Patents

Literature

196results about How to "Reduce focal ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron coke for blast furnace and preparing method thereof

InactiveCN103468289AEnsure Strength IndexBest heating speedCoke ovensBlast furnace detailsCoke ovenUltimate tensile strength

The invention relates to iron coke for a blast furnace and a preparing method thereof. The iron coke comprises 5wt%-20wt% of iron ore powder and 80wt%-95wt% of mixed coal; the mixed coal is formed by mixing 25wt%-29wt% of one third of coking coal, 40wt%-44wt% of coking coal, 7wt%-11wt% of lean coal, 6wt%-10wt% of gas-fat coal and 12wt%-16wt% of fat coal; the iron ore powder and the mixed coal are mixed uniformly with water and tamped before entering the blast furnace, and are placed into the blast furnace when the temperature is 800 DEG C, the temperature is increased at the speed of 2 DEG C per minute to 3 DEG C per minute, the iron ore powder and the mixed coal are discharged from the blast furnace when the temperature is 950-1050 DEG C, and the iron coke is obtained by adopting a wet way of quenching the coke. According to the iron coke and the preparing method, the performance, the ratio, the particle size and the composition and the like of the iron ore powder and the mixed coal are optimized, and the strength and the reactivity of the iron coke can meet the requirement of the blast furnace process under the circumstance of not adding binding agents.

Owner:WUHAN UNIV OF SCI & TECH

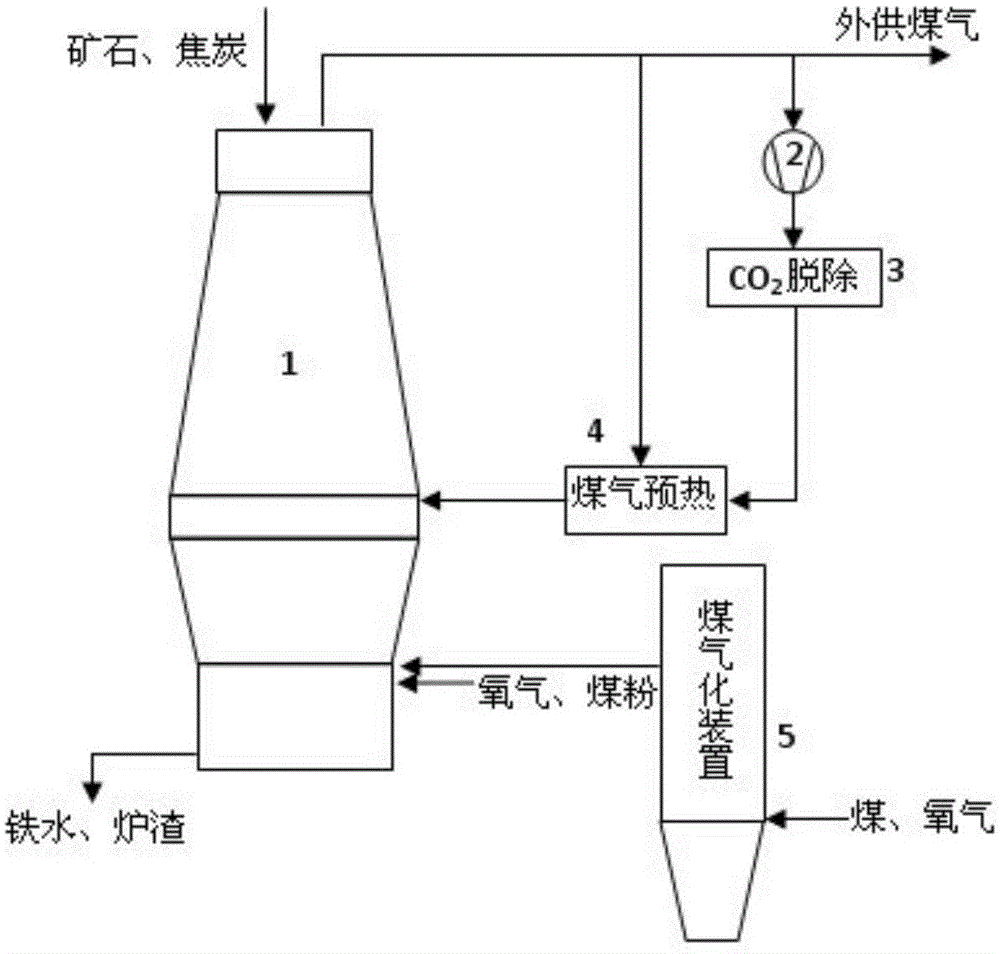

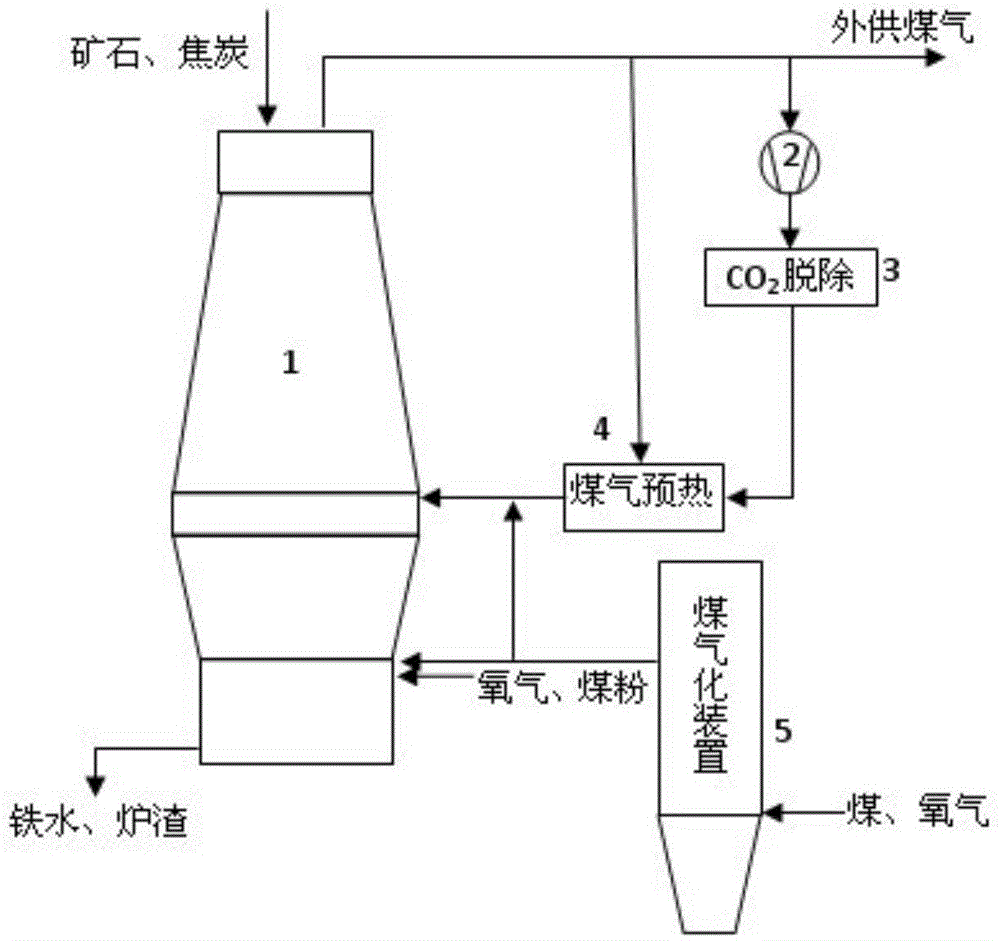

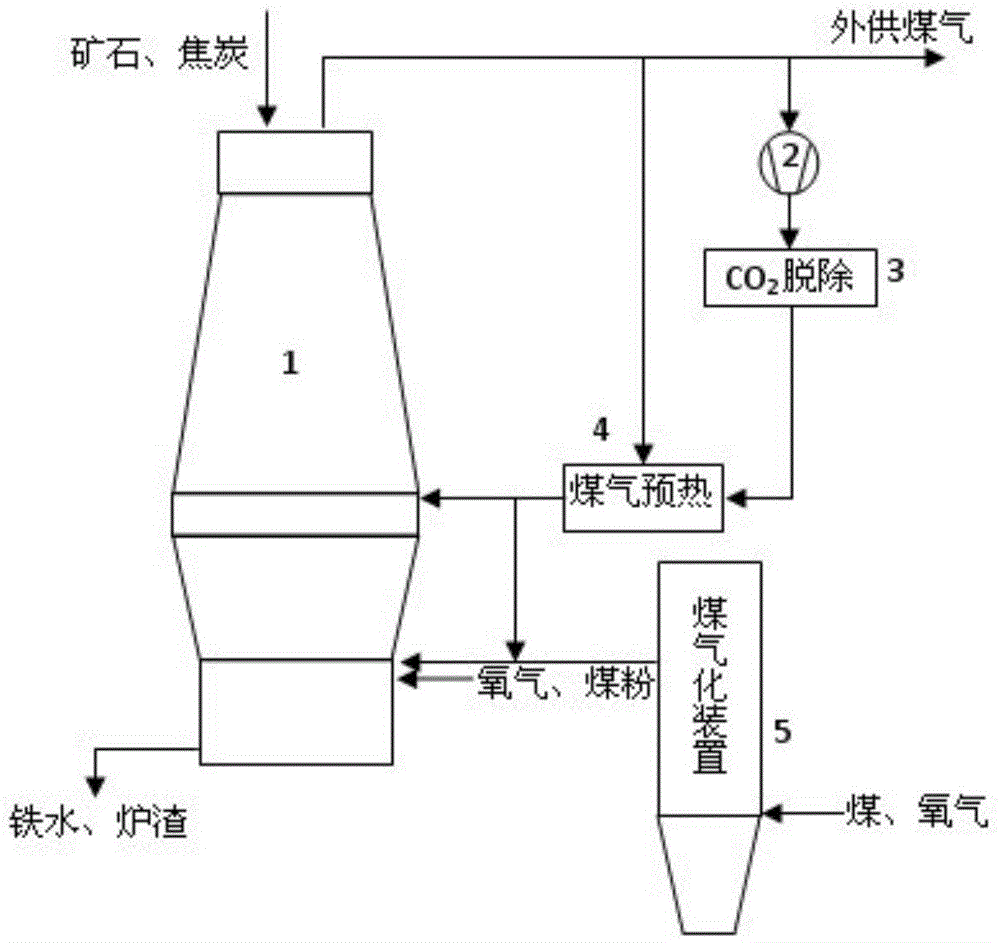

High-temperature gas injection-based iron-making technology

InactiveCN104131122ALower quality requirementsLow priceBlast furnace detailsGas emission reductionCo2 removalCapacity factor

The invention discloses a high-temperature gas injection-based iron-making technology and belongs to the field of black metallurgy. The high-temperature gas injection-based iron-making technology utilizes oxygen-rich normal-temperature air blasting to replace hot air operation, and high-temperature gas produced by a coal gasification device and CO2-free furnace top recycled gas are mixed and are respectively pumped into a blast furnace from the furnace body and the hearth so that furnace top recycled gas CO2 removal is realized. The high-temperature gas injection-based iron-making technology has a coal ratio of 240-350kg / tHM, a coal gasification unit coal-use amount of 50-250kg / tHM and a coke ratio of 180-260kg / tHM and a blast furnace capacity factor of 6.0-7.5, reduces operation costs of oxygen-containing blast furnace top gas CO2 removal and recycled gas pre-heating to a temperature of 900-1300 DEG C, realizes coke reduction and coal use increasing in blast furnace production, improves an iron-making technology energy structure and stabilizes gas balance of a steel enterprise.

