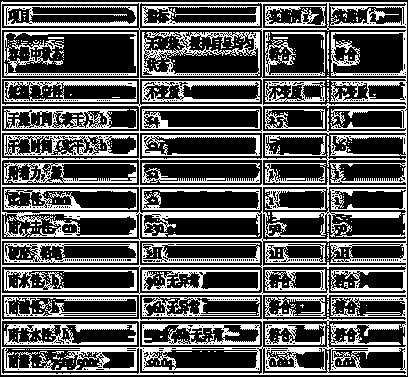

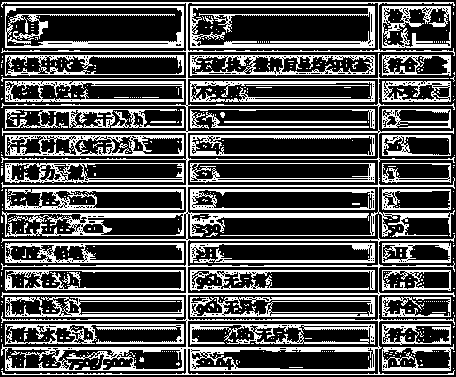

Patents

Literature

99results about How to "Strong coating adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Textured medical devices

InactiveUS7753962B2Strong coating adhesionReduce riskBone implantSurgeryBiocompatible coatingMedical device

Disclosed are medical devices having textured surfaces and biocompatible coatings disposed thereon. The textured surfaces allow for durable coatings to be applied to the medical device without a previous pre-coating having been applied. The biocompatible coating can further comprise a bioactive agent.

Owner:MEDTRONIC VASCULAR INC

Textured Medical Devices

InactiveUS20080183276A1Strong coating adhesionReduce riskStentsBone implantBiocompatible coatingMedical device

Disclosed are medical devices having textured surfaces and biocompatible coatings disposed thereon. The textured surfaces allow for durable coatings to be applied to the medical device without a previous pre-coating having been applied. The biocompatible coating can further comprise a bioactive agent.

Owner:MEDTRONIC VASCULAR INC

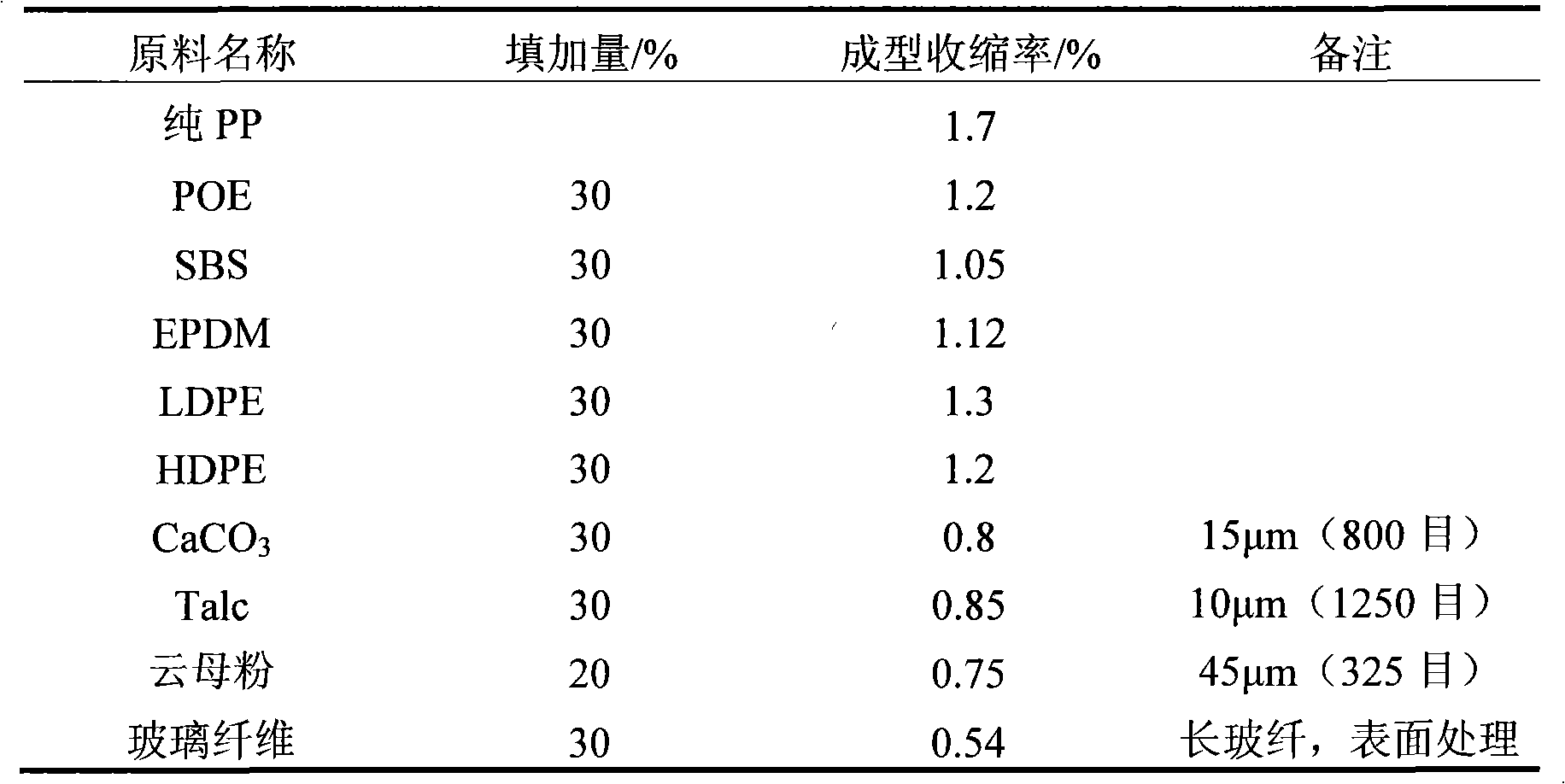

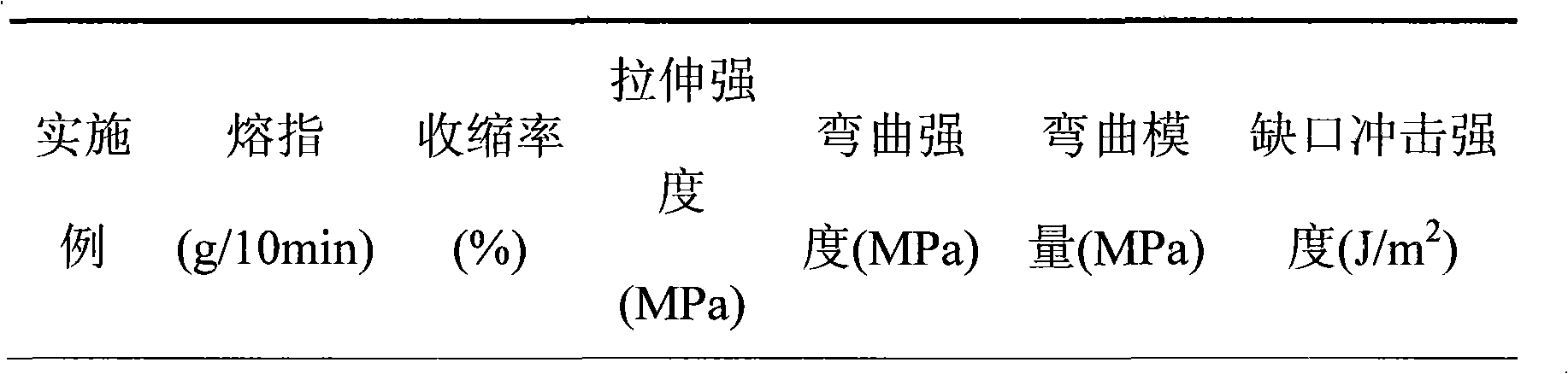

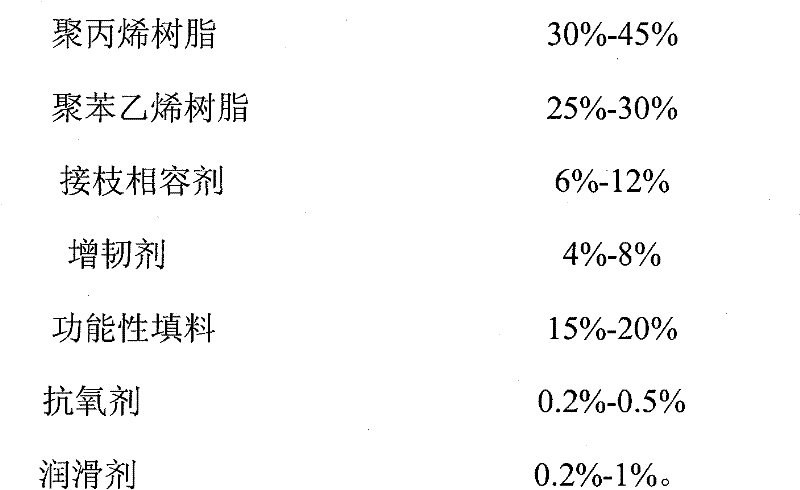

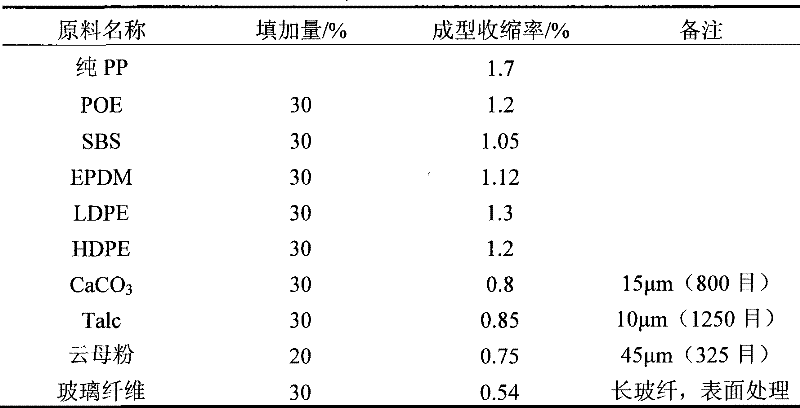

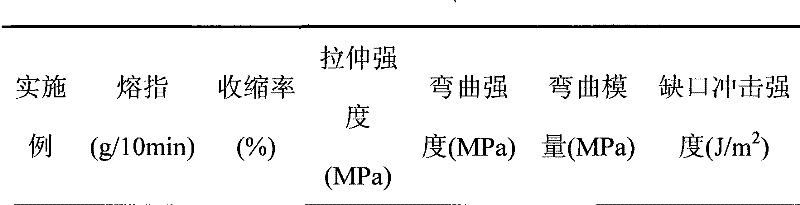

Low-shrinkage sprayable PP/PS blend alloy and preparation method thereof

The invention discloses a low-shrinkage sprayable PP / PS blend alloy and a preparation method thereof. The low-shrinkage sprayable PP / PS blend alloy is prepared from the following components in percentage by weight: 30 to 45 percent of polypropylene resin, 25 to 30 percent of styrene resin, 6 to 12 percent of graft compatilizer, 4 to 8 percent of toughening agent, 15 to 20 percent of functional filler, 0.2 to 0.5 percent of antioxidant, and 0.2 to 1 percent of lubricant. The forming shrinkage of the low-shrinkage sprayable PP / PS blend alloy is as low as 0.7 to 0.9 percent and is closed to the level of ABS, and the low-shrinkage sprayable PP / PS blend alloy can directly replace the ABS under the condition of no die repair and does not influence the appearance of an injection molding product.

Owner:KINGFA SCI & TECH CO LTD +1

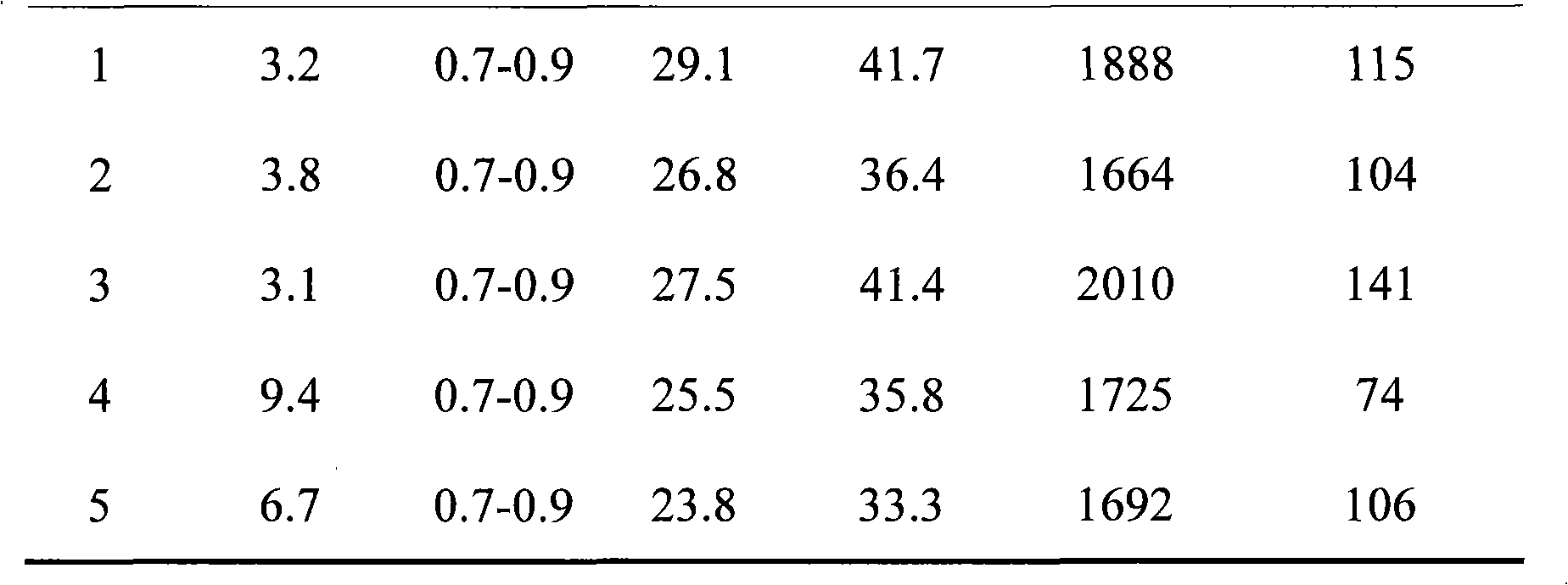

Innovative flame-retardant, water-proof, mildew-proof and radiation-proof insulating mortar and product

