Patents

Literature

476results about How to "Reduce the chance of shedding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

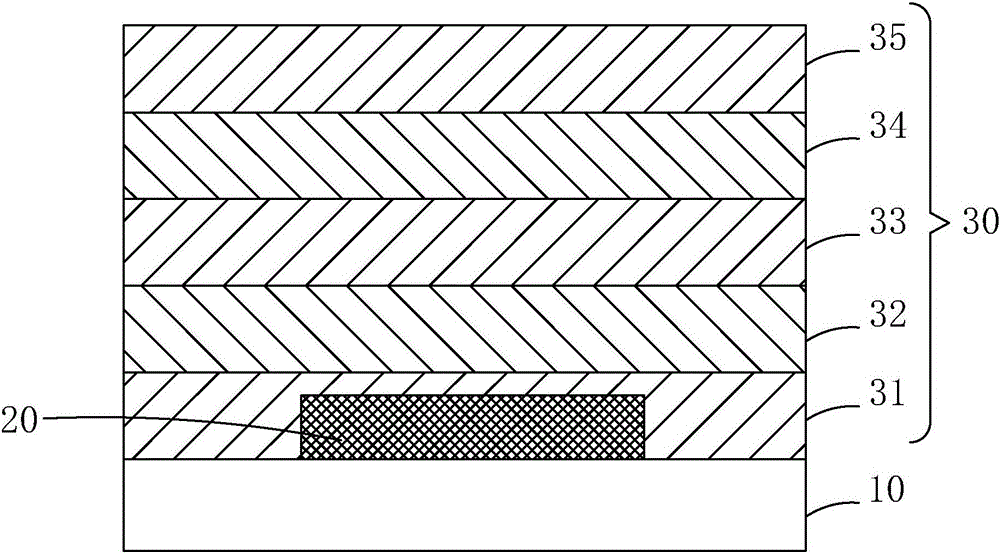

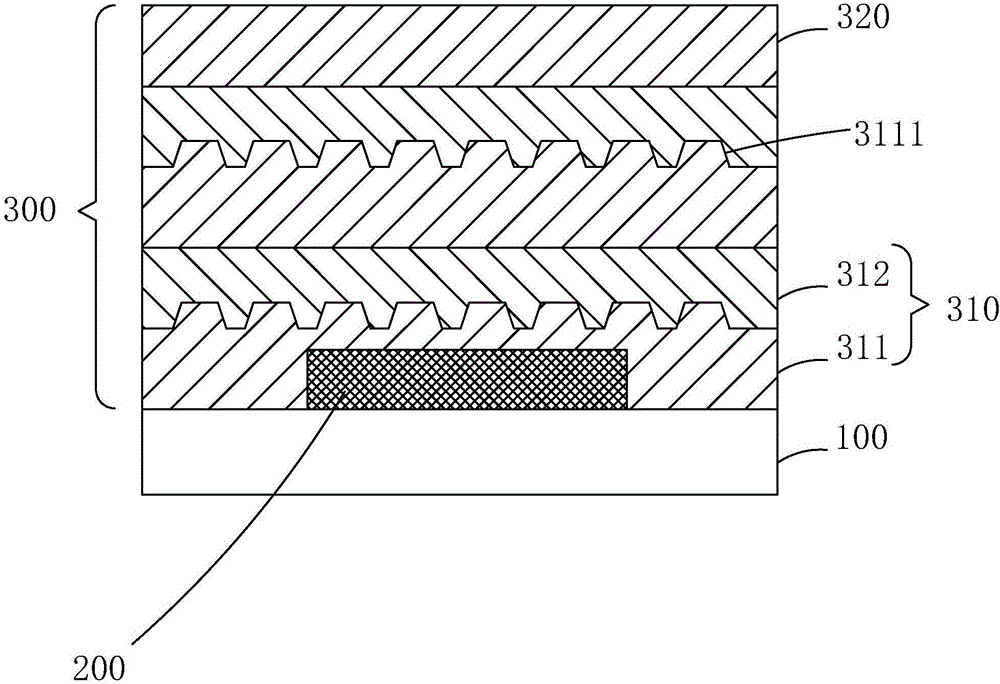

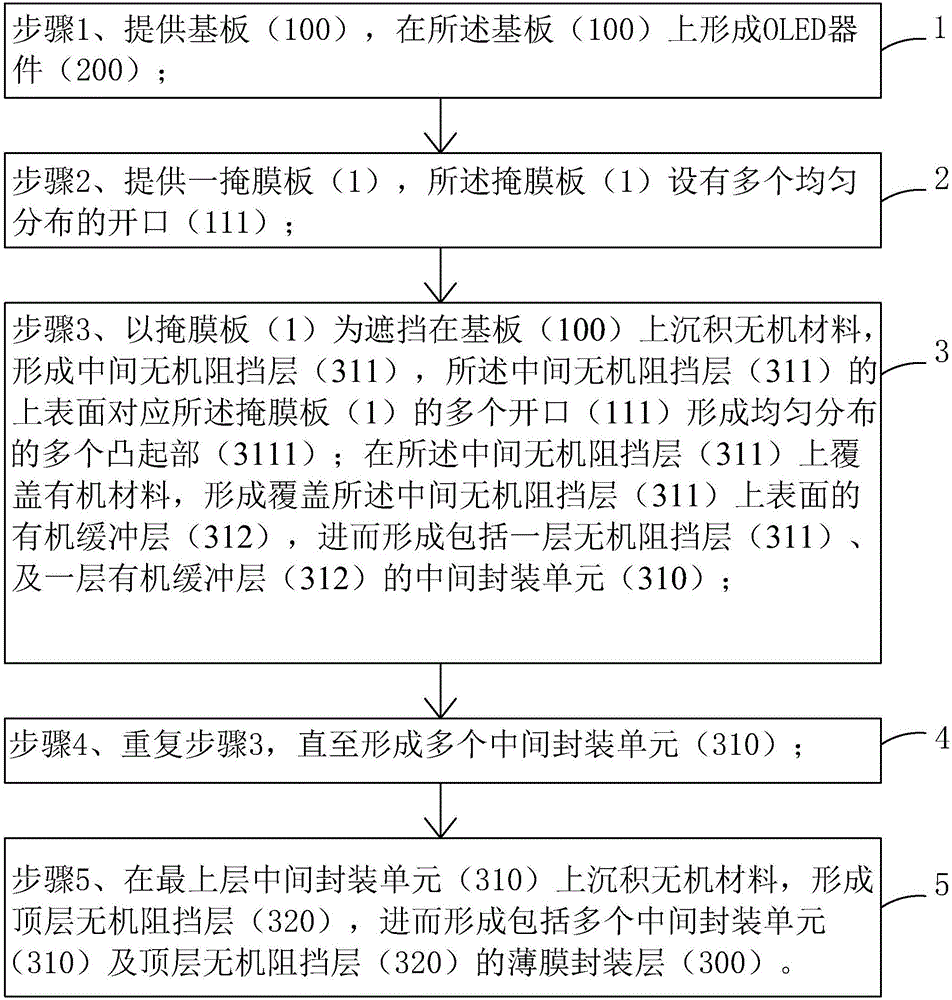

OLED display device and fabrication method thereof

ActiveCN106328826ABlock movementBlock movement, prevent water and oxygen molecules from continuing to invadeSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOxygen

The invention provides an OLED display device and the fabrication method thereof. The invention uses a mask with multiple openings as the cover to form the middle inorganic blocking layer in the film encapsulation layer, making the upper surface of the middle inorganic blocking layer has many evenly distributed bulges, greatly increasing the contact area between the organic buffer layer covered on the middle inorganic blocking layer and the middle inorganic blocking layer, thus increasing the adhesive force between the middle inorganic blocking layer and the organic buffer layer at the interface and greatly reducing the probability the partition between the inorganic blocking layer and the organic buffer layer. The bulges can prevent water and oxygen molecules from moving on the interface between the middle inorganic blocking layer and the organic buffer layer and prevent water and oxygen molecules from continuing to intrude into the internal part of the OLED display device, which will influence efficiency of the components of OLED.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

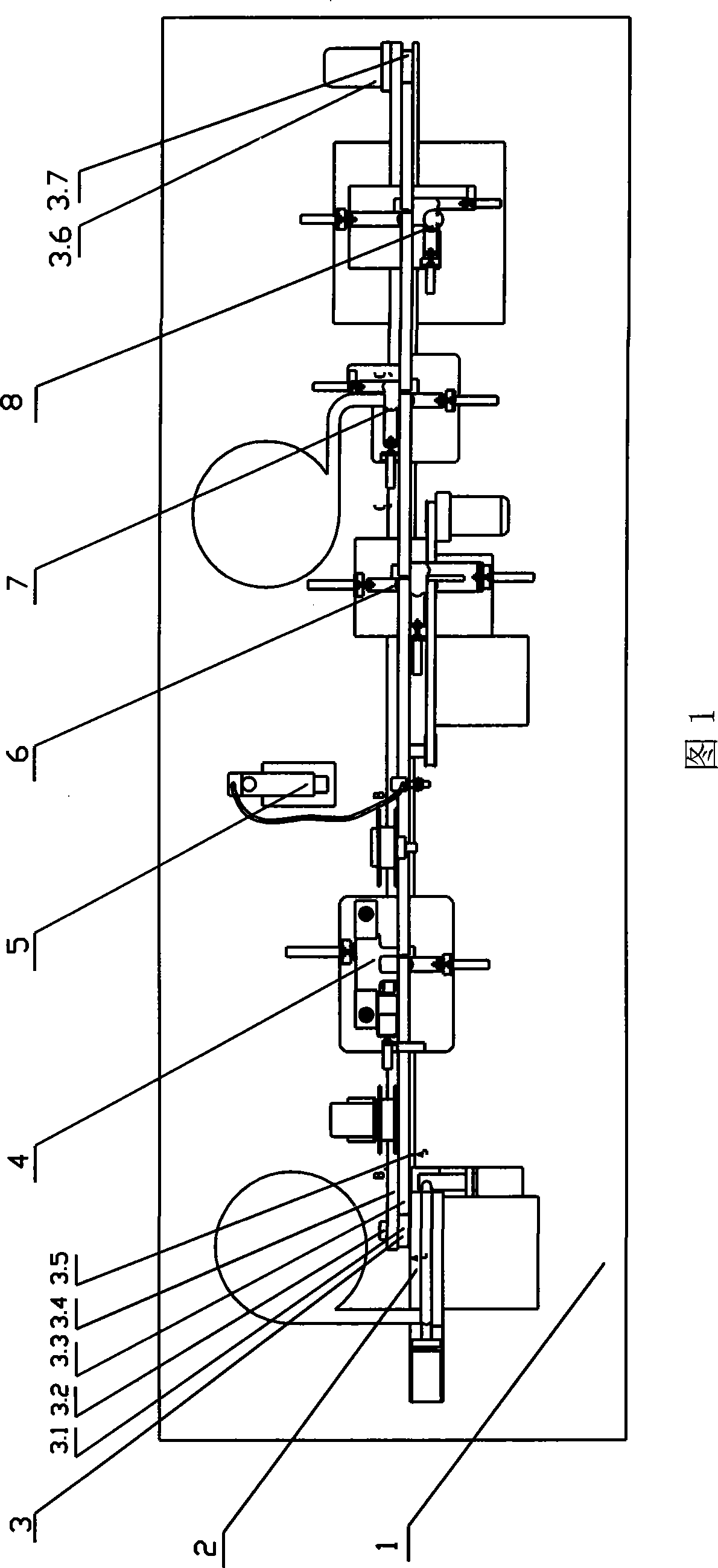

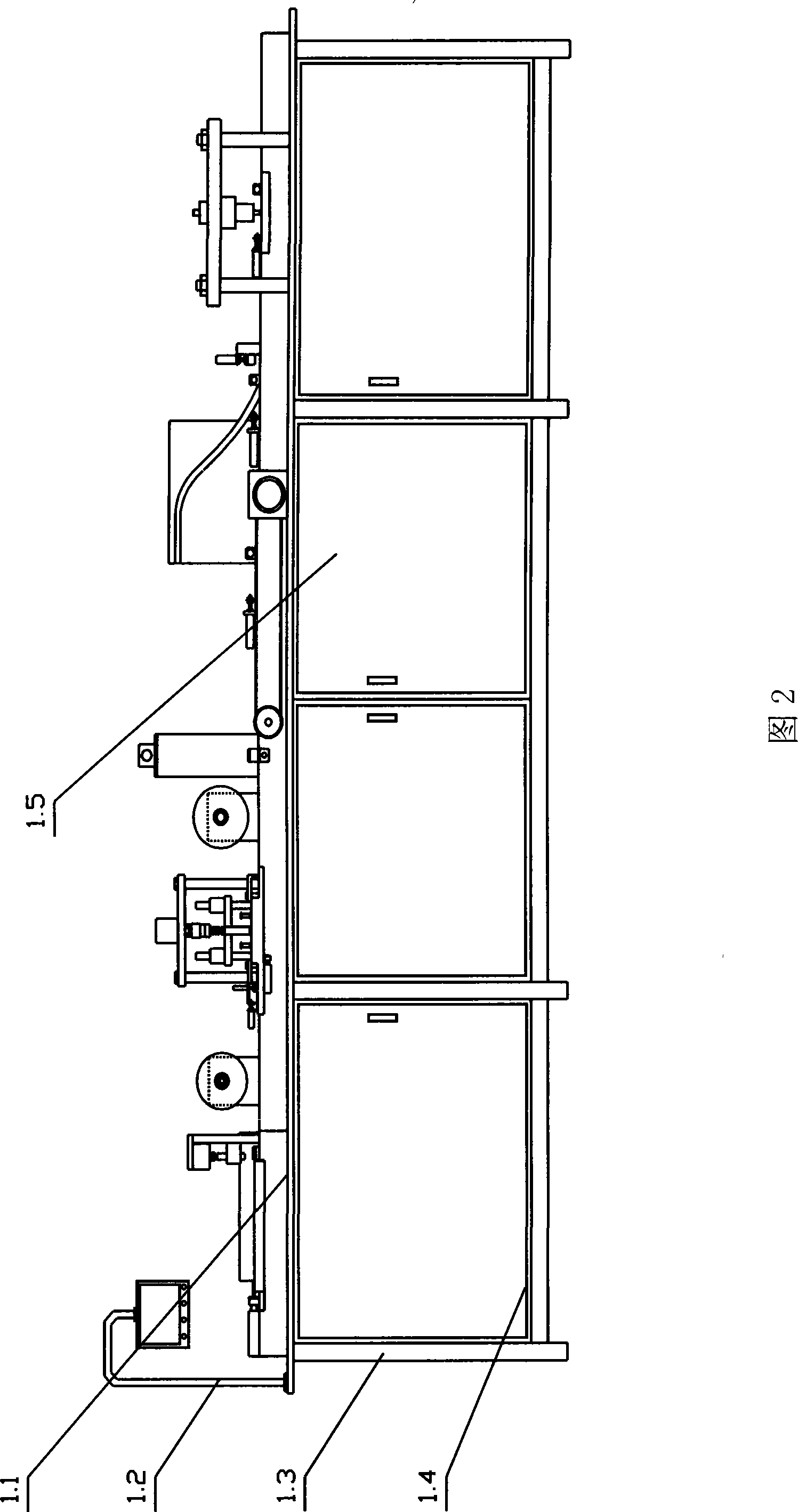

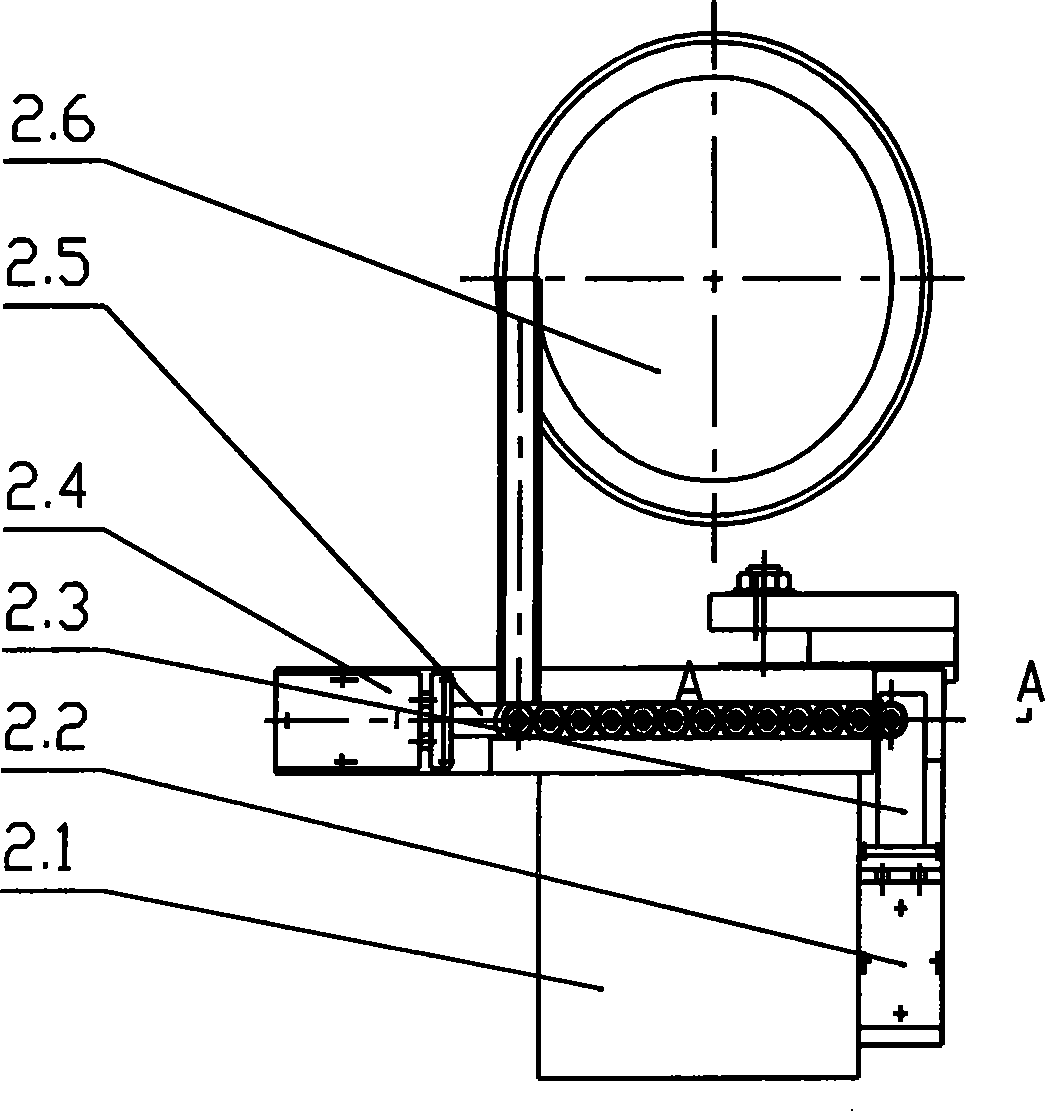

Button cell battery production line

InactiveCN101252194AAdvanced technologyEasy to controlFinal product manufactureNon-aqueous electrolyte cellsProduction lineLithium

The invention relates to a button cell production line, being characterized in comprising a rack component, a lithium chip loading mechanism, a paper cutting mechanism, a filling mechanism, a manganese chip loading mechanism, an anode case loading mechanism, a sealing mechanism, a main transmission mechanism, a pneumatic control system and an electrical apparatus control system as well as a control program; the rack component comprises a large worktable and a rack fastened on the lower surface of the large worktable, a lower base plate of the rack is arranged on a lower beam of the rack, a control cabinet is arranged on the upper part of the lower base plate of the rack; the lithium chip loading mechanism, the main transmission mechanism, the paper cutting mechanism, the filling mechanism, the manganese chip loading mechanism, the anode case loading mechanism and the sealing mechanism are arranged on the large worktable in turn; the pneumatic control system is arranged on the lower base plate of the rack; the electrical apparatus control system and the control program are arranged inside the control cabinet; a touch screen support is vertically arranged on the upper surface of the large worktable close to one end of the lithium chip loading mechanism.

