Patents

Literature

676 results about "Fluid property" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Viscosity is the fluid property that determines the amount of resistance of the fluid to shear stress. It is the property of the fluid due to which the fluid offers resistance to flow of one layer of the fluid over another adjacent layer.

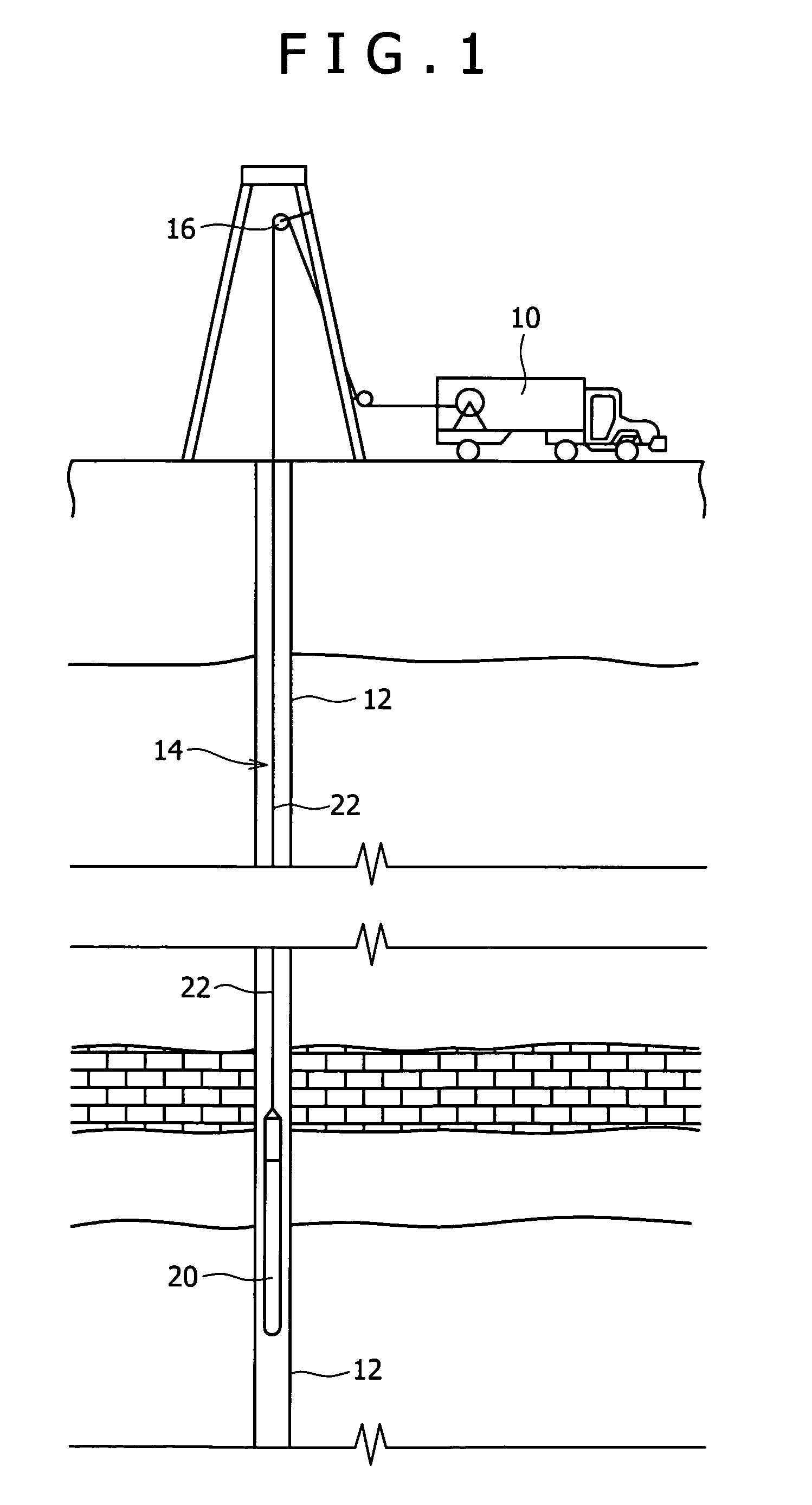

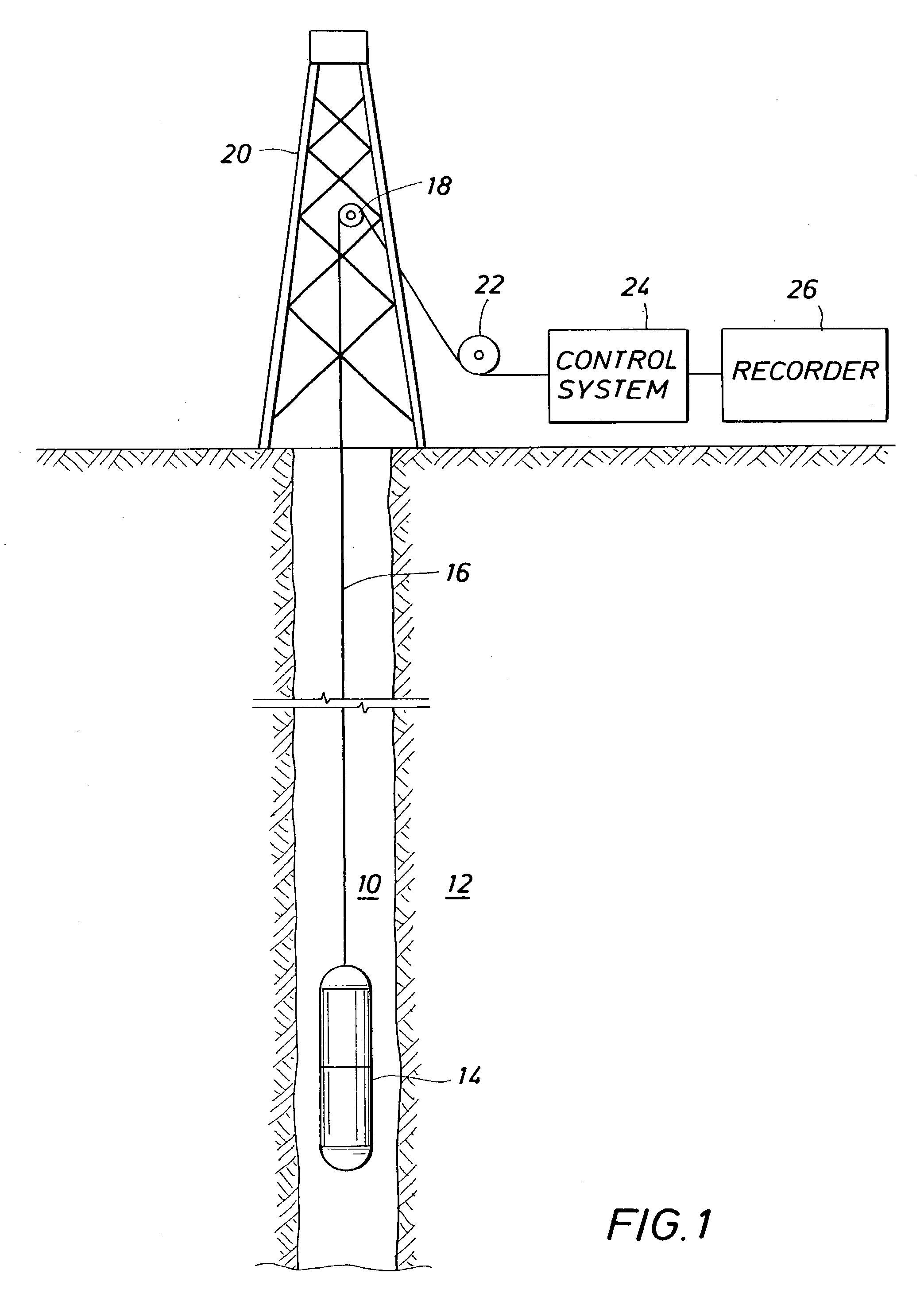

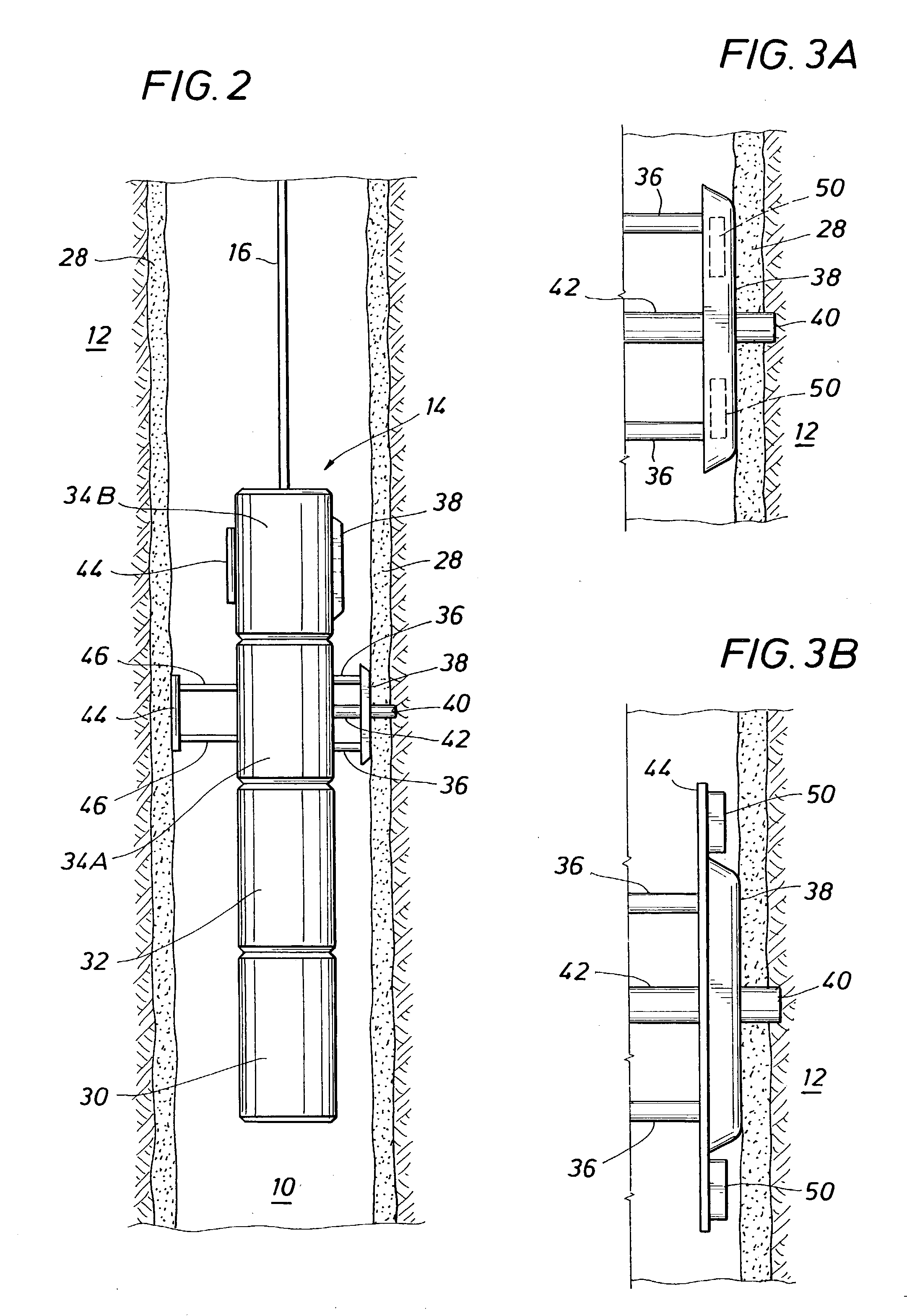

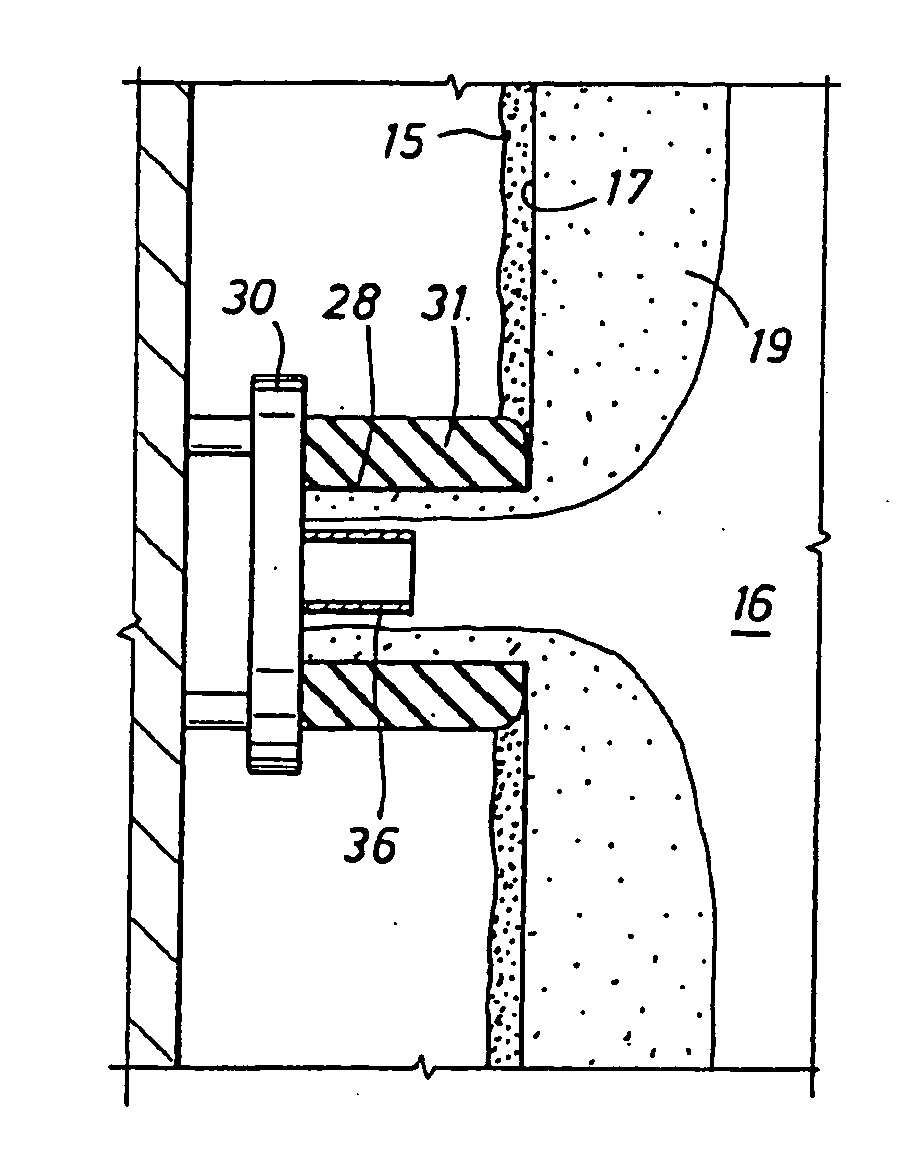

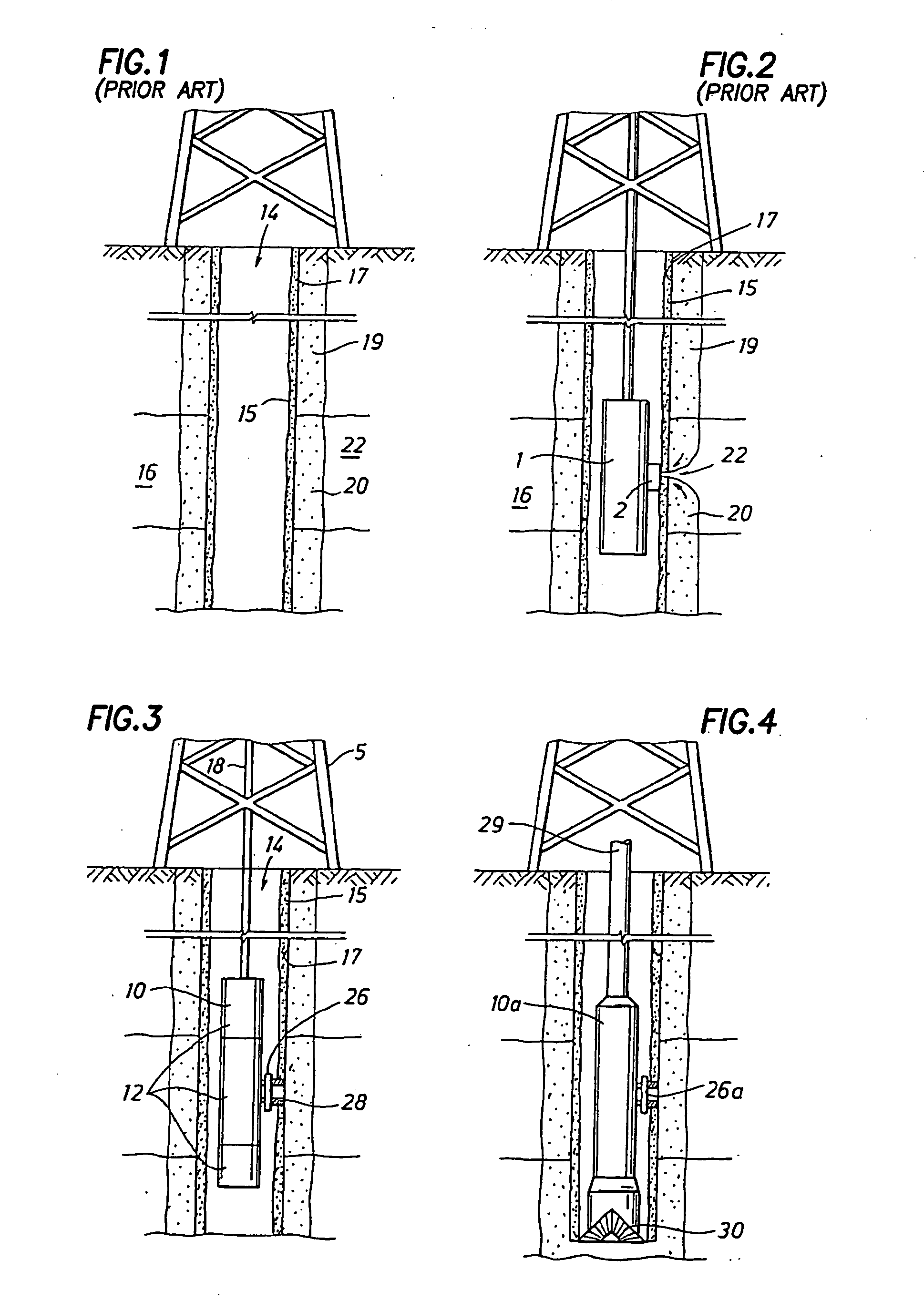

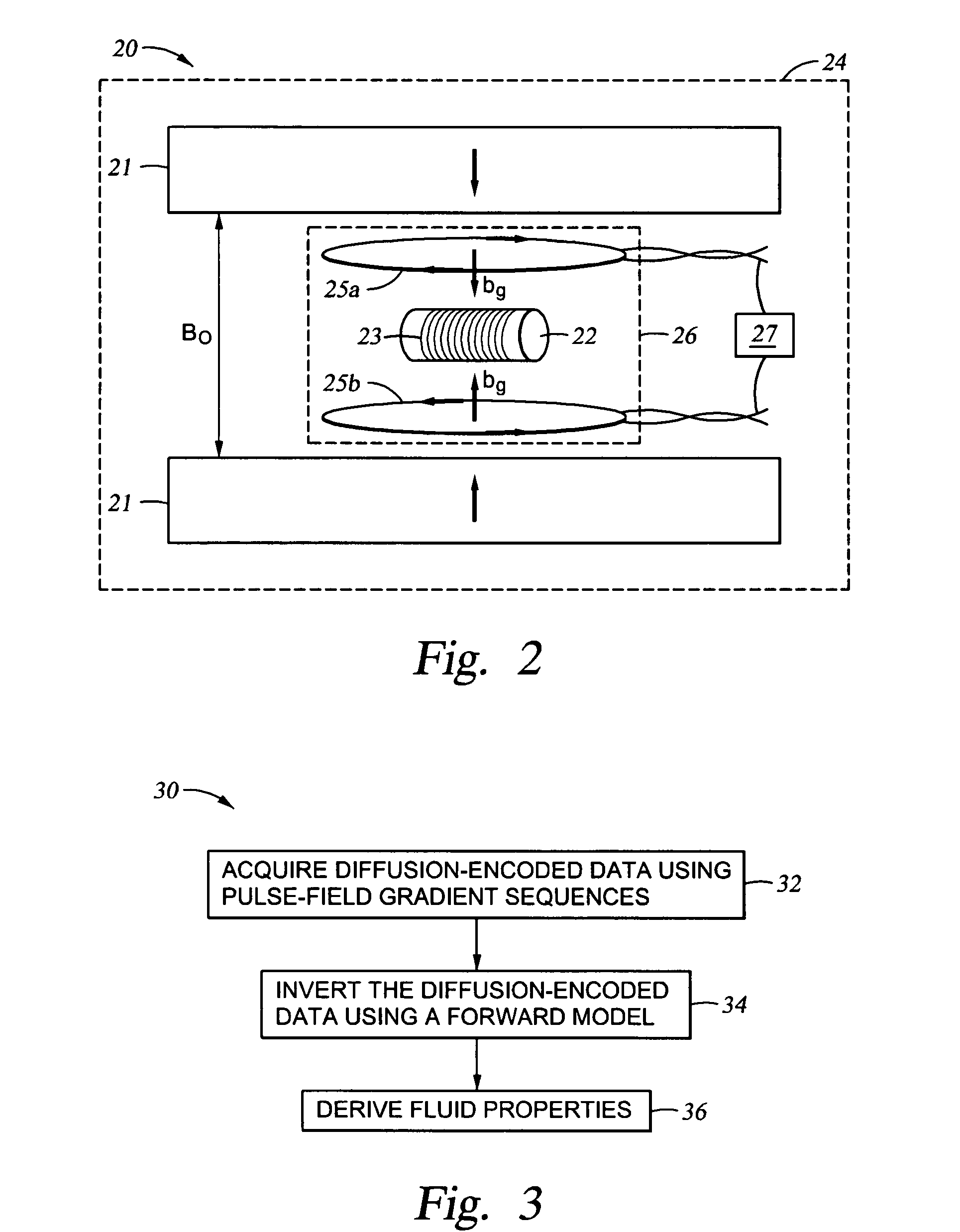

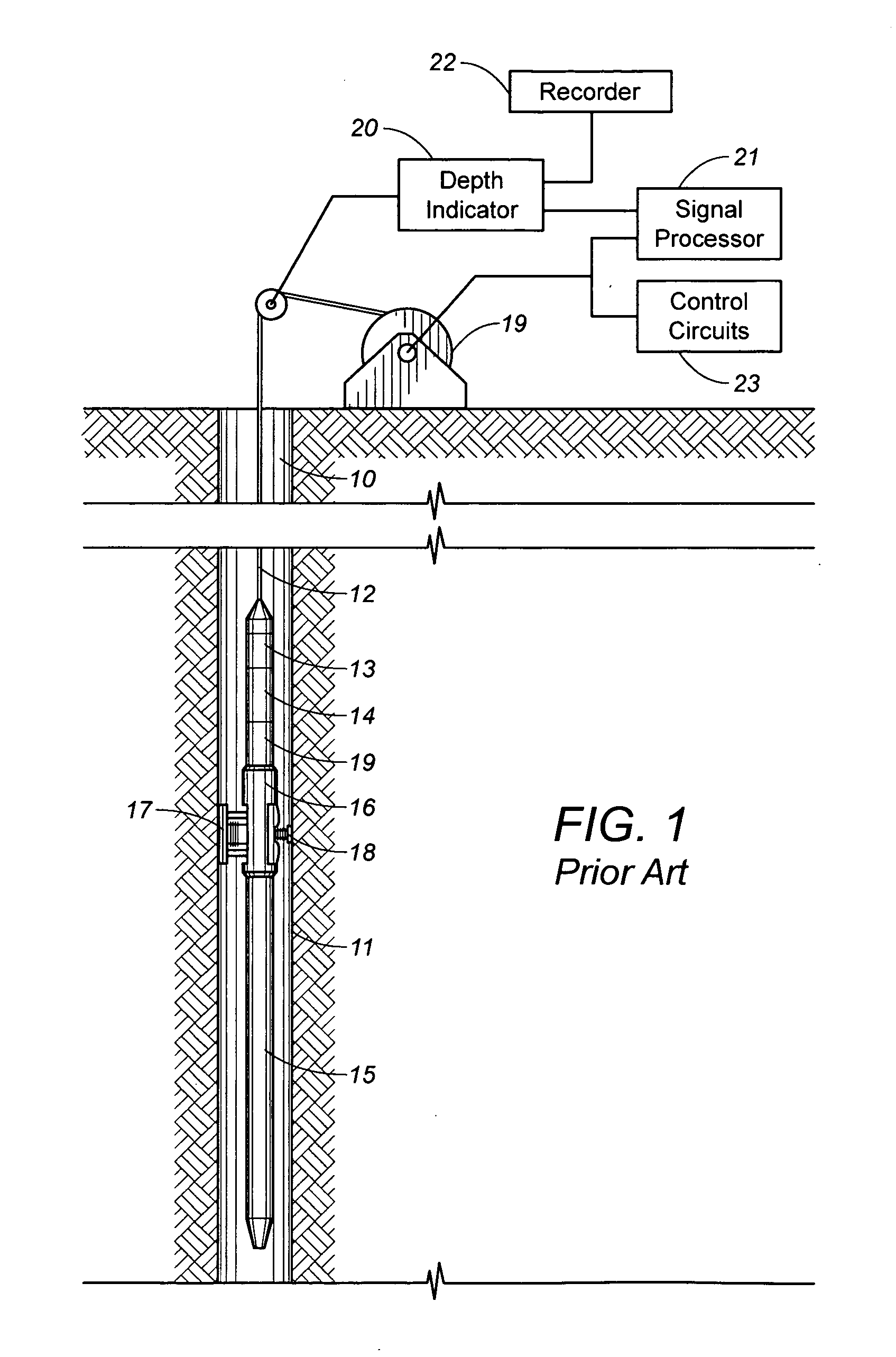

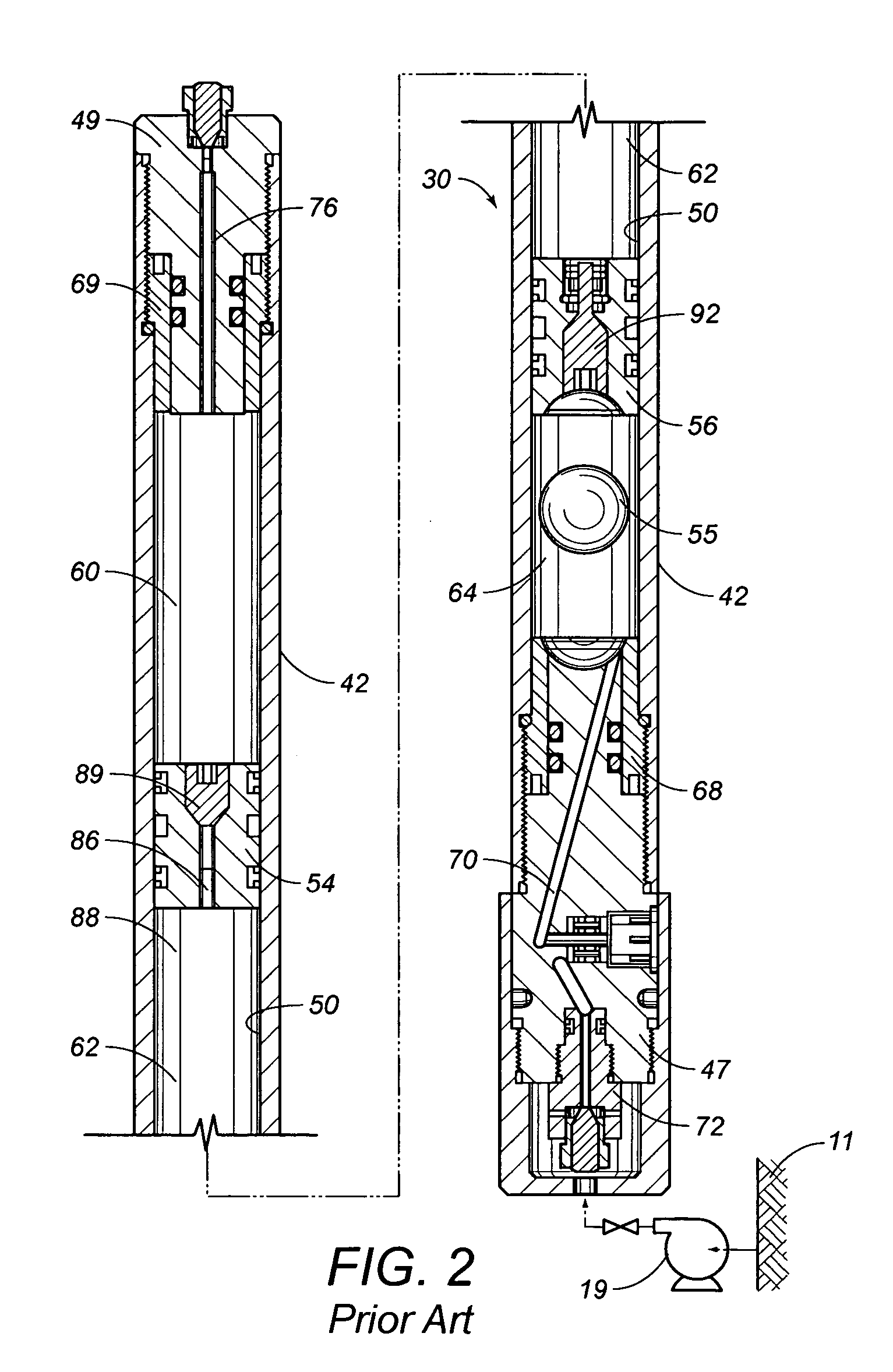

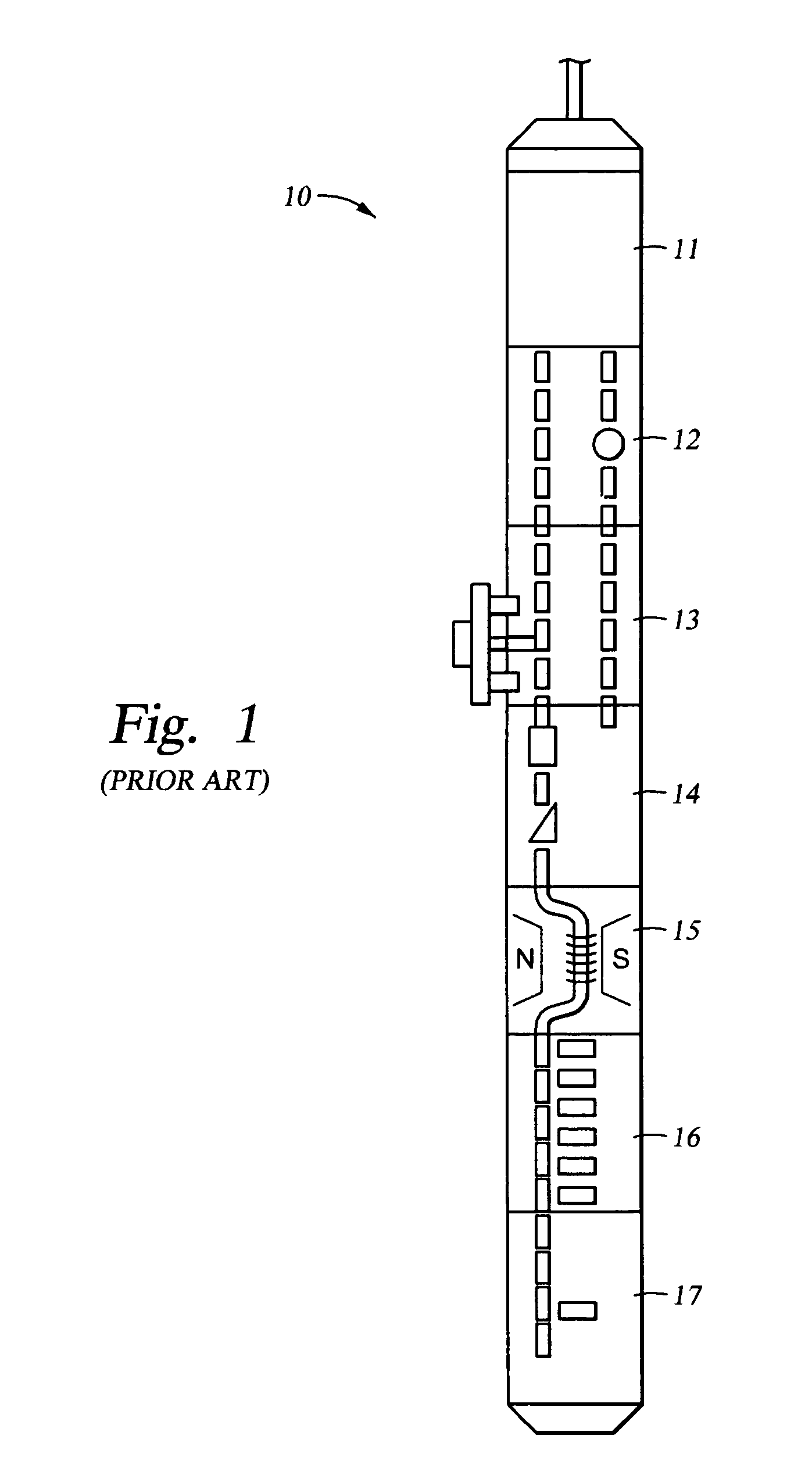

Method and apparatus for subterranean formation flow imaging

InactiveUS6856132B2Accurate measurementAccurately determineElectric/magnetic detection for well-loggingMaterial analysis by using resonanceMri imageGeophysics

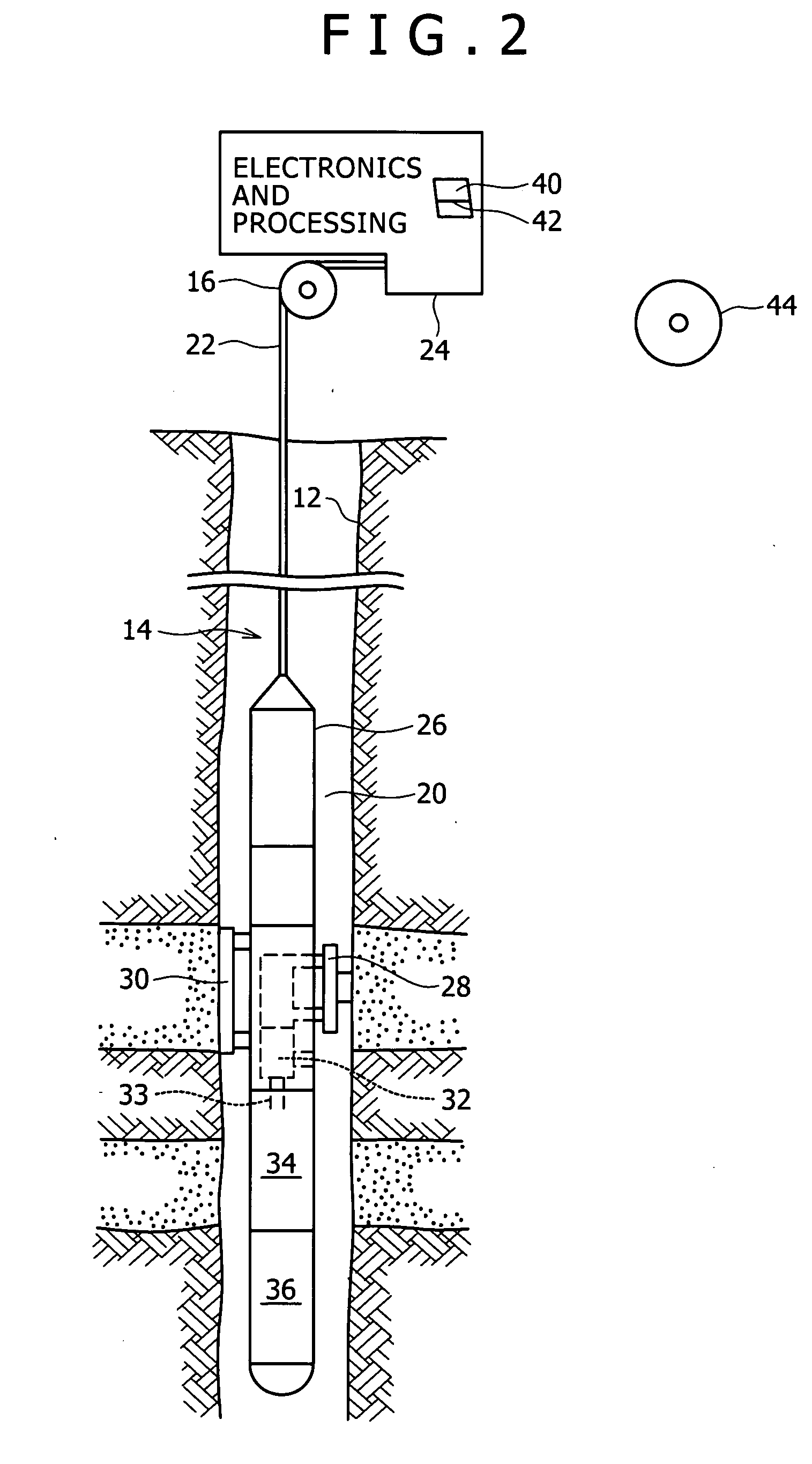

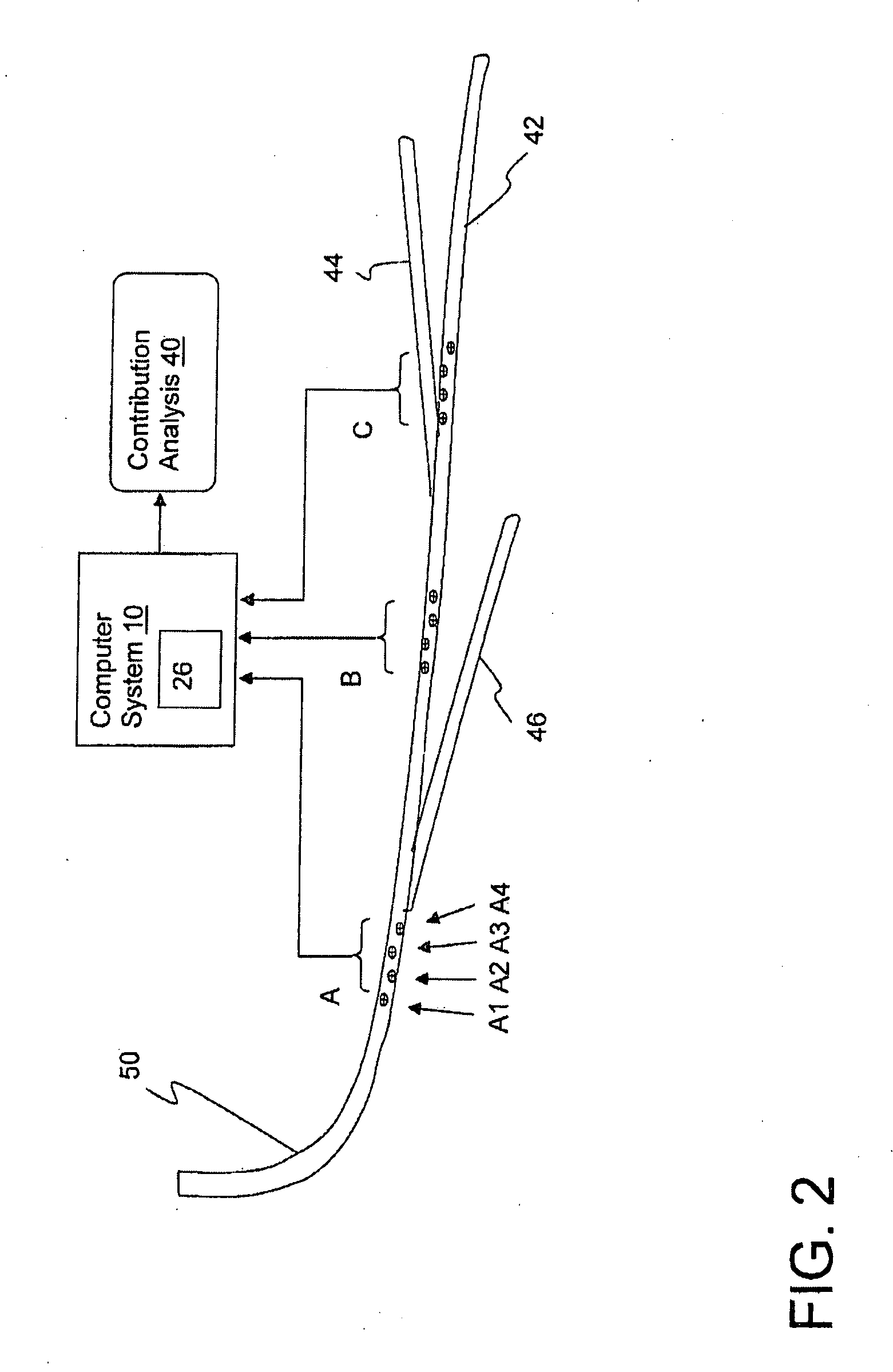

The present invention relates to a method and apparatus for measuring a property relating to fluid flow in an earth formation, more specifically to directly measuring formation permeability and other fluid characteristics. The present invention provides a method for determining the permeability of a hydrocarbon bearing earth formation, which method comprises the steps of: locating a tool at a selected position in a borehole penetrating the earth formation; inducing a flow of fluid within the earth formation to said tool; creating at least two MRI images of said fluid while flowing within the earth formation to said tool, said at least two images being created at different times; determining displacement of said fluid within the earth formation between said different times, using the at least two MRI images.

