Lead-free busbar paste for front electrode of silicon solar cell and preparation method thereof

A silicon solar cell, front electrode technology, applied in conductive materials, circuits, photovoltaic power generation, etc. dispersed in non-conductive inorganic materials, can solve the problem of waste material use and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Another object of the present invention is to provide a method for preparing a lead-free busbar paste for front electrodes of silicon solar cells, including:

[0030] According to the component distribution ratio described in claim 1, put the weighed glass powder and organic carrier into the ball milling equipment, add zirconium balls according to the ratio of material: zirconium balls = 1:1, and carry out mixing and ball milling for 15-24 hours After the fineness is ≤7 μm, the material is filtered and discharged, and then mixed with spherical silver powder and flake silver powder and rolled by a three-roll mill to a fineness of ≤7 μm to obtain a lead-free busbar paste for the front electrode of a silicon solar cell.

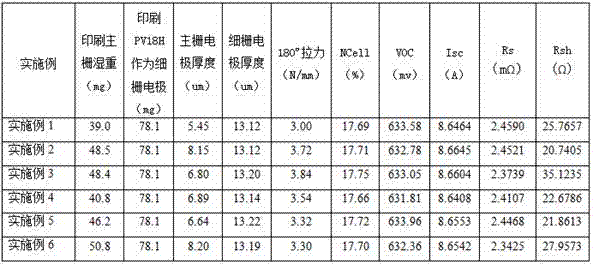

[0031]Another object of the present invention is to provide the application of the lead-free busbar paste for the front electrode of the silicon solar cell to the front electrode of the silicon solar cell. The lead-free busbar paste for the front electrod...

Embodiment approach 1

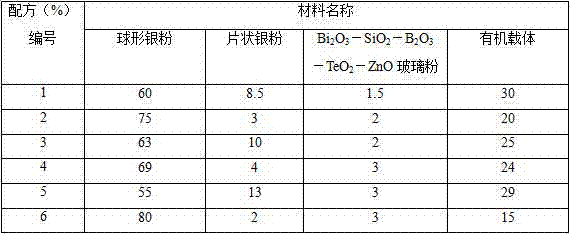

[0033] Embodiment 1, a lead-free busbar paste for the front electrode of a silicon solar cell, the lead-free busbar paste includes the following components in weight percentage: spherical silver powder 55-75wt%, flake silver powder 2.5-10wt%, glass powder 1-3wt% and organic vehicle 15-40wt%, the particle diameter of the spherical silver powder is 0.5-2.5µm, the tap density is 3.0-4.0 g / ml, the particle diameter of the flake silver powder is 2.5-5µm, The tap density is 2.0-3.5 g / ml, and the glass powder is Bi 2 o 3 - SiO 2 -B 2 o 3 -TeO 2 - ZnO glass system.

Embodiment approach 2

[0034] Embodiment 2 is the same as Embodiment 1, except that the particle diameter of the glass powder is 0.1-3 µm, and the specific surface area is 3.5-5.5 m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com