Patents

Literature

121results about How to "Achieve the effect of turning waste into treasure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sludge plant growth substrate and side slope sludge soil replacement greening method

ActiveCN103641648AAvoid churnSolve the problem of insufficient organic matterExcavationsHorticultureFiberSludge compost

The invention relates to a sludge plant growth substrate and a side slope sludge soil replacement greening method. The sludge plant growth substrate comprises main materials and auxiliary materials, the main materials comprise straw fiber and mature sludge compositing, the auxiliary materials comprise one or a mixture of a chemical fiber, a water-retaining agent, an adhesive, bacterial manure, a soil conditioner, a microelement fertilizer or a disinfect insecticide; the part by weight ratio of the straw fiber to the mature sludge compositing to the auxiliary materials is (7-17):(80-90):(2-5). According to the sludge plant growth substrate and the side slope sludge soil replacement greening method provided by the invention, the turfy soil is replaced by qualified sludge compositing for the field of ecological restoration, the problems that the soil replacement is easy to lose and the organic matter is insufficient in the side slope repairing are solved; furthermore, the loss of the nutrient in the substrate is avoided, the effects of avoiding weakness and turning waste into wealth are achieved, and the potential risk is eliminated.

Owner:BEIJING ORIENT LANDSCAPE

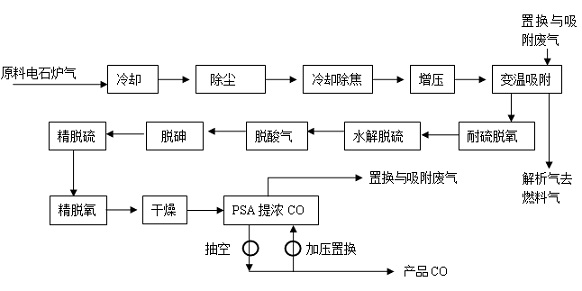

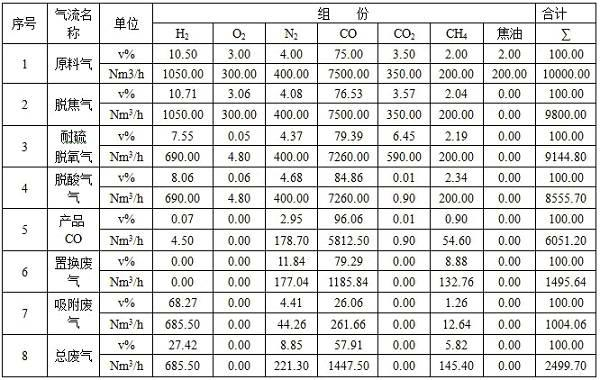

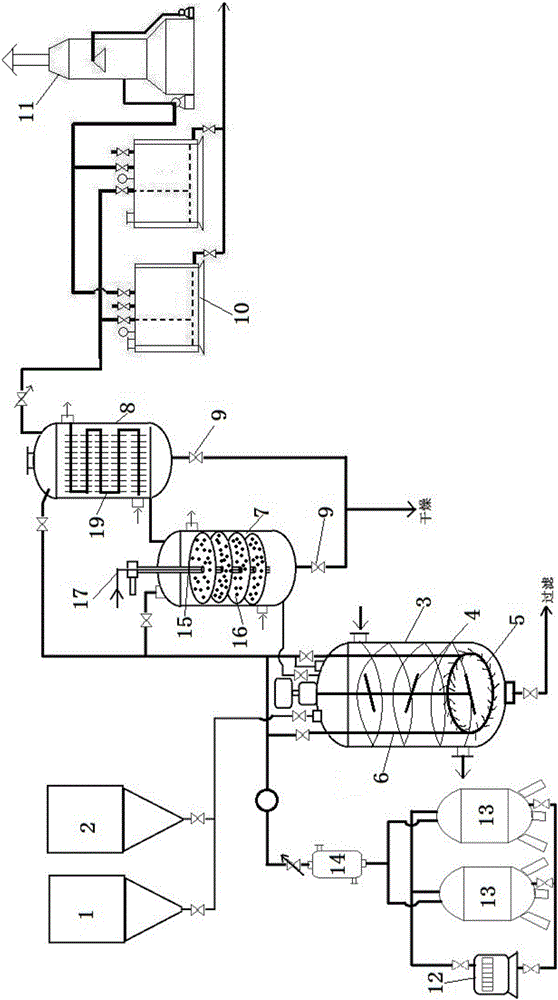

Method for purifying and concentrating CO from calcium carbide furnace gas

ActiveCN102627280AIncrease profitHigh CO yieldCalcium carbideCarbon monoxideDeoxygenationIndustrial scale

The invention discloses a method for purifying and concentrating CO from calcium carbide furnace gas and belongs to a tail gas purification method. The method provided by the invention respectively comprises the following steps of: raw material calcium carbide furnace gas dedusting, cooling and decoking, temperature swing adsorption and precleaning, supercharging, sulphur tolerant catalytic deoxygenation, hydrolysis desulfidation, acid gas removal, arsenic removal, fine desulphurization, fine deoxidation, drying, pressure swing adsorption and concentration of CO. The invention relates to a packaged technology for purifying and concentrating CO from calcium carbide furnace gas. The technology is suitable for industrial scale application and can be adopted to make calcium carbide furnace gas containing various impurities into high-purity CO gas which is suitable for CO raw material for carbonyl synthesis or other chemical production.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

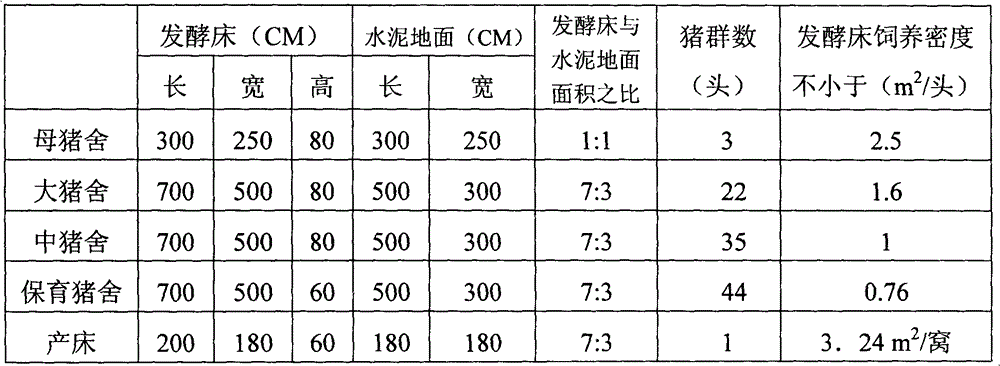

Low-carbon environment-friendly micro-ecological fermentation bed pig farming technology

The invention relates to a low-carbon environment-friendly micro-ecological fermentation bed pig farming technology which comprises the following steps of: 1) manufacturing of a pigsty; 2) manufacturing of a fermentation bed; and 3) management of the padding of the fermentation bed and the pigs. In the invention, the microbial fermentation bed farming technology is adopted for thoroughly solving the environmental pollution caused by livestock farming; and since the organic padding contains special beneficial microorganisms with equivalent activity, the manure excreta of the pigs can be quickly and effectively degraded and digested. Since the pigsty does not need to be flushed, the sewage for flushing the pigsty is avoided; and moreover, the padding of the fermentation bed is changed once in 1-3 years, and the replaced old padding is re-fermented to produce natural organic fertilizer, thereby preventing the waste from being discharged out of the pig farm and really achieving the aim of zero emission in pig farming.

Owner:董锦铭

Preparation process of sesame oil with strong flavor

InactiveCN103666744AReduce manufacturing costReduce labor intensityFatty-oils/fats productionBiotechnologyMaillard reaction

The invention provides a preparation process of sesame oil with strong flavor. The sesame oil with strong flavor is prepared via a Maillard reaction. The process comprises the following steps: smashing high-temperature sesame cakes; adding water for dissolving, and mixing; adding alkaline protease for performing enzymolysis; deactivating the enzymatic hydrolysate; mixing the enzymatic hydrolysate with refined sesame oil; heating to 130-150 DEG C; making amino acid in sesame undergo the Maillard reaction with reducing sugar generate a substance with strong flavor; after finishing the reaction, cooling, centrifuging and filtering to obtain the sesame oil with strong flavor. The obtained sesame oil has the advantages of strong flavor, good product quality, low process cost, high yield and easiness in popularizing.

Owner:湖北长坂雄风植物油股份有限公司

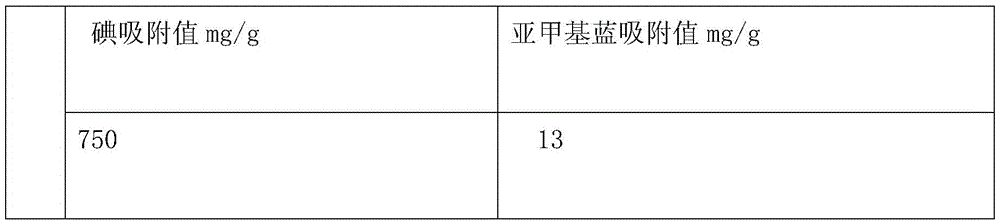

Method for preparing modified activated carbon from coffee residues

The invention provides a method for preparing modified activated carbon from coffee residues. The method includes soaking raw materials, namely, the coffee residues, in sodium hydroxide solution at first; carbonizing the coffee residues at the high temperatures to increase the specific surface areas of the coffee residues, spraying potassium chloride solution on the coffee residues, activating the coffee residues at the high temperatures again and keeping the temperatures of the coffee residues constant; activating the coffee residues by the aid of water vapor, spraying iron sulfate solution on the coffee residues and carrying out activating treatment on the coffee residues; adding silane coupling agents into the coffee residues and grinding and smashing the silane coupling agents and the coffee residues; adding potassium ferrate, diatomaceous earth and MnO2 into the coffee residues, sufficiently grinding the potassium ferrate, the diatomaceous earth, the MnO2 and the coffee residues and sufficiently mixing the potassium ferrate, the diatomaceous earth, the MnO2 and the coffee residues with one another to obtain mixtures; calcining and cooling the mixtures to obtain the modified activated carbon which is a final product. The method has the advantages that the modified activated carbon has abundant micropores, the micropores are slightly larger than harmful gas, the specific surface area of the modified activated carbon is larger than 3000 square meters / gram, the modified activated carbon is high in efficiency and adsorption capacity for toxic and harmful gas such as benzene, formaldehyde and ammonia gas, gaseous pollutants and harmful repugnant substances in indoor air can be effectively removed, purposes of reducing pollution and purifying the air can be achieved, and increase of the formaldehyde in the indoor air can be effectively inhibited.

