Patents

Literature

784results about How to "Reduce water content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

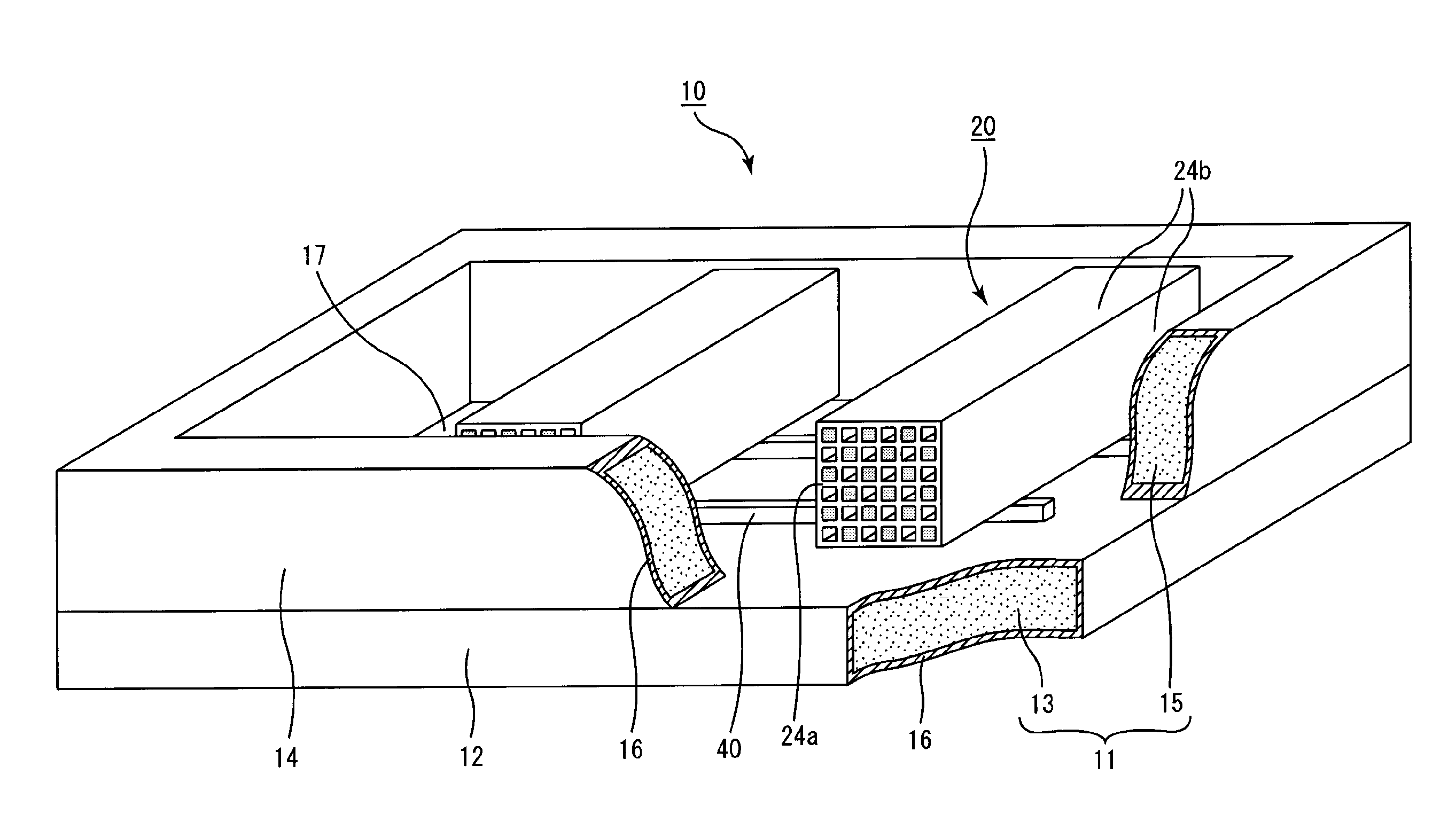

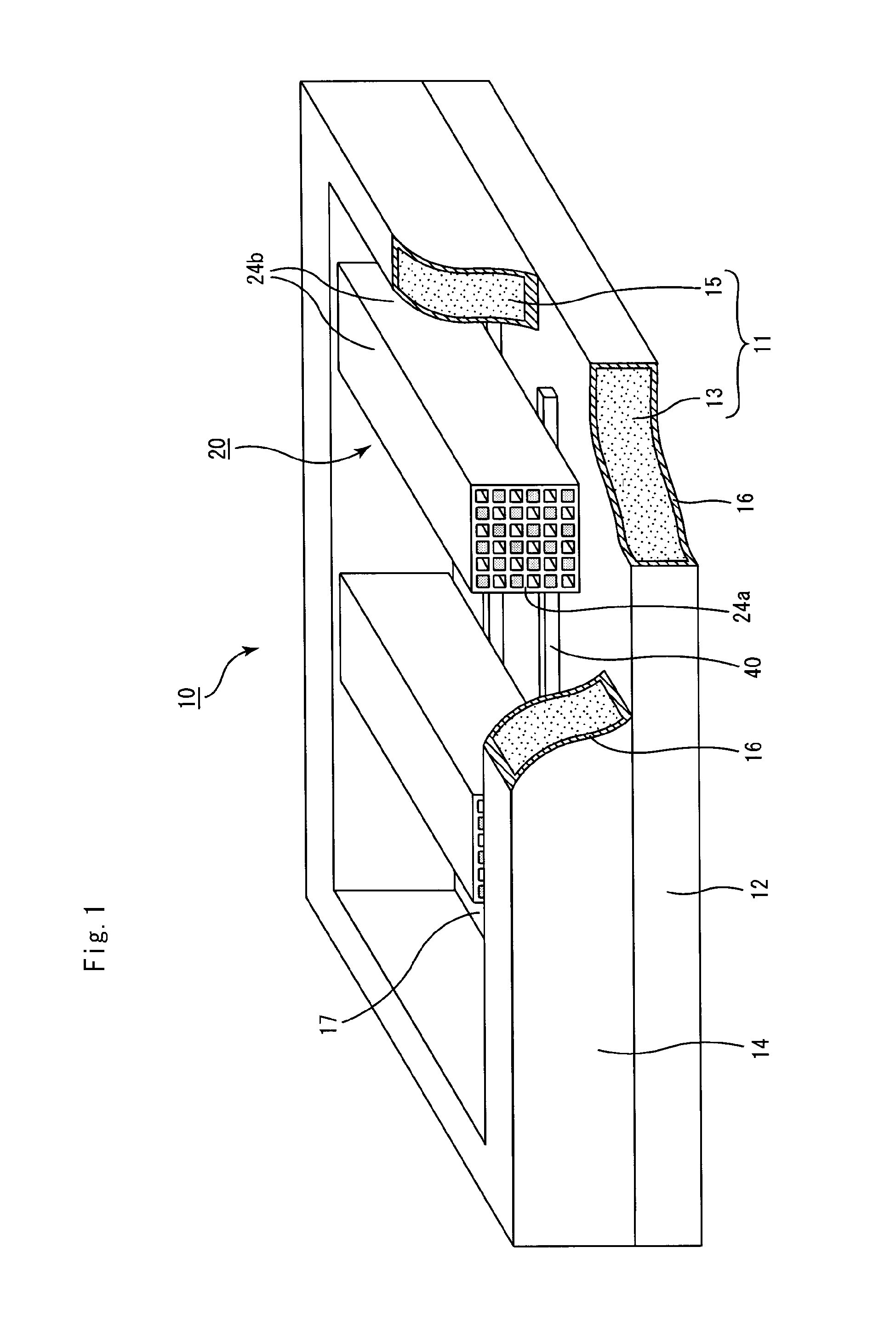

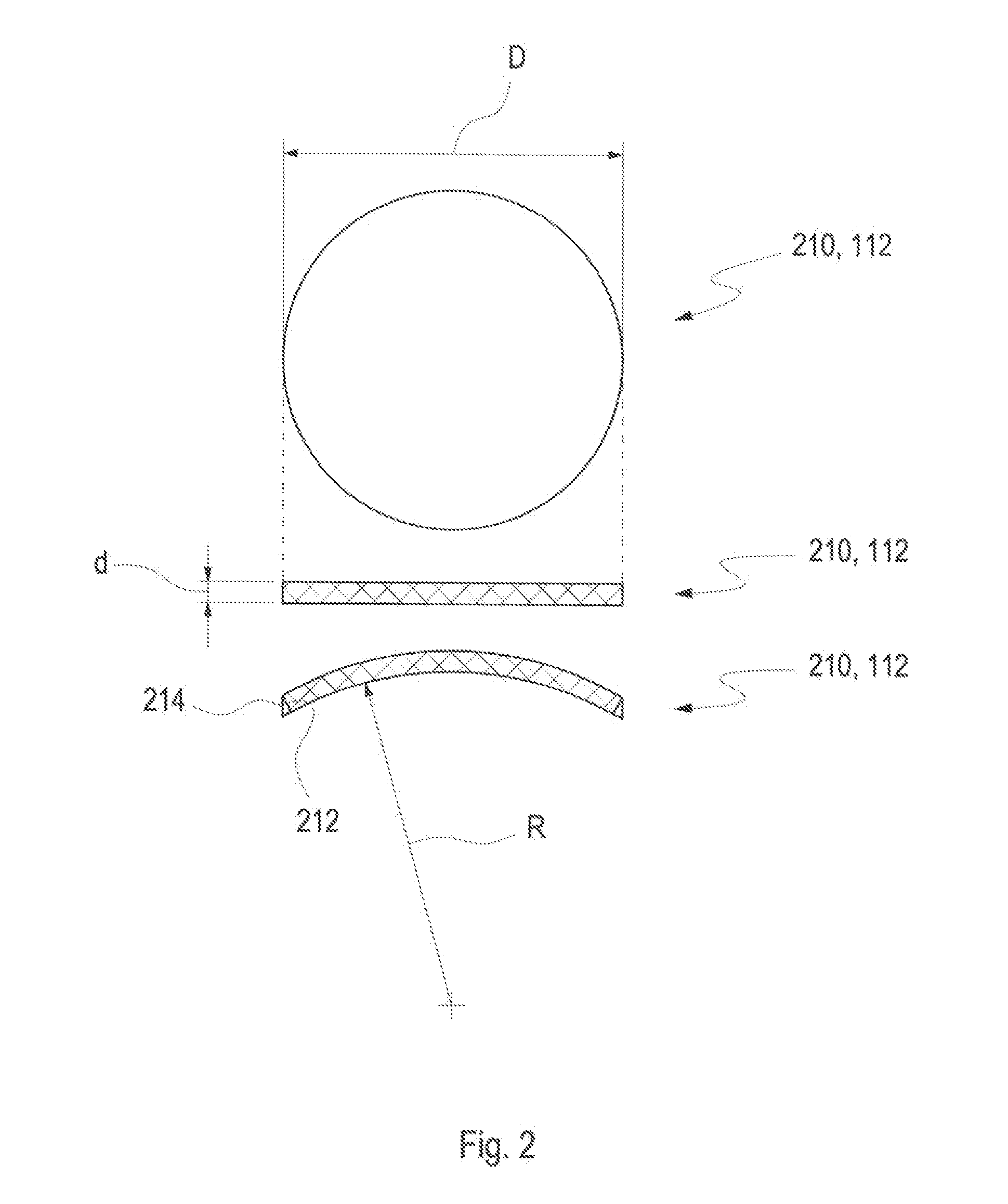

Firing jig and method for manufacturing honeycomb structure

InactiveUS20080305259A1Reduce yieldReduced strengthLayered productsCharge supportsHoneycomb structureSilicon carbide

A firing jig for a honeycomb molded body includes a housing body configured to place a pillar-shaped honeycomb molded body including silicon carbide as a main component with a side face of the honeycomb molded body facing down, and a coat layer formed on at least a placing face of the housing body configured to place the honeycomb molded body thereon. A main component of the coat layer is silicon carbide, the coat layer having an arithmetic average height Ra of about 10 μm or less obtained in conformity with JIS B 0601 (2001).

