Automatic rubber-coating device installed on automatic coil winding machine

A technology of automatic winding machine and encapsulation device, applied in the direction of coil manufacturing, etc., can solve the problems of partial encapsulation, high quality requirements of enameled wires, large space occupation, etc., so as to improve the yield of encapsulation and ensure that the encapsulation does not pick up the wire. , The effect of reducing installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

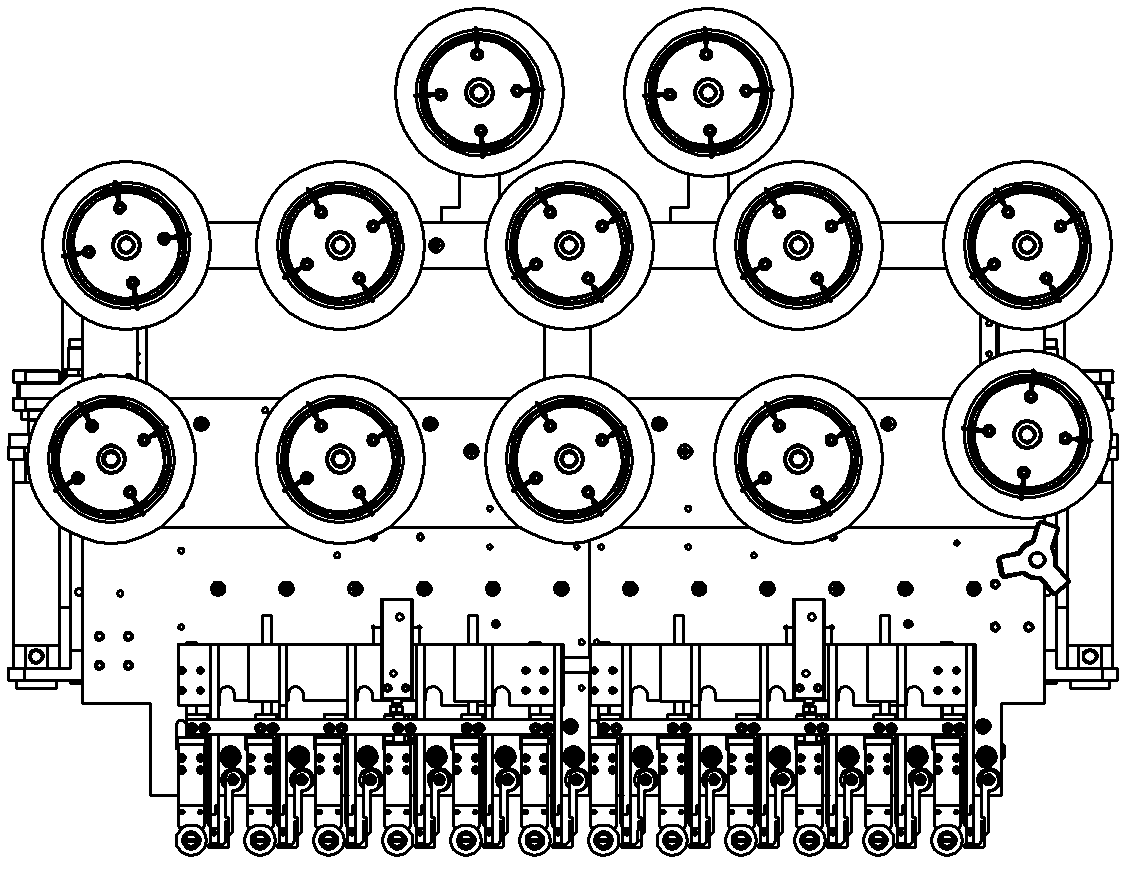

