Patents

Literature

45results about How to "Mix well and effectively" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Meteorologic balloon and production method thereof

ActiveCN101592742AThere will be no problem of uneven distributionAgainst destructive powerInstrumentsPotassium hydroxideDioctyl sebacate

The invention discloses a meteorologic balloon and a production method thereof. The raw materials consist of a solid raw material, an oily raw material and a gluey raw material; the solid raw material comprises the following components by weight: 0 to 0.30 portion of potassium hydroxide, 0 to 0.15 portion of casein, 0 to 0.10 portion of peregal O, 1.00 to 3 portions of sulfur, 1.00 to 2 portions of N-phenyl-2-naphthylamine, 1.00 to 2 portions of N-phenyl-N'-isopropyl-ursol, 1.50 to 3 portions of ethyl-phenyl-zinc dithiocarbamate, 0.20 to 5 portions of zinc oxide, and 5 to 30 portions of chloroprene polymer; the oily raw material is dioctyl sebacate, and the weight rate of the dioctyl sebacate is 5.00 to 10.0 portions; and the gluey raw material is centrifugally-concentrated natural latex, and the adding amount of the centrifugal concentrated natural latex is 100 portions. The weight of the meteorologic balloon is 1,600 to 1,700 grams, the length of the balloon body is 3.05 to 3.55 meters, the width of the ball handle is 10 to 11 centimeters, and the length of the ball handle is 12 to 16 centimeters. The meteorologic balloon can adapt to the requirement of probing high-altitude meteorological elements of more than 35,000 meters, has the advantages of good aging resistance, high blastoff height, long balloon service time and the like, and can effectively overcome the morning-evening difference.

