Patents

Literature

318 results about "Co2 removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

CO2 Removal. While CO2 is commonly found in natural gas throughout many locations, CO2 removal from gas is necessary in order to deliver the gas to the pipeline. When CO2 is mixed with water, the result is a corrosive carbonic acid. CO2 is also known to reduce the BTU value in gas, ultimately making it unmarketable.

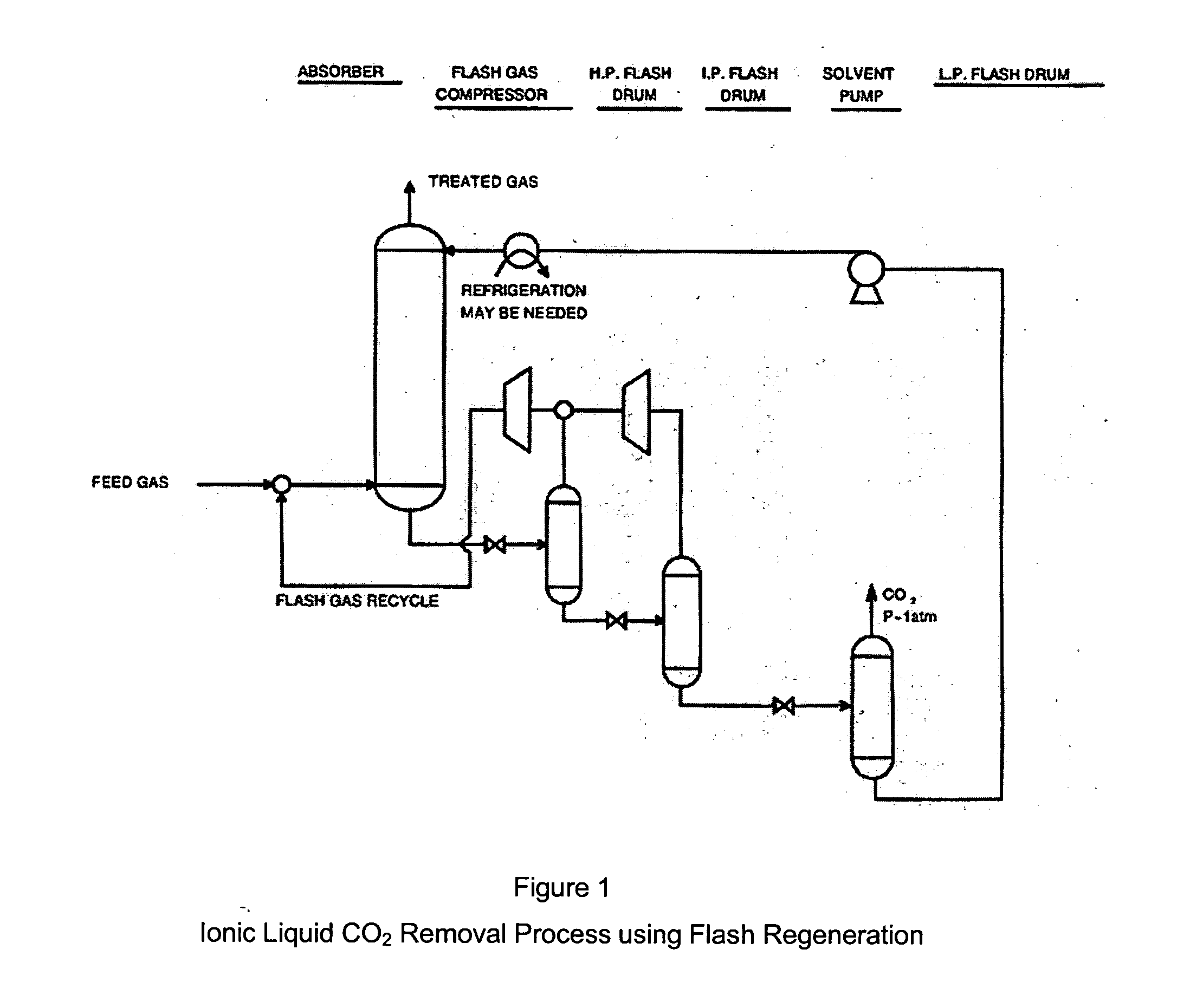

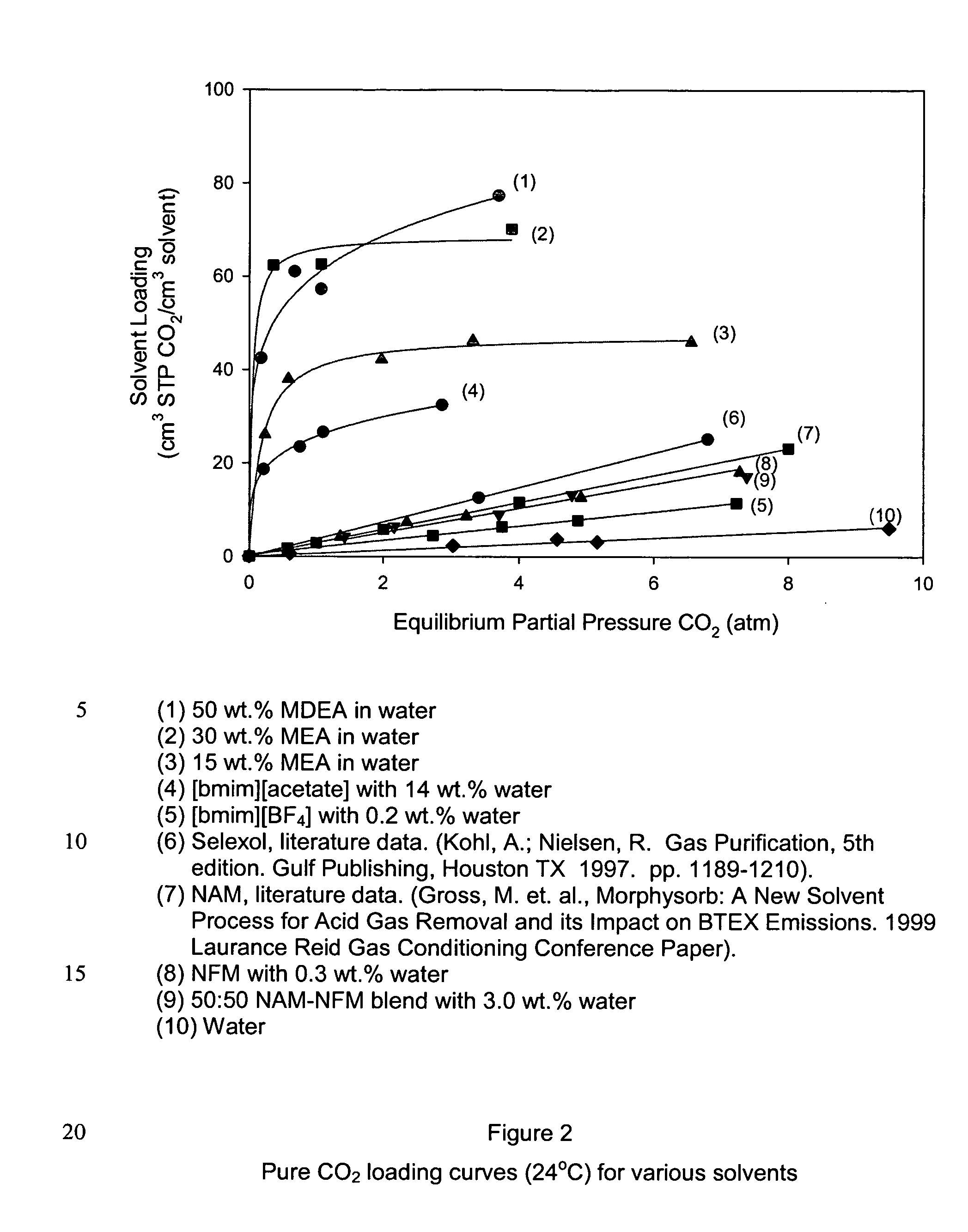

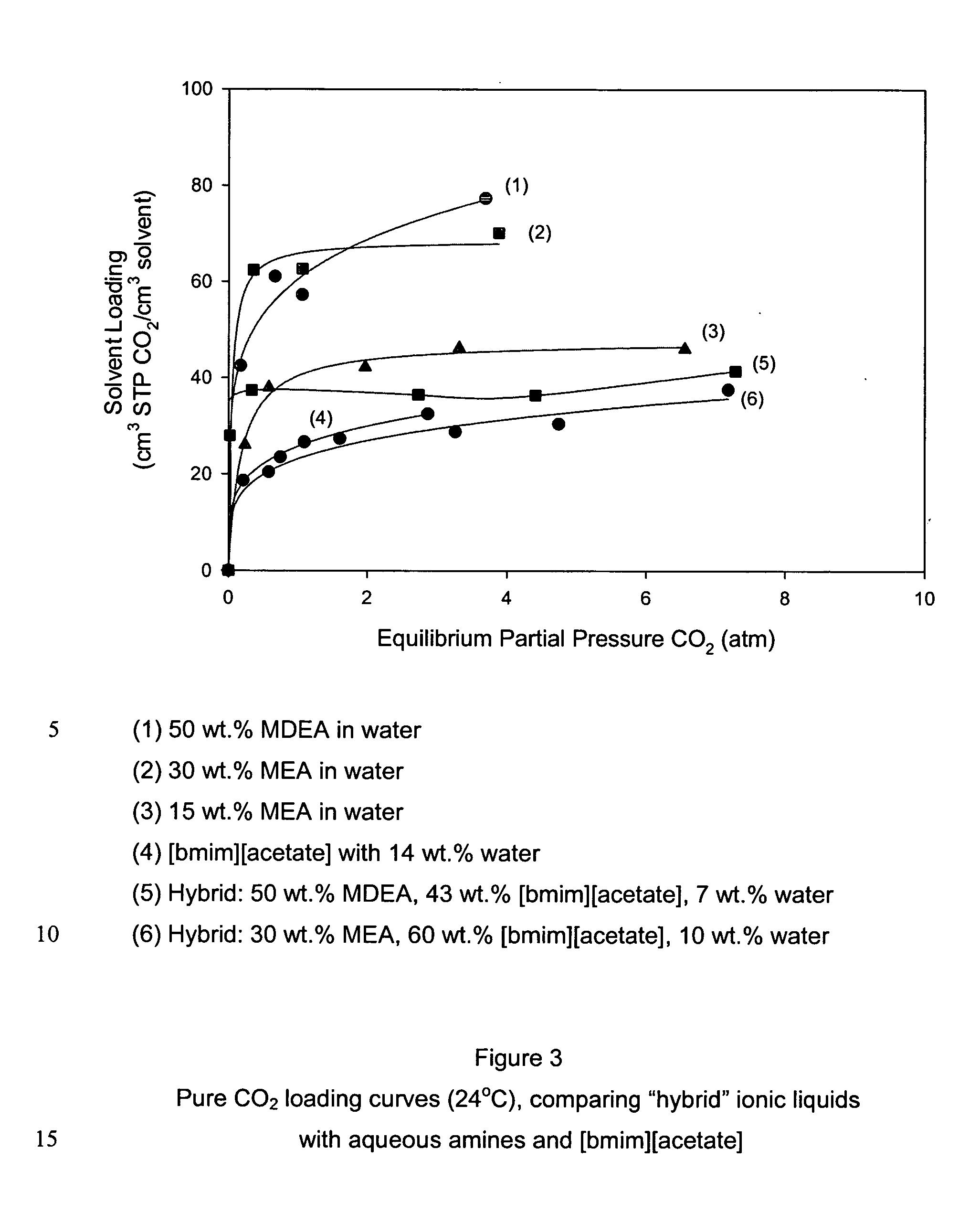

CO2 removal from gas using ionic liquid absorbents

InactiveUS20050129598A1High CO capacityLow hydrocarbon solubilityHydrogen sulfidesDispersed particle separationCo2 removalSorbent

A process and method for separating CO2 from a gaseous stream such as natural gas. An ionic liquid comprising an anion having a carboxylate function is used as an adsorbent to selectively complex the CO2 yielding a gaseous stream with a greatly reduced CO2 content. The ionic liquid can then be readily be regenerated and recycled.

Owner:CHEVROU USA INC

Separation of carbon dioxide (CO2) from gas mixtures

ActiveUS7618606B2Good repeatabilityMaterial nanotechnologyCombustible gas catalytic treatmentCo2 removalSorbent

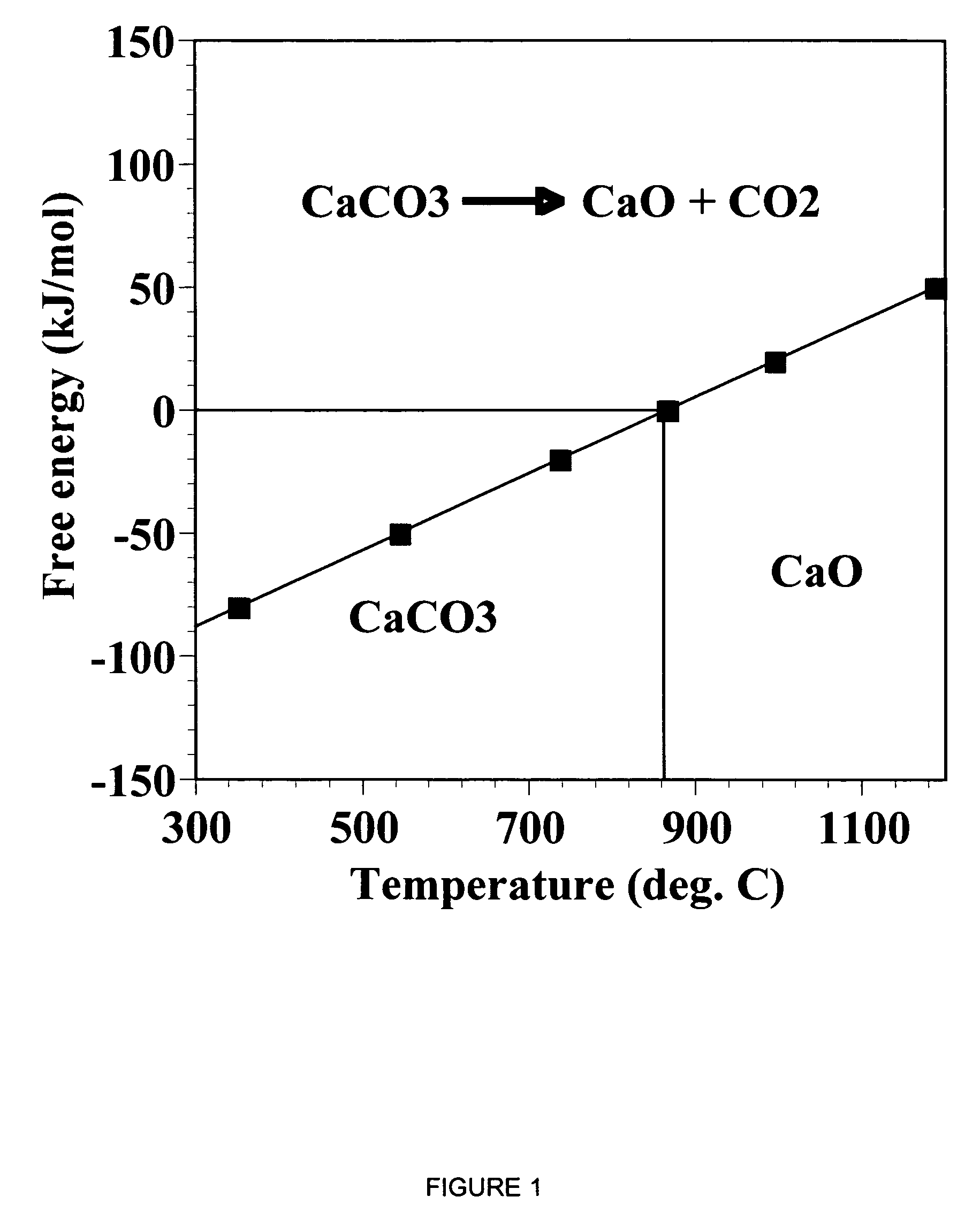

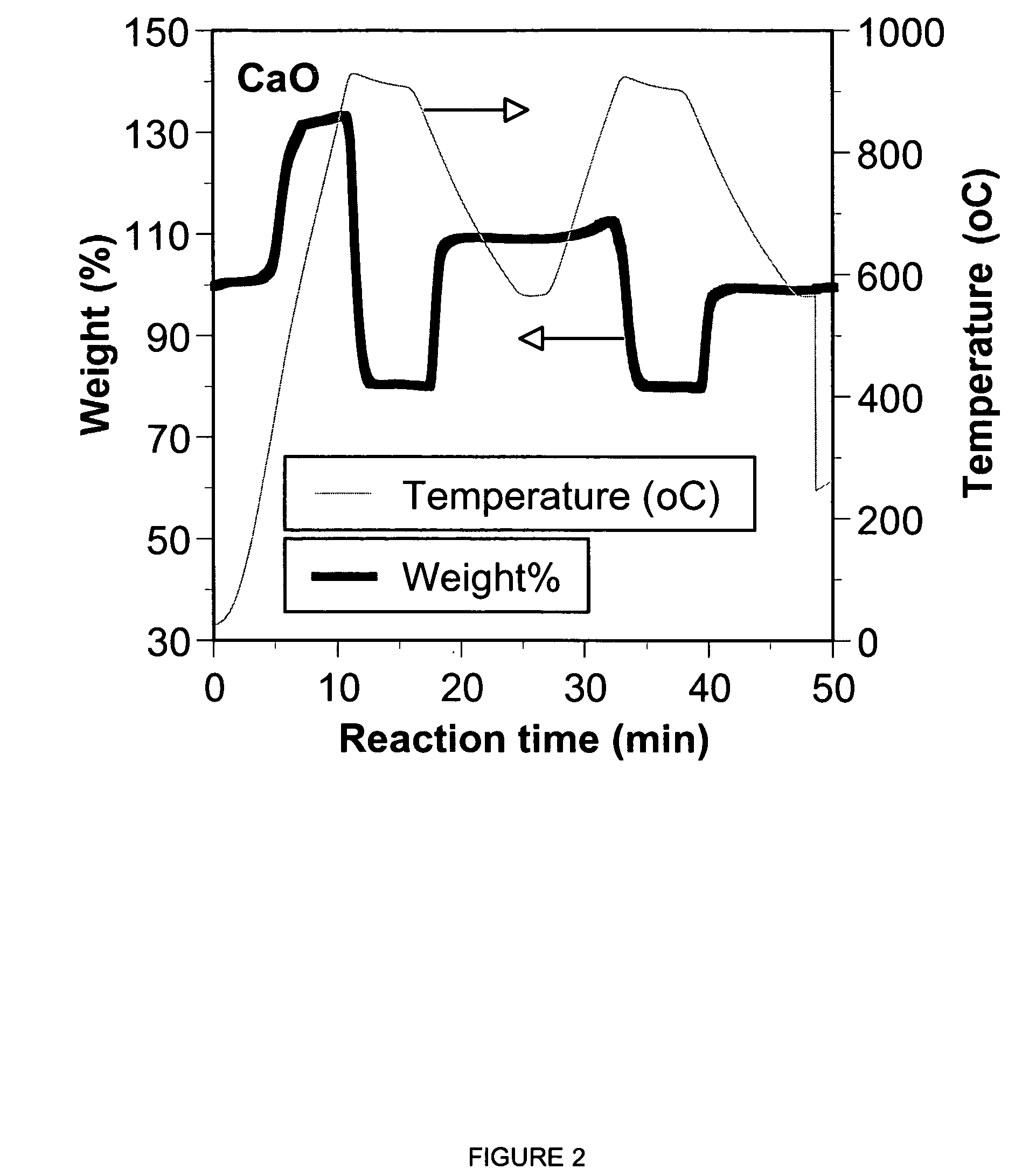

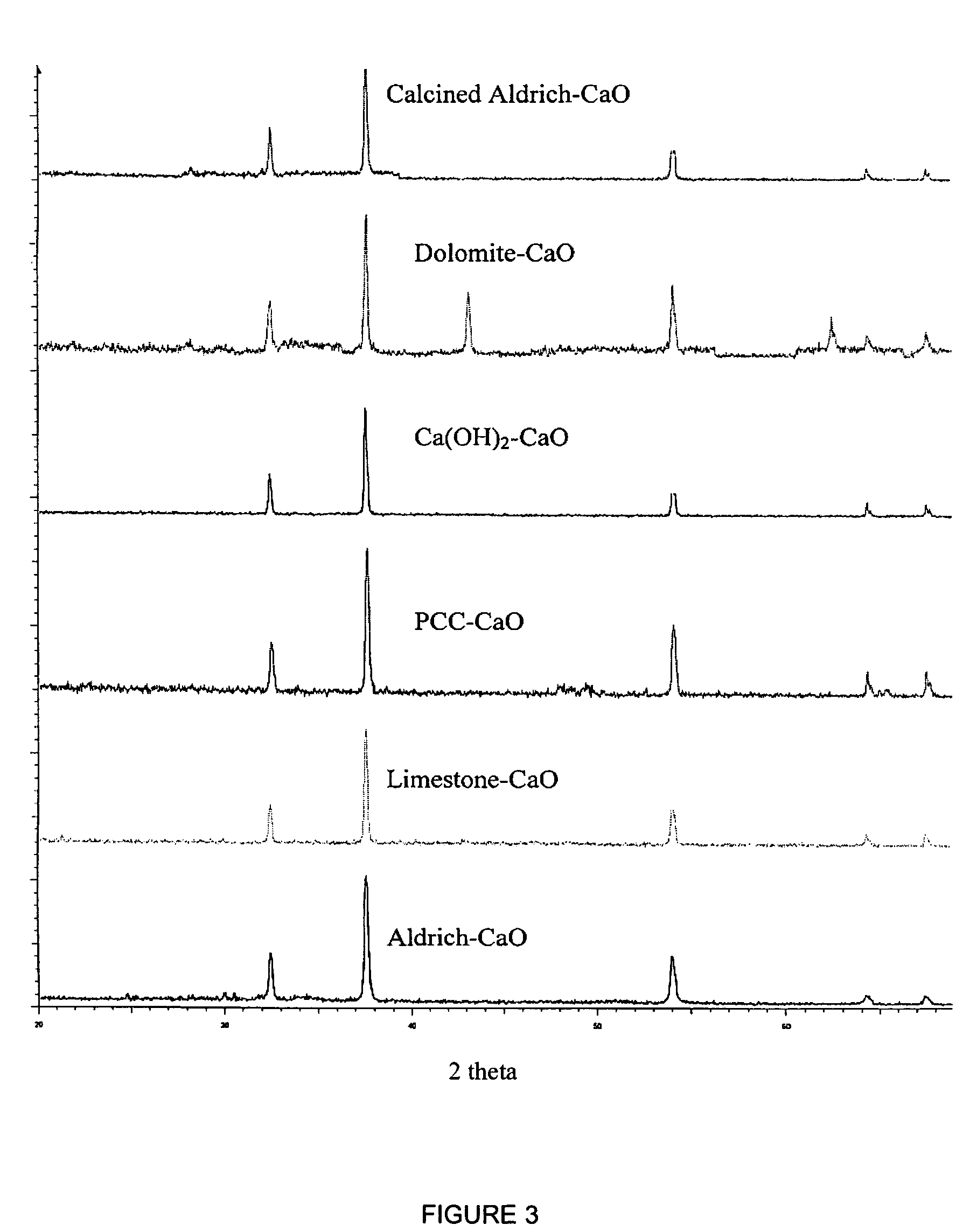

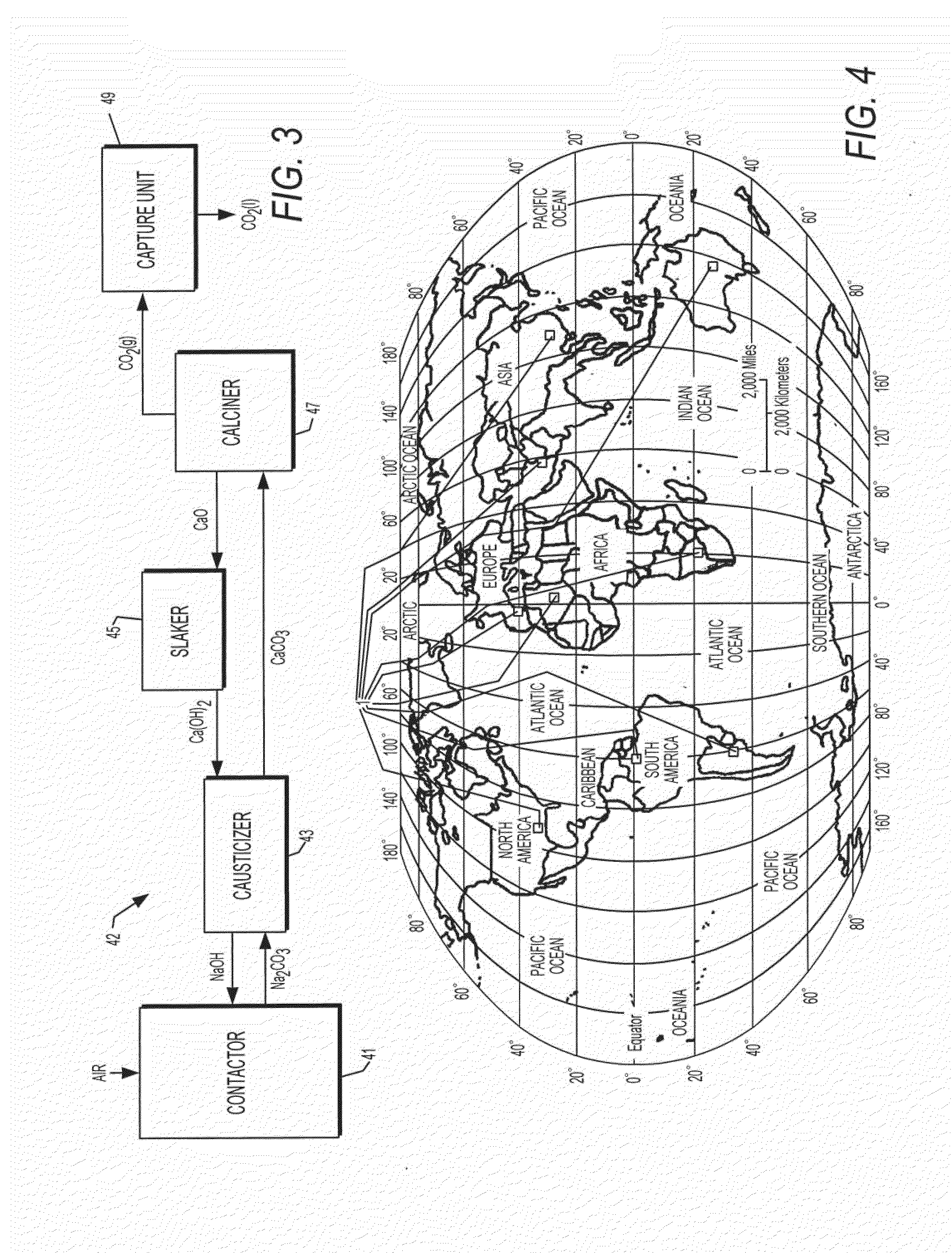

A reaction-based process has been developed for the selective removal of carbon dioxide from a multicomponent gas mixture. The proposed process effects the separation of CO2 from a mixture of gases by its reaction with metal oxides. The Calcium based Reaction Separation for CO2 process consists of contacting a CO2 laden gas with calcium oxide in a reactor such that CaO captures the CO2 by the formation of calcium carbonate. Once “spent”, CaCO3 is regenerated by its calcination leading to the formation of fresh CaO sorbent. The “regenerated” CaO is then recycled for the further capture of more CO2. This process also identifies the application of a mesoporous CaCO3 structure, that attains >90% conversion over multiple carbonation and calcination cycles. Lastly, thermal regeneration (calcination) under vacuum provided a better sorbent structure that maintained reproducible reactivity levels over multiple cycles.

