Patents

Literature

1456results about How to "Absorb more" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

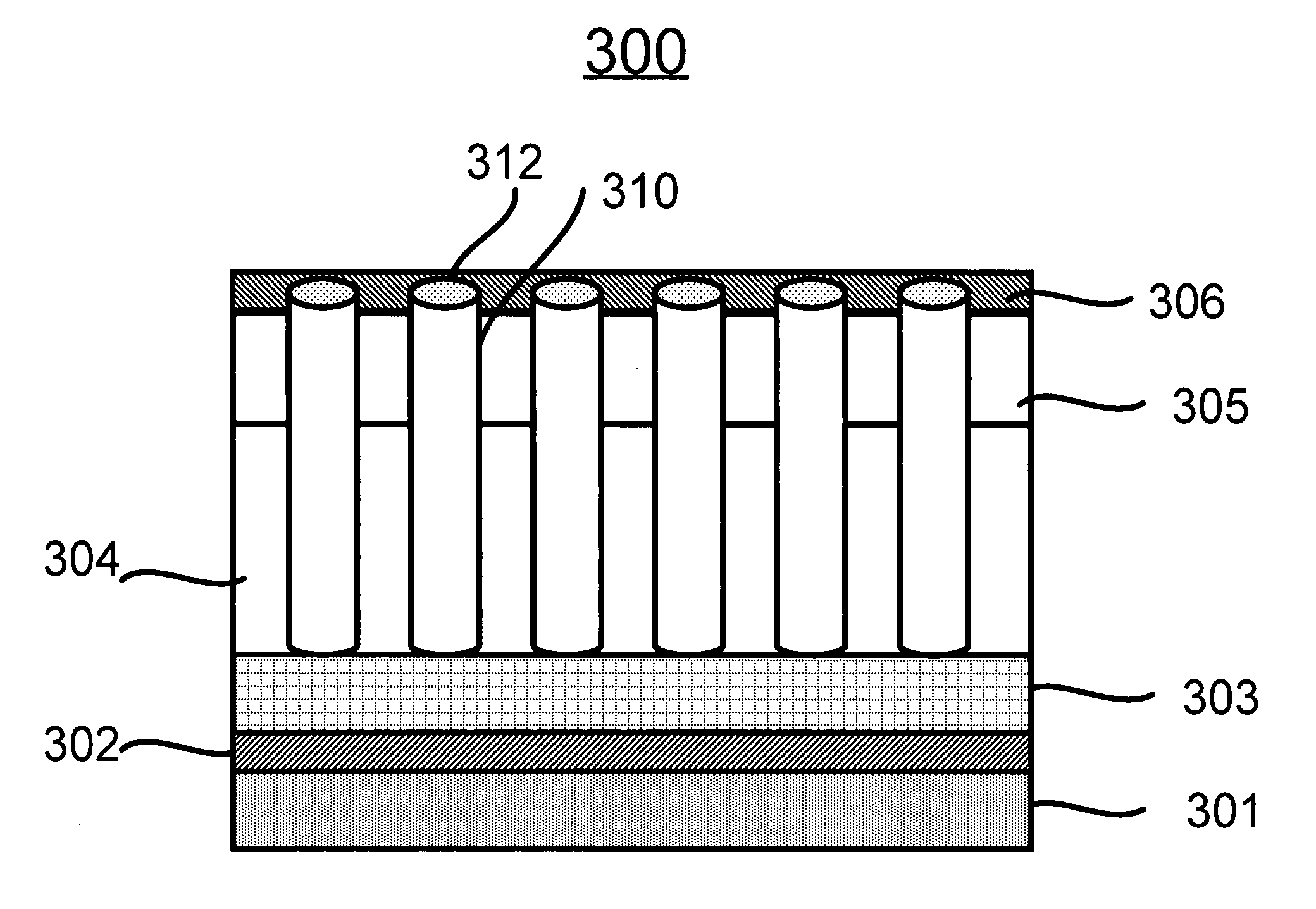

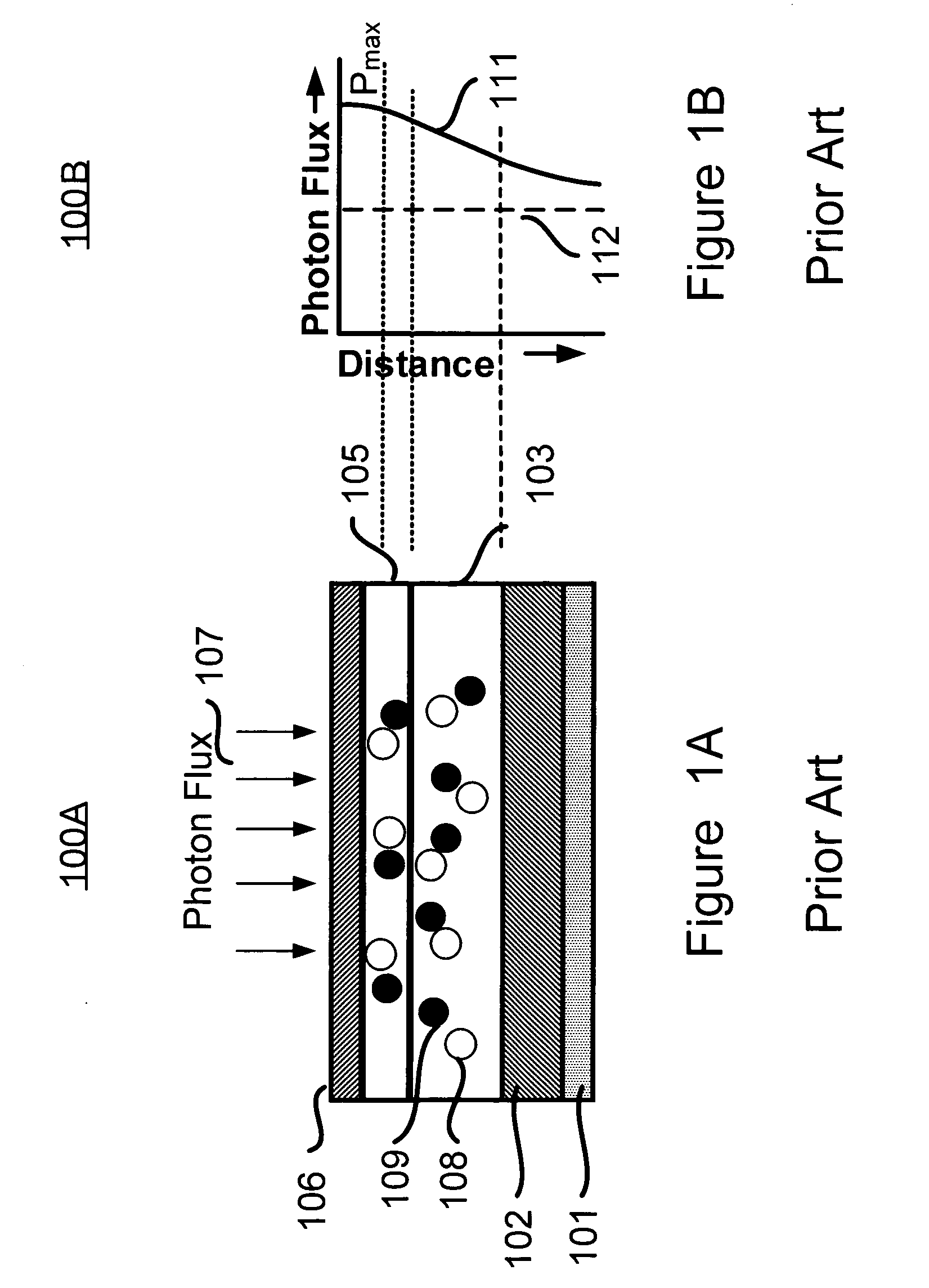

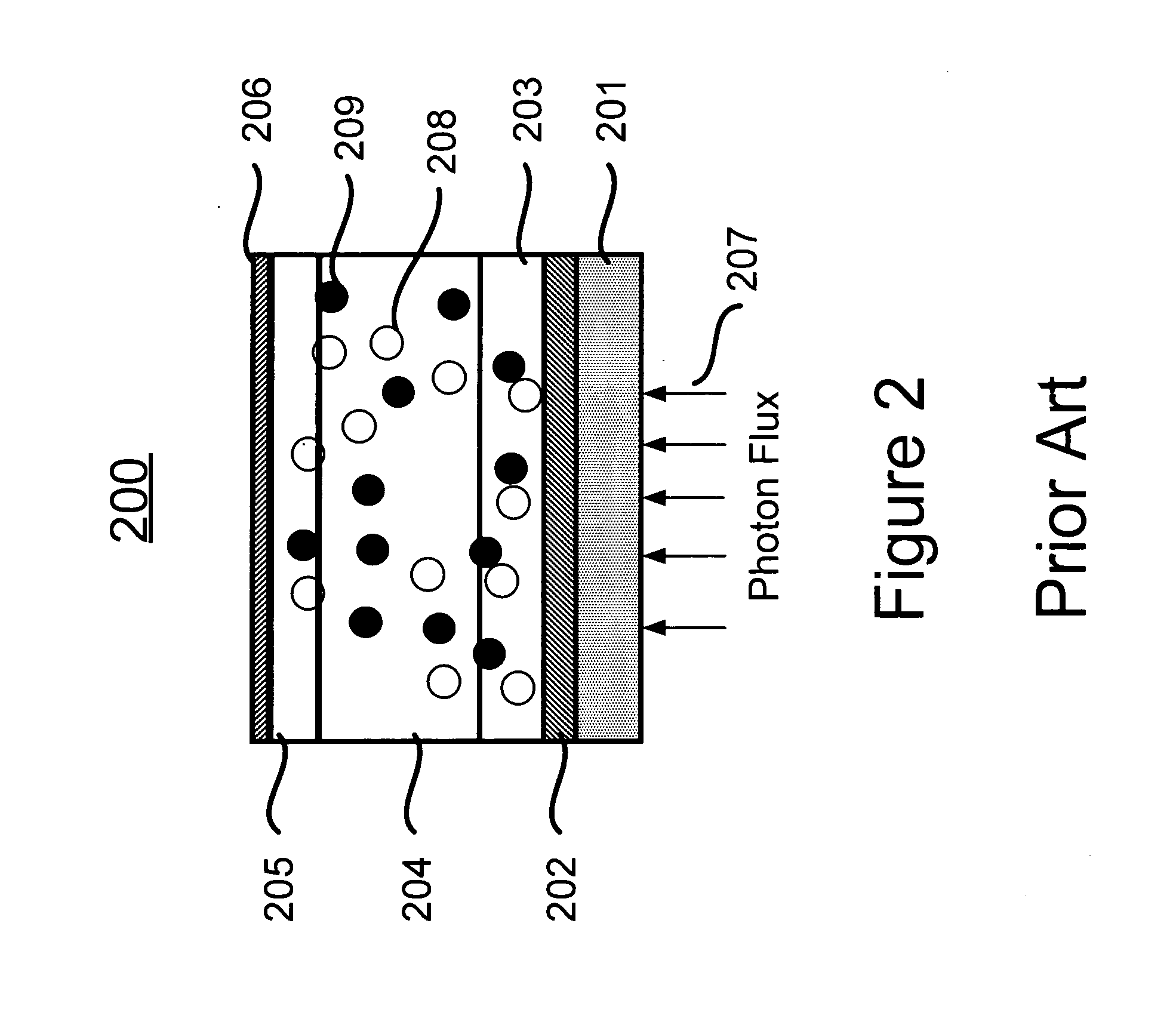

Hybrid photovoltaic device

ActiveUS20090165844A1Easy to collectAbsorb moreNanotechPhotovoltaic energy generationEngineeringNanostructure

A hybrid photovoltaic device comprising a plurality of nanostructures embedded in a matrix of a photosensitive material including one or more layers. A combination of innovative structural aspects of the hybrid photovoltaic device results in significant improvements in collection of incident light from the solar spectrum, better absorption of light, and better collection of the photo-carriers generated in response to the incident light, thereby improving efficiency of the hybrid photovoltaic device.

Owner:BANPIL PHOTONICS

Fruit and vegetable soybean milk drink and preparation method thereof

InactiveCN104997103AGreat tasteRetain nutritional valueFood ingredient functionsOligosaccharide food ingredientsBiotechnologyNutritive values

The present invention discloses a fruit and vegetable soybean milk drink which is prepared from the following raw materials in parts by weight: fruit juice 10-15 parts, vegetable juice 5-10 parts, Chinese red date soybean milk 3-5 parts, white granulated sugar 3-5 parts, high glucose syrup 2-3 parts, xylo-oligosaccharide 1-2 parts, malic acid 2-5 parts, citric acid 0.1-0.2 part, stabilizer 0.1-0.15 part and pure water 77.15-87.3 parts. The preparation method of the fruit and vegetable soybean milk drink comprises the following steps: (1) preparing the fruit juice; (2) preparing the vegetable juice; (3) preparing the Chinese red date soybean milk; (4) blending; (5) homogenizing and degassing; and (6) sterilizing and bottling. The prepared fruit and vegetable soybean milk drink increases the taste, improves the mouthfeel, maintains the nutritional values and increases the nutrients of the soybean milk, not only satisfies the people's pursuit for taste preferences, but also maintains and adds more nutrients, and has higher nutritional values.