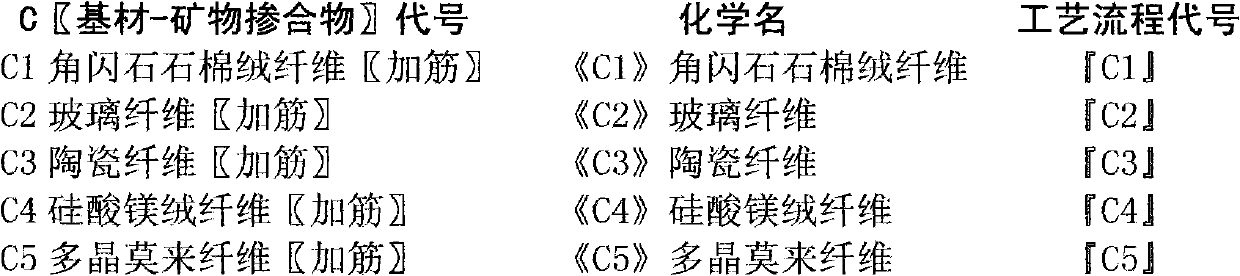

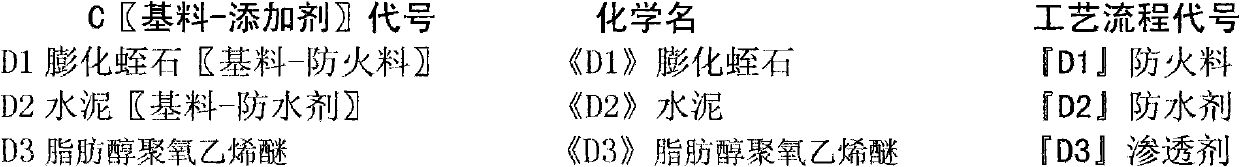

The invention discloses innovative flame-retardant, water-proof, mildew-proof and radiation-proof insulating mortar and products, which comprise nine base materials resisting the temperature of 80 DEG C below zero to 1,000 DEG C, i.e., aluminum silicate, magnesium oxide [1,500 DEG C], diatomite [1,000 DEG C], vitrified micro bubbles [1,000 DEG C], silicon nitride [1,000 DEG C], bentonite [900 DEG C], expanded perlite [800 DEG C], expanded vermiculite [800 DEG C] and magnesium chloride [800 DEG C], two mineral admixtures, five reinforcements, i.e., amphibole asbestos wool fiber, glass fiber, ceramic fiber, magnesium silicate wool fiber and polycrystalline mullite fiber and 14 base material-additives of different functions, i.e., a fire-proof material, a water-proof agent, an anti-radiation agent, an anti-mildew agent, an adhesive, an anti-freezing agent, a thixotropic agent, a curing agent, a brightening agent, an early strength agent, a foaming agent, an expanding agent and a masking agent, wherein nine kinds of low-carbon fire-proof insulating mortar which are used in different environments are developed through an innovative technical formula and are used for coating interior and exterior walls and manufacturing an insulating material for various plates, pipes and irregularly-shaped products; and the innovative flame-retardant, water-proof, mildew-proof and radiation-proof insulating mortar and product are national initiative environment-friendly low-carbon and fire-proof insulating mortar and product.

Owner:于斌 +2

Method for Improving Oxidation Resistance of Graphite Electrodes by Chemical Vapor Deposition SIC/C Gradient Surface Coating

InactiveCN102277560AGood permeabilityStrong coating adhesionElectric discharge heatingChemical vapor deposition coatingOxidation resistantGraphite

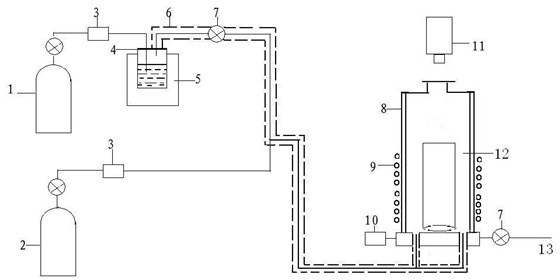

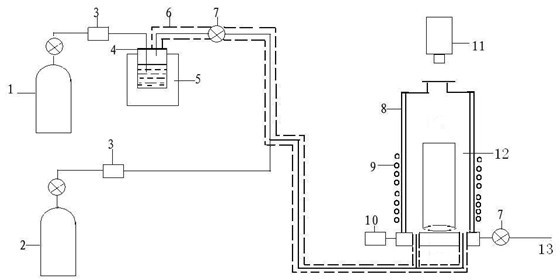

The invention discloses a method for improving the oxidation resistance of a graphite electrode by obtaining a SiC / C gradient surface coating through chemical vapor deposition. The method comprises the following steps of: performing surface pretreatment on the graphite electrode; fixing the graphite electrode which is subjected to surface pretreatment on a support in a water-cooled reaction furnace of chemical vapor deposition equipment, and vacuumizing in the furnace; heating the graphite electrode in the reaction furnace, and aerating CH4 gas to form a layer of pyrolytic carbon on the surface of the graphite electrode; keeping the temperature of a cavity unchanged, aerating carrier gas H2 to pass through boiling SiCl4 liquid, and reacting SiCl4 gas carried by the carrier gas H2 and the CH4 gas on the surface of the graphite electrode and depositing; and after the deposition is finished, keeping the temperature of the cavity unchanged, maintaining H2 atmosphere, performing in-situ heat treatment on the graphite electrode in the furnace, and cooling the graphite electrode to room temperature in the furnace after the heat treatment is finished so as to obtain the graphite electrodewith a SiC / C gradient functional surface protective layer. The invention has the advantages that: the permeability is high, the coating can permeate into any fine pores on the surface of a matrix of the graphite electrode, and a good effect of resisting the oxidation of surface voids can be achieved.

Owner:NANJING UNIV OF SCI & TECH +1

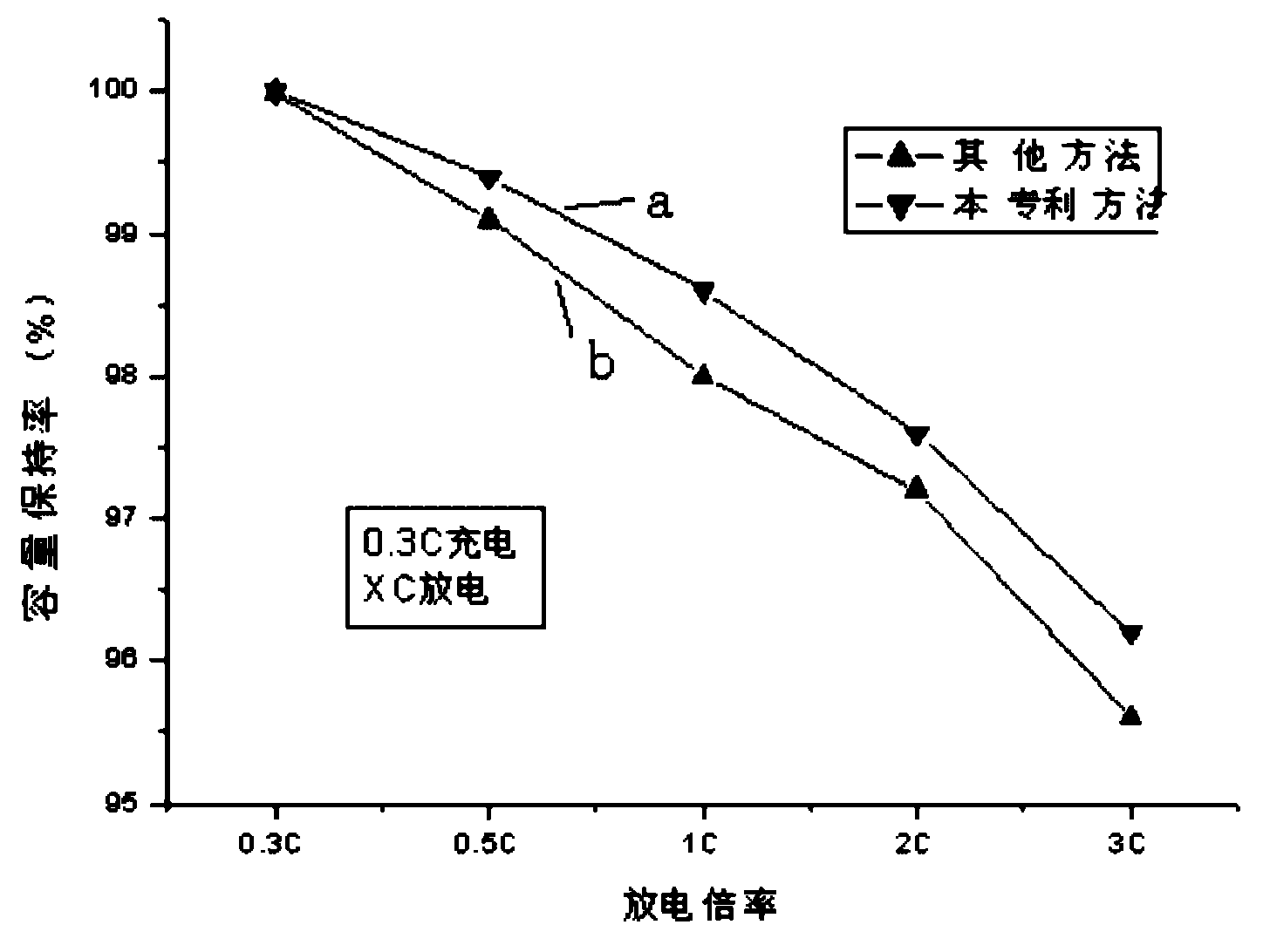

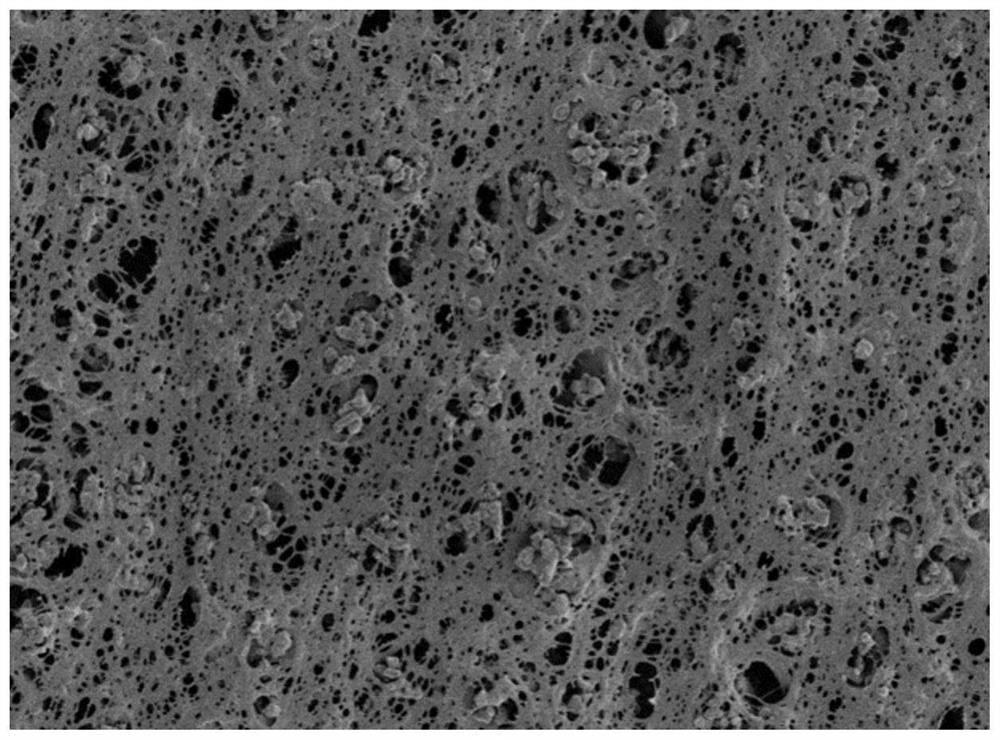

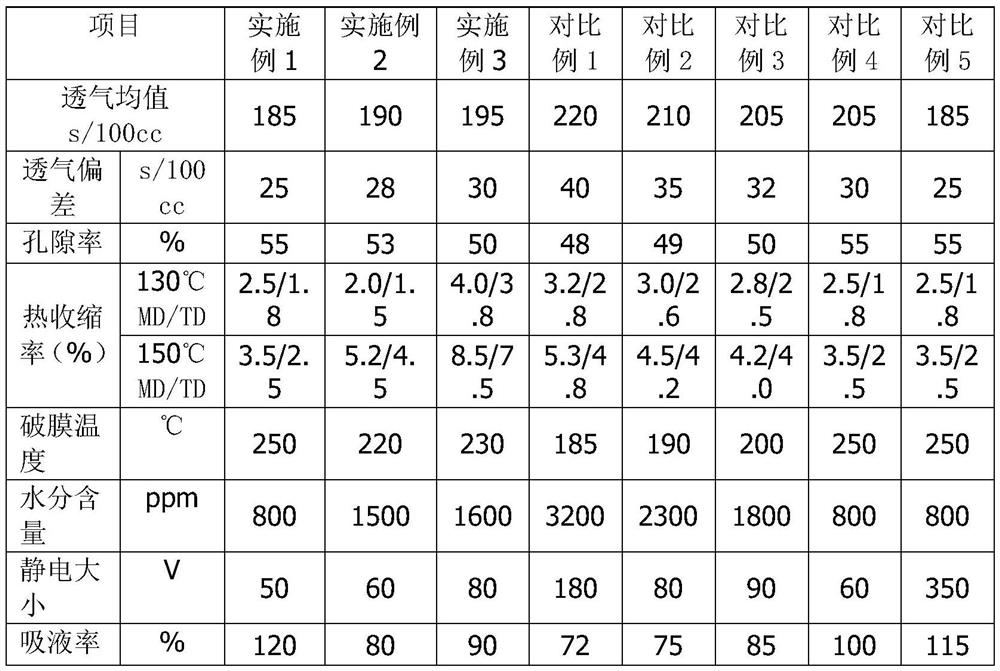

Inorganic/organic compound functional porous isolating membrane and preparation method as well as lithium ion battery adopting inorganic/organic compound functional porous isolating membrane

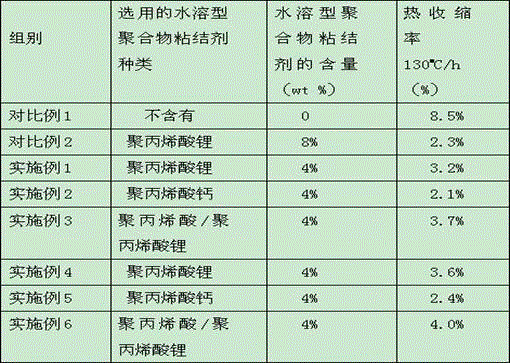

ActiveCN105789523AGood dispersionImproved high temperature thermal stabilitySecondary cellsCell component detailsPorous substrateOrganic compound

The invention provides an inorganic / organic compound functional porous isolating membrane. The inorganic / organic compound functional porous isolating membrane comprises a porous substrate and an inorganic functional coating which is adhered to at least one surface of the porous substrate, wherein the inorganic functional coating is prepared from inorganic ceramic particles, a water-soluble macromolecular thickening agent, a water emulsion type polymer binding agent and a water soluble type polymer binding agent; the water emulsion type polymer binding agent is a macromolecular polymer with the surface tensile force of 40dyne / cm to 50dyne / cm, and a water drip contact angle of water emulsion type polymer binding agent dry glue is 100 degrees to 130 degrees; the water emulsion type polymer binding agent is a polar macromolecular polymer with the glass transition temperature of 100 DEG C to 150 DEG C. Therefore, the inorganic / organic compound functional porous isolating membrane has the advantages that the heat stability of the isolating membrane can be effectively improved, and the moisture content of the inorganic coating can also be reduced, so that the safety performance of a battery and the stability of long-period cycle are improved.

