Patents

Literature

53 results about "Chicane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A chicane (/ʃɪˈkeɪn/) is a serpentine curve in a road, added by design rather than dictated by geography. Chicanes add extra turns and are used both in motor racing and on roads and streets to slow traffic for safety. For example, one form of chicane is a short, shallow S-shaped turn that requires the driver to turn slightly left and then slightly right to continue on the road, requiring the driver to reduce speed. The word chicane is derived from the French verb chicaner, which means "to create difficulties" or "to dispute pointlessly", "quibble".

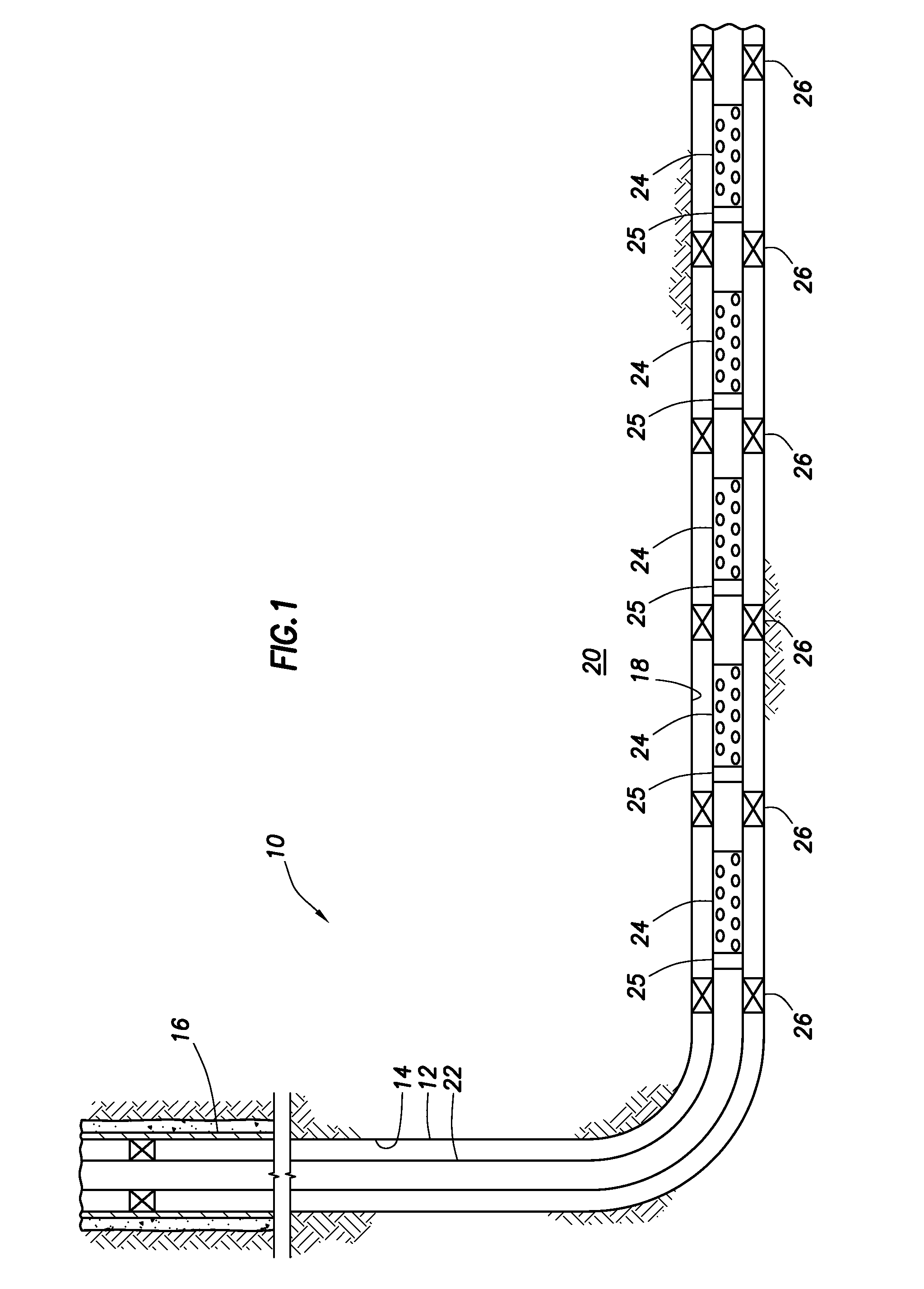

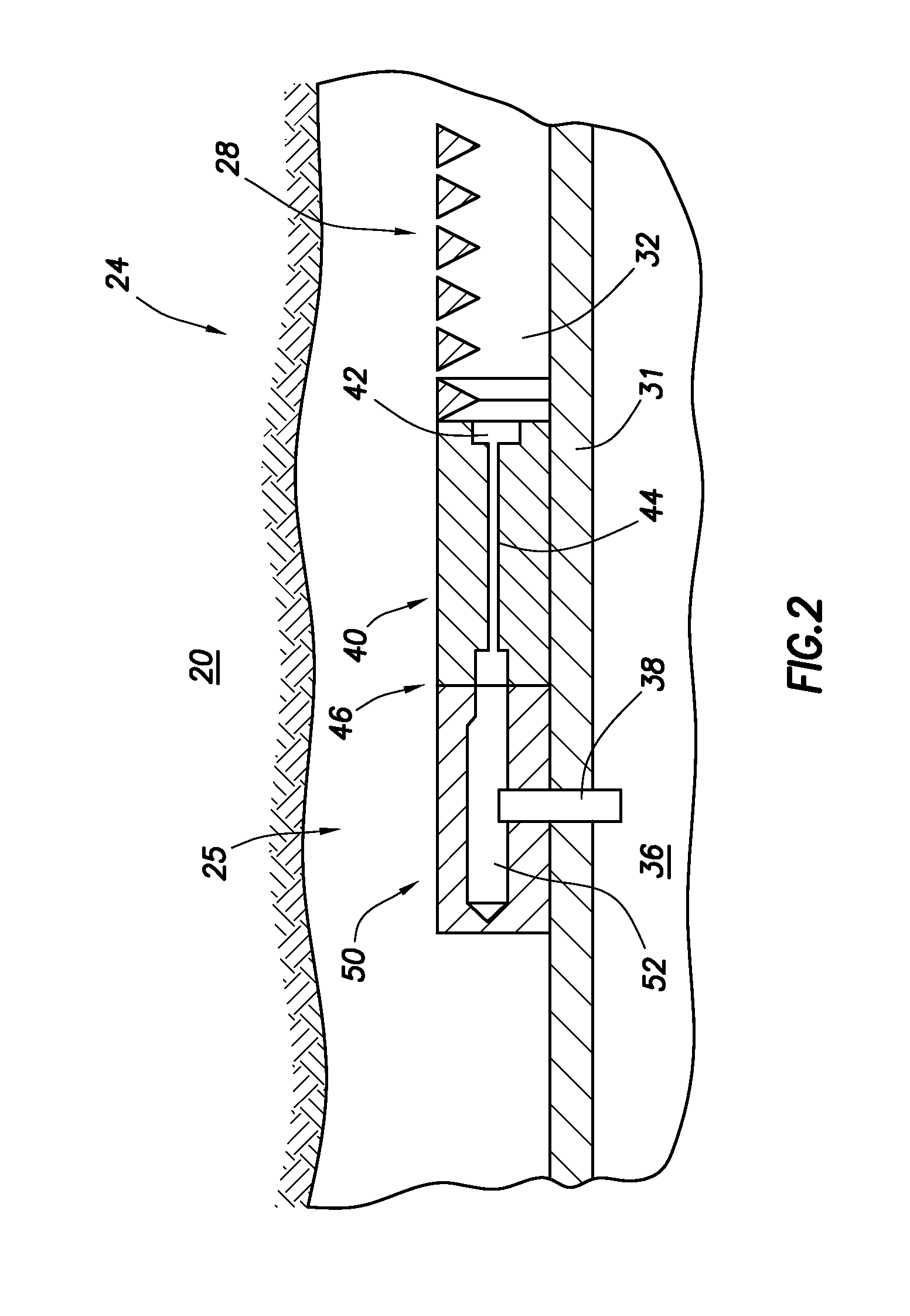

Method and apparatus for controlling fluid flow in an autonomous valve using a sticky switch

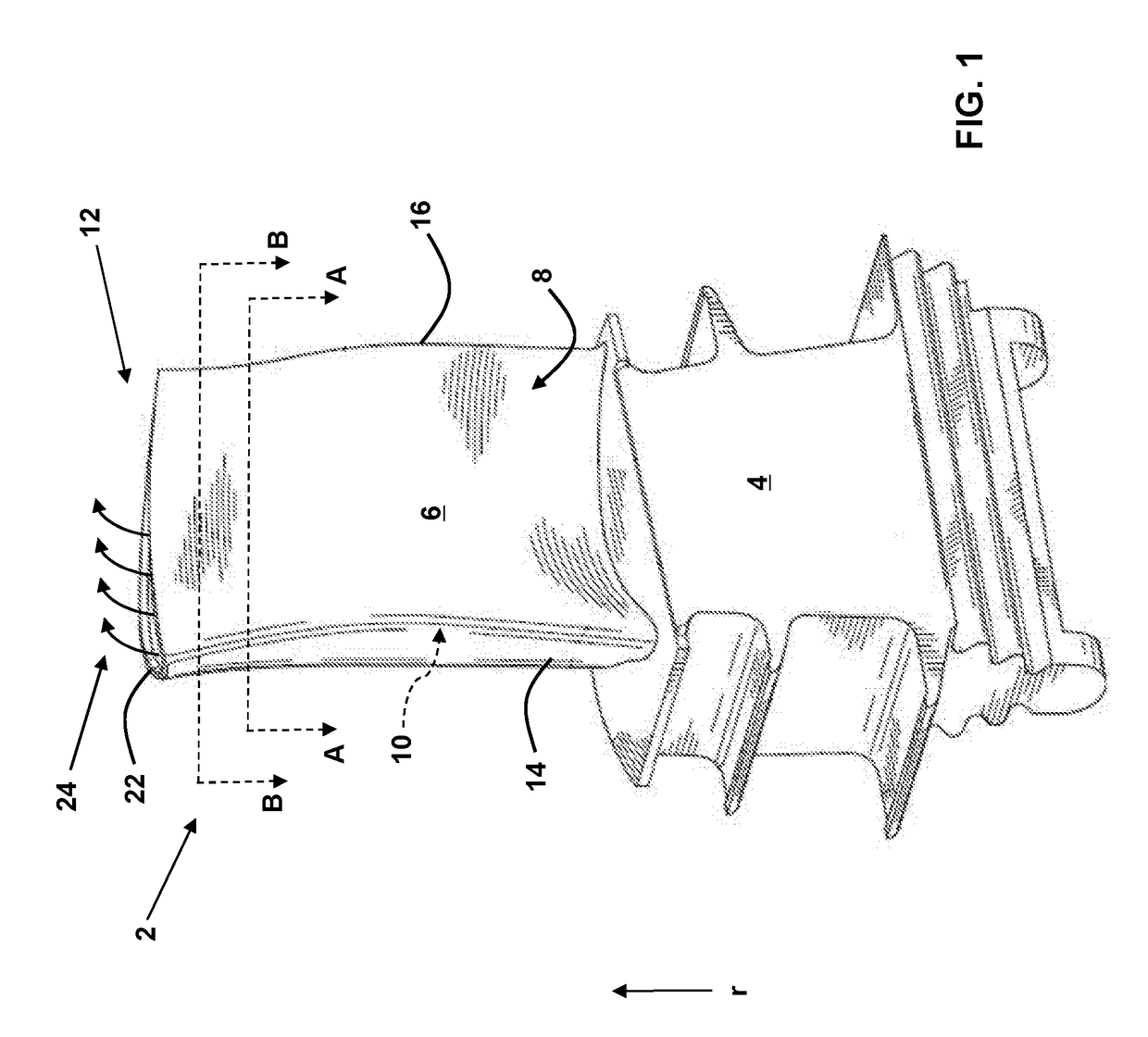

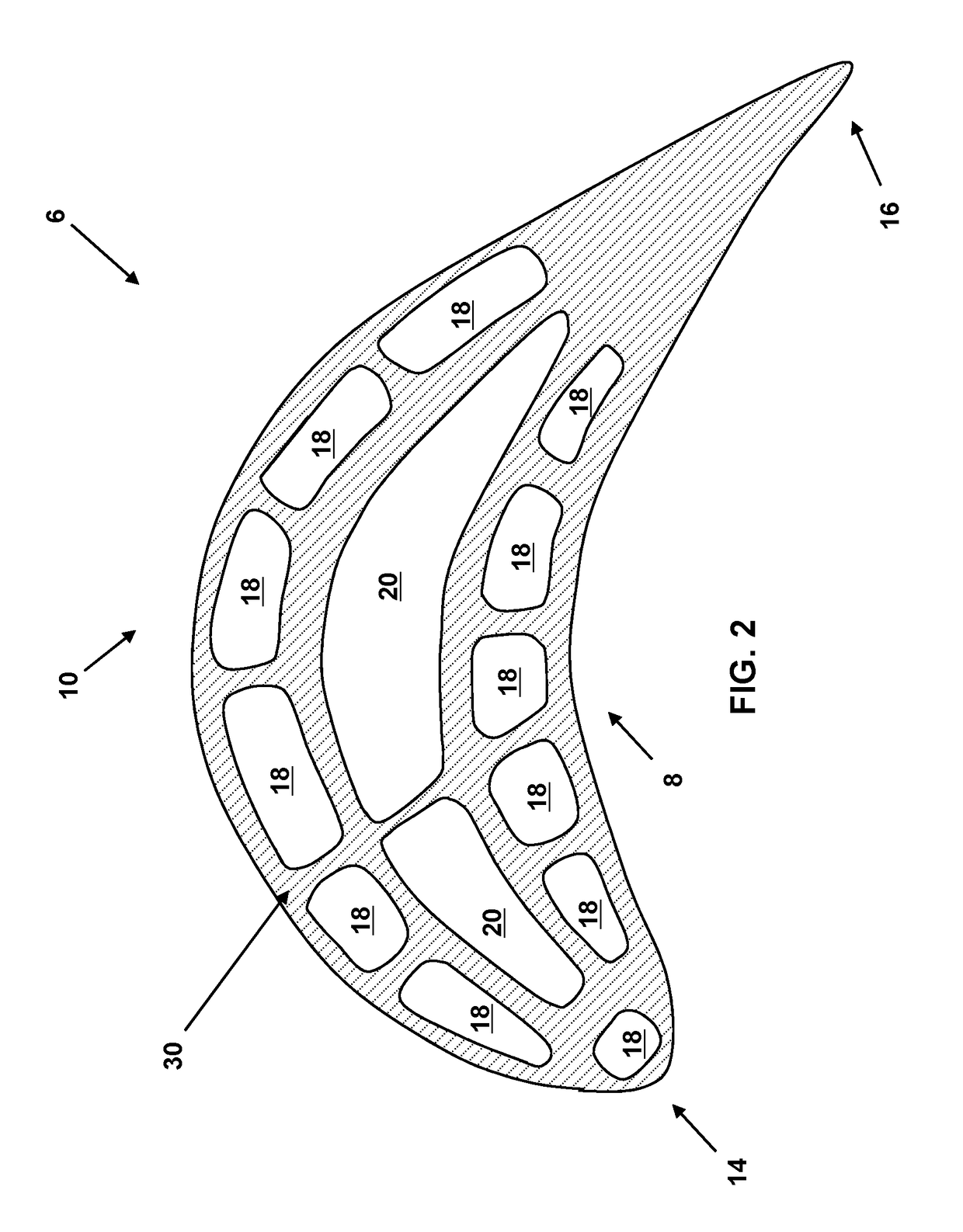

Apparatus and methods are described for autonomously controlling fluid flow in a tubular in a wellbore. A fluid is flowed through an inlet passageway into a biasing mechanism. A fluid flow distribution is established across the biasing mechanism. The fluid flow distribution is altered in response to a change in the fluid characteristic over time. In response, fluid flow through a downstream sticky switch assembly is altered, thereby altering fluid flow patterns in a downstream vortex assembly. The method “selects” based on a fluid characteristic, such as viscosity, density, velocity, flow rate, etc. The biasing mechanism can take various forms such as a widening passageway, contour elements along the biasing mechanism, or a curved section of the biasing mechanism passageway. The biasing mechanism can include hollows formed in the passageway wall, obstructions extending from the passageway wall, fluid diodes, Tesla fluid diodes, a chicane, or abrupt changes in passageway cross-section.

Owner:HALLIBURTON ENERGY SERVICES INC

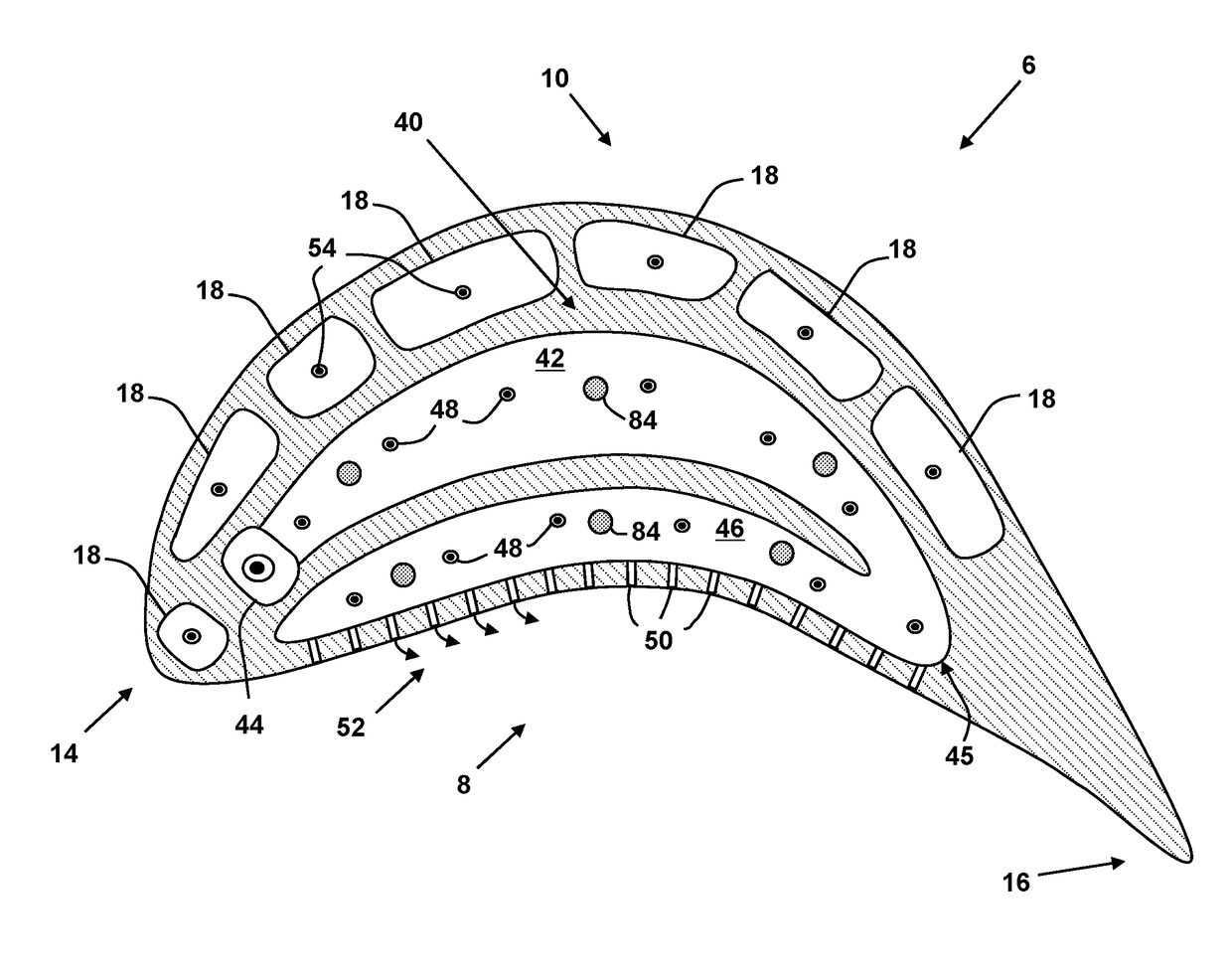

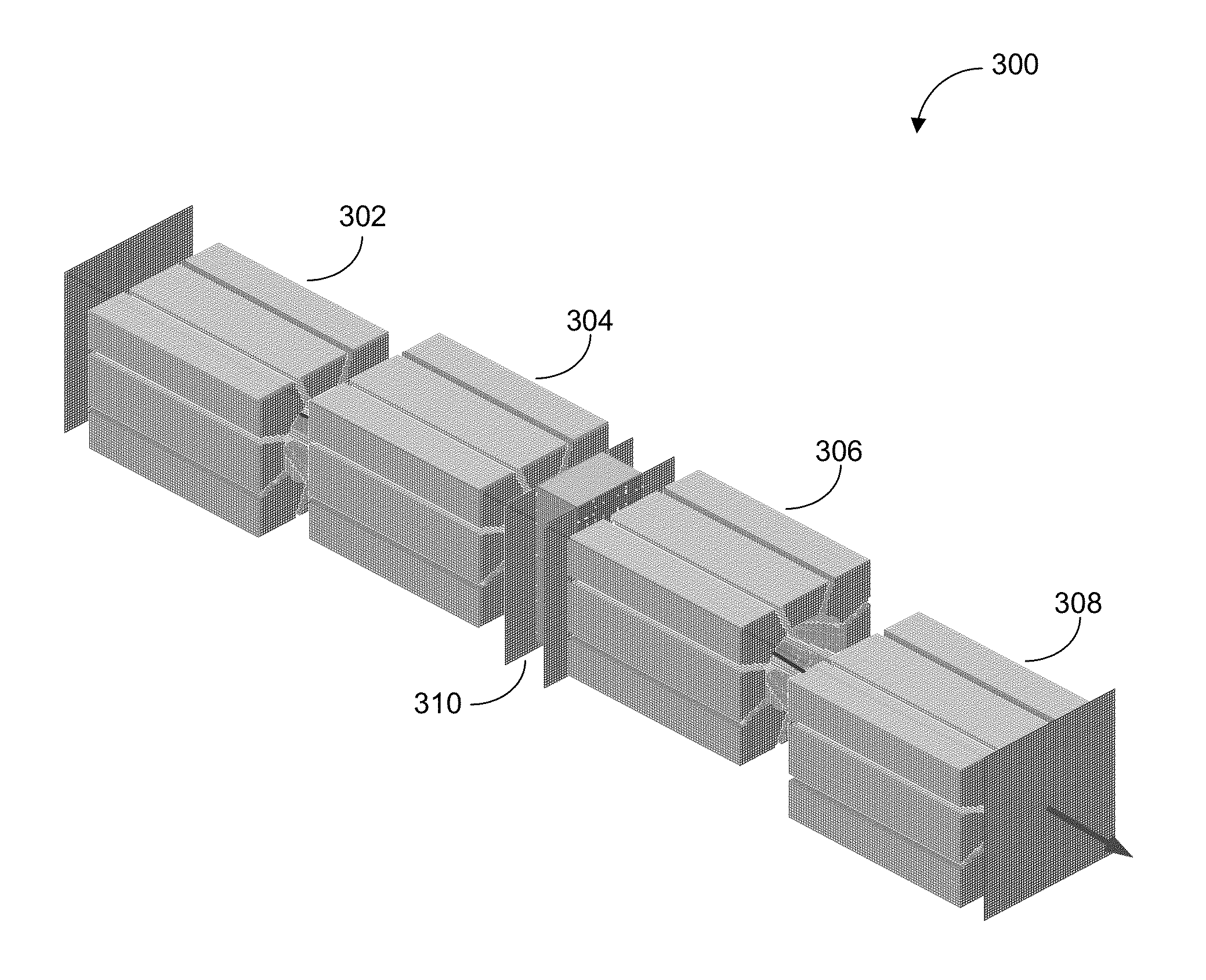

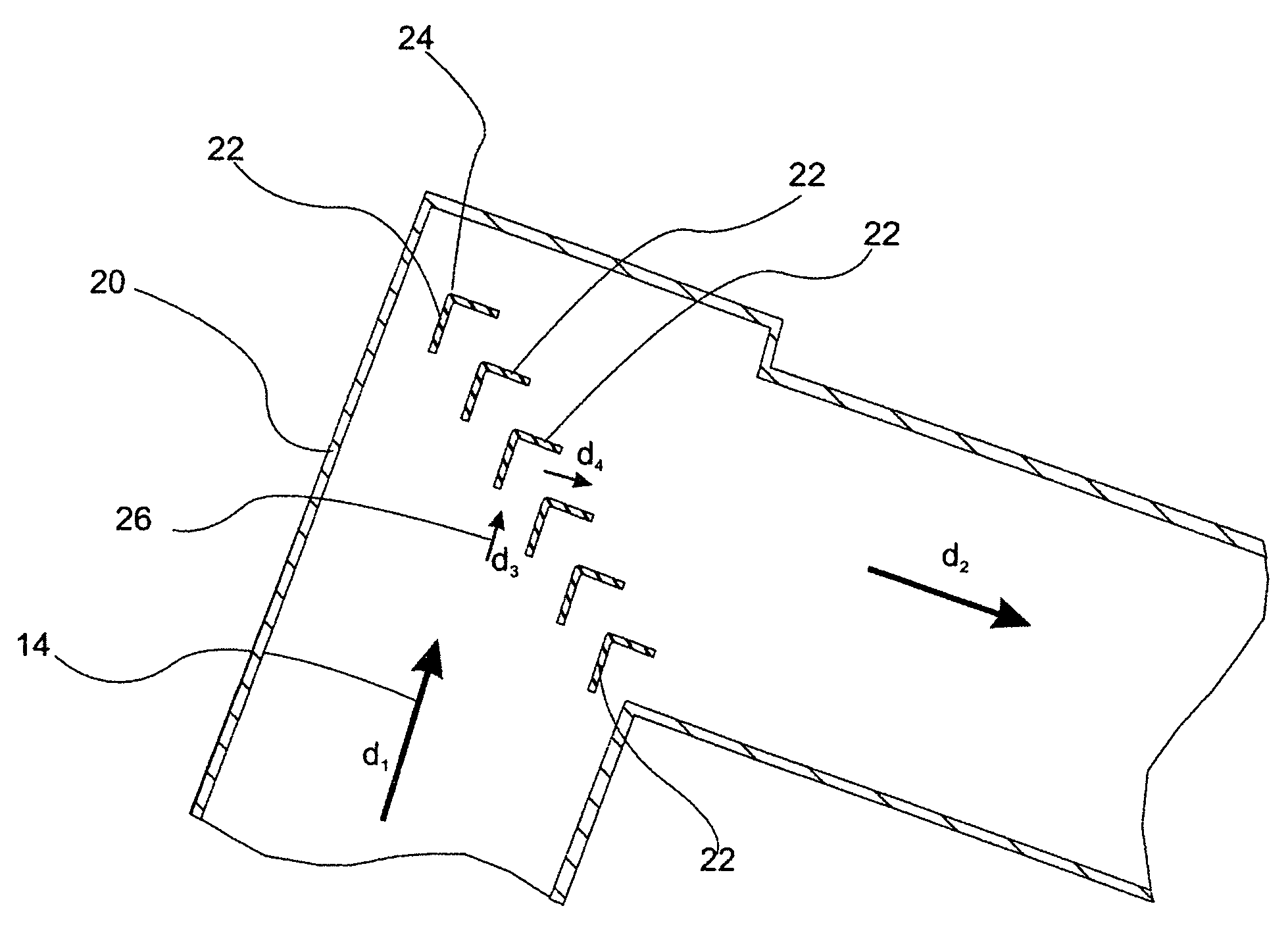

Cooling circuit for a multi-wall blade

A cooling system according to an embodiment includes: a serpentine cooling circuit, the serpentine cooling circuit including a first leg extending in a first direction, a second leg extending in a second direction, and a turn fluidly coupling the first leg and the second leg; and an air feed cavity for supplying cooling air to the serpentine cooling circuit; wherein the first leg of the serpentine cooling circuit extends radially outward from and at least partially covers at least one central plenum of a multi-wall blade, and wherein the second leg of the serpentine cooling circuit extends radially outward from and at least partially covers a first set of near wall cooling channels of the multi-wall blade.

Owner:GENERAL ELECTRIC CO

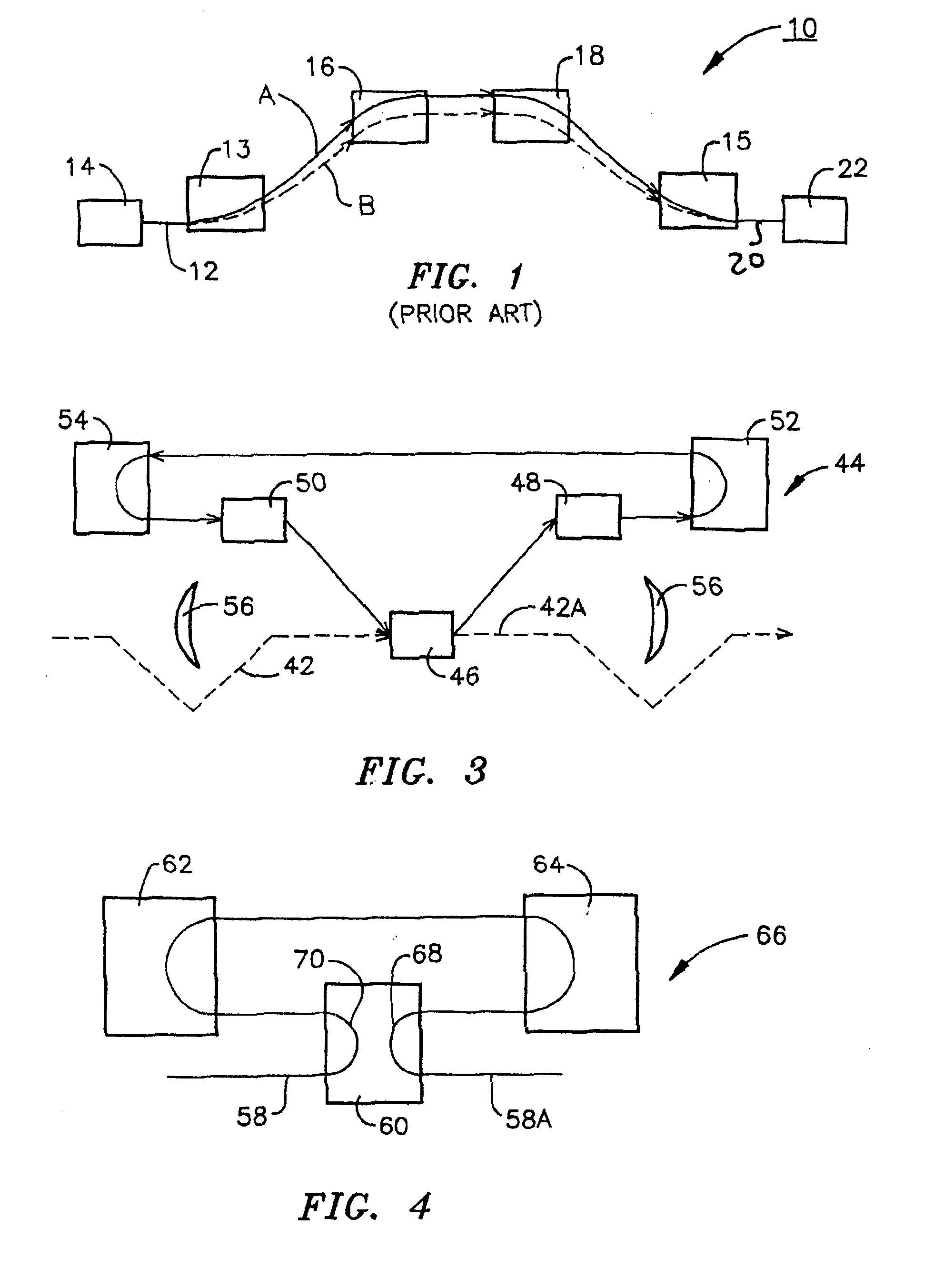

Charged particle energy filter

ActiveUS20130112890A1High beam qualityImproved energy resolutionStability-of-path spectrometersBeam/ray focussing/reflecting arrangementsLight beamQuadrupole

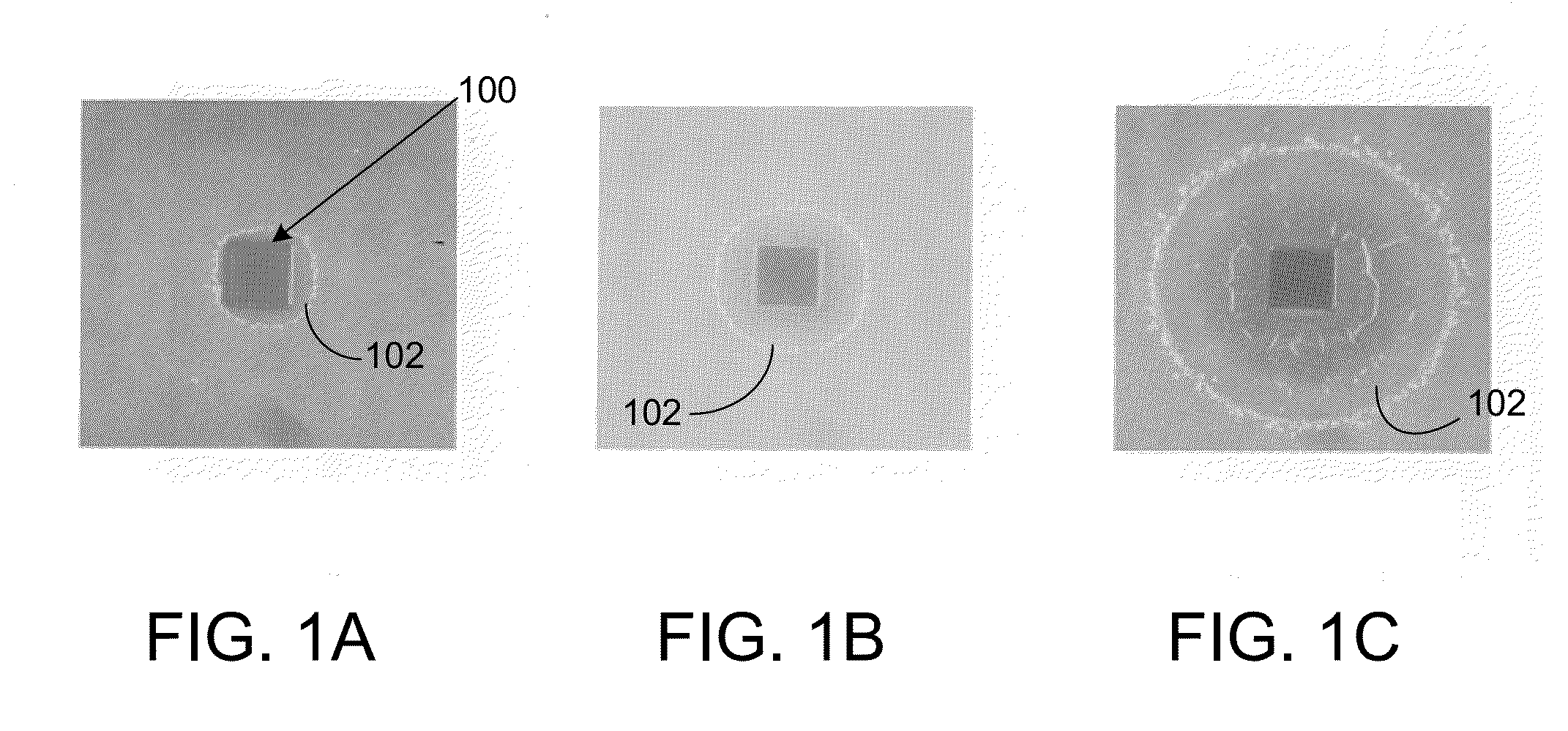

A multi-element electrostatic chicane energy filter, with the addition of electrostatic quadrupole and hexapole excitations to the dipole elements. A charged particle energy filter according to the present invention with a combination of dipole, quadrupole, and hexapole elements capable of producing a line focus at an aperture reduces space-charge effects and aperture damage. A preferred embodiment allows the filter to act as a conjugate blanking system. The energy filter is capable of narrowing the energy spread to result in a smaller beam.