Owner:SHELL OIL CO

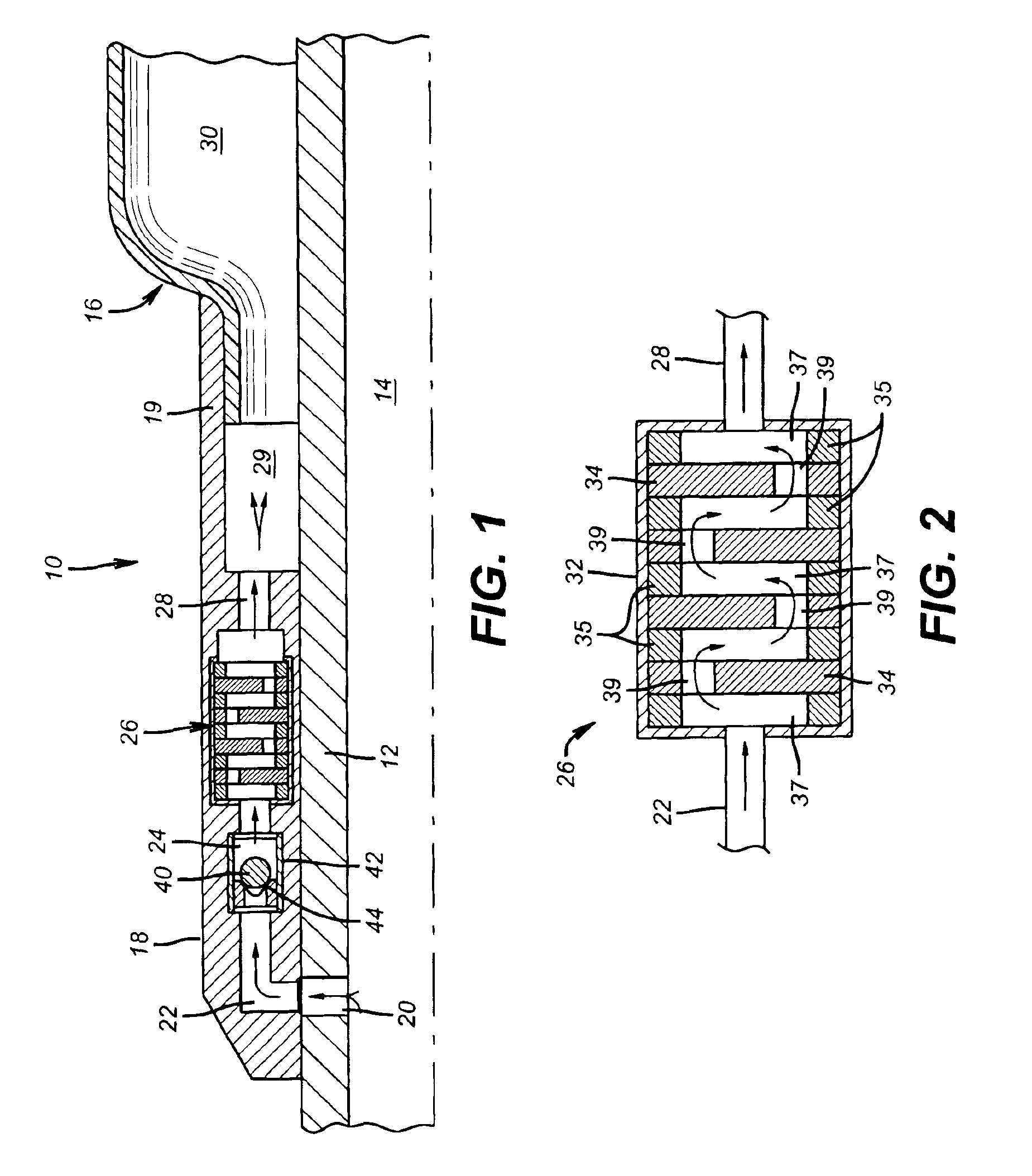

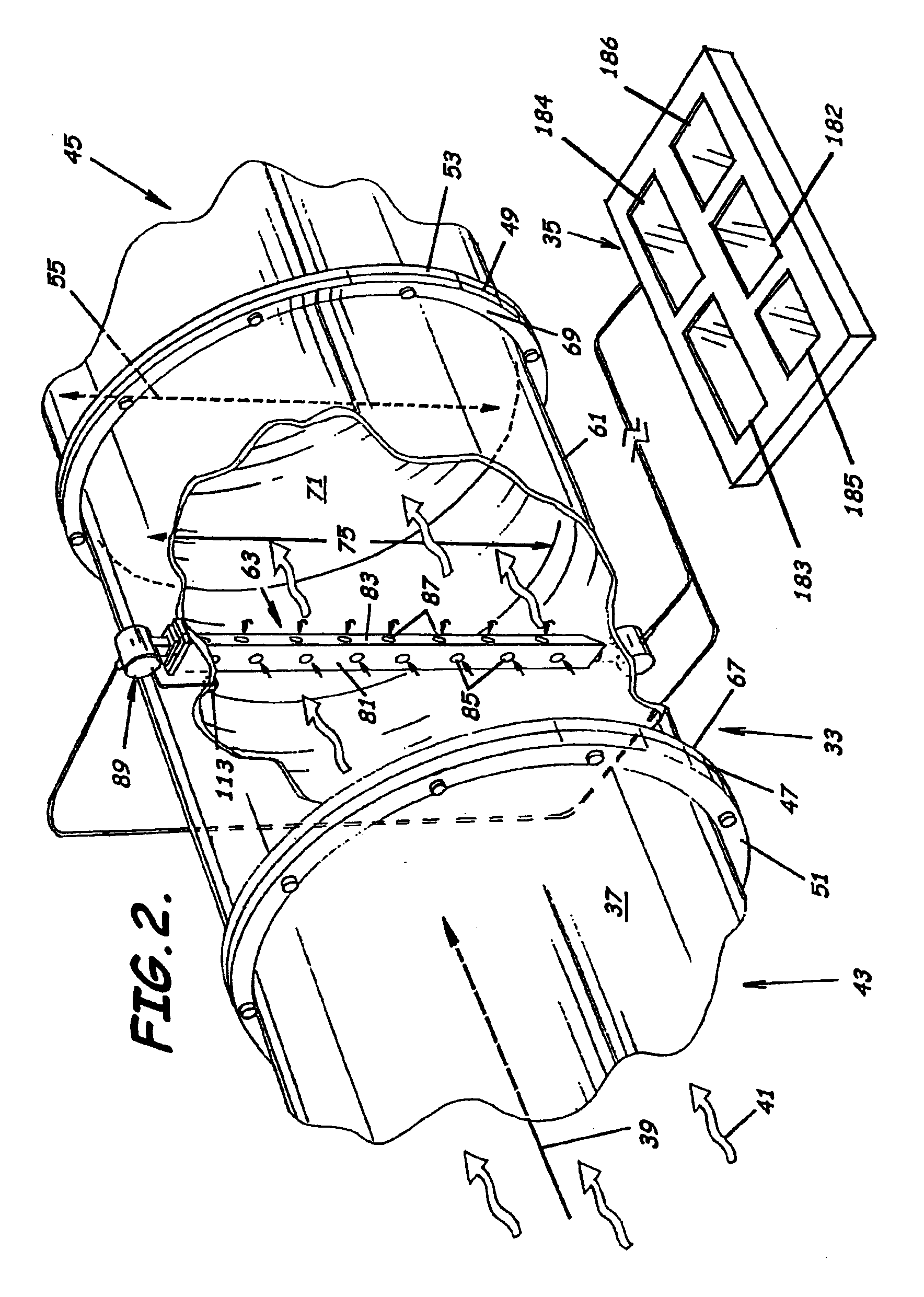

Shear activated inflation fluid system for inflatable packers

A subterranean well packer is inflated by a pumped transfer of rheotropic fluid through a tortuous flow channel into a packer sealing element expansion chamber. The tortuous flow channel and fluid delivery pressure are coordinated with the fluid properties to impose sufficient fluid shear stress for inducement of a substantial phase change in said rheotropic fluid after entry into expansion chamber.

Owner:BAKER HUGHES INC

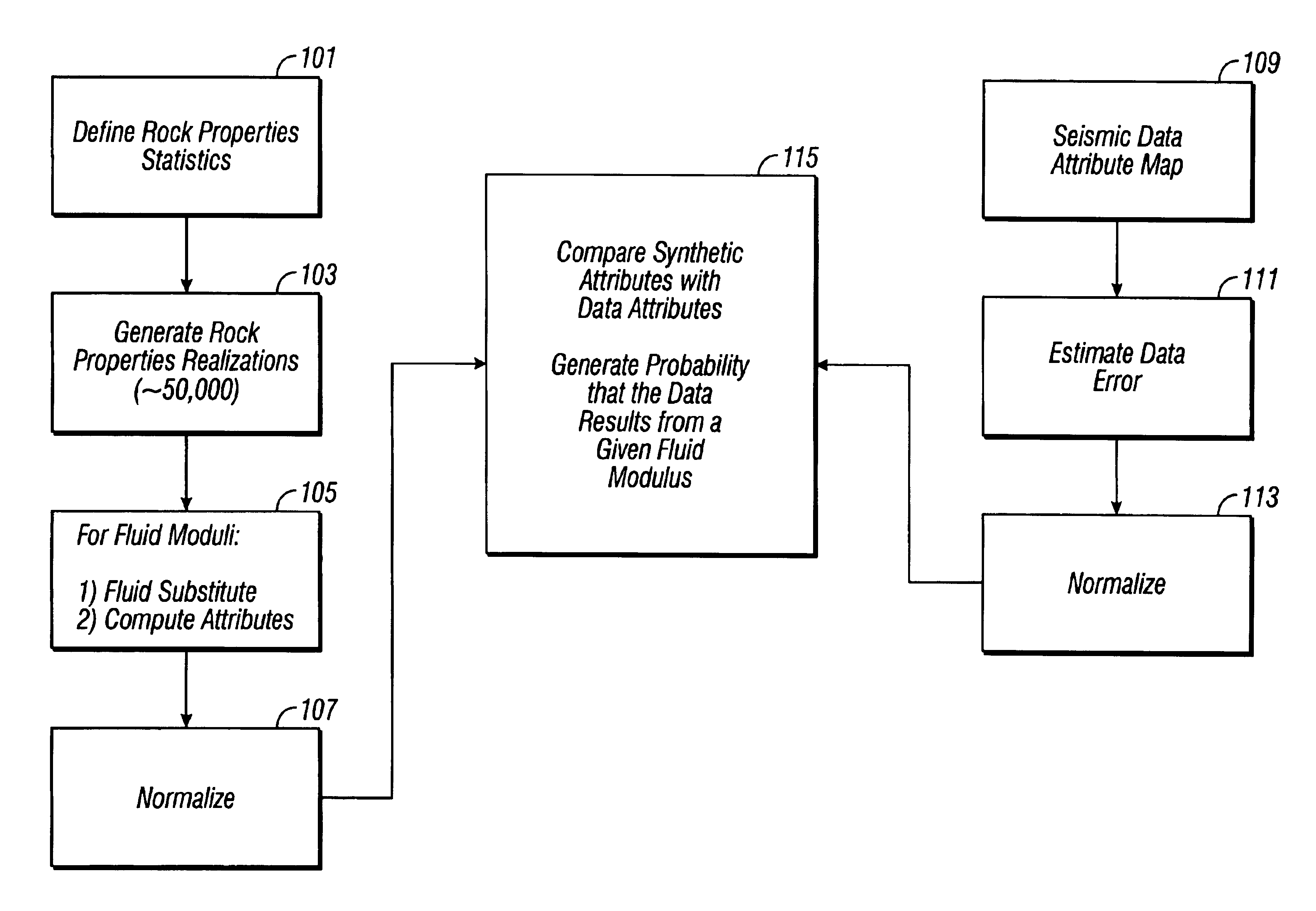

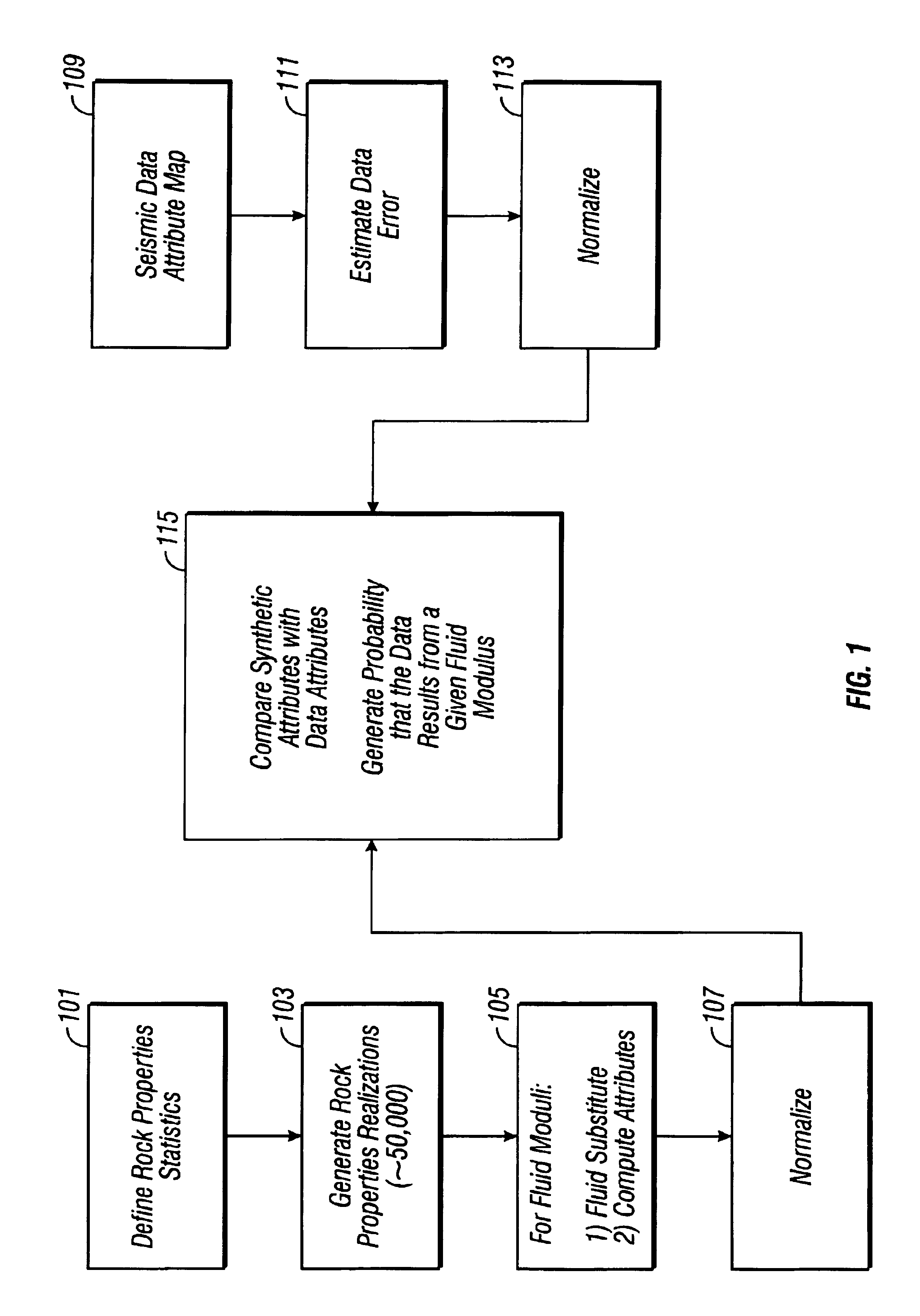

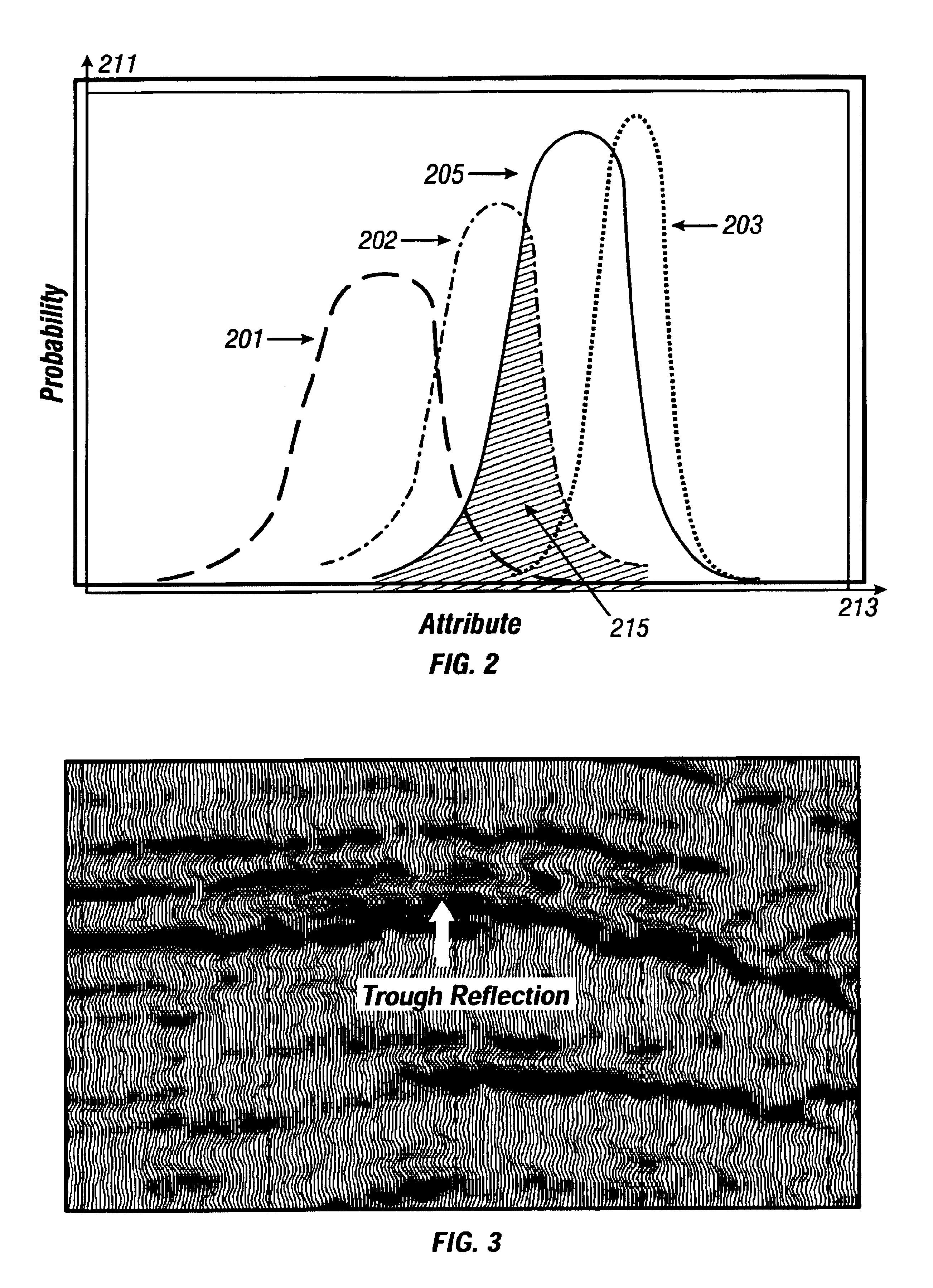

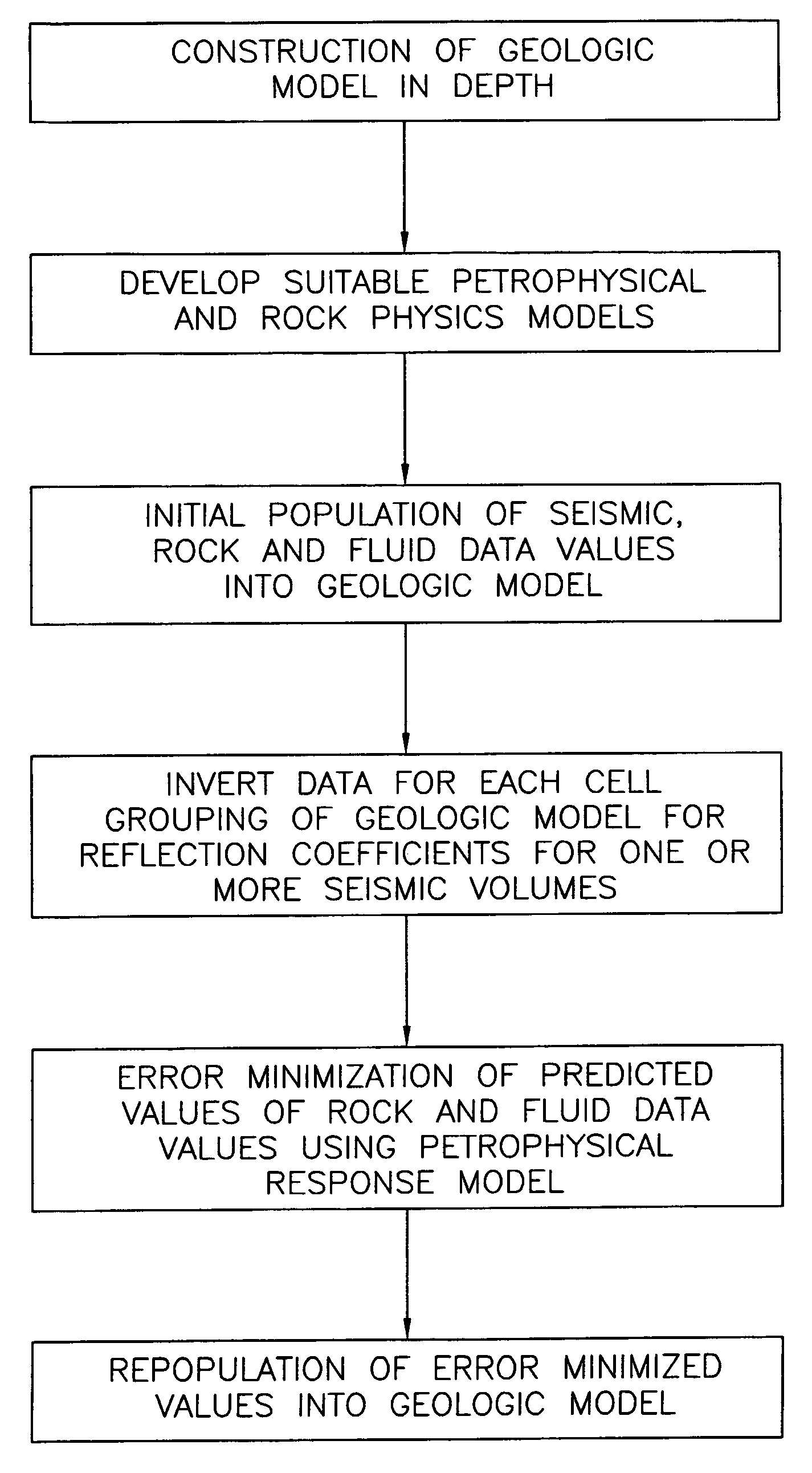

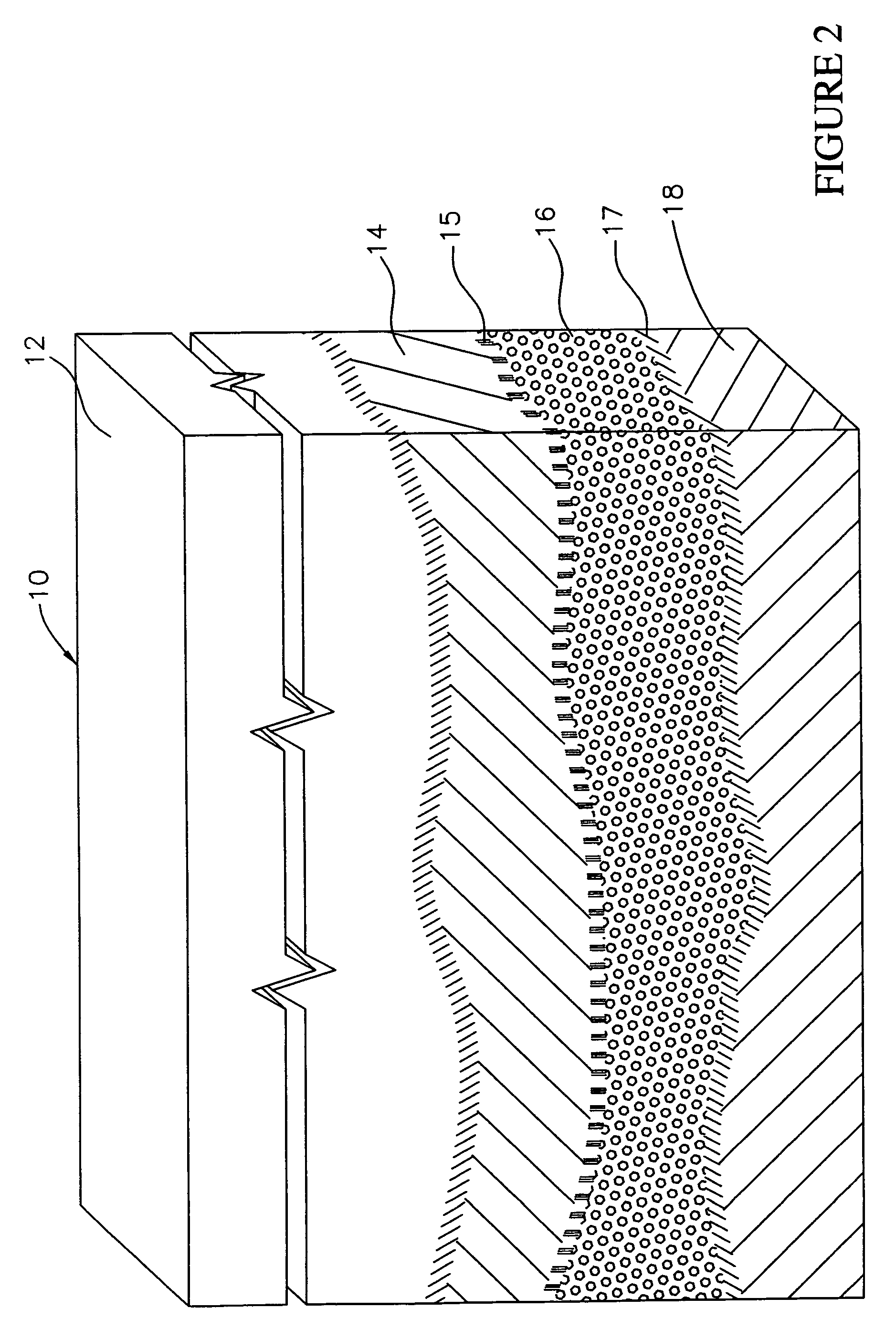

Determination of fluid properties of earth formations using stochastic inversion

ActiveUS6970397B2Electric/magnetic detection for well-loggingSeismic signal processingSeismic attributeTest region

A method of determining a fluid property in a subsurface region of interest of an earth formation uses measurements of seismic attributes on seismic data. For a test region, a plurality of realizations of rock properties are specified, and for each of the realizations and a selected value of a fluid property, the seismic attribute is modeled. This defines a probability density function (PDF). Comparison of the PDF of the model output with the PDF on the measured seismic data is used to determine the likelihood of the selected fluid property.

