Patents

Literature

123results about How to "Reduce ironmaking costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

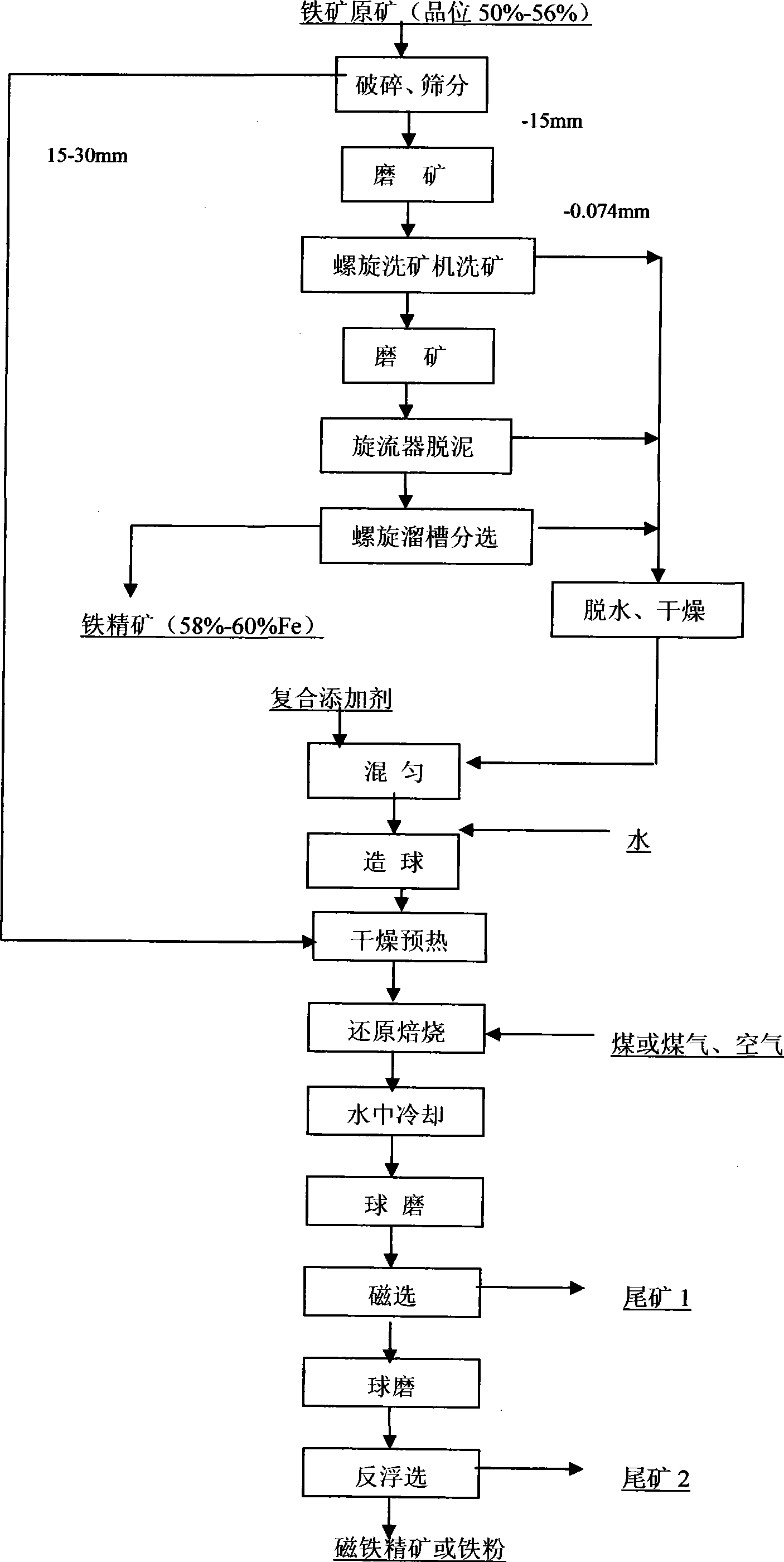

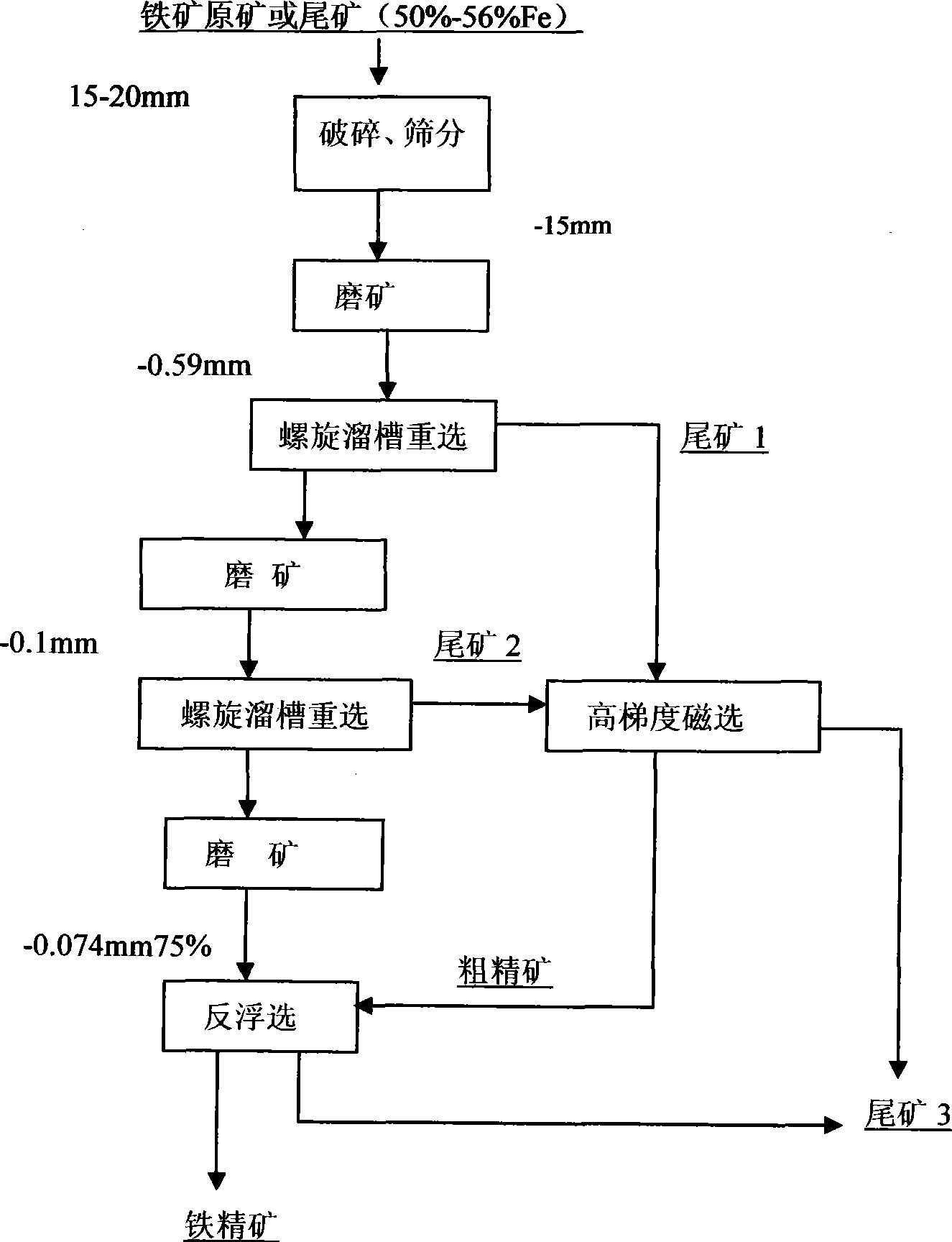

