Ingredient weighing device for glutinous rice wine production

A weighing device and glutinous rice wine technology, which is applied in the direction of measuring device, detailed information of weighing equipment, weighing, etc., can solve the problems of inconvenient processing and production of glutinous rice wine, inability to realize mixing process conveniently and effectively, and low production efficiency , to achieve the effect of improving convenience, convenient pick and place, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

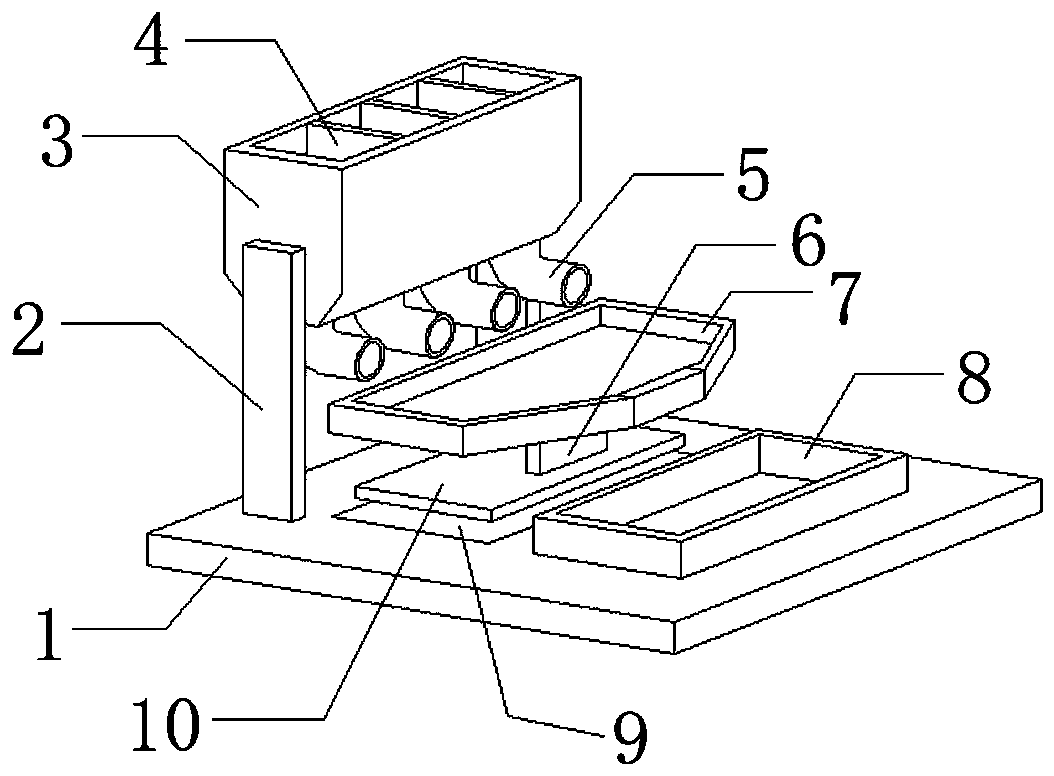

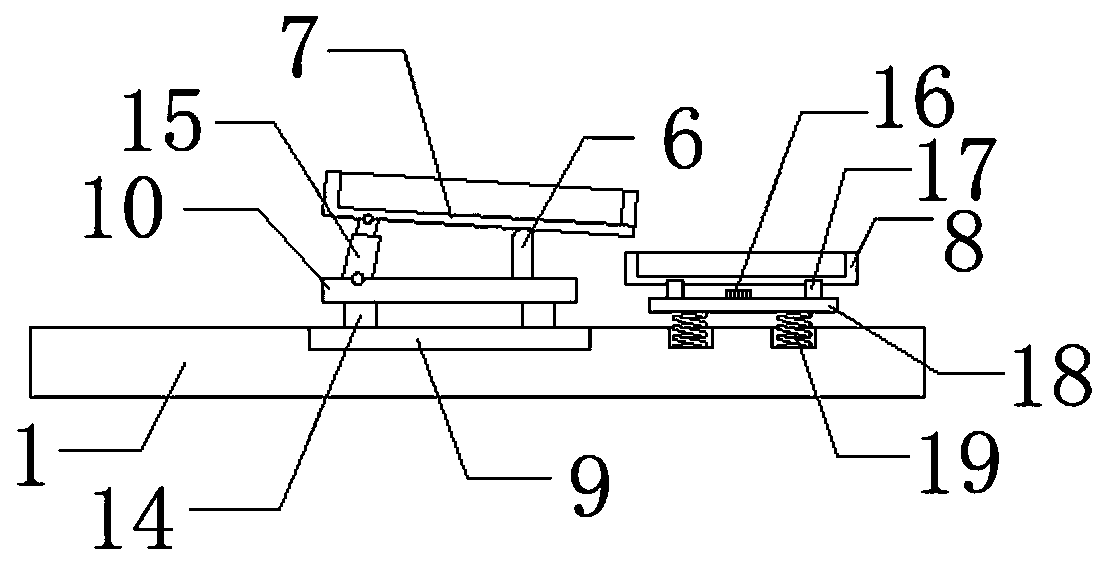

[0027] Embodiment 1: a kind of glutinous rice wine production batching weighing device, such as Figure 1-3 As shown, including the support base 1 and the material storage box 3, the outer walls at both ends of the top side of the support base 1 are connected with the first support plate 2 by bolts, and the top outer walls of the adjacent ends of the two first support plates 2 are respectively Bolts are connected to the outer walls at both ends of the material storage box 3, and the outer wall on the other side of the top of the support base 1 is provided with four first grooves distributed in an array, and the inner