Owner:IBIDEN CO LTD

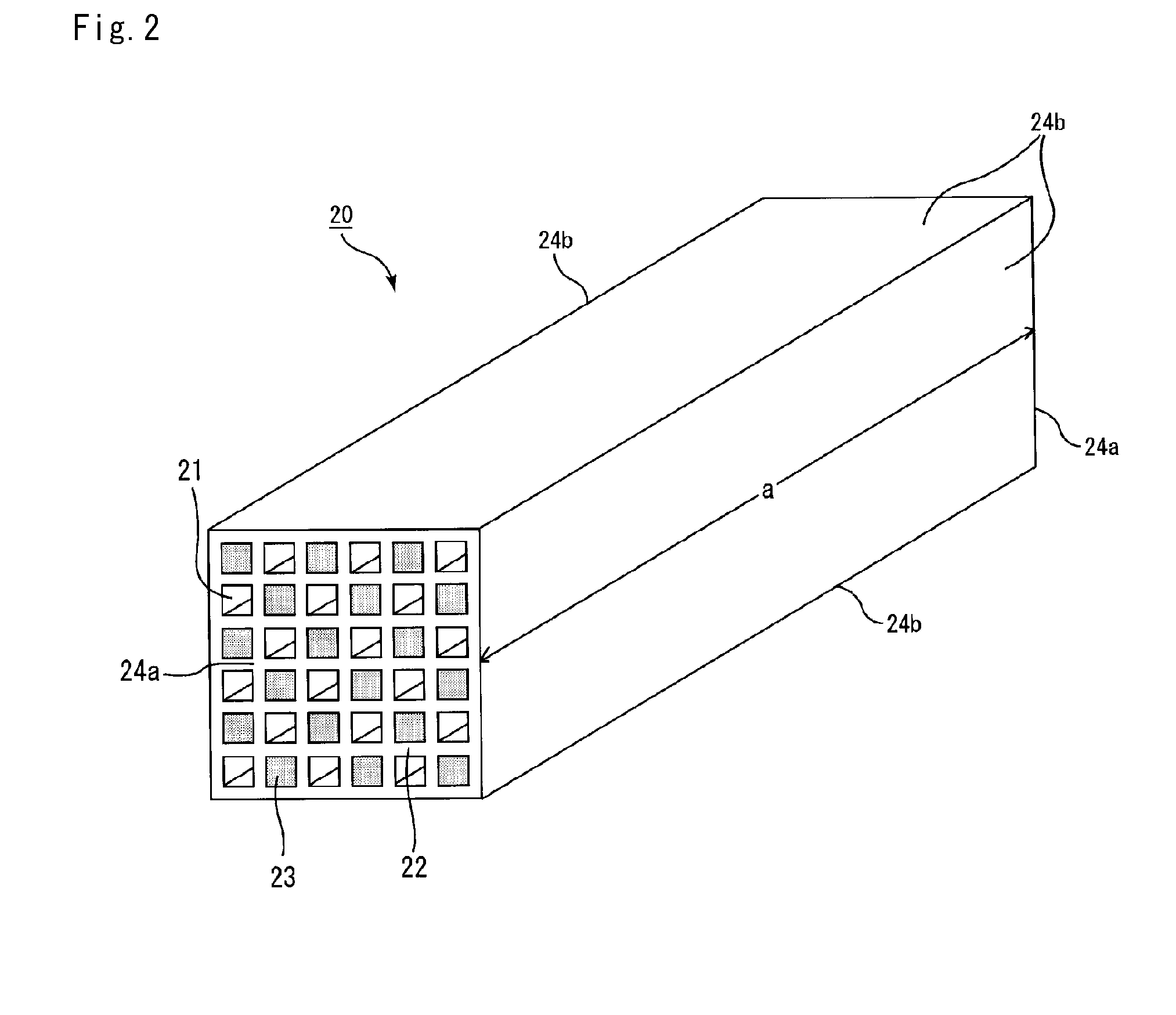

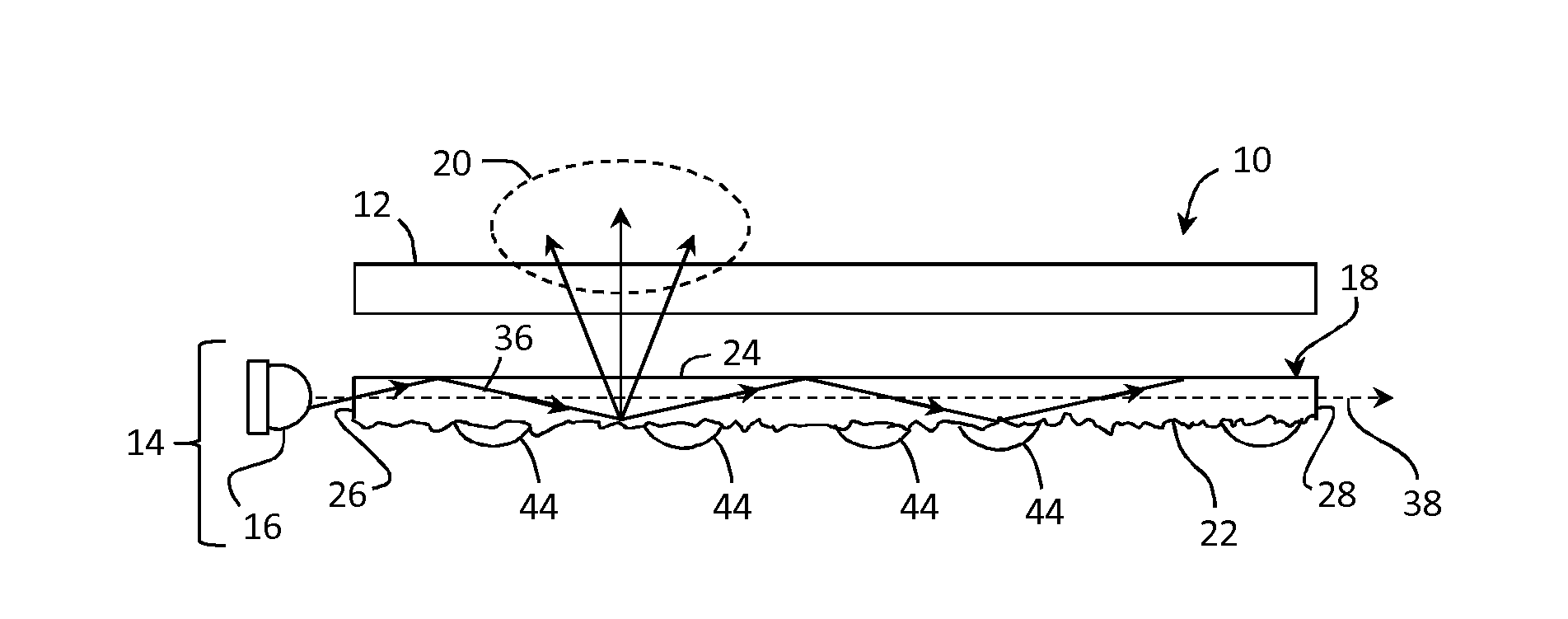

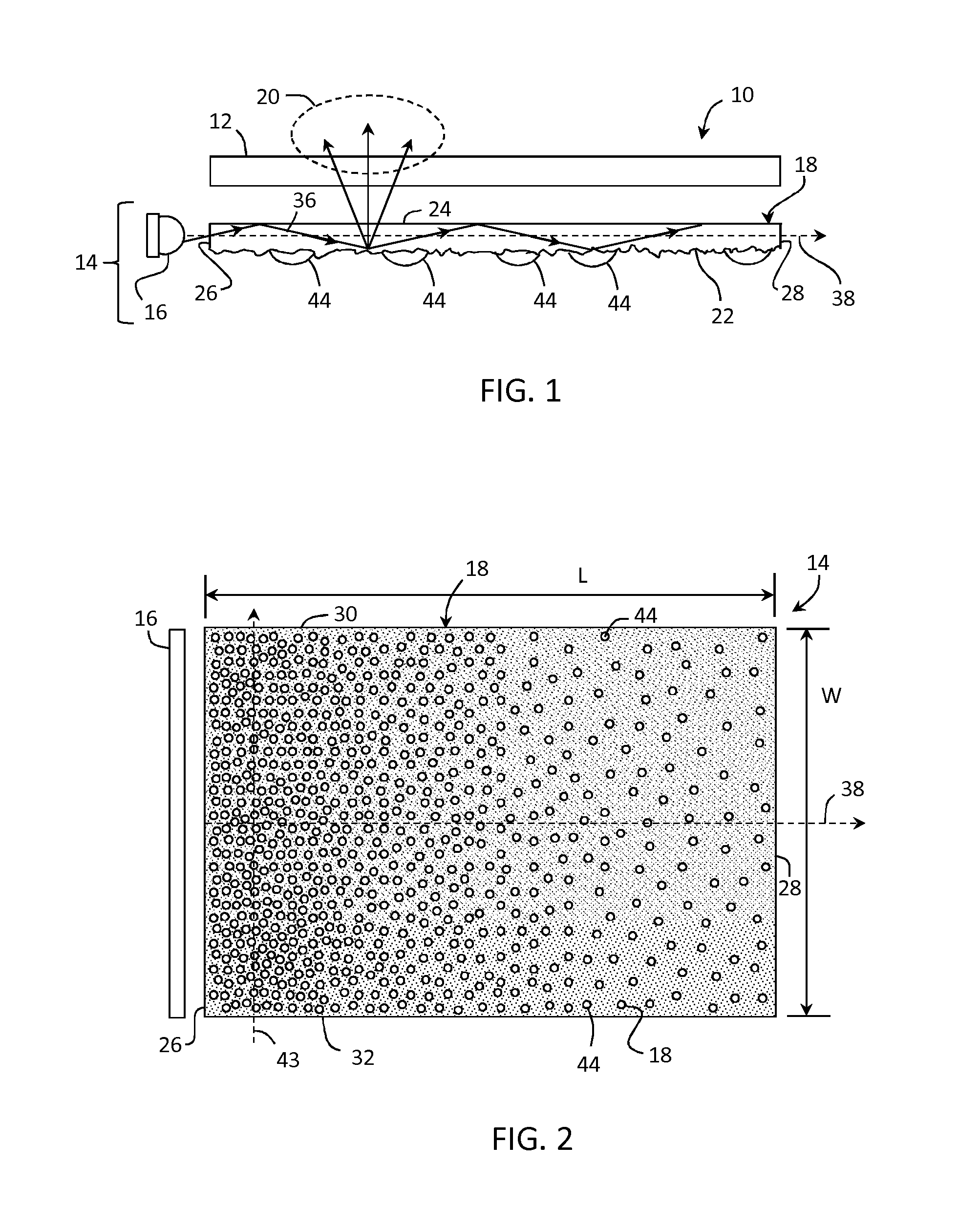

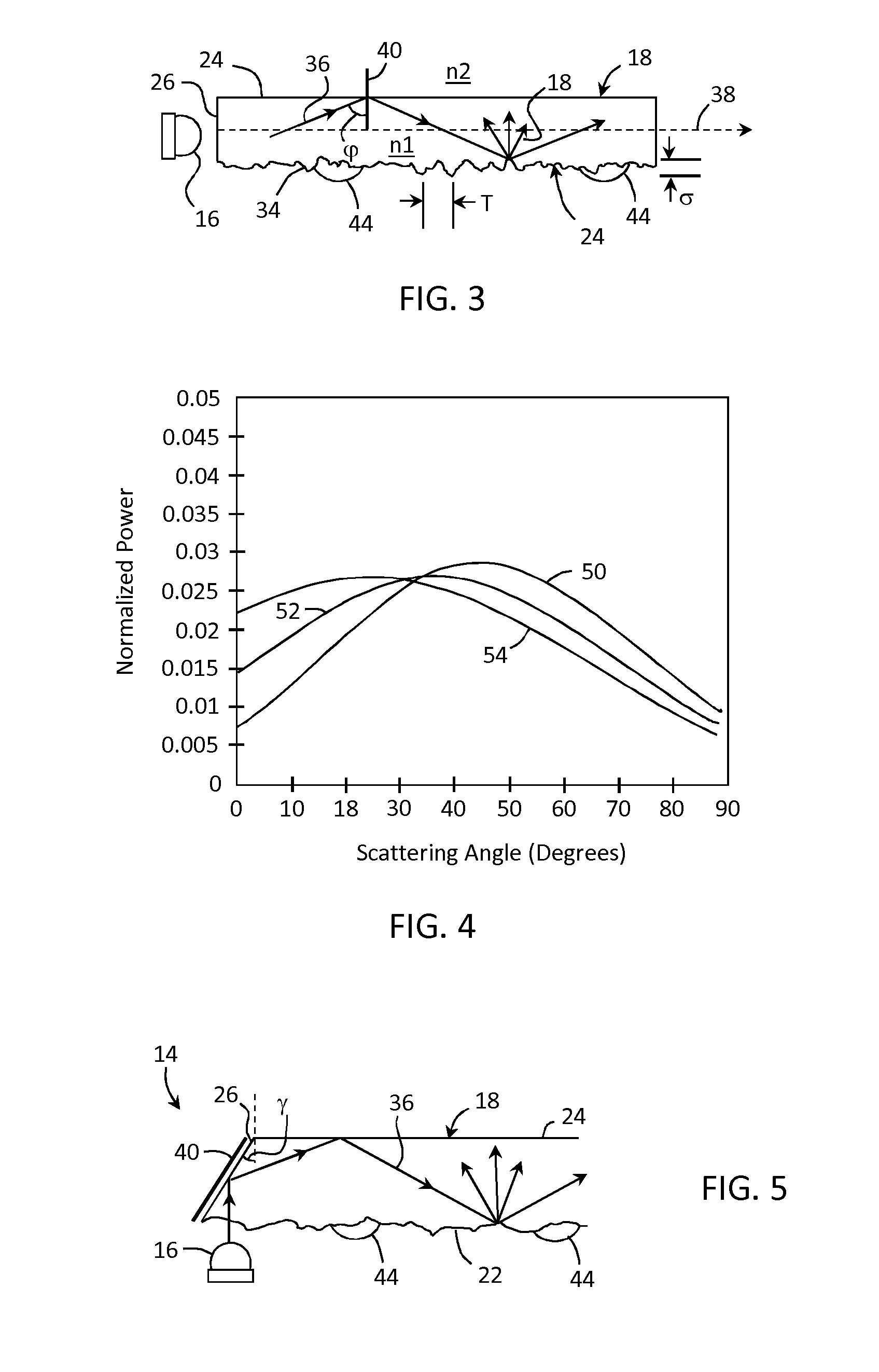

Textured surfaces for display applications

ActiveUS20160313494A1Provide protectionHigh light transmittanceMechanical apparatusDiffusing elementsLight guideDisplay device

A substrate with a textured surface is disclosed. The substrate may be, for example, a light emitter comprising a light guide, for example a backlight element for use in a display device, wherein a surface of the light guide, for example a glass substrate, is configured to have a textured surface with a predetermined RMS roughness and a predetermined correlation length of the texture. A plurality of light scatter supressing features can be provided on the textured surface. Textured surfaces disclosed herein may be effective to reduce electrostatic charging of the substrate surface. Methods of producing the textured surface are also disclosed.

Owner:CORNING INC

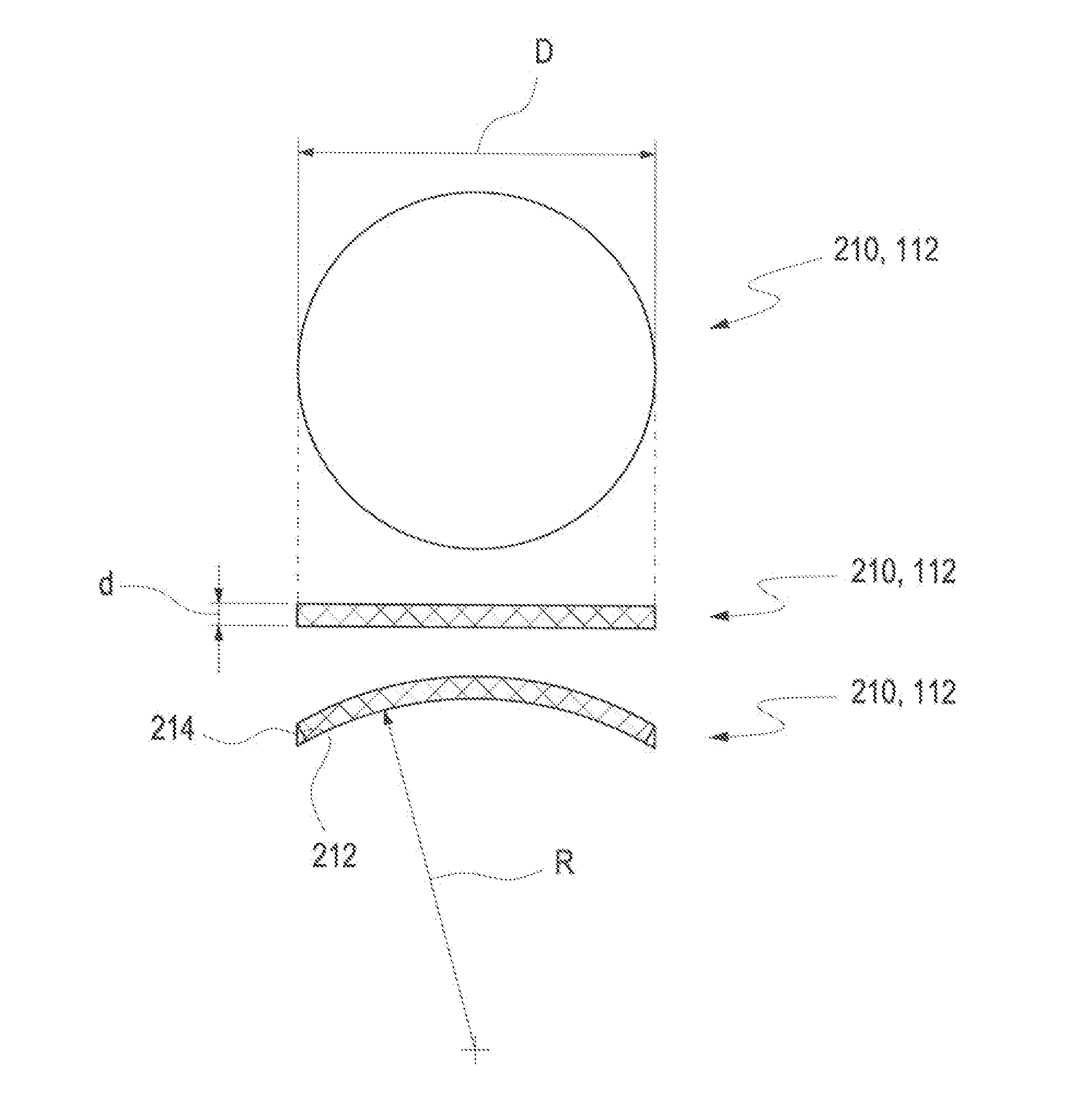

Hydrogel implant for sensing metabolites in body tissue

ActiveUS20100331634A1Good mechanical strengthHigh network densityMaterial analysis by observing effect on chemical indicatorCatheterMetaboliteBody fluid

An implant (110) for detecting at least one analyte (126) in a body fluid, in particular an eye fluid, is proposed. The implant (110) is designed to be implanted in a tissue layer and / or a chamber of an eye of a patient, the implant (110) having a hydrogel matrix (110) with at least one hydrogel (114). The implant (110) also has sensor particles (116) dispersed in the hydrogel matrix (110), the sensor particles (116) having at least one sensor matrix (120) with a sensor matrix material (122) and at least one sensor material (124).

Owner:EYESENSE AG

Mixtures and emulsions to reduce energy in gypsum wallboard manufacture

ActiveUS20100186870A1Simple preparation processReduce moistureLaminationLamination apparatusWaxEmulsion

Provided herein are mixtures, emulsions and other additives for use in manufacturing gypsum wallboard. The mixtures and emulsions may be wax-based emulsions or wax-free mixtures or emulsions, with wax-based emulsions including water; at least one wax, a dispersant which may include sulfur or a sulfur-containing group, and a particular wetting agent or surfactant. Mixtures may also be prepared including water, a dispersant, and a particular wetting agent or surfactant. Gypsum slurries may be prepared using such emulsions and mixtures.

