Patents

Literature

233 results about "Salt crystallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Salt crystallization or formation of salt crystals in rocks is known as haloclasty and it is one of the main causes of breaking down of rocks into smaller pieces. Crystallization of Salt. The process of crystallization of salts causes disintegration or weathering of rocks.

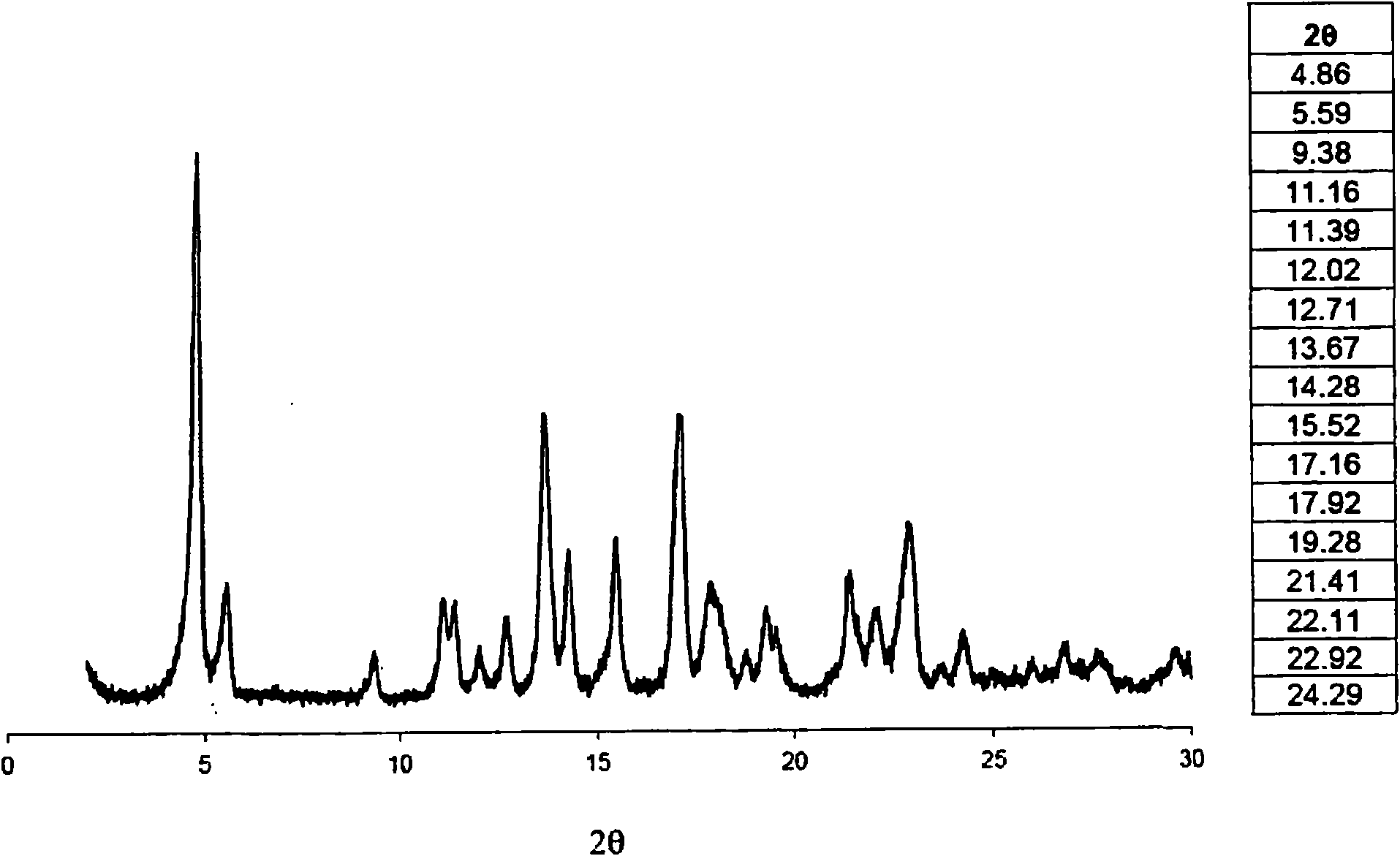

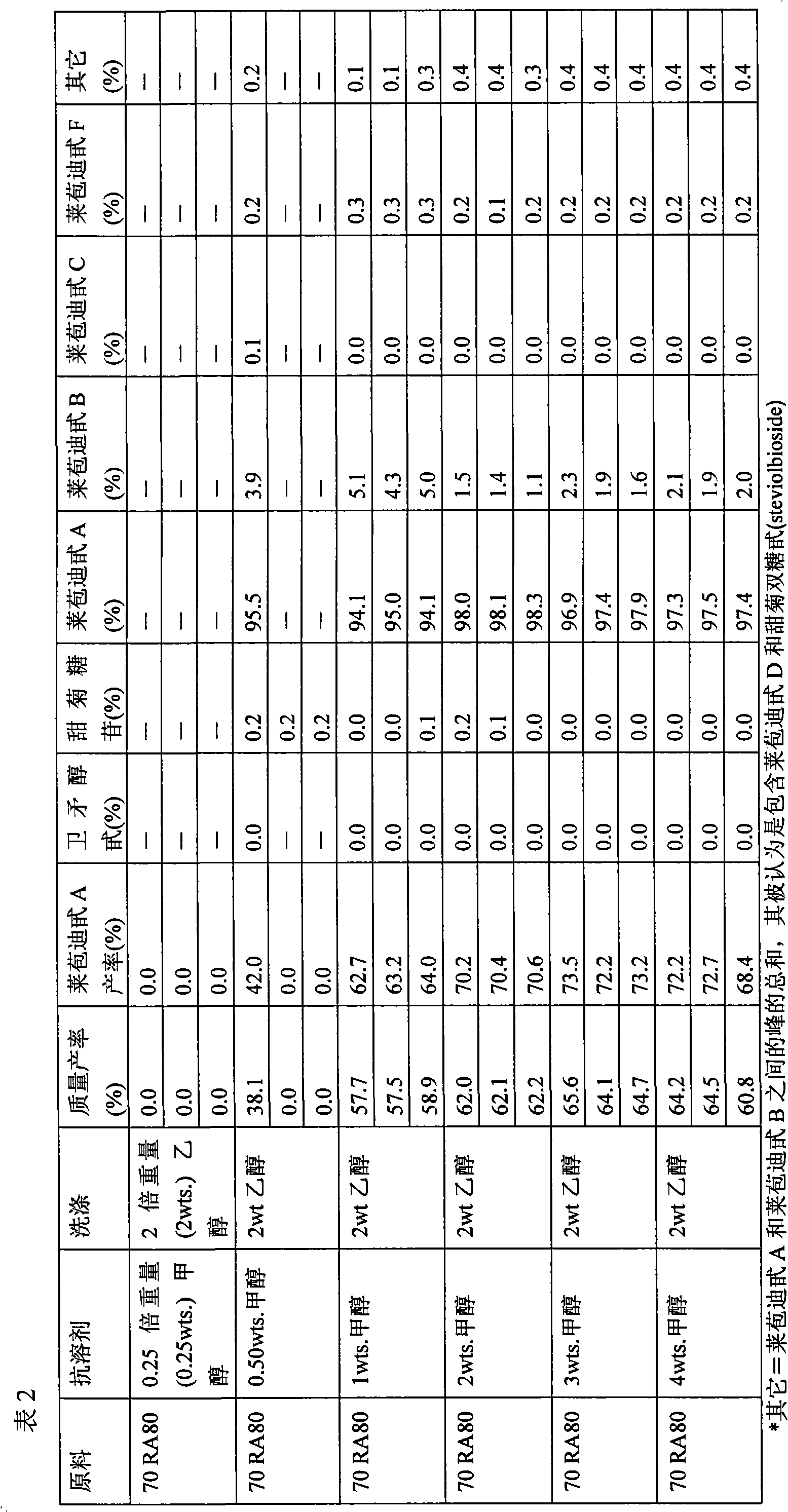

Method of producing purified rebaudioside a compositions using solvent/antisolvent crystallization

The invention provides methods of purifying rebaudioside A from a mixture comprising glycosides of the plant Stevia rebaudiana. The methods of the invention are useful for preparing highly pure rebaudioside A compositions from crude Stevia starting compositions that are typically considerably lower in rebaudioside A concentration. The highly pure rebaudioside A compositions are useful as non-caloric sweeteners in edible or chewable compositions such as food, beverages, medicine, candy, chewing gum, and the like.

Owner:CARGILL INC

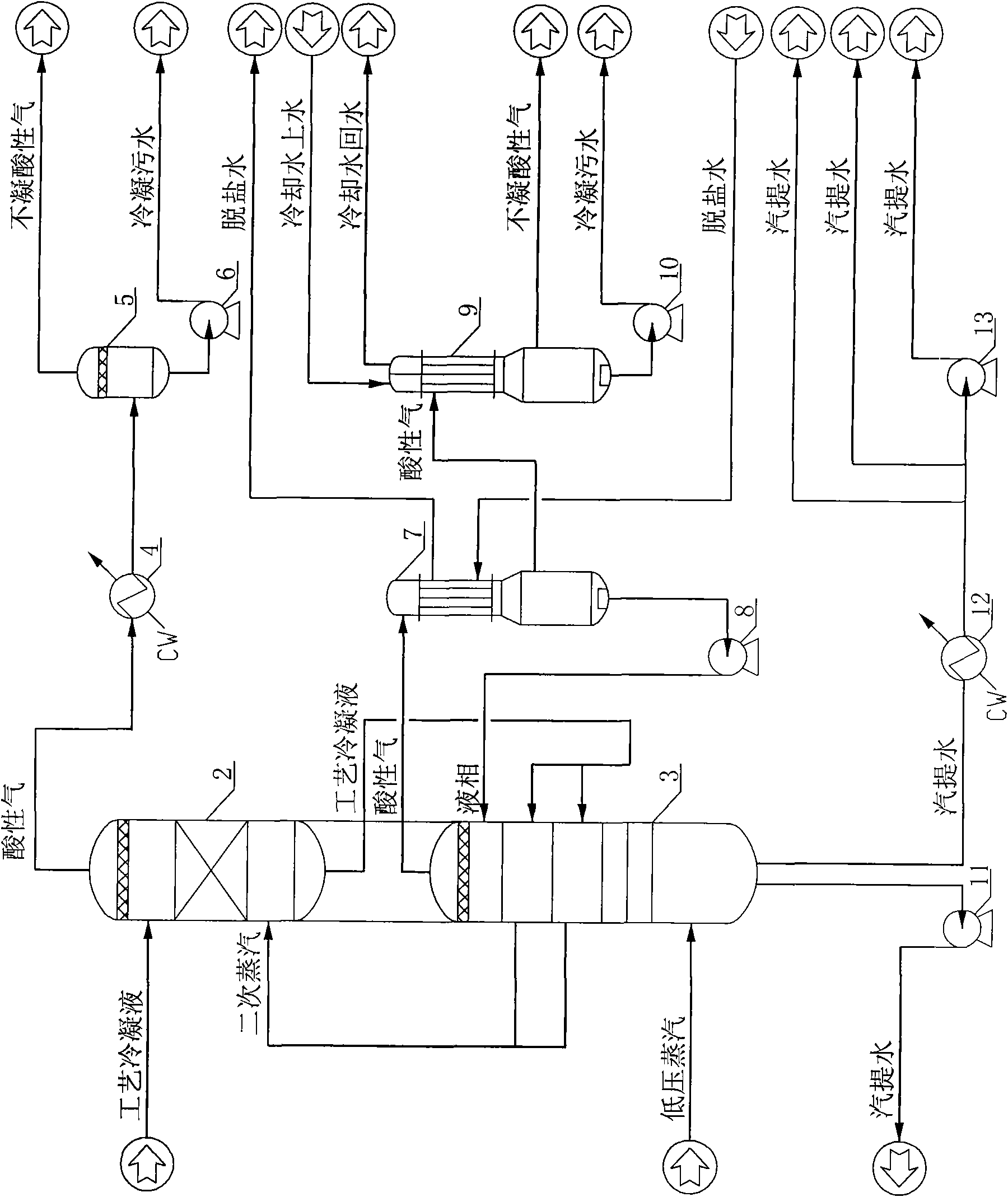

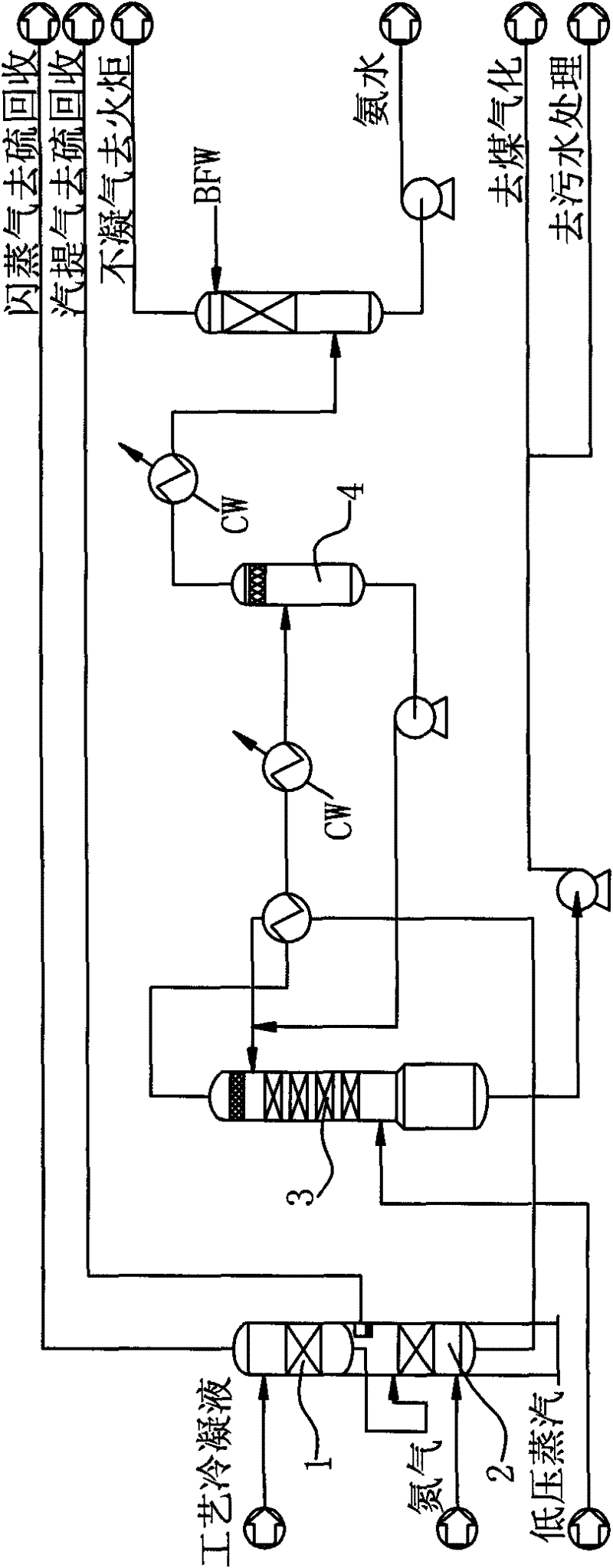

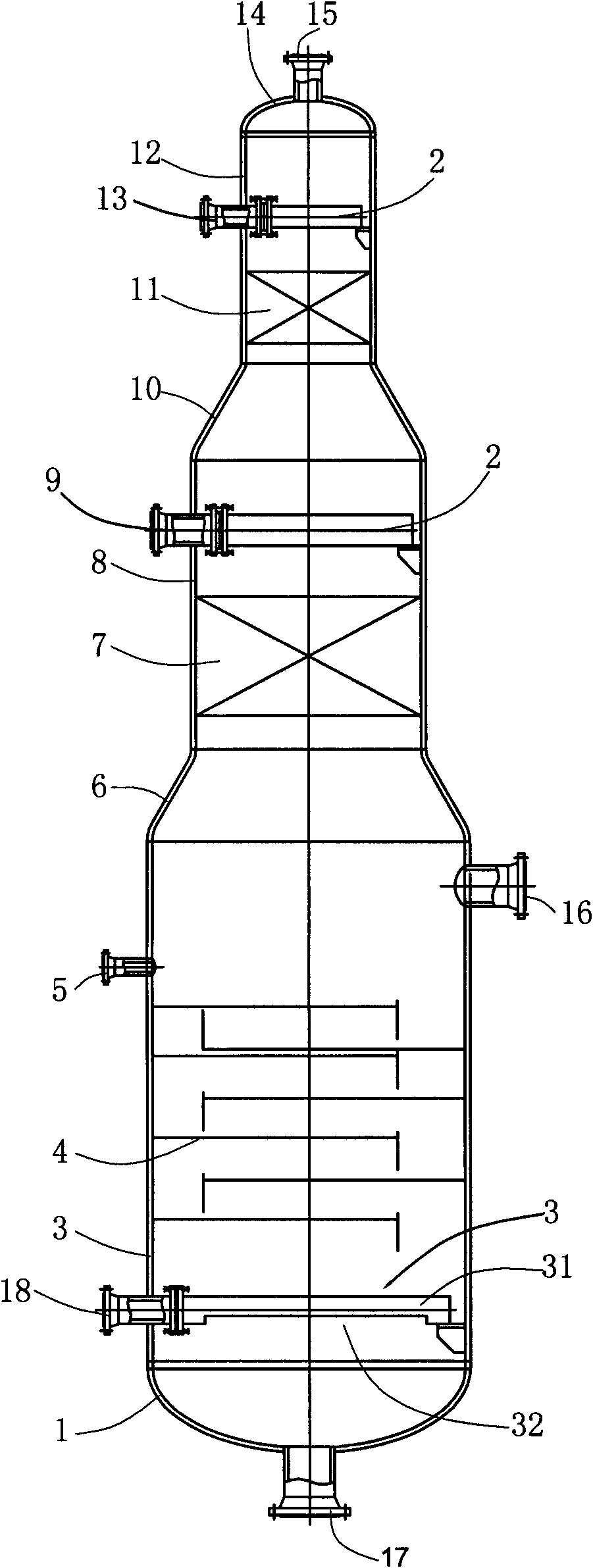

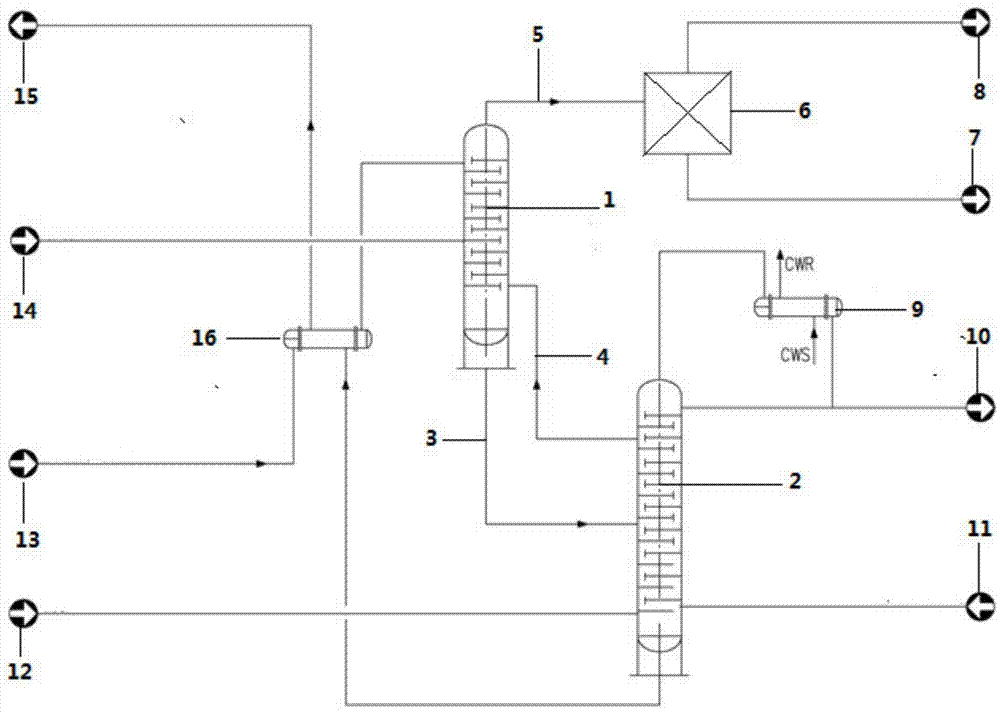

Steam stripping method of process condensate in CO conversion

ActiveCN101570350AAvoid the possibility of simultaneousSolve the blockageWater/sewage treatment by heatingWater/sewage treatment by degassingGas phaseEvaporation

The invention relates to a steam stripping method of process condensate in CO conversion. The invention is characterized in that the process condensate firstly enters the upper part of a carbon dioxide steam stripping tower for flashing evaporation; secondary steam from the upper part of an ammonia-evaporated steam stripper tower enters the bottom part of the carbon dioxide steam stripping tower and steam strips carbon dioxide by countercurrent contacting with the process condensate after flashing evaporation; the process condensate after flash evaporation and the steam stripped carbon dioxide carry out countercurrent contact; the process condensate after flash evaporation and steam stripping enters the upper part of the ammonia-evaporated steam stripper tower from the bottom part of the carbon dioxide steam stripping tower and is steam-stripped by low-pressure steam entering from a kettle of the ammonia-evaporated steam stripper tower; gas phase is treated by secondary condensation to obtain non-acid-coagulated gas and condensate sewage; and steam stripping water is obtained from the bottom part of the ammonia-evaporated steam stripper tower. The invention carries out steam stripping on the upper and lower towers to carbon dioxide and ammonia in the process condensate respectively, thus avoiding the possibility of coexistence of carbon dioxide and ammonia in a condensing system, effectively solving the problem that the steam stripping system of the process condensate in the conversion procedure occurs ammonium salt crystallization blockage and prolonging the period of stable operation of a conversion device.

