Patents

Literature

247results about How to "Not easy to crack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Raw material formula of bronzy sculpture

The invention discloses a raw material formula of a bronzy sculpture. The raw material formula of bronzy sculpture includes the following substances in parts by weight: 40-50 parts of paraffin wax, 20-30 parts of talcum powder, 15-20 parts of bronze powder, 5-8 parts of rosin, 10-15 parts of magnesium oxide, 2-5 parts of a flexibilizer and 1-3 parts of a catalyst, wherein the catalyst is selected from phosphate, sulphate and oxalic acid; the flexibilizer is selected from plant straw fine powder, glass fibres and organic fibres. The raw material formula of bronzy sculpture disclosed by the invention has the following beneficial effects: the raw material formula of bronzy sculpture is more time-saving and labour-saving while realizing a bronzy effect compared with the mode of producing a sculpture by virtue of water-based clay and then manually polishing; moreover, the raw material formula of bronzy sculpture is good in viscosity, not liable to crack, and convenient to store for a long time.

Owner:厦门鼎艺雕塑有限公司

Cement-based grouting material and preparation method thereof

The invention relates to a cement-based grouting material and a preparation method thereof. The cement-based grouting material comprises a component A, a component B and a component C, wherein the component A comprises the following components by weight part: 80 to 90 parts of epoxy resin, 1 to 10 parts of diluents, 0 to 1 part of defoaming agent and 1 to 5 parts of coupling agent; the component B comprises a water-soluble amine curing agent with an emulsification function; the component C comprises the following components by weight part: 30 to 50 parts of cement, 2 to 4 parts of ultrafine mineral powder, 0 to 1 part of silica micropowder, 2 to 4 parts of expanding agent, 0 to 1 part of water-reducing agent and 40 to 60 parts of river sand; and the weight ratio among the component A, the component B and the component C is (60 to 100) : (90 to 150) : (400 to 800). Mechanical indexes, such as compressive strength, breaking strength and the like, of the cement-based water-soluble epoxy resin grouting material are far more excellent than those of the common cement grouting material.

Owner:天津天盈新型建材有限公司

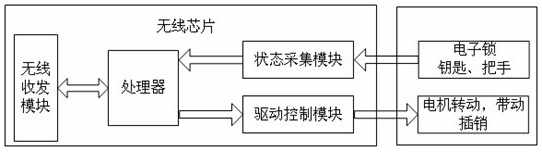

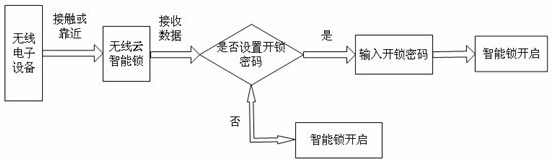

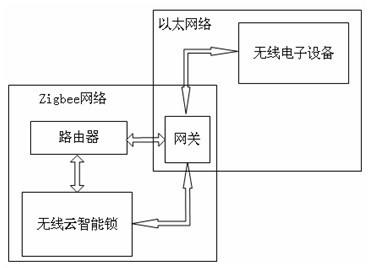

Wireless cloud intelligence lock and working method thereof

ActiveCN102561826AImprove securityNot easily identifiableTransmission systemsElectric permutation locksComputer hardwareWireless transceiver

The invention discloses a wireless cloud intelligence lock and a working method thereof. One end of a processor of a circuit part is connected with a wireless transceiver module; the other end of the processor is connected with a state acquisition module and a driving control module; the processor is also connected with external wireless control equipment via a gateway or a router; the bolt of a lockset part and a motor are connected; the motor is connected with the driving control module; and an electronic lock is electrically connected with the state acquisition module via a circuit. The working method of the intelligence lock comprises a short-range unlocking mode and a remote unlocking mode. According to the wireless cloud intelligence lock and the working method thereof, the safety is improved, and the problems in the prior art that the intelligence lock is difficult to unlock and is not provided with functions of tracing to the source and checking are solved.

Owner:NANJING IOT SENSOR TECH

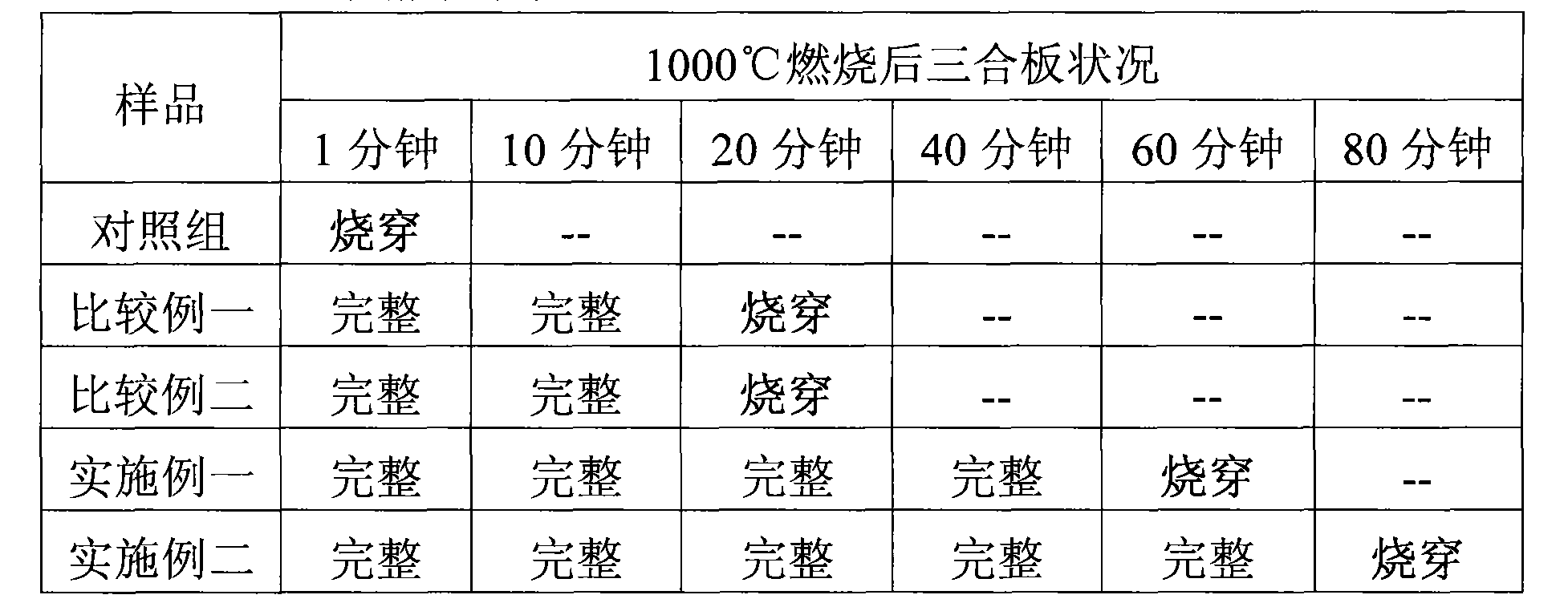

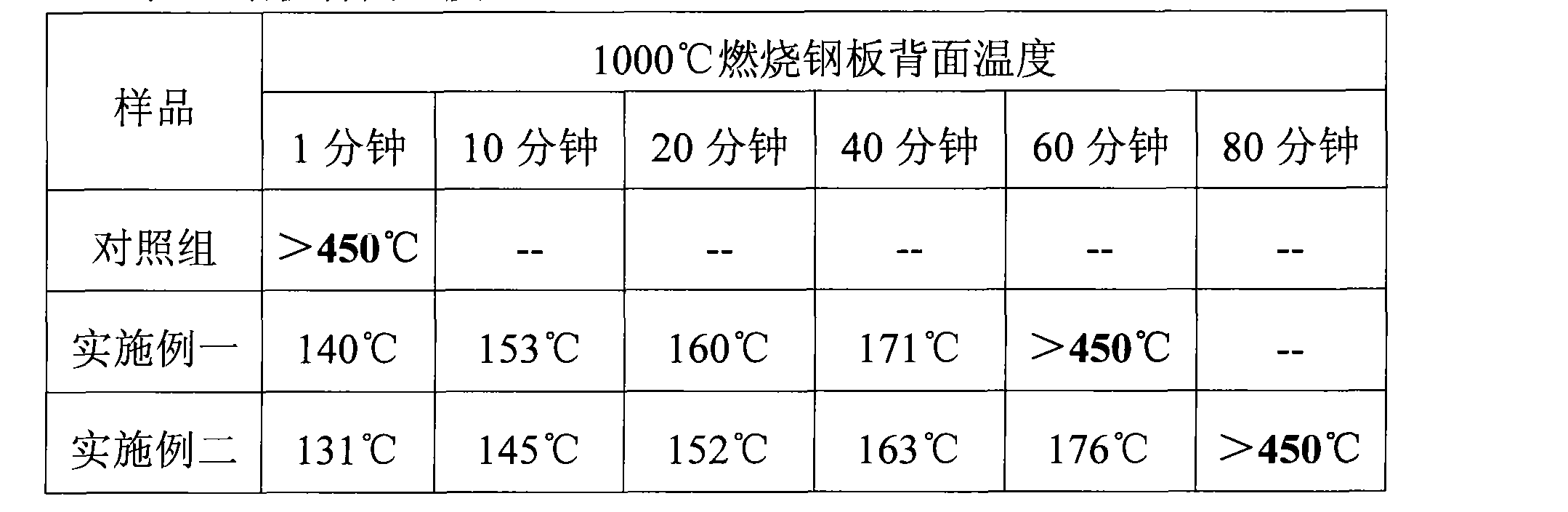

Transparent halogen-free fire-resisting paint constituent

InactiveCN101434760AImprove toughnessNot easy to crackFireproof paintsPolyurea/polyurethane coatingsSolventChemistry

The invention provides a transparent halogen-free fire-retardant paint composition, which consists of 100phr (Parts per Hundred of Resin) of adhesive, 50-400phr of solvent, 50-300phr of foaming agent, 10-200phr of carburetant, 1-100phr of carbonizing promoter and 0-100phr of auxiliary additive; wherein, the carbonizing promoter is a phosphorus-containing compound with reaction functional groups. A coat formed by the transparent halogen-free fire-retardant paint composition nearly generates no smoke when being heated but instantly generates an expanding layer of high toughness. The expanding layer is not likely to crack, does not melt, drop and droop and moreover, is capable of effectively obstructing oxygen and heat to fulfill fire-retardant effect. The paint composition has excellent compatibility and dispersibility among the ingredients, therefore has eminent transparency and can be used for the fire prevention of various buildings, furniture or in decoration without damaging the original appearance view thereof.

Owner:CHINA GENERAL PLASTICS

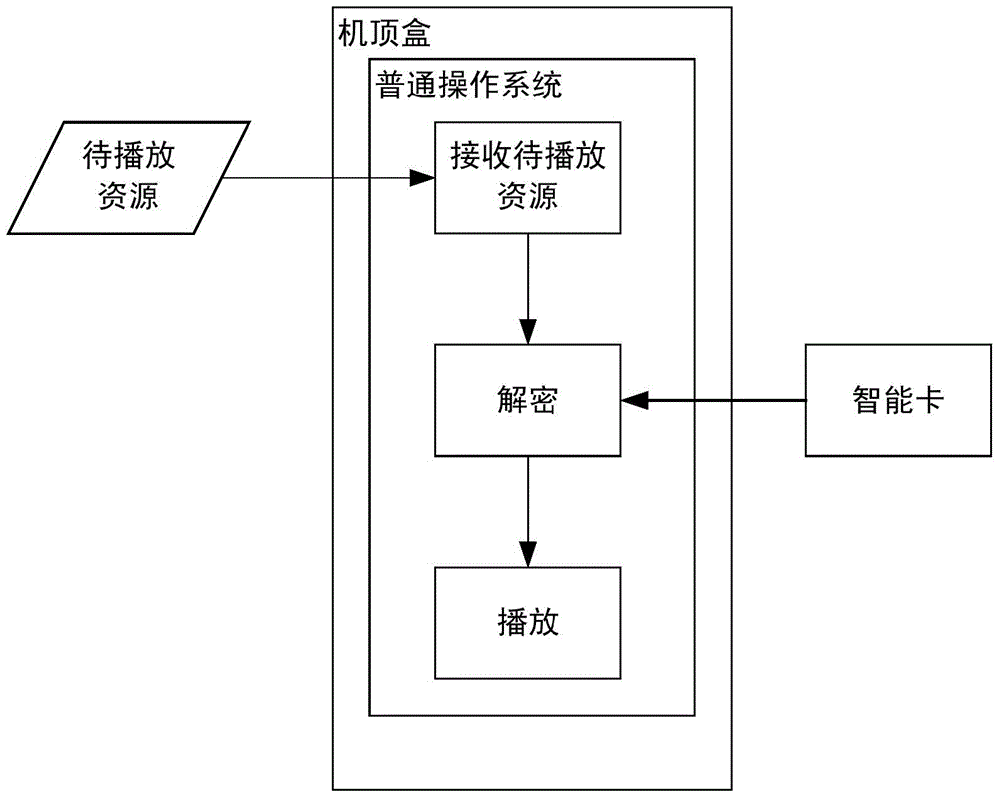

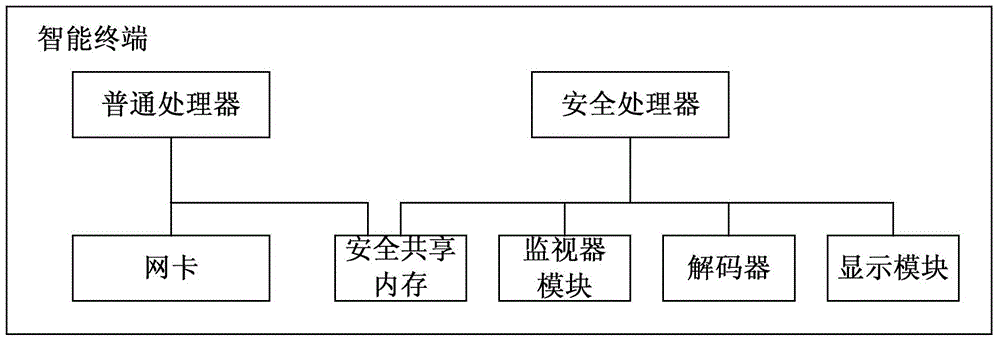

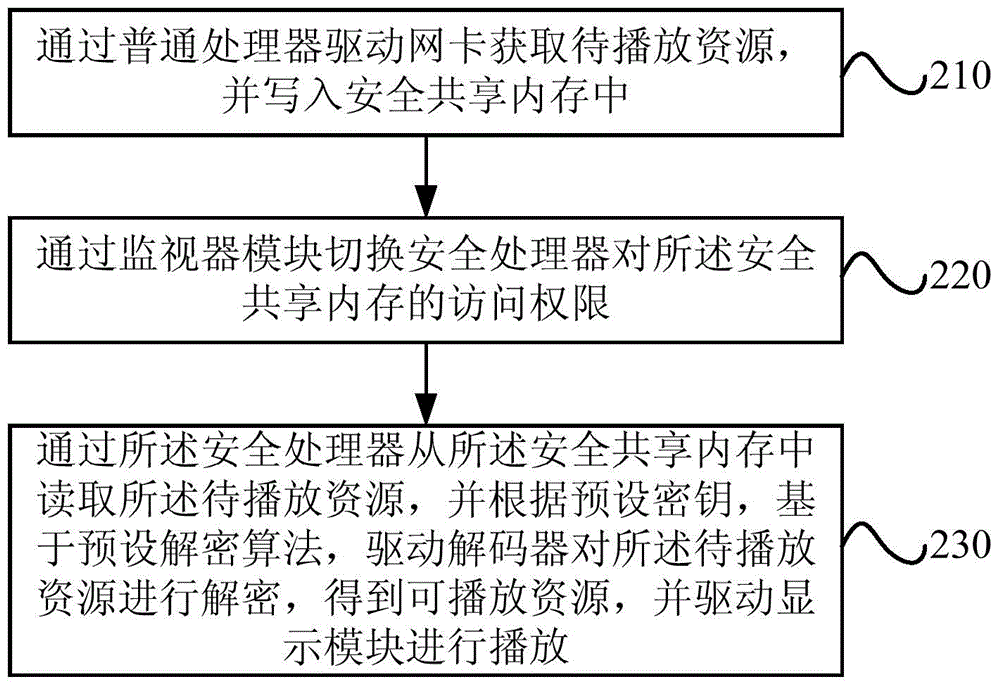

Resource play method and system for intelligent terminal

ActiveCN104918116AEnsure safetyNot easy to monitorSelective content distributionSafe handlingNetwork interface controller

The invention provides a resource play method and system for an intelligent terminal. The method comprises that a common processor drives a network card to obtain resource to be played, and writes the resource to be played in a safe shared memory, and the resource to be played is an encrypted resource; a monitor module switches the access authority of a safe processor to the safe shared memory; and the safe processor reads to resource to be played from the safe shared memory, a decoder is driven to decipher the resource to be played according to a preset secrete key and on the basis of a preset deciphering algorithm, resource that can be played is obtained, and a display module is driven to play the obtained resource. Thus, the secret key which needs to be deciphered tends not to monitor or crack, and the deciphering and playing safety of the resource to be played is ensured.

