Early-strength fast-track concrete for repairing cement-concrete road surface

A cement concrete and pavement repair technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of low early strength, high engineering cost, long maintenance period, etc. The effect of reduced quantity, rapid development and stable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

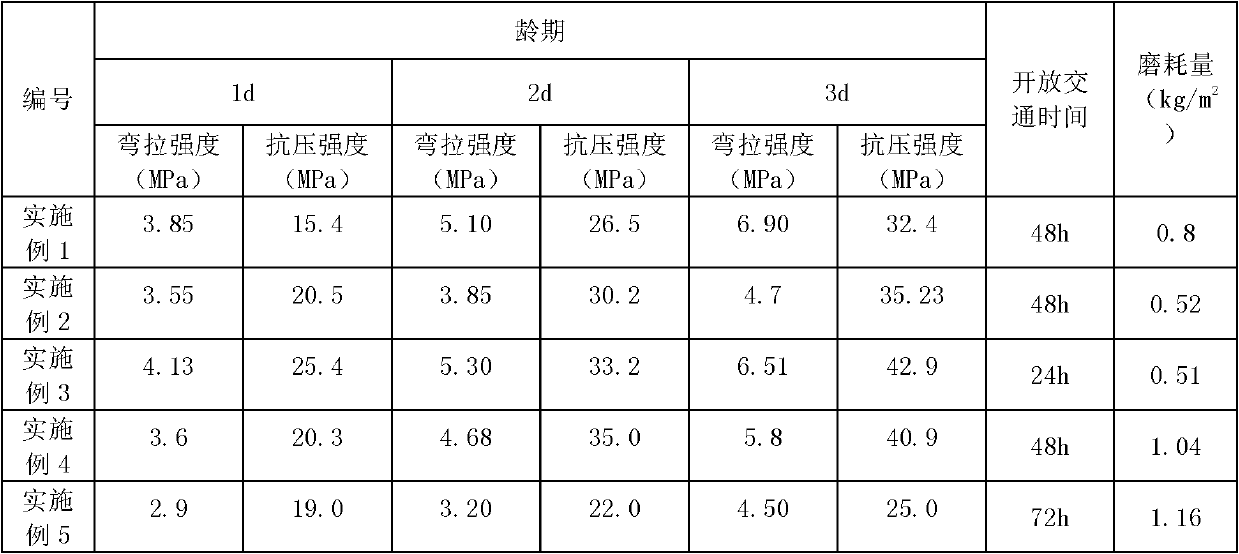

Embodiment 1

[0028] Early-strength and fast-pass concrete for repairing cement concrete pavement, the formula is as follows: PR42. 0.03%, fly ash content 0.5%, silica fume content 0.5%.

Embodiment 2

[0030] Early-strength and fast-pass concrete for repairing cement concrete pavement, the formula is as follows: PR42.5 cement content 16%, water content 7%, sand content 30%, stone content 46%, high-efficiency water reducing agent content 0.04%, early strength agent content 0%, fly ash content 0.4%, silica fume content 0.6%.

Embodiment 3

[0032] Early-strength and fast-pass concrete for repairing cement concrete pavement, the formula is as follows: PR42.5 cement content 15.5%, water content 7%, sand content 30%, stone content 47%, high-efficiency water reducing agent content 0.04%, early-strength agent content 0%, fly ash content 0%, silica fume content 0.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com