Owner:CHINA PETROCHEMICAL CORP +2

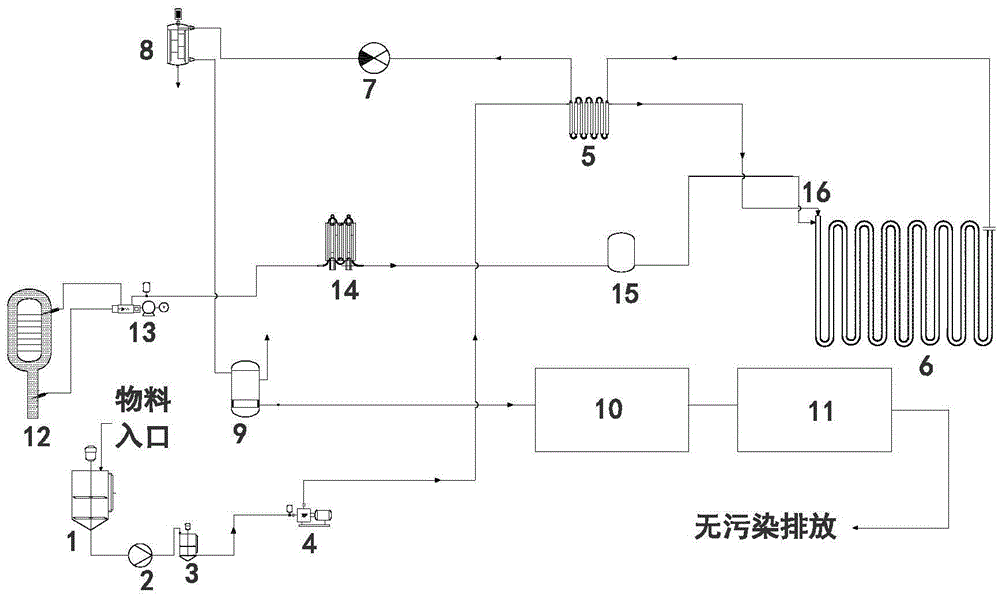

Advanced oxidation-separate salt crystallization combination system of high-salt-salt industrial wastewater

ActiveCN105540980AReduce COD concentrationOvercoming removalTreatment involving filtrationEnergy based wastewater treatmentChemical oxygen demandEvaporation

The invention provides an advanced oxidation-separate salt crystallization combination system and technique of high-salt-salt industrial wastewater, relating to the technical field of water treatment. The technique comprises the following steps: sending high-salt-salt industrial wastewater treated by a pretreatment membrane system into an ozone advanced oxidation device, and standing in the presence of an ozone catalyst at the ozone specific loss of 1.2-3.0 kg O3 / kg COD (chemical oxygen demand) for 2-4 hours, wherein the COD of the treated effluent water is less than 50 mg / L; and sending into a crystallizing system to carry out crystallization treatment, wherein sodium sulfate concentrated water enters a refrigerating crystallizing system, and sodium chloride concentrated water enters a multi-effect evaporation (or MVR (mechanical vapor recompression) evaporation) device. The technique greatly lowers the wastewater COD content, increases the crystal salt purity, has the characteristics of simple operation, low cost, high water treatment quantity, high adaptability and stable water quality, and reduces the blockage problem of the crystallizing equipment.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

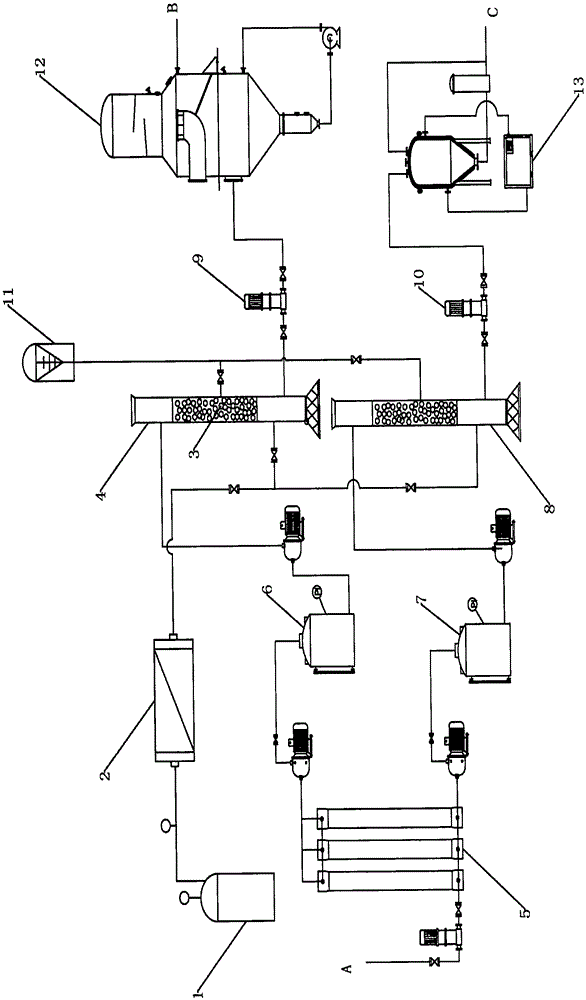

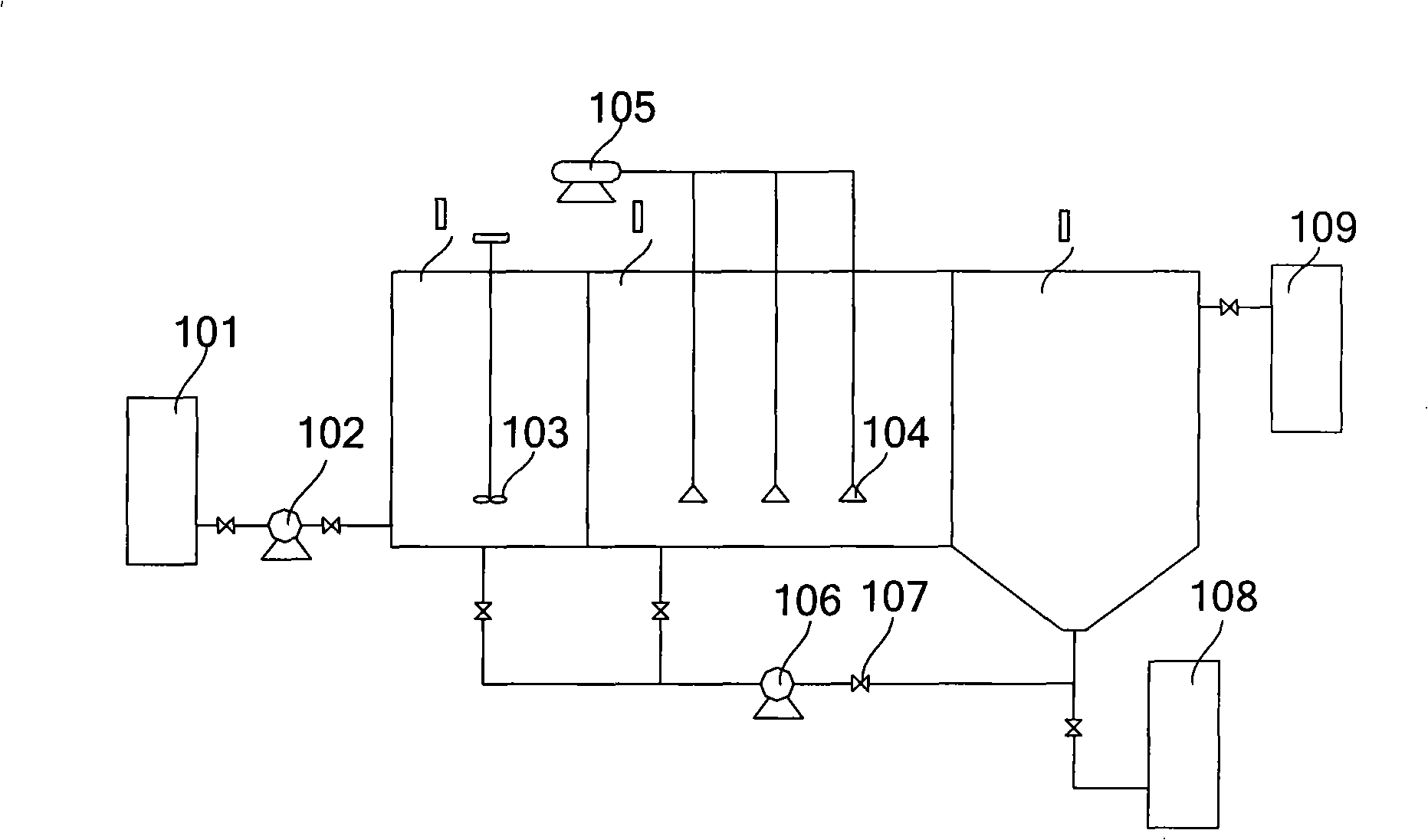

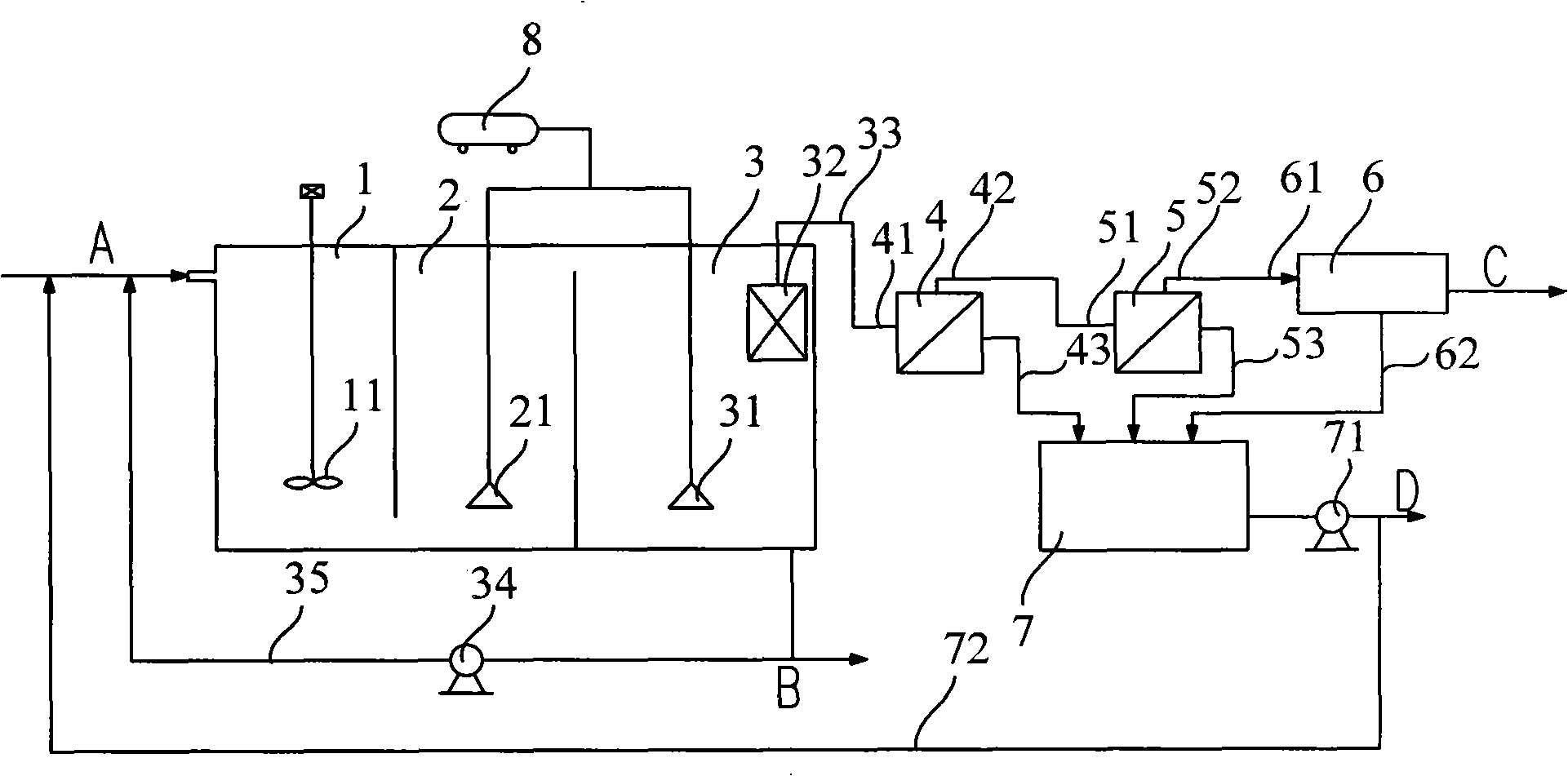

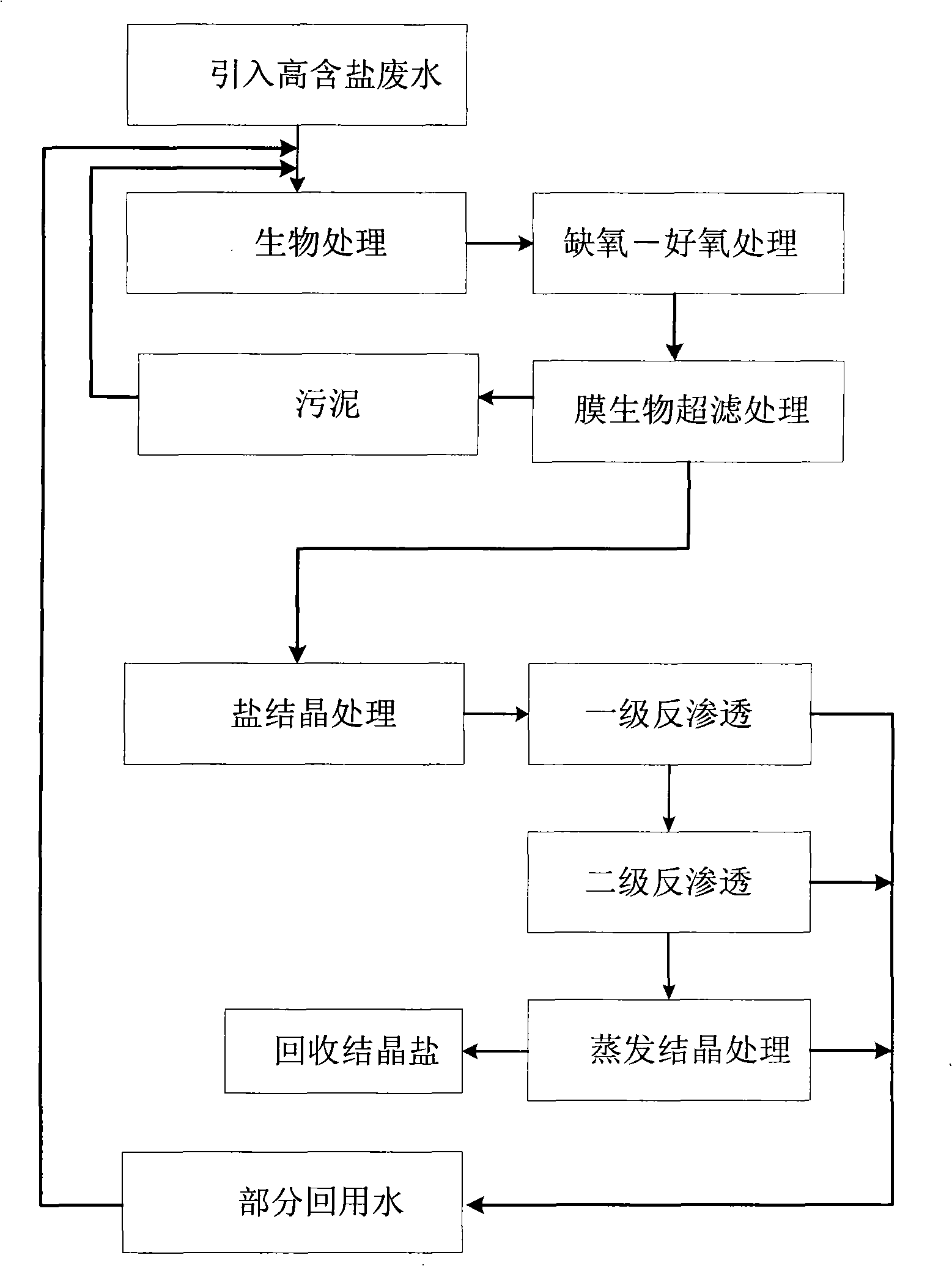

Treatment system and method for high-salt wastewater

InactiveCN101402509AImprove water qualityAvoid pollutionWater/sewage treatment bu osmosis/dialysisTreatment with aerobic and anaerobic processesAir compressionWater quality

The invention discloses a wastewater treatment system for treating highly salt-contained wastewater and a treatment method thereof, which belongs to the field of water treatment. The system comprises a biological treatment sub system and a salt crystallization sub system, wherein the biological treatment sub system is formed by the order connection of an anoxia pond, an aeration pond and a membrane biological reactor, wherein the anoxia pond is provided with a wastewater inlet through which the highly salt-contained wastewater is introduced to the anoxia pond, the inner parts of the aeration pond and the membrane biological reactor are both provided with aeration heads connected with an air compression device, and the membrane biological reactor is provided with a after-filter water outlet pipeline for water discharging; and the after-filter water outlet pipeline of the membrane biological reactor of the biological treatment sub system is connected with a water inlet of the salt crystallization sub system, and the salt crystallization sub system is provided with a salt crystal outlet and a reutilized water outlet. By utilizing the membrane biological reactor, the system solves the problem that because the sedimentation performance of the highly salt-contained wastewater is poor in the biological treatment sub system, the quality of the discharged water is poor; and by the salt crystallization sub system, the system reclaims salt, thereby obtaining salt resources and avoiding water pollution.

Owner:BEIJING SOUND ENVIRONMENTAL ENG

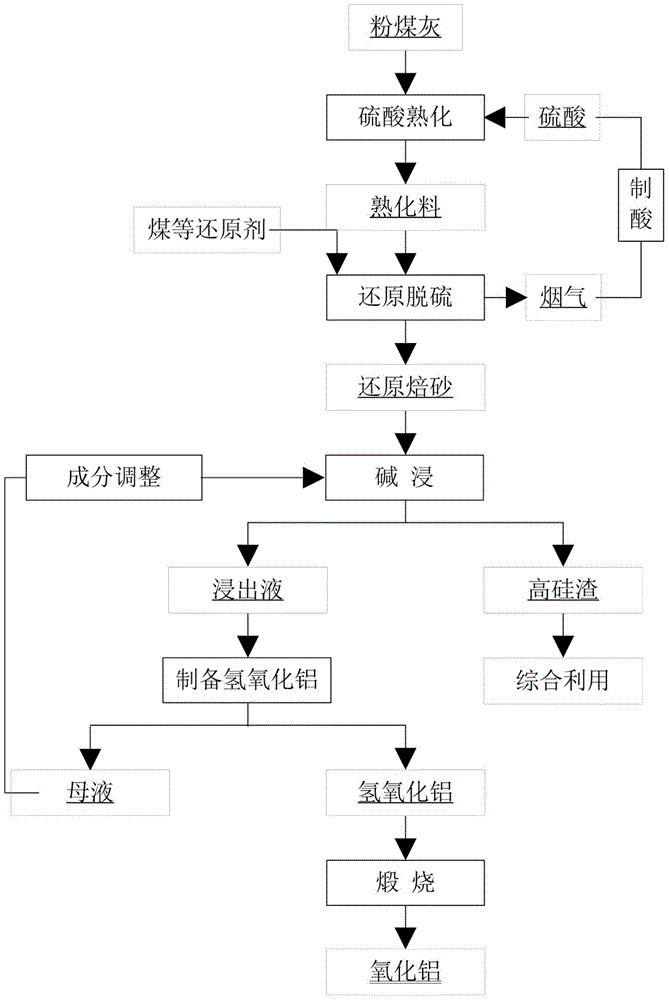

Method for extracting aluminum oxide from fly ash by acid-alkali combination process

The invention discloses a method for extracting aluminum oxide from fly ash by an acid-alkali combination process. The method comprises the following steps of uniformly mixing and curing fly ash and an appropriate amount of concentrated sulfuric acid, by virtue of residual carbon in the fly ash and appropriately supplementing a reducing agent, carrying out high-temperature rapid reduction, calcining and desulfurization, preparing sulfur-containing flue gas into acid to achieve regeneration recycling of sulfuric acid and producing aluminum oxide from the reduced calcined product by virtue of alkaline leaching. According to the method, advantages of fly ash acid method and alkali method for extracting aluminum oxide are integrated and shortcomings of both are effectively avoided. High-energy-consumption evaporative crystallization of aluminum salt and decomposition process of aluminum salt crystallization water in the conventional acid method process are omitted and thus a great deal of energy consumption is saved; compared with the conventional alkali method process, high-energy-consumption calcining process is not needed, the amount of slag is low and the slag can be used as a silicon raw material for recycling, the yield of wastes is small and thus the real reduction environment-friendly clean product is achieved; the aluminum oxide product has good quality, the method has the advantages of high recovery rate, low energy consumption and small corrosion to the device and the large-scale industrialization is easily implemented.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