Owner:北京视博数字电视科技有限公司

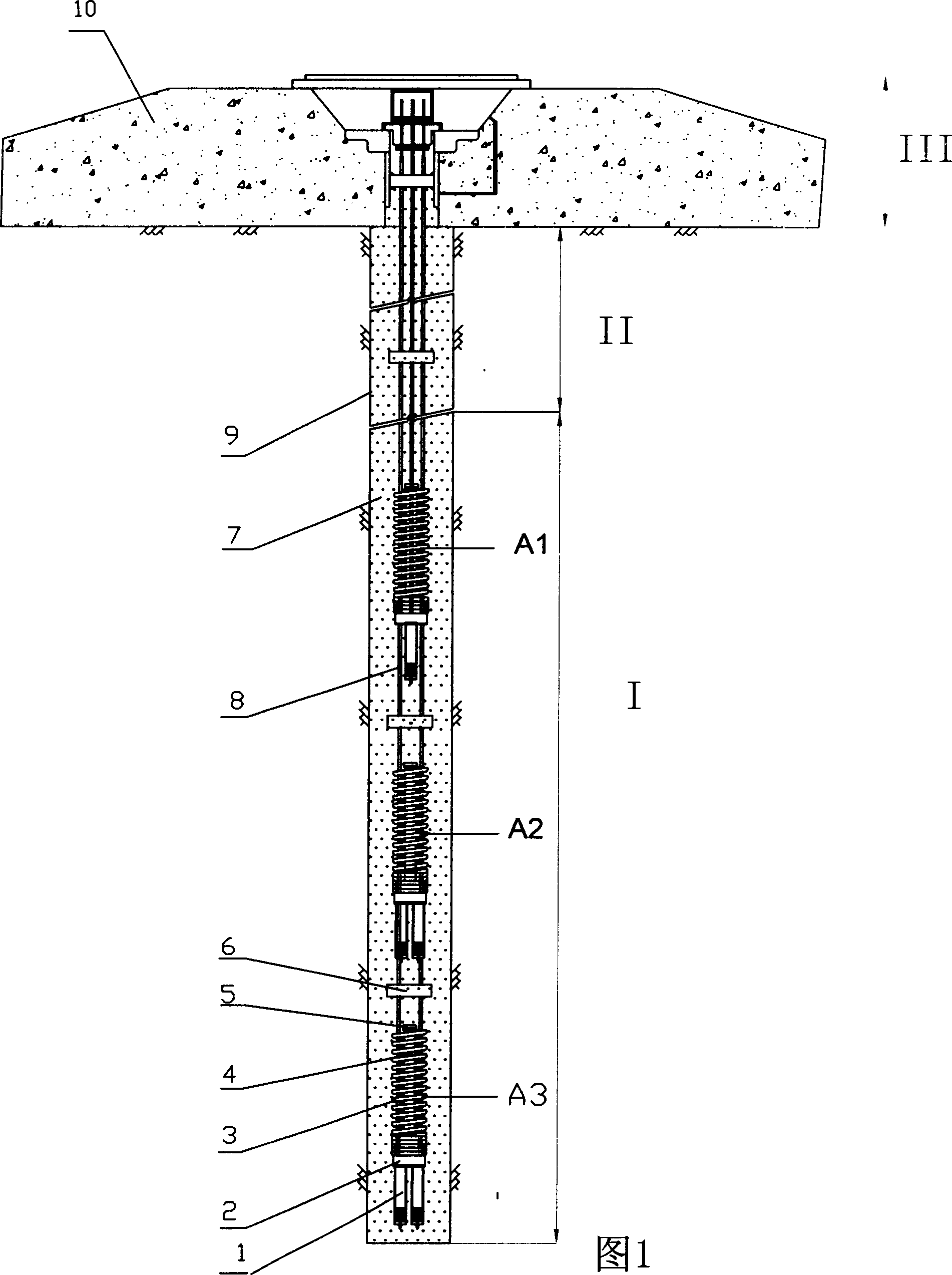

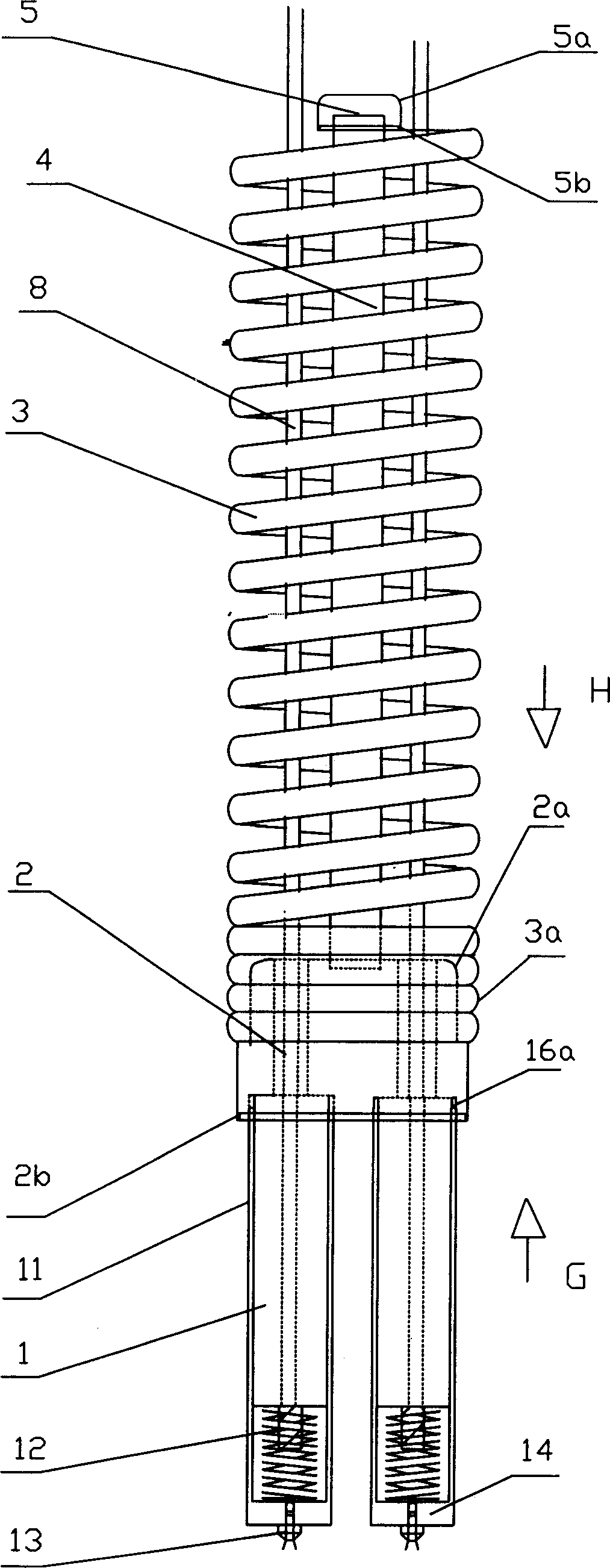

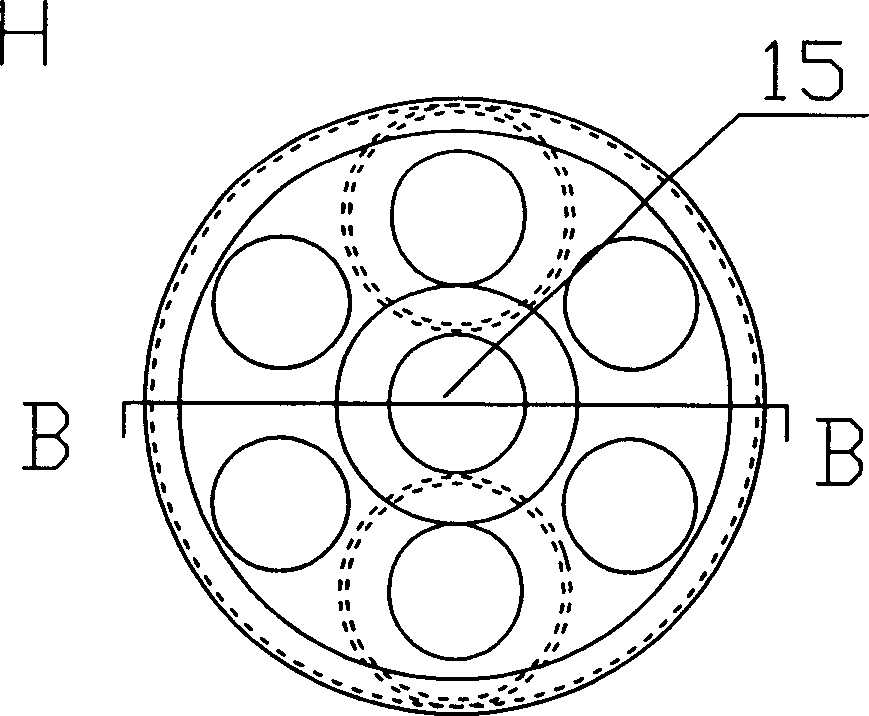

Permanent anchor rope used for side slope stabilization

ActiveCN1651660ANot easy to crackPrevent groundwater infiltrationExcavationsBulkheads/pilesRebarEngineering

The permanent anchor rope for stabilizing slope is composed of external anchoring head, internal anchoring part and free part, and said internal anchoring part is formed from guy rope and more than one group of internal anchoring end bearing components which are distributed along the vertical direction, every group of bearing components has pressure-bearing plate and vertical pressure-beaning column whose lower end is fixedly connected with pressure-bearing plate, and the upper end of the guy rope is anchored to the external anchoring head, and its lwoer end is grouped and distributed in different bearing components, and respectively fixedly connected with pressure-bearing plate of correspondent group bearing component. Said invention can make the stretching force of anchor rope obtain permanent retention.

Owner:李炳奇

Corundum breathable seat brick with high thermal shock resistance and production method thereof

The invention discloses a corundum breathable seat brick with high thermal shock resistance. The brick consists of mixed corundum, a magnesium-containing material, a binding agent, chromium oxide, a water reducing agent and an explosion-proof agent. The production method of the corundum breathable seat brick comprises the following steps: dosing, and mixing to prepare mud; placing the mud in a mould, performing shake densification, demoulding, and drying to obtain a breathable seat green brick; and heating the breathable seat green brick, and roasting to obtain the corundum breathable seat brick with thermal shock resistance. The component ratio is reasonable, the production and preparation method is simple, the prepared breathable seat brick has good high-temperature strength and thermal shock resistance; and the service life of the breathable seat brick can be effectively prolonged, the use security of the breathable brick can be increased, the replacement times of the breathable brick can be reduced, the production cost of enterprises can be reduced and the production efficiency of ferrous metallurgy can be increased. The corundum breathable seat brick can replace the existing breathable seat brick and be suitable for industrial production.

Owner:CENT SOUTH UNIV

Environment-friendly PE gloss black piano lacquer

ActiveCN101654586ASolve the problem of not being able to transport to the northObvious superiorityPolyester coatingsLacquerOxygen

The invention discloses an environment-friendly PE gloss black piano lacquer, which comprises a main agent, a diluting agent, an accelerating agent and an initiator, wherein the main agent mainly comprises the following components in portion by weight: 75 to 85 portions of unsaturated polyester finishing paint resin, 0.2 to 0.5 portion of wetting dispersing agent, 0.8 to 1.1 portions of carbon black, 4 to 6 portions of hexamethoxymethyl melamine resin, 0.3 to 0.6 portion of anti-sagging agent, 0.02 to 0.04 portion of polymerization inhibitor, 0.2 to 0.4 portion of butanone, 13 to 17 portions of styrene, and 0.2 to 0.4 portion of levelling agent; the diluting agent mainly comprises 100 portions of the styrene; the accelerating agent contains 100 portions of cobalt naphthenate solution with6 percent of Co<2+>; and the initiator contains 100 portions of butanone peroxide solution with 10 percent of active oxygen. The environment-friendly PE gloss black piano lacquer can obtain a bright film coating without polishing, has better mechanical properties and fullness, is difficult to have cooling cracks, can solve the problem of northward transportation of south musical instruments, and simultaneously completely uses active diluting agent and is very favorable for environmental protection.

Owner:珠海展辰新材料股份有限公司

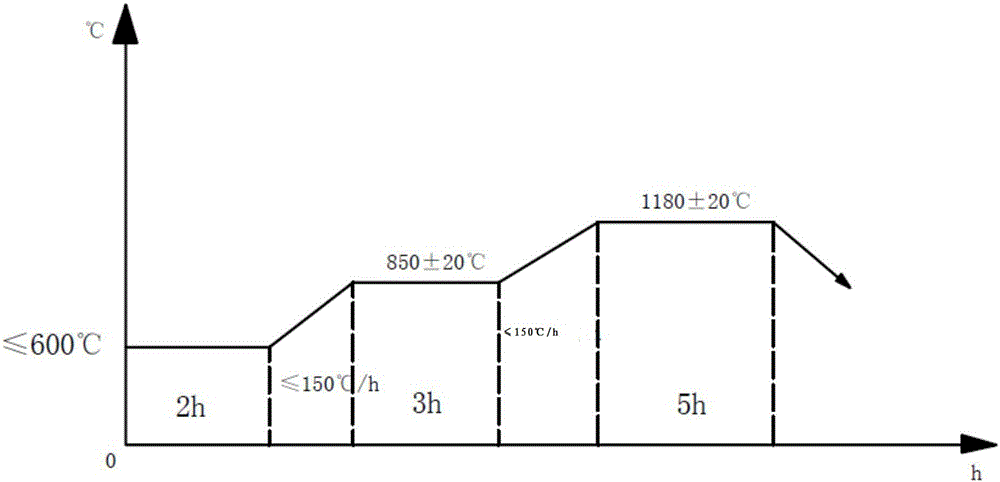

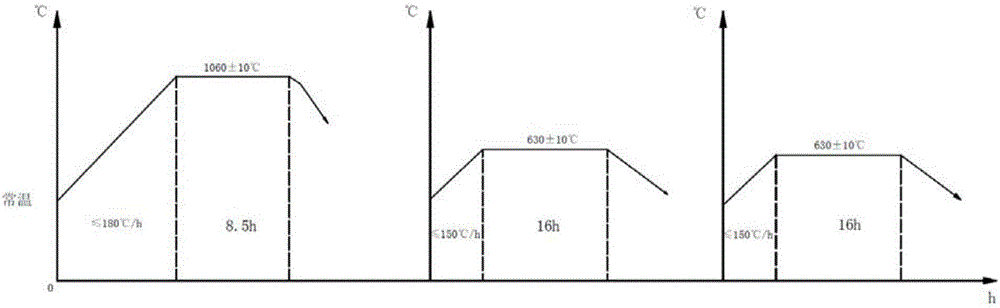

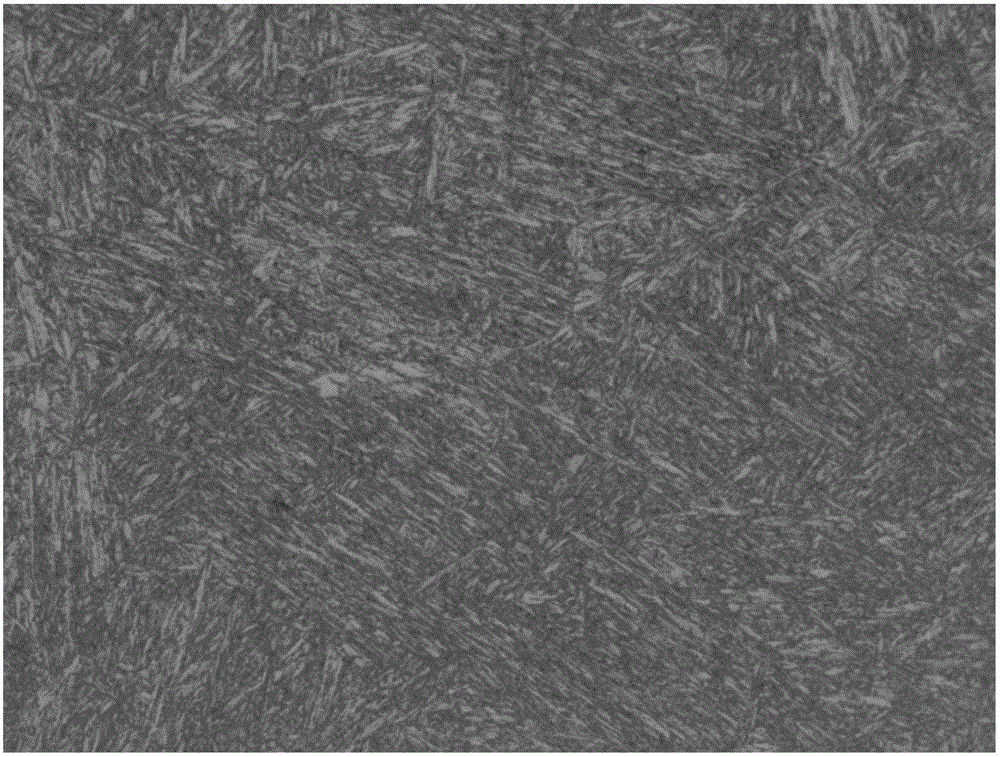

2Cr11MoVNbN forge piece for steam turbine and manufacturing method of forge piece

The invention discloses a 2Cr11MoVNbN forge piece for a steam turbine and a manufacturing method of the forge piece. The method comprises the steps that firstly, discharging is carried out; secondly, the charging temperature is raised and controlled to be smaller than 600 DEG C, preheating is carried out for 2 hours, the temperature is raised to 830 DEG C to 850 DEG C at the rising speed smaller than or equal to 150 DEG C / h, the temperature is kept for 3 hours, the temperature is raised to 1160 DEG C to 1200 DEG C at the rising speed smaller than or equal to 150 DEG C / h, the temperature is kept for 5 hours, and cooling is carried out; thirdly, forging is carried out; fourthly, annealing after forging is carried out; fifthly, preheat treatment is carried out, and incomplete annealing is achieved; sixthly, quenched-tempered heat treatment is carried out, wherein the temperature is raised to 1050 DEG C to 1070 DEG C at the rising speed smaller than or equal to 180 DEG C / h, the temperature is kept for quenching for 8.5 h, medium water cooling is carried out, the temperature rises to 620 DEG C to 640 DEG C at the rising speed smaller than or equal to 150 DEG C / h, the temperature is kept for one-time tempering for 16 h, air cooling is carried out, the temperature rises to 620 DEG C to 640 DEG C at the rising speed smaller than or equal to 150 DEG C / h, the temperature is kept for secondary tempering for 16 h, and air cooling is carried out; seventhly, stress relief annealing is carried out. In the forging and heat treatment process, a blank is not prone to cracking, high-temperature durability is good, and the mechanical property of products meets the requirement.