Owner:深圳市旭然电子有限公司

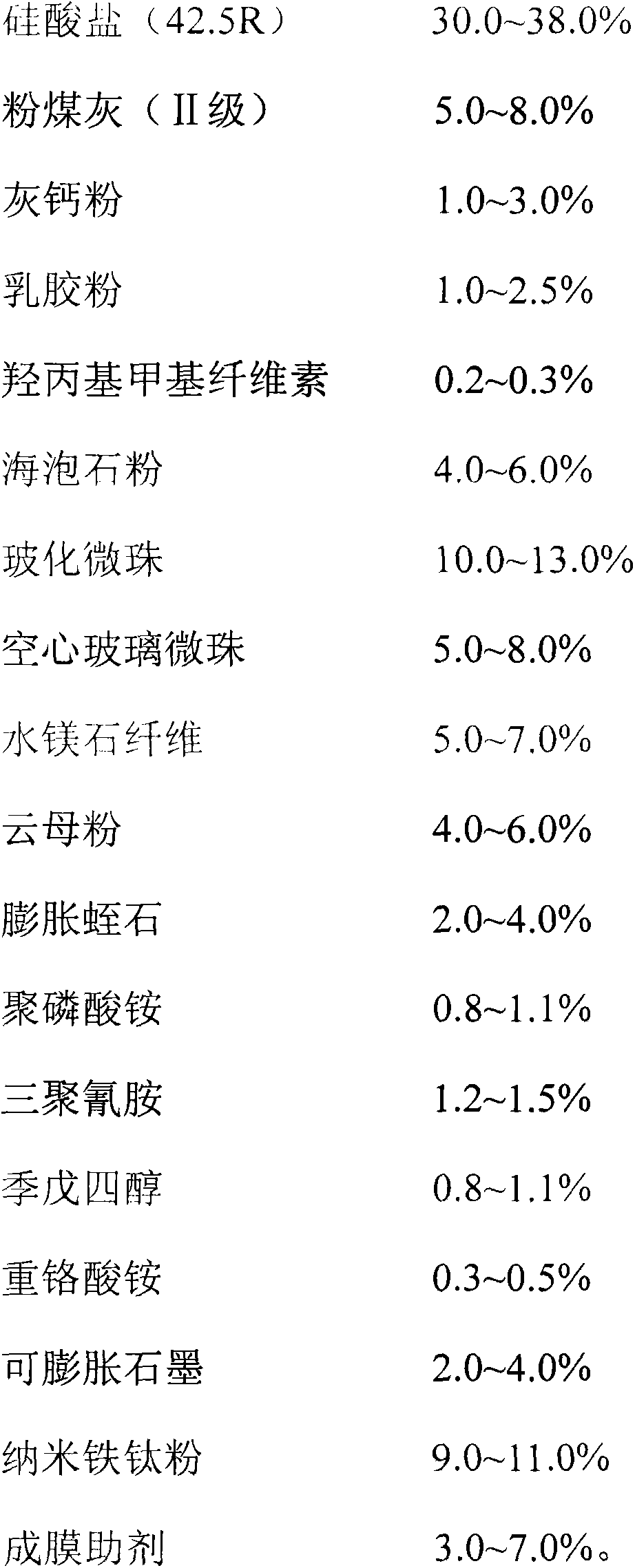

Hydrocarbon-resistant outdoor thick fireproofing coating for steel structures

ActiveCN103450716ALow thermal conductivityImprove fire and corrosion resistanceFireproof paintsAnti-corrosive paintsFiberFireproofing

The invention provides a hydrocarbon-resistant outdoor thick fireproofing coating for steel structures, wherein the fireproofing coating is prepared from the following raw materials in percentage by weight: 30.0-38.0% of silicate (42.5R), 5.0-8.0% of coal ash (II-grade), 1.0-3.0% of ash calcium powder, 1.0-2.5% of latex powder, 0.2-0.3% of hydroxypropyl methyl cellulose, 4.0-6.0% of sepiolite powder, 10.0-13.0% of glass beads, 5.0-8.0% of hollow glass beads, 5.0-7.0% of brucite fiber, 4.0-6.0% of mica powder, 2.0-4.0% of expanded vermiculite, 0.8-1.1% of ammonium polyphosphate, 1.2-1.5% of melamine, 0.8-1.1% of pentaerythritol, 0.3-0.5% of ammonium dichromate, 2.0-4.0% of expansible graphite, 9.0-11.0% of nano iron-titanium powder and 3-7% of a coalescing agent. The hydrocarbon-resistant outdoor thick fireproofing coating has binding strength, good water resistance and acid-base resistance property, and is safe and non-toxic, little in smoke, thermocycling resistant, excellent in corrosion resistance, and hydrocarbon fire resistant; the fireproofing coating can be widely used for fireproofing and anti-corrosion coating protection of indoor and outdoor steel structures.

Owner:石家庄雅致化工有限公司

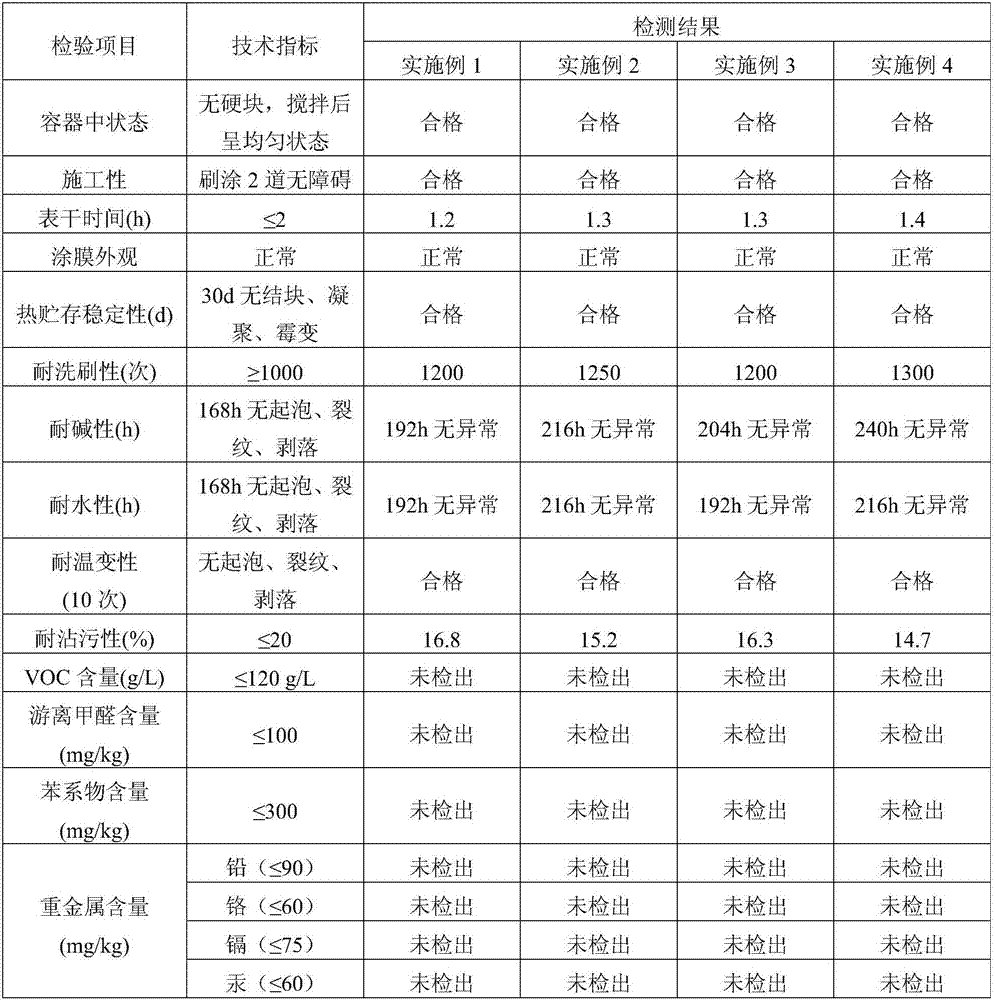

Novel environment-friendly waterborne inorganic paint and preparation method thereof

InactiveCN107266944AFire retardantAntibacterial and antifungalFireproof paintsAntifouling/underwater paintsPolyvinyl alcoholFire resistance

The invention discloses novel environment-friendly waterborne inorganic paint and a preparation method thereof. The novel environment-friendly waterborne inorganic paint is prepared from, by weight, 55-65 parts of kaolin, 12-20 parts of sodium silicate, 20-30 parts of titanium dioxide, 1-5 parts of nano zinc oxide, 5-10 parts of ultrafine wollastonite powder, 1-10 parts of nano calcium carbonate, 1-5 parts of ultrafine white mica powder, 7-15 parts of polyvinyl alcohol, 1-4 parts of ultrafine molybdenum disulfide powder, 2-10 parts of nano silicon dioxide, 2-12 parts of nano magnesium oxide, 2-12 parts of nano aluminum oxide, 1-3 parts of magnesium chloride, 1-3 parts of a sodium silicate hardening accelerator, 2-5 parts of a pH value regulating agent, 1-8 parts of a waterproof agent, 6-10 parts of an antifoaming leveling agent, 1-3 parts of a thickening anti-settling agent and 280-310 parts of water. The novel environment-friendly waterborne inorganic paint which is environment-friendly waterborne inorganic paint for buildings is high in storage stability, excellent in water resistance and alkali resistance, strong in adhesion, high in fire resistance, high in strength and hardness, resistant to scratching and contamination, excellent in corrosion resistance and antibacterial property, free of formaldehyde, benzene compounds, VOC (volatile organic compounds) and heavy metal elements, completely environmental friendly and nontoxic, suitable for industrial production, easy for painting and convenient and quick in construction.