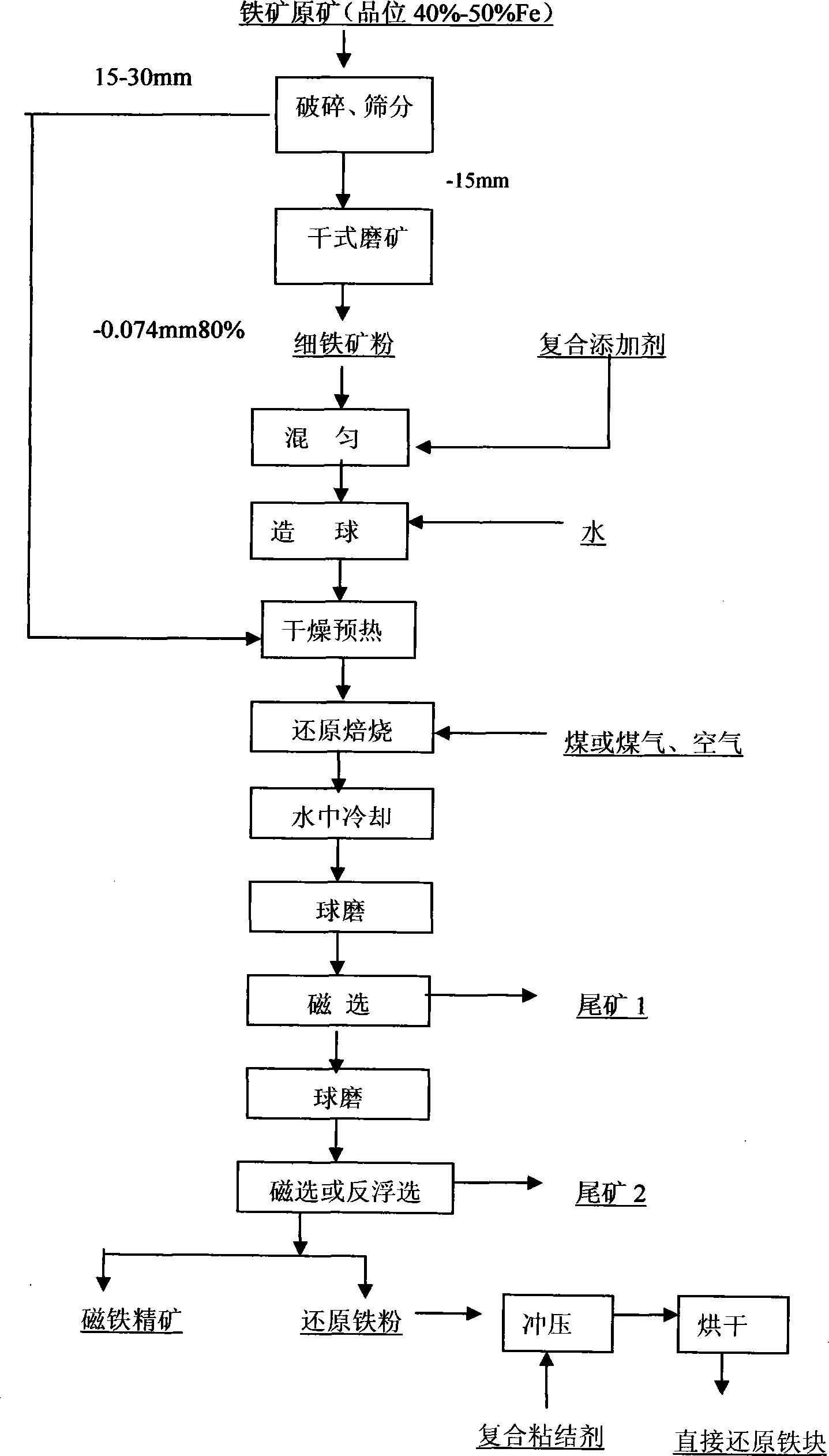

Method for efficiently separating low-ore grade and complicated iron ore

ActiveCN101413057ALow grain sizeHigh content of water of crystallizationProcess efficiency improvementIronstoneIron powder