Owner:THE OHIO STATES UNIV

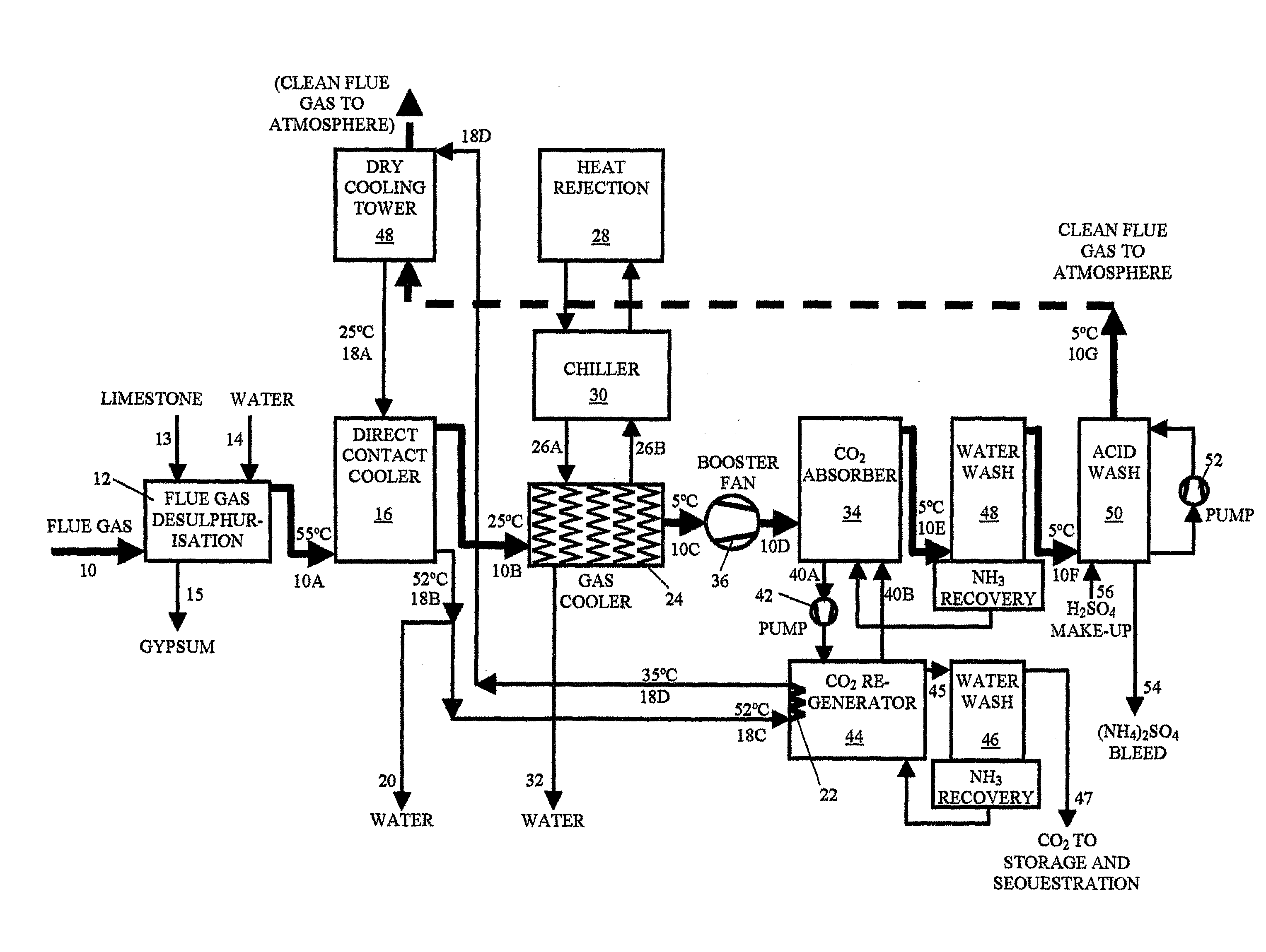

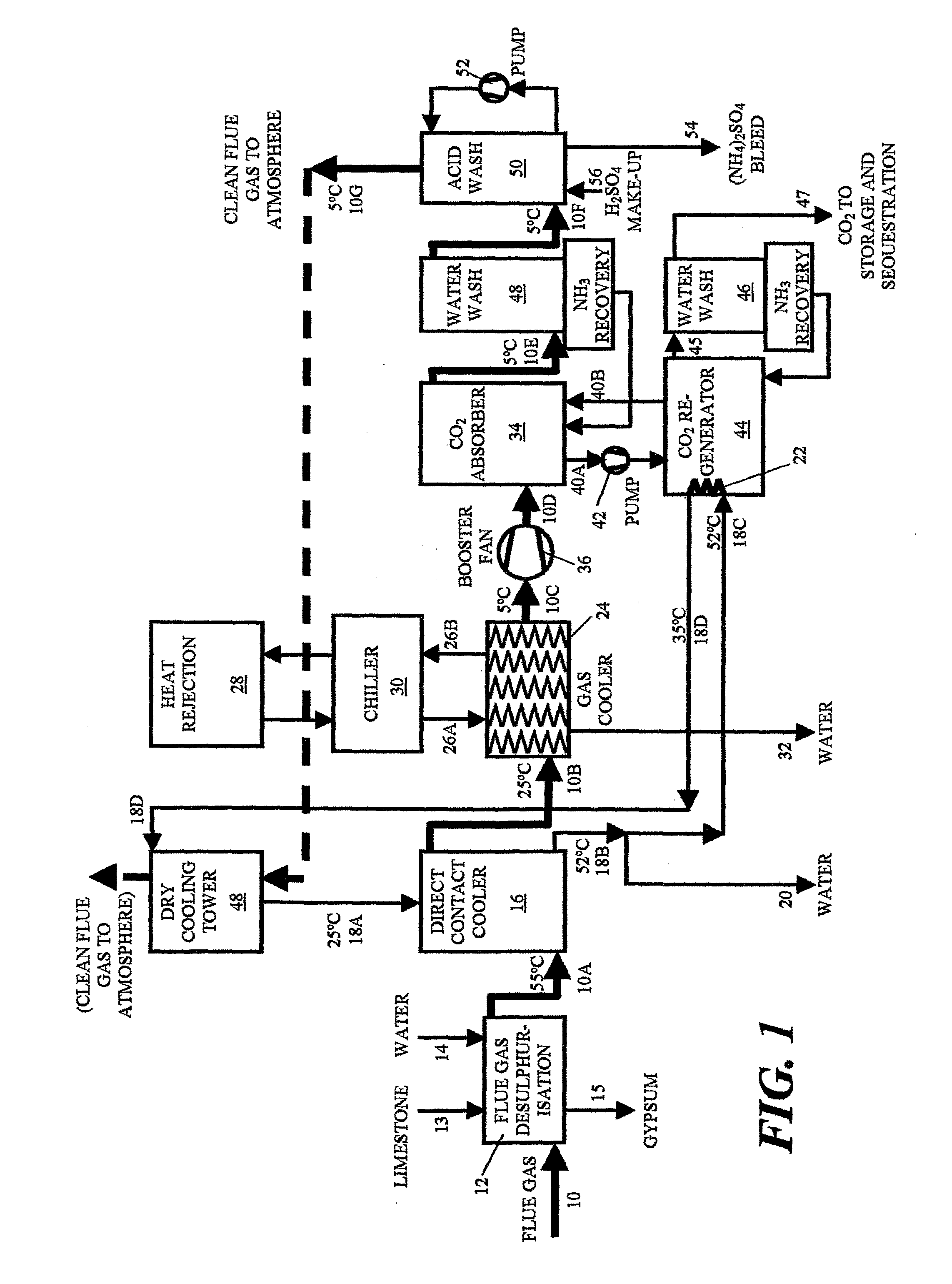

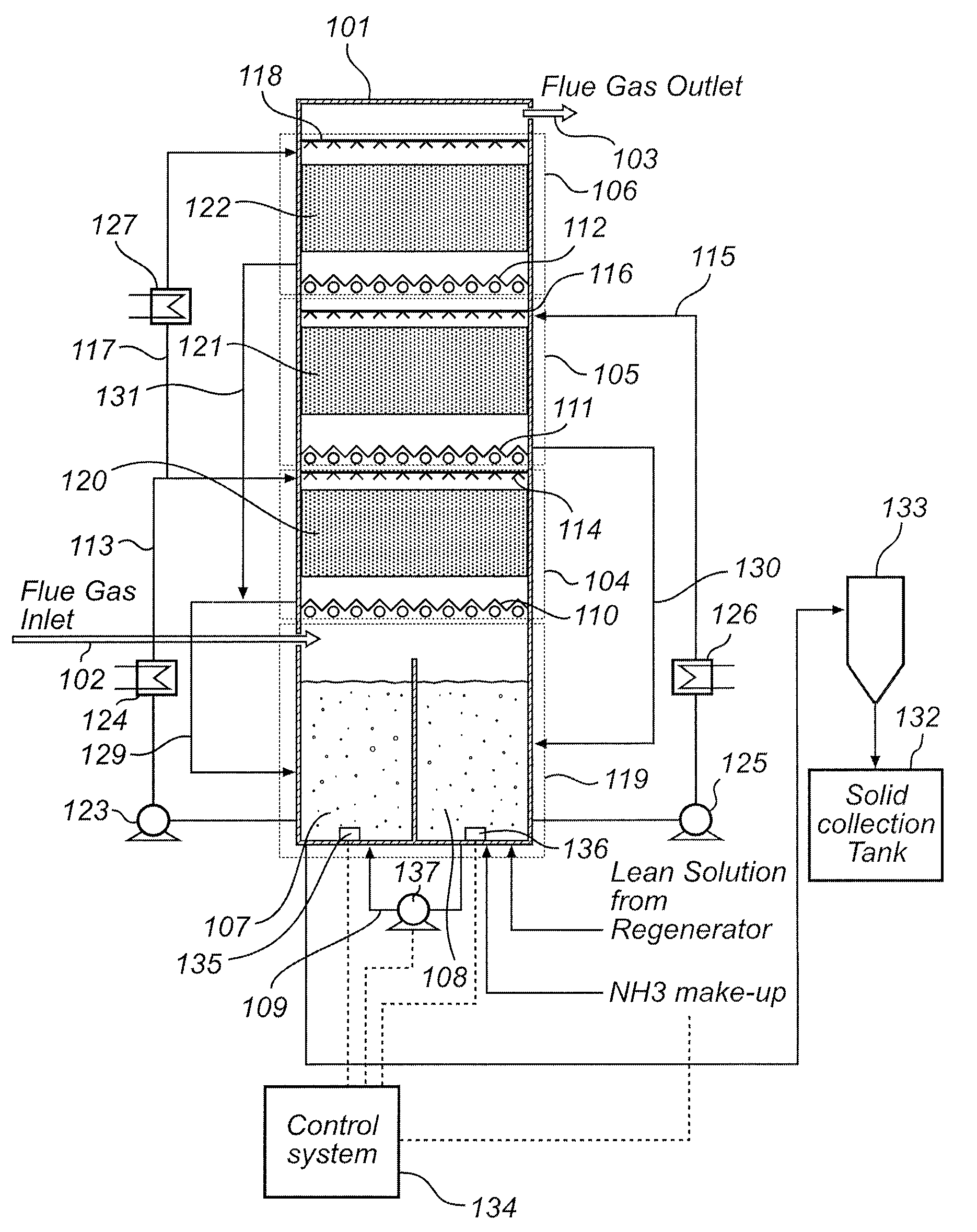

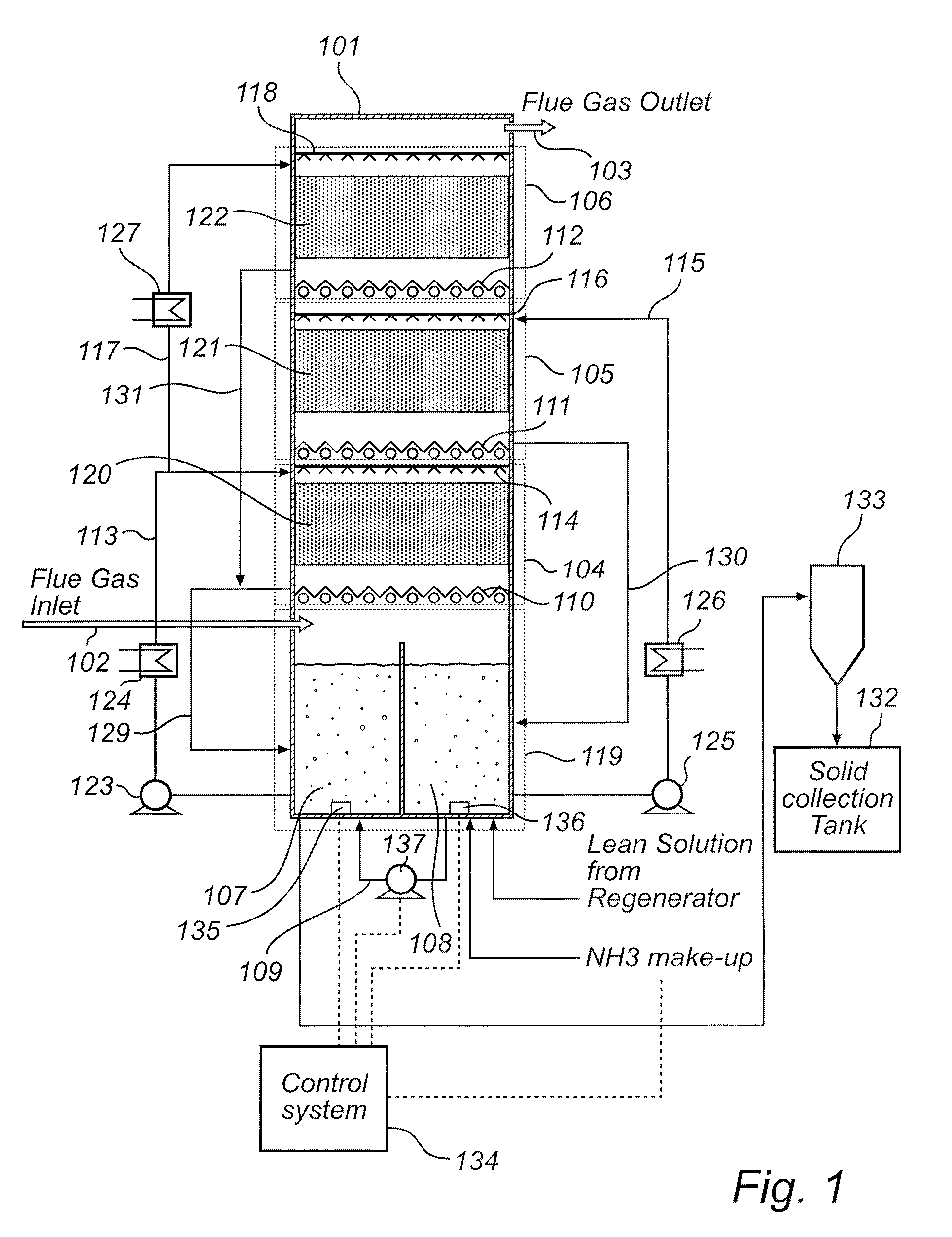

Ultra Cleaning of Combustion Gas Including the Removal of Co2

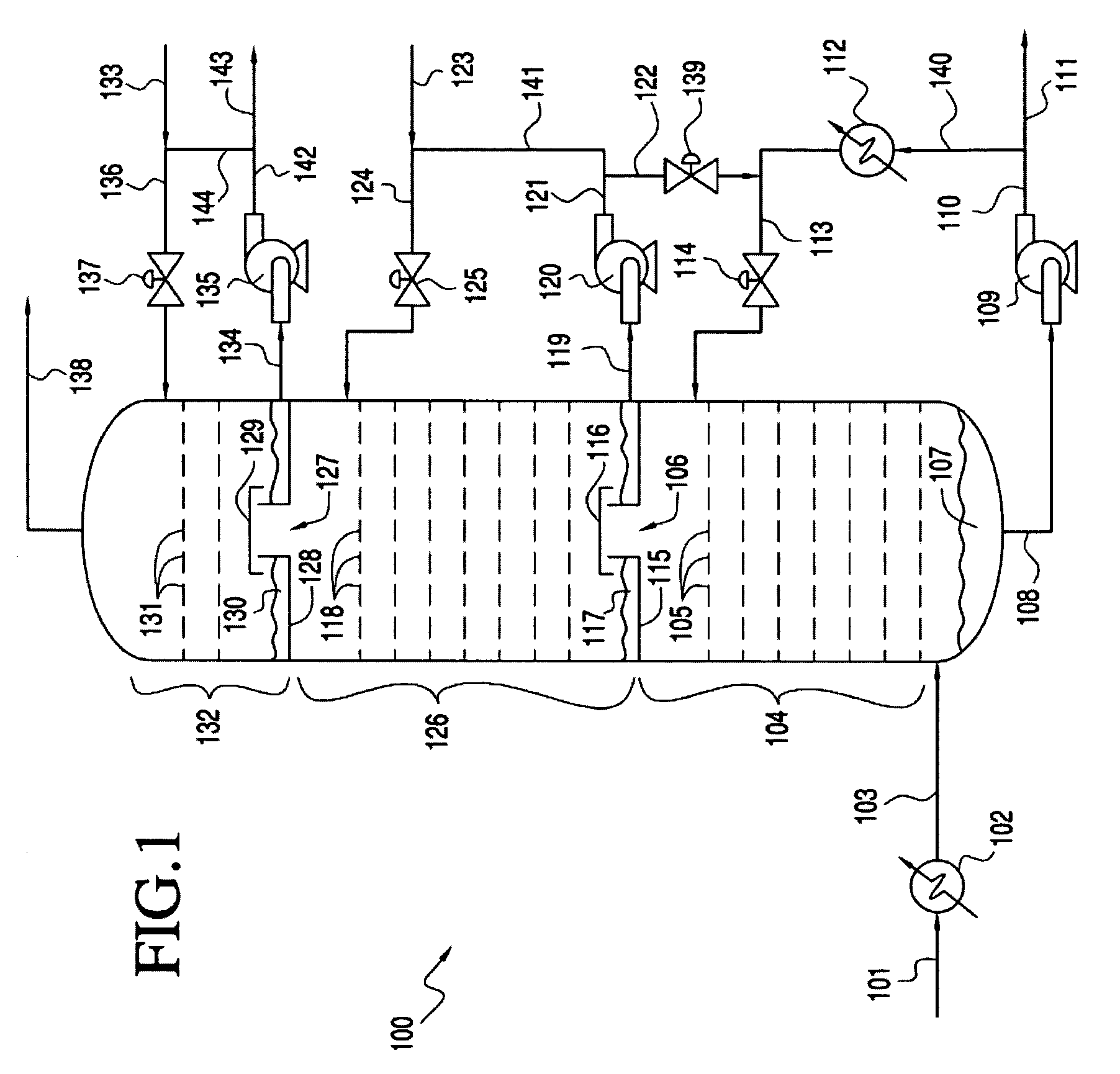

ActiveUS20080072762A1Reduce evaporationMinimize energy consumptionUsing liquid separation agentEmission preventionCo2 removalCombustion

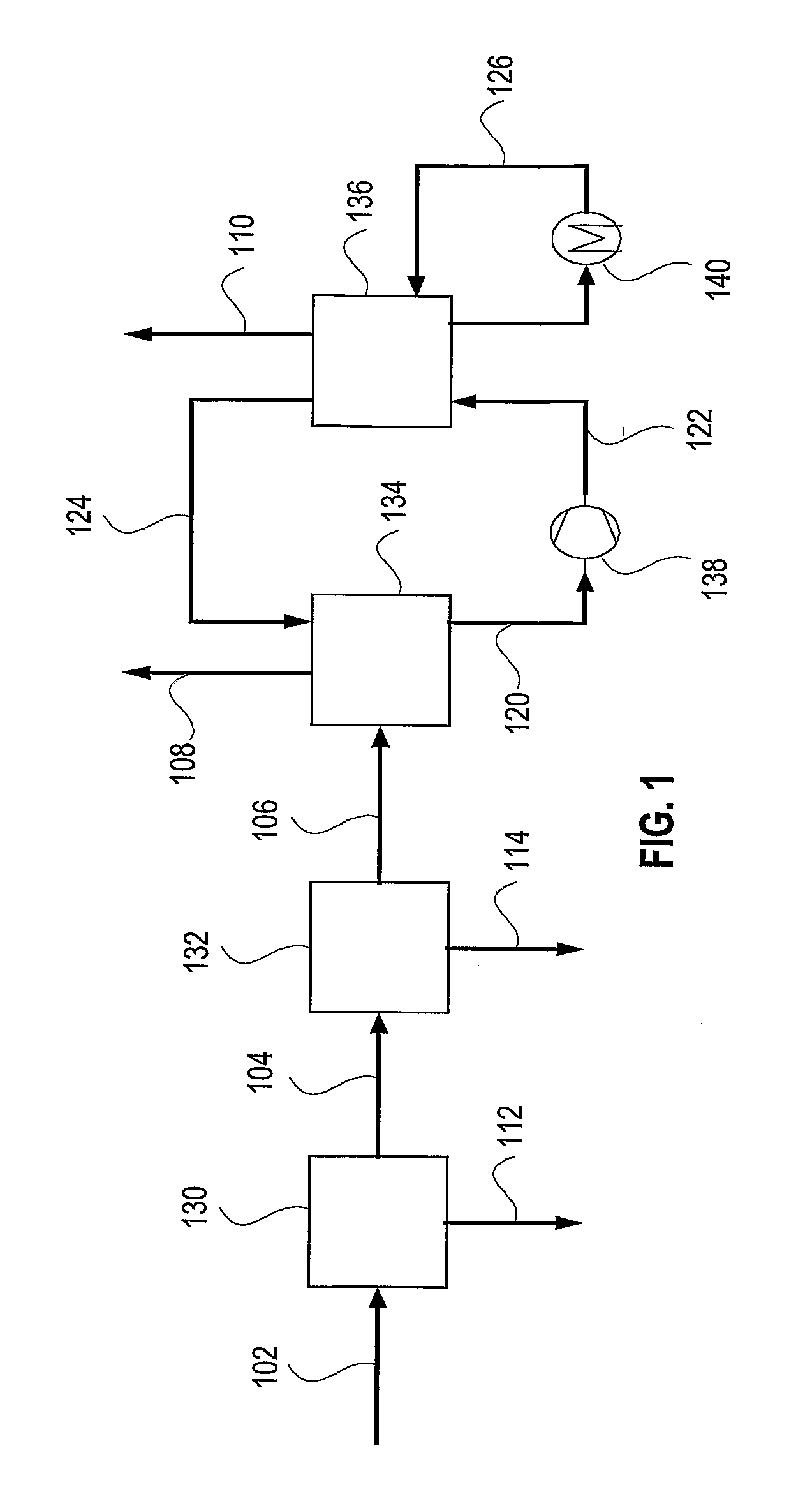

Ultra cleaning of combustion gas to near zero concentration of residual contaminants followed by the capture of CO2 is provided. The high removal efficiency of residual contaminants is accomplished by direct contact cooling and scrubbing of the gas with cold water. The temperature of the combustion gas is reduced to 0-20 degrees Celsius to achieve maximum condensation and gas cleaning effect. The CO2 is captured from the cooled and clean flue gas in a CO2 absorber (134) utilizing an ammoniated solution or slurry in the NH3—CO2H2O system. The absorber operates at 0-20 degrees Celsius. Regeneration is accomplished by elevating the pressure and temperature of the CO2-rich solution from the absorber. The CO2 vapor pressure is high and a pressurized CO2 stream, with low concentration of NH3 and water vapor is generated. The high pressure CO2 stream is cooled and washed to recover the ammonia and moisture from the gas.

Owner:GENERAL ELECTRIC TECH GMBH

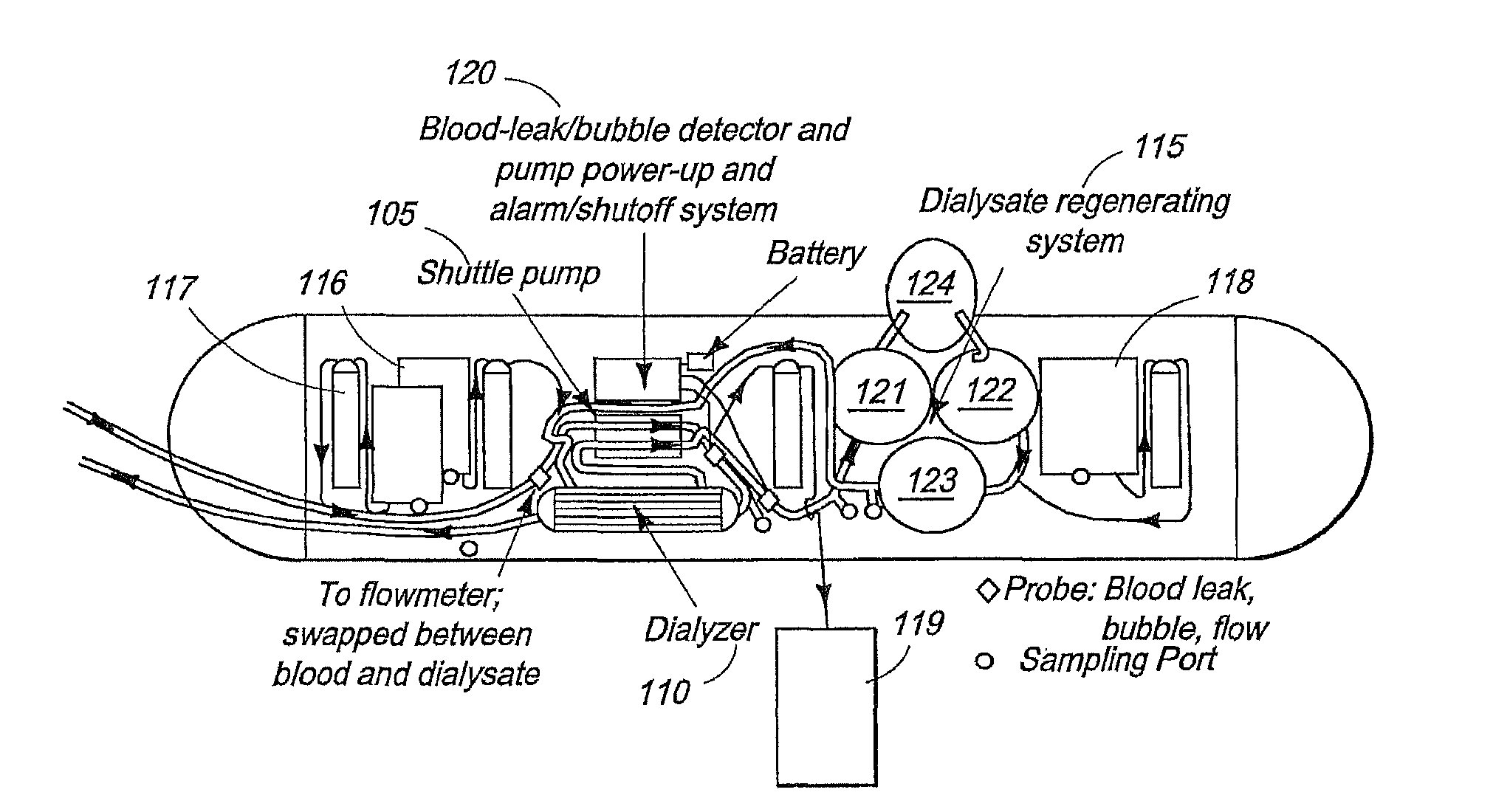

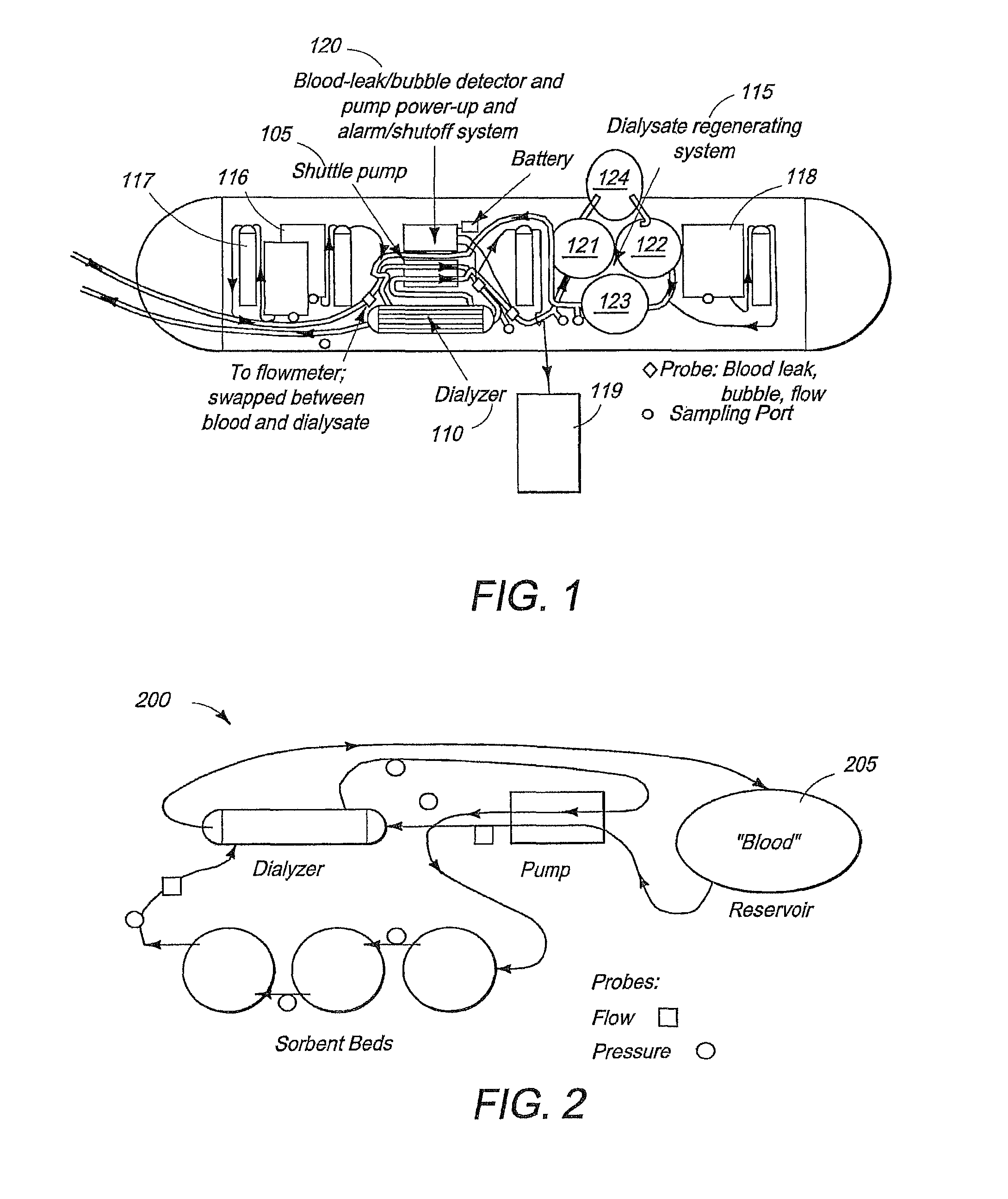

Carbon dioxide gas removal from a fluid circuit of a dialysis device

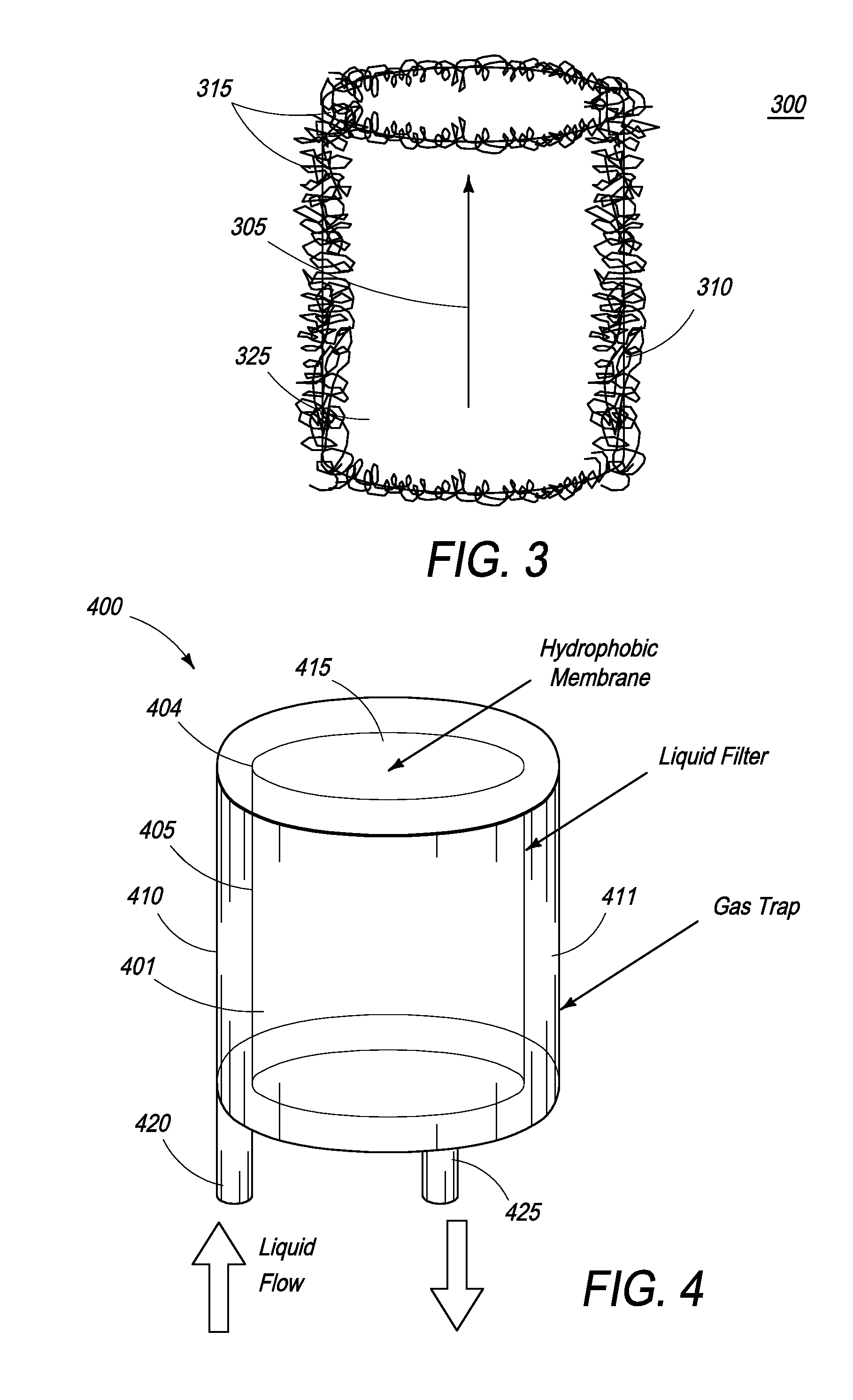

InactiveUS8034161B2Efficient removalSmall sizeSemi-permeable membranesSolvent extractionAtmospheric airProduct gas

The present invention is directed to degassing devices for dialysate circuits. One embodiment has a first housing and a second housing positioned within the first housing in an annular relationship. A second embodiment comprises a dialysate regeneration system with urease, a dialyzer, and a housing with an external wall, where the external wall is exposed to atmosphere and comprises a material that passes gas but does not pass liquid and where the housing is positioned between the urease and dialyzer.

Owner:FRESENIUS MEDICAL CARE HLDG INC

Carbon Dioxide Removal Process

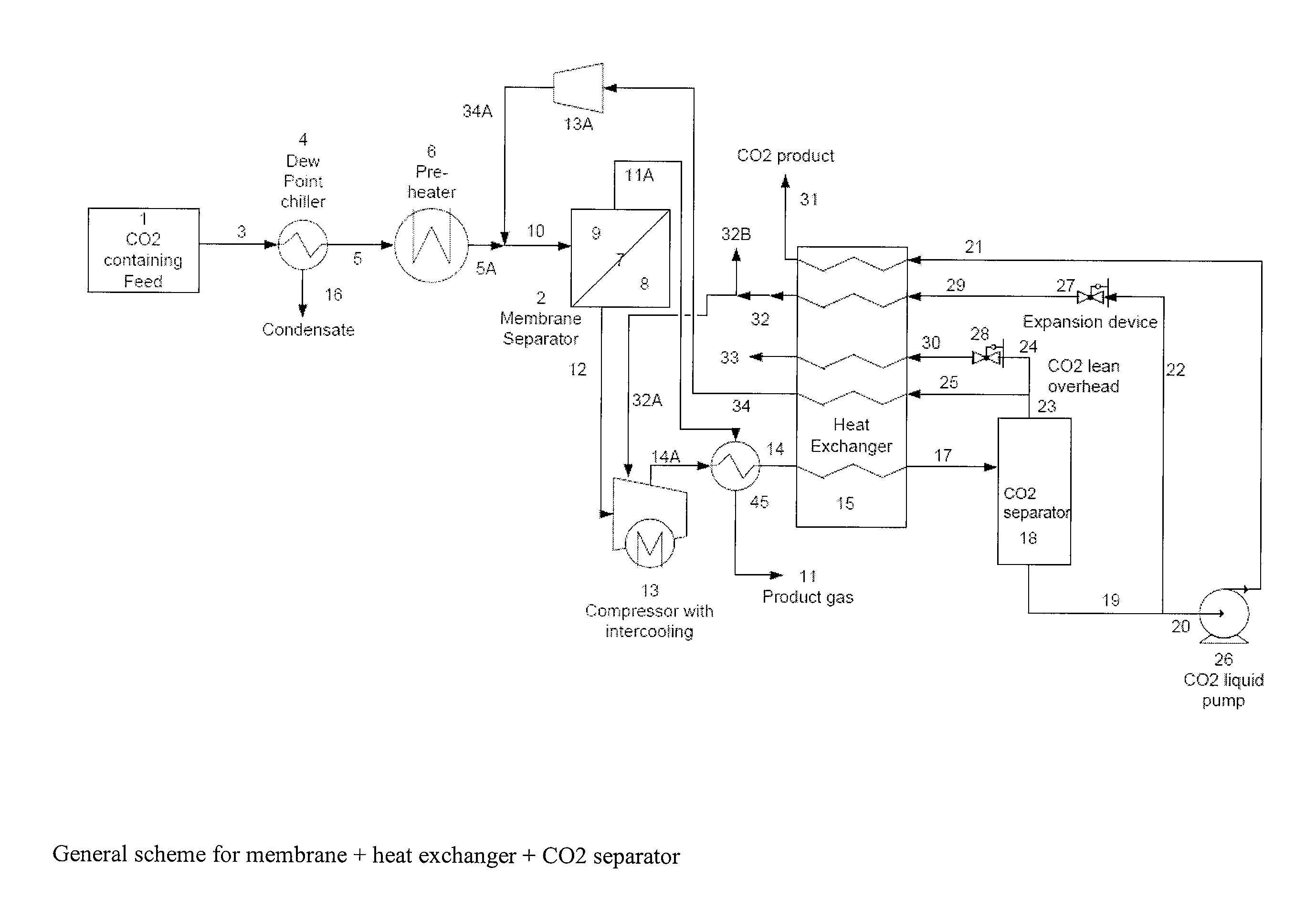

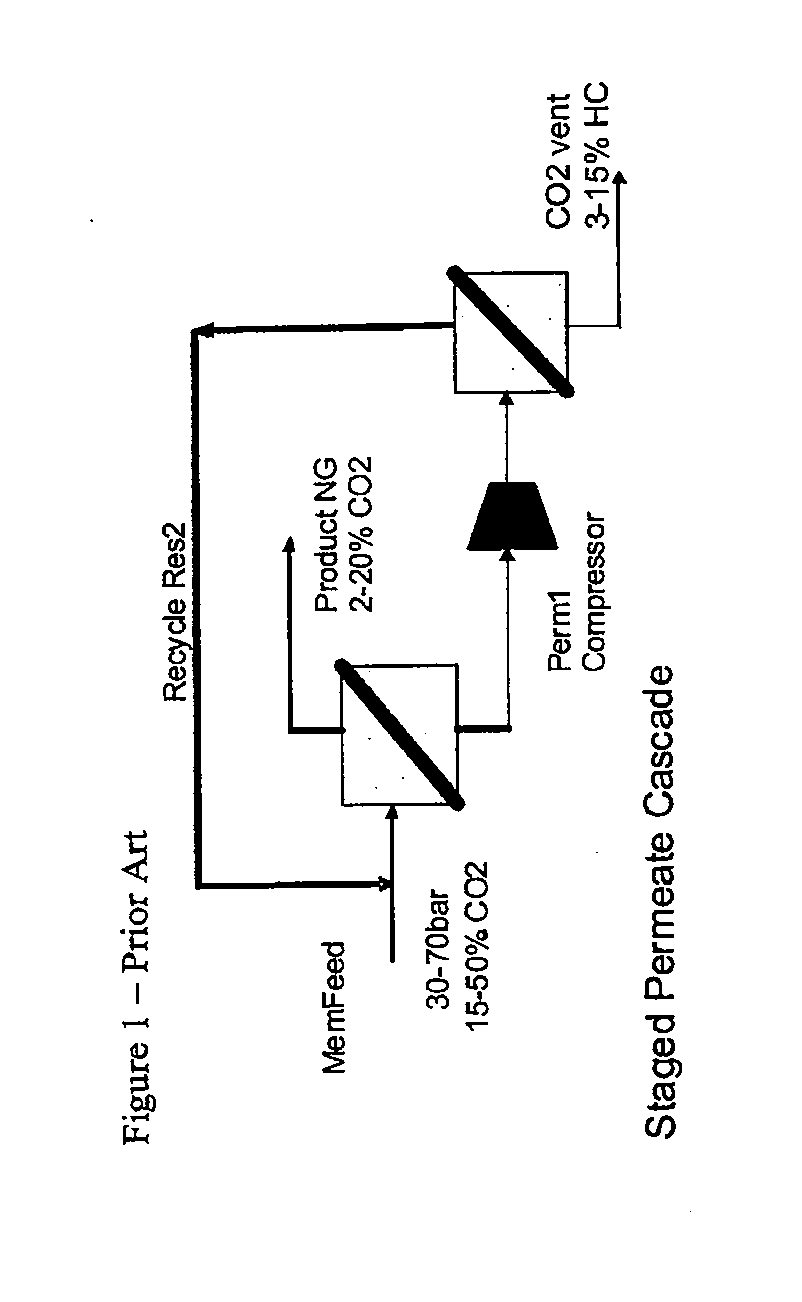

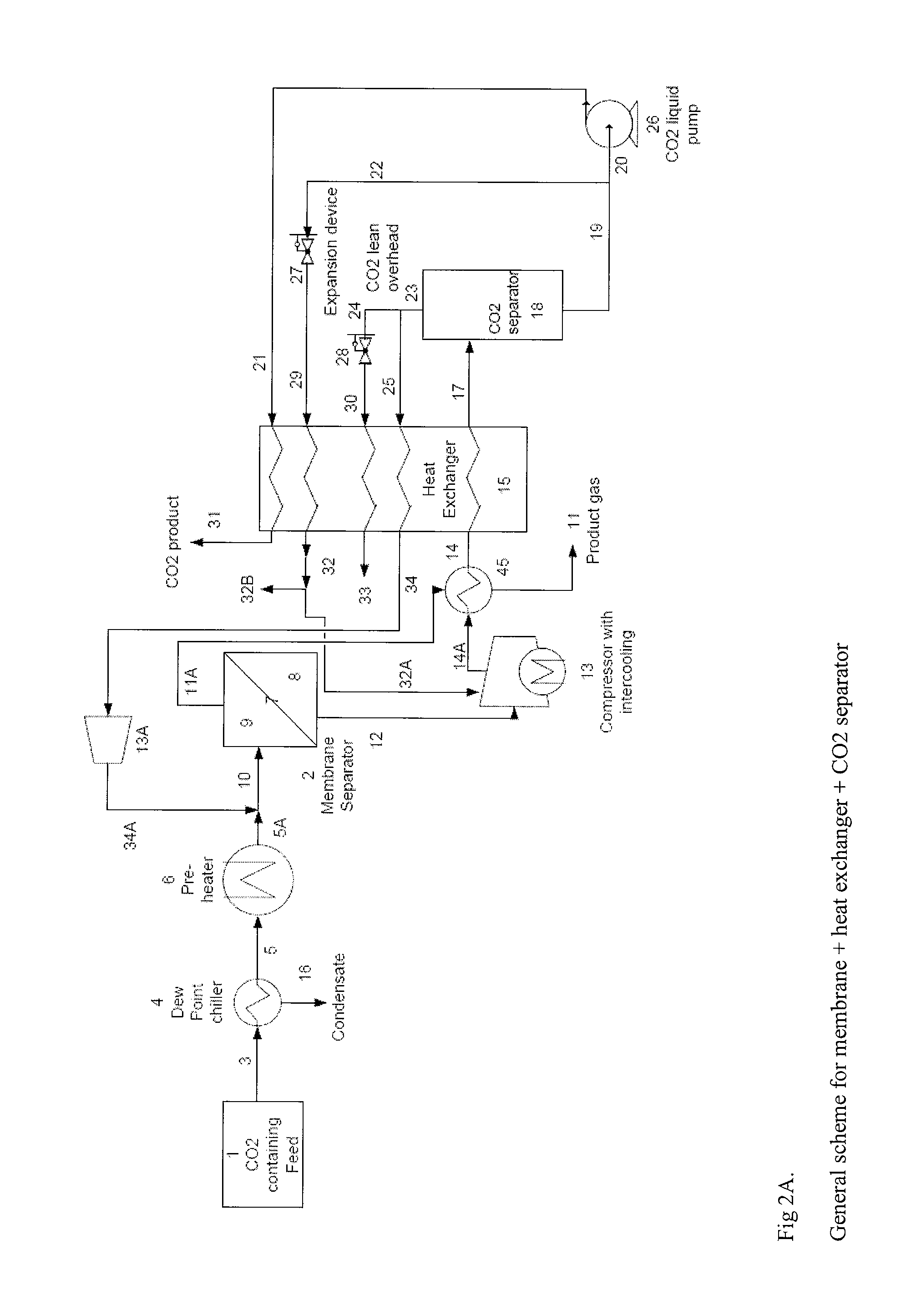

ActiveUS20120111051A1Reduce lossesIncrease pressureSolidificationLiquefactionCooling effectHydrocarbon

