Patents

Literature

121results about How to "Rapid early strength development" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

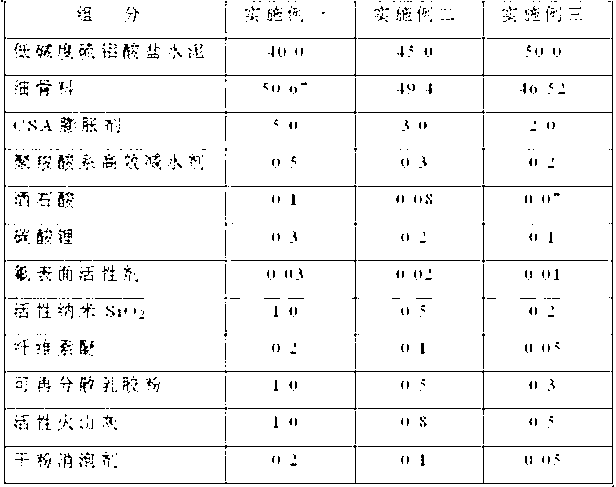

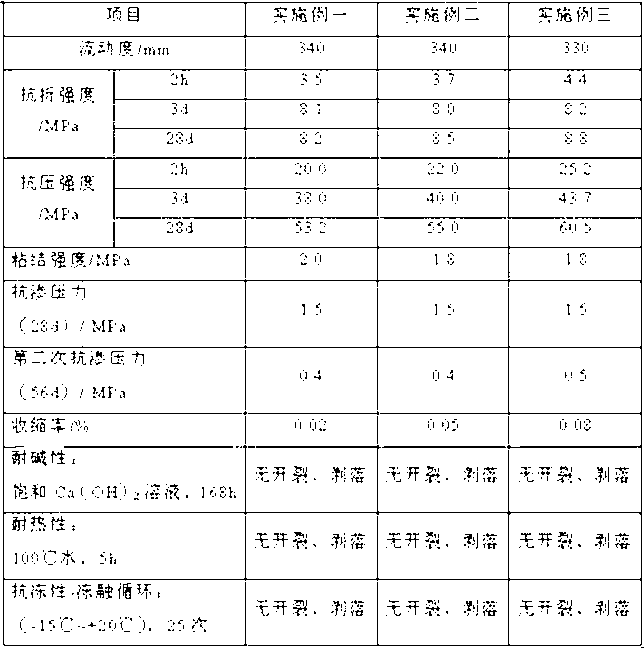

Concrete healant

The invention discloses concrete healant, which comprises following components by weight percent: 30 to 55 percent of gelatinization materials, 40 to 65 percent of fine aggregates, 0.1 to 0.5 percent of water reducing component, 0.05 to 0.5 percent of early-strengthening component, 0.05 to 0.2 percent of delayed-coagulation component, 0.2 to 1.0 percent of nano materials, 0.5 to 1.0 percent of high-activity substances, 0.01 to 0.2 percent of water retention thickening component, 0.2 to 2.0 percent of polymer and 0.02 to 0.2 percent of defoaming agent. The concrete healant not only has characteristics of good mobility, fast strength development, high adhesion strength and small retraction, but also can fill active substances into original concrete gaps and can produce compact crystals, so that the cohesion strength of the new and the old concrete interfaces can be remarkably improved, and the concrete healant is applicable to the concrete mending projects of bridges, caves, industrial workshops and civil construction.

Owner:苏州市姑苏新型建材有限公司

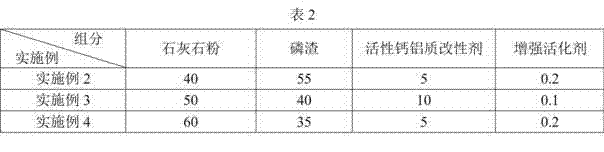

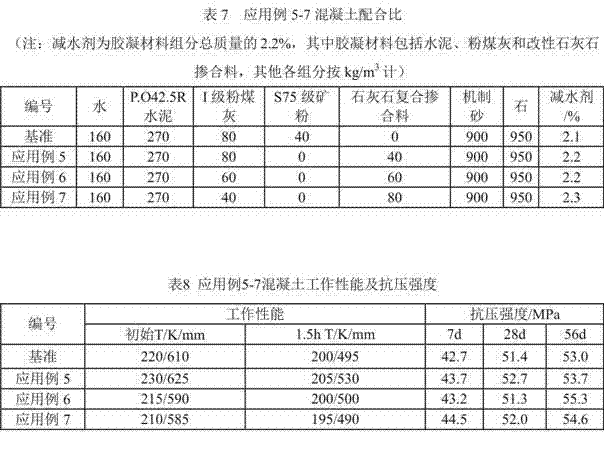

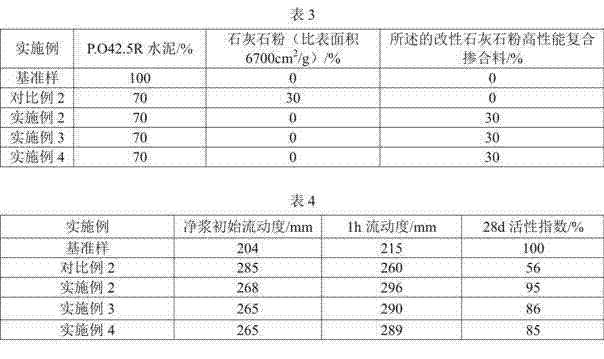

Modified limestone powder high-performance mineral admixture and preparation method thereof

The invention relates to a modified limestone powder high-performance mineral admixture and a preparation method thereof. The invention is characterized in that the modified limestone powder high-performance mineral admixture is prepared by mixing and grinding the following raw materials in parts by mass: 40-60 parts of limestone powder, 35-55 parts of phosphorus slag, 5-10 parts of active calcium aluminum modifier and 0.1-0.2 part of reinforced activator. The concrete mineral admixture prepared by the method solves the problems of high loss of concrete workability, low strength and the like in the common limestone powder admixture; when substituting 50-100% of I-grade fly ash or 20-50% of I-grade fly ash and 100% of S75-grade mineral powder in concrete by equal quality, the concrete mineral admixture can improve the concrete workability, and has the characteristics of quick development of early strength and stable later strength.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

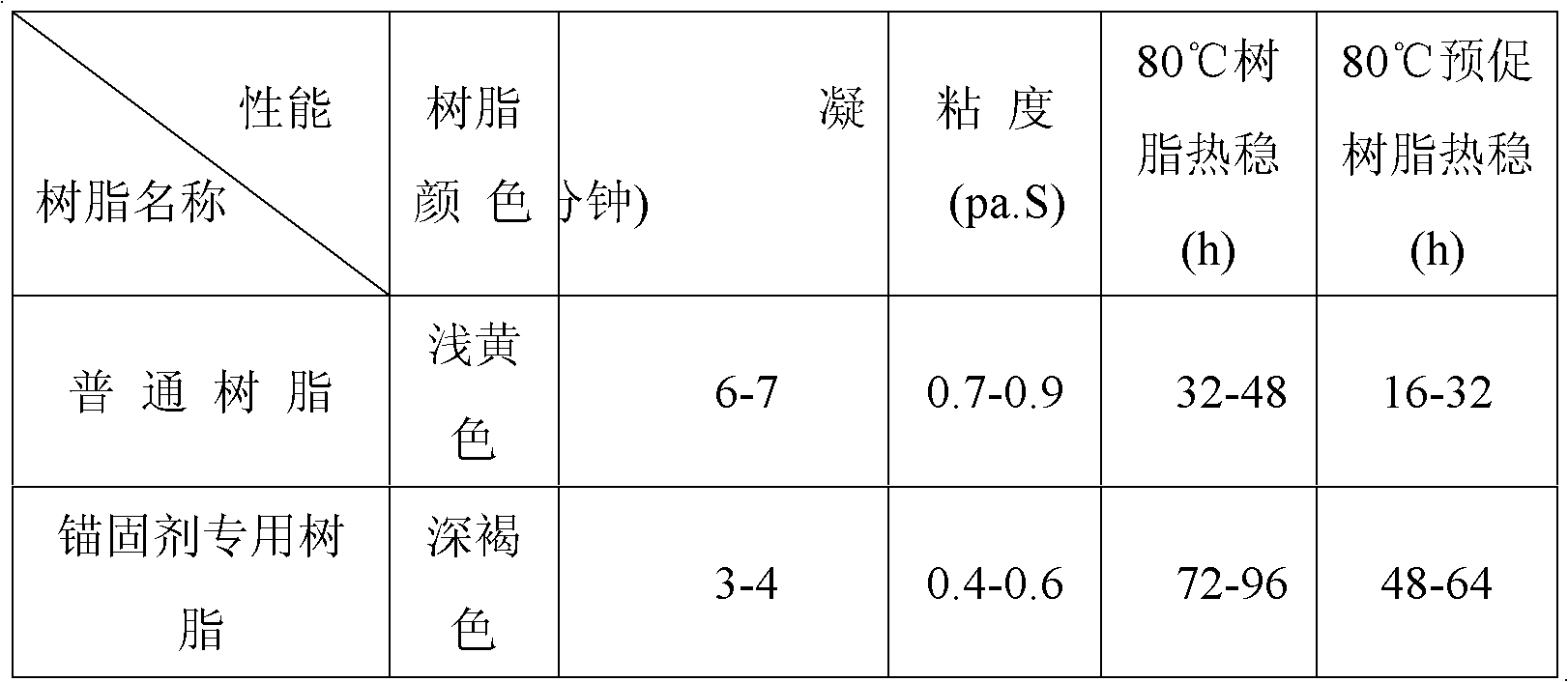

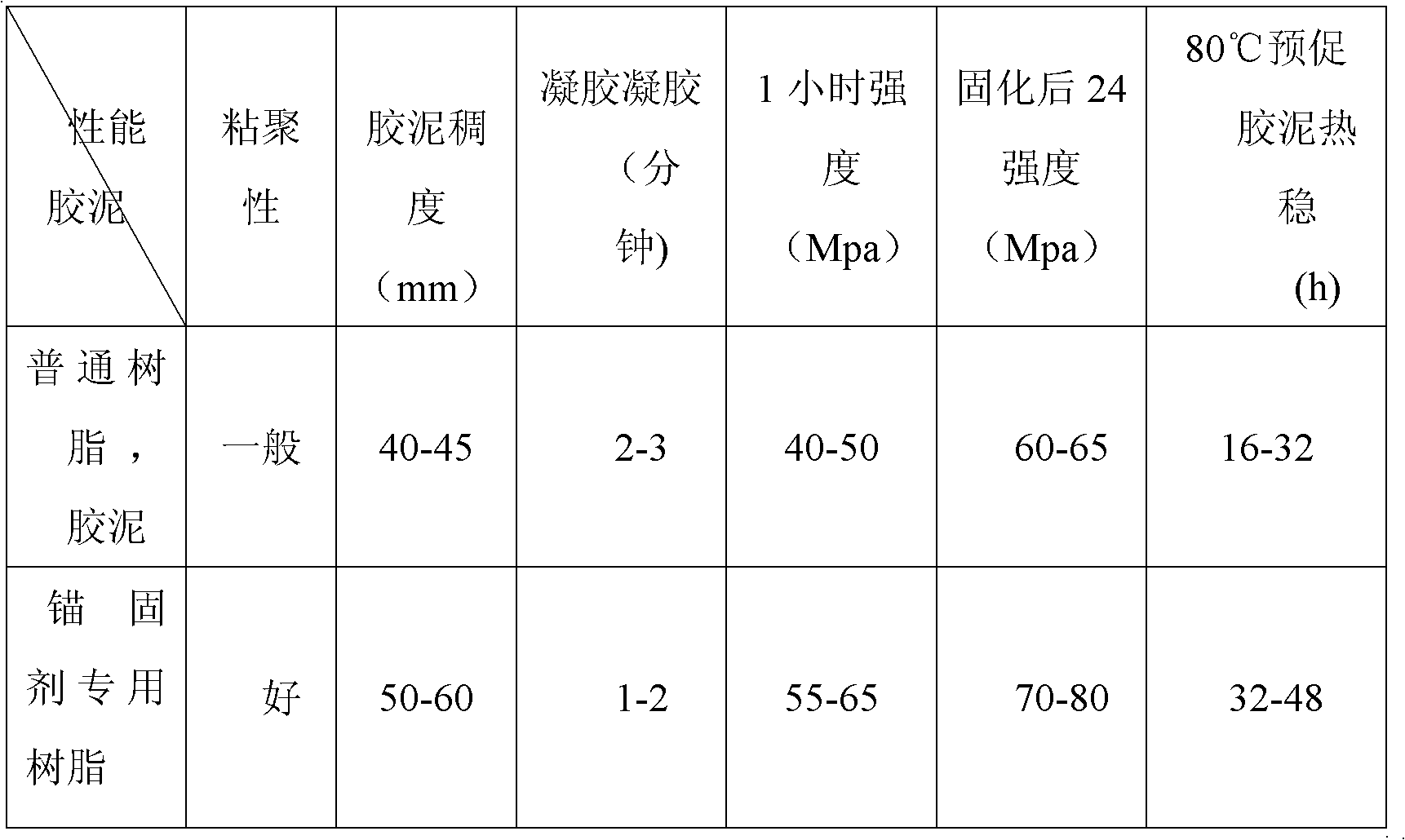

Resin special for anchoring agent and preparation method thereof

The invention discloses a resin special for an anchoring agent and a preparation method thereof. The resin is mainly prepared from terephthalic acid, fumaric acid, abietic acid, maleic anhydride, oxalic acid, glycerol, diglycol, a catalyst, a polymerization inhibitor, a stabilizing additive and styrene according to a certain proportion. A special resin which is most suitable to serve as an anchoring agent product is provided through means such as the adoption of a reasonable production process design formula, the adding of some chemical additives and the like. The gel time of the resin is short and is slightly affected by the temperature, the final curing strength is high, the early strength is quickly developed, the storage stability is high, the resin has high adhesion to mountain flourand has high adaptability to the mountain flour, and the doping amount of the mountain flour is large; and the cost is low, and each ton of the resin is 10 to 20 percent cheaper than each ton of an ordinary unsaturated resin.

Owner:淮南舜天合成材料有限责任公司

Full-solid waste weak concrete material prepared with solid sulphur slag of fluidized bed fire coal

The invention discloses a concrete material which totally adopts industry solids waste to replace cement preparation, comprising a gelled material and a skeletal material. The gelled material is composed of the components with the following weight portions of 36 to 75 portions of fluidized bed burning coal solid sulfur clinker, 9 to 25 portions of acetylene sludge and 6 to 15 portions of phosphogypsum; because the cementing materials such as cement, lime, asphalt, and the like, are not needed at all, material costs are remarkably reduced, great amount of industry solids waste is used to produce building materials, especially the fluidized bed burning coal solid sulfur clinker is used to serve as raw material, environment pollution is avoided, and land resources are saved.

