Patents

Literature

278 results about "Diisopropylamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diisopropylamine is a secondary amine with the chemical formula (CH₃)₂HC-NH-CH(CH₃)₂. It is best known as its lithium derivative of its conjugate base, lithium diisopropylamide, known as "LDA". LDA is a strong, non-nucleophilic base.

Preparation method of N,N-diisopropylethylamine

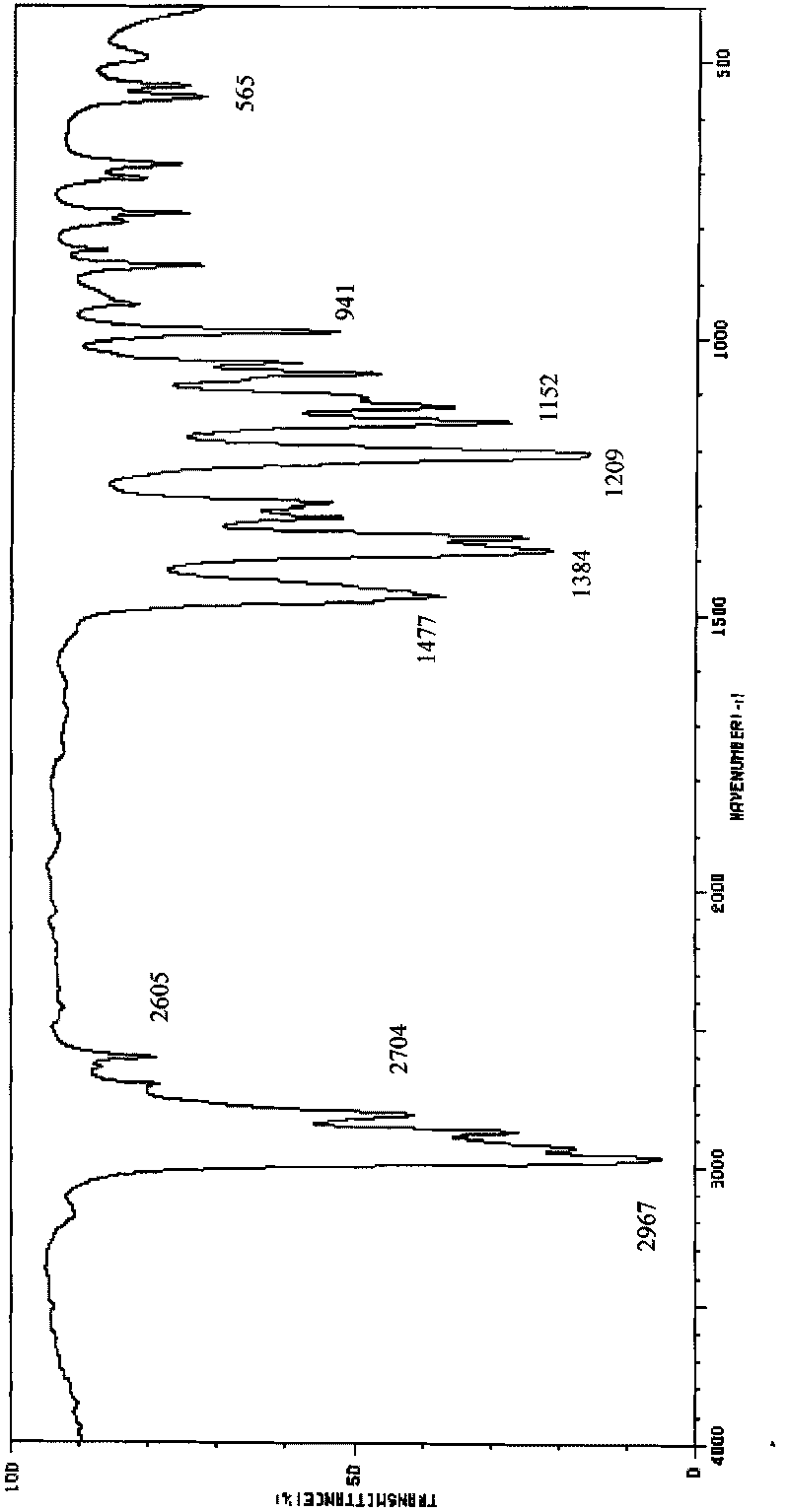

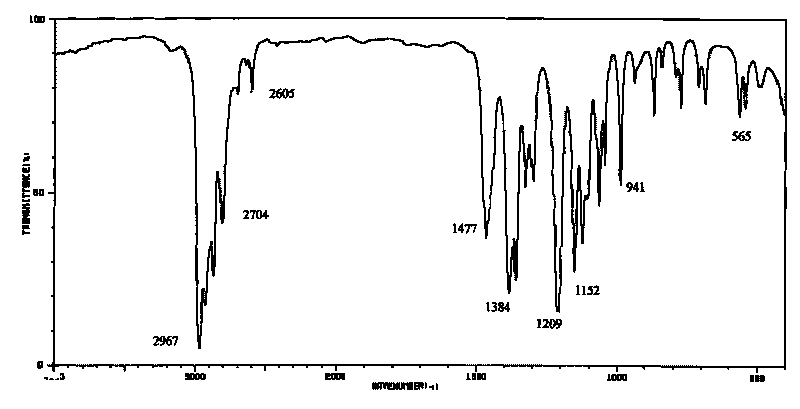

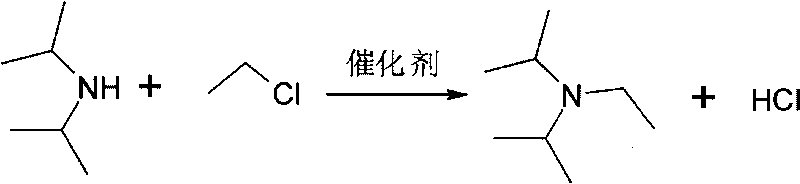

InactiveCN101759571AIncrease profitLow costAmino preparation by functional substitutionDiisopropylamineReaction temperature

The invention discloses a preparation method of N,N-diisopropylethylamine, which comprises the following steps of: reacting diisopropylamine and ethyl chloride as raw materials in a high-pressure autoclave by adopting an MIX type catalyst, wherein the mol ratio of the diisopropylamine to the ethyl chloride is 2-4:1, the mass ratio of the MIX type catalyst to the ethyl chloride is 1:20-10, the reaction temperature is 130-230 DEG C, the reaction pressure is 0.8-2.5MPa, and the reaction time is 4-10 hours; and adding a strongly alkaline solution into the obtained reaction liquid until the pH is 12.5-13.5, and then carrying out liquid separation and rectification to obtain the N,N-diisopropylethylamine. The preparation method of the N,N-diisopropylethylamine has the characteristics of simple process, high yield, low cost and little discharge of the three wastes.

Owner:ZHEJIANG UNIV

Sacubitril derivatives and medicine compositions, preparation methods and application thereof

ActiveCN105693543AEasy to prepareCrystal form controllableAmino compound purification/separationOrganic compound preparationEthylenediamineArginine

The invention provides sacubitril derivatives and medicine compositions, preparation methods and application thereof and belongs to the fields of medicine compounds and preparation thereof. The sacubitril derivatives comprise sacubitril lithium salt, sacubitril kali salt, sacubitril magnesium salt, sacubitril calcium salt, sacubitril strontium salt, sacubitril zinc salt, sacubitril ferric salt, sacubitril ammonium salt, sacubitril diethylamine salt, sacubitril ethylenediamine salt, sacubitril piperazine salt, sacubitril N-(2-ethoxyl)-pyrrolidine salt, sacubitril choline salt, sacubitril cholamine salt, sacubitril diethanol amine salt, sacubitril triethanolamine salt, sacubitril tromethamine salt, sacubitril meglumine salt, sacubitril diisopropylamine salt, sacubitril tert-butylamine salt, sacubitril N, N'-bis-benzyl ethylenediamine salt, sacubitril L-lysine salt, sacubitril L-arginine salt or sacubitril L-histidine salt.

Owner:SICHUAN HAISCO PHARMA CO LTD

Method for producing isopropanol by acetone hydrogenation

InactiveCN102690172AReduce water contentImprove cleanlinessOrganic compound preparationHydroxy compound preparationEconomic benefitsDiisopropylamine

The invention aims at solving the problems of isopropanol production by acetone hydrogenation and impurity removal, especially water removal from isopropanol, and provides a method for producing qualified isopropanol products by converting acetone into isopropanol through hydrogenation, entraining water in the isopropanol by using diisopropylamine as an entrainer, and removing heavy components. The method for producing isopropanol in the invention has a short production flow, is easy to master, and has high economic benefits. Isopropanol can be produced in an isopropylamine production device; diisopropylamine is used as an entrainer; no new substance is introduced; not only the cleanness of the device system is guaranteed, but also the increase of investment for separation equipment and storage tank equipment is not necessary; and the production cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

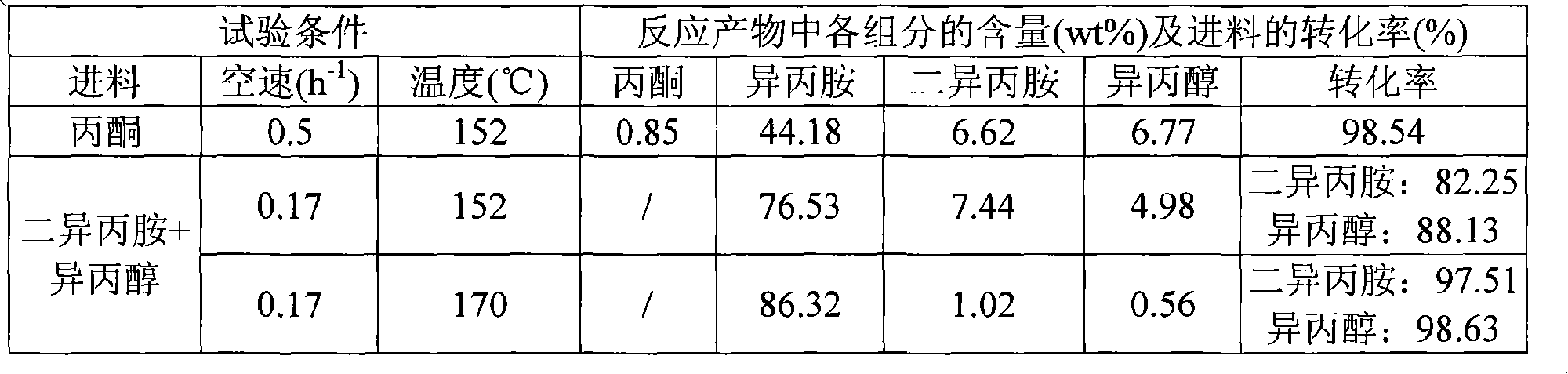

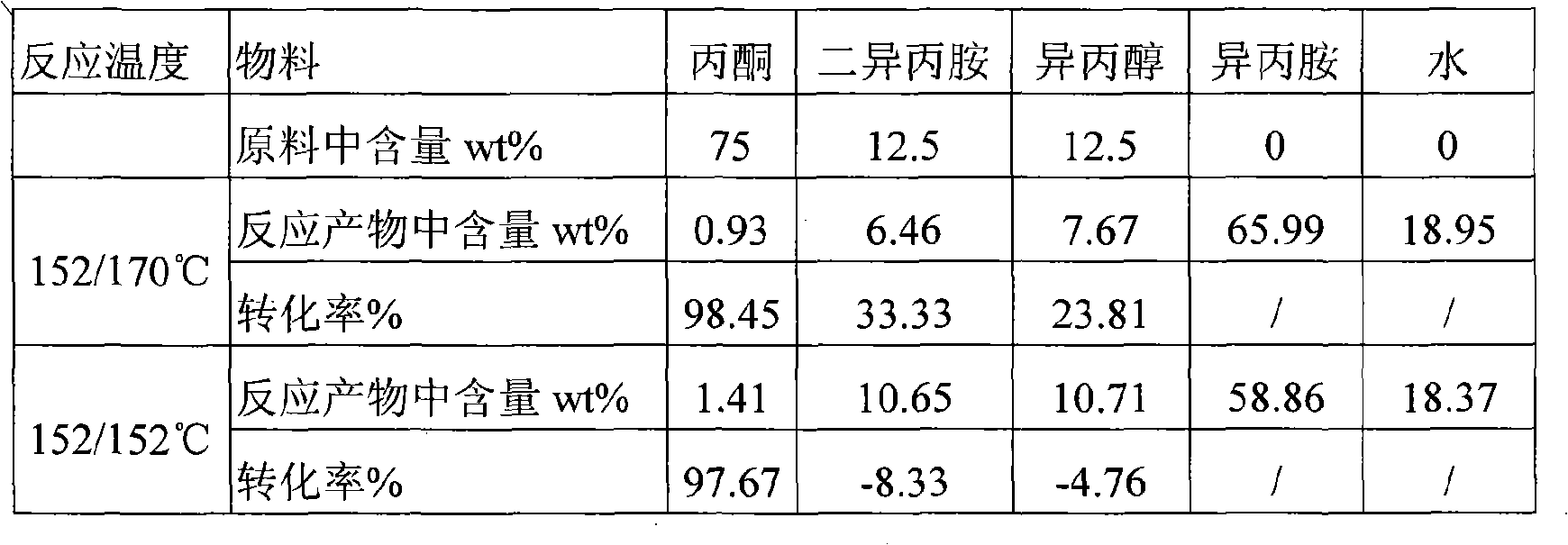

Method for synthesizing isopropamide

ActiveCN101880236AReduce generationSimple production processOrganic compound preparationPreparation by reductive alkylationFatty amineReaction temperature

The invention discloses a method for synthesizing isopropamide, belonging to the technical field of synthesizing fatty amine. In order to improve the conversion efficiency and the selectivity of catalysts for synthesizing isopropamide, propanone or isopropanol is used as the raw material, in the presence of hydrogen and a nickel-based catalyst, amination is carried out to synthesize isopropamide under the conditions that the reaction temperature is 110-200 DEG C, the reaction pressure is 0.1-1.0MPa, and the mole ratio of propanone or isopropanol to hydrogen to ammonia is 1:(1-5):(1-5), wherein the catalyst contains a carrier and nickel active components loaded on the carrier, and over 90 percent of the nickel active components are distributed in a region with the depth of 0.7 mm from the surface of the carrier. The method in the invention can ensure that the conversion efficiency of the propanone is improved, has higher propanone conversion efficiency under the condition of same nickel content and better selectivity, reduces the generation amount of diisopropylamine, simplifies the production process flows of the isopropamide, and lowers the production cost of the isopropamide.

