Catalyst for preparing C2-C3 lower aliphatic amine and production method thereof

A production method and a catalyst technology, which are applied in the field of catalysts for the preparation of amines by ammoniation and the field of preparation thereof, can solve the problems of unreported application examples of lower aliphatic amines, complex preparation of catalysts, cumbersome impregnation process, etc., and achieve good mechanical strength and stability , long service life, easy and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

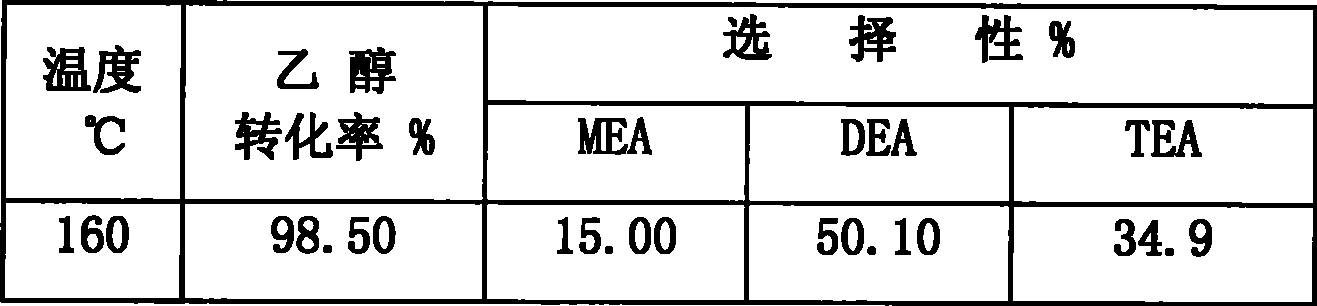

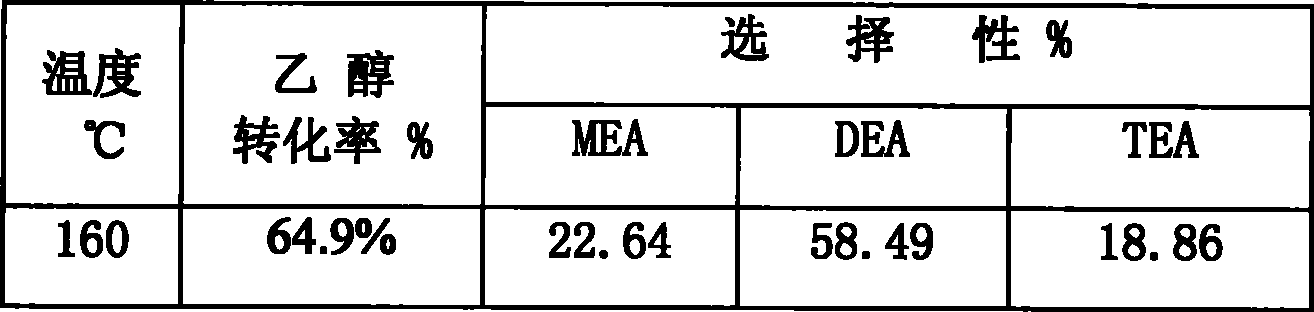

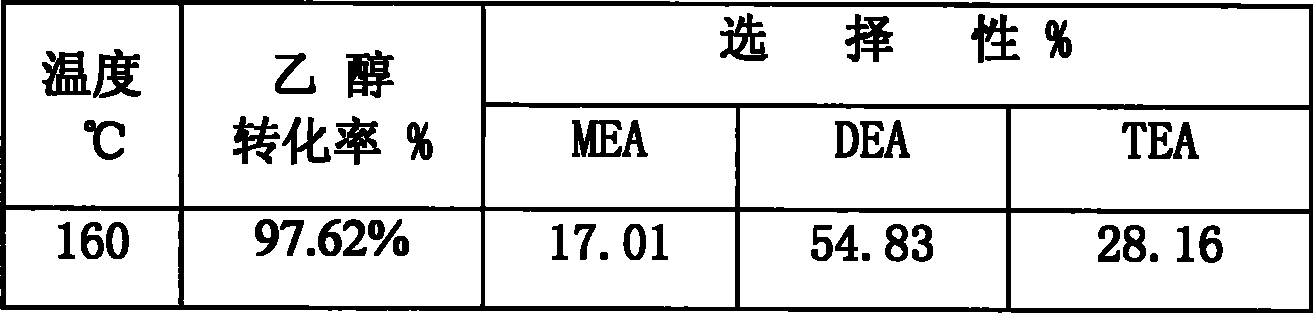

Examples

Embodiment 1

[0031] Embodiment 1, a kind of for preparing C 2 ~C 6 The production method of the catalyst of lower aliphatic amine, carries out following steps successively:

[0032] 1), preparation carrier:

[0033] Adopt the pseudo-boehmite 500g of the macropore high specific surface of low silicon (or high silicon), add 30g carbon black, add mass concentration 65% (Wt) nitric acid aqueous solution 10ml, add the phosphoric acid aqueous solution 2ml of 98% (Wt) again and 20 ml of aqueous solution prepared with 5 g of citric acid, and kneaded for 60 to 100 minutes by a kneader. Then it is extruded into a φ3.5mm×5.0m strip by an extruder, and dried at 80-160°C to obtain an initial alumina carrier.

[0034] Put the initial alumina carrier into a muffle furnace at 950°C for 12 hours to obtain Al 2 o 3 carrier.

[0035] 2), preparation catalyst:

[0036]First, dissolve 170g of cobalt nitrate, 18.5g of nickel nitrate, 6.0g of iron nitrate, and 6.9g of magnesium nitrate in 60g, 6.0g, 2g, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com