Owner:TIANJIN POLYTECHNIC UNIV

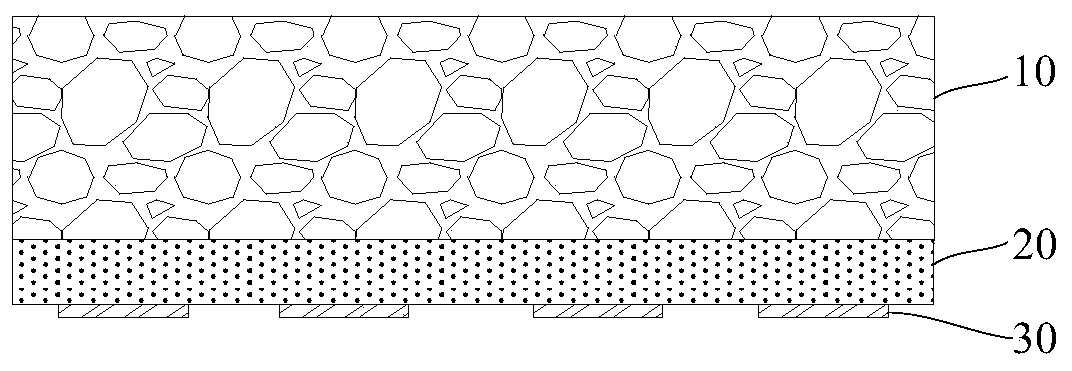

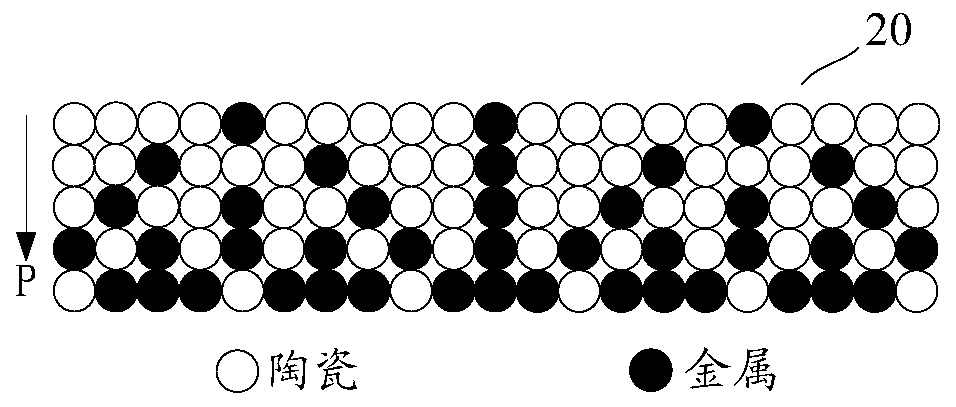

Electronic cigarette atomizer, electronic cigarette, atomizing assembly and preparation method of atomizing assembly

ActiveCN109875123AReduce deformationReduce the chance of sheddingTobacco devicesElectronic cigaretteTransition layer

The invention discloses an electronic cigarette atomizer. The electronic cigarette atomizer comprises an e-liquid storage cavity and an atomizing assembly; the atomizing assembly comprises a porous body and a porous transition layer which are stacked; the porous transition layer comprises a first surface back on to the porous body, and a heating element is arranged on at least a part of the firstsurface; the porous body comprises a first material, the heating element comprises a second material, and the porous transition layer comprises a first material and a second material. According to theatomizing assembly adopted by the atomizer, connection between the porous body and the heating element is achieved through the transitional porous transition layer, on one hand, the interface difference between the two materials when the porous body is directly combined with the heating element can be eliminated, and the combination stability is improved, on the other hand, the performance of thetransition layer can be slowly changed along with changes of components and structures of the materials, and the consistency of resistance values of various areas of the sintered heating element canbe ensured.

Owner:SHENZHEN FIRST UNION TECH CO LTD

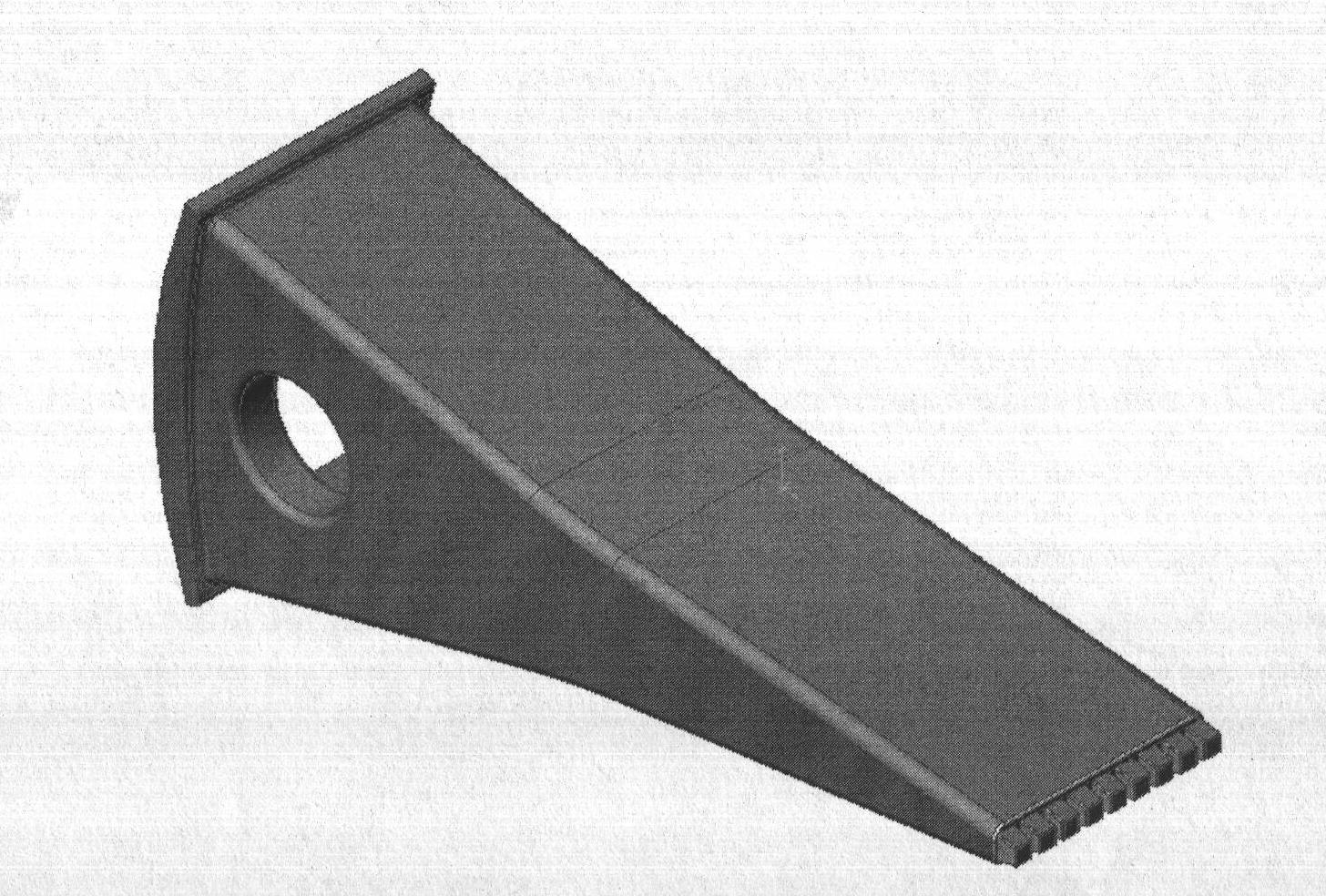

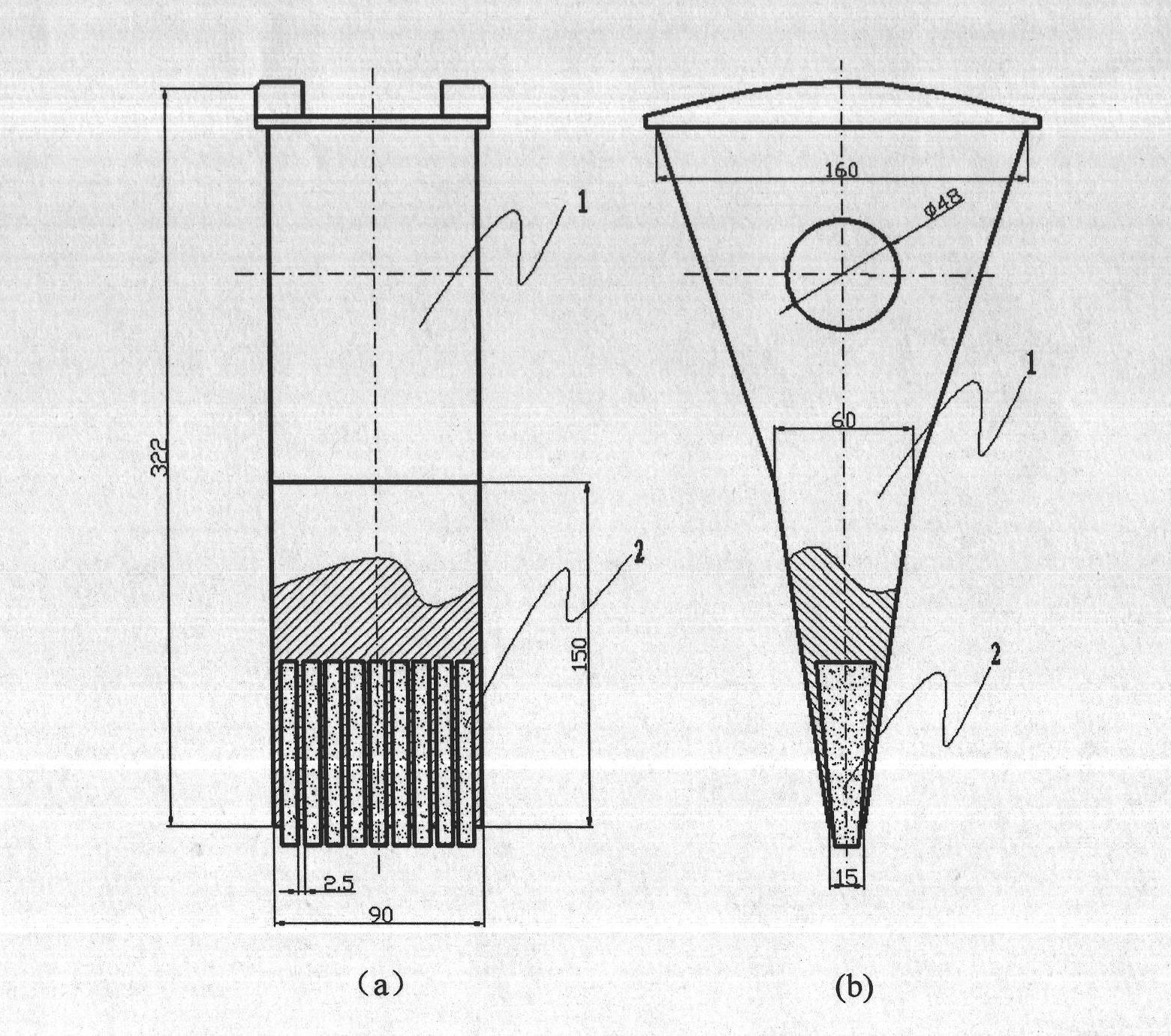

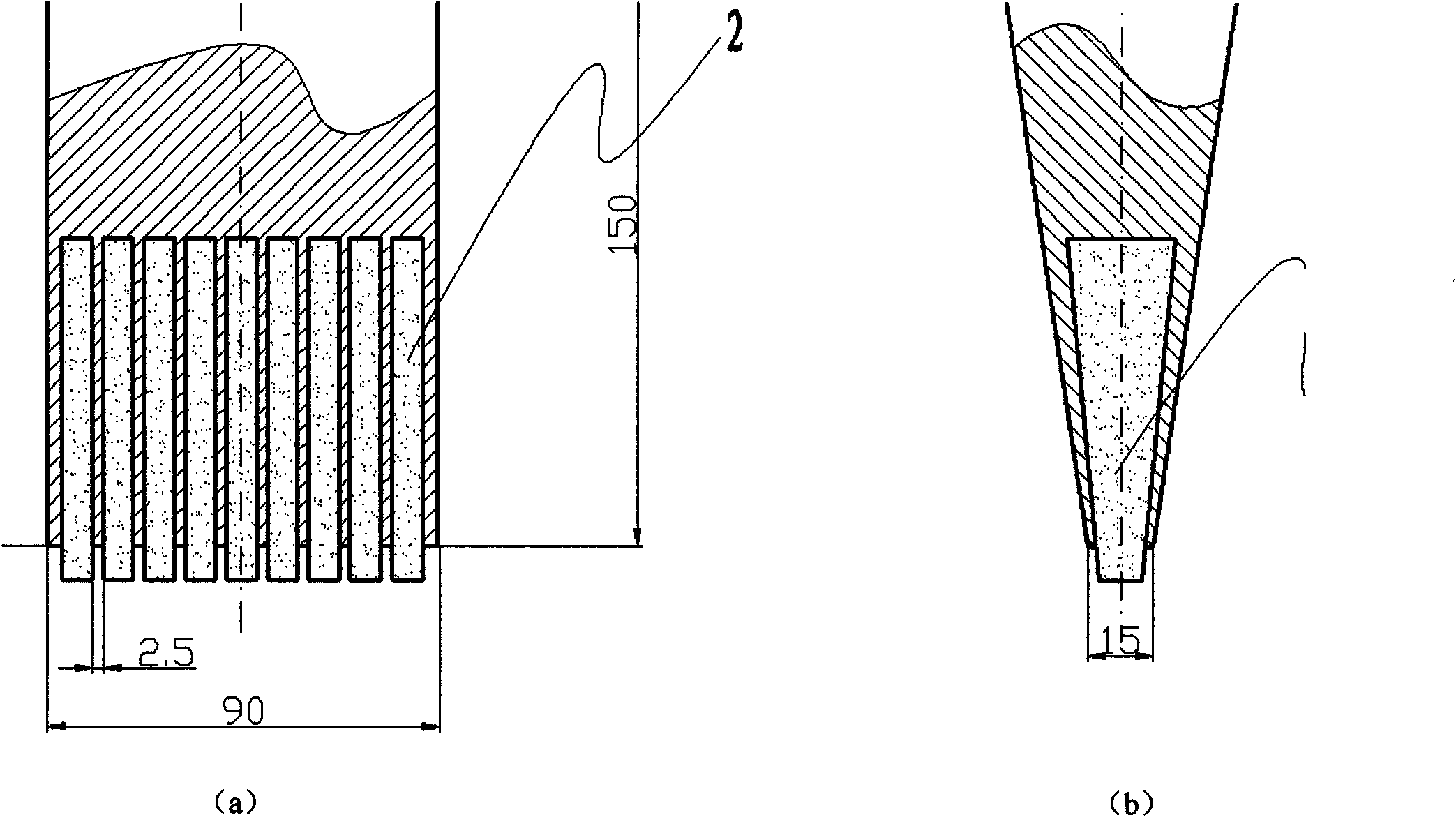

Composite dipper tooth of excavator and manufacturing method thereof

InactiveCN102182223AHigh hardnessHigh strengthSoil-shifting machines/dredgersExcavatorUltimate tensile strength

The invention relates to a composite dipper tooth of an excavator and a manufacturing method thereof, belonging to the field of high-tech engineering materials and application thereof. The novel composite dipper tooth comprises two parts of a bar type tooth tip (tooth bar) and a dipper tooth substrate (tooth substrate) and is formed by high temperature casting. The tooth bar material is novel high-rigidity and high-strength composite metal ceramics and comprises one or more of WC, TiCN, TiN or TiC-based composite metal ceramics; the tooth substrate is high / low chrome alloy steels or high manganese steels with higher rigidity and strength; a composite dipper tooth structure comprises a plurality of tooth bars of wedge shapes, the tooth bars are embedded at the front end of the tooth substrate, and a small section of each tooth bar is exposed out of a steel body, and a certain distance is arranged between tooth bars. The manufacturing method of the composite dipper tooth of the excavator sequentially comprises the following steps of: prefabricating the tooth bars; smelting alloy steels; casting the composite dipper tooth; and demolding. The tooth bar material is characterized by high rigidity, high strength and wearing resistance; the wearing resistance of the dipper tooth is improved and the consumption of wearing materials is reduced due to an intermittent structure, raw materials are saved, the cost is lowered, a contact area between the tooth bars and the tooth substrate is increased, the binding force is improved and the service life of the dipper tooth is prolonged.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

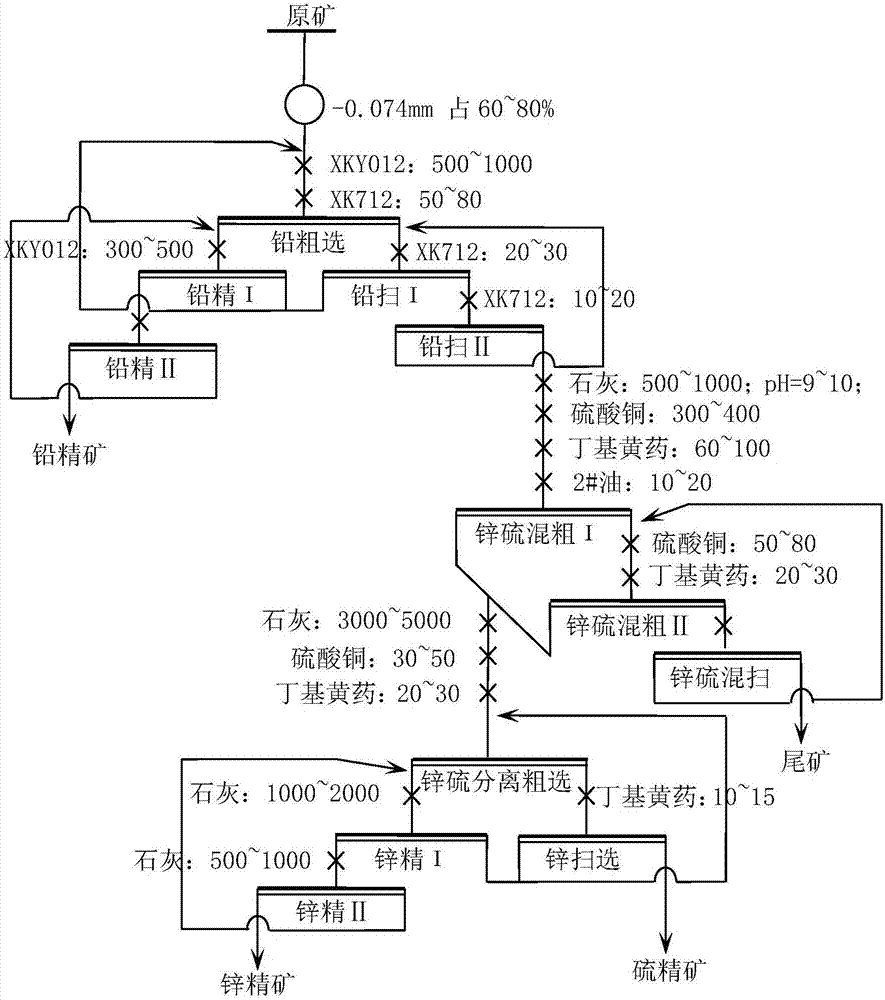

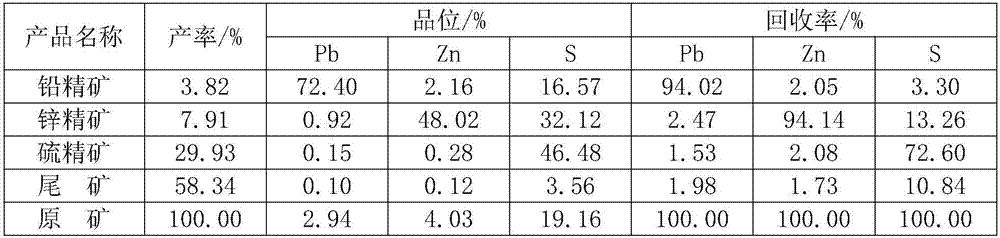

Flotation separation technology for high-sulfur lead-zinc ore in high-concentration environment

ActiveCN107999267AImprove acceleration performanceStrengthen the arching effectFlotationWet separationHigh concentrationSeparation technology

The invention discloses a flotation separation technology for high-sulfur lead-zinc ore in a high-concentration environment. The flotation separation technology aims at high-sulfur lead-zinc sulfide ore containing associated gold and silver, and flotation of lead and associated gold and silver minerals is preferentially carried out in a high-concentration and neutral natural pH flotation environment; and lead-flotation tailings are subjected to two-stage rough flotation so as to realize bulk flotation of zinc-sulfur minerals, the pH value and the potential of ore pulp are regulated and controlled by adopting lime in the zinc-sulfur separation flotation process so as to realize zinc-sulfur separation, and a small amount of activating agents and collecting agents are added to strengthen flotation of zinc minerals difficult to float. According to the flotation separation technology, the defects that in the lead flotation process of high-alkali mediums, the recovery rate of lead, gold andsilver is low, the usage amount of agents is large, the floatation process is not stable, and the like can be overcome; and meanwhile, a zinc-sulfur mineral inhibitor XKK012 and a lead-gold-silver collecting and frothing agent XKY712 are invented, so that the problems that the lead-zinc-sulfur separation efficiency is low, the separation precision is poor, and the hydrophobic capacity of part of lead-gold-silver minerals is weak can be solved, and the technology has the advantages of being energy-saving, environment-friendly, non-toxic, harmless, low in beneficiation cost, high in recovery efficiency and suitable for comprehensive recovery of valuable metal minerals in the high-sulfur silver-lead-zinc-contained ore.

