Patents

Literature

344results about How to "Uniform expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Structural reinforcement

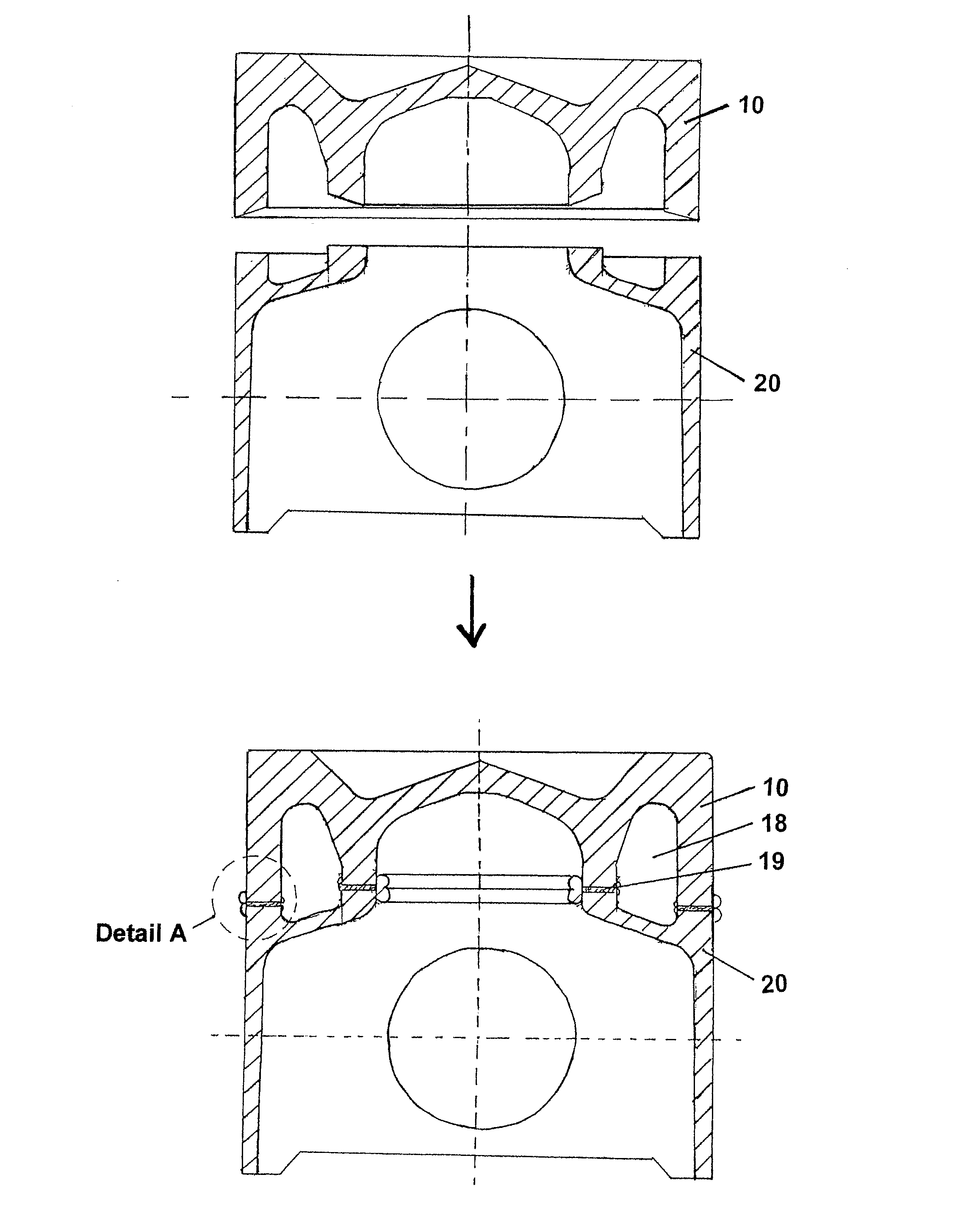

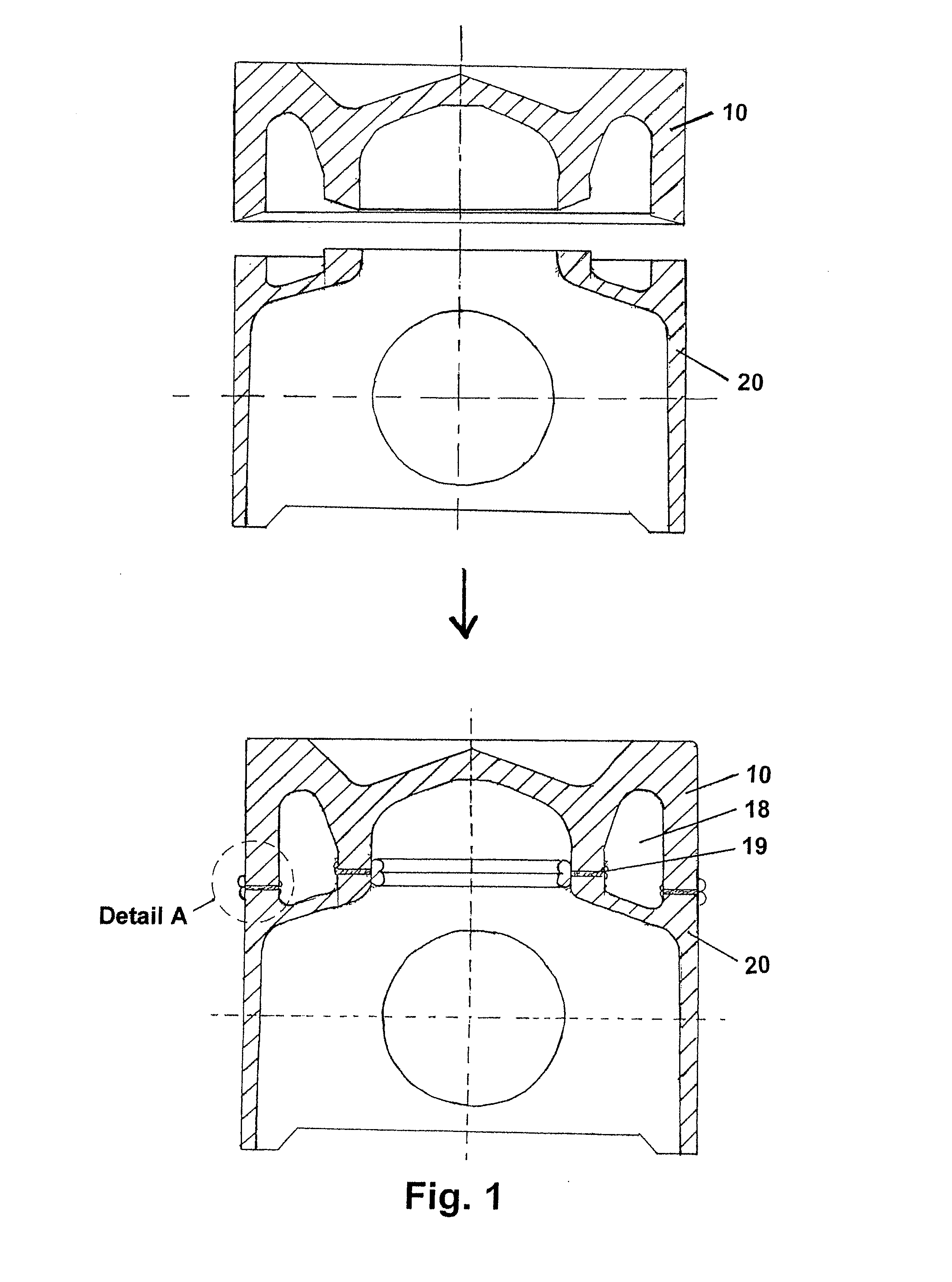

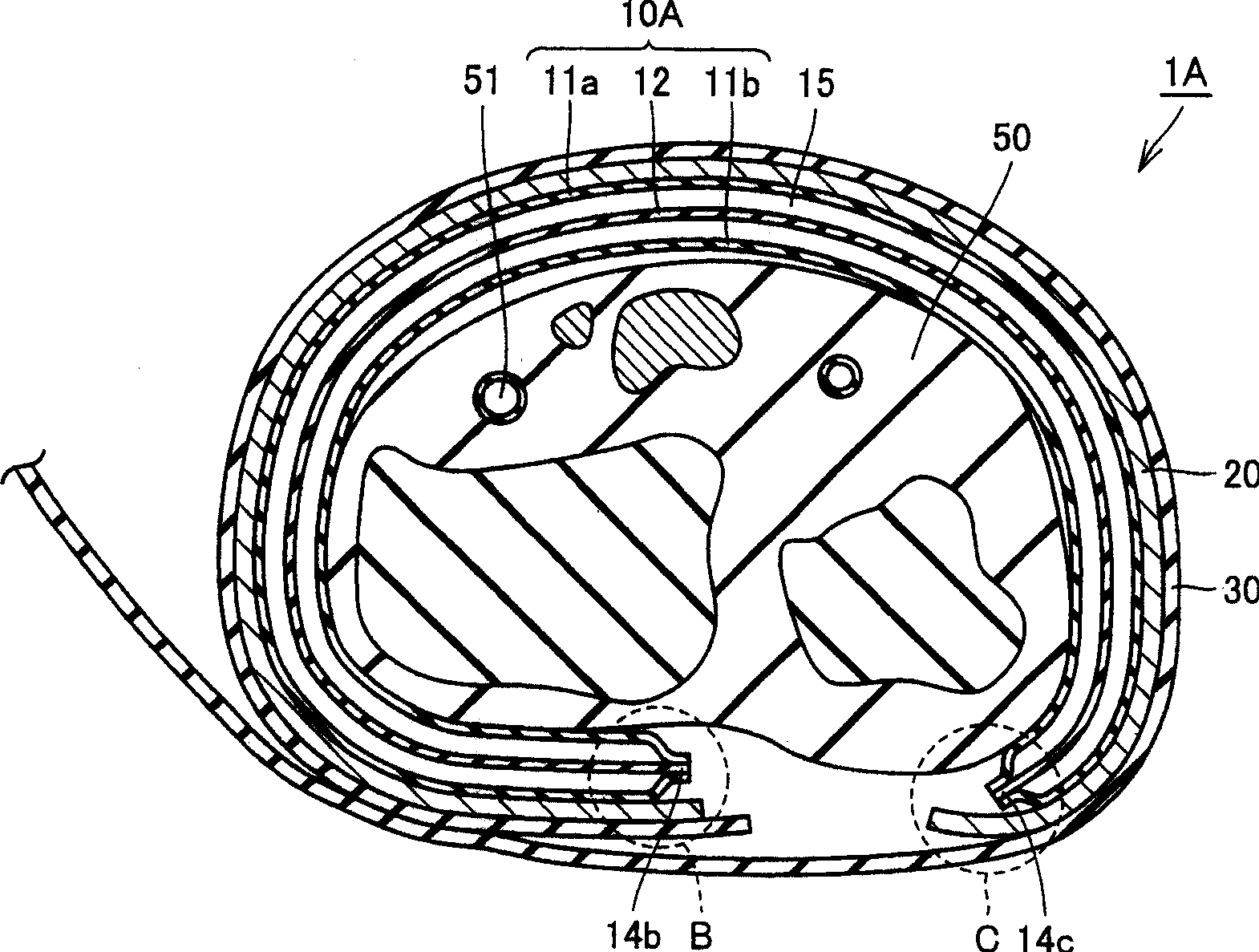

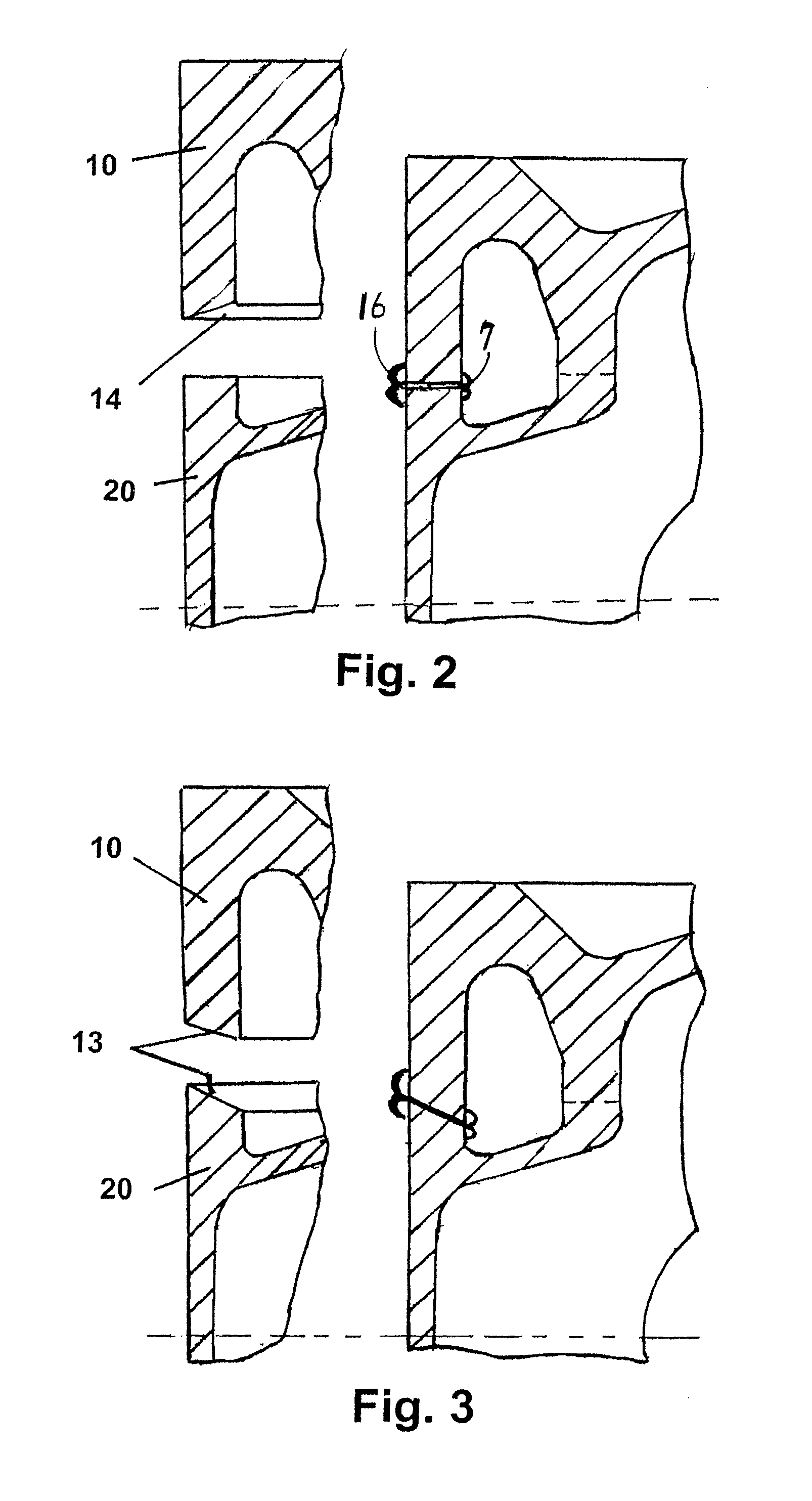

InactiveUS6941719B2Reduced strengthSatisfies requirementVehicle seatsStructural elementsAdhesive materialsBiomedical engineering

