Acidic water treatment method

A treatment method, acidic water technology, applied in water/sewage treatment, multi-stage water/sewage treatment, degassed water/sewage treatment, etc., can solve problems affecting the long-term operation of the conversion device, clogged pipes, and tower top heat exchangers Corrosion and other problems, to achieve the effect of circular economy, reduce equipment selection, and reduce investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

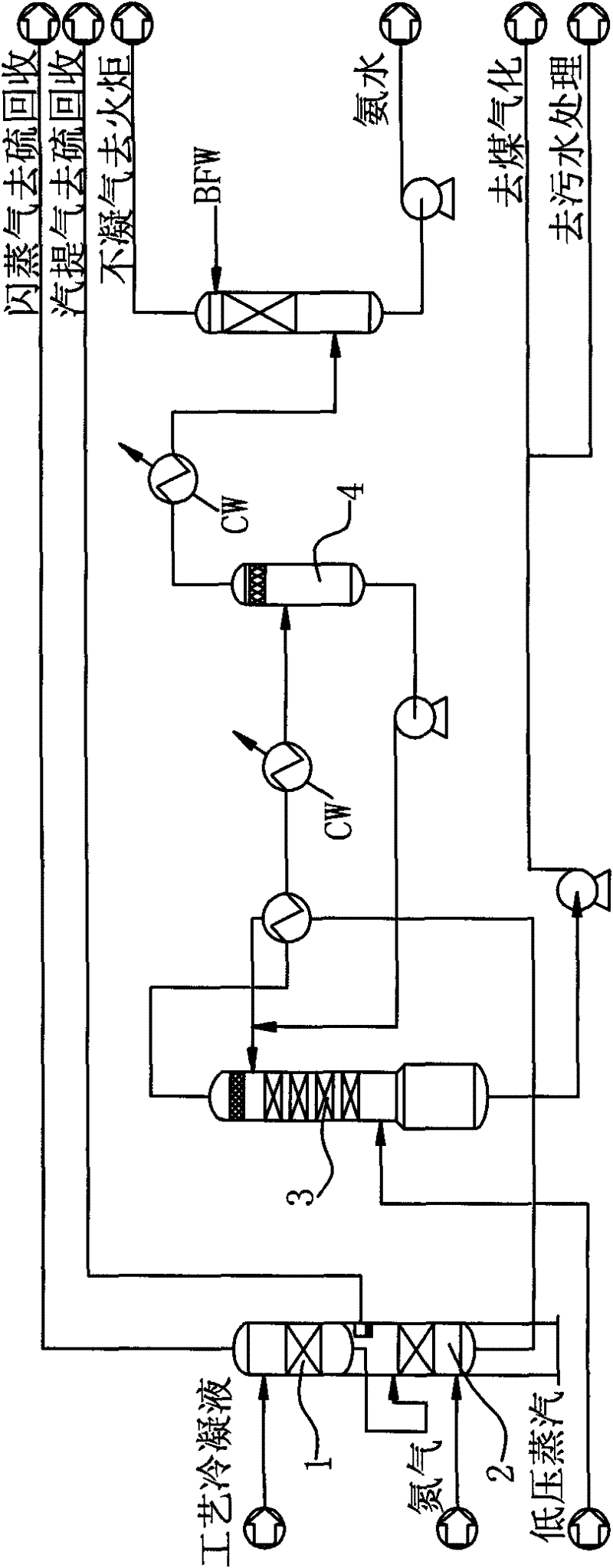

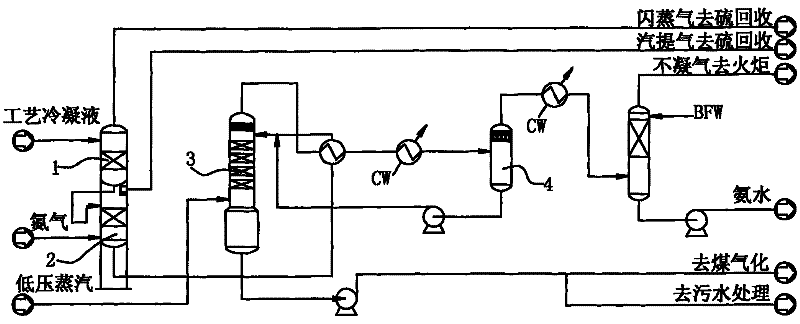

[0018] Such as figure 1 Shown, this sour water treatment method comprises the steps:

[0019] The process condensate from the gas-liquid separator in the transformation process is 295 tons of acidic water, about 310m 3 , its pressure is 55 barg, temperature 95~100 ℃, first enters flash tower 1 to flash, and the pressure of control flash tower is 8 barg. Part H 2 S and CO 2 . The gas phase obtained at the top of the flash tower is sent to the sulfur recovery unit, and the liquid in the bottom of the tower is sent to the nitrogen stripping tower described below.

[0020] The tower bottom liquid after flashing enters from the top of nitrogen stripping tower 2, and nitrogen enters from the bottom of nitrogen stripping tower 2, and the pressure of controlling nitrogen stripping tower is 5barg, and the flow rate of nitrogen is 1800Nm 3 ; Nitro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com