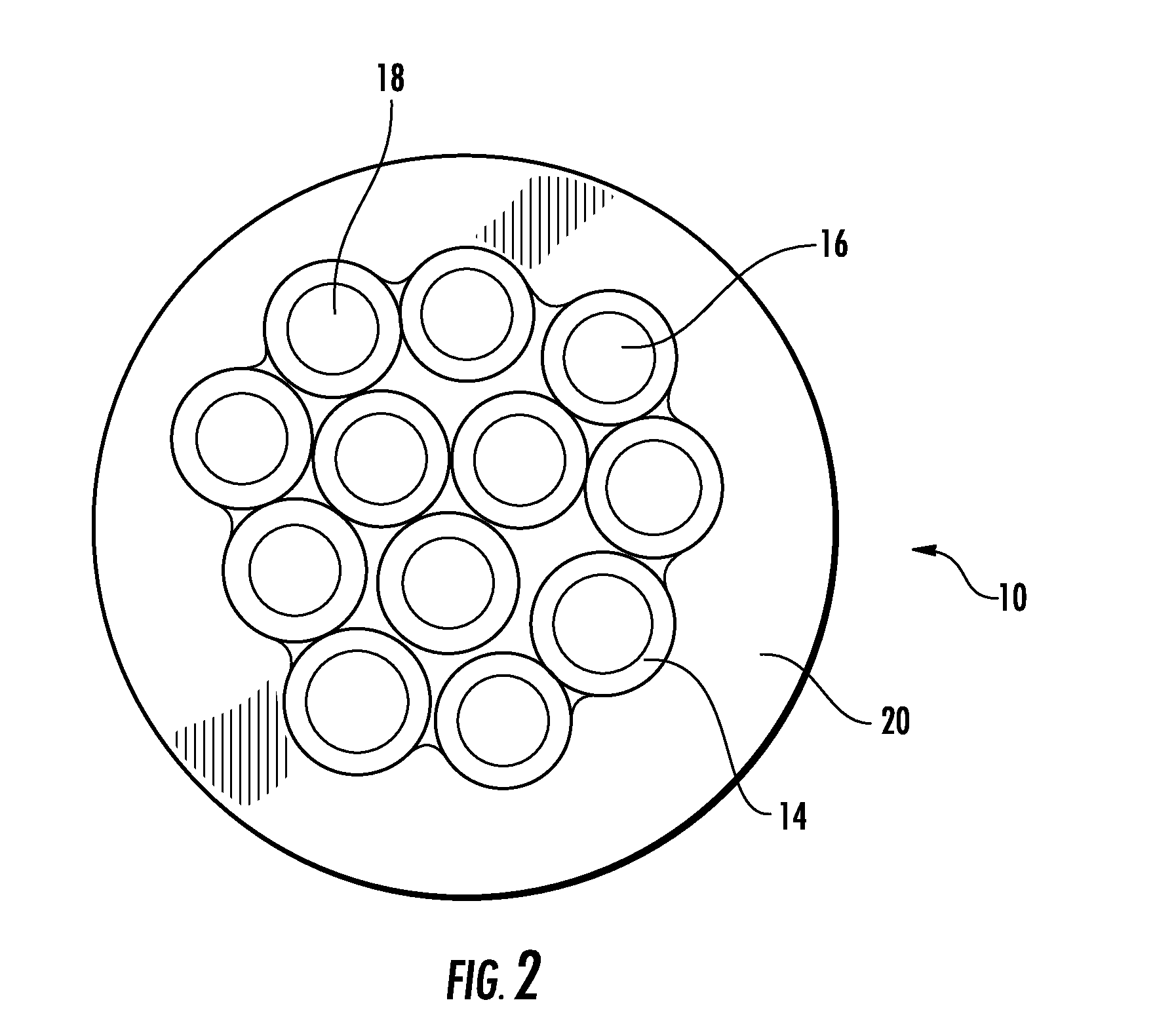

Rugged Fiber Optic Cable

ActiveUS20120155814A1Improve crush resistanceIncrease exposureFibre mechanical structuresFiberEngineering

There is provided an optical fiber cable having a plurality of optical fiber members. Each optical fiber member includes an optical fiber and a protective coating surrounding the optical fiber. A polymer coating surrounds the plurality of optical fiber members and a portion of the polymer coating is located between at least some of the optical fiber members. The optical fiber members and the polymer coating form an optical fiber unit. A tight buffer surrounds the optical fiber unit.

Owner:OPTICAL CABLE CORPORATION

Preparation method of high-stability high-purity extra-coarse tungsten carbide powder

InactiveCN102557028ANarrow particle size distributionImprove stabilityTungsten/molybdenum carbideGranularityCarbonization

A preparation method of a high-stability high-purity extra-coarse tungsten carbide powder contains the following steps of: (1) grinding a high-purity extra-coarse tungsten carbide powdered raw material with its chemical purity being greater than or equal to 99.98 wt%, and carrying out size grading to obtain the required average granularity and a high-purity extra-coarse tungsten powder according to the particle size distribution; (2) carrying out carbon addition by the use of carbon black according to the total carbon content of the obtained tungsten carbide powder being 6.13+ / -0.05%, followed by ball milling and mixing to obtain a ball-milling mixture; (3) filling the obtained ball-milling mixture into a graphite boat and a carbide furnace, and carrying out high-temperature carbonization at 1600-2500 DEGC for the carbonization time of 1-10 hours; and (4) carrying out coarse crushing on the obtained carbonized material, followed by grinding and crushing, and carrying out size grading to obtain the high-purity extra-coarse tungsten carbide powder. The method provided by the invention can be adopted to produce the high-purity extra-coarse tungsten carbide powder with good crush resistance, morphology and structure and excellent thermal stability. The high-purity extra-coarse tungsten carbide powder is used to prepare an extra-coarse crystal cemented carbide product with high performance.

Owner:江西耀升钨业股份有限公司 +1

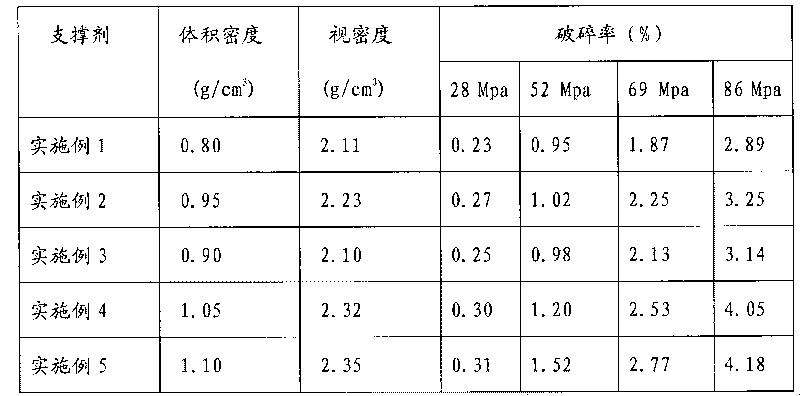

Propping agent and preparation method thereof

ActiveCN102234504AHigh strengthImprove crush resistanceChemical industryFluid removalAdhesiveRoom temperature

The invention relates to a propping agent, which comprises silica sand, an inorganic adhesive, and an organic adhesive. Based on 100 weight parts of silica sand, the content of the inorganic adhesive is 5 to 35 weight parts, and the content of the organic adhesive is 0.5 to 15 weight parts. The invention also provides a method for preparing the propping agent. The method comprises the following steps of: uniformly mixing the silica sand and the inorganic adhesive in the presence of a solvent, roasting in an oven at the temperature of between 140 and 160DEG C for 1.5 to 2.5 hours, uniformly mixing with the organic adhesive at the temperature of between 190 and 210DEG C, and cooling to room temperature. The propping agent can be applied to reservoir stratums under medium and high cloture pressure; and the propping agent has high strength, high crush resistance, and higher guiding capacity than ceramic particles; and the preparation method is simple, energy-saving, low in cost and wide in application range, and the silica sand is easily obtained.