Owner:戴旭 +1

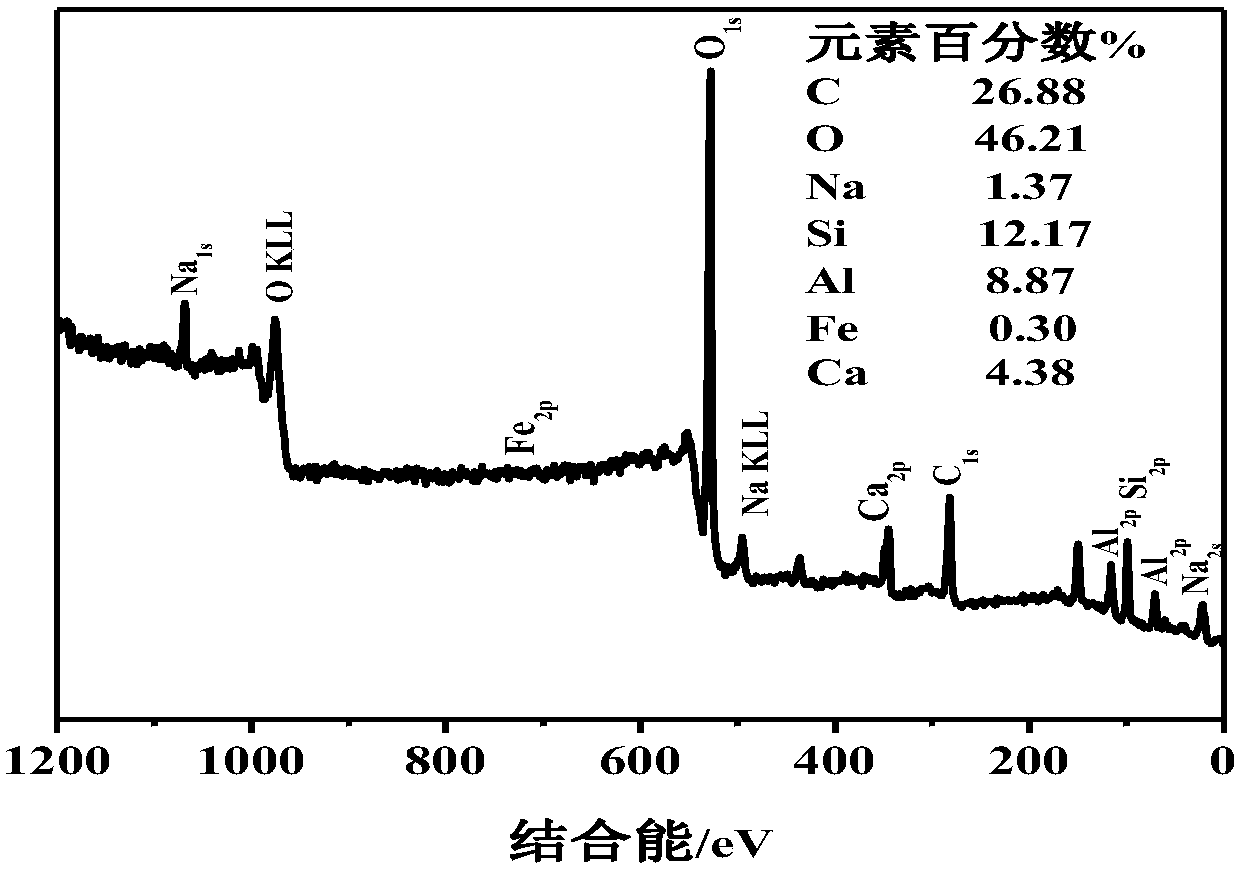

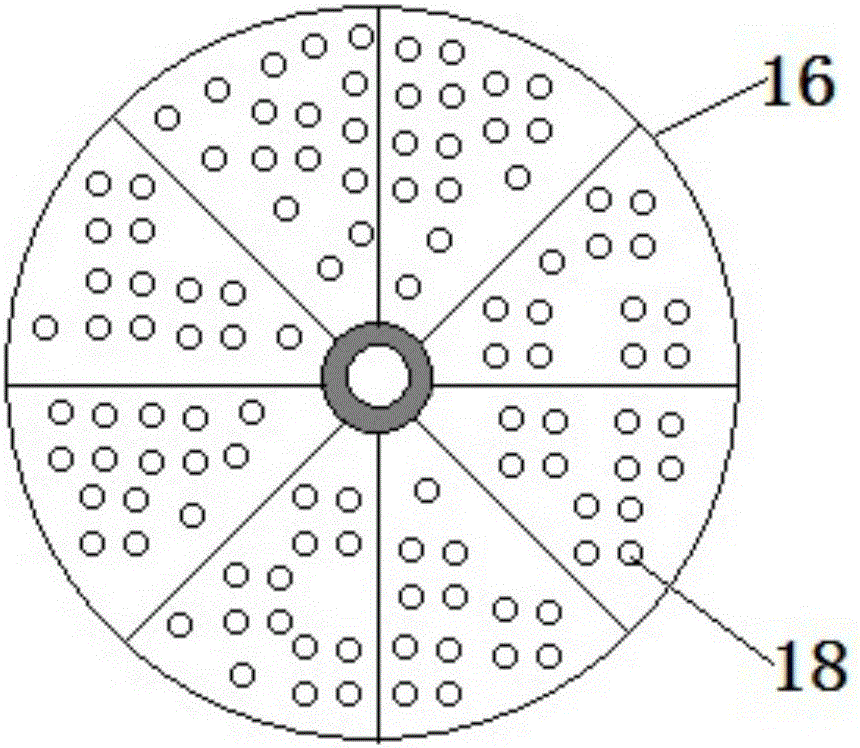

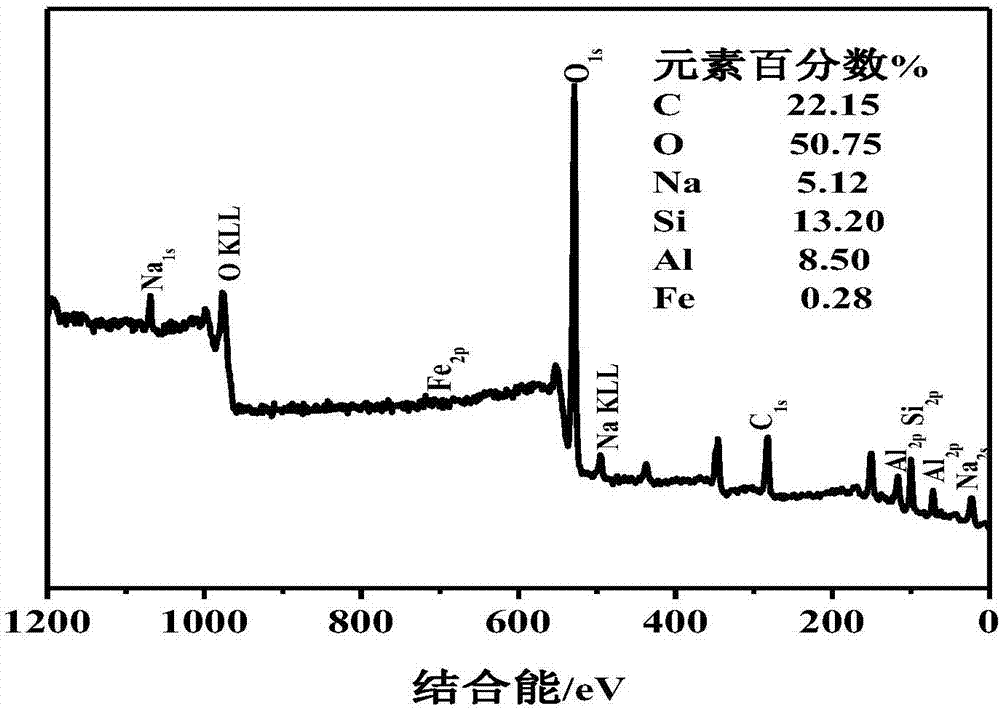

Method for preparing magnetic P-type molecular sieve by using coal gangue

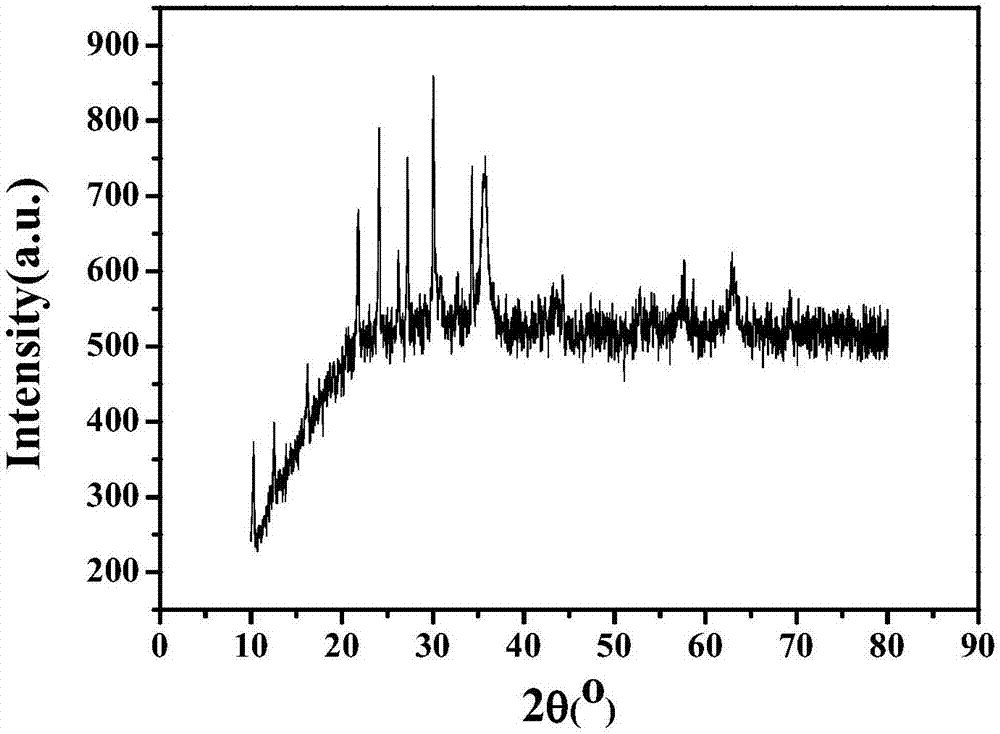

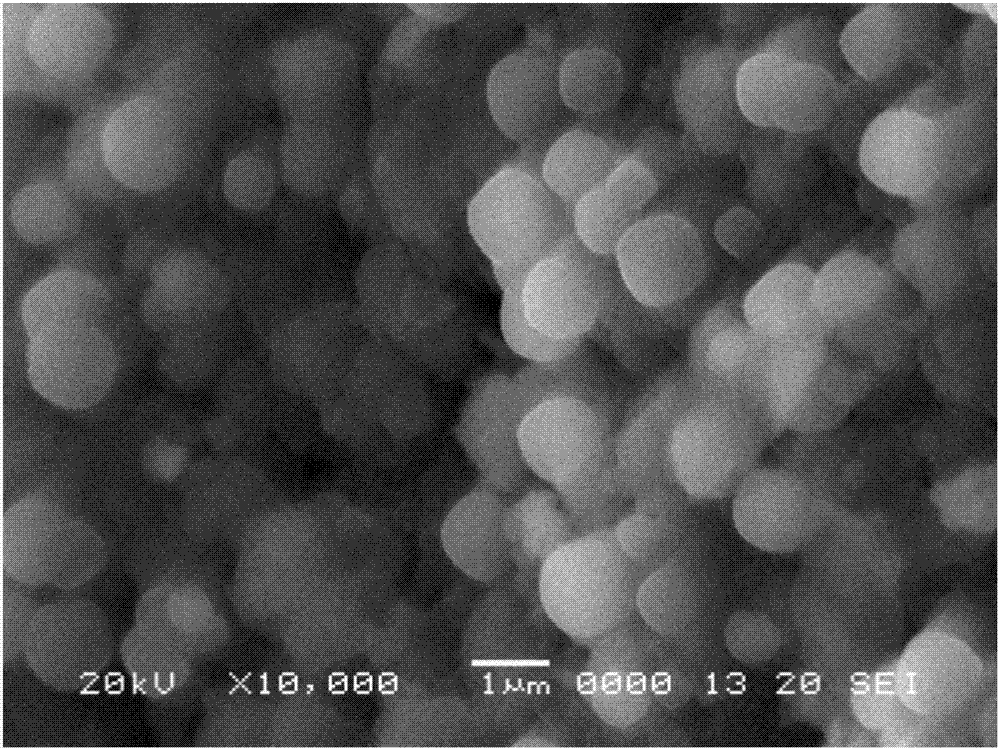

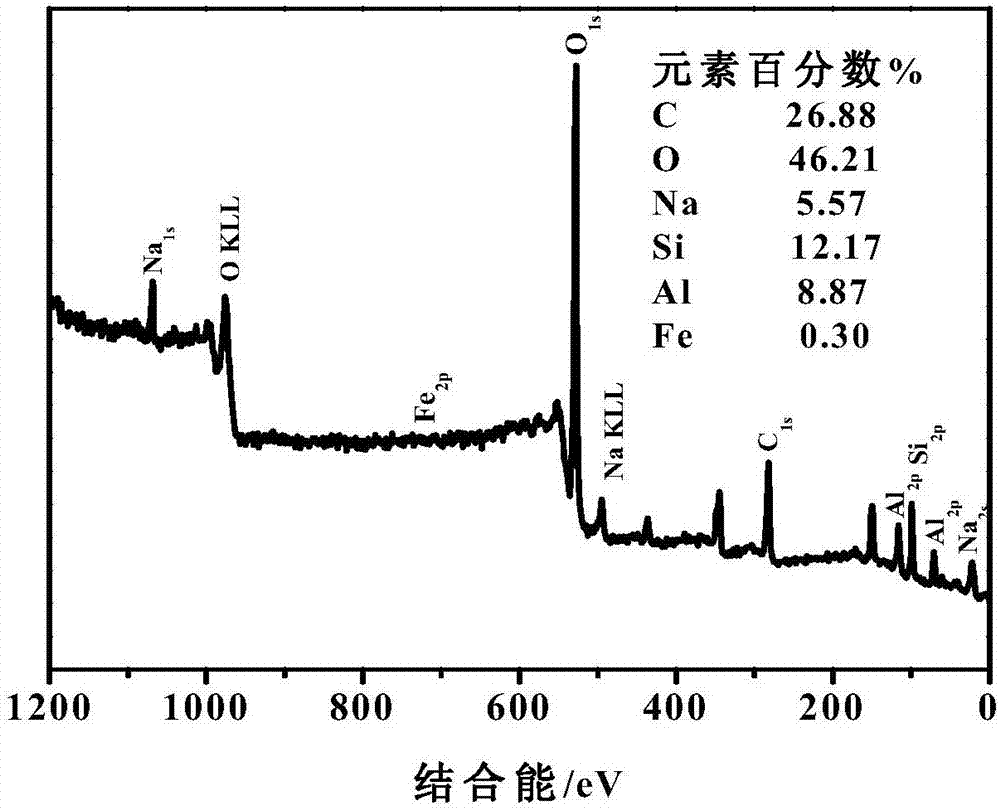

InactiveCN107285341AReduce preparation and application costsShort reaction timeOther chemical processesMolecular-sieve and base-exchange compoundsMolecular sieveChemistry

The invention discloses a method for preparing a magnetic P-type molecular sieve by using coal gangue. The method comprises: 1, grinding coal gangue, and carrying out high temperature calcining activating on the grinded coal gangue by using sodium carbonate; 2, oxidizing at a low temperature, adding hydrochloric acid, soaking, and filtering; 3, preparing an iron-doped molecular sieve from the filtration residue and the filtrate obtained after the filtration; and 4, placing the iron-doped molecular sieve in a porcelain boat, placing the porcelain boat in a tubular furnace, introducing nitrogen into the tube furnace, introducing hydrogen after the air in the tubular furnace is completely discharged, heating to a temperature of 650-700 DEG C, continuously carrying out a reduction reaction for 2-3 h, introducing nitrogen after completing the reaction, and cooling to a room temperature to obtain the magnetic P-type molecular sieve. According to the present invention, the coal gangue is used as the raw material, the Fe<3+> dissolution is performed with hydrochloric acid and is complexed by adding oxalic acid, and finally high temperature reduction is performed to prepare the magnetic P-type molecular sieve; the magnetic P-type molecular sieve has characteristics of high specific surface area and strong adsorption performance; and the magnetic P-type molecular sieve is easy to separate and recover through the external magnetic field, and the problem of high cost of the molecular sieve synthesis is solved.