Owner:FEI CO

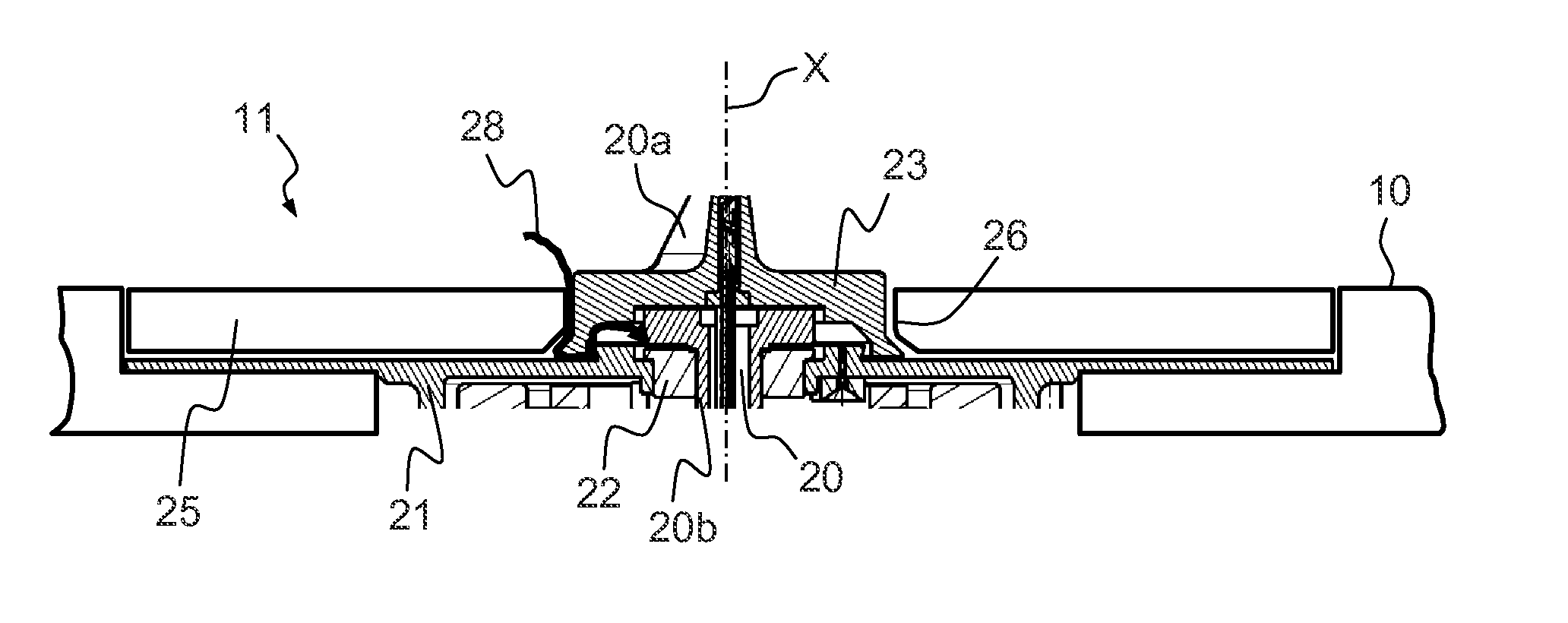

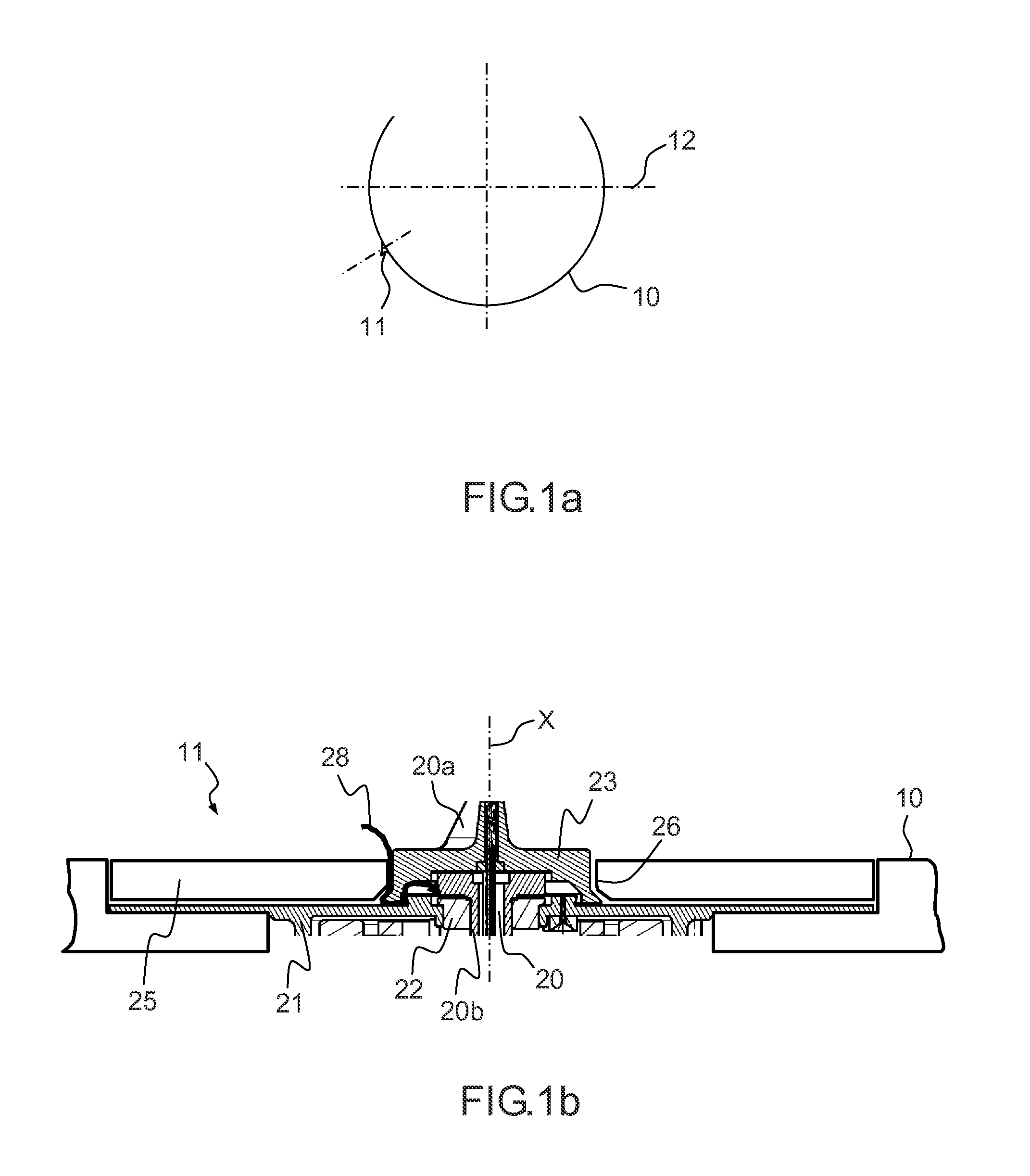

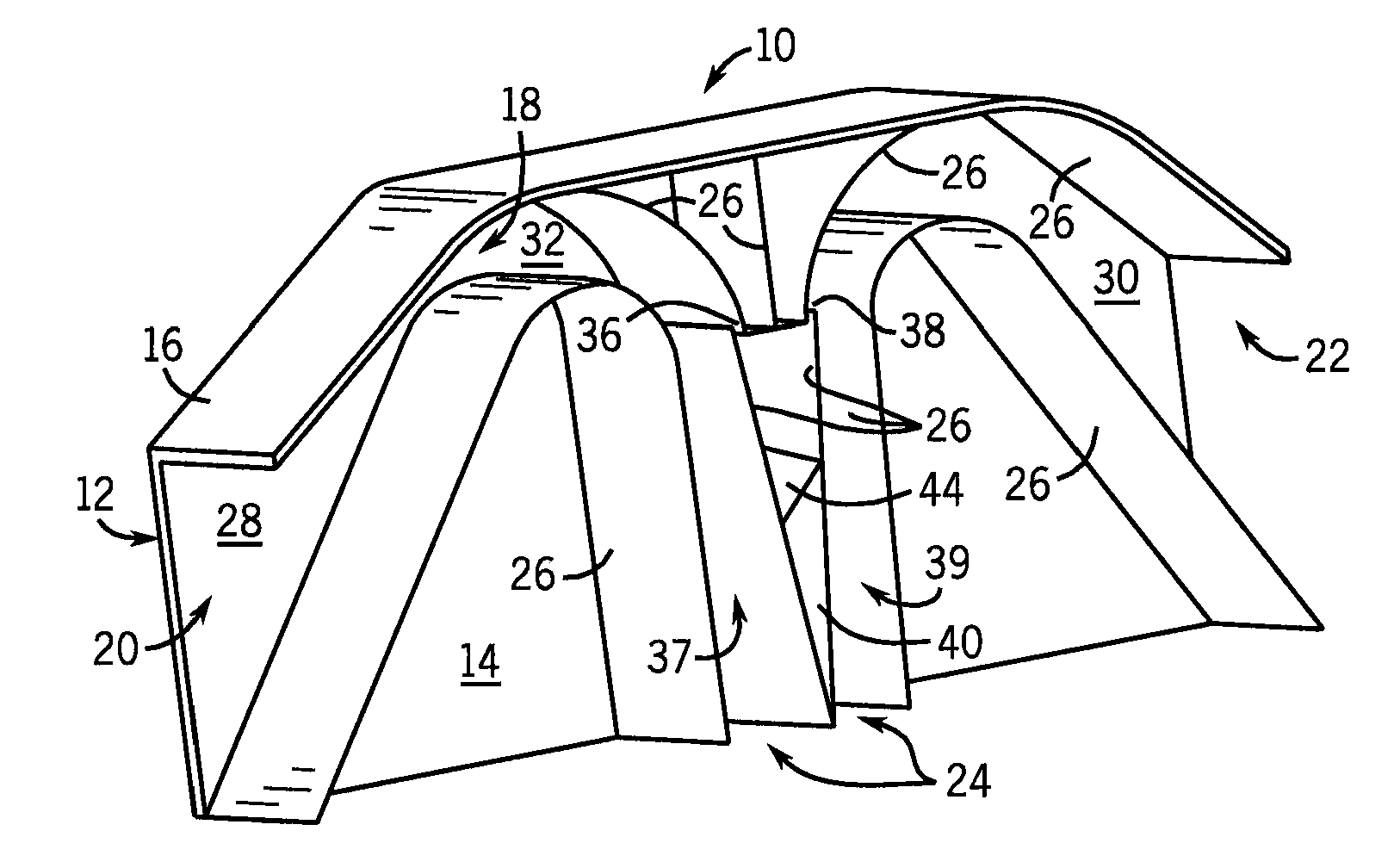

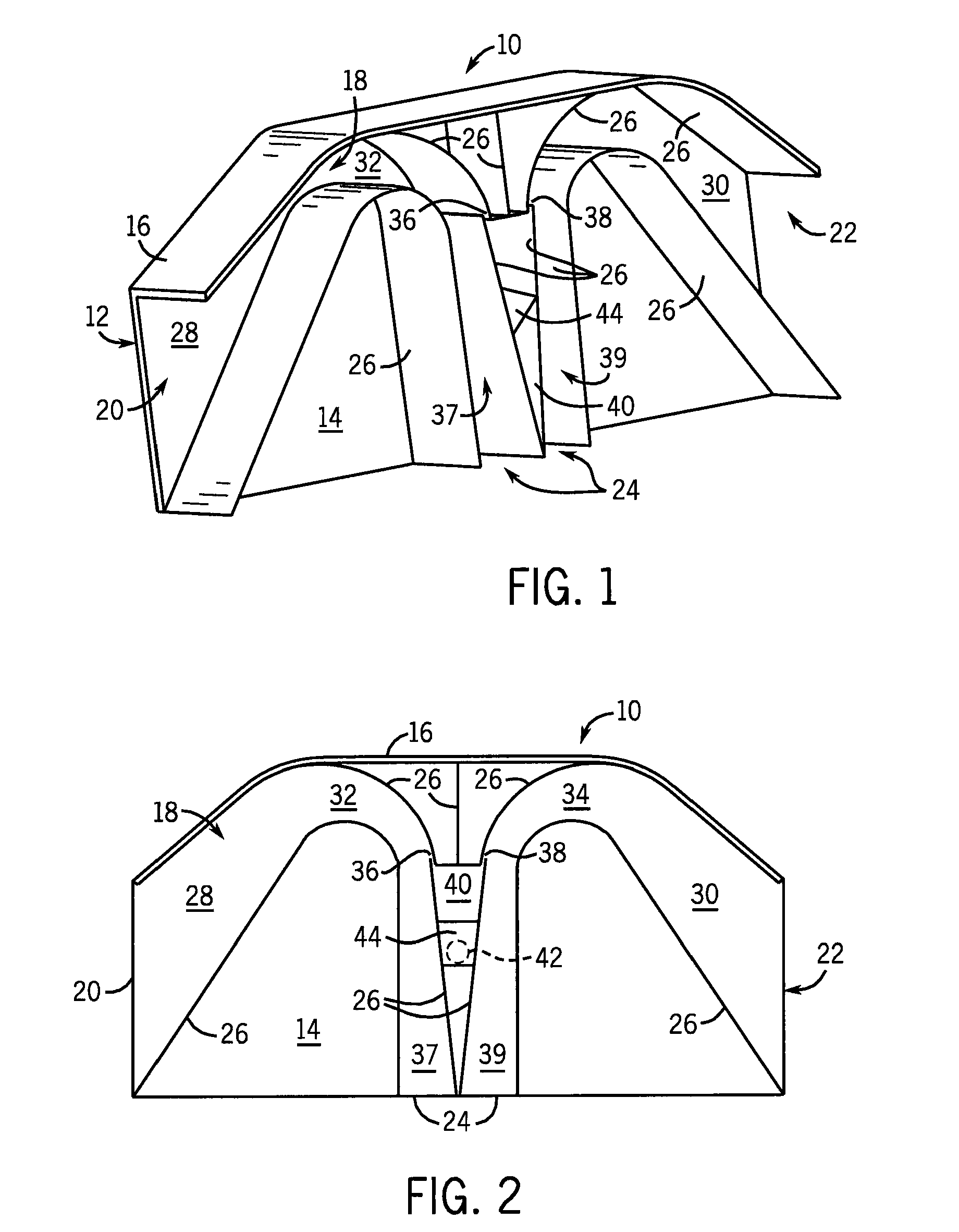

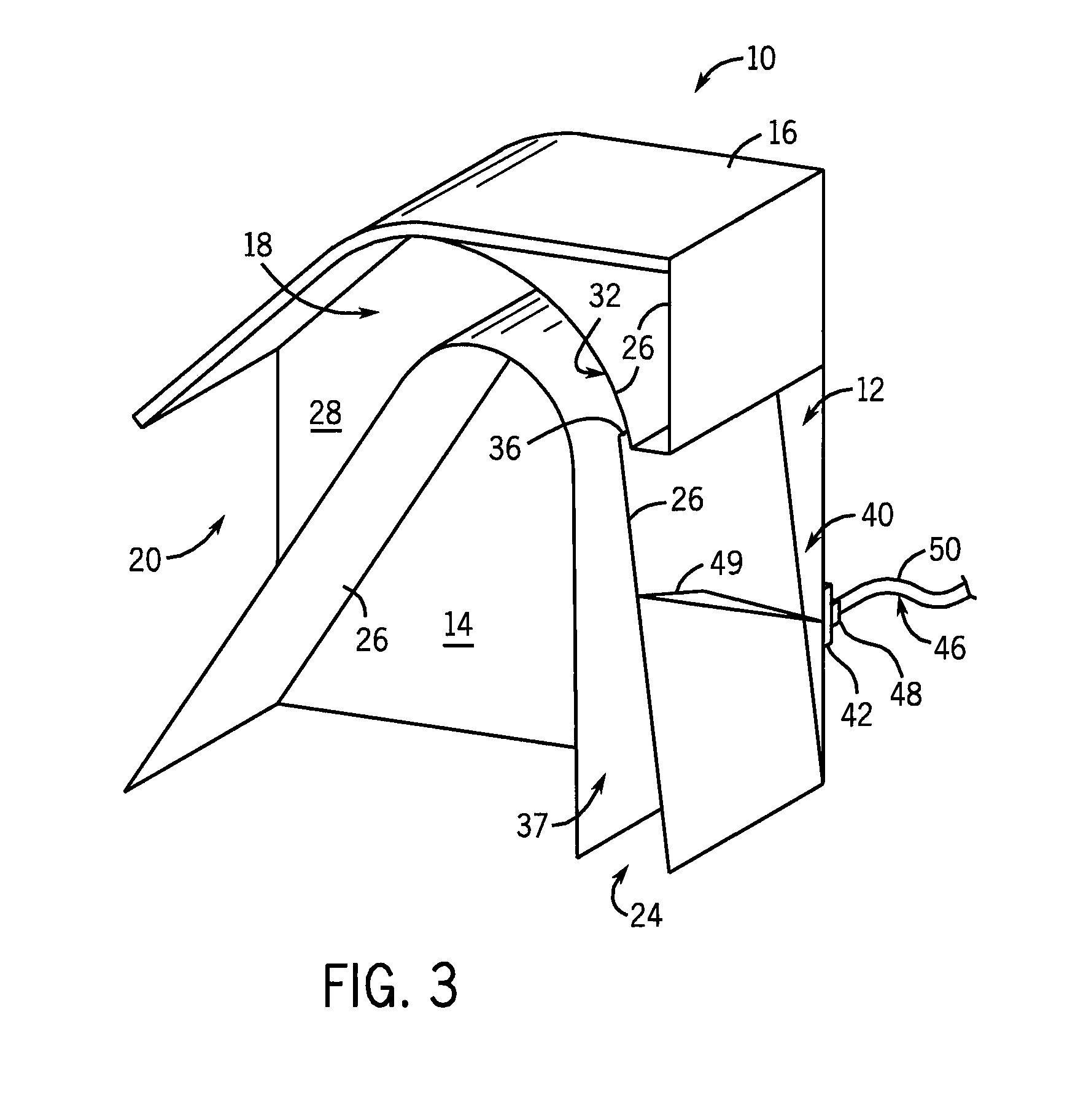

Aerodynamic measurement probe with evacuation of penetrated liquid by gravity

ActiveUS20150082878A1Avoid transportRestricts passageIndication/recording movementNavigation instrumentsEngineeringChicane

An aerodynamic measurement probe intended to measure a local angle of attack of an airstream flowing along the fuselage of an aircraft, comprises a support and a shaft that is able to rotate about a longitudinal axis with respect to the support. The support and the shaft are configured to form between one another a plurality of successive chicanes about the longitudinal axis. Each chicane makes it possible to transport liquid that has penetrated into the chicane: along a first path, under the effect of gravity, towards an evacuation circuit associated with the chicane and formed in the support, and along a second path, and counter to the effect of gravity, towards a successive chicane or towards the shaft. The evacuation circuit of each of the chicanes makes it possible to evacuate liquid out of the support under the effect of gravity moving away from the shaft.

Owner:THALES SA

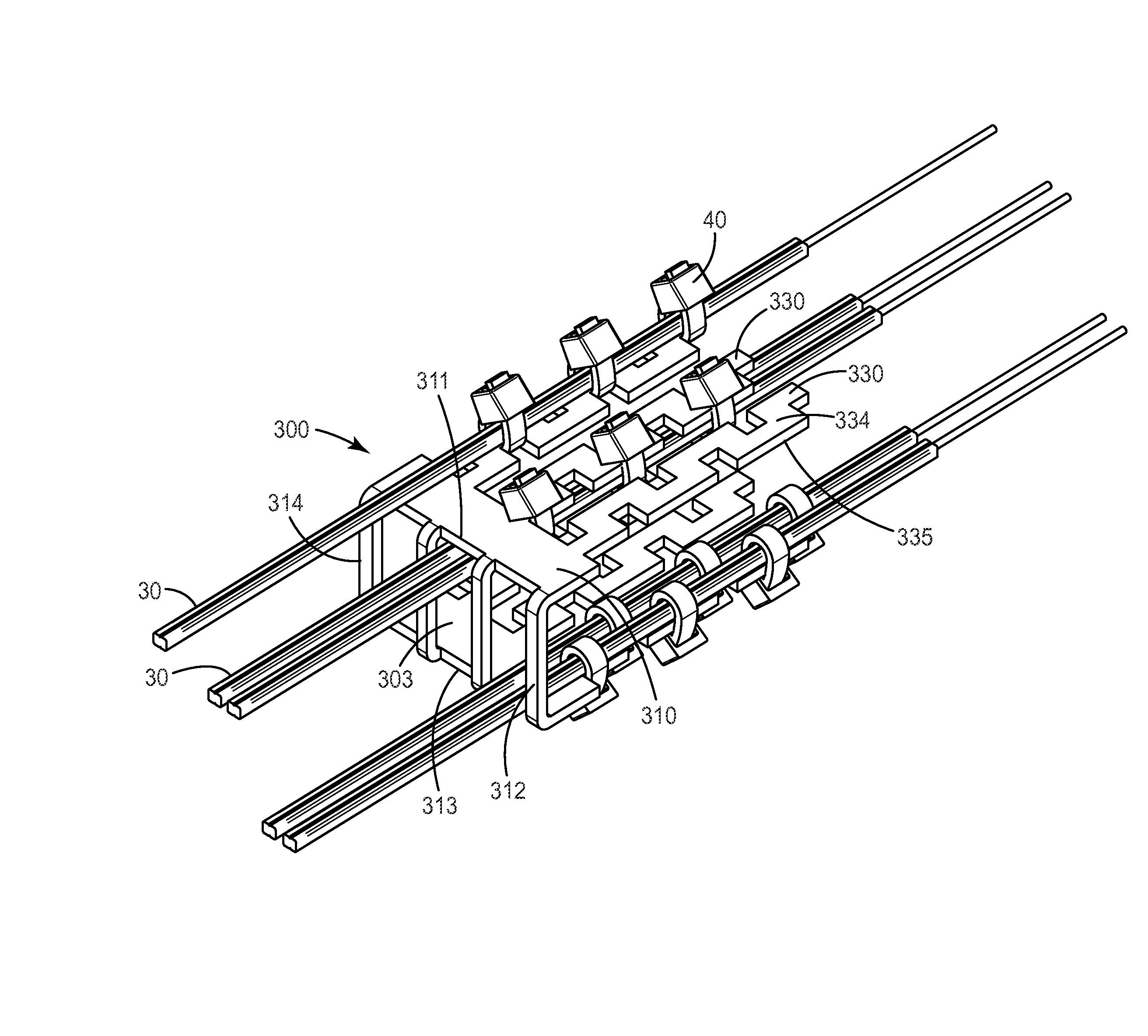

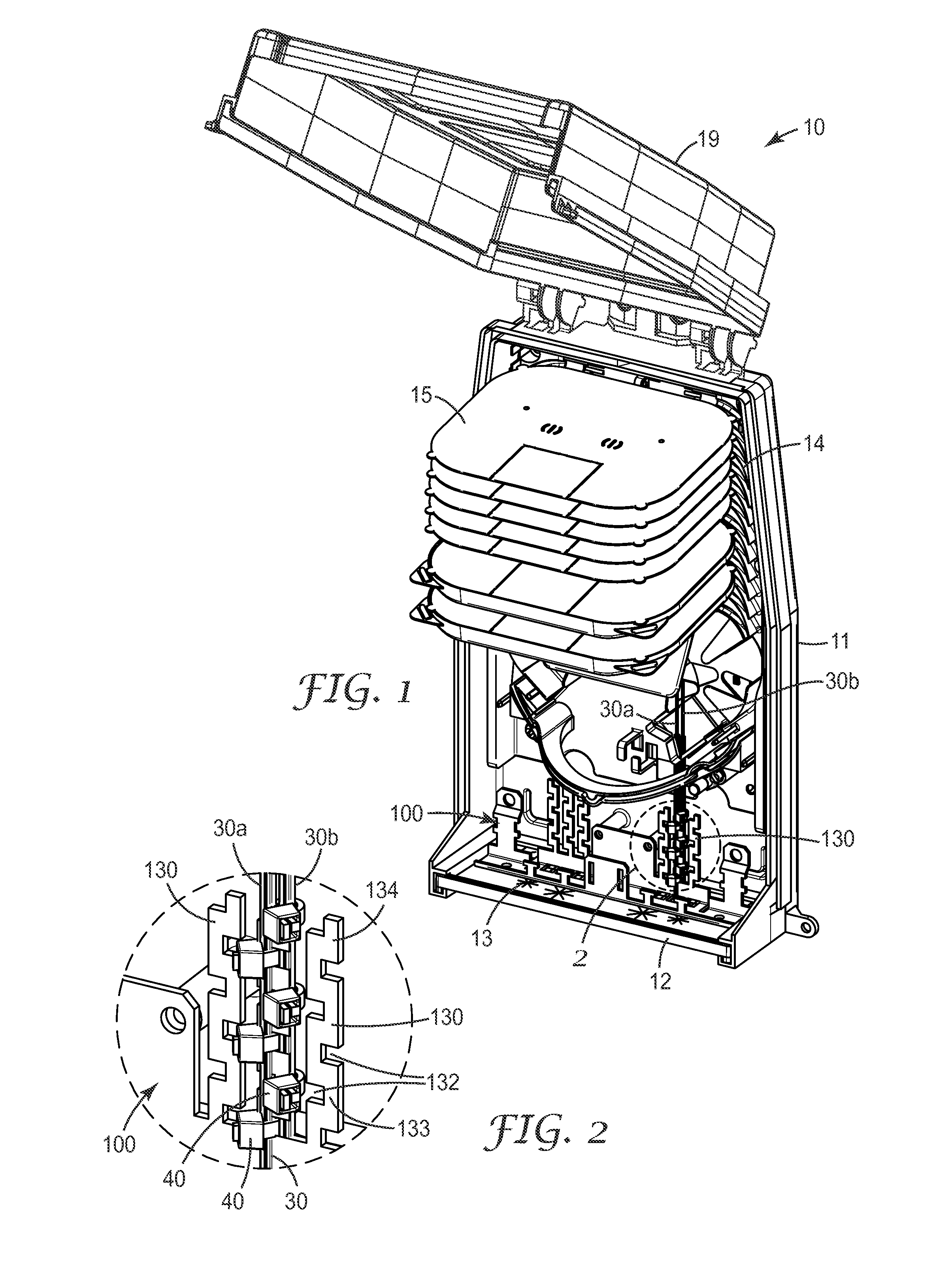

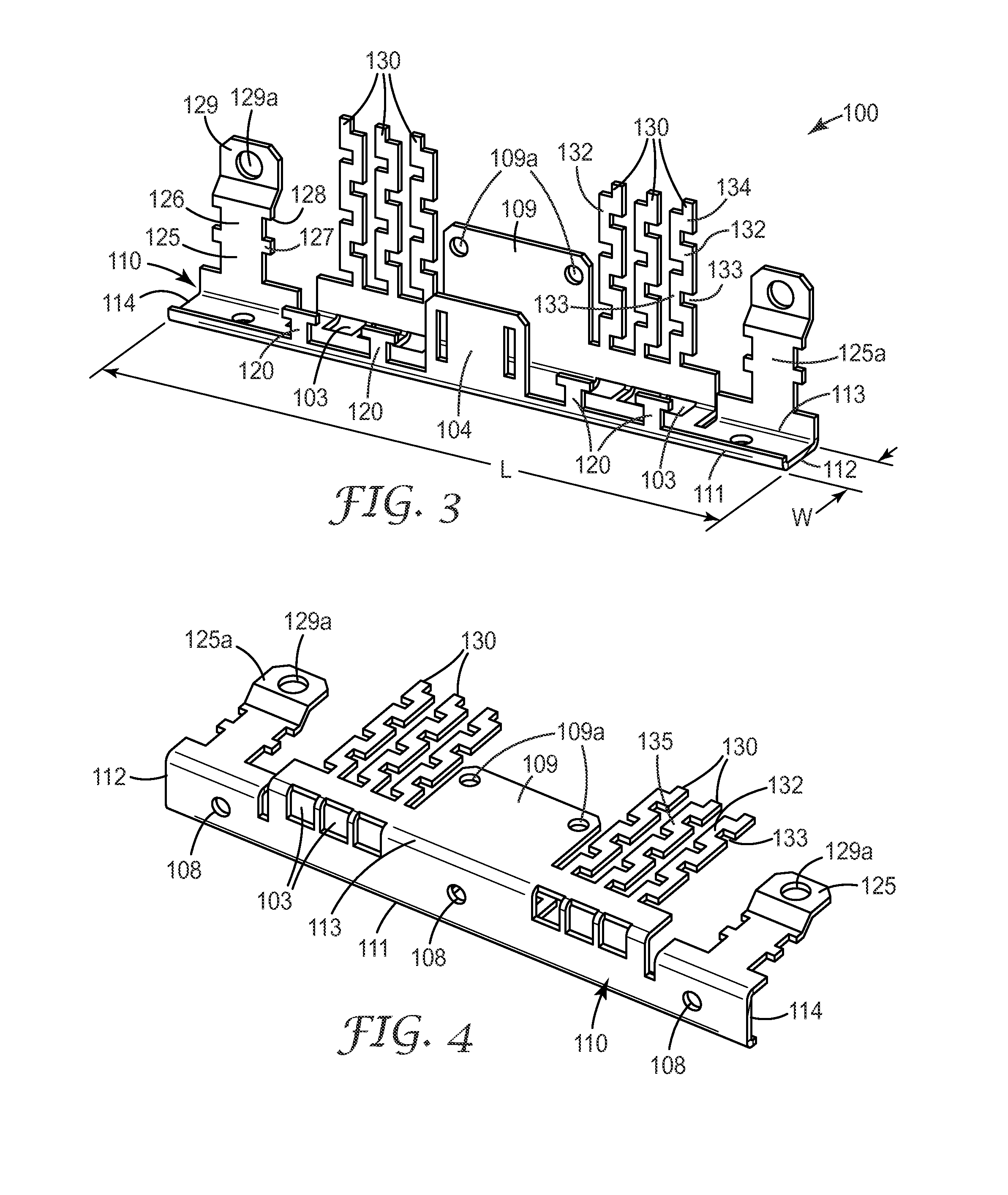

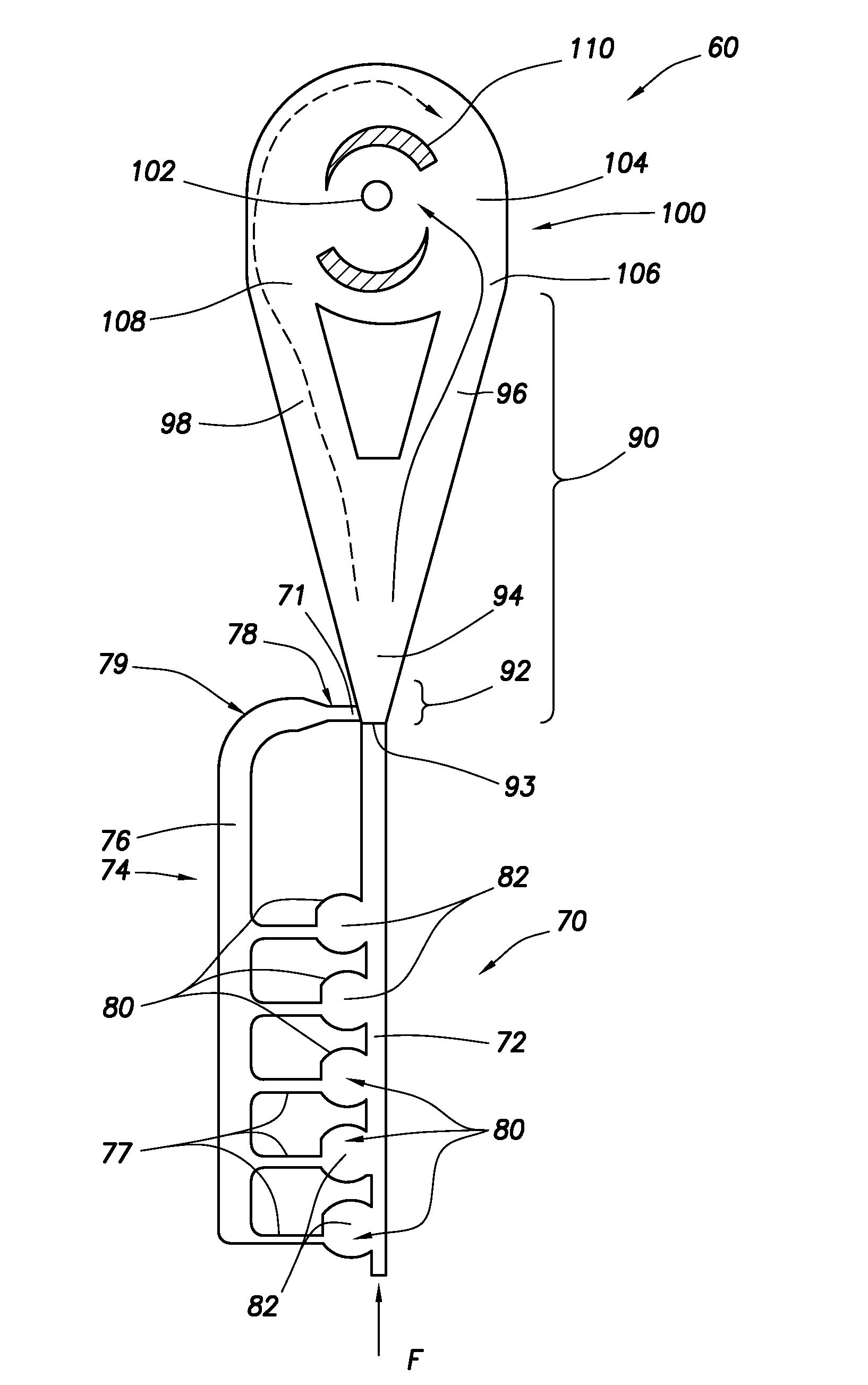

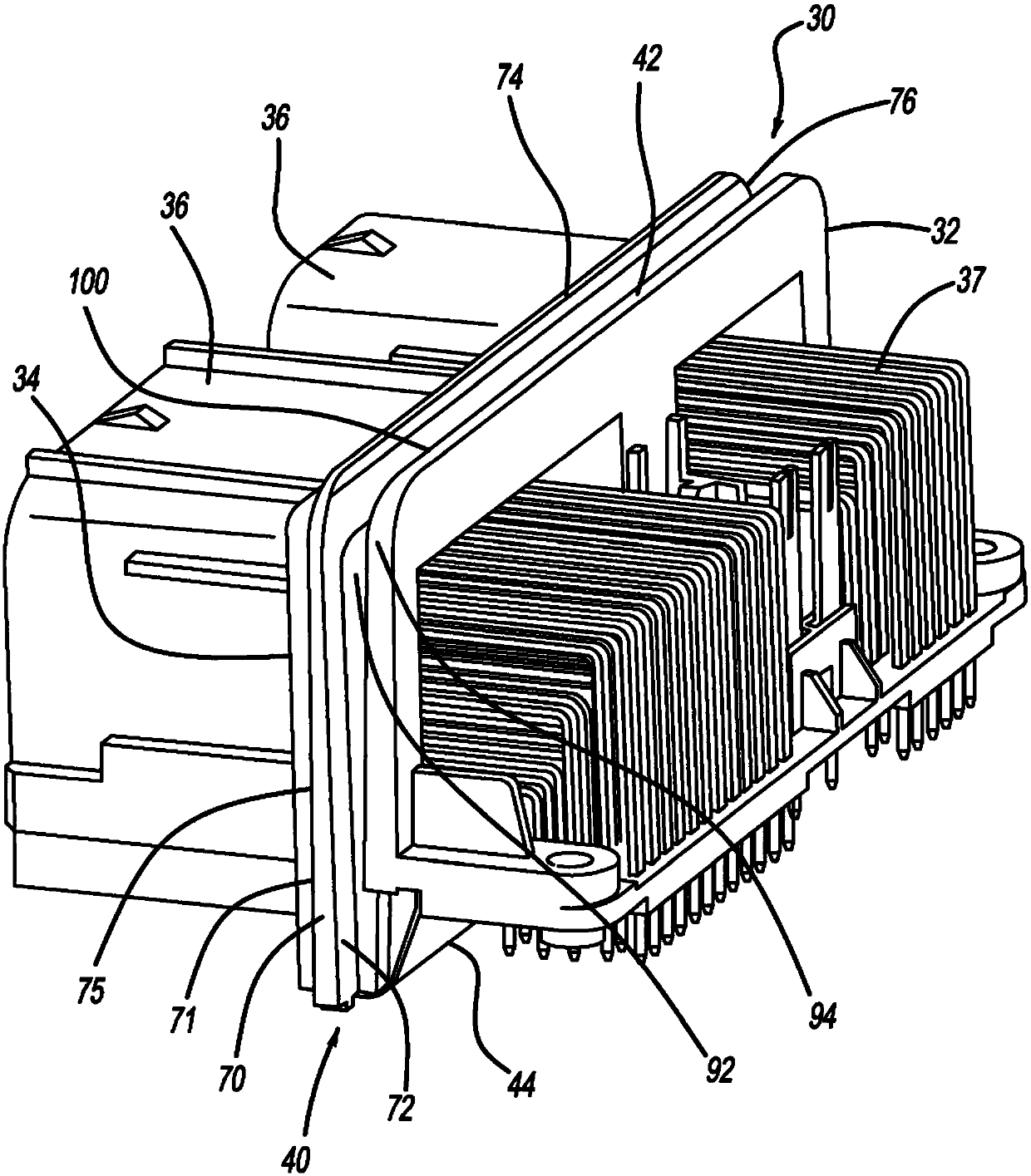

Strain relief device for low friction drop cable

InactiveUS20160134092A1Easy to handlePipe supportsAdjusting/maintaining mechanical tensionChicaneBiomedical engineering

The present invention relates to a strain relief device for use in a telecommunication enclosure. The exemplary strain relief device includes a bracket body base and a plurality of retention fingers extending from the bracket body base. Each of the plurality of retention fingers has a series of slots that define a plurality of tie down points for securing a drop cable at a plurality of points along one of the plurality of retention fingers. Each of the plurality of retention fingers has one of a chicane configuration, a serpentine configuration, comb configuration, and a rectangular configuration.

