Nano-modified ultrahigh-strength steel fiber concrete and preparation method thereof

A fiber-reinforced concrete and ultra-high-strength steel technology, applied in the field of building concrete, can solve the problems of negligible strain softening performance and burst damage, and achieve the effects of good volume stability, no cracks, and rapid strength development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

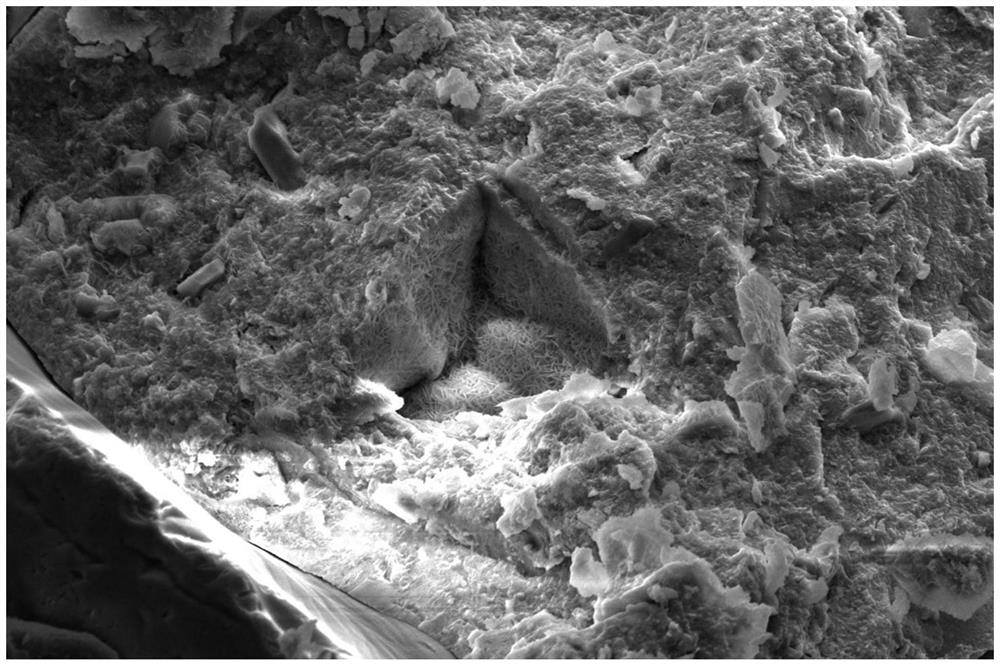

Image

Examples

Embodiment 1

[0041] The nano-modified ultra-high-strength steel fiber concrete provided by the embodiment of the present invention has the following specific components and parts by weight: 400 parts of Portland cement, 100 parts of mineral powder, 40 parts of fly ash microbeads, 40 parts of silica fume, polycarboxylate 16 parts of acid high-performance water reducer, 80 parts of steel fiber, 0.15 parts of graphene oxide, 10 parts of nano silicon dioxide, 700 parts of sand, 950 parts of stone and 115 parts of tap water.

[0042] The present invention also provides a preparation method of the nano-modified ultra-high-strength steel fiber concrete, comprising the following steps:

[0043] Step 1: According to the proportion, feed Portland cement, mineral powder, fly ash beads, silica fume, nano-silica, sand and stones in sequence, and dry mix them in a concrete mixer to mix them evenly;

[0044] Step 2: Add graphene oxide solution, water and high-performance water reducer to the mixture obta...

Embodiment 2

[0051]The nano-modified ultra-high-strength steel fiber concrete provided by the embodiment of the present invention has the following specific components and parts by weight: 380 parts of Portland cement, 120 parts of mineral powder, 35 parts of fly ash microbeads, 40 parts of silica fume, polycarboxylate 13 parts of acid high-performance water reducer, 120 parts of steel fiber, 0.10 parts of graphene oxide, 12 parts of nano silicon dioxide, 700 parts of sand, 950 parts of stone and 110 parts of tap water.

Embodiment 3

[0053] The nano-modified ultra-high-strength steel fiber concrete provided by the embodiment of the present invention has the following specific components and parts by weight: 415 parts of Portland cement, 85 parts of mineral powder, 48 parts of fly ash microbeads, 55 parts of silica fume, polycarboxylate 16 parts of acid high-performance water reducer, 40 parts of steel fiber, 0.25 parts of graphene oxide, 20 parts of nano silicon dioxide, 780 parts of sand, 1100 parts of stone and 125 parts of tap water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com