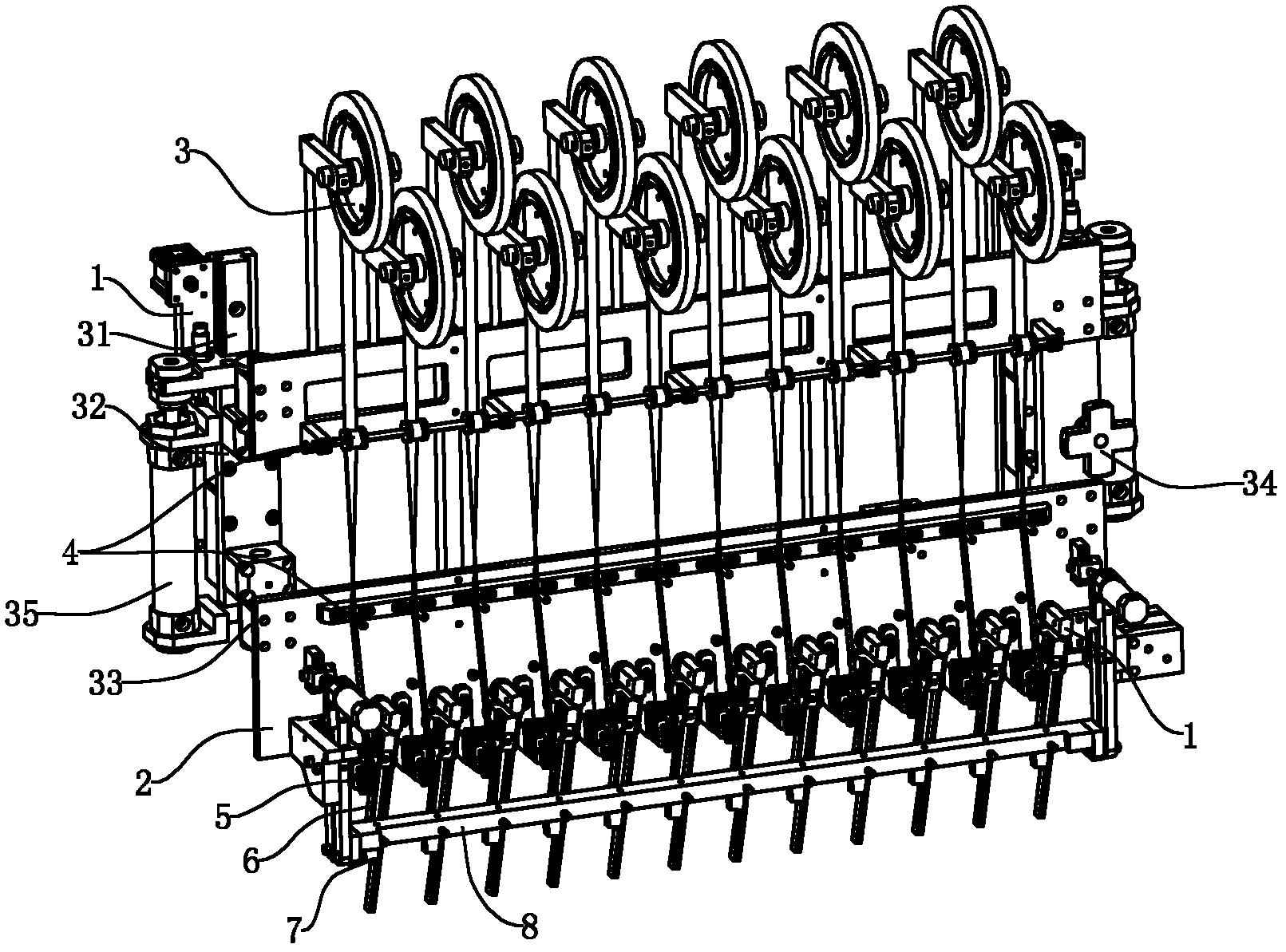

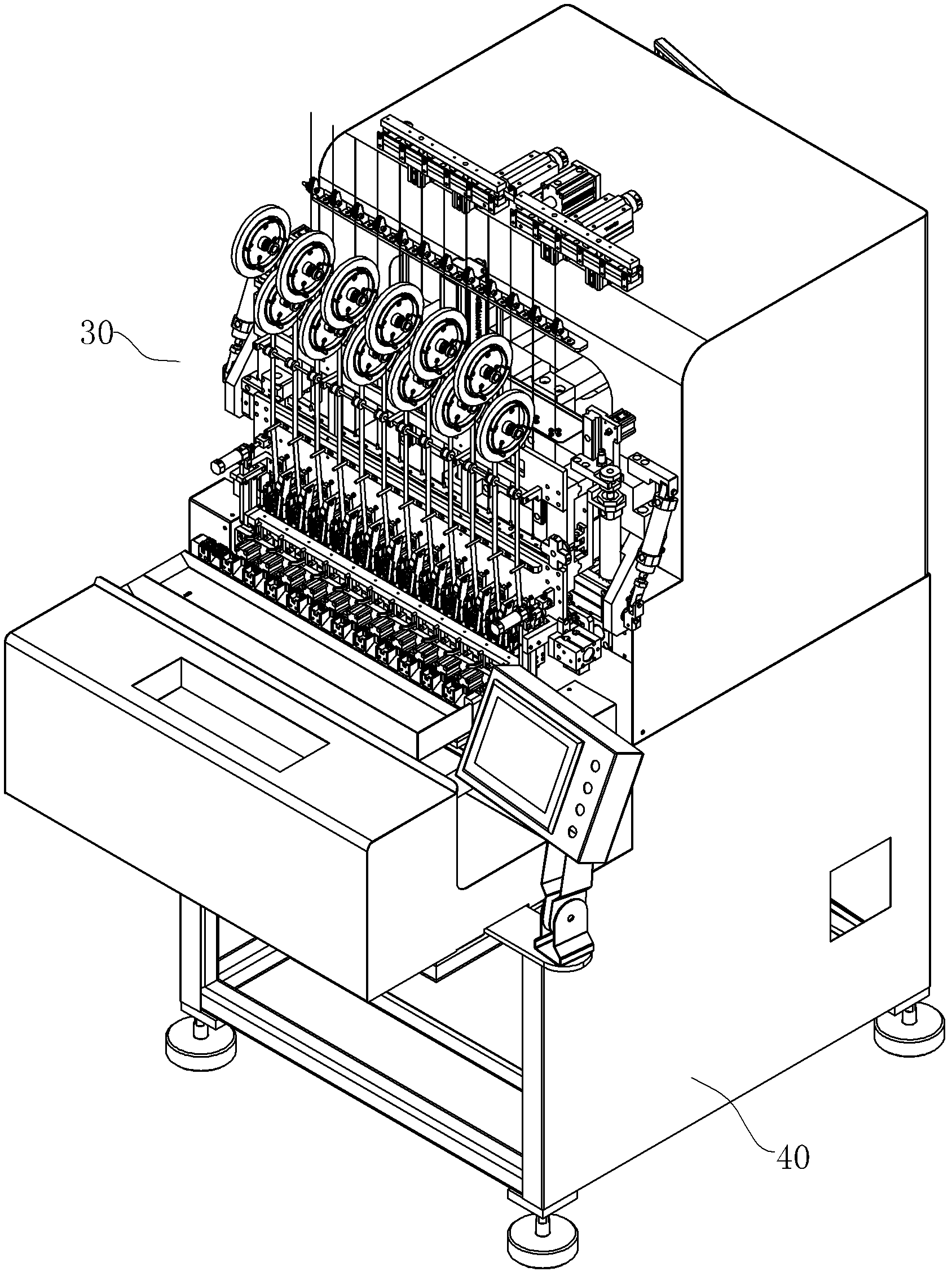

[0027] see figure 2 and image 3 , the automatic encapsulation device 30 of the present invention can be installed in image 3 The multi-axis automatic winding machine 40 shown is used to wrap the adhesive tape 10 on the winding rubber part 501 of the rubber covering part 50 (such as a coil bobbin) after winding, so that the rubber covering part 50 The windings are insulated, and the operation of the automatic rubber wrapping device 30 can be centrally controlled by the control unit (such as a programmable controller) of the automatic winding machine 40 . Such as figure 2 The automatic rubber wrapping device 30 includes a rubber wrapping base 1, a bottom plate 2, a tape unwinding wheel assembly 3, a tape guide assembly 4, a tape anti-deviation limit assembly 5, a tape winding assembly 6, a tape cutting assembly 7, a press Belt assembly 8, etc., wherein, tape unwinding wheel assembly 3, tape guide assembly 4, tape winding assembly 6, tape cutting assembly 7 and belt pressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com