Owner:HEILONGJIANG TIANYI AGRI TECH DEV

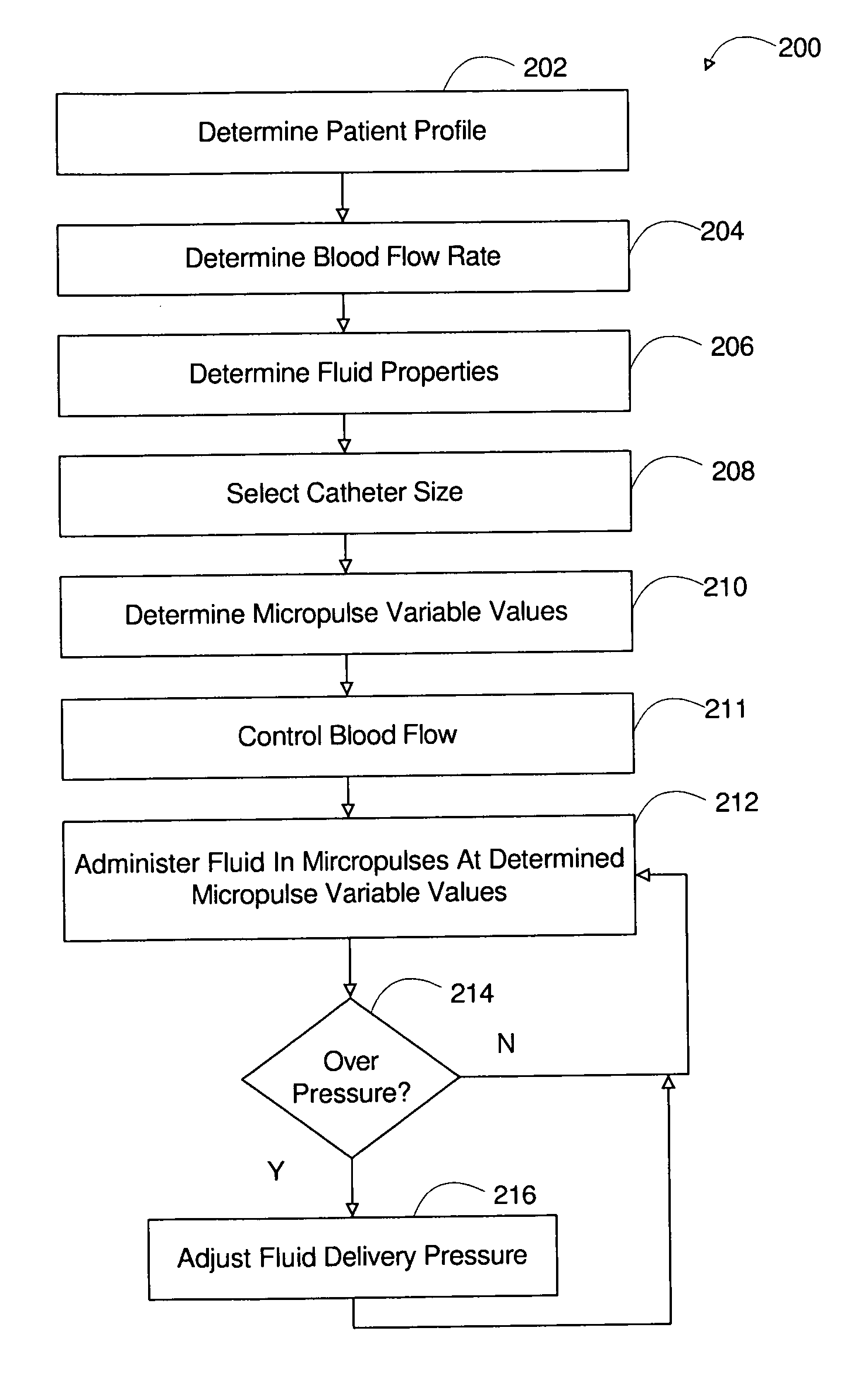

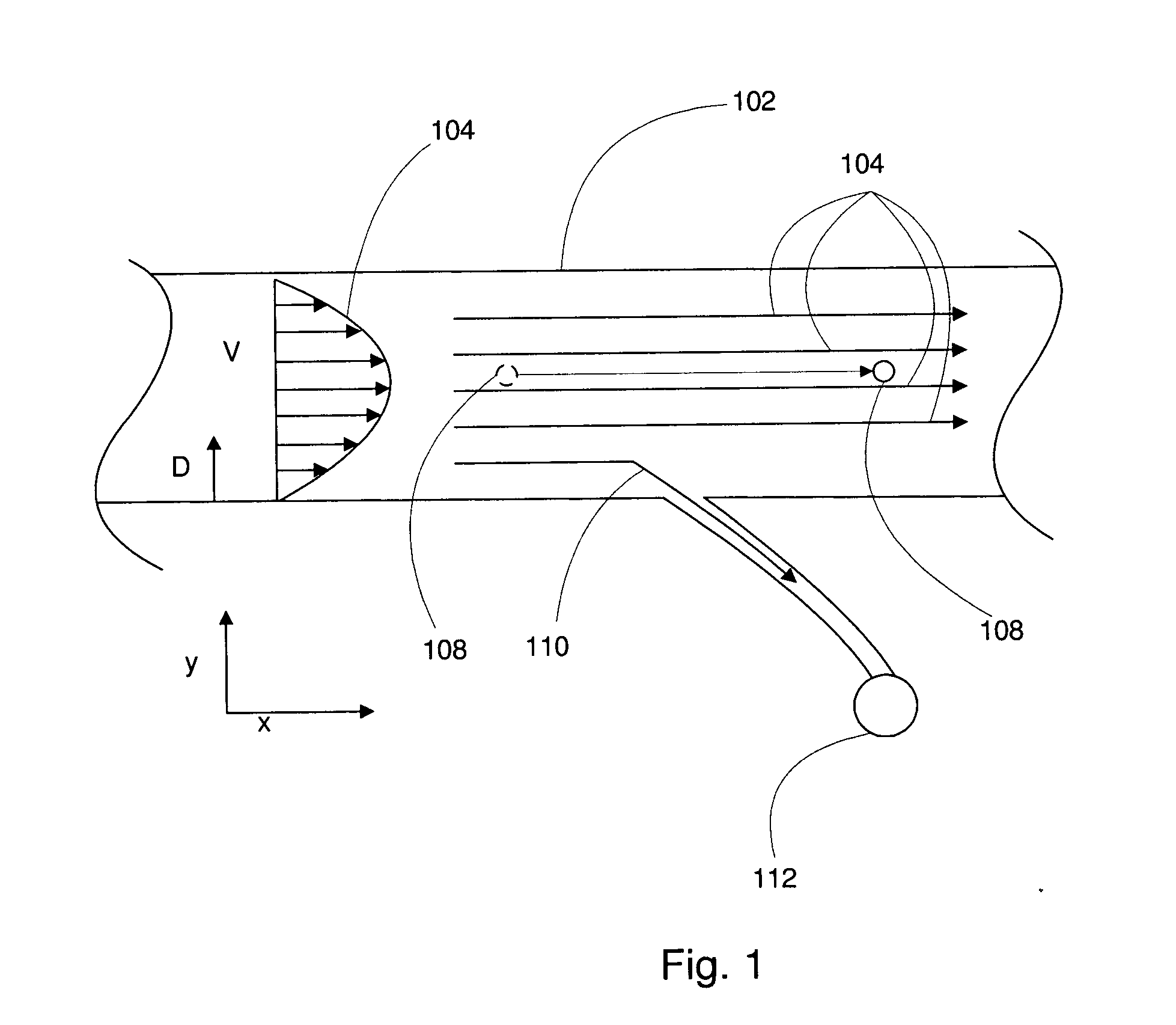

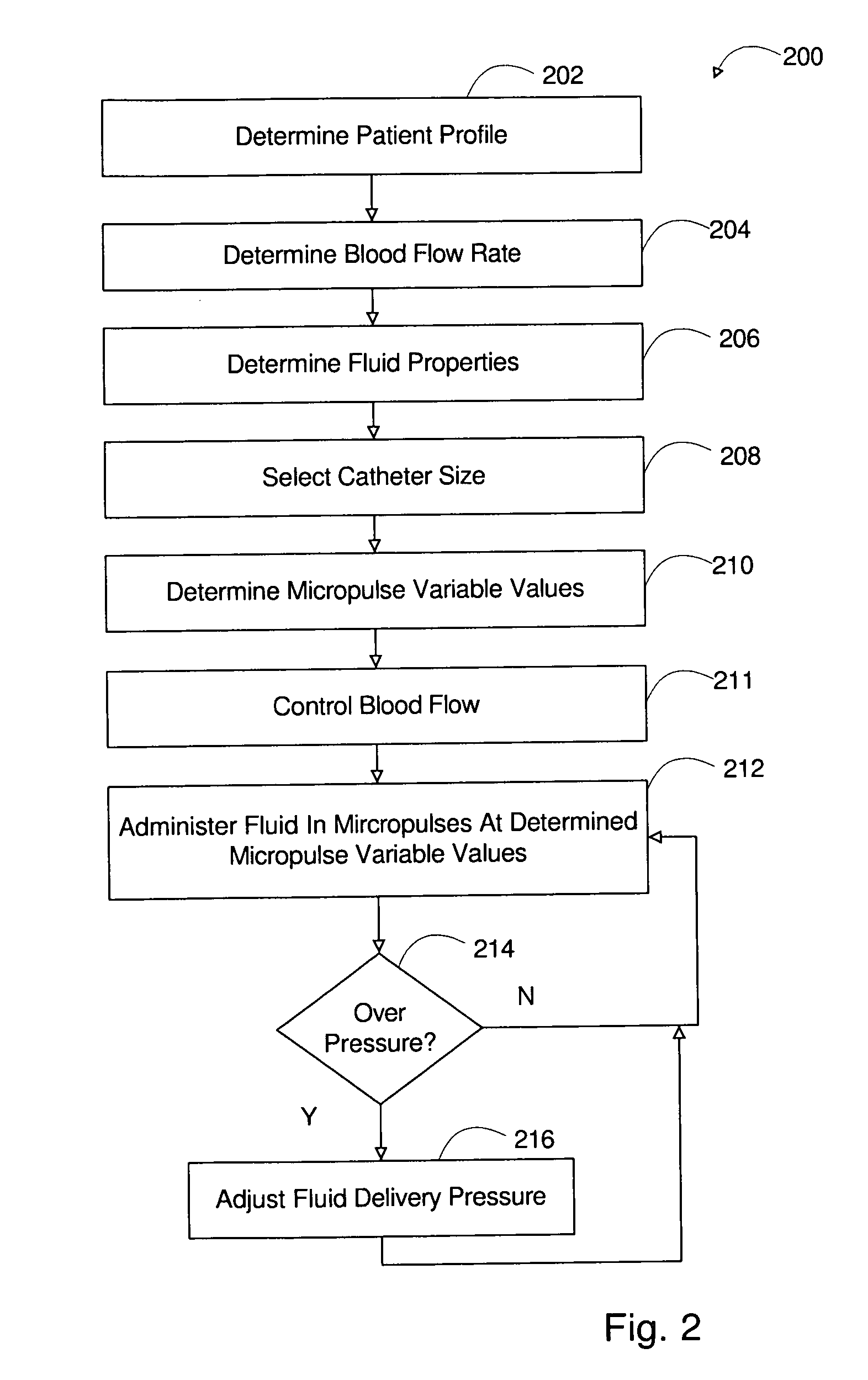

Programmed pulsed infusion methods and devices

InactiveUS20060135940A1Great efficient use of fluidAbsorb moreComputer controlDrug and medicationsInfusion methodBlood flow

This invention disclosed herein provides methods, devices, software products, and systems for infusing a fluid into a blood vessel is provided that includes the step of administering the fluid into the blood vessel in programmed pulses. The programmed pulses generally defined by programmed pulse variables that include a fluid flow rate, a frequency, and a duration. Values of the programmed pulse variables may be determined based at least in part on a fluid property of the fluid to be infused that is relevant to streaming, blood flow in the blood vessel to be infused, a catheter size, or a patient profile.

Owner:TRISTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK THE

Ultraviolet-light deeply cross-linked halogen-free flame-retardant polyolefin cable material and method for preparing ultraviolet-light deeply cross-linked halogen-free flame-retardant polyolefin cable insulating or sheathing layer from same

ActiveCN102153802AEnhanced cross-linking efficiencyIncreased uniform photocrosslinking depthPlastic/resin/waxes insulatorsInsulated cablesCross-linkPolyolefin

The invention relates to ultraviolet-light deeply cross-linked halogen-free flame-retardant polyolefin cable material and a method for preparing an ultraviolet-light deeply cross-linked halogen-free flame-retardant polyolefin cable insulating or sheathing layer from the same. The method comprises the following steps: adding a metal hydroxide flame retardant, a cationic photoinitiator, a free radical photoinitiator, a multi-functional cross-linking agent, a compound antioxidant, a flame-retardant synergist, a synergistic smoke suppressant and a processing aid to polyethylene or grafted and modified polyethylene and / or ethylene vinyl acetate or grafted and modified copolymer thereof which are used as base materials, compounding, mixing the materials uniformly according to the proportion, granulating, extruding to prepare the ultraviolet-light cross-linked halogen-free flame-retardant polyolefin cable insulating or sheathing layer, and immediately irradiating with a specific ultraviolet-light source to obtain the deeply cross-linked halogen-free flame-retardant polyolefin cable insulating or sheathing layer. The cross-linking equipment used for preparing the novel material by using anovel technology has low investment, and the process is simple and environmental friendly, saves energy, ensures high production efficiency and low cost and good quality of product and can be widely used for producing high-performance special wire and cable products and the like.

Owner:HEILONGJIANG MINGXIANG TECH

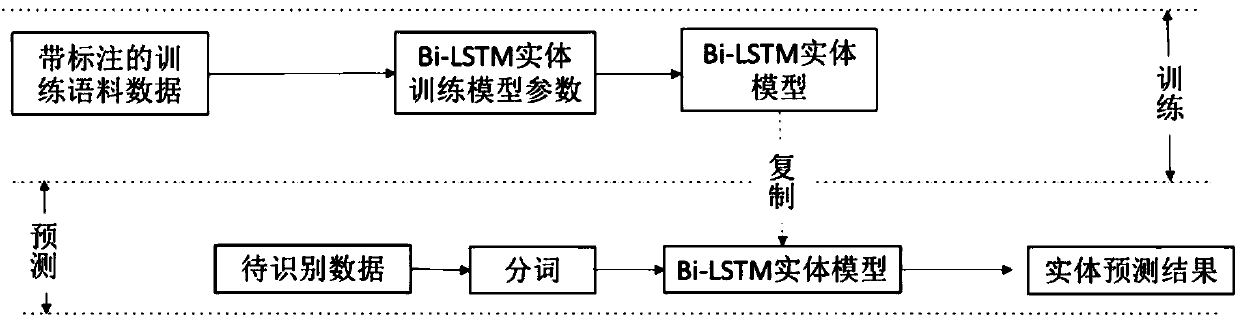

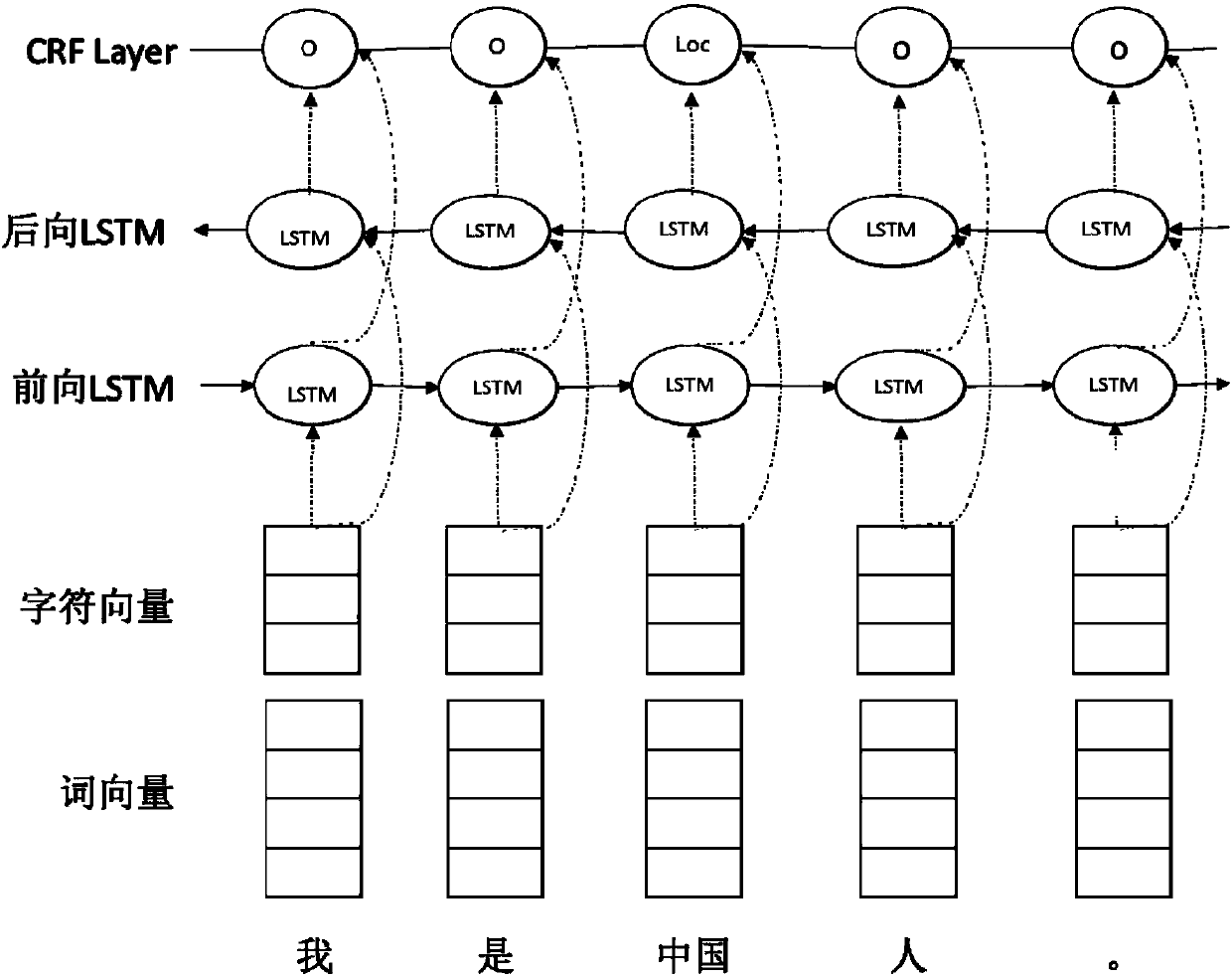

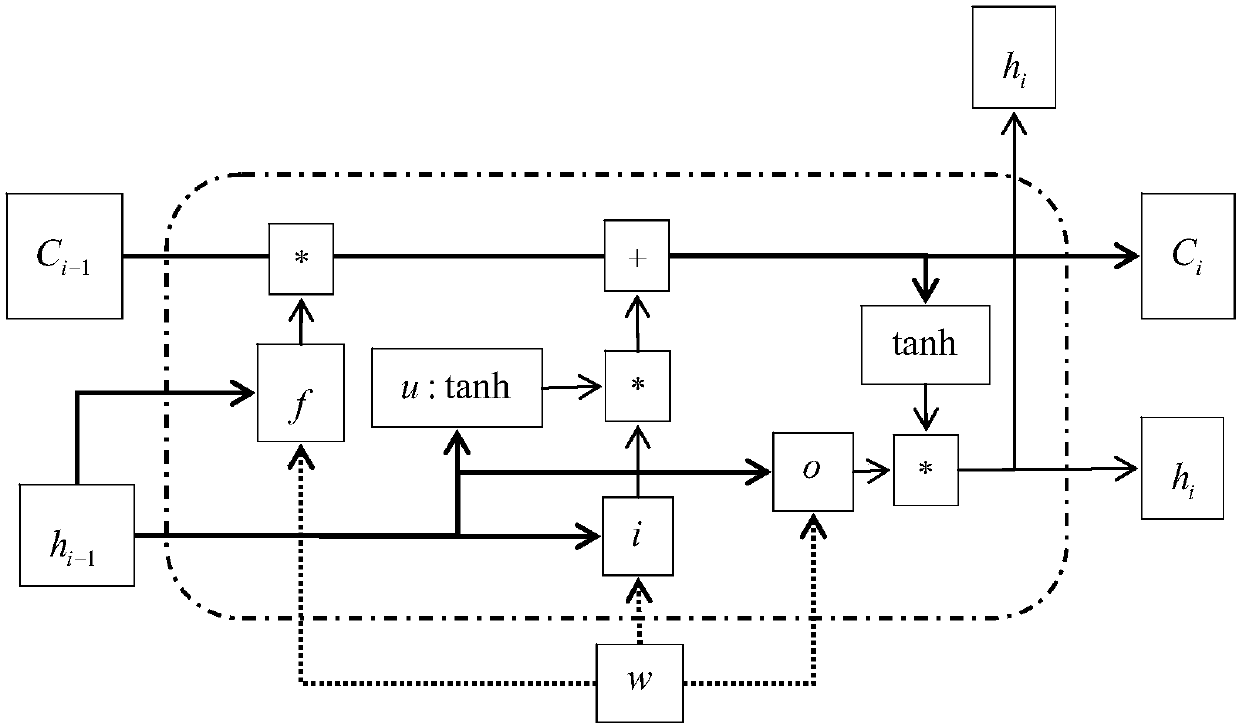

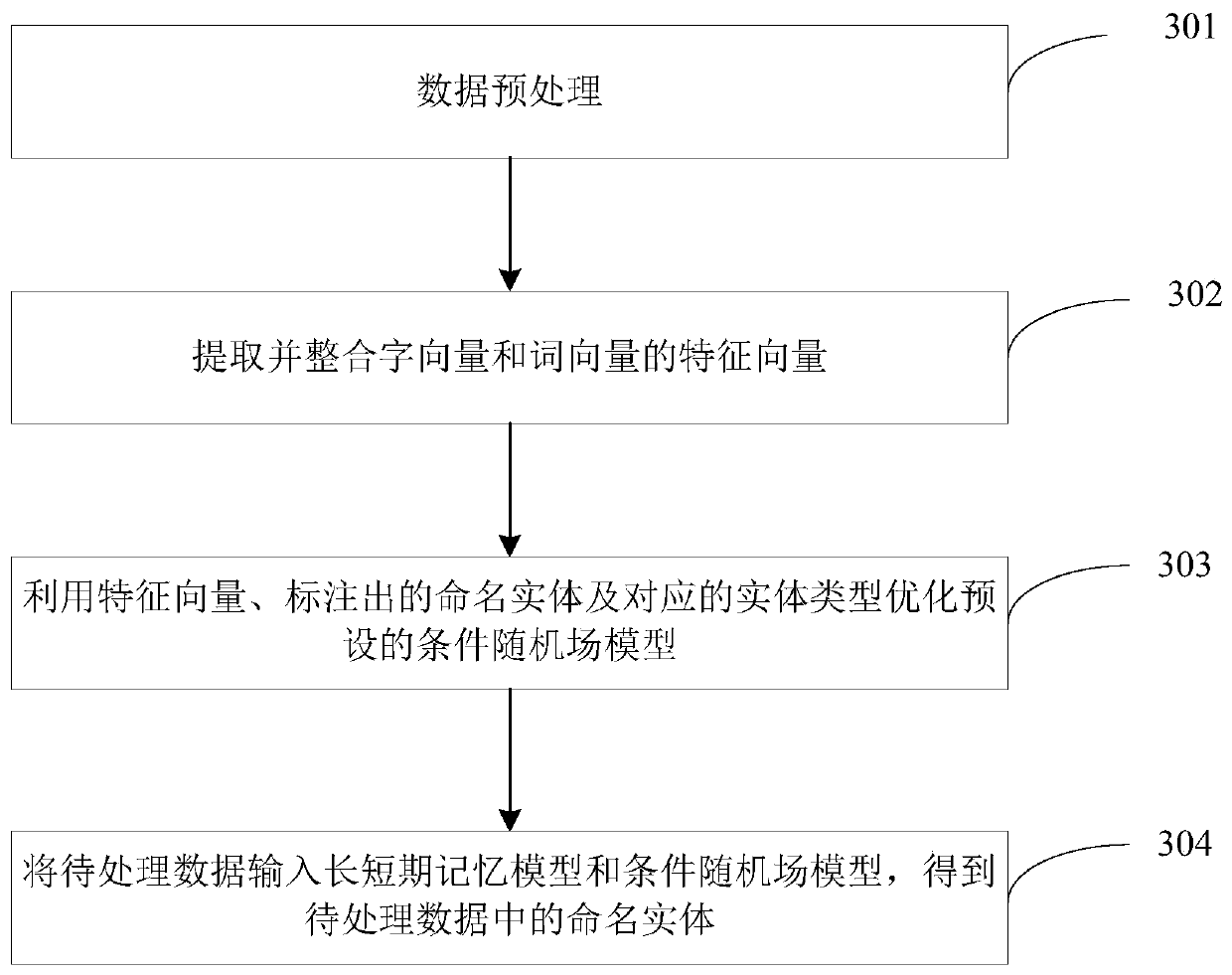

Bi-LSTM-based named entity identification method

InactiveCN107908614AHigh precisionAvoid the problem of unregistered wordsNatural language data processingSpecial data processing applicationsPattern recognitionNamed-entity recognition

The invention relates to a Bi-LSTM-based named entity identification method. The method comprises the steps that 1, a training corpus for named entity identification is tagged to form a tagged corpus;2, words and characters in the tagged corpus are converted into vectors; 3, a Bi-LSTM-based named entity identification model is built through the vectors of the words and the characters, and parameters of the Bi-LSTM-based named entity identification model are trained; and 4, named entity identification prediction is conducted on to-be-predicted data through the trained named entity identification model. According to the method, by adopting the vectors based on the words and the characters, features of the characters and the words can be obtained simultaneously, and meanwhile the unknown word problem can be avoided; and in addition, compared with a traditional pure CRF model algorithm, by adopting a bidirectional long short-term memory (Bi-LSTM) neural network, the method has the advantage that more character and word features can be absorbed, and therefore the entity identification precision can be improved.

