Patents

Literature

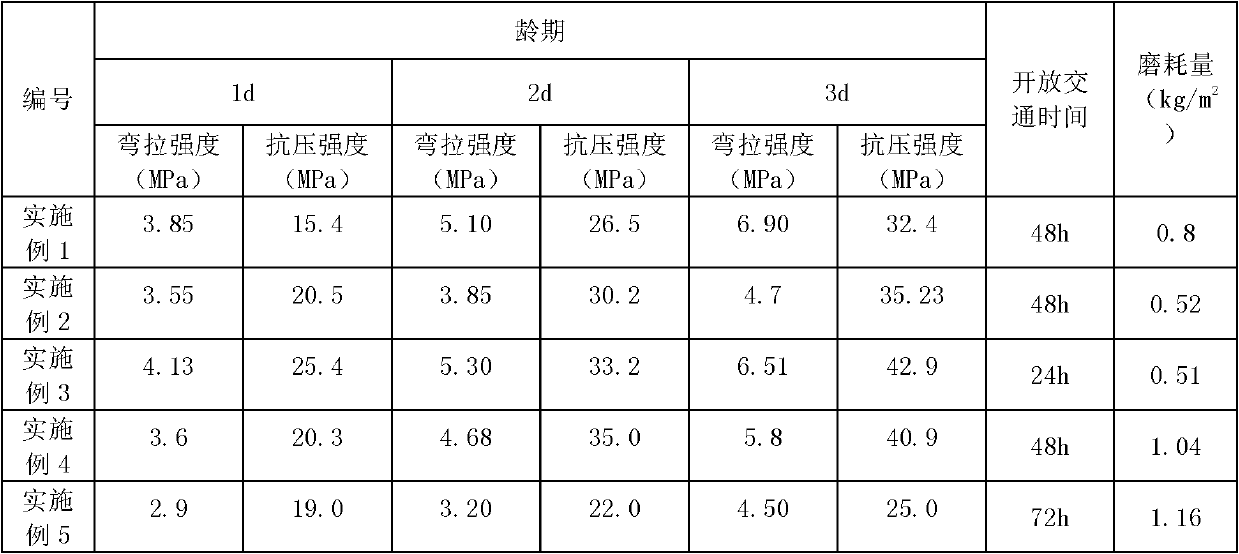

173results about How to "Reduce drying shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

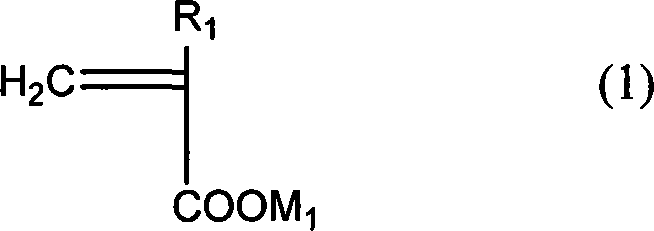

Super plasticizer of polyether for rapid hardening concrete

ActiveCN101066853AReduce drying shrinkageOvercoming the defect of increasing concrete drying shrinkageWater basedPlasticizer

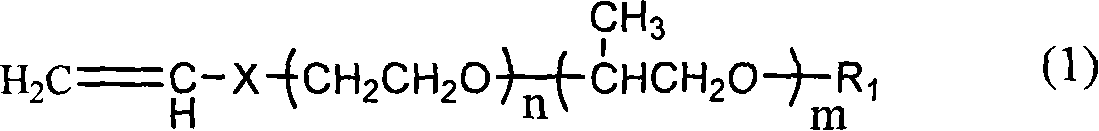

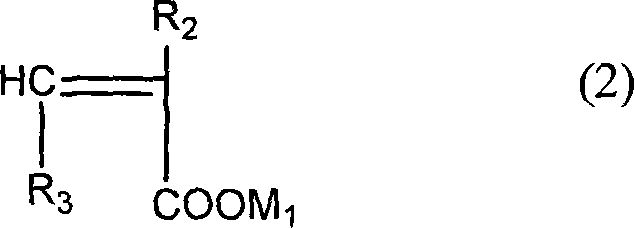

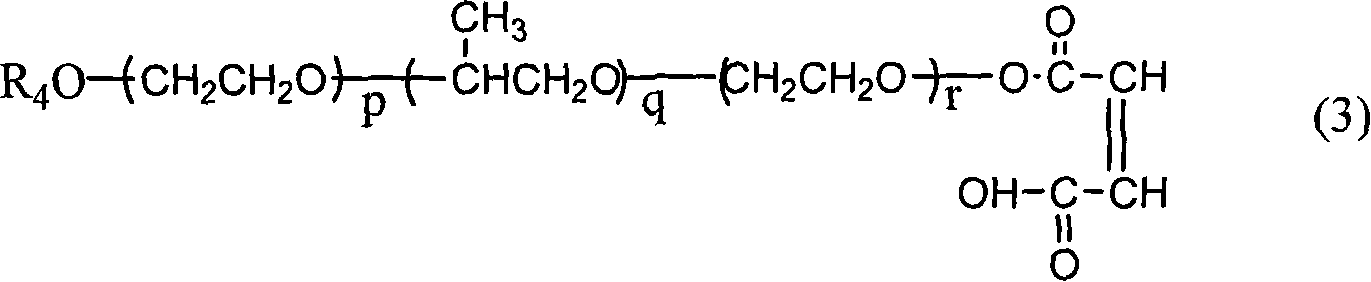

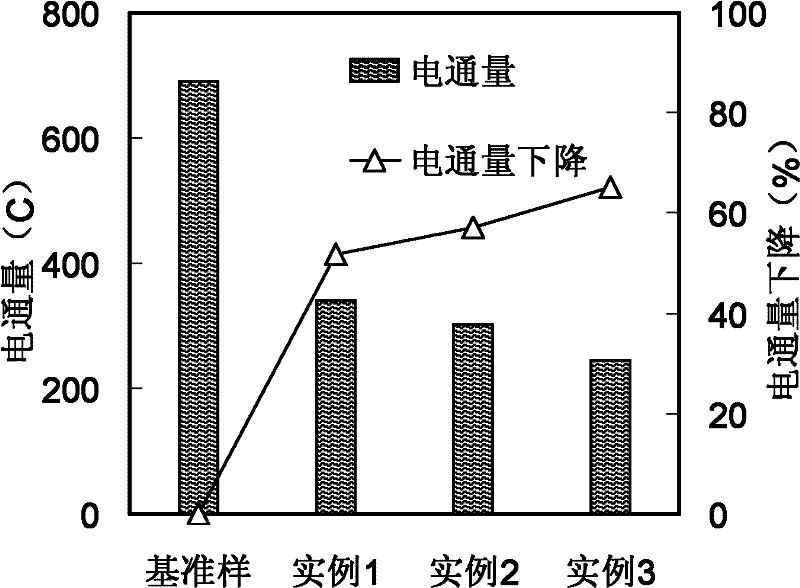

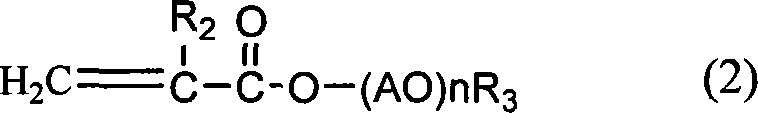

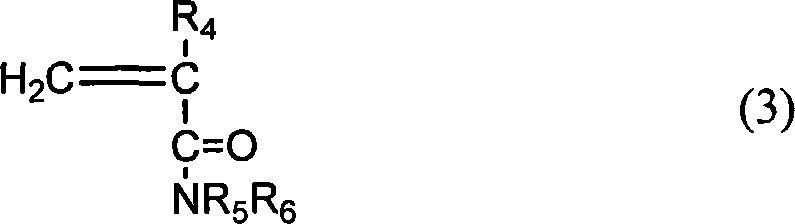

The present invention relates to one kind of super plasticizer of polyether for rapid hardening concrete. The super plasticizer is prepared through the first free radical copolymerization of monomer A in 84-94 wt%, monomer B in 5-15 wt% and monomer C in 1-3 wt% in water-base medium; and the subsequent neutralization reaction of the copolymer and alkoxyl organic amine to regulate the pH value of the copolymer to 6.0-7.5. The super plasticizer has excellent dispersing performance and reinforcing effect, especially obvious early reinforcing effect, and is favorable to raise construction speed and raising the durability of concrete.

Owner:JIANGSU SOBUTE NEW MATERIALS

Modified metakaolin-based permeation-resistant and crack-resistant agent for concrete

