Solar cell and corresponding electrode screen printing plate

A technology for solar cells and cells, applied in printing, printing presses, rotary printers, etc., can solve the problems of increasing the bending degree of cells, falling off of battery electrode busbars, reducing effective light area, etc., so as to reduce production costs. , The effect of reducing the probability of falling off and increasing the effective light area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

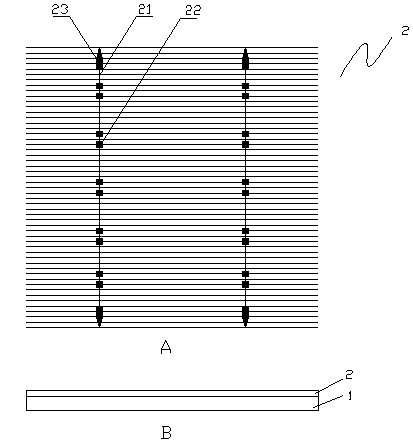

[0023] like figure 2 As shown, a kind of solar cell according to the present invention includes a cell substrate 1 (such as figure 2 B) and the electrode 2 printed on the substrate, the electrode 2 includes two main grid lines 21, the main grid lines 21 are linear, and the wire diameter is about 0.4 mm. There are 12 square nodes 22 and triangular nodes 23 for testing on each busbar 21, wherein there are 10 square nodes 22 on the busbar 21, and the side length of the square nodes is about 1.5mm. There are two triangular nodes 23 on the ends of the busbar 21, and the length of the base of the triangular nodes 23 is about 1.5 mm. The centerline of the busbar 21 bisects the node 22 and the node 23 equally.

[0024] According to another aspect of the present invention, the present invention also provides a screen for printing the above-mentioned solar cell electrode, the screen can be made of any material combined with any process, and the screen is provided with a The busbar ...

Embodiment 2

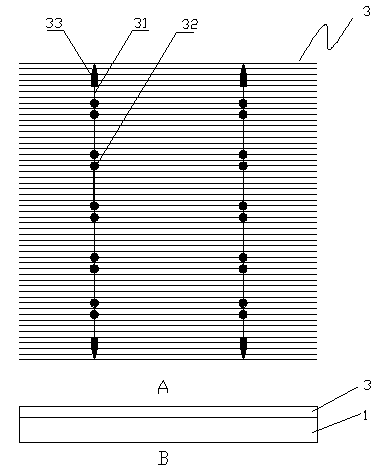

[0026] like image 3 As shown, a kind of solar cell according to the present invention includes a cell substrate 1 (such as image 3 B) and the electrode 3 printed on the substrate, the electrode includes two main grid lines 31, the main grid lines are linear, and the wire diameter is about 0.4 mm. The busbar 31 has 12 nodes for testing, wherein, there are 10 circular nodes 32 on the busbar 31, and the diameter of the circular node is about 1.5mm, and there are 2 nodes on the busbar 31 terminal. A triangular node 33, the length of the base side is about 1.5mm. The center line of the busbar 31 bisects the node 32 and the node 33 equally.

[0027] According to another aspect of the present invention, the present invention also provides a screen for printing the electrodes of the above-mentioned solar cells, which can be made of any material combined with any process, and the screen is provided with a main screen for forming the electrodes. Patterns of gridlines and nodes. Pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com