Owner:XIAN UNIV OF SCI & TECH

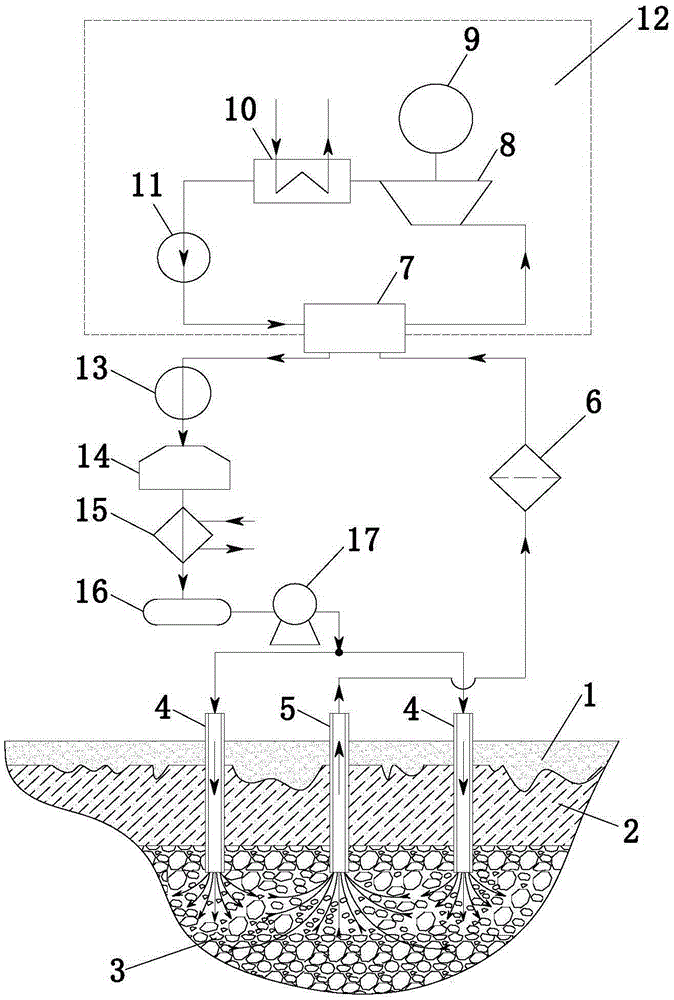

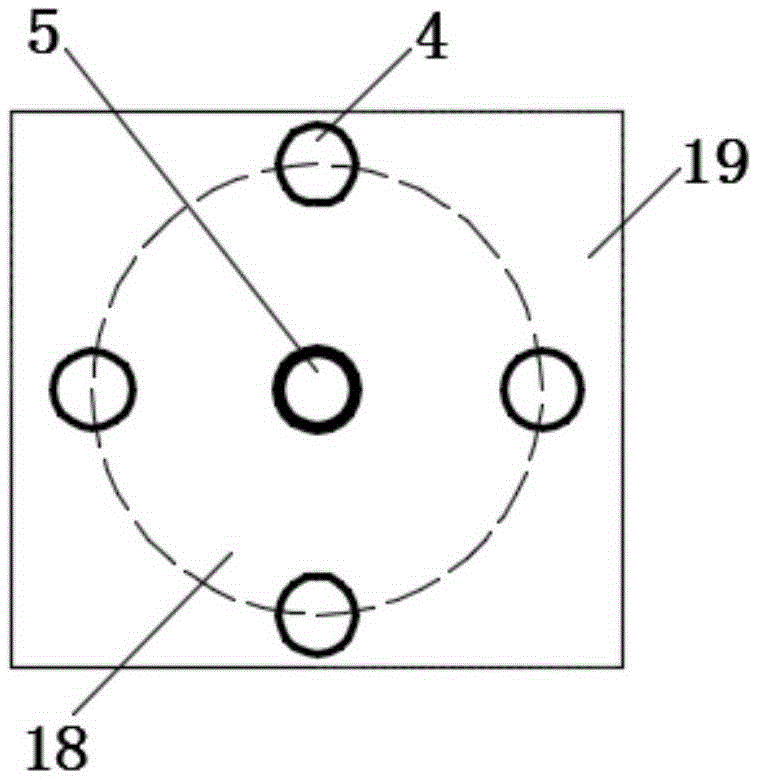

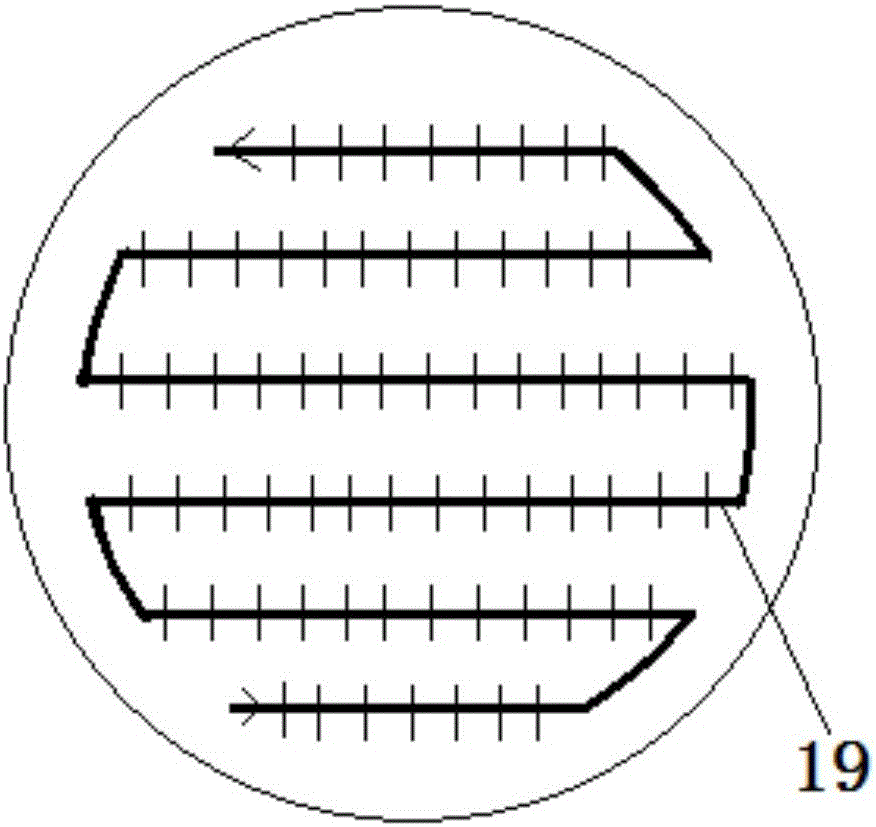

Extracting and converting method for heat energy in coal field fire zone

ActiveCN105298569AAvoid getting lostImplement extractionSteam engine plantsThermal energyOrganic Rankine cycle

An extracting and converting method for heat energy in a coal field fire zone belongs to heat energy extracting and converting methods. A flame retardant filling material is utilized to cover air inlet and air outlet channels in a high temperature zone, such as earth surface cracks and collapse pits, injecting and pumping drill holes for a heat extracting medium are constructed from the earth surface to an underground coal fire high-temperature zone, and the injecting drill holes are distributed on the circumference with the pumping drill hole as a center. A gaseous heat medium is pressed into the injecting drill holes by a gas booster pump, then, a vacuum pump pumps out heat medium mixed gas finishing heat exchange and guides the heat medium mixed gas into a filter, the filtered gas enters an evaporator so as to finish heat exchange, and exchanged heat energy is converted to electricity by an organic Rankine cycle system. Then, other gasses are separated out of the heat medium mixed gas by a gas component separating station, and the rest heat medium is input into a low-temperature gas storage tank after being cooled by a cooler. Finally, the heat medium is pressed into the injecting drill holes again by the gas booster pump, and cycle is finished. The method has the advantages that not only are the extracting and conversion of waste heat energy in the coal field fire zone realized, and the purpose of fire zone treatment is also achieved, and has wide practicability.

Owner:CHINA UNIV OF MINING & TECH +1

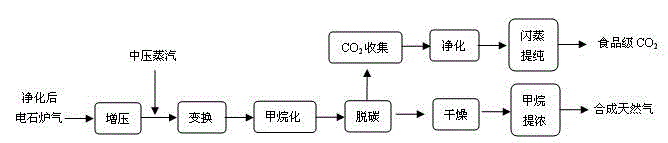

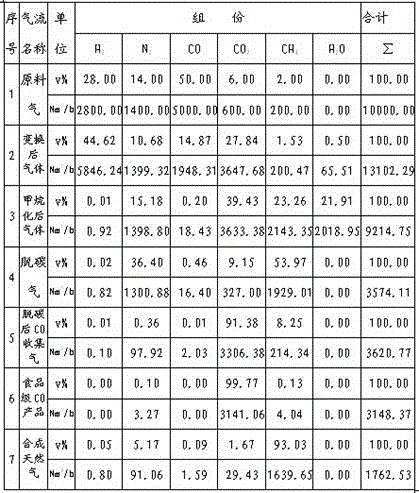

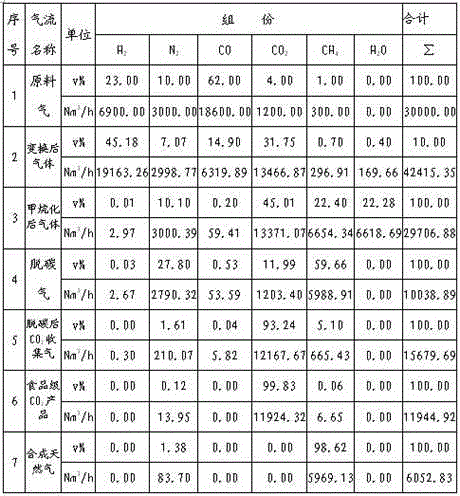

Process for co-producing and synthetic natural gas and food-grade carbon dioxide by using calcium carbide furnace gas

InactiveCN102977960AGuaranteed uptimeImprove reliabilityCarbon compoundsGaseous fuelsCo2 removalFood grade

The invention discloses a process for co-producing synthetic natural gas and food-grade carbon dioxide by using calcium carbide furnace gas. The process sequentially comprises the steps that after purified calcium carbide furnace gas is pressurized and mixed with medium-pressure steam and then the obtained mixture enters a shift-converter to carry out shift-conversion, the obtained gas enters a methanation reactor to carry out methanation, and then enters a decarbonization system to remove CO2; the gas subjected to CO2 removal is dried, and then enters a methane concentration system to carry out concentration, thereby obtaining synthetic natural gas; and the removed CO2 is prepared into food-grade CO2 through a recovery unit. The decarbonization system can adopt a PSA (pressure swing adsorption) dry decarburization process, and also can adopt a wet decarburization process. The wet decarburization is implemented by removing CO2 by using a thermokalite method or MDEA washing. A CO2 recovery unit has the functions of CO2 collecting, purifying, and purification by flash distillation. The methane concentration can be implemented by concentrating methane by using a PSA method, and also can be implemented by concentrating methane through low-temperature separation. The process disclosed by the invention is a packaged technology for co-producing synthetic natural gas and food-grade carbon dioxide by using calcium carbide furnace gas, which is suitable for industrial scale applications.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

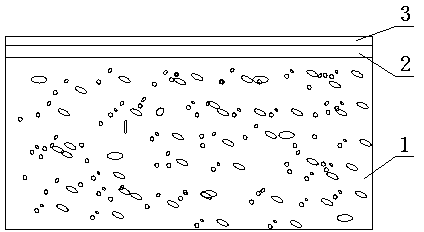

Sintered shale micropore building block and manufacturing method thereof

The invention discloses a sintered shale micropore honeycomb glaze building block and a manufacturing method thereof. The manufacturing method includes: stirring and mixing raw materials comprising shale, building spoil, sludge, rubbish, straw (such as tree branches, leaves, rotten wood or tree), coal gangue, water, and the like to obtain a viscous mixture, extruding and forming to obtain a workblank of the building block, coating at least one side surface of the workblank of the building block with a clay layer and a glaze layer, sintering and forming. The building brick is manufactured by the method. The building block and the manufacturing method have advantages of low cost, short production period, low energy consumption, high building block strength, light unit weight, low heat conductivity coefficient, and good energy-conservation, heat insulation, sound insulation effects. The building block is provided with the glaze layer and can be directly used as a wall surface, thus shortening the building period, reducing cement consumption, reducing environment pollution, and avoiding hazards of dropping of external tiles. In addition, the building block and the manufacturing method achieve processing of the agriculture straw, the coal gangue, the rubbish, and other waste and turn the waste into things of value, thus achieving effects of energy conservation and environmental protection.