Owner:北京知道未来信息技术有限公司

Preparation method for edible fungus flavor food

The invention discloses a preparation method for an edible fungus flavor food. The edible fungus can be any one from edible agaricus bisporus, straw mushrooms, oyster mushrooms, shii-take, needle mushrooms, pleurotus nebrodensis, pleurotus eryngii, agrocybe aegerita, hypsizigus marmoreus, agaricus pratensis schaeff, spring mushrooms, stropharia rugoso-annulata, sparassis crispa, macrolepiota procera, tremellodon gelatinosum, black trumpet mushrooms, hericium erinaceus, pholiota nameko, lepista personata, mitake mushrooms, lactarius hatsudake, golden oyster mushrooms, pholiota adiposa, cantharellus cibarius, termitomyces albuminosus, tricholoma giganteum, pleurotus citrinopileatus, calocybe gambosa, truffle, amillariella mellea, fungus suillus, beef-steak fungus, lactarius deliciosus, tricholoma matsutake, agaricus bitorquis, pleurotus pulmonarius, toadstool and russula vinosa, and after treatment, the edible fungus is steeped into a steeping liquor prepared from red wine vinasse, high quality dry red wine and a flavouring agent in a vacuum and normal temperature and normal pressure combined condition, so as to obtain the flavor food; the edible fungus flavor food for leisure is prepared through oil-bath dewatering; a flavor food flavor puffed food is obtained through a swelling process, so as to meet consumers' hobbies and requirements.

Owner:徐州绿之野生物食品有限公司

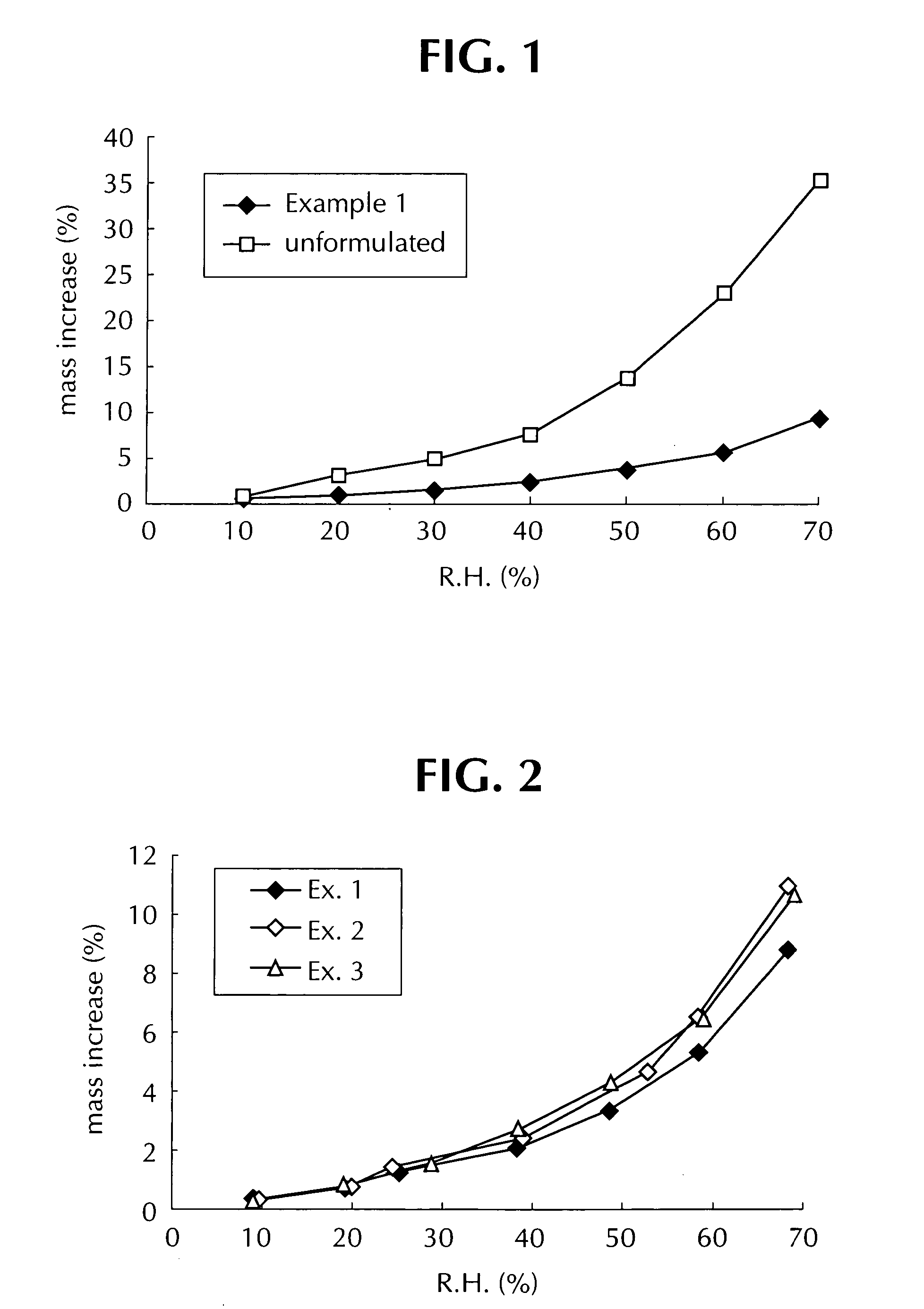

Solid dispersions comprising a hygroscopic and/or deliquescent drug

InactiveUS20050013856A1Easy to mergeAbsorb morePowder deliveryOrganic active ingredientsPolyethylene glycolCyclodextrin

A pharmaceutical composition is provided comprising a drug and a carrier medium, wherein the carrier medium comprisese (a) a matrix forming agent selected from the group consisting of hydroxyethylcelluloses, hydroxypropylcelluloses, hydroxypropylmethylcelluloses, hydroxypropylmethylcellulose phthalates, polyvinylpyrrolidones, polyethylene glycols, polyglycolized glycerides, cyclodextrins, carbomers and combinations thereof, and (b) a filler; and wherein the drug is hygroscopic and / or deliquescent and is dispersed in the carrier medium, and wherein the composition is a solid dispersion and is acceptably non-hygroscopic.

Owner:PHARMACIA CORP

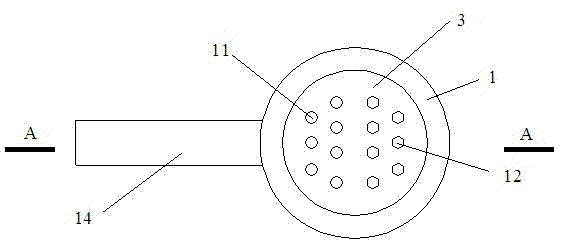

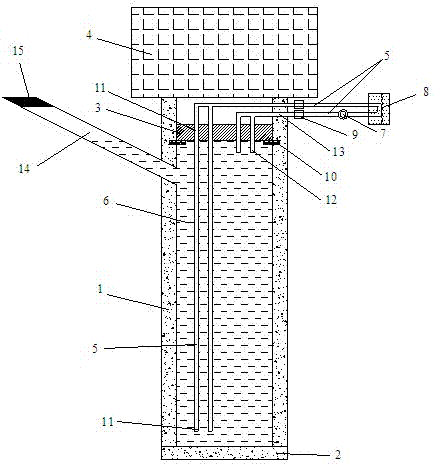

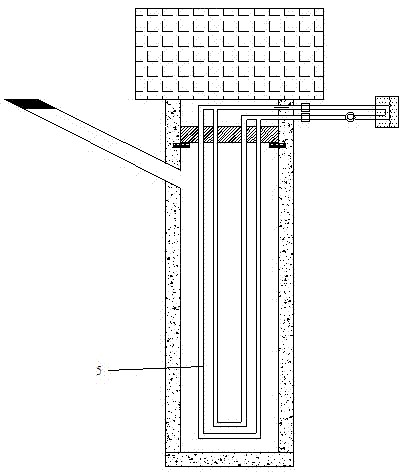

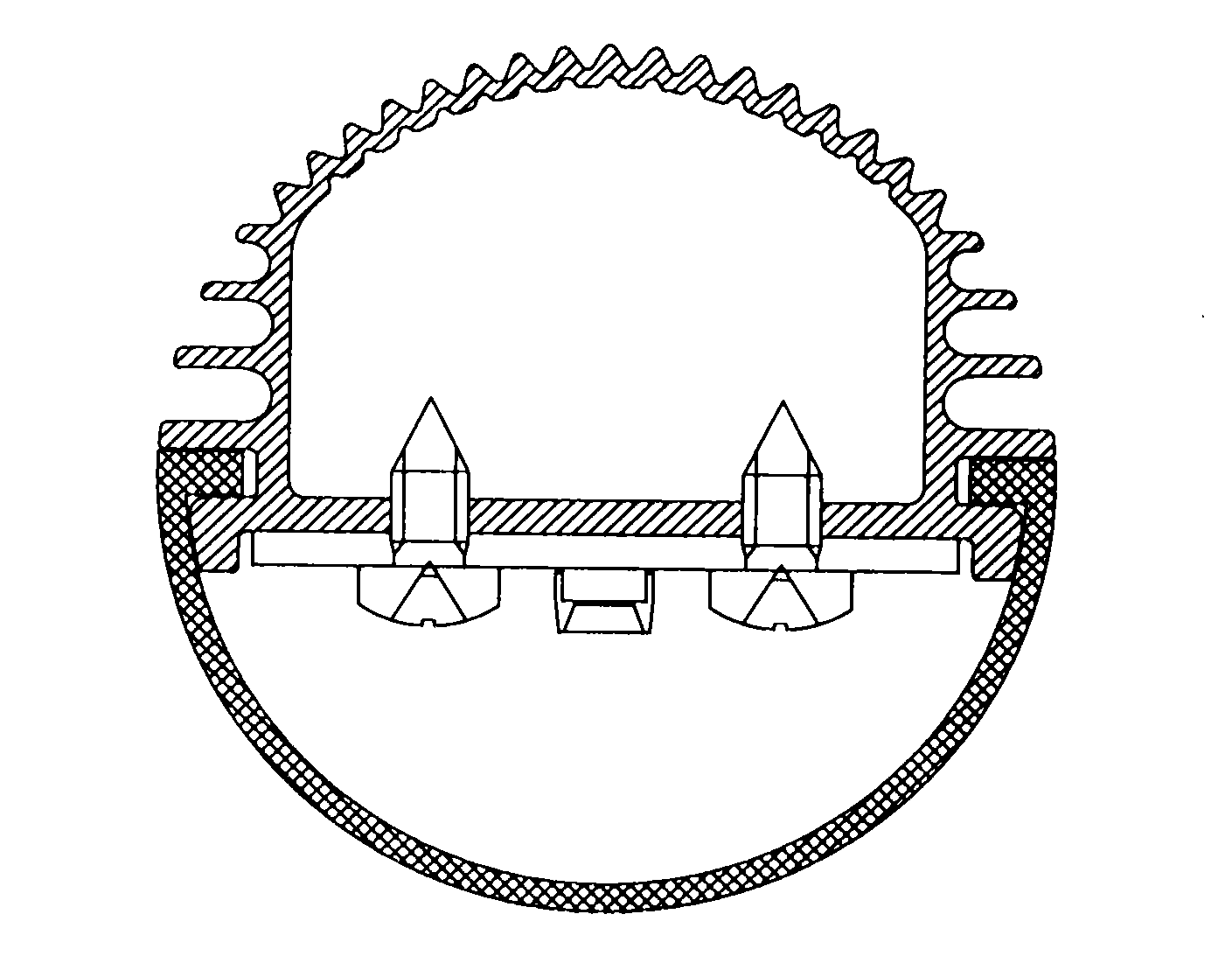

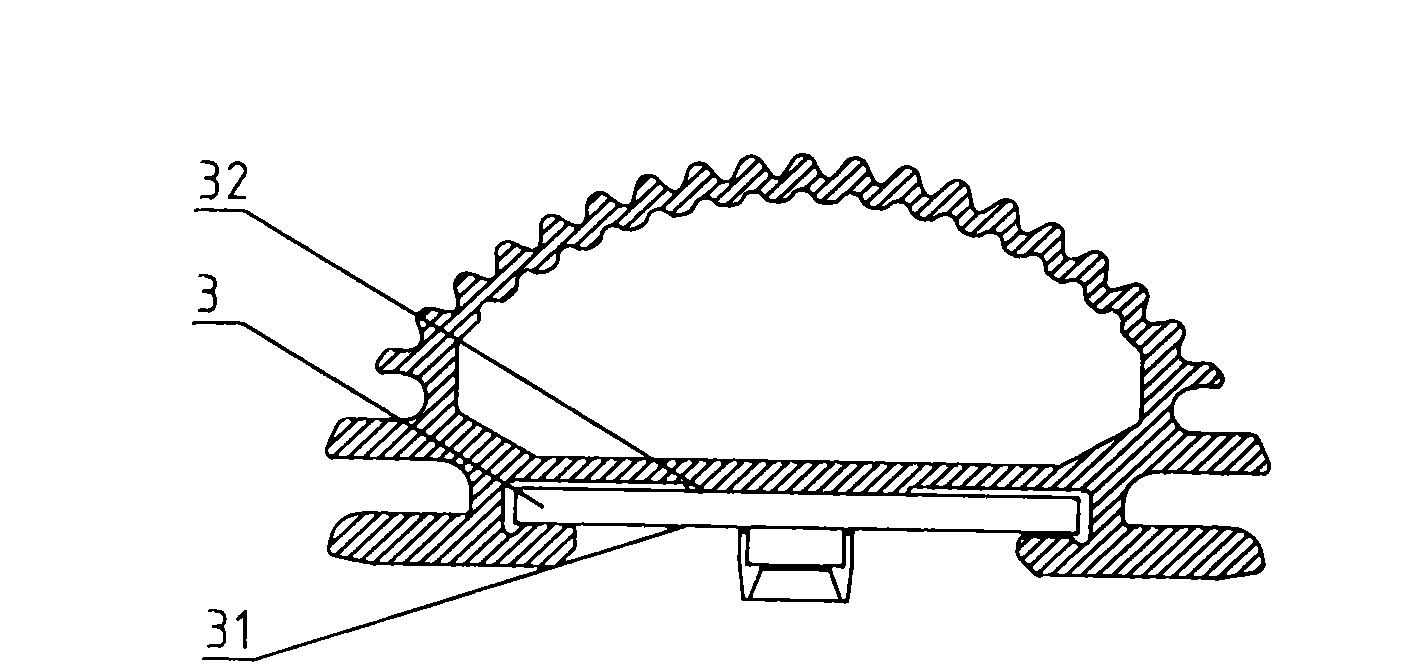

PCC (Large Diameter Pipe Pile by using Cast-in-place Concrete) energy pile and manufacturing method thereof

ActiveCN102808405AImprove sealingAbsorb moreOther heat production devicesGeothermal energy generationHeat conductingClassical mechanics

The invention discloses a PCC (Large Diameter Pipe Pile by using Cast-in-place Concrete) energy pile. The PCC energy pile comprises a PCC pile, a heat conducting liquid, a cover plate, a bottom plate, a heat conducting pipe, a heat collecting device and an inspection channel, wherein the bottom of the PCC pile is fully closed; a cover plate with holes is arranged at the top of the PCC pile; prepared holes are formed in one side at the upper part of the PCC pile; the heat conducting liquid is filled up in a cavity in the PCC pile; the heat conducting pipe penetrates through the holes in the cover plate and extends into the heat conducting liquid in the cavity in the PCC pile; the heat conducting pipe extending into the cavity in the PCC pile can adopt opened and closed modes; the inspection channel is formed in the side wall of the PCC pile; and the heat conducting pipe is led out of the cavity in the PCC pile through the holes in the cover plate or the inspection channel and connected with the heat collecting device to form a circulating channel of the heat conducting liquid. The invention further discloses a manufacturing method for the pile. The manufacturing method comprises the technical steps as follows: pouring the PCC pile; excavating pile core soil; making a bottom plate; mounting the heat conducting pipe and the cover plate; filling the heat conducting liquid; and starting a ground heat pump for forming a loop. The PCC energy pile is convenient to overhaul and maintain, wide in application range and low in construction cost, does not influence the bearing capacity, and is an economic, efficient, energy-saving and emission-reducing pile.