The invention provides an efficient separation method for low-grade and complex iron ores. The method is characterized in that the complex iron ores of different grades and species are classified, so as to obtain lump ores and mineral powder which are balled, dried and preheated; reduction roasting, cooling, ball milling, magnetic separation, ball milling and magnetic separation or reverse flotation are performed in turn, so as to obtain iron ore concentrate or reduced iron powder; classification treatment is to crush and screen the iron ores with iron-containing grade between 50 and 56 percent and then dry and preheat obtained ores; fine-grained mineral powder is ground, washed, ground, deslimed and separated so as to obtain the iron ore concentrate and slime containing 58 to 60 percent of iron; the slime which is washed, deslimed, and separated is dewatered and dried and is added to and well mixed additives, so as to be balled then; the iron ores with the iron-containing grade between 40 and 50 percent are crushed and screened so as to obtain the lump ores which are directly dried and preheated, while the fine-grained mineral powder is obtained through dry-type grinding and then is added to and well mixed the additives so as to be balled then; and the iron ores with the iron-containing grade between 25 and 40 percent are crushed and screened so as to obtain the lump ores which are dried and preheated, while the fine-grained mineral powder is subjected to grinding, gravity separation or high-gradient magnetic separation and reverse flotation, so as to obtain coarse iron concentrate powder which is added to and well mixed with the additives and then is balled.