Owner:GAS TECH INST

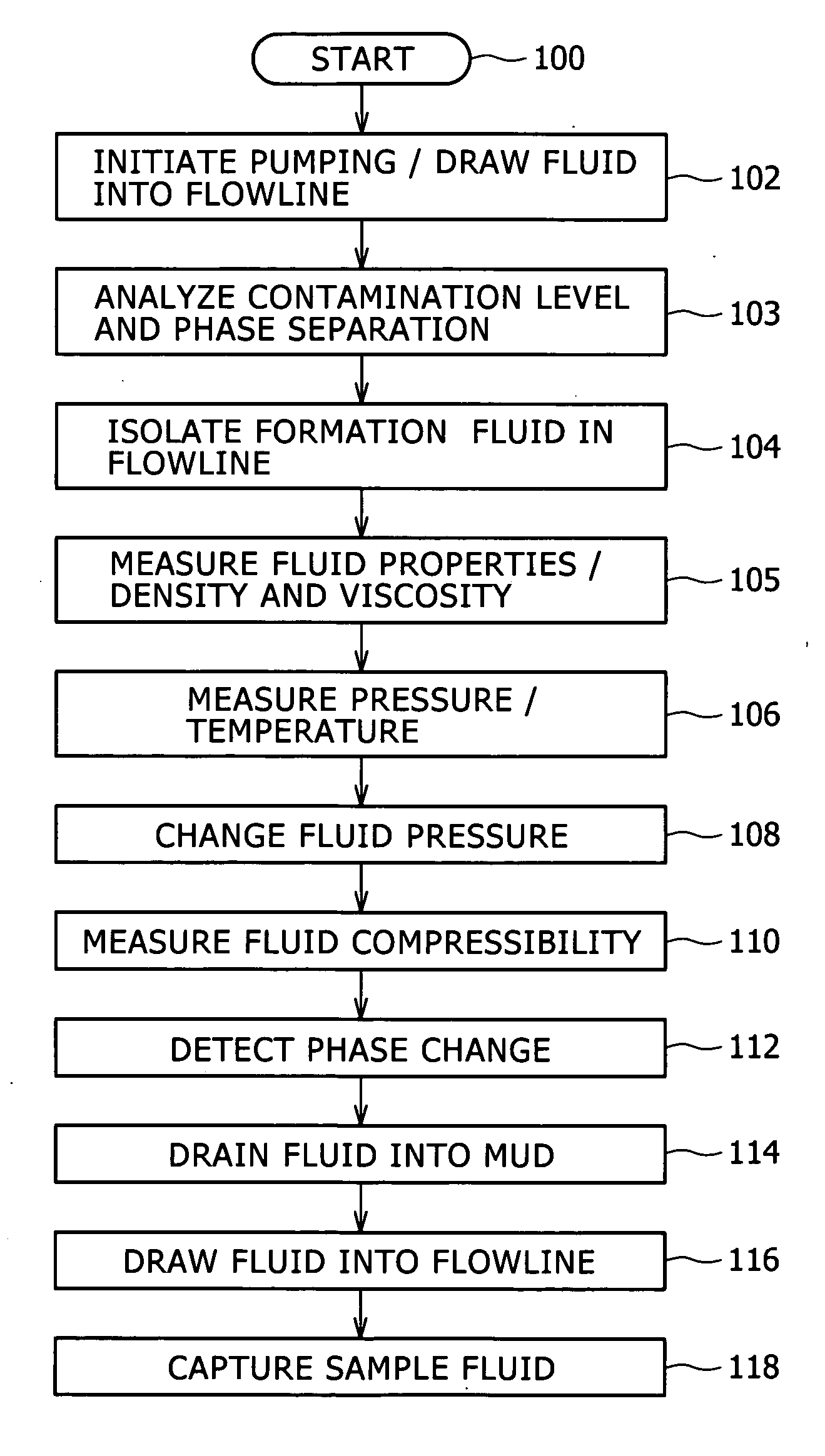

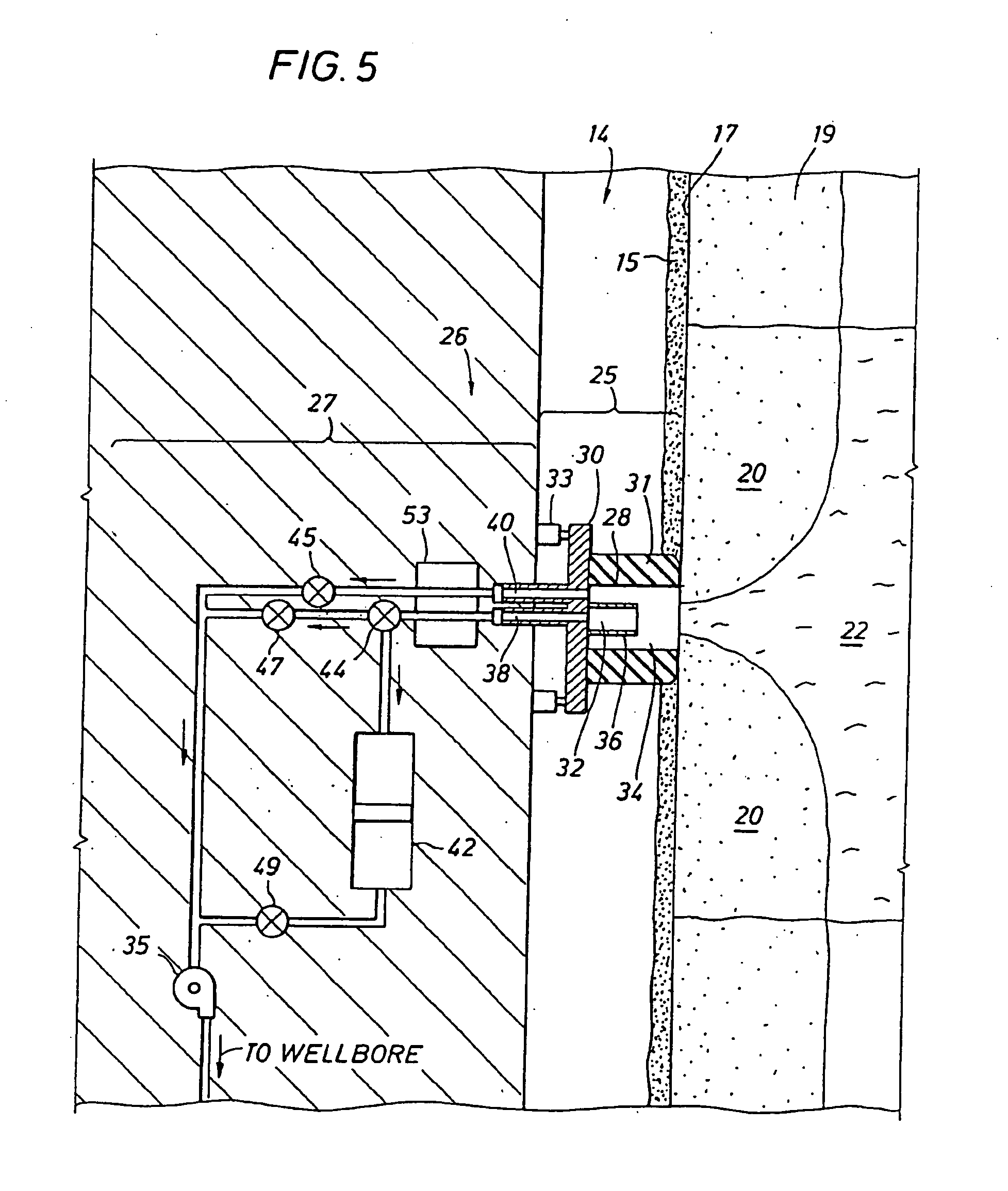

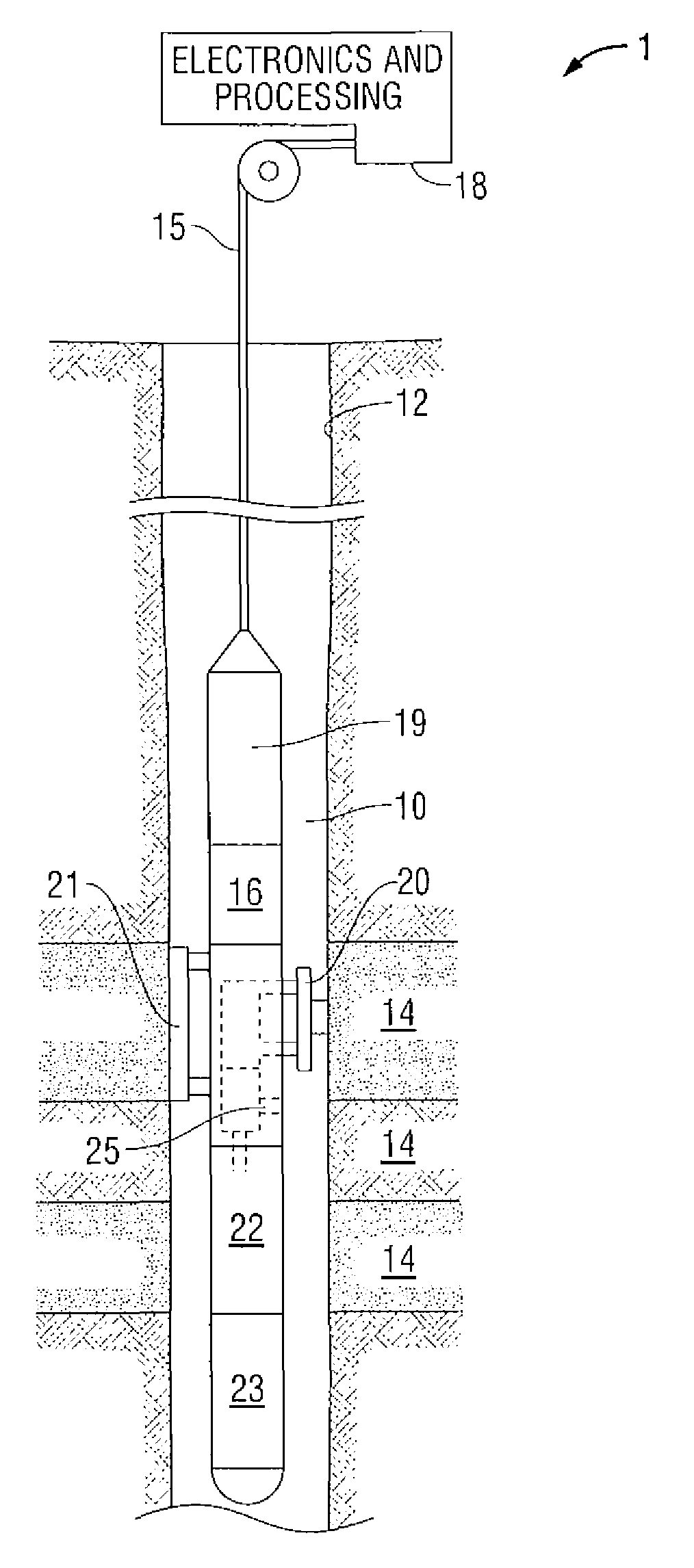

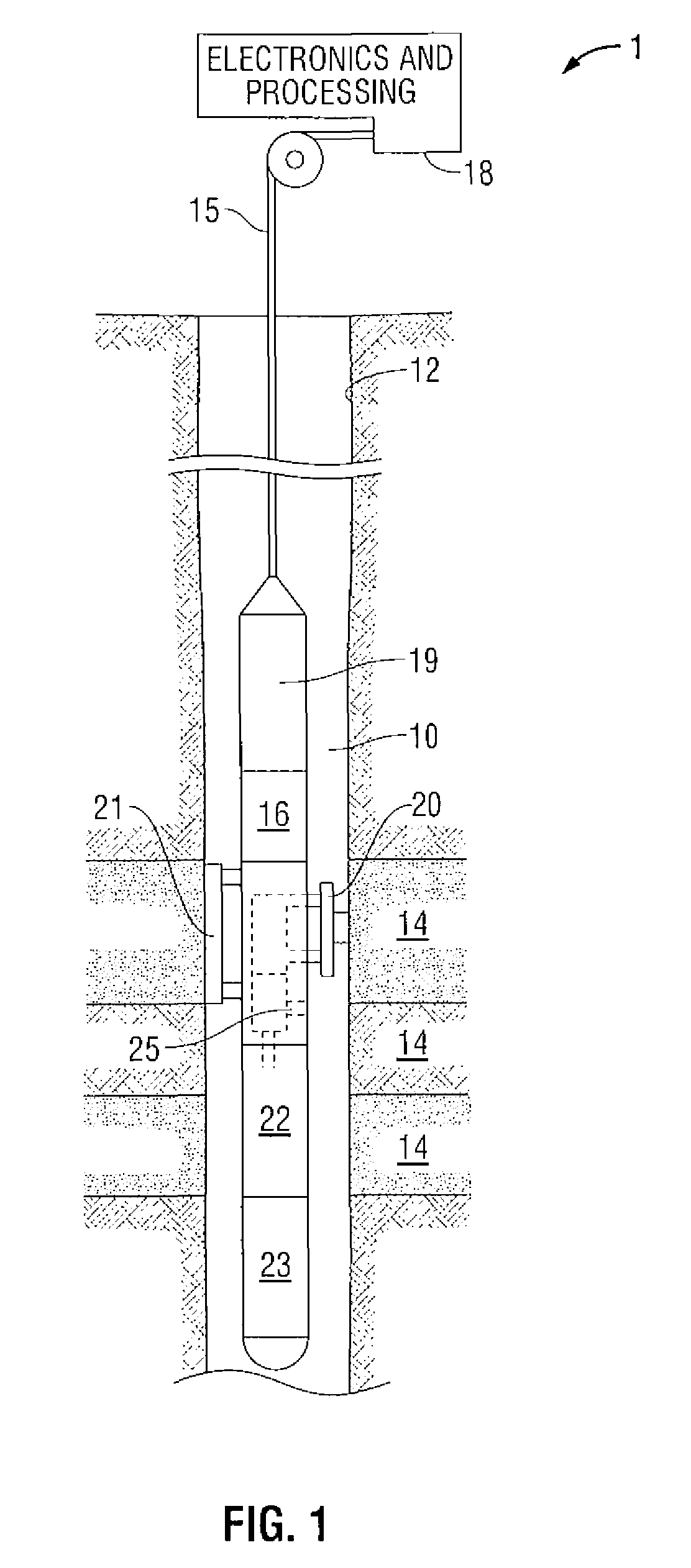

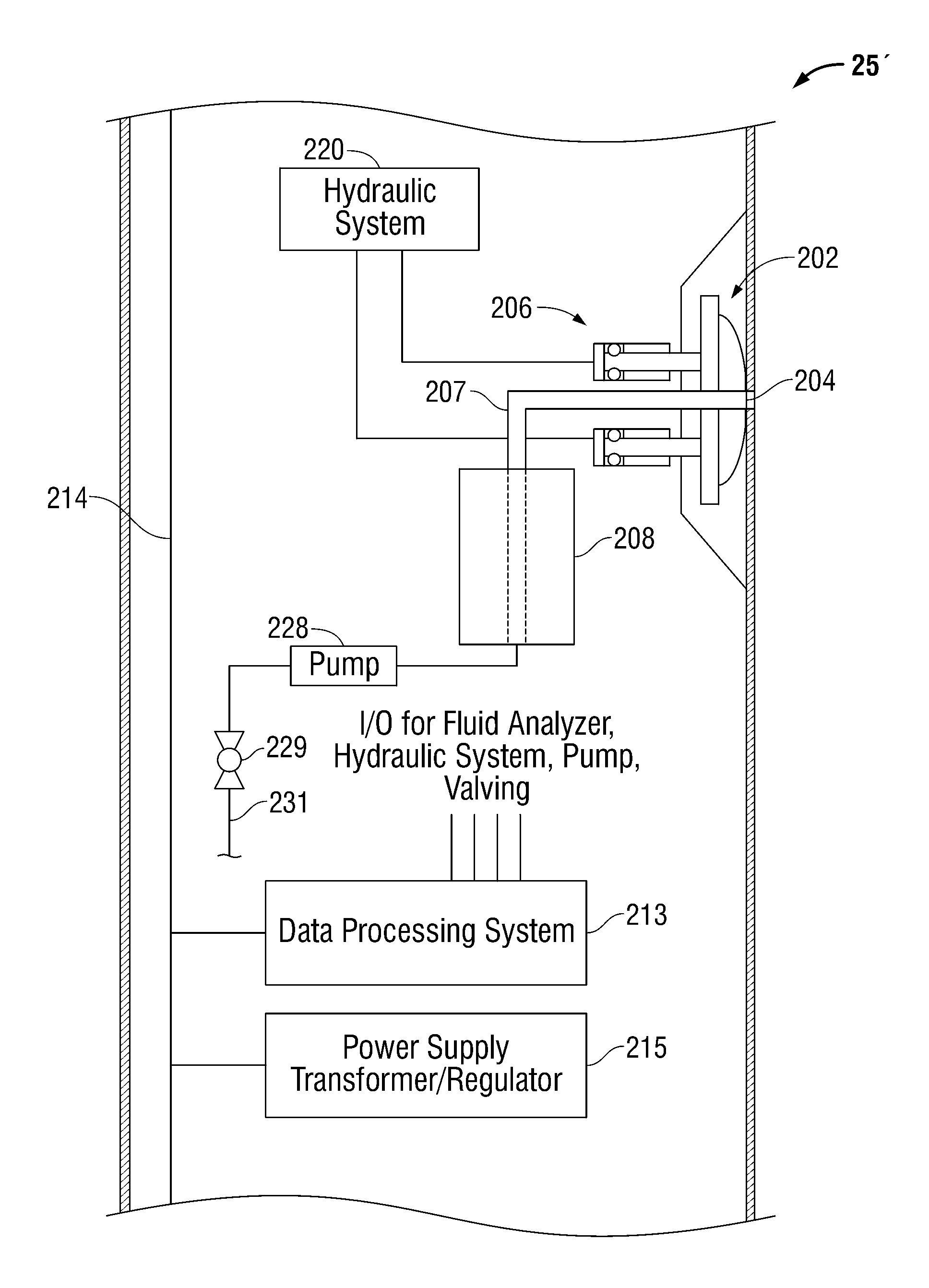

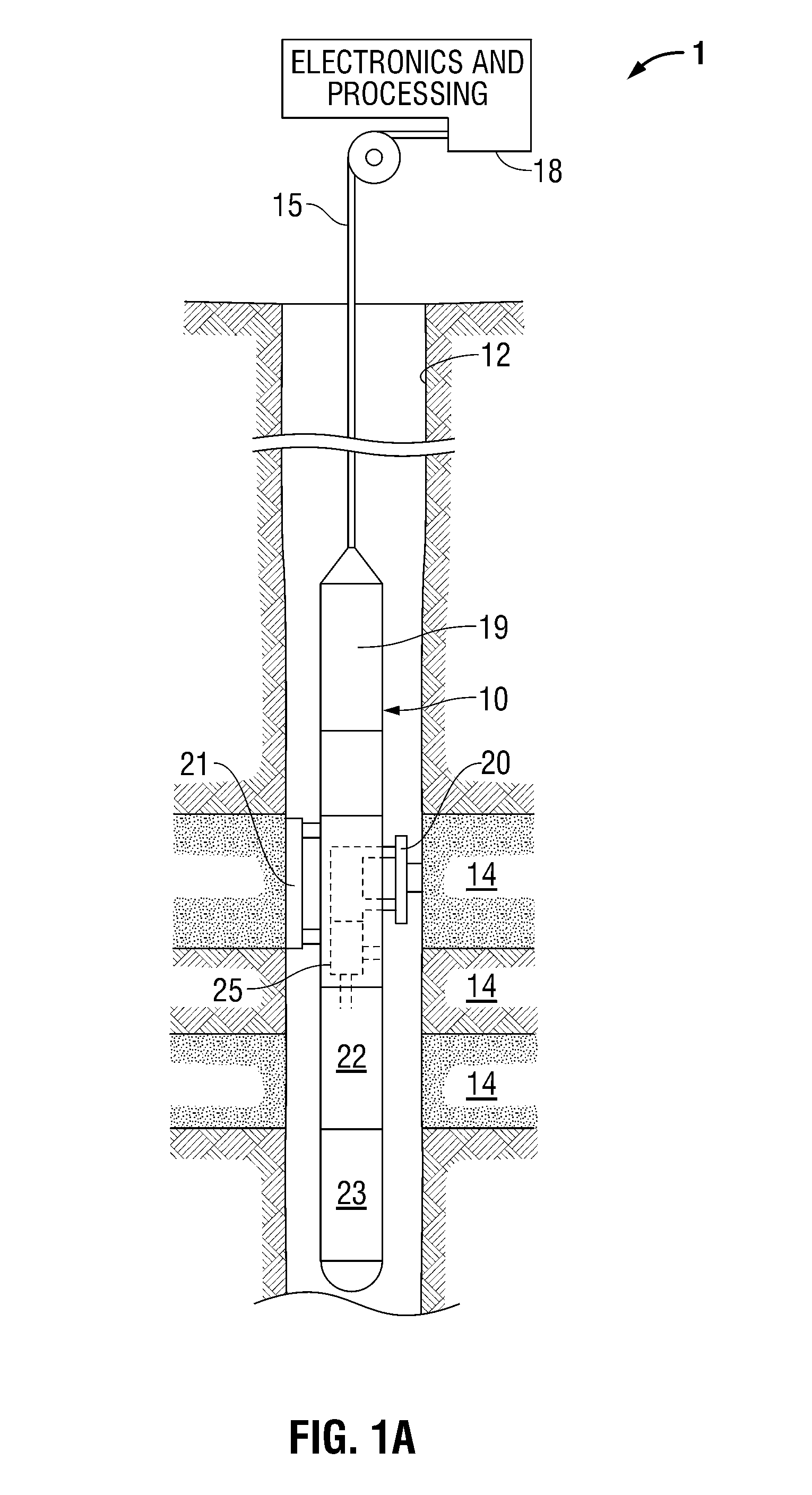

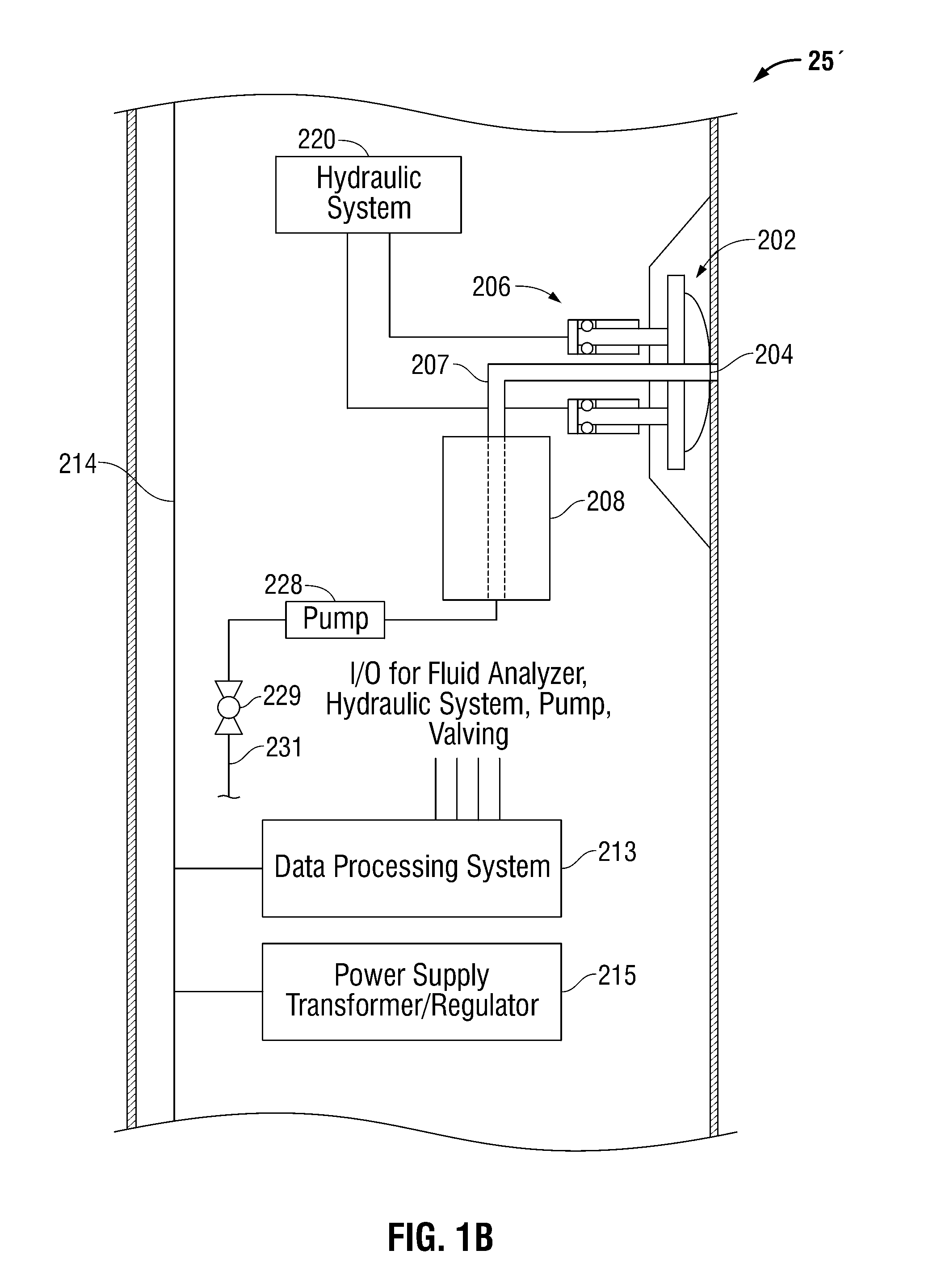

Methods and apparatus of downhole fluid analysis

ActiveUS7461547B2Check of qualityQuality improvementSurveyIndirect flow property measurementReal time analysisFormation fluid

Owner:SCHLUMBERGER TECH CORP

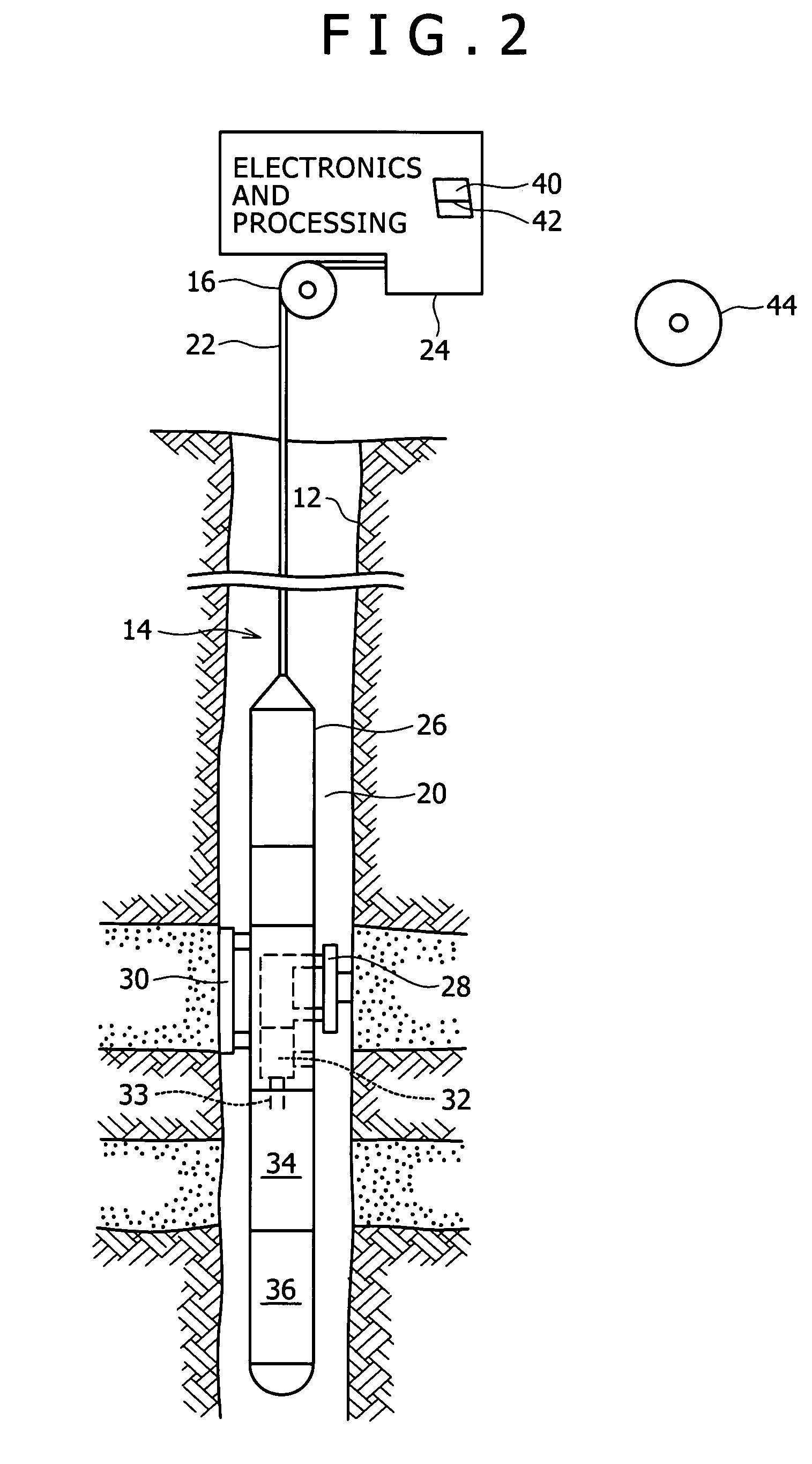

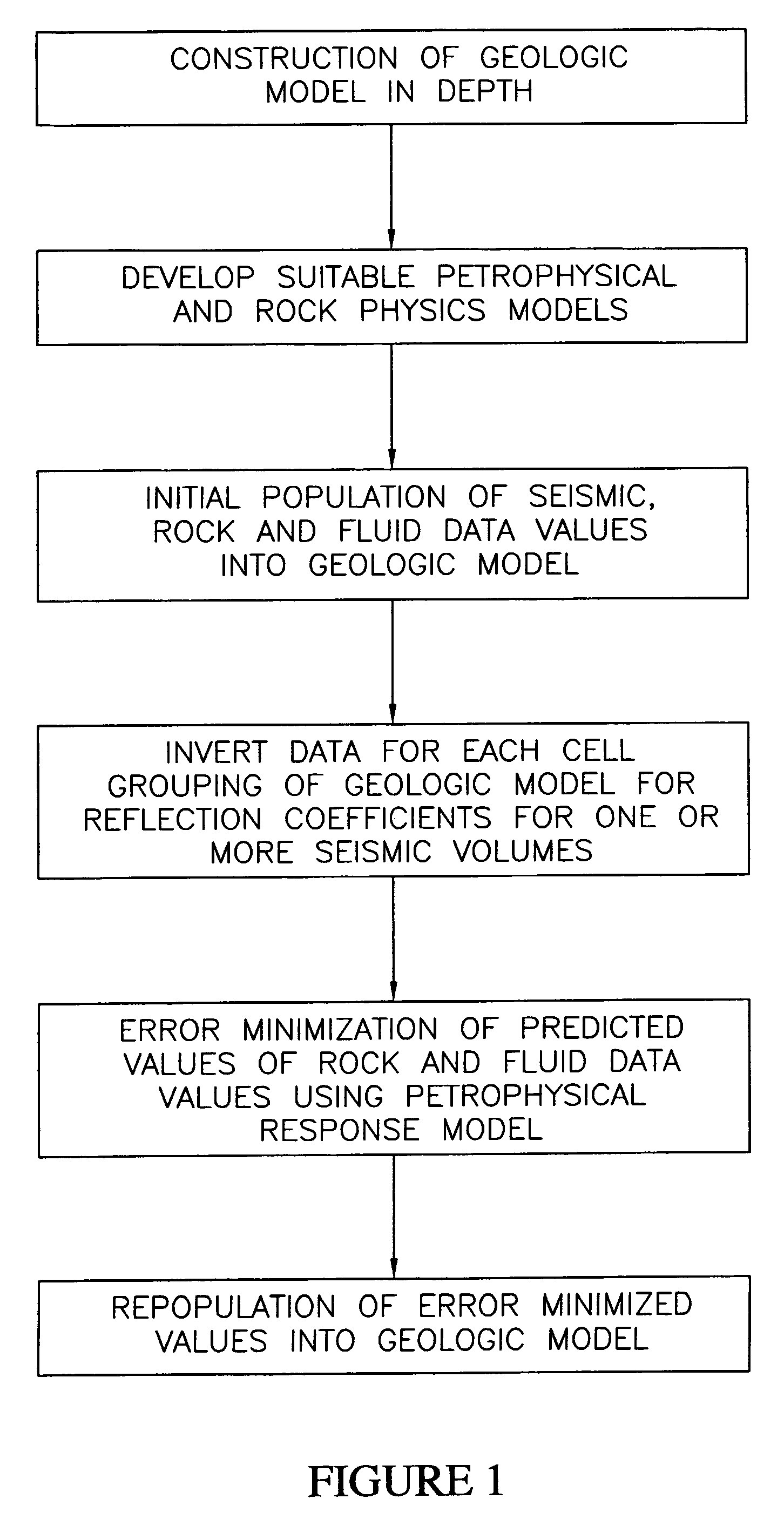

Method for predicting quantitative values of a rock or fluid property in a reservoir using seismic data

InactiveUS7373251B2Provide consistencySeismic signal processingSpecial data processing applicationsScale modelMulti dimensional

A method is provided for predicting a value of a designated rock or fluid property in a subterranean geologic volume. A first predicted value of the designated rock or fluid property is also assigned to a volume of a multi-dimensional, multi-scale model. A first predicted value of seismic response for the model volume is calculated from a response model using the first predicted value of the designated rock or fluid property, wherein the response model is responsive to changes in predicted values of the designated rock or fluid property. A synthetic trace is generated and iteratively compared to the corresponding trace obtained from one or more sets of actual seismic data to determine a difference while consistency is maintained between the types, scales and dimensions of values and data. The first predicted value of the designated rock or fluid property is adjusted in response to the difference to create a second predicted value of the designated rock or fluid property, wherein the second predicted value generally reduces the difference.

Owner:CGG SERVICES SA

Methods and apparatus of downhole fluid analysis

ActiveUS20060243047A1Accurate representationCheck of qualitySurveyIndirect flow property measurementReal time analysisFormation fluid

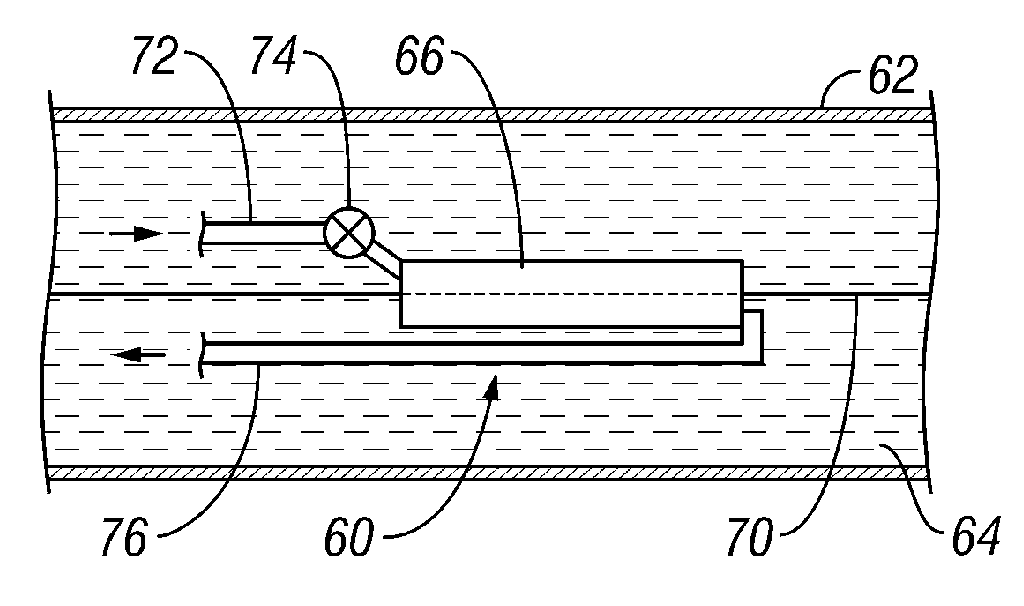

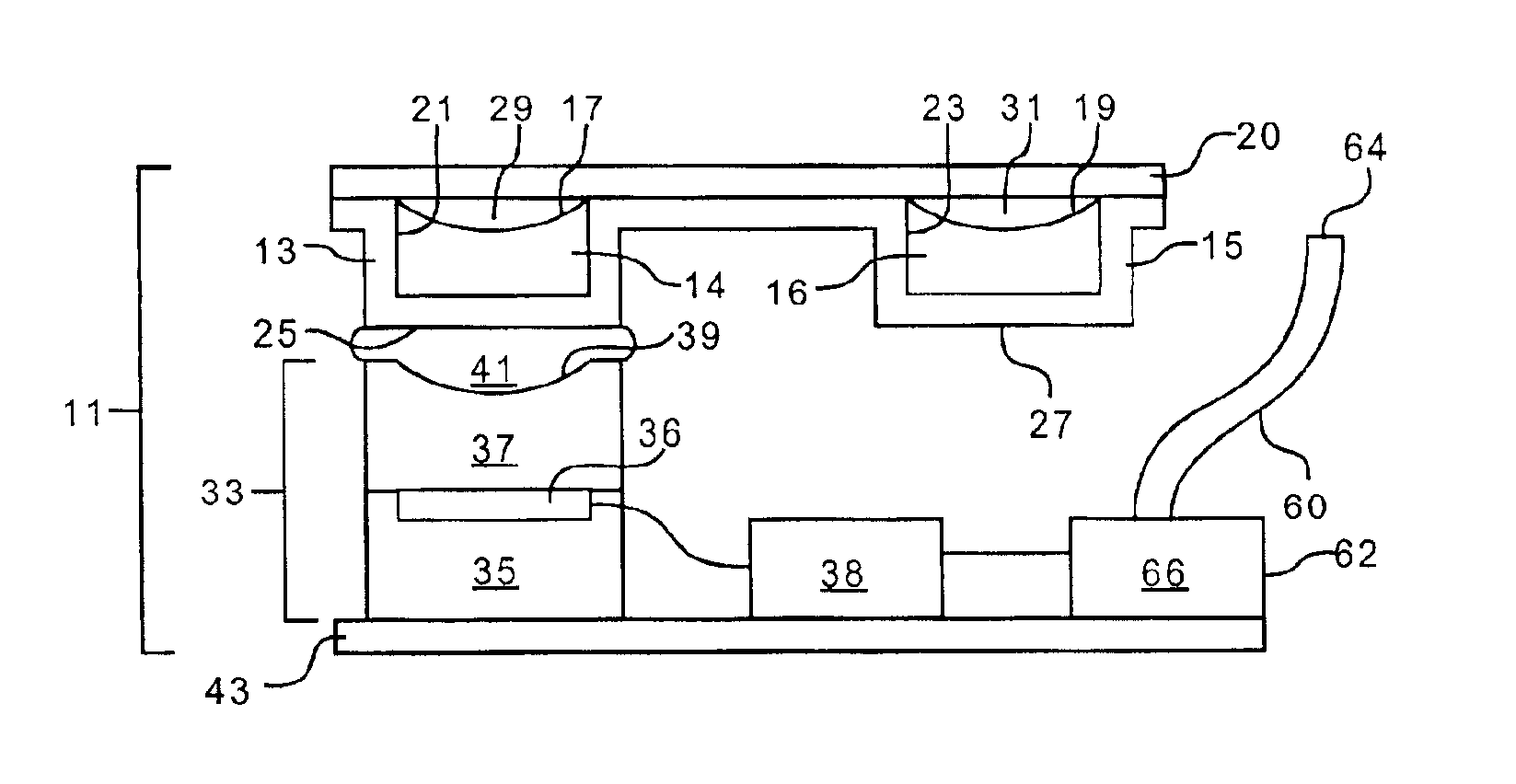

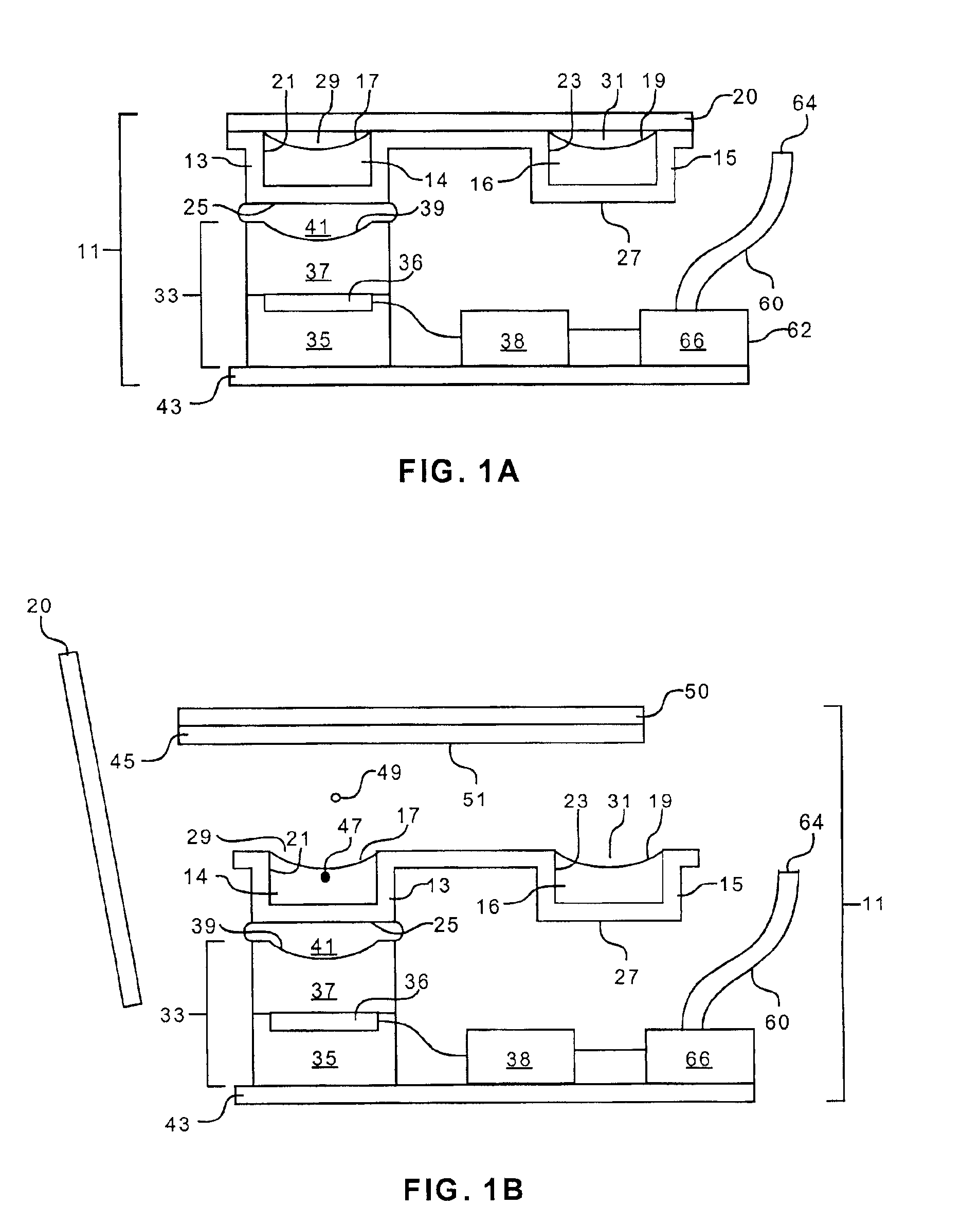

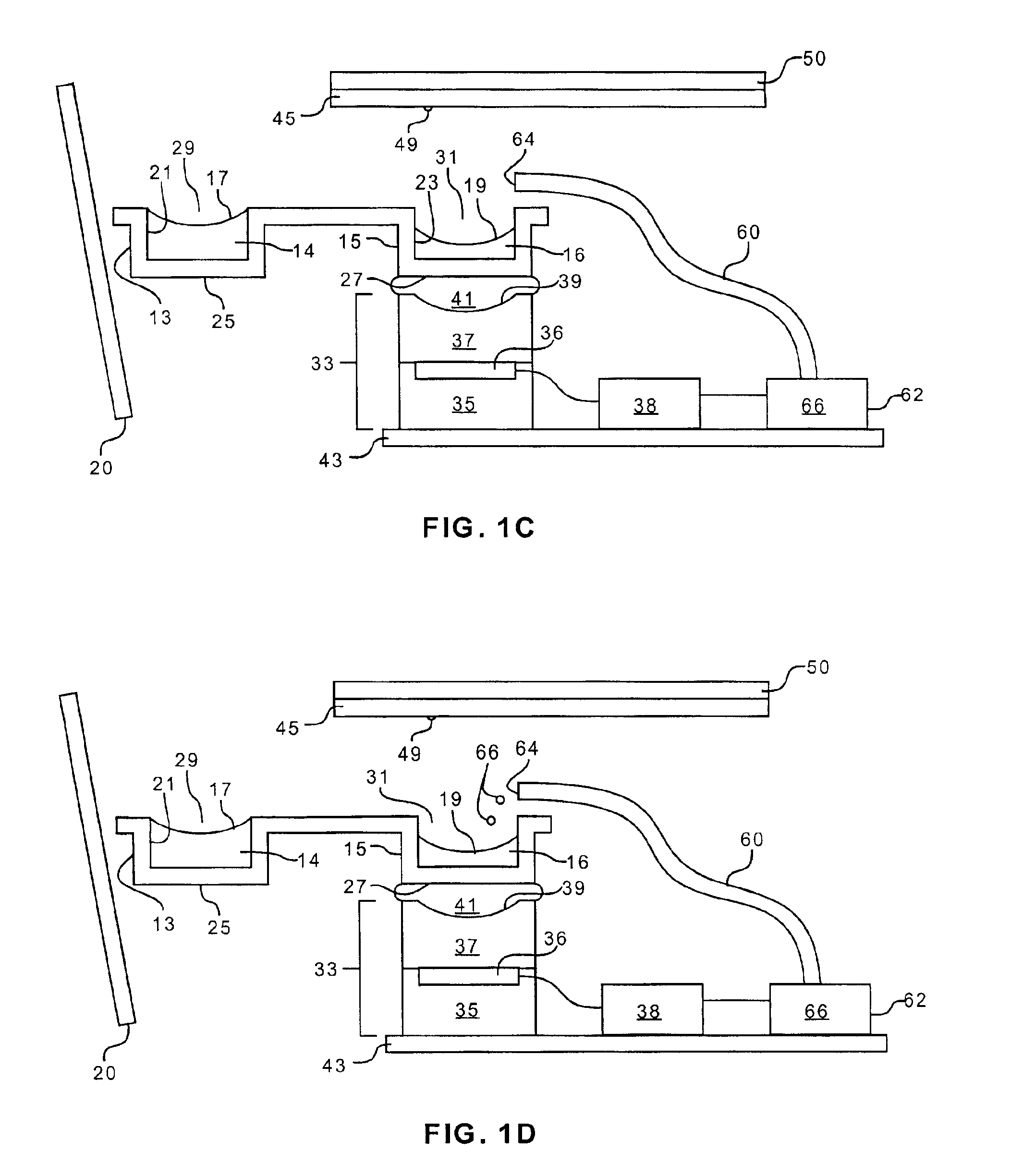

Methods and apparatus for downhole analysis of formation fluids by isolating the fluids from the formation and / or borehole in a pressure and volume control unit that is integrated with a flowline of a fluid analysis module and determining fluid characteristics of the isolated fluids. Parameters of interest may be derived for formation fluids in a static state and undesirable formation fluids may be drained and replaced with formation fluids that are suitable for downhole characterization or surface sample extraction. Isolated formation fluids may be circulated in a loop of the flowline for phase behavior characterization. Real-time analysis of the fluids may be performed at or near downhole conditions.

Owner:SCHLUMBERGER TECH CORP

Method and Apparatus for Measuring Fluid Properties

InactiveUS20060010973A1Simple methodEnsure correct executionSurveyConstructionsThermal energyEngineering

A method of measuring fluid properties such as flow velocity, flow rate, and fluid composition comprises positioning a heat exchange element with a temperature sensor, such as an optical fiber temperature sensor, arranged centrally inside the element in thermal contact with a fluid of interest, heating or cooling the heat exchange element to cause a temperature difference and exchange of thermal energy between the element and the fluid, using the temperature sensor to measure the temperature of the heat exchange element during the exchange of thermal energy, and determining properties of the fluid from the temperature measurement. A second temperature sensor can be provided offset from the first sensor to provide additional measurements to improve accuracy, and a plurality of heat exchange elements with temperature sensors can be used together to determine fluid properties over a large region.

