Process for co-producing and synthetic natural gas and food-grade carbon dioxide by using calcium carbide furnace gas

A technology for synthesizing natural gas and calcium carbide furnace gas, which is applied in the petroleum industry, inorganic chemistry, gas fuel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

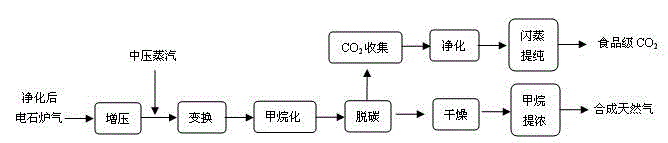

Method used

Image

Examples

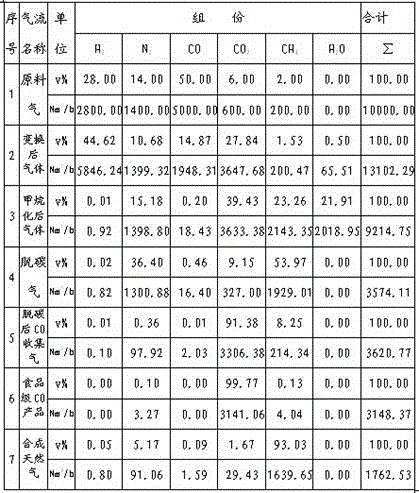

Embodiment 1

[0069] Table 1 Composition of calcium carbide furnace gas

[0070] Component H 2 N 2 CO CO 2 CH 4 pressure MPa Flow Nm 3 / h V% 28.00 14.00 50.00 6.00 2.00 0.003 10000

[0071] Will 10000Nm 3 / h The purified calcium carbide furnace gas is compressed to 3.0MPa by the compressor, mixed with saturated steam with a flow rate of 2500kg / h, a temperature of 234°C and a pressure of 3.0MPa in the mixer, and then enters the shift reaction preheater to be heated to 200°C. Then it enters the shift reactor, under the action of the catalyst, 61% of the CO in the gas undergoes a shift reaction, and the shifted hot gas enters the shift preheater to preheat the raw material mixture, and enters the methanation reaction system after being cooled to 280°C , the methanation reaction occurs under the action of the catalyst. The methanation reaction system consists of two methanation reactors. After each stage of methanation reaction, a waste heat boile...

Embodiment 2

[0084] Table 3 Composition of raw calcium carbide gas

[0085] Component H 2 N 2 CO CO 2 CH 4 pressure MPa Flow Nm 3 / h V% 17.00 6.00 75.00 1.50 0.50 0.003 20000

[0086] 20000Nm 3 / h The purified calcium carbide furnace gas is compressed to 5.0MPa by the compressor, mixed with saturated steam with a flow rate of 8600kg / h, a temperature of 265°C and a pressure of 5.0MPa in the pipeline, and then enters the shift reaction preheater to be heated to 250°C. Then it enters the transformation reaction system. The transformation reaction system is composed of two reactors. After each reaction, a waste heat boiler is set to recover heat and produce steam by-product. Under the action of the catalyst, 70% of the CO in the gas undergoes a shift reaction, and the shifted hot gas enters the shift preheater to preheat the raw material gas, and enters the methanation reaction system after heat exchange to 300°C, where methane is generated under th...

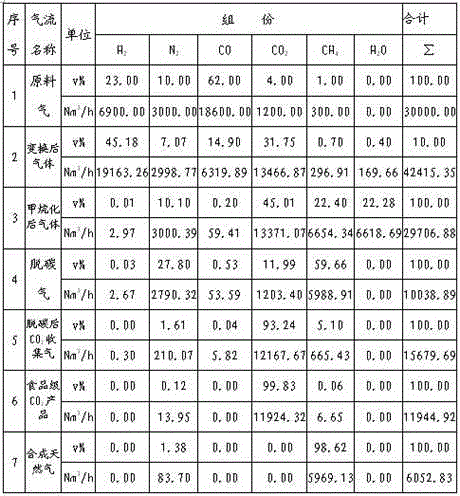

Embodiment 3

[0100] Table 5 Composition of raw calcium carbide gas

[0101] Component H 2 N 2 CO CO 2 CH 4 pressure MPa Flow Nm 3 / h V% 23.00 10.00 62.00 4.00 1.00 0.003 30000

[0102] 30000Nm 3 / h The purified calcium carbide furnace gas is compressed to 4.0MPa by the compressor, mixed with saturated steam with a flow rate of 10000kg / h, a temperature of 250°C and a pressure of 4.0MPa in a mixer, and then enters the shift reaction preheater to be heated to 220°C , and then enter the shift reaction system, which consists of three reactors. After each reaction, a waste heat boiler is set to recover heat and produce steam by-product. Under the action of the catalyst, 66% of the CO in the gas undergoes a shift reaction, and the shifted hot gas enters the shift preheater to preheat the raw material mixture, and after cooling to 290°C, it enters the methanation reaction system, where methane is generated under the action of the catalyst reaction. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com