Owner:晏兴洪

Preparation method of dephosphorisation absorptive material and application thereof

InactiveCN101966444AEasy to makeLow costOther chemical processesWater/sewage treatment by sorptionSorbentManganese

The invention discloses a preparation method of dephosphorisation absorptive material, comprising the following steps: washing manganese ore tailing with clean water, grinding to powder and meshing, adding acid fluid to the meshed manganese ore powder, filtering the solution, taking the solution and adding proper amount of alkali to neutralize till the pH is 6 to 8, adding oxidant solution to the filtrate while agitating, controlling the pH to be 6 to 8 during the reaction process, thoroughly shaking, ageing, neutralizing, washing, filtering and drying to obtain the product. The preparation of dephosphorisation absorptive material using natural manganese ore tailing as raw material has simple process and low cost, and has thye effect of changing wastes into valuables. The absorptive agent can remove the phosphorous well, and the saturated absorption quantity is 12.5mg / g. The absorptive agent has fast absorptive speed, large absorptive volume and good purification effect.

Owner:NORTHWEST A & F UNIV

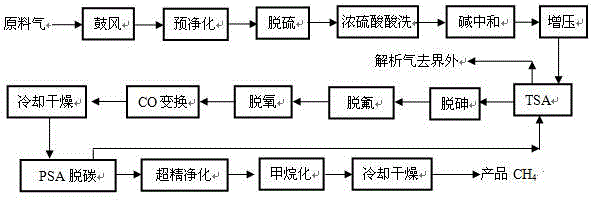

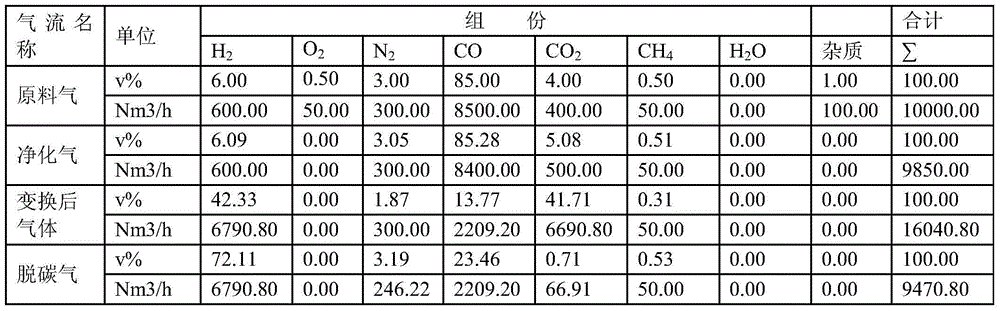

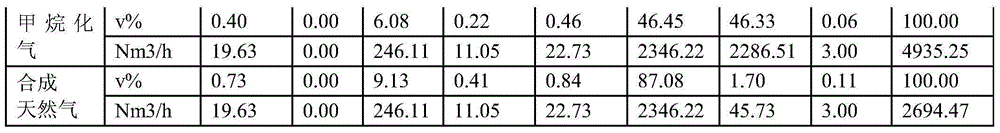

Process of preparing synthetic natural gas by using yellow phosphorus tail gas

The invention belongs to the field of resource recycling of industrial tail gases and particularly relates to a process of preparing synthetic natural gas by using yellow phosphorus tail gas. The process comprises the following steps: carrying out blowing and pressurization, pre-cleaning, desulfuration, pickling by concentrated sulfuric acid, alkali neutralization, pressurization, temperature swing adsorption purification, dearsenification, defluorination, deoxygenation, CO conversion, cooling and drying, decarbonization, superfine purification, methanation and cooling and drying on raw material yellow phosphorus tail gas, and thus finally preparing a natural gas product. The process provided by the invention is a yellow phosphorus tail gas purifying and synthetic natural gas preparing packaged technology suitable for industrial scale application and can prepare high purity methane gas by taking the yellow phosphorus tail gas containing various impurities as fuel gases or chemical materials for users to use.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

High-hydroxy phenolic resin prepared by using phenols residues as raw material, and application of high-hydroxy phenolic resin to production of high-temperature-resistant paint

InactiveCN102757544AAchieve emissionsSolve pollutionPolyurea/polyurethane coatingsChemical reactionSolvent

The invention provides a high-hydroxy phenolic resin. Phenols residues and aldehydes compounds are used as main raw materials and are subjected to function modification by using an unsaturated compound or polymer, the high-hydroxy phenolic resin is obtained through a series of chemical reactions, then the high-hydroxy phenolic resin is used as a main film forming material, is compounded with laminar inorganic mineral materials such as glass flakes, and then crosslinked and cured by using polyurethane resin or amino resin to prepare the high-temperature-resistant paint which has the advantages of high drying speed, good adhering force, large hardness, high gloss, good heat resistance, water resistance, strong solvent resistance and the like, and is suitable for heat-resistant corrosion-proof coatings with high decoration on the surface of devices such as a chemical machinery device, a pipeline, a flue, a storage tank and a heat radiator. According to the invention, zero emission of the phenols residues is realized, the problem of environment pollution caused by the phenols residues is radically solved, and the effects of comprehensive treatment and waste material recycling is achieved. Meanwhile, a new variety of coating products is increased, the application range of phenolic coatings is enlarged, and the cost of corresponding coatings is lowered.

Owner:LANZHOU PETROCHEM COLLEGE OF VOCATIONAL TECH

Method of improving saline-alkali soil to plant plants by using prepared sludge nutrient substrate

InactiveCN107285940AImprove hydrolysis efficiencyIncrease PotassiumBio-organic fraction processingBioloigcal waste fertilisersAlkali soilSurface layer

The invention relates to a method for improving saline-alkali soil to plant plants based on a prepared sludge nutrient substrate, and belongs to the technical field of sludge treatment and saline-alkali land treatment. The method comprises the steps that on the basis of the prepared sludge nutrient substrate, firstly, the sludge nutrient substrate is spread in the surface layer of the saline-alkali soil, and then ploughing, soil preparing and digging of parallel planting ditches are conducted; then the sludge nutrient substrate, a water retaining agent and crushed plant waste are mixed evenly, and sludge migrated soil is obtained; the sludge migrated soil is applied to the bottoms of the planting ditches to form the a migrated soil layer, plant seeds are sowed in the migrated soil layer, the upper side of the migrated soil layer is covered with non-woven fabric, and then regular irrigation and routine management are carried out. The method achieves the purposes of soil optimization and sludge treatment in saline-alkali land, soil optimization and sludge treatment are organically combined, environmental problems are solved by making full use of sludge wastes, and favorable conditions are provided for agro-forestry production.