Owner:CHENGDU POLYTECHNIC

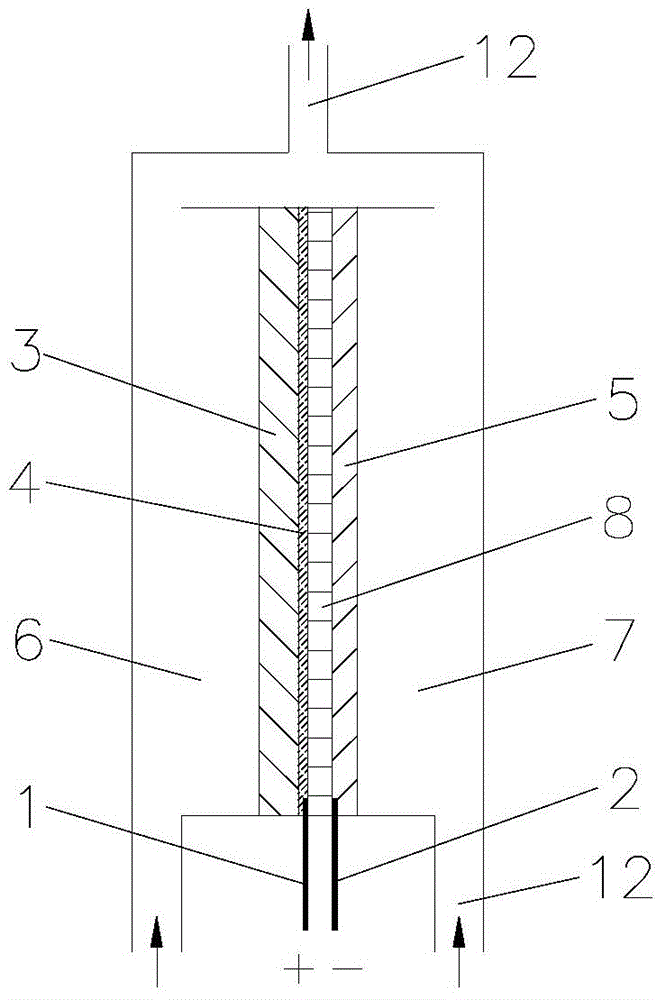

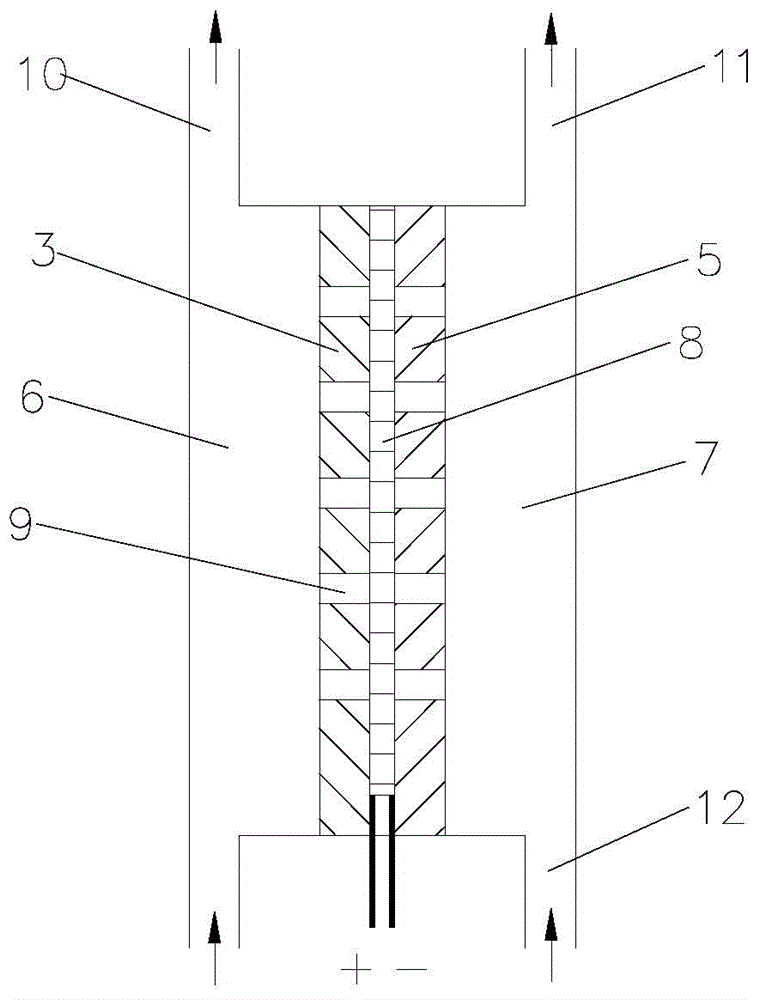

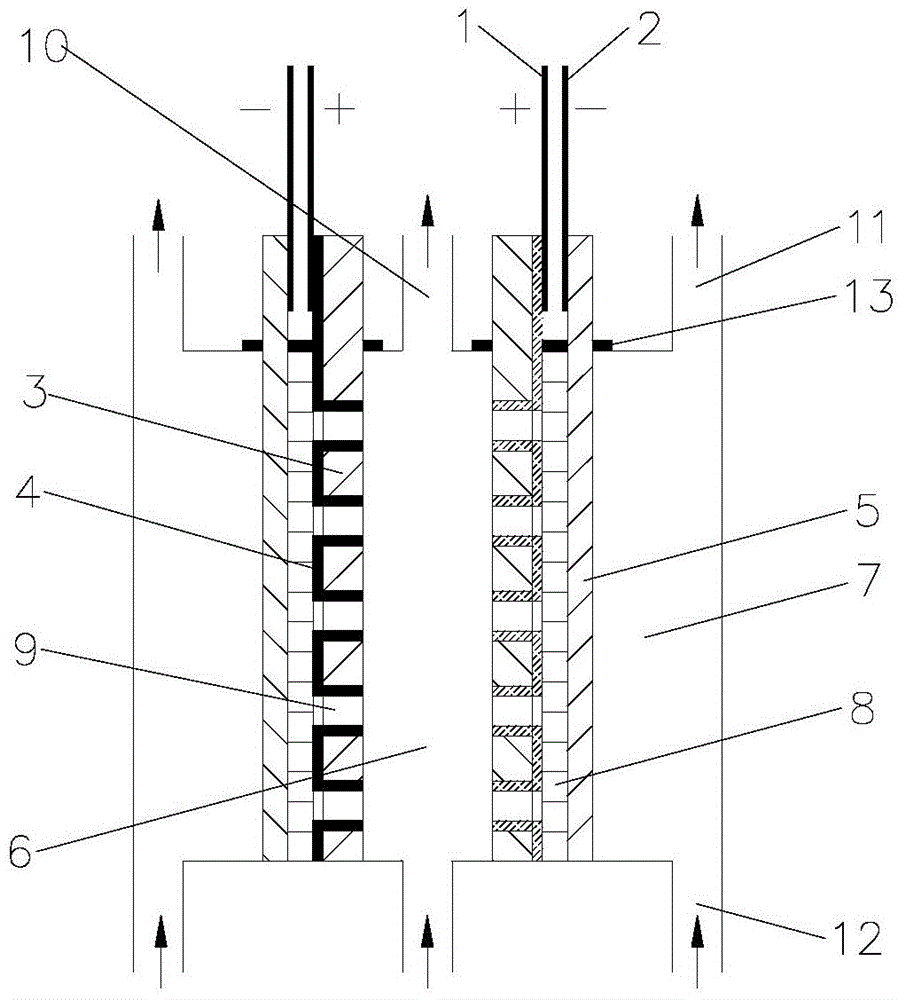

Electrolytic cell device provided with separated cathode and anode chambers and used for preparing ozone water through electrolysis

The invention discloses an electrolytic cell device provided with separated cathode and anode chambers and used for preparing ozone water through electrolysis. The electrolytic cell device comprises an electrolytic cell, wherein cathode electrodes and anode electrodes are arranged inside the electrolytic cell; the bottoms of the cathode electrodes and anode electrodes are in complete contact with the bottom end of the electrolytic cell to divide the electrolytic cell into anode chambers and cathode chambers independent to one another; a proton exchange membrane for allowing ions to permeate, but preventing hydrogen from permeating into the anodic area is arranged at the separated part of each anode chamber and the corresponding cathode chamber. Through the adoption of the structural design, the anode chambers and the cathode chambers are separated and not communicated, so that water in the cathode chambers cannot enter the anode chambers, and further, the situation that hydrogen generated in the cathode chambers enters the anode chambers to be in neutralization reaction with ozone O3 is avoided; therefore, the consumption amount of ozone O3 is reduced, the production efficiency of ozone O3 is improved, and the content of ozone O3 is increased.

Owner:GUANGZHOU DEPOSON ELECTRIC TECH

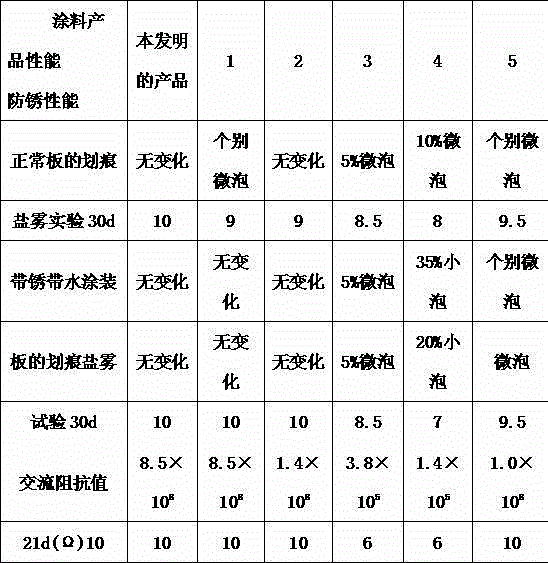

Water-based paint and preparation and application methods thereof

ActiveCN107083170AReduce pollutionGood surface adaptabilityFireproof paintsAntifouling/underwater paintsWater basedAcrylic resin

The invention provides a water-based paint and preparation and application methods thereof. The water-based paint is mainly prepared from a specific amount of water-based polyurethane resin, water-based organosilicon-modified polyurethane dispersion, organic silicon resin, water-based fluorocarbon resin, water-based organosilicon-modified acrylate, polyethylene wax slurry and water-based acrylic resin. The water-based paint is moderate in viscosity, uniform in raw material dispersion, good in physical property, good in film-forming property, leveling property, heat stability and glossiness, good in anti-ultraviolet property, antifouling property and wear-resisting property, and high in operability, can be used in a simple wiping manner, and is free of waste, free of pollution, safe and environment-friendly. The preparation method of the water-based paint is simple and suitable for large-scale production. The water-based paint can be used in manners, such as wiping, brush coating, roller coating and spray coating, especially can be used in a wiping manner, and is time-saving and labor-saving.

Owner:青岛光辉彩饰有限公司

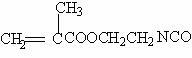

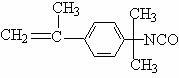

Urethanation modified hybrid phenolic resin and preparation method thereof

Urethanation modified hybrid phenolic resin is prepared through the following steps: the grafting of linear phenolic resin and ethylene monoisocyanates is conducted through the phenol hydroxyl urethanation reaction, then the linear phenolic resin serves as a high-polymer monomer to conduct the second radical linear polymerization independently or jointly with other ethylene monomers to obtain the hybrid phenolic resin; the weight-average molecular weight of the urethanation modified hybrid phenolic resin is 7.500 to 150.000; and the temperature of the softening point is 80 to 220 DEG C. The urethanation modified hybrid phenolic resin is used for thermosensitive flat printing plates, and can obviously enhance the solvent resistance and the durability of the thermal plate due to the existence of strongly polar urethane links, and the flat printing plate has the advantages of strong coating adhesion and toughness.

Owner:LUCKY HUAGUANG GRAPHICS

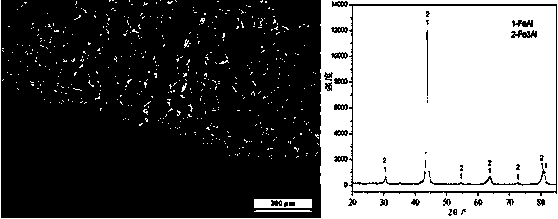

Corrosion resistant surface treatment method of chain parts

ActiveCN103628015AImprove corrosion resistanceStrong coating adhesionHot-dipping/immersion processesTemperingMetallurgy

The invention relates to surface treatment of chain parts, and particularly relates to a corrosion resistant surface treatment method of chain parts. A Fe-Al intermetallic compound corrosion resistant coating is obtained by adopting liquid state aluminum impregnation and following diffusion treatment for parts of a chain, such as a chain plate, a pin roll, a sleeve and a roller. The process flow comprises the following steps: pretreatment, aluminum impregnation, diffusion treatment and following quenching and tempering, wherein aluminum impregnation is performed in an aluminum liquid for 1-5 minutes at 720-750 DEG C; diffusion annealing is performed for 30 minutes to 2 hours at 850-1000 DEG C in a protective atmosphere; the intermetallic compound corrosion resistant coatings with different thicknesses are obtained by adjusting the temperature and time of diffusion treatment; after diffusion treatment, oil quenching is performed, and then tempering is performed for 2 hours at an intermediate temperature of 400-450 DEG C or a low temperature of 180-220 DEG C. The method provided by the invention has the characteristics of simple and convenient process, low cost, strong binding force of the coating, adaptability to batch production of small pieces and the like, can be used for producing chains in a corrosive environment, the treated chain can replace common chains or stainless steel chains, the performance and service life can be improved, and the alloy resources can be saved.

Owner:东台市溱东科技发展有限公司 +1

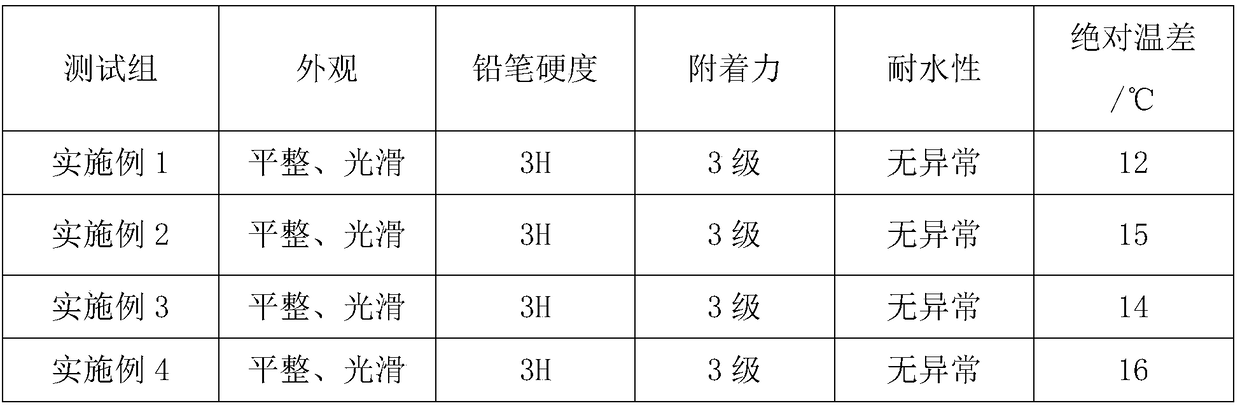

Building glass heat-insulating coating and preparation method thereof

InactiveCN108795181AGood thermal insulation effectStrong coating adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsArchitectural glassEmulsion

The invention discloses building glass heat-insulating coating and a preparation method thereof and relates to the field of coatings. The building glass heat-insulating coating comprises, by weight, 18-24 parts of acrylic emulsion, 10-16 parts of waterborne polyurethane emulsion, 1-4 parts of palm oil, 4-7 parts of nano silica, 4-7 parts of nano titania, 2-5 parts of aerogel, 4-7 parts of hollow glass microspheres, 2-5 parts of nano silicon nitride, 2-5 parts of modified zinc oxide, 1-3 parts of an adhesion promoter, 0.2-0.6 part of a defoaming agent, 0.6-1.2 parts of a dispersing agent, and 0.6-1.2 parts of a film-forming aid. The building glass heat-insulating coating made with the synergic materials has good heat insulation, a layer of the coating has good adhesion and good resistance to mechanical impact, and the preparation method has a simple process and is easy to perform.

Owner:HEFEI LIYUTAI GLASS PROD CO LTD

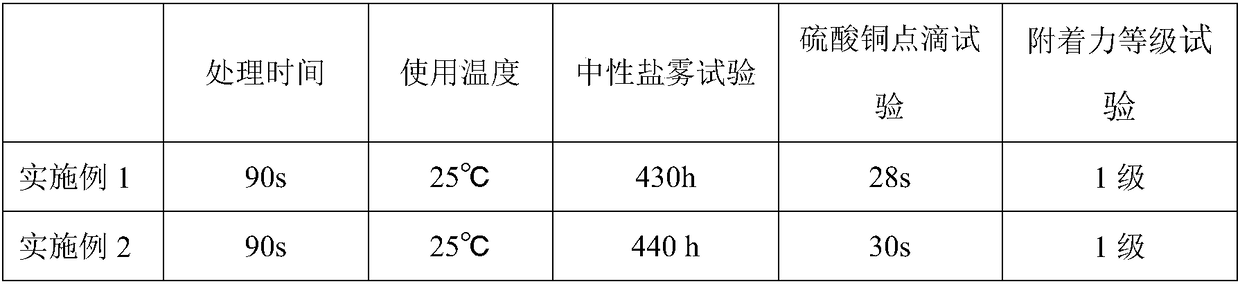

Metal surface silane treatment agent and preparation method thereof

The invention discloses a metal surface silane treatment agent and a preparation method thereof, and relates to the technical field of metal surface treatment. The silane treatment agent is prepared from a component A and a component B, and the component A comprises, by weight, 4-10 parts of gamma-aminopropyltriethoxysilane, 1-3 parts of gamma-glycidyloxypropyltrimethoxysilane, 0.2-0.8 part of gamma-chloropropyltriethoxysilane, 0.4-1.2 parts of methyltriethoxysilane, 0.1-0.3 part of benzotriazole, 6-12 parts of polyol and 90-110 parts of water; and the component B comprises, by weight, 12-18 parts of gamma-aminopropyltriethoxysilane, 0.2-0.8 part of gamma-chloropropyltriethoxysilane, 0.2-0.8 part of N-(beta-aminoethyl)-gamma-aminopropyltriethoxysilane, 10-17 parts of polyol and 60-80 partsof water, and a weight ratio of the component A to the component B is 1:(0.8-1.25). The silane treatment agent has a good stability, a film formed on the metal surface is stable and uniform, and thepolycondensation reaction of the silane treatment agent does not occur in advance, so the defects of poor stability and polycondensation loss before film formation of silane coupling agents in the prior art are overcome.