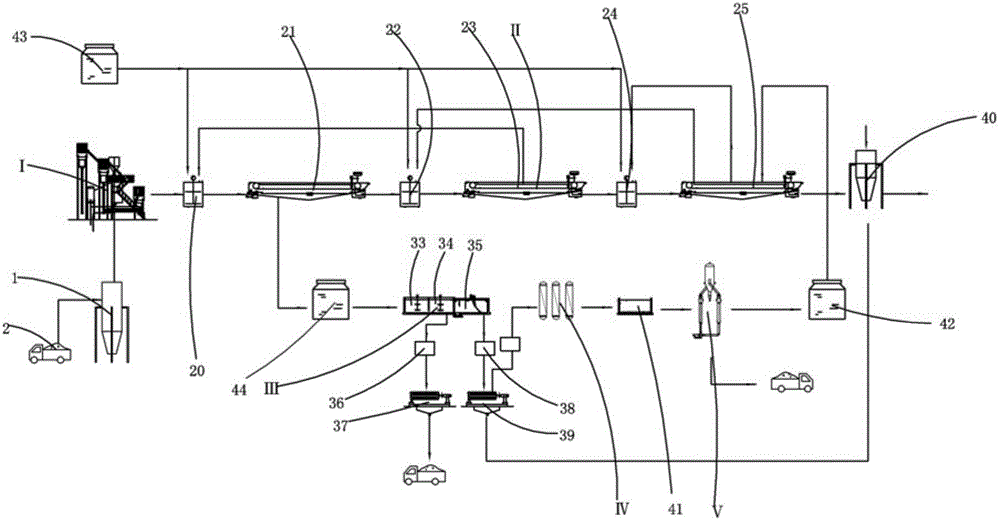

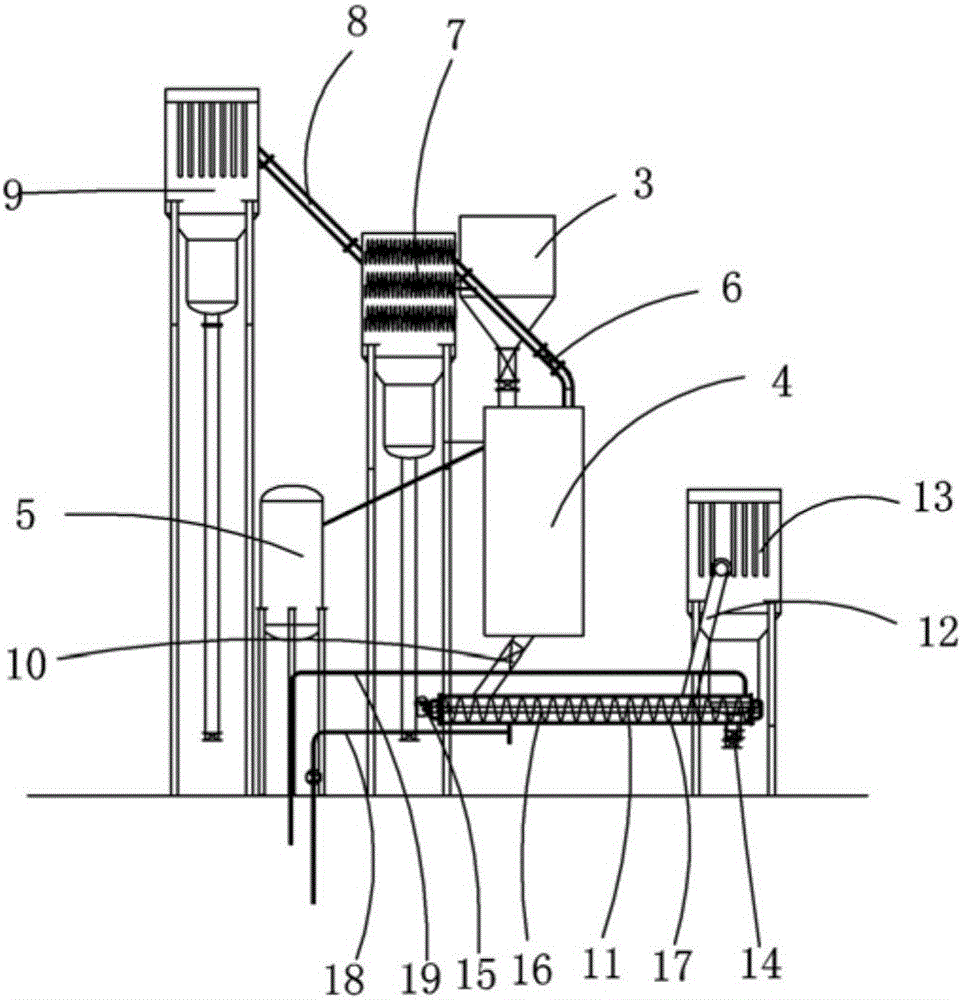

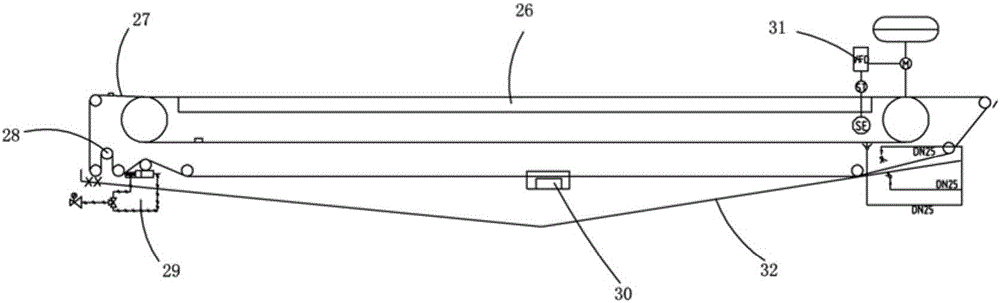

Flying ash harmless treatment resource recycling utilization device and treatment method

ActiveCN106391663AHigh detoxification efficiencyReduce energy consumptionTransportation and packagingSolid waste disposalThree levelResource utilization

The invention relates to a flying ash harmless treatment resource recycling utilization device and a treatment method. The flying ash harmless treatment resource recycling utilization device comprises a solid-phase catalytic dechlorination detoxification dioxin-removing system, waste incineration flying ash three-level water-washing desalination system, a heavy metal removing system, a membrane distillation concentration system and a salt crystallization system. The solid-phase catalytic dechlorination detoxification dioxin-removing system removes dioxin in flying ash. The waste incineration flying ash three-level water-washing desalination system removes a large amount of salt in the dioxin-removed flying ash. Part of heavy metal residues still exists in a three-level water-washing filtrate obtained after water washing. The heavy metal removing system removes a large number of calcium and magnesium ions and a few of heavy metal ions contained in the three-level water-washing filtrate, and a heavy-metal-removed supernatant is obtained. The membrane distillation concentration system conducts distillation contributing water reusing on the supernatant, and a concentrated solution is generated. The salt crystallization system conducts evaporative crystallization on the concentrated solution, and crystal salt containing 7% of water and condensate water are obtained. Through the flying ash harmless treatment resource recycling utilization device and the treatment method, the flying ash can be subjected to harmless treatment, and resource utilization can be achieved.

Owner:湖州京兰环保科技有限公司

Acidic water treatment method

ActiveCN102225819ALong cycleAvoid crystal pluggingMultistage water/sewage treatmentWater/sewage treatment by heatingSulfurNitrogen

The present invention relates to an acidic water treatment method, which is characterized by firstly separating H2S and CO2 with a nitrogen stripping tower, and then sending the tower kettle liquid to a steam stripping tower for extracting NH3. Preferably, in order to save the amount of nitrogen, H2S and CO2 can also be separated by first flash evaporation and then nitrogen stripping. Compared with the prior art, the step-by-step stripping method provided by the present invention removes H2S, CO2 and ammonia from the acidic water, avoids the simultaneous existence of H2S, CO2 and NH3 in the stripping tower top system, effectively solves the problems of pipeline blockage and equipment corrosion caused by ammonium salt crystallization, prolongs the stable operation period of a conversion device, simultaneously reduces the treatment difficulty of a sulfur recovery unit and facilitates the long-term stable operation of the sulfur recovery unit.

Owner:CHINA PETROLEUM & CHEM CORP +2

Method for refining long-chain biatomic acid

The invention relates to a kind of method for abstracting and refining long chain binary acid by water phase from C10-C18 regular normal-structure alkane or mixed normal-structure alkane fermenting liquor. The invention solves the disadvantages of low purity and high chroma in the production made by existing water phase. The method can decline the content of impurity such as protein and chroma effectively, and can be combined with the steps of thalline separation, acid-out and crystallization, drying and so on, to manufacture long chain binary acid product with total acid content more than 99wt% and white appearance. It uses the technique combining long chain binary mono-salt crystallization and salting-out, so it can leave the step of binary acid recovering treatment with salting-out mother liquor and mono-salt filter liquor out, save treatment cost, and improve product yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

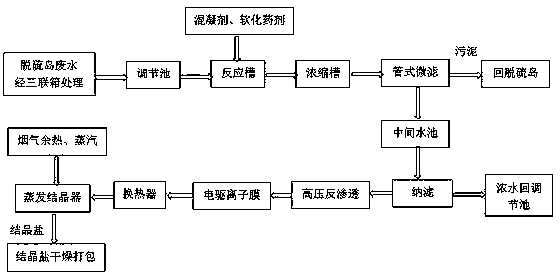

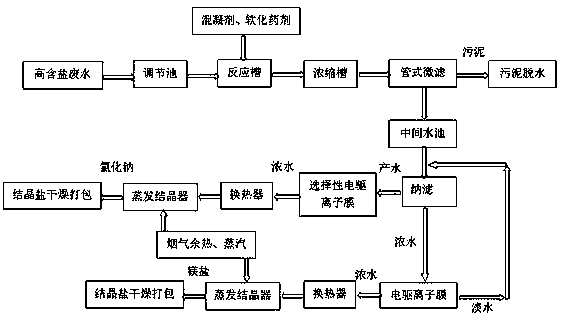

Salt crystallization separation device and process capable of realizing zero emission

InactiveCN107915360AReduce pollutionImprove efficiencyMultistage water/sewage treatmentWater/sewage treatment by heatingMicrofiltration membraneEvaporation

The invention relates to a salt crystallization separation device and process capable of realizing zero emission and discloses a zero-emission treatment method and device for high-salt wastewater. Wastewater is subjected to intensified softening treatment with a tubular microfiltration membrane and then enters a special separation membrane for separation of monovalent ions and divalent ions. Further concentration is performed with a high-pressure reverse osmosis or selective permeable electric ionic membrane according to the properties of materials on a fresh water side and a concentrated water side, and the evaporation system treatment scale and scaling tendency are reduced to the maximum extent. Crystalline salt is obtained by use of a low-temperature normal-pressure crystallizer at an evaporative crystallization section, wastewater and crystalline salt are finally recycled, the investment is saved, the wastewater operation cost is significantly reduced, and zero emission of wastewater can be really realized.

Owner:国能朗新明环保科技有限公司

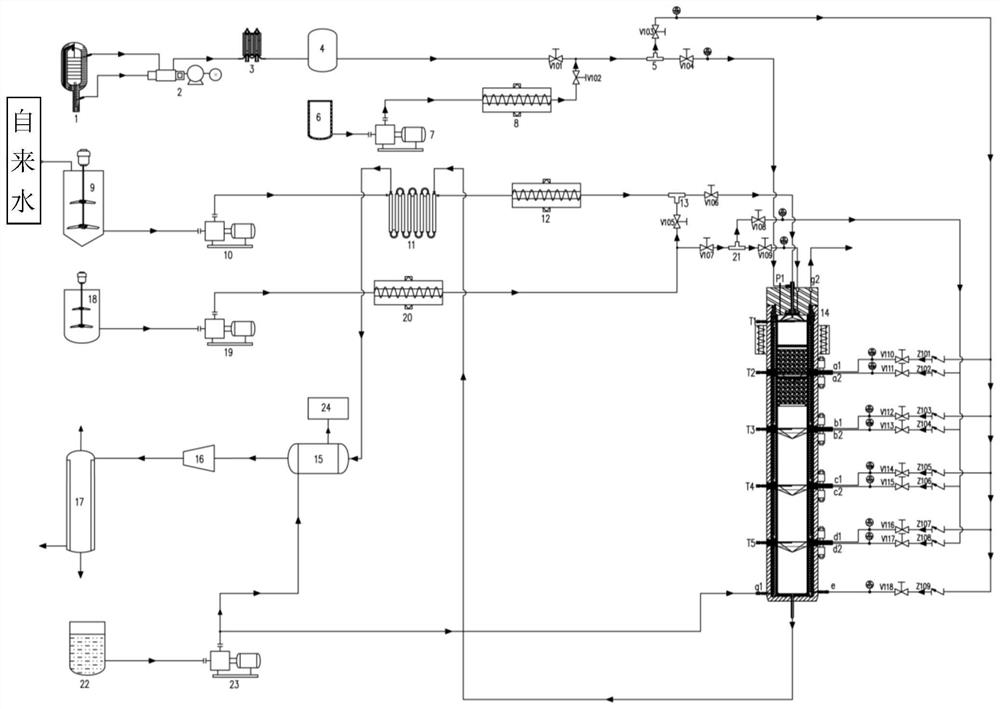

Multifunctional supercritical water enhanced oxidation system for degradation-resistant nitrogen-containing and high-salt organic pollutants

InactiveCN111762866ASmall sizeLow temperature resistanceWater contaminantsWater/sewage treatment by oxidationCatalytic oxidationSupercritical water oxidation

The invention relates to a multifunctional supercritical water enhanced oxidation system for degradation-resistant nitrogen-containing and high-salt organic pollutants. The multifunctional supercritical water enhanced oxidation system comprises an oxidant pretreatment unit, a material pretreatment unit, a medicament pretreatment unit, a supercritical water oxidation unit, a water supply unit and aproduct subsequent treatment unit. In the supercritical water oxidation system, a plurality of enhanced oxidation technologies such as reactor inner wall surface catalysis, heterogeneous metal oxidecatalysis, co-oxidation of auxiliary aids, sectional oxidation, sectional co-oxidation and catalytic oxidation of inorganic salt are coupled at one time, one or a combination of more than one of the enhanced technologies can realize synergistic and efficient removal of COD and ammonia nitrogen from the nitrogen-containing organic pollutants under relatively mild reaction conditions, so that the operating conditions of the system and the investment cost of equipment are reduced, and the economy, safety and reliability of the system are improved. And meanwhile, the phenomena of salt crystallization, deposition and blockage of equipment such as a preheater and a heater and connecting pipelines thereof in the preheating process are avoided, and the running reliability of the system is improved.

Owner:XI AN JIAOTONG UNIV

Composite anti-salt agent and applications thereof

ActiveCN107699209AImprove solubilityStrong complexationPipeline systemsDrilling compositionSolubilityFerrocyanide

The invention discloses a composite anti-salt agent, which mainly comprises a ferrocyanide solubilizer A and a complexone B, and can further comprise a polymer lattice modifier C and / or water. According to the present invention, the composite anti-salt agent has a synergistic effect, wherein the ferrocyanide solubilizer A in the composite anti-salt agent can substantially increase the solubility of the salt, and provides the main effect of the composite anti-salt agent, the complexone B in the composite anti-salt agent has good complexation effects on metal ions and can change the metal ion concentration of the salt crystal so as to reduce the solubility product of the salt crystal, and the polymer lattice modifier C can change the compact structure of the salt into the loose structure soas to make the salt be easily carried away by the flowing of the solution. According to the present invention, the composite anti-salt agent can provide excellent salt crystallization prevention effect on salt solutions with highly mineralized sodium chloride, and further can provide good salt release effects on salt solutions with highly mineralized sodium chloride, calcium chloride and magnesiumchloride.

Owner:CHINA PETROLEUM & CHEM CORP +1

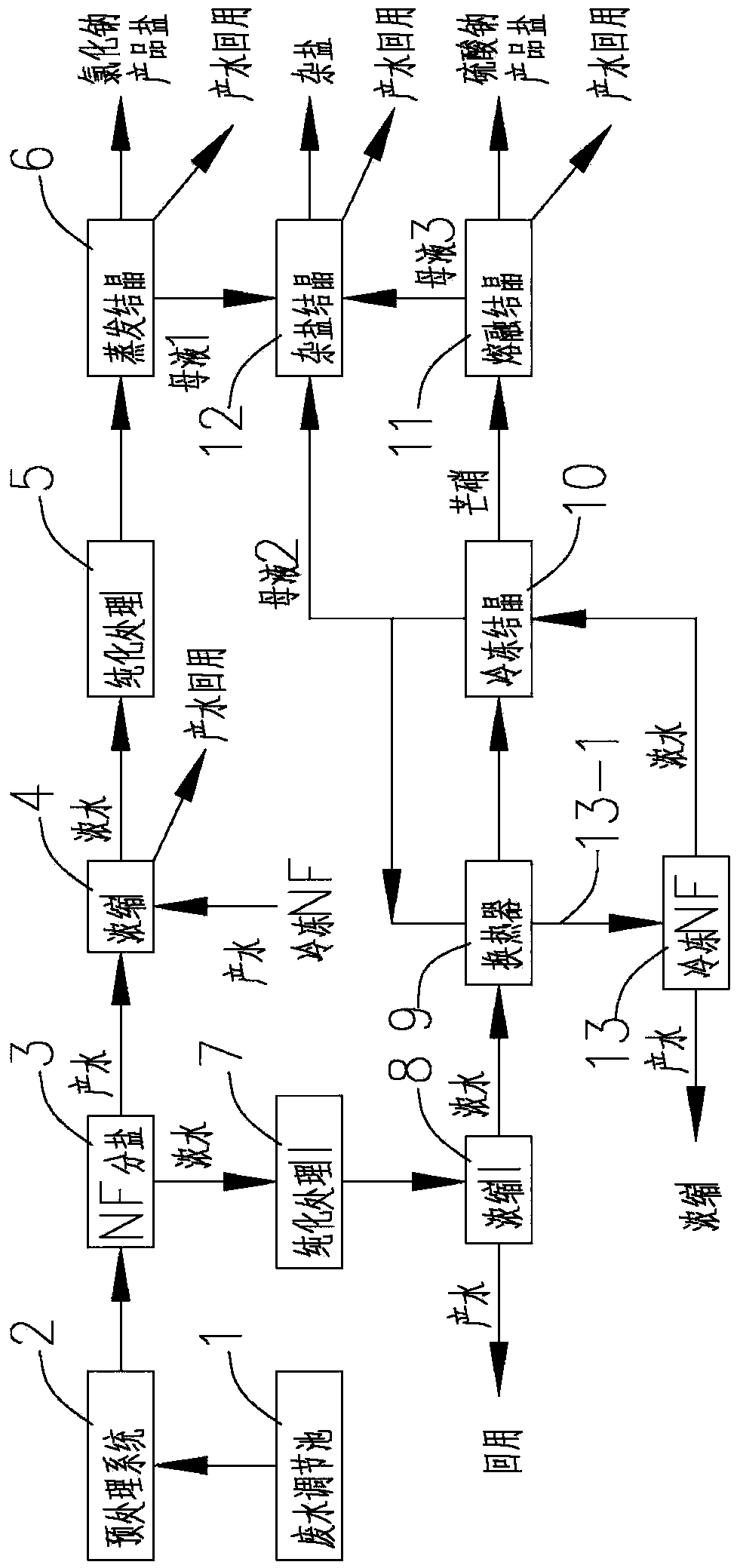

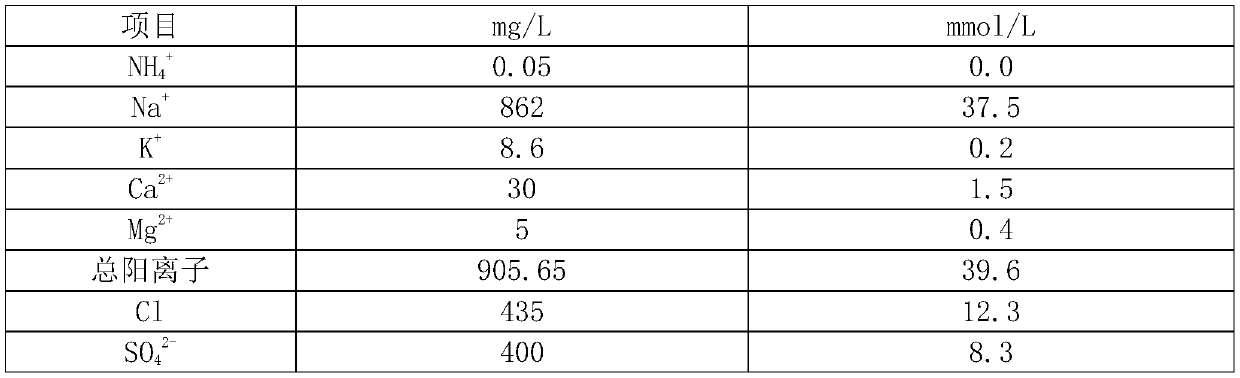

Thorough salt separation crystallization technology and system for high-salt wastewater

InactiveCN108996785ASimple technologyTreatment involving filtrationWater/sewage treatment by ion-exchangeNitrateEvaporation

The invention discloses a thorough salt separation crystallization technology for high-salt wastewater, wherein the high-salt wastewater enters an NF salt separation system after being treated by a pretreatment system; NF produced water enters an evaporation crystallization system after being concentrated and purified, and finally sodium chloride crystal salt is produced; NF concentrated water enters a freezing crystallization and melt crystallization system after being purified and concentrated, and finally sodium sulfate crystal salt is produced; part of mother liquor of the freezing crystallization enters a freezing NF system for further salt-nitrate separation, and freezing NF concentrated water is returned to a freezing crystallization unit, and the freezing NF produced water is sentto be mixed with the NF produced water. By adopting the technology provided by the invention, the stability and the high efficiency of salt separation when the water quantity and quality of the systemfluctuate can be ensured, the thorough separation of salt and nitrate is realized, the purity of product salt is high, the recovery rate of the product salt is high, and the production of abraum saltis reduced to the maximum.

