Patents

Literature

765results about "Iron sulfates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

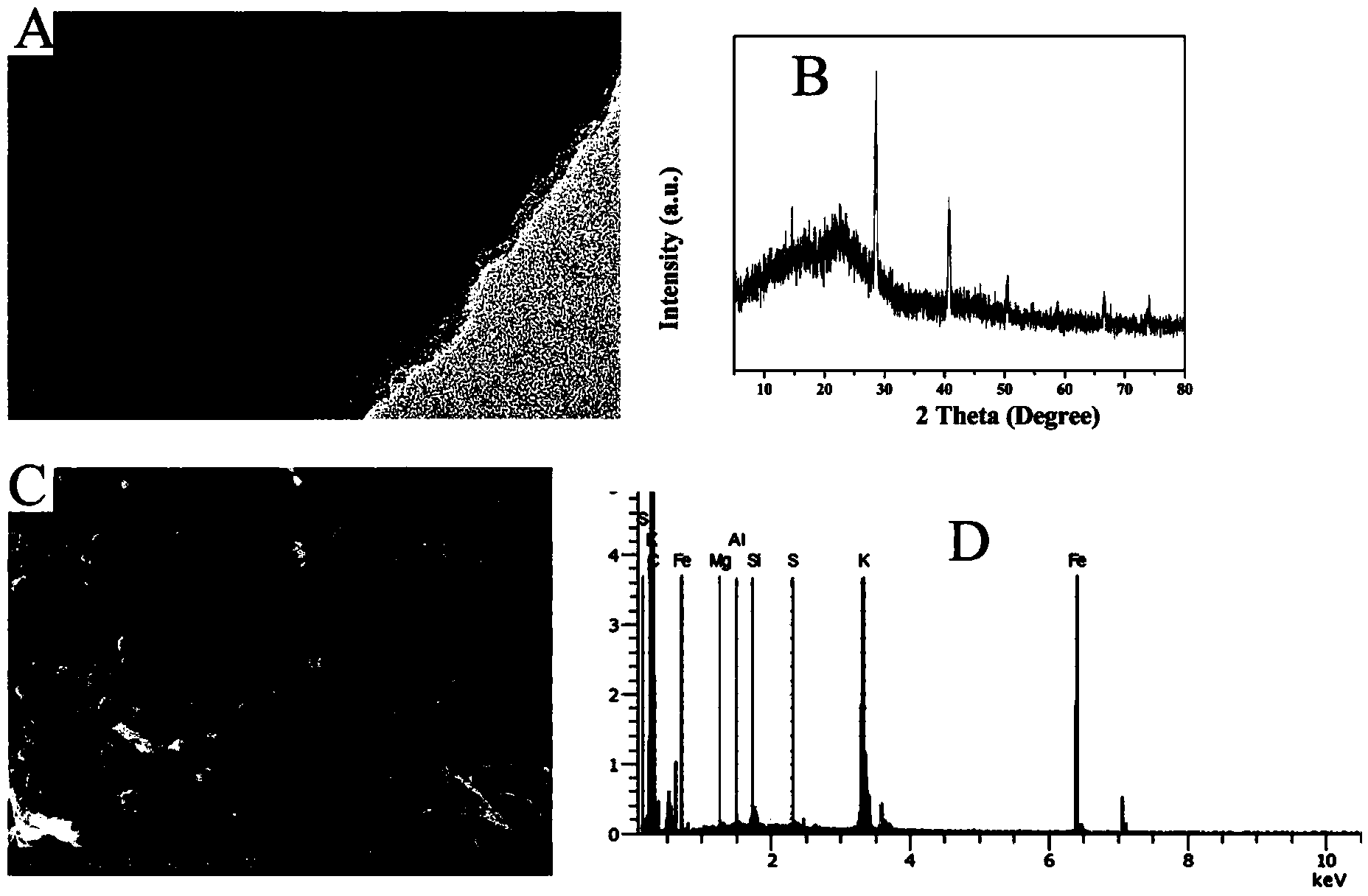

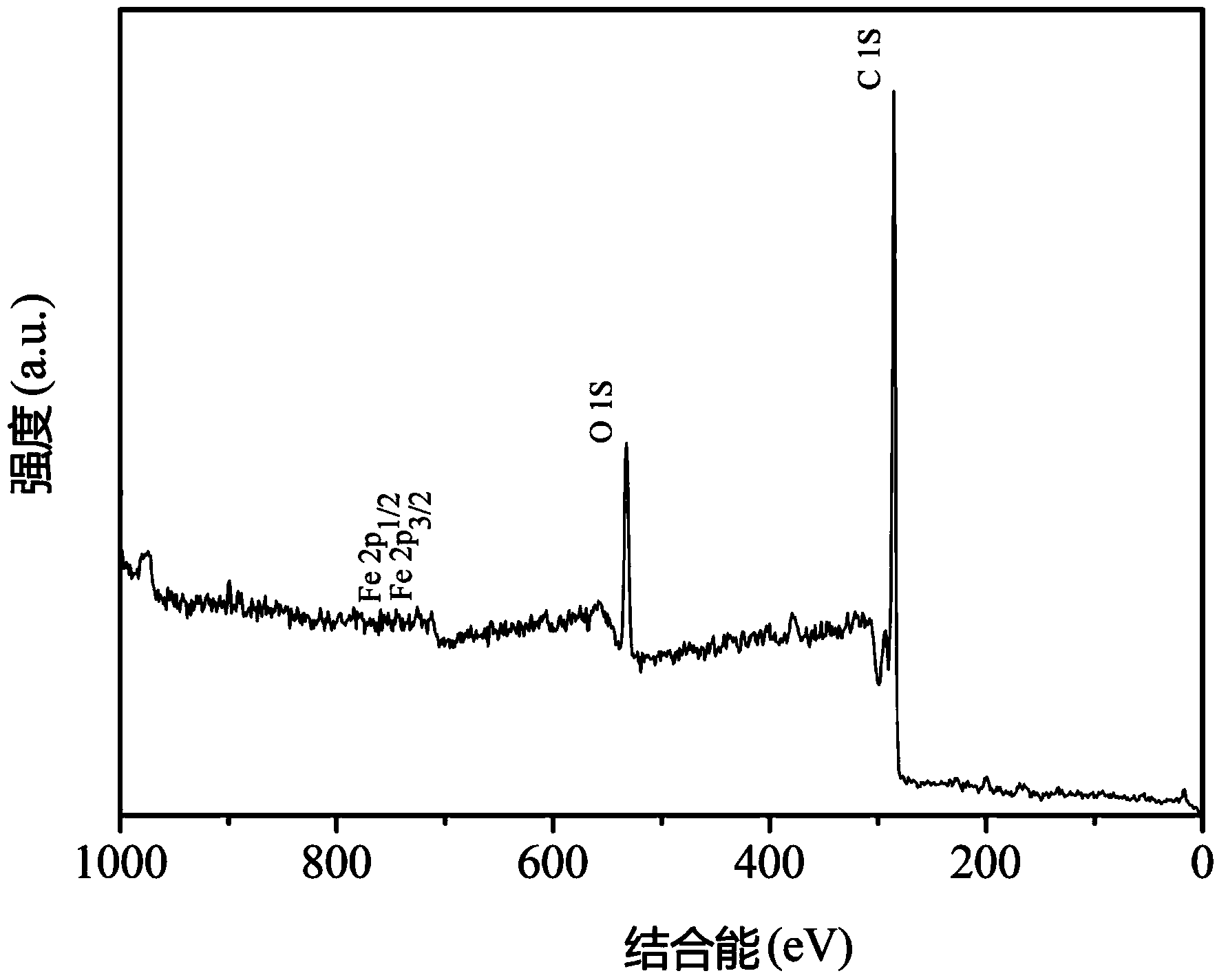

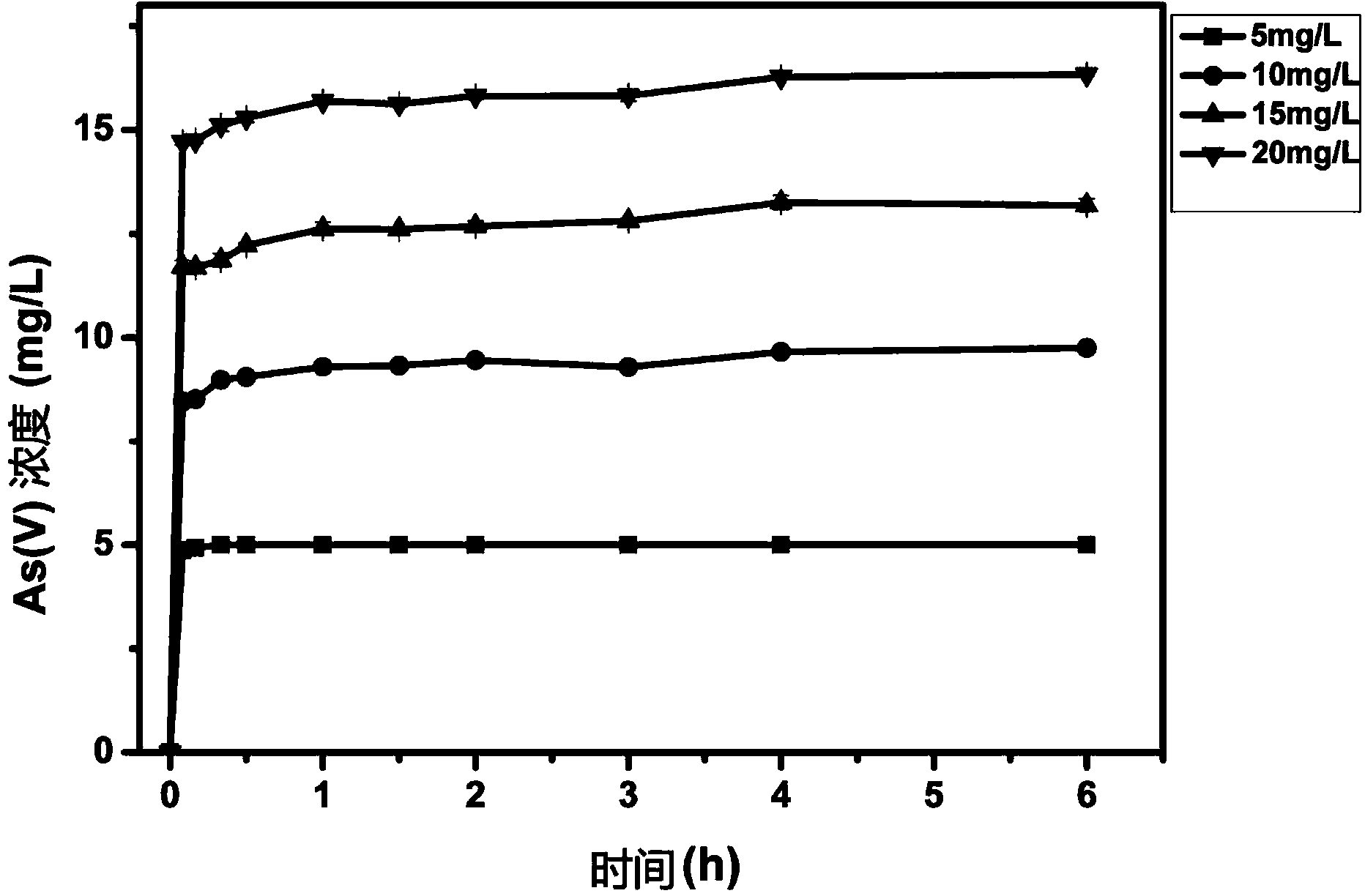

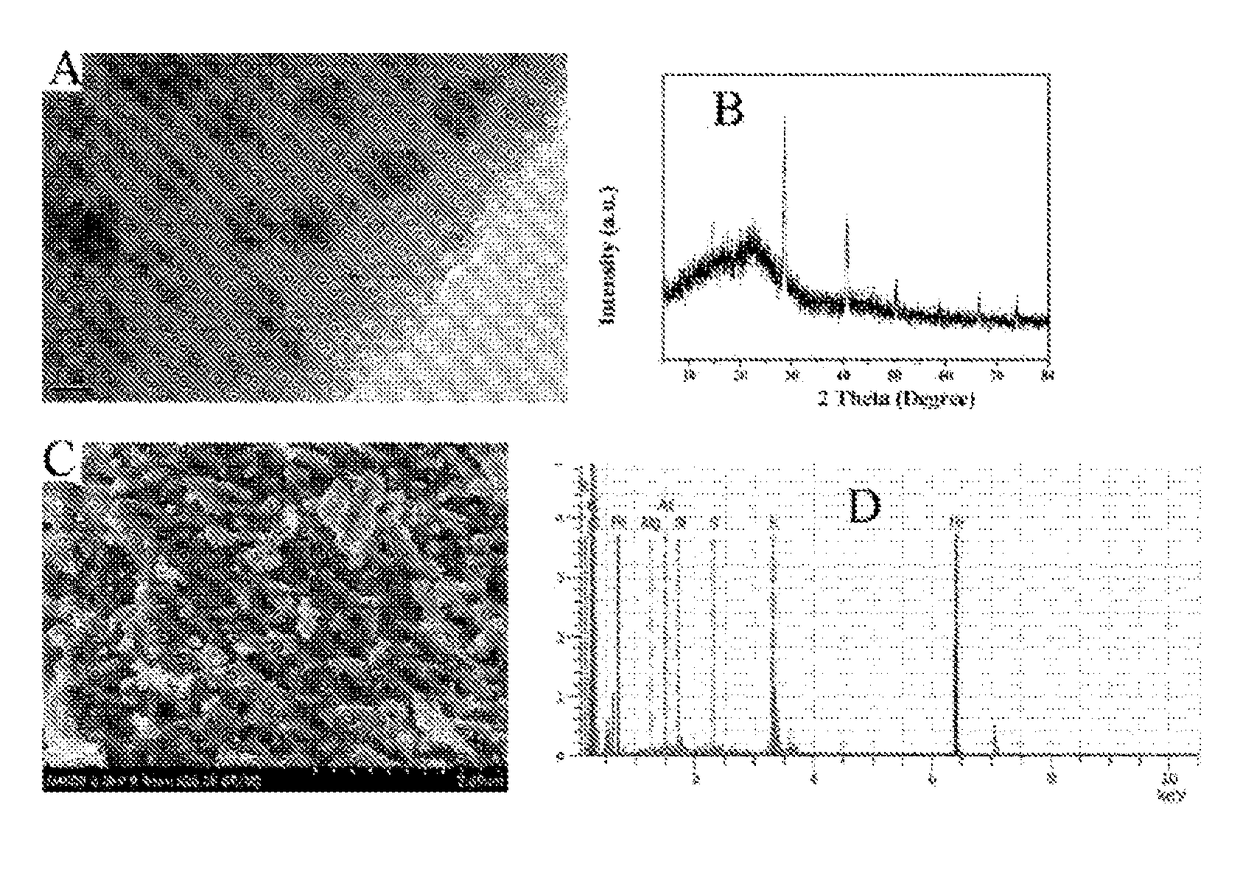

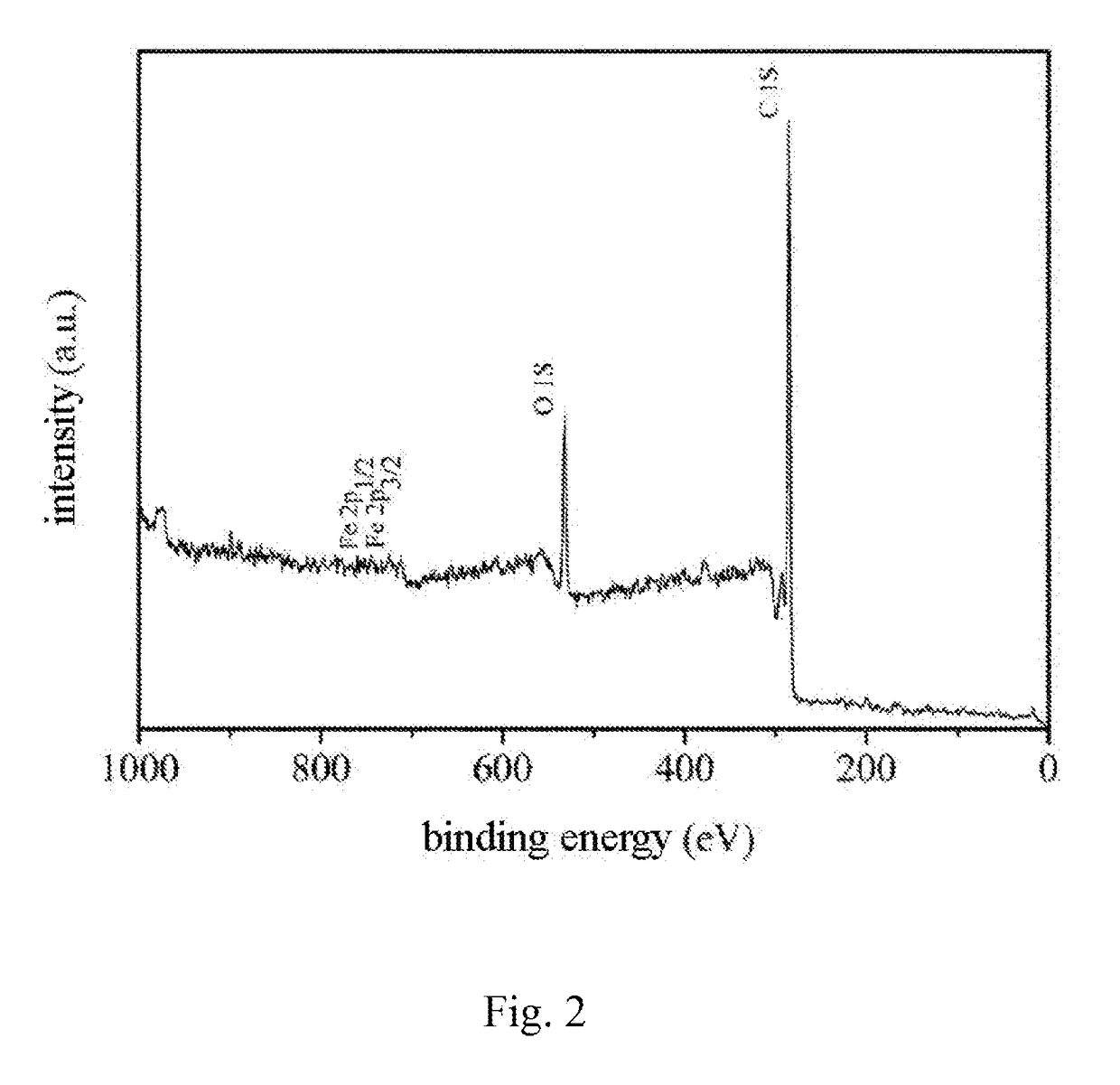

Iron-based bio-char material, preparation process thereof, and application thereof in soil pollution treatment

ActiveCN104388094AImprove performanceReduced bioavailabilityTransportation and packagingContaminated soil reclamationCarbonizationSoil heavy metals

The invention relates to the technical field of soil heavy metal remediation, and specifically discloses a method for preparing an iron-based bio-char material, a prepared iron-based bio-char material, and a method for applying the iron-based bio-char material in treating soil heavy metal pollution. According to the material, biomass is adopted as a raw material; a high-temperature carbonization method is adopted; during the bio-char preparation process, an iron-containing compound is added, such that iron is doped according to a certain ratio, and the iron-based bio-char material with special structure and function is formed. The material has the advantages of simple preparation process, low production cost, and short production period. The obtained iron-based bio-char material has a unique effect in repairing arsenic-cadmium composite polluted soil. With the material, bio-availability of arsenic and cadmium in soil can be effectively reduced, arsenic and cadmium contents in agricultural products planted in the arsenic-cadmium composite polluted soil can be greatly reduced, and no toxic or side effect is caused on crops. The material is safe to apply, and can be used in a large scale in treatment of arsenic-cadmium composite polluted soil.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