Owner:宁波际超新材料科技有限公司

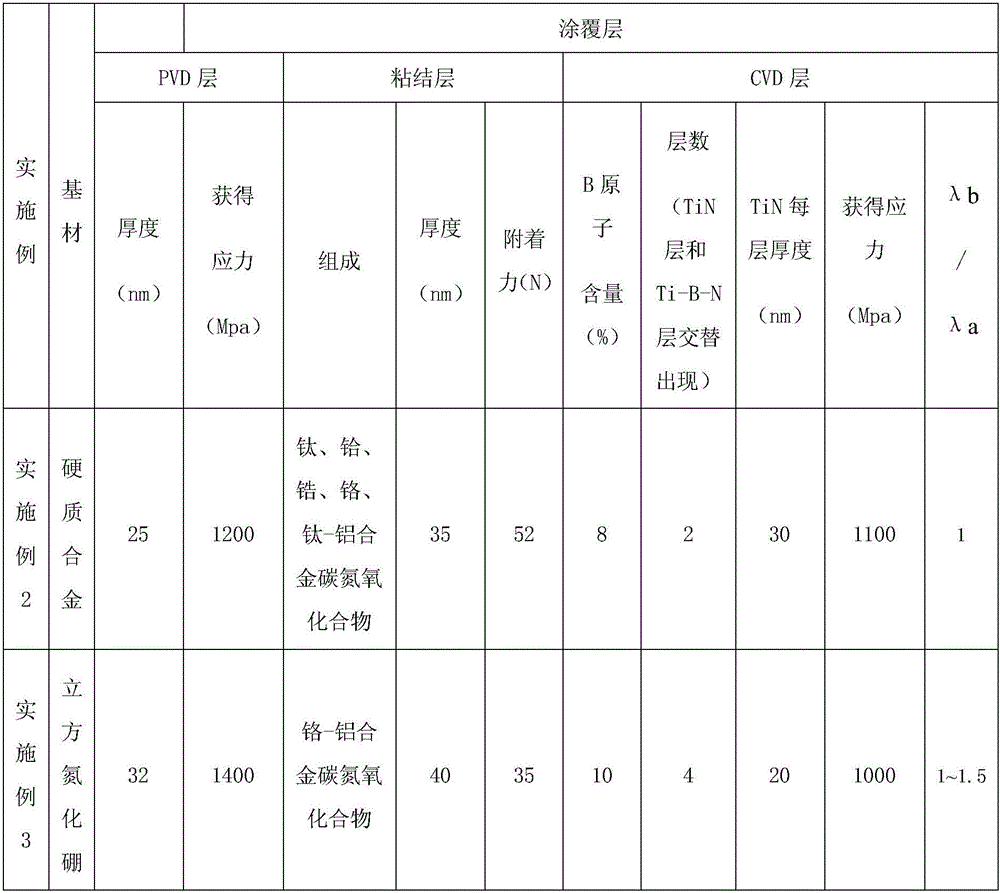

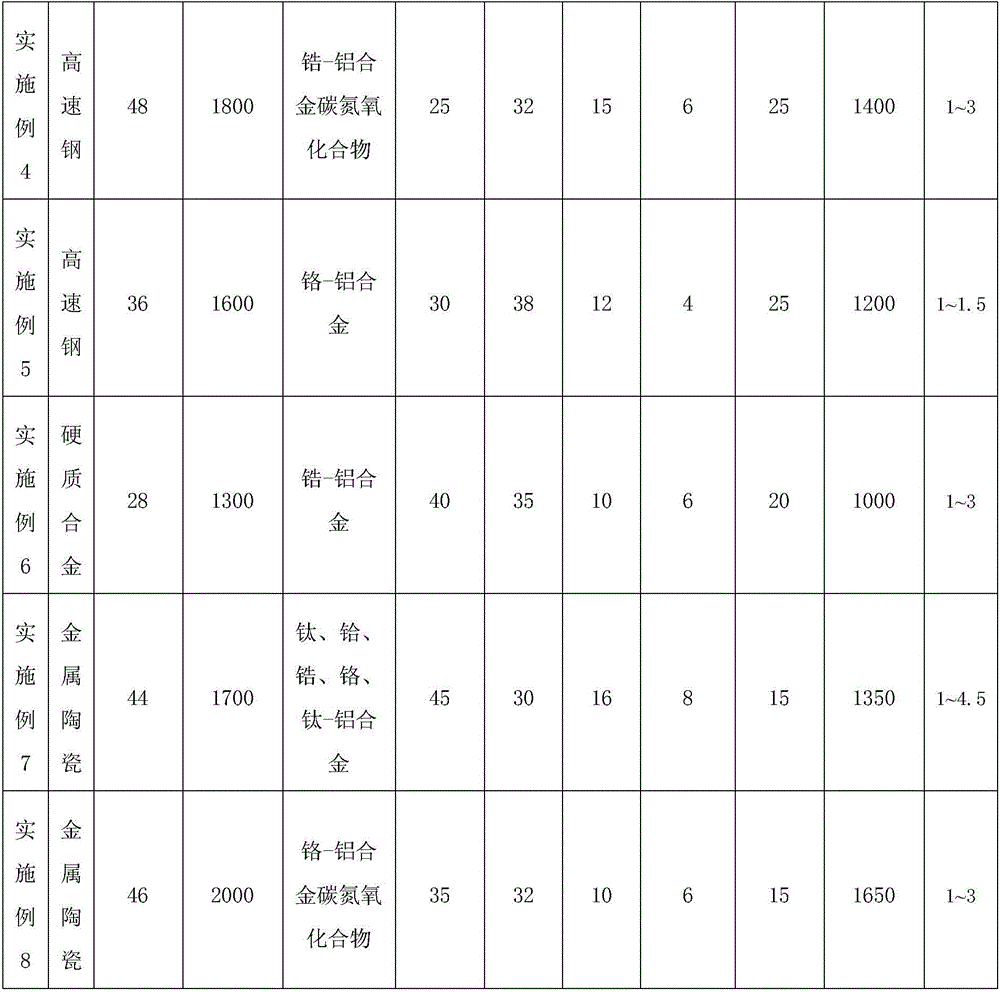

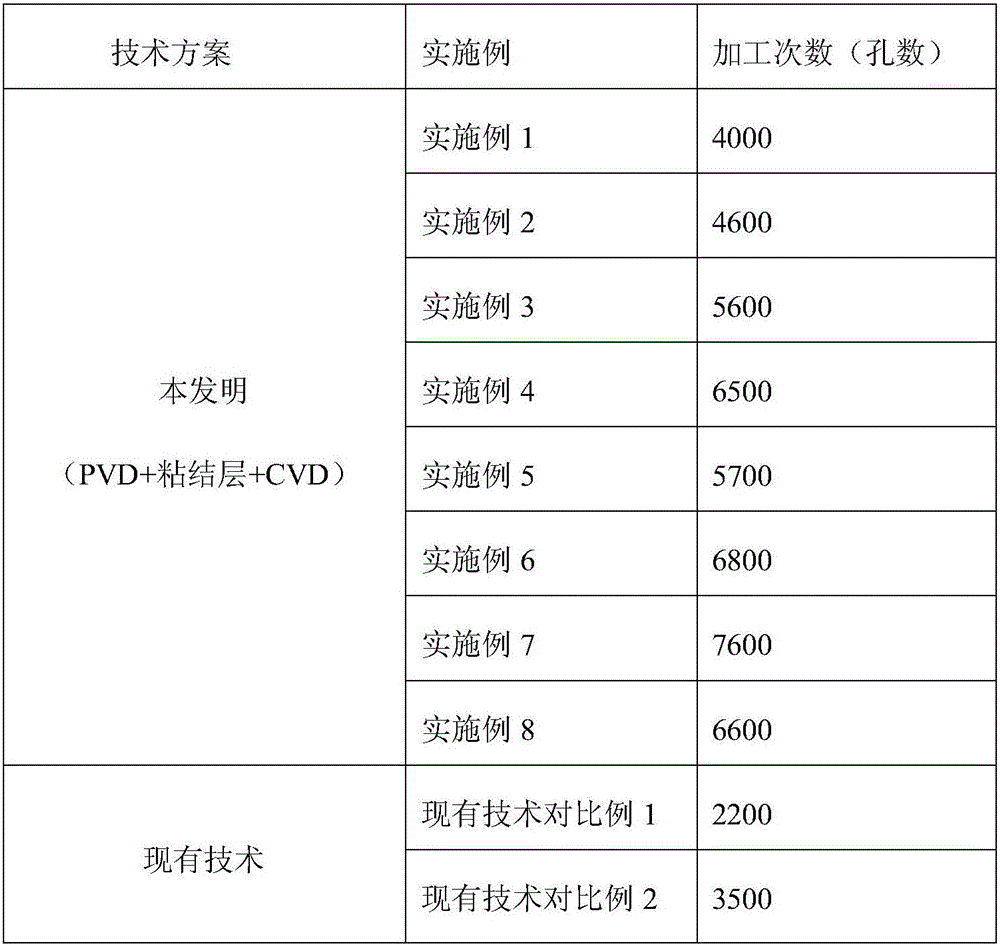

Coated cutting tool and preparation method thereof

ActiveCN105965043AImprove toughnessImprove wear resistanceTransportation and packagingVacuum evaporation coatingOxygen compoundWear resistance

The invention provides a coated cutting tool which comprises a base material and a coated layer. The coated cutting tool is characterized in that the coated layer comprises an inner PVD layer and an outer CVD layer; the CVD layer serves as at least one TiN layer or Ti-B-N layer, or adopts the structure that a plurality of TiN layers and Ti-B-N layers are alternated; the content of B in each Ti-B-N layer is 8-16at%; a bonding layer is formed between the PVD layer and the CVD layer, and made of a metal carbon-nitrogen-oxygen compound; and the structural thickness of each TiN layer or Ti-B-N layer ranges between 0.2-150 nm. The coated cutting tool provided by the invention adopts a coated technology scheme which combines the PVD layer with the CVD layer, so that not only is the toughness good, but also the abrasive resistance is high and the coating adhesion is excellent. Accordingly, the coated cutting tool is relatively long in service life.

Owner:常州市迈瑞廷涂层科技有限公司

Precoating steel plate for building structure and production method thereof

InactiveCN102242310AExtended service lifeStrong coating adhesionHot-dipping/immersion processesAlkaline waterSheet steel

The invention relates to a precoating steel plate for a building structure and a production method thereof. The precoating steel plate comprises the following components in percentage by weight: 0.14-0.20% of C, 0.06-0.20% of Si, 0.50-0.90% of Mn, less than or equal to 0.02% of P, less than or equal to 0.012% of S, 0.02-0.08% of solAl, less than or equal to 0.005% of N, less than 0.005% of Ti, less than 0.005% of Nb and the balance of Fe and inevitable impurities. The production method comprises the following steps: desulfurizing molten iron, smelting in a converter, carrying out continuous casting so as to form a blank and carrying out hot rolling and acid washing; carrying out cold rolling with five racks; annealing; carrying out hot-dip galvanizing; performing hydrocooling; finishing; carrying out tension leveling; washing with alkaline water; carrying out roller painting pretreatment on the surface of the steel plate; carrying out primary baking; carrying out conventional priming coat; carrying out secondary baking; carrying out conventional top coat; carrying out ternary baking and cooling; coiling; and packaging for later use. The precoating steel plate has the excellent coating adhesion and good corrosion resistance, and the cost is reduced by 10-15% as compared with the general precoating plate for the sibling structure, thereby improving market competitiveness.

Owner:武钢集团有限公司

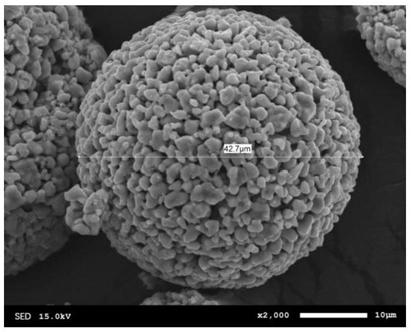

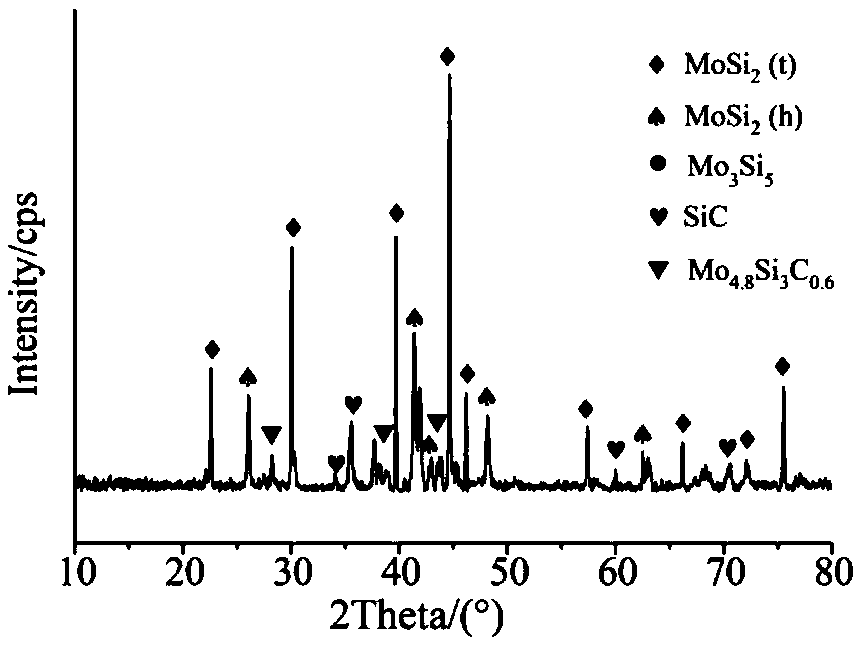

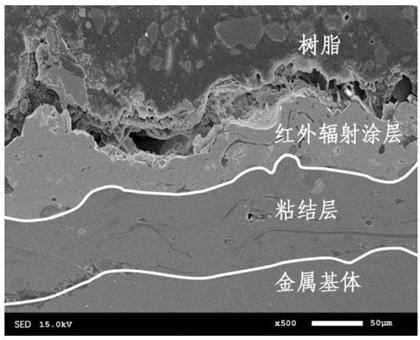

Preparation method of high-temperature-resistant high-infrared-emissivity coating

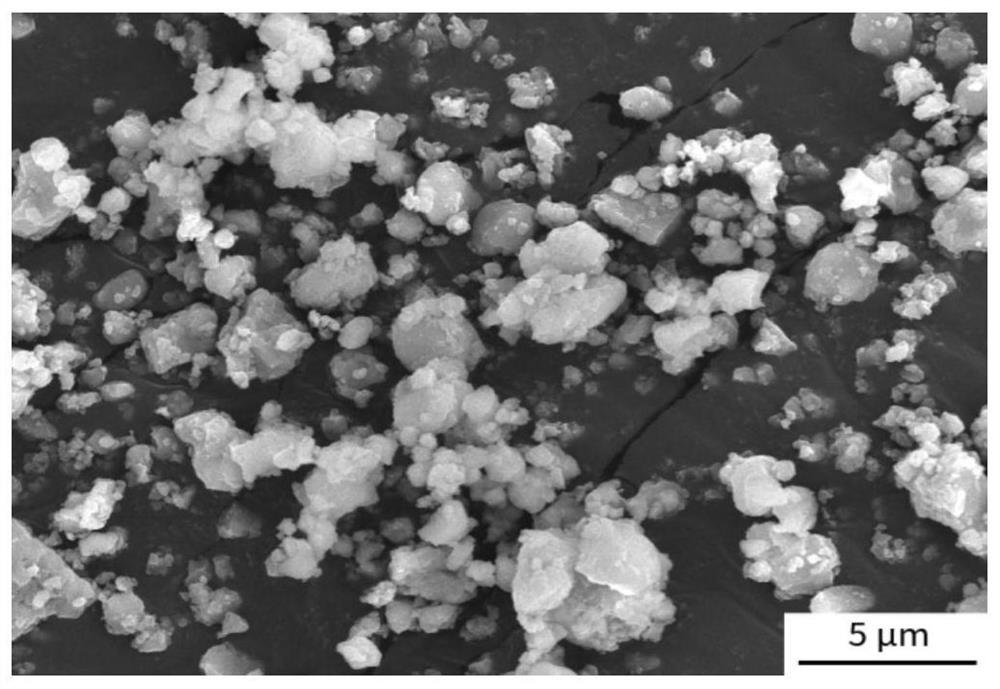

InactiveCN108950456ASolving difficult-to-attach puzzlesSolve the problem of low infrared radiation rate in the short-wave bandMolten spray coatingSpray GranulationThermal spraying

The invention provides a preparation method a high-temperature-resistant high-infrared-emissivity coating. The preparation method comprises the following steps that different proportions of MoSi2 powder and SiC powder are evenly mixed with a binding agent, a defoaming agent and a dispensing agent, and then water is added to an obtained mixture to conduct grinding, so that uniform pulp with certainviscosity is obtained; spray granulation is conducted on the pulp, so that spray powder with a high degree of sphericity is obtained; the obtained powder is placed under an Ar atmosphere at the temperature of 1400 DEG C so as to be roasted for 2 hours, so that compact spherical powder is obtained; and the high-temperature-resistant high-infrared-emissivity coating is obtained on the surface of stainless steel subjected to roughing treatment through the atmospheric plasma spraying technique. The infrared radiation coating prepared through the thermal spraying method can achieve metallurgical bonding with a matrix and is high in bonding capacity and not prone to cracks and stripping, and the problem that it is different for infrared radiation ceramic to adhere to a metal matrix is solved; and meanwhile, the technical problems that an existing high-temperature infrared radiation coating is provided with a short-wave section low in infrared radiancy and is poor in thermal shock resistanceare also solved.