Owner:UNIV OF SCI & TECH BEIJING

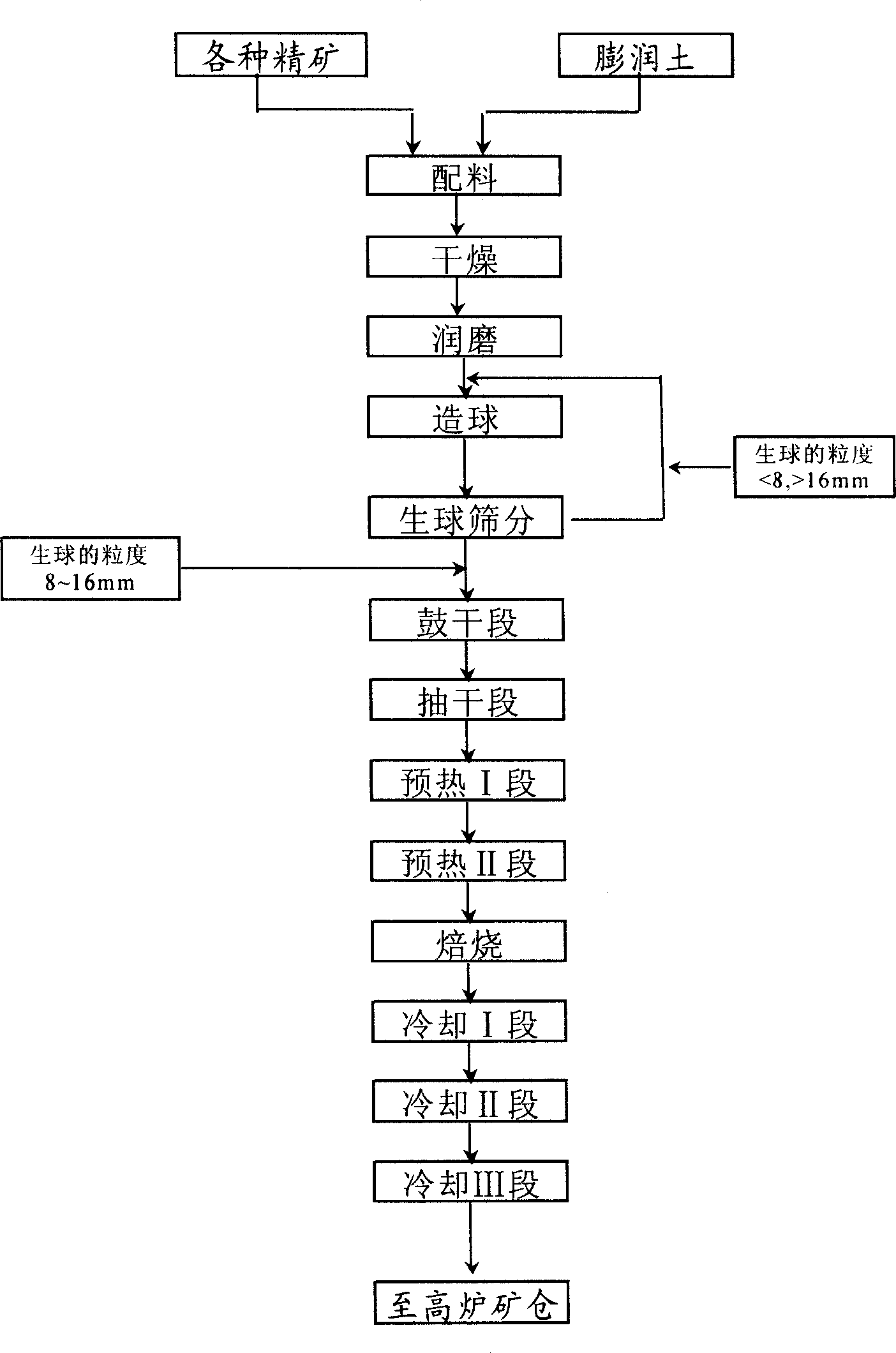

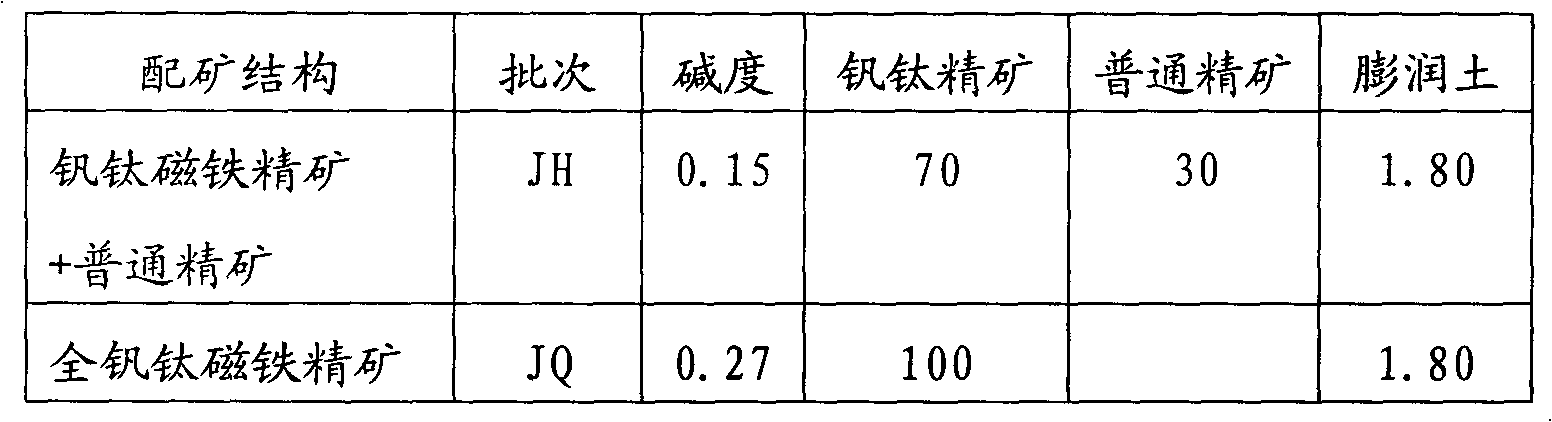

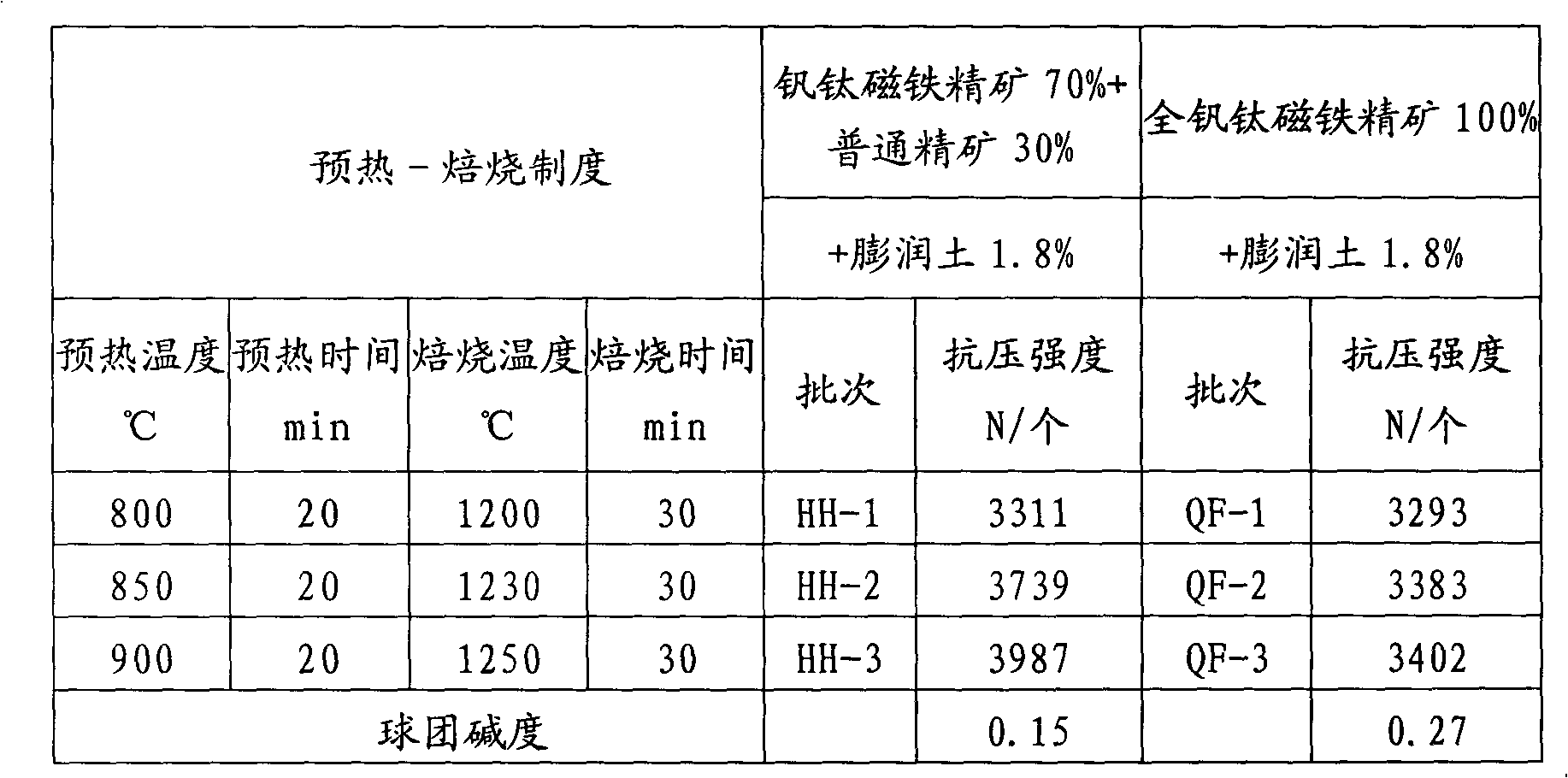

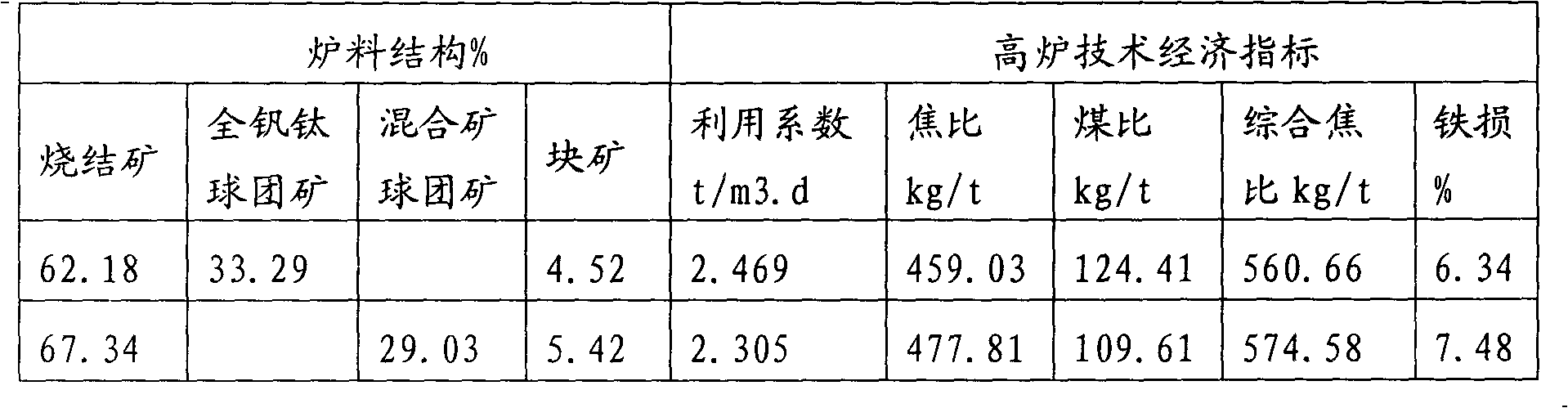

Method for producing high titanium type acid pellet vanadium titanium by chain grate - rotary kiln

This invention discloses a method for producing Ti-rich V-Ti oxidized pellets by chain grate and rotary kiln. The method comprises: mixing vanadic titanomagnetite concentrate with common magnetite concentrate at a weight ratio of 7:3, adding 2.0 wt. % of bentonite, palletizing to obtain 8-16 mm pellets by a disc pelletizer, drying (50-350 deg.C) and pre-heating (500-1000 deg.C) by a chain grate for 12 min, sending dried pellets into a rotary kiln, torrefying at 1150-1300 deg.C and 1.0 r / min for 30-35 min, and cooling torrefied pellets. The obtained Ti-rich V-Ti oxidized pellets have compression strength higher than 1800 N, and TiO2 content of 7.0%, thus can meet the requirement of blast furnace smelting.

Owner:攀枝花钢城集团有限公司球团厂

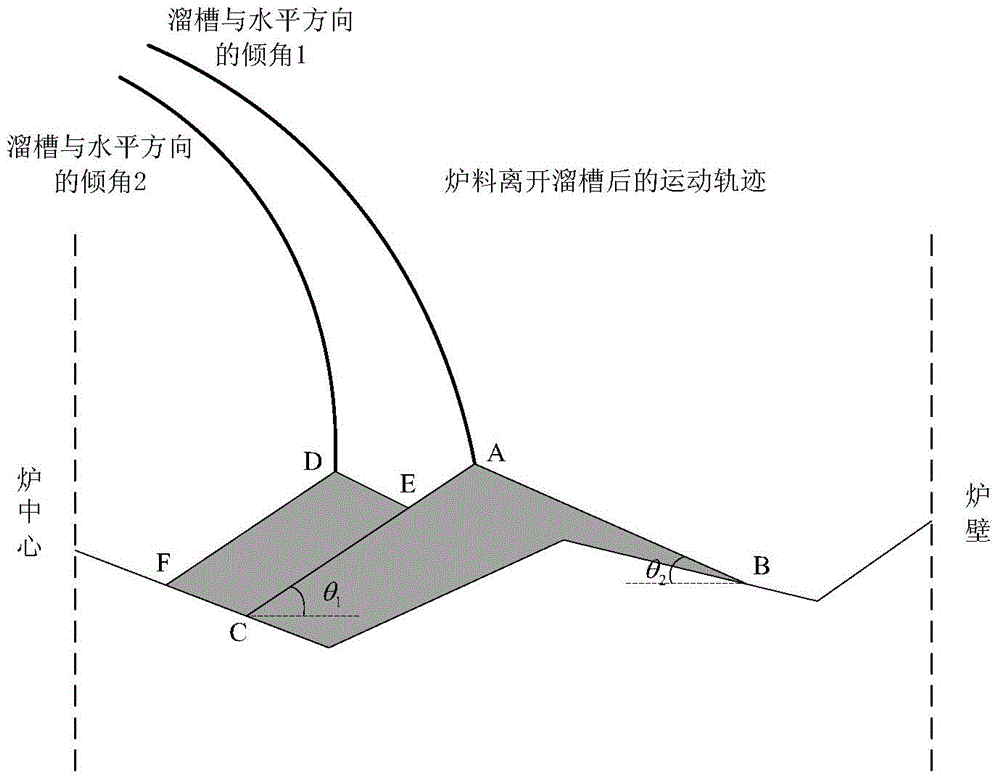

Blast furnace chute polycyclic distributing method

InactiveCN101250602AIncrease production capacityUniform material layerBell-and-hopper arrangementBlast furnace detailsRing numberGravitation

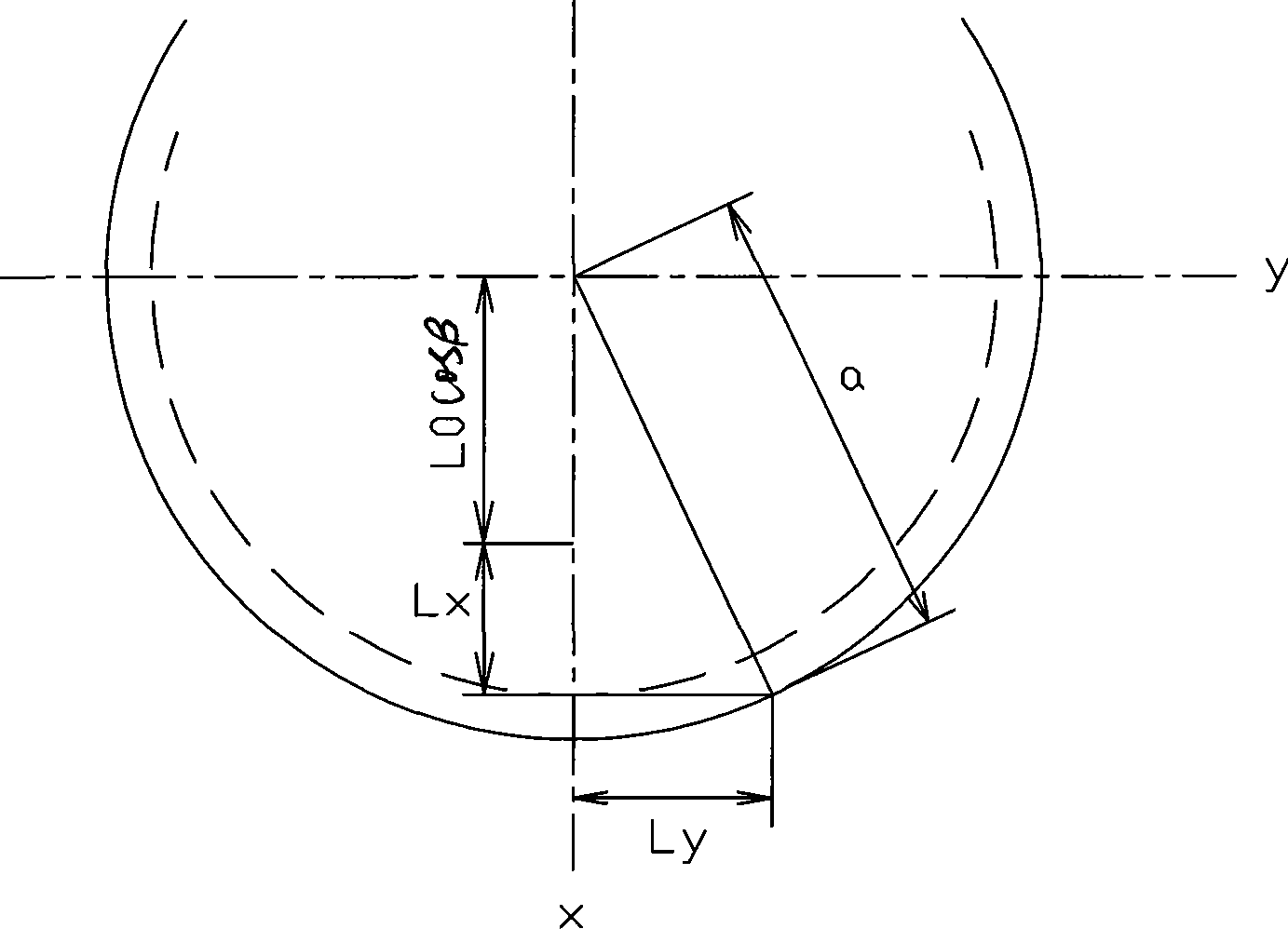

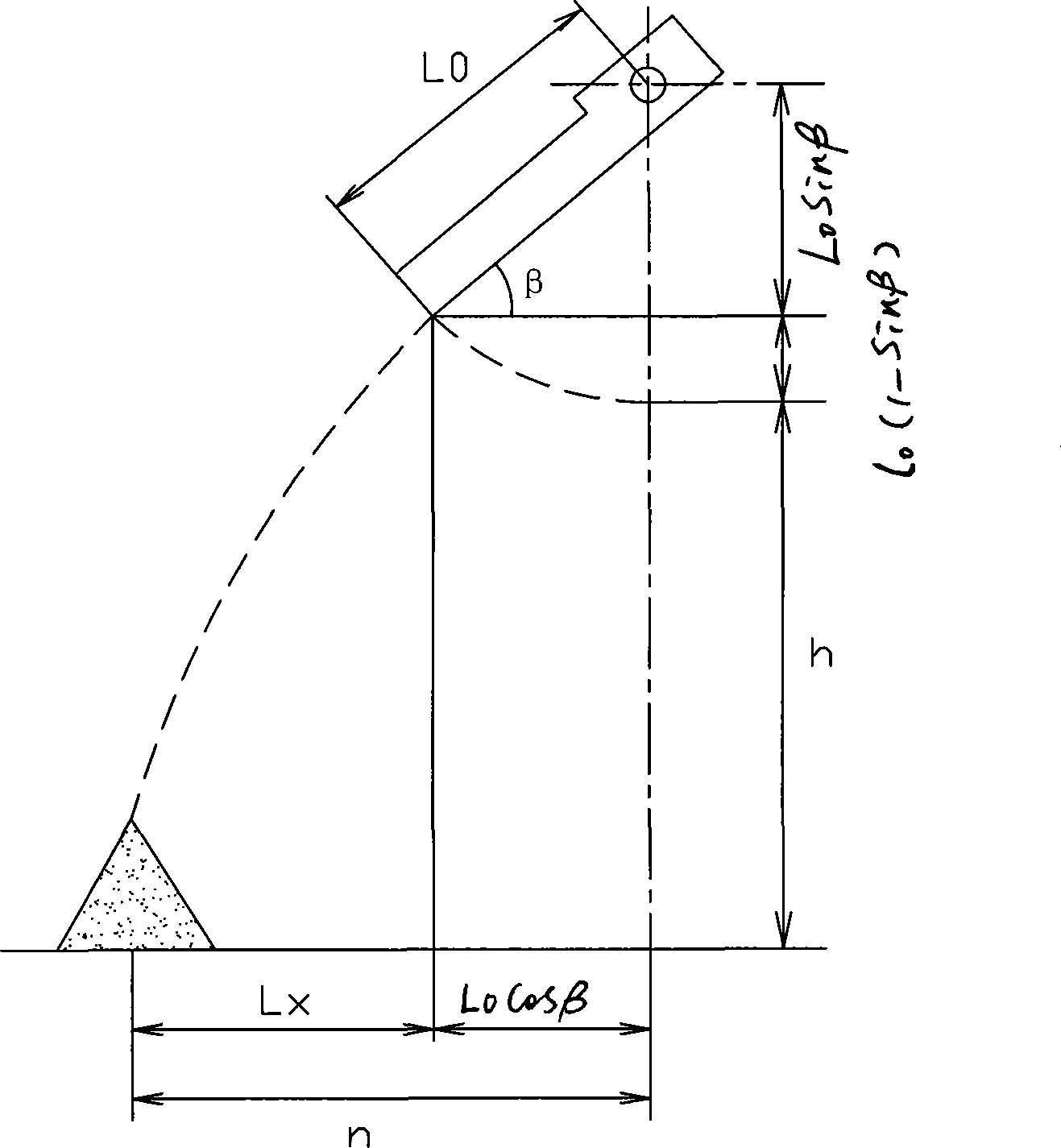

The invention discloses a blast furnace chute multi-ring burden distribution, which comprises firstly calculating the distance from the center of furnace burden from the center of a blast furnace after furnace burden fell into an xy plane, secondly deciding largest and smallest burden distribution angles in theory, thirdly deciding the actual burden distribution angles of outer ring and inner ring of ores and coke, fourthly deciding the burden distribution ring number of ores and coke, determining the burden distribution angle of middle ring of ores and coke and the angel difference of adjacent rings, and sixthly determining the burden distribution rings of each ring in ores and coke. The process largely enriches the regulating method on the upper portion of the blast furnace, changes coal gas distribution, effectively increases the coal gas usage of the blast furnace, reduces coke ratio, realizes the stable and long term operation of the blast furnace, has strong loading material capacity, can eliminate furnace burden gravity segregation and the existing of pile top, much reasonably distributes furnace burden, is beneficial for strengthening smelting, and improves the press amount relationship and further increases the air quantity of the blast furnace.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

