Nitrogen-doped carbon material encapsulated cobalt catalyst and method of using the catalyst to prepare secondary amine compounds

A technique of encapsulating cobalt catalyst and nitrogen-doped carbon, which is applied in the field of encapsulating cobalt catalyst with nitrogen-doped carbon material and using it to prepare secondary amine compounds, can solve problems such as limitations, achieve low cost, high reaction selectivity, and the preparation method Simple and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

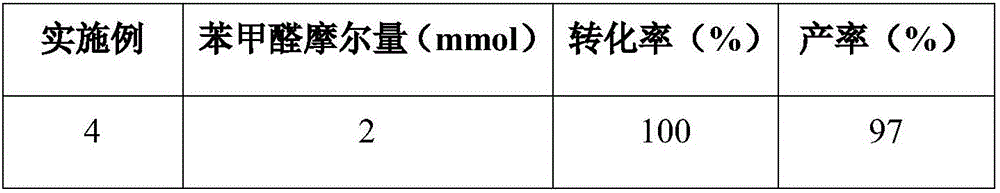

Examples

Embodiment 1

[0028] A nitrogen-doped carbon material comprising a cobalt catalyst prepared by:

[0029] 1) Dissolve 5.5g of 2-methylimidazole in 20mL of water to obtain a 2-methylimidazole solution, add 2mL of silica sol to the 2-methylimidazole solution, and disperse evenly to obtain a lyosol. Dissolve 0.45g of cobalt nitrate hexahydrate in 3mL of water to obtain a cobalt nitrate solution. Add the cobalt nitrate solution dropwise to the silica sol while stirring at room temperature (25°C). Stir and react for 6 hours. , methanol, and vacuum-dry the resulting solid to obtain ZIF-67@SiO 2 Material;