Owner:ZHANGJIAGANG HAILU ANNULAR FORGINGS

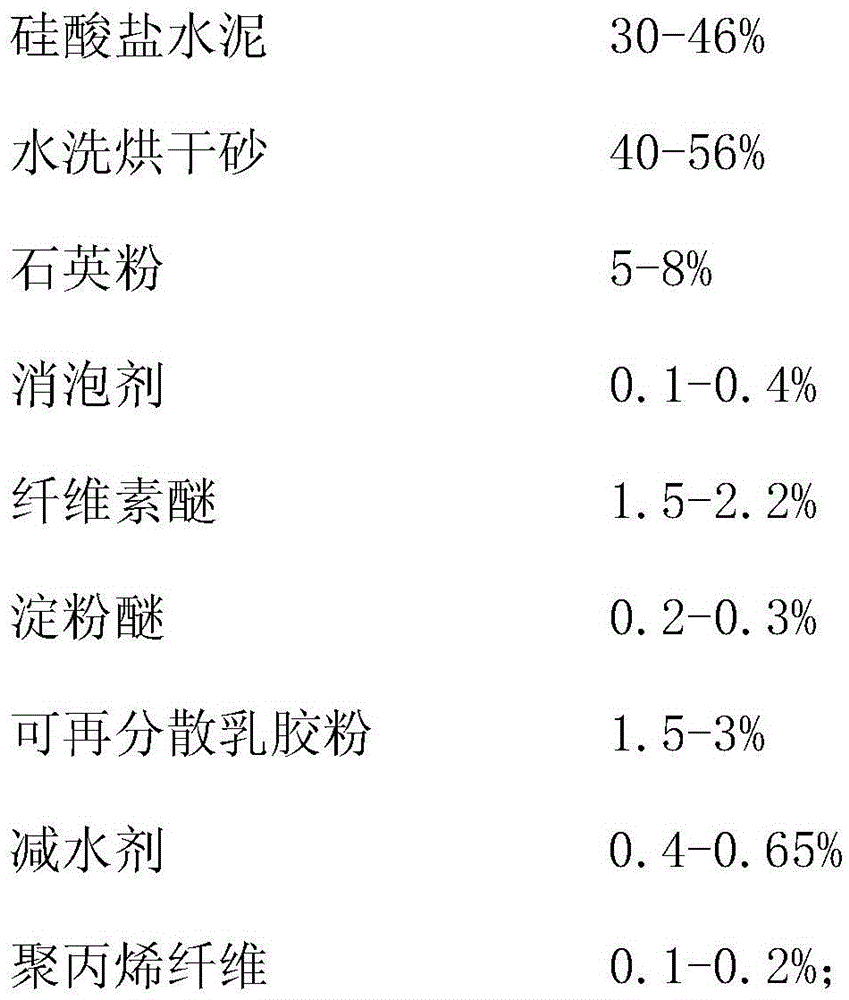

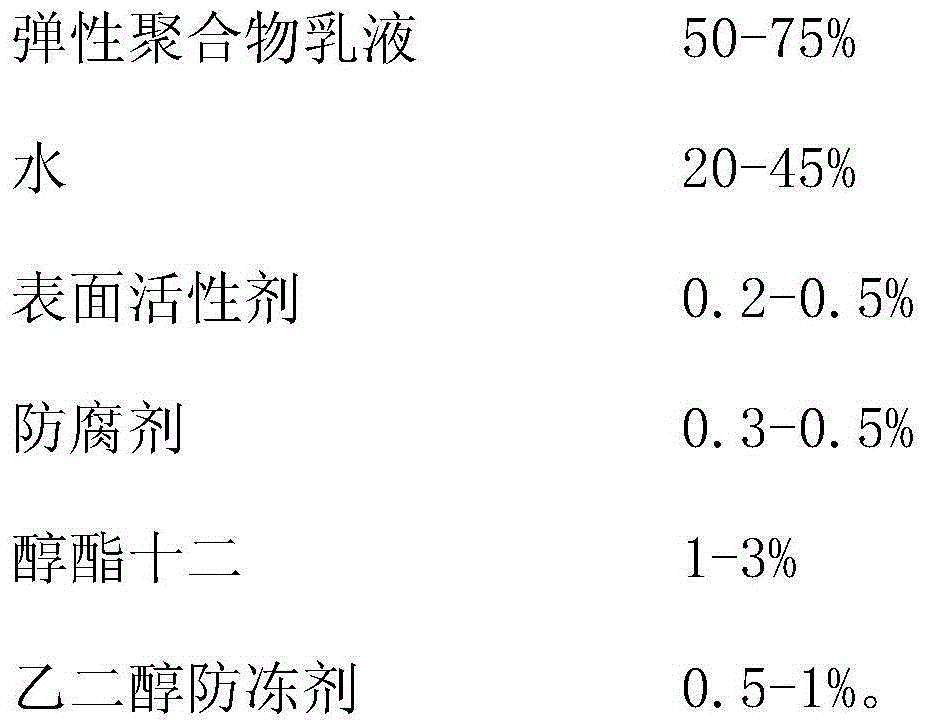

Flexible tile adhesive

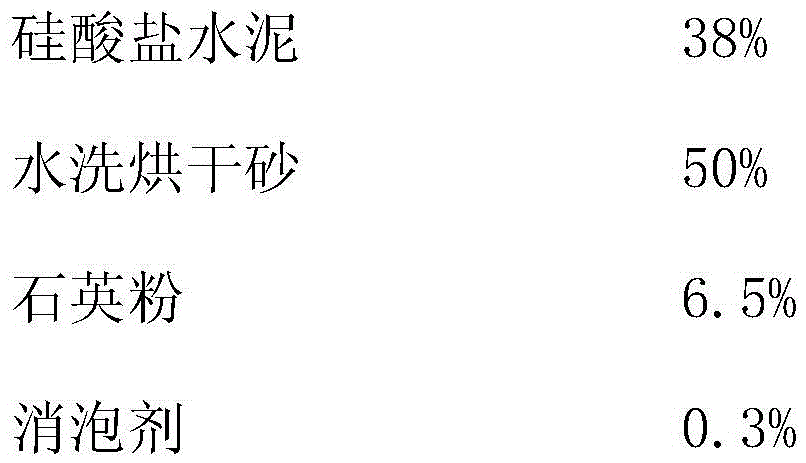

The invention relates to a flexible tile adhesive which comprises a component A and a component B. Mass ratio of the component A to the component B is 3:1. The component A is prepared from the following raw materials (by weight): 30-46% of Portland cement, 40-56% of washed-out baked sand, 5-8% of quartz powder, 0.1-0.4% of an antifoaming agent, 1.5-2.2% of cellulose ether, 0.2-0.3% of starch ether, 1.5-3% of redispersible latex powder, 0.4-0.65% of a water reducer and 0.1-0.2% of polypropylene fiber. The component B is prepared from the following raw materials (by weight): 50-75% of an elastic polymer emulsion, 20-45% of water, 0.2-0.5% of a surfactant, 0.3-0.5% of a preservative, 1-3% of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate and 0.5-1% of an ethylene glycol antifreezing agent. The flexible tile adhesive has certain flexibility, is not easy to crack, hollow or fall, has good bleeding resistance, strong scratch resistance and shock resistance, and is easy to operate.

Owner:SHUN TAN SHANGHAI NEW MATERIALS CO LTD

Handicraft clay sculpture material and preparation method thereof

InactiveCN104261794AGuaranteed patch improvementsThe formula is scientific and reasonableOperabilityChloride

The invention discloses a handicraft clay sculpture material. The handicraft clay sculpture material is prepared from the following raw materials in parts by weight: 2-3 parts by weight of borax, 1-2 parts by weight of ammonium dihydrogen phosphate, 4-6 parts by weight of magnesium oxide, 0.5-1 part by weight of aluminum chloride, 0.5-1 part by weight of sodium humate, 50-60 parts by weight of kaolin, 10-20 parts by weight of calcium carbonate, 30-40 parts by weight of quartz powder, 10-20 parts by weight of white mica powder, 1-3 parts by weight of gypsum, 0.5-1 part by weight of hydroxyethyl cellulose and water, wherein the total amount of the water is the required amount for realizing a dough-like plastic state of a product. The handicraft clay sculpture material disclosed by the invention can be used under any conditions, has the advantages of reasonable and scientific formula, easiness in obtainment of the raw materials, low cost and easiness in dispersion and stirring, the surface of a work is less prone to cracking in a hardening process and is dense and smooth, and the handicraft clay sculpture material can be widely used in the fields of sculptures, clay sculptures, models and the like. The invention further discloses a preparation method of the handicraft clay sculpture material, and the preparation method has the advantages of simple process steps and strong operability.

Owner:HUANGHE S & T COLLEGE

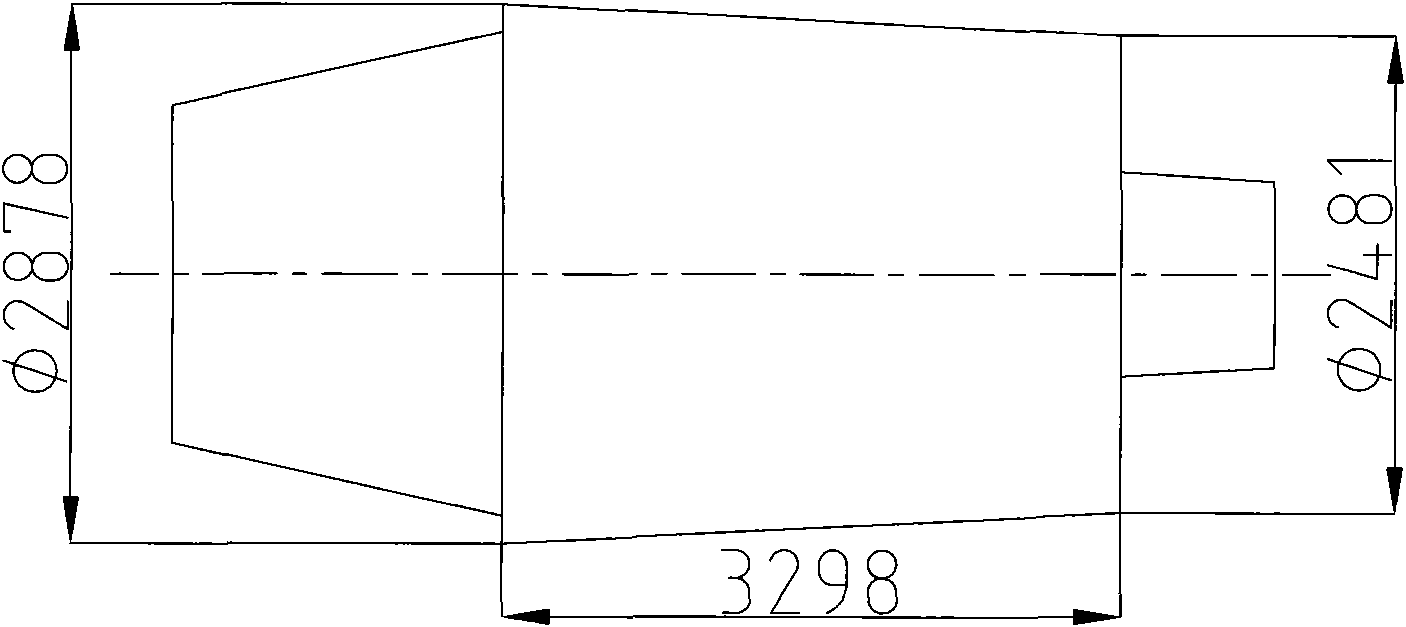

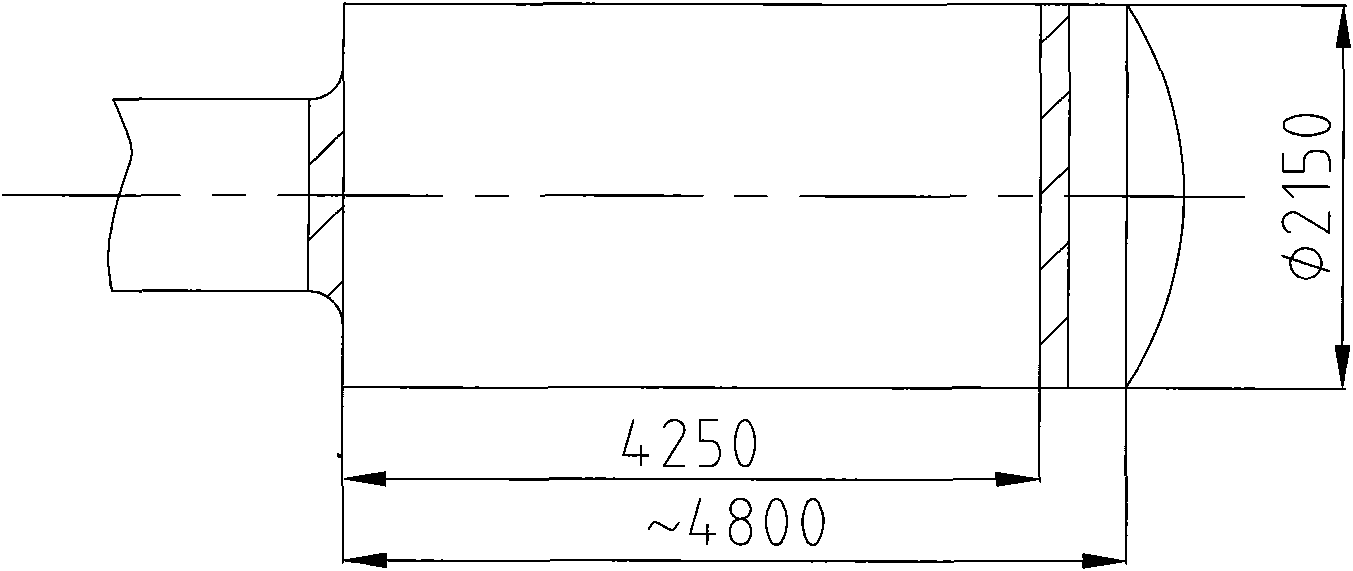

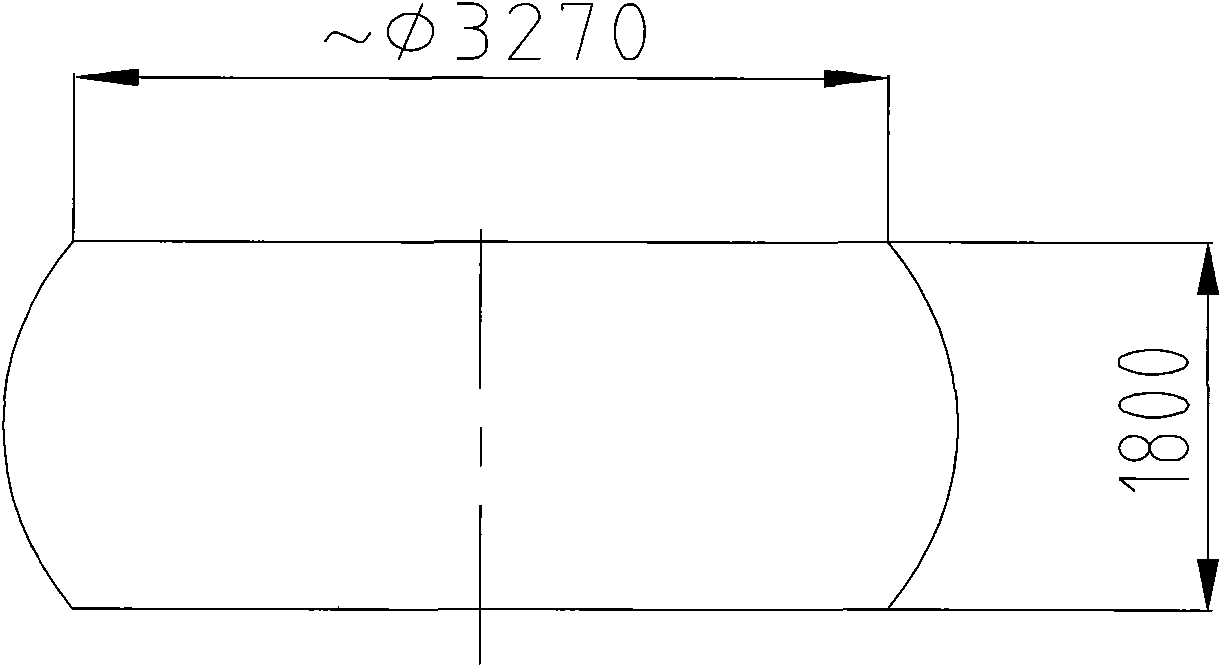

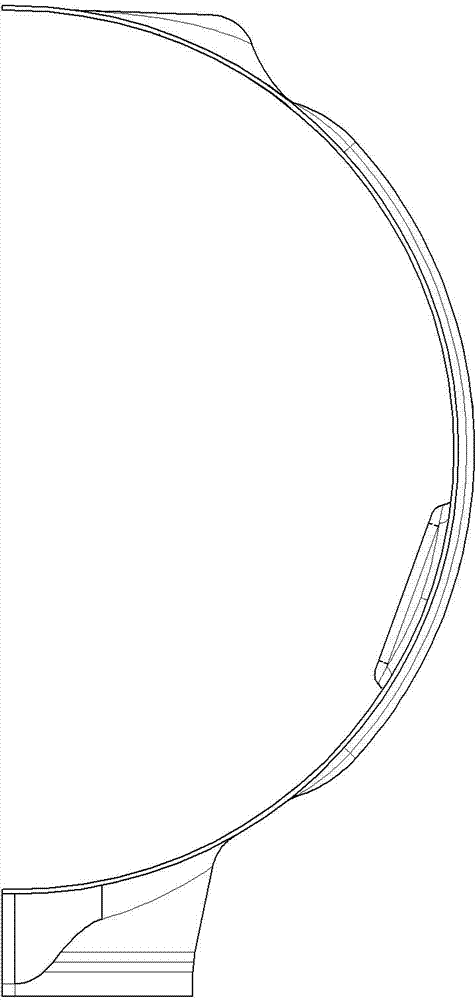

Forging method of conical cylinder body of nuclear power equipment

InactiveCN101987343ANot easy to crackUniform wall thicknessMetal-working apparatusNuclear power plantNuclear power