Acidic full-vanadium-titanium pellets and preparation method thereof

Owner:PANZHIHUA IRON AND STEEL +1

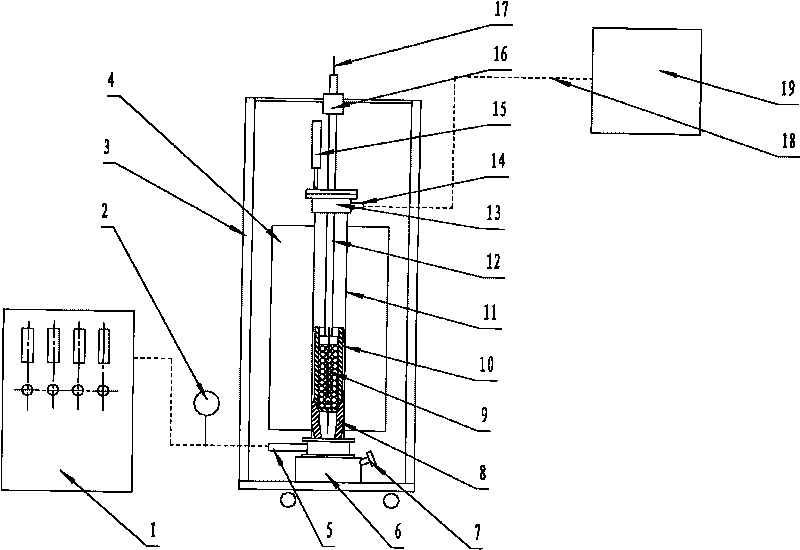

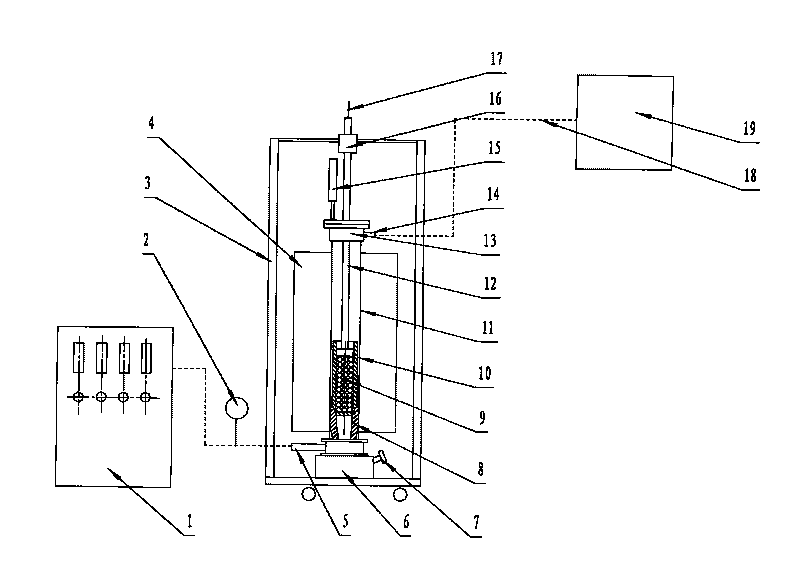

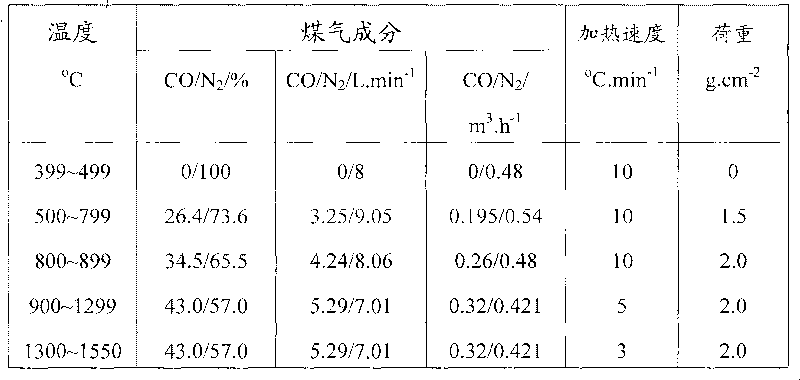

Blast furnace first slag experiment method and first slag experimental furnace

InactiveCN101701770ASimple structureReduce manufacturing costFuel testingFurnace typesElectric arc furnaceSlag

The invention relates to a blast furnace first slag experiment method and a first slag experimental furnace which solves the problem that the current experiment method can not well guide the optimization of furnace material structure for first slag can not be acquired. The first slag experimental furnace comprises an electric furnace and an air distribution cabinet, wherein the electric furnace is provided with a hearth pipe; a graphite crucible positioned on a graphite base is arranged in the hearth pipe; the upper end of the graphite crucible is provided with a center press rod, and the upper end of the center press rod penetrates through the hearth pipe and is provided with an inserted thermocouple; a material surface load readjusting device is arranged on the center press rod; the upper end of the hearth pipe is provided with an upper cover, an exhaust opening and a displacement sensor, and the lower end is provided with a material receiving box and communicated with the air distribution cabinet by a reducing gas inlet; and a pressure difference transmitter is arranged on a connecting pipeline of the reducing gas inlet and the air distribution cabinet. The experiment method obtains first slag by simulating the blast furnace condition through the first slag furnace, records all detecting data on line and carries out chemical analysis and microscopic detection on the first slag, thereby having important guide significance for optimizing the furnace material structure.

Owner:武钢集团有限公司 +1

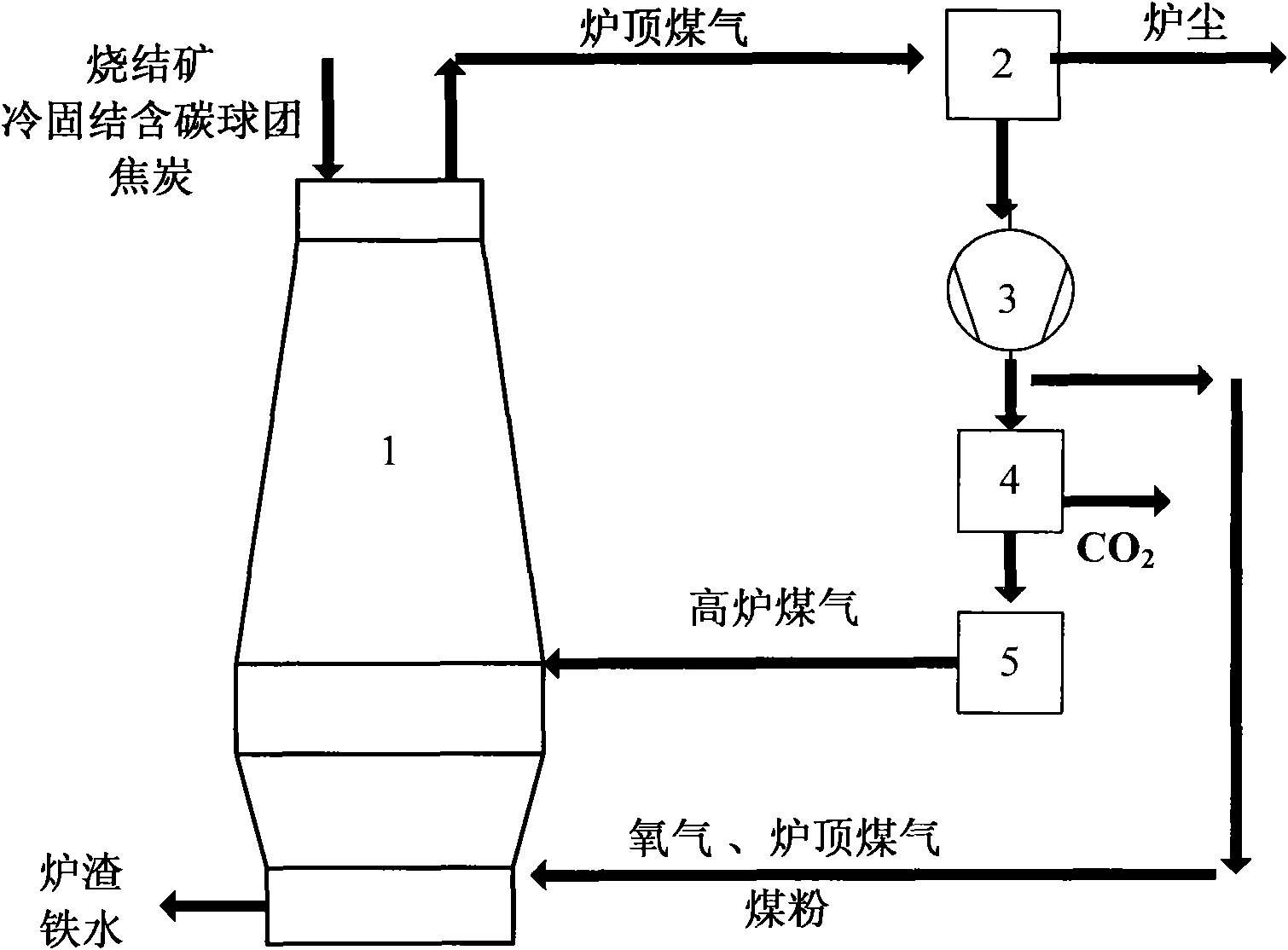

Oxygen blast furnace iron-making method based on cold-bonded carbonic pellet

InactiveCN101555532AReduce pollutionReduce dosageBlast furnace detailsGas emission reductionCombustionGas phase

An oxygen blast furnace iron-making method based on cold-bonded carbonic pellet belongs to the blast furnace iron-making field. The oxygen blast furnace iron-making method based on cold-bonded carbonic pellet is characterized in that 70 to 100 percent of carbonic pellet and 0 to 30 percent of sintered ore are adopted as materials for iron-making and added to a blast furnace from the top of the blast furnace; coke and coal injection are adopted as fuel of the blast furnace, wherein each ton of iron consumes 200 to 250kg / t HM of coke; the carbon content of the carbonic pellet is 1 to 20 percent and TFe content is 50 to 65 percent; mean compressive strength of the carbonic pellet is 1000 to 2000N / each; the carbonic pellet is subjected to an automatic reduction process in the blast furnace so as to change gas-phase partial pressure of reduction reaction and reduce coke load of the blast furnace; simultaneously, oxygen of normal temperature is injected through a blast-furnace tuyere to displace the traditional air heating furnace; the applied amount of oxygen is 200 to 500 Nm / t HM; coal gas with high heating value (7000 to 8000KJ / Nm) can be provided outward by the blast furnace, and the coal gas generated by the blast furnace can be recycled after going through a dust-removing and pre-heating device and then is respectively injected into the blast furnace from the blast-furnace tuyere and the lower part of the blast furnace body; the theoretical combustion temperature of the method provided is controlled to be between 1900 and 2300 DEG C; and the coke ratio of the oxygen blast furnace iron-making method can be reduced to 200 to 250 kg / t HM, and the coal ratio is above 200 to 300 kg / t HM.

Owner:UNIV OF SCI & TECH BEIJING

Method for reclaiming and reusing iron-making dust in blast furnace

InactiveCN1632136AFavorable nodulationHelps eliminate nodulesBlast furnace detailsIron powderBlast furnace smelting

A method for recycling blast furnace ironmaking dust. The bag dust, gravity ash and other iron-containing dust recovered in the blast furnace smelting process are evenly mixed with coal powder, and sprayed into the hearth from the tuyere of the blast furnace. It is required that there is no accumulation in the hearth before injection. , no nodules in the furnace throat, and its process parameters: spray bag dust, the injection amount is 6-10Kg / t iron, hot air temperature> 1000 ℃, blast furnace zinc load <0.15Kg / t iron; spray gravity ash, injection amount is 6Kg / t iron ~ 15Kg / t iron, hot air temperature > 1050°C; spray other iron-containing dust, injection amount < 8Kg / t iron, dust particle size < 0.5mm, hot air temperature > 1050°C; the present invention has the functions of increasing iron, Saving coke, benefiting silicon reduction in molten iron, promoting smooth operation of blast furnace and strengthening smelting, benefiting safe coal injection, reducing nodulation in blast furnace, protecting the environment, and clean production, etc.

Owner:INST OF METALLURGICAL TECH DONGBEI UNIV SHENYANG

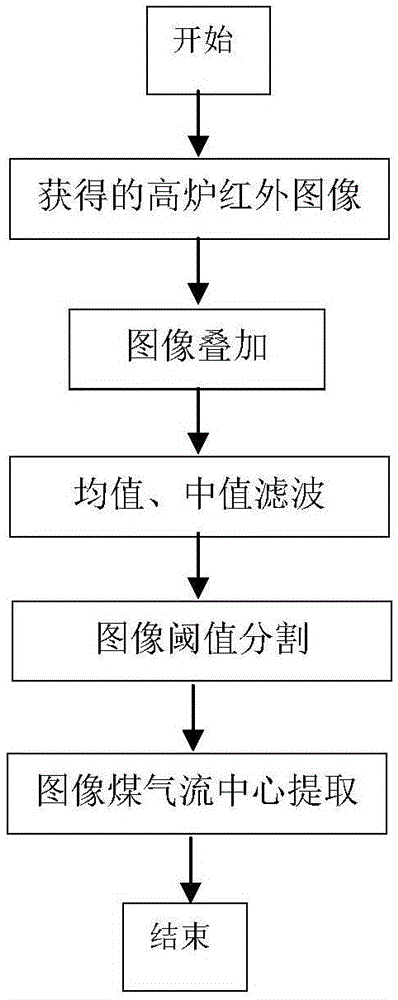

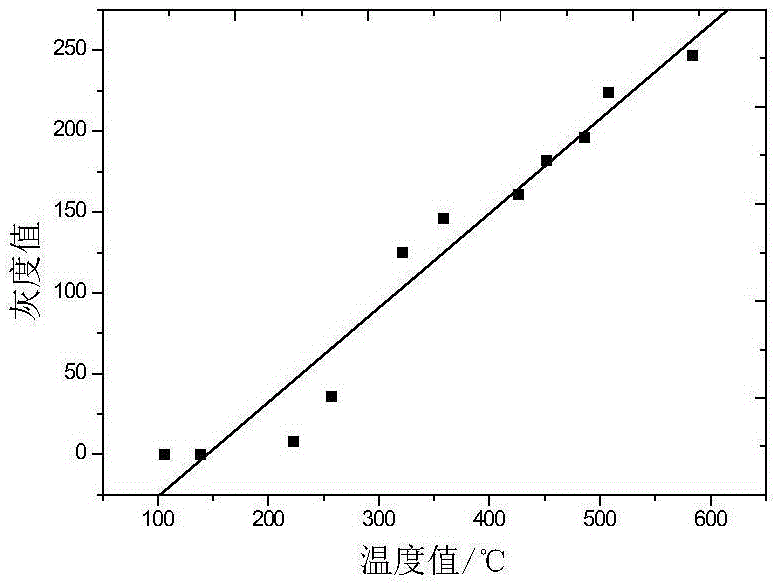

Method for processing coal gas flow center dynamic tracking and monitoring coal gas utilization rate