Owner:WUHAN UNIV OF TECH

Highly chlorinated polyethylene fireproof coating

InactiveCN103627263AGood protection and decorationGood chemical resistanceFireproof paintsXylyleneAcrylic resin

The invention provides a highly chlorinated polyethylene fireproof coating, which is composed of the following ingredients in parts by mass: 100 parts of highly chlorinated polyethylene, 40-50 parts of fireproof flame retardant, 5-10 parts of acrylic resin, 5-10 parts of titanium dioxide, 15-20 parts of ammonium polyphosphate, 15-20 parts of antimonous oxide, 10-15 parts of pentaerythritol, 10-15 parts of chlorinated paraffin, 10-15 parts of foaming agent, 10-20 parts of xylene, 5-10 parts of reinforcing agent, 10-15 parts of butyl acetate and 5-10 parts of zinc oxide. The highly chlorinated polyethylene fireproof coating product can be dried in 2-3 hours; the highly chlorinated polyethylene fireproof coating has relatively good protection and decoration effects on various substrates; the thickness of the coating film is less than or equal to 3mm and the fire endurance of the coating film is 100 minutes; the highly chlorinated polyethylene fireproof coating has excellent resistance to heat and humidity and is capable of bearing the influence of high and low temperature cycles; besides, the product is excellent in fire resistance and up to the first level national standards; therefore, the coating film is high in adhesion, good in resistance to chemicals, and thus can be widely produced in stead of the existing materials step by step.

Owner:江苏博思源防火材料科技有限公司

Antiskid powder coating and online coating method thereof

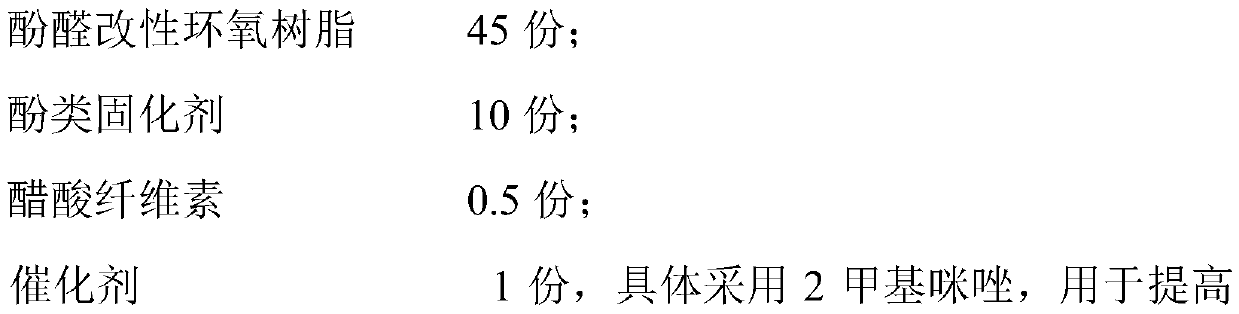

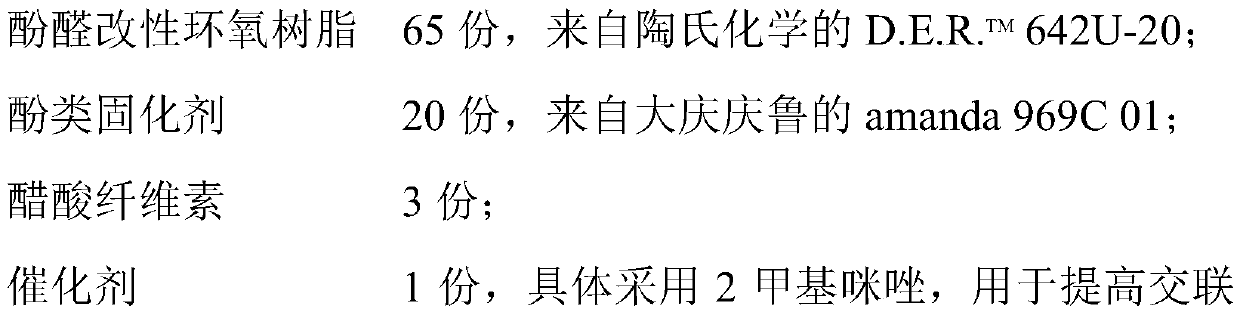

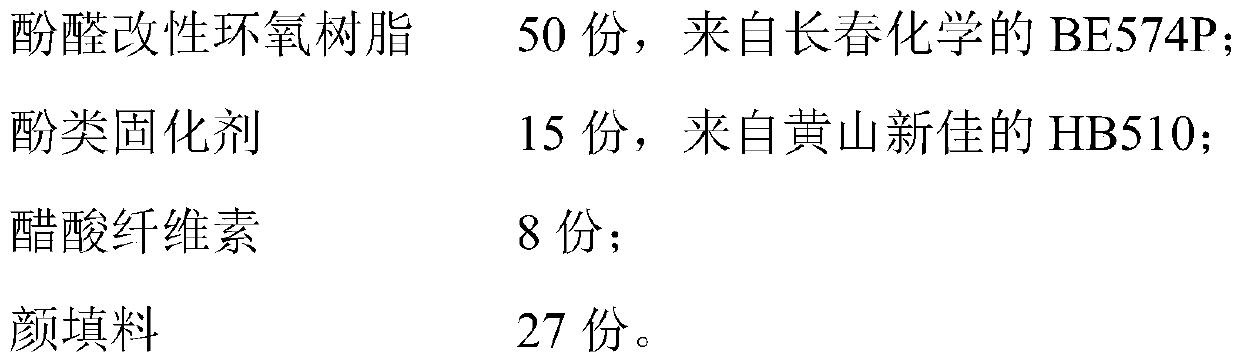

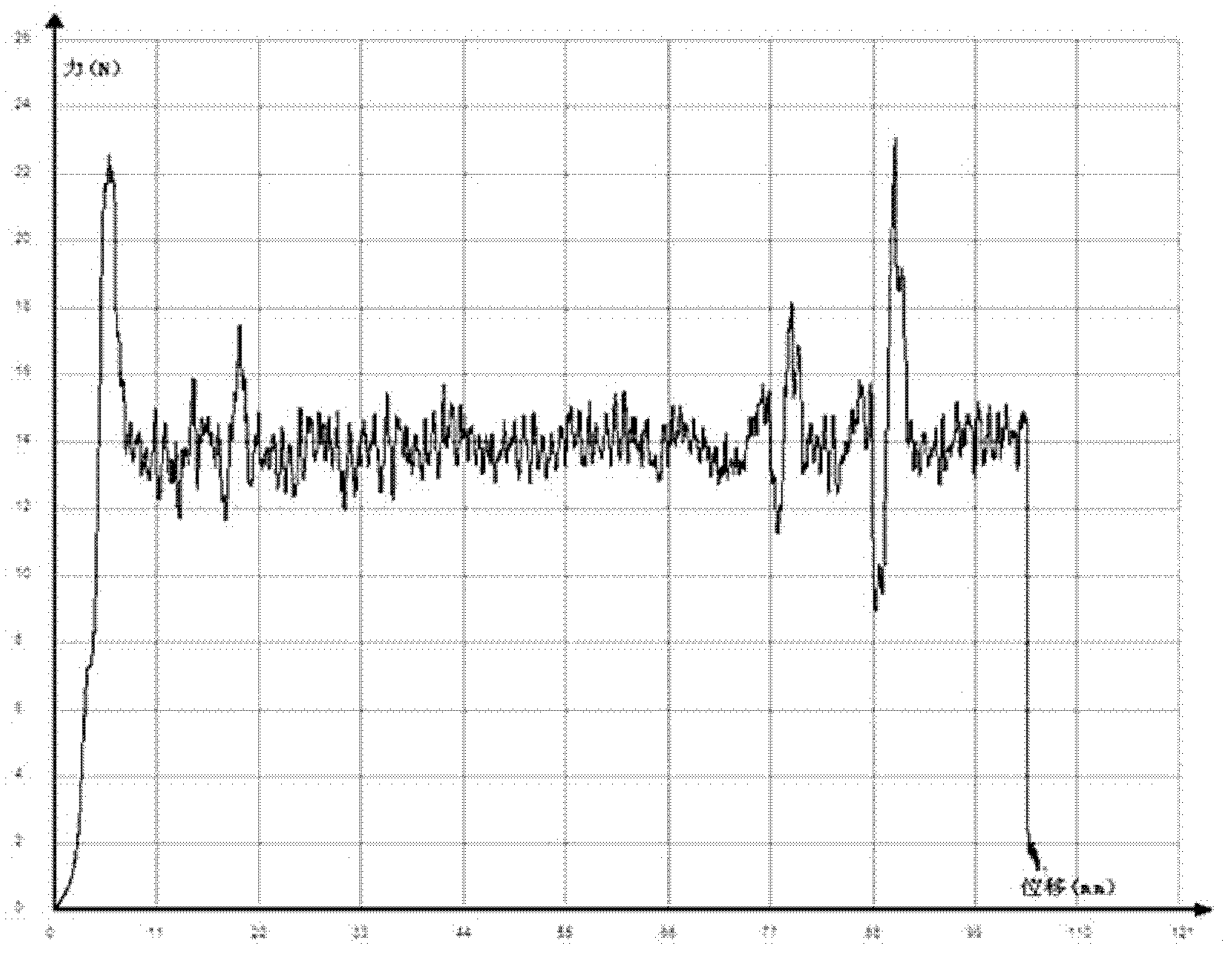

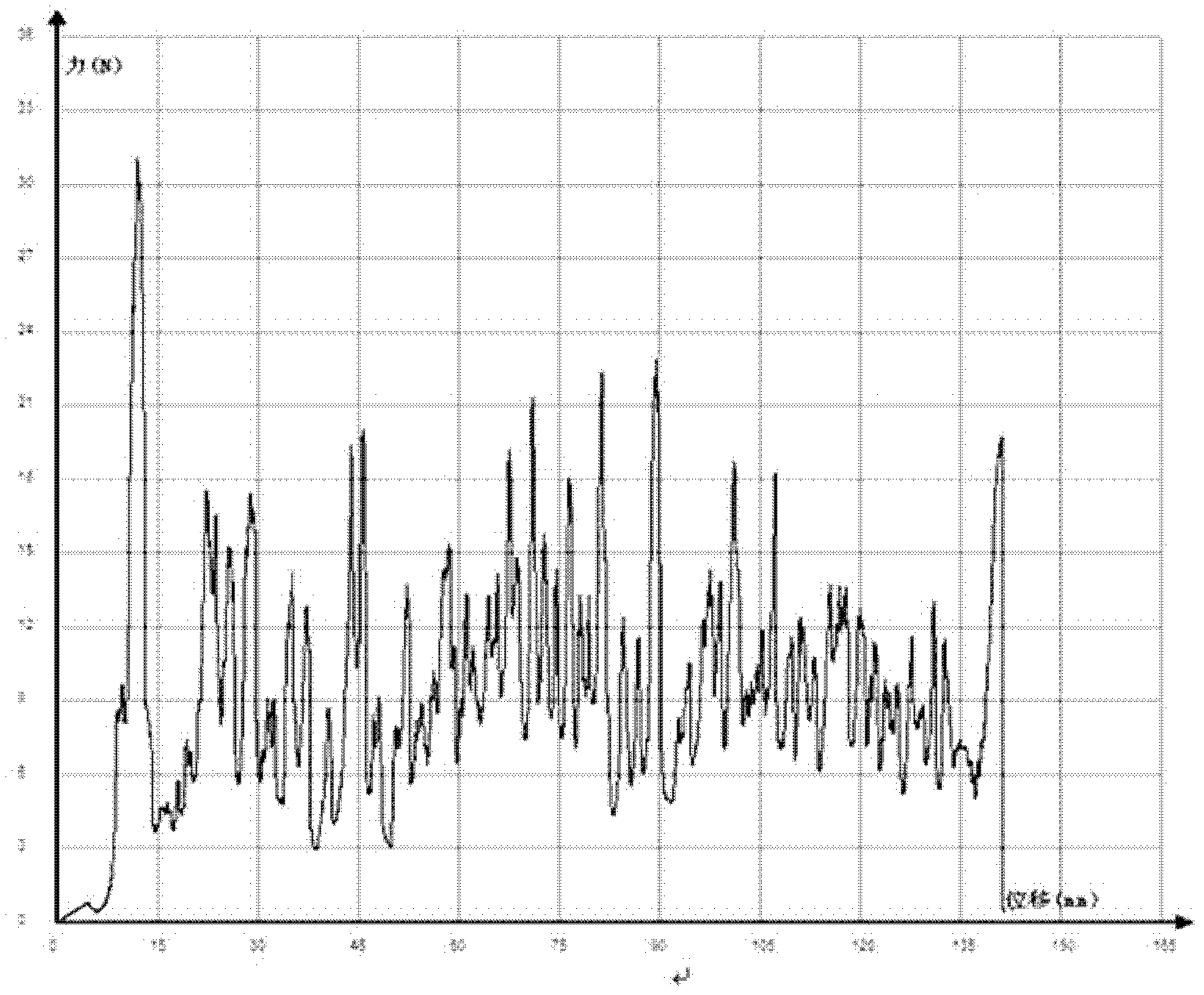

ActiveCN110982376AStrong coating adhesionPretreated surfacesPowdery paintsFirming agentPowder coating

The invention discloses an antiskid powder coating and an online coating method thereof. The antiskid powder coating comprises the following raw materials: phenolic aldehyde modified epoxy resin, a phenolic curing agent for curing the phenolic aldehyde modified epoxy resin and an antiskid agent, wherein the phenolic aldehyde modified epoxy resin and the phenolic curing agent can be subjected to across-linking curing reaction under a curing condition, and the anti-skid agent is used for generating coating anti-skid lines during the curing reaction so that the adhesion force between the coatingfilm and the base material and the anti-skid performance of the surface of the coating film can be improved simultaneously. With creatively screening and designing the characteristics of the raw material formula, the anti-skid property of the coating film can be effectively improved on the premise of ensuring good adhesion performance of the coating film, and the antiskid powder coating is quitesuitable for meeting the requirements of the field of coating protection with excellent anti-skid property requirements.