Owner:OU HENRY

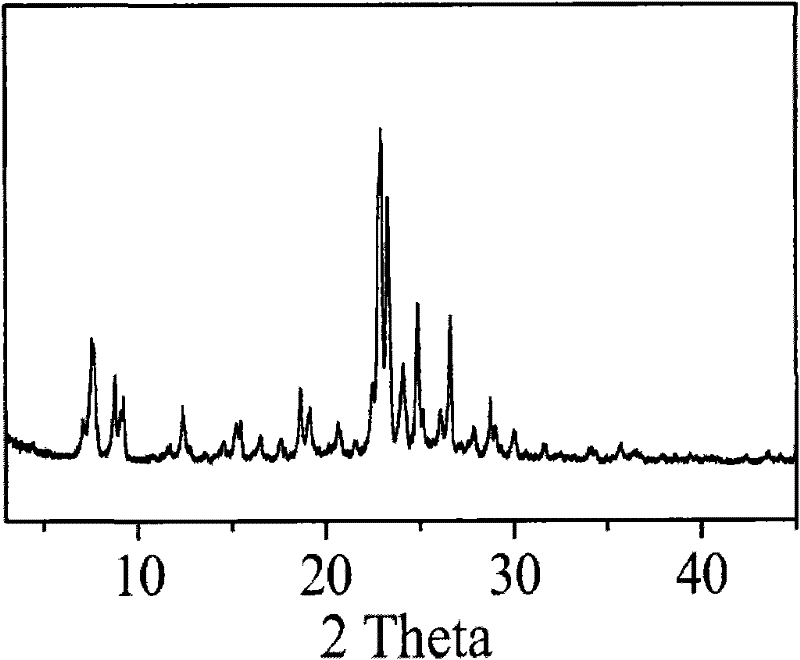

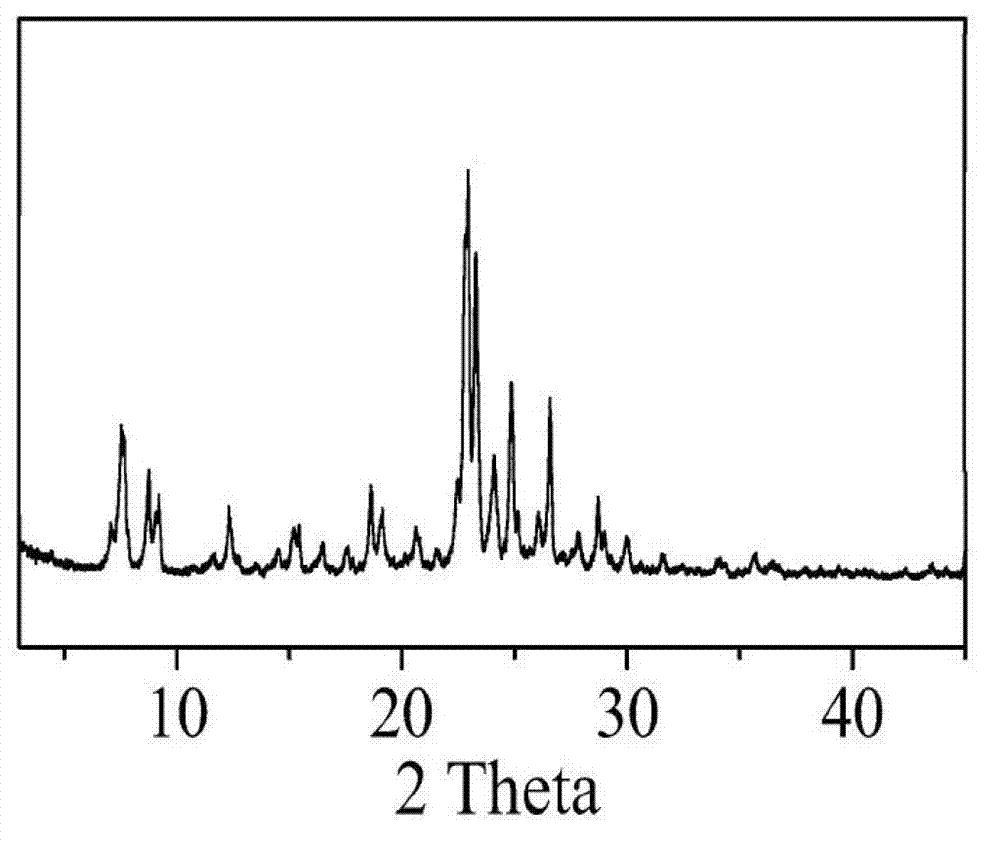

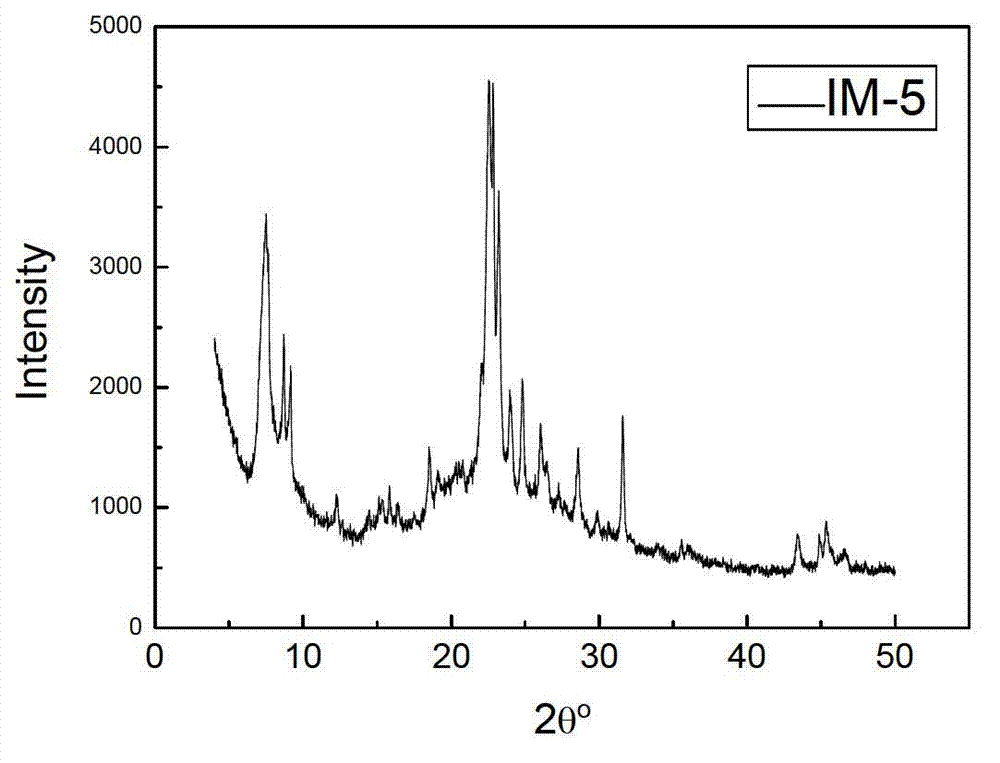

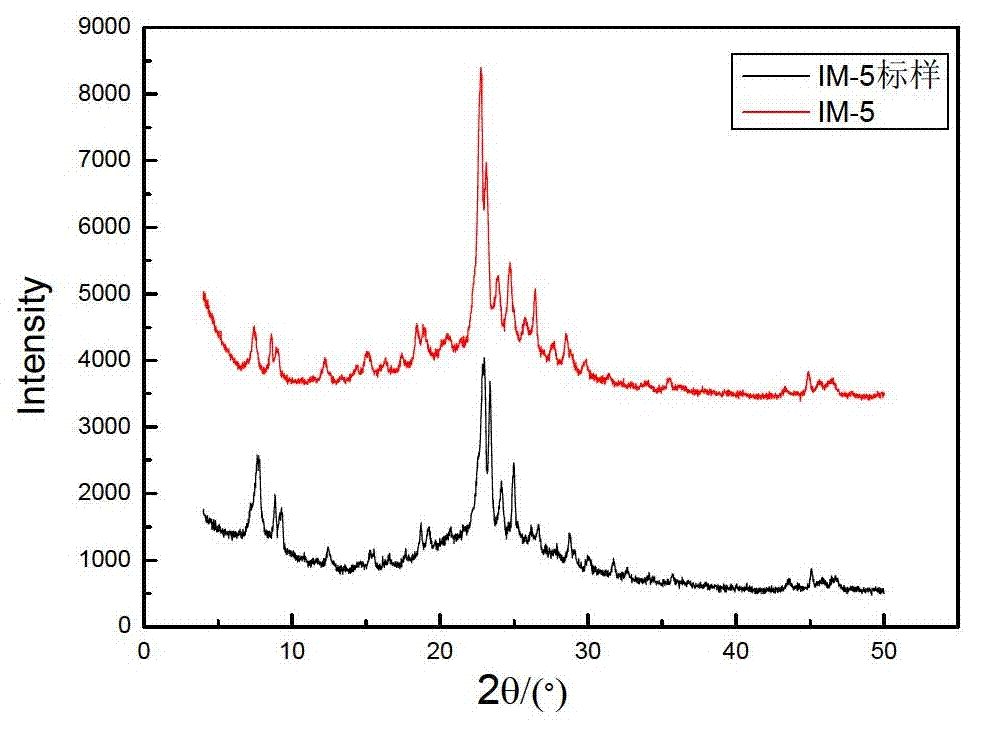

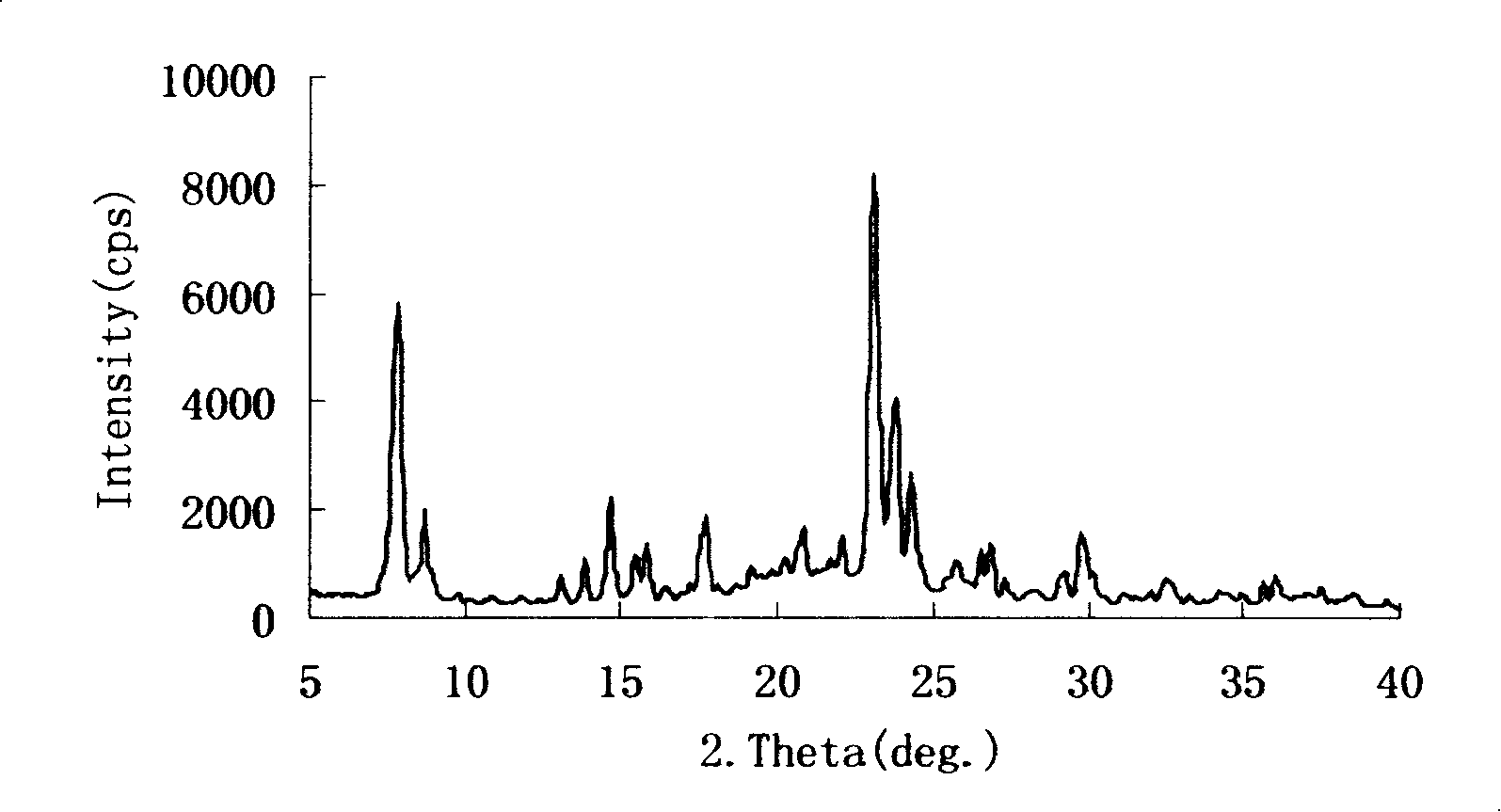

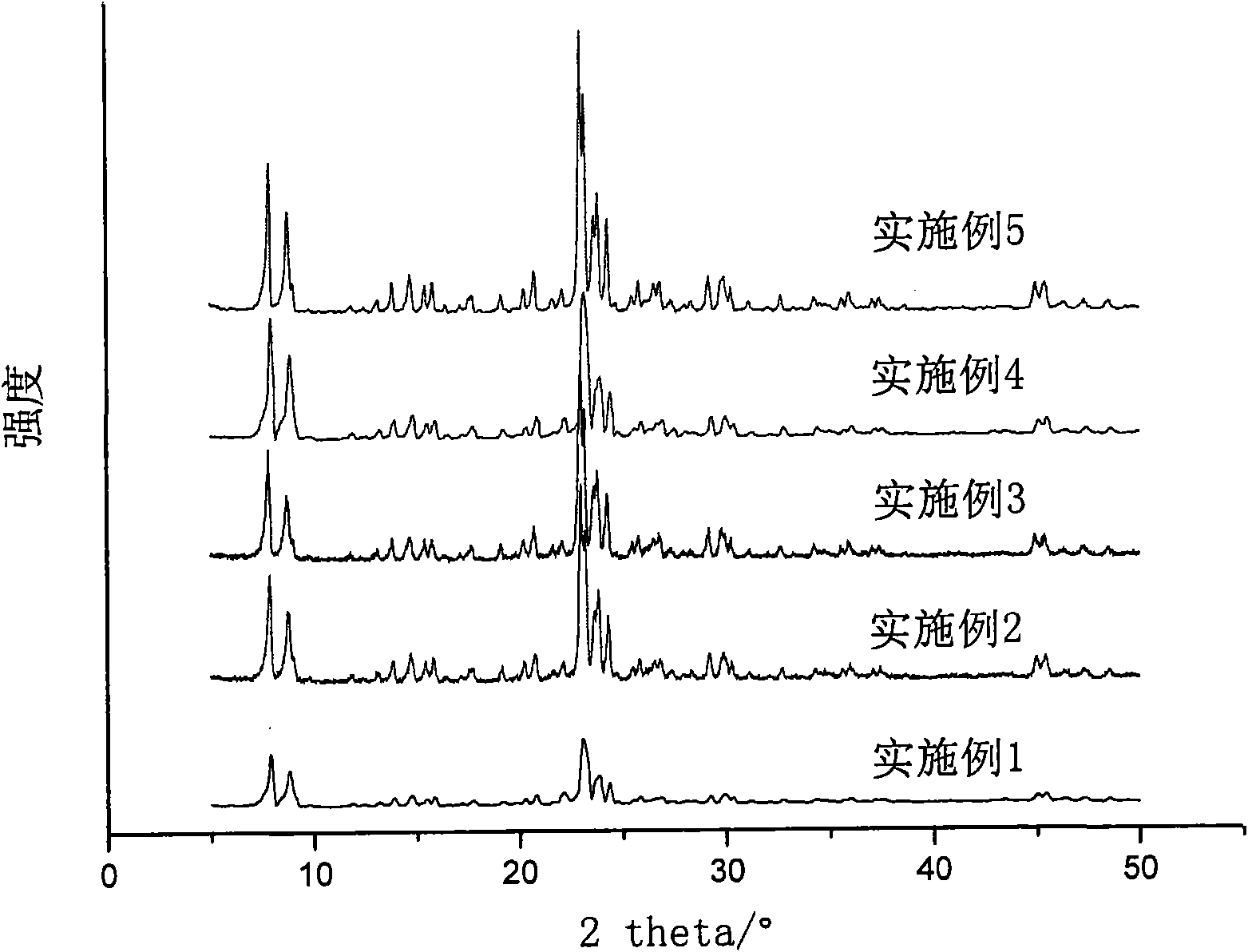

Method of synthesizing IM-5 molecular sieve by using composite template

ActiveCN102452667AReduced nucleation timeShorten crystallization timeCrystalline aluminosilicate zeolitesMolecular sieveAlkali metal oxide

The invention provides a method of synthesizing IM-5 molecular sieve by using a composite template. The method comprises the following steps: (1) dissolving an inorganic base, an aluminum source and two templates in deionized water and carrying out uniform mixing so as to prepare a mixed solution; (2) adding a silicon source into the mixed solution obtained in step (1), optionally adding an additive and carrying out uniform mixing so as to prepare colloid or a solid-liquid mixture; (3) transferring the colloid or the solid-liquid mixture obtained in step (2) to a crystallization kettle, carrying out hydrothermal crystallization at a temperature of 120 to 200 DEG C for 1 to 10 d, carrying out cooling after crystallization and rinsing, filtering and drying the obtained mixed liquor so as to obtain raw powder of the IM-5 molecular sieve. A mole ratio of reactants satisfies the equation of SiO2: Al2O3: M2O: R1: R2: H2O = 60: 0.4-6: 6-21: 0.6-18: 0.6-12: 300-1800, wherein M2O is an alkali metal oxide, R1 is a first template, and R2 is a second template. The method provided in the invention widens the range of mixing ratios of raw materials, improves yield of a single kettle and enables time for crystallization to be further shortened and enlarged production to be easier.

Owner:CHINA PETROLEUM & CHEM CORP +1

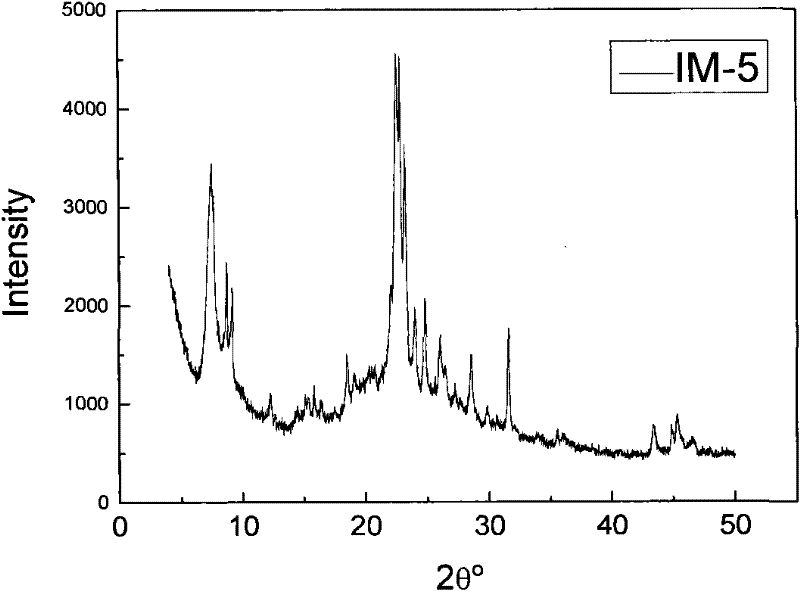

IM-5 molecular sieve synthesis method

ActiveCN103708491APromote depolymerizationIncrease concentrationCrystalline aluminosilicate zeolitesMolecular sieveSynthesis methods

An IM-5 molecular sieve synthesis method comprises the following steps: 1, dissolving an inorganic alkali, an aluminum source and a template in deionized water, and uniformly mixing to prepare a mixed solution; 2, adding a solid silica gel to the mixed solution obtained in step 1, adding a template precursor, and uniformly mixing to prepare a colloid or a solid-liquid mixture; and 3, transferring the colloid or solid-liquid mixture obtained in step 2 to a crystallization kettle, carrying out hydrothermal crystallization for 1-10 days, cooling after the crystallization to obtain a mixed liquid, and washing, filtering and drying the mixed liquid to obtain raw IM-5 molecular sieve powder, wherein reactants comprise SiO2, Al2O3, M2O, R, A and H2O, a molar ratio of SiO2:Al2O3:M2O:R:A:H2O is 60:(0.3-6):(6-20):(4-15):(1.2-6):(300-1200), M2O is an alkali metal oxide, R is the template, and A is the template precursor. The IM-5 molecular sieve synthesis method has the advantages of good product repeatability, effective reduction of the water content, increase of the concentration of the template, crystallization time shortening and single kettle yield increase.

Owner:CHINA PETROLEUM & CHEM CORP +1

Microcapsule containing magnetic fluid, manufacturing method, and use thereof

InactiveUS6106946AFracture and deformationImprove liquidityGlass/slag layered productsWood layered productsBuilding materialEngineering

PCT No. PCT / JP97 / 00646 Sec. 371 Date Sep. 11, 1998 Sec. 102(e) Date Sep. 11, 1998 PCT Filed Mar. 4, 1997 PCT Pub. No. WO97 / 33686 PCT Pub. Date Sep. 18, 1997Provided are microcapsules enclosing therein a magnetic fluid, which are useful for imparting sound-absorbing and insulating ability to building materials, etc. by incorporation thereinto or adhesion thereto by means of an adhesive, and processes for producing the microcapsules. The heat-expandable microcapsule of the present invention comprises (i) a shell composed of a thermoplastic resin and (ii) a magnetic fluid which is a dispersion of magnetic substance fine particles having an average particle diameter of 5-200 nm in a hydrophobic organic solvent and a hydrophobic liquid foaming agent, both enclosed in the shell. The hollow microcapsule of the present invention comprises (i) a shell composed of a thermoplastic resin, and (ii) a magnetic fluid which is a dispersion of magnetic substance fine particles having an average particle diameter of 5-200 nm in a hydrophobic organic solvent and a vacant cell both included in the shell. The coating material of the present invention comprises at least one of these sound-absorbing and insulating microcapsules.

Owner:MATSUMOTO YUSHI SEIYAKU +1

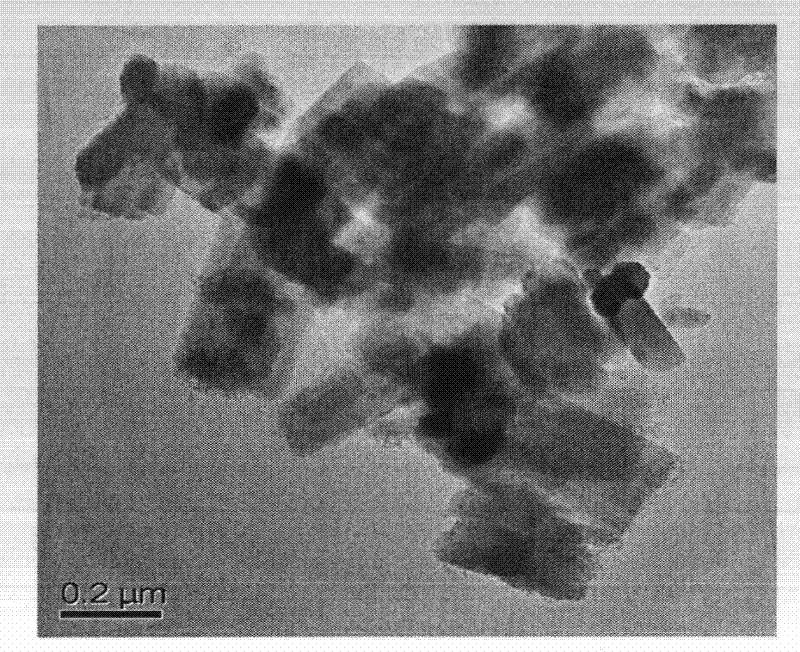

Method for preparing nano molecular sieve

ActiveCN101182004ANarrow particle size distributionMass transfer limitationNanostructure manufactureCrystalline aluminosilicate zeolitesSolubilityMolecular sieve

The invention discloses a preparation method of nanometer molecular sieve. The method is to firstly mix hydrocarbon components and surfactants evenly, then add silica gel and silica-alumina gel, and continue to stir until the raw materials are evenly mixed to obtain a super-solubilizing system of oil-in-melt, and then undergo crystallization, drying and roasting Finally, nano molecular sieves are obtained. The crystallization of the molecular sieve in the present invention is carried out in a supersolubilized micelle system of molten silica gel or silica-alumina gel in oil, and the growth of the molecular sieve crystal is limited in the nano-micelle to avoid excessive growth of the molecular sieve crystal. The surfactant and hydrocarbon components used in the method of the invention are used in small amounts and low in cost. The method has a simple process and can be used for large-scale industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of preparing ZSM-5 molecular sieves

The invention provides a method of preparing ZSM-5 molecular sieves, which is favorable to the yield increase of the ZSM-5 molecular sieves. The method comprises the steps: using solid silica gel as all or partial silica sources, preparing the solid silica gel and water into reaction mixture gel at certain temperature and alkalinity, and carrying out hydrothermal crystallization of the reaction mixture gel by a conventional method in the presence of seed crystals. The molar ratio of components of the reaction mixture gel conforms to the following formula: 3-15 Na2O: 1Al2O3: 20-100SiO2: 100-1200 H2O. The invention can greatly improve the yield of synthesized ZSM-5 molecular sieves.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