A process for efficiently removing carbon dioxide from a hydrocarbon containing feed stream utilizing a membrane separation unit in conjunction with a heat exchanger and a carbon dioxide separation unit wherein the streams obtained in the carbon dioxide separation unit are utilized to provide the cooling effect in the heat exchanger.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

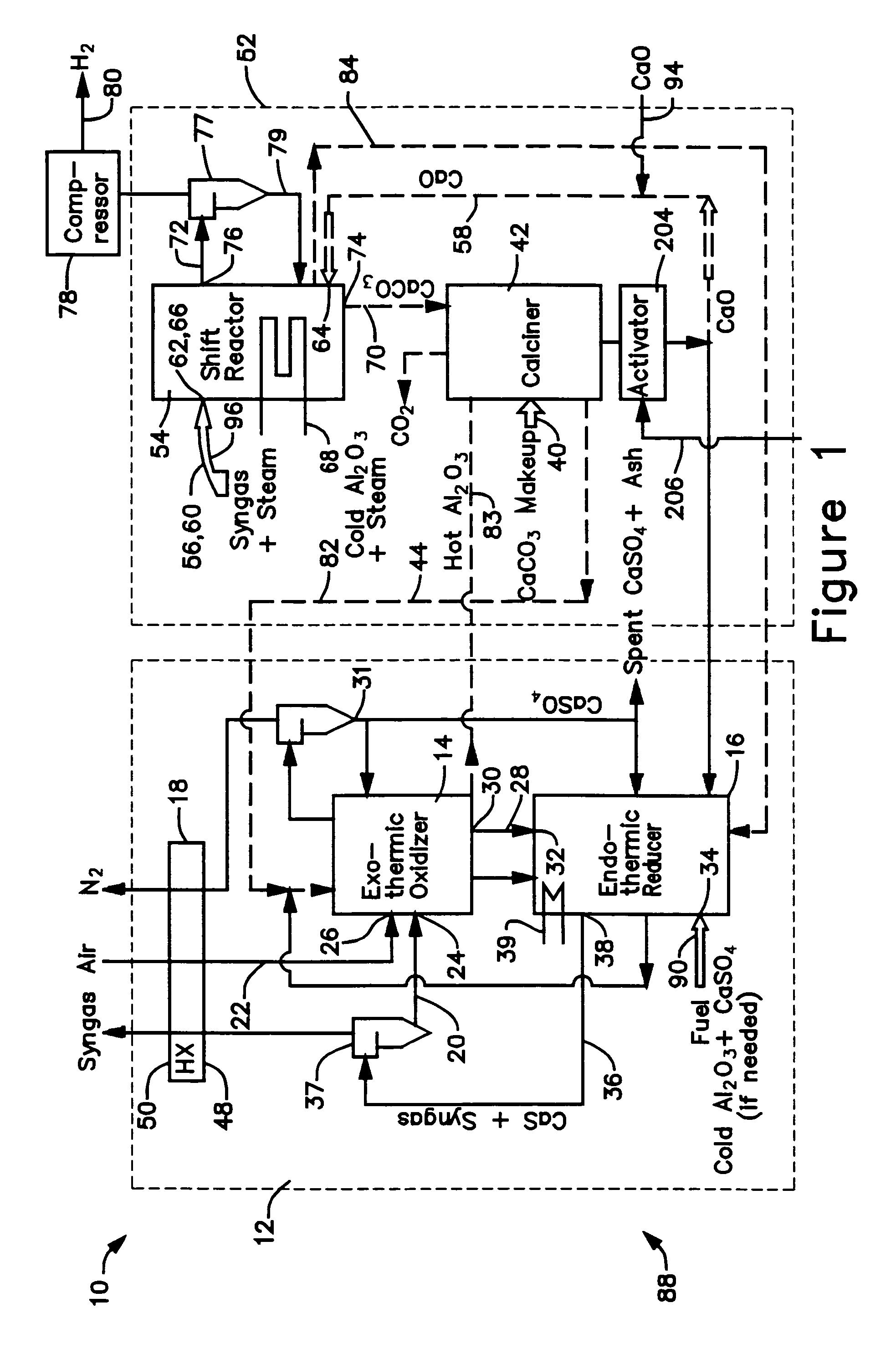

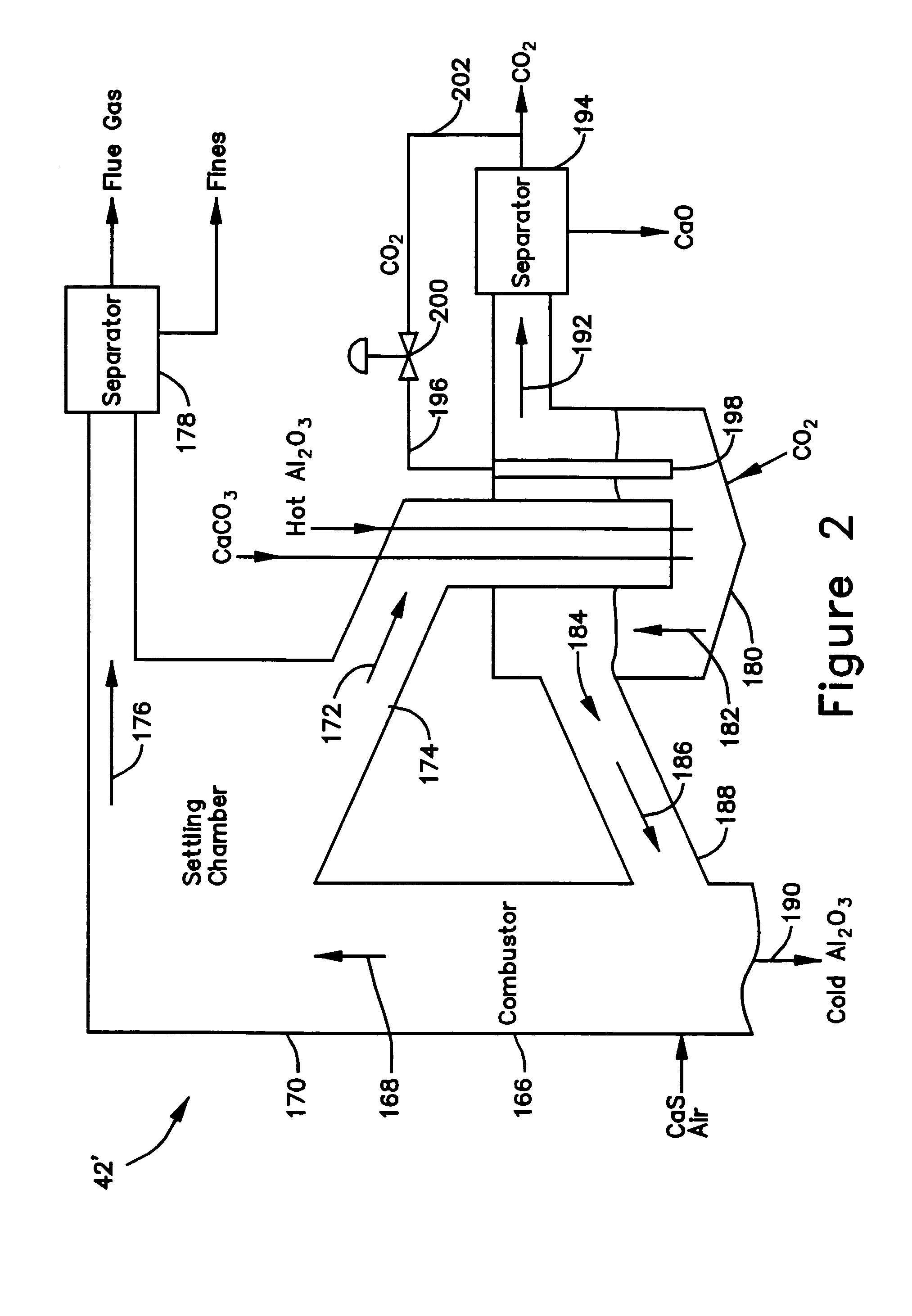

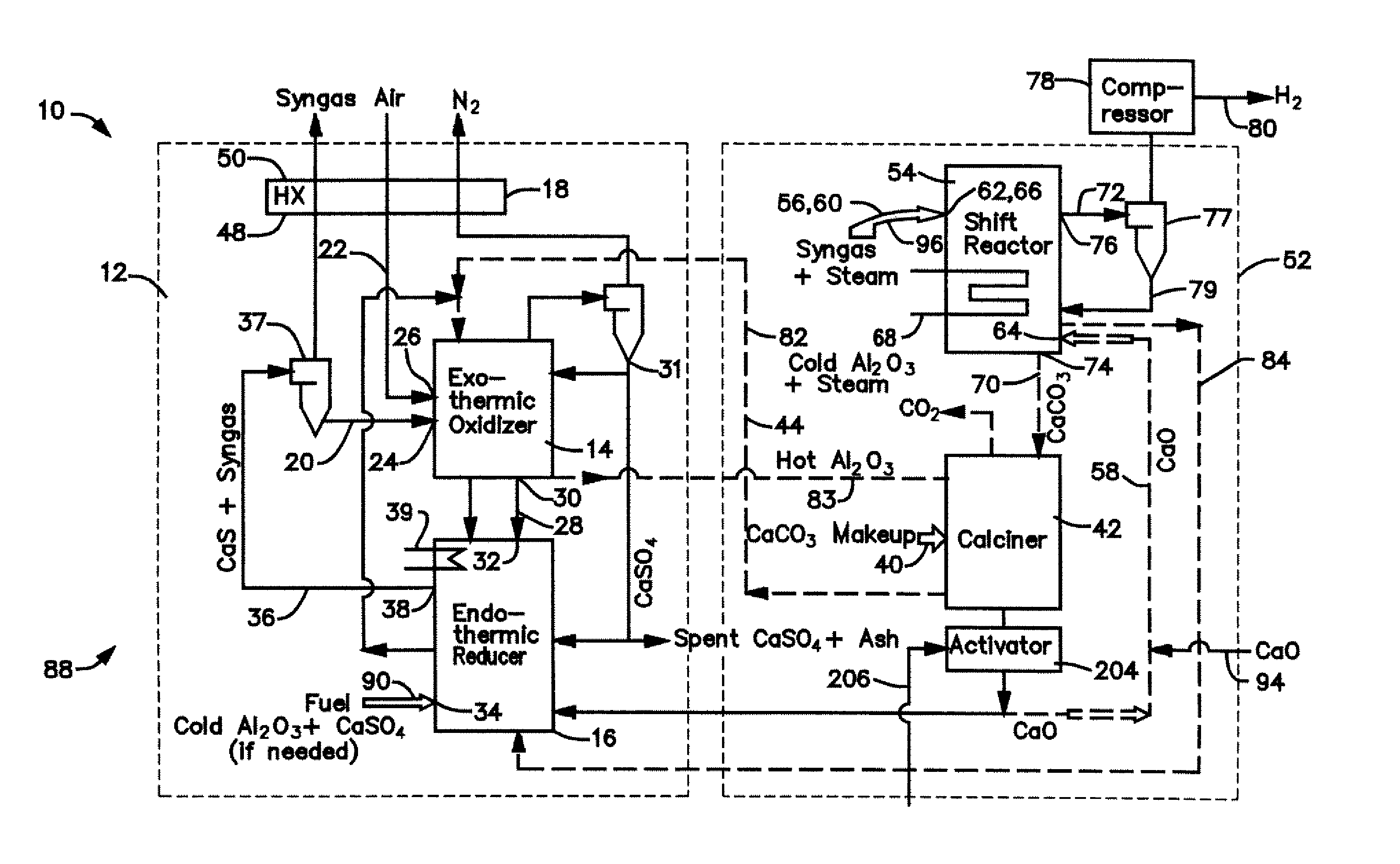

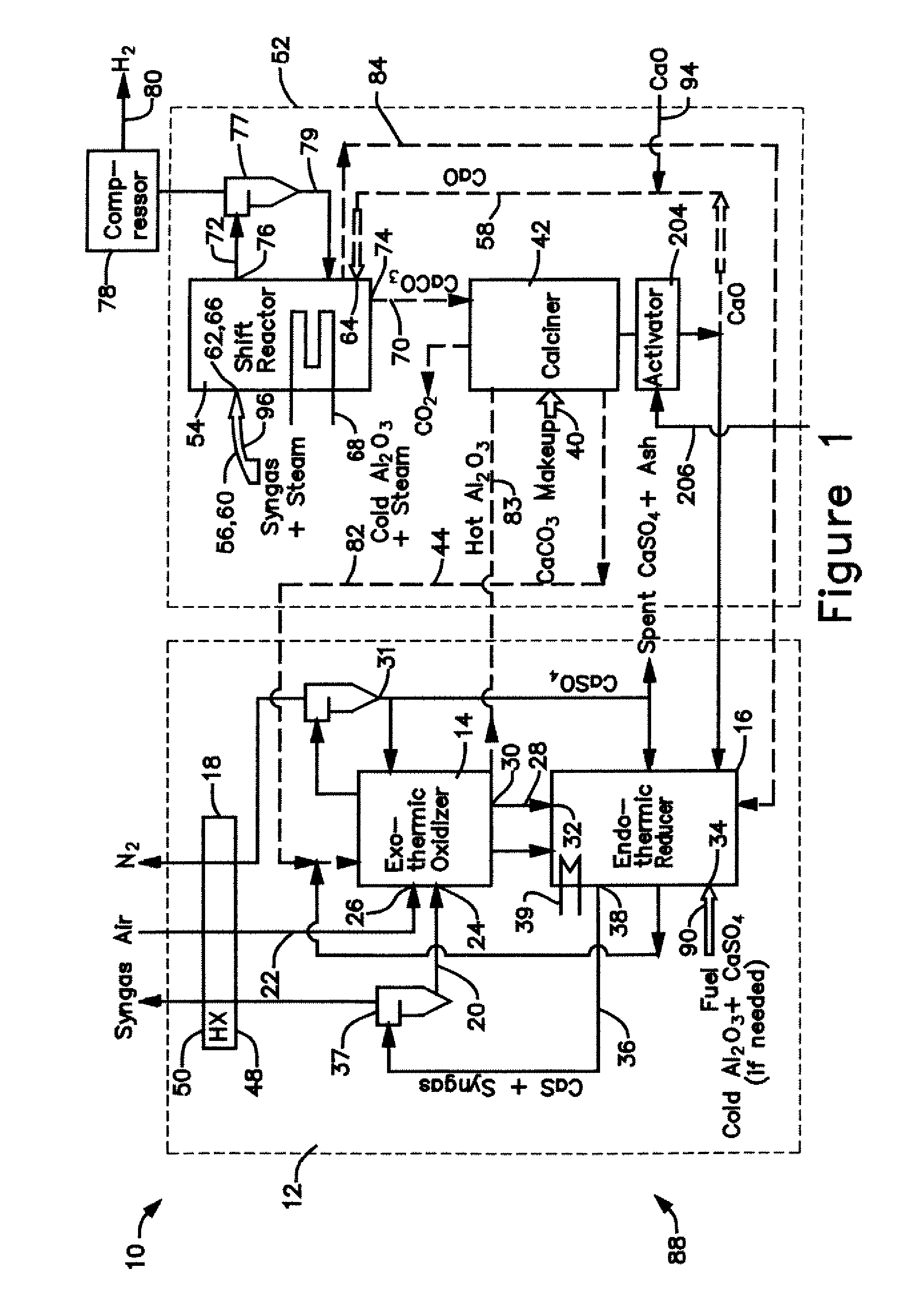

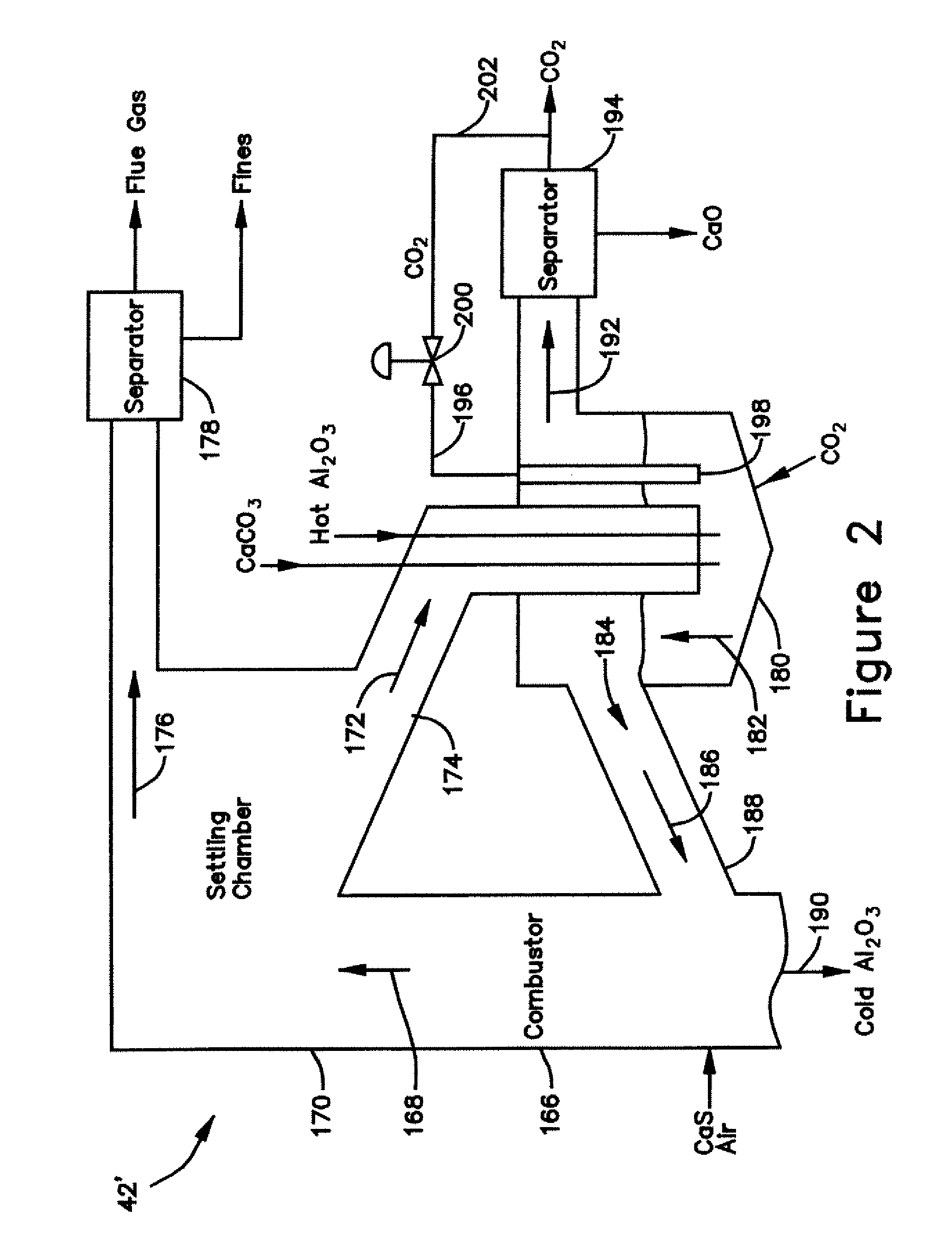

Hot solids gasifier with CO2 removal and hydrogen production

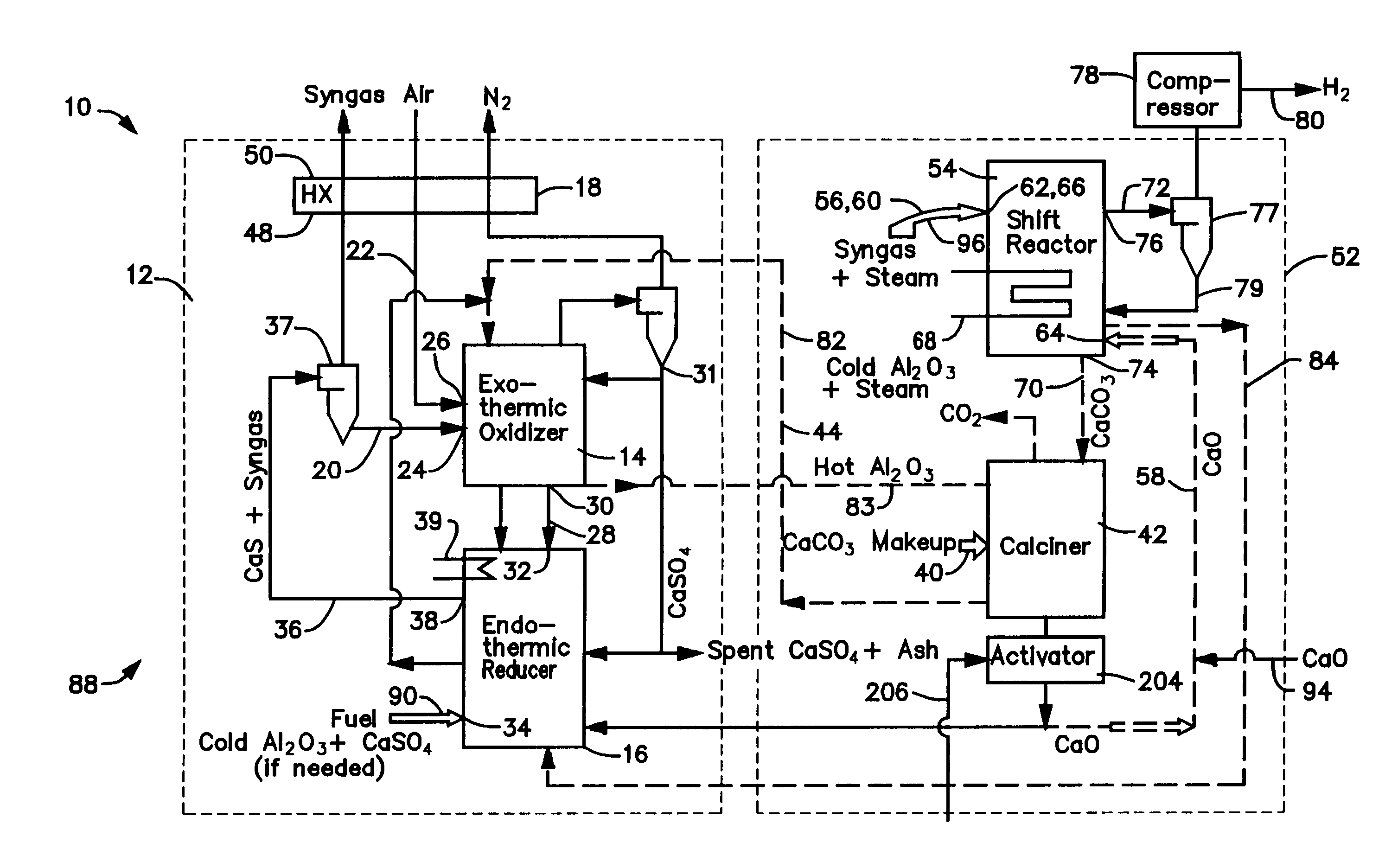

ActiveUS7083658B2Avoid entrainmentEfficient captureMuffle furnacesGas modification by gas mixingCo2 removalWater-gas shift reaction

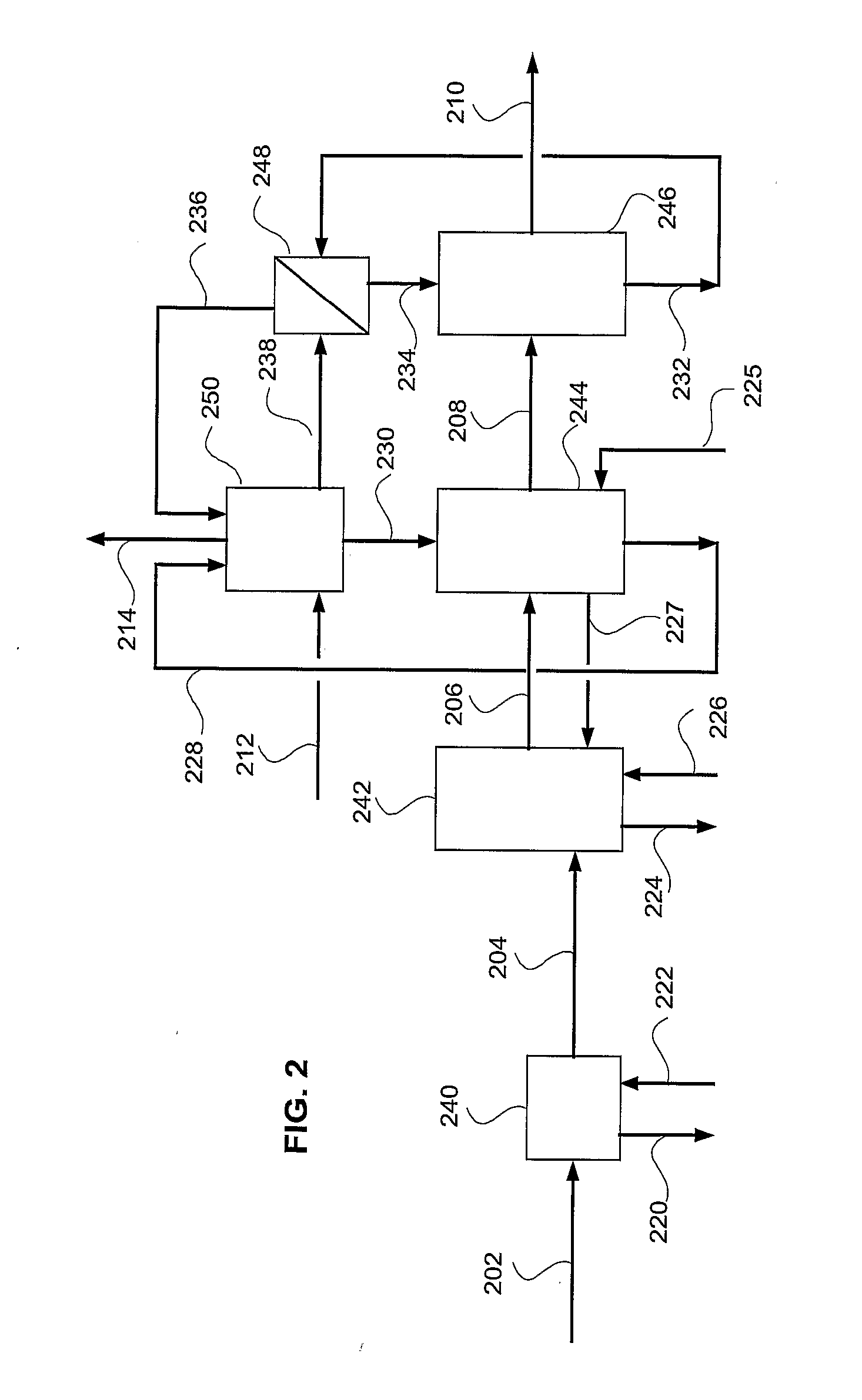

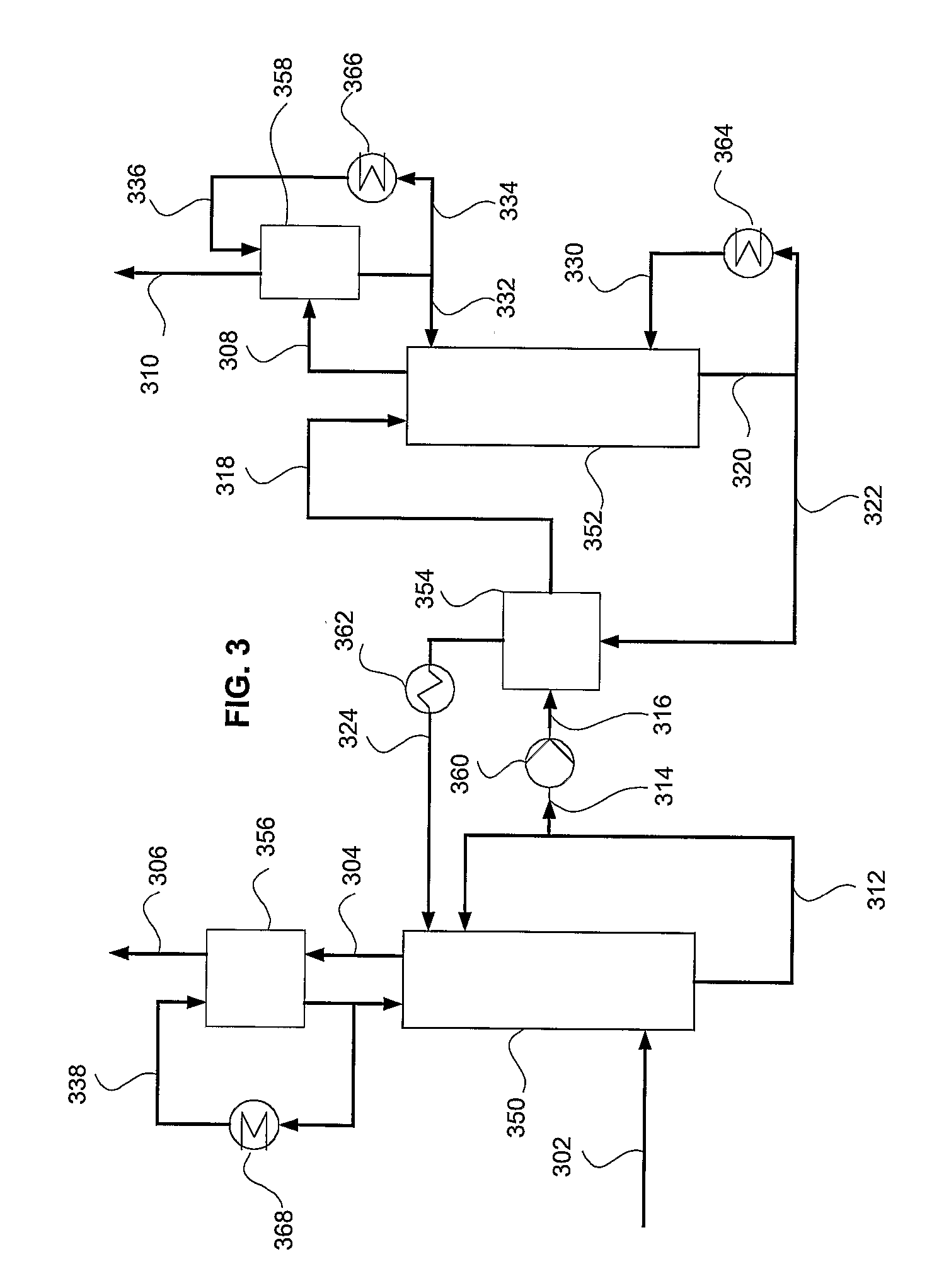

A gasifier 10 includes a first chemical process loop 12 having an exothermic oxidizer reactor 14 and an endothermic reducer reactor 16. CaS is oxidized in air in the oxidizer reactor 14 to form hot CaSO4 which is discharged to the reducer reactor 16. Hot CaSO4 and carbonaceous fuel received in the reducer reactor 16 undergo an endothermic reaction utilizing the heat content of the CaSO4, the carbonaceous fuel stripping the oxygen from the CaSO4 to form CaS and a CO rich syngas. The CaS is discharged to the oxidizer reactor 14 and the syngas is discharged to a second chemical process loop 52. The second chemical process loop 52 has a water-gas shift reactor 54 and a calciner 42. The CO of the syngas reacts with gaseous H2O in the shift reactor 54 to produce H2 and CO2. The CO2 is captured by CaO to form hot CaCO3 in an exothermic reaction. The hot CaCO3 is discharged to the calciner 42, the heat content of the CaCO3 being used to strip the CO2 from the CaO in an endothermic reaction in the calciner, with the CaO being discharged from the calciner 42 to the shift reactor 54.