Owner:LUOYANG MAOSHENG BIOTECH

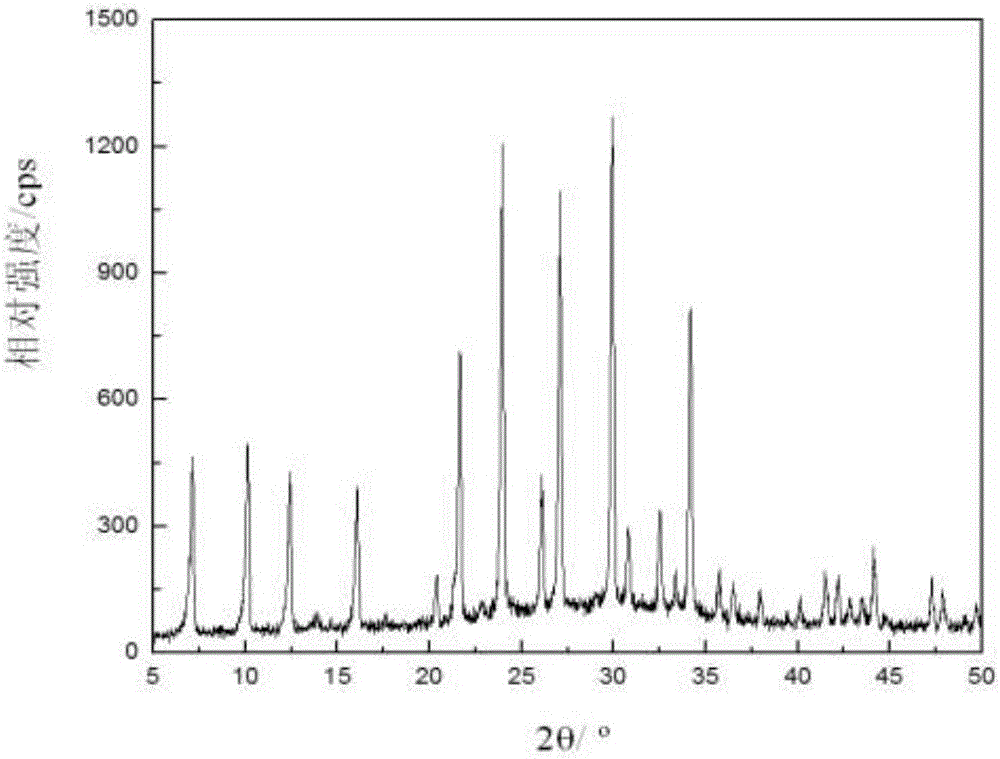

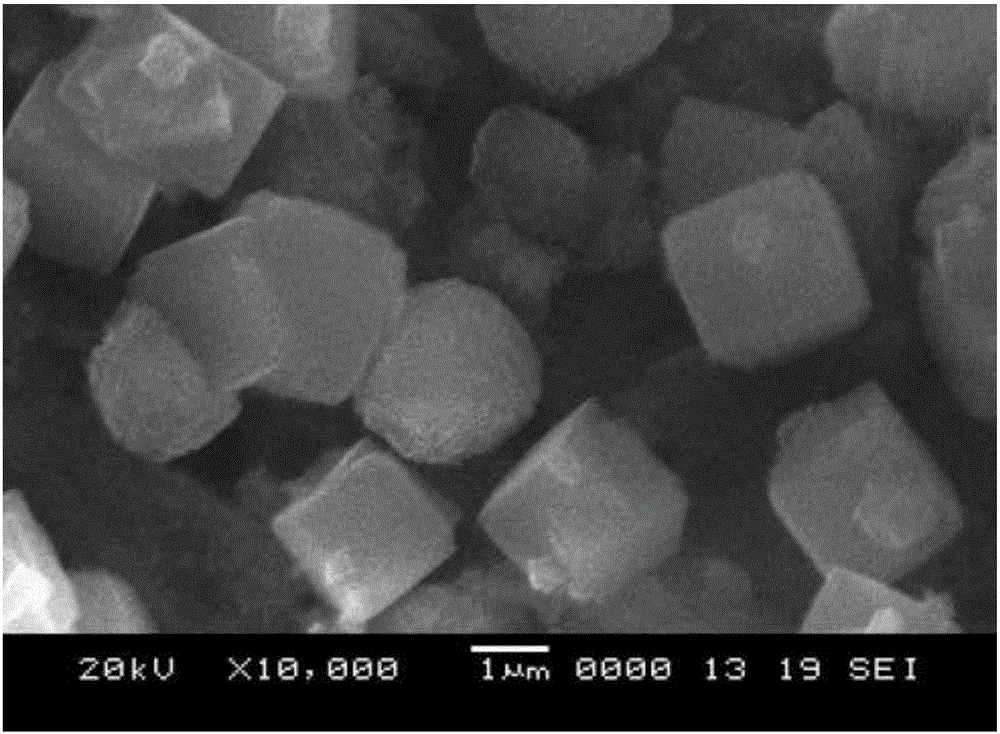

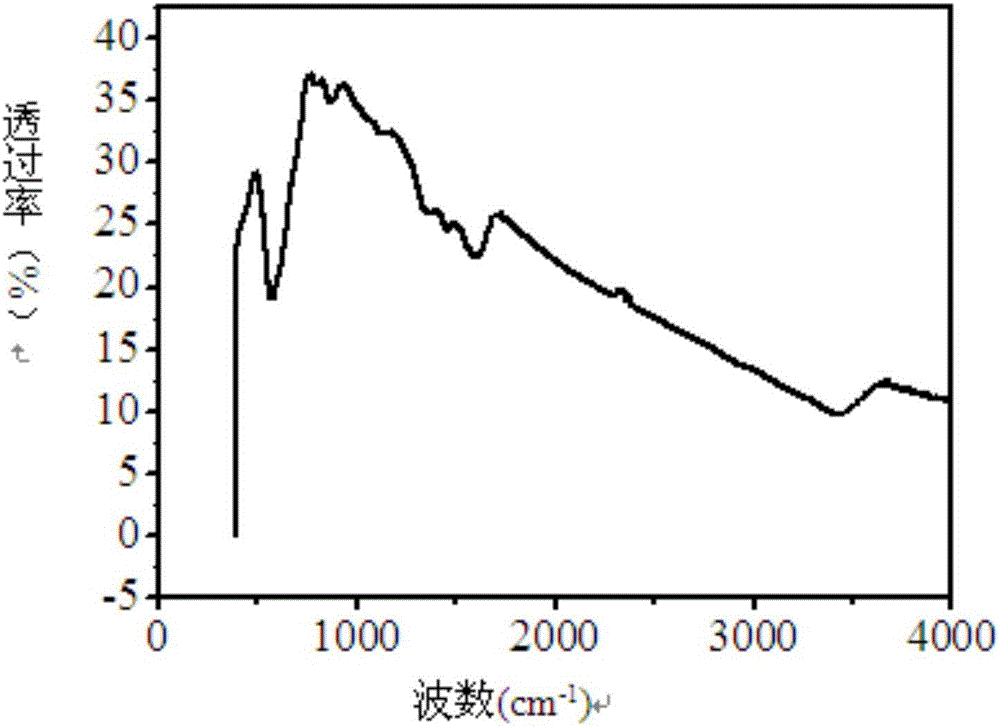

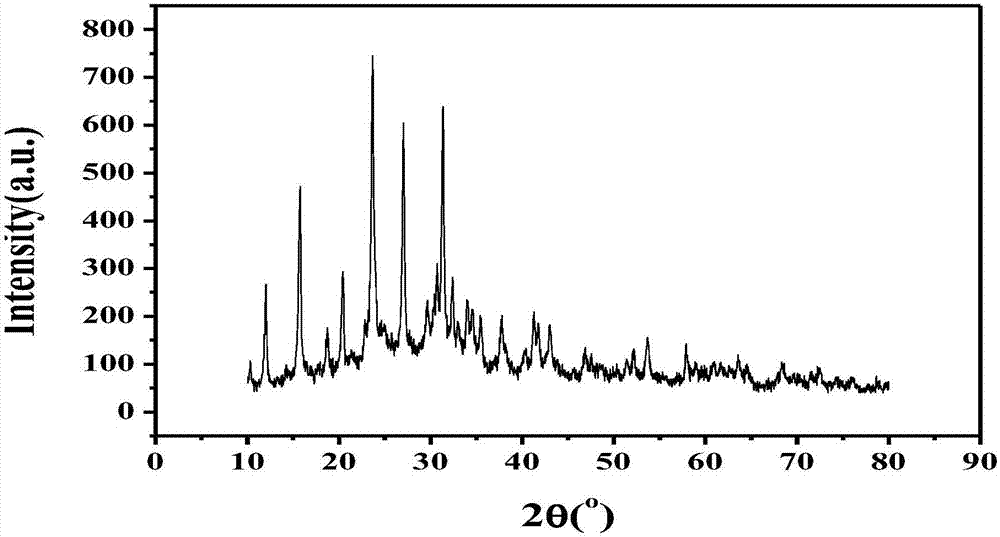

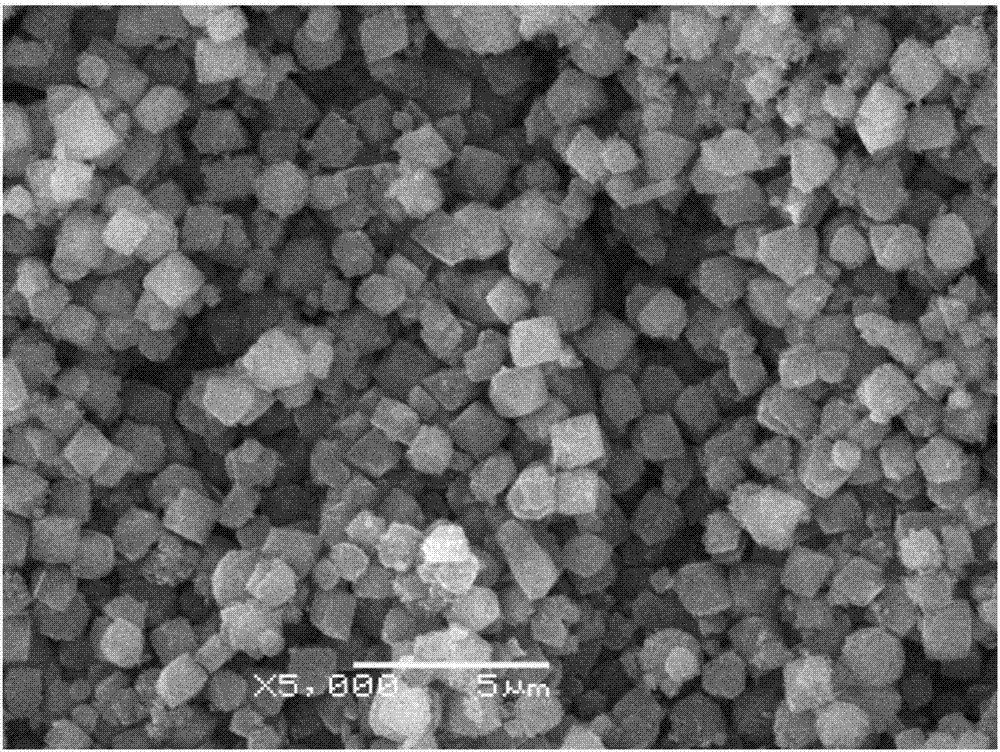

Method for preparing magnetic 5A molecular sieve from coal gangue and application of magnetic 5A molecular sieve

InactiveCN107673367AHigh crystallinityEvenly distributedWater contaminantsWater/sewage treatment by magnetic/electric fieldsFiltrationSodium hydroxide

The invention discloses a method for preparing a magnetic 5A molecular sieve from coal gangue and application of the magnetic 5A molecular sieve. The method comprises the following steps: after milling coal gangue, performing high-temperature roasting by using sodium carbonate to activate the coal gangue; performing oxidization at low temperature, adding hydrochloric acid, performing soaking at 90DEG C, performing filtration, and adding sodium hydroxide and cobalt acetate into the filtrate to prepare iron cobaltate; after washing the solid, performing drying, adding a sodium hydroxide solid,performing uniform mixing by grinding, and performing low-temperature alkali fusion; and adding deionized water, calcium chloride and citric acid, performing aging at 60 DEG C, adding the iron cobaltate, and performing ultrasonic treatment to synthesize the magnetic 5A molecular sieve by crystallization. The 5A molecular sieve prepared by the method has the advantages of favorable oxidation resistance, high specific surface area, high adsorbability and the like, and the product can be easily subjected to solid-liquid separation through an external magnetic field; and the 5A molecular sieve solves the problem of high synthesis cost of the molecular sieve, provides a new way for cyclic, refined and efficient utilization of coal gangue, achieves the effect of changing wastes into valuable substances, and satisfies the requirements of environmental protection and low carbon.

Owner:XIAN UNIV OF SCI & TECH

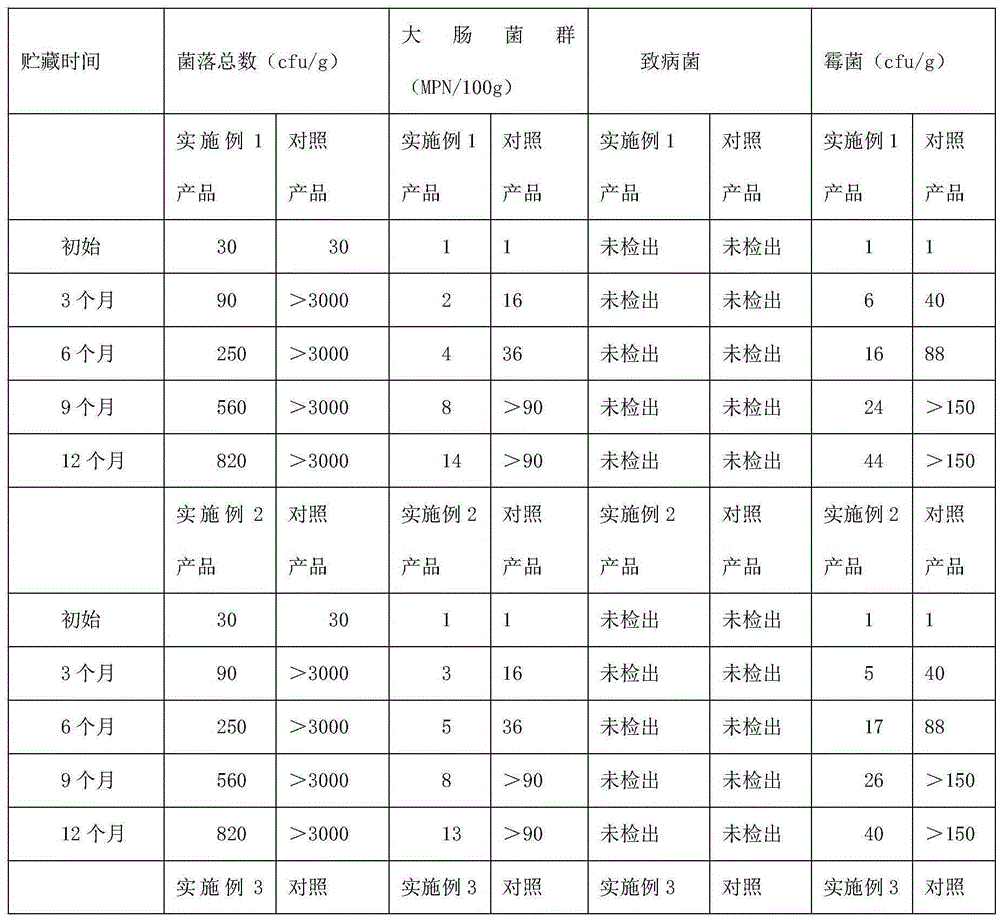

Fresh keeping coating agent and application thereof in fresh keeping of medium-humidity dried longan pulp and medium-humidity dried litchi pulp

InactiveCN105285078AEnhanced inhibitory effectExtended shelf lifeFruits/vegetable preservation by coatingSnow moldEssence oil

The invention discloses a fresh keeping coating agent and application thereof in the fresh keeping of medium-humidity dried longan pulp and medium-humidity dried litchi pulp. According to the fresh keeping coating agent disclosed by the invention, waste products in the processing course of the dried longan pulp and the dried litchi pulp, namely longan husks, longan seeds, litchi husks and litchi seeds are used as raw materials and are scientifically extracted so that a extract mixture is obtained, and the synergistic bacteriostasis effects of the extract mixture, pimaricin, honeysuckle essential oil and mint essential oil are sufficiently exerted to have better effects of restraining bacteria, yeast and / or mould, which are easy to produce in the fresh keeping process of dried fruits. Based on the extract mixture, chitosan in a reasonable proportion is utilized so that a film is successfully formed, the quality guarantee period of medium-humidity dried fruits is successfully prolonged in a manner of coating fresh keeping for the dried fruits, and the effects of comprehensively utilizing the raw materials and turning waste into wealth are achieved.