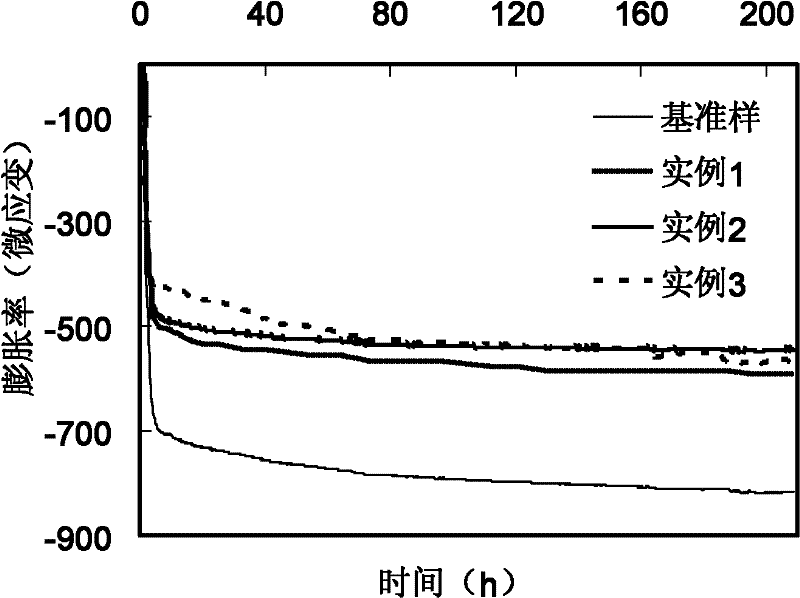

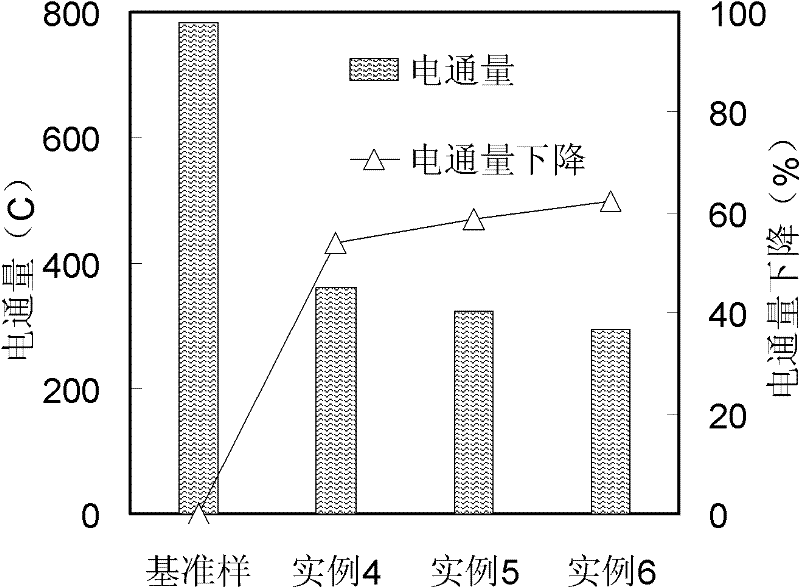

The invention discloses a modified metakaolin-based permeation-resistant and crack-resistant agent for concrete. The modified metakaolin-based permeation-resistant and crack-resistant agent for concrete comprises: by mass, 10 to 75% of modified metakaolin, 5 to 40% of fine limestone powder, 4 to 40% of superfine coal ash, 1 to 20% of calcined hydrotalcite, 2 to 40% of fine quartz sand and 0.2 to 20% of solid silane powder. A preparation method of the modified metakaolin comprises the following steps of putting dry and washed kaolin into a bowl mill, carrying out grinding to obtain kaolin powder, carrying out calcination of the kaolin powder at a temperature of 500 to 1000 DEG C for 0.5 to 6.0 hours to obtain metakaolin, putting the metakaolin into a dispersion machine, adding an organic modifier of sulfamate or triethanolamine into the metakaolin, wherein a mass ratio of the metakaolin and the organic modifier is in a range of (5000: 1) to (100: 1), and carrying out dispersion to obtain the modified metakaolin having a contact angle of 50 to 100 degrees and a specific surface area of 8000 to 15000m<2> / kg. The modified metakaolin-based permeation-resistant and crack-resistant agentfor concrete can be utilized as a concrete additive, improves strength of concrete at different ages, does not produce obvious influences on concrete work performances, obviously improves anti-chloride ion penetration capability of concrete, reduces total shrinkage of concrete and improves crack resistance of concrete.

Owner:WUHAN UNIV OF TECH +1

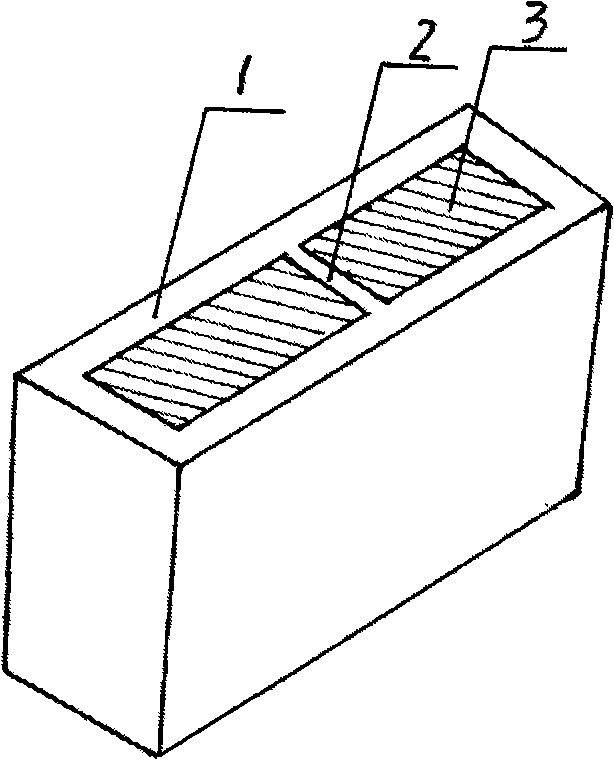

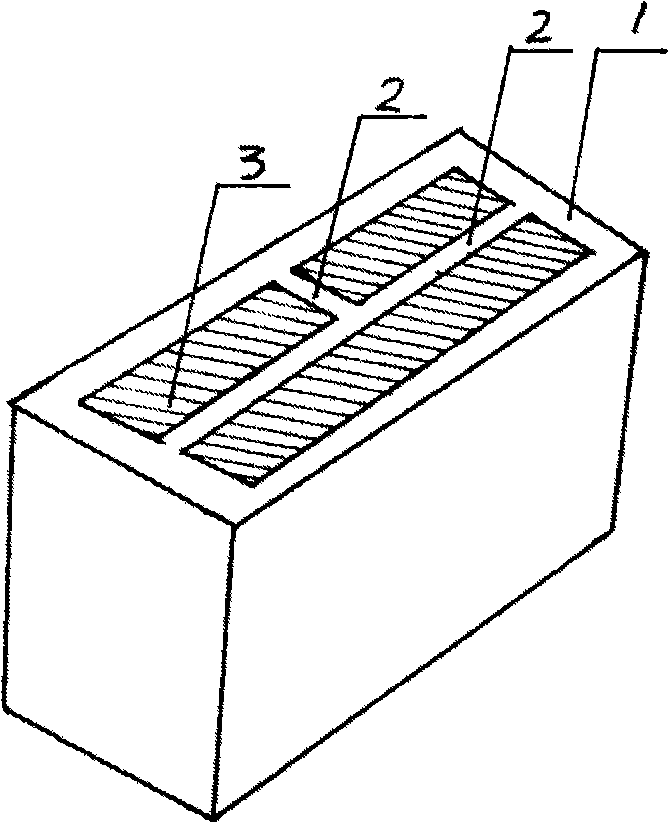

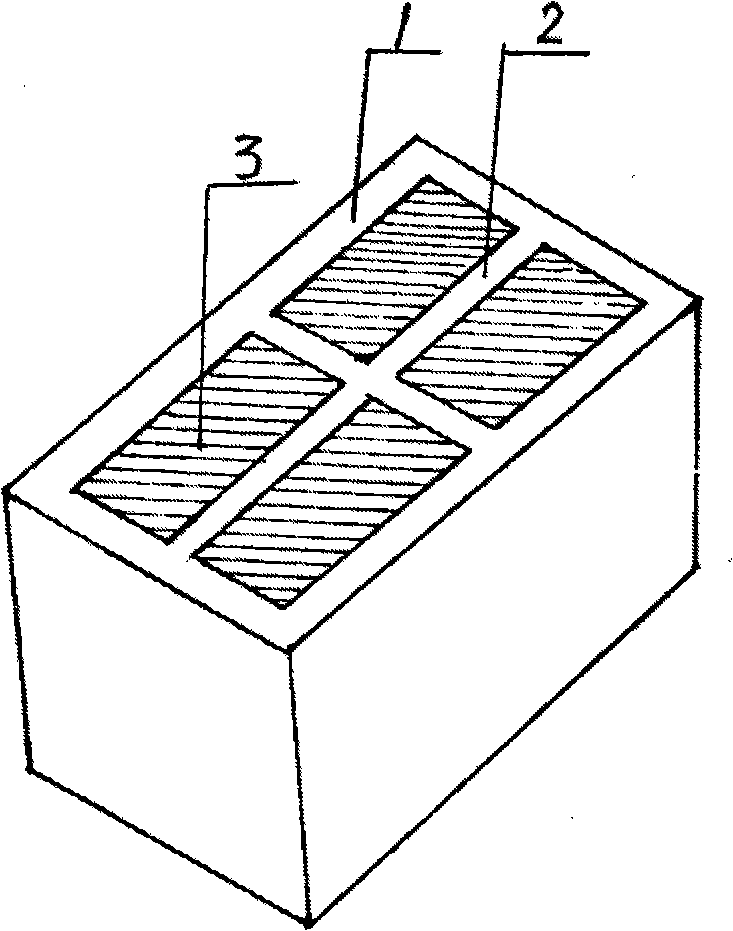

Steam pressurized concrete composite heat insulation building blocks and its production process

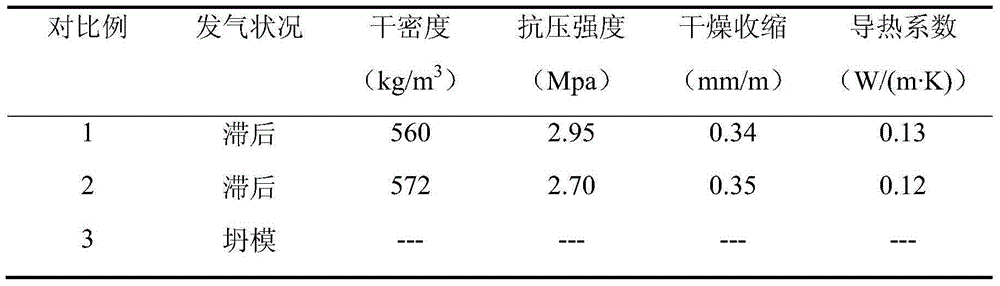

InactiveCN101265737AImprove thermal insulation performanceLight weightConstruction materialSolid waste managementSlurryAutoclaved aerated concrete

The invention discloses an autoclaved aerated concrete composite heat preservation building block and a production method thereof. The building block external wall and the building block are made of the autoclaved aerated concrete, the hole formed by the building block external wall and the building block rib is filled with heat preservation and insulation fillers for a second time. The building block adopts the autoclaved aerated concrete as the raw material and the preset mould core structure. The mould core is extracted after the slurry is poured so as to form a hollow structure in the building block body in the molding process, the void ratio of the hollow structure reaches 30%-70%. The light heat preservation and insulation material is filled for the second time after autoclaved curing the hollow structure block body, which reduces the production volume weight, improves the heat preservation and insulation performance of the material and facilitates the construction. Based on the application requirement, the absolute dry volume weight is adjustable in a range of 300-600kg / m<3>, the heat transfer coefficient amounts to less than 0.5W / m<2>.K, the method has a remarkable effect of energy saving, the single wall body material reaches 65% of the national building energy saving requirement, the energy-saving effect is obvious. The building block is widely applicable to industrial and civil building wall bodies.

Owner:ZHANGYE QINGTIAN BUILDING MATERIALS

Natural mineral-based high-temperature anti-oxidation decarbonization coating

InactiveCN102786822AGood dispersionImprove high temperature resistanceCoatingsPhysical chemistrySlurry

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Multifunctional anti-leakage shrinkage type concrete surface layer reinforcer

The invention relates to a multifunctional anti-leakage shrinkage type concrete surface layer reinforcer which is prepared from the following components in percentage by weight: 10-20 percent of high polymer, 1-7 percent of film forming aided compound, 5-10 percent of surface layer active agent compound, 1-4 percent of leakage aided compound, 1.5-4.5 percent of active compound and the balance of water. The invention has good concrete surface layer enhancement effect, can obviously reduce the shrinkage of surface layer concrete, obviously improves the carbonization resistance and the medium leakage resistance of surface layer concrete, has convenient construction and obvious economic benefit and can be widely applied to the strengthening treatment operations on the surface layers of cement and concrete pouring components, concrete components under corrosion environment conditions such as piers, dams, and the like and deformed concrete components difficult to be strengthened by adopting a conventional method.