Owner:CHEMCHINA ZHUZHOU RUBBER RES & DESIGN INST

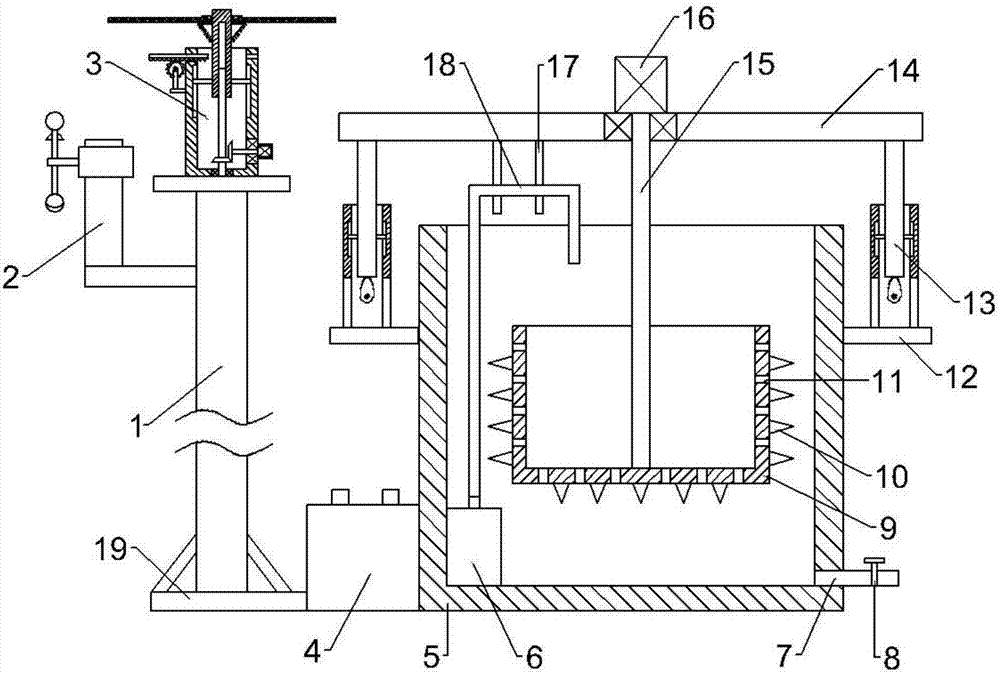

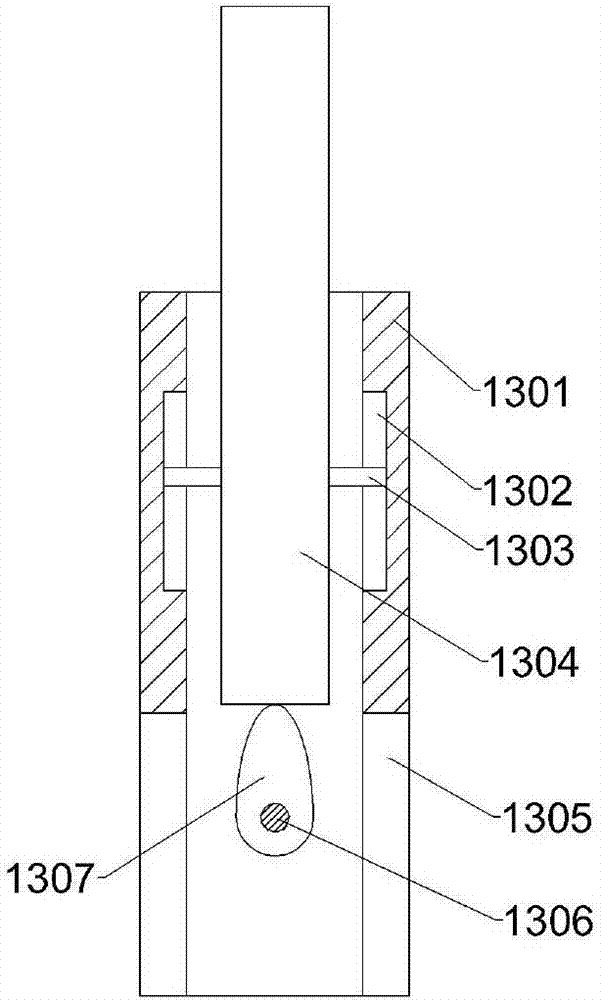

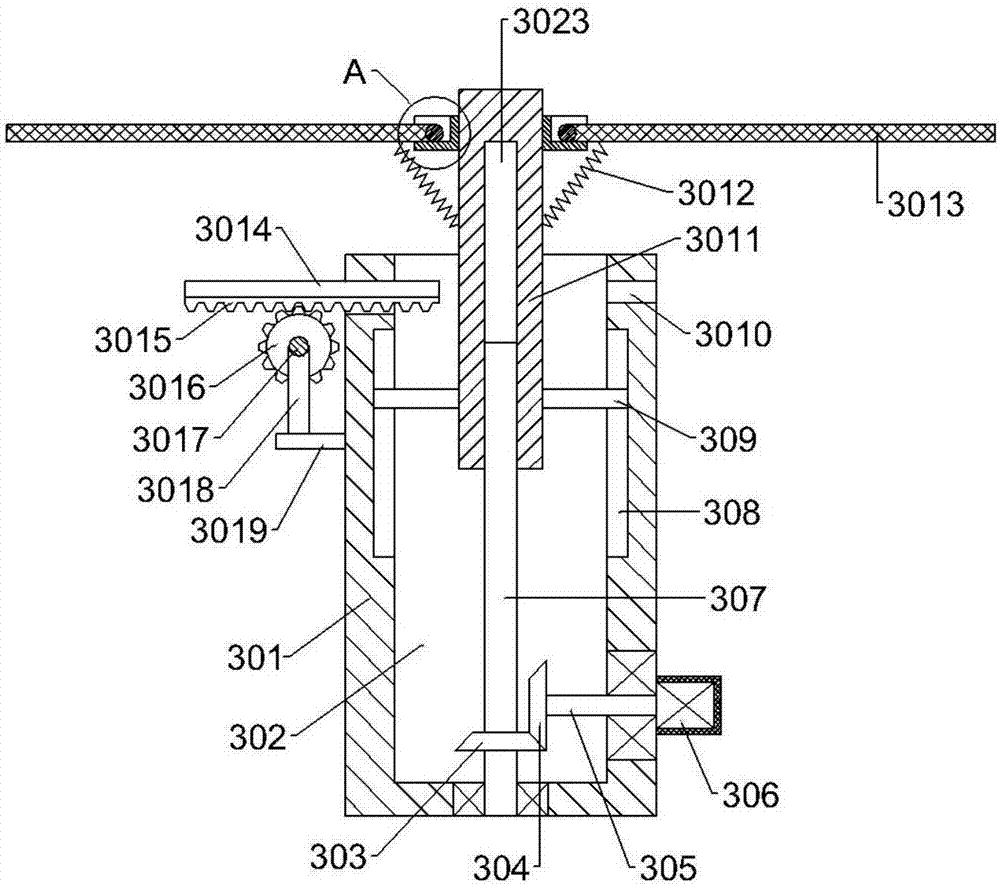

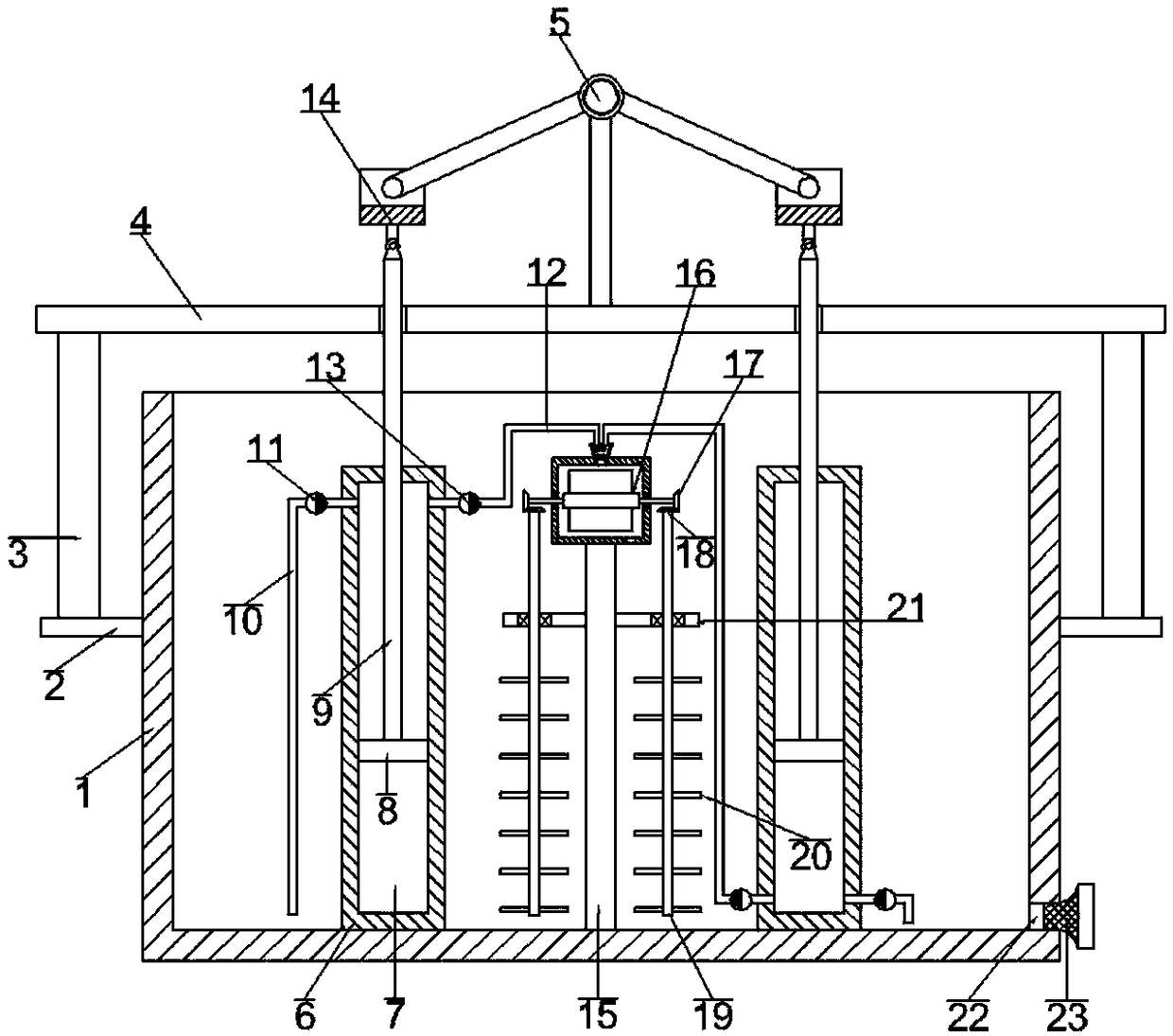

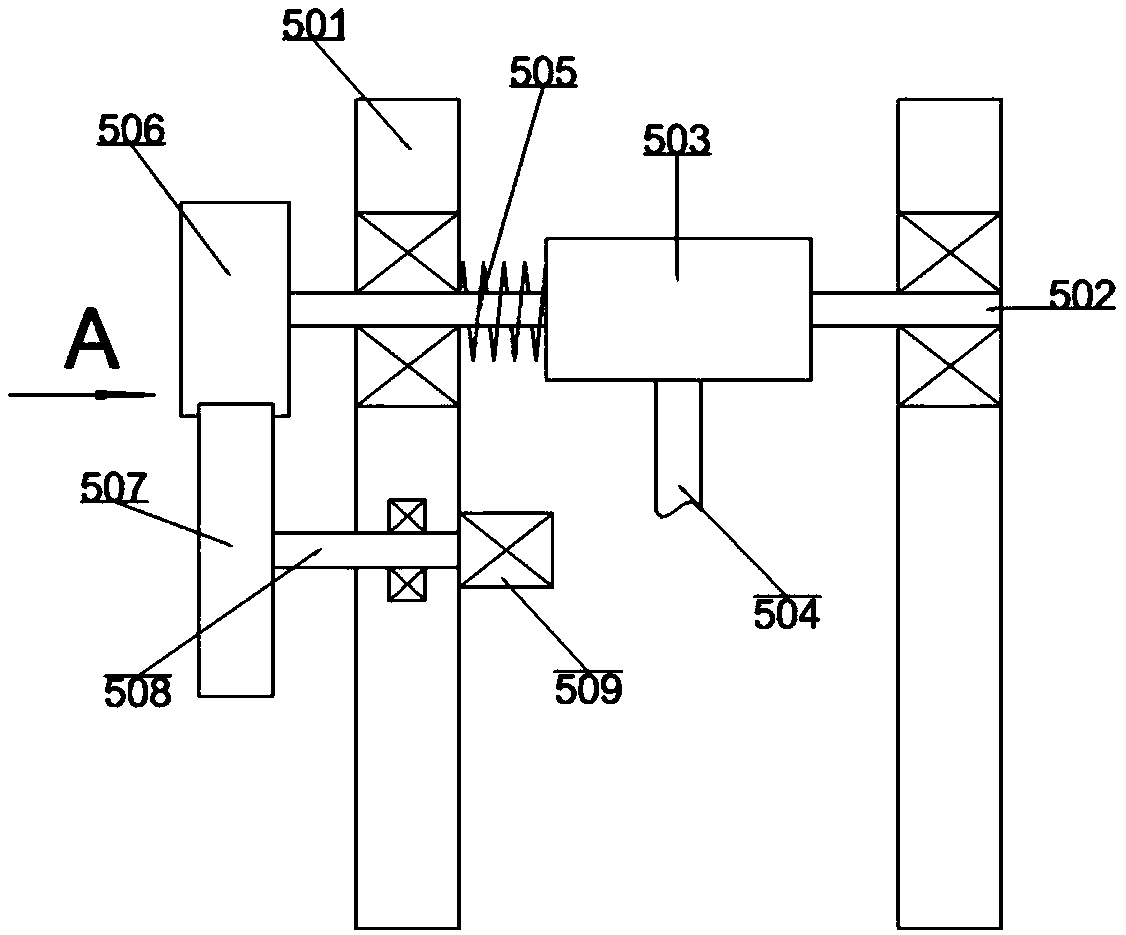

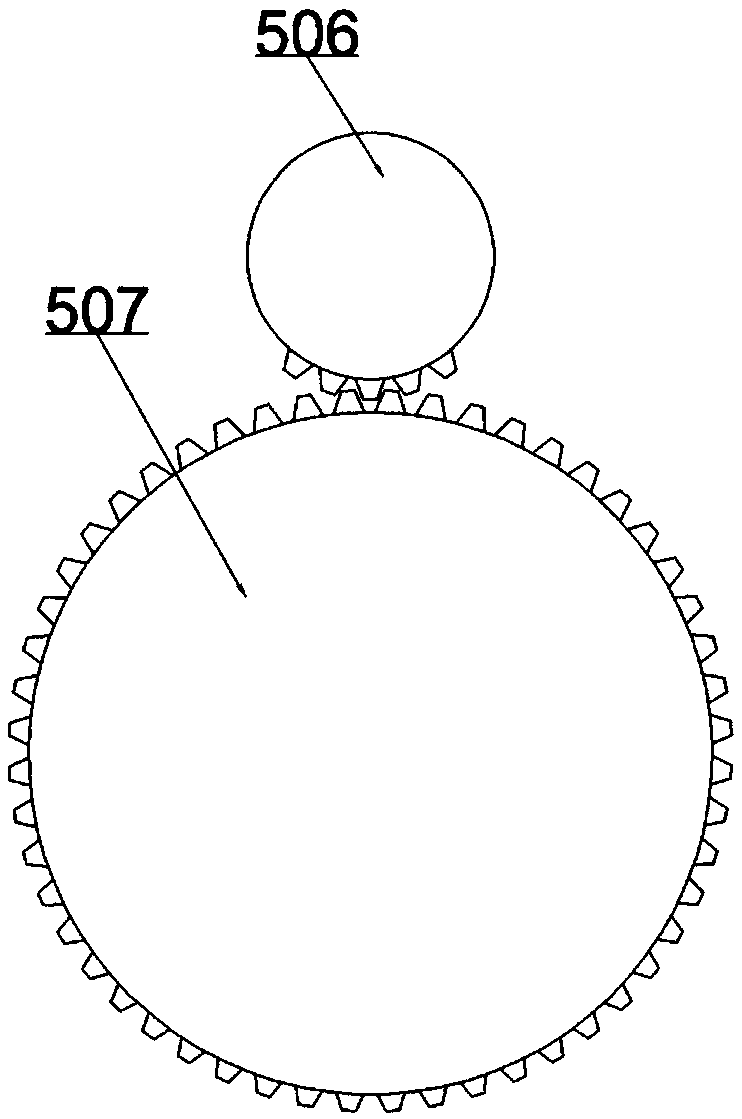

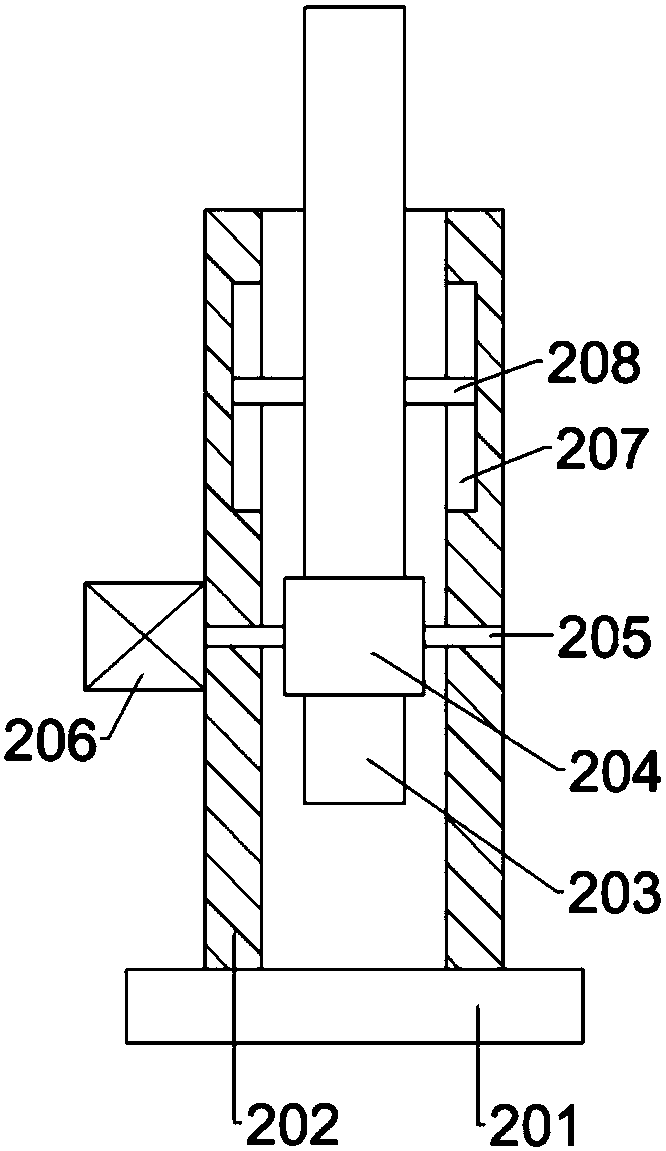

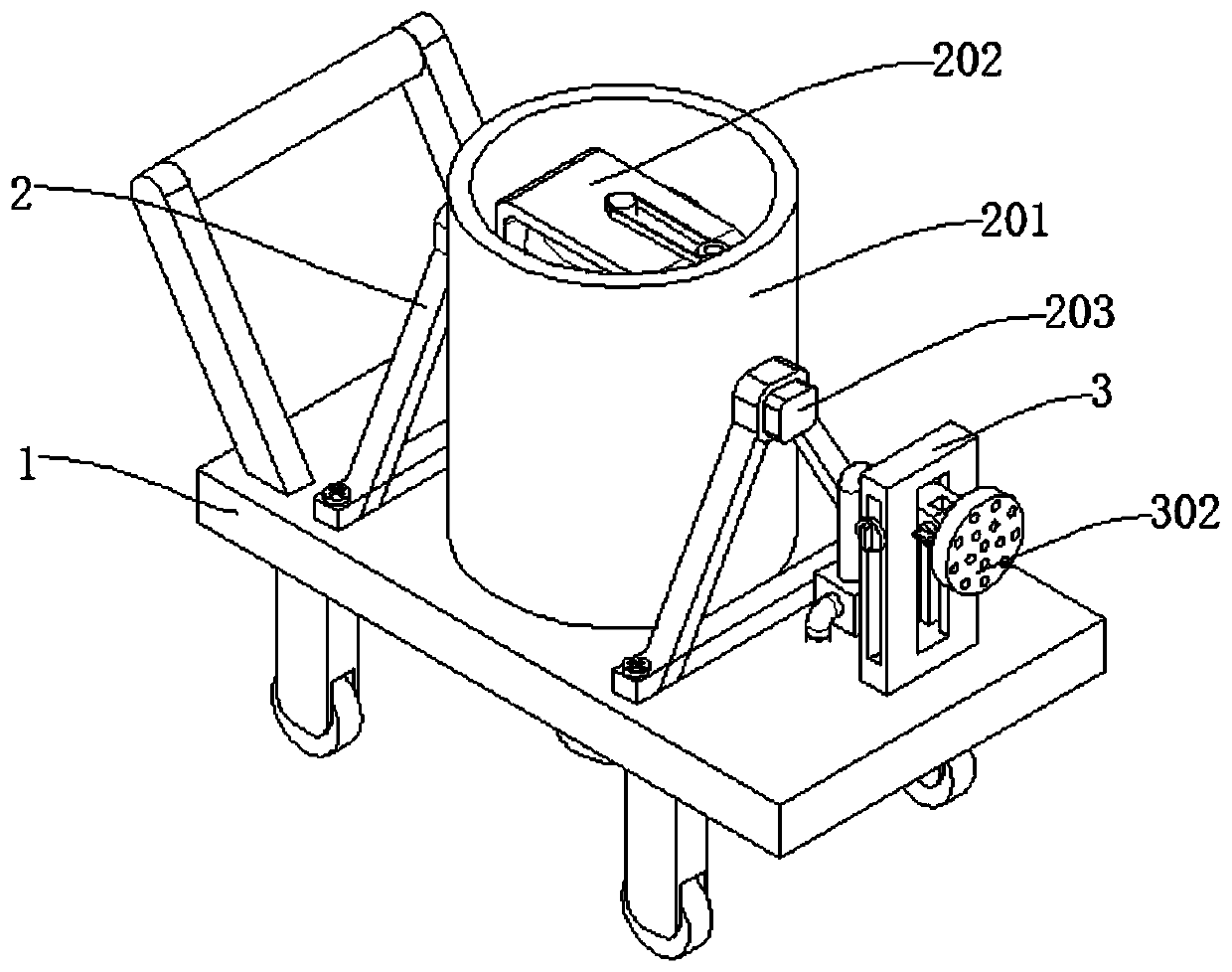

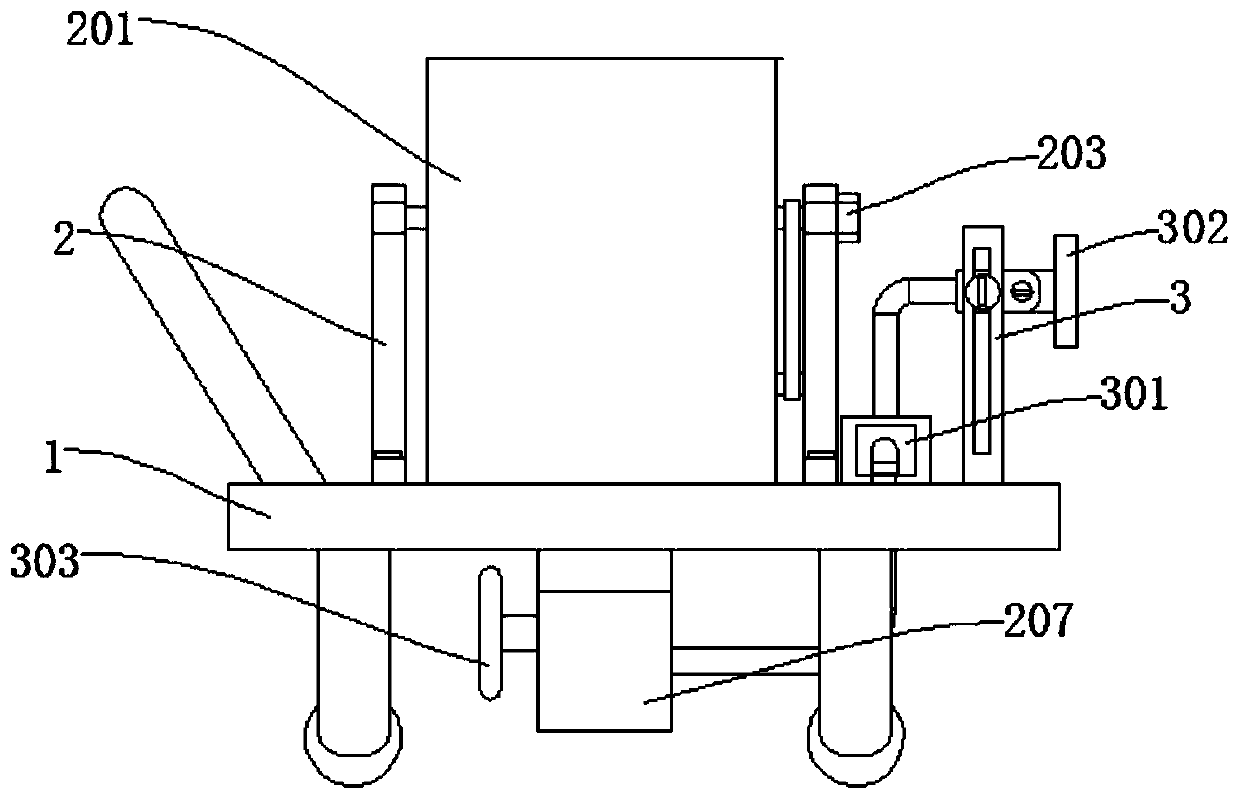

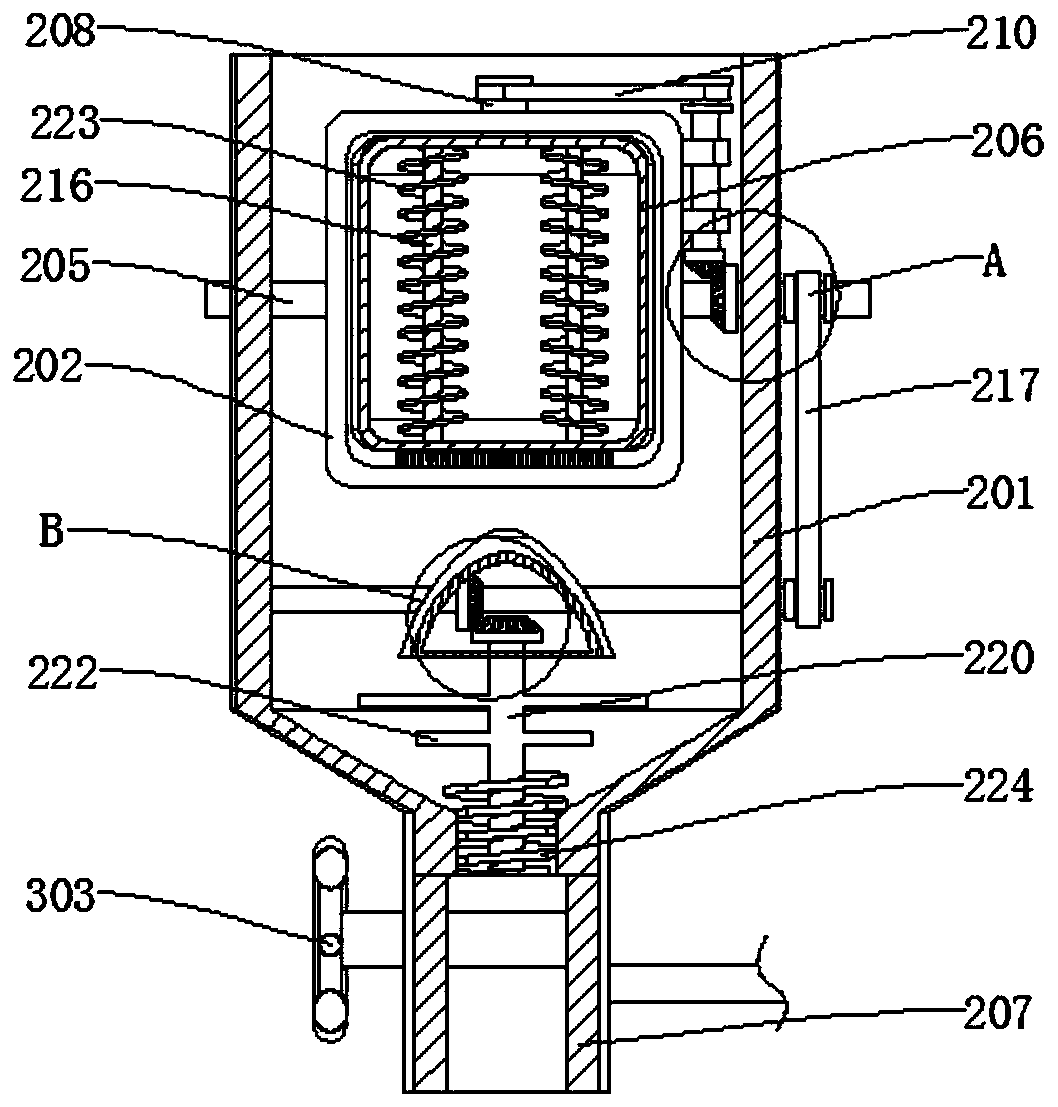

Water purifying plant based on complementary power supply by solar energy and wind energy

InactiveCN107265589AReduce erosionExtended service lifeWind motor with solar radiationWind energy with electric storageElectric power systemEngineering

The invention provides a water purifying plant based on complementary power supply by solar energy and wind energy. The water purifying plant comprises a mounting base; the upper side of the mounting base is fixedly connected with a support bar; the top end of the support bar is fixedly connected with a solar power generation device; the sidewall of the support bar is fixedly connected with a wind power generation device; the right side of the support bar is provided with a sewage treating device; the sewage treating device comprises a treating tank; the upper part of the treating tank is opened; the outer side wall of the treating tank is fixedly connected with two symmetric first installation seats; and the first installation seats are fixedly connected with a device carrying out reciprocating motion up and down. The water purifying plant provided by the invention has the following beneficial effects: solar cell panels in the solar power generation device can be hidden in rainy weather, so erosion of rain and water to the solar cell panels is reduced, and thus, the service life of the solar cell panels is prolonged; and the solar power generation device and the wind power generation device are employed for providing electric power sources to sewage treatment, so energy is effectively saved, and environmental protection is implemented.

Owner:邢均利

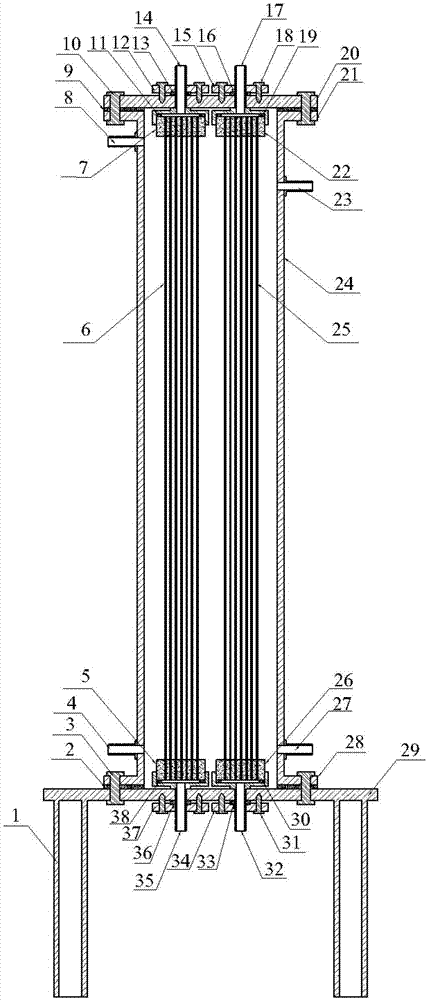

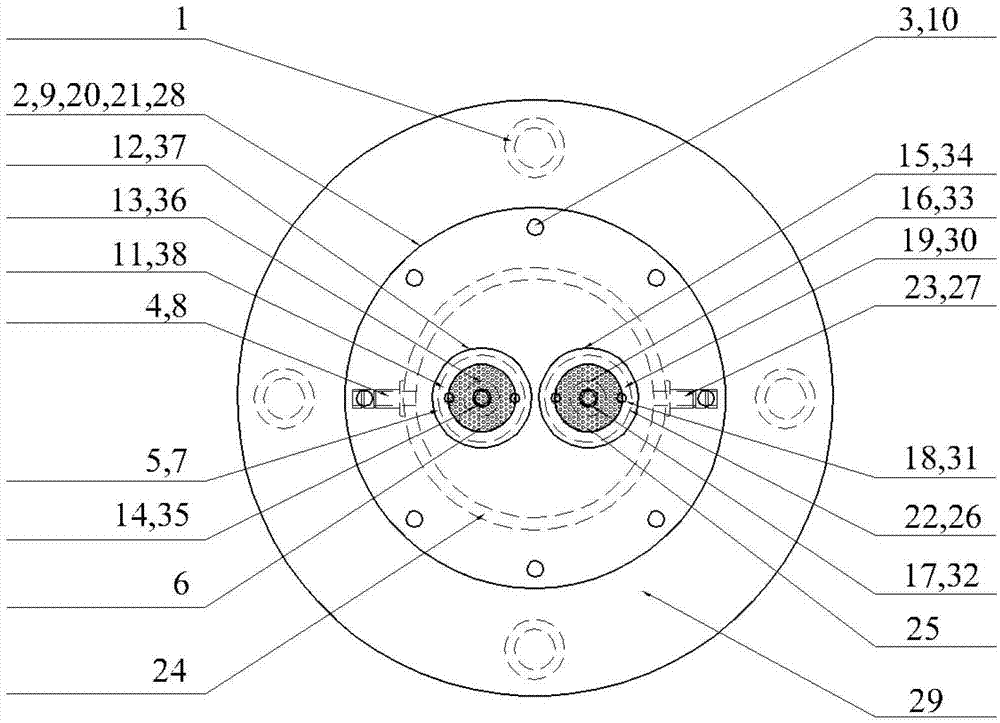

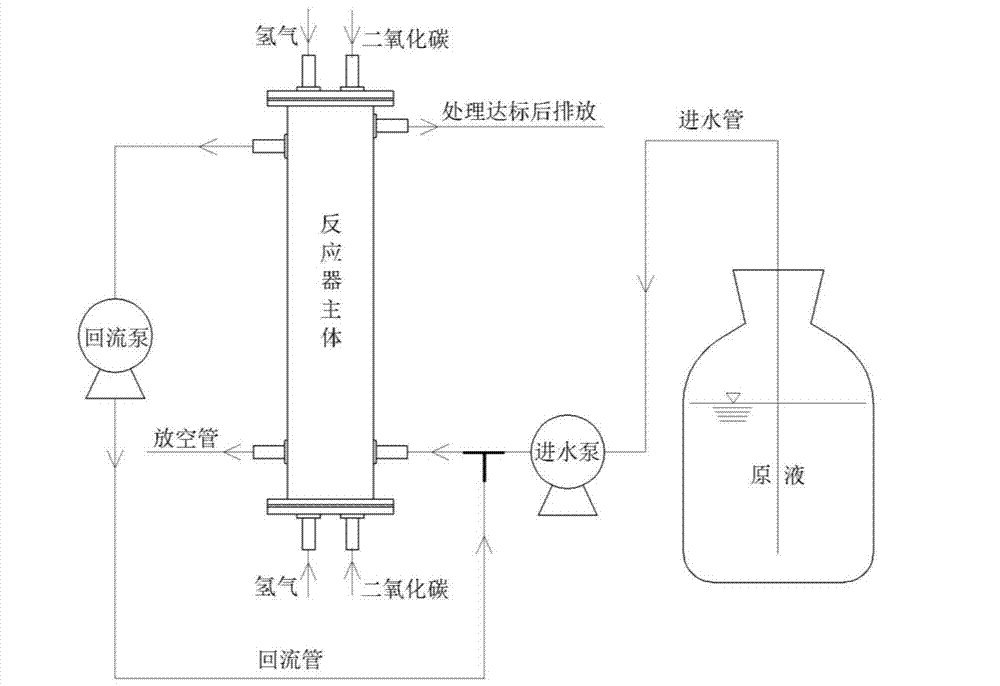

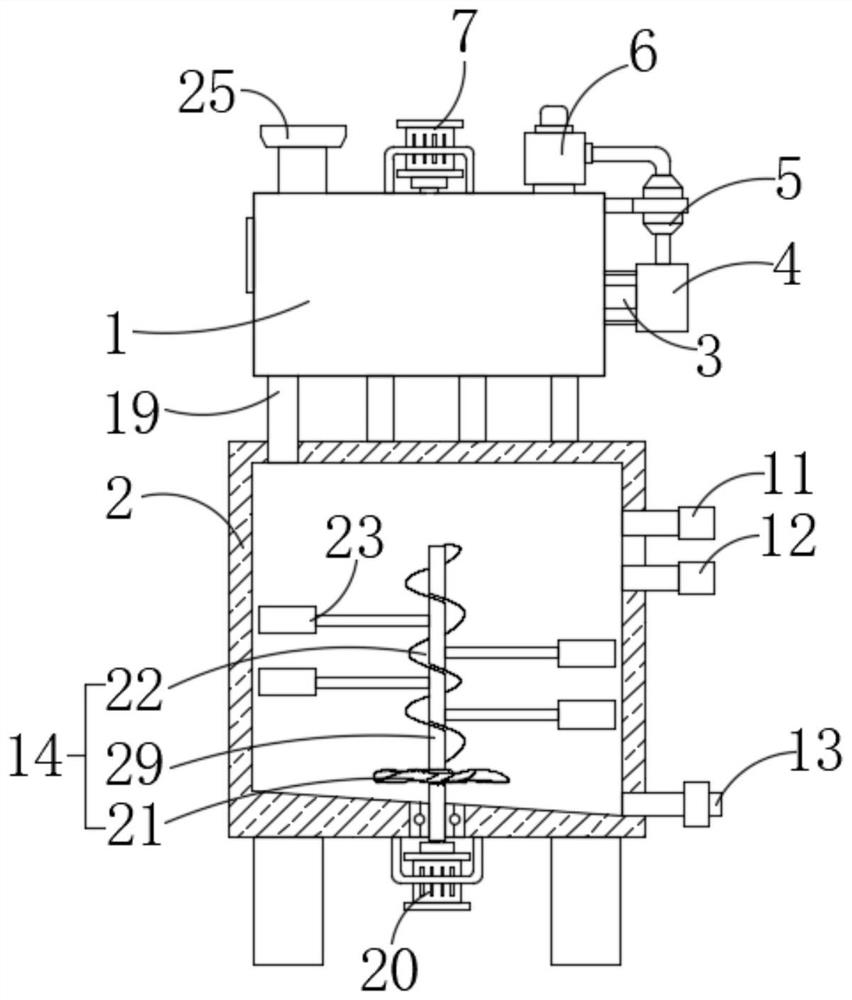

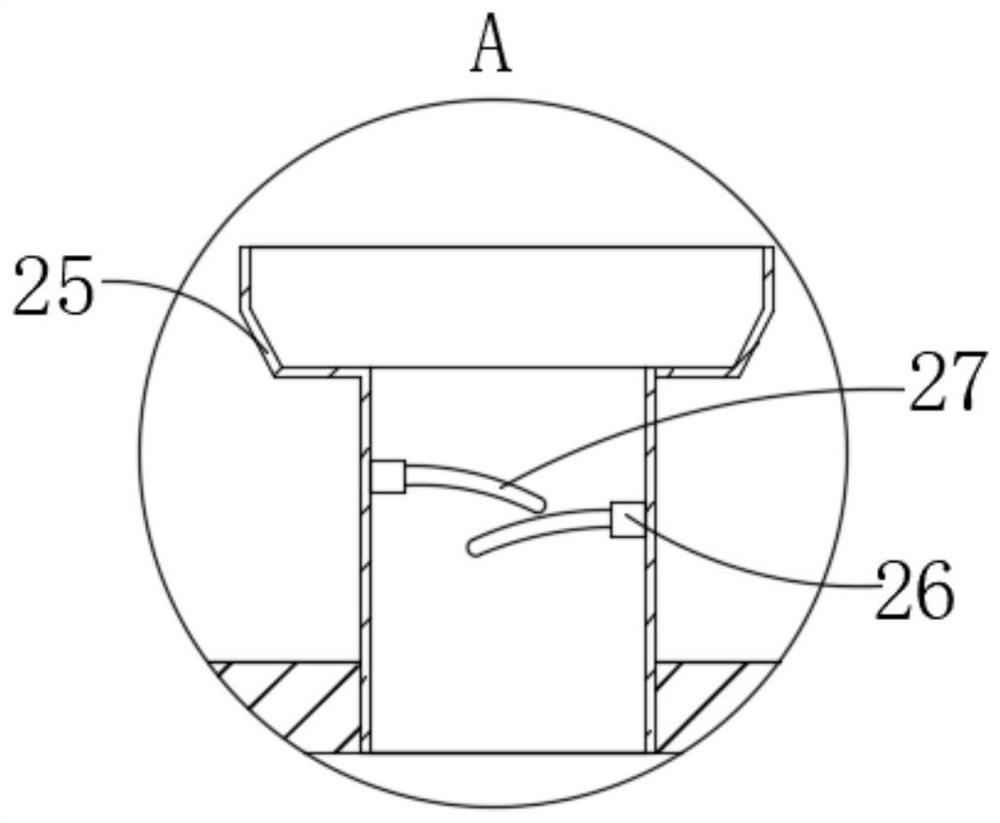

Backflow type hydrogen matrix bio-membrane reactor with carbon dioxide serving as carbon source