Owner:CORNING RES & DEV CORP

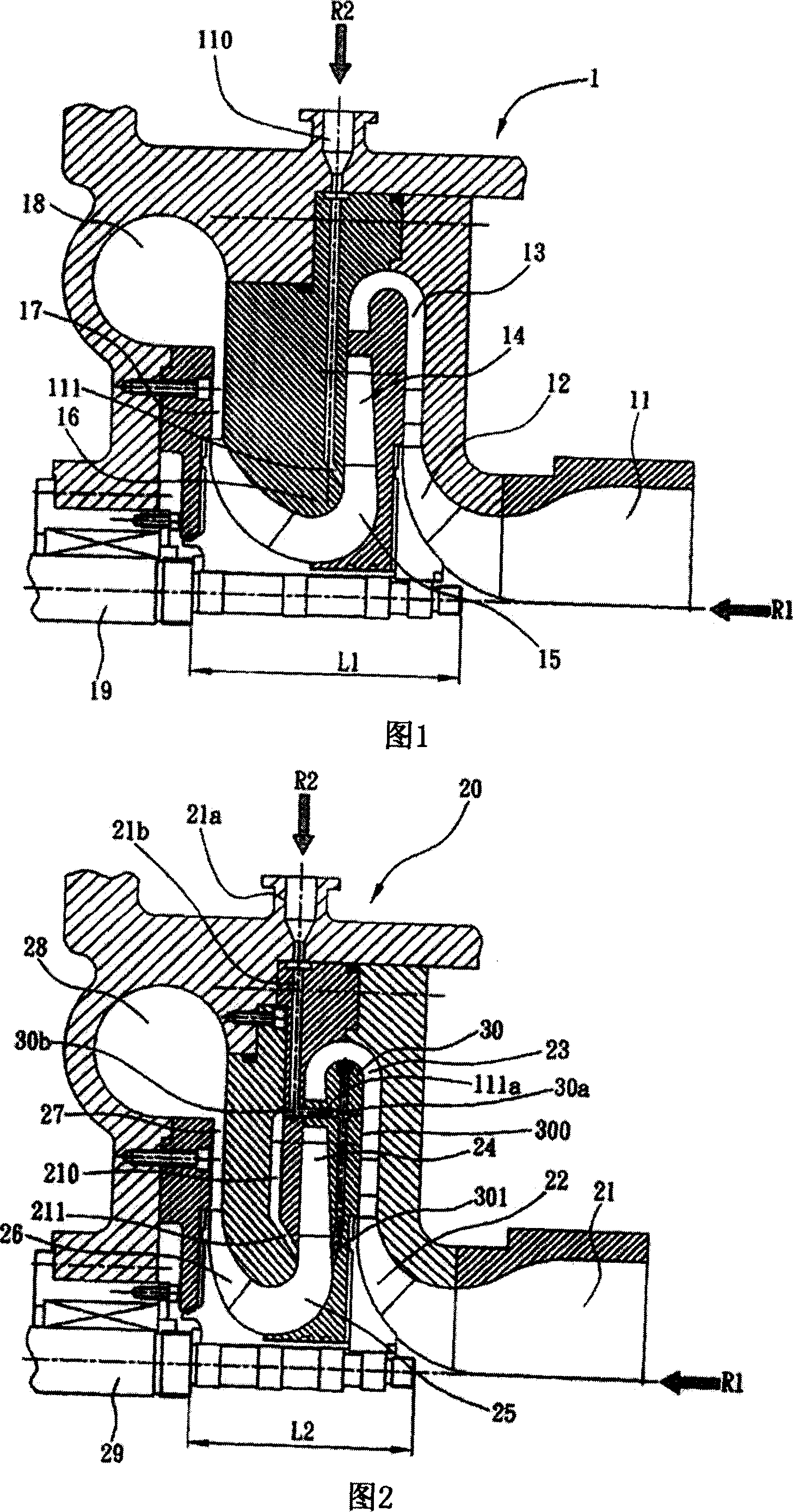

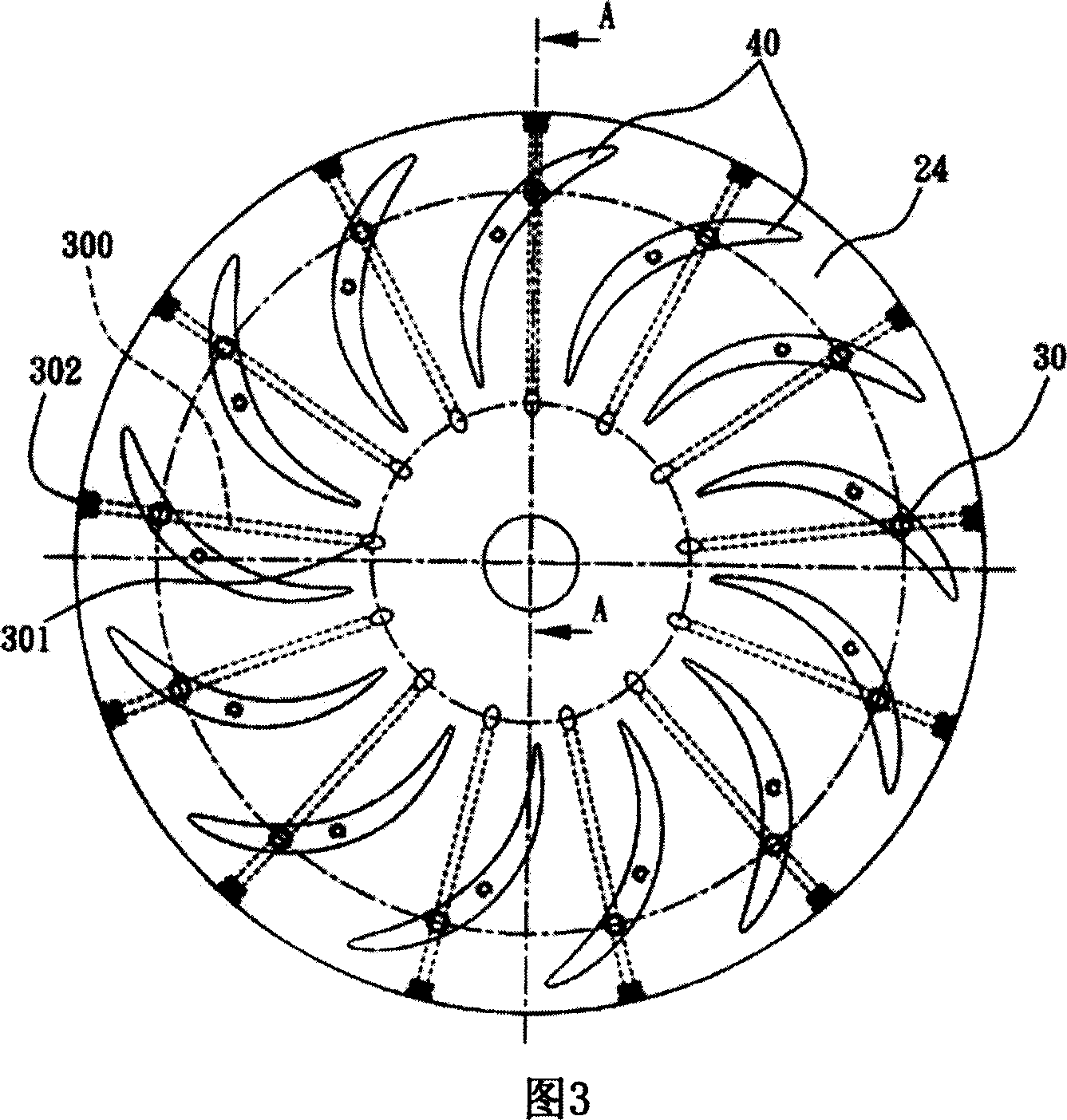

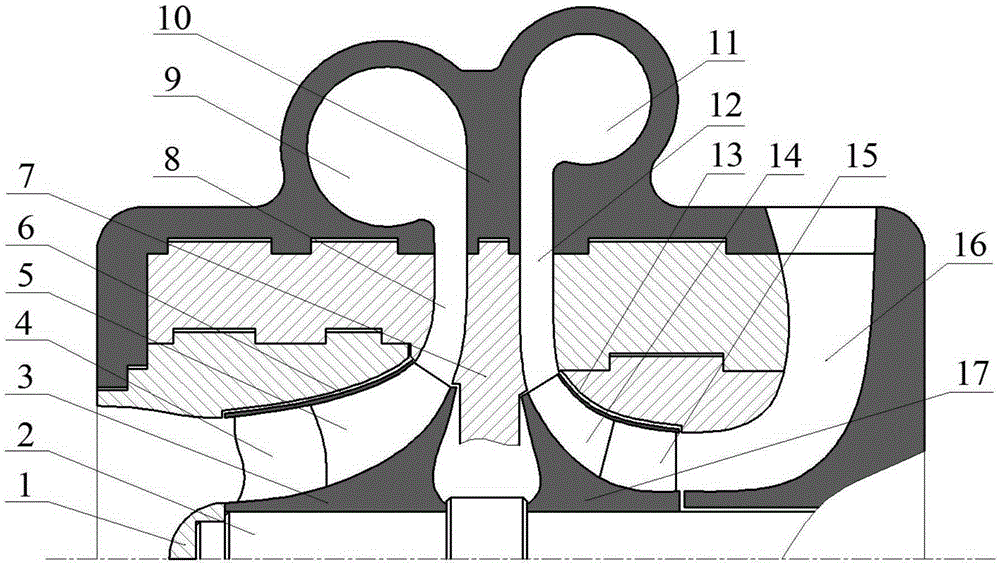

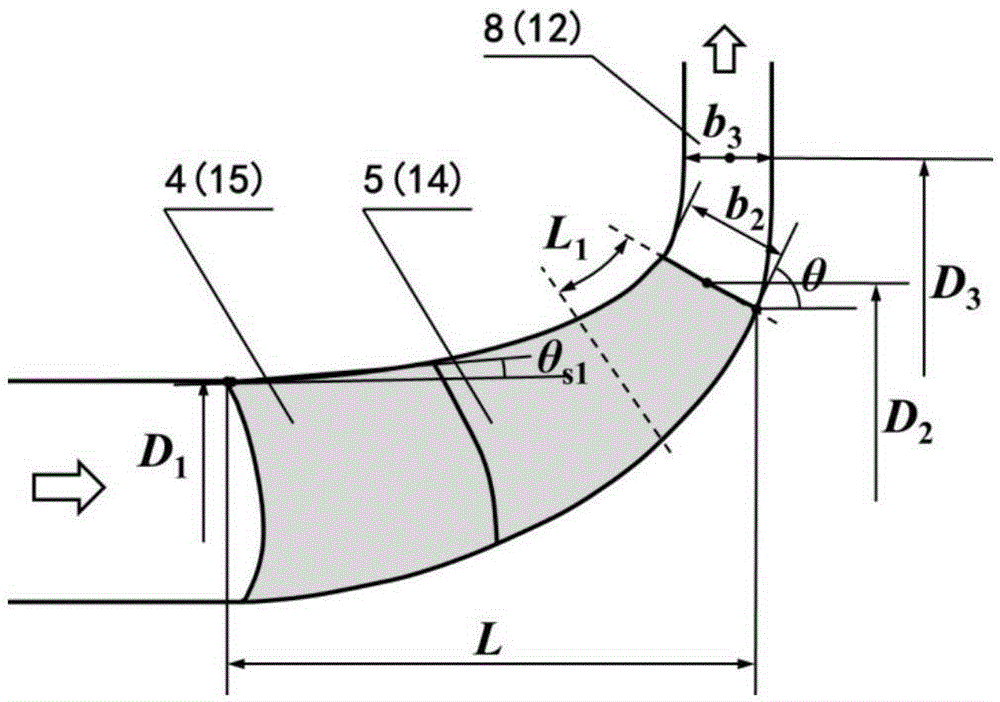

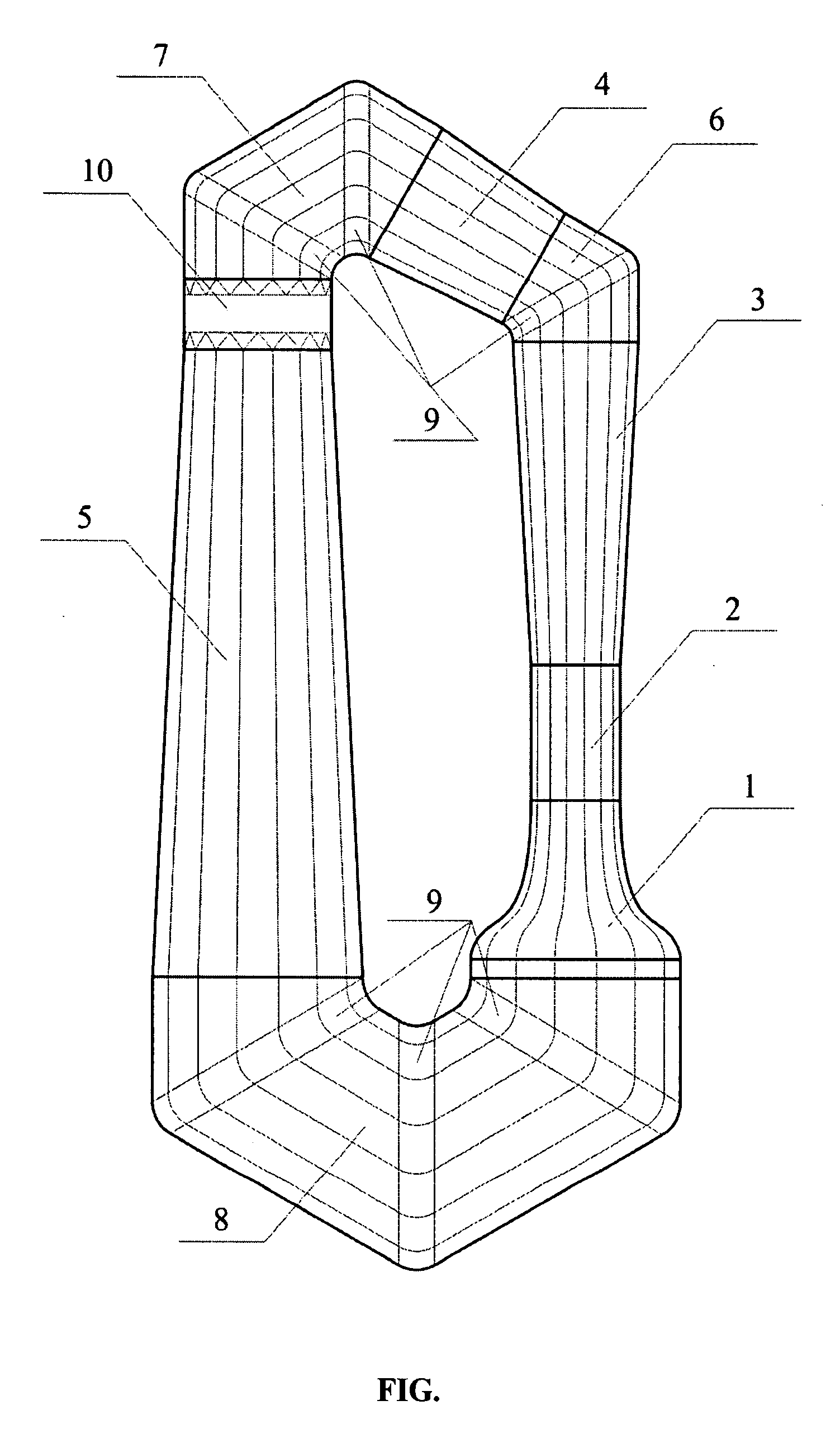

Compressor jet flow path structure

ActiveCN1987119AReduce distractionsMix well and effectivelyPump componentsRadial flow pumpsJet flowEngineering

A spray channel structure for the multi-class centrifugal compressor with curved reflux channel and reflux guide blade is composed of a bidirectional flow channel for the bidirectional division of the refrigerant filled externally and with the first and the second outlets, the first lateral spray channel communicated with the first outlet, and the second lateral spray channel communicated with the second outlet. Its advantages are uniform mixing of refrigerant and short channel and rotary axle.

Owner:IND TECH RES INST

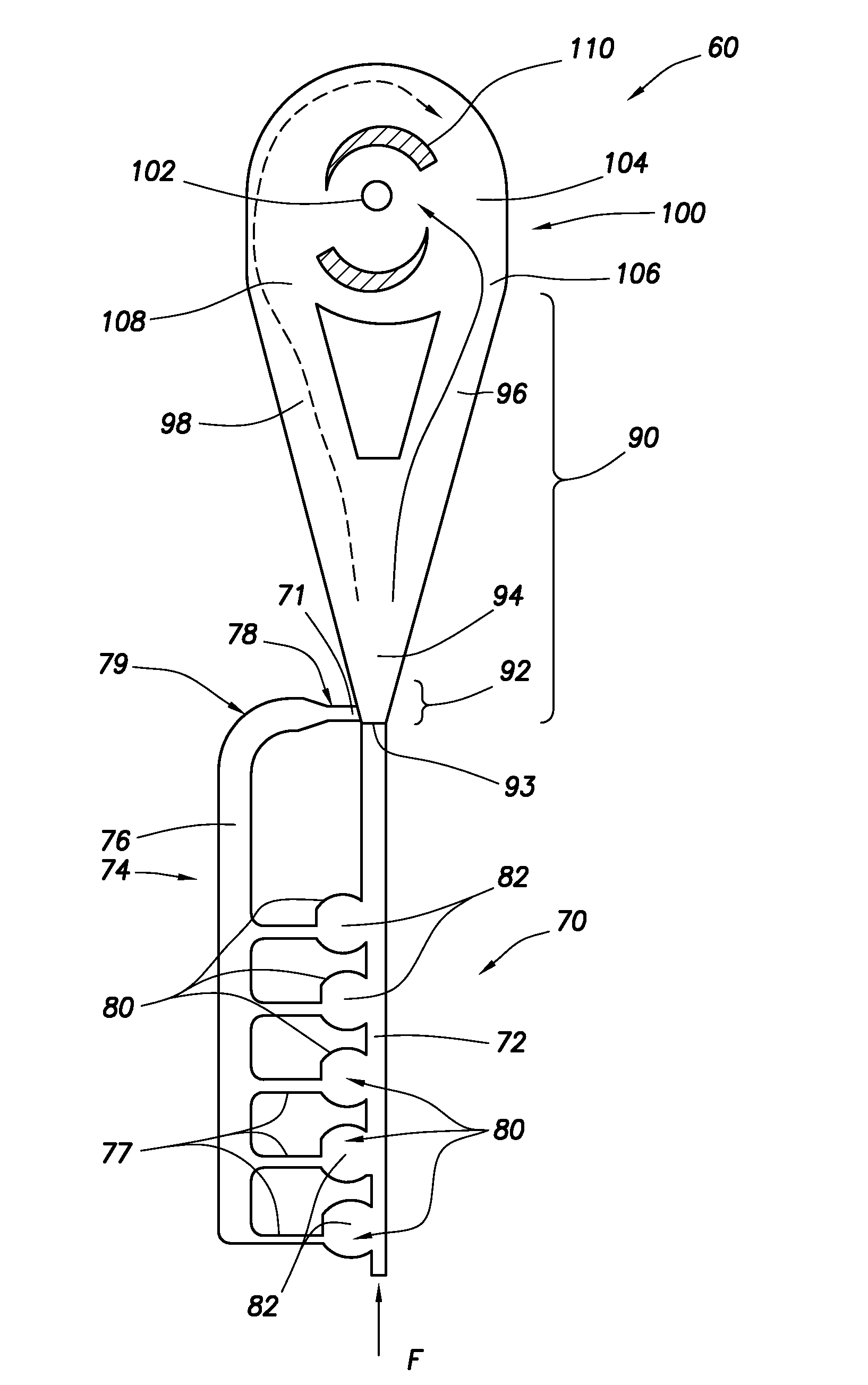

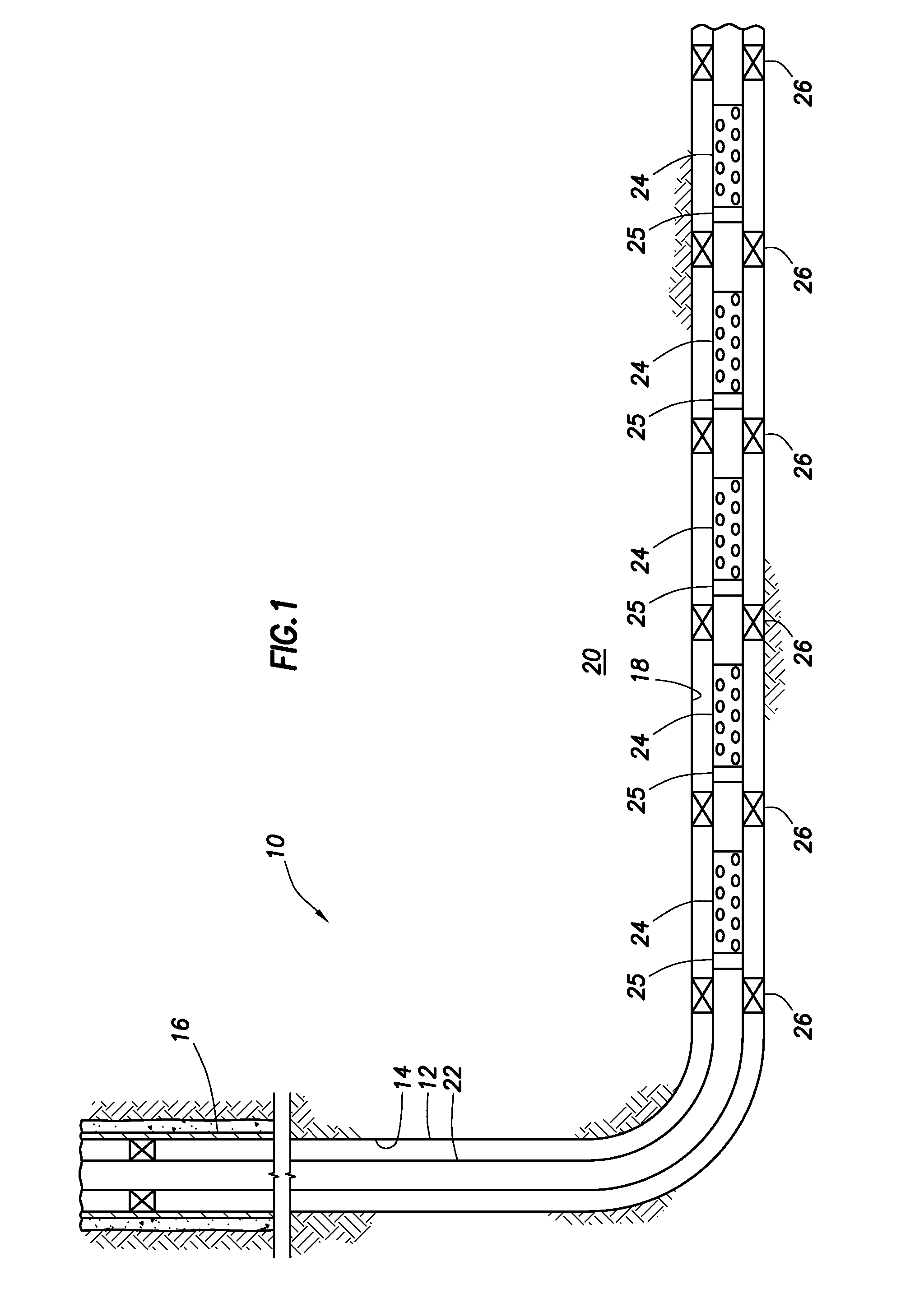

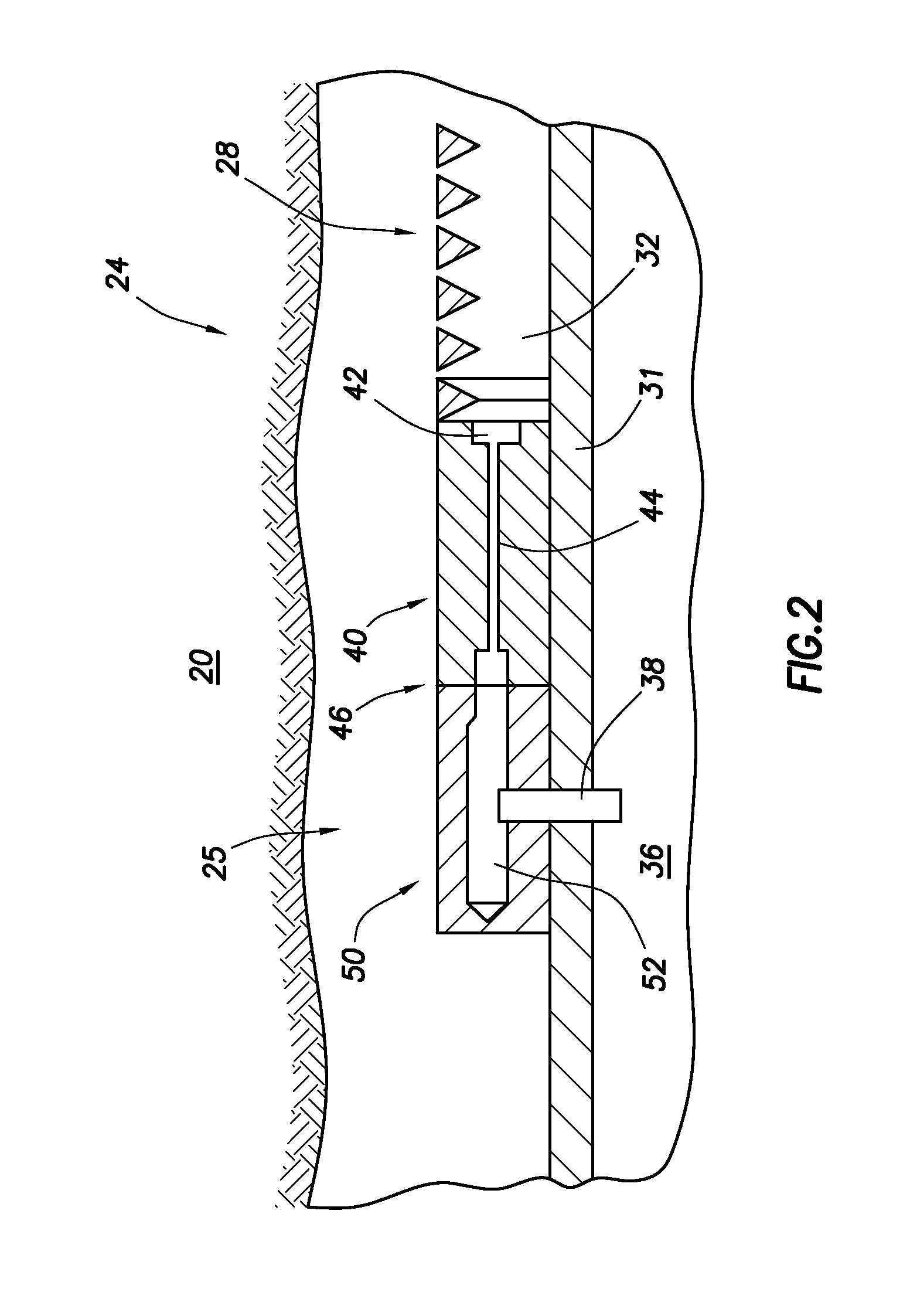

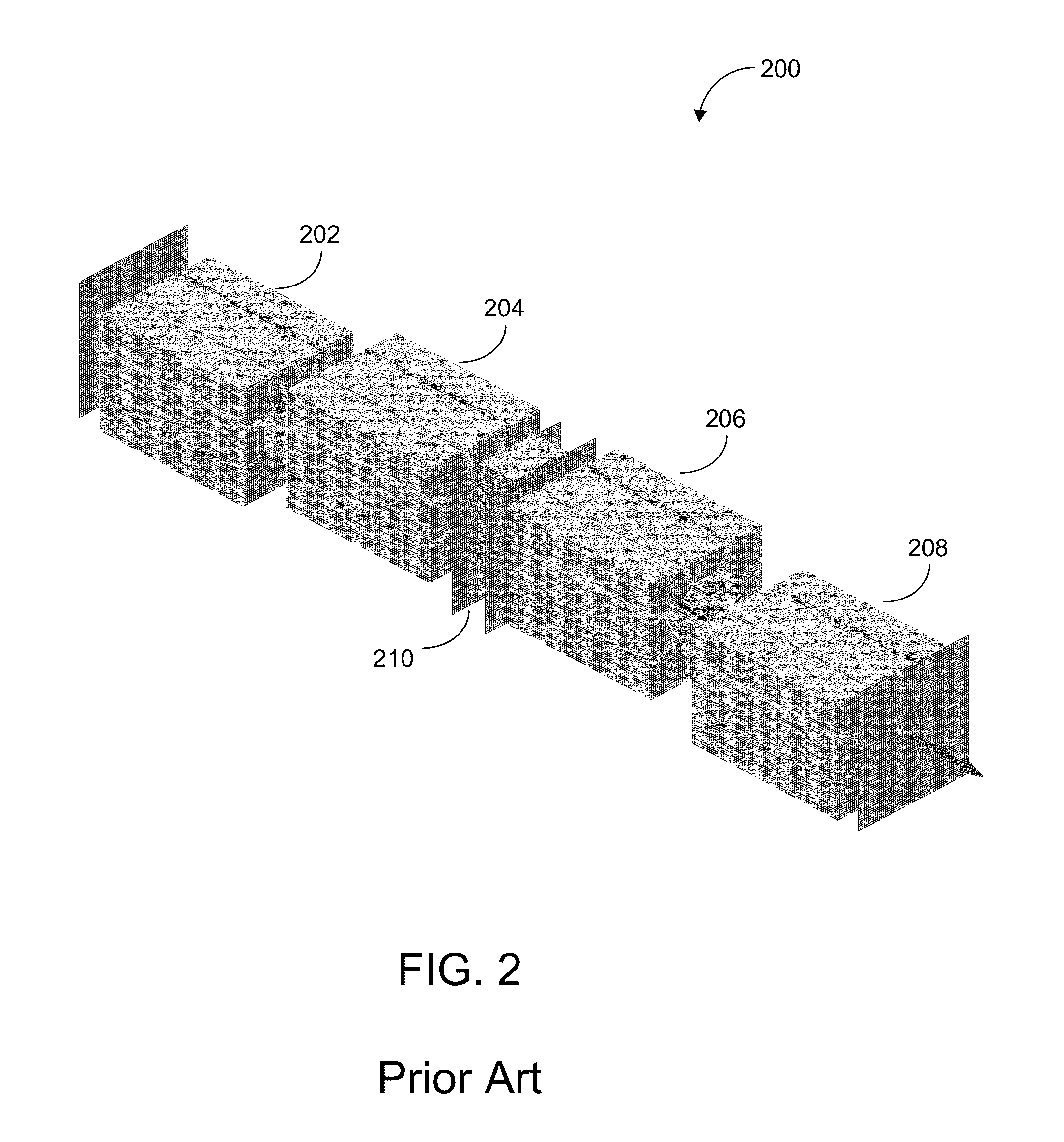

Method and apparatus for controlling fluid flow in an autonomous valve using a sticky switch

Apparatus and methods are described for autonomously controlling fluid flow in a tubular in a wellbore. A fluid is flowed through an inlet passageway into a biasing mechanism. A fluid flow distribution is established across the biasing mechanism. The fluid flow distribution is altered in response to a change in the fluid characteristic over time. In response, fluid flow through a downstream sticky switch assembly is altered, thereby altering fluid flow patterns in a downstream vortex assembly. The method “selects” based on a fluid characteristic, such as viscosity, density, velocity, flow rate, etc. The biasing mechanism can take various forms such as a widening passageway, contour elements along the biasing mechanism, or a curved section of the biasing mechanism passageway. The biasing mechanism can include hollows formed in the passageway wall, obstructions extending from the passageway wall, fluid diodes, Tesla fluid diodes, a chicane, or abrupt changes in passageway cross-section.

Owner:HALLIBURTON ENERGY SERVICES INC

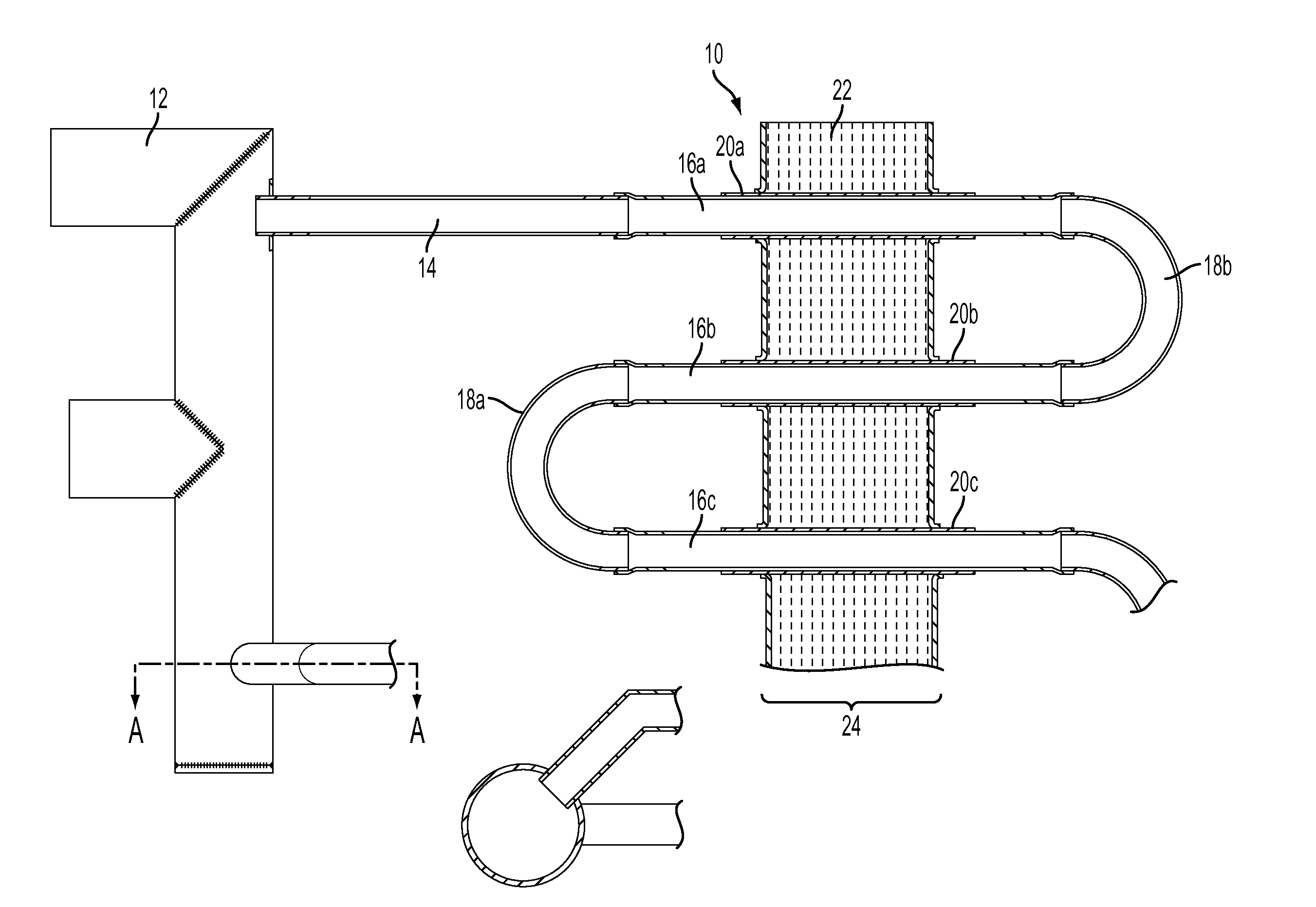

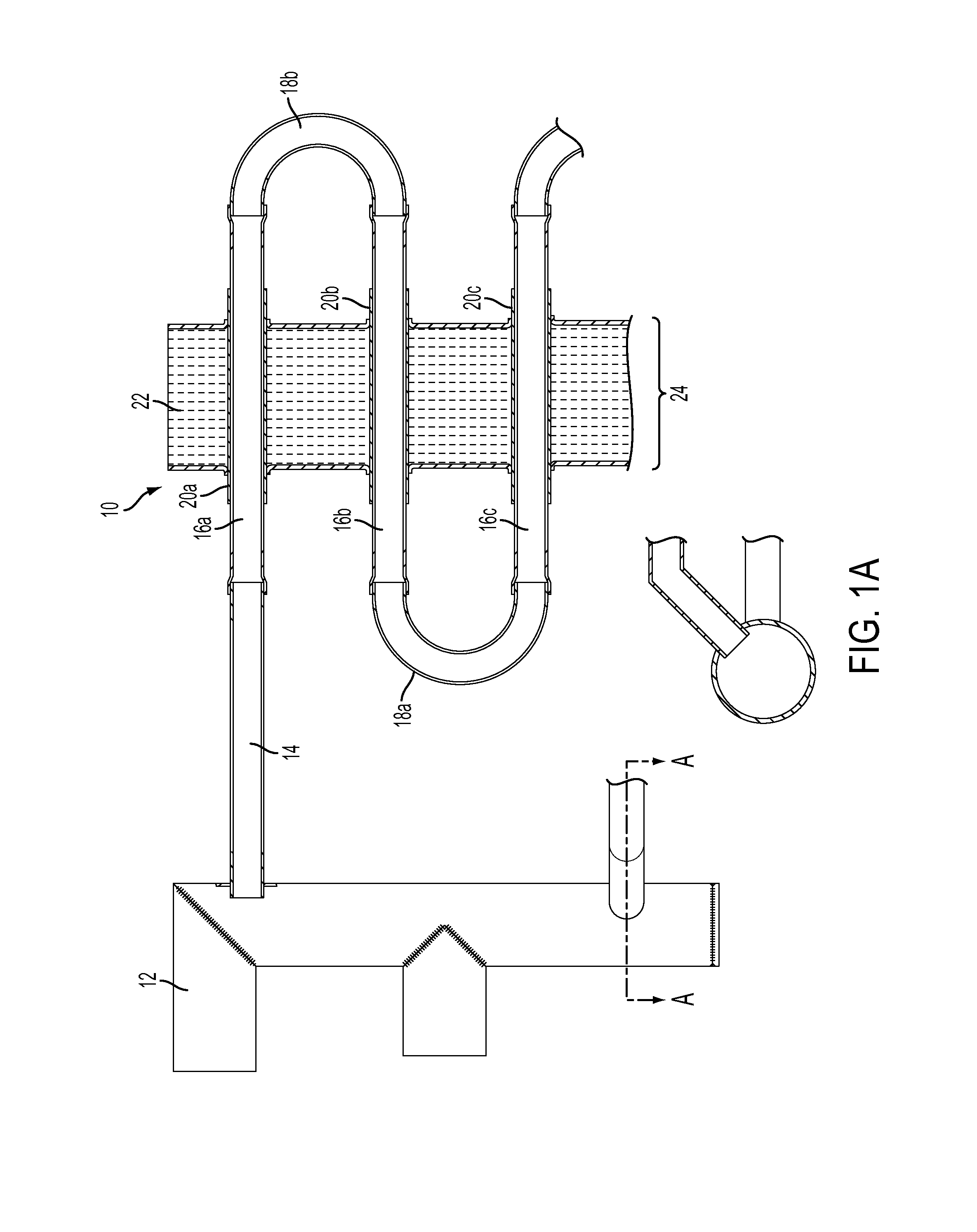

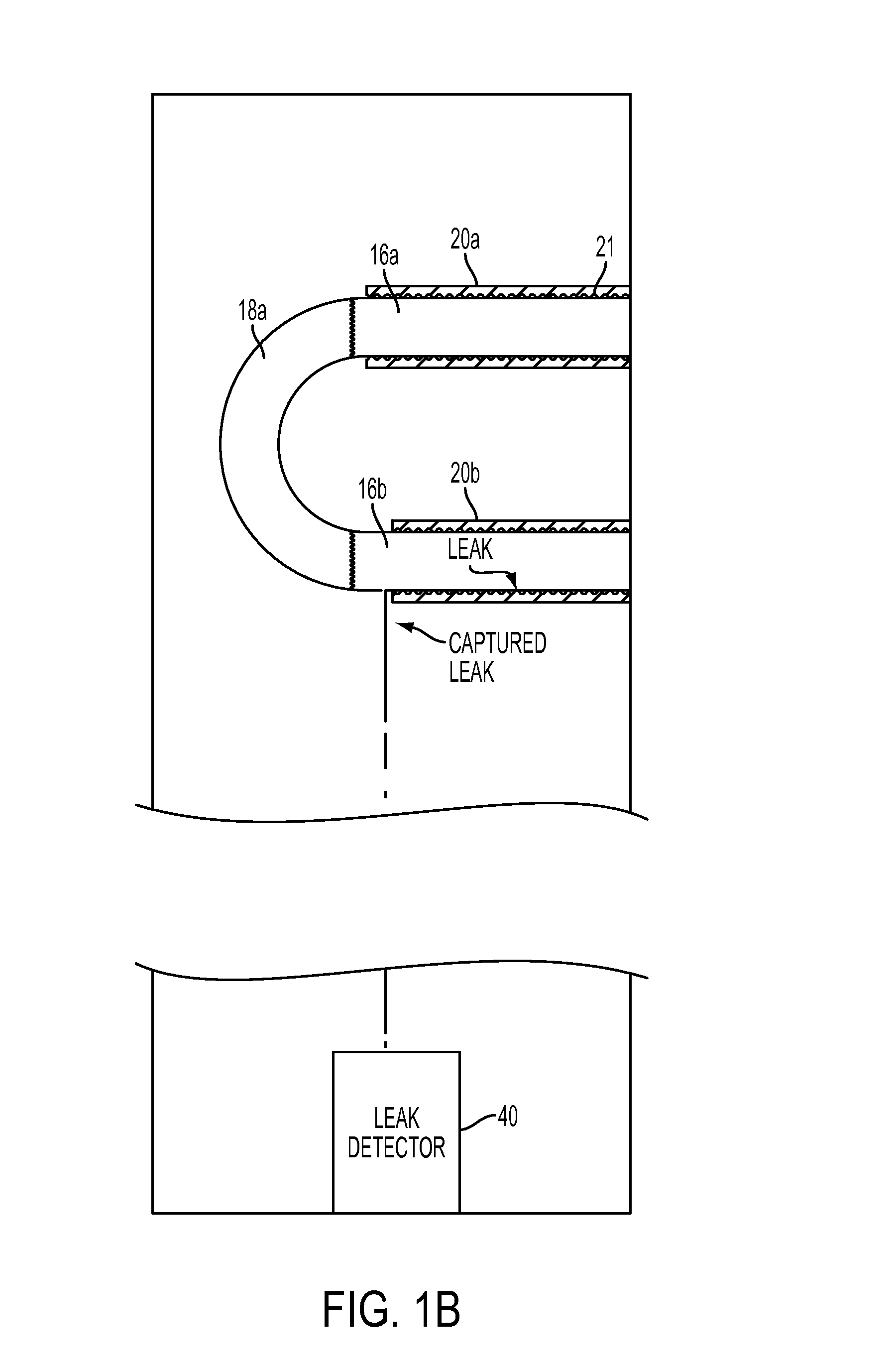

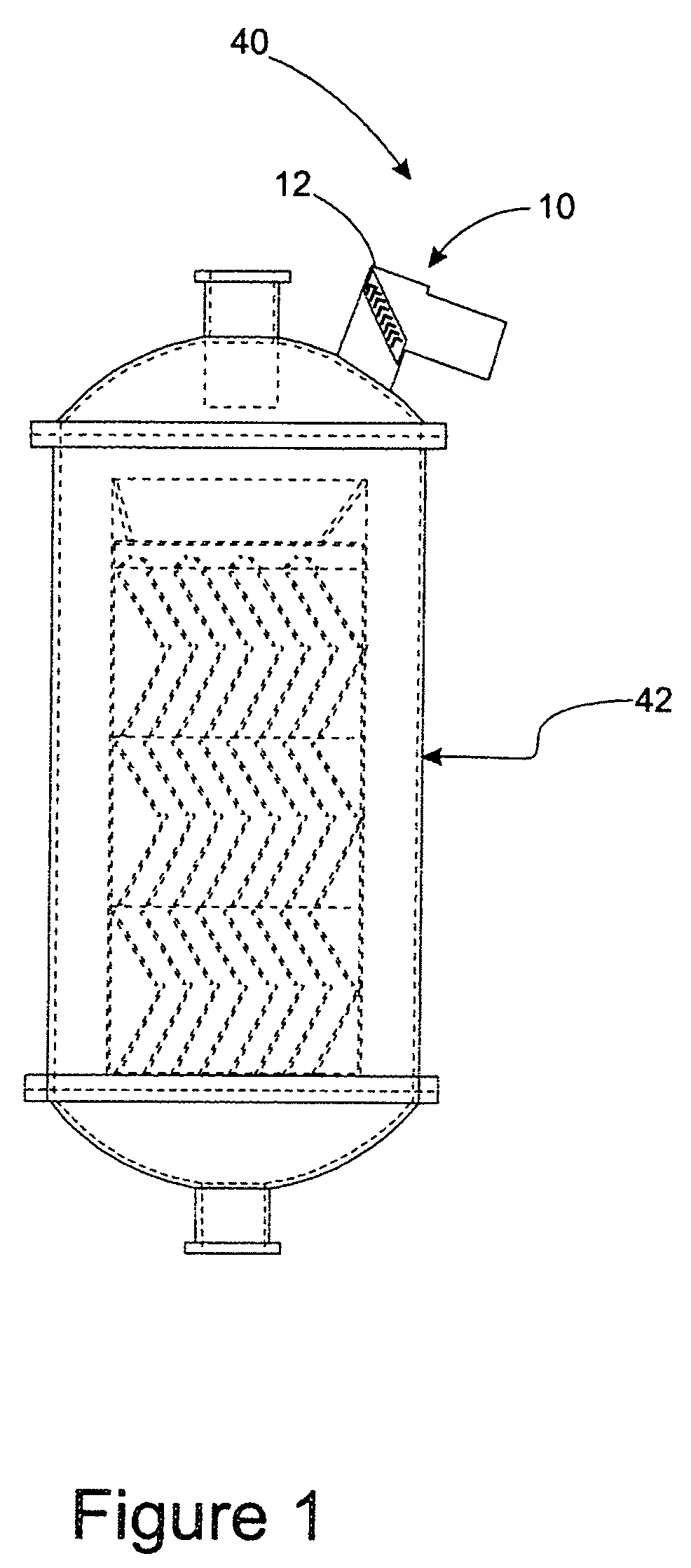

Double-Walled Dry Heat Exchanger Coil With Single-Walled Return Bends

ActiveUS20140138050A1Guaranteed uptimeAvoid less flexibilityHeat exhanger sealing arrangementStationary tubular conduit assembliesDouble wallEngineering

A dry heat exchanger coil having a plurality of straight inner tubes connected by a plurality of return bends. The return bends are located outside of the air flow passing over the coil. The inner tubes are situated within a corresponding outer or “safety” tube. The outer tubes do not contain and are not connected to return bends, but the ends of the outer tubes are located outside of the air flow path. Leaks in the inner tubes are captured by the outer tubes and the leaking fluid will flow in the space between the inner and outer tubes, flow out the end of the outer tube, to be captured in a drip pan at the bottom of the coil housing. Leaks occurring in the return bends will also be captured in drip pan.

