Patents

Literature

497results about "Preparation by reductive alkylation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cycloalkyl substituted polyamines for cancer therapy and methods of synthesis therefor

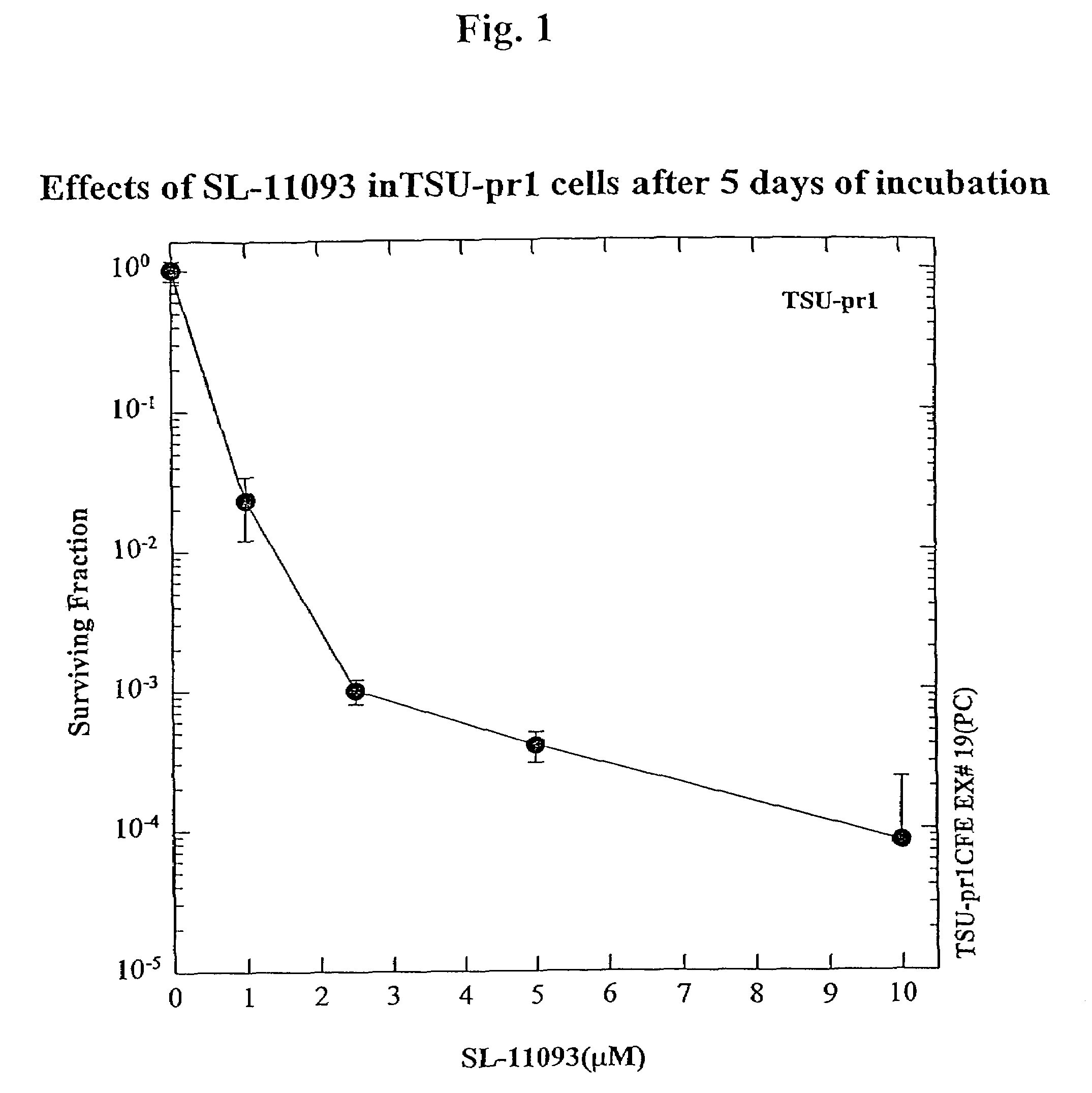

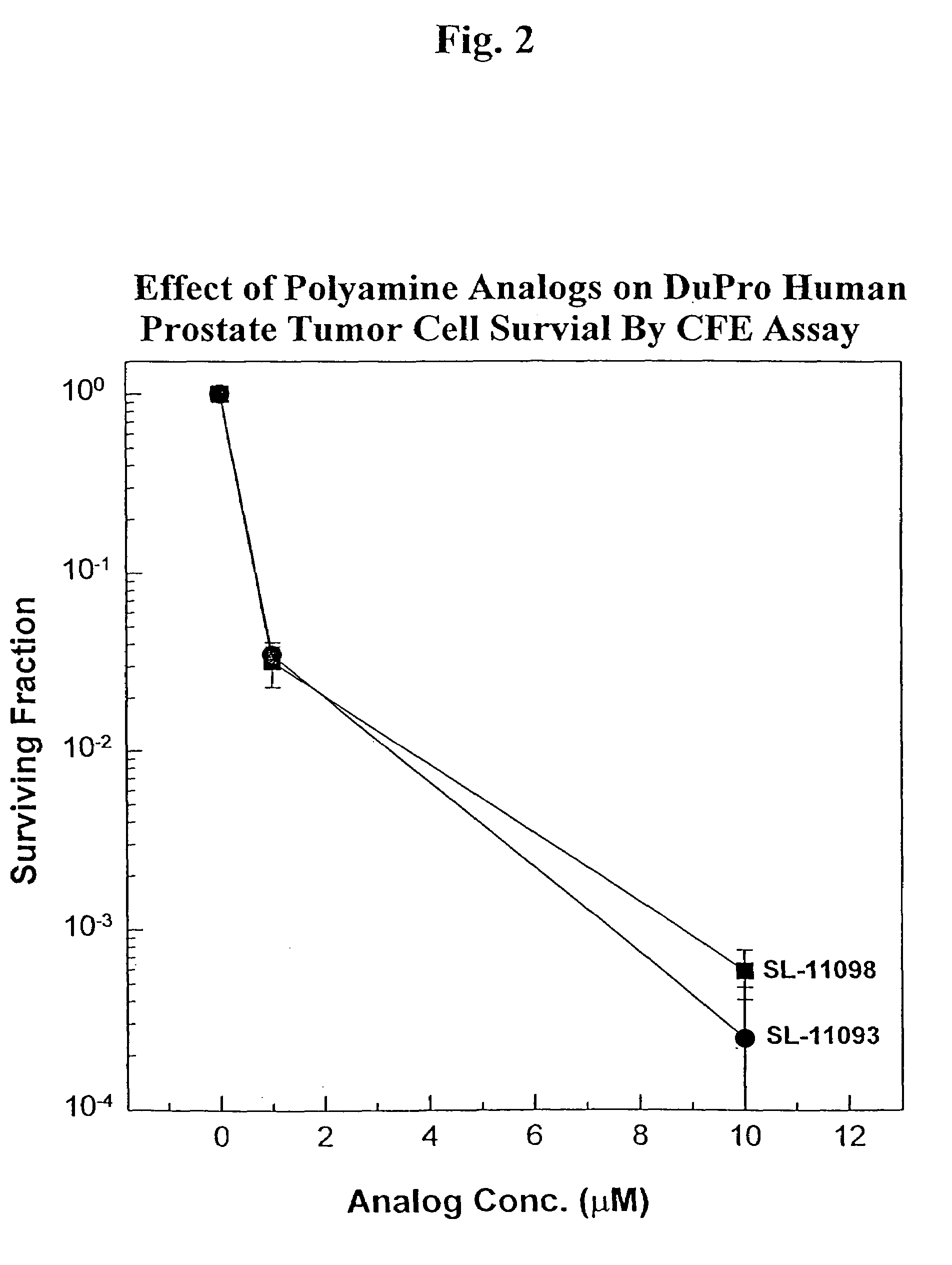

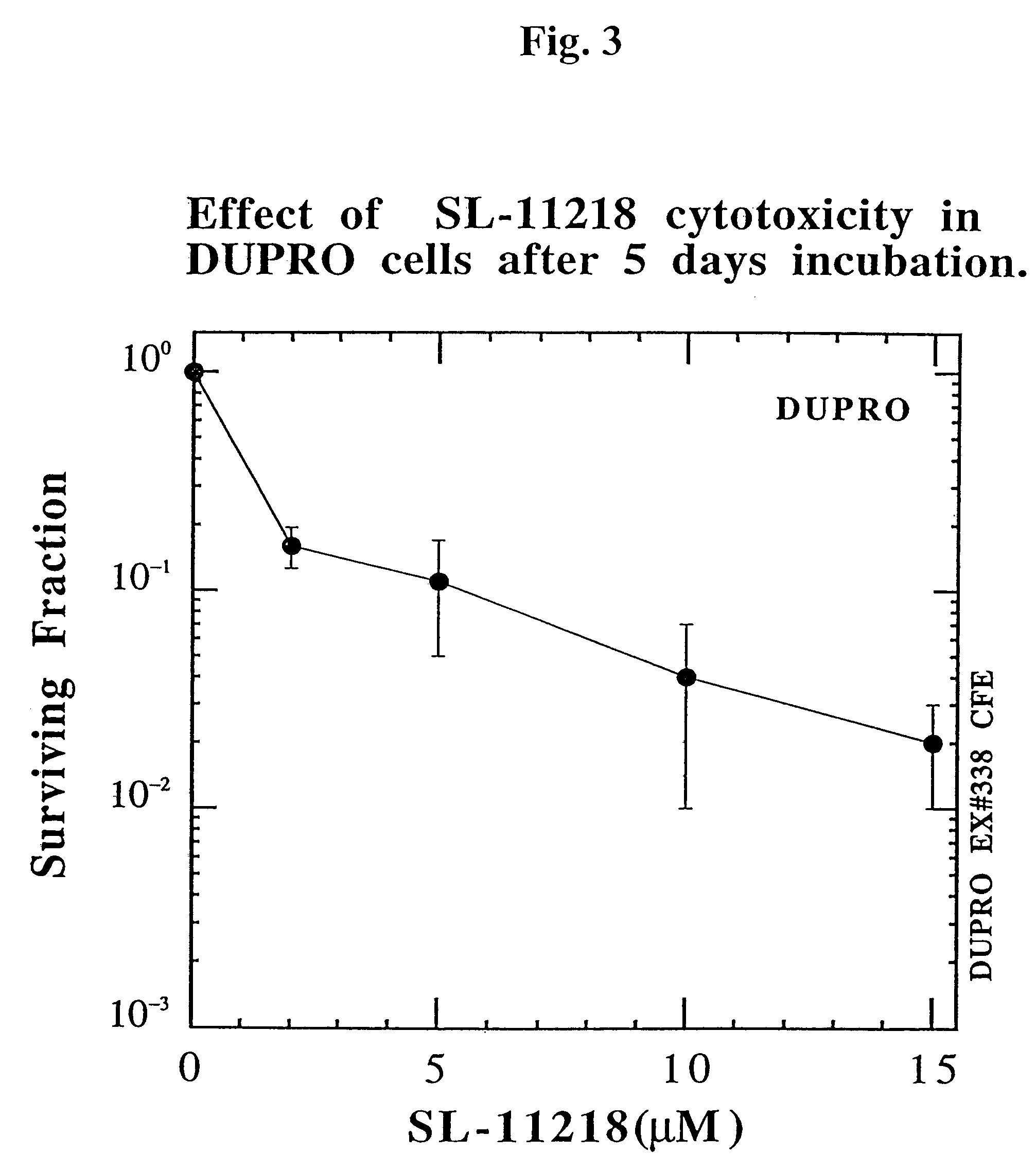

Conformationally restricted polyamine compounds useful in treatment of cancer and other diseases marked by abnormal cell proliferation are disclosed. Improved methods of synthesizing such compounds are also disclosed. In one method of the invention, a carbene-bearing or carbene equivalent-bearing compound is reacted with the double bond of an alkene compound to form a cyclopropyl ring as the first step in the synthesis.