Owner:CHONGQING UNIV

Preparation method of synthetic type polycarboxylic acid water reducer

The invention discloses a preparation method of a synthetic type polycarboxylic acid water reducer. The synthetic type polycarboxylic acid water reducer has a solid content of 40-50%, and is prepared from the following raw materials in parts by weight: 100 parts of unsaturated polyoxyethylene ether, 7-15 parts of unsaturated acid, 4-10 parts of unsaturated ester, 1-3 parts of an amide derivative, 0.5-2 parts of an oxidant, 0.2-1.2 parts of a chain transfer agent, 0.3-2 parts of a reducing agent, 0.1-1 part of a crosslinking agent, 0.01-0.1 part of ferrous sulfate heptahydrate, 5-10 parts of a commercially available mud-resistant auxiliary agent, 90-130 parts of deionized water and an appropriate amount of liquid caustic soda. The preparation method disclosed by the invention adopts a normal-temperature oxidation-reduction initiating system to synthesize the synthetic type polycarboxylic acid water reducer which not only has functions of water reduction and slump loss resistance, but also has functions of mud resistance and early strength, heating is not needed for reaction, the energy consumption is reduced, and the production cost is greatly reduced.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

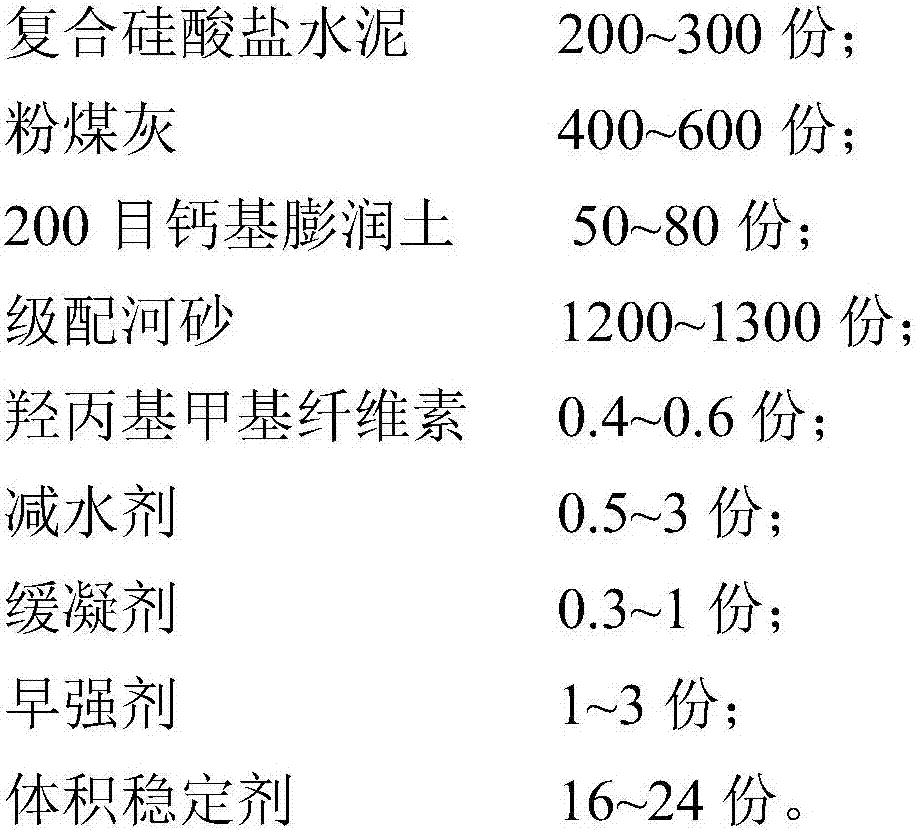

Shield synchronous grouting construction material

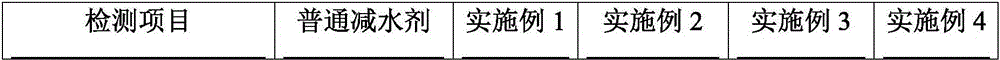

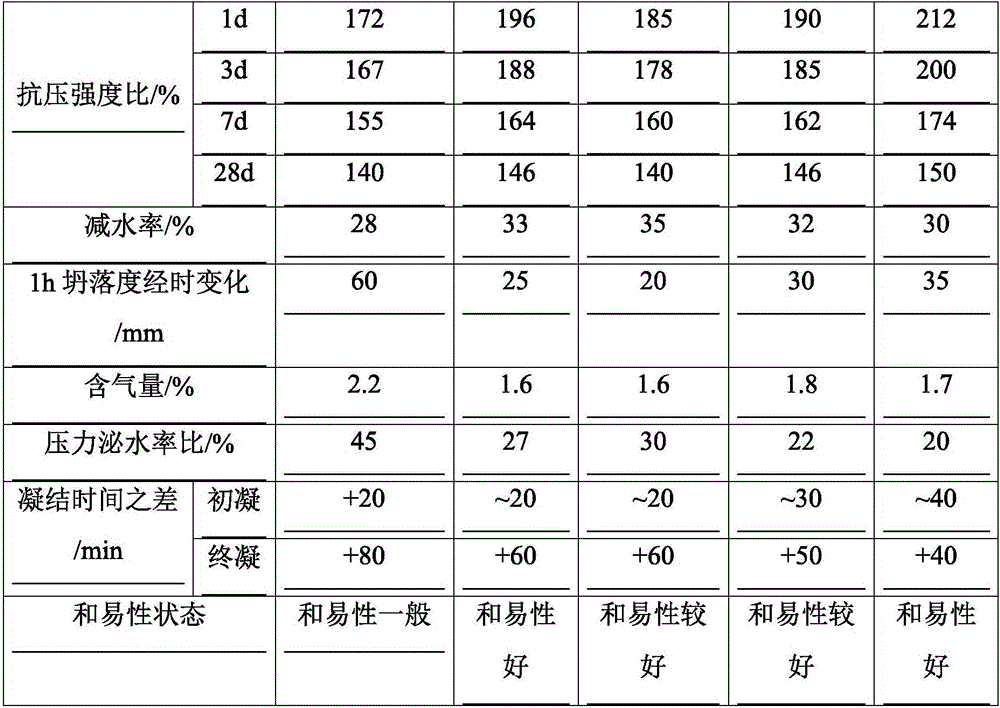

ActiveCN106946522AControl the compressive strengthControl bleeding rateSodium BentonitePortland cement

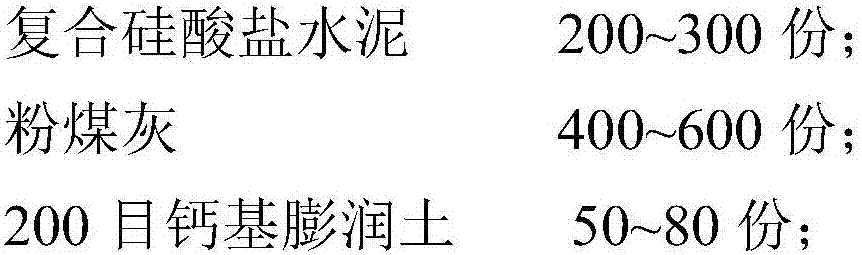

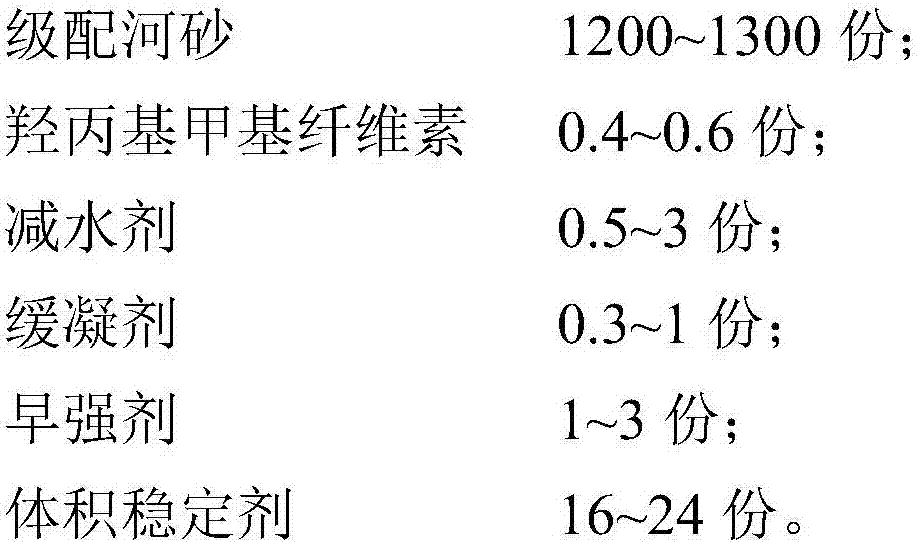

The invention discloses a shield synchronous grouting construction material including, by weight, 200-300 parts of composite Portland cement, 400-600 parts of fly ash, 50-80 parts of 200-mesh calcium based bentonite, 1200-1300 parts of grading river sand, 0.4-0.6 parts of hydroxypropylmethyl cellulose, 0.5-3 parts of a water reducer, 0.3-1 part of a retarder, 1-3 parts of an early strength agent and 16-24 parts of a volume stabilizing agent. Through reasonable adjustment of composition and content of the components, the compressive strength, bleeding ratio, setting time and flowability of the construction material are controlled, so that the construction material has long initial setting time, is quick in early strength development, is not liable to dissociation, has good volume stability, can effectively fill in gaps in buildings and prevent floatation and deformation of tunnel segments, has good flowability and anti-dispersing property, and is easy to transport and to store for a long period.

Owner:北京艺高世纪科技股份有限公司

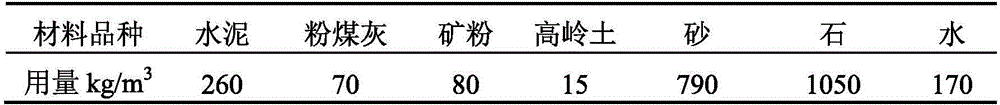

Non-steam autoclaved high performance concrete tube pile using calcium silicate hydrate seed powder as exciting agent, and preparation method of non-steam autoclaved high performance concrete tube pile

InactiveCN105777006ALow costSimple preparation processShaping reinforcementsCalcium silicateHigh energy

The invention belongs to the technical field of building materials, and particularly relates to a non-steam autoclaved high performance concrete tube pile using calcium silicate hydrate seed powder as an exciting agent, and a preparation method of the non-steam autoclaved high performance concrete tube pile. The concrete tube pile is prepared from ordinary Portland cement, mineral additives, the calcium silicate hydrate seed powder, sand, stones, a water reducing agent and an antifoaming agent. According to the non-steam autoclaved high performance concrete tube pile and the preparation method thereof disclosed by the invention, the calcium silicate hydrate seed powder is used as the exciting agent, so that a nucleation potential barrier of cement hydration can be reduced, besides, preferential adsorption nucleation is performed on reactant ions, the cement hydration is promoted, the pozzolanic effect of the mineral additives can also be advanced, the early strength of the concrete is improved from many aspects, and the non-steam autoclaved purpose is realized. According to the non-steam autoclaved high performance concrete tube pile and the preparation method thereof disclosed by the invention, the defects of low early strength, complex production technology, high energy consumption and the like of a conventional high performance concrete tube pile can be overcome, the equipment purchase cost and the equipment maintenance cost can also be reduced, and good economic and social benefits can be achieved.

Owner:TONGJI UNIV

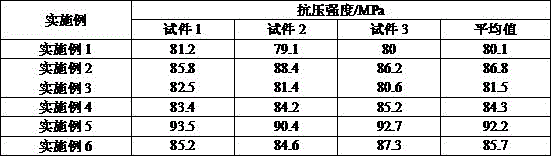

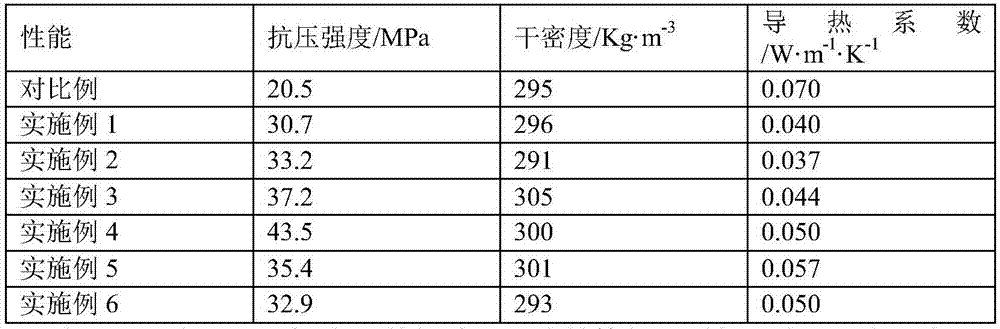

Foam concrete

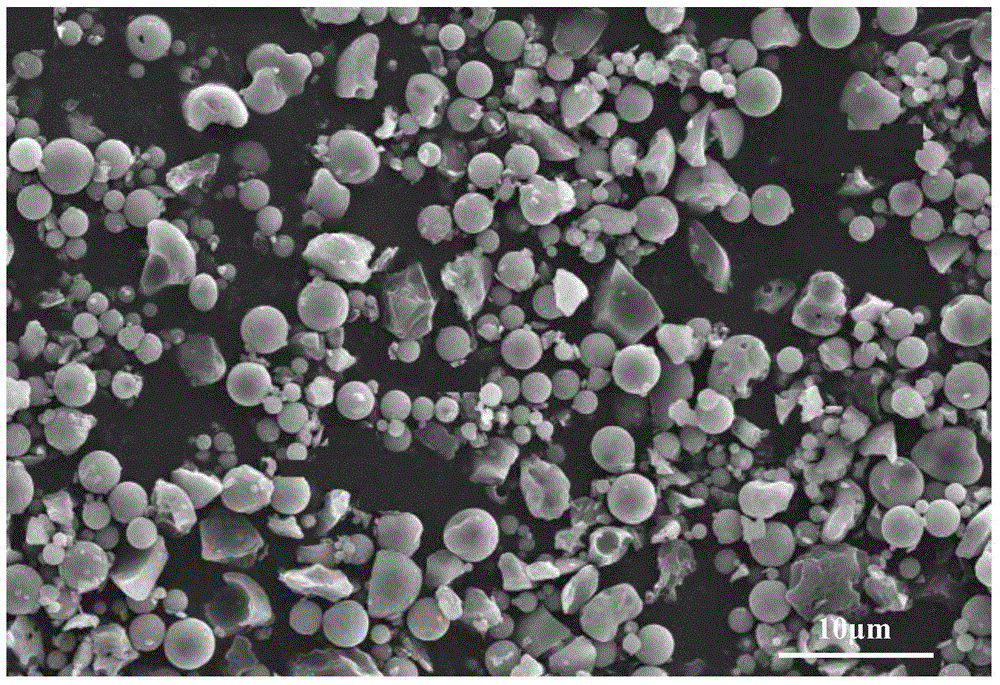

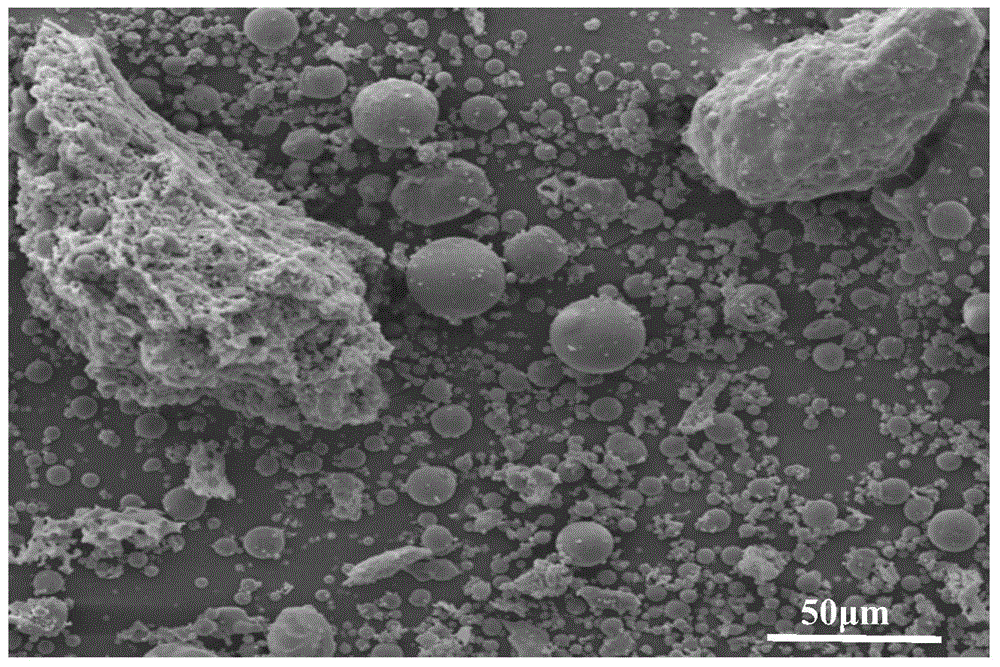

The invention discloses foam concrete. The foam concrete comprises following raw materials in parts by mass according to a formula: 210-300 parts of cement, 1.0-1.5 parts of a water reducing agent, 5.1-5.5 parts of an early strength agent, 2.1-2.9 parts of a coagulant, 1.7-3.4 parts of fibers, 12-20 parts of a chemical foaming agent, 0-90 parts of superfine slag powder and 100-160 parts of water, wherein the superfine slag powder is formed by aluminosilicate glass particles smaller than 15 mu m, and the specific surface area is 450-500 m<2>*kg<-1>. The compressive strength of the foam concrete is improved on the premise that the foam concrete keeps low density.