Owner:HOHAI UNIV +1

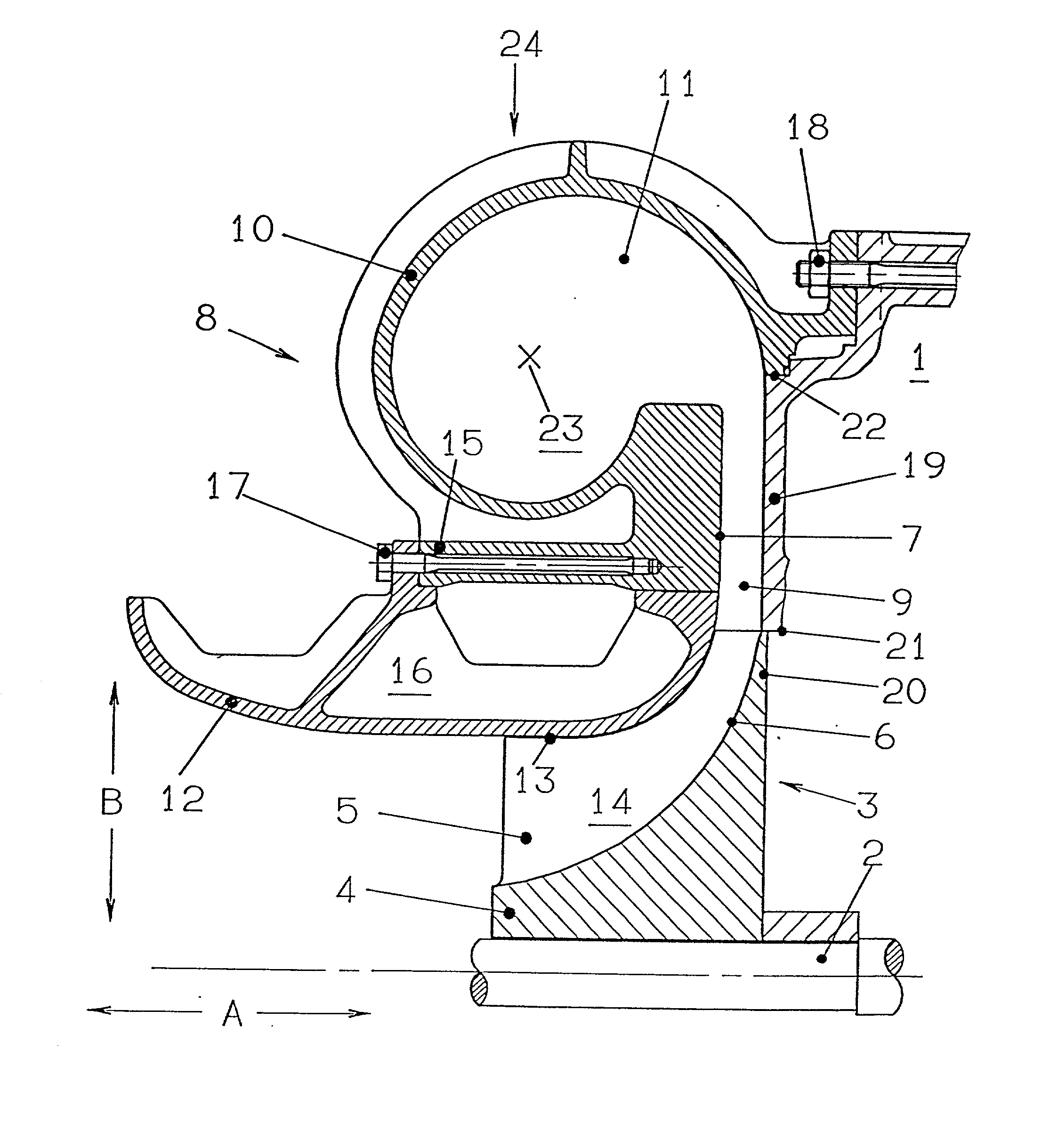

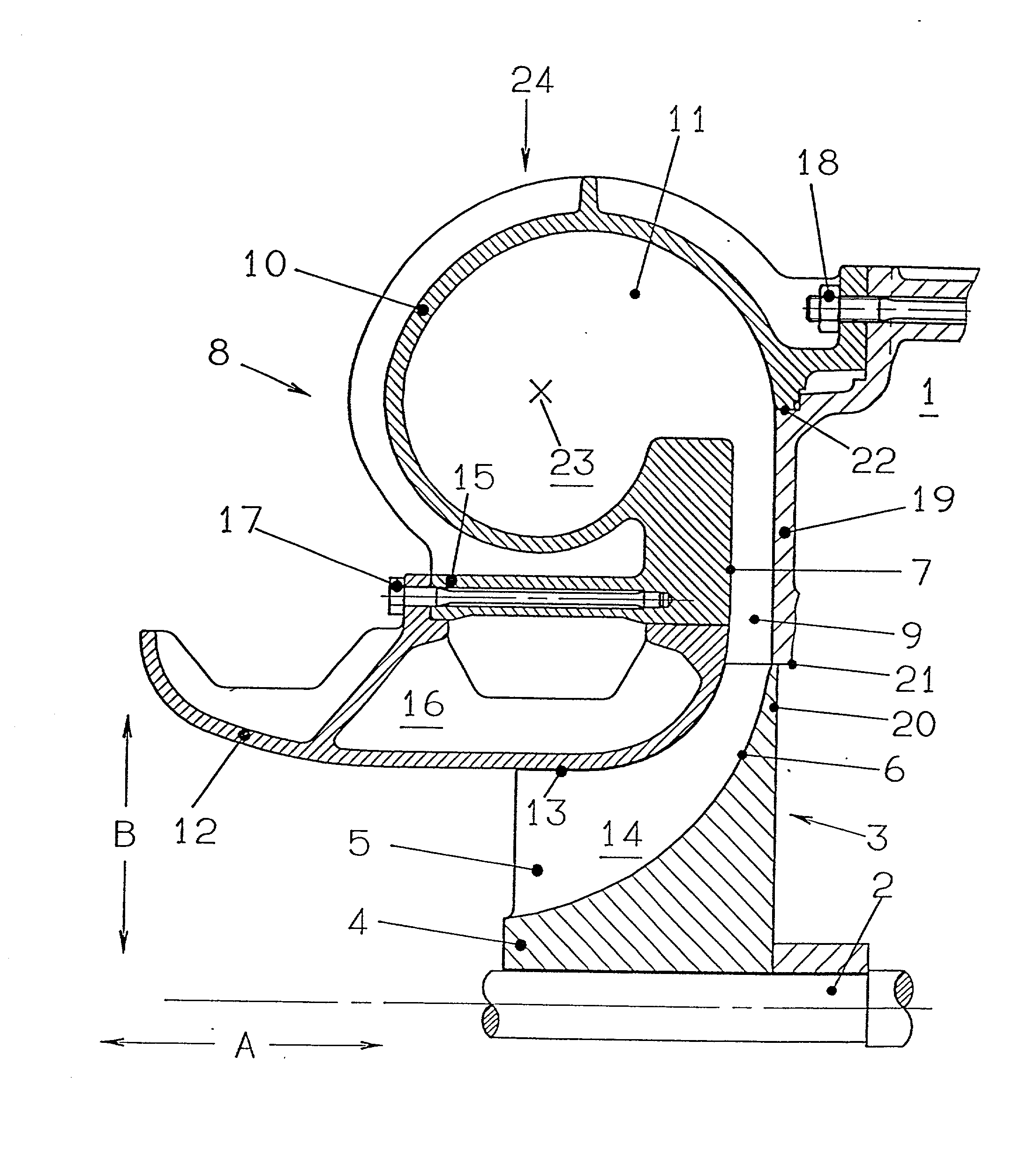

Turbomachine with radial-flow compressor impeller

A compressor casing with a volute-shaped flow duct is fastened by means of a rigid fixing arrangement to the bearing casing of the turbomachine, with simple and low-cost means in such a way that the emergence of fragments of a burst compressor impeller from the compressor casing can be prevented. The compressor casing has an outer spiral casing, which surrounds a duct section of the flow duct deflected towards the outside into the radial direction (B), and an inner casing insert piece, which is provided in the radial direction (B) between the spiral casing and the compressor impeller and whose inner contour, together with the outer contour of the hub of the compressor impeller, forms the duct section of the flow duct extending essentially in the axial direction (A). The spiral casing is configured with an inner cylinder at least partially surrounding the casing insert piece, on which inner cylinder the casing insert piece is attached by means of a fixing arrangement, which is flexible in the axial direction (A), to form a hollow space. The flexible fixing arrangement of the casing insert is less secure against fracture than the rigid fixing arrangement of the compressor casing on the bearing casing.

Owner:MAN B & W DIESEL AG

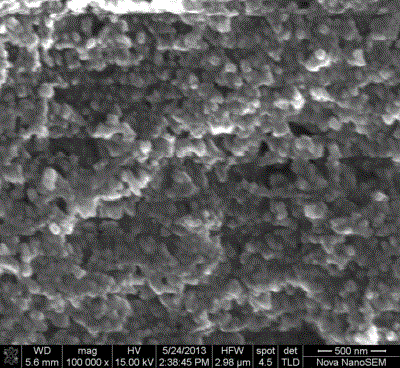

Semiconductor superhydrophobic paint and preparation method thereof

ActiveCN104403453ALong-term superhydrophobicityLong-term self-cleaningPolyurea/polyurethane coatingsElectrically-conductive paintsThermoplasticOrganic solvent

The invention relates to the field of hydrophobic paint, in particular to a semiconductor superhydrophobic paint and a preparation method thereof. The method comprises the steps of: a. firstly shearing and stirring hydrophobic nanoparticles and a semiconductive filler evenly, then adding 70%-80% of an organic solvent and conducting mixing; b. mixing thermoplastic film-forming resin with the remaining organic solvent, and performing shearing and stirring evenly; c. mixing the solution obtained in step a with the solution obtained in step b, then adding a low surface energy substance, a curing agent and an additive; and d. subjecting the solution obtained in step c to ultrasonic treatment for 2-20min, and then conducting stirring for 5min-2h till uniform stirring, thus obtaining the product. The semiconductor superhydrophobic paint adopting the scheme provided by the invention can realize self-repair, has no power consumption, and does not decompose surface organic substances.

Owner:CHONGQING UNIV +1

Ultraviolet deep-crosslinked expansion flame-retardant polyolefine cable material, and preparation method of insulating or jacket layer thereof

ActiveCN102161793AImprove deep penetrating abilityImprove efficiencyInsulated cablesInsulated conductorsAntioxidantUltraviolet

The invention relates to an ultraviolet deep-crosslinked expansion phosphorus-nitrogen flame-retardant polyolefine cable material, and a preparation method of an insulating or jacket layer thereof. Polyethylene or graft-modified polyethylene and / or ethylene-vinyl acetate or graft-modified copolymer thereof are used as base materials, surface-modified expansion phosphorus-nitrogen halogen-free flame retardant, cation photoinitiator, free-radical photoinitiator, polyfunctional group crosslinking agent and composite antioxidant are added, and flame-retardant synergist, synergistic smoke suppressor and processing assistant are matched to obtain the ultraviolet deep-crosslinked expansion phosphorus-nitrogen flame-retardant polyolefine cable material. The preparation method comprises the following steps: proportionally and evenly mixing the materials to obtain granules, extruding to obtain an optical crosslinked expansion flame-retardant wire cable insulating layer or jacket layer, and radiating by a specific ultraviolet source for several seconds to obtain the deep-crosslinked insulating layer or jacket layer. The new material and new technology have the advantages of low investment required for crosslinking equipment, simple technique, energy saving, environmental protection, high production efficiency, low cost and good product quality, and can be widely used for manufacturing rail transportation cables, various mechanical wires, indoor assembly wires and the like.

Owner:HEILONGJIANG MINGXIANG TECH

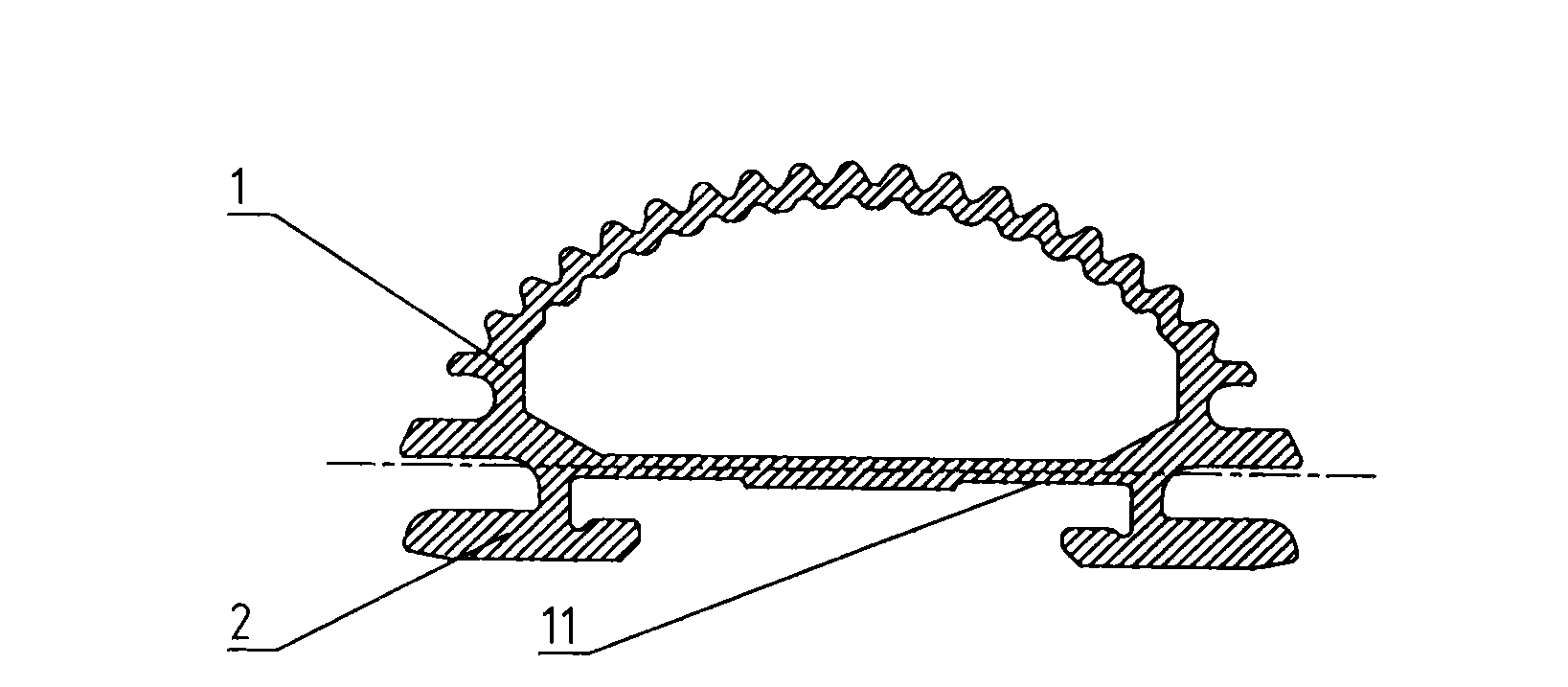

Manufacturing method of lamp-cover-supporting LED tubular lamp with self-clamping heat transmission substrate

InactiveCN103411140AAbsorb moreReduce absorptionPoint-like light sourceLighting heating/cooling arrangementsHeat transmissionEffect light

The invention discloses a manufacturing method of a lamp-cover-supporting LED tubular lamp with a self-clamping heat transmission substrate, and belongs to the technical field of supporting or hanging or connecting of lighting devices. The manufacturing method of the LED tubular lamp includes the steps that S1, the heat transmission substrate is inserted into strip-shaped clamping grooves from side ports of the strip-shaped clamping grooves; S2, after the heat transmission substrate is installed in the strip-shaped clamping grooves, a lamp cover covers a radiator; S3, the lamp cover exerts two acting forces on two T-shaped hooks, and the heat transmission substrate is installed in the strip-shaped clamping grooves in a clamped mode; S4, the radiator, the heat transmission substrate and the lamp cover form a lamp tube of the LED tubular lamp, and two end covers are installed at the two ends of the lamp tube of the LED tubular lamp. According to the lamp-cover-supporting LED tubular lamp with the self-clamping heat transmission substrate, the heat transmission substrate can be arranged in the strip-shaped clamping grooves in the clamped mode because the strip-shaped clamping grooves are formed in an installing part of the heat transmission substrate, heat dissipation efficiency can be improved, and the heat transmission substrate is prevented from thermal deformation.

Owner:辽宁三维传热技术有限公司 +1

Method for preparing hydrocracking catalyst

ActiveCN103191774AIncrease the apertureLow pore volumeMolecular sieve catalystsHydrocarbon oil crackingPolymer scienceFiltration

The invention discloses a method for preparing a hydrocracking catalyst. The method comprises the following steps of carrying out hydrothermal treatment on alumina dry gel powder, uniformly mixing the treated alumina dry gel powder and at least one acidic cracking material powder, dipping the mixture into a hydrogenation active ingredient-containing metal salt solution, carrying out filtration, drying and crushing, adding a peptizing agent or a binder into the crushed product, and carrying out molding, drying and calcination to obtain the hydrocracking catalyst. The hydrocracking catalyst has high hydrogenation active ingredient content, a large pore volume, a large aperture size and a large specific surface area, and is suitable for hydrocracking of a heavy vacuum distillate having a higher boiling point.

Owner:CHINA PETROLEUM & CHEM CORP +1

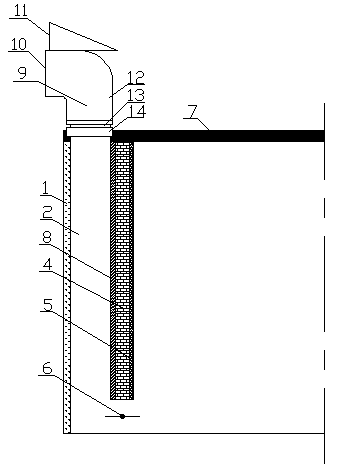

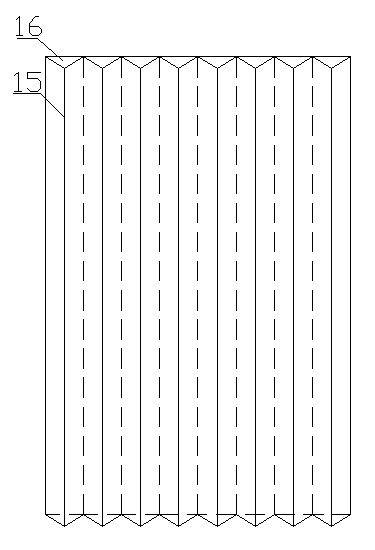

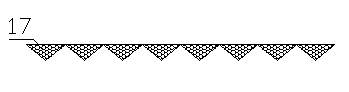

Modified solar chimney system

InactiveCN103134060AImprove ventilationImprove heat transfer effectSolar heat devicesChimneysGlass coverEngineering

The invention discloses a modified solar chimney system which comprises a transparent glass cover plate, a solar collecting panel mounted on a outer wall facing the south, an air passage formed between the transparent glass cover plate and the solar collecting panel, and wind guide rotating exhaust hood disposed at the top of the air passage. A plurality of longitudinal ribs protruding towards the air passage are disposed on the solar collecting panel, so that solar collecting area is increased effectively, more solar radiation can be absorbed, and heat exchange effect between the air and the solar collecting panel can be intensified by the longitudinal ribs.