The invention discloses a forging method of a conical cylinder body of nuclear power equipment. The conical cylinder body is formed by forging 18MND5 and 185 tons of double vacuum steel ingots by using a 16,500-ton hydraulic press. The forging method comprises the following steps of: drawing out; oxygen-acetylene cutting; continuous upsetting; forging a center hole; drawing out and separating materials; and reaming. According to the forging method of the conical cylinder body of the nuclear power equipment, the temperature can be strictly controlled in the forging process, so that the temperature of a forging piece is always maintained in a range of 850-1,240 DEG C, the forging ratio at each step can be ensured and the forging piece formed by forging is not easy to generate cracks and hasuniform wall thickness; and the forging piece has the advantages of dense material, uniform components, reasonable metal streamline distribution and stable performance.

Owner:SHANGHAI HEAVY MACHINERY PLANT

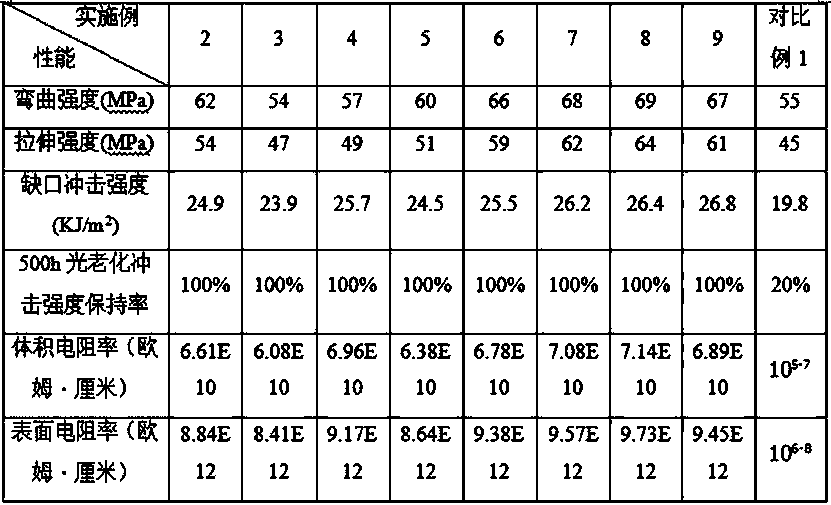

Antistatic anti-aging plastic and preparation method thereof

ActiveCN103396596AImprove notched impact strengthImprove bending strengthPolymer sciencePolyvinyl chloride

The invention discloses an antistatic anti-aging plastic and a preparation method thereof. The antistatic anti-aging plastic is mainly prepared from the following raw materials in parts by weight: 110-130 parts of HDPE (high-density polyethylene), 40-55 parts of PVC (polyvinyl chloride), 30-40 parts of PA6 (polyamide 6), 10-15 parts of coupling agent, 10-12 parts of hydroxymethyl fatty amine, 10-20 parts of shock-resistant modifier, 14-18 parts of polyalcohol, 5-10 parts of antistatic agent, 10-20 parts of carbon black, 5-10 parts of antioxidant, 10-20 parts of DOP (dioctyl phthalate), 10-15 parts of ultraviolet absorbent, 5-10 parts of epoxy octyl stearate and 1-5 parts of barium stearate. The preparation method comprises the following steps: thoroughly mixing the components uniformly, adding the mixture into a double screw extruder, granulating by melting and plastification under certain conditions, and carrying out injection molding on the granules under certain conditions. The method disclosed by the invention is simple in technique, and convenient for large-scale production; and the product has the advantages of high notch impact strength, high bending strength, high hardness, and favorable antistatic and aging resistance.

Owner:ANHUI ANYUAN PLASTIC

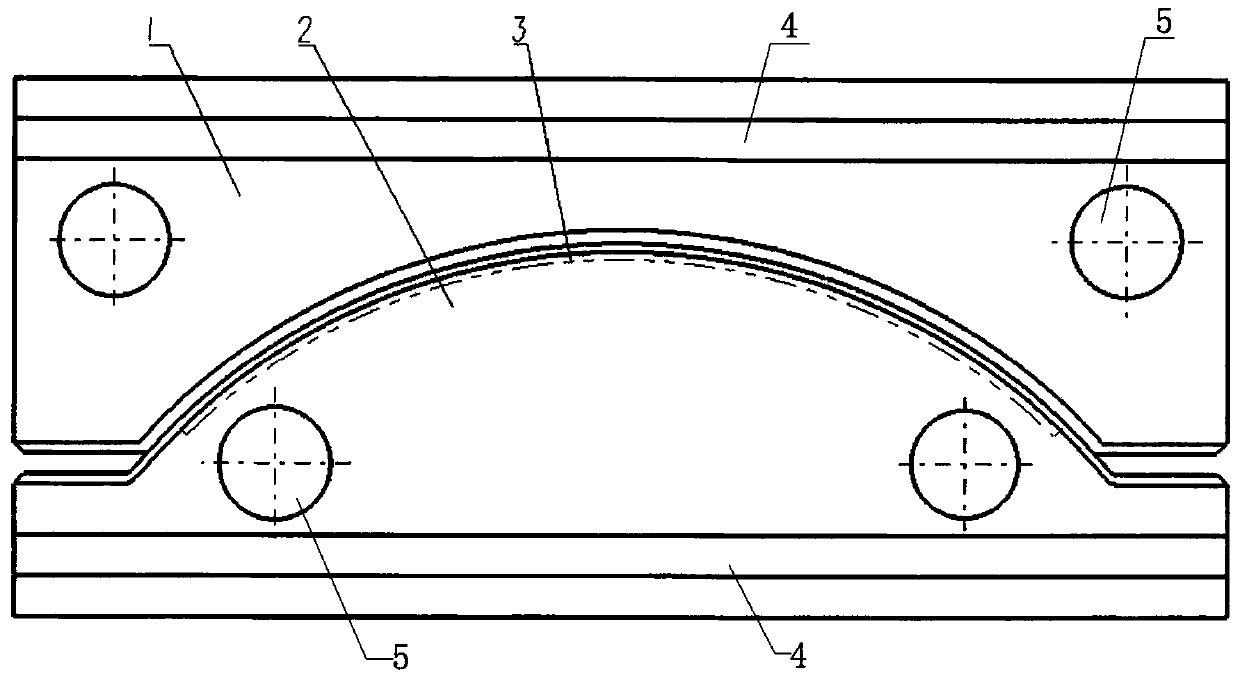

Method for forming titanium alloy sheet metal part

The invention provides a method for forming a titanium alloy sheet metal part. The method is simple, and effectively achieves heated equipment, devices and high temperature resistant moulds in the titanium alloy sheet metal part heating forming method in the prior art and lubrication and pollution prevention under high temperature, heat preservation and pressure maintaining are mainly carried out on titanium alloy materials for a certain time for forming at the temperature of stress relaxation and the creeping state, and high-quality and high-stability forming can be carried out on the titanium alloy sheet metal part successfully.

Owner:SHENYANG AIRCRAFT CORP

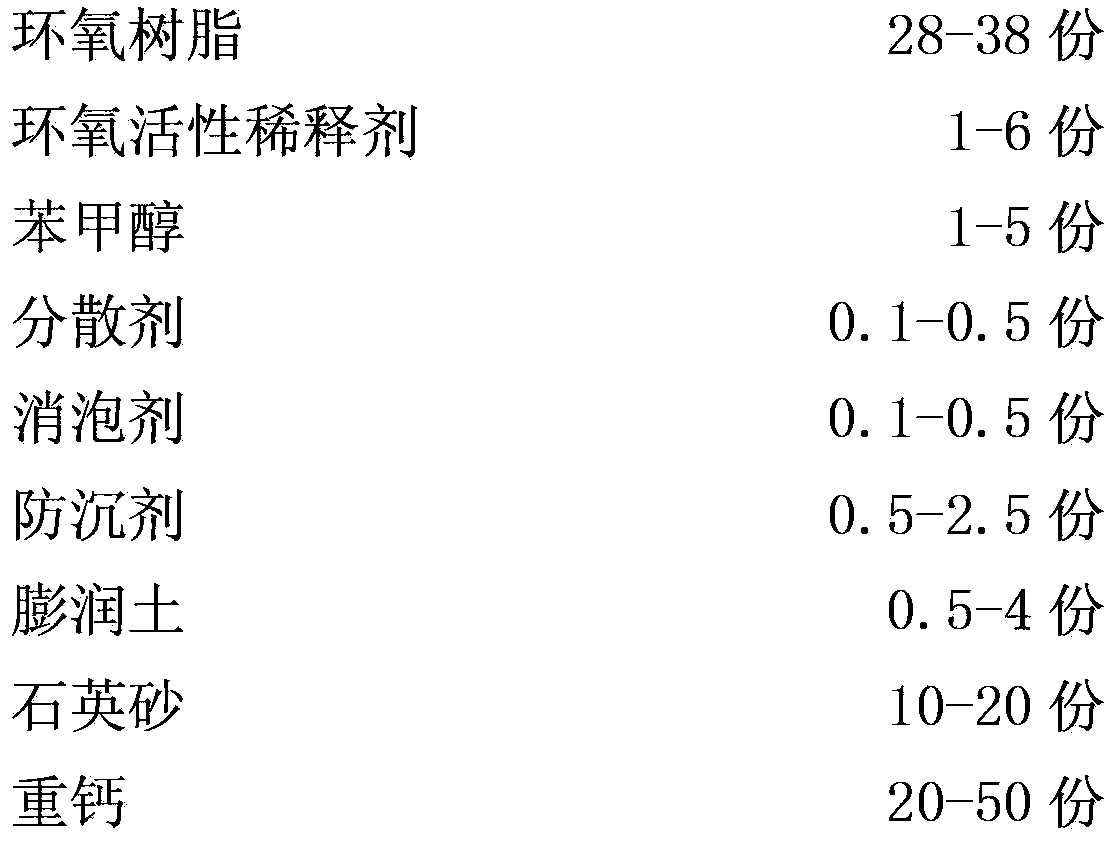

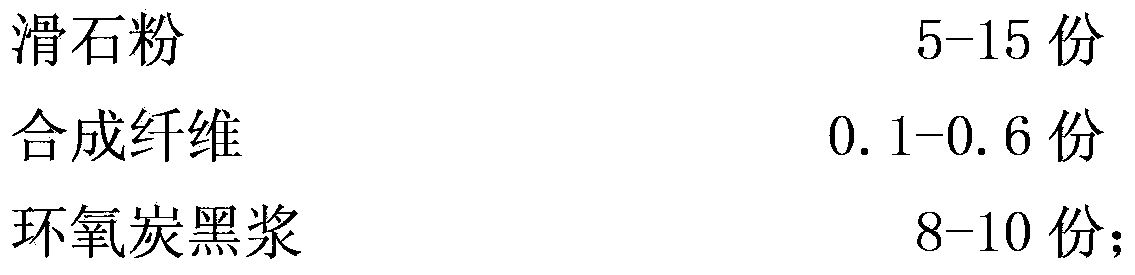

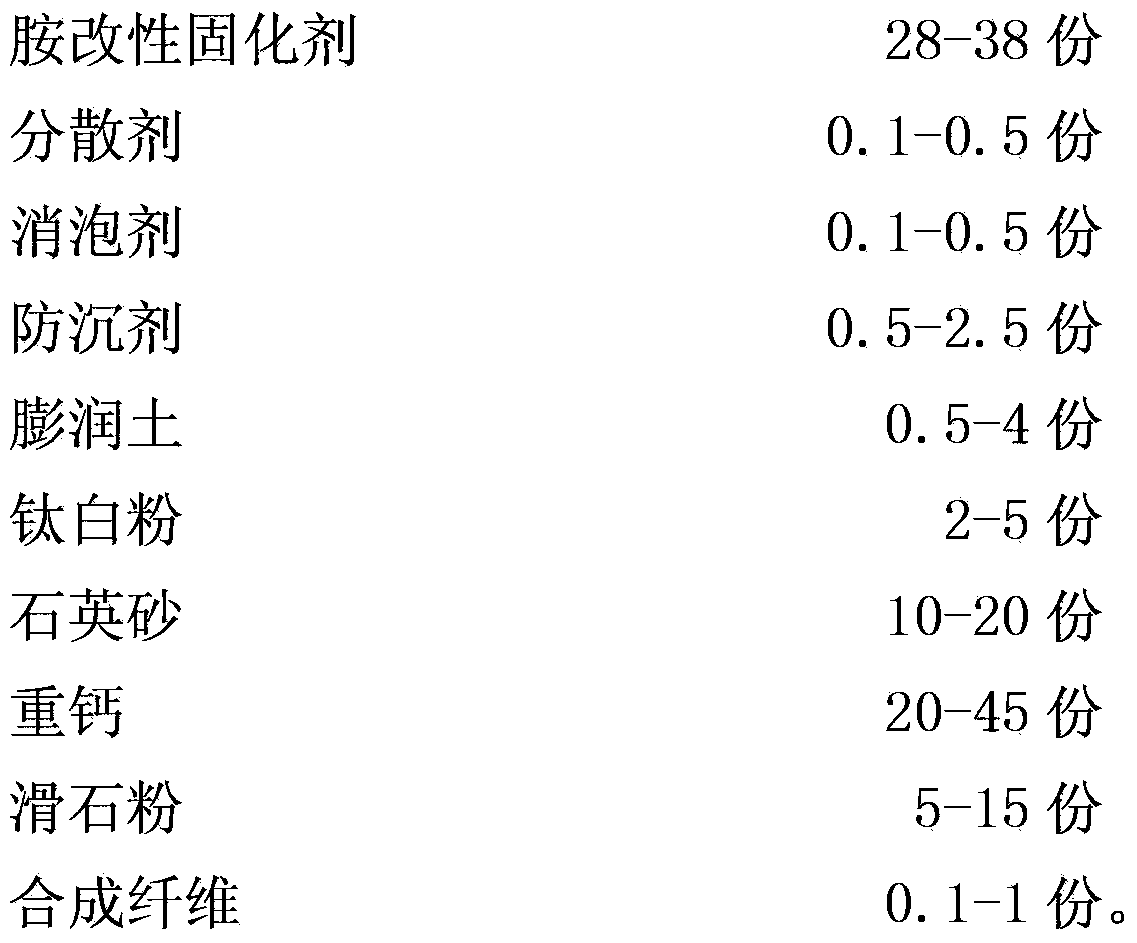

Environment-friendly epoxy seaming paste and preparation method thereof

ActiveCN103509507AStrong adhesionNot easy to crackNon-macromolecular adhesive additivesOther chemical processesSubstance contentCarbon black

The invention relates to environment-friendly epoxy seaming paste and a preparation method thereof. The environment-friendly epoxy seaming paste is formed by mixing main paint with a curing agent according to a mass ratio of 2 to (0.8-1.2), wherein the main paint comprises the following components in parts by weight: 28-38 parts of epoxy resin, 1-6 parts of an epoxy reactive diluent, 1-5 parts of phemethylol, 0.1-0.5 part of a dispersant, 0.1-0.5 part of a defoamer, 0.5-2.5 parts of an anti-settling agent, 0.5-4 parts of bentonite, 10-20 parts of quartz sand, 20-50 parts of heavy calcium carbonate, 5-15 parts of talcum powder, 0.1-0.6 part of synthetic fibers and 8-10 parts of epoxy carbon black slurry; the curing agent comprises the following components in parts by weight: 28-38 parts of an amine-modified curing agent, 0.1-0.5 part of the dispersant, 0.1-0.5 part of the defoamer, 0.5-2.5 parts of the anti-settling agent, 0.5-4 parts of the bentonite, 2-5 parts of titanium dioxide, 10-20 parts of the quartz sand, 20-45 parts of heavy calcium carbonate, 5-15 parts of the talcum powder and 0.1-1 part of the synthetic fibers. The environment-friendly epoxy seaming paste prepared by the method has the advantages of very high bonding force, low possibility of cracking, water resistance and low harmful substance content, and is good in constructability.