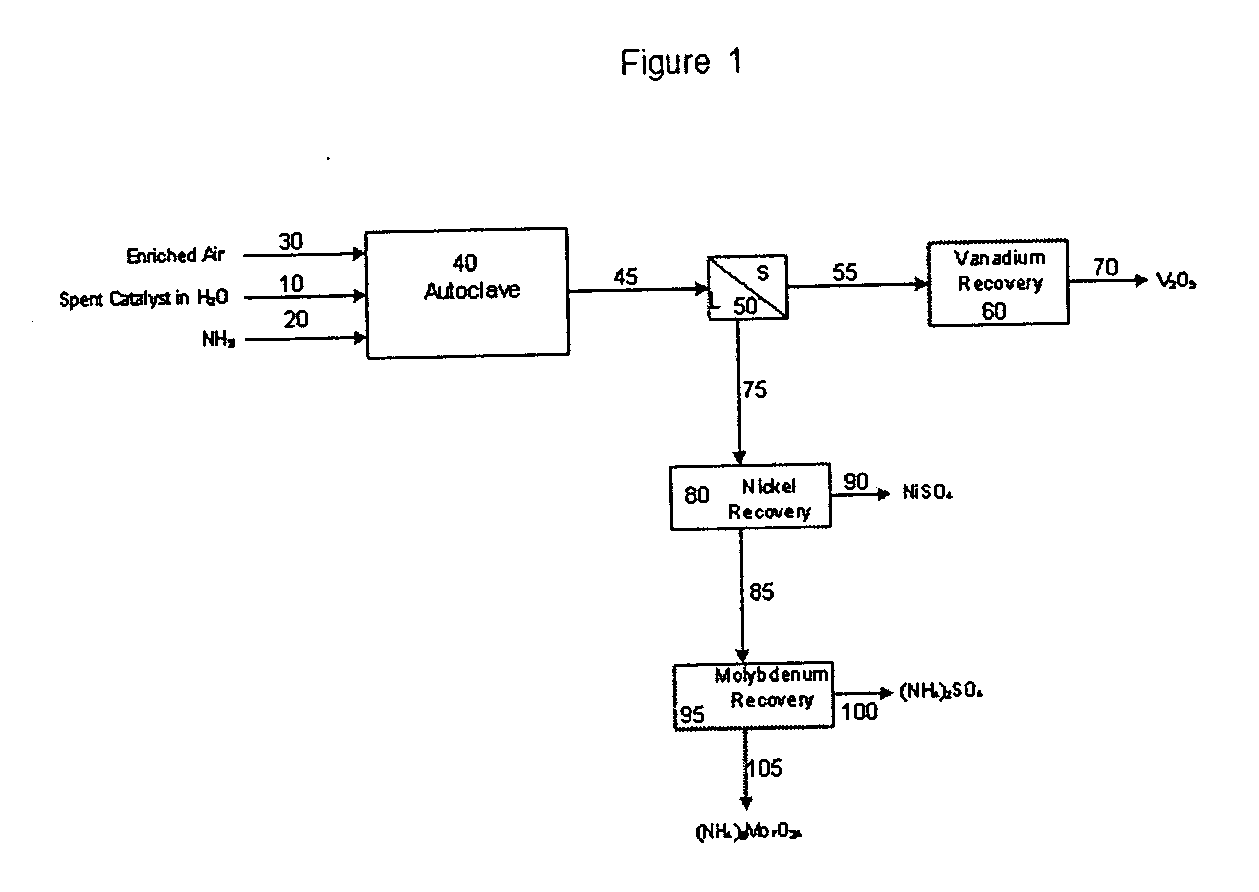

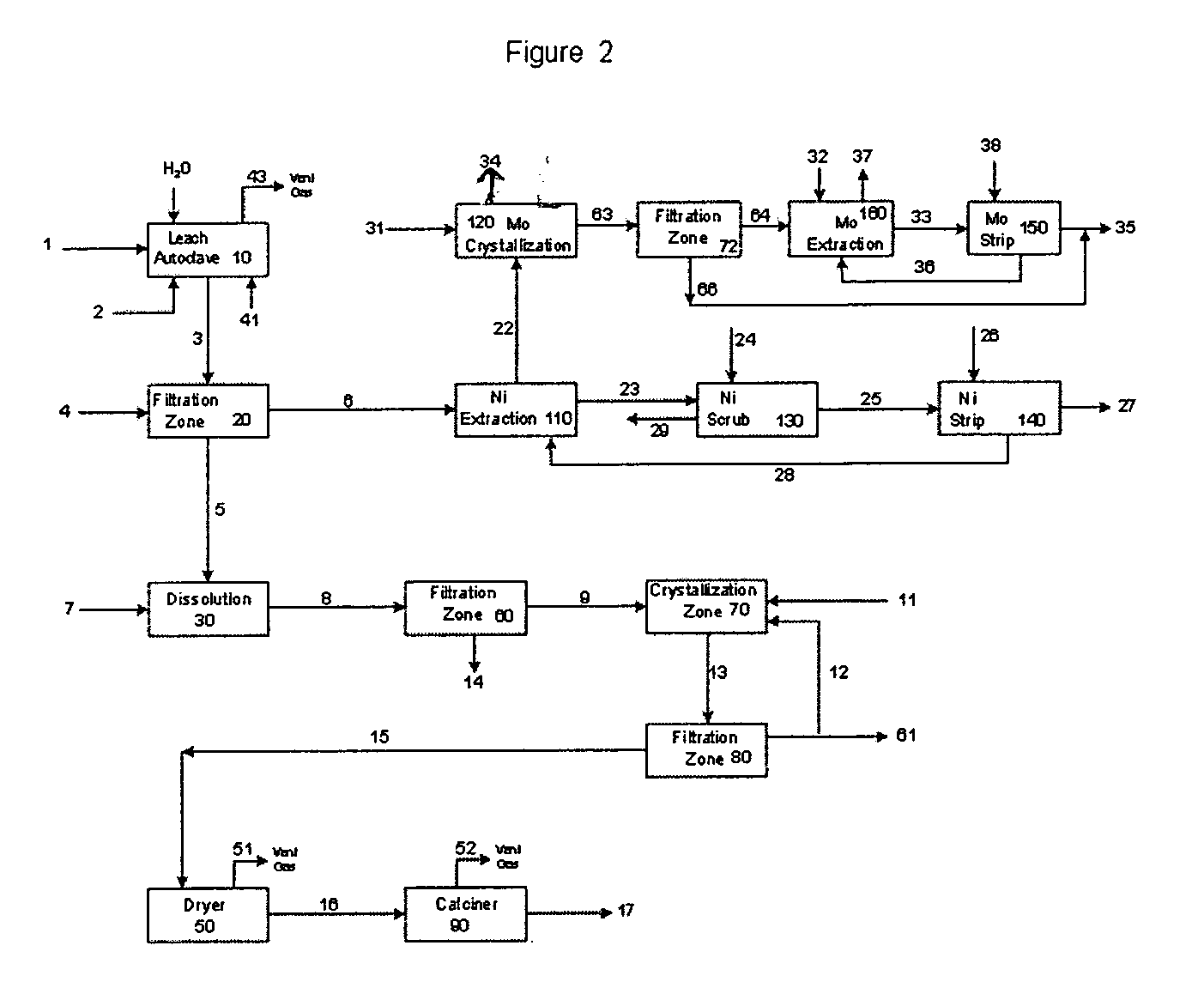

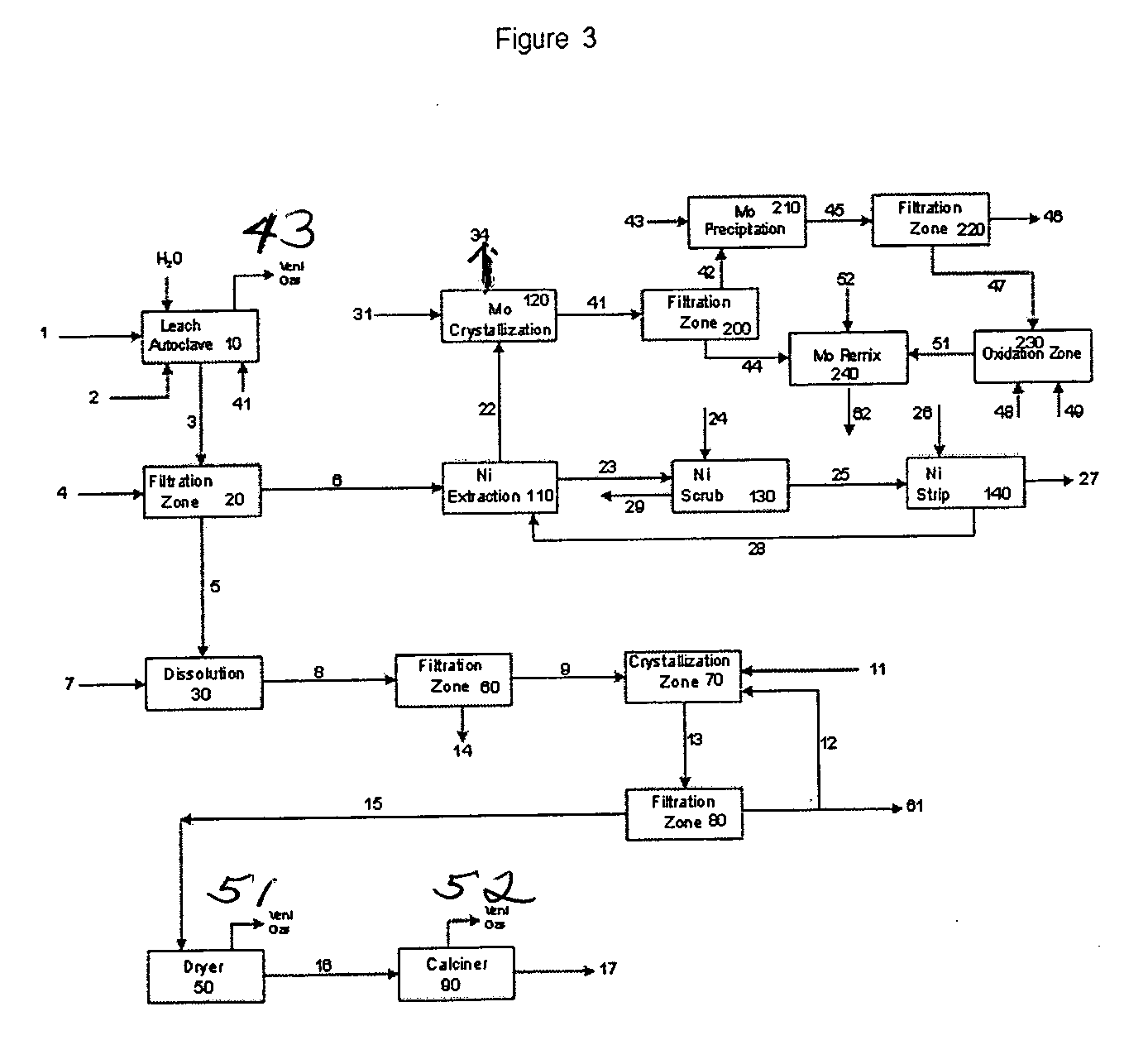

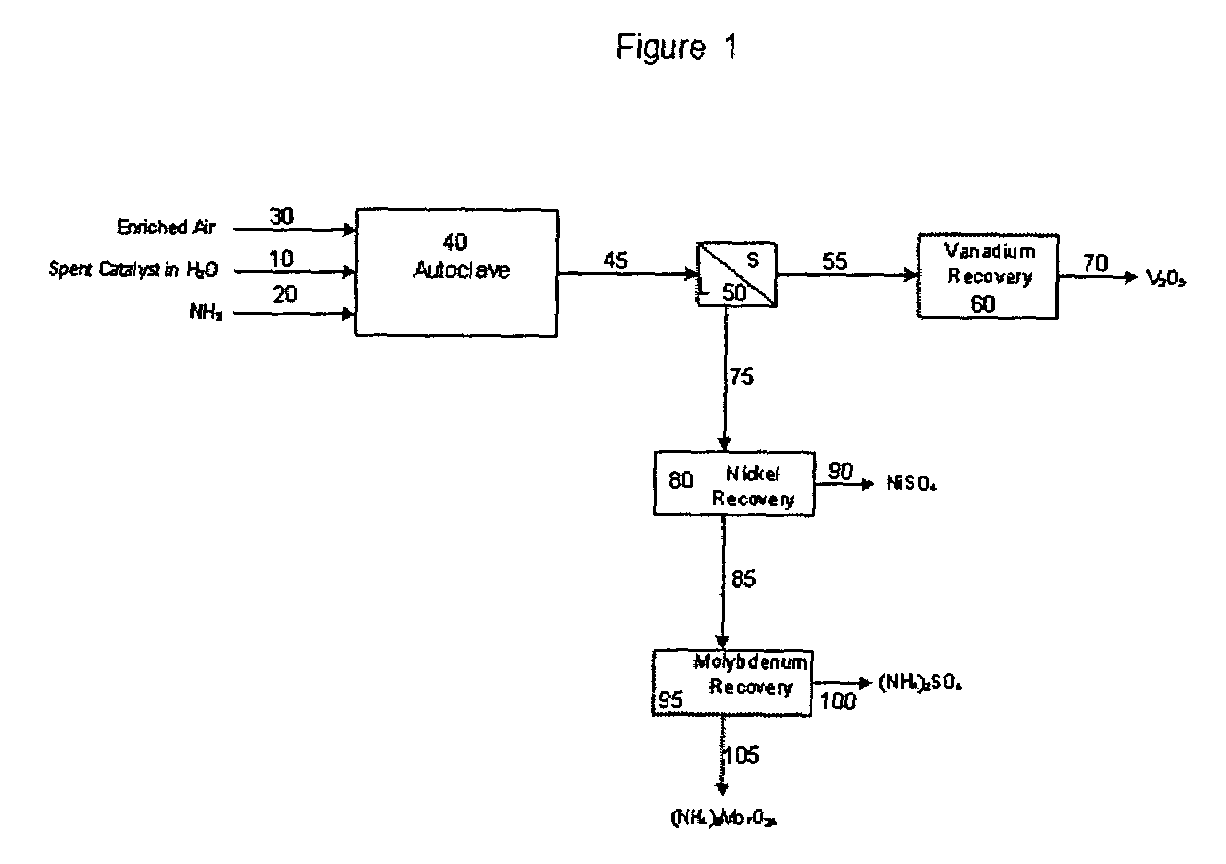

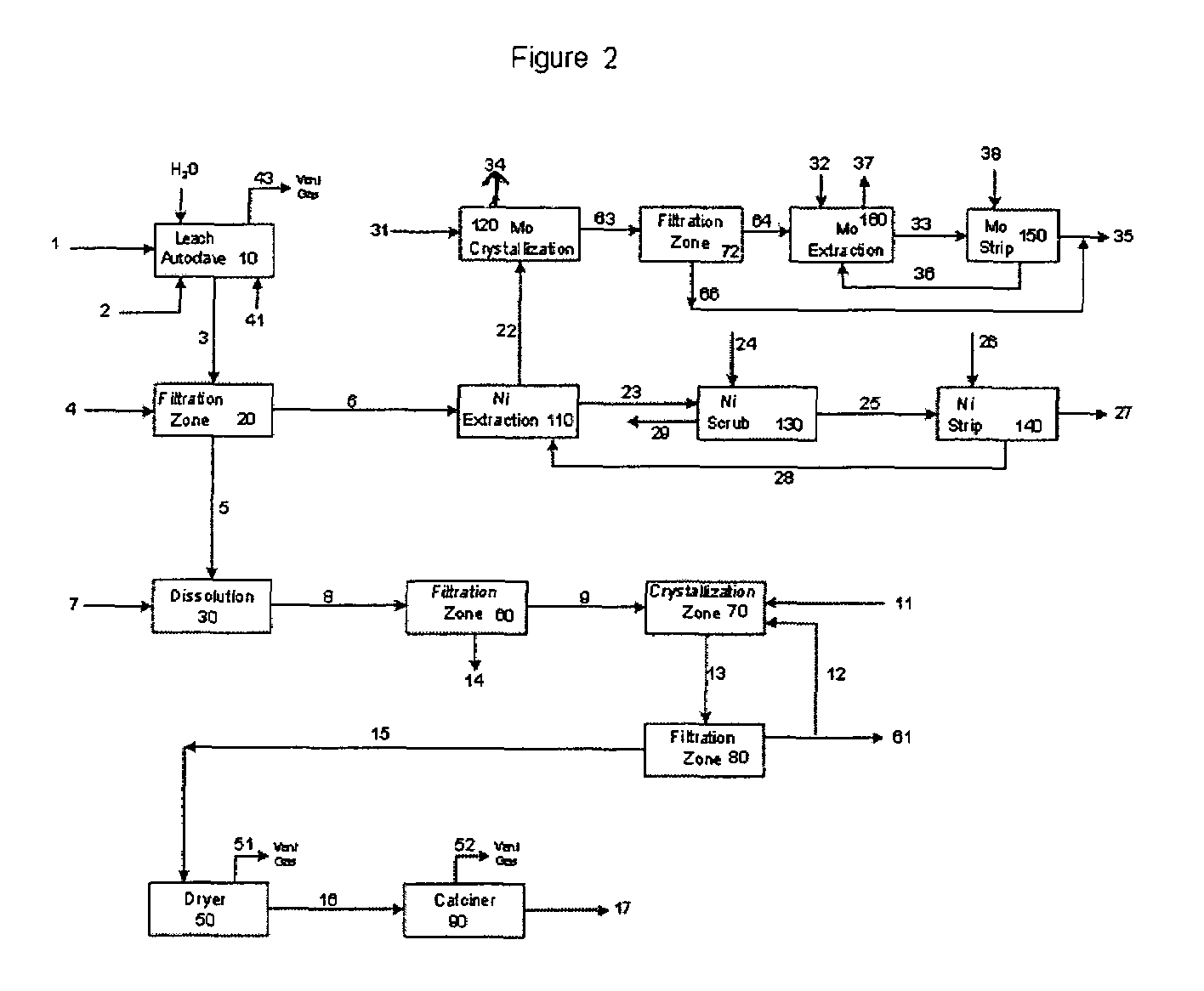

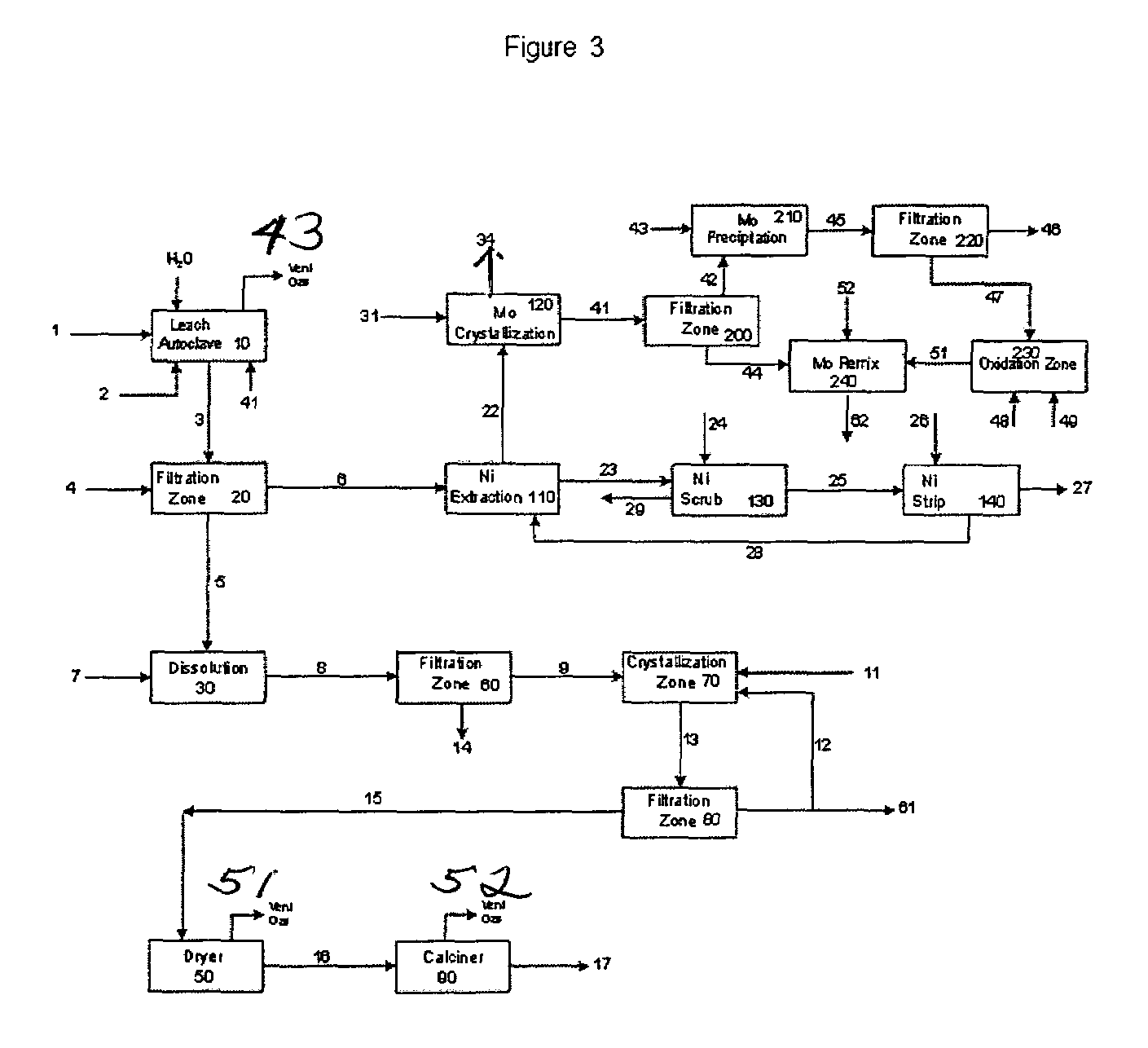

Process for metals recovery from spent catalyst

The process of this invention is directed to the removal of metals from an unsupported spent catalyst. The catalyst is subjected to leaching reactions. Vanadium is removed as a precipitate, while a solution comprising molybdenum and nickel is subjected to further extraction steps for the removal of these metals. Molybdenum may alternately be removed through precipitation.