Owner:WESTERN MINING CO LTD +2

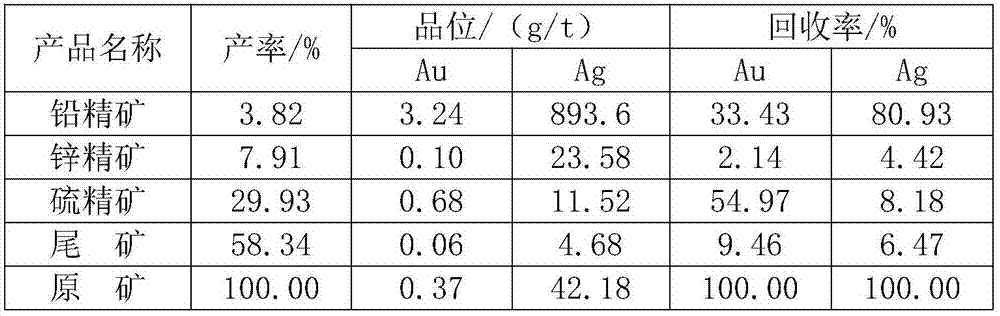

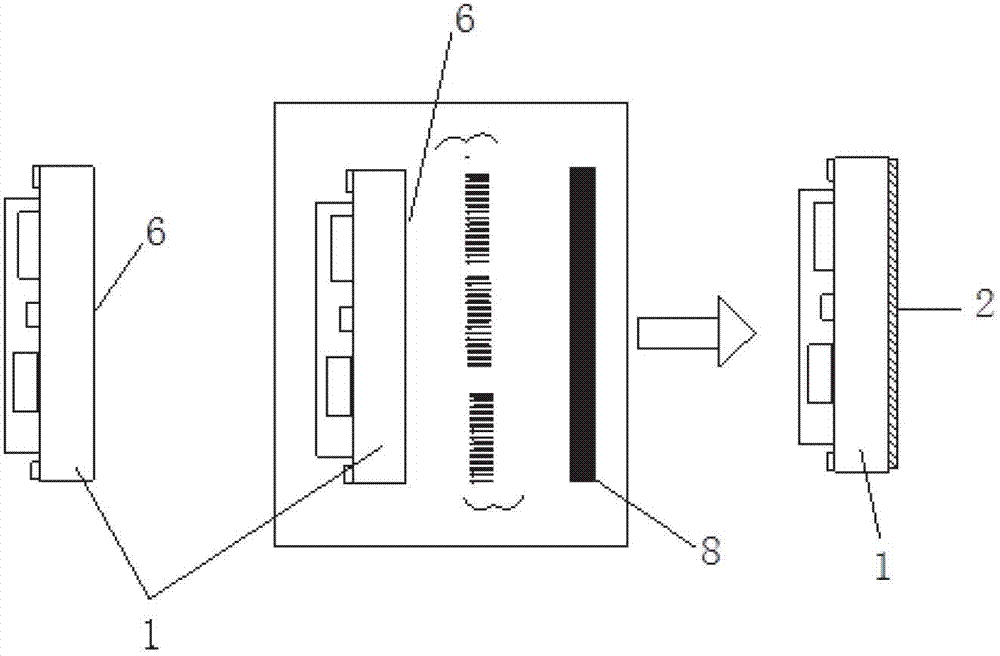

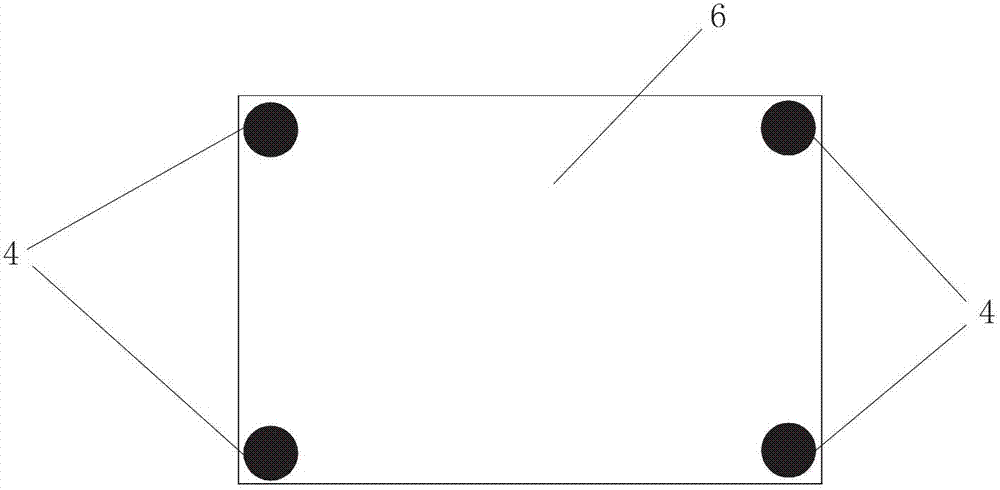

Process for welding electronic microcomponents based on multi-temperature gradient

InactiveCN102950350AEfficient removalNo discharge restrictionsSoldering apparatusElectronic componentRecoil pressure

The invention discloses a process for welding electronic microcomponents based on a multi-temperature gradient. The process is simple, convenient, efficient, stable and reliable in processing quality, good in welding flowability and little in welding hollows. The process is realized by the following technical scheme: designing the temperature gradient of welding fluxes according to melting points of different welding fluxes and respectively manufacturing welding flux slices at different temperature gradients from a secondary high temperature to a minimum temperature; dividing a function substrate and a transition parent plate on each electronic microcomponent into welding surfaces of the welding fluxes at different temperature gradients and coating a welding flux film coating layer on the welding surfaces directly and respectively by sputter coating; arranging welding flux thickness control pins at more points on the welding surfaces of the electronic component; laminating the electronic microcomponents (1), the welding flux slices (3) and the substrate component (5) sequentially, putting into a clamp with a counter-recoil pressure holding mechanism and putting the clamp into a furnace for vacuum welding; firstly completing the welding at a high temperature gradient, and then protecting other surfaces, which are not used for the welding at the next temperature gradient, of the substrate component, and coating one welding flux film coating layer on the welding surfaces respectively by the sputter coating at the next temperature gradient.

Owner:10TH RES INST OF CETC

Preparation method of AIDS (acquired immune deficiency syndrome) virus affinity adsorbent

InactiveCN104801278AReduce the chance of sheddingReduce rateOther chemical processesAlkali metal oxides/hydroxidesImmune deficiency syndromeAmino acid

The invention discloses a preparation method of an AIDS (acquired immune deficiency syndrome) virus affinity adsorbent. According to the method, amino acid is utilized to process virus adsorption microspheres connected with ligands, the ligands on the virus adsorption microspheres are combined more firmly, so that the probability and the speed of falling of the AIDS virus affinity adsorbent are reduced, and the safety of the AIDS virus affinity adsorbent during applying is improved.

Owner:WUHAN RUIFA MEDICAL DEVICES CO LTD

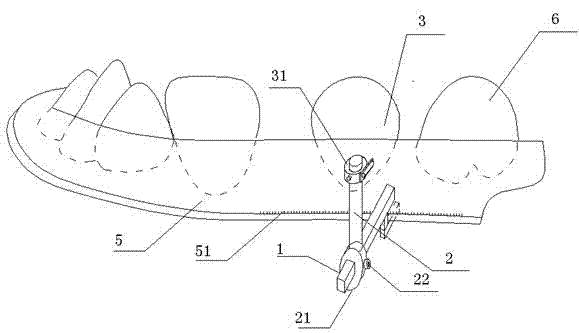

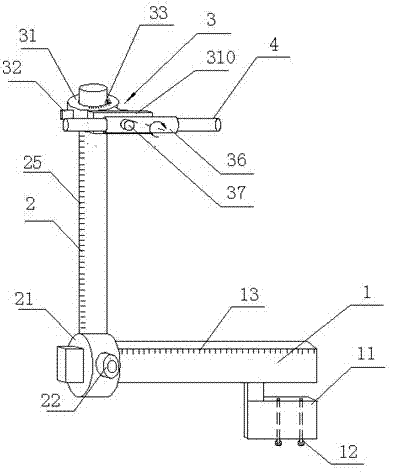

Method and device for implanting and locating micro planting nail for orthodontics

InactiveCN104720902AHigh precisionReduce the chance of sheddingDental implantsOthrodonticsMedicineOcclusal plane

The invention relates to a method for implanting and locating a micro planting nail for orthodontics. The method comprises the steps that an oral cavity to be implanted with the micro planting nail is subjected to CBCT (Cone Beam Computed Tomography); a three-dimensional reconstruction for an oral cavity structure is performed; a three-dimensional entity image model is formed; a micro planting nail model is imported into a computer; a preset planting position for the micro planting nail is determined; an occlusal plane plate is put in a mouth of a patient; a horizontal movable unit is arranged on the occlusal plane plate; a lifting and rotation unit connected with a planting gun guide tube is arranged on the movable unit; a vertical distance between the planting gun guide tube and the occlusal plane plate and a planting direction of the micro planting nail are determined; and a planting gun is finally connected with the planting gun guide tube for planting operation. The method has the benefits that the implantation precision of the micro planting nail can be improved effectively; an implantation falling-off rate of the micro planting nail is reduced; a good correction effect is achieved; the pain and the hospitalization cost of a patient can be relieved and reduced; and the clinical working time of a doctor is saved.

Owner:季骏

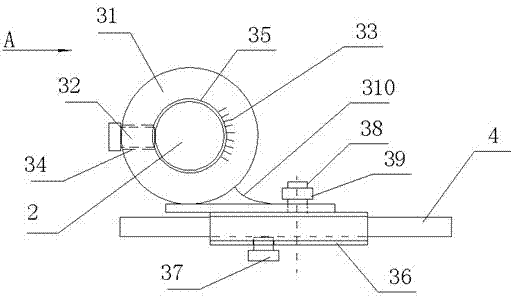

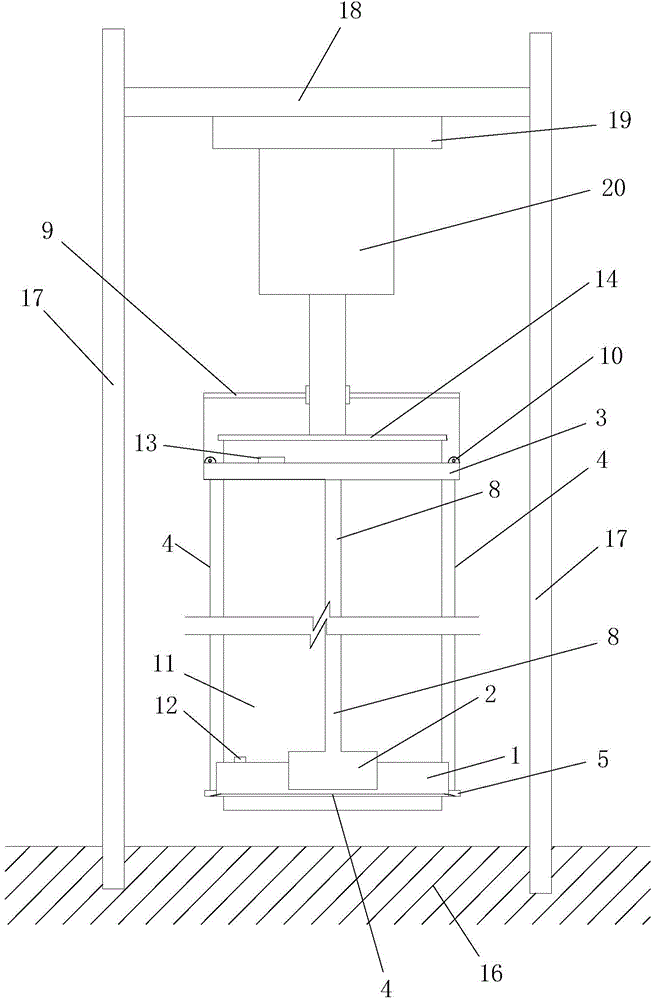

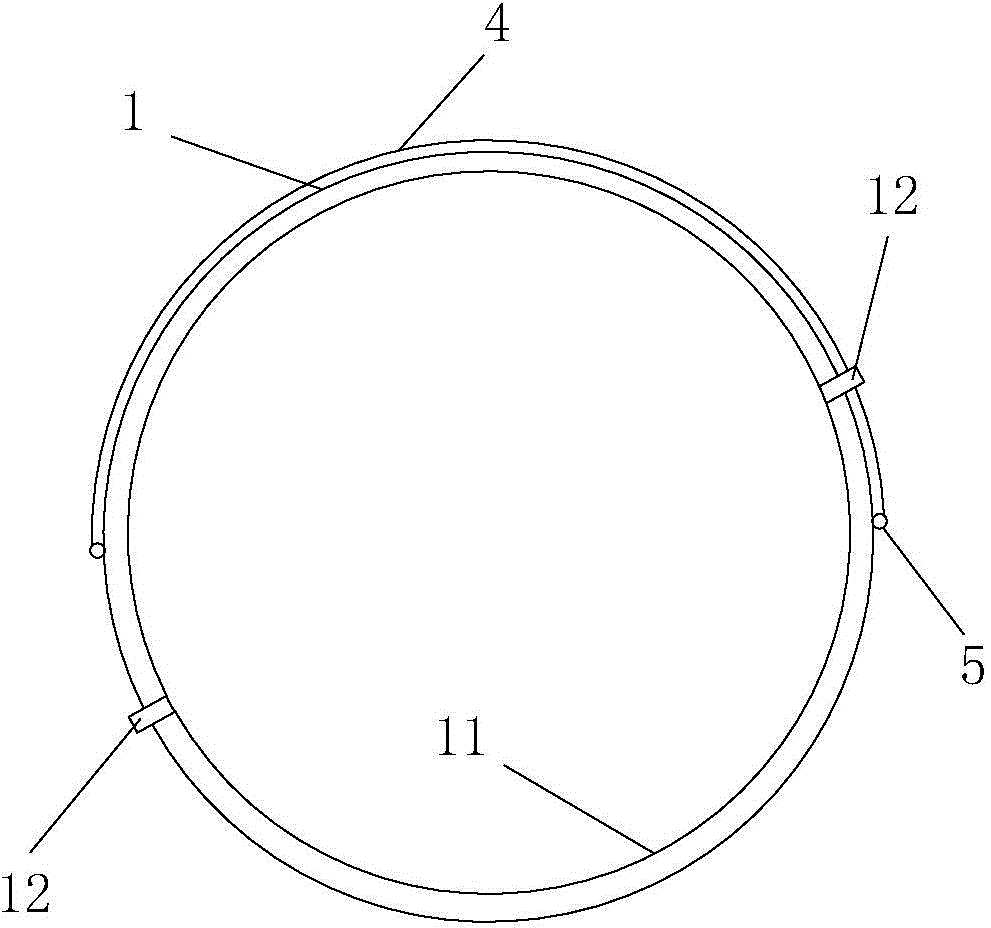

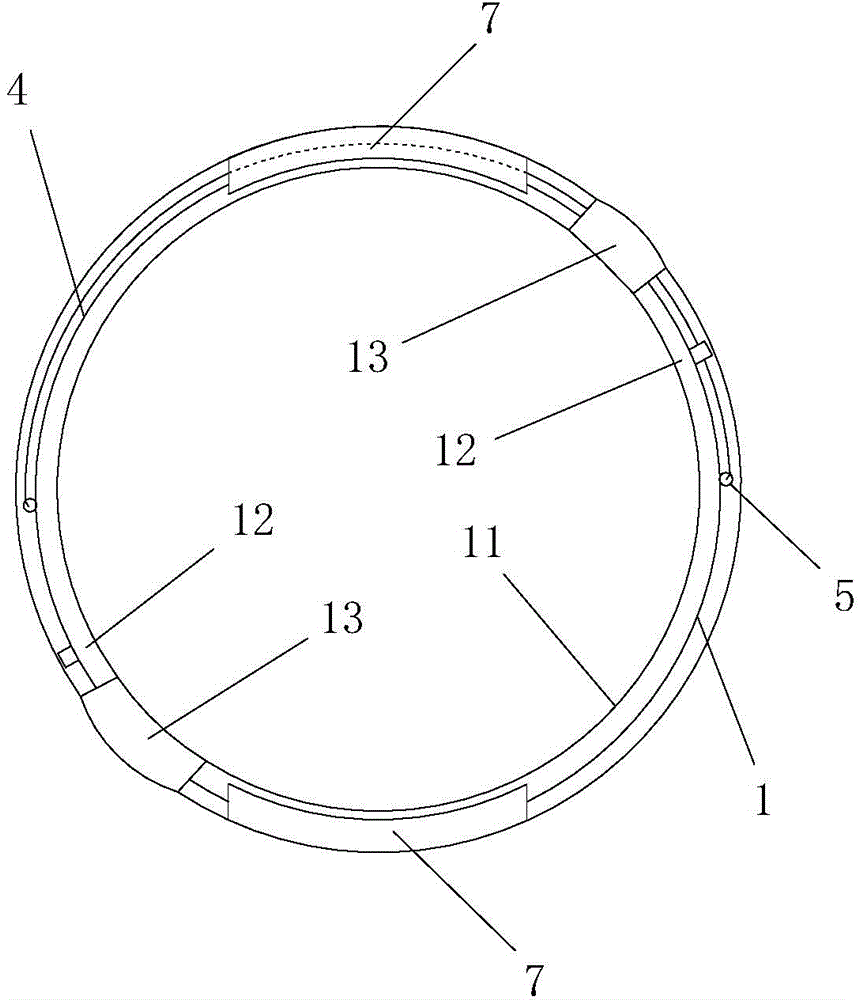

Soil sample sampling equipment based on combined-type soil sample horizontal cutting apparatus

InactiveCN105675332ASimple structureReasonable designWithdrawing sample devicesAnnular cutterEngineering

The present invention discloses soil sample sampling equipment based on a combined-type soil sample horizontal cutting apparatus, the soil sample sampling equipment includes two stand columns, an upper beam, an electric rotating seat, an electric lower press head, a soil sampling cutter located just below the electric lower press head, a lower press plate installed on the upper part of the soil sampling cutter and the combined-type soil sample horizontal cutting apparatus arranged on the outer side of the soil sampling cutter, the soil sampling cutter comprises an annular cutter and a cylindrical protection tube, a control box is arranged on the stand columns, the combined-type soil sample horizontal cutting apparatus comprises a lower position limitation ring, a plurality of side pushing panels and an upper pressure ring; the lower position limitation ring is a round ring with a cutting steel wire winding around the outer wall of one side, and the bottom of the lower position limitation ring is provided with a cutter edge, the outer side wall of the bottom of the lower position limitation ring is provided with two horizontal rings, two ends of the cutting steel wire respectively pass through the two horizontal rings, the side pushing panels are fixed on the upper pressure ring by a vertical connecting plate. The soil sample sampling equipment is simple in structure, reasonable in design, easy in use and operation, and good in use effect, and can simply and rapidly complete a sampling procedure, and the sampling effect is good.

Owner:XIAN KUOLI MACHANICAL & ELECTRICAL TECH

Method for fresh-keeping of sugar citrus with leaves

ActiveCN102461651AShorten shelf lifeImprove the preservation effectFruit and vegetables preservationSugarMethyl palmoxirate

The invention relates to a method for fresh-keeping of sugar citrus with leaves, which is used for treating the fruits of the sugar citrus with 0.5-20 ppm of 1-methylcyclopropene (1-MCP) as an ethylene action inhibitor for certain time so as to efficiently slow down the aging (etiolating, browning or rotting) and falling off of the leaves during post-harvest storage, greatly enhance the fresh-keeping effect of sugar citrus with leaves and maintain quality of the fruits. The method disclosed by the invention is adopted to keep the sugar citrus with leaves fresh; and after storage at low-temperature of 4-8 DEG C for 50 days, or at room-temperature of 15-25 DEG C for 15-30 days, the leaves of sugar citrus are still green, the falling-off rate of the leaves is under 5% and the original quality and marketability of the fruits are still kept.