InactiveCN103043777APrevent precipitationMix well and effectivelyContaminated groundwater/leachate treatmentBiological water/sewage treatmentTherapeutic effectMembrane reactor

The invention relates to a backflow type hydrogen matrix bio-membrane reactor with carbon dioxide serving as a carbon source. The backflow type hydrogen matrix bio-membrane reactor comprises a reactor barrel body (24), wherein a water outlet (8) and a backflow port (23) are formed at the upper end of the reactor barrel body (24); a water inlet (27) and an emptying port (4) are formed at the lower end of the reactor barrel body (24); an 1# membrane module for feeding H2 and a 2# membrane module for feeding CO2 are arranged in the reactor barrel body (24); and membrane silks for forming the membrane modules are marketed PVDF (Polyvinylidene Fluoride) hollow fiber membranes which have outside diameter of 1.0 to 3.0mm, inside diameter of 0.5 to 1.5mm and membrane pore size of 0.01 to 0.4 microns. The backflow type hydraulic matrix bio-membrane reactor is reasonable in structure and good in treatment effect; CO2 can provide the carbon source for oligotrophic underground water and can stabilize the pH (Potential Of Hydrogen) of the environment; and the membrane aeration promotes the gas to dissolve in the water phase, thus the utilization rate of the gas can be improved, and the overflowing and waste of CO2 in the conventional aeration method can be avoided; the inner part of the reactor is kept in a complete mixing state by a backflow system, thus the benefit is provided for removing pollutants; the upper end and the lower end are used for ventilating, so that the shortcomings that the gas cannot be uniformly spread due to the on-way resistance and the utilization rate is low can be avoided; and the membrane can be cleaned without disassembling the membrane modules. The backflow type hydrogen matrix bio-membrane reactor with the carbon dioxide serving as the carbon source can be used for effectively treating oxidation pollutants in the underground water.

Owner:TONGJI UNIV

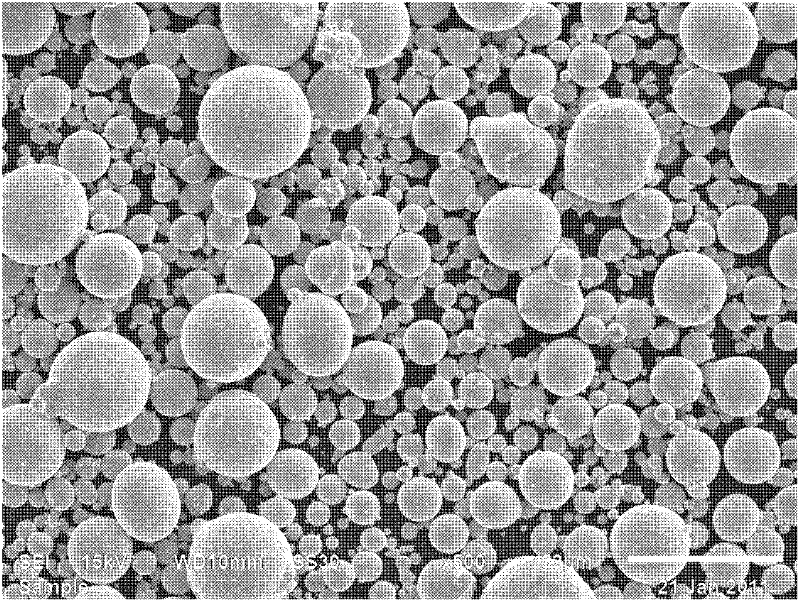

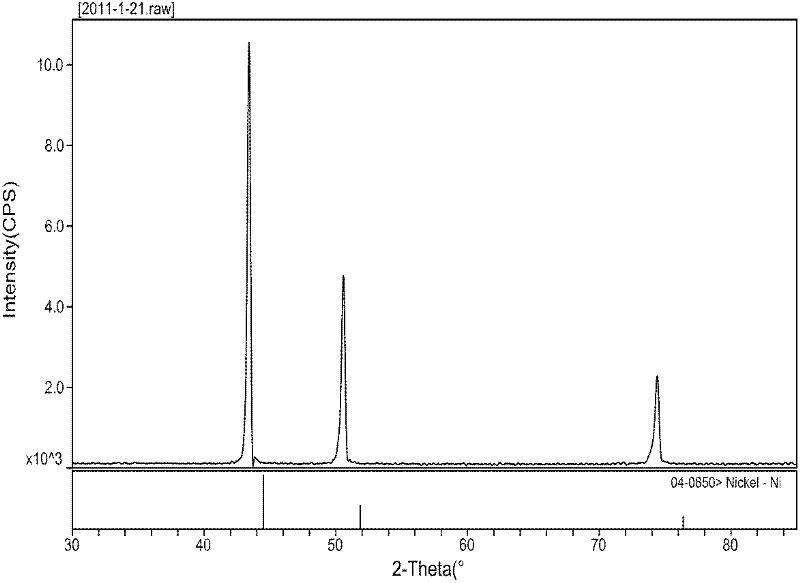

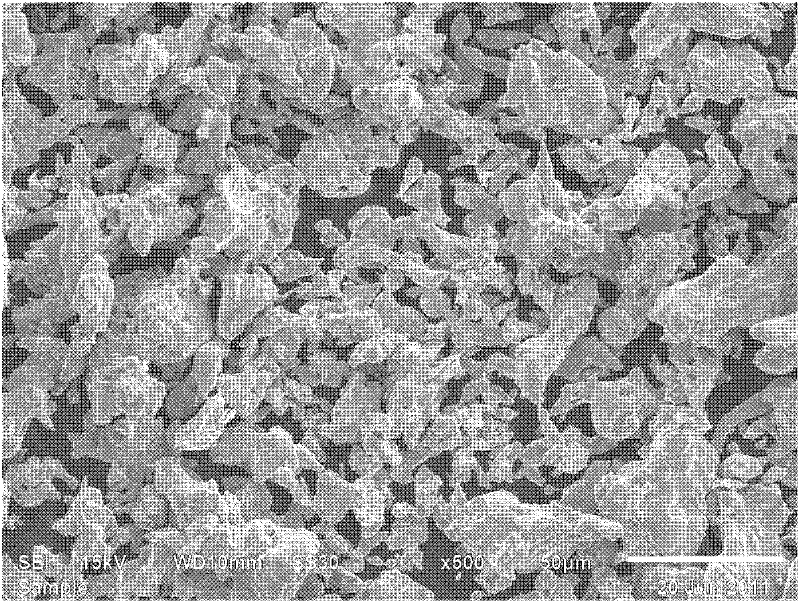

Method for preparing nickel-cobalt-manganese alloy powder

InactiveCN102513541AUniform compositionThe composition is uniform and denseMisch metalHydrometallurgy

The invention provides a method for preparing nickel-cobalt-manganese alloy powder. Molten mixed metal liquid is atomized through high-pressure gas or high-pressure water of specific pressure intensity to form particles, and the alloy powder is used for preparing a precursor of a ternary lithium ion battery anode material. The nickel-cobalt-manganese alloy powder prepared by adopting the method has the advantages of uniform and compact components, high density and controllable granularity, so that uniformity, compactness, high density and controllable and adjustable granularity of a nickel-cobalt-manganese oxide precursor prepared in the subsequent prepared ternary material are ensured, the precursor can be mixed with a lithium compound uniformly, and the obtained ternary material has uniform component and high density. The preparation technology and the subsequent ternary material preparation technology do not involve hydrometallurgy, do not product waste water, and are environment-friendly.

Owner:先进储能材料国家工程研究中心有限责任公司

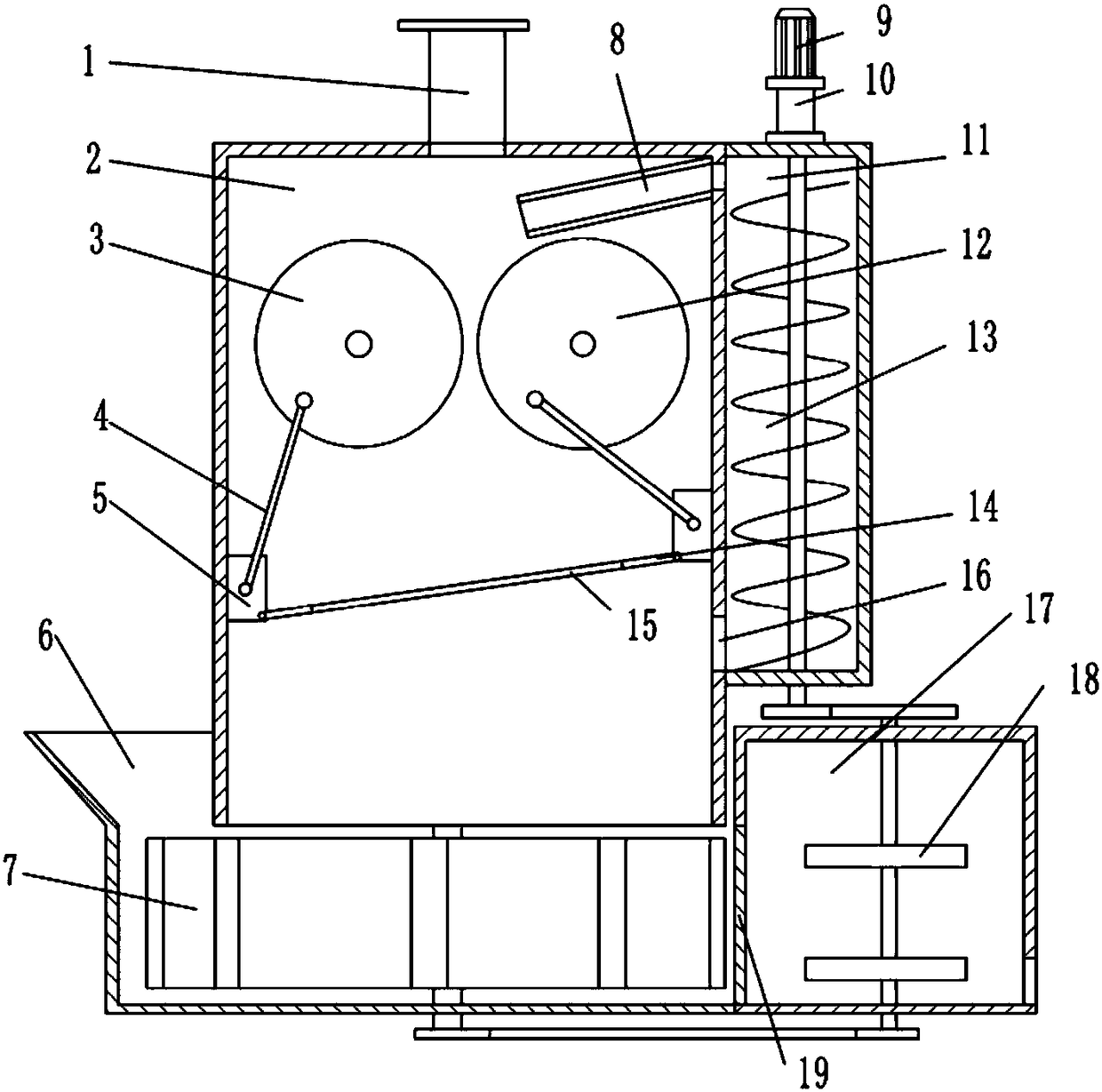

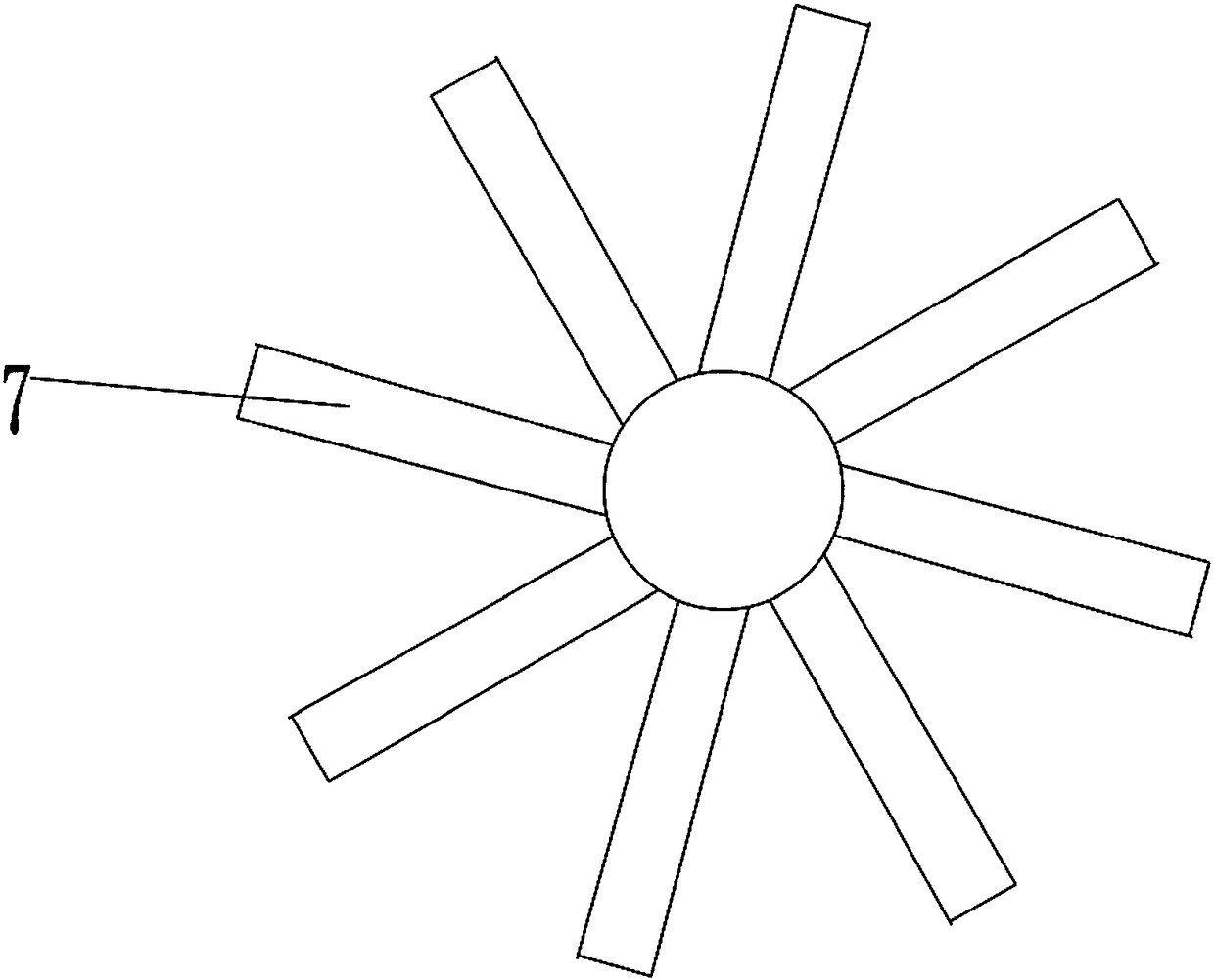

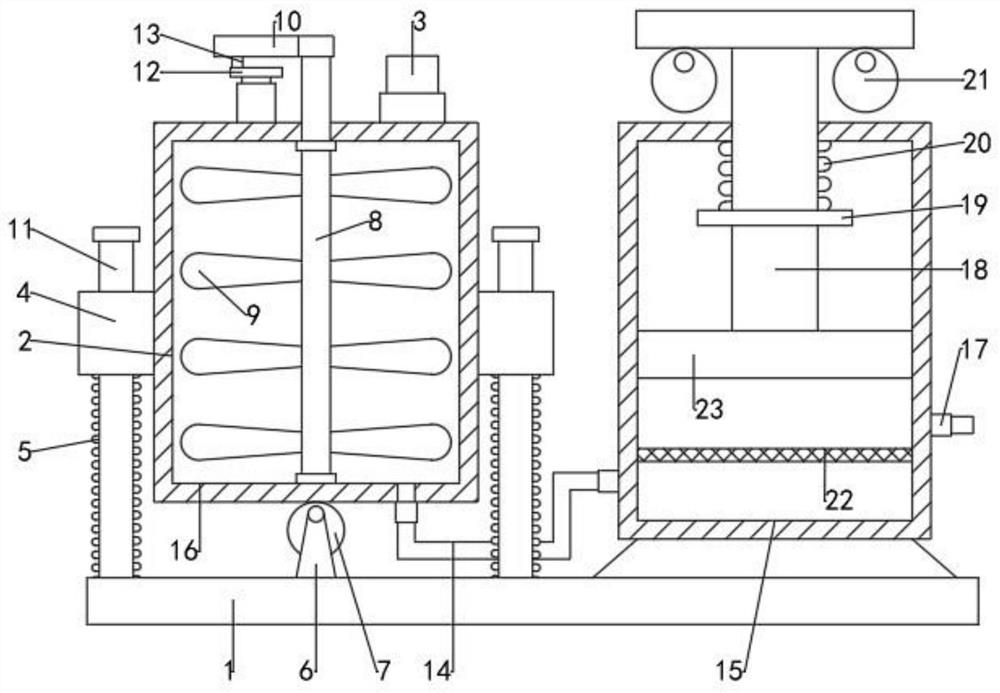

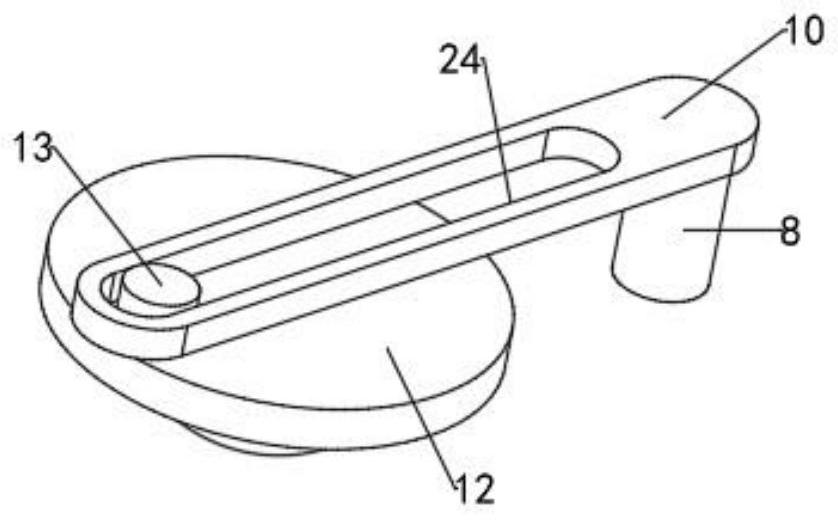

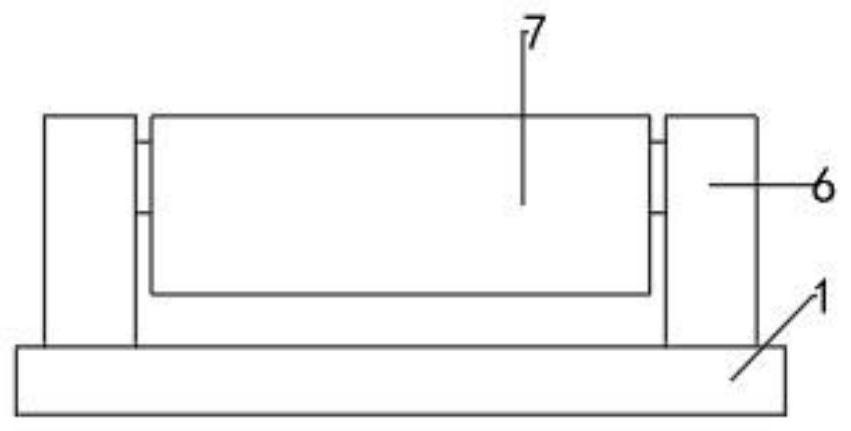

Heat-preservation material mixing device

InactiveCN108057381ATo vibrateAvoid cloggingRotary stirring mixersTransportation and packagingMechanical engineeringCrankshaft

The invention belongs to the technical field of material mixing devices and in particular discloses a heat-preservation material mixing device which comprises a crushing part, a conveying part and a mixing part, wherein a first crushing roller and a second crushing roller are arranged inside a crushing bucket to crush raw materials; the first crushing roller, the second crushing roller, connectingrods and sliding blocks form a bias crankshaft sliding block mechanism; a filtering net is arranged between the two sliding blocks; a material circulation hole is formed in a side wall when the sliding blocks are moved to a lowest point; a circulation bucket with spiral conveying blades is mounted outside the material circulation hole; the circulation bucket is communicated with the upper part ofa crushing bucket; the conveying part is communicated with the lower end of the crushing part; the conveying part comprises a conveying bucket; a second feeding hole and shifting blades are arrangedinside the conveying bucket; the mixing part is communicated with the conveying part; the mixing part comprises a mixing bucket; stirring blades and a discharge hole are arranged inside the mixing bucket. By adopting the scheme of the invention, the problems that heat-preservation materials are not uniformly mixed and the stirring time is too long, are solved.

