Method for concentrating waste sulfuric acid by utilizing waste heat of titanium dioxide calcinator

A titanium dioxide and roasting furnace technology, applied in the direction of manganese sulfate, magnesium sulfate, iron sulfate, etc., can solve the problems of frequent scaling cleaning, increasing the diameter of graphite tube heat exchangers, and high energy consumption for cooling and heating processes. Achieve significant social and environmental benefits, reduce equipment investment and operating costs, and achieve high device production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

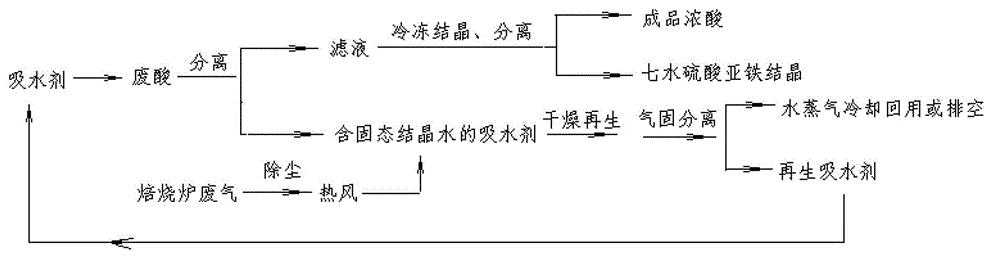

Method used

Image

Examples

Embodiment 1

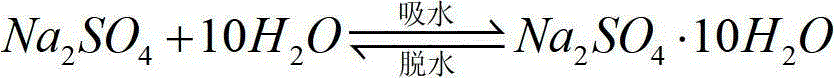

[0043] 1) Under normal temperature and pressure and stirring (60r / min), add 300g of anhydrous sodium sulfate to 1000g of titanium white waste acid containing about 20% sulfuric acid, continue stirring for 30min, let the suspension cool to room temperature, and separate the solid and liquid Na 2 SO 4 10H 2 O crystallization; Gained filtrate was added 250g of anhydrous sodium sulfate under normal temperature and pressure and under stirring, continued to stir for 30min, allowed the suspension to be cooled to normal temperature, and the solid-liquid separation went out Na 2 SO 4 10H 2 O crystallization. The second filtrate was cooled to -5°C while stirring, and kept stirring at this temperature for 30 minutes to allow the FeSO 4 ·7H 2 Inorganic salts such as O are fully crystallized and precipitated. Then solid-liquid separation to obtain FeSO 4 ·7H 2 O and other inorganic salt crystallization and filtrate. The mass percent concentration of sulfuric acid in the filtrate ...

Embodiment 2

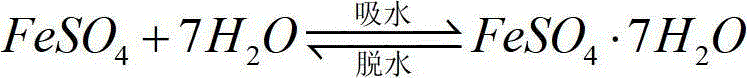

[0046] 1) Under normal temperature and pressure and stirring (80r / min), add 500g of anhydrous ferrous sulfate to 1000g of titanium white waste acid containing about 25% sulfuric acid, continue stirring for 30min, let the suspension cool to room temperature, and separate the solid and liquid FeSO 4 ·7H 2 O crystallization; the obtained filtrate was added with 300 g of anhydrous ferrous sulfate under stirring at normal temperature and pressure, and continued to stir for 30 minutes, allowing the suspension to cool to normal temperature, and the solid-liquid separation of FeSO 4 ·7H 2 O crystallization; the obtained secondary filtrate was added with 200 g of anhydrous ferrous sulfate at normal temperature and pressure under stirring, and continued to stir for 30 min, allowing the suspension to cool to normal temperature, and the solid-liquid separation of FeSO 4 ·7H 2 O crystallization; three filtrates were cooled to 10°C with stirring, and kept stirring at this temperature for...

Embodiment 3

[0049] 1) Under normal temperature and pressure and stirring (80r / min), add 600g ferrous sulfate monohydrate to 1000g titanium white waste acid containing about 23% sulfuric acid, continue stirring for 30min, let the suspension cool to room temperature, and separate the solid and liquid FeSO 4 ·7H 2 O crystallization; Gained filtrate adds 500g ferrous sulfate monohydrate again under the same condition as above, stirs, separates; Gained secondary filtrate adds 400g ferrous sulfate monohydrate again at normal temperature and pressure and under stirring, continues stirring, is cooled to normal temperature , Separation of FeSO 4 ·7H 2 O crystallization; three filtrates were cooled to 10°C with stirring, and kept stirring at this temperature for 30min, allowing FeSO 4 ·7H 2 Inorganic salts such as O are fully crystallized and precipitated. Then solid-liquid separation. The mass percent concentration of sulfuric acid in the filtrate is 64.2%, which is sent to the acid hydrolys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com