Owner:BEIJING MINJIA NEW BUILDING MATERIALS CO LTD

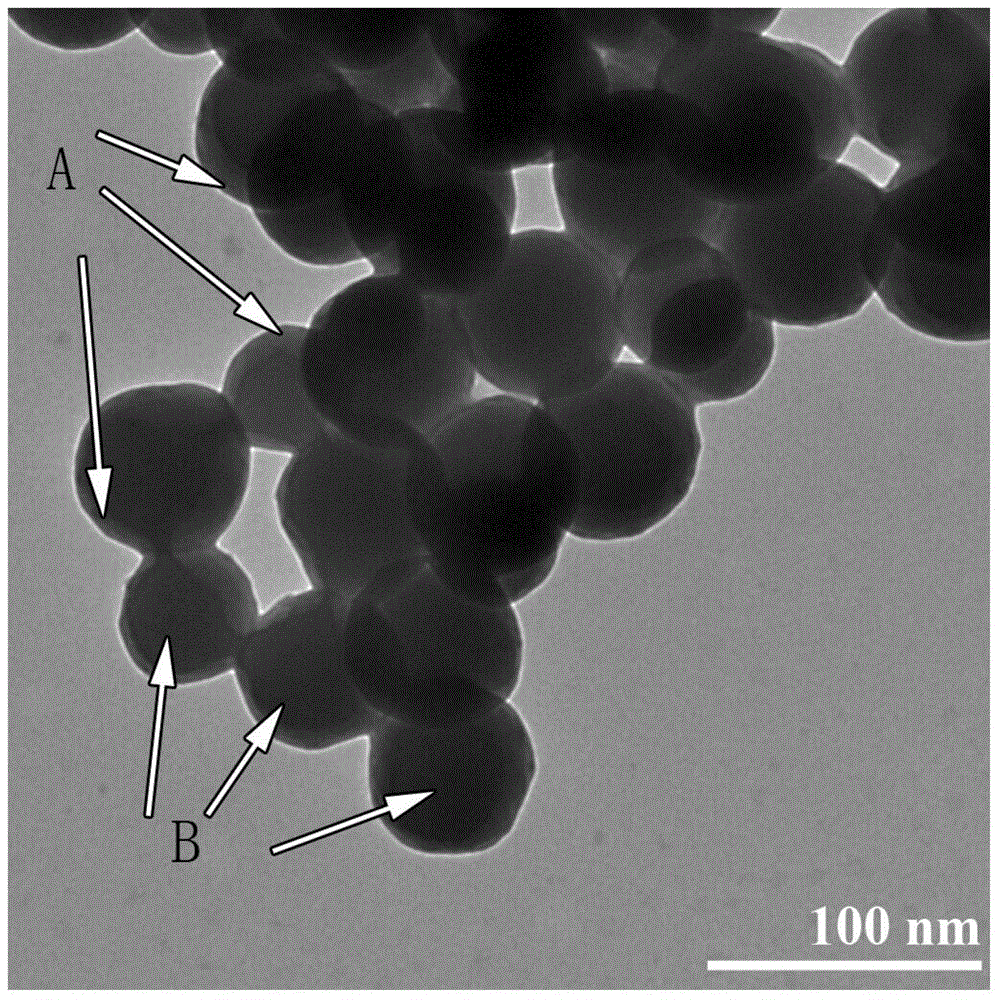

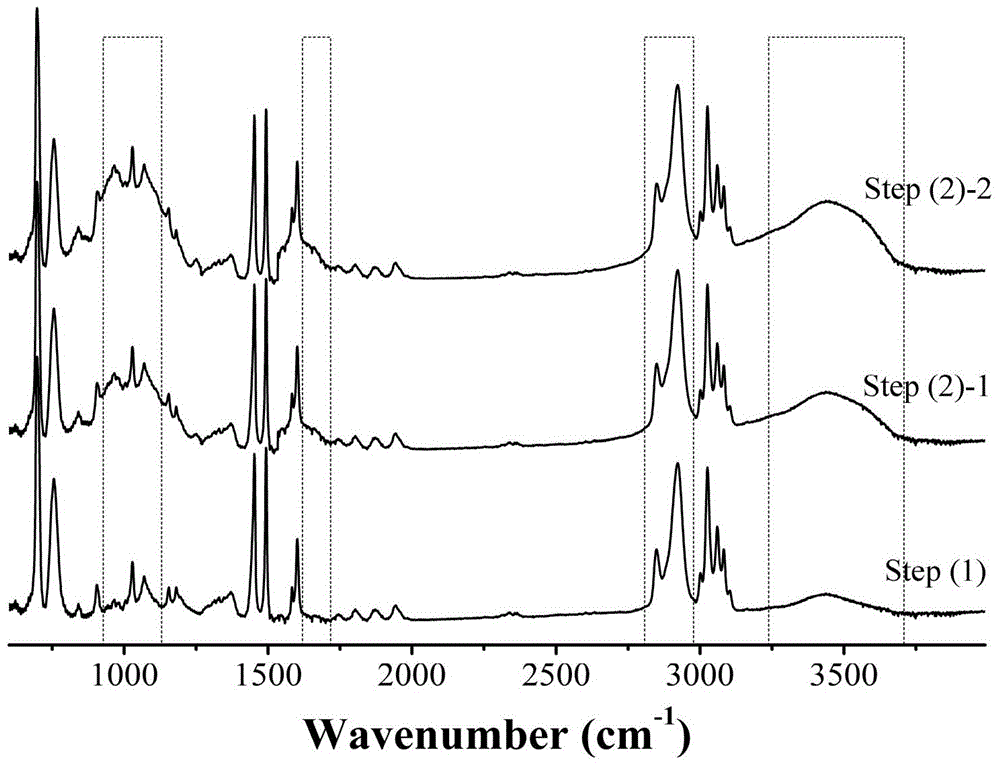

Additive capable of improving bending strength and tensile strength of cement base material and its preparation method

The invention discloses an additive capable of improving bending strength and tensile strength of a cement base material. The additive is an aqueous dispersion of organic-inorganic hybrid particles with core-shell structures. Each organic-inorganic hybrid particle is composed of inner and outer layers, wherein the inner layer is an organic polymer core; the outer layer is an inorganic composite oxide or an inorganic composite oxide covalently connected with an organic functional group; the inorganic composite oxide is a silicon-calcium composite oxide or a silicon-magnesium composite oxide or a silicon-calcium-magnesium composite oxide; and the outer layer is in covalent connection with an electronegative organic polyelectrolyte internally. Compared to the mixing amount of a polymer or polymer fiber in a pure polymer-modified cement base material or a polymer fiber-modified cement base material, the mixing amount of the additive in the cement base material can be greatly reduced; and the additive can more obviously improve the splitting tensile and bending resistant performances of the cement base material in comparison with a traditional polymer emulsion in the same mixing amount. Therefore, the additive overcomes the disadvantage that the high polymer mixing amount of the traditional polymer modified cement base material affects the compressive strength of the cement base material, and can effectively improve the bending strength and tensile strength (or splitting tensile strength) of the cement base material.

Owner:JIANGSU SOBUTE NEW MATERIALS

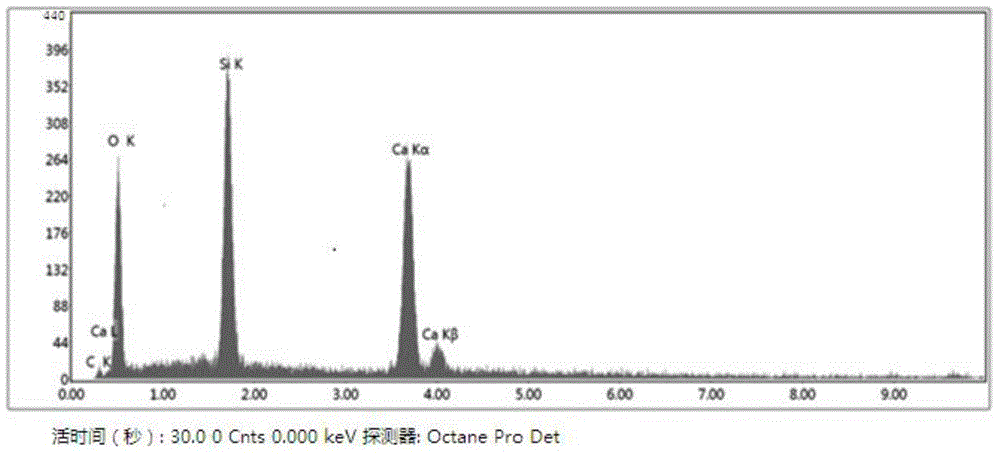

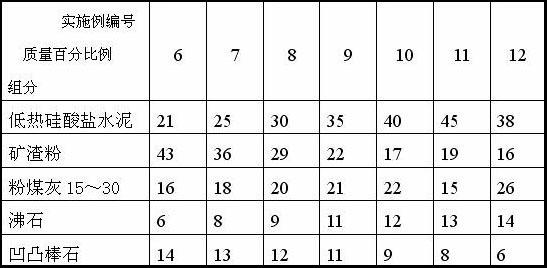

High-salt high-alkali Medium-low-level radioactive liquid waste cement solidified body and preparation method thereof

InactiveCN102169737AStrong adsorption capacityIncrease retention capacityRadioactive decontaminationSlagCoal

The invention discloses a high-salt high-alkali medium-low-level radioactive liquid waste cement solidified body which is composed by mixing the following components: high-salt high-alkali medium-low-level radioactive liquid waste and, solidification material, water glass and cellulose ether, wherein the high-salt high-alkali medium-low-level radioactive liquid waste to the solidification material is 0.55-0.75: 1 in mass proportion; the modulus of the water glass is 2.5-3.5 based on Na2O in the water glass and the mass of the solidification material is 1-3% of the mass of the water glass ; the mass of the solidification material is 0.05-0.5% of the mass of the cellulose ether; the component mass percent of the solidification material is as follows: 20-40% of low-heat Portland cement, 15-50% of slag powder, 15-30% of coal ash, 5-15% of zeolite and 5-15% of attapulgite; and the cement solidification body with various properties meeting the requirements is obtained by carrying out normal-temperature maintenance on the mixed slurry which obtained by mixing and stirring. The high-salt high-alkali medium-low-level radioactive liquid waste cement solidified body is suitable for the solidification of the medium-low-level radioactive liquid waste, which has the total salt concentration being 100-400g / L, the pH value being larger than 13 and the nuclide being 90Sr or / and 137 Cs.