Owner:SKSHU PAINT

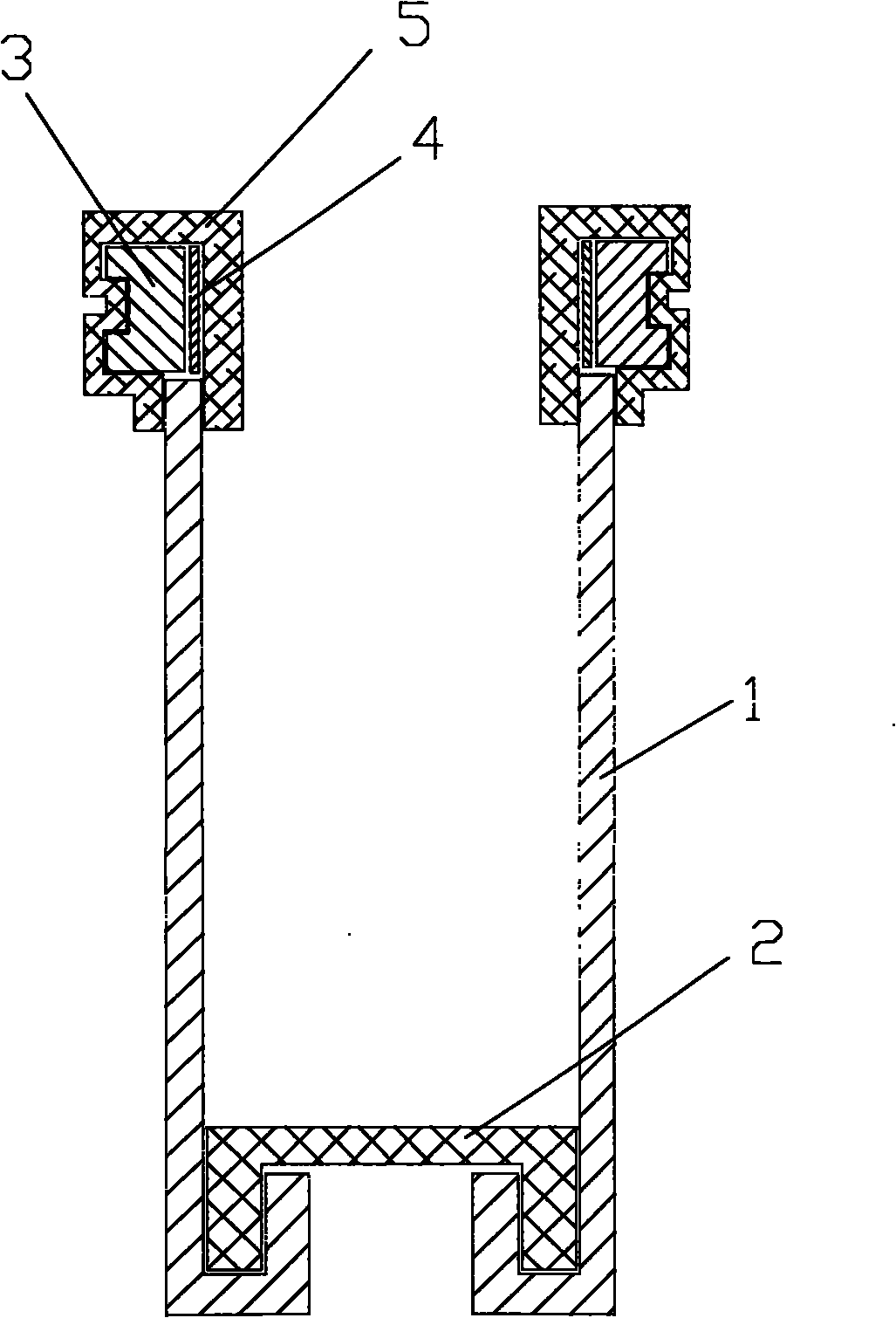

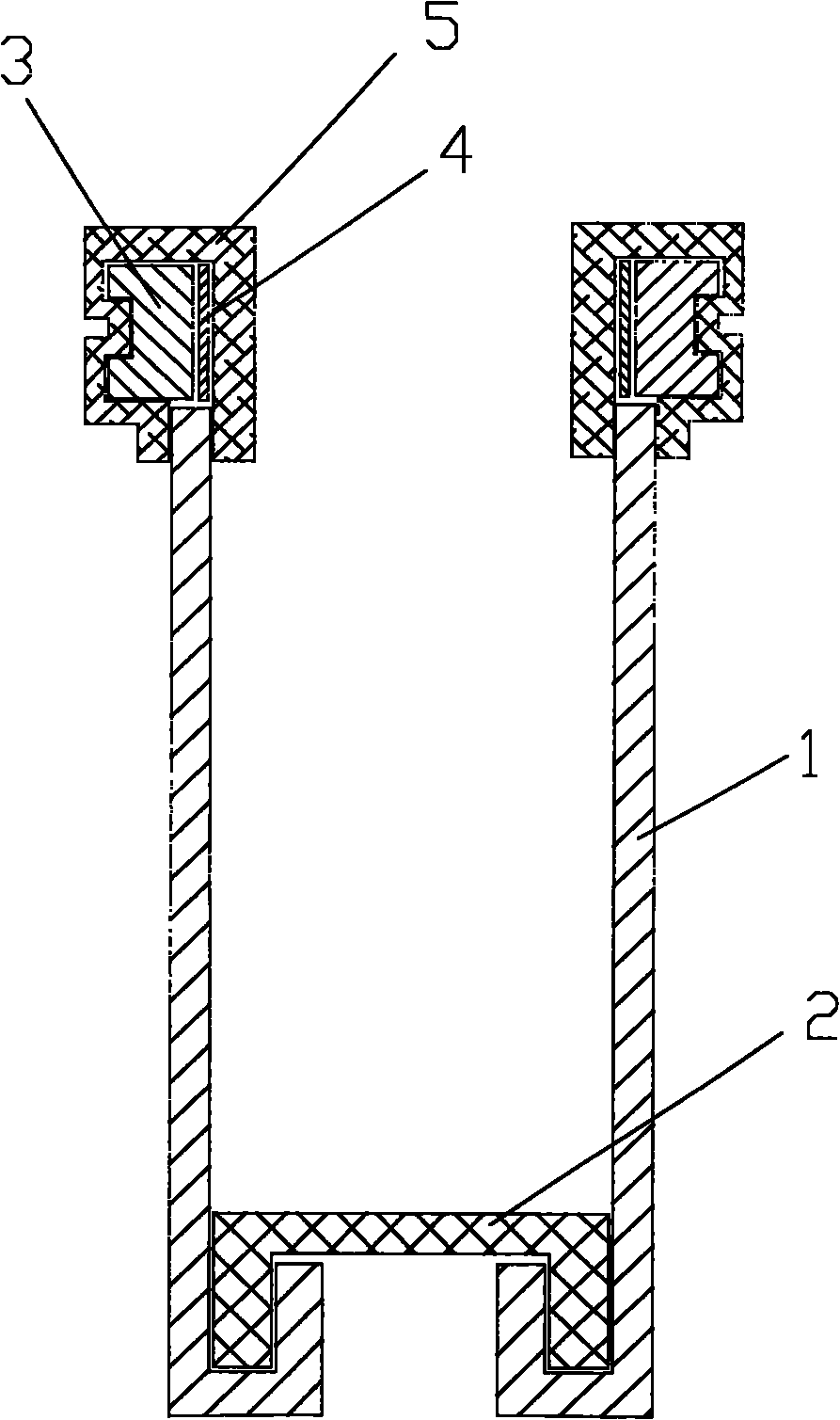

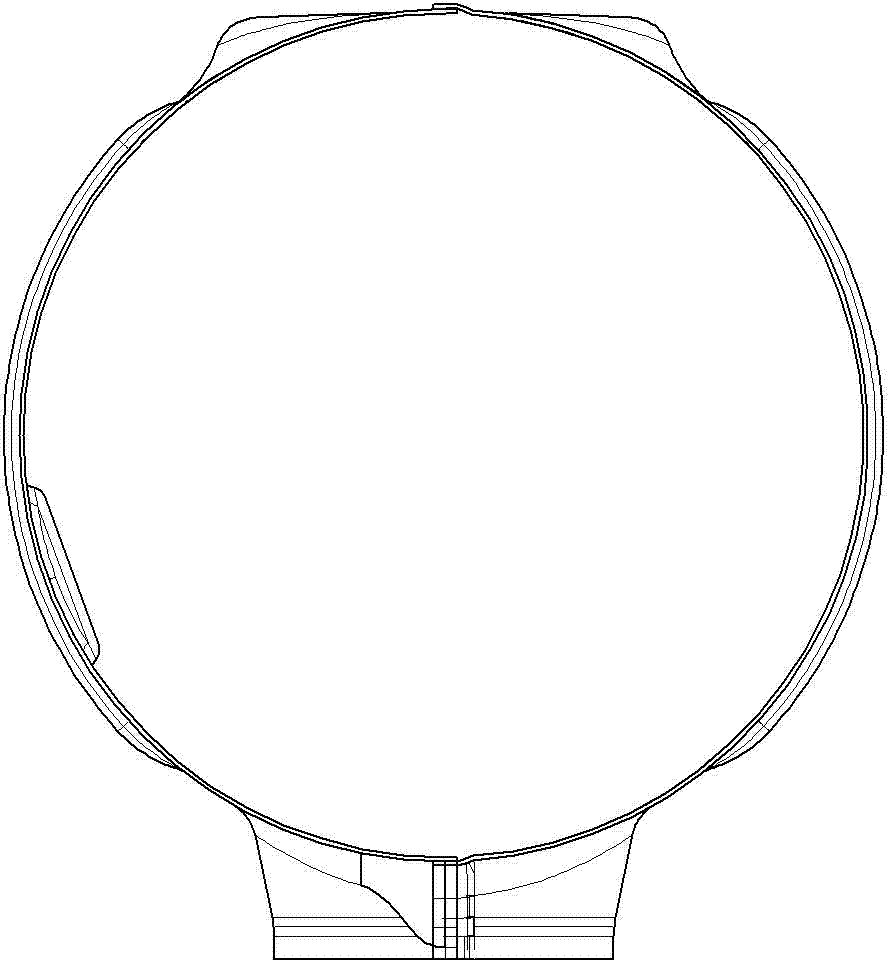

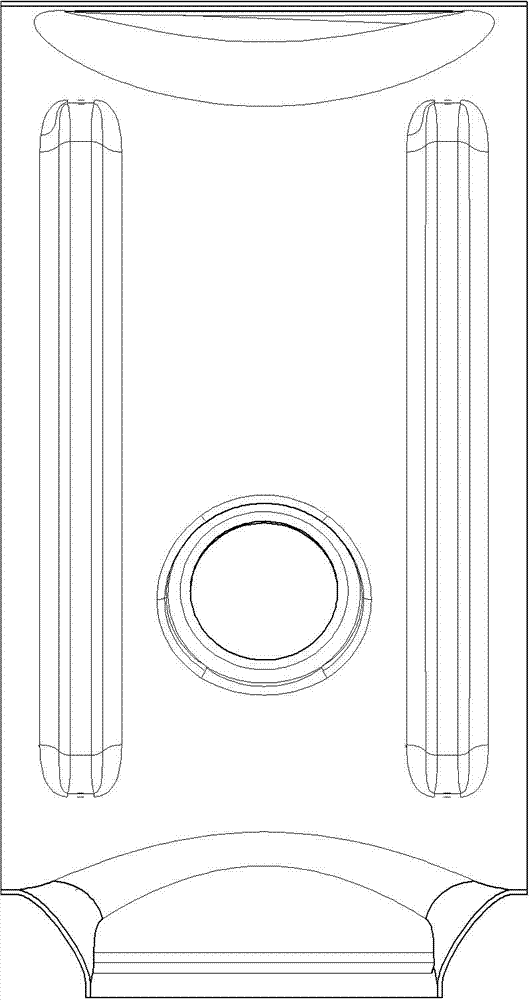

A kind of preparation method of dust filter bag

ActiveCN102284215ANot easy to crackImprove work efficiencyDispersed particle filtrationAirflowEngineering

The invention discloses a method for preparing a dust removal filter bag. The method comprises the steps of preparing a bag body, preparing a bag mouth and preparing a bag bottom and specifically comprises the following steps of: 1, preparing the bag body through ultrasonic welding; 2, preparing the bag mouth in a mode of sewing three layers of filter cloth and embedding a packing into the bag mouth; and 3, preparing the bag bottom in a mode of turning over the bag body and embedding the edge of the bag bottom. By the method for preparing the dust removal filter bag, the bag mouth is not easy to damage, and the service life is long; the cloth eyelets are avoided on the connection part of the bag body, so that the connection part of the bag body can bear high-pressure air flow; and the connection part of the bag bottom does not leak dust so as to bear high-pressure air flow.

Owner:JIANGSU FILTERTEX FILTER MATERIAL

Forming process of automobile engine exhaust system heat insulation cover

ActiveCN104259771ANot easy to crackGuarantee processing qualityEngine componentsEngineeringForming processes

The invention provides a forming process of an automobile engine exhaust system heat insulation cover and solves the problems of lower forming quality and high machining cost caused by integral casting and forming currently. The cold stamping machining and forming process is adopted, the automobile engine exhaust system heat insulation cover is divided into a left half cover and a right half cover through a longitudinal central line of an exhausting tube port, the left half cover and the right half cover are stamped and formed respectively, and the stamped and formed left half cover and right half cover are welded integrally.

