Compressor jet flow path structure

A technology of compressors and centrifugal compressors, applied in mechanical equipment, radial flow pumps, machines/engines, etc., can solve the problems of increased material costs, poor controllability of refrigerant mixing, and reduced aerodynamic efficiency, so as to reduce material costs cost, improve compression efficiency, and reduce interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

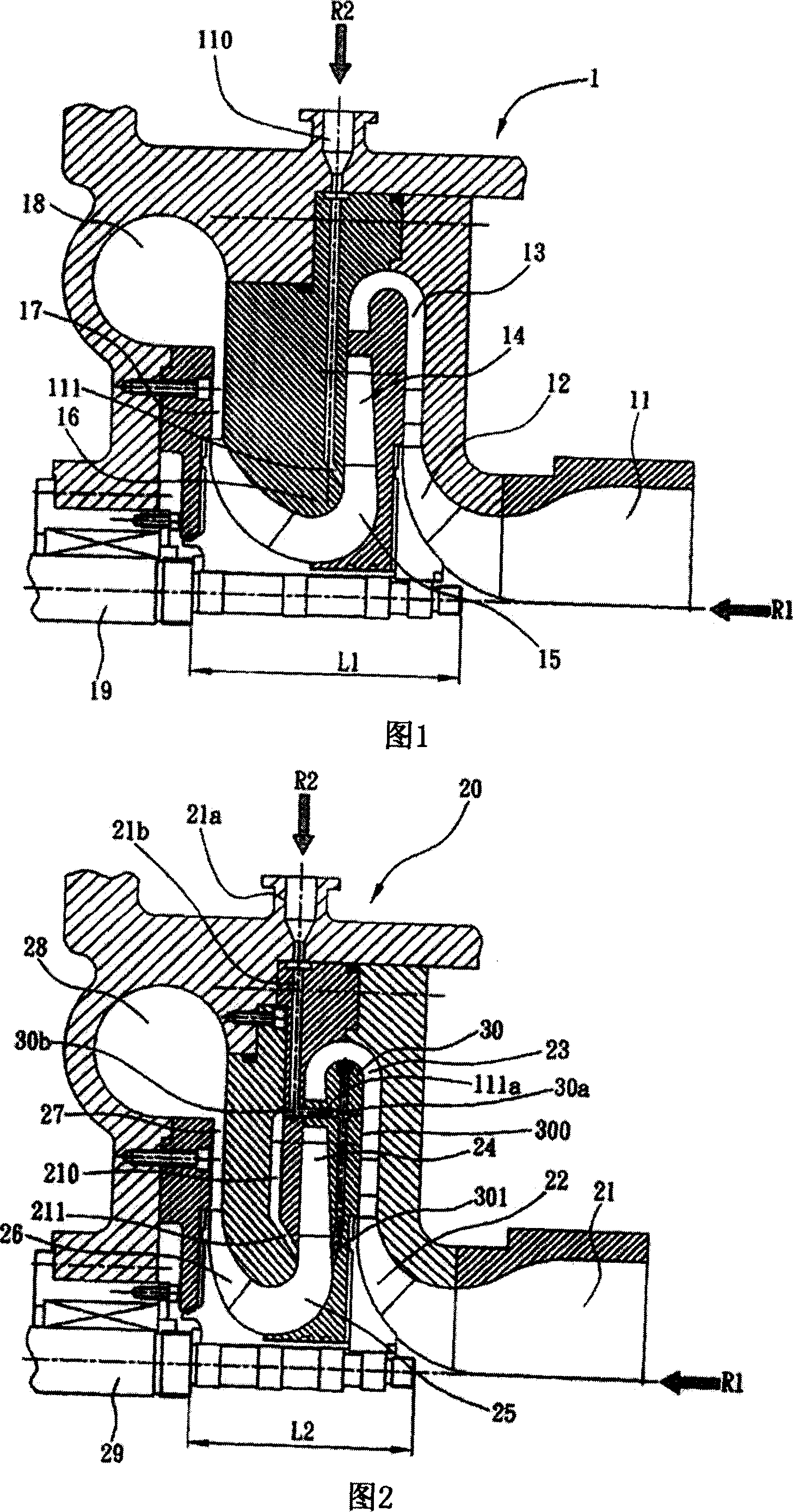

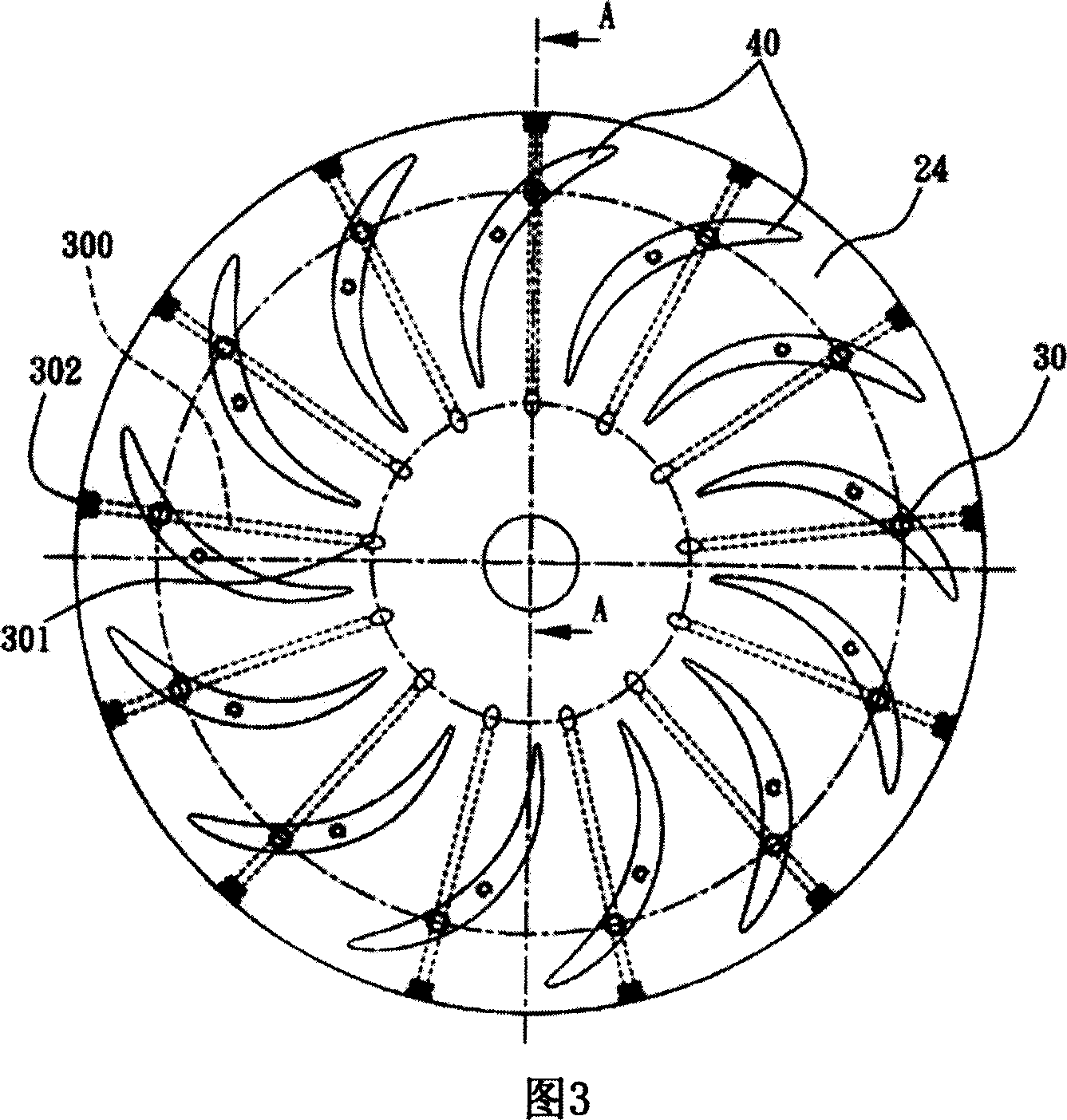

[0025] The compressor spray channel structure proposed by the present invention is arranged in a multi-stage centrifugal compressor, as shown in the embodiment shown in Figure 2, the multi-stage centrifugal compressor 20 is based on a two-stage centrifugal compressor For example, it comprises compressor inlet 21, first stage centrifugal compression impeller 22, first stage diffuser flow channel 23, return guide vane 24, return flow bend 25, second stage centrifugal compression impeller 26 as existing compressor , second-stage diffuser channel 27, volute 28 and other compression / diffuser flow components, and a high-speed shaft 29 (L2<L1) with an axial cantilever extension length of L2; at the same time, the outer high-speed shaft 29 The cantilever is connected in series with the first-stage centrifugal compression impeller 22 and the second-stage centrifugal compression impeller 26 .

[0026] At the same time, the compressor spray channel structure of the present invention is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com