Owner:宁波得晴电器科技有限公司

Efficient printing and dyeing stirrer

ActiveCN107233838AMix well and effectivelyImprove the mixing effectShaking/oscillating/vibrating mixersRotary stirring mixersEngineeringMixing effect

The invention discloses an efficient printing and dyeing stirrer which comprises a workbench, wherein a protecting box is fixedly connected with the top of the workbench; a shell is fixedly connected with the top of the protecting box; a second motor is fixedly connected with the rear side of the inner wall of the shell. According to the invention, through the cooperative use of a second bevel gear, a support pillar, the protecting box, a first stirring shaft, a first stirring blade, a shell, a second stirring blade, a second stirring shaft, a first bevel gear, a first motor, an electric stretchable rod, a first spring, a connecting block, a slide rod, a slide block, a slide slot, a second spring, the second motor, a gear and a toothed plate, various printing and dyeing auxiliaries can be uniformly and efficiently mixed, the advantage of better mixing effect can be achieved, the problem of poor mixing effect caused by the mixing for various materials of the present spinning stirrer can be solved, the quality of the printing and dyeing fabric can be guaranteed, the user can conveniently use and the practicability of the spinning stirrer can be promoted.

Owner:SUZHOU CHENHAO TEXTILE TECH CO LTD

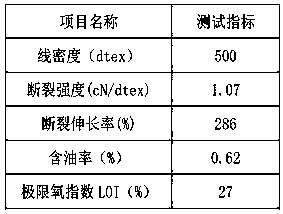

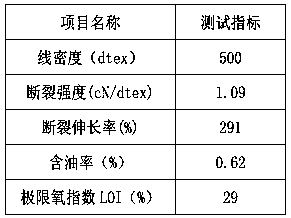

Preparation method of halogen-free flame retarding PETG composite fibers

InactiveCN108842203AImprove flame retardant performanceImprove heat resistanceFlame-proof filament manufactureArtificial thread manufacturing machinesFiberPolyester

The invention relates to the technical field of production of polyester fibers, in particular to a preparation method of halogen-free flame retarding PETG composite fibers. The preparation method comprises the specific steps of (1) preparation of halogen-free flame retarding master batches, (2) preparation of halogen-free flame retarding nascent fibers with the Y-shaped sections, and (3) winding forming of the halogen-free flame retarding fibers. The obtained halogen-free flame retarding PETG composite fibers have significant effects in flame retardance and heat resistance, the limit oxygen index (LOI) of the halogen-free flame retarding PETG composite fibers can be 29, and the halogen-free, low-smoke and environment-friendly flame retarding requirements are met. In addition, the sectionsof the fibers are designed in a Y shape, so that the fibers can absorb, deliver, diffuse and volatilize water rapidly, and obtained products are soft and comfortable and have the moisture absorption and quick-drying effects.

Owner:新凤鸣集团股份有限公司

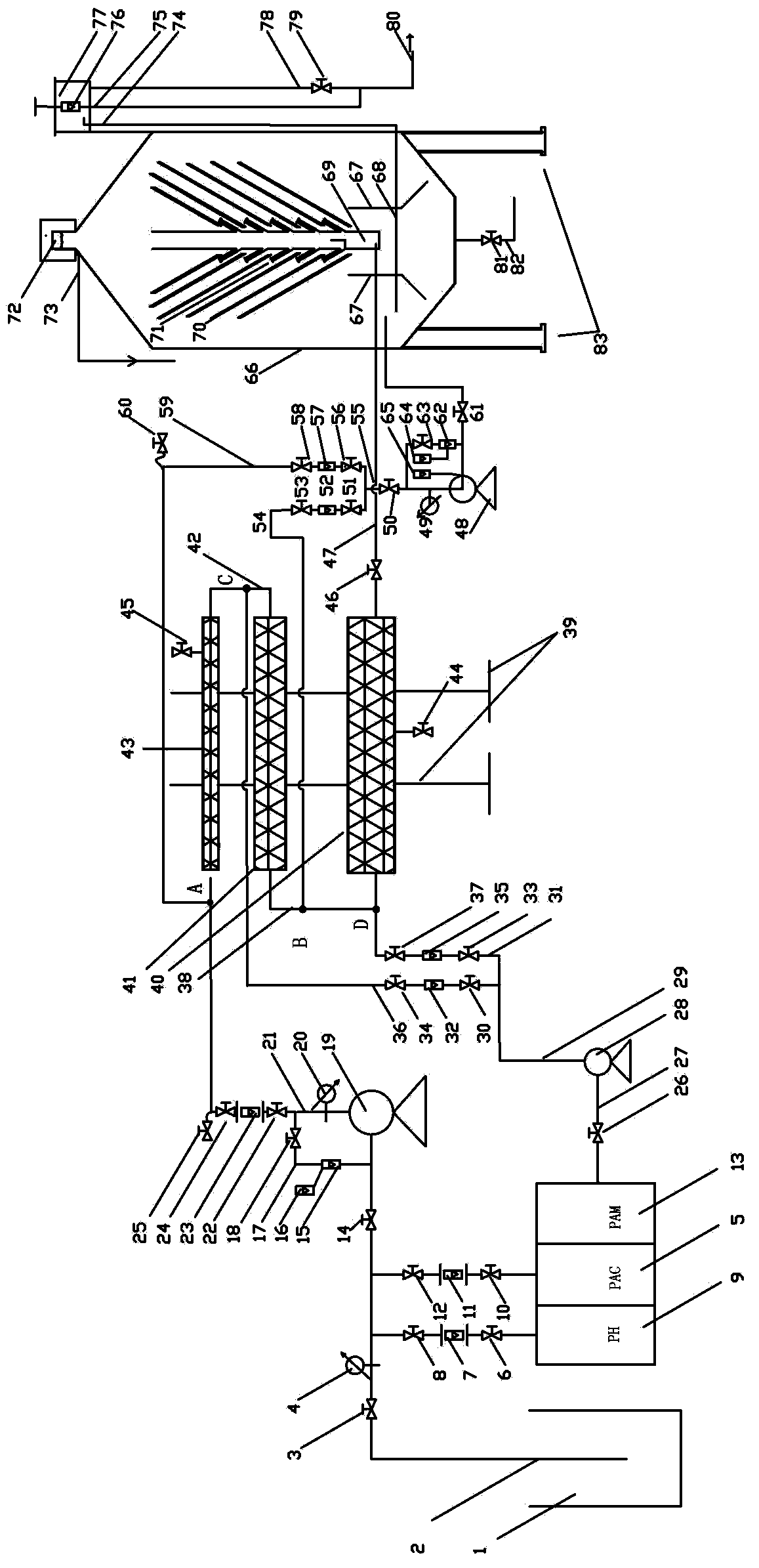

Coagulation-floatation and co-coagulation solid-liquid separation device and solid-liquid separation method

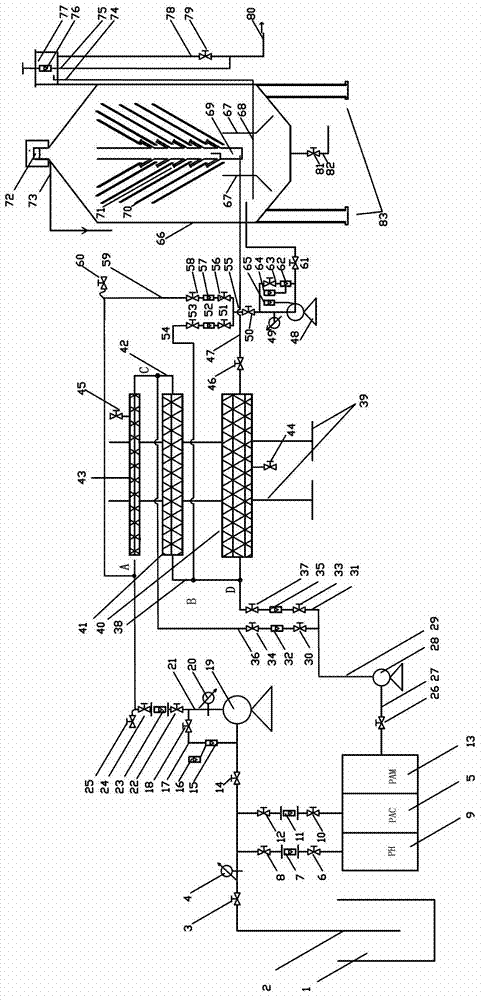

InactiveCN103112971AImprove separation efficiencyImprove stabilityMultistage water/sewage treatmentWater/sewage treatment by flotationWastewaterEngineering

The invention belongs to sewage treatment equipment, and particularly relates to a coagulation-floatation and co-coagulation solid-liquid separation device and a solid-liquid separation method. The separation device is characterized by being formed by sequentially installing a sewage medicating-mixing system, a multiphase medium pump air-dissolving system, a mixed reaction co-coagulation system and a co-coagulation solid-liquid separation device at a sewage pool; the separation device disclosed by the invention is reasonable in design and compact in structure, and provided with an independent mixed co-coagulation reaction and co-coagulation solid-liquid separation system; moreover, optimization for a coagulation-floatation and co-coagulation-floatation separation process is realized, and a variable-water-level dross removal method is used for dross removal; and the separation device has the characteristics of being simple and convenient, small in overall floor area, less in investment, high in efficiency, and the like. The separation device and the separation method are especially suitable for treating colloids and suspended matters in sewage and waste water generated during production and life processes, so as to realize solid-liquid separation.

Owner:DALIAN JIAOTONG UNIVERSITY

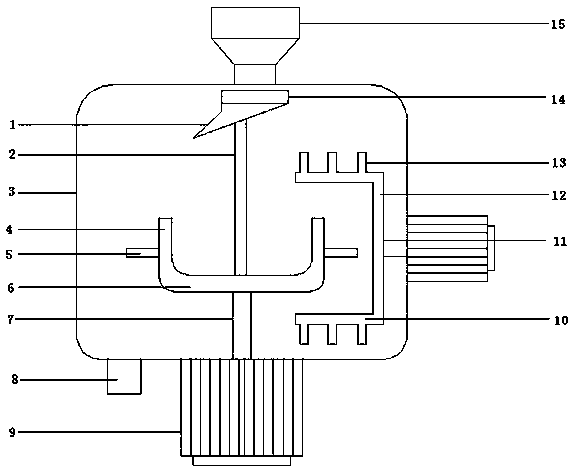

Biogas production device with high biomass energy utilization rate

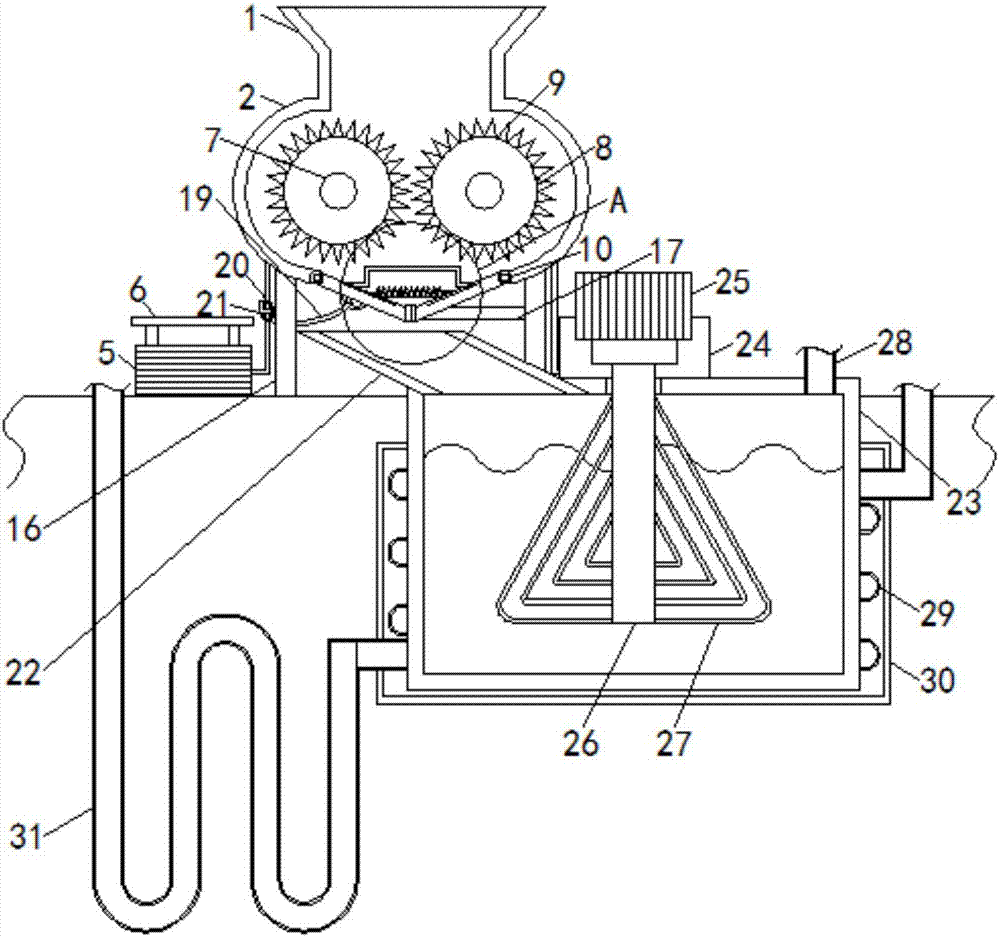

ActiveCN107988050AHigh utilization rate of biomass energyIncrease profitBioreactor/fermenter combinationsBiological substance pretreatmentsEcological environmentNew energy

The invention relates to the technical field of new energy sources and discloses a biogas production device with a high biomass energy utilization rate. The biogas production device comprises a feeding hopper, wherein the bottom of the feeding hopper is fixedly connected with a crushing cylinder; the back surface of the crushing cylinder is fixedly connected with a supporting plate; two crushing motors are fixedly mounted at the top of the supporting plate; opposite sides of the two crushing motors are electrically connected with a power accumulation box. By adopting the biogas production device with the high biomass energy utilization rate, a lot of electric energy is saved and the utilization rate of the new energy sources is improved; the contact area of anaerobic fermentation materialsis enlarged and a proper reaction amount of reactants is controlled; the anaerobic reaction efficiency is improved; meanwhile, the reactants can be sufficiently and effectively mixed and the speed ofanaerobic reaction is improved; reaction temperature which is most suitable for the anaerobic reaction is provided and the decomposition of raw materials is accelerated so that the biogas productionamount is greatly improved and the energy sources are saved; meanwhile, the utilization rate of biomass energy is greatly improved and pollution to an ecological environment is effectively avoided.

Owner:杭州皖云科技有限公司

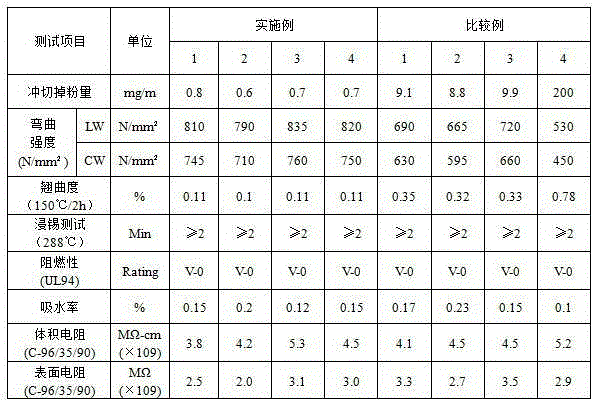

Imidazole compound, preparation method and thermosetting composition containing imidazole compound

The invention discloses a general formula (I) of an imidazole compound. The novel imidazole compound is prepared by prepolymerizing macromolecular or super-large molecular compounds such as buna-n rubber, polymethyl methacrylate and phenoxy resin which are difficult to dissolve with other chemical components with imidazole; the relevant problems generated when the materials such as the buna-n rubber, the polymethyl methacrylate and the phenoxy resin are applied to a thermosetting composition are solved, and the excellent characteristics such as the high tenacity, the high strength, the shock resistance, the low deformation and the performance of being free of powder dropping in die cutting of the imidazole compound are fully achieved by evenly and effectively mixing the imidazole compound with an epoxy compound, a curing cross-linking agent, a curing accelerator, granulous reinforced inorganic filler and the like; a die pressing material, a laminated material, a casting material and the like which are prepared from the thermosetting composition have the advantages of being excellent in tenacity, strength and shock resistance, low in deformation after thermal shock, free of powder dropping in die cutting and the like.

Owner:GUANGDONG HINNO TECH CO LTD

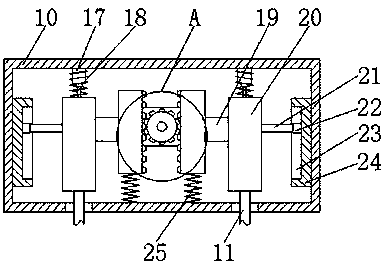

Left-right swinging type based flocculating agent mixing equipment for sewage treatment

PendingCN108793367AAchieving re-stirringImprove the mixing effectTransportation and packagingMixersCheck valveSewage sludge treatment

The invention provides left-right swinging type based flocculating agent mixing equipment for sewage treatment. The left-right swinging type based flocculating agent mixing equipment comprises a tankbody, wherein two mounting seats are symmetrically and fixedly connected with an outer side wall of the tank body; supporting columns are fixedly connected onto the mounting seats; a supporting plateis commonly fixedly connected with the top ends of the two supporting columns; a left-right swinging device is fixedly connected with the middle of the upper side of the supporting plate; two mountingcolumns are symmetrically and fixedly connected with the bottom in the tank body; cavities are formed in the mounting columns; extruding plates are arranged in the cavities; a liquid inlet pipe and aliquid outlet pipe are connected with the mounting column above the extruding plate at the left side; a liquid inlet pipe and a liquid outlet pipe are connected with the mounting column above the extruding plate at the right side; each liquid inlet pipe is provided with a liquid inlet check valve and each liquid outlet pipe is provided with a liquid outlet check valve. The left-right swinging type based flocculating agent mixing equipment for the sewage treatment, provided by the invention, has the following beneficial effects that an extruding column at the left side drives the extruding plate to move upward and an extruding column at the right side drives the extruding plate to move downward; the two extruding plates are used for extruding mixed liquid in the cavities through the liquidoutlet pipes.