Owner:SCHLUMBERGER TECH CORP

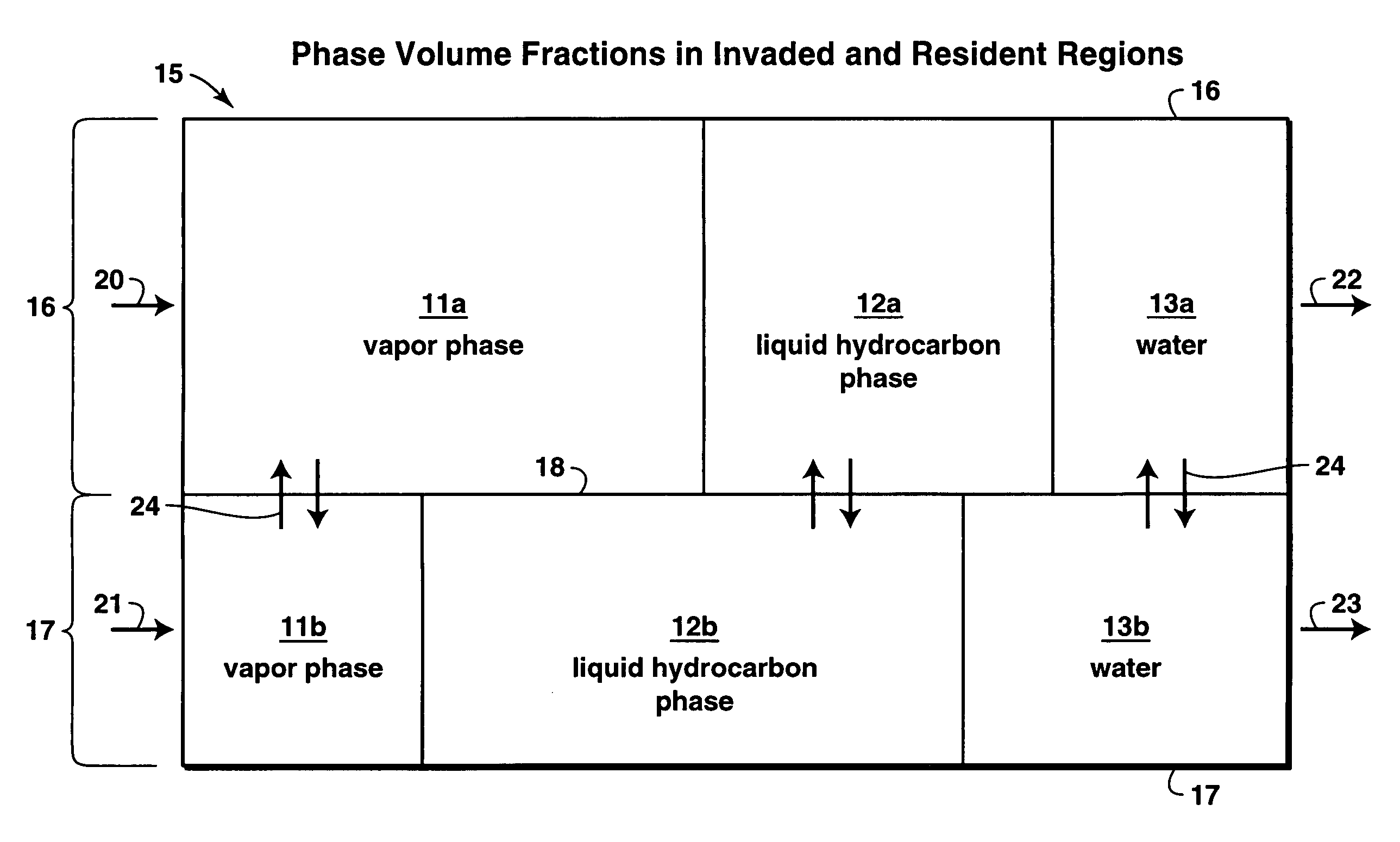

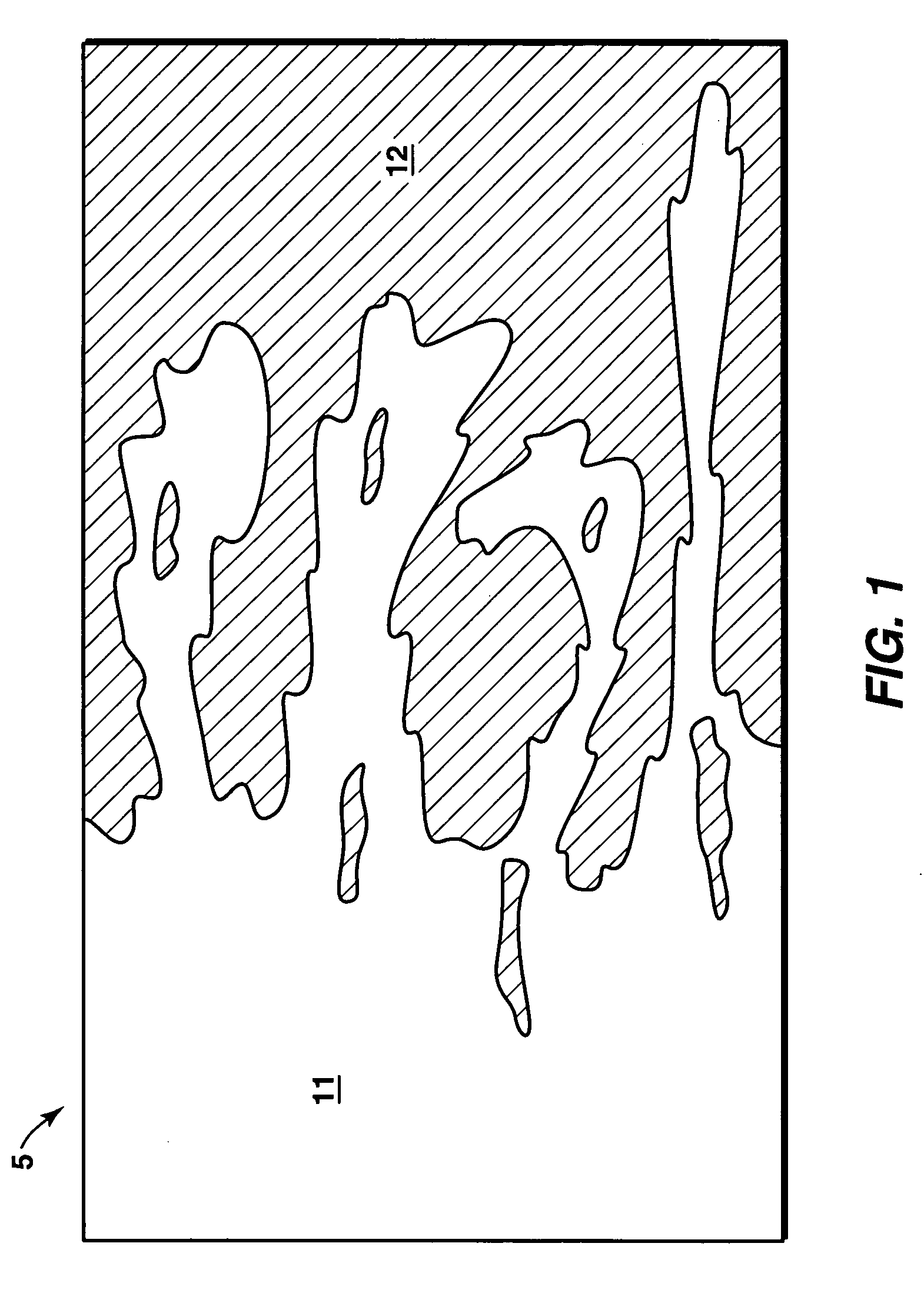

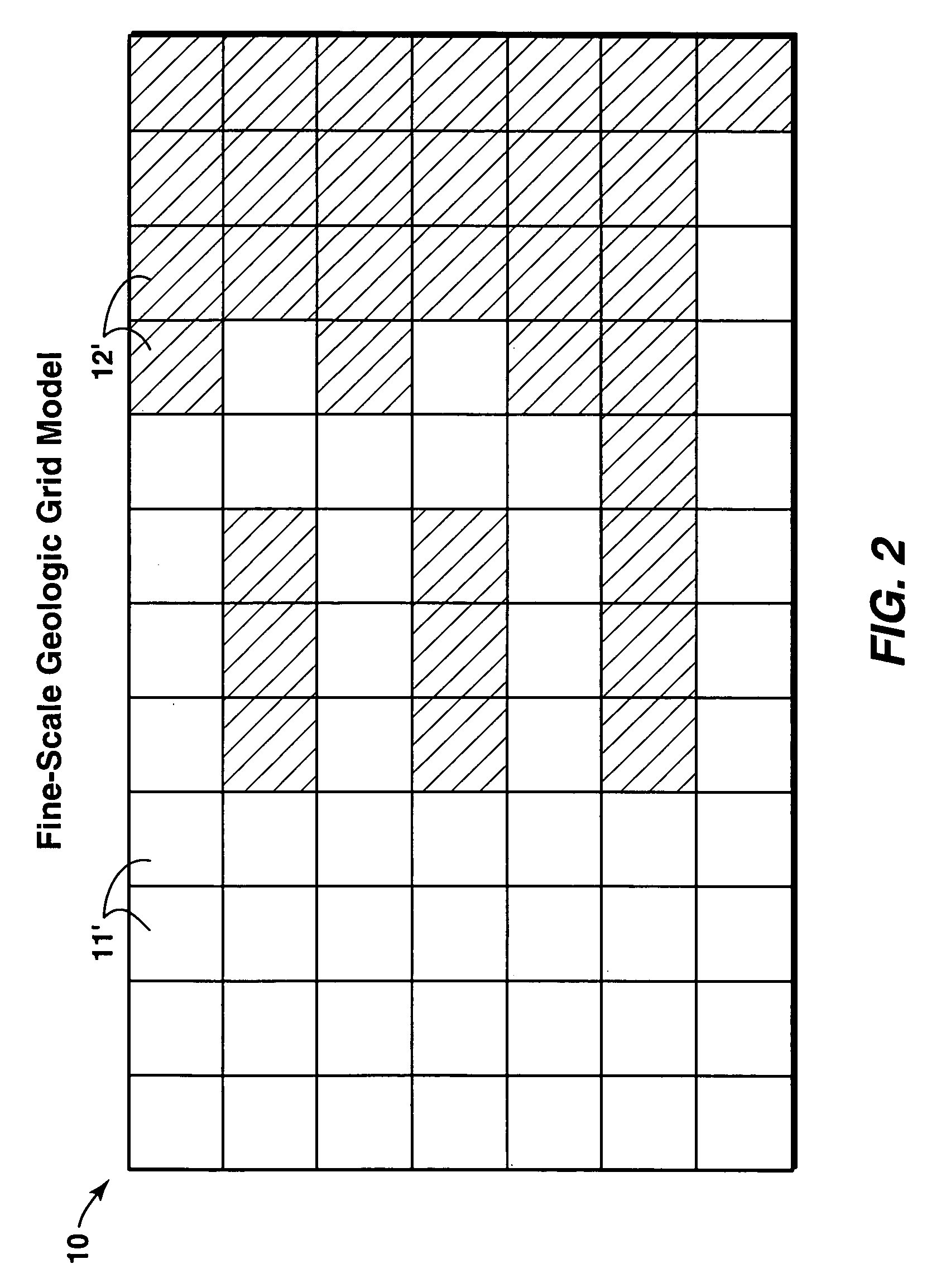

Method and system for simulating a hydrocarbon-bearing formation

Owner:EXXONMOBIL UPSTREAM RES CO

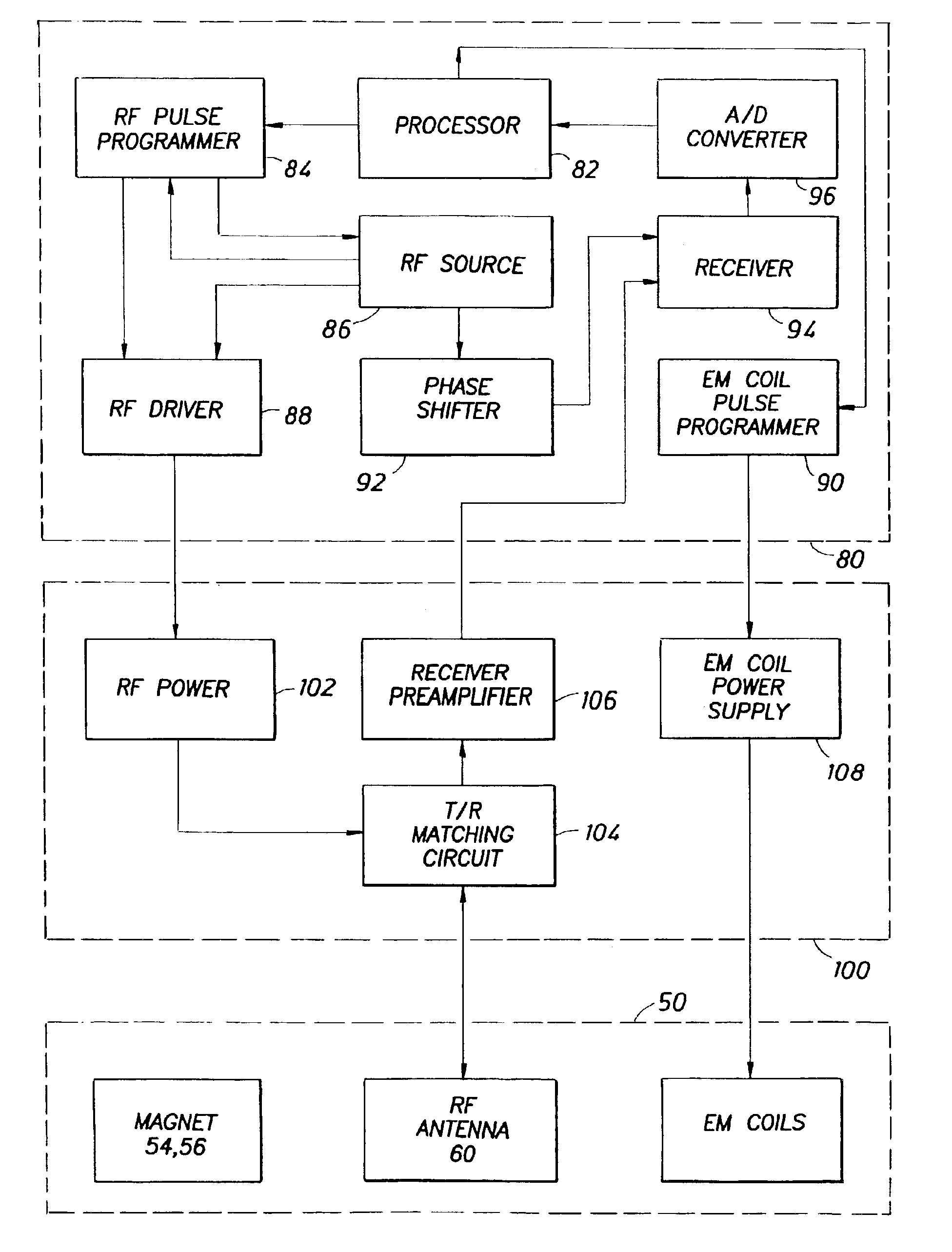

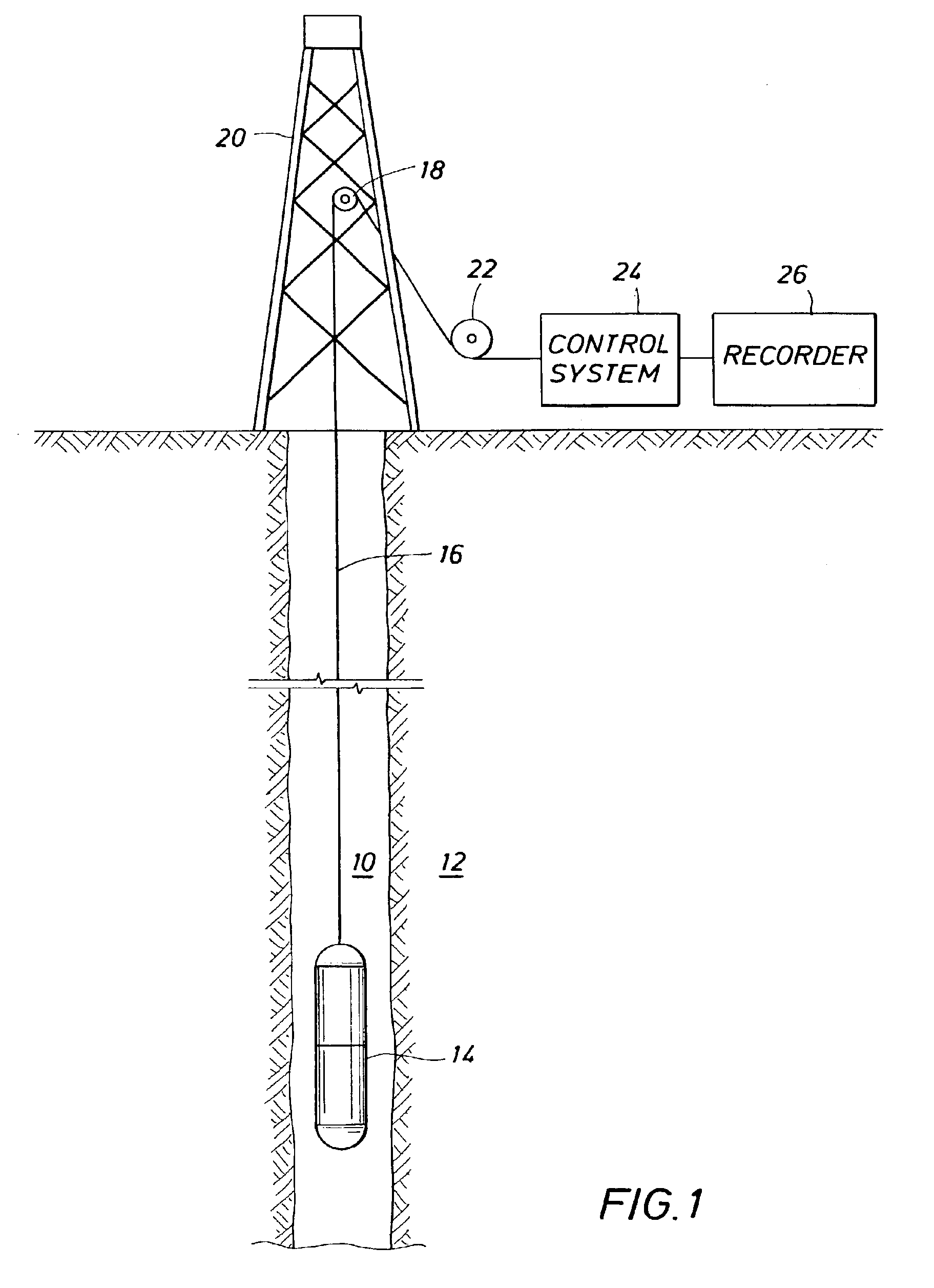

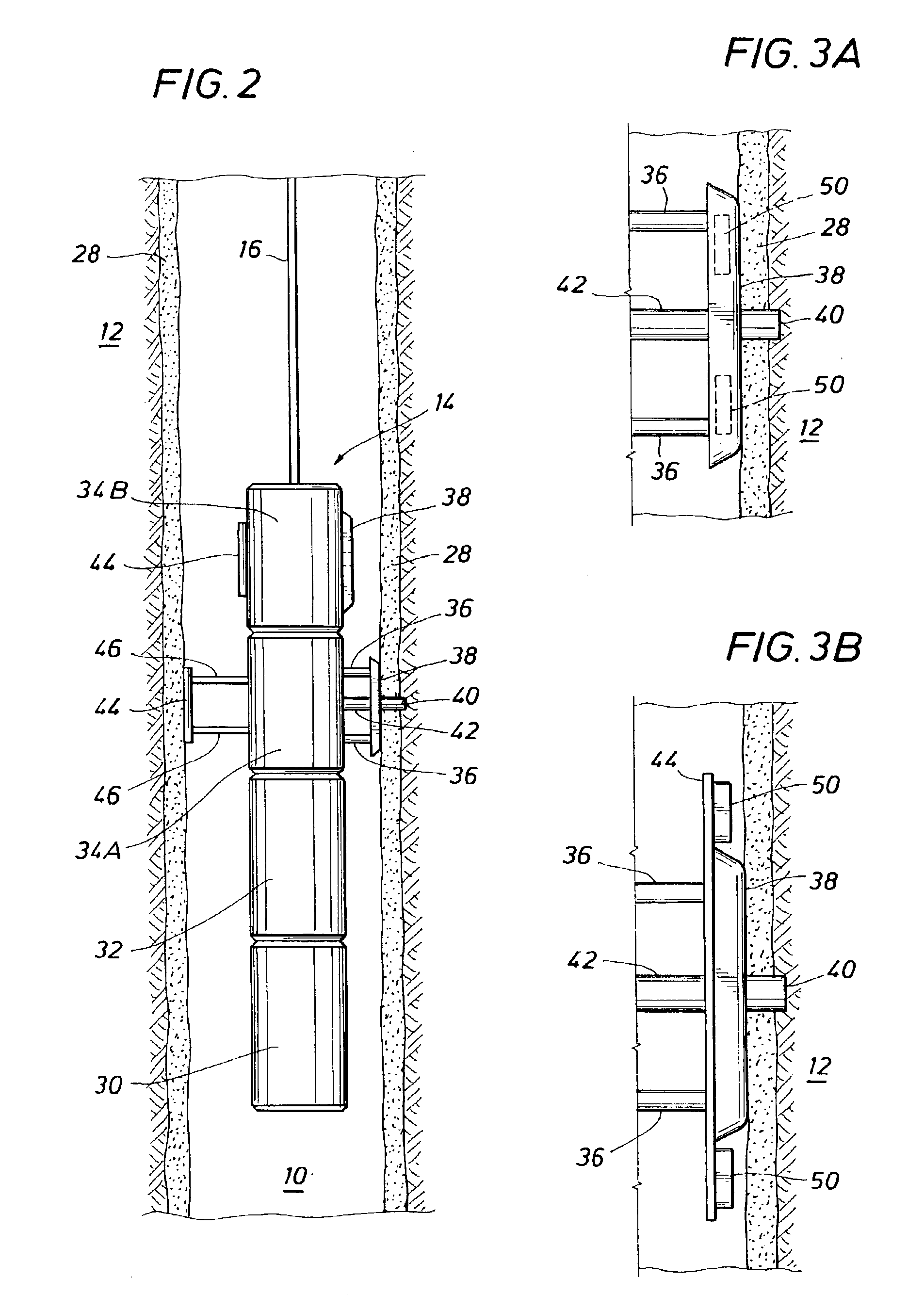

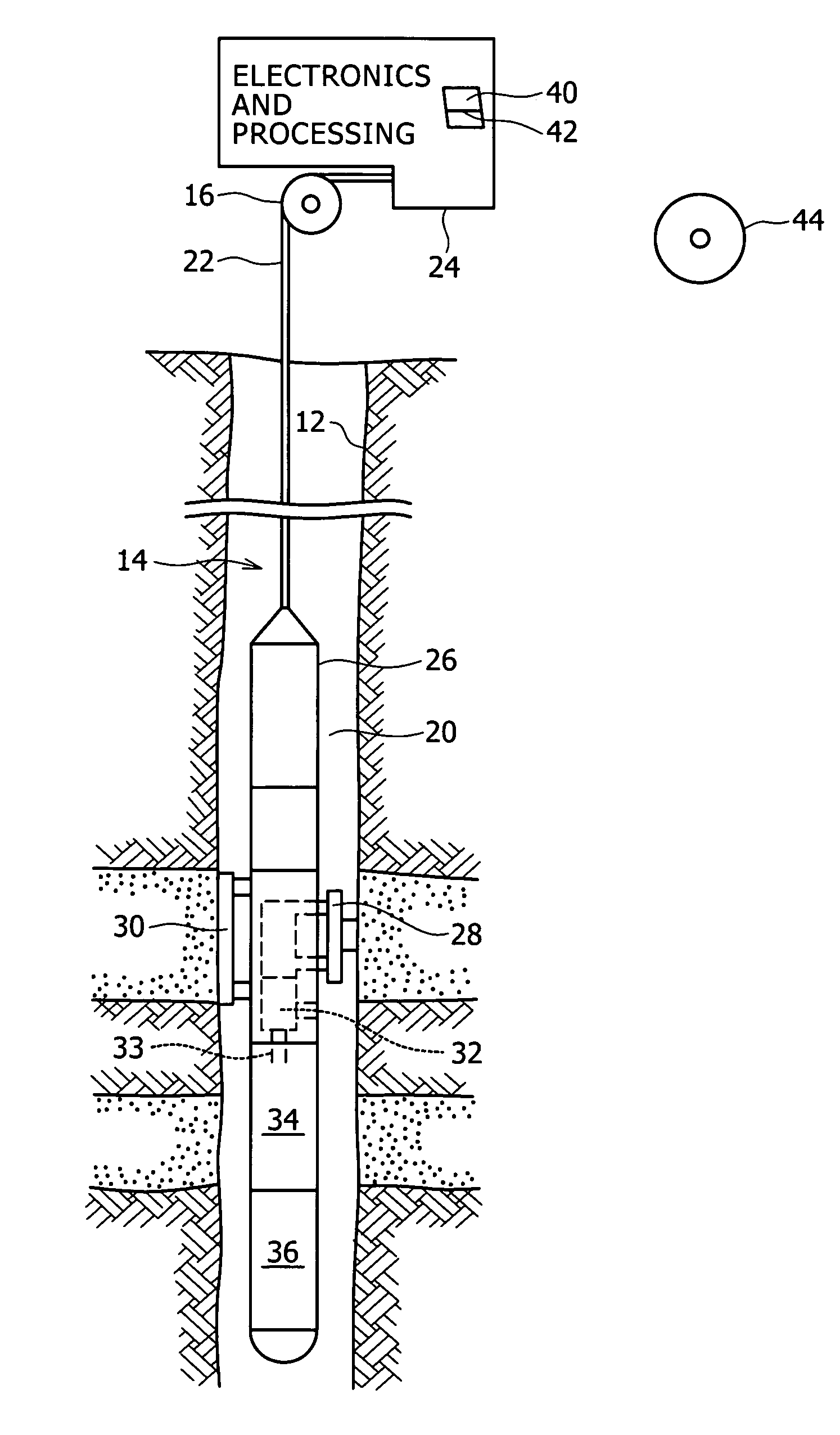

Method and apparatus for subterranean formation flow imaging

InactiveUS20040090230A1Accurately determine formation parameterAccurate measurementElectric/magnetic detection for well-loggingMaterial analysis by using resonanceMri imageGeophysics

The present invention relates to a method and apparatus for measuring a property relating to fluid flow in an earth formation, more specifically to directly measuring formation permeability and other fluid characteristics. The present invention provides a method for determining the permeability of a hydrocarbon bearing earth formation, which method comprises the steps of: locating a tool at a selected position in a borehole penetrating the earth formation; inducing a flow of fluid within the earth formation to said tool; creating at least two MRI images of said fluid while flowing within the earth formation to said tool, said at least two images being created at different times; determining displacement of said fluid within the earth formation between said different times, using the at least two MRI images.

Owner:SHELL OIL CO

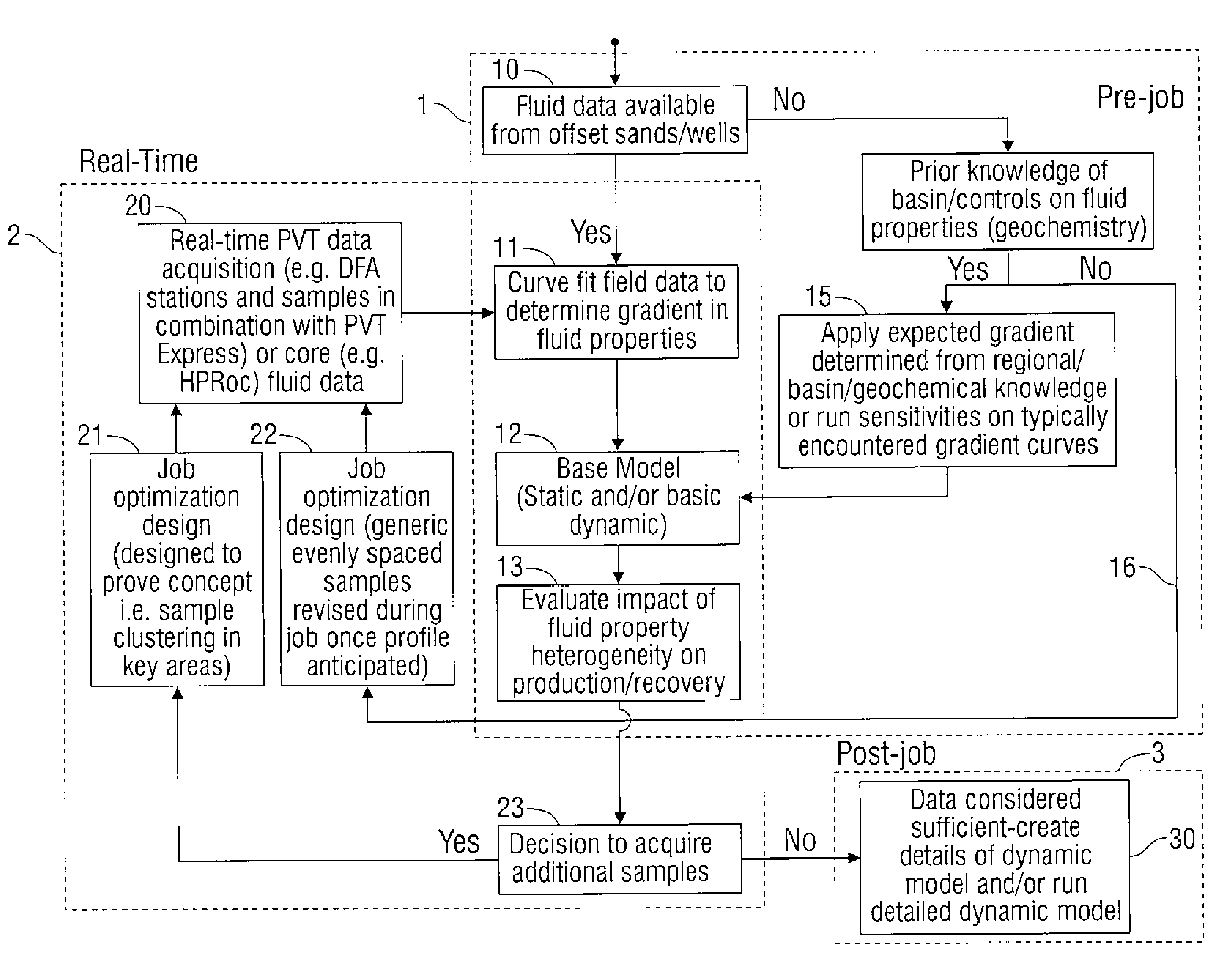

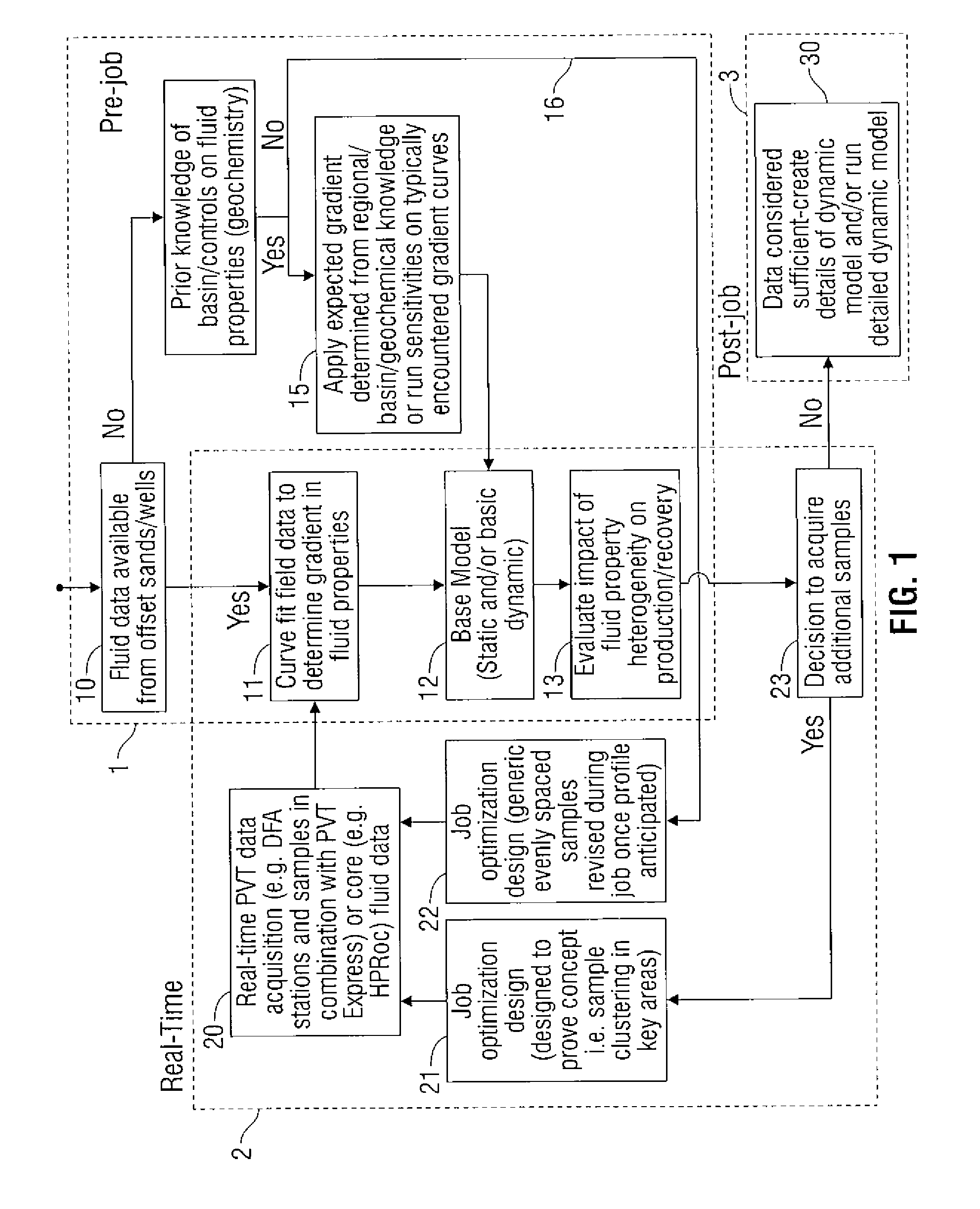

Methods for optimizing petroleum reservoir analysis

InactiveUS20090071239A1Radiation pyrometryMaterial analysis by optical meansRecovery performancePetroleum reservoir

Owner:SCHLUMBERGER TECH CORP

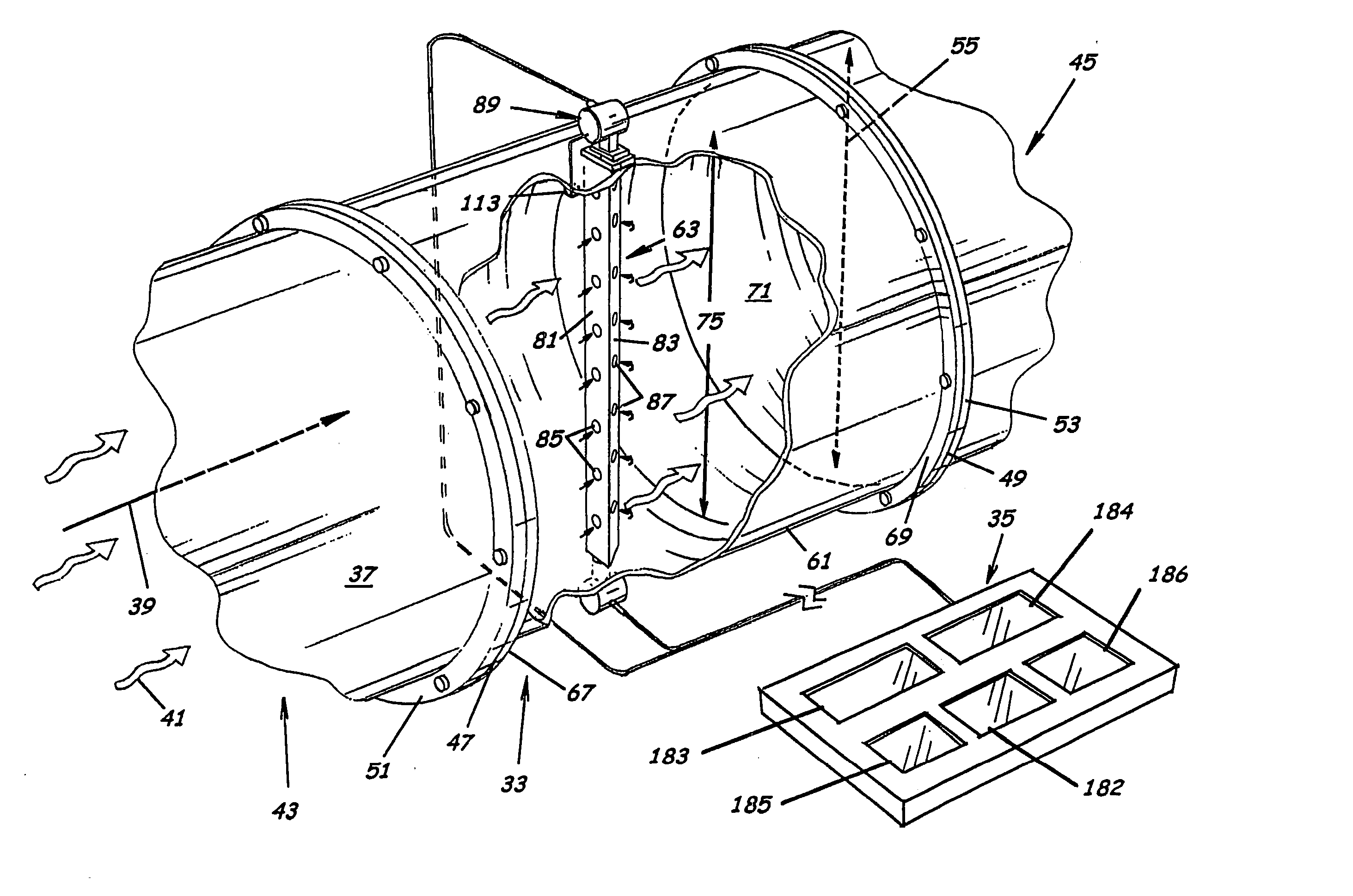

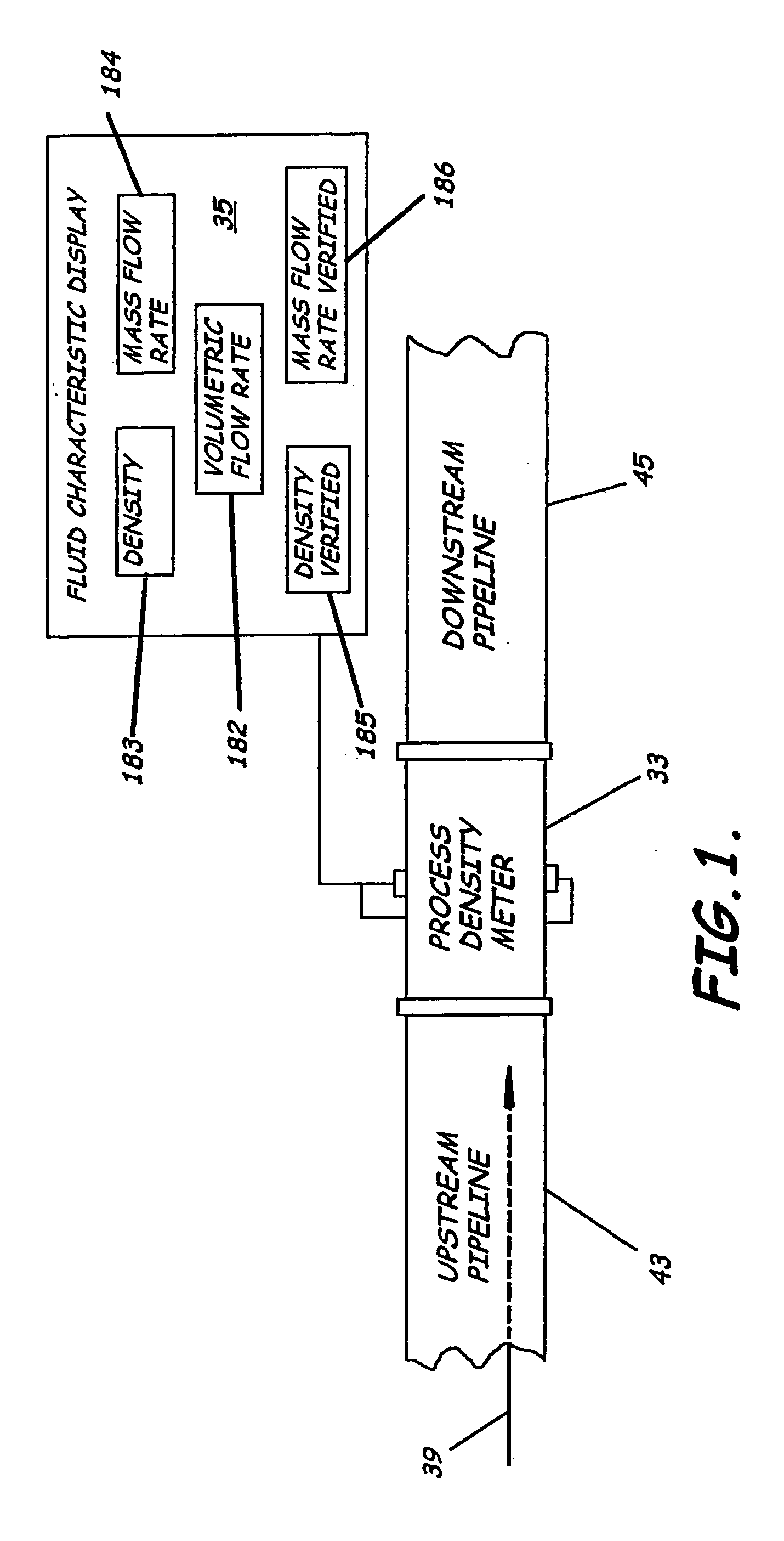

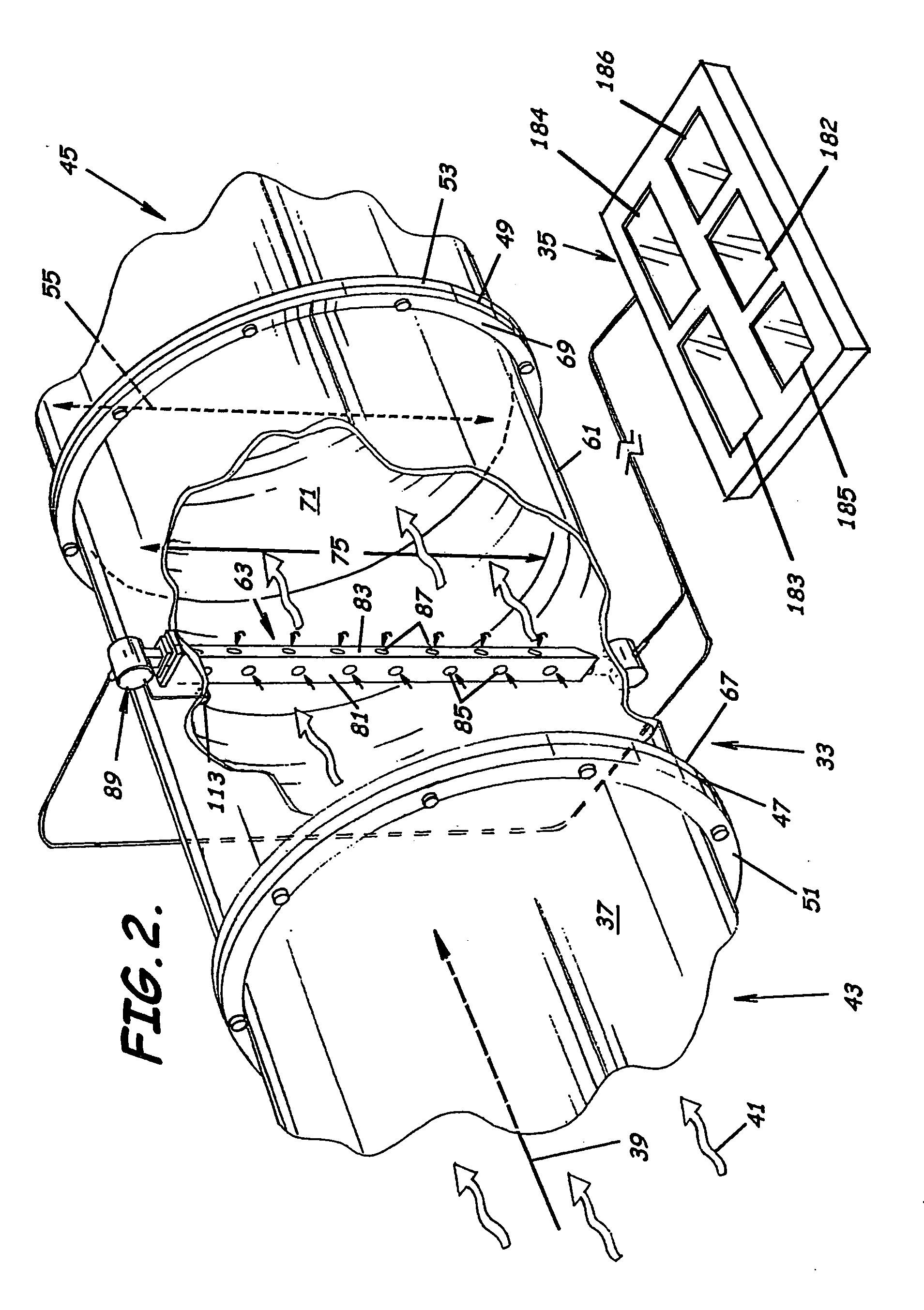

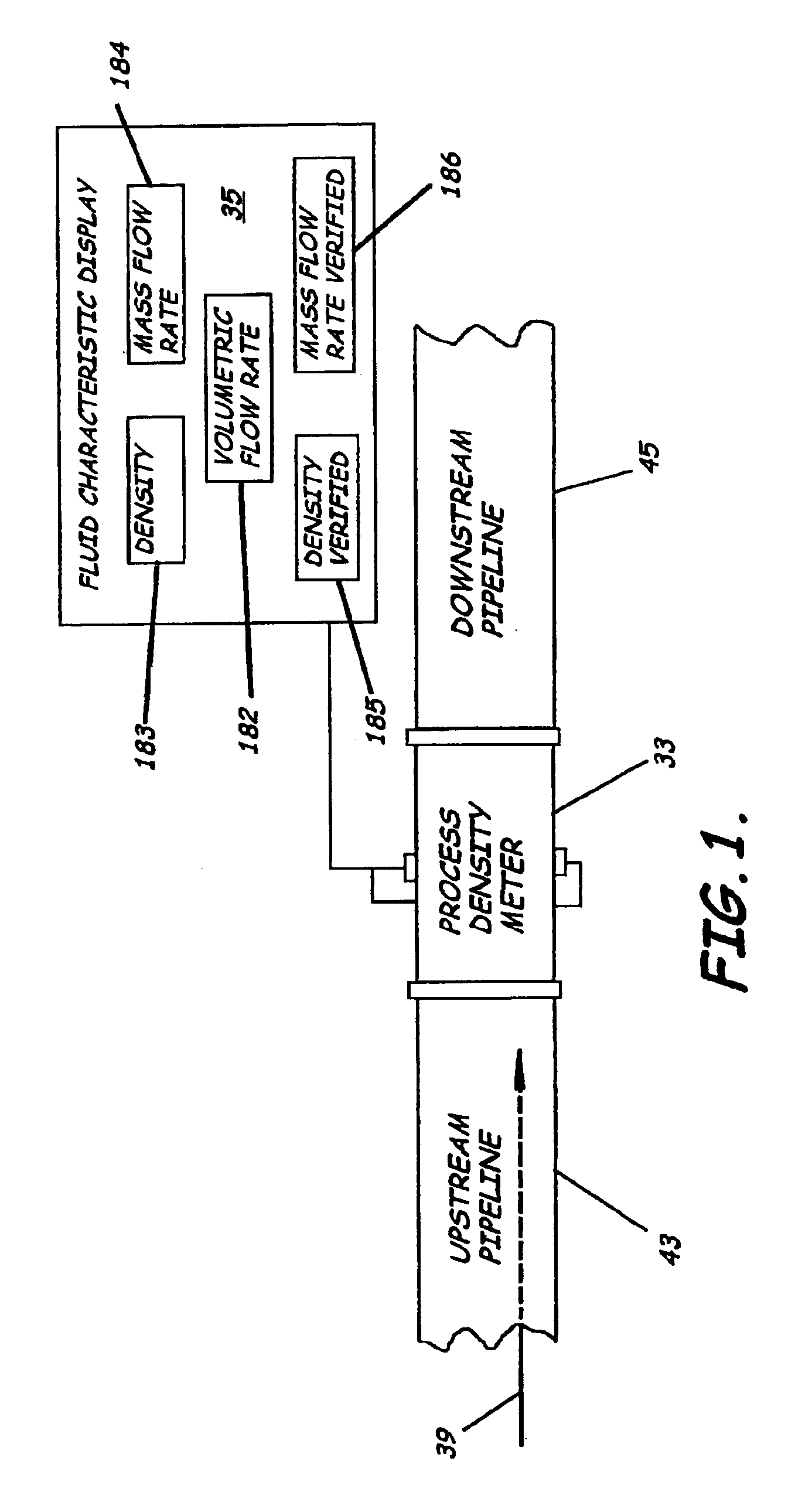

System to measure density, specific gravity, and flow rate of fluids, meter, and related methods

ActiveUS20050034535A1Little maintenanceMinimization needsVolume/mass flow by thermal effectsVolume/mass flow by dynamic fluid flow effectDifferential pressureDisplay device

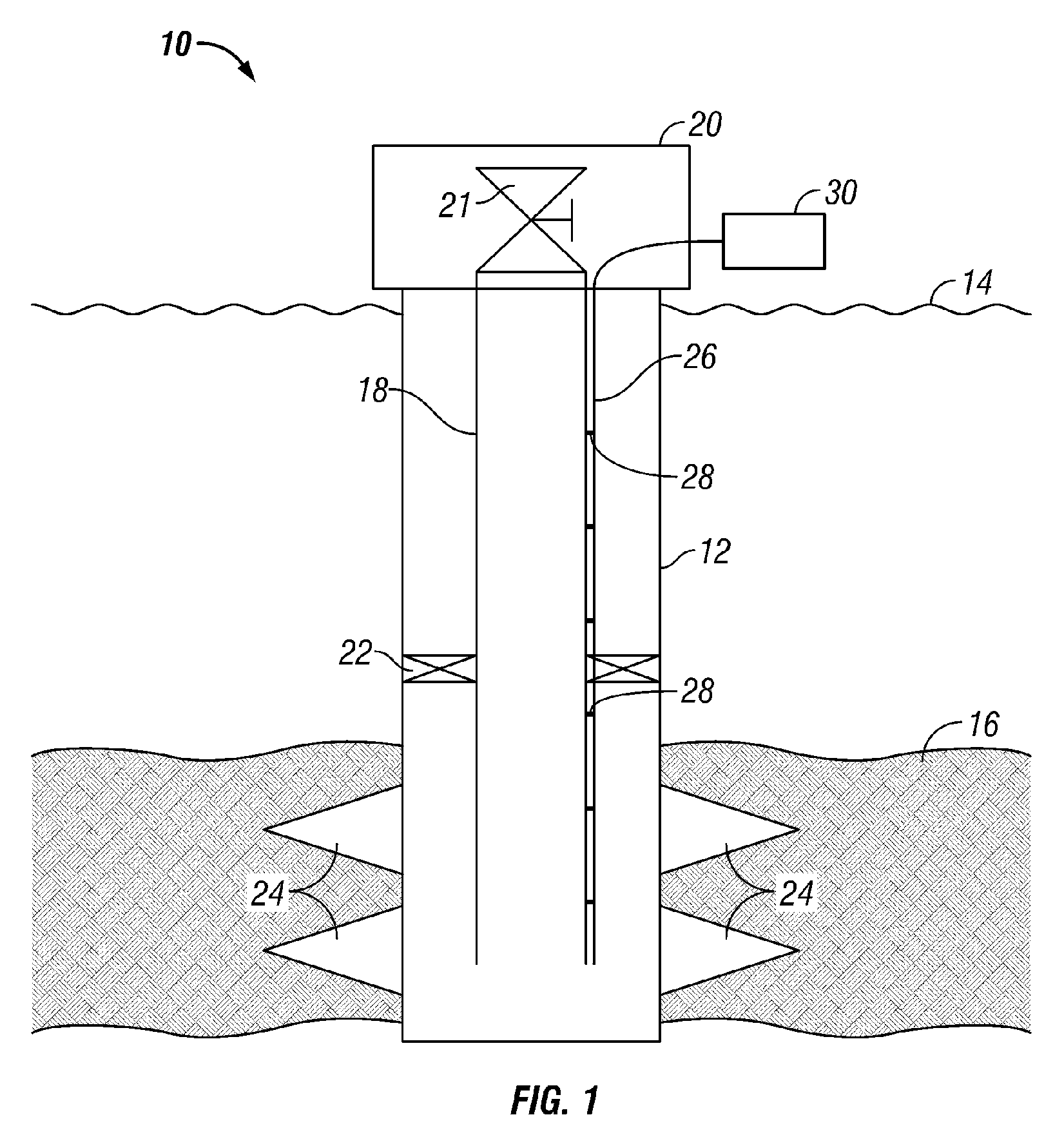

A system to measure fluid flow characteristics in a pipeline, meter, and methods includes a pipeline having a passageway to transport flowing fluid therethrough, a process density meter including at least portions thereof positioned within the pipeline to provide flowing fluid characteristics including volumetric flow rate, fluid density, and mass flow rate of the flowing fluid, and a fluid characteristic display to display the fluid characteristics. The process density meter includes a vortex-shedding body positioned within the pipeline to form vortices and a vortex meter having a vortex frequency sensor to measure the frequency of the vortices and to determine the volumetric flow rate. The process density meter further includes a differential pressure meter positioned adjacent the vortex-shedding body to produce a differential pressure meter flow rate signal indicative of the density of fluid when flowing through the pipeline. The process density meter also includes a thermal flow meter positioned adjacent the vortex-shedding body to produce a mass flow rate signal indicative of the mass flow rate of fluid when flowing through the pipeline. The process density meter produces an output of a volumetric flow rate, a flowing fluid density, and a mass flow rate to be displayed by the fluid characteristic display.