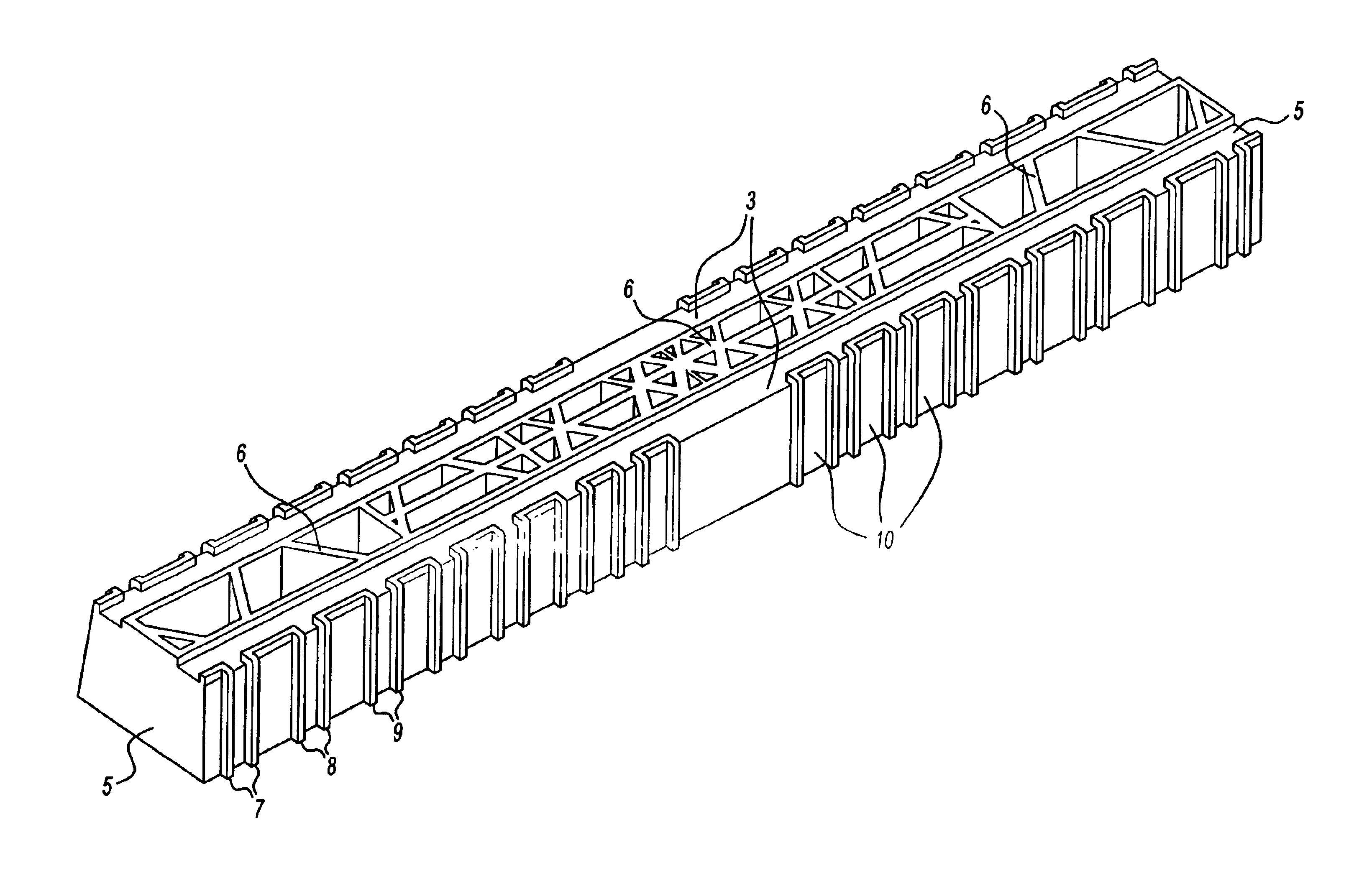

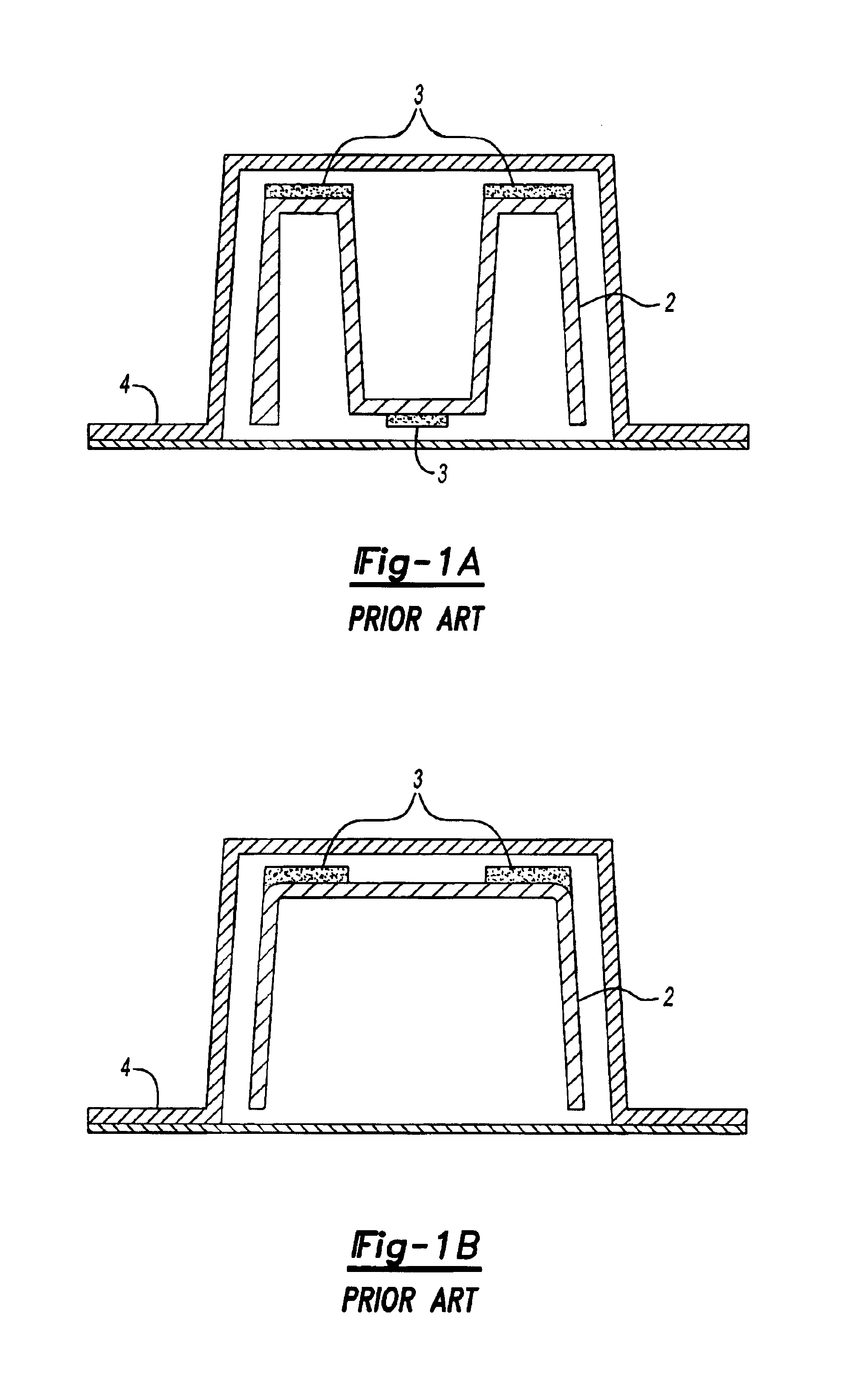

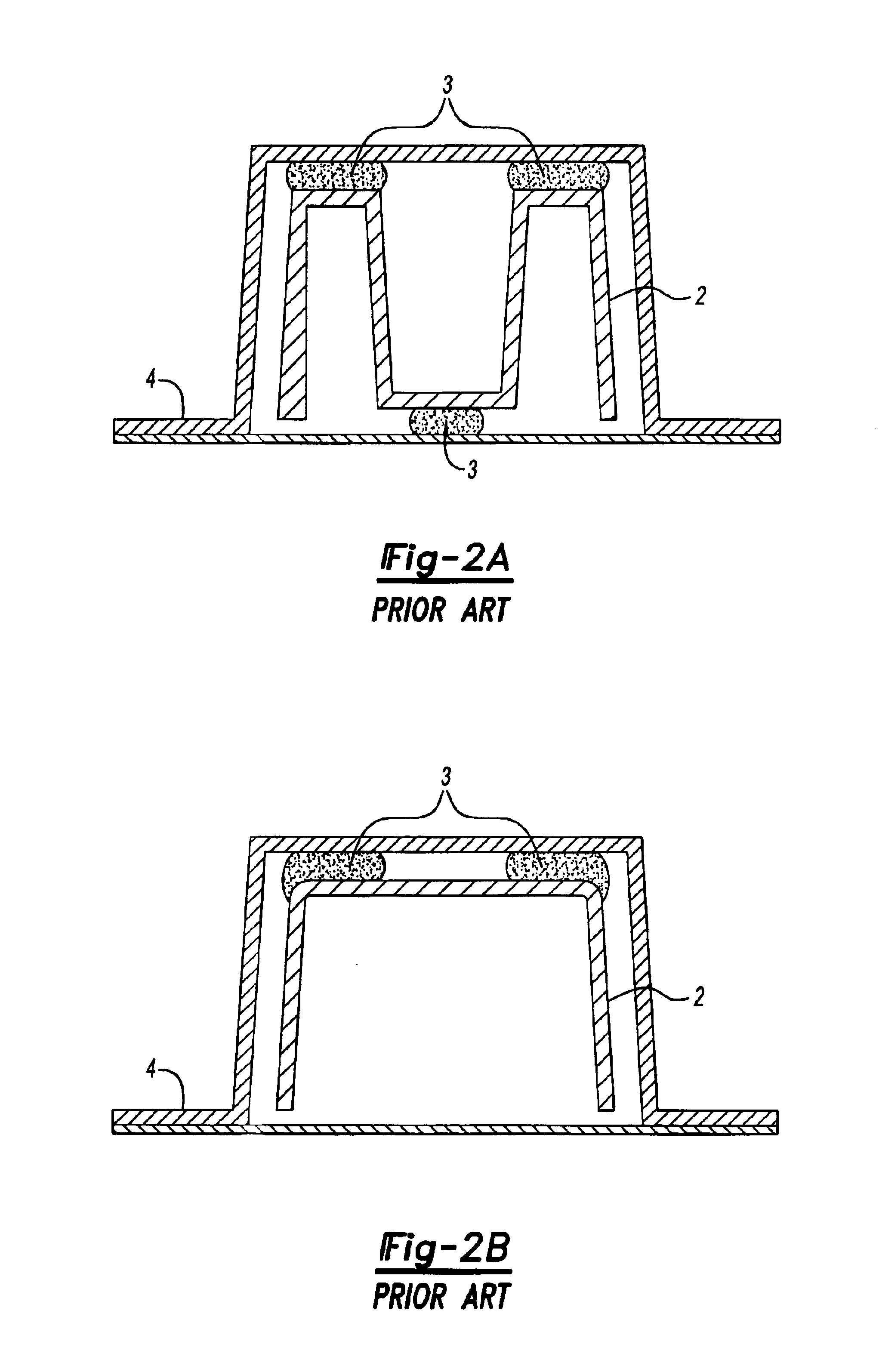

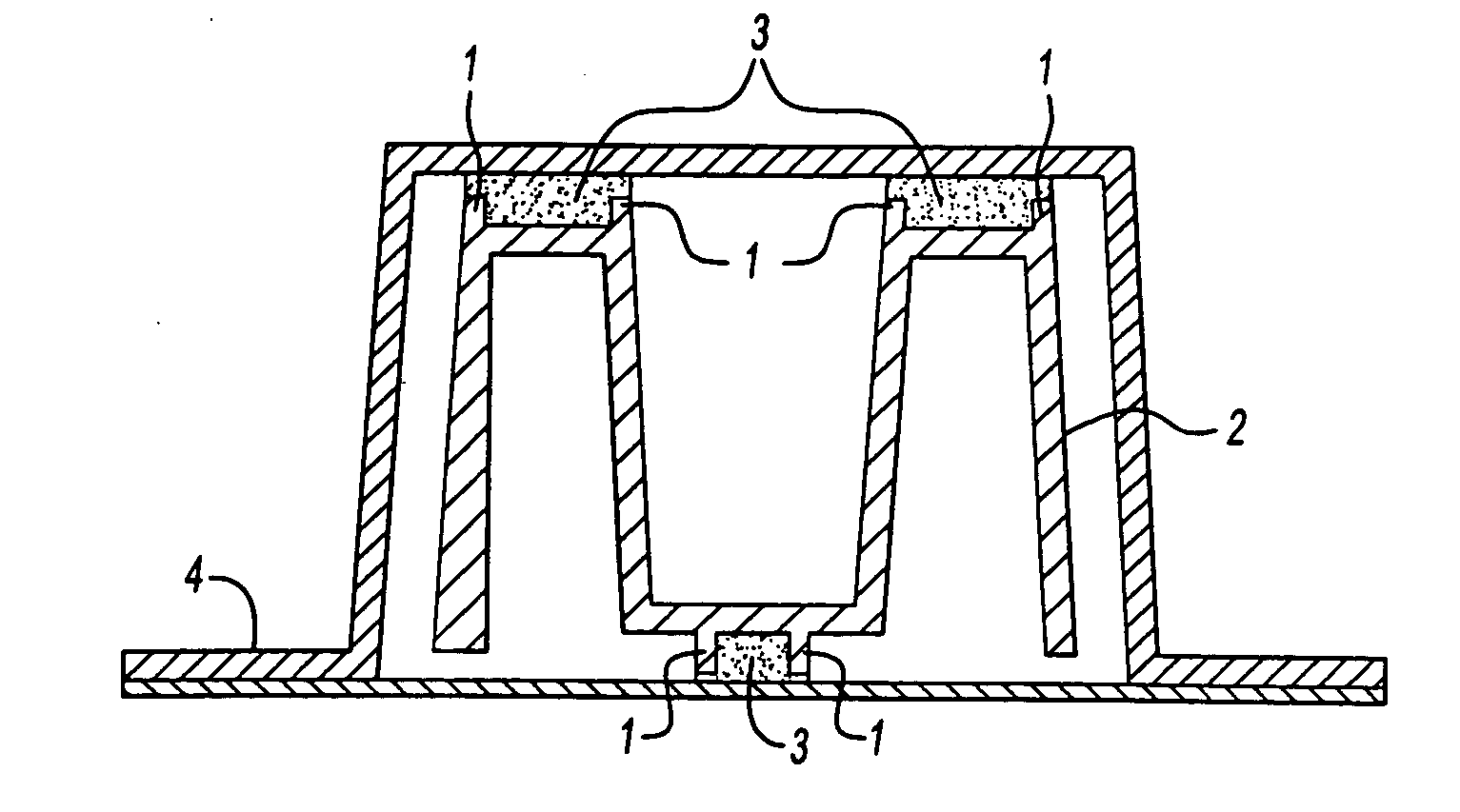

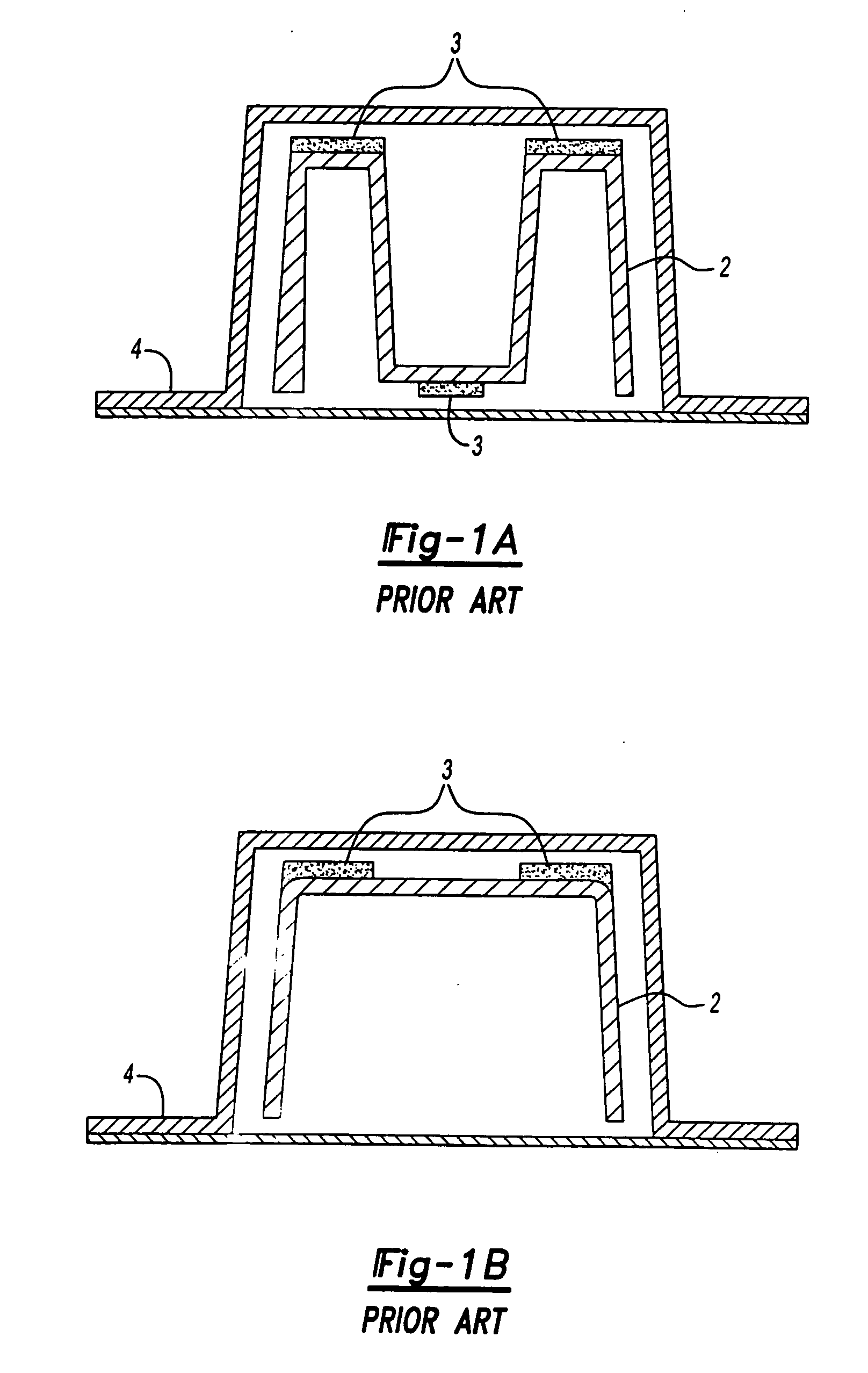

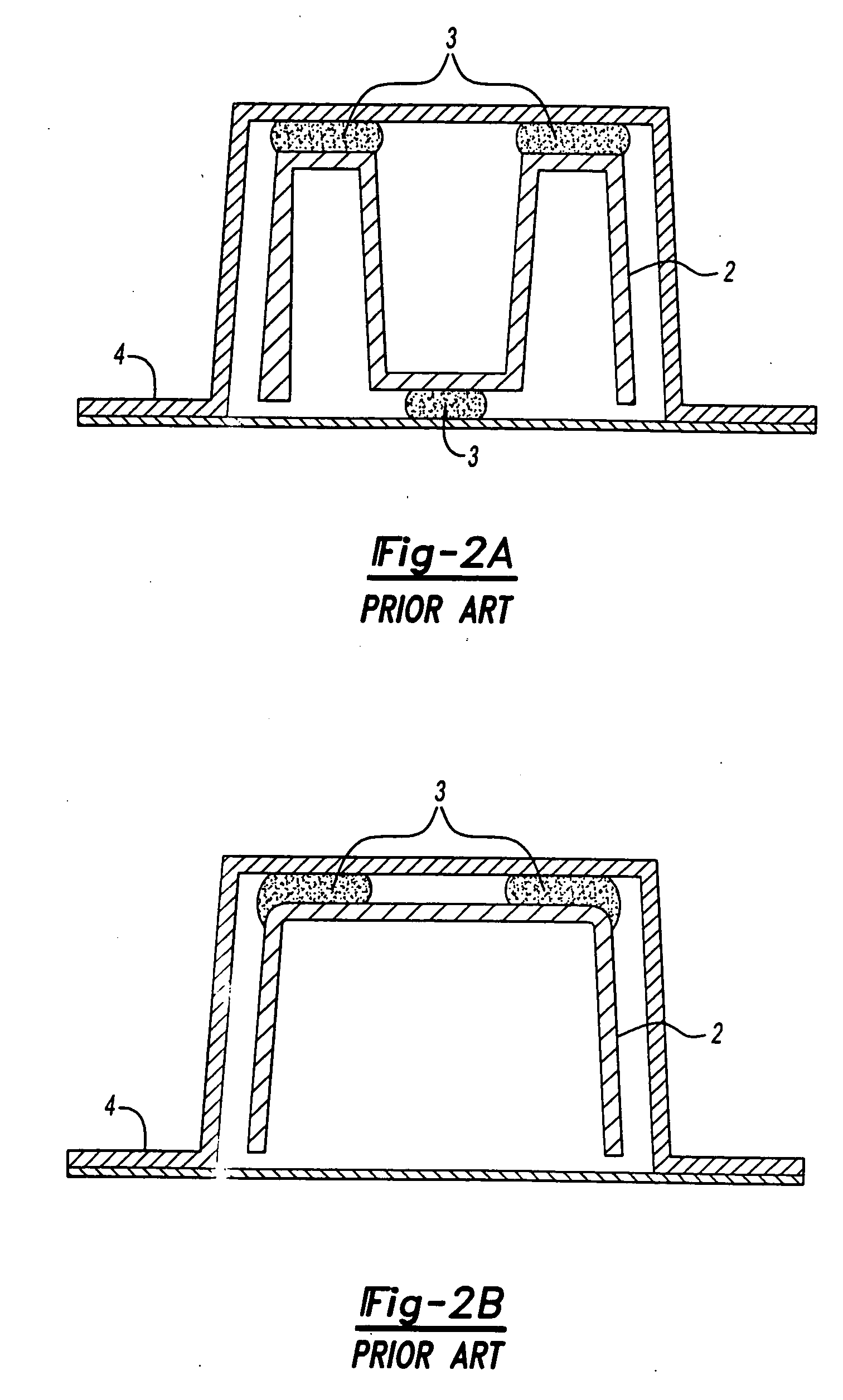

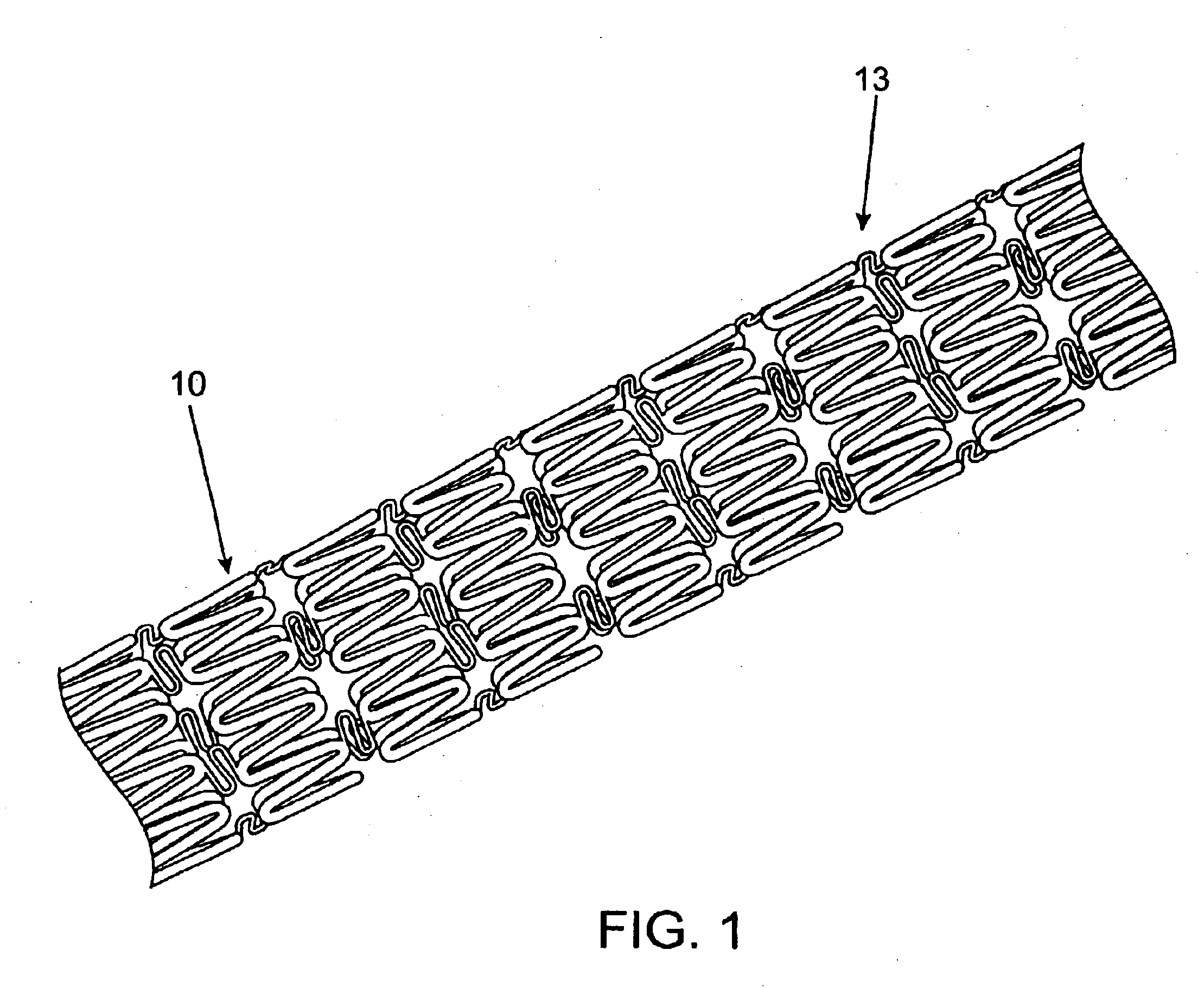

A structural reinforcement for a hollow member comprising a rigid reinforcing member having a shape that substantially conforms to the cross section of the hollow member to be reinforced with an expandable adhesive material over at least a portion of the surface of the structural reinforcement having one or more extensions on its external surface which control and direct the direction in which the adhesive material expands to bond the reinforcing member to the internal surface of the hollow member, some of the extensions also provide improved reinforcement.