Owner:EVAPCO

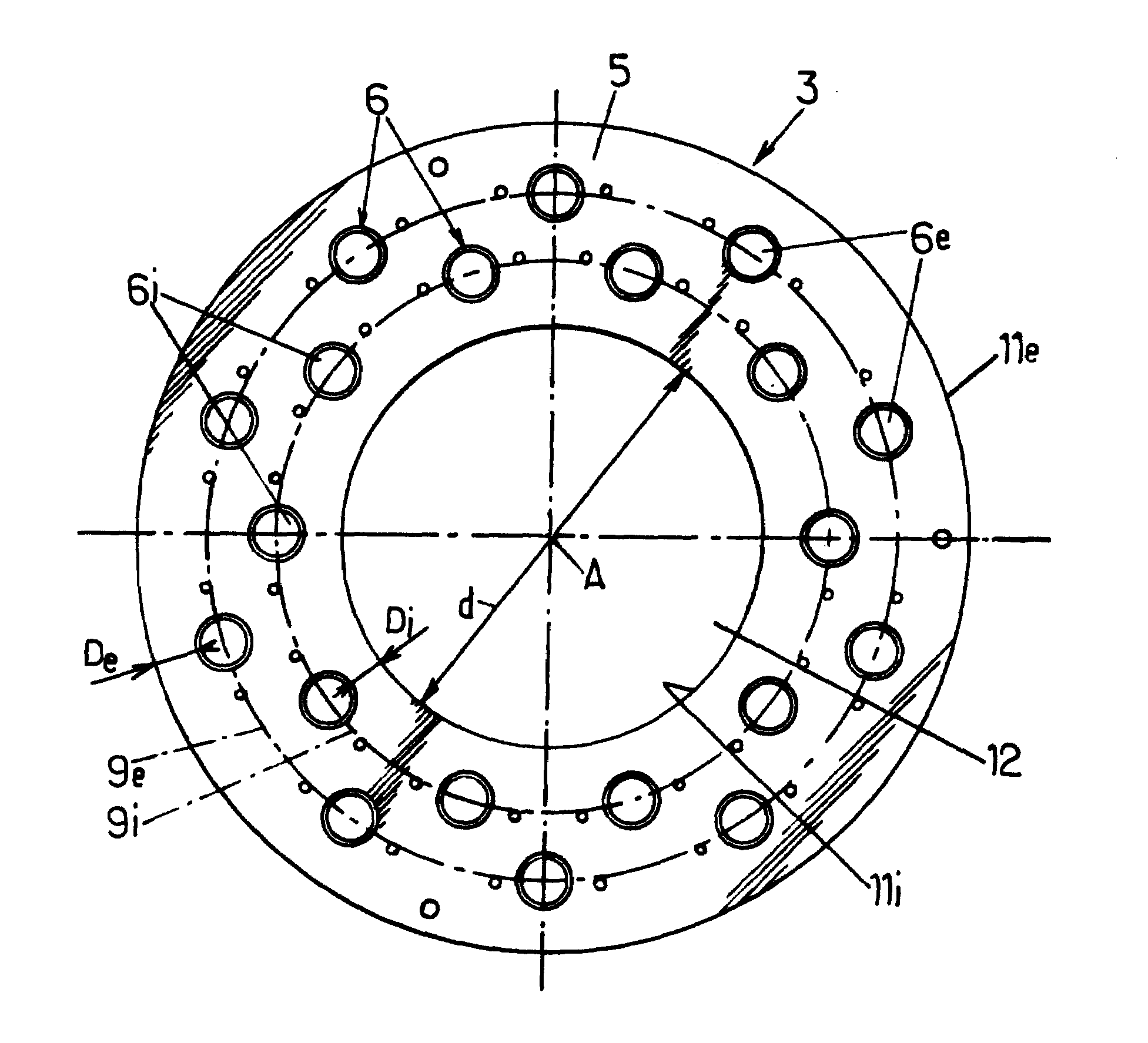

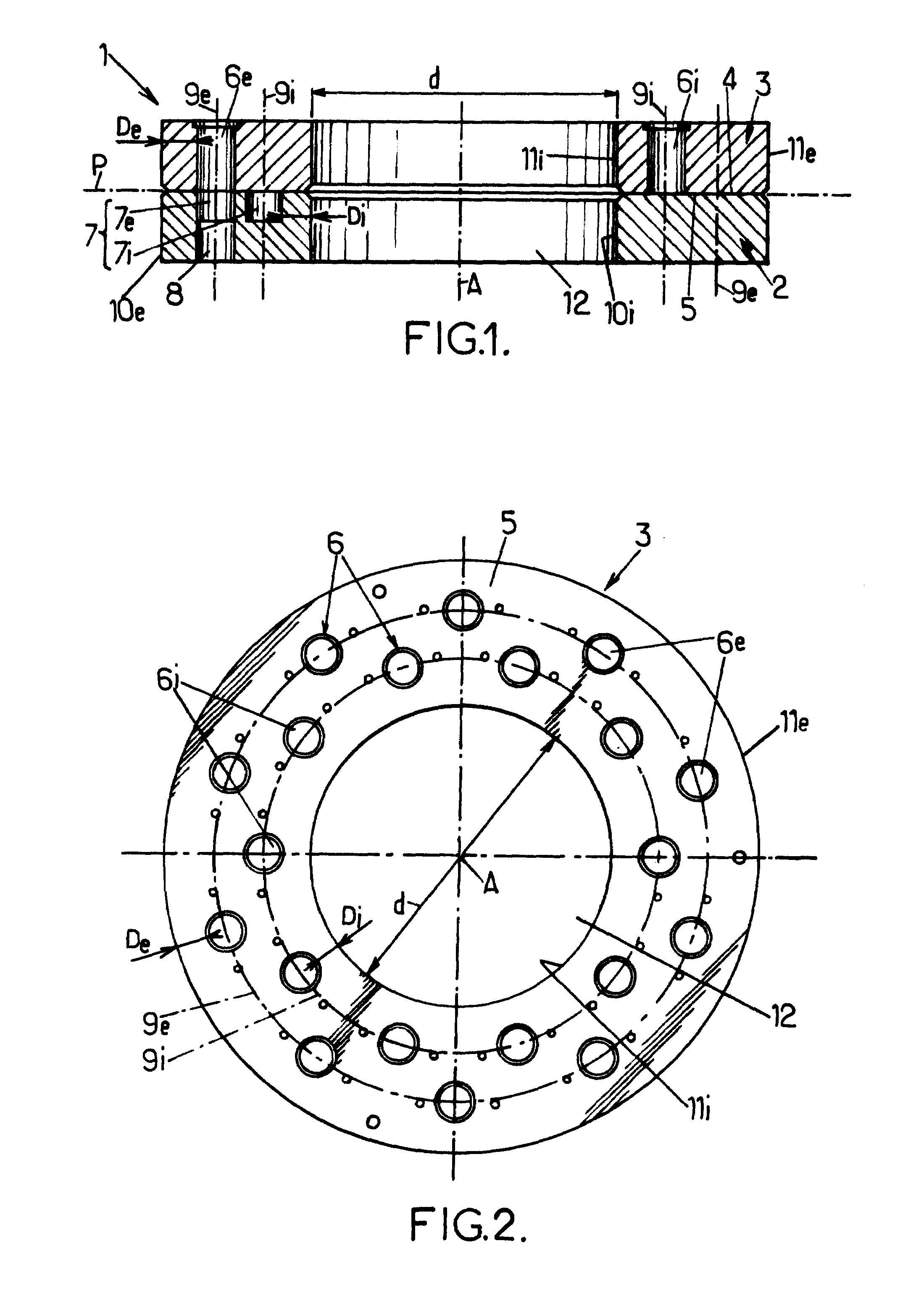

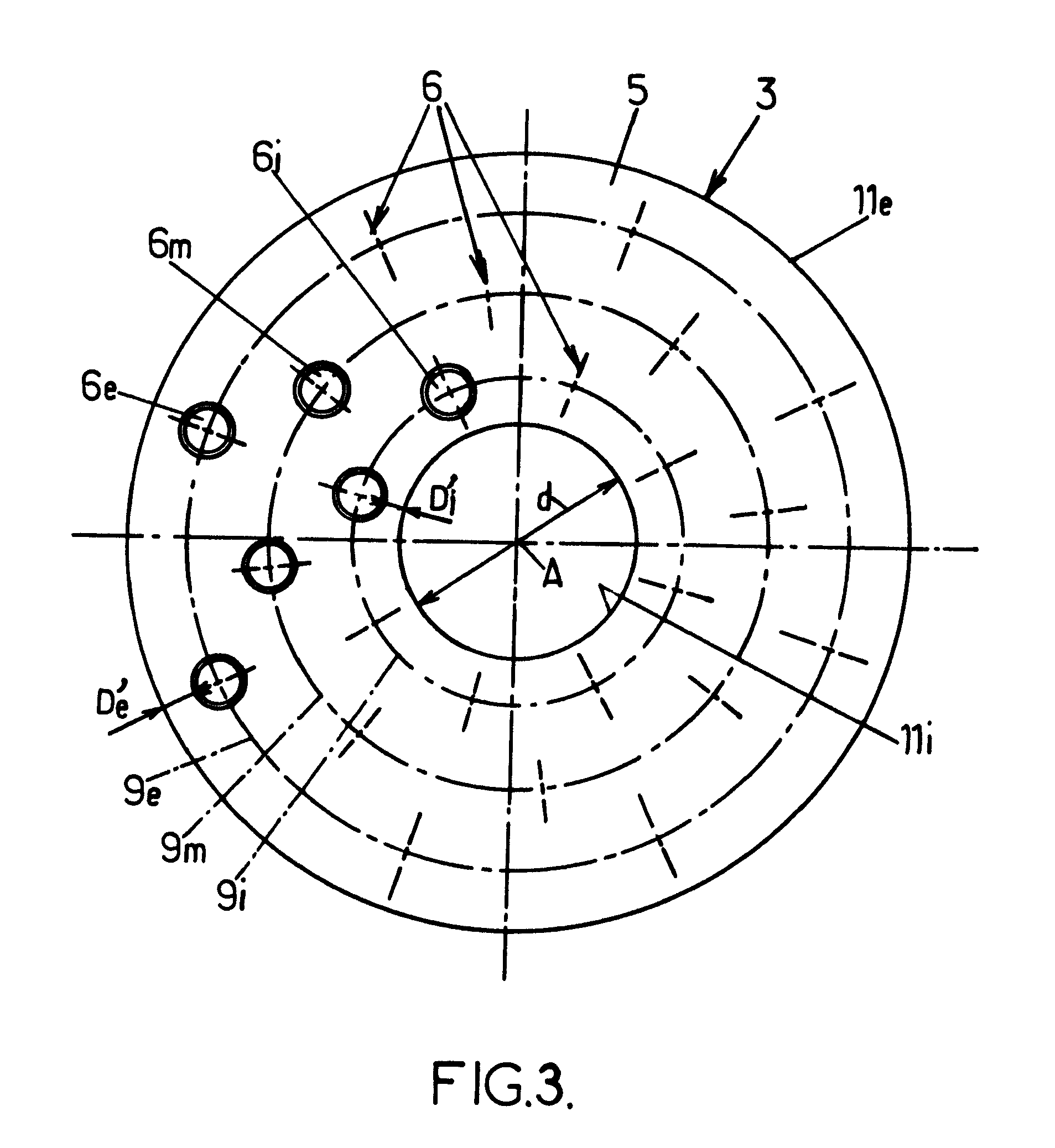

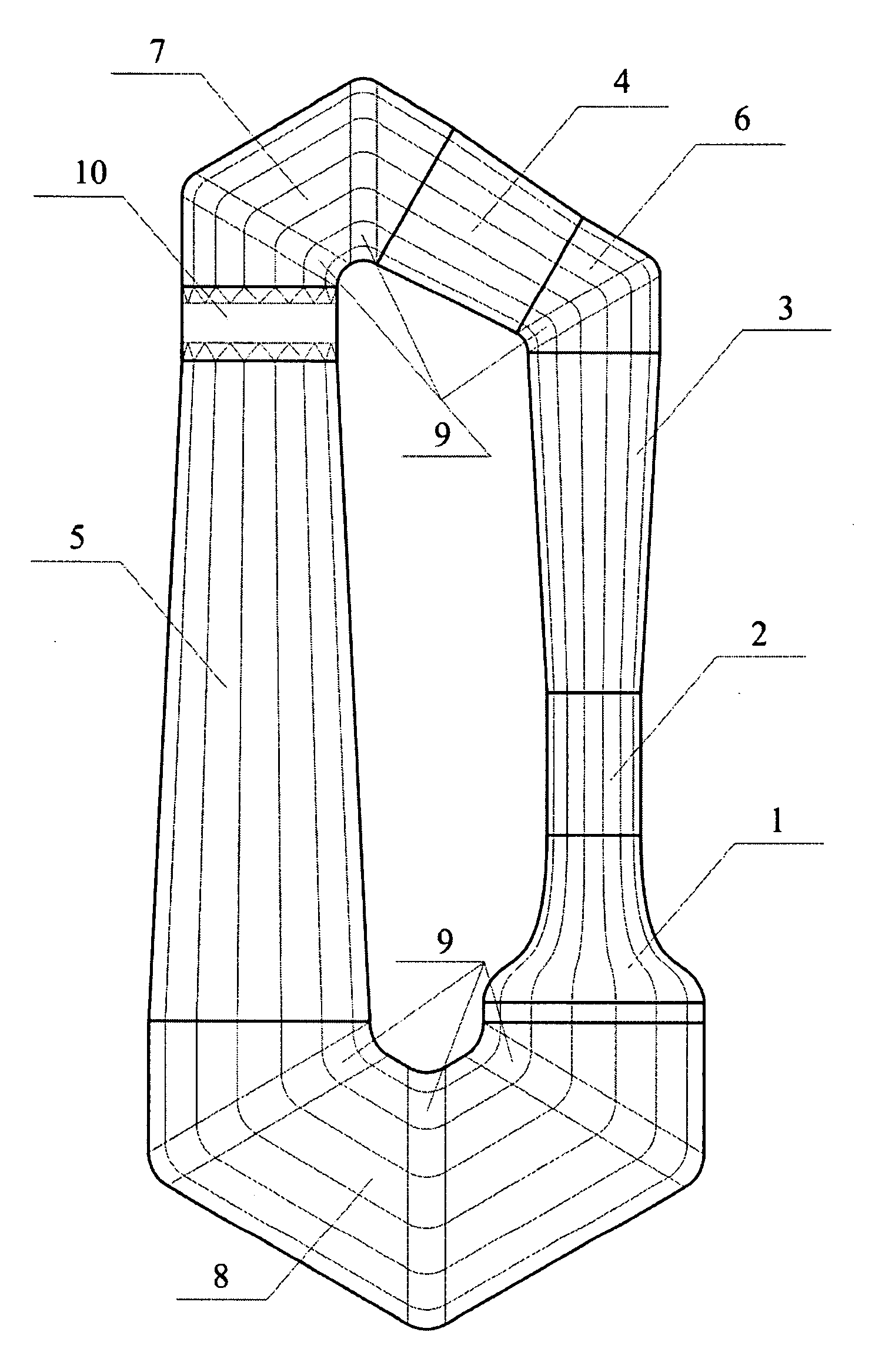

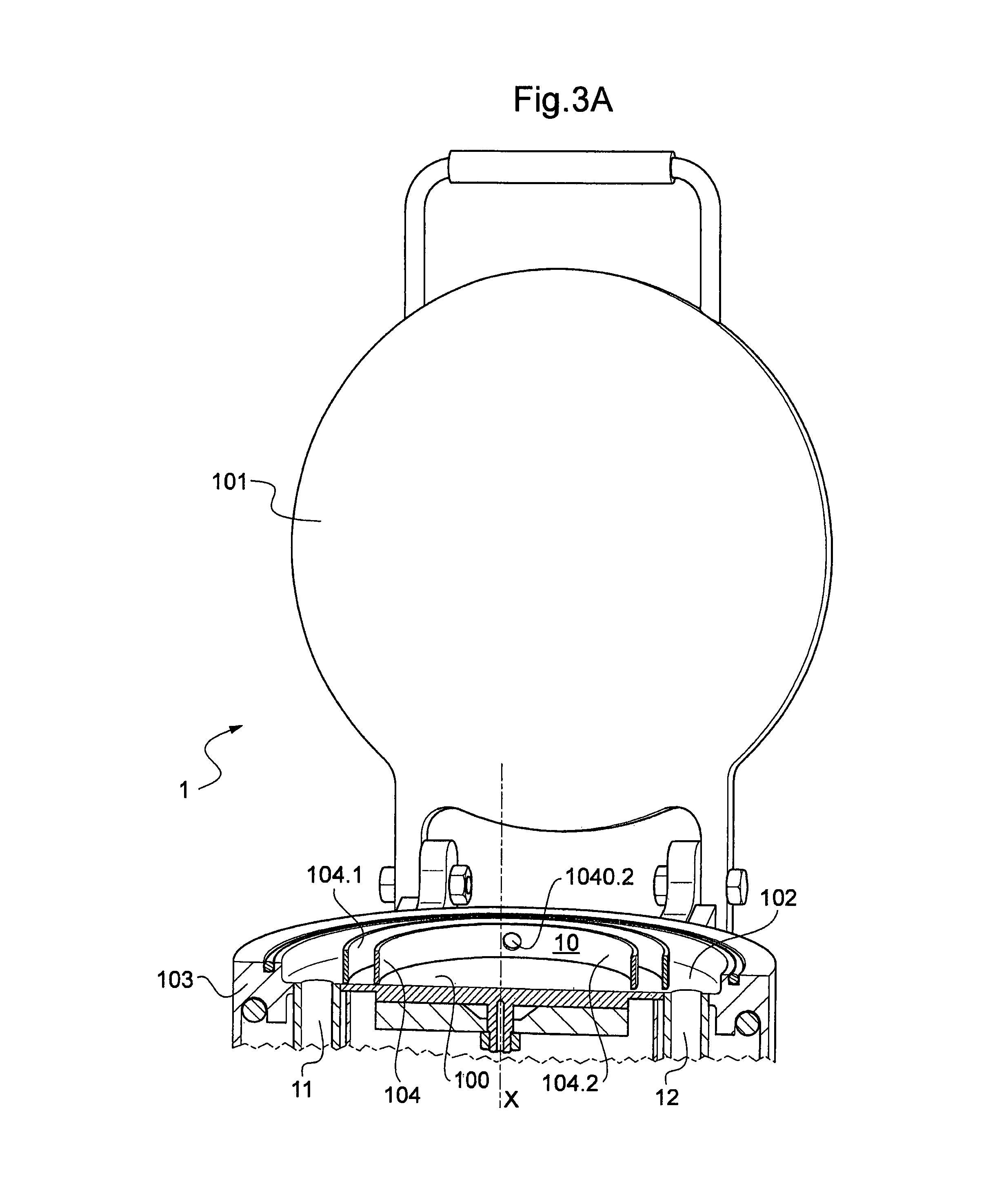

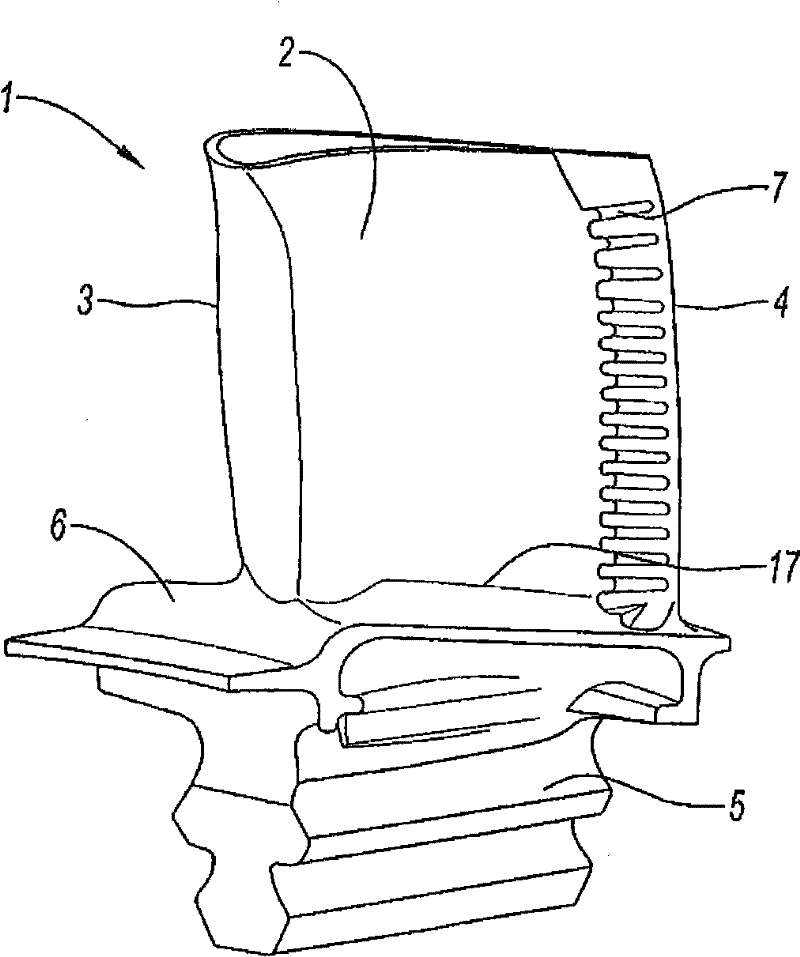

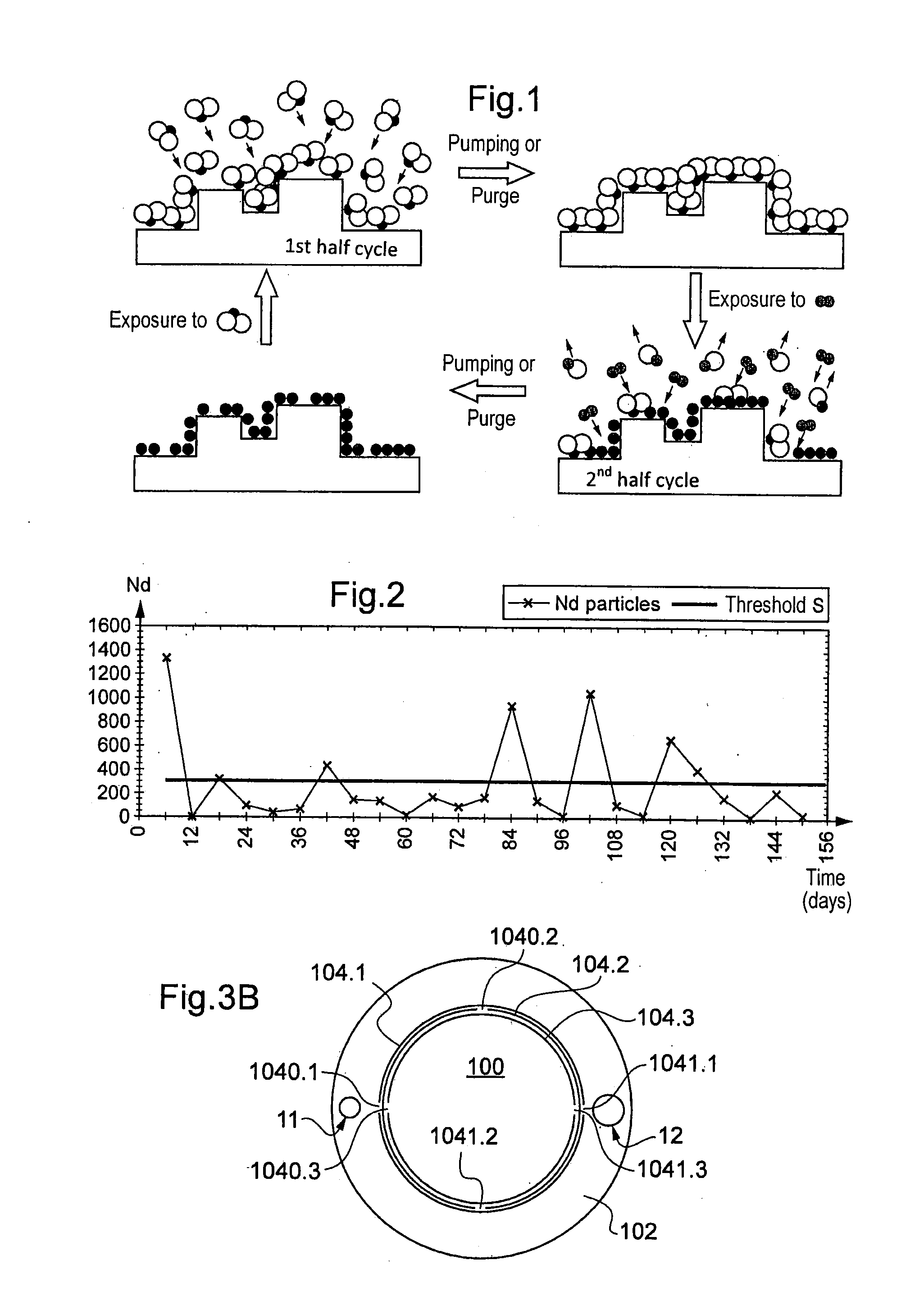

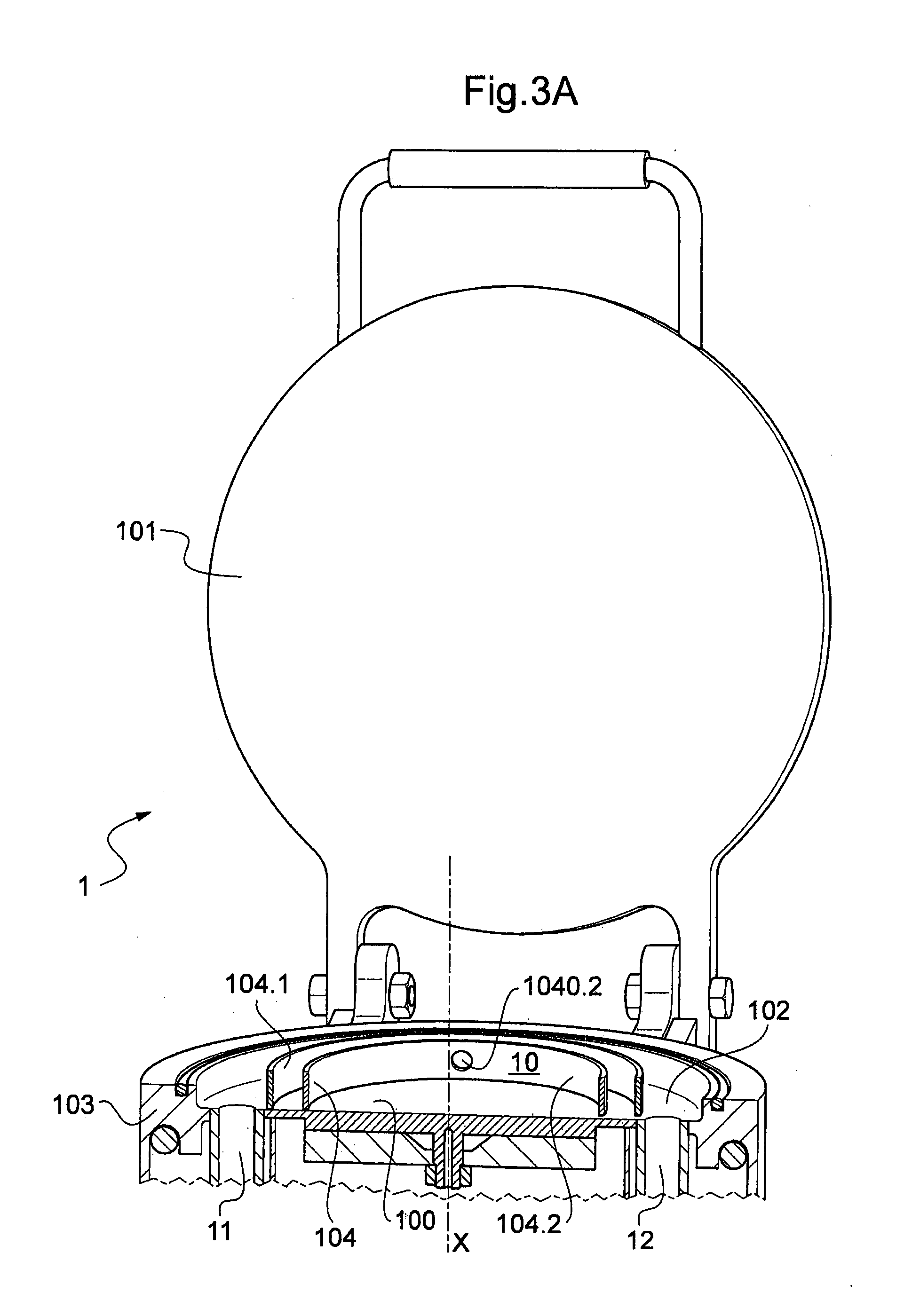

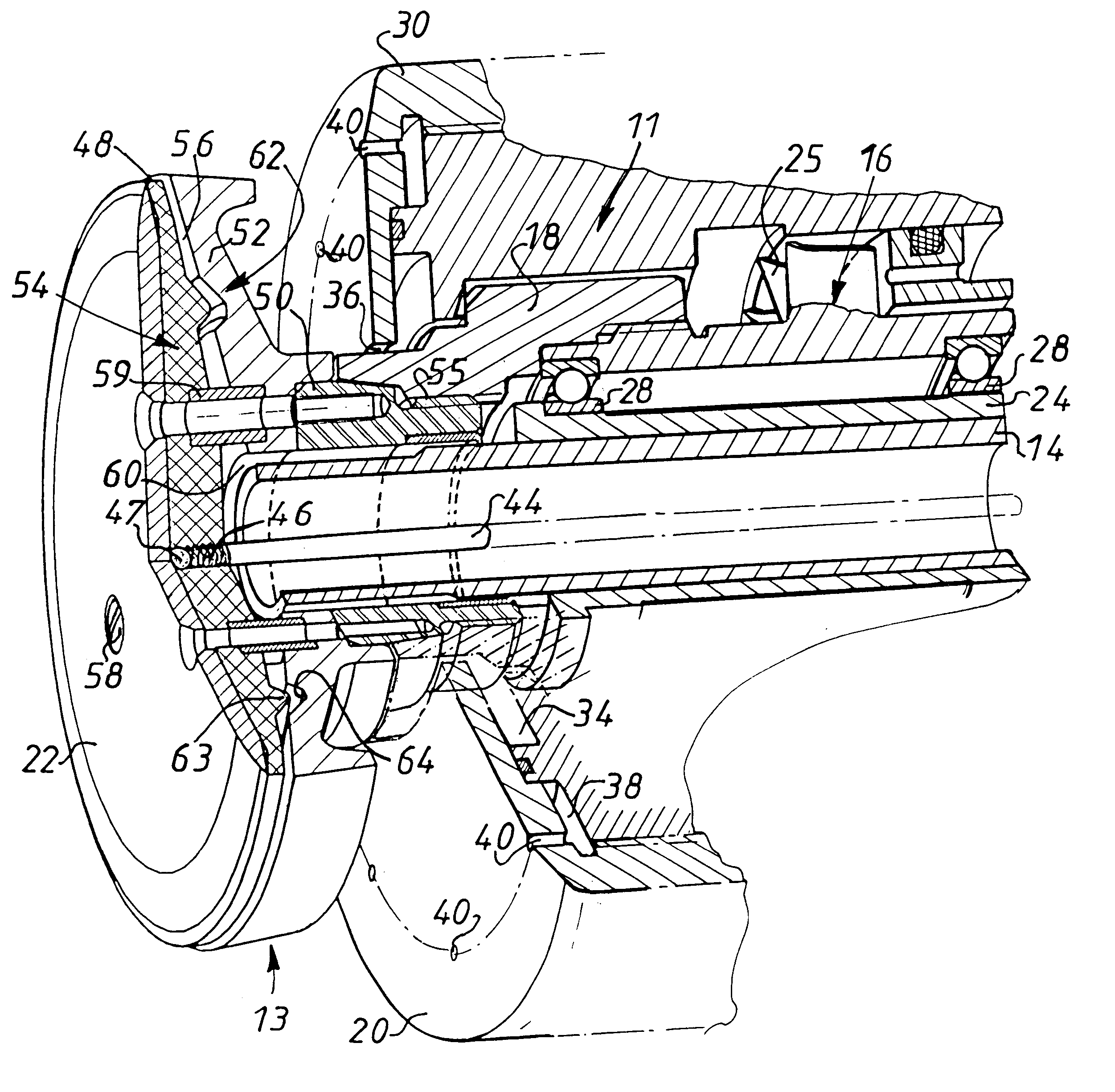

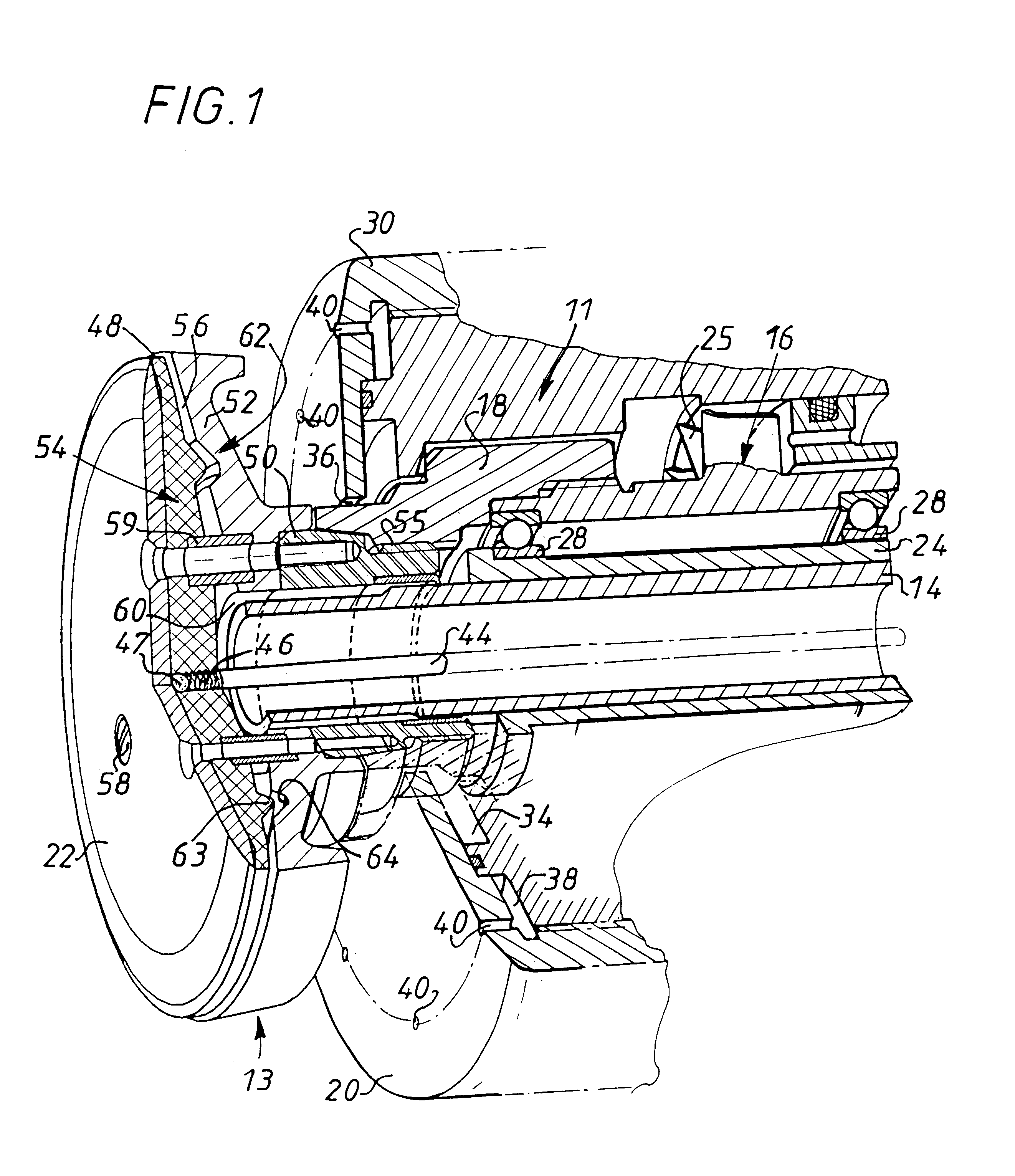

Rotating pressure distributor and carousel-type machine for treating hollow bodies which is equipped therewith

InactiveUS20080087222A1Manufacturing cost is increasedConvenient ArrangementLiquid surface applicatorsEngine sealsEngineeringDistributor

Rotating pressure distributor (1) for a carousel-type machine for treating hollow bodies in a plurality of identical treatment stations, comprising two rings, (2) fixed and (3) rotating, in sealing contact, the ring (3) having orifices (6) each adapted for being connected to a station and opening onto the contact face (5) thereof, the ring (2) having at least one aperture (7) which may be connected to a pressure source and opening onto the contact face (4) thereof by being on the trajectory of the orifices (6); grease is spread between the contact faces (4, 5) of the two rings (2, 3) to provide the seal; at least one annular channel (13) covers the annular opening (19) of the joint plane (P) and is connected to the atmosphere; in the channel respective flanges (14) are mutually interlaced without contact with one another, forming chicanes; the channel is filled with grease.