Owner:CHEVROU USA INC

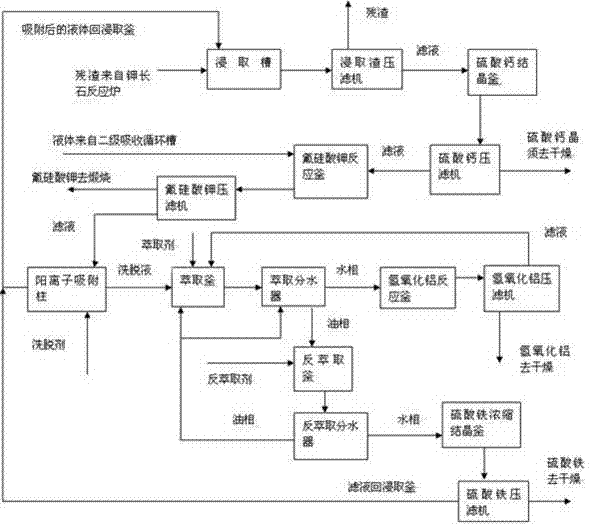

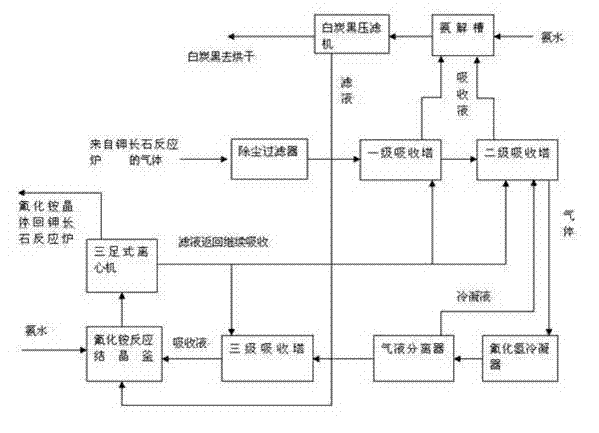

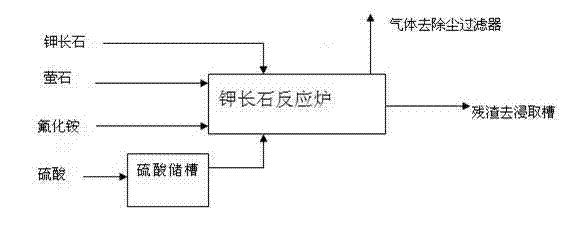

Process for decomposing potassium feldspar by adopting low-temperature semidry method for comprehensive utilization

ActiveCN103172074AAvoid wastingLower requirementSilicon halogen compoundsSilicaAluminium hydroxideDecomposition

The invention relates to potassium feldspar decomposition and comprehensive utilization technology and in particular relates to a process for decomposing potassium feldspar by adopting a low-temperature semidry method for comprehensive utilization. The process comprises the steps of fully mixing potassium feldspar, fluorite and sulfuric acid, then adding the mixture to a converter reactor to react at 180-250 DEG C, separating SiF4 and HF generated through a reaction from a system under the condition of negative pressure, carrying out absorption with ethanol and water solution to prepare white carbon black, recovering fluorine resources in the process from the solution in the forms of ammonium fluoride and other aids by adopting the method of adding ammonia water and applying the recovered fluorine sources to decomposition of potassium feldspar and carrying out a series of processes such as extraction on the solids after a reaction to obtain calcium sulfate whisker, potassium fluosilicate, aluminium hydroxide and ferric sulfate products. Compared with the method for decomposing potassium feldspar by a high temperature method, the process has the advantages that the reaction conditions are mild and the requirements for equipment are lower; the white carbon black is directly prepared through gas hydrolysis, thus avoiding the tedious course from solid phase separation; and the fluorine resources introduced to the decomposition course are recycled by adopting the mode of ammonium fluoride, thus avoiding waste of the fluorine resources.

Owner:LUOYANG FLUORIDE & POTASSIUM TECH +1

Iron-based biochar material, preparation therefor and use thereof in soil pollution control

ActiveUS20170282229A1Reduce cadmium-arsenic combined pollutionMaintain stable propertiesMixing methodsTransportation and packagingCarbonizationSoil heavy metals

The present invention belongs to the technical field of soil heavy metal remediation, specifically discloses a method for preparing the iron-based biochar material, the iron-based biochar material prepared there from and a method for controlling the heavy metal pollution in soil using the iron-based biochar material. For the iron-based biochar material of the present invention, by using a method of high-temperature carbonization, a biomass is used as a raw material and an iron-containing compound is add in the process of preparing biochar, wherein iron is incorporated in a specific ratio, to form the iron-based biochar material with a special structure and function. The material has a simple preparation process, low cost and a short production period; the prepared iron-based biochar material has an unique effect on the arsenic-cadmium combined pollution soil remediation, can effectively reduce the bioavailability of arsenic and cadmium in the soil, significantly reduces the arsenic and cadmium contents in the agricultural products planted in the arsenic-cadmium combined pollution soil, and has no toxic and side effects on the crops, is safe to apply and can be applied to the control of arsenic-cadmium combined pollution soil in a large scale.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

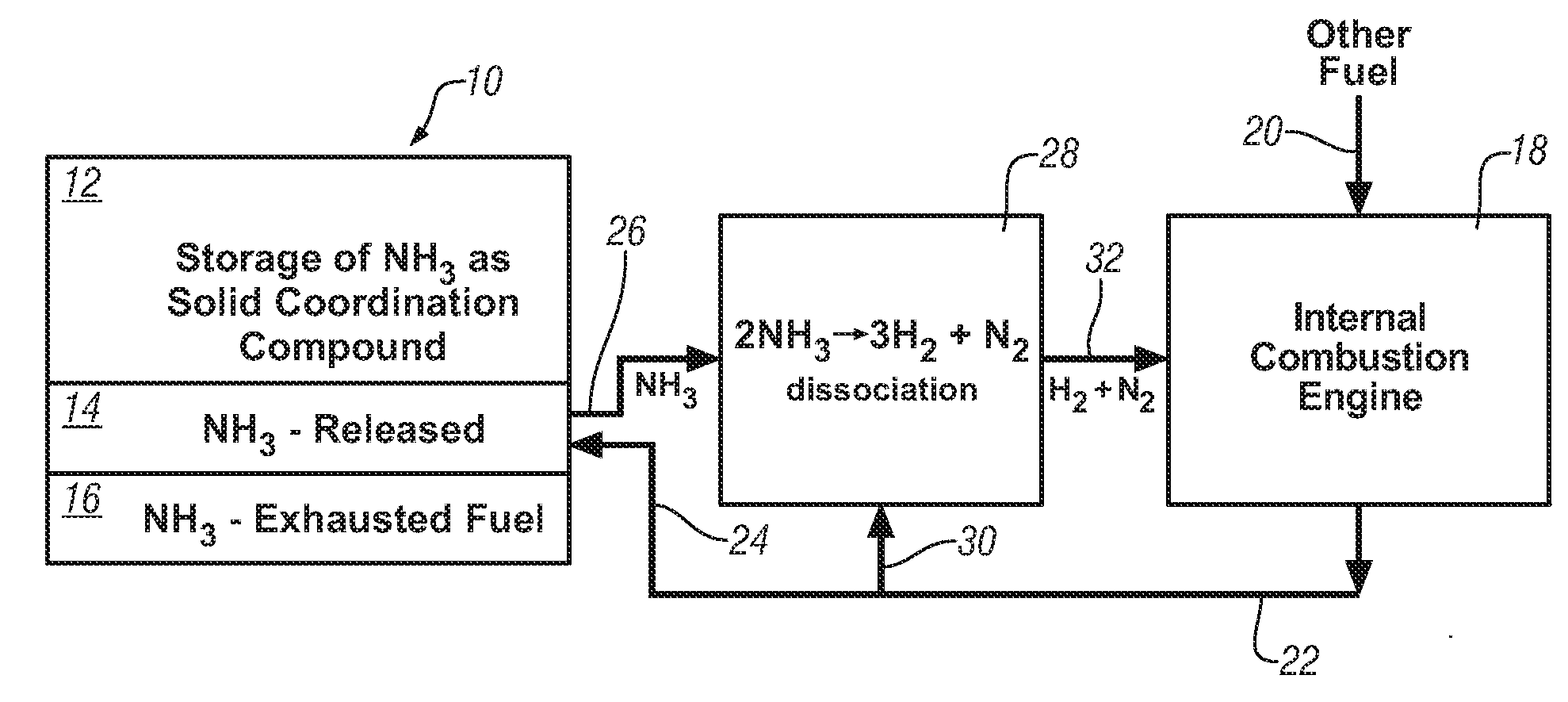

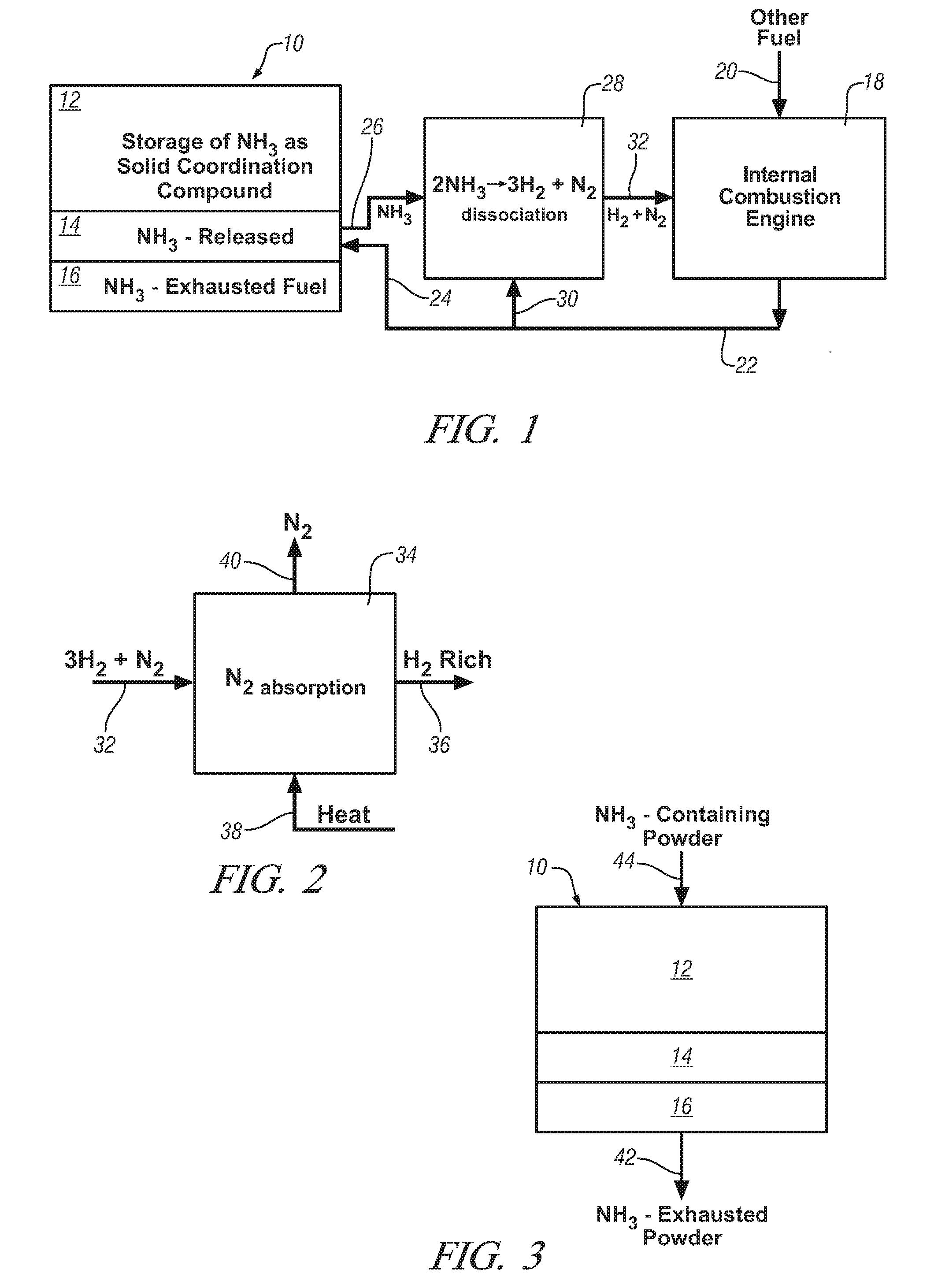

Ammonia storage for on-vehicle engine

InactiveUS20080241033A1Efficient and reversible processCobalt ammonia complexesCyanogen compoundsAmmonia storageExternal combustion engine

Ammonia is used as precursor source of hydrogen fuel in an on-vehicle internal combustion engine. Ammonia is stored as, for example, a ligand in an on-vehicle transition metal composition. Upon demand for hydrogen by the vehicle's engine control system, ammonia is expelled as a gas from some of the composition and the ammonia gas is dissociated into a mixture of hydrogen and nitrogen and delivered as a fuel-containing mixture to the engine. In a preferred embodiment, the hydrogen is used as a supplement to gasoline as a fuel for engine operation.