Owner:ZEPHYROS INC

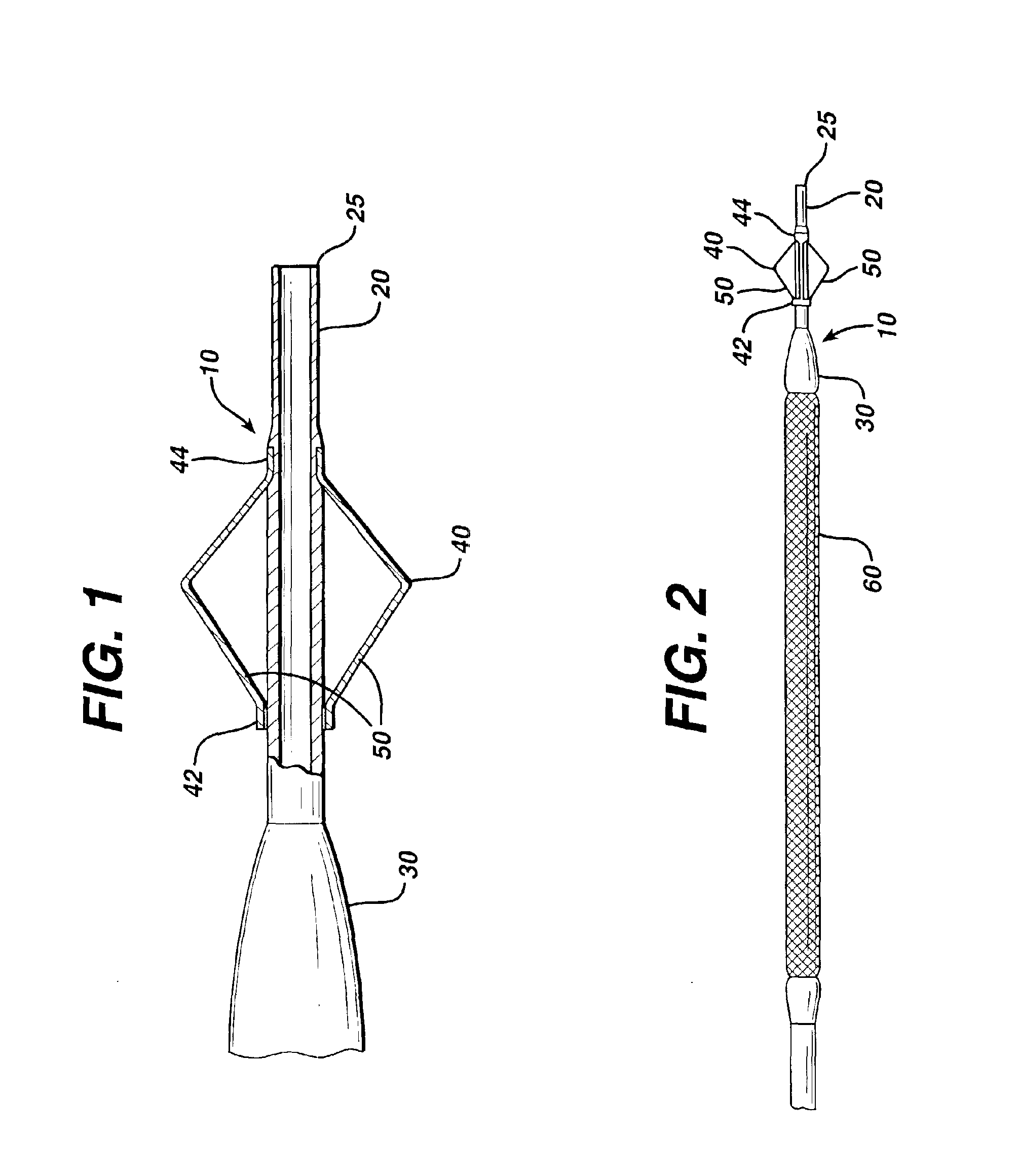

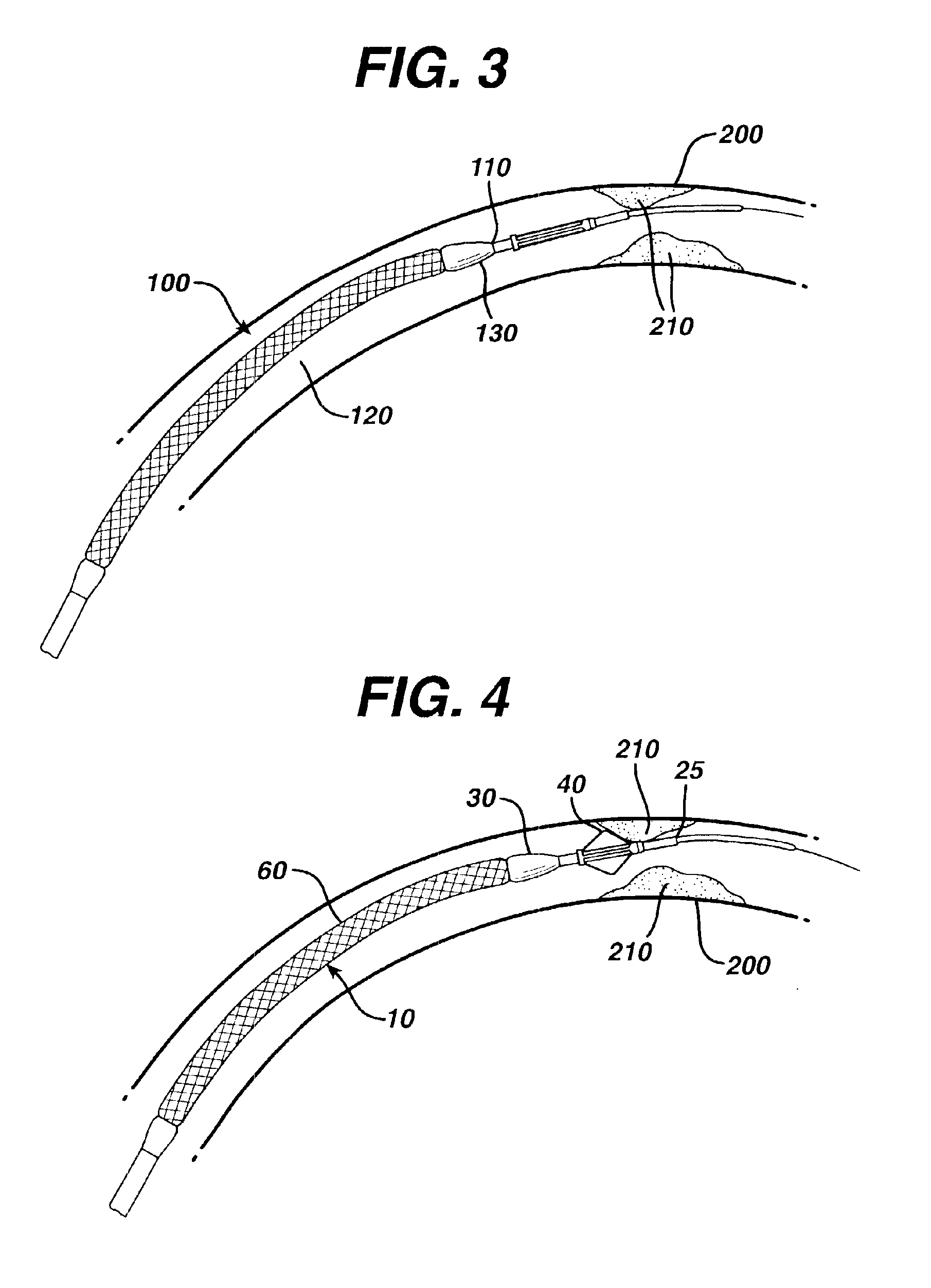

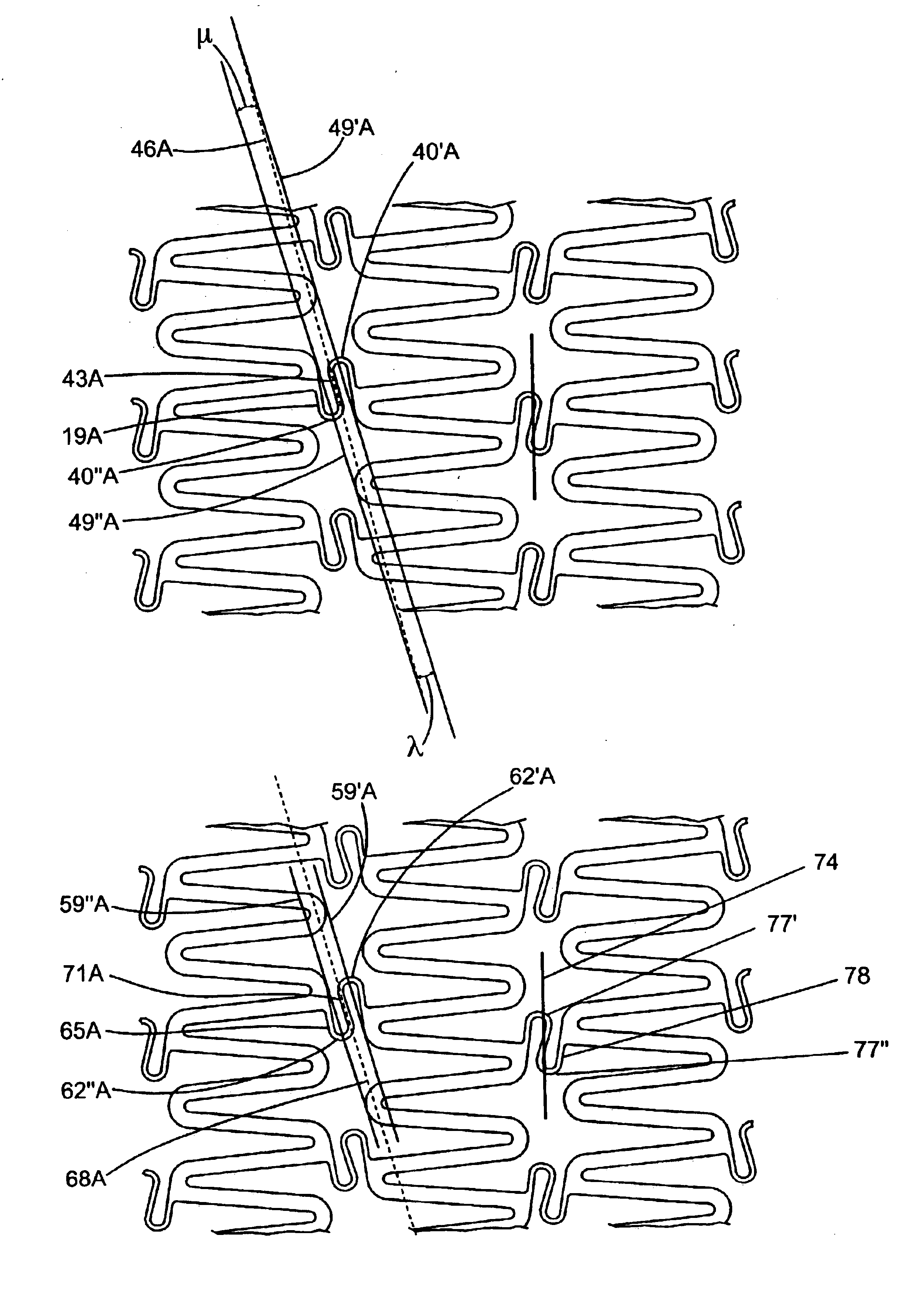

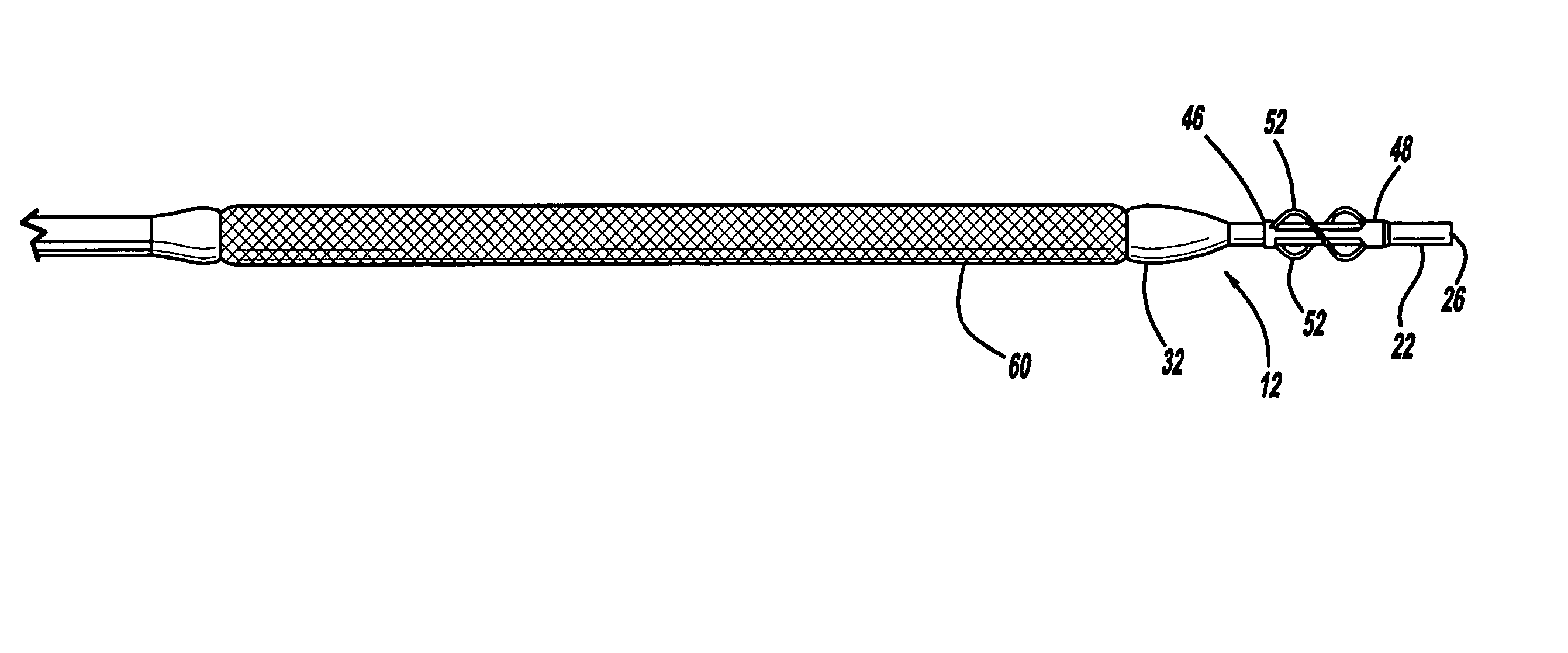

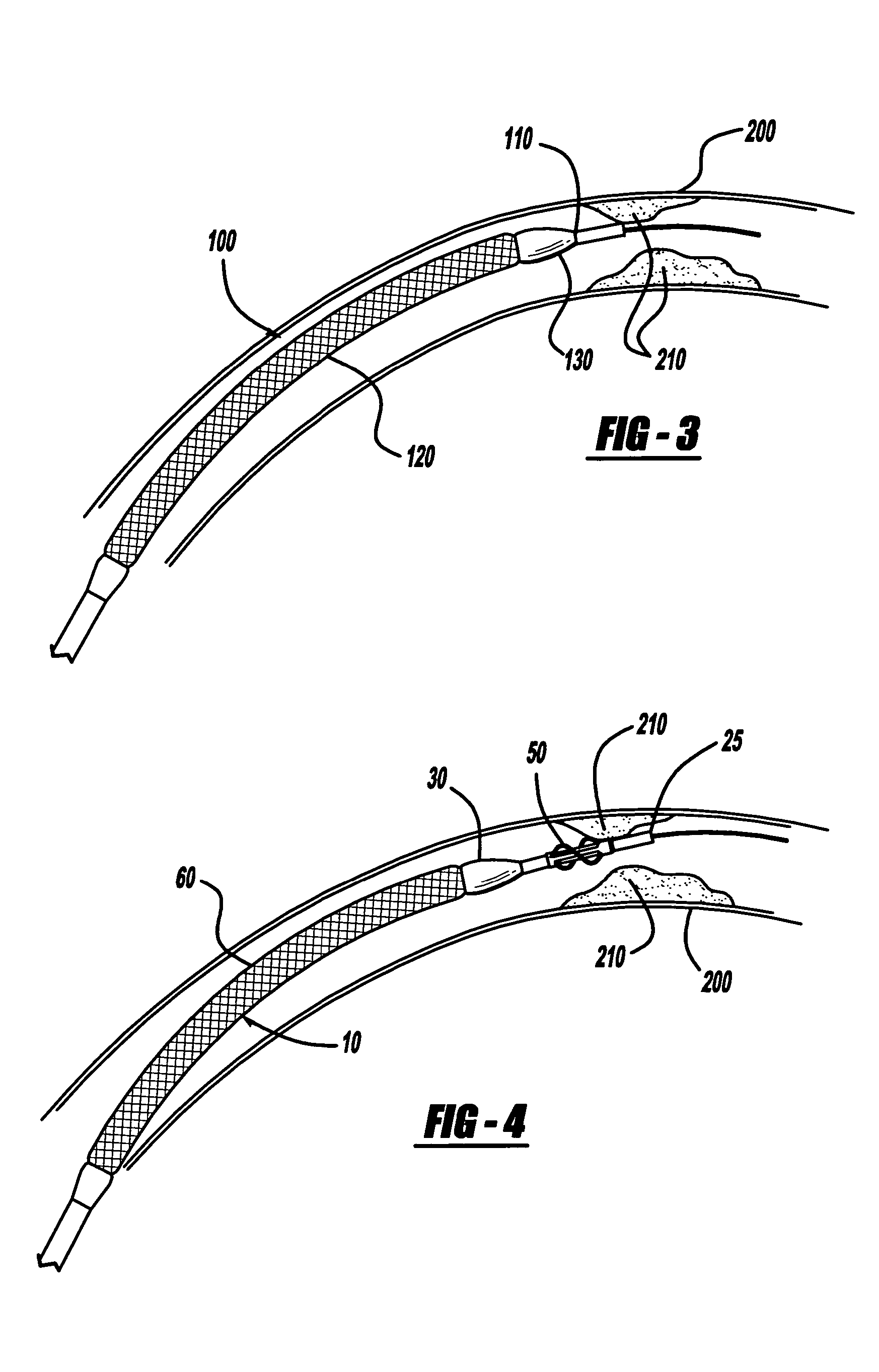

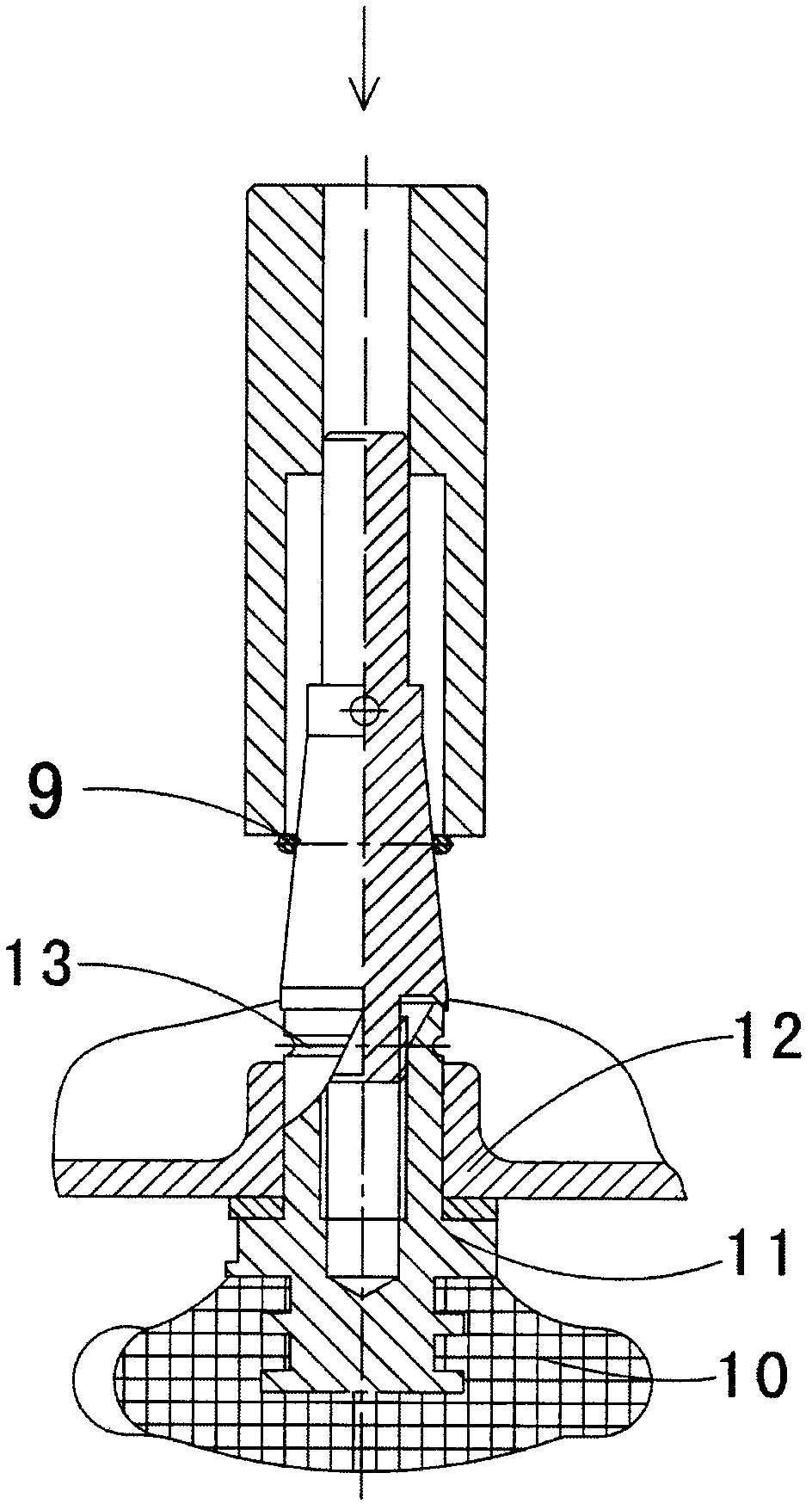

Centering catheter

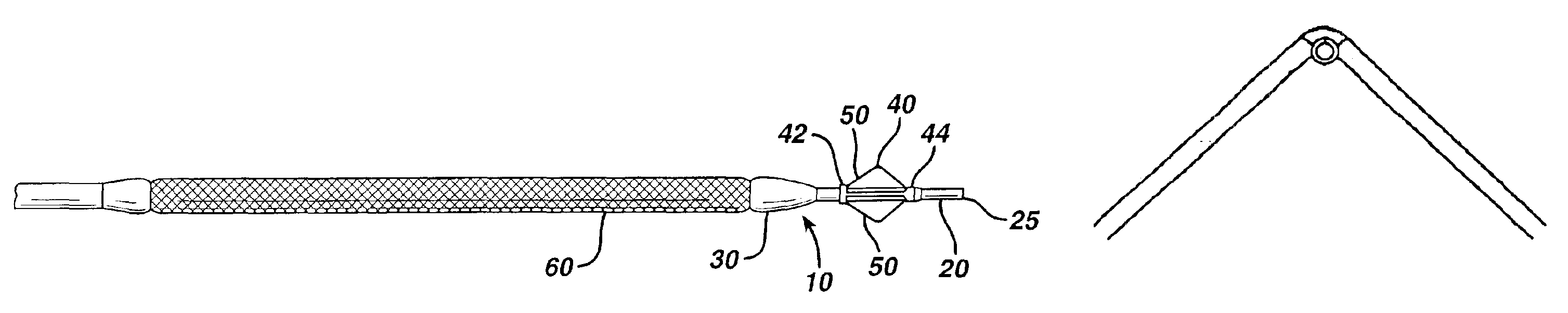

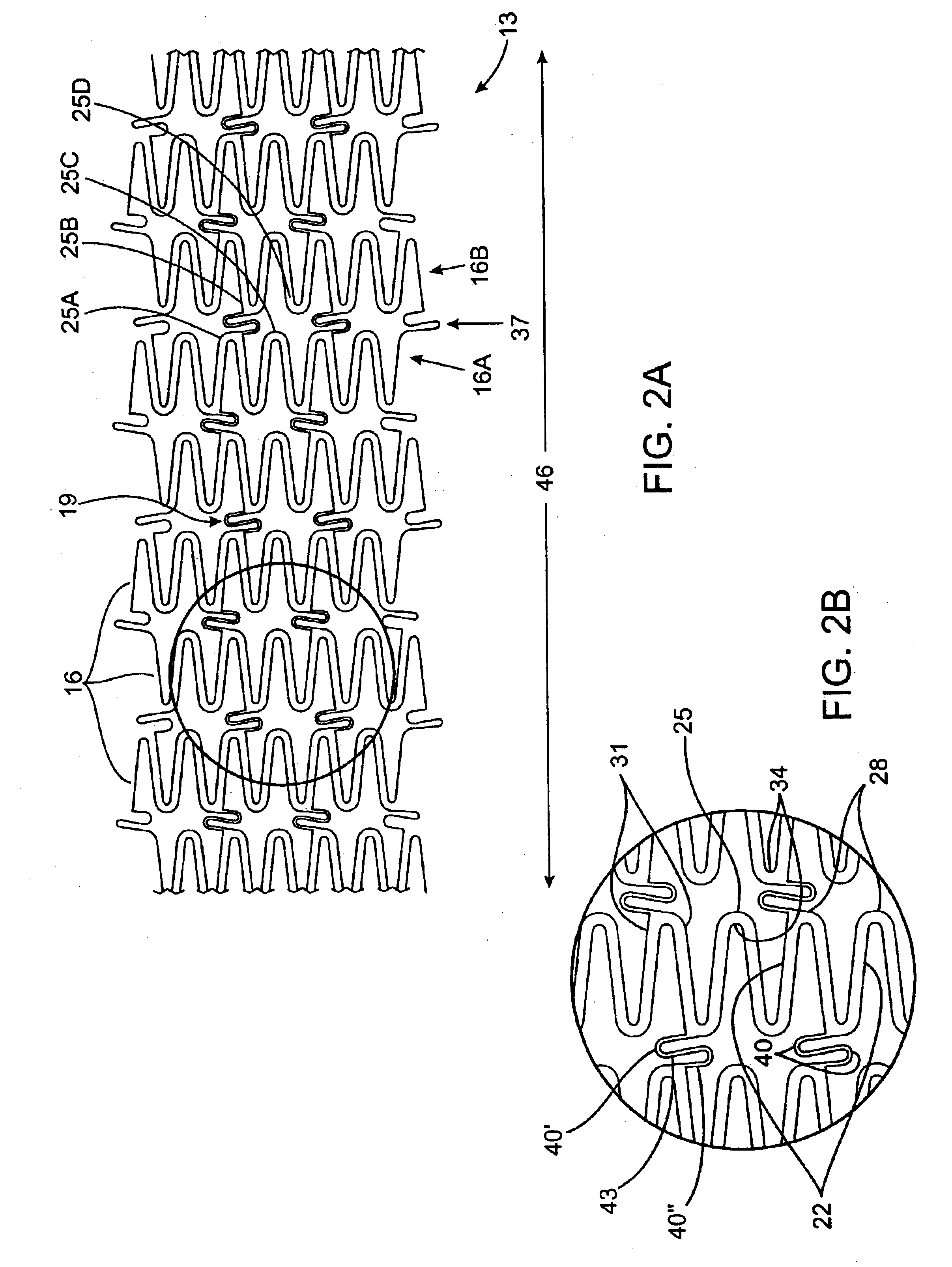

A catheter with at least one centering device attached near a distal end of the catheter. The centering device has at least two struts extending between a proximal end and a distal end. The centering device has a variable diameter and tends to center the distal end of the catheter, steering the catheter away from the vessel wall during insertion through the vasculature and toward the treatment site. The centering catheter may facilitate access to tortuous anatomy by preventing the catheter tip from catching on irregularities in the lumenal surface. The centering catheter may also facilitate uniform stent expansion by stabilizing the catheter during stent deployment.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