Owner:广州汉泰环境技术有限公司

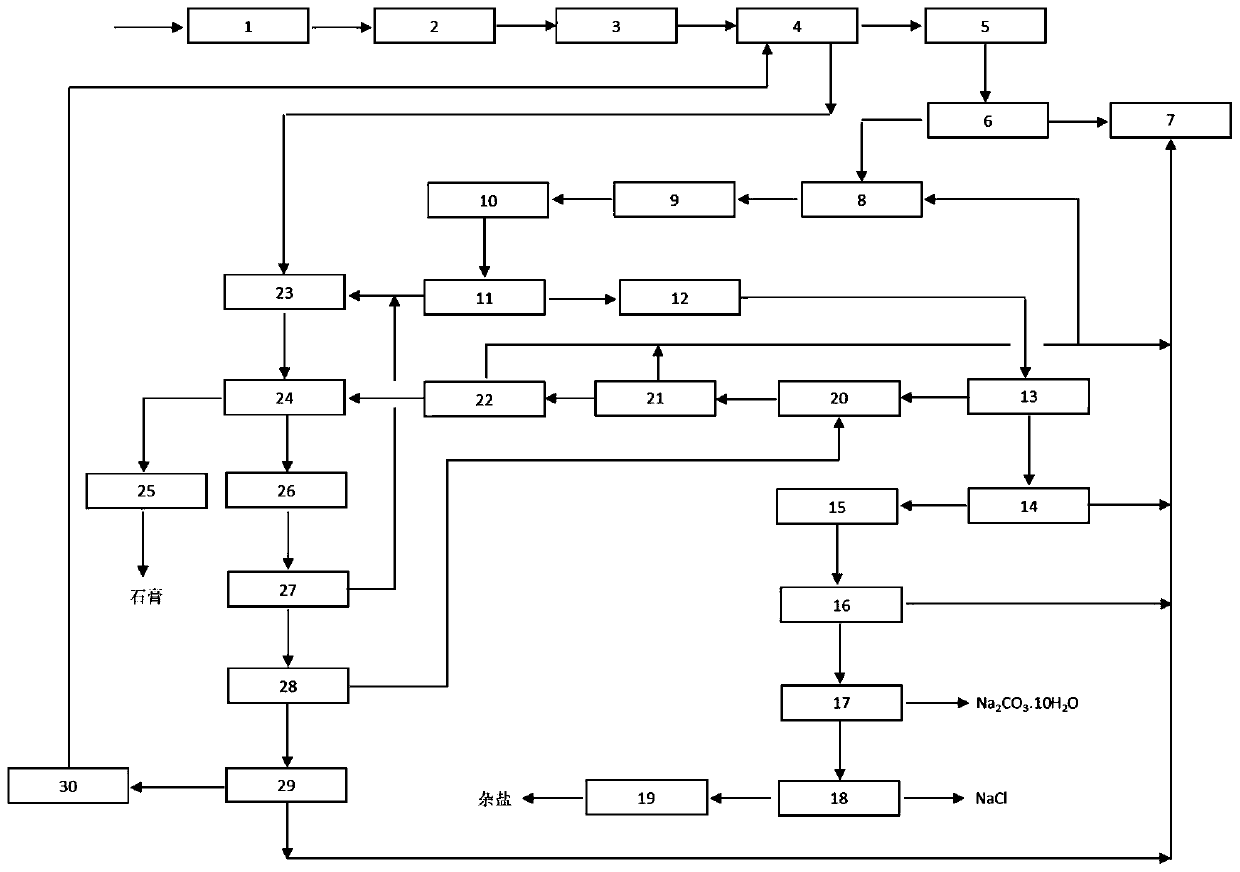

High-salinity coal mine water standard treatment and resource utilization device and use method thereof

ActiveCN111362453AReduce softening and hardening costsStable calcium sourceWaste water treatment from quariesGeneral water supply conservationWater desalinationLiquid storage tank

The invention relates to a high-salinity coal mine water standard treatment and resource utilization device and a use method thereof. The device comprises a homogenizing adjusting tank, a high-densityclarification tank, a gravity type filter tank, a sodium bed device, an ultrafiltration device, a reverse osmosis device, a recycled water tank, an ozone reaction tank, a concentrated water high-density clarification tank, a multi-media filter, a concentrated water weak acid resin bed, a concentrated water ultrafiltration device, a nanofiltration device, a nanofiltration produced water reverse osmosis device, a strong brine tank, a nanofiltration produced water evaporation concentration device, a sodium carbonate decahydrate freezing crystallization device, a sodium chloride evaporation crystallization device, an impure salt crystallization device, a nanofiltration concentrated water tank, a nanofiltration concentrated water evaporation concentration device, a sodium sulfate decahydrate freezing crystallization device, a resin regeneration waste liquid storage tank, a calcium sulfate settling tank, a calcium sulfate dehydrator and the like. The device has the advantages that the structural design is reasonable, consumption of softening agents for mine water desalination treatment is reduced, the system reliability is improved, the additional value of salt products is increased, and maximum utilization of resources is achieved.

Owner:BEIJING BAILINGTIANDI ENVIRONMENTAL PROTECTION TECH

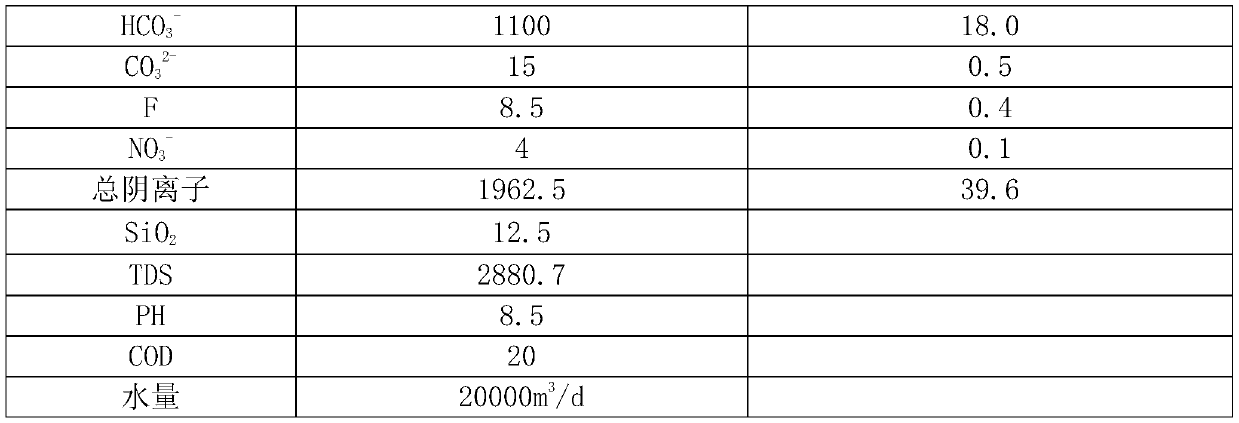

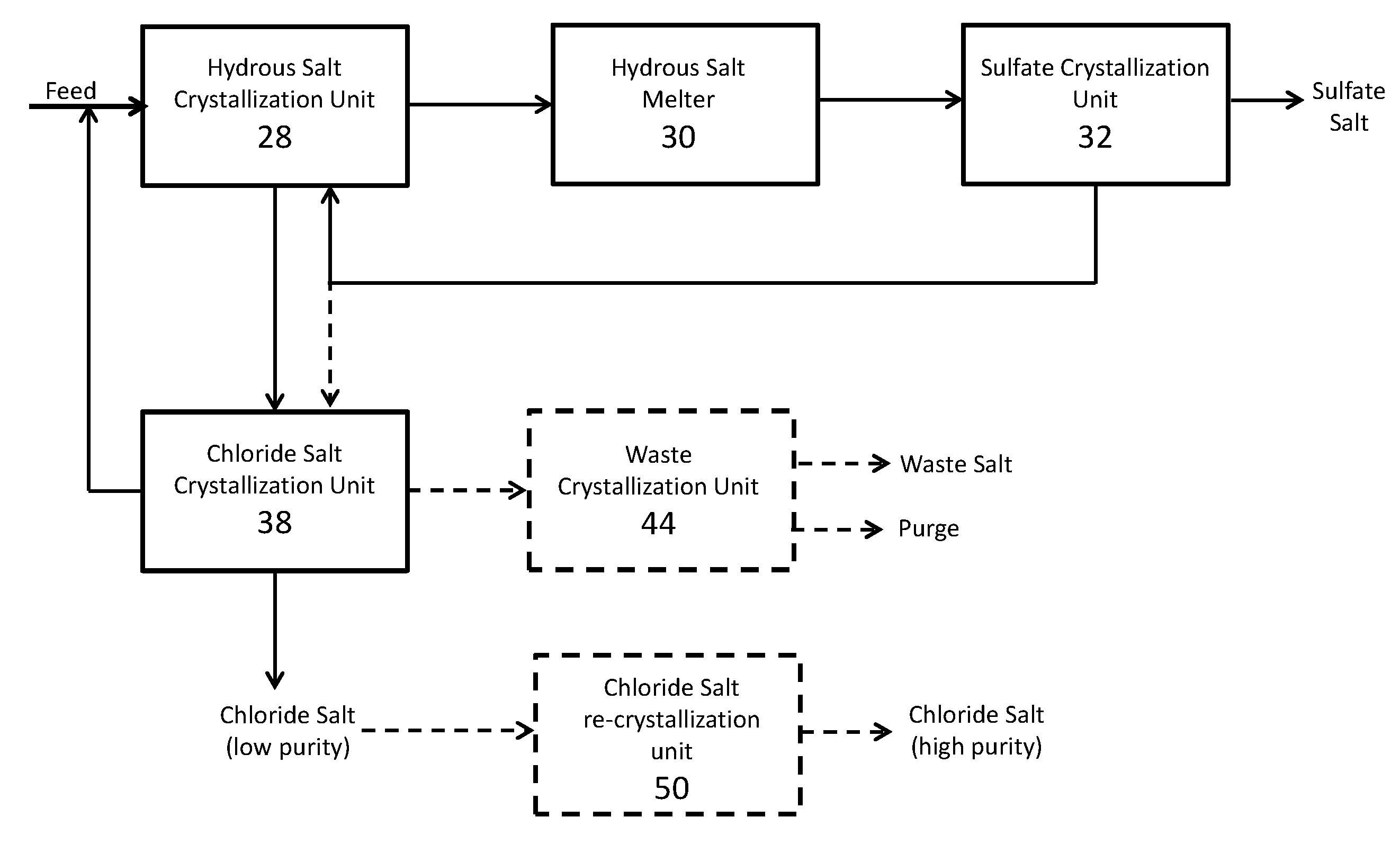

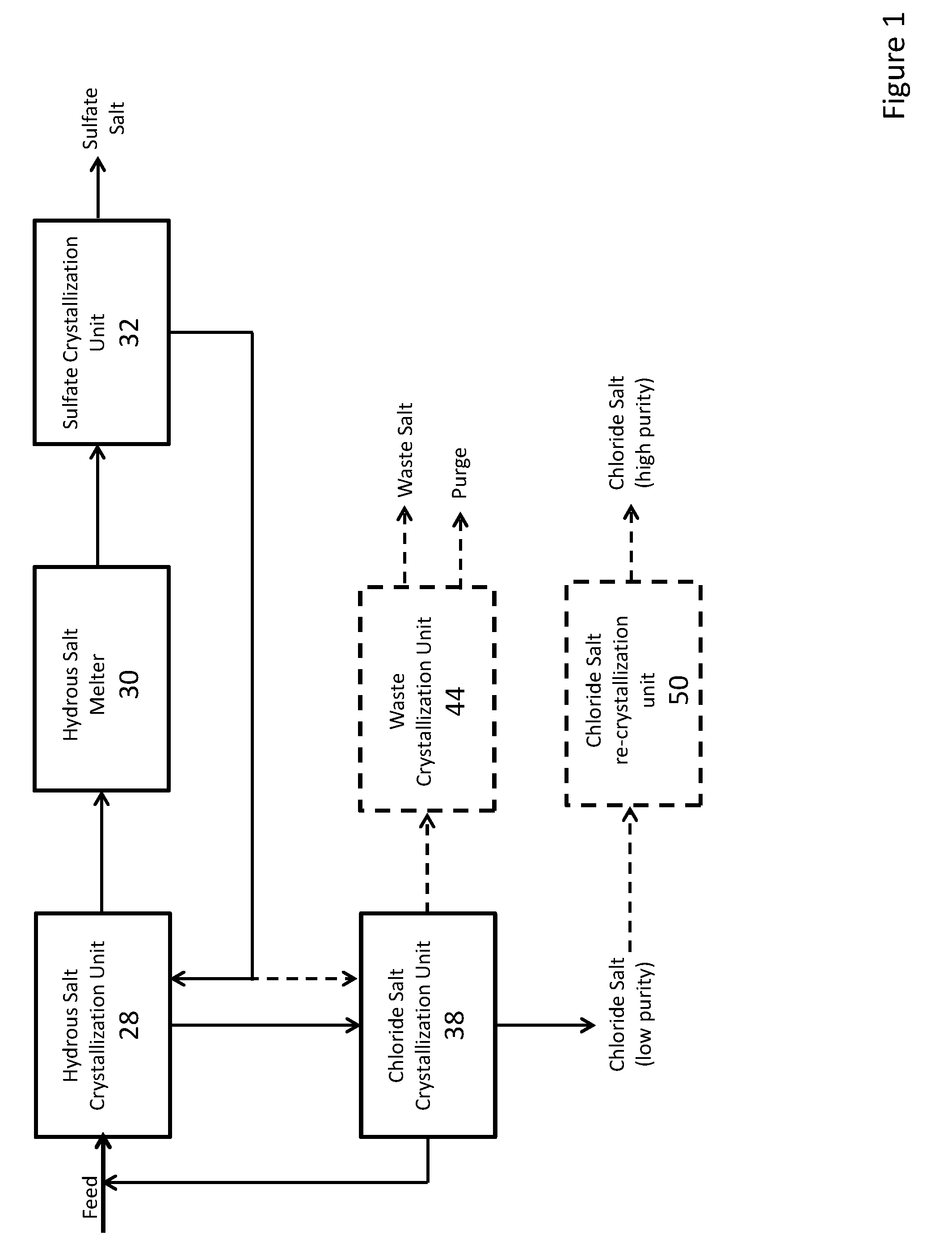

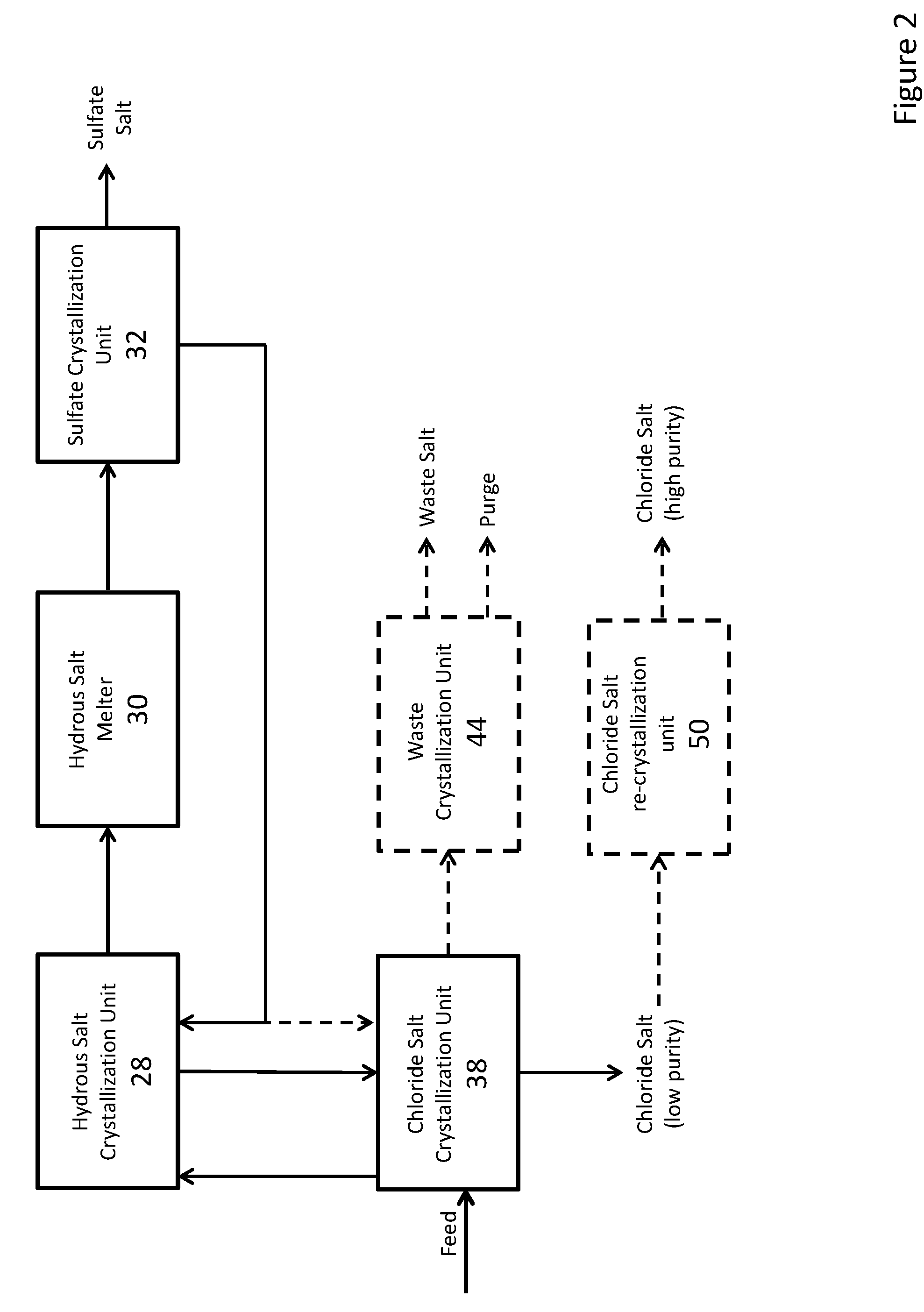

Process for recovering sulfate and chloride salts from wastewater, mixed salts, and brines

ActiveUS20160280571A1Reduce the amount requiredSafe releaseWaste water treatment from quariesSulfate preparationMetal chlorideChloride salt

A process is described for recovering alkali-chloride and alkali-sulfate salts from a salt solution. The salt solution comprises alkali metal, chloride and sulfate ions and is directed to a hydrous salt crystallization unit which crystallizes hydrated sulfate salts that comprise sulfate and at least one alkali metal. A purged solution from the hydrous salt crystallization unit is directed to a chloride salt crystallization unit while the hydrated sulfate salt crystals are melted to form an aqueous sulfate solution which is directed to a sulfate crystallization unit. Anhydrous sulfate salts are crystallized from the aqueous sulfate solution to form sulfate salt crystals comprising sulfate and at least one alkali metal. In the chloride salt crystallization unit, chloride salt is crystallized to form chloride salt crystals. A purge from the chloride salt crystallization unit is directed to the hydrous salt crystallization unit.