Owner:AIR PROD & CHEM INC +1

Metal organic framework polymer mixed matrix membranes

InactiveCN102652035AReduces hydrocarbon fouling problemsImprove separation permeability performanceSemi-permeable membranesGas treatmentCo2 removalPolymer science

Metal-organic framework (MOF)-polymer mixed matrix membranes (MOF-MMMs) can be prepared by dispersing high surface area MOFs into a polymer matrix. The MOFs allow the polymer to infiltrate the pores of the MOFs, which improves the interfacial and mechanical properties of the polymer and in turn affects permeability. These mixed matrix membranes are attractive candidates for practical gas separation applications such as CO2 removal from natural gas.

Owner:UOP LLC

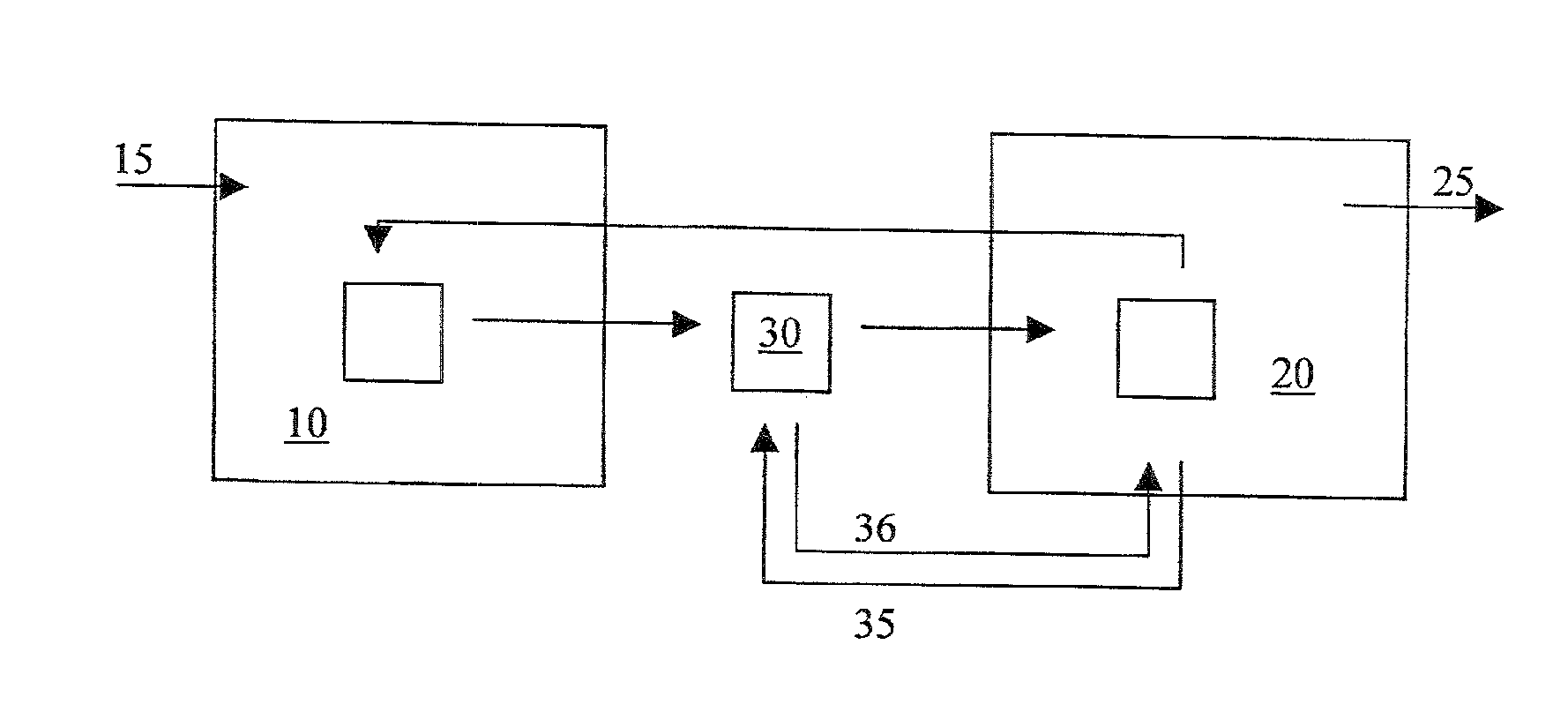

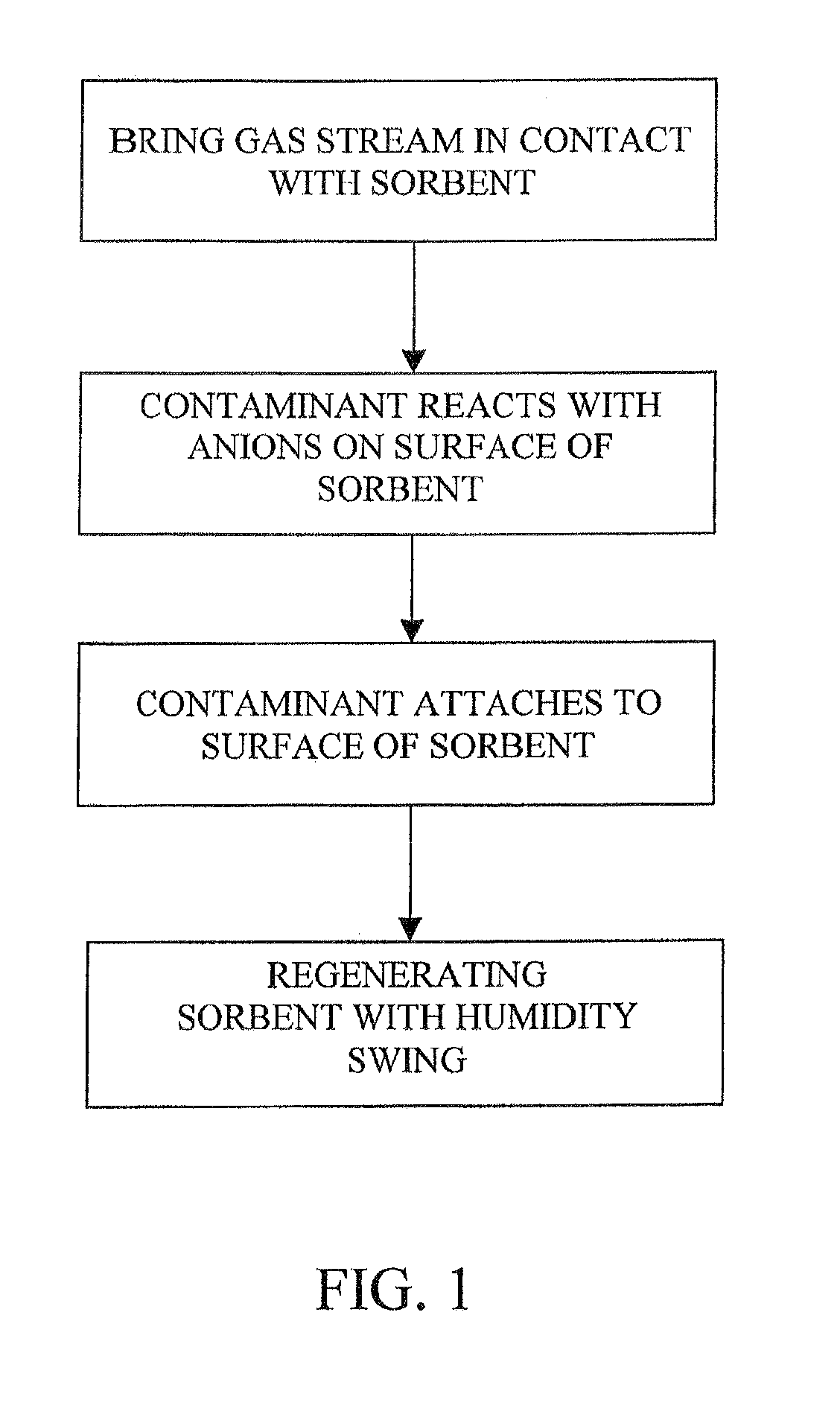

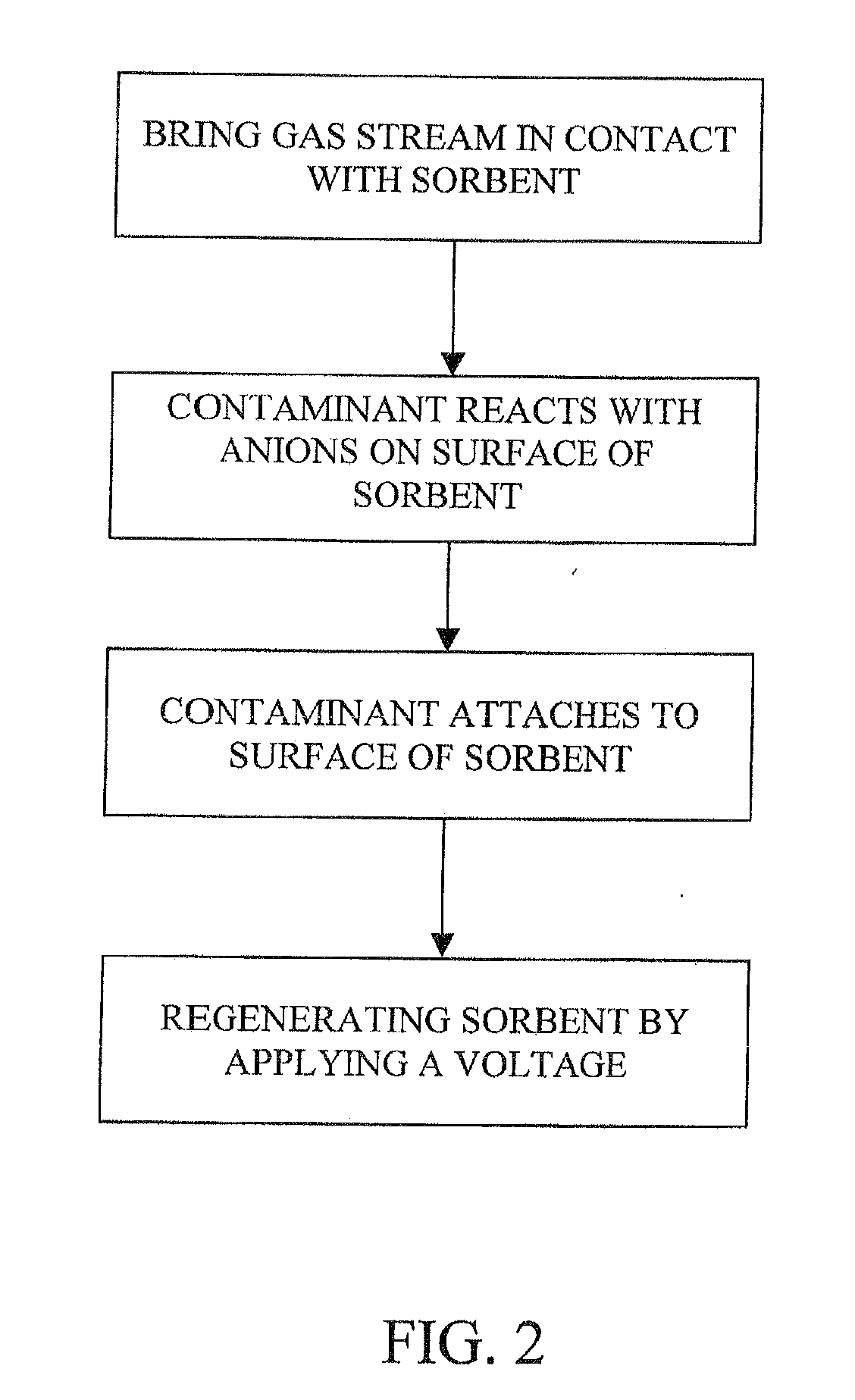

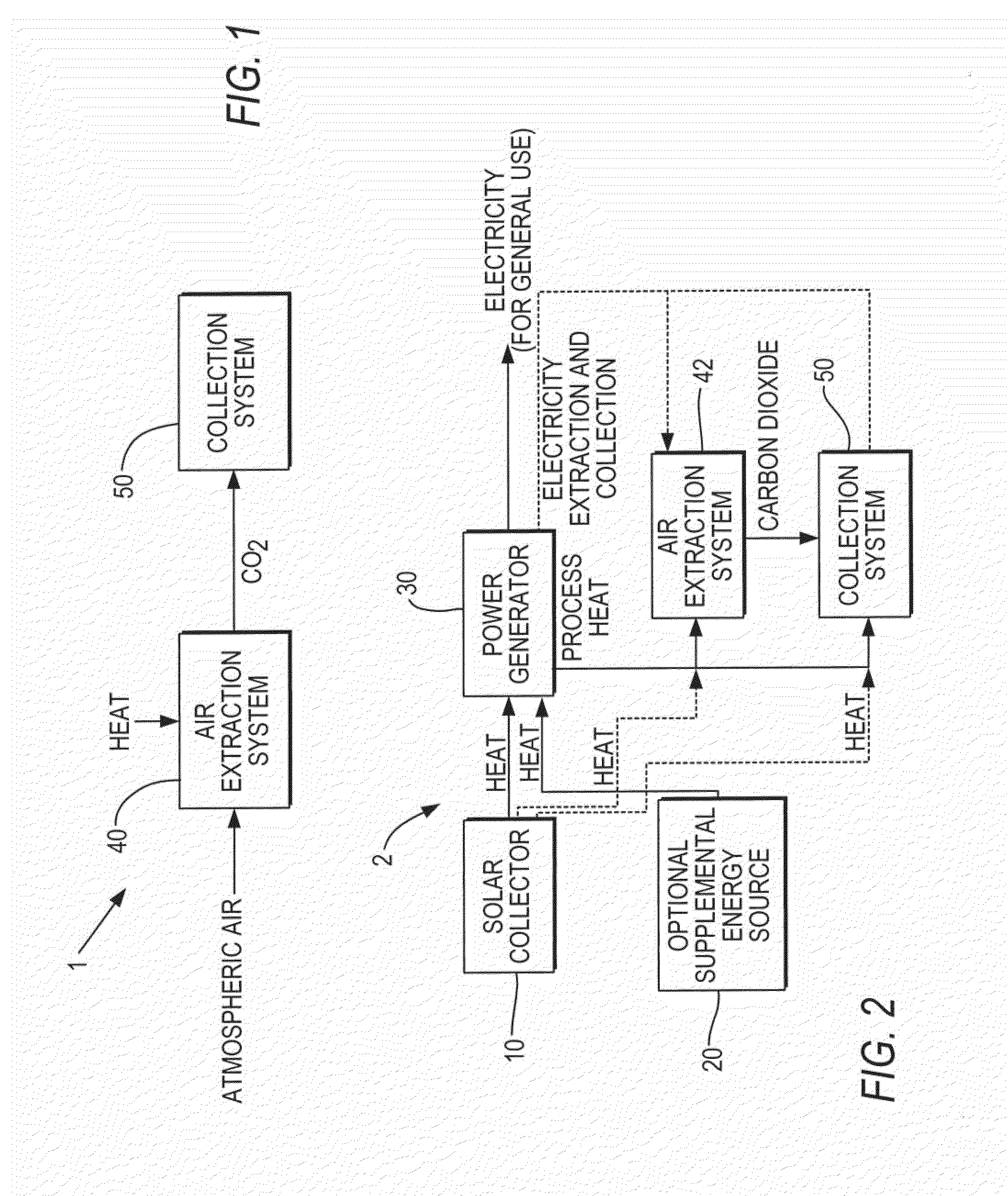

Removal of carbon dioxide from air

The present invention provides a method and apparatus for removing a contaminant, such as carbon dioxide, from a gas stream, such as ambient air. The contaminant is removed from the gas stream by a sorbent which may be regenerated using a humidity swing, a thermal swing, or a combination thereof. The sorbent may comprise a substrate having embedded positive ions and individually mobile negative ions wherein the positive ions are sufficiently spaced to prevent interactions between the negative ions. Where a thermal swing is used, heat may be conserved by employing a heat exchanger to transfer heat from the regenerated sorbent to an amount of sorbent that is loaded with the contaminant prior to regeneration.

Owner:KILIMANJARO ENERGY

Integrated process for acetic acid and methanol

InactiveUS7470811B2Improve matchIncrease productionOrganic compound preparationCarboxylic acid esters preparationSteam reformingCo2 removal

Owner:ACETEX

Novel solid materials and method for co2 removal from gas stream

InactiveUS20100154636A1Efficient removalGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsCo2 removalCombustion