Owner:湖州苏博特新材料有限公司

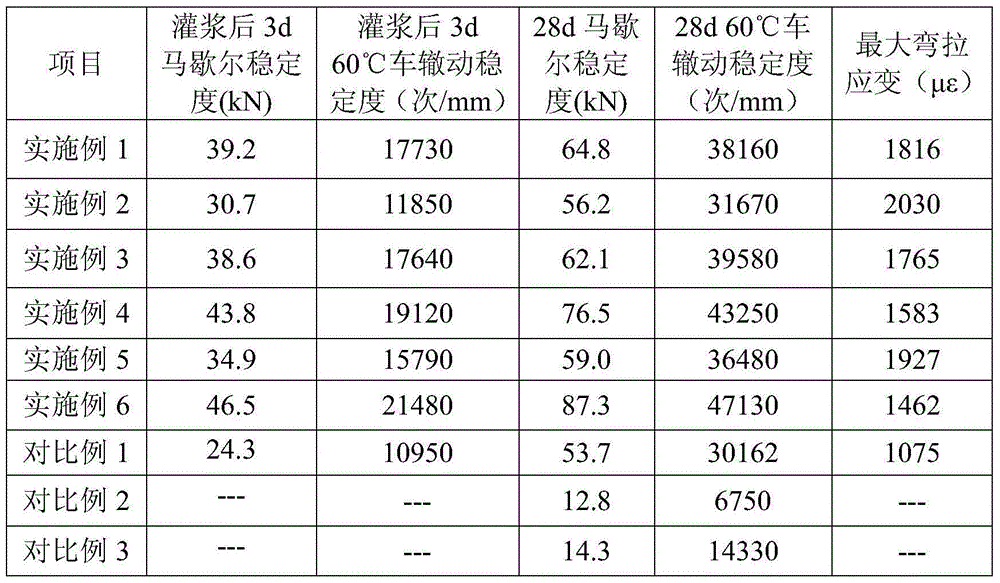

Semi-flexible anti-rut pavement material and preparation method thereof

The invention relates to a semi-flexible anti-rut pavement material which comprises the following components in percentage by weight: 65-88% of big-void cement-base mixture and 12-35% of flexible grouting material. The big-void cement-base mixture comprises 1 part of cement, 4-6 parts of coarse aggregate, 0.4-1.0 part of fine aggregate, 0.1-0.3 part of water and 0-0.006 part of water reducing agent. The flexible grouting material comprises 1 part of cement, 0.65-1 part of modified emulsified asphalt, 0.1-0.35 part of water-based epoxy resin emulsion, 0-0.03 part of ground tire, 0.0025-0.007 part of water reducing agent, 0.05-0.2 part of expanding agent and 0.05-0.15 part of water. The semi-flexible anti-rut pavement material has the characteristics of high rut resistance, favorable flexibility and toughness, no seam, fewer cracks, low carbon, environmental protection and the like, can be constructed at room temperature, and is suitable for road rut treatment.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Polyethers ultra early and strong type concrete superplasticizer

The invention relates to a polyether early- strength super-plasticizing agent. The preparation method comprises following steps: (1) copolymerization of water- borne free radical: 5%- 15% monomer a, 82%- 92% monomer b, 2%- 8% monomer c, and 1%- 3% monomer d copolymerizes in water- borne medium, the total amount of said monomers is 100%; (2) neutralizing reaction: adding alkoxy organic amine e showed in general formula (6) and (7) into copolymer after polymerizing reaction for neutralization, moderating the copolymer pH to be between 6.0- 7.5. The invention is characterized in that: (1) the dispersing performance and strengthening effect are outstanding at very low amount, and the strengthening effect at normal temperature or lower temperature at early stage is excellent, and the effect at middle and later stage grows stably; (2) it can reduce the concrete contract, and the contract rate is less than 90% of that of standard concrete; (3) it barely contains no chloride ion and is helpful for concrete durability increase.

Owner:JIANGSU SOBUTE NEW MATERIALS

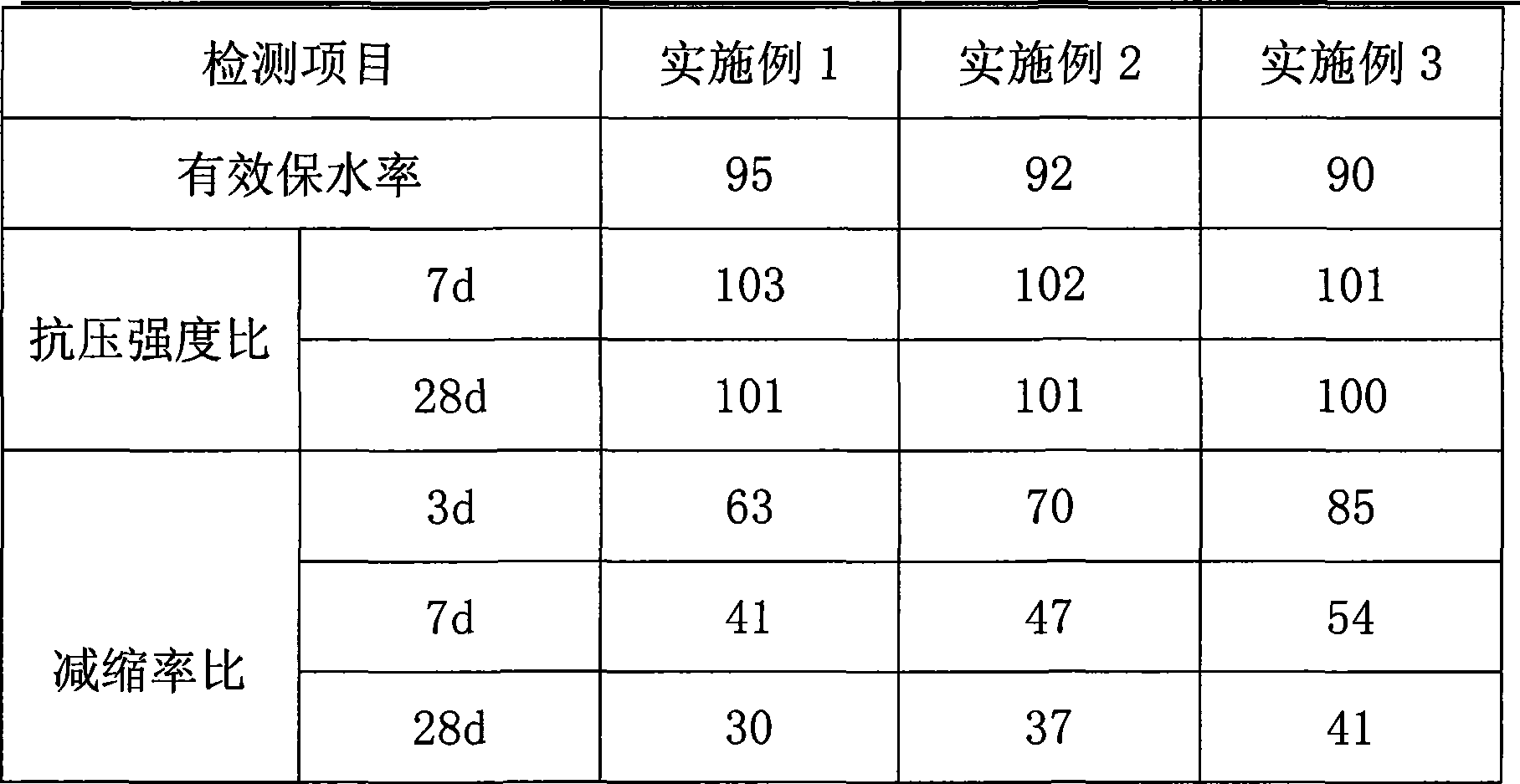

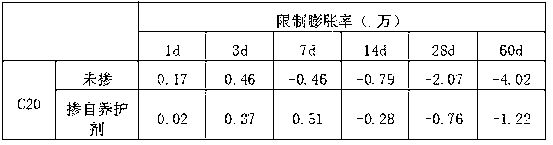

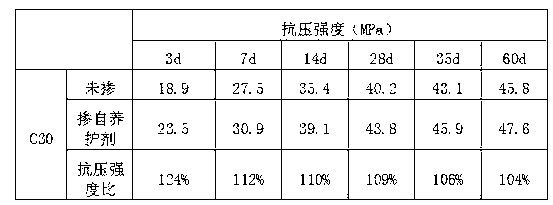

Shrinkage reducing and curing agent for concrete

The invention relates to a shrinkage reducing and curing agent for concrete, which has double functions of a shrinkage reducing agent for concrete and a curing agent for concrete and belongs to a building material. The shrinkage reducing and curing agent for concrete comprises a multifunctional high molecular polymer, and is a high-efficiency shrinkage and reducing curing agent comprising a water-soluble organic high-molecular film-forming agent, an inorganic densification agent, a shrinkage reducing agent, and the like. The shrinkage reducing and curing agent is directly brushed on the concrete surface layer to prevent water evaporation, and is capable of permeating through the capillary pores of the concrete to block the channel from which water in the capillary pores evaporates outwards. Meanwhile, the shrinkage reducing and curing agent can reduce the surface tension of water in the capillary pores so as to reduce the drying shrinkage of the concrete, thereby playing a good role in reducing shrinkage, conserving water and curing.

Owner:JIANGSU NIGAO SCI & TECH +1

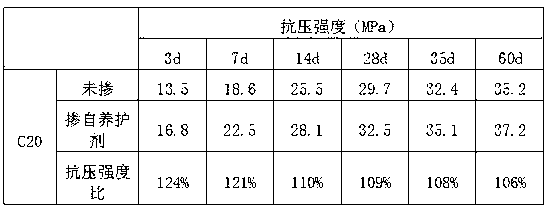

Autogenous curing agent for cement-based material and preparation method thereof

The invention provides an autogenous curing agent for a cement-based material and a preparation method thereof. The cement-based material just needs to be simply covered without later watering conservation after being poured. The autogenous curing agent for the cement-based material comprises the components in weight percent of 5-50% of super absorbent resin, and 50-95% of inorganic admixture, wherein the inorganic admixture is one or more of coal ash, slag powder, silicon ash, metakaolin, rice hull ash, steel slag powder, zeolite powder, bentonite and attapulgite. The preparation method of the autogenous curing agent comprises the steps of 1) weighing materials according to the formula ratio; 2) baking each material of the inorganic admixture and then cooling; 3) adding to a blender, firstly, slowly stirring, rapidly stirring, stagnating, then rapidly stirring and slowly stirring orderly; 4) heating the inorganic admixture, and 5) starting the blender, and slowly adding the super absorbent resin and mixed inorganic admixture when slowly stirring, rapidly stirring, stagnating, rapidly stirring, and then slowing stirring orderly, taking out the mixture and placing in a dry sealed container.