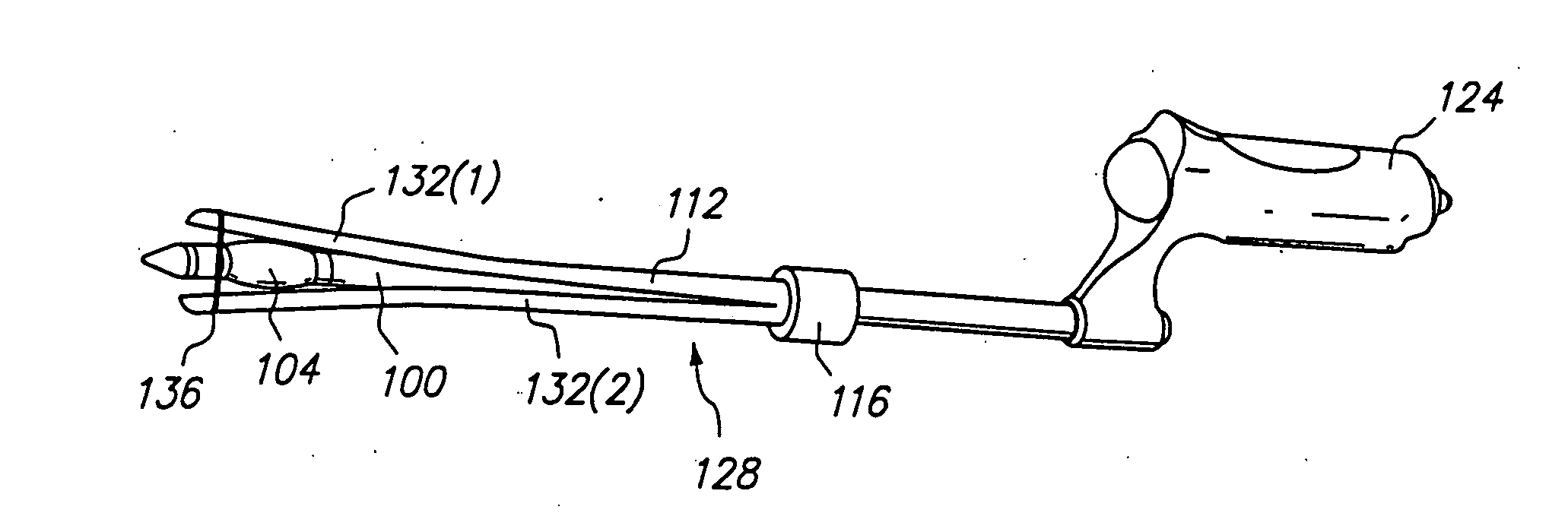

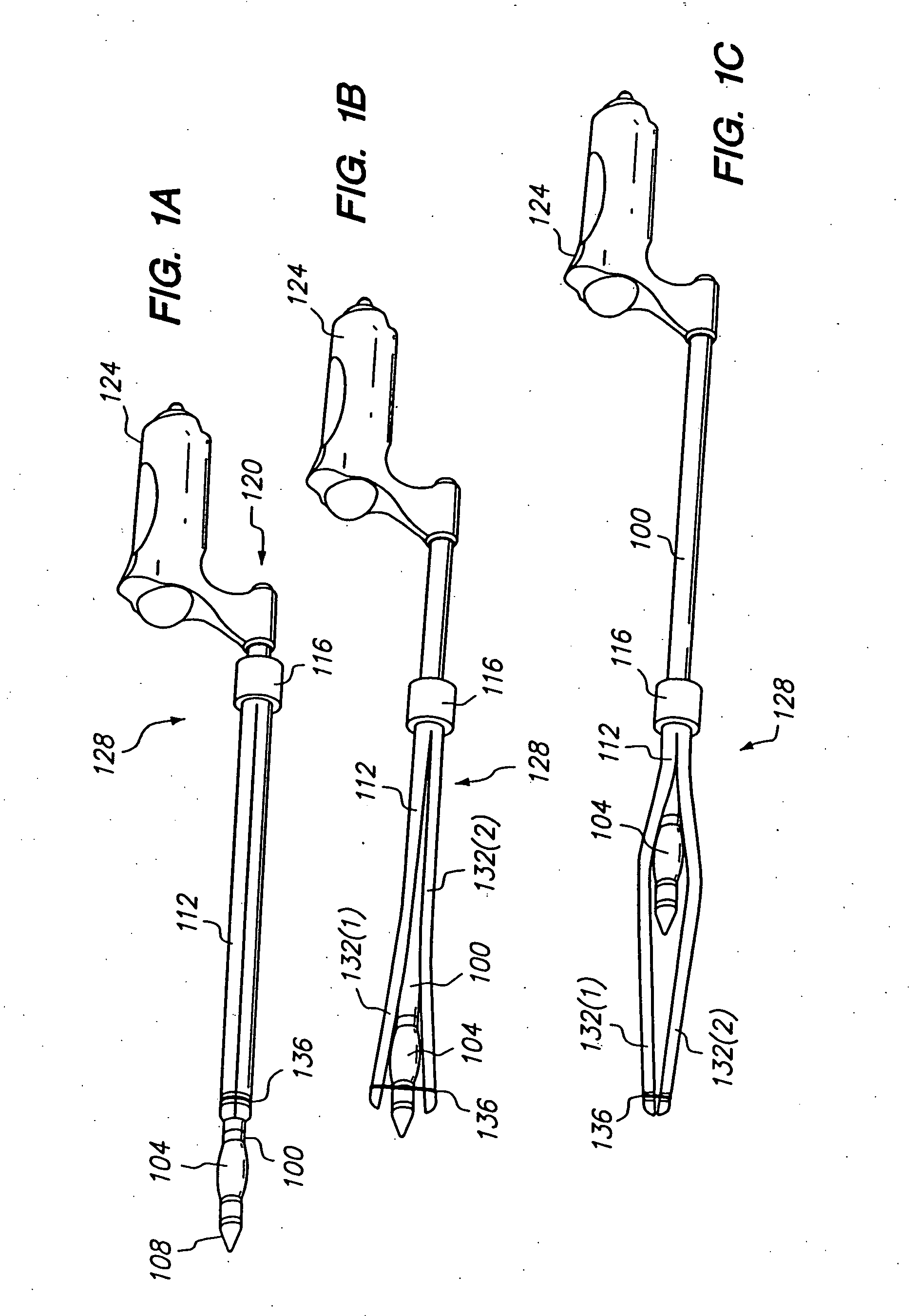

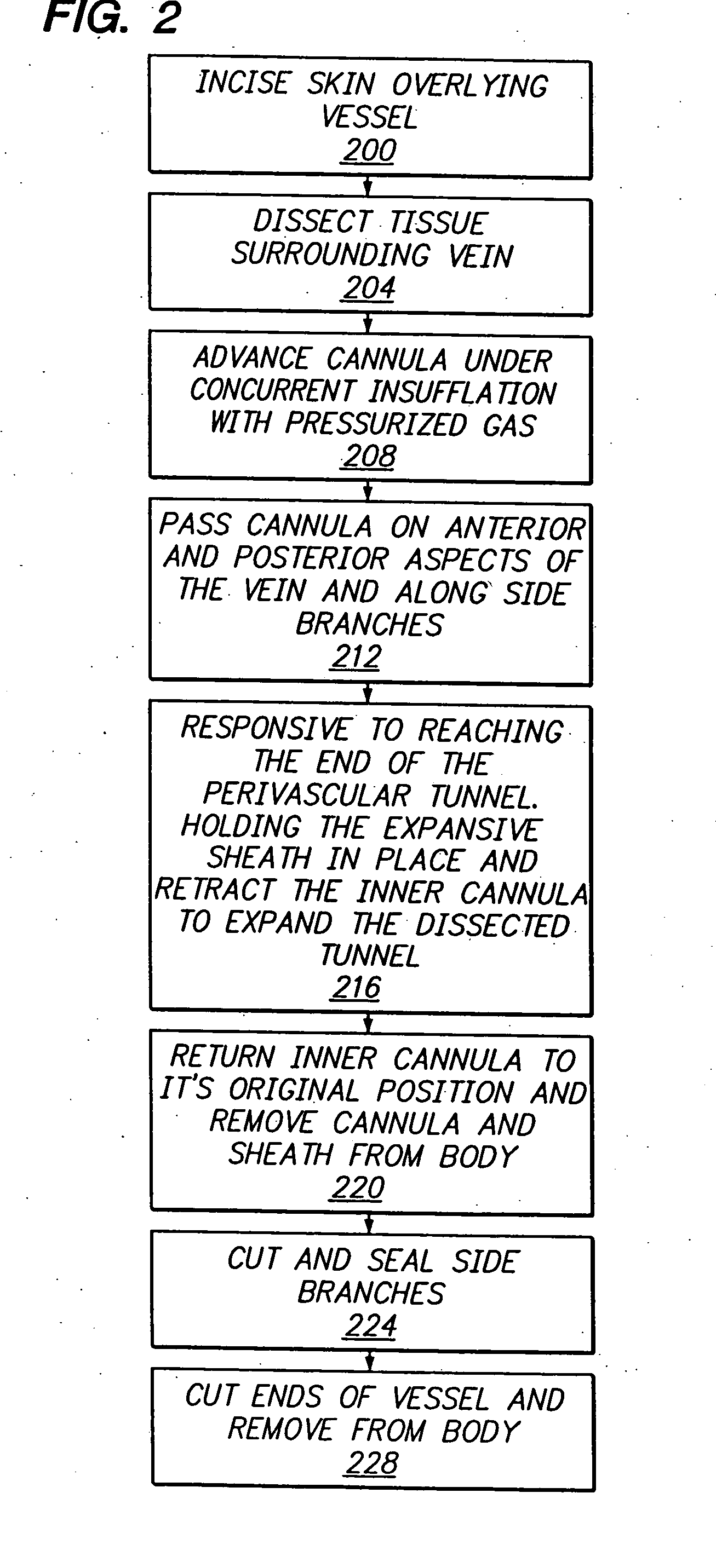

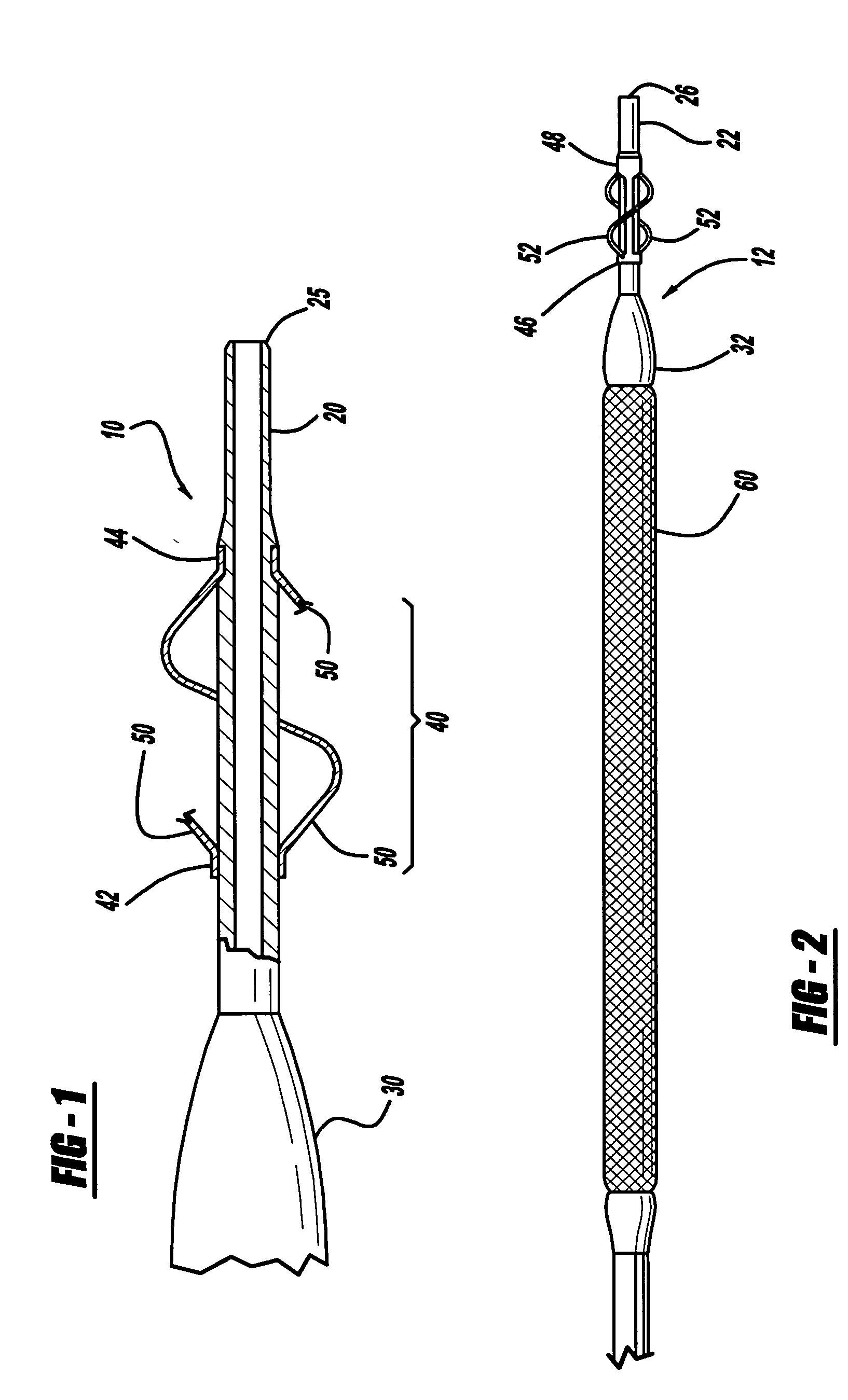

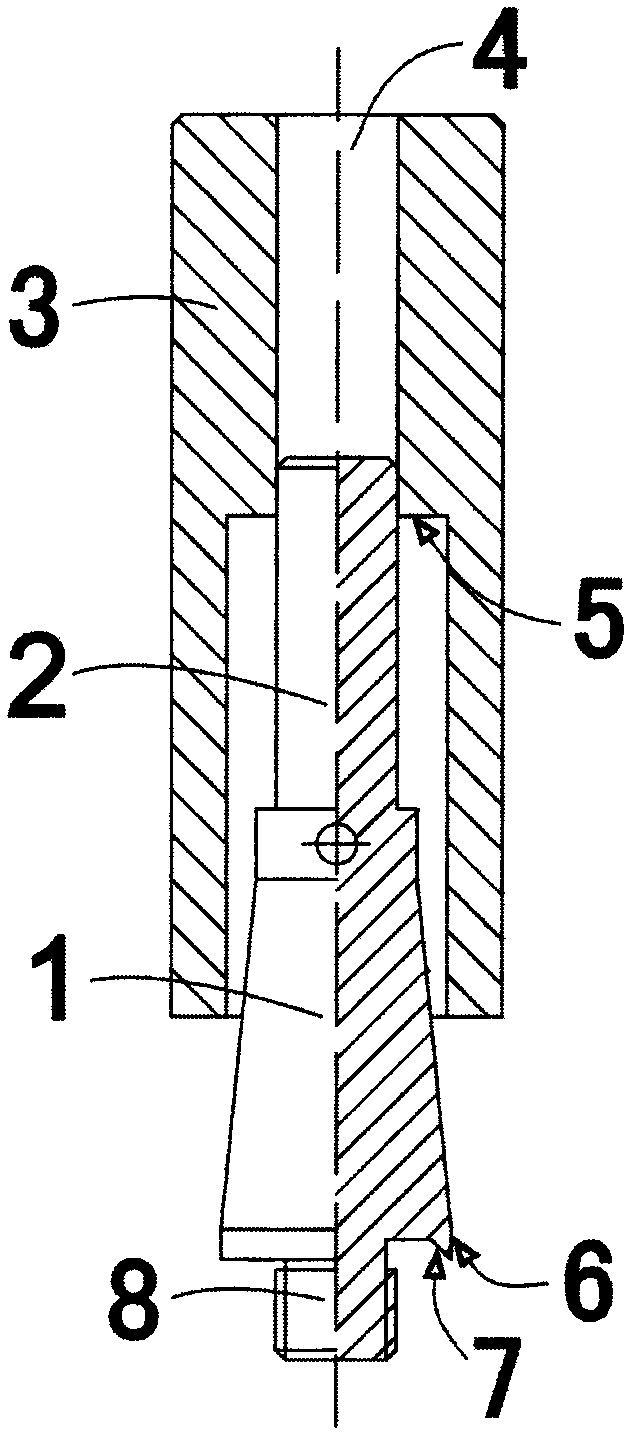

Longitudinal dilator

Apparatus and method for dilation of tissue utilize a tissue expansion device positioned on an inner cannula with an outer overlying expansive sheath that expands upon translation of the tissue expansion device therethrough. The tissue expansion device may be an olive or wedge formed near the tip of the cannula, and the expansible sheath includes two elongated shells that are fixably attached near proximal ends, and that are resiliently connected near distal ends. Translating the tissue expansion device through the expansible sheath expands the dimension of the shells to provide even dilation of surrounding tissue. Additionally, tissue dilation is performed in one continuous motion of retracting the inner cannula through the expansible sheath or pushing the tissue expansion device through the expansible sheath. The outer expansible sheath may be removed from the inner cannula to provide a dissection instrument having minimal outer diameter. The tissue expansion device may provide two stage expansion from a minimal outer dimension in one configuration to a second larger outer dimension in response to an applied axial force to provide enhanced tissue dilation.

Owner:MAQUET CARDIOVASCULAR LLC

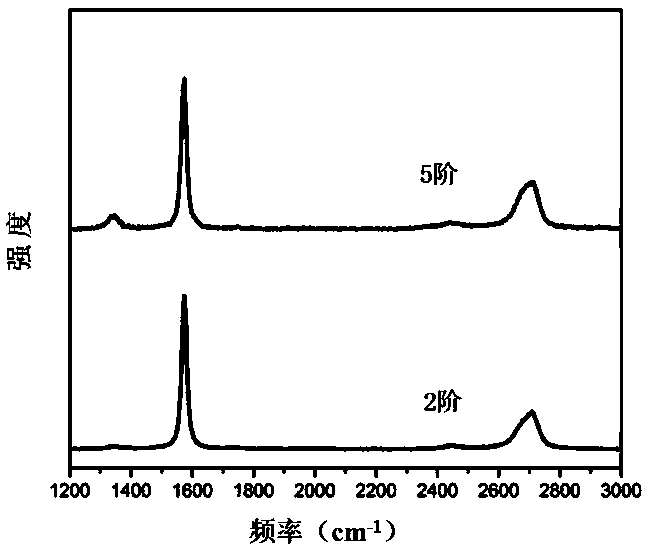

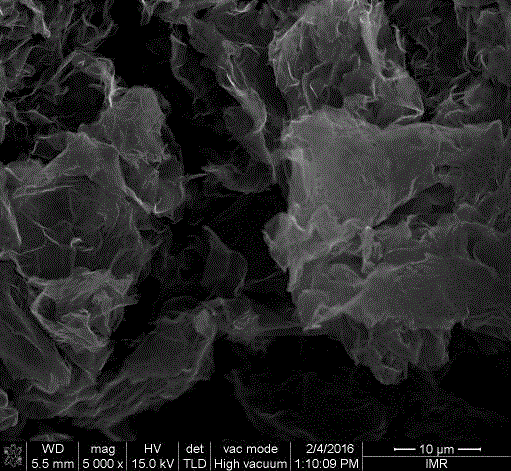

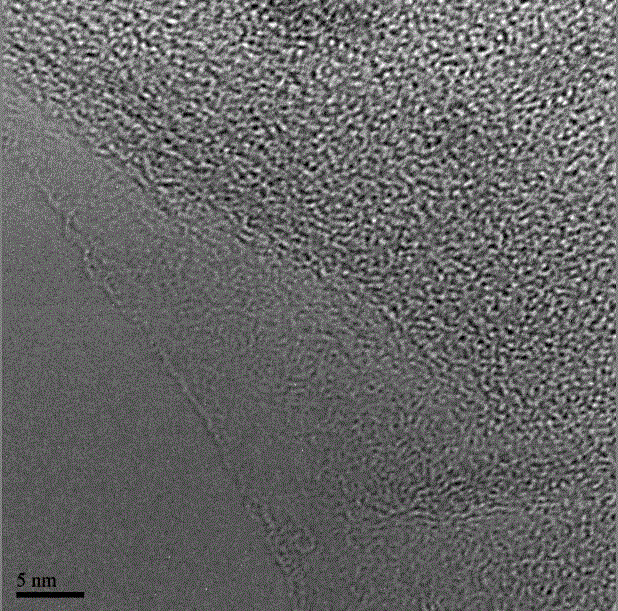

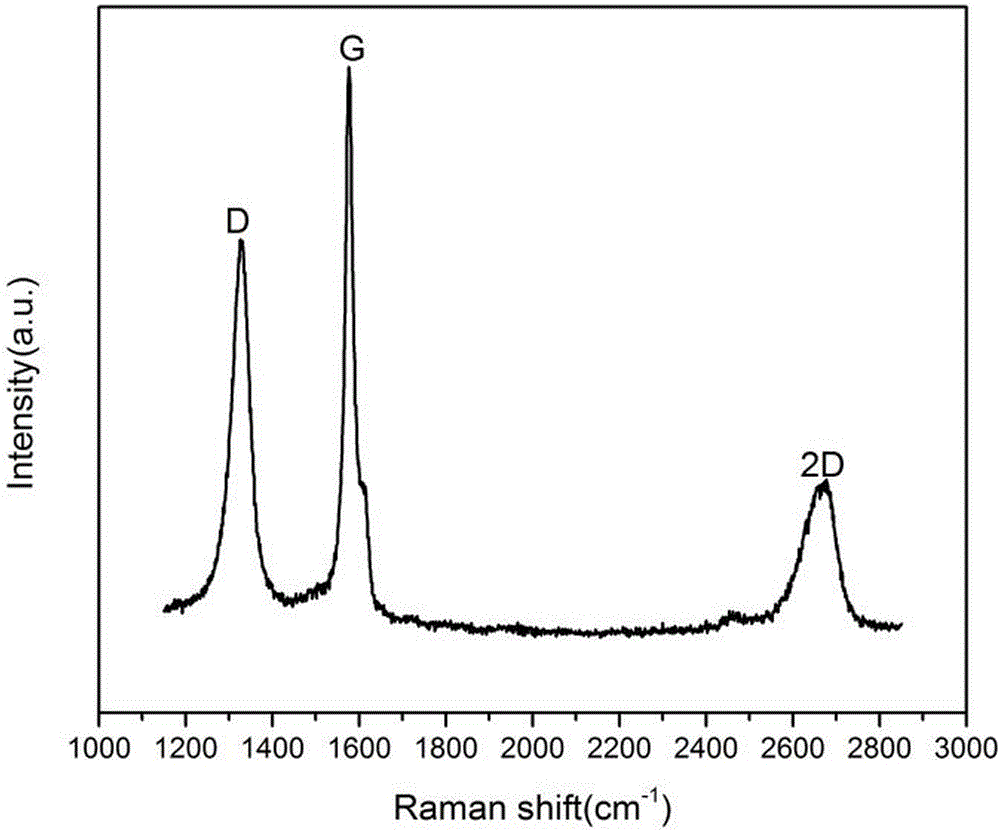

Method for preparing large-size high-quality graphene with controllable number of layers

The invention discloses a method for preparing large-size high-quality graphene with controllable number of layers, wherein graphite powder or flake graphite is mainly adopted as a raw material. The method specifically comprises the steps of intercalating the graphite raw material by virtue of an intercalating agent to initially weaken the intercalation interaction force and obtain different orders of graphite intercalation compounds (GICs); soaking the GICs in an appropriate expander, and then under the case that an auxiliary agent is added or not, enabling the intercalation materials to be quickly reacted with the expander to release a gases to obtain highly expanded wormlike graphene aggregate and further to cause the distances among graphene lamellar layers to be increased; and after certain processing, peeling, and then repeatedly centrifuging and dispersing to obtain a graphene dispersion with different numbers of layers. According to the method disclosed by the invention, the intercalation-expansion-peeling process is involved, raw materials are cheap, the reaction process is simple and easily controlled, and the number of layers of graphene is precisely controlled; the obtained graphene lamellar layers have the advantages of few defects, large size, high conductivity, high yield and the like, the large-scale industrial production is easily implemented, and the problems of high cost, low productivity, poor quality, small size, uncontrollable number of layers and the like in an existing graphene preparation technology are solved.

Owner:安徽百特新材料科技有限公司

Structural reinforcement

InactiveUS20050276970A1Low mobilityReduce pointsSuperstructure subunitsThin material handlingAdhesive materialsBiomedical engineering

A structural reinforcement for a hollow member comprising a rigid reinforcing member having a shape that substantially conforms to the cross section of the hollow member to be reinforced with an expandable adhesive material over at least a portion of the surface of the structural reinforcement having one or more extensions on its external surface which control and direct the direction in which the adhesive material expands to bond the reinforcing member to the internal surface of the hollow member, some of the extensions also provide improved reinforcement.

Owner:ZEPHYROS INC

Vascular prosthesis

InactiveUS6916336B2Easy to trackImprove consistencyStentsBlood vesselsHinge regionVascular prosthesis

Owner:ALTAI MEDICAL TECH

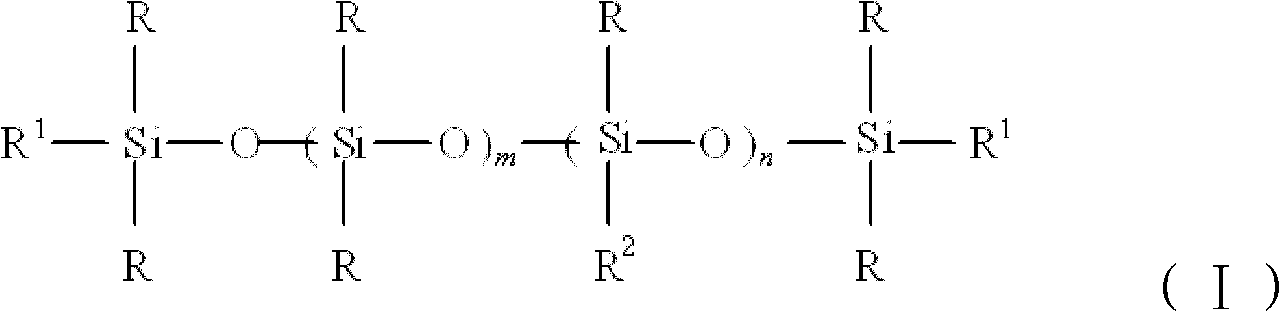

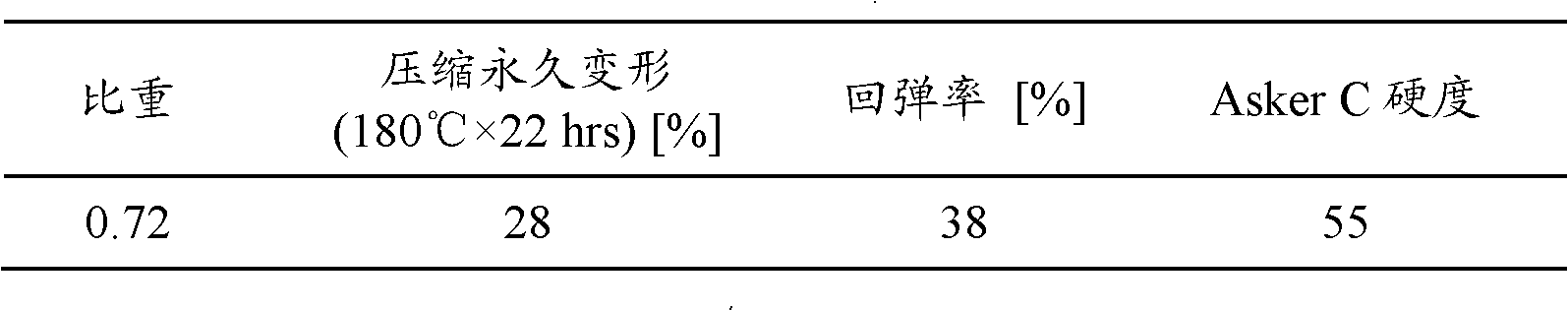

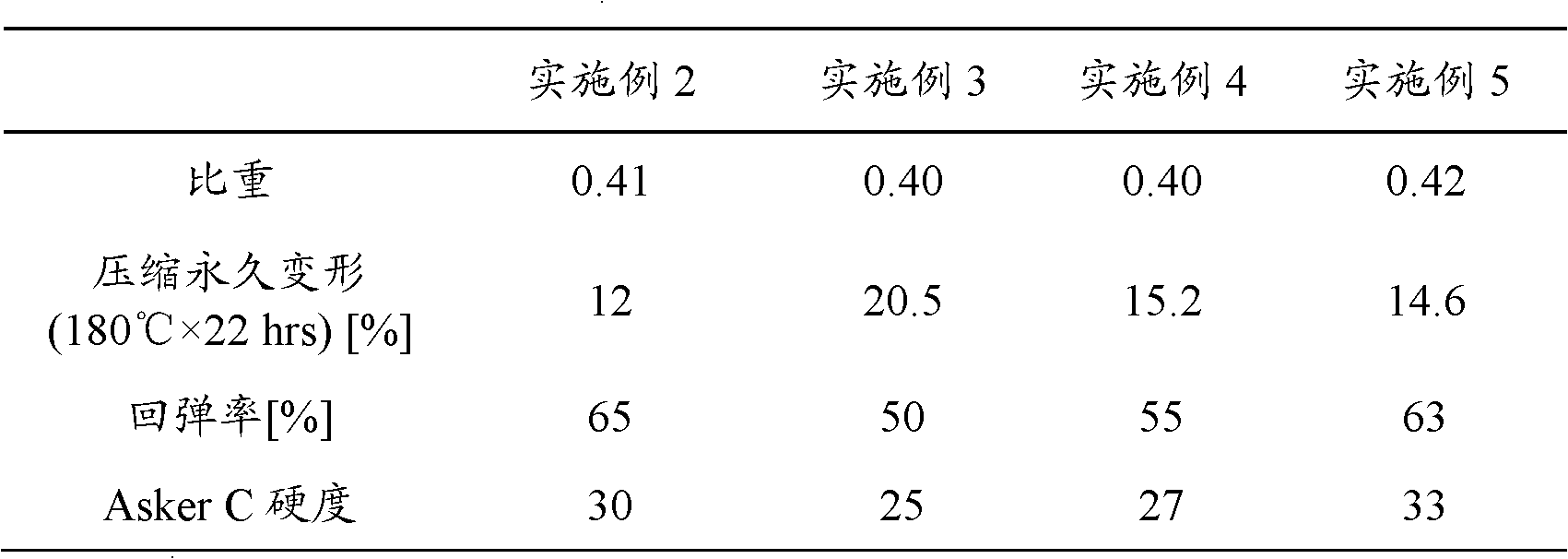

Liquid silicon rubber composition and preparation method thereof

The invention relates to a liquid silicon rubber composition which comprises the following components in parts by mass: 100 parts of polydimethylsiloxane with vinyl as an end group, 1-400 parts of inorganic reinforcing agent, 1-20 parts of low-viscosity polydimethylsiloxane with a vinyl-containing side group, 0.01-10 parts of cross-linking agent, 1-30 parts of polydimethylsiloxane with hydroxyl as an end group, and a platinum catalyst capable of curing the liquid silicon rubber composition. The invention further relates to a preparation method of the liquid silicon rubber composition. The liquid silicon rubber composition has low viscosity and good fluidity before being cured and is applicable to injection molding; and the composition has excellent resilience and low compression deformation ratio after being cured. The liquid silicon rubber composition can be applied to an elastomer, a pressure roll and an image heating and fixing device in a copier and a laser printer as well as certain silicon rubber products in need of the properties.