Owner:GENERAL ELECTRIC TECH GMBH

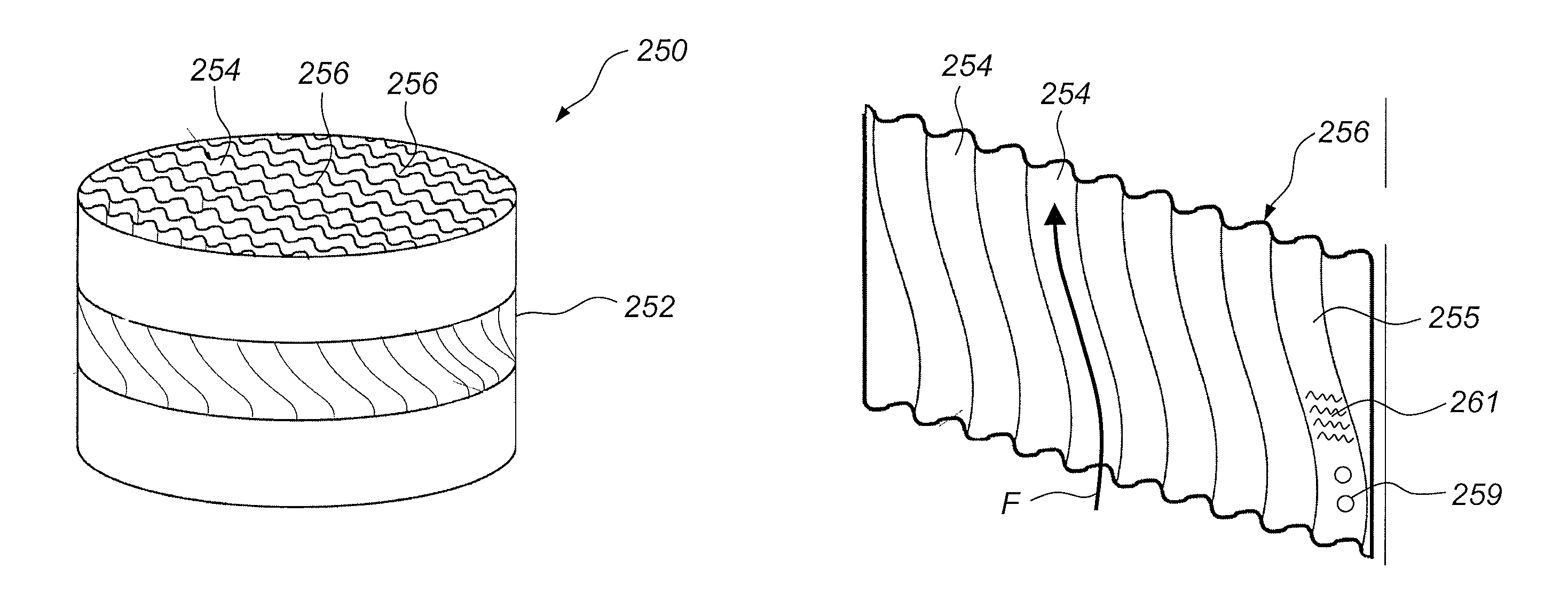

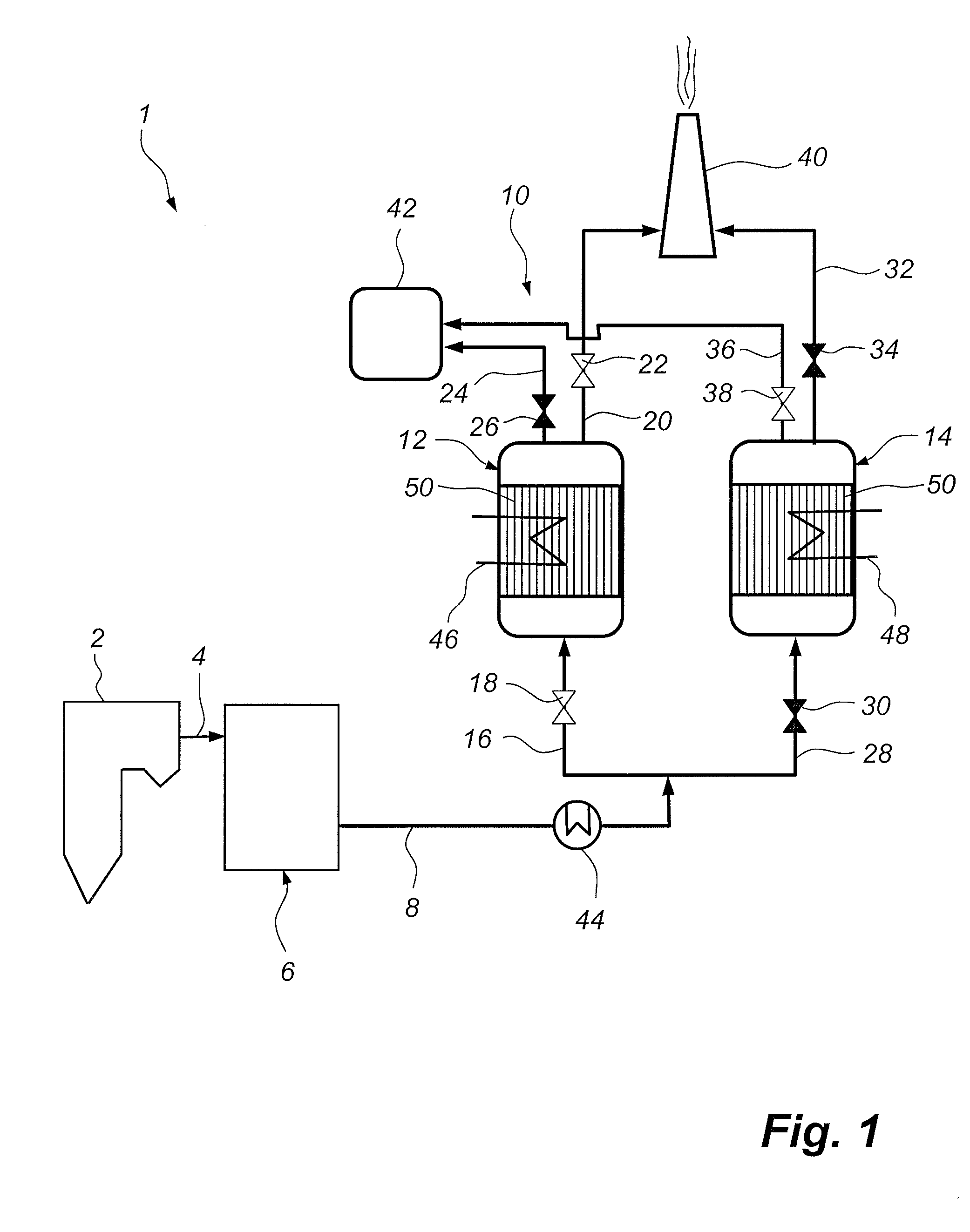

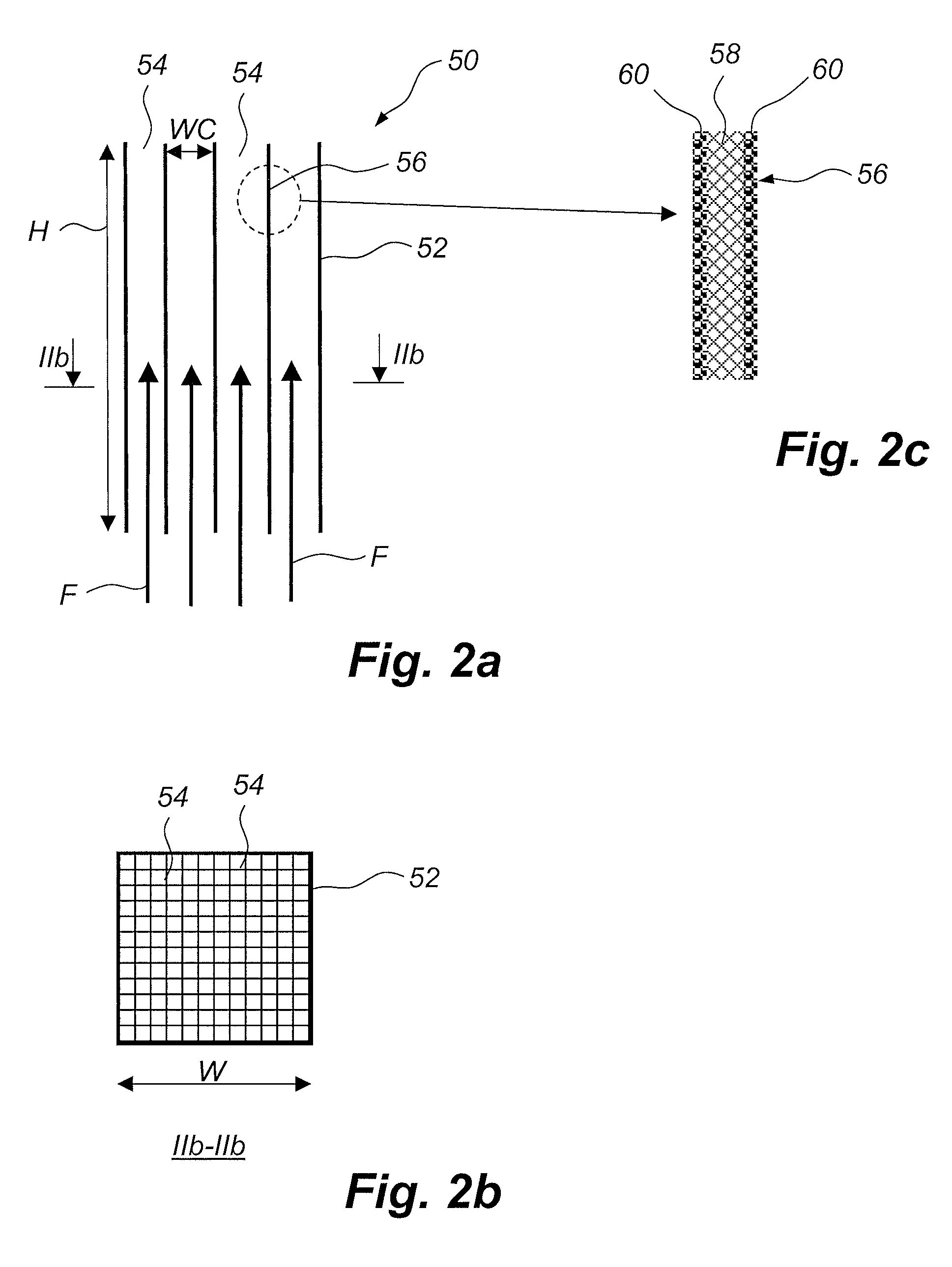

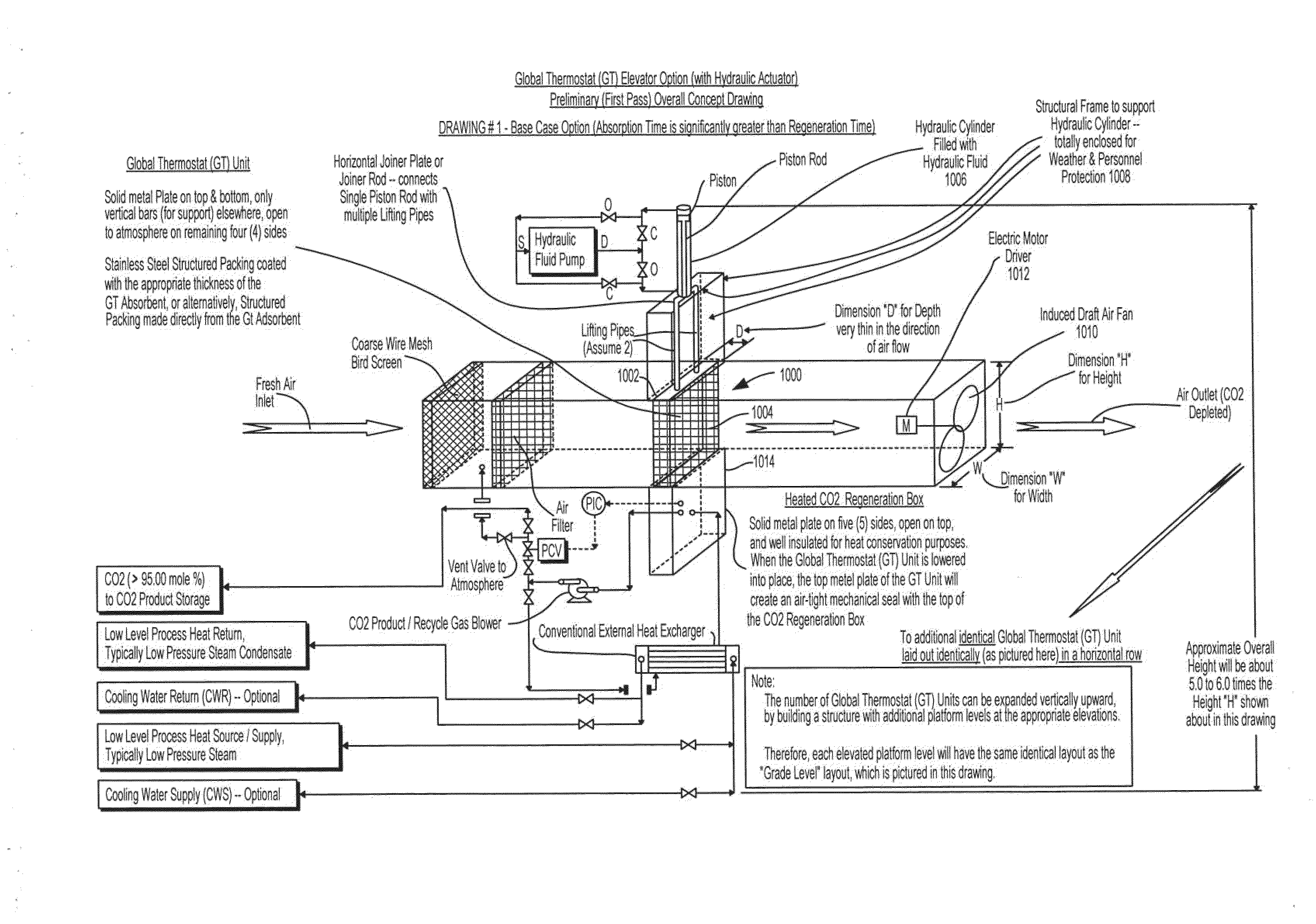

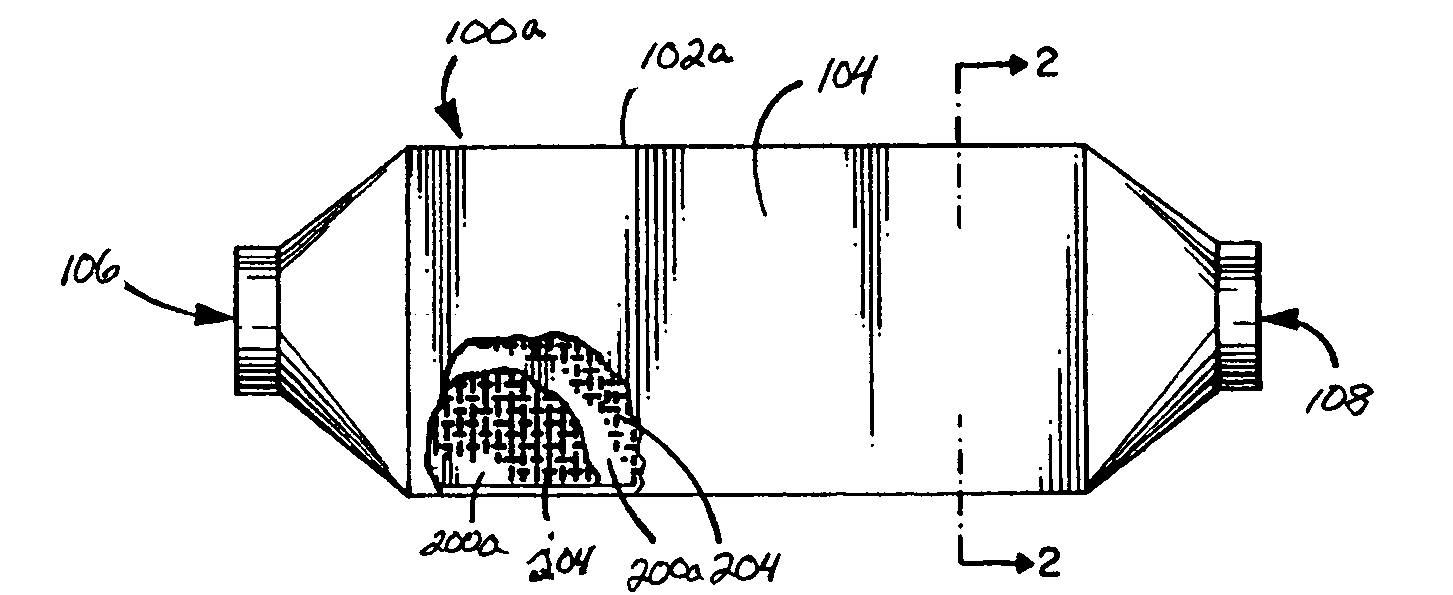

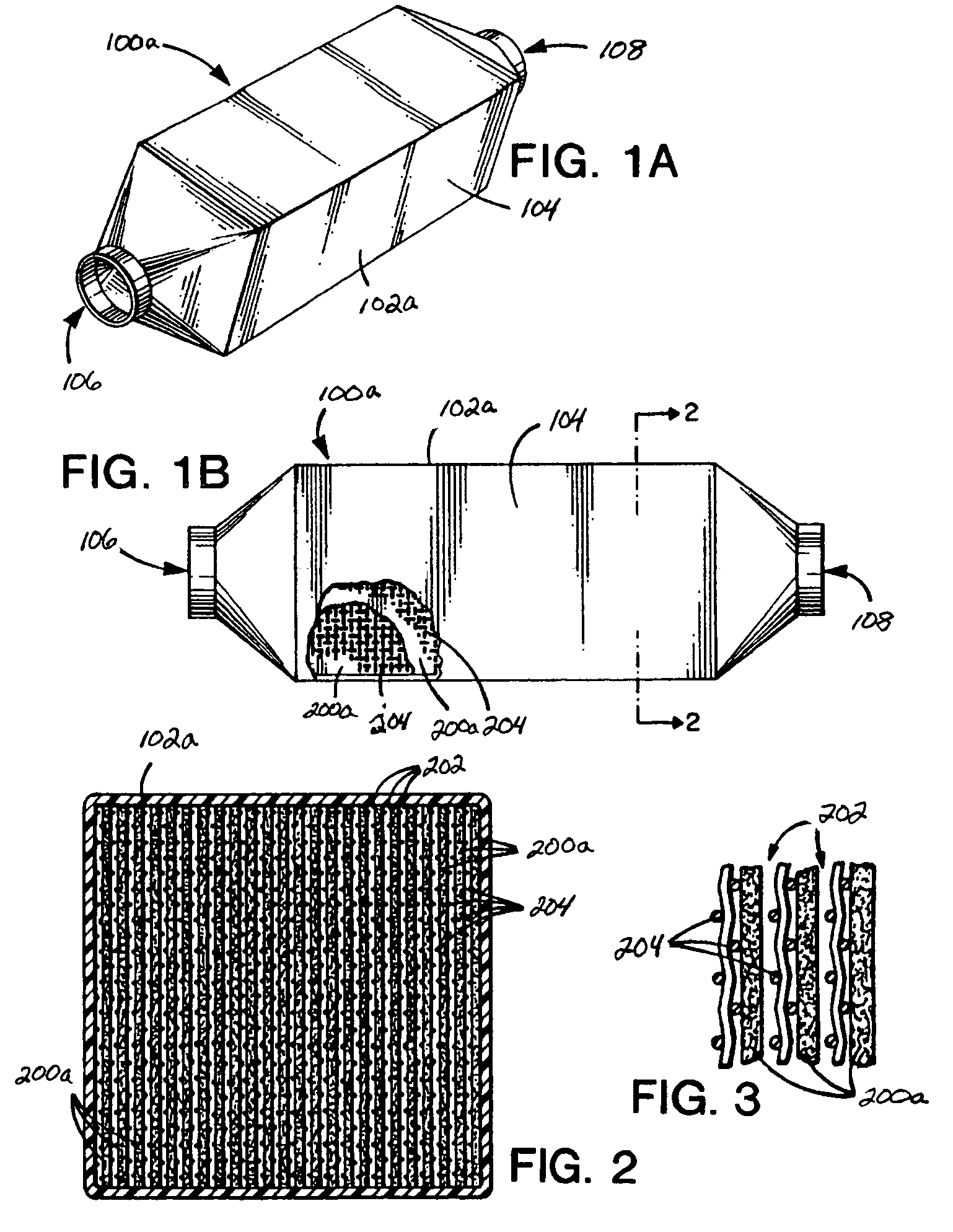

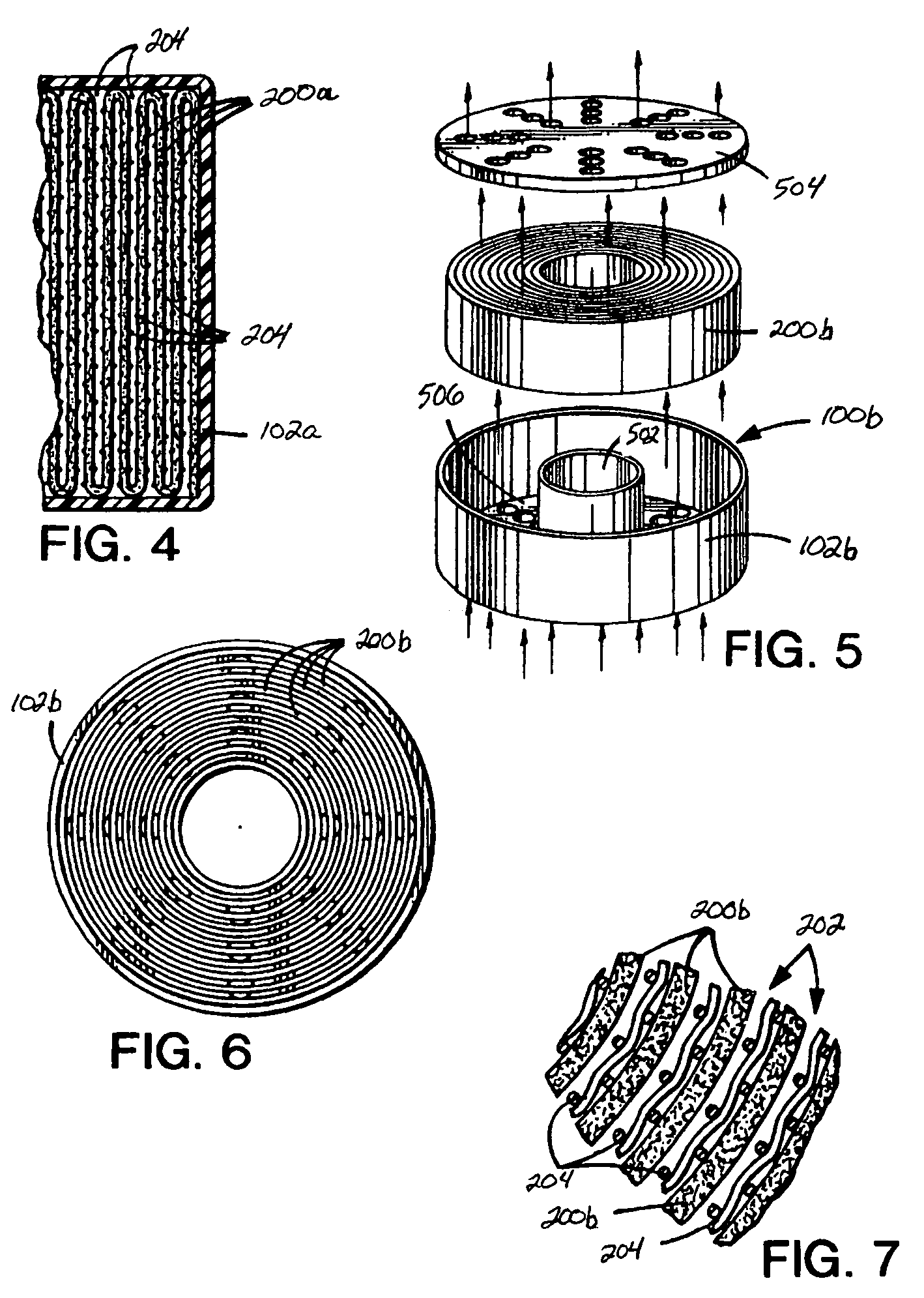

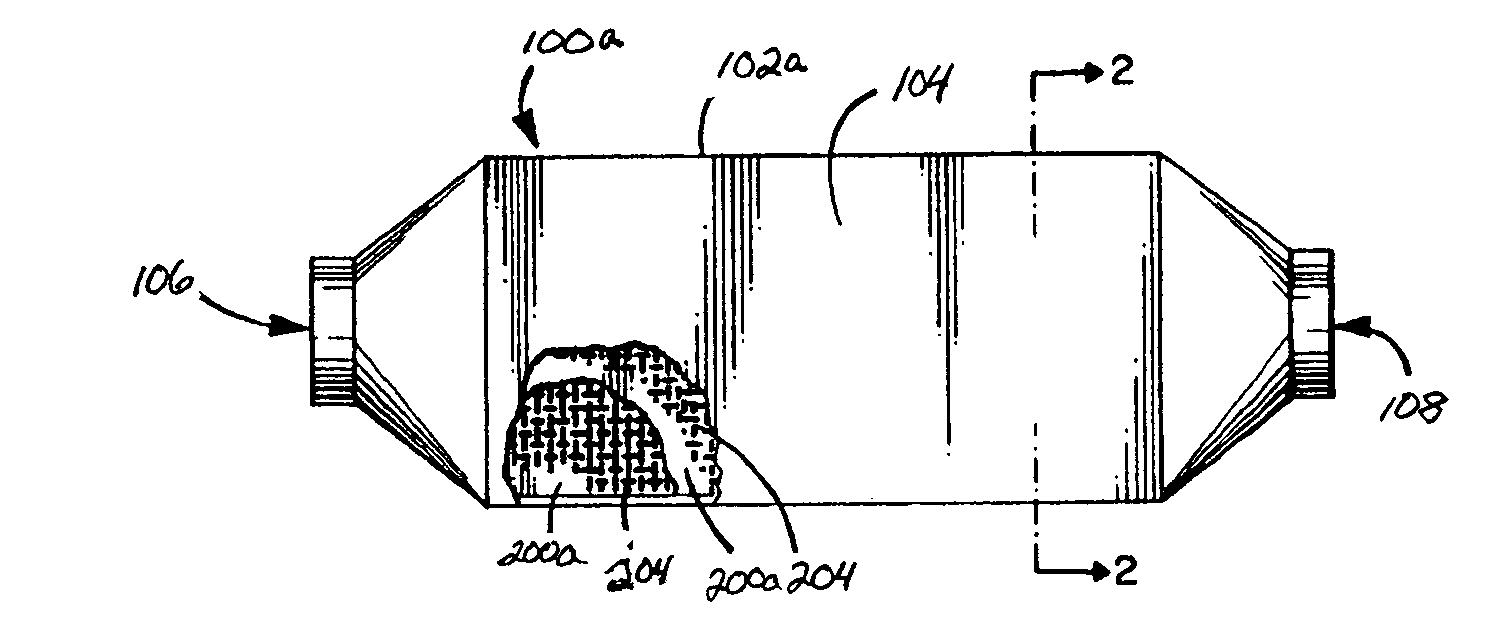

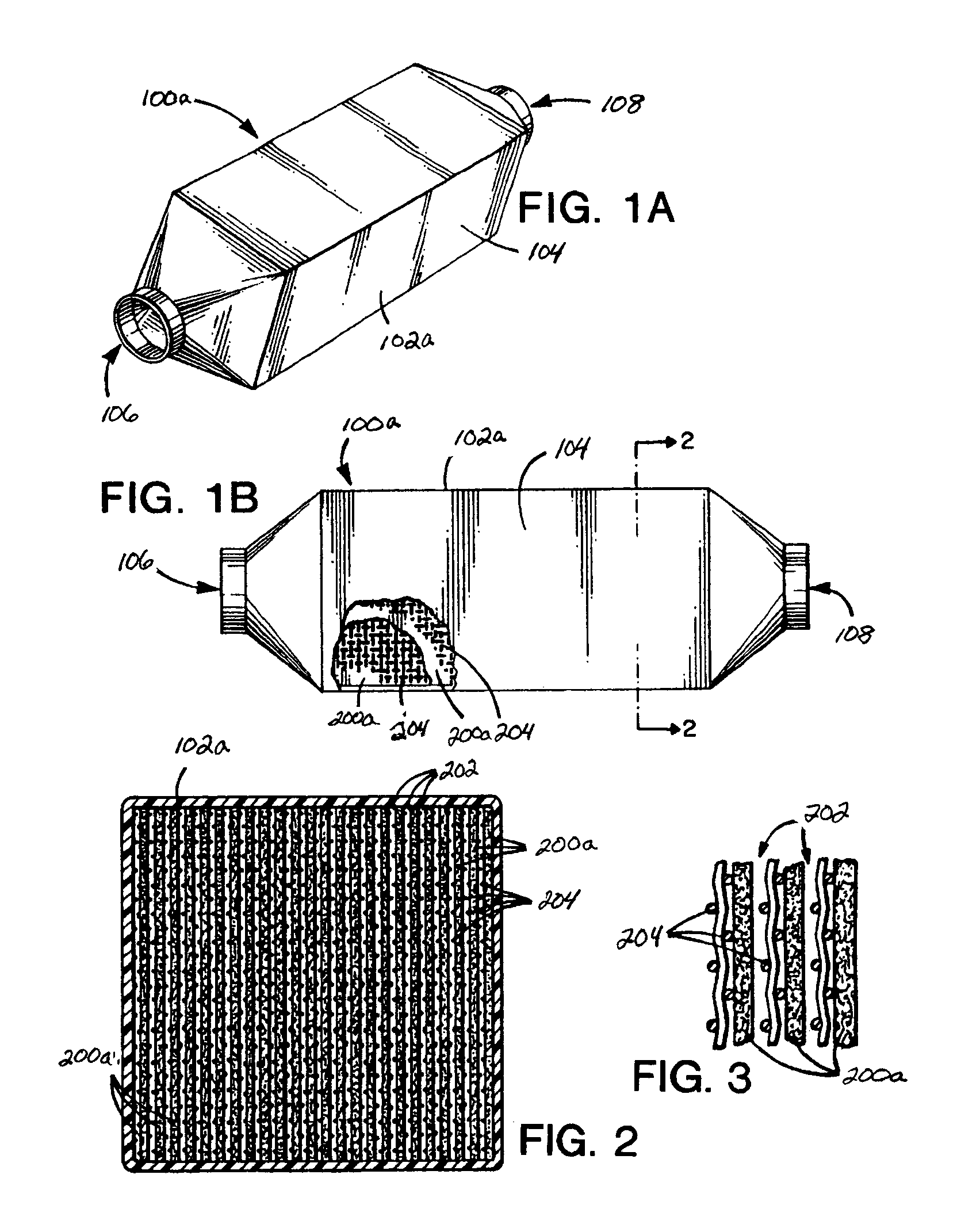

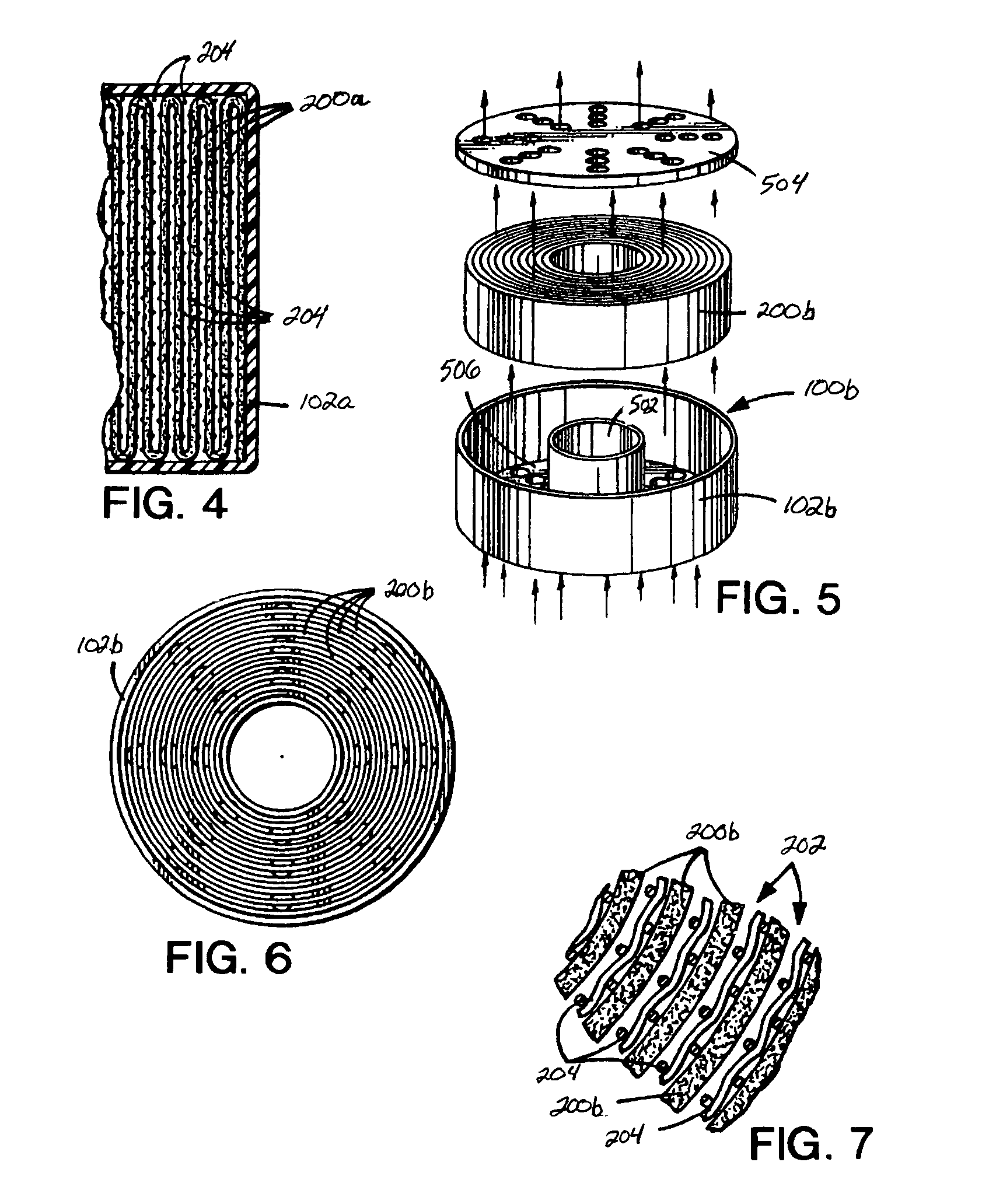

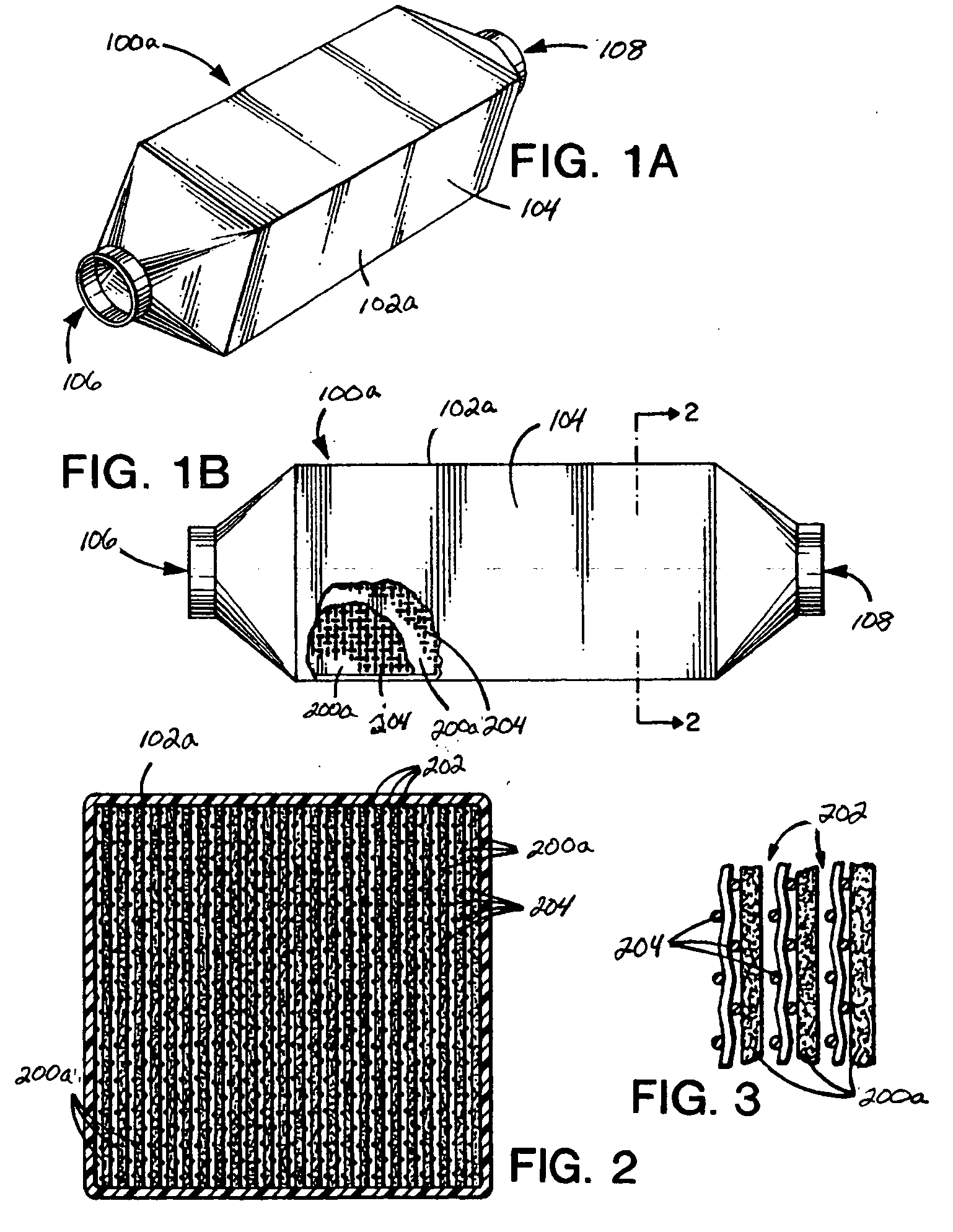

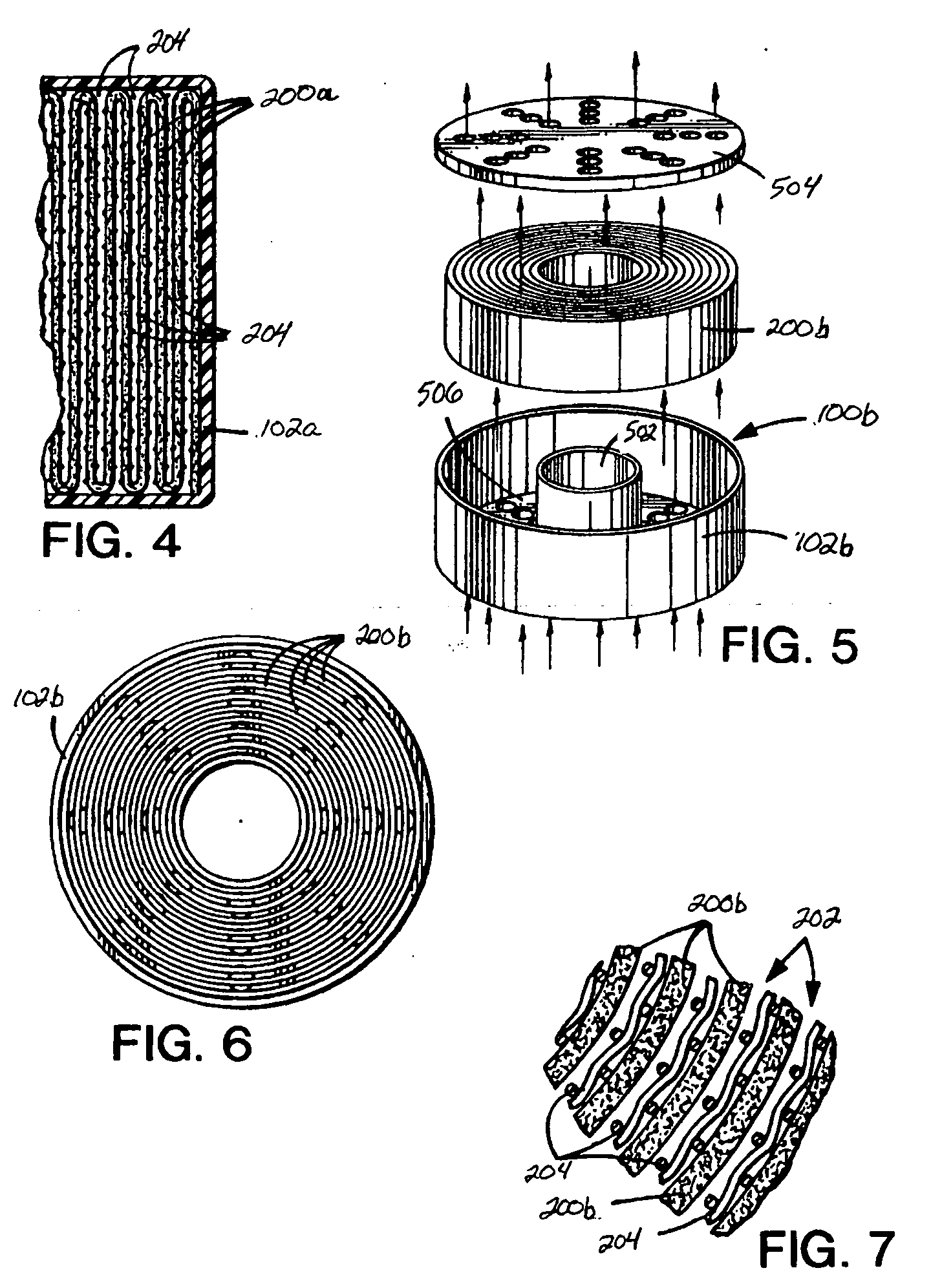

Carbon Dioxide Capture/Regeneration Structures and Techniques

New and useful system and method concepts are provided, for removing carbon dioxide from a flow of carbon dioxide laden air. More specifically, a sorbent structure is used in new and useful structures and techniques to bind carbon dioxide in a carbon dioxide laden air stream, and process heat is used to separate carbon dioxide from the sorbent structure and regenerate the sorbent structure.

Owner:GLOBAL THERMOSTAT OPERATIONS LLC

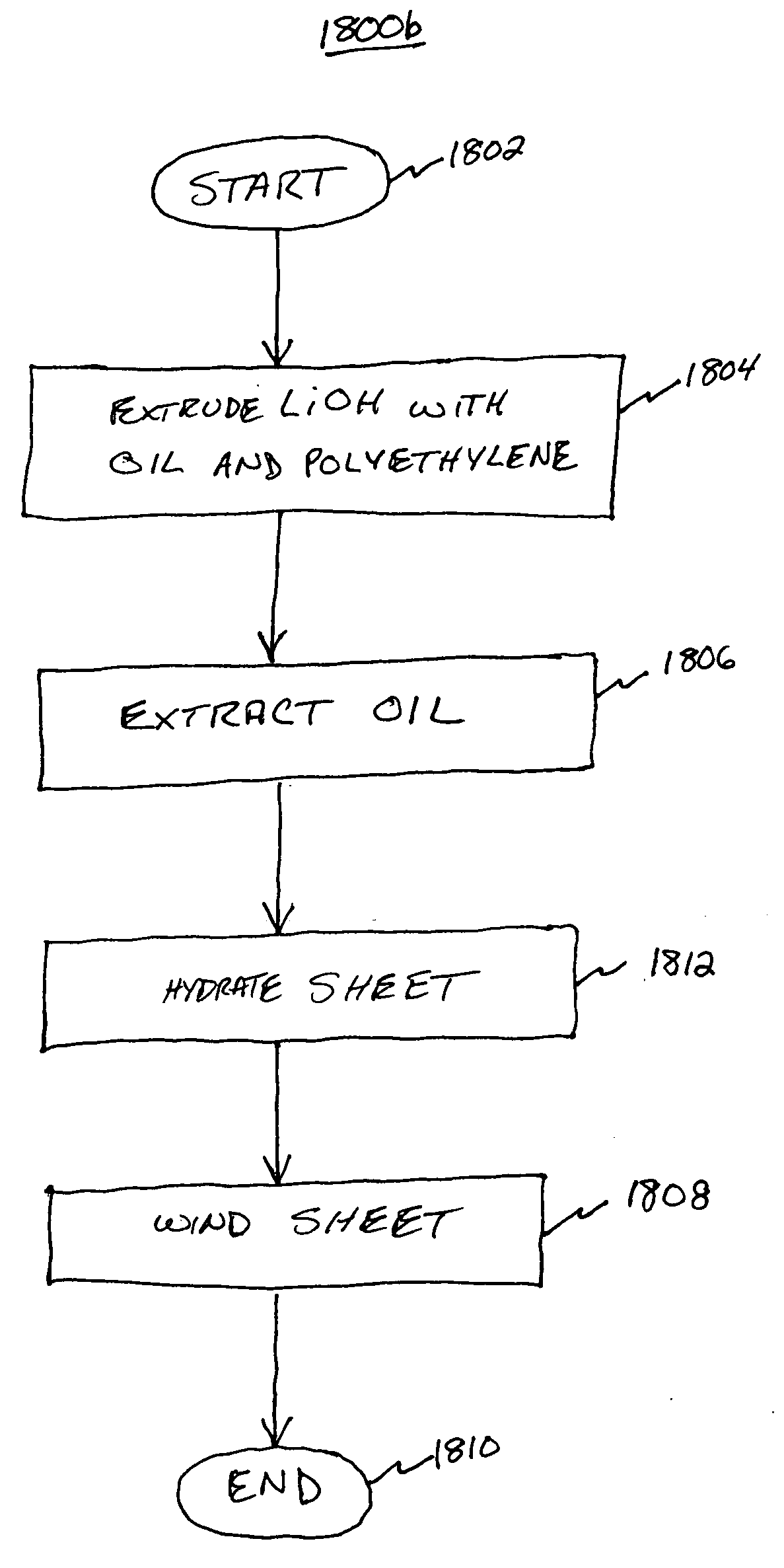

Method of manufacturing and using enhanced carbon dioxide adsorbent

A method of processing carbon dioxide adsorbent for use in a CO2 removal system. The method includes combining a polymer, lithium hydroxide (LiOH), and lubricant that dissolves the polymer to form a first LiOH adsorbent. A structure may be formed using the first LiOH adsorbent. The lubricant may be extracted from the structured LiOH adsorbent using a solvent to form a second LiOH adsorbent. The solvent may be removed from the second LiOH adsorbent to form a third LiOH adsorbent. The third LiOH adsorbent may be hydrated to form a fourth LiOH adsorbent having a water content above an anhydrous level.

Owner:MICROPORE

Oxygen reduction electrode

The invention refers to an oxygen reduction electrode comprising at least three layers: a current collector; a diffusion layer comprising at least PTFE; and a catalytical active layer, comprising at least a mixture of perovskites and pyrolysed macrocycles. In this way, oxygen may be utilised from air without an initial removal of carbon dioxide. Moreover, the invention refers to methods for preparing the electrode, as well as fuel cells and other products wherein the electrode can be used.