Owner:SOUTHWEAT UNIV OF SCI & TECH

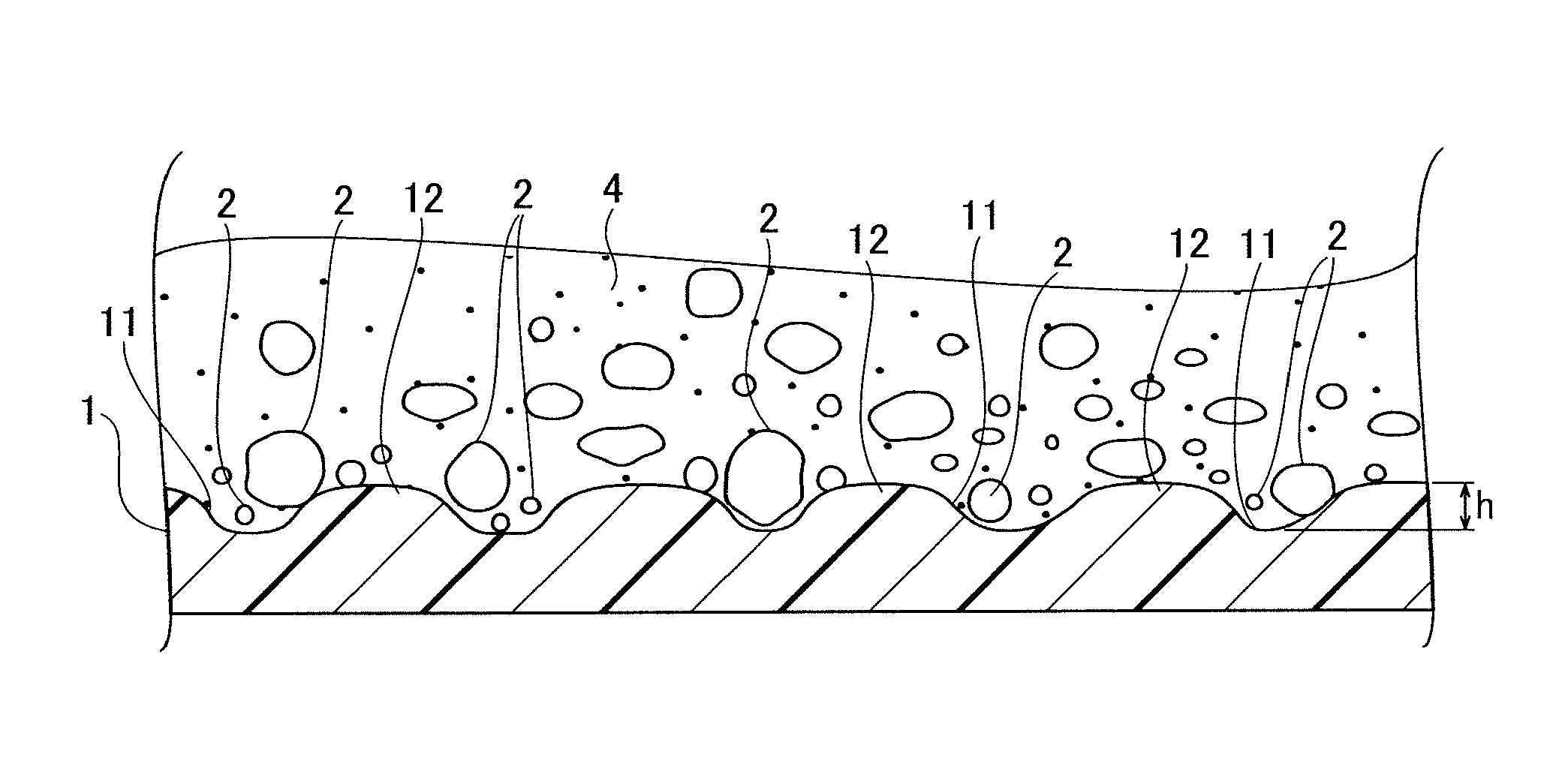

Fiber reinforced cement based mixed material

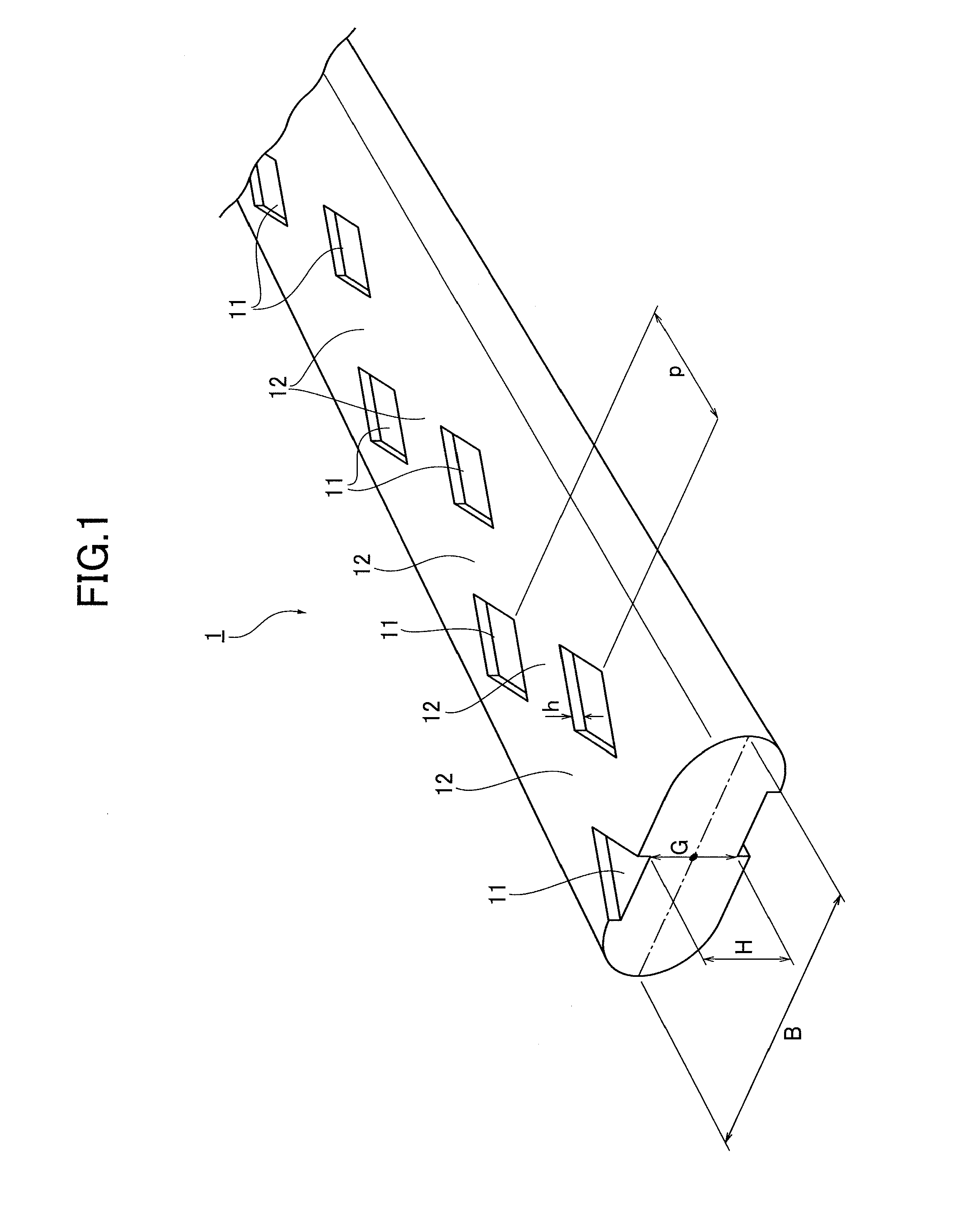

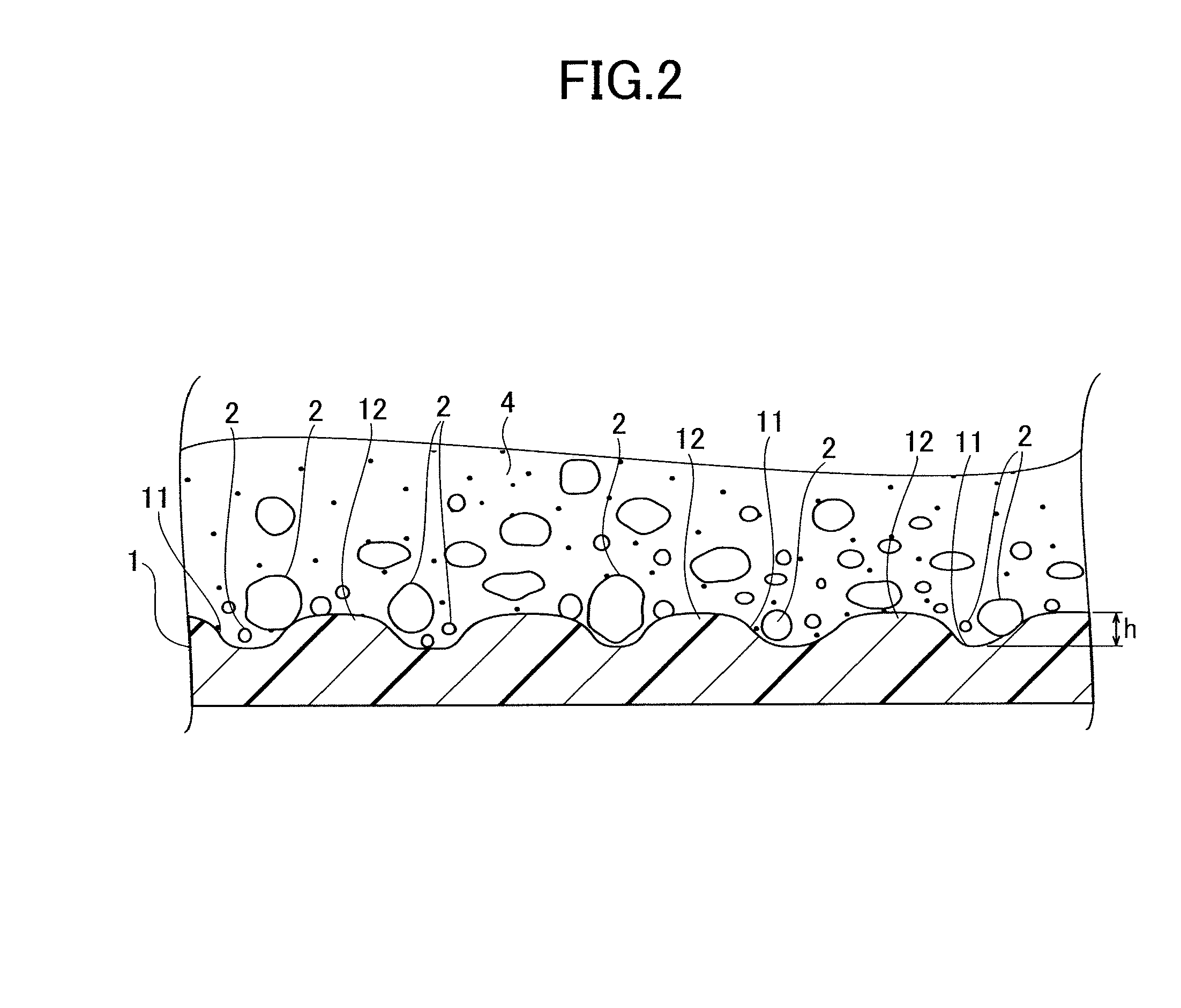

ActiveUS20140326168A1Small amount of shrinkageRapid early strength developmentSolid waste managementChemical admixturePolymer science

Provided is a fiber reinforced cement based mixed material having high tensile strength and high toughness, the mixed material comprising a cementitious composition with fast development of early strength; a small hydration heat temperature; and a small shrinkage during curing. The fiber reinforced cement based mixed material contains 100 wt. parts of cement, 5-30 wt. parts of silica fume, 30-80 wt. parts of at least one pozzolanic material excluding the silica fume, 5-25 wt. parts of limestone powder, at least one chemical admixture, water, 70-150 wt. parts of aggregate having a largest aggregate diameter of 1.2-3.5 mm, and fibers, wherein at least some of the fibers comprise a fiber having asperities formed in the surface, the fiber having asperities being formed such that a ratio (h / H) of a depth h of each of recessed portions among the asperities to a smallest cross-sectional diameter H thereof is 0.05-0.8.

Owner:TAISEI CORP

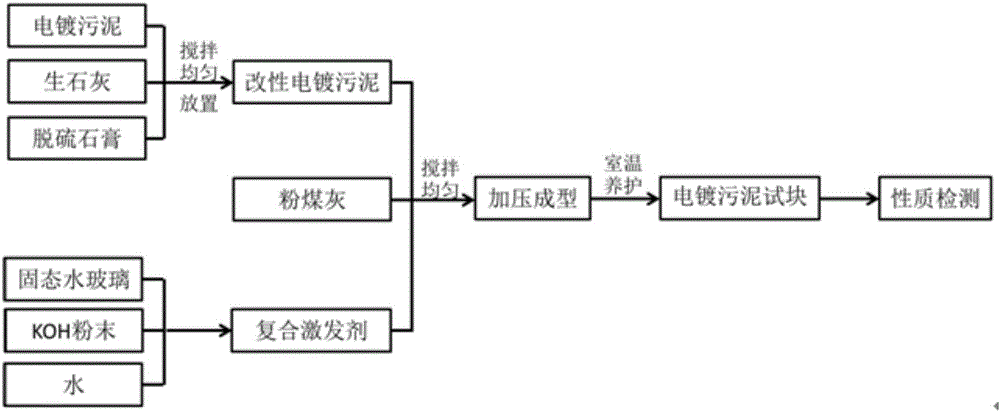

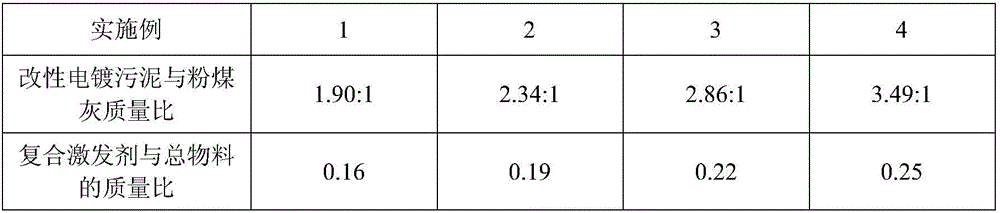

Harmless treatment method for electroplating sludge

ActiveCN105948589AImprove developmentSimple processSolid waste managementCorrosion resistantHeavy metals

The invention belongs to the technical filed of environmental protection engineering and particularly relates to a harmless treatment method for electroplating sludge. The harmless treatment method comprises the following steps: the electroplating sludge is taken, certain amount of quicklime and flue gas desulfurization gypsum is added, crushed sufficiently and stirred uniformly, the mixture is left to stand for a period of time, and modified electroplating sludge is obtained; the modified electroplating sludge and fly ash are taken and stirred uniformly, a certain amount of a composite activator is added and stirred sufficiently again, and a mixture is obtained; an electroplating sludge test block is obtained in a pressure forming manner and cured in a room-temperature environment for 7-28 days, and a solidified electroplating sludge body is obtained. The harmless treatment method adopted for treating the electroplating sludge has the advantages of simple process, low cost, large electroplating sludge curing amount, small capacity increase and the like, meanwhile, the solidified electroplating sludge body obtained after treatment is highly corrosion-resistant, stable for a long time and low in heavy metal leaching toxicity, has certain compressive strength and can be taken as general solid waste to be subjected to landfill treatment.