ActiveCN105002321ARealize dynamic trackingRealize real-time monitoringBlast furnace detailsChecking devicesData acquisitionDistribution characteristic

The invention discloses a method for processing coal gas flow center dynamic tracking and monitoring coal gas utilization rate. The method comprises the steps of 1 data collecting and processing; 2 infrared imagery processing; 3 temperature field calibration; 4 coal gas flow center dynamic tracking; 5 coal gas utilization rate monitoring. The method has the advantages that implementation is easy, temperature field calibration is achieved through the treatment on the collected infrared imagery combining crossed thermometry data and blast furnace design data, dynamic tracking on charge-level coal gas flow center fall point distribution is achieved, the coal gas flow center distribution characteristics and the corresponding coal gas utilization rates are classified, the relation between the coal gas center change and the blast furnace coal gas utilization rate is confirmed, real-time monitoring on the coal gas utilization rate is realized, the dynamic changing condition of the coal gas flow center and the relation between the dynamic changing condition of the coal gas flow center and the corresponding coal gas utilization rate can be recognized timely and accurately, on-line monitoring and visual control on the burden distribution operation of the blast furnace are achieved, and the advantages of being high in accuracy rate and strong in real-time performance are achieved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

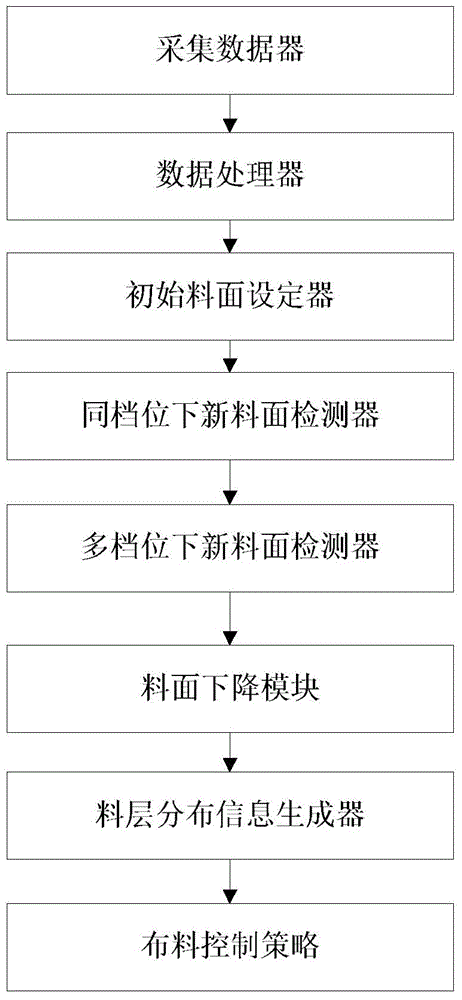

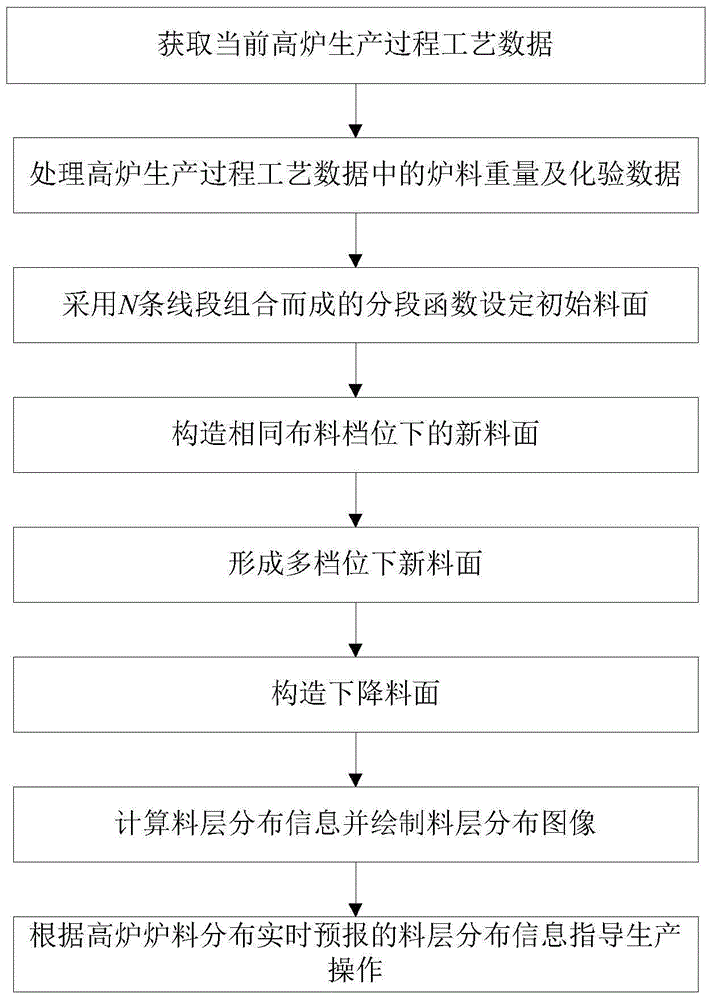

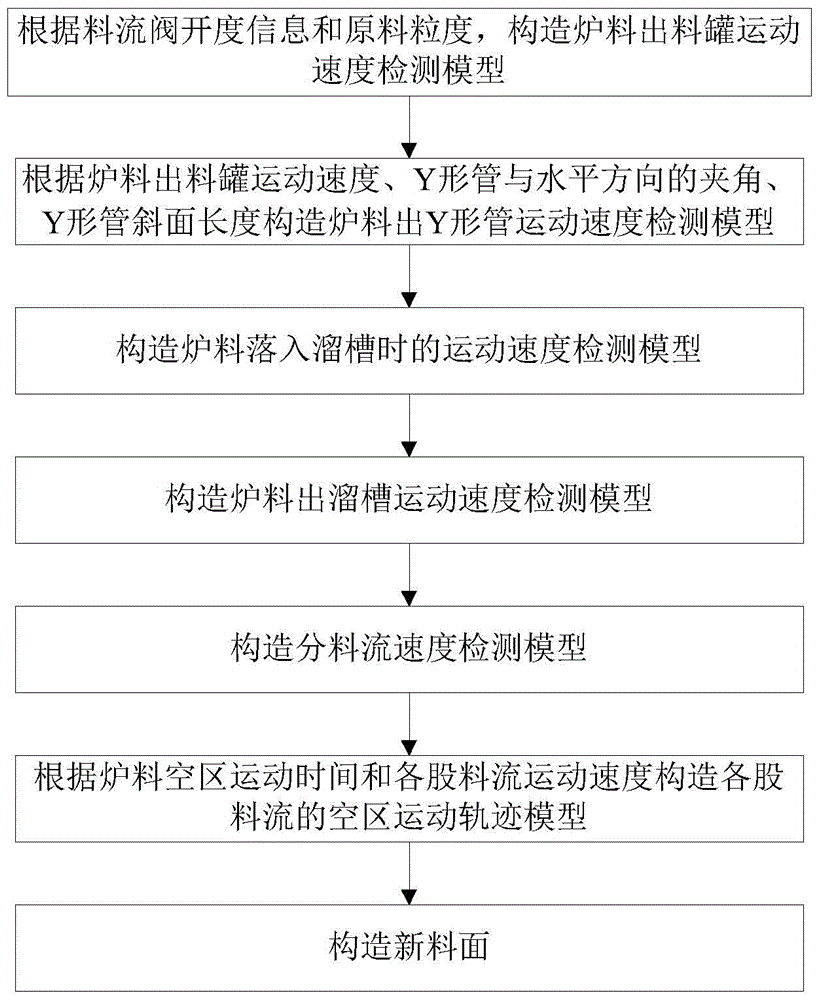

Blast furnace charge distribution real-time forecasting system and blast furnace charge distribution real-time forecasting method

ActiveCN104531924AStable productionQuality productionBlast furnace detailsChecking devicesDowntimeCharge layer

The invention provides a blast furnace charge distribution real-time forecasting system and a blast furnace charge distribution real-time forecasting method. The blast furnace charge distribution real-time forecasting system comprises a data acquisition device, a data processor, an initial charge level setter, an identical-level new charge level detector, a multi-level new charge level detector, a charge level descending module, a charge level distribution information generator and a distribution controller. The method comprises the steps of acquiring process data of a blast furnace in the production process; processing furnace charge weight and test data in the process data of the blast furnace in the production process; setting an initial charge level; establishing a new charge level under a same distribution level; forming a multi-level new charge level; establishing a descending charge level; calculating the distribution information of a charge layer, and drawing a charge layer distribution image; instructing the production and operation according to the charge layer distribution information forecasted according to the distribution of the blast furnace charge in real time. The method for combining a mechanism model and data drive is adopted, the distribution of blast furnace ore coke can be reasonably adjusted according to the judgment of the ore coke distribution furnace condition and the output result of the distribution model, the fluctuation of the furnace condition can be prevented, and the downtime ratio caused by the abnormality of the furnace situation can be reduced.

Owner:NORTHEASTERN UNIV

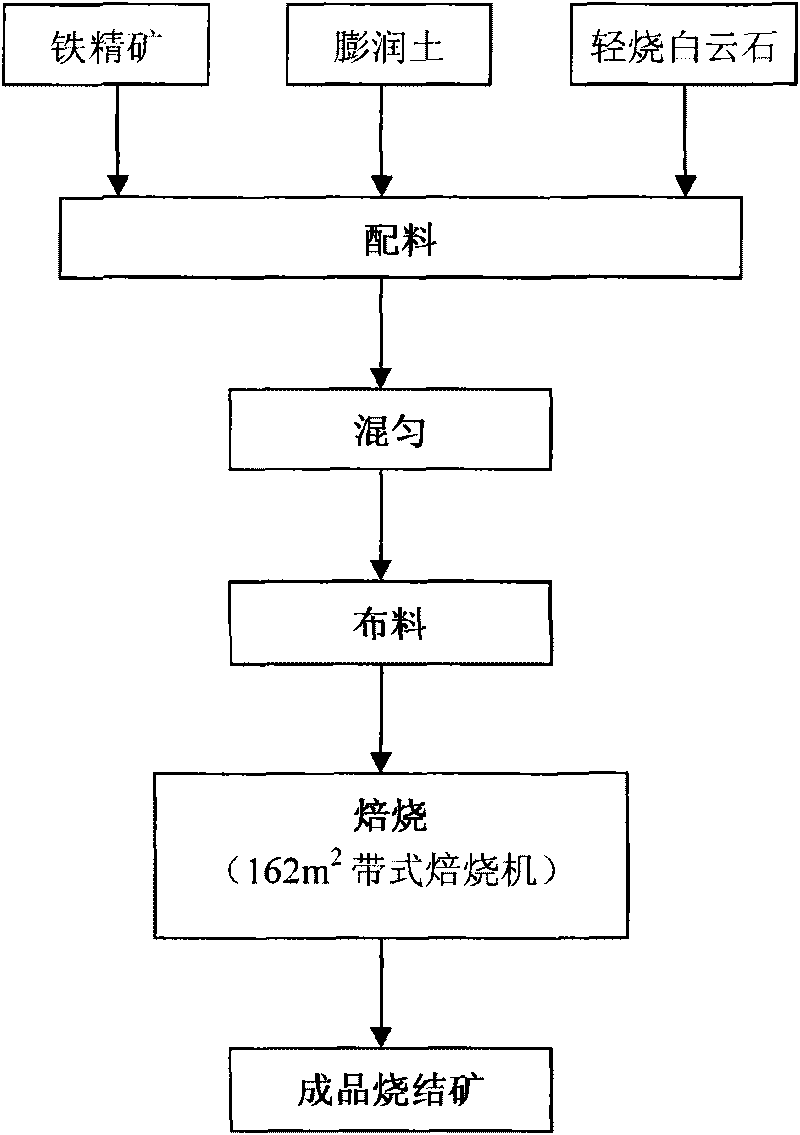

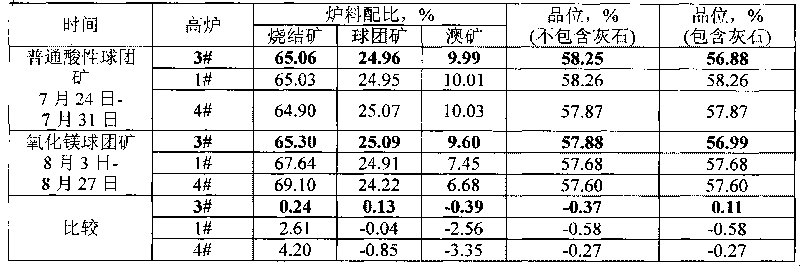

Fluorine-containing magnesium oxide pellet ore

The invention relates to a fluorine-containing magnesium oxide pellet ore which comprises the following raw materials: an iron material, bentonite and caustic calcined dolomite. The iron material is the mixed iron ore concentrate of Baotou steel Baiyun'ebo iron ore concentrate and common iron ore concentrate; the proportion of the Baiyun'ebo iron ore concentrate in the iron material is larger than 0 and not larger than 60wt percent, the bentonite accounts for 1.0-1.2wt percent relative to the raw materials, and the caustic calcined dolomite accounts for 3-4wt percent relative to the raw materials, wherein in the caustic calcined dolomite, CaO content is larger than 40wt percent, MgO content is not smaller than 28wt percent, SiO2 content is smaller than 8.0wt percent, and the proportion of granularity of 200 meshes is not smaller than 80wt percent; and MgO / SiO2 content in the fluorine-containing magnesium oxide pellet ore is not larger than 0.5. The invention fully utilizes Baotou steel Baiyun'ebo iron ore resources and can reduce the dosage of the bentonite and improve the reducibility and dropping temperature of the pellet ore by adjusting the pellet ore alkalinity and magnesium oxide content through adopting the dolomite; compared with acid pellet ore, the magnesium oxide pellet ore improves the reducibility and a low-temperature reduction degradation index, reduces the expansion ratio, and can meet the production requirement of a large blast furnace though with slightly reduced compressive strength of the pellet ore.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