Owner:CHINA PETROLEUM & CHEM CORP +1

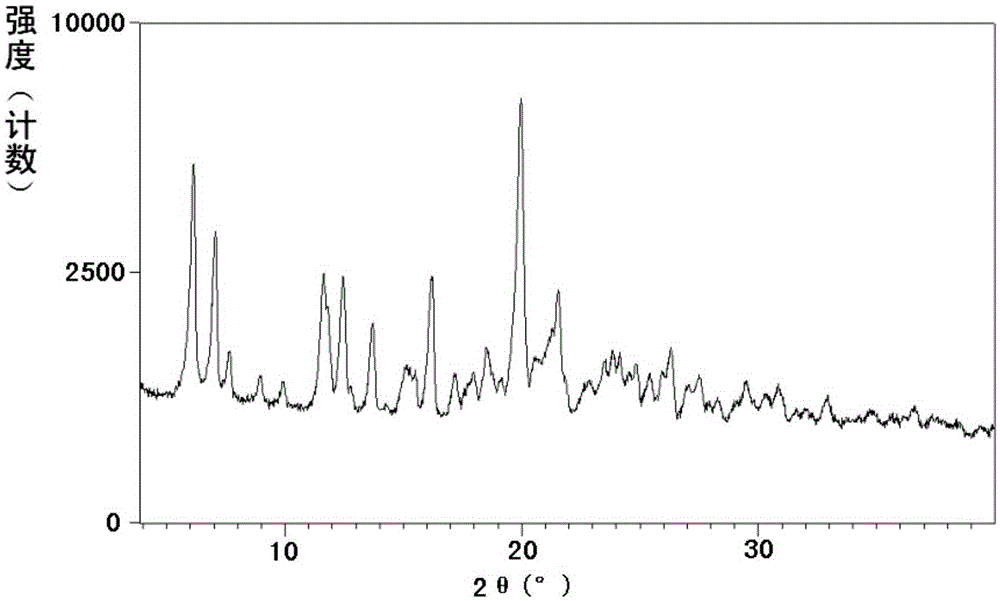

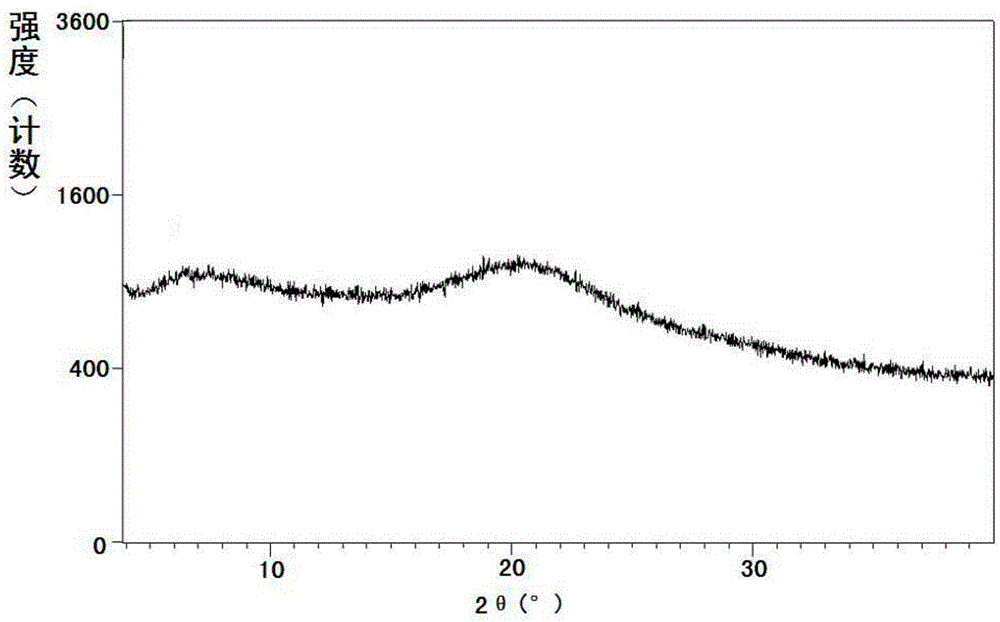

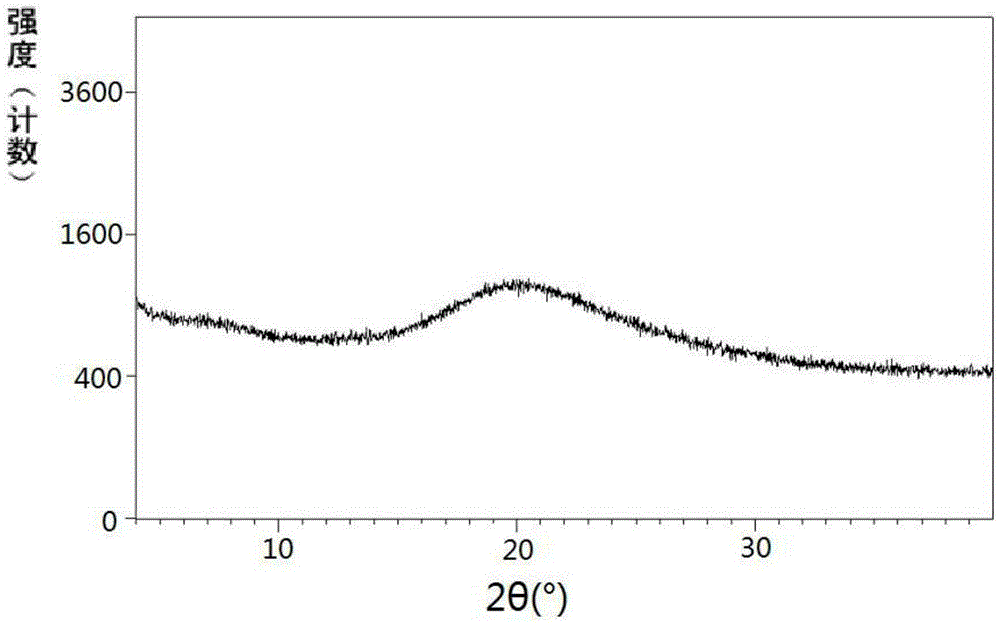

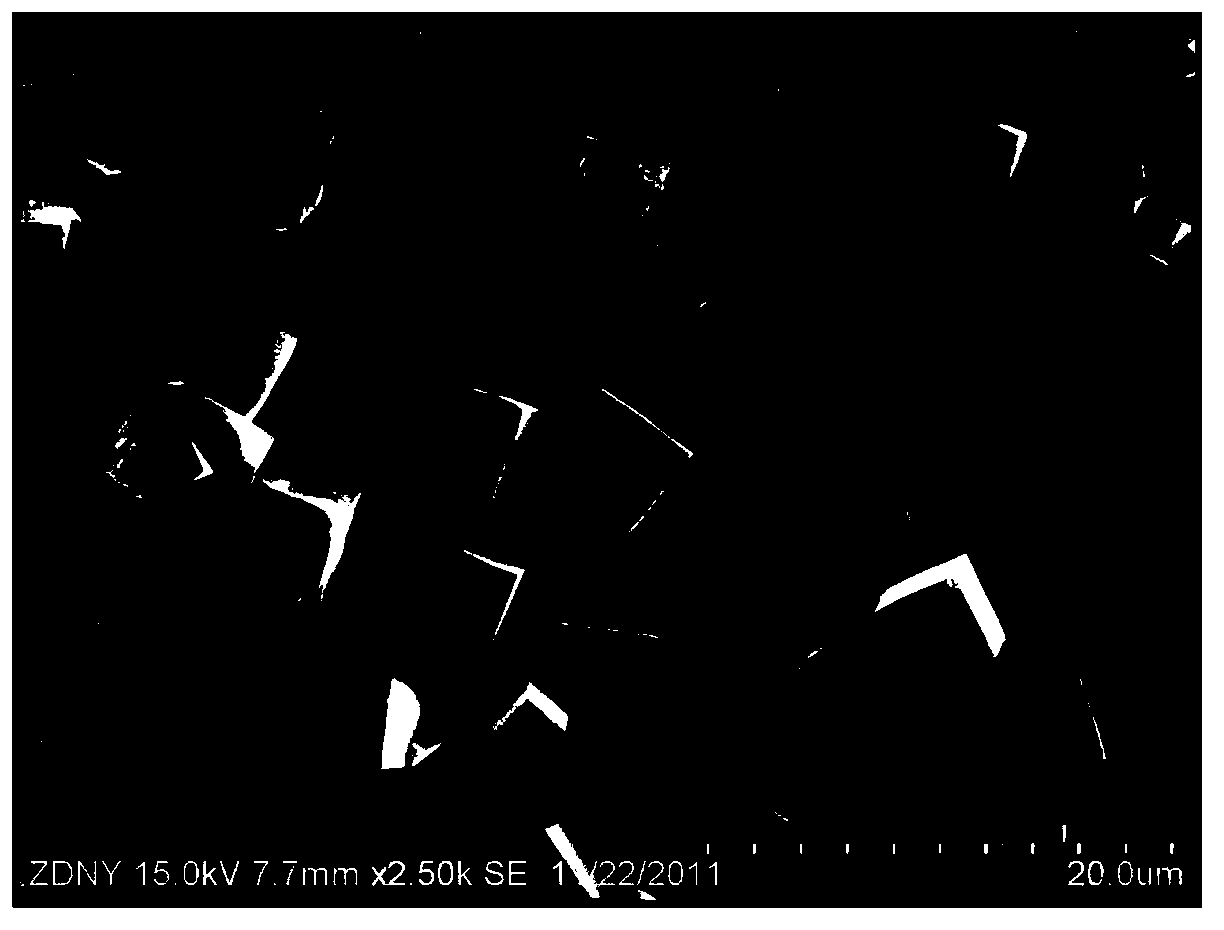

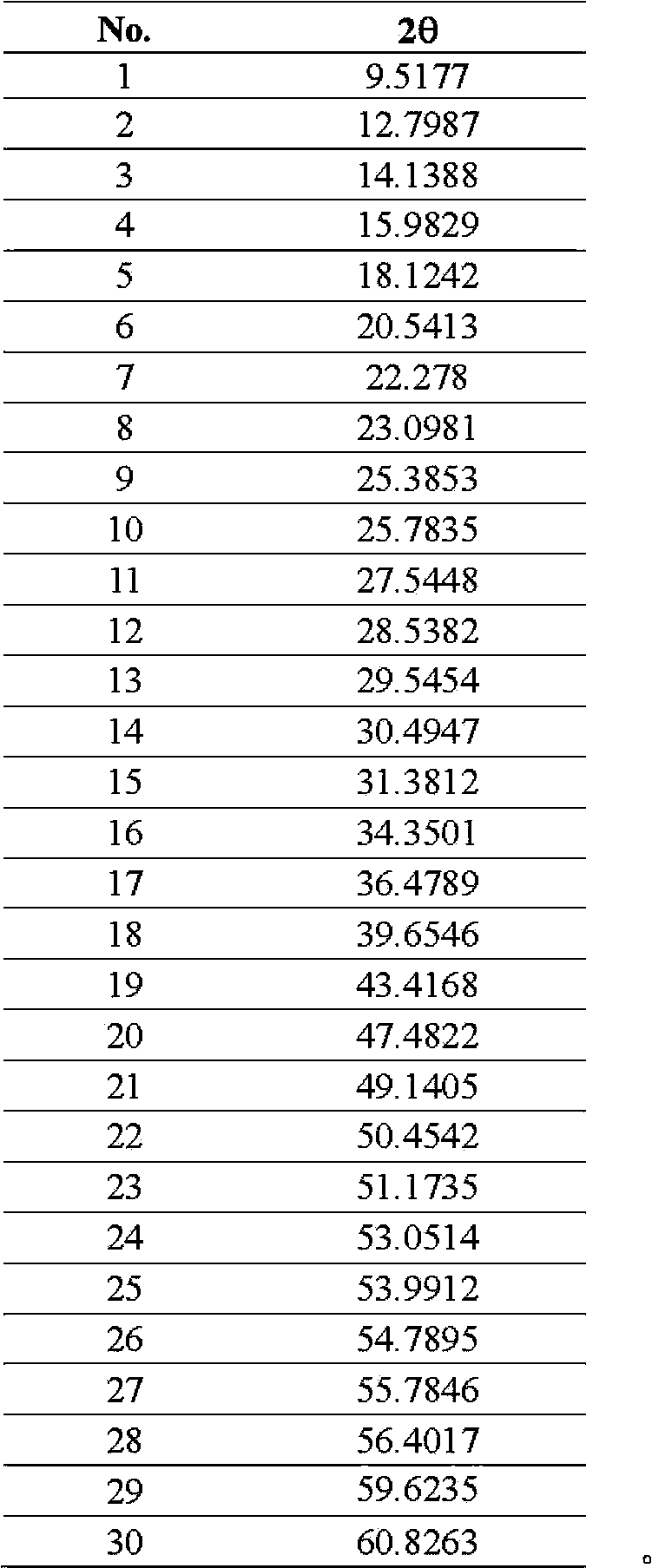

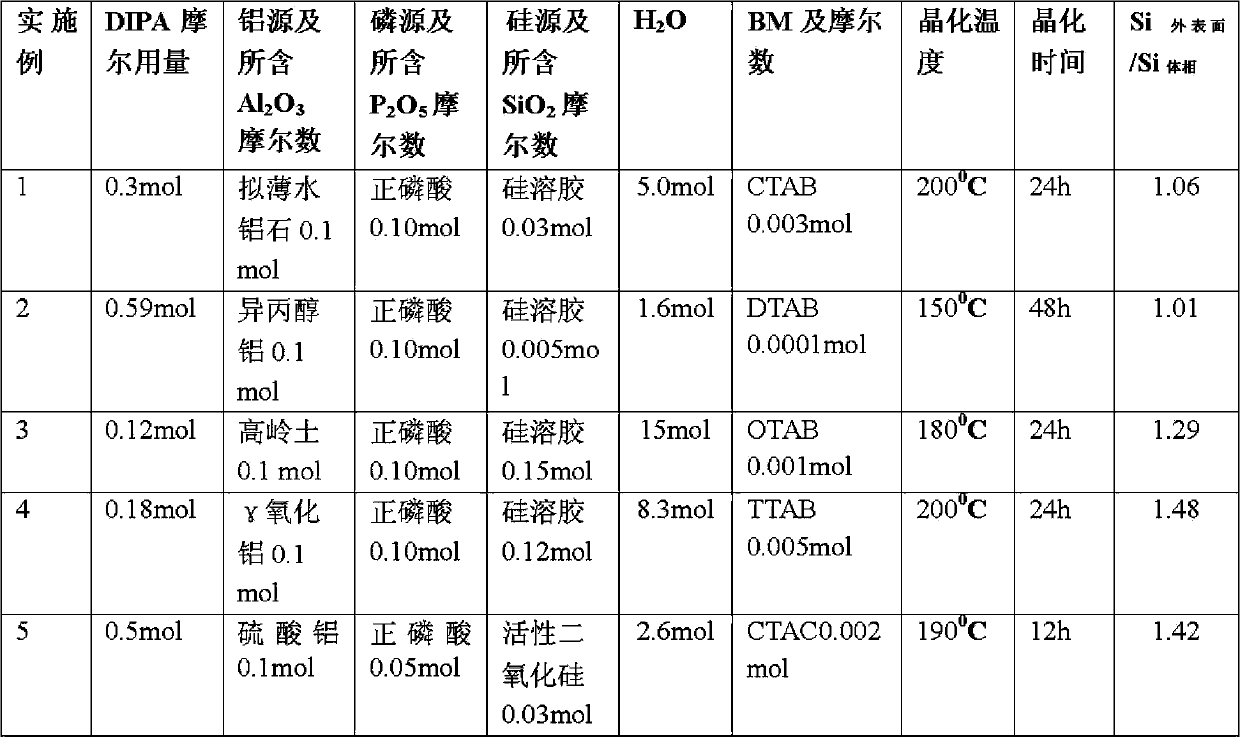

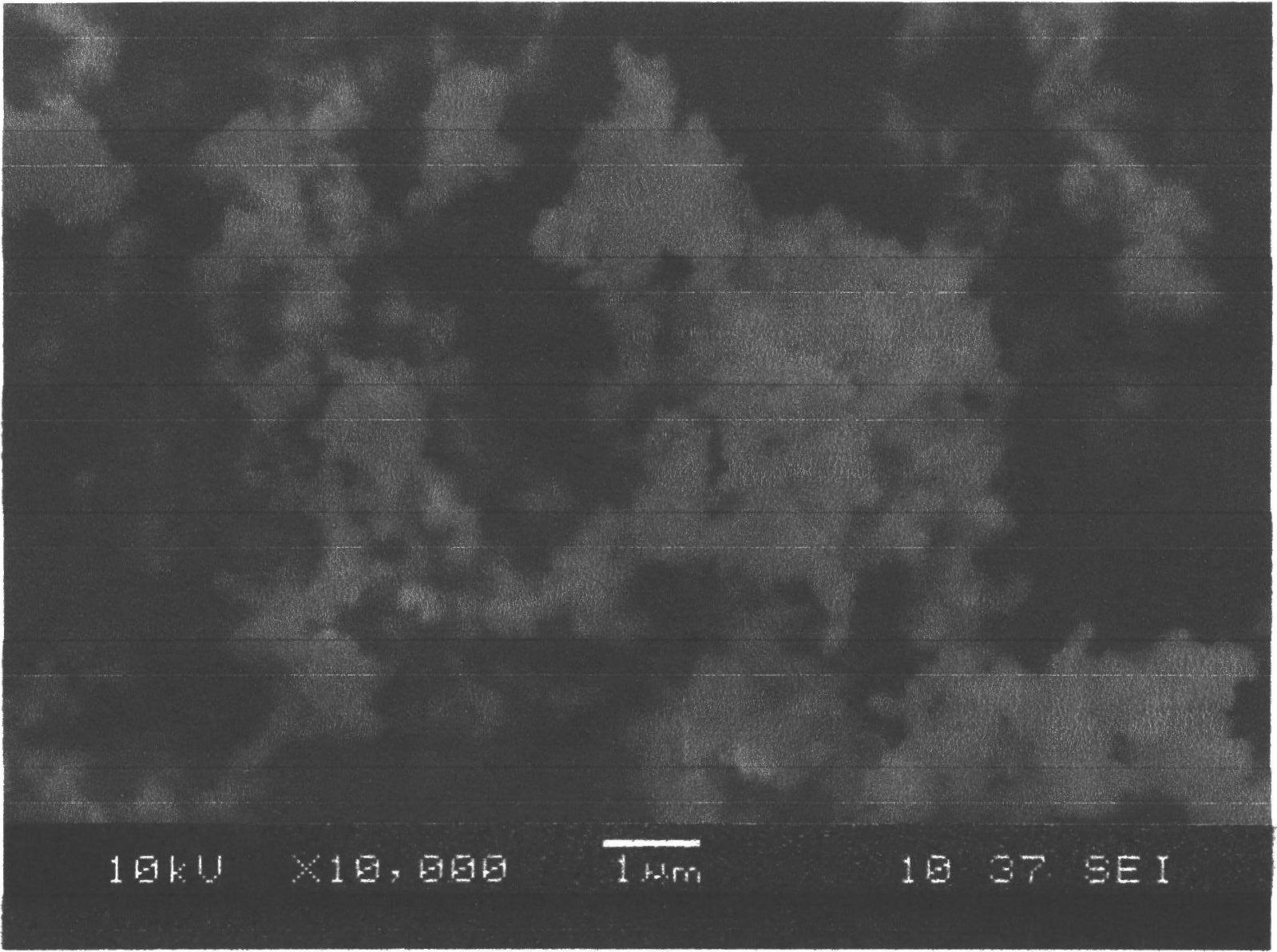

SAPO-34 molecular sieve and synthesis method thereof

ActiveCN103663490AImprove catalytic performanceMolecular-sieve and base-exchange phosphatesMolecular sieveChemical composition

The invention discloses a SAPO-34 molecular sieve. The invention is characterized in that the anhydrous chemical composition of the molecular sieve can be mDIPA.(SixAlyPz)O2, wherein DIPA is diisopropylamine and is distributed in molecular sieve cages and pores; m is the mole number of the diisopropylamine template in every mole of (SixAlyPz)O2, and m=0.03-0.25; and x, y and z respectively represent mole fractions of Si, Al and P, x=0.01-0.30, y=0.40-0.60, z=0.25-0.49, and x+y+z=1. The molecular sieve surface is slightly rich in silicon, and the ratio of the silicon content on the external surface to the bulk-phase silicon content in the crystal is 1.48-1.01. The invention relates to a synthesis and preparation method of the SAPO-34 molecular sieve. The invention also relates to application of the SAPO-34 molecular sieve in acid catalyzed reaction. The invention also relates to application of the SAPO-34 molecular sieve in catalysis of reaction for preparing low-carbon olefins by converting oxygen-containing compounds.