Owner:刘丽

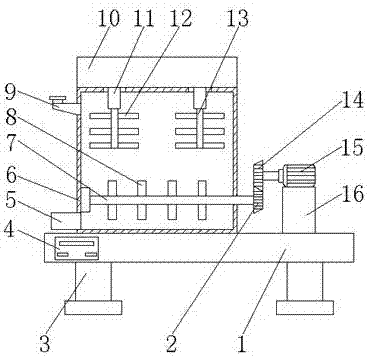

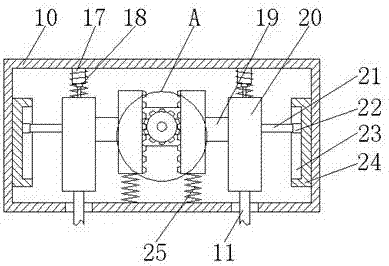

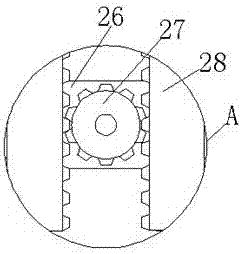

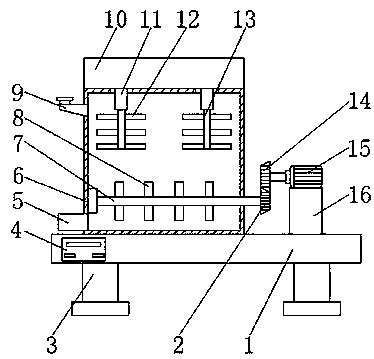

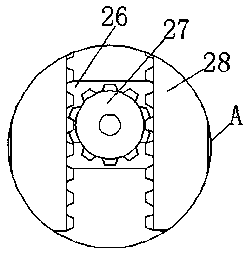

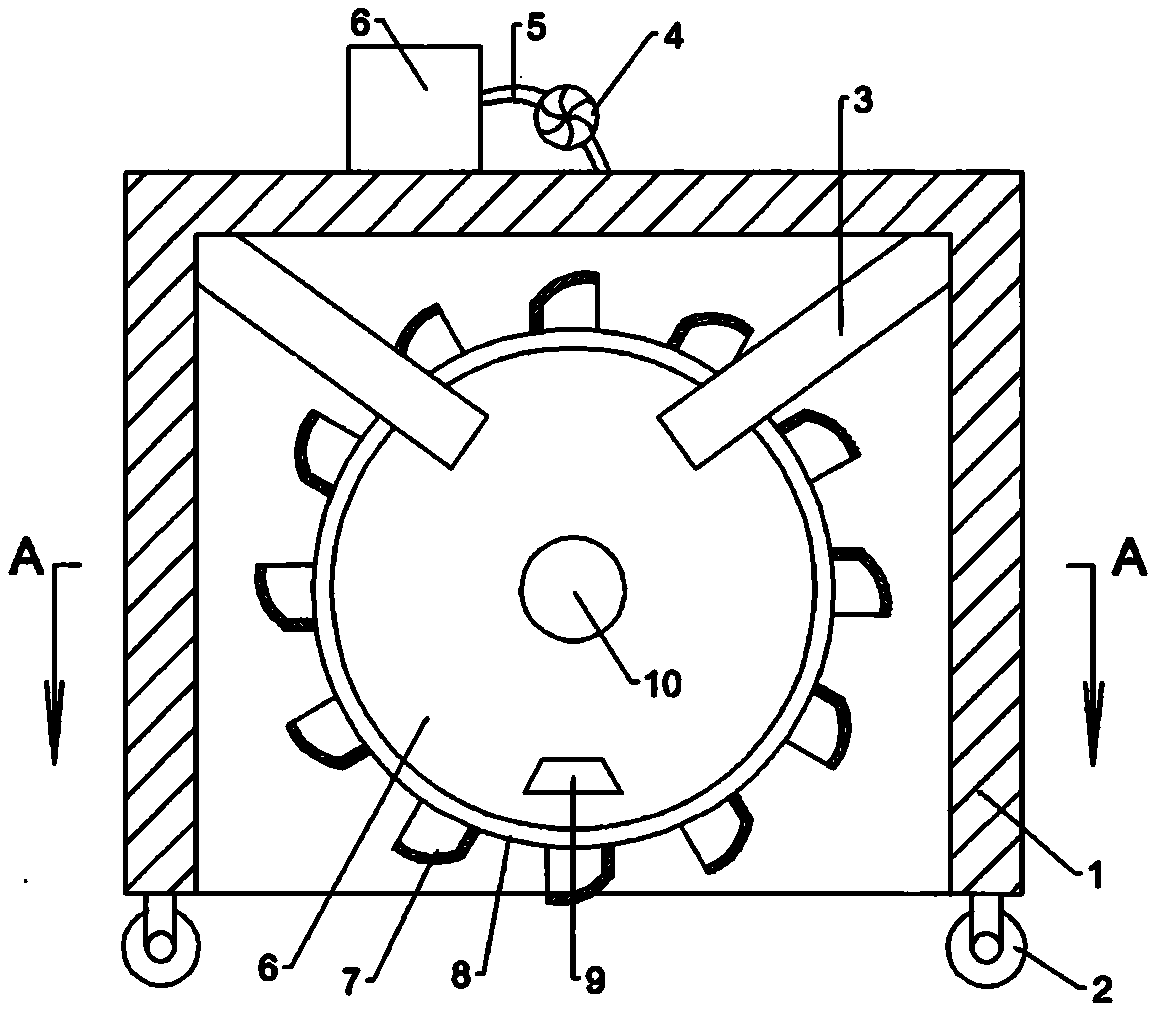

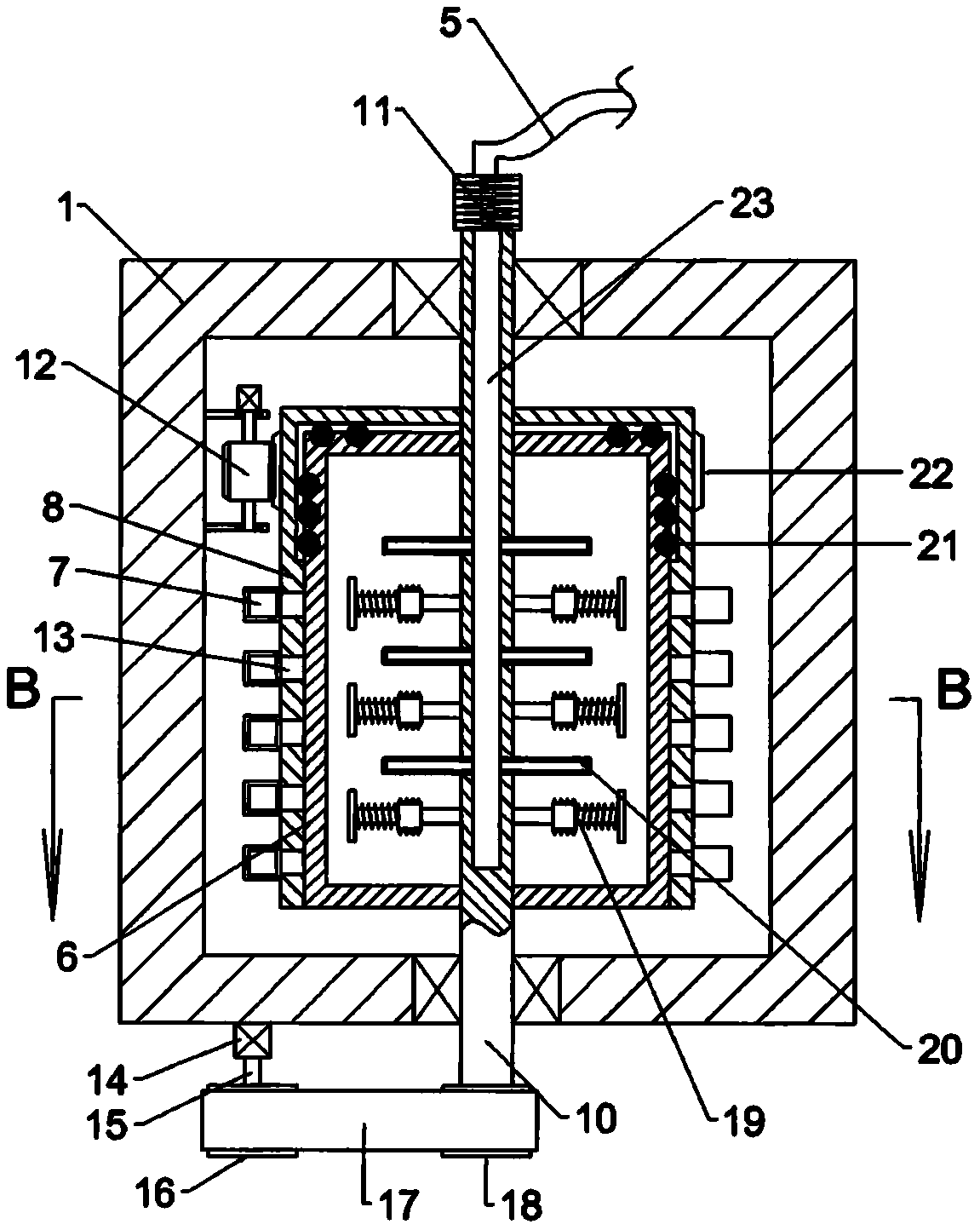

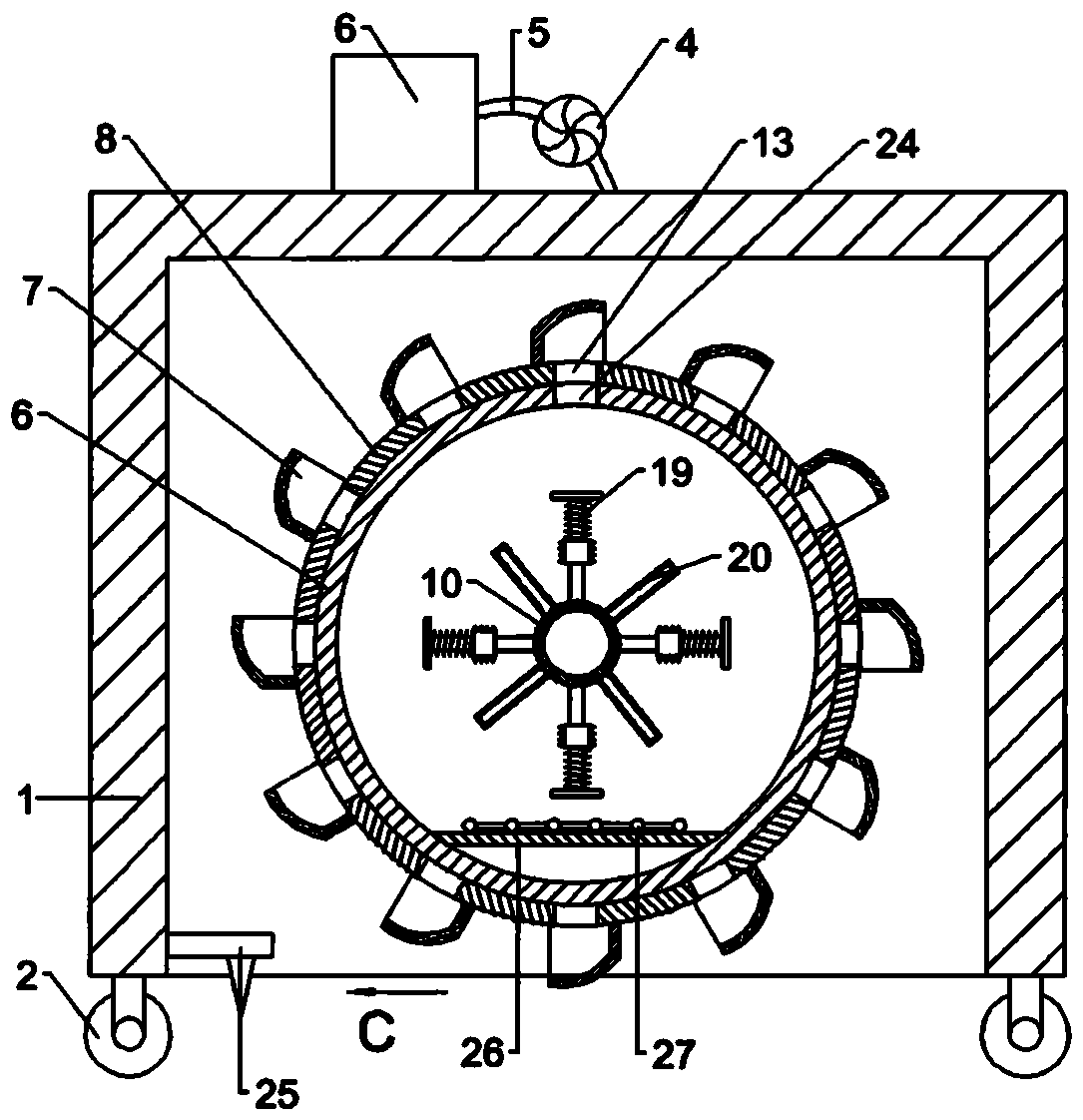

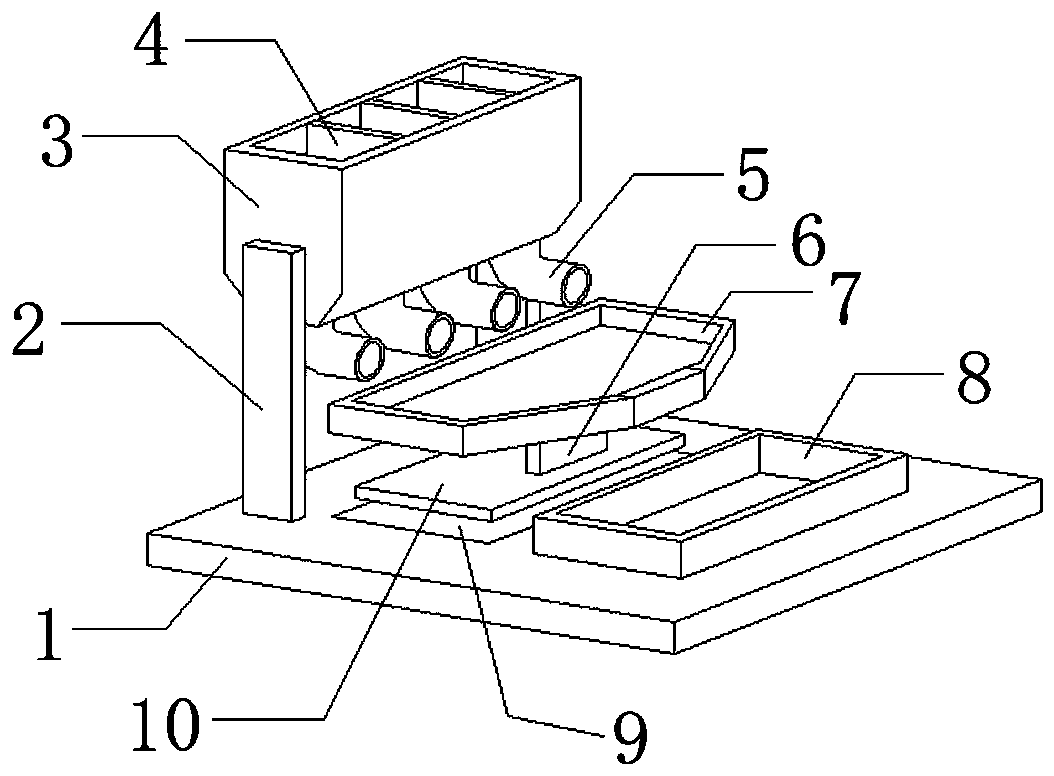

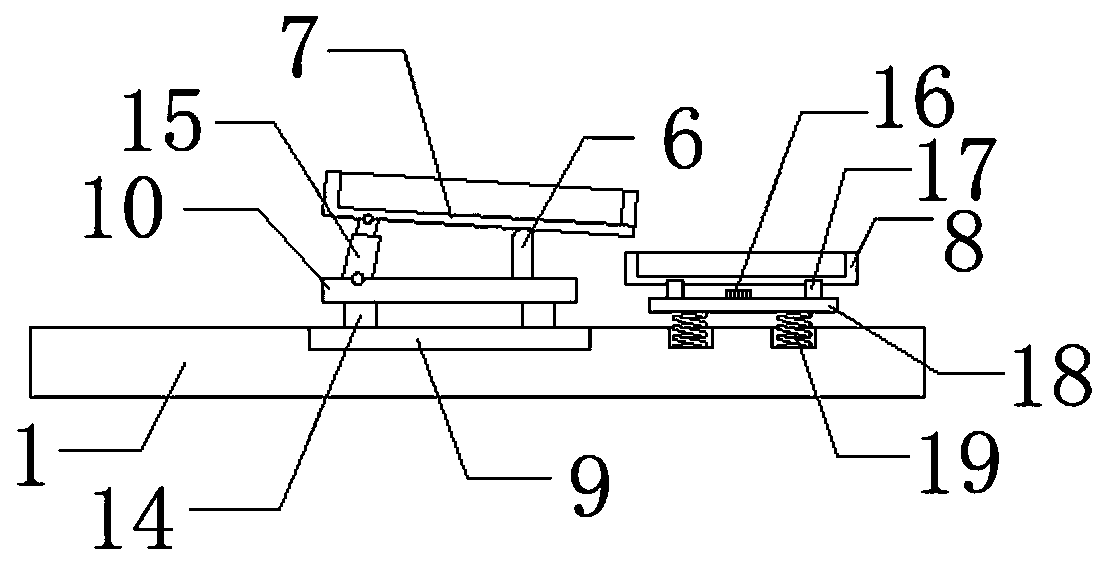

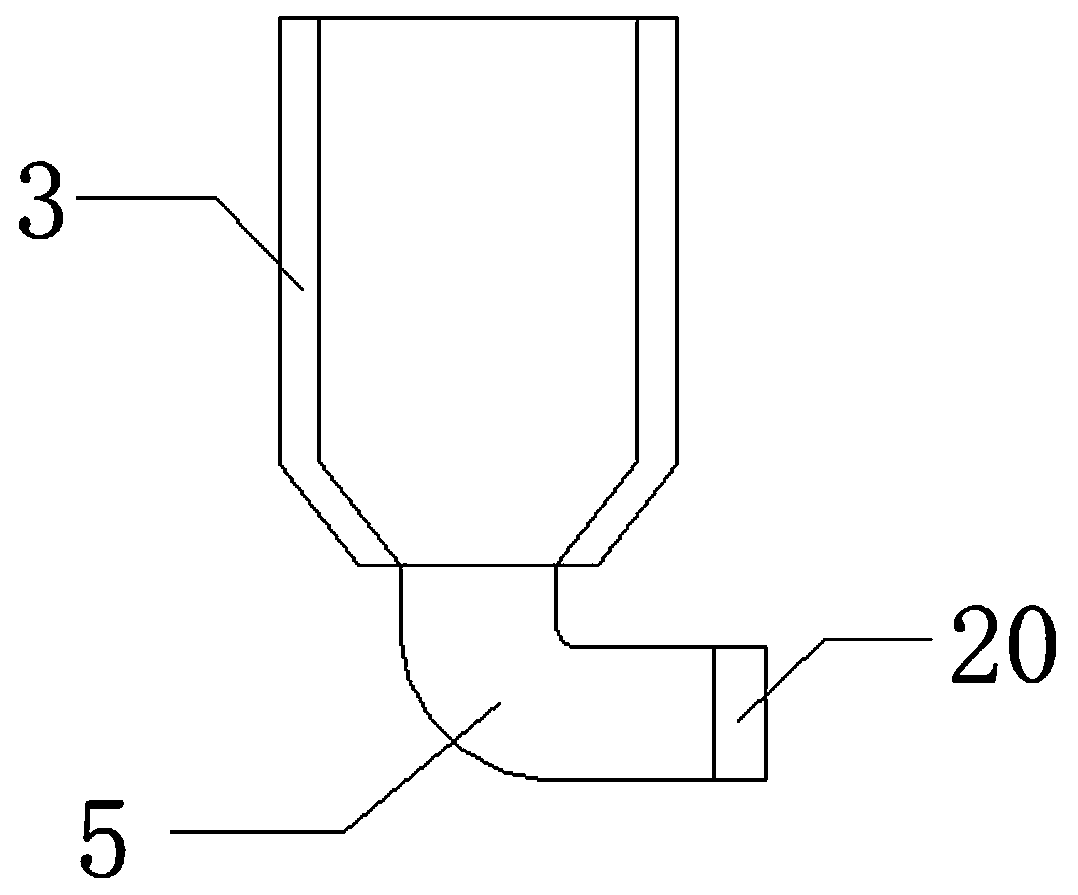

Textile slurry mixing device on basis of gear and rack lifting

InactiveCN108404722AIncrease heightMix well and effectivelyShaking/oscillating/vibrating mixersRotary stirring mixersEngineeringSlurry

The invention discloses a textile slurry mixing device on the basis of gear and rack lifting. The textile slurry mixing device comprises a shell. Gear and rack lifting devices are arranged on the outer side wall of the shell and comprise mounting seats, sleeves are fixedly connected onto the mounting seats, racks are arranged in the sleeves, gears mesh with the front sides of the racks, first rotary shafts are fixedly connected onto the gears and are erected on the sleeves, and the outer ends of the first rotary shafts are fixedly connected with output shafts of first motors; a first cylinderis fixedly connected to the middle of the inner bottom of the shell, and a first cavity is arranged inside the first cylinder. The textile slurry mixing device has the advantages that the gears can bedriven by the first motors to rotate, the racks which mesh with the gears can upwardly move, and accordingly a support plate can rise; elevated materials can be fed into a second cavity via feed through holes, then can be ejected from discharge through holes and can be collided with barriers in ejection procedures, and accordingly materials can be uniformly and effectively mixed and treated by the aid of the textile slurry mixing device.