Owner:SAFECLEEN TECH

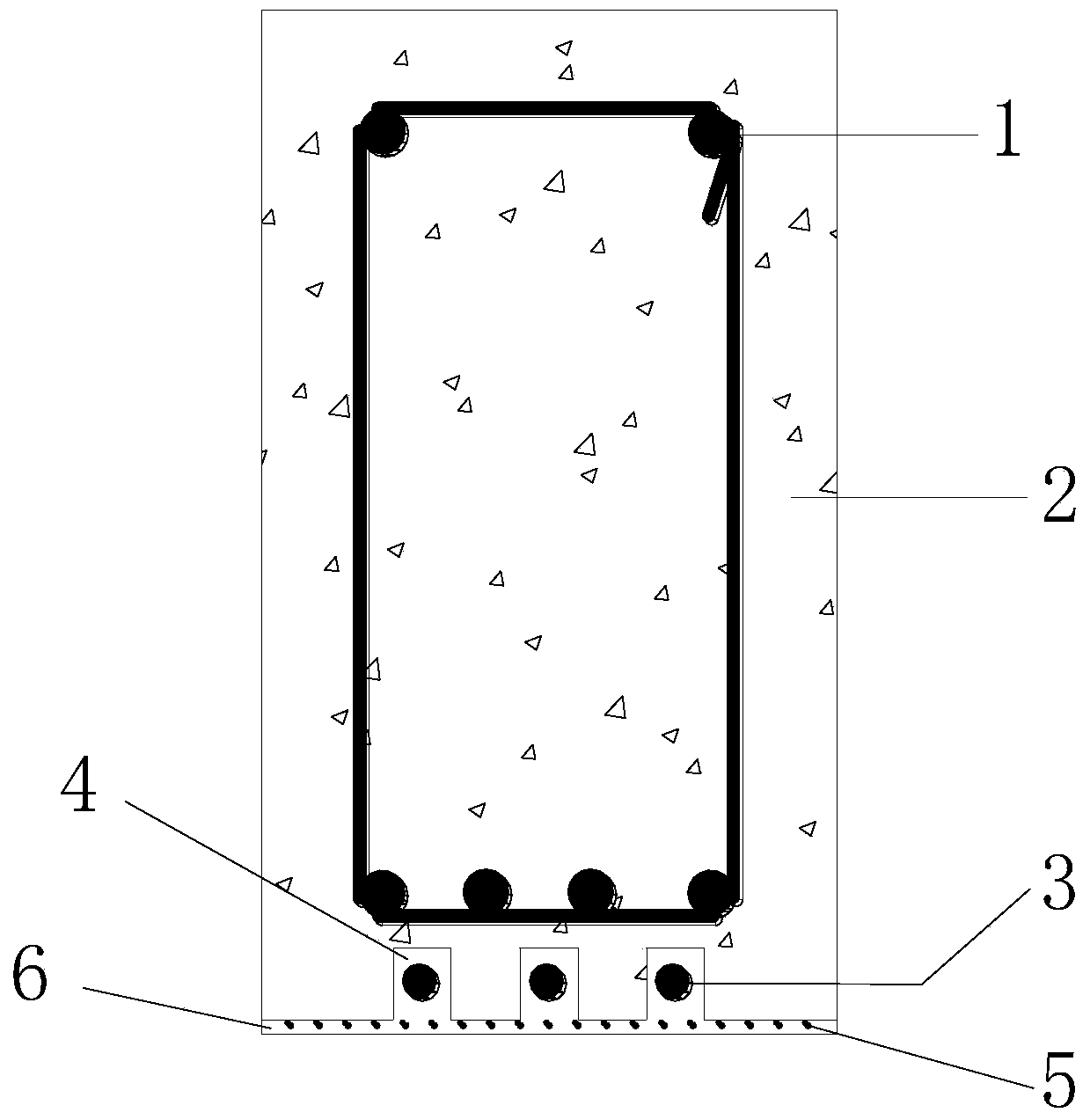

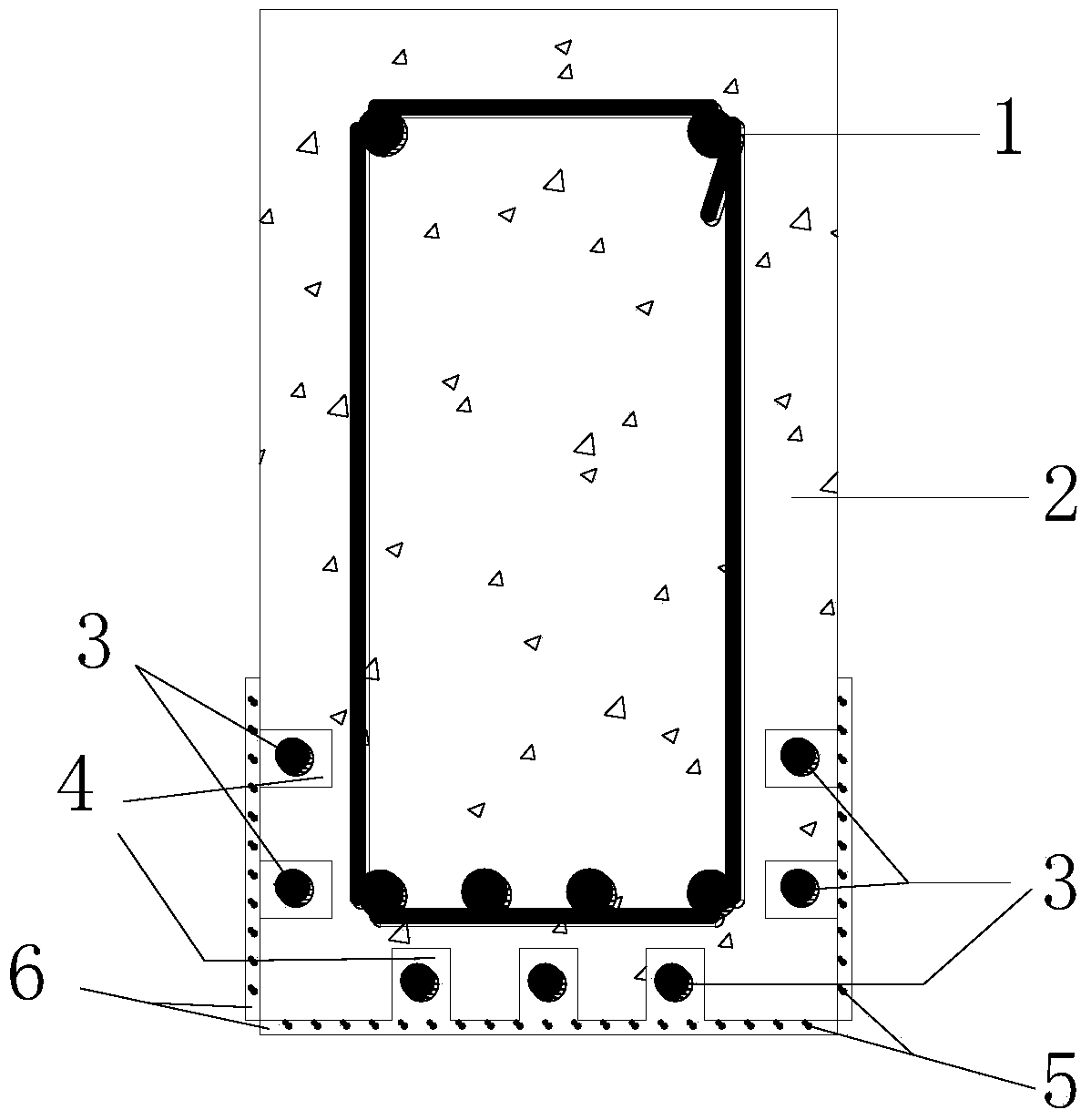

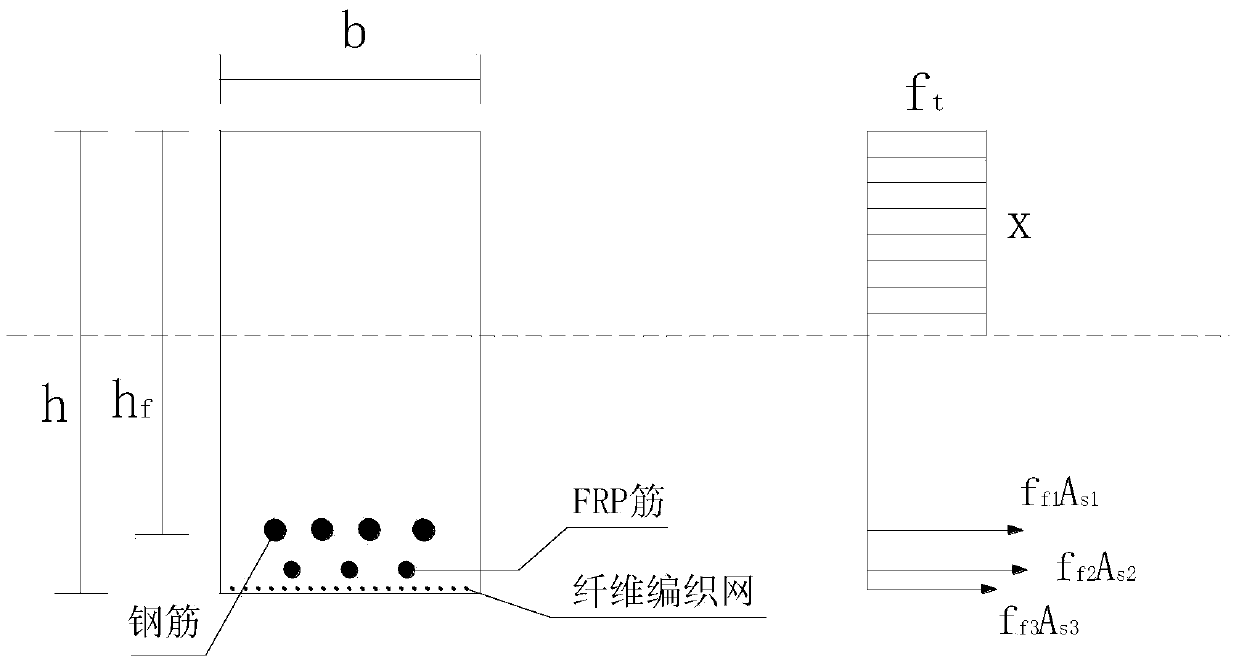

Method for repairing and reinforcing concrete structure under severe environment

The invention provides a method for repairing and reinforcing a concrete structure under a severe environment, and belongs to a method for repairing and reinforcing a concrete structure. The method specifically includes the step of FRP rib reinforcement and the step of fiber woven mesh reinforcement. In the step of FRP rib reinforcement, grooving and dust removing are conducted in a concrete protection layer of a beam to be reinforced through a cutting machine, wherein the surface of concrete is kept dry and is not wet; a half of the portion inside each groove is filled with epoxy resin and epoxy resin curing agents or high-performance fine concrete bonding materials; FRP ribs are placed in the grooves, and the grooves are filled with the bonding materials by slightly conducting extrusion; the surfaces are smeared flat, and operators need to wait till the bonding agents are solidified. In the step of fiber woven mesh reinforcement, firstly, the surface of a building to be reinforced is machined to be uneven; the surface of the building to be reinforced is wetted by water, and stirred fine concrete is sprayed to the structure and the surfaces of fiber woven meshes; a layer of fine concrete is sprayed on each layer of fiber woven mesh each time a layer of fiber woven mesh is laid, and water curing is conduced on the fine concrete through water till the age. By means of the good corrosion resistance of the FRP ribs and the fiber woven meshes, the method is more effective under the severe environment such as ocean.

Owner:CHINA UNIV OF MINING & TECH

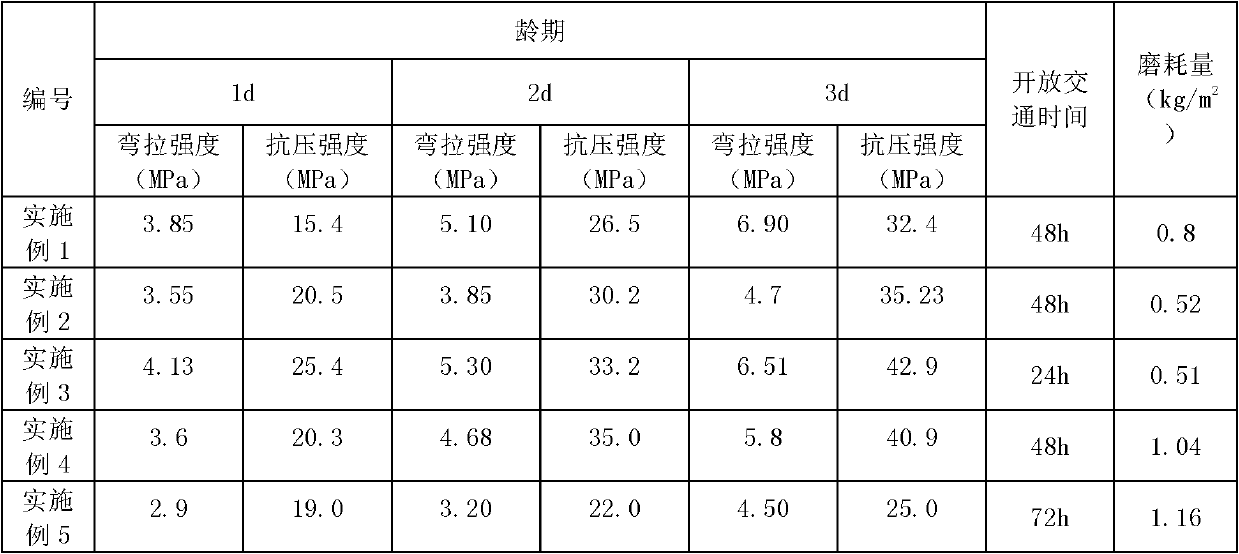

Early-strength fast-track concrete for repairing cement-concrete road surface

InactiveCN102167550AWidely used valueSmall shrinkageSolid waste managementRepair materialRoad surface

The invention relates to early-strength fast-track concrete for repairing a cement-concrete road surface. The early-strength fast-track concrete comprises cement, sand, stone and water, and is characterized by also comprising additives and a mineral admixture, and concretely comprising 10 to 20 percent of cement, 5 to 10 percent of water, 28 to 32 percent of sand, 44 to 48 percent of stone and 0 to 1.0 percent of mineral admixture. The invention overcomes defects of not high early strength, long curing period and traffic impact of the conventional common curing repair material for the cement-concrete road surface and defects of low durability and high construction cost of partial quick curing repair materials, and provides economical and practical early-strength fast-track concrete which meets the requirement of durability of the cement-concrete road surface and quickly cures and repairs the cement-concrete road surface.

Owner:交通运输部公路科学研究院

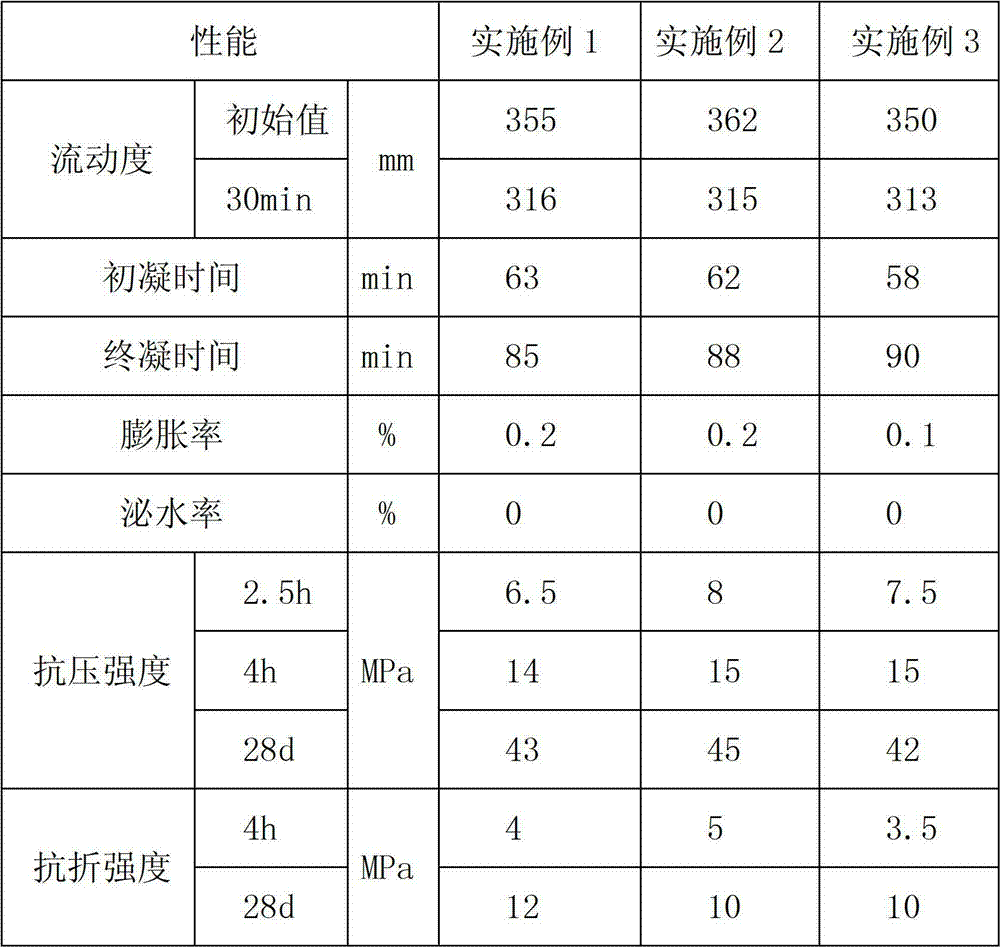

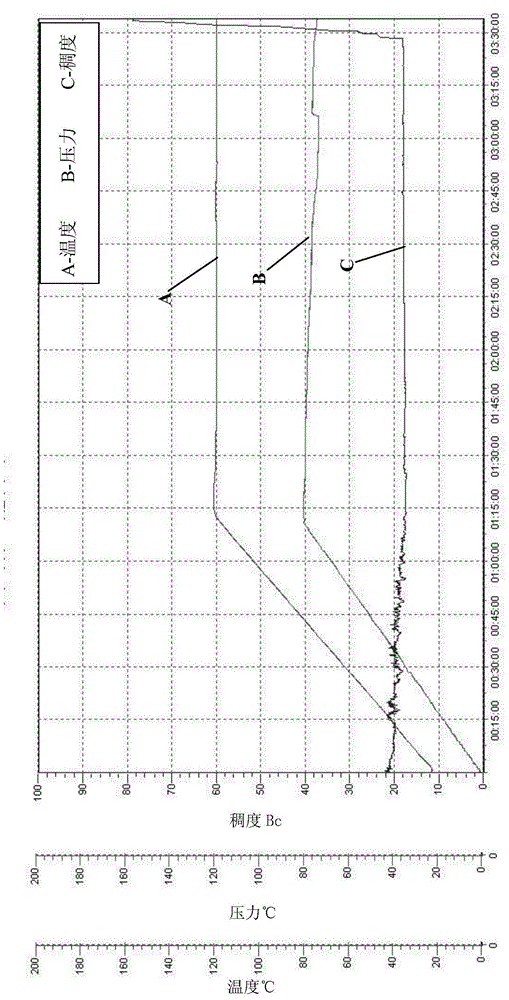

Composite cement-based quick-setting dry material and mortar for maintaining ballastless tracks and method for preparing same

ActiveCN102924021ARapid early strength developmentShort interval between initial and final condensationFiberMaterials preparation

The invention relates to a composite cement-based quick-setting dry material for maintaining plate ballastless tracks. The material comprises, by weight, 25% to 45% of composite cement, 7.8% to 15% of composite mineral admixtures, 0.05% to 0.1% of retarders, 0.05% to 0.11% of antifoaming agents, 0% to 0.01% of water-retaining agents, 0.26% to 1% of thickening agents, 0.1% to 0.16% of a water reducing agent, 0.05% to 0.1% of fibers and 46% to 62.5% of quartz sand. The invention further discloses quick-setting mortar which is manufactured by mixing, by weight, 83% to 86% of the dry material and 14% to 17% of water. The invention further discloses a process which comprises steps of material preparation, material mixing, hydration and the like. The composite cement-based quick-setting mortar can achieve gravity grouting, initial and final setting time intervals are short, early strength develops quickly, later strength is not decreased, no water is secreted, no sedimentation exists, the inflation is tiny, the anti-freezing performance is good, obvious contraction does not exist, and the like.

Owner:CHINA RAILWAY 23RD BUREAU GRP RAILTRANSIT ENG CO LTD

Rolling basalt fiber cement concrete material and construction method for pavement surface thereof

The aim of the invention is to utilize a grinding basalt fiber cement concrete material with good workability and physical mechanics performance and perfect durability. The material is formed by mixing, stirring and grinding of the following components in weight portion: 3 to 5 portions of basalt fiber, 180 to 400 portions of cement, 3 to 5 portions of cement-based capillary crystalline material, 120 to 180 portions of mineral admixture, 0 to 5 portions of water reducing agent, 1750 to 1850 portions of sandstone and 100 to 180 portions of water; when the material is applied to a road surface concrete, the material can improve the tensile strength, impermeability, cracking resistance, shock resistance, deformation resistance, frost resistance and anti-fatigue of the concrete road surface, and the material also has the advantages of easy construction, reasonable price and suitable popularization and application. The invention also provides a construction method for utilizing the grinding basalt fiber cement concrete material as a road surface.

Owner:CHONGQING UNIV

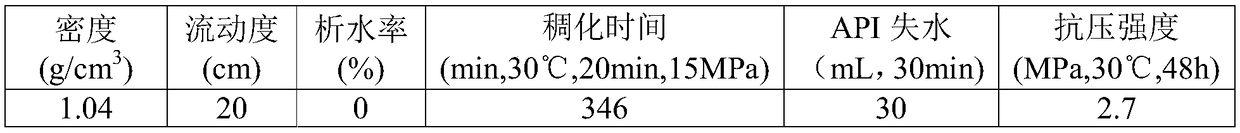

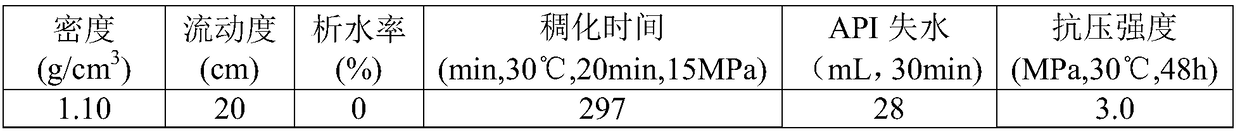

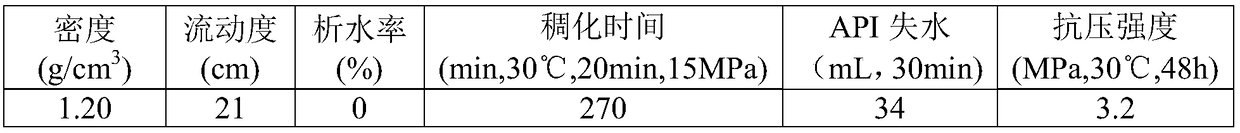

Ultralow-density cement paste system for well cementing

InactiveCN109265093AReduce water lossWith low temperature quick settingDrilling compositionPalygorskiteWell cementing

The invention discloses an ultralow-density cement paste system for well cementing. The system comprises, by weight, 100 parts of oil well cement, 5-8 parts of micro silicon, 0-4 parts of oil well ultrafine cement, 25-40 parts of lightening materials, 2-5 parts of suspension stabilizer, 0-5 parts of coagulant, 1.0-1.2 parts of fluid loss agent, 1.0-1.5 parts of dispersing agent and 95-125 parts ofwater, wherein the particle size of the micro-silicon is 0.2-2 micron; the lightening materials comprise at least two of sodium bentonite, palygorskite, expanded perlite, hollow glass beads and hollow ceramic micro-beads. The ultralow-density cement paste system for the well cementing is suitable for well cementing operation of a low-pressure stratum which is likely to leak, and the manimum density can be 1.04 g / cm<3>. The ultralow-density cement paste system has the advantages of being rapid in setting at low temperature, rapid in strength development in the early stage, good in sedimentation stability and low in water loss.