Owner:WUXI DAWN DIE & STAMPING

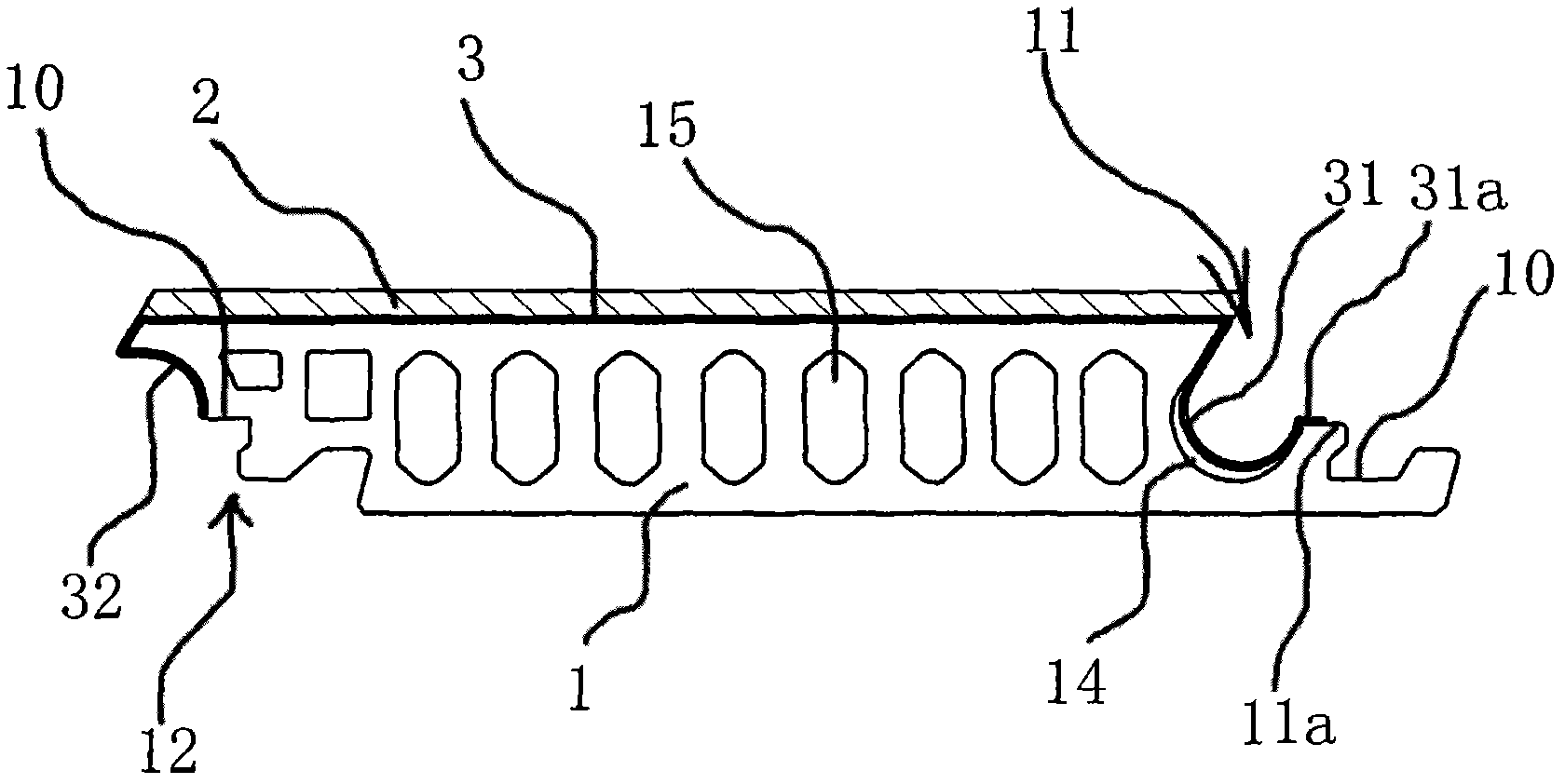

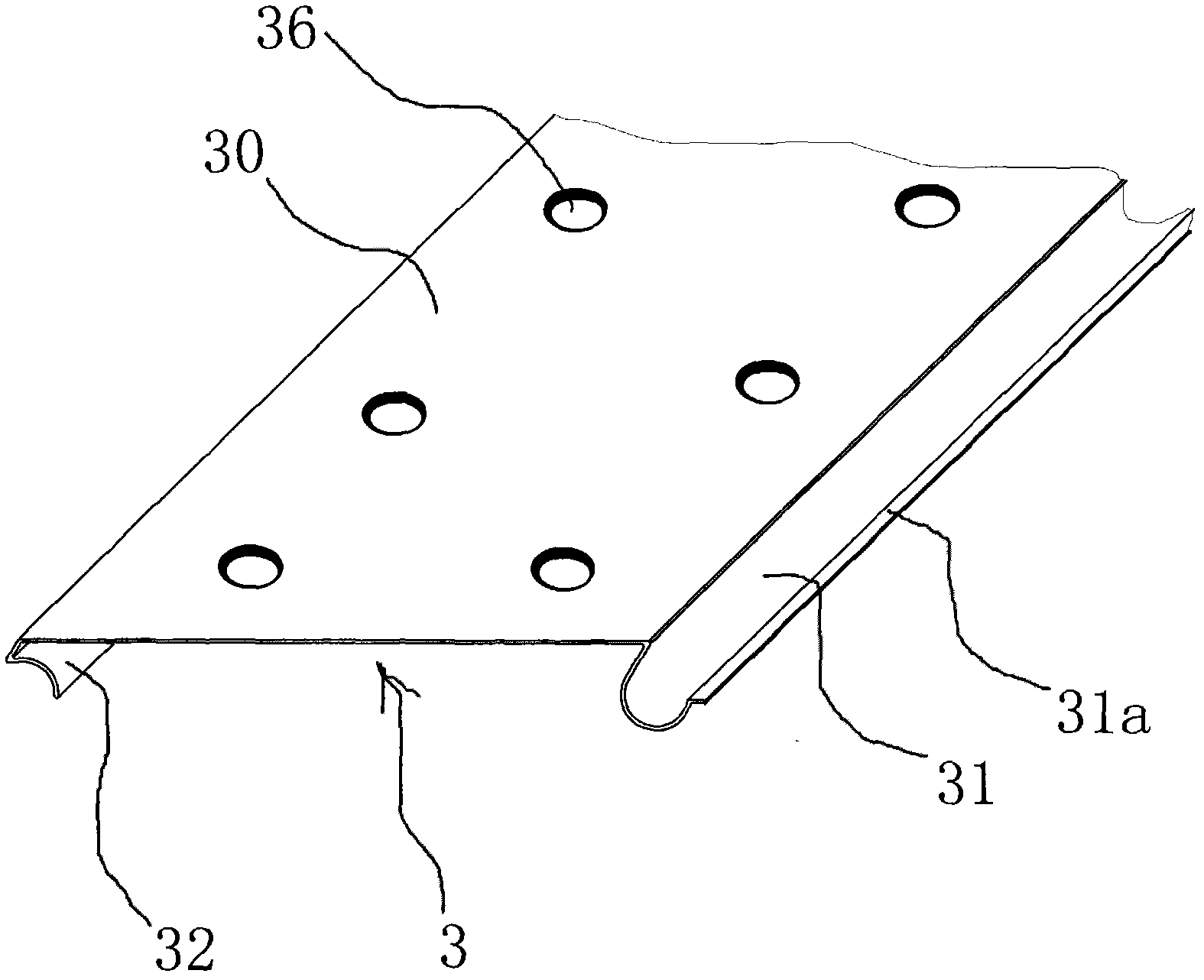

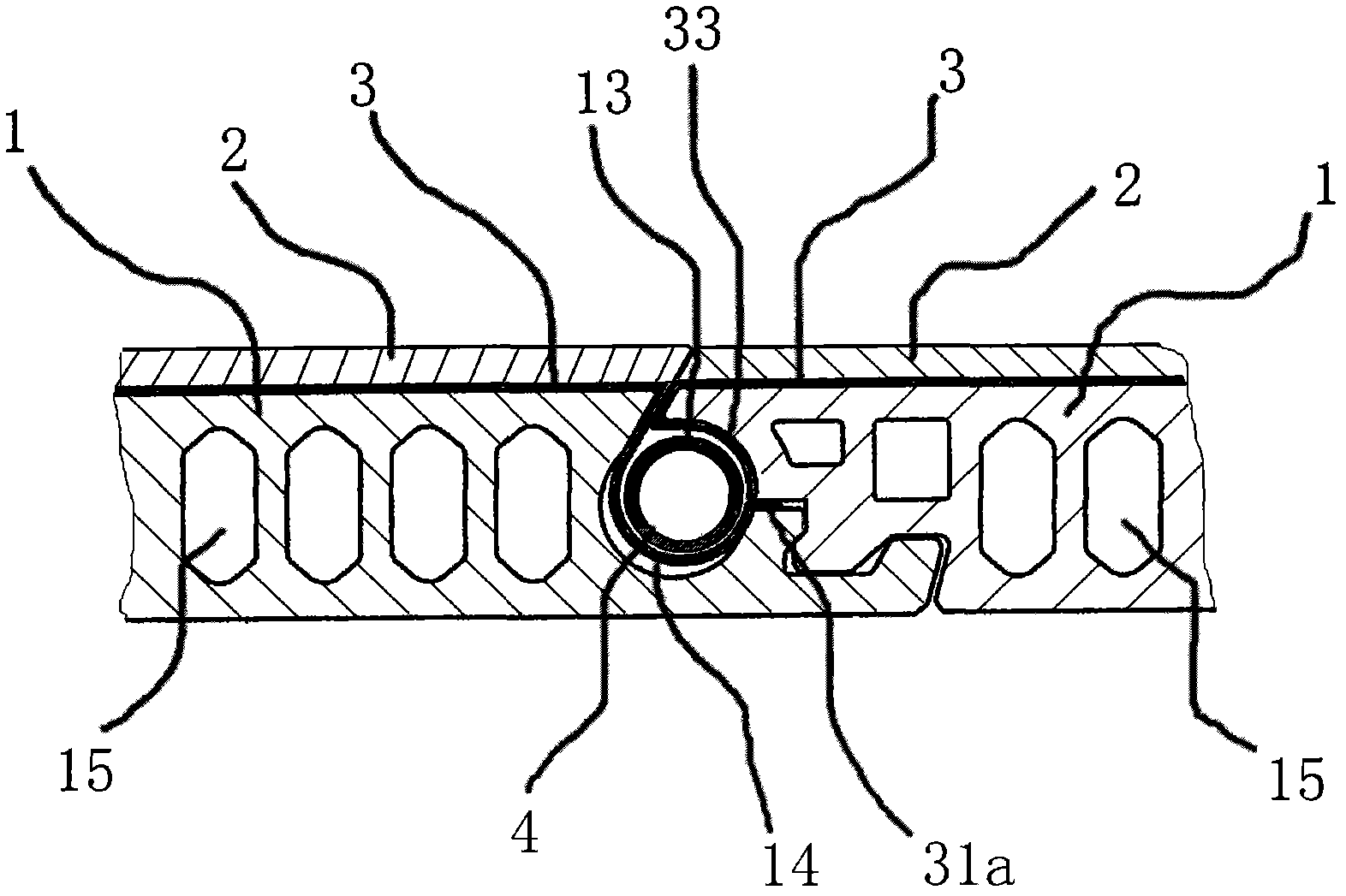

Floorboard for floor heating

InactiveCN102174851AShort delivery pathReduce lossLighting and heating apparatusElectric heating systemHeat conductingEngineering

Owner:上海暖捷环境科技有限公司

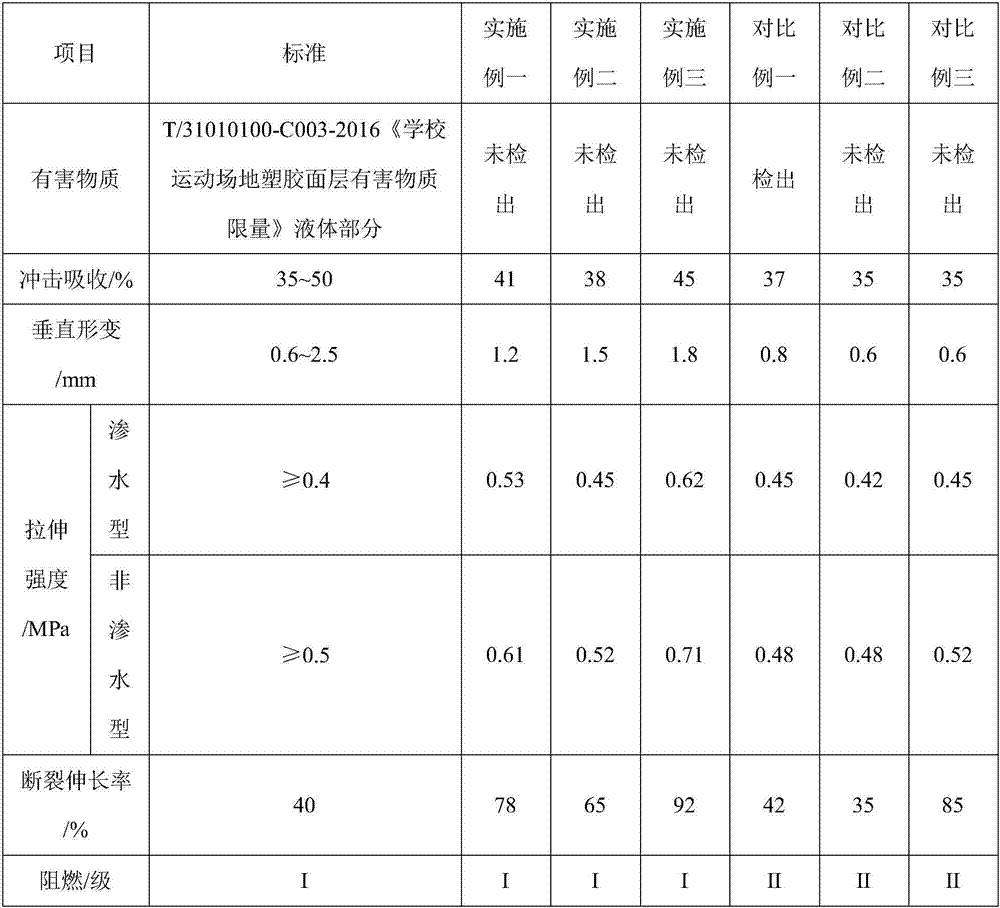

Water-based environment-friendly plastic track adhesive and preparation method thereof

ActiveCN106867431AGood weather resistanceGood alkali resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesWater basedEmulsion

The invention discloses a water-based environment-friendly plastic track adhesive and a preparation method thereof. The technical scheme is as follows: the water-based environment-friendly plastic track adhesive comprises a component A and a component B. The component A comprises the following substances in percentage by weight: 19-48% of deionized water, 0.3-0.8% of dispersing agent, 0.5-0.7% of defoaming agent, 0.2-0.5% of thickener, 1-2% of hydroxyethyl cellulose ether, 0.5-1% of film forming aid, 40-60% of water-based acrylate emulsion and 0.5-2% of bactericide. The component B comprises the following substance in percentage by weight: 5-10% of amine curing agent. The water-based environment-friendly plastic track adhesive substitutes the adhesive prepared from aromatic diisocyanates in the prior art. Even in hot days or under ultraviolet irradiation, the adhesive disclosed by the invention can not release aromatic toxic gases, thereby greatly enhancing the environment friendliness of the adhesive.

Owner:苏州大乘环保新材有限公司

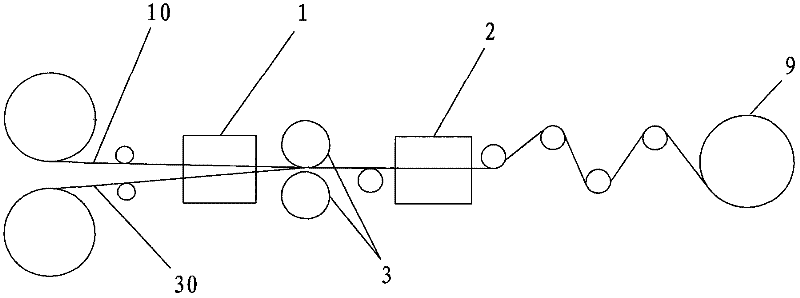

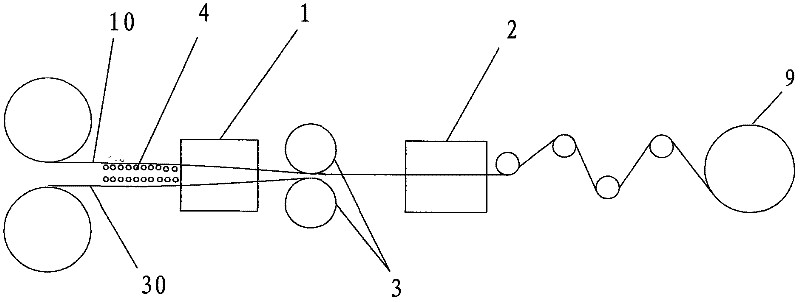

Microfiber artificial leather adhered with TPU film, and production process thereof

InactiveCN102442041APromote environmental protectionIncrease elasticitySynthetic resin layered productsLaminationEngineeringCold resistance

The present invention relates a microfiber artificial leather product, and the technical field of a microfiber artificial leather production process, especially to a microfiber artificial leather adhered with a TPU film, and a production process thereof. The microfiber artificial leather adhered with the TPU film comprises a microfiber artificial leather layer, wherein the microfiber artificial leather layer is adhered with a TPU layer by a glue adhering manner or a hot pressing manner. With the present invention, the performances of environmental protection, elasticity, toughness, abrasion resistance, cold resistance and the like of the microfiber artificial leather are substantially improved; crack and rupture are not easily generated; the manufacture costs of luggages, building materials, shoe materials and other products are substantially reduced.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

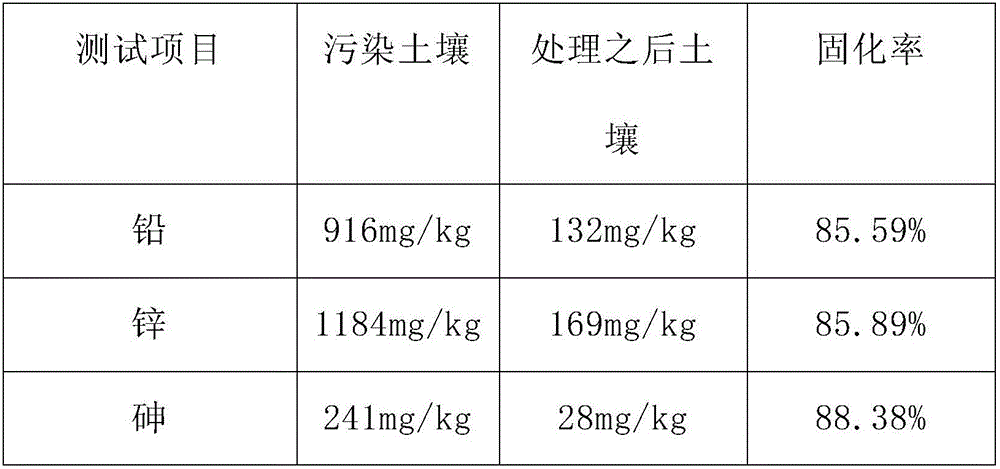

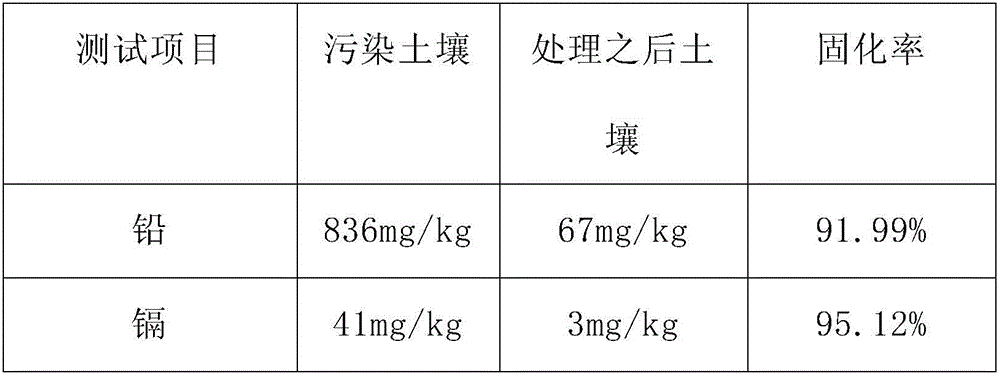

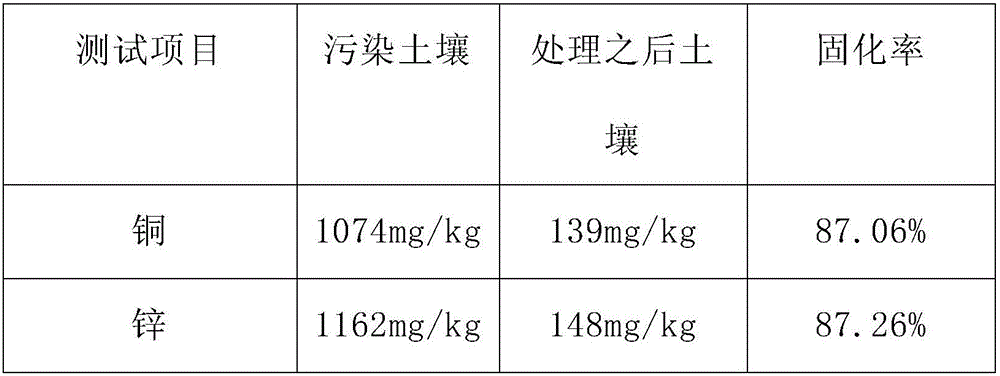

Heavy metal pollution soil restoration agent and use method thereof

InactiveCN106433668AImprove adsorption capacityEffectively fixedOrganic fertilisersSoil conditioning compositionsSocial benefitsTO-18

The invention provides a heavy metal pollution soil restoration agent, and relates to a soil restoration agent. The restoration agent comprises a pretreatment curing ingredient and an excitation curing ingredient, wherein the pretreatment curing ingredient comprises modified expanded vermiculite; the excitation curing ingredient comprises 4 to 18 percent of slaked lime, 4 to 10 percent of chitosan, 16 to 34 percent of water glass and 45 to 60 percent of fly ash. The heavy metal pollution soil restoration agent and the use method have the advantages that the efficient curing of soil heavy metal can be realized; the soil heavy metal pollution problem is solved; in addition, the high acidity or high alkality and secondary pollution can be effectively avoided; the uniformity of environment benefits and social benefits is realized.