Owner:内蒙古仁创沙产业有限公司

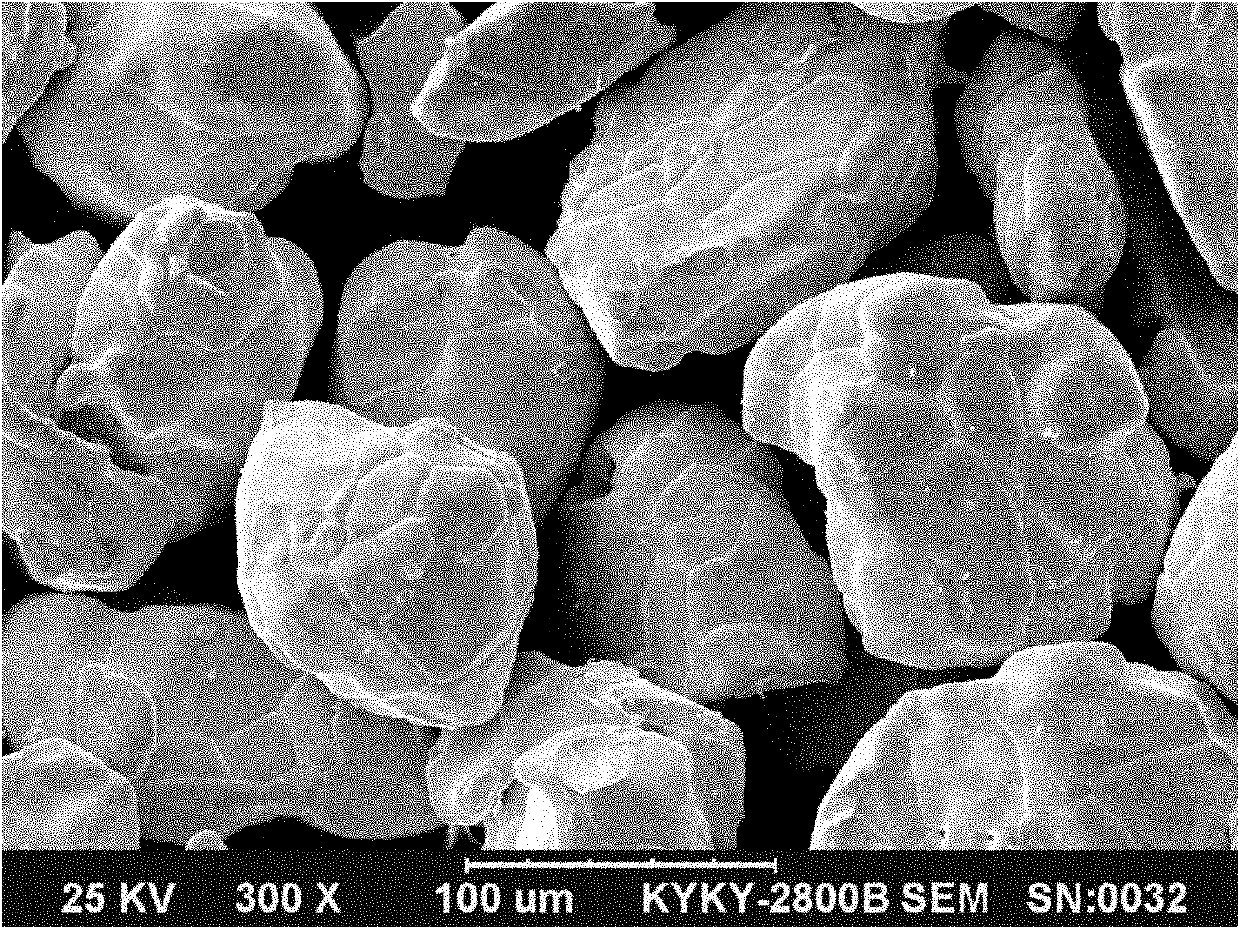

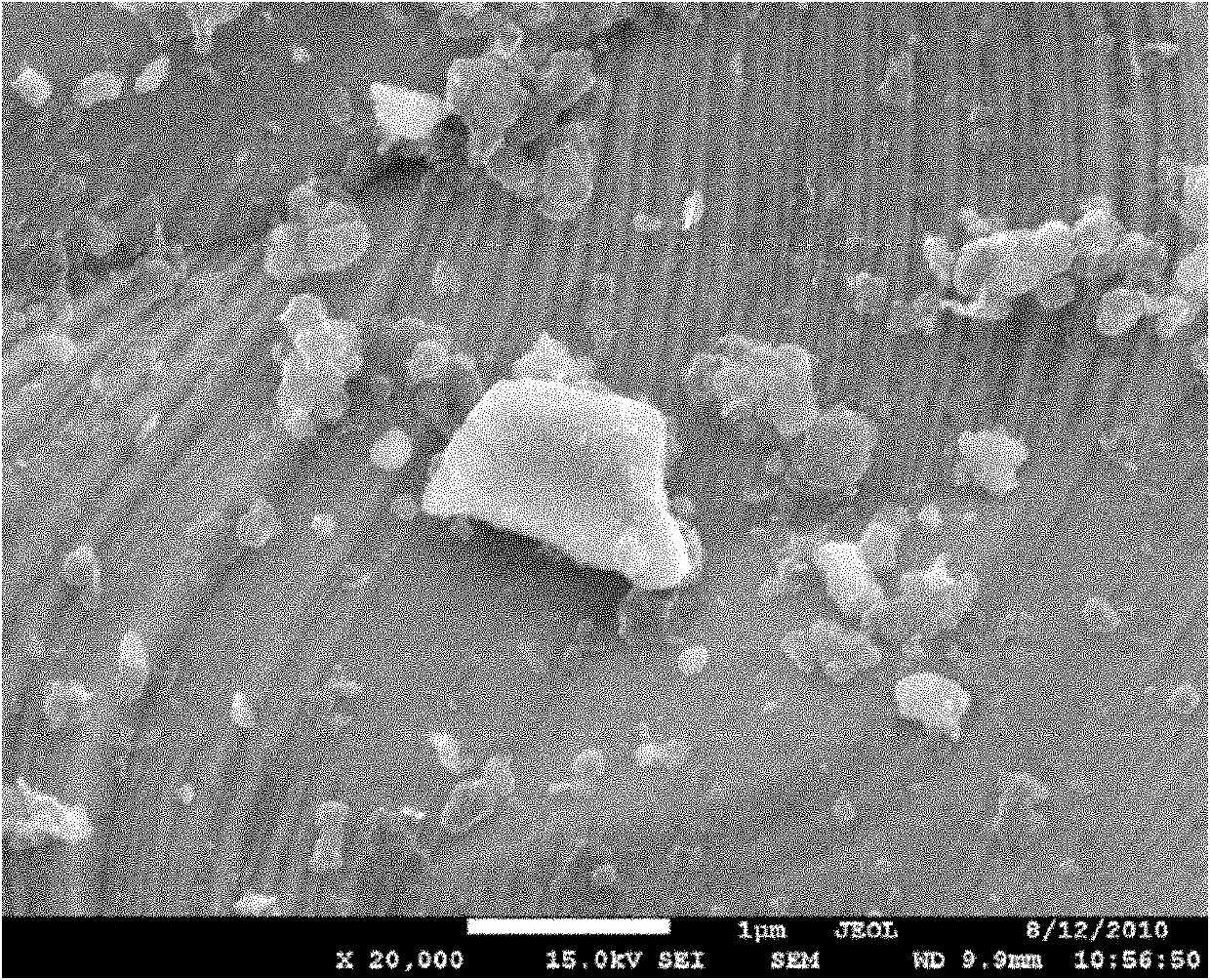

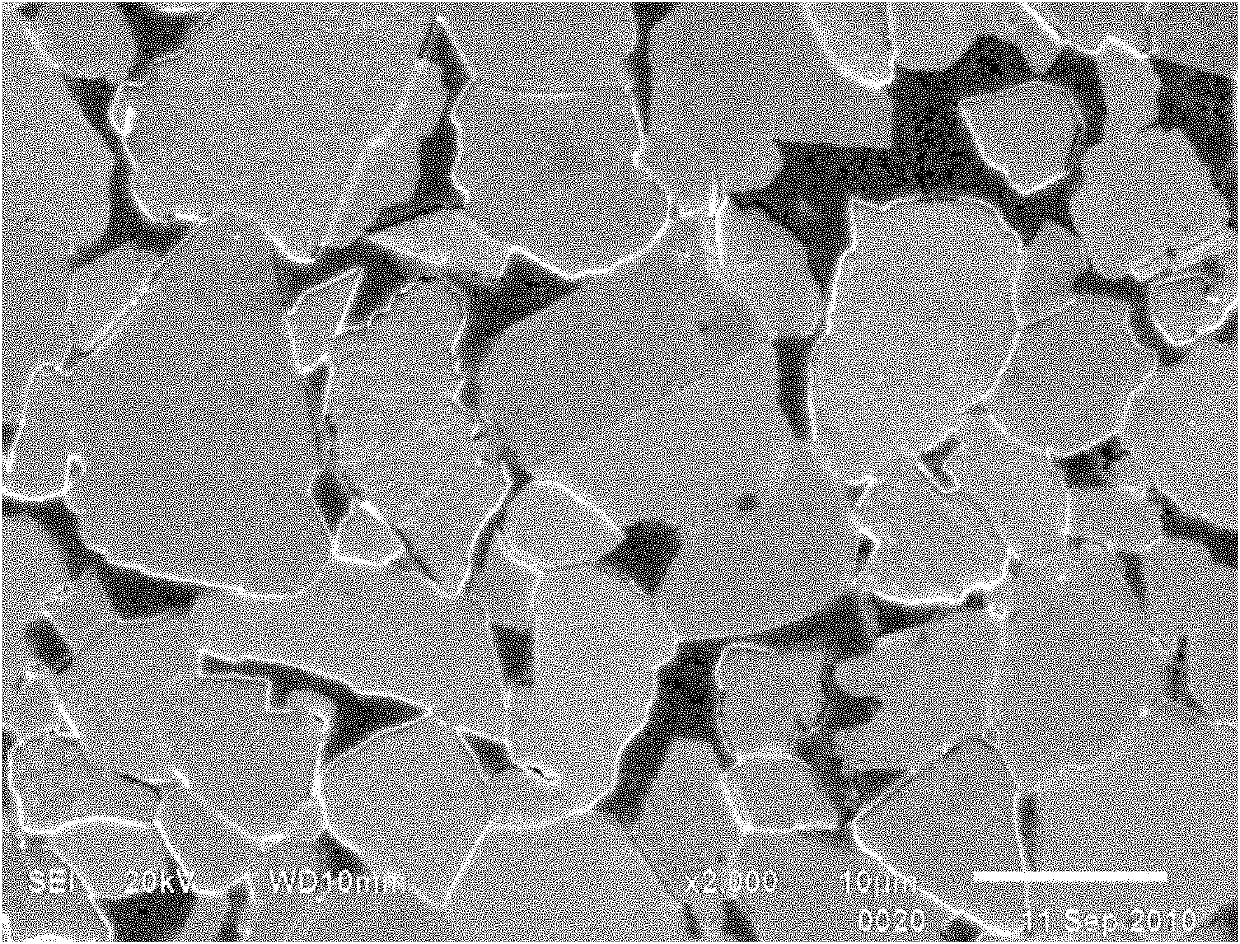

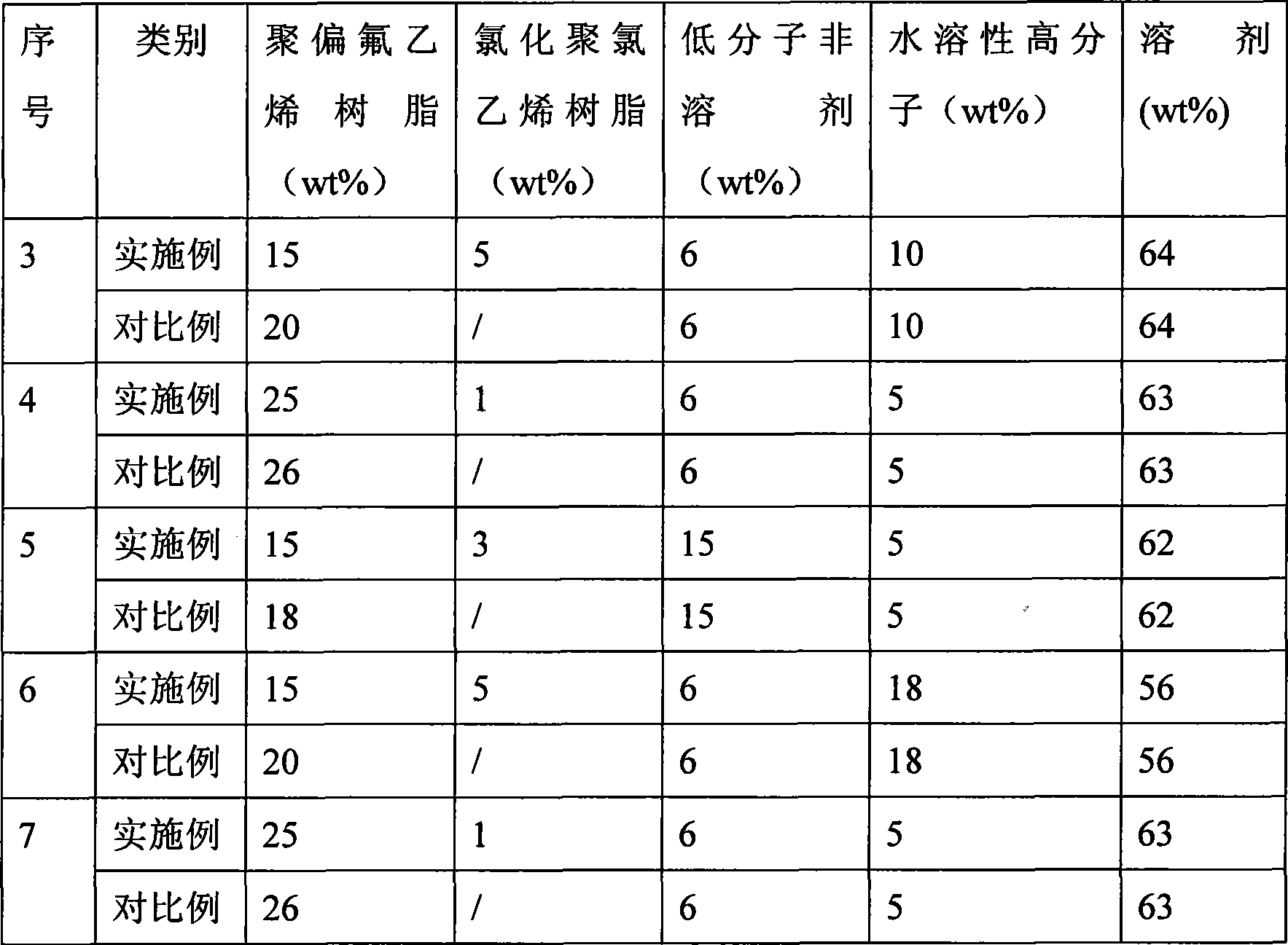

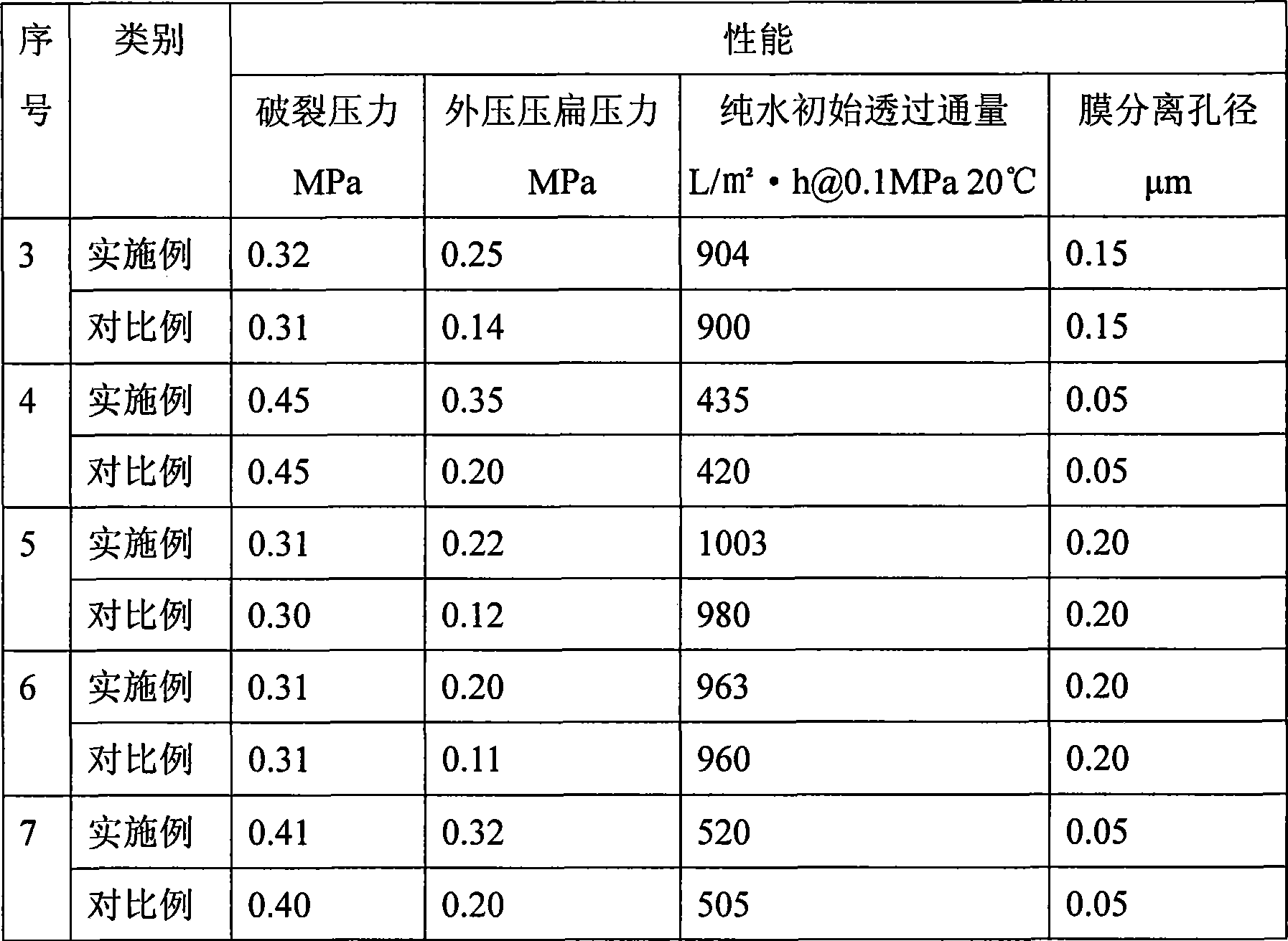

Method for preparing polyvinylidene fluoride hollow fiber alloy film

ActiveCN101485961AStable chemical propertiesImprove crush resistanceSemi-permeable membranesPolyvinylidene fluorideHollow fibre membrane