Owner:SIDEL PARTICIPATIONS SAS

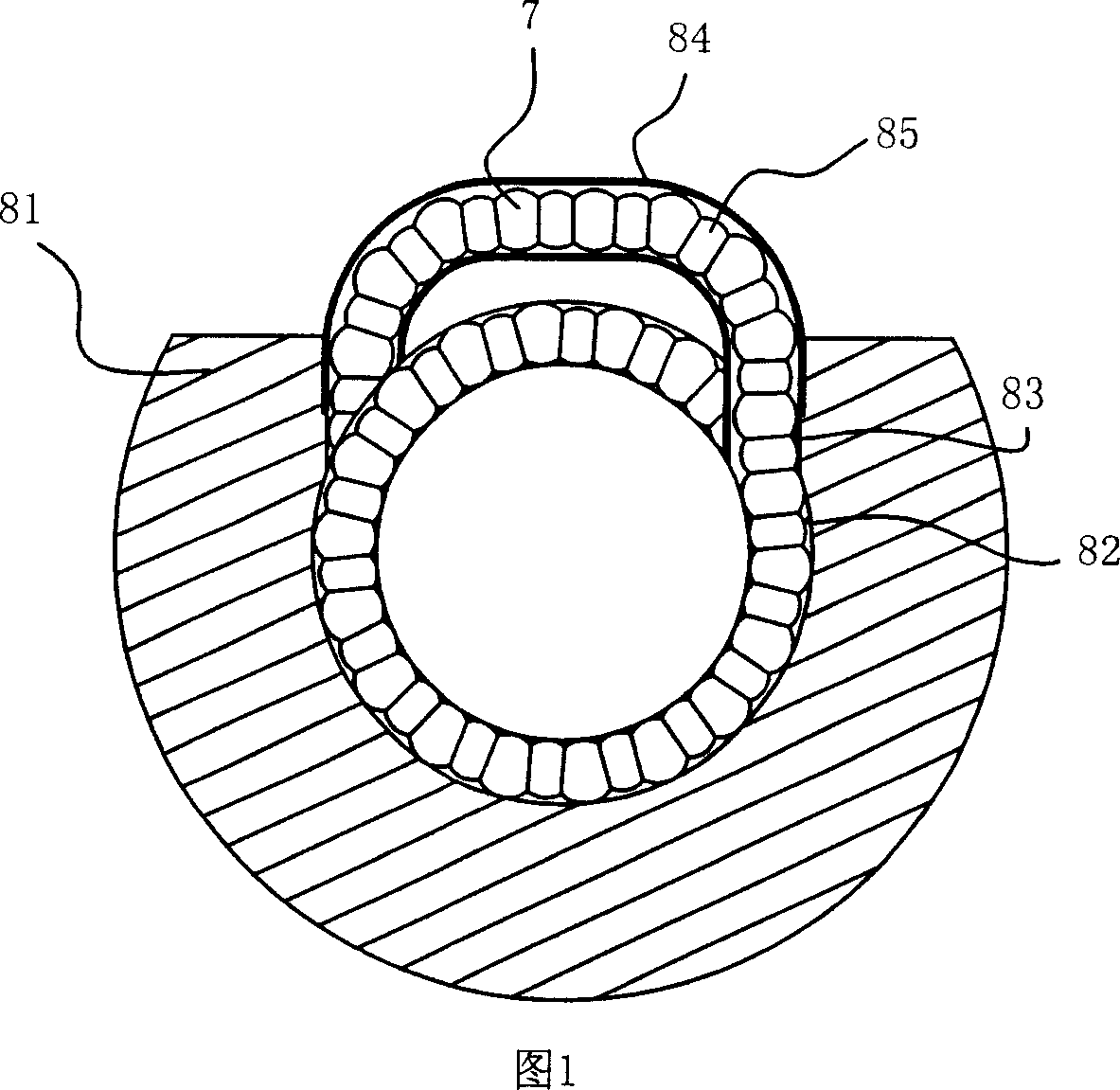

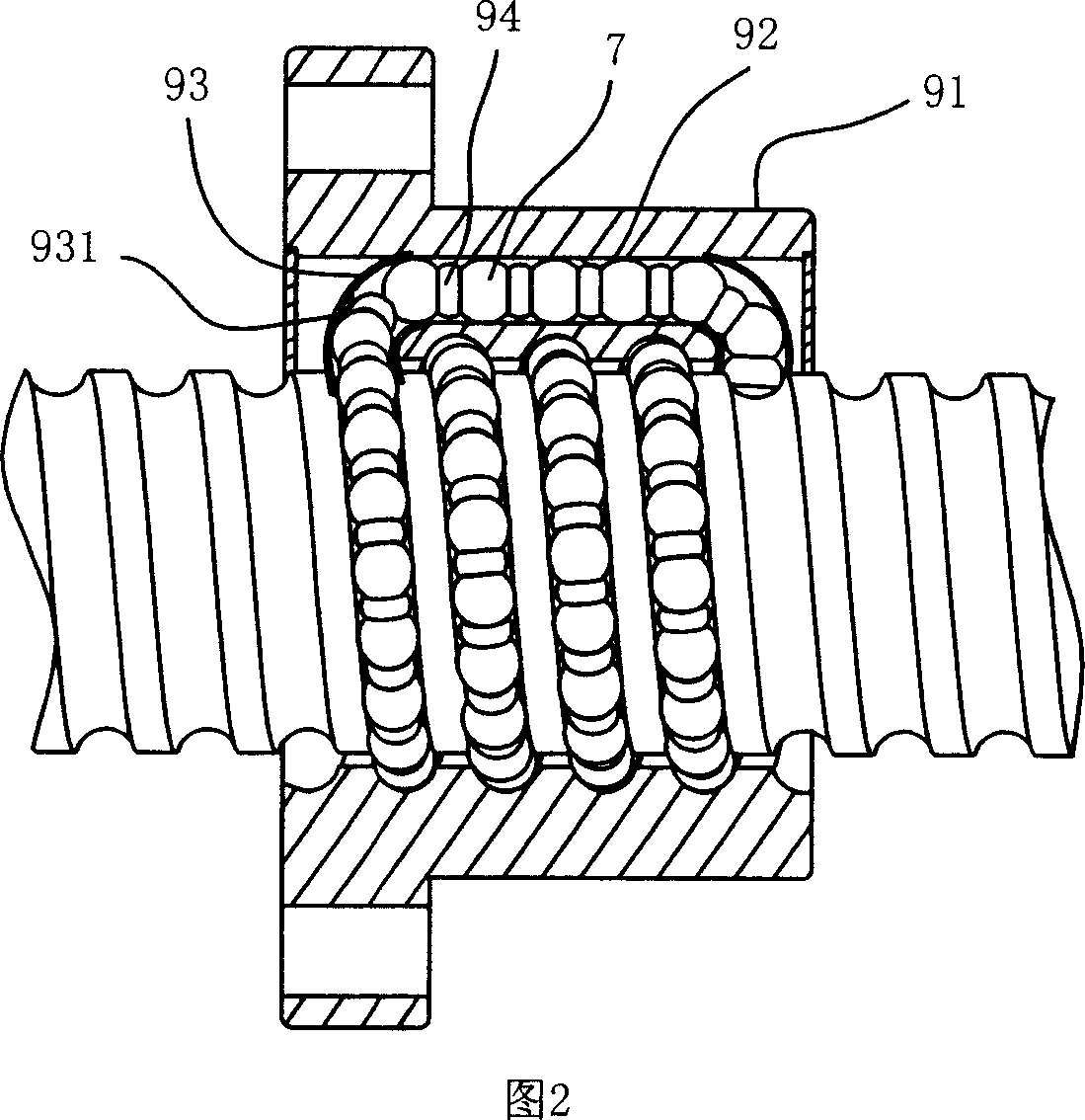

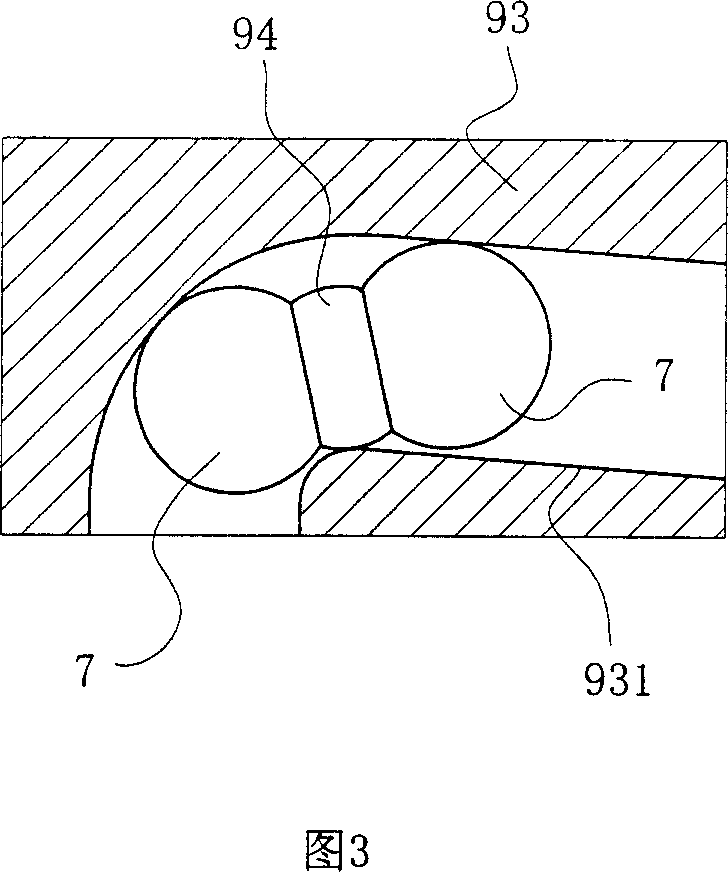

Return way structure of ball screw

The return way structure of ball screw is used for connecting the screw groove of screw nut and return flow hole so as to constitute one path for balls and distance pieces to circulate. Each of the distance pieces in shifting is held by two balls, so that the distance piece in the curved return flow path will be extruded inwards. The present invention shifts the circle center of the inner ace line in the curved return flow path outwards and increases its curvature radius to reduce curving degree, so that the distance piece extruded inwards will not collide with the inner guide surface in the curved return flow path for fluently passing through.

Owner:HIWIN TECH

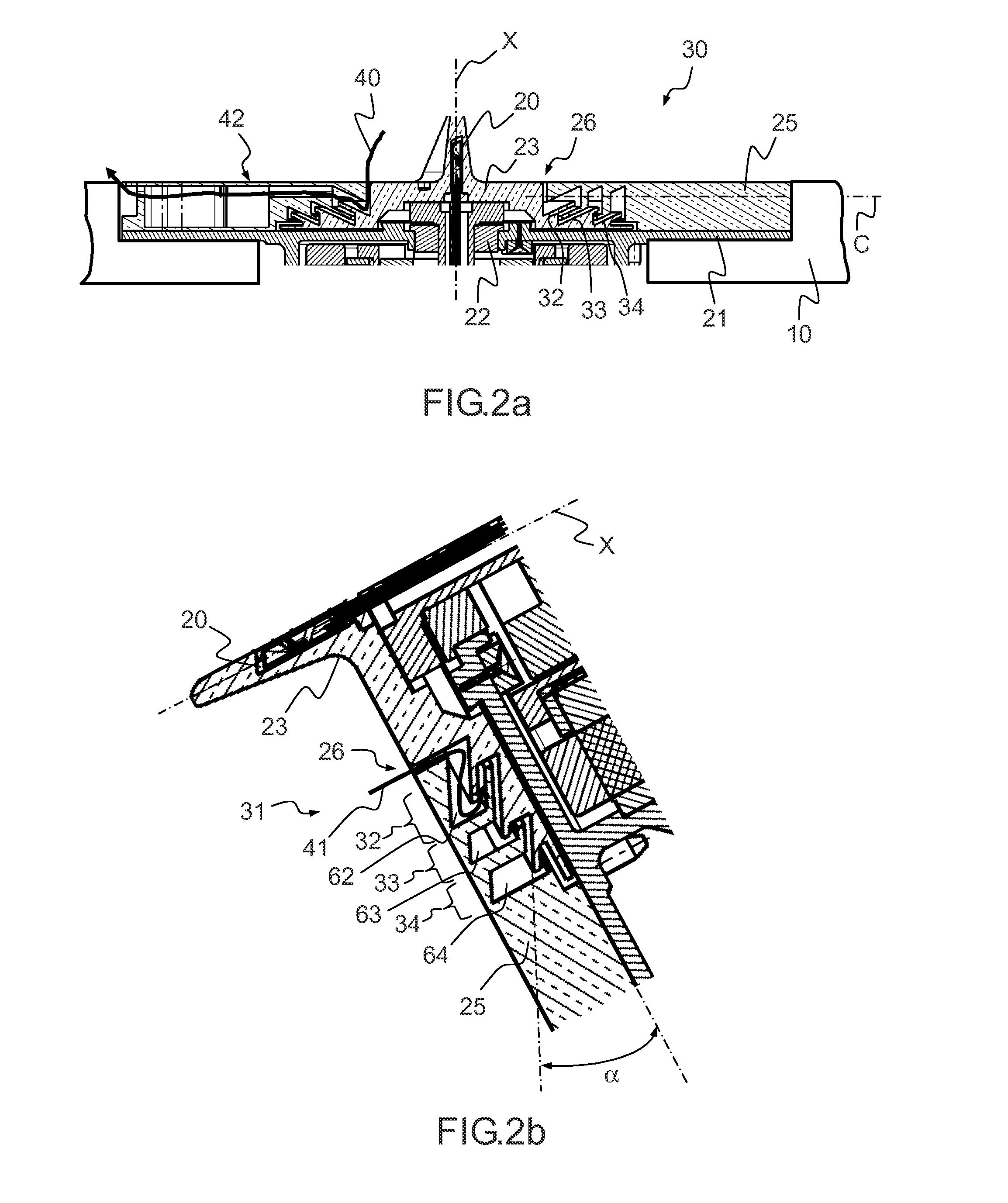

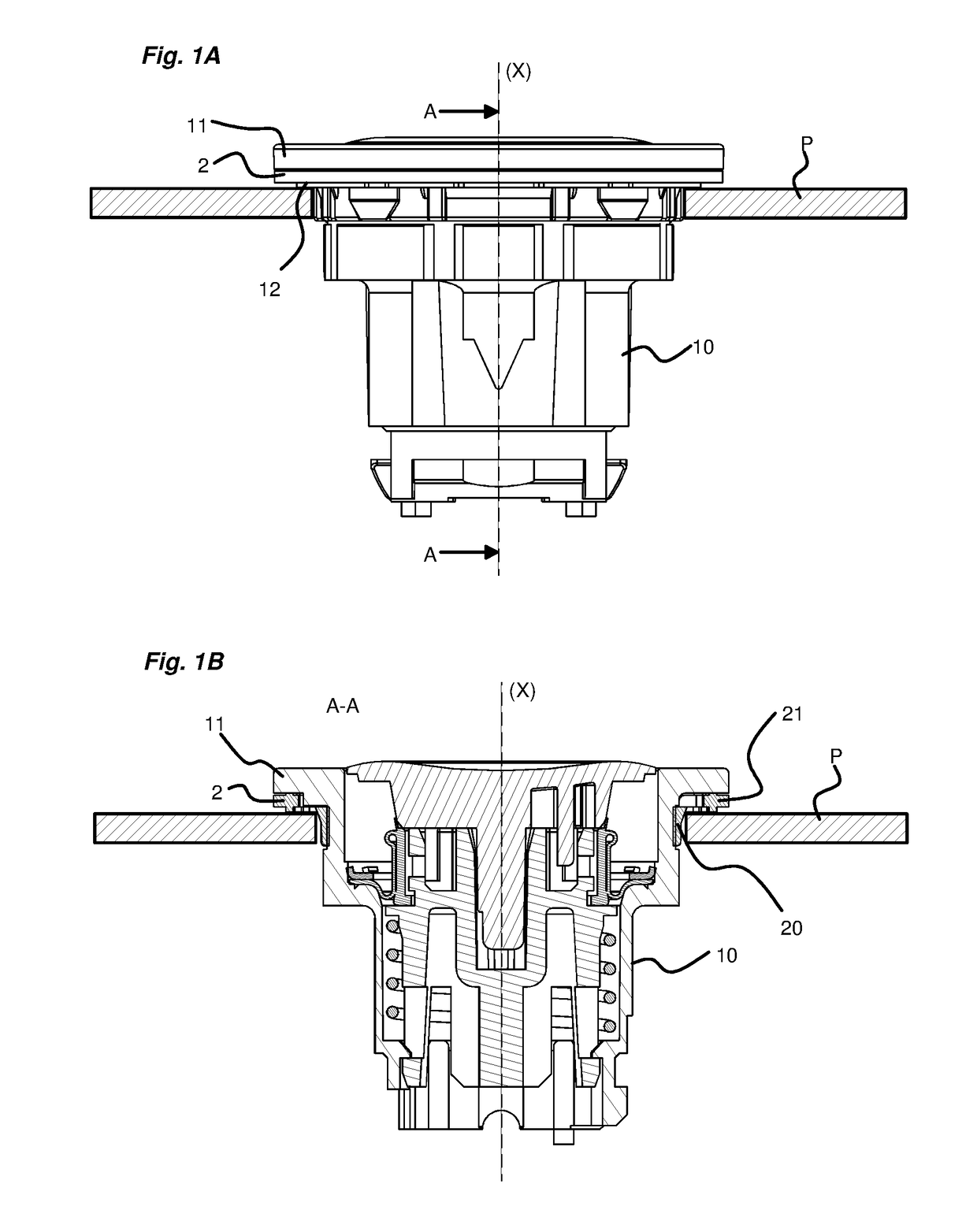

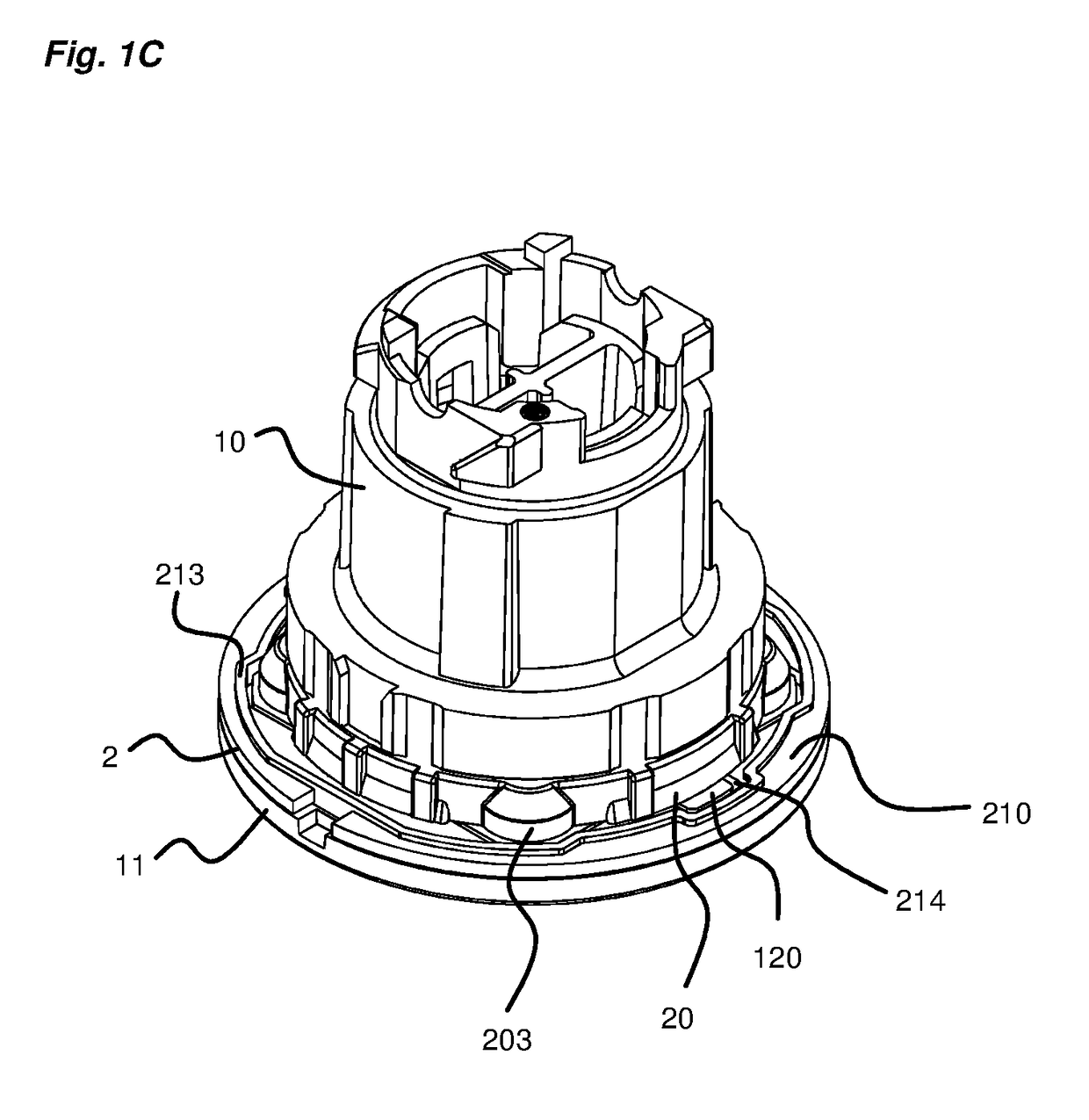

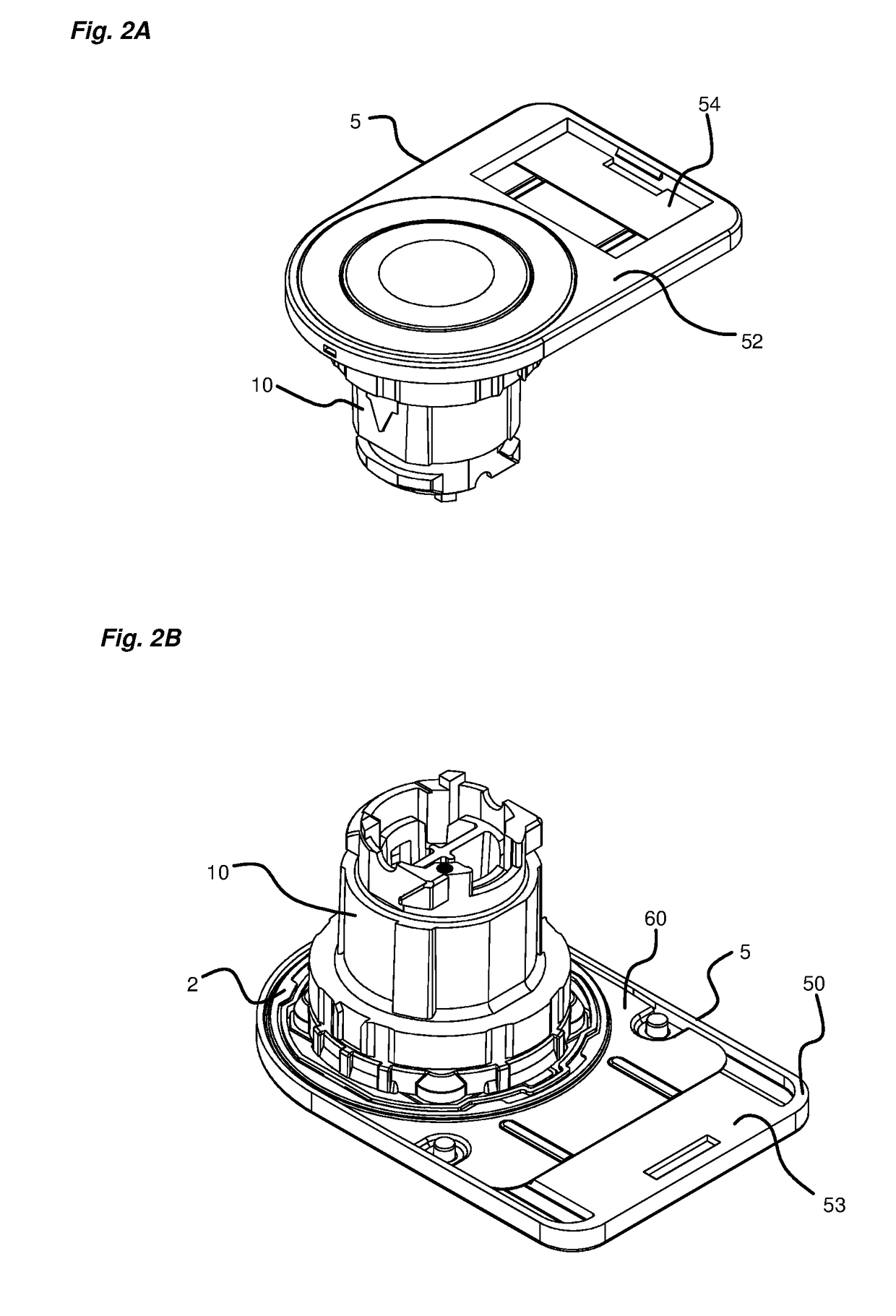

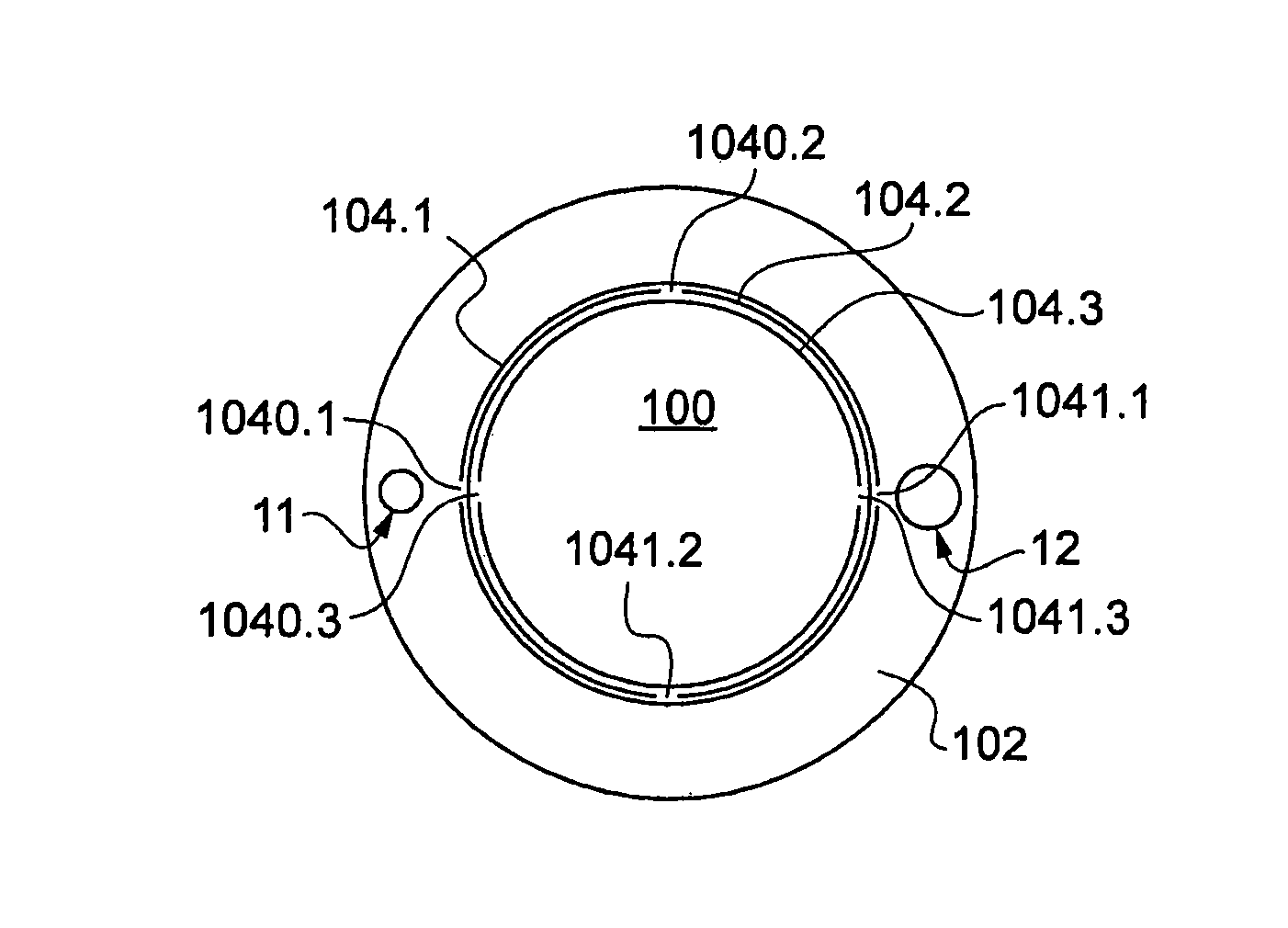

Sealing device for a human-machine dialogue element

ActiveUS20190088422A1Reduce the overall heightEngine sealsContact operating partsChicaneMechanical engineering

A sealing device for a human-machine dialogue element intended to be fixed through a wall, the device including a seal formed in a ring around an axis, the seal including a first annular edge and a second annular edge. The second edge follows a path including a plurality of chicanes so as to form at least one concave part delimiting a bearing zone on one face of the seal and at least one convex part delimiting a disengagement zone on the face of the seal to circumvent a positioning element of the seal.