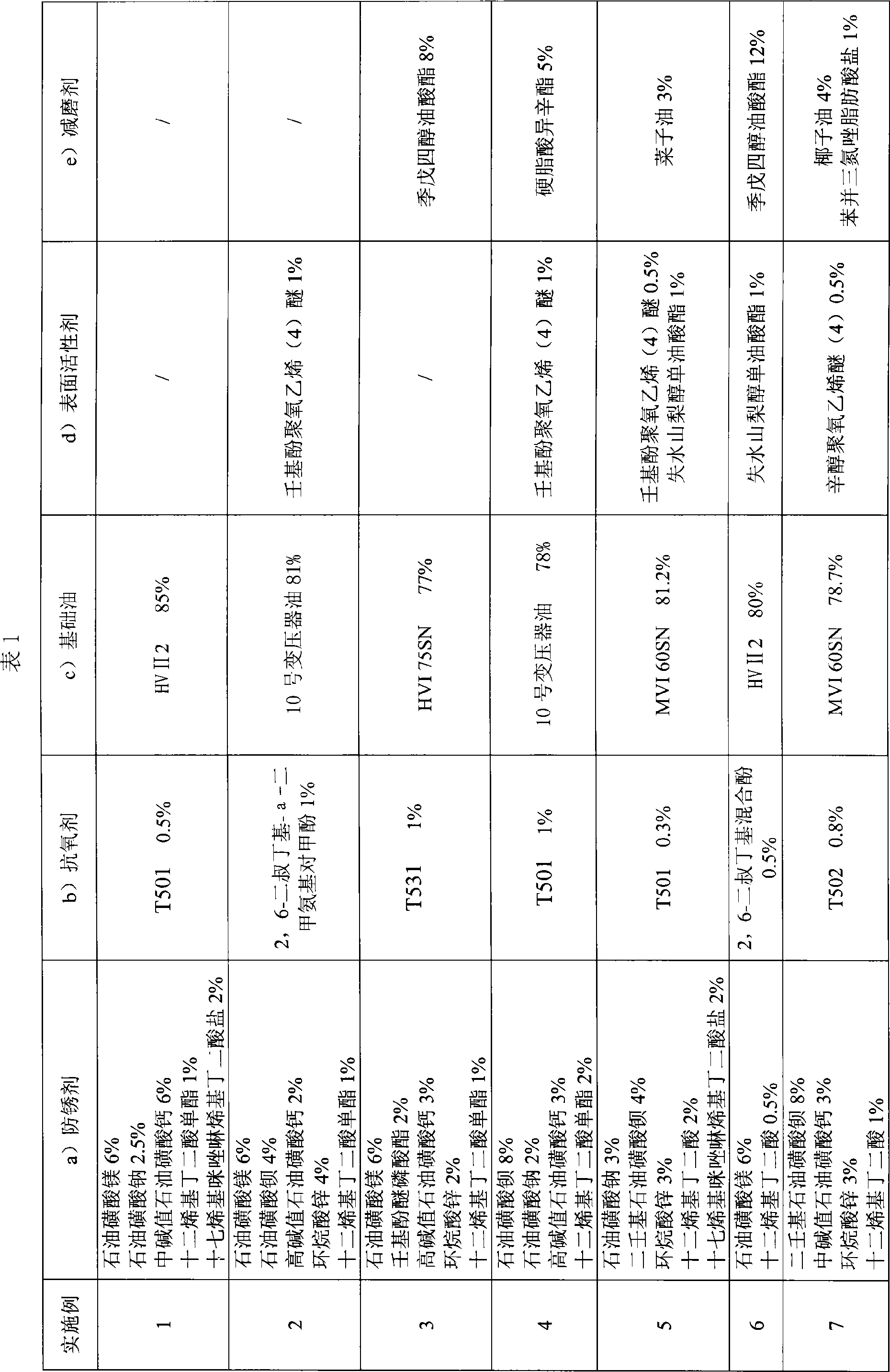

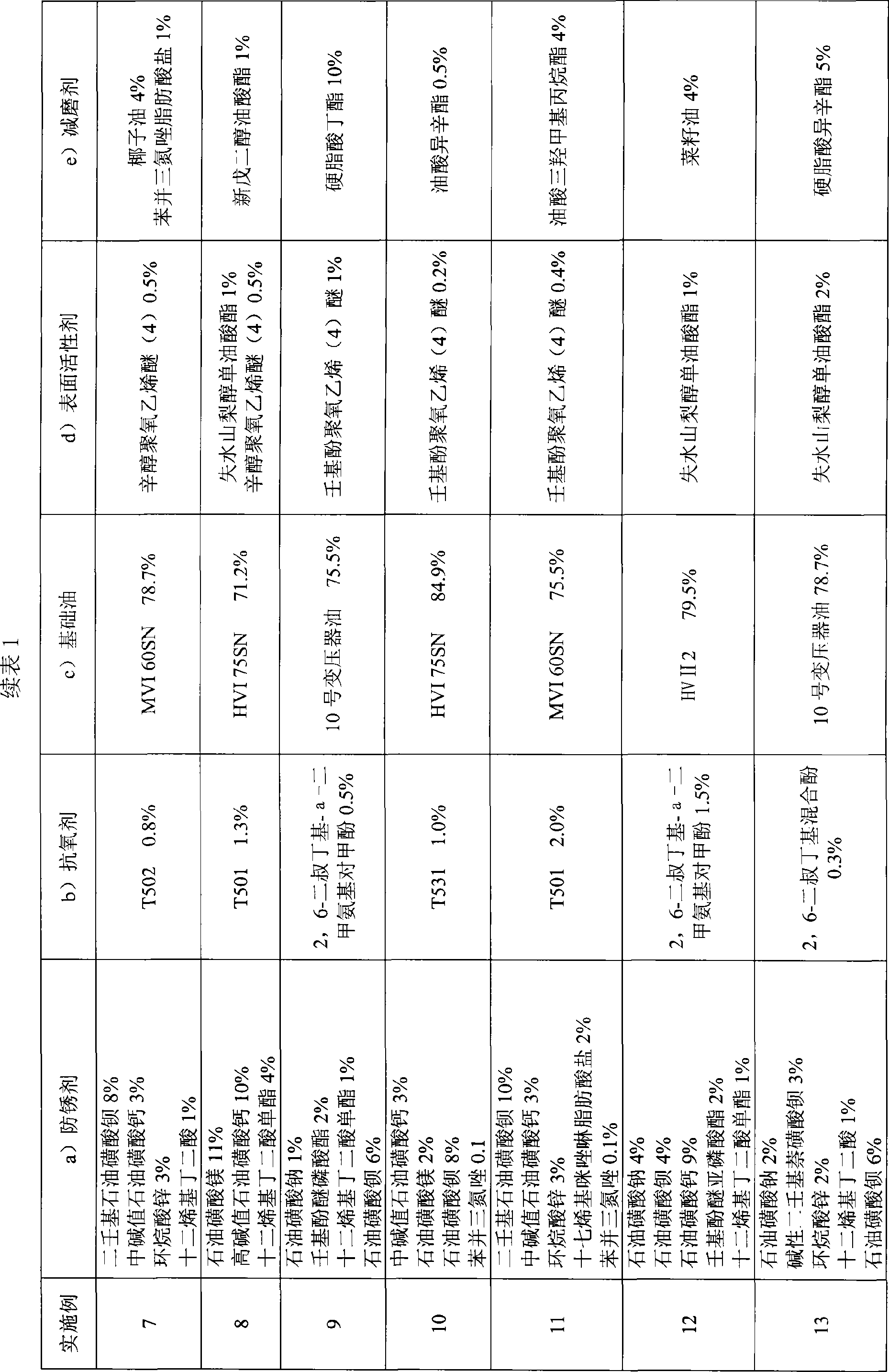

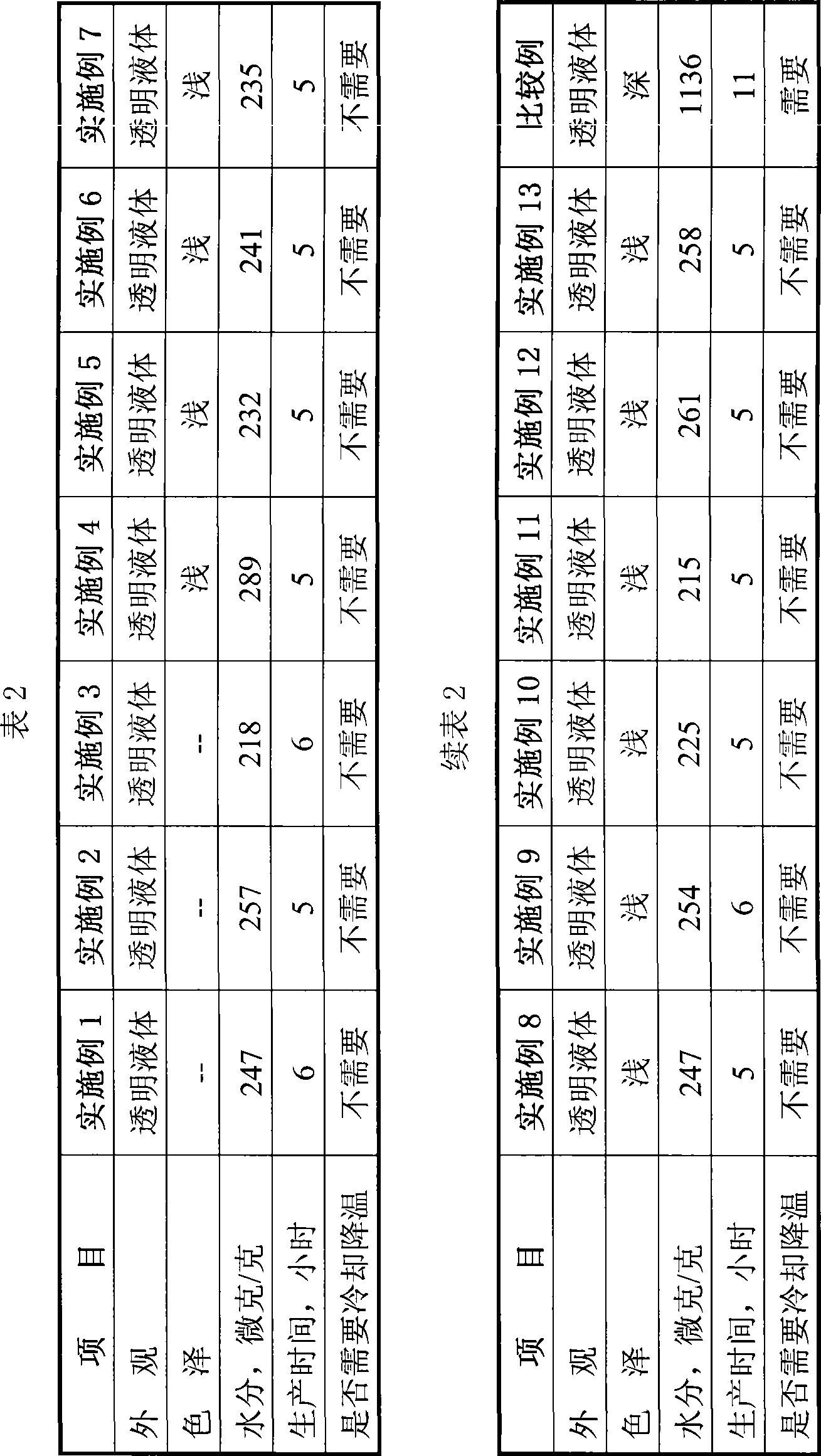

Method for producing anticorrosive oil composition

ActiveCN101503644AReduce water contentShorten production timeAdditivesBase-materialsHigh energyAntioxidant

The invention relates to a method for producing an anti-rust oil composition and mainly solves the problems of the prior art that the production of the anti-rust oil composition requires long time and high energy consumption and an oil product is susceptible to over oxidation which influences anti-rust effect. For better solving the problems, the method adopts a technical proposal that: 1) 40 to 80 weight percent of base oil is heated with stirring to be between 50 and 100 DEG C; 2) an antirust and an antioxidant in required amount are added into the base oil of the step 1), and the antirust, the antioxidant mixture and the base oil are continuously heated to be between 95 and 130 DEG C and stirred at a constant temperature for 0.5 to 6 hours to form a mixture I; and 3) the balance of base oil is added into the mixture I, and the base oil and the mixture I are uniformly stirred to form the anti-rust oil composition. The method can be used in the industrial production of the anti-rust oil composition.

Owner:CHINA PETROLEUM & CHEM CORP

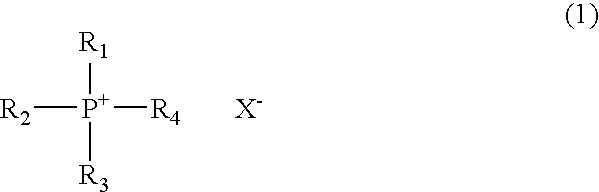

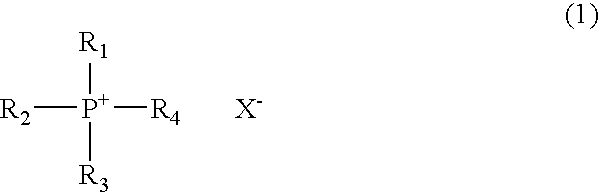

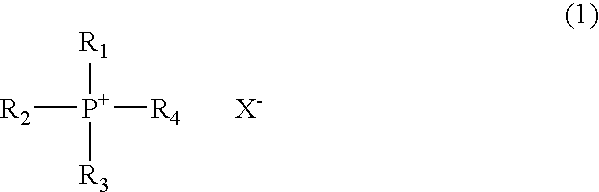

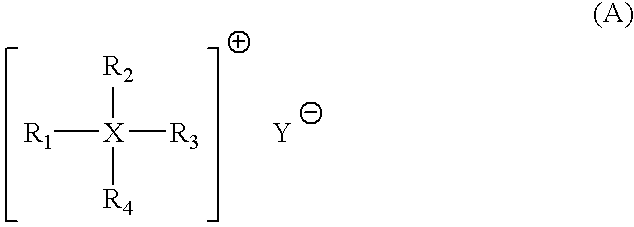

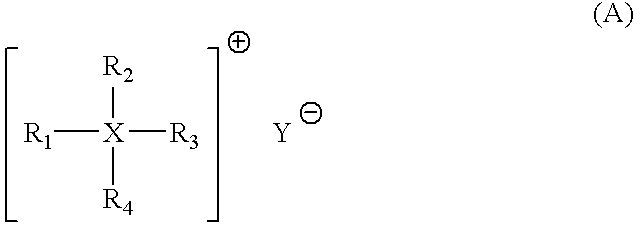

Novel phosphonium salt ionic liquid and reaction solvent including the same

InactiveUS20080221353A1Low reactivityLow water contentSulfonic acid amide preparationPhosphorus organic compoundsIonSolvent

The present invention provides an ionic liquid including a quaternary phosphonium salt represented by general formula (1):wherein R1, R2, R3, and R4 each represent a linear alkyl group having 1 to 6 carbon atoms, a branched alkyl group having 3 to 6 carbon atoms, an alicyclic alkyl group having 3 to 6 carbon atoms, or an alkoxyalkyl group represented by —(CH2)nO—R5 (wherein n is an integer of 1 to 6; and R5 represents a methyl group or an ethyl group); at least one of R1, R2, R3, and R4 is an alkoxyalkyl group; R1, R2, R3, and R4 may be the same or different; R1 and R2 together may form a ring; and X represents an anion. The present invention also provides a reaction solvent including the ionic liquid.

Owner:NIPPON CHECMICAL IND CO LTD

Method for stabilizing and conditioning urban and industrial wastewater sludge

InactiveUS20050077245A1Improving sludge filtering capacityReduce water contentSludge treatment by de-watering/drying/thickeningWater treatment parameter controlChemistryHydrogen peroxide

The invention concerns a method for stabilizing and conditioning wastewater sludge. The invention is characterized in that it consists in treating sludge in an acid environment (3.0≦pH≦5.0), with an inorganic acid and two oxidizing agents, that is a ferric iron salt and hydrogen peroxide. The ferric iron salt is used in such an amount as to obtain a concentration ranging between 5 and 40 kg of Fe per iron of dry sludge; the hydrogen peroxide is used in such an amount as to obtain a concentration ranging between 5 and 40 kg of H2O2 per ton of dry sludge; mixing the treated sludge for a time interval sufficient to stabilize the sludge and improve its dehydrability; then flocculating the stabilized sludge by adding an organic polymer; then dehydrating the flocculated sludge. Said method enables to significantly improve the dehydrability properties of the sludge while increasing the dry solid content during its mechanical dehydration.

Owner:CORP BIOLIX +1

Catalyst for preparing mixing alcohol with low carbon from synthesis gas and its preparing method

InactiveCN1431049AGuaranteed stabilityGuaranteed lifeOrganic compound preparationHydroxy compound preparationHigh resistanceMANGANESE ACETATE

A catalyst for preparing low-carbon alcohol mixture from synthetic gas contains Mo (2-40 %), Ni (4-10%), Mn (0.1-5.0%), K (5-15%), S (20-40%) and bentone, and is prepared through reaction of ammoniumsulfide solution or hydrogen sulfide gas on ammonium molybdate, adding concentrated acetic acid, thermal stirring, cooling for deposition, adding deionized water for dissolving doposit to obtain solution of ammonium thiomolybdate, dropping the solution along with the mixed solution of nickel acetate and manganese acetate in acetic acid to form black deposit, filtering, washing, baking, mixing with bentone, and tabletting. Its advantages are high resistance to S and no carbon deposit.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