The invention provides-uses chlorinated polynvinyl chloride resin for preparing a polyvinylidene fluoride hollow fiber alloy membrane to solve the problem of the permanent hydrophilicity of the polyvinylidene fluoride hollow fiber alloy membrane and improve the compressive rigidity of the polyvinylidene fluoride hollow fiber alloy membrane. The invention also provides a method for preparing the polyvinylidene fluoride hollow fiber alloy membrane, which adopts a wet method or a dry-wet method spinning process. The mass percent of spinning membrane producing liquid takes the total mass of the spinning membrane producing liquid as reference. The invention adopts the chlorinated polynvinyl chloride resin to perform blending modification on polyvinylidene fluoride membrane material to prepare the polyvinylidene fluoride hollow fiber alloy membrane. The method has the advantages of obtaining the polyvinylidene fluoride alloy membrane with lasting hydrophilicity, having the capability of improving the anti-squeezing property of polyvinylidene fluoride membrane, strengthening the function of the differential phase of the spinning membrane producing liquid, and obtaining the high flux hollow fiber membrane.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT +1

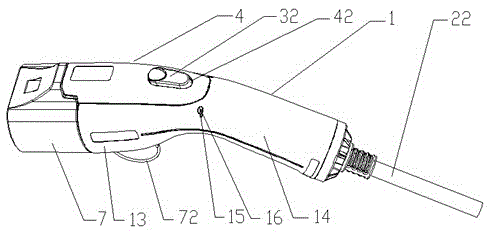

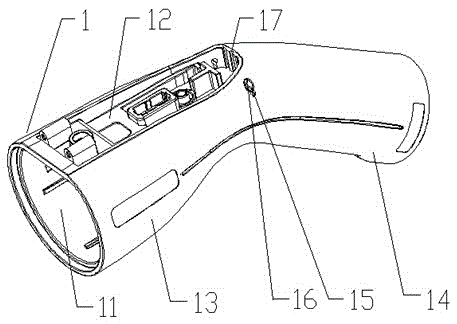

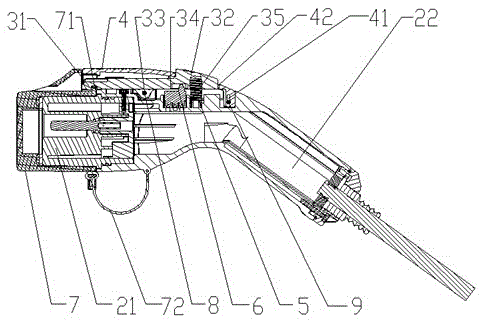

Charging gun

InactiveCN105634070AImprove structural strengthExtended service lifeHybrid vehiclesMobile unit charging stationsElectric vehicleElectrical and Electronics engineering

The invention discloses a charging gun suitable for a charging process for an electric vehicle or a hybrid electric vehicle. The charging gun comprises a gun shell, wherein the gun shell adopts an integrally-formed circular smooth transitional structure; the gun shell comprises a complete inner cavity; a charging assembly is fixedly arranged in the inner cavity; the charging assembly comprises a charging connector and a charging cable; an assembling cavity is arranged above the inner cavity; a locking plate and a gun upper cover are both connected with the gun shell through the assembling cavity; and a reset spring and a microswitch are also arranged in the assembling cavity. According to the charging gun, the waterproof performance of the charging gun is improved effectively; meanwhile, the overall structural strength of the charging gun is improved as well; due to water discharging holes, water drops permeated to the charging gun shell can be discharged smoothly, so that the service life of the charging gun is prolonged; and meanwhile, due to the microswitch, the locking and buckling process of the charging gun has a co-movement performance, so that the reliability of the charging gun in the use process is improved.

Owner:SUZHOU CHILYE GREEN TECH

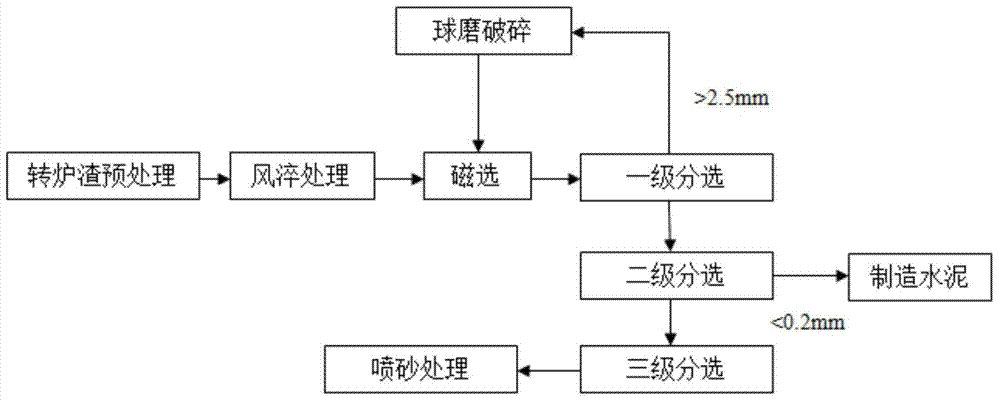

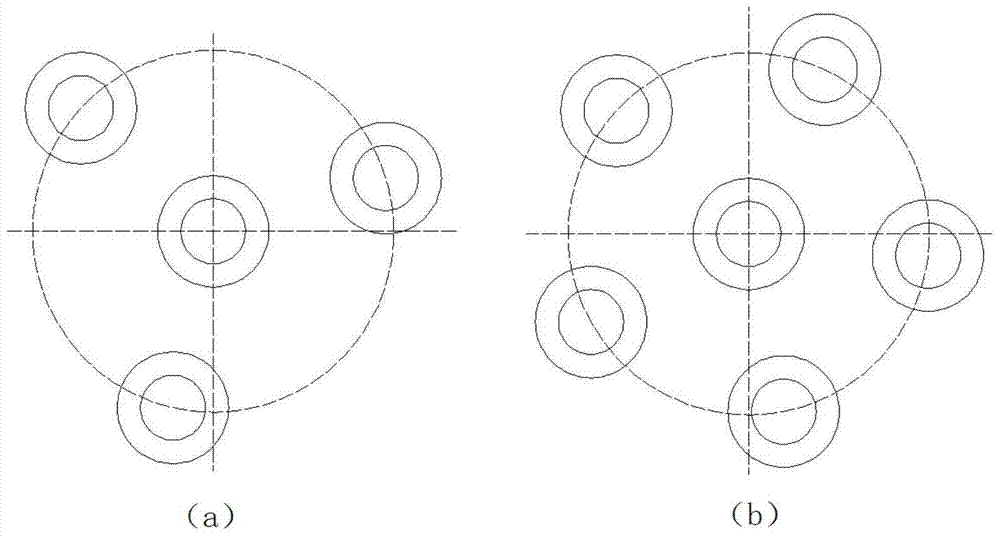

Method for sandblasting surface of workpiece by utilizing steelmaking converter slag

ActiveCN103707204ARealize resource utilizationGood yieldAbrasion apparatusManufacturing convertersSteelmakingThree level

The invention discloses a method for sandblasting the surface of a workpiece by utilizing steelmaking converter slag, and belongs to the technical field of comprehensive utilization of the steelmaking converter slag. The method comprises the following steps: 1, converter slag pretreatment: adding a flux into a converter at the final converter steelmaking stage to carry out converter slag pretreatment; 2, converter slag air quenching treatment: sending liquid converter slag into an air quenching treatment station through a slag tank vehicle, allowing the liquid converter slag to flow out of a tundish, blowing through air injected through a Laval nozzle, and crushing to particles; 3, converter slag sorting treatment: carrying out three-level sorting of the obtained magnetically-separated converter slag particles; and 4, sandblasting, wherein sandblasting nozzles comprise a center nozzle and circumferential nozzles, 3-5 circumferential nozzles are uniformly distributed in the periphery of the center nozzle, and each of the center nozzle and the circumferential nozzles is a Venturi nozzle. The steelmaking converter slag has the advantages of good abrasive crushing resistance, benefiting for the recycle, realization of the circulating frequency reaching 10, and great reduction of the sandblasting cost as a sandblasting abrasive.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

High anti-extrusion petroleum casing pipe and method for producing same

InactiveCN1664147AReduce residual stressImprove crush resistanceDrilling rodsDrilling casingsPetroleumHeat treated

A petroleum branch pipe with high collapsing strength and production method, which belongs to petroleum branch pipe technology. Steel element of branch pipe comprises 0.34-0.39 wt% of C, 0.20-0.35 wt% of Si, 1.25-1.50 wt% of Mn, 0.06-0.09 wt% of Al, S less than 0.010 wt%, P less than 0.015 wt%, Cr less than 0.20 wt%, Ni less than 0.20 wt% and Cu less than 0.20 wt%. Said branch pipe adopts heat treating process of quenching first and drawing second, in which hardening agent is water, hardening temperature is 860+ / -10 Deg. C and drawing temperature is more than 500 Deg. C. After heat treating, branch pipe is treated with hot straightening under the temperature between 450 and 480 Deg, C. Collapsing strength of the branch pipe is higher than API normalized value, whereas the cost of manufacture is less than 5%.

Owner:WUXI SEAMLESS OIL PIPE

Material for curable aqueous overcoating material and coating material using same

InactiveCN101278019AImprove wear resistanceImprove crush resistanceLiquid surface applicatorsSynthetic resin layered productsEndcappingPolyrotaxane

A curable aqueous overcoating material is obtained by blending 1-90% by mass of a hydrophilic polyrotaxane relative to the coating film-forming component. The hydrophilic polyrotaxane has a cyclic molecule, a linear molecule passing through the cyclic molecule and enclosed thereby, and blocking groups arranged on both ends of the linear molecule for preventing elimination of the cyclic molecule, and at least one of the linear molecule and the cyclic molecule has a hydrophilic modification group.

Owner:NISSAN MOTOR CO LTD +1

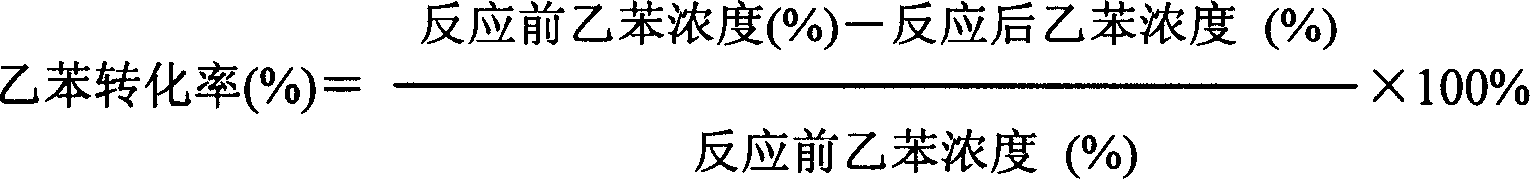

Catalyst for alkyl aromatics dehydrogenation

InactiveCN1490084AHigh activityLow crush resistanceHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsLithium oxidePotassium

Owner:CHINA PETROLEUM & CHEM CORP +1

Fiber reinforced bituminous pavement stress absorbing layer and construction method thereof

InactiveCN103774518AImprove crack resistanceImprove deformation resistanceIn situ pavingsGlass fiberSurface layer

The invention discloses a fiber reinforced bituminous pavement stress absorbing layer. Each cubic meter of the fiber reinforced bituminous pavement stress absorbing layer comprises 2.0 to 3.2 kg of SBS modified emulsified asphalt, 80 to 160 g of a glass fiber or basalt fiber and 16 to 24 kg of broken stone. A construction method for the layer comprises the following steps: successively sprinkling the SBS modified emulsified asphalt, the glass fiber or basalt fiber, the SBS modified emulsified asphalt and the broken stone on the surface of a clean and dry road base surface; and rolling the pavement 4 to 6 times 20 min after completion of sprinkling. According to the invention, the prepared fiber reinforced bituminous pavement stress absorbing layer is firmly bonded with a subbase layer and an upper asphalt layer, can prevent occurrence of asphalt surface course reflection cracks and pit slots and damage of a road base and a surface layer by water and prolongs the service life of the pavement.