Owner:VEOLIA WATER TECH INC

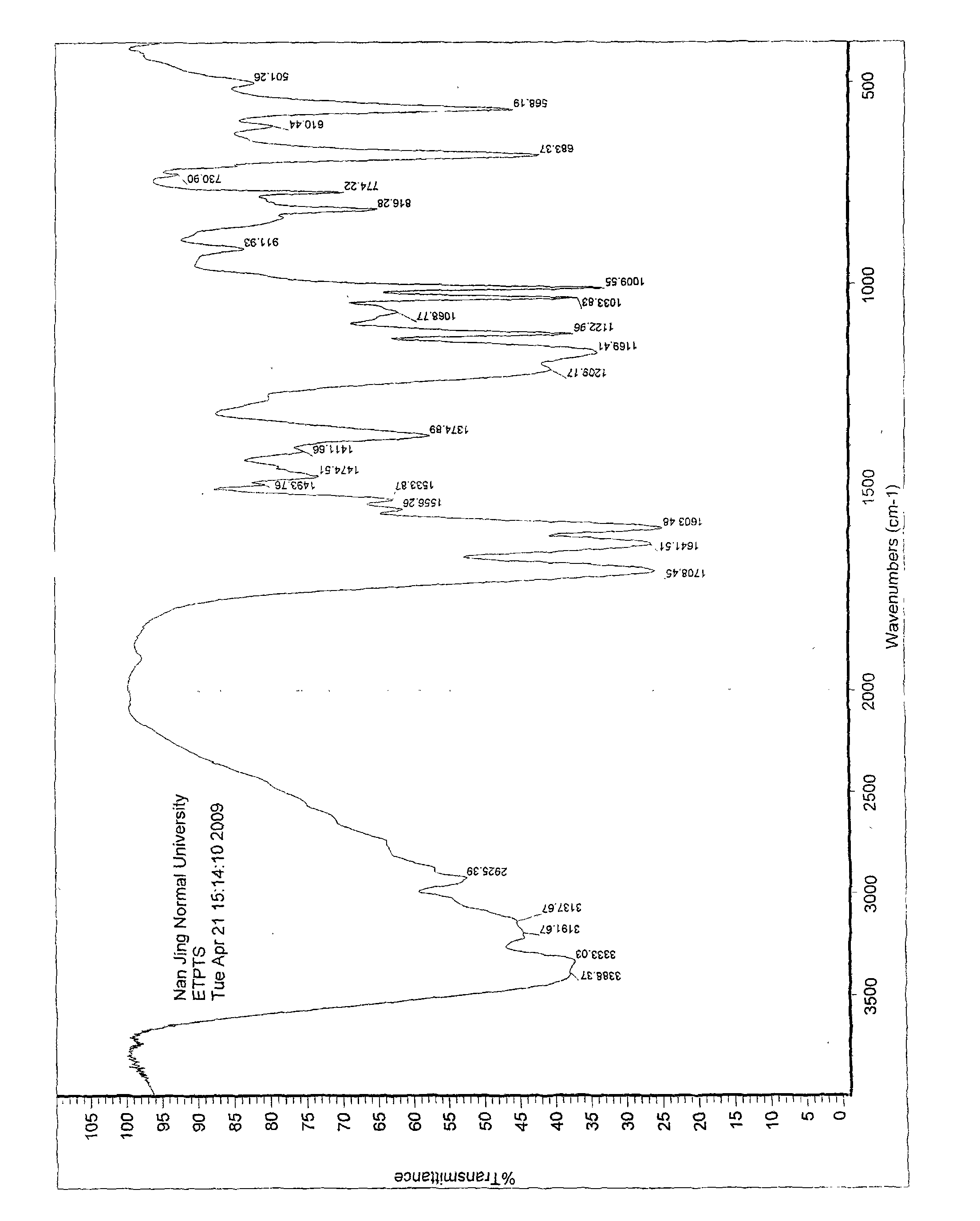

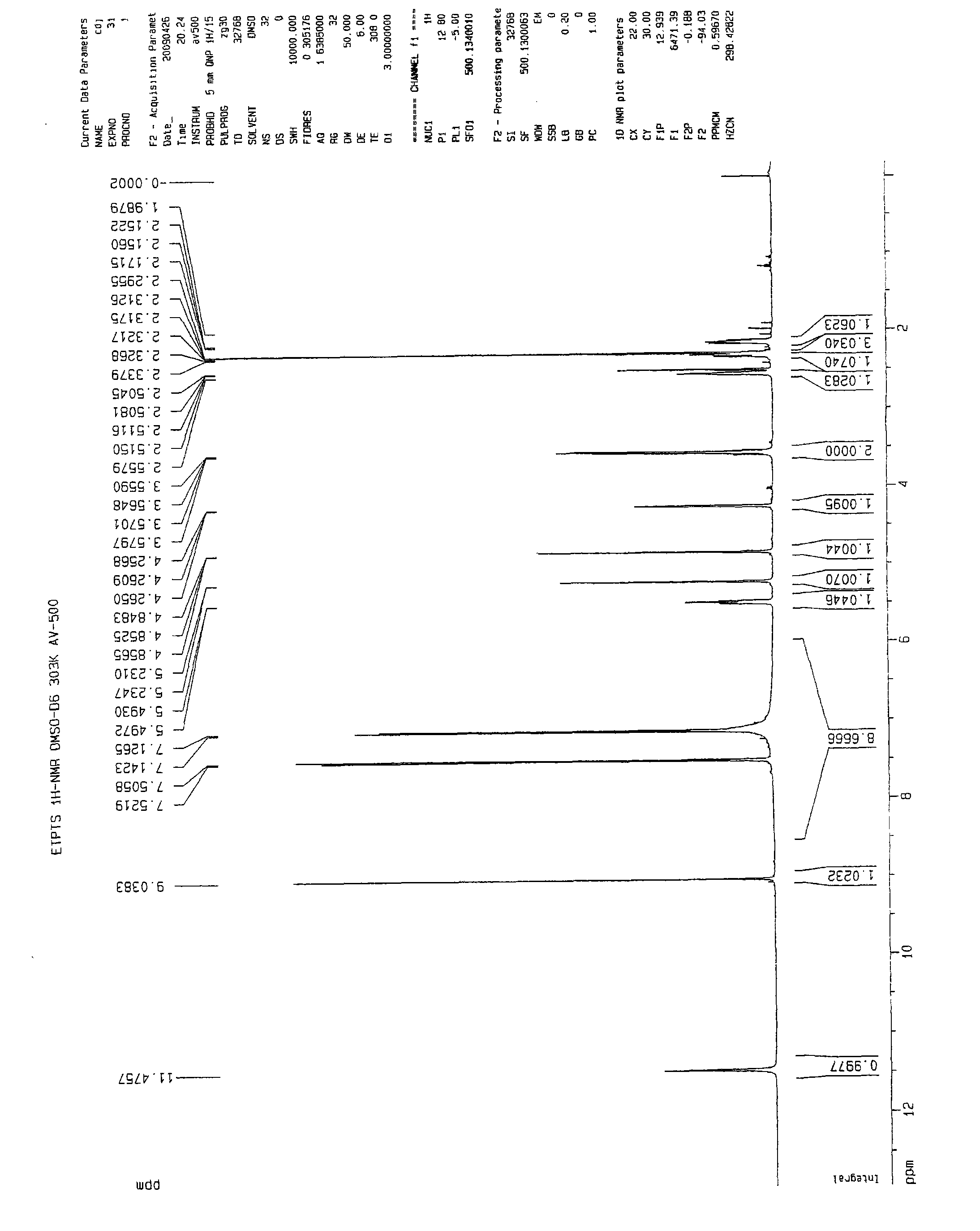

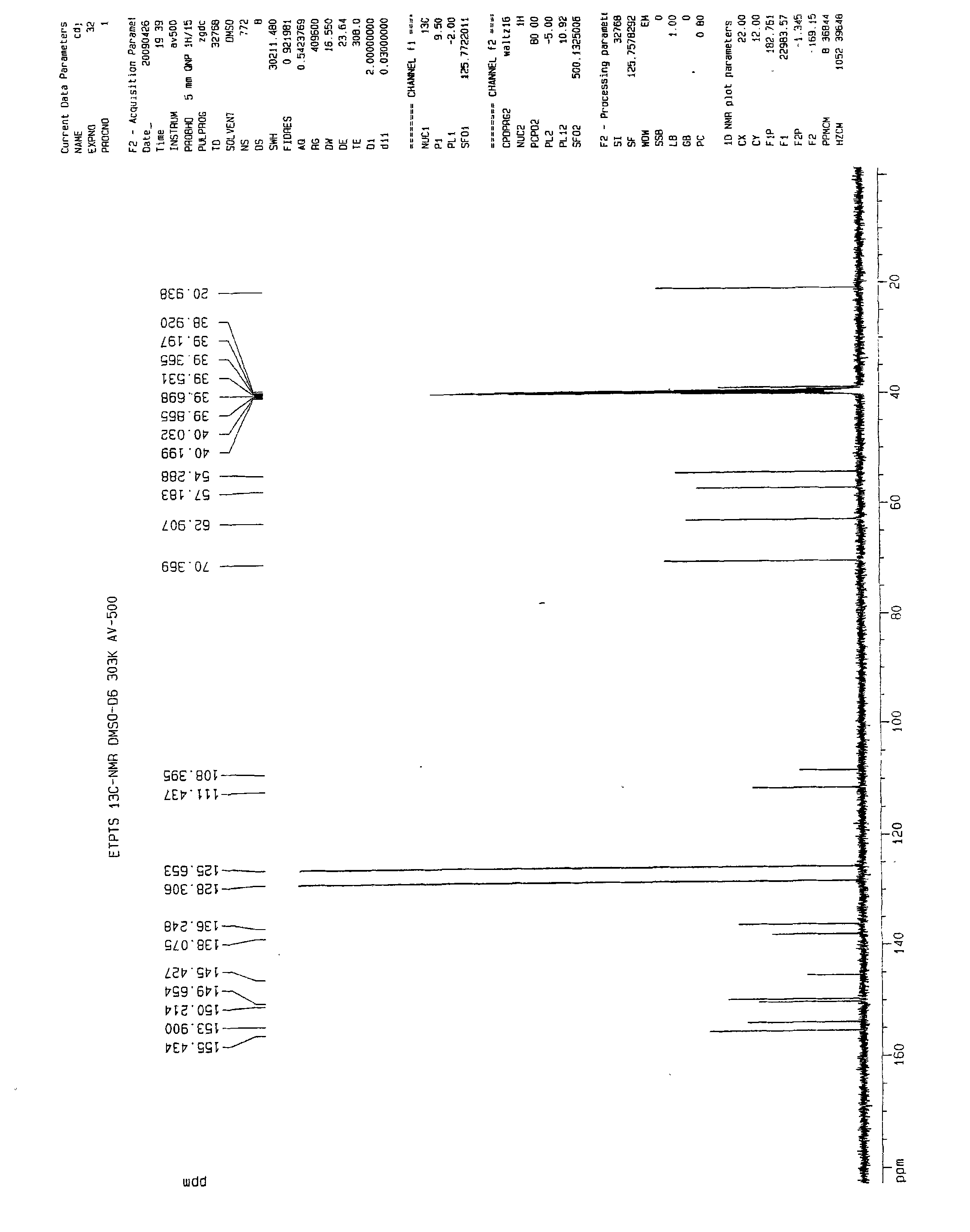

Entecavir salt compound, preparation method and medicine application thereof

ActiveCN101781300ALigands are safe and reliableNo side effectsOrganic chemistryDigestive systemFiltrationRoom temperature

The invention provides entecavir acid addition salt compound, in particular relates to addition salt of toluene sulfonic acid (including para-, iso- and o- of methyl in benzene ring) and entecavir, a preparation method and medicine application thereof; the specific preparation method is that: under the condition with the temperature between room temperature and solvent backflow temperature, the entecavir and toluenesulfonic acid are contacted in solvent and are reacted to form salt, and then salt crystallization is carried out under the room temperature condition or at the temperature lower than the room temperature, extraction filtration, water pumping after washing is carried out and drying are carried out to obtain the entecavir toluene sulfonic acid, or the hydrate of the entecavir toluene sulfonic acid; and the invention further relates to the application of the entecavir toluene sulfonic acid to the medicines.

Owner:FUJIAN COSUNTER PHARMA CO LTD

Valve controlling sealed lead-acid battery negative pole plate salt crystallization activation method

InactiveCN1933233AExtended service lifeReduce wasteLead-acid accumulatorsWaste accumulators reclaimingCapacitanceActivation method

This invention discloses an activation method for salt crystals of negative pole plates of valve controlled sealed Pb acid storage cells characterizing in opening a hole at the place corresponding to the cell mechanism at the cell bottom, injecting pure water in the safety valve hole to dilute electrolyte in the original cell tank and discharging part of the electrolyte from the bottom hole to dilute it then to be activated by pulse electricity, crystallizing the sulfate on the negative pole plate, the voltage of a grid reaches to 2.35V and large amount of air bubbles are emited, then adjusting the density of the electrolyte to seal the bottom hole and charge to resume the capacitance.

Owner:李建德

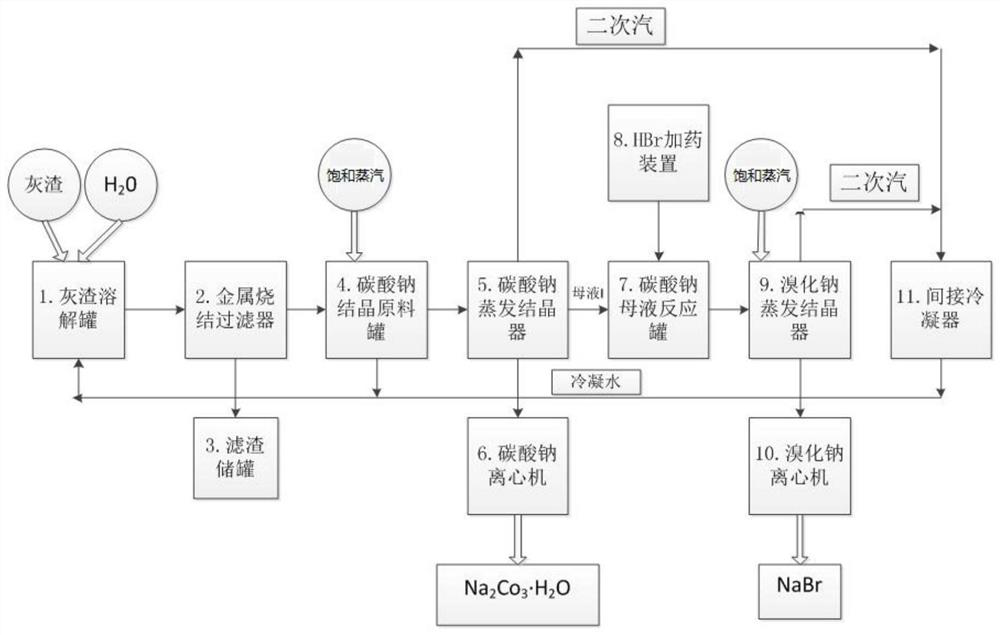

PTA incineration boiler ash residue solution salt separation crystallization process

ActiveCN112811444AFulfill quality requirementsRealize resourcesAlkali metal carbonates shape formationEnergy inputPhysical chemistryWastewater

The invention relates to a PTA incineration boiler ash residue solution salt separation crystallization process, and belongs to the technical field of evaporative crystallization. The process comprises the following steps of: dissolving ash of the PTA incineration boiler with waste heat into a nearly saturated solution of sodium carbonate and sodium bromide, and removing metals and other insoluble substances from the solution by adopting a metal sintering filter, separating the obtained filtrate by adopting an evaporative crystallization method to obtain sodium carbonate monohydrate crystals, removing sodium carbonate from the mother liquor by adopting a replacement method, and then separating by adopting an evaporative crystallization method to obtain sodium bromide crystals. Sodium carbonate and sodium bromide in the PTA boiler ash are separated and recovered by adopting an evaporative crystallization method, the process flow is simple, the operation conditions are simple, convenient and stable, and industrialization is facilitated; the high-purity sodium carbonate and sodium bromide recovered by the method can meet the quality requirements of industrial-grade products and can be directly recovered and reused or sold as by-products, so that the purpose of treating waste residues and wastewater is achieved, the requirements of the current environmental protection situation are met, waste can be turned into wealth, recycling of salt is realized, and the benefits of factories are improved.

Owner:河北工大晟珂工程科技有限公司

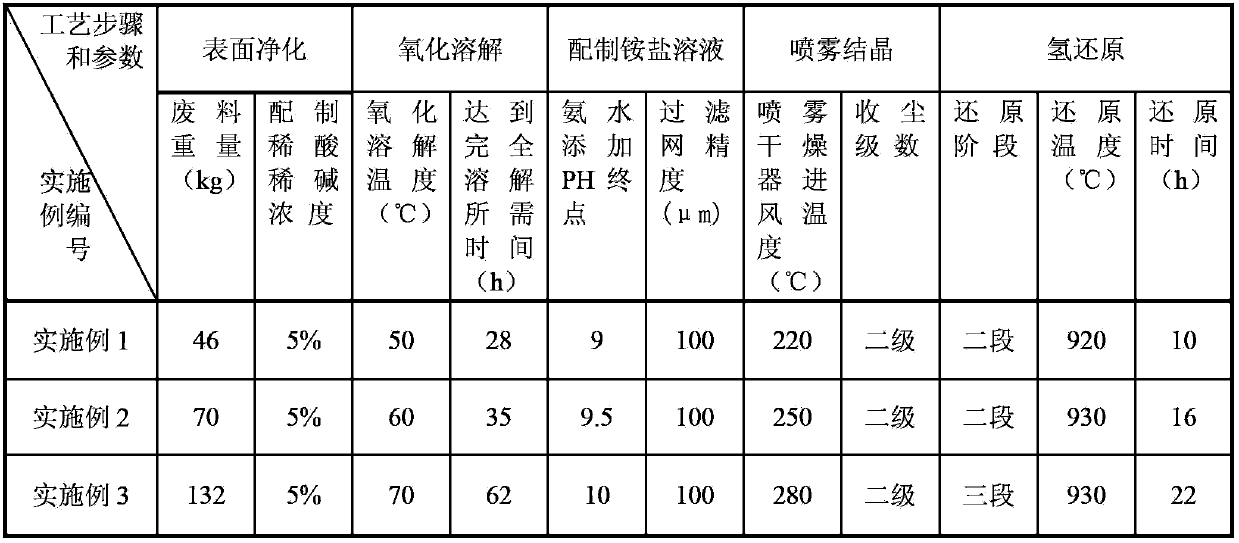

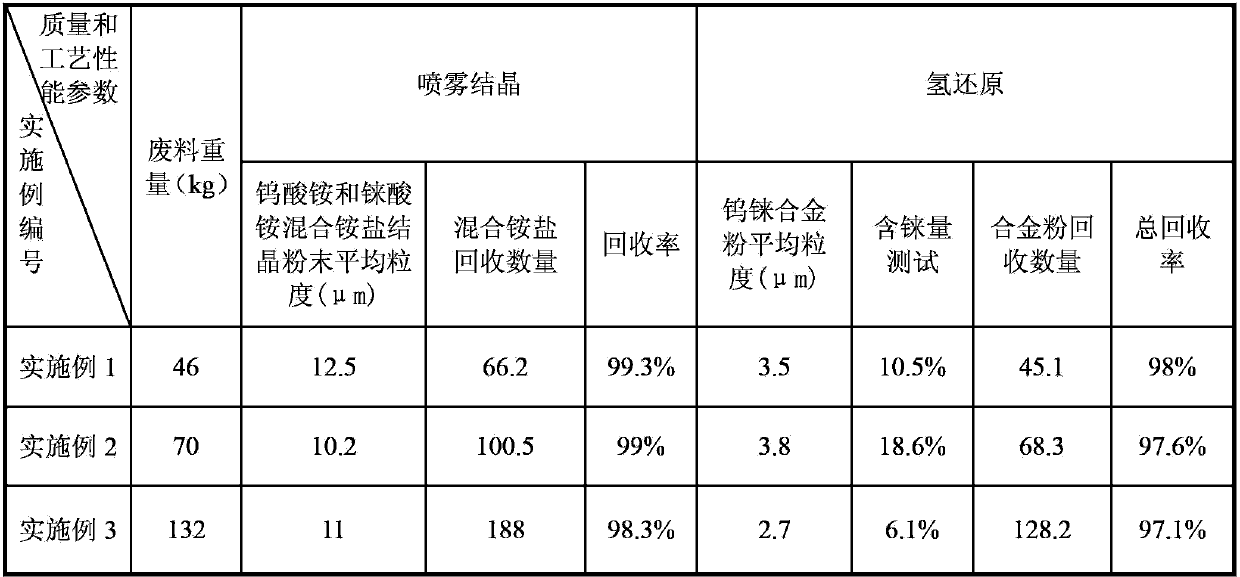

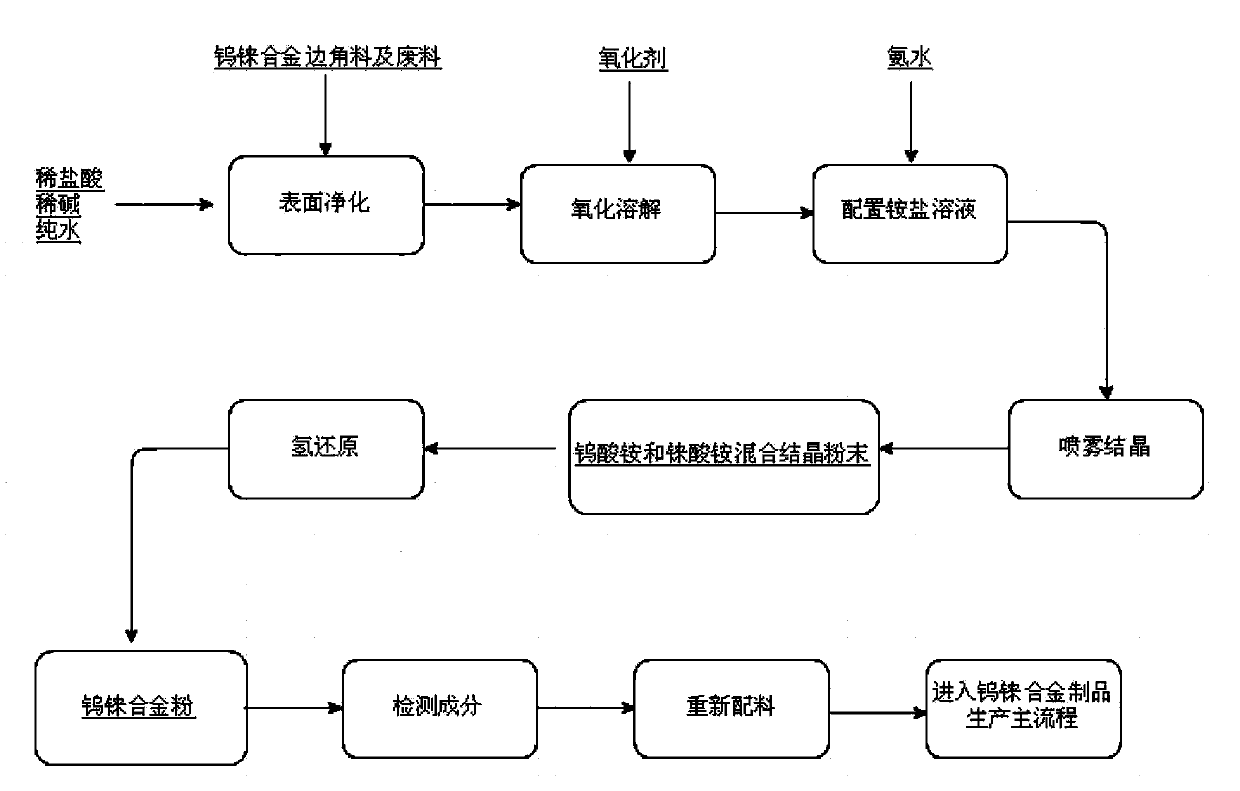

New method for recycling tungsten-rhenium alloy leftover materials and waste materials

Many leftover materials and waste and defective materials are produced in the tungsten-rhenium alloy machining process. Due to very similar chemical properties of tungsten and rhenium, the separation and extraction with a traditional chemical method is difficult. The present invention originally provides a new idea and a new method for processing and recycling the tungsten-rhenium alloy waste materials, and the recycling rate is more than 97%. The method is as follows: first cleaning the tungsten-rhenium alloy waste material surfaces, then dissolving the tungsten-rhenium alloy waste materials in an oxidizing reagent, adding ammonia to form a mixed ammonium salt solution, controlling the solution PH range and temperature for stabilization of the solution without precipitation of any crystal substances, performing spray drying on the solution to produce mixed tungsten rhenium ammonium salt crystallization powder even in components, performing hydrogen reduction to prepare tungsten rhenium alloy powder, analyzing the rhenium containing components, and again returning into a material mixing process in a main technological cycle. The originally-created special recovery method, compared with traditional methods, has the advantages of short technological route, low recovery cost, high recovery efficiency and good recovery quality.