Owner:SHENZHEN CITY SQUARE SILICONE MATERIALS

Spiral centering catheter

InactiveUS20050171592A1Through simpleAvoiding adverse lumen contactStentsBalloon catheterDistal portionStent deployment

A catheter with proximal and distal ends having a spiral centering device attached near the catheter distal end. The spiral centering device has at least one spiral strut having a proximal end and a distal end. The spiral centering device resiliently tends to center the distal end portion of the catheter, steering the catheter away from the vessel wall during insertion through the vasculature and toward the treatment site. The spiral centering catheter may facilitate access to tortuous anatomy by preventing the distal catheter tip from catching on irregularities in the lumenal surface. If a stent is provided on the catheter, the spiral centering catheter may also facilitate uniform stent expansion by stabilizing the catheter during stent deployment.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

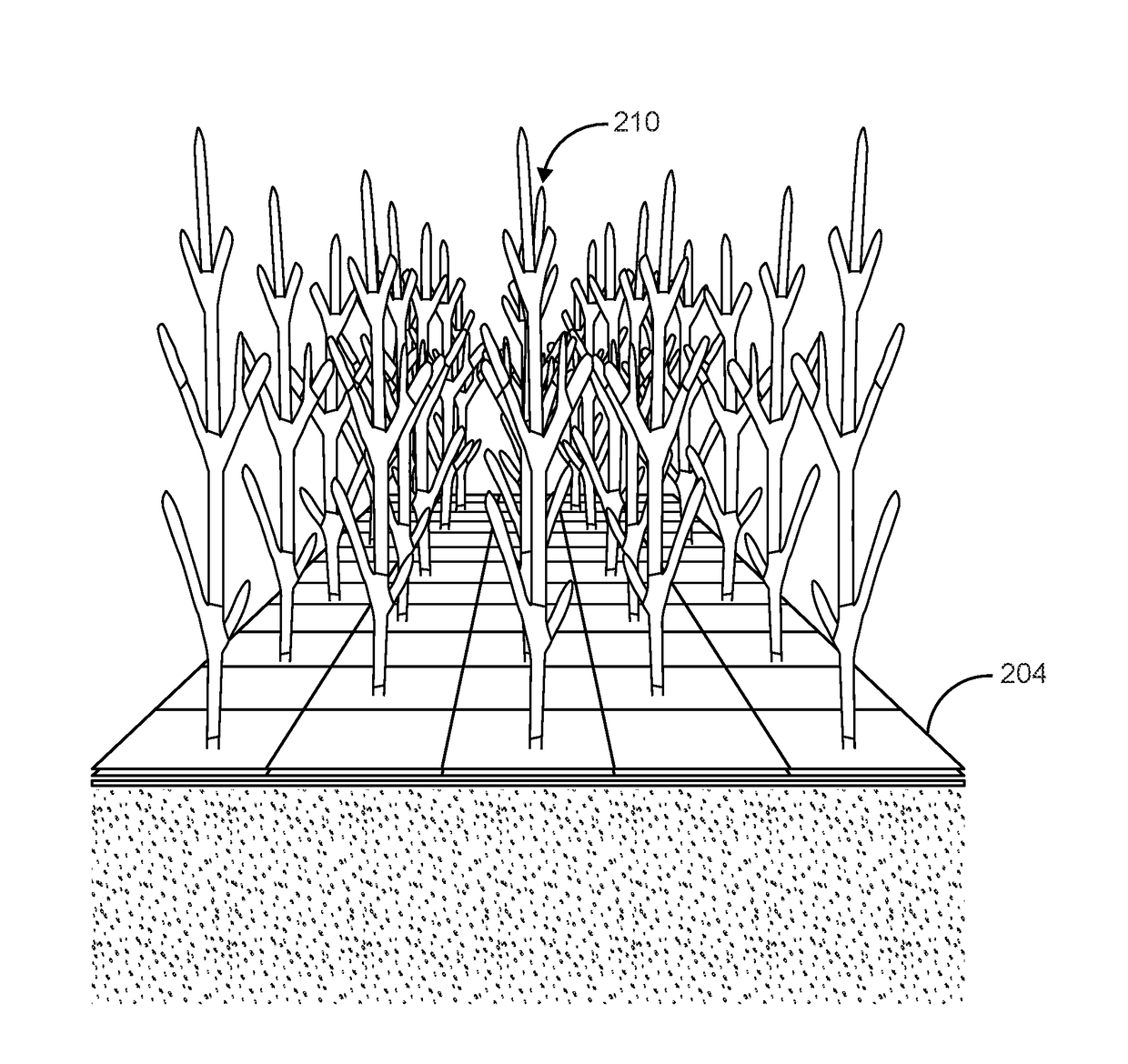

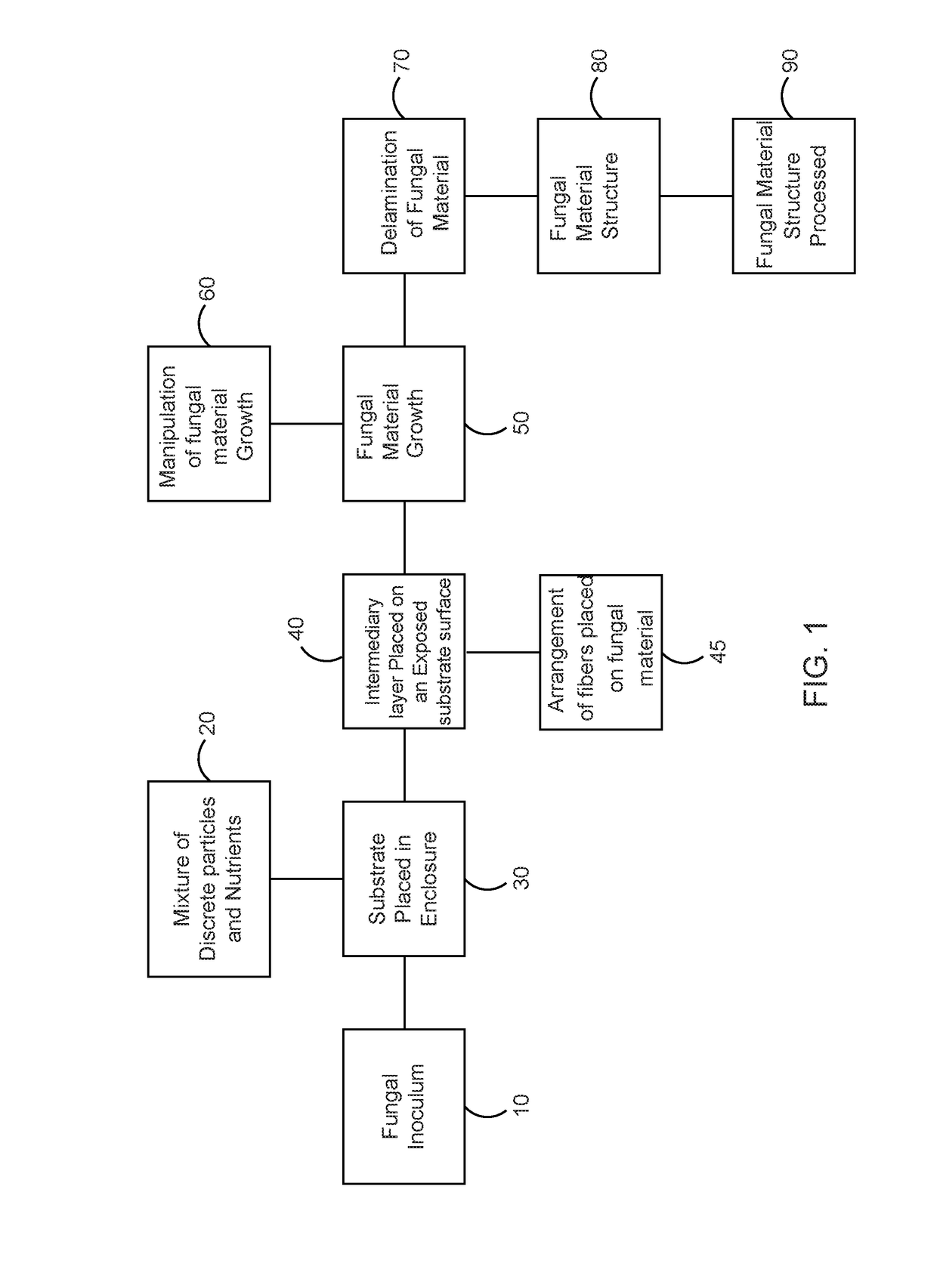

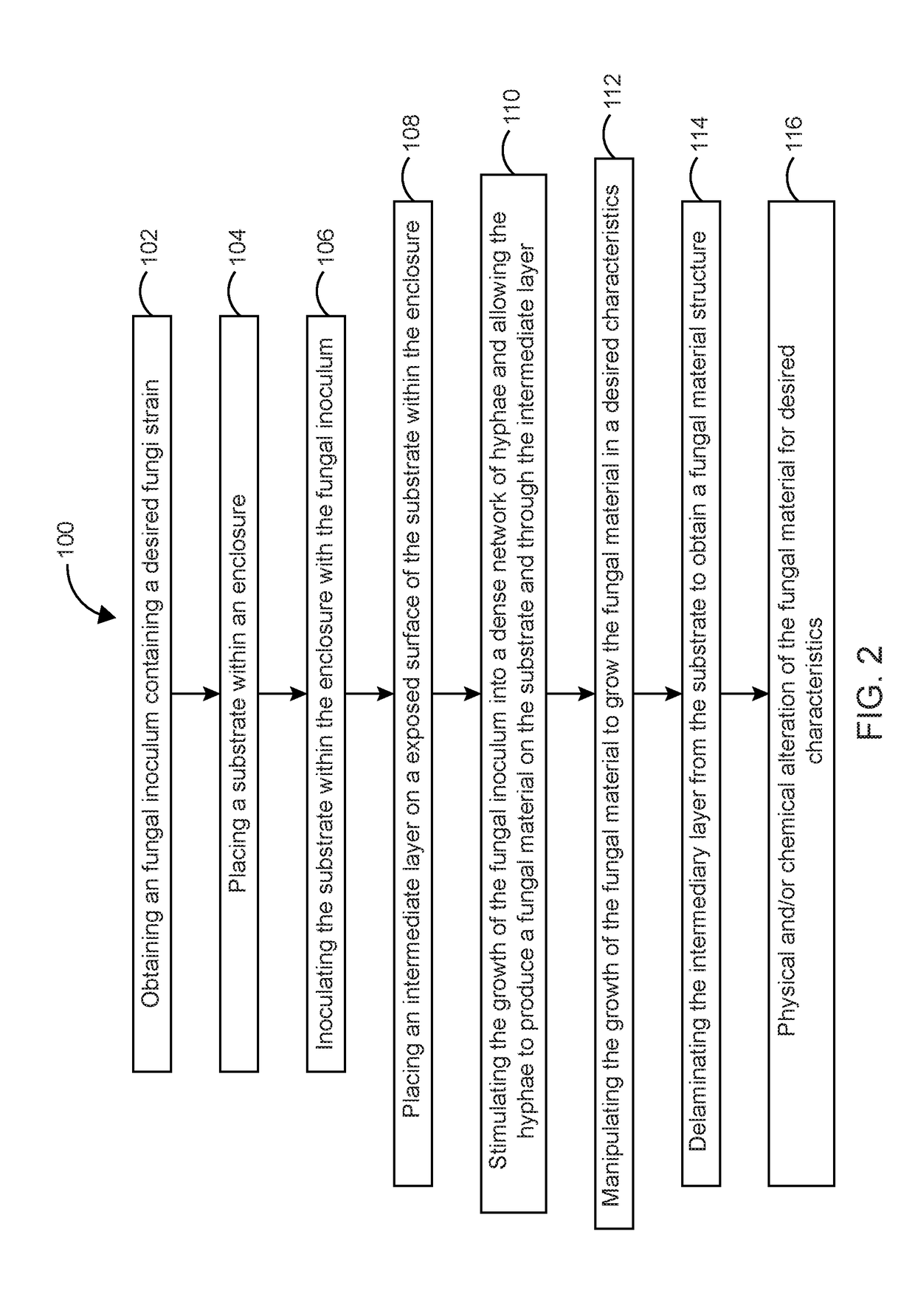

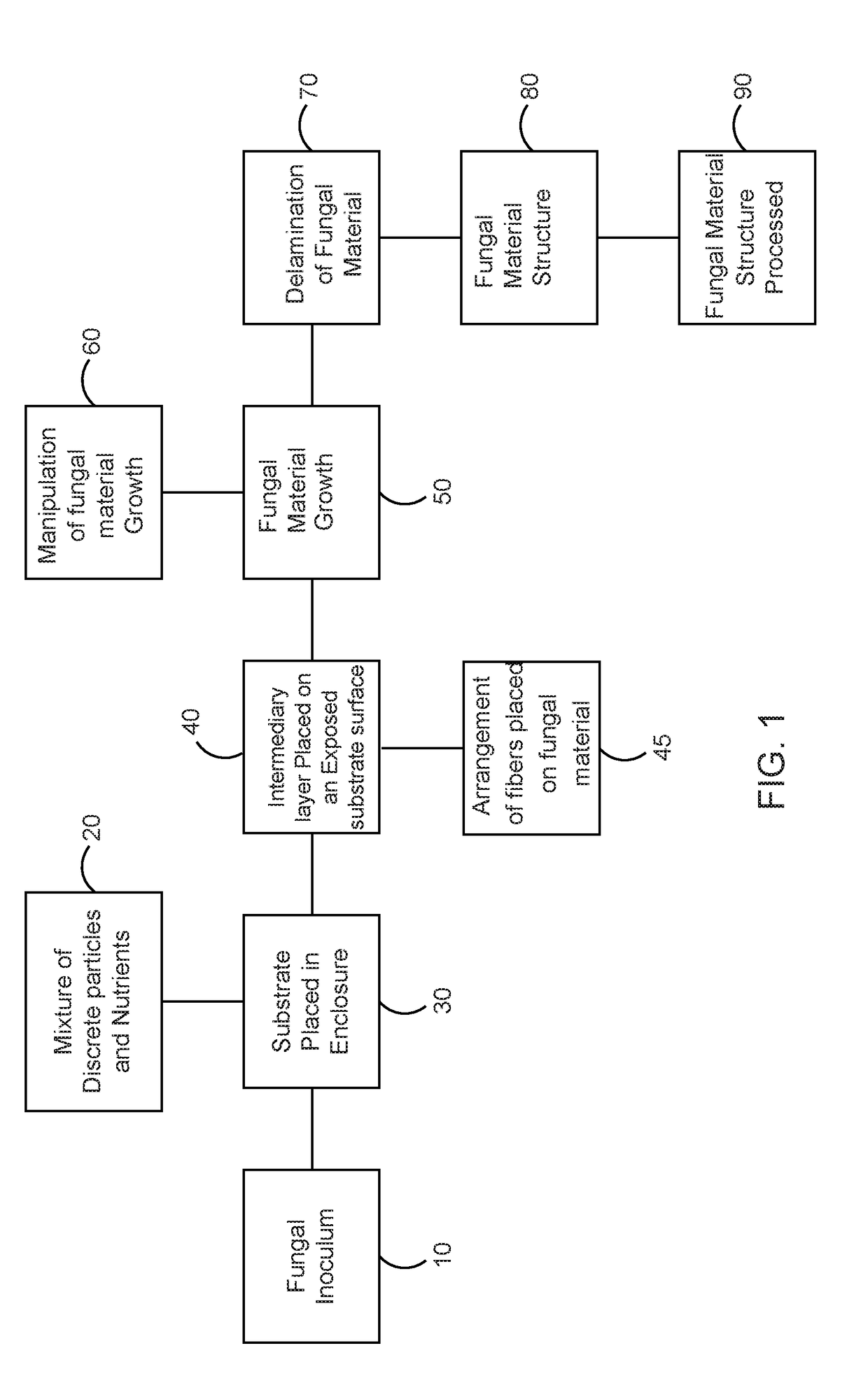

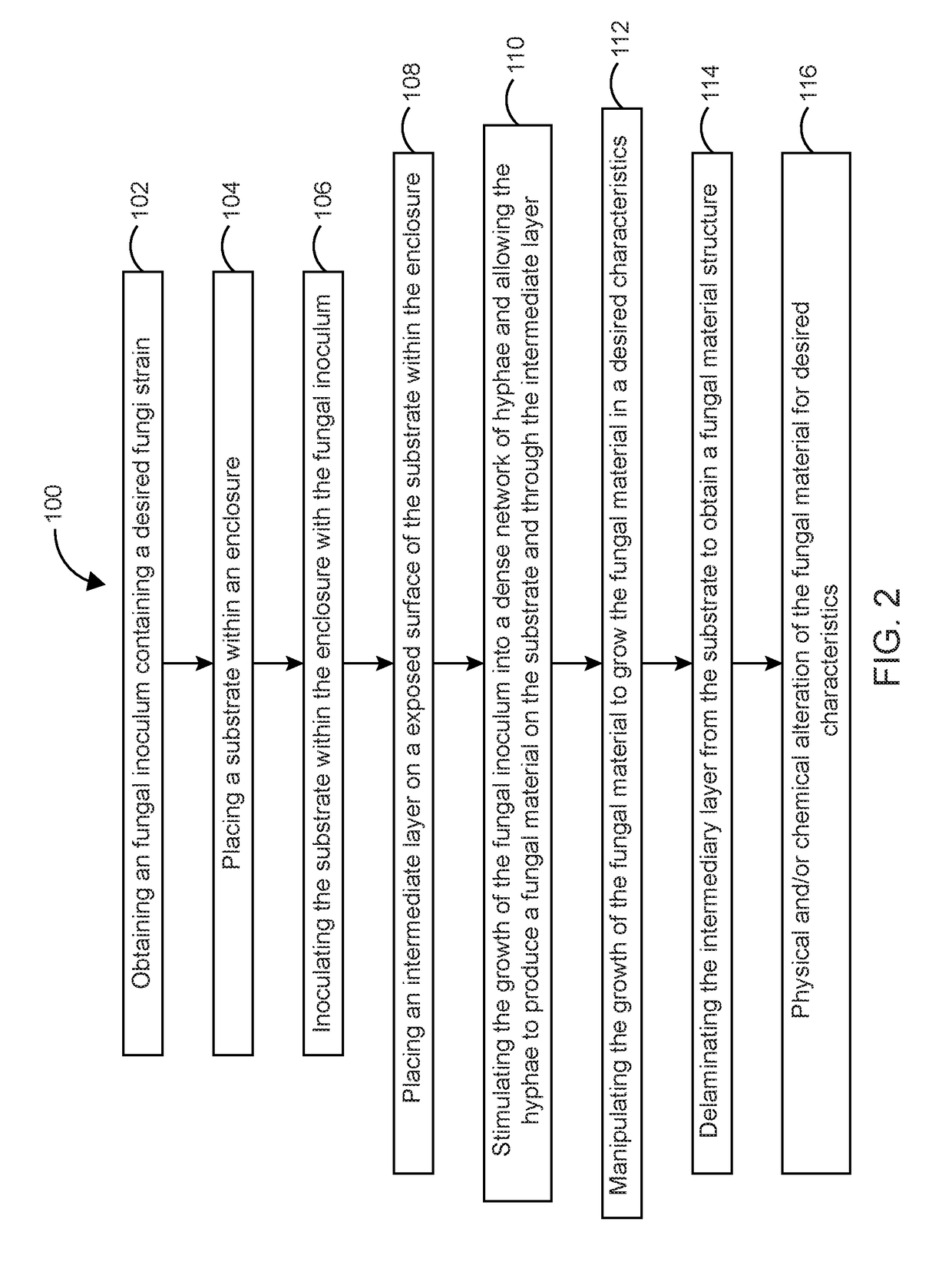

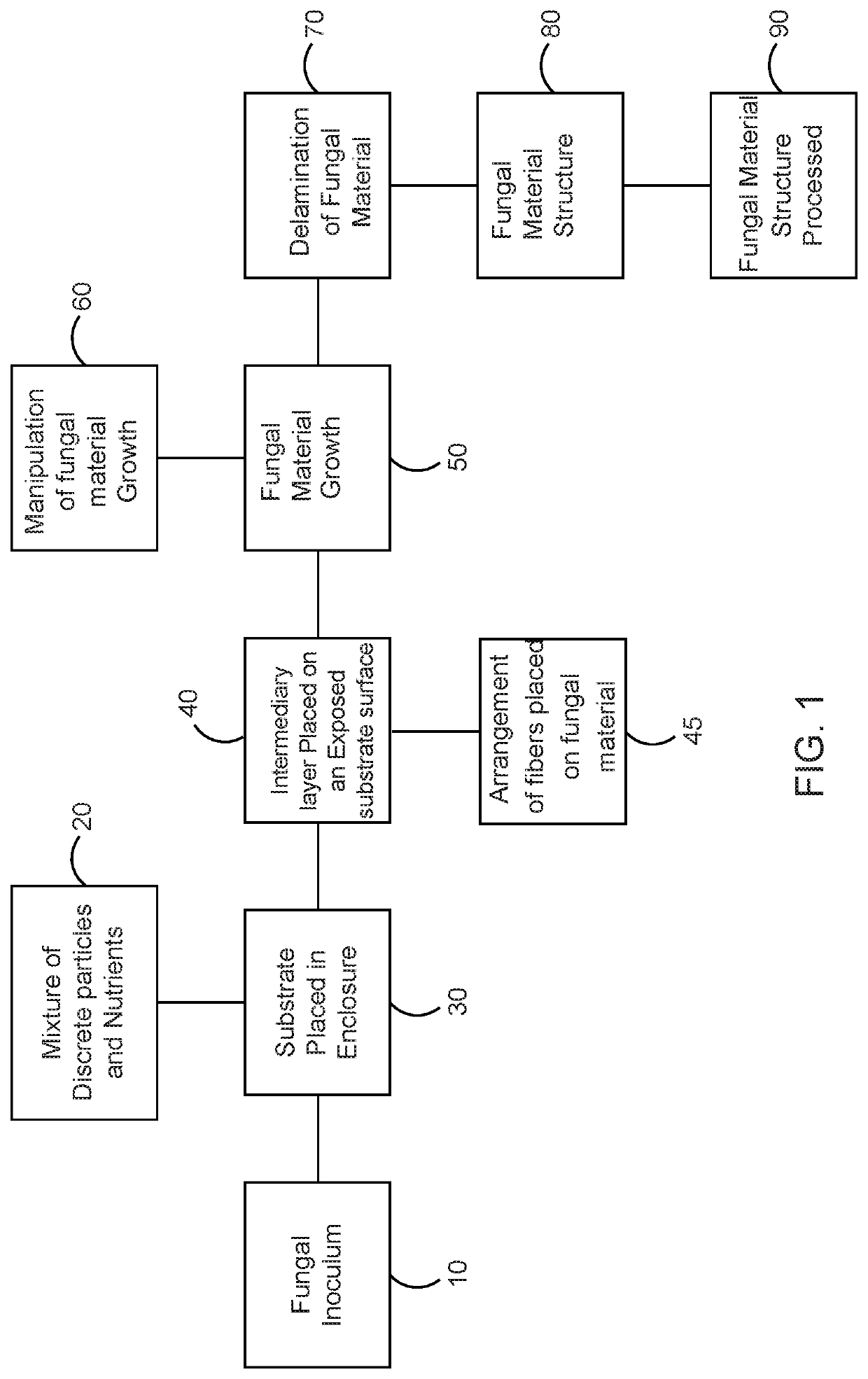

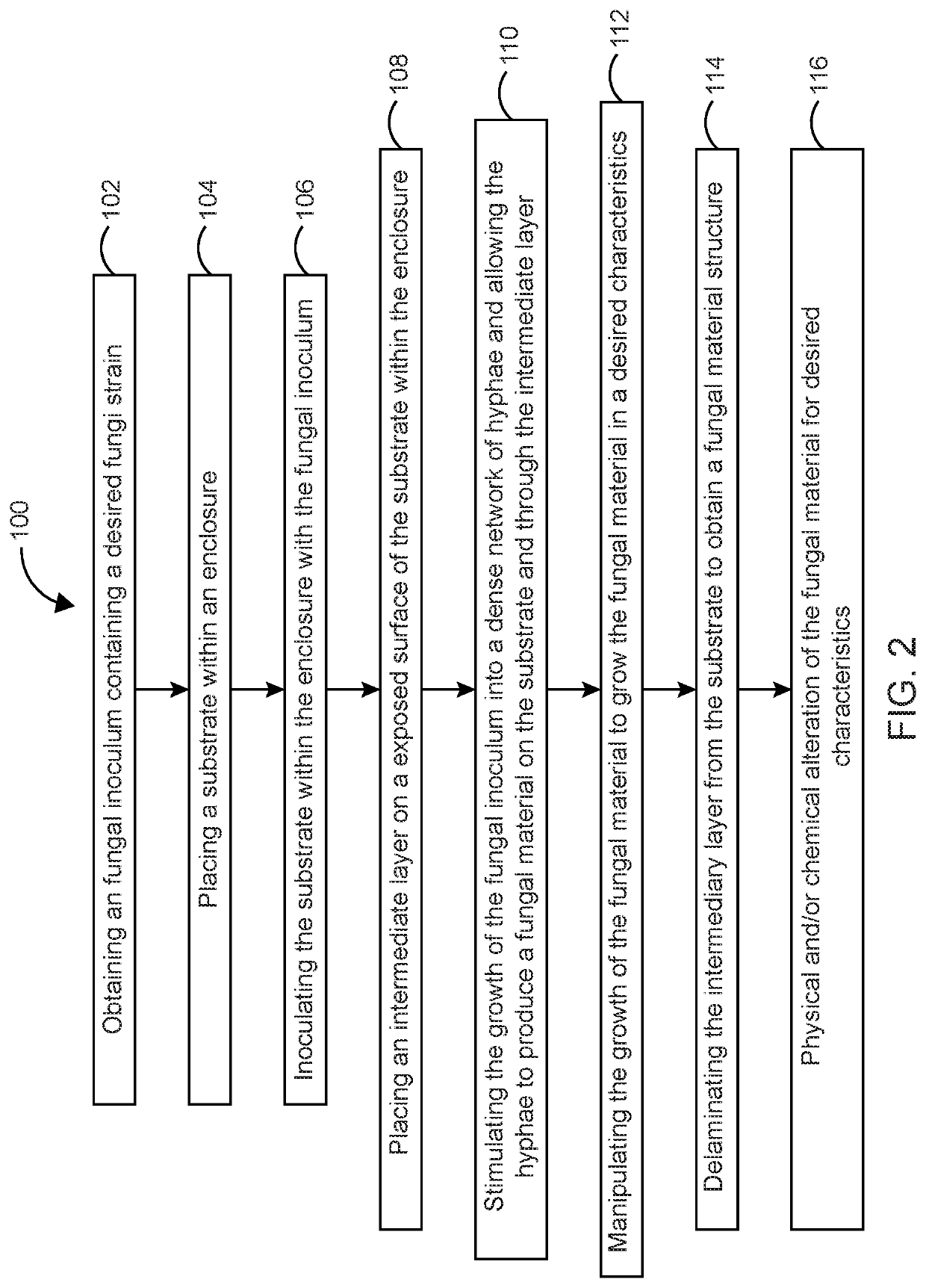

Method of Producing Fungal Materials and Objects Made Therefrom

A method of forming fungal materials and fungal objects from those fungal materials, the method comprising the steps of growing a first fungal tissue in contact with a nutritive vehicle; supplying a porous material in contact with said first fungal tissue; directing growth of said fungal tissue through said porous material such that a portion of said fungal tissue comprises a first fungal material having first fungal hyphae; optionally incorporating composite material; directing a change in the composition or growth pattern of at least some of said first fungal hyphae; separating at least a portion of the first fungal material from said nutritive vehicle; obtaining a second fungal material having second fungal hyphae; and forming a fungal object by encouraging fused growth between said first fungal material and said second fungal material and optionally incorporating composite material.