Owner:CELLGATE

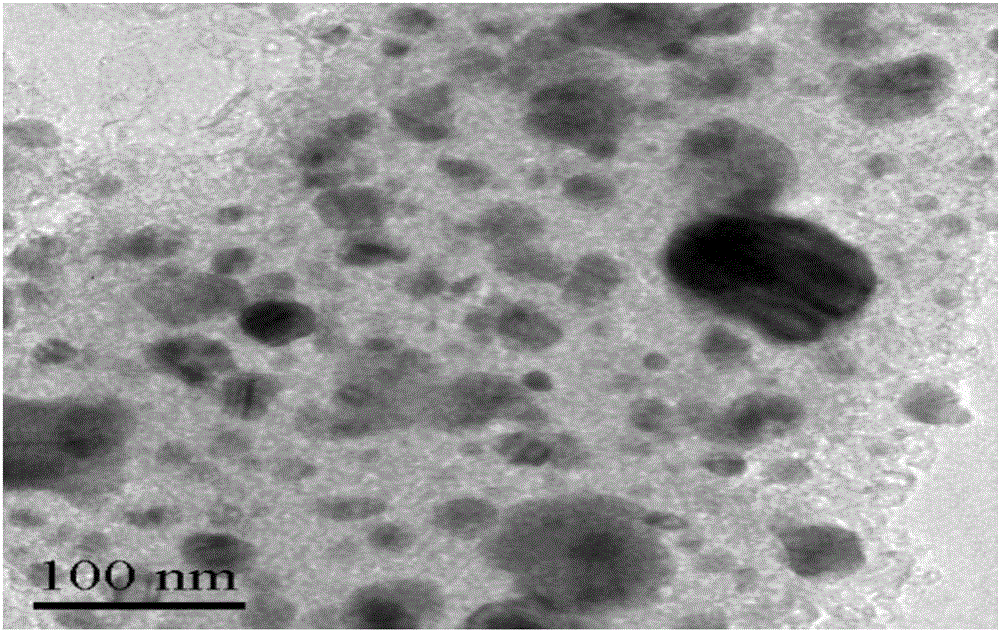

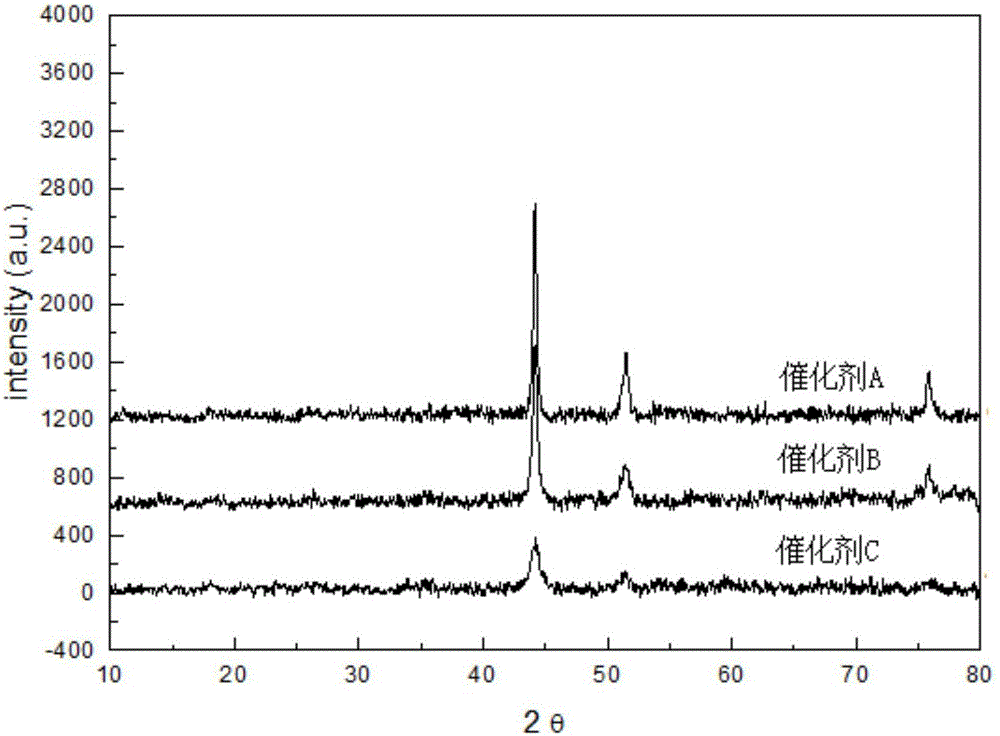

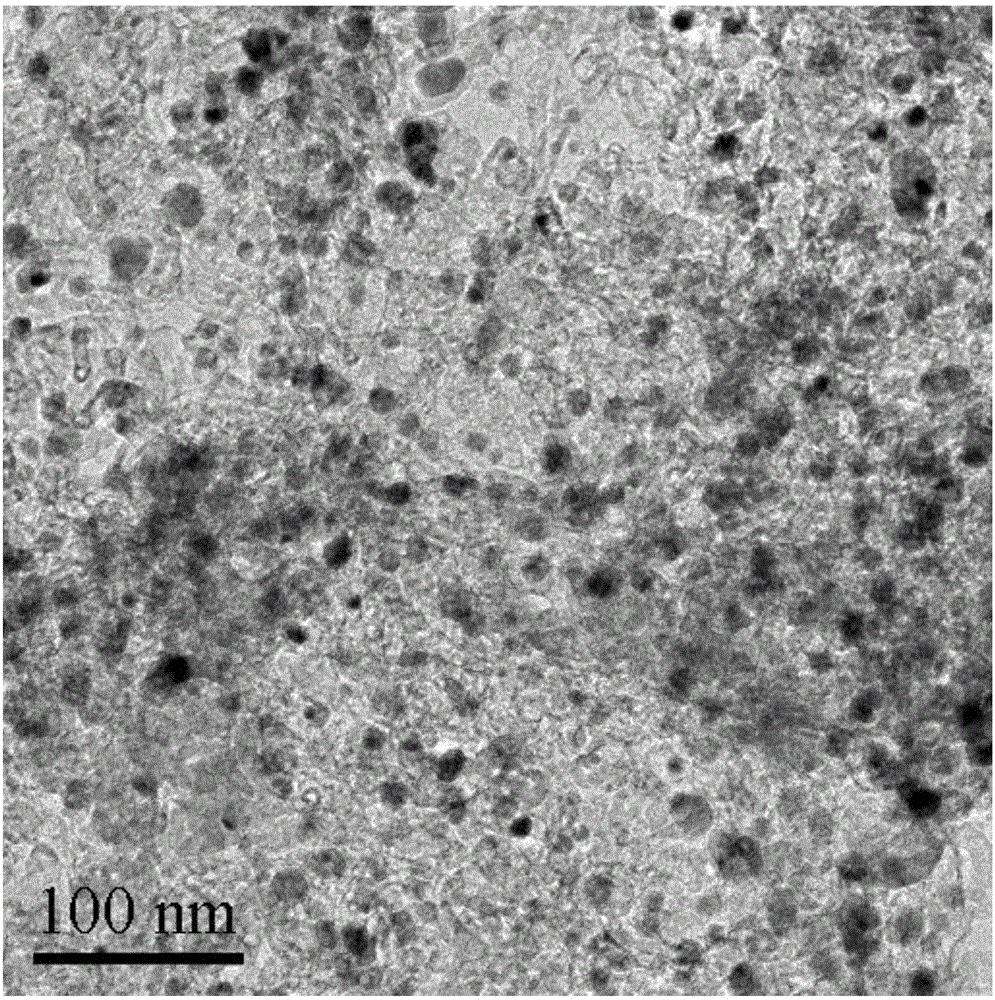

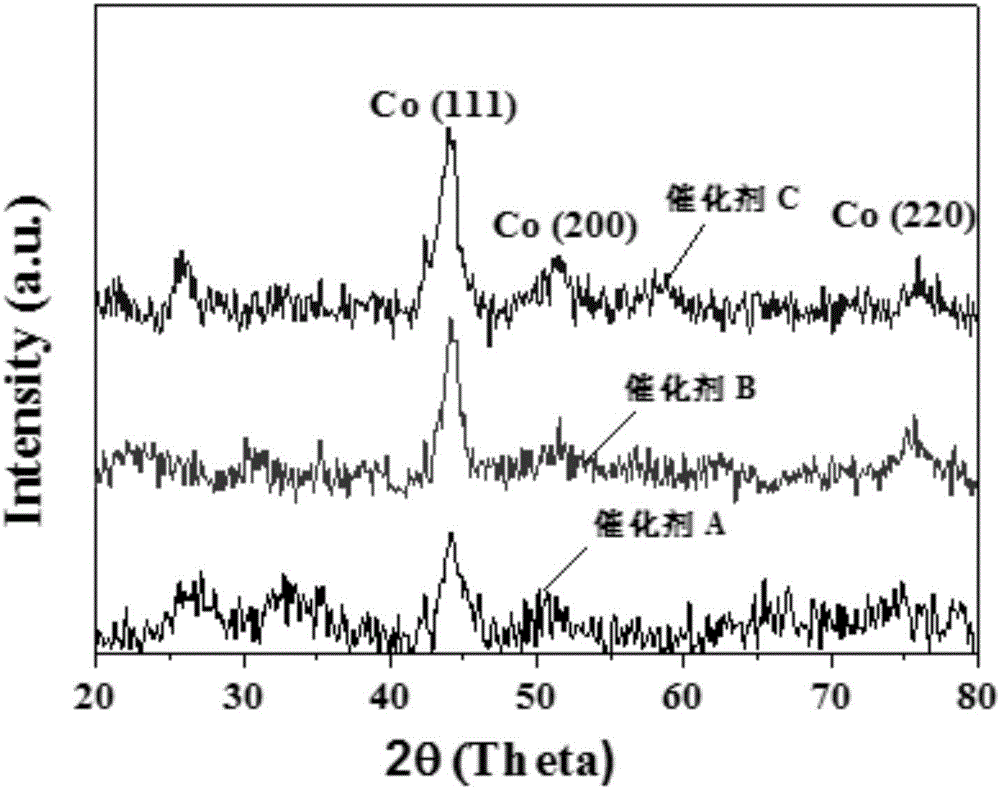

Nitrogen-doped carbon material supporting cobalt catalyst and method therewith of catalytic hydrogenation reductive amination to produce amine compounds

InactiveCN106552661AEasy to prepareReduce manufacturing costOrganic compound preparationCatalyst activation/preparationReaction temperatureNitrogen gas

The invention discloses a nitrogen-doped carbon material supporting cobalt catalyst and a method therewith of catalytic hydrogenation reductive amination to produce primary amine compounds. The catalyst is prepared through the steps of: 1) preparing a MOF material ZIF-67; and 2) under protection of nitrogen gas, calcining the MOF material ZIF-67 at 200-1000 DEG C for 1-10 h to produce the nitrogen-doped carbon material supporting cobalt catalyst Co / N-C. The method of catalytic hydrogenation reductive amination to produce the primary amine compounds with the catalyst includes the steps of: in an organic solvent, adding a carbonyl compound, ammonia water and the nitrogen-doped carbon material supporting cobalt catalyst, feeding hydrogen gas, and performing a reaction at 50-150 DEG C under 0.1-5 MPa for 0.5-20.0 h to produce the amine compounds. The preparation method of the catalyst is simple in operations. The catalyst can be used for producing the primary amine compounds in a manner of catalytic hydrogenation reductive amination. In the method, the primary amine compounds are produced with the carbonyl compound as a raw material through catalytic hydrogenation by means of the catalyst, so that the method has mild reaction conditions and is high in yield.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