Owner:CENT SOUTH UNIV

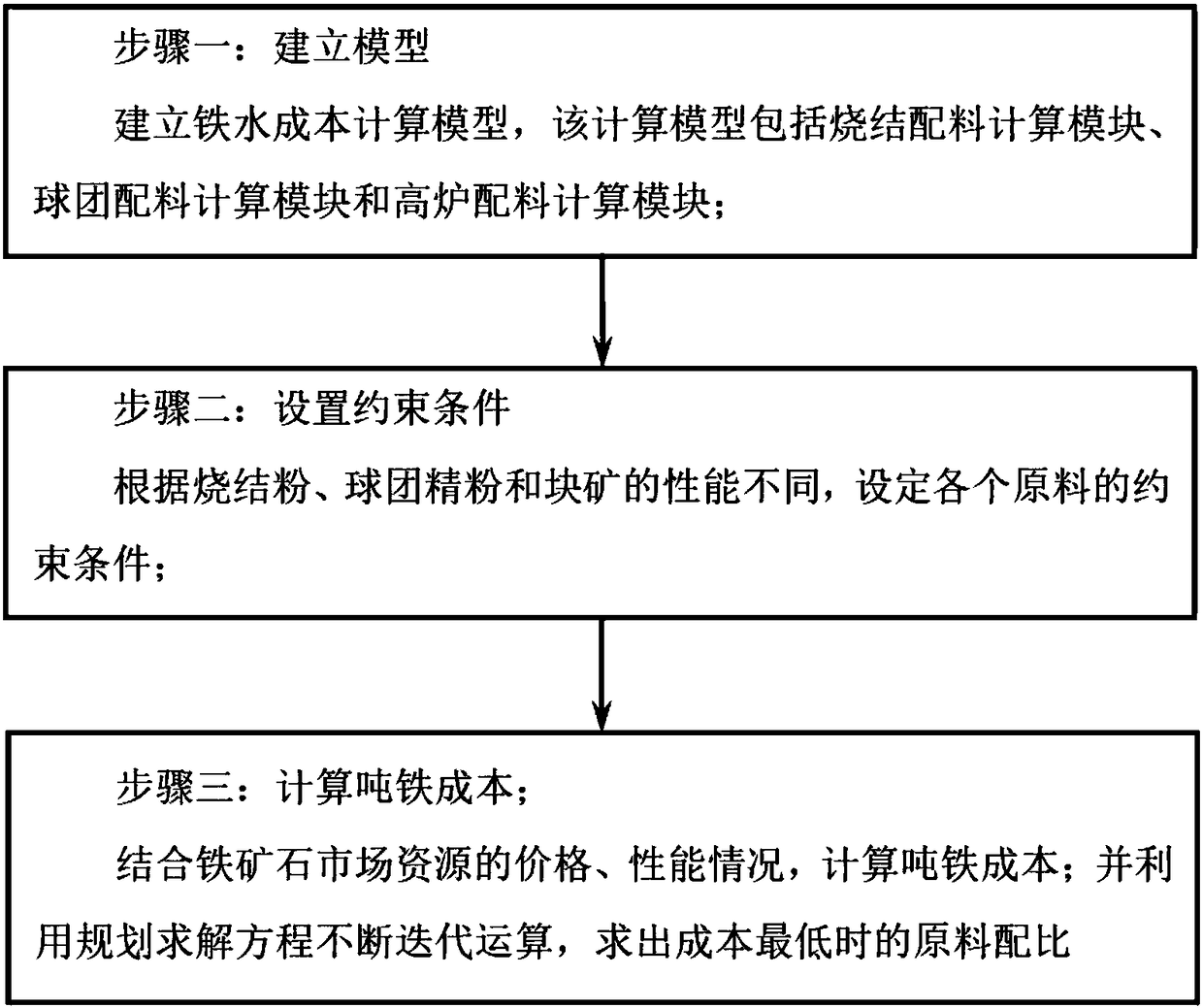

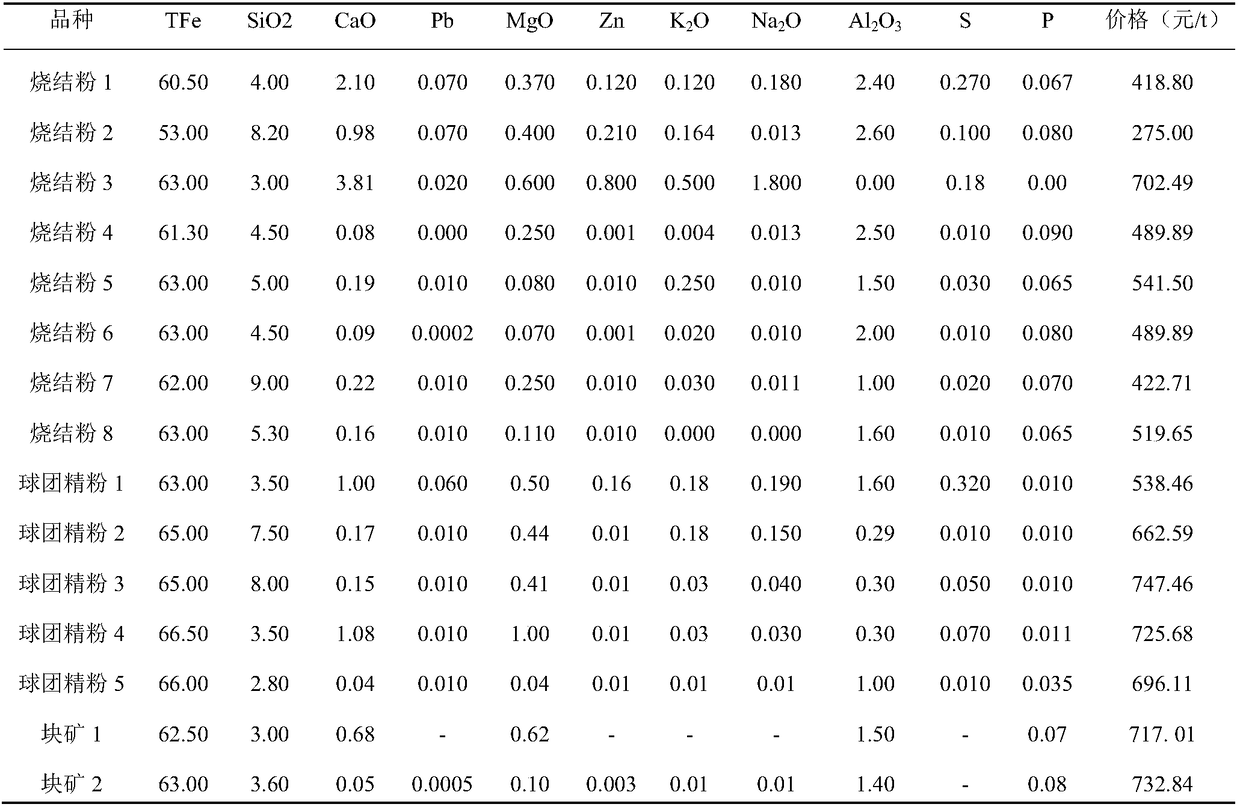

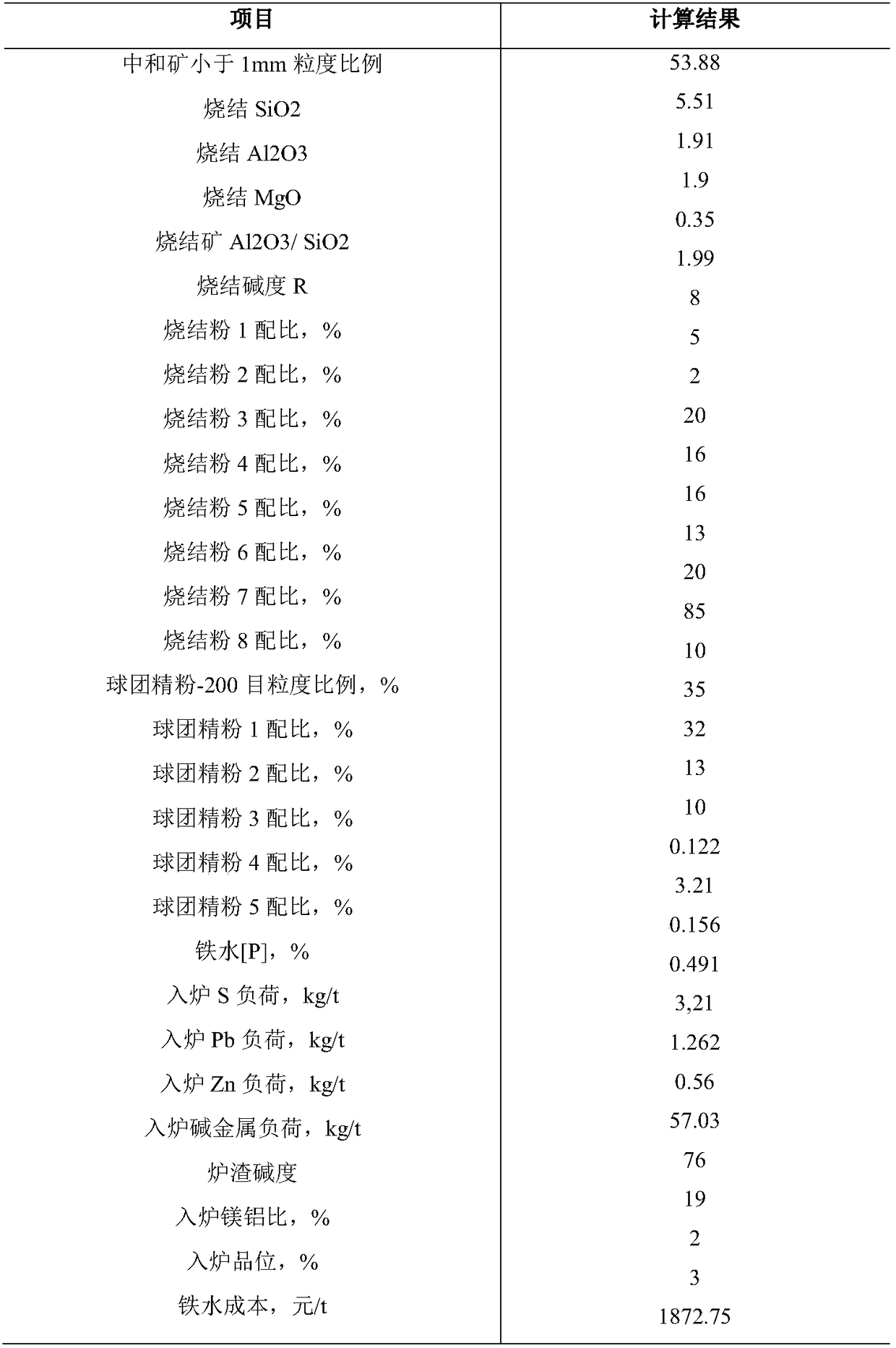

Optimized ore blending method based on sintering-pelletizing-ironmaking linkage

PendingCN108154295AReduce the ratioReduce the cost of hot metalResourcesManufacturing computing systemsChemical compositionShaft furnace

The invention discloses an optimized ore blending method based on sintering-pelletizing-ironmaking linkage, and belongs to the technical field of optimized ore blending before ironmaking. The method comprises the steps: 1, building a model, building a molten iron cost calculation model, wherein the calculation model comprises a sintering mixture calculation module, a pelletizing mixture calculation module and a shaft furnace mixture calculation module; 2, setting a constraint condition, and setting constraint conditions of all raw materials according to the performance difference of sinteringpowder, pelletizing fine powder and lump ore; 3, calculating the cost of iron per ton: calculating the cost of the iron per ton through combining with the price and performance conditions of the resources in the iron ore market, carrying out the continuous iteration calculation through a planning solving equation, and solving the raw material ratio when the cost is minimum. Through combining withthe conditions of resources in the iron ore market and the effective chemical components, the method takes the cost of molten iron as an optimization target, performs the continuous iteration calculation through the planning solving equation, solves the optimal raw material ratio, and achieves the purpose of optimizing the ore blending.

Owner:LIUZHOU IRON & STEEL +1

Blast furnace smelting method by using vanadium-titanium two-phase sintering ore

ActiveCN104673951AReduce ironmaking costsImprove utilization factorBlast furnace detailsIronstoneBlast furnace smelting

