Method for individually processing high-iron zinc sulfide concentrate

A technology of zinc sulfide concentrate and high-speed iron, applied in the direction of improving process efficiency, etc., to achieve the effects of improving recovery rate, strong process pertinence, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

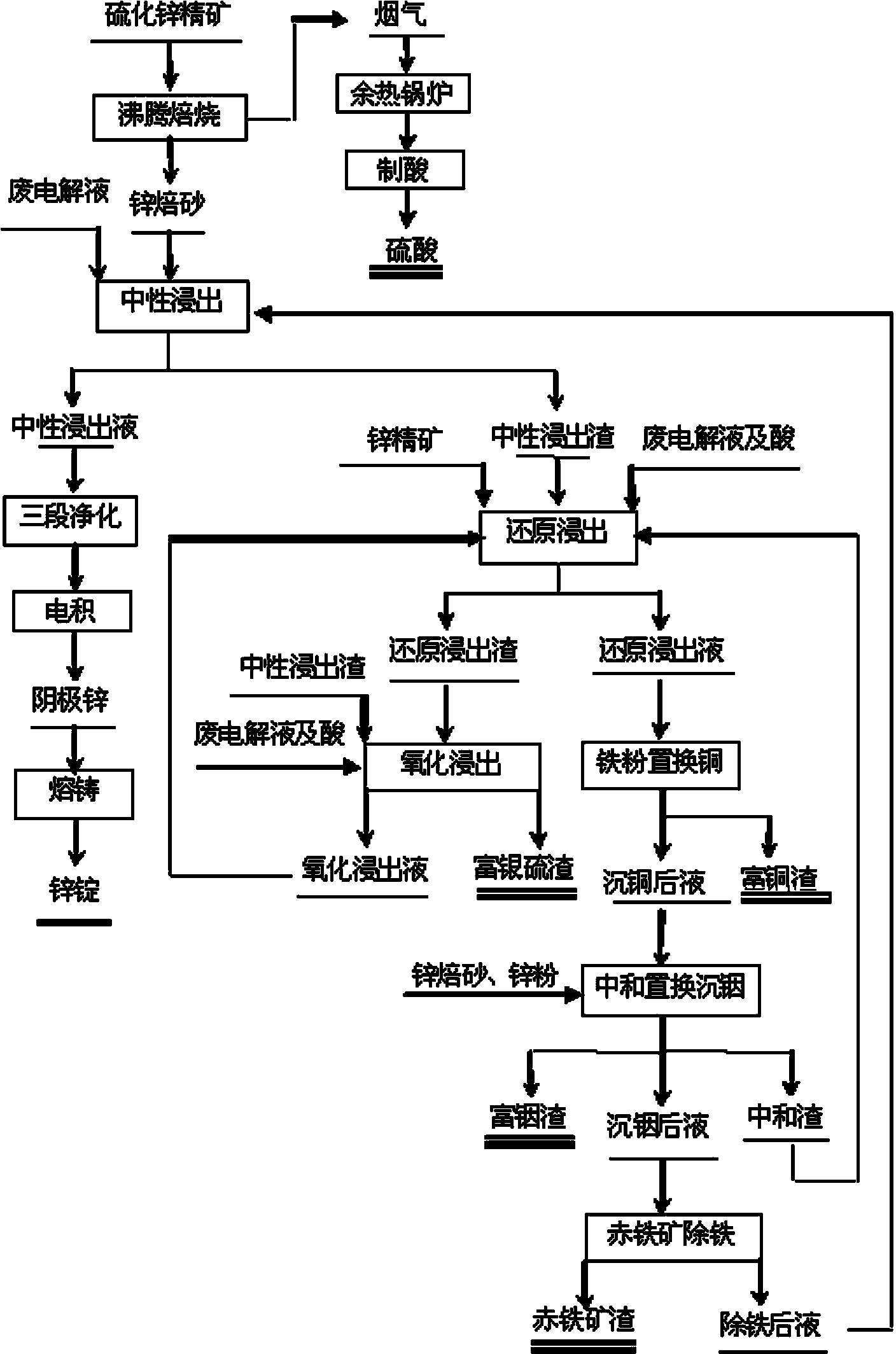

Method used

Image

Examples

Embodiment 1

[0026] 1. Mix 100kg of zinc calcine with 376L of iron removal solution containing 45g / L of sulfuric acid and 98g / L of zinc, 214L of waste electrolyte containing 165g / L of sulfuric acid and 37.5g / L of zinc for neutral leaching to obtain zinc-containing 138g / L neutral leaching solution, the neutral leaching solution is sent to purification electrolysis; output neutral leaching residue 65kg, its composition is as follows (wt%): Zn: 25.94, Fe: 26.58, In: 0.051, Cu: 1.00, Pb: 0.099.

[0027] 2. Mix 51.2kg of the above-mentioned neutral leaching slag with 15.3kg of high-iron zinc sulfide concentrate, and mix it with 173L of oxidation leaching solution containing 30g / L sulfuric acid and 46g / L zinc, and waste electrolyzer containing 165g / L sulfuric acid and 37.5g / L zinc. 182L of solution, 23L of concentrated sulfuric acid with a concentration of 98% and 21L of water were mixed for reduction leaching, the leaching temperature was 90°C, and the leaching time was 3h to obtain 385L of redu...

Embodiment 2

[0034] 1. Mix 100kg of zinc calcined sand with 378L of iron removal solution containing 48g / L of sulfuric acid and 105g / L of zinc, 212L of waste electrolyte containing 165g / L of sulfuric acid and 37.5g / L of zinc for neutral leaching to obtain zinc-containing 141g / L neutral leaching solution, the neutral leaching solution is sent to purification electrolysis; the output neutral leaching residue is 62kg, the composition is as follows (wt%): Zn: 25.94, Fe: 26.58, In: 0.051, Cu: 1.00, Pb: 0.099.

[0035] 2. Mix 52kg of the above-mentioned neutral leaching slag with 11kg of high-iron zinc sulfide concentrate, mix with 130L of oxidation leaching solution containing 28g / L of sulfuric acid and 42g / L of zinc, 186L of spent electrolyte containing 165g / L of sulfuric acid and 37.5g / L of zinc , 25L of concentrated sulfuric acid with a concentration of 98% and 33L of water were mixed for reduction leaching, the leaching temperature was 95°C, and the leaching time was 2h to obtain 358L of red...

Embodiment 3

[0042] 1. Mix 100kg of zinc calcined sand with 375L of iron-removing solution containing 46g / L of sulfuric acid and 103g / L of zinc, 215L of waste electrolyte containing 165g / L of sulfuric acid and 37.5g / L of zinc for neutral leaching to obtain zinc-containing 138g / L neutral leaching solution, the neutral leaching solution is sent to purification electrolysis; 64kg of neutral leaching residue is produced, the composition is as follows (wt%): Zn: 25.94, Fe: 26.58, In: 0.051, Cu: 1.00, Pb: 0.099.

[0043] 2. Mix 53kg of the above-mentioned neutral leaching slag with 12.5kg of high-iron zinc sulfide concentrate, mix it with 146L of oxidation leachate containing 30g / L of sulfuric acid and 45g / L of zinc, and waste electrolyte containing 165g / L of sulfuric acid and 37.5g / L of zinc 180L, 24L of concentrated sulfuric acid with a concentration of 98% and 27L of water were mixed for reduction leaching, the leaching temperature was 85°C, and the leaching time was 4h to obtain 372L of reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com