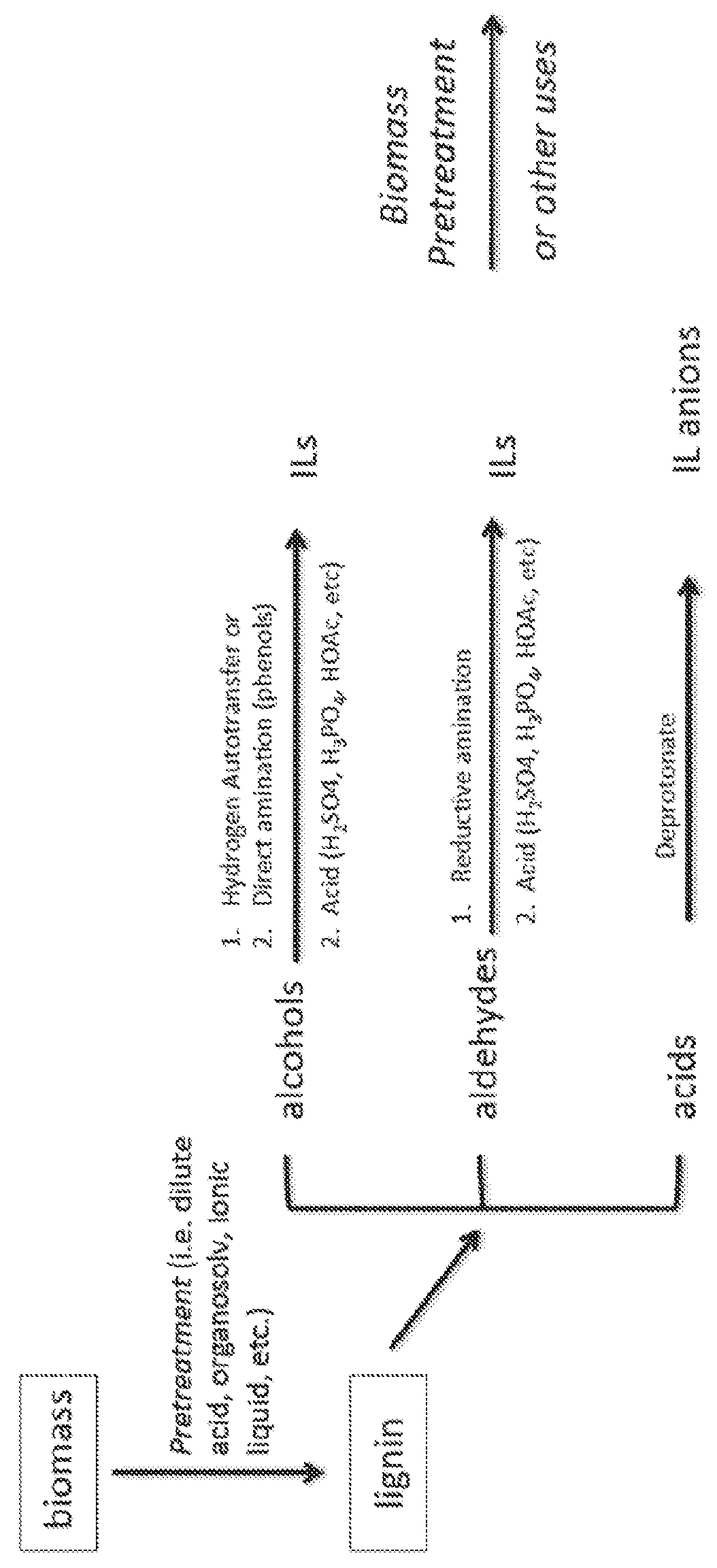

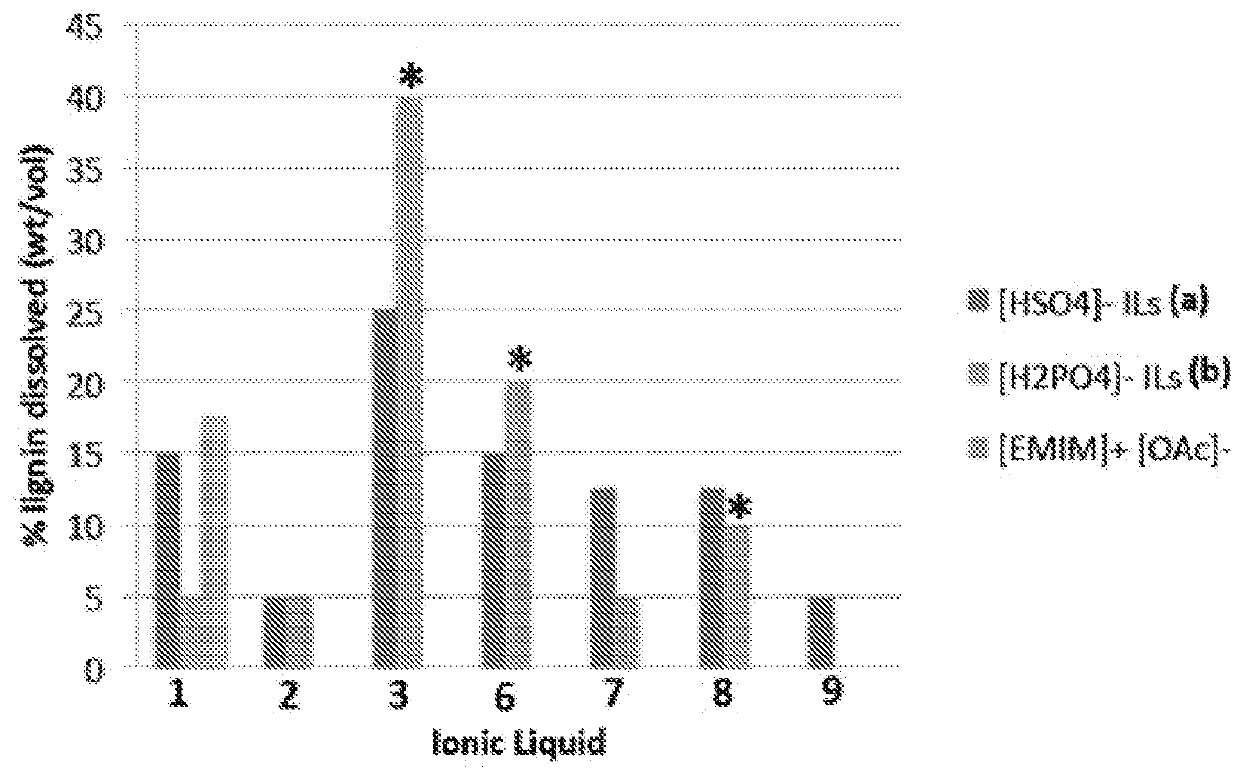

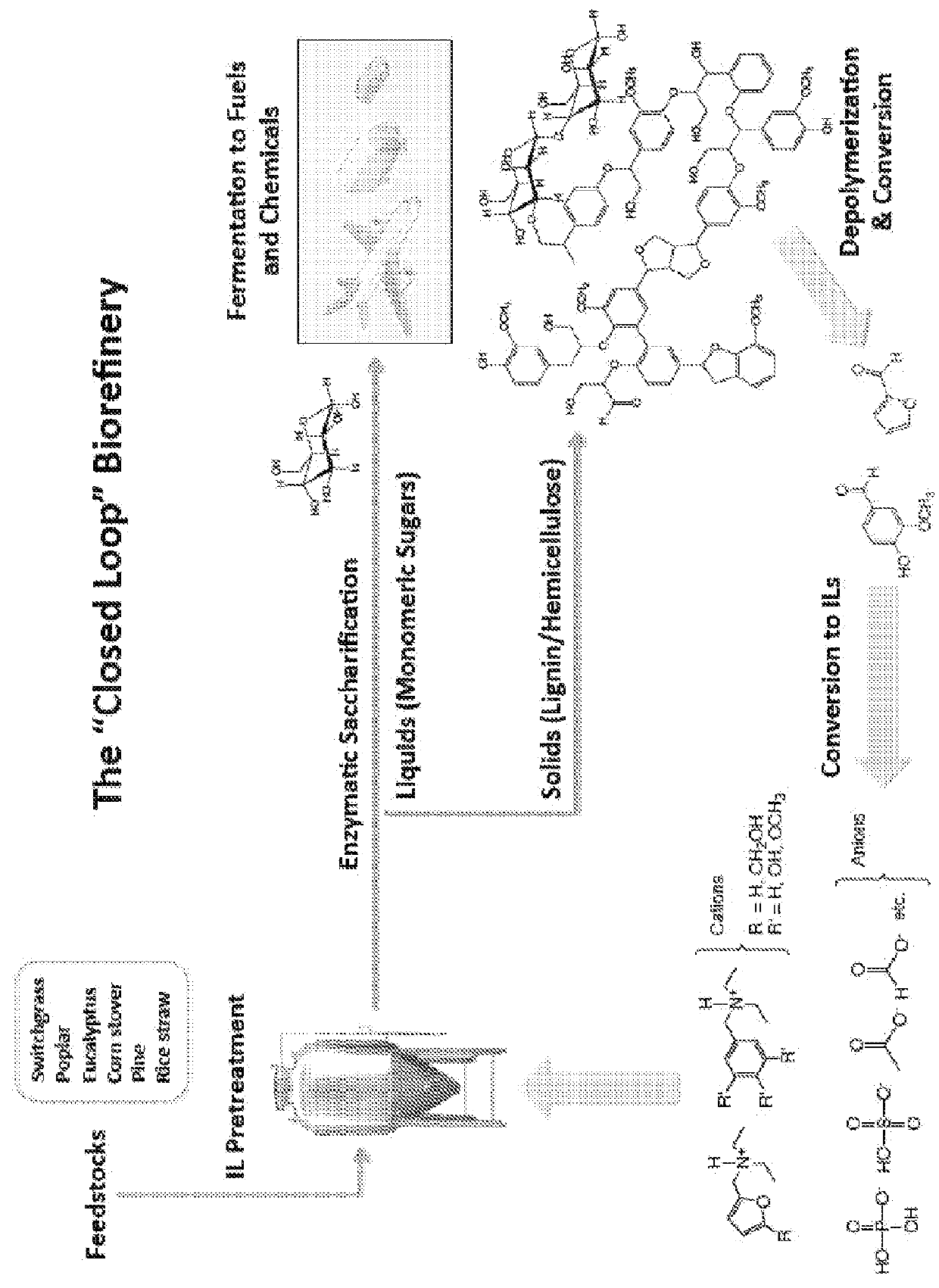

Synthesis of novel ionic liquids from lignin-derived compounds

Methods and compositions are provided for synthesizing ionic liquids from lignin derived compounds comprising: contacting a starting material comprising lignin with a depolymerization agent to depolymerize the lignin and form a mixture of aldehyde containing compounds; contacting the mixture of aldehyde containing compounds with an amine under conditions suitable to convert the mixture of aldehyde containing compounds to a mixture of amine containing compounds; and contacting the mixture of amine containing compounds with an acid under conditions suitable to form an ammonium salt, thereby preparing the ionic liquid.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC +1

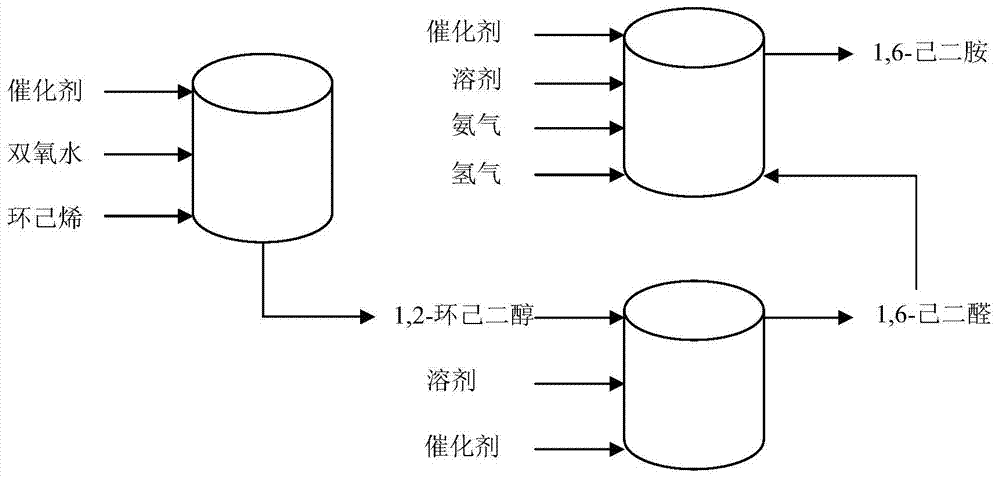

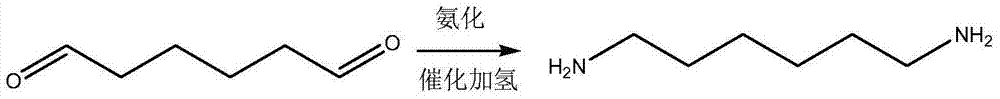

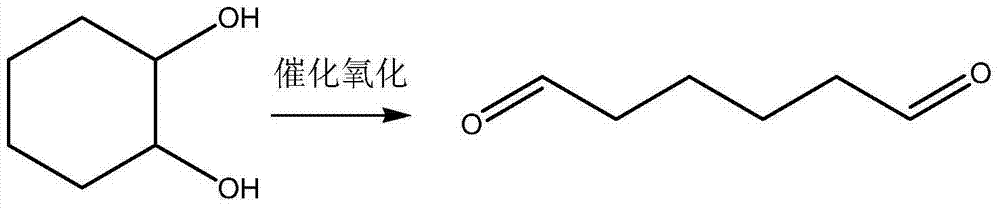

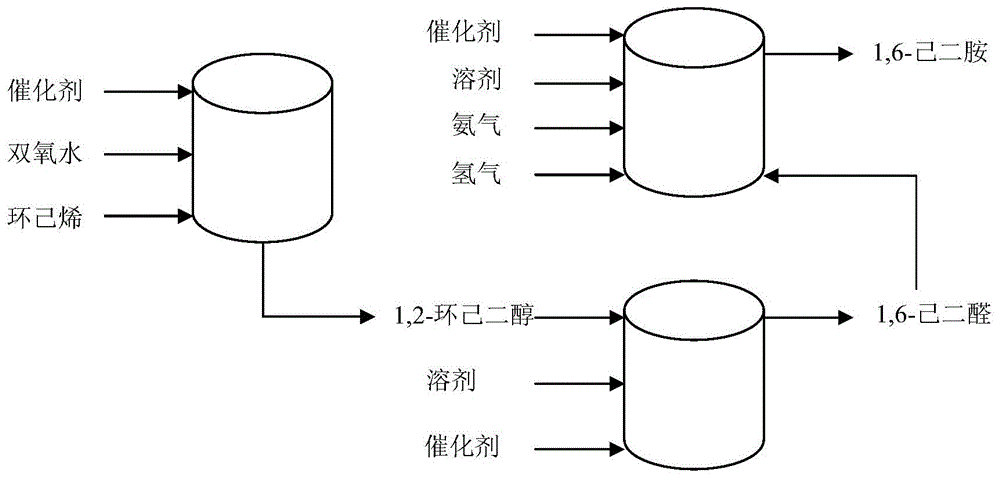

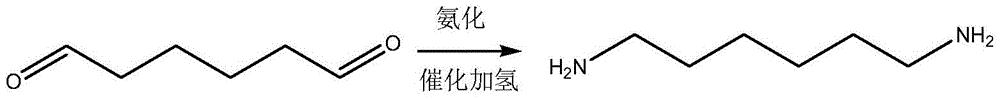

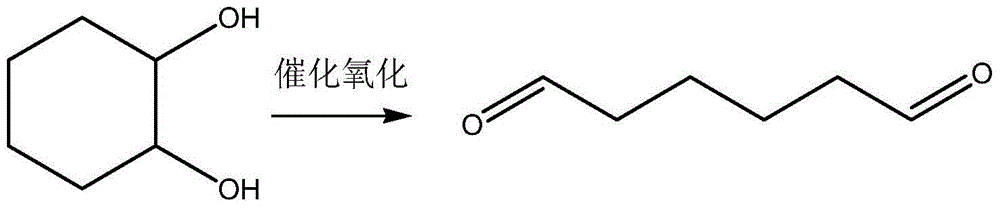

Preparation method of hexamethylenediamine

ActiveCN104262168AEasy to separateHigh catalytic activityPreparation by reductive alkylationHexamethylenediamineEnergy consumption

The invention discloses a preparation method of hexamethylenediamine. The method is used for preparing 1, 6-hexamethylenediamine by virtue of carrying out ammoniation and catalytic hydrogenation on 1, 6-adipaldehyde. The method is simple in process, low in cost, high in yield, low in energy consumption and free from industrial three wastes.

Owner:BEIJING RISUN TECH CO LTD

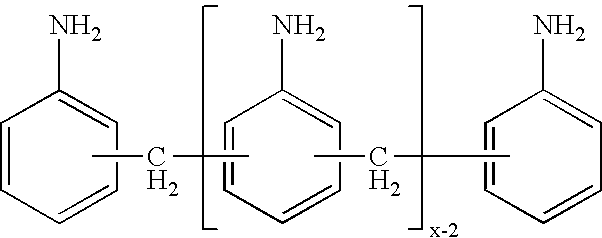

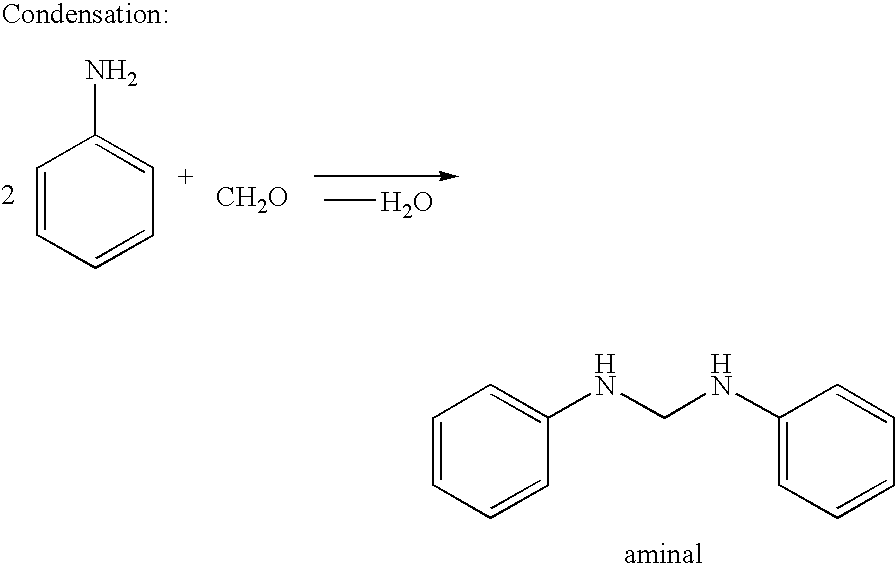

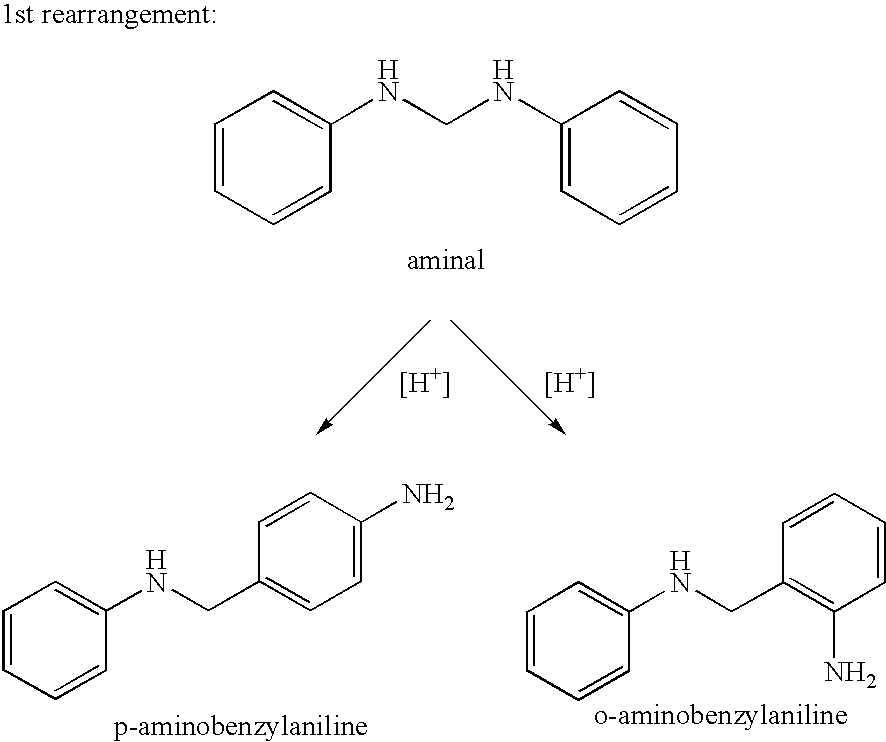

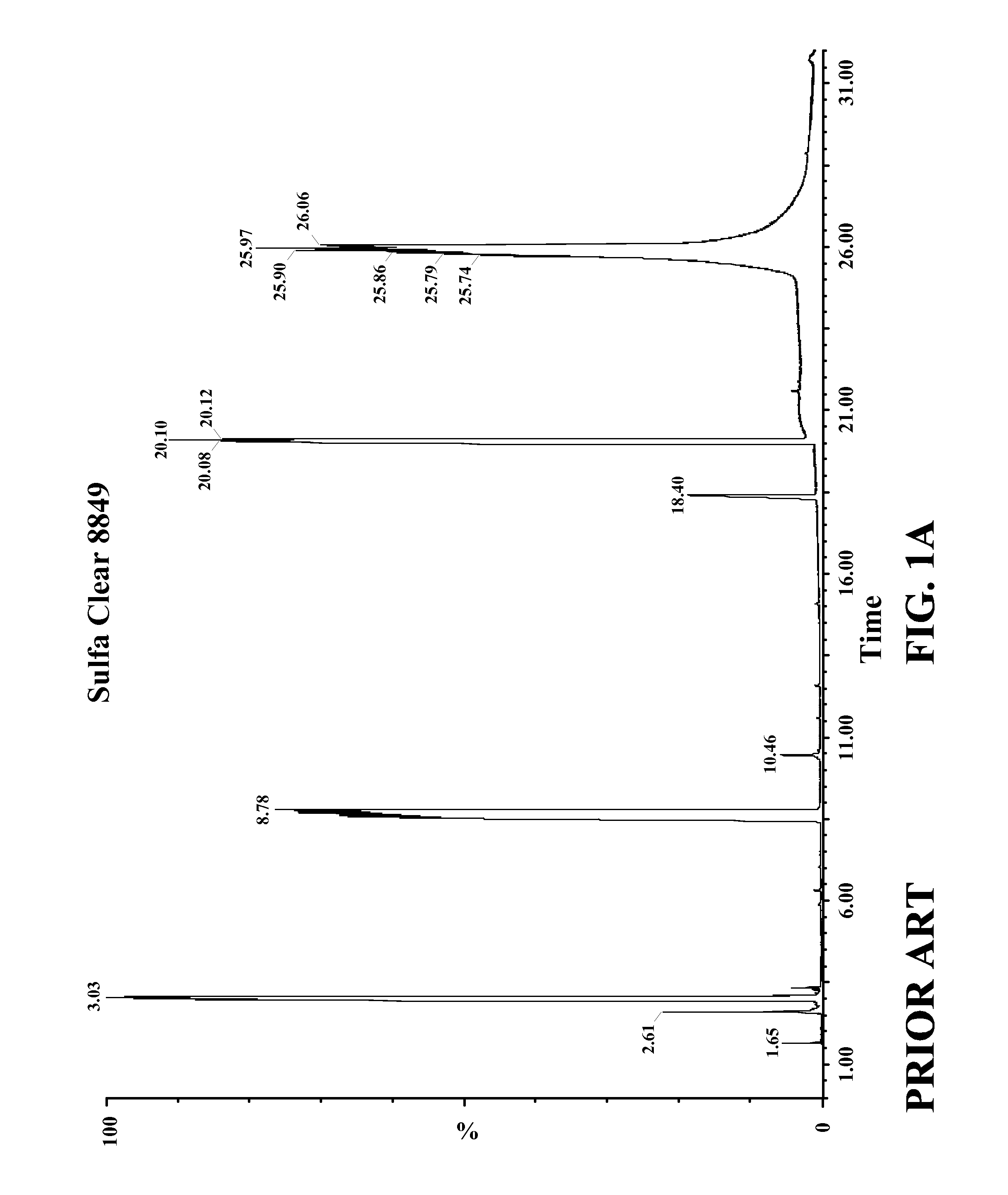

Process for the preparation of polyamines of the diphenylmethane series at a low degree of protonation