Owner:SOUTHEAST UNIV

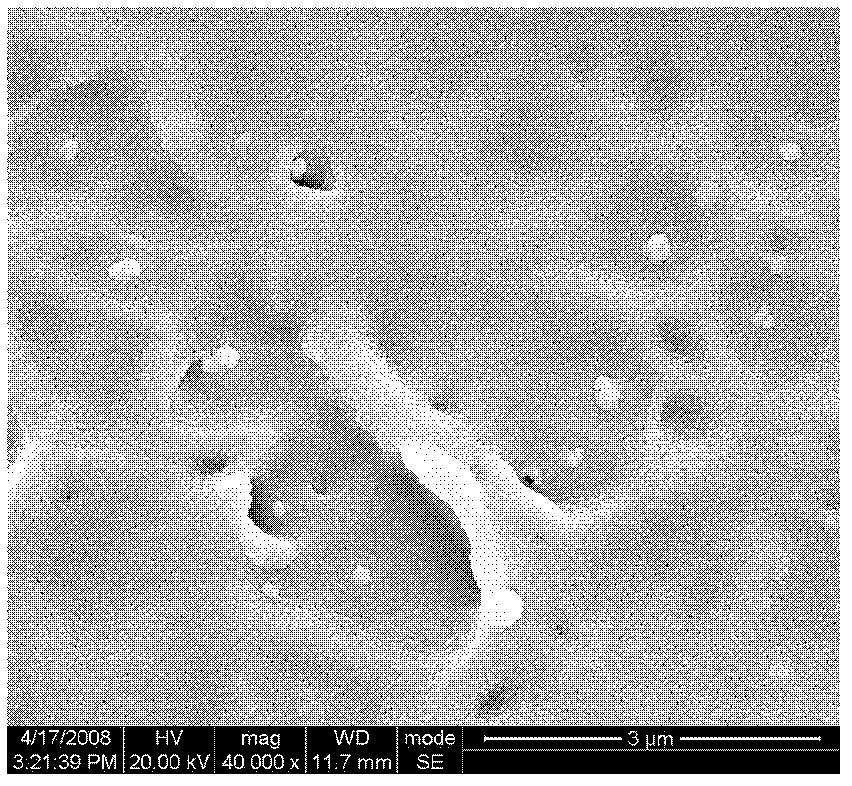

Preparing method for nanometer toughening ultra-fine grain WC-Co cemented carbide

ActiveCN107475548AUniform particle sizeNarrow normal distribution of particle sizePorosityFlexural strength

The invention discloses a preparing method for nanometer toughening ultra-fine grain WC-Co cemented carbide. The preparing method for the nanometer toughening ultra-fine grain WC-Co cemented carbide comprises the following steps of that 0.1-0.5 micron ultra-fine powder of WC hard phase and Co binder phase is prepared by adopting an airflow crushing classification method and a high-pressure water atomization method correspondingly, and the ultra-fine grain cemented carbide is prepared through material matching and nano-metal mixed additives adding, airflow mixed powder sieving, ball milling waxing and drying sieving, mold pressing and cold isostatic pressing molding and pressure sintering and heat treating, wherein the nano-metal mixed additives are prepared by adopting vacuum electric arc smelting ingot casting plus rapid-in-situ packaging plasma arc process discharging method. The nano-metal mixed additives play the role of refining the cemented carbide granules, improving the material wettability, reducing the porosity and enhancing the local grain boundary strength, so that macro performances such as hardness, flexural strength and fracture toughness of the alloy are improved greatly. The preparing method for the nanometer toughening ultra-fine grain WC-Co cemented carbide has the advantages of being high in production efficiency, low in production cost, high in product quality and purity, and a great deal of man-hour and energy consumption are saved.

Owner:SHENYANG SHENGSHI WUHUAN TECH CO LTD

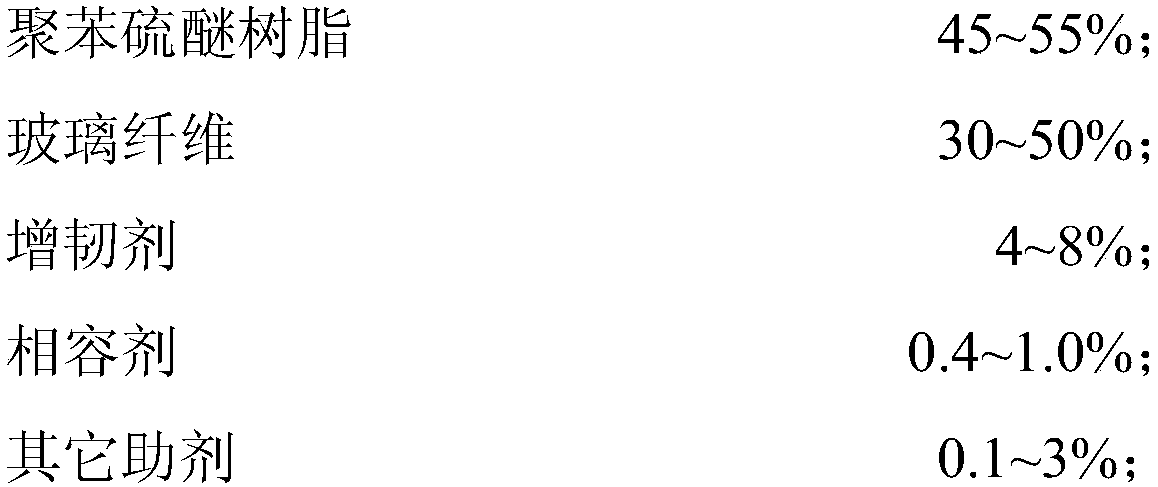

High strengthening and toughening type polyphenylene sulfide composite material and preparation method thereof

The invention discloses a high strengthening and toughening type polyphenylene sulfide composite material. 100 wt% of the composite material comprises 45-55 wt% of polyphenylene sulfide resin, 30-50 wt% of glass fibers, 4-8 wt% of a toughening agent, 0.4-1.0 wt% of a compatibilizer and 0.1-3 wt% of other additives; the surface of the glass fibers is impregnated with a silane coupling agent; the toughening agent is at least one selected from nylon 6, nylon 66, ethylene-methyl acrylate-glycidyl methacrylate and a maleic anhydride grafted styrene-ethylene-butadiene-styrene block copolymer elastomer; and the compatibilizer is selected from epoxy resins. The polyphenylene sulfide composite material disclosed in the invention has the advantage of high rigidity, high toughness and high flame retardation property, is especially suitable for producing small parts and ultrathin parts which have high requirements for the impact performance, and greatly broadens the application range of a phenyl sulfide material.

Owner:CGN JUNER NEW MATERIALS +1

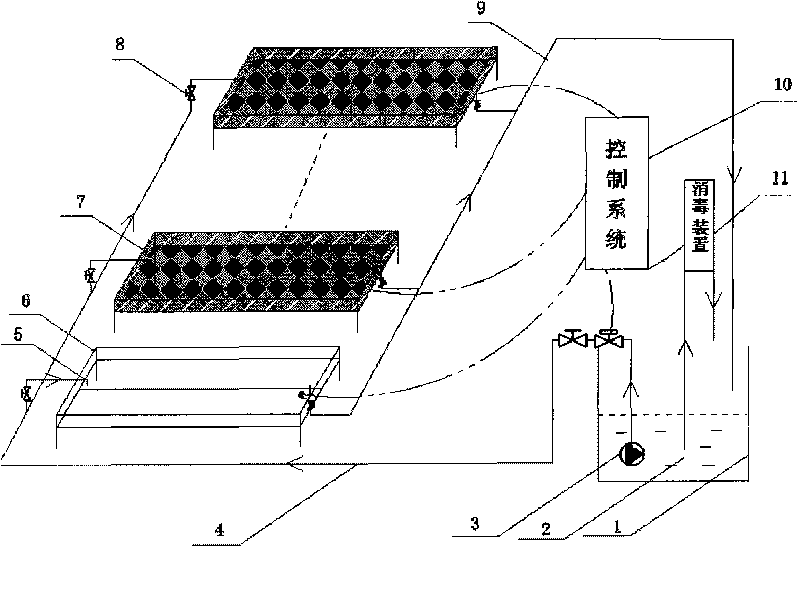

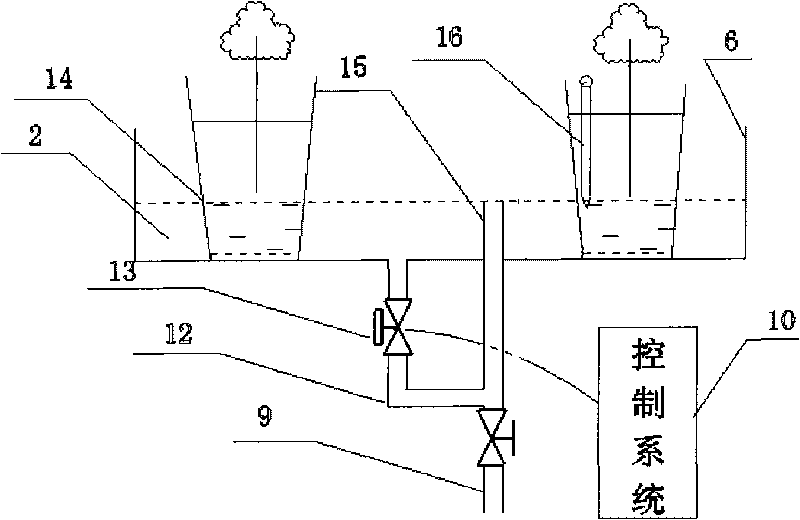

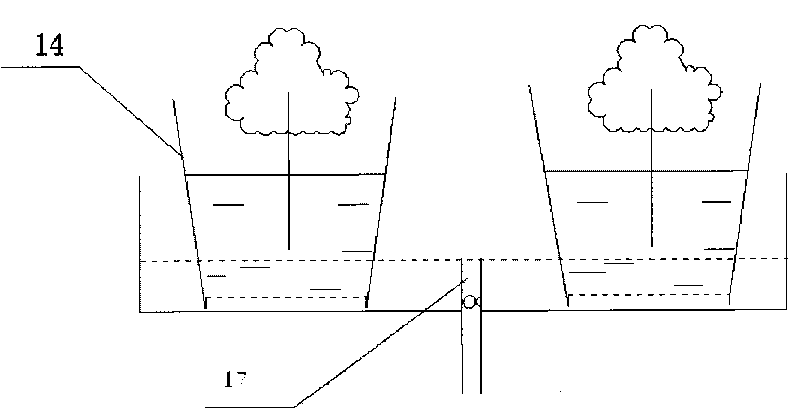

Soilless culture system

InactiveCN101743896AAvoid churnStable medium water vapor contentAgriculture gas emission reductionCultivating equipmentsNutrient solutionEngineering

The invention discloses a novel soilless culture system which belongs to the field of soilless culture. An outlet of a nutrient solution pool (1) in the system is connected with a liquid inlet of a liquid containing tank (6) via a water pump (3), and a liquid outlet end of the liquid containing tank (6) is connected with an inlet of the nutrient solution pool (1) via a liquid return main pipe (9); two or more liquid containing tanks are connected in parallel, a culture pot or culture bag is arranged in the liquid containing tank (6), and a disinfection device (11) and the nutrient solution pool (1) form a loop for disinfecting nutrient solution independently; and the liquid outlet ends of the liquid containing tanks (6) have two structures both of which can meet the requirement of tide-type irrigation. The system can realize the tide-type irrigation and the enclosed recycling use of the nutrient solution simultaneously, is suitable for the soilless culture of crops such as vegetables, flowers and the like, and has the advantages of simple technology and equipment, low cost, stable and reliable operation and the like.

Owner:CHINA AGRI UNIV

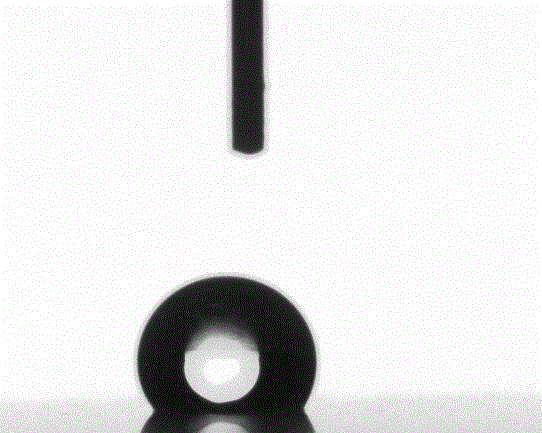

Anti-myopia paper, as well as preparation method and application thereof

ActiveCN103225235AReduce reflectionAbsorb moreSpecial paperPulp bleachingEconomic benefitsBlue green color

The invention discloses a piece of anti-myopia paper. The anti-myopia paper is characterized by being capable of reflecting colored light with the reflection wavelength of 460-510nm and displaying blue-green color with the luminance of 54%-58%. The paper can be not only prepared by adding a dye into paper pulp but also prepared by printing color on a piece of white paper. The reflection wavelength of the blue-green paper is within a spectral range of 460-510nm, and the color of the paper is darker than white and yellow, so that the colored light reflection is reduced, more colored light can be absorbed, the propor color is strong, the reflection is low and a role of preventing the eyes of students with weak hard light reflecting capabilities from myopia can be played, and the vision of the students is benefited; and the paper is easy to popularize and implement, and the social and economic benefits are obvious.

