Preparation method of high-temperature-resistant high-infrared-emissivity coating

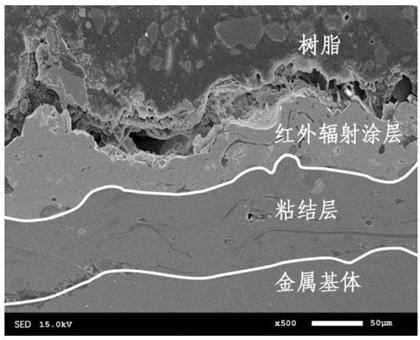

A technology with infrared emissivity and high temperature resistance, which is applied in coating, metal material coating process, molten spraying, etc., can solve the problems of low radiation heat dissipation capacity, short service life of coating, poor high temperature thermal shock performance, etc., and achieve Not easy to crack and peel off, strong coating adhesion and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing a novel high-temperature-resistant high-infrared emissivity coating, comprising the steps of:

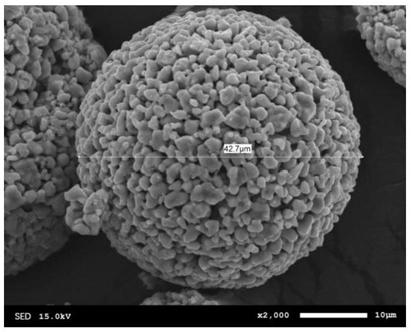

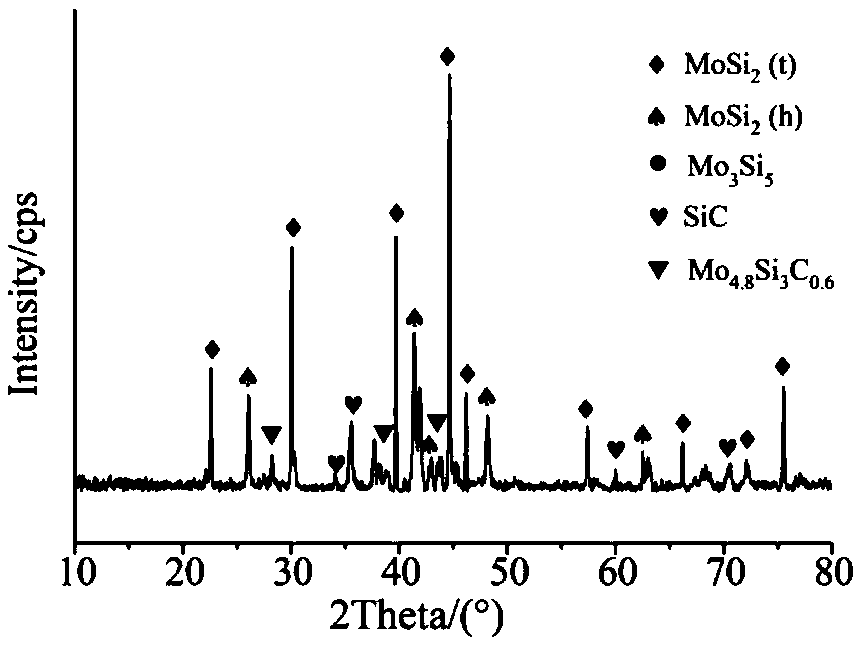

[0027] 1. Weigh 400g MoSi 2 Powder (particle size 1-2μm) and 100g SiC powder (particle size 500nm), add 500g deionized water, mix 5g binder, 1g defoamer and 2g dispersant, pour into the colloid mill and grind for 1 hour, then pump into the spray powder tower to complete the powder making process. During the granulation process, the air inlet temperature was set to 180°C, the air outlet temperature was set to 140°C, and the slurry feeding speed was 45ml min -1 , the rotation speed of atomizing disc is 25000~30000r·min -1 . The original powder is obtained after granulation;

[0028] 2. Put the obtained raw powder in an alumina crucible for atmosphere-protected roasting, the roasting temperature is 1400°C, the roasting time is 2 hours, and the protective atmosphere is Ar gas; after roasting, sieve to obtain 250-300 mesh thermal spray powder ;

[0029...

Embodiment 2

[0033] A method for preparing a novel high-temperature-resistant high-infrared emissivity coating, comprising the steps of:

[0034] 1. Weigh 450g MoSi 2 Powder (particle size 1-2μm) and 50g SiC powder (particle size 500nm), add 500g deionized water, mix 5g binder, 1g defoamer and 2g dispersant, pour into the colloid mill and grind for 1 hour, then pump into the spray powder tower to complete the powder making process. During the granulation process, the air inlet temperature was set to 180°C, the air outlet temperature was set to 140°C, and the slurry feeding speed was 45ml min -1 , the rotation speed of atomizing disc is 25000~30000r·min -1 , to obtain the original powder after granulation;

[0035] 2. Put the obtained raw powder in an alumina crucible for atmosphere-protected roasting, the roasting temperature is 1400°C, the roasting time is 2 hours, and the protective atmosphere is Ar gas; after roasting, sieve to obtain 250-300 mesh thermal spray powder ;

[0036] 3....

Embodiment 3

[0040] A method for preparing a novel high-temperature-resistant high-infrared emissivity coating, comprising the steps of:

[0041] 1. Weigh 350g MoSi 2 Powder (particle size 1-2μm) and 150g SiC powder (particle size 500nm), add 500g deionized water, mix 5g binder, 1g defoamer and 2g dispersant, pour into the colloid mill and grind for 1 hour, then pump Enter the spray powder making tower to complete the powder making process. During the granulation process, the air inlet temperature was set at 180°C, the air outlet temperature was set at 140°C, the slurry feeding speed was 45ml·min-1, and the rotation speed of the atomizing disc was 25000-30000r·min-1. The original powder is obtained after granulation;

[0042] 2. Put the obtained raw powder in an alumina crucible for atmosphere-protected roasting, the roasting temperature is 1400°C, the roasting time is 2 hours, and the protective atmosphere is Ar gas; after roasting, sieve to obtain 250-300 mesh thermal spray powder ; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com