ActiveUS20060287555A1Reduce the probability of reactionLong dwell timeIsocyanic acid derivatives preparationOrganic compound preparationDiphenylmethaneProtonation

The invention provides a process for the preparation of polyamines of the diphenylmethane series. This process comprises a) reacting aniline and formaldehyde in a molar ratio of 1.5:1 to 6:1, in the presence of an acid catalyst at temperatures of 20° C. to 100° C., in which the water content in the acid reaction mixture is <20 wt. % and a degree of protonation of <15% is established, and b) increasing the temperature of the reaction to a temperature of 110° C. to 250° C. when the ratio of the weight contents of p-aminobenzylaniline to 4,4′-MDA in the reaction mixture falls below a value of 1.00.

Owner:COVESTRO DEUTSCHLAND AG

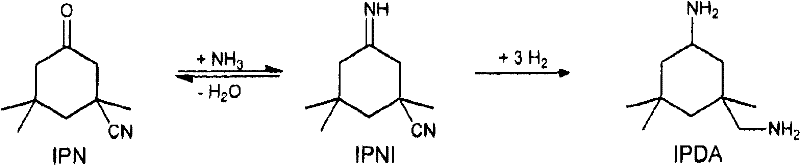

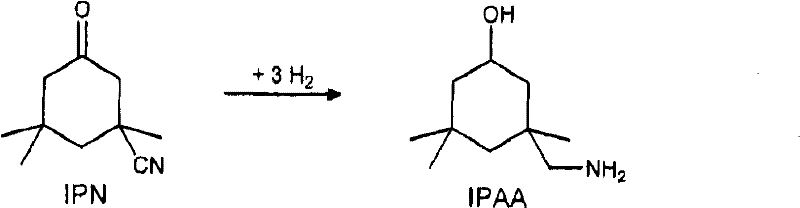

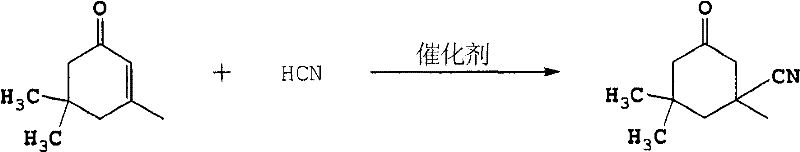

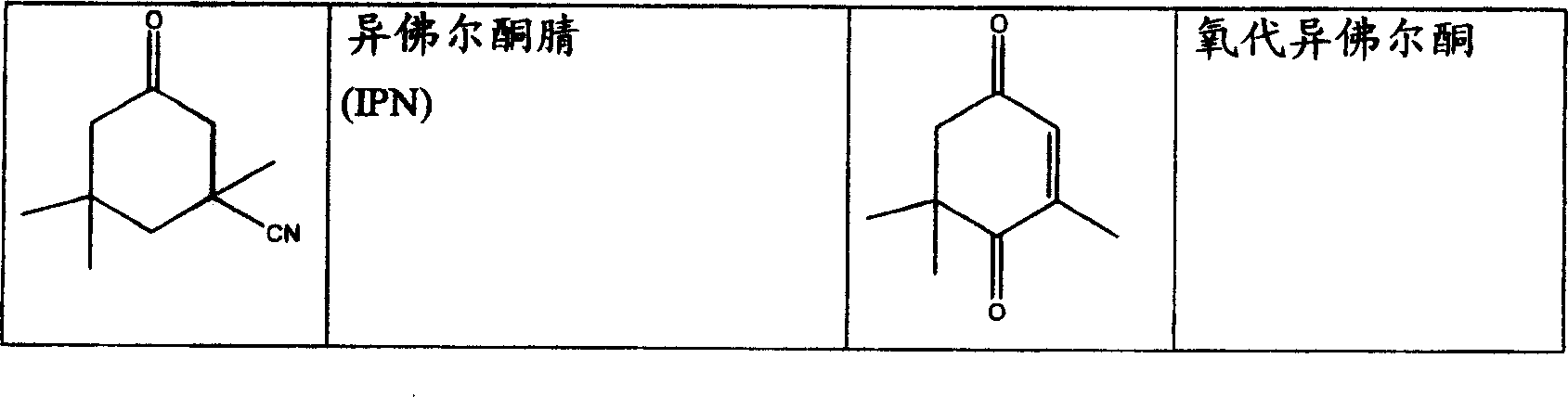

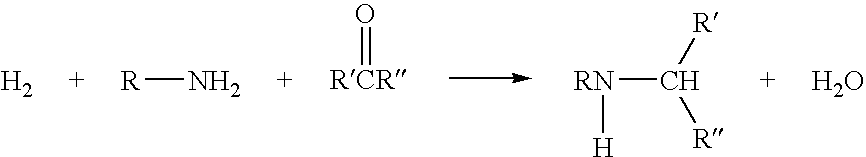

Method for preparing 3-aminomethyl-3,5,5-trimethylcyclohexylamine

ActiveCN101386579ASimple methodReduce construction costsPreparation by reductive alkylationCyclohexanonePolymer science

The present invention discloses a method for preparing 3-aminomethyl-3,5,5-trimethyl cyclohexylamine(isophorone diamine, IPDA) from 3-cyan-3,5,5-trimethyl cyclohexanone(IPN). The method comprises the following steps 3-cyan-3,5,5-trimethyl cyclohexanone, ammonia, an alcohol and / or ether solvent, a hydrogenation catalyst and a promoter are reacted at a temperature of between 50 and 120 DEG C and a hydrogen pressure of between 5 and 15 MPa so as to obtain 3-aminomethyl-3,3,3-trimethyl cyclohexylamine. The method simplifies the prior process for preparing IPDA from IPN, is low in equipment cost, mild in reaction conditions and high in offspring yield.

Owner:WANHUA CHEM GRP CO LTD +1

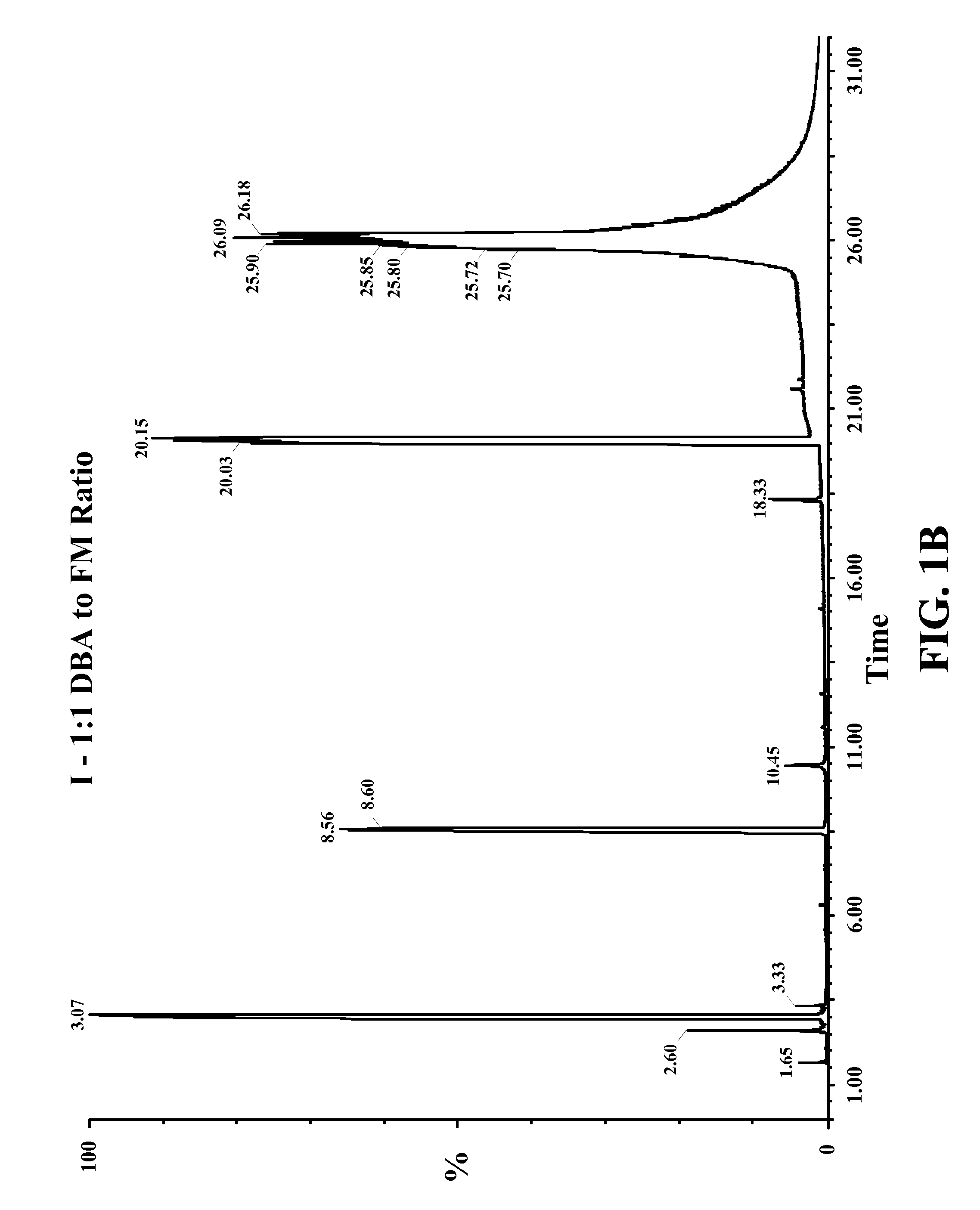

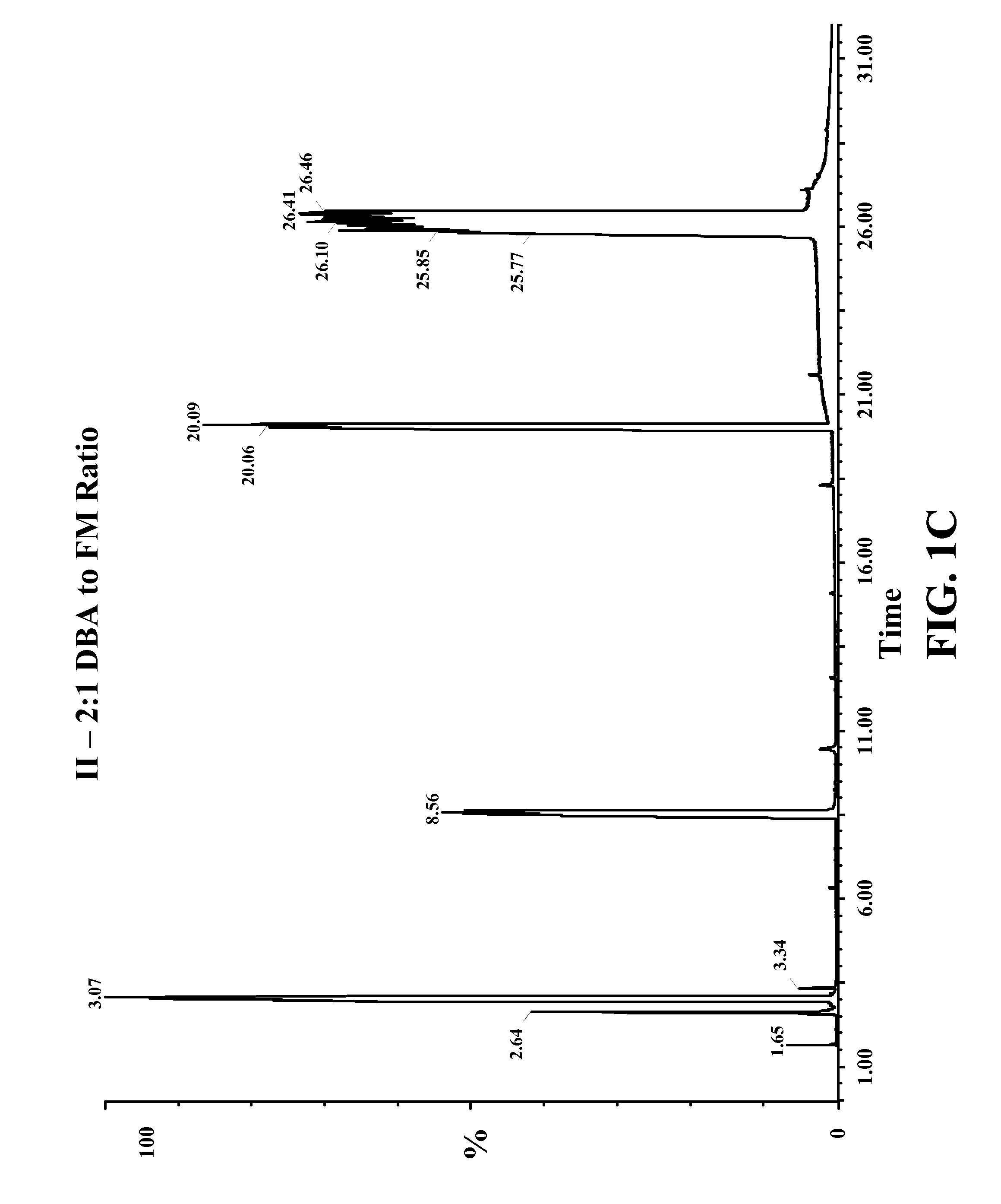

Aldehyde-amine formulations and method for making and using same

A novel method for producing amine-aldehyde sulfur scavenging compositions are disclosed, where the method comprises contacting an amine containing component and a aldehyde containing component in the presence of an alcohol at an amine to aldehyde ratio of between about 0.8 and 0.45 for a reaction time and at a reaction temperatures sufficient to produce an amine-aldehyde adduct product having a specific gravity between about 3% and 7% less than the specific gravity of a mixture of starting materials.