Owner:逄鲁锋

High-strength mining expansion filling fireproofing and extinguishing material and application method thereof

The invention discloses a high-strength mining expansion filling fireproofing and extinguishing material and an application method thereof. The material comprises the following substances in parts by weight: 16-25 parts of aluminate cement clinker, 12-20 parts of Portland cement clinker, 4-16 parts of active calcic material, 6-15 parts of setting accelerator, 5-10 parts of quicklime, 22-40 parts of fly ash, 0.1-1 part of zinc powder foaming agent, 0.5-2 parts of thickening time control agent, 1-2 parts of aluminum hydroxide, 1-3 parts of dispersing agent and a proper amount of sodium hydroxide. By adding the sodium hydroxide, the pH value of the prepared slurry is 12-13. The material can obviously enhance the compression strength of the filled body, can enhance the critical fracture toughness and stability of the filled body, implements long-distance line delivery, and also implement quick filling and high-efficiency fireproofing and extinguishment.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Blank body of fine porcelain ceramic, preparation method and application thereof

The invention relates to a blank body of fine porcelain ceramic, a preparation method and an application thereof. The raw materials of the blank body comprise the following components in the percentage by weight: 30-50% of calcined kaolin with high aluminum, low contraction and low thermal expansion, 10-20% of porcelain waste powder, 10-20% of quartz sand and 20-40% of ball clay. The invention also further discloses fine porcelain ceramic and a preparation method thereof. The fine porcelain ceramic can be used for casting a product with the size greater than 1,000 mm, and the product is flat, straight and regular and is not easy to deform.

Owner:LIXIL AS SANITARY MFG (SHANGHAI) CO LTD

Curing agent in concrete and preparation method and use method thereof

The invention discloses a curing agent in concrete, which comprises the following components: hydroxyl starch, starch grafted hydroxyethyl methacrylate, methyl cellulose, polyacrylamide, lignin sulfonate and aqua is preferred, wherein alcohol can be also added in as co-solvent. The curing agent in concrete has small admixture amount, is convenient to use, has very strong water absorbing and conserving capability in the concrete and blocks the water in the concrete from being evaporated externally; and even if the concrete is not cured by the water (moisture) from the outside environment after being cast, gelled material can have good hydration reaction, thereby greatly improving the strength of the concrete, reducing dryness and shrinkage, and preventing cracking.

Owner:广西红墙新材料有限公司

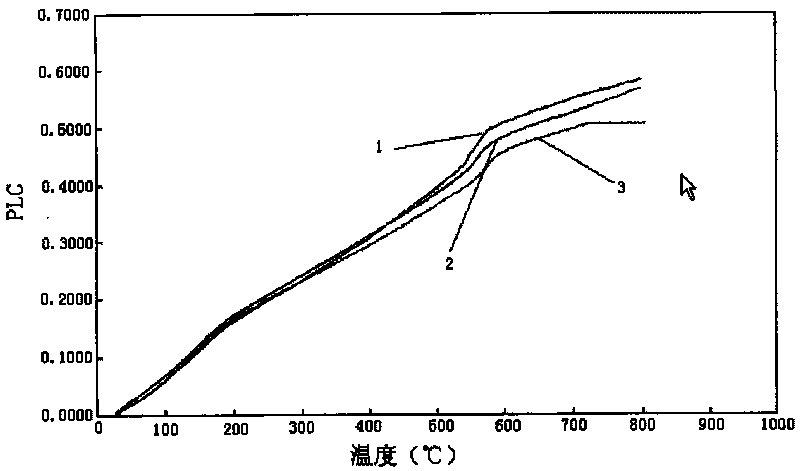

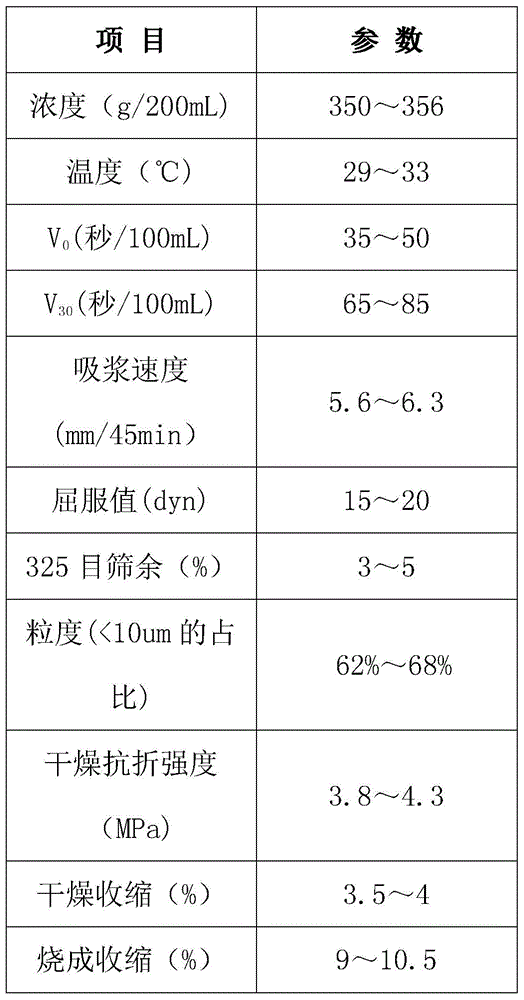

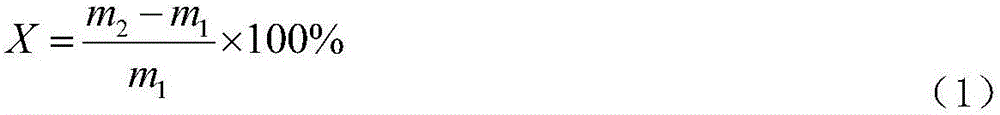

Mud for sanitary ceramics and mud preparation process

InactiveCN102603268ASmall coefficient of thermal expansionLess free quartz contentClaywaresPyrophylliteGranularity

The invention discloses mud for sanitary ceramics and a mud preparation process. The mud is mainly made of multiple raw materials and water by means of mixing and ball milling. The raw materials include 30-50wt% of water washed kaolin, 10-20wt% of weathered feldspar, 15-25wt% of pyrophyllite, 20-30wt% of sericite, 0.1-4wt% of wollastonite and 0.1-4wt% of calcined talc, and usage of water is 40-45wt% of the amount of the raw materials. The pyrophyllite, the water washed kaolin, the wollastonite and the calcined talc which have low-temperature sintering characteristics and the sericite and the weathered feldspar which have high high-temperatuare fusibility are used as the raw materials, and by means of the reasonable proportion, high-temperature components SiO2+Al2O3 of mud can be controlled within a low range, MgO, CaO,K2O and Na2O which are high in fusibility are increased, and the components with granularity smaller than 10um in the mud account for 65wt%-70wt%, so that the mud can be easily sintered. Compared with the prior art, the mud has the advantages that the mud can be formed by sintering at a low temperature (1150 DEG C), so that energy saving and consumption reduction are realized.

Owner:HUIHUANG PLUMBING GROUP

Sanitary ceramics slip and preparation technology thereof

The invention discloses sanitary ceramics slip and a preparation technology thereof. The sanitary ceramics slip mainly comprises, by weight, 30-70 parts of illite-structure clay, 5-15 parts of kaolin, 6-14 parts of ball clay, 8-13 parts of potassium feldspar, 5-10 parts of pyrophyllite, 5-10 parts of sericite, 0.1-3 parts of dolomite and 40-45 parts of water. Sanitary ceramics prepared from the sanitary ceramics slip are low in firing temperature, little in energy consumption and high in strength, and slip casting qualified rate, semi-finished product qualified rate and firing qualified rate can reach 98%, 96% and 92% respectively.

Owner:福建科福材料有限公司

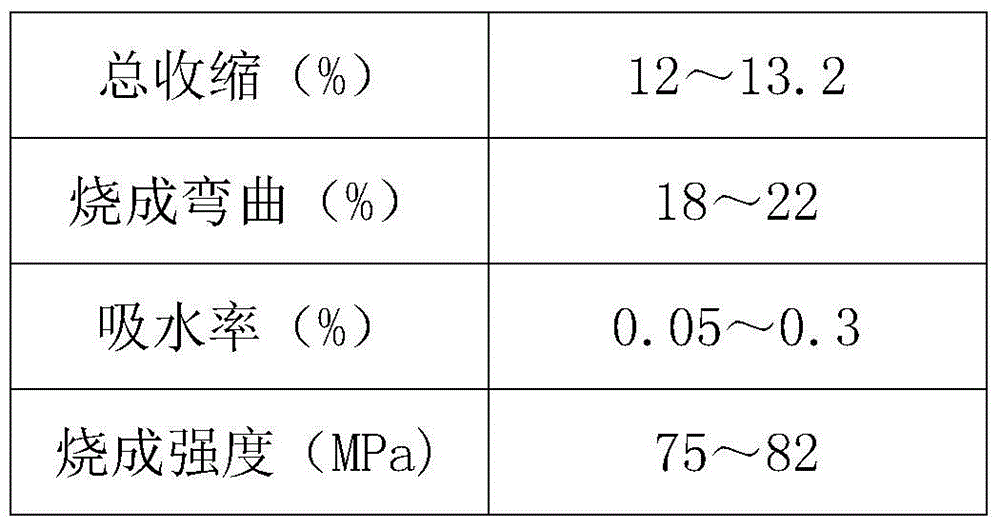

Early-strength fast-track concrete for repairing cement-concrete road surface

InactiveCN102167550AWidely used valueSmall shrinkageSolid waste managementRepair materialRoad surface

The invention relates to early-strength fast-track concrete for repairing a cement-concrete road surface. The early-strength fast-track concrete comprises cement, sand, stone and water, and is characterized by also comprising additives and a mineral admixture, and concretely comprising 10 to 20 percent of cement, 5 to 10 percent of water, 28 to 32 percent of sand, 44 to 48 percent of stone and 0 to 1.0 percent of mineral admixture. The invention overcomes defects of not high early strength, long curing period and traffic impact of the conventional common curing repair material for the cement-concrete road surface and defects of low durability and high construction cost of partial quick curing repair materials, and provides economical and practical early-strength fast-track concrete which meets the requirement of durability of the cement-concrete road surface and quickly cures and repairs the cement-concrete road surface.