Owner:ULTRA MINOR METALS

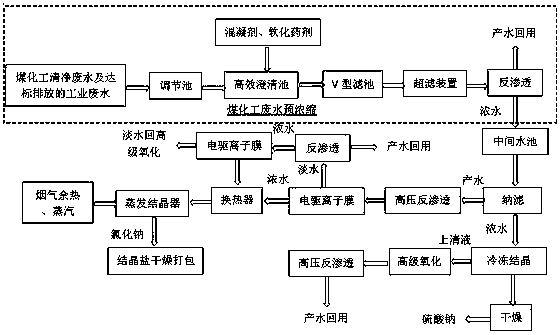

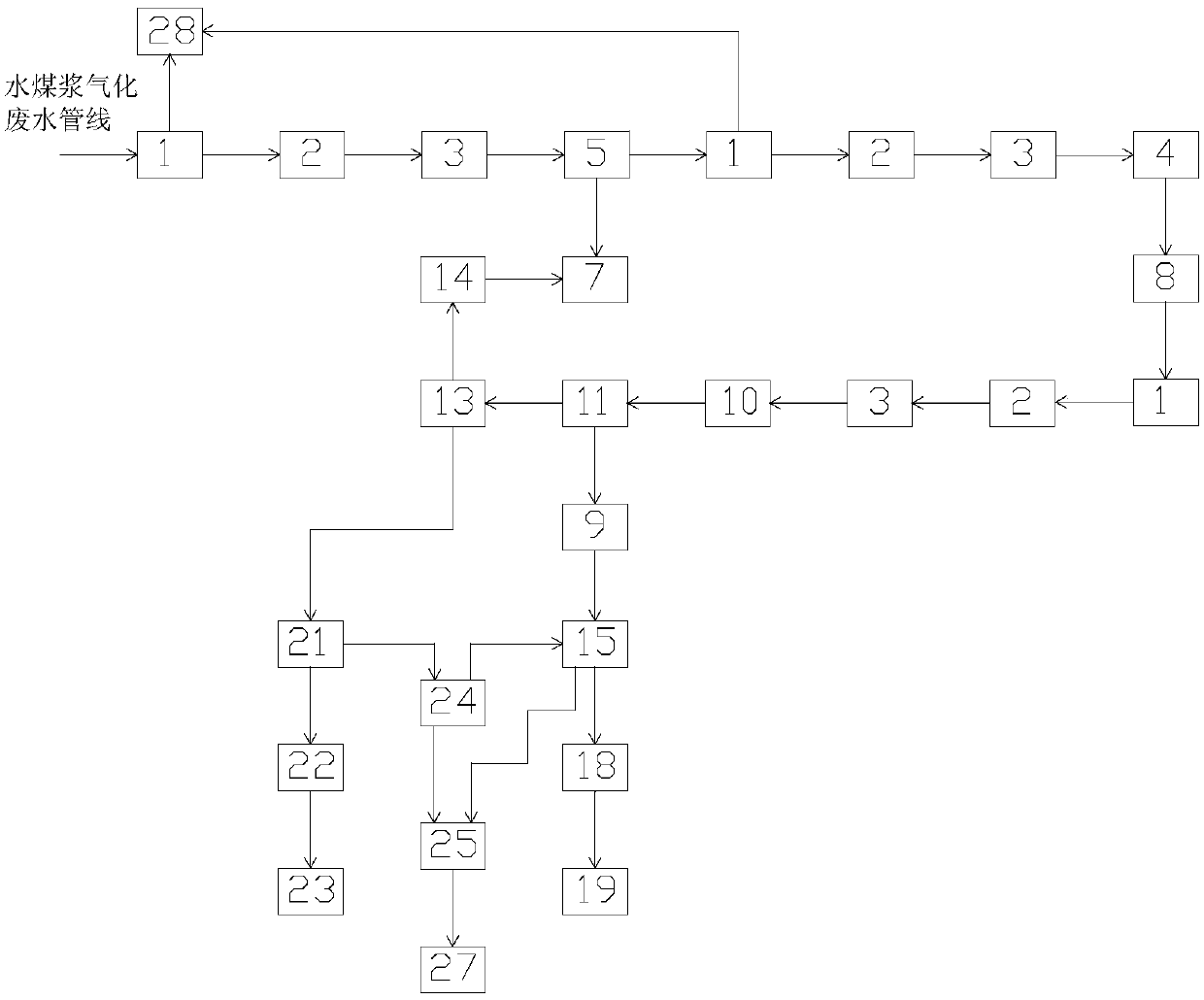

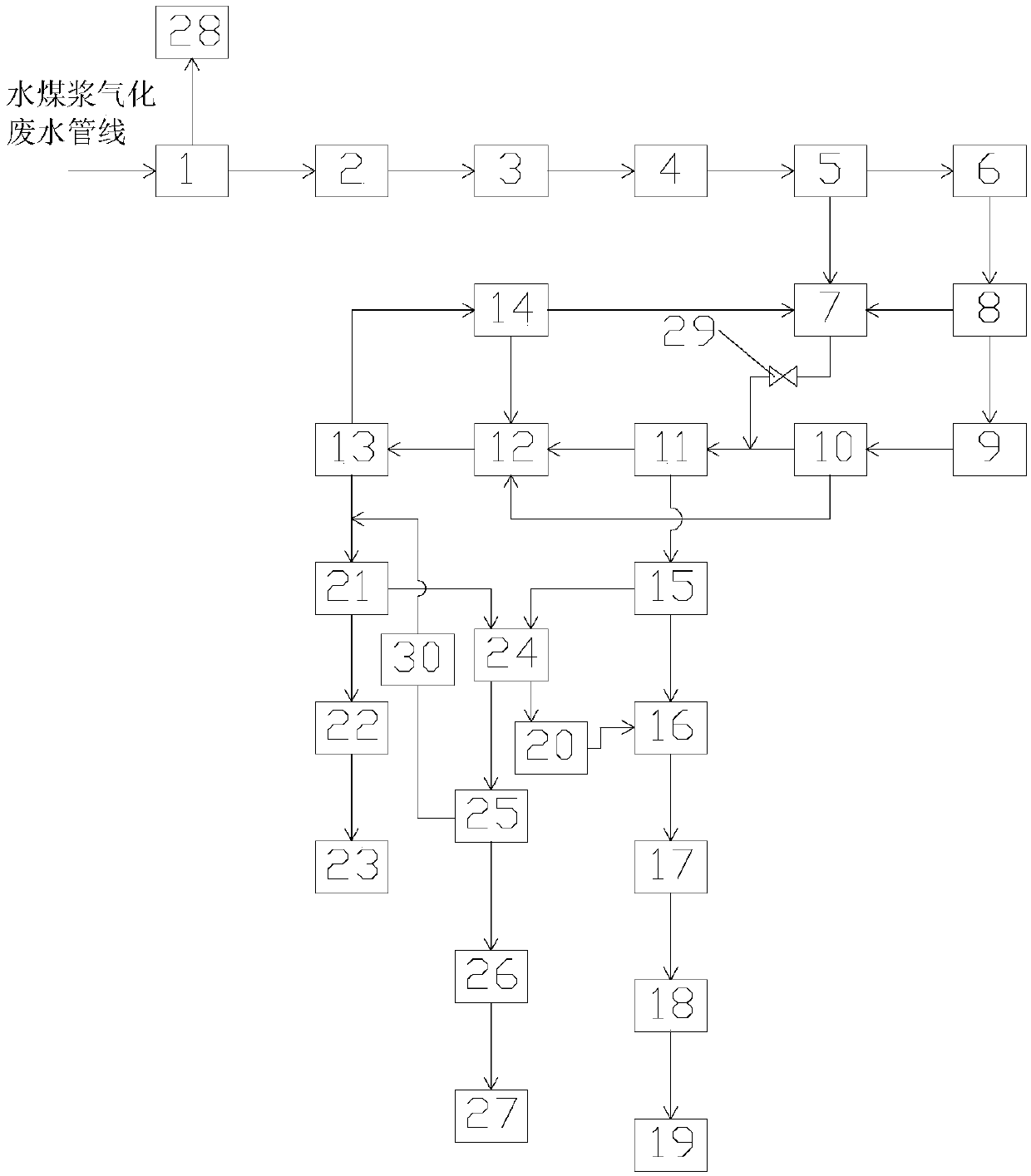

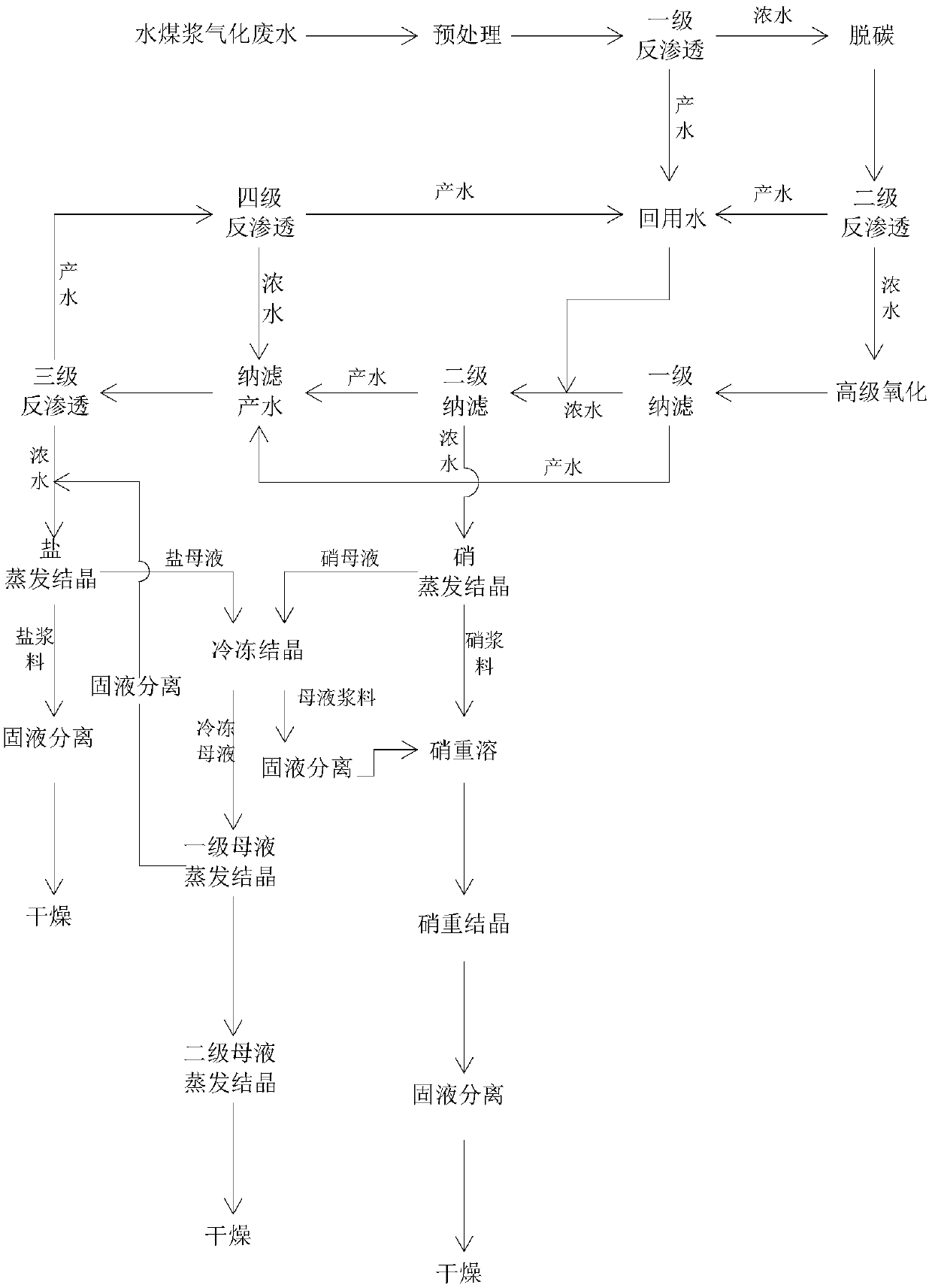

Coal water slurry gasification wastewater salt separation and crystallization zero discharge treatment system and coal water slurry gasification wastewater salt separation and crystallization zero discharge treatment method

PendingCN110357334AReduce energy consumptionReduce investment and construction costsScale removal and water softeningTreatment involving filtrationFiltrationReverse osmosis

The invention discloses a coal water slurry gasification wastewater salt separation and crystallization zero discharge treatment system and a coal water slurry gasification wastewater salt separationand crystallization zero discharge treatment method, wherein the system comprises a pretreatment system, a salt separation system, a mirabilite crystallization system and a salt crystallization system. The method comprises: S1, pretreatment, S2, salt separation, S3, output of sodium chloride, S4, output of sodium sulfate, and S5, treatment of mother liquor. According to the present invention, on the basis of meeting of the operation requirements of the system, the repeated arrangement of the chemical softening, the filtering and the membrane system in the treatment of the coal water slurry gasification wastewater by the traditional high salt content wastewater treatment system is simplified so as to reduce the investment and construction cost of the system and reduce the energy consumptionof the pretreatment system; the salt separation system is optimized, wherein the reverse osmosis production water is mixed with the first nano-filtration concentrated water according to a certain ratio, and the obtained mixture is subjected to second-stage nano-filtration, such that the operating pressure of the second-stage nano-filtration is reduced, the recovery rate of the second-stage nano-filtration is improved, and the service life of the equipment is prolonged; and the crystallization system is optimized, and the recovery rates and the purities of sodium chloride and sodium sulfate are improved.

Owner:INNER MONGOLIA RONGXIN CHEM CO LTD

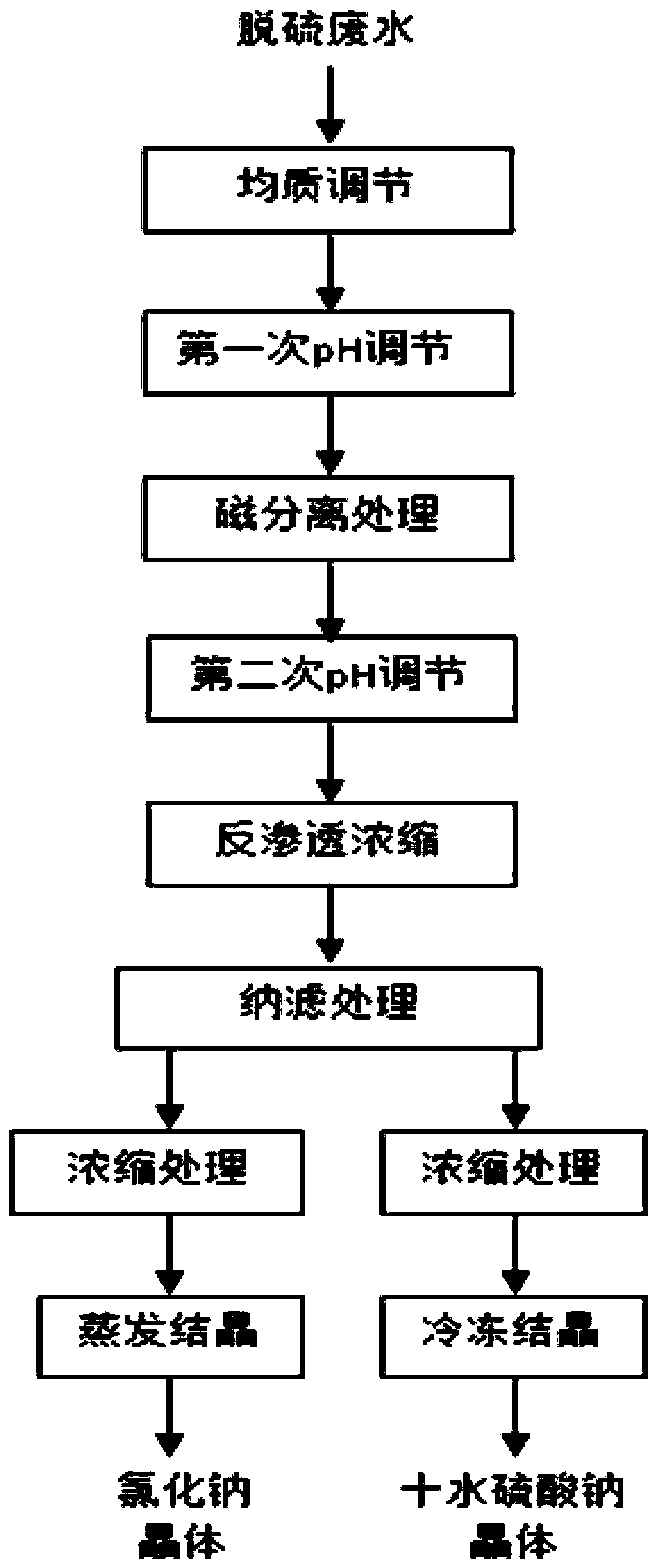

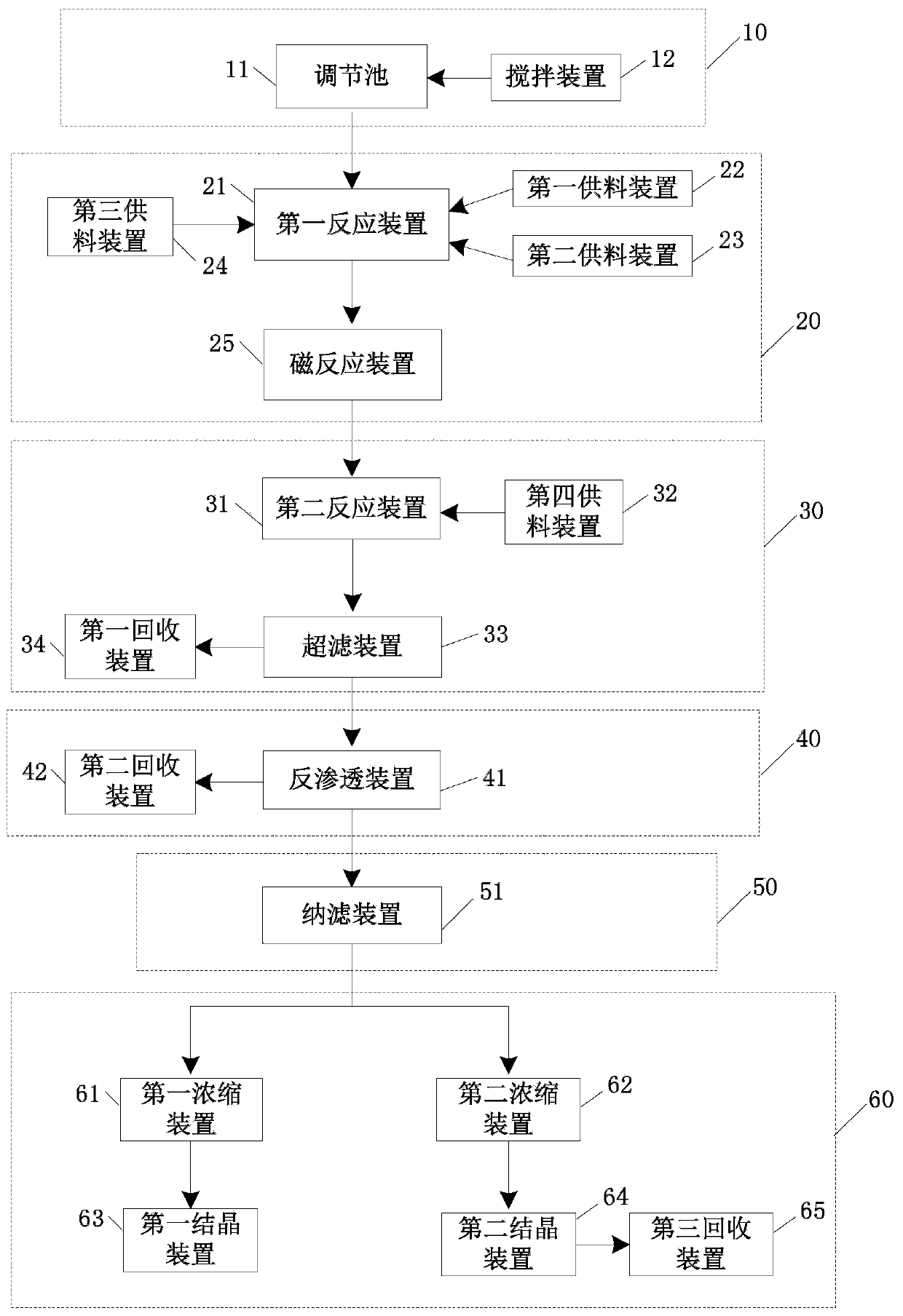

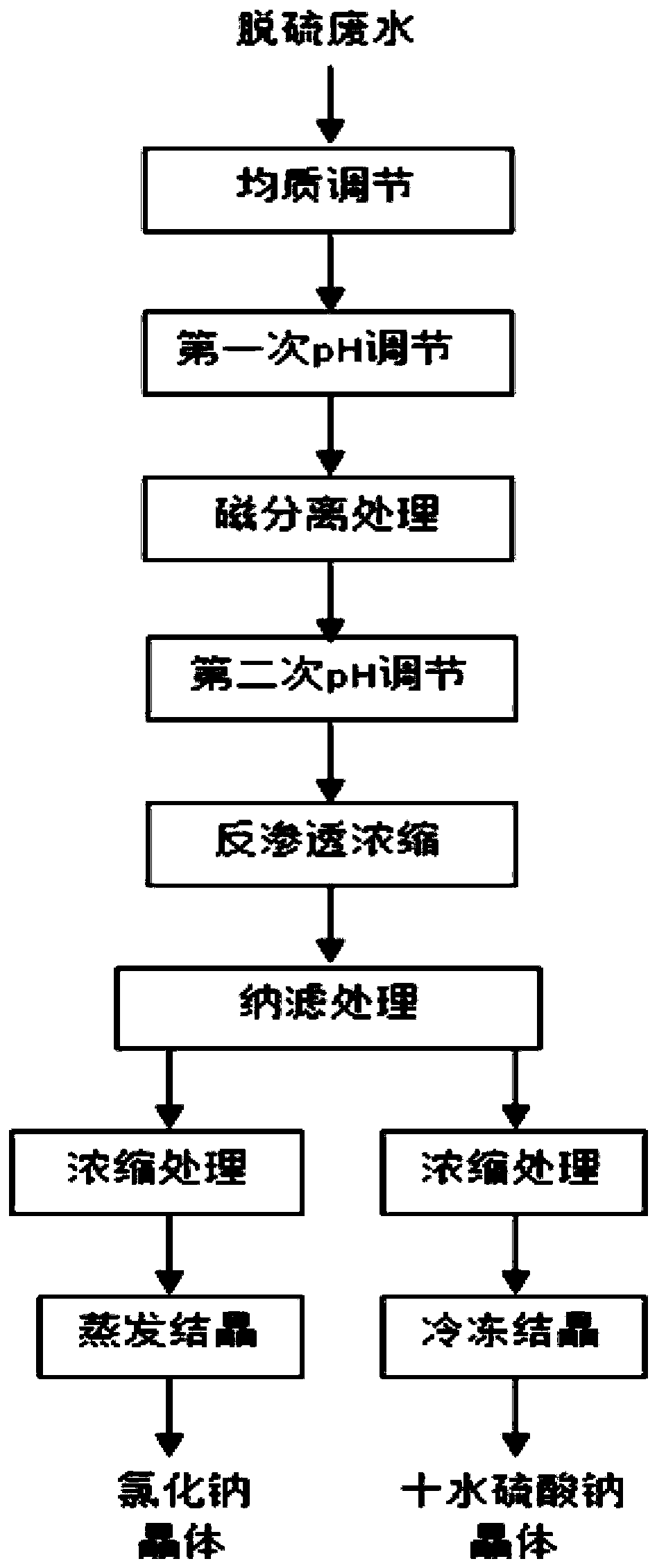

Desulfurization wastewater quality-divided crystallization processing method and processing device

PendingCN109970267ARealize fractional crystallizationReduce usageAlkali metal sulfites/sulfates preparation formWater contaminantsUltrafiltrationFiltration

The invention provides a desulfurization wastewater quality-divided crystallization processing method and a processing device. Desulfurization wastewater contains sodium chloride and sodium sulfate. The method comprises following steps: adjusting the pH of desulfurization wastewater to 9-12 for the first time, adding an organic sulfur agent and iron ore particles into adjusted desulfurization wastewater, carrying out magnetic separation to obtain precipitates and supernate; adjusting the pH of the supernate to 6.5-7.5 for a second time, carrying out ultrafiltration to obtain concentrated water; subjecting the concentrated water to a reverse osmosis treatment to obtain a reverse osmosis concentrated solution; subjecting the reverse osmosis concentrated solution to a nano filtration treatment to obtain nano filtration producing water and nano filtration concentrated water; subjecting the nano filtration producing water to a concentration treatment and a crystallization treatment in sequence to obtain sodium chloride crystals; and subjecting the nano filtration concentrated water to a concentration treatment and a crystallization treatment in sequence to obtain sodium sulfate decahydrate crystals. Solved are the problems that in conventional desulfurization wastewater quality-divided crystallization processing, the effect is influenced by heavy metal ions, and the salt crystallization amount is large.