Owner:JIANGSU ZENGGUANG COMPOSITE MATERIAL TECH

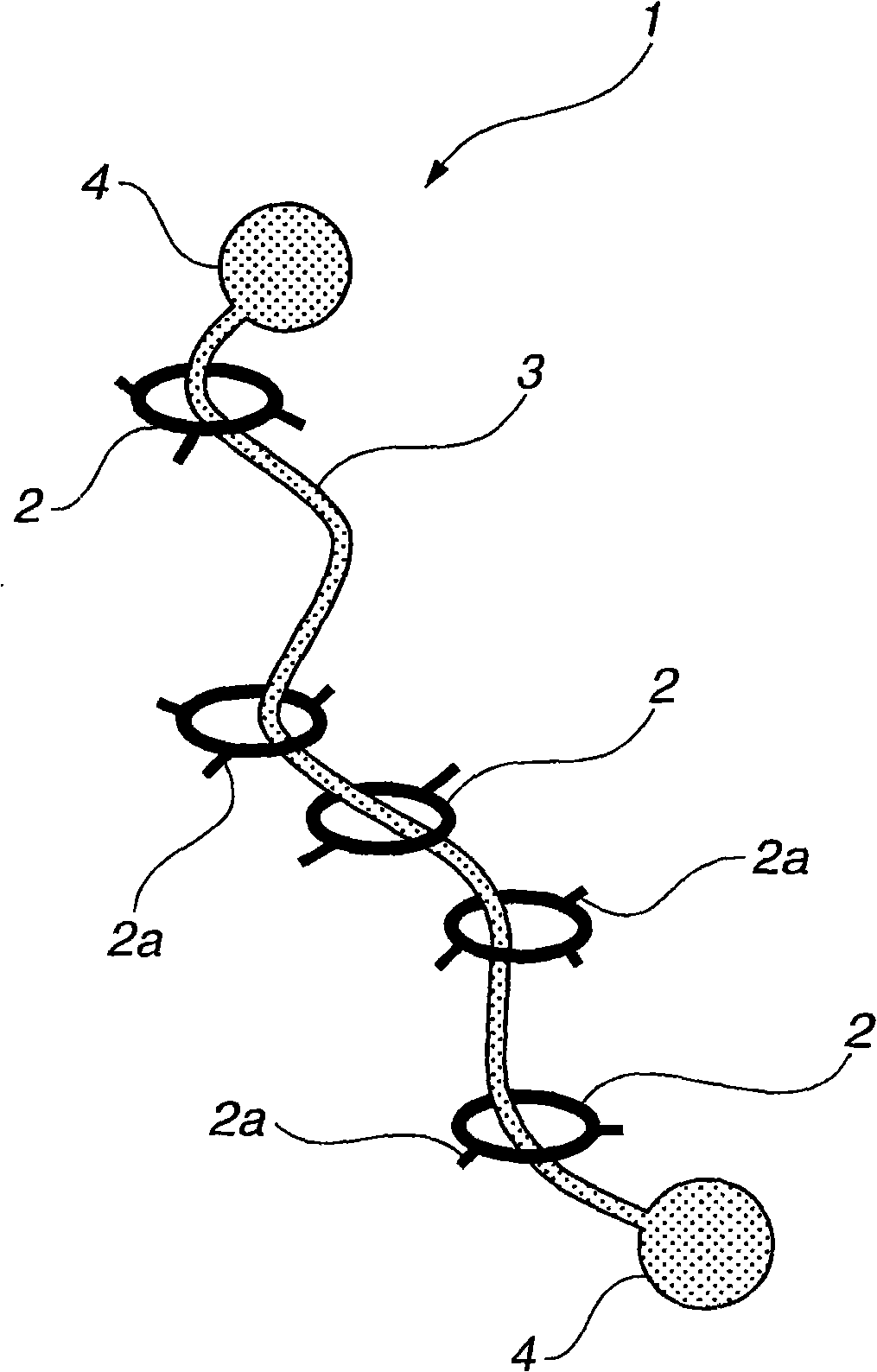

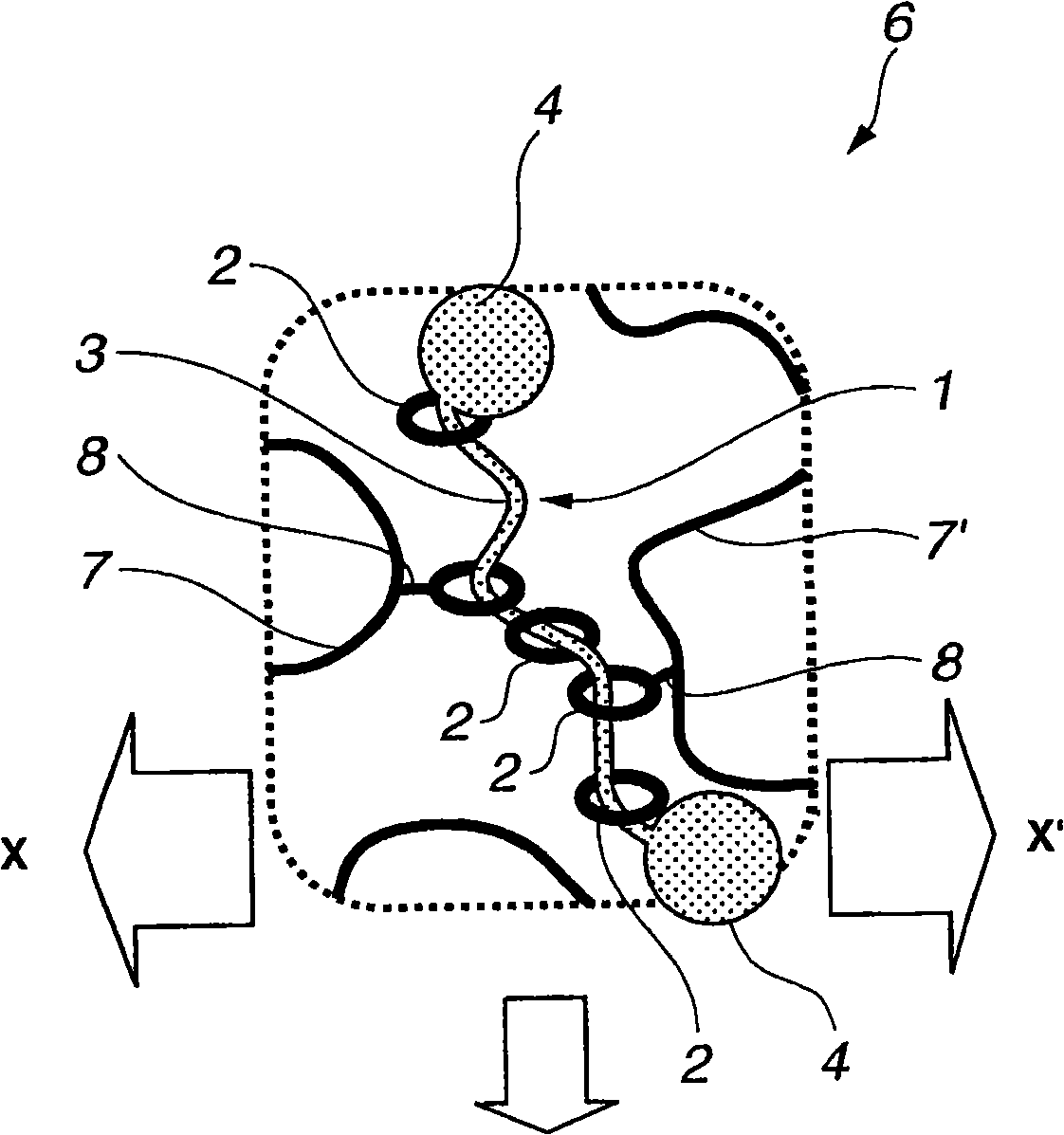

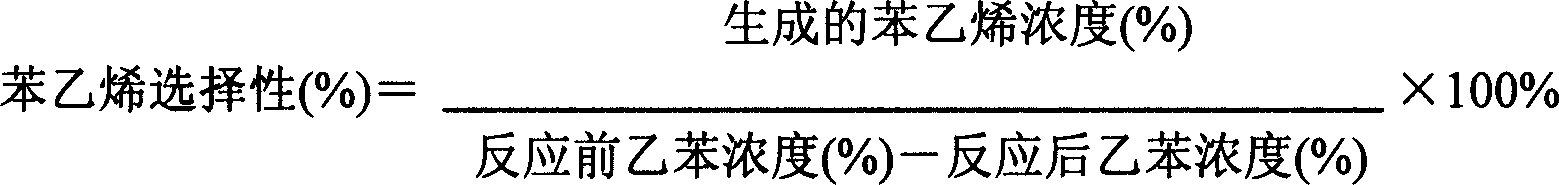

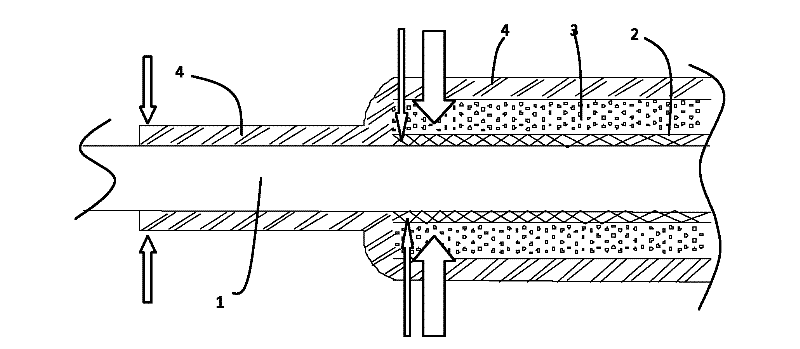

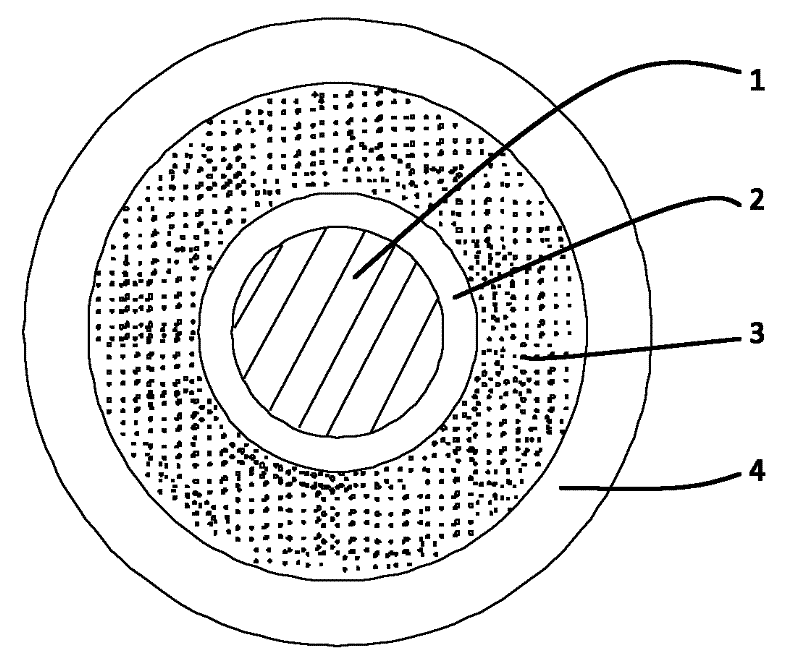

Production method of fiber cement-stone compound plate and product thereof

InactiveCN102493617BImprove flexural strengthHigh strengthCovering/liningsGlass fiberFiberglass mesh

The invention relates to a fiber cement-stone compound plate and a product thereof. The product comprises a panel 1 and a cement-containing base material plate 3, and the compound plate is formed by bonding through a bonding layer 2 constituted by polyacrylic ester-modified cement slurry and performing pressure forming, wherein the preparation of the base material plate 3 is as follows: sequentially injecting materials of various layers into a mold frame for respectively forming a bottom layer, a lower interlayer, a middle layer, an upper interlayer and a surface layer, wherein the bottom layer and the surface layer are made of modified cement, the upper and the lower interlayers are of glass fiber nets, the components of the middle layer comprise cement, light ceramsite, fiber and polyacrylic ester emulsion or the middle layer is made of foam cement mortar with gas content of 20%-50%; and the thickness of the base material plate 3 is 12mm-16mm, and the base material plate is further bonded with the panel made of stone for forming the compound plate. The product is high in bending strength and flexural strength, low in thermal expansion coefficient and hygroscopic expansion coefficient, heat-insulating, weather-resistant, simple and convenient to mount and suitable for various floors.