Owner:SCHNEIDER ELECTRIC IND SAS

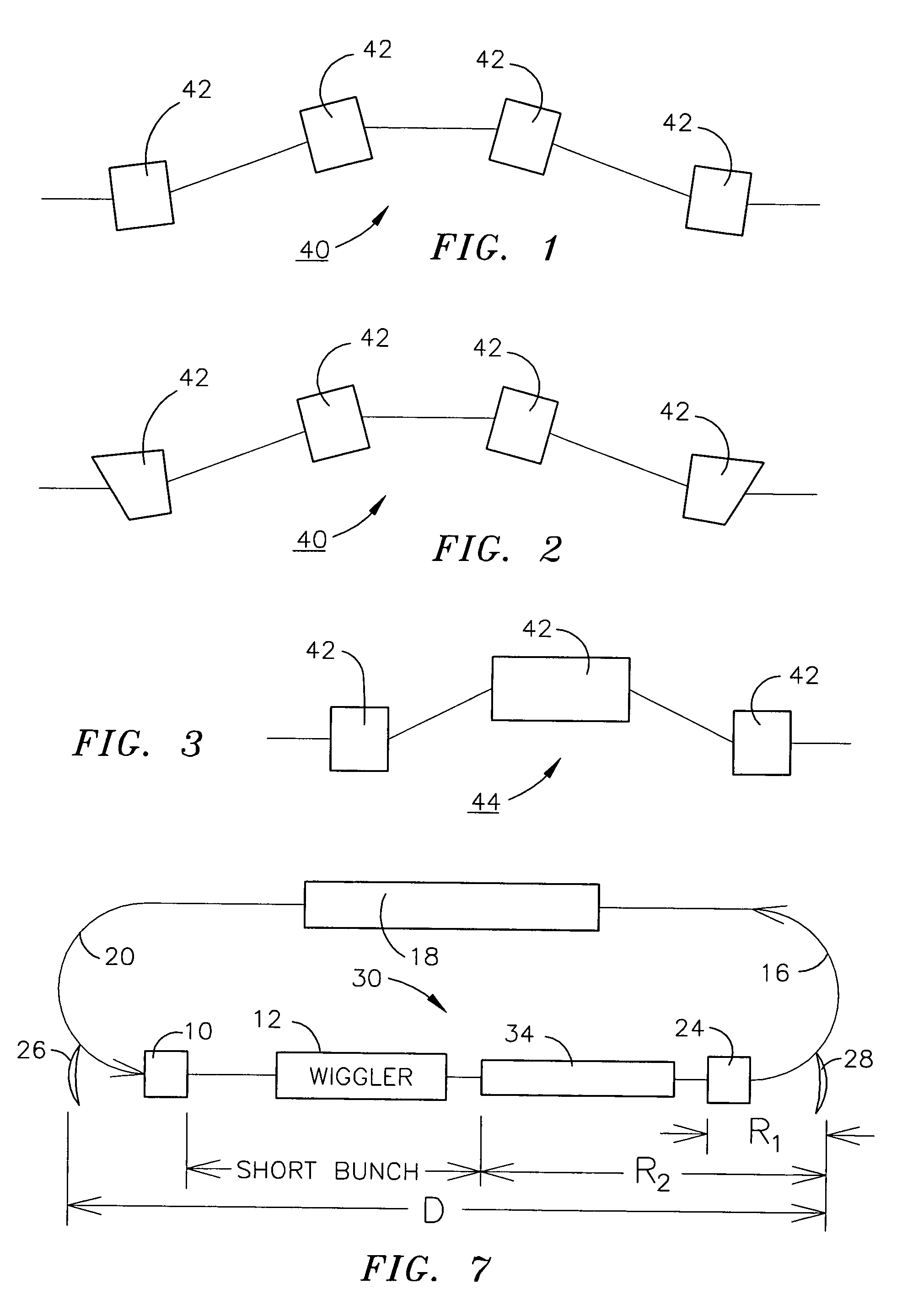

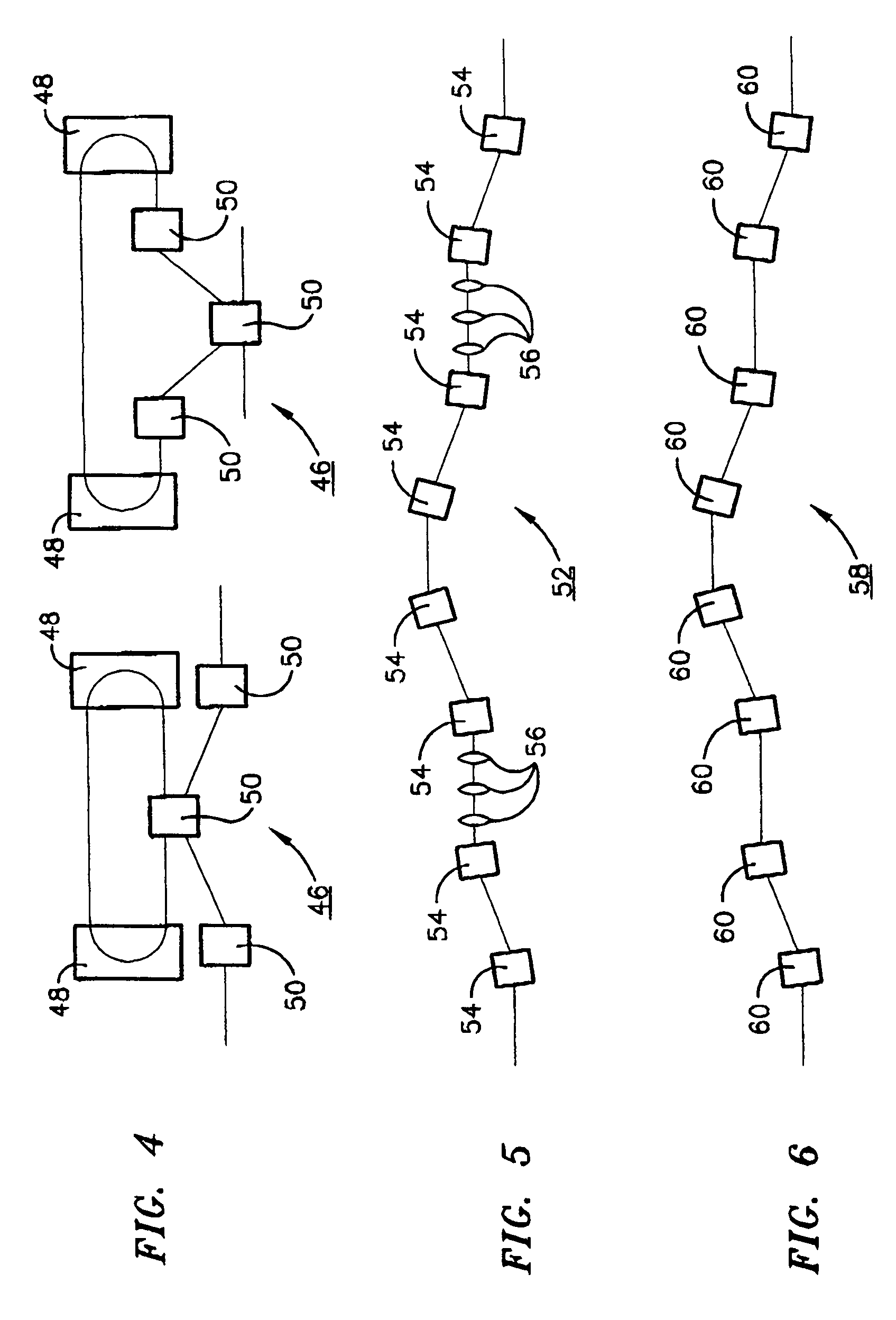

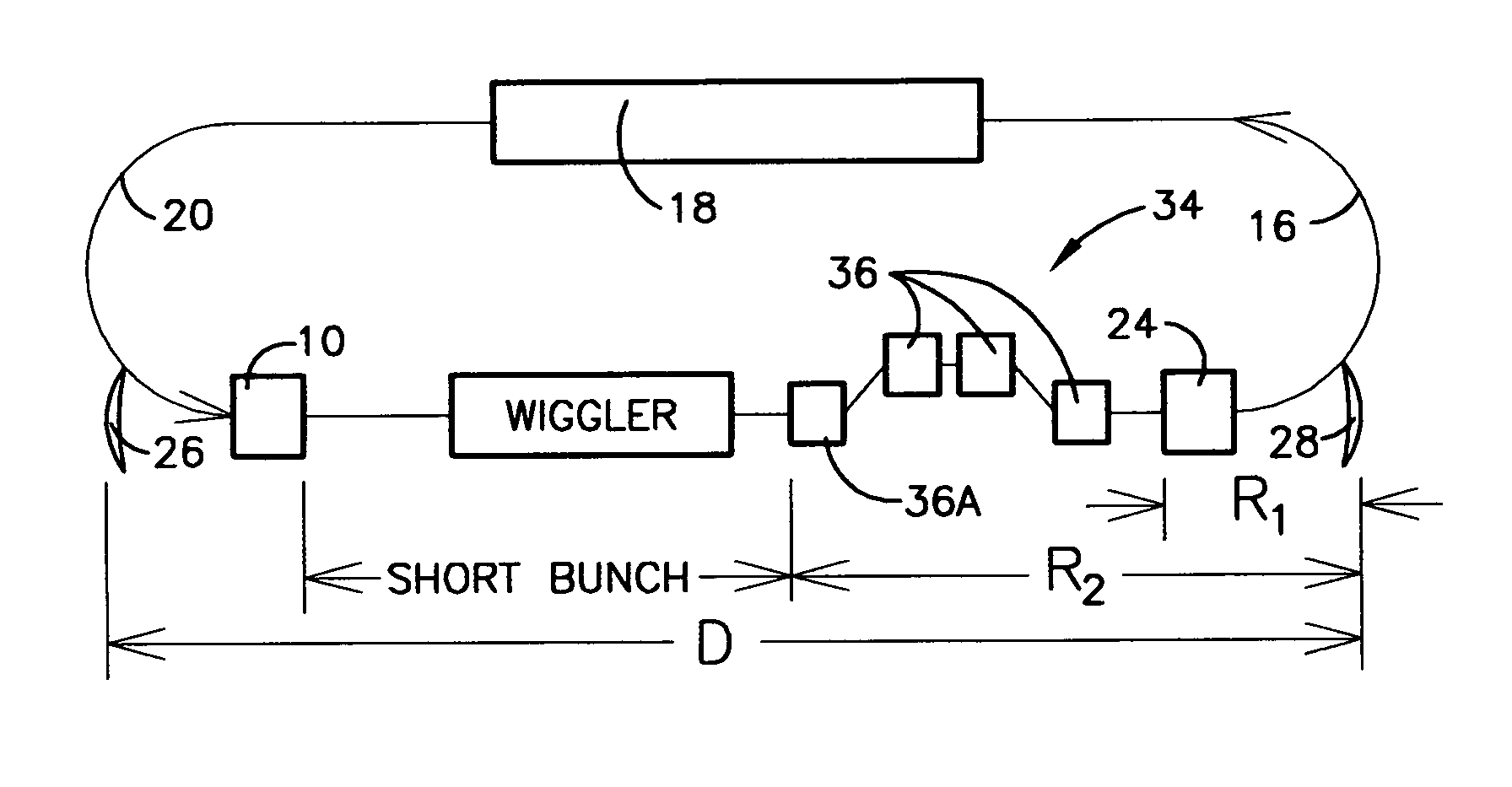

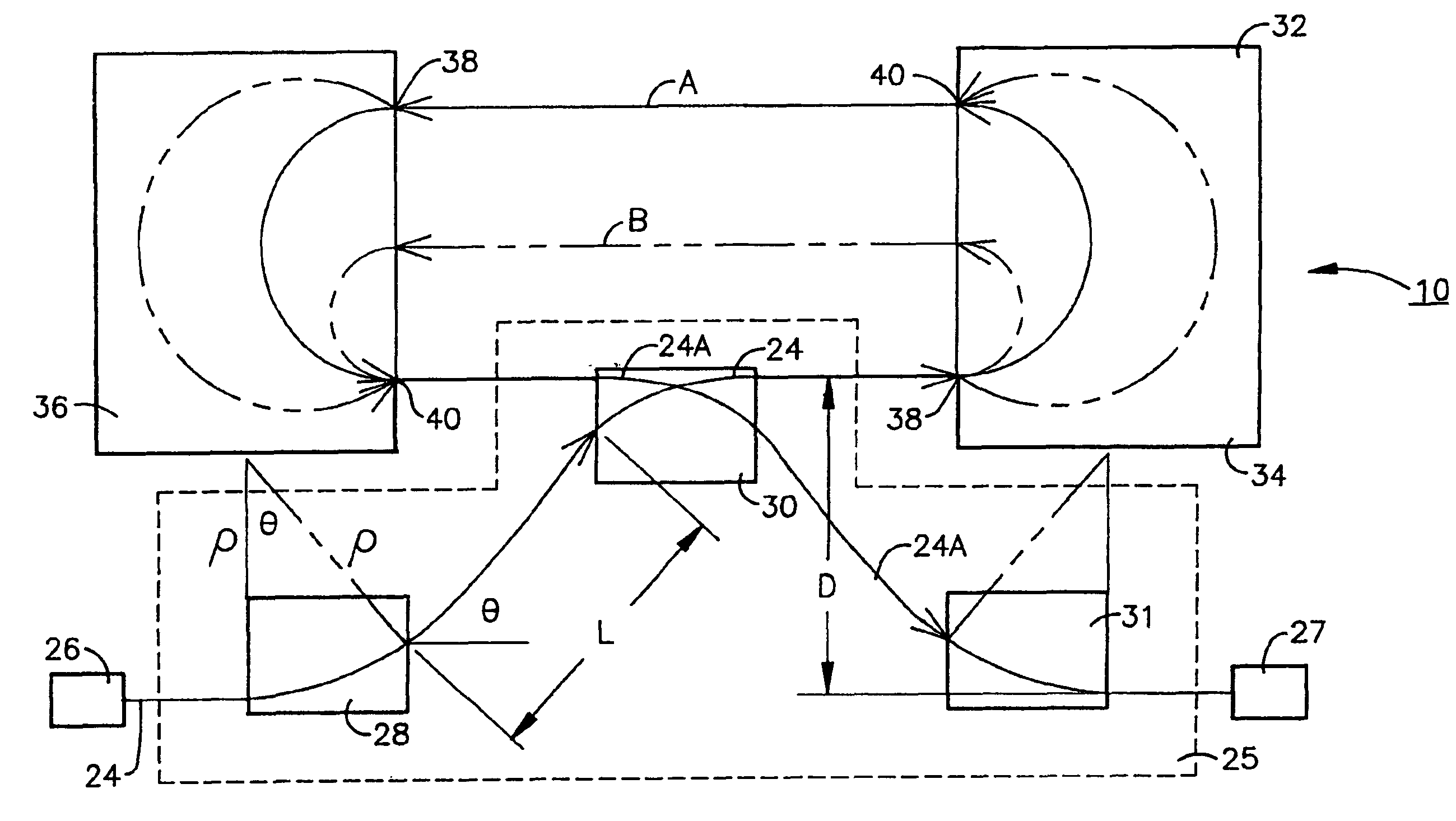

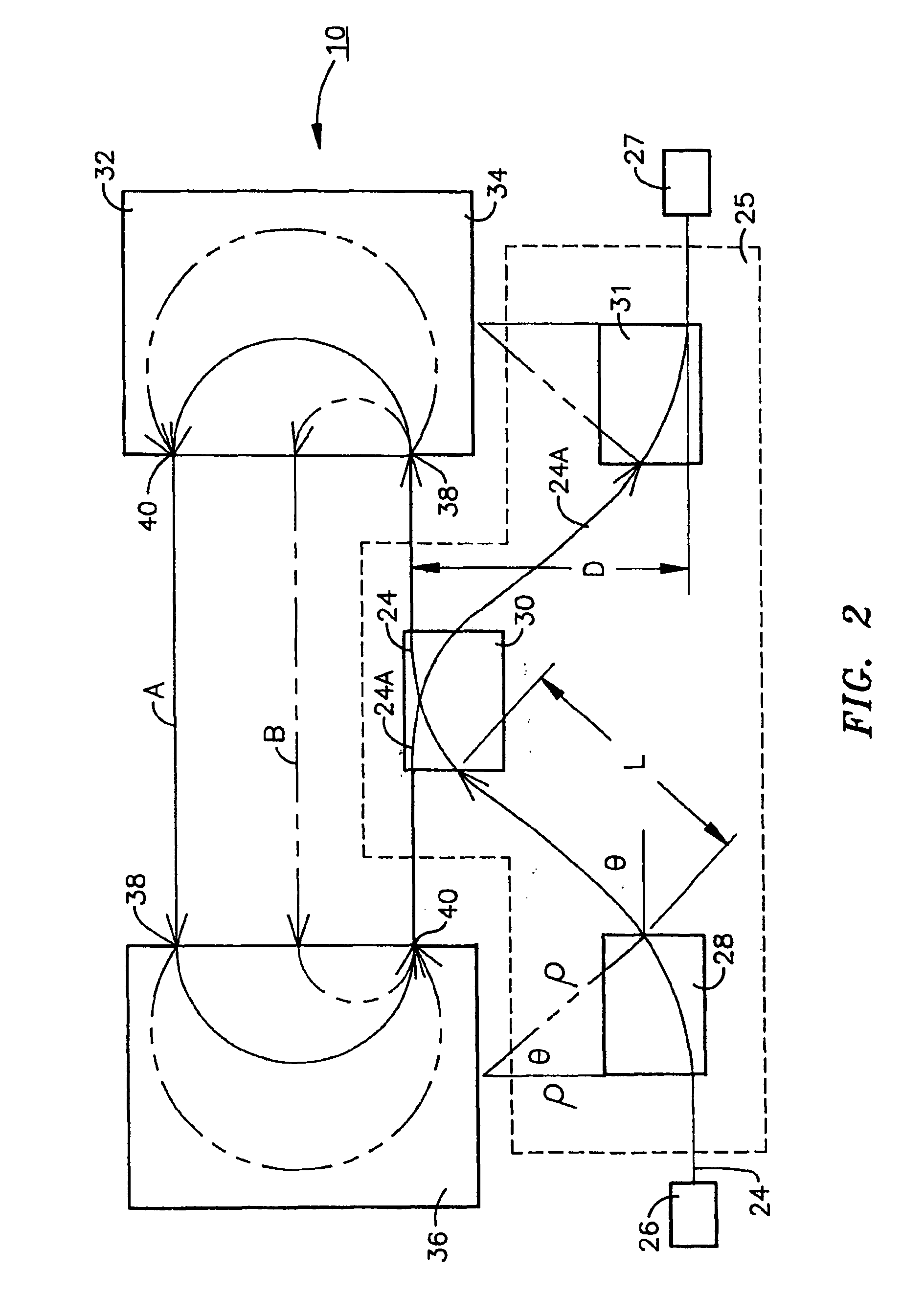

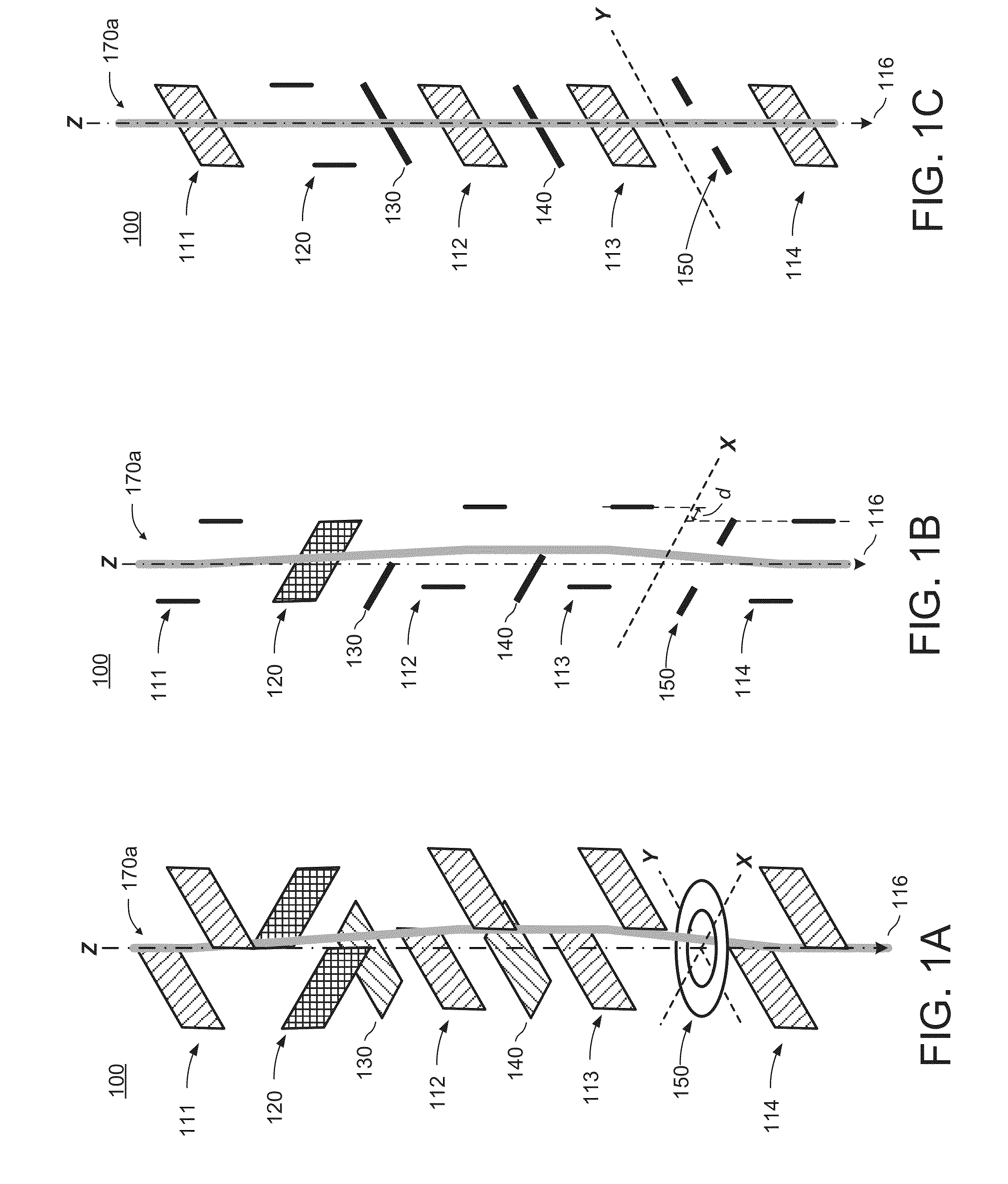

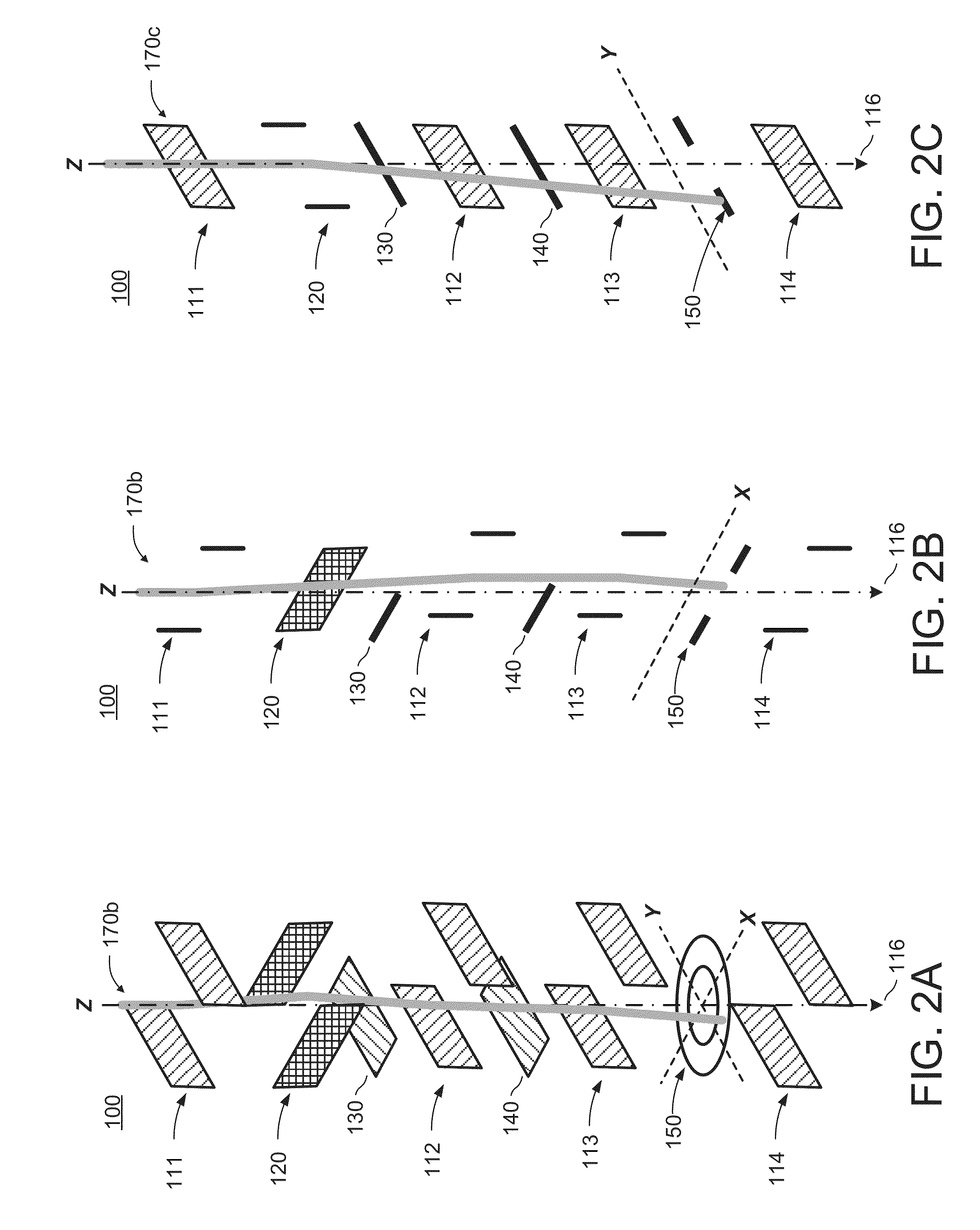

Skew chicane based betatron eigenmode exchange module

InactiveUS7858951B1Reduced footprintConsolidating the functionalities of skew-quadLaser detailsMagnetic induction acceleratorsLight beamEngineering

A skewed chicane eigenmode exchange module (SCEEM) that combines in a single beamline segment the separate functionalities of a skew quad eigenmode exchange module and a magnetic chicane. This module allows the exchange of independent betatron eigenmodes, alters electron beam orbit geometry, and provides longitudinal parameter control with dispersion management in a single beamline segment with stable betatron behavior. It thus reduces the spatial requirements for multiple beam dynamic functions, reduces required component counts and thus reduces costs, and allows the use of more compact accelerator configurations than prior art design methods.

Owner:JEFFERSON SCI ASSOCS LLC

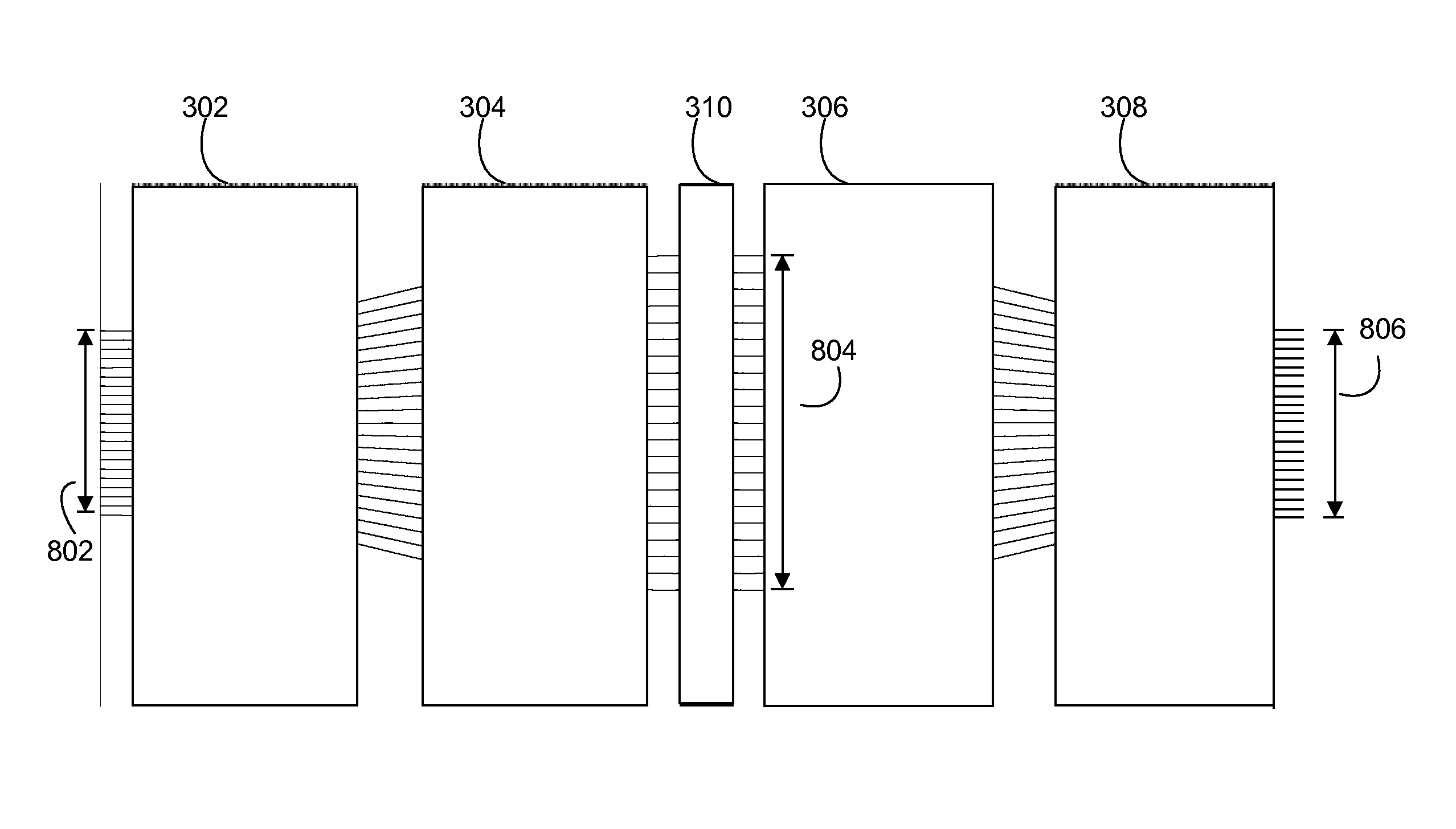

Charged particle energy filter

ActiveUS9111715B2High beam qualityImproved energy resolutionElectric discharge tubesLight beamQuadrupole

A multi-element electrostatic chicane energy filter, with the addition of electrostatic quadrupole and hexapole excitations to the dipole elements. A charged particle energy filter according to the present invention with a combination of dipole, quadrupole, and hexapole elements capable of producing a line focus at an aperture reduces space-charge effects and aperture damage. A preferred embodiment allows the filter to act as a conjugate blanking system. The energy filter is capable of narrowing the energy spread to result in a smaller beam.

Owner:FEI CO

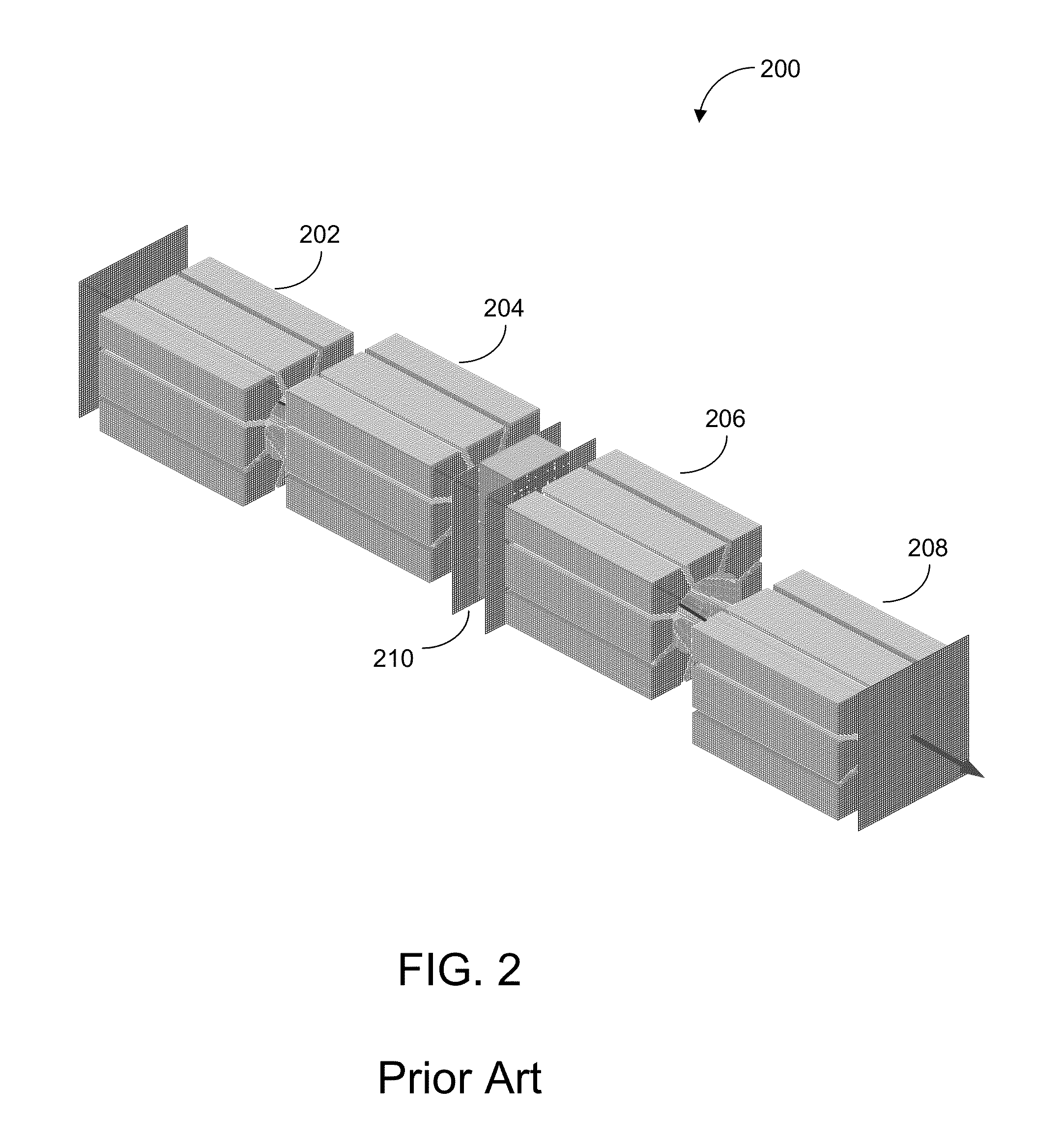

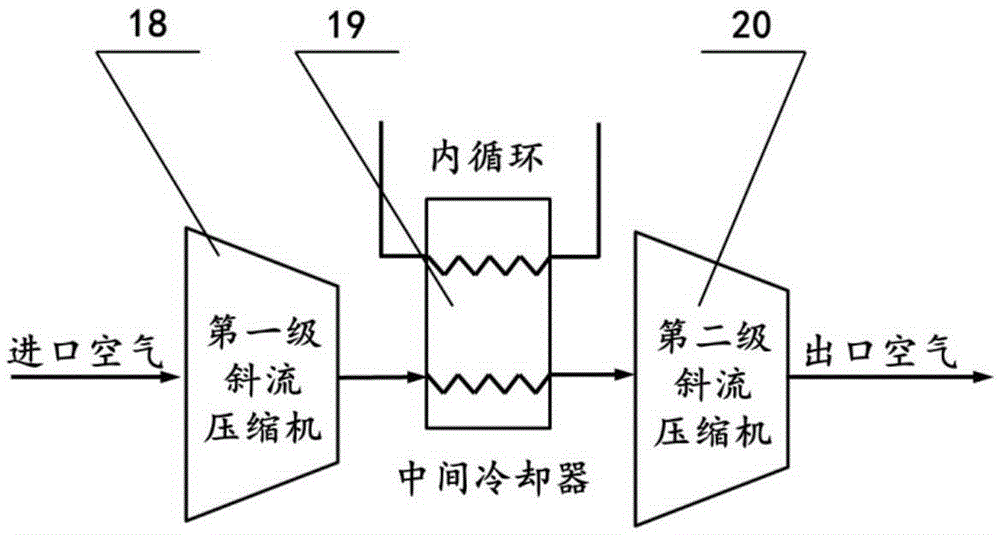

Two-stage mass-flow oblique flow compressor with stage intercooling

ActiveCN105275853AMeet needsOvercome first-level design difficultiesPump componentsPump installationsOff designEngineering

The invention discloses a two-stage mass-flow oblique flow compressor with stage intercooling. The two-stage mass-flow oblique flow compressor comprises two stages of oblique flow compressor bodies, and an interstage cooler is connected between the stages. The two-stage mass-flow oblique flow compressor is characterized in that an oblique flow impeller with obvious axial characteristic at the front end and the blade top large curvature characteristic at the back end is matched with an inlet gradually-decreased type curve vaneless diffuser to improve the performance of the first stage of impeller, and the requirement of the mass-flow compressor is met; and meanwhile, in the second stage, the oblique flow impeller and the oblique flow vaneless diffuser are adopted for improving the off-design performance of the impeller. The two-stage mass-flow oblique flow compressor has the beneficial effects of being large in flow, saving in power dissipation, high in efficiency, simple and compact in structure and the like; the problems that when a multi-stage centrifugal compressor structure is adopted in an existing extra-large and oversized order air separation set, the design difficulty is too large, and the performance is bad are solved, the problems that when a multi-stage axial flow and centrifugal compressor is adopted, the structure is complex, and the reliability is poor are solved, the performance of the second-stage compressor body can be improved, and the two-stage mass-flow oblique flow compressor is particularly suitable for the air separation set with the order ranging from 110000 Nm<3> / h to 150000 Nm<3> / h.