Owner:中科催化新技术(大连)股份有限公司

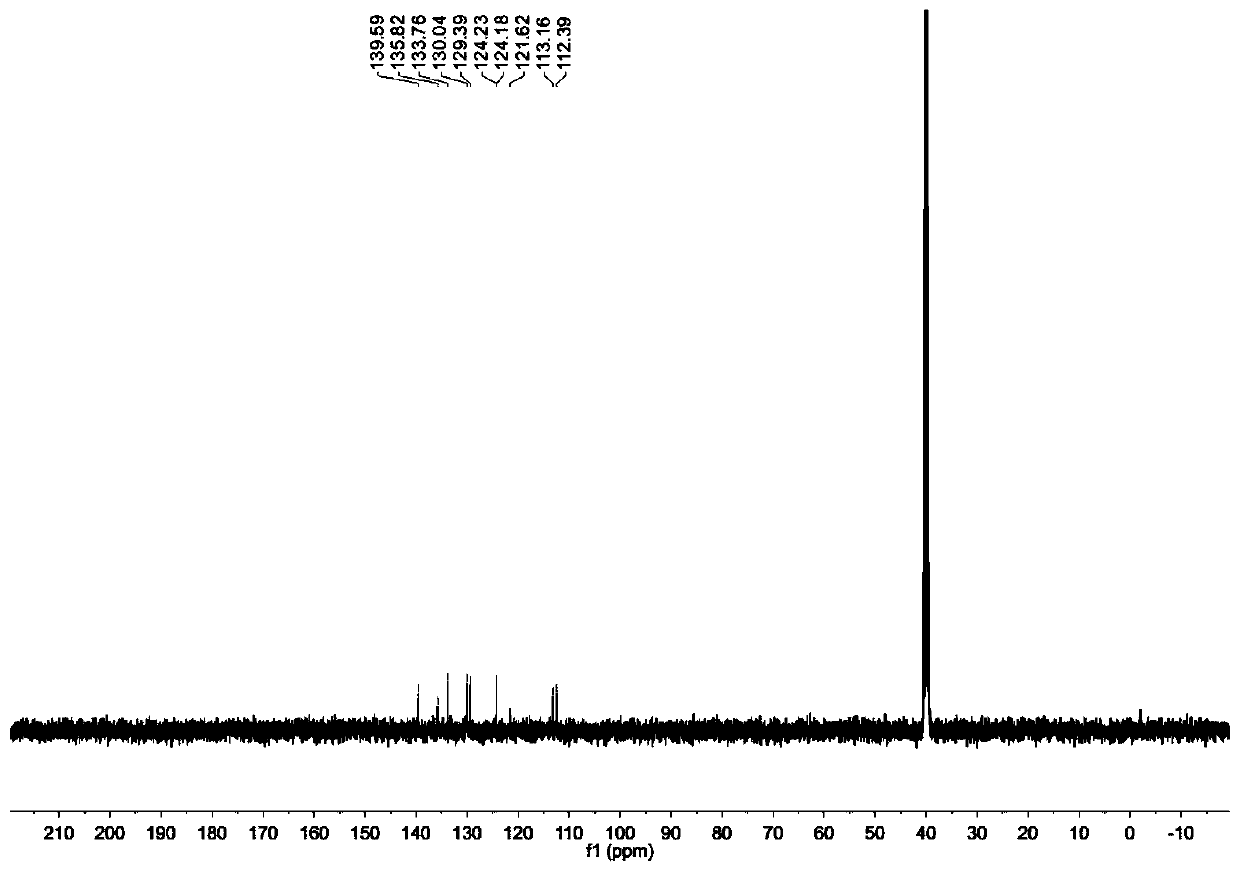

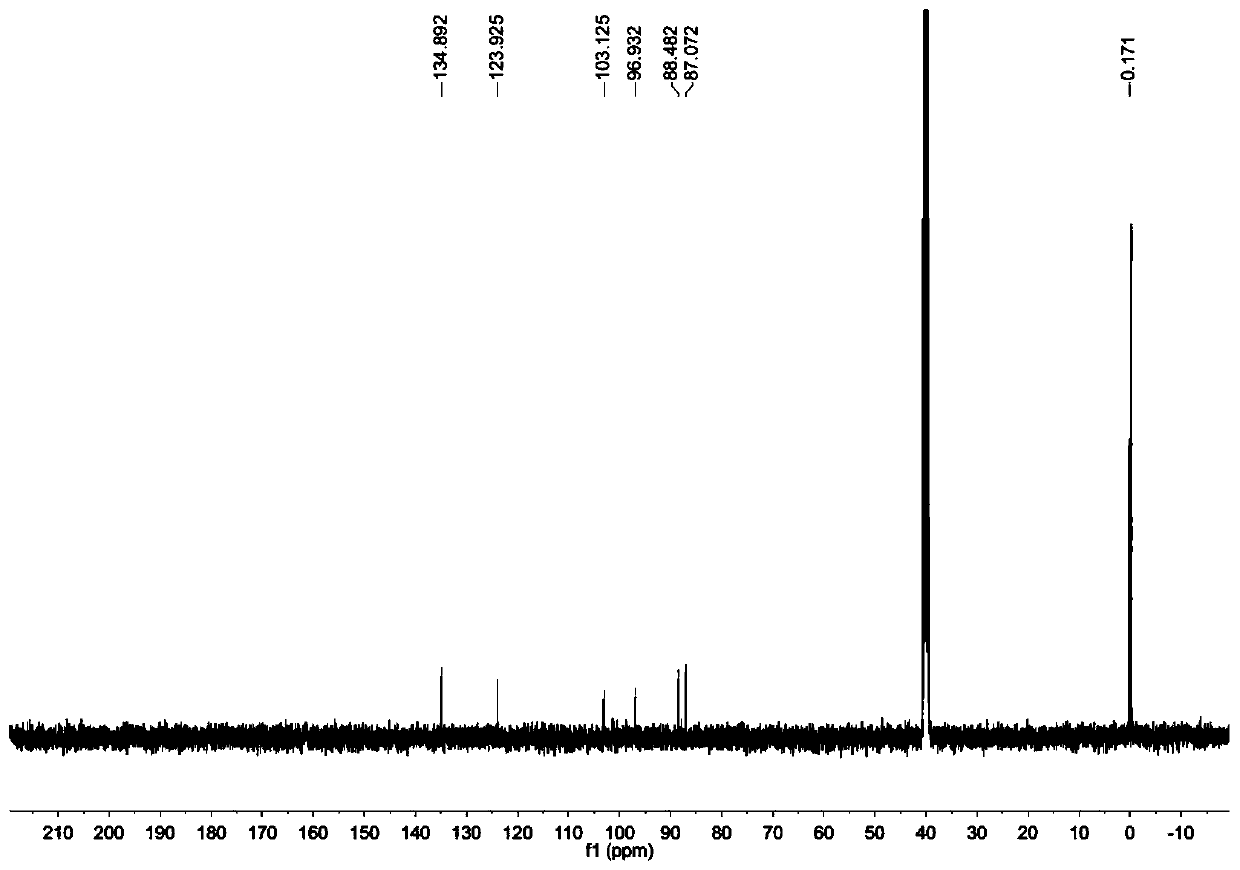

Conjugated microporous polymer, and preparation method and application thereof

ActiveCN110016126ANovel structureImprove toleranceOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsPalladium catalystP-Aminophenol

The invention discloses a conjugated microporous polymer, and a preparation method and application thereof. The preparation method of the conjugated microporous polymer comprises the following steps:under the atmosphere of argon or nitrogen, mixing a compound II, a compound III, cuprous iodide and a palladium catalyst into an diisopropylamine / organic solvent mixed solution, and uniformly carryingout stirring at room temperature; carrying out ultrasonic dispersion, carrying out freezing and deoxidizing, then carrying out heating to 50-120 DEG C, and carrying out a reaction for 24-72 hours; and carrying out cooling to room temperature, and carrying out filtering, washing and drying. An ion-loaded nano-composite catalytic material is prepared by taking the conjugated microporous polymer asa carrier to load nano-silver particles. The composite catalytic material can be used for efficient catalytic reduction of industrial pollutant p-nitrophenol, and the industrial pollutant p-nitrophenol is converted into common medicines and chemical raw material p-aminophenol. In addition, the catalyst has good solvent tolerance, stability and recyclability.