Owner:梅志江

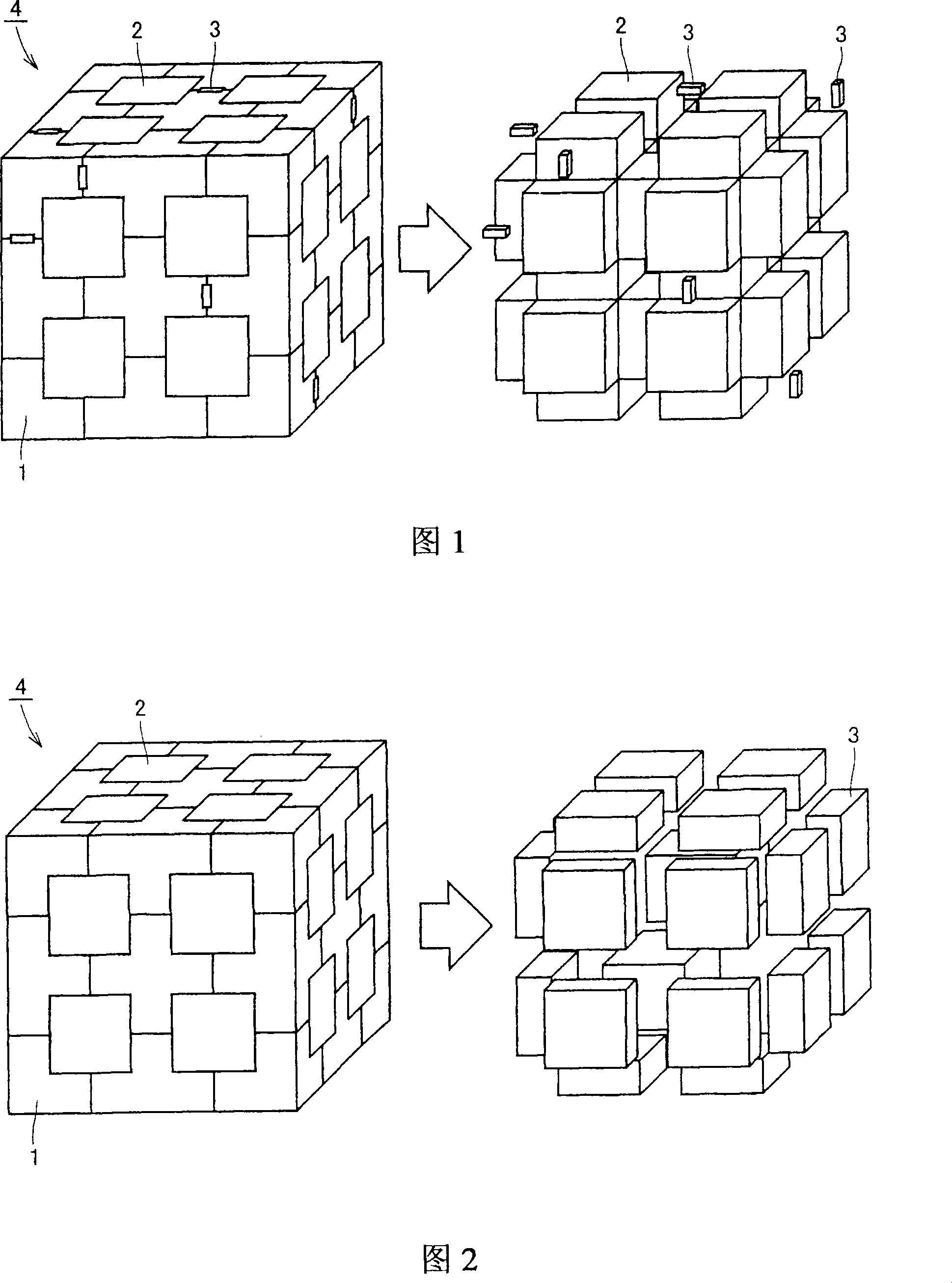

Preparation method of petroleum propping agent

The invention discloses a preparation method of a petroleum propping agent. The method comprises the main steps that S1, firstly, raw materials are smashed and screened, raw materials with the grain size being not larger than 5.5 mm are collected, and the raw materials not meeting the requirement for the grain size continues to be subjected to the smashing process for use; S2, according to the weight component, the prepared raw materials are ground, screened and heated to 300-350 DEG C for use; S3, the materials in S2 are stirred and heated under the constant temperature of 150 DEG C, then, acuring agent, a lubricating agent and a surface active agent are added in sequence, and stirring continues to be performed for 2 min for use; S4, the materials in S3 are cooled, smashed and screened to obtain a finished product.

Owner:南通市飞宇石油科技开发有限公司

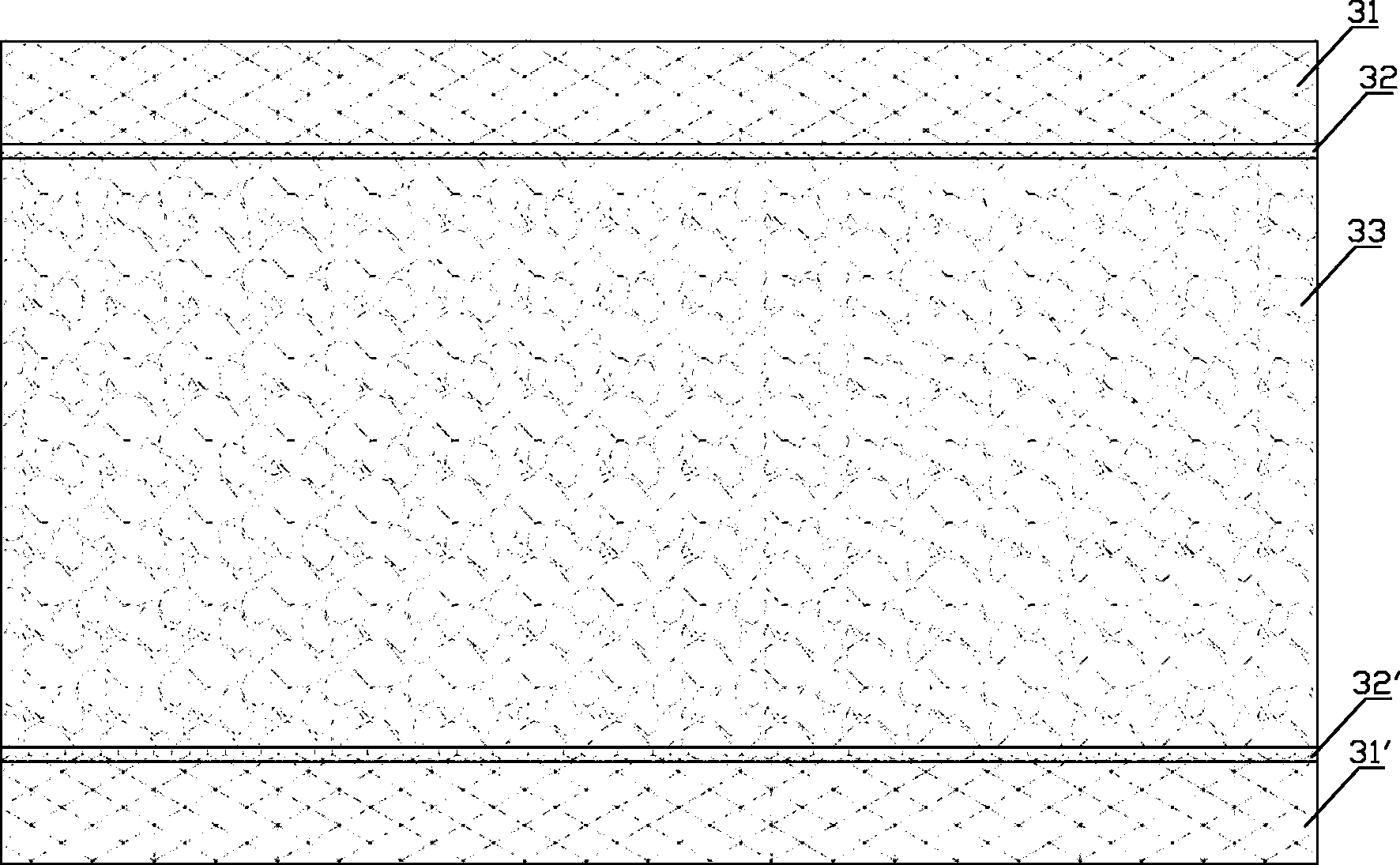

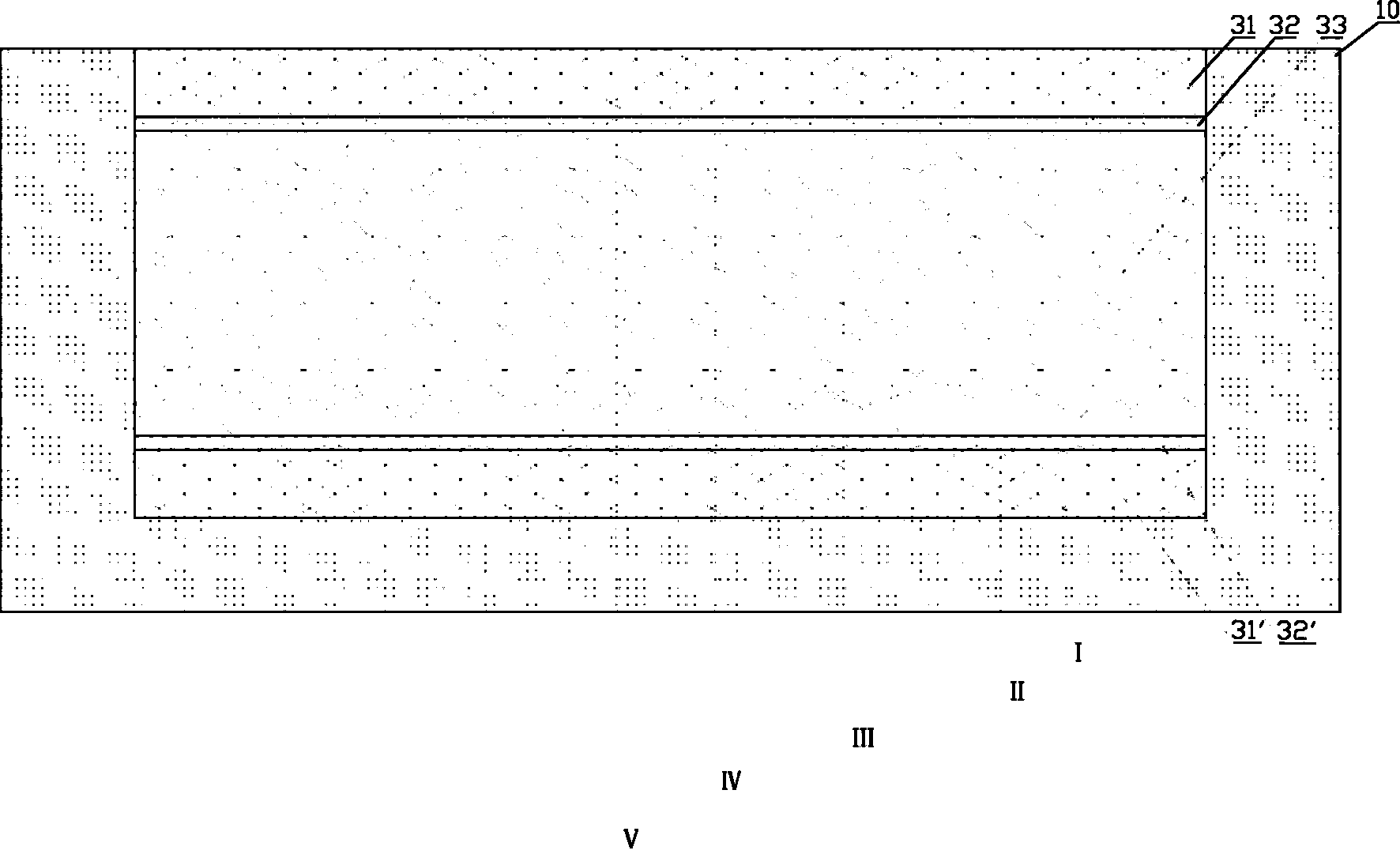

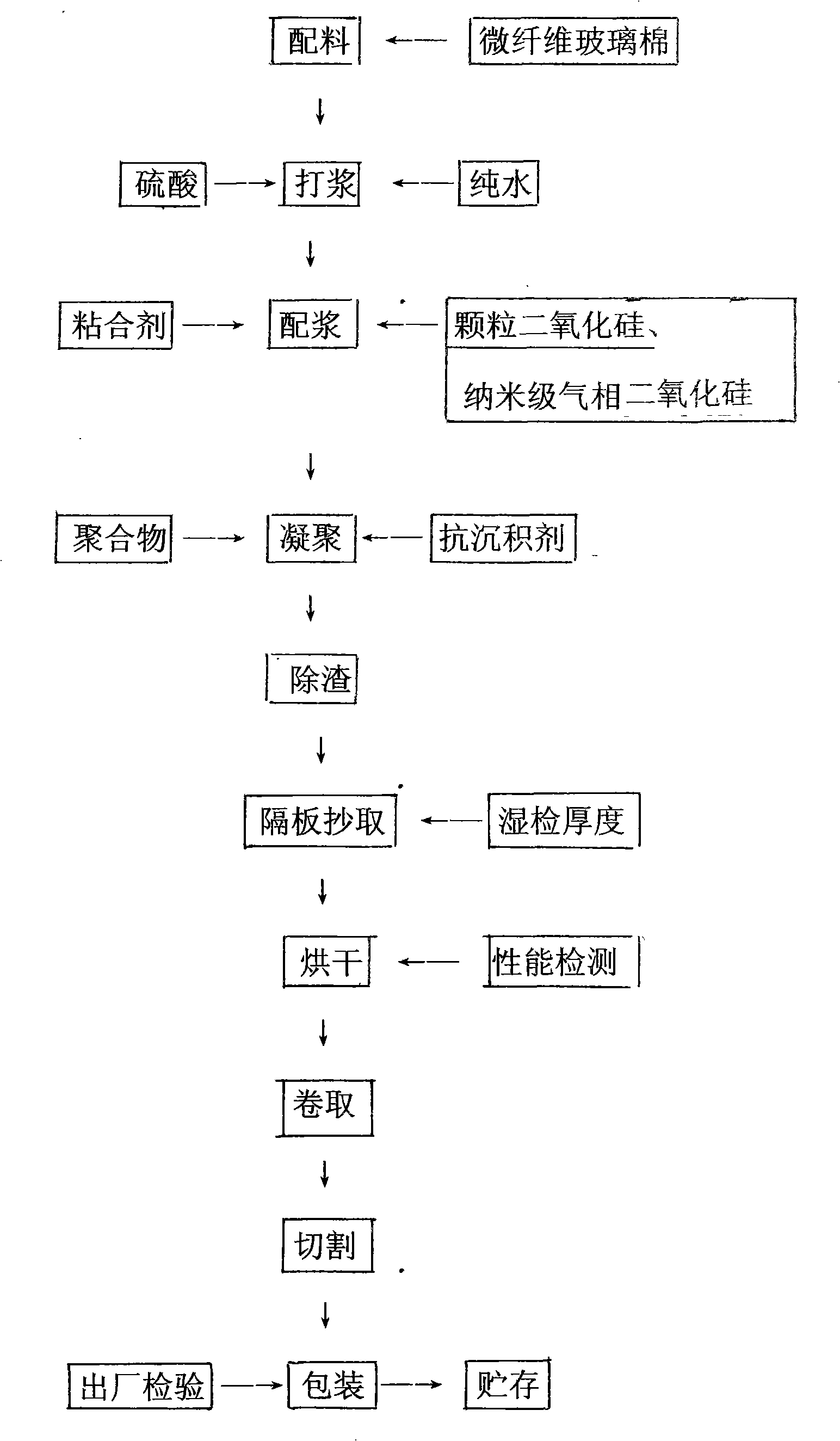

Silicon glass spacing plate for accumulator as well as preparing technique thereof

The invention discloses a silicon glass clapboard for a accumulator and preparation technique thereof. Weight ratios of the silicon glass clapboard are: 60-90 parts of micro-fiber glass wool; 20-50 parts of mixture of silicon dioxide particles and nano-stage gas-phase silicon dioxide; 1-10 parts of adhesive; and 1-10 parts of polymers and deposition resisting agent. The preparation technique includes: pulping raw material(the micro-fiber glass wool) by adding water and sulfuric acid; preparing pulp by adding the mixture of the silicon dioxide particles and the nano-stage gas-phase silicon dioxide, and the adhesive; coacervation(adding the polymers and the deposition resisting agent); removing slag; fetch the clapboard; drying; coiling; cutting; and packaging. The silicon glass clapboard is adapted for accumulator, in particular for energy-stored battery used for automobile, ship, train, electric motorcycle, wind energy, solar energy and electric network adjustment, and UPS power supply battery.