Owner:李雨茜

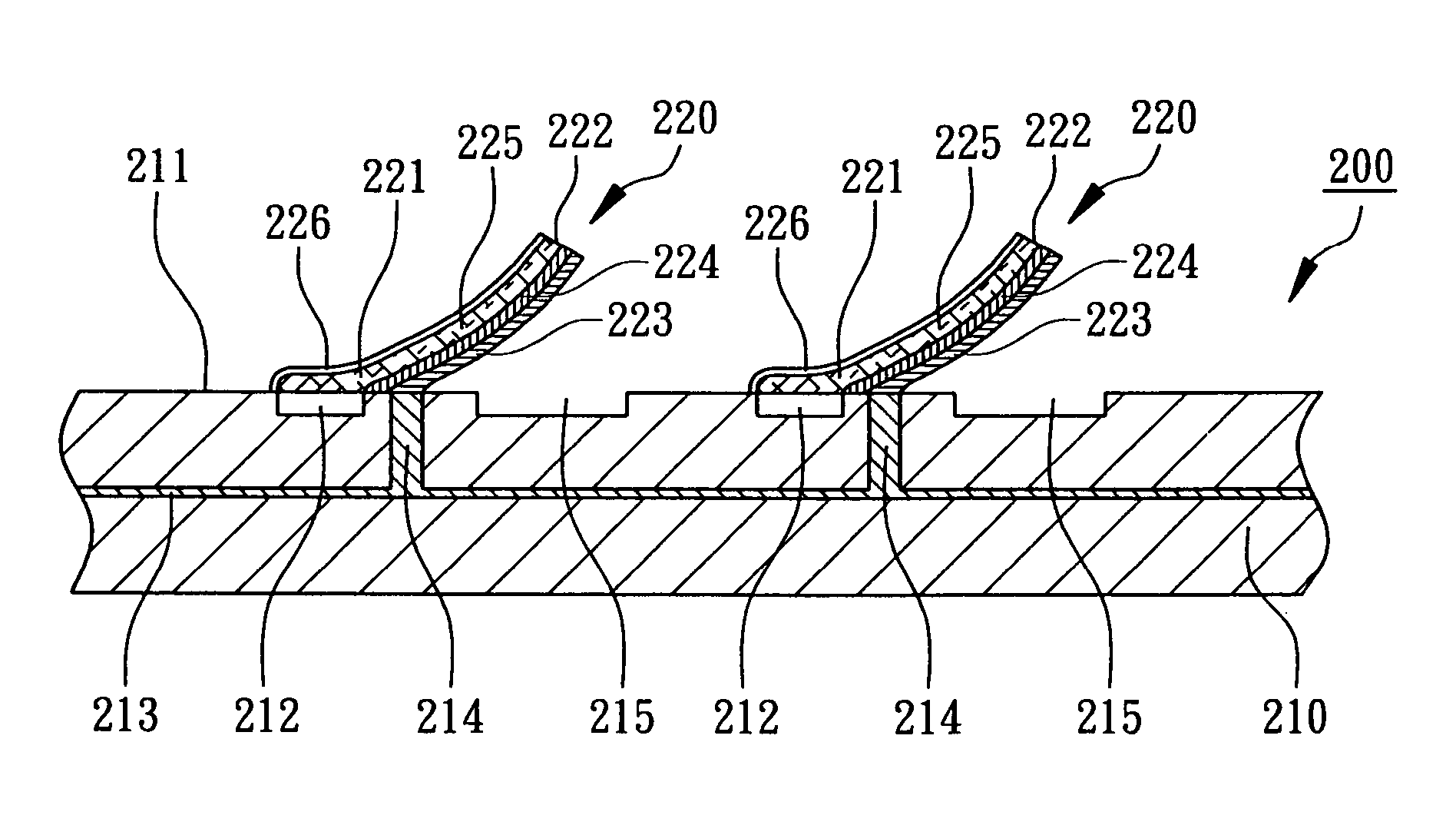

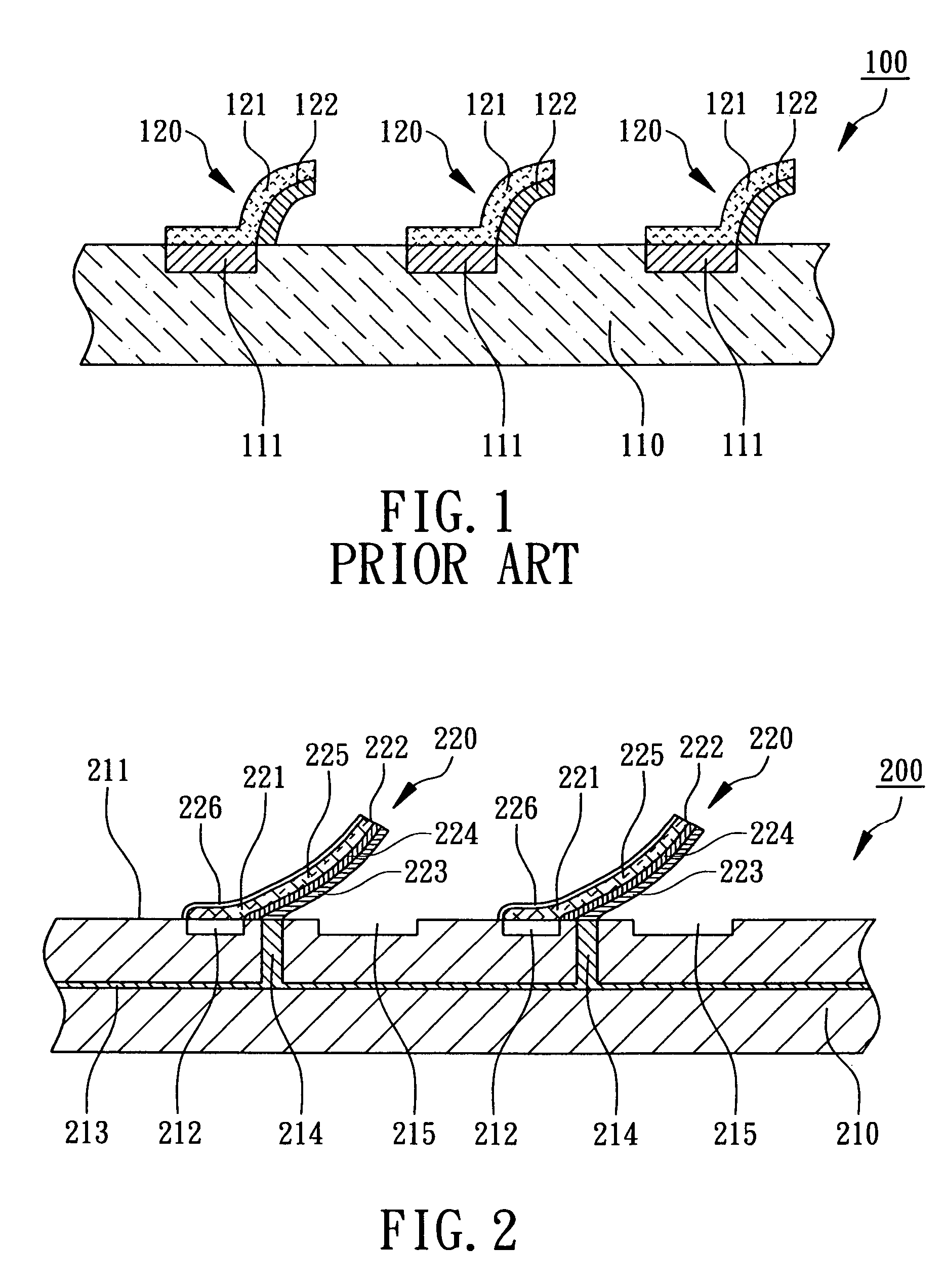

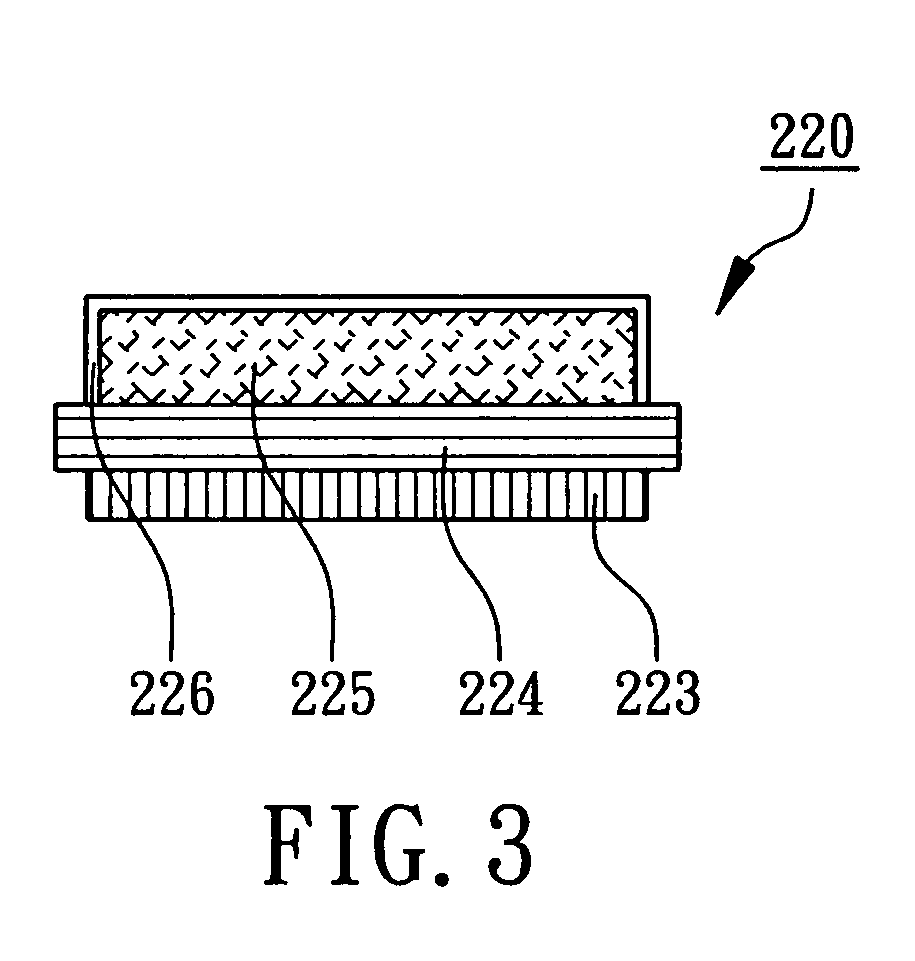

Electronic device with a warped spring connector

InactiveUS20060042834A1Absorb moreAvoid Metal ContaminationElectrical measurement instrument detailsSemiconductor/solid-state device detailsGround planeThermal expansion

An electronic device comprises a substrate and at least a warped spring connector. The substrate has a signal bonding pad and a ground plane. The warped spring connector is disposed on the substrate and is connected to the bonding pad. The warped spring connector includes at least a ground lead electrically connected to the ground plane, a dielectric layer on the ground lead, and a transmitting lead on the dielectric layer. The transmitting lead is bonded to the bonding pad. The ground lead is isolated from and close to the transmitting lead to solve cross-talk and noise problem. Furthermore, the coefficient of thermal expansion of the transmitting lead is different from that of the dielectric layer or the ground lead such that the warped spring connector has a suspending end suspending away from the substrate.

Owner:CHIPMOS TECH INC

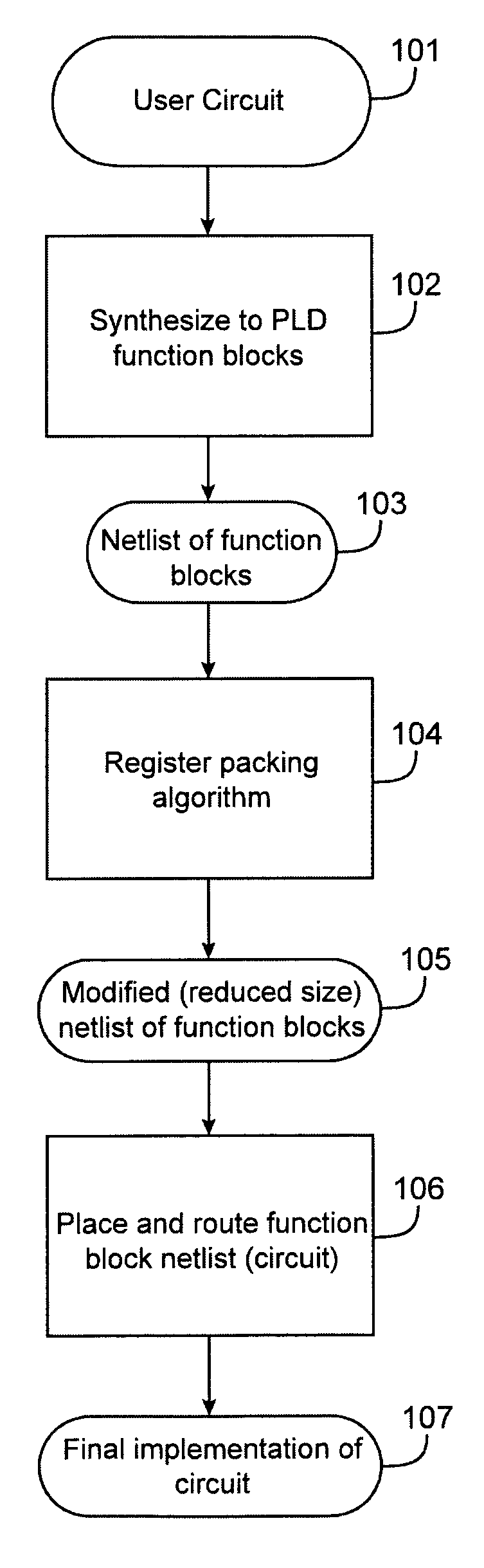

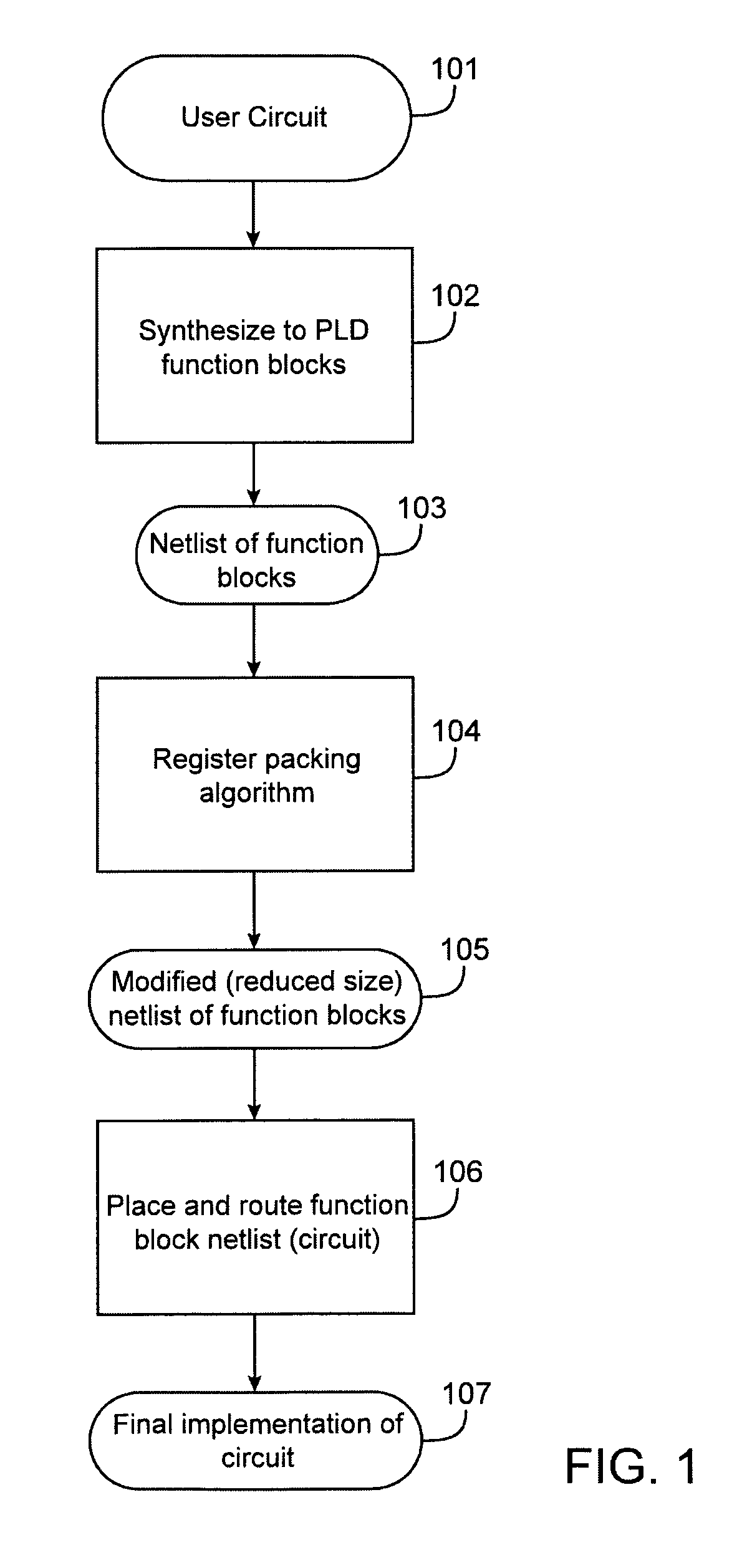

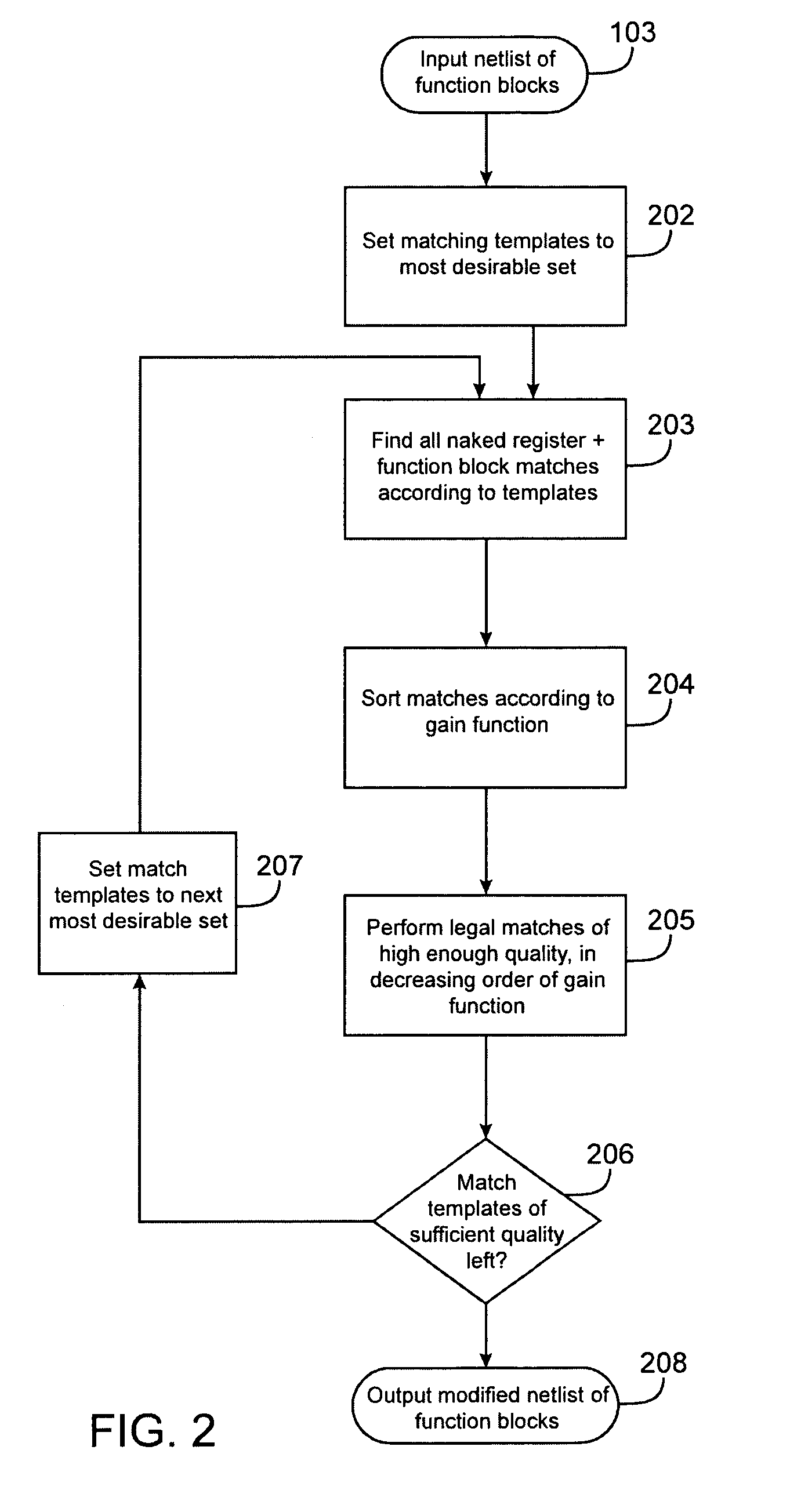

Techniques for identifying functional blocks in a design that match a template and combining the functional blocks into fewer programmable circuit elements

InactiveUS6957412B1Rout delay be minimizeDelay minimizationCAD circuit designProgram controlTemplate matchingProgrammable circuits

Techniques are provided that combine functional blocks in a user design into fewer programmable circuit elements. Systems and methods of the present invention can combine functional blocks in a user design into a single programmable circuit element. A plurality of functional blocks in a user design that can be combined are identified. The possible combinations of functional blocks can be sorted according to a gain function. The gain function can, for example, weigh routing delays caused by a combination. The most desirable combination is selected from the sorted list of possible combinations. The selected combination is checked to see if it is feasible in light of electrical and user-specified constraints. If the combination is feasible, the combination is performed. Combinations continue to be performed by selecting the most desirable combinations from the sorted list.

Owner:ALTERA CORP

Disposable controlled completely-degradable plastic packing bag and preparation method thereof

The invention discloses a disposable controlled completely-degradable plastic packing bag, which is formed through melting, blending, extruding and film-blowing of components comprising in parts by weight: 20 to 45 parts of polyvinyl alcohol, 72 to 87 parts of starch, 10 to 20 parts of micromolecule plasticizer, 0.2 to 2 parts of modified inorganic nanometer additive, 0.1 to 1.5 parts of antioxidant, 0.5 to 3 parts of compatibilizer, 8 to 15 parts of inorganic filler, 0.1 to 1 part of ultraviolet absorber, and 0.1 to 1 part of pigment. The invention further discloses a preparation method of the plastic packing bag. The nanometer composite modifier in the packing bag adopts a micromolecule plasticizer easy to form a hydrogen bond with the starch, a certain amount of inorganic nanometer additives subject to surface treatment are added in the packing bag, so that after PVA (polyvinyl acetate) is modified by the nanometer composite modifier, the use amount of the molecule plasticizers is reduced greatly, the cost is lowed, the reduction of the mechanical property of a film is avoided, and the controlled completely-degradable film with excellent mechanical property and the use performance can be obtained.