Owner:XI AN JIAOTONG UNIV

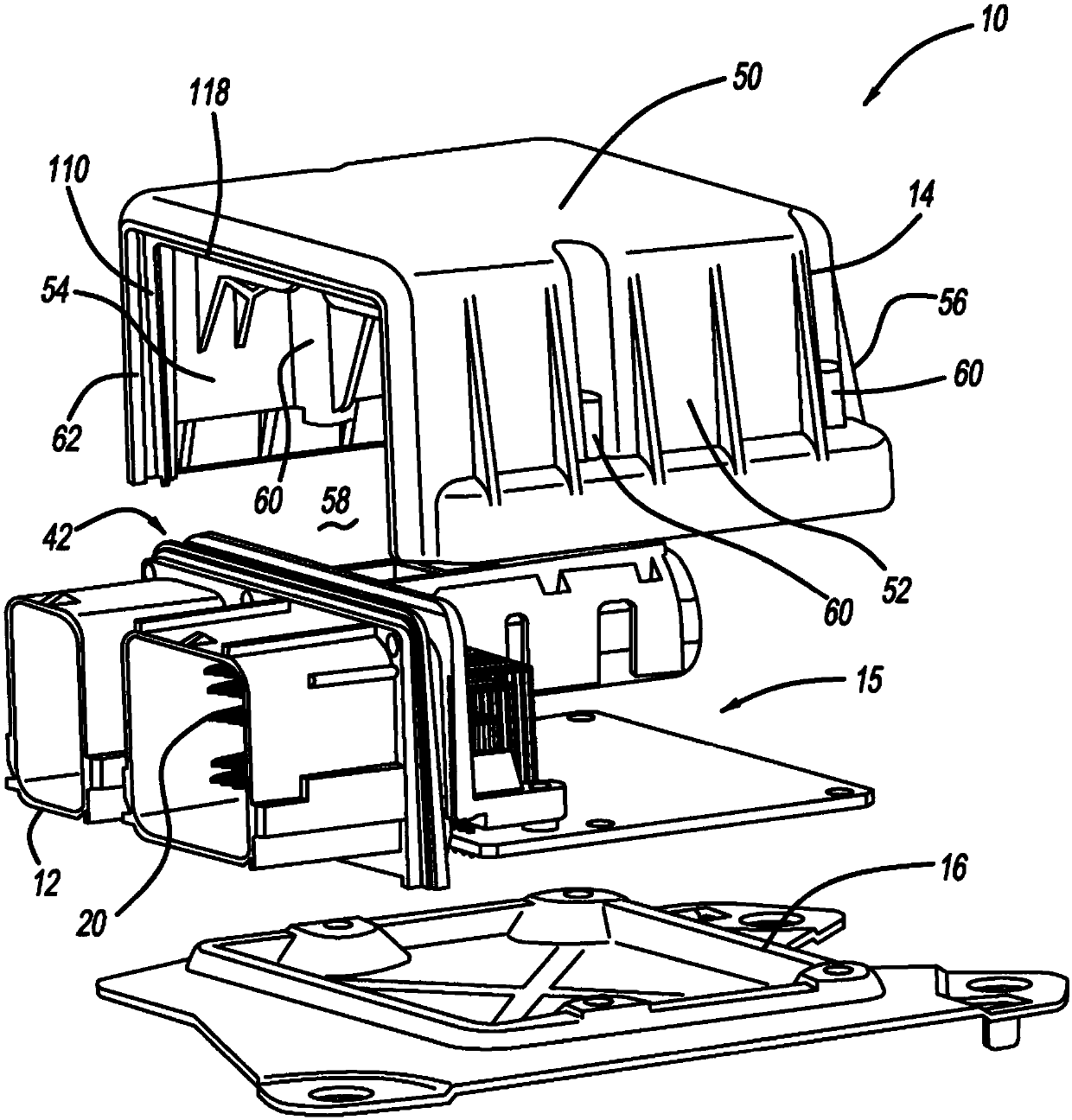

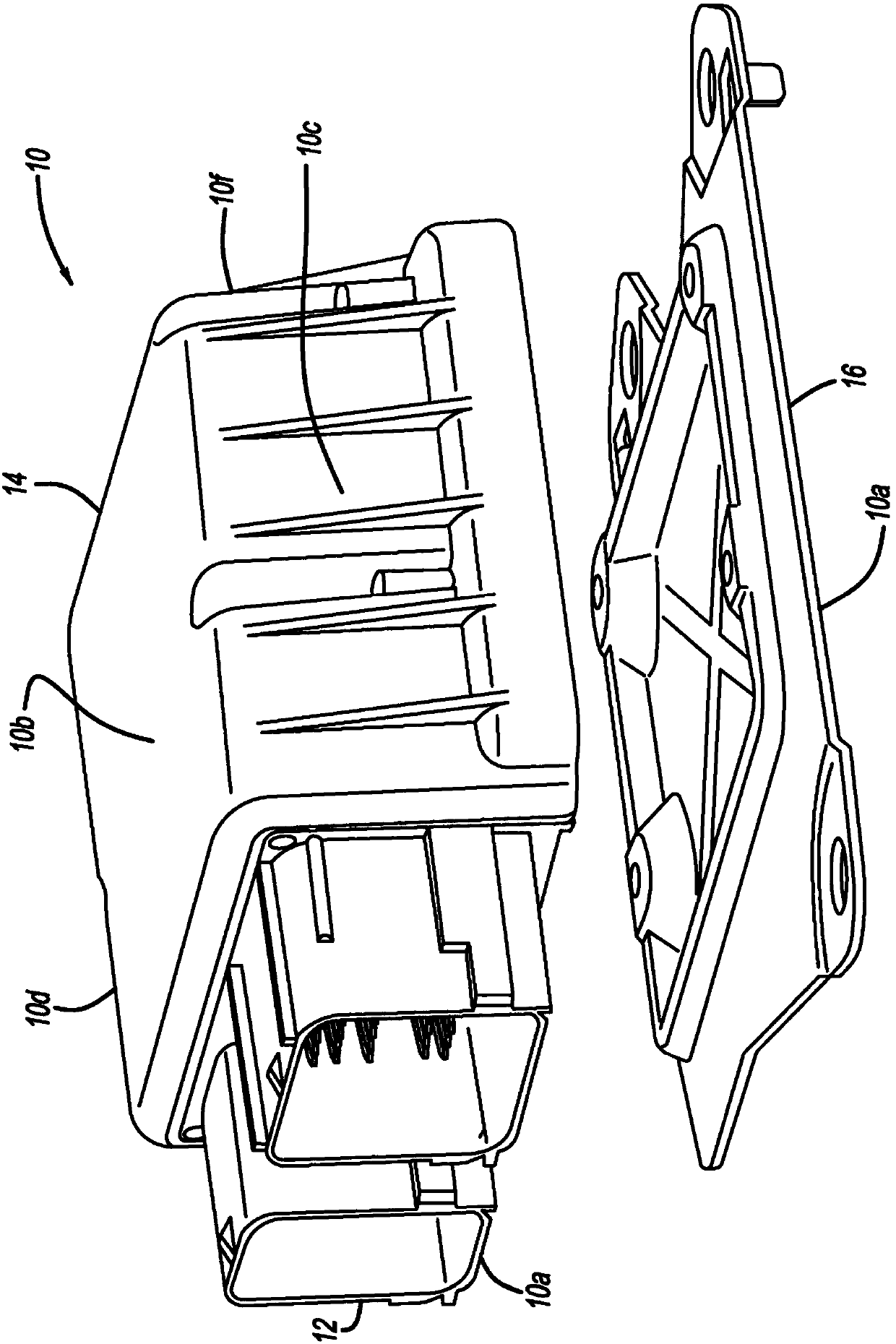

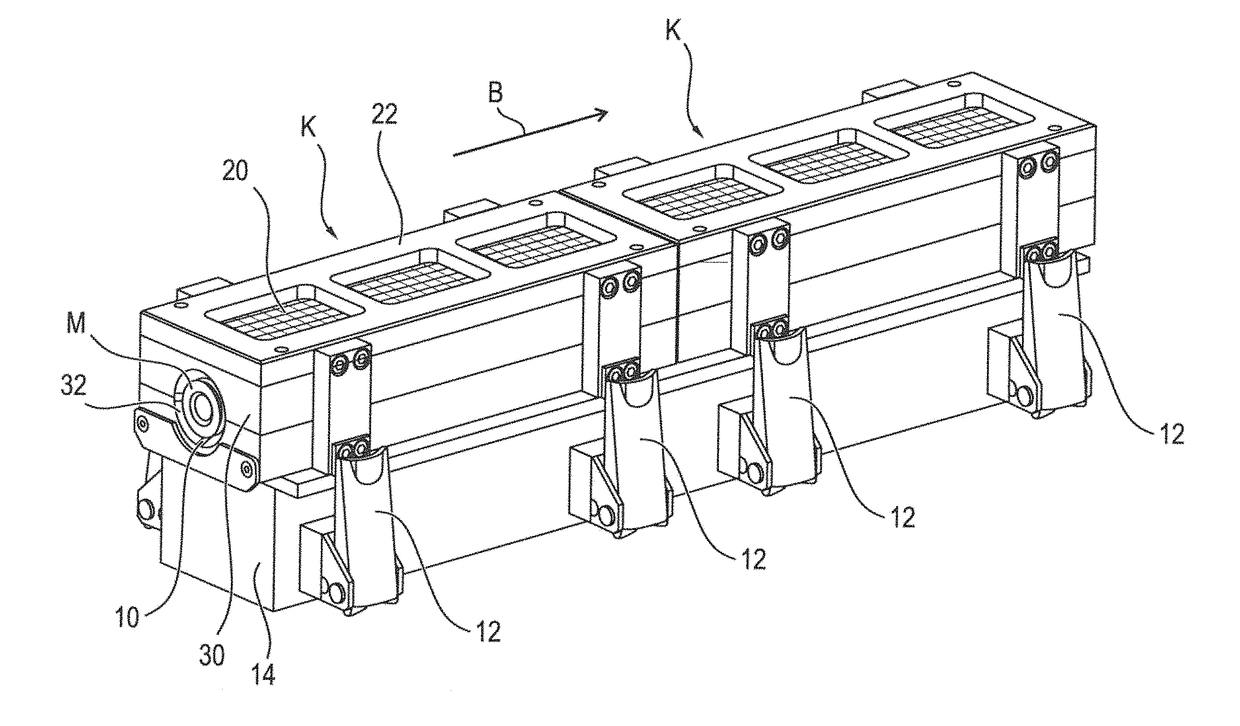

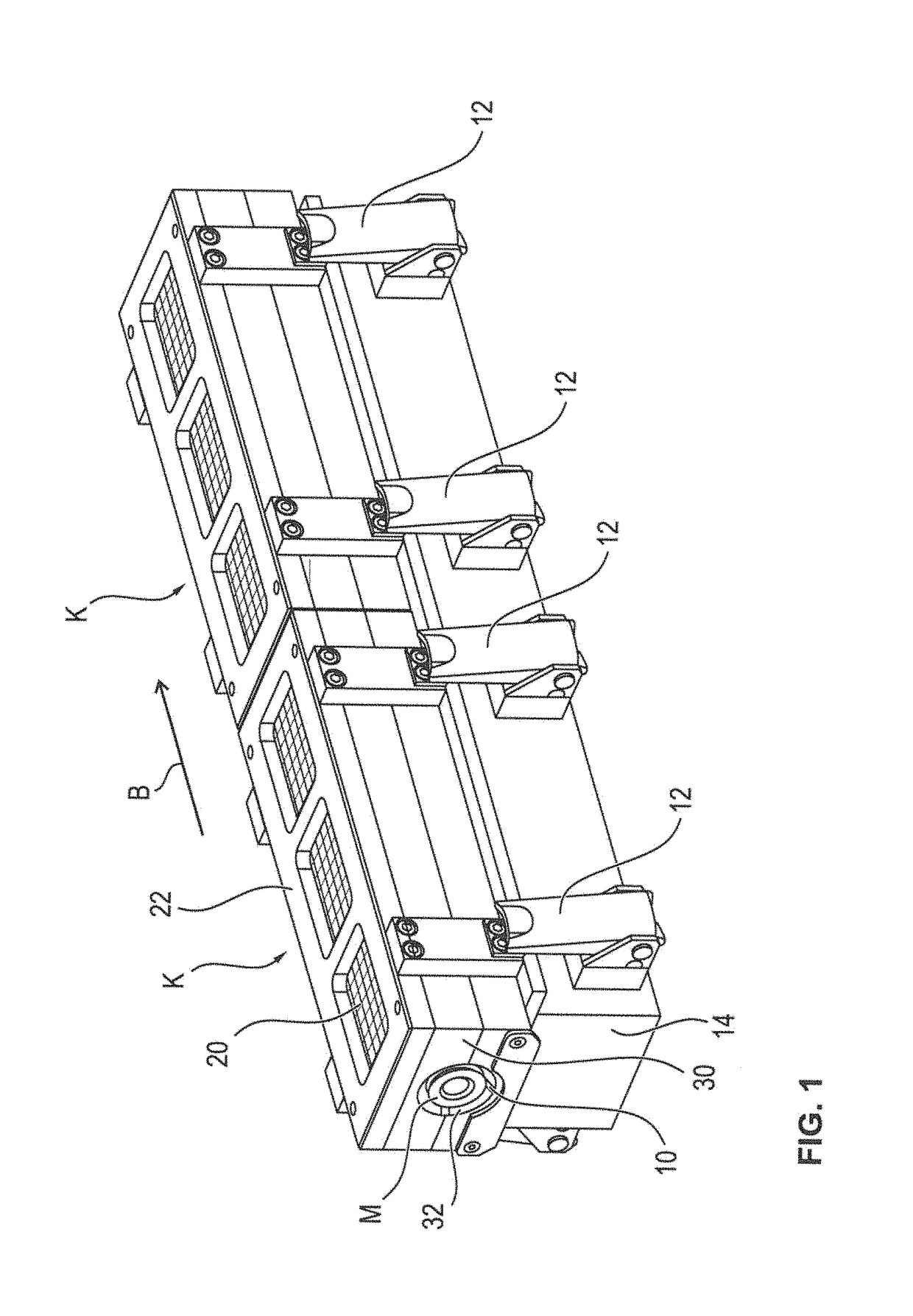

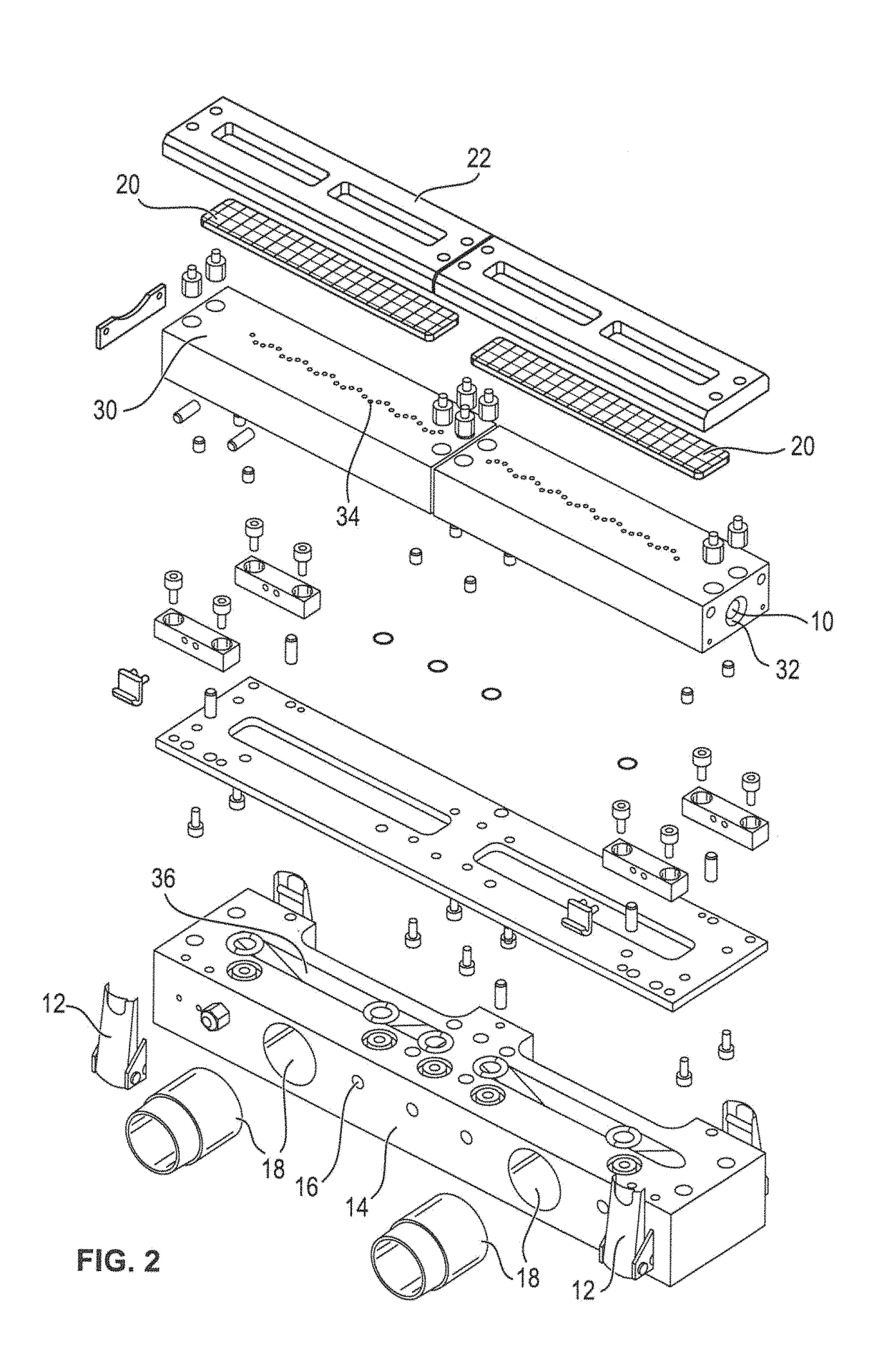

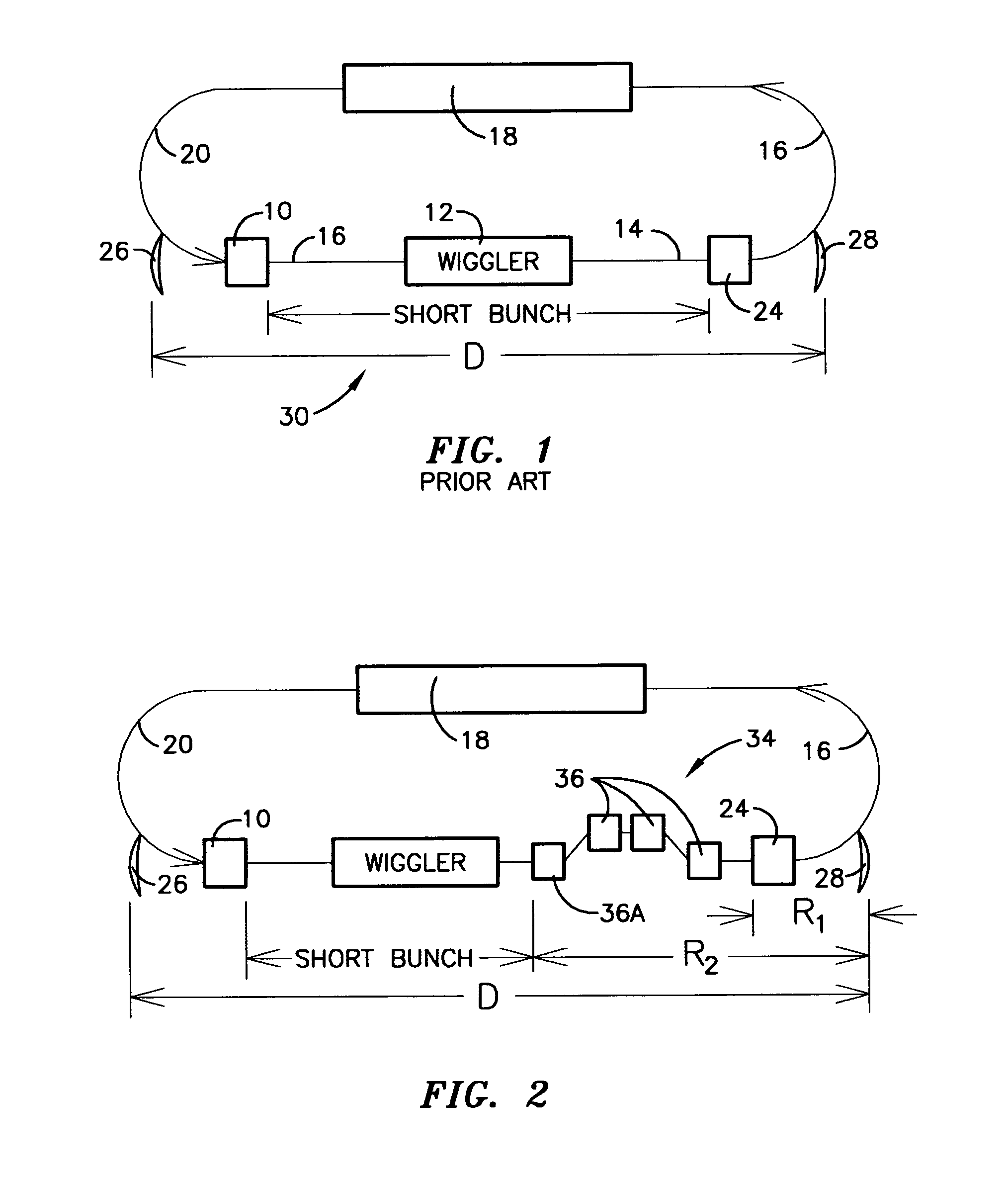

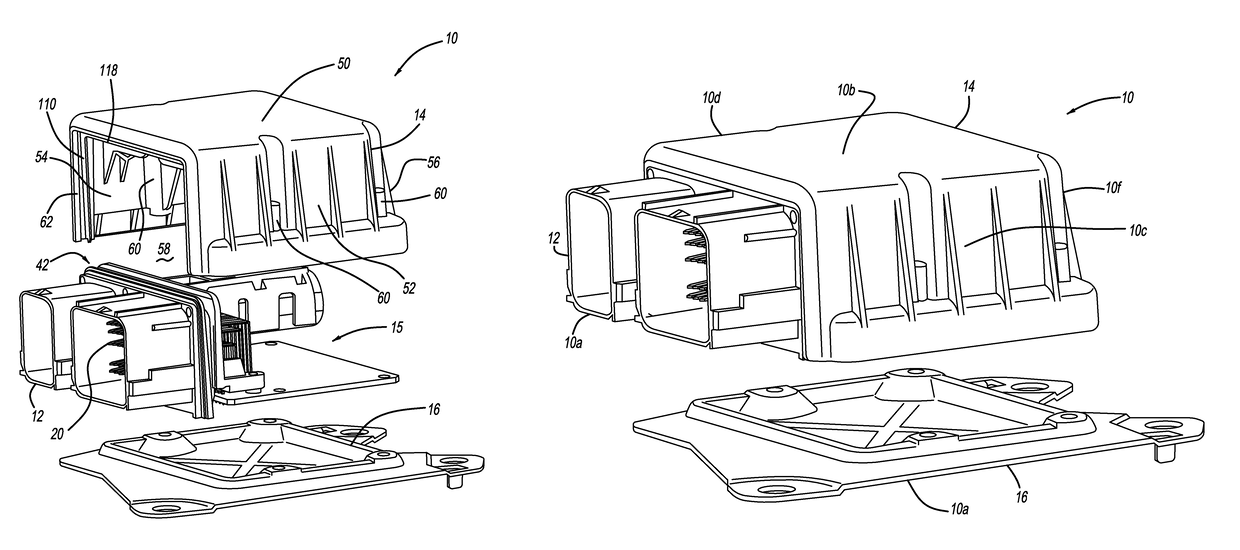

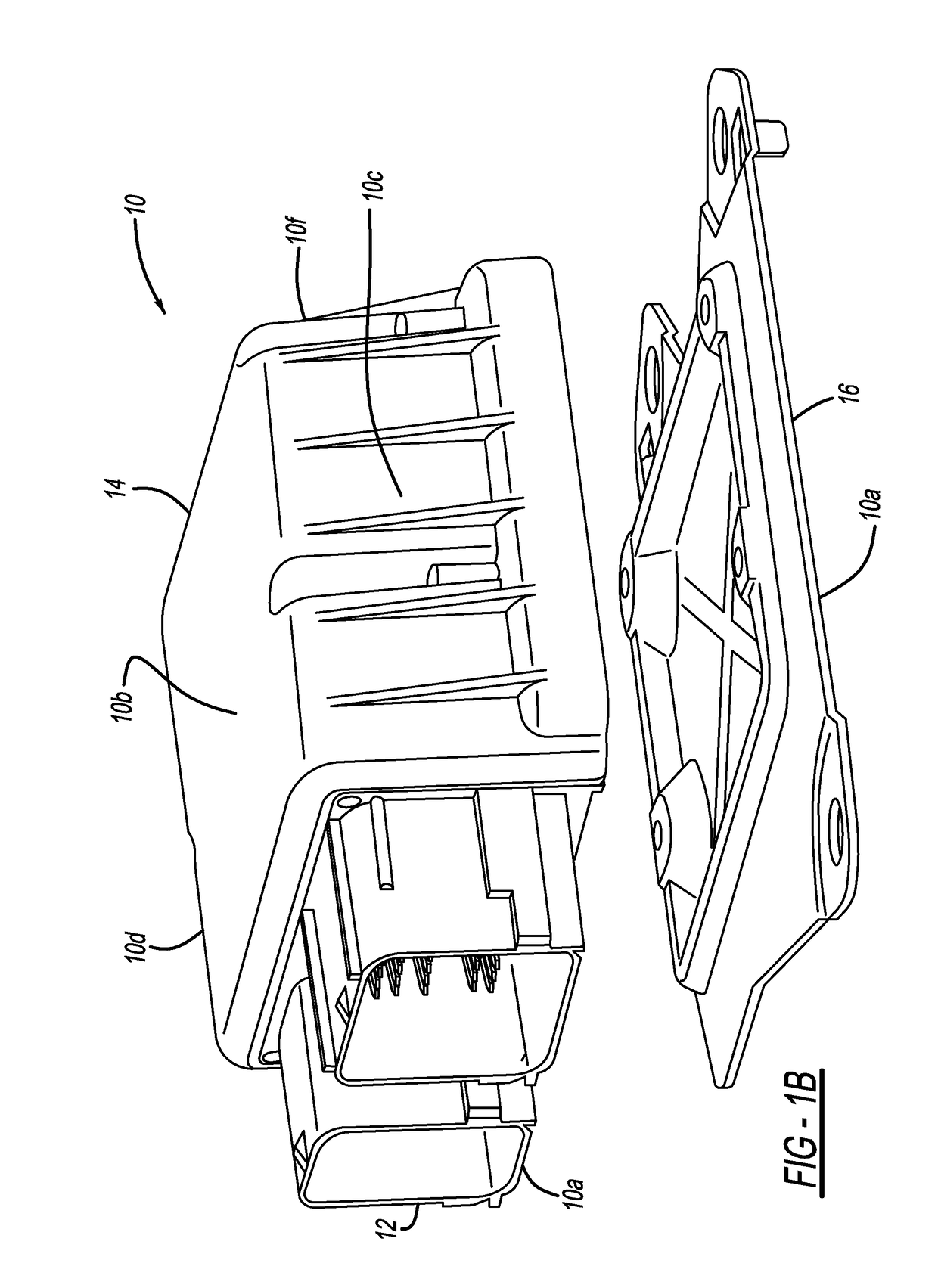

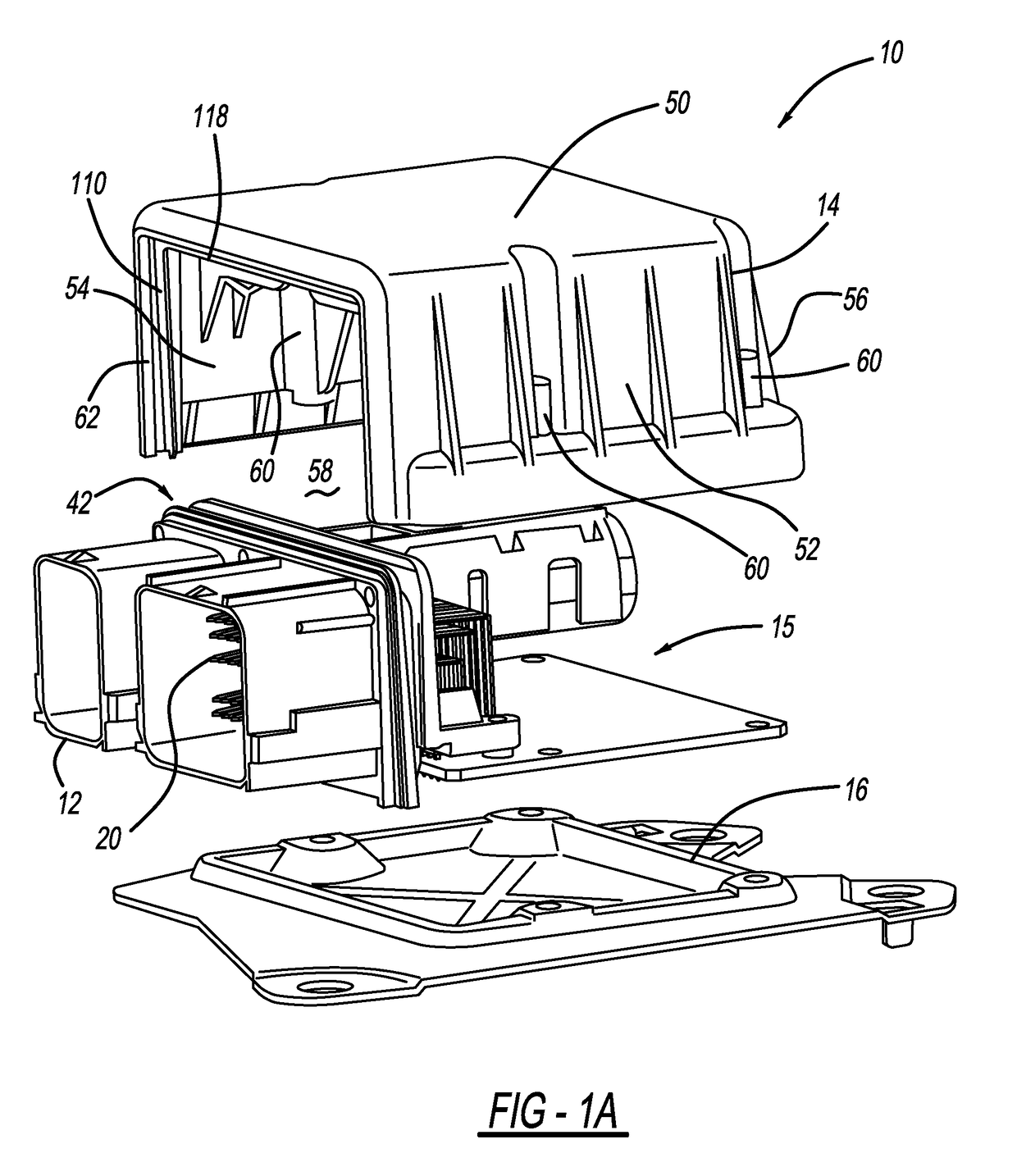

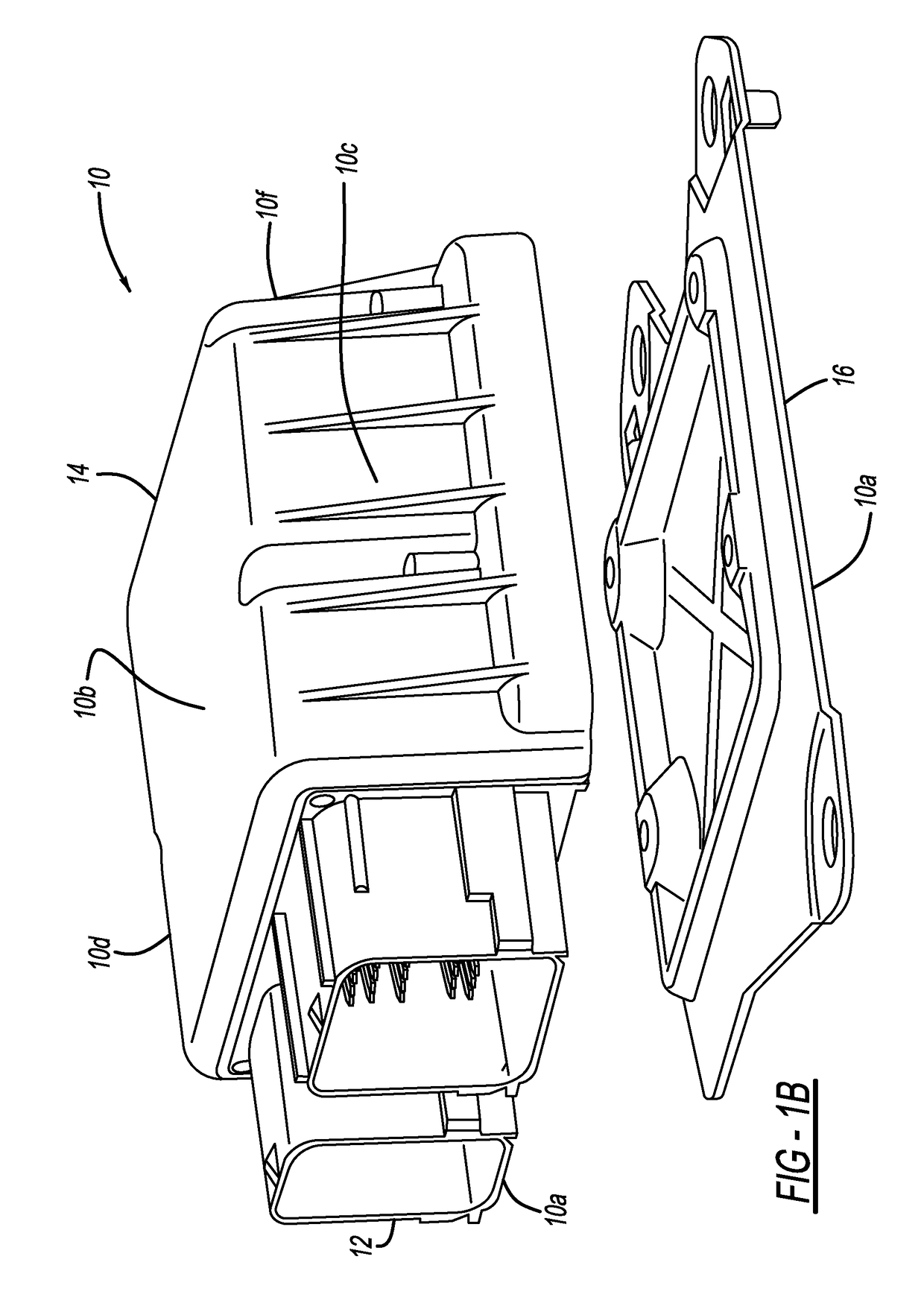

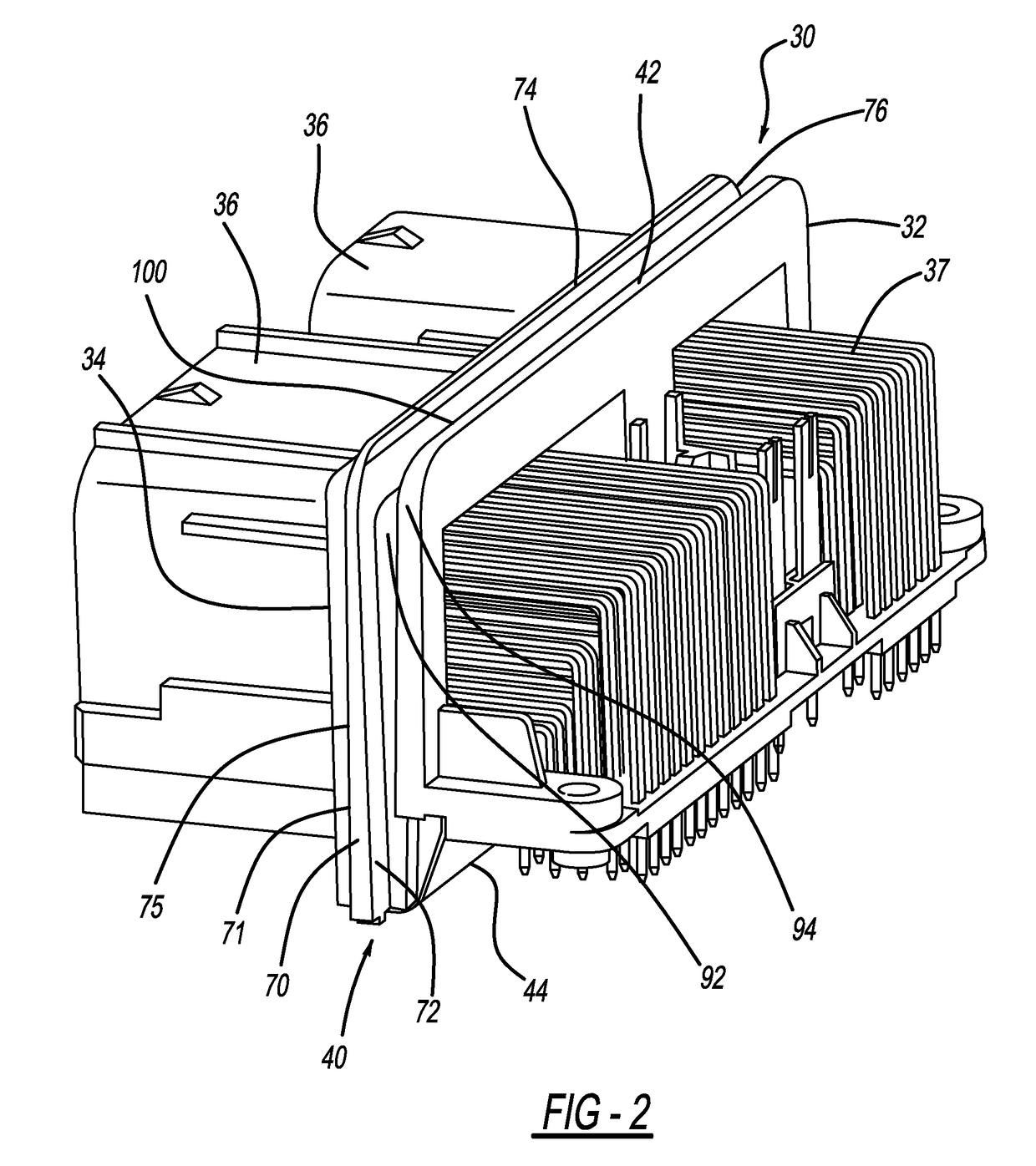

Mechanical housing and connector

ActiveCN107926131ACasings/cabinets/drawers detailsCouplings bases/casesStructural engineeringChicane

An electronics module includes a housing, a connector, and a baseplate. The housing and connector are attached to each other and mounted to the baseplate. The housing includes a protrusion that is received between an inner flange and an outer flange of the connector. The housing and connector combine to define a sealing plane that extends to co-planar bottom surfaces of the housing and connector.The housing and connector, when assembled, define a water intrusion path between an outer protrusion of the housing and the outer flange of the connector. The water intrusion path includes a pluralityof chicanes that reduces the pressure of water that enters the path. The bottom surface of the housing defines a recessed channel to receive water.

Owner:VEONEER AMERICAN SECURITY SYST LLC

Run-through cleaning device and cleaning method therefor

InactiveUS20170361358A1Enhanced removal of contaminantLittle effortCleaningSpray nozzlesCleaning methodsChicane

Owner:OSSBERGER GMBH CO

Wind tunnel

InactiveUS20090277263A1Reduce the required powerReduce material consumptionAerodynamic testingChicaneReturn channel

The invention relates to closed-circuit tunnels used for aerodynamic researches, sportsmen-parachutists training and other purposes. The inventive closed-circuit tunnel comprises a confuser, a working area, a diffuser, one or several return channels, a blower unit and turning bends having different flow deflection angle, wherein the bend having the smaller flow deflection angle is placed in a high-speed flow cross-section, whereas the bend having the greater flow deflection angle is arranged in a low flow speed cross-section. In a preferred embodiment, the tunnel comprises a first turning bend containing one turning gut for turning the airflow at 60 degrees, a second turning bend containing two turning guts for turning the airflow at 120 degrees, and a third turning bend containing three turning guts for turning the airflow at 180 degrees. The invention makes it possible to reduce air pressure losses, the drive power and a specific amount of metal per structure.

Owner:PETRUK VICTOR

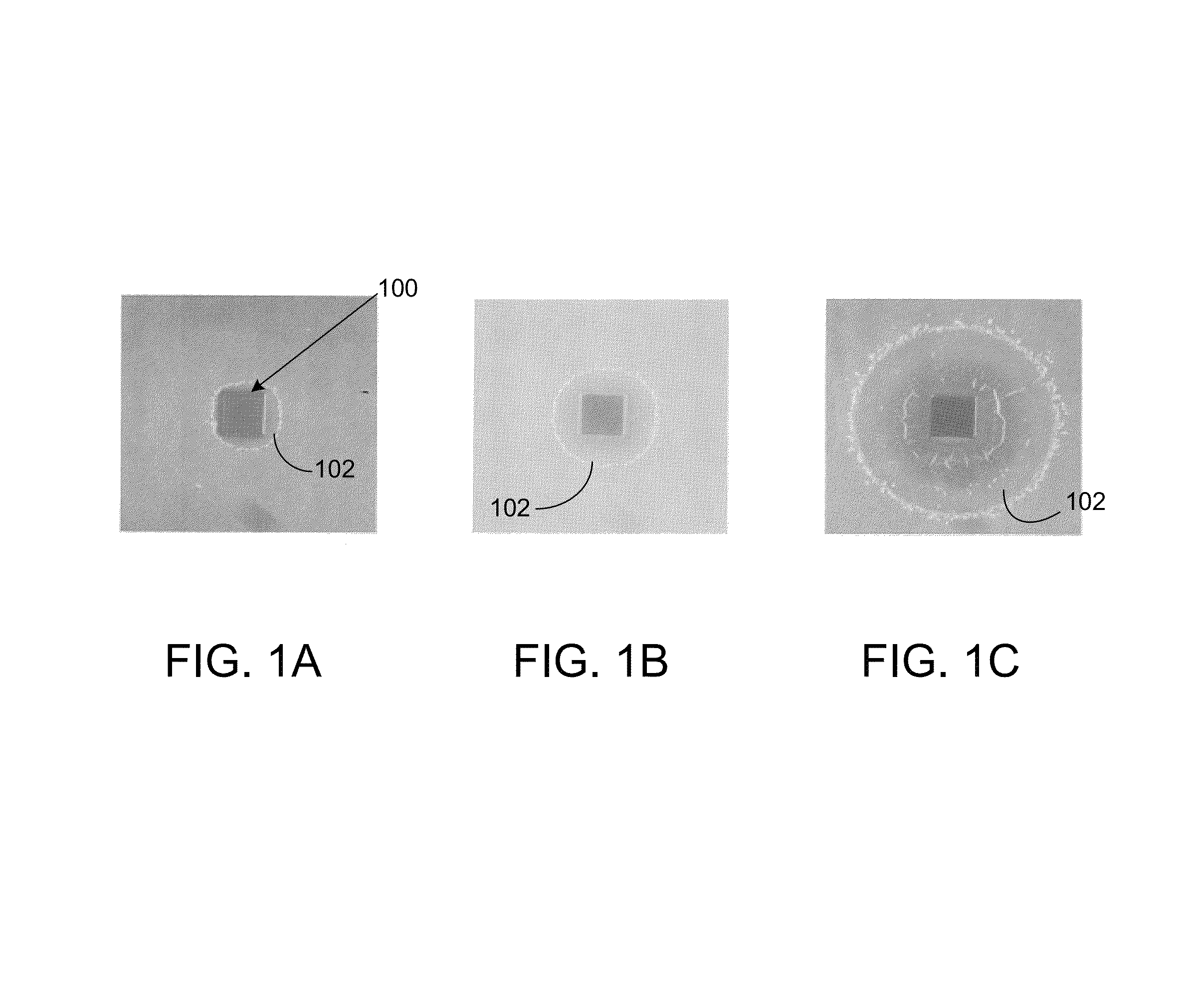

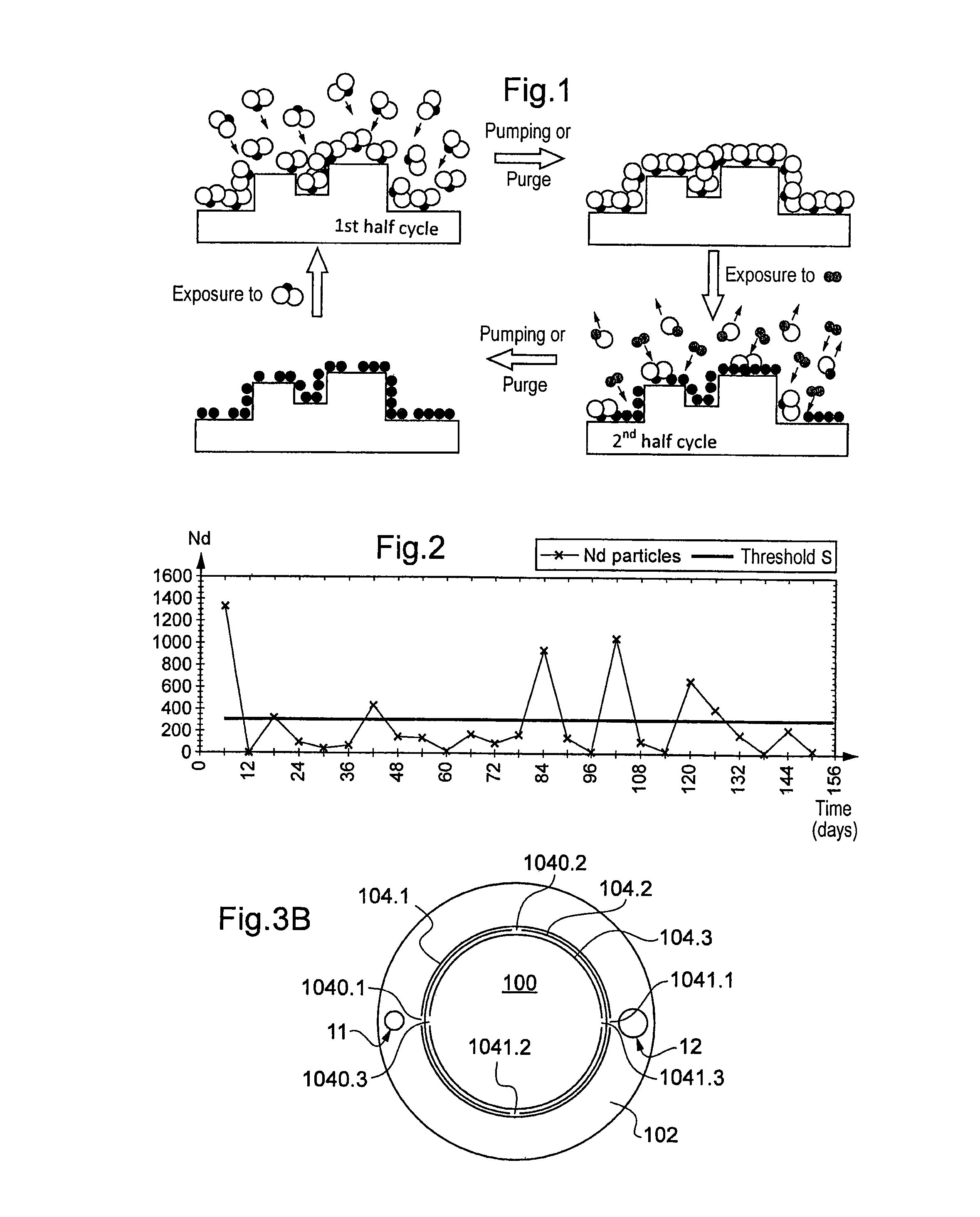

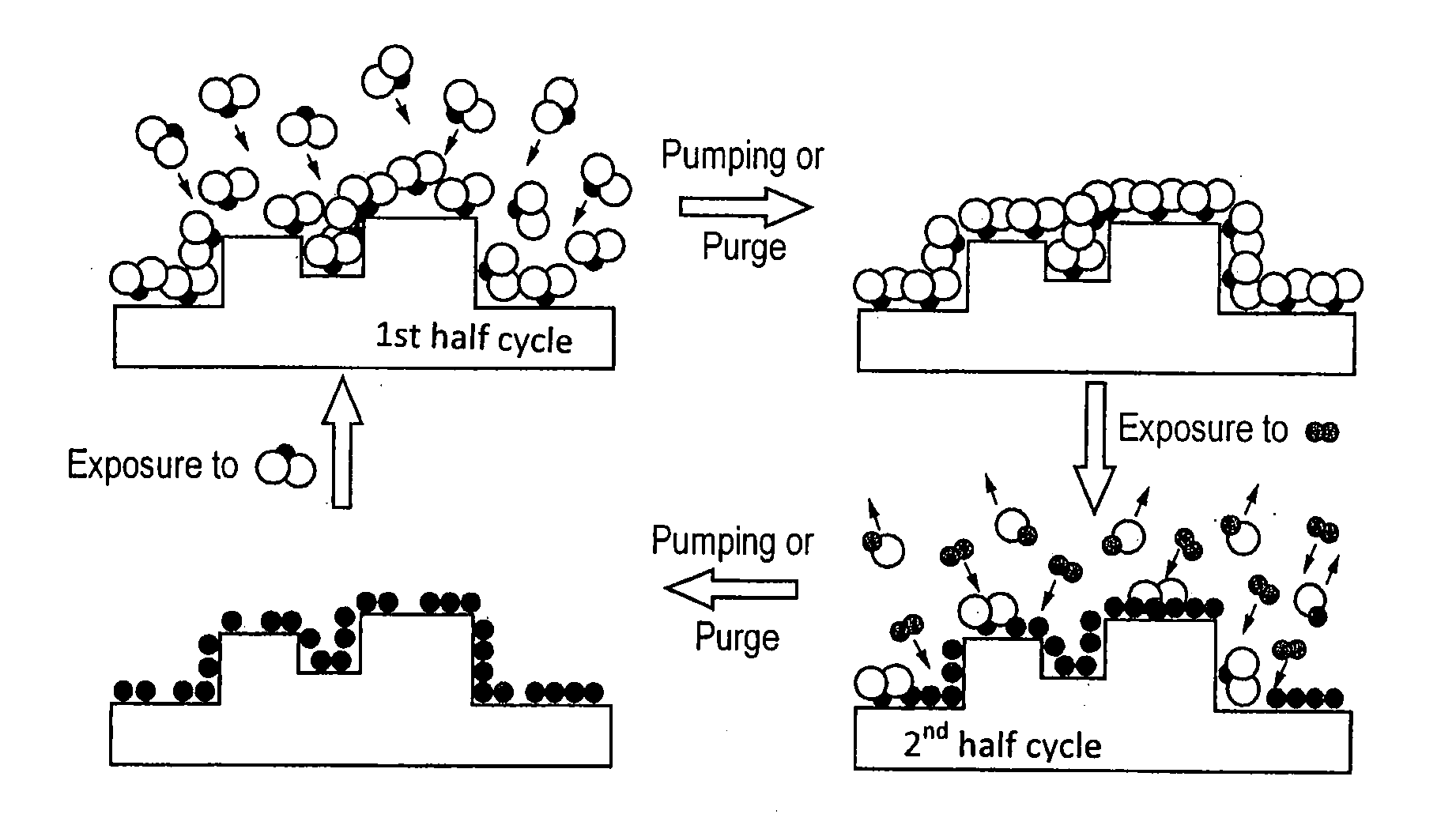

Reactor for atomic layer deposition (ALD), application to encapsulation of an OLED device by deposition of a transparent AI2O3 film

InactiveUS9083005B2Reduce in quantityAvoid Particle ContaminationElectroluminescent light sourcesSolid-state devicesEngineeringChicane

The present invention relates to a reactor for atomic layer deposition (ALD), comprising a reaction chamber comprising a platen and bounded internally by surfaces; at least one inlet orifice and at least one outlet orifice, each emerging from one of the surfaces bounding the chamber. The reactor furthermore comprises, within it, at least one wall apertured with at least one orifice, the apertured wall extending around the platen and over at least most of the height between the lower surface and the upper surface, at least one orifice in at least one of the apertured walls not facing the inlet orifice so as to form chicanes in the flow of gaseous precursor from each inlet orifice to the platen.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

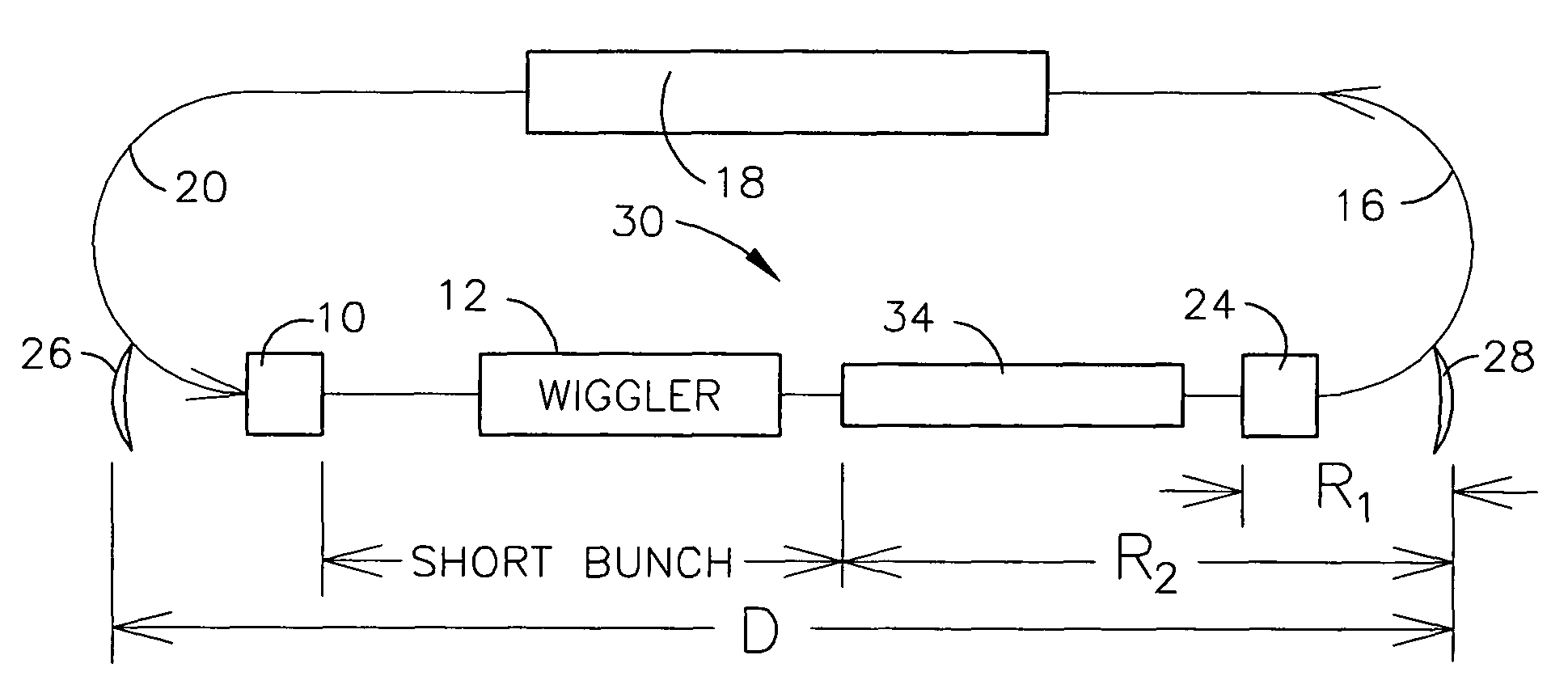

Magnetic chicane for terahertz management

The introduction of a magnetic electron beam orbit chicane between the wiggler and the downstream initial bending dipole in an energy recovering Linac alleviates the effects of radiation propagated from the downstream bending dipole that tend to distort the proximate downstream mirror of the optical cavity resonator.

