Method for treating threonine mother liquor

A treatment method and technology of threonine mother, applied in the field of threonine production, can solve the problems of low pollution and high energy efficiency, and achieve the effects of simple process, reduced investment, and avoidance of potential feed safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for processing threonine mother liquor, comprising the steps of:

[0021] Centrifugal separation: Use a high-speed disc separator to separate the bacterial protein in the threonine mother liquor. The speed of the high-speed disc separator is about 4000-5000r / min, recover the bacterial protein precipitate, and collect the supernatant.

[0022] Membrane filtration for secondary removal of bacterial protein: filter the supernatant obtained in step 1) with a ceramic membrane with a membrane pore size of 40nm, wherein the filtration temperature is 37°C, the membrane inlet pressure is 2.0bar, the bacterial protein is recovered by filtration, and collected filtrate.

[0023] Cellular protein treatment: Combine the bacterial protein in step 1) and step 2) into the stirring reactor, add an appropriate amount of warm water and mix thoroughly, adjust the solid content to 8%, adjust the enzymolysis reaction temperature to 55°C, add a little sulfuric acid to adjust the pH t...

Embodiment 2

[0026] Using the enzymolyzed protein paste obtained in Example 1 as a nitrogen source to replace commercially available yeast powder, a threonine fermentation test was carried out, and the average fermentation parameters of 5 consecutive tanks were respectively:

[0027] Using the enzymolyzed protein paste prepared in Example 1 as a nitrogen source, the fermented broth produced 12% acid, the fermentation period was 28 hours, and the fermentation sugar-acid conversion rate was 66%.

[0028] Using commercially available yeast powder as a nitrogen source, the fermentation broth produced 14% acid, the fermentation period was 28 hours, and the fermentation sugar-acid conversion rate was 67%.

[0029] Through the above comparison, the product produced by the present invention can completely replace commercially available yeast powder products for threonine fermentation, thereby greatly reducing the cost of threonine fermentation.

[0030] Through high-performance liquid chromatograp...

Embodiment 3

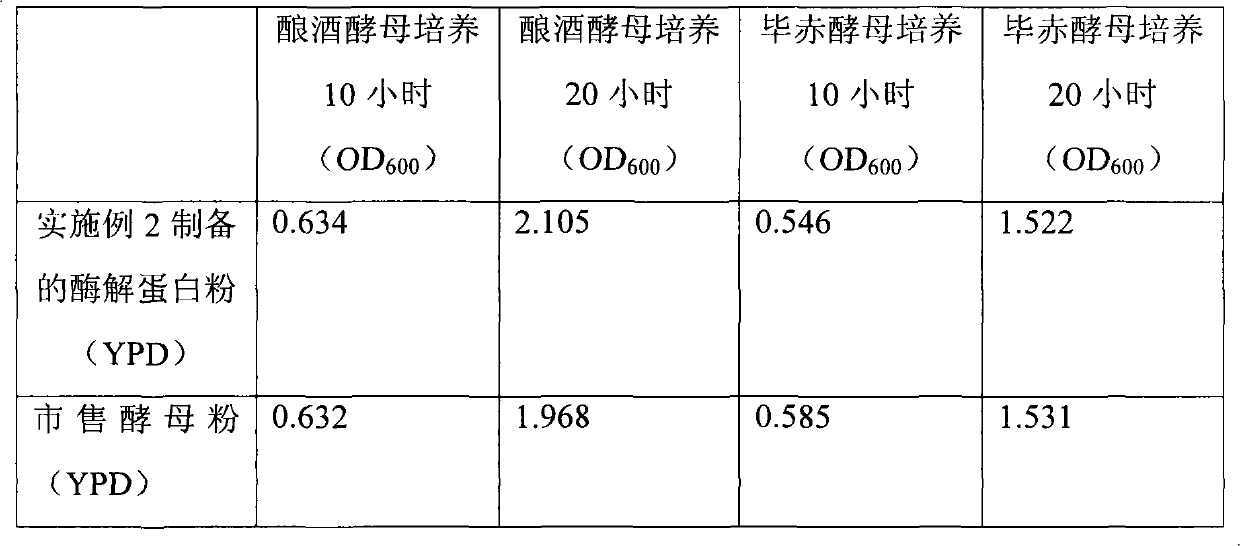

[0032] The enzymolyzed protein paste prepared in Example 1 is dried by spray granulation fluidized bed, and the obtained finished product is packaged into enzymatic bacterial protein powder (hot air temperature of spray granulation fluidized bed<150°C), replacing the standard The yeast powder in the YPD medium, and the rest of the ingredients remain unchanged. Saccharomyces cerevisiae and Pichia pastoris are cultivated under the same conditions, and the culture effect of the product is evaluated by comparing the growth of the cells.

[0033]

[0034] Determination of OD by nephelometric method 600 The growth of the cells was characterized, indicating that this product can replace commercially available yeast powder products and achieve the desired effect.

[0035] Compared with the conventional process, the present invention has stable and reliable product quality and greatly reduced production cost. For monosodium glutamate production enterprises, it can not only reduce en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com