Owner:CNPC BOHAI DRILLING ENG

Cement concrete admixture for quickly repairing cement concrete roads

InactiveCN101708969ARapid early strength developmentReduce maintenance traffic timeRoad surfaceMaterials science

The invention belongs to the technical field of cement concrete admixtures. A cement concrete admixture for quickly repairing cement concrete roads consists of the following components in percentage by weight: 70 to 90 percent of inorganic basis material, 10 to 30 percent of early strength admixture, 5 to 20 percent of water reducing agent, 0 to 20 percent of cement-coagulation agent and 0 to 5 percent of rust inhibitor. The admixture can ensure that the traffic opening time of the maintenance of cement concrete pavements is shortened to 8 hours, has the characteristics of high early strength, no shrinkage at later stages, adjustable hardening and setting time, wide applicable temperature range, low mixing amount and the like, and is mainly applicable to the quick construction of engineering maintenance such as various airport runways, concrete pavements of highways, bridges, culverts, tunnels and the like.

Owner:惠州市富力新技术有限公司

Construction waste recycled concrete

The invention relates to construction waste recycled concrete, and belongs to the technical field of concrete. The construction waste recycled concrete comprises fly ash, stone powder, recycled coarseaggregate, recycled fine aggregate, an early strength agent, a water reducing agent, an air entraining agent and a reinforcing component, wherein the recycled coarse aggregate is formed by crushing and screening waste bricks; the recycled fine aggregate is formed by crushing and screening waste concrete; and the reinforcing component comprises basalt fibers, polypropylene reticular fibers, metakaolin and a CABR-MS605 corrosion inhibitor. According to the technical scheme, the impermeability of the recycled concrete can be improved.

Owner:BEIJING GAOQIANG CONCRETE

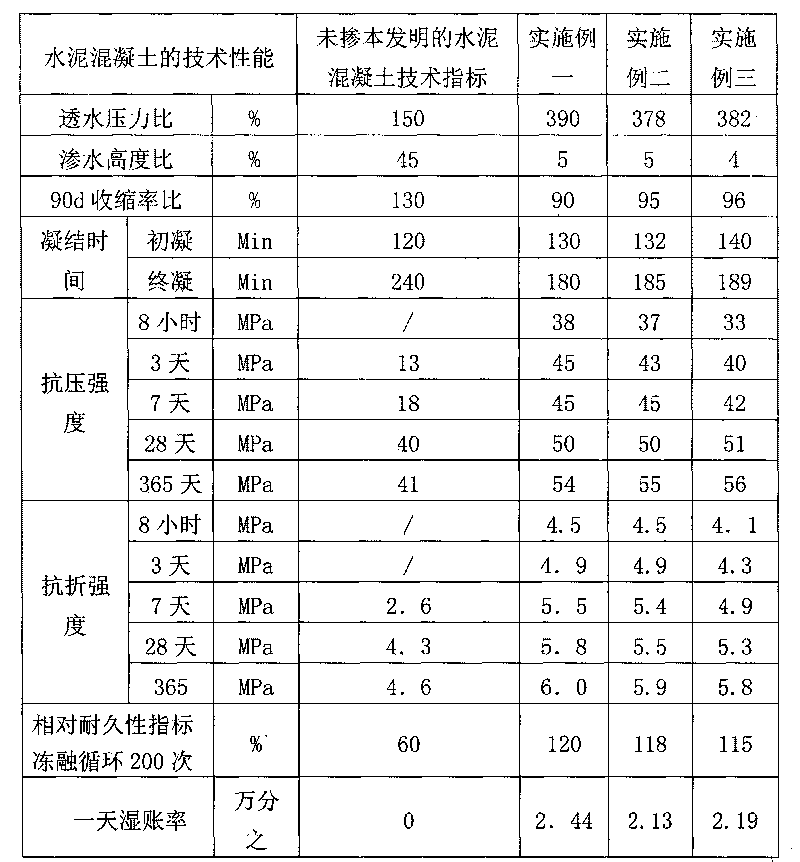

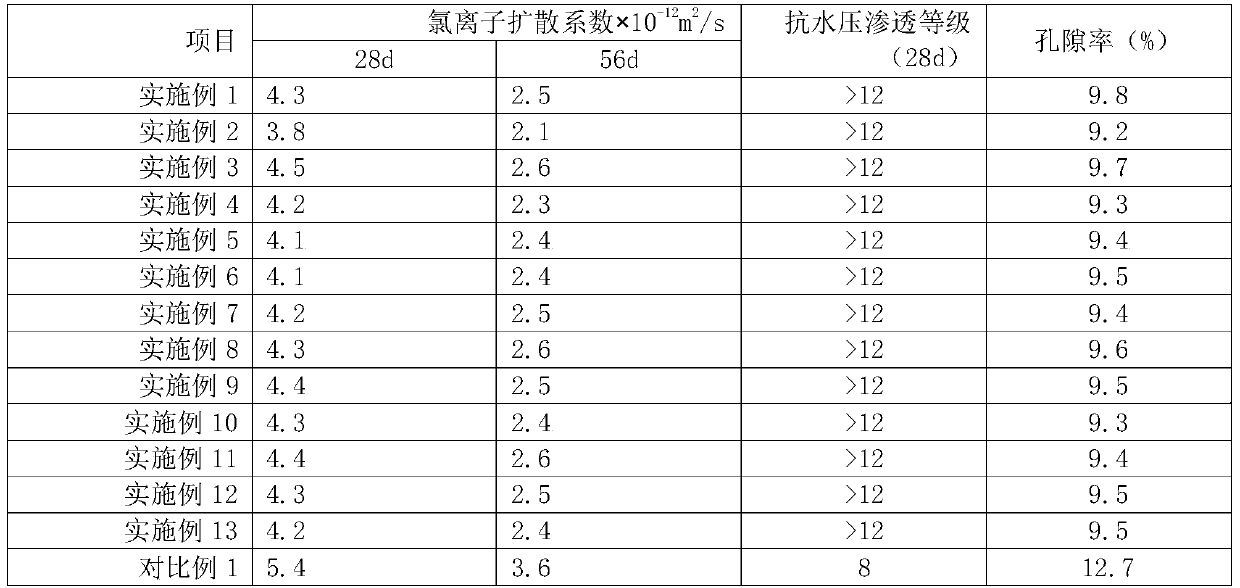

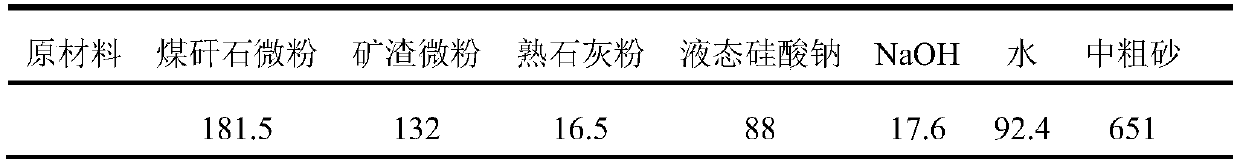

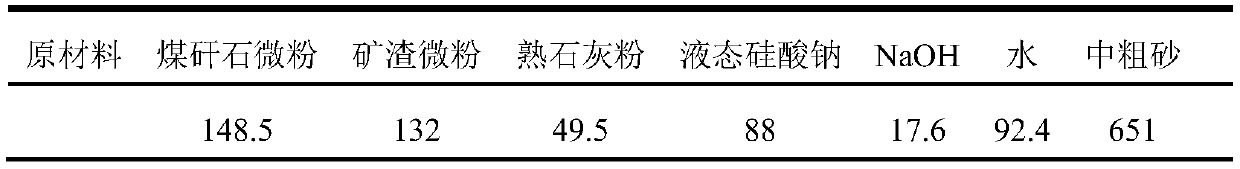

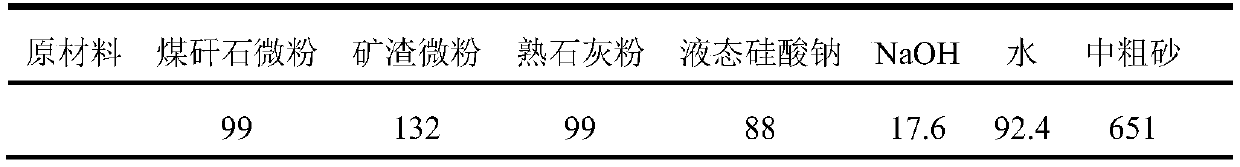

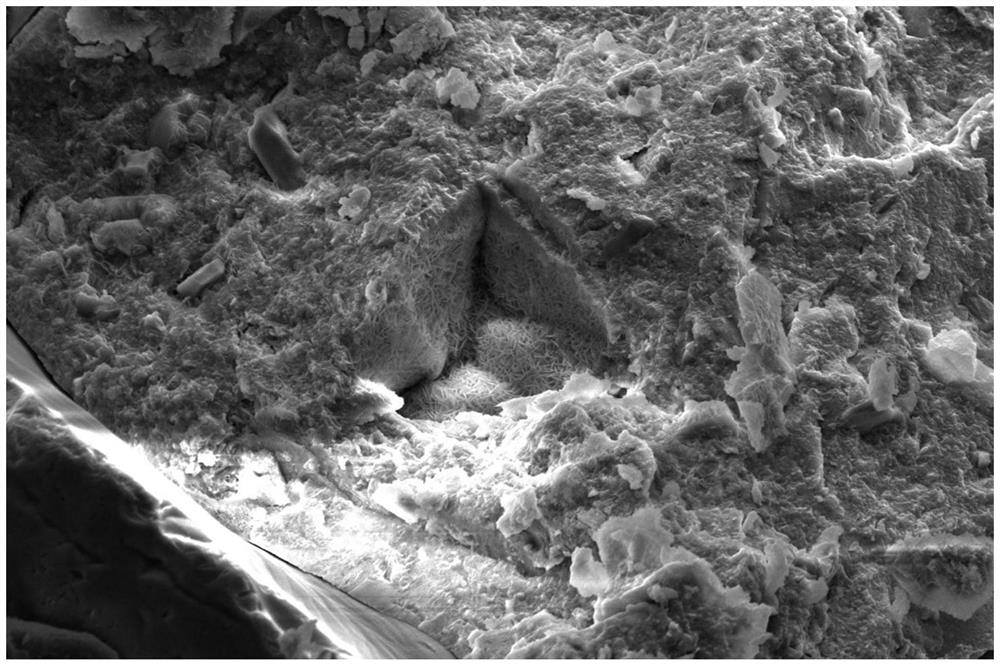

Preparation method of quick setting and rapid hardening gangue alkali-activated rapid repairing material

The invention relates to a preparation method of a quick setting and rapid hardening gangue alkali-activated rapid repairing material. The content of active calcium is increased by doping an appropriate amount of hydrated lime powder, the process of a polymerization reaction and formation of polymer products are promoted, the setting time of the coal gangue alkali-activated material is obviously shortened, the early strength is greatly improved, and finally application of the coal gangue alkali-activated material in serving as a rapid repairing material in engineering. The coal gangue alkali-activated rapid repairing material can adjust the setting time by itself, the excellent cohesiveness, early strength and high strength characteristics are achieved, and the material is very suitable for serving as the rapid repairing material for use. The coal gangue alkali-activated rapid repairing material can replace a cement repairing material for use, not only can the environmental pollution problem caused by large accumulation of waste coal gaugue can be eliminated, but also excessive dependence on cement can be relieved, and excessive consumption of non-renewable resources is reduced, and the method has great significance to countries such as China serious in energy shortage and environmental pollution.

Owner:ANHUI UNIV OF SCI & TECH

Nano-modified ultrahigh-strength steel fiber concrete and preparation method thereof

InactiveCN112960956AImprove interface microstructureImprove mechanical propertiesSilica fumeGraphite oxide

The invention discloses nano-modified ultrahigh-strength steel fiber concrete and a preparation method thereof, and relates to the technical field of building concrete. The concrete disclosed by the invention is prepared from the following components in parts by weight: 370 to 420 parts of Portland cement, 80 to 120 parts of mineral powder, 30 to 50 parts of fly ash microbeads, 30 to 60 parts of silica fume, 12 to 20 parts of a high-performance water reducing agent, 40 to 160 parts of steel fibers, 0.05 to 0.25 part of graphene oxide, 3 to 20 parts of nano silicon dioxide, 600 to 800 parts of sand, 900 to 1100 parts of stones and 110 to 130 parts of tap water. The nano-modified ultrahigh-strength steel fiber concrete provided by the invention contains the substances such as the steel fiber, the graphene oxide and the nano silicon dioxide, so that the interface microstructure of set cement and aggregate can be improved, and the mechanical property, the impermeability and the durability of the concrete can be remarkably improved.