Owner:THE LUBRIZOL CORP

4,4'-diamido diphenylmethane direct preparation method

InactiveCN101007767AHigh activityHigh stereoselectivityPreparation by reductive alkylationDiphenylmethaneMolecular sieve

The invention discloses a catalytic synthesizing technique of 4, 4'-diamino diphenylmethane, which comprises the following steps: adopting phenylamine and formaldehyde as raw material to do one-step condensed reaction intervally acted by solid acid catalyst; setting the molar rate of phenylamine and formaldehyde at 10 / 1-2 / 1 under 100-200 deg.c for 1-8h; circulating diamino diphenylmethane; recycling USY to synthesize the product with high activity.

Owner:ZHEJIANG UNIV

Process for preparing 3-aminomethyl-3,5,5-trimethylcyclohexylamine

InactiveCN102531916AIncrease concentrationOrganic compound preparationWater/sewage treatment by heatingIsophoroneAsymmetric hydrogenation

The invention relates to an improved process for preparing 3-aminomethyl-3,5,5-trimethylcyclohexylamine, referred to hereinafter as isophoronediamine or, in abbreviated form, IPDA, by: I. preparation of isophorone by catalyzed aldol condensations with acetone as reactant; II. Reaction of isophorone with HCN to form isophoronenitrile (IPN, 3-cyano-3,5,5-trimethylcyclohexanone); III. catalytic hydrogenation and / or catalytic reductive amination (also referred to as aminative hydrogenation) of 3-cyano-3,5,5-trimethylcyclohexanone, hereinafter called isophoronenitrile or, in abbreviated form, IPN, to give the isophoronediamine.

Owner:EVONIK DEGUSSA GMBH

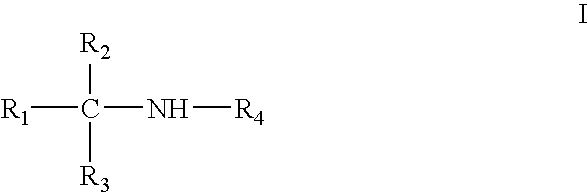

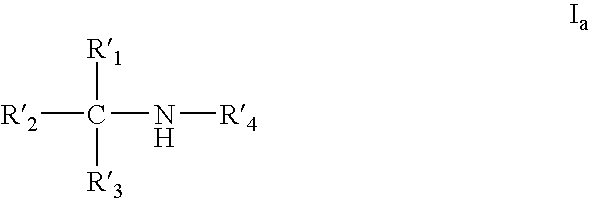

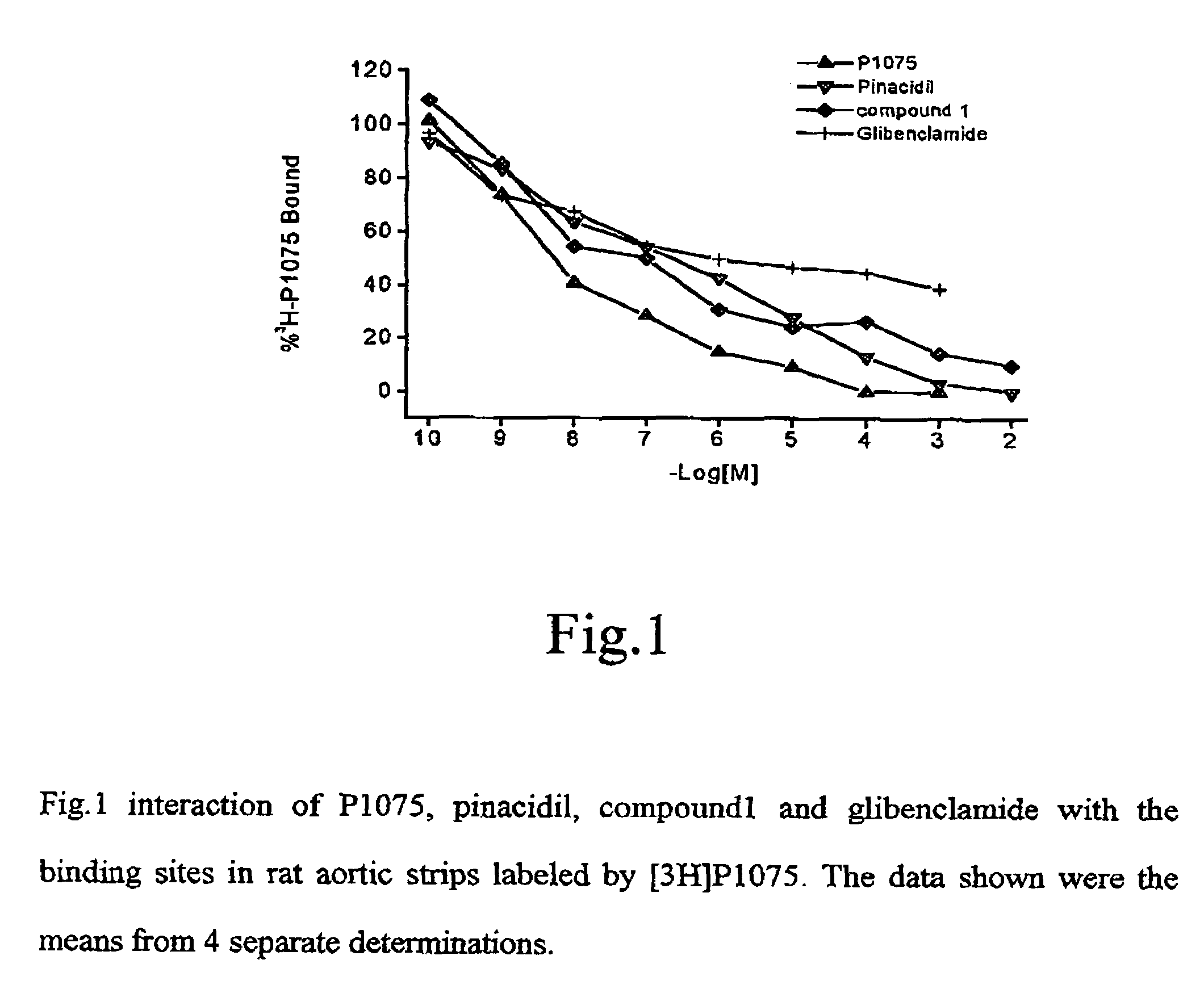

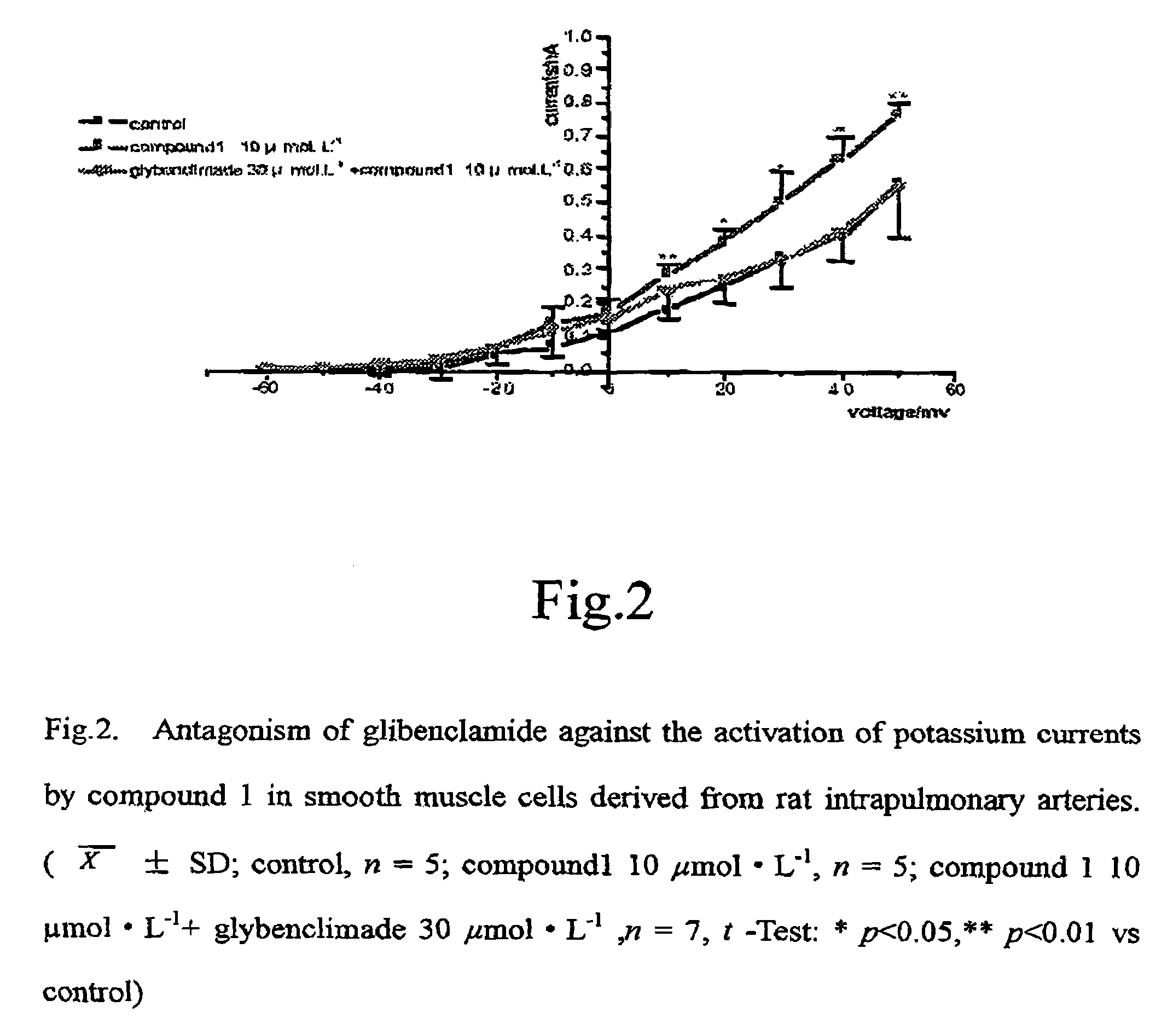

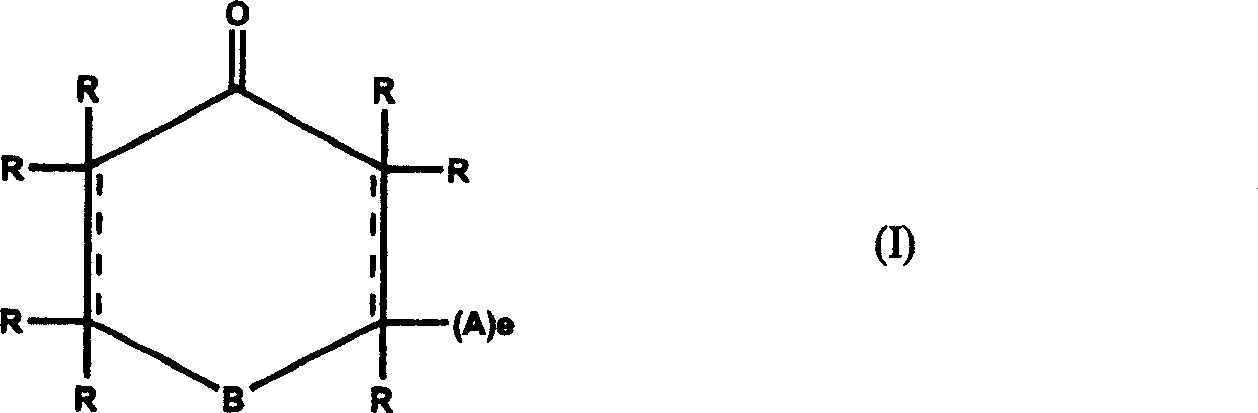

Amine derivative with potassium channel regulatory function, its preparation and use

The present invention provides amine derivatives represented by formula I, its isomers, racemes or optical isomers, pharmaceutical salts thereof, its amides or esters, pharmaceutical compositions containing said compounds and the preparation methods thereof. The invention also relates to the use of the above mentioned compounds in the preparation of drugs for the prophylaxis or treatment of cardiovascular diseases, diabetes, bronchial and urinary smooth muscle spasm as well as ischemic and anoxic nerve injury. The above compounds can be used to treat hypertension, angina diaphragmatic, myocardial infarction, congestive heart failure, arrhythmia, diabetes, spasmodic bronchial diseases, spasmodic bladder or ureter diseases, and depression.