The invention belongs to the technical field of iron and steel metallurgy, in particular relates to a blast furnace smelting method by using a vanadium-titanium two-phase sintering ore. The blast furnace smelting method by using vanadium-titanium two-phase sintering ore is characterized in that the blast furnace burden structure is as follows: 70-100wt% of vanadium-titanium two-phase sintering ore, 0-30wt% of vanadium titanium magnetite pellet and 0-10wt% of common iron ore, wherein the common iron ore is an iron ore containing no vanadium or titanium. The invention provides the blast furnace smelting method by using vanadium-titanium two-phase sintering ore, and the method is low in cost; vanadium-titanium titanic magnetite for blast furnace smelting is provided by the vanadium-titanium two-phase sintering ore, so as to optimize the blast furnace burden structure, improve the breathability of the blast furnace burden structure and perfect the technical-economic indicator of blast furnace smelting.

Owner:攀钢集团西昌钢钒有限公司

Method and system for improving metallurgical coke strength by utilizing waste plastics

The present invention relates to a method for raising strength of metallurgical coke and its system. Said invention adopts traditional coking process and equipment, and adds waste plastics in the course of coking process, and is characterized by that after the waste plastics and additive are processed, they are added into coking furnace to implement co-coking with coking coal, at the same time of that the waste plastics are charred at high temp., and converted into coke, tar and gas the coke quality can be improved, crushing strength of coke M40 can be raised, abrasive resistance index of coke M10 is reduced, coke reactivity CPI is reduced and coke postreaction strength can be raised. Said system includes waste plastics processing system, additive and waste plastics mixing system, waste plastics and additive mixture and coking coal mixing system and traditional coking system.