Owner:GM GLOBAL TECH OPERATIONS LLC

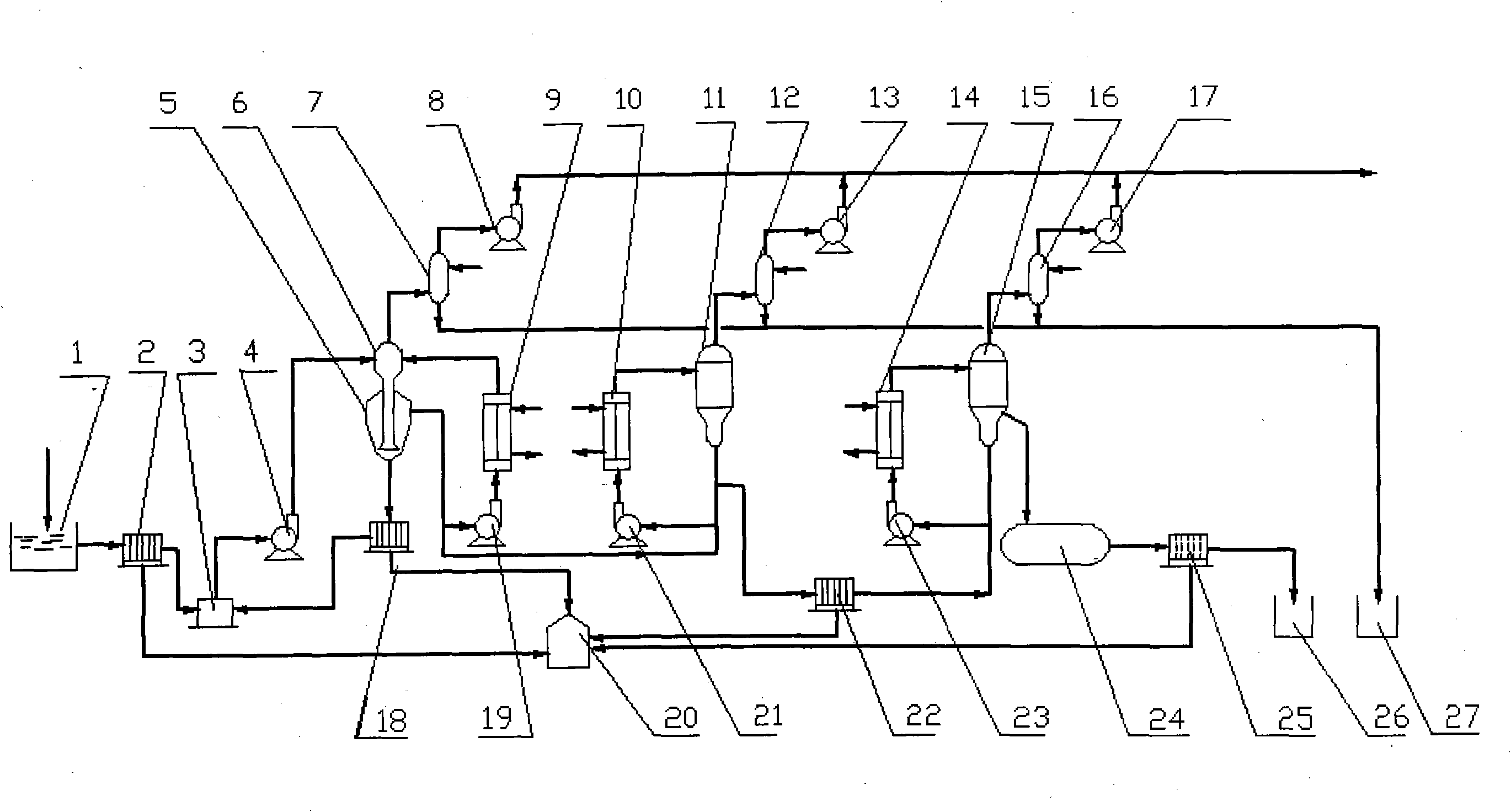

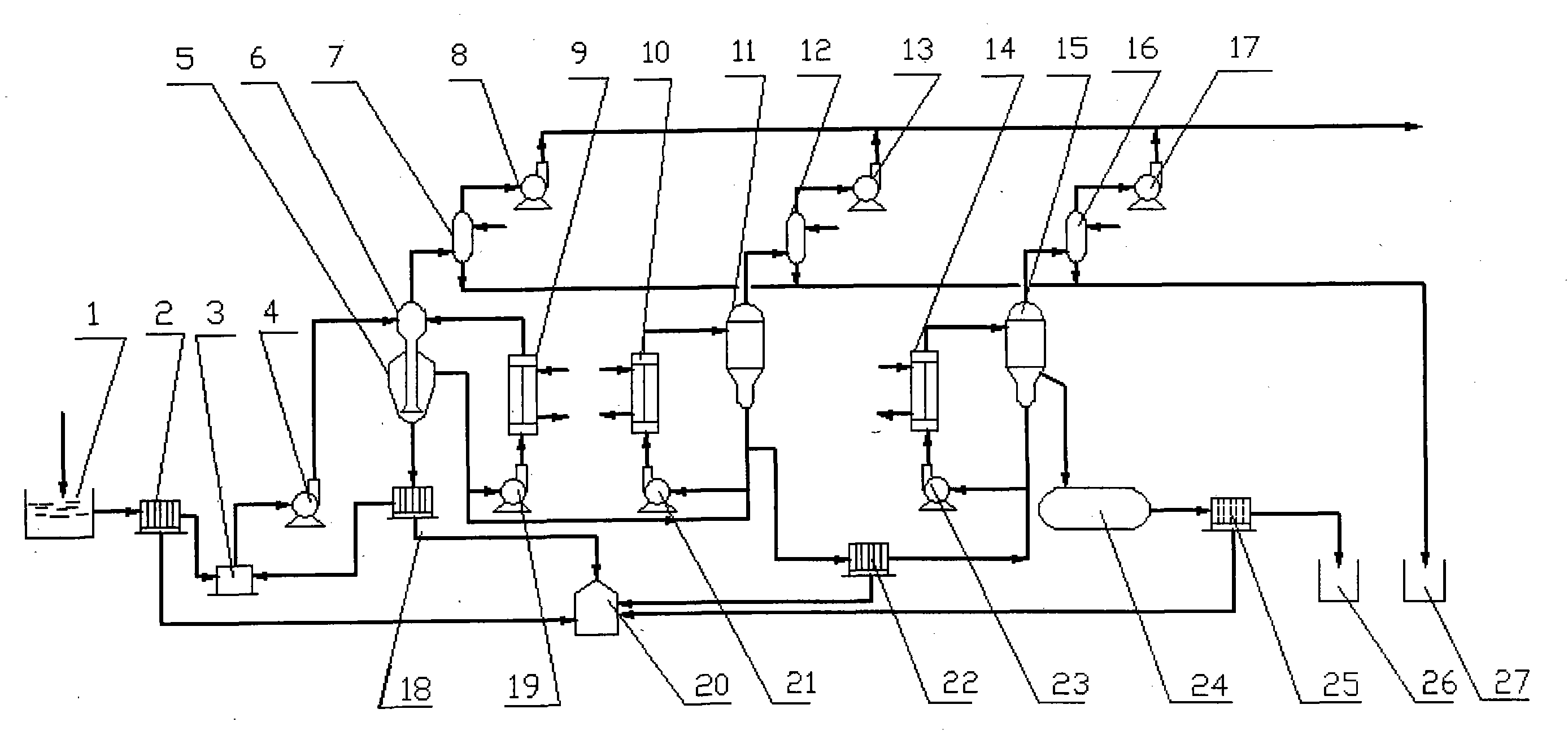

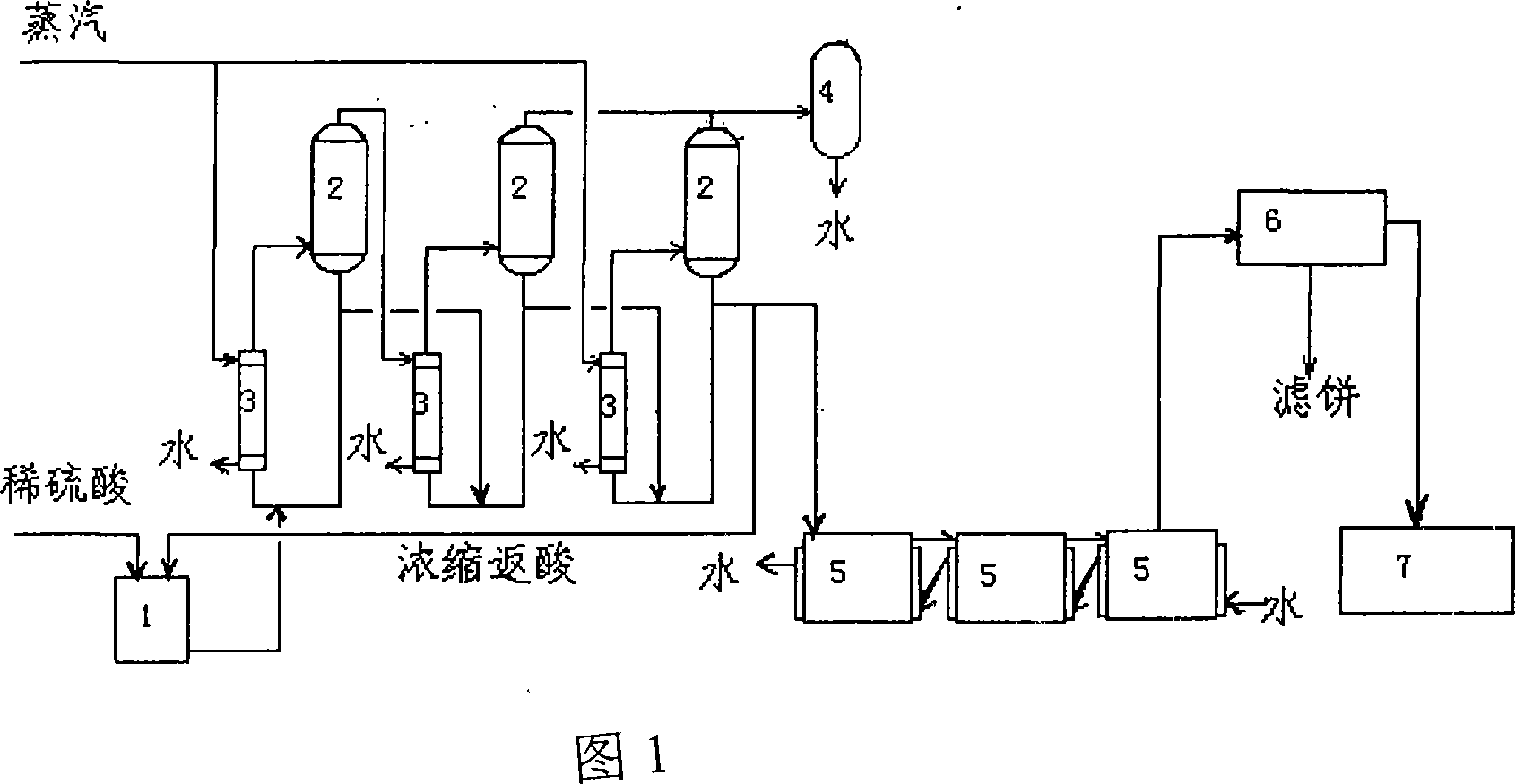

Process for recovering sulfuric acid and sulfate from waste acid generated in preparation of titanium dioxide by using sulfuric acid method

InactiveCN102079512AImprove recycling ratesIncrease concentrationSulfur-trioxide/sulfuric-acidIron sulfatesHigh concentrationWater vapor

The invention relates to a process for recovering sulfuric acid and sulfate from waste acid generated in the preparation of titanium dioxide by using a sulfuric acid method, belonging to the technical field of waste acid treatment in the industrial production. The invention recovers sulfuric acid and sulfate products from waste acid generated in the production process for preparing the titanium dioxide by using the sulfuric acid method through the sedimentation pretreatment and the simple process including the first segment of flash evaporation-crystallization, concentration and separation, the second segment of vacuum evaporation, concentration and separation and the third segment of vacuum evaporation, concentration and separation. The invention has simple process, convenience of operation, simple equipment, high performance price ratio and high yield, high concentration and less impurities of the product acid, can recycle resources without waste liquid or waste residue emission and can be favorable to environmental protection and energy saving, and emitted exhaust mainly contains air and less vapor, is non-toxic to the environment and can effectively overcome the difficulties of fouling and clogging of the equipment. The invention can be widely applied to the recovery of waste acid in the industrial production and be particularly suitable for recovering the waste acid generated in the preparation of titanium dioxide by using the sulfuric acid method.

Owner:CHONGQING UNIV

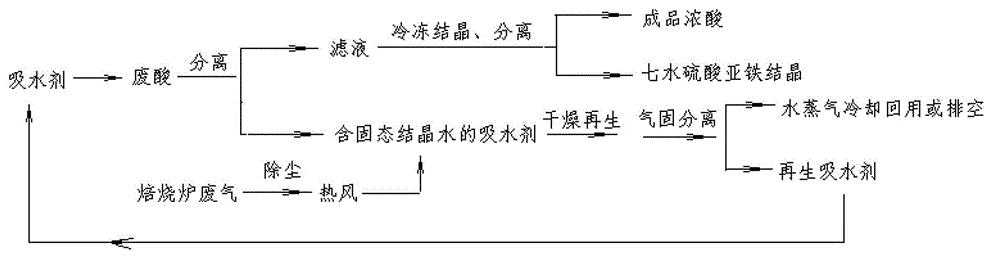

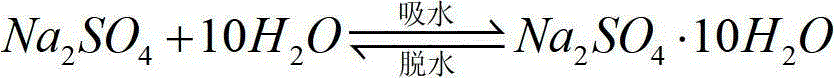

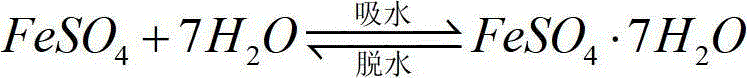

Method for concentrating waste sulfuric acid by utilizing waste heat of titanium dioxide calcinator

InactiveCN102910594ASolve manySolve process problemsSulfur compoundsEnergy inputLiquid waterOperability

The invention discloses a method for concentrating waste sulfuric acid by utilizing waste heat of a titanium dioxide calcinator, comprising the following steps: at normal temperature and pressure, proper amount of water absorbent is added to titanium dioxide waste acid, liquid water is dissolved out in the form of solid crystal water through the water absorbent, filtrate after solid-liquid separation is cooled, iron vitriol in the solution is crystallized and dissolved out, and the acid liquid is further concentrated; the two steps are repeatedly carried out until the concentration of sulfuric acid in the final filtrate reaches more than 60%, and then the final filtrate is utilized in the acid hydrolysis procedure; and the water absorbent is dehydrated and dried to be regenerated by taking dustproof tail gas of the calcinator, and the steam generated in the drying and regeneration is cooled and flows back to technological process as washing water in titanic acid rinsing or is drained. The method provided by the invention solves the problems of more equipment, long flow and easy blockage in the existing technology, and the equipment investment and operating cost are reduced; and the water absorbent is recycled after being regenerated, so that the energy is saved, the consumption is reduced, and the efficiency is obvious; no wastewater, waste gases and residues are generated in the whole technology, the operability is strong, the productivity of equipment is high, the flow is simple, the investment is less, the cost is low, energy is saved, emission is reduced, and the benefit is obvious.

Owner:黄正源

Method for purifying ferrous sulfate heptahydrate byproduct in titanium white production

The invention discloses a method for purifying a ferrous sulfate heptahydrate byproduct in titanium white production, which comprises the following steps of: (1) adding a solvent into the byproduct in titanium white production, heating to the temperature of between 65 and 105 DEG C, and stirring for dissolution to prepare saturated solution; (2) adding iron powder at the temperature of between 95 and 105 DEG C; (3) adding phosphoric acid and heating at the temperature of between 95 and 105 DEG C for 10 to 20 minutes; (4) cooling the mixture to the temperature of between 80 and 90 DEG C, adding sulfide, stirring for 30 to 60 minutes, and adding sulphuric acid; (5) adding polyacrylamide, stirring for 3 to 10 minutes, precipitating, and filtering to obtain ferrous sulfate solution; and (6) cooling and crystallizing the ferrous sulfate solution, filtering and separating to prepare ferrous sulfate crystals. The content of the ferrous sulfate heptahydrate prepared is over 20.1 percent, and the content of titanium, lead, cadmium, chromium and magnesium is less than 10ppm based on the lead. The process is simple and the process flow is short.

Owner:LOMON BILLIONS GRP CO LTD

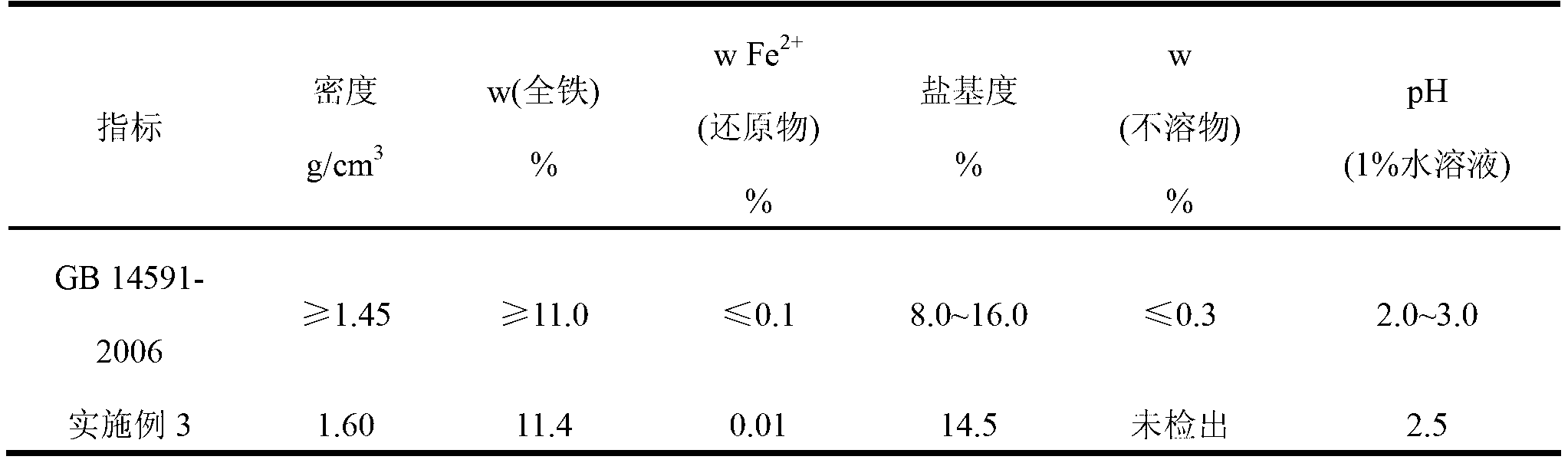

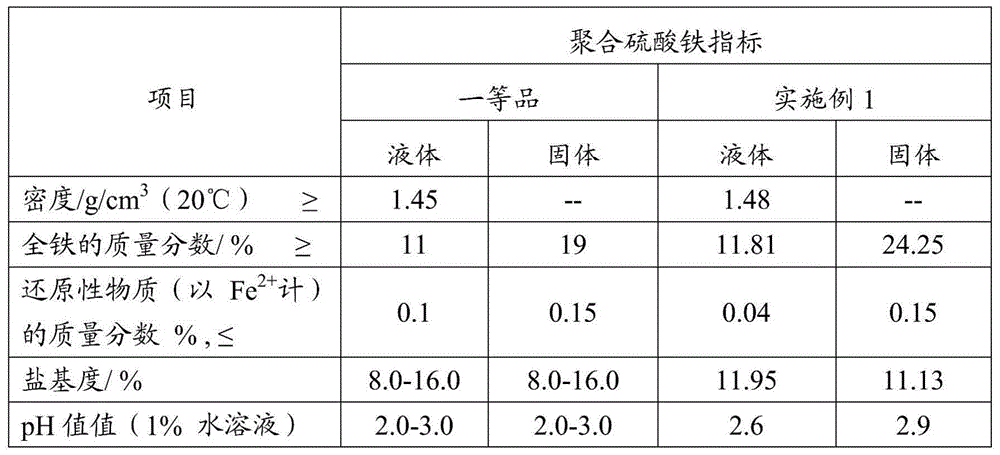

Polymerization ferric sulfate water treatment agent and preparation method thereof

ActiveCN103224256AGuaranteed utilizationFast productionIron sulfatesWater/sewage treatment by flocculation/precipitationSulfateReaction temperature

The present invention discloses a polymerization ferric sulfate water treatment agent and a preparation method thereof. According to the present invention, H2O2 and FeSO4.7H2O are adopted, a molar ratio of the H2O2 to the FeSO4.7H2O is 1.1-2.0:2, and the H2O2 and Fe<2+> are subjected to an oxidation reaction to prepare the polymerization ferric sulfate water treatment agent so as to rapidly produce products meeting user requirements, wherein production is rapid, a reaction temperature is controlled no higher than 40 DEG C so as to ensure a H2O2 utilization rate and a Fe<2+> conversion rate, and raw material utilization rate can be more than 95%; and the method has characteristics of simple production process, simple reaction apparatus, easy operation, low raw material consumption, and low cost, and can be used for industrial production.

Owner:SOUTH CHINA UNIV OF TECH

Concentrating and impurity removing method for dilute sulfuric acid in titanium dioxide powder production process by employing sulfuric acid process

ActiveCN101214931ALow flow resistanceReduce heat transfer efficiencySulfur-trioxide/sulfuric-acidIron sulfatesSulfateEconomic benefits

The invention discloses a concentration and impurity removal method of dilute sulfuric acid in producing titanium dioxide through a sulfuric acid method, which includes the following steps: first the dilute sulfuric acid is fed into a mixing acid tank; after the dilute sulfuric acid is concentrated into concentrated sulfuric acid, part of the concentrated sulfuric acid returns to the mixing acid tank to be mixed into 25 percent to 35 percent of feed acid, and fed into a steam concentration system to receive multi-effect evaporation concentration; part of the concentrated sulfate material returns to the mixing acid tank and the rest enters into a serial back-flow cooling curing crystal growth tank; in the back-flow cooling curing crystal growth tank, the sulfate material after curing crystal growth cooling is fed into a solid-liquid separator to receive solid-liquid separation, and the filtrate is a concentrated sulfuric acid product. Therefore, the invention not only can realize the long-period good operation of devices, but also is characterized by simple process, less investment, low manufacturing expense, obvious economic benefit, etc., and belongs to a novel method of energy saving and emission reduction.

Owner:龚家竹

Preparation method of polysilicate aluminium ferric flocculant

ActiveCN102120623AOxidationLow costIron sulfatesWater/sewage treatment by flocculation/precipitationLiquid productPolymerization

The invention discloses a preparation method of a polysilicate aluminium ferric flocculant, which comprises the steps of: dissolving ferrous sulfate heptahydrate, which is a by-product of a titanium white industry and used as a main raw material, in water, regulating the pH value of the dissolved ferrous sulfate heptahydrate to be 0.6-1.0, and then adding titanium white for oxidation; adding aluminum sulfate for polymerization reaction for 30-50min at the water bath temperature of 50-100 DEG C to obtain the polysilicate aluminium ferric flocculant; adding H3PO3 to be used as a stabilizer in the polymerization reaction process; adding a small amount of Na2CO3 when the liquid is even to regulate the alkalization degree of the mixed liquid to be 0.05-0.6; and finally, obtaining a dark-brown polymerized liquid product, i.e. the silicate aluminium ferric flocculant. The preparation method provided by the invention has the advantages of simple process, low cost, and no waste liquid, waste gas, and waste residues in a production process. The product has high content of active flocculation components, is superior to the traditional industrial product in full-ferric content and the flocculation property, and can be widely applied to feed water treatment and sewage and wastewater treatment.