Owner:NINGXIA GREEN BIODEGRADABLE PROD +1

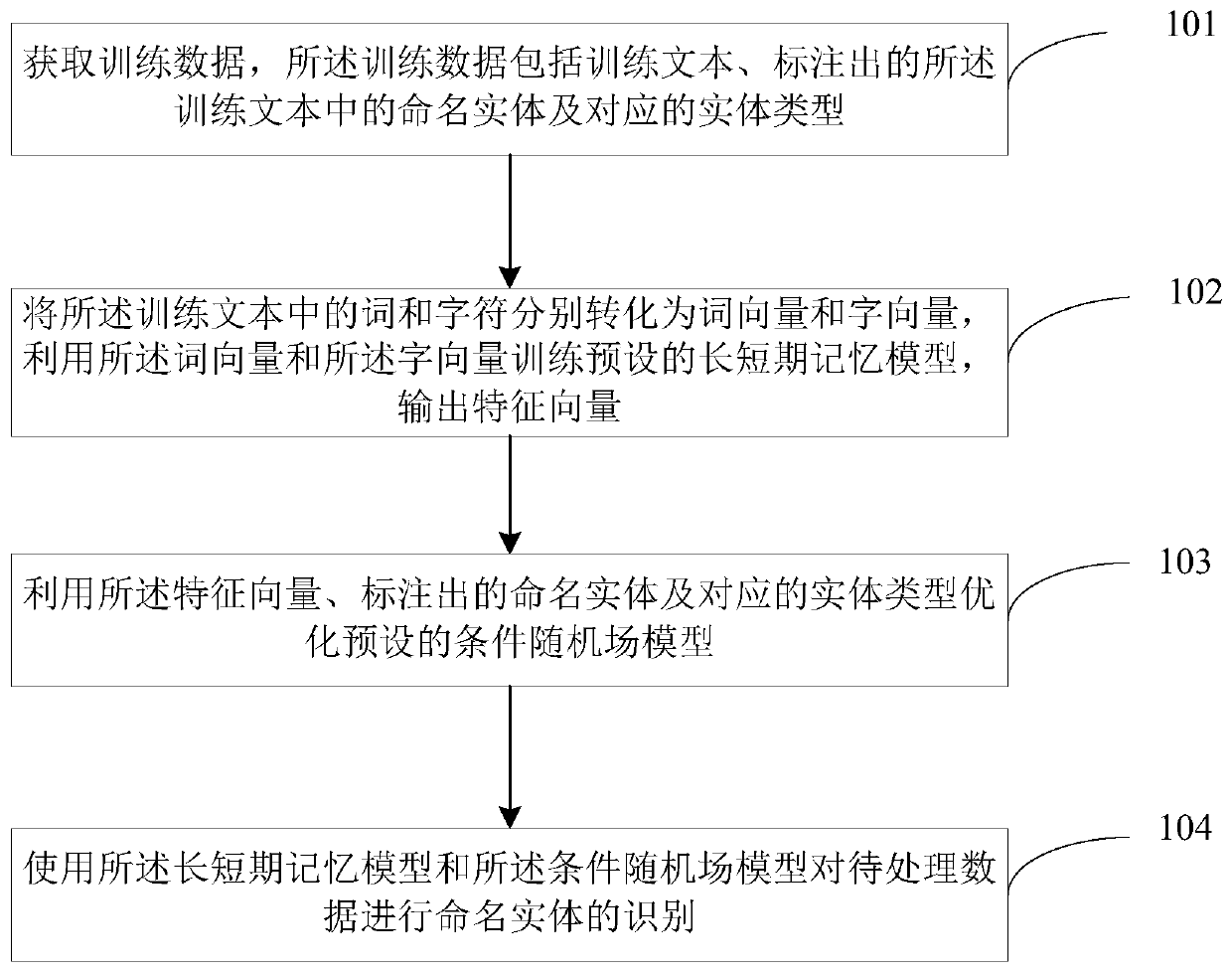

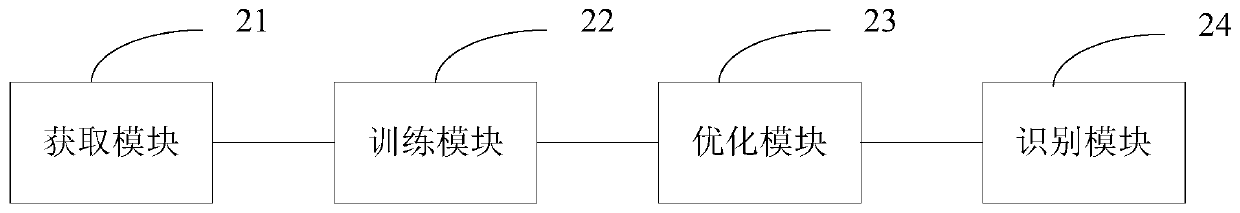

Named entity identification method and device

ActiveCN109871545AReduce errorsHigh precisionMathematical modelsNatural language data processingFeature vectorConditional random field

The invention provides a named entity identification method and device, and belongs to the technical field of information. The named entity recognition method comprises the steps that training data are acquired, and the training data comprise a training text, named entities in the marked training text and corresponding entity types; the method comprises the following steps of converting words andcharacters in the training text into word vectors and character vectors respectively, training a preset long-short-term memory model by using the word vectors and the character vectors, and outputtingfeature vectors; optimizing a preset conditional random field model by utilizing the feature vector, the marked named entity and the corresponding entity type; And performing named entity identification on to-be-processed data by using the long short-term memory model and the conditional random field model. According to the technical scheme, the named entity identification precision can be improved.

Owner:BOE TECH GRP CO LTD

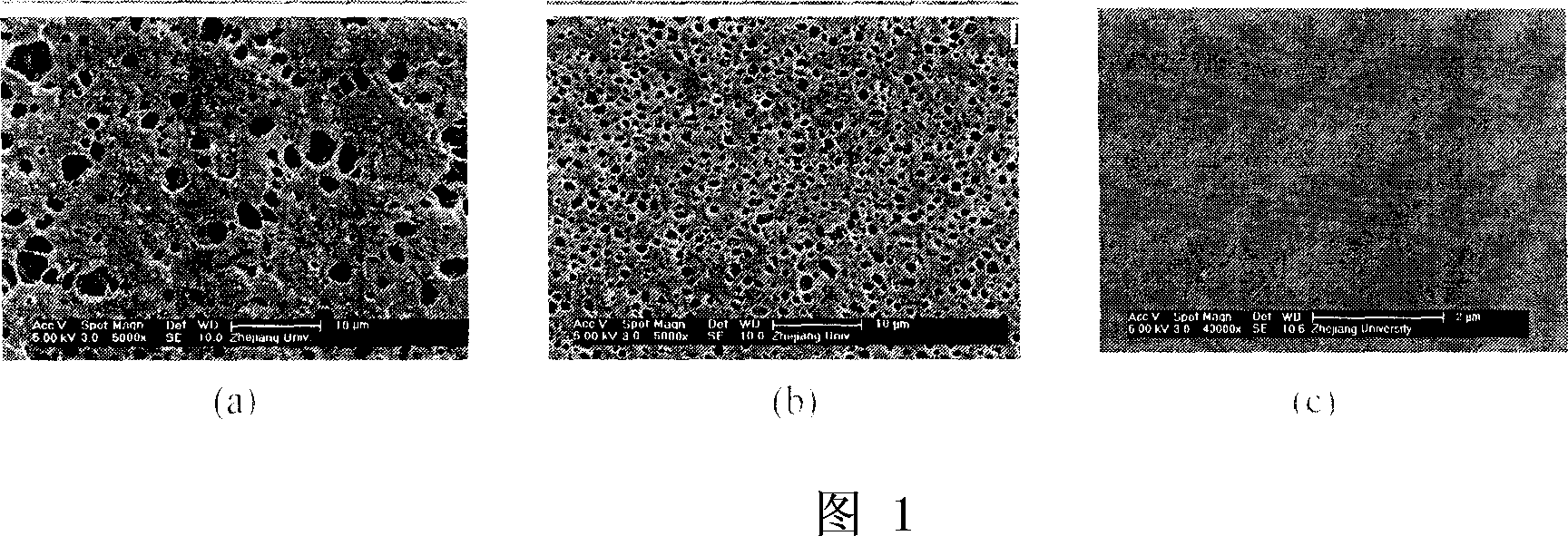

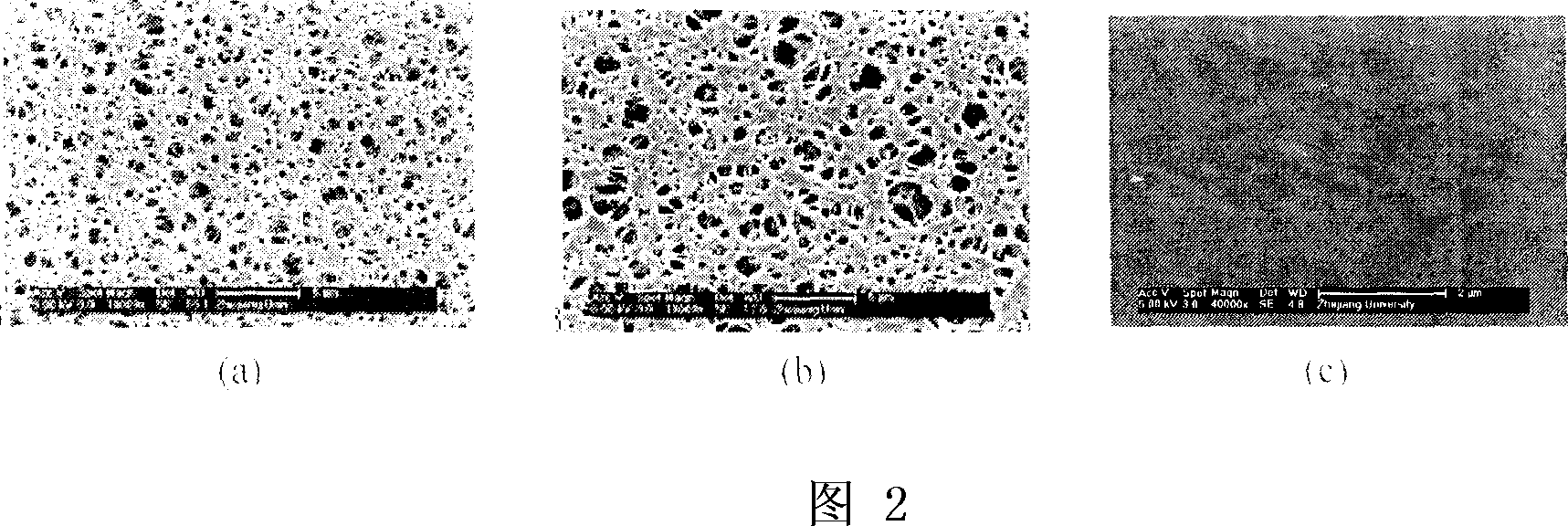

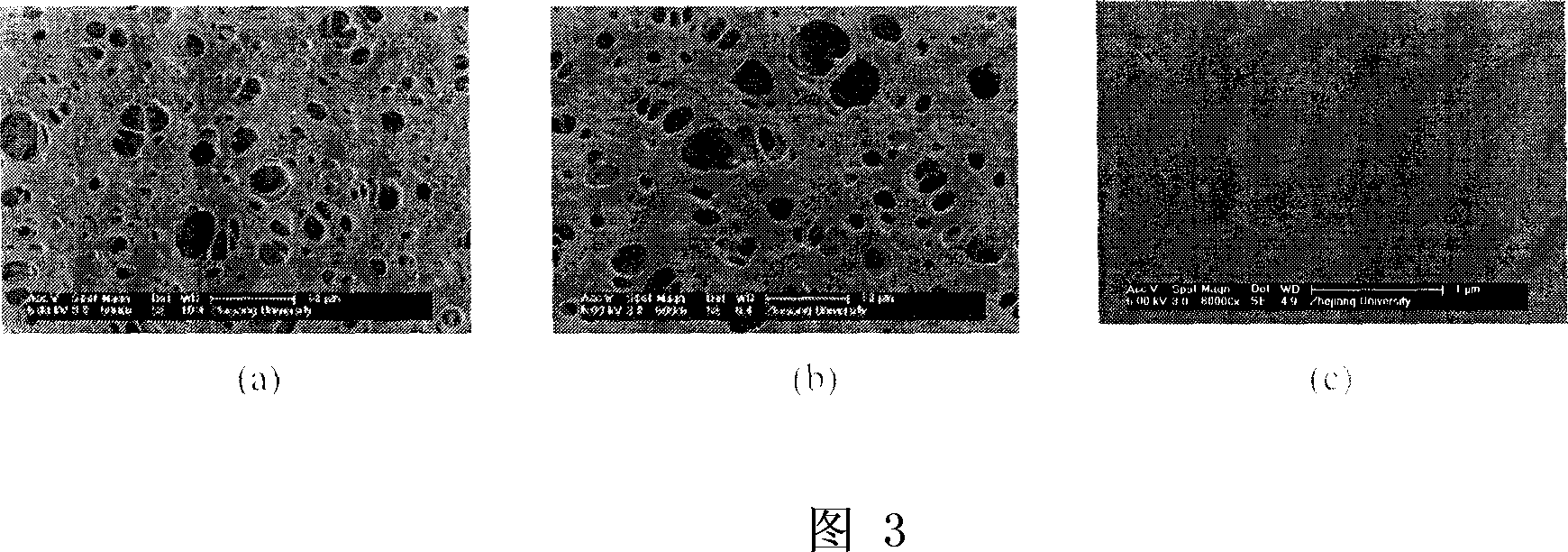

Lithium ion conducting gel film containing porous polymer framework and preparation method thereof

InactiveCN1927921ANo leakageImprove securitySecondary cellsCell component detailsCross-linkPhase conversion

The present invention discloses conducting lithium gel film containing porous polymer skeleton and its preparation process. The preparation process includes following steps: 1. preparing porous polypropylene glycol modified polyvinylidene fluoride or polyether sulfone film through phase conversion; 2. preparing electrolyte through mixing carbonate, lithium salt, polyglycol and diisocyanate at 10-20 deg.c; 3. soaking the porous film in the electrolyte at 10-20 deg.c for 10-30 min; and 4. treating electrolyte adsorbing porous film at 60 deg.c for 8-10 for cross-linking to form gel. The conducting lithium gel film has high strength, stable shape, high lithium salt electrolyte loading amount and conductivity of 10<-3>-10<-2> S / cm, and is suitable for use in polymer lithium cell with integrated diaphragm and electrolyte.

Owner:ZHEJIANG UNIV

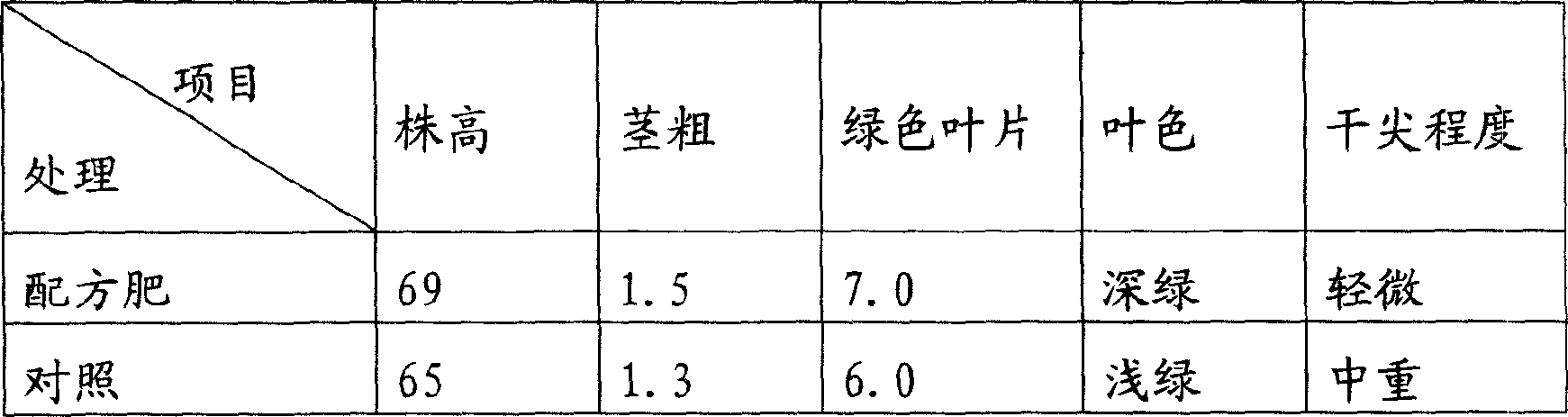

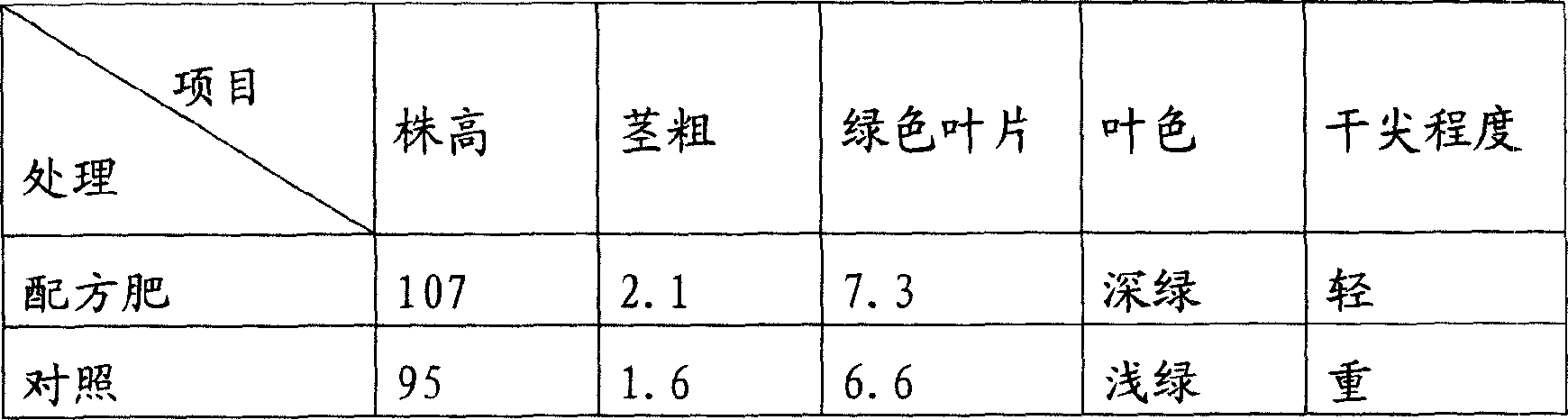

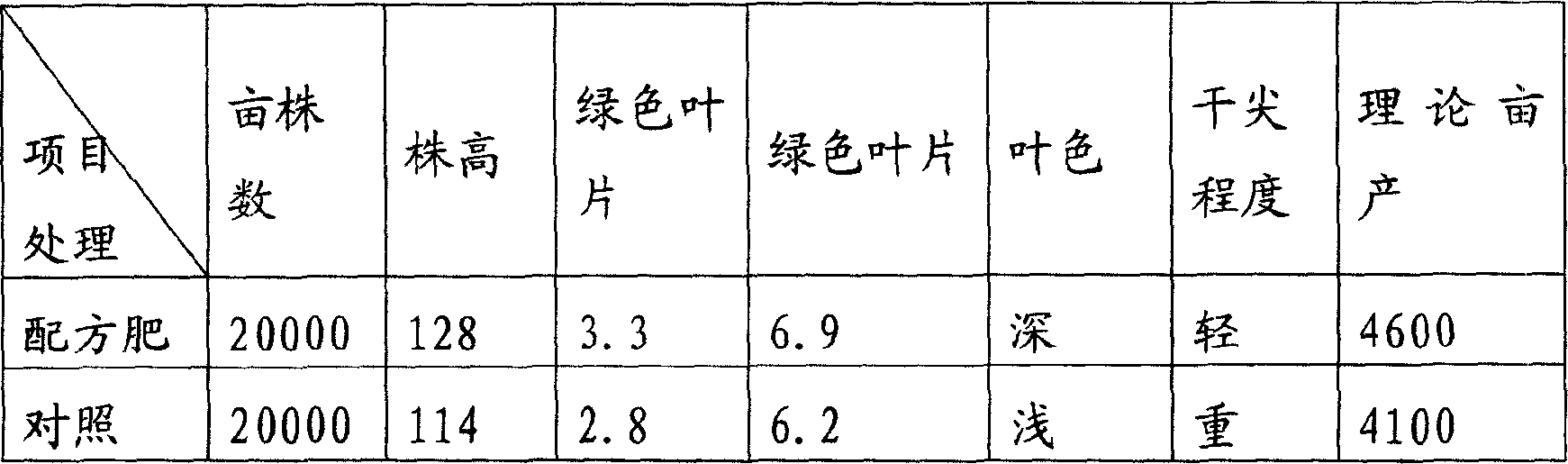

Full element formula fertilizer and its preparing method and use

InactiveCN1944356AAbsorb moreAbsorption overall balanceFertilizer mixturesNitrogen fertilizerCrop quality

The present invention discloses one kind of full element fertilizer and its preparation process and application. The full element fertilizer consists of nitrogen fertilizer 20 wt%, phosphate fertilizer 15 wt%, potash fertilizer 15 wt%, calcium fertilizer 20 wt%, magnesium fertilizer 15 wt%, silicon fertilizer 6 wt%, sulfur fertilizer 2 wt%, zinc fertilizer 2 wt% and humic acid 5 wt%. The full element fertilizer has obvious yield increasing and crop quality raising effects, is suitable for different stages of crop and environment friendly.