walls of the four first grooves are all connected with springs by bolts 19. The top outer walls of the four springs 19 are connected with the same fourth support plate 18 by bolts, and the top four corner outer walls of the fourth support plate 18 are connected with the insertion rod 17 by bolts, and the top central outer wall of the fourth support plate 18 is conn...

Embodiment 2

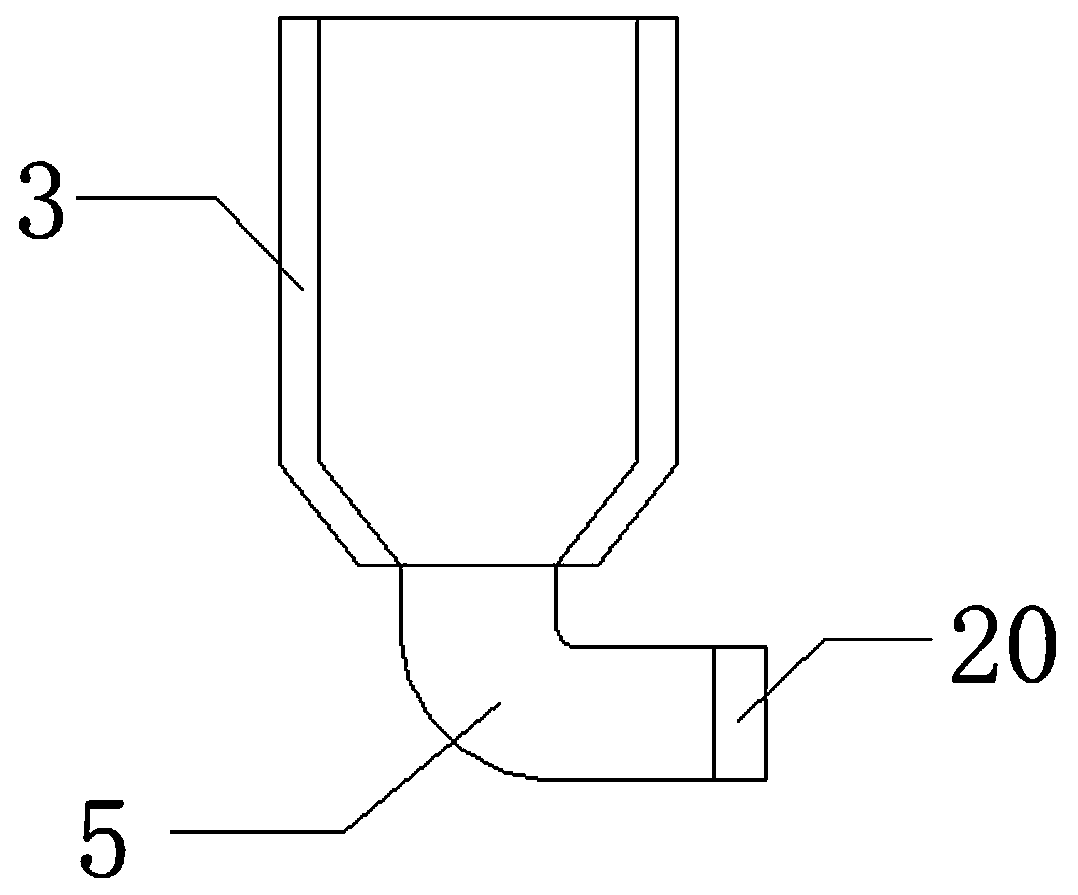

[0031] Embodiment 2: a kind of glutinous rice wine production batching weighing device, such as figure 1 , 2 Shown in and 4, also comprise the rotating motor 11 that is installed on the bottom outer wall of four discharge pipes 5 sides by bolt respectively, and the output shaft of rotating motor 11 is connected with the rotating rod 12 that horizontally arranges by bolt, the circumference of rotating rod 12 The outer wall is connected with auger blades 13 by bolts.

[0032] In this embodiment, during the discharge process, the rotating motor 11 can drive the auger blade 13 to rotate, which not only improves the stability of the discharge, but also prevents the material from being blocked in the discharge pipe 5, and improves the discharge efficiency. fluency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com