Owner:SOUTH CHINA UNIV OF TECH

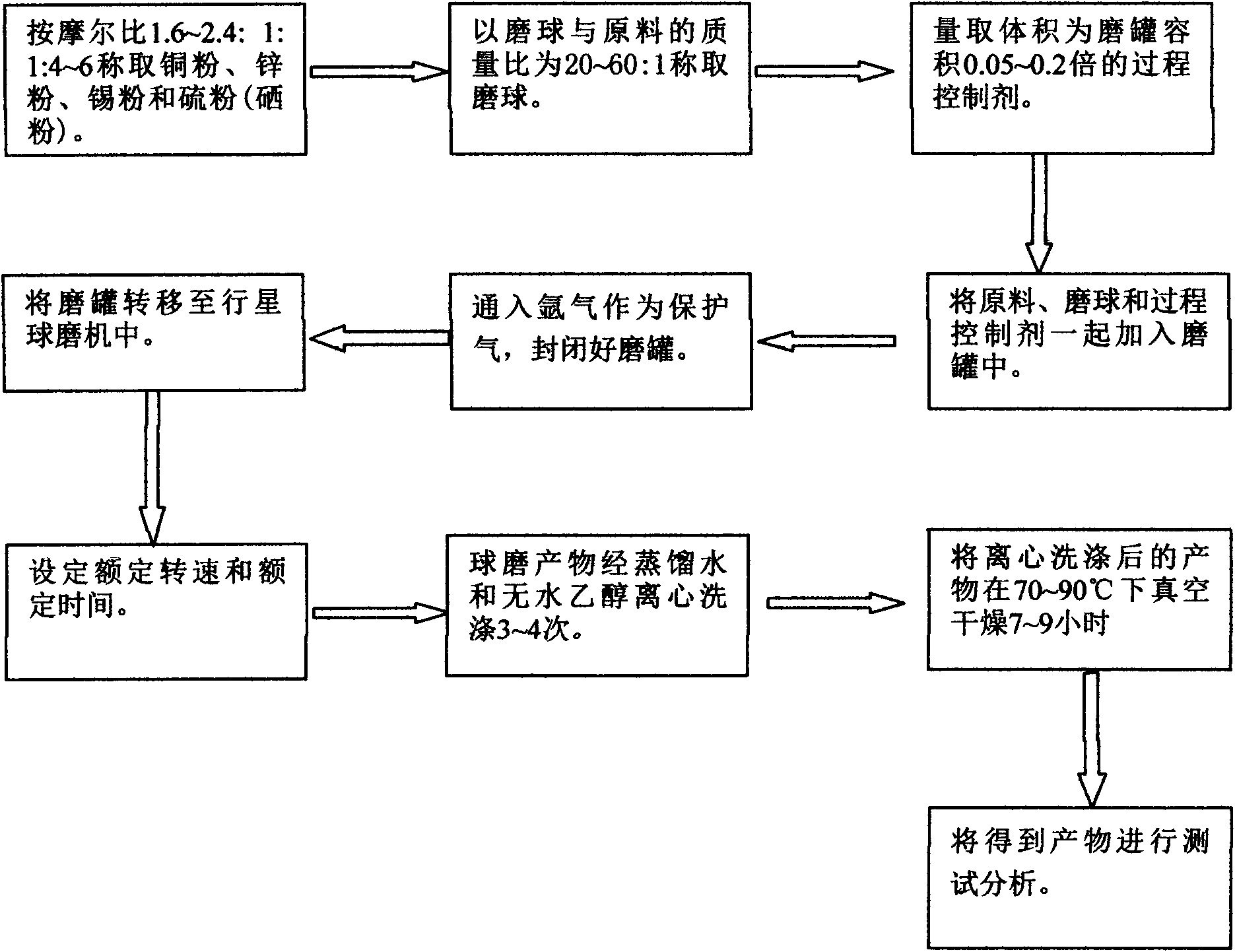

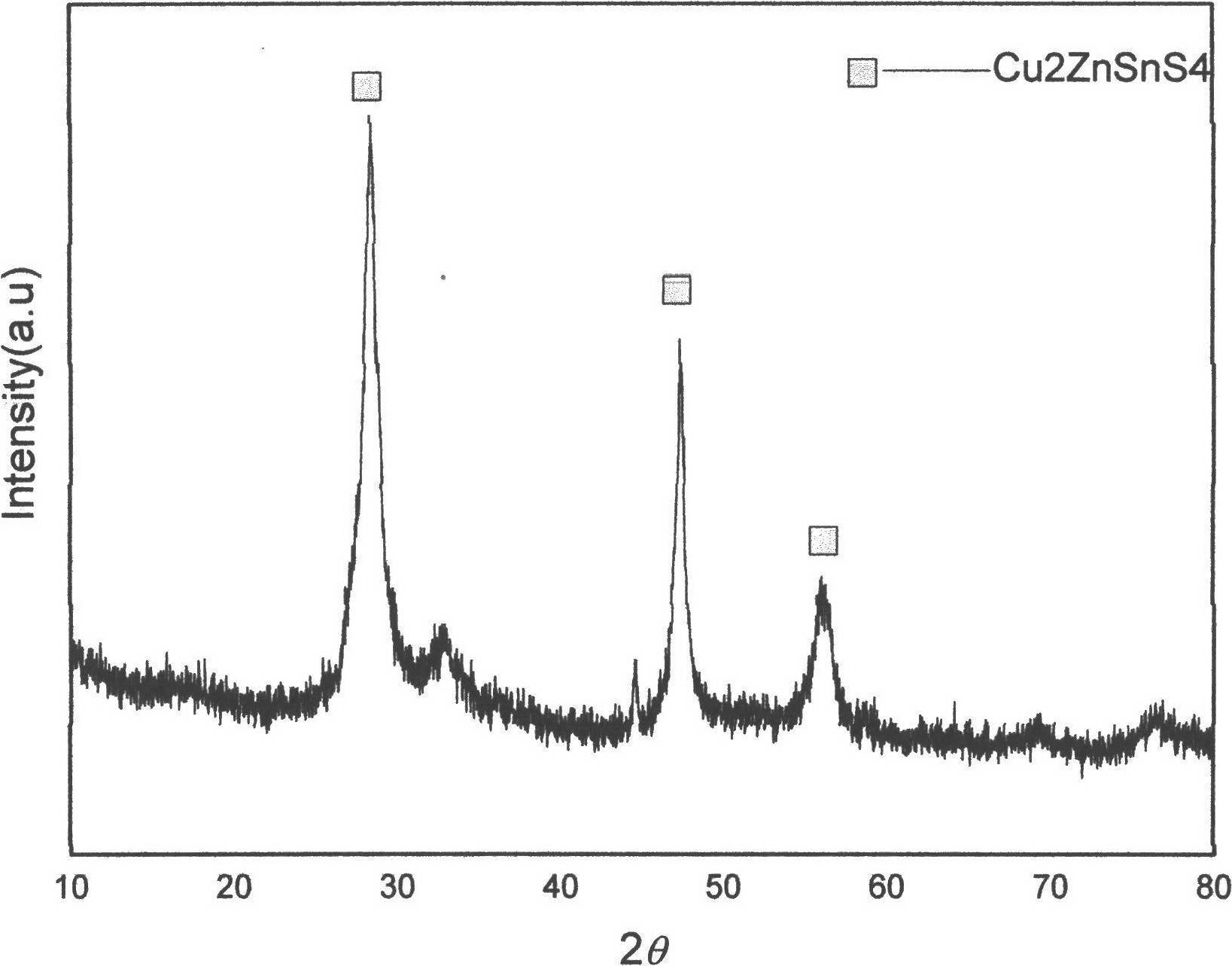

Method for preparing CZTS (Copper Zinc Tin Sulfide) (Se) series nanometer powder by low-temperature mechanical alloying

InactiveCN102642818AAvoid introducingReaction raw materials are readily availableTin compoundsSelenium/tellurium compundsIsobutanolHexamethylenediamine

The invention discloses a method for preparing CZTS (Copper Zinc Tin Sulfide) (Se) series nanometer powder by low-temperature mechanical alloying. Elementary substances Cu powder, Zn powder, Sn powder and S (Se) powder are added into a ball-milling tank according to a certain mole ratio, an alcohol and amine mixed liquor is used as a process control agent, ball milling is carried out according to a rated ratio of grinding media to material, a set rotational speed and ball milling time, and a ball-milled product is centrifugally washed and dried to obtain a target product. In the raw materials, elementary substances sulfur powder and selenium powder can be exchanged in any mole ratio; and the process control agent is the mixed liquor of alcohol and amine with the volume ratio of 1-20:1, the alcohol is one of ethanol, ethylene glycol, normal butanol, isobutanol, isoamylol, tertiary amyl alcohol and glycerol, and the amine is one of ethanediamine, iso-butylamine, diisopropylamine, hexamethylenediamine and triethylamine. The method disclosed by the invention has the advantages of easy obtainment of raw materials, pure products, low energy consumption, easy control in product shape and appearance, simple process and the like, and is suitable for industrial production.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

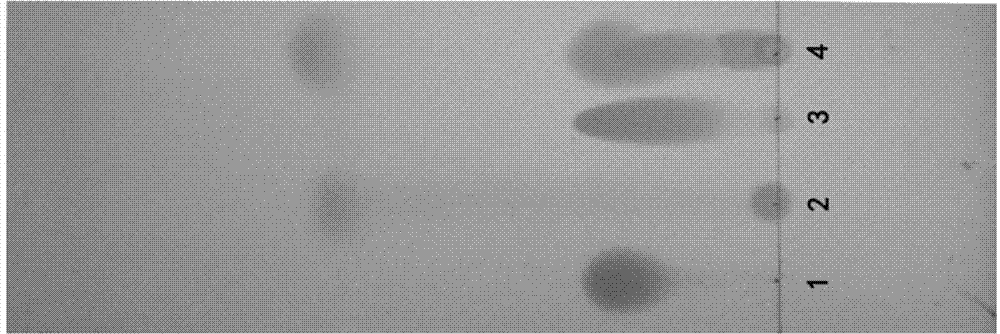

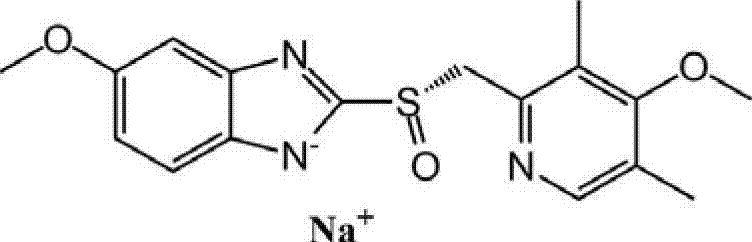

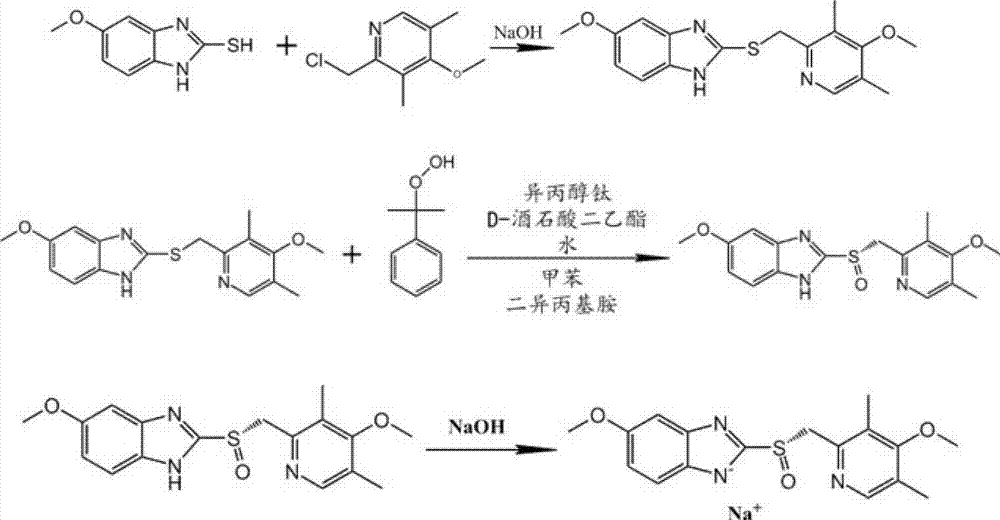

Method for synthesizing esomeprazole sodium

The invention discloses a method for synthesizing esomeprazole sodium. The method comprises the steps as follows: preparing 5-methoxy-2-(4-methoxy-3,5-dimethyl-2-pyridyl) methylthio-1H-benzimidazole, namely prochirality thioether; preparing crude esomeprazole sodium; refining the crude esomeprazole sodium; adding the prepared prochirality thioether and dried methylbenzene into D-(-) diethyl tartrate and water by stirring, adding titanium isopropylate, and stirring; and adding diisopropylamine at constant temperature, stirring, dropwise adding cumyl hydroperoxide with the mass concentration of 80%, ending the reaction, extracting, salifying, concentrating, washing and carrying out vacuum drying to obtain a crude product, and refining the crude product to obtain the esomeprazole sodium. The method is low in cost, toxicity and pollution, easy to operate, short in reaction time, high in product purity and easy for industrial production.

Owner:KAMP PHARMA

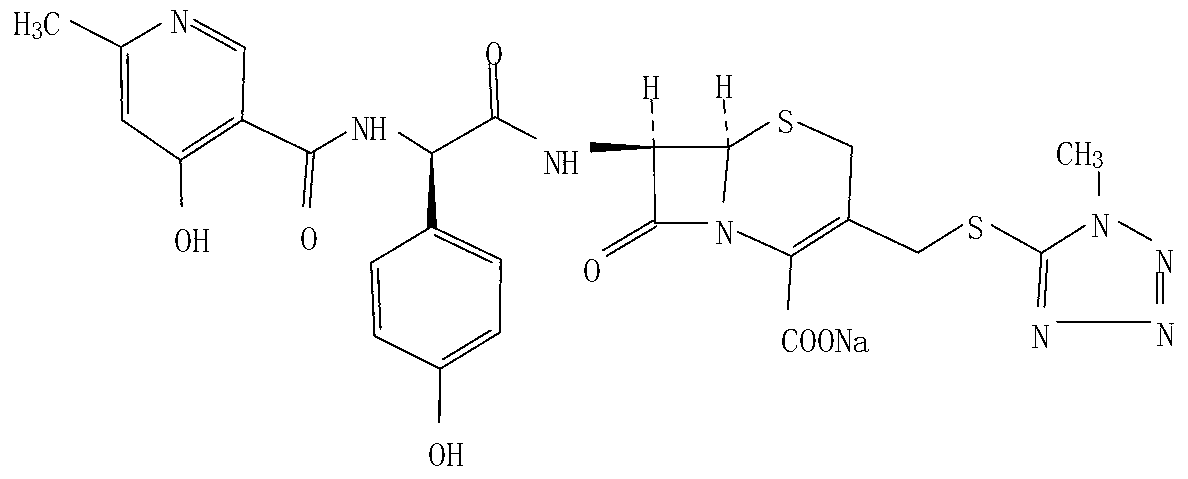

Method for preparing ampicillin sodium

InactiveCN101486717AEasy to recycleEasy to produceAntibacterial agentsOrganic chemistryManufacturing cost reductionOrganic solvent

The invention discloses a preparation method of ampicillin sodium, which comprises the steps: (a) a 15%-50% sodium iso-octoate solution is prepared; (b) ampicillin amine slat is prepared: firstly, ampicillin is dissolved in an organic solvent to prepare an organic ampicillin solution which is then dehydrated till the moisture thereof is lower than 1% and then reacts with diisopropylamine; (c) the amine salt obtained from step (b) is pressed into a crystallizing tank and added with the sodium iso-octoate solution for two times, and after crystallization the growing of crystal is carried out; and (d) after the crystallization reaction is finished, separation, washing and menstruum recovering processes are carried out. The preparation method has simple processes and easy operation, is capable of further improving the quality of the finished ampicillin sodium products and being beneficial to the recovery of the menstruum in the technical system, and can effectively reduce the production costs simultaneously.

Owner:NORTH CHINA PHARMA COMPANY

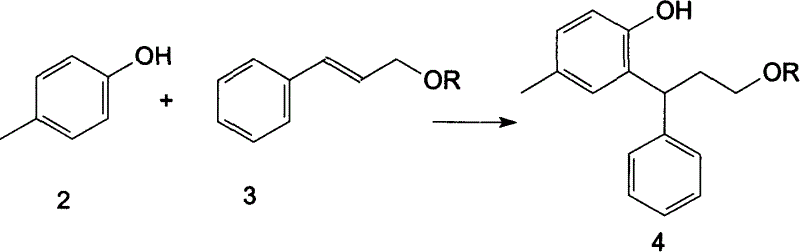

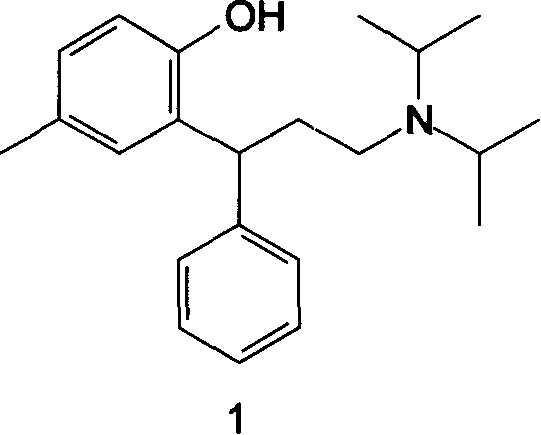

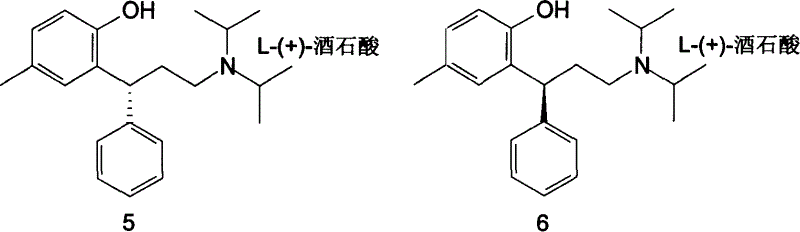

Method for preparing Tolterodine and tartrate

ActiveCN1626504AGood curative effectMild reaction conditionsOrganic compound preparationAmino-hyroxy compound preparationAlcoholOrganic solvent

A process for preparing Tuoteluoding and its tartrate includes condensation reaction between anti-styryl alcohol ester and methylphenol, direct alkalizing, extracting in organic solvent, vacuum distilling to remove solvent, purifying to obtain Tuoteluoding, condensation reaction on diisopropylamine, reacting on L-(+) tartaric acid to become salt, splitting it into (L-(+)-tartrate-R-Tuoteluoding) and (L-(+)-tartrate-S-Tuoteluoding), reaction of L-(+)-tartrate-S-Tuoteluoding on alkali, butyl lithium, or magnesium isopropyl bromide, and reacting no tartaric acid to obtain L-(+)-tartrate-R-Tuoteluoding.