Owner:TIGER NEW SURFACE MATERIALS QINGYUAN CO LTD

Coating for preventing surface rusting of color steel plate of solar water tank

InactiveCN106590358AExtended service lifeImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsAcrylic resinSolar water

The invention relates to the technical field of solar equipment, in particular to a coating for preventing surface rusting of a color steel plate of a solar water tank. Most of solar water tanks are made of color steel plates, the installation environment of the solar water tanks is adverse, and the easiness in corrosion and rusting of the color steel plates by water, temperature and air pollution of surrounding environment is caused; the color steel plate is thinner, and the easiness in breaking is caused. The coating comprises the following raw materials of modified vinyl resin, thermosetting acrylic resin, bisphenol-A-type epoxy resin, talcum powder, glass powder, precipitated barium sulfate, nanometer material, compound ferric and titanium powder, zeolite, tributyl phosphate, ammonia water, solvent, pigment, synergist, flatting agent, dispersant and antirust agent. The coating has the advantages that by adding the nanometer material, the film forming density of the coating is improved, the hardness of a paint film is improved, and the hand feel is improved; the anti-rust property and anti-corrosive property are good, the adhesion force of a coating film is strong, and the pollution-resistant property and the acid and alkaline-resistant property are good.

Owner:钦州太平电子科技有限公司

Coating, aqueous flexible anode piece prepared through adopting it, and lithium ion battery

ActiveCN102827541AOvercome the defect of high brittlenessGood flexibilityElectrode manufacturing processesConjugated diene hydrocarbon coatingsElectrochemistryLithium-ion battery

The invention belongs to the technical field of lithium ion batteries, and concretely discloses a coating used for preparing an aqueous flexible anode piece, the aqueous flexible anode piece prepared through adopting the coating, and a lithium ion battery adopting the anode piece. The coating used for preparing the aqueous flexible anode piece is basically composed of 90-98wt% of an anode powder, 0.5-3wt% of an aqueous dispersant, 1-5wt% of an aqueous thermoelastic binder and 0.5-8wt% of a conductive agent. The flexibility of the anode piece prepared through adopting the aqueous flexible anode piece coating is good, so a defect of large brittleness of present aqueous anode pieces is overcome; and the adhesion of the prepared anode piece is strong, so requirements of various battery making technologies can be satisfied, and requirements of various electrochemical performances are satisfied.

Owner:中创新航科技(江苏)有限公司

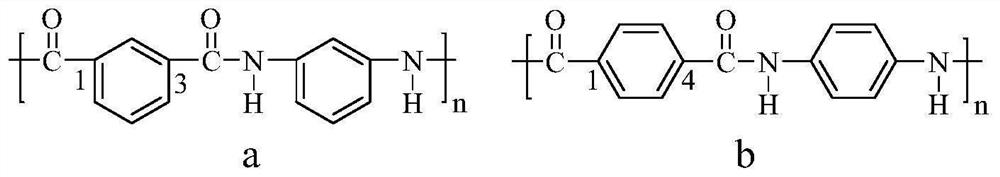

Modified composite heat-resistant lithium ion battery diaphragm and preparation method thereof

InactiveCN112216928AImprove electrochemical performanceImprove mechanical propertiesSecondary cellsNanotechnologyHeat resistanceLithium-ion battery

The invention belongs to the field of high polymer materials, and discloses a preparation method of a modified composite heat-resistant lithium ion battery diaphragm, which comprises the following steps: A, modifying aramid fibers; B, modifying an inorganic nano material; C, mixing the modified aramid fiber slurry and the modified inorganic nano slurry with a solvent in proportion to prepare organic-inorganic mixed modified slurry; and D, coating a base membrane with the organic-inorganic mixed modified slurry, and carrying out moisture solidification, washing, solvent removal and drying to obtain the modified composite heat-resistant lithium ion battery diaphragm. The problems of insufficient heat resistance, high moisture, large static electricity and the like of an existing aramid fibercoating diaphragm are solved.

Owner:长园泽晖新能源材料研究院(珠海)有限公司

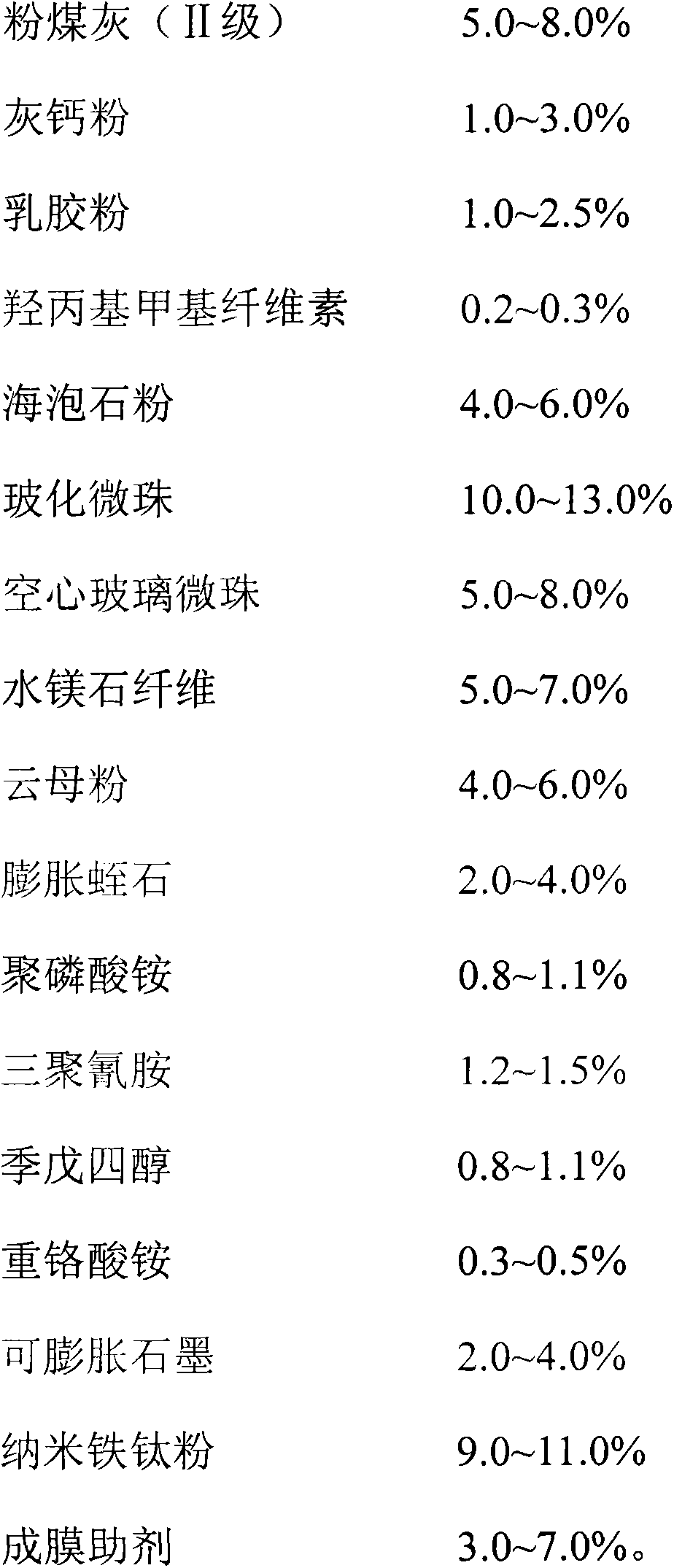

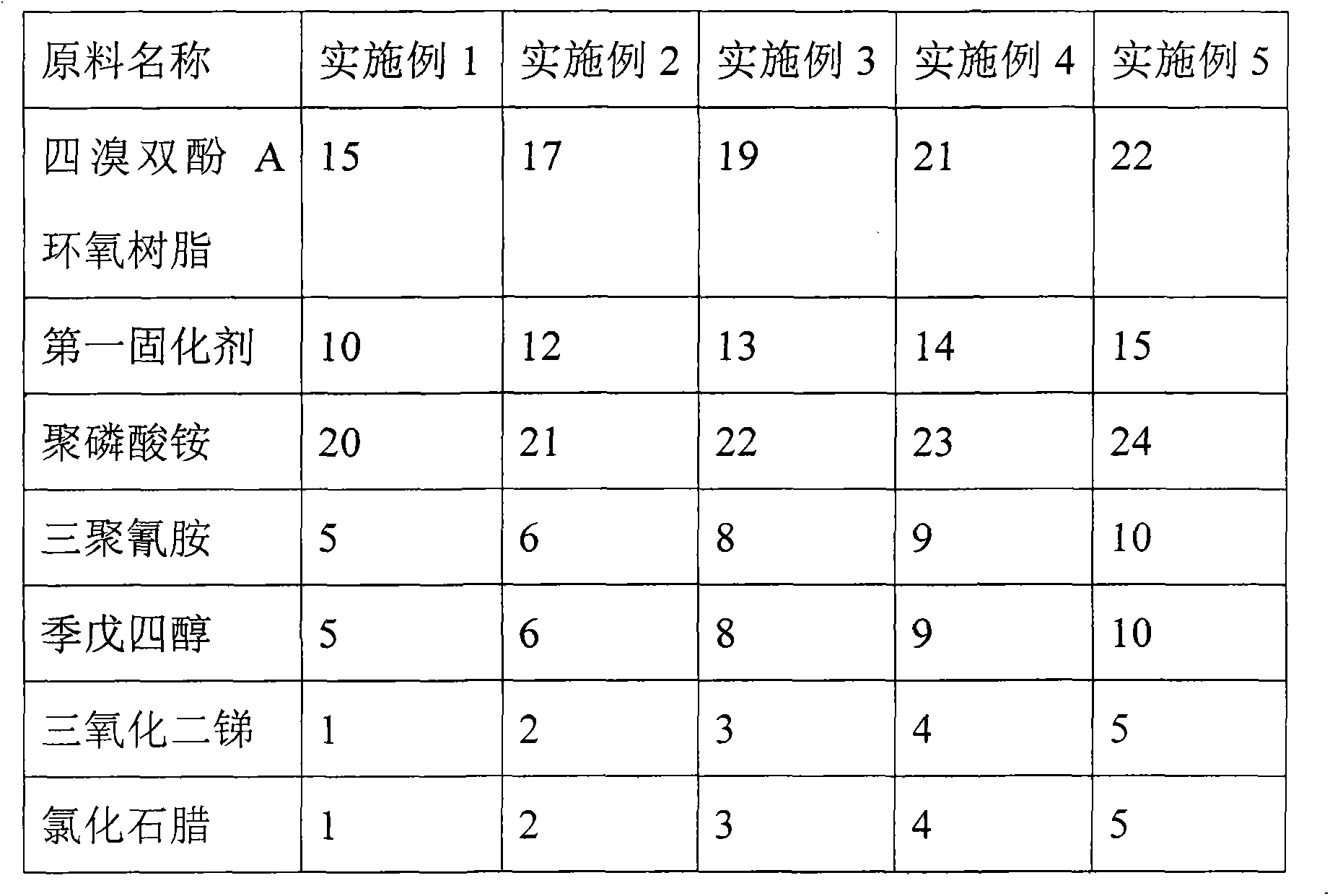

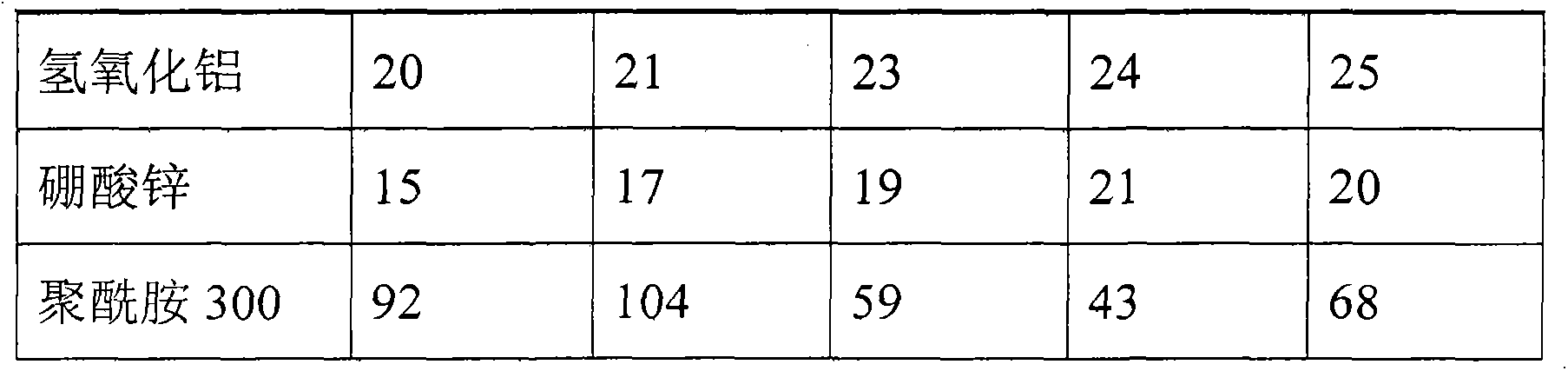

Hydrocarbon-resistant indoor thin fireproofing coating for steel structures

InactiveCN103450781AGood foaming effectLow smoke productionFireproof paintsEpoxy resin coatingsEpoxyTetrabromobisphenol A

The invention discloses a hydrocarbon-resistant indoor thin fireproofing coating for steel structures, aiming at solving the problems of general thin fireproofing coatings for steel structures which are easy to peel off in case of fire disaster, poor in adhesion performance, and poor in fireproofing and heat insulation effects. The technical scheme is as follows: the fireproofing coating is prepared from a component A: TBA type epoxy resin fireproofing coating, and a component B, namely polyamide 300 curing agent, at (1-3):1 in parts by mass, wherein the component A, namely TBA type epoxy resin fireproofing coating, consists of the following materials in parts by weight: 15-22 parts of TBBP-A epoxy resin, 10-15 parts of first curing agent, 20-24 parts of ammonium polyphosphate, 5-10 parts of melamine, 5-10 parts of pentaerythritol, 1-5 parts of antimonous oxide, 1-5 parts of chlorinated paraffin, 20-25 parts of aluminum hydroxide and 15-20 parts of zinc borate. The fireproofing coating has the advantages of good foaming effect, massive generation of carbide, little smoke, strong adhesion force, good acid-base resistance property and good fireproofing and heat insulation effects.