Owner:SHENZHEN UNIV

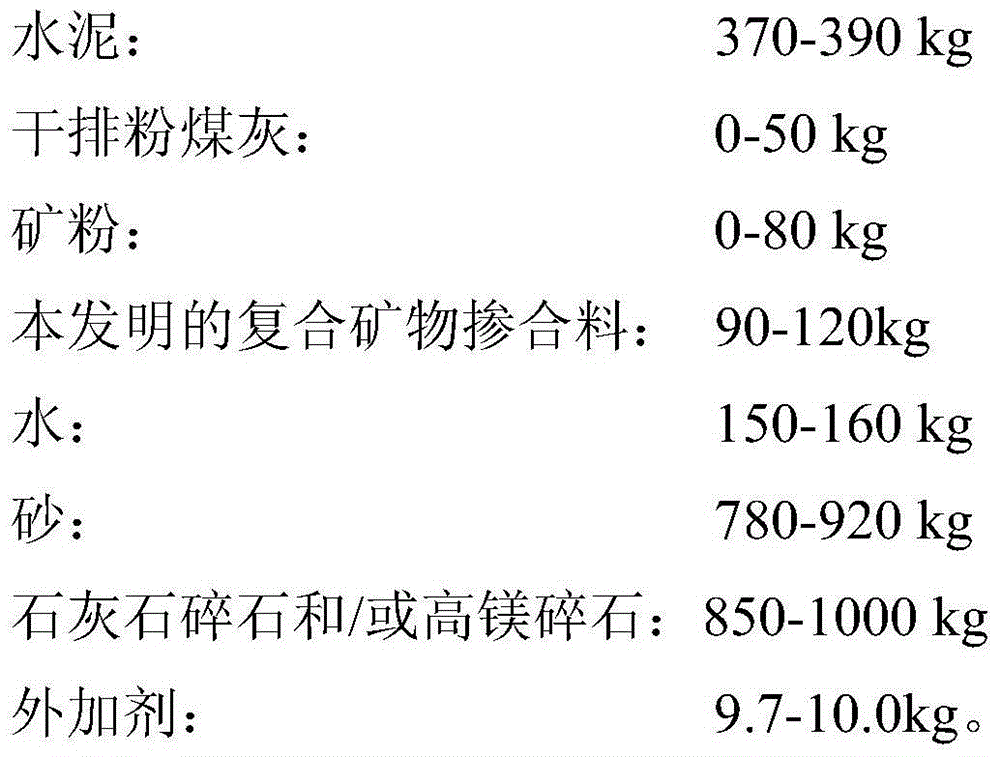

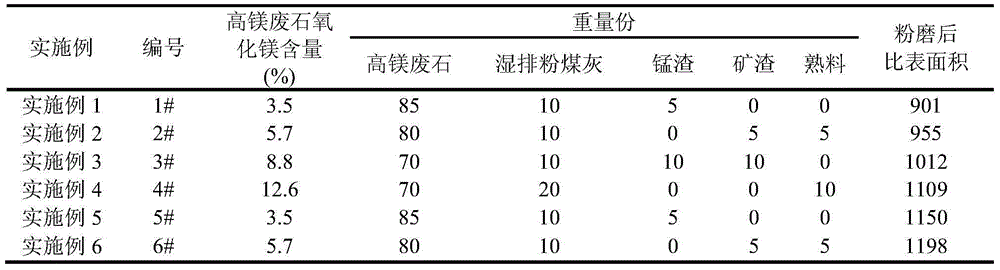

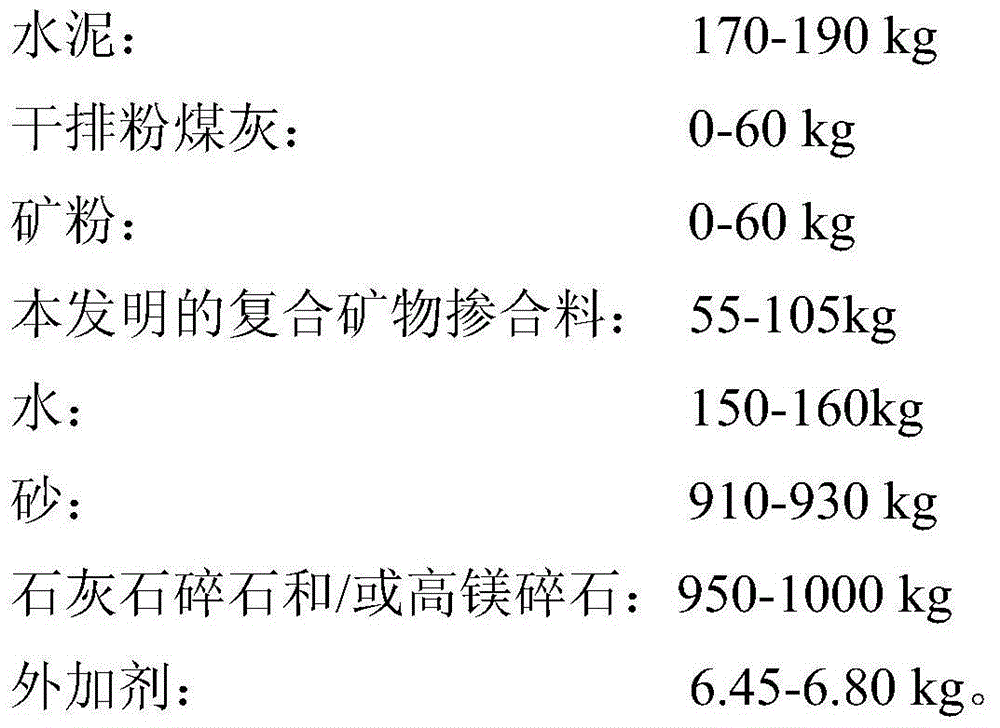

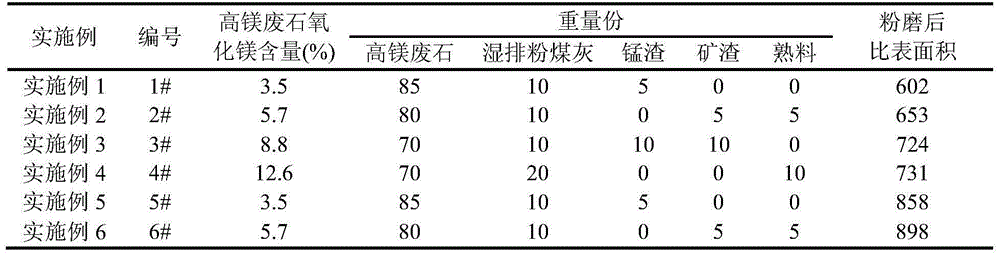

Waste high-magnesium rock flour-based composite mineral admixture and application of same in high-strength concrete

The invention discloses a waste high-magnesium rock flour-based composite mineral admixture and application of the same in high-strength concrete. A preparation method for the admixture comprises the following steps: (1) drying waste high-magnesium rock, wet discharged fly ash and manganese slag until water content is lower than 1.0%; and (2) separately grinding 70 to 85 parts by weight of the dried waste high-magnesium rock, 10 to 20 parts by weight of the dried wet discharged fly ash, 0 to 10 parts by weight of the dried manganese slag, 0 to 10 parts by weight of mineral waste residue and 0 to 10 parts by weight of clinker, and then carrying out mixing or carrying out mixing and then grinding until the specific surface area of the obtained mixture is 901 to 1200 m2 / kg so as to obtain the waste high-magnesium rock flour-based composite mineral admixture. According to the invention, the morphological effect and filling effect of the waste high-magnesium rock flour are utilized to improve compactness of a concrete mixture and fluidity of concrete; slump loss is small, and adsorption of additives like polycarboxylic acid is low; and early strength of the concrete develops fast, and later strength of the concrete develops steadily. Moreover, both the admixture provided by the invention and coarse and fine waste high-magnesium rock aggregate can be applied in the concrete, so the utilization rate of the waste high-magnesium rock is substantially increased.

Owner:华润水泥技术研发(广西)有限公司

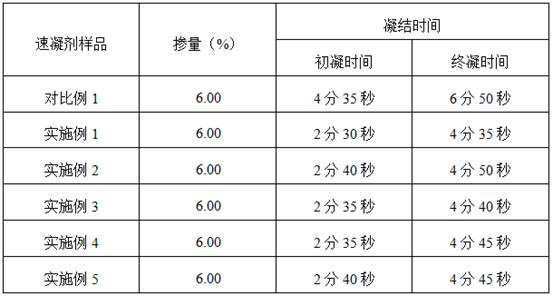

High-performance alkali-free liquid accelerator and preparation method thereof

The invention relates to a high-performance alkali-free liquid accelerator and a preparation method thereof. The high-performance alkali-free liquid accelerator comprises the following components: 30-45% of active aluminum hydroxide, 3-15% of a fluorine-aluminum complex, 0.5-8% of an early strength coagulation accelerating component, 2-8% of an alcohol amine substance, 5-15% of a nano silica sol,0.5-2% of a dispersing agent and water. The high-performance alkali-free liquid accelerator disclosed by the invention can weaken adverse effects on later mechanical strength and durability of concrete while achieving a good accelerating effect, can effectively inhibit expansion cracking of the concrete, improves early strength and cement adaptability, and is low in dosage. The preparation methodis simple to operate and mild in condition.

Owner:湖南加美乐素新材料股份有限公司

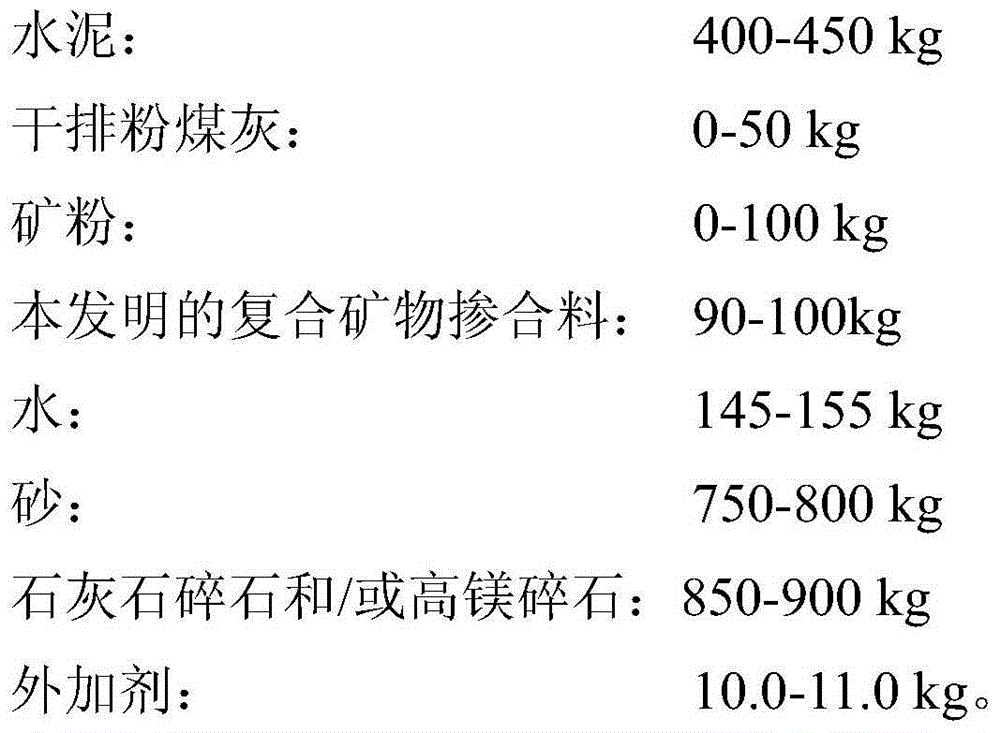

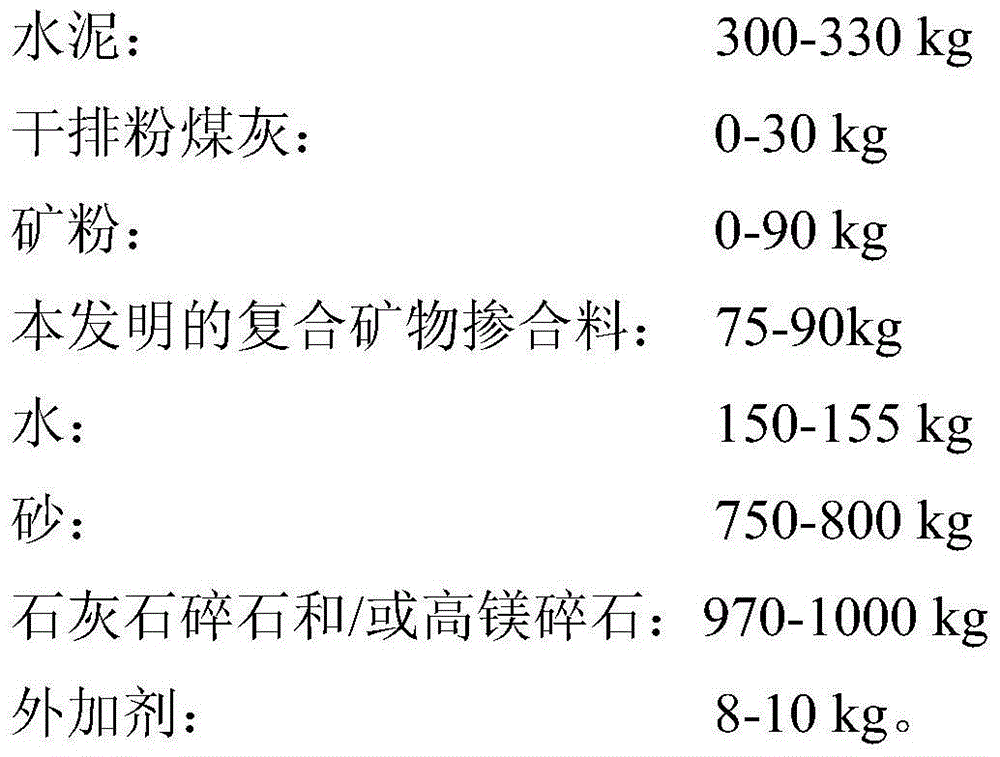

High-magnesium waste stone dust-based composite mineral admixture, and applications thereof in medium-strength concrete

The invention discloses a high-magnesium waste stone dust-based composite mineral admixture, and applications thereof in medium-strength concrete. The high-magnesium waste stone dust-based composite mineral admixture is prepared via following steps: (1) high-magnesium waste stone, wet discharged fly ash, and manganese residue are dried until water content is lower than 1.0%; and (2) by weight, 70 to 85 parts of the dried high-magnesium waste stone, 10 to 20 parts of the dried wet discharged fly ash, and 0 to 10 parts of the dried manganese residue, 0 to 10 parts of mineral waste residue, and 0 to 10 parts of a clinker are smashed into powder respectively and then are mixed, or are mixed and then are smashed into powder with a specific surface area ranging from 601 to 900m2 / kg so as to obtain the high-magnesium waste stone dust-based composite mineral admixture. According to the high-magnesium waste stone dust-based composite mineral admixture, morphology effects and filling effects of high-magnesium waste stone powder are used so as to increase compactness of concrete mixtures, and increase fluidity of concrete; slump loss is less; less additives such as polycarboxylic acid are absorbed; concrete early-stage strength development is accelerated, and later-stage development is stabilized. And in addition, the high-magnesium waste stone dust-based composite mineral admixture can be applied to concrete together with high-magnesium waste stone coarse and fine aggregates so as to increase utilization ratio of high-magnesium waste stone greatly.

Owner:华润水泥技术研发(广西)有限公司

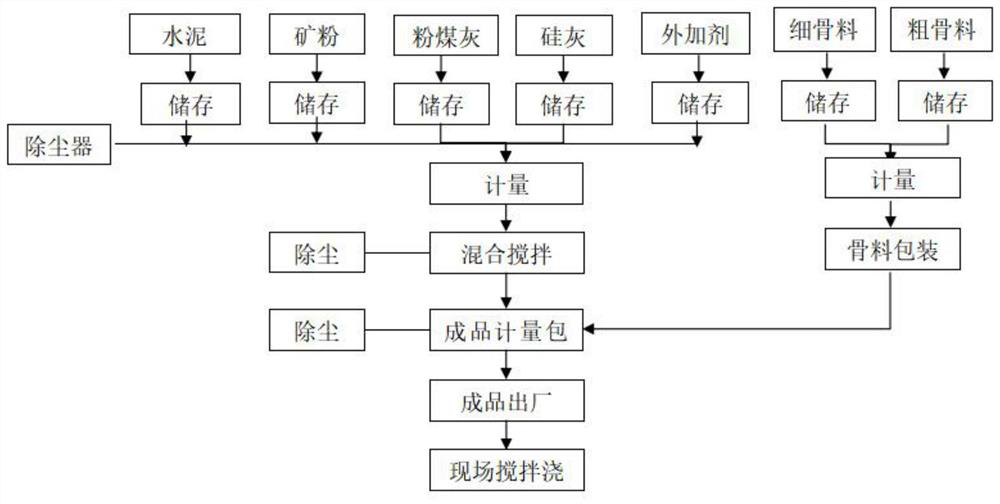

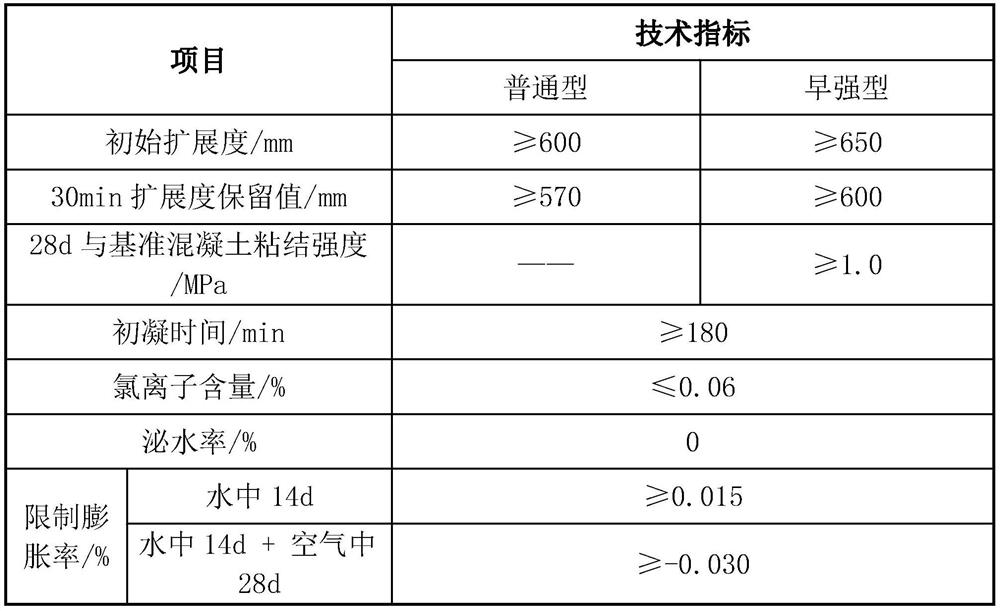

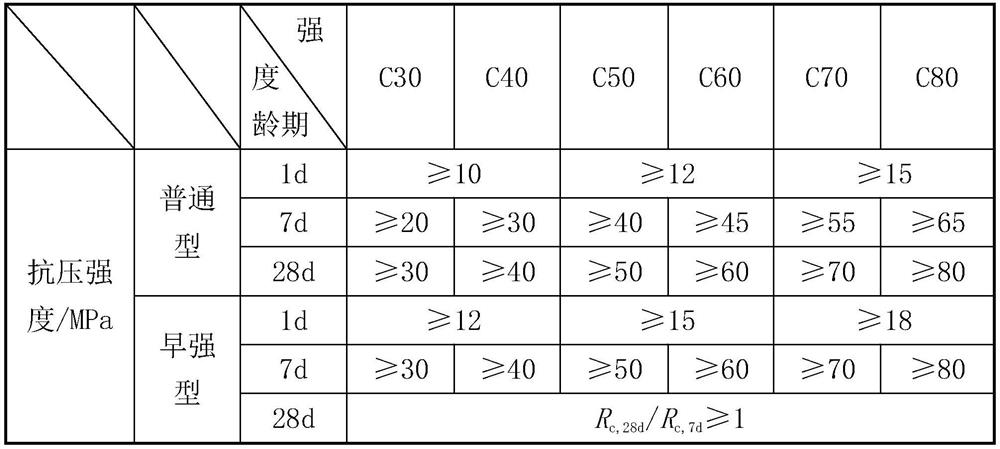

Special concrete for structure reinforcement and preparation method thereof

InactiveCN112341100ASmall shrinkageFill the gap in the marketBuilding material handlingFiberReinforced concrete

The invention belongs to the technical field of concrete, and discloses special concrete for structural reinforcement and a preparation method thereof. The special concrete is prepared from cement, mineral powder, fly ash, silica fume, fine aggregate, coarse aggregate, a water reducing agent, a shrinkage compensation admixture, anti-cracking fibers and a binder. The special reinforced concrete hasthe characteristics of self-compaction, no segregation, fast early strength development, controllable later strength, low shrinkage and the like, fills the market vacancy of reinforced concrete, is classified according to use conditions, avoids using one product to cope with all the conditions, and is divided into a common type and an early strength type according to different ages reaching the design strength. The common type is suitable for newly-added components in transformation and reinforcement and the situation that concrete vibration is difficult in a beam column joint steel bar densearea, a post-cast strip, a constructional column and the like in a newly-built project. The early strength type is suitable for transformation and reinforcement of locally-added components with the increased cross section and the tight construction period and suitable for concrete replacement.