Owner:LUNAN PHARMA GROUP CORPORATION

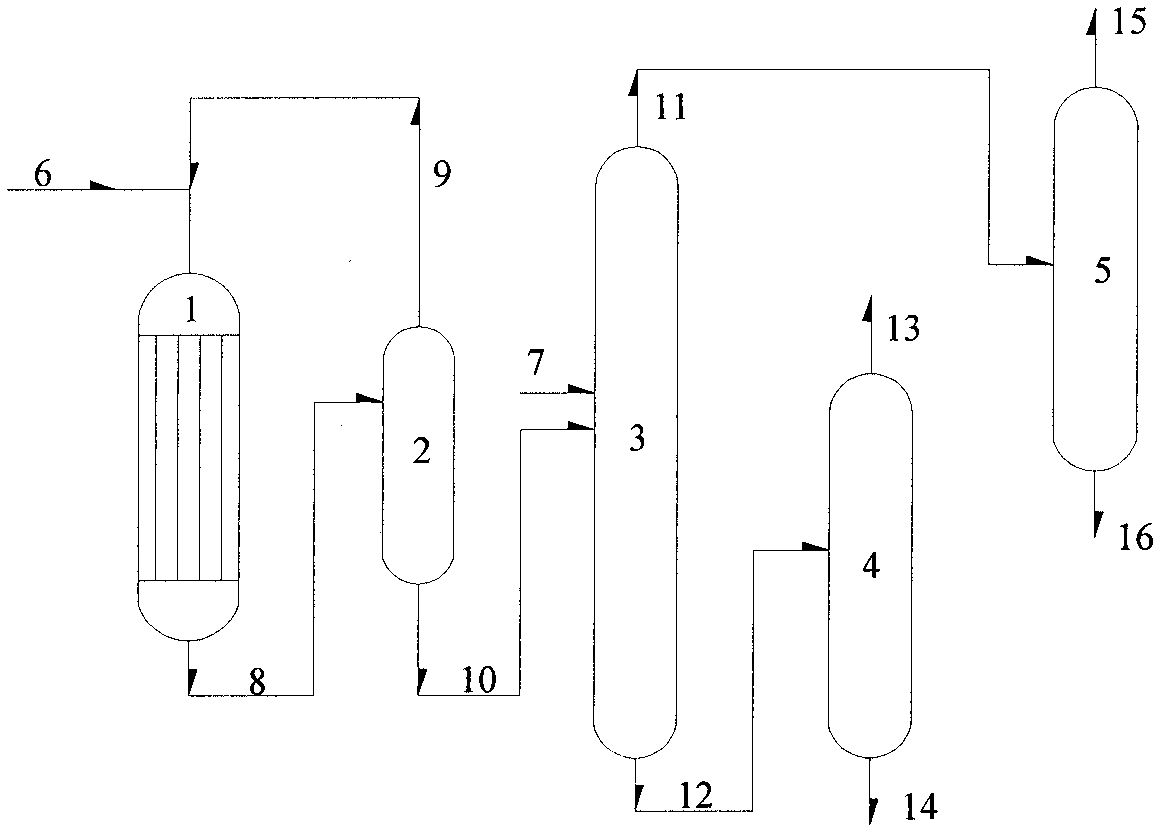

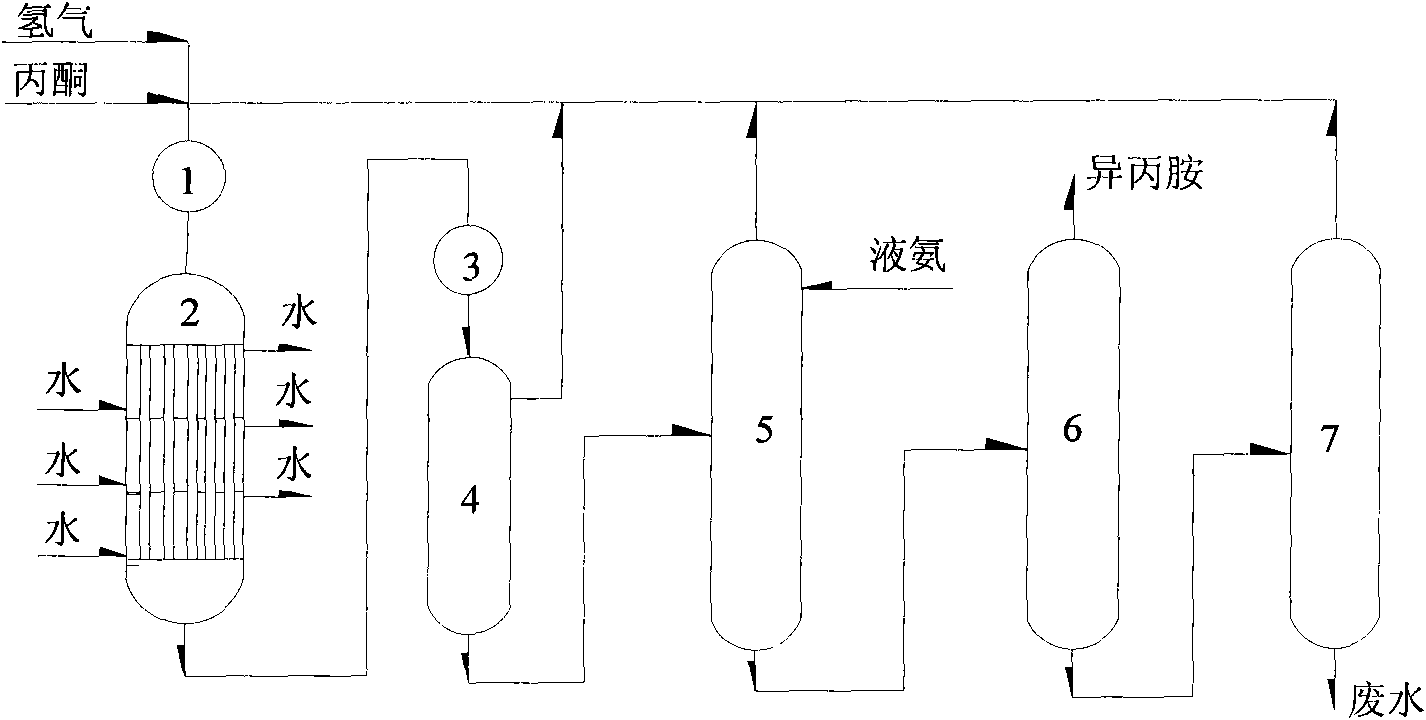

Method for producing isopropylamine

ActiveCN101684073AReduce heatReduce energy costsAmino compound purification/separationPreparation by reductive alkylationReaction temperatureEconomic benefits

Owner:CHINA PETROLEUM & CHEM CORP +1

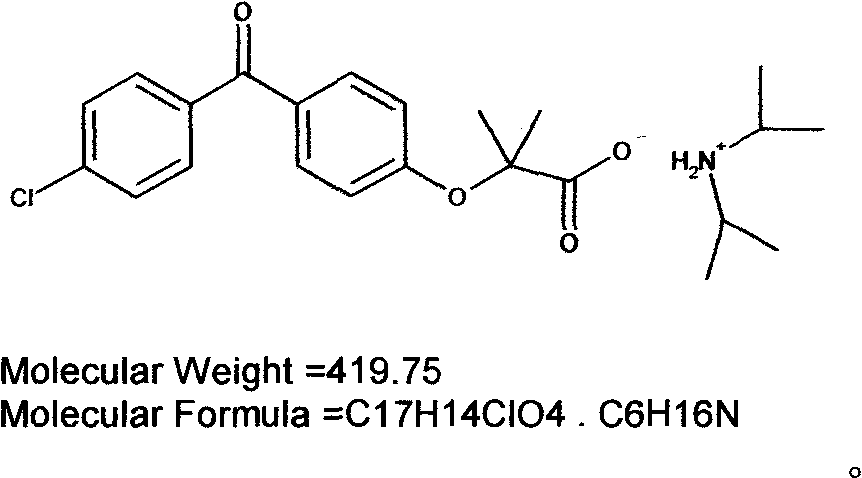

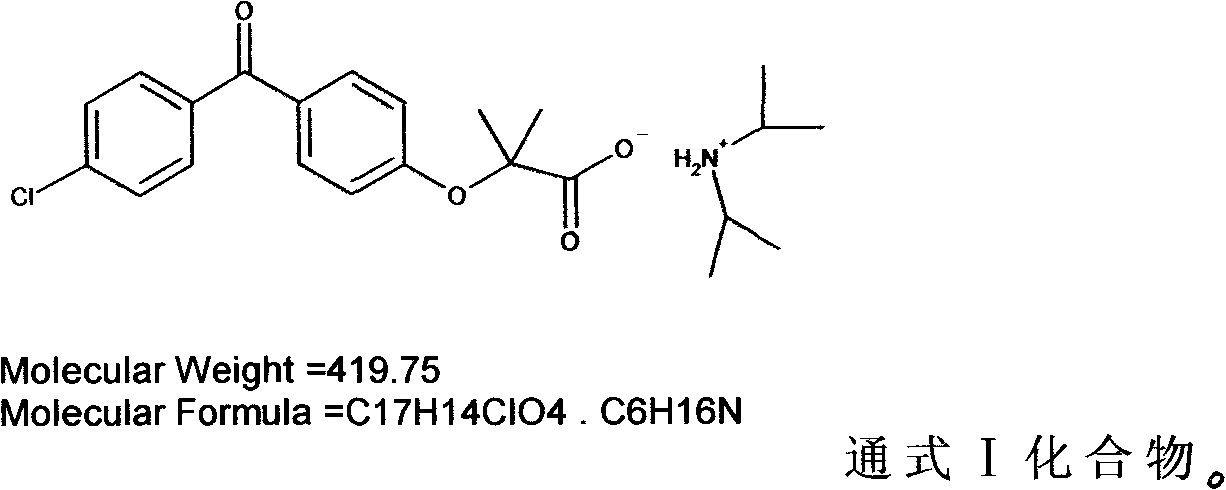

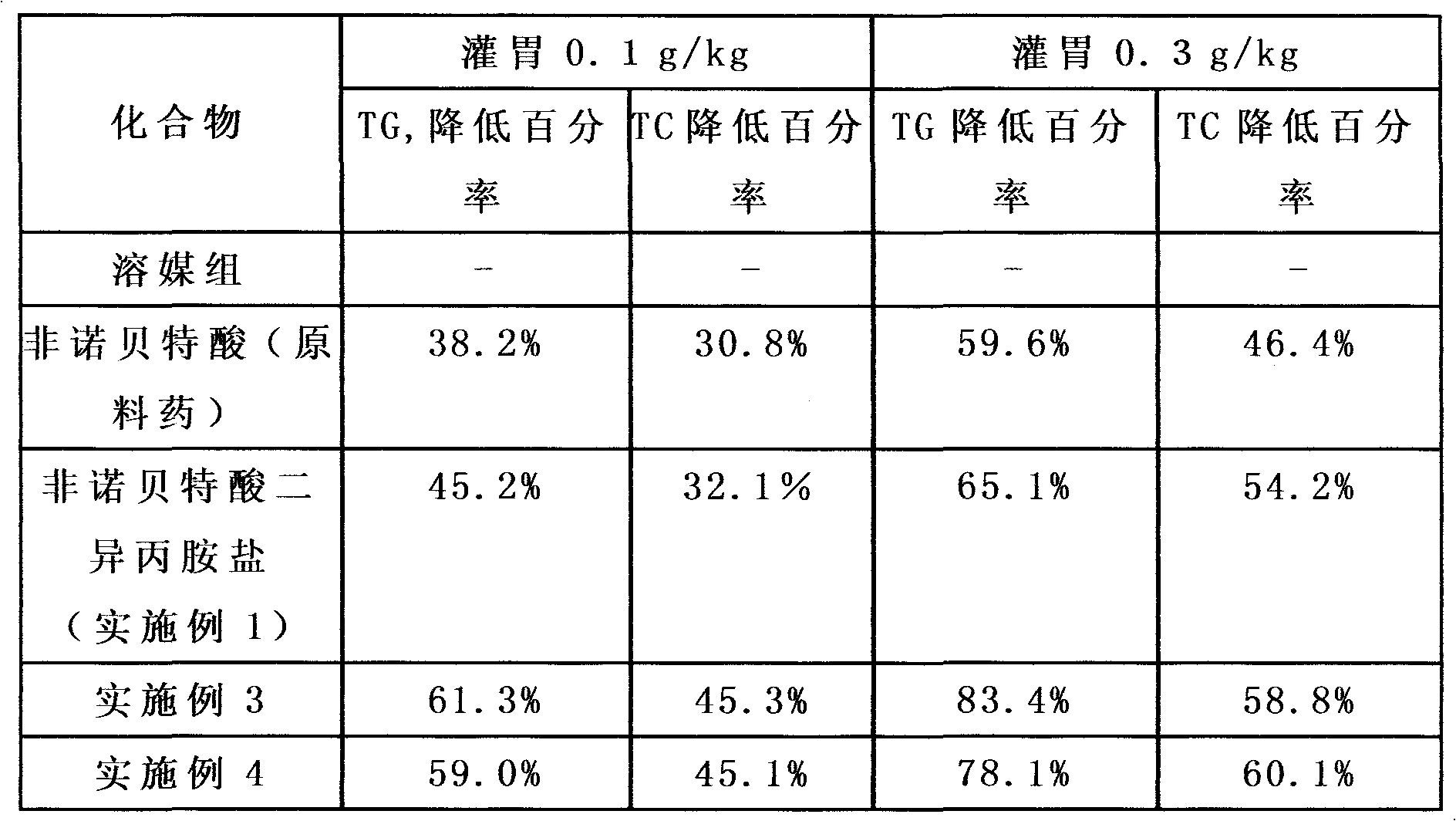

Diisopropylamine fenofibrate, preparation method of same, medicinal composition and use of same

InactiveCN101823956AReduce oxidationReduce storageOrganic active ingredientsMetabolism disorderSolubilitySide effect

The invention discloses a diisopropylamine fenofibrate, a preparation method of the same, a medicinal composition and use of the same, relating to the field of medicaments for lowering blood fat and treating fatty liver. The problems that fenofibric acid products is poor in water solubility, has toxic and side effects and the like in the prior art are solved. A product of the invention is obtained through the following steps of: adding a fenofibric acid and diisopropylamine into a solvent, heating to 35-70 DEG C, cooling, separating out a solid, pumping a filtrate, washing the solid with ether, and drying to obtain a white solid which is the diisopropylamine fenofibrate. A diisopropylamine part in the invention can overcome the side effect that the fenofibric acid is heated to be converted into ammonia enzyme and blood sugar and exerts a synergetic effect of lowering the blood fat together with fenofibrate.

Owner:曹桂英

Long chain branched polylactic acid grafted by free radicals of melt and preparation method thereof

The invention relates to long-chain-branched polylactic acid grafted by free radicals of melt and a preparation method thereof. The long-chain-branched polylactic acid is prepared by the following components in parts by weight: 80-100 parts of polylactic acid (PLA), 0.1-0.5 part of diisopropylamine peroxide (DCP), 6-10 parts of pentaerythritol triacrylate (PETA) and 0.1-0.5 part of antioxidant. The peroxide DCP and PETA are added into PLA, and the obtained PLA is subjected to free-radical reaction of the melt to generate long branch chains, so that the crystallization property of the material is improved and the physical property of the material is also improved. The method has the advantages that the reaction time is short, the processing period can be shortened and more convenience is brought for industrial production of the PLA material.

Owner:HEFEI GENIUS NEW MATERIALS

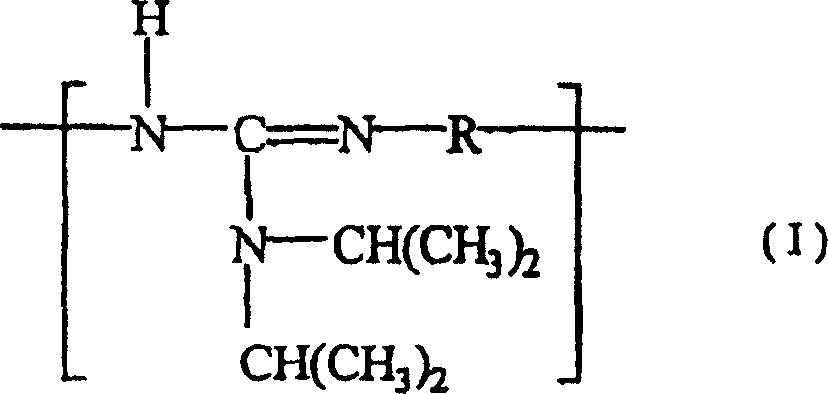

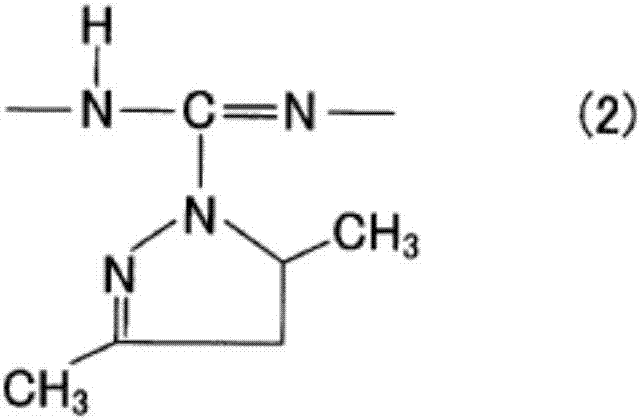

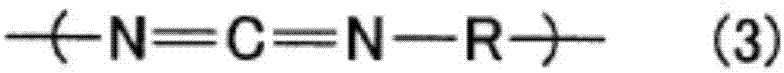

Modified polycarbodiimide composition and modified polycarbodiimide

Modified polycarbodiimide compounds and modified polycarbodiimide have character in store stability in state of solution is improved, reformed polycarbodiimide after dryness has high thermostability and caking capacity, no amine residue to etch metal are provided. Wherein, modified polycarbodiimide is obtained by using diisopropylanmine modify polycarbodiimide obtained from aromatic diisocyanate compounds.