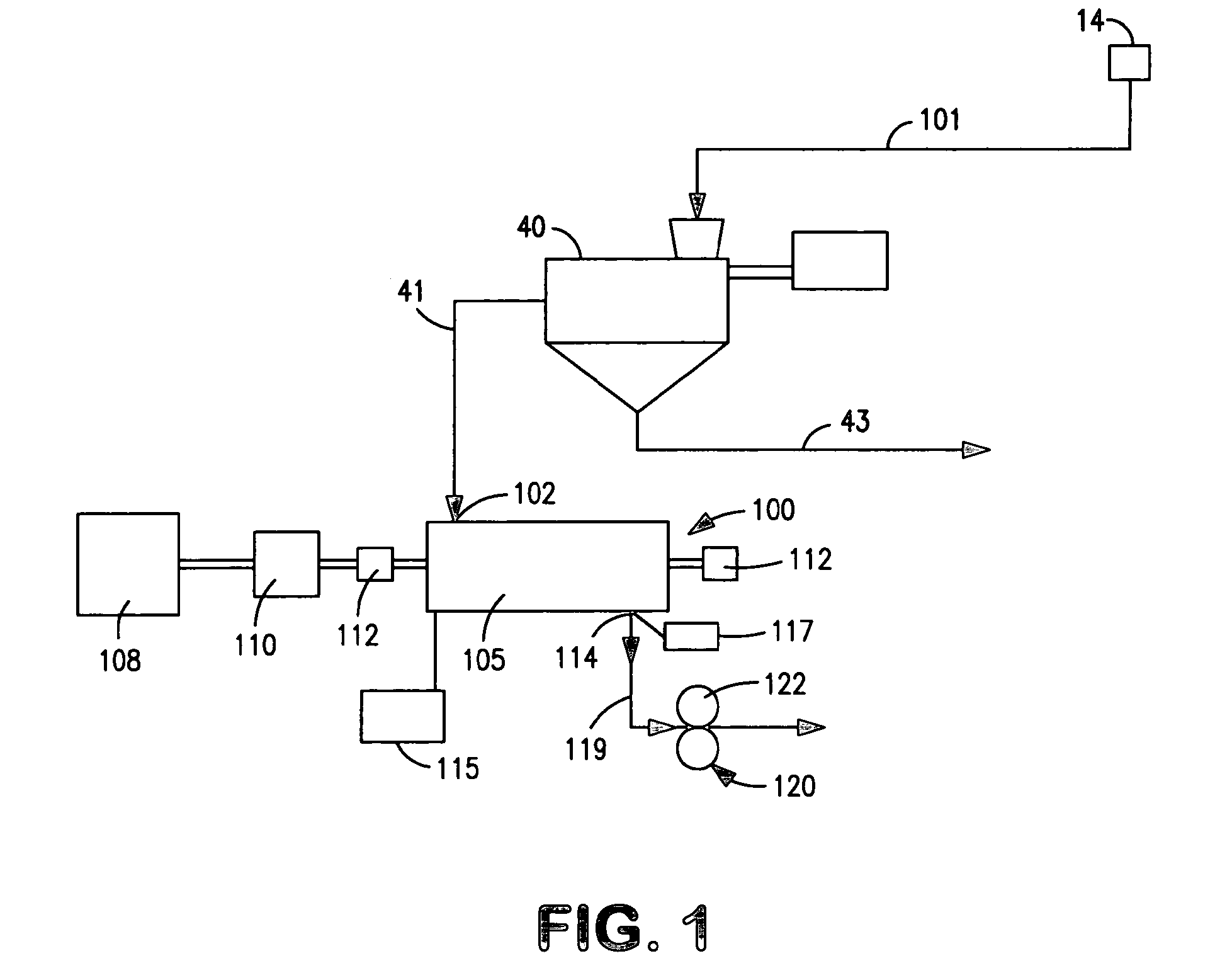

Elastomer composite and method for producing it

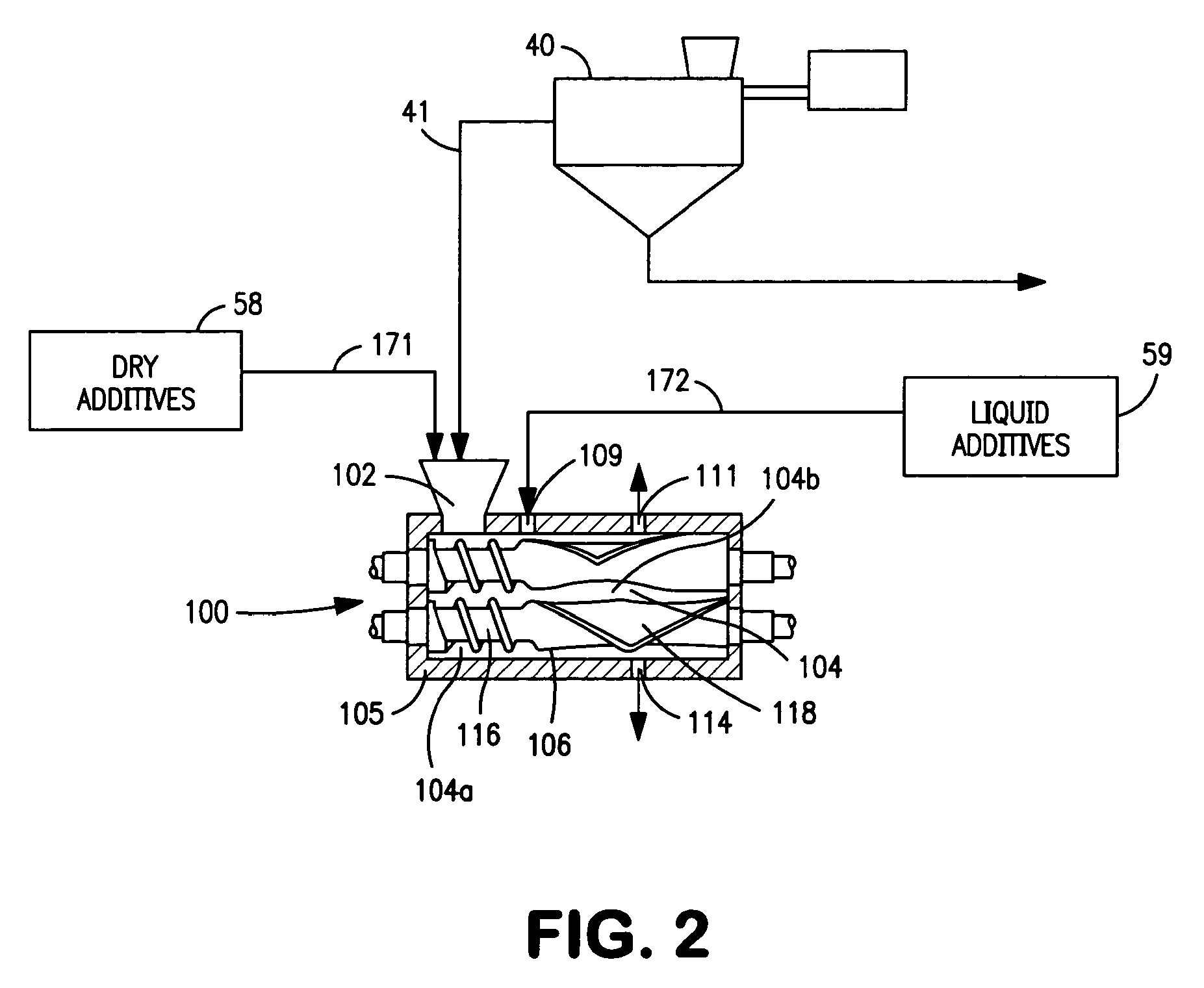

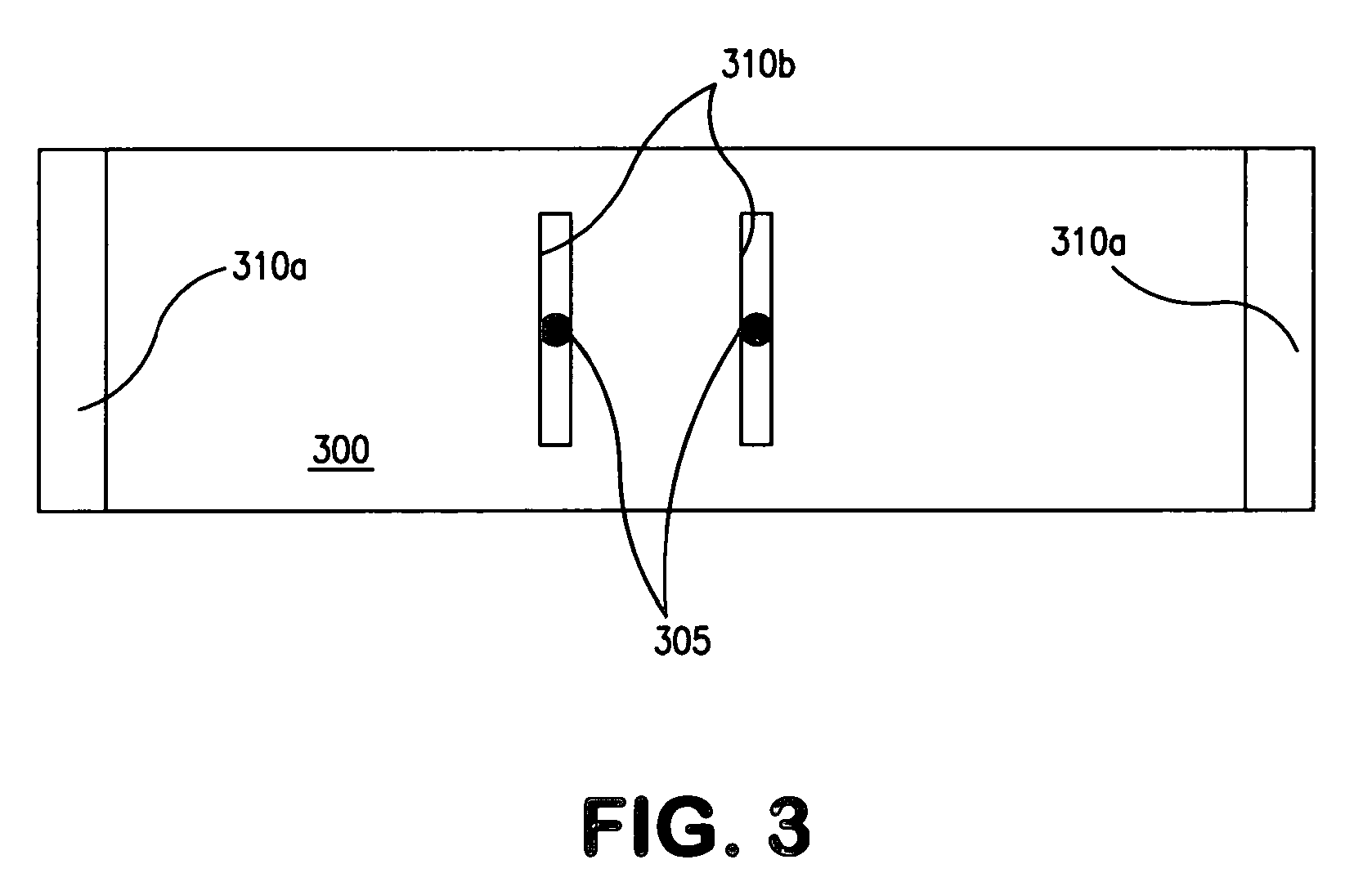

A method of producing an elastomer composite. The method includes A) combining a first fluid comprising elastomer latex with a second fluid comprising particulate filler; B) causing the elastomer latex to coagulate, thereby forming masterbatch crumb; C) bringing the masterbatch crumb to a water content of about 1 weight percent to about 20 weight percent, thereby forming a dewatered coagulum; D) removing water from the dewatered coagulum by subjecting the dewatered coagulum to mechanical energy, thereby causing the dewatered coagulum to heat as a result of friction, while allowing the dewatered coagulum to achieve a temperature of about 130° C. to about 190° C., wherein water content is reduced to about 0.5% to about 3% and wherein substantially all of the decrease in water content is accomplished by evaporation, thereby producing a masticated masterbatch; and E) subjecting the masticated masterbatch to at least an additional 0.3 MJ / kg of mechanical energy while further reducing the water content.

Owner:CABOT CORP

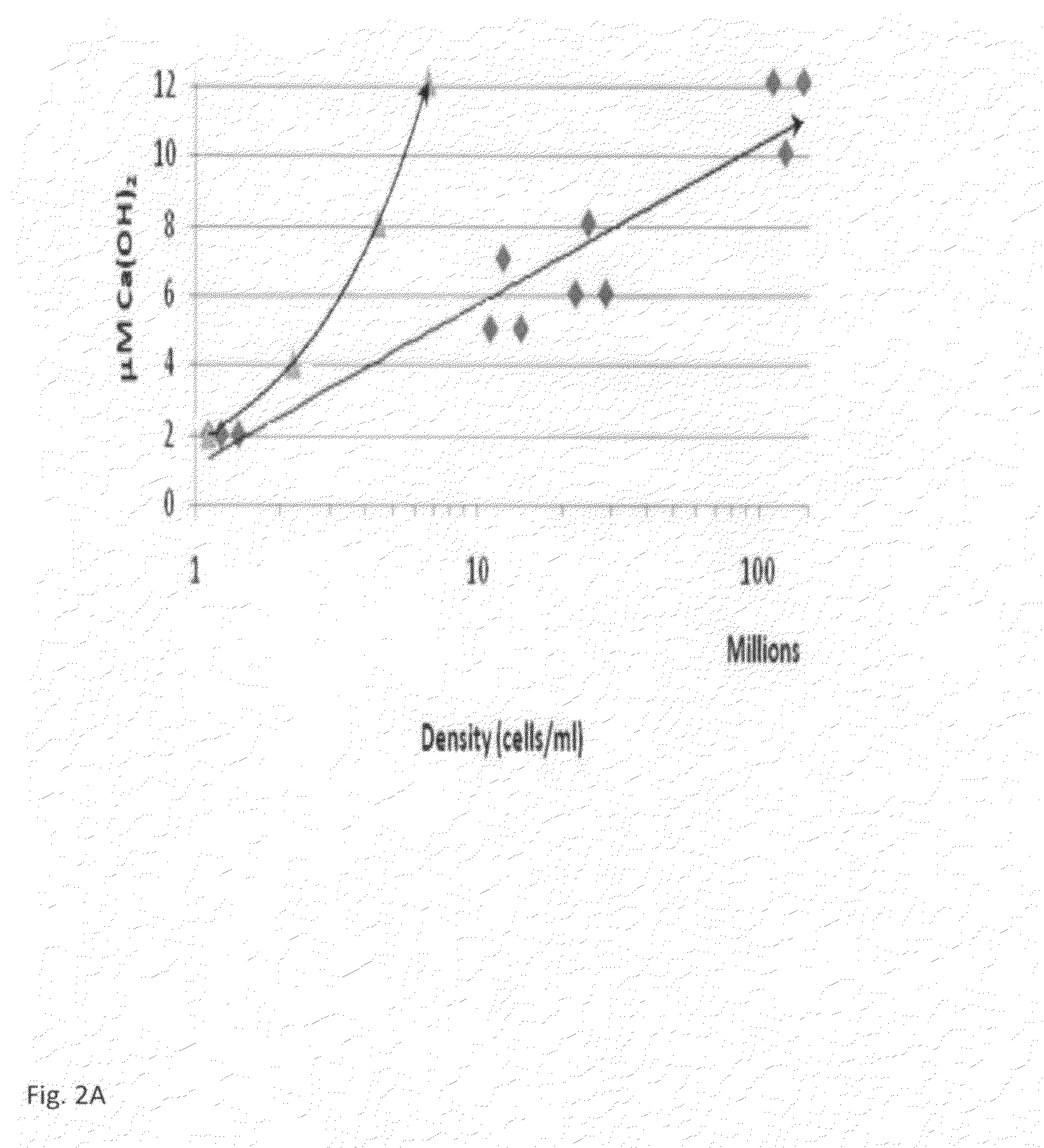

Method and system for efficient harvesting of microalgae and cyanobacteria

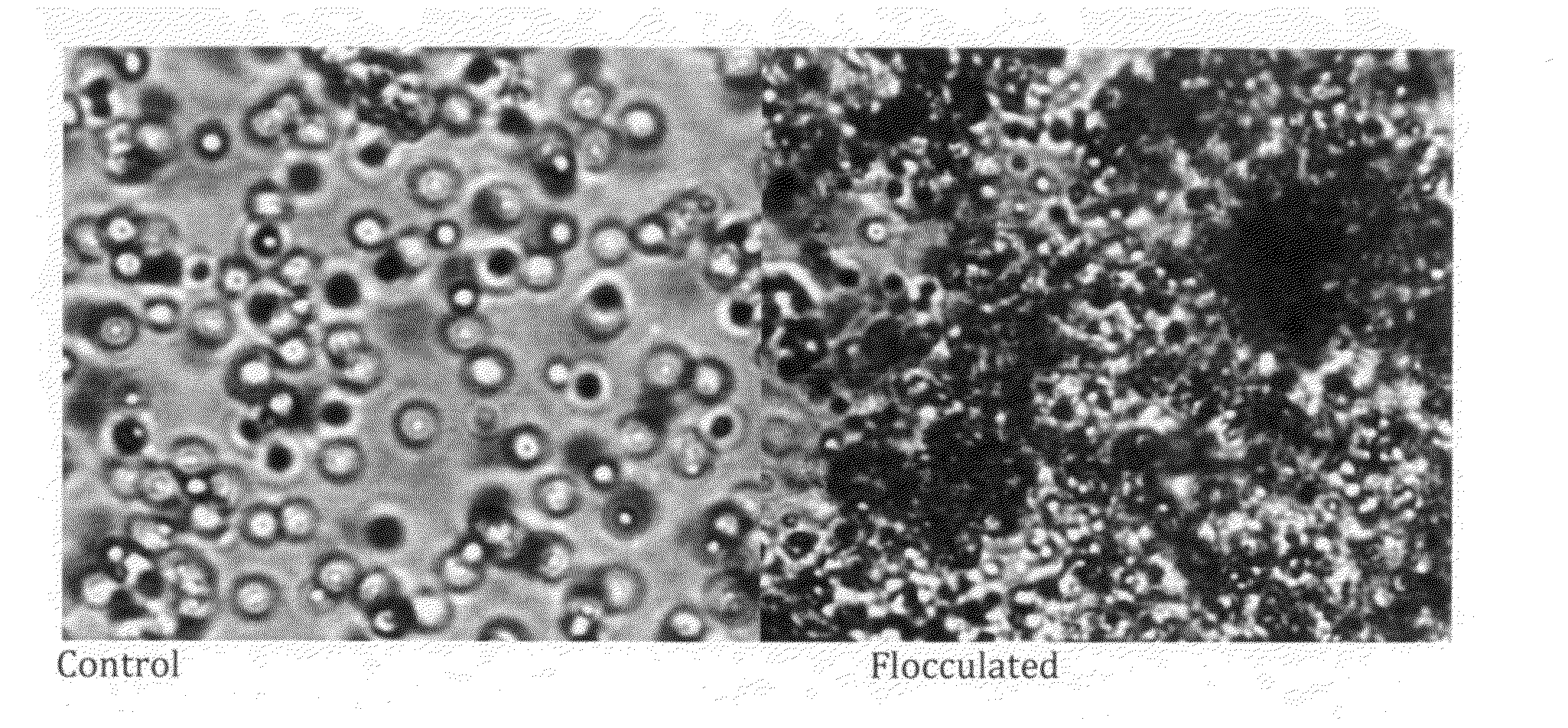

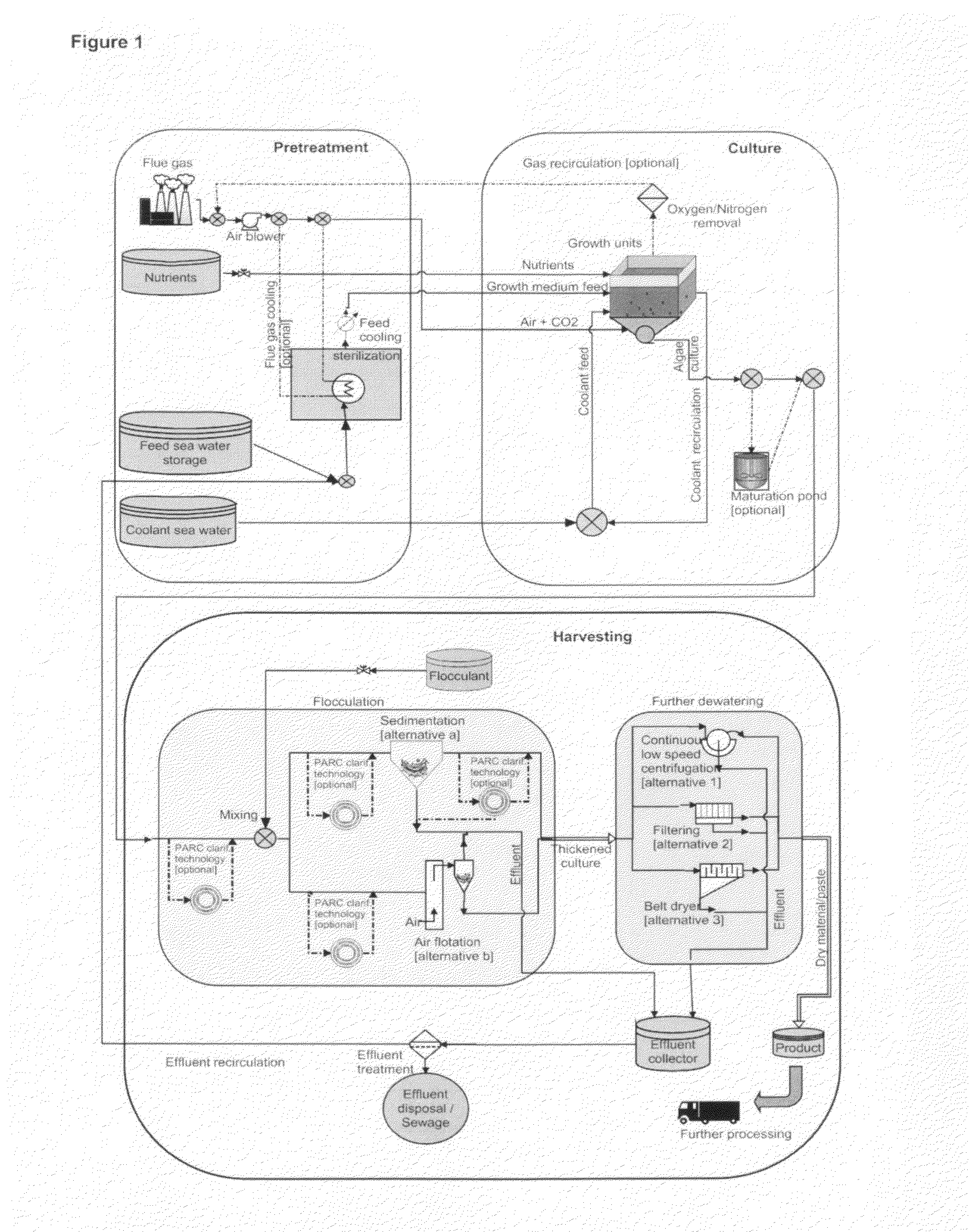

The high-speed centrifugation heretofore required for harvesting micro algae and cyanobacteria cultured for biofuels and other co-products is a major cost constraint. Mixing algae / cyanobacteria at high-density culture with far less alkali than previously assumed is sufficient to flocculate the cells. The amount of flocculant required is a function of the logarithm of cell density, and is not a linear function of cell density as had been thought. The least expensive alkali treatments are with slaked limestone or dolomite (calcium hydroxide and magnesium hydroxides). Further water can be removed from the floc by sedimentation, low speed centrifugation, dissolved air flotation or filtration, prior to further processing to separate oil from valuable co-products.

Owner:TRANSALGAE ISRAEL

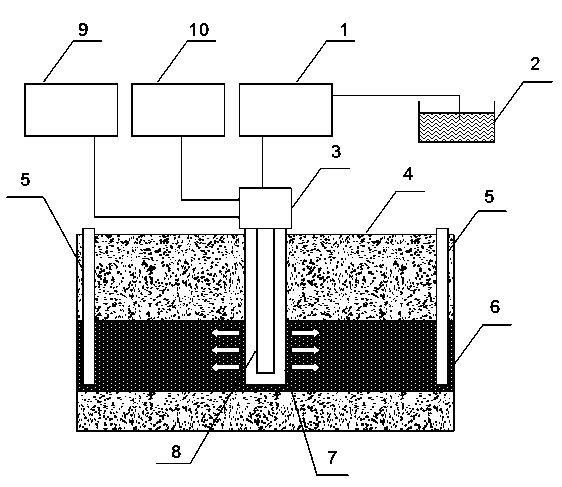

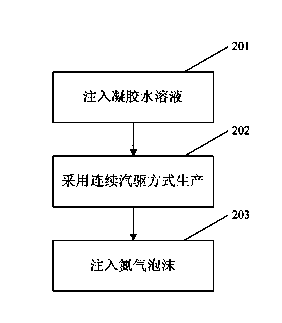

Thermal production well filling vapor and nitrogen foam profile control technique

InactiveCN101016835AExpand the affected volumeIncrease crude oil productionFluid removalChemistryNitrogen gas

The invention relates to a thermal developing well pouring steam nitrogen foam adjusting method comprising steam, nitrogen and foaming agent pouring method and nitrogen generating pouring method, wherein the steam is poured via an oil tube, the nitrogen and the foaming agent are poured in via a muffle, while the mass ratio between the foaming agent, steam is 1:250-500, the mass ratio between the nitrogen and the stem is 50-80:1, the pouring speed is steam at 10-13t / h, foaming agent at 0.1-0.5t / h, and nitrogen at 900-1000Nm3 / h. And the invention uses four-section plug pouring process, while the first section plug pours nitrogen via the muffle for 12h at 900-1000Nm3 / h, the second section plug pours the steam via the oil tube for 24h at 10-13t / h, and the third section plug pours steam via the oil tube and pours nitrogen and foaming agent via the muffle at 10-13t / h, 900-1000Nm3 / h, and 0.1-0.5t / h for 2h, the fourth section plug stops pouring foaming agent and holds the pouring speed of the nitrogen and the steam for 12h, repeats the steps of four section plugs until preset demand, closes the well, then opens well to produce.