Owner:交通运输部公路科学研究院

Preparation method for silicon-dioxide-based carbon fiber composite adsorbent

InactiveCN105771887AReduce drying shrinkageImprove adsorption capacityGas treatmentOther chemical processesFiberN dimethylformamide

The invention particularly relates to a preparation method for a silicon-dioxide-based carbon fiber composite adsorbent. Firstly, tetraethyl orthosilicate (TEOS), redistilled water, absolute ethyl alcohol, N,N-dimethylformamide and ammonia water are mixed to prepare sol, then nanometer active carbon fiber is added, an extremely slow heating mode is adopted to heat a mixture to a certain temperature, a gel mixture is obtained and then subjected to aging, solvent exchange and hydrophobic modification, gel is cleaned by n-hexane, drying treatment is performed finally, and the silicon-dioxide-based carbon fiber composite adsorbent is obtained.

Owner:CHANGZHOU UNIV +1

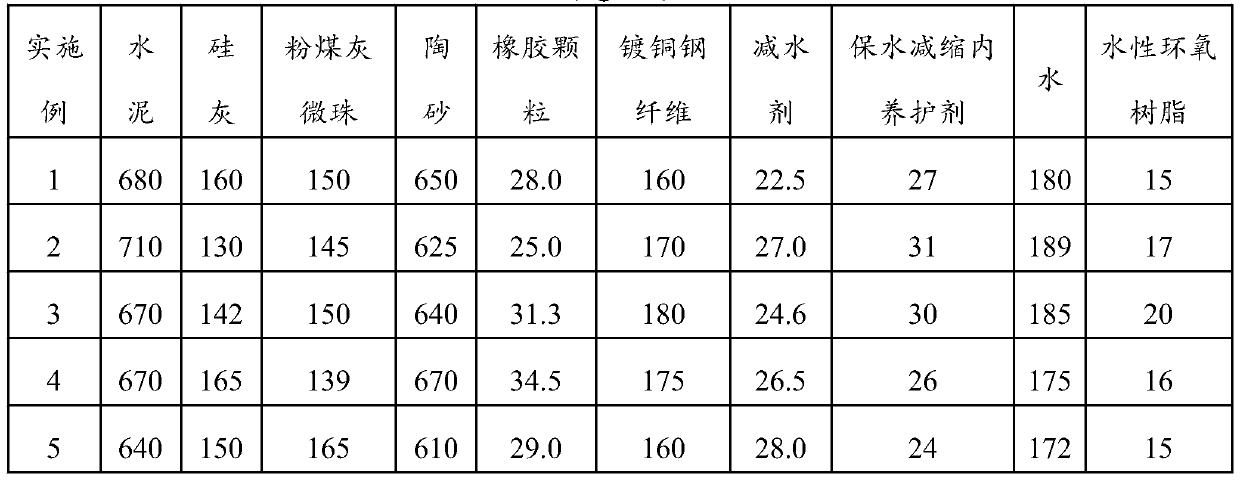

Modified rubber particle lightweight ultra-high performance concrete and preparation method thereof

The invention discloses modified rubber particle lightweight ultra-high performance concrete and a preparation method thereof. The concrete is prepared from cement, fly ash microbeads, silica fume, pottery sand, rubber particles, copper-plated steel fibers, waterborne epoxy resin, a water-retaining shrinkage-reducing internal curing agent, a water reducing agent and water as main raw materials, wherein the rubber particles are prepared by crushing waste tires and then modifying the crushed waste tires. The modified rubber particle lightweight ultra-high performance concrete has the advantagesof light weight, high strength, high impact toughness, abrasion resistance and good volume stability, and has practical application value.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

