Method for sandblasting surface of workpiece by utilizing steelmaking converter slag

A technology for sand blasting and workpiece surface, which is applied in recycling technology, manufacturing tools, manufacturing converters, etc. It can solve the problems of poor resistance to crushing, achieve the effects of improving adhesion, facilitating recycling, and cheap prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

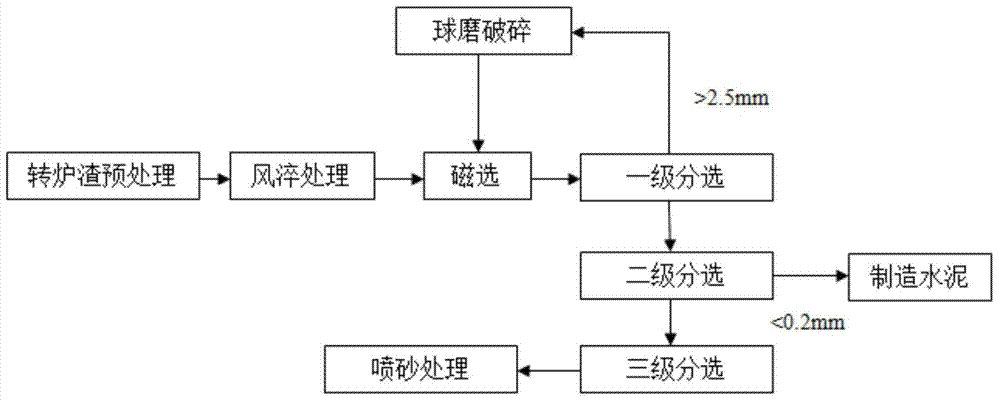

[0032] Such as figure 1As shown, a method for blasting the surface of a workpiece using steelmaking converter slag in this embodiment, the steps are:

[0033] Step 1. Pretreatment of converter slag: molten steel is smelted in a converter. At the end of converter steelmaking, the converter slag is pretreated by adding flux into the converter. In this embodiment, the amount of flux added is 3.3kg / ton of steel, which helps The composition of the flux is a mixture of CaO and MgO. In this example, the mass ratio of CaO and MgO is 1:1.2; after pretreatment and adjustment, the converter slag can include the following mass percentages: 1.87-2.35% Al 2 o 3 , 42.51~45.37%CaO, 0.82~0.91%FeO, 11.83~12.95%MgO, 0.51~1.78%MnO, 0.78~0.91%P, 0.09~0.18%S, 12.34~13.59%Si 2 O, 23.53-24.31% TFe, 0.58-0.73% f-CaO, the converter slag after pretreatment adjustment in this embodiment contains the following components by mass percentage: 1.93% Al 2 o 3 , 44.81%CaO, 0.84%FeO, 12.45%MgO, 1.34%MnO, 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com