Owner:CHINA ENFI ENGINEERING CORPORATION

Lemon flavored nutritional bean curd (tofu) and preparation method thereof

ActiveCN102499294ASave raw materialsFull of nutritionCheese manufactureFood scienceKidney stoneAdditive ingredient

The invention relates to lemon flavored nutritional bean curd (tofu) and a preparation method thereof. The lemon flavored nutritional tofu comprises soybean milk and lemon juice, wherein the weight ratio of the lemon juice and the soybean milk is (1-3):100, and is prepared by the steps of carefully selecting raw materials, pulping, boiling pulp, adding lemon juice, compression moulding, and othersteps. The lemon flavored nutritional tofu has the color and fragrance of lemon, rich nutrient and tender mouthfeel. The preparation method of the lemon flavored nutritional tofu uses fresh lemons directly without addition of other coagulators, only uses the action of lemon self to achieve the coagulating effect of tofu, so as to simplify preparation process, prevents environmental pollution and fully utilize raw materials. The obtained tofu has the fragrance and nutritional ingredients of lemon. The preparation method of the invention does not use calcium salts and magnesium salts, and citrate contained in the lemon juice can inhibit calcium salts crystallization, thereby preventing the formation of renal calculi, even dissolving the calculi formed previously. The lemon flavored nutritional tofu of the invention is suitable for a large range of people.

Owner:陈日光

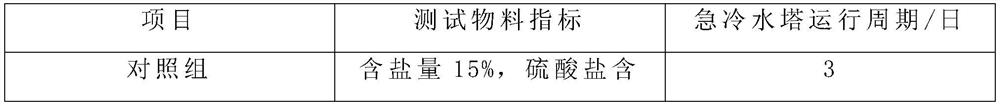

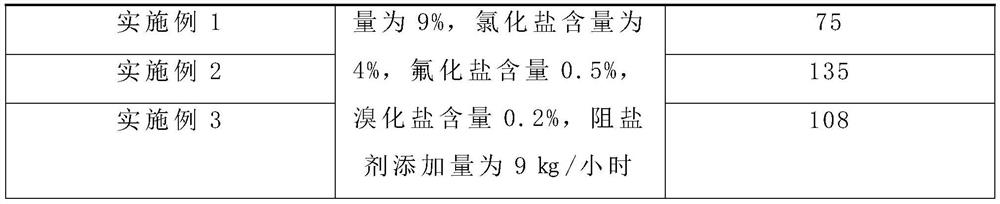

Salt inhibitor as well as preparation method and application thereof

InactiveCN111747589AExtended operating cycleReduce disposal costsScale removal and water softeningWater/sewage treatmentPhysical chemistryALLYL SUCROSE

The invention discloses a salt inhibitor as well as a preparation method and application thereof. The salt inhibitor is prepared from polyacrylic acid, sodium polyacrylate, a maleic acid-acrylic acidcopolymer, polyepoxysuccinic acid and hydrolyzed polymaleic anhydride in a volume ratio of (20-50):(30-40):(20-25):(10-20):(10-20). The salt inhibitor is prepared by stirring and mixing the componentsaccording to the volume ratio in a normal-pressure reaction kettle. The salt inhibitor can change the salt crystallization process in a solution and the adhesive force on the surfaces of salt particles to the maximum extent, the number of crystal nucleuses is greatly increased and the salt crystallized particles become fine; meanwhile, the binding force between the salt particles becomes extremely weak, the salt particles are not prone to being gathered into large particles, and therefore formation of large salt blocks is restrained, stopped or reduced. The salt inhibitor can be used for treating salt-containing wastewater of a hazardous waste incineration system, formation of salt blocks in the salt-containing wastewater can be inhibited, and the operation period of a quenching water tower of the hazardous waste incineration system is prolonged.

Owner:中节能(连云港)清洁技术发展有限公司

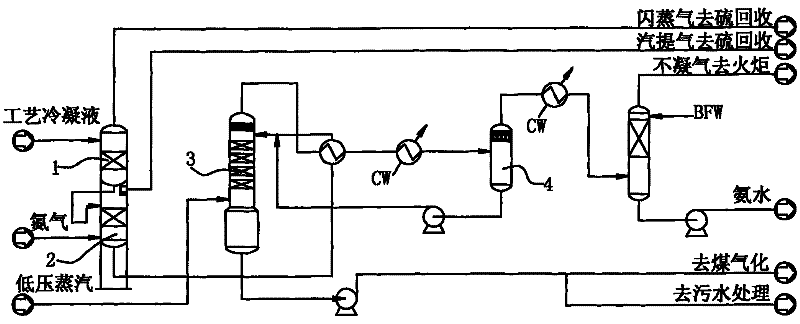

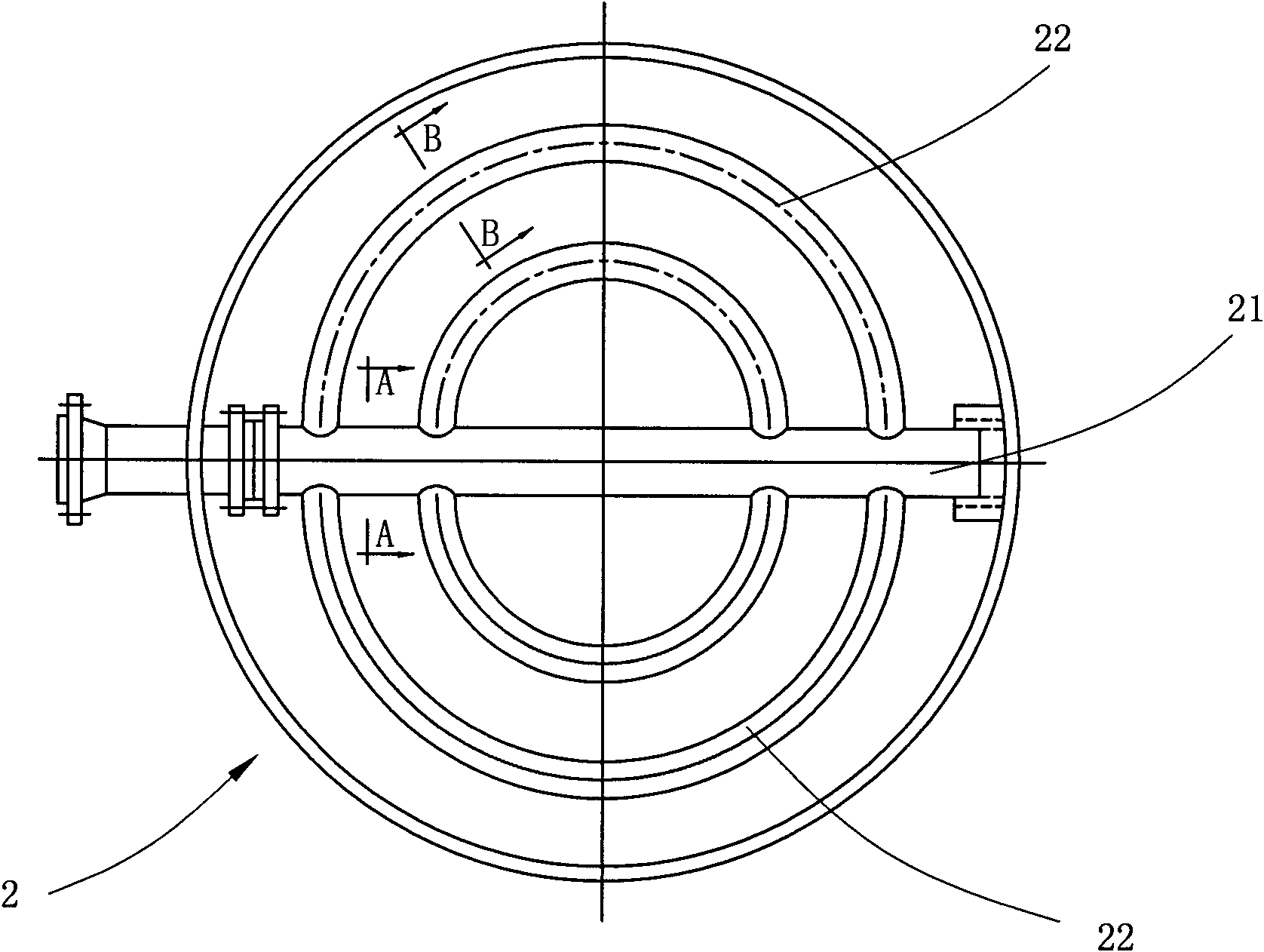

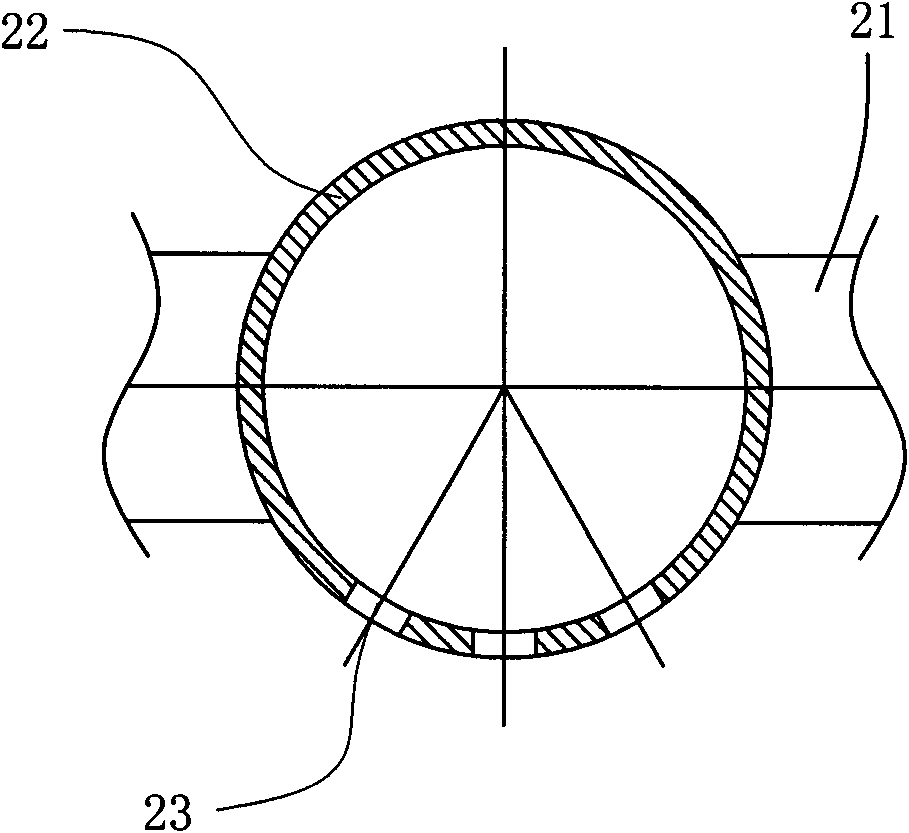

Stripping tower for CO conversion condensate

ActiveCN102963944AEasy to controlEasy to operateWater/sewage treatment by heatingWater/sewage treatment by degassingWater useEnergy gradient

Owner:CHINA PETROLEUM & CHEM CORP +2

Process for treating low-temperature condensate at conversion section

InactiveCN104495965AIncrease consumptionAchieve recyclingWater/sewage treatment by heatingWater/sewage treatment by degassingDistillationFlash-gas

The invention provides a process for treating low-temperature condensate at the conversion section. According to the process, a two-tower process of CO2 stripper series connected with an NH3 stripper is adopted for stripping of CO2 and H2S, and stripping and distillation of NH3. The process for treating low-temperature condensate at the conversion section effectively utilizes low-quality waste heat in a gasification device such as low flash gas, so that the energy consumption of the device is reduced, and the operation cost is greatly reduced; the method disclosed by the invention can be used for realizing the separation of acidy gas and NH3, solving the problems of no receiving users, ammonium salt crystallization and the like caused by overhigh sulfur content in ammonia obtained according to the existing processes, and finishing the receiving treatment of high flash gas of the gasification device; and based on the process disclosed by the invention, the NH3 content of waste water of an entire coal chemical device is effectively reduced, the environmental pollution is reduced, and the process is feasible and simple to operate, and has good economic benefits and environmental benefits.

Owner:CHINA TIANCHEN ENG +1

High-salt wastewater salt separation system and process

PendingCN110342545AAchieve recyclingAvoid destructionWater/sewage treatmentAlkali metal chloridesEvaporationWater quality

The invention discloses a high-salt wastewater salt separation system. The high-salt wastewater salt separation system comprises a raw water tank, a nanofiltration unit, a sodium chloride evaporationand crystallization unit, a sodium sulfate evaporation and crystallization unit, an organic concentration unit, an ozone reaction tank and a mixed salt evaporation and crystallization unit; and zero discharge of high-salt water can be achieved, water resources are saved, the environment is protected, operation is stable, safety and reliability are achieved, operating cost is low, and certain economic and social benefits are achieved. The invention further discloses a high-salt wastewater salt separation process. The high-salt wastewater salt separation process comprises the following steps ofstep one, nanofiltration, step two, sodium chloride crystallization and sodium sulfate crystallization, step three, organic concentration; step four, ozone oxidation, and step five, abraum salt crystallization. The water quality of produced reuse water meets the standard of ''Quality standards of reclaimed water for circulating cooling water HG-T3923-2007''; industrial sodium chloride produced reaches the A-level standard of refined industrial dry salt, and can be packaged for sale; and industrial sodium sulfate produced reaches first-class standard of I-class salt, and can be packaged for sale.