Owner:KTH HLDG AG

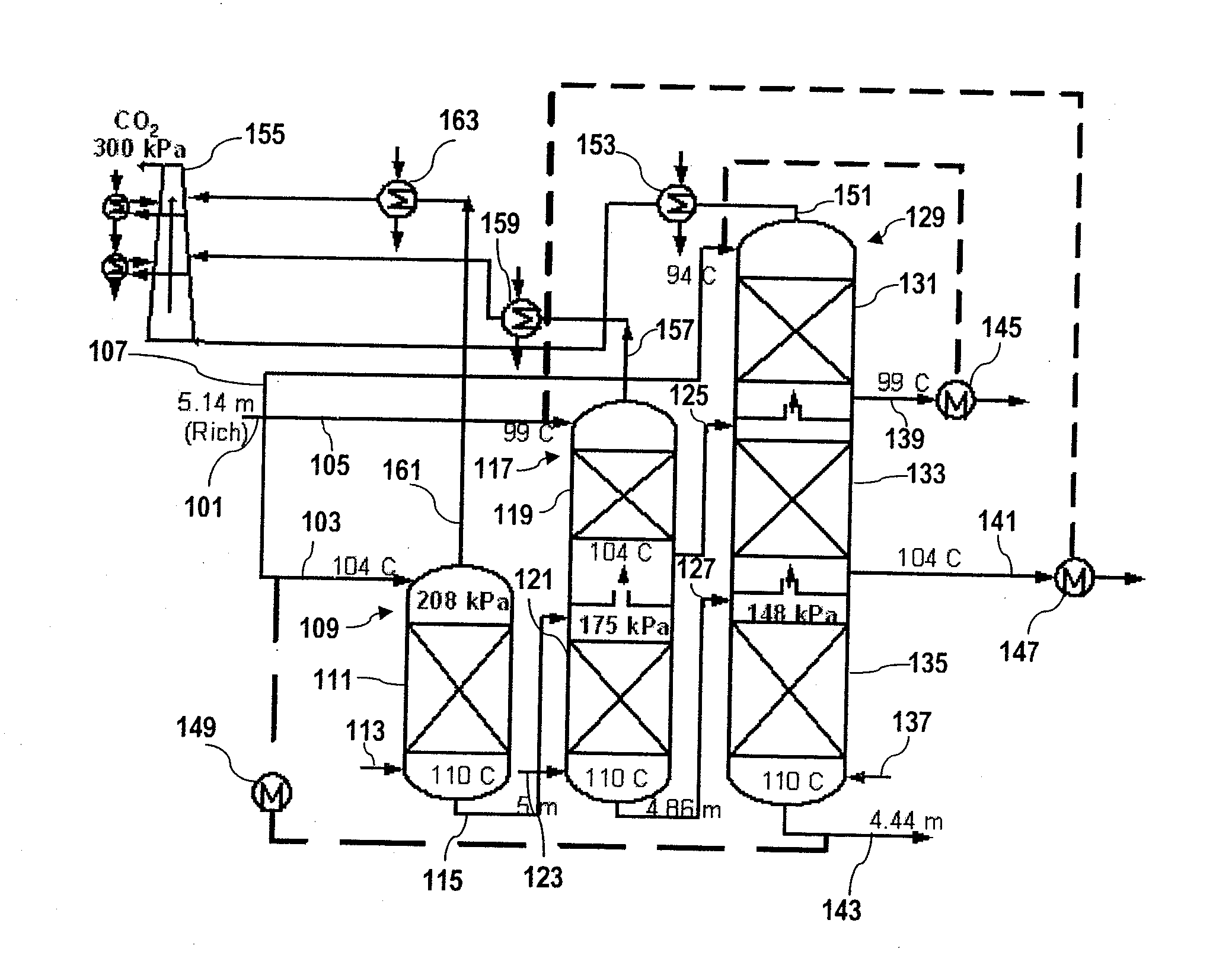

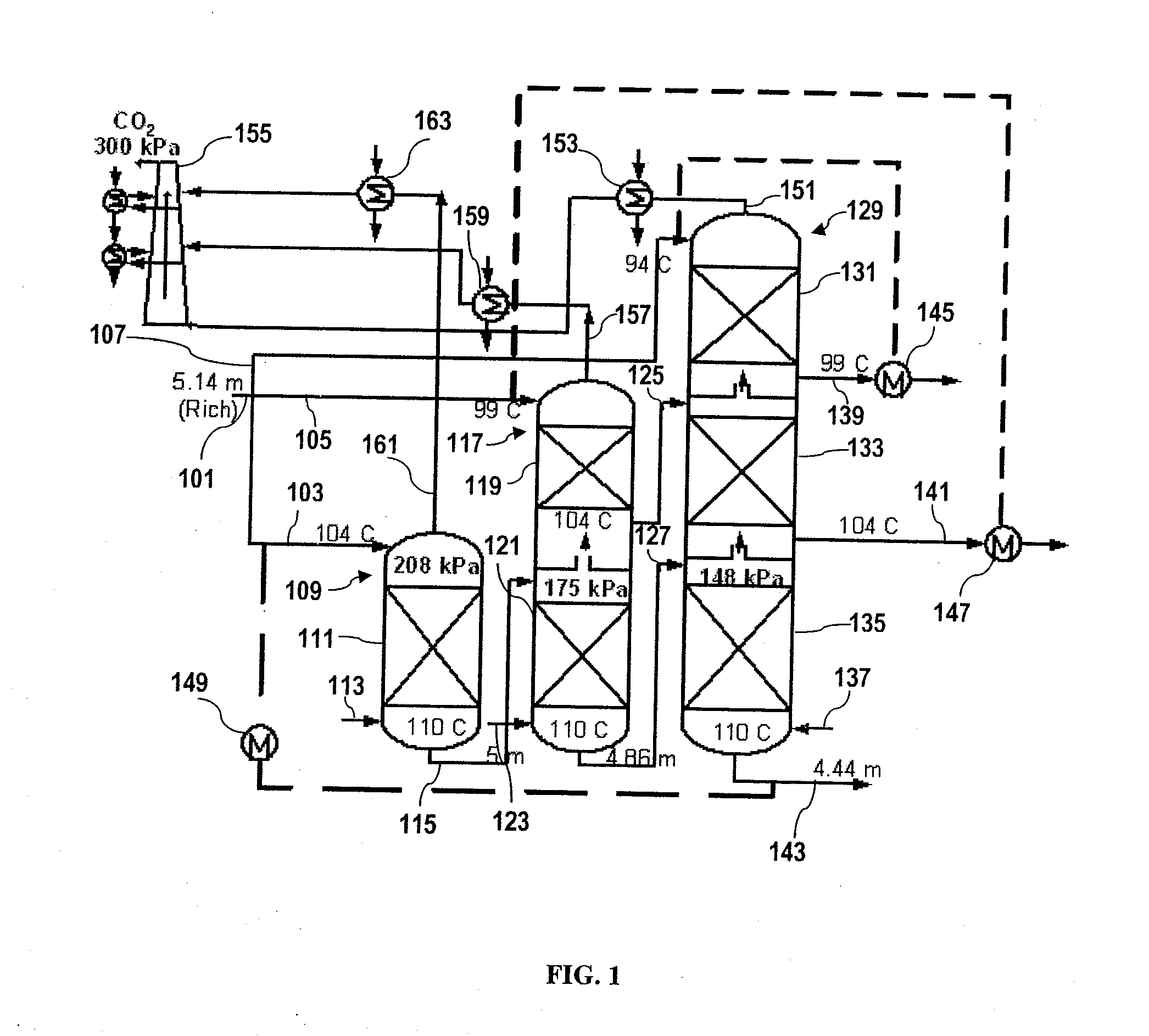

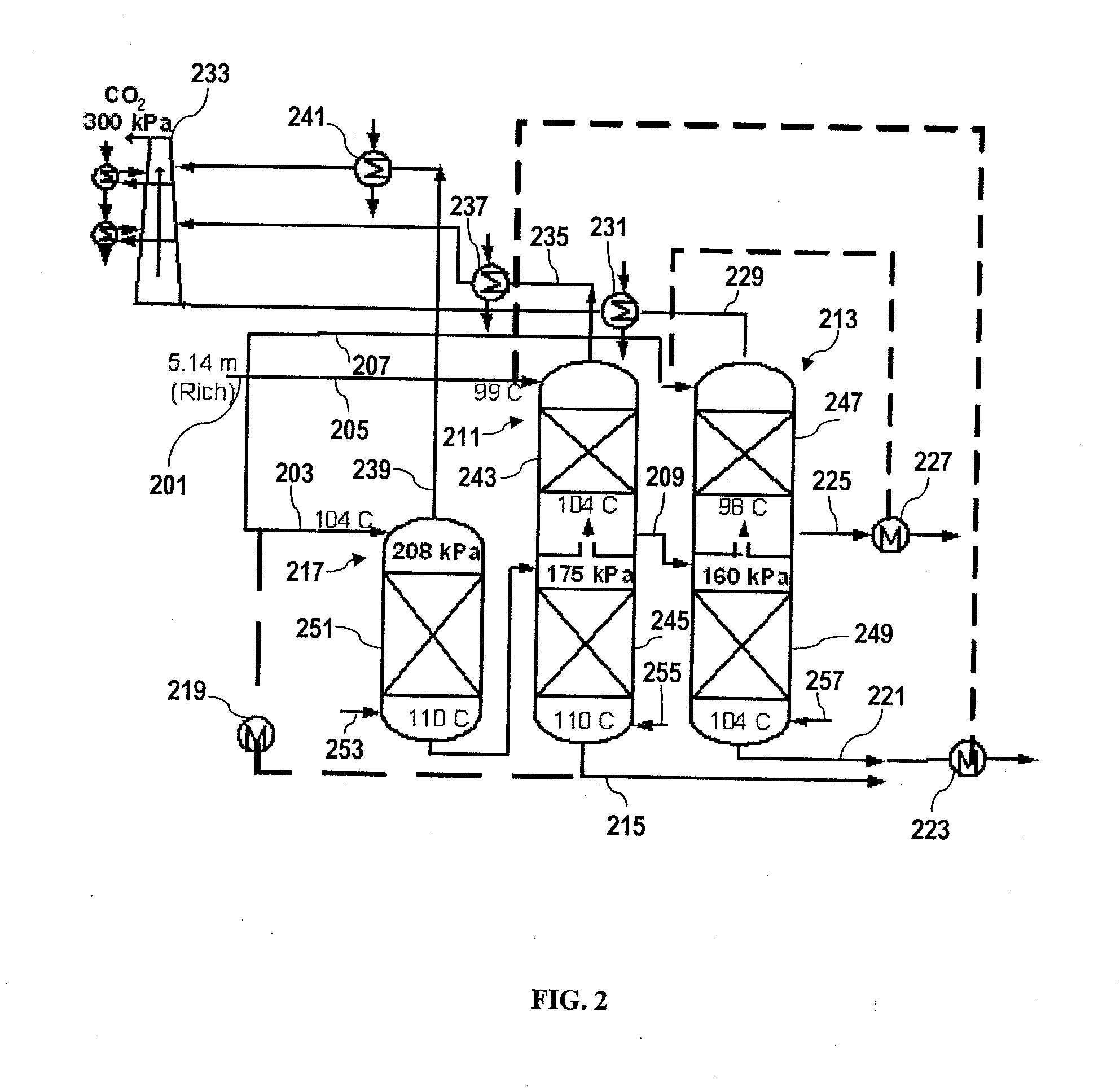

Regeneration of an Aqueous Solution from an Acid Gas Absorportion Process by Matrix Stripping

Carbon dioxide and other acid gases are removed from gaseous streams using aqueous absorption and stripping processes. By replacing the conventional stripper used to regenerate the aqueous solvent and capture the acid gas with a matrix stripping configuration, less energy is consumed. The matrix stripping configuration uses two or more reboiled strippers at different pressures. The rich feed from the absorption equipment is split among the strippers, and partially regenerated solvent from the highest pressure stripper flows to the middle of sequentially lower pressure strippers in a “matrix” pattern. By selecting certain parameters of the matrix stripping configuration such that the total energy required by the strippers to achieve a desired percentage of acid gas removal from the gaseous stream is minimized, further energy savings can be realized.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Enhanced carbon dioxide adsorbent

A CO2 removal system including a member having a first opening and a second opening to enable air flow containing carbon dioxide (CO2) to pass from the first opening to the second opening and lithium hydroxide (LiOH) supported by the member and having an initial water content above an anhydrous level. In one embodiment, LiOH adsorbent density is a maximum of approximately 1.0 g / cm3.

Owner:MICROPORE

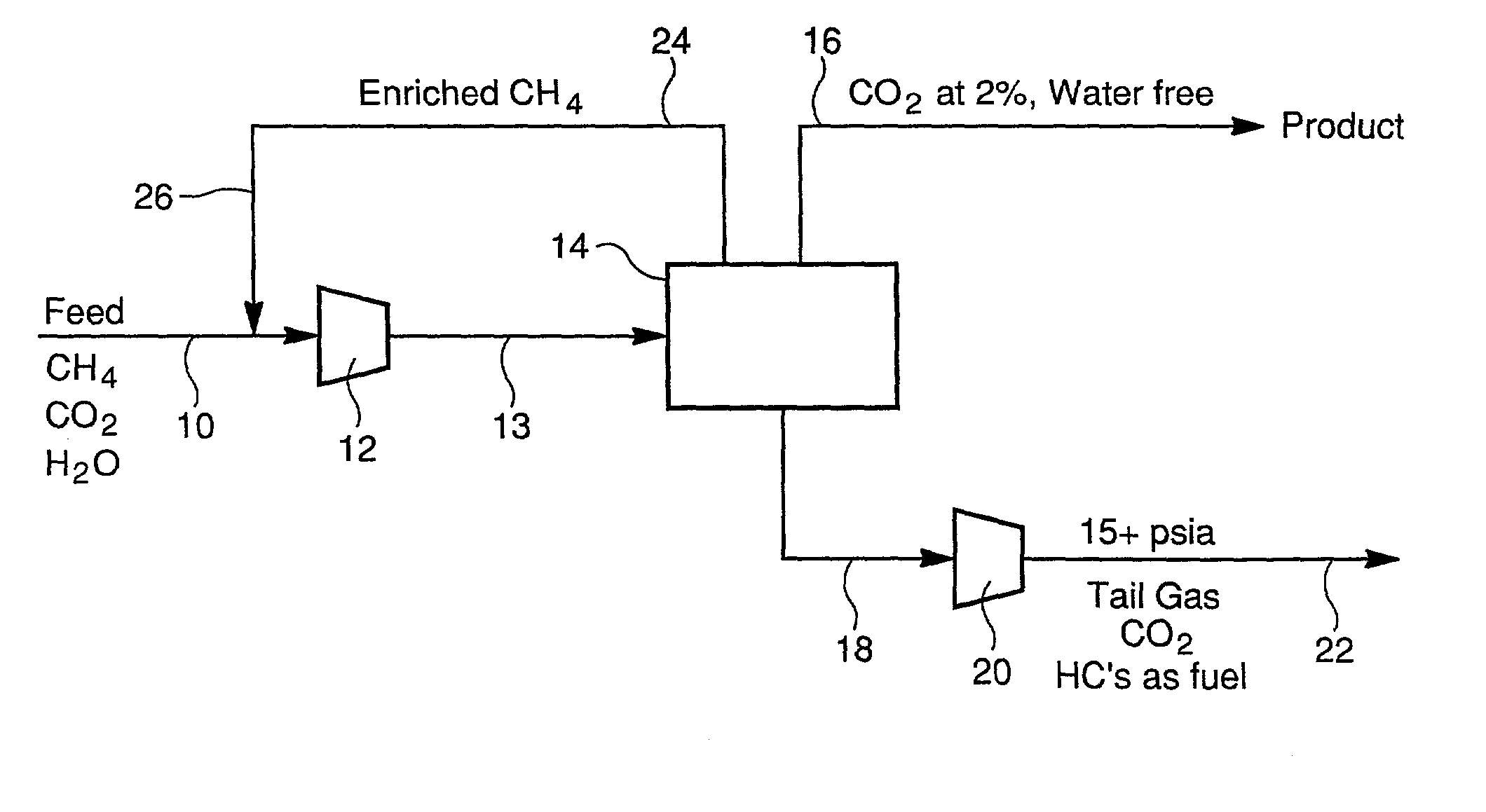

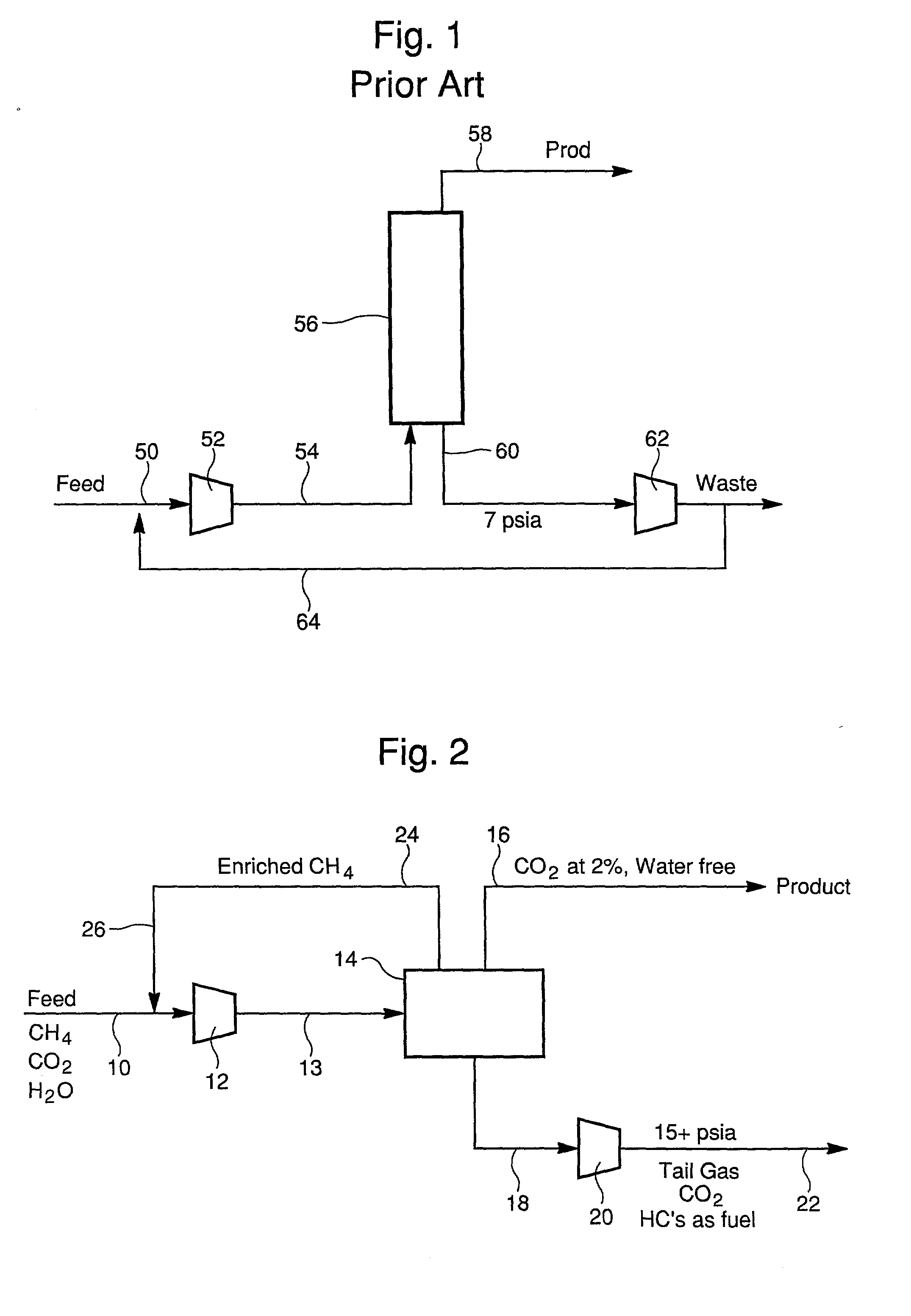

CO2 rejection from natural gas

An improved pressure swing adsorption process is provided for removing or separating a gas from a mixture of gases. The PSA process comprises selectively adsorbing a gas from the mixture to form a product gas having a reduced concentration of the selectively adsorbed gas and a low pressure purge stream containing a higher level of the selectively adsorbed gas than contained in the mixture. During regeneration of the adsorbent a co-current recycle stream is provided which has a pressure less than the product stream, but greater than the purge stream for recycle to feed so as to minimize loss of the product gas to purge. The PSA process is particularly useful for removing carbon dioxide from coal bed methane.

Owner:ENGELHARD CORP

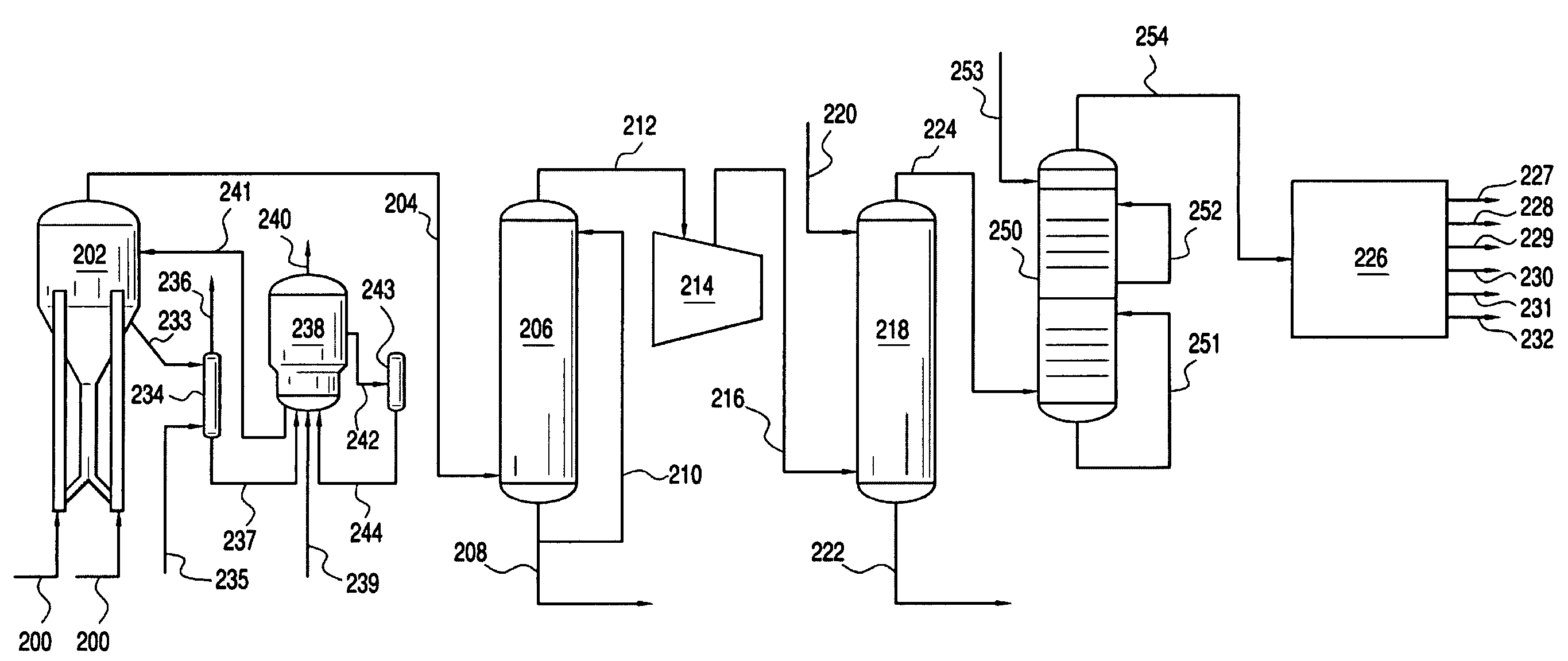

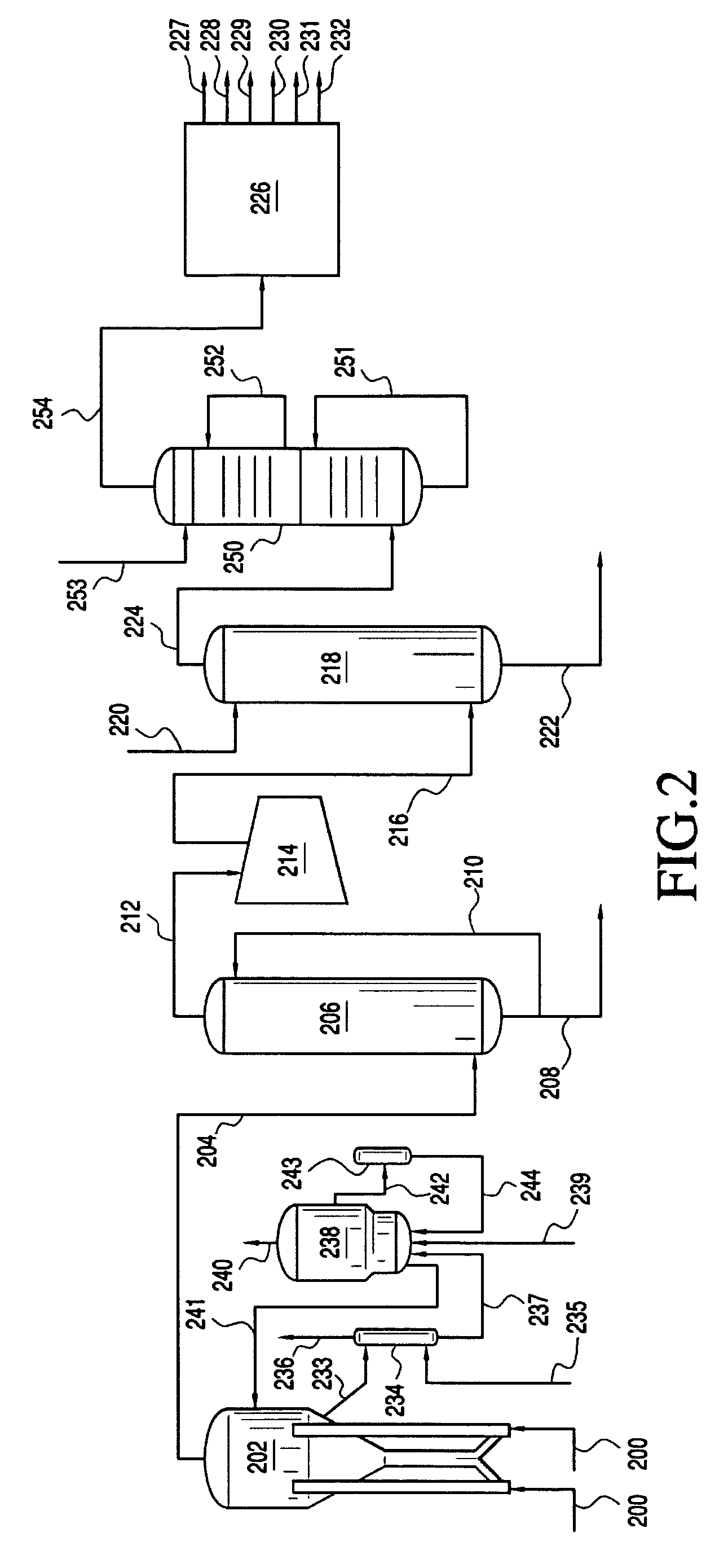

Removing carbon dioxide from an oxygenate to olefins reaction effluent

The present invention provides processes for removing CO2 from an effluent stream derived from an oxygenate to olefins reaction system. In one embodiment, the invention comprises contacting the effluent stream with a first CO2 removal medium in a first CO2 removal zone under conditions effective to remove a first portion of the CO2 from the effluent stream and form a first CO2 depleted stream. The first CO2 depleted stream is contacted with a second CO2 removal medium in a second CO2 removal zone under conditions effective to remove a second portion of the CO2 from the first CO2 depleted stream and form a second CO2 depleted stream comprising less than about 0.5 vppm CO2.

Owner:EXXONMOBIL CHEM PAT INC

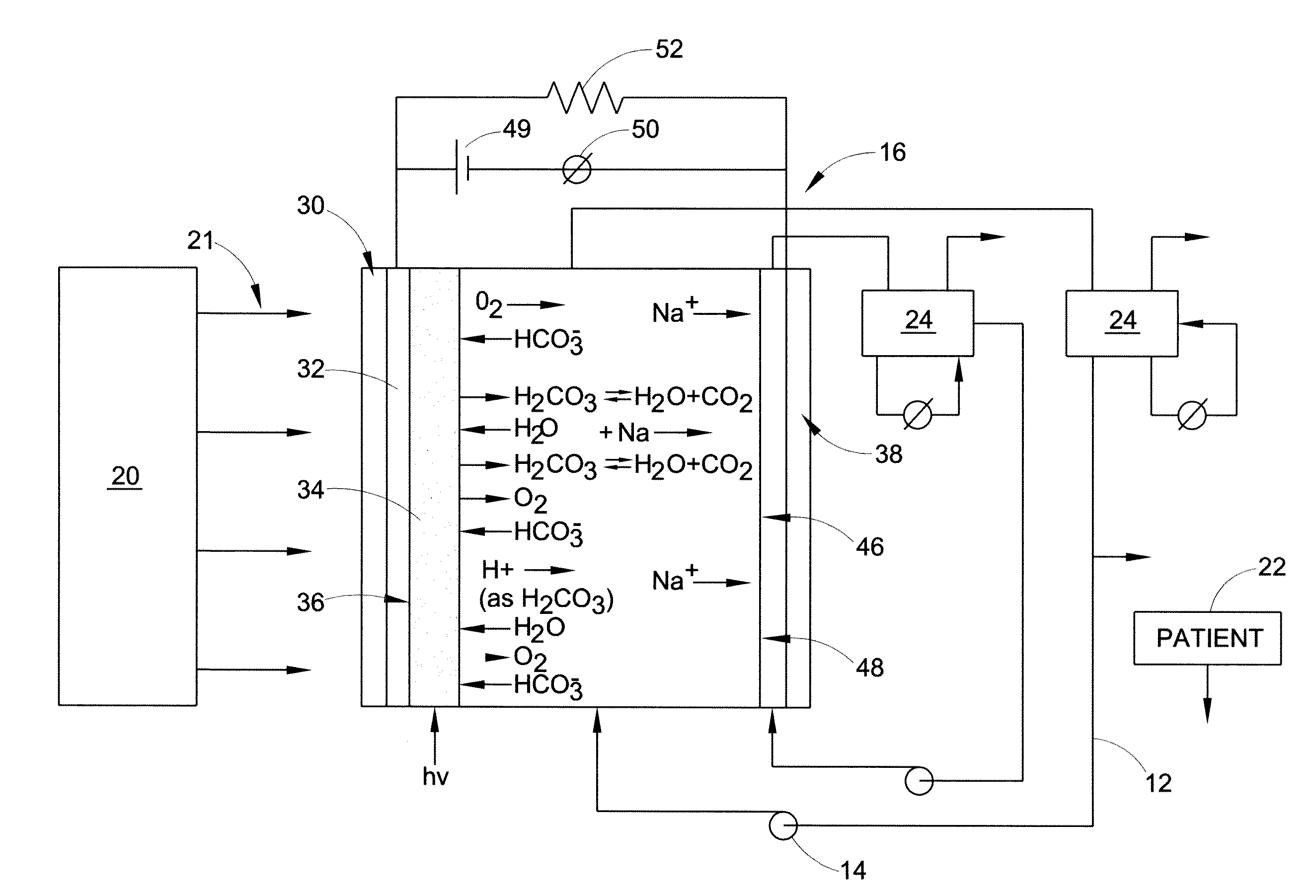

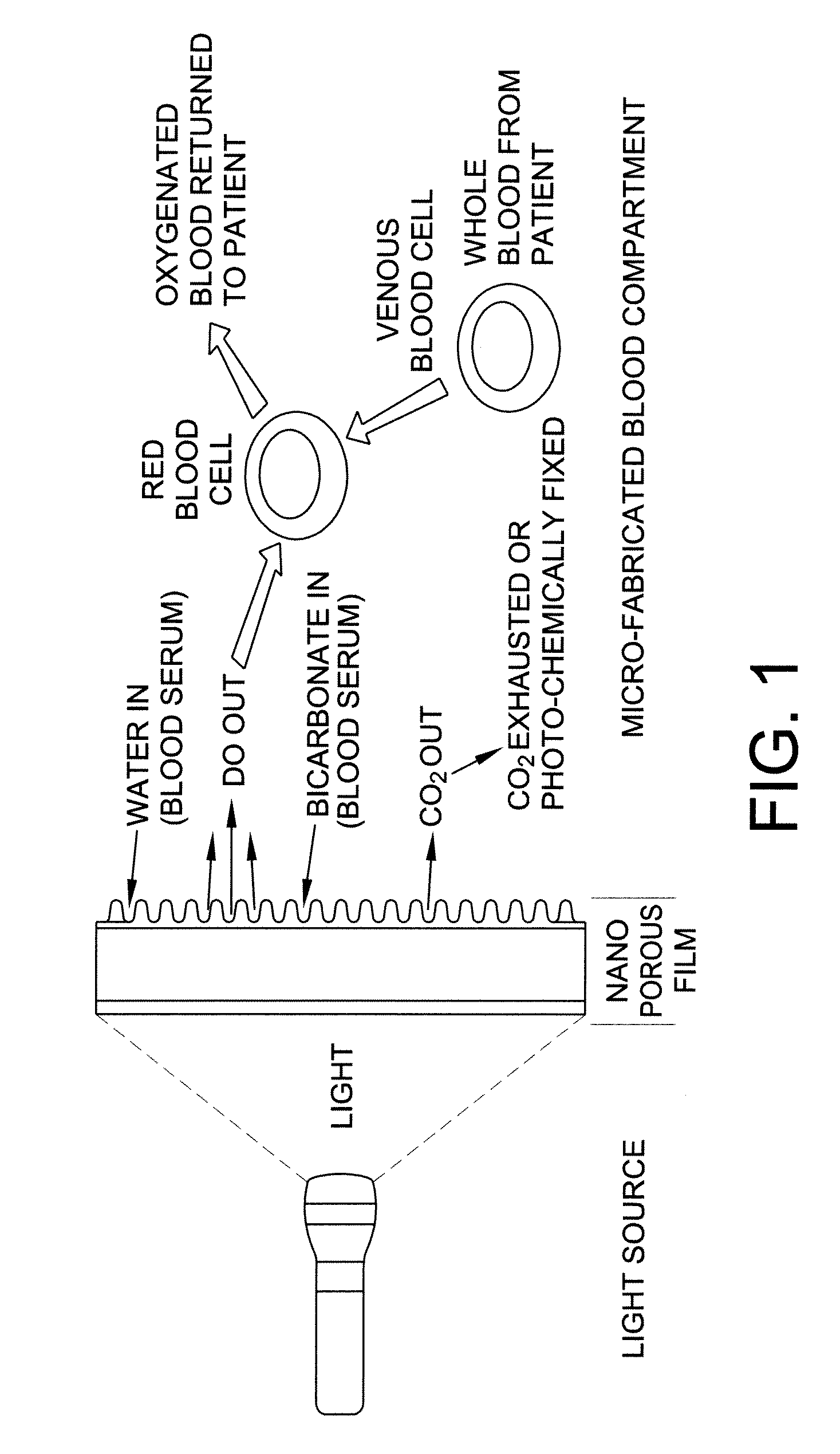

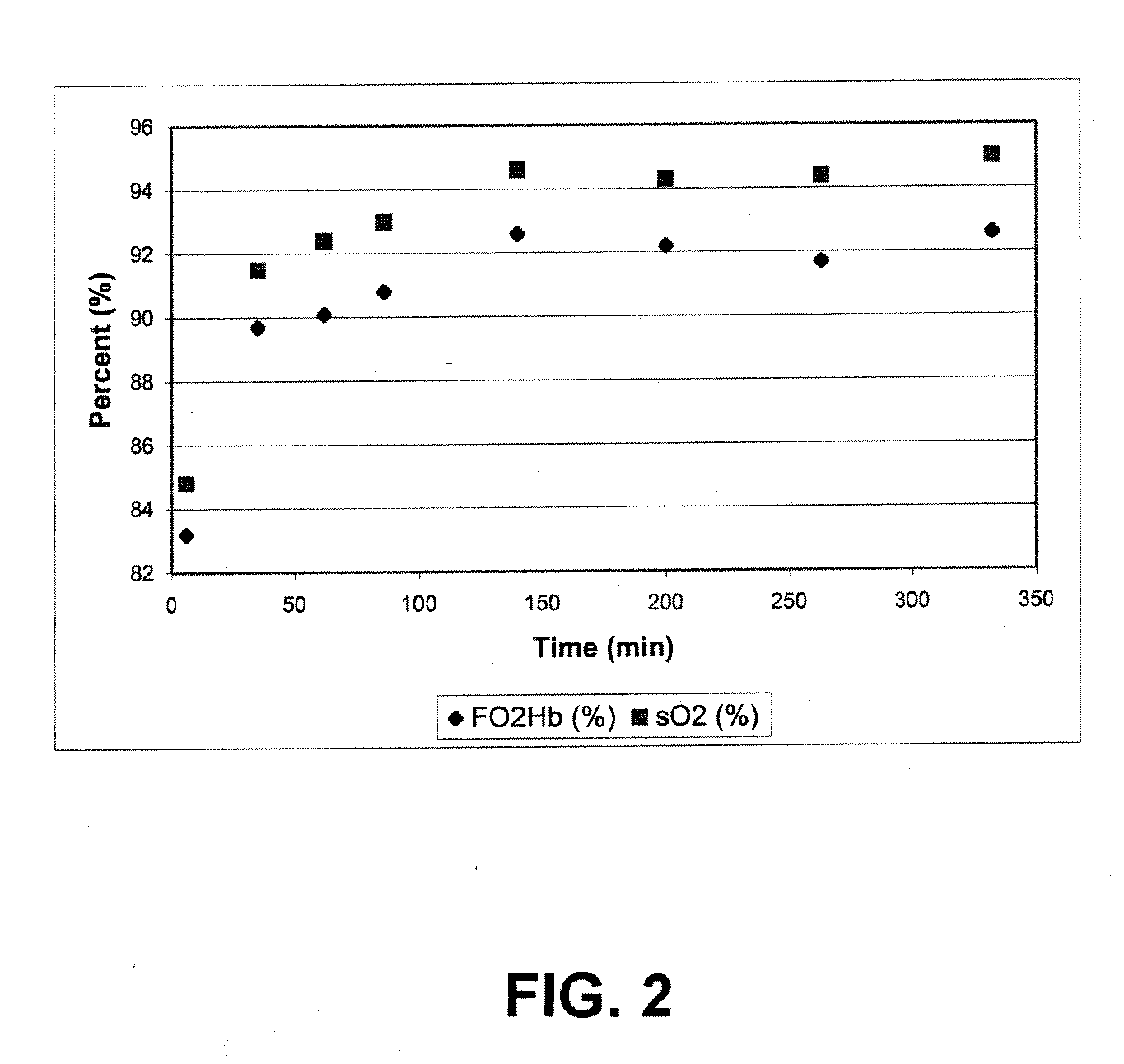

Carbon dioxide removal from whole blood by photolytic activation

Apparatus and methods for removing carbon dioxide from whole blood. Hydrogen ions are generated from water in the blood, resulting in the formation and release of carbon dioxide from the blood.

