High-temperature gas injection-based iron-making technology

A gas and high temperature technology, applied in blast furnaces, blast furnace details, reducing gas emissions, etc., can solve the problems of large emissions, low productivity, serious environmental pollution, etc., and achieve the effect of improving blast furnace productivity, reducing ironmaking costs, and reducing prices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

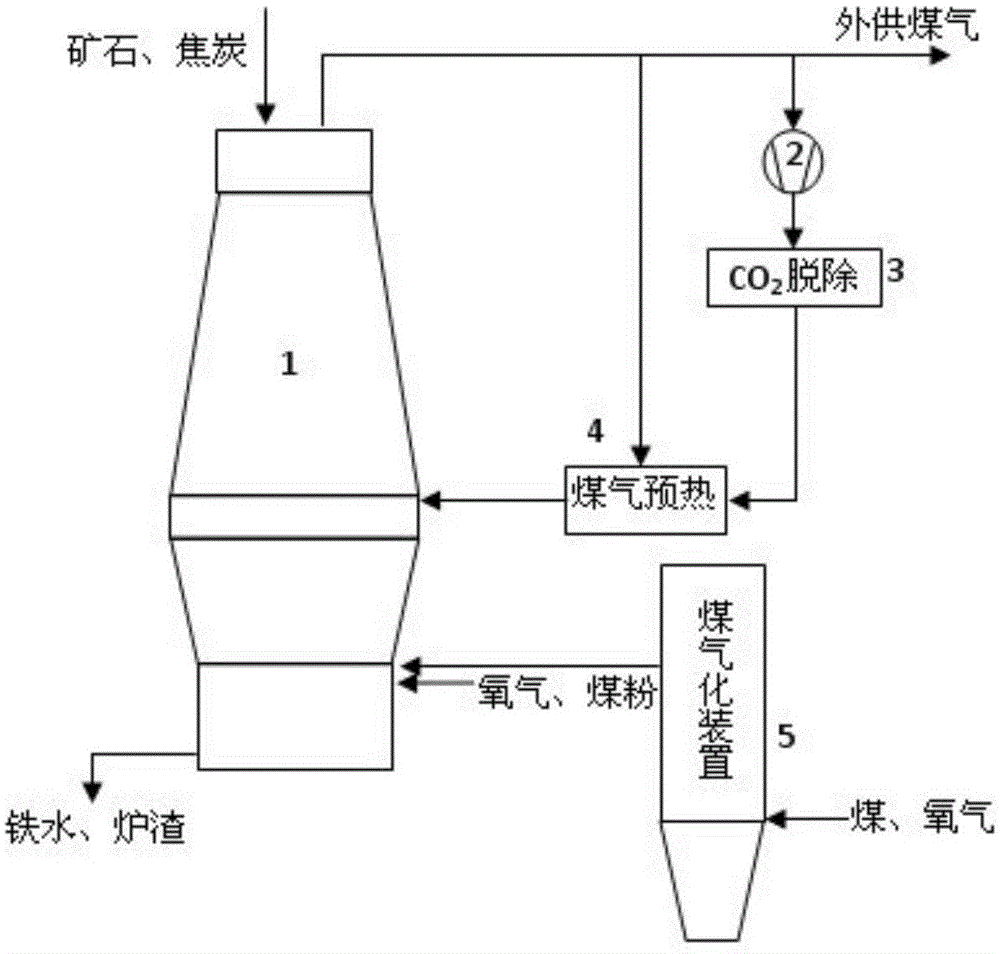

[0031] Theoretical calculations show that 73% sintered ore, 21% pelletized ore, and 6% lump ore are used as raw materials in the oxygen blast furnace, and the high-temperature gas generated by coal gasification is injected into the hearth tuyeres by this process to replace all the circulating gas , injecting oxygen and coal powder at the same time, injecting circulating gas from the tuyere at the lower part of the furnace body into the top of the furnace, the process flow chart is shown in the attached page of the manual figure 1 As shown, its economic and technical indicators are as follows:

[0032] Coke ratio: 220kg / tHM

[0033] Tuyere coal injection: 200kg / tHM

[0034] Oxygen consumption at tuyere: 258.49m 3 / tHM

[0035] Coal consumption of coal gasification unit: 152.88kg / tHM

[0036] Oxygen consumption of coal gasification unit: 112.56Nm 3 / tHM

[0037] Hearth tuyere circulating gas volume: 0Nm 3 / tHM

[0038] Hearth tuyere coal gasification high temperature gas...