Owner:SAUDI ARABIAN OIL CO

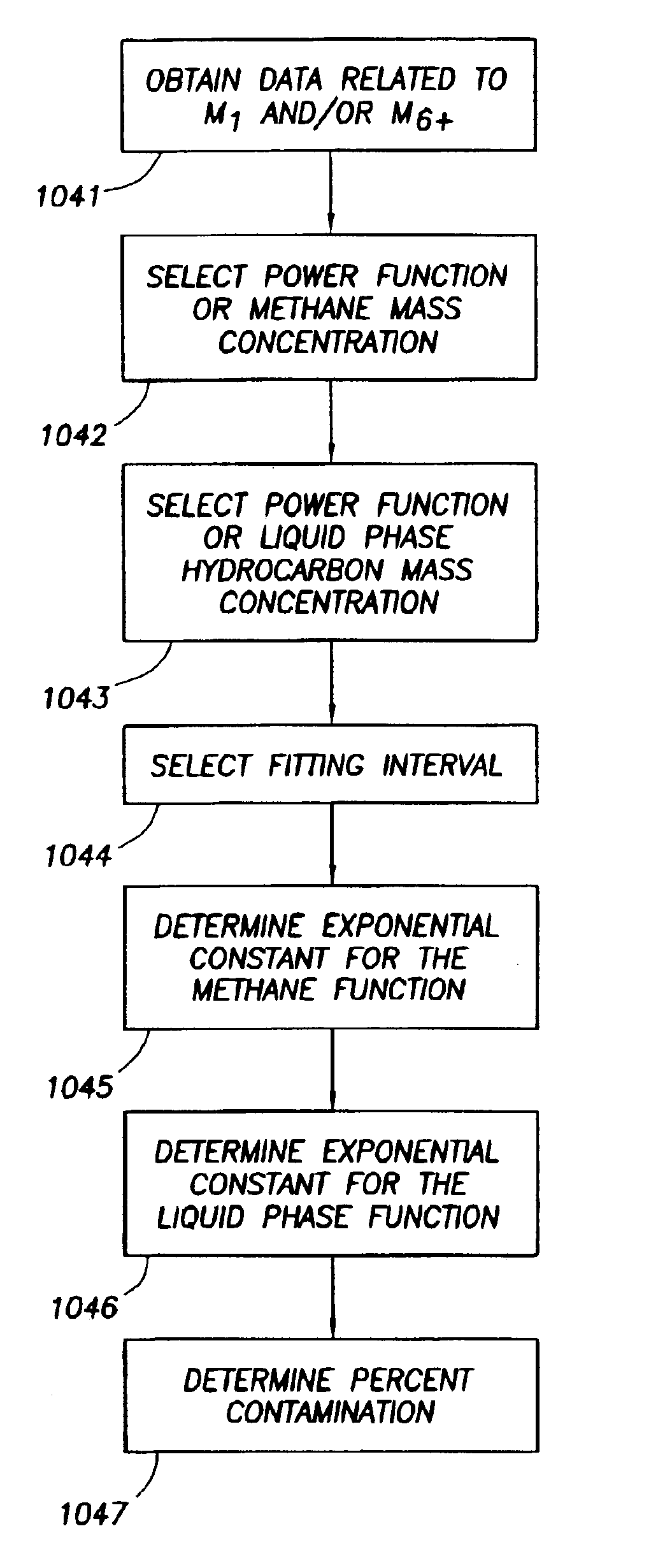

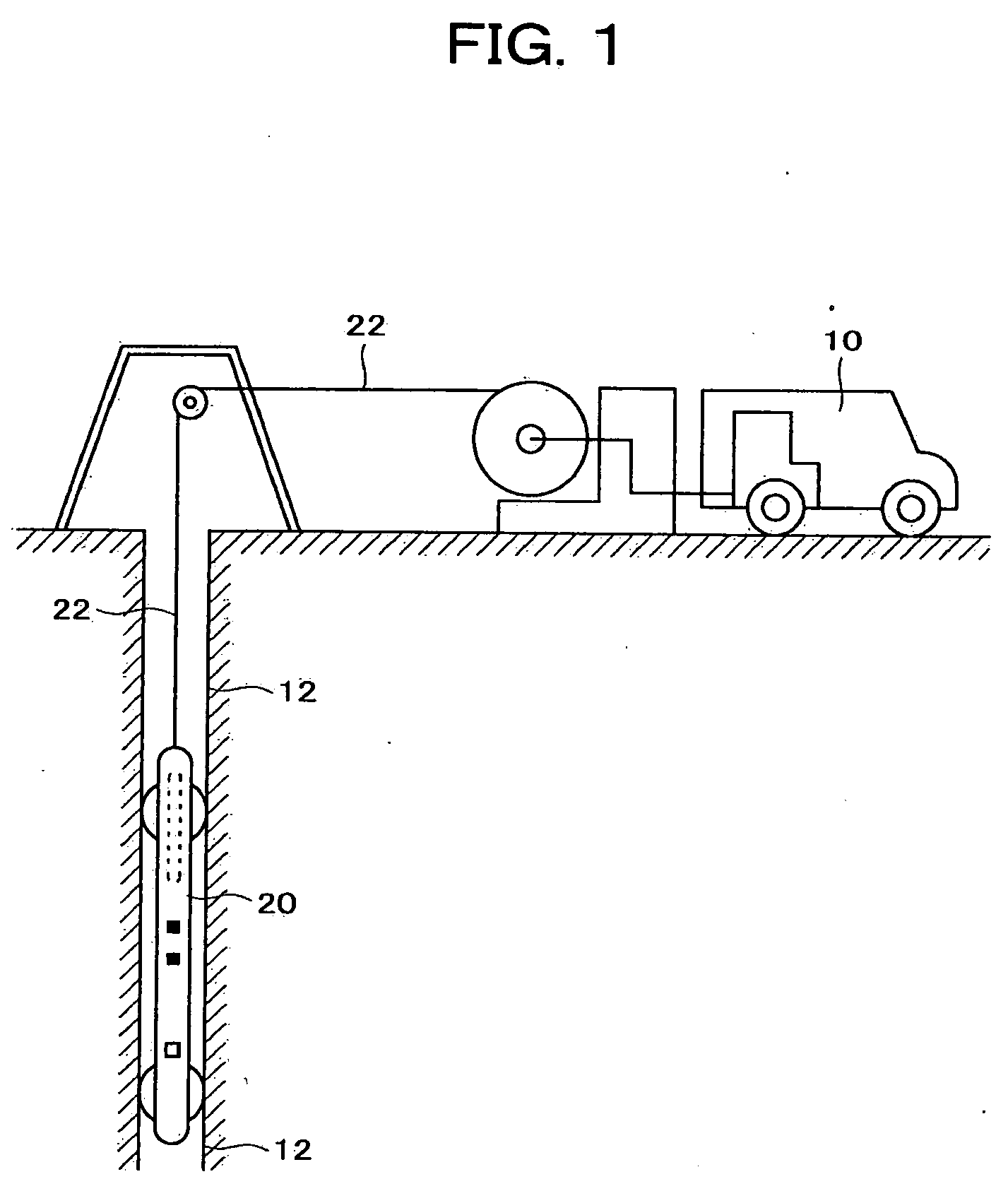

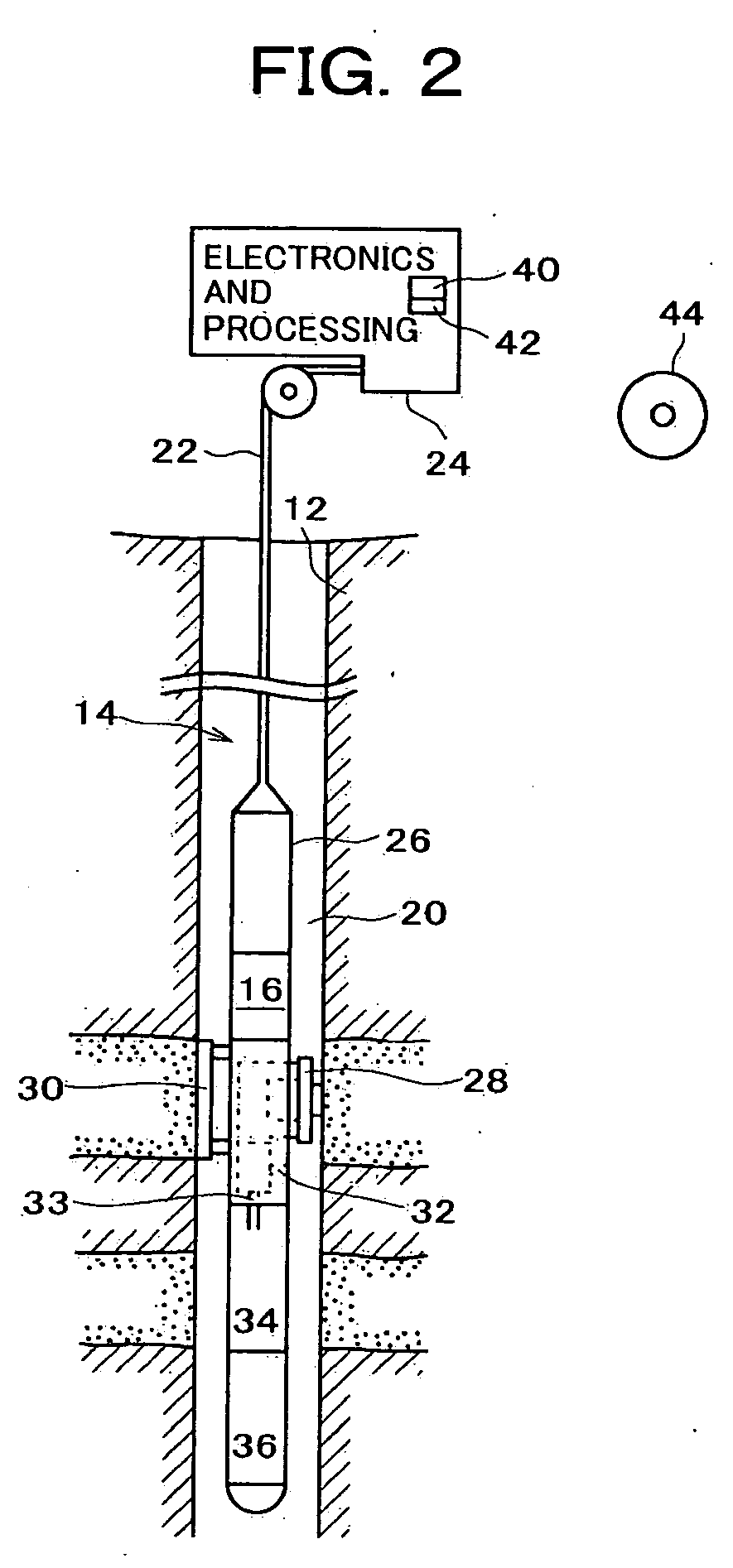

Formation evaluation system and method

A method of evaluating a fluid from a subterranean formation drawn into a downhole tool positioned in a wellbore penetrating the subterranean formation is provided. The method involves drawing fluid from a formation into an evaluation flowline, drawing fluid from a formation into a cleanup flowline, measuring a property of the fluid in the evaluation flowline and detecting stabilization of the property of the fluid in the evaluation flowline. Fluid properties in a combined flowline may be generated from the evaluation and cleanup flowlines. The fluid properties of the combined flowline may be used to project future evaluation flowline fluid properties. Contamination levels for a given fluid property of a given flowline may also be determined.

Owner:SCHLUMBERGER TECH CORP

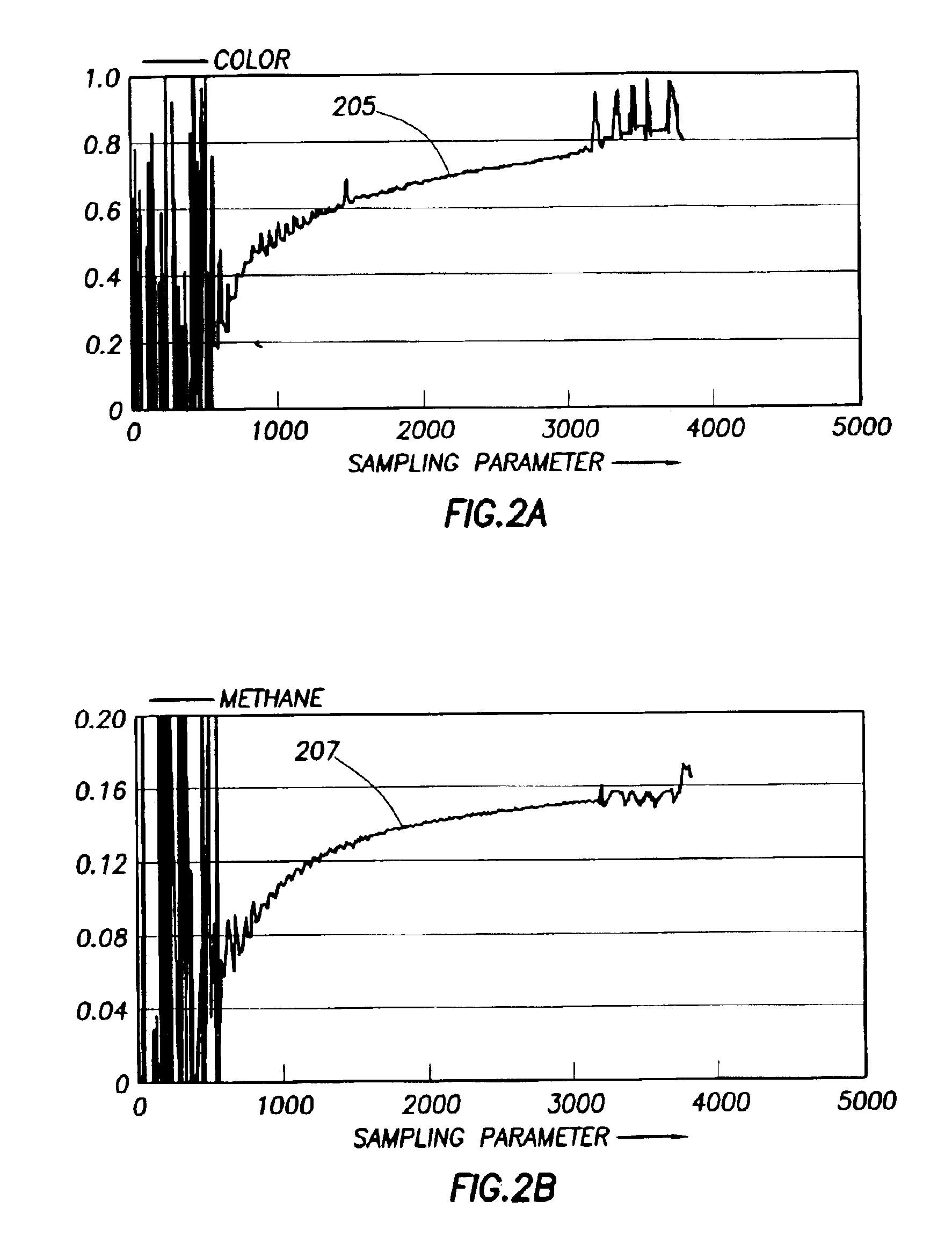

Determining fluid properties from fluid analyzer

A method for determining properties of a formation fluid including obtaining data related to an optical density at a methane peak and an optical density at an oil peak for a fluid sample at a plurality of times, calculating an apparent gas-oil-ratio of the sample fluid from the optical density of the fluid sample at the methane peak to the optical density of the fluid sample at the oil peak at each of the plurality of times based on the data, selecting a power function of a sampling parameter for a buildup of the apparent gas-oil-ratio, calculating an exponential constant of the power function based on the data, and determining at least one selected from the group consisting of a contamination free gas-oil-ratio and a percent contamination.

Owner:SCHLUMBERGER OILFIELD SERVICES

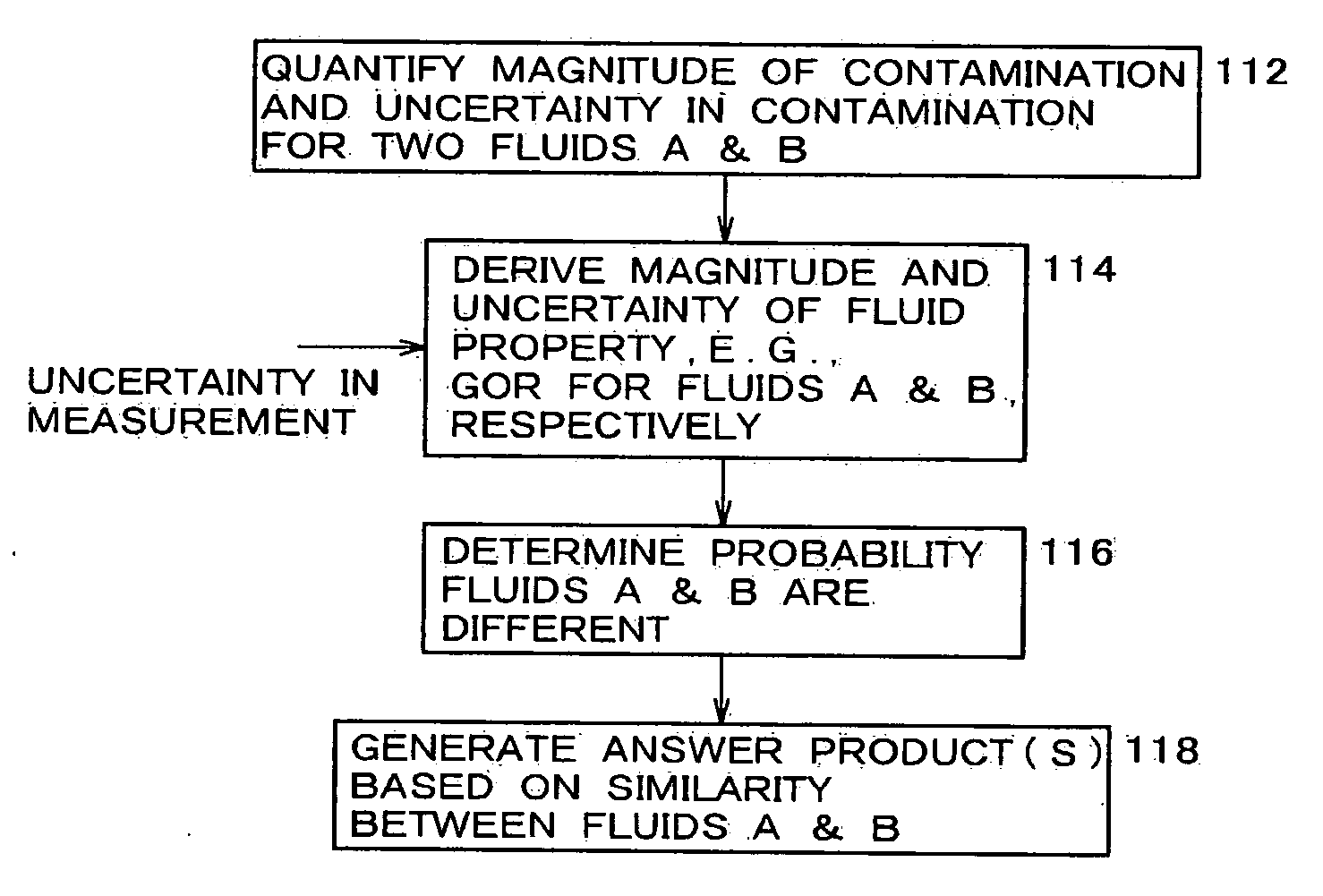

System and methods of deriving fluid properties of downhole fluids and uncertainty thereof

ActiveUS20060155474A1Less sensitive to systematic error in dataGood basisElectric/magnetic detection for well-loggingSurveyFormation fluidContamination

Methods and systems are provided for downhole analysis of formation fluids by deriving fluid properties and associated uncertainty in the predicted fluid properties based on downhole data, and generating answer products of interest based on differences in the fluid properties. Measured data are used to compute levels of contamination in downhole fluids using an oil-base mud contamination monitoring (OCM) algorithm. Fluid properties are predicted for the fluids and uncertainties in predicted fluid properties are derived. A statistical framework is provided for comparing the fluids to generate, in real-time, robust answer products relating to the formation fluids and reservoirs thereof. Systematic errors in measured data are reduced or eliminated by preferred sampling procedures.