Owner:BATTELLE MEMORIAL INST

Method of manufacturing and using enhanced carbon dioxide adsorbent

A method of processing carbon dioxide adsorbent for use in a CO2 removal system. The method includes combining a polymer, lithium hydroxide (LiOH), and lubricant that dissolves the polymer to form a first LiOH adsorbent. A structure may be formed using the first LiOH adsorbent. The lubricant may be extracted from the structured LiOH adsorbent using a solvent to form a second LiOH adsorbent. The solvent may be removed from the second LiOH adsorbent to form a third LiOH adsorbent. The third LiOH adsorbent may be hydrated to form a fourth LiOH adsorbent having a water content above an anhydrous level.

Owner:MICROPORE

Carbon capture system and process

A system and process is provided primarily for use in hot climates, using ammonia solution to remove carbon dioxide from desulphurised water-vapour-containing flue gases of a fossil fuel power plant, while outputting useful streams of water and fertiliser.

Owner:GENERAL ELECTRIC TECH GMBH

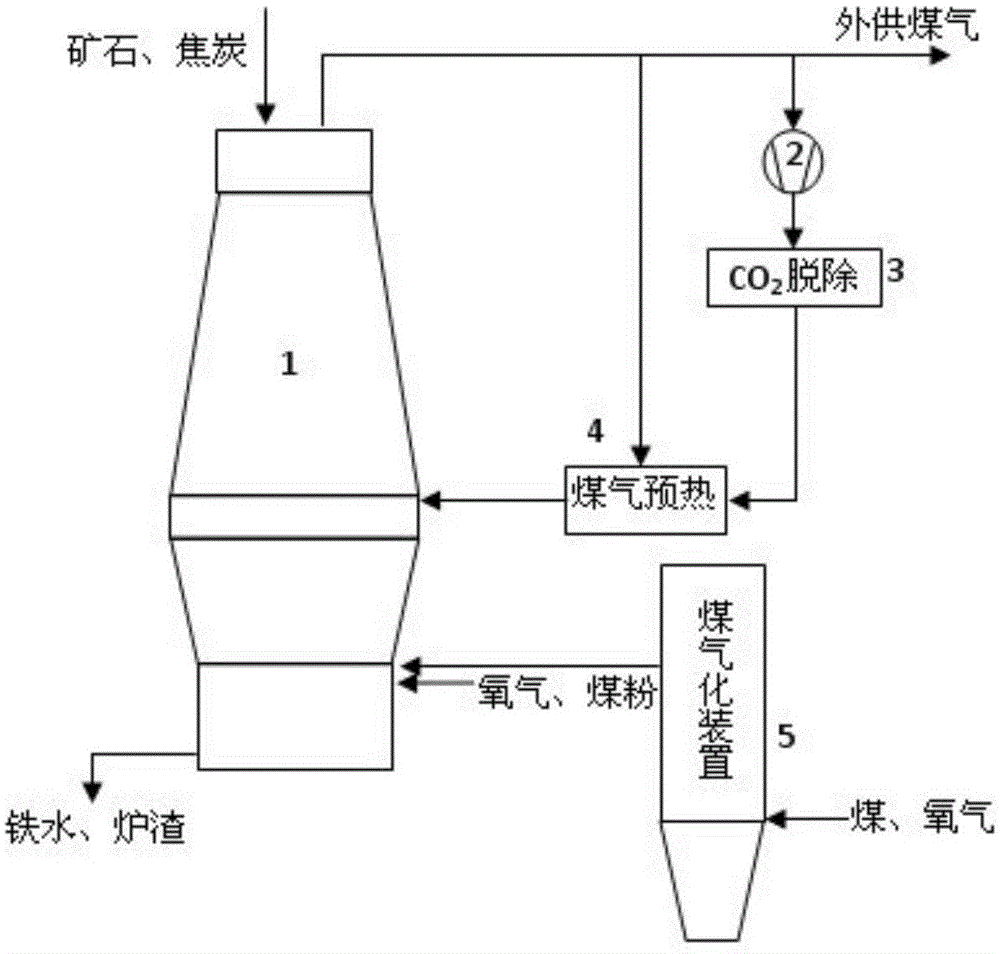

High-temperature gas injection-based iron-making technology

InactiveCN104131122ALower quality requirementsLow priceBlast furnace detailsGas emission reductionCo2 removalCapacity factor

The invention discloses a high-temperature gas injection-based iron-making technology and belongs to the field of black metallurgy. The high-temperature gas injection-based iron-making technology utilizes oxygen-rich normal-temperature air blasting to replace hot air operation, and high-temperature gas produced by a coal gasification device and CO2-free furnace top recycled gas are mixed and are respectively pumped into a blast furnace from the furnace body and the hearth so that furnace top recycled gas CO2 removal is realized. The high-temperature gas injection-based iron-making technology has a coal ratio of 240-350kg / tHM, a coal gasification unit coal-use amount of 50-250kg / tHM and a coke ratio of 180-260kg / tHM and a blast furnace capacity factor of 6.0-7.5, reduces operation costs of oxygen-containing blast furnace top gas CO2 removal and recycled gas pre-heating to a temperature of 900-1300 DEG C, realizes coke reduction and coal use increasing in blast furnace production, improves an iron-making technology energy structure and stabilizes gas balance of a steel enterprise.

Owner:UNIV OF SCI & TECH BEIJING

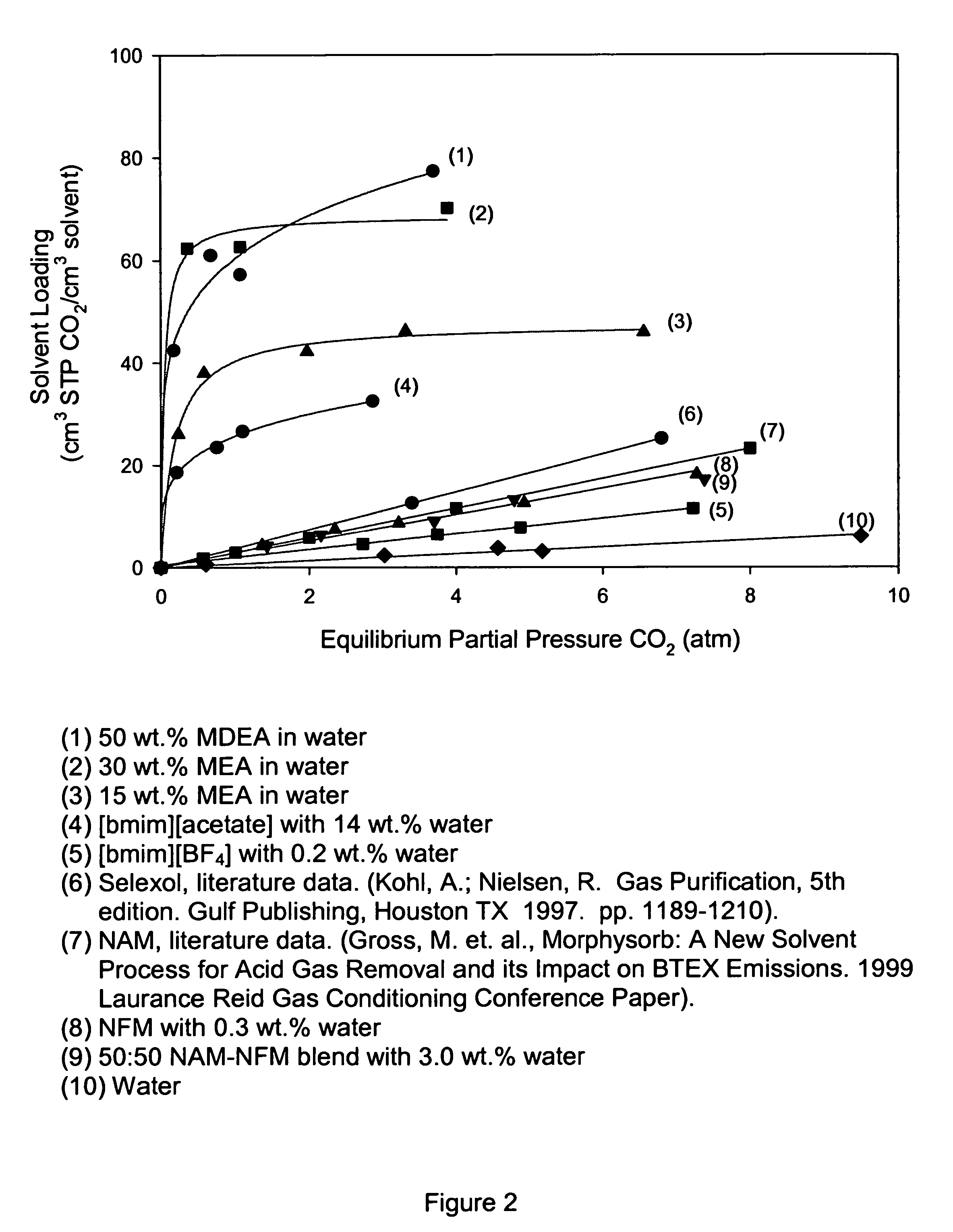

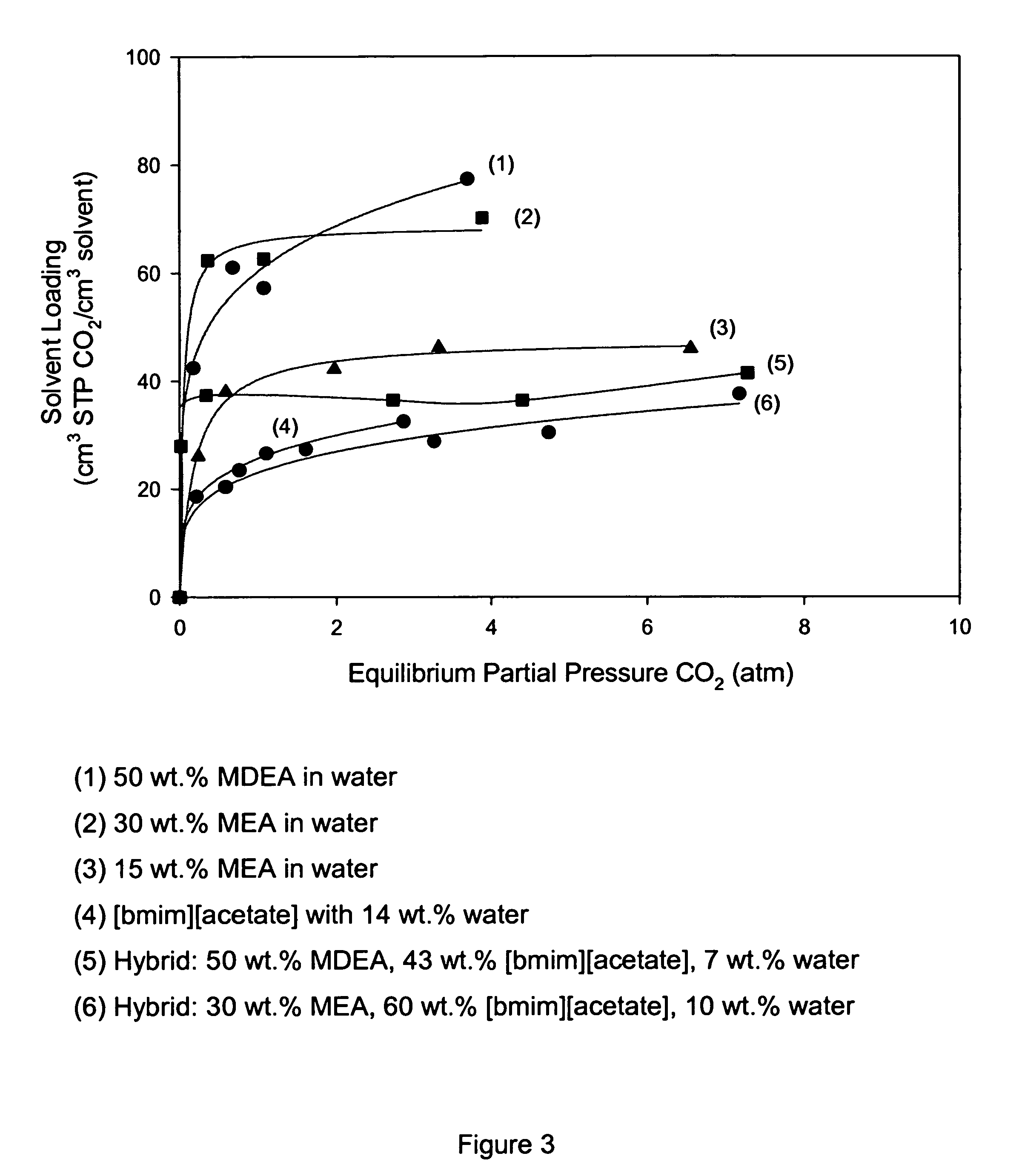

CO2 removal from gas using ionic liquid absorbents

A process and method for separating CO2 from a gaseous stream such as natural gas. An ionic liquid comprising an anion having a carboxylate function and an effective amount of water is used as an adsorbent to selectively complex the CO2 yielding a gaseous stream with a greatly reduced CO2 content. The ionic liquid can then be readily be regenerated and recycled.

Owner:CHEVROU USA INC

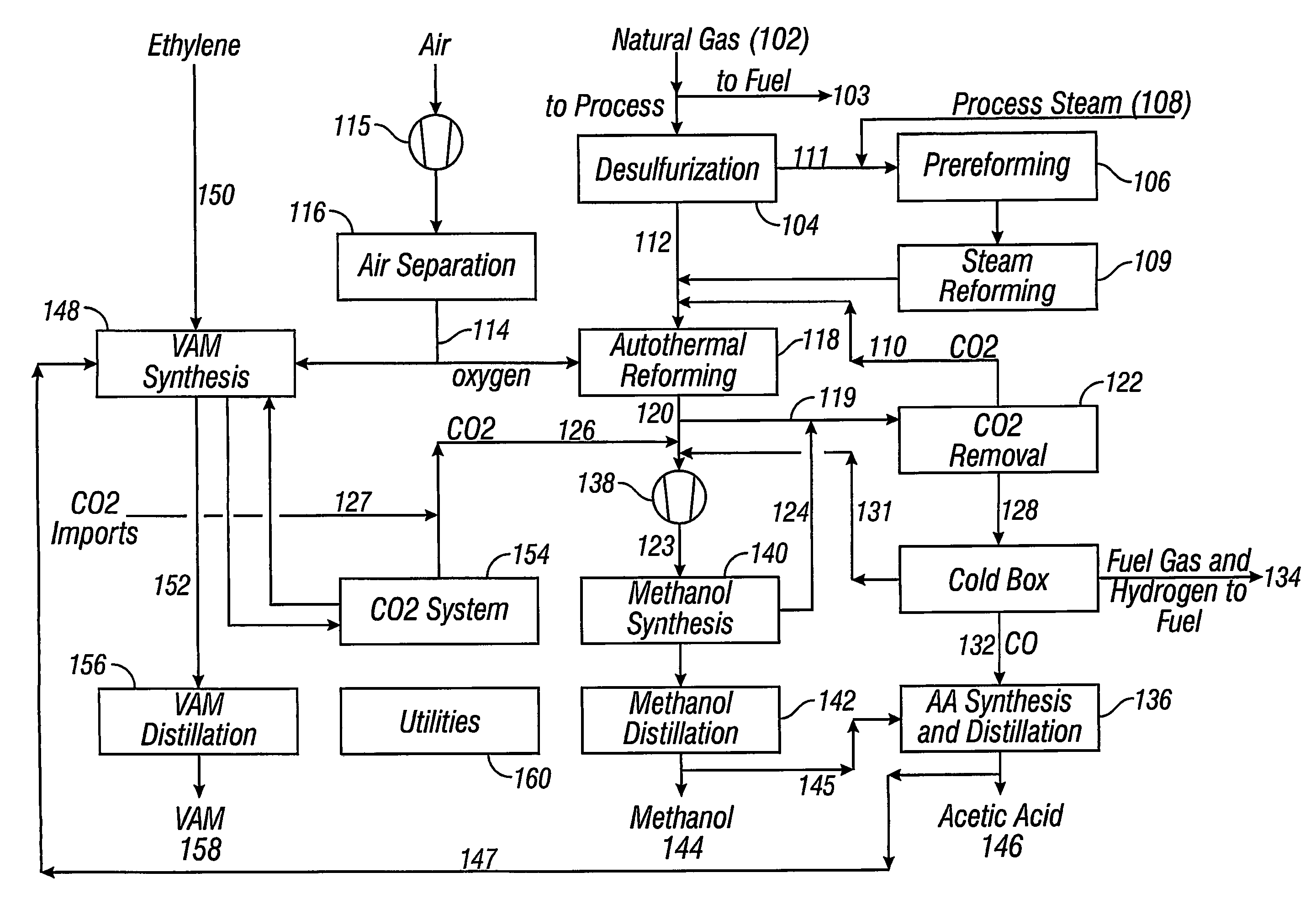

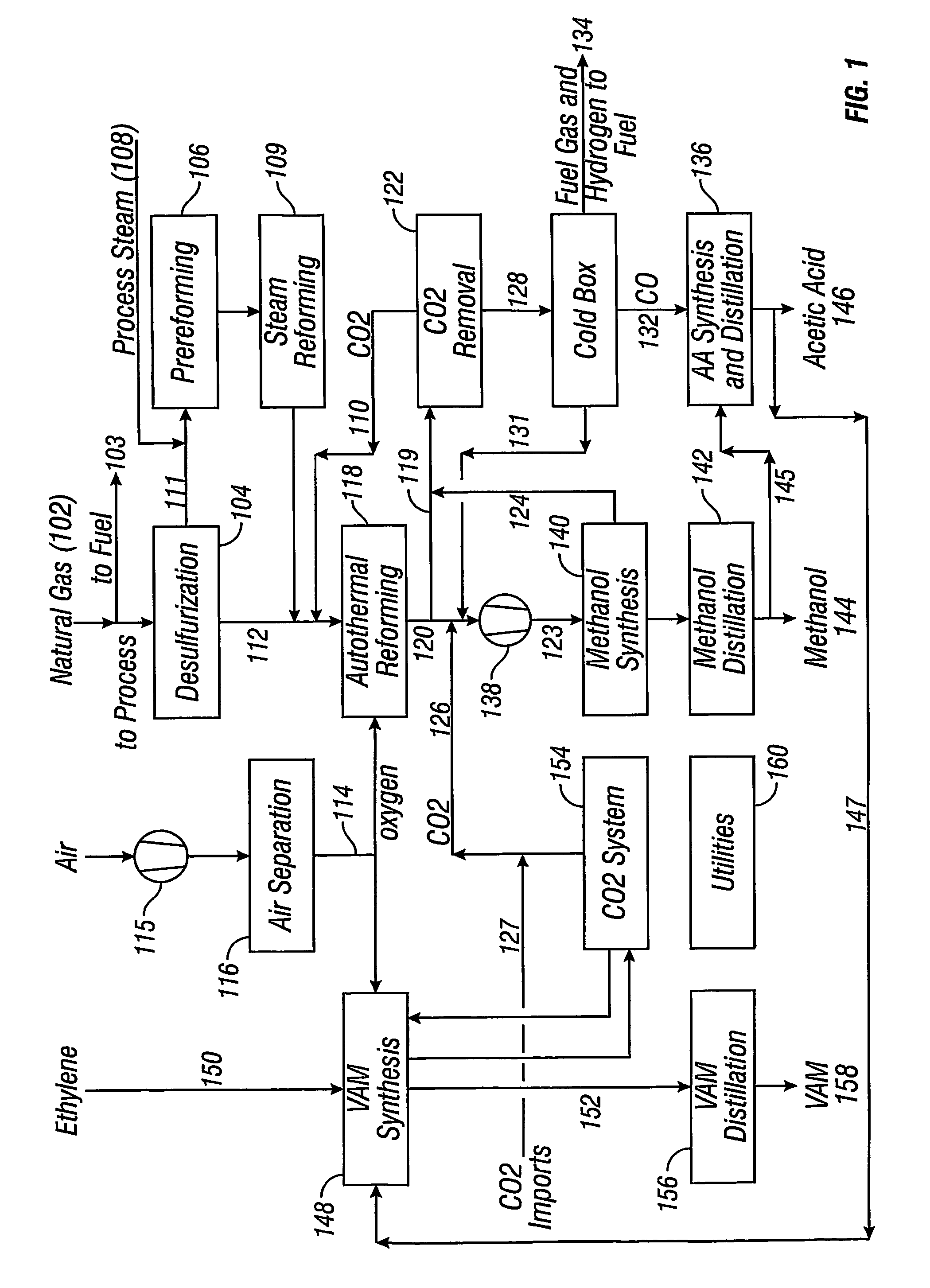

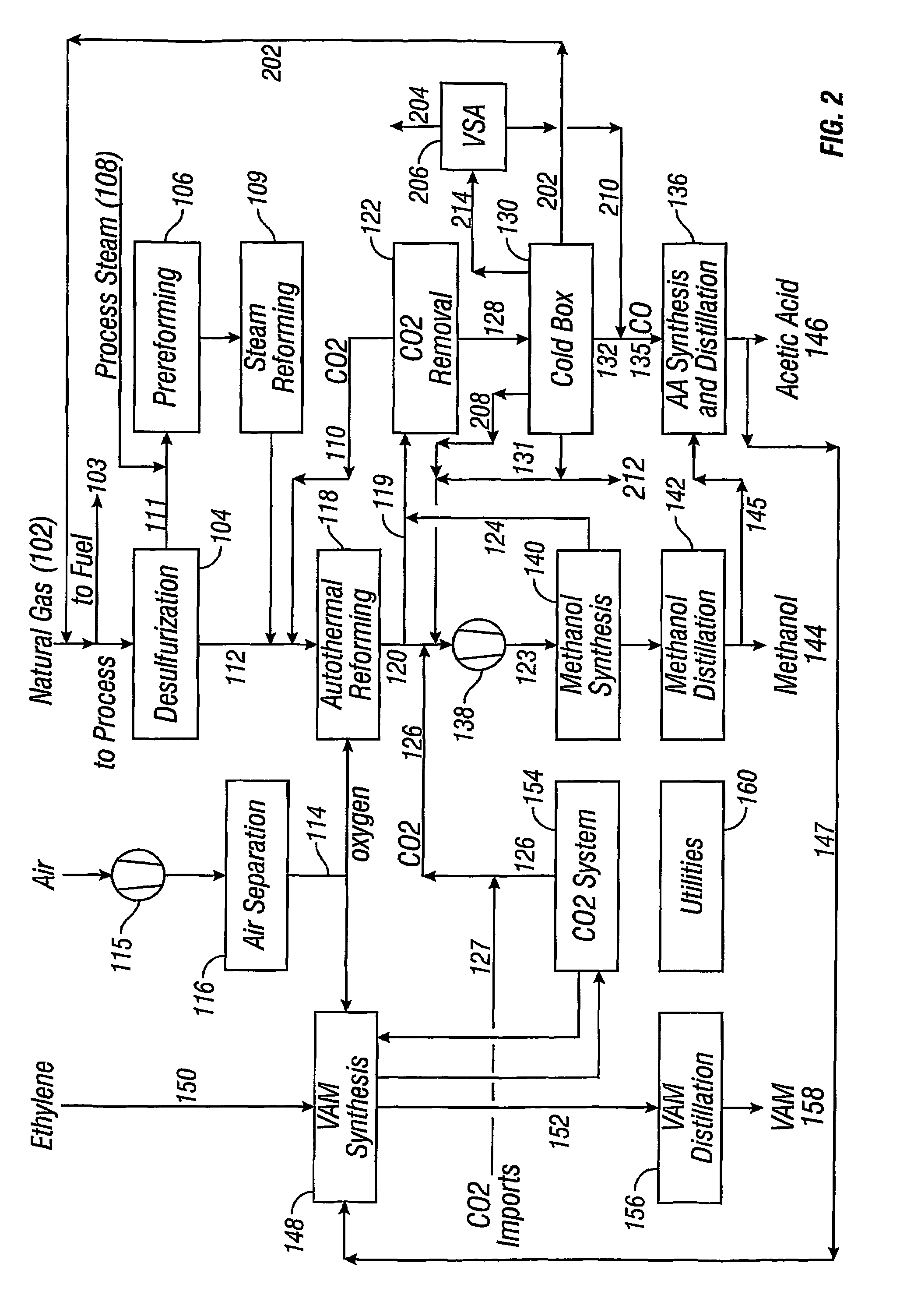

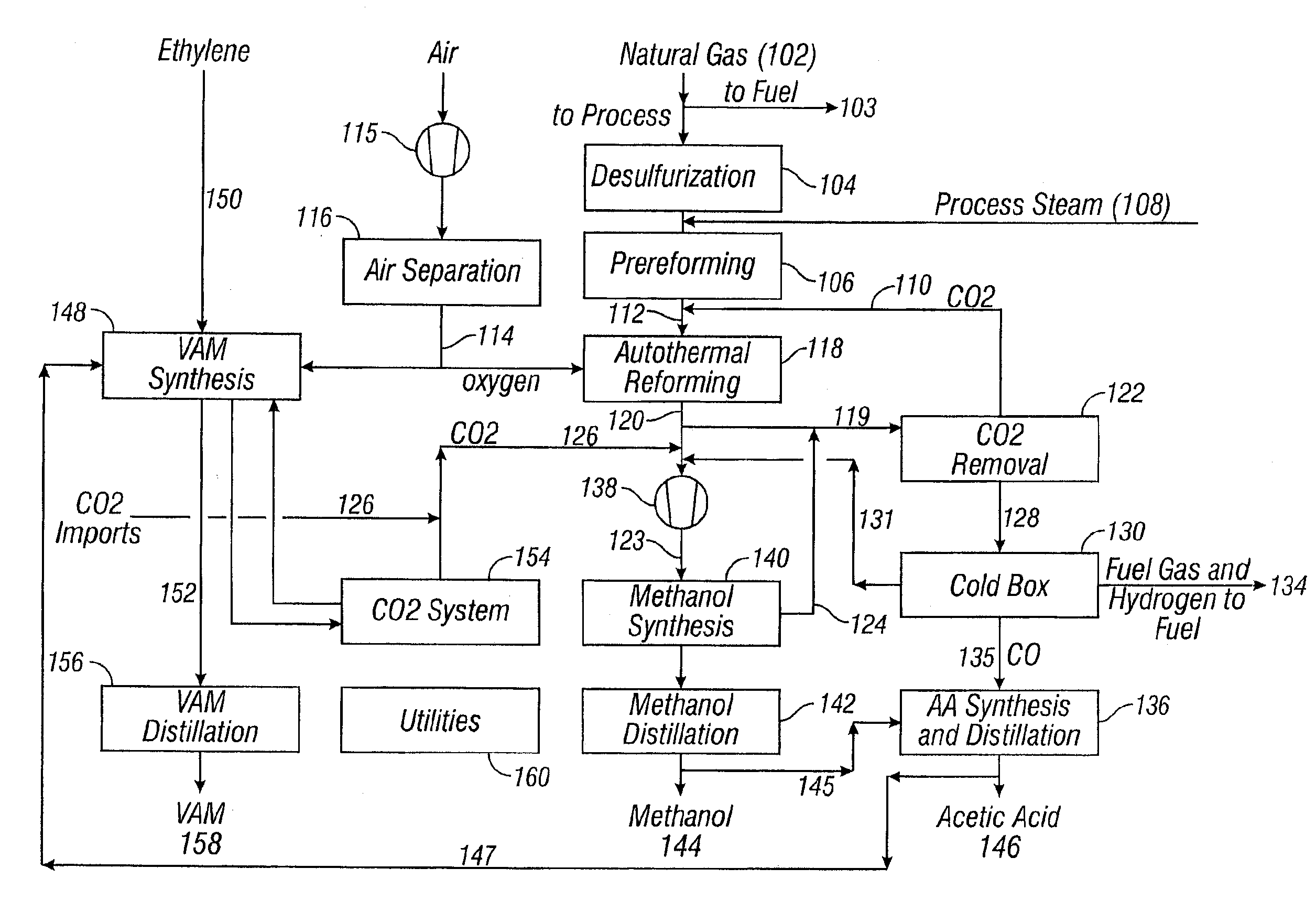

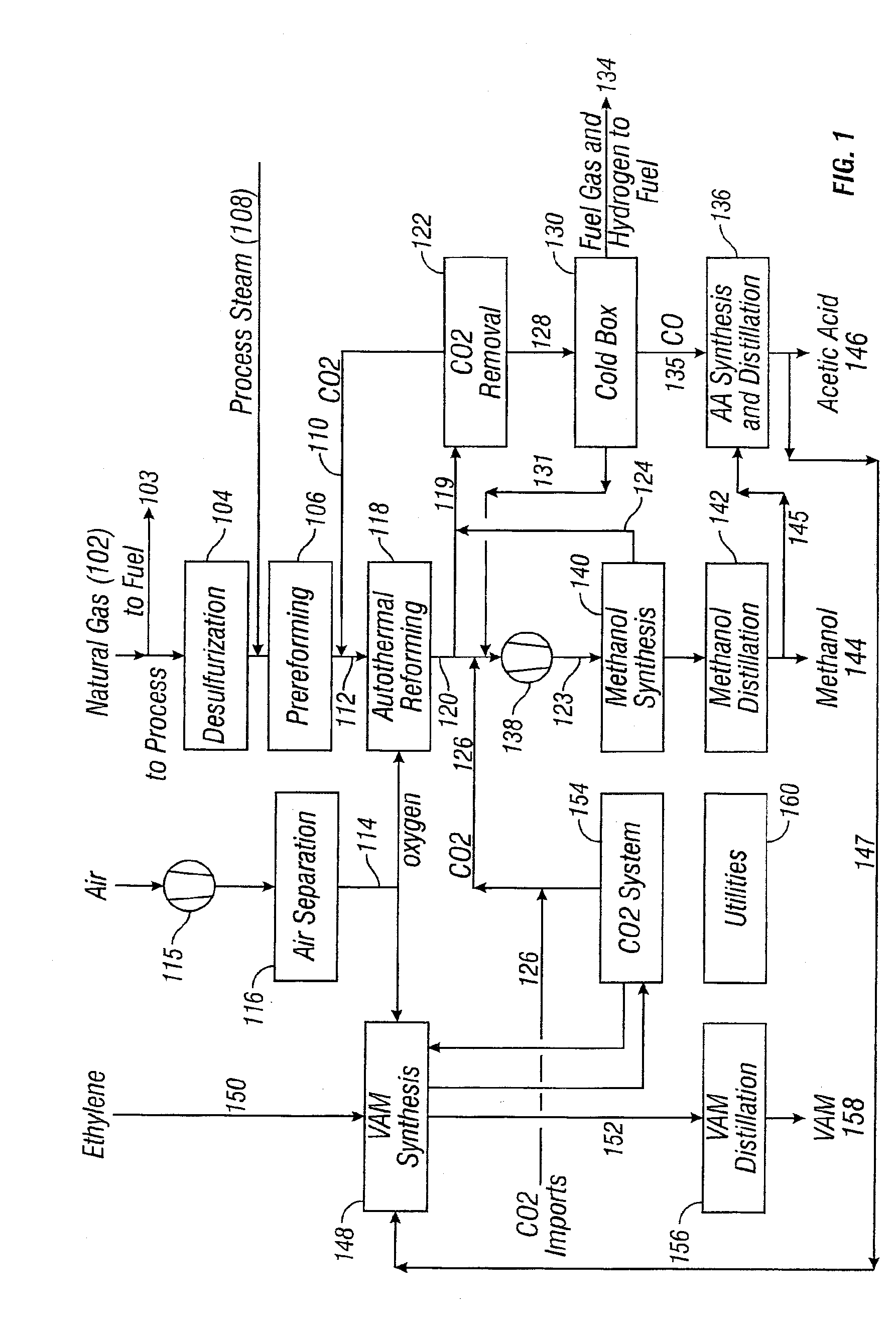

Integrated process for acetic acid and methanol

An integrated large capacity, single-train process for making 1,00020,000 MTPD methanol and 3006,000 MTPD acetic acid is disclosed. Syngas 120 is produced by autothermal reforming 118 of natural gas 102 where the feed 112 of the natural gas is supplied with oxygen and CO2 recycle 110 to the autothermal reformer (ATR) 118. A portion (5-50%) of the syngas is fed to CO2 removal 122 to obtain the recycle CO2 and cold box 130 to obtain a hydrogen stream 131 and a CO stream 135. The 50-95% remaining syngas, hydrogen stream 131 and optionally any CO2 from an associated process are fed to methanol synthesis 140, which produces the methanol. The methanol is supplied to an acetic acid unit 136 with the CO 135 to make the acetic acid, which in turn can be supplied to a VAM synthesis unit 148. Oxygen for the ATR and any VAM synthesis can be supplied by a single common air separation unit 116, and utilities such as steam generation can further integrate the process.