Owner:JEFFERSON SCI ASSOCS LLC

Mechanical housing and connector

ActiveUS20170079154A1Reduce water pressureCasings/cabinets/drawers detailsHermetically-sealed casingsChicaneFlange

An electronics module includes a housing, a connector, and a baseplate. The housing and connector are attached to each other and mounted to the baseplate. The housing includes a protrusion that is received between an inner flange and an outer flange of the connector. The housing and connector combine to define a sealing plane that extends to co-planar bottom surfaces of the housing and connector. The housing and connector, when assembled, define a water intrusion path between an outer protrusion of the housing and the outer flange of the connector. The water intrusion path includes a plurality of chicanes that reduces the pressure of water that enters the path. The bottom surface of the housing defines a recessed channel to receive water.

Owner:VEONEER US LLC

Mechanical housing and connector

An electronics module includes a housing, a connector, and a baseplate. The housing and connector are attached to each other and mounted to the baseplate. The housing includes a protrusion that is received between an inner flange and an outer flange of the connector. The housing and connector combine to define a sealing plane that extends to co-planar bottom surfaces of the housing and connector. The housing and connector, when assembled, define a water intrusion path between an outer protrusion of the housing and the outer flange of the connector. The water intrusion path includes a plurality of chicanes that reduces the pressure of water that enters the path. The bottom surface of the housing defines a recessed channel to receive water.

Owner:VEONEER US LLC

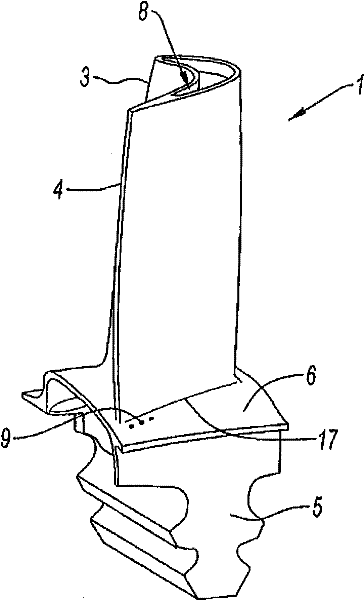

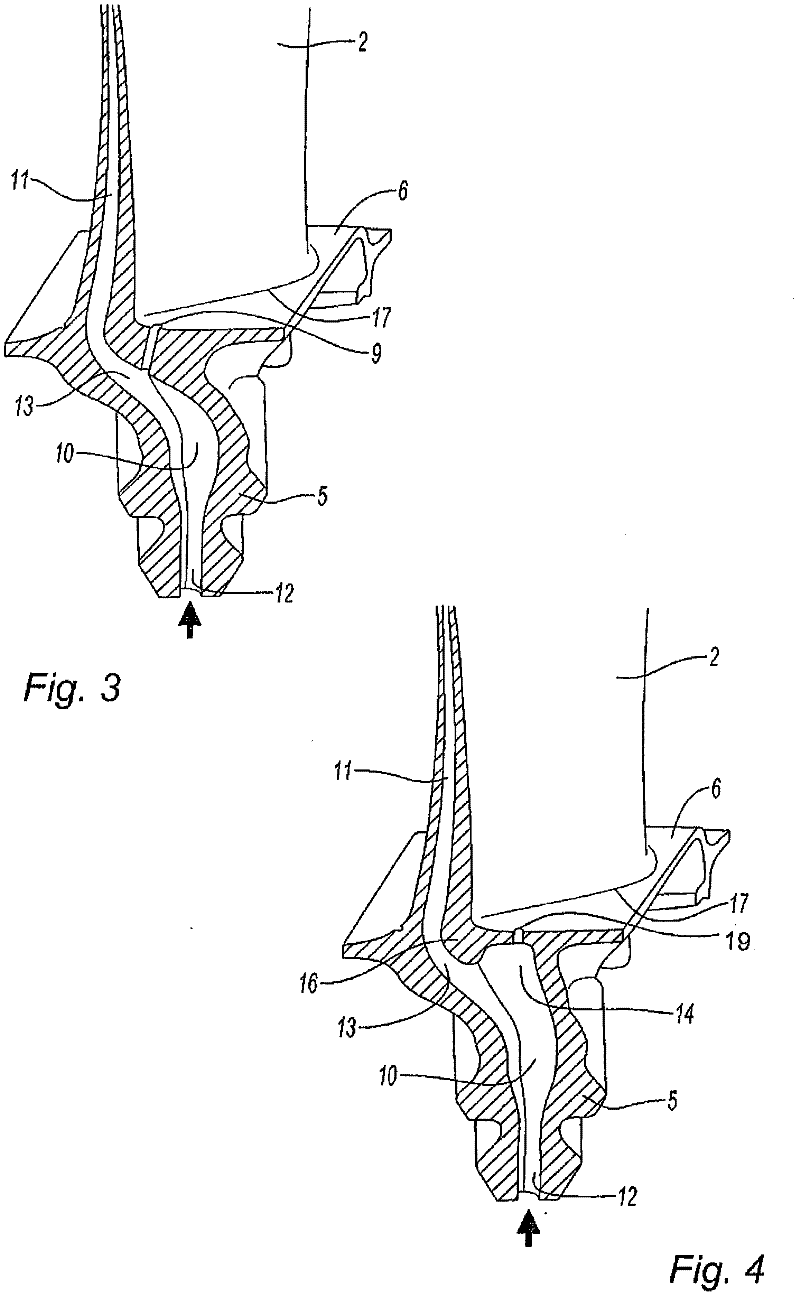

Turbine vane with dusting hole at the base of the blade

The invention relates to a cooled turbine vane for a turbine engine, that comprises a blade (2) mounted on a platform (6) carried by a base (5), said blade having one or more cavities formed therein for cooling air circulation, the cavity (11) extending along the trailing edge and being supplied with cooling air by a supply duct (10) connecting an air intake (12) located in the lower portion of the base (5) and the cavity (11) of the trailing edge by defining a bend (13) within said base, characterised in that the duct (10) comprises, on an axis substantially radial relative to the air intake (12) a bell-shaped niche (14) located under the platform (6), said niche being open at the top thereof via a dusting hole (19) extending through the platform and being defined at the foot of the base (5) by walls extending substantially radially from the platform (6) in order to close it laterally.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

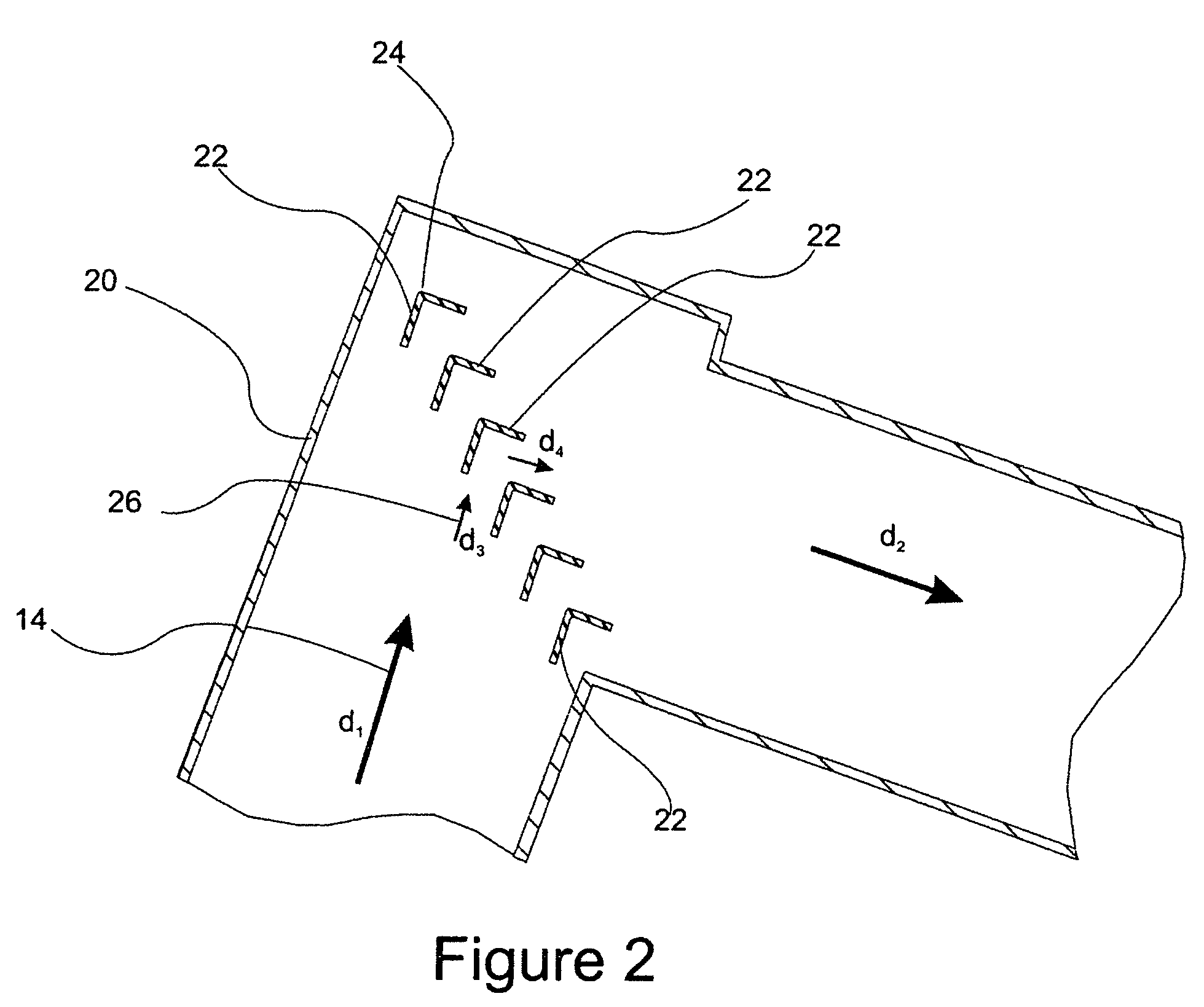

Gas-liquid separator utilizing turning vanes to capture liquid droplets as well as redirect the gas flow around a bend

A gas-liquid separation enhancer includes a plurality of longitudinally extending turning vanes distributed within a bent conduit section. At least a portion of the vanes have a bend that redirects a portion of a flowing gas stream from an initial direction to a final direction. Each of the vanes have a first end and a second end and are positioned in the bent conduit section to direct a portion of any liquid contacting the vanes to either the first end or the second end when the gas-liquid separation enhancer is incorporated into an outlet conduit. The separation is positioned in an outlet conduit such that captured liquid droplets are returned to the vessel from which they originate.

Owner:ALPEK POLYESTER SA DE CV

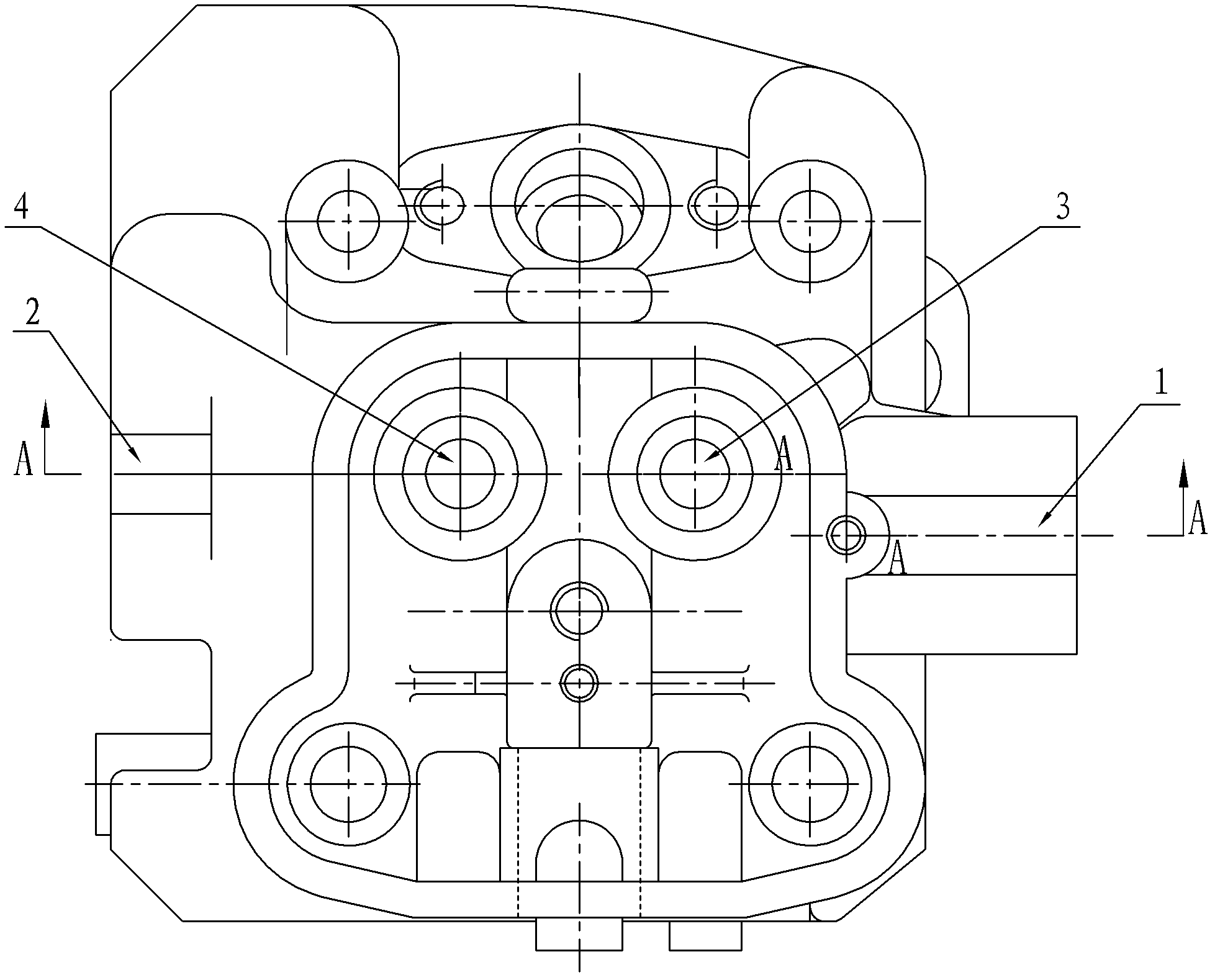

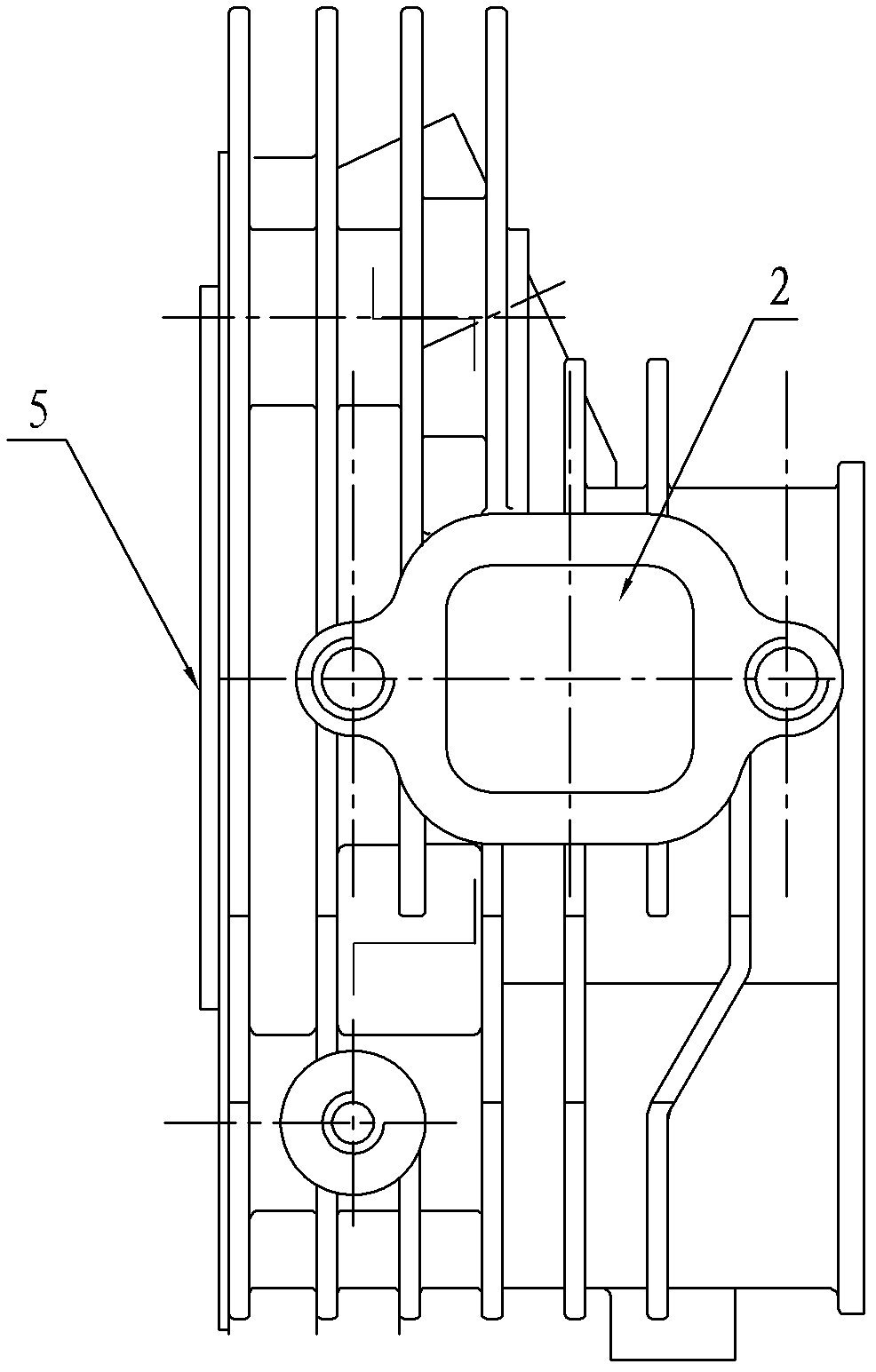

Die-cast air cylinder cover of air-cooled single-cylinder diesel engine

InactiveCN102322367AIncrease output powerImprove flow characteristicsCylinder headsCylindersPilot holeExhaust valve

The invention relates to a die-cast air cylinder cover of an air-cooled single-cylinder diesel engine. The pattern drafts of an air-inlet channel cast hole segment and an air-outlet channel cast hole segment are both smaller than 3 percent; the air-inlet channel cast hole segment and the air-outlet channel cast hole segment are geometrically intersected with an air-inlet channel processed hole and an air-outlet channel processed hole to form curved channels of an air-inlet channel and an air-outlet channel; the maximum sizes of the cross sections of the air-inlet channel cast hole segment and the air-outlet channel cast hole segment at the geometrically intersected part are respectively equal to the diameters of the air-inlet channel processed hole and the air-outlet channel processed hole; the distances between the bottom surface of the air-inlet channel processed hole and the lower end surface of an air-inlet valve pilot hole as well as between the bottom surface of the air-outlet channel processed hole and the lower end surface of an exhaust valve pilot hole are 0-3mm; the cross-section areas of the intersected parts of the air-inlet and the air-outlet channel cast hole segments and the air-inlet and the air-outlet channel cast hole segments are maximum; the included angles between the axis of the air-inlet channel cast hole segment and the mounting surface of the air cylinder cover as well as between the axis of the air-outlet channel cast hole segment and the mounting surface of the air cylinder cover are 20-45 DEG; and compared with the traditional air cylinder cover of the 170F diesel engine, the die-cast air cylinder cover has the advantages that: the flow coefficients of the air-inlet channel and the air-outlet channel are increased by 15-23 percent, the power output is increased by 8-11 percent, the fuel consumption is reduced to 2-6 percent, air is exchanged thoroughly, and pollutants discharged by the diesel engine can be reduced.

Owner:CHANGZHOU TANCHAI ELECTROMECHANICAL

Reactor for Atomic Layer Deposition (ALD), Application to Encapsulation of an OLED Device by Deposition of a Transparent Al2O3 Film

InactiveUS20130280833A1Reduce in quantityAvoid Particle ContaminationElectroluminescent light sourcesSolid-state devicesEngineeringChicane

The present invention relates to a reactor for atomic layer deposition (ALD), comprising a reaction chamber comprising a platen and bounded internally by surfaces; at least one inlet orifice and at least one outlet orifice, each emerging from one of the surfaces bounding the chamber. The reactor furthermore comprises, within it, at least one wall apertured with at least one orifice, the apertured wall extending around the platen and over at least most of the height between the lower surface and the upper surface, at least one orifice in at least one of the apertured walls not facing the inlet orifice so as to form chicanes in the flow of gaseous precursor from each inlet orifice to the platen.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Achromatic recirculated chicane with fixed geometry and independently variable path length and momentum compaction

A particle beam recirculated chicane geometry that, through the inducement of a pair of 180 degree bends directed by the poles of a pair of controllable magnetic fields allows for variation of dipole position, return loop radii and steering / focussing, thereby allowing the implementation of independent variation of path length and momentum compaction.

Owner:JEFFERSON SCI ASSOCS LLC

System for spraying a powder coating product and sprayhead incorporated in it

A system for spraying a powder coating product includes a rotary sprayhead which is preferably of the type which is electrostatically charged. The sprayhead has a rotary part which can be driven in rotation. A narrow flow space in the sprayhead in the form of a flat ring incorporates a flow chicane forming an impact surface on the path of the coating product.

Owner:SAMES KREMLIN

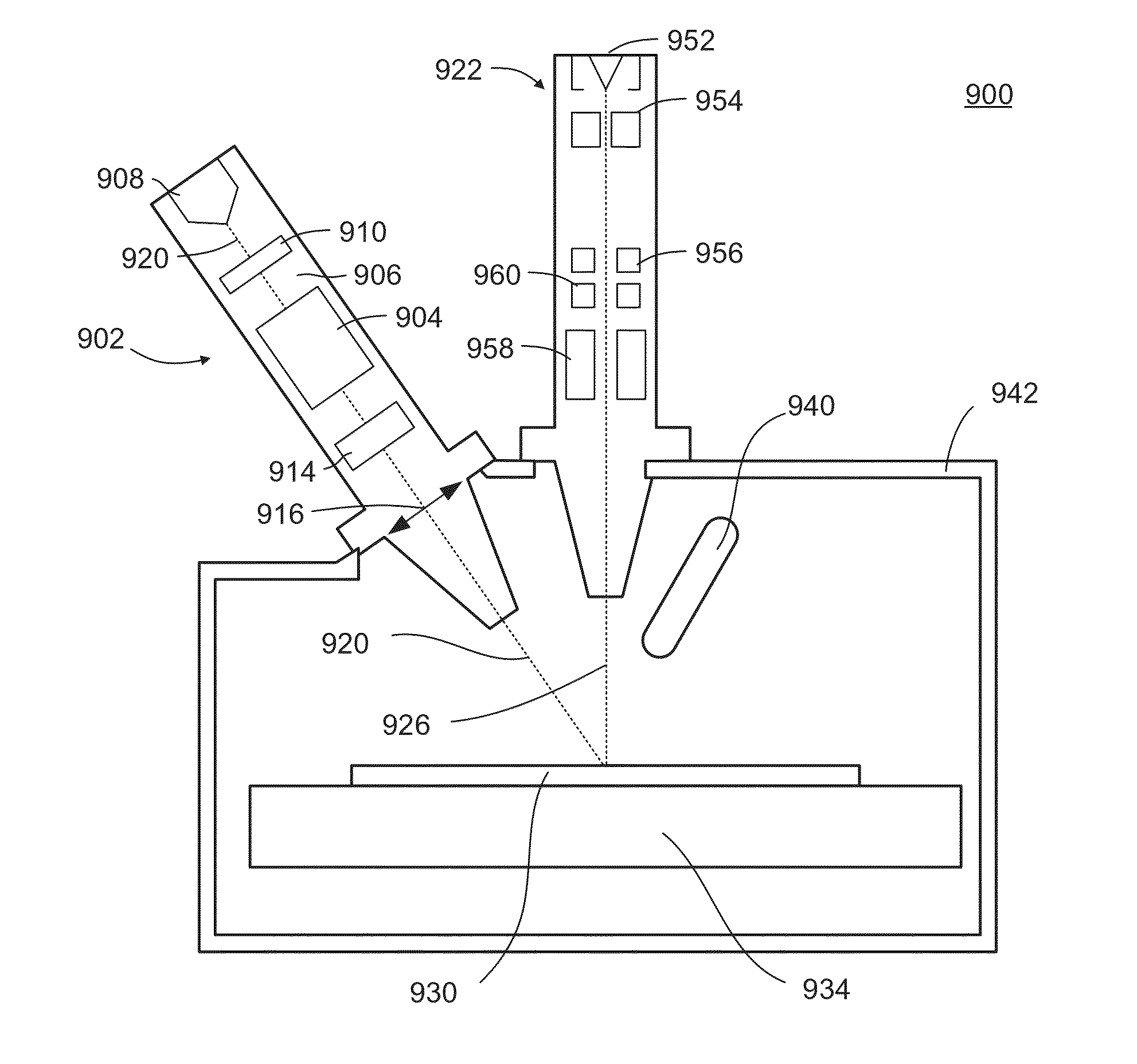

Chicane Blanker Assemblies for Charged Particle Beam Systems and Methods of Using the Same

ActiveUS20160093470A1Preventing neutralAvoid influenceMaterial analysis using wave/particle radiationRadiation/particle handlingLight beamBlock structure

A chicane blanker assembly for a charged particle beam system includes an entrance and an exit, at least one neutrals blocking structure, a plurality of chicane deflectors, a beam blanking deflector, and a beam blocking structure. The entrance is configured to accept a beam of charged particles propagating along an axis. The at least one neutrals blocking structure intersects the axis. The plurality of chicane deflectors includes a first chicane deflector, a second chicane deflector, a third chicane deflector, and a fourth chicane deflector sequentially arranged in series between the entrance and the exit and configured to deflect the beam along a path that bypasses the neutrals blocking structure and exits the chicane blanker assembly through the exit. In embodiments, the chicane blanker assembly includes a two neutrals blocking structures. In embodiments, the beam blocking structure is arranged between the third chicane deflector and the fourth chicane deflector.

Owner:FEI CO

Controlled flow air precleaner

InactiveUS20120272630A1Reduce total pressure lossOptimized areaCombustion-air/fuel-air treatmentDispersed particle separationCentrifugal forceChicane

An air precleaner includes a housing defining an air chamber with a downwardly opening outlet and a pair of side inlets. A plurality of vanes in the air chamber define two pathways for intake air to flow from the inlet openings around bends of more than 90 degrees to the outlet opening. The pathways initially narrow to increase the velocity of air in the bends. An ejection compartment between the pathways includes two ejection openings at the ends of the bends for receiving contaminants transferred to an outer layer of the air by centrifugal force. The collected contaminants exit the housing through an evacuation opening. Downstream of the ejection openings, the pathways gradually widen to decrease the velocity of the precleaned air prior to reaching the outlet opening. The precleaner may be applied to an engine intake air cleaner or to the intake air of a cooling package.

Owner:DEERE & CO

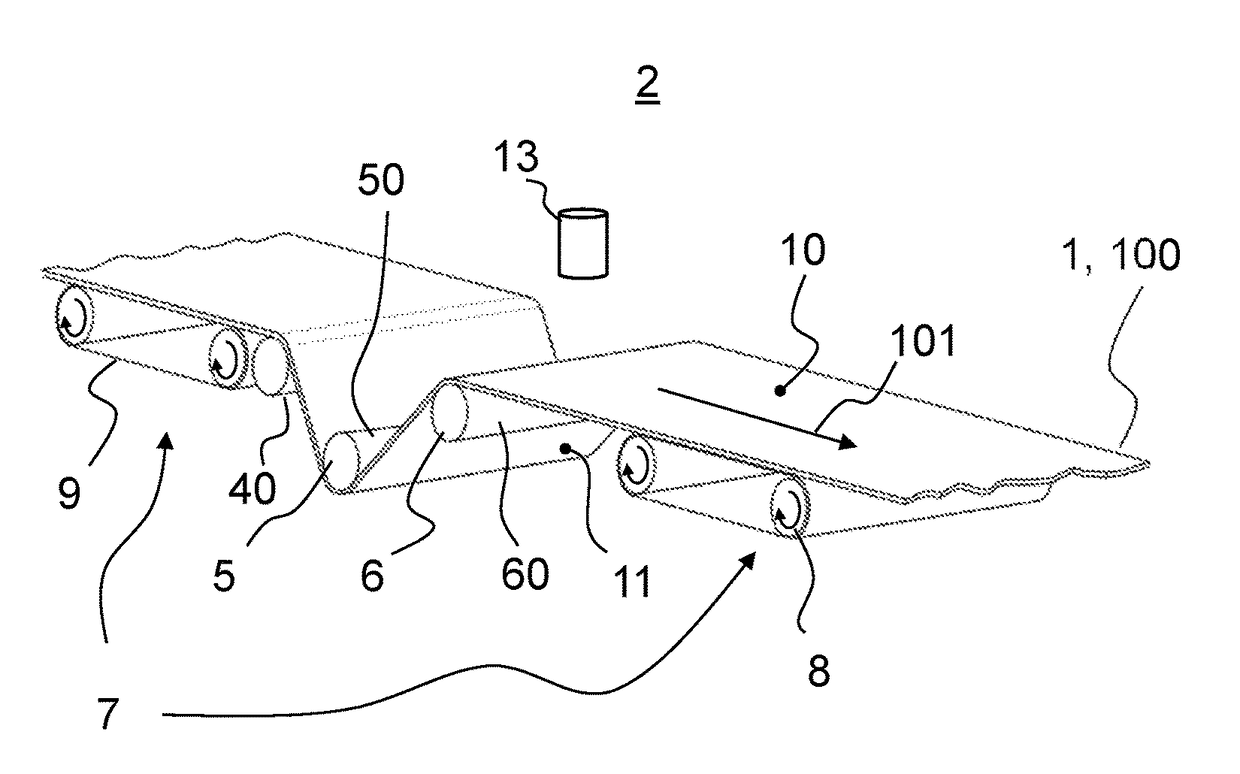

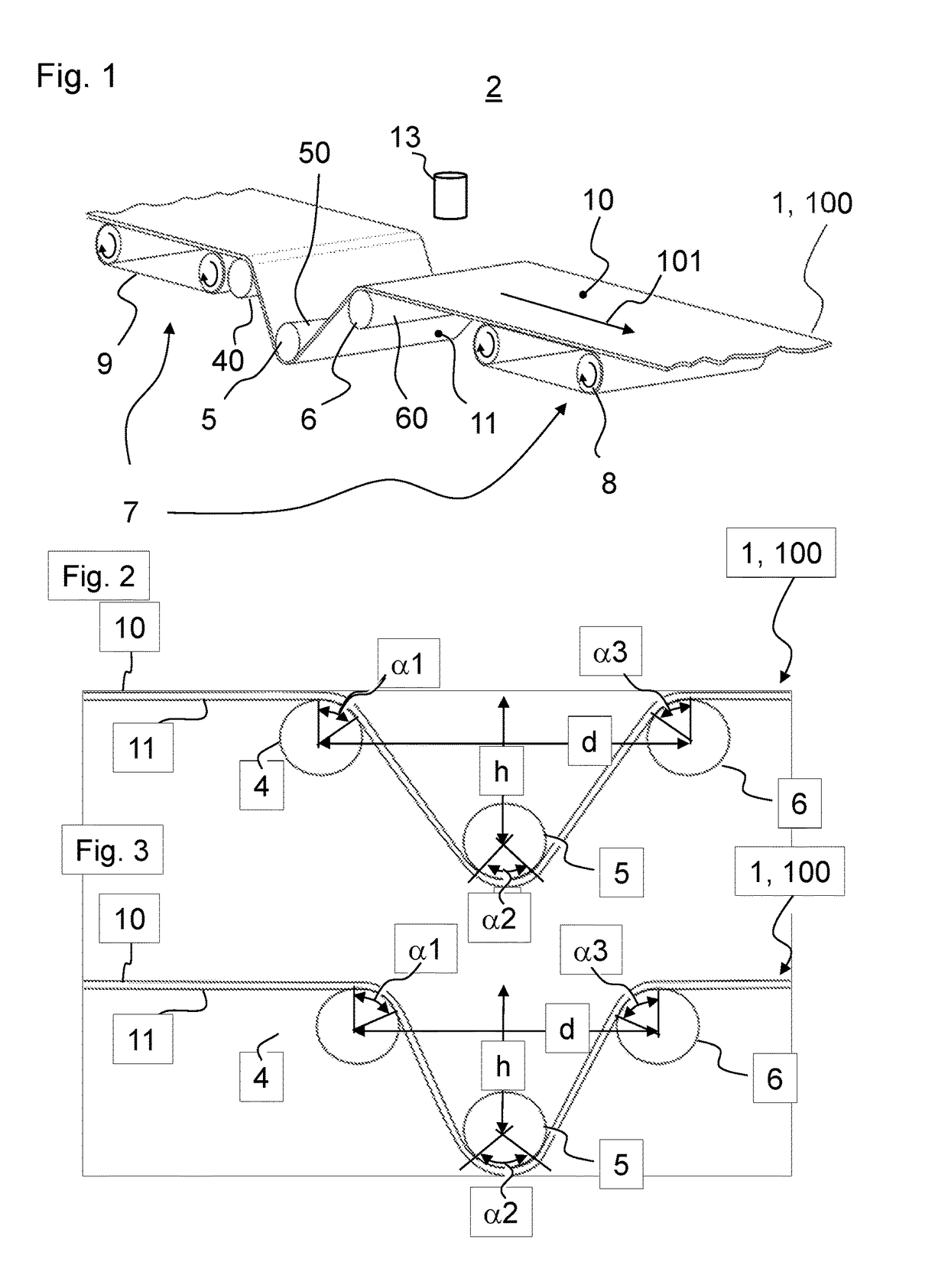

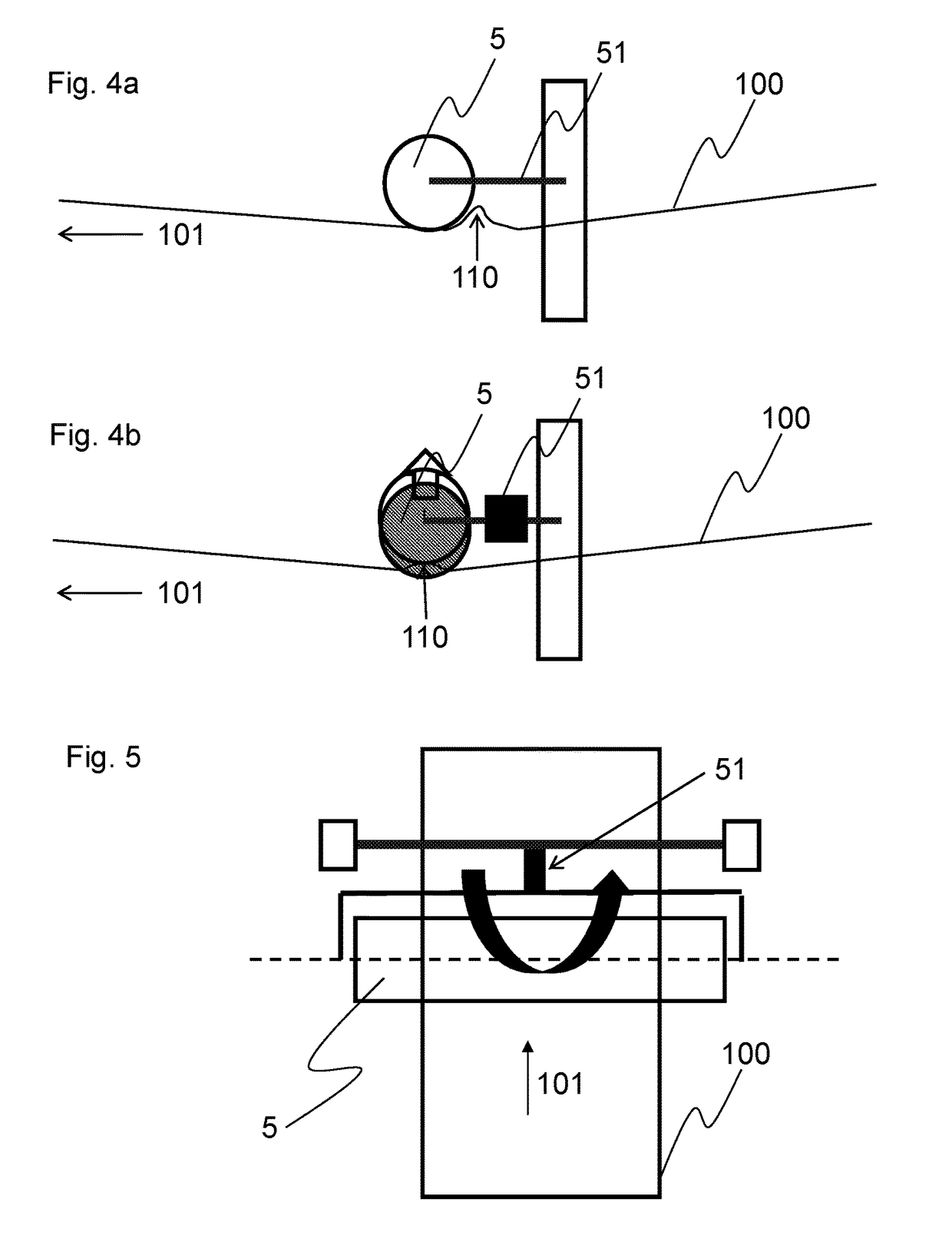

Apparatus and method for stabilizing sheets of a hard brittle material

ActiveUS20170073264A1High strengthShort durationGlass transportation apparatusGlass reforming apparatusClassical mechanicsStructural engineering

A method and an apparatus for stabilizing the position of a sheet-like element made of hard brittle material during transportation thereof along a transport path is provided in which the element is guided through a roller chicane having three rollers.

Owner:SCHOTT AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com