Owner:SOUTH CHINA BOTANICAL GARDEN CHINESE ACADEMY OF SCI

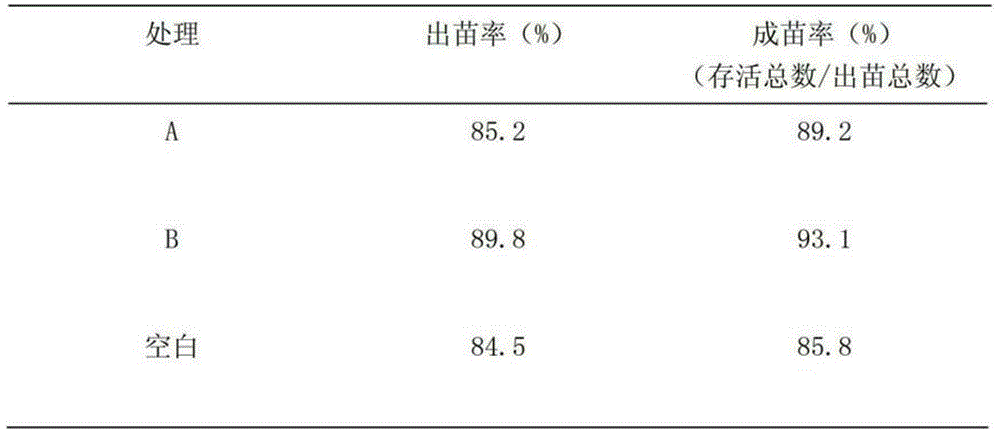

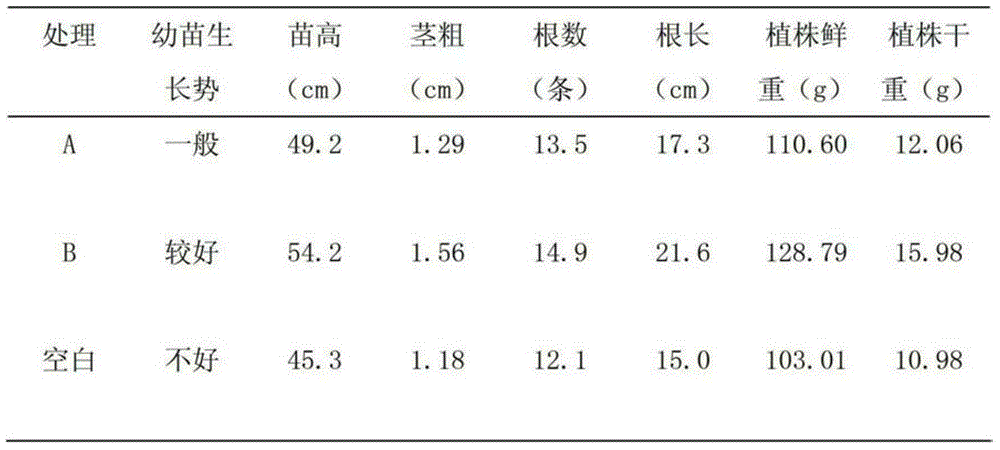

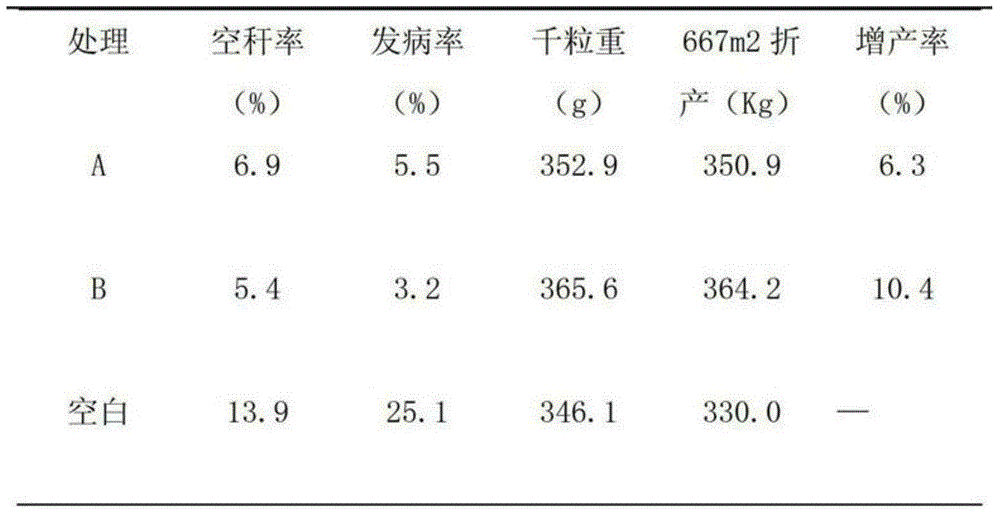

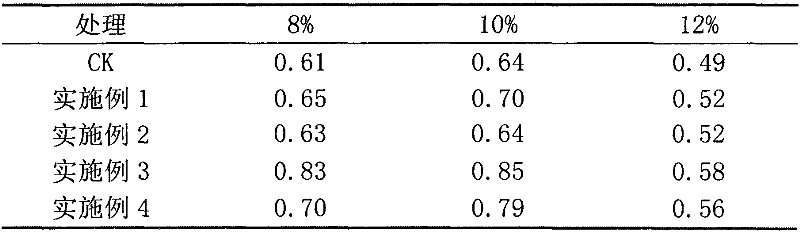

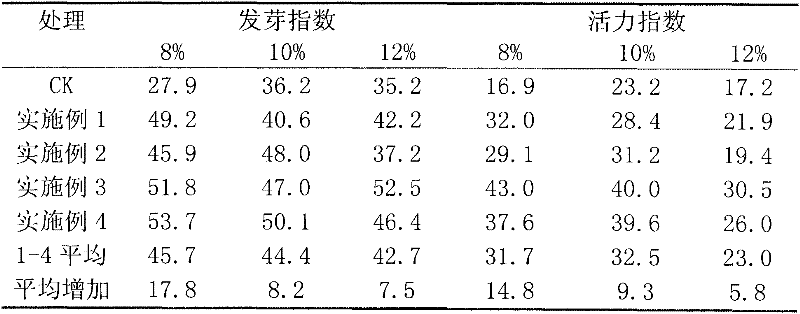

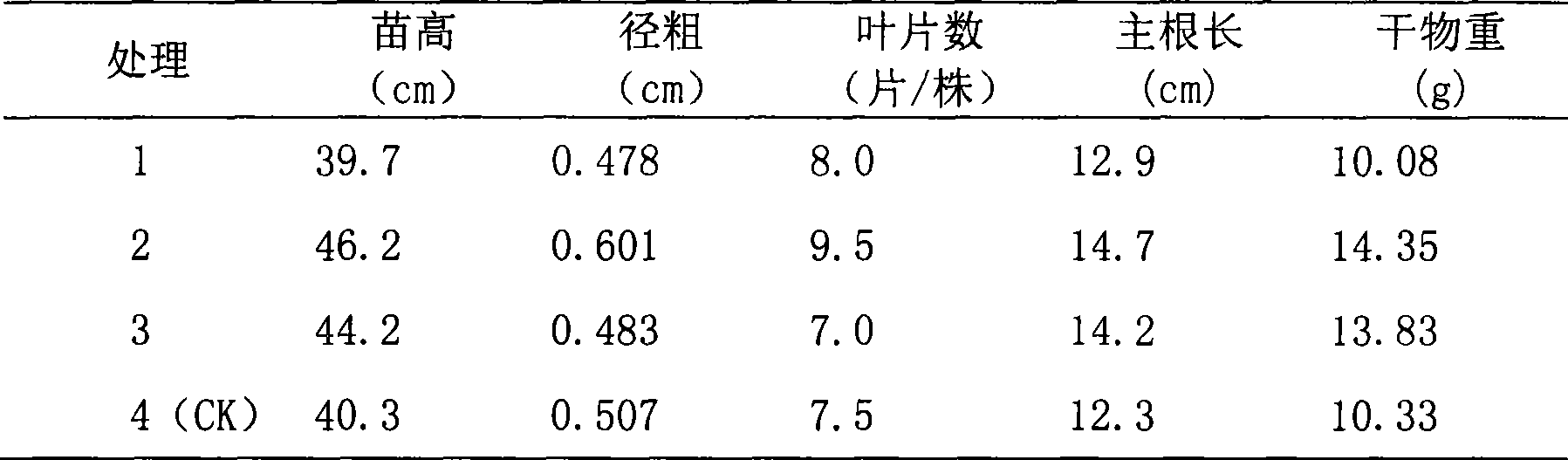

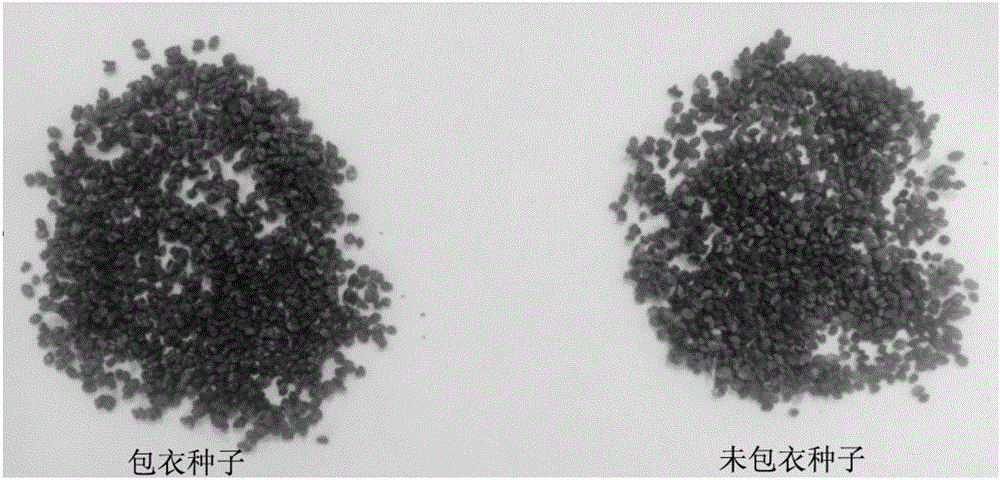

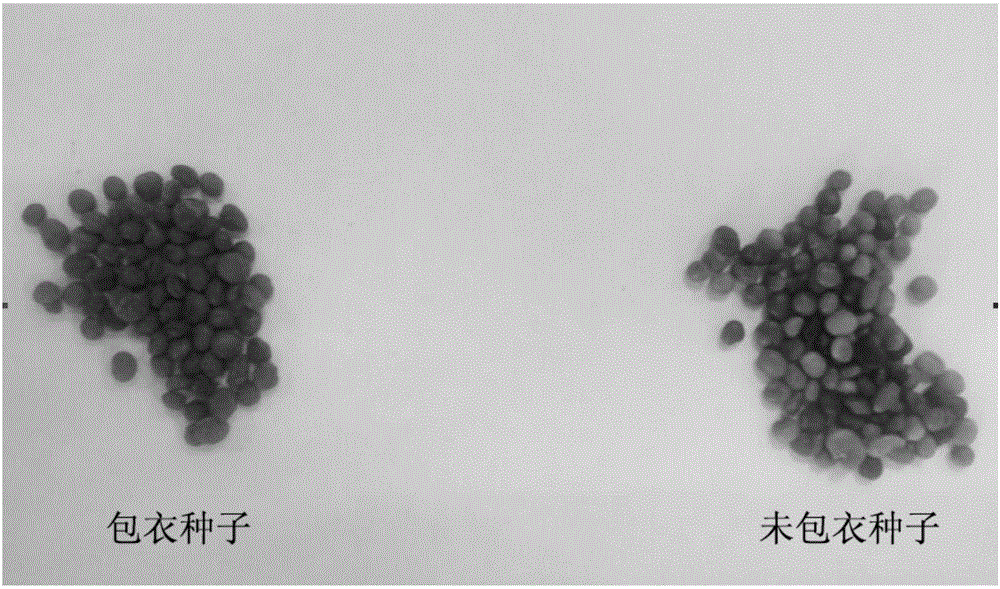

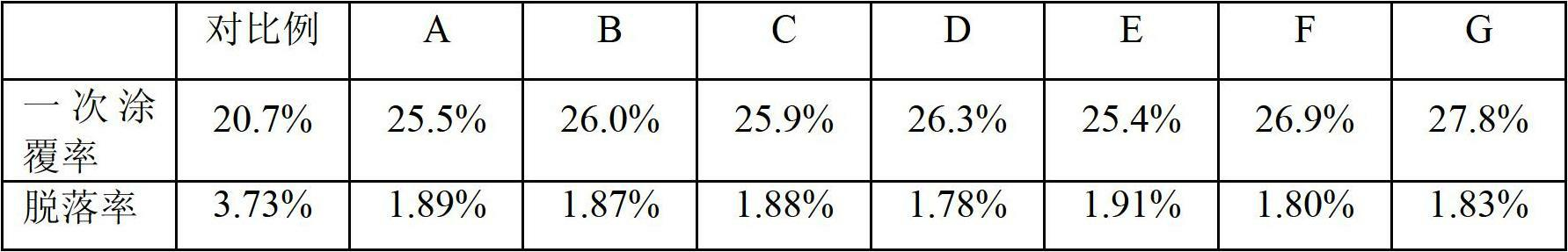

Efficient seed coating agent, preparation method and applications thereof, and method using same to process seeds

InactiveCN105052933AStrong targetingImprove versatilityBiocideFungicidesEnvironmental resistanceFruit tree

The invention belongs to the technical field of seed processing, and especially relates to an efficient seed coating agent, a preparation method and applications thereof, and a method using the same to process seeds. The efficient seed coating agent comprises the following components: amino-oligosaccharin, a dispersant, an adhesive, a surfactant, vigilance dye, and water. The preparation method comprises the following steps: weighing all raw materials other than amino-oligosaccharin according to a certain ratio, evenly mixing the weighed raw materials, then adding amino-oligosaccharin, and grinding the mixture until the particles of each component is less than 5 mm. The efficient seed coating agent is mixed with seeds according to a mass ratio of 1:50 to coat the seeds. The efficient seed coating agent can be used to prevent and treat diseases of fruit trees, vegetables, underground roots, tobaccos, traditional Chinese herbals, grain crops, cotton, and the like. The seed coating agent has the advantages of strong pertinence, good universality, sustain-released property, and fertilizer-retaining performance, and is capable of preventing the diseases and pests. Moreover, the raw materials are easily-available and cheap, so the production cost is low. Besides the raw materials are environment-friendly and harmless, and meet the nuisance-free requirements.

Owner:山东亿嘉农化有限公司

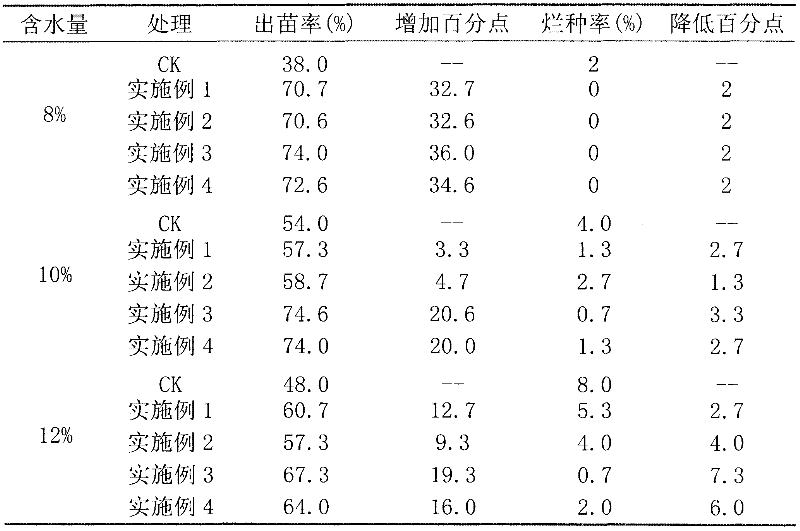

A kind of anti-low temperature cotton seed coating agent

InactiveCN102293209AImprove drought resistanceImprove cold resistanceBiocidePlant growth regulatorsGibberellic acidAcetic acid

The invention relates to a low-temperature resistance cotton seed coating agent, which is composed of a bactericide, a plant-growth regulator, a film forming agent, an antifoaming agent and an warning color, and is characterized in that the cotton seed coating agent comprises the following components by mass percentage: 4.0%-4.2% of Seedvax, 4.0%-4.2% of thiram, 0.002%-0.01% of naphthyl acetic acid, 0.002%-0.01% of gibberellin, 0.2%-0.5% of polyvinyl alcohol, 0.3%-0.5% of carboxymethylcellulose sodium, 0.4%-0.5% of antifoaming agent, 1.5%-2.0% of warning color and the balance of water. The low-temperature resistance cotton seed coating agent has the effects of resisting low temperature, preventing disease in seedling stage, promoting the seed germination and rooting and promoting the seedling growth, and also has the advantages of high suspension rate, good film forming ability, even dressing, low shedding rate, low toxicity and convenient usage.

Owner:新疆农业科学院核技术生物技术研究所

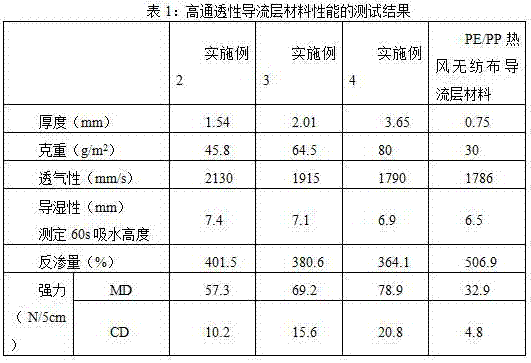

High-permeability diversion layer material and preparation method thereof

ActiveCN106937902AReduce heavinessGood moisture permeabilityAbsorbent padsBaby linensFiberReverse osmosis

The invention discloses a high-permeability diversion layer material and a preparation method thereof, and relates to the field of disposable sanitary products. The preparation method of the high-permeability diversion layer material is characterized in that by compound-superimposing and selecting an upper layer vertical net and a bottom layer direct laying net, matching coarse denier profiled cross-section fibers and fine denier hydrophilic double components in the upper layer vertical net, reasonably matching hydrophilic and water-repellent double-component fiber in the bottom layer direct laying net, selecting a hot air penetration thermal stabilization mode and reasonably selecting lustring and setting technological parameters of a hot pressing roll, the high-permeability diversion layer material with good permeability is prepared. Therefore, the technical problems of poor diversion performance, inability in storing liquid, poor transient sucking effect, complex technology, poor permeability and difficulty in quantity production of a diversion layer material are solved, and the effects of enabling the diversion layer material to have good abilities of transient suction property, diversion property, barrier property and temporary liquid storage and to have good effects of ventilation, moisture permeation and reverse osmosis prevention are achieved.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

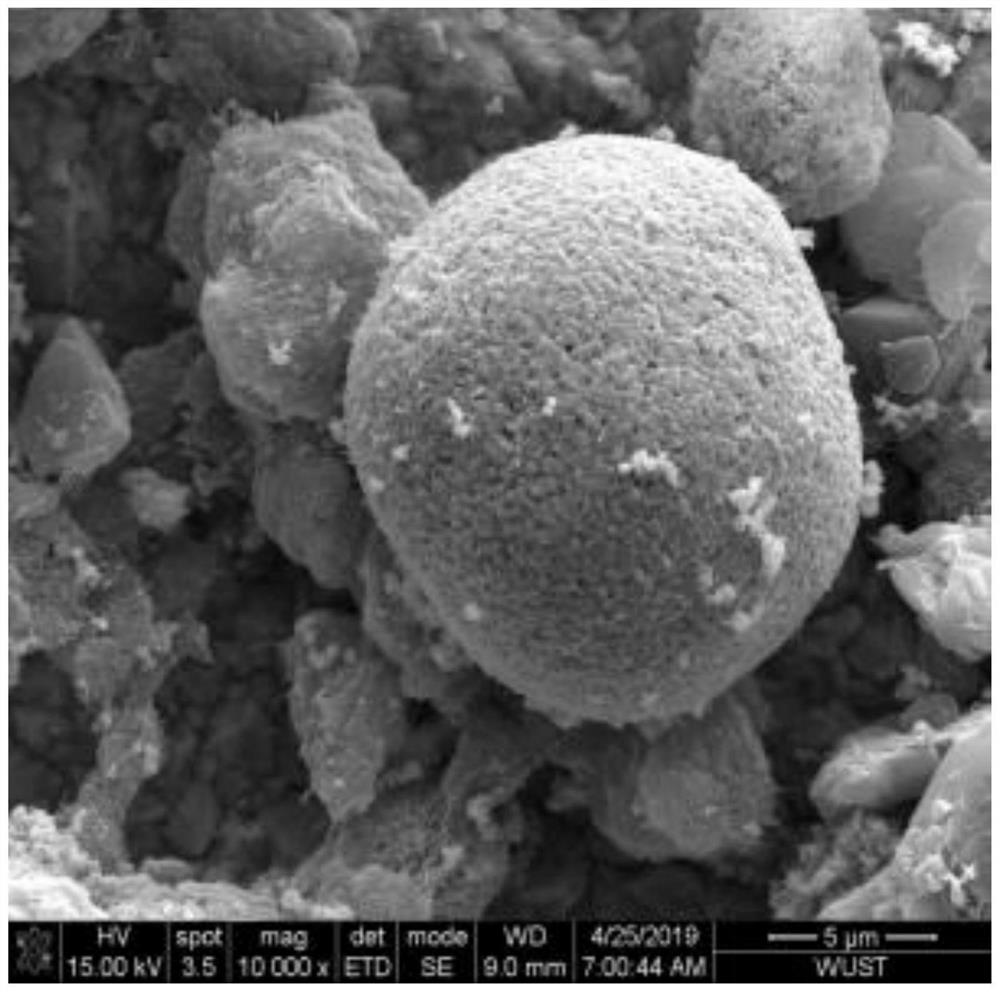

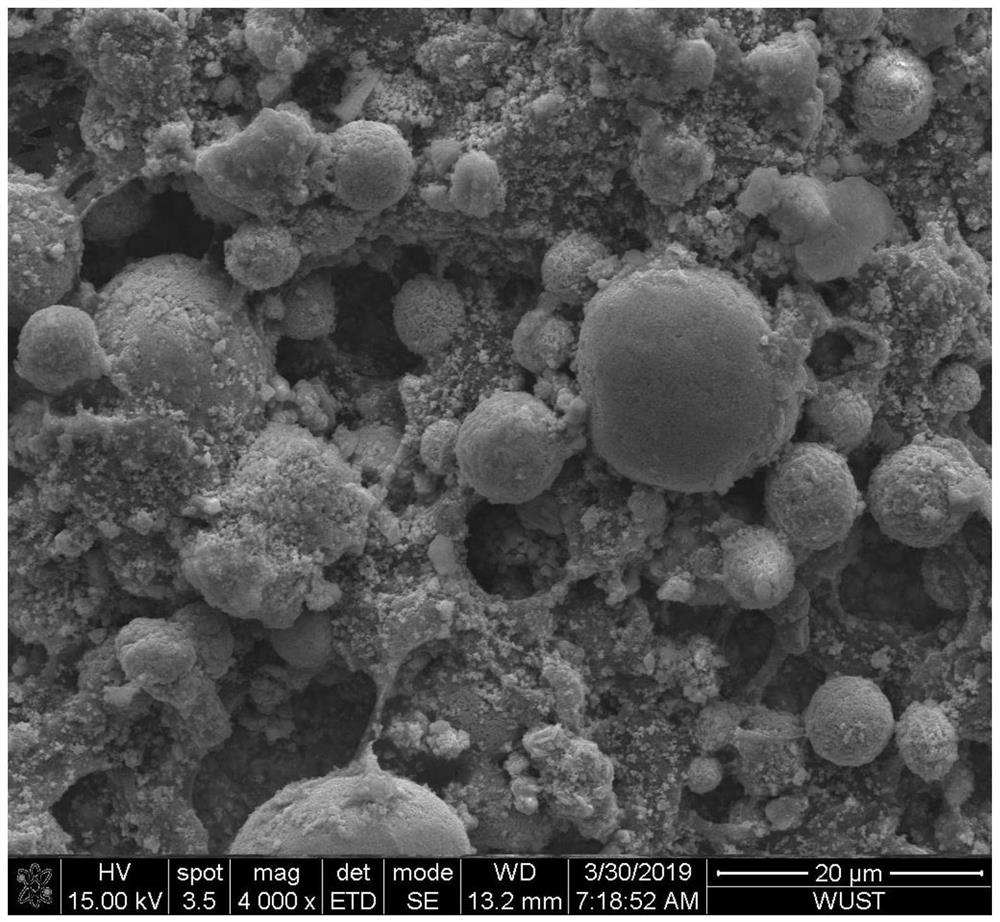

Three-dimensional composite current collector and preparation method thereof

PendingCN112670516AHigh specific surface areaReduce the actual current densityElectrode carriers/collectorsSecondary cellsComposite materialLithium dendrite

The invention provides a three-dimensional composite current collector and a preparation method thereof. The three-dimensional composite current collector provided by the invention comprises a copper foil base layer and a lithium battery negative electrode lithium-philic material coating coated on the copper foil base layer, wherein the lithium battery negative electrode lithium-philic material coating comprises a plurality of micron-sized three-dimensional spherical structures, and the lithium battery negative electrode lithium-philic material is composed of a carbon material, a lithium-philic metal oxide, a binder and a lithium salt. The preparation method comprises the following steps: firstly, preparing lithium battery negative electrode lithium-philic material slurry, then coating a copper foil base layer with the slurry to form a lithium battery negative electrode lithium-philic material coating, and preparing the lithium battery negative electrode three-dimensional composite current collector. According to the lithium battery negative electrode lithium-philic material, a copper foil is coated with a composite coating with a micron-sized three-dimensional spherical structure, so that the current density of a lithium metal negative electrode can be effectively reduced, the generation of lithium dendrites is effectively relieved and reduced, and the cycle performance and the safety performance of a lithium metal battery are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

High-efficiency, broad and environmental friendly corn seed coating agent

InactiveCN101313680AReduce pollutionImprove the effect of prevention and controlBiocideFungicidesAntifoam agentAvicide

The invention discloses an efficient, broad-spectrum and environment-friendly maize seed coating agent. The compositions in percentage by weight of raw materials used to prepare the maize seed coating agent are: 3 to 8 percent of chlopyrifos, 0.5 to 5 percent of tebuconazole, 5 to 10 percent of trametan, 1 to 2 percent of film former, 2 to 5 percent of an emulsifying agent, 2 to 5 percent of dispersing agent, 0.1 to 1 percent of antifoam agent, 4 to 5 percent of antifreezing agent, 0.5 to 1.5 percent of warning coloration and the balance being water, wherein pesticide is chlopyrifos; and bactericide consists of tebuconazole and trametan. The product of the maize seed coating agent can be used in maize seed; moreover, the seed coating agent product has the advantages of high efficiency, low toxity, environment protection and convenient use, etc., and can effectively control cornfield soil insects such as white grub, wireworm, cutworm and darkling beetle and so on as well as maize diseases such as maize head smut, common smut and caudex rot disease and so on.