Owner:绍兴柯桥双典纺织有限公司

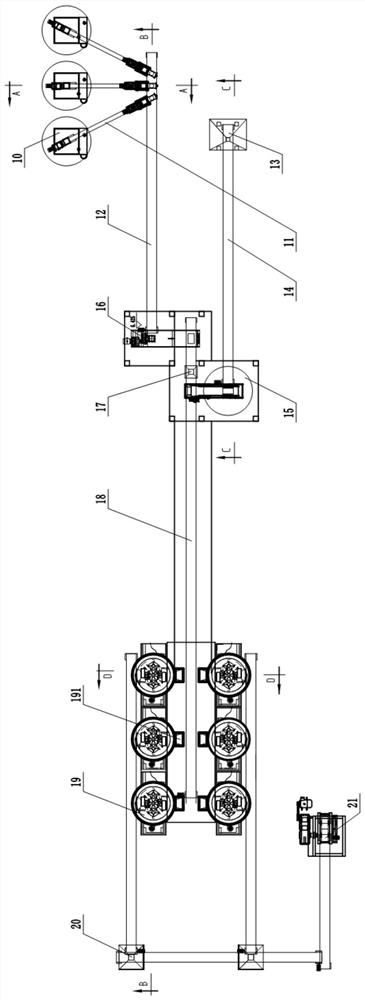

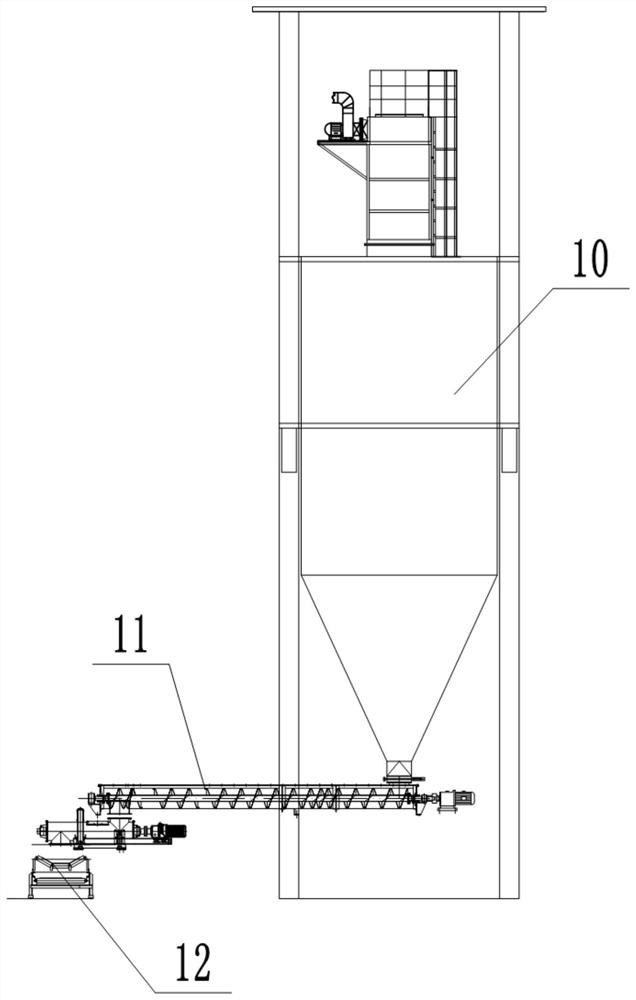

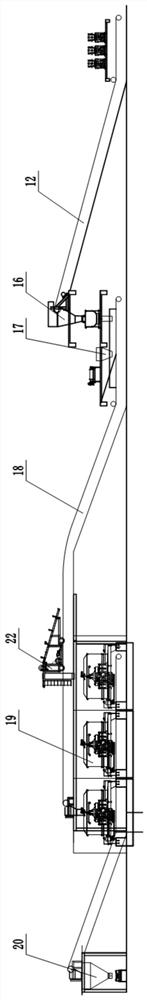

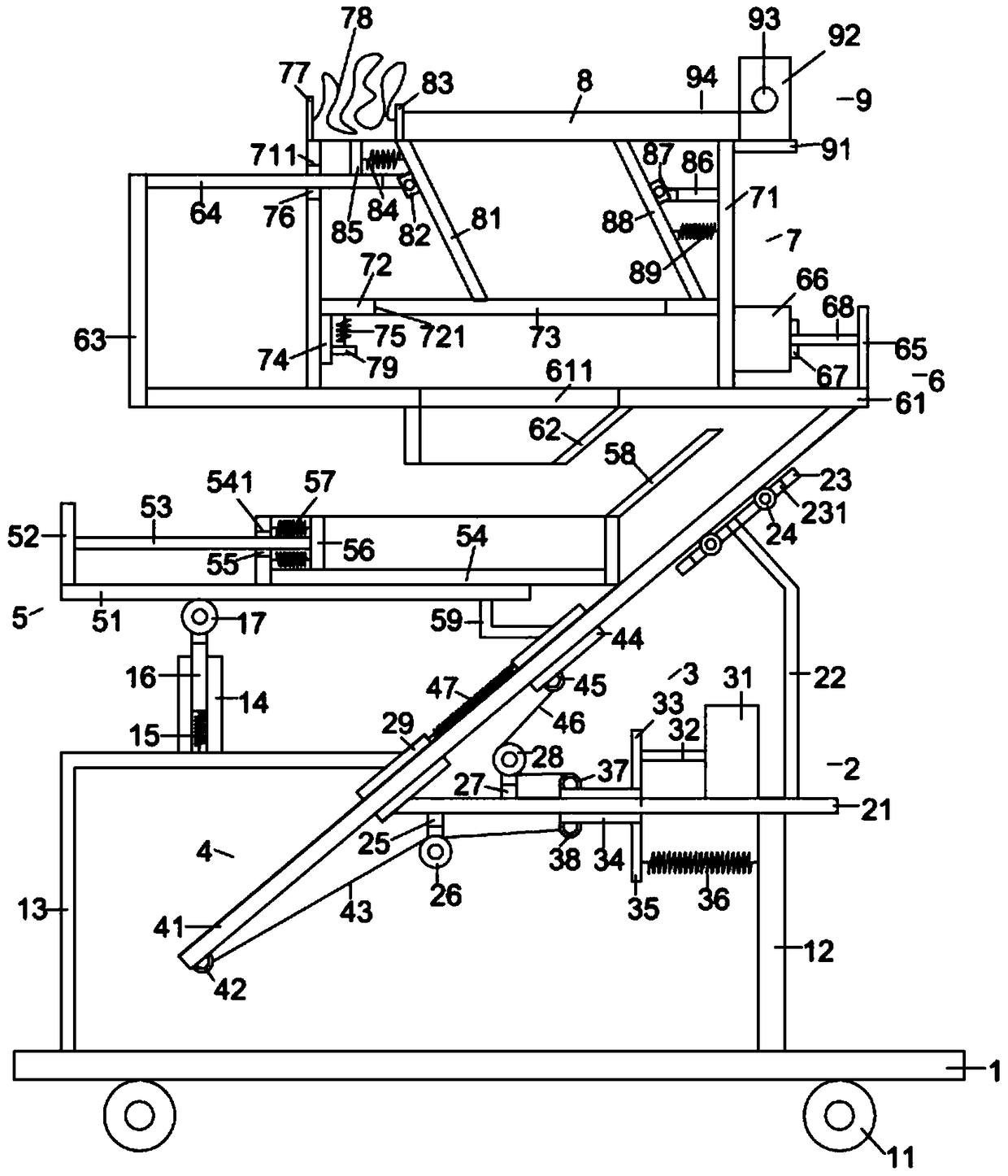

Dedusting ash cooling ball forming production line

ActiveCN111690809AHigh hardnessReduce porosityProcess efficiency improvementCalcium hydroxideProduction line

The invention belongs to the technical field of environment-friendly equipment in the metallurgical industry, and particularly relates to a dedusting ash cooling ball forming production line. The dedusting ash cooling ball forming production line comprises a wetting device, a binder feeding device, an iron-containing dust feeding system, a dedusting ash feeding system for conveying dedusting ash to the wetting device, a reaction kettle for enabling materials to be subjected to a magnesium cement reaction, and a ball press machine for pressing the materials into balls; delivery devices are arranged between the wetting device and the reaction kettle, between the binder feeding device and the reaction kettle and between the iron-containing dust feeding system and the reaction kettle; a conveying device is arranged between the reaction kettle and the ball press machine; and the wetting device is used for converting 30-60% of calcium oxide in the dedusting ash into calcium hydroxide. The wetting device is used for carrying out semi-digestion treatment on the dedusting ash, so that the finally obtained dedusting ash cooling balls are high in curing hardness and few in pores, and therefore, the dedusting ash cooling balls can bear the impact force falling from an overhead bunker and are not easy to crush.

Owner:CHONGQING ZHONGZHA METALLURGY RENEWABLE RESOURCESCO

Preparation method of superhydrophobic and superoleophobic magnetic composite microspheres

InactiveCN109705288ANo lossEffective control of circulationOrganic/organic-metallic materials magnetismCross-linkPolymer science

The invention provides a preparation method of superhydrophobic and superoleophobic magnetic composite microspheres. The preparation method comprises the following steps: adding a cross-linking agentand an initiator to ethylene and acrylic monomers used as polymer monomers, dropwise adding monodisperse Fe3O4 nanoparticles modified with a modifier, carrying out heterophase polymerization to form magnetic polymer microspheres with a surface secondary structure, and then modifying the magnetic polymer microspheres with fluorine-containing silane to obtain the superhydrophobic and superoleophobicmagnetic polymer microspheres.

Owner:SUZHOU ZEMAN BIOTECH CO LTD

A printing and dyeing mixer

ActiveCN107233838BMix well and effectivelyImprove the mixing effectShaking/oscillating/vibrating mixersRotary stirring mixersArchitectural engineeringMixing effect

The invention discloses a high-efficiency printing and dyeing agitator, which includes a workbench, the top of the workbench is fixedly connected with a protection box, the top of the protection box is fixedly connected with a casing, and the back of the inner wall of the casing is fixedly connected with a second Two motors. The present invention sets the second bevel gear, the support column, the protection box, the first stirring shaft, the first stirring blade, the housing, the second stirring blade, the second stirring shaft, the first bevel gear, the first motor, the electric The telescopic rod, the first spring, the connecting block, the sliding rod, the sliding block, the chute, the second spring, the second motor, the gear and the gear plate are used together to mix various printing and dyeing auxiliaries evenly and effectively, achieving The advantage of better mixing effect solves the problem of poor mixing effect when the existing textile agitator needs to mix a variety of materials, ensures the quality of printed and dyed textile fabrics, facilitates the use of users, and improves the quality of textile materials. The practicality of the mixer.

Owner:SUZHOU CHENHAO TEXTILE TECH CO LTD

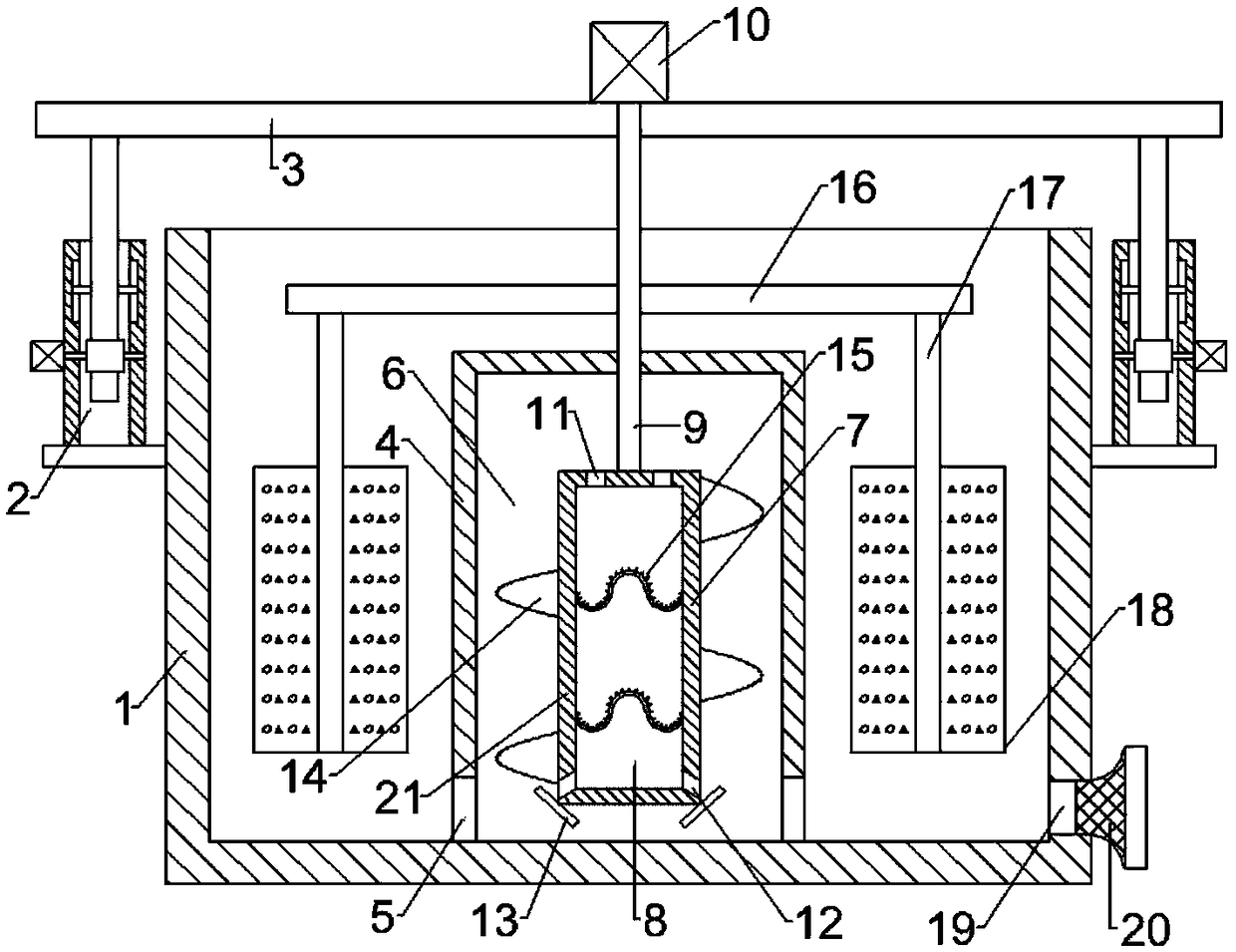

Soil remediation equipment with in-soil mixing function

PendingCN110252797AUniform and effective mixingEasy to handleSoil lifting machinesContaminated soil reclamationChemical treatmentSoil mixing

The invention discloses soil remediation equipment with an in-soil mixing function. The equipment comprises a support frame, which has a sleeve shape with a downward opening. Four universal wheels are uniformly arranged on the bottom end of the support frame. A soil loosening device is arranged in the left side of the bottom of the interior of the support frame. A cylinder is horizontally arranged in the support frame. Two ends of the cylinder are both fixedly connected to the top of the interior of the support frame through connection rods. A rotary sleeve sleeves the outer wall of the cylinder. The soil remediation equipment has the advantages that (1) the soil is loosened by the teeth of a soil loosening device so as to enhance the effect; (2) a first driving device is used to drive the rotary sleeve to rotate, and the released soil is lifted and delivered into the interior of the cylinder by a lifting device to carry out a chemical treatment; and (3) the soil in the cylinder is uniformly and effectively mixed by a mixing device, a chemical reagent is uniformly mixed with the soil by a liquid distribution rod, and the soil remediation effect is effectively improved.

Owner:诸暨市众创机械设备厂

Ingredient weighing device for glutinous rice wine production

InactiveCN110736532AImprove fully and effectivelyEasy accessShaking/oscillating/vibrating mixersTransportation and packagingEngineeringMaterial storage

The invention discloses an ingredient weighing device for glutinous rice wine production, and relates to the technical field of glutinous rice wine production. The objective of the invention is to solve the problem that effective mixing treatment cannot be conveniently and effectively carried out on weighed ingredients. The ingredient weighing device specifically comprises a supporting base and amaterial storage box body, first supporting plates are fixedly mounted on the outer walls of the two ends of one side of the top of the supporting base correspondingly, the outer walls of the tops ofthe adjacent ends of the two first supporting plates are connected with the outer walls of the two ends of the material storage box body through bolts correspondingly, and four first grooves distributed in an array mode are formed in the outer wall of the other side of the top of the supporting base. According to the invention, by arranging the partition plate and arranging the four discharging pipes at the bottom of the material storage box body, four different materials can be placed into the material storage box body, discharged into the material guide groove plates through the dischargingpipes respectively and weighed through pressure sensors, and then the convenient and effective weighing and proportioning effect of different materials is achieved.

Owner:HUNAN YUHAITANG BIOTECH

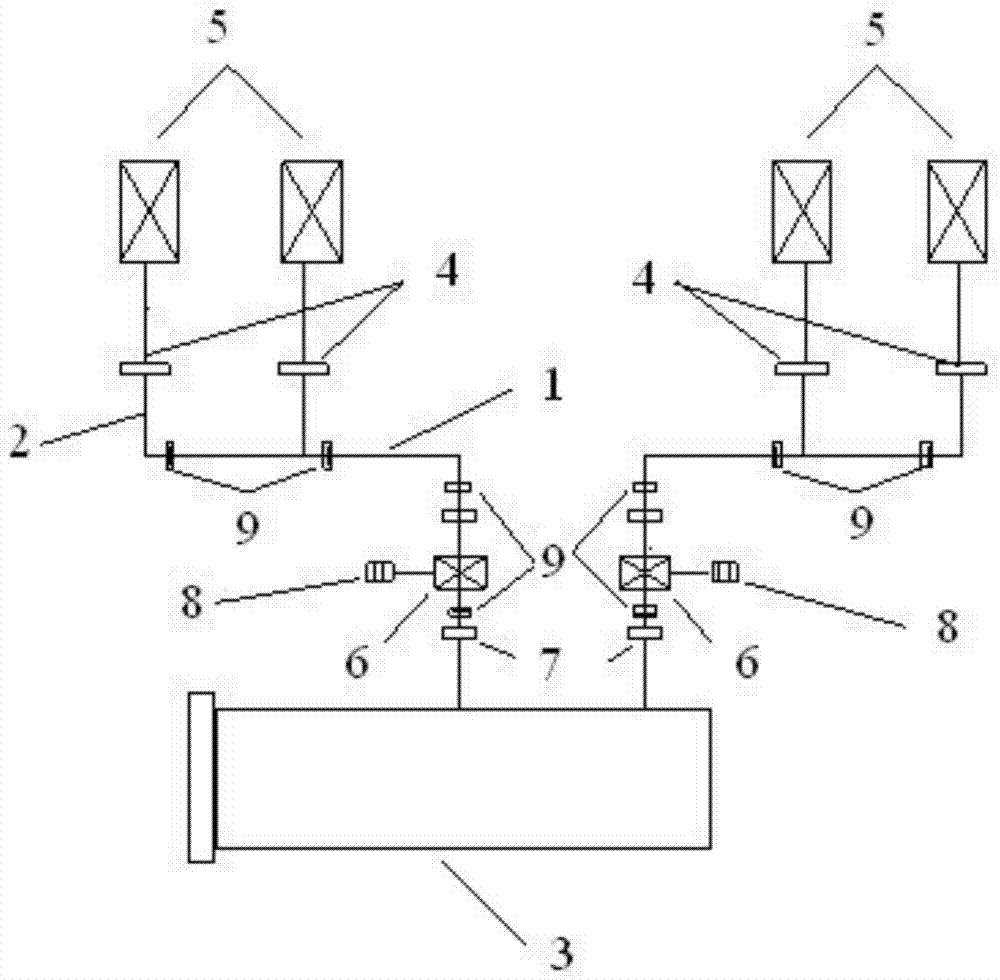

Automatic smoke mixing device for multiple sintering machines

InactiveCN104296532ADevice resistance is smallHigh adjustment accuracyFurnace typesWaste heat treatmentSmokeMechanical engineering

The invention relates to an automatic smoke mixing device for multiple sintering machines. The automatic smoke mixing device comprises a plurality of smoke pipelines, two air inlet branch pipelines are arranged at one end of each smoke pipeline, and the other end of each smoke pipeline is connected with a smoke mixing pipeline. The two air inlet branch pipelines are each provided with an air inlet, the two air inlets are connected with two main sintering exhaust fans in a sintering machine set respectively, a booster fan is further arranged on each smoke pipeline, the booster fans are used for adjusting the pressure and the flow of smoke so that the pressure and the flow of the smoke of all the smoke pipelines are at the similar level when the smoke enters the smoke mixing pipeline. The automatic smoke mixing device can automatically mix various types of smoke.