Owner:INST OF PHARMACOLOGY & TOXICOLOGY ACAD OF MILITARY MEDICAL SCI P L A

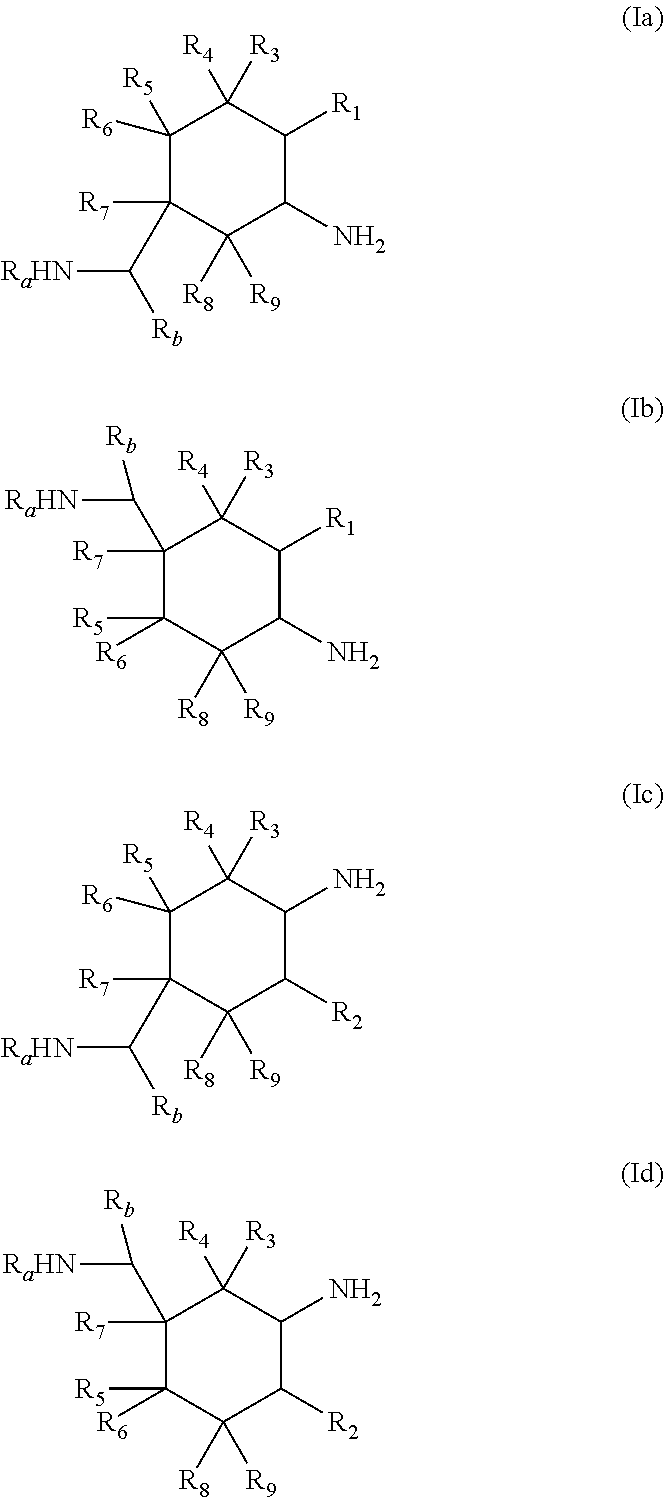

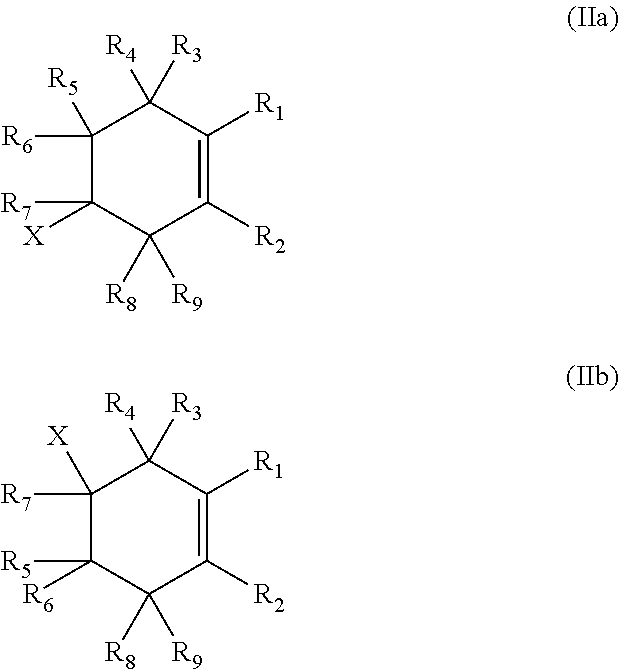

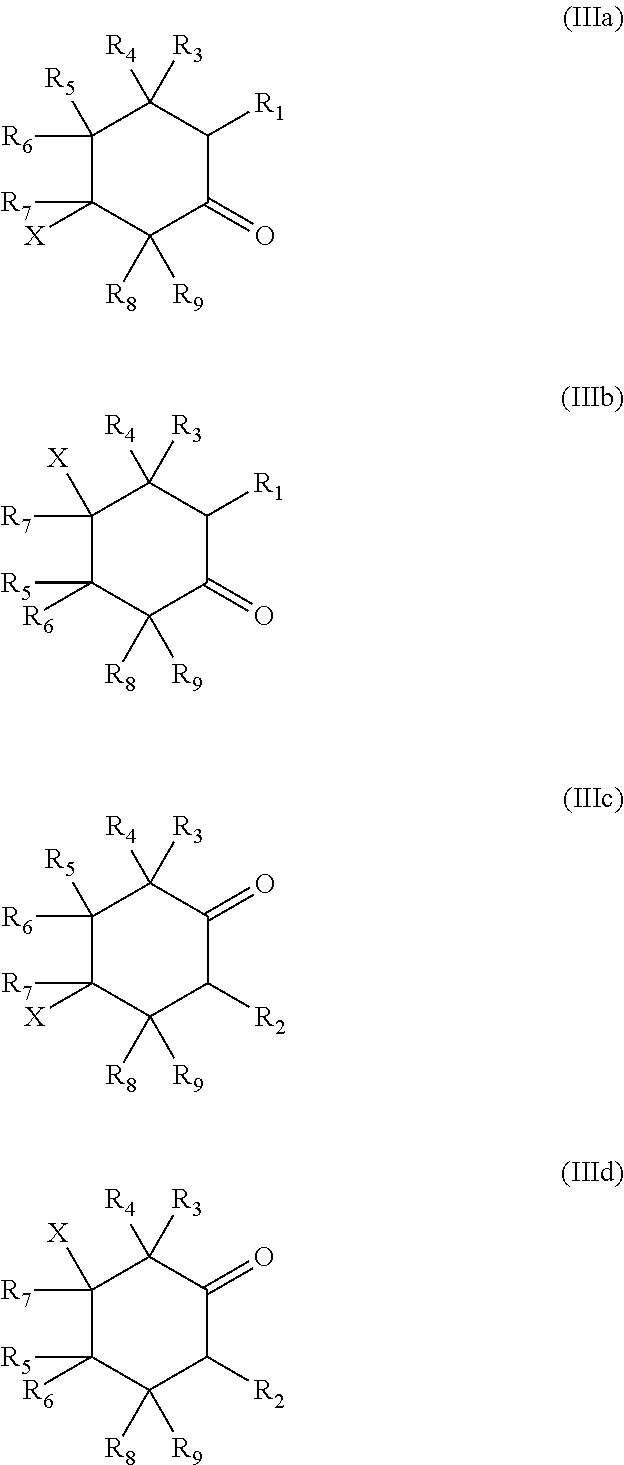

Alicyclic polyamines and process for the preparation thereof

InactiveUS6100430AImprove isolationEasy to purifyPhysical/chemical process catalystsOrganic compound preparationArylHydrogen atom

PCT No. PCT / JP98 / 00192 Sec. 371 Date Sep. 10, 1998 Sec. 102(e) Date Sep. 10, 1998 PCT Filed Jan. 20, 1998 PCT Pub. No. WO98 / 32729 PCT Pub. Date Jul. 30, 1998An alicyclic polyamine of the formula (1) wherein Y1 represents a saturated aliphatic hydrocarbon group and R1 through R4 are the same or different and each represents hydrogen atom, an alkyl group, a cycloalkyl group, an aryl group, or an aralkyl group. The alicyclic polyamine can be obtained by subjecting a 3-formylcycloalkanone or 3-formylcycloalkenone to reductive amination reaction.

Owner:DAICEL CHEM IND LTD

Method for synthesizing isopropamide

ActiveCN101880236AReduce generationSimple production processOrganic compound preparationPreparation by reductive alkylationFatty amineReaction temperature

The invention discloses a method for synthesizing isopropamide, belonging to the technical field of synthesizing fatty amine. In order to improve the conversion efficiency and the selectivity of catalysts for synthesizing isopropamide, propanone or isopropanol is used as the raw material, in the presence of hydrogen and a nickel-based catalyst, amination is carried out to synthesize isopropamide under the conditions that the reaction temperature is 110-200 DEG C, the reaction pressure is 0.1-1.0MPa, and the mole ratio of propanone or isopropanol to hydrogen to ammonia is 1:(1-5):(1-5), wherein the catalyst contains a carrier and nickel active components loaded on the carrier, and over 90 percent of the nickel active components are distributed in a region with the depth of 0.7 mm from the surface of the carrier. The method in the invention can ensure that the conversion efficiency of the propanone is improved, has higher propanone conversion efficiency under the condition of same nickel content and better selectivity, reduces the generation amount of diisopropylamine, simplifies the production process flows of the isopropamide, and lowers the production cost of the isopropamide.

Owner:CHINA PETROLEUM & CHEM CORP +1

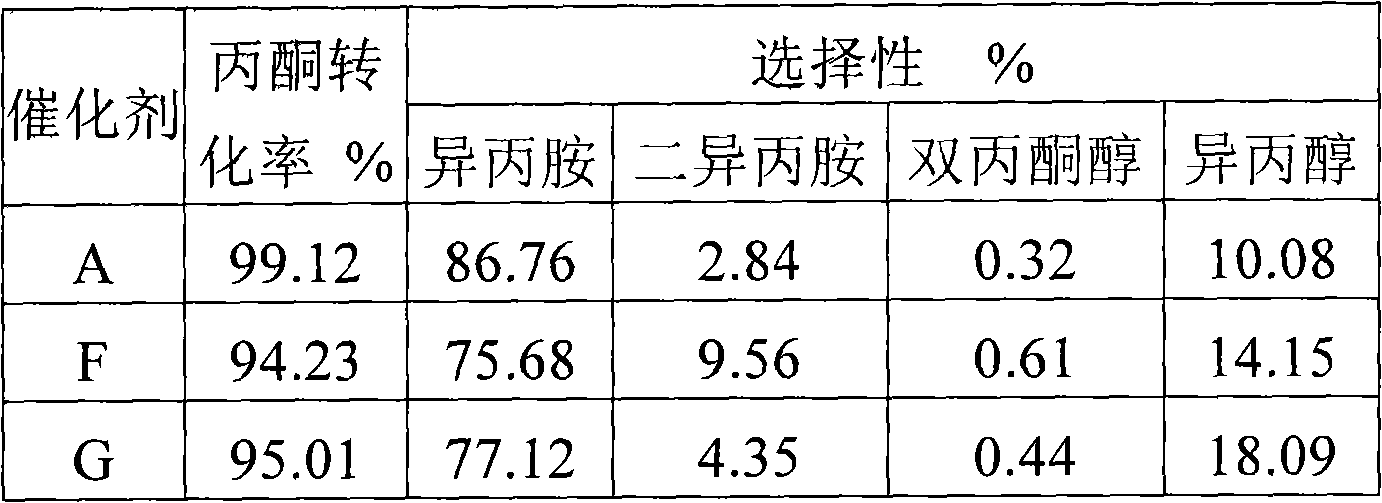

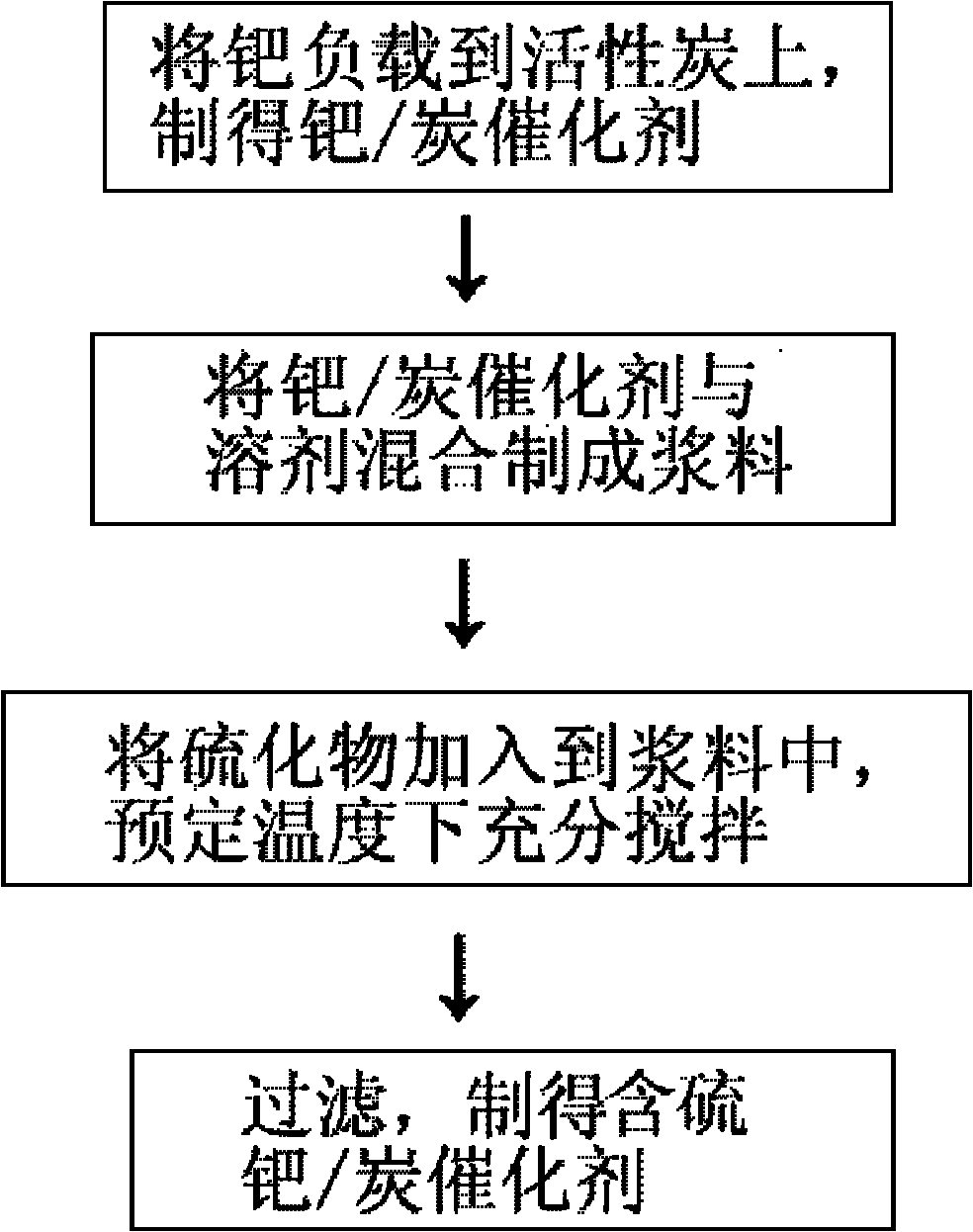

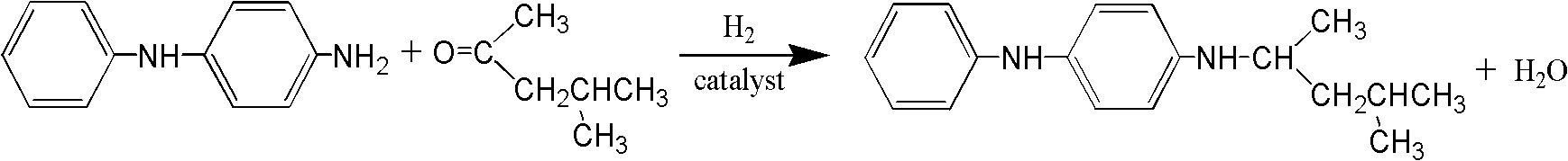

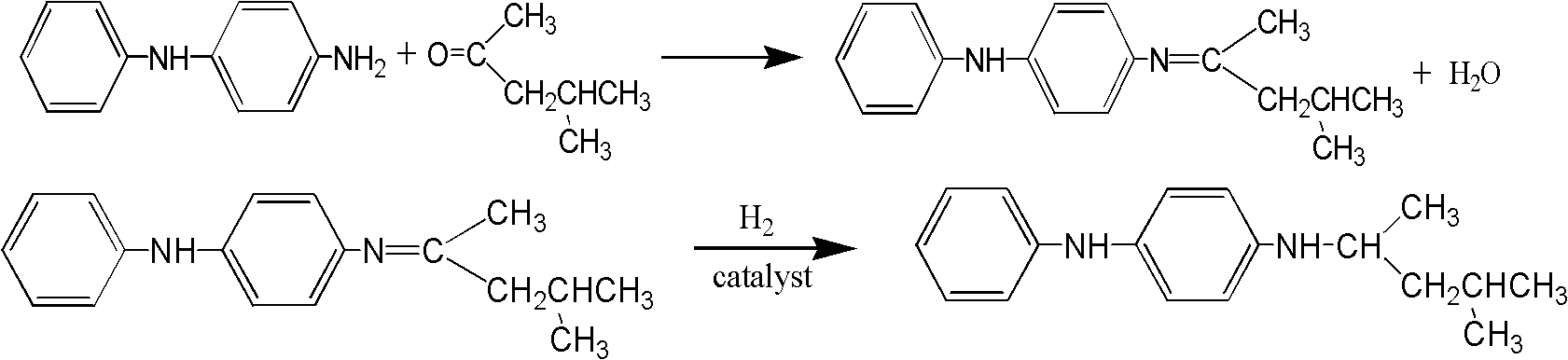

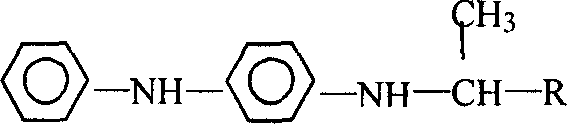

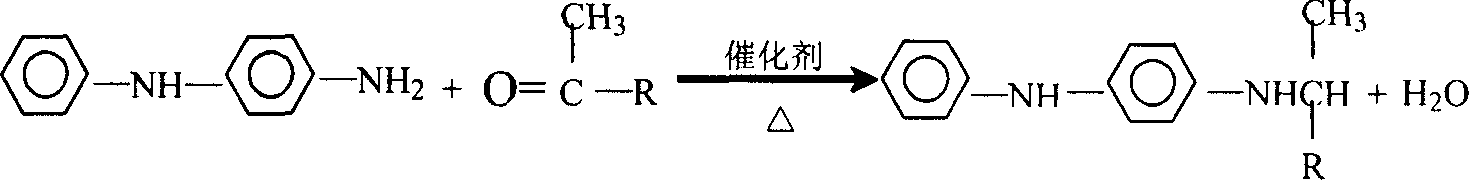

Sulfur-containing palladium/carbon catalyst, preparation method thereof, and preparation method of p-phenylenediamine anti-aging agents

