Amino acid fermentation bacteria utilization method

A technology of glutamic acid fermenting bacteria and cells, which is applied in the field of preparing enzymatic protein paste and protein powder to achieve the effects of convenient operation, easy enzymatic hydrolysis and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Firstly, 10 cubic meters of glutamic acid fermentation broth is separated from the fermentation cells by a disc separator. Liquid and thalline protein were separated to obtain thalline protein 6500kg.

[0022] (2) Add the above bacterial protein into the stirring reactor, add an appropriate amount of warm water and mix thoroughly, adjust the solid content to 8%, adjust the enzymolysis reaction temperature to 55°C, add a little sulfuric acid to adjust the pH to 6.5, and add lysozyme 10kg / m 3 , acid protease 25Kg / m 3 , β-glucanase 5Kg / m 3 , slowly stirring the enzymolysis time for 6 hours, and using an amino acid analyzer to measure the contents of various amino acids in the enzymolysis solution.

[0023] (3) The above-mentioned enzymatic hydrolysis solution is separated and removed by a disc separator to remove the cell wall, and the obtained supernatant is evaporated at a low temperature by a three-effect plate evaporator. The first-effect feed temperature of the ...

Embodiment 2

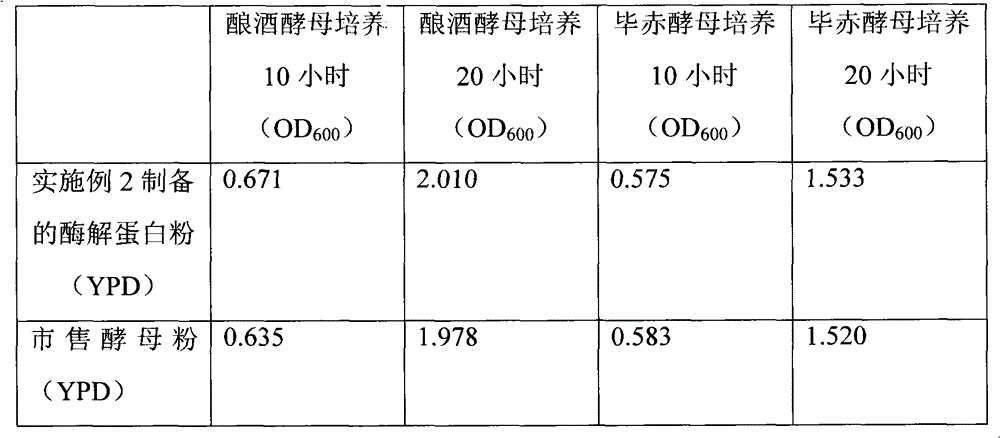

[0026] The enzymolyzed bacterial protein paste obtained in Example 1 was dried in a spray granulation fluidized bed, and the obtained finished product was packaged into enzymatic bacterial protein powder, and the temperature of the hot air in the spray granulation fluidized bed was 130°C.

Embodiment 3

[0028] Using the enzymolyzed protein paste obtained in Example 1 as a nitrogen source to replace commercially available yeast powder, a threonine fermentation test was carried out, and the average fermentation parameters of 5 consecutive tanks were respectively:

[0029] Using the enzymolyzed protein paste prepared in Example 1 as a nitrogen source, the fermentation broth produced 13% acid, the fermentation period was 28 hours, and the fermentation sugar-acid conversion rate was 68%.

[0030] Using commercially available yeast powder as a nitrogen source, the fermentation broth produced 14% acid, the fermentation period was 28 hours, and the fermentation sugar-acid conversion rate was 67%.

[0031] Through the above comparison, the product produced by the present invention can completely replace commercially available yeast powder products for threonine fermentation, thereby greatly reducing the cost of threonine fermentation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com