Owner:杨秀宇

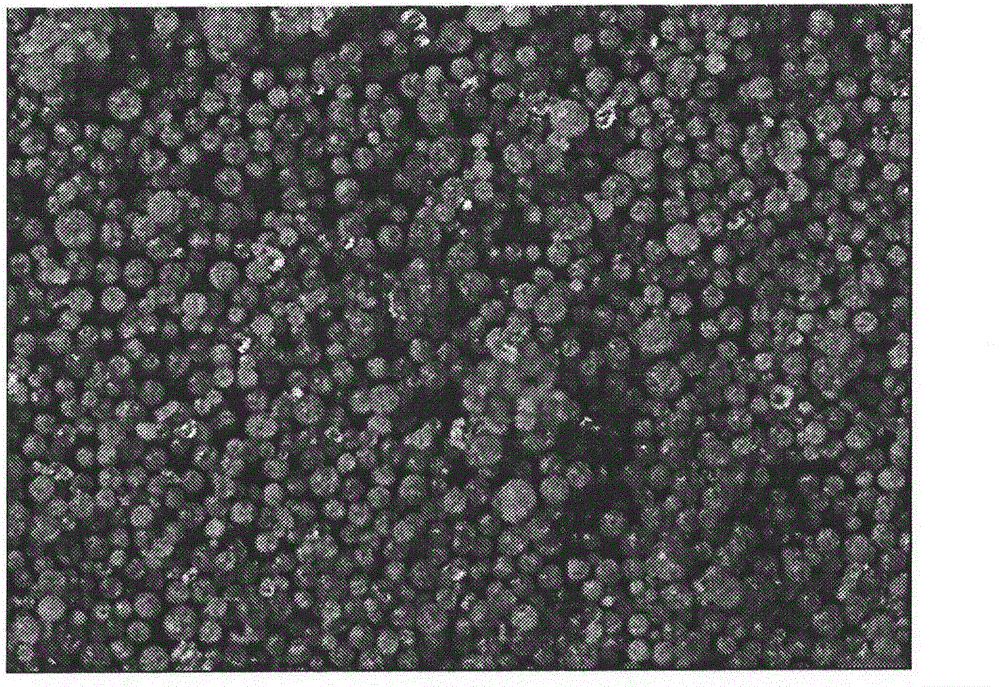

Method for preparing proppant

The invention relates to a method for preparing a proppant in a hydraulic fracturing technique. The proppant uses walnut shells as an aggregate. The method comprises the following steps: firstly, soaking the walnut shells with alkaline solution; secondly, washing and drying the walnut shells; thirdly, mixing the walnut shells with resin and a solidifying agent; and finally, heating, crushing and screening the mixture to obtain the proppant. The method adopts alkali as a modifying agent, and the walnut shells after being modified are activated, and interact with a resin layer by chemical bonds, so the resin layer of the proppant prepared by the method is firmly bonded with the surfaces of the walnut shells, cannot be peeled off from the walnut shells easily and reduces the breakage rate, and the proppant has good anti-breakage capacity.

Owner:BEIJING RECHSAND SCI & TECH GRP

Method for planting timothy in sandy saline-alkali soil and improving soil fertilizer condition

InactiveCN108293625ALower pHChange structureCalcareous fertilisersHops/wine cultivationAlkali soilTurpentine

The invention discloses a method for planting a timothy in sandy saline-alkali soil and improving a soil fertilizer condition. The method comprises the steps of land parcel adjustment, seed treatment,seeding, field management and timely harvest. According to the method, sandy saline-alkali soil modified fertilizer containing fertilizer A and fertilizer B is added during planting, the fertilizer Ais composed of plant straw particle, animal manure, attapulgite clay, humic acid, peat, saline-alkali soil modifying agent and microbial flora powder of which weight ratio is 25-35: 20-30: 14-16: 14-16: 8-12: 2-4: 1-3, and the fertilizer B is a sand soil binding agent composed of gelatin, sodium silicate, modified waterborne polyurethane, gypsum, turpentine and manganese dioxide of which weight ratio is 35-45: 8-12: 18-22: 16-20: 4-8: 4-8. The method for planting the timothy in the sandy saline-alkali soil and modifying the soil fertilizer condition has the advantages that the measures such as improving sandy saline-alkali soil fertilizer, planting the timothy and the like are adopted, the timothy has high yield and good quality, the soil improvement effect of the whole sandy saline-alkali soil is outstanding, the improving process is green, environmentally friendly and pollution free, good economic and social benefits are provided, so the method for planting the timothy in the sandysaline-alkali soil and modifying the soil fertilizer condition is an application technology worthy of large-scale promotion.