Owner:SHOUGANG CORPORATION

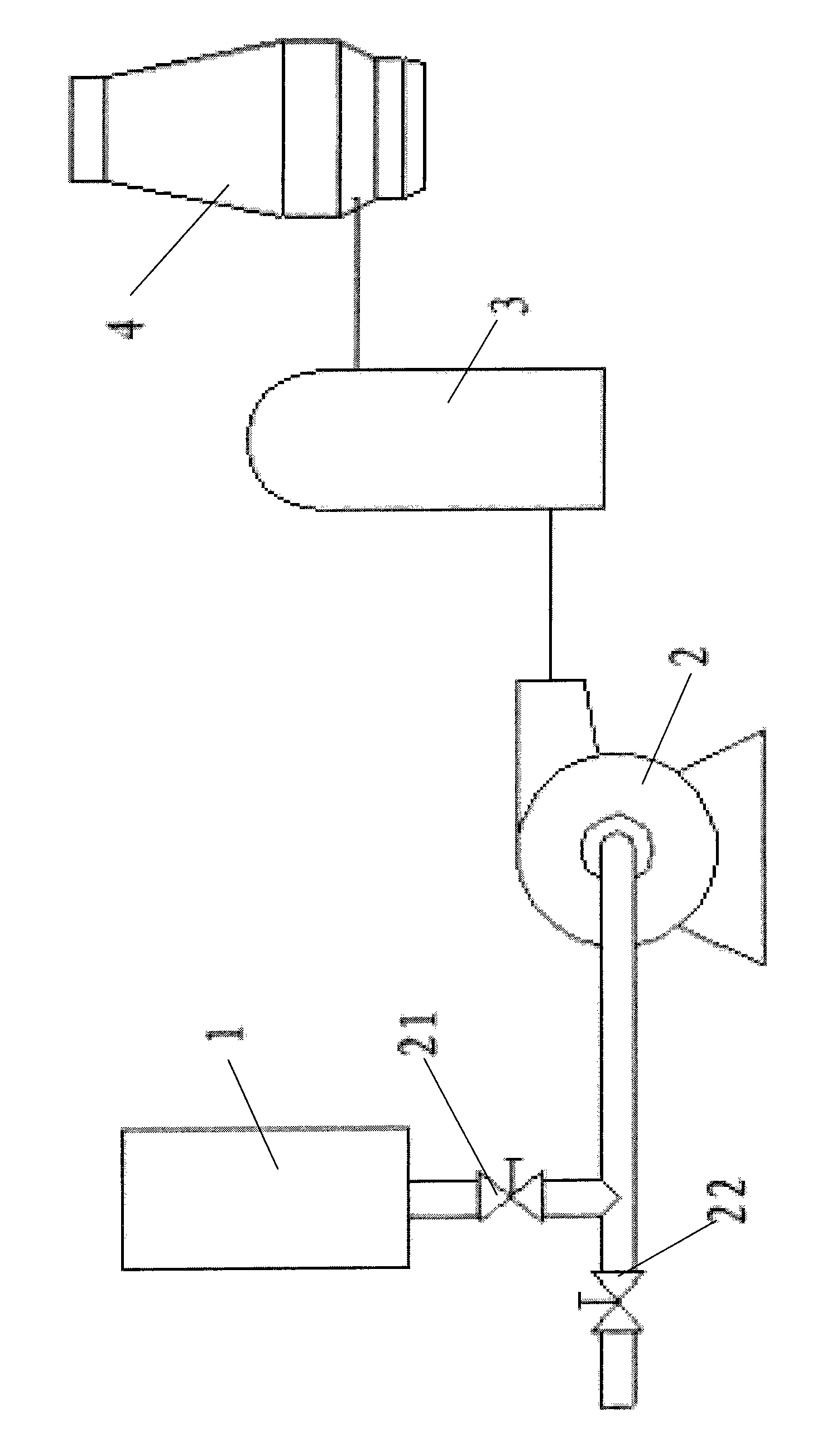

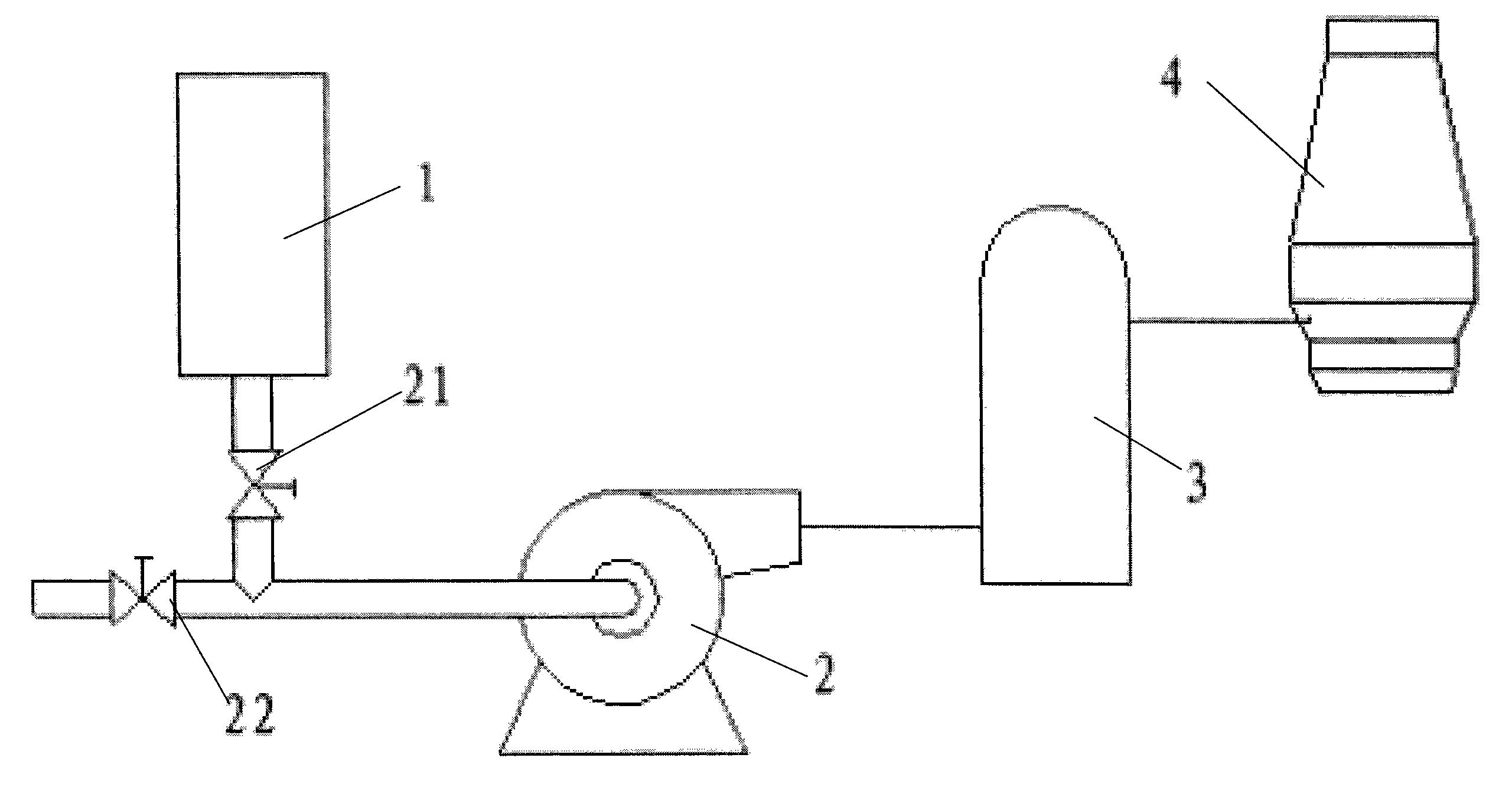

Process for blasting oxygen-enriched hot blast to blast furnace and device applied to same

ActiveCN102010919ACalculation of energy saving effectEmission reductionBlast furnace componentsBlast furnace detailsHigh concentrationCoal

The invention relates to a process for blasting oxygen-enriched hot blast to a blast furnace and a device applied to the same. The process comprises the following steps: producing oxygen-enriched air, preheating the oxygen-enriched air or air mixture of the oxygen-enriched air and the air to obtain oxygen-enriched hot blast and blasting the oxygen-enriched hot blast to the blast furnace. The device comprises an enriched oxygen producing device, a blower and a hot blast furnace, wherein the inlet of the blower is communicated with the outlet of the enriched oxygen producing device and the air respectively via pipelines; the outlet of the blower is communicated with the air inlet of the hot blast furnace; and the air outlet of the hot blast furnace is communicated with the tuyere of the blast furnace. By blasting the oxygen-enriched hot blast with higher concentration to the blast furnace and improving the coal injection ratio, utilization factor and yield of the blast furnace by preheating, the invention has the advantages of reducing the coke ratio, improving the ironmaking efficiency, lowering the ironmaking cost and reducing CO2 exhaust. The invention can also compute the energyconservation effect of oxygen-enriched blast more precisely and provide a good medium for energy performance contracting.

Owner:ANSHAN PUBEIDA TECH

Preparation of all-sefstromite concentrate pellet ore

InactiveCN101302580AHigh compressive strengthMeet the requirements of smeltingTitaniumCompressive strength

The invention relates to a method for preparing all vanadium titanium iron ore concentrate pellet ore. The preparation method comprises the following steps that: the all vanadium titanium iron ore concentrate is added with 1.5 to 2.5 percent bentonite, evenly mixed, grinded, pelletized, dried, oxidized and roasted, thereby preparing the all vanadium titanium iron ore concentrate pellet ore; when a pellet is preheated, the temperature is between 800 and 1000 DEG C, and the time is between 10 and 15 minutes; when the pellet is roasted, the temperature is between 1200 and 1250 DEG C, and the roasting time is between 15 and 25 minutes. The all vanadium titanium iron ore concentrate pellet ore prepared by the invention comprises 10 to 14 percent of TiO2 and 0.4 to 0.7 percent of V2O5 and has the pressive strength reaching 2400 to 3800 N / each, can meet the smelting need of a large-scale blastfurnace; and the all vanadium titanium iron ore concentrate has low roasting temperature and is easy to realize industrialized production.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