Owner:NISSHINBO IND INC

Method and composition for removal of mercaptans from gas streams

A composition for removing mercaptan from a gas stream containing at least one acid gas in addition to a mercaptan, the composition comprising a physical and / or chemical solvent for H2S and an inclusion compound for the mercaptan. A process of treating gas stream using the composition. The inclusion compound is selected from the group consisting of, cyclodextrin, cryptand, calixarene. cucurbituril. The chemical solvent may be monoethanolamine (MEA), diethanolamine (DEA), triethanolamine (TEA, diisopropylamine (DIPA), diglycolamine (DGA) and methyldiethanolamine (MDEA). Examples of useful physical solvents include cyclotetramethylene sulfone (sulfolane) and its derivatives, aliphatic acid amides, NMP (n-methylpyrrolidone), N-alkylated pyrrolidones and corresponding piperidone methanol and mixtures of dialkethers of polyethylene glycols. The method copirses scrubbing preferably the natural gas with an aqueous solution comprising the above compounds followed by a stripping regeneration step.

Owner:DOW GLOBAL TECH LLC

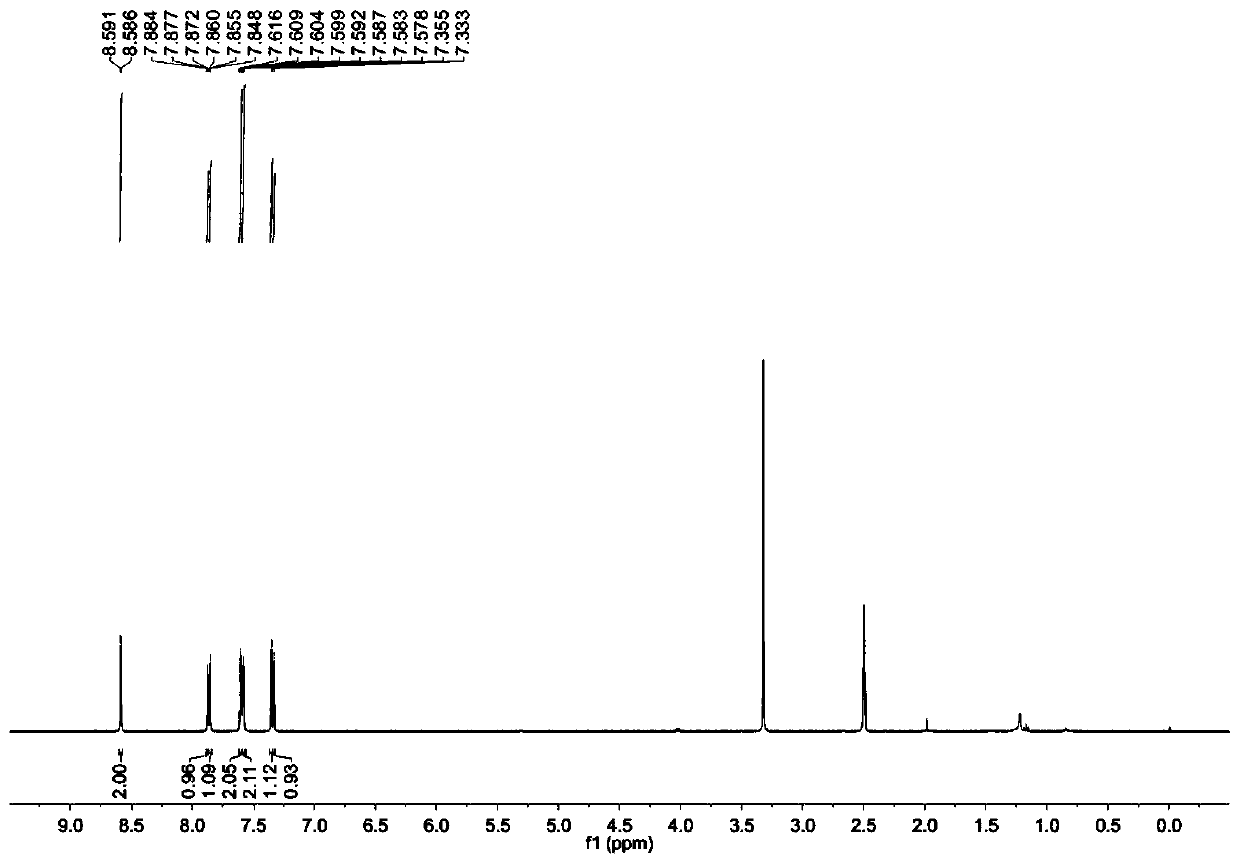

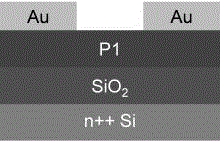

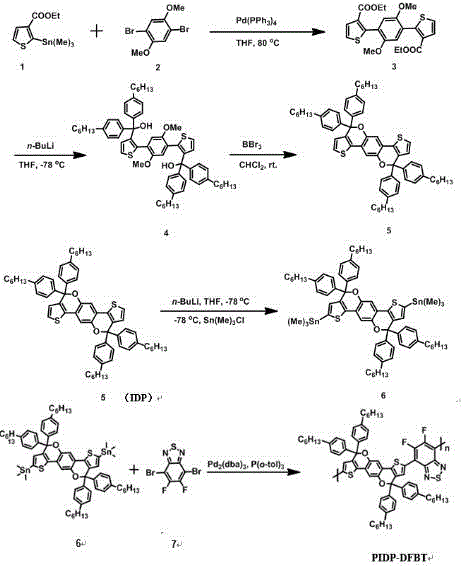

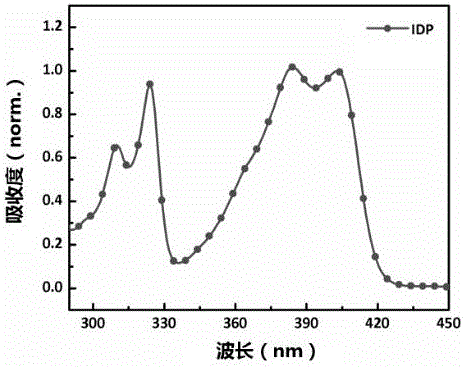

Organic field effect transistor material based on oxa-condensed ring, and synthetic method and application thereof

ActiveCN106749318AImprove solubilityImprove mobilityOrganic chemistrySolid-state devicesSolubilityTrimethyltin chloride

Owner:SUZHOU JOYSUN ADVANCED MATERIALS CO LTD

Method for crystallizing and producing cefpiramide sodium crystals

The invention discloses a method for crystallizing and producing cefpiramide sodium crystals. The method comprises the steps that: (a) cefpiramide acid and an transamination agent are dissolved in a solvent I, wherein the transamination agent is any one selected from triethylamine, diisopropylamine, and isopropylamine; and a temperature is controlled, and the materials are stirred until completely dissolved; (b) a salt-forming agent is added into a solvent II, wherein when the salt-forming agent is sodium ethylhexanoate, the solvent II is an acetone solvent, and when the salt-forming agent is sodium hydroxide, the solvent II is any one or a mixture of two selected from methanol and tetrahydrofuran; and the materials are stirred until completely dissolved; (c) the salt-forming agent solution is uniformly added into the solution of cefpiramide amine salt; the temperature is controlled, and crystal seeds are added; curing crystallization is carried out; acetone is added into the crystallization system for regulating the pH value of the crystallization system and for carrying out solvent-out crystallization; and filtering, washing, and drying are carried out, such that the cefpiramide sodium crystals are obtained. The method provided by the invention has the advantages of simple operation, uniform crystals, high purity, low impurity content, good stability, easy storage, and the like.

Owner:NORTH CHINA PHARMA HEBEI HUAMIN PHARMA

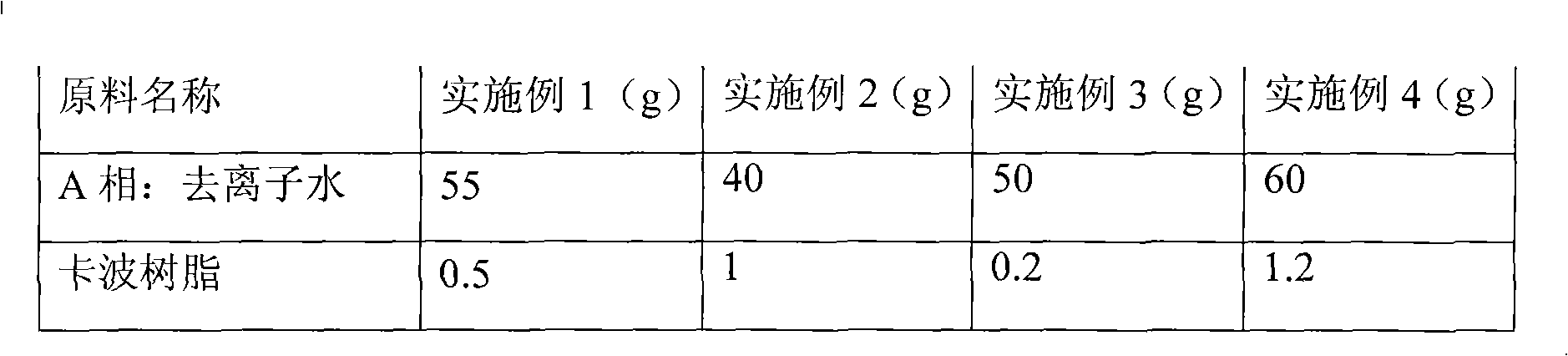

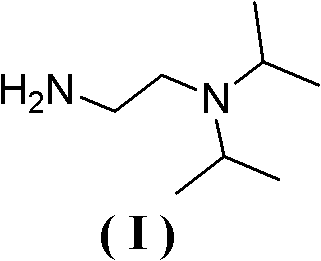

Long-acting mosquito-driving condensation dew

InactiveCN101491491AReduce divergenceImprove cool feelingCosmetic preparationsToilet preparationsAlcoholDiisopropylamine

The invention relates to a long-acting mosquito expelling gel and belongs to the field of daily chemical goods. The long-acting gel comprises an A phase, a B phase and a C phase in percentage by weight: the A phase: 40.00 to 60.00 percent of deionized water, 0.20 to 1.20 percent of carbomer resin, 0.05 to 1.00 percent of hydroxypropylmethyl cellulose and 0.01 to 1.00 percent of disodium EDTA; the B phase: 10.00 to 30.00 percent of alcohol, 10.00 to 25.00 percent of dimethyl phthalate, 0 to 10.00 percent of geranium extract and 0.01 to 1.00 percent of menthyl lactate; and the C phase: 0.10 to 1.00 percent of diisopropylamine. The long-acting mosquito expelling gel has a mild formulation, comfortable coating feel, is fresh and not sticky, has safe use and remarkable mosquito expelling effect which reaches over 10 hours and meets requirement of medicine specially needed for military.

Owner:北京如日中天科技发展有限公司

Method and composition for removal of mercaptans from gas streams

A composition for removing mercaptan from a gas stream containing at least one acid gas in addition to a mercaptan, the composition comprising a physical and / or chemical solvent for H2S and an inclusion compound for the mercaptan. A process of treating gas stream using the composition. The inclusion compound is selected from the group consisting of, cyclodextrin, cryptand, calixarene, cucurbituril. The chemical solvent may be monoethanolamine (MEA), diethanolamine (DEA), triethanolamine (TEA, diisopropylamine (DIPA), diglycolamine (DGA) and methyldiethanolamine (MDEA). Examples of useful physical solvents include cyclotetramethylene sulfone (sulfolane) and its derivatives, aliphatic acid amides, NMP (n-methylpyrrolidone), N-alkylated pyrrolidones and corresponding piperidone, methanol and mixtures of dialkethers of polyethylene glycols. The method comprises scrubbing preferably the natural gas with an aqueous solution comprising the above compounds followed by a stripping regeneration step.

Owner:DOW GLOBAL TECH LLC

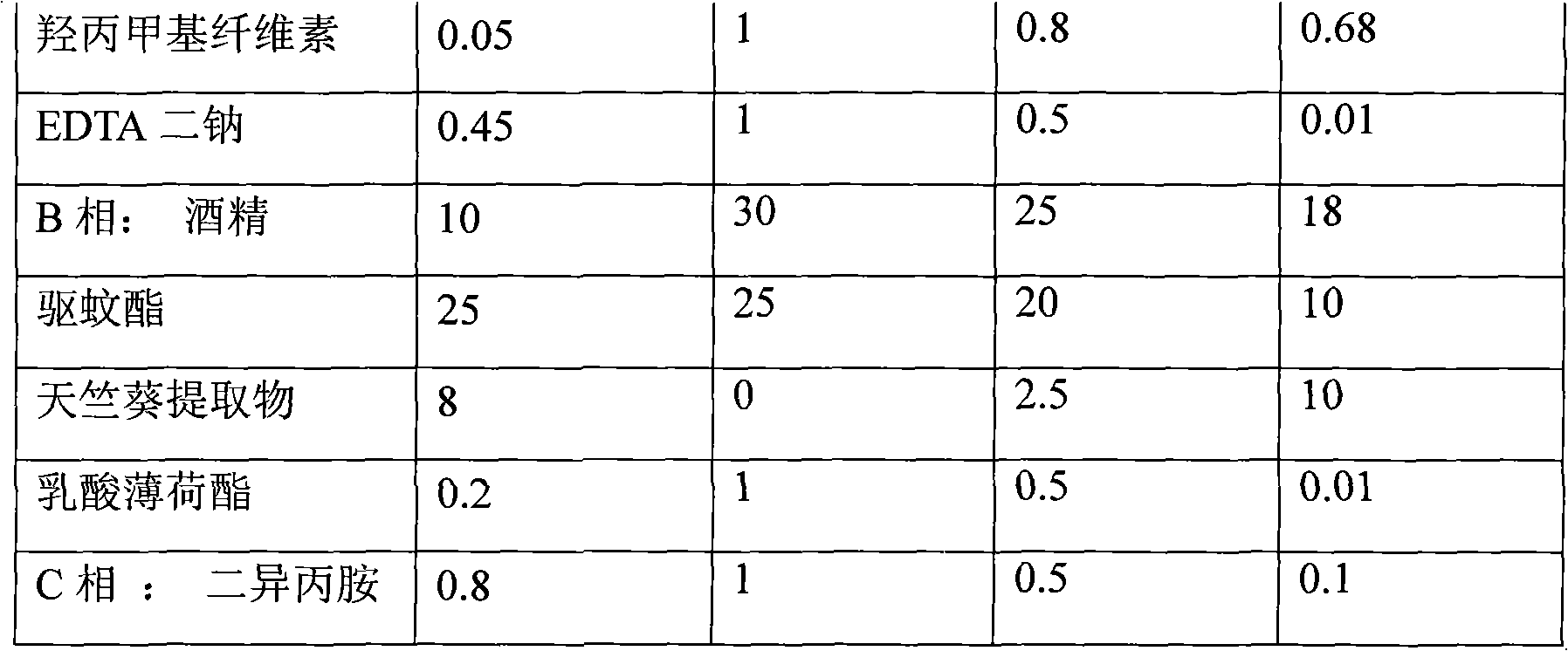

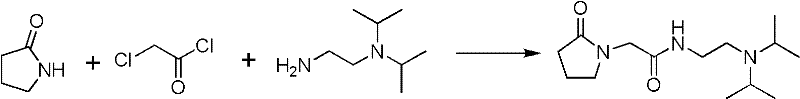

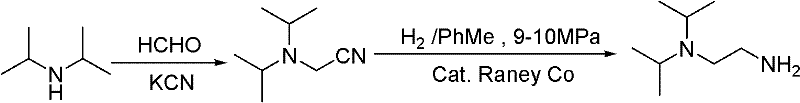

Synthesis method of N,N-diisopropyl quadrol

ActiveCN102249928ARaw materials are cheap and easy to getMild reaction conditionsPreparation by rearrangement reactionsSynthesis methodsDiisopropylamine

The invention discloses a synthesis method of N,N-diisopropyl quadrol. According to the synthesis method, N,N-diisopropyl quadrol is synthesized through Michael addition and Hoffmann degradation by taking acrylamide and diisopropylamine as starting raw materials. The synthesis method has the advantages of advanced process route, reasonable process condition, cheap and available raw materials, mild reaction conditions, high atom economy, low production cost and less three wastes, is simple and safe to operate, is suitable for industrial production, and has a large implementation value and large social and economic benefits.