Owner:王海辉

Water soluble inorganic silicon solution rust-inhibiting primer and preparation method thereof

The invention relates to rust-inhibiting primer of water-soluble inorganic silicon solution and a process for preparation. The process comprises first, weighing water 5-40, inorganic silicon solution (TZG) 5-30, dispersing agent (5040) 0.2-0.6, defoaming agent (SA-3) 0.05-0.3, wetting agent (PE-100) 0.05-0.3, neutralizing agent (Amp-95) 0.05-0.3, and alcohol 1-5 into a synthesis autoclave according to percentage by weight of components and contents, dispersing for 10-20 minutes in low speed, second, weighing iron-oxide red 5-40, iron-oxide red earth 1-10, precipitated barium carbonate 1-10, zinc phosphate 0.3-5, and heavy calcium 1-10 into the synthesis autoclave according to percentage by weight of components and contents, and dispersing for 25-40 in high speed, third, sanding in a sand crusher, the degree of fineness is <=64um, fourth, weighing emulsion20-50, film former 0.5-3, and thickening agent 0.1-1 into the synthesis autoclave according to percentage by weight of components and contents, and adjusting the viscosity to be >=30, finally, getting end products after filtering. The invention has the advantages of environmental protection, strong tarnish proofness, excellent matching property with finish, long life span, low production cost and the like.

Owner:刘刚

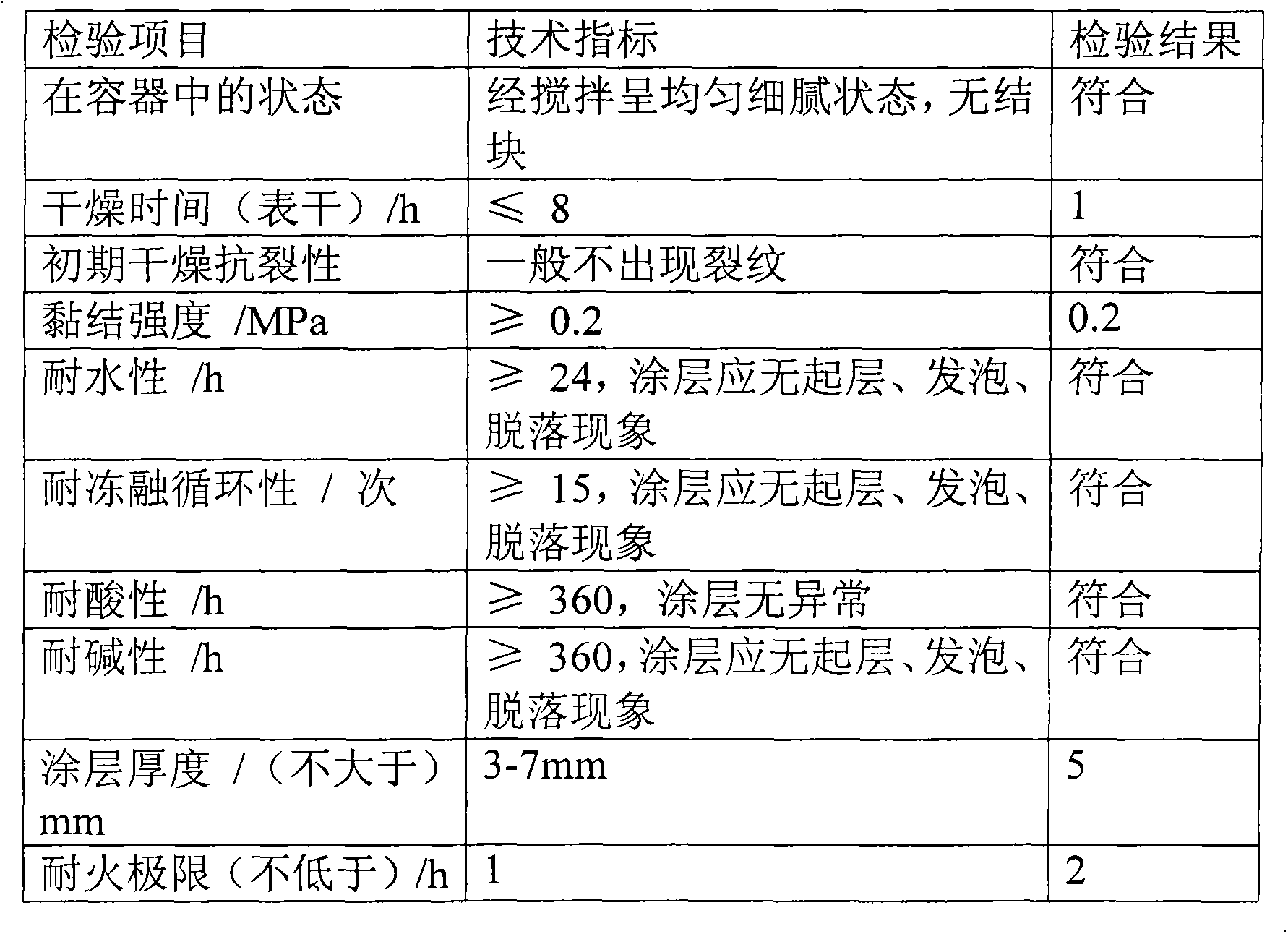

Porous polyether-ether-ketone-based coating material and preparation method thereof

PendingCN113304314AIncrease contact areaImprove bindingTissue regenerationCoatingsCalcium silicatePoly ether ether ketone

The invention discloses a porous polyether-ether-ketone-based coating material and a preparation method thereof. The surface of polyether-ether-ketone is treated, a porous structure is formed on the surface of polyether-ether-ketone, degradable material powder is deposited on the surface of the porous structure of polyether-ether-ketone by adopting a cold spraying technology or a vacuum cold spraying technology, and the porous polyether-ether-ketone-based composite material is obtained. The degradable material powder is one or more of hydroxyapatite, calcium silicate and beta-tricalcium phosphate. The surface of the polyether-ether-ketone is treated to be of a porous structure, the contact area of the coating and a polyether-ether-ketone base material is effectively increased, cold spraying or vacuum cold spraying is adopted, it can be ensured that a degradable material enters the porous structure, and the bonding strength of the coating and the polyether-ether-ketone base material is effectively improved. The coating is made of a degradable material, can guide or induce new bone tissues to grow into the porous structure, and can greatly enhance the osseointegration and stability of a bone / implant interface.

Owner:THE SECOND AFFILIATED HOSPITAL OF XIAN JIAOTONG UNIV

Low-surface treatment rusty rust inhibiting primer and preparation method thereof

InactiveCN106752659AStrong adhesionExcellent anti-corrosion and anti-rustAnti-corrosive paintsEpoxy resin coatingsEpoxyLacquer

The invention relates to a low-surface treatment rusty rust inhibiting primer and a preparation method thereof. The low-surface treatment rusty rust inhibiting primer comprises a component A and a component B; The component A comprises the following raw materials in parts by weight: 5-50 parts of epoxy resin, 5-50 parts of a filler, 1-10 parts of a rust-converting agent, and 1-50 parts of an anti-rust pigment; and the component B comprises the following raw materials in parts by weight: 30-80 parts of a curing agent, 1-10 parts of a promoter, and 1-15 parts of a silane coupling agent. The low-surface treatment rusty rust inhibiting primer has good adhesion and excellent physical machinery, corrosion and rust protection as well as low-surface treatment performance, the construction performance is good, the low-surface treatment rusty rust inhibiting primer can be taken as a low-surface treatment primer by cooperating with a conventional protection paint, and can be individually used as a functional rusty primer.

Owner:HENAN RUNNAN PAINT IND

Low-shrinkage sprayable PP/PS blend alloy and preparation method thereof

The invention discloses a low-shrinkage sprayable PP / PS blend alloy and a preparation method thereof. The low-shrinkage sprayable PP / PS blend alloy is prepared from the following components in percentage by weight: 30 to 45 percent of polypropylene resin, 25 to 30 percent of styrene resin, 6 to 12 percent of graft compatilizer, 4 to 8 percent of toughening agent, 15 to 20 percent of functional filler, 0.2 to 0.5 percent of antioxidant, and 0.2 to 1 percent of lubricant. The forming shrinkage of the low-shrinkage sprayable PP / PS blend alloy is as low as 0.7 to 0.9 percent and is closed to the level of ABS, and the low-shrinkage sprayable PP / PS blend alloy can directly replace the ABS under the condition of no die repair and does not influence the appearance of an injection molding product.

Owner:KINGFA SCI & TECH CO LTD +1

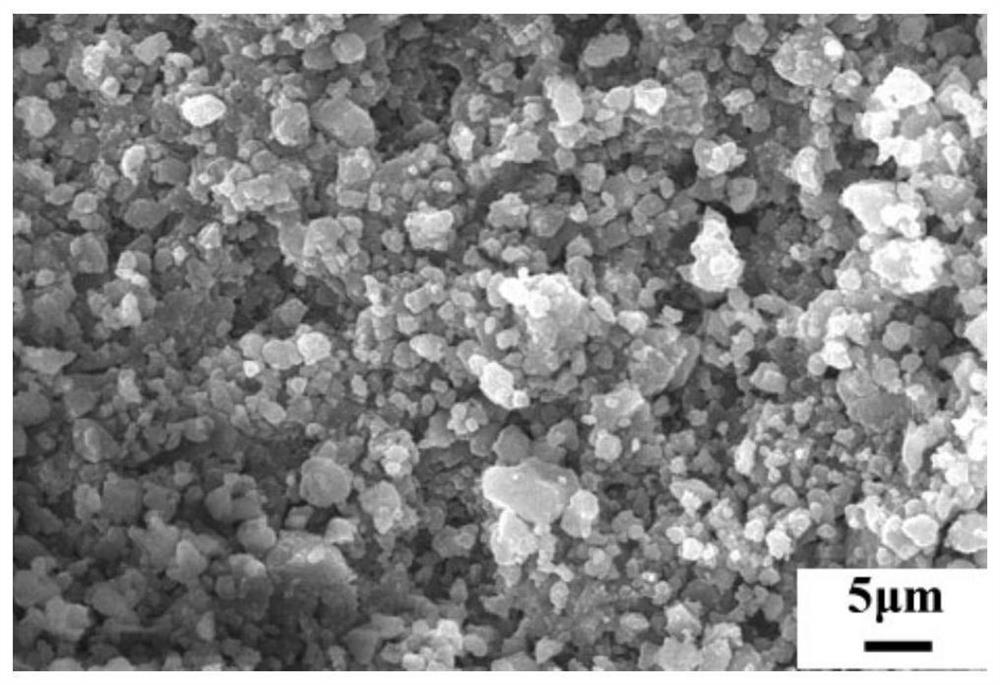

Nickel-based alloy powder for high-speed laser cladding and cladding method of nickel-based alloy powder

PendingCN112281153AStrong coatingStrong coating adhesionMetallic material coating processesSocial benefitsEconomic benefits

The invention provides nickel-based alloy powder for high-speed laser cladding and a cladding method of the nickel-based alloy powder, and relates to the technical field of inorganic materials. The nickel-based alloy powder comprises the components of 80wt%-83wt% of Ni, 10wt%-12wt% of Al, 4wt%-6wt% of Si, 1wt%-3wt% of WC, and the balance inevitable trace impurities. The invention further providesthe cladding method of the nickel-based alloy powder on a crystallizer copper plate base body. The cladding method mainly comprises the steps that the pretreated crystallizer copper plate base body ispreheated, and heat preservation is carried out on the crystallizer copper plate base body in the cladding process. A laser cladding layer coating obtained through the cladding mode of the nickel-based alloy powder on a crystallizer copper plate is high in binding force and good in compactness, and the crystallizer copper plate is heated lightly, so that the deformation amount is small; the crystallizer copper plate has good machinable machining performance, so that the abrasion resistance, corrosion resistance and cladding efficiency of a crystallizer are greatly improved; and the cladding method can be suitable for new manufacturing and repairing of the crystallizer copper plate, and has remarkable economic benefits and social benefits.

Owner:ANHUI MA STEEL SURFACE TECH CO LTD

Waterborne epoxy self-leveling anti-scratch floor paint and preparation process thereof

InactiveCN108300126AHigh hardnessImprove scratch resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyDefoaming Agents

The invention relates to a waterborne epoxy self-leveling anti-scratch floor paint and a preparation process thereof. The waterborne epoxy self-leveling anti-scratch floor paint is characterized by being prepared from a component A and a component B, wherein the component A comprises, by mass, 80 parts of waterborne epoxy resin and 20 parts of an active diluent; and the component B comprises, by mass, 20-25 parts of a waterborne epoxy curing agent, 22-33 parts of deionized water, 0.2-0.6 part of a wetting and dispersing agent RS610, 0.3-0.5 part of a defoaming agent DF681F, 0.5-1 part of an anti-scratch aid, 0.2-0.4 part of an alkali swelling thickener A401, 4-6 parts of titanium dioxide, 2-3 parts of phthalocyanine blue BGS, 1-1.5 parts of strontium chrome yellow 801, 10-15 parts of lightcalcium carbonate, 20-25 parts of precipitated barium sulfate, 2-3 parts of an anti-scratch agent and 10-15 parts of ultrafine talcum powder. The paint provided by the invention utilizes water as a dispersion medium, does not contain volatile organic solvents such as toluene and xylene, saves a lot of resources, eliminates the possibility of fire hazards during construction, reduces pollution tothe atmosphere, and enhances working environment conditions. A coating formed by the paint has good adhesion; and a paint film formed by the paint has greatly improved scratch resistance and good adhesion to most substrates.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

Mold release film

InactiveCN101184619AStrong coating adhesionLess oligomer precipitationSynthetic resin layered productsPolyesterAfter treatment

A mold release film comprising a coating layer and a mold release layer provided in this order on one surface of a polyester film which is stretched at least in the monoaxial direction, the coating layer comprising an aluminum chelate compound and / or a zirconium chelate compound, the mold release film having a critical destruction load (CDC) on the mold release side of 40 mN or higher, and the quantity of an oligomer extracted with dimethylformamide from the surface of the mold release layer after treatment at 180 DEG for 10 minutes being 1.5 mg / m2 or less. In the mold release film, the quantity of an oligomer precipitated therefrom is quite small and the adhesion of the mold release layer to a coating film is good.

Owner:MITSUBISHI POLYESTER FILM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com