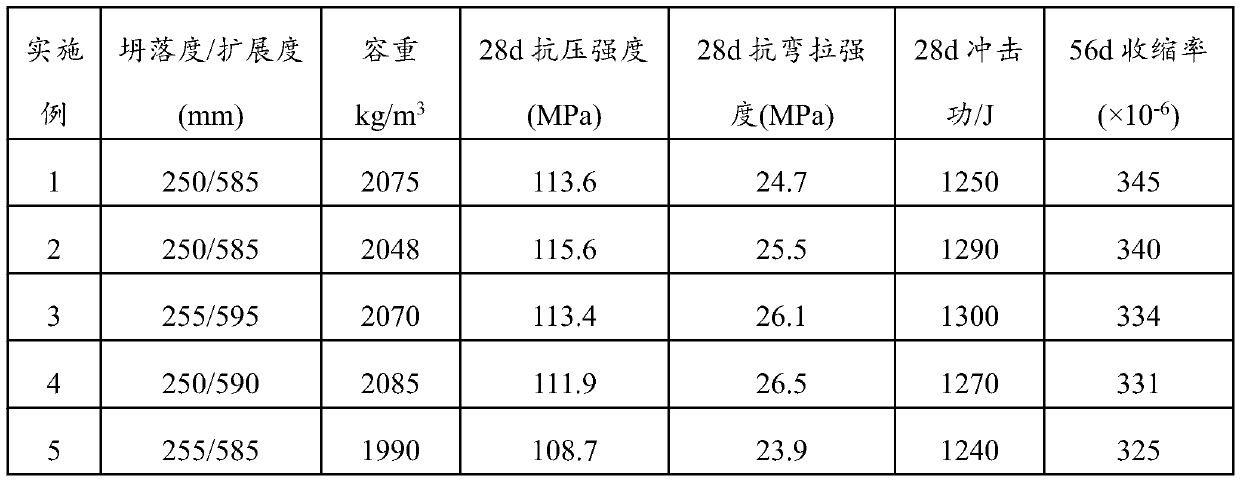

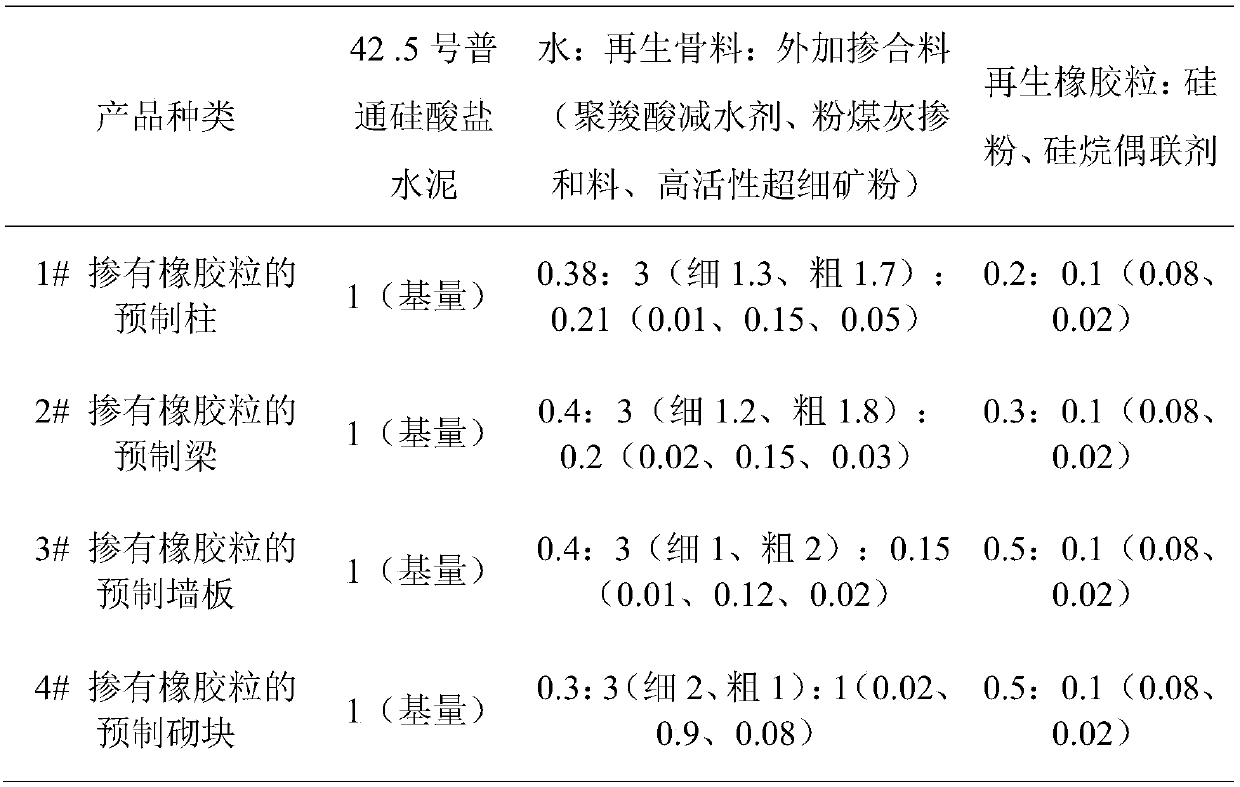

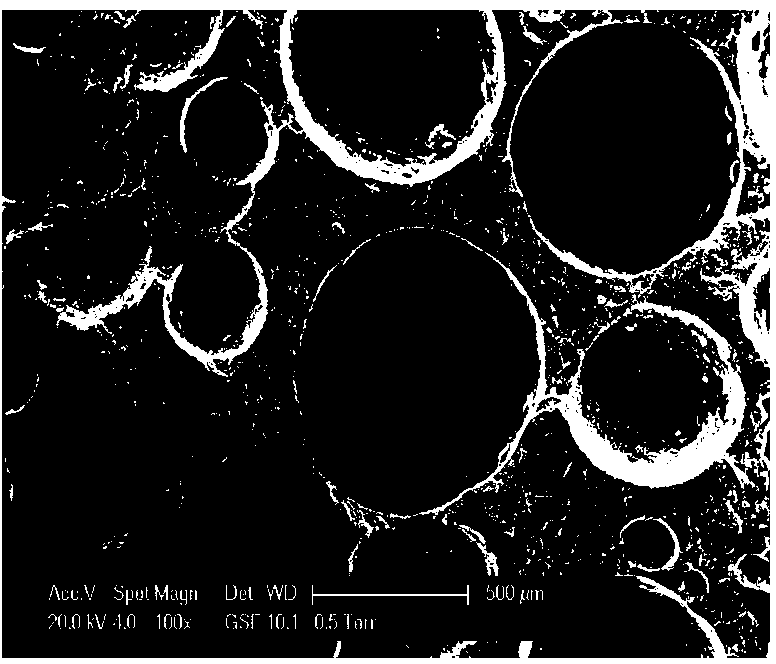

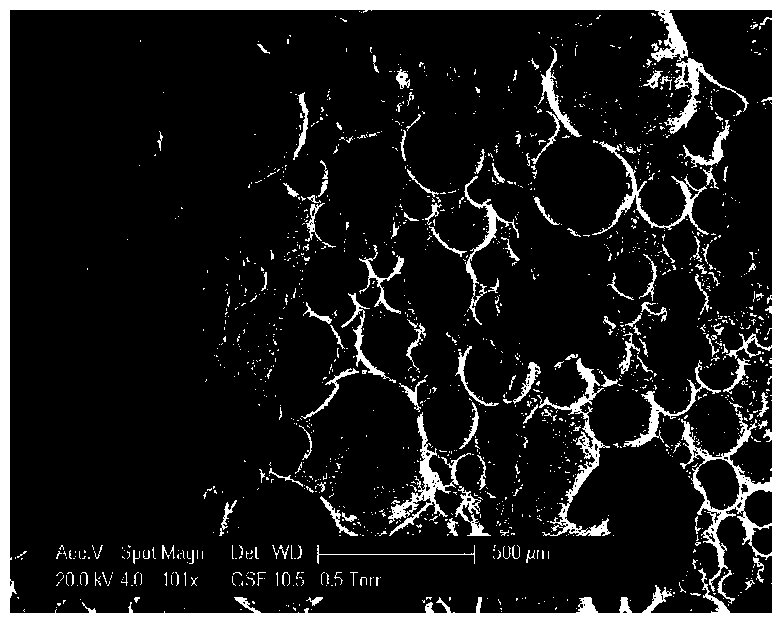

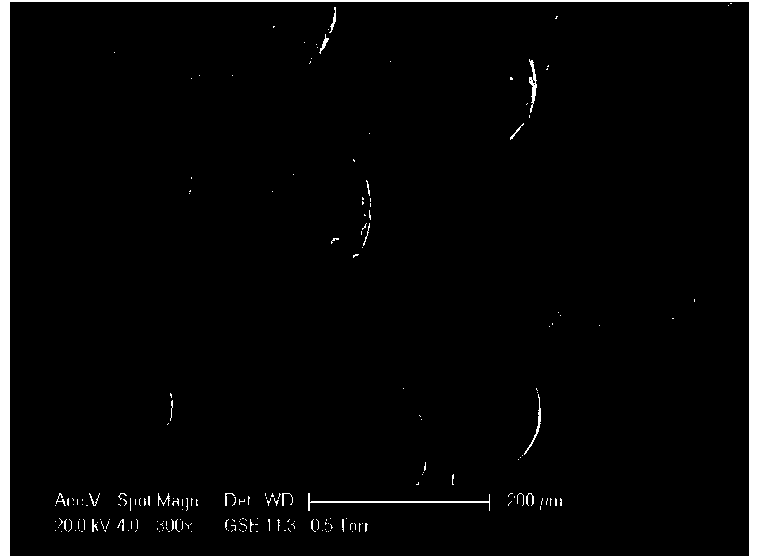

Recycled concrete doped with rubber particles as well as preparation method and application thereof

The invention provides recycled concrete doped with rubber particles as well as a preparation method and application thereof. Construction garbage is disinfected, broken, decontaminated, sieved, strengthened and the like to prepare recycled aggregates; abandoned rubber tyres and the like are used for preparing rubber particles through technologies including disinfection, breaking, preprocessing, temperature change fluid method processing, strengthening processing and the like; the obtained recycled composite aggregates, silicate cement, water and other mineral admixture are mixed to prepare different concrete products, including recycled concrete prefabricated wall panels, building blocks and the like doped with rubber particles, through a subsequent technology by controlling different proportions. The concrete prepared with the method has the advantages of environment protection, low price, stable mechanical property, good durability and the like.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

High efficiency concrete composite admixture

InactiveCN103588415ALate strengthDelay the initial setting and final setting time of concrete without affecting the later strengthSuperplasticizerWater reducer

The invention discloses a high efficiency concrete composite admixture, which comprises the following components: by weight, 5%-20% of triethanolamine, 10%-15% of sodium lignin sulfonate, 2% - 3% of a naphthalene-series high efficiency water reducer, 1% - 2% of bone glue, 5% - 15% of tartaric acid, 2% - 3% of rosin, 3% - 5% of sodium dodecyl benzene sulfonate, and the balance of water. The high efficiency concrete composite admixture has the advantages of simple process and excellent performances.

Owner:JIANGSU BAIRUIJI NEW MATERIAL

Light aggregate cell concrete self-insulating building block and preparation method thereof

ActiveCN103771807AGood self-care effectImprove performanceSolid waste managementCeramicwareCompressive resistanceEnvironmental resource management

The invention discloses a light aggregate cell concrete self-insulating building block and a preparation method thereof. The building brick is prepared by dosing, stirring, mixing, foaming, injecting and moulding, maintaining and hardening the following components in percentage by weight: 25-30% of cement, 10-20% of industrial residue admixtures, 20-35% of industrial residue aggregates, 25-30% of water, 1.0-3.5% of a compound additive and 0.1-0.3% of a foamer. The light aggregate cell concrete self-insulating building block prepared by the method disclosed by the invention is high in strength and low in density, wherein the apparent density is 500-1200kg / m<3>, the compressive strength is 3.5-15.0MPa, and the heat conductivity coefficient is 0.08-0.25W / (m.K). The building brick has good fireproof and flame retardant performances as well as heat-preserving and heat-insulating properties, and satisfies the demand of national energy conservation by 65%. Meanwhile, a plenty of industrial residue light aggregates are utilized, so that cement is saved, thereby facilitating energy conservation and emission reduction and maintenance of the ecological environment.

Owner:SOUTHEAST UNIV

Low-heat anti-cracking portland cement

The invention discloses low-heat anti-cracking Portland cement. The cement clinker of the cement consists of the following minerals in percentage by weight: 40 to 70 percent of dicalcium silicate, 10 to 35 percent of tricalcium silicate, 1 to 4 percent of tricalcium aluminate, 15 to 30 percent of tetra calcium aluminoferrite, and 0.1 to 0.8 percent of free calcium oxide, wherein the content of magnesium oxide in the cement is between 3.5 and 5.0 percent, the content of alkali is not more than 0.55 percent, and the content of sulfur trioxide is not more than 3.5 percent. The cement has the main technical indexes that the ignition loss is less than or equal to 3wt%, the specific area is less than or equal to 340m<2> / kg, the stability is qualified, 3-day tensile strength is not required, the 7-day tensile strength is more than or equal to 13MPa, the 28-day tensile strength is between 42.5MPa and 52.5MPa, the 3-day breaking strength is not required, the 7-day breaking strength is more than or equal to 3.5MPa, the 28-day breaking strength is more than or equal to 7.0MPa, the 3-day hydration heat is less than or equal to 220KJ / kg, and the 7-day tensile strength is less than or equal to 250KJ / kg. The cement can be used for remarkably improving the cracking resistance of hydraulic concrete.

Owner:CHINA THREE GORGES CORPORATION

Concrete curing agent

The invention discloses a concrete curing agent, which comprises the following components in parts by mass: 20-25 parts of styrene-acrylic emulsion, 7-10 parts of acrylamide solution, 7-9 parts of sodium silicate solution, 6-9 parts of organic silicon solution 8 parts, 1-3 parts of methyl methacrylate, 1-3 parts of polyethylene glycol monomethyl ether acrylate, 3-5 parts of polyethylene glycol, 1-3 parts of polyvinyl alcohol, 4-6 parts of styrene , 6-8 parts of methyl acrylate, 5-7 parts of butyl methacrylate, 3-5 parts of butyl acrylate, 4-6 parts of ethyl methacrylate, 1-3 parts of ammonium thiosulfate, EPDM 1-3 parts of rubber, 0.7 parts of butyl citrate, 1 part of soda ash, 0.5 parts of gypsum powder, 0.1 part of periodate lignin, 0.1 part of surfactant, 0.2 part of defoamer, 0.3 part of leveling agent and benzene 1 part methanol. The curing agent disclosed by the invention can effectively prevent water loss inside the concrete, and is environmentally friendly and pollution-free.

Owner:CHINA ROAD & BRIDGE

Photocureable coating for anodization

InactiveCN102604529AReduce drying shrinkageGood adhesionPolyurea/polyurethane coatingsSolventFunctional monomer

The invention discloses a photocureable coating for anodization. The photocureable coating comprises the following compositions by weight: a photoinitiator, a flatting agent, an adhesion promoter, hexa-functional polyurethane resin, bifunctional polyurethane resin, tri-functional solvent polyurethane, a bifunctional monomer, a single-functional monomer, a tri-functional monomer and thermoplastic acrylic resin, wherein the hexa-functional polyurethane resin and the bifunctional polyurethane resin are aliphatic functional polyurethane acrylates, and the tri-functional solvent polyurethane is modified solvent polyurethane resin. Based on such a mode, the photocureable coating for anodization provided by the invention can be used for carry outing one-time coating without pretreatment, thereby saving the cost, the working hour and labor; meanwhile, the adhesion of the coating on anodic metal polar materials is ensured, and the strict performance test requirements of products can be guaranteed, so that the photocureable coating for anodization achieves a good protective anti-scratching and aesthetic effect on anodic electrophoretic workpieces coated with the photocureable coating.

Owner:CHANGSHU FANGTA COATING CHEM

Aerated concrete manufactured by stone material waste and manufacturing method thereof

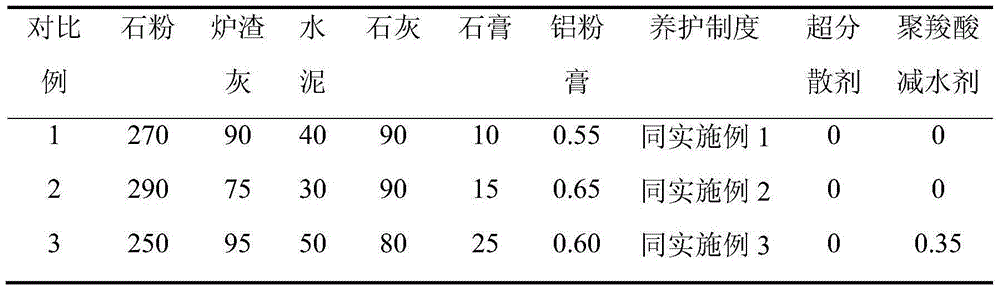

InactiveCN105110811ASolve the use problemSave natural resourcesSolid waste managementCeramicwareThermal insulationSlag

The invention discloses aerated concrete manufactured by stone material waste. The aerated concrete is manufactured by a pretreated stone powder material, slag ash, cement, unslaked lime, desulfurized gypsum, powdered aluminum paste and a hyper-dispersant, wherein the pretreated stone powder material is produced by crushing, mixing and grinding stone material machining waste and waste aerated concrete building blocks. The stone material machining waste and industrial wet furnace slag ash are machined and re-treated, the utilization problem of a stone material and other waste is effectively solved, energy is saved, and environment is protected. A related manufacturing process is simple and low in cost. The hyper-dispersant can effectively improve the dispersing performance of concrete slurry, the viscous resistance of stone powder granules is reduced, and early-stage coordination between aeration and densification of the slurry is ensured, so that the aerated concrete has the advantages of being low in drying shrinkage value, good in thermal insulation property, high in compressive strength and the like. In addition, natural stone material waste, waste aerated concrete and furnace slag ash are recycled to slow down soil degradation, underground water pollution, dust pollution and other environmental problems, and the aerated concrete is suitable for popularization and application.