Owner:SCHLUMBERGER TECH CORP

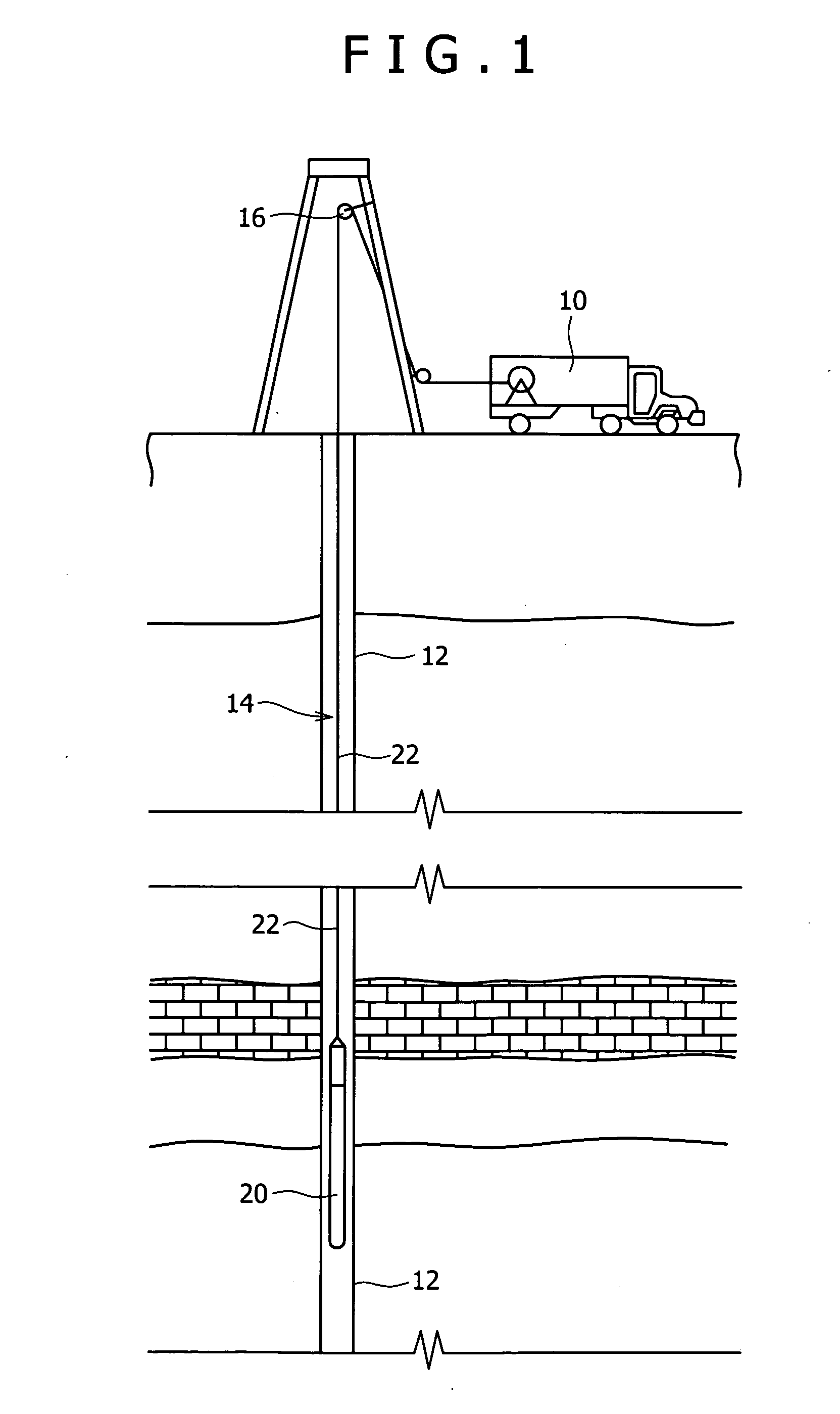

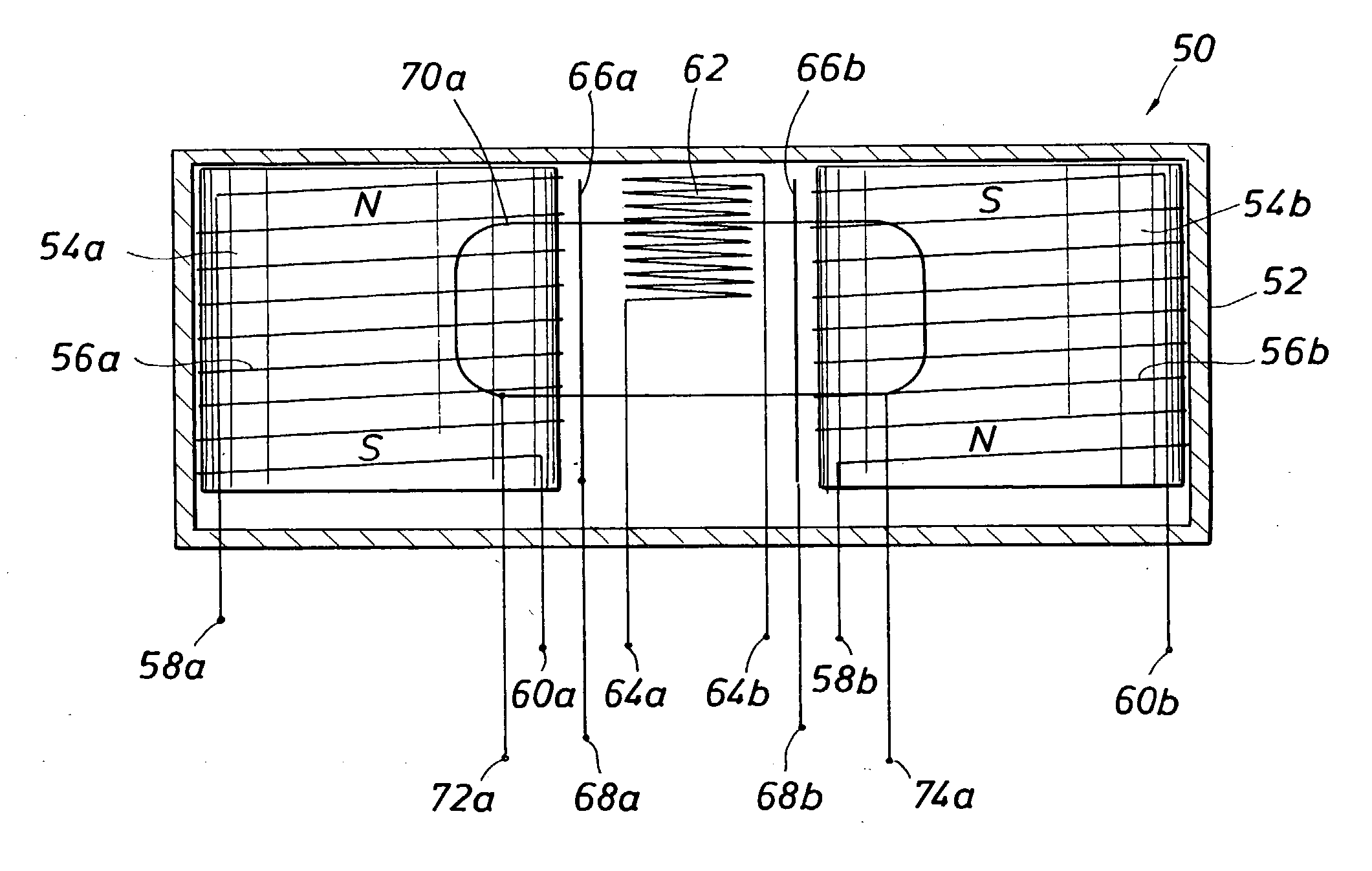

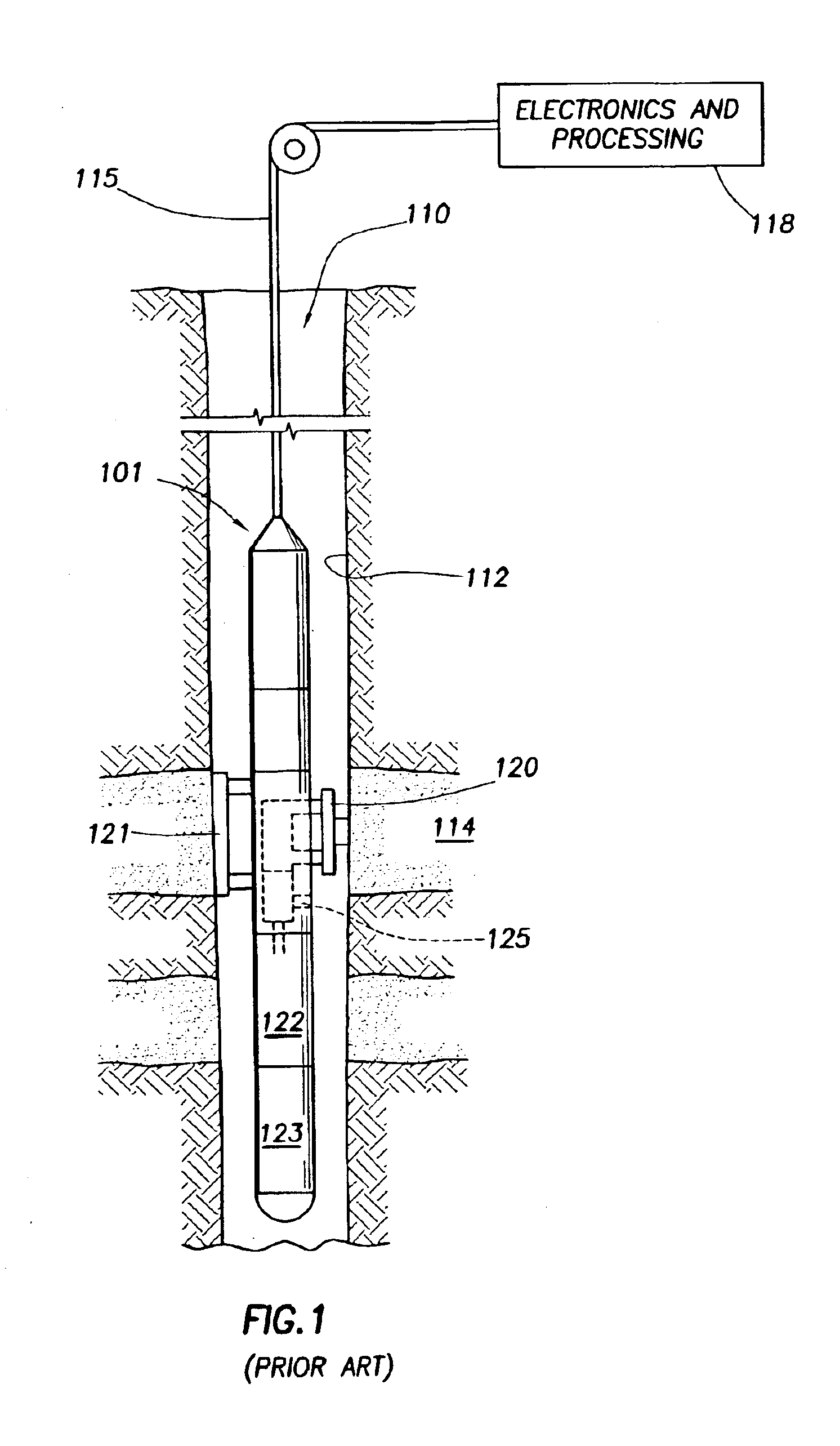

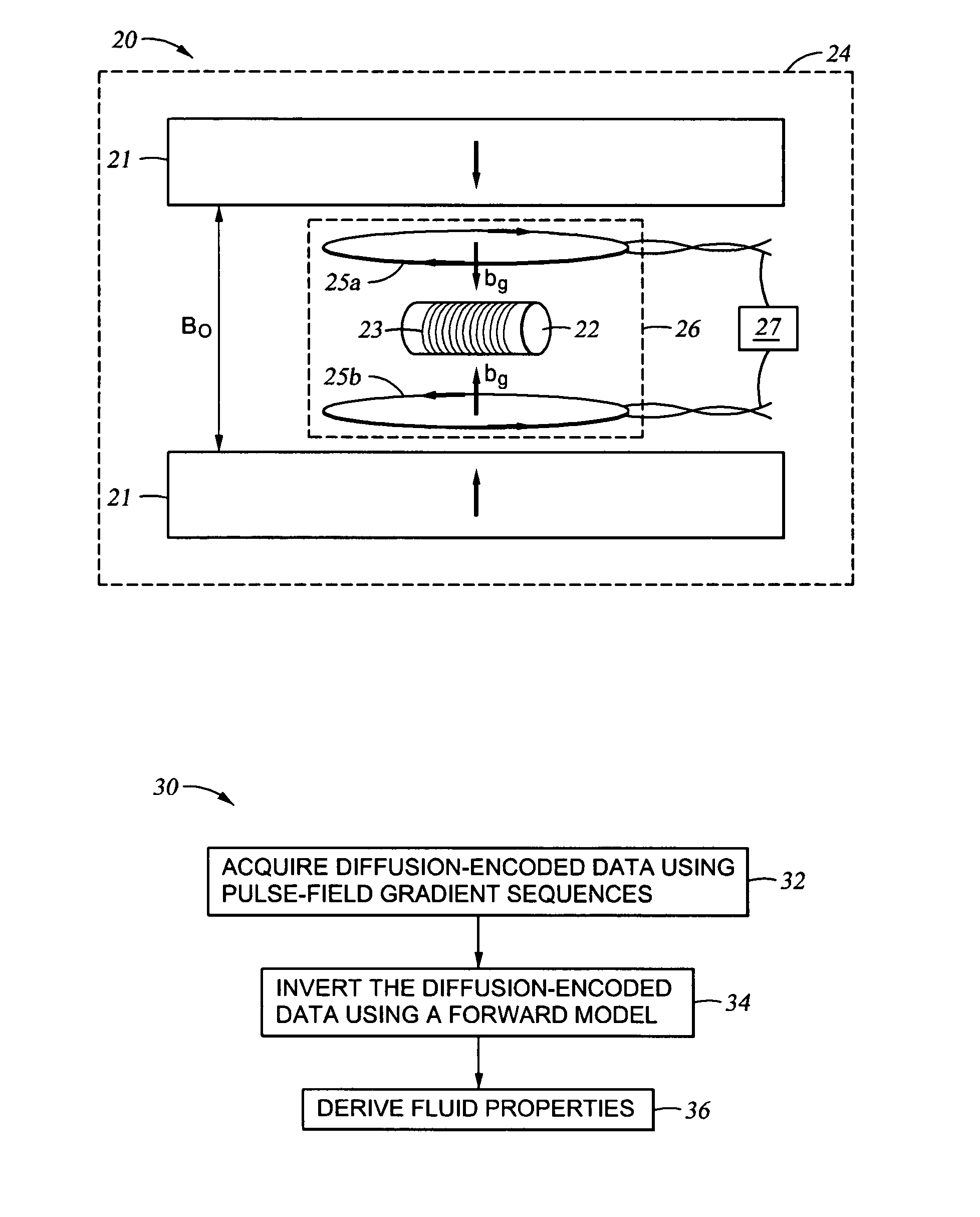

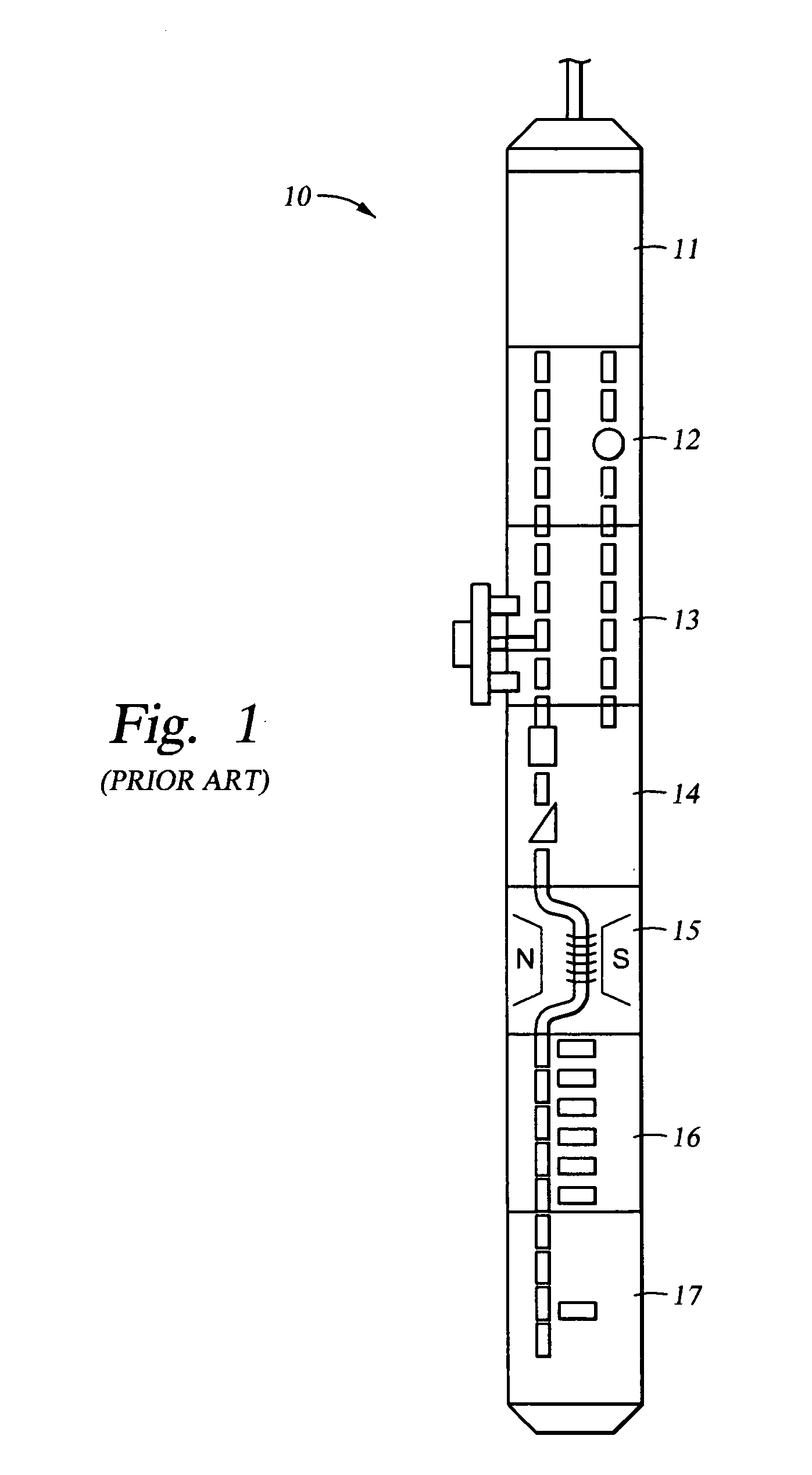

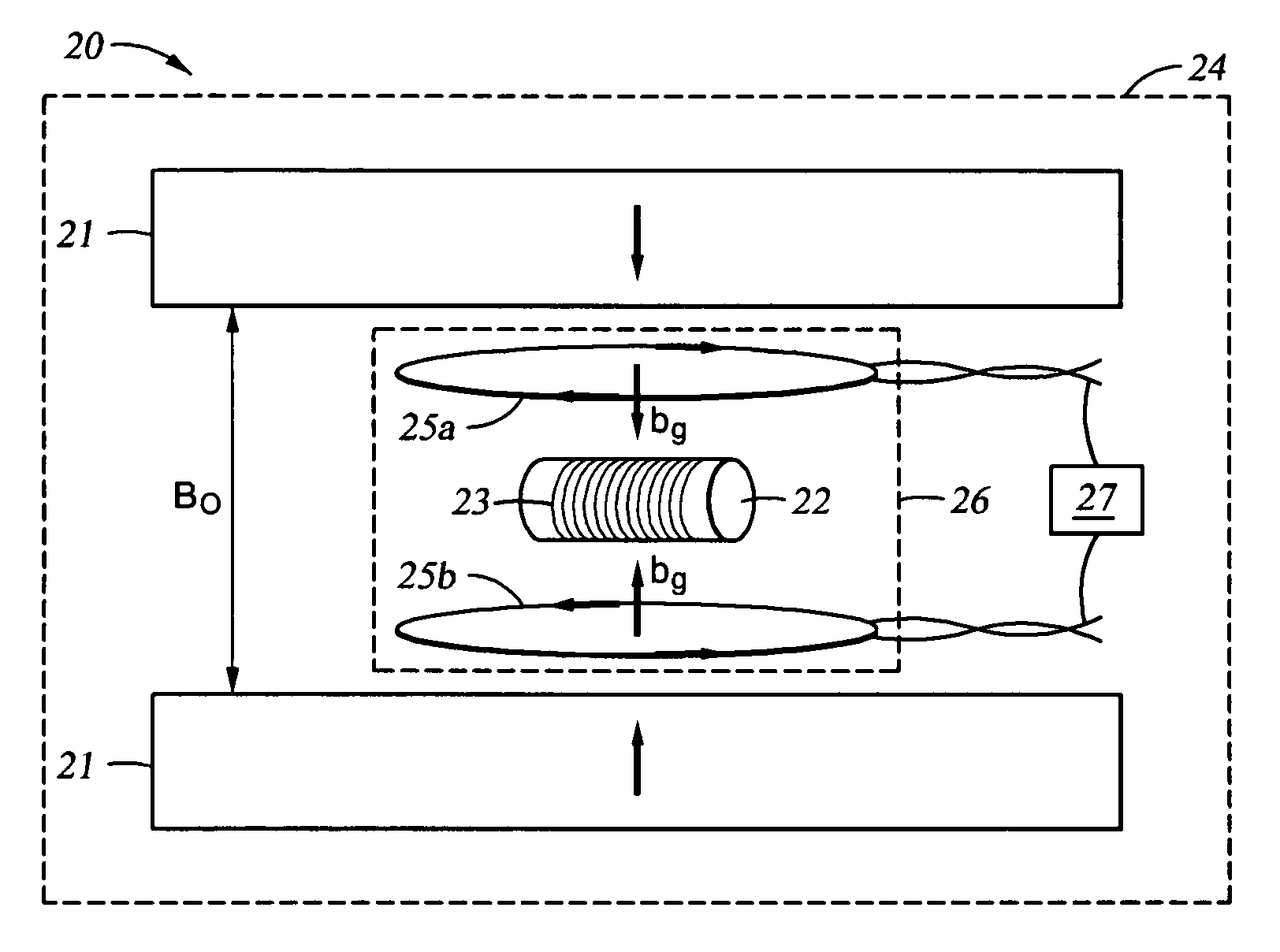

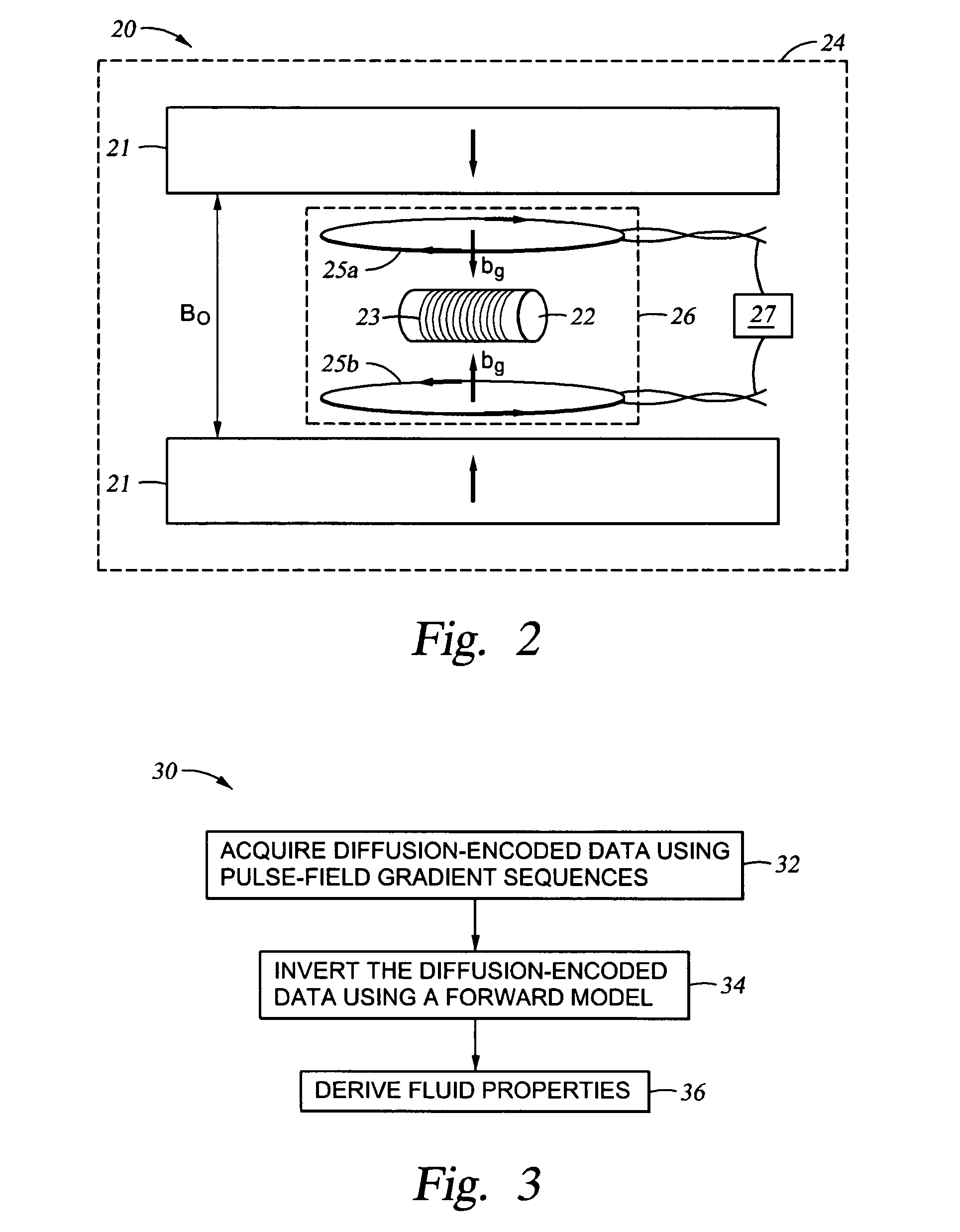

Method and apparatus for using pulsed field gradient NMR measurements to determine fluid properties in a fluid sampling well logging tool

InactiveUS20050270023A1Easy to detectRaise the ratioElectric/magnetic detection for well-loggingSurveyDiffusionNMR - Nuclear magnetic resonance

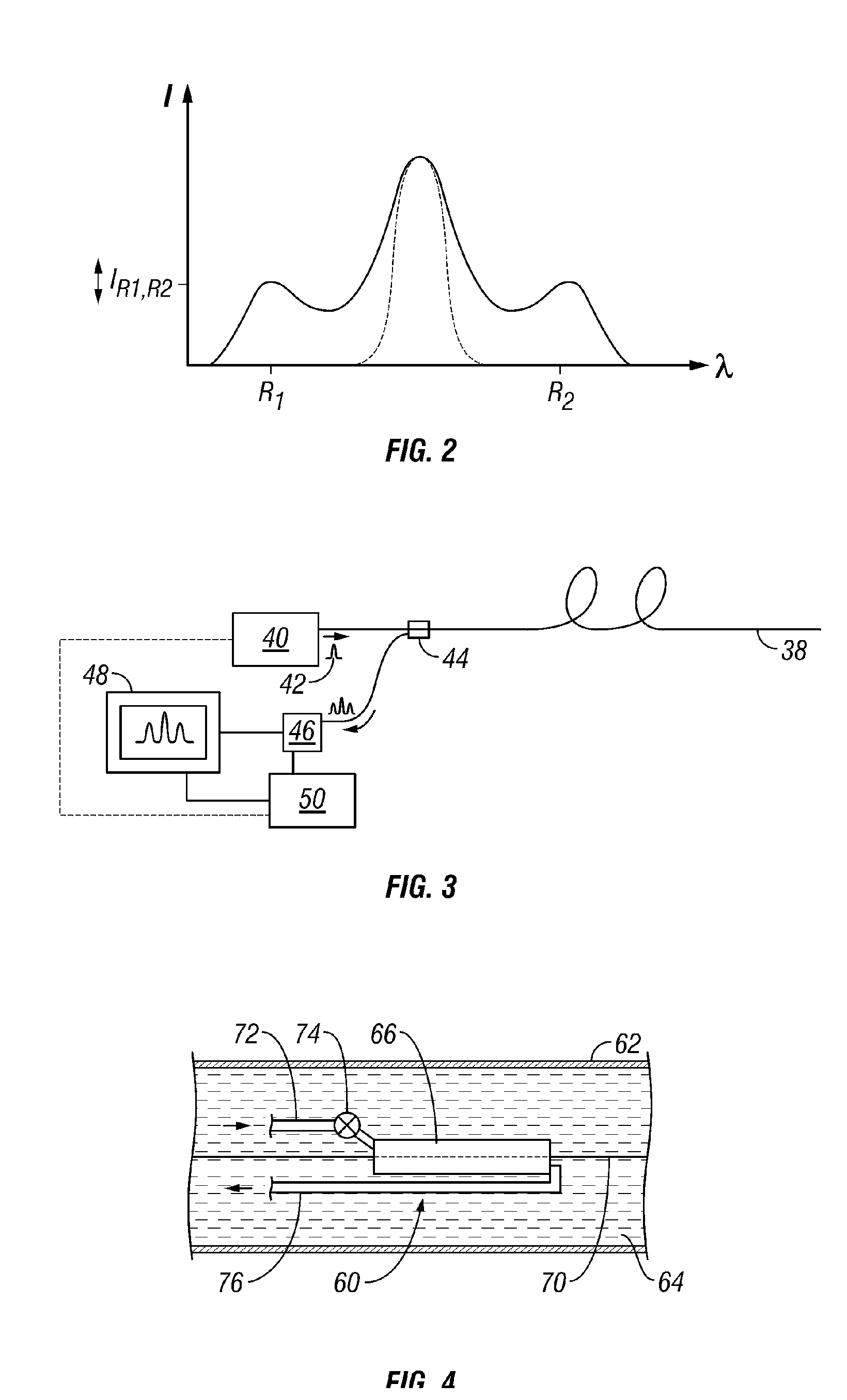

A method for determining a formation fluid property includes acquiring a suite of nuclear magnetic resonance (NMR) measurements of a fluid sample using a pulse sequence that includes pulsed field gradient pulses for encoding diffusion information, wherein each NMR measurement in the suite is acquired with a different value in a parameter in the pulsed field gradient pulses for producing a different diffusion effect, wherein the acquiring is performed in a formation fluid sampling tool in a borehole; inverting the suite of NMR measurements to produce a distribution function that relates diffusion properties of the fluid sample with an NMR property of the fluid sample; and determining the formation fluid property from the distribution function.

Owner:SCHLUMBERGER TECH CORP

Unanchored sensor for fluid characteristics

A device and method for sensing fluid characteristics, including, temperature, pH and chemistry, comprises a switch affixed to or embedded in a container of a size, shape and density such that said container floats stable in said liquid sensors which measure and report other characteristics of the liquid, such as temperature, pH, viscosity, chemistry or biochemistry.

Owner:HARVARD APPARATUS

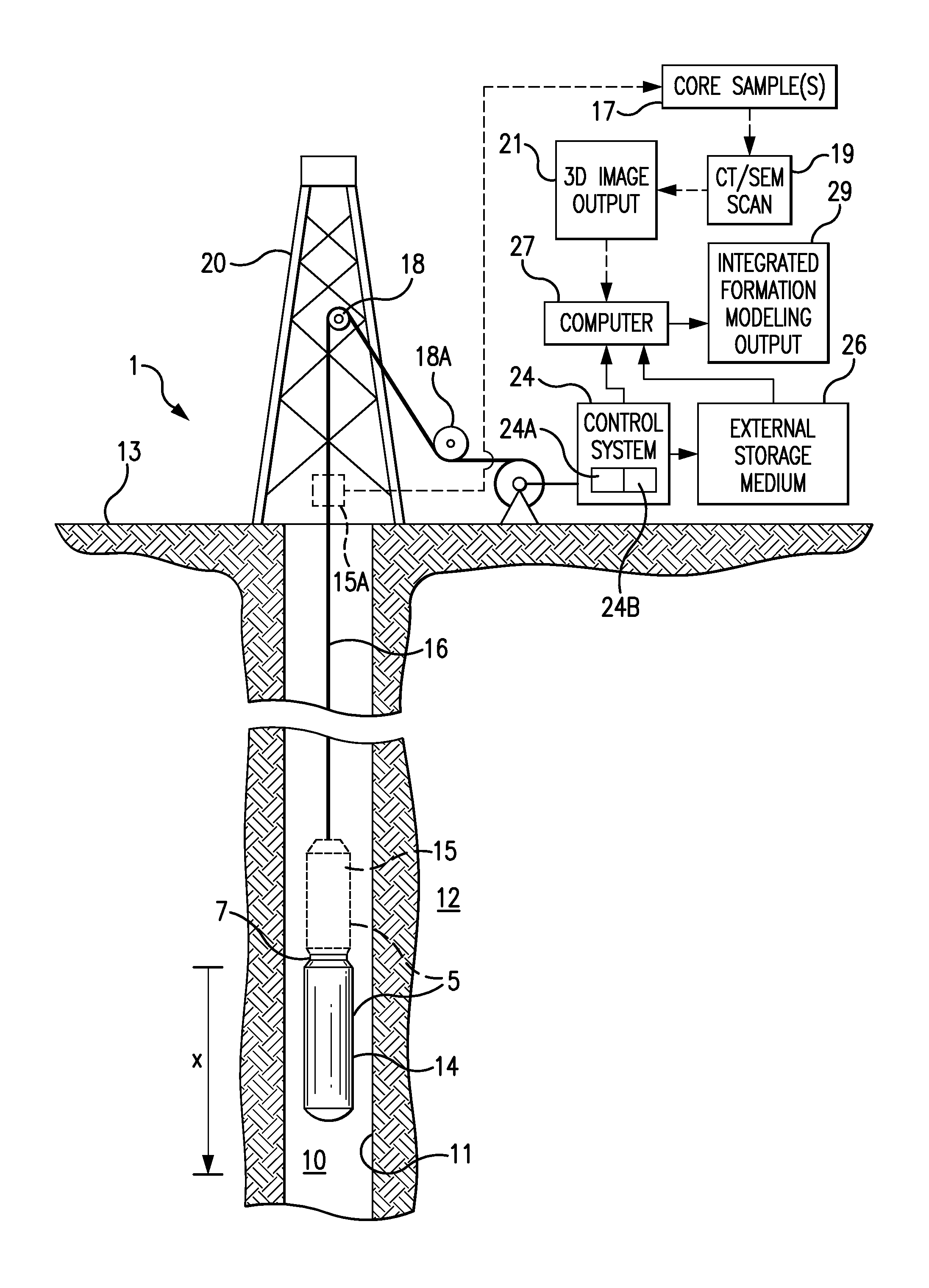

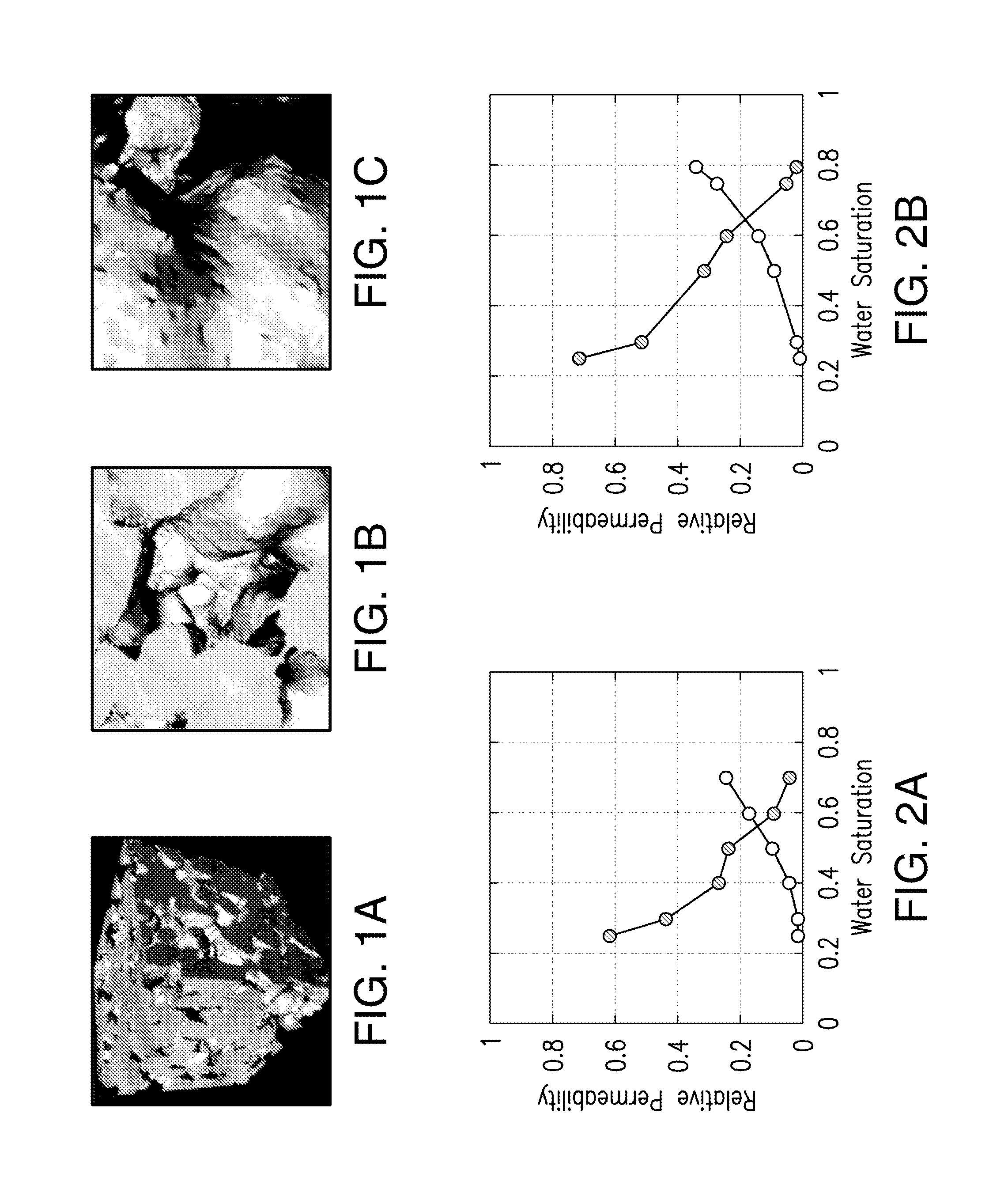

Method and system for integrating logging tool data and digital rock physics to estimate rock formation properties

ActiveUS9507047B1Material analysis using wave/particle radiationNuclear radiation detectionPorosityCt scanners

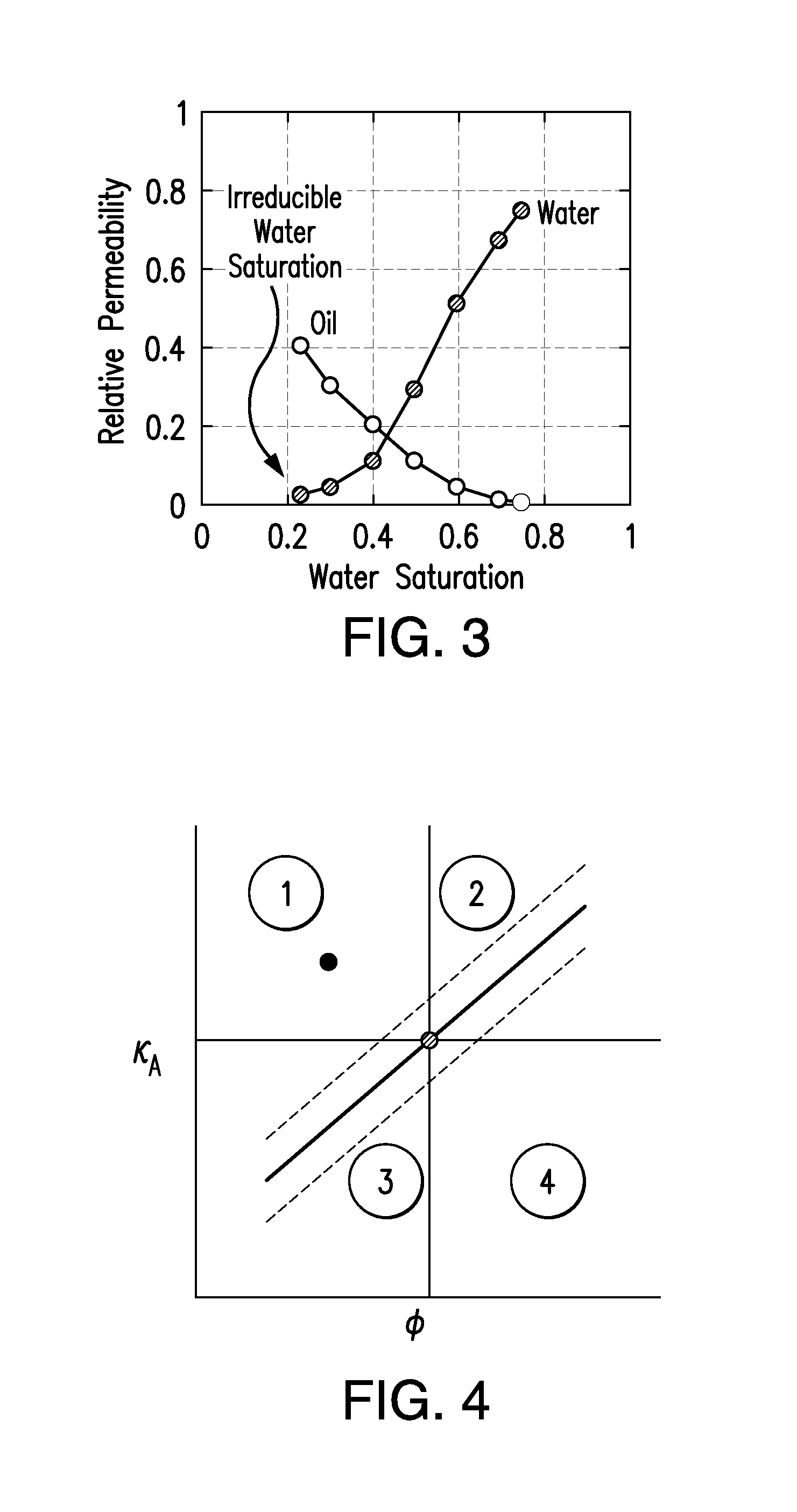

The present invention relates to a method and system for integrating logging tool data and digital rock physics to estimate rock formation properties. A rock sample from a logging tool such as a sidewall plug or large enough cutting can be extracted by the logging tool at approximately the same well bore location that the logging tool measures fluid properties. The rock samples thus obtained is scanned using a CT scanner, scanning electron microscope or other suitable scanning device. The resulting scanned rock image can be segmented and rock properties comprising porosity, absolute permeability, relative permeability, capillary pressure and other relevant rock properties are calculated. The resulting digital calculations are integrated with logging tool data and rock property estimates to improve the accuracy and timeliness of the logging tool data.

Owner:HALLIBURTON ENERGY SERVICES INC

Single tube densitometer

InactiveUS6912904B2Improve accuracyImprove reliabilityVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesMeasurement deviceComputer module

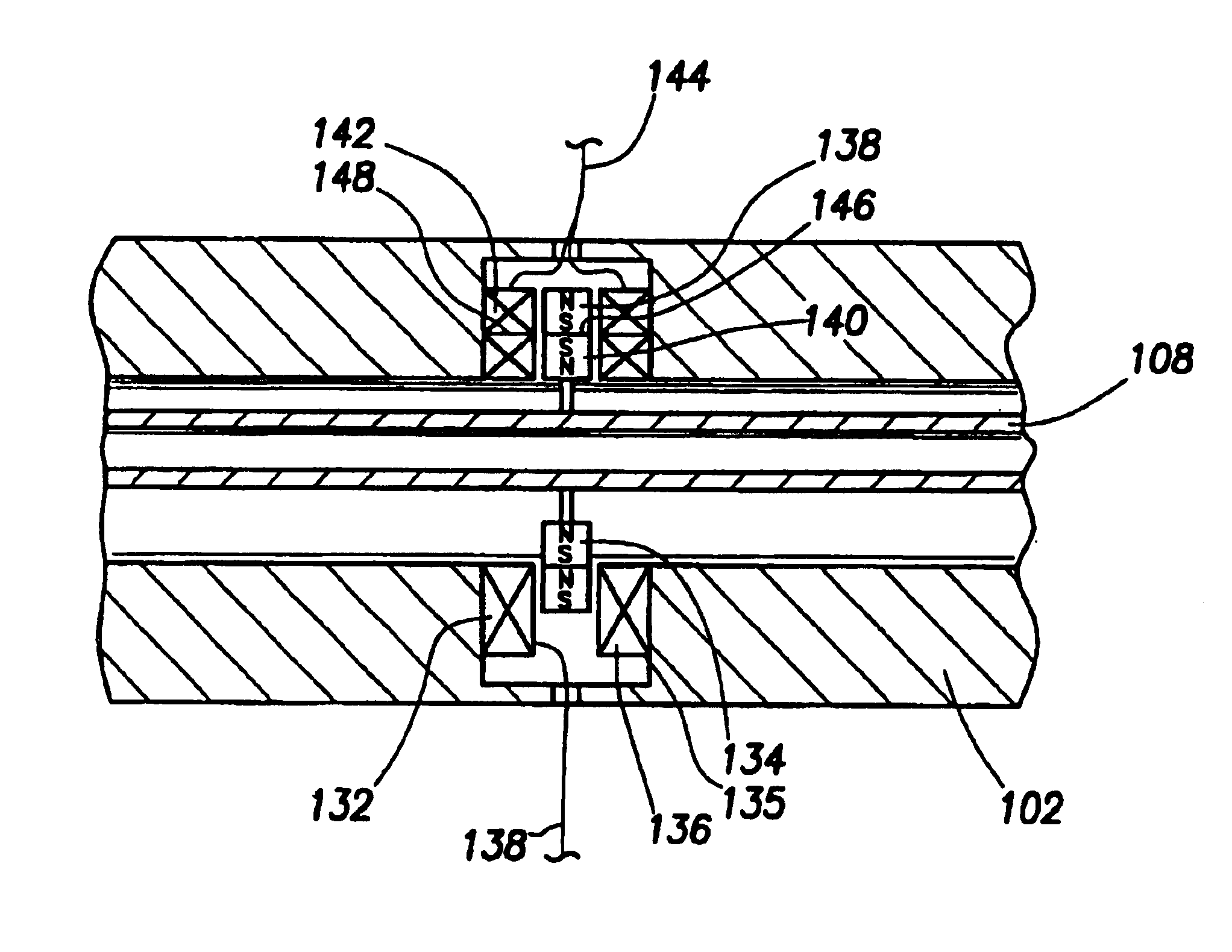

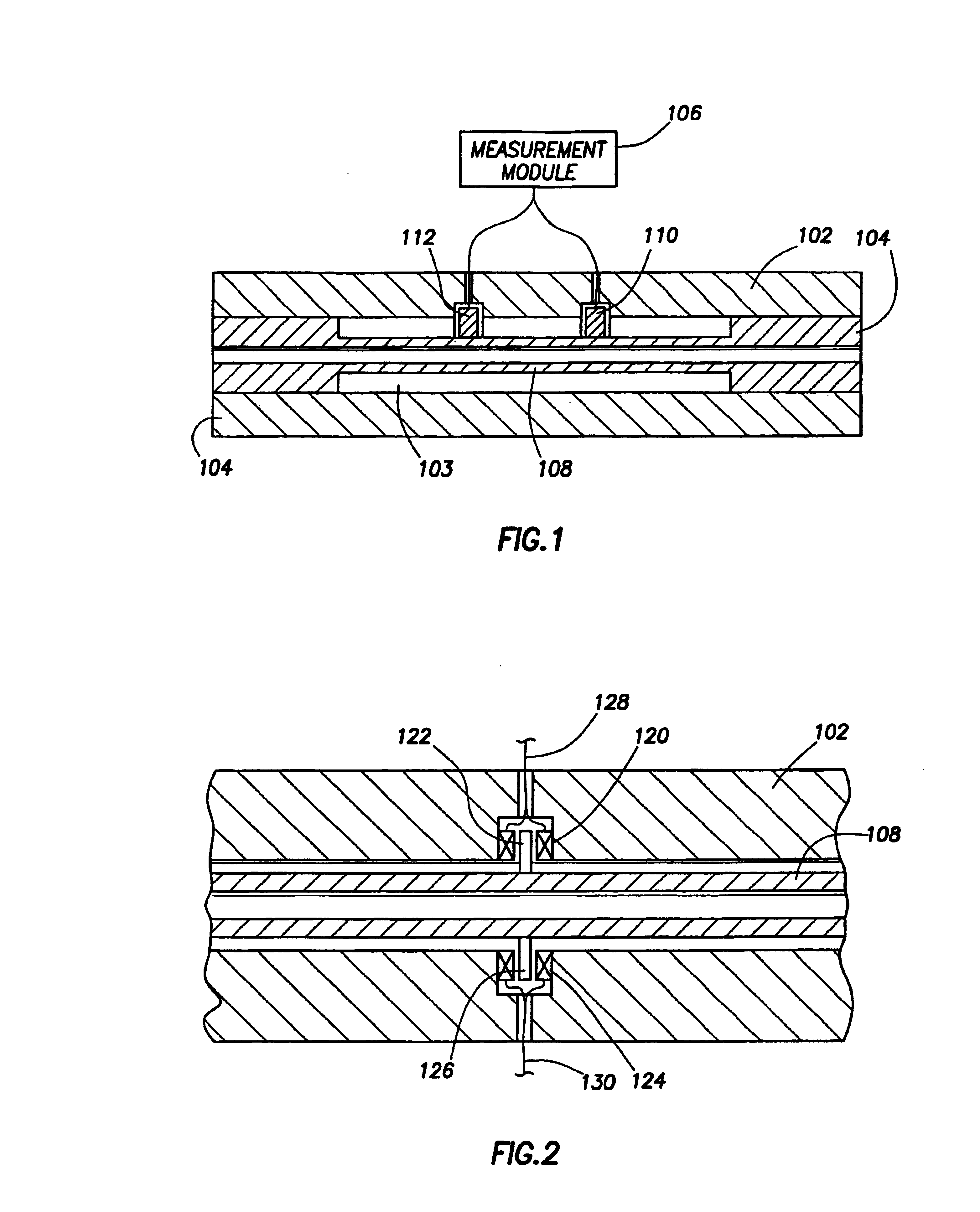

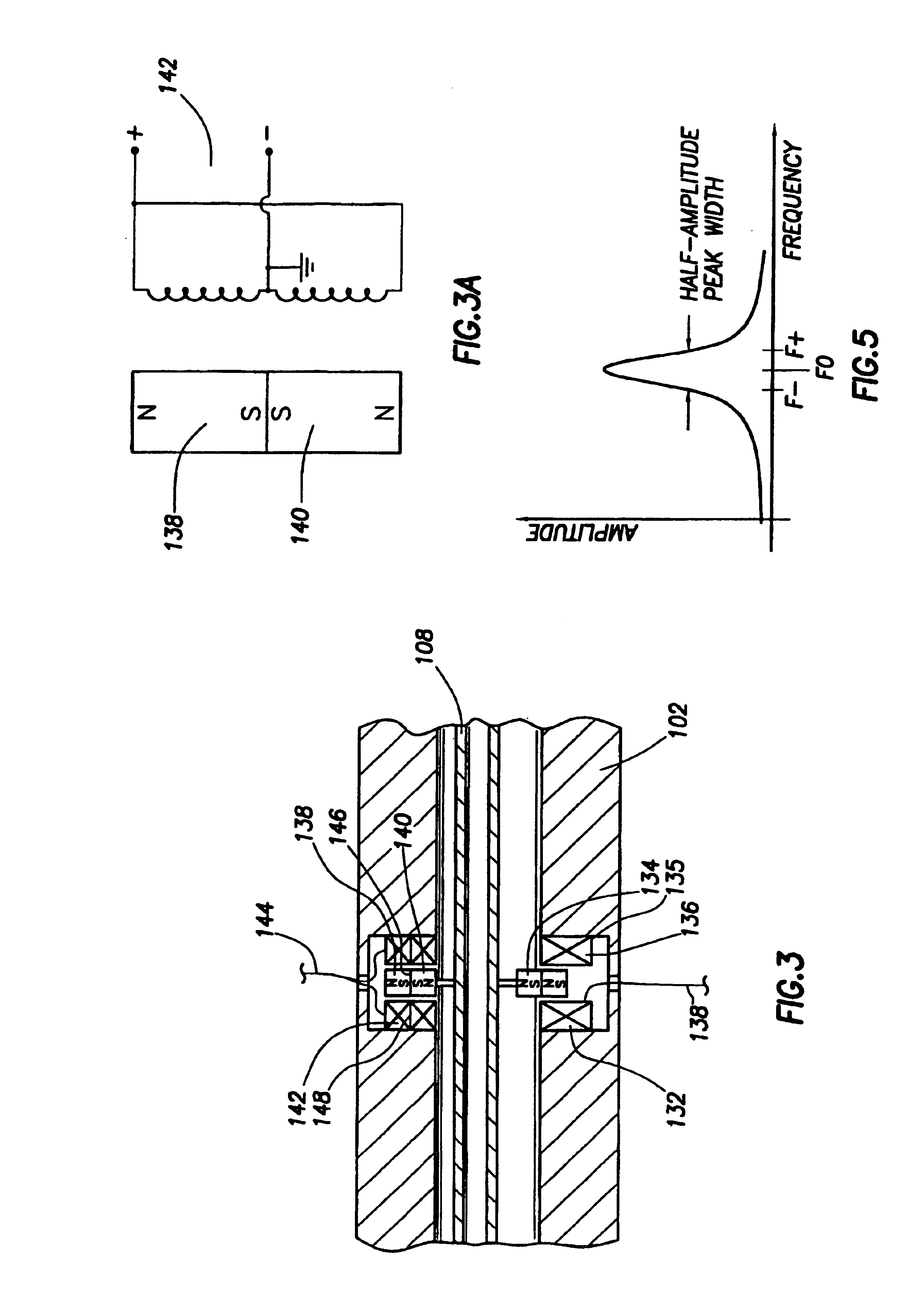

A measurement device is provided that determines fluid properties from vibration frequencies of a sample cavity. In one embodiment, the measurement device includes a sample flow tube, vibration source and detector mounted on the tube, and a measurement module. The sample flow tube receives a flow of sample fluid for characterization. The measurement module employs the vibration sources to generate vibrations in the tube. The measurement module combines the signals from the vibration detector on the tube to determine properties of the sample fluid, such as density, viscosity, compressibility, water fraction, and bubble size. The measurement module may further detect certain flow patterns such as slug flow, for example. To measure the sample fluid density, the measurement module determines the resonant frequency of the sample flow tube. The density can then be calculated according to a formula that compensates for the temperature and pressure of the system.