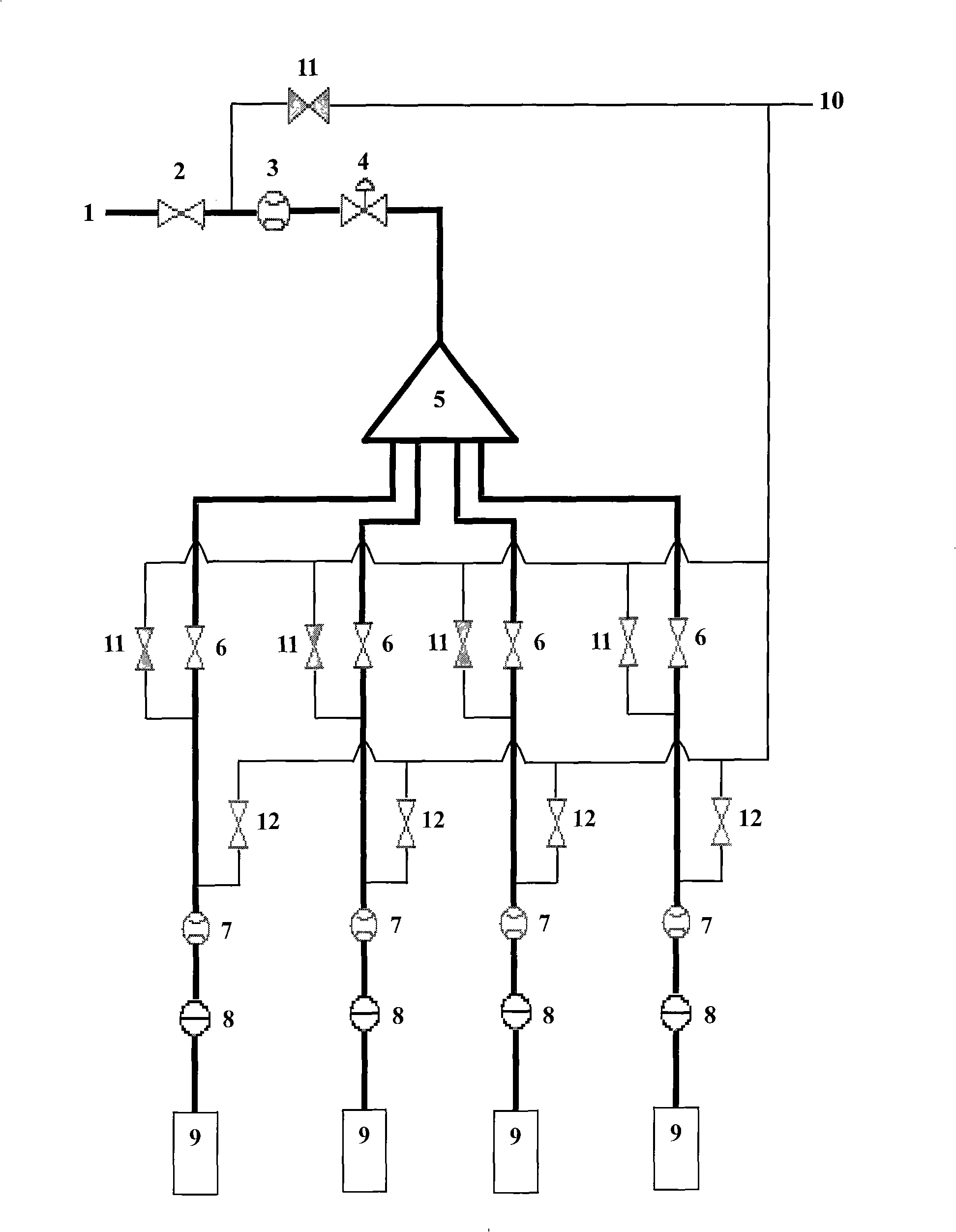

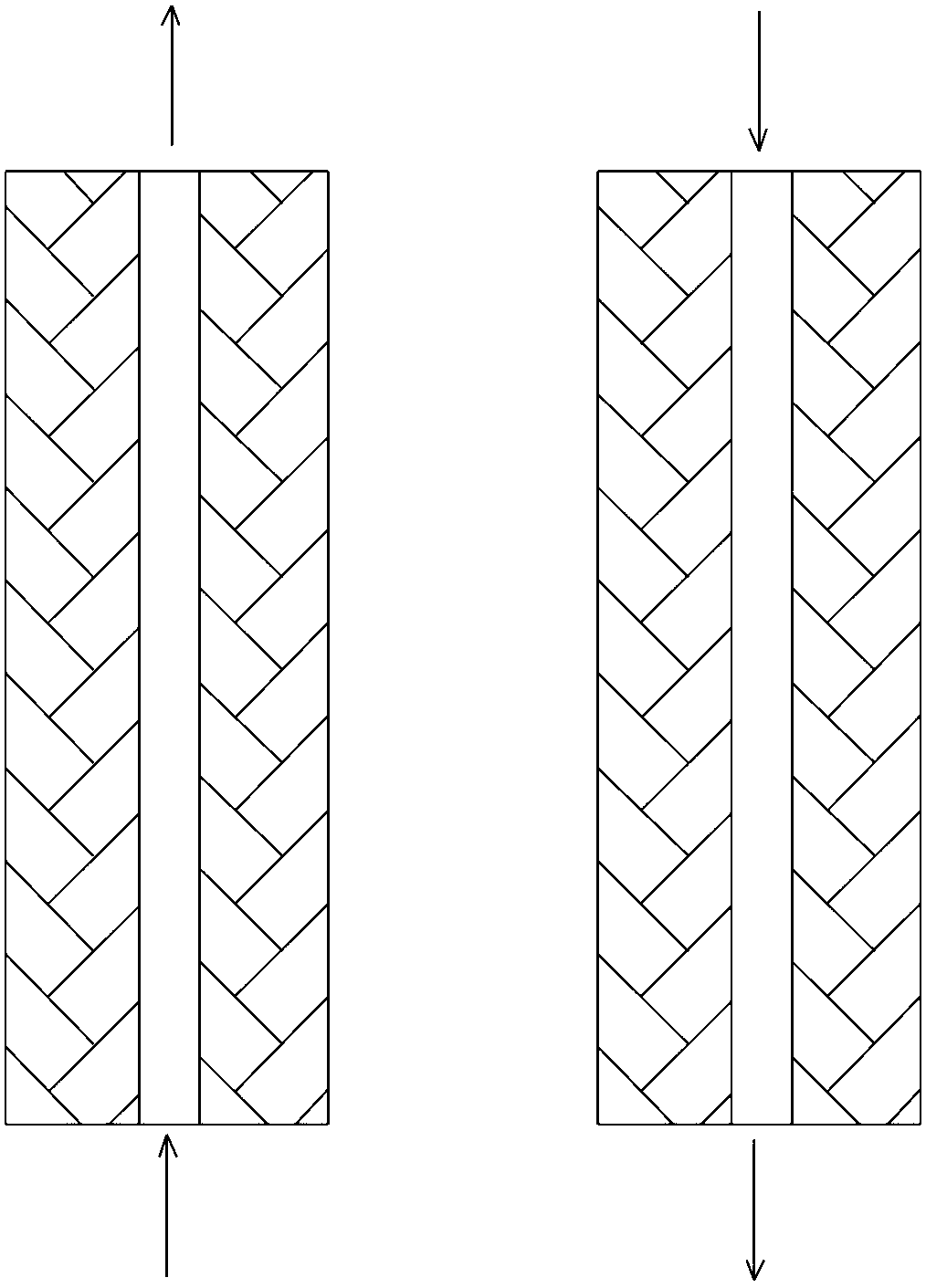

Two-stage type blowing breeze method and apparatus for blast furnace

InactiveCN101492748AOperational Metric ImpactIncreased drum strengthTuyeresBlast furnace detailsProduct gasEngineering

The invention relates to a method for two-stage coal injection in blast furnace ironmaking and a device thereof. The invention is characterized in that the inventive two-stage coal injection device provided with a special distributor, an inert gas special pipeline, a plurality of control valves, a flowmeter and a control meter is utilized, fixed operational programs are executed and partial technological parameters are controlled, thus realizing the two-stage coal injection of the blast furnace; through practical production verification for 40 days, by adopting the device and method, blockage of injection guns is effectively avoided; the average coal ratio of the blast furnace is increased by 11.35kg / tHM; and the coke ratio is reduced by 9.87kg / tHM.

Owner:NORTHEASTERN UNIV

Compound type binder used for pellet

The invention discloses a compound type binder used for pellet, which comprises the following raw materials in percentage by weight: 70-80% of clay powder, 10-20% of sodium humate, 3-6% of sodium carboxymethyl cellulose and 2-4% of sodium carbonate. The compound type binder used for the pellet of the invention is a pellet binder prepared by combining inorganic substance and organic substance, hasgood hydrophily and high viscosity, can be dissolved into water, replaces bentonite completely, has extremely low carry-in amount of detrimental impurity of the inorganic substance and does not influence the iron grade of the pellet; and when added into iron finemeal pellet for production, the invention does not change the original process and is an ideal and synergistic pellet binder.

Owner:王建忠

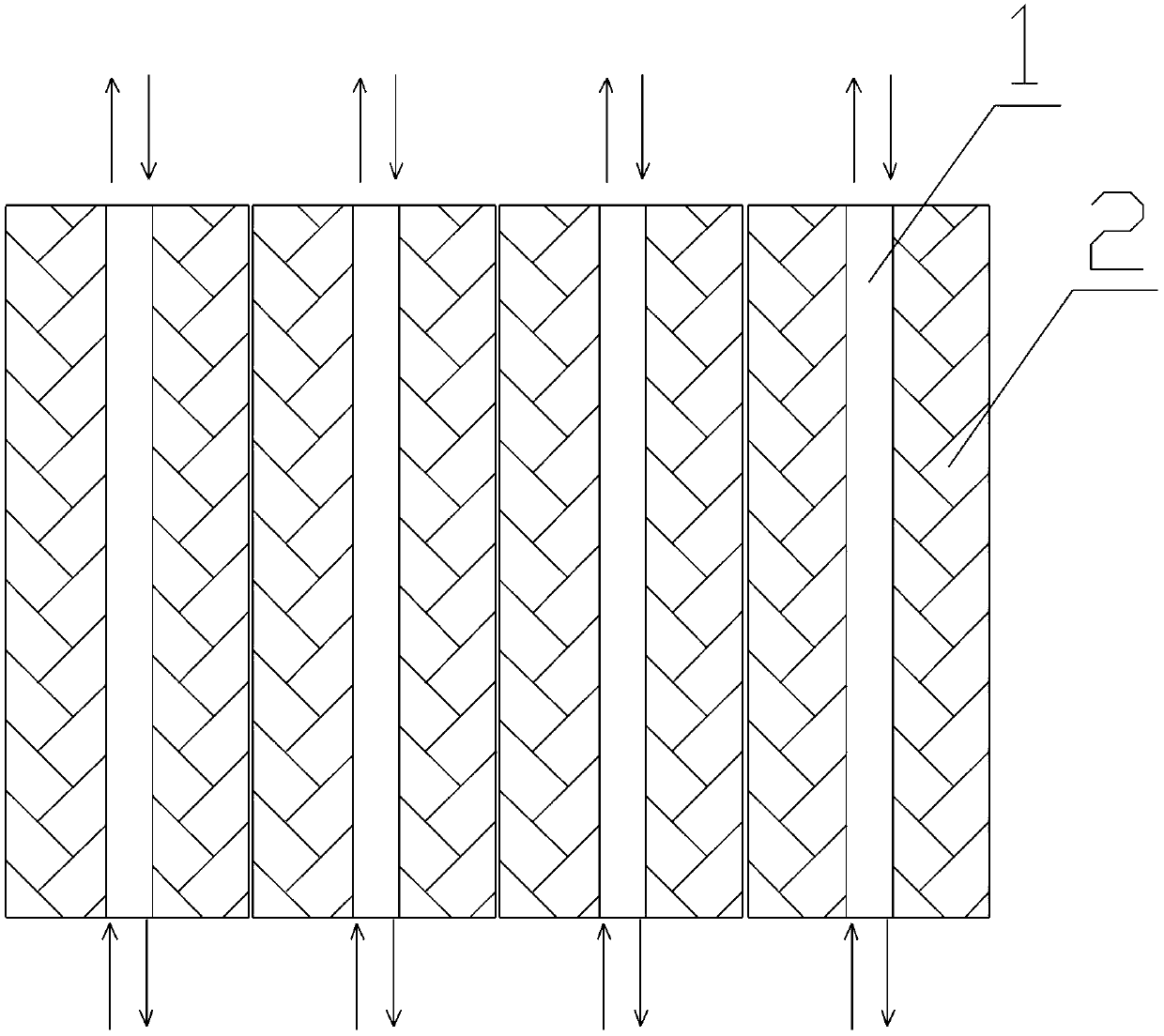

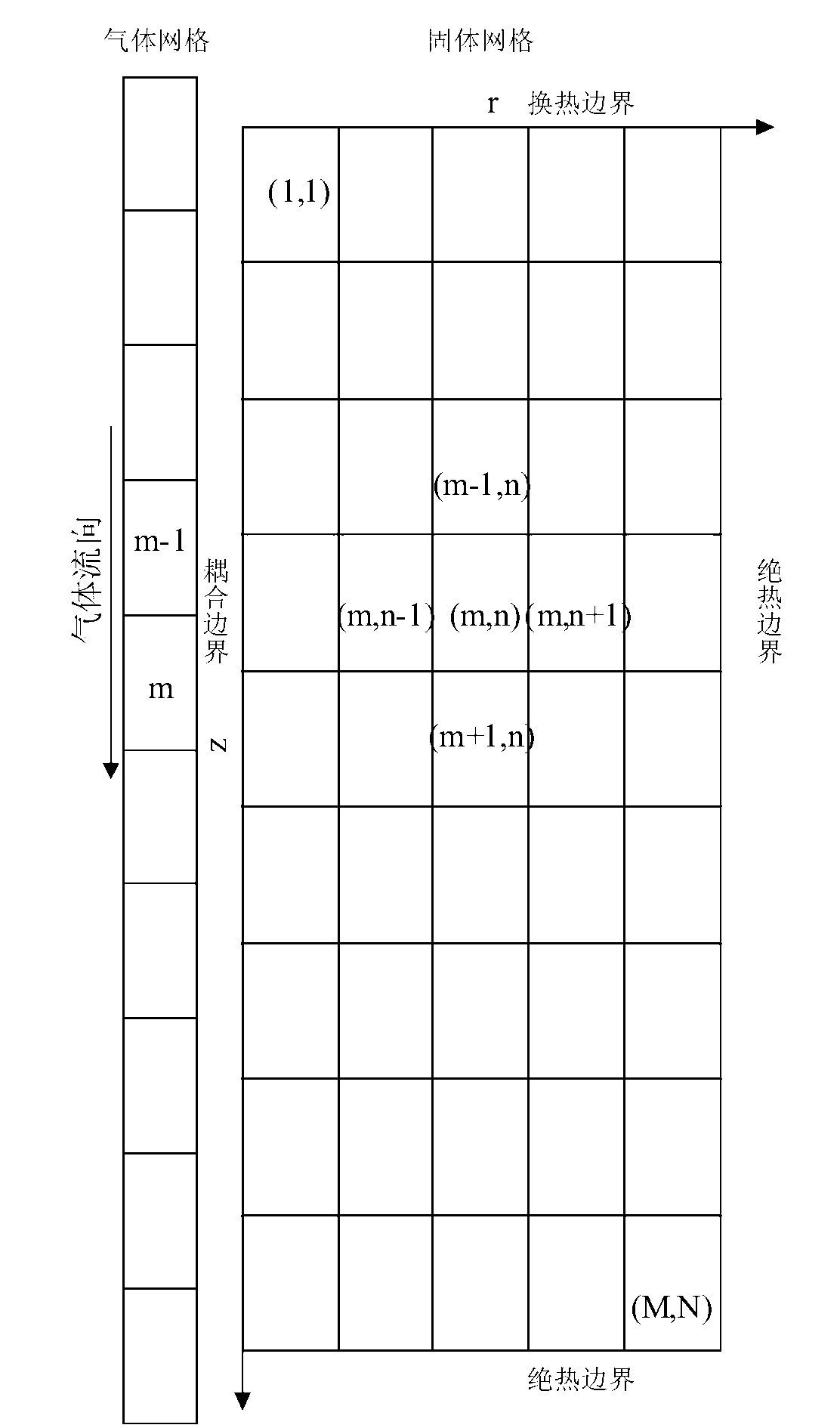

Modeling method and application of heat transfer and heat storage simulation model of hot blast stove

ActiveCN102819643AIncrease temperatureIncrease productionSpecial data processing applicationsModel methodCombustion

The invention discloses a modeling method and application of a heat transfer and heat storage simulation model of a hot blast stove. The method comprises the following steps of: calculating theoretical combustion waste gas temperature, waste gas flow and waste gas composition of the hot air stove according to parameters such as gas composition, gas flow, gas inlet temperature, combustion-supporting air inlet temperature and air / fuel ratio to provide basis for parameter calculation of the heat transfer and heat storage model; performing meshing on a cellular temperature field; establishing a numerical solving equation for heat conduction in a heat storage body and a heat exchange condition with gas; and performing numerical solving on the variation in time and space along with temperature so as to obtain a heat transfer and heat storage simulation model of the hot air stove. By using the heat transfer and heat storage simulation model of the hot air stove established by the invention, the added value and the consumed time of heat storage quantity when the combustion final point is reached under different combustion strategies can be calculated under the same initial condition, and the optimal combustion strategy, i.e., the combustion strategy with the highest efficiency, is obtained through comparison, so that the energy accumulated in a heat storage period is improved to the greatest extent, and the aim of improving the air temperature is fulfilled.

Owner:WISDRI ENG & RES INC LTD

Iron ore pellet and its preparation method

The invention discloses an iron ore pellet preparing method, Which comprises the following steps: putting 2-4wt% forsterite and 0. 2-0. 8wt% agglomerant in iron ore; mixing up water (the water content of mixture: 6-11wt%); making ball and drying; preheating at the temperature of 900-1000 deg. c for 15-25min; roasting at the temperature of 1260-1320deg. c for 20-40min; mixing up 20-40% jevigating, 5-10% polyacrylamide, 0-5% polypropylene, 0-5% sodium humate, 20-40% twaterproof putty powder, 3-5% caoline and 5-10% copperas in mass fraction to obtain agglomerant. The invention can improve the strength of green-ball and the heat endurance.

