2Cr11MoVNbN forge piece for steam turbine and manufacturing method of forge piece

A manufacturing method and steam turbine technology, applied in the field of ring forging forging, can solve the problems of high requirements, high temperature and durability, difficulty in meeting the requirements, cracking, etc., and achieve the effect of satisfactory product mechanical properties, long high temperature durability, and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is further illustrated by the following examples: According to the following examples, the present invention can be better understood. However, those skilled in the art can easily understand that the specific material ratios, process conditions and results described in the examples are only used to illustrate the present invention, and should not and will not limit the present invention described in the claims.

[0035] (1) Steel ingot smelting

[0036] Using electric furnace + vacuum smelting + vacuum degassing,

[0037] The chemical composition of steel ingots includes: C: 0.15~0.2; Si: 0.2~0.6; Mn: 0.6~0.9; P≤0.025; S≤0.025; Cr: 10~11.5; Mo: 0.7~1; Ni: 0.3~ 0.6; Cu≤0.25; W≤0.25; V: 0.15~0.25; Nb: 0.05~0.15; N: 0.05~0.09; Al: ≤0.04; Co≤0.25; Ti≤0.04;

[0038] (2), blanking

[0039] The steel ingot is an electroslag round ingot with a size of Φ600×680mm;

[0040] (3), heating

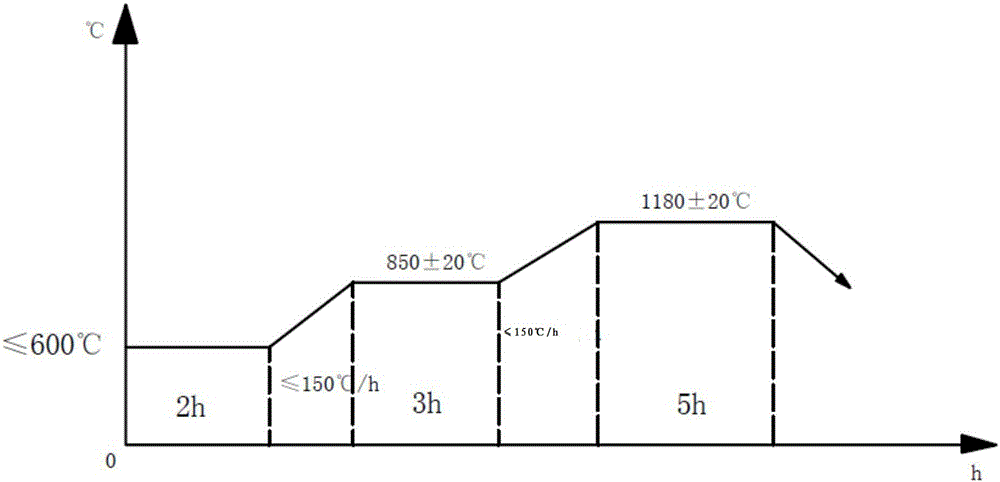

[0041] combine figure 1 As shown, control the furnace temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com