Owner:ZHEJIANG UNIV OF TECH +1

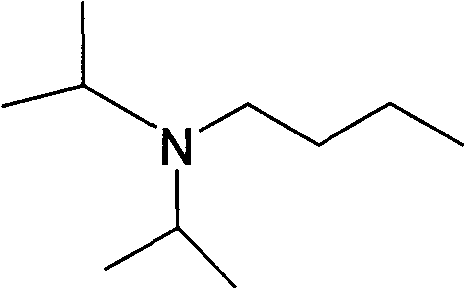

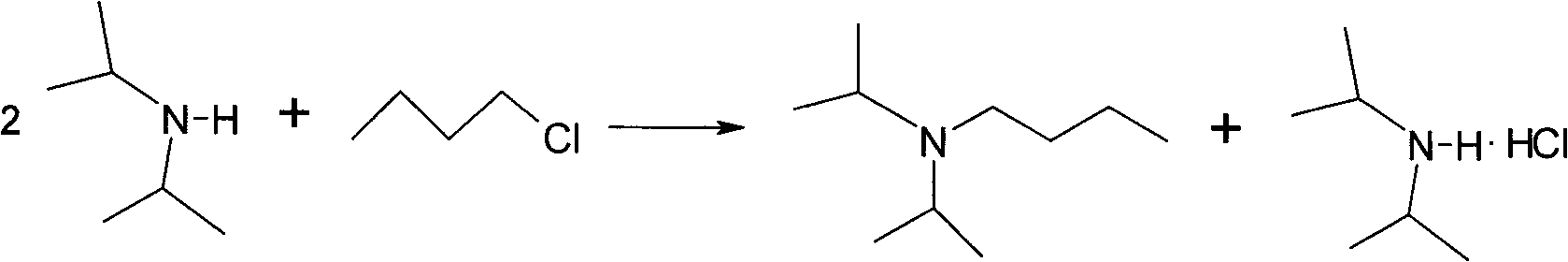

Synthesizing method of N,N-diisopropyl butylamine

InactiveCN101638370ARaw materials are cheap and easy to getReduce manufacturing costAmino preparation by functional substitutionReaction temperatureDiisopropylamine

The invention discloses a synthesizing method of N,N-diisopropyl butylamine, which comprises the following steps: using diisopropylamine and 1-chlorobutane as raw materials to carry out a reaction in a high-pressure kettle under reaction pressure of 1.05-2.0Mpa and a reaction temperature of 150-250 DEG C for 4-10 hours in a molar ratio of the diisopropylamine to the 1-chlorobutane of 2-5:1; regulating the pH of the resulting reaction solution to be 12.5-13.5; and then separating out an organic phase to rectify so as to obtain the N,N-diisopropyl butylamine. The N,N-diisopropyl butylamine synthesized by the method has the characteristics of low production cost, simple process, high yield, and the like.

Owner:ZHEJIANG UNIV

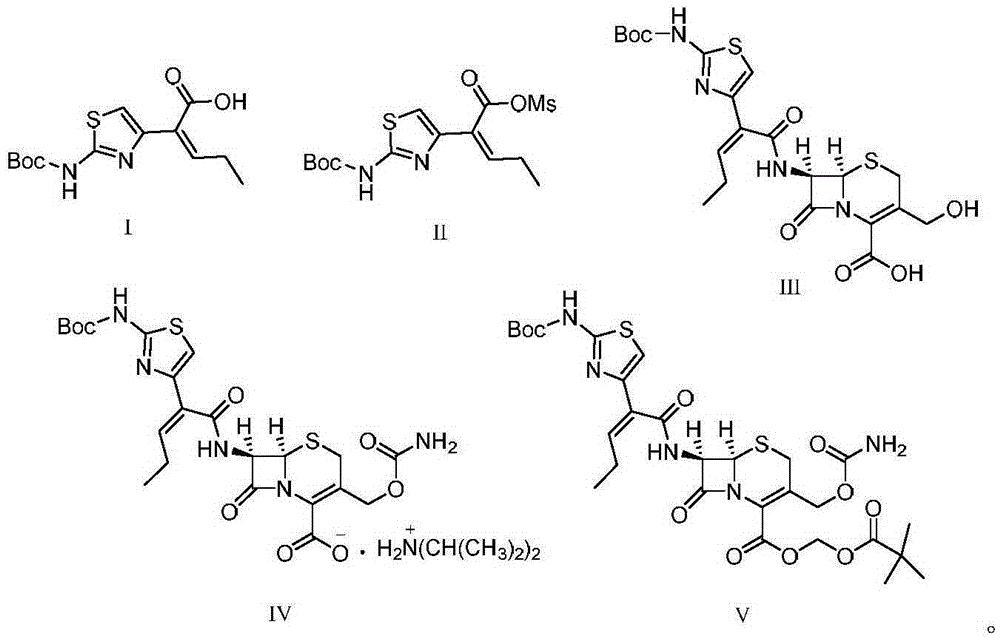

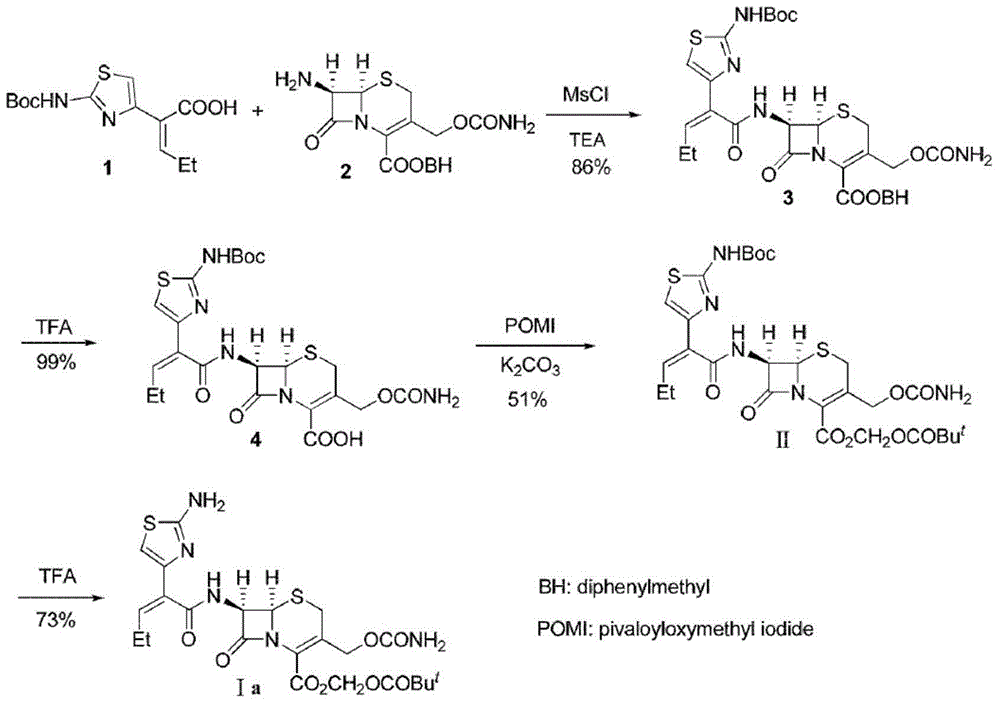

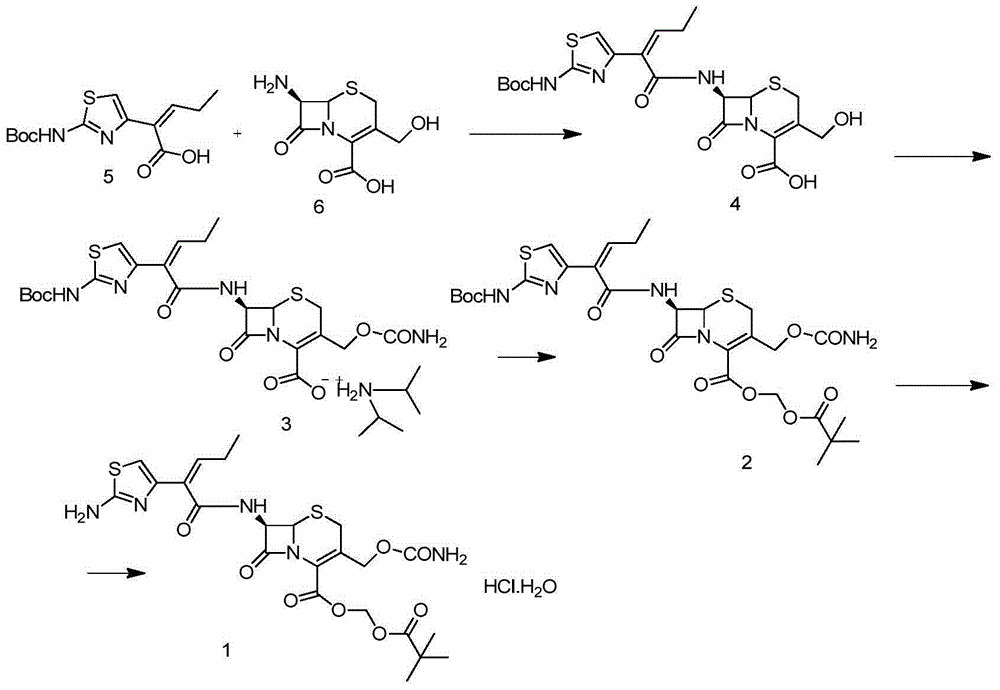

Preparation method for cefcapene pivoxil hydrochloride

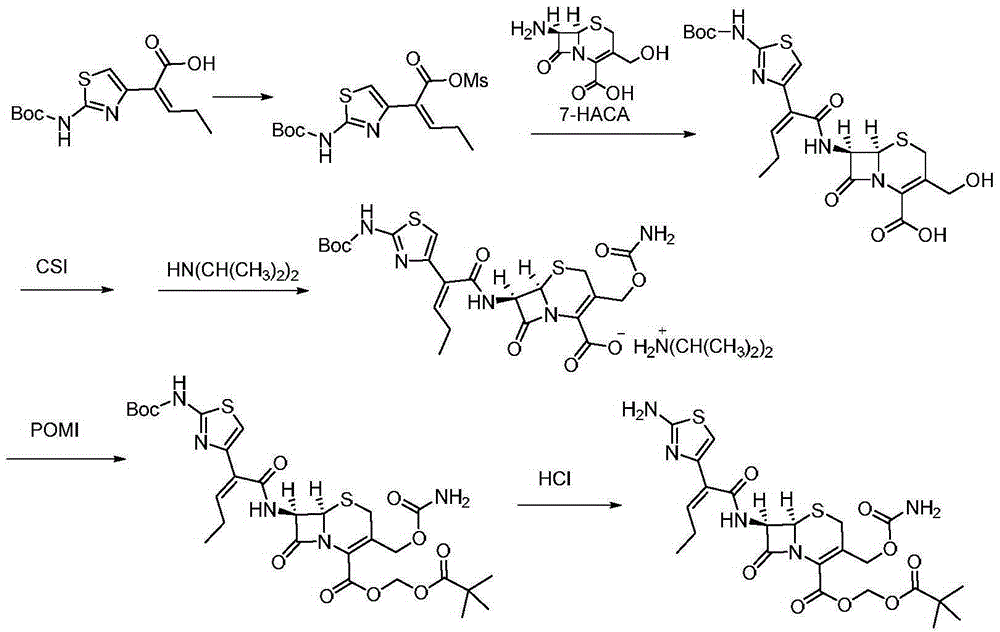

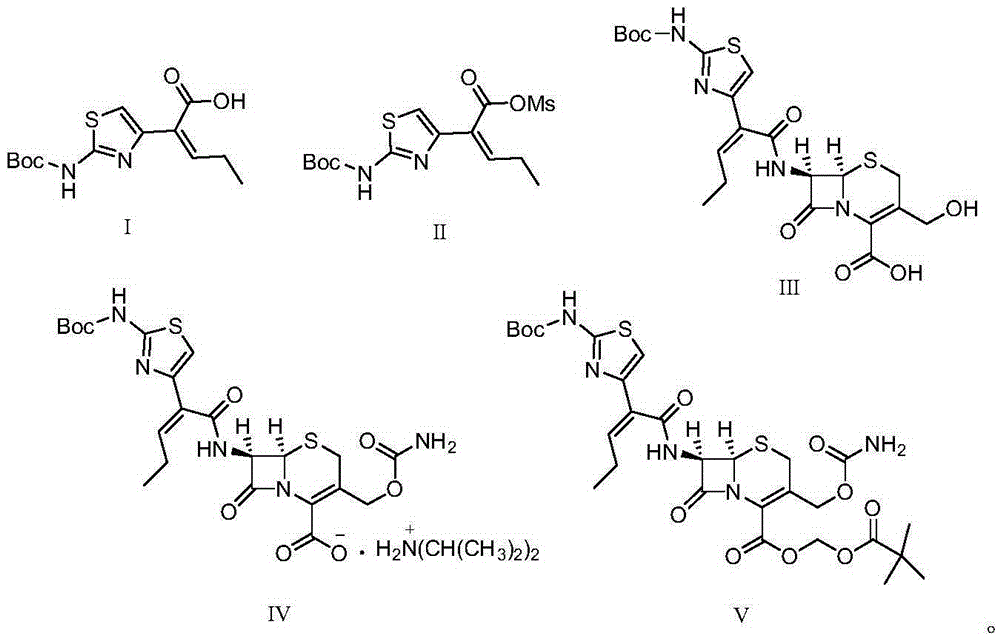

ActiveCN105254649ASimple and fast operationConducive to follow-up reactionsOrganic chemistryBulk chemical productionMethanesulfonyl chlorideCefcapene pivoxil hydrochloride

The invention discloses a preparation method for cefcapene pivoxil hydrochloride. The method comprises the following steps: (1) stirring and dissolving a compound which is shown as formula (I) in pyridine, adding methylsufonyl chloride to react to obtain a liquid which contains the compound shown as formula (II), placing the liquid at -15 DEG C to 0 DEG C for later use; (2) in the existence of proline and diisopropylamine, enabling 7-HACA and the liquid which contains the compound shown as the formula (II) to react in methyl alcohol to obtain the compound which is shown as formula (III); (3) adding diisopropylamine, enabling the compound which is shown as the formula (III) and chlorosulfonyl isocyanate to react, regulating the pH to 4 to 5, cooling the organic phase, and adding the diisopropylamine to obtain the compound which is shown as formula (IV); (4) in the existence of potassium phosphate and copper acetate, enabling the compound which is shown as the formula (IV) and iodomethyl pivalate to react in DMF (Dimethyl Formamide) to obtain the compound which is shown as formula (V); (5) removing protecting groups from the compound which is shown as the formula (V) in the methanol solution of hydrochloric acid to obtain the cefcapene pivoxil hydrochloride. According to the method, the product yield is greatly improved, and the method is suitable for industrial production.