Method for leakage detecting and handling of blast furnace soft water closed circulating cooling system

InactiveCN103031396AAvoid freezing and other vicious accidentsSave time at workCooling devicesExpansion tankTerra firma

The invention provides a method for the leakage detecting and handling of a blast furnace soft water closed circulating cooling system. Through the liquid level difference variation of an expansion tank of a soft water system, the coal gas pressure direction in the expansion tank or a degassing tank can be detected, the phenomenon of bubbles or white turbidity is generated in water flow in a flap flowmeter on a cooling wall of the closed circulating cooling system; during the process that the pH value is continuously and slowly reduced, seepages of water stain and mirabilite can be judged to be generated on an eye plate of a blast furnace shell, so that the judgment shows that the cooling wall or an inner wall of a pipeline is damaged; the flap flowmeter is then utilized, the damage point location of a cooling wall water pipe is determined, and longitudinal treatment is carried out; and a pressure gauge installation pressing leakage detection method is utilized to determine the damage point location of the cooling water pipe, and the lateral treatment is carried out. By the method, the working efficiency is increased, the labor intensity is reduced, leakage points can be found out and treated in real time, and solid foundation is laid for the safety, success production and stable production of a blast furnace.

Owner:BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

Pellet ore binder prepared by taking sludge generated in sewage treatment as raw material

InactiveCN102409169AAdhesiveHarmlessSludge treatmentProcess efficiency improvementActivated sludgeMineral Sources

The invention relates to a pellet ore binder prepared by taking sludge generated in sewage treatment as a raw material. The binder comprises sludge in a preliminary sedimentation tank, sludge in a coagulation sedimentation basin or residual activated sludge, wherein the sludge in the preliminary sedimentation tank, sludge in the coagulation sedimentation basin or residual activated sludge are powdery sludge obtained by drying, crushing and treating. The invention also relates to an application and a usage method of the pellet ore binder prepared by sludge. The pellet ore binder prepared by sludge generated in sewage treatment is capable of raising the grade and the metallurgy performance of a furnace ore, reducing the iron-making cost, reducing the resource consumption and energy consumption, minimizing the pollutant discharge capacity and raising the capability of national steel material and product in the competition of international markets. The sludge generated in sewage treatment which is difficult to be treated can be obtained resource utilization with high efficiency, so that the mineral product resource such as bentonite and the like can be saved.

