Inorganic/organic compound functional porous isolating membrane and preparation method as well as lithium ion battery adopting inorganic/organic compound functional porous isolating membrane

A composite function, porous technology, applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems of safety performance degradation, impact on battery performance, battery chemical performance degradation, etc., to suppress shrinkage and deformation, reduce short circuit. risk, the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

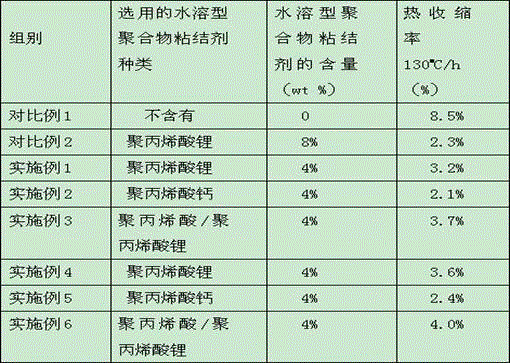

Examples

Embodiment 1

[0042] Preparation of Inorganic / Organic Composite Functionalized Porous Separator Membrane

[0043] The coating slurry formula is based on the weight percentage of the dry material. The coating slurry is composed of 4wt% styrene / acrylate copolymer emulsion, 4wt% lithium polyacrylate, 1wt% carboxymethyl cellulose sodium, and 91wt% inorganic ceramic particles. , where the inorganic ceramic particles are selected from Al 2 o 3 , and its particle size D50 is 0.6 μm to 1.0 μm. The water-emulsion polymer binder is selected from styrene / acrylate copolymer emulsion, its surface tension is 42 dyne / cm, and the contact angle of dry glue water drop is 125. o , with a glass transition temperature of 25 o c. The water-soluble polymer binder is lithium polyacrylate, the weight average molecular weight is about 100,000g / mol, the pH value of its 20wt% aqueous solution is about 5, and the glass transition temperature is about 120 o c. During the preparation of the slurry, the solvent is d...

Embodiment 2

[0063] The difference between embodiment 2 and embodiment 1 is the composition of coating slurry:

[0064] The coating slurry formula consists of four parts: 4wt% styrene / acrylate copolymer emulsion, 4wt% calcium polyacrylate, 1wt% carboxymethyl cellulose sodium, and 91wt% inorganic ceramic particles, in terms of weight percentage of dry material, of which inorganic ceramic Al 2 o 3 , and its particle size D50 is 0.6 μm to 1.0 μm. The water-emulsion polymer binder is selected from styrene / acrylate copolymer emulsion, its surface tension is 42 dyne / cm, and the contact angle of dry glue water drop is 125. o , with a glass transition temperature of 25 o c. The water-soluble polymer binder is calcium polyacrylate, the weight average molecular weight is about 100,000g / mol, the pH value of its 20wt% aqueous solution is about 5, and the glass transition temperature is about 135 o c. During the preparation of the slurry, the solvent is deionized water, wherein the weight of the ...

Embodiment 3

[0067] The difference between embodiment 3 and embodiment 1 is the composition of coating slurry:

[0068]The coating slurry formula is based on the weight percentage of the dry material. It consists of four parts: 4wt% styrene / acrylate copolymer emulsion, 4wt% polyacrylic acid / lithium polyacrylate, 1wt% carboxymethyl cellulose sodium, and 91wt% inorganic ceramic particles. Among them, the inorganic ceramic particles are selected from Al 2 o 3 , and its particle size D50 is 0.6 μm to 1.0 μm. The water-emulsion polymer binder is selected from styrene / acrylate copolymer emulsion, its surface tension is 42 dyne / cm, and the contact angle of dry glue water drop is 125. o , with a glass transition temperature of 25 o c. The water-soluble polymer binder is polyacrylic acid / lithium polyacrylate, the weight average molecular weight is about 100,000g / mol, the pH value of its 20wt% aqueous solution is about 5, and the glass transition temperature is about 115 o c. During the prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com