Owner:湖北凌晟药业股份有限公司

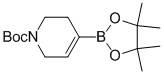

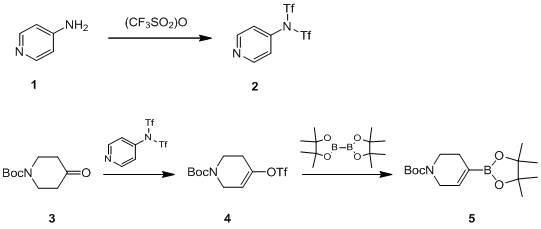

Method for synthesizing N-tert-butoxycarbonyl-1,2,5,6-tetrahydropyridine-4-boronic acid pinacol ester

InactiveCN102153579AShort process routeThe synthesis process is simpleGroup 3/13 element organic compoundsTrifluoromethanesulfonic anhydrideChemical synthesis

The invention provides a novel method for synthesizing N-tert-butoxycarbonyl-1,2,5,6-tetrahydropyridine-4-boronic acid pinacol ester, which belongs to the technical field of chemical synthesis. The method comprises the following steps of: obtaining a target product, namely the N-tert-butoxycarbonyl-1,2,5,6-tetrahydropyridine-4-boronic acid pinacol ester through a three-step reaction by taking N-(tert-butoxycarbonyl)-4-piperidone, 4-aminopyridine, trifluoromethanesulfonic anhydride, n-butyl lithium, bis(pinacolato)diboron, triethylamine, diisopropylamine and potassium acetate as raw materials,dichloromethane, tetrahydrofuran and dioxane as solvents, and [1,1'-bis(diphenylphosphino)ferrocene]dichloropalladium(II) as a catalyst; and characterizing data through liquid chromatogram, nuclear magnetic spectrum and mass spectrum. By the method, the production period is short, the synthetic cost is low, a synthetic process is safe and reliable, and a post-treatment method is simple, convenient and quick; and the yield of a product is high (51 to 58 percent) and the purity of the product is high (98.2 to 99.6 percent).

Owner:LANZHOU MINUO BIOLOGICAL TECH

Preparation method for cefcapene pivoxil hydrochloride

The invention belongs to the technical field of antibiotic synthesis, and relates to a preparation method for cefcapene pivoxil hydrochloride. The preparation method comprises the following steps: (1) reacting 7-ACA with sodium hydroxide in a solution with quaternary ammonium salt under the temperature of (-5 DEG C)-5 DEG C to generate 7-DACA; (2) adding (cefcapene pivoxil side chain acid, compound 5) into the solution containing 7-DACA, diisopropylamine and phenyltriethylammonium chloride under the temperature of 0-10 DEG C to react with a methylsufonyl chloride reaction solution under the temperature of (-15 DEG C)-0 DEG C to obtain a compound (4); reacting the compound 4 and chlorosulfonyl isocyanate to obtain a compound (3); further reacting the compound (3) with iodomethyl pivalate to obtain a compound (2); removing the protection base of the compound (2) in a hydrochloric acid methanol solution to obtain the cefcapene pivoxil hydrochloride (compound 1).

Owner:SHANDONG LUOXIN PARMACEUTICAL GROUP STOCK CO LTD

Production method of isopropylamine

ActiveCN103420846AHigh selectivitySimple methodOrganic compound preparationHydroxy compound preparationDistillationFixed bed

The invention relates to a production method of isopropylamine, and puts forward that: segmentally loading a fixed bed reactor with catalysts of different properties, loading an entrance end with a spherical nickel-base catalyst of moderate activity, loading an outlet end with a strip-type nickel-based catalyst of higher activity, under suitable reaction conditions, performing an hydrogen ammoniation reaction of acetone to produce the isopropylamine, and thus obtaining a isopropylamine product via necessary separation and refining. Through use of the production method of the isopropylamine, circulation of diisopropylamine and isopropyl alcohol can be avoided, energy consumption can be reduced, and a diisopropylamine distillation system inconvenient to operate can be omitted; and the production method of the isopropylamine is simple, feasible and easy to implement, and has considerable industrial application value and economic benefit.

Owner:ZHEJIANG XINHUA CHEM +1

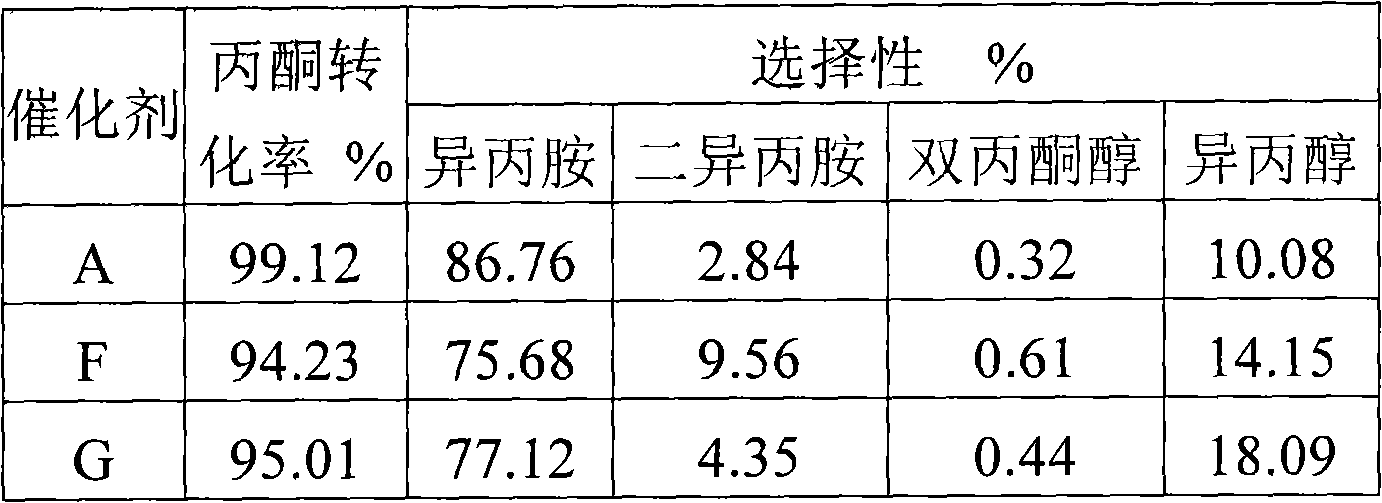

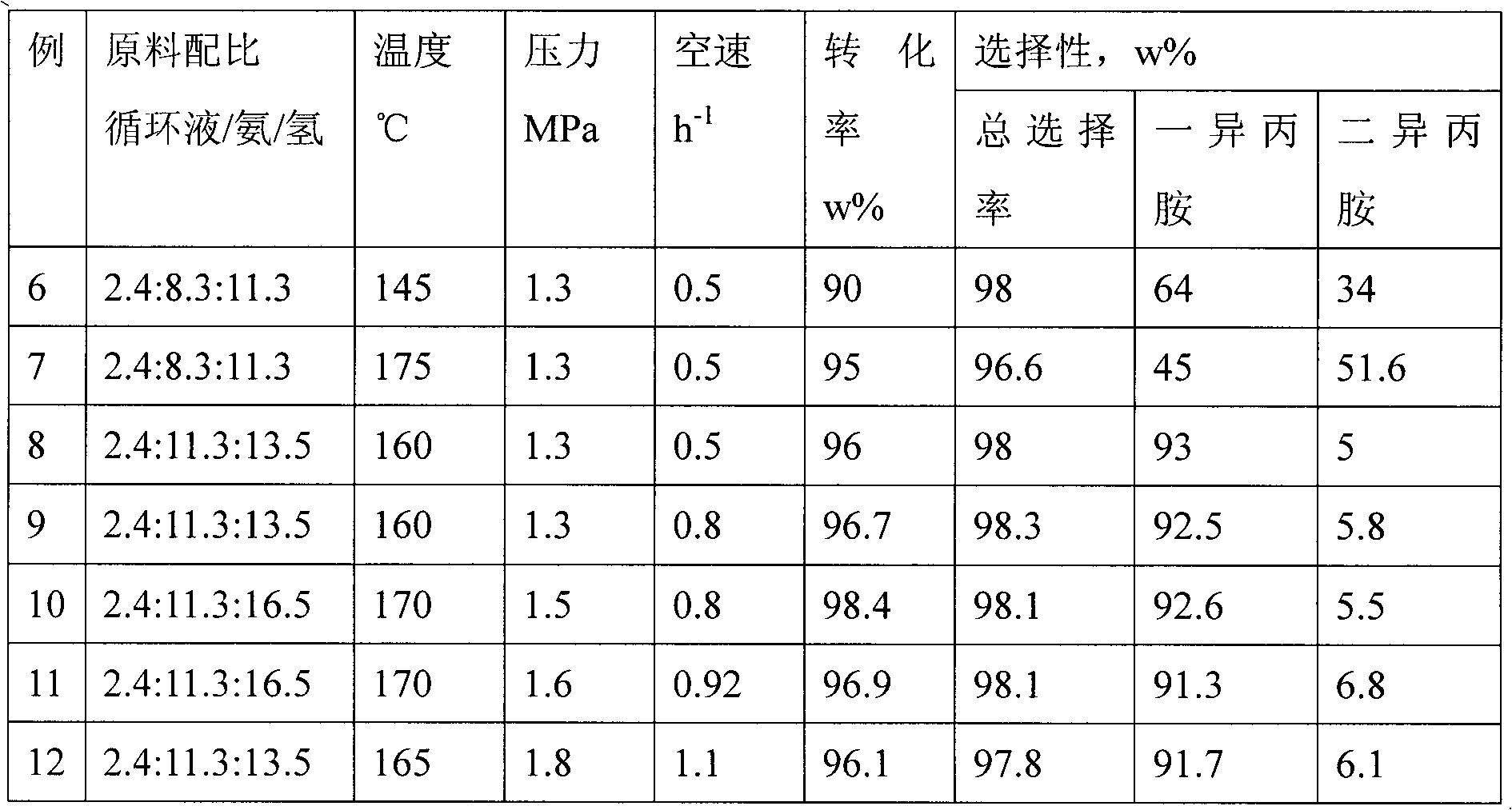

Catalyst for synthesizing isopropamide products, preparation method and application

ActiveCN102172530AHigh catalytic activityGood choicePreparation by reductive alkylationMetal/metal-oxides/metal-hydroxide catalystsMixed oxideIsopropamide

The invention relates to a catalyst for synthesizing isopropamide products by utilizing isopropamide circulation fluid, a preparation method and an application thereof. The catalyst provided by the invention is composed of mixed oxide of Ni, Co, Fe, Cu and Ru and diatomite, and the catalyst has excellent catalytic activity and selectivity and good stability. By adopting the catalyst and process method provided by the invention, the conversion rate of isopropamide circulation fluid is high, the selectivity of mono isopropylamine and diisopropylamine products is high, and the life of the catalyst is long.

Owner:ZHEJIANG XINHUA CHEM

Preparation method of catalyst for alpha-pinene hydrogenation

InactiveCN106582803AGood crystalline phaseLow costMolecular sieve catalystsMolecular sieve catalystFiltrationHydrogen pressure

The invention relates to a preparation method of a catalyst for alpha-pinene hydrogenation, and belongs to the field of chemical engineering. The method comprises the processing steps that aluminum hydroxide, orthophosphoric acid, diisopropylamine, H2O and Al2O3 are mixed and stirred and then put in a stainless steel reaction kettle, crystallization is conducted in a drying oven with the temperature of 180-210 DEG C for 18-120 hours, filtration, washing and drying are conducted, and a well-crystallized molecular sieve APO-11 is obtained after calcinations is conducted for 1-10 hours at the temperature of 550 DEG C, wherein the molar ratio of aluminum hydroxide to orthophosphoric acid to diisopropylamine is 1:1:(1-3), and the molar ratio of H2O to Al2O3 is 20:1; the prepared APO-11 is mixed with NiCl2.6H2O according to the mass ratio of 1:(1-3), pH is regulated to 7-9, then NaH2PO2-H2O is added for reduction, and Ni-P / APO-11 is prepared after the reaction is conducted for 1-12 hours, wherein the molar ratio of Ni to P is 1:(2-6); the prepared Ni-P / APO-11 is added to a high-pressure reaction kettle, the high-pressure reaction kettle is sealed, N2 replacement and H2 replacement are conducted respectively, then hydrogen pressure is raised to 2-5 Mpa, pressure maintaining and leakage detecting are conducted, the reaction is conducted for 45-180 minutes at the temperature of 120-140 DEG C, and high-selectivity pinane is obtained, wherein the mass of the Ni-P / APO-11 accounts for 3-7% of the mass of turpentine oil. According to the method, the cost of the raw materials is low, the crystallization conditions are mild, energy consumption is low, and when the prepared material is used in an alpha-pinene hydrogenation reaction, high-selectivity cis-pinane can be obtained.

Owner:KUNMING UNIV OF SCI & TECH

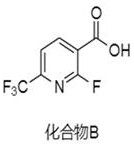

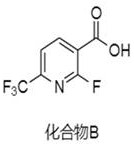

Synthesis method of (2-fluoro-6-(trifluoromethyl) pyridine-3-yl) methanol

Owner:阿里生物新材料(常州)有限公司

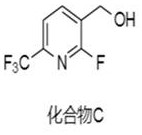

Liquid crystal compound contg. oligothiophene skeleton, preparing process thereof

InactiveCN1401732ADisplays smectic liquid crystal propertiesLiquid crystal compositionsLithiumDry ice

A liquid crystal compound containing oligothiophene skeleton is prepared through adding the tetrahydrofuran solution of DBr3T to the tetrahydrofuran solution of lithium diisopropylamine, stirring while reaction, adding dry ice and diluted hydrochloric acid, filtering to remove THF and H2O, water washing, drying, adding to 1,2-dichloroethane solution of sulfoxide chloride, reflux reaction, reaction with n-alkylamine in dichloromethane solution, removing solvent, and separating with silica gel column.

Owner:SOUTH CHINA UNIV OF TECH

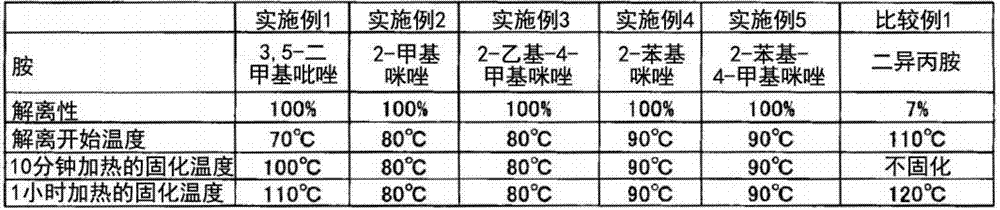

Modified polycarbodiimide compound, curing agent, and thermosetting resin composition

This modified polycarbodiimide compound is obtained by modifying a polycarbodiimide compound derived from a diisocyanate compound with an aromatic heterocyclic compound having a secondary amine nitrogen within the ring thereof. A curing agent according to the present invention contains the modified polycarbodiimide compound. As a result, it is possible to provide: a modified polycarbodiimide compound in which the dissociation of amine starts at a lower temperature compared to modified polycarbodiimide compounds obtained by modifying a polycarbodiimide compound derived from a diisocyanate compound with diisopropylamine; and a curing agent that contains the modified polycarbodiimide compound.

Owner:NISSHINBO CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com