Owner:善水(南通)工业技术有限公司

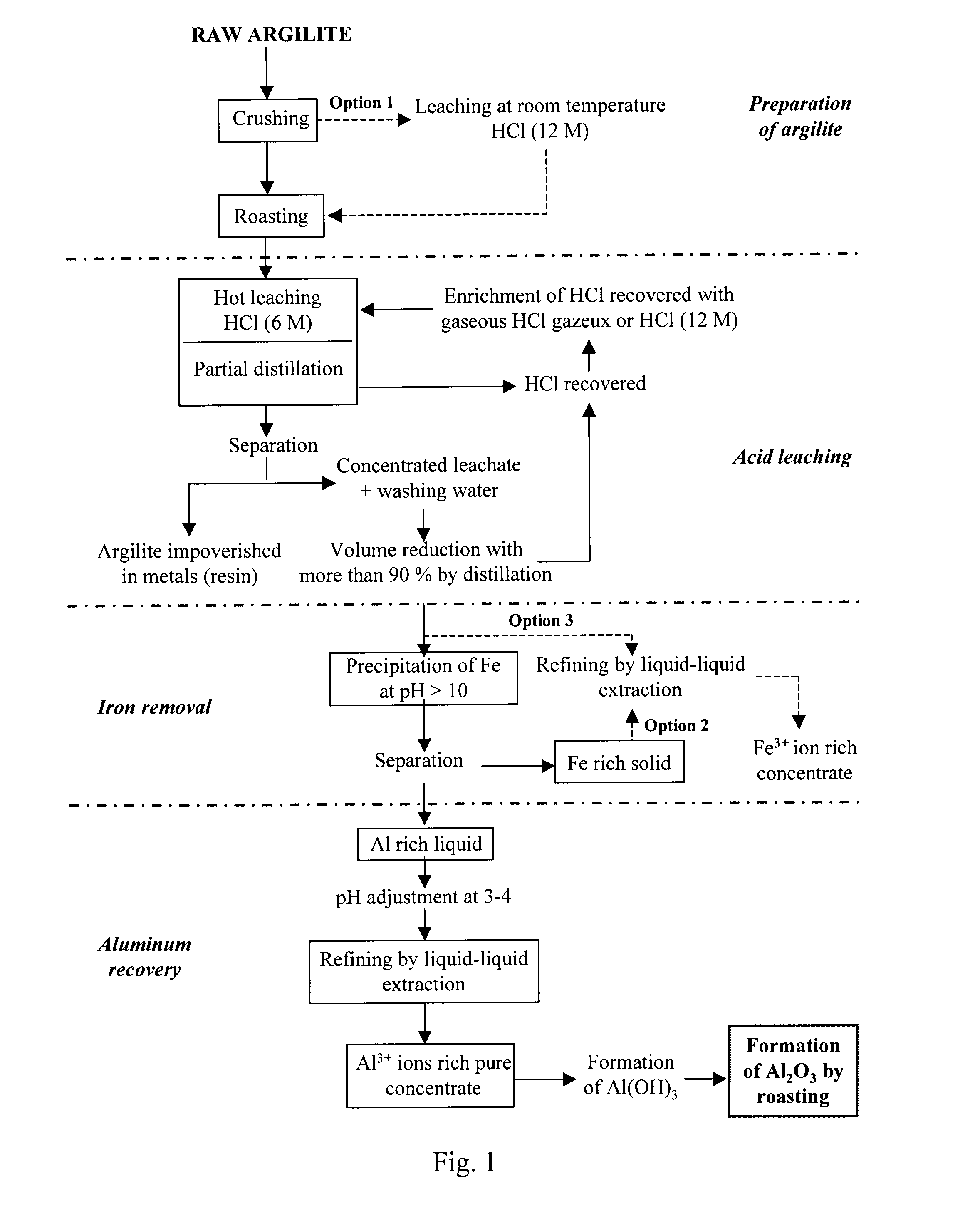

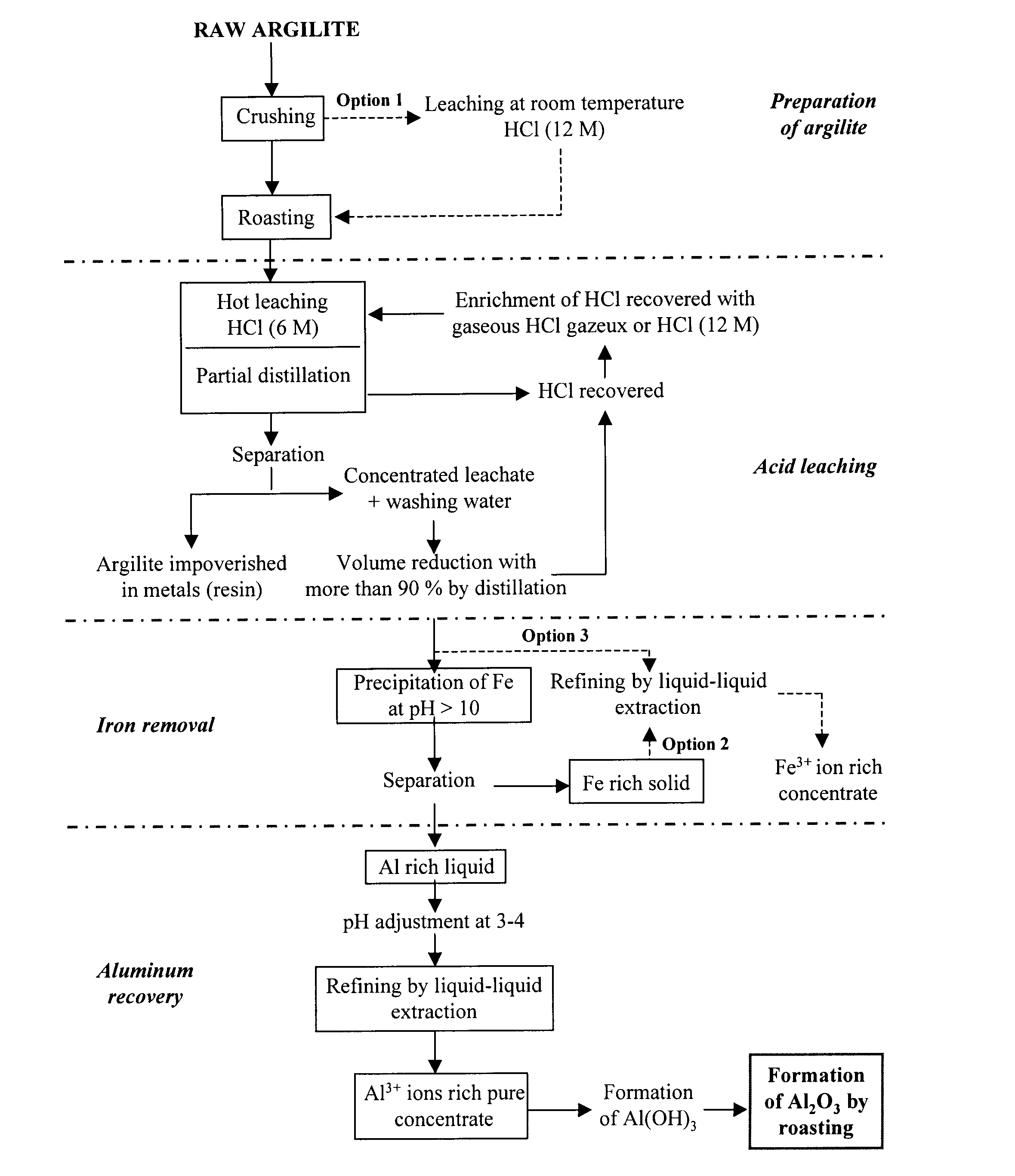

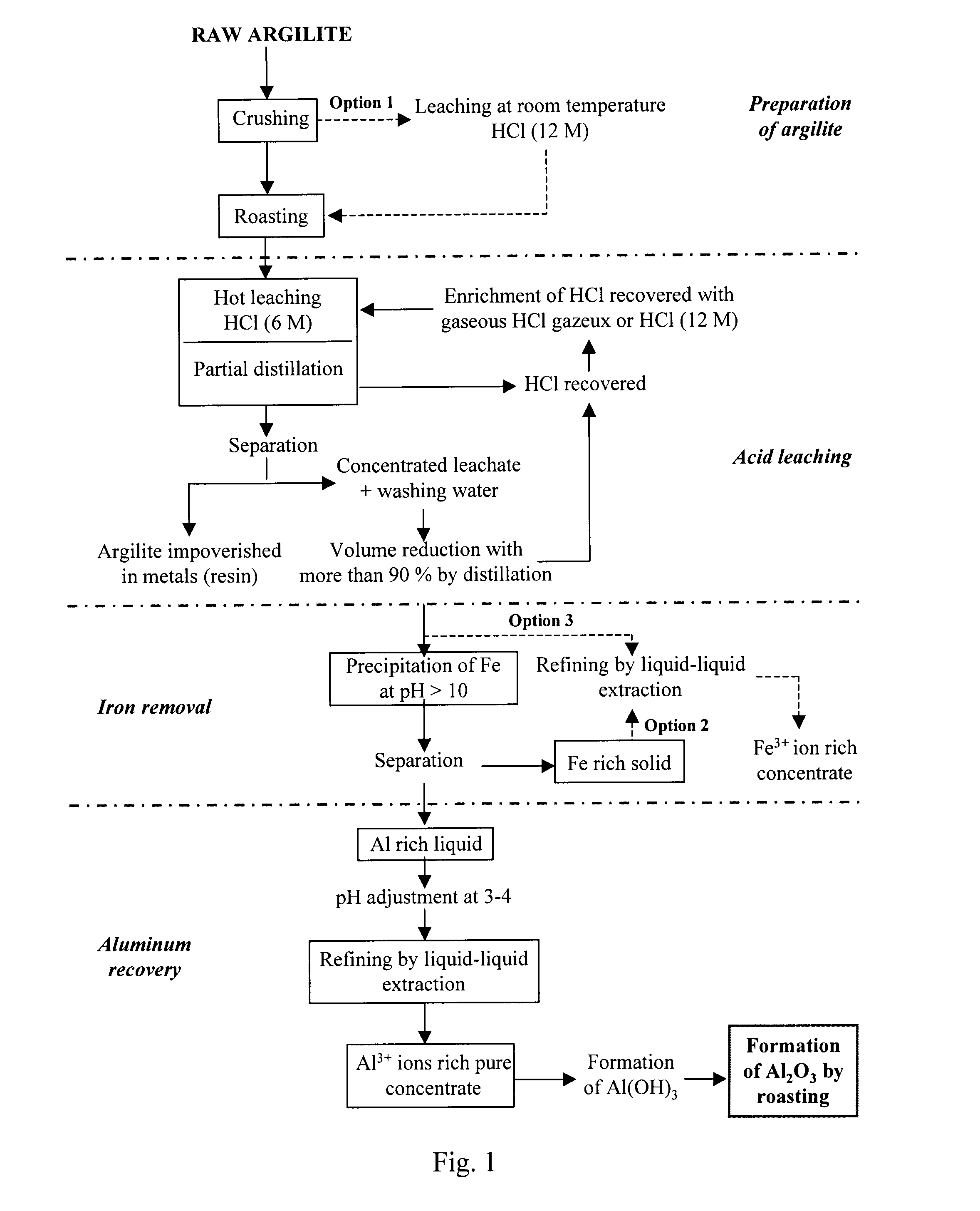

Processes for extracting aluminum and iron from aluminous ores

Owner:ORBITE ALUMINAE INC

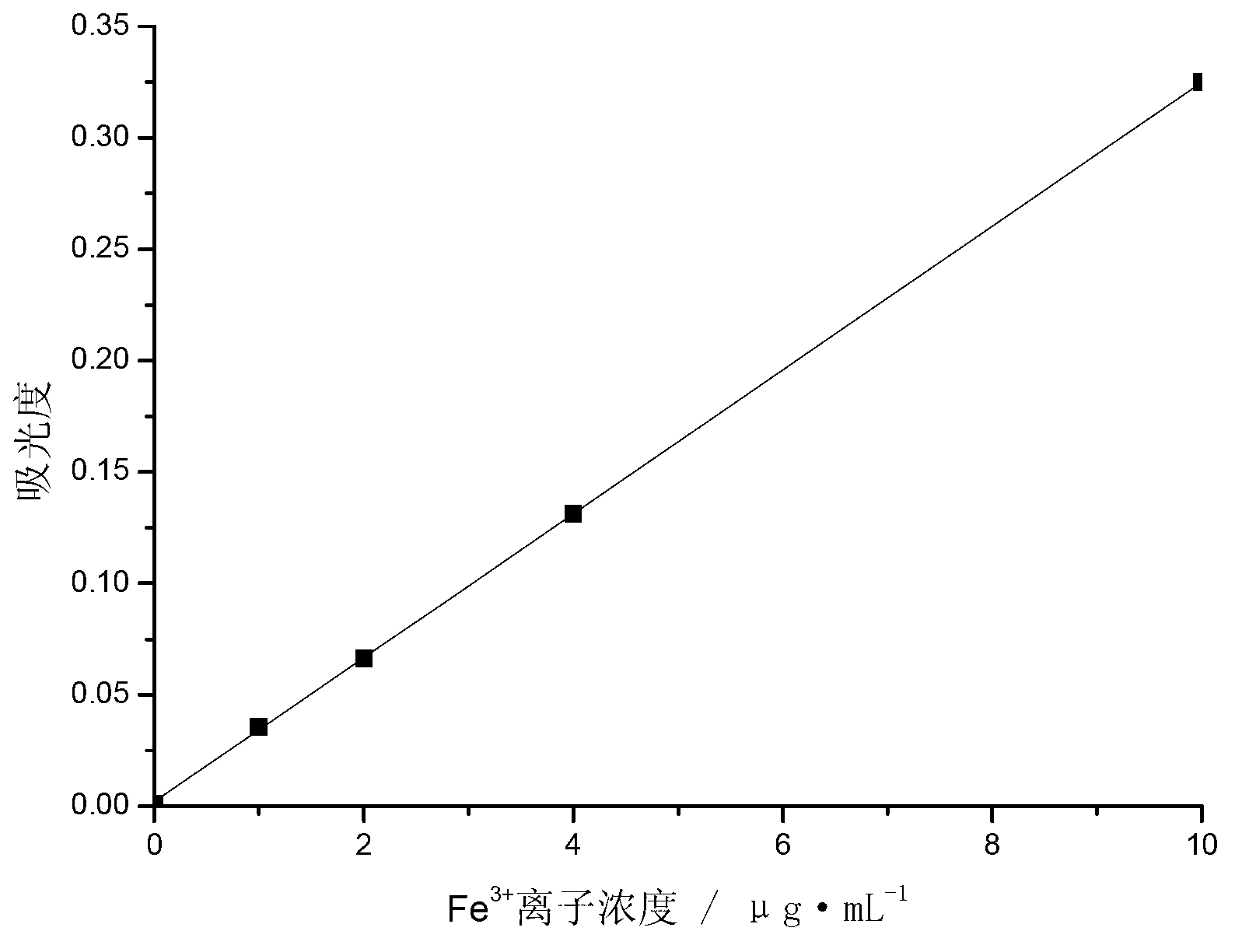

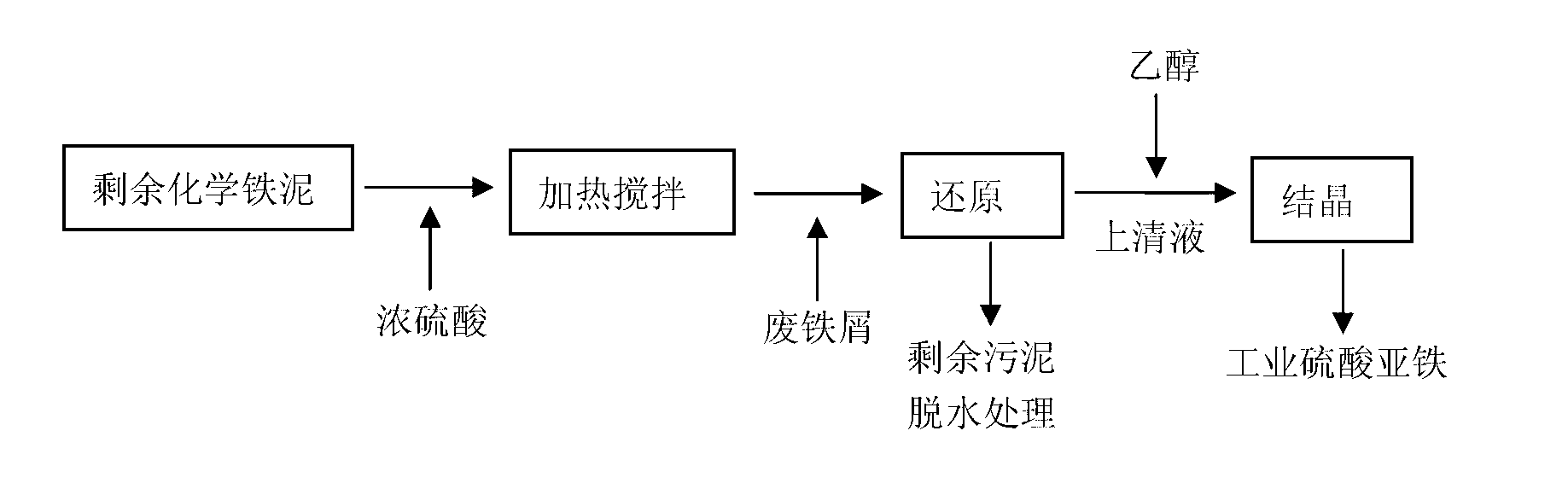

Resource utilization method of Fenton iron sludge

The invention discloses a resource utilization method of Fenton iron sludge. The method comprises the following steps of: (1) treating Fenton; adding the rest of ferrum into concentrated sulfuric acid; and controlling the temperature to be between 70 and 75 DEG C to stir for 30 minutes; (2) adding excessive quantities of scrap iron chips into an iron sludge solution obtained in the step (1) to reduce; detecting Fe3<+> by using a phenol solution until Fe<3+> is totally reduced into Fe<2+>; and (3) after the reduction is finished, standing for precipitating for 30 minutes; extracting supernate; adding ethanol according to the proportion that V(supernate) / V(ethanol) is equal to 10 to 1 and shortening the crystallizing time of ferrous sulfate; and after the crystallization is finished, obtaining an industrial FeSO4.7H2O finished product. According to the method, the bottle neck problem of Fenton technology promotion can be solved, the resource utilization of solid wastes is realized, and Fenton iron sludge is turned from waste into treasure, so that sustainable development of human society is facilitated.

Owner:GUANGXI UNIV

Processes for extracting aluminum and iron from aluminous ores

Owner:ORBITE ALUMINAE INC

Process for metals recovery from spent catalyst

The process of this invention is directed to the removal of metals from an unsupported spent catalyst. The catalyst is subjected to leaching reactions. Vanadium is removed as a precipitate, while a solution comprising molybdenum and nickel is subjected to further extraction steps for the removal of these metals. Molybdenum may alternately be removed through precipitation.