Owner:内蒙古晶泰环境科技有限责任公司 +1

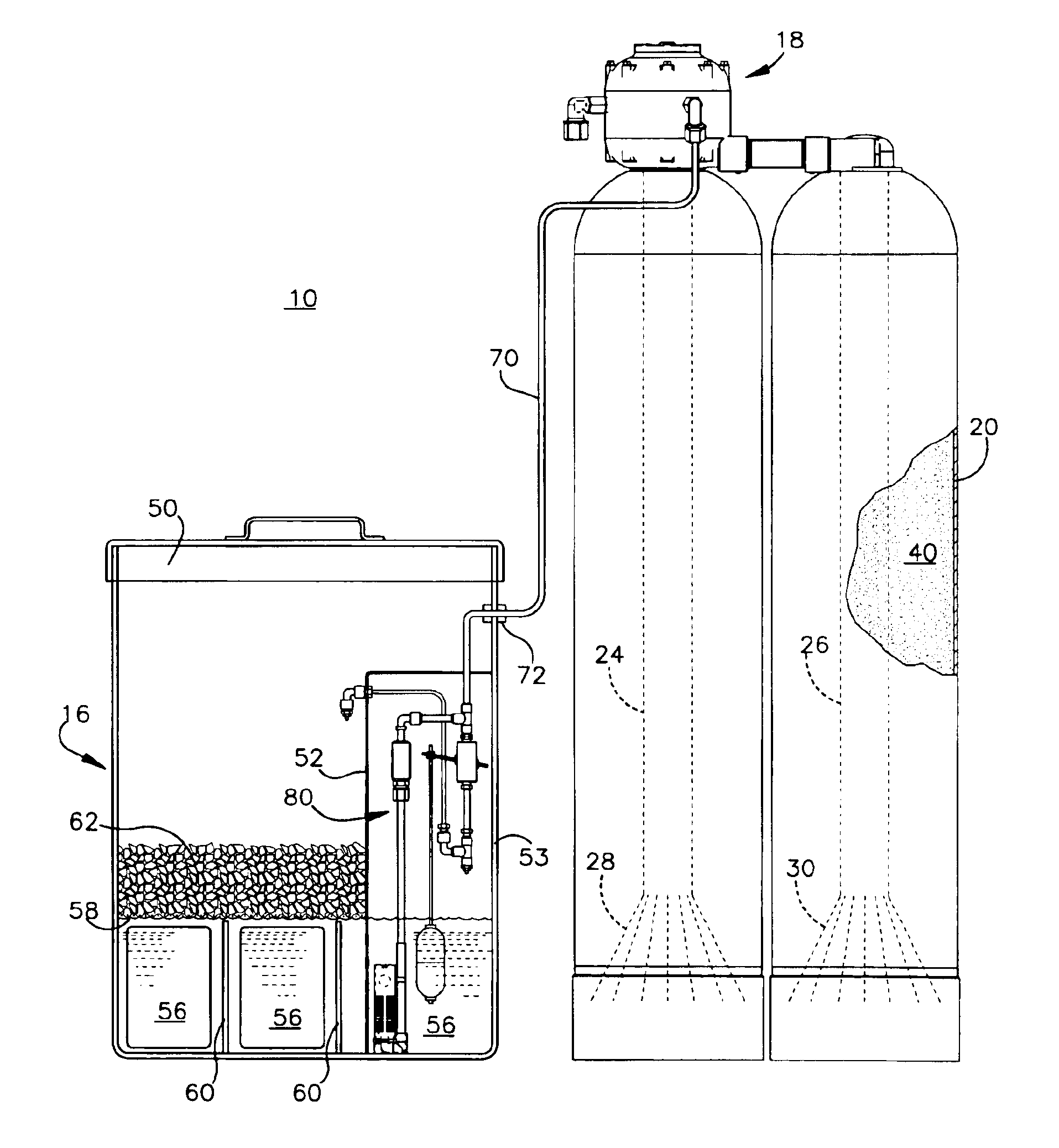

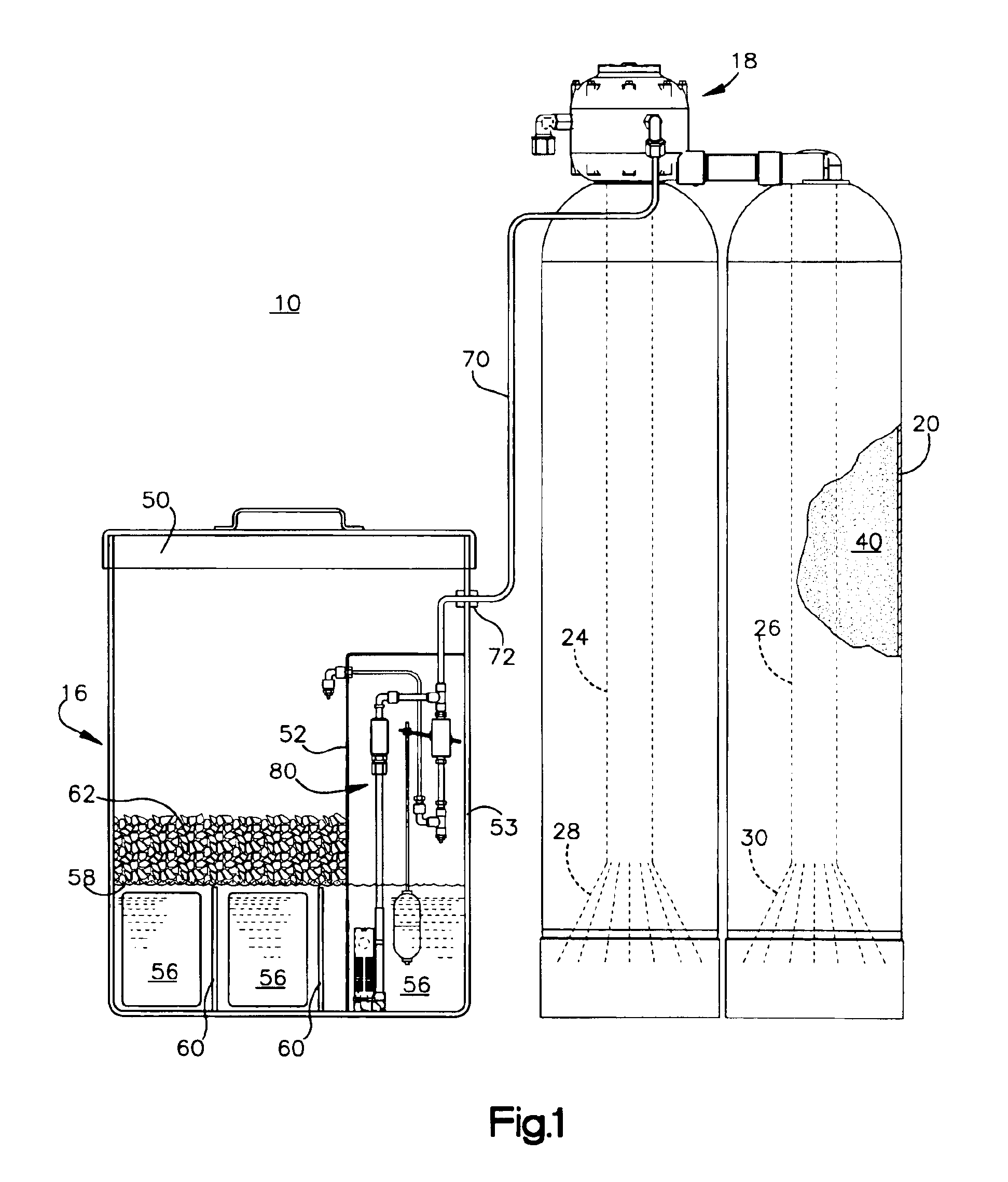

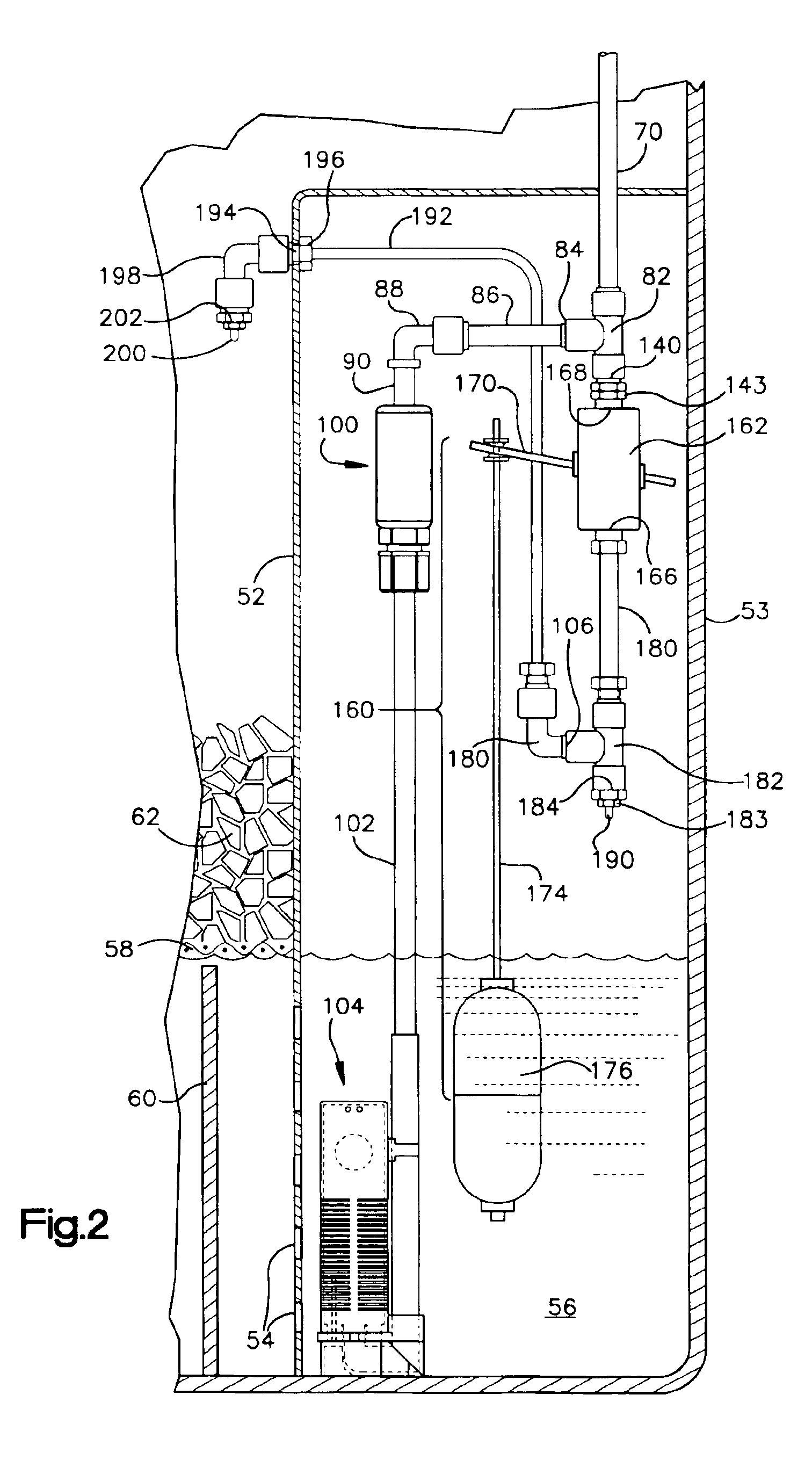

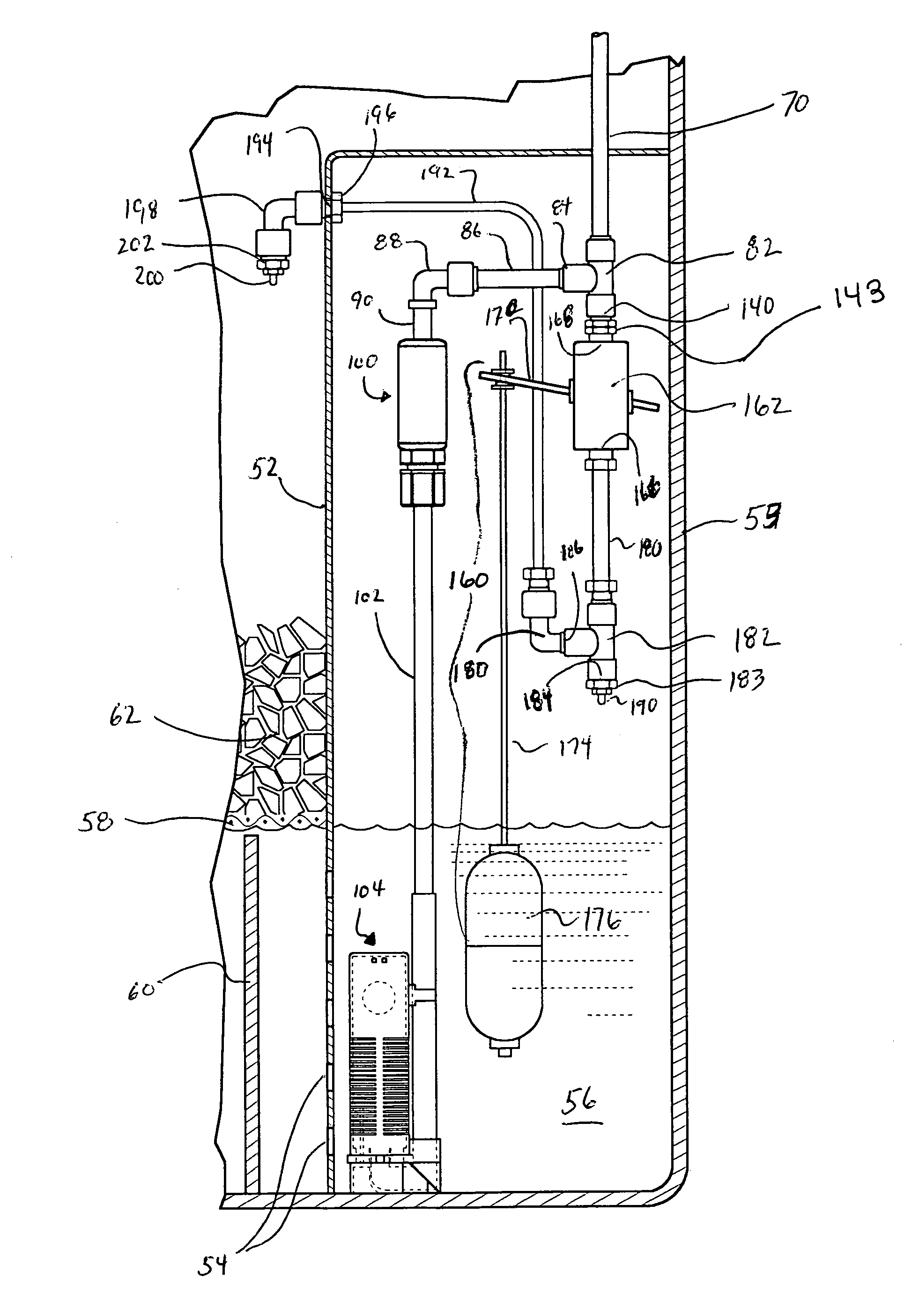

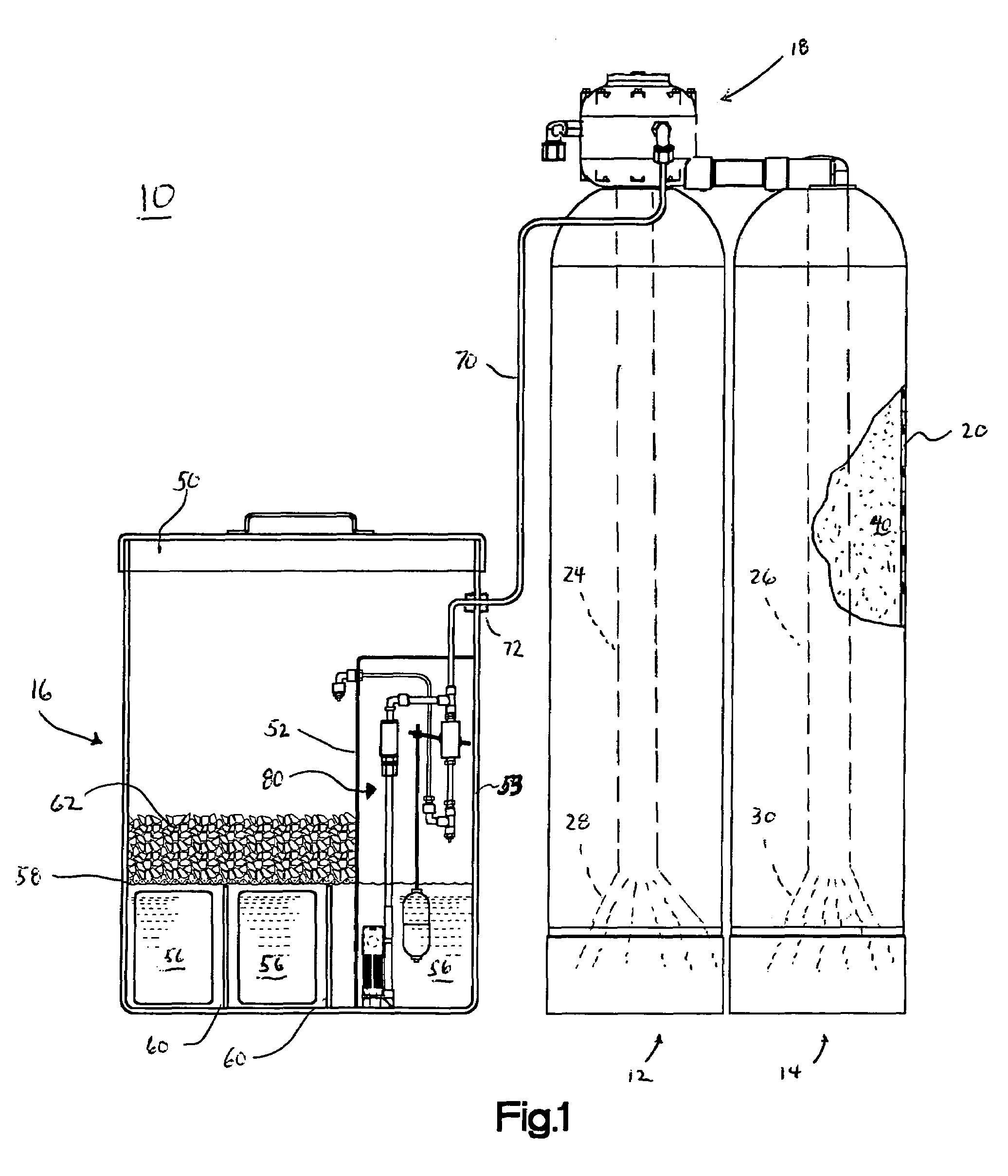

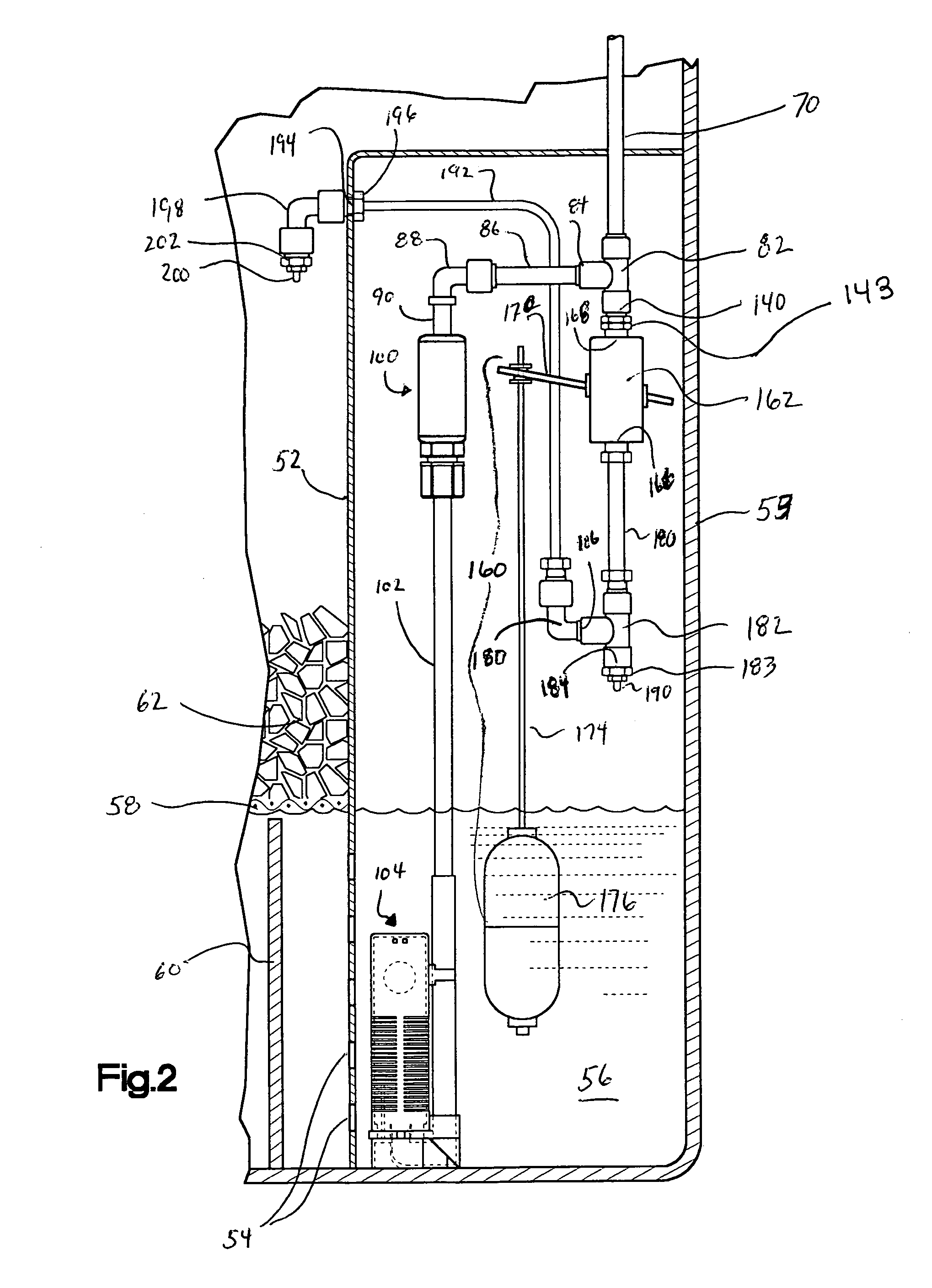

Water treatment system

InactiveUS6962657B2Avoid failureIon-exchanger regenerationScale removal and water softeningSaline waterWater treatment system

A water treatment system for removing hard ions from source water. The water treatment system is of the type that includes a pair of ion-exchange water softener tanks connectable to a source of pressurized water and with a water system to supply softened water to the water system, the tanks each being capable of regeneration by flushing with a regeneration solution to replenish depleted ions. A process for preventing system failure due to salt crystallization includes flowing water during brine replenishment from a second nozzle and a first nozzle at a defined ratio. The first nozzle diluted the brine in a reservoir after regeneration cycle is complete. The second nozzle replenishes brine by flowing water directly onto a salt material.

Owner:KINETICO

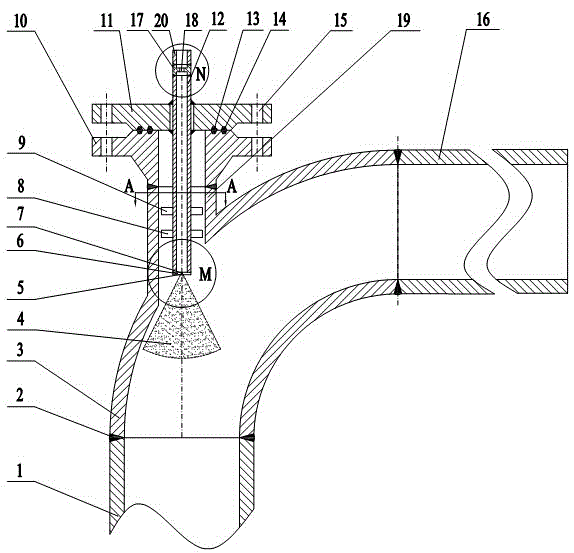

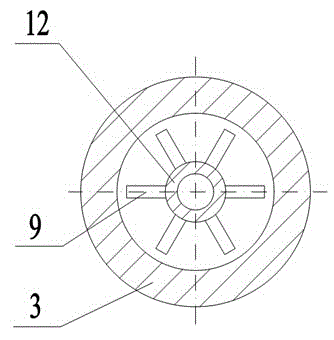

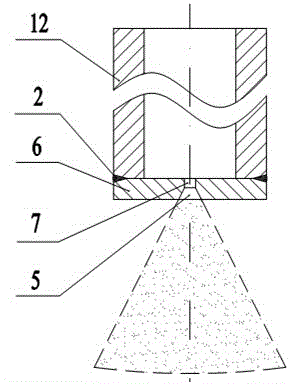

Technological injectant device for controlling flow-induced corrosion failure of pipelines

ActiveCN104923148AGuaranteed reliabilityLess corrosiveSpray nozzlesPipe elementsSalt crystallizationCorrosion

The invention discloses a technological injectant device for controlling flow-induced corrosion failure of pipelines. An injectant sleeve is vertically arranged on the back of a 90-degree bend to form a combined elbow, the upper end of the combined elbow is fixedly connected with the lower end face of a lower flange, a sealing ring is arranged between an upper flange and the lower flange, an injectant pipeline is inserted into the elbow from the upper and lower flanges, the lower end face of the injectant pipeline is fixedly connected with an atomizing nozzle, two radial plates on the outer wall of the lower end of the injectant pipeline and the injectant sleeve form a floating support, the injectant pipeline is fixed in an upper flange hole, and the injectant pipeline located outside the upper flange is communicated with a third straight pipe section via a restriction orifice. Two ends of the elbow are communicated with a first straight pipe section and a second straight pipe section respectively. The injectant sleeve and the elbow are cast integrally, and reliability of high-pressure injectant is guaranteed; as the atomizing nozzle is arranged, injected injectant is atomized into small droplets to be fully mixed with an oil-gas phase medium in the elbow, and risk of dew point corrosion of the multiphase flow medium or corrosion caused by ammonium salt crystallization deposit is lowered; due to the restriction orifice, self-balancing effect during multi-point simultaneous injection when multiple air coolers or heat exchangers are connected in parallel is enhanced.

Owner:ZHEJIANG SCI-TECH UNIV

Process for the preparation of common salt of high purity from brines in solar salt pans

ActiveUS8021442B2High purityFormation of such insoluble magnesium compounds is minimizedCrystallization separationMagnesium chloridesAlumAqueous solution

The process of the invention is an improvement over the existing process of producing salt of high purity from alum-treated brine disclosed recently in the prior art. More particularly, the invention rectifies the ratio of Ca2+ to Mg2+ from a value <1 to a value in the range of 2-3 desired by chlor-alkali and soda ash industries. The improved process involves the adjustment of pH of clarified brine with aqueous HCl so as to carry out salt crystallization at a pH of 6.5 instead of at the natural pH of 7. The pH adjustment reduces the Mg2+ impurity in salt while slightly raising the Ca2+ impurity in the salt and thereby achieving the desired ratio.

Owner:COUNCIL OF SCI & IND RES

Near zero emission treatment system and method for high-concentration organic wastewater and sludge

ActiveCN105601017AEfficient separationStabilized landfillTreatment involving filtrationMultistage water/sewage treatmentHigh concentrationSludge

The invention discloses a near zero emission treatment system and method for high-concentration organic wastewater and sludge, and belongs to the technical field of chemical engineering and environment protection. The supercritical water oxidation technology is used as the core, waste water and sludge are ground through a sludge homogeneity pump first and are then pressurized through a high-pressure plunger pump and conveyed to a subsequent pipeline to be preheated and mixed with oxygen, and supercritical water oxidation reaction is conducted in a reactor. Fluid obtained after reaction sequentially passes through a self-washing filter and a gas-liquid separator after being subjected to pressure reduction of a pressure reduction device so that insoluble solid and gas can be separated, the fluid then crystallizes through the mechanical vapor recompression (MVR) technology, soluble salt crystallization is conducted, and near zero emission of fed materials is achieved. Meanwhile, the conventional water treatment technologies (such as coagulating sedimentation, the membrane biology technology and the membrane technology) are used for assisting the SCWO technology, running parameters of the SCWO reactor are appropriately decreased, a part of residual COD is processed through the conventional water treatment technology, and the running cost is effectively reduced.

Owner:XI AN JIAOTONG UNIV +1

Water treatment method

InactiveUS7261819B2Ion-exchanger regenerationScale removal and water softeningSaline waterWater treatment system

A water treatment system for removing hard ions from source water. The water treatment system is of the type that includes a pair of ion-exchange water softener tanks connectable to a source of pressurized water and with a water system to supply softened water to the water system, the tanks each being capable of regeneration by flushing with a regeneration solution to replenish depleted ions. A process for preventing system failure due to salt crystallization includes flowing water during brine replenishment from a second nozzle and a first nozzle at a defined ratio. The first nozzle diluted the brine in a reservoir after regeneration cycle is complete. The second nozzle replenishes brine by flowing water directly onto a salt material.

Owner:KINETICO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com