Owner:广东省润土环境治理有限公司

Five-layer co-extrusion laminated board for sanitary ware and preparation method thereof

InactiveCN101670694ASolve ABSSolving Consistency IssuesSynthetic resin layered productsLaminationCrack resistanceUltraviolet

The invention discloses a five-layer co-extrusion laminated board for sanitary ware and a preparation method thereof, wherein the first layer and the fifth layer are made from PMMA and UV; the secondlayer and the fourth layer are made from the PMMA, ABS, the UV and a titanium dioxide color master batch; and the third layer is made from the ABS and the titanium dioxide color master batch. The preparation method of the board comprises the following steps: uniformly mixing and stirring the raw materials of each layer in respective mixing hoppers; drying the raw materials and then plasticizing, melting and extruding the raw materials into corresponding flow channels of a distributor at a certain temperature by three extruders; and extruding the raw materials by a T-shaped die head and flattening the raw materials through a flattening system to prepare the board. The invention has the advantages that after long-term uneven cold and hot changes, the board is not easy to generate delamination to crack, has good hot water circulation resistance and the function of ultraviolet ray resistance, can be guaranteed to be not easy to fade during use and have cracking resistance, chemical corrosion resistance, hot water circulation resistance, stable color, difficult fading after being exposed to the sun and the rain for a long term, and the like. The invention is also widely suitable for other fields such as indoor and outdoor decoration, and the like.

Owner:CHANGZHOU BOSHUANG PLASTICS

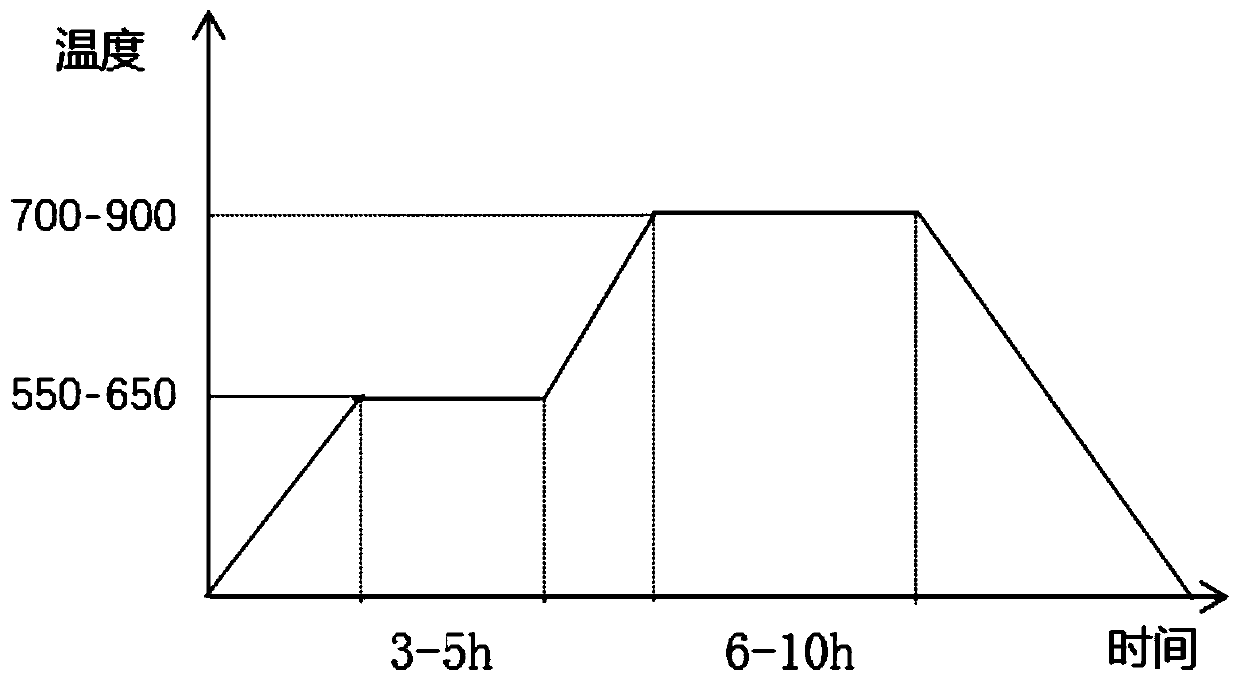

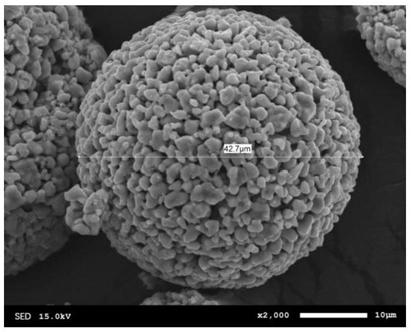

Preparation method of ternary precursor with bulk phase doped with rare earth elements and positive electrode material of ternary precursor

ActiveCN111018004AImprove firmnessNot easy to crackCell electrodesSecondary cellsRare-earth elementLithium hydroxide

The invention provides a preparation method of a ternary precursor with the bulk phase doped with rare earth elements and a positive electrode material of the ternary precursor, and belongs to the field of lithium ion battery positive electrode materials. The preparation method is suitable for industrial mass production. The preparation method comprises the following steps: preparing a nickel-cobalt-manganese rare earth salt solution, an alkaline solution and a base solution, injecting the solutions into a reaction kettle at a certain rate, carrying out a coprecipitation reaction, regulating parameters in real time, monitoring the growth condition of particles, and carrying out suction filtration and drying to obtain the precursor NixCoyMnzREk(OH)2; and mixing the prepared precursor with lithium hydroxide, carrying out high-temperature sintering, crushing the sintered material by adopting a coarse crushing and fine crushing process, and carrying out particle size grading and magnetic foreign matter removal by virtue of a screening and iron removing machine so as to complete the preparation of the bulk-phase doped ternary positive electrode material. The rare earth La<3+> / Tb< 3+> / Eu<3+> element has a specific outer layer electronic configuration, and can be used for doping crystal lattices of NiCoMn(OH)2 to improve the electronic conductivity of the material and inhibit cation mixed arrangement in the crystal lattices, and Tb-O bonds are stronger than Ni-O and Mn-O bonds in energy, so that the doped material has good electrochemical cycle performance and structural stability.

Owner:浙江尚特新能源科技有限公司

Thermal mortar and preparation method thereof

InactiveCN108002775AEasy constructionNot easy to produce surface hollowingCeramicwarePortland cementCoal

The invention discloses thermal mortar and a preparation method thereof and relates to the technical field of thermal mortar. The thermal mortar comprises the following raw materials in parts: 65-75 parts of portland cement, 45-55 parts of modified coal ash, 40-45 parts of modified fiber reinforced particles, 25-35 parts of modified glass beads, 20-25 parts of glutinous rice glue, 15-20 parts of modified nanocarbon, 15-20 parts of an additive and 120-150 parts of water. The thermal mortar preserves heat, is toughened, has good workability, has low probability arousing such problems as surfacehollowing, cracking and falling, and is prolonged in service life.

Owner:明光市泰丰新材料有限公司

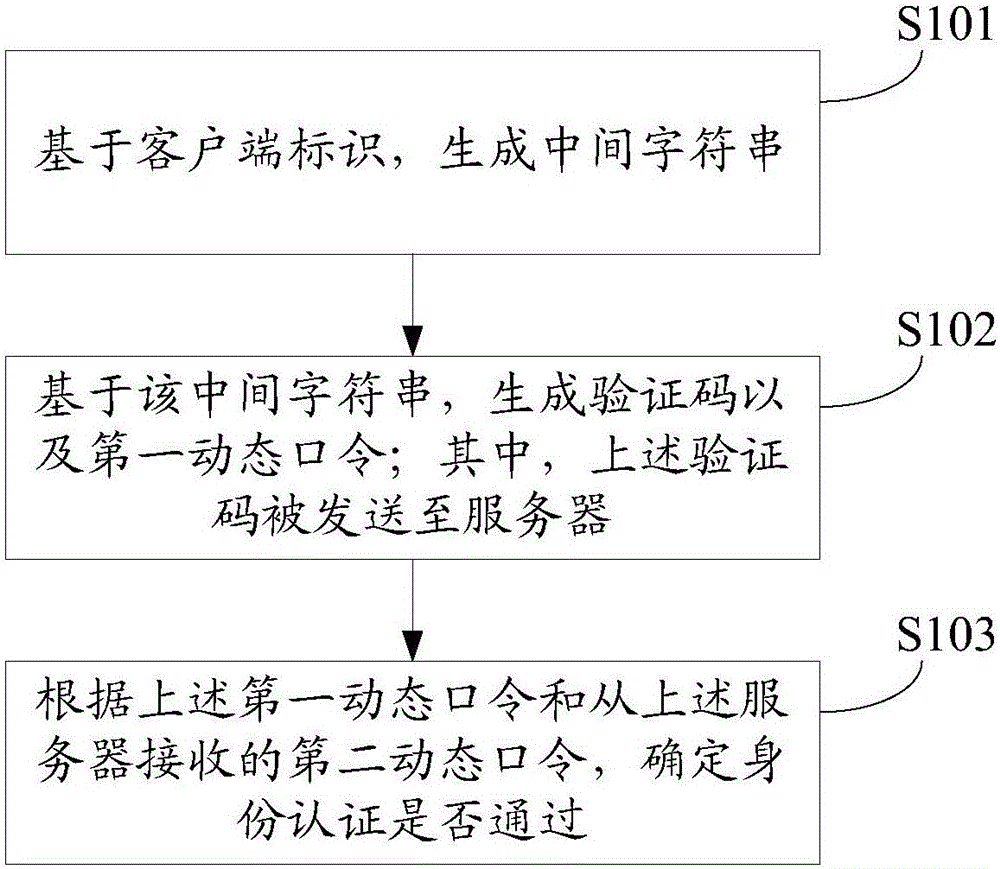

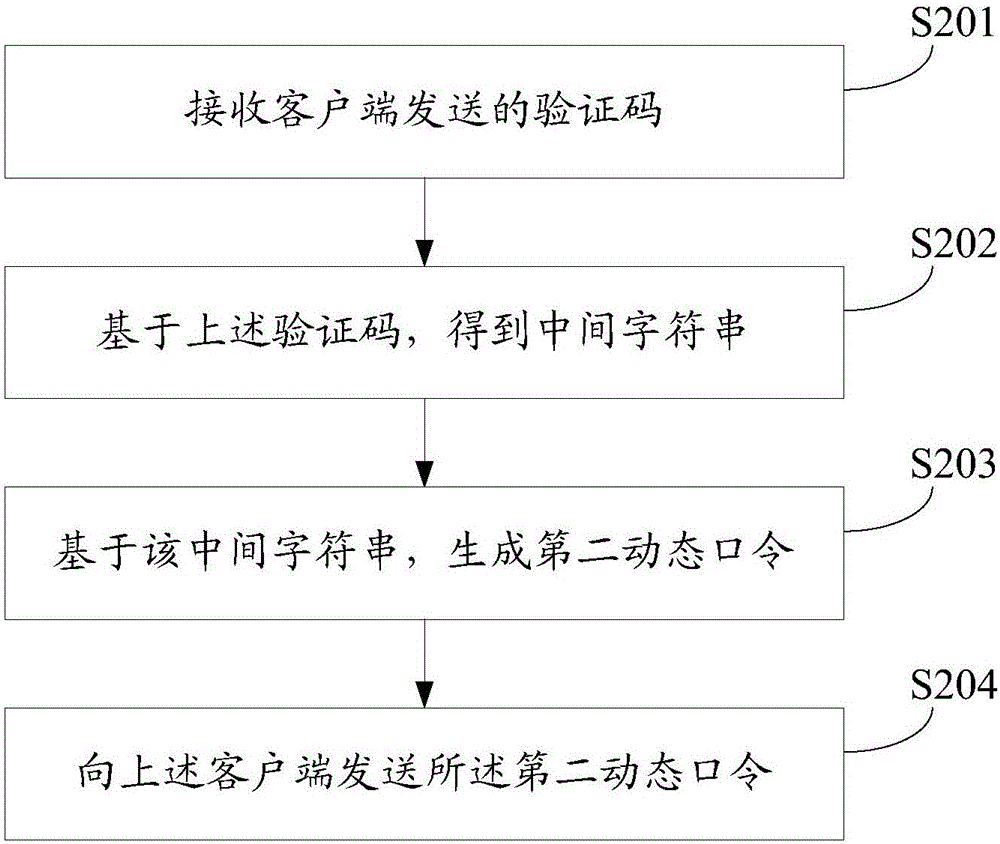

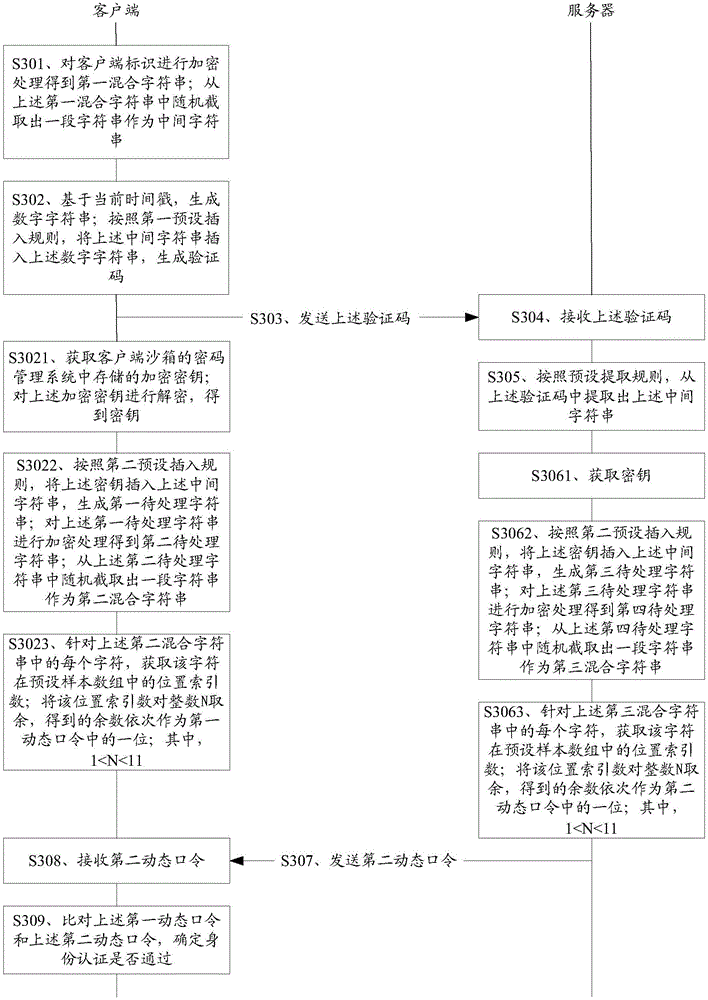

Identity authentication method, client side, server and system

InactiveCN105827591AThe generation process is rigorousNot easy to crackTransmissionClient-sidePassword

The invention discloses an identity authentication method, a client, a server and a system, which can realize two-way identity authentication between the client and the server, thereby ensuring the security of the system. The identity authentication method includes: generating an intermediate character string based on the client identifier; generating a verification code and a first dynamic password based on the intermediate character string; wherein, the verification code is sent to the server; according to the first dynamic password and from the The second dynamic password received by the server determines whether the identity authentication is passed.