Owner:常同忠

Moisture-absorbing and bacteriostatic base cloth of beauty mask made of spunlace non-woven fabric and preparation method thereof

ActiveCN108166157AImprove the problem of viscosity instabilityGood viscosity stabilityNon-woven fabricsArtifical filament manufactureYarnViscose

The invention discloses moisture-absorbing and bacteriostatic base cloth of a beauty mask made of spunlace non-woven fabric and a preparation method thereof, relating to the technical field of non-woven fabrics. The moisture-absorbing and bacteriostatic base cloth is composed of following fibers, by weight, 40-60% of sodium alginate viscose fibers and 40%-60% of chitosan viscose fibers. The preparation method comprises the following steps: firstly preparing the sodium alginate viscose fibers and the chitosan viscose fibers; next, respectively opening and carding the chitosan viscose fibers; then, netting in an intersected manner; reinforcing a fiber net that is laid well by spunlace, drying the fiber net so as to obtain the base cloth. Sodium alginate and chitosan are respectively added into viscose primary liquid to spin viscose yarns. Epichlorohydrin is utilized such that sodium alginate and chitosan are closely combined with viscose. Sodium alginate viscose fibers and chitosan viscose fibers produced show great air permeability, water retention and moisture absorption capabilities and are capable of eliminating bacteria and inhibiting bacteria. Then, non-woven fabric made by intersecting netting and spunlace reinforcement can be used for material of base piece of the mask. The moisture-absorbing and bacteriostatic base cloth is comfortable and skin-friendly and capable of diminishing inflammation and inhibiting bacteria. Skin can be cleaned and effectively protected. The damage of cosmetics to the skin is minimized.

Owner:HEFEI C&P NONWOVEN PROD

Chinese traditional medicine composition for treating arthritis hyperosteogeny intervertebral disc hernia ion

InactiveCN101095785AQuick resultsGood curative effectAnthropod material medical ingredientsSkeletal disorderArthritisANGELICA ROOT

The invention discloses a Chinese medicinal composition for treating arthritis, osteoproliferation and disc protrusion, which comprises the following raw material constituents (by weight ratio): large-leaf gentian root, ledebouriella root, Ligusticum wallichii, Clematis chinensis, achyranthes and cyathula root, root of herbaceous peony, prepared rehmannia root, Chinese angelica root, eucommia bark, Cinnamomum cassia, wolferry fruit, morinda root, dipsacus root, poria cocos, Chinese ephedra, Loranthus mulberry mistletoe, cassia twig, corydalis tuber, notoginseng, notopterygium root, root of red rooted saliva, tetrandra root, spatholobus stem, dried orange peel, licorice root, pangolin scales, buthus martensi karsch, earthworm, wood louse, dragon's blood resin, wasp's nest and drynaria.

Owner:韩世昌

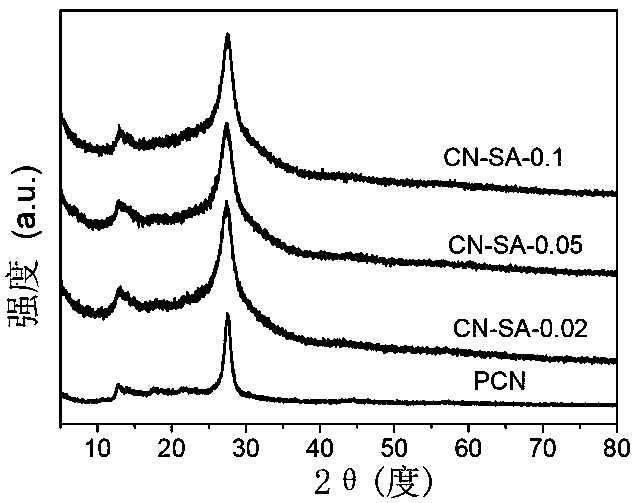

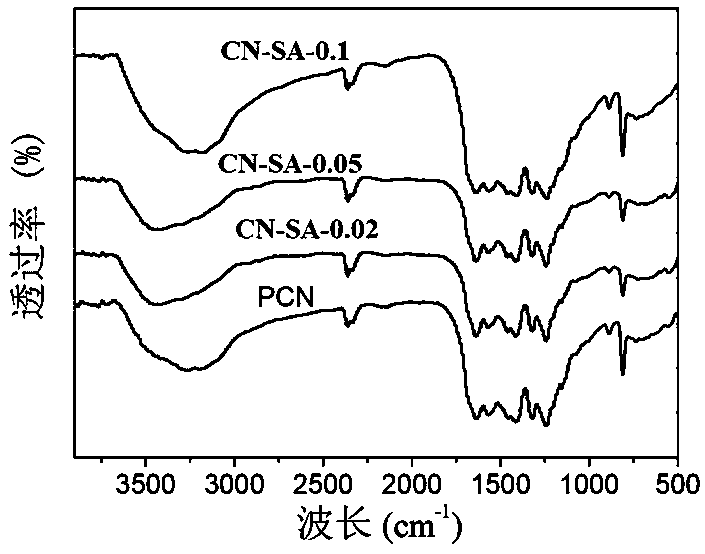

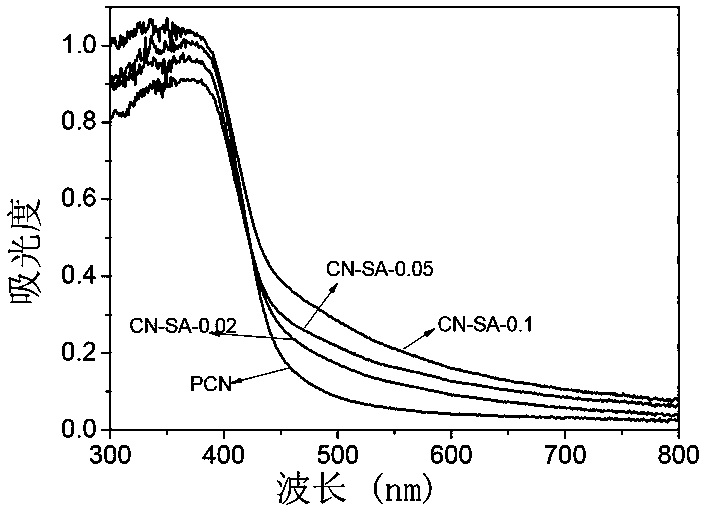

Modified graphite phase carbon nitride photocatalyst as well as preparation method and application thereof

ActiveCN108940344AHigh specific surface areaEasy transferPhysical/chemical process catalystsWater/sewage treatment by irradiationElectron holeReactive site

The invention discloses a modified graphite phase carbon nitride photocatalyst as well as a preparation method and application thereof. The modified graphite phase carbon nitride photocatalyst is prepared from urea and salicylic acid serving as raw materials by virtue of calcination, wherein a mass ratio of urea to salicylic acid is 1:(0.002-0.02). The modified graphite phase carbon nitride photocatalyst disclosed by the invention has the advantages of being high in specific surface area, wide in light absorption range, low in electron-hole pair recombination rate, excellent in photocatalyticperformance and the like, and has multiple reactive sites, excellent application value and application prospects. The preparation method has the advantages of being simple in process, wide in raw material source, low in cost, high in preparation efficiency, high in yield and the like, is suitable for large-scale preparation and is favorable for industrial production. The modified graphite phase carbon nitride photocatalyst disclosed by the invention can be used for degrading organic pollutants, has the advantages of being simple in process, convenient to operate, low in cost, high in treatmentefficiency, excellent in degradation effect and the like, and has excellent effects of degrading the various organic pollutants.

Owner:HUNAN UNIV

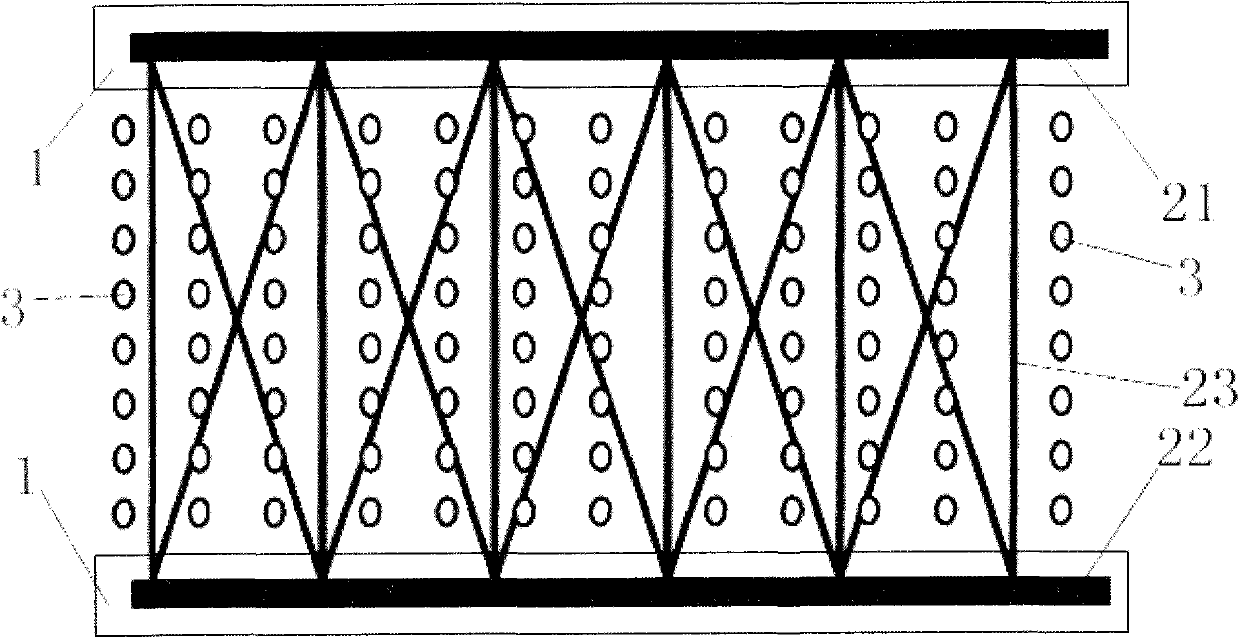

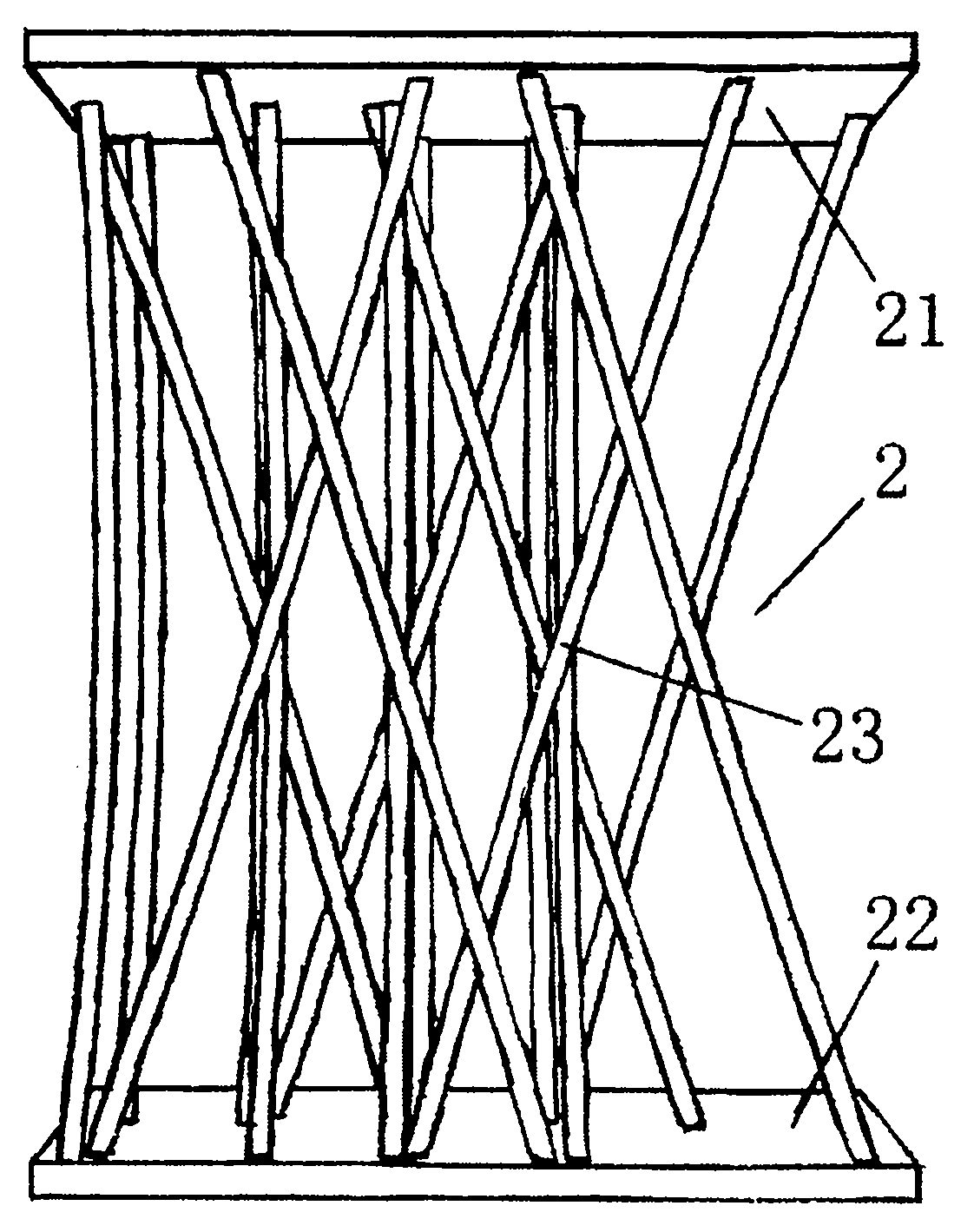

Shock-resisting flexible protection structure and manufacturing method

InactiveCN104213322AGive full play to the thickening effectAbsorb moreWarp knittingLiquid statePolyethylene glycol

The invention relates to the technical field of a protection structure, in particular to a shock-resisting flexible protection structure and also provides a manufacturing method of the shock-resisting flexible protection structure. The shock-resisting flexible protection structure comprises silicone rubber, a three-dimensional warp-knitted spacer fabric and a shear thickening solution, wherein the shear thickening solution comprises nano silicon dioxide particles and polyethylene glycol, the shear thickening solution is filled in an intermediate layer of the warp-knitted spacer fabric, the silicone rubber is used for packaging two sides and periphery of the warp-knitted spacer fabric to form a leak-proof bagged sealing structure. By utilizing the nano silicone dioxide particles, the thickening effect of the shear thickening solution can be adequately played, the nano silicon dioxide particles can be instantaneously converted from liquid state to solid state when suffering the shock effect, and the intelligent conversion is realized; by utilizing the warp-knitted spacer fabric, the entire flexible protection structure is stable, the mechanical property is excellent, and the shock-resisting flexible protection structure can be used for bending parts and curve structure parts such as joints.

Owner:YANCHENG INST OF TECH

Fertilizer special for vegetables and preparation method thereof

InactiveCN106588501AHigh porosityImprove permeabilityExcrement fertilisersPotassium fertilisersEcological environmentSodium Bentonite

The invention discloses a fertilizer special for vegetables and a preparation method thereof. The fertilizer comprises the following raw materials in parts by weight: 60-80 parts of straws, 30-45 parts of animal wastes, 4-15 parts of powdered rock phosphate, 8-20 parts of potassium mineral powder, 1.5-3.5 parts of saccharides, 0.4-0.7 part of EM bacterium liquid, 5-9 parts of modified vermiculite power, 1-4 parts of bentonite, 1-4 parts of diatomite, 0.2-0.8 part of a plant growth regulator, 10-16 parts of traditional Chinese medicine dregs and 0.05-0.12 part of an enzymic preparation. According to the fertilizer special for vegetables and the preparation method thereof provided by the invention, the formula is reasonable, the occurrence rate of vegetable insect pests is reduced, and the stress resistance of the vegetables is improved. Meanwhile, the ecological environment of soil is improved, the soil fertility and sustainability are improved, the absorption of the vegetables on nutrients is comprehensive, the absorption efficiency is high, the quality of the vegetables is improved, and the yield of the vegetables is increased.

Owner:李梦

Microbial soil restorative and preparation method thereof

InactiveCN101642771AIncrease profitPromote growthContaminated soil reclamationPhosphateChloride sodium

The invention relates to a microbial soil restorative prepared by fermenting corn stalks, wheat straw, wheat bran, corn meal, rapeseed meal, lime, potassium dihydrogen phosphate, sodium chloride, water and liquid strains in a fermentation bin. The preparation method of the microbial soil restorative comprises the following steps: firstly, crushing the corn stalks and the wheat straw into particleswith diameters smaller than 5 mm; proportionally adding and mixing the wheat bran, the corn meal, the rapeseed meal, the potassium dihydrogen phosphate, the sodium chloride and the lime; then, adding25 percent of water; sending the mixture to an air steamer; adding high-pressure steam to the air steamer so as to increase the air pressure to 1-2 MPa and the temperature to 140-200 DEG C; pressuring for 4-6 minutes; releasing the mixture in the air steamer so that the temperature of the mixture falls to 30-37 DEG C; inoculating 5 percent of strains; fermenting in the fermentation bin at the temperature of 32-37 DEG C for 72 hours; discharging from the bin; and bagging to obtain a finished product. The produced microbial soil restorative contains a great amount of active substances, such asmicroorganisms, and the like, is capable of replacing fertilizer, has the growth-stimulating and disease-resistant functions, increases the yield by more than 20 percent and has low cost and easy industrialized production.

Owner:张培举

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com