Owner:WUHAN UNIV OF SCI & TECH

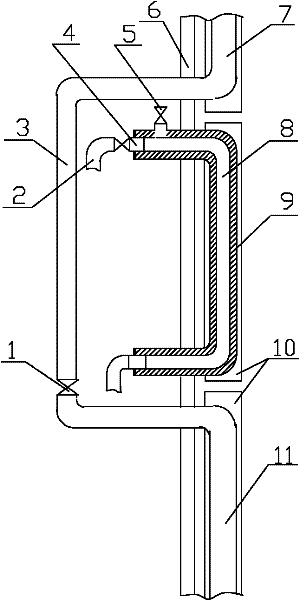

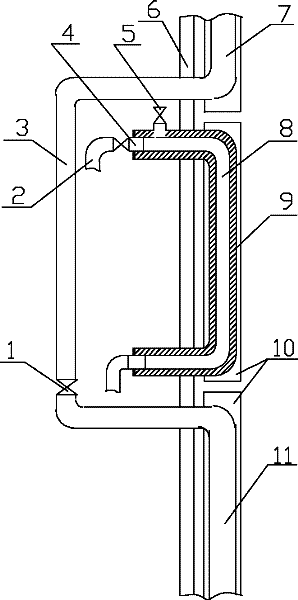

Replacement method for cooling water pipe of cooling wall of blast furnace

InactiveCN102534078AThe replacement method is simple and easyEasy to operateCooling devicesFurnace temperatureWater leakage

The invention provides a replacement method for a cooling water pipe of a cooling wall of a blast furnace. A broken cooling water pipe is disconnected with a front cooling water pipe and a rear cooling water pipe; and the front cooling water pipe and the rear cooling water pipe are connected through an external water pipe, so that cooling water is directly circulated across the broken cooling water pipe. Meanwhile, a metal hose is penetrated in the broken cooling water pipe and is connected to a replaced cooling water pipe, which is communicated with an external water source, through seamless steel pipes at the two ends, so that cooling water in the metal hose independently forms a passage to continuously realize a cooling function. By using the method, quick replacement of the broken cooling water pipe is realized without affecting normal water supply cooling of other cooling water pipes, the water leakage phenomenon in the blast furnace is eliminated, the problem of increased coke ratio caused by reduced furnace temperature is prevented, the cooling function of the broken cooling water pipe is restored, the cooling effect of the cooling wall is guaranteed, and the service life of the cooling wall can be prolonged.

Owner:ANGANG STEEL CO LTD

Method and system for improving metallurgical coke strength by utilizing waste plastics

The present invention relates to a method for raising strength of metallurgical coke and its system. Said invention adopts traditional coking process and equipment, and adds waste plastics in the course of coking process, and is characterized by that after the waste plastics and additive are processed, they are added into coking furnace to implement co-coking with coking coal, at the same time of that the waste plastics are charred at high temp., and converted into coke, tar and gas the coke quality can be improved, crushing strength of coke M40 can be raised, abrasive resistance index of coke M10 is reduced, coke reactivity CPI is reduced and coke postreaction strength can be raised. Said system includes waste plastics processing system, additive and waste plastics mixing system, waste plastics and additive mixture and coking coal mixing system and traditional coking system.

Owner:SHOUGANG CORPORATION

Composite low-carbon ironmaking method based on blast furnace blowing coke oven coal gas

InactiveCN110241272AImprove the "cool" phenomenonEffective thermal compensationBlast furnace detailsBlast furnace smeltingCoke oven

The invention provides a composite low-carbon ironmaking method based on blast furnace blowing coke oven coal gas. The method takes a blast furnace as smelting equipment, ore layers and coke layers are taken as furnace charge, the furnace charge is loaded into the blast furnace from the top of the blast furnace, and the ore layers and the coke layers are alternately arranged inside the blast furnace; and the coke oven coal gas is blown at a blast furnace tuyere, meanwhile, two sections of blowing at a furnace top circulating coal gas tuyere and a furnace body are carried out, then blast furnace smelting is carried out by adopting high oxygen enrichment, hot air and coal injection operation, and finally molten iron and furnace slag are obtained. According to the method, the blast furnace smelting efficiency can be improved, the energy conversion and utilization inside the blast furnace can be optimized, the coke ratio can be reduced to the maximum extent, and the emission of carbon dioxide can be reduced.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Furnace-protecting material for blast furnaces and preparation and application methods thereof

ActiveCN103468840AReduce titanium contentReduce the impact of liquidityBlast furnace componentsBlast furnace detailsCoke rateSlag

The invention provides a furnace-protecting material for blast furnaces and preparation and application methods thereof. The furnace-protecting material for the blast furnaces comprises the following components: 30-39% of ilmenite concentrate, 5-8% of CDQ (Coke Dry Quenching), and 51-65% of pulverized coal. The preparation method of the furnace-protecting material for the blast furnaces is implemented through uniformly mixing the CDQ powder with the pulverized coal in proportion so as to obtain a mixture, heating the mixture, dehydrating the mixture, and grinding and separating the mixture; uniformly mixing the ilmenite concentrate with the mixture so as to obtain the furnace-protecting material for the blast furnaces. When the temperatures of bottom and basque detecting couples rise or the temperature difference of cooling water rises, the furnace-protecting material for blast furnaces is injected; the furnace-protecting material is injected after roughing slags in the process of tapping, and after normal coal blending is performed for 2 hours, the furnace-protecting material is injected again; oxygen-enriched injection is performed in the process of injecting the furnace-protecting material. According to the invention, the influence of the titanium content of scrap iron in the slags on the flowability of the scrap iron in the slags can be reduced, so that while the disposal capacity of metallurgical wastes is reduced, the furnace-protecting cost and coke rate of blast furnaces are lowered, the efficiency and effect of furnace protecting are improved, and the service cycle of a furnace hearth is relatively extended.

Owner:ANGANG STEEL CO LTD

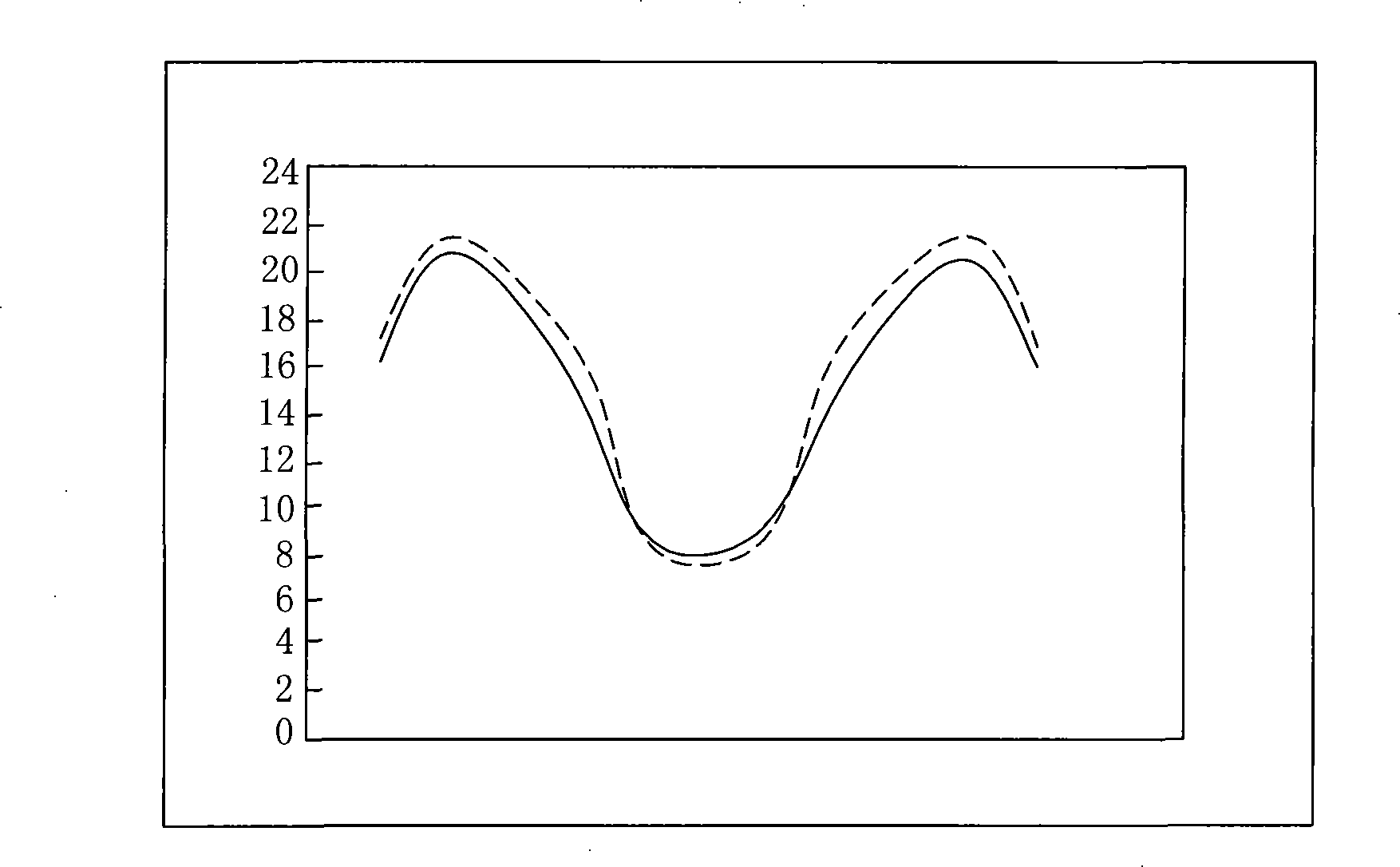

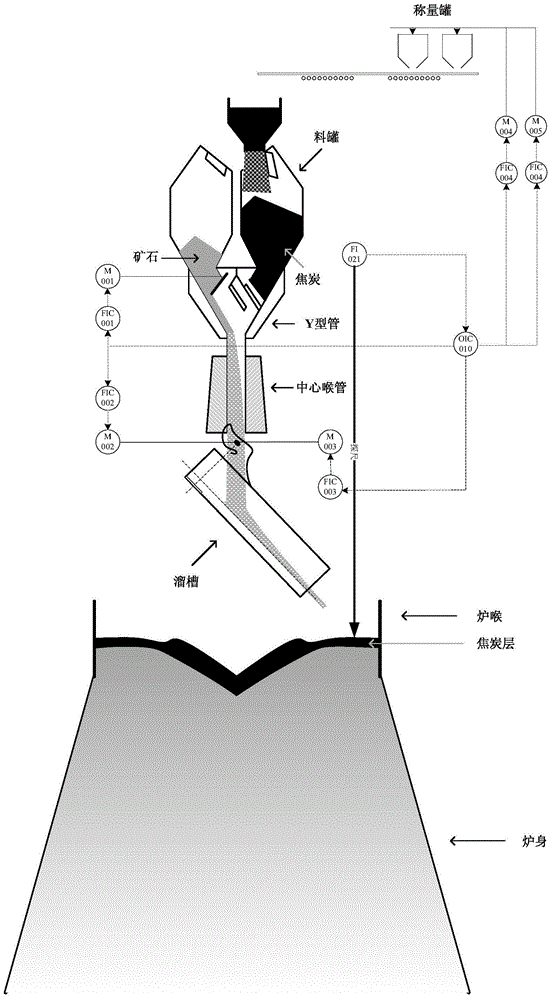

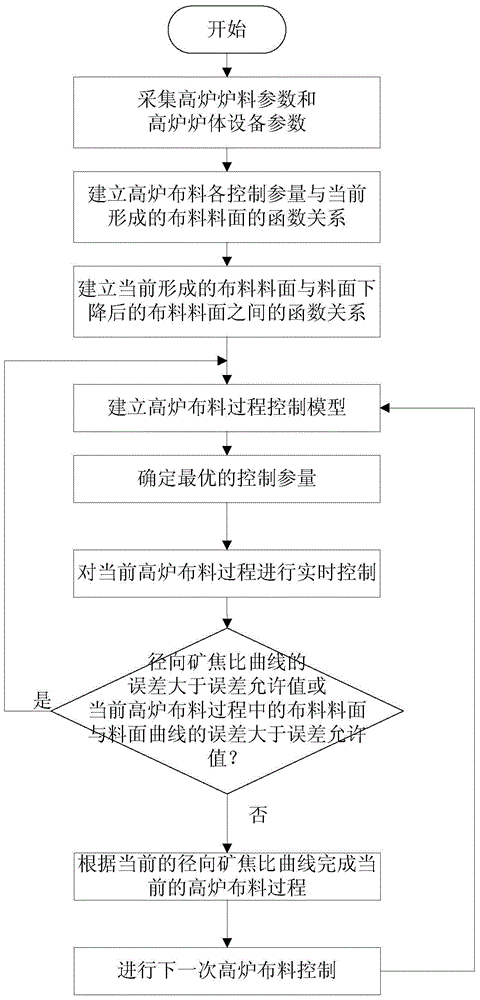

Method for controlling radial ore to coke ratio in blast furnace burden distribution process

ActiveCN104133945AIncrease productionStable furnace conditionSpecial data processing applicationsDistribution matrixTime control

The invention provides a method for controlling the radial ore to coke ratio in a blast furnace burden distribution process. The method comprises the following steps that: a blast furnace burden parameter and a blast furnace body equipment parameter are collected; the function relationship between each control parameter in the blast furnace burden distribution process and the current formed burden distribution burden level is built; the function relationship between the current formed burden distribution burden level and the burden distribution burden level after the burden level reduction is built; a blast furnace burden distribution process control model is built and is used for describing the relationship between a blast furnace burden distribution radial ore to coke ratio curve and each control parameter; the optimum control parameter is determined by using the blast furnace burden distribution process control model, and the current blast furnace burden distribution process is controlled in real time; and when the error of the radial ore to coke ratio curve in the real-time control process of the current blast furnace burden distribution process is greater than an error allowable value, the blast furnace burden distribution process control model is rebuilt, and otherwise, the current blast furnace burden distribution process is completed according to the current ore to coke ratio curve. The method provided by the invention has the advantages that the real-time burden level shape can be provided, so that operators can be effectively guided for improving a charging system, modifying a burden distribution matrix and regulating the furnace burden distribution.