Owner:CHEVROU USA INC

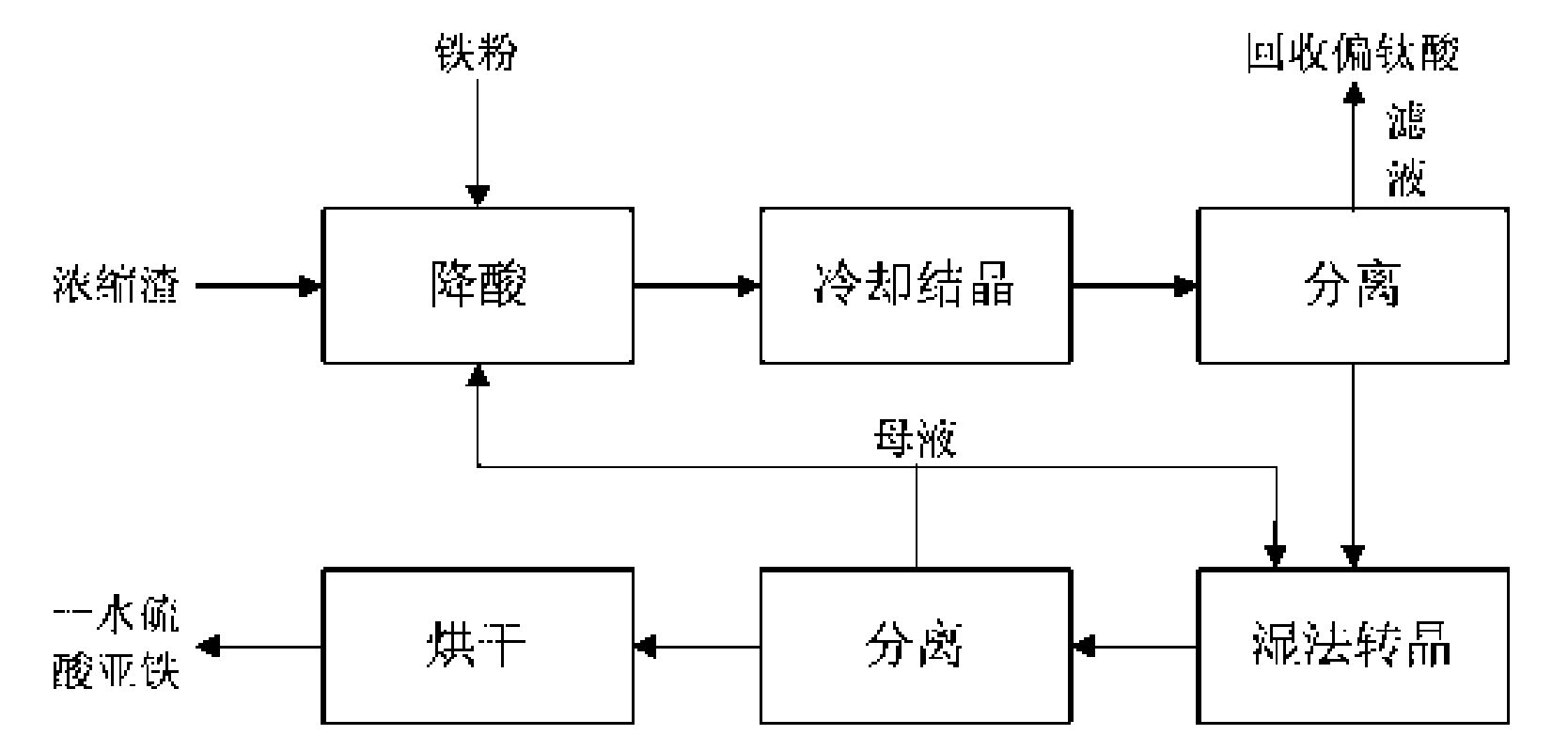

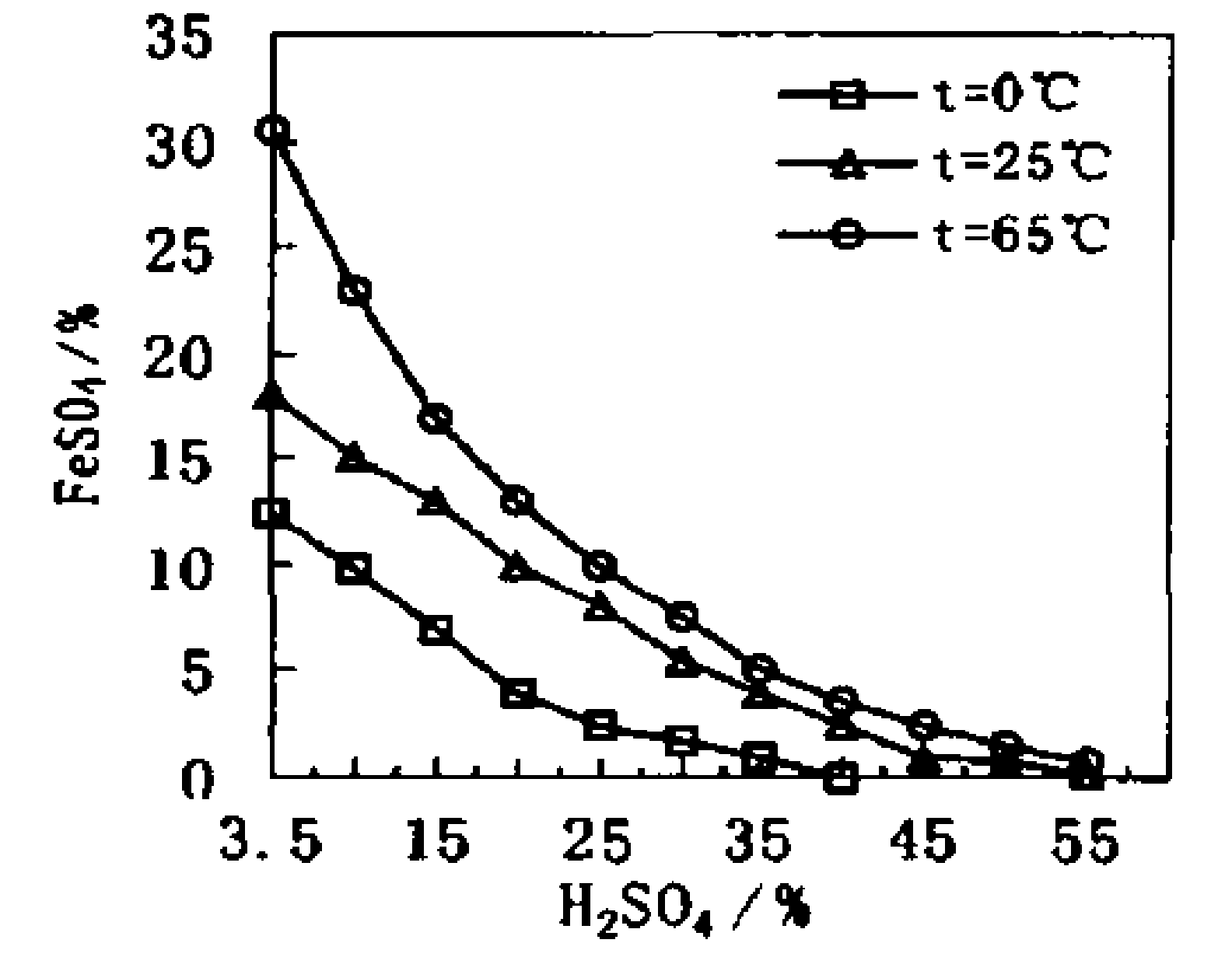

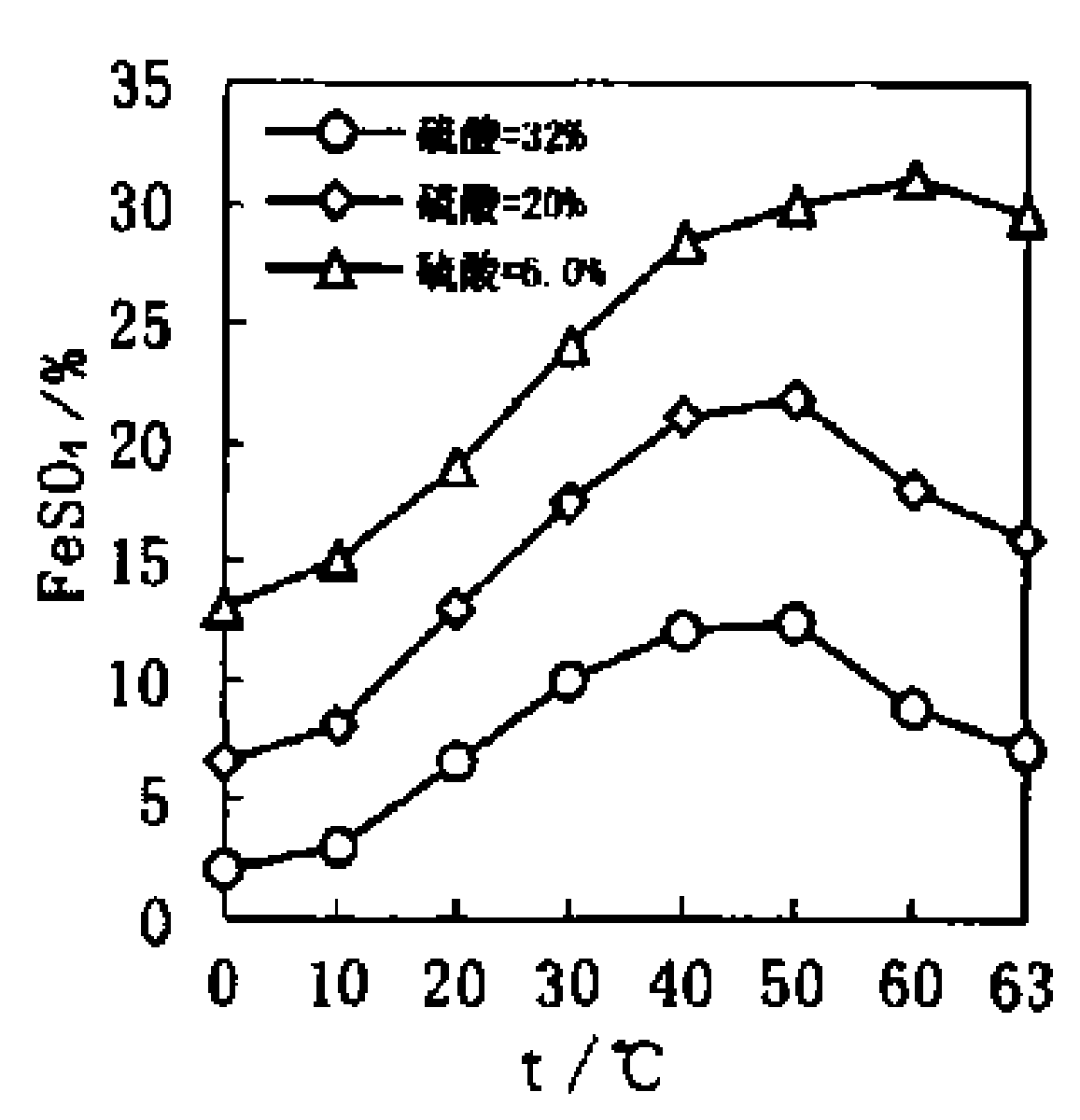

Method for producing feed grade ferrous sulfate monohydrate from titanium pigment waste acid condensed slag

The invention discloses a production method of feed grade ferrous sulfate monohydrate. Titanium white waste acid condensed slag is used as the raw material, and is subject to the processes of deacidification, pexitropy, separation, crystal transform and the like to produce the feed grade ferrous sulfate monohydrate, thereby realizing the comprehensive utilization of the titanium pigment waste acid condensed slag as the byproduct for the sulfuric acid method. The method comprises the following steps: mixing mother solutions generated in the ferrous sulfate monohydrate production processes by condensed slag and wet method, using iron powder to reduce the sulfuric acid content to 4% or so, slowly cooling and crystallizing the slurry to generatecoarse ferrous sulfate heptahydrate crystals, and separating impurities from the ferrous sulfate by using the particle size differences between the ferrous sulfate heptahydrate crystals and the impurity particles, thereby purifying the ferrous sulfate in the condensed slag and widening the application field of the condensed slag. The ferrous sulfate heptahydrate is transformed into ferrous sulfate monohydrate at high temperature to produce the qualified feed grade ferrous sulfate monohydrate in huge market demands, thereby changing the waste slag into valuable resources.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

Recyclable desulfurizer and preparation method thereof and regeneration method

ActiveCN101898108AHigh sulfur capacityLoose structureOther chemical processesIron oxides/hydroxidesCarboxymethyl celluloseSulfur

The invention relates to a recyclable dry desulfurizer with high sulfur capacity. The desulfurizer contains not less than 88% of substances containing FeOOH and not less than 7% of organic binders, wherein the organic binder is one or more of sodium carboxymethyl cellulose, sesbania and cellulose powder. The invention further discloses a preparation method of the desulfurizer and a regeneration method of waste agents generated after the desulfurizer is used. The invention solves the following problems in the prior art: the dry-formed desulfurizer has low sulfur capacity, and after the dry-formed desulfurizer is used once, the waste agents can not be regenerated or the regeneration cost is high, so that great amount of waste agents are only buried, thus not only wasting the effective resources in the original desulfurizer but also leading to new environmental pollution problems.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Preparation method for battery grade ferrous sulfate heptahydrate crystal

The preparation method for battery grade ferrous sulfate heptahydrate crystal of the present invention includes using ferrous sulphate which is the by-product in the titanium dioxide production as raw material, using the operation of purification, filtration, crystallization and dryness, and preparing ferrous sulfate heptahydrate by using the difference of the solubility of ferrous sulphate changing with the temperature. The operation of purification includes performing reduction of ferric iron in ferrous sulphate which is the by-product in the titanium dioxide production to ferrous iron by using a reducing agent, adding ferrous sulfide to remove the heavy metal ions such as cobalt, nickel, zinc, copper, plumbum and cadmium, and using fluoride to remove calcium and magnesium ions. The preparation method uses vacuum drying and packaging, and the main content of ferrous sulfate heptahydrate in the dried material is more than 99.7%. The preparation method has simple technology and low cost, can recycle fluorinion by precipitation conversion, and can reduce the discharge of hazardous waste. Moreover, the prepared product has high purity, low impurity and ferric iron contents, and can be long-term storage. The recovery rate of ferrous sulphate is greatly improved.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

Refining method of titanium dioxide by-product ferrous sulphate

The invention provides a refining method of titanium dioxide by-product ferrous sulphate. The method comprises: (1) preparing a ferrous sulfate heptahydrate solution by using the titanium dioxide by-product ferrous sulphate; (2) adjusting a pH value of the solution to 1-2.5, and performing titanium hydrolysis of the titanium dioxide by-product ferrous sulphate; (3) adding iron powder or iron sheets into the ferrous sulfate heptahydrate solution after the titanium hydrolysis, reducing Fe<3+> in the solution, adjusting a pH value of the solution to 6.0-6.5, and performing a magnesium, manganese and zinc precipitation treatment for the titanium dioxide by-product ferrous sulphate; and (4) adding a flocculating agent into the above solution, stirring, standing, settling and filtering to obtain the refined ferrous sulphate solution. The method can effectively remove impurities such as titanium, magnesium, zinc, manganese and other ions in the titanium dioxide by-product ferrous sulphate, and obtain the high-purity refined ferrous sulphate.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