Owner:洛阳市农业科学研究院

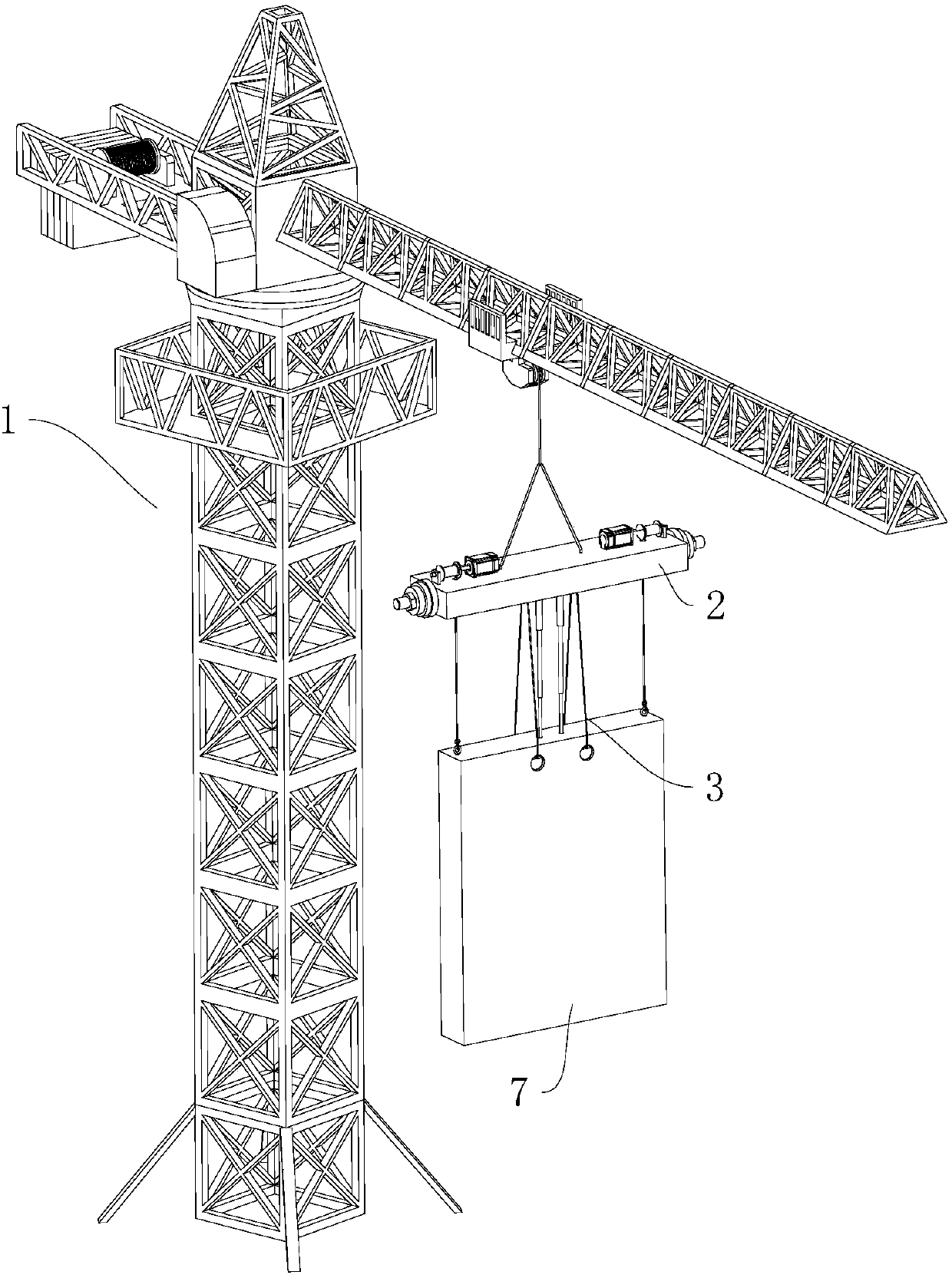

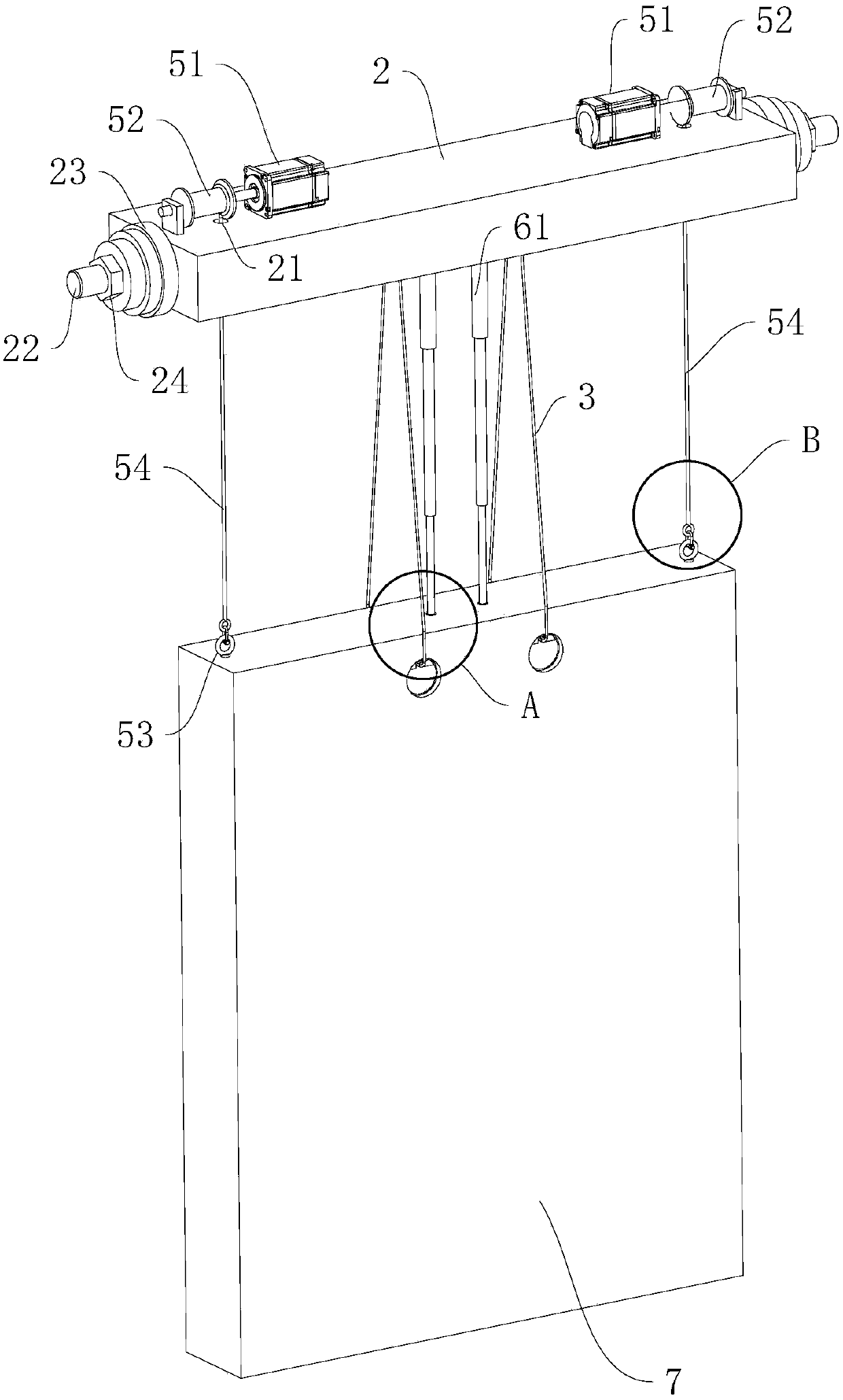

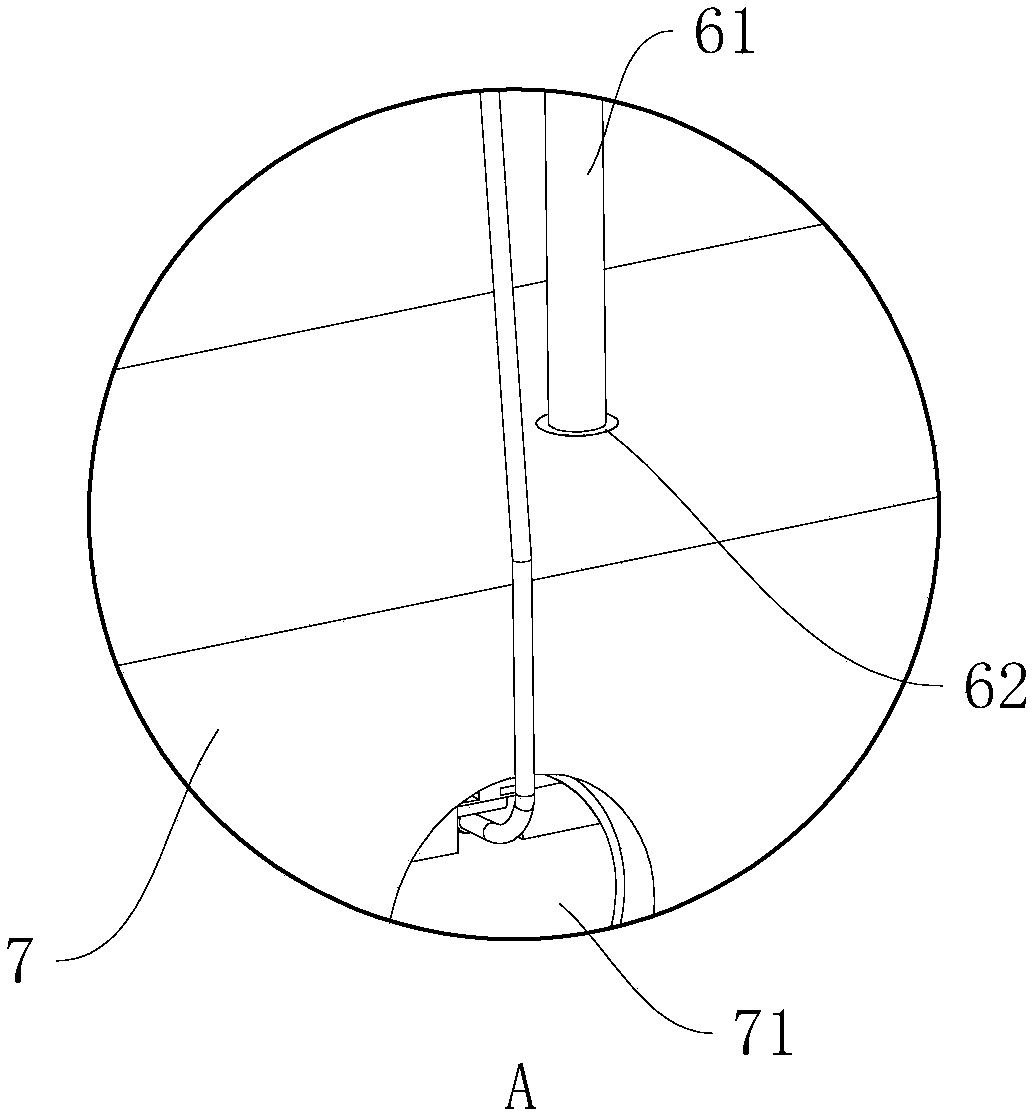

Lifting device for prefabricated concrete outer wallboard and lifting method of lifting device

ActiveCN107673185AImprove securityReduce sheddingBuilding material handlingLoad-engaging elementsClassical mechanicsStructural engineering

The invention discloses a lifting device for a prefabricated concrete outer wallboard and a lifting method of the lifting device and solves the problem of infirm lifting of outer wallboards in the prior art. According to the technical scheme, the lifting device for the prefabricated concrete outer wallboard is characterized by comprising a transverse lifting beam and first lifting chains fixed atthe lower end of the transverse lifting beam and further comprises no less than two groups of lifting assemblies matched with the first lifting chains to lift the prefabricated concrete outer wallboard; each lifting assembly comprises a metal pipe embedded in the upper end of the prefabricated concrete outer wallboard and a supporting block mounted on the inner side of the pipe wall of the metal pipe, the corresponding first lifting chain penetrates through the metal pipe, a supporting groove allowing the first lifting chain to penetrate is formed in the supporting block, and the bottom surface of the supporting groove is a downwards-bulging arc surface. By the aid of the lifting device for the prefabricated concrete outer wallboard, the prefabricated concrete outer wallboard is lifted more safely and firmly.

Owner:萧云建设股份有限公司

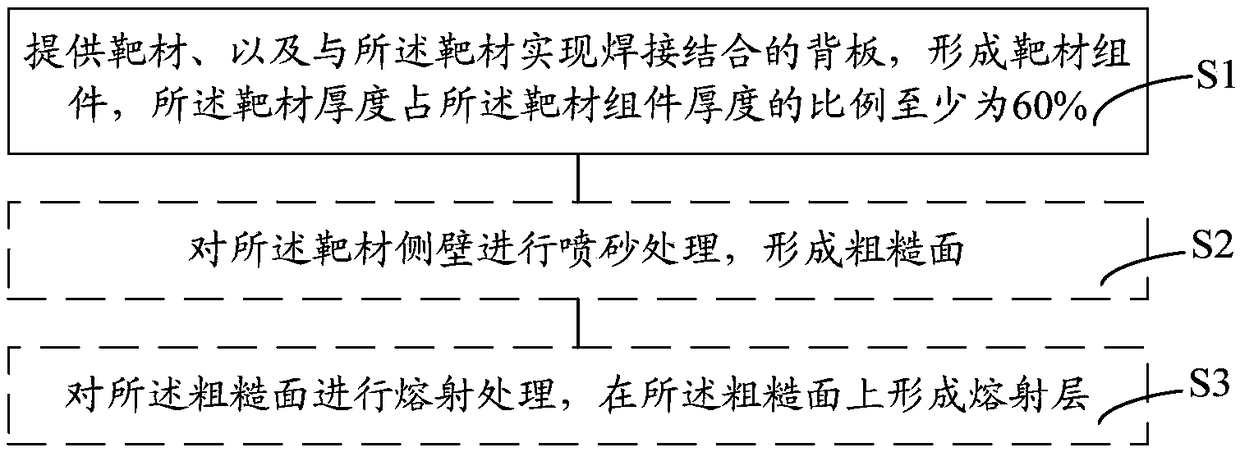

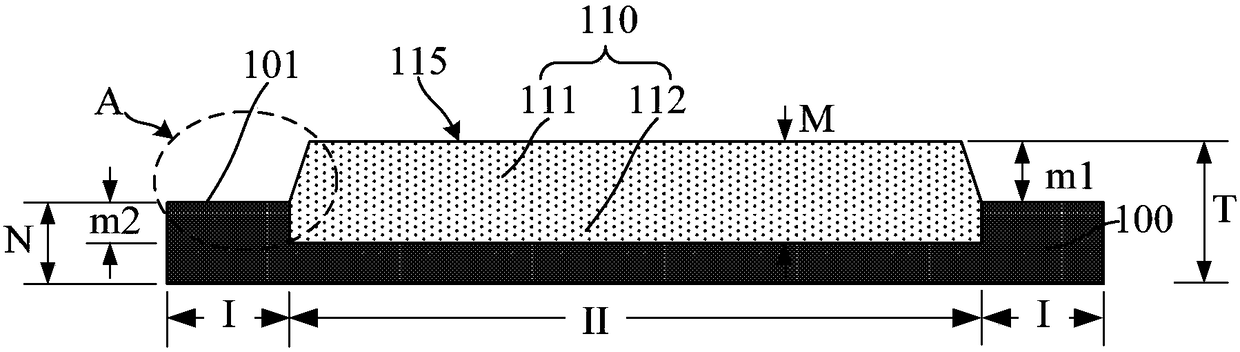

Target material assembly and manufacturing method thereof

InactiveCN109385608AUnchanged thicknessIncreasing the thicknessVacuum evaporation coatingSputtering coatingProcess efficiencyMaterials science

The invention provides a target material assembly and a manufacturing method thereof. The manufacturing method comprises the following step: providing a target material and a back plate capable of bonding with the target material in a welded manner so as to form the target material assembly, wherein the thickness of the target material accounts for at least 60% of the thickness of the target material assembly. According to the invention, the thickness of the target material accounts for at least 60% of the thickness of the target material assembly; thus, compared with a scheme that the thickness of the target material accounts for a smaller proportion of the thickness of the target material assembly, the target material assembly provided by the invention has the following advantages: the thickness of the target material can be increased under the condition that the thickness of the target material assembly is unchanged, and the part of the target material for sputtering is correspondingly increased, so the service life of the target material assembly is effectively prolonged; the replacement frequency of the target material assembly is effectively reduced; improvement of process efficiency and reduction of process cost can be easily realized; meanwhile, the thickness of the target material assembly can remain unchanged, so a sputtering machine bench does not need to adjust thespacing between the target material and a product about to undergo film formation (such as a wafer), and adverse effects on the initial sputtering rate and film-forming uniformity of the target material assembly are avoided.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