Owner:NORTHEASTERN UNIV

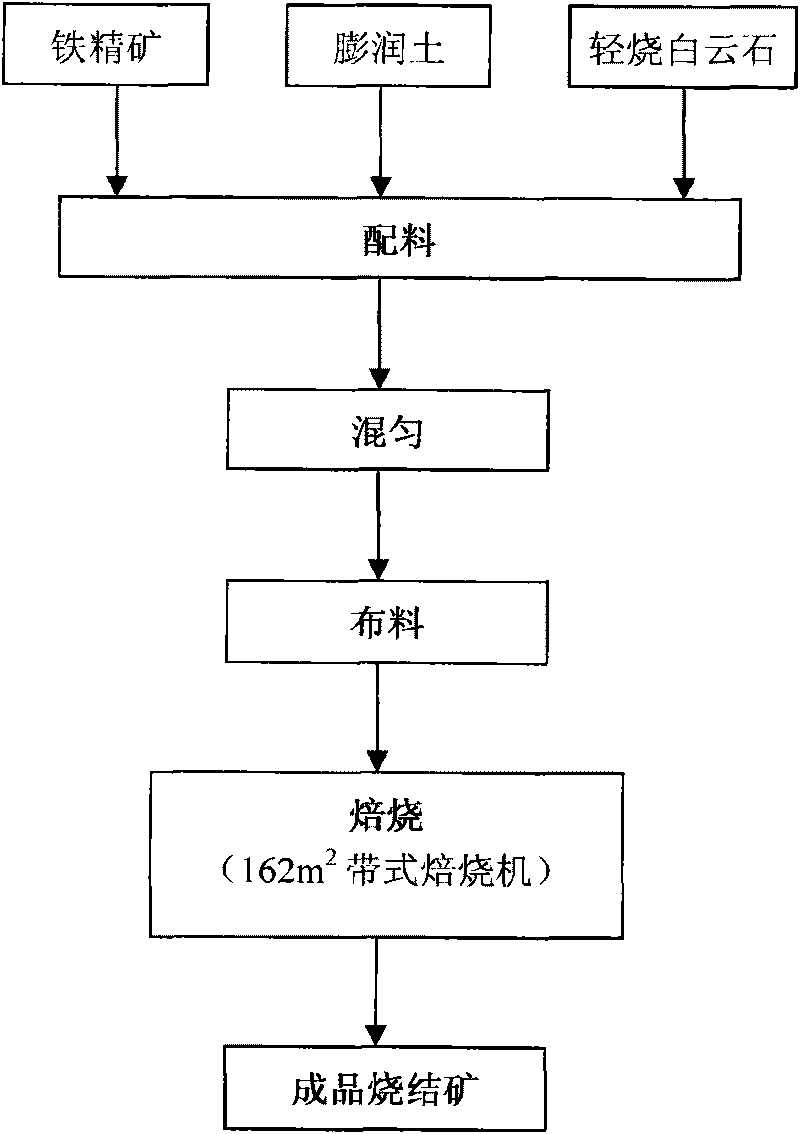

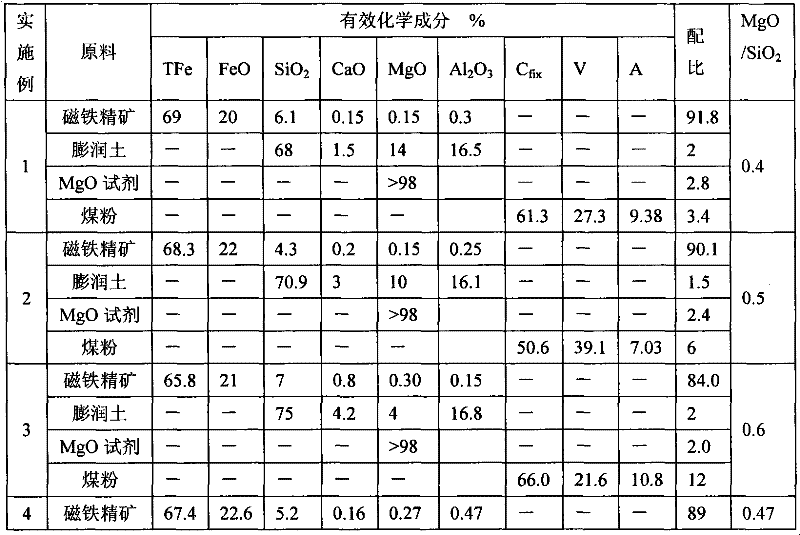

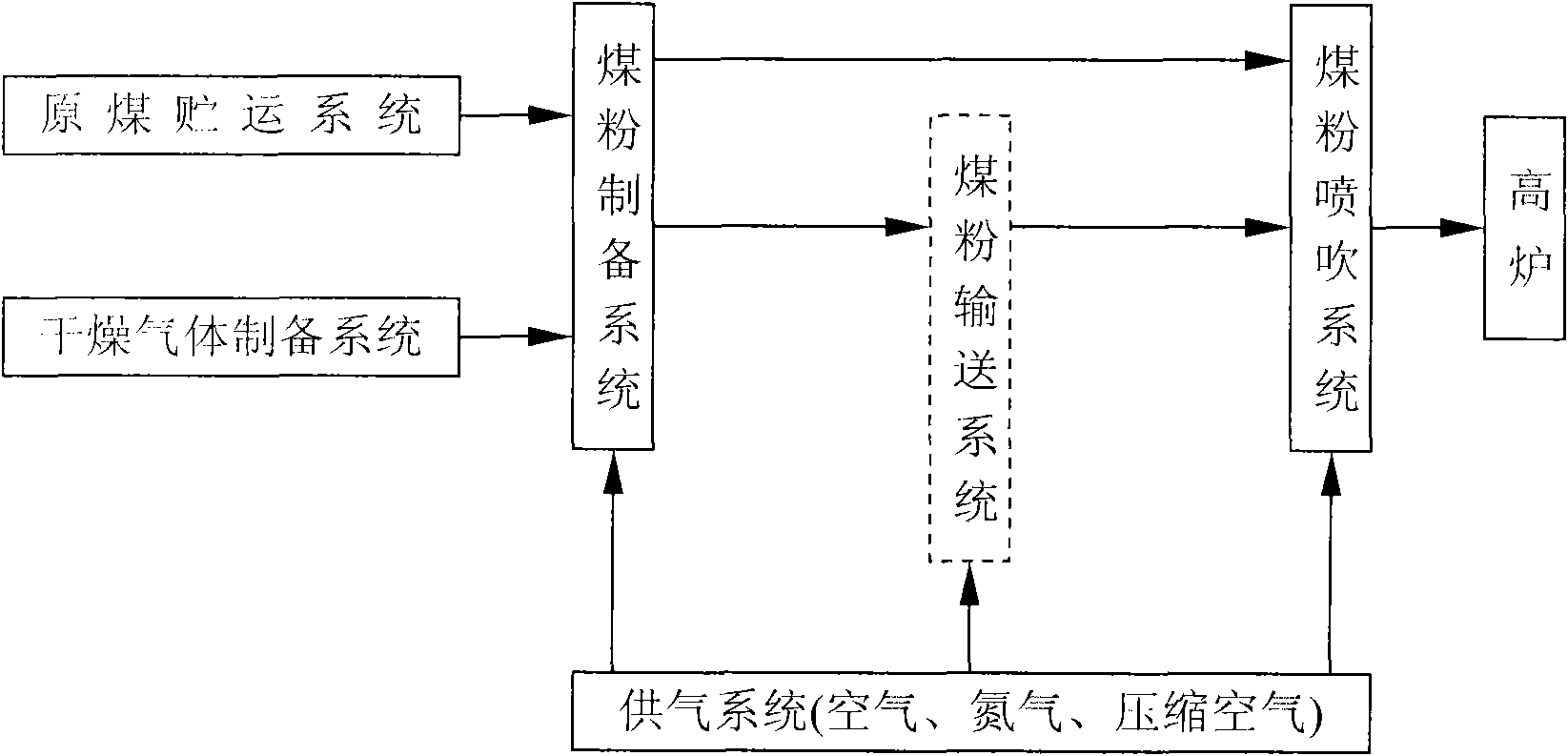

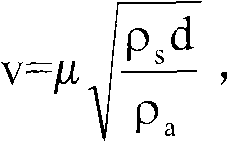

High-mechanical strength carbon-containing pellets for blast furnace and production method for high-mechanical strength carbon-containing pellets

The invention discloses high-mechanical strength carbon-containing pellets for a blast furnace. The pellets comprise the following raw materials in percentage by weight: 80 to 92 percent of magnetite concentrate, 1 to 2 percent of bentonite, 2 to 12 percent of coal dust, 2 to 14 percent of magnesium rock flour and 0.4 to 0.6 percent of MgO / SiO2 which is controlled in the raw materials. The production method for the pellets comprises the following steps of: weighing 80 to 92 percent of magnetite concentrate, 2 to 12 percent of coal dust, 1 to 2 percent of bentonite and 2 to 14 percent of magnesium rock flour according to a proportion and batching to ensure that 0.4 to 0.6 percent of MgO / SiO2 is contained in the mixed materials; spraying water, uniformly mixing, controlling the water content of the mixed materials to be 8 to 9 percent, and steaming for 30 to 60 minutes; preparing green pellets by using a pelletizing machine, screening the green pellets, and thus obtaining qualified screen pellets with the particle size of 9 to 16mm; and roasting at the temperature of between 1,250 and 1,300 DEG C for 10 to 15 minutes, and thus obtaining finished pellets with higher strength. By the method, the strength of the carbon-containing pellets is improved, the carbon-containing pellets with a certain metallization rate are obtained, and extremely high value for energy conservation and consumption reduction of the blast furnace is realized.

Owner:ANGANG STEEL CO LTD

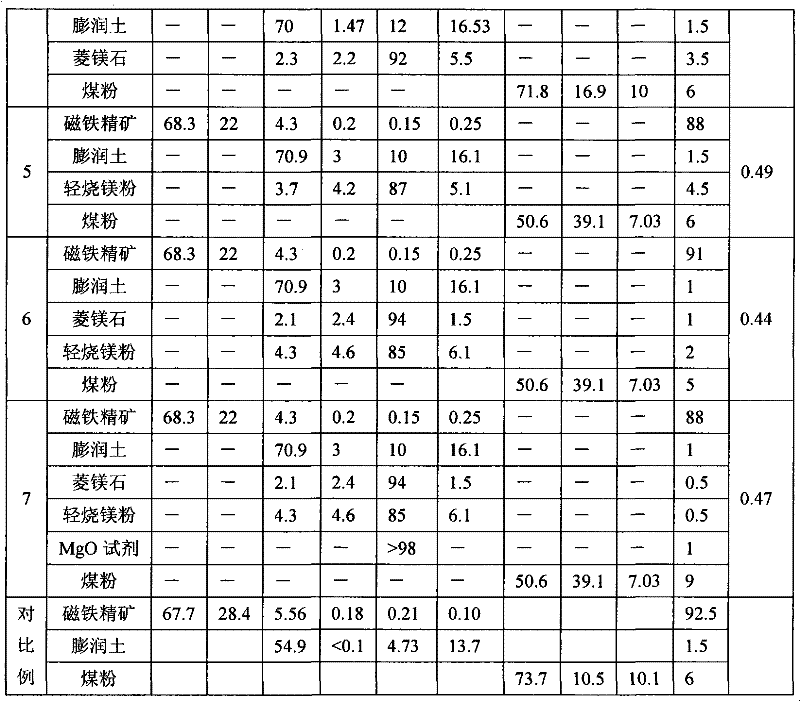

Method by adopting carbon dioxide as transmission medium for blast furnace coal injection

The invention relates to a blast furnace iron smelting field, in particular to a method by adopting carbon dioxide as transmission medium for blast furnace coal injection, which comprises the following steps that: a. storing and transporting raw coal; b. preparing dry gases; c. preparing pulverized coal; d. transporting the pulverized coal; and e. injecting and blowing the pulverized coal, and the method is characterized in that: d. when the pulverized coal is transported, the carbon dioxide is adopted as a carrier for the pulverized coal, and the pulverized coal is transported to a transportation pipeline through pressure difference; and e. when the pulverized coal is injected and blown, carbon dioxide gas is adopted as the carrier for the pulverized coal, and the pulverized coal is delivered into the transportation pipeline through the pressure difference to be injected a blast furnace. Due to the adoption of the method, the coke ratio and the consumption of expensive coke can be reduced, and the purity and the heat value of the blast furnace coal gas can be improved.

Owner:SHANGHAI GUOYE ENGINEERING TECHNOLOGY CO LTD

Coke passivator and preparation method thereof

ActiveCN101186853AReduce washoutReduced responseSolid fuelsHigh magnesiumCoke strength after reaction

The invention belongs to the technical field of ironmaking, in particular relating to a coke passivator and process for preparation. The coke passivator is produced by the raw materials at different part by weight, including 15-30 parts of boracic acid, 15-30 parts of borax, 30-50 parts of high magnesium powder, 5-15 parts of aluminum silicon powder, and 5-20 parts of calcium silicon powder. The coke passivator can uniformly form a layer of protective coating, which can reduce the erosion of the coke caused by CO2, decrease the reactivity of the coke, increase the coke strength after reaction, improve the utilization coefficient and the service life of the blast fumace and reduce the coke ratio. Utilizing the concentration of 0.3kg / t can reduce the reactivity of the coke by 5%, increase the coke strength after reaction by 7% and improve the production of the blast furnace by more than 3%-5%. The invention is an ideal product for blast furnace ironmaking which has the advantages of saving energy, reducing consumption, increasing production, improving benefits and protecting environment.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Sintered ore pulverization inhibitor and adding method thereof

The invention provides sintered ore pulverization inhibitor and an adding method thereof. The sintered ore pulverization inhibitor comprises the following chemical components by weight percentage: 65-85% of MgCl2, 3-7% of CaCl2, 5-15% of H3BO2 and 5-15% of CaO B2O3 4H2O. The adding method comprises the following steps that: pulverization inhibitor which is prepared and uniformly mixed is stored in a liquid storage pool; at a first spraying point, a 4.5kw pump and a spray tube are adopted for spraying sintered ores in a circular cooler; at a second spraying point, a 4.5kw pump and a spray nozzle are adopted for spraying a finished sintered ore belt; and at a third spraying point, a 7.5kw pump and an atomizing spray gun are adopted for spraying a finished product belt. After the pulverization inhibitor is sprayed to the finished sintered ores, the low-temperature reduction degradation index of the sintered ores is reduced, the breathability of a blast furnace is improved, the comprehensive coke ratio is reduced, and the yield of ferrum is improved; the content of chlorine is reduced, so the corrosion on a bag-type dust collector of the blast furnace is relieved; and simultaneously, the generation amount of TCDD (tetrachlorodibenzo-p-dioxin) is reduced, so the environmental pollution is avoided.

Owner:ANGANG STEEL CO LTD

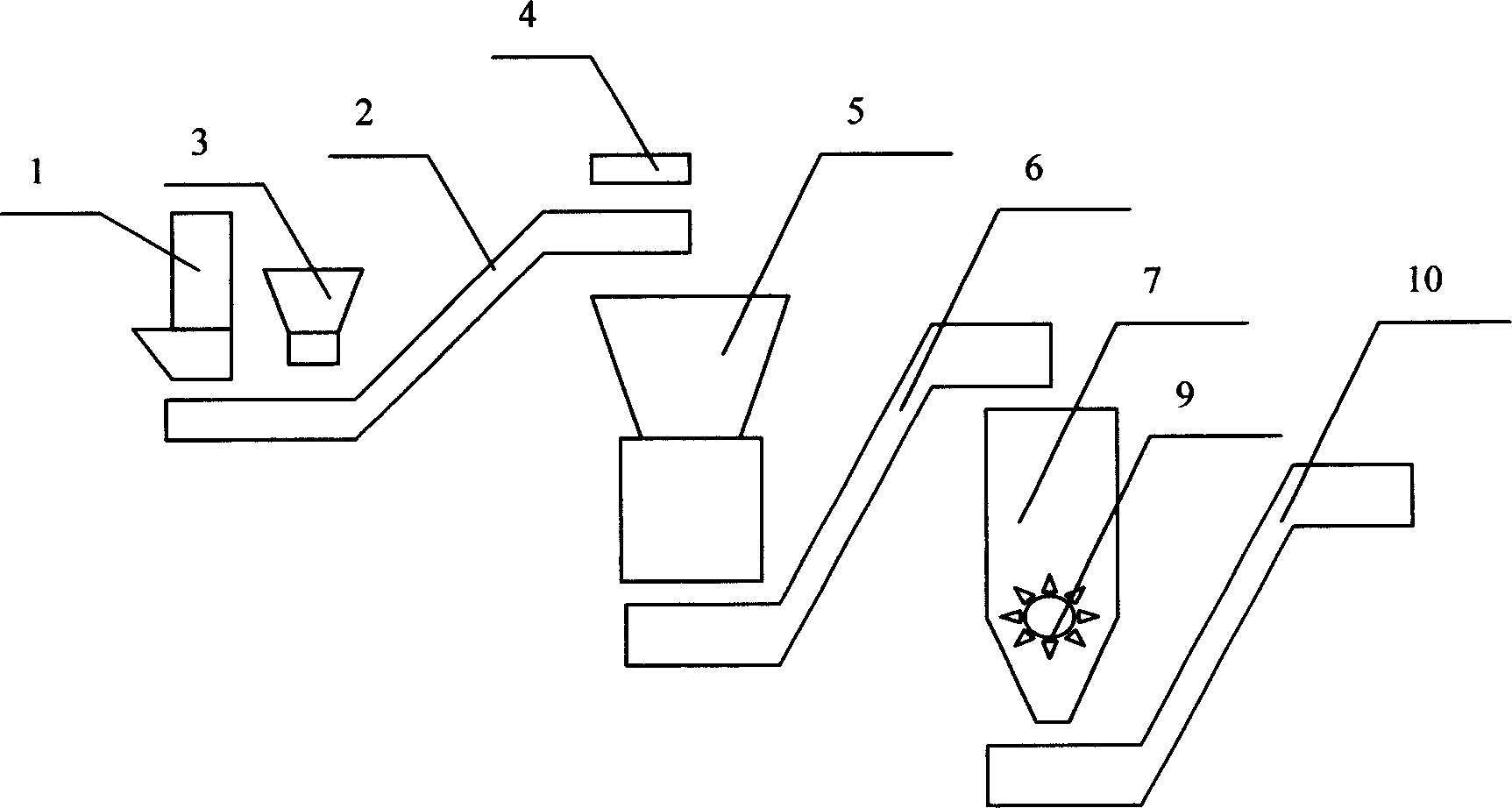

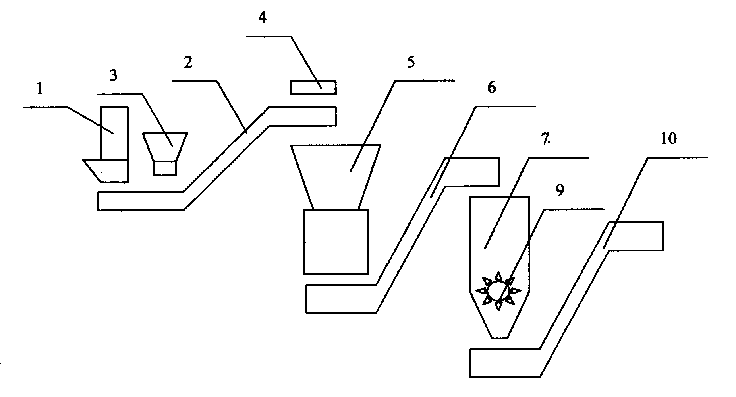

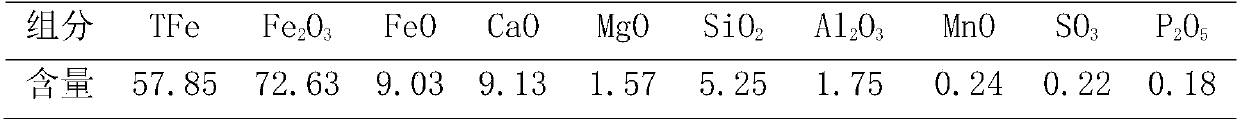

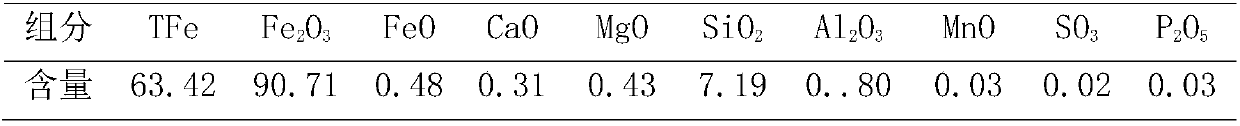

Nickel oxide ore dressing process

InactiveCN101392329AHighlight substantiveHighlight substantive featuresMagnetic separationEconomic benefitsMixed materials

The invention provides a concentration technology of nickel oxide ore. The concentration technology includes the following steps: material proportioning and granulation: nickel oxide ore is carried out bypass-recrushing and sifting so as to obtain fine ore which is carried out ore proportioning to obtain mixed mine, the mixed mine cooperates with a reducing agent and a flux to obtain mixed material which is further pelletized to obtain green pellets; reduction and roasting: the green pellets are put in roasting equipment to carry out reduction and roasting to obtain roasted pellets; protective quencher is carried out to the roasted pellets; magnetic concentration: after cooling off the roasted pellets, by ball milling and sifting, fine ore is obtained and put into magnetic-selection equipment to carry out magnetic concentration, and initial concentrate is obtained by magnetic concentration; and electrical selection: SiO2 is removed from the initial concentrate by electrical selection and final concentrate is obtained. The concentration technology is favorable to blast furnace ferronickel smelting with large scale, high efficiency and low energy consumption, has short technological process, low cost, notable anaphase economic benefits and strong controllability, and is favorable to refining nickel oxide ore and saving energy and reducing emission.