Owner:SINOPEC SHENGLI OILFIELD

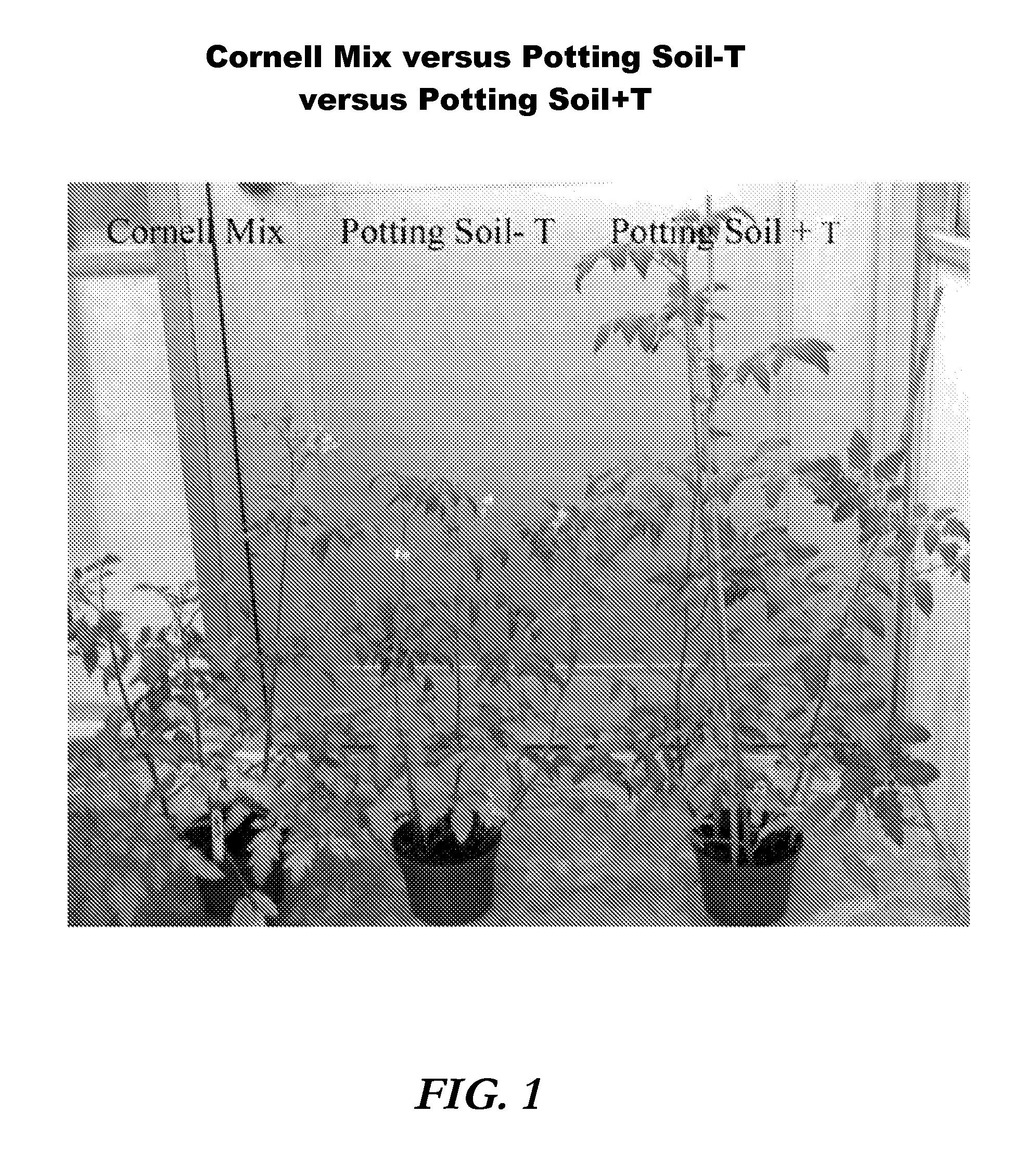

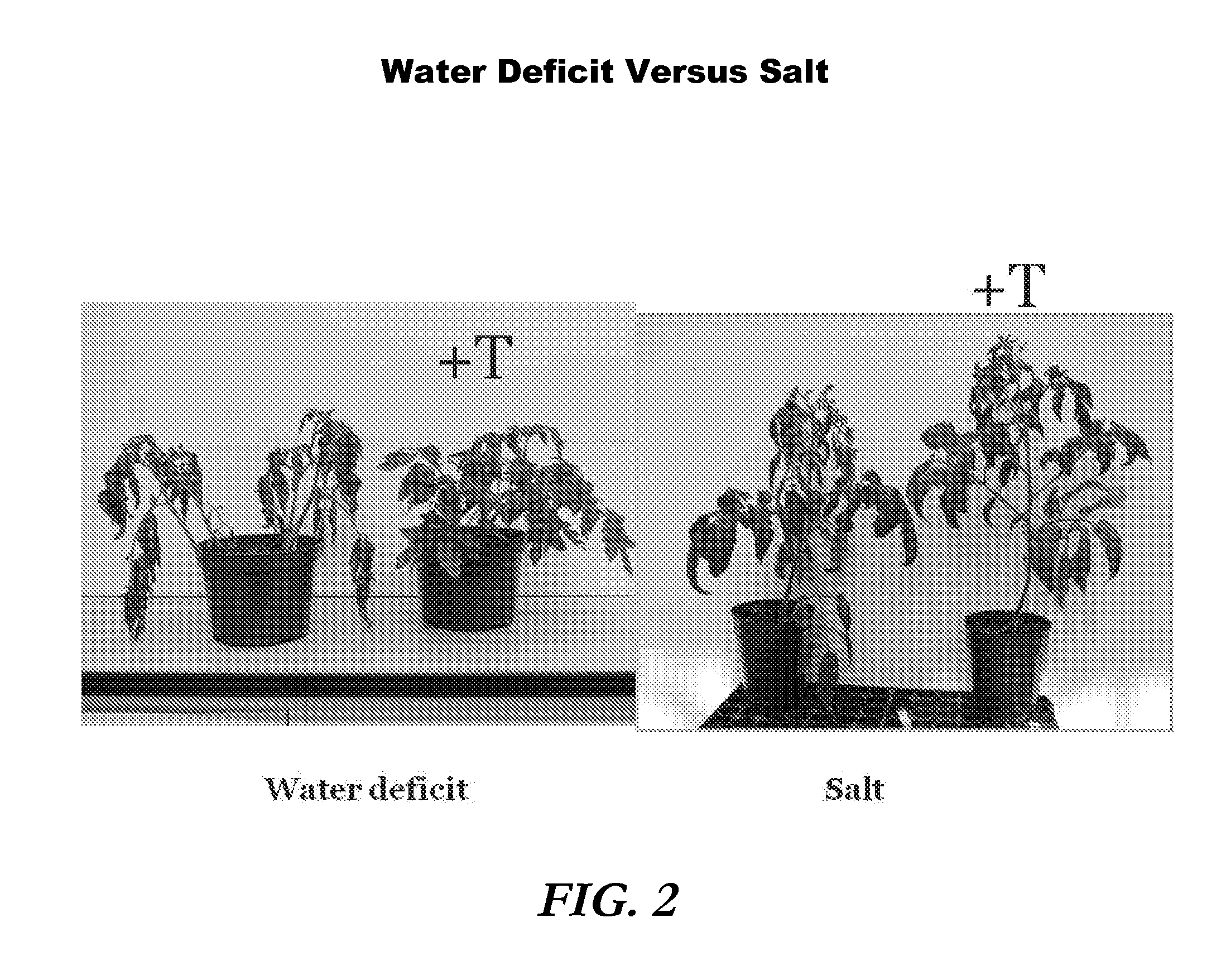

Plant propagation medium and methods of making and using it

ActiveUS20130055635A1Easy to useIncrease in mediumSeed and root treatmentExcrement fertilisersPlant propagationMoisture

The present invention provides a plant propagation medium, the improvement comprising a manure having a moisture content of 10 to 35 wt % with a salt level sufficient to achieve a conductivity of less than 0.35 dS / m. Also disclosed is a method of manufacturing a manure product and the manure product itself.

Owner:CORNELL UNIVERSITY

Anti-shrinkage agent for hydraulic material

The present invention is related to a shrinkage reducing agent for hydraulic materials which comprises at least one polymer selected from the group consisting of (a) a polymer having a structure derived from the residue of a compound containing 2 to 30 carbon atoms and one active hydrogen atom by the binding thereto of one oxyalkylene chain having a carboxyl-containing side chain, (b) a polymer having a structure derived from the residue of a compound containing 4 to 30 carbon atoms and two active hydrogen atoms by the binding thereto of at least one oxyalkylene chain having a carboxyl-containing side chain, (c) a polymer having a structure derived from the residue of a compound containing 1 to 30 carbon atoms and at least three active hydrogen atoms by the binding thereto of at least one oxyalkylene chain having a carboxyl-containing side chain and (d) a polymer having a structure derived from the residue of an amine by the binding thereto one oxyalkylene chain having a carboxyl-containing side chain.

Owner:NIPPON SHOKUBAI CO LTD

Encapsulation of sensitive components using pre-emulsification

ActiveUS7431986B2Increase stabilityIncrease bioavailabilityPowder deliveryLiquid surface applicatorsWater contentOmega 3 fatty acid

A stabilized emulsion is employed to produce shelf stable, controlled release, discrete, solid particles or pellets which contain an encapsulated and / or embedded component, such as a readily oxidizable component, such as omega-3 fatty acids. An oil encapsulant component which contains an active, sensitive encapsulant, dissolved and / or dispersed in an oil is admixed with an aqueous component and a film-forming component to form an emulsion. An antioxidant for prevention of oxidation of the active, sensitive encapsulant, and a film-softening component or plasticizer for the film-forming component may be included in the emulsion. The emulsion is stabilized by subjecting it to homogenization. The pellets are produced by first reducing the water content of the stabilized emulsion so that the film-forming component forms a film around the oil droplets and encapsulates the encapsulant. In embodiments of the invention, the water content of the homogenized emulsion may be reduced by spray-drying to produce a powder. In other embodiments of the invention, after homogenization, the water content of the emulsion may be reduced by admixing the emulsion with at least one matrix material to thereby encapsulate the film-coated oil droplets within the matrix material. After the water content of the emulsion is reduced, a protective coating is applied on the film-coated oil droplets to obtain pellets.

