Catalyst for synthesizing isopropamide products, preparation method and application

A catalyst, propylamine technology, applied in reductive alkylation preparation, chemical instruments and methods, physical/chemical process catalysts and other directions, can solve the problems of reducing the service life of the catalyst, the conversion rate of the ammoniation reaction is not high, affecting the activity of the catalyst, etc. , to achieve the effect of long catalyst life, high target conversion rate and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 82.24 g Ni(NO 3 ) 2 ·6H 2 O, 217.32 g Co(NO 3 ) 2 ·6H 2 O, 12.54 g Fe(NO 3 ) 3 ·6H 2 O, 13.96 g Cu(NO 3 ) 2 ·6H 2 O, 1.26 g Ru(NO 3 ) 2 ·6H 2 O was mixed with 350 milliliters of deionized water (the mass ratio of Ni / Co / Fe / Cu / Ru was 8.5:22:1:1.5:0.16), and 133.68 grams of diatomaceous earth was added and mixed with 0.3 molar concentration Na 2 CO 3 Co-precipitation by solution co-current method, control the pH value to 9.0, age for 4 hours under stirring at 75-90°C, filter the precipitate and wash it repeatedly with deionized water until it is almost neutral, and then put the washed precipitate at 120°C After drying for 6 hours, roast at 400°C for 6 hours to obtain an oxidized mixture of Ni-Co-Fe-Cu-Ru. The oxidized mixture is ground into a powder (referred to as dry material) by a ball mill, and an appropriate amount of nitric acid is added to the powder. Ionized water is used to make wet materials, the addition of nitric acid is 1.2w% of the dry materia...

Embodiment 6

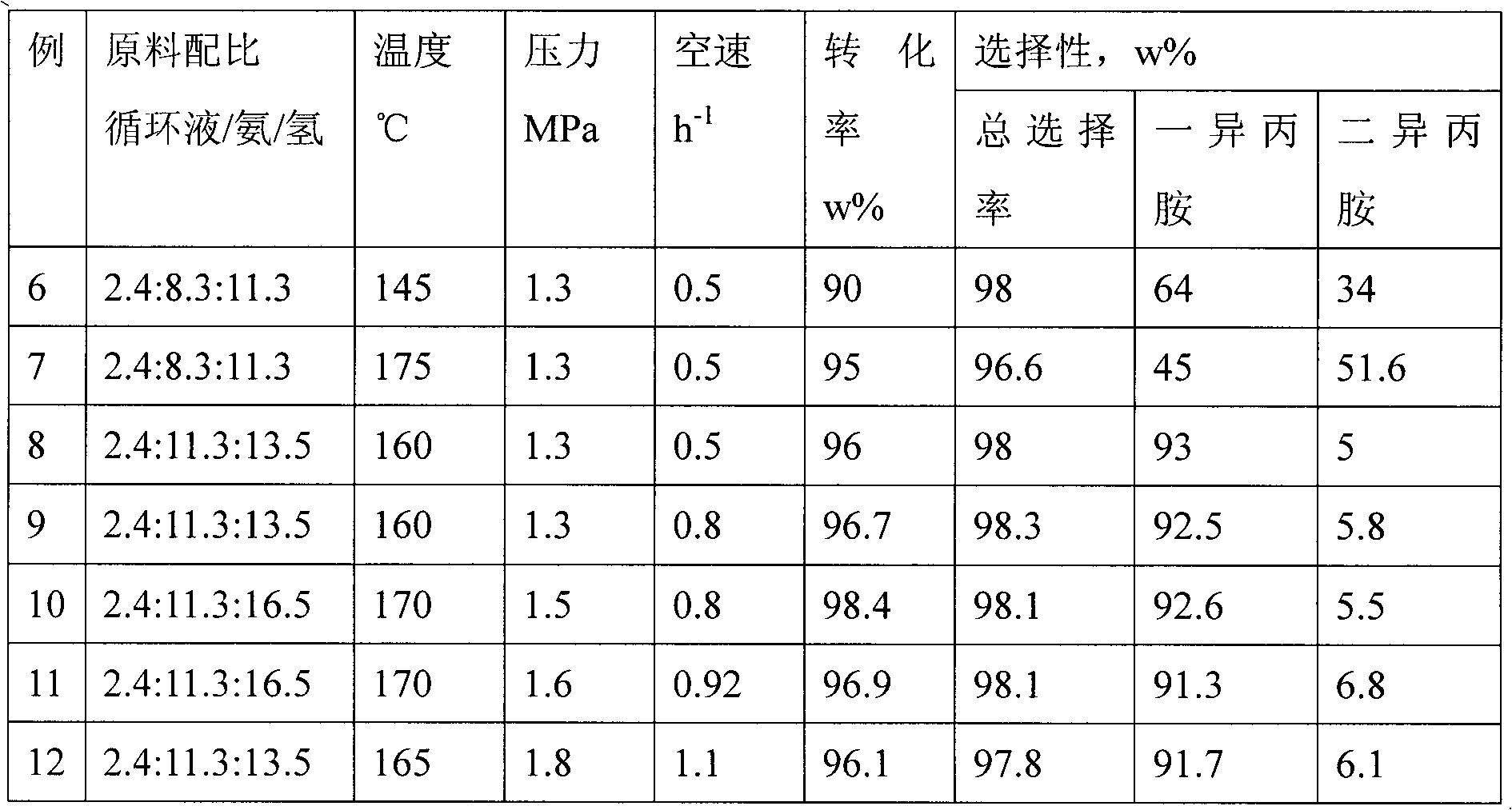

[0036] Use the catalyzer that embodiment 1-5 prepares, add 160 gram catalyzers on the reactor (reactor inner diameter 20mm, long 550mm) of small-scale continuous hydrogenation reaction device, after 8 hours with hydrogen reduction in the scope of 350-450 ℃, pass Enter the reaction raw material (isopropylamine circulation liquid: ammonia: hydrogen=2.4: 8.3: 11.3) to carry out hydrogenation amination reaction, reaction temperature 145 ℃, reaction pressure 1.3MPa, space velocity 0.5h -1 , the conversion rate of circulating fluid is 90%, and the total selectivity of mono- and diisopropylamine is 98% (wherein mono-isopropylamine is 64%, and diisopropylamine is 34%).

Embodiment 7

[0038] On the reaction device of embodiment 6, use the catalyst of embodiment 6 to carry out hydrogenation ammonification reaction, raw material feed ratio is still isopropylamine circulation liquid: ammonia: hydrogen=2.4: 8.3: 11.3, reaction temperature 175 ℃, reaction pressure 1.3MPa, air speed 0.5h -1 , the conversion rate of circulating liquid is 95%, and the total selectivity of mono- and diisopropylamine is 96.6% (wherein mono-isopropylamine is 45%, and diisopropylamine is 51.6%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com