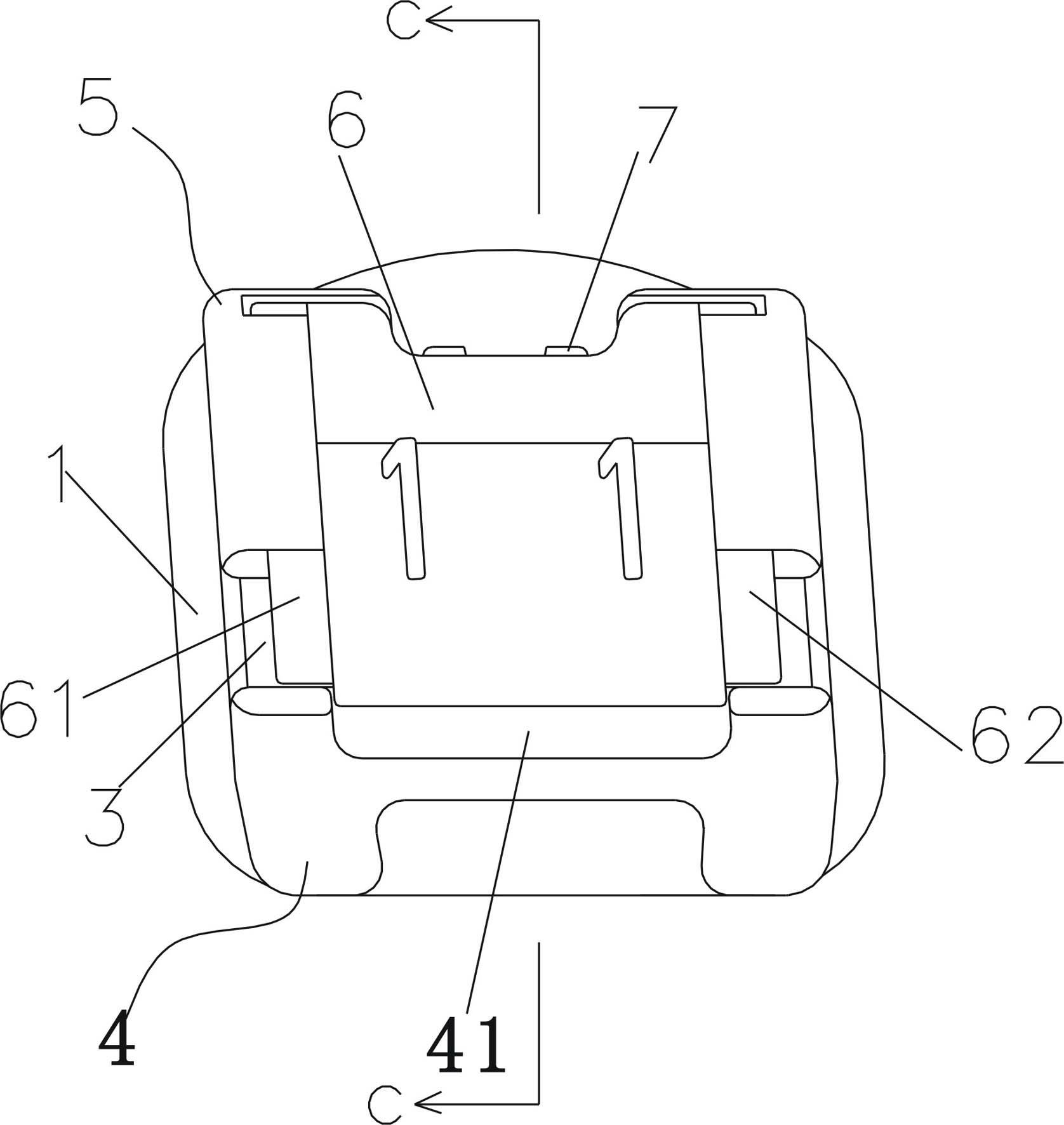

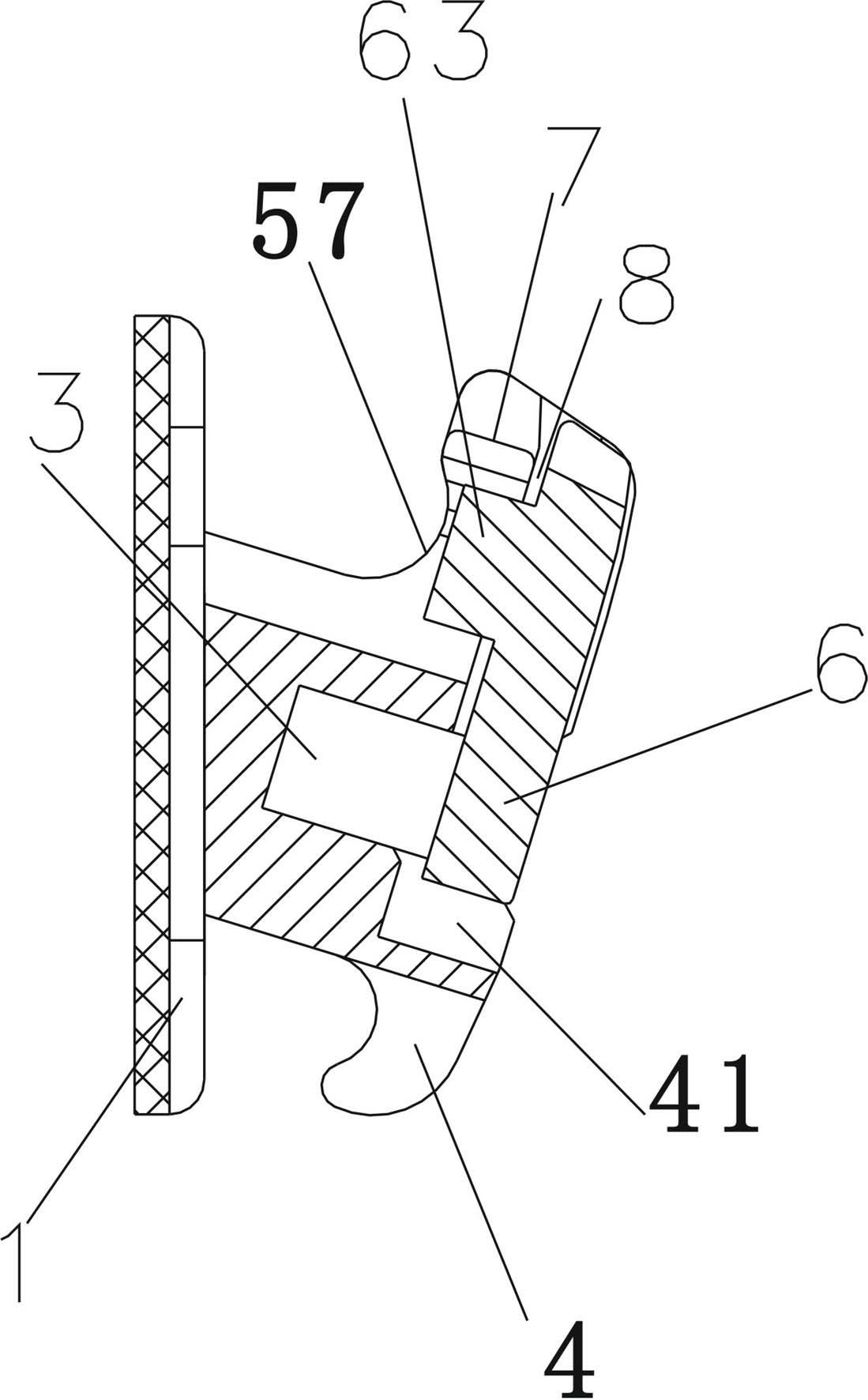

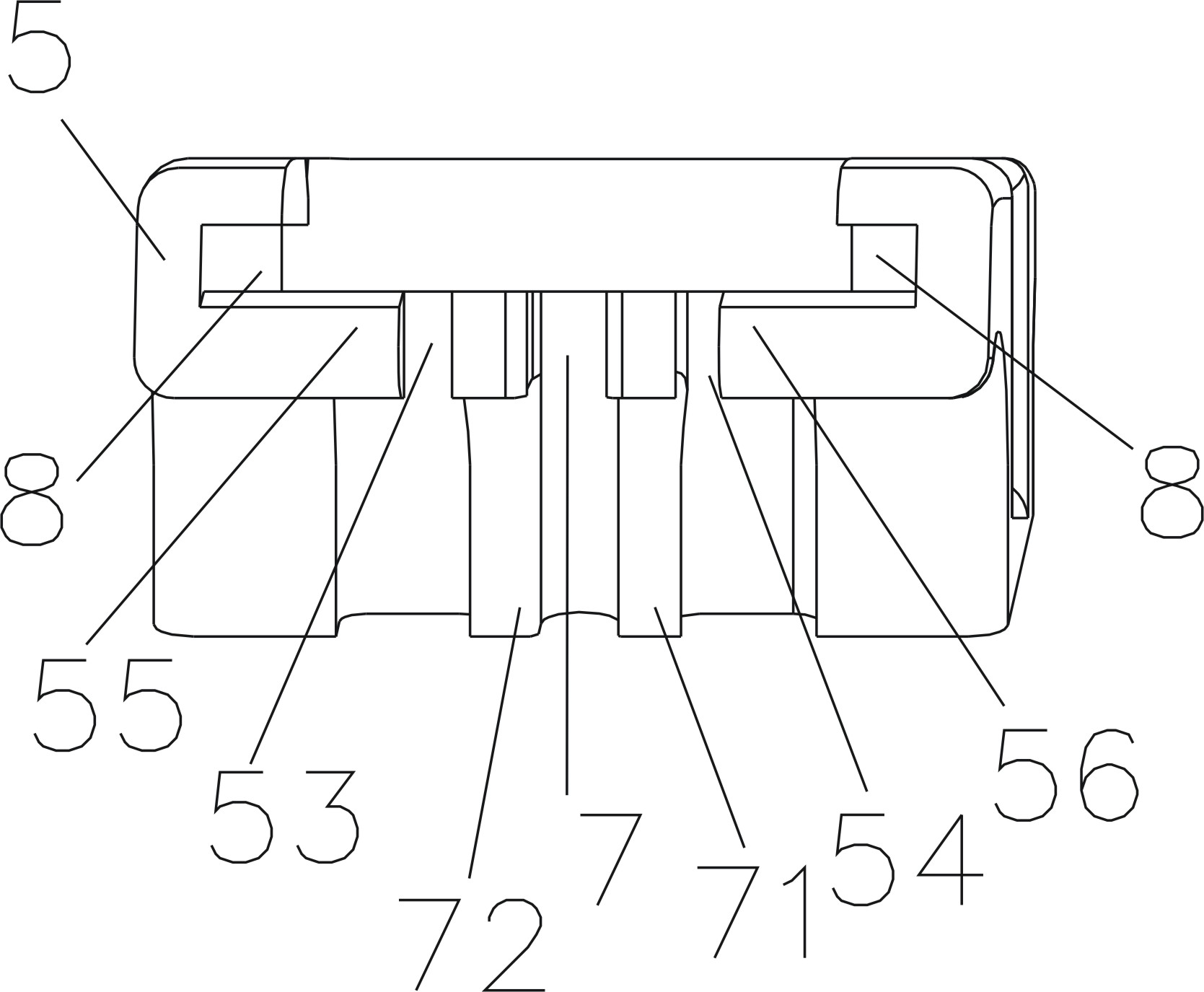

Orthodontics self-locking bracket

ActiveCN102688104ADoes not affect normal movementEasy to operateArch wiresBracketsArch wiresSelf locking

The invention discloses an orthodontics self-locking bracket which comprises a base bottom plate and a bracket body with an arch wire slot, wherein the bracket body comprises two separated working wings which are located on the two sides of the arch wire slot respectively; the working wing on one side is provided with an open slot, and a sliding locking sheet is arranged in the open slot; the sliding locking sheet comprises a sheet body; a round latch and two positioning blocks are arranged on the lower surface of the sheet body; the two positioning blocks are located on the two sides of the round latch respectively; a round locking slot device matched with the round latch and two positioning blocks on the lower surface of the sheet body of the sliding locking sheet is arranged in the open slot; the round locking slot device comprises a round locking slot and two stop slide ways; the round locking slot is matched with the round latch; the two stop slide ways are in one-to-one matching with the two positioning blocks respectively; and the sliding locking sheet is used for covering the arch wire slot. The orthodontics self-locking bracket disclosed by the invention is convenient to operate.

Owner:ZHEJIANG PROTECT MEDICAL EQUIP

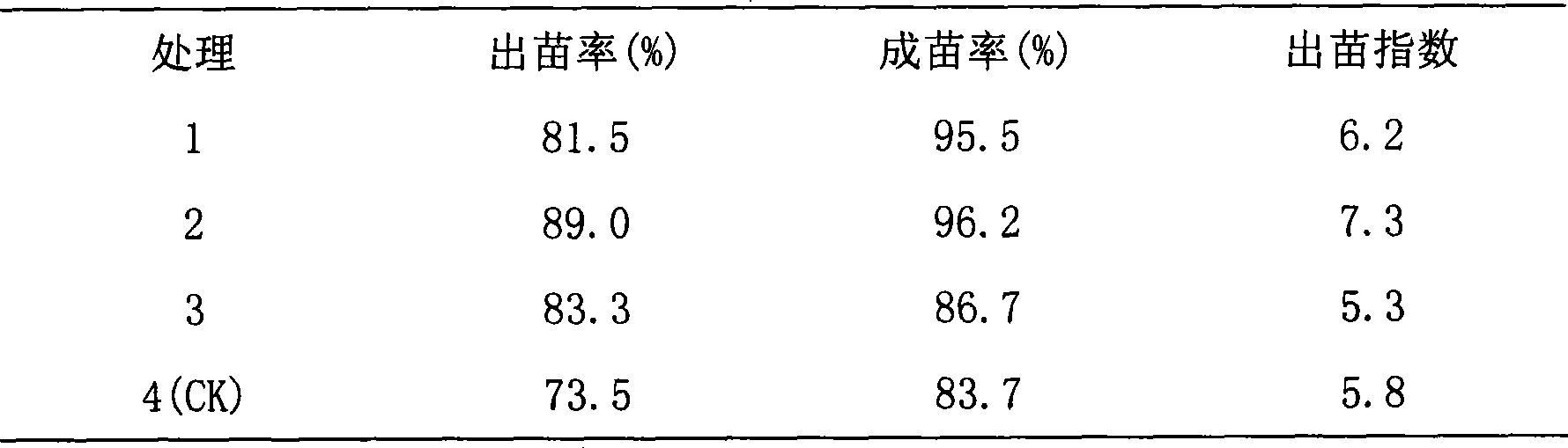

Long-acting slow-release seed coating for preventing and curing corn diseases and insect pests

InactiveCN101919405AHigh suspension rateGood film formingBiocidePlant growth regulatorsDiseaseChlorpyrifos

The invention discloses a long-acting slow-release seed coating for preventing and curing corn diseases and insect pests, comprising an insecticide and bactericide, a growth regulator, a film-forming agent and a suspension agent, which is characterized by comprising the following components based on a weight ratio: 5.0-11.0% of amicarthiazol, 5.0-12.0% of thiram, 6.0-12.0% of chlorpyrifos, 10-20%of humic acid, 6-12% of xanthan gum, 6-15% of bentonite, 1.0-6.0% of antifoaming agent, 6-12% of aposematic colouration and the balance water. The seed coating can be prepared by the following steps:adding the humic acid, the xanthan gum and the bentonite in the water for dissolving, then adding the amicarthiazol, the thiram, the chlorpyrifos, the antifoaming agent and the aposematic colouration, stirring at a high speed, and obtaining the finished product after coarse grinding and fine grinding. The finished product has the characteristics of good film formation, even coating, low toxicity,environment protection and low cost. Under the unique soil and weather conditions in Xinjiang, the field germination rate for corn seeds can be improved by about 10% and the effect for preventing andcuring the diseases and the insect pests reaches above 85%.

Owner:新疆农业科学院核技术生物技术研究所 +1

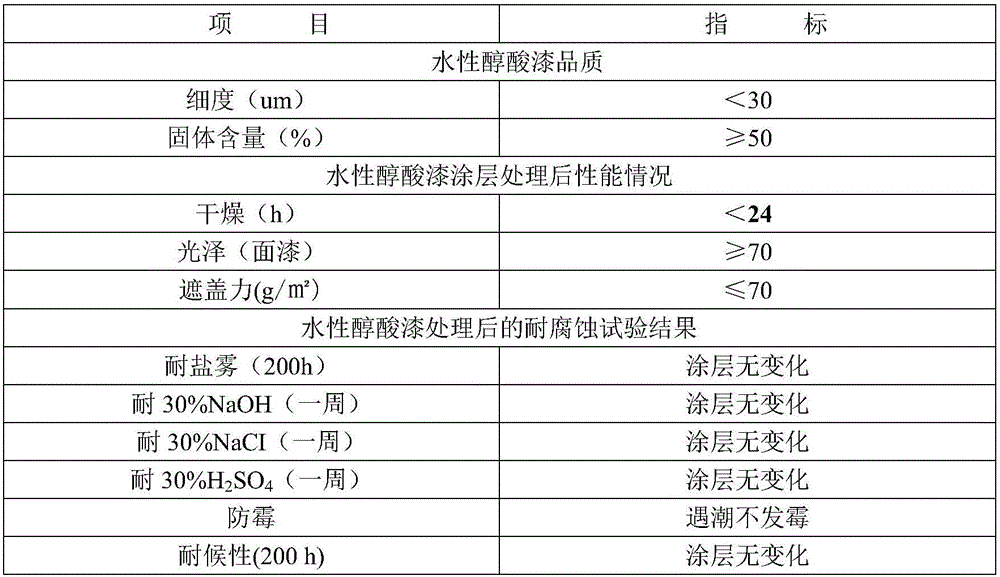

Waterborne alkyd paint and preparation method thereof

InactiveCN106280933AQuality improvementImprove adhesionAnti-corrosive paintsPolyester coatingsLacquerOil paint

The invention relates to the technical field of oil paint and especially relates to a waterborne alkyd paint and a preparation method thereof. The waterborne alkyd resin, titanium dioxide flour, barium sulfate, ferrotitanium flour, waterborne dispersing agent, defoamer, antirust agent, thickener and water are selected and coordinated, so that the acquired waterborne alkyd paint has quality stability, high adhesive force, higher antirust capacity and higher covering capacity; the expulsion rate in the steel structure can be reduced; the anticorrosive period of the steel structure can be prolonged.

Owner:NANFENG HOUSE KEEPING ELECTRIC APPLIANCES ZUNYI

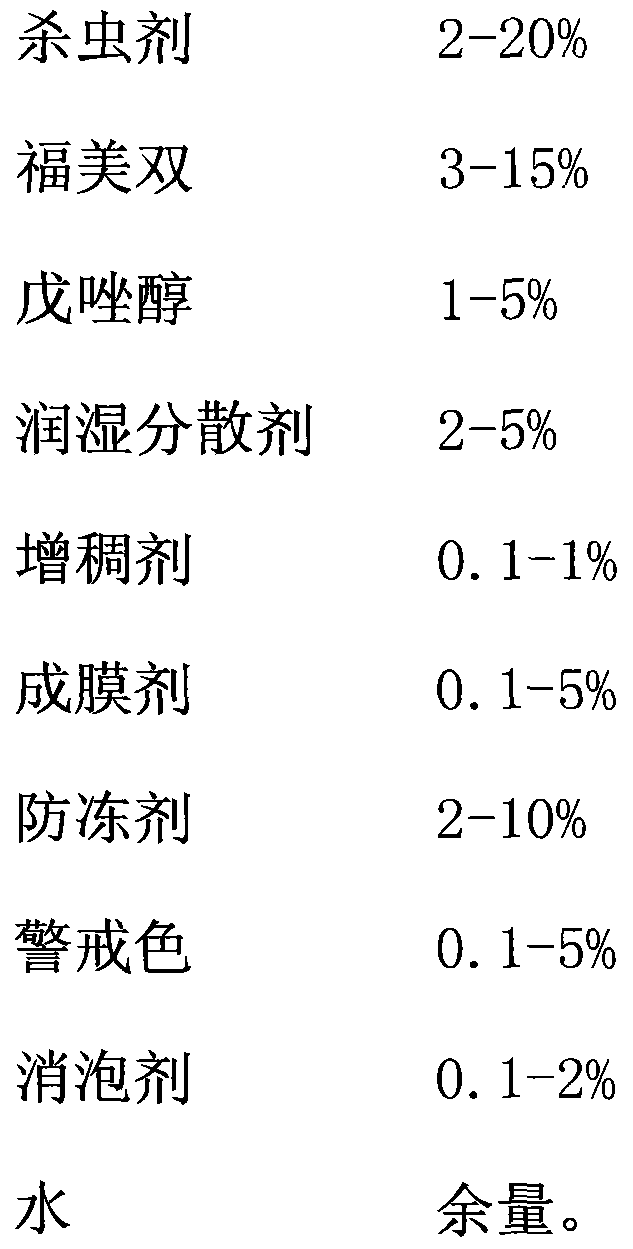

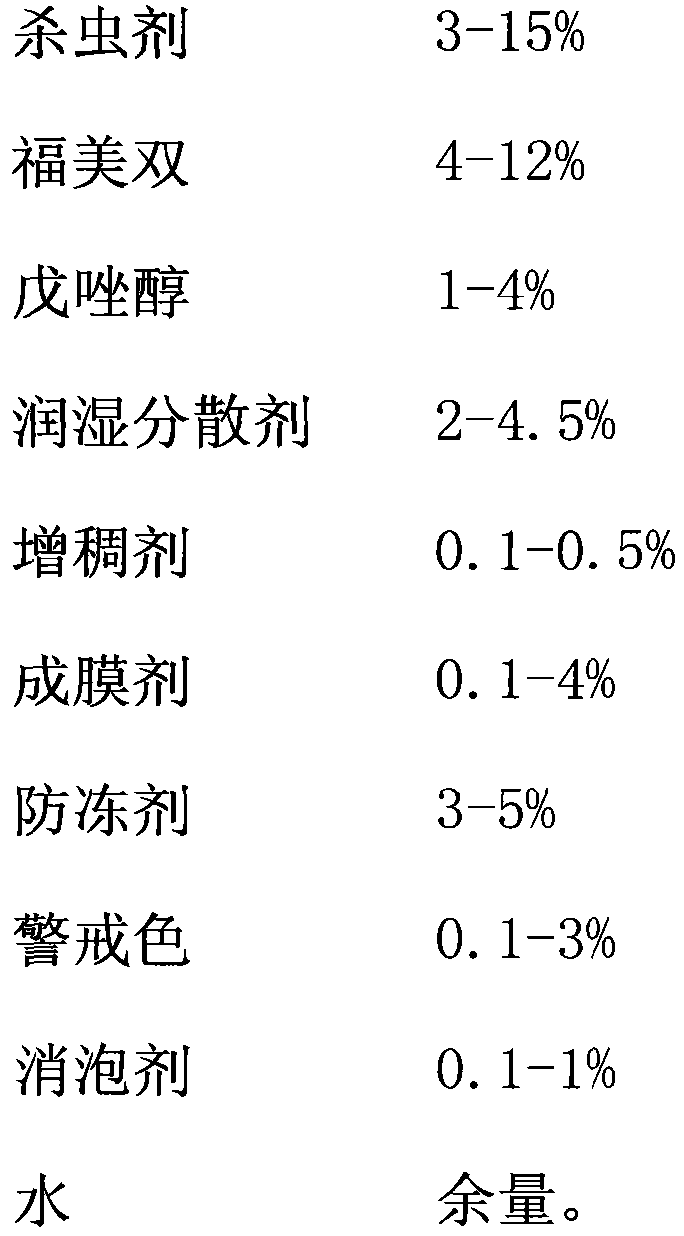

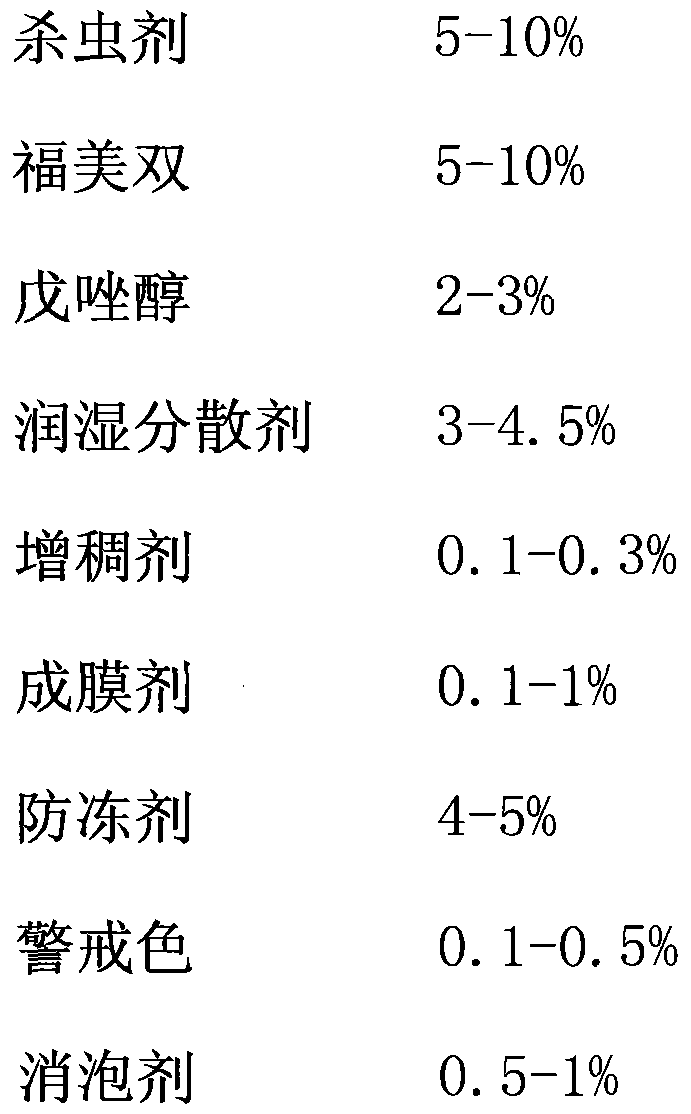

Suspension seed coating agent for controlling insect disease at corn seedling stage

ActiveCN103651466AMeet the needs of different groups of peopleEasy to prepareBiocideFungicidesDiseaseUstilago

The invention relates to the field of pesticide preparations, disclosed a suspension seed coating agent which comprises the active components chlorantraniliprole and thiram and has the effects of killing insects and preventing diseases. The seed coating agent is characterized by being composed of the following compositions in percent by weight: 3.0-20.0% of chlorantraniliprole, 4.0-12.0% of thiram, 1.0-4.0% of tebuconazole, 2.0-4.5% of a wetting dispersant (prepared by compounding pesticide emulsifier 34 and HY-2), 0.1-0.5% of a thickening agent, 0.1-4.0% of a film forming agent, 3.0-5.0% of an antifreezing agent, 0.1-3.0% of an aposematic agent, 0.1-1.0% of an antifoaming agent and the balance water. The seed coating agent provided by the invention has the characteristics of being convenient to prepare, uniform in coating, low in shedding rate, high in efficiency, low in toxicity, relatively safe to environment and the like, and has substantial control effect on corn seedling-stage insect diseases such as sphacelotheca reiliana, ustilago maydis, stem rot, cutworms, athetis lepigone, grub and the like, the control effect on corn seedling-stage insect diseases reaches 90% or more, and the persistent period reaches about 2 months.