Embodiment 2

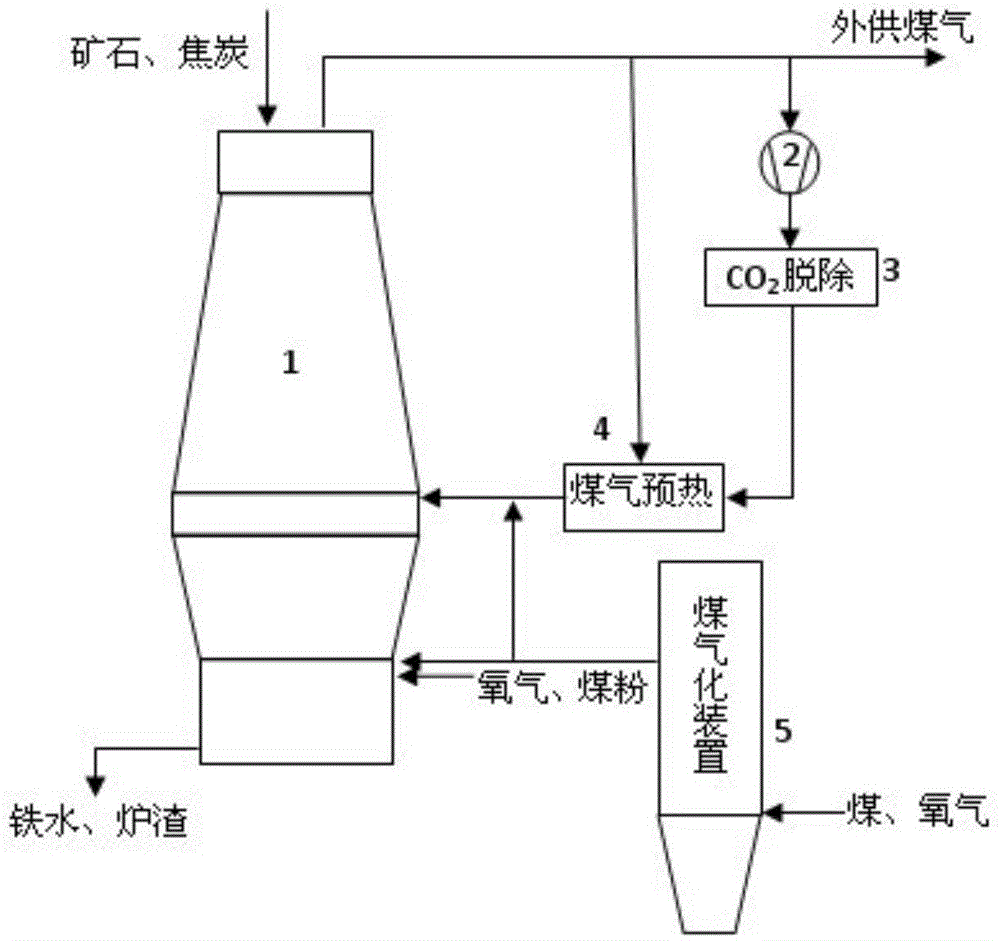

[0048] Theoretical calculations show that 73% sintered ore, 21% pelletized ore, and 6% lump ore are used as raw materials in the oxygen blast furnace, and the high-temperature gas generated by coal gasification is injected into the hearth tuyeres by this process to replace all the circulating gas , while injecting oxygen and pulverized coal, injecting high-temperature gas from coal gasification from the tuyeres at the lower part of the furnace to replace part of the circulating gas, instead of the 200m in Example 1 3 Furnace cycle gas, the process flow chart is shown in the attached page of the manual figure 2 As shown, its economic and technical indicators are as follows:

[0049] Coke ratio: 220kg / tHM

[0050] Tuyere coal injection: 200kg / tHM

[0051] Oxygen consumption at tuyere: 258.49m 3 / tHM

[0052] Coal consumption of coal gasification unit: 240.24kg / tHM

[0053] Oxygen consumption of coal gasification unit: 176.88Nm 3 / tHM

[0054] Hearth tuyere circulating ga...