Owner:NINGBO IRON & STEEL

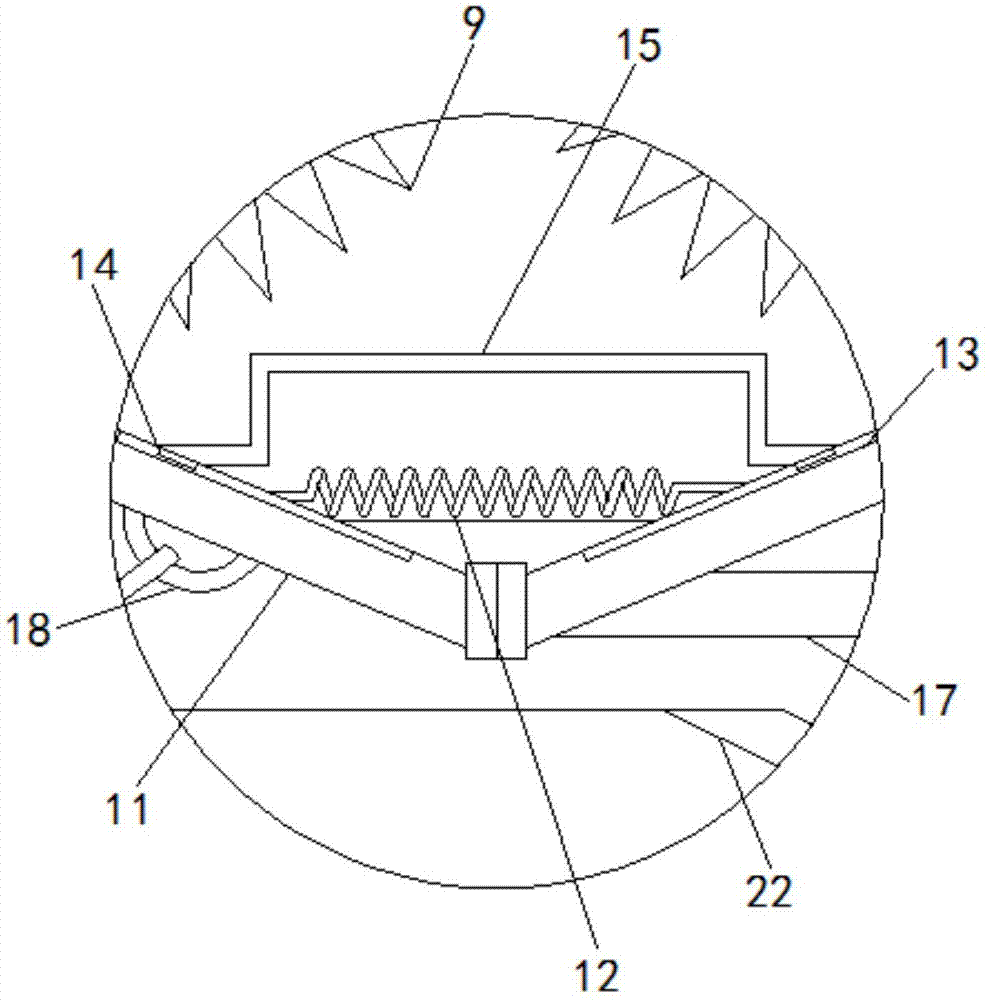

Filtering and extracting device for stem cell exosome

InactiveCN112680321AMix well and effectivelyPrevent splashBioreactor/fermenter combinationsBiological substance pretreatmentsDrive wheelElectric machinery

The invention discloses a filtering and extracting device for stem cell exosome. The filtering and extracting device comprises a base, wherein a diluting cavity and a separating cavity which communicating with each other are distributed on the base at intervals, the diluting cavity and the base are movably installed, a feeding hopper is distributed on one side of the upper end face of the diluting cavity, and a stirring mechanism is distributed in the diluting cavity. The filtering and extracting device for the stem cell exosome drives a driving wheel to operate through a driving motor, so that a stirring shaft drives stirring blades to perform orderly reciprocating rotation, and the cooperation of a vibration mechanism is assisted, so that a diluent and a sample are uniformly and effectively mixed, the dilution quality is ensured, subsequent filtering and extracting are facilitated, through cooperation of an eccentric wheel and a reset spring, a rubber plug can slide in an orderly reciprocating mode along the inner wall of a separation cavity, the filtering and extracting speed can be conveniently controlled, the load exceeding a filtering layer is avoided, and a vertical guide spring is installed on an assembly rod, so that the dilution cavity is oscillated stably, and splashing of the sample and the diluent is avoided.

Owner:菲尔生物工程技术有限公司

Nutritious edible mixed oil promoting intestinal tract digestion and a preparing method thereof

InactiveCN105901175AGood heat-clearing and detoxifying effectNo lossEdible oils/fatsBiotechnologyWatermelon seed oil

Nutritious edible mixed oil promoting intestinal tract digestion and a preparing method thereof are provided. The mixed oil and the method are characterized in that raw materials include 9-14 parts by weight of rapeseed oil, 11-14 parts by weight of hawthorn oil, 7-9 parts by weight of fish oil, 3-6 parts by weight of rice oil, 12-16 parts by weight of peanut oil, 12-14 parts by weight of soybean oil, 5-8 parts by weight of corn oil, 8-13 parts by weight of olive oil, 4-7 parts by weight of sunflower seed oil, 2-4 parts by weight of tea polyphenols, 7-11 parts by weight of watermelon seed oil, 1-2 parts by weight of garlic and 1-2 parts by weight of welsh onion. Through application of the raw materials, the mixed oil can effectively promote intestinal tract digestion of a human body. The preparing method ensures that nutrients of the raw materials do not lose. The mixed oil and the preparing method can adapt to industrialized processing and production and further popularization and application.

Owner:ANHUI HUAAN FOOD CO LTD

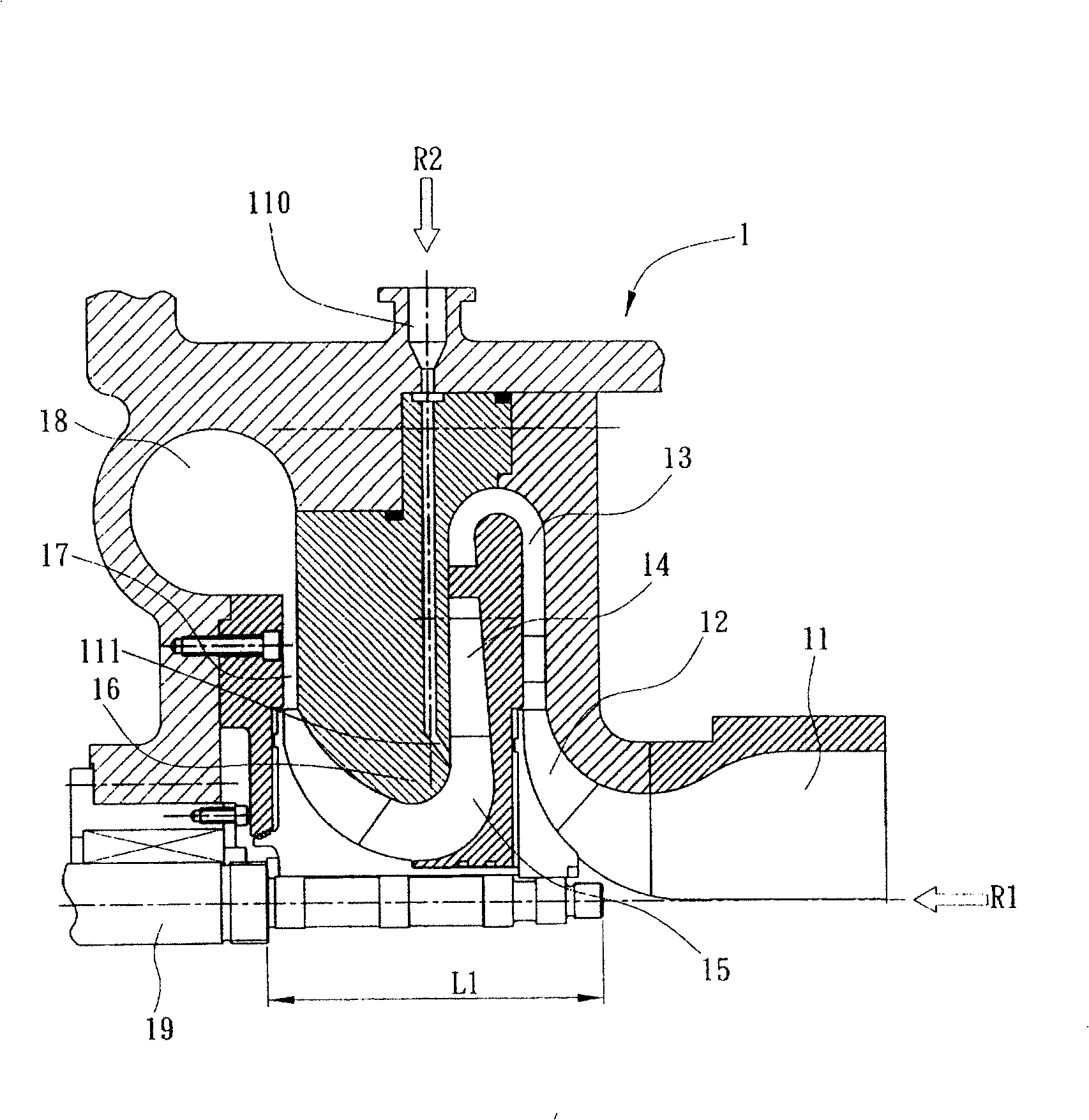

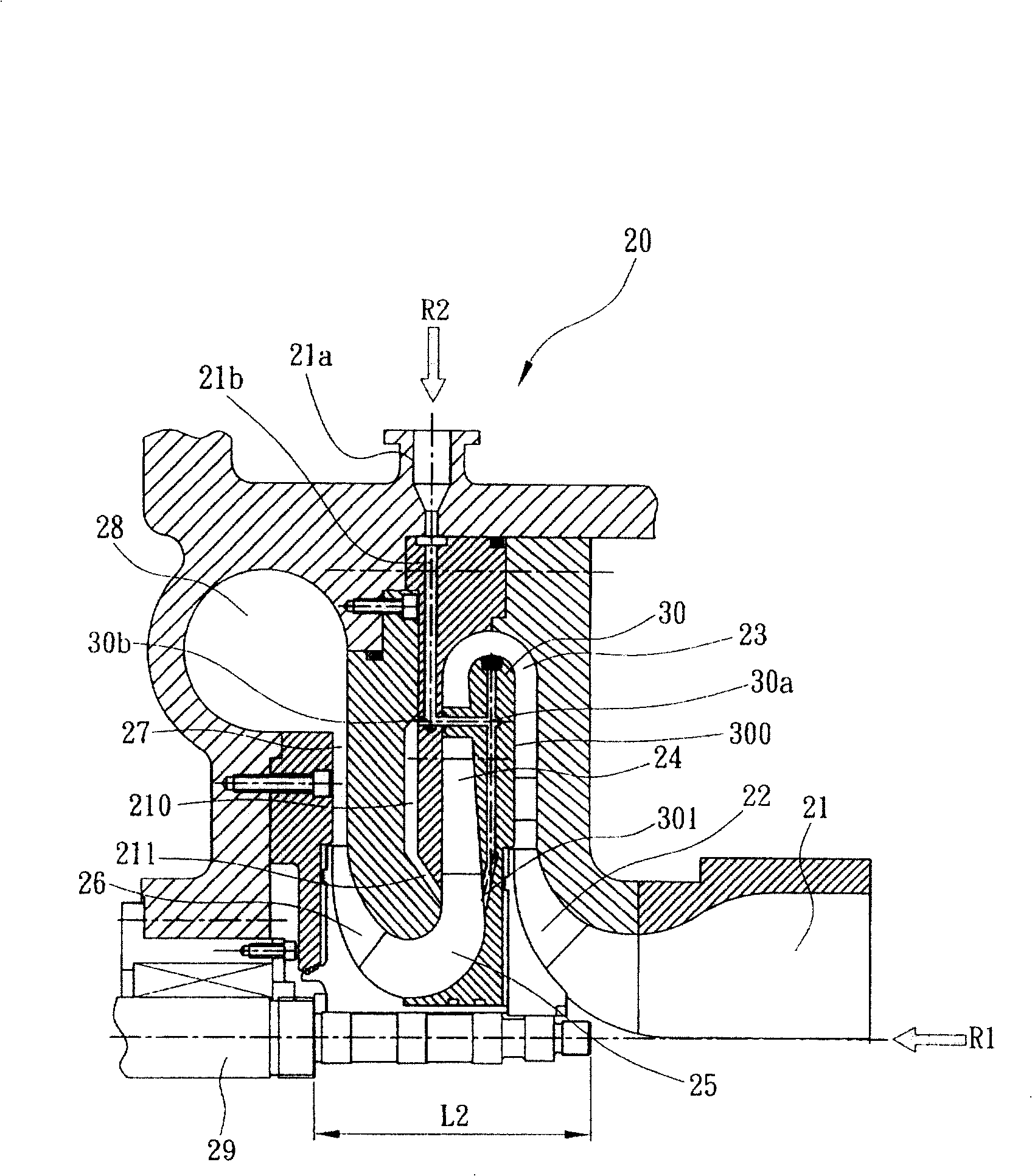

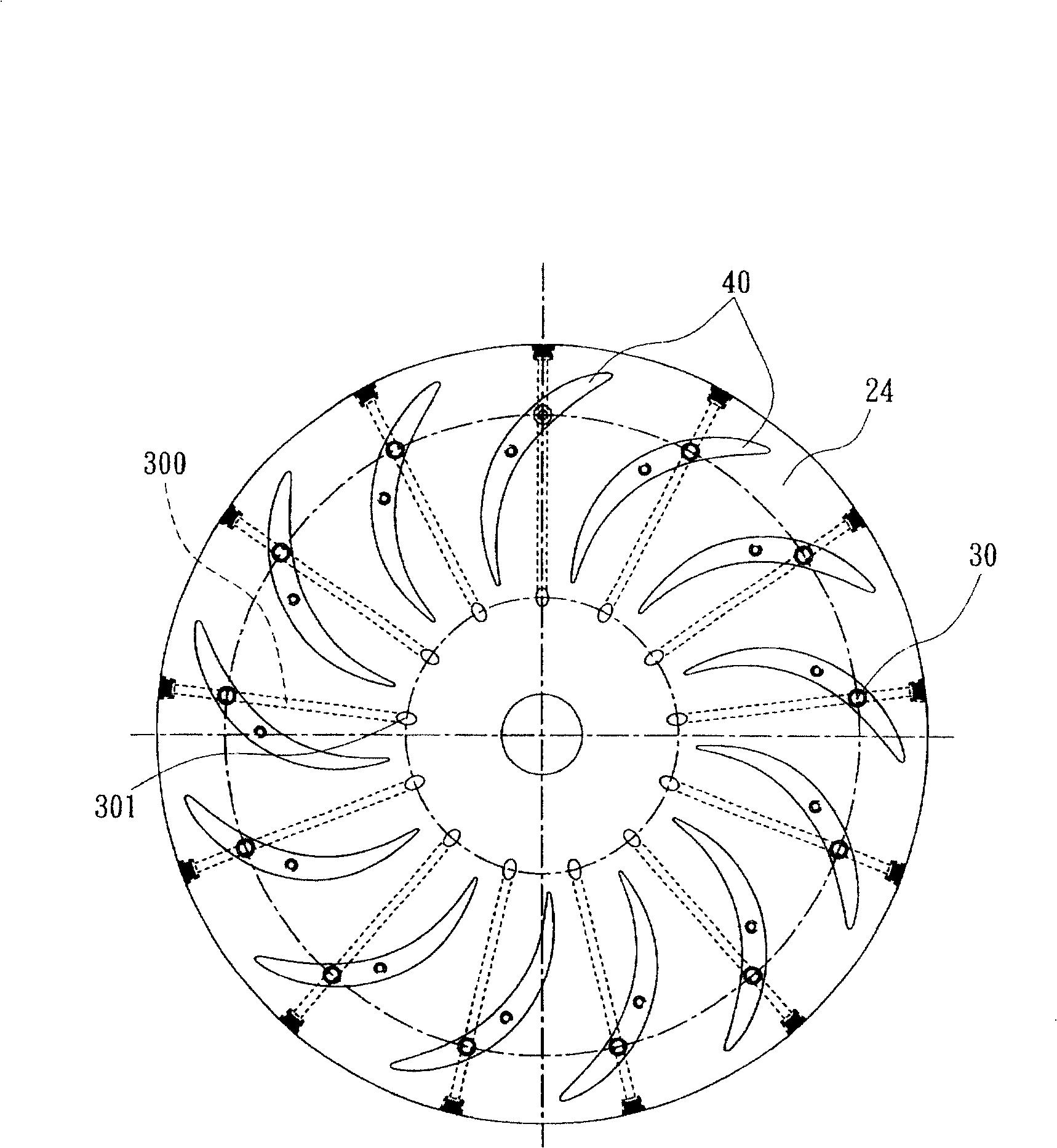

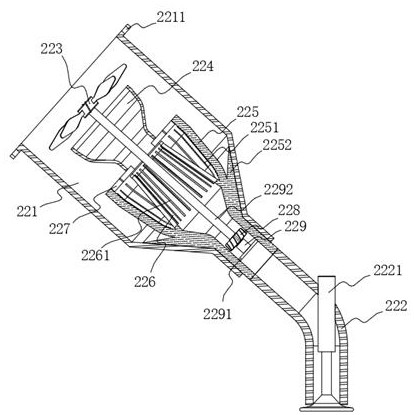

Compressor jet flow path structure

ActiveCN100455819CReduce distractionsMix well and effectivelyPump componentsRadial flow pumpsJet flowChicane

A spray channel structure for the multi-class centrifugal compressor with curved reflux channel and reflux guide blade is composed of a bidirectional flow channel for the bidirectional division of the refrigerant filled externally and with the first and the second outlets, the first lateral spray channel communicated with the first outlet, and the second lateral spray channel communicated with the second outlet. Its advantages are uniform mixing of refrigerant and short channel and rotary axle.

Owner:IND TECH RES INST

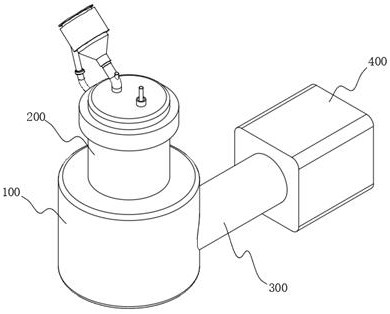

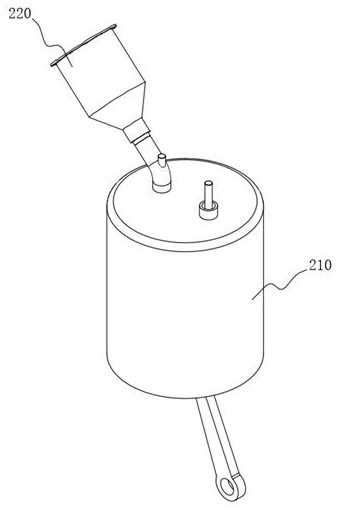

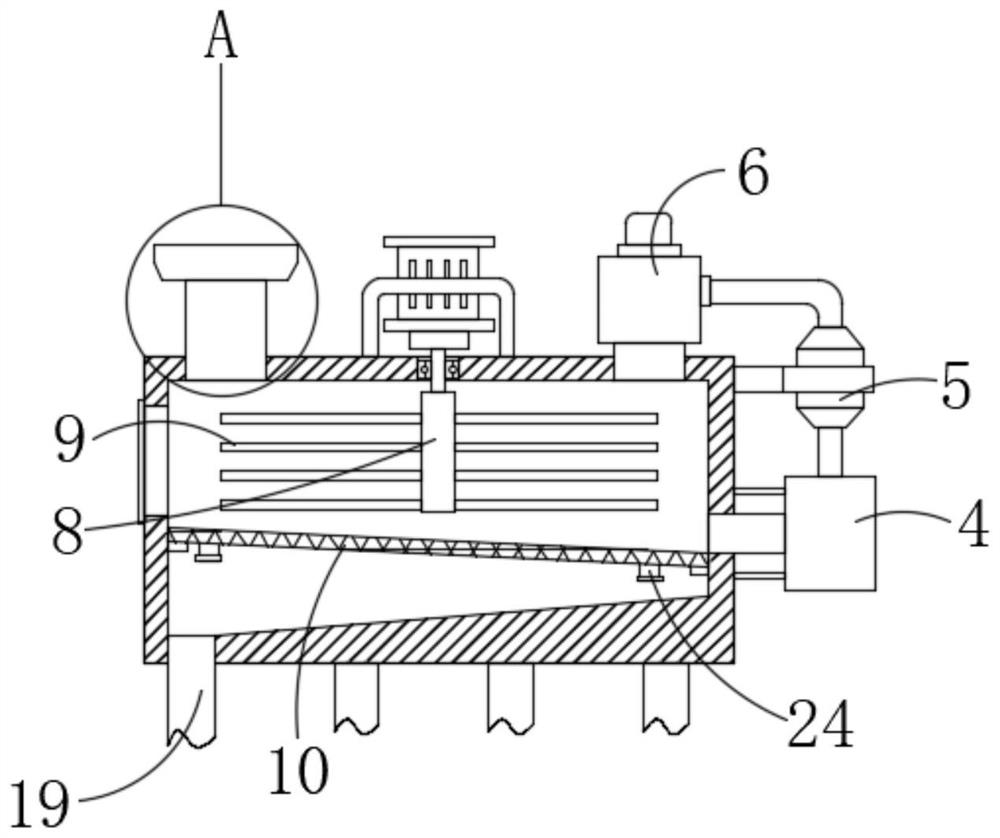

Biomass gas internal combustion generator set

ActiveCN114562364AImprove uniformitySolve the problem of difficult to mix completelyInternal combustion piston enginesFuel supply apparatusEngineeringInternal combustion engine

The invention relates to an internal combustion generating set, in particular to a biomass gas internal combustion generating set. The device comprises a driving main body, an internal combustion mechanism is arranged at the top of the driving main body, a crank-link mechanism is arranged in the driving main body, the internal combustion mechanism uses biomass gas as energy to drive the crank-link mechanism for transmission, a power generation main body is arranged on one side of the driving main body, and a storage battery is arranged on one side of the power generation main body. According to the invention, the mixing inner pipe and the mixing outer pipe are arranged, and the outer pipe mixing groove and the inner pipe mixing groove are correspondingly formed outside the mixing inner pipe and the mixing outer pipe, so that biomass gas and air can converge and circulate in the outer pipe mixing groove and the inner pipe mixing groove after entering the outer pipe body, and shuttle back and forth between the outer mixing cavity and the inner mixing cavity in the circulation process; therefore, the purpose of mixing the biomass gas and the air is achieved.