Owner:MYCOWORKS INC

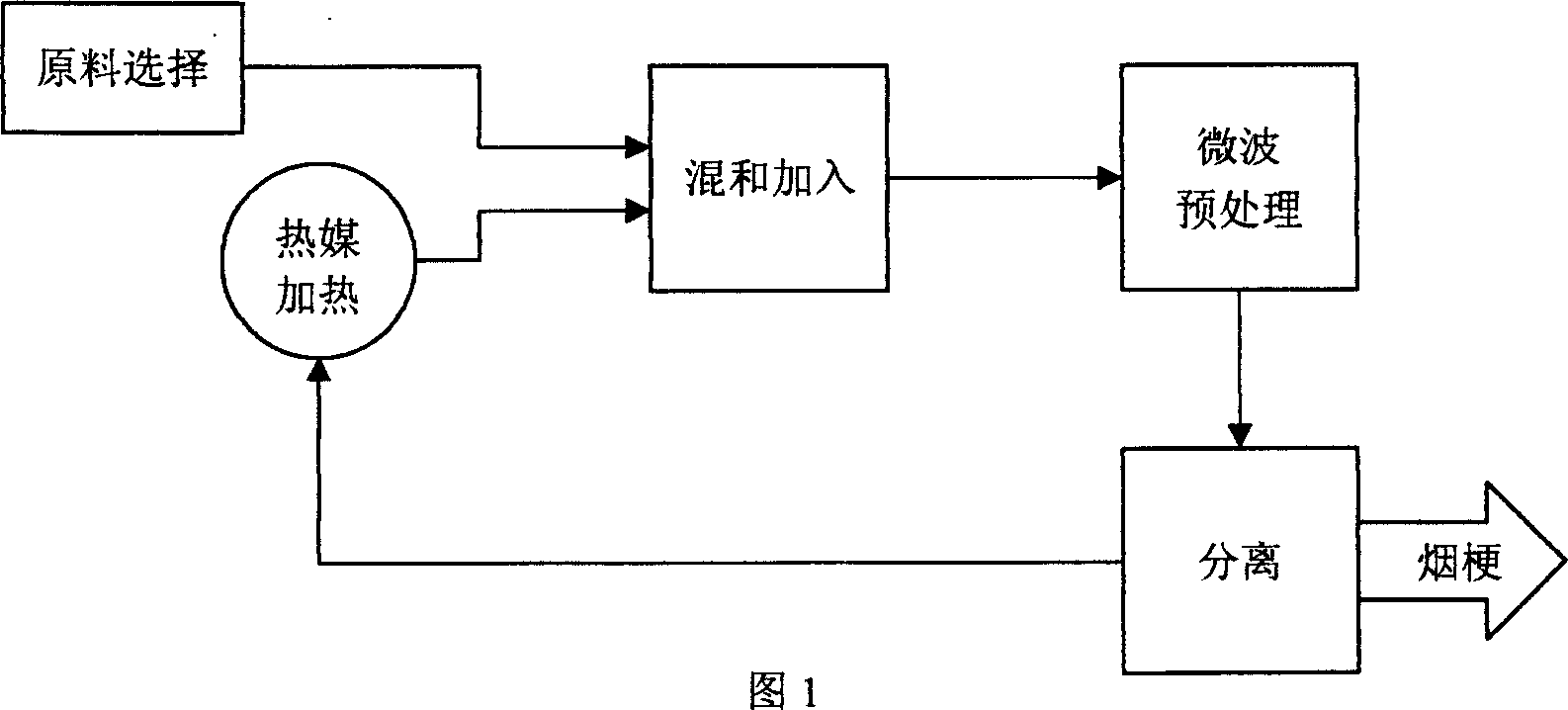

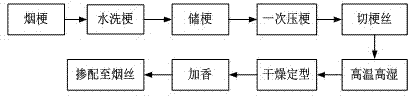

Technology for processing tobacco stalk into shreds

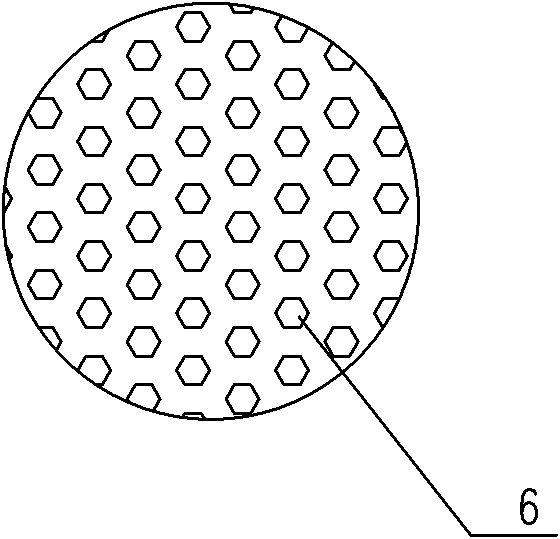

ActiveCN102631016AUniform expansionSimilar expansion rateTobacco preparationTobacco treatmentMicrowaveTar

The invention provides a technology for processing tobacco stalk into shreds, and belongs to the technical field of tobacco processing. The technology disclosed by the invention has the following steps of: pretreating tobacco stalk, expanding the tobacco stalk with microwave, washing the tobacco with water, storing the tobacco stalk, straightening out the tobacco stalk, slicing the tobacco stalk, charging and storing stalk slices, shredding the stalk slices, drying and shaping the stalk shreds, and perfuming the stalk shreds and storing the stalk shreds. Equipment used in the technology is purchased from the market, wherein the equipment which is purchased from the market, adopts a low-frequency (915MHz) high-power (more than 10kW) microwave magnetron, and transports the tobacco stalk by a belt is improved into equipment which adopts an ultrahigh-frequency (2450MHz) single-pipe low-power (1.5kW) microwave magnetron, performs group control on the microwave magnetron and transports tobacco stalk by a drum. The technology has the characteristics that the tobacco stalk shreds are good in quality consistency and more similar to tobacco leaf shreds in the physical property, and have high sensory quality and filling value; and uniformity, stability and mixing proportion of the tobacco stalk shreds are improved when the tobacco stalk shreds are mixed with the tobacco leaf shreds, the quality of cigarette is improved, the application range and use ratio of the tobacco stalk shreds in the cigarette are improved, and the aims of tar reducing, harm reducing, cost reducing and efficacy enhancing are achieved.

Owner:YUNNAN RES INST OF TOBACCO SCI

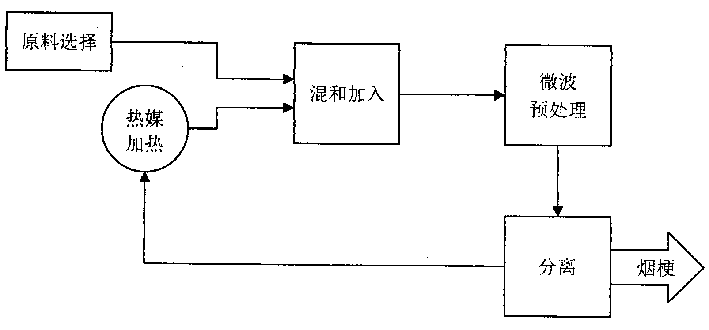

Technique for pretreating cabo

InactiveCN1518906AReduce energy consumptionGood smokeTobacco preparationPretreatment methodMicrowave

A technology for pre-processing the stems of tobacco leaves includes heating the low-loss granular solid microwave medium as thermal medium to 100-200 deg.c, mixing said stems with said thermal medium, heating in microwaven over for puffing the stems, and separating the tobacco stems from thermal medium. The pre-processed stems feature high loseness and elasticity, and good smell.

Owner:SHENZHEN HONGXIANG YISHENG TECH CO LTD

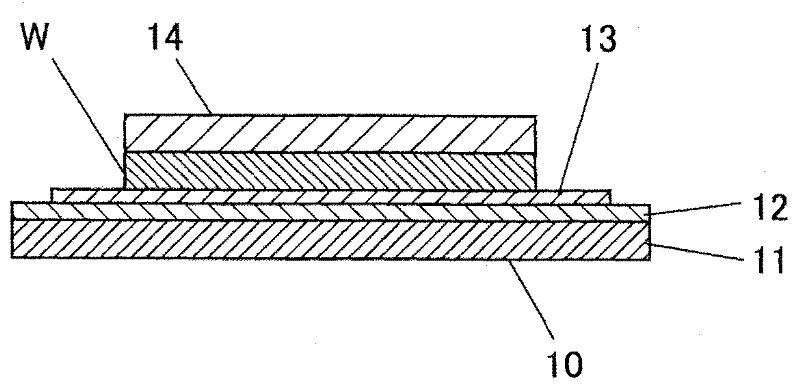

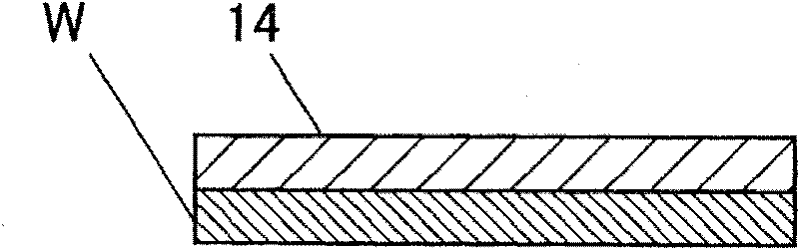

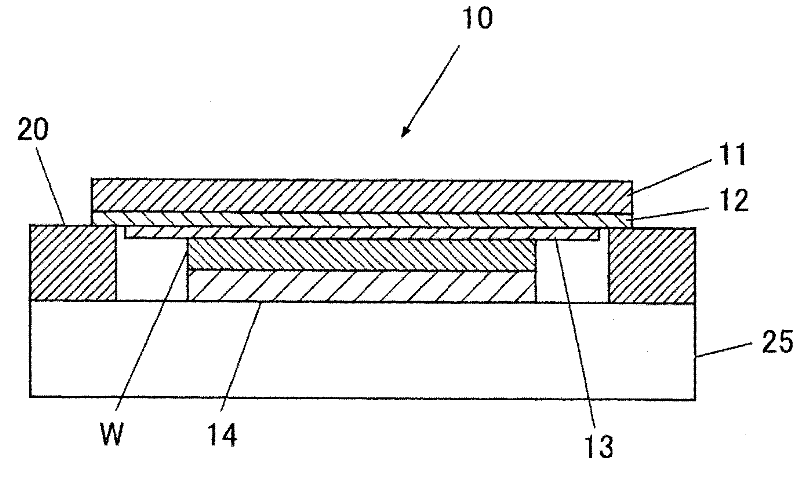

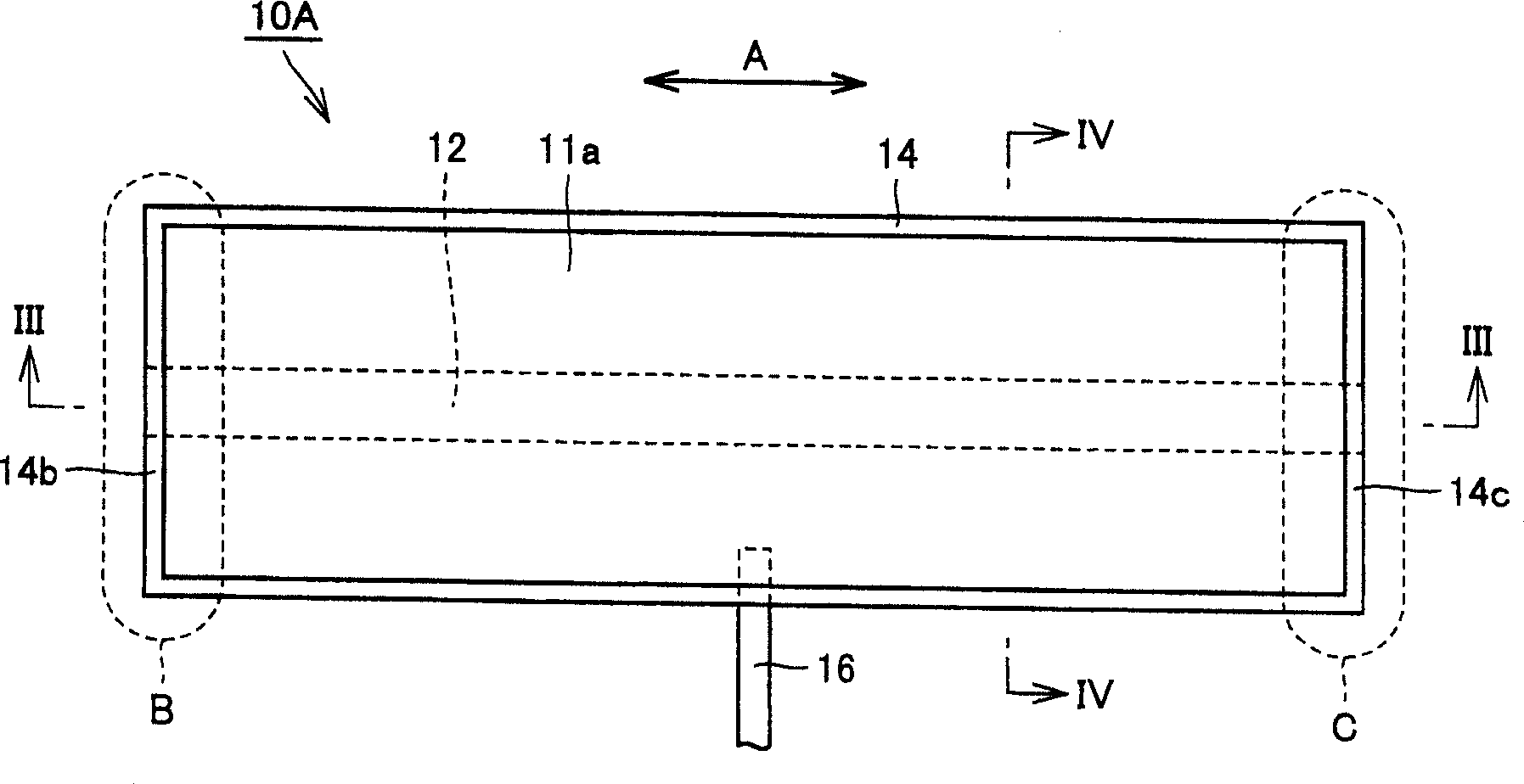

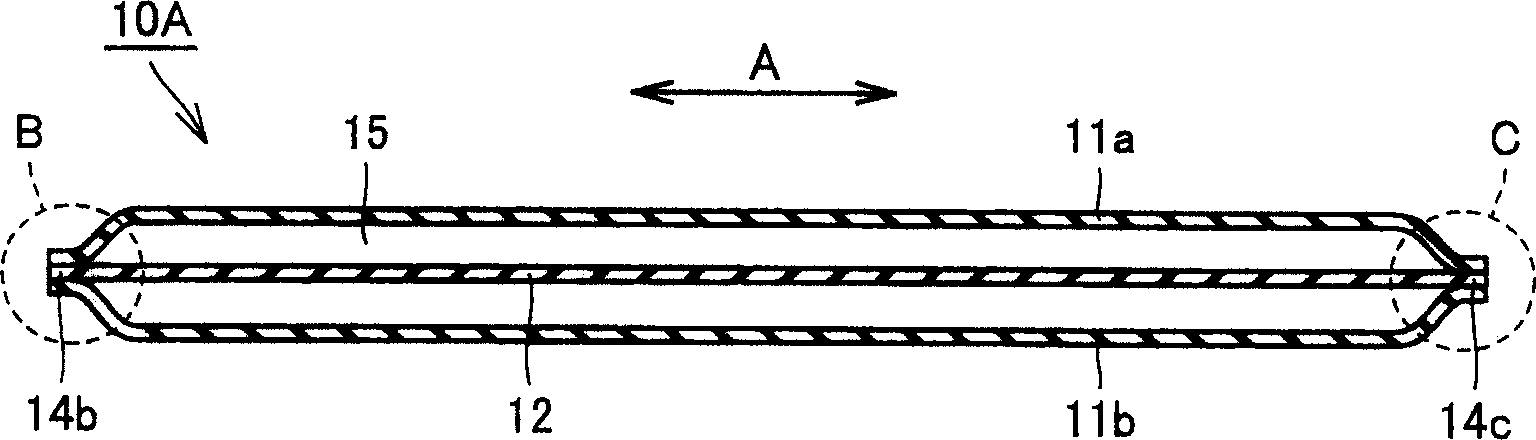

Adhesive tape for wafer processing

ActiveCN102206469ANo bad situationUniform expansionFilm/foil adhesivesSemiconductor/solid-state device manufacturingSoftening pointCement

The invention provides adhesive tape for wafer processing, which has uniform expansion suitable for application for truncating cement layers through expansion and sufficient shrinkage shown in a heating contraction process and results in no unfavorable conditions due to relaxation after the heating contraction process. The expansive adhesive tape 10 which is suitably applied for truncating a cement layer (13) along the wafer through expansion has a base material film 11 which is made of thermoplastic crosslinking resin provided with a Vickers softening point more than 50 DEG but less than 90 DEG as specified in JIS K7206 and having a stress increased over 9 MPa due to heating contraction.

Owner:FURUKAWA ELECTRIC CO LTD

Method for preparing polyurethane/rubber interpenetrating network type water-swellable rubber

The invention belongs to the technical field of sealing materials and relates to a method for preparing polyurethane / rubber interpenetrating network type water-swellable rubber. The method comprises the following steps: firstly, mixing rubber and super-absorbent resin for 10 to 40 minutes in an open mill; further adding solid softener, colorant, anti-ager and promoter to the open mill, and mixing for 10 to 40 minutes; then, adding zinc oxide, reinforcing agent and plasticizer to the open mill, and mixing for 10 to 50 minutes; further adding vulcanizer to the open mill, and mixing to obtain a mixture A; evenly mixing polyethylene glycol and MDI (methyl-di-p-phenylene isocyanate) by equal molar weight to obtain a mixture B; blending the mixture A and the mixture B in the open mill to obtain a product; and finally, vulcanizing the product in a mold on a plate vulcanization machine with the temperature and pressure being respectively controlled at 150 to 160 DEG C and at 10MPa to 15MPa, to obtain the interpenetrating network type water-swellable rubber. The method of the invention has the advantages of simple preparation process, high product expansion ratio, high ion resistance and controllable water absorption rate and mechanical properties.

Owner:QINGDAO UNIV OF SCI & TECH +1

Method for electrochemically preparing graphene

The invention discloses a method for electrochemically preparing graphene. The method comprises the following steps: 1, intercalating and expanding graphite paper by adopting graphite paper as a positive electrode and an aqueous intercalator solution as an electrolyte to obtain expanded graphite; 2, filtering and washing the expanded graphite, and carrying out ultrasonic peeling treatment on the expanded graphite to obtain a flocculent graphene slurry; and 3, filtering the graphene slurry, and drying the graphene slurry through adopting a microwave vacuum drier to obtain fluffy graphene powder. The electrochemical method solves the problem of use of heavy metal-containing reagents, strong acids, strong oxidants and expensive organic liquids in the graphene preparation process in the prior art, and has the advantages of simple preparation technology, low energy consumption and low cost.

Owner:DEYANG CARBONENE TECH

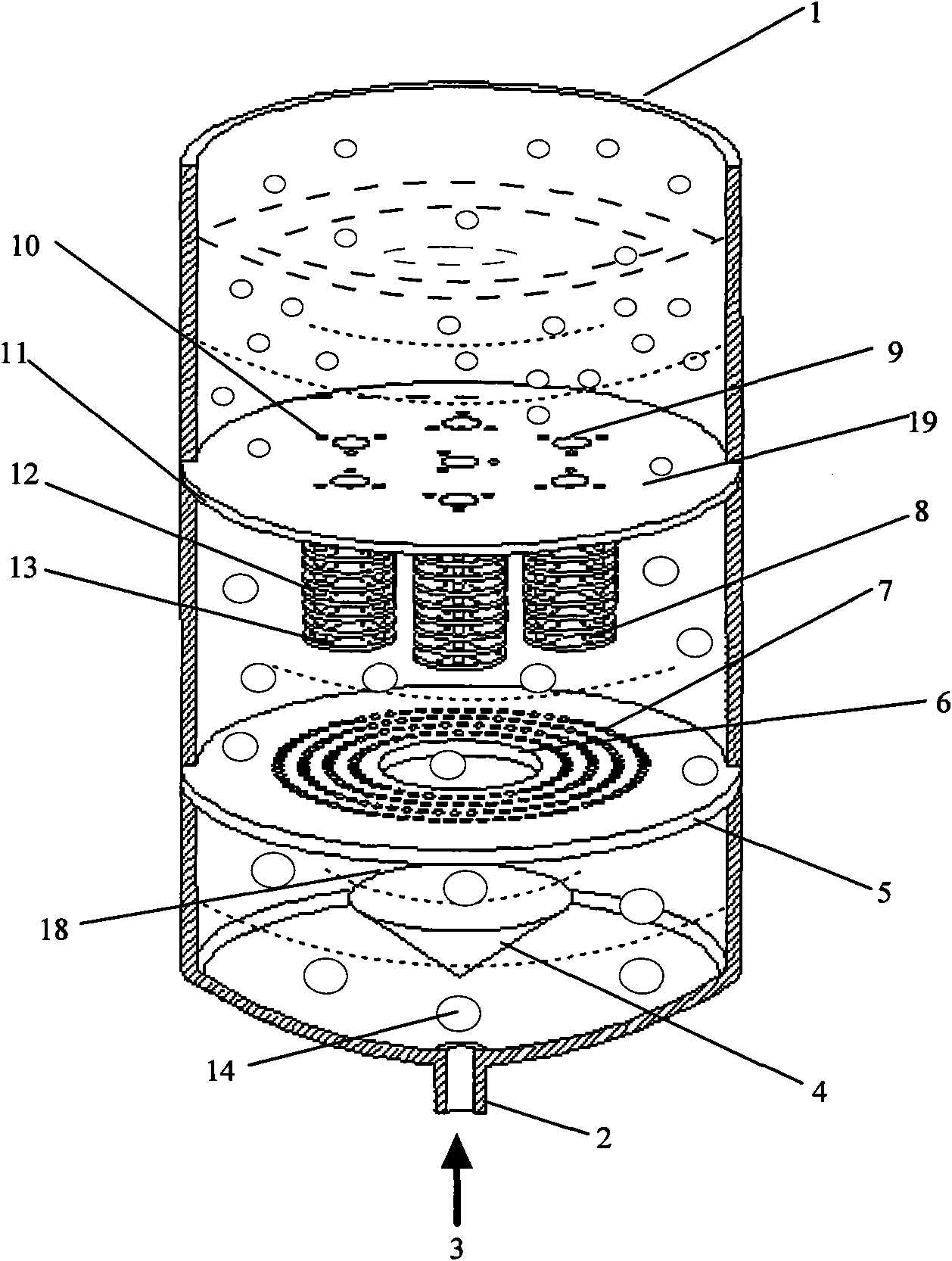

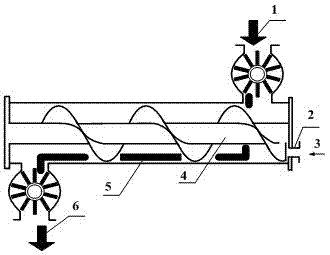

Up-flow reactor and application thereof

ActiveCN101632911AEvenly distributedSimple structureHydrocarbon oils refiningChemical/physical processesWaxShortest distance

The invention discloses an up-flow reactor, which comprises an initial distributor positioned at the bottom of the reactor and an intermediate distributor above the initial distributor. The initial distributor consists of a conical traverse baffle and a sieve plate positioned above the conical traverse baffle; and the intermediate distributor consists of an open pore sieve plate and a sieve plate string structure. The up-flow reactor provided by the invention can realize even distribution of gas in the reactor in short distance so as to improve the utilization rate of a catalyst and increase the space of a catalyst bed layer in the reactor. The up-flow reactor of the invention is particularly applied to a hydrogenation process of heavy oil (comprising wax oil, residual oil, coal liquefied oil and the like).

