High-strength mining expansion filling fireproofing and extinguishing material and application method thereof

A fire-proof and high-strength technology, which is applied in the fields of flame-retardant and fire-fighting, mine filling and airtightness, roadway goaf filling, goaf grouting to prevent fire-fighting, and mining fire-proof material filling. Unsatisfactory compressive strength, low flame retardancy, etc., to achieve the effect of enhancing critical fracture toughness and stability, reducing the possibility of drying shrinkage and cracking, and good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

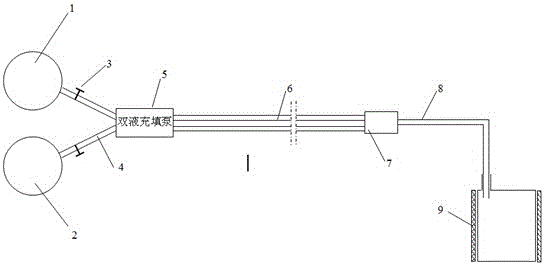

Method used

Image

Examples

Embodiment 1

[0036] A high-strength mine-used expansion filling fire-proof material, which includes the following substances in parts by weight: 24 parts of aluminate cement clinker (12 parts of sulphoaluminate cement clinker and 12 parts of high-alumina refractory cement clinker) , 18 parts of Portland cement clinker, 12 parts of active calcium-containing materials (8 parts of water-quenched blast furnace slag and 4 parts of water-quenched steel slag), 9 parts of anhydrite, 8 parts of quicklime, 35 parts of fly ash, 0.2 parts of zinc powder Foaming agent, 0.7 part of sodium chloride and 0.3 part of sodium carbonate, 1 part of aluminum hydroxide, 1.5 parts of sodium tripolyphosphate and an appropriate amount of sodium hydroxide, and the content of the sodium hydroxide makes the pH of the prepared slurry It is between 12-13, wherein, the weight ratio of expansion filling fire extinguishing material to water is 1:1.15.

[0037] Test the high-strength expansion-filled fire-proofing material i...

Embodiment 2

[0043] A high-strength mine-used expansion filling fire-proof material, which includes the following substances in parts by weight: 20 parts of aluminate cement clinker (10 parts of sulphoaluminate cement clinker and 10 parts of high-alumina refractory cement clinker) , 20 parts of Portland cement clinker, 9 parts of active calcium-containing materials (6 parts of water-quenched blast furnace slag and 3 parts of water-quenched steel slag), 7 parts of dihydrate gypsum, 7 parts of quicklime, 32 parts of fly ash, 0.4 parts of zinc Powder foaming agent, 0.4 part of calcium chloride and 0.5 part of sodium sulfate, 1 part of aluminum hydroxide, 2 parts of sodium tripolyphosphate and an appropriate amount of sodium hydroxide, and the content of the sodium hydroxide makes the prepared slurry The pH is between 12-13, and the weight ratio of expansion filling fire-proof material to water is 1:1.2.

[0044] Utilize the test method in the first embodiment to test the performance of its sa...

Embodiment 3

[0046] A high-strength mine-used expansion filling fire-proof material, which includes the following substances in parts by weight: 22 parts of aluminate cement clinker (11 parts of sulphoaluminate cement clinker and 11 parts of high-alumina refractory cement clinker) , 15 parts of Portland cement clinker, 12 parts of active calcium-containing materials (8 parts of water-quenched blast furnace slag and 4 parts of water-quenched steel slag), 5 parts of anhydrite and 3 parts of dihydrate gypsum, 8 parts of quicklime, 30 parts of pulverized coal Ash, 0.6 parts of zinc powder blowing agent, 0.5 parts of sodium chloride, 0.3 parts of sodium sulfate and 0.9 parts of sodium carbonate, 2 parts of aluminum hydroxide, 1.5 parts of sodium tripolyphosphate and an appropriate amount of sodium hydroxide, and the hydroxide The content of sodium makes the pH of the prepared slurry between 12-13, wherein the weight ratio of the expansion filling fire extinguishing material to water is 1:1.25. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com