Owner:HUIZHOU SIJIXIAN GREEN FOOD +1

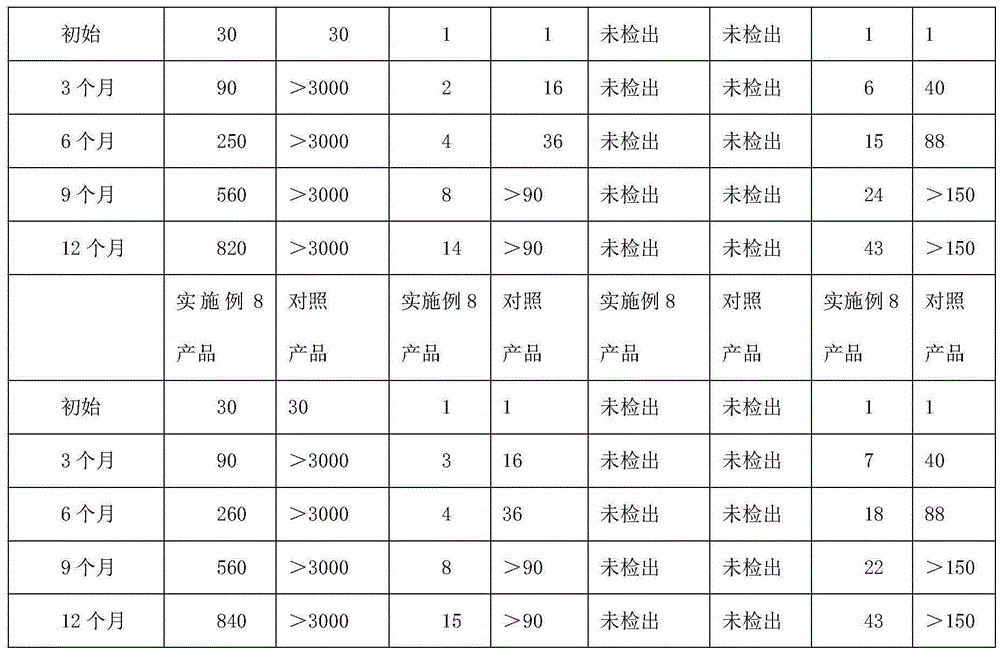

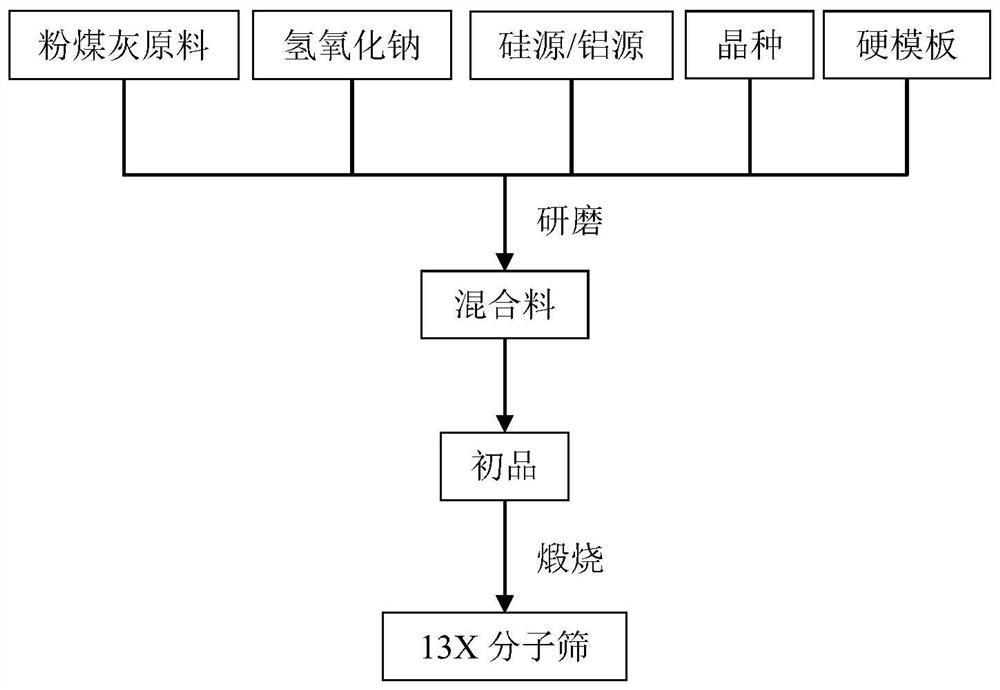

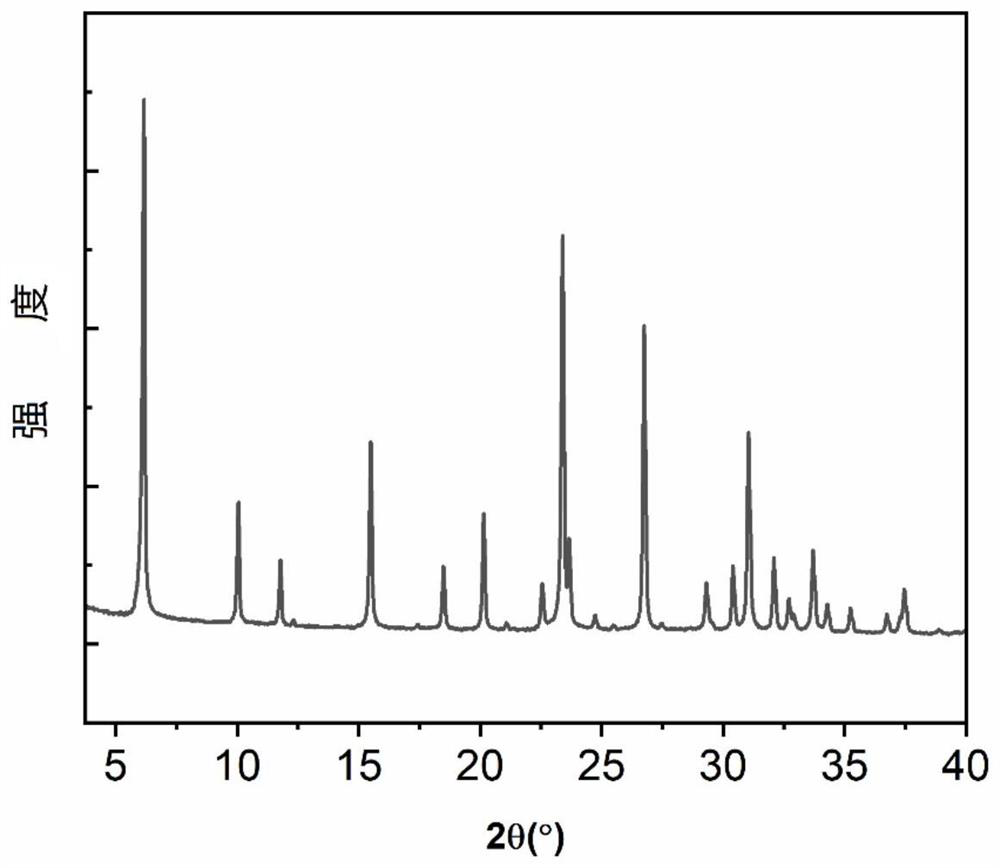

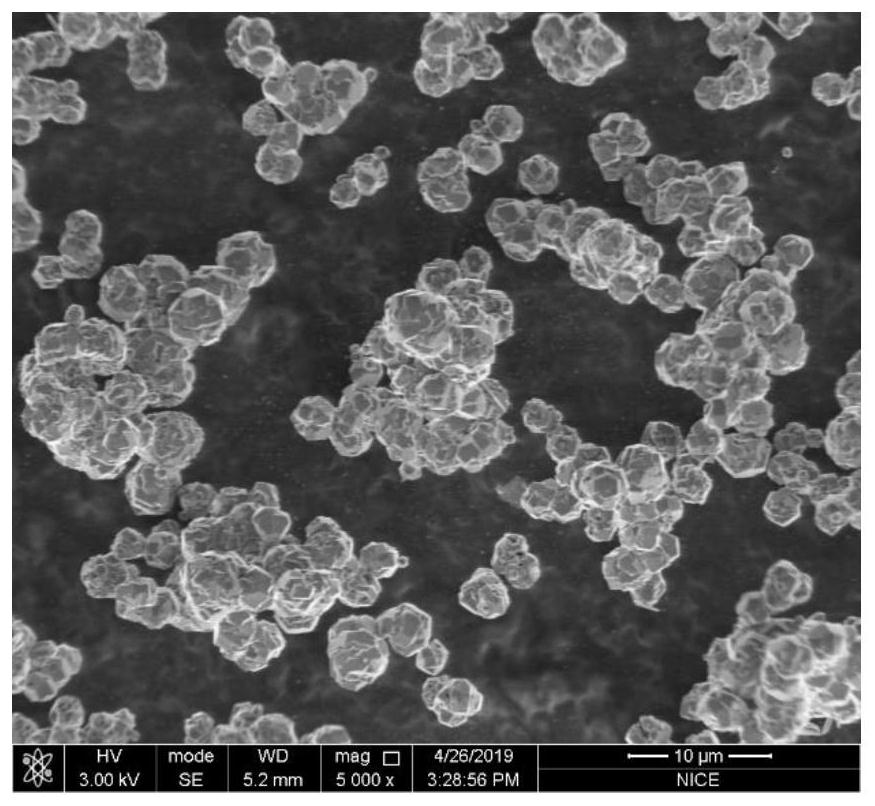

Preparation method of 13X molecular sieve and 13X molecular sieve

InactiveCN111847475ADoes not require roasting activationHigh yieldFaujasite aluminosilicate zeoliteMolecular sievePhysical chemistry

The invention discloses a preparation method of a 13X molecular sieve and the 13X molecular sieve, and belongs to the technical field of solid waste treatment in the field of environmental protection.The preparation method comprises the following steps: providing a fly ash raw material, wherein the mass percentage of the fly ash is 66-85%, mixing the fly ash raw material with sodium hydroxide, asilicon source, an aluminum source, a 13X molecular sieve seed crystal and a hard template, grinding to obtain a mixture, wherein the range of the silica-alumina ratio in the mixture is 3-11, the masspercent of the 13X molecular sieve seed crystal is 8-15% and the mass percent of the hard template is 2-5%, crystallizing the mixture for 15-24 hours at the temperature of 80-98 DEG C to obtain a crystallized product, and cooling the crystallized product to obtain a primary product; and calcining the primary product for 4-8 hours at the temperature of 500-600 DEG C to obtain a calcined product, sequentially cooling, washing and filtering the calcined product, and drying for 10-15 hours at the temperature of 50-70 DEG C to obtain the 13X molecular sieve. According to the preparation method ofthe 13X molecular sieve and the 13X molecular sieve, a roasting activation link is not needed.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Microbial starter for treating municipal sludge and preparation method thereof

The invention belongs to the technical field of fermentative organisms, and particularly relates to a microbial starter for treating municipal sludge and a preparation method thereof. By adding a soybean extract into the starter, the activity of microorganisms and enzymes in the starter is increased greatly, the temperature rising and fermentation time in a substrate fermentation process is shortened, the nutrients after fermentation are enriched, and the working efficiency is increased. The soybean extract is mixed together with complex liquid after ultrasonic treatment, so that components in the complex liquid and the soybean extract are mixed uniformly, the absorption and utilization ratios of the starter by the substrate are increased, and substrate fermentation is more complete. Moreover, ultrasonic treatment is performed intermittently, so that damages of ultrasonic waves to components in the soybean extract are prevented. A preparation process is simple, multiple nutrient substances in the municipal sludge can be decomposed in combination with multiple microorganisms and enzymes, the effect of changing waste into valuable is achieved, urban beautification is promoted, and a nutritional substrate is provided for the growth of plants.

Owner:HENAN UNIV OF SCI & TECH

Process and device for preparing gas-phase white carbon black and recycling metal by taking industrial waste residues containing silicate as raw materials

ActiveCN105967192AAchieve the effect of turning waste into treasureLow costSilicaAluminium fluoridesGas phaseToxic industrial waste

The invention provides a process for preparing gas-phase white carbon black at a low temperature and recycling metal by taking industrial waste residues containing silicate as raw materials. In the process, wastes including the industrial waste residues and the like are used as the raw materials and are reacted with fluorine-containing acid liquid, hydrochloric acid and nitric acid to prepare the product gas-phase white carbon black with a high additional value and the metal is recycled; in the prepared product, the content of SiO2 is more than 99.9 percent and the specific surface area measured by a multi-point BET method is: 350m<2> / g to 500m<2> / g, so that the effect of changing wastes into valuable things is realized; after acidic gas generated in the preparation process is absorbed by a negative-pressure water absorption tank, corresponding acid liquid can be prepared; when the acid liquid is concentrated to a certain concentration, the acid liquid can be circularly utilized. Meanwhile, the invention further provides a production device used for the process; all parts of the production device are common devices in chemical plants and the cost is low, so that large-scale industrial production can be realized.