Owner:CHINA PETROLEUM & CHEM CORP +1

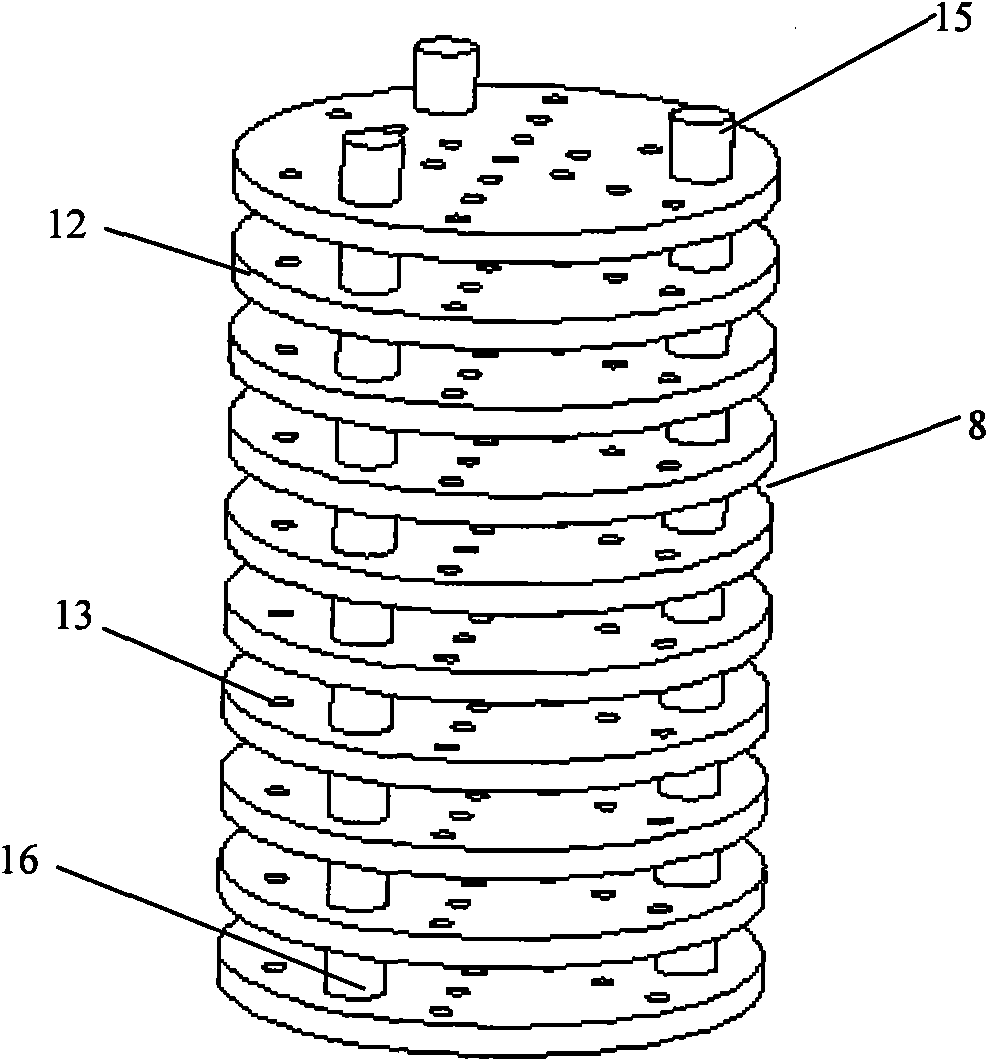

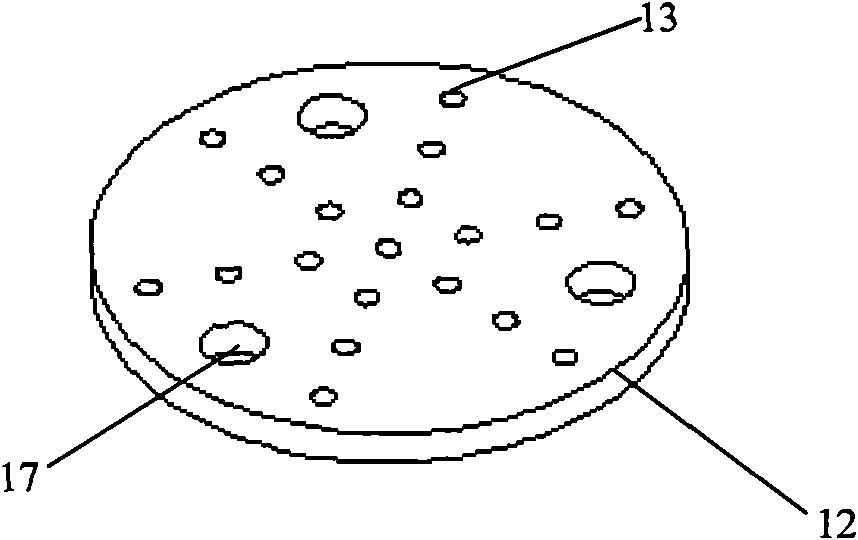

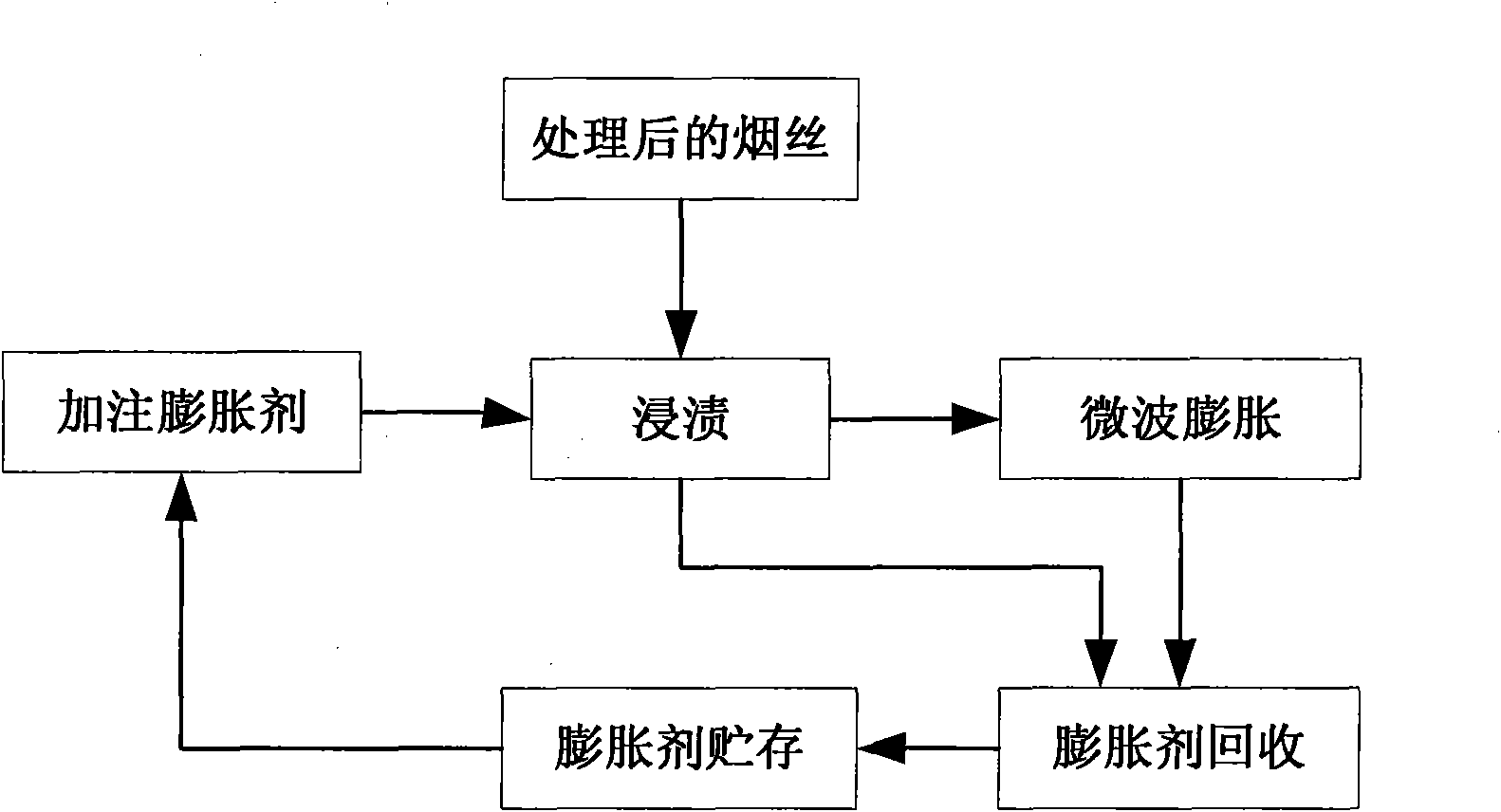

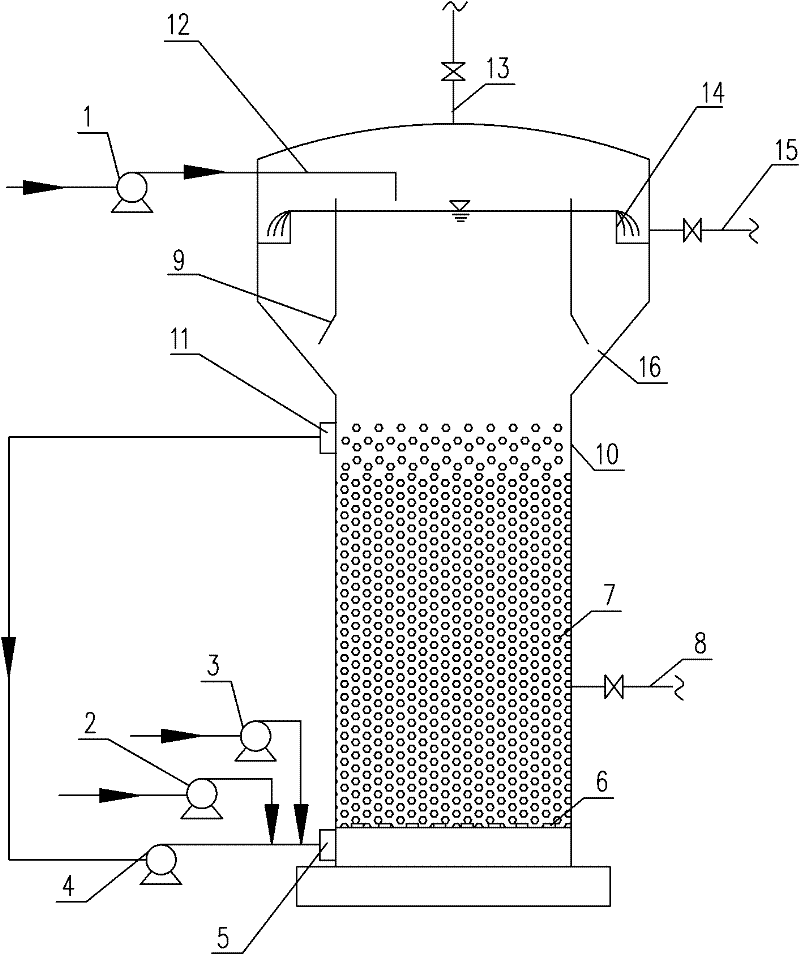

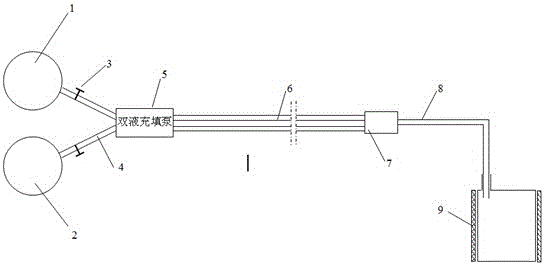

Method for continuous microwave expansion of cut tobacco

ActiveCN101617855AStable internal and external temperature changesNo damageTobacco preparationAlkaneMicrowave

A method for continuous microwave expansion of cut tobacco comprises the following steps: impregnating the cut tobacco in an expanding agent; recycling the expanding agent in an impregnating device after impregnation; carrying out microwave expansion on the impregnated cut tobacco by a microwave dryer to obtain the expanded cut tobacco. The expanded cut tobacco comprises one or more than two components of ethanol with 4-12 carbon atoms, ketone with 4-12 carbon atoms, halogenether with 2-12 carbon atoms, alkane with 3-12 carbon atoms or alkane with 3-12 carbon atoms substituted by 2 halogen atoms. The filling value of the expanded cut tobacco reaches above 7.5, the cutting ratio is above 90%, the moisture content after expansion is 12-13%, the expansion of the cut tobacco is even without water damaged cut tobacco; the whole set of devices has low energy consumption and high automation, and continuous closed mass production can be carried out.

Owner:BEIJING INST OF AEROSPACE TESTING TECH +1

Method of sterilizing polymeric struts and stents

InactiveUS7964136B2FunctionalQuality improvementSurgical needlesMedical devicesMechanical propertyBiodegradable polymer

It has been determined that gamma sterilization of biodegradable polymer stents does not cause significant polymer cross-linking and collapse. Using sufficient spacing can lead to stents that display little if any detrimental effects from the procedure. In certain embodiments, using structures in the general region of about 100 micron spacing between the struts leads to highly functional stents that do not fuse. Further, the resulting stent has radially homogenous mechanical properties. Therefore, the stent has a uniform expansion within the lumen.

Owner:SAHAJANAND TECHNOLOGIES PRIVATE LTD

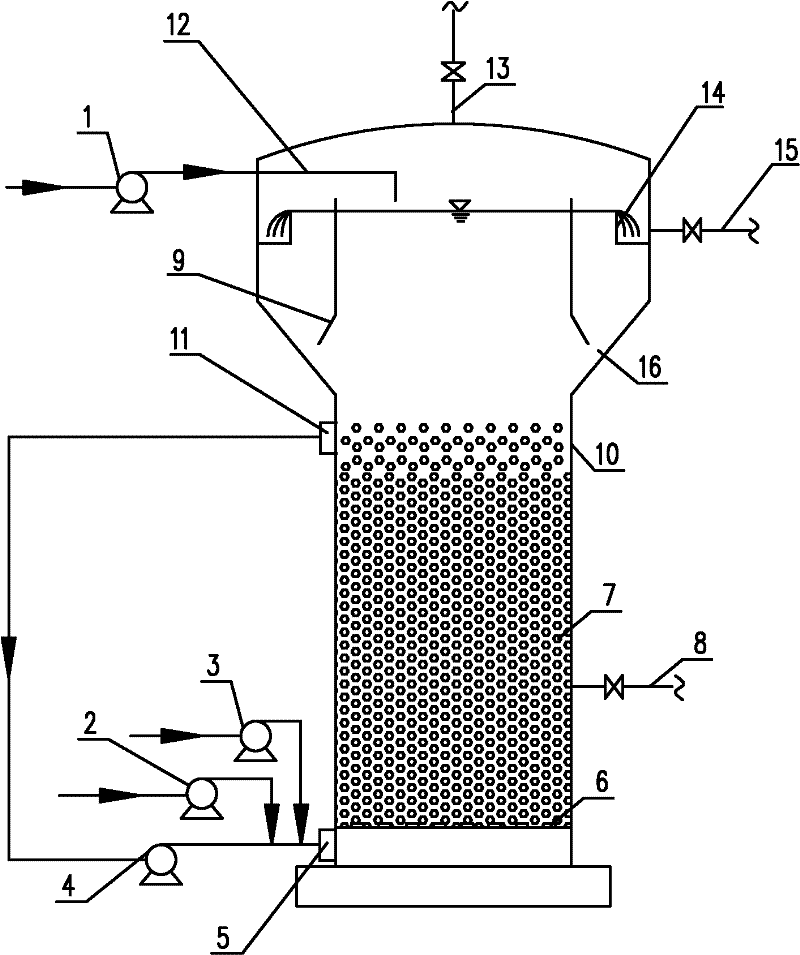

Circulating fluidized bed advanced treatment equipment for industrial wastewater

ActiveCN102249393ASmooth layoutIncrease profitWater/sewage treatment by oxidationIndustrial effluentSludge

The invention discloses circulating fluidized bed advanced treatment equipment for industrial wastewater. The equipment comprises a tank body for the Fenton oxidation reaction of wastewater, wherein the tank body is divided into a circulating water distribution zone, a FeOOH crystallization zone and a gas-water separation zone from bottom to top in turn; the circulating water distribution zone is provided with a water distributor and a circulating water inlet; the circulating water inlet is connected with the output ends of a FeSO4 dosing pump, a H2O2 dosing pump and a circulating pump simultaneously; the FeOOH crystallization zone is provided with a crystal bed layer, a solid discharge pipe and a circulating water outlet; the circulating water outlet is connected with the input end of the circulating pump; the gas-water separation zone is provided with a gas-water separation barrel, a wastewater input pipe extending to the gas-water separation barrel, a gas discharge pipe, an annular effluent weir and a purified water discharge pipe; and the wastewater input pipe is connected with the output end of an influent pump. The equipment has the characteristics of low operating cost, low sludge yield and good treatment effect, is flexibly and conveniently operated, and is particularly suitable for the industrial wastewater containing non-degradable organic matters.

Owner:上实环境控股(武汉)有限公司

Meteorologic balloon and production method thereof

ActiveCN101526630AImprove anti-aging performanceImprove overall machining performanceInstrumentsPotassium hydroxideCasein

The invention relates to a meteorological balloon and a production method thereof. The meteorological balloon has the quality of 700g to 800g, the length of a balloon body is 205 cm to 255 cm, and a balloon handle has a width of 9 cm to 10 cm and a length of 10 cm to 14 cm. The meteorological balloon comprises a solid raw material, an oil raw material and a colloid raw material, wherein the solid raw material comprises the ingredients by weight ratio: 100 parts of centrifugal concentrated natural latex, 0 part to 0.30 part of potassium hydroxide, 0 part to 0.15 part of casein, 0 part to 0.10 part of leveling agent O, 1.00 part to 3 parts of sulfur, 1.00 part to 2 parts of antioxidant D, 1.00 part to 2 parts of 4010NA, 1.50 part to 3 parts of rubber accelerator PX and 0.20 parts to 5 parts of zinc oxide; the oil raw material comprises 7.00 parts to 10.0 parts of mechanical oil by weight ratio; and the colloid raw material comprises neoprene latex which is added by the mixed weight ratio of the mixture of the solid raw material and the oil raw material to the neoprene latex, namely 1 to 10. The neoprene latex is added in a raw material formulation so as to improve the anti-aging performance and the whole processing performance of the meteorological balloon, ensure the streamlined appearance of the meteorological balloon, improve the evenness degree of a balloon surface and enable the balloon surface to swell evenly in the discharge process.

Owner:CHEMCHINA ZHUZHOU RUBBER RES & DESIGN INST

Meteorologic balloon and production method thereof

ActiveCN101592742AThere will be no problem of uneven distributionAgainst destructive powerInstrumentsPotassium hydroxideDioctyl sebacate

The invention discloses a meteorologic balloon and a production method thereof. The raw materials consist of a solid raw material, an oily raw material and a gluey raw material; the solid raw material comprises the following components by weight: 0 to 0.30 portion of potassium hydroxide, 0 to 0.15 portion of casein, 0 to 0.10 portion of peregal O, 1.00 to 3 portions of sulfur, 1.00 to 2 portions of N-phenyl-2-naphthylamine, 1.00 to 2 portions of N-phenyl-N'-isopropyl-ursol, 1.50 to 3 portions of ethyl-phenyl-zinc dithiocarbamate, 0.20 to 5 portions of zinc oxide, and 5 to 30 portions of chloroprene polymer; the oily raw material is dioctyl sebacate, and the weight rate of the dioctyl sebacate is 5.00 to 10.0 portions; and the gluey raw material is centrifugally-concentrated natural latex, and the adding amount of the centrifugal concentrated natural latex is 100 portions. The weight of the meteorologic balloon is 1,600 to 1,700 grams, the length of the balloon body is 3.05 to 3.55 meters, the width of the ball handle is 10 to 11 centimeters, and the length of the ball handle is 12 to 16 centimeters. The meteorologic balloon can adapt to the requirement of probing high-altitude meteorological elements of more than 35,000 meters, has the advantages of good aging resistance, high blastoff height, long balloon service time and the like, and can effectively overcome the morning-evening difference.

Owner:CHEMCHINA ZHUZHOU RUBBER RES & DESIGN INST

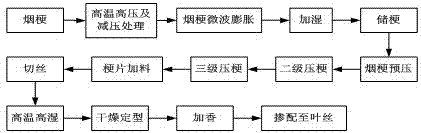

Tobacco stem pressing and shredding technology

The invention discloses a tobacco stem pressing and shredding technology and belongs to the technical field of tobacco processing. The technology comprises the steps of conducting high-temperature high-pressure and decompression preprocessing on tobacco stems, conducting microwave expansion on tobacco stems, humidifying and storing tobacco stems, heating and humidifying tobacco stems, pre-pressing tobacco stems, conducting secondary stem pressing, conducting ternary stem pressing, feeding stems, shredding stems, shaping and drying stem shreds, and perfuming and storing stem shreds. The technology has the advantages that the quality consistency of stem shreds is good, the physical property of stem shreds is closer to that of leaf shreds, organoleptic quality and padding value are high, the uniformity, stability and blending ratio of stem shreds blended with leaf shreds are improved, cigarette quality is improved, the application range and utilization rate of stem shreds in cigarettes are increased, and tar reduction, harm reduction, cost reduction and benefit increasing are realized.