Owner:河南浩迪农业科技有限公司

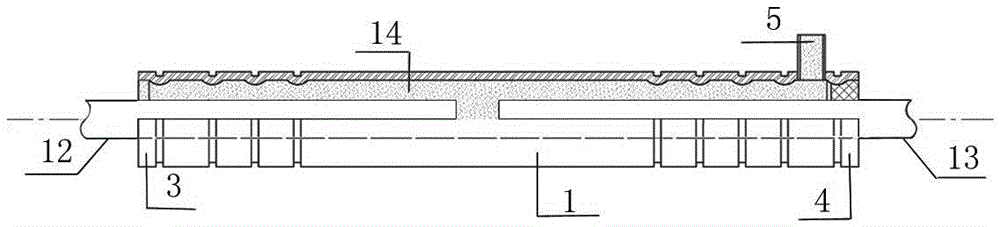

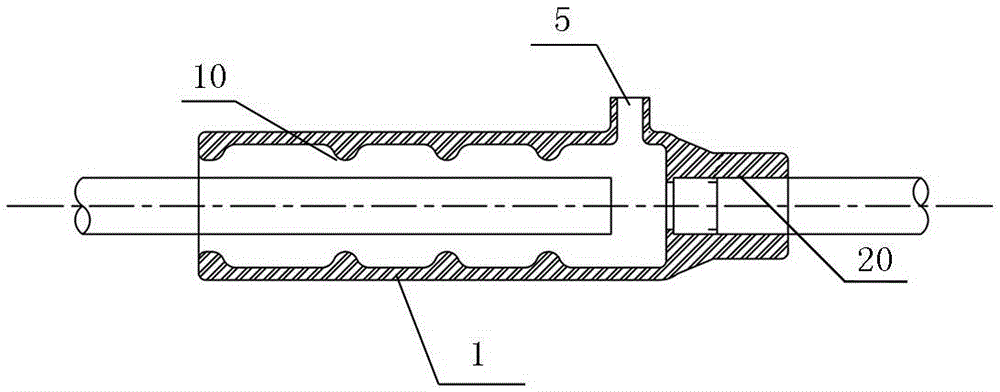

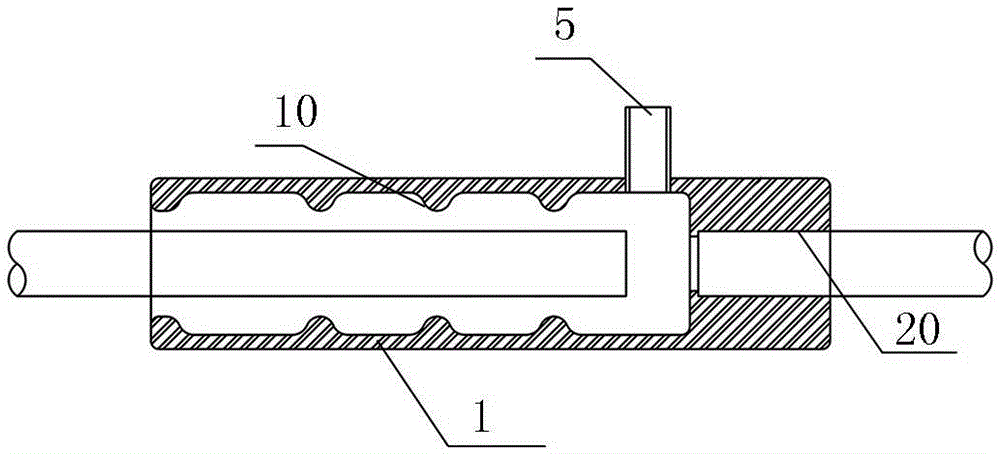

Independent-grouting-opening-free reinforcing steel bar grouting connecting sleeve, system and construction method

ActiveCN105298134AOvercome the problem of easy slurry leakageOvercome leaksBuilding material handlingSteel barGrout

The invention provides an independent-grouting-opening-free reinforcing steel bar grouting connecting sleeve system and a construction method thereof. The system comprises a plurality of independent-grouting-opening-free reinforcing steel bar grouting connecting sleeves and a reinforcing steel bar grouting connecting sleeve with a grouting opening and grout outlets, or comprises a plurality of independent-grouting-opening-free reinforcing steel bar grouting connecting sleeves and a grouting pipe. The system is characterized in that only the grout outlets A are formed in the side walls of sleeve bodies. Compared with frequently-used reinforcing steel bar grouting connecting sleeves, grouting openings special for the side walls are omitted, and therefore machining cost of the sleeves is reduced, and the potential quality hazard that grout is prone to leaking from the grouting pipe and the grouting openings in the construction process is avoided. In addition, by means of the independent grouting openings, fewer grouting pipes and grout outlet pipes are distributed, the technological requirements for constructors are lowered, and construction efficiency and construction quality are effectively improved.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

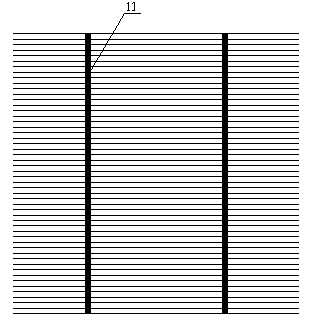

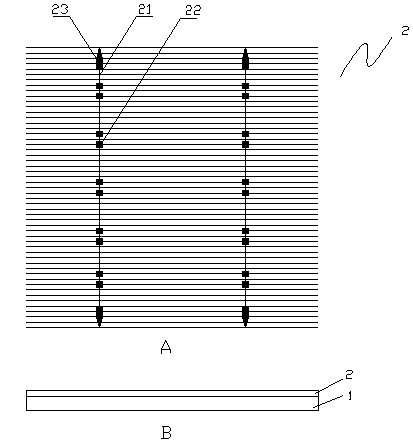

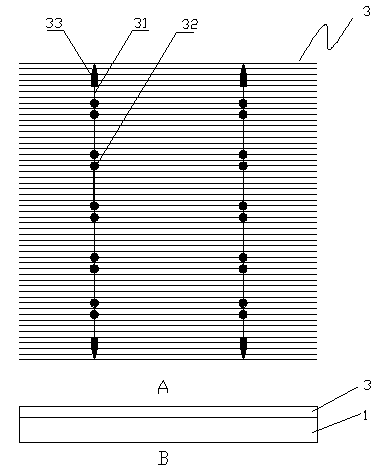

Solar cell and corresponding electrode screen printing plate

InactiveCN103178129AObvious negative effectIncrease the effective lighting areaScreen printersSemiconductor devicesPhysicsEngineering

The invention provides a solar cell. The solar cell comprises a cell substrate and an electrode printed on the substrate, wherein the electrode comprises a plurality of main grid lines; each main grid line is provided with a plurality of nodes used for testing; and the diameter of each main grid line is 0.1-1 mm. The solar cell provided by the invention can enlarge effective illumination area of the solar cell, reduce dropping probability of the main grid lines of the solar cell and reduce large-scale production cost.

Owner:KUN SHAN POWER STENCIL

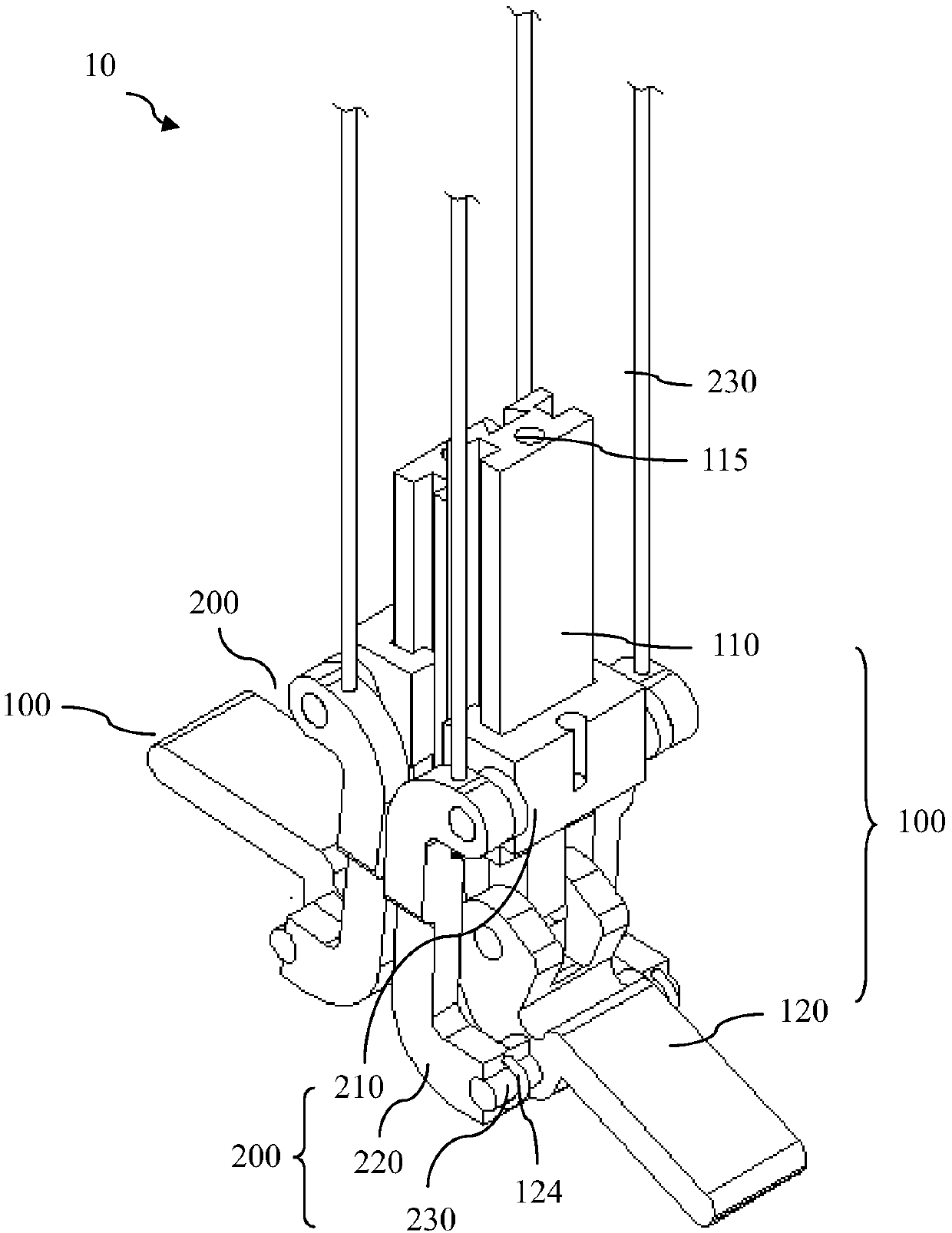

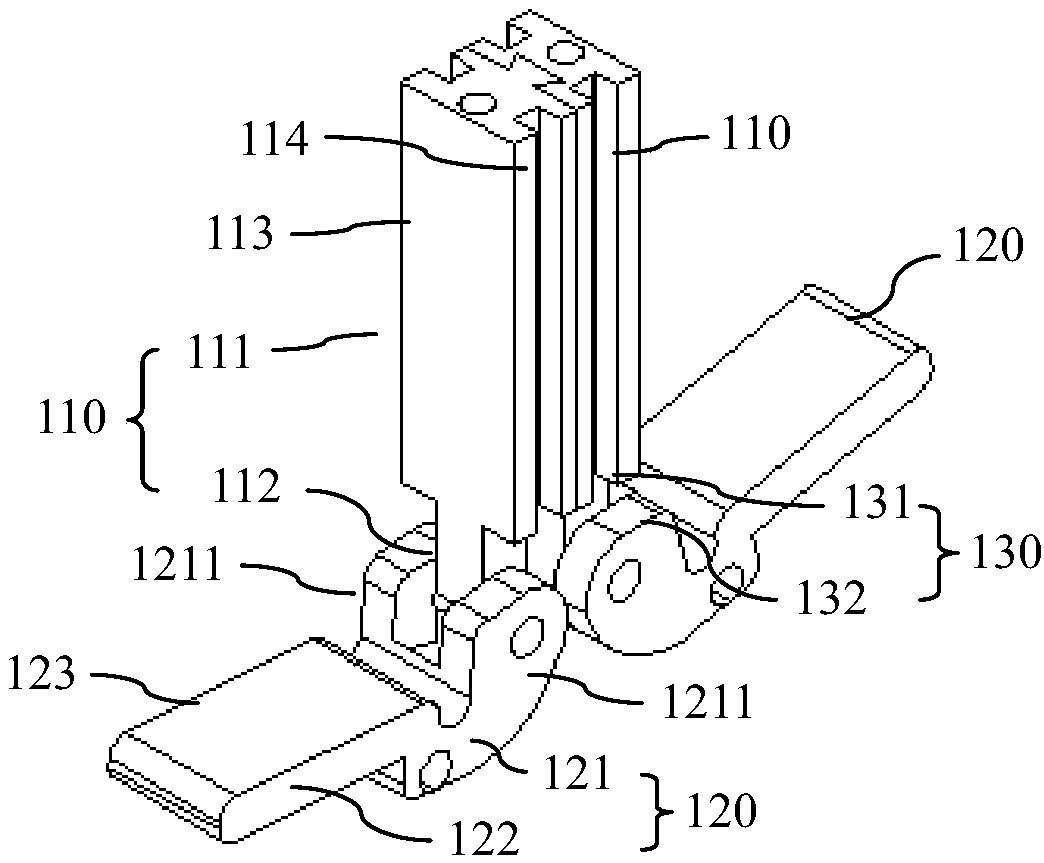

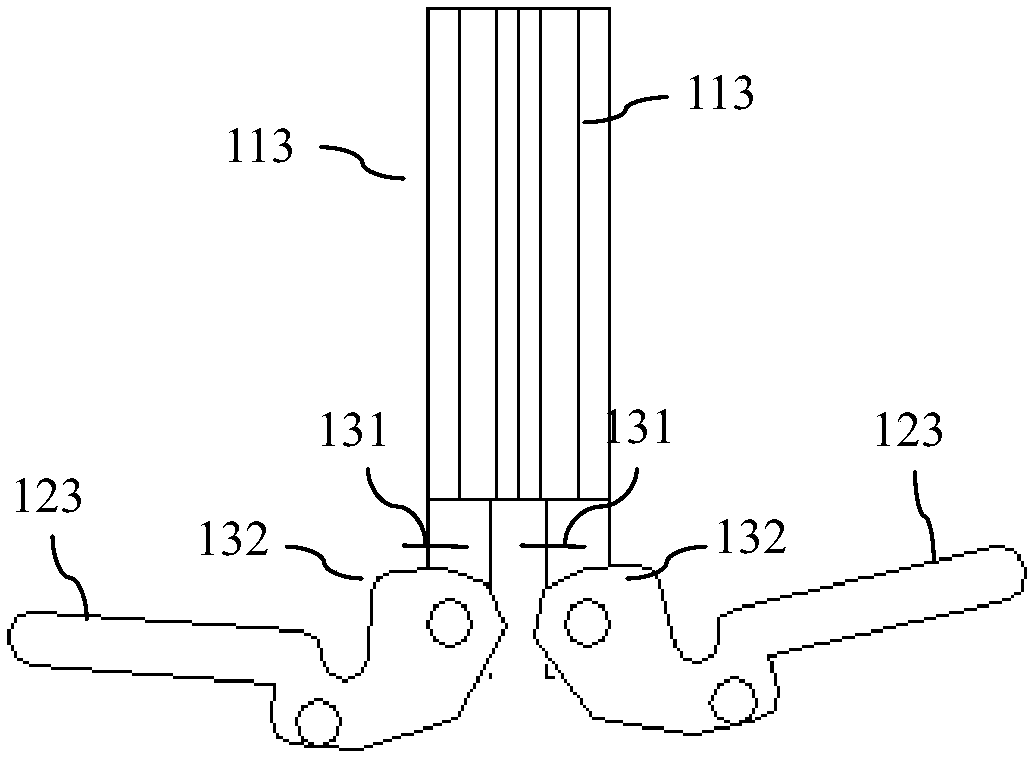

Clamping device and system for fixing tissues

The invention discloses a clamping device and a system for fixing tissues. The clamping device comprises at least one clamping unit; the clamping unit includes a clamping mechanism for capturing the tissues; the clamping mechanism comprises a first clamping part and a second clamping part rotationally connected to the first clamping part; the clamping unit further includes a pull rod mechanism detachably connected on the clamping mechanism, one end of the pull rod mechanism is slidably connected on the first clamping part, the other end of the pull rod mechanism is rotationally connected to the second clamping part, and the proximal end, facing to the first clamping part, of the pull rod mechanism drives the second clamping part to rotate relative to the first clamping part to make the clamping mechanism closed during movement, and the pull rod mechanism is divorced from the clamping mechanism after the clamping mechanism is closed. The beneficial effects comprise that the pull rod mechanism is divorced from the clamping mechanism after the clamping mechanism is closed, so the overall weight of the clamping device is reduced and the burden of the valves is reduced.

Owner:LIFETECH SCIENTIFIC (SHENZHEN) CO LTD

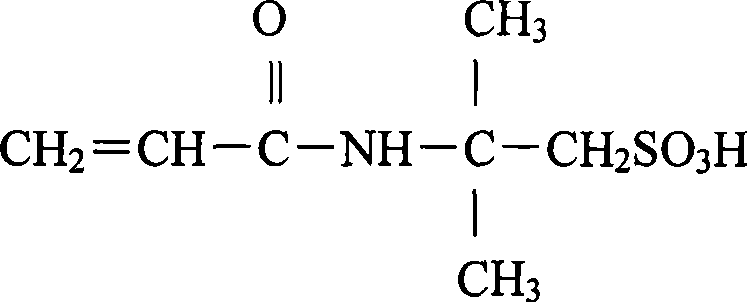

A film-builder used for seed-coating agent

InactiveCN101444206AEasy to filmFunction increaseBiocideAnimal repellantsMethacrylateBiocompatibility Testing

The present invention discloses a film-builder used for seed-coating agent, which is a copolymer produced by initiation and co-polymerization of AMPS monomer and at least one vinyl monomer. In the co-polymer, mole percentage of AMPS monomer is from 0.5% to 30%, and the balance is vinyl monomer, wherein the vinyl monomer is chosen from acrylic ester or metacrylic acid ester or vinyl acetate or phenyl ethylene or acrylic amide. The film-builder has good film building and sustained-release function, high film building strength, water adsorb and resistance, and chemical stability, and favorable biocompatibility with agronomic crop. The shedding rate of seed lagging cover after drying low, film after absorbing water and expansion ventilated and not dissolvable, active ingredient can be released slowly, and favorable growing microenvironment for plant especially crops can be produced.