Owner:SHANGHAI MEICHUANG ARCHITECTURAL MATERIALS

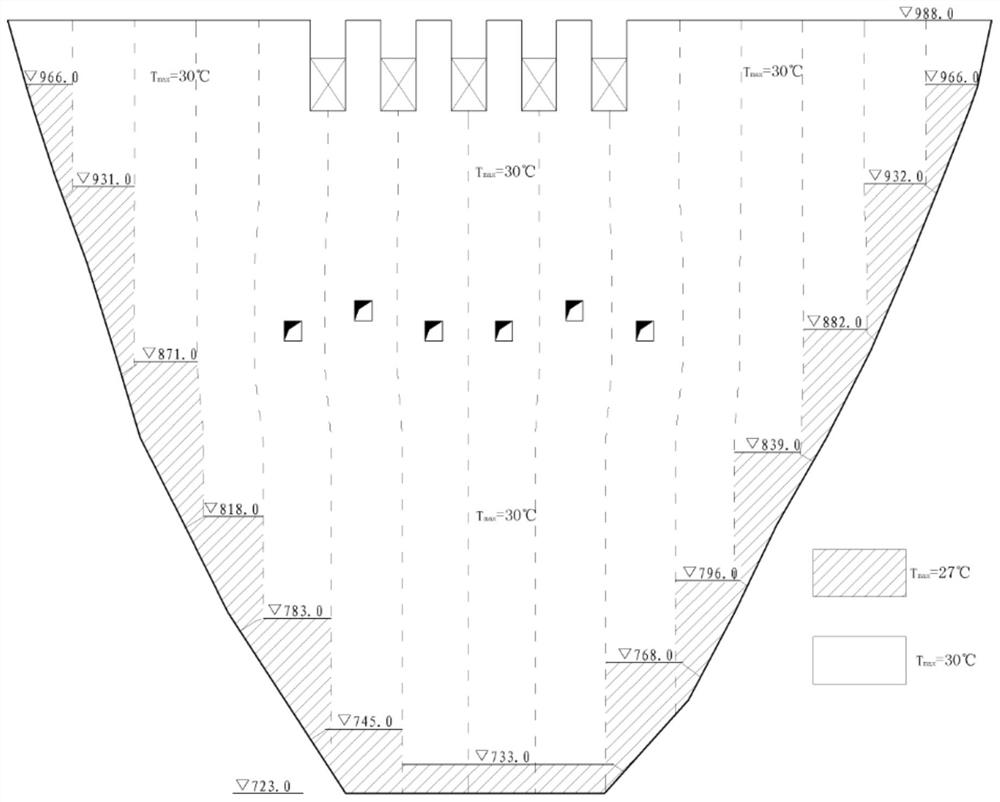

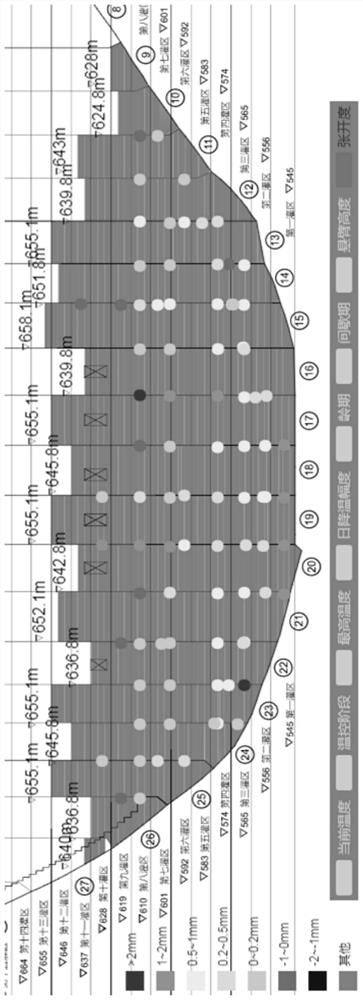

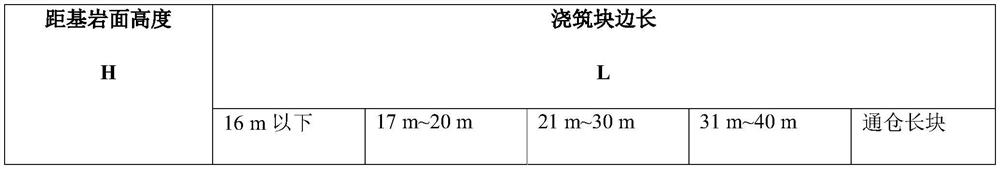

Control method for highest temperature interval of high-arch-dam low-heat cement concrete

ActiveCN112462818AIncreased safety against crackingEnsure arch integrityTemperature control using electric meansTemperature controlCrack resistance

The invention provides a control method for a highest temperature interval of high-arch-dam low-heat cement concrete. The characteristics of the low-heat cement concrete are combined, and the advantages of the low-heat cement concrete can be exerted to improve the crack resistance safety of dam concrete, the influence on the joint grouting quality of the transverse joint due to too small opening degree of the transverse joint in the construction period of the arch dam caused by too low maximum temperature control of concrete can be prevented, and the arch sealing integrity of the arch dam is ensured; too low maximum temperature control of concrete can be prevented, and particularly, when the environment temperature in autumn and winter is low, the highest temperature of the low-heat cementconcrete is easier to be too low. After the lower limit value of the highest temperature of the concrete is set, the highest temperature can be properly increased by adjusting a concrete pre-coolingmeasure, a water cooling measure and the like, so that the temperature control cooling engineering quantity and investment are obviously saved; and after the highest temperature interval control standard is set, the temperature control operation on the concrete in the actual construction process is more flexible, and field construction control is facilitated.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

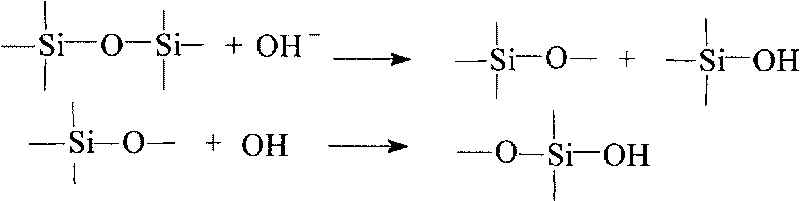

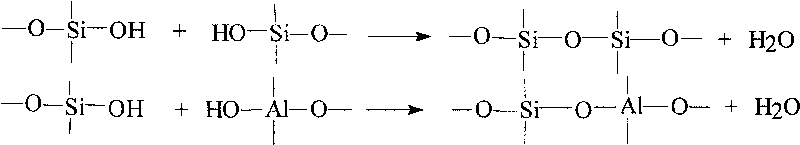

Silicon-aluminum gelatinized material produced by pulverized fuel ash and application method thereof

The invention provides a silicon-aluminum gelatinized material produced by pulverized fuel ash and an application method thereof. In the method, a coal gangue is crushed and ground to obtain a powder body, and the powder body is calcined for 0.5 to 2 hours under the temperature of 500 to 750 DEG C, so as to obtain calcined kaolin clay. Ball milling is carried out on the pulverized fuel ash, lime and the calcined kaolin clay in a ball milling machine according to certain proportion so as to obtain pulverized silicon-aluminum gelatinized material, and then sealing and packaging are carried out. Uniform mixing is carried out according to certain proportion so as to obtain a solid additive, and then sealing and packaging are carried out. When in use, the additive is dissolved in water to prepare additive solution (the proportion of the using quantity of the silicon-aluminum gelatinized material, the additive and the water is 100: (5-10): (40-50), the additive solution is slowly added to the pulverized silicon-aluminum gelatinized material, on-site pouring or forming is carried out after uniform mixing, and then the maintenance is carried out to the specified age under normal temperature (equal to or higher than 20 DEG C). The invention has the following characteristics: sources of raw materials are wide, the production cost is low, the processing is simple, and the implementation and popularization are convenient.

Owner:昊青薪材(北京)技术有限公司

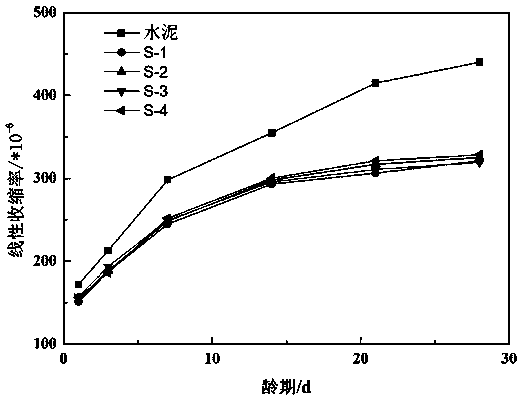

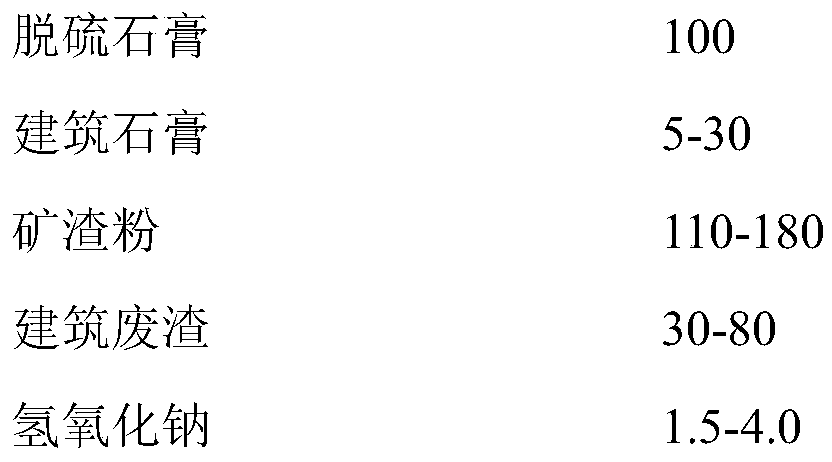

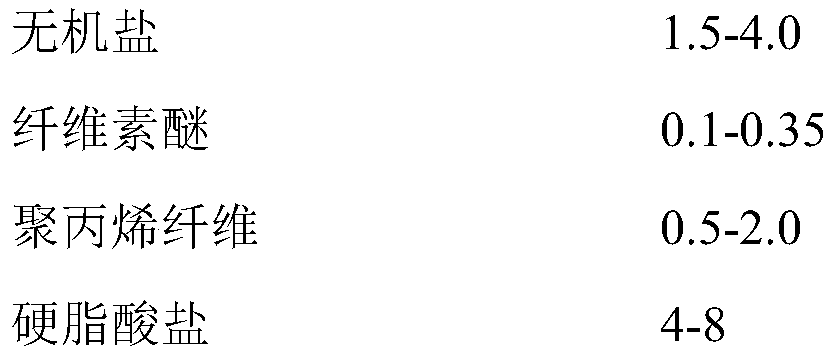

High-performance environment-friendly soft soil curing agent and preparation method thereof

ActiveCN110964534ASimple preparation processRaw materials are easy to getBuilding constructionsOrganic fertilisersCelluloseFirming agent

The invention belongs to the technical field of advanced civil engineering materials, and particularly relates to a high-performance environment-friendly soft soil curing agent and a preparation method thereof. Adopted raw materials comprise desulfurized gypsum, building gypsum, slag powder, building waste residue, sodium hydroxide, inorganic salt, cellulose ether, polypropylene fiber and stearate. The preparation method comprises the steps: grinding and modifying the slag powder, building waste residues, sodium hydroxide and inorganic salt in a ball mill; followed by adding the desulfurized gypsum and building gypsum, grinding finely and mixing; and finally adding the cellulose ether, polypropylene fibers and stearate to finish mixing, and thus obtaining the product. According to the invention, the building and industrial wastes are reused by utilizing a grinding modification and activity excitation technology, and the product has the excellent performances, such as fast early strength development, small shrinkage distortion, good water stability and the like, is suitable for reinforcing various soft soil bodies, and has wide application fields.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP +1

Composite lightening material for well cementation, preparation method of composite lightening material, deep well composite cement paste and application of composite cement paste

ActiveCN104419391ASimple manufacturing processImprove pressure bearing capacityDrilling compositionSealing/packingWell cementingCement paste

The invention discloses a composite lightening material which comprises the following components in parts by weight: 100 parts of coal ash, 10-15 parts of expanding materials and 5-10 parts of toughening materials, wherein the particle size range of the coal ash is 5-10 microns. The invention also relates to a preparation method of the composite lightening material, and the preparation method comprises the following steps: i) carrying out smashing and ball milling on the coal ash through an overhang roll mill, classifying the smashed and ball-milled coal ash through a classifier, and collecting the coal ash with the particle size range of 5-10 microns after the classification to obtain modified coal ash; and ii) mixing the modified coal ash obtained in the step i) with the expanding materials and the toughening materials according to the proportion so as to obtain the composite lightening material. Meanwhile, the invention also discloses deep well composite cement paste and an application of the composite cement paste in well cementing of oil / gas wells.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fiber restricted expansion mortar as well as dry mixture, wet mixture and preparation method of fiber restricted expansion mortar

The invention relates to the field of building materials and in particular relates to a fiber restricted expansion mortar as well as a dry mixture, wet mixture and preparation method of the fiber restricted expansion mortar. Due to the addition of a foaming agent, a CSA expanding agent, a stabilizer and polypropylene chopped fibers, mortar is subjected to a whole string of reaction processes including foaming, flowing, bubble breakage, concrete contraction, restricted expansion of an expanding agent, plasticity change caused by plasticity stability neutralizing fibers and the foaming agent andmechanical property improvement by the polypropylene chopped fibers to finally form repair mortar with high early strength development speed, volume restricted expansion, high tensile strength, highultimate tensile rate and high toughness. Due to the addition of the fibers, the tensile and crack resistance of the repair mortar are greatly improved; due to the addition of the expanding agent, themortar generates a restricted expansion effect so as to be more densely filled, the performances such as fracture resistance, tensile strength and durability of the hardened repair mortar are more excellent than those of other repairing agents, and the problem of poor restricted expansion property of the current repair mortar is solved.

Owner:河南中建西部建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com