Owner:ACETEX

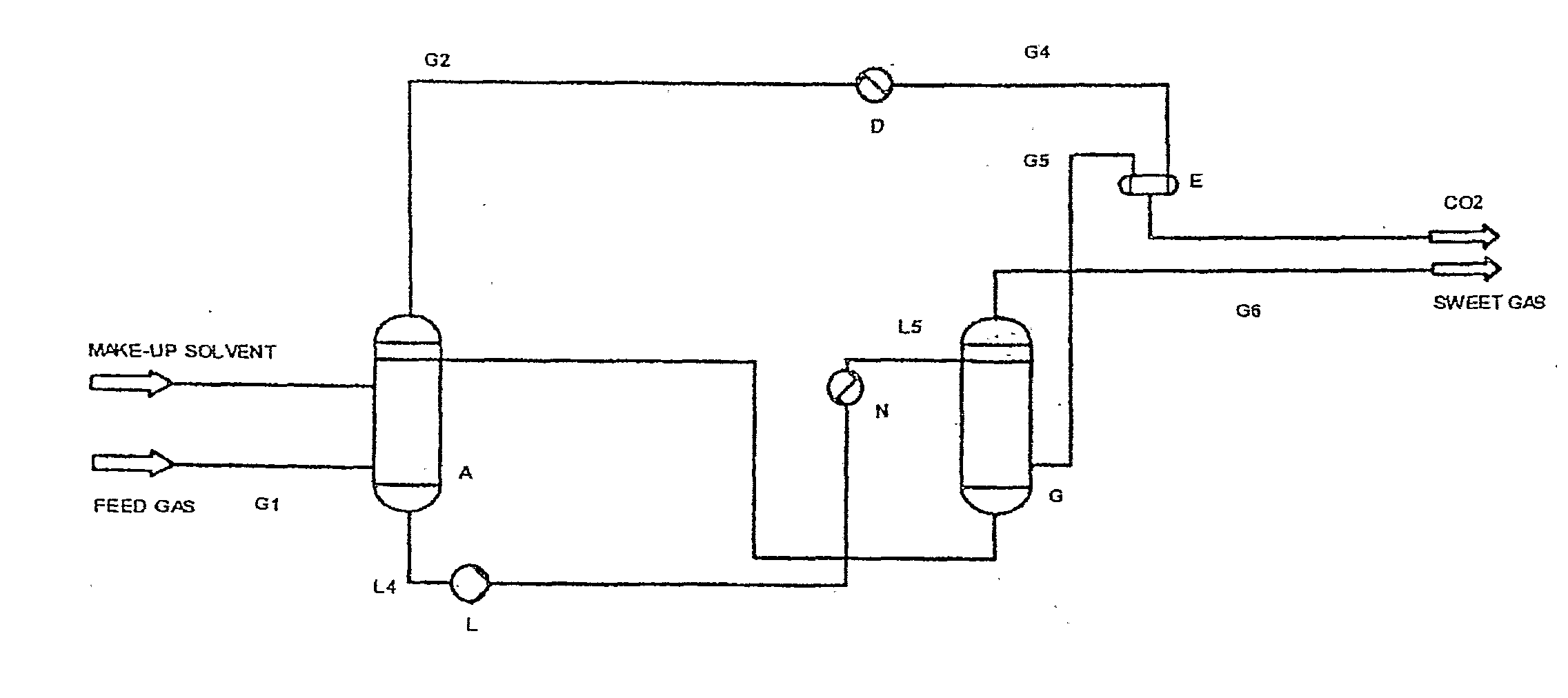

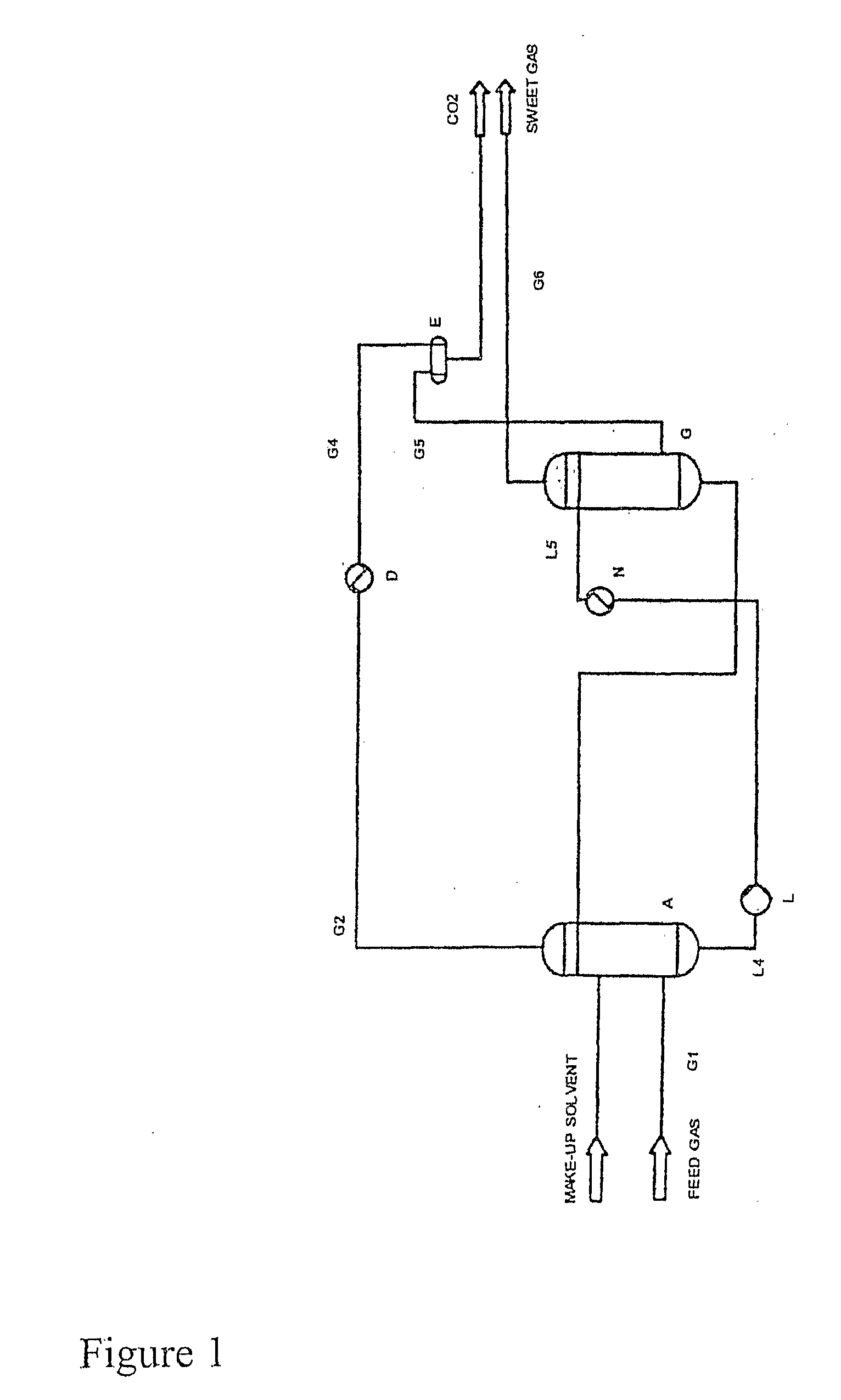

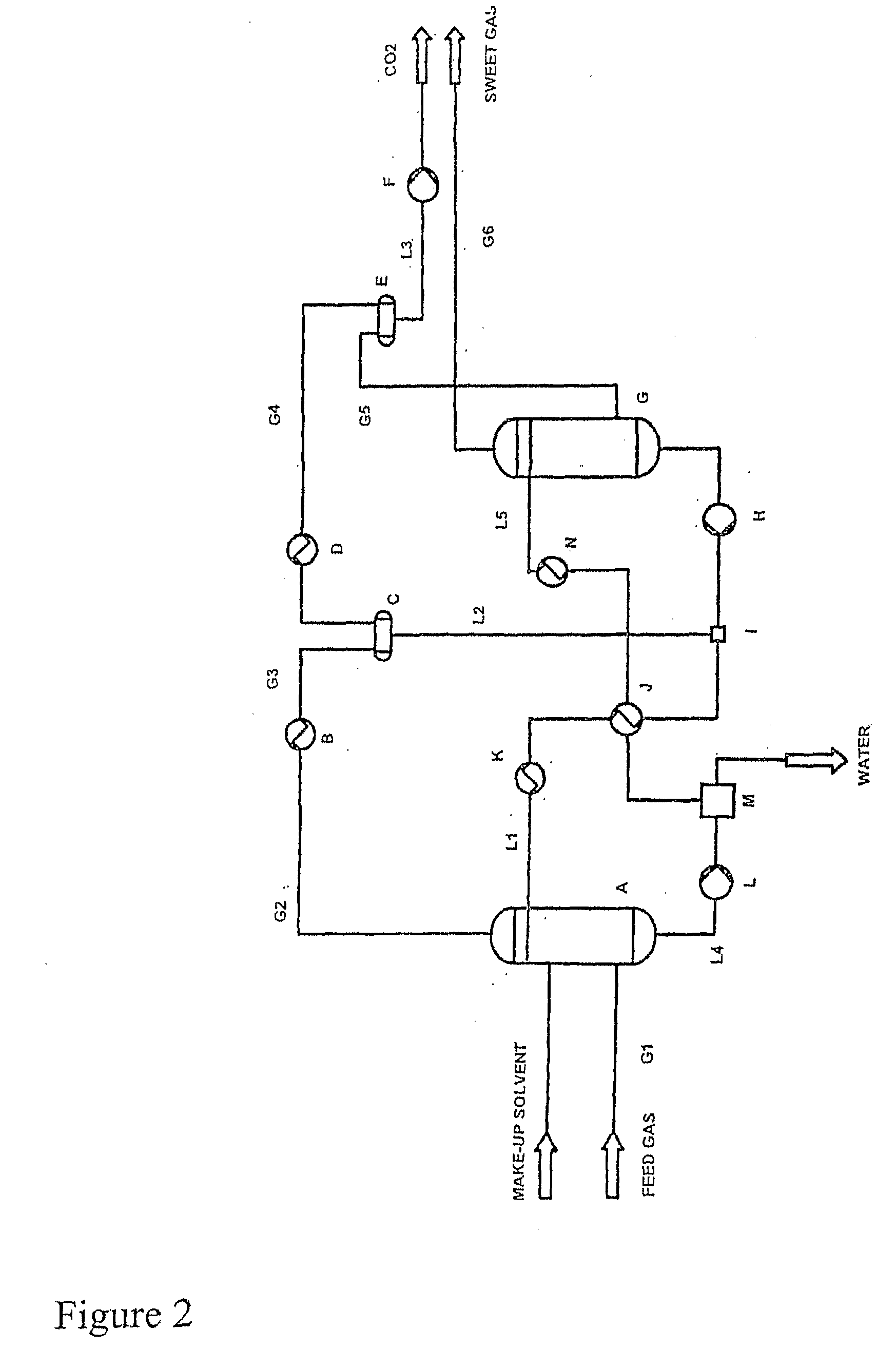

Removal of carbon dioxide from a feed gas

ActiveUS20100278711A1No production costs for altering the pressure within the plantConstant pressureLiquid degasificationCarbon compoundsCo2 removalEnvironmental engineering

The present invention relates to a new process for removal of carbon dioxide from a feed gas, wherein the feed gas is fed to and concentrated in a stripper column (A) before condensation of the gaseous carbon dioxide. The present invention also relates to different uses of the removed carbon dioxide and to a plant for removal of carbon dioxide from the feed gas.

Owner:UNION ENG

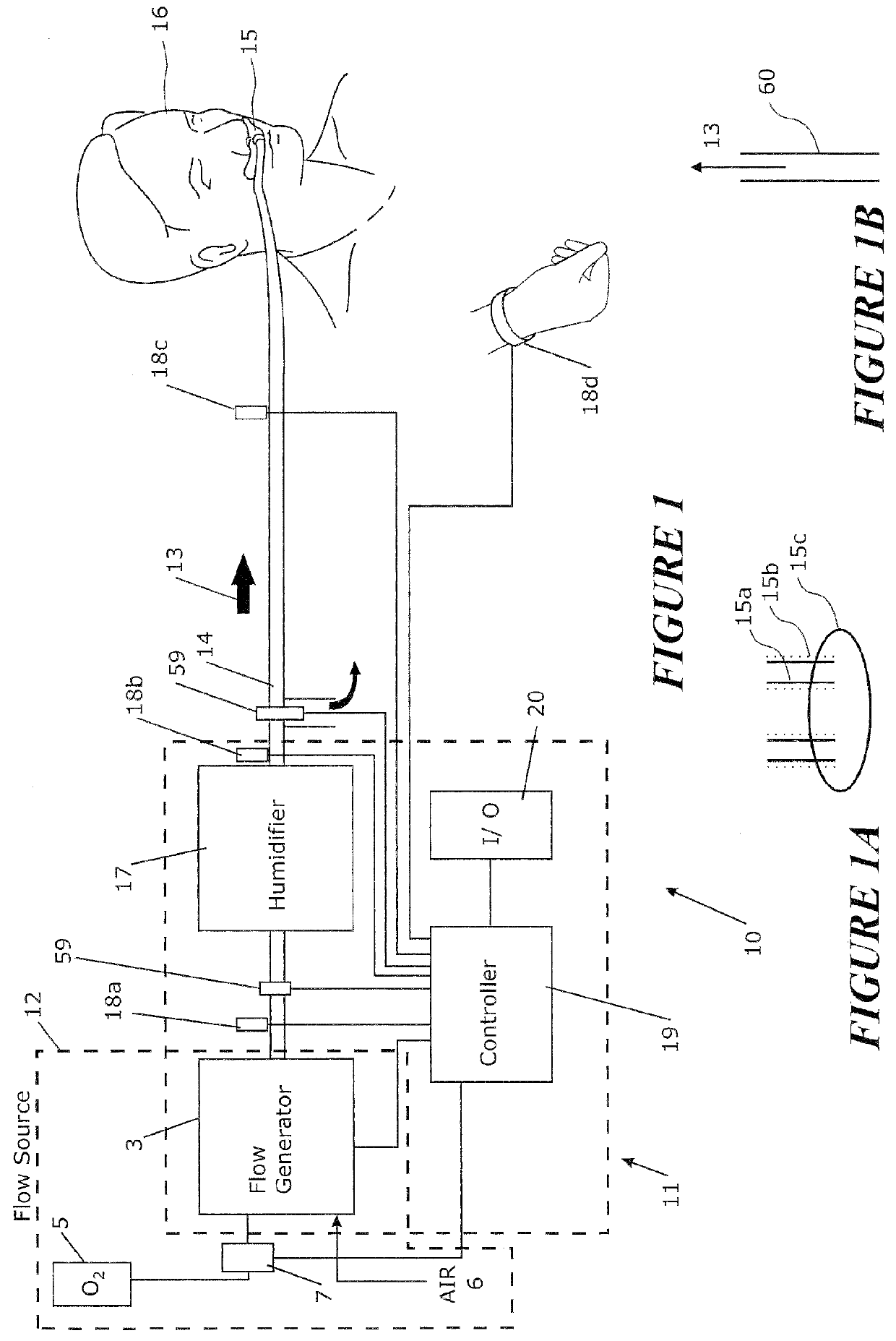

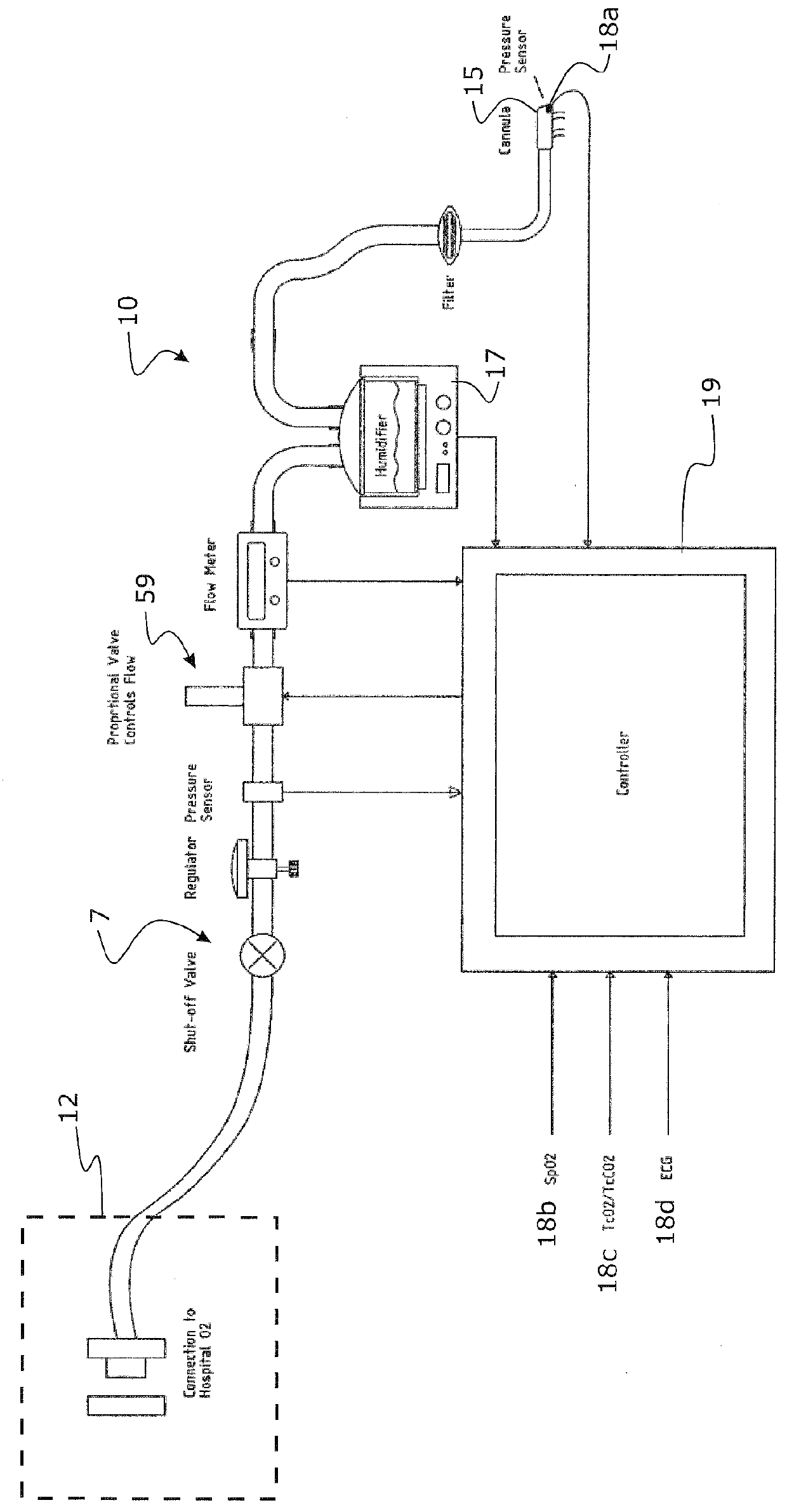

Methods and apparatus for oxygenation and/or co2 removal

Described is an apparatus for oxygenation and / or CO2 clearance of a patient, comprising: a flow source or a connection for a flow source for providing a gas flow, a gas flow modulator, a controller to control the gas flow, wherein the controller is operable to: receive input relating to heart activity and / or trachea gas flow of the patient, and control the gas flow modulator to provide a varying gas flow with one or more oscillating components with a frequency or frequencies based on the heart activity and / or trachea flow of the patient.

Owner:FISHER & PAYKEL HEALTHCARE LTD

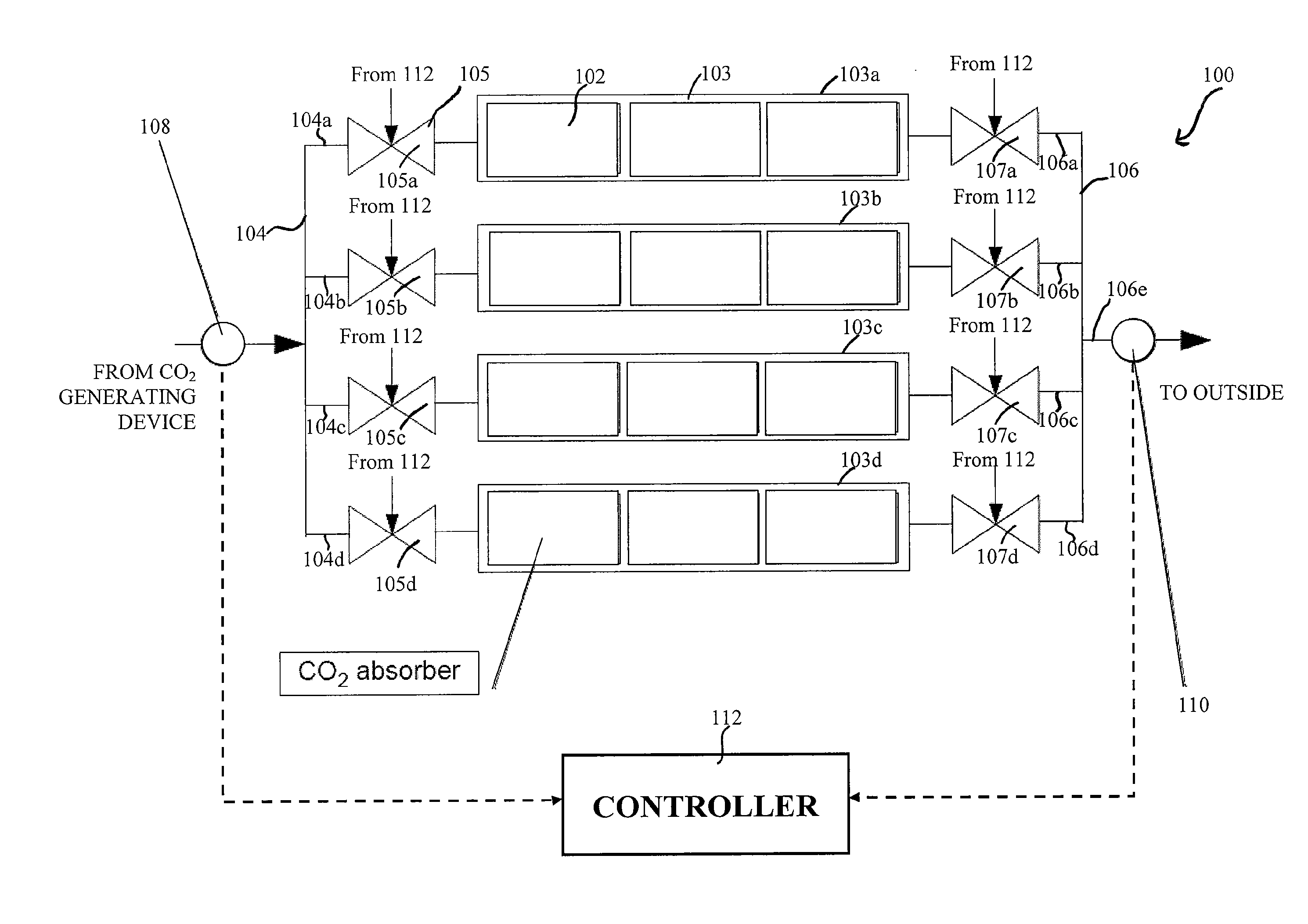

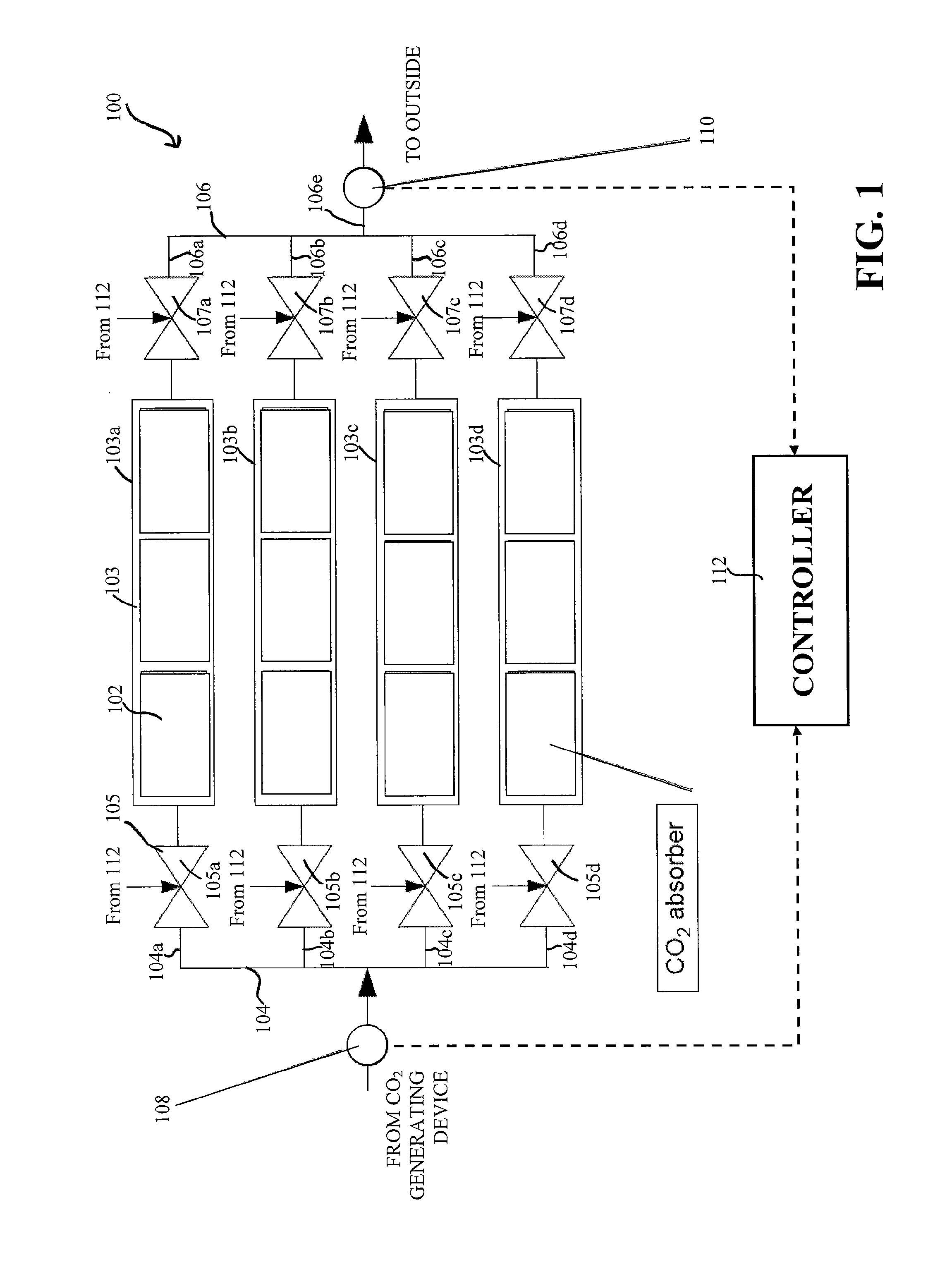

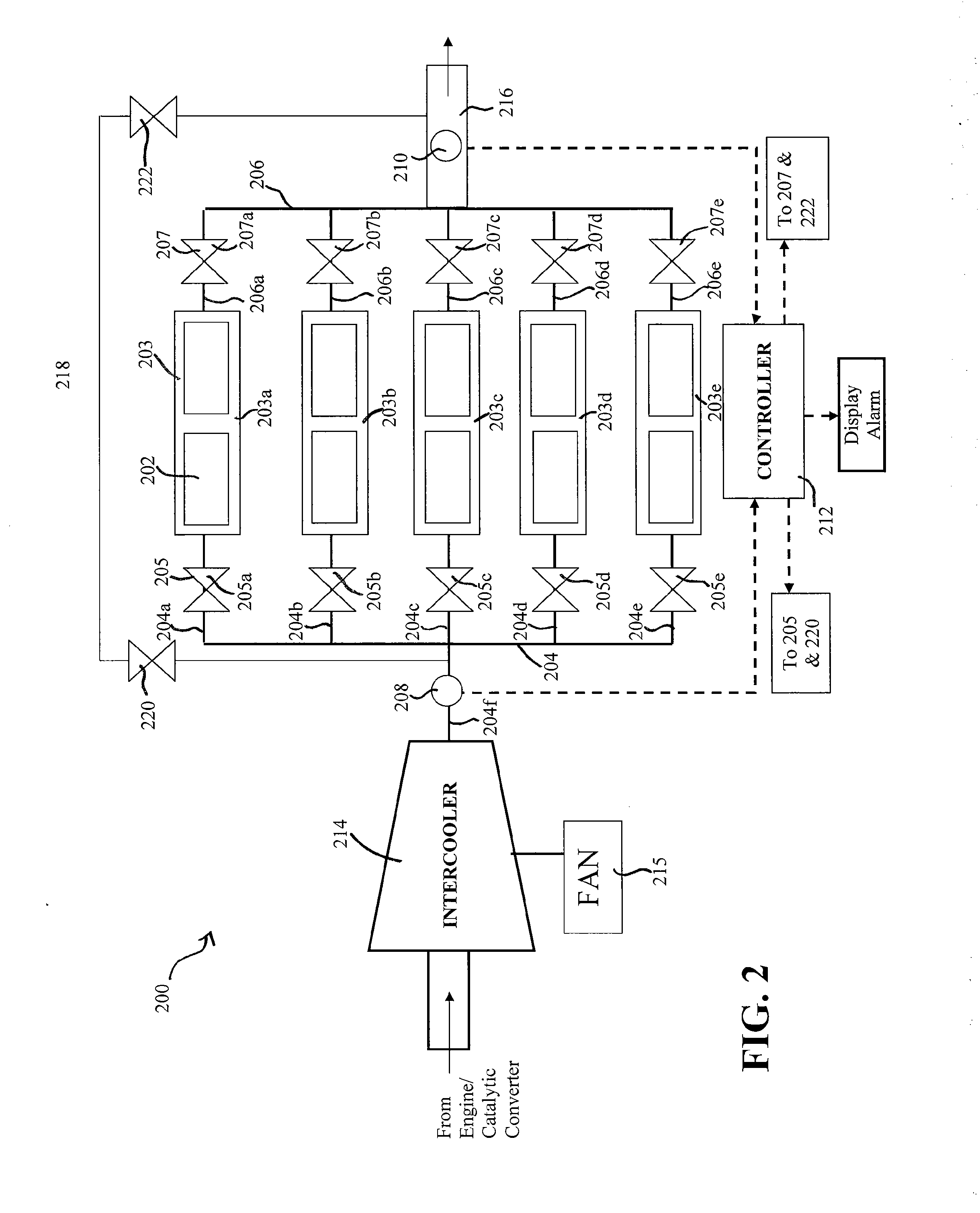

Method and apparatus for removal of carbon dioxide from automobile, household and industrial exhaust gases

InactiveUS20140044632A1Easy to doGood removal effectCombination devicesGas treatmentProcess engineeringCarbon dioxide

An exhaust processing assembly for an exhaust generating device, the exhaust processing assembly comprising one or more cartridges, each of the cartridges including a housing and a constituent housed in the housing and capable of at least partially removing carbon dioxide from the exhaust of the exhaust generating device, said constituent being one or more of a solid absorber and any other constituent, wherein the cartridges are one of: removable from the exhaust processing assembly and replaceable with other like cartridges, and refillable with new constituent.

Owner:RYNCOSMOS

Co-formed base-treated aluminas for water and CO2 removal

Base treated aluminas exhibit improved CO2 capacity over untreated aluminas. Base treated aluminas prepared by physically mixing alumina and base during forming have (1) a higher surface area, (2) less hydrothermal aging, (3) improved CO2 capacity and (4) lower cost than base treated aluminas produced by aqueous impregnation. A method for removing at least CO2 and water from a gas stream includes providing an adsorbent formed from a process comprising physically mixing activated alumina solids and solid salts of alkali metals, alkaline earth metals or ammonium ion; and contacting the gas stream with the adsorbent.

Owner:AIR PROD & CHEM INC +1

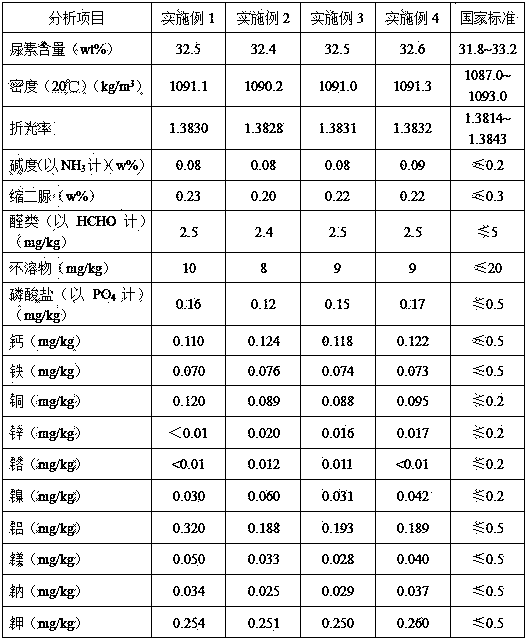

Method for preparing vehicle urea solution

InactiveCN104289106AReduce contentReduce production linksDispersed particle separationCo2 removalMicropore Filter

The invention discloses a method for preparing a vehicle urea solution. The method comprises the following steps: treating industrial desalted water by a reverse osmosis device, a microporous filter and an EDI electric deionizing device and then sterilizing to obtain high purity water, wherein the resistivity of the high purity water is equal to or greater than 16 Momega.cm at 25 DEG C; mixing the high purity water with a high temperature urea solution which is subjected to ammonia and CO2 removal by virtue of flash evaporation during production of urea to prepare a urea aqueous solution with the concentration of 48-55wt% and the temperature of 68-72 DEG C; then cooling to 18-25 DEG C, filtering to obtain crystallized urea, mixing the crystallized urea and the high purity water to prepare another urea aqueous solution with the concentration of 31.8-33.2wt%; finally filtering by a filter film with the aperture of 0.2-0.5 micron to obtain the final vehicle urea solution. According to the method, the vehicle urea solution is directly produced without an external heating source, the contents of biuret, metal ions, insoluble substances and the like are relatively low, the method is especially suitable for directly producing vehicle urea in a urea production factory, and the cost during production is reduced.

Owner:HENAN HONGKANG ENVIRONMENTAL PROTECTION TECH

Hot solids gasifier with co2 removal and hydrogen production

InactiveUS20060207177A1Avoid entrainmentEfficient captureMuffle furnacesGas modification by gas mixingCo2 removalWater-gas shift reaction

A gasifier 10 includes a first chemical process loop 12 having an exothermic oxidizer reactor 14 and an endothermic reducer reactor 16. CaS is oxidized in air in the oxidizer reactor 14 to form hot CaSO4 which is discharged to the reducer reactor 16. Hot CaSO4 and carbonaceous fuel received in the reducer reactor 16 undergo an endothermic reaction utilizing the heat content of the CaSO4, the carbonaceous fuel stripping the oxygen from the CaSO4 to form CaS and a CO rich syngas. The CaS is discharged to the oxidizer reactor 14 and the syngas is discharged to a second chemical process loop 52. The second chemical process loop 52 has a water-gas shift reactor 54 and a calciner 42. The CO of the syngas reacts with gaseous H2O in the shift reactor 54 to produce H2 and CO2. The CO2 is captured by CaO to form hot CaCO3 in an exothermic reaction. The hot CaCO3 is discharged to the calciner 42, the heat content of the CaCO3 being used to strip the CO2 from the CaO in an endothermic reaction in the calciner, with the CaO being discharged from the calciner 42 to the shift reactor 54.

Owner:GENERAL ELECTRIC TECH GMBH

Single absorber vessel to capture co2

ActiveUS20110120308A1Easy to recycleEasy to removeGas treatmentUsing liquid separation agentFlue gasFlue

A system for removing carbon dioxide from a flue gas stream is provided, the system comprising an absorber vessel configured to receive a flue gas stream, the absorber vessel comprising a first absorption stage configured to receive the flue gas stream and contact it with a first ionic solution, a second absorption stage configured to receive flue gas which has passed the first absorption stage and contact it with a second ionic solution, a first sump vessel, and a second sump vessel. Furthermore, a method for removing CO2 from a flue gas stream containing CO2 is provided, the method comprising the steps of a) contacting a flow of a first ionic solution comprising NH3 with a flue gas stream to remove a first portion of CO2 from the flue gas stream, b) collecting the used ionic solution from step a) in a first sump vessel, c) recycling ionic solution from the first sump vessel to step a), d) contacting a flow of a second ionic solution comprising NH3 with the flue gas stream to remove a second portion of CO2 from the flue gas stream, e) collecting the used ionic solution from step d) in a second sump vessel, and f) recycling ionic solution from the second sump vessel to step d).

Owner:GENERAL ELECTRIC TECH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com