Owner:安徽省农业科学院原子能农业应用研究所 +1

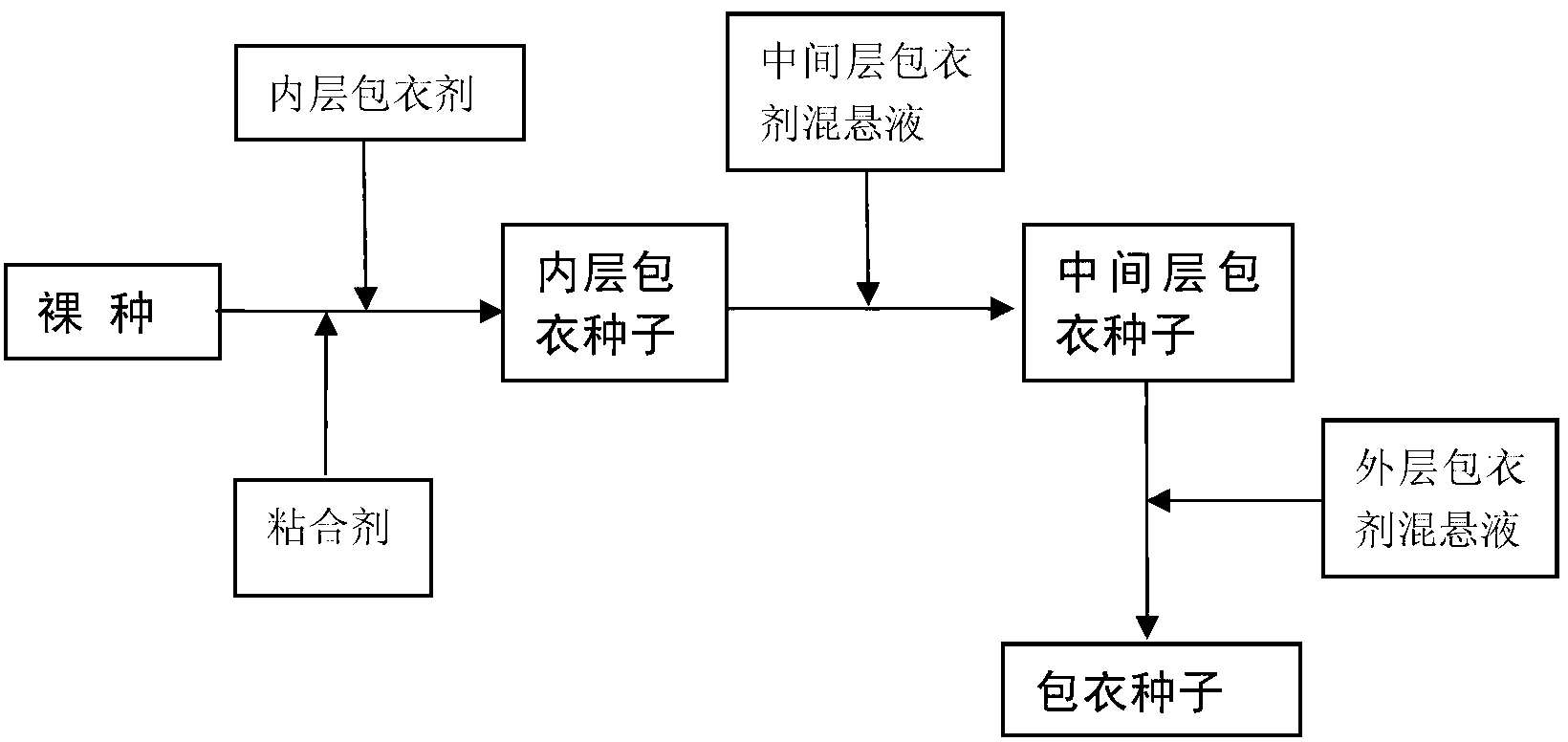

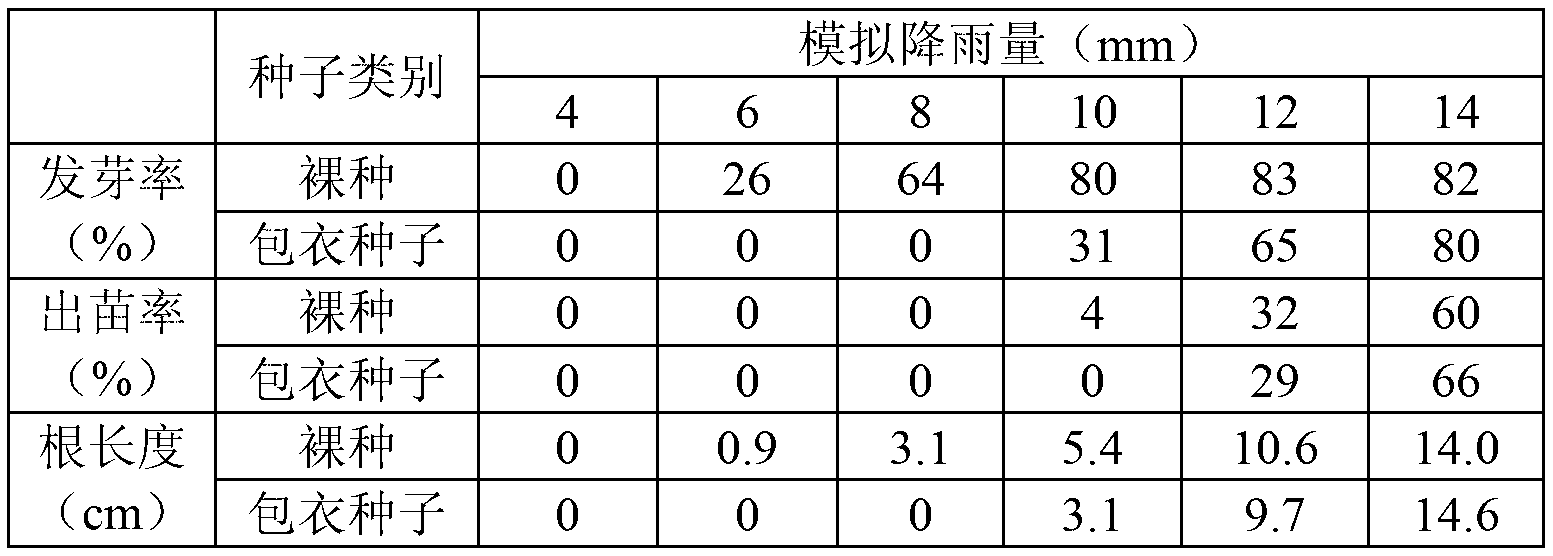

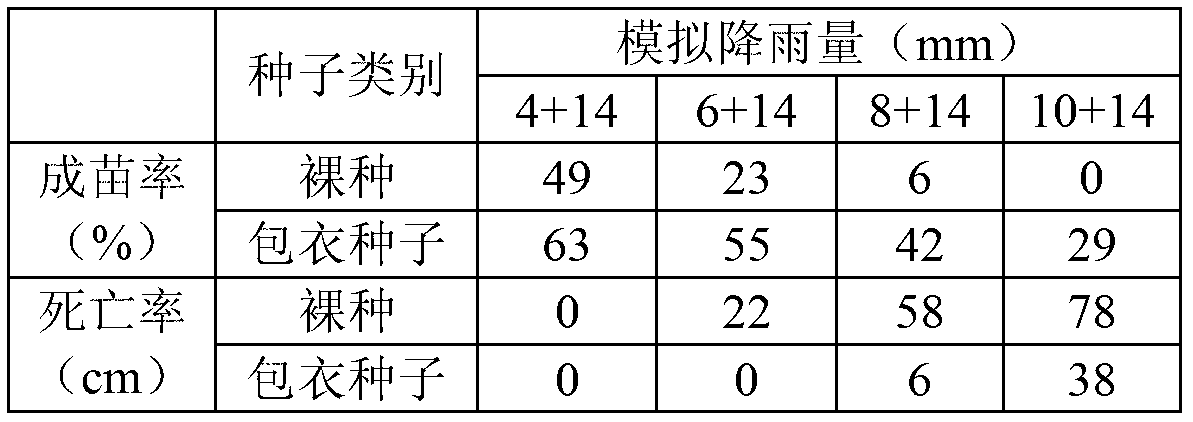

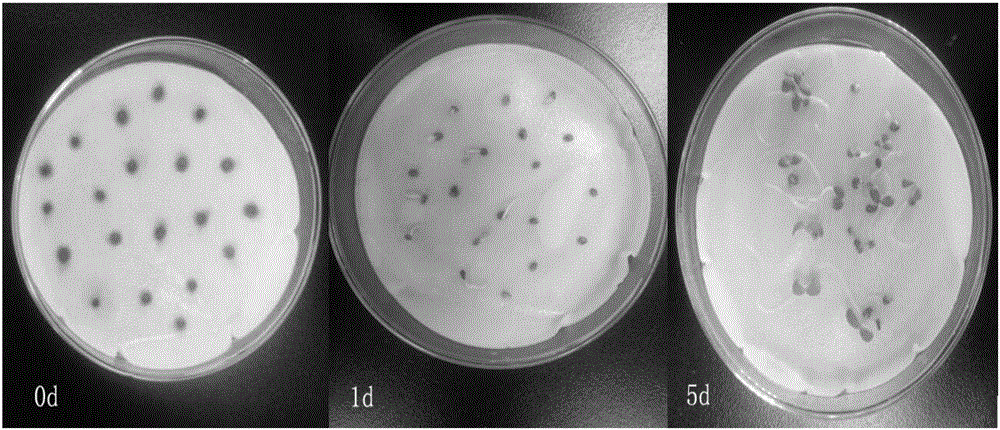

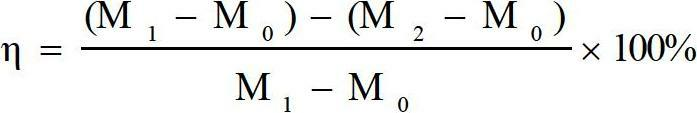

Seed germination control coating material, coated seed and preparation method thereof

ActiveCN103299744ANot easy to stickHigh single seed rateSeed coating/dressingSolubilityControl layer

The invention relates to a seed germination control drought-resistant coating material, a coated seed and a preparation method thereof. The coating material mainly comprises an inner layer of the coating material (a water-retaining layer), an intermediate layer of the coating material (a buffer layer) and an outer layer of coating (water control layer). The water-retaining layer contains a water-retaining agent and can play functions of water storing and water retaining; on the one hand, the buffer layer can smoothen and round the surface of the water-retaining layer so as to wrap the water control layer, and on the other hand, the buffer layer can absorb a small amount of water which permeates the water control layer due to the water solubility; the water control layer cannot dissolve in water but can swell to control the pore sizes of water passing pore passages so as to control the water feeding. When the rainfall is small and cannot enable seeds to germinate into seedlings, a micro amount of water permeates the water control layer, then is absorbed by the buffer layer and the water-retaining layer but does not enter the seeds; when the rainfall is abundant, a large amount of water permeates the water control layer, at the moment, the buffer layer is completely corroded, the water-retaining agent absorbs water to rapidly expand so as to break the water control layer, so that the seeds start to absorb water to germinate and successfully grow into the seedlings under the action of the water-retaining agent.

Owner:BEIJING FORESTRY UNIVERSITY

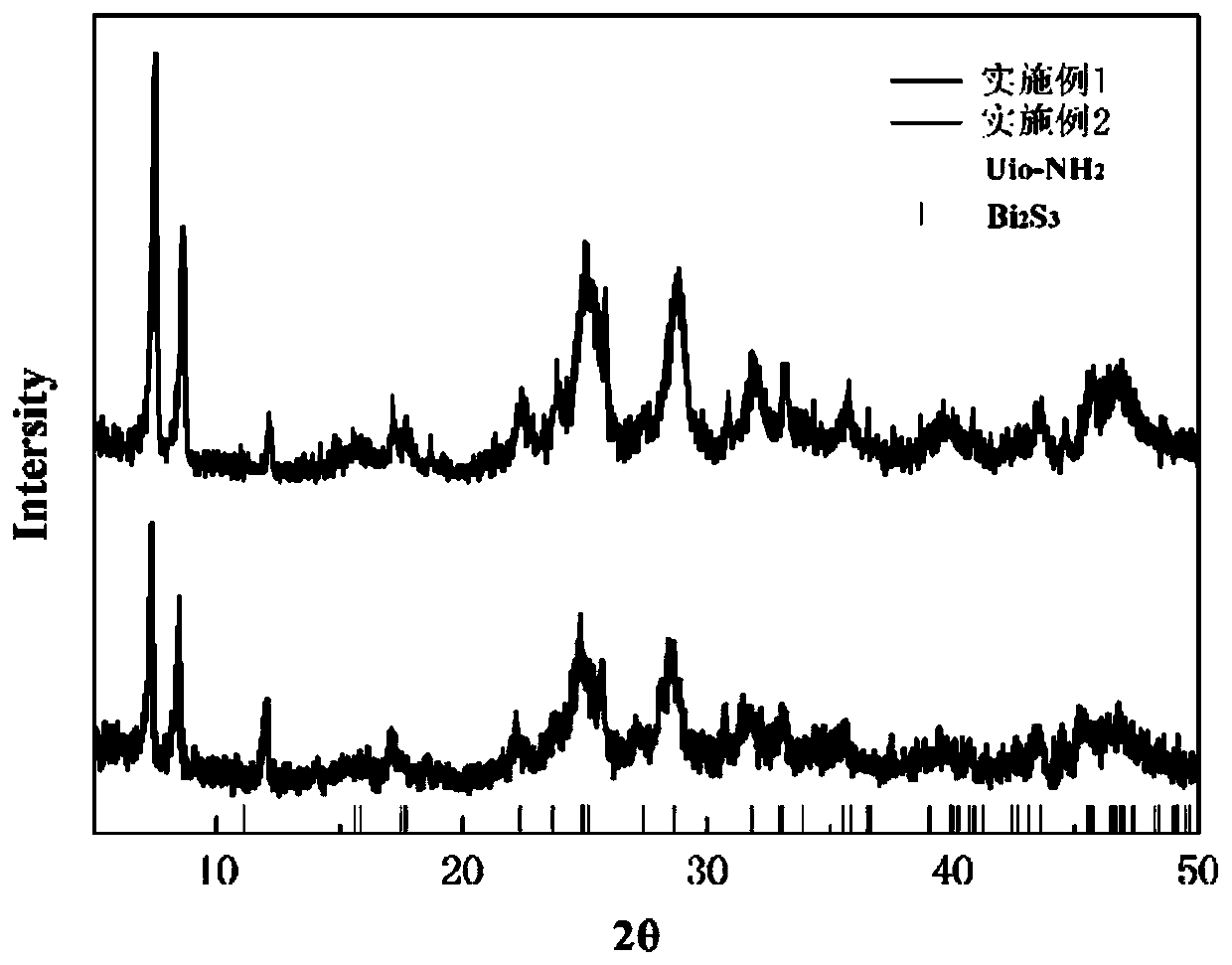

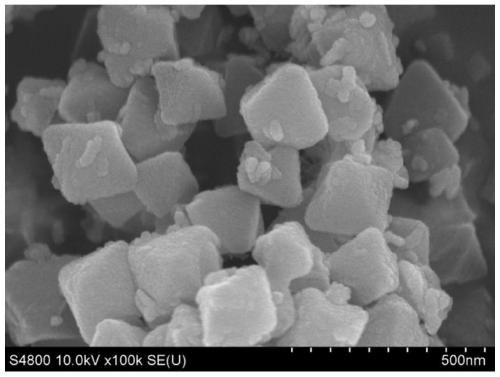

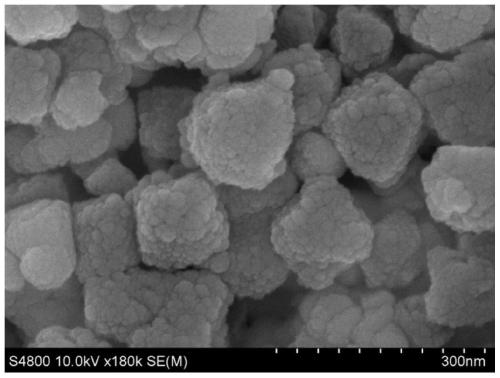

Bismuth sulfide based composite visible-light-induced photocatalyst and preparation method thereof

InactiveCN111359666AImprove interface tightnessIncrease profitWater/sewage treatment by irradiationWater treatment compoundsBismuth sulfideOrganic dye

The invention discloses a preparation method of a Bi2S3@UiO-66-NH2-SH based visible-light-induced photocatalyst with a core-shell structure and a preparation method thereof. The ratio of Bi: Zr of Bi2S3 and UiO-66-NH2 is 1-4:2. The preparation method comprises the following steps: preparing UiO-NH2 with a regular octahedron morphology by adopting a solvothermal method, and then modifying UiO-NH2 by mercapto-acetic acid to uniformly load bismuth sulfide nano particles on the surface of UiO-NH2, thereby obtaining the composite visible-light-induced photocatalyst taking UiO-NH2 as a core and Bi2S3 as a shell. The preparation method of the composite visible-light-induced photocatalyst is simple; the composite visible-light-induced photocatalyst has high visible-light response and better photocatalytic effect than that of pure bismuth sulfide, methyl orange can be degraded by 95% within 90 min under visible-light irradiation, and the composite visible-light-induced photocatalyst is expectedto be applied to the fields of photocatalytic degradation of organic dyes, antibiotics and the like on a large scale.

Owner:SHANGHAI INST OF TECH

Multifunctional medicinal plant seed coating agent and preparation and coating methods thereof

InactiveCN106689183ALong duration of actionImprove stress resistanceBiocidePlant growth regulatorsBULK ACTIVE INGREDIENTActive ingredient

The invention belongs to the technical field of pesticides and in particular to relates to a multifunctional medicinal plant seed coating agent and preparation and coating methods thereof. The multifunctional medicinal plant seed coating agent comprises active ingredients, auxiliary agents and water. The multifunctional medicinal plant seed coating agent comprises the following raw materials in percentage by mass: the active ingredients: 6-18% of a bactericide, 5-15% of an insecticide, 3-6% of a balancing fertilizer and 0.03-0.04% of a growth regulator; 11-19% of the auxiliary agents; and the balance of water, totaling 100%. According to the technical scheme, the invention also provides the preparation method of the coating agent. The method is simple and feasible and easy to be industrially popularized.

Owner:SHAANXI UNIV OF CHINESE MEDICINE

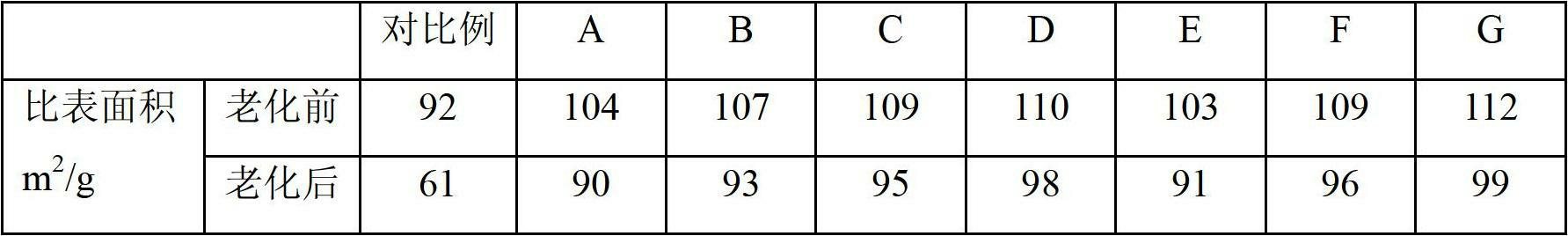

High temperature-resisting active coating and preparation method thereof

ActiveCN102671716AGood heat stabilitySimple methodCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsAluminium oxideSlurry

The invention relates to a high temperature-resisting active coating for a three-way catalyst for purifying automobile exhaust. The high temperature-resisting active coating comprises the following components by weight percent: 20-80wt% of aluminum oxide, 5-50wt% of oxygen storage material, 0.5-5wt% of silica sol, 1-20wt% of metal nitrate, 0.1-5wt% of dispersant, and the balance of water, wherein the aluminum oxide is a mixture of pseudoboehmite and gamma-Al2O3; and the average particle size of the silica sol is 10-20nm. The preparation method comprises the steps of uniformly mixing materials; adding nitric acid to regulate the pH value to be 3.5-4.0 to obtain an active coating slurry; coating the slurry on a honeycomb ceramic carrier; blowing out excess slurry in the hole channel by using the compressed air; and finally, drying and roasting the product to obtain the high temperature-resisting active coating. The active coating has excellent heat-resisting stability, low expulsion rate and good coating effect. The preparation method is simple, is easy to operate and is suitable for commercial production.

Owner:JIANGSU GAOCHUN CERAMICS +1

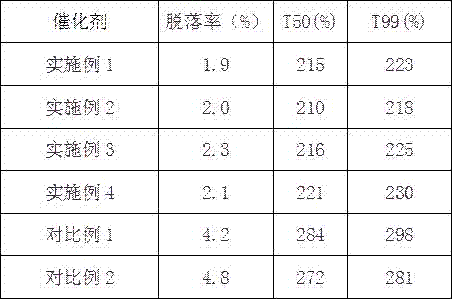

VOCs (Volatile Organic Chemicals) catalyst taking foam titanium as carrier and preparation method thereof

ActiveCN107983365AReduce the chance of sheddingEvenly distributedGas treatmentHeterogenous catalyst chemical elementsActive componentCatalytic oxidation

The invention provides a VOCs (Volatile Organic Chemicals) catalyst taking foam titanium as a carrier and a preparation method thereof. The preparation method comprises the following steps: pretreating the foam titanium serving as a substrate to generate a titanium dioxide precursor on the surface and in the pore canal of the foam titanium; then, calcining the titanium dioxide precursor at a hightemperature to obtain foam titanium-titanium dioxide; loading active components, namely, copper oxide and manganese oxide, as well as co-catalysts, namely, neodymium oxide and cobalt oxide through a self-propagating calcining method by taking the foam titanium-titanium dioxide as a carrier to obtain a catalyst to be applied to catalytic oxidation of VOCs. The preparation method has the advantagesof lowering the production cost, increasing the contact area with reactants, increasing the catalytic activity, overcoming the defects of the conventional particle or integral VOCs oxidization catalyst, and facilitating industrial popularization, simple preparation process, adoption of readily-available raw materials, uniform distribution of active components, and low expulsion rate.

Owner:JIANGSU LONGKING COALOGIX CATALYST REGENERATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com