ActiveCN103008008AHigh activityGood choiceOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAlcoholSlurry

The invention discloses a sulfur-containing palladium / carbon catalyst, a preparation method thereof, and a preparation method of p-phenylenediamine anti-aging agents. The sulfur-containing palladium / carbon catalyst preparation method comprises the steps that: palladium is loaded on active carbon, such that a palladium / carbon catalyst is prepared; the palladium / carbon catalyst and a solvent are mixed and prepared into slurry; a sulfide is added into the slurry; the mixture is stirred under a preset temperature; and the mixture is filtered, such that the sulfur-containing palladium / carbon catalyst is prepared. When the sulfur-containing palladium / carbon catalyst provided by the invention is applied in the preparation of p-phenylenediamine anti-aging agents, p-phenylenediamine anti-aging agent yield is improved, a phenomenon that raw material is reduced into corresponding alcohol is inhibited, and selectively is improved.

Owner:JIANGSU SINORGCHEM TECH CO LTD

Process for preparing amines and zirconium dioxide- and nickel-containing catalysts for use therein

InactiveUS7754922B2Reduced responseEnhances their economic viabilityOrganic compound preparationHeterogenous catalyst chemical elementsKetoneOxygen compound

Processes comprising: (i) providing a reactant selected from the group consisting of primary alcohols, secondary alcohols, aldehydes, ketones and mixtures thereof; and (ii) reacting the reactant with hydrogen and a nitrogen compound selected from the group consisting of ammonia, primary amines, secondary amines and mixtures thereof, in the presence of a catalyst comprising a zirconium dioxide- and nickel-containing catalytically active composition, to form an amine; wherein the catalytically active composition, prior to reduction with hydrogen, comprises oxygen compounds of zirconium, copper, nickel and cobalt, and one or more oxygen compounds of molybdenum in an amount of 5.5 to 12% by weight, calculated as MoO3.

Owner:BASF AG

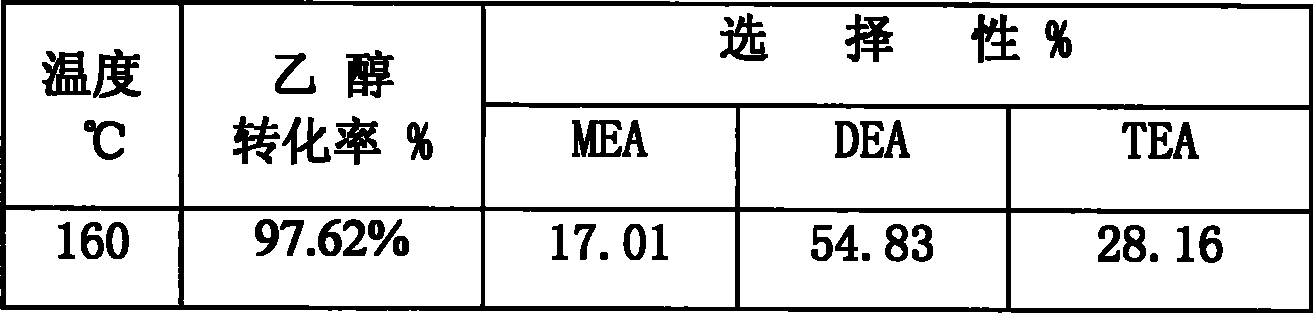

Catalyst for preparing C2-C3 lower aliphatic amine and production method thereof

InactiveCN101455963AModerate reaction conditionsIncrease reaction ratePreparation by reductive alkylationMetal/metal-oxides/metal-hydroxide catalystsReduction treatmentHydrogen

The invention discloses a catalyst for preparing C2-C6 low-grade aliphatic amine. The catalyst comprises a carrier and an active component, wherein the active component accounts for 10 to 60 percent of the total weight of the catalyst, and the active component is Co or consists of Co, Ni and Fe. The invention also discloses a method for producing the catalyst, which comprises the steps of putting the carrier into an aqueous solution of the active component for impregnation, loading the active component onto the carrier, drying the impregnated carrier at a temperature between 100 and 180 DEG C and then decomposing the carrier at a temperature between 250 and 550 DEG C, using hydrogen to perform reduction treatment at a temperature between 250 and 650 DEG C and obtaining the catalyst. The catalyst adopted to prepare the C2-C6 low-grade aliphatic amine can be more beneficial to the generation of tertiary amine.

Owner:ZHEJIANG JIANYE CHEM

Method for producing an amine

InactiveUS7750189B2Reduced responseEnhances their economic viabilityOrganic compound preparationHeterogenous catalyst chemical elementsKetoneOxygen compound

Processes comprising: (i) providing a reactant selected from the group consisting of primary alcohols, secondary alcohols, aldehydes, ketones and mixtures thereof; and (ii) reacting the reactant with hydrogen and a nitrogen compound selected from the group consisting of ammonia, primary amines, secondary amines and mixtures thereof, in the presence of a catalyst comprising a zirconium dioxide- and nickel-containing catalytically active composition, to form an amine; wherein the catalytically active composition, prior to reduction with hydrogen, comprises oxygen compounds of zirconium, copper, and nickel, and one or more oxygen compounds of silver in an amount of 0.5 to 6% by weight, calculated as AgO.

Owner:BASF AG

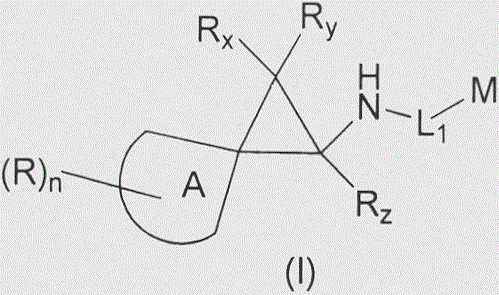

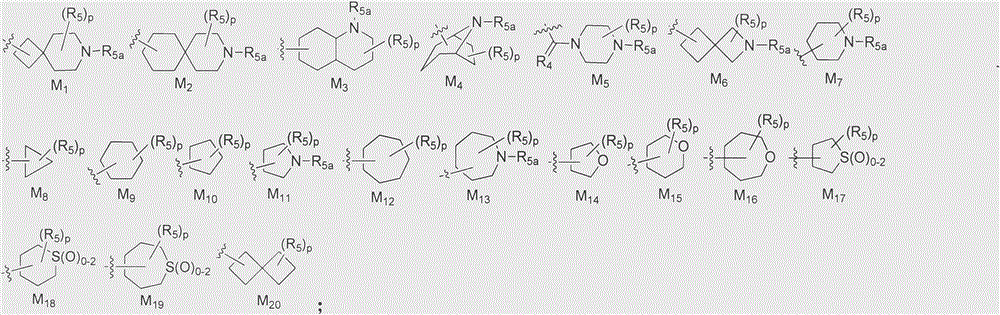

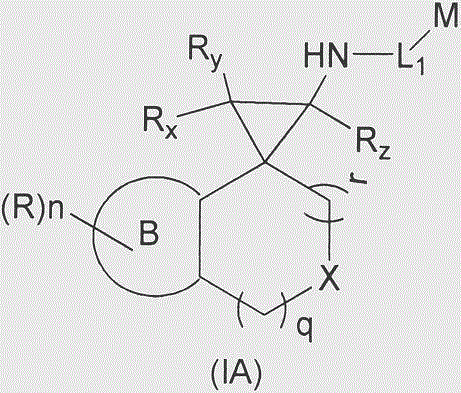

Cyclopropylamine spiro(hetero)cyclic compound, and pharmaceutical composition and application thereof

The invention relates to a preparation method for a cyclopropylamine spiro(hetero)cyclic compound and a composition containing the same, and application of the compound and the composition as an inhibitor for human lysine-specific demethylase (LSD1). The inhibitor is the cyclopropylamine spiro(hetero)cyclic compound as shown in a formula (I) which is described in the specification, or a pharmaceutically acceptable salt, predrug, solvate, polymorphic crystal or stable isotope derivative thereof. The compound can be used for treating or preventing diseases related to human lysine-specific demethylase, e.g., cancers and nerve diseases.

Owner:SHANGHAI DE NOVO PHARMA

Amine derivative with potassium channel regulatory function, its preparation and use

Owner:INST OF PHARMACOLOGY & TOXICOLOGY ACAD OF MILITARY MEDICAL SCI P L A

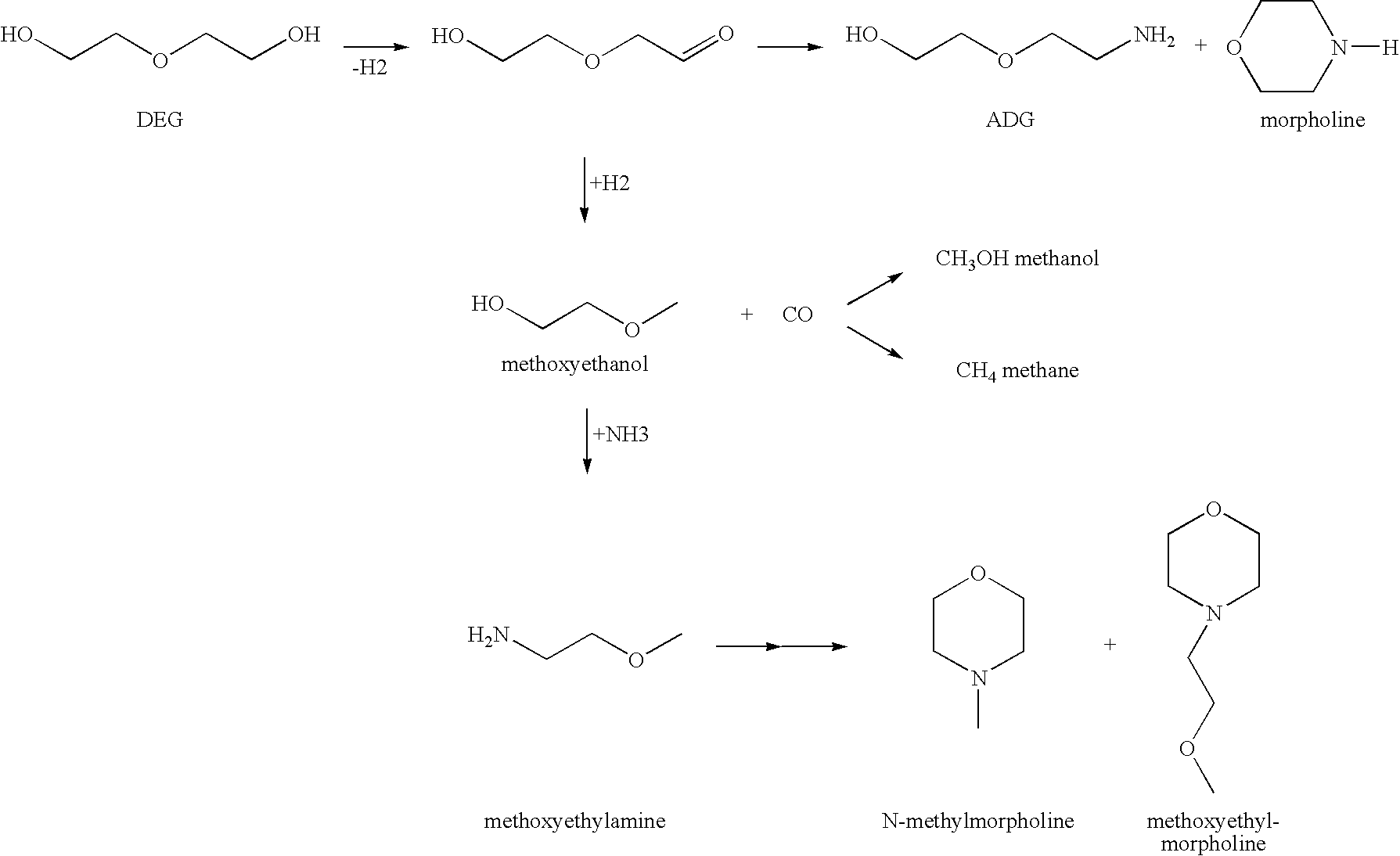

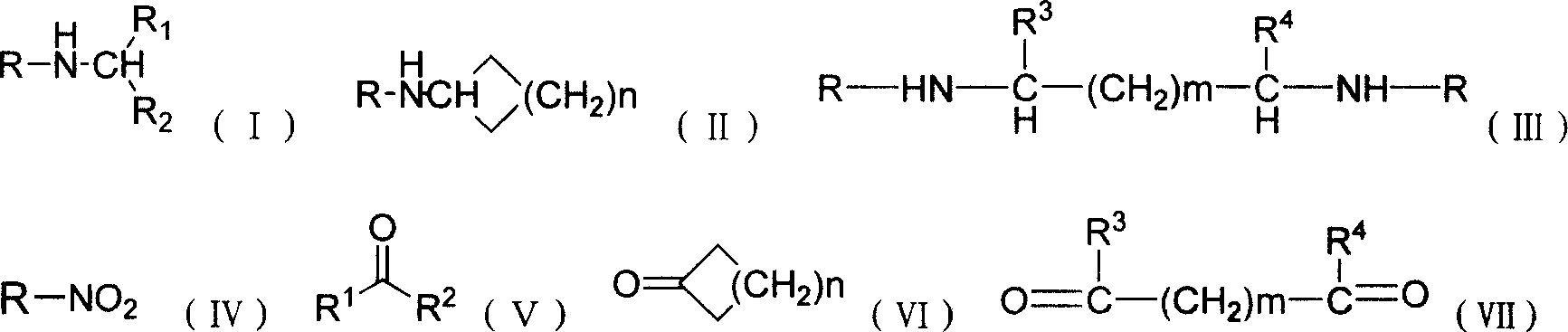

Method for the production of amines by reductive amination of carbonyl compounds under transfer-hydrogenation conditions

InactiveUS7230134B2Efficiently obtainedOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenMetal catalyst

This application claims the benefit of German priority Application No. 10138140.9, filed on Aug. 9, 2001, and International Application No. PCT / EP02 / 08748, filed on Aug. 6, 2002. The invention relates to the production of amines by the reaction of aldehydes or ketones with ammonia or primary or secondary amines in the presence of a hydrogen-donor and the presence of homogeneous metal catalysts of the eighth sub-group under mild conditions.