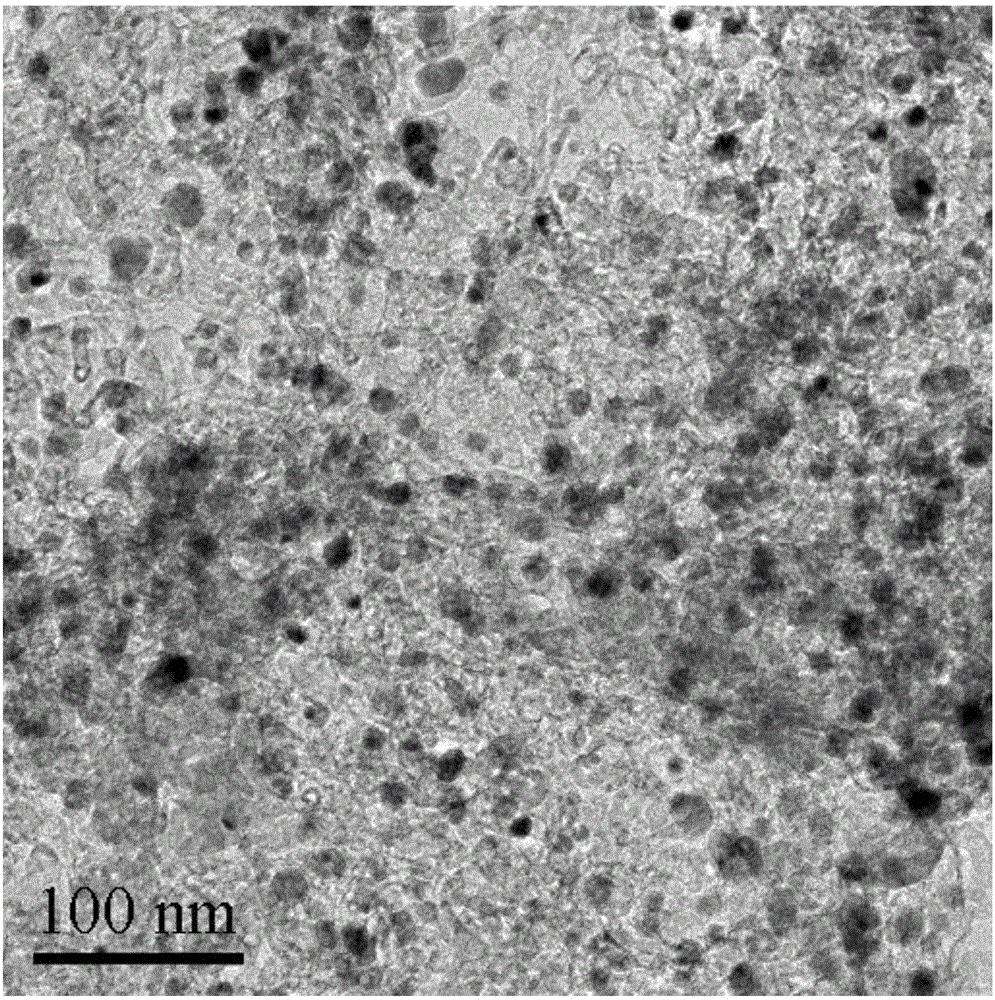

[0030] 2) Under the protection of nitrogen, the ZIF-67@SiO obtained in step 1) 2 The material was calcined at 600°C for 8h. After the calcination was completed, the obtained product was soaked in 10wt.% hydrofluoric acid solution for 5h to remove SiO 2 And cobalt nanoparticles with unstable surface, washed with distilled water until neutral, and dried to obtain a nitrogen-doped carbon materia...

Embodiment 2

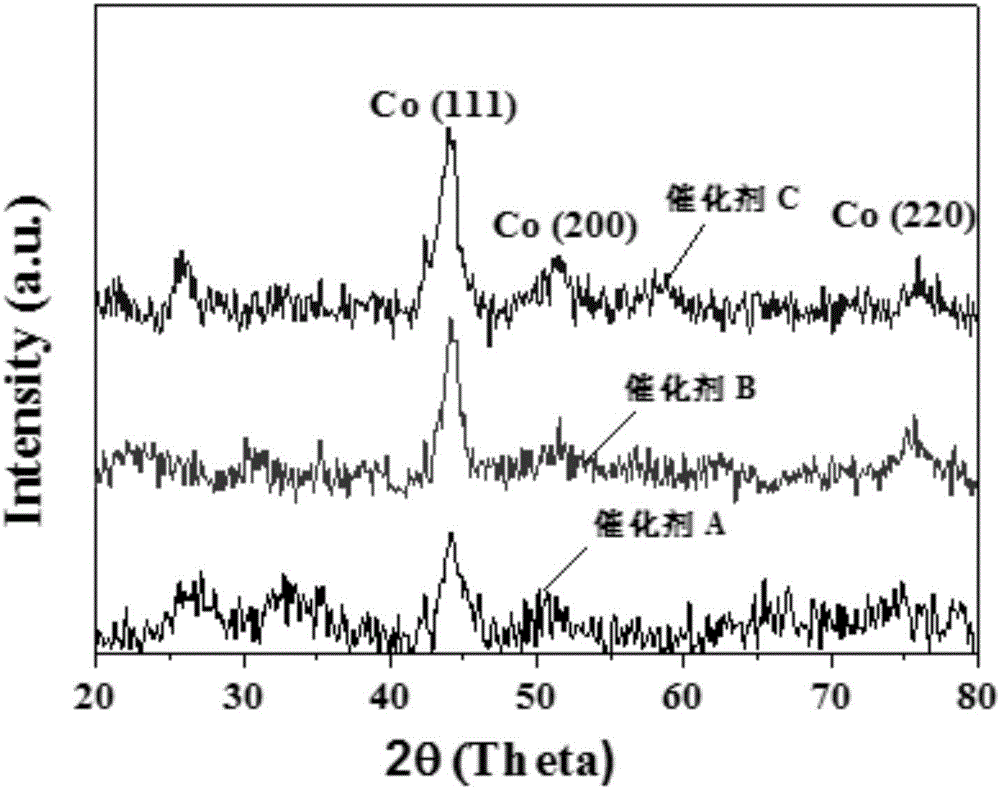

[0033] The operation and steps are the same as in Example 1, only the calcination temperature is changed, and the calcination temperature is changed to 800°C, and the obtained nitrogen-doped carbon material wraps the cobalt catalyst CN@Co, which is marked as catalyst B.

Embodiment 3

[0035] The operation and steps were the same as in Example 1, only the calcination temperature was changed, and the calcination temperature was changed to 900°C, and the obtained nitrogen-doped carbon material wrapped the cobalt catalyst CN@Co, which was marked as catalyst C.

[0036] Carry out X-ray diffraction analysis to the nitrogen-doped carbon material wrapped cobalt catalyst prepared in embodiment 1-3, the obtained X-ray diffraction pattern is as follows figure 2 shown, from figure 2 It can be seen that the three peaks at 2θ=44.1°, 51.5° and 75.8° are characteristic peaks of cobalt nanoparticles, further indicating the presence of cobalt nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com