Owner:HUBEI UNIV +1

Bumpy cement concrete road surface mending agent

The invention relates to road construction field, in particular to a bumpy cement concrete road surface mending agent, aiming at solving such problems of mending materials adopted in current cement concrete road surface mending as slow strength development, poor combination with original cement concrete layer, easy contraction and cracking and the like. The invention comprises 15-25% of acrylic ester elastic latex, 5-20% of 108 adhesive, 5-10% of AKD latex, 8-15% of polyvinyl alcohol fiber, 0.5-2% of common silicate cement, 1-3% of sand and balance water. The mending agent has good tenacity and anti-deformation capability, reduces drying shrinkage, has higher cementing strength with the old concrete interface, good compatibility, enhanced rupture strength and antifatigue property, increased fatigue life and good mechanical property, satisfies the requirement of fast mending the cement concrete road surface, improves use property of the road surface, prolongs service life of the road surface, saves project cost, shortens construction period and is beneficial for enhancing mending quality and speed of cement road surface.

Owner:亢吉田

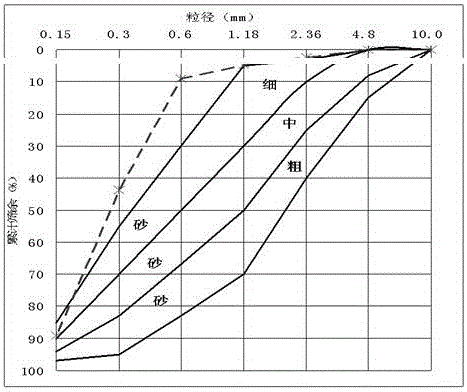

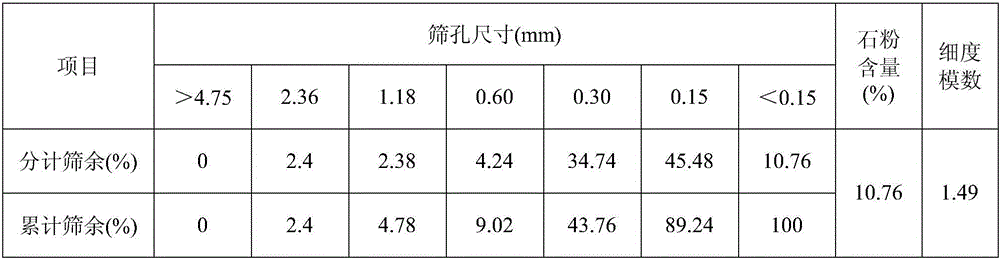

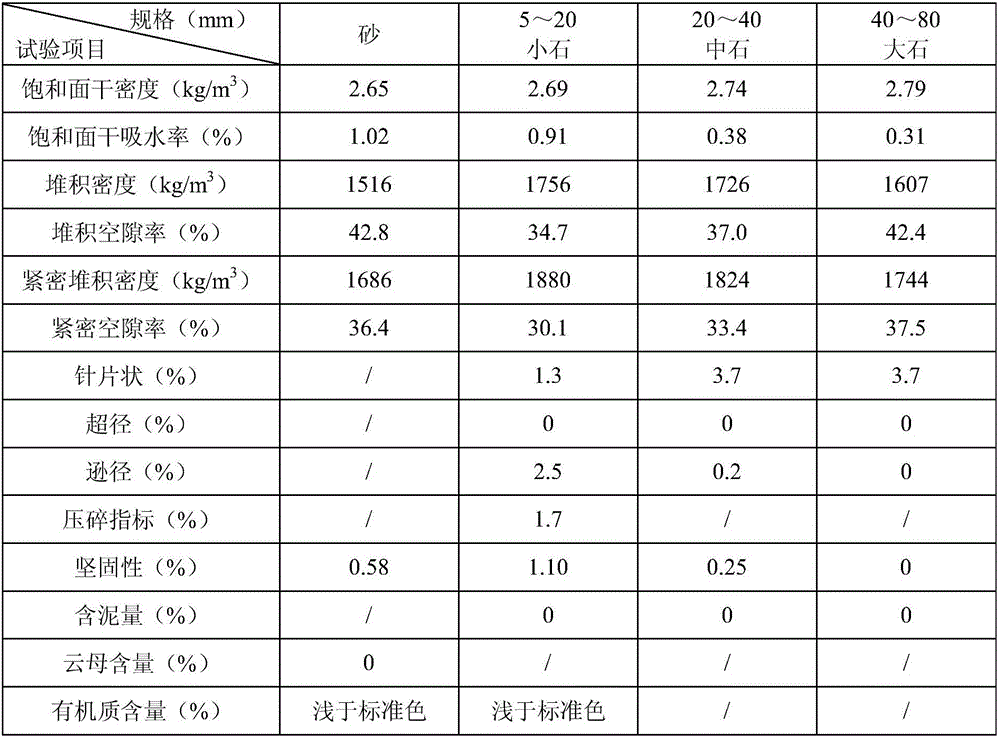

Special fine sand hydraulic large volume normal-state concrete

The invention discloses a special fine sand hydraulic large volume normal-state concrete, wherein stirring of special fine sand is used, an admixture is added during the stirring process by using an external adding way, the sand ratio and the water-cement ratio are reduced, the stirring time is prolonged, and the early curing of the concrete is strengthened, wherein the admixture is a composite fiber expanding agent. According to the present invention, the externally adding of the composite fiber expanding agent is used, such that the sand ratio of the concrete of the present invention is improved by 3-5% compared to the sand ratio of the conventional special fine sand concrete; and with the improvement of the contents and the proportions of each index in the matching ratio, the reduction of the dry shrinkage value of the concrete, and the improvement of the durability of the concrete, the large number of the special fine sand can be used in the hydraulic large volume concrete.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

Gypsum-based heat-insulation mortar and preparation method thereof

The invention discloses gypsum-based heat-insulation mortar and a preparation method thereof. The gypsum-based heat-insulation mortar is prepared from the following ingredients in parts by weight: 15to 25 parts of Portland cement, 30 to 40 parts of building plaster, 10 to 20 parts of glass bead, 10 to 30 parts of converter steel slag, 10 to 20 parts of coal ash, 5 to 15 parts of nano silicon dioxide powder, 15 to 25 parts of ash calcium powder, 5 to 10 parts of modified pulpified starch, 2 to 8 parts of dispersible latex powder, 5 to 15 parts of cellulose ether, 3 to 8 parts of crack-resistant fiber, 5 to 15 parts of modified talcum powder, 4 to 10 parts of binder, 0.3 to 0.7 part of air entraining agent, 0.2 to 0.6 part of water repellent, 0.1 to 0.5 part of water reducing agent and 40 to 60 parts of water. The gypsum-based heat-insulation mortar disclosed by the invention has the advantages of high strength, good heat insulation, small drying shrinkage, no easiness in cracking and the like. The gypsum-based heat-insulation mortar can meet a requirement of building industry to mortar performance indexes and can be widely applied to projects of heat insulation and the like of outer walls and inner walls of buildings.

Owner:HEFEI OAKS NEW BUILDING MATERIAL CO LTD

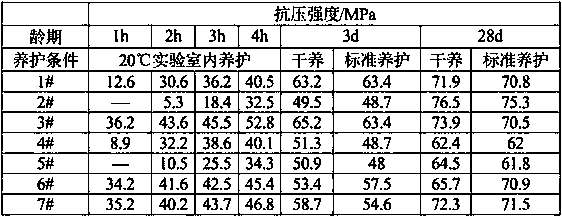

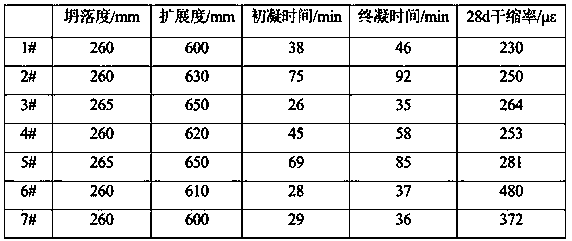

Shrinkage-compensating rapid repairing material for bridge expansion joints

The invention discloses a shrinkage-compensating rapid repairing material for bridge expansion joints. The shrinkage-compensating rapid repairing material is prepared from 25-40 parts of cement, 0-4 parts of gypsum powder, 2-4 parts of silica powder, 1-4 parts of an expanding agent, 25-33 parts of quartz sand and 32-40 parts of gravel, 0.05-0.1 part of a water reducing agent, 0.05-0.15 part of a retarder, 0.01-0.1 part of super absorbent resin, 0.005-0.01 part of a lithium salt and 0-0.01 part of a defoaming agent. The raw materials used in the invention are reasonably proportioned; early strength is high, the fastest 1h can reach 30MPa or above; the later strength is stably increased, the 28-day strength can reach 60 MPa or above, when the shrinkage-compensating rapid repairing material is used as a bridge expansion joint or concrete pavement repairing material, the self internal curing effect of the concrete can be enhanced, the volume shrinkage of the hardened concrete is reduced, the volume stability of the hardened concrete is enhanced, and the requirement for rapid traffic opening is met.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