Owner:WEIFANG YOURONG IND

Surface coated filter method

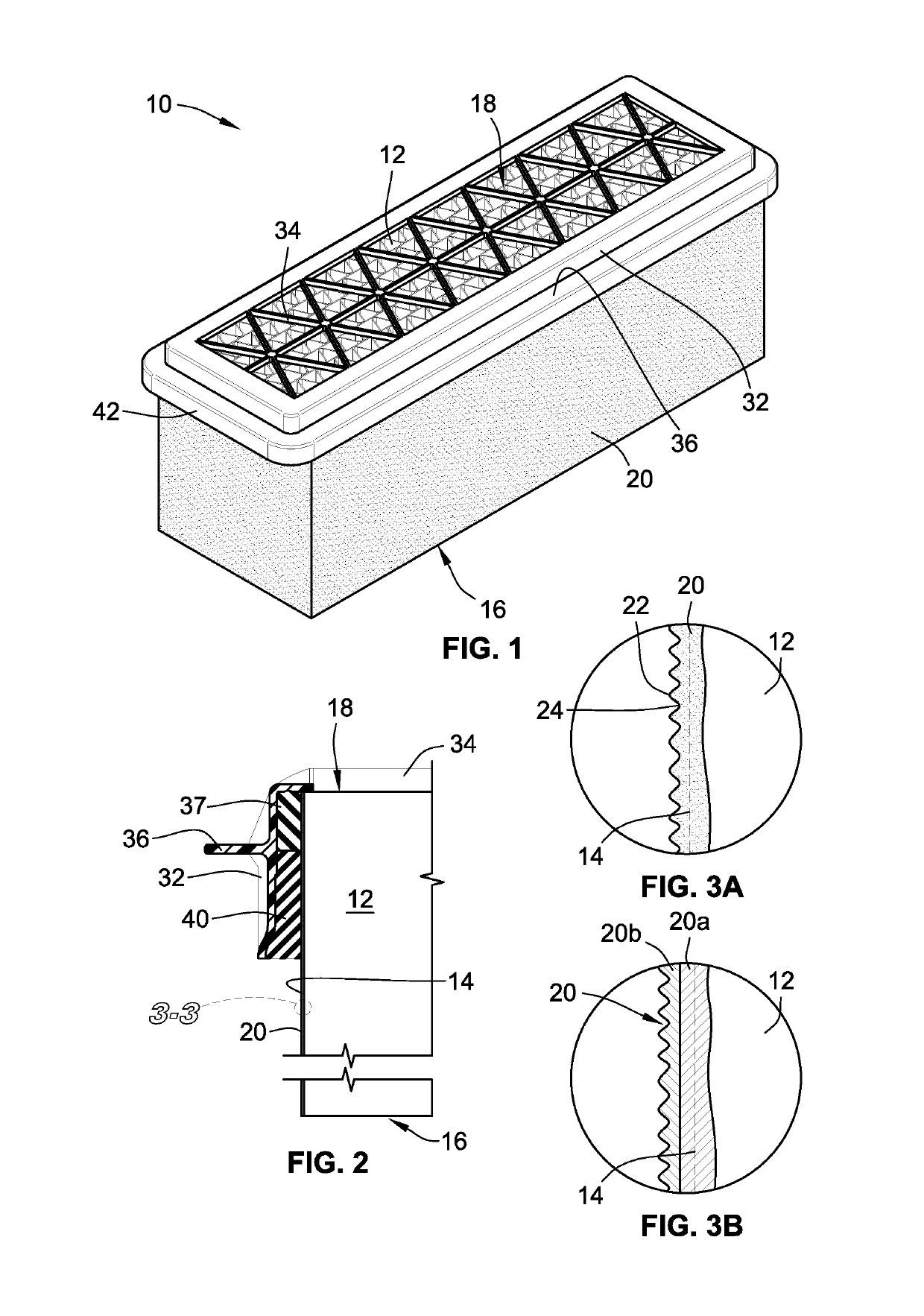

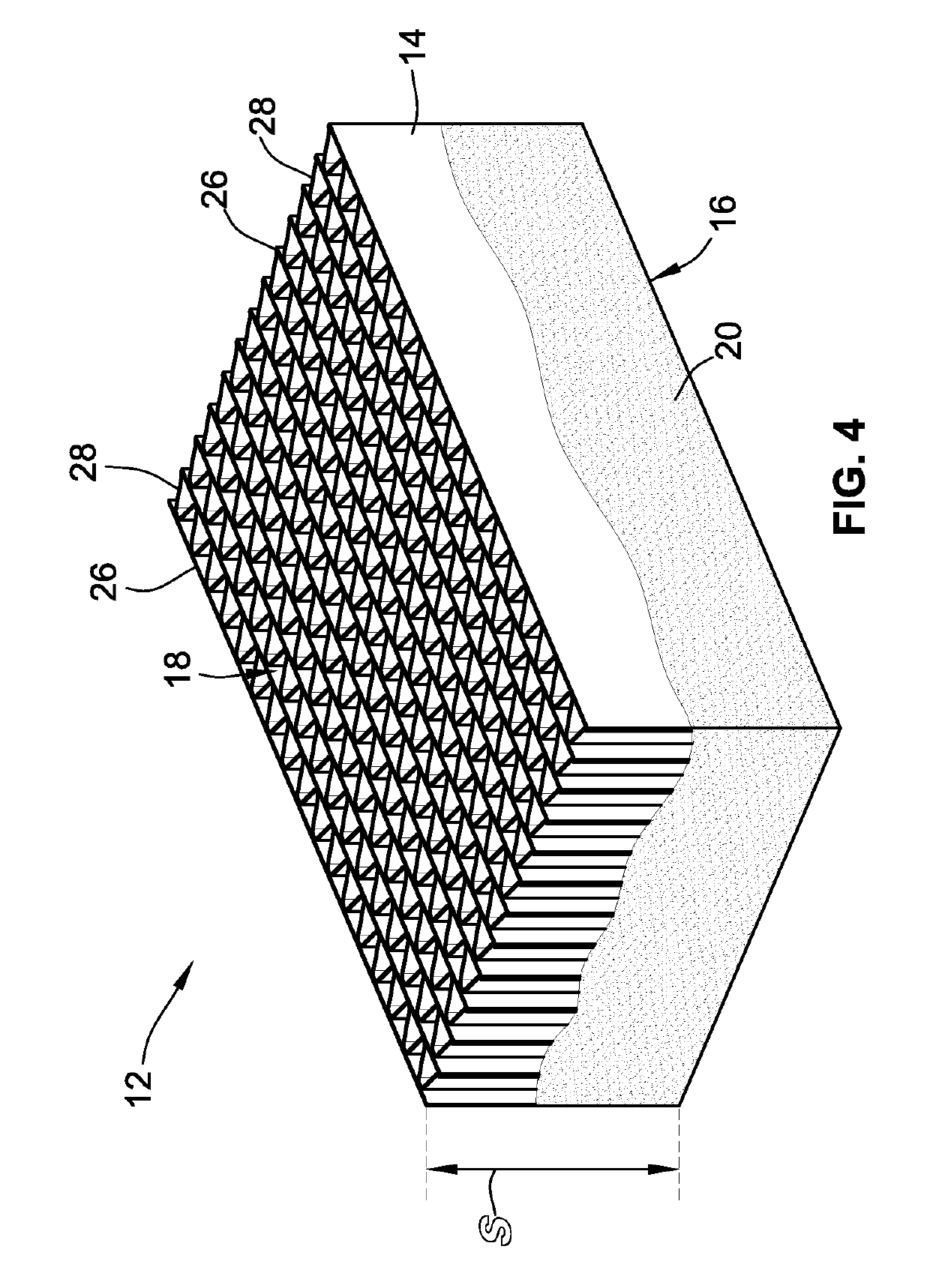

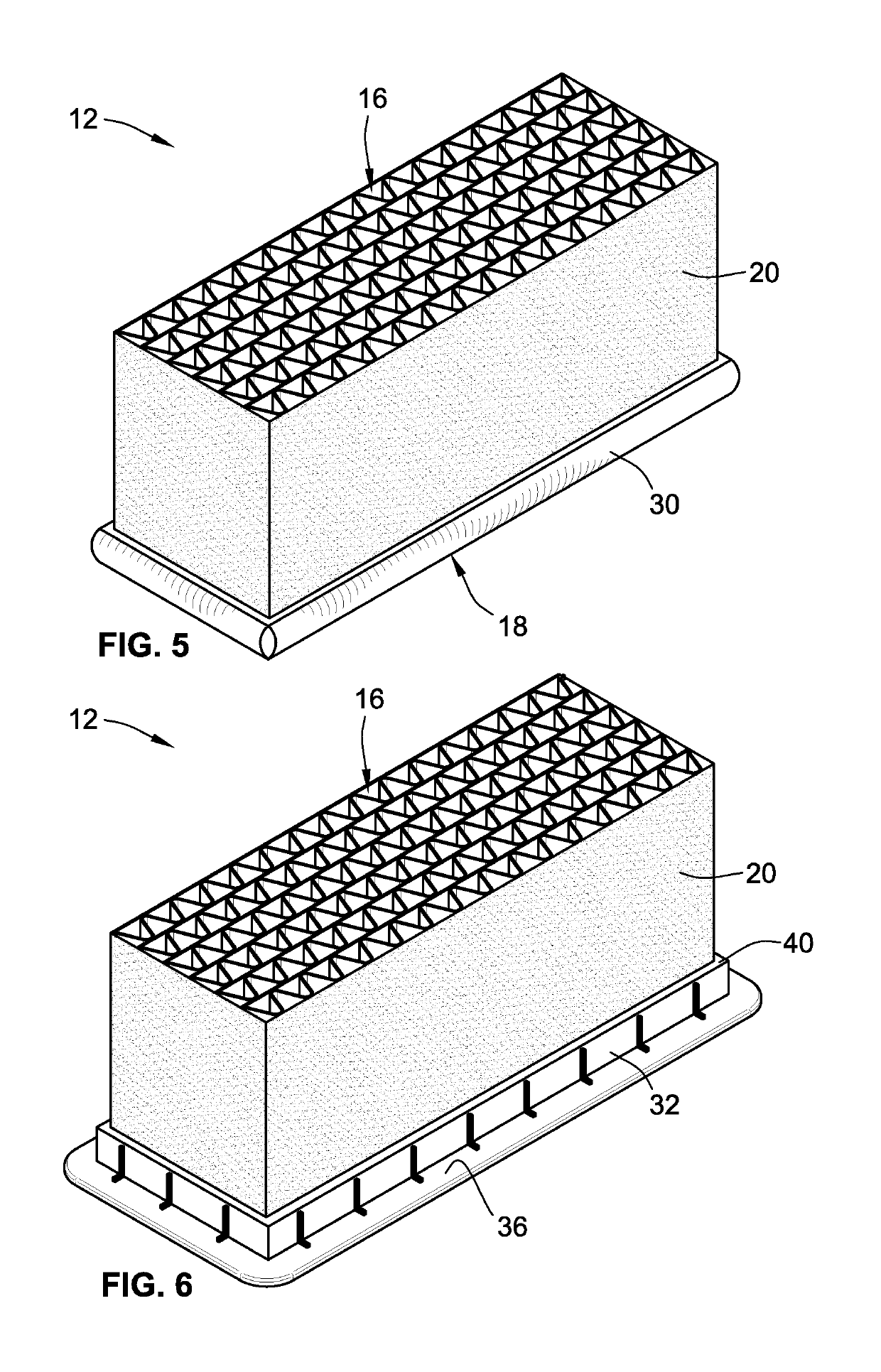

ActiveUS20190105593A1Improve crush resistanceImprove puncture resistanceDispersed particle filtrationTransportation and packagingFilter mediaSurface roughness

A filter element is provided. The filter element includes a filter media pack including an outer surface. The outer surface extending between a first flow face and a second flow face. The filter element also includes a polymeric coating applied to the outer surface of the filter media pack, wherein the polymeric coating is not a molded structure. In embodiments, the polymeric coating covers at least 25% of a span between the first flow face and the second flow face and has an average thickness of between 0.005 and 0.100 in. In other embodiments, the polymeric coating has a surface roughness of at least 50 μin to provide an outer gripping surface. A method and system for applying the polymeric coating to the filter element are also provided.

Owner:BALDWIN FILTERS

Catalyst component for olefin polymerization, method for preparing catalyst component, catalyst for olefin polymerization and method for olefin polymerization

The invention relates to a catalyst component for olefin polymerization and a method for preparing the catalyst component, the catalyst component contains a magnesium halide adduct, a titanium compound and a product which is obtained from the reaction of an internal electron donor compound, wherein the magnesium halide adduct contains magnesium halide, alcohol except methanol, methanol and ortho hydroxyl-benzoate ester, and contains or does not contain water. The invention further relates to a catalyst which contains the catalyst component and is used for olefin polymerization, an application of the catalyst for olefin polymerization and a method for olefin polymerization. The catalyst particles for olefin polymerization have smooth surfaces, uniform sizes, stronger breakability resistance during the polymerization process and better hydrogen adjustment sensitivity for olefin polymerization.

Owner:CHINA PETROLEUM & CHEM CORP +1

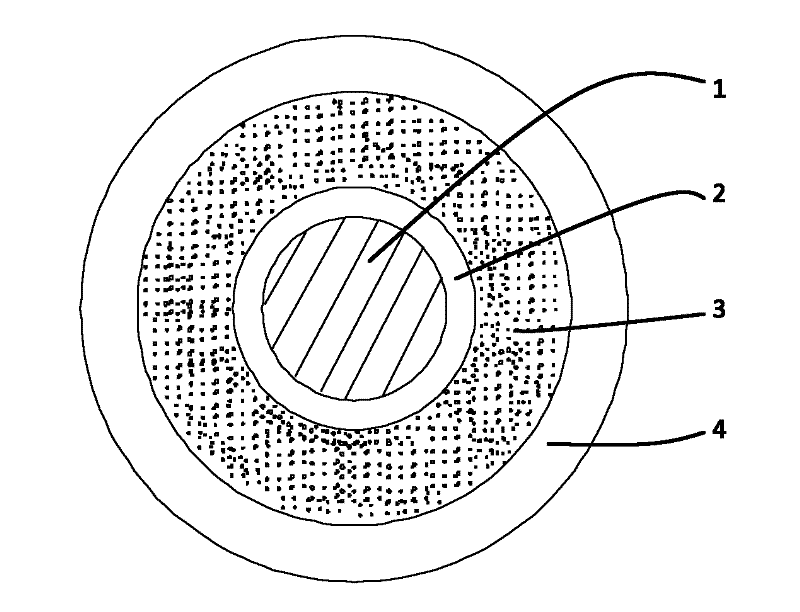

Compressive skin-foam-skin insulated single wire and preparation method thereof

The invention relates to a compressive skin-foam-skin insulated single wire. The compressive skin-foam-skin insulated single wire comprises a copper conductor, an inner skin layer wrapped outside the copper conductor, a central foam layer wrapped outside the inner skin layer and an outer skin layer wrapped outside the central foam layer, wherein the outer skin layer is made of a high-strength macromolecular insulating material. The compressive skin-foam-skin insulated single wire has low cost and relatively strong compressive performance. The invention also relates to a preparation method of the compressive skin-foam-skin insulated single wire. The method comprises the following steps of: extruding the outer skin layer, and extruding the inner skin layer and the central foam layer together after the outer skin layer is completely and uniformly wrapped on the copper conductor. Therefore, the problem that the outer skin layer made of the high-strength macromolecular insulating material cannot be smoothly extruded from a nose is well solved.

Owner:CHINA XIDIAN GRP CO LTD

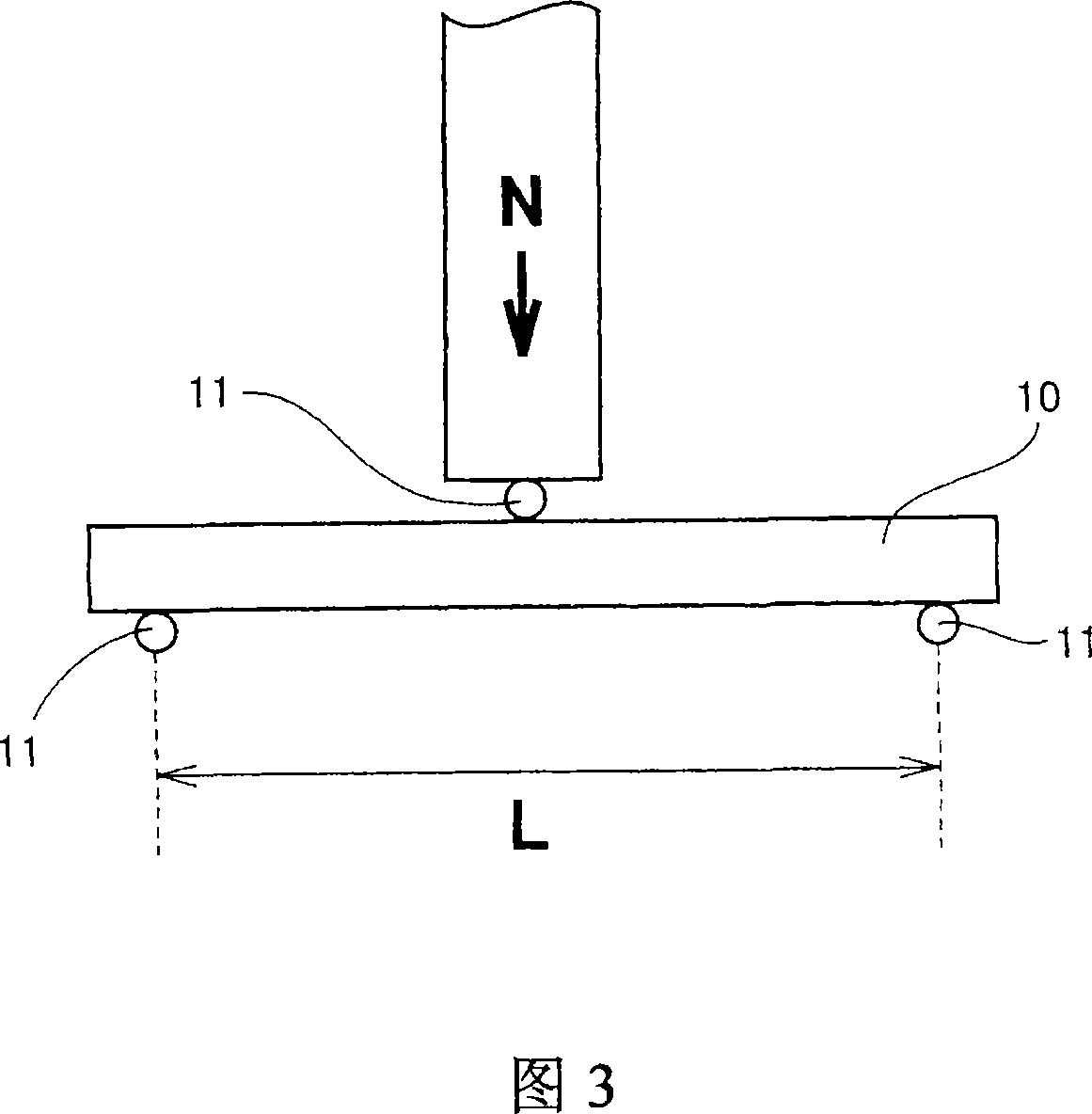

Composite sintered compact

ActiveCN101218189AImprove heat resistanceImprove toughnessTurning toolsThin material handlingBoron nitrideMaterials science

A composite sintered compact containing at least a cubic boron nitride and a binding material, characterized in that a plurality of cubic boron nitride particles are bound to each other, and thereby the cubic boron nitride has a continuous structure, and a plurality of binding material particles being present in the region except the binding interface, in which the above cubic boron nitride particles are bound to each other, and thereby the binding material also has a continuous structure.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

Method for producing dried cheese

ActiveCN105722400AEasy to manufactureExcellent stringinessCheese manufactureFreeze-dryingThermal water

Provided is a method for producing a dried cheese, said method including freeze-drying a cheese block immersed in an aqueous medium. The cheese block immersed in an aqueous medium is prepared by embedding the whole or a part of a cheese block in an aqueous medium or a material impregnated with an aqueous medium. This method can easily produce a dried cheese in which the original good quality of material cheese is kept and which is reconstitutable with hot water.