Owner:马和平 +2

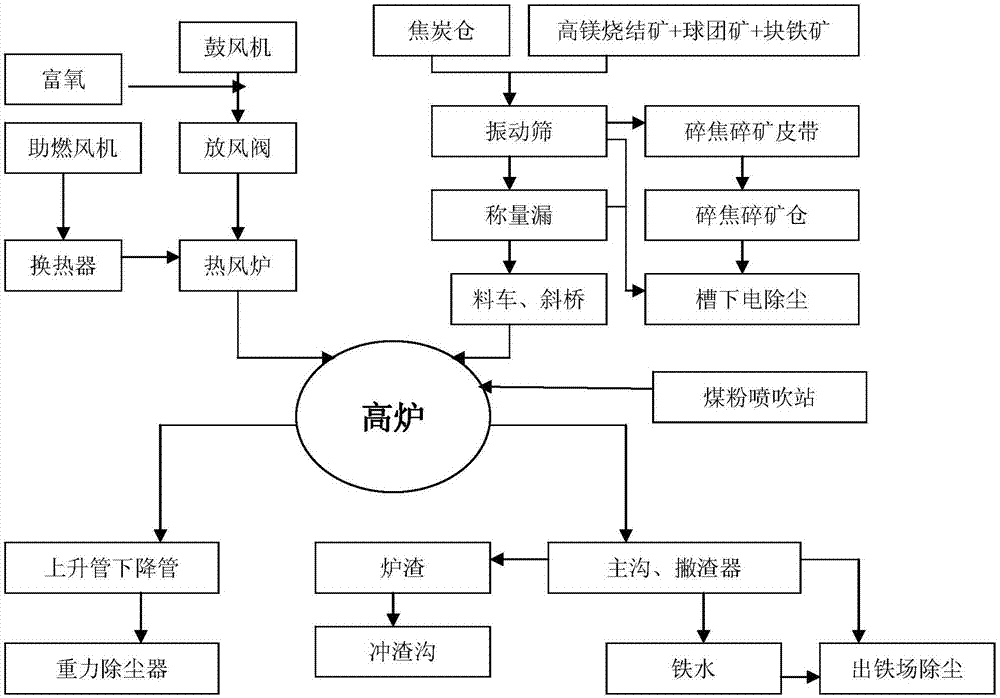

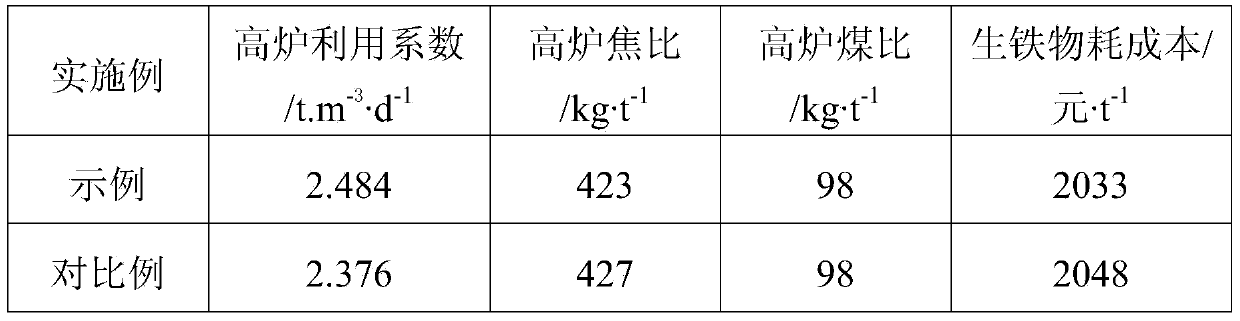

Blast furnace smelting method of high-grade high-vanadium chromium-contained type vanadium-titanium iron ore concentrates

A blast furnace smelting method of high-grade high-vanadium chromium-contained type vanadium-titanium iron ore concentrates comprises the following steps that (1) high-grade high-vanadium chromium-contained type vanadium-titanium iron ore concentrate fines, iron ore concentrate powder, magnesite, lime, return mines and fuel are mixed, and high-magnesium sintered ore is made; (2) high-grade high-vanadium chromium-contained type vanadium-titanium iron ore concentrate fines, bentonite and fuel are compacted to be pellets; (3) the high-magnesium sintered ore and the pellets are mixed, lump iron is added, and blast furnace burden materials are made; (4) blast furnace smelting is started, and blast furnace smelting comprises a charging system, an air blowing system, a thermal system and a slag forming system; the wind-warm syndrome is 1100-1200 DEG C, the coke ratio is 330-380 kg / t, and the coal ratio is 160-200 kg / t; and (5) tapping is conducted on molten iron every 70-90 min, and the temperature of the molten iron is 1430-1500 DEG C. According to the blast furnace smelting method of the high-grade high-vanadium chromium-contained type vanadium-titanium iron ore concentrates, the proportion of the high-vanadium chromium-contained type vanadium-titanium iron ore concentrates in blast furnace smelting raw materials is improved, and the ironmaking cost is reduced; and the blast furnace utilization factor is improved, the comprehensive coke ratio is greatly reduced, and meanwhile the metal yield is kept at a high level.

Owner:NORTHEASTERN UNIV

Blast furnace burden and method for improving comprehensive feeding grade of vanadium titano-magnetite blast furnace

ActiveCN103725812AImprove the furnace gradeIncrease productionBlast furnace detailsBlast furnace smeltingTitanium

The invention provides a blast furnace burden and a method for improving comprehensive feeding grade of a vanadium titano-magnetite blast furnace. The blast furnace burden comprises the components in percentage by weight as follows: 64%-90% of vanadium-titanium sintering ore, 1%-35% of vanadium-titanium pellet, 0-9% of acidic lump ore and 1%-10% of high-grade lump ore, wherein the weight percentage of Fe in the high-grade lump ore is 40%-65%, and the weight percentage of SiO2 is 5%-15%. The invention further discloses the method for improving the comprehensive feeding grade of the vanadium titano-magnetite blast furnace, and the method comprises the step that the blast furnace burden is subjected to blast furnace smelting. According to the invention, the feeding grade of the blast furnace can be improved, the production of the blast furnace is increased, the focal ratio is reduced, and the cost of the blast furnace burden is reduced.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

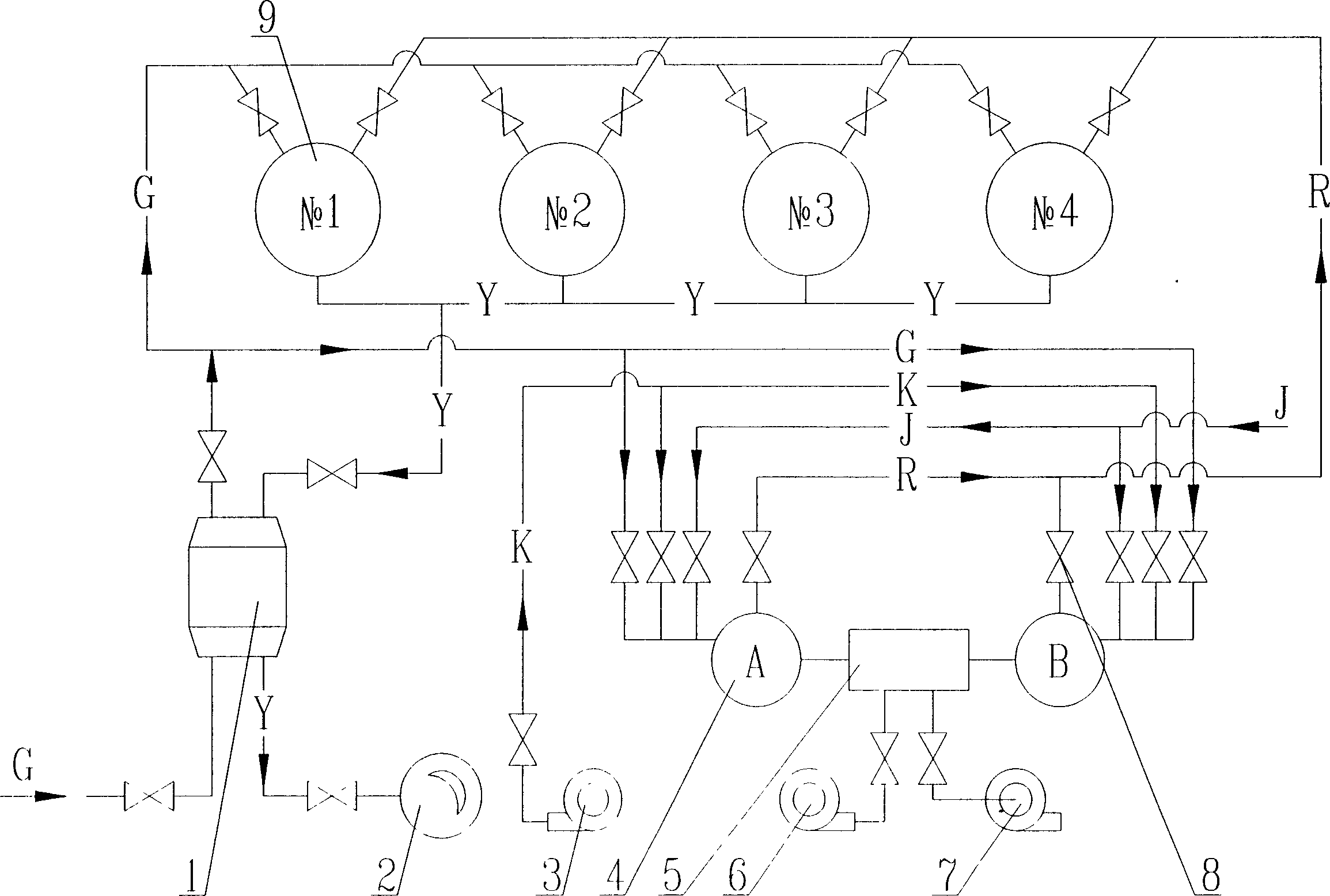

Warm up method of combustion supporting air through coal gas from blast furnace hot blast stove in high temperature

InactiveCN1600868AReduce focal ratioIncrease the amount of coal injectionBlast furnace detailsHeating stovesAutomatic controlEngineering

This invention provides a method for preheating hot-blast gas and combustion supporting air. It is characterized that: a non-motor heat-transfer heat-exchanger is used to heat hot-blast gas, which is used for hot-blast furnace and small-sized high-efficiency heat-storage burner, to temp. of 170-190 deg.C, by using 280-320 deg.C hot-blast flue-gas. A couple computer controlled burner burns said hot-blast gas at the temp. of 170-190 deg.C to preheat combustion-supporting air of hot-blast furnace to 1050-1100 deg.C, so to keep the temp. of the hot-blast of the hot-blast furnace at 1300-1350 deg.C. Advantages are: less equipment of preheating system, long service life, high efficiency, small-sized, computer-controlled, saving fuel gas, high hot-blast air temp. of 1300-1350 deg.C, saving coke, iron prodn, increased by 9-10.5%.

Owner:UNIV OF SCI & TECH BEIJING

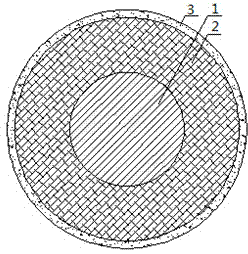

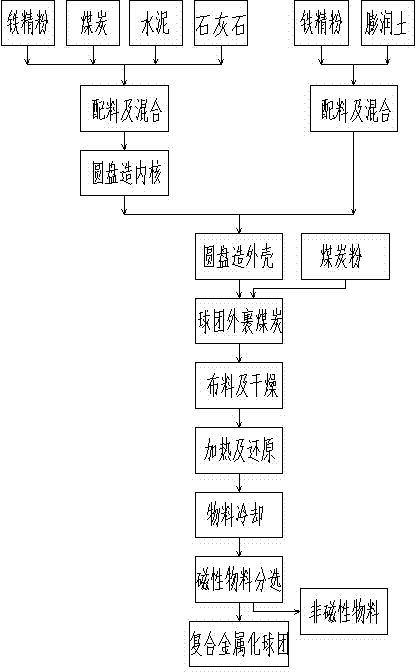

Self-fluxing composite metallized pellet and production process thereof

InactiveCN104745809AIncrease the atmosphere concentration and reduction reaction speedIncrease the speed of the reduction reactionProcess efficiency improvementCoalEnergy consumption

The invention relates to the technical field of metallurgy and mineral engineering, and discloses a self-refluxing composite metallized pellet and a production process thereof. The self-refluxing composite metallized pellet comprises an inner core and an outer shell, wherein the inner core is formed by mixing iron ore concentrate, limestone, coal powder and cement in a proportion of 330:(300-350):(80-120):(6-9); the outer shell is formed by mixing iron core concentrate and bentonite in a mass ratio of 1320:(22-25), the grain size of the inner core is 20-25mm, and the thickness of the outer shell is 5-10mm. The production process for the self-refluxing composite metallized pellet comprises the following steps: preparing the inner core and packaging the outer shell to form a composite metallized pellet; packaging the composite metallized pellet with a reducing layer, distributing and drying the composite metallized pellet, reducing and roasting the composite metallized pellet, cooling and sorting the high-temperature reduced composite metallized pellet. According to the self-refluxing composite metallized pellet and the production process thereof disclosed by the invention, limestone is mixed into the inner core, and CO2 generated by heating and decomposing the limestone in a reducing process of the composite metallized pellet is used as an oxygen producer to participate in gasification reaction of the coal, so that CO concentration inside the pellet is increased, the reducing speed of the pellet is increased, and the energy consumption is reduced.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Pellet ore binder prepared by taking sludge generated in sewage treatment as raw material

InactiveCN102409169AAdhesiveHarmlessSludge treatmentProcess efficiency improvementActivated sludgeMineral Sources

The invention relates to a pellet ore binder prepared by taking sludge generated in sewage treatment as a raw material. The binder comprises sludge in a preliminary sedimentation tank, sludge in a coagulation sedimentation basin or residual activated sludge, wherein the sludge in the preliminary sedimentation tank, sludge in the coagulation sedimentation basin or residual activated sludge are powdery sludge obtained by drying, crushing and treating. The invention also relates to an application and a usage method of the pellet ore binder prepared by sludge. The pellet ore binder prepared by sludge generated in sewage treatment is capable of raising the grade and the metallurgy performance of a furnace ore, reducing the iron-making cost, reducing the resource consumption and energy consumption, minimizing the pollutant discharge capacity and raising the capability of national steel material and product in the competition of international markets. The sludge generated in sewage treatment which is difficult to be treated can be obtained resource utilization with high efficiency, so that the mineral product resource such as bentonite and the like can be saved.

Owner:BEIJING JUNZHIQING SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com