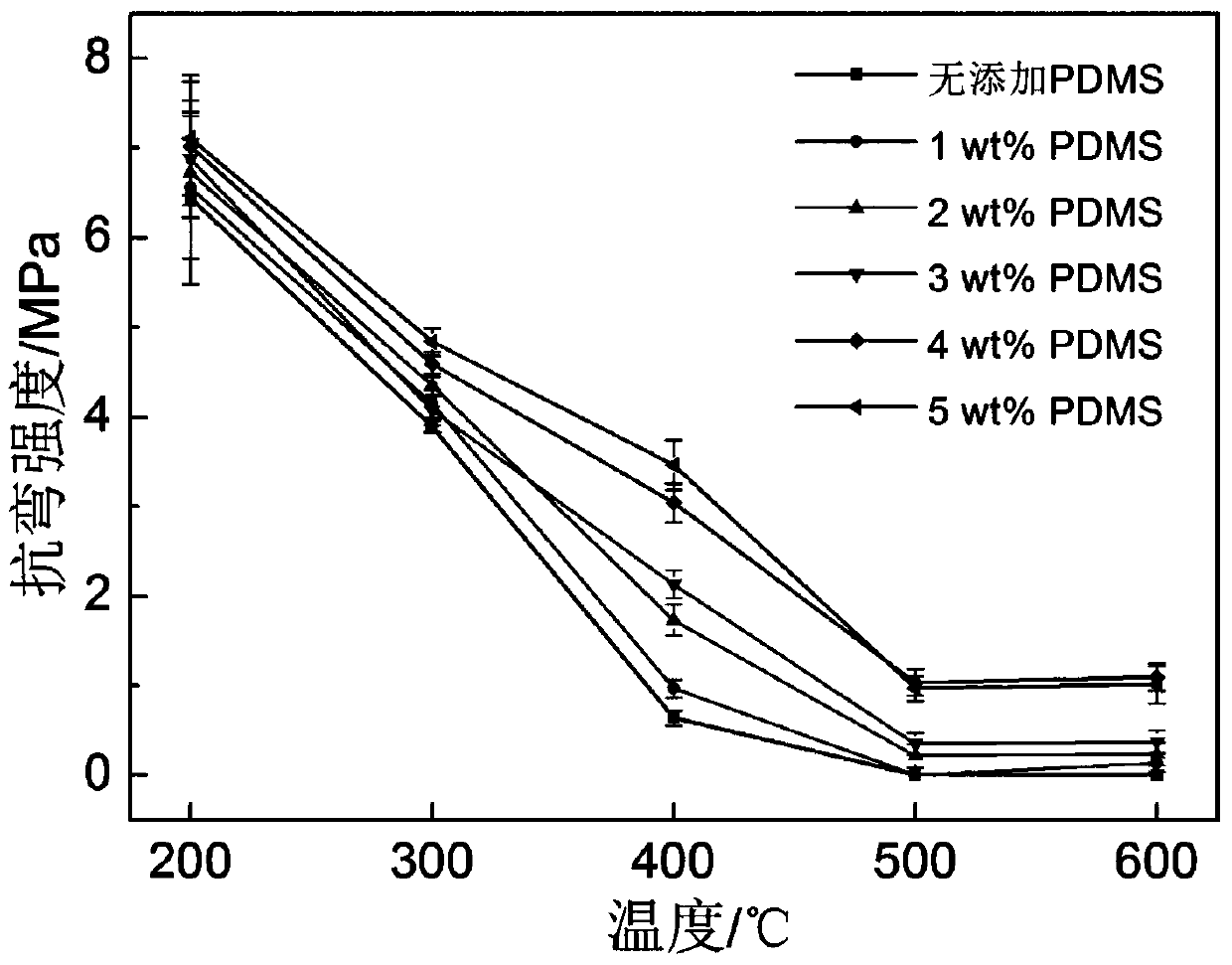

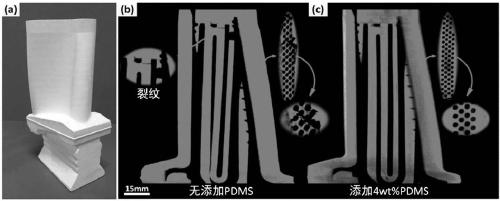

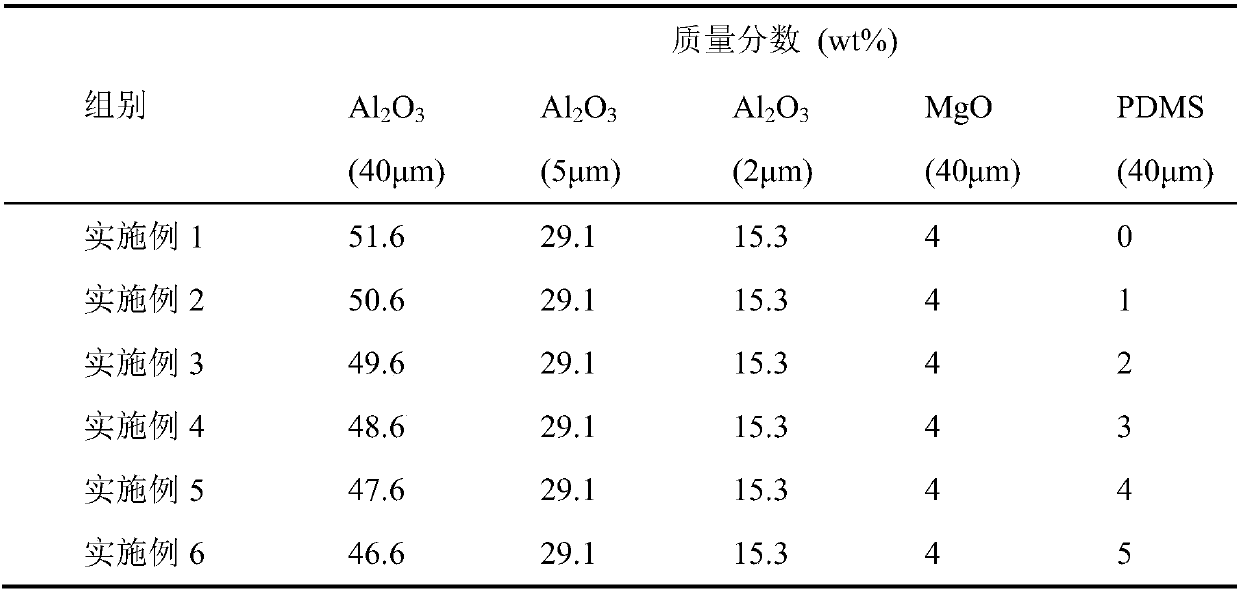

Method for improving degreasing strength of additive manufacturing formed ceramic part

InactiveCN109534794AImprove degreasing strengthSufficient strength marginUltrasound attenuationPrill

The invention discloses a method for improving the degreasing strength of an additive manufacturing formed ceramic part. The method comprises the following steps that polydimethylsiloxane is added into a ceramic powder material, and required raw material powder is obtained after even dispersing; the powder material and a liquid phase solvent are mixed, and ceramic slurry is prepared after even ball-milling; a ceramic part blank is formed through an additive manufacturing method, and after the blank is dried, degreasing and glue discharging are conducted; and in the degreasing heating process,the polydimethylsiloxane is softened and molten to permeate into adjacent ceramic particle gaps, and ceramic particles are wrapped. The polydimethylsiloxane is simple in molecular structure, low in carbon content and low in pyrolysis ignition lost rate, thus the wrapping bonding effect on the ceramic particles is small along with thermal attenuation of the temperature, the degreasing strength of the part can be established, and it is ensured that the blank has the sufficient strength margin to resist damage of gravity and thermal stress in a degreasing technology. The method can be used for improving the degreasing strength of the additive manufacturing ceramic part, and is especially suitable for additive manufacturing forming of ceramic parts of complex structures.

Owner:XI AN JIAOTONG UNIV

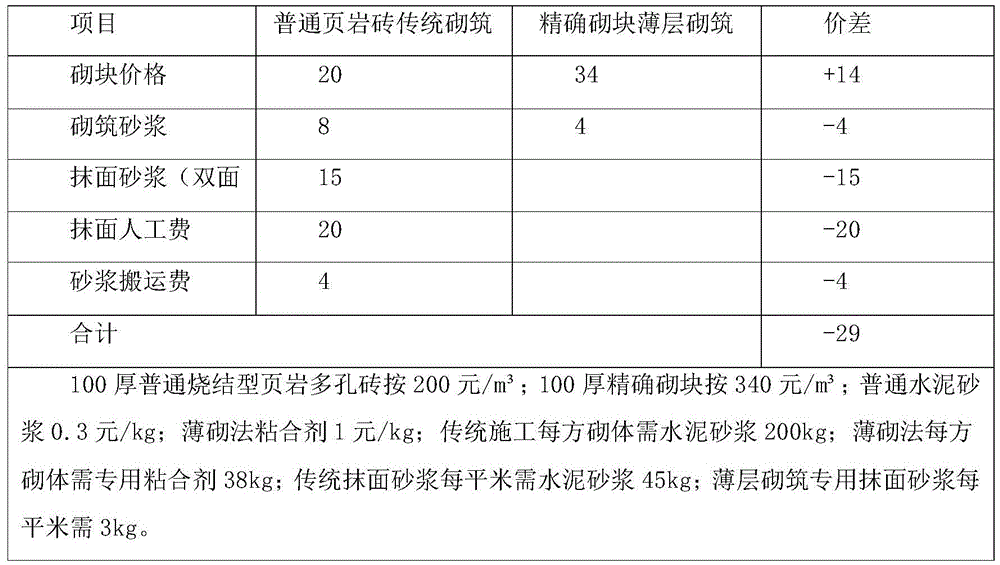

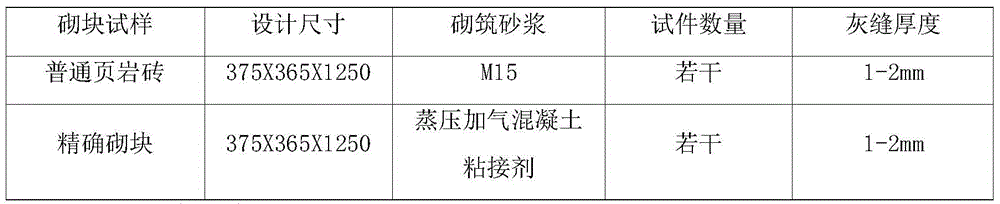

Thin-layer mortar masonry method for autoclaved aerated accurate blocks

InactiveCN105464243AReduce moisture contentReduce dosageWallsReinforced concrete columnThermal insulation

The invention discloses a thin-layer mortar masonry method for autoclaved aerated accurate blocks. The method comprises following steps: (1) base cleaning, positioning, and paying off; (2) block arranging; (3) adhesive mixing; (4) block wall laying through a dry construction manner; (6) the connection of blocks and reinforced concrete columns or the wall; (7) staggered overlapping of upper and lower blocks; and (8) checking and finishing. The construction is carried out through a self-thermal insulation wall dry construction manner by the use of special-purpose adhesives, motor joints are strictly controlled, the correction factor of a heat conductivity coefficient is 1.0, construction processes can be greatly simplified, and an engineering construction period can be shortened. The thin-layer mortar masonry method for autoclaved aerated accurate blocks can solve problems in the prior art that the autoclaved aerated concrete block construction progress is slow and wall cracking and empty phenomena are easily caused due to a wet construction manner.

Owner:重庆市泰日建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com