Owner:北京启迪思创科技有限公司

Coating and preparation method and application thereof

ActiveCN103571303AAdhesive connection is reliableNot easy to crackNon-macromolecular adhesive additivesLayered productsCorrosion resistantMechanical properties of carbon nanotubes

The invention relates to a coating and a preparation method and application thereof. The coating is characterized by comprising the following raw materials in parts by weight: 10-11 parts of metal powder and glass fiber powder in total, and 6-10 parts of glue components. The part between a metal plate and a fiberglass plate is coated with a plurality of layers of coatings at different raw material ratios, is solidified and formed into a composite board with the coefficient of linear expansion gradually varying to fiberglass coefficient of linear expansion from metal coefficient of linear expansion, so that the metal plate and the fiberglass plate are bonded more firmly and are not easy to shed, and the composite board is endowed with both good mechanical property and good corrosion resistance and impact resistance.

Owner:梁明森

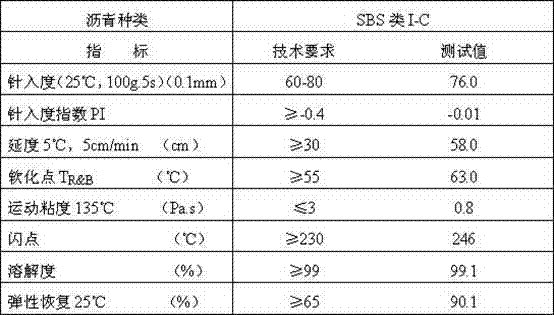

Preparation method of paving asphalt modified at normal temperature

ActiveCN102190898ASimple processShorten the production cycleBuilding insulationsRoom temperatureRoad surface

The invention provides a preparation method of paving asphalt modified at a normal temperature. The invention belongs to the preparation field of pavement materials and comprises the following steps of cracking, low pressure separation, diluent preparation, high-molecular resin modifier preparation, modification and blending. The preparation method adopts improved technical processes, thus a process of heating matrix asphalt is avoided and purposes of short production period, low production cost and environmental protection are realized.

Owner:SICHUAN GUOXING POLYMER RESIN CO LTD

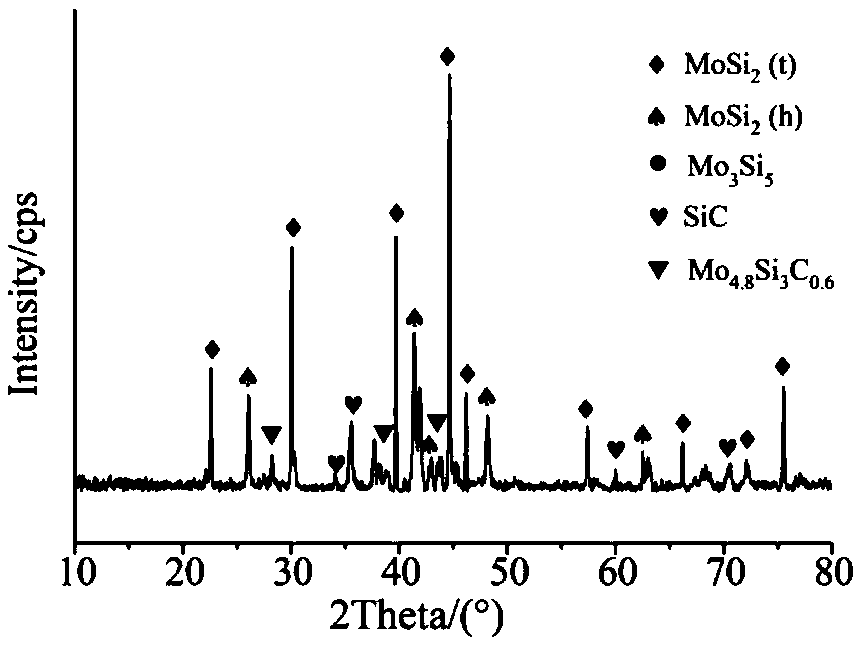

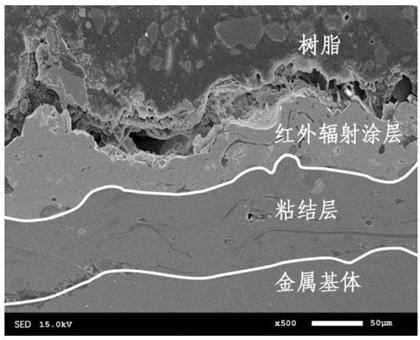

Preparation method of high-temperature-resistant high-infrared-emissivity coating

InactiveCN108950456ASolving difficult-to-attach puzzlesSolve the problem of low infrared radiation rate in the short-wave bandMolten spray coatingSpray GranulationThermal spraying

The invention provides a preparation method a high-temperature-resistant high-infrared-emissivity coating. The preparation method comprises the following steps that different proportions of MoSi2 powder and SiC powder are evenly mixed with a binding agent, a defoaming agent and a dispensing agent, and then water is added to an obtained mixture to conduct grinding, so that uniform pulp with certainviscosity is obtained; spray granulation is conducted on the pulp, so that spray powder with a high degree of sphericity is obtained; the obtained powder is placed under an Ar atmosphere at the temperature of 1400 DEG C so as to be roasted for 2 hours, so that compact spherical powder is obtained; and the high-temperature-resistant high-infrared-emissivity coating is obtained on the surface of stainless steel subjected to roughing treatment through the atmospheric plasma spraying technique. The infrared radiation coating prepared through the thermal spraying method can achieve metallurgical bonding with a matrix and is high in bonding capacity and not prone to cracks and stripping, and the problem that it is different for infrared radiation ceramic to adhere to a metal matrix is solved; and meanwhile, the technical problems that an existing high-temperature infrared radiation coating is provided with a short-wave section low in infrared radiancy and is poor in thermal shock resistanceare also solved.

Owner:WUHAN UNIV OF TECH

Terminal, shell, middle frame, and processing method of middle frame

PendingCN106432771AGood surface toughnessNot easy to crackLiquid surface applicatorsPolyurea/polyurethane coatingsUrethane acrylateElastomer

The invention discloses a terminal, a shell, a middle frame, and a processing method of the middle frame. The middle frame is used in the terminal, and comprises a middle frame body, wherein the middle frame body is processed with at least a UV painting layer which comprises polyurethane acrylate elastomer resin. The obtained middle frame has good tenacity in surface coat and is not prone to craze, and the yield is high.

Owner:SHENZHEN HEYTAP TECHNOLOGY CO LTD

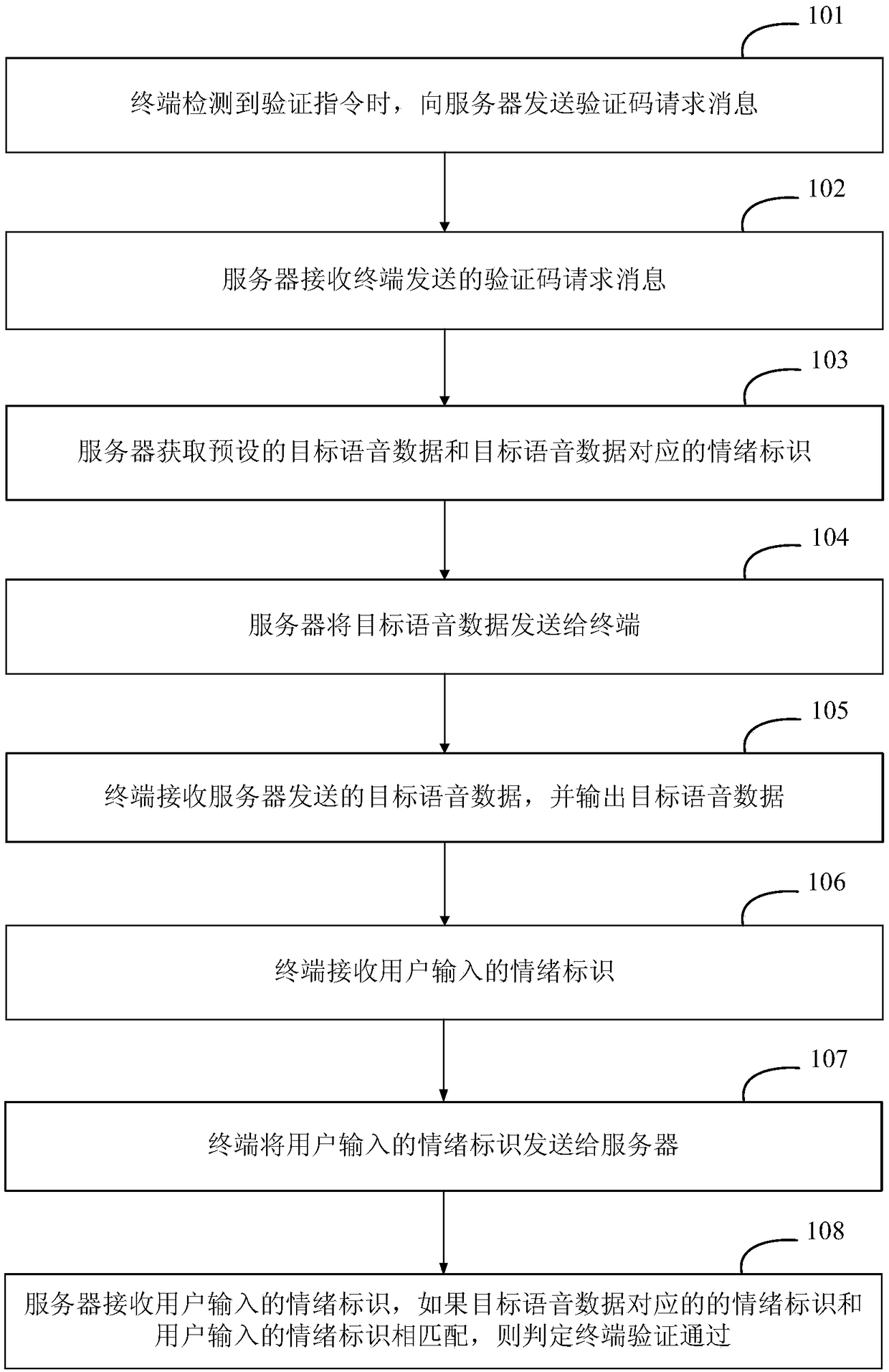

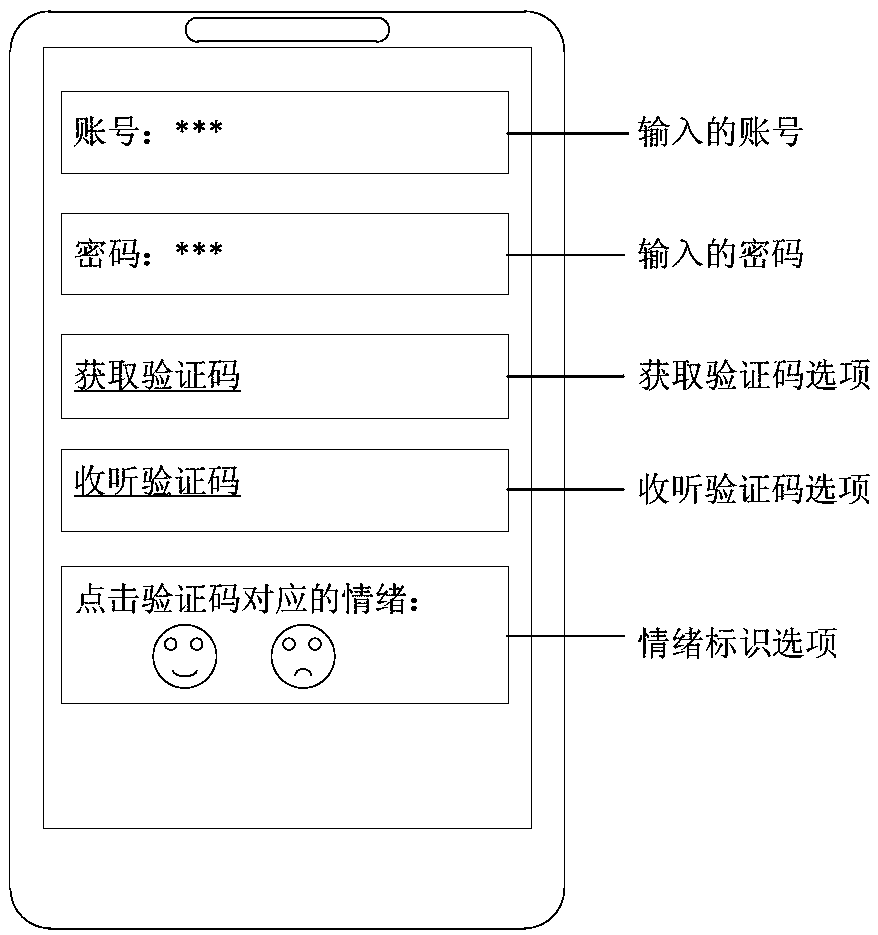

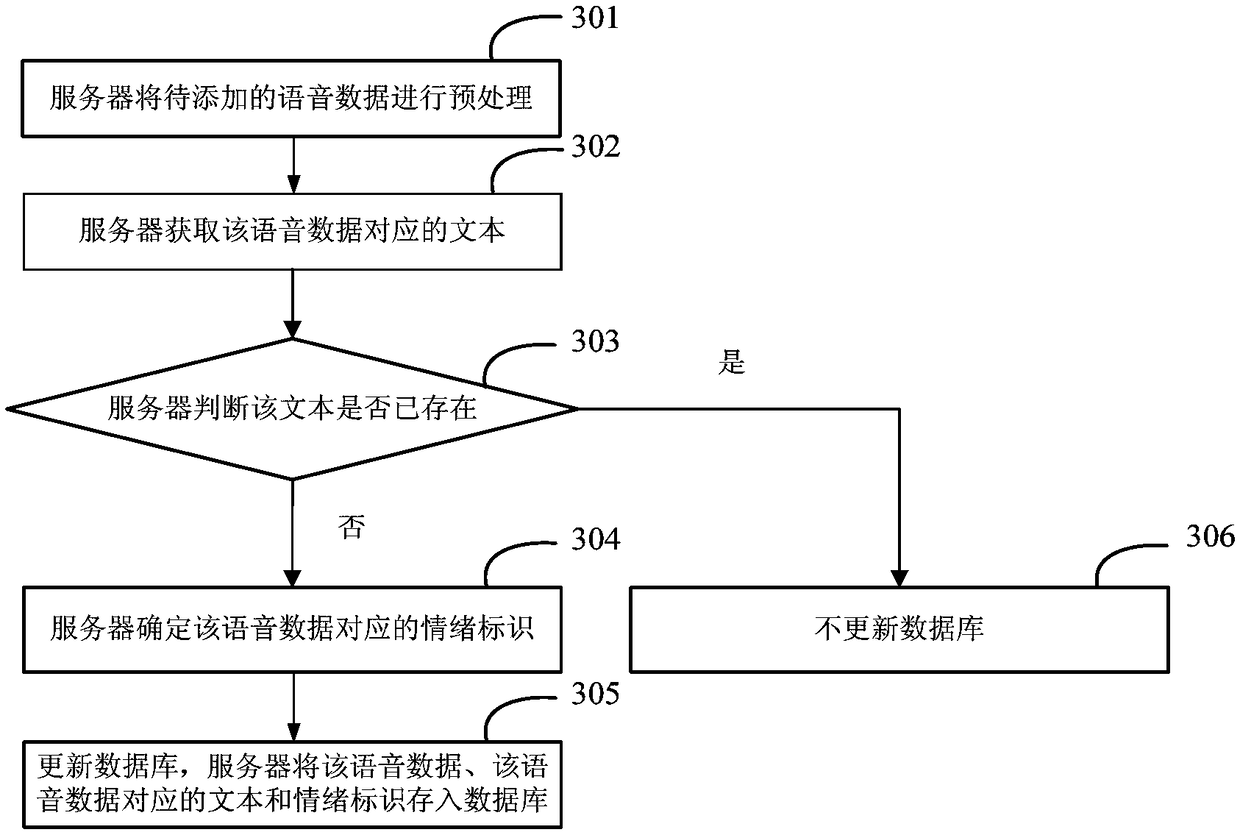

Verification method and device, server and terminal

ActiveCN108173835AImprove securityNot easy to crackSpeech recognitionTransmissionVerification systemVoice data

The embodiment of the invention discloses a verification method and device, a server and a terminal and belongs to the field of a computer. The method comprises the steps that the server receives a verification code request message sent by the terminal; preset target voice data and an emotion identity corresponding to the target voice data are obtained; the target voice data is sent to the terminal; and the emotion identity input by a user is received, and if the emotion identity corresponding to the target voice data matches the emotion identity input by the user, it is judged that the terminal is verified successfully. Through adoption of the method, the device, the server and the terminal, the security of a verification system can be improved.

Owner:BEIJING QIYI CENTURY SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com