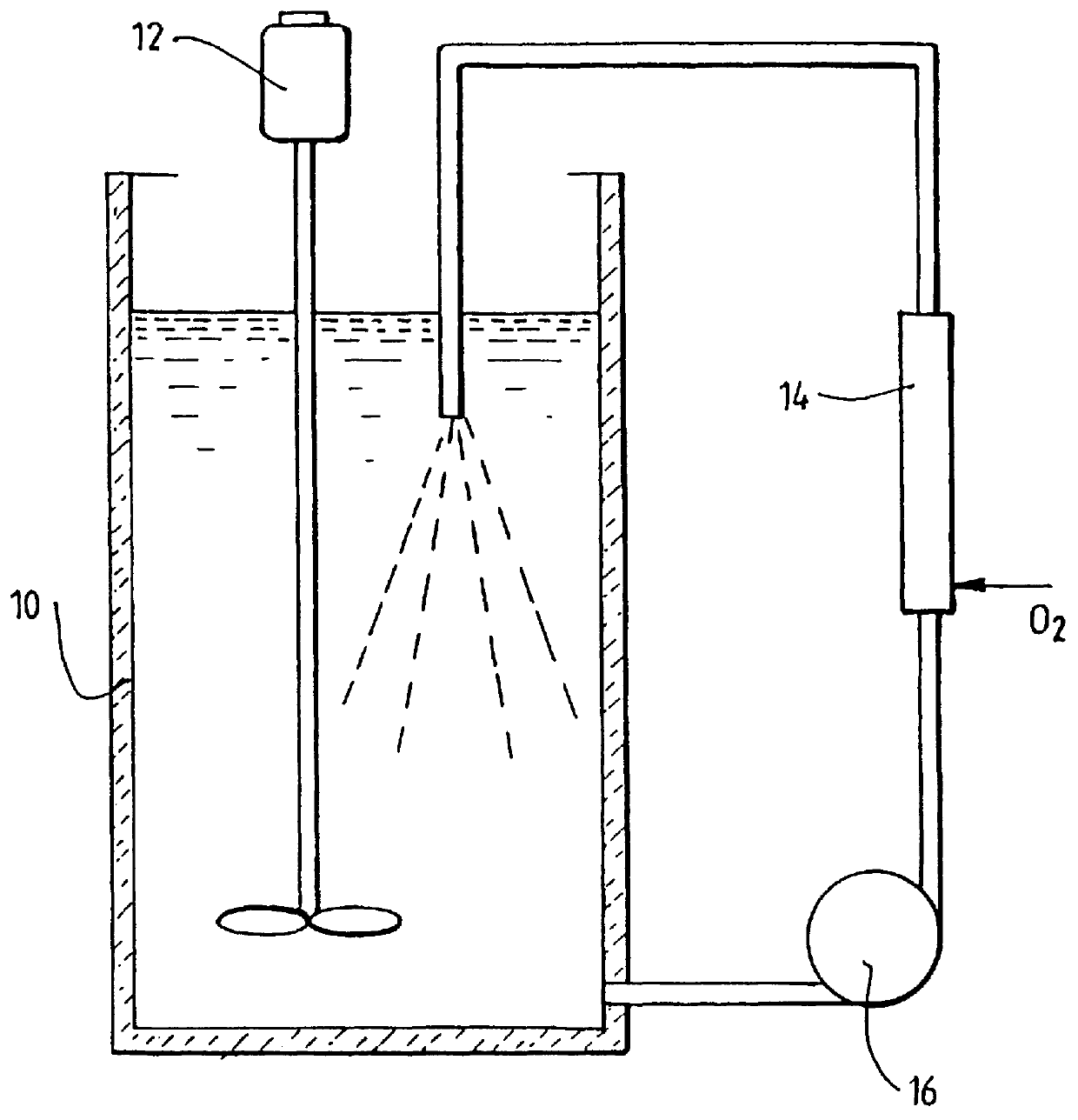

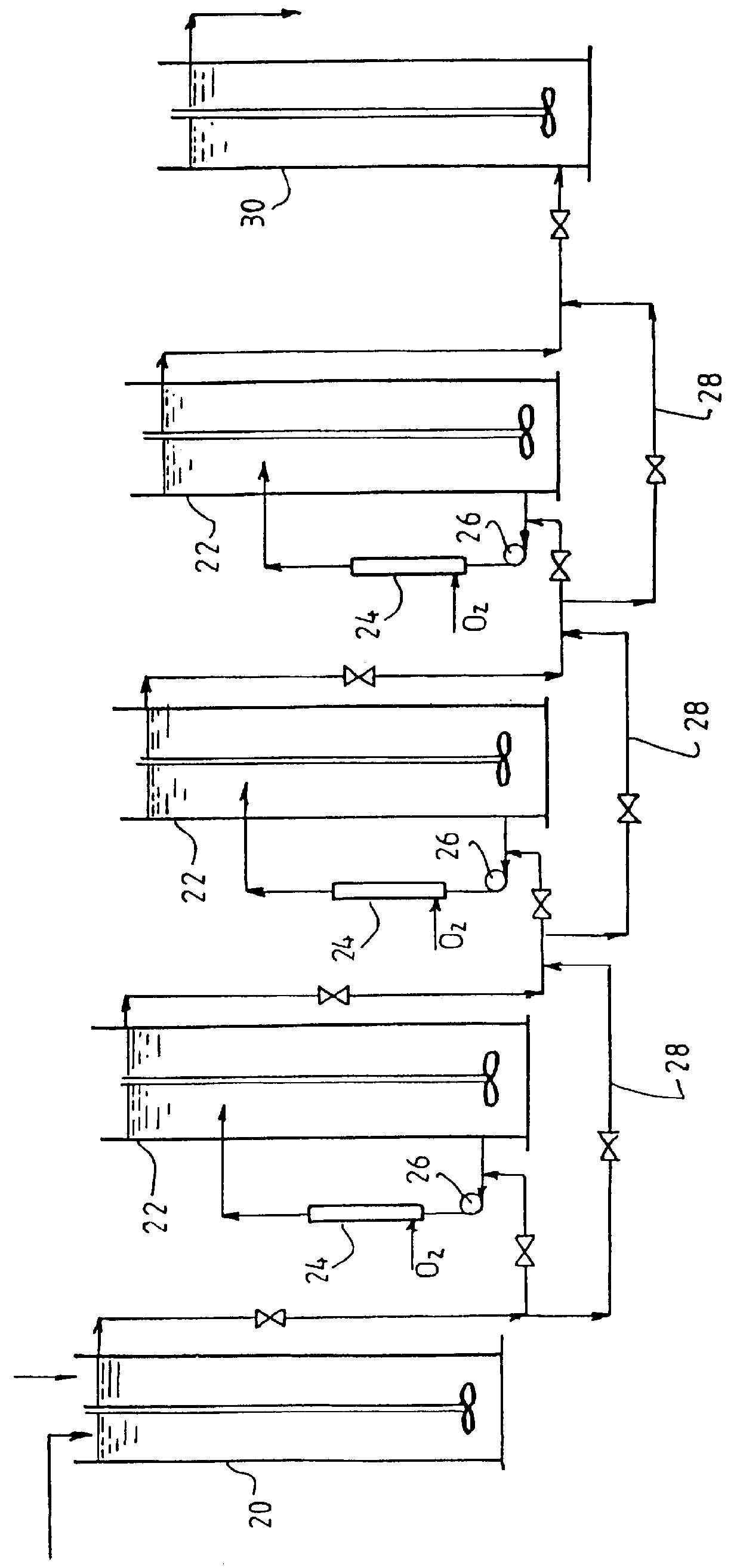

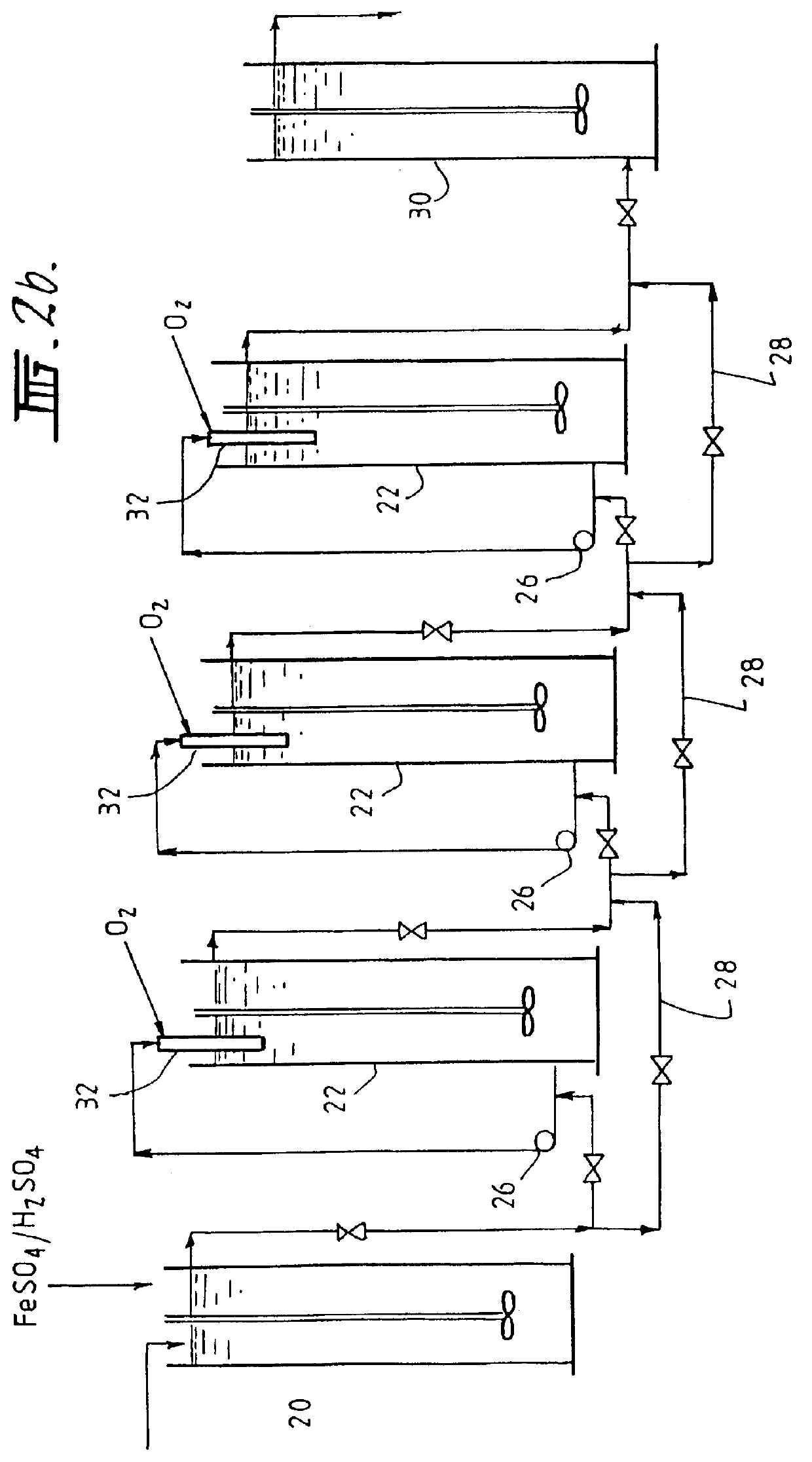

Leaching of mineral ores

A process for oxidation of ferrous ions in solution, and more particularly a process for improved base metal and / or uranium leaching from ores, concentrates or tailings using ferric ion as an oxidizing agent. A reaction vessel (10) holds a ferrous ion-containing solution, for example, a copper sulphide leach slurry or concentrate. An agitator (12) may be provided to promote leaching of the base metal into solution. Some of the ferrous ion-containing solution is drawn off from the reaction vessel (10) and pumped through an in-line mixer (14) via a feed pump (16). Oxygen is injected into the reactor (14) to facilitate oxidation of the ferrous sulphate to form ferric sulphate. The ferric ion-containing solution is then recirculated back to the reaction vessel (10) where the ferric ions are reused in the dissolution of copper sulphide into soluble copper sulphate. The two processes of ferrous oxidation and metal leaching can be conducted either simultaneously or sequentially to effect recovery of copper, other base metals or uranium from ores, concentrates or tailings.

Owner:ATOMAER

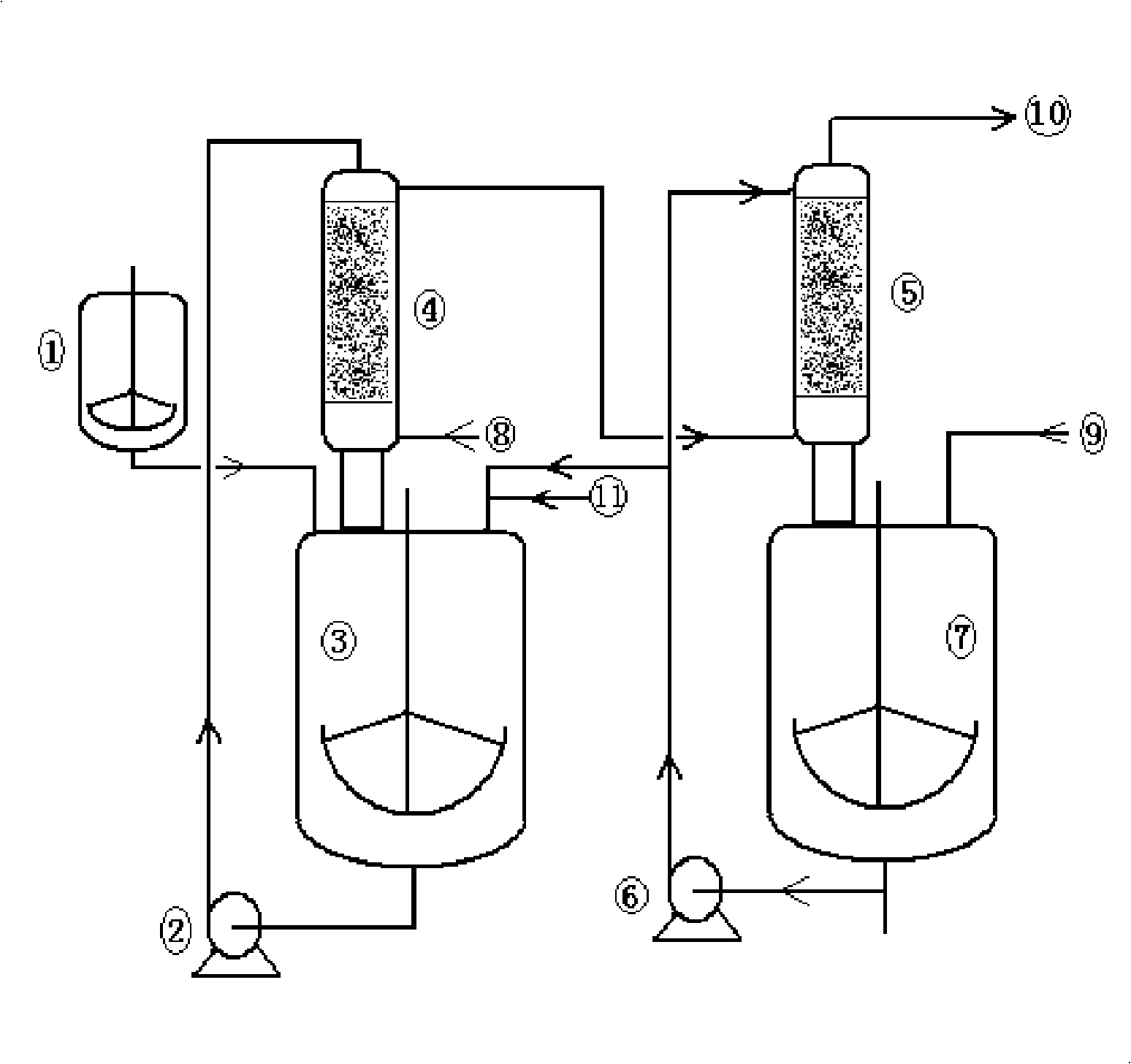

Method for synthesizing polymeric ferric sulphate

InactiveCN101249987AEfficient use ofAvoid pollutionIron sulfatesWater/sewage treatment by flocculation/precipitationIron sulfateSlag

The invention discloses a method for synthesizing polymeric ferric sulfate, which employs air, oxygen or oxygen-enriched air as an oxidizing agent, uses ferric persulfate, sulfuric acid or waste acid of titanium white by sulfuric acid process raw materials, using acid nitric ferric sulfate as an accelerating agent and synthesizing the polymeric ferric sulfate in an enamel autoclave which is provided with a packed tower, finally, using ferric persulfate to process the oxidation off-gas. The invention has the advantages of low energy consumption, low cost and convenient operation, not only effectively utilizing the industrial waste acid and the industrial waste slag, but also avoiding polluting to the environment.

Owner:李绍通

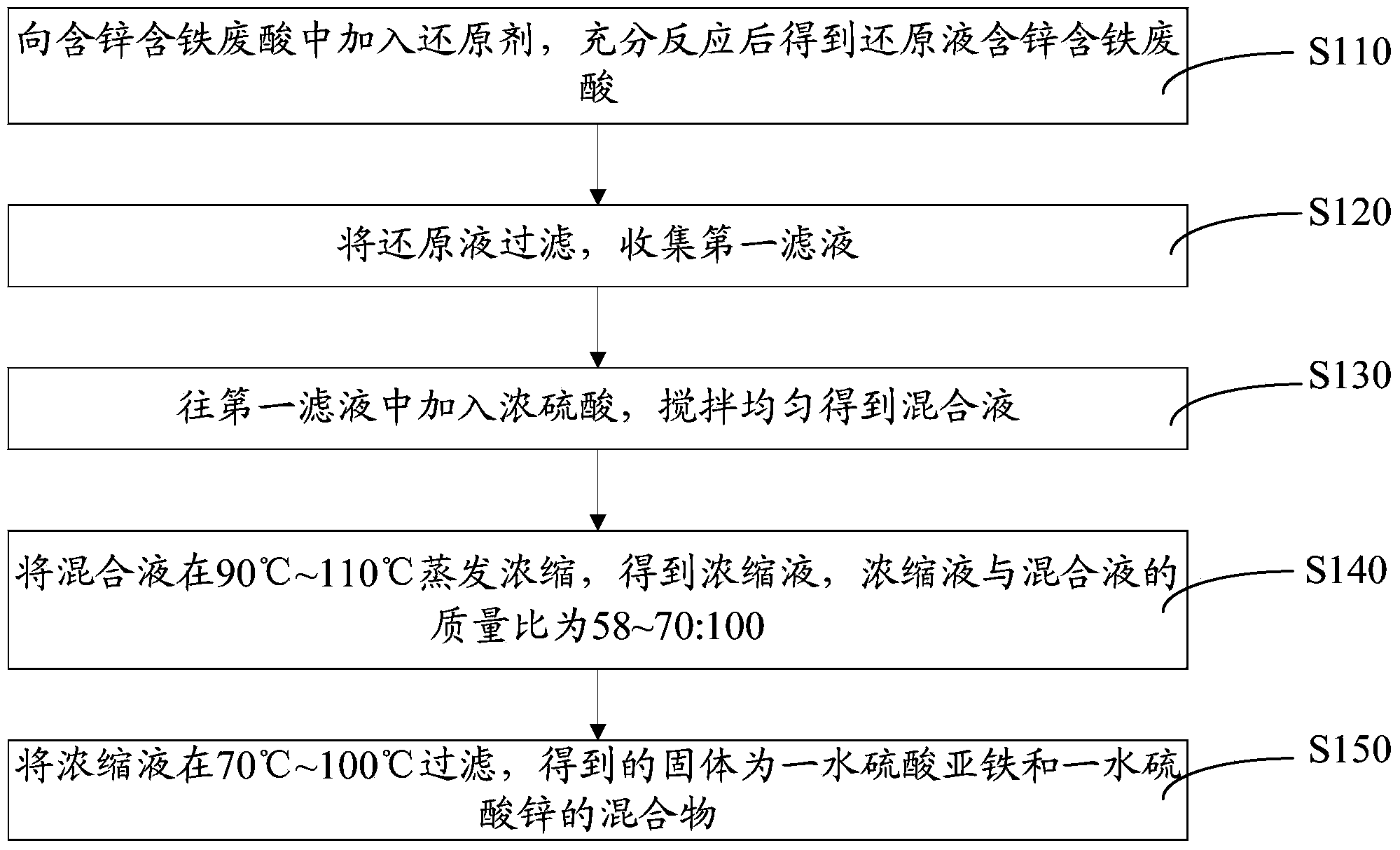

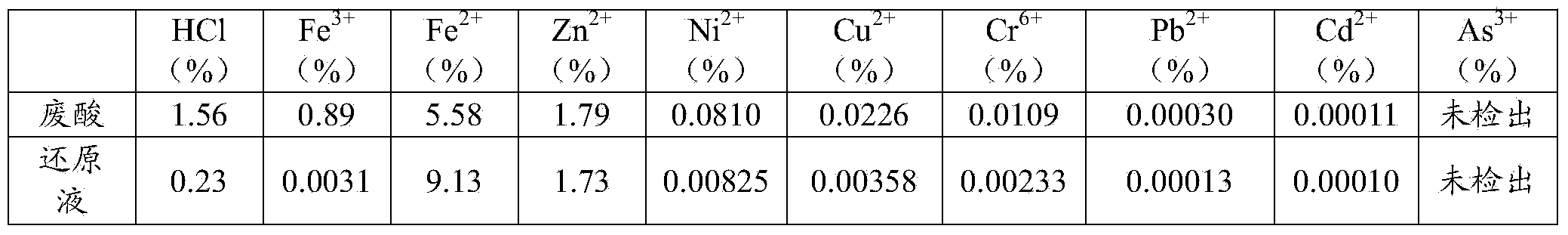

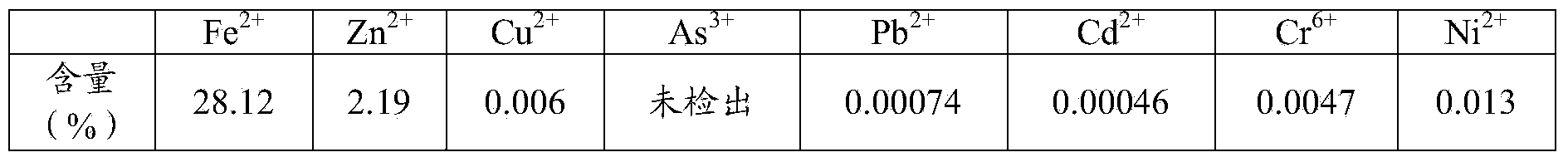

Treatment method of zinc-containing and iron-containing waste acid

The invention relates to a treatment method of a zinc-containing and iron-containing waste acid. The method comprises the following steps: adding a reducing agent to the zinc-containing and iron-containing waste acid, and fully reacting to obtain a reducing liquid; filtering the reducing liquid to collect a first filtrate; adding concentrated sulfuric acid into the first filtrate, and uniformly stirring to obtain a mixed liquid; evaporating and concentrating the mixed liquid at 90-110 DEG C to obtain a concentrated liquid; filtering the concentrated liquid at 70-100 DEG C to obtain a mixture with solids of FeSO4.H2O and ZnSO4.H2O. A certain amount of zinc-containing and iron-containing waste acid and concentrated sulfuric acid is added into the filtered second filtrate for a concentration and crystallization process in the next cycle. According to the treatment method of the zinc-containing and iron-containing waste acid, heavy metal ions are replaced to single substances, and after solid impurities in the reducing liquid are filtered to remove, the concentrated sulfuric acid is added. The mixture is evaporated, concentrated and filtered to obtain the crystal mixture with solids of FeSO4.H2O and ZnSO4.H2O. The crystal mixture can be used as a mineral additive for feed. According to the treatment method of the zinc-containing and iron-containing waste acid, the recovery rates of zinc and iron are higher, and the product has broad market prospect.

Owner:3R ENVIRONMENTAL TECH CO LTD

Method for preparing solid polymeric aluminum ferric sulfate

InactiveCN101423259ASolve pollutionExtended service lifeIron sulfatesWater/sewage treatment by flocculation/precipitationLiquid productCatalytic oxidation

The invention discloses a preparation method of solid polymeric ferroaluminum sulfate, comprising the following steps: (1) basic ferric sulfate is prepared from ferrous sulfate; (2) water, sulfuric acid and hydrogen peroxide are added into the basic ferric sulfate in sequence, stirring and standing; (3) an aluminized compound is added and further stirred; (4) being self-cured and precipitated under dry condition; and (5) being aged at room temperature and crushed so to obtain a product. The invention uses a blast oxidation process and solves the pollution problem which is generated by the catalytic oxidation process in the traditional iron-based coagulant industry. The polymeric ferroaluminum sulfate is a solid product; compared with the liquid product, the polymeric ferroaluminum sulfate has advantages of storage and transportation, has long service life, and does not need evaporation or decompression evaporation process, and the coagulation active component of the product is retained to the largest extent. Quality indicators such as basicity, active component, and the like are all higher than the quality indicators in the prior art. When in actual implementation and embodiment of water body, the effect of the polymeric ferroaluminum sulfate is better than the effect of the inorganic coagulant such as polyaluminum chloride polymeric ferroaluminum sulfate and the like.