Embodiment 3

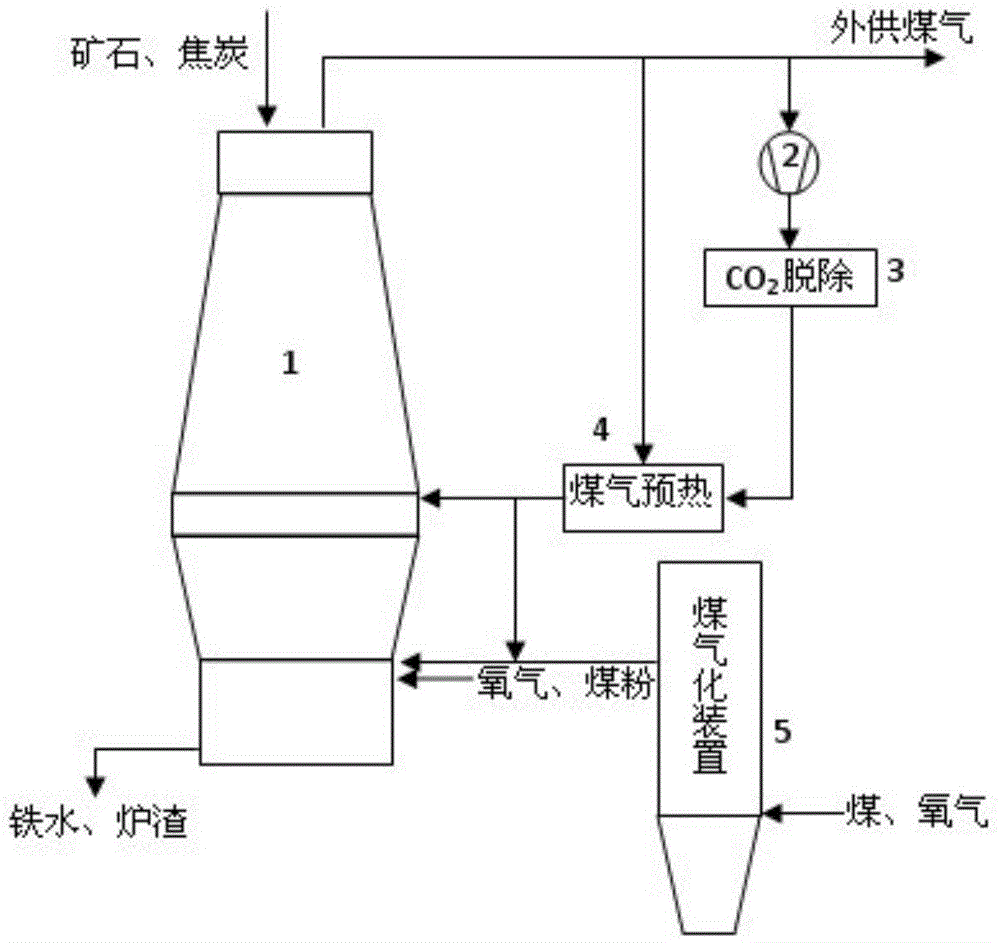

[0065] Theoretical calculations show that 73% sintered ore, 21% pelletized ore, and 6% lump ore are used as raw materials in the oxygen blast furnace, and the high-temperature gas produced by coal gasification is injected into the furnace hearth tuyere to replace part of the circulating gas. , instead of 150m in Example 1 3 The furnace hearth circulates the gas, injects oxygen and coal powder at the same time, and injects the furnace top circulation gas from the tuyere at the lower part of the furnace body. The process flow chart is shown in the attached page of the manual. image 3 As shown, its economic and technical indicators are as follows:

[0066] Coke ratio: 220kg / tHM

[0067] Tuyere coal injection: 200kg / tHM

[0068] Oxygen consumption at tuyere: 258.49m 3 / tHM

[0069] Coal consumption of coal gasification unit: 65.52kg / tHM

[0070] Oxygen consumption of coal gasification unit: 48.24Nm 3 / tHM

[0071] Hearth tuyere circulating gas volume: 200Nm 3 / tHM

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com