Owner:山东赛马力发电设备有限公司

Novel soil treatment equipment in field of resource processing

The invention discloses novel soil treatment equipment in the field of resource processing. The novel soil treatment equipment comprises a base plate, a bracket device located on the upper part of thebase plate, an electric cylinder device arranged on the bracket device, a moving device, a collecting device arranged on the moving device, a driving device located above the collecting device, a frame device arranged on the driving device, a grinding device arranged in the frame device, and a motor device. According to the novel soil treatment equipment in the field of resource processing, block-shaped soil can be sufficiently and effectively grinded into powder, the grinding effect is remarkable; the soil can be sufficiently grinded for many times until being grinded to the required particle size, and the strength between first and second grinding plates can be adjusted to ensure that the soil is effectively grinded into powder, the processing and treatment effects of the soil are ensured, and the quality of the soil after grinding is improved.

Owner:吉效晋

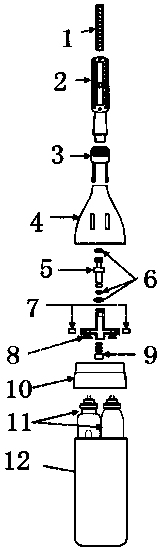

Raw material treatment device for rumen bypass nicotinic acid coating and treatment method

PendingCN113877806AAvoid blockingGuaranteed screening effectSievingScreeningAcidum NicotinicumEngineering

The invention discloses a raw material treatment device for rumen bypass nicotinic acid coating. The raw material treatment device comprises a raw material screening box and a mixing box, wherein the raw material screening box is fixedly installed at the upper end of the mixing box through a stand column, a material returning opening is formed in the raw material screening box, a material returning box is fixedly connected to the side wall of the raw material screening box through a connecting column, the material returning opening communicates with the interior of the material returning box, a pneumatic conveyor is fixedly installed on the portion, located at the upper end of the material returning box, of the side wall of the raw material screening box, the feeding end of the pneumatic conveyor communicates with the interior of the material returning box through a connecting pipe, a smashing mechanism is fixedly installed at the upper end of the raw material screening box, the discharging end of the pneumatic conveyor communicates with the smashing mechanism through a connecting pipe, and the discharging end of the smashing mechanism communicates with the interior of the raw material screening box. According to the raw material treatment device for the rumen bypass nicotinic acid coating and the treatment method, nicotinic acid raw materials are screened through the raw material screening box, the first driving motor is adopted to drive a crushing rod to scatter the caked nicotinic acid raw materials during screening, and the screening effect of the nicotinic acid raw materials is ensured.

Owner:INNER MONGOLIA AUTONOMOUS REGION ACAD OF AGRI & ANIMAL HUSBANDRY SCI +1

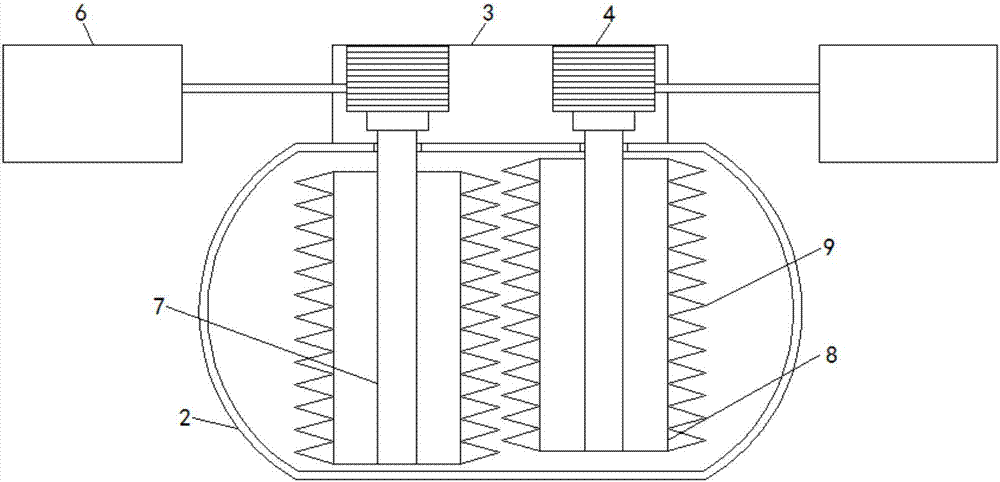

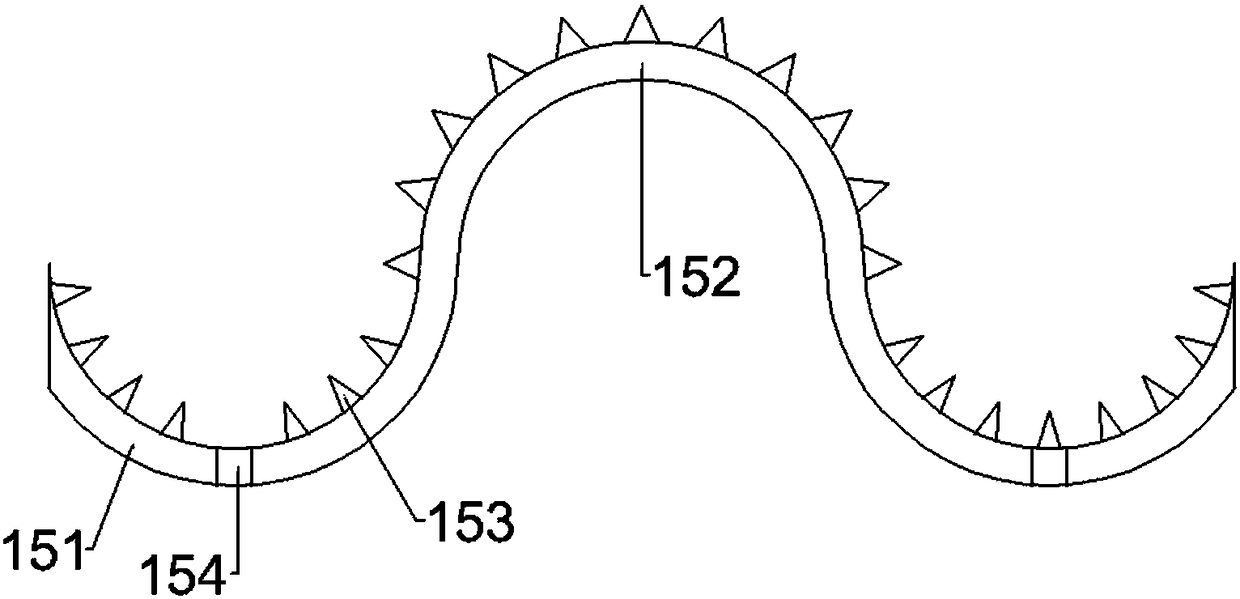

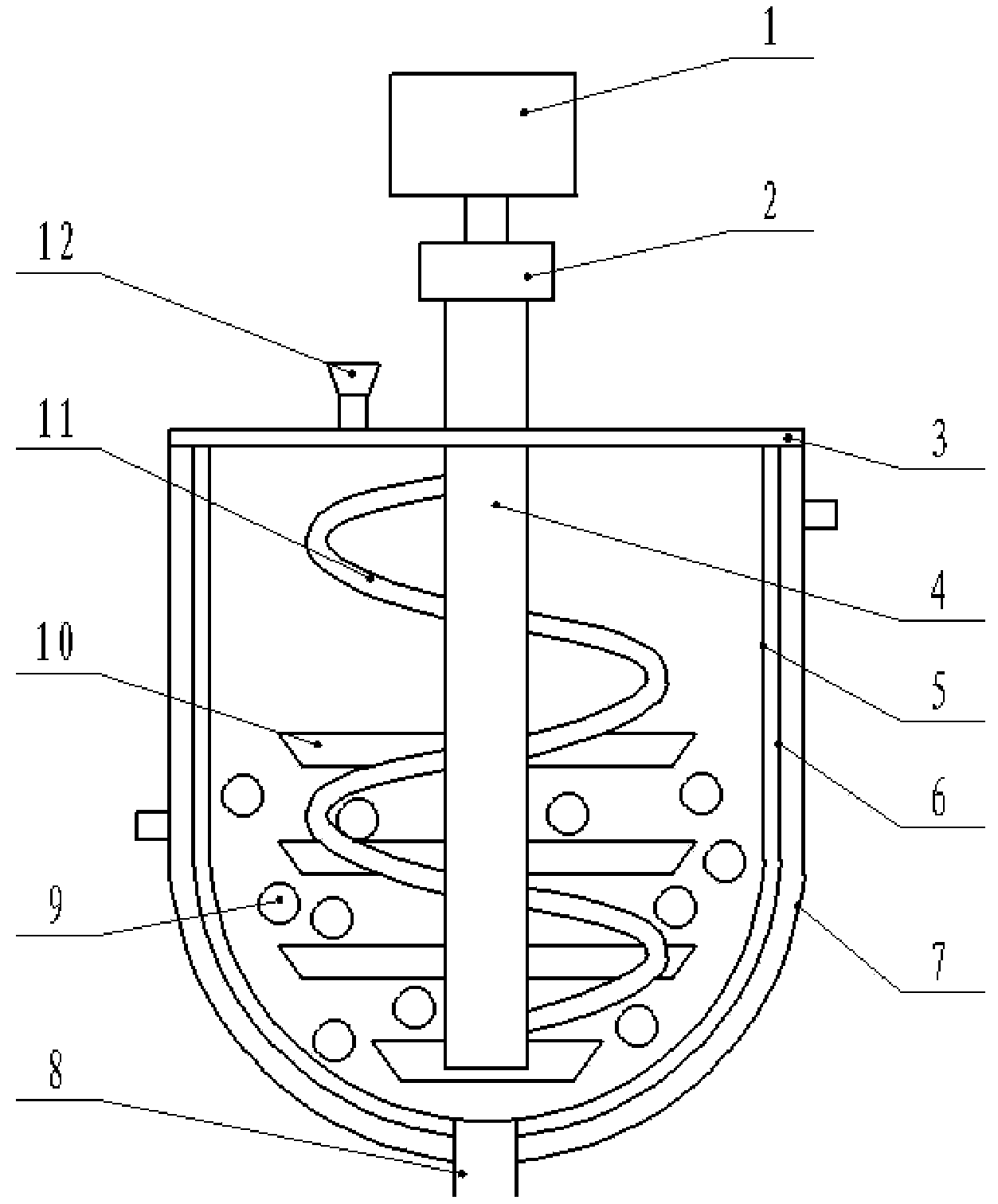

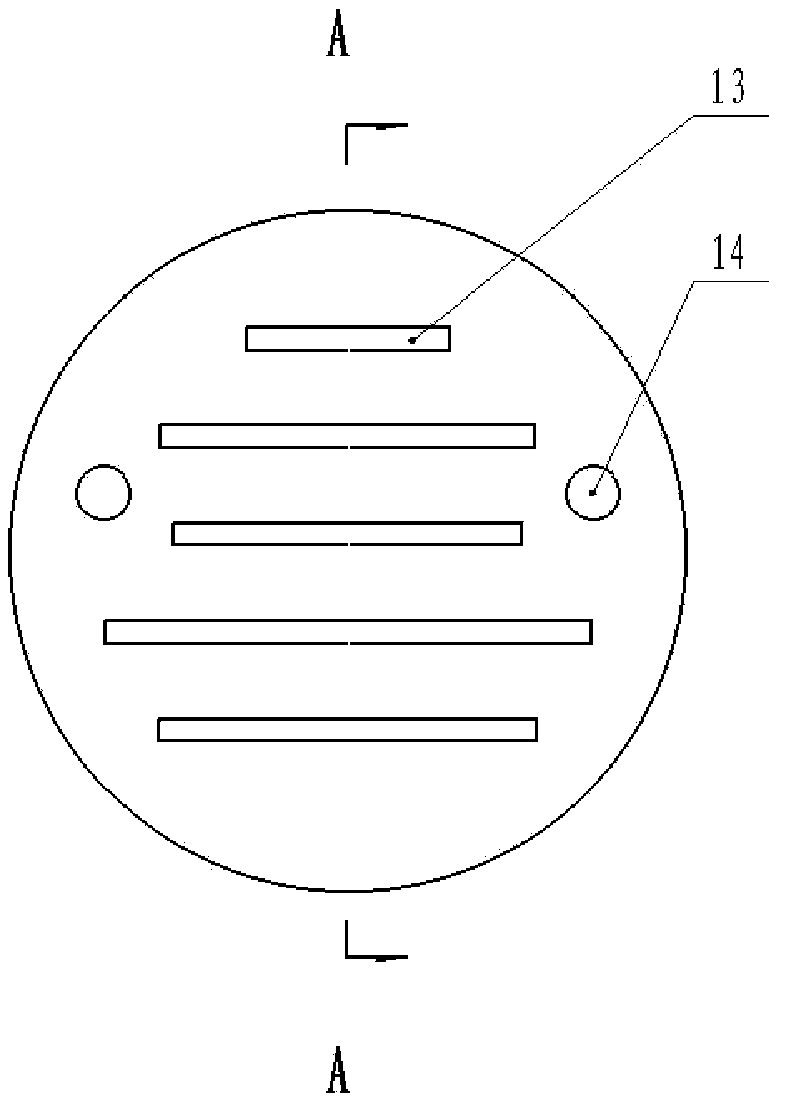

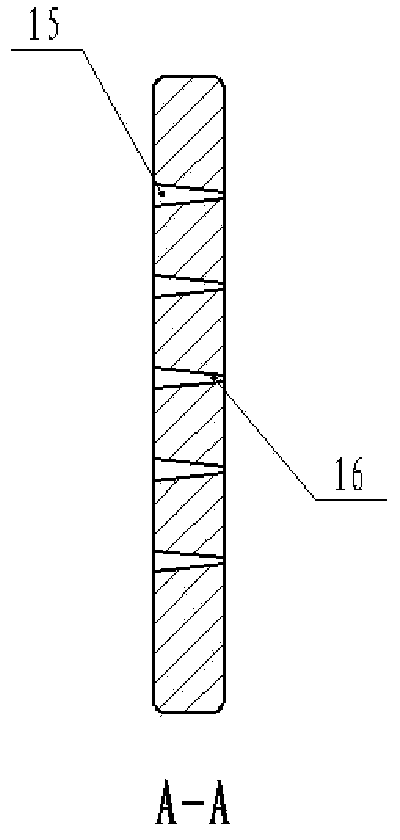

Vertical modified stir ball-milling reactor for reinforcing polysaccharide polymers

ActiveCN102935350BImprove the perturbation effectHigh activityChemical/physical/physico-chemical stationary reactorsGrain treatmentsReaction fieldSpiral blade

The invention relates to a vertical modified stir ball-milling reactor for reinforcing polysaccharide polymers, and a stirring shaft is driven by a drive unit through a coupling. The reactor further comprises a cylinder cover plate, a grinding inner cylinder, a lining plate, a funnel type material feeding port, a material discharging port and grinding balls. A stirring blade set composed of inclined plate blades and an S-shaped spiral blade is mounted on the stirring shaft, the inclined plate blades are mounted on the stirring shaft in parallel, and the S-shaped spiral blade is vertically mounted on the stirring shaft; and a plurality of through holes for grinding balls in the grinding inner cylinder to pass through are arranged on the inclined plate blades. According to the reactor, the stirring blade set is added, so that materials can be mixed evenly, and accordingly, the production efficiency is improved. Simultaneously, the stirring shaft and the S-shaped spiral blade are manufactured into hollow structures, and fed cooling substances are helpful for keeping the temperature to be uniform and the constant-temperature reaction field; and the bottom of grinding inner cylinder is hemispherical, so that grinding dead angles are avoided.

Owner:广西防城港五星环保科技股份有限公司

Coagulation-floatation and co-coagulation solid-liquid separation device and solid-liquid separation method

InactiveCN103112971BImprove separation efficiencyImprove stabilityMultistage water/sewage treatmentWater/sewage treatment by flotationWastewaterEngineering

The invention belongs to sewage treatment equipment, and particularly relates to a coagulation-floatation and co-coagulation solid-liquid separation device and a solid-liquid separation method. The separation device is characterized by being formed by sequentially installing a sewage medicating-mixing system, a multiphase medium pump air-dissolving system, a mixed reaction co-coagulation system and a co-coagulation solid-liquid separation device at a sewage pool; the separation device disclosed by the invention is reasonable in design and compact in structure, and provided with an independent mixed co-coagulation reaction and co-coagulation solid-liquid separation system; moreover, optimization for a coagulation-floatation and co-coagulation-floatation separation process is realized, and a variable-water-level dross removal method is used for dross removal; and the separation device has the characteristics of being simple and convenient, small in overall floor area, less in investment, high in efficiency, and the like. The separation device and the separation method are especially suitable for treating colloids and suspended matters in sewage and waste water generated during production and life processes, so as to realize solid-liquid separation.

Owner:DALIAN JIAOTONG UNIVERSITY

Production method of special enzyme for suckling piglets

InactiveCN108576402AReduce negative impactImprove immune system developmentAccessory food factorsAmylaseAntigen

The invention aims to provide a production method of a special enzyme for suckling piglets.100g of the special enzyme is characterized by comprising the following components of 2-5g of mannase of which the raw material enzyme activity is 50000U / g, 1-5g of xylanase of which the raw material enzyme activity is 400000U / g, 0.1-1g of cellulases of which the raw material enzyme activity is 20000U / g, 50-60g of neutral protease of which the raw material enzyme activity is 50000U / g, 5-10g of low-temperature amylases of which the raw material enzyme activity is 10000U / g, 1-2g of acid lipase of which theraw material enzyme activity is 20000U / g, 10-15g of talcum powder, 0.07g of Shenweixian II, and the balance of starch. Through an antigen proteolysis technique, the negative effect of antigen proteinon piglets can be effectively reduced, the decomposition of mannan and the digestion of starch can be reinforced, the diarrhoea proportion is effectively reduced, and the food consumption is increased.

Owner:昆明三正生物科技(集团)有限公司

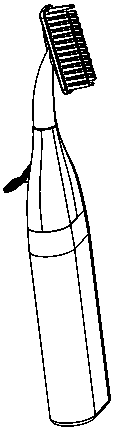

Quantity limitation material supply mechanism for hair dyeing comb

The invention discloses a quantity limitation material supply mechanism for a hair dyeing comb. The quantity limitation material supply mechanism consists of a paste storage chamber and a quantity limitation rod, wherein the paste storage chamber is used for connecting the connecting-in end of a paste storage tank; a material discharging passage is also arranged in the paste storage chamber; the upper end of the quantity limitation rod is fixed; the lower end of the quantity limitation rod is inserted into the upper section and the middle section of the material discharging passage of the paste storage chamber; the tail end of the quantity limitation rod is provided with a sealing ring; a material discharging passage is formed in the quantity limitation rod; the upper end of the material discharging passage of the paste storage chamber can be sealed by the tail end, provided with the sealing ring, of the quantity limitation rod. The quantity limitation material supply mechanism mainlyhas the quantity limitation paste discharging advantage; meanwhile, the functions of automatically stirring and mixing the hair dyeing paste and auxiliary agents can also be realized; the utilizationefficiency is improved; the dyeing paste is sufficiently utilized, so that the professional operation effect can be achieved by the self help hair drying.

Owner:邓伟文

A kind of preparation method of sweet potato leaf tea

InactiveCN103976093BStrong overall senseThe rope is tightly knotted and evenTea substituesDiuresisThirst

The invention especially discloses a preparation method for sweet potato leaf tea. The preparation method comprises the following steps: (1) blending of attached liquids; (2) spraying; (3) drying; and (4) shaping and fragrance promotion. The invention has the following beneficial effects: the preparation method is simple, raw materials can be fully and uniformly mixed, and the prepared sweet potato leaf tea presents a strong sense of wholeness and has compact and uniform cords and an oily color; raw materials are scientifically proportioned, so the prepared sweet potato leaf tea has good quality, presents pure, fresh and agreeable taste and rich delicate fragrance without losing lingering charm of original tea when drunk, is convenient to drink, endures brewing, has balanced nutrients, exerts a good health care effect on a human body, enables people to feel tasty, quench thirst and enjoy after-taste sweetness after drinking of the sweet potato leaf tea, can clear the liver, improve eyesight, relax the bowels and promote diuresis and is capable of enhancing immunity, delaying aging, clearing lung-heat, reducing phlegm, moistening the intestines, reducing blood pressure, preventing dyspepsia and the like after long-term drinking.

Owner:山东华夏茶联信息科技有限公司

Agricultural machine for fertilization

InactiveCN110959359AWell mixedQuality improvementTransportation and packagingFertiliser distributersAgricultural scienceAgricultural engineering

An agricultural machine for fertilization comprises a bottom plate, a first support and a second support are connected to the top wall of the bottom plate, a first barrel body is connected to the inner wall of the first support, a frame is connected into the first barrel body, a motor is connected to the outer wall of the first support, and a first rotating shaft is connected to the output end ofthe motor; the end, away from the motor, of the first rotating shaft penetrates through the first support and is fixedly connected with the frame, a second rotating shaft is further connected to the outer wall of the frame, the end, away from the frame, of the second rotating shaft penetrates through the first barrel and is rotationally connected to the inner wall of the first support, and a second barrel is rotationally connected into the frame and internally provided with a stirring and mixing mechanism. A spraying mechanism is connected to the outer wall of the second support and communicates with the discharging port. The agricultural machine for fertilization is suitable for applying liquid fertilizer and solid fertilizer, and the solid fertilizer and the liquid fertilizer can be fully and effectively mixed, so that the fertilizer applying quality is effectively improved.

Owner:刘璐

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com