Owner:BEIJING JUNZHIQING SCI & TECH

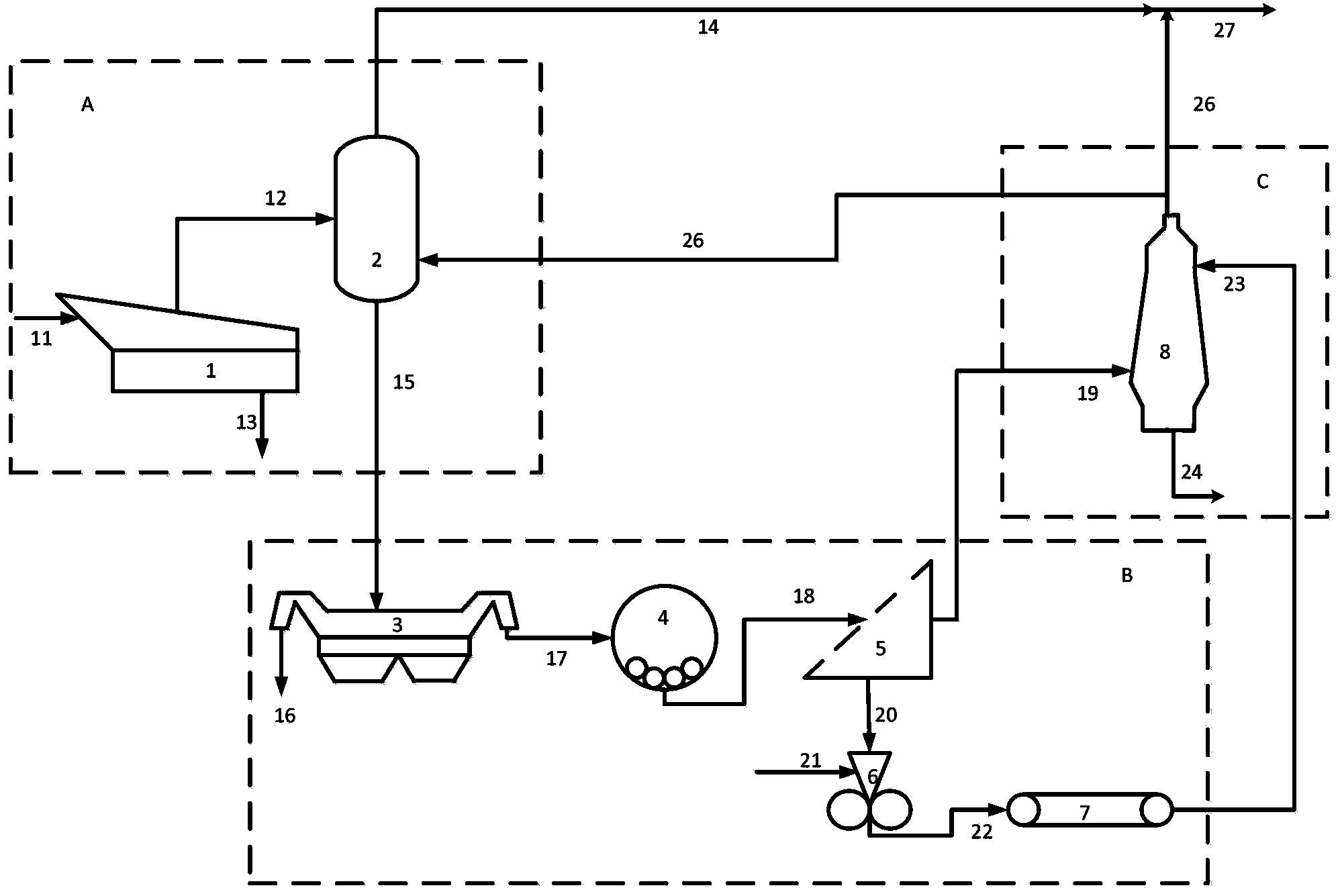

System and method for carrying out blast furnace ironmaking by using small-particle-size bituminous coals

InactiveCN103451332ASolve the use problemAlleviate resource scarcityBlast furnace detailsCrusherCoal pyrolysis

The invention discloses a system and a method for carrying out blast furnace ironmaking by using small-particle-size bituminous coals. The system comprises a pyrolyzing furnace, a semi-coke outlet of the pyrolyzing furnace is communicated with an inlet of a crusher, an outlet of the crusher is communicated with an inlet of a sieve shaker, a fine coke powder outlet of the sieve shaker is communicated with a powder spraying inlet of a blast furnace, a large-particle semi-coke outlet of the sieve shaker is communicated with an inlet of a former, an outlet of the former is communicated with an inlet of a sintering furnace, an outlet of the sintering furnace is communicated with a sintered ore inlet of the blast furnace, and a flue gas outlet of the blast furnace is divided into two paths, one path is communicated with a gas inlet of the pyrolyzing furnace, and the other path is communicated with a flue gas outlet of the pyrolyzing furnace. According to the invention, a problem of utilizing lots of small-particle-size coals produced by coal mining is solved; a shortage problem of coal resources for injection is alleviated, and a way for the utilization of semi-coke from coal pyrolysis is provided; semi-coke powder and iron ore powder are formed by mixing and sintered for use, so that resources are fully used; flue gas produced by blast furnace ironmaking is used for the pyrolysis of bituminous coal, and the heat in the flue gas is recovered, thereby reducing the energy consumption, and improving the utilization efficiency.

Owner:SHAANXI COAL & CHEM TECH INST