Owner:CHINA TOBACCO YUNAN NEW MATERIAL

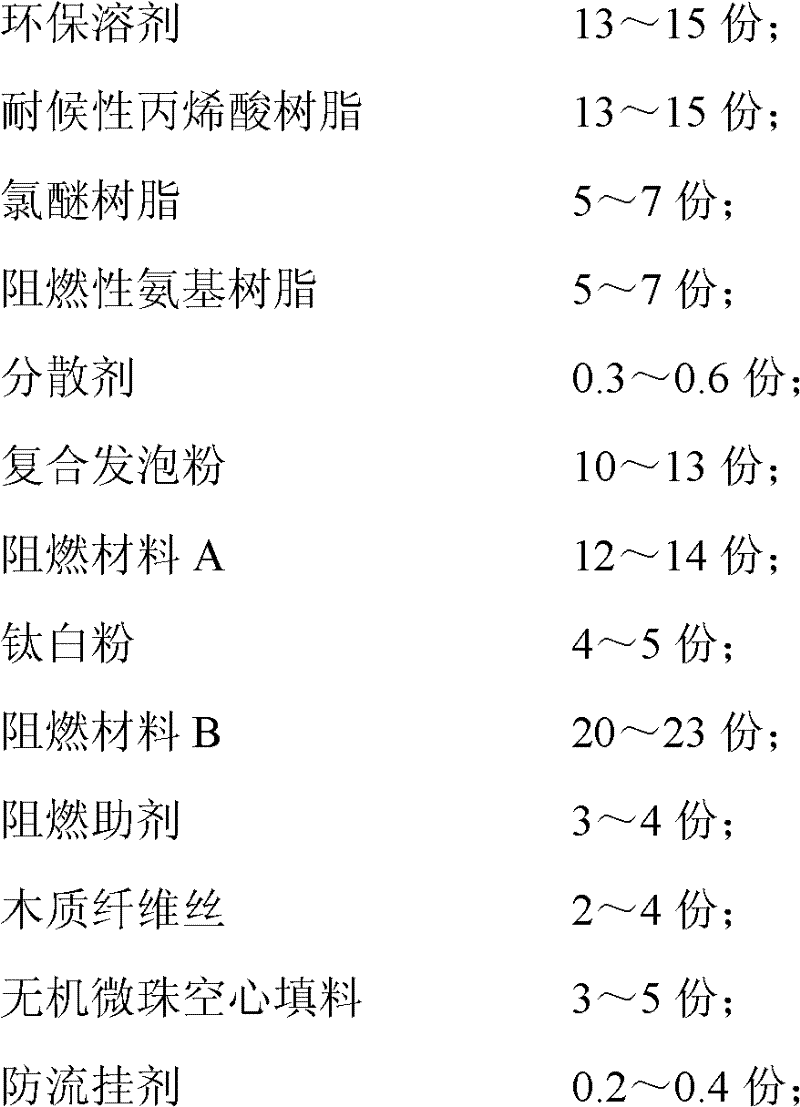

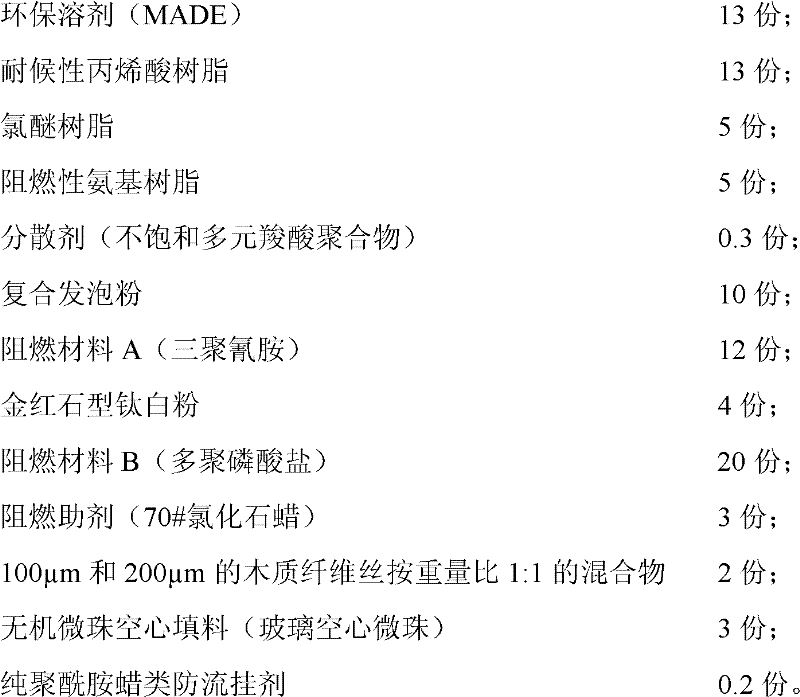

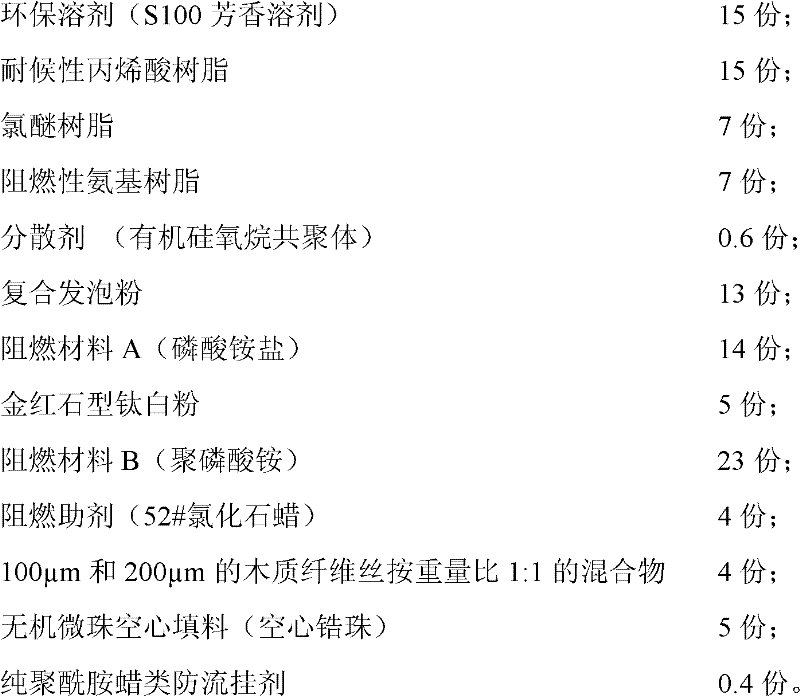

Fire retardant coating and preparation method thereof

ActiveCN102408802AExcellent weather resistanceStrong adhesion and durabilityFireproof paintsSolventWeather resistance

The invention discloses a fire retardant coating, which comprises the following components: an environment-friendly solvent, weather-proof acrylic resin, chlorinated polyether resin, flame retardant amino resin, a dispersing agent, composite foaming powder, a flame retardant material A, titanium white, a flame retardant material B, a flame retardant aid, wood fibers, an inorganic microbead hollowfiller and an anti-sagging agent. The invention also provides a preparation method for the fire retardant coating. The fire retardant coating can be coated on various substrates, is extra-thin, efficient and durable, is specially used outdoors, is resistant to the fire combustion of hydrocarbons, and has high chemical properties such as weather resistance, acid resistance, alkali resistance and the like, high adhesion and an attractive decorative effect, and paint films are fine; the fire retardant coating is uniformly expanded, and has a special foam structure and a high fireproof effect; and the product is environment-friendly and pollution-free, a production process is simplified, and the fire retardant coating is convenient to construct and can be used for coating with various fireproof requirements.

Owner:WUXI HUHUANG PAINT

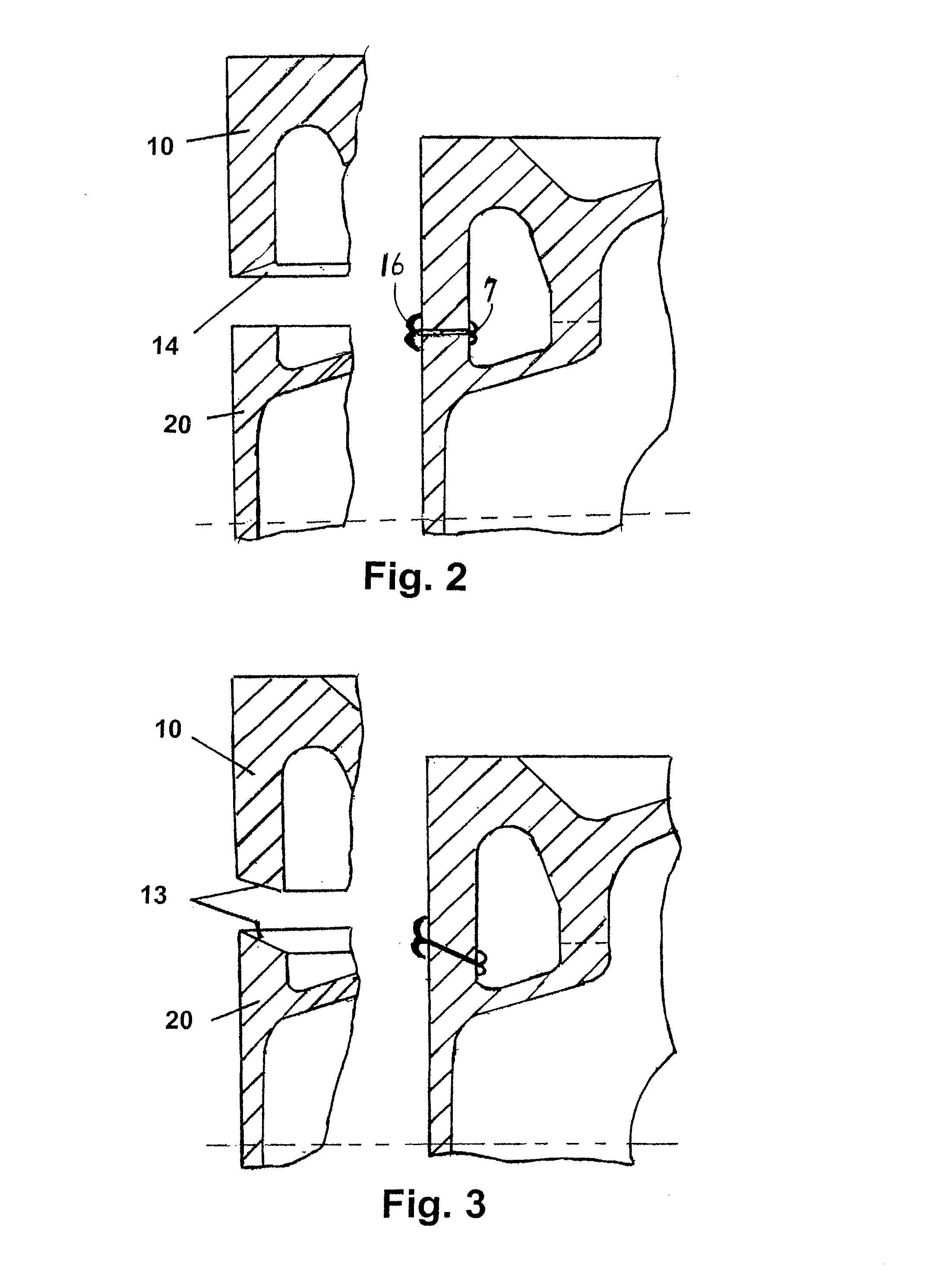

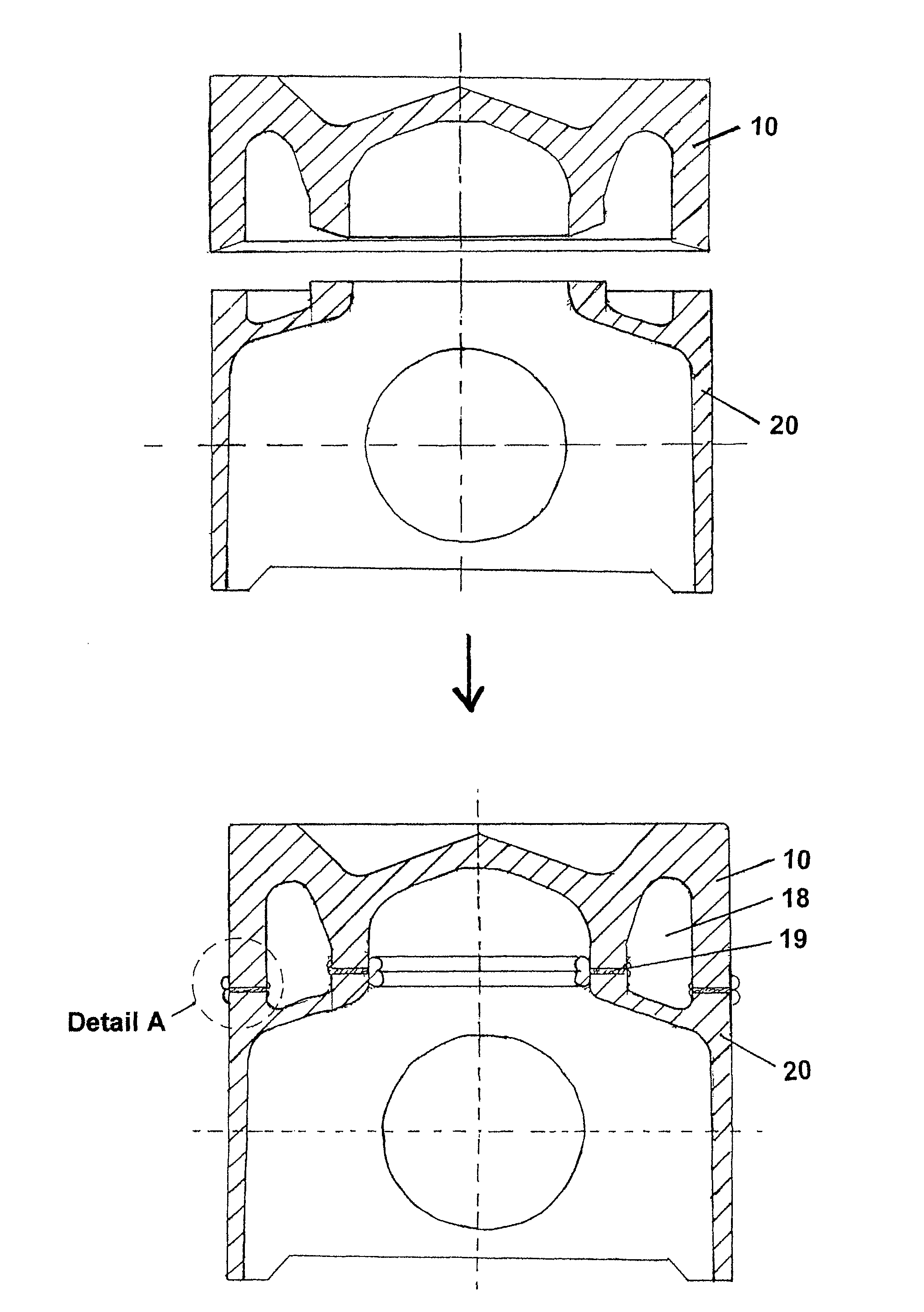

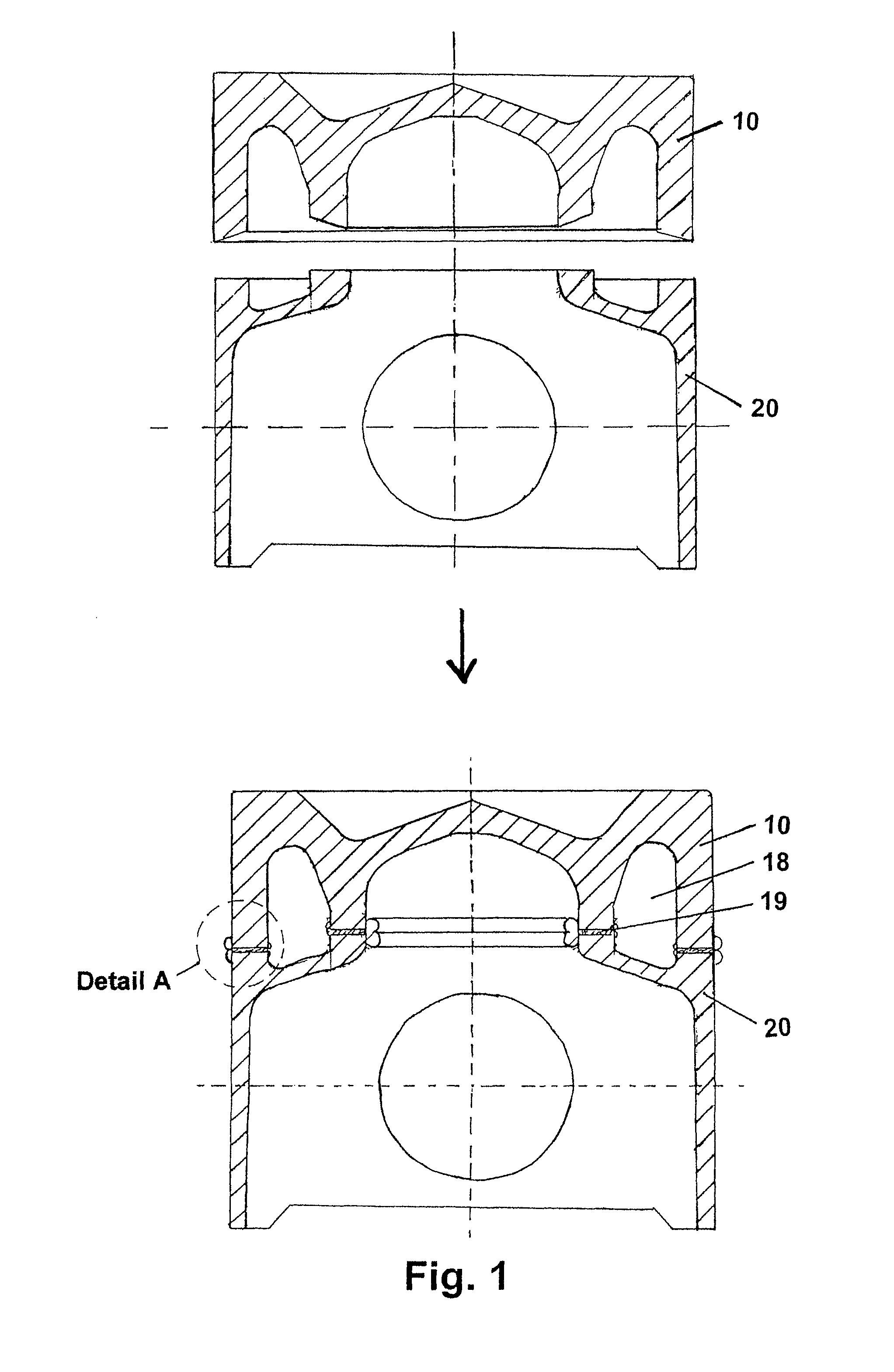

Method of friction welding of a piston having a cooling duct

InactiveUS20110132971A1Reduce decreaseUniform expansionWelding/cutting auxillary devicesMachines/enginesFriction weldingEdge surface

A method of friction welding a head part to a skirt part of a piston having a hollow cooling duct in which the internal connection surface of the first part to be welded is reciprocally arranged with an internal connection surface of the second part to be friction welded, so that they form a unsymmetrical contact area, so that the resulting weld of the first and the second parts produces a weld bead that is located predominantly outside of the hollow cooling duct. The unsymmetrical contact area can be formed by chamfered, angled edge surfaces that produce, for example, a wedge-shaped space, or partially matched, inter-fitting surfaces that remain out of contact and produce a gap at sides facing the hollow space.

Owner:GESENKSCHMIEDE SCHNEIDER GMBH

Cuff for blood pressure monitor

InactiveCN1748637AMeasure high and stableUniform expansionEvaluation of blood vesselsAngiographyBand shapeBlood pressure monitors

The invention provides a cuff for a blood pressure monitor which is wound around a measurement site of the living body, and includes an air bag having an inflated / deflated space formed therein by melting and bonding rims of an outer wall portion and an inner wall portion together. The air bag contains a band-shaped connecting portion, which has ends respectively attached to one end and the other end of the air bag in its winding direction around the living body, so as to extend substantially continuously from the one end to the other end of the air bag. The band-shaped connecting portion is arranged inside the inflated / deflated space of the air bag. With this configuration, a cuff for a blood pressure monitor permitting uniform inflation of the air bag over the entire region when the pressurized air is introduced therein is obtained.

Owner:OMRON HEALTHCARE CO LTD

Method of friction welding of a piston having a cooling duct

InactiveUS8286852B2Reduce decreaseUniform expansionWelding/cutting auxillary devicesMachines/enginesFriction weldingEdge surface

Owner:GESENKSCHMIEDE SCHNEIDER GMBH

Objects Made From Fungal Materials

A fungal growth structure comprising a nutritive vehicle, a porous material, an administrable space. fungal tissue comprising fungal hyphae having a growth pattern, the fungal tissue connecting said nutritive vehicle to said porous material to said administrable space, wherein the fungal tissue within said space defines at least one successive fungal material layer; and a chemically or physically altered separated portion of fungal material, the separated portion separated from said fungal tissue.

Owner:MYCOWORKS INC

Method of producing fungal materials and objects made therefrom

A method of forming fungal materials and fungal objects from those fungal materials, the method comprising the steps of growing a first fungal tissue in contact with a nutritive vehicle; supplying a porous material in contact with said first fungal tissue; directing growth of said fungal tissue through said porous material such that a portion of said fungal tissue comprises a first fungal material having first fungal hyphae; optionally incorporating composite material; directing a change in the composition or growth pattern of at least some of said first fungal hyphae; separating at least a portion of the first fungal material from said nutritive vehicle; obtaining a second fungal material having second fungal hyphae; and forming a fungal object by encouraging fused growth between said first fungal material and said second fungal material and optionally incorporating composite material.

Owner:MYCOWORKS INC

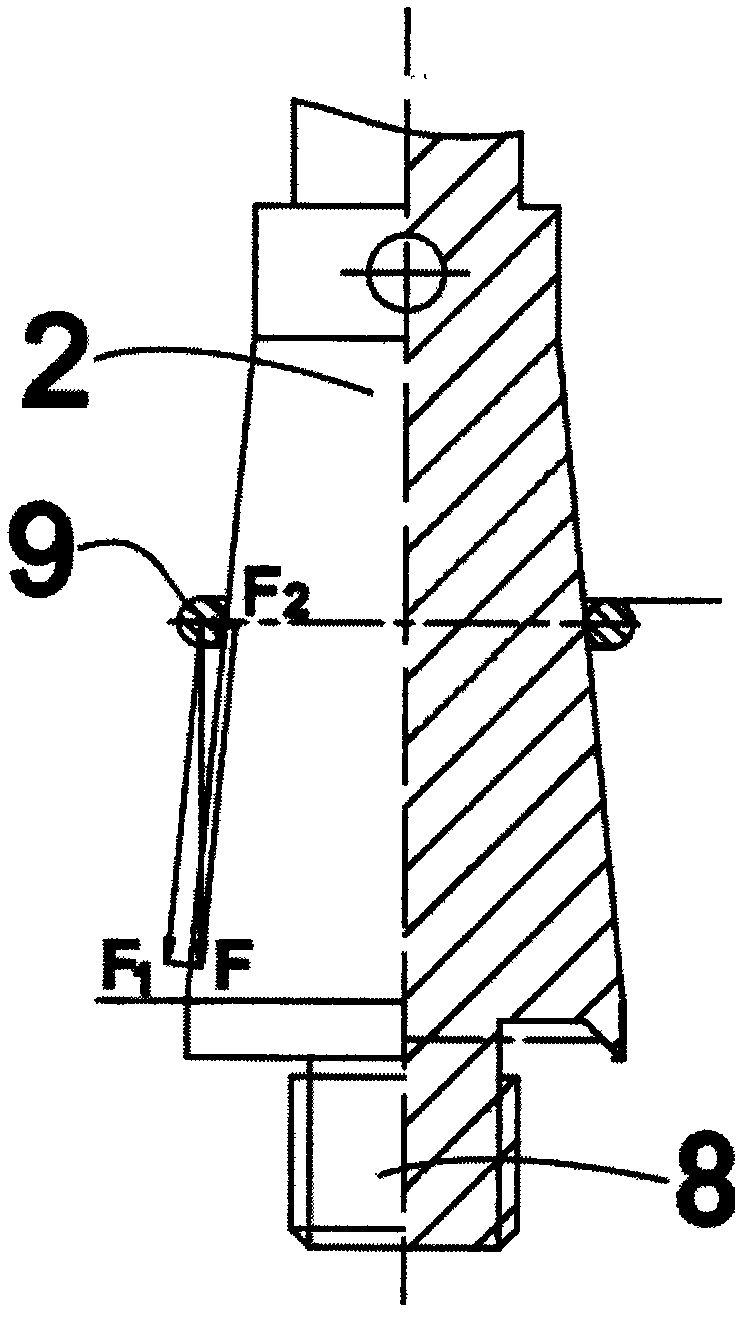

Mounting tool for spring ring

InactiveCN102357868AUniform expansionAvoid serious local deformationMetal-working hand toolsMaximum diameterEngineering

The invention discloses a mounting tool for a spring ring. The mounting tool comprises a guiding body and a pushing sleeve, wherein the guiding body has a shape of circular platform; the pushing sleeve is in clearance fit with the guiding body; an inner diameter of the pushing sleeve is slightly more than a maximum diameter of the guiding body and is less than an outer diameter of a mounted spring ring; a minimum diameter of the guiding body is less than an inner diameter of the mounted spring ring; the guiding body is a circular platform at a small conical degree; the maximum diameter of the guiding body is slightly more than the diameter of an axle of the mounted spring ring; a connecting threaded pillar is arranged on an end face of a maximum-diameter end of the guiding body; and the threaded pillar is coaxial with the guiding body. The mounting tool for the spring ring has a simple structure, is portable and conveniently used, is capable of flexibly moving and can be used for mounting the spring ring. Under the guidance of the guiding body, the spring ring is uniformly expanded, thereby avoiding a situation of serious local deformation of the spring ring caused by an unevenly pressed local part, ensuring the precision of the outer surface of the axle of the mounted spring ring, and improving the service life of the spring ring and assembling efficiency.

Owner:CHONGQING PUSH MECHANISM

High-strength mining expansion filling fireproofing and extinguishing material and application method thereof

The invention discloses a high-strength mining expansion filling fireproofing and extinguishing material and an application method thereof. The material comprises the following substances in parts by weight: 16-25 parts of aluminate cement clinker, 12-20 parts of Portland cement clinker, 4-16 parts of active calcic material, 6-15 parts of setting accelerator, 5-10 parts of quicklime, 22-40 parts of fly ash, 0.1-1 part of zinc powder foaming agent, 0.5-2 parts of thickening time control agent, 1-2 parts of aluminum hydroxide, 1-3 parts of dispersing agent and a proper amount of sodium hydroxide. By adding the sodium hydroxide, the pH value of the prepared slurry is 12-13. The material can obviously enhance the compression strength of the filled body, can enhance the critical fracture toughness and stability of the filled body, implements long-distance line delivery, and also implement quick filling and high-efficiency fireproofing and extinguishment.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Water-swelling rubber composite material, and preparation method and application thereof

InactiveCN103570985AImprove mechanical propertiesHigh expansion ratioDrilling compositionPolyethylene glycolAccelerant

The invention discloses a water-swelling rubber composite material. The rubber composite material is formed from the following components in parts by weight: 100 parts of rubber, 30-100 parts of super adsorbent resin, 2-10 parts of metal ion sealing agent, 0.5-2.5 parts of solid softening agent, 0.5-3.5 parts of coloring agent, 1-7 parts of anti-aging agent, 1-7 parts of accelerant, 1-8 parts of zinc oxide, 5-45 parts of reinforcing agent, 5-20 parts of plasticizer, 0.1-2.6 parts of vulcanizing agent, and 5-45 parts of mixture of PEG (polyethylene glycol) and MDI (diphenylmethane diisocyanate) at a molar ratio of 1:1. The invention further provides a preparation of the rubber composite material, in particular provides an application of the rubber composite material as superfine rubber swelling particles in a large pore path or high-permeability belt of a reservoir deep strata for profile control and water shutoff of an oil-water well.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com