Owner:GENERAL MILLS INC

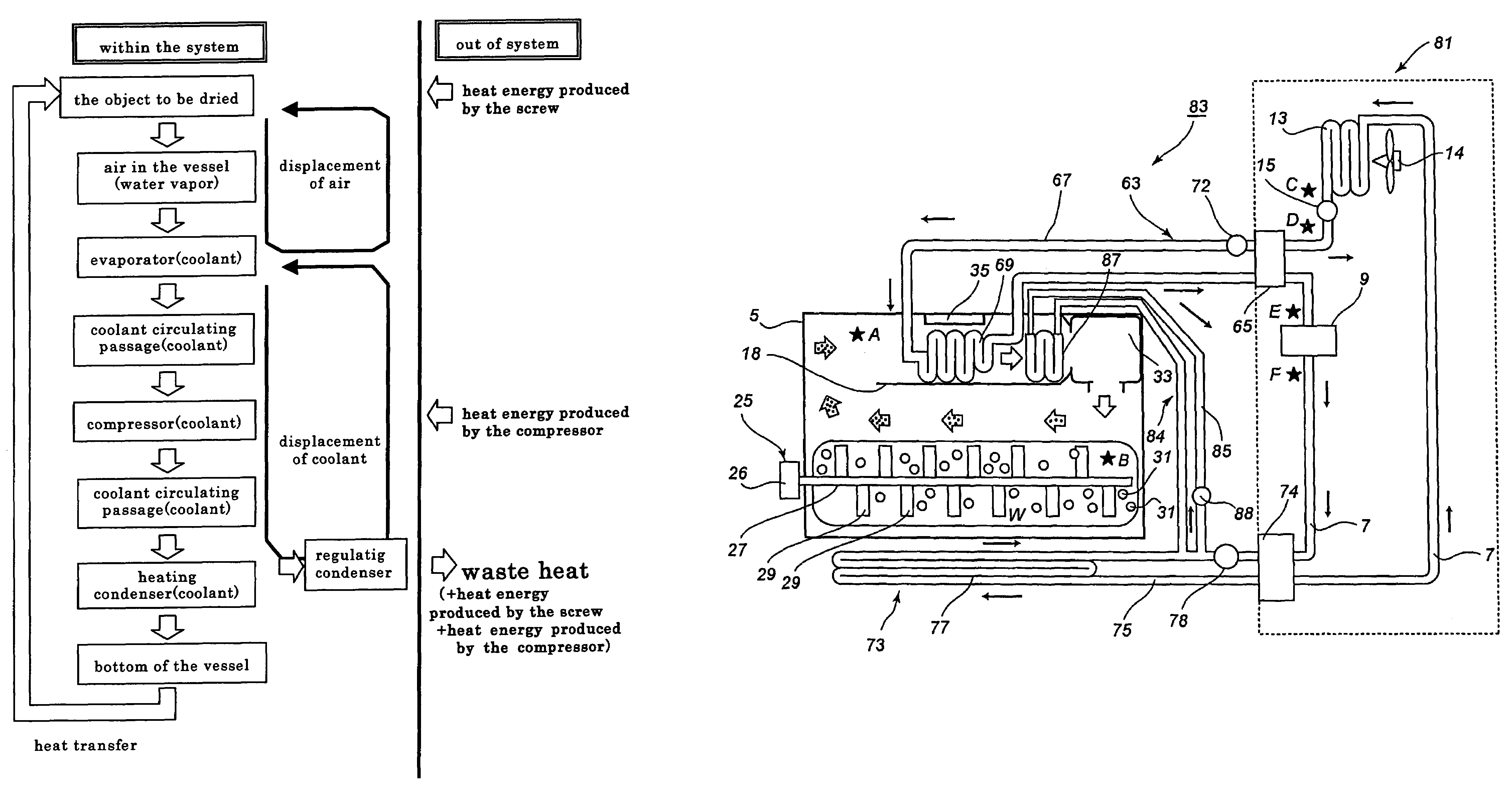

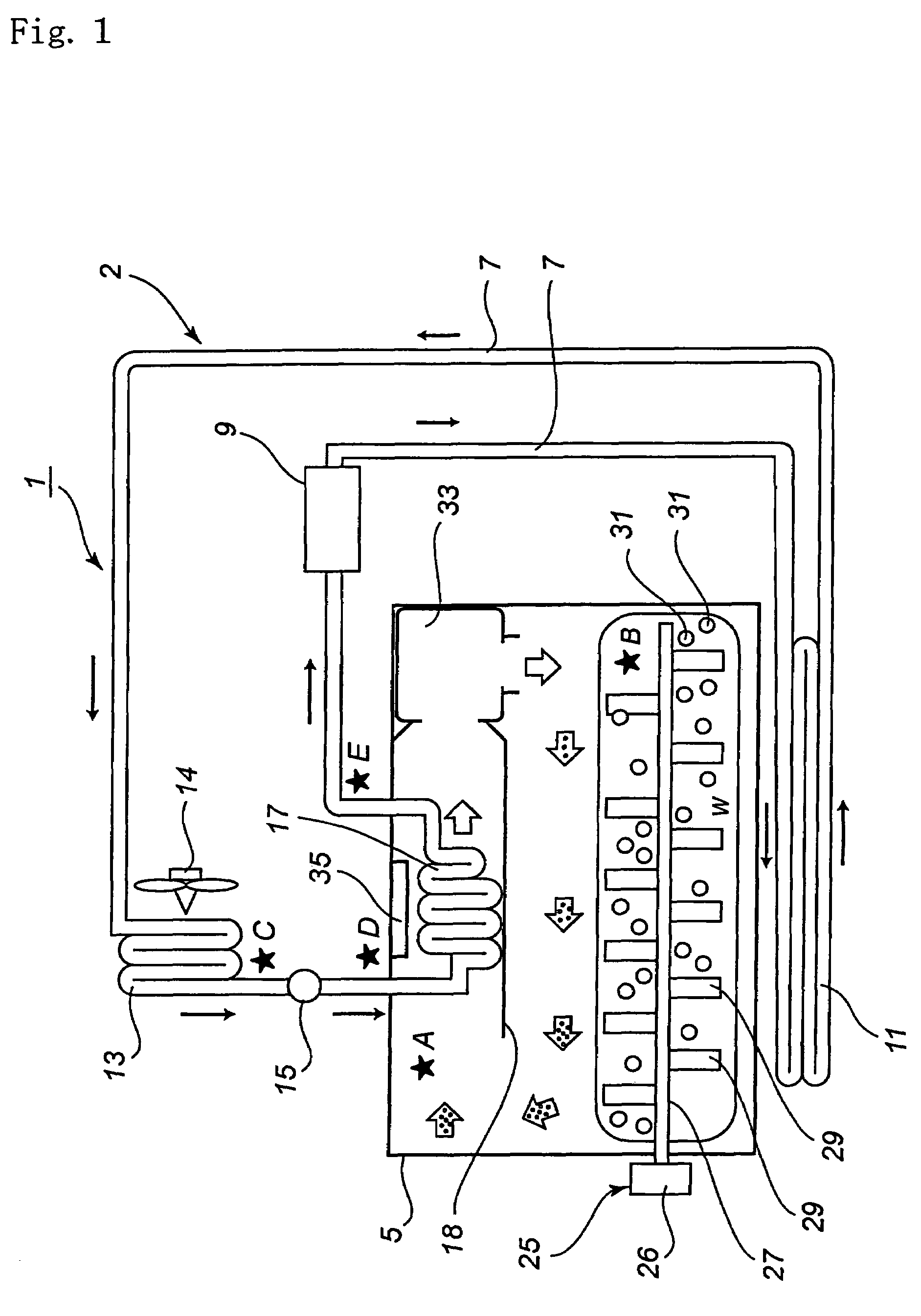

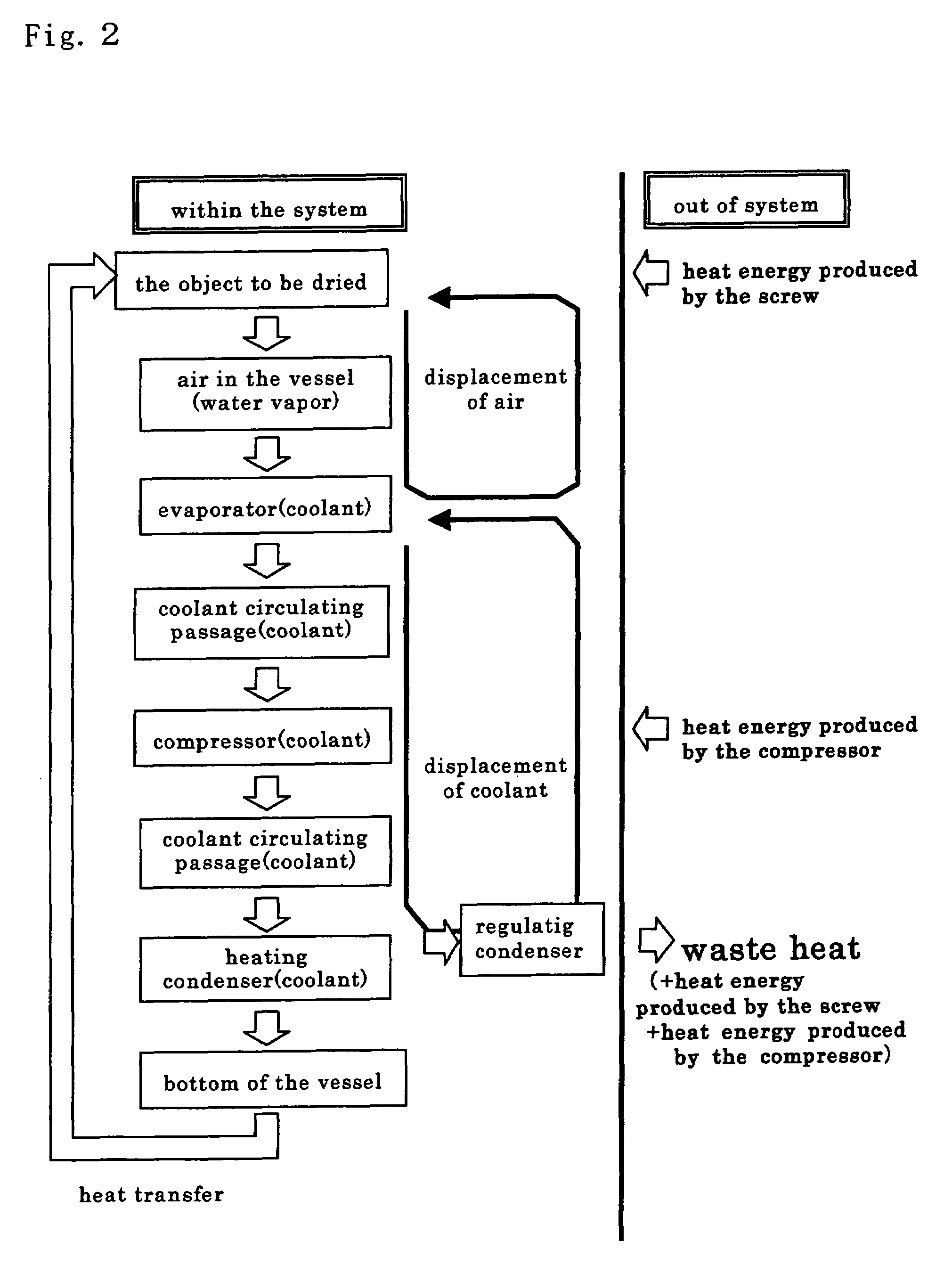

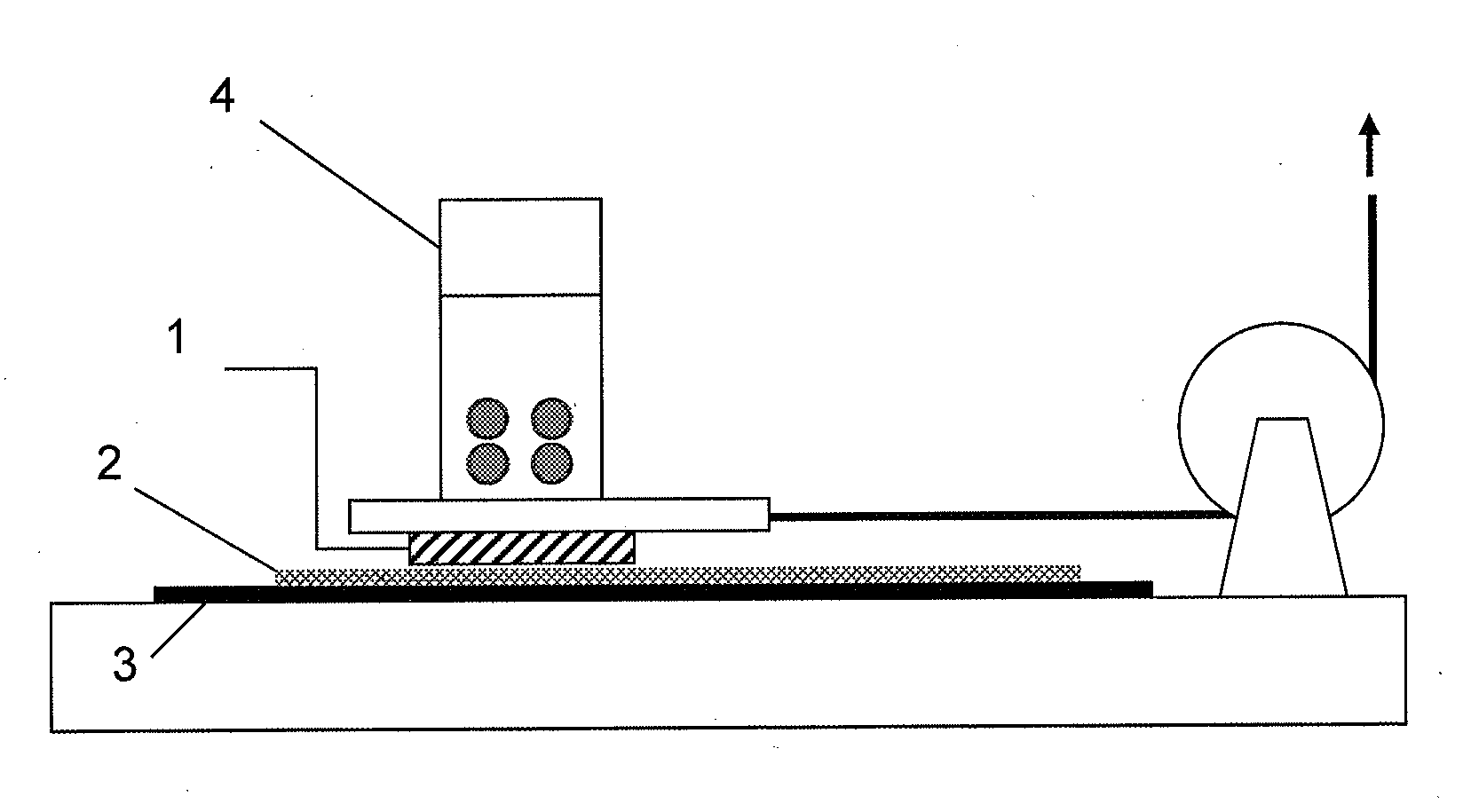

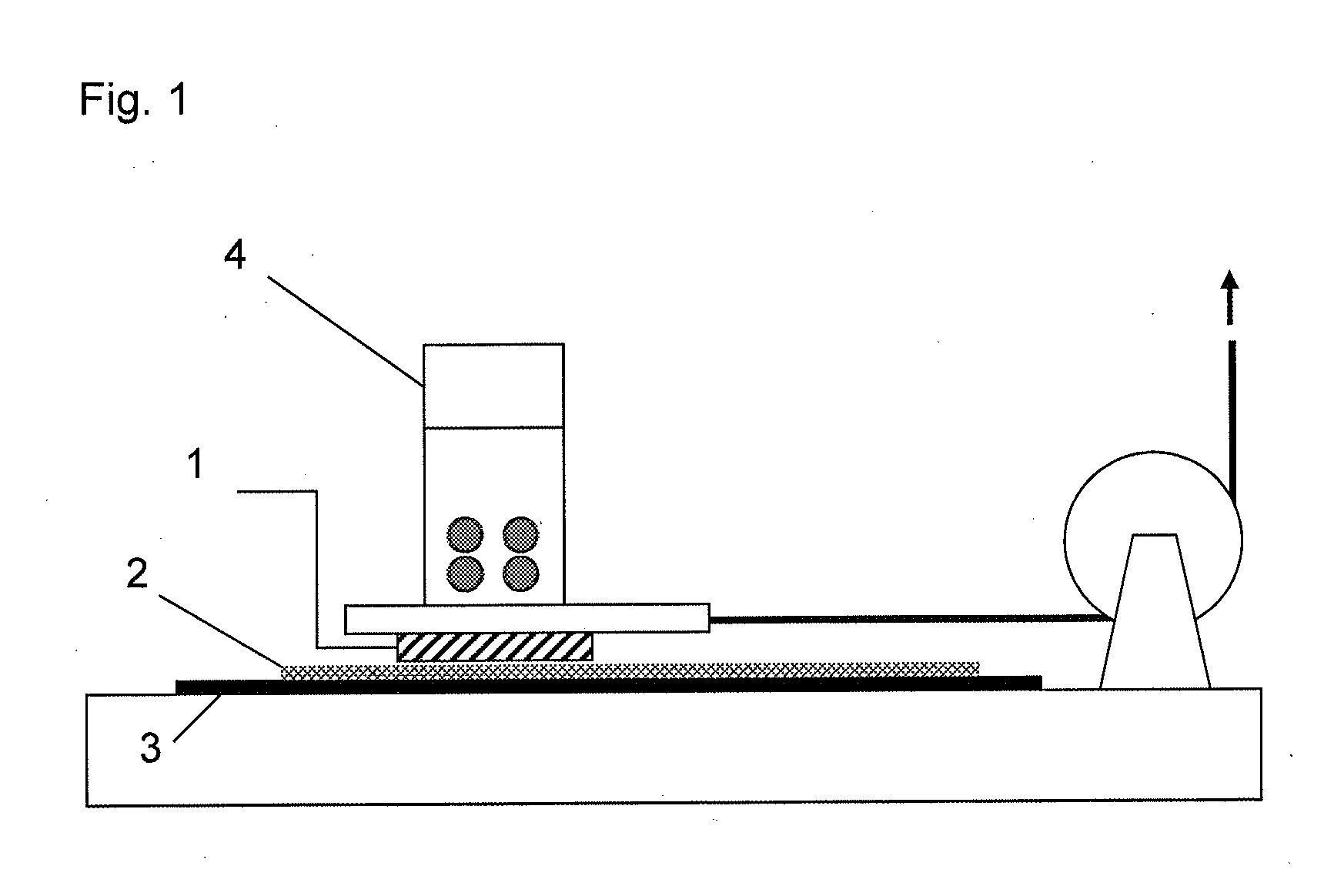

Drying system

InactiveUS7624514B2Improve drying efficiencyReduce water contentDrying solid materials with heatHeat recovery systemsVaporizationEngineering

In a drying system using a compression refrigeration system, a condenser is divided into a regulating condenser and a heating condenser. The regulating condenser is capable of regulating the amount of exhaust heat discharged to outside the system. The heating condenser produces moist air by feeding heat to an aqueous object to be dried placed in a processing vessel to evaporate the moisture in the object. Heat of condensation of steam is recovered by an evaporator as heat of a refrigerant, and the recovered heat is discharged in the heating condenser to use it for the vaporization of the moisture in the object, and excess heat is discharged by the regulating condenser to outside the system.

Owner:GREEN SEIJU CO LTD

Cement-free refractory

InactiveUS20120142518A1Shorten drying timeIncrease refractorinessBlast furnace componentsWood working apparatusRefractoryLiquid metal

A cement free refractory mixture contains aluminum oxide, silicon carbide, fumed silica, aluminum metal, an anti-oxidant, reactive alumina, and a carbon-bearing material. The mixture can be formed by conventional techniques to create refractory articles to contain or direct the flow of liquid metals. Refractory articles formed by the mixture do not require firing to achieve an initial cure.

Owner:VESUVIUS USA CORP

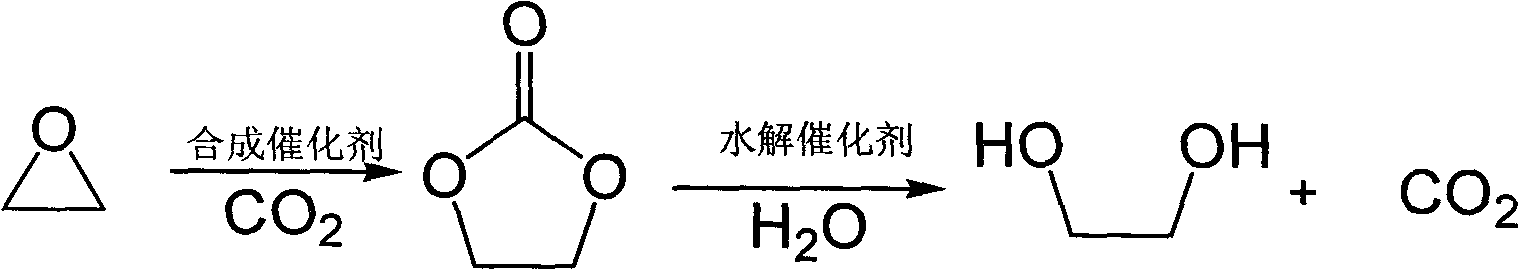

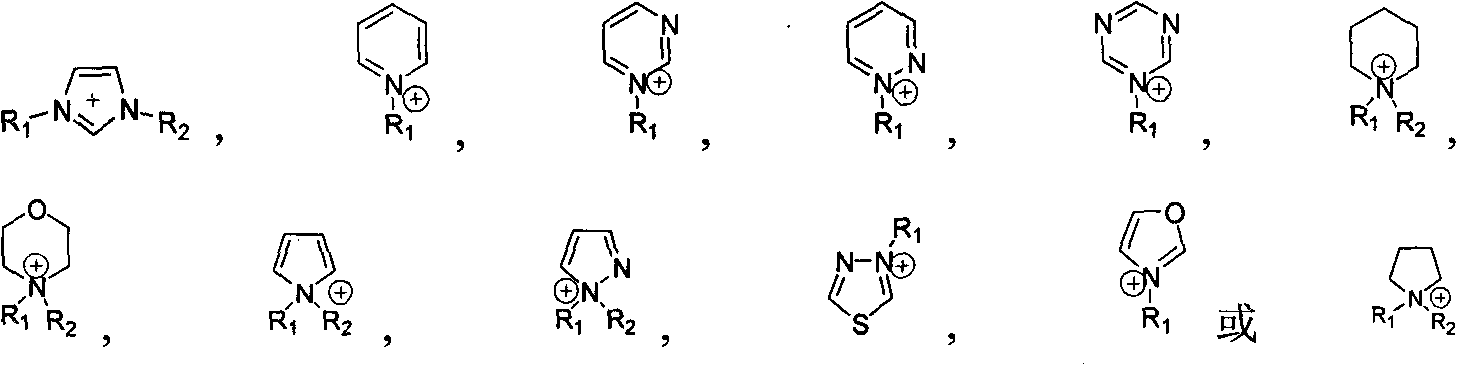

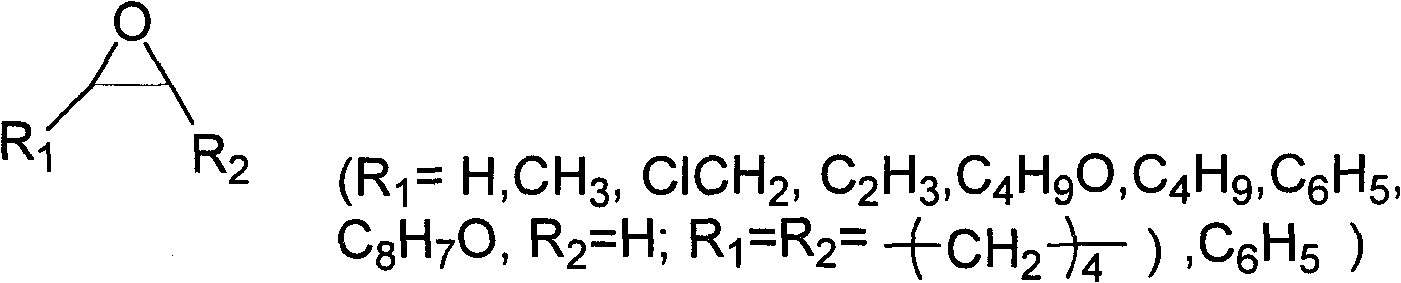

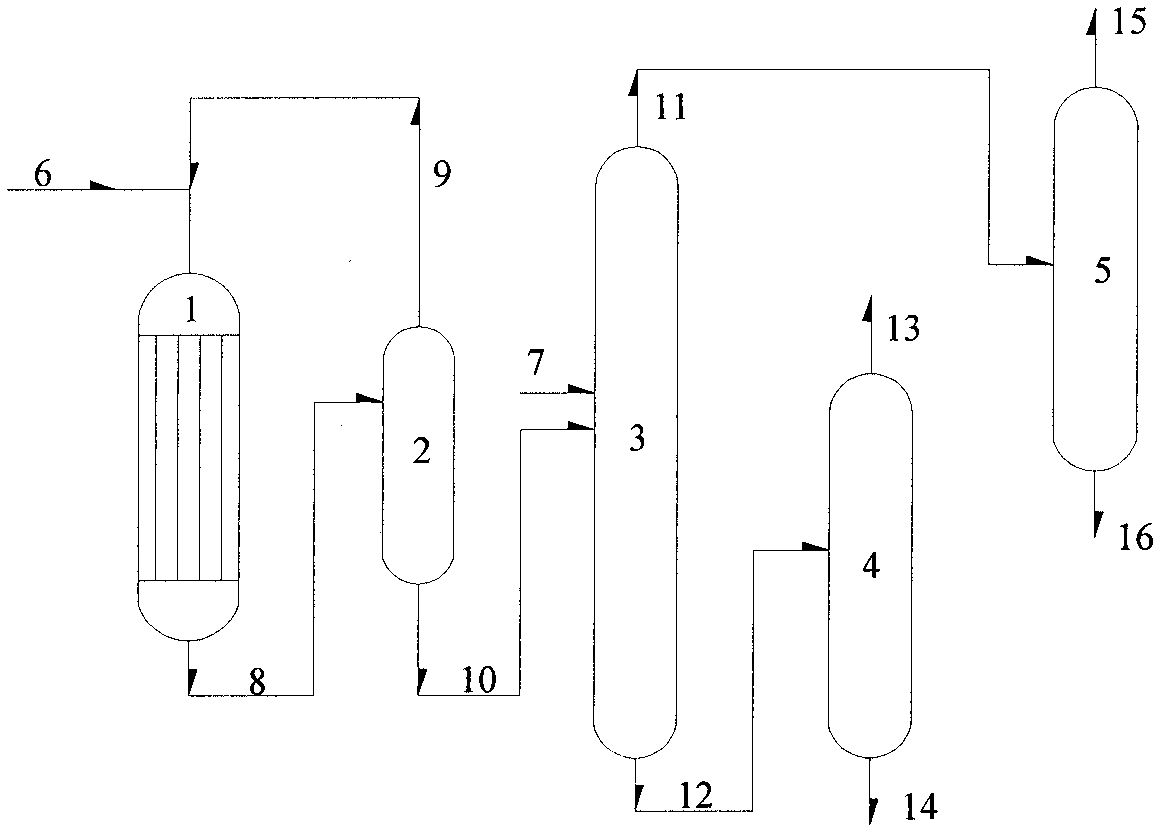

Method for preparing dibasic alcohol

The invention discloses a method for preparing dibasic alcohol by hydrolyzing cyclic carbonate prepared from an epoxy compound and carbon dioxide. A system consisting of metal salt, ionic liquid and quaternary ammonium salt is taken as a catalyst in addition reaction, the cycloaddition of the carbon dioxide and the compound is catalyzed to prepare the cyclic carbonate, and the cyclic carbonate from which the catalyst is separated is subjected to hydrolysis reaction in the presence of a supported alkaline ionic liquid catalyst. The method can overcome the defects of high energy consumption and water ratio in the process of directly hydrating the epoxy compound, and also can overcome the defects of low conversion rate and selectivity of the method for preparing the dibasic alcohol through the ester exchange of the cyclic carbonate and methanol.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for stabilizing and conditioning urban and industrial wastewater sludge

InactiveUS7497956B2Reduce moistureLower the volumeWater treatment parameter controlSludge treatment by de-watering/drying/thickeningIndustrial effluentSolid content

The invention concerns a method for stabilizing and conditioning wastewater sludge. The invention is characterized in that it consists in treating sludge in an acid environment (3.0≦pH≦5.0), with an inorganic acid and two oxidizing agents, that is a ferric iron salt and hydrogen peroxide. The ferric iron salt is used in such an amount as to obtain a concentration ranging between 5 and 40 kg of Fe per ton of dry sludge; the hydrogen peroxide is used in such an amount as to obtain a concentration ranging between 5 and 40 kg of H2O2 per ton of dry sludge; mixing the treated sludge for a time interval sufficient to stabilize the sludge and improve its dehydrability; then flocculating the stabilized sludge by adding an organic polymer; then dehydrating the flocculated sludge. Said method enables to significantly improve the dehydrability properties of the sludge while increasing the dry solid content during its mechanical dehydration.

Owner:CORP BIOLIX +1

Method for producing isopropanol by acetone hydrogenation

InactiveCN102690172AReduce water contentImprove cleanlinessOrganic compound preparationHydroxy compound preparationEconomic benefitsDiisopropylamine

The invention aims at solving the problems of isopropanol production by acetone hydrogenation and impurity removal, especially water removal from isopropanol, and provides a method for producing qualified isopropanol products by converting acetone into isopropanol through hydrogenation, entraining water in the isopropanol by using diisopropylamine as an entrainer, and removing heavy components. The method for producing isopropanol in the invention has a short production flow, is easy to master, and has high economic benefits. Isopropanol can be produced in an isopropylamine production device; diisopropylamine is used as an entrainer; no new substance is introduced; not only the cleanness of the device system is guaranteed, but also the increase of investment for separation equipment and storage tank equipment is not necessary; and the production cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ketone-aldehyde resins having low water content, high thermal stability and yellowing resistance

InactiveUS20060074217A1Reduce water contentHigh thermal stability and yellowing resistanceKetoneThermal stability

The invention described herein provides ketone-aldehyde resins, especially cyclohexanone-formaldehyde resins, with low water content and high thermal stability and yellowing resistance, and to a process for preparing them and their use.