Owner:HUANGGANG NORMAL UNIV +1

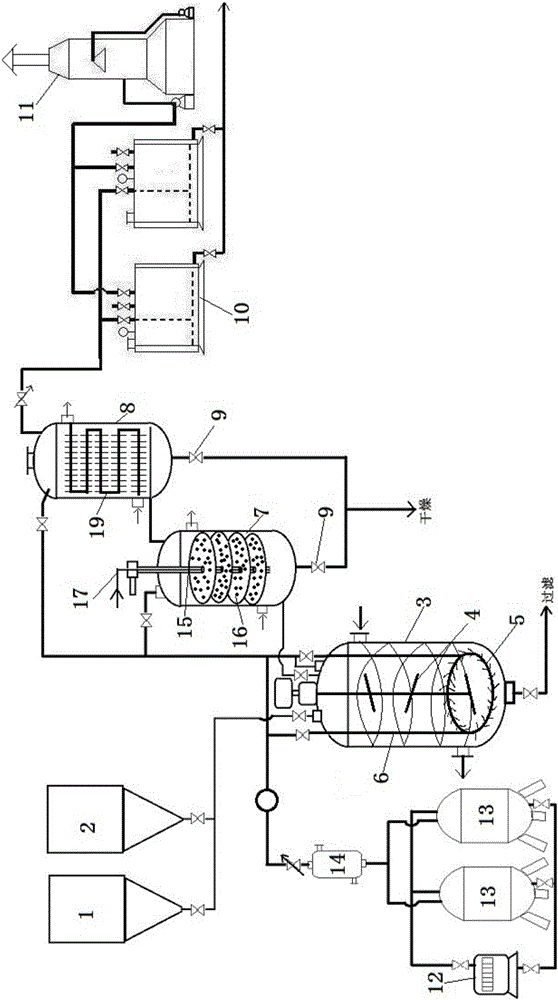

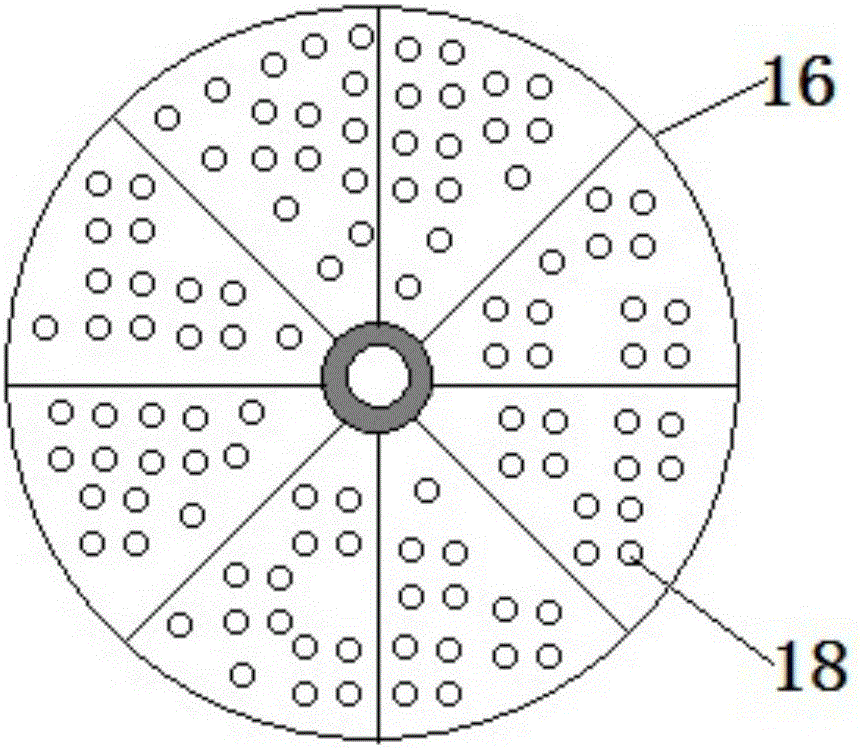

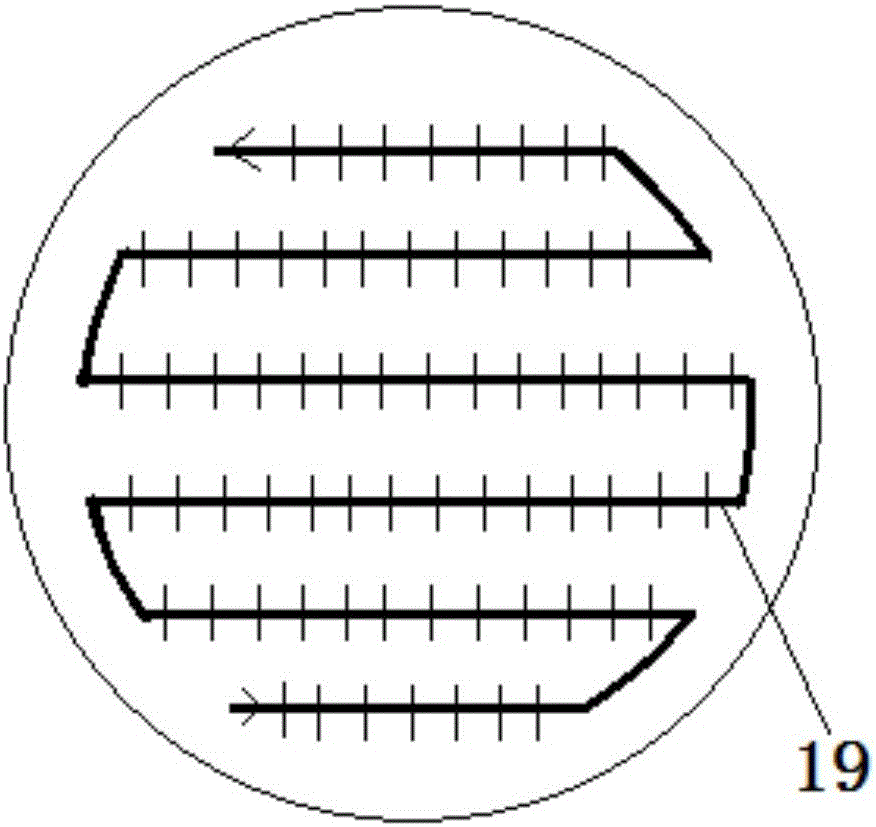

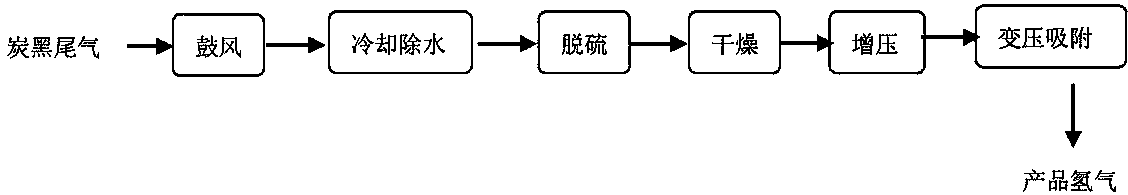

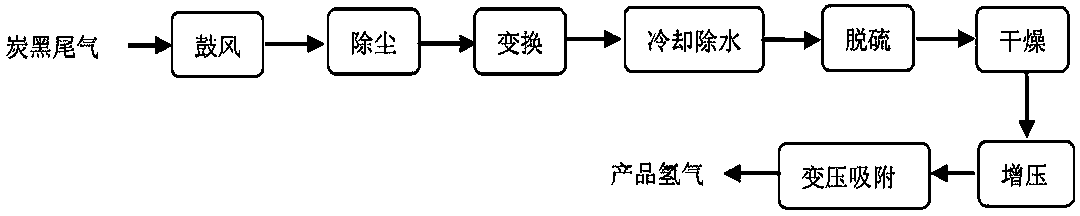

Process for producing hydrogen by use of burning carbon black tail gas

ActiveCN103523749AAchieve recyclingGuaranteed uptimeHydrogen separationIndustrial effluentWater vapor

The invention discloses a process for producing hydrogen by use of burning carbon black tail gas. The process comprises the following steps of blasting the burning carbon black tail gas, cooling for dewatering, desulfurizing, drying, pressurizing, and carrying out pressure swing adsorption and separation to obtain the hydrogen. The process has the beneficial effects that (1) the process used for purifying the hydrogen from the burning carbon black tail gas in an industrial scale manner is firstly proposed, so that a great amount of the burning carbon black tail gas blown into atmosphere at present is produced into the hydrogen, and the device is stable to operate, has high reliability and high heat utilization ratio, and can achieve the effects of recycling the industrial effluent gas, saving energy, reducing emission and turning wastes into wealth; (2) high-temperature heat released in the production process of a carbon black plant is utilized, the used heat and the heat released are comprehensively considered, the whole process flow is designed reasonably, and the heat of all operating units can be utilized comprehensively, so that an external heat source is not required to be supplemented, and the energy can be saved; (3) hydrogen sulfide and water vapor in the burning carbon black tail gas originally are utilized for sulfur tolerant conversion directly, and the process flow is simple; (4) the hydrogen with high purity can be produced as a hydrogen source required by chemical engineering.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Method for preparing plasticizer by using purified terephthalic acid (PTA) residue

The invention discloses a method for preparing a plasticizer by using purified terephthalic acid (PTA) residue. According to the method, the mixed benzoate plasticizer is prepared by taking the PTA solid residue as a raw material; the impurities such as a catalyst in the PTA residue are recycled, and the mixed benzoate plasticizer is prepared by enabling the PTA residue to have an esterification reaction with monohydric alcohol by using a one-pot method under the efficient catalysis of acidic ionic liquid. The ionic liquid used in the method can be recycled and has a good catalytic effect; the plasticizer is good in plasticizing performance, and can realize the efficient recycling of the PTA residue so as to change waste into valuable, thus having good economic benefit and social benefit.

Owner:青州市瑞鑫再生资源科技有限公司

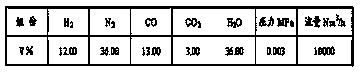

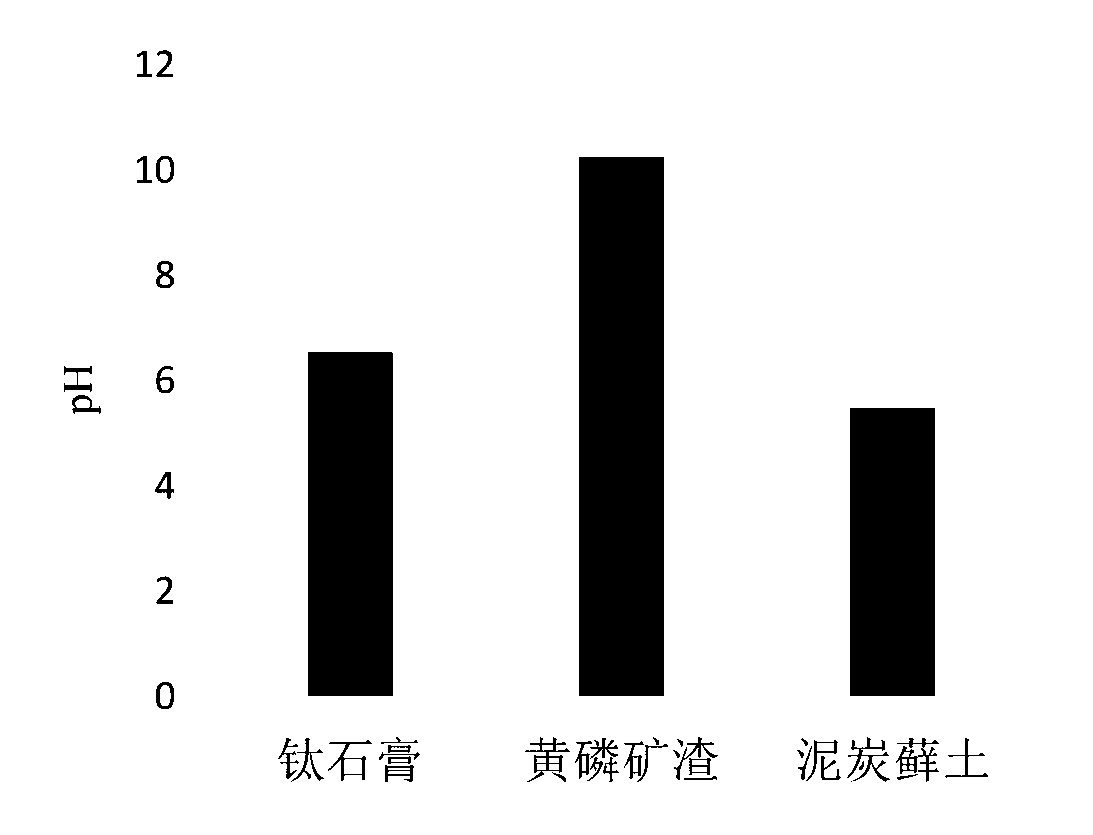

Soil heavy metal pollution conditioner and preparation method thereof

InactiveCN109942349ASimple preparation processEasy to operateBio-organic fraction processingOrganic fertiliser preparationSlagPeat

The invention discloses a soil heavy metal pollution conditioner and a preparation method thereof. The soil heavy metal pollution conditioner is prepared from a component A mineral including yellow phosphorus slag, peat moss soil, titanium gypsum and the like, a component B mixture including dry distillers' grains, animal waste, crop straw, bagasse, bran, mushroom culture medium materials and thelike, and a C component active fermenting material including yogurt, distillers' grains and the like. According to the conditioner, mainly industrial and agricultural by-products are adopted, the conditioner is prepared through a simple fermentation process, heavy metals in soil can be effectively fixed, the content of organic matter and nutrient elements in the soil can be increased, the conditioner contains a large number of microorganisms, and the organic matter in the soil can be decomposed into ingredients easier for plants to absorb. The conditioner is low in raw material cost, the riskof secondary pollution is avoided, the passivation rate of the heavy metals is high, the fertility of the soil can be improved, and and the comprehensive effect of soil conditioning is good.