Owner:EVONIK DEGUSSA GMBH

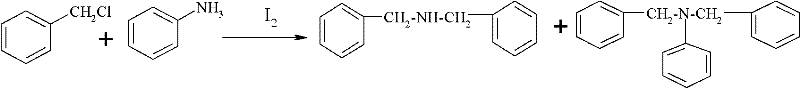

Production of secondary-amine compound

InactiveCN1939890AThe reaction process is simpleHigh reaction conversion ratePreparation by reductive alkylationNitro compoundSolvent

Production of secondary amine compound is carried out by taking nitro-compound, phenol or aldehyde compound as raw materials, catalytic hydrogenation reacting for 1-20hrs at 0.5-5.0MPa and 30-200 degree under the existence of solvent and catalyst, and separation purifying to obtain the final product. The solvent is fatty alcohol containing 1-4 atoms or its solution or water; the catalyst can be Raney Ni catalyst or nickel-carried catalyst or noble- metal-carried catalyst; the noble-metal-carried catalyst can be palladium-carried or platinum-carried or ruthenium-carried catalyst. It's simple and cheap, has higher conversion percent and better selectivity.

Owner:ZHEJIANG UNIV OF TECH

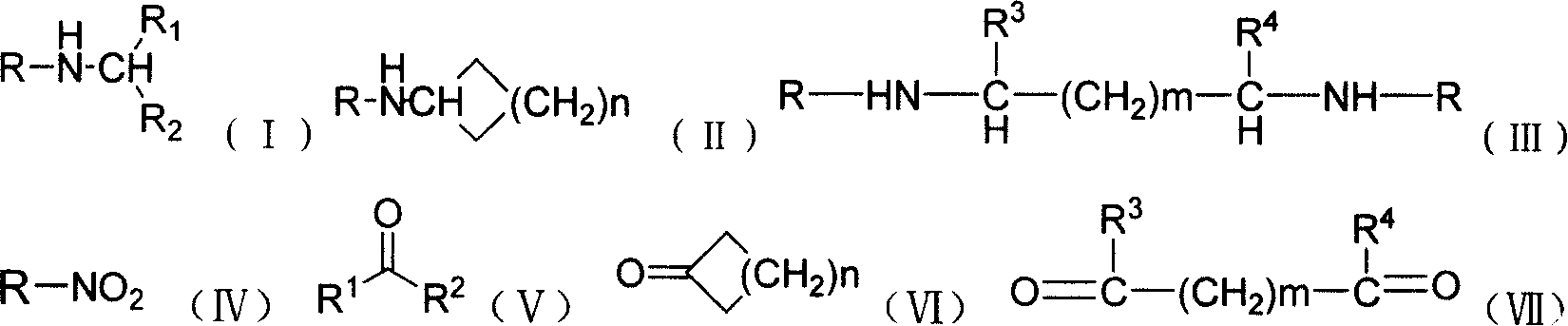

Preparation of secondary amines

InactiveUS20040015016A1Amino compound purification/separationOrganic compound preparationAlkyl transferHydrogen

Disclosed herein is a process for the reductive alkylation of primary amines to form secondary amines, by high pressure reaction of the primary amine with an alkylating agent and hydrogen in the presence of a catalyst which comprises metallic palladium. A process of the present invention is characterized in having high conversion rates and high selectivities, both greater than 95% on a first pass through the reactor. According to a preferred embodiment, the secondary amine produced comprises at least one 2-alkyl group bonded to the nitrogen atom of the primary amine product.

Owner:HUNTSMAN PETROCHEMICAL LLC

Nitrogen-doped carbon material encapsulated cobalt catalyst and method of using the catalyst to prepare secondary amine compounds

InactiveCN106622244AEasy to prepareLow costOrganic compound preparationPreparation by reductive alkylationNitro compoundHydrofluoric acid

The present invention discloses a nitrogen-doped carbon material encapsulated cobalt catalyst and a method of using the catalyst to prepare secondary amine compounds. The preparation method of the catalyst comprises the following steps: 1) silica sol is added into a 2-methylimidazole solution and dispersed uniformly to obtain liquid sol, a stirring is conducted while adding cobalt nitrate liquid into the liquid sol, a stirring reaction is conducted for 3-10 h, and after the reaction is completed, centrifuging, filtering, washing and drying are conducted to obtain ZIF-67@SiO<2> materials; 2) under nitrogen protection, the ZIF-67@SiO<2> materials are calcined at 400-1,200 DEG C for 6-10 h, the calcined materials are soaked with hydrofluoric acid solution, the soaked calcined materials are water washed to neutral, the washed calcined materials are dried to obtain CN@Co materials. The method of using the catalyst to prepare the secondary amine compounds is as follows: in an organic solvent, nitro-compounds, formic acids, carbonyl compounds and the CN@Co materials are added, nitrogen is ventilated to replace oxygen in the reaction system, and the reaction is conducted at 90-220 DEG C for 15-18 hours in an air isolation condition to obtain the secondary amine compounds. The catalyst can be used in the preparation of the secondary amine compounds, reduces the requirements and costs of the reaction to devices and is relatively high in reaction selectivity and yield.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

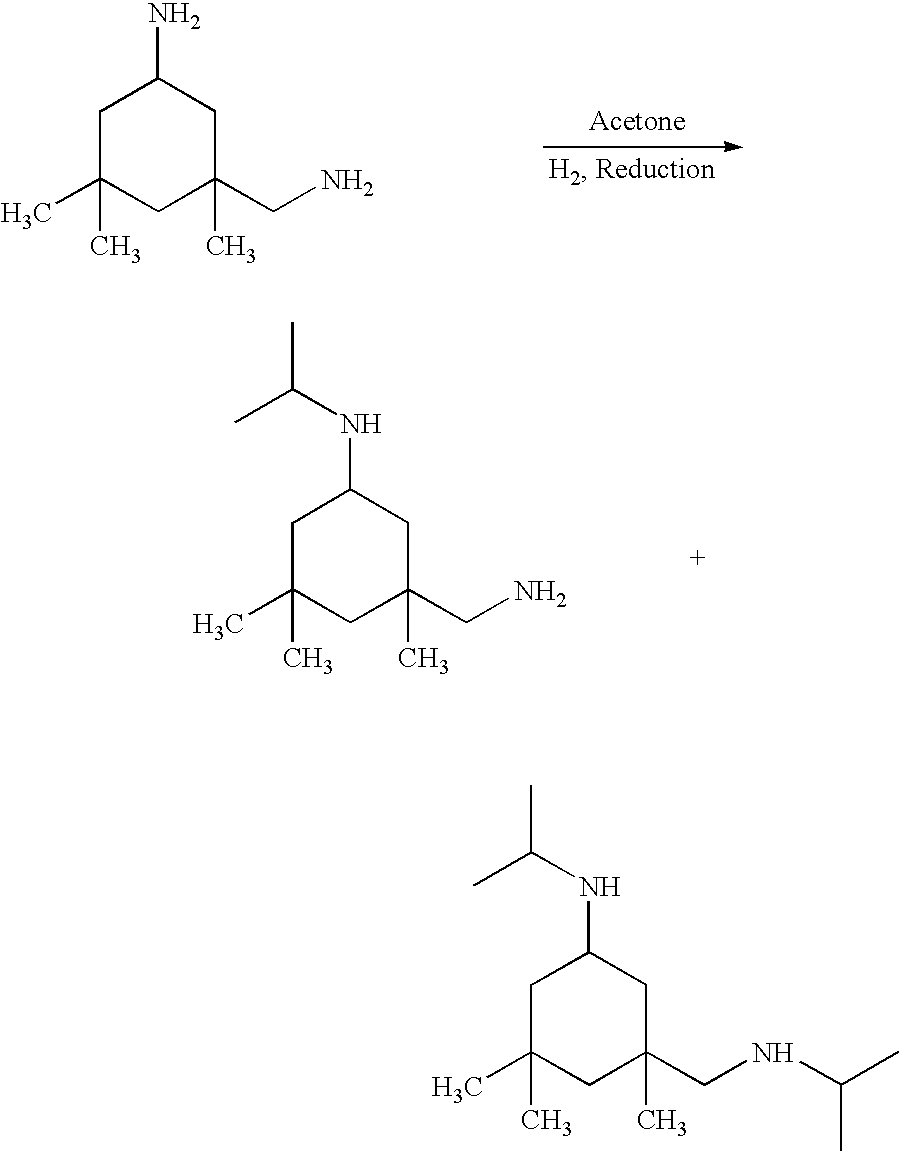

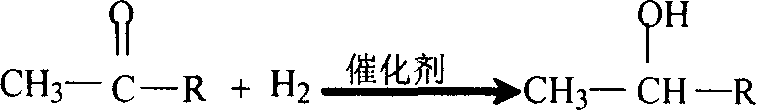

Condensating reductive alkylation catalyst, preparation method and uses thereof

ActiveCN101204658AAppropriate areaAvoid wastingPreparation by reductive alkylationMetal/metal-oxides/metal-hydroxide catalystsWater useOrganic acid

The invention provides a condensation reductive alkylation catalyst and preparation method and use thereof. The catalyst pertains to copper-based catalyst, and is prepared by coprecipitation method with acid or salt thereof as precipitator. The preparation method is energy saving and environment friendly for including no impurity natrium, which avoids environmental protection problem existing in catalysis preparation technology with traditional precipitation method and reduces washing water use. The specific surface area of the catalyst is 30.0 to 75.0m<2> / g and pore volume 0.08 to 0.15ml / g. The catalyst can be used in condensation technology of RT Base and aliphatic ketone to inhibit an unnecessary side reaction in production of anti-aging agent 4010NA and 4020, especially to a reaction of aliphatic ketone alkylation regent hydrogenated to corresponding mellow.

Owner:SINOPEC NANJING RES INST OF CHEM IND CO LTD

A kind of preparation method of hexamethylenediamine

ActiveCN104262168BEasy to separateHigh catalytic activityPreparation by reductive alkylationHexamethylenediamineEnergy consumption

The invention discloses a preparation method of hexamethylenediamine. The method is used for preparing 1, 6-hexamethylenediamine by virtue of carrying out ammoniation and catalytic hydrogenation on 1, 6-adipaldehyde. The method is simple in process, low in cost, high in yield, low in energy consumption and free from industrial three wastes.

Owner:BEIJING RISUN TECH CO LTD

Pretreating process for preparing copper base catalyst of p-phenylenediamine anti-aging agent

ActiveCN101733169AQuick selectionCatalyst activation/preparationPreparation by reductive alkylationAlkyl transferHydrogen

The invention provides a pretreating process for preparing a copper base catalyst of a p-phenylenediamine anti-aging agent. Before use, the main active component copper of the copper base catalyst exists in an oxide form. The process comprises the following steps: (1) heating and dewatering step: heating a copper base catalyst bed to remove the water content contained in the copper base catalyst; (2) hydrogenation reducing step: introducing hydrogen to the copper base catalyst after dewatering to reduce the copper base catalyst and obtain the activated copper base catalyst, wherein, water generated in reaction is carried over; and (3) passivating treatment step: passivating the activated copper base catalyst so that the activity and selectivity thereof are suitable for N-alkylation reaction. The pretreating process of the invention can enable the copper base catalyst to reach the activity and selectivity required by reaction in a short time, shorten the pretreating time of the copper base catalyst, reduce the reject ratio of the p-phenylenediamine anti-aging agent products, and even eliminate rejected products.

Owner:JIANGSU SINORGCHEM TECH CO LTD

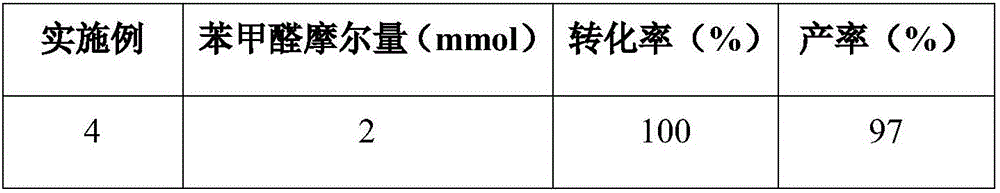

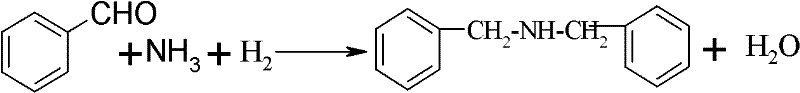

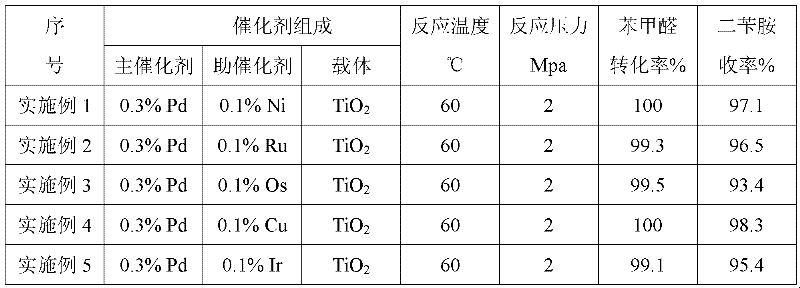

Preparation method of dibenzylamine

InactiveCN102503836AExtended service lifeReduce manufacturing costPreparation by reductive alkylationHydrogenBenzaldehyde

The invention relates to a chemical preparation method, and particularly relates to a preparation method of dibenzylamine. The invention prepares dibenzylamine by using benzaldehyde and ammonia as raw materials; the reaction temperature is 10-100 DEG C; the gauge pressure meter hydrogen reaction pressure is 1.0-5.0 Mpa; water, or lower aliphatic alcohol with 1-4 carbon atoms, or a mixture is used as a solvent; and the reaction is performed under the action of a catalyst for 0.1-5 hours; the catalyst comprises precious metal palladium used as a main catalyst; at least one of Ni, Ru, Os, Ir, Cu, Sn is selected and added as a cocatalyst; at least one of TiO2, SiO2, CeO2, SnO2 is used as a carrier; the advantages of the invention are that the preparation catalyst has a prolonged service life; the preparation cost is reduced; the conversion rate of benzaldehyde is high; and the dibenzylamine yield is increased.

Owner:ZHEJIANG XINHUA CHEM

Process for removing formaldehyde from a composition comprising glycolaldehyde

ActiveUS20160002137A1Reducing percentage by weightLower the volumeFruit and vegetables preservationSugar derivativesAlcoholReactive distillation

A process for reducing the percentage by weight of formaldehyde present in a composition comprising glycolaldehyde, wherein formaldehyde is transformed into one or more formaldehyde acetal(s) and removed from the reactive distillation reaction solution by reactive distillation in the presence of at least one alcohol and a catalyst.

Owner:HALDOR TOPSOE AS

Process for preparing cyclic diamines

InactiveUS8592632B2Simple and inexpensiveCarboxylic acid nitrile preparationOrganic compound preparationPolymer sciencePolyamide

The present invention relates to a process for preparing a cyclic diamine, comprising the reaction of at least one cyclic alkene with a gas mixture (G) comprising dinitrogen the subsequent conversion of monoxide to give at least one cyclic ketone and then converting the at least one cyclic ketone to a cyclic diamine. The invention also relates to the use of a cyclic diamine with primary and secondary amine functions thus obtained to prepare polyamides and polyurethanes.

Owner:BASF AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com