Owner:MEIJI CO LTD +1

Steel for heat-resistant high-strength sleeve and preparation process of steel

The invention discloses steel for a heat-resistant high-strength sleeve and a preparation process of the steel. The steel consists of the following chemical components in percentage by weight: 0.10-0.25% of C, 0.10-0.30% of Si, 0.70-1.30% of Mn, 0.05-0.30% of Hf, 0.001-0.006% of B, 0-0.20% of Mo, 0-0.25% of W, 0-0.15% of Nb, 0-0.20% of Ta, 0-0.18% of Ti, 0-0.18% of Zr, 0.01-0.20% of RE, not greater than 0.008% of P, not greater than 0.004% of S and the balance of Fe. According to the steel for the heat-resistant high-strength sleeve and the preparation method of the steel, a high-temperature deformation quenching process is adopted for the whole sleeve, so that a relatively high dislocation density and other deformation defects are kept to obtain the sleeve with uniform tissue and high toughness; a medium-temperature section long-time thermal insulation process and a high-temperature section short-time thermal insulation process are adopted, so that relatively high strength is kept and the toughness is remarkably improved; elements such as Nb, W, Hf, Mo, Re and the like are added and quickly cooled to a temperature lower than 260 DEG C to preserve the heat for a long time, so that heat resistance, high strength, high toughness and high impact resistance of the sleeve are effectively guaranteed.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

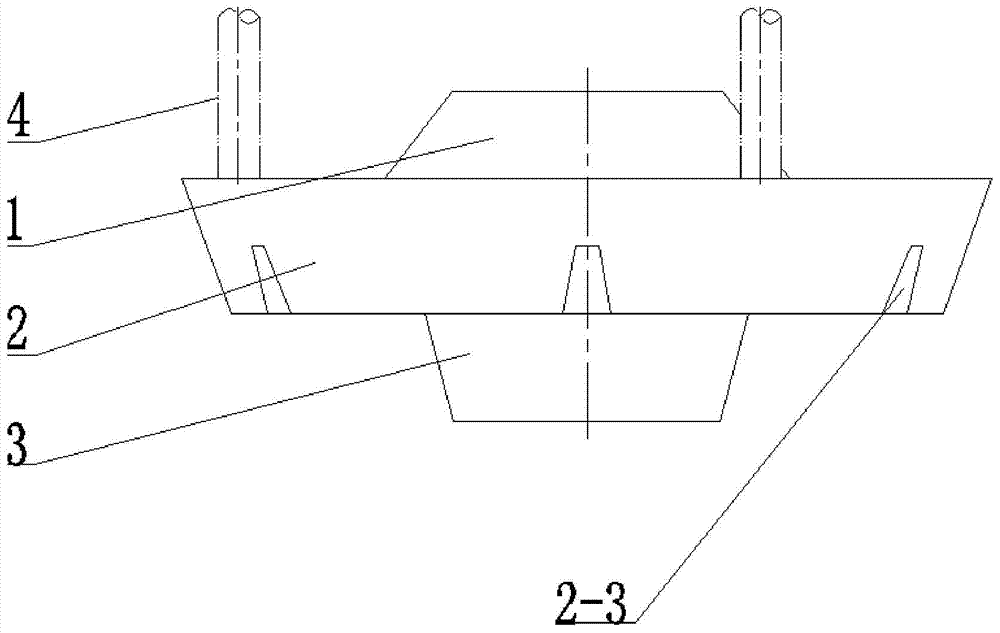

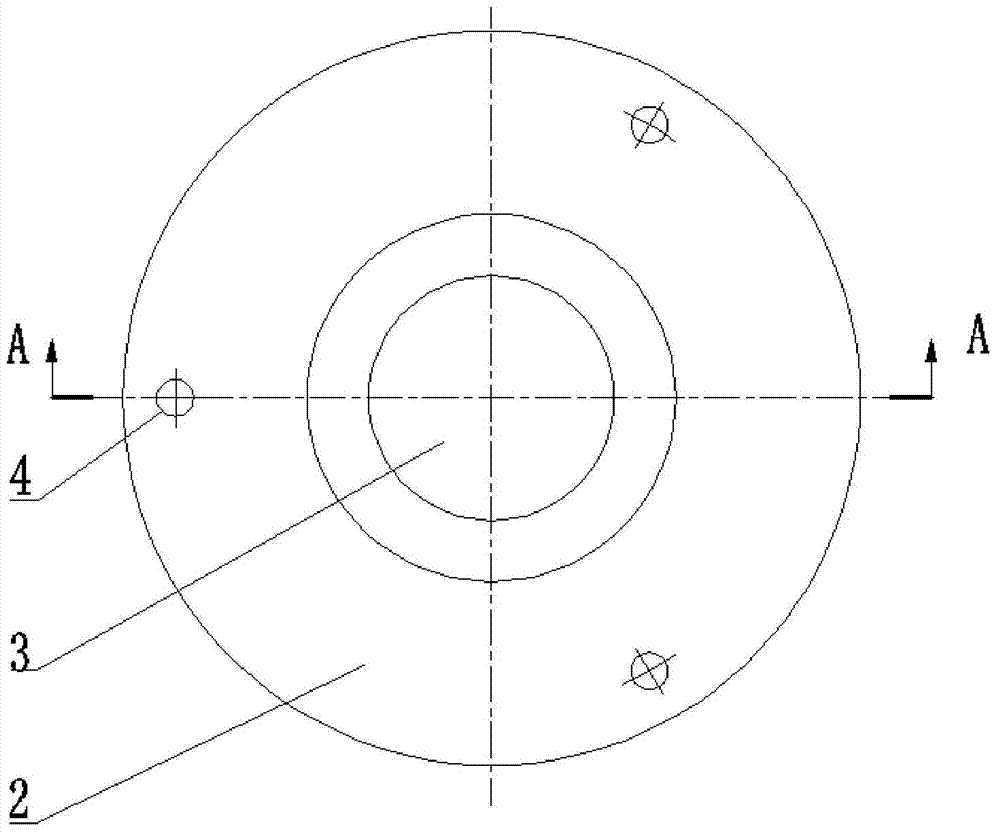

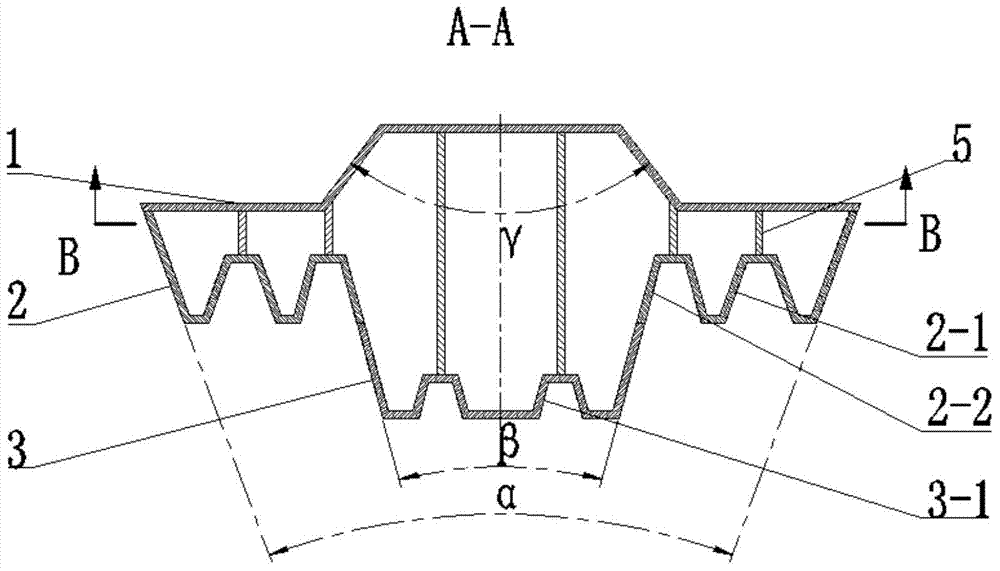

Double-truncated-cone type pile shoe

InactiveCN103485341AImprove crush resistanceImprove rigidityBulkheads/pilesStructural engineeringEngineering

The invention discloses a double-truncated-cone type pile shoe. The double-truncated-cone type pile shoe comprises a casing, reinforcing ribs arranged in the casing and a shoe cover connected with the upper end of the casing. The casing is composed of at least two inverted hollow truncated cones from top to bottom, wherein the upper truncated cone is provided with a coaxial central hole with the diameters tapering from top to bottom, and the lower truncated cone is in a bucket shape, the diameter of the mouth of the bucket is identical to the aperture of the small-diameter central hole of the upper truncated cone, and the mouth of the bucket is connected with the small-diameter central hole of the upper truncated cone; the end surface where the upper truncated cone and the lower truncated cone are connected is provided with a truncated cone shoulder which is provided with a plurality of ring grooves; a plurality of straight grooves are distributed on the circumferential surface along the radial direction from the center of the truncated cones; the bottom of the bucket of the lower truncated cone is provided with at least one ring groove; the circumferential surface of the upper end surface of the upper truncated cone, which is close to the edge of the upper truncated cone, is evenly provided with three holes for mounting chord members of a pile leg. The double-truncated-cone type pile shoe improves the compression-resisting capacity of the pile shoe and meanwhile has the advantages of lateral sliding resistance and ocean current scouring resistance.

Owner:JIANGSU UNIV OF SCI & TECH

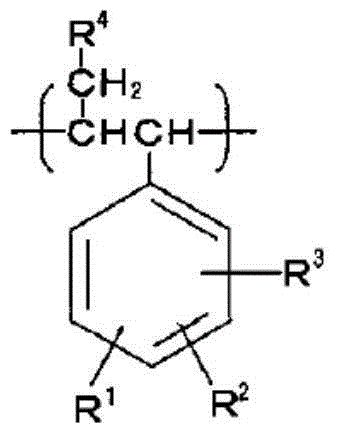

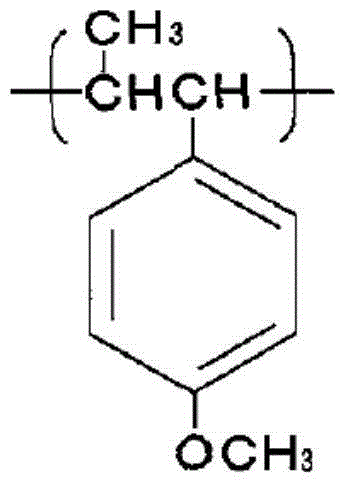

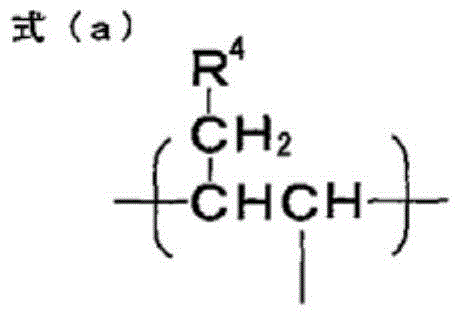

Toner for electrostatic image development

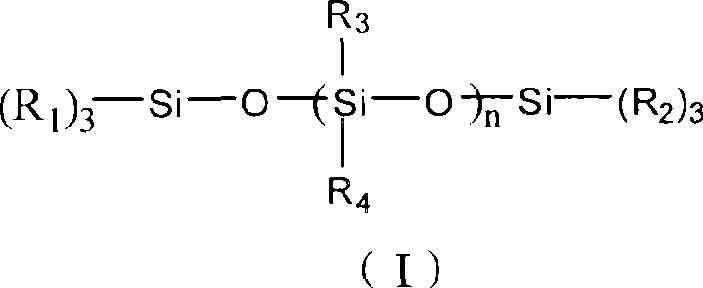

ActiveCN103823337ASufficient low temperature fixabilityImprove heat resistanceDevelopersHydrogen atomHalogen

A toner for electrostatic image development having sufficient low-temperature fixing properties, and excellent heat resistant storage stability and crush resistance is provided. In toner particles containing at least a binder resin, the binder resin contains a polymer having a structural unit represented by a general formula (1), wherein R1, R2, and R3 each independently represent a hydrogen atom, a hydroxyl group, or an alkoxy group, or two adjacent groups of R1, R2, and R3 combine to form -O(CH2)iO-, where i represents an integer of 1 or 2, provided that at least one of R1, R2, and R3 is an alkoxy group, or two adjacent groups combine to form -O(CH2)iO-; and R4 represents a hydrogen atom, a halogen atom, an alkyl group, a hydroxyl group, or an alkoxy group.

Owner:KONICA MINOLTA INC

Method for planting Russian red clover on sandy saline-alkali soil and improving soil and fertilizer conditions

InactiveCN108235903ALower pHChange structureCalcareous fertilisersFabaceae cultivationAlkali soilRed Clover

The invention discloses a method for planting Russian red clover on sandy saline-alkali soil and improving soil and fertilizer conditions. The method comprises the following steps: carrying out soil preparation on a plot, carrying out seed treatment, sowing, carrying out field management and harvesting in good time. In a planting process, sandy saline-alkali soil improvement fertilizers A and B are added, the fertilizer A is composed of plant straw particles, animal manure, attapulgite clay, humic acid, peat, a saline-alkali soil improvement agent and microbial flora powder in a weight ratio of (25-35):(20-30):(14-16):(14-16):(8-12):(2-4):(1-3), and the fertilizer B is a sandy soil binding agent composed of gelatin, water glass, modified waterborne polyurethane, gypsum, turpentine and manganese dioxide in a weight ratio of (35-45):(8-12):(18-22):(16-20):(4-8):(4-8). The method disclosed by the invention has the advantages that measures such as sandy saline-alkali soil improvement fertilizers and plantation of the Russian red clover are adopted for improving the saline-alkali soil, yield of the Russian red clover is high, soil improvement effect on the whole sandy saline-alkali soilis also outstanding, and an improvement process is green, environment-friendly and pollution-free and has good economic and social benefits, so that the method disclosed by the invention is an application technology worthy of large-area popularization.

Owner:WEIFANG YOURONG IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com