Owner:HALLIBURTON ENERGY SERVICES INC

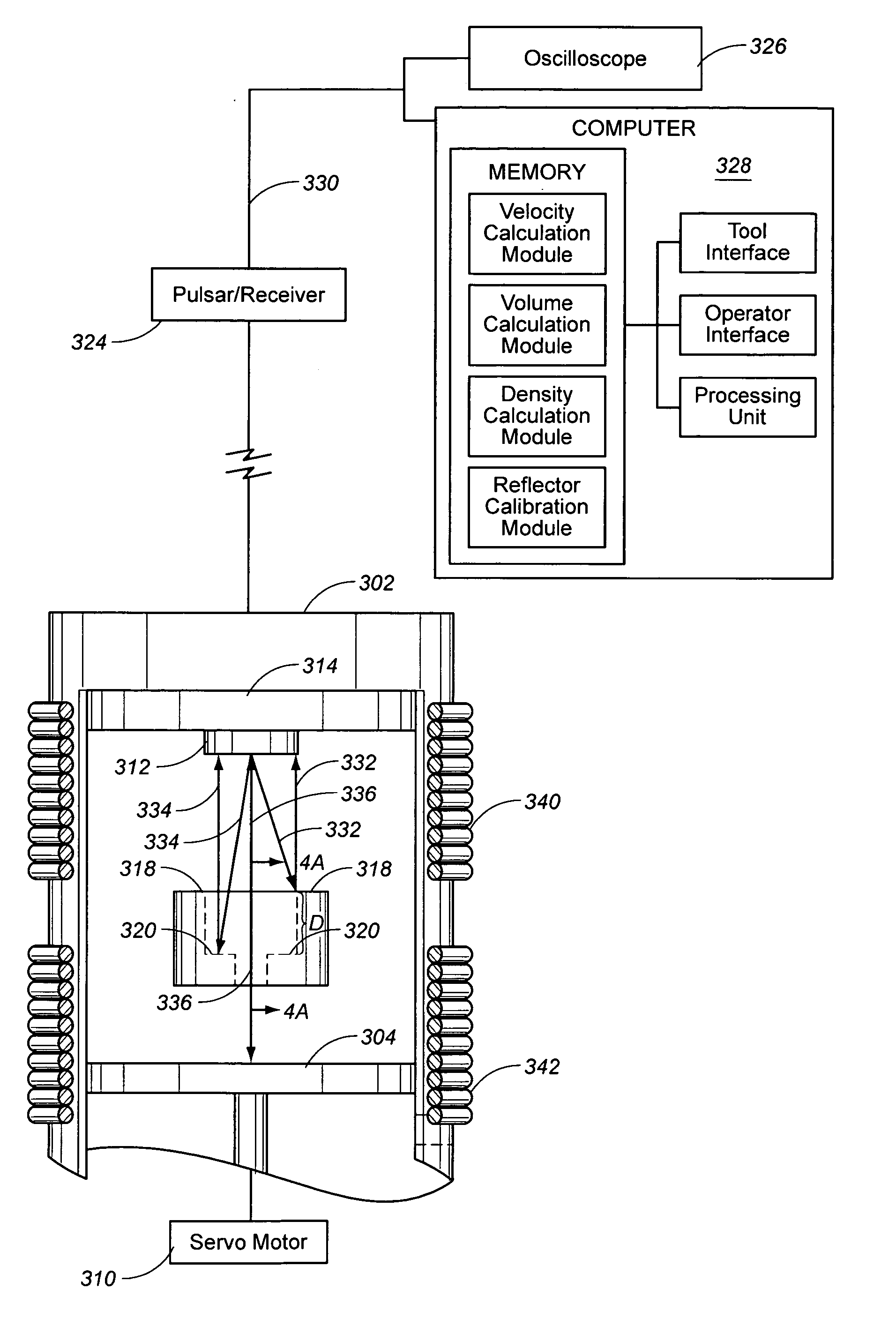

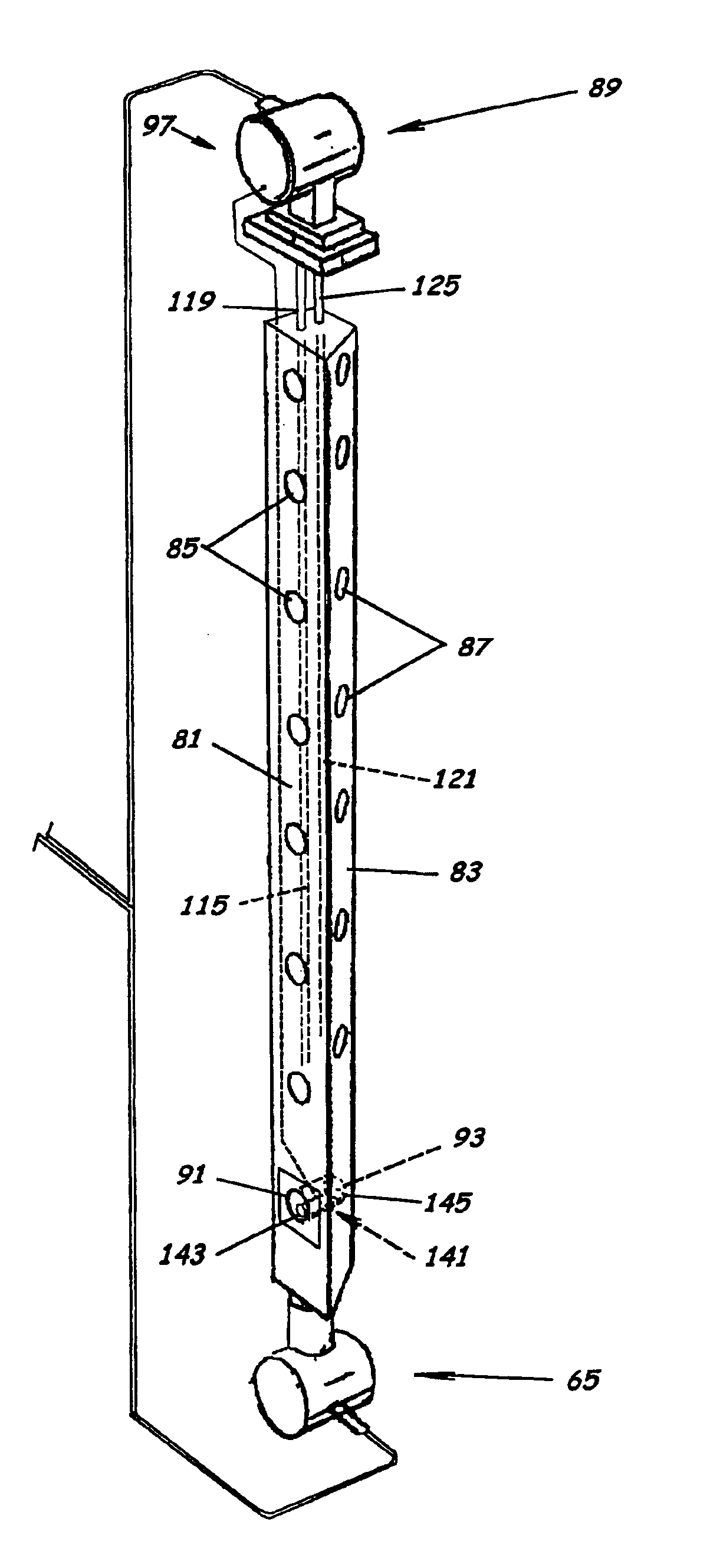

Apparatus and methods for acoustically determining fluid properties while sampling

ActiveUS20050223808A1Vibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesAcoustic propertyTransmitter

An apparatus and methods for acoustically analyzing a fluid sample and determining one or more properties of the sample are disclosed by the present invention. The apparatus comprises a chamber, a transmitter positioned within the chamber for transmitting an acoustic signal through the fluid, a reflector movably positioned within the fluid inside the chamber for reflecting the acoustic signal, and a receiver positioned within the chamber for detecting reflections of the acoustic signal. The methods employ the use of a transmitter, a reflector movably positioned within the fluid inside the chamber, and a receiver to characterize the fluid sample based on one or more of its acoustic properties.

Owner:SHELL OIL CO

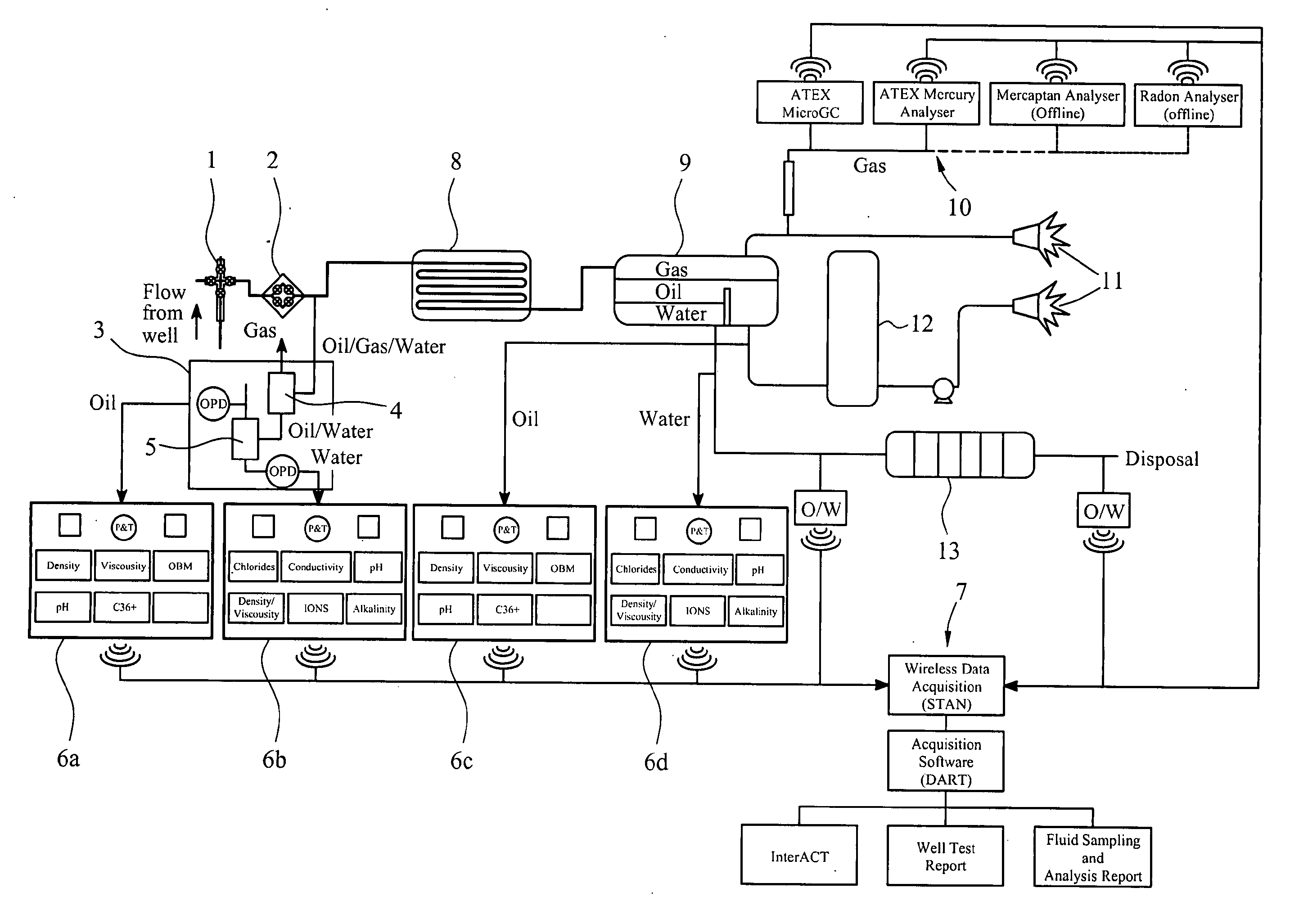

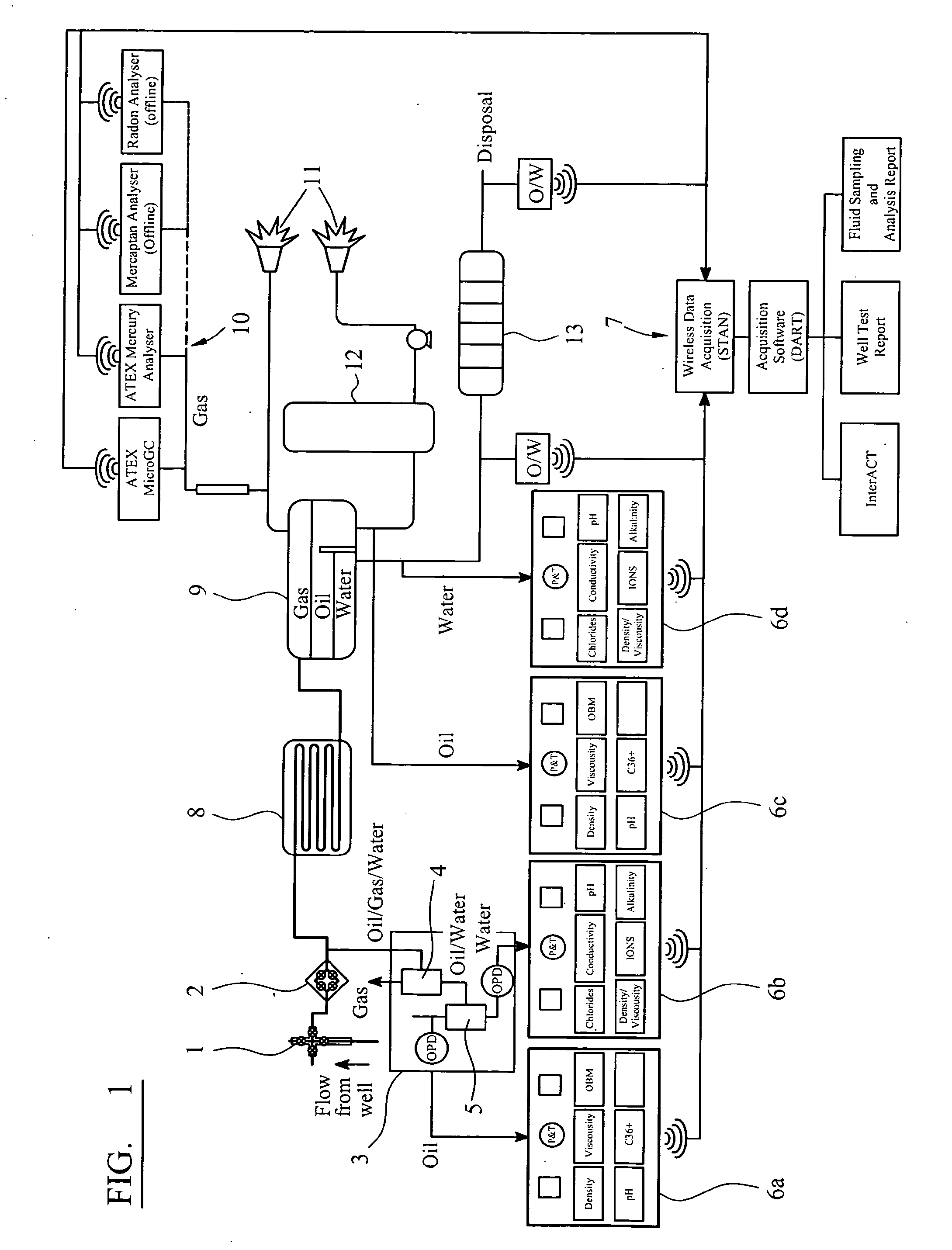

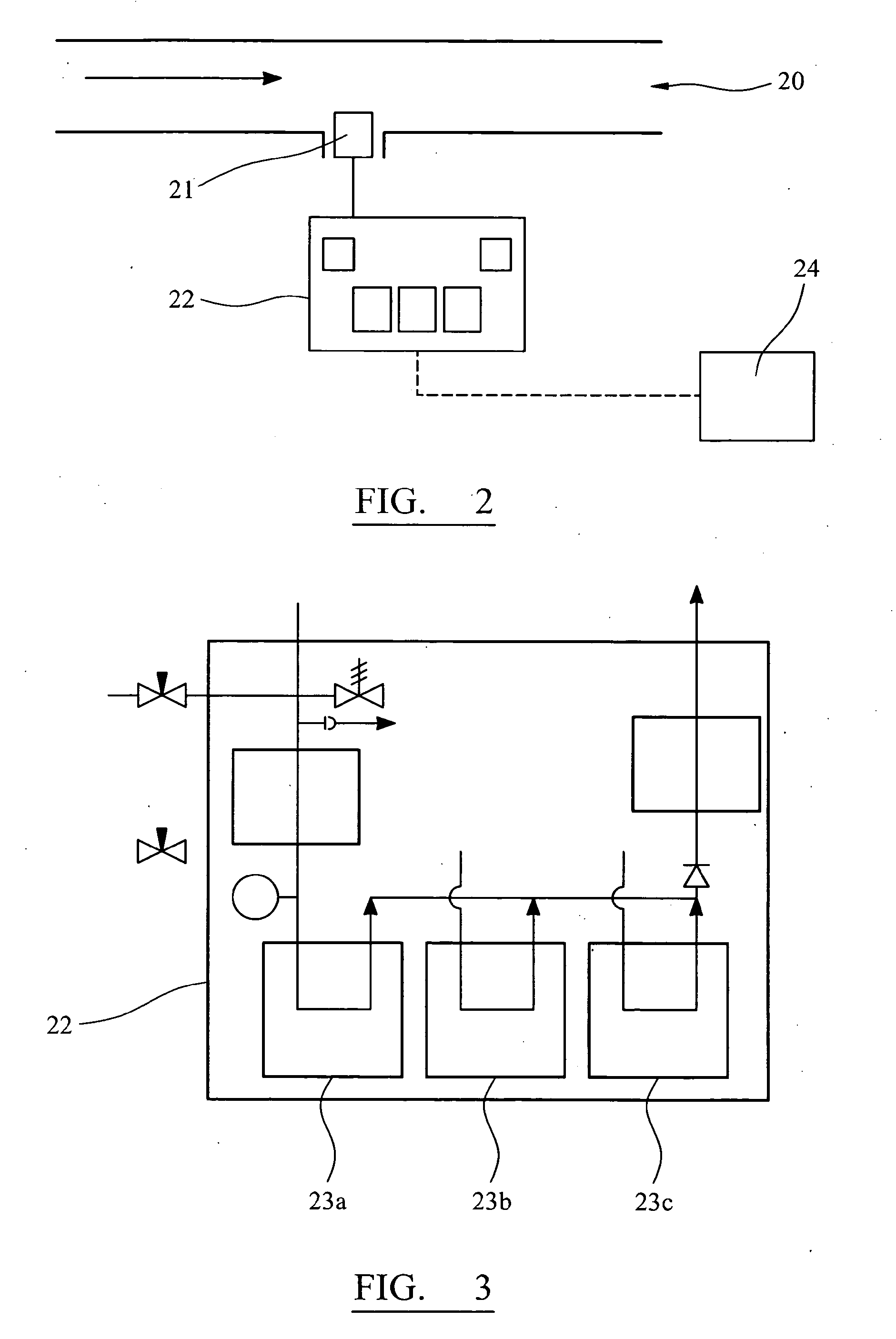

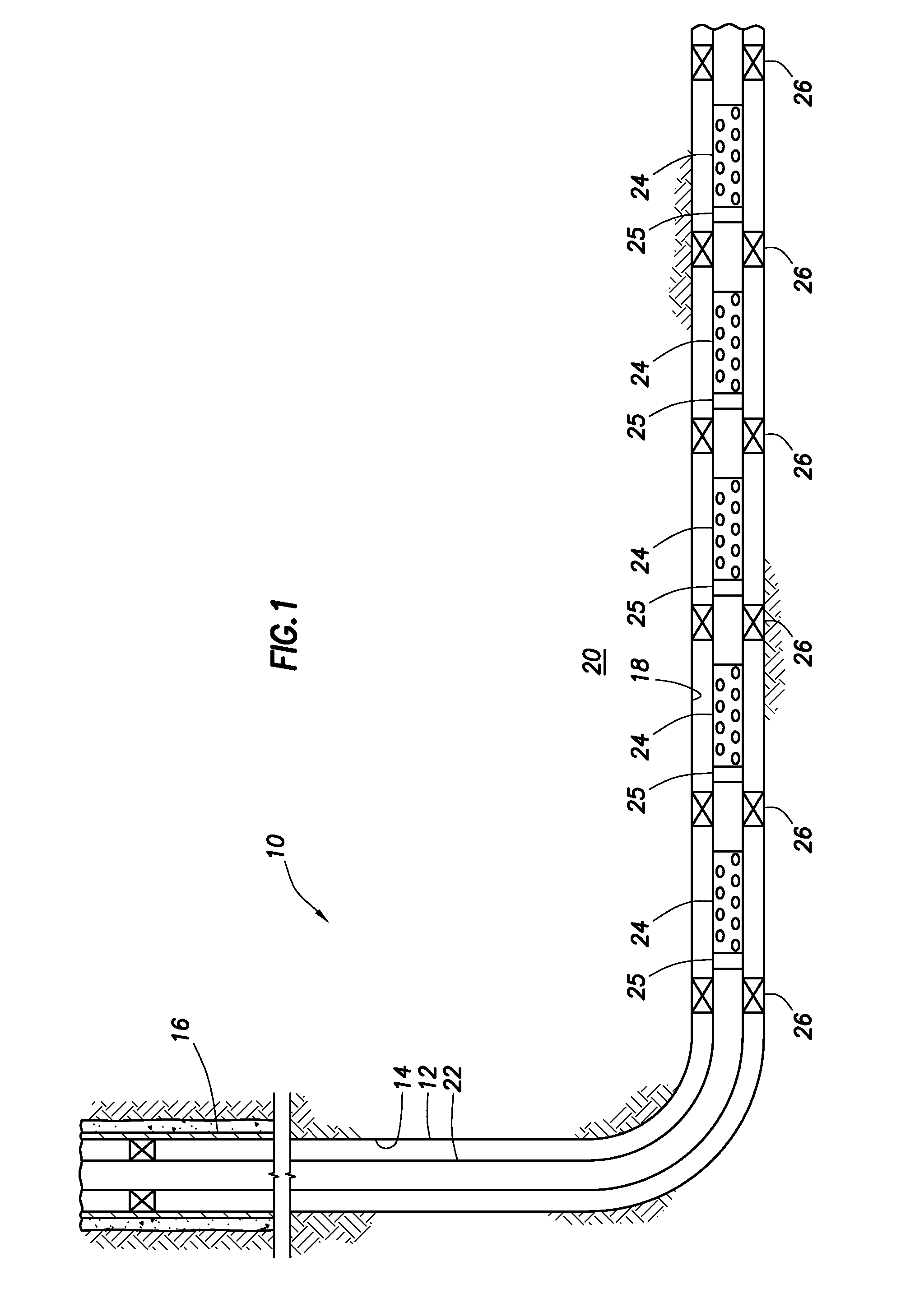

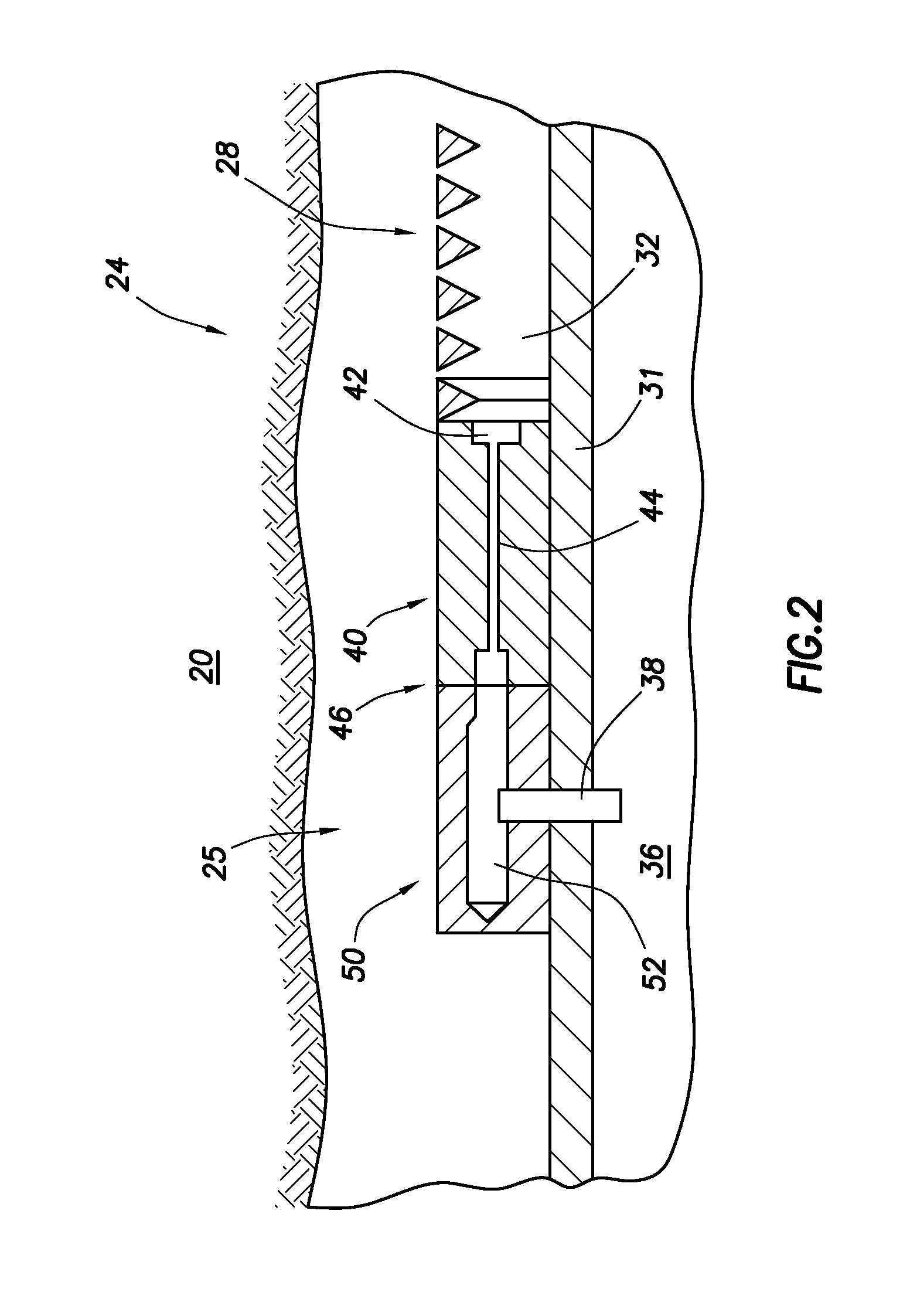

Real-time measurement of reservoir fluid properties

ActiveUS20110040501A1Eliminates long delayImprove securitySurveyFlow propertiesLine tubingReal time analysis

A system, method, and fluid analysis module are provided for the real-time analysis of multiphase fluids. The system generally comprises means for directing a fluid stream from a flow line to a fluid analysis module, a processor and communication means. The fluid analysis module comprises sensor for measurement of at least one property of the fluid. The processor processes the measurement data from the sensor, and the communication means communicates the processed data to a central acquisition unit or computer.

Owner:SCHLUMBERGER TECH CORP

System to measure density, specific gravity, and flow rate of fluids, meter, and related methods

ActiveUS6957586B2Little maintenanceMinimization needsVolume/mass flow by thermal effectsSpecific gravity using flow propertiesDifferential pressureDisplay device

A system to measure fluid flow characteristics in a pipeline, meter, and methods includes a pipeline having a passageway to transport flowing fluid therethrough, a process density meter including at least portions thereof positioned within the pipeline to provide flowing fluid characteristics including volumetric flow rate, fluid density, and mass flow rate of the flowing fluid, and a fluid characteristic display to display the fluid characteristics. The process density meter includes a vortex-shedding body positioned within the pipeline to form vortices and a vortex meter having a vortex frequency sensor to measure the frequency of the vortices and to determine the volumetric flow rate. The process density meter further includes a differential pressure meter positioned adjacent the vortex-shedding body to produce a differential pressure meter flow rate signal indicative of the density of fluid when flowing through the pipeline. The process density meter also includes a thermal flow meter positioned adjacent the vortex-shedding body to produce a mass flow rate signal indicative of the mass flow rate of fluid when flowing through the pipeline. The process density meter produces an output of a volumetric flow rate, a flowing fluid density, and a mass flow rate to be displayed by the fluid characteristic display.

Owner:SAUDI ARABIAN OIL CO

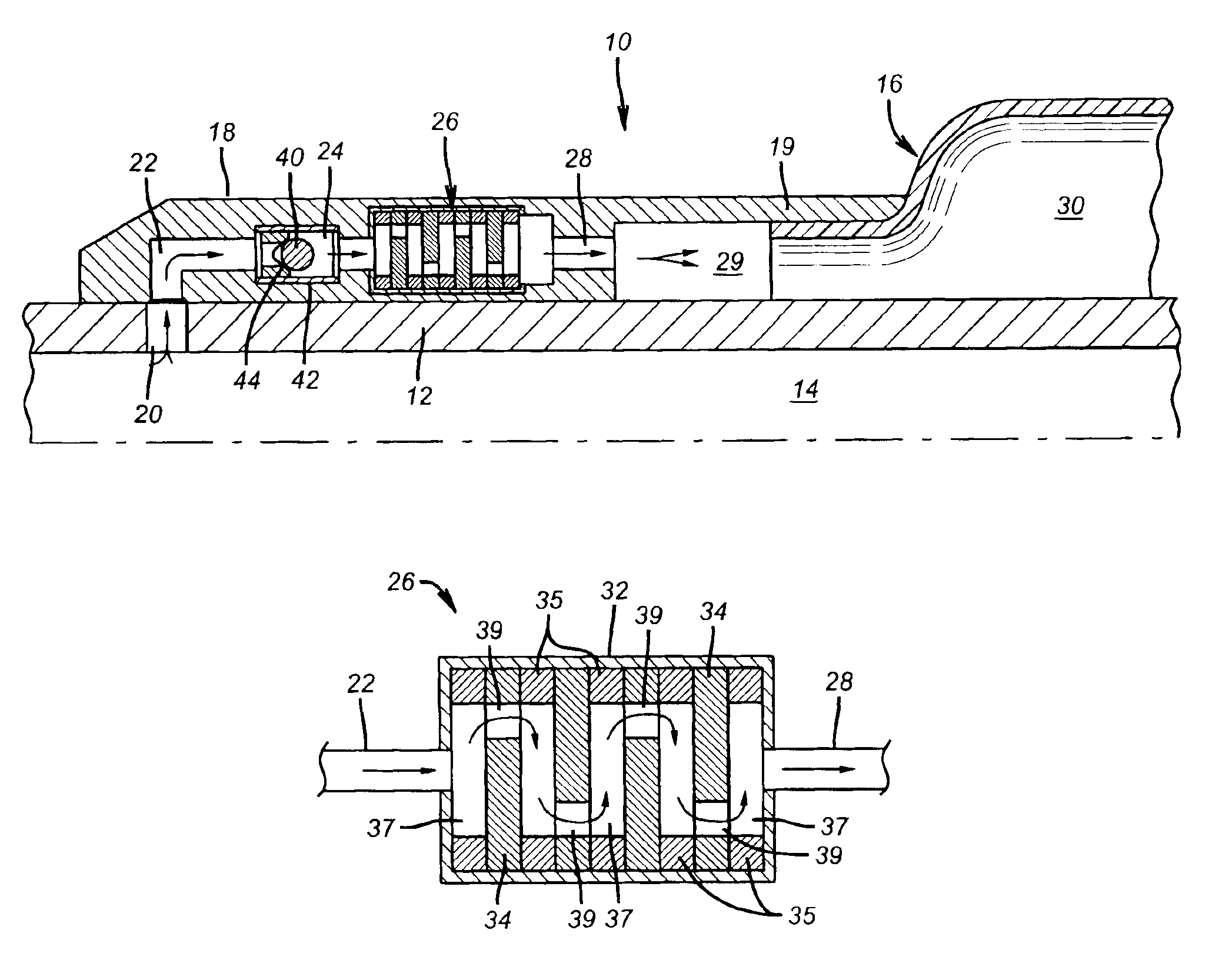

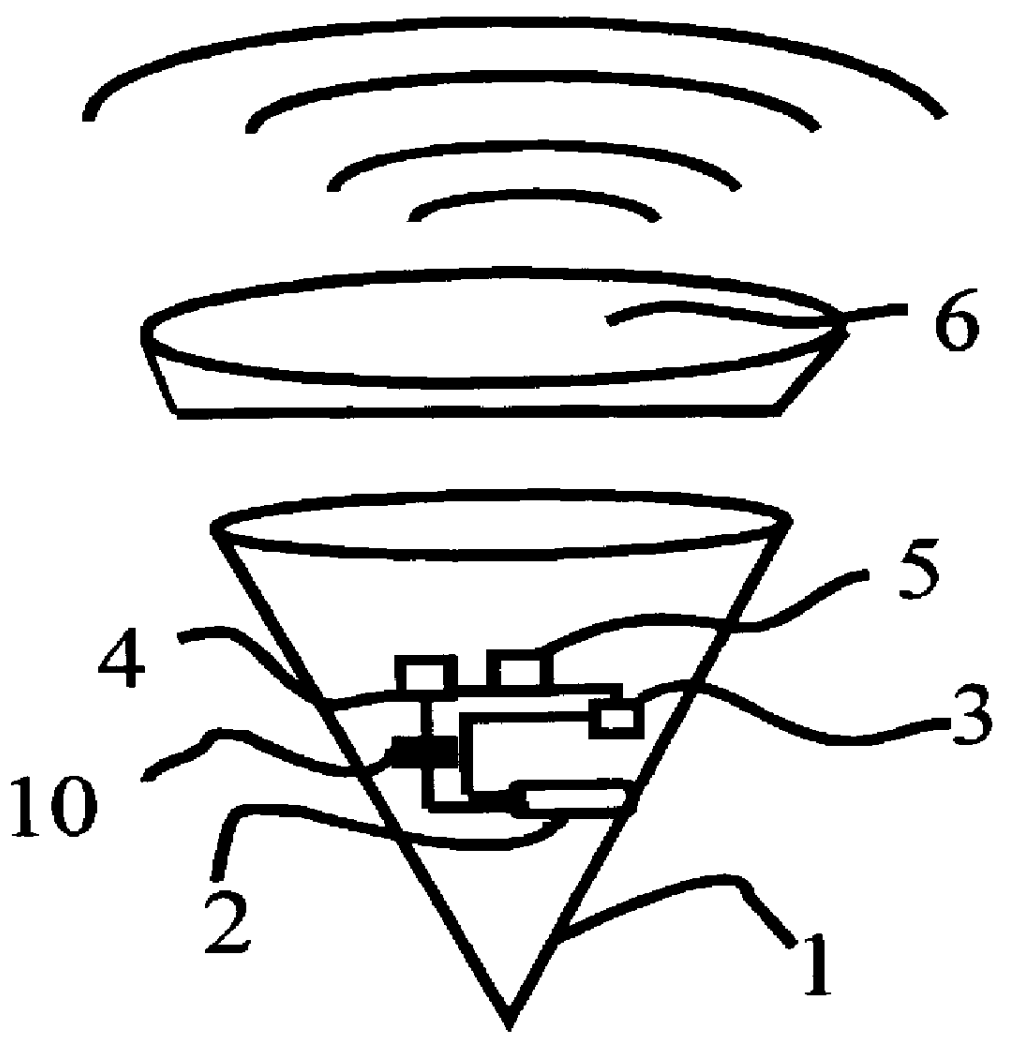

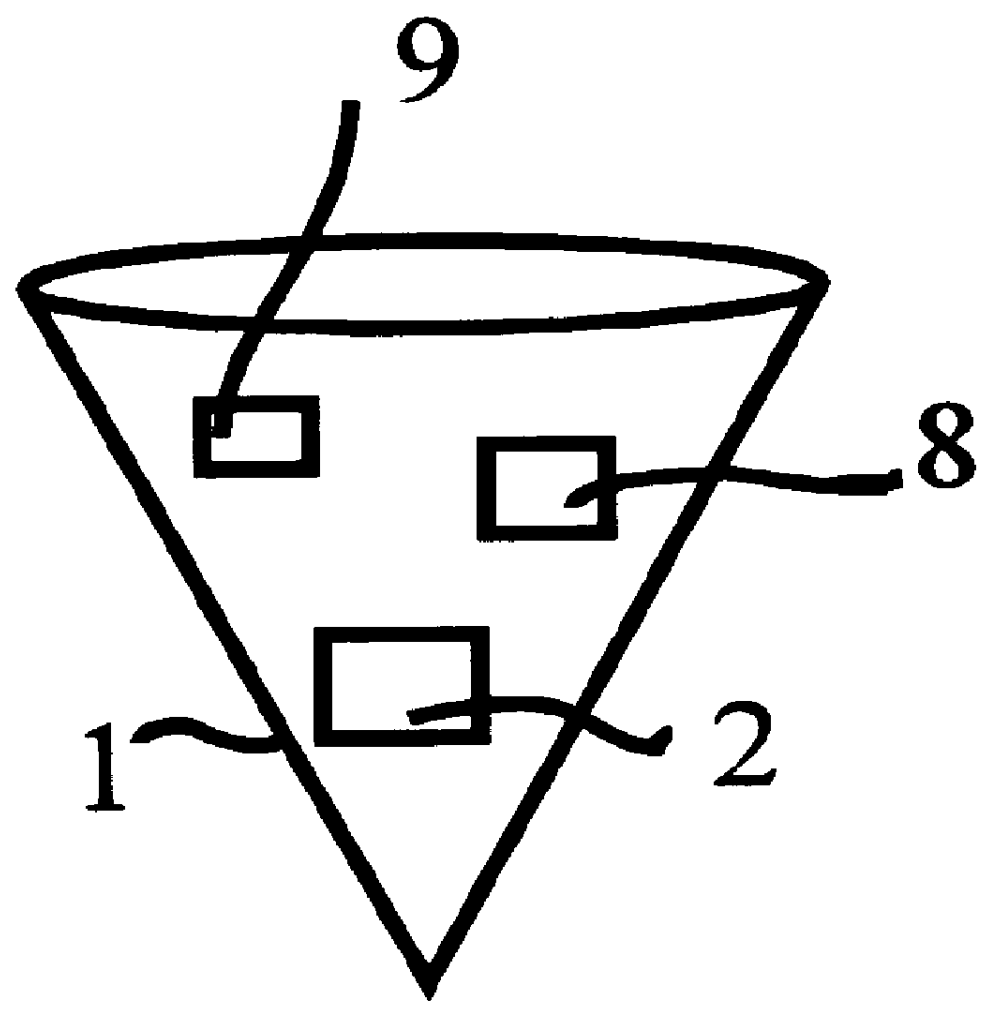

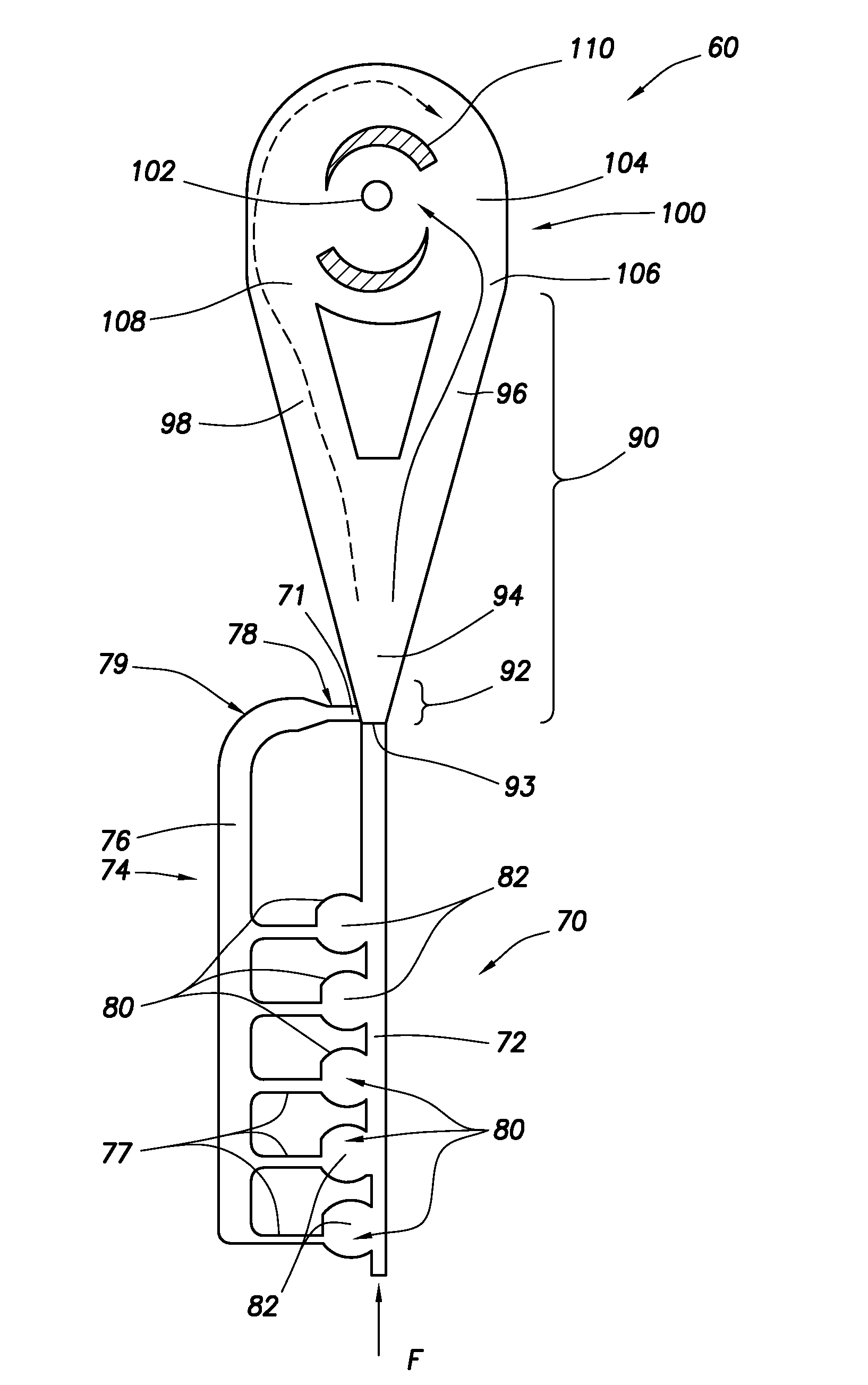

Method and apparatus for controlling fluid flow in an autonomous valve using a sticky switch

Apparatus and methods are described for autonomously controlling fluid flow in a tubular in a wellbore. A fluid is flowed through an inlet passageway into a biasing mechanism. A fluid flow distribution is established across the biasing mechanism. The fluid flow distribution is altered in response to a change in the fluid characteristic over time. In response, fluid flow through a downstream sticky switch assembly is altered, thereby altering fluid flow patterns in a downstream vortex assembly. The method “selects” based on a fluid characteristic, such as viscosity, density, velocity, flow rate, etc. The biasing mechanism can take various forms such as a widening passageway, contour elements along the biasing mechanism, or a curved section of the biasing mechanism passageway. The biasing mechanism can include hollows formed in the passageway wall, obstructions extending from the passageway wall, fluid diodes, Tesla fluid diodes, a chicane, or abrupt changes in passageway cross-section.