Owner:CHINA THREE GORGES UNIV +1

Preparation method of pyrolysis oil urea-formaldehyde resin organic covering mat

InactiveCN107599455AHigh value utilizationSolve processing problemsBio-organic fraction processingOrganic fertiliser preparationLandscapingPhenol

The invention relates to a preparation method of a pyrolysis oil urea-formaldehyde resin organic covering mat, and belongs to the technical field of landscaping. According to the preparation method, landscaping waste is taken as raw materials, landscaping waste pyrolyzate pyrolysis oil is used for preparing pyrolysis oil urea-formaldehyde resin, and the organic covering mat is prepared by gluing the pyrolysis oil urea-formaldehyde resin and the crushed landscaping waste, so that the shifting and loss problems of a traditional organic mat due to blowing and raining are effectively solved, and the life cycle and the environmental protection effect of the organic covering mat are ensured. Furthermore, the organic covering mat can serve as an effective slow release nitrogenous fertilizer, andthe promoting effect on plant growth is improved; phenols substances are added to the pyrolysis oil urea-formaldehyde resin due to the pyrolysis oil, so that the effect of inhibiting weed seeds from germinating and growing is improved; and the organic covering mat has better mildewproof and antibacterial effects, and the aging resistance of the organic covering mat is improved. The organic covering mat can improve the supply of soil nutrients and inhibit weeds, and is long in life cycle and obvious in economic benefit.

Owner:BEIJING FORESTRY UNIVERSITY

Method and device for comprehensive utilization of copper tailing sludge and tailing obtained after copper smelting beneficiation

ActiveCN106086433AAchieve the effect of turning waste into treasureLow costSilicaProcess efficiency improvementSludgeSulfide minerals

The invention provides a method for comprehensive utilization of copper tailing sludge and tailing obtained after copper smelting beneficiation. The method comprises the steps that valuable metal in the sludge or the tailing obtained after copper smelting beneficiation in a dissolved mode with nitric acid with oxidizability, sulfur in sulfide minerals such as copper sulphide is oxidized into sulfuric acid, and nitrate is generated by other metal and left in acid liquor; filtering is conducted, filtrate is treated independently, and thus relevant metal such as silver, gold, platinum, rhodium, nickel and molybdenum are separated out; and then filter residues are prepared into a high-added-value product, namely fumed silica, the content of SiO2 in the prepared product is higher than 99.9%, the specific surface area measured through a multi-point BET method is 350-500 m<2> / g, and the effect of recycling waste is achieved. Meanwhile, the invention provides a production device for the method. Parts of the production device are all common parts in a chemical plant, cost is low, and large-scale industrial production can be achieved.

Owner:HUANGGANG NORMAL UNIV +1

Wear-resisting cable for ship and manufacturing method thereof

InactiveCN105421119ALow priceProtect environmentMelt spinning methodsConjugated synthetic polymer artificial filamentsEnvironmental resistancePlasticizer

The invention provides a wear-resisting cable for a ship and a manufacturing method thereof, and relates to the field of ship equipment manufacturing. Plastic shells of waste motorcycles, waste planes and waste household appliances, and waste tires of automobiles and motorcycles are used as main raw materials, and mixed with other auxiliary material ingredients. The wear-resisting cable is prepared from 80-85% of PP, 10-15% of PE, 1-5% of an oily material, 1-3% of plasticizer and 0.1-1% of an auxiliary. By means of the unique process, the high-strength and wear-resistant ship cable is manufactured, the service life is 2-3 times that of a common ship cable, as the waste plastic and rubber products are adopted as the raw materials of the cable mostly, the raw materials are low in price and easy to obtain, the price of finished products is low, the wear-resisting cable saves energy and is environmentally friendly, waste and rubbish are recycled, the policy of environmental protection of the nation is met, economic benefits are increased, national environment is protected, and the effect of turning waste into wealth is achieved.

Owner:ANHUI TENGYUE ALUMINUM PLASTIC

Method for preparing magnetic 4A molecular sieve from coal gangue

InactiveCN106745041ALow costAchieve the effect of turning waste into treasureOther chemical processesAluminium silicatesMolecular sieveUltrasonic vibration

The invention discloses a method for preparing a magnetic 4A molecular sieve from coal gangue. The method comprises steps as follows: 1, grinding coal gangue and then roasting and activating the coal gangue at the high temperature with ammonium chloride; 2, preparing magnetic Fe3O4 from FeCl2.4H2O, FeCl3.6H2O and NH3.H2O; 3, preparing a ferroferric oxide dispersion liquid; 4, allowing the activated coal gangue to react with the ferroferric oxide dispersion liquid to prepare the magnetic 4A molecular sieve. The coal gangue is adopted as a raw material, the magnetic 4A molecular sieve is prepared under the action of ultrasonic vibration heating, the prepared magnetic 4A molecular sieve has the advantages that the specific surface area is large, the adsorption performance is high, solid-liquid separation of a product can be realized easily through an external magnetic field and the like, besides, the problem of high synthesis cost of the molecular sieve is solved, a new way is provided for recycling, refinement and efficient utilization of the coal gangue, waste is turned into wealth, and the requirements of environmental protection and low carbon are met.

Owner:XIAN UNIV OF SCI & TECH

Process and device for preparing gas-phase white carbon black by taking quartziferous fluorite tailings as raw materials

ActiveCN105967190AAchieve the effect of turning waste into treasureLow costSilicaCalcium/strontium/barium fluoridesGas phaseRaw material

The invention provides a process for preparing gas-phase white carbon black at a low temperature by taking quartziferous fluorite tailings as raw materials. In the process, wastes including the quartziferous fluorite tailings and the like are used as the raw materials and are reacted with fluorine-containing acid liquid, hydrochloric acid and nitric acid to prepare the product gas-phase white carbon black with a high additional value and high-valence metal and fluorite powder are recycled; in the prepared product, the content of SiO2 is more than 99.9 percent and the specific surface area measured by a multi-point BET method is: 350m<2> / g to 500m<2> / g, so that the effect of changing wastes into valuable things is realized; after acidic gas generated in the preparation process is absorbed by a negative-pressure water absorption tank, corresponding acid liquid can be prepared; when the acid liquid is concentrated to a certain concentration, the acid liquid can be circularly utilized. Meanwhile, the invention further provides a production device used for the process; all parts of the production device are common devices in chemical plants and the cost is low, so that large-scale industrial production can be realized.

Owner:HUANGGANG NORMAL UNIV +1

Utilization method of marigold flower wastewater

InactiveCN110386839ARealize resource utilizationSolve pollutionCalcareous fertilisersMagnesium fertilisersDry seasonDecomposition

The invention discloses a utilization method of marigold flower wastewater. The utilization method of the marigold flower wastewater includes the steps that (1), the marigold wastewater is taken, andKOH is added to the marigold wastewater; (2), a mixed solution of the marigold wastewater and the KOH is put into a fermentation tank, and a catalyst is put into the fermentation tank; (3) organic carbon liquid is added and standing is carried out; (4), one or more of glucose, urea, KH2PO4, MgSO4.7H2O, CaCl2, NaHCO3 of 42.35mg / l, peat or lignite or fly ash or straw ash, urea, potassium dihydrogensulfate, decomposition bacteria and ammonia bicarbonate; and (5), a supernatant in a sedimentation tank is taken out, and organic calcium fertilizer and rooting water are added into the supernatant. According to the utilization method of the marigold flower wastewater, the utilization of waste resources is realized, and the effect of turning waste into treasure is achieved, that is, the problem ofenvironmental pollution caused by the wastewater is solved, and the trouble of wastewater treatment in enterprises is reduced; and in a dry land crop planting area, it is still in a dry season when sowing or planting are carried out, and lack of water is common, and by using the organic liquid fertilizer as the rooting water, the organic liquid fertilizer can be used as base fertilizer, and the problem of water is solved.

Owner:贵州御凤天泓生物科技发展有限公司

Preparation method and application of magnetic X type molecular sieve

InactiveCN107352554ASolve the problem of high cost synthesisReduce manufacturing costOther chemical processesWater contaminantsSodium hydroxideCoal gangue

The invention discloses a preparation method and an application of a magnetic X type molecular sieve. The preparation method comprises steps as follows: after grinding, coal gangue is subjected to high-temperature roasting and activating with sodium carbonate; the coal gangue is oxidized at the low temperature, hydrochloric acid is added, soaking is performed at the temperature of 90 DEG C, a mixture is filtered, oxalic acid is added to a filtrate, and the filtrate is standby; solids are washed and then dried, sodium hydroxide solids are added, a mixture is ground to be uniformly mixed, and then the mixture is subjected to low-temperature alkali fusion; deionized water and citric acid are added, the mixture is aged at the temperature of 60 DEG C, the standby filtrate is added, a mixed solution is subjected to ultrasonic crystallization, and iron-doped molecular sieve is synthesized; an iron-doped molecular sieve sample is put in a tubular furnace and subjected to high-temperature reduction, and the magnetic X type molecular sieve is prepared. The prepared magnetic X type molecular sieve has the advantages that specific surface area is large, adsorptive property is high, solid-liquid separation of a product can be realized easily through an external applied magnetic field and the like, the problem of high synthesis cost of the molecular sieve is solved, meanwhile, a new way is provided for recycling, refining and efficient utilization of the coal gangue, waste is changed into wealth, and the environment-friendly and low-carbon requirements are met.

Owner:XIAN UNIV OF SCI & TECH

Method for preparing matrix of raw winter vegetables with municipal sludge

ActiveCN103833426AReduce heating and fermentation timePromote absorption and utilizationClimate change adaptationSewage/sludge fertilisersLeavening agentEnvironmental chemistry

The invention belongs to the field of biological technologies, and particularly relates to a method for preparing a matrix of raw winter vegetables with municipal sludge. According to the method, acetic acid and rotten oranges are added into the municipal sludge, and then, the municipal sludge is treated by ultrasonic so as to effectively remove heavy metals in the municipal sludge, thus guaranteeing the vegetables to be eaten safely. The method uses rotten oranges, thus playing the effect of turning waste into wealth, removing the heavy metals and solving the problem of environment pollution caused by the rotten oranges. A leavening agent with soybean extractive is used for fermenting, thus greatly lowering the fermentation time and temperature rising time of wheat straw and municipal sludge, improving absorption and utilization of the leavening agent by the fermentation matrix, enriching the nutritional ingredients after fermentation, and improving the work efficiency. The soybean extractive is firstly treated by ultrasonic and then is mixed with a complex liquid, so that the ingredients in the complex liquid and the soybean extractive are uniformly mixed, and the absorption and utilization ratio of the leavening agent by the municipal sludge and straw is improved.

Owner:HENAN UNIV OF SCI & TECH

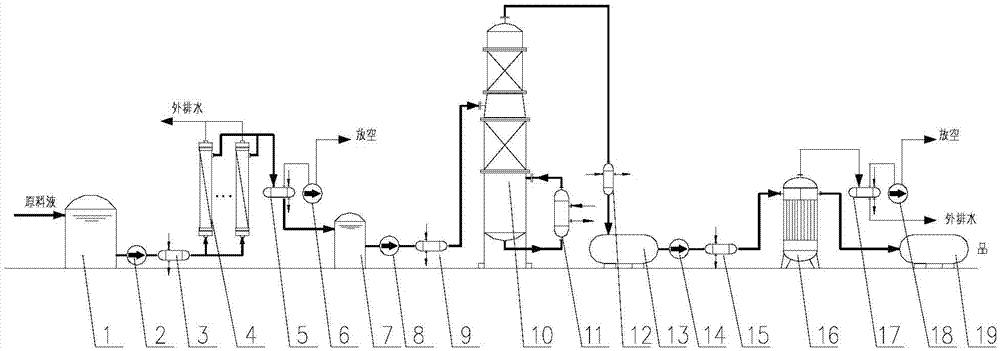

Device and method for recycling low-concentration organic solvent

ActiveCN103613480AReduce operating energy consumptionImprove economyOrganic compounds purification/separation/stabilisationChemical industryDistillationHigh energy

The invention discloses a device and method for recycling a low-concentration organic solvent, belonging to the technical field of environmental protection and solving the technical problems of high energy consumption, low purity of the recycled organic solvent and the like of the prior art. The device comprises a separation system, a concentration system and a dehydration system, wherein the separation system comprises a raw material liquid tank, a first delivery pump, a first heater, a pervaporation membrane component, a first condenser and a first vacuum pump; the concentration system comprises a separation liquid tank, a second delivery pump, a second heater, a distillation tower and a second condenser; the dehydration system comprises a concentration liquid tank, a third delivery pump, a third heater, a vapor permeation membrane component, a third condenser, a second vacuum pump and a product tank. In the device and method disclosed by the invention, the energy consumption for recycling the low-concentration organic solvent is low, and a high-purity organic solvent can be recycled, thereby saving the energy, protecting the environment and realizing an effect on turning waste into wealth.

Owner:上一环保科技(杭州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com