Owner:SOUTH CHINA NORMAL UNIVERSITY

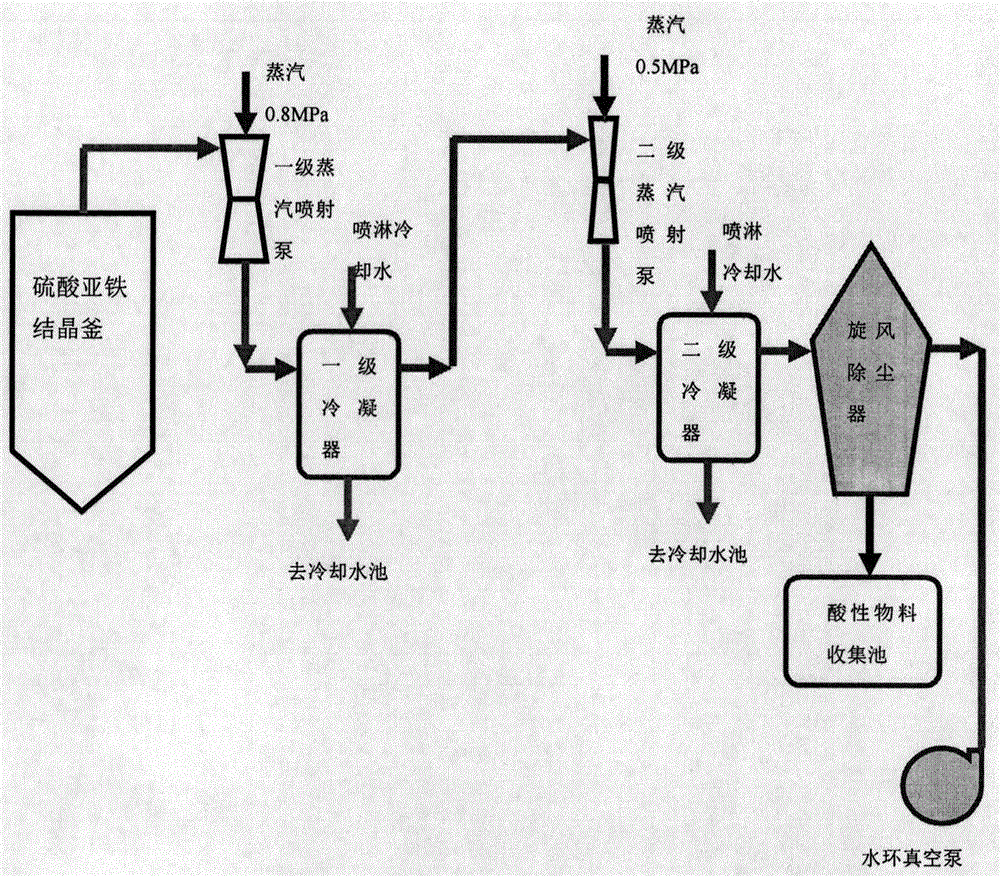

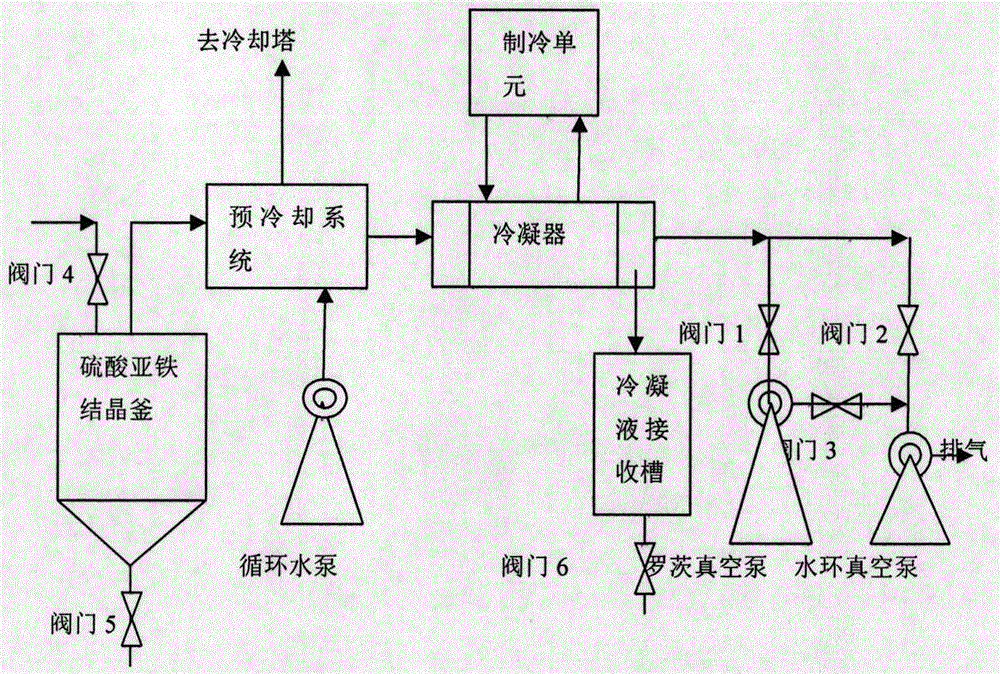

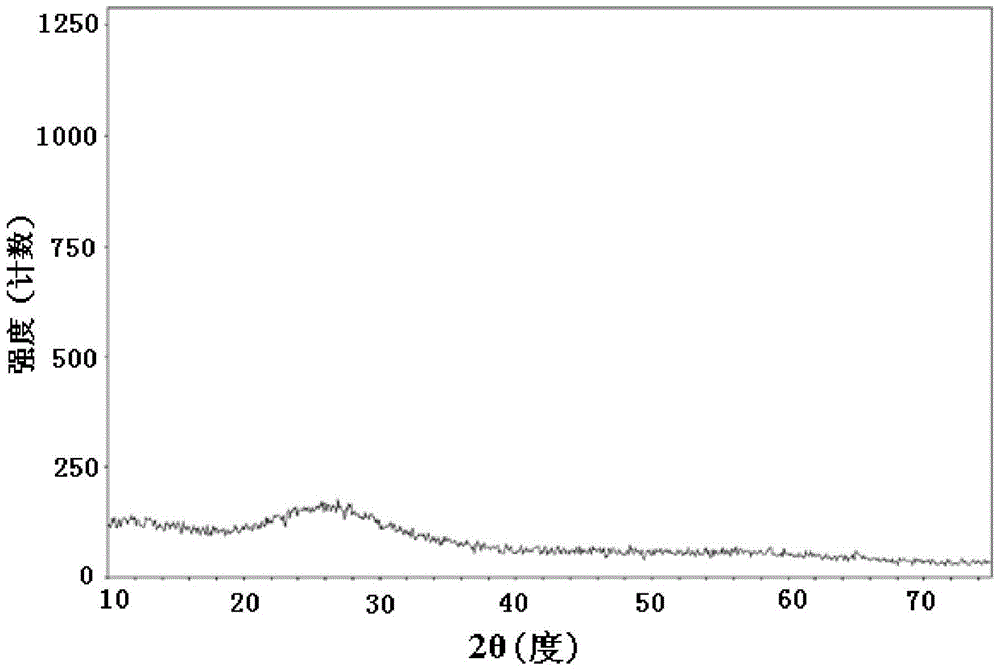

Novel method for performing vacuum crystallization on ferrous sulfate from titanium liquid in titanium dioxide production process

InactiveCN105289036ARealize cleaner productionReduce manufacturing costSolution crystallizationIron sulfatesSulfatePhysical chemistry

The invention discloses a novel method for performing vacuum crystallization on ferrous sulfate from titanium liquid in titanium dioxide production. According to the method, the conventional ferrous sulfate vacuum crystallization process and equipment are innovated. The process innovation refers to the operation of replacing the conventional method for generating vacuum by virtue of steam jet by a method for condensing water vapor above titanium liquid in a crystallization kettle so as to generate vacuum by virtue of cryogenic refrigeration. The equipment innovation refers to the operation of replacing the conventional secondary steam jet equipment and circulating cooling water equipment for cooling high-temperature acid containing liquid by the complete refrigerating equipment generating a certain low temperature. According to the method disclosed by the invention, ferrous sulfate is separated from the titanium liquid in the crystallization kettle, lots of high-temperature high-pressure steam can be saved, and the production cost of titanium dioxide by sulfuric acid method is greatly reduced. In addition, the acidic condensate extracted from the crystallization kettle by vacuum can return to be used for an ilmenite powder sulfuric acid dissolving process, so that the amount of sulfuric acid in the process of generating titanium dioxide by a sulfuric acid method is reduced, the emission amount of acid waste liquid is greatly reduced, and clean production is realized.

Owner:NANJING BAIYUN CHEM ENVIRONMENTAL MONITORING

Purification method of ferrous sulfate as byproduct of titanium dioxide

InactiveCN108046337AMeet the requirements for the production of battery grade iron phosphateIron sulfatesPurification methodsManganese

The invention discloses a purification method of ferrous sulfate as a byproduct of titanium dioxide. The ferrous sulfate as the byproduct of the titanium dioxide contains titanium, magnesium and manganese impurity elements. The preparation method comprises the following steps: (1) dissolving the ferrous sulfate as the byproduct of the titanium dioxide with water to obtain a ferrous sulfate solution; (2) adding iron powder into the ferrous sulfate solution obtained in the step (1), heating to 90 DEG C or above, and adding phosphoric acid till the pH value of the solution is up to 3 to 4.5; (3)adding sulfide and fluoride into the solution obtained in the step (2), and stirring; (4) adding a flocculant into the solution obtained in the step (3), and then removing flocculating sediment to obtain a purified ferrous sulfate solution. The impurity element content of the extracted ferrous sulfate can meet the requirement of producing battery grade iron phosphate.

Owner:绵阳天明新能源科技有限公司 +1

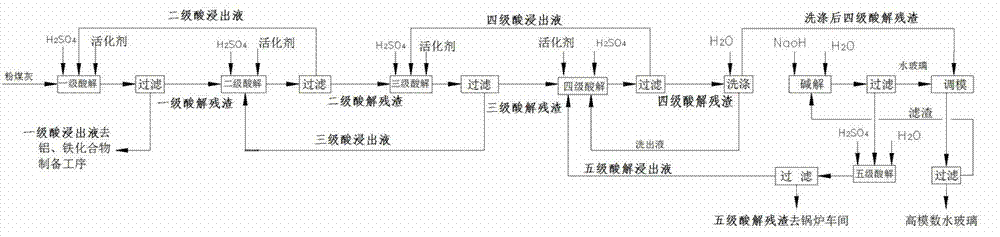

Fly ash decomposition method

The invention discloses a fly ash decomposition method. The method comprises the following steps: sending fly ash powder to an acidolysis process, adding sulfuric acid or hydrochloric acid or nitric acid to carry out a multistage acidolysis reaction with fluorite or industrial calcium fluoride as an activator in order to convert aluminum and iron elements in the fly ash powder into corresponding soluble salts entering a liquid phase, filtering, and separating to obtain an acid leachate containing aluminum salt and iron salt; washing acidolysis residues, mixing the acidolysis residues with water, adding sodium hydroxide to carry out an alkaline hydrolysis reaction, and filtering to prepare high modulus water glass; and washing alkaline hydrolysis residues, filtering, and sending the obtained acid leachate to a fore acidolysis process in order to be used for burdening. The decomposition rates of alumina and iron oxide in the fly ash reach above 90% and above 85% respectively; the modulus of the water glass is controlled between 3.2 and 3.8, the device investment is reduced, and the energy consumption and the raw material cost are reduced; and the method realizes recycling of decomposition residues, eliminates influences of secondary waste residues on environment, and lays a foundation for the preparation of aluminum, iron and silicon compounds.

Owner:NANYANG ORIENTAL APPL CHEM RES INST

Comprehensive utilization method of titanium white waste acid

Disclosed is a comprehensive utilization method of titanium white waste acid which comprises, (1) neutralizing free sulfuric acid in the waste acid with calcium carbonate, filtering so as to obtain plaster stone dust cake and ferrous sulfate filter liquor, (2) baking the obtained dust cake with rotary kiln or ebullition fluidized-bed plants, obtaining calcium sulphate product, (3) neutralizing the obtained ferrous sulfate solution with caustic soda to obtain ferrous hydroxide, letting in air for oxidizing under normal temperature so as to produce iron red seed crystal, (4) at the presence of seed crystal, heating with steam, carrying out two step oxidization with air, charging ferrous sulfate and caustic soda in a balanced manner, terminating reaction by selecting various time so as to obtain iron-oxide red slurry with different colors, when the reaction ends, subjecting the iron-oxide red slurry to white washing, sieving, filtering, drying and disintegrating, thus obtaining the iron-oxide red product.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

Waste acid and wastewater treatment process in processes of pickling and purifying quartz or feldspar

ActiveCN103950991AProcess step keyNo emissionsCalcium/strontium/barium sulfatesIron sulfatesChloridePollution

The invention discloses a waste acid and wastewater treatment process in processes of pickling and purifying quartz or feldspar. The process comprises three steps of treatment of the waste acid, treatment of washing water and treatment of wastewater. The waste acid is processed by cation-anion resin, the washing water is fed to a neutralizing tank to process by using lime milk, the wastewater is processed by a concentrated sulfuric acid, and the waste acid and the wastewater generated in the processes of pickling and purifying the quartz or feldspar are completely recycled and applied in cycle. Especially, the wastewater containing calcium chloride which cannot be removed by the prior art is successfully processed, and zero pollution and zero emission are really achieved.

Owner:田辉明

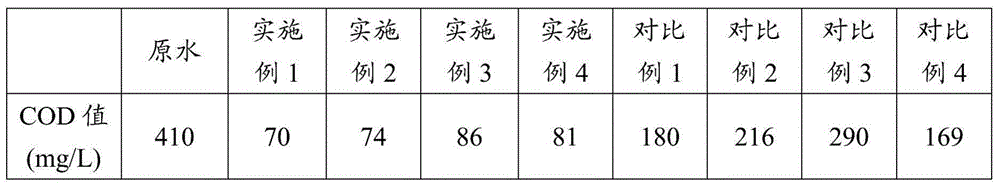

Preparation method of polyferric sulfate

ActiveCN104692467AImprove oxidation capacityReduce dosageIron sulfatesWater/sewage treatment by flocculation/precipitationIron sulfateStrong acids

The invention provides a preparation method of polyferric sulfate. The method is that a sulfuric acid aqueous solution and ferrous sulfate are mixed to obtain a mixing solution of which the pH is 0.5 to 1.5; the mixing solution and hydrogen peroxide respectively individually flow through independent flowing channels and then are synchronously poured into a reaction system to react to obtain polyferric sulfate. With the adoption of the method, the oxidizing capacity of hydrogen peroxide can be improved, the rate of converting ferrous ions into ferric ions can be increased, and moreover, ferrous ions and hydrogen peroxide can fully contact and rapidly react; therefore, the problem of decomposing of hydrogen peroxide at a high temperature or strong acid condition in the prior art can be effectively solved, the dosage of hydrogen peroxide can be reduced, the cost input can be decreased, the operation process is simplified, and the reaction time is greatly reduced. The quality of polyferric sulfate prepared by the method meets indicators as specified by national standard on top quality goods; with the adoption of the polyferric sulfate to treat wastewater, the COD of drained water can be stabilized to be less than or equal to 86mg / L, so that the method is applicable to industrial production.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

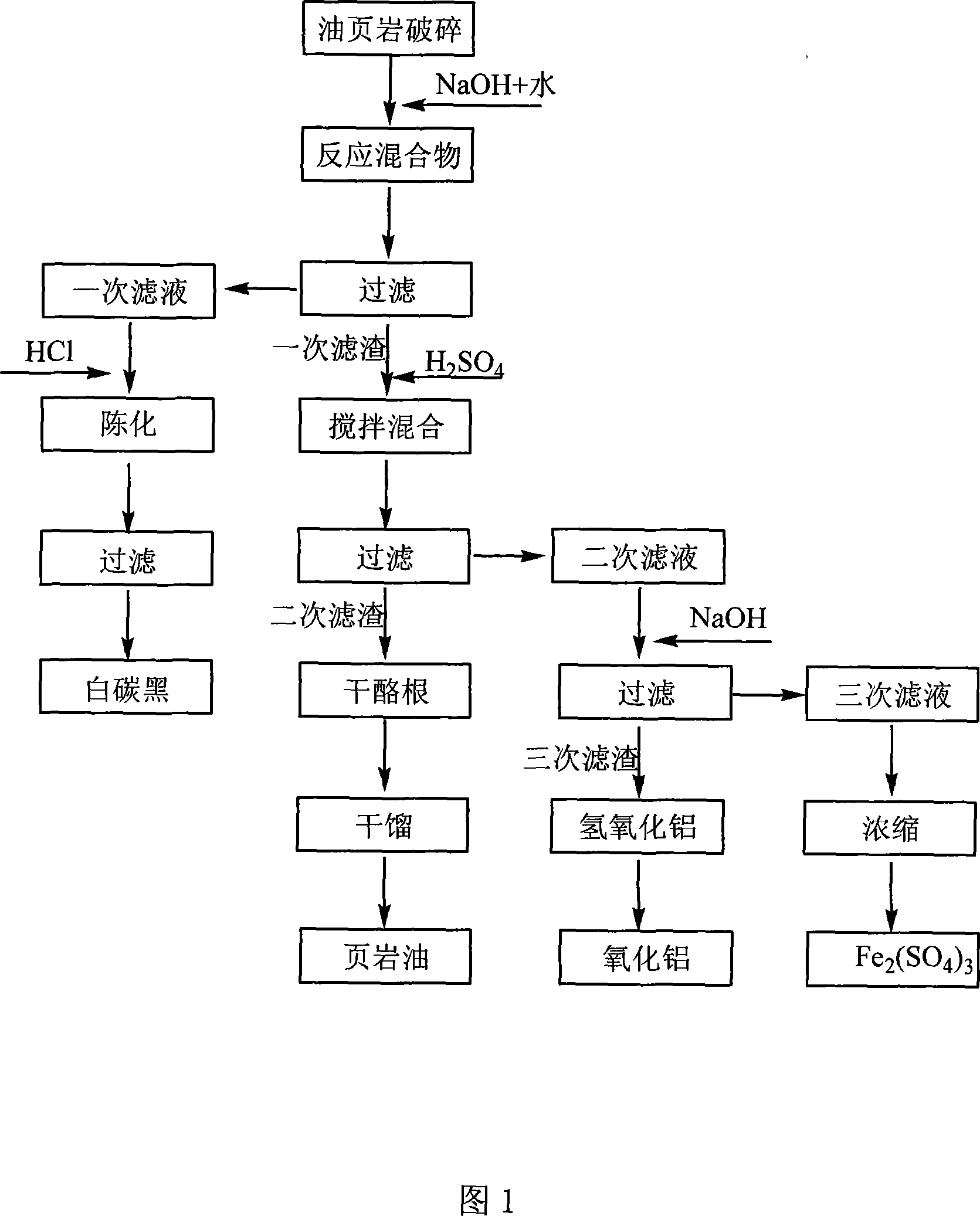

Method for co-production of white carbon black, aluminum oxide and kerogen by kerosene shale

InactiveCN101112990AWide variety of sourcesSimple technologySilicon oxidesIron sulfatesKerogenKerosene

The invention relates to a method for preparing white carbon black, alumina and kerogen with oil shale, comprising the steps that: (1) the oil shale is crumbled into grains with a diameter less than 0.84 mm or less; (2) the oil shale, NaOH and water are added into a reactor for reaction for 0.5 to 24 hours at 20 DEG C to 200 DEG C, then filtration is made and a first filtrate and a first filter cake are obtained, then inorganic acid is used to adjust the pH value of the first filtrate and dispersant is added, and the white carbon black is obtain after 0.5 to 24 hours of aging; (3) the first filter cake is mixed with inorganic acid, the acid leaching temperature is 20 DEG C to 100 DEG C and the acid leaching time is 0.5 to 24 hours, then a second filter residues and a second filtrate are obtained upon filtration; (4) aqueous slkali is added into the second filtrate to adjust and control the pH value till precipitate Al(OH)3 is produced, then filtration is made and a third residues Al(OH)3 precipitate and a third filtrate are obtained; the Al(OH)3 precipitate can be used for preparing Al2O3 products with different contents by being sintered at 450 DEG C to 1250 DEG C; (5) the third filtrate can be prepared into Fe2(SO4)3 concentrated solution with different density after being concentrated, then the concentrated solution is further processed and Fe2(SO4)3 product is prepared. The invention has simple technique and low energy consumption.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com