Owner:HALLIBURTON ENERGY SERVICES INC

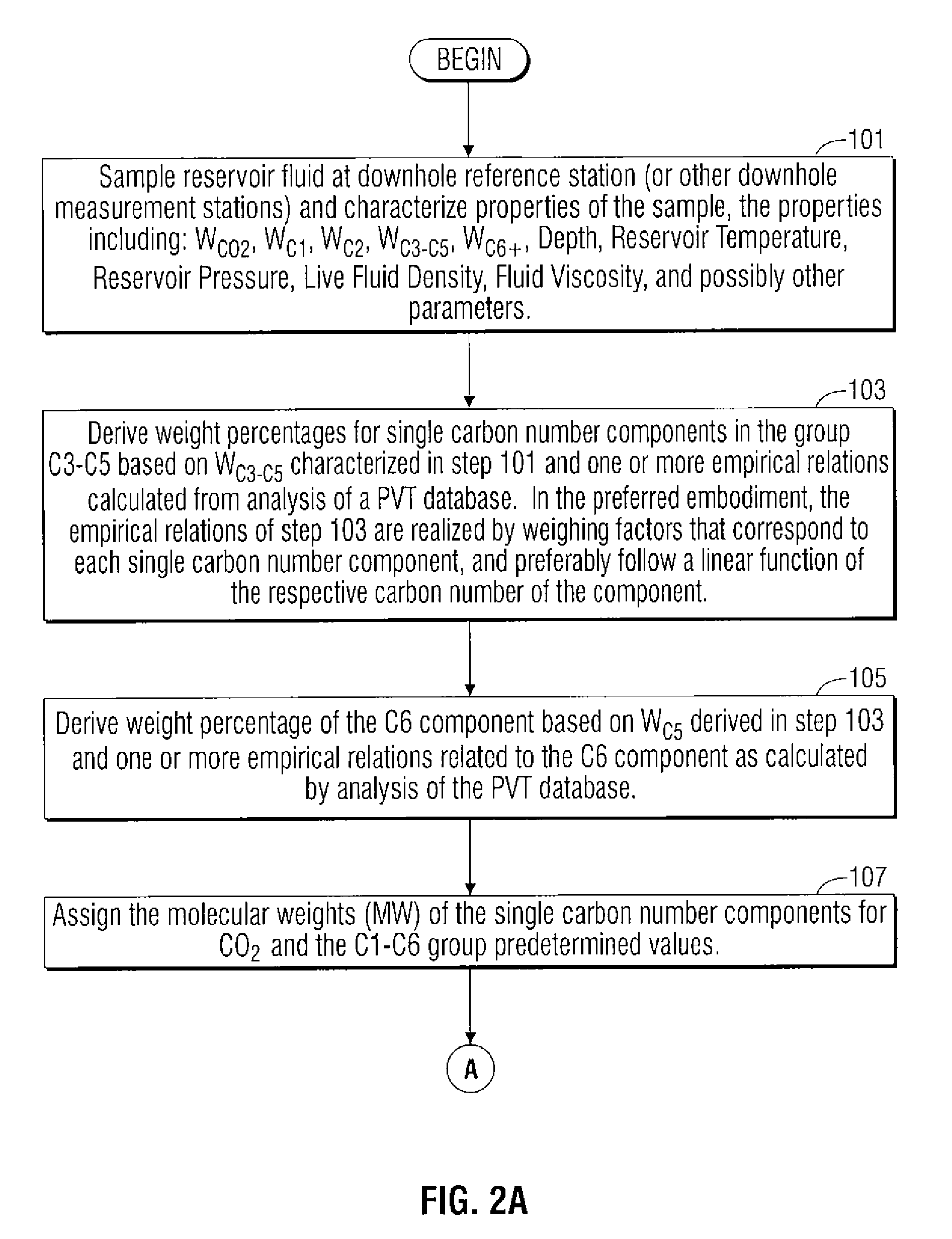

Methods and apparatus for characterization of petroleum fluid and applications thereof

ActiveUS7920970B2Accurately reflectElectric/magnetic detection for well-loggingComputation using non-denominational number representationSoil scienceImproved method

Owner:SCHLUMBERGER TECH CORP

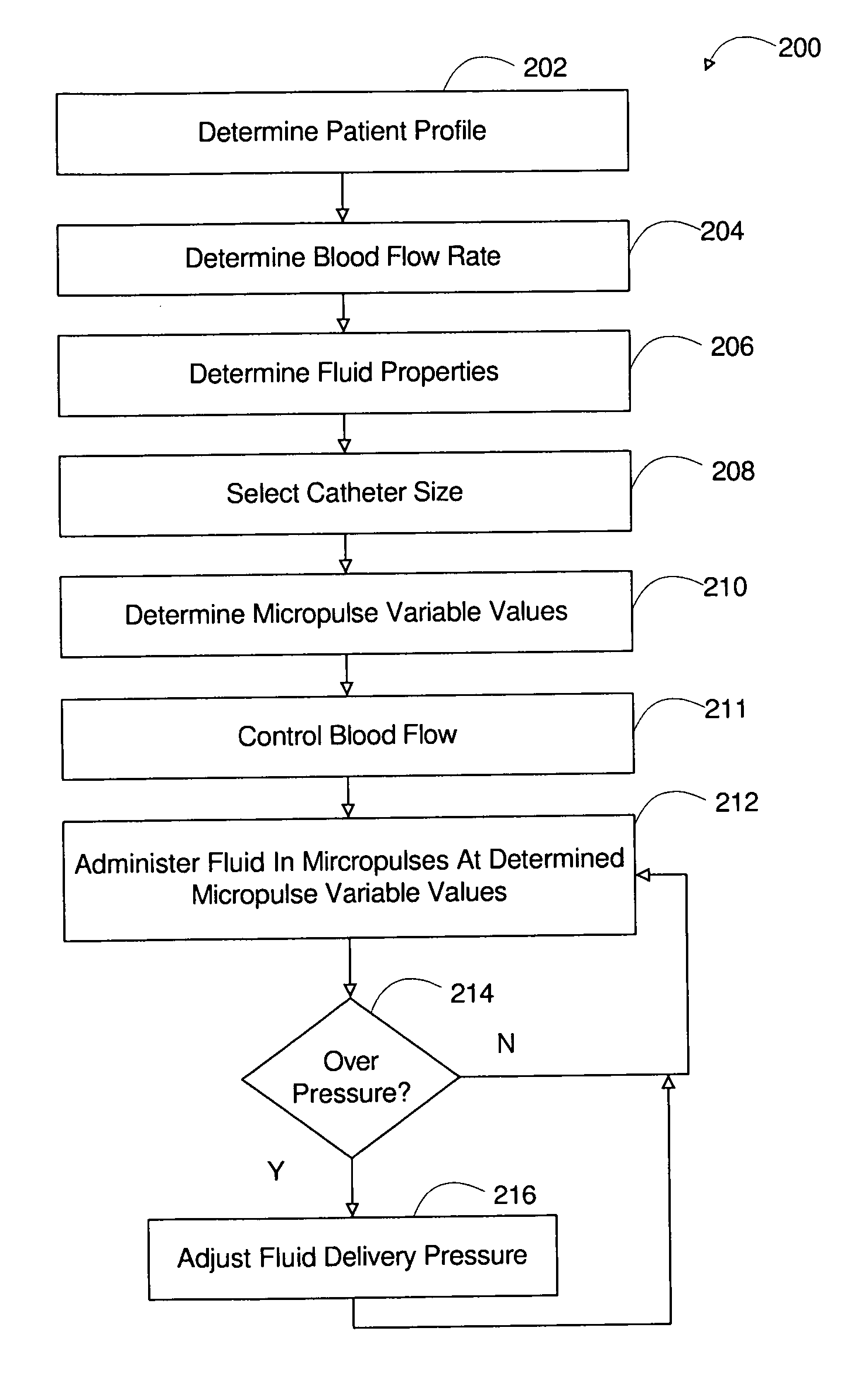

Programmed pulsed infusion methods and devices

InactiveUS20060135940A1Great efficient use of fluidAbsorb moreComputer controlDrug and medicationsInfusion methodBlood flow

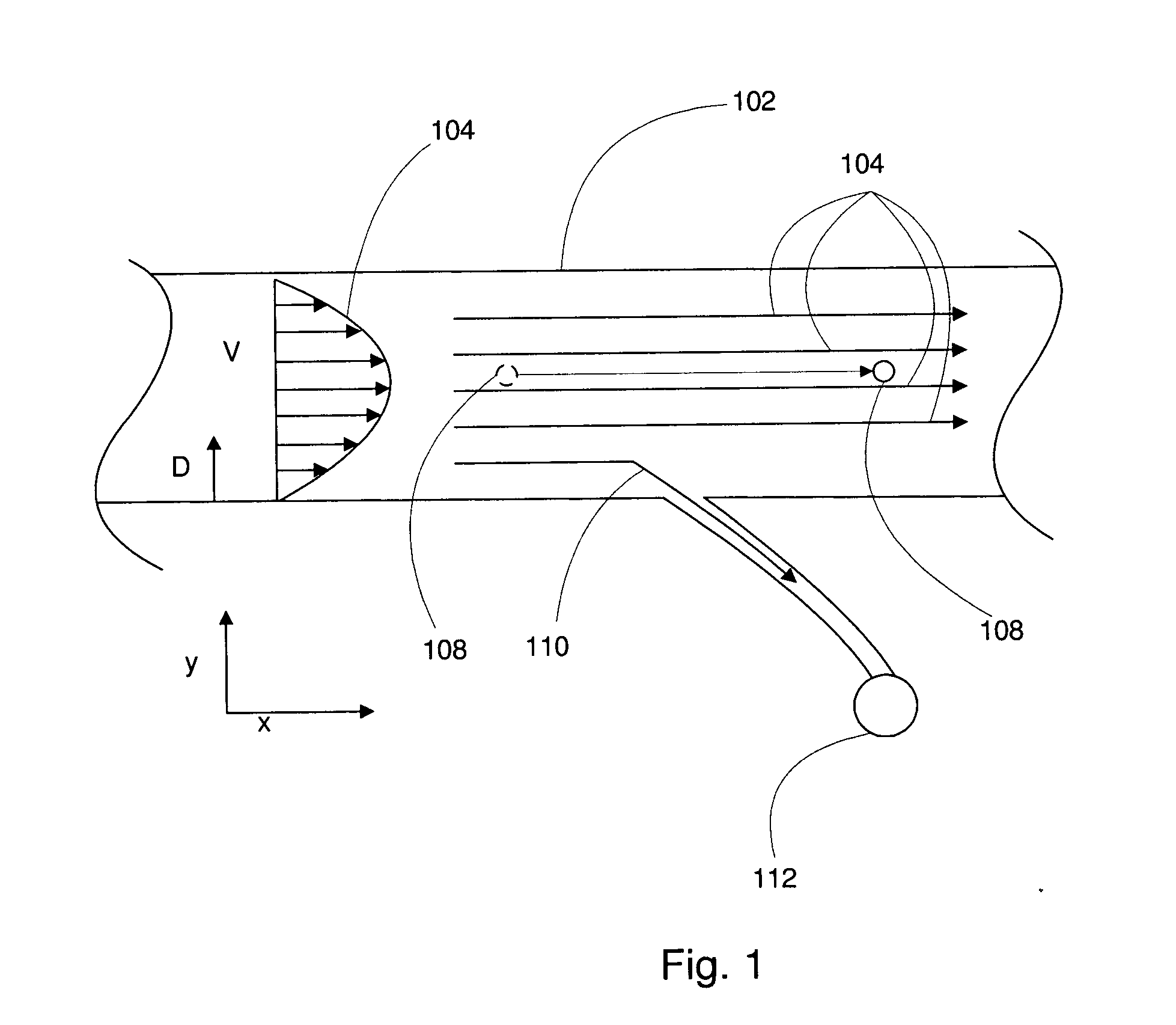

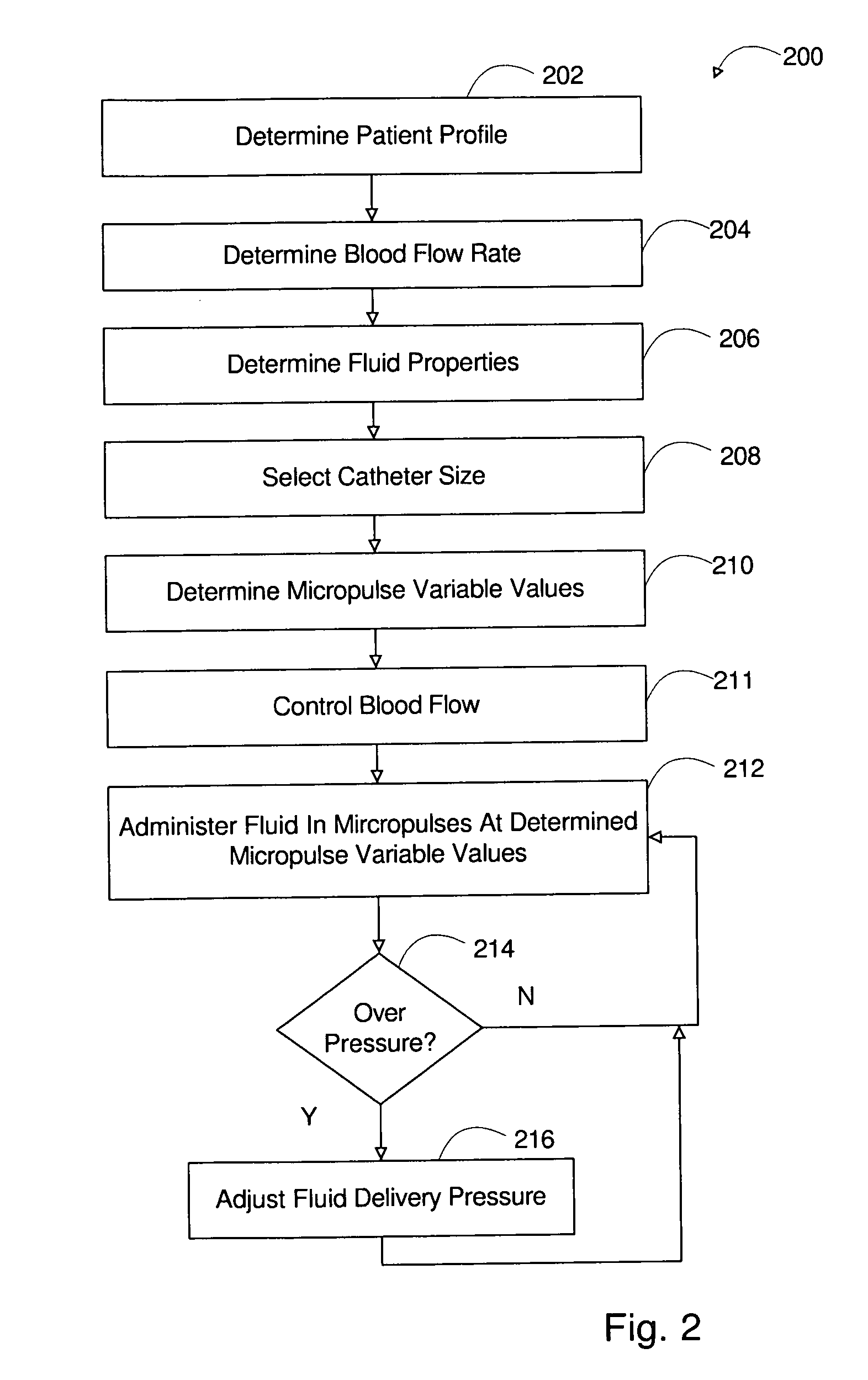

This invention disclosed herein provides methods, devices, software products, and systems for infusing a fluid into a blood vessel is provided that includes the step of administering the fluid into the blood vessel in programmed pulses. The programmed pulses generally defined by programmed pulse variables that include a fluid flow rate, a frequency, and a duration. Values of the programmed pulse variables may be determined based at least in part on a fluid property of the fluid to be infused that is relevant to streaming, blood flow in the blood vessel to be infused, a catheter size, or a patient profile.

Owner:TRISTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK THE

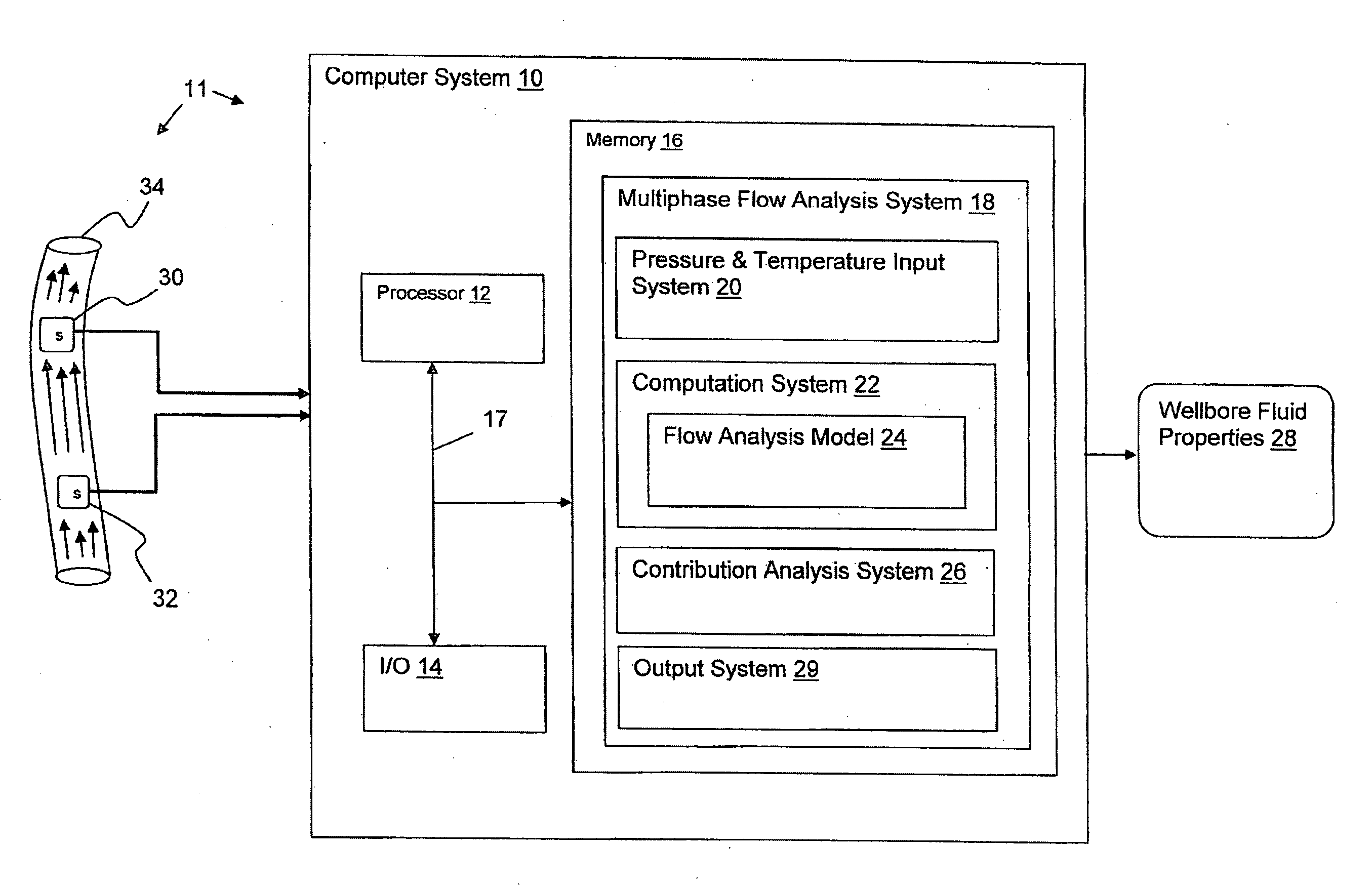

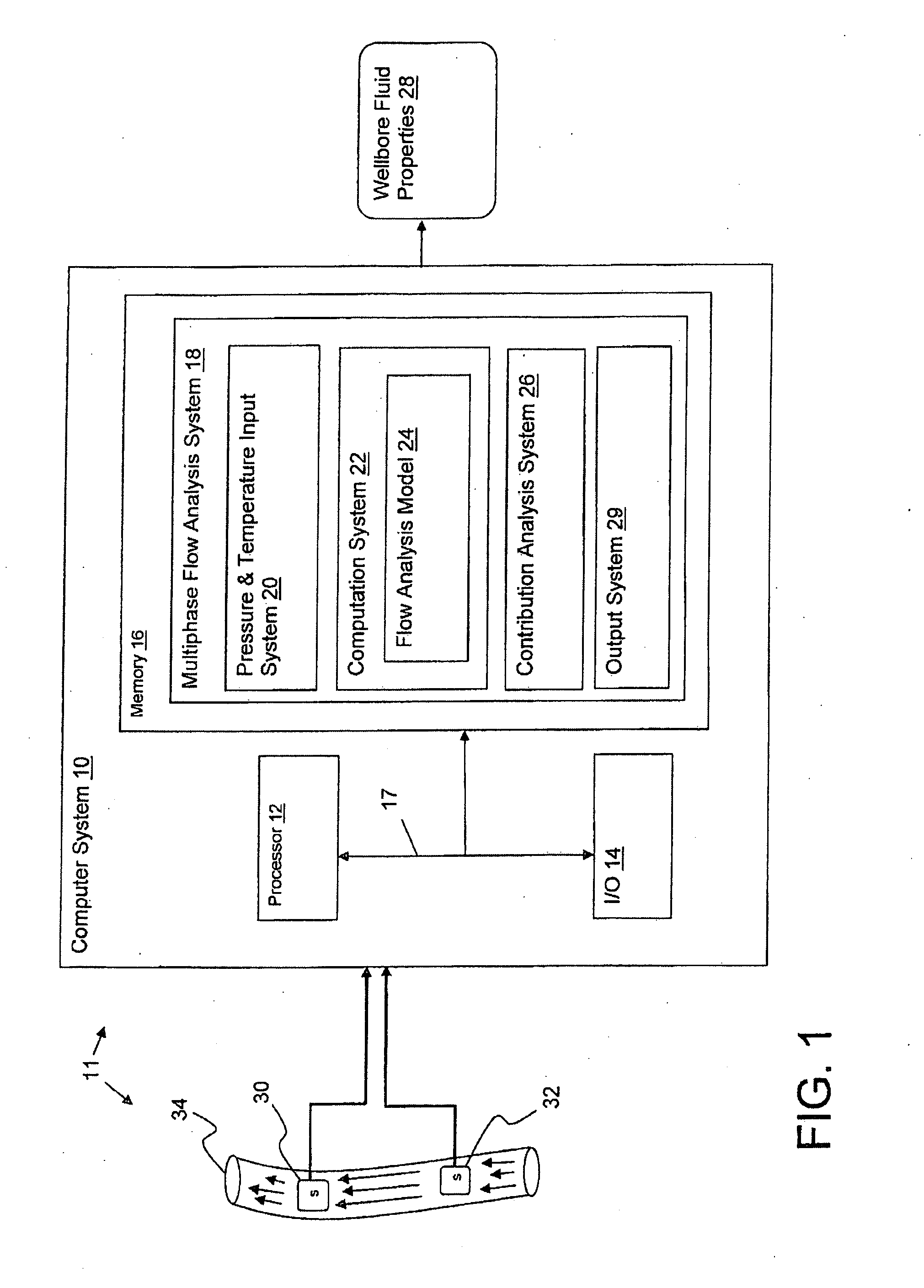

Evaluating multiphase fluid flow in a wellbore using temperature and pressure measurements

InactiveUS20090308601A1Reliable and accurate and continuousSurveyAnalogue processes for specific applicationsPhase velocityViscosity

A system, method and program product for analyzing multiphase flow in a wellbore. A system is provided that includes: an input system for receiving pressure and temperature readings from a pair of sensors located in the wellbore; a computation system that utilizes a flow analysis model to generate a set of wellbore fluid properties, wherein the set of wellbore fluid properties includes at least one of: a fluid mixture value, a phase velocity value, a flow rate, a mixture density, a mixture viscosity, a fluid holdup, and a slip velocity; and a system for outputting the wellbore fluid properties.

Owner:SCHLUMBERGER TECH CORP

Acoustic control of the composition and/or volume of fluid in a reservoir

InactiveUS6932097B2Efficient transportFunctional valve typesLarge containersAuditory radiationEngineering

The invention provides a device for controlling the composition and / or volume of a fluid within a reservoir. The device includes a reservoir adapted to contain at least one fluid, a means for monitoring a characteristic of the fluid contained in the reservoir, and a means for introducing additional fluid into the reservoir according to the fluid characteristic monitored by the monitoring means. The device also includes an acoustic generator for generating acoustic radiation. A dispensing means may be provided as well. Other devices and methods that use acoustic radiation to control the composition and / or volume of a fluid within a reservoir are included.

Owner:LABCYTE

Method and apparatus for using pulsed field gradient NMR measurements to determine fluid properties in a fluid sampling well logging tool

InactiveUS7053611B2Easy to detectRaise the ratioElectric/magnetic detection for well-loggingSurveyDiffusionNMR - Nuclear magnetic resonance

A method for determining a formation fluid property includes acquiring a suite of nuclear magnetic resonance (NMR) measurements of a fluid sample using a pulse sequence that includes pulsed field gradient pulses for encoding diffusion information, wherein each NMR measurement in the suite is acquired with a different value in a parameter in the pulsed field gradient pulses for producing a different diffusion effect, wherein the acquiring is performed in a formation fluid sampling tool in a borehole; inverting the suite of NMR measurements to produce a distribution function that relates diffusion properties of the fluid sample with an NMR property of the fluid sample; and determining the formation fluid property from the distribution function.

Owner:SCHLUMBERGER TECH CORP

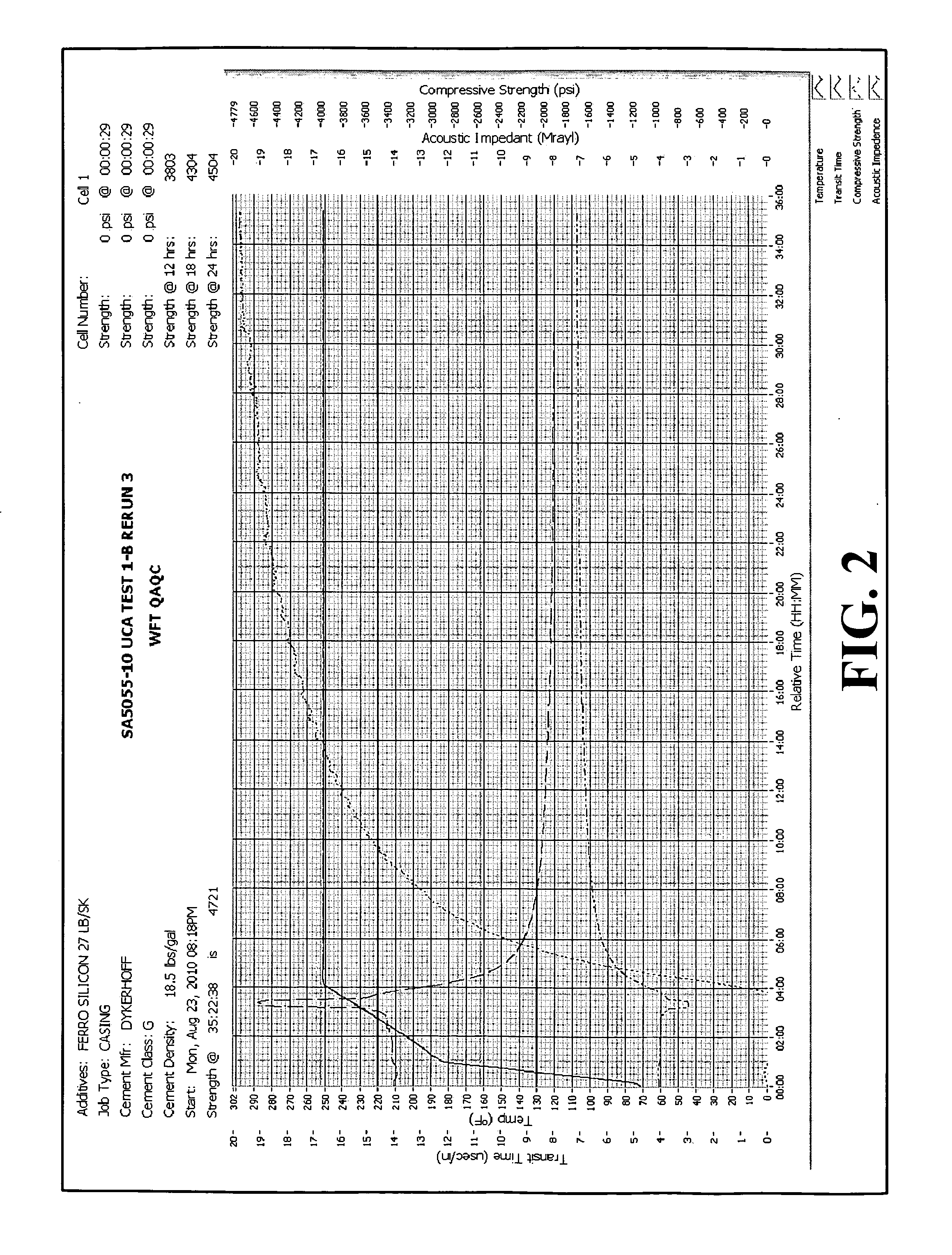

Novel Weight Materials for Use in Cement, Spacer and Drilling Fluids

InactiveUS20120073813A1Improve propertiesEffective amountSolid waste managementFluid removalHigh densitySilicon alloy

A drilling fluid, spacer fluid and cementing compositions for use in subterranean wells are disclosed along with methods for making using same, where the compositions include a weighting system having an effective amount of a metal silicon alloy, mixtures of metal silicon alloys, or mixtures of metal silicon alloys and conventional weighting agents, to produce compositions having a desired high density, while retaining other fluid properties such as pumpability, gas tight sealing, low tendency to segregate, and reduced high temperature cement strength retrogression.

Owner:WEATHERFORD TECH HLDG LLC

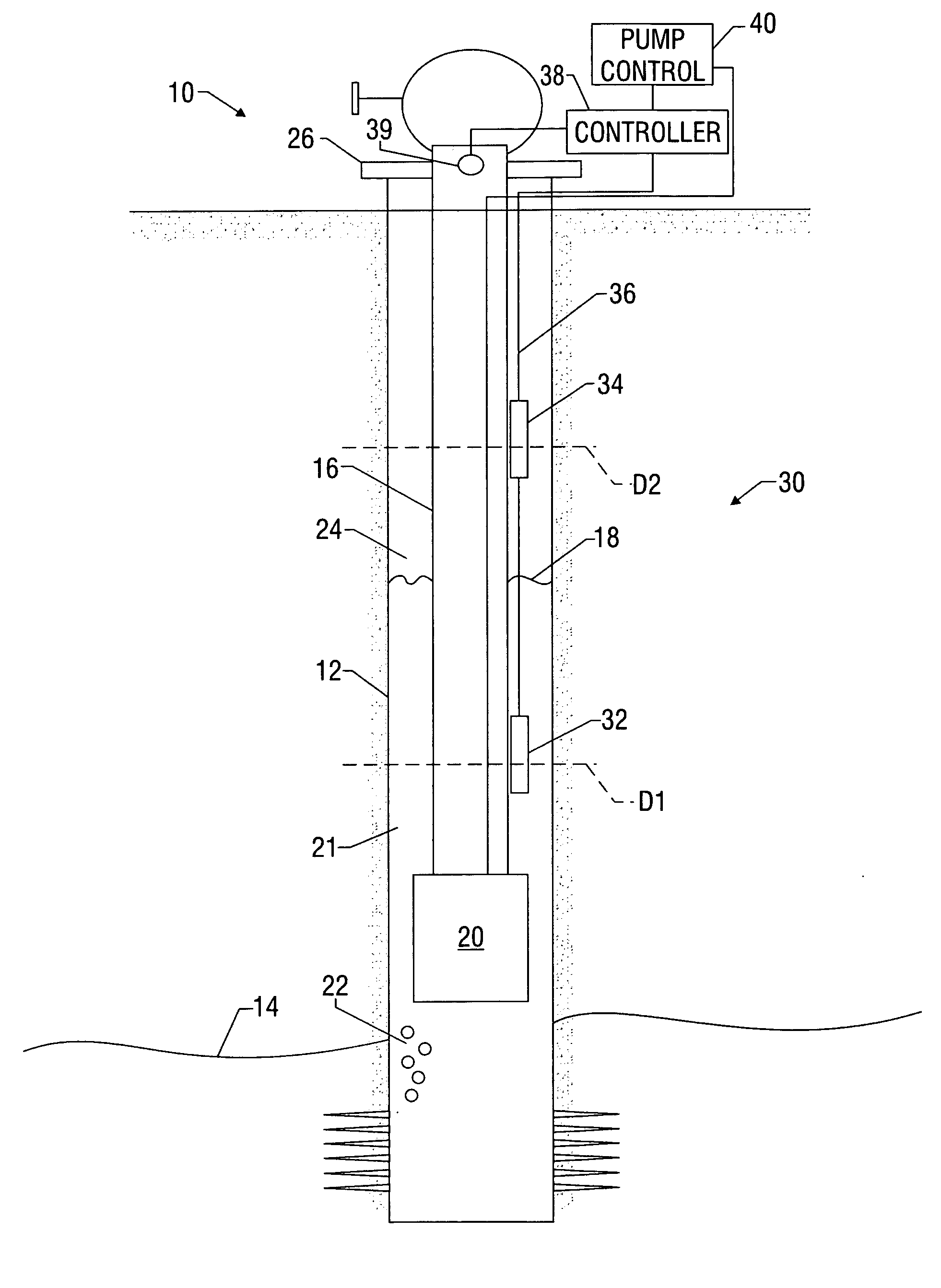

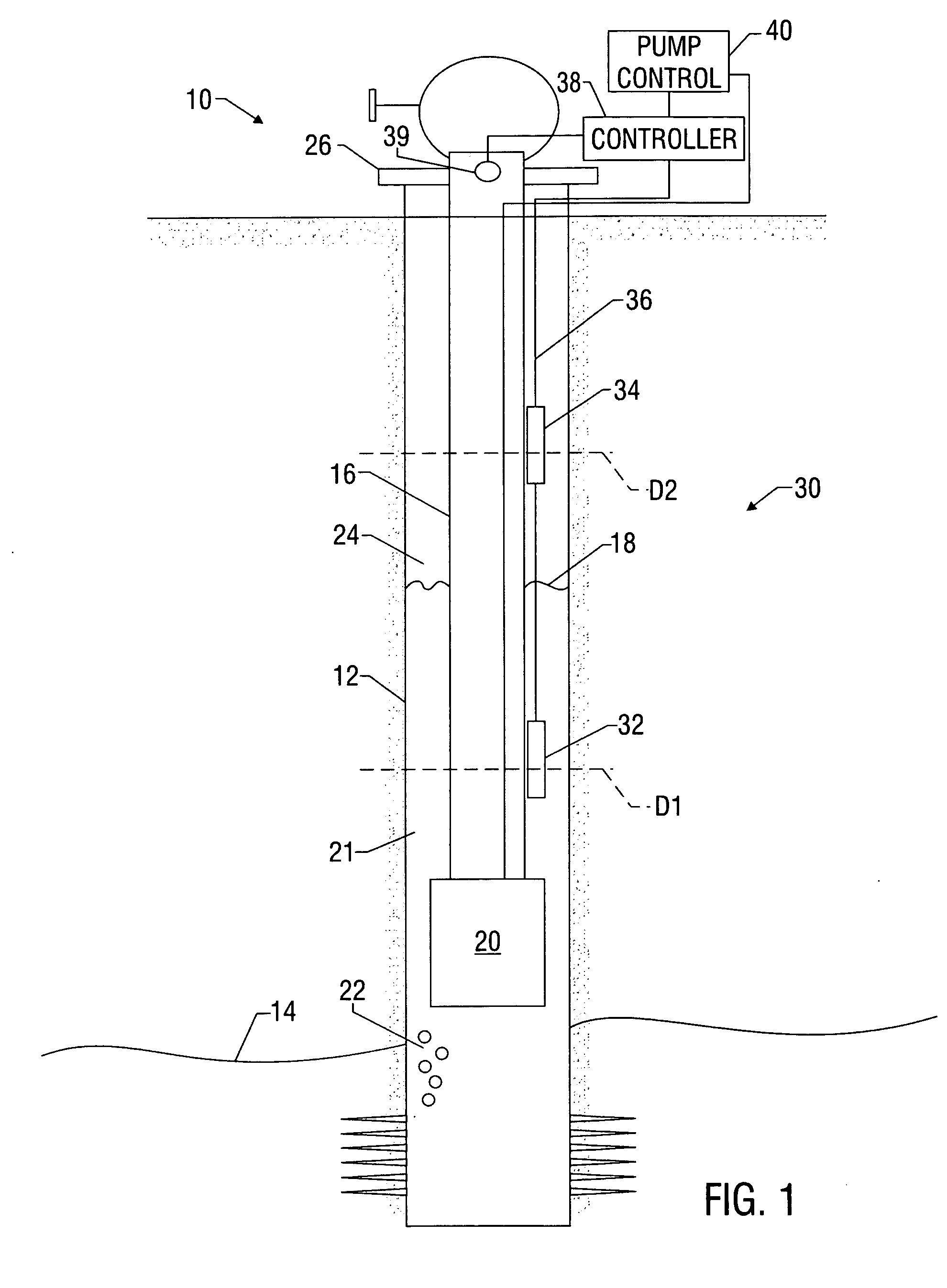

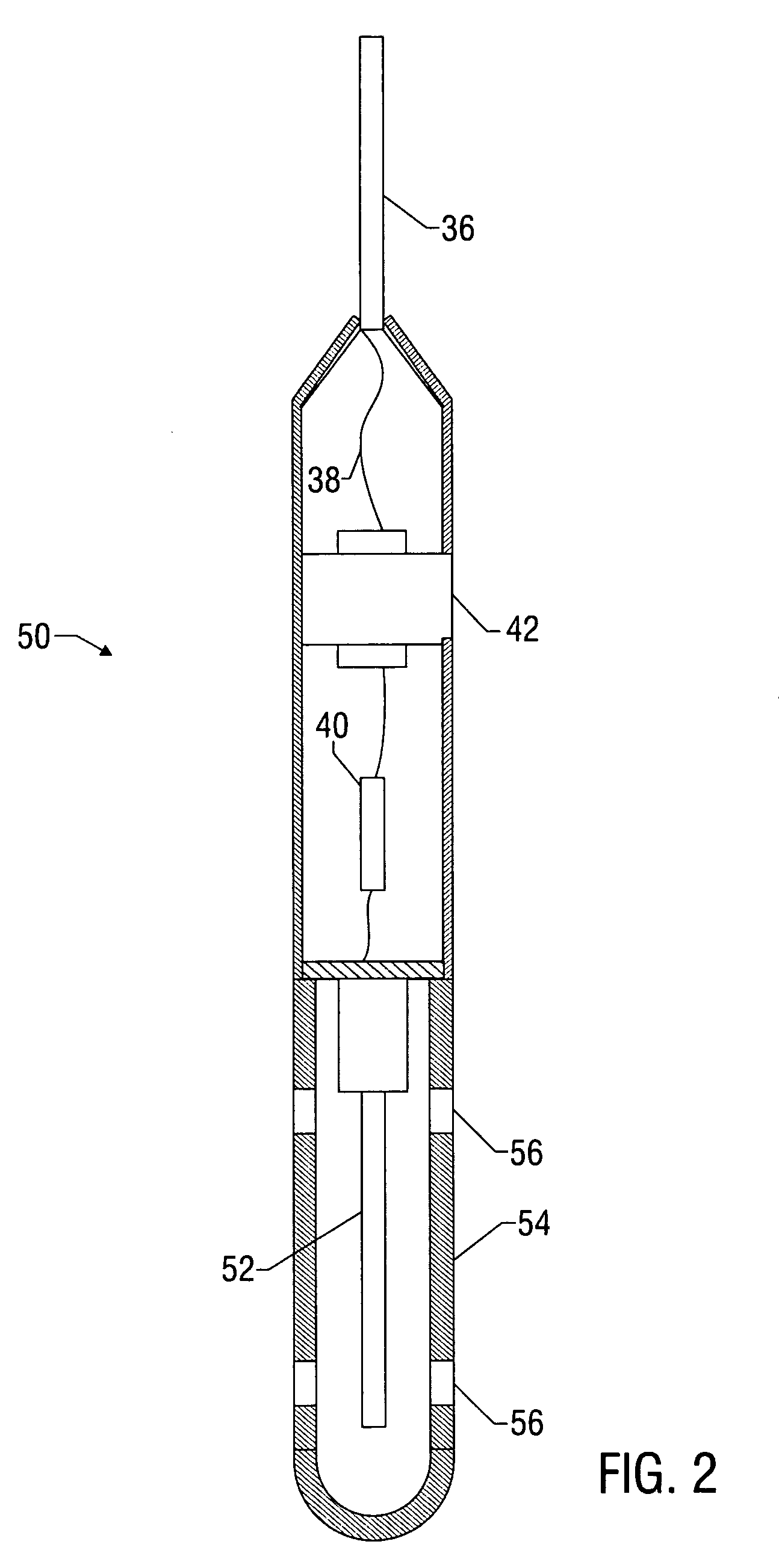

Systems and methods for controlling flow control devices

A device for determining a location of an interface between a first fluid and second fluid includes a non-mechanical sensor that measures a selected parameter of interest relating to the fluid surrounding the sensor (“the surrounding fluid”) and a processor for processing the sensor measurements. The non-mechanical sensor measures a parameter relating to the surround fluid without physically co-acting with the surrounding fluid. Exemplary parameters such as thermal properties, electrical properties, fluid properties, and magnetic properties can be measured. The processor is programmed to process the sensor measurements to identify one or more characteristics in the measurements that can indicate the nature of the fluid being measured and thereby determine the location of the interface. The determined location can be used to operate a downhole device such as a pump, to provide real-time monitoring of well conditions, to record data for long-term reservoir characterization, or to actuate an alarm.

Owner:CORE LAB CANADA

Methods and Apparatus for Characterization of Petroleum Fluids Contaminated with Drilling Mud

ActiveUS20110088949A1Avoids computational delayCompensation differenceElectric/magnetic detection for well-loggingFlushingGas oil ratioWell drilling

A method and system for characterizing formation fluids contaminated with drilling mud that compensates for the presence of such drilling mud. The operations that characterize formation fluids contaminated with drilling mud can be carried out in real-time. The operations also characterize a wide array of fluid properties of petroleum samples contaminated with drilling mud in a manner that compensates for the presence of drilling mud. The operations characterize the viscosity and density of petroleum samples contaminated with drilling mud at formation conditions in a manner that compensates for differences between formation conditions and flowline measurement conditions. The operations also derive live fluid density unaffected by contamination of mud filtrate based on a scaling coefficient dependent on measured gas-oil ratio of the formation fluid. This scale factor accounts for excess volume created during mixing processes, which increases the accuracy of characterizations for high gas-oil ratio samples, especially gas condensate.

Owner:SCHLUMBERGER TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com