Owner:DEGUSSA AG

Catalyst for synthesizing low carbon mixed alcohol by synthetic gas and its preparation method

InactiveCN1631527AHas low hydrocarbon selectivityHigh activityOrganic compound preparationHydroxy compound preparationAcetic acidAlcohol

This is about a kind of catalyst to make complexes ether of low carbon, whose weight rate is: Mo: 20--40%, soil: 15--30%, Ma: 5--20%, K: 5--15%, S: 20--40%. Take the changing S reactivity to the S hua ammonia solution and Mo acid ammonia, add heavy Acetic acid, filter, dry, and make S dai Mo acid ammonia ether solution: make Ma salt ether solution, mixing them and take supersonic reaction, then get the precipitation, wash, dry and mix with K salt, crash, fire after taking protection air, add soil, mix, press to sheet, shape. The way of the invention is simple, easy to operate, high activity, high choosing ability of ether and low choosing ability of Hydrocarbon.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

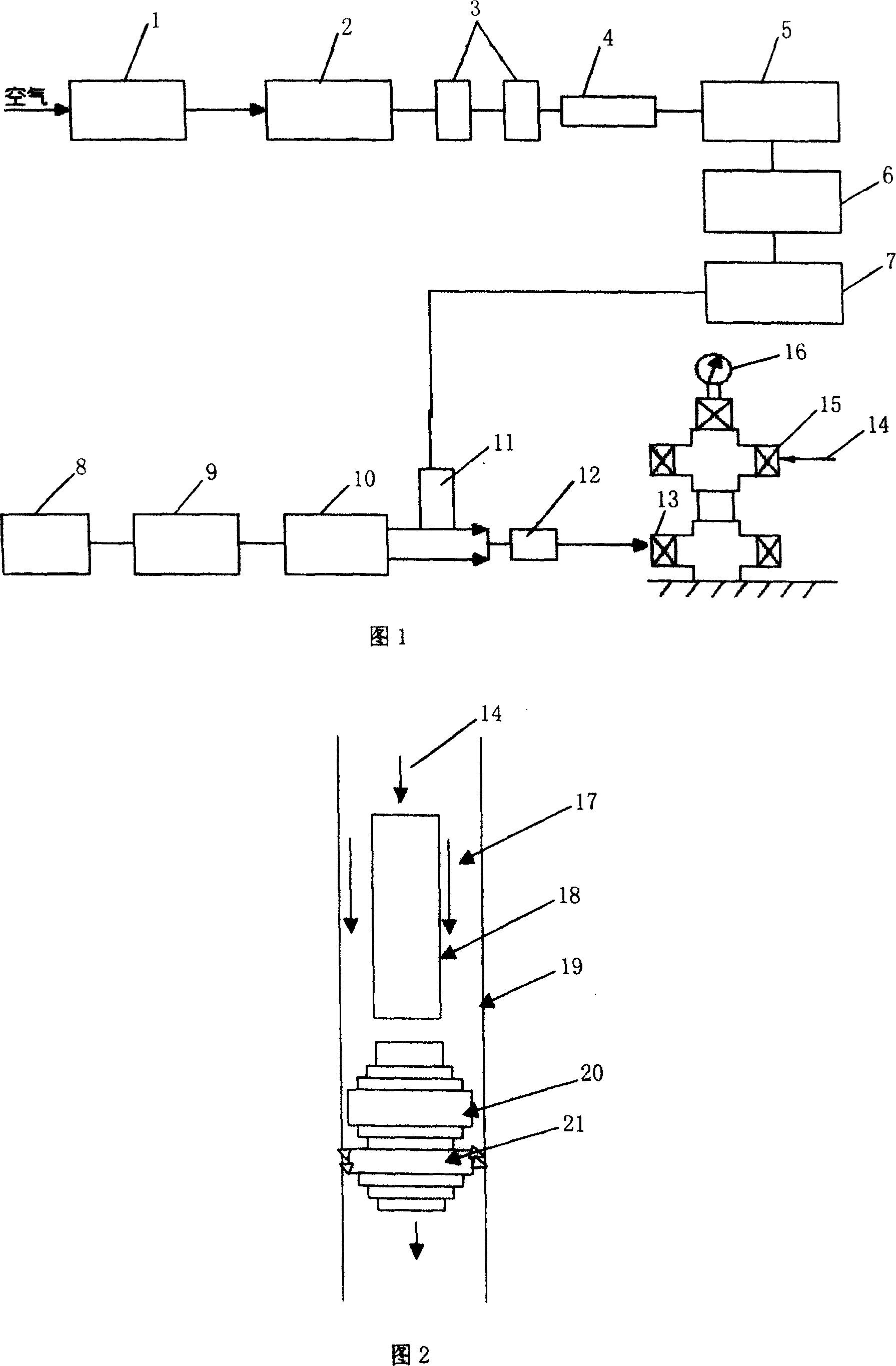

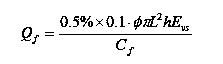

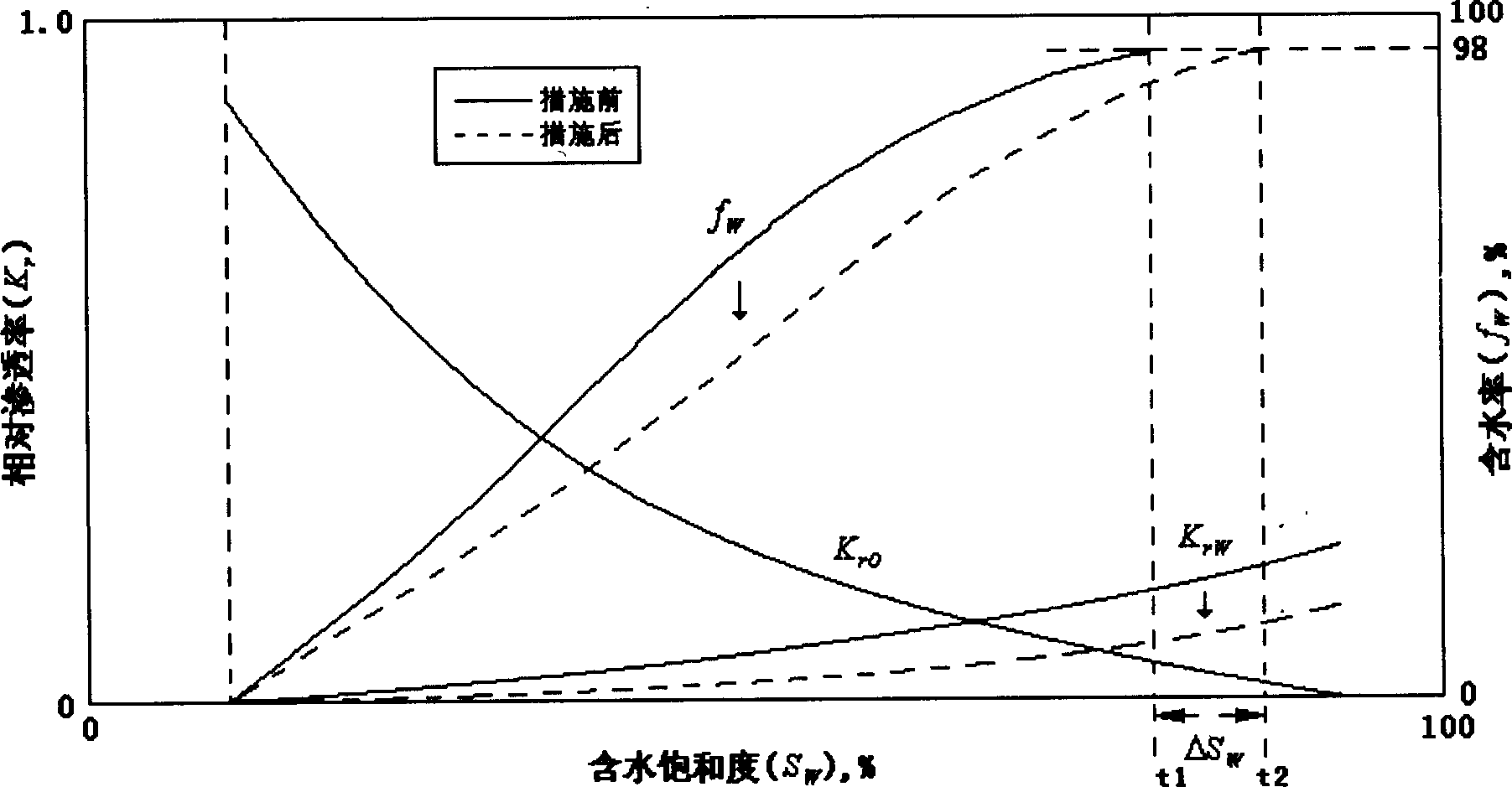

High-temperature blocking and adjusting device and method for super-heavy oil reservoir steam flooding

ActiveCN103541705AExpand the affected volumeReduce water contentFluid removalFoaming agentGas oil ratio

The invention provides a high-temperature blocking and adjusting device and method for super-heavy oil reservoir steam flooding. The high-temperature blocking and adjusting device for super-heavy oil reservoir steam flooding comprises an injection device, a thermal-recovery steam injection well mouth, a nitrogen injection device and a steam injection device. The injection device is connected with the thermal-recovery steam injection well mouth for injecting gel solutions or foaming agent solutions, the nitrogen injection device is connected with the thermal-recovery steam injection well mouth and used for generating and injecting high-purity nitrogen, and the steam injection device is connected with the thermal-recovery steam injection well mouth and used for generating and injecting high-dryness steam. According to the high-temperature blocking and adjusting device and method for super-heavy oil reservoir steam flooding, gel and nitrogen foams are combined, comprehensive water content of a steam flooding well group can be obviously lowered, the gas oil ratio can be obviously improved, the high-temperature blocking and adjusting effect of a super-heavy oil reservoir can be greatly improved, and blocking and adjusting cost is saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

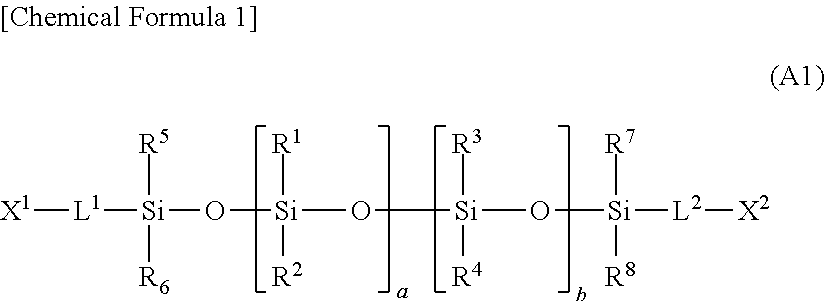

Low water content soft lens for eye, and method for producing the same

ActiveUS20120314183A1Reduce and avoid phenomenonHigh oxygen permeabilitySpectales/gogglesEye implantsPolymer chemistryPolymer

A low water content soft lens for eye is provided, which includes a layer made of an acidic polymer and a basic polymer on at least a part of a surface of a base material containing a polysiloxane compound. Adhesion of the lens to the cornea during wear, which has hitherto been regarded as a problem in a conventional low water content soft lens for eye, can be reduced or avoided when using the low water content soft lens.

Owner:TORAY IND INC

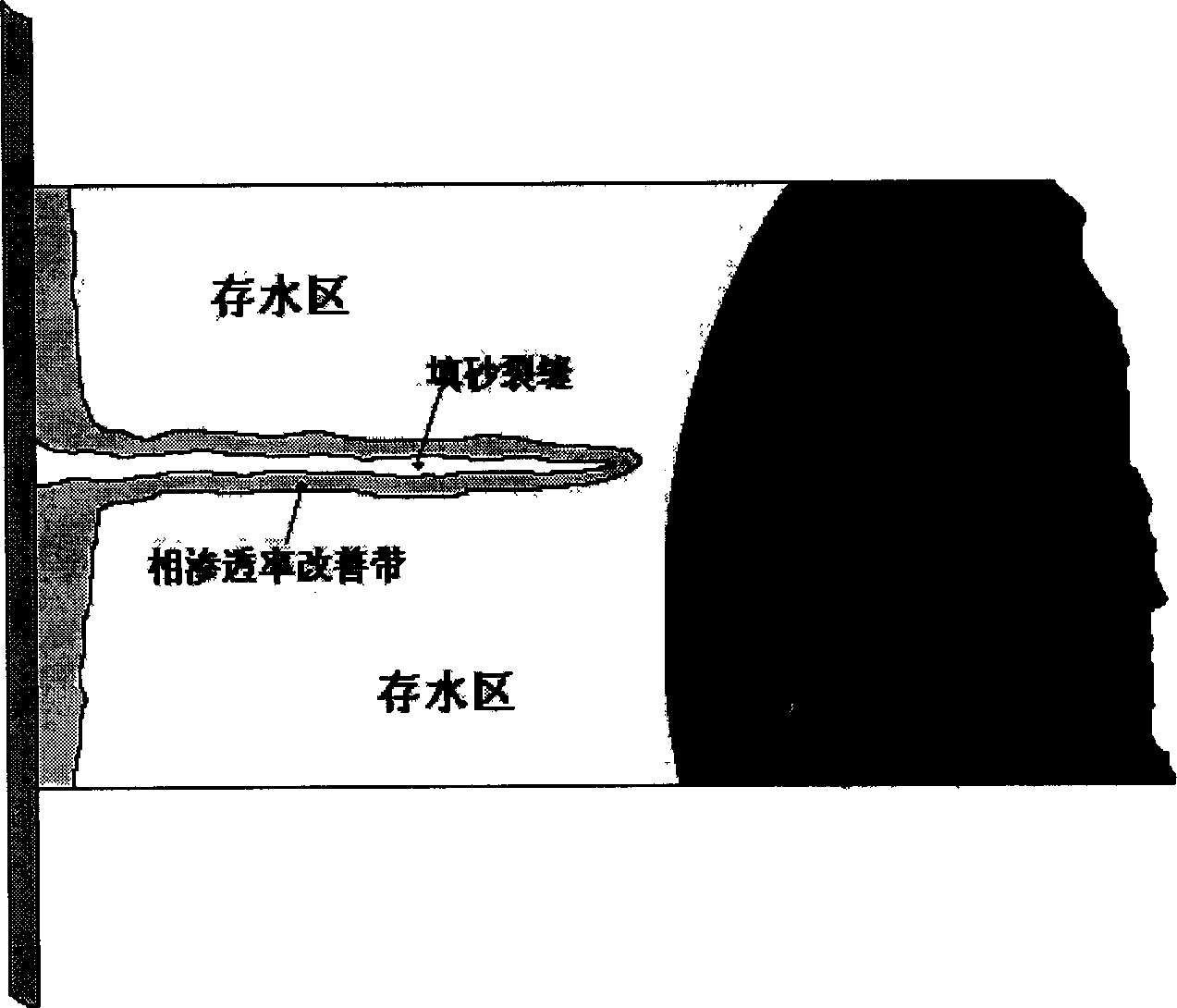

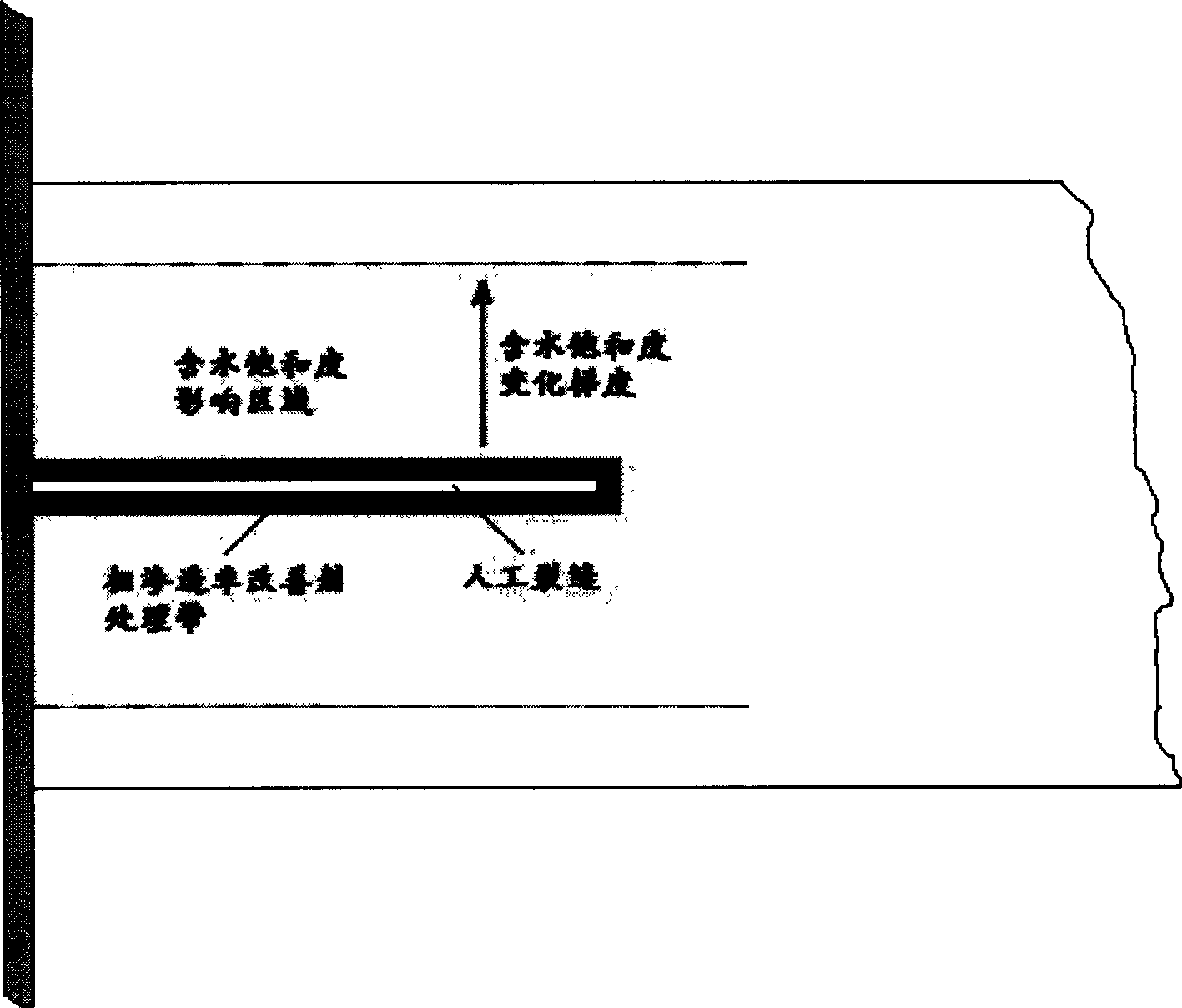

Fracturing method for improving recovering ratio by phase permeability improver

InactiveCN1614193AReduce water contentIncrease fluid productionFluid removalHydraulic fracturingOil water

A fracturing method for increasing the recovering rate of oil well by use of phase permeability improver features that the hydraulic fracturing method is used to generate artificial crack and the phase permeability improver is filled in the stratum via oil well to form a phase permeability improved zone around the artificial crack, which has the selectivity to the osmotic oil-water flow, reducing the relative permeability of water.

Owner:DAQING OILFIELD CO LTD

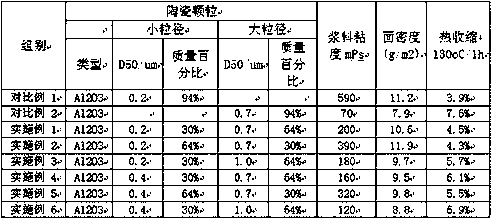

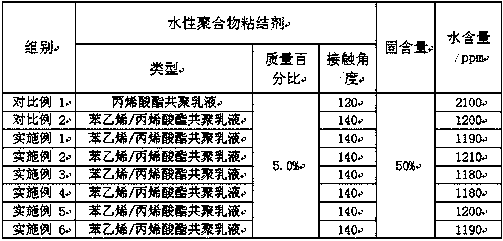

Inorganic/organic composite porous isolating membrane, preparation method and lithium-ion battery thereof

InactiveCN107895765AHigh mechanical strengthImprove reliabilityCell component detailsSecondary cells servicing/maintenancePolymer adhesiveSlurry

The invention discloses an inorganic / organic composite functional porous isolating membrane. The isolating membrane comprises porous base material and at least one inorganic functional coating adhering to the surface of the porous base material, and aqueous slurry prepared for the inorganic functional coatings is prepared from inorganic ceramic particles, water-soluble polymer thickener and aqueous polymer adhesive; the inorganic ceramic particles comprise the same substance in two types of particle sizes, wherein the average particle size (D50) of the smaller inorganic ceramic particles is 0.2-0.5 micrometer, and the average particle size (D50) of the larger inorganic ceramic particles is 0.6-1.0 micrometer; the aqueous polymer adhesive is a hydrophobic high-molecular polymer with the water drop contact angle of the dry adhesive of the aqueous polymer adhesive 110-140 degrees; the solid content of the aqueous slurry is 40-60%. According to the inorganic / organic composite functional porous isolating membrane, the high-temperature thermal stability of the isolating membrane can be effectively improved by means of the inorganic functional coatings, and the water content of the inorganic coatings is effectively reduced, so that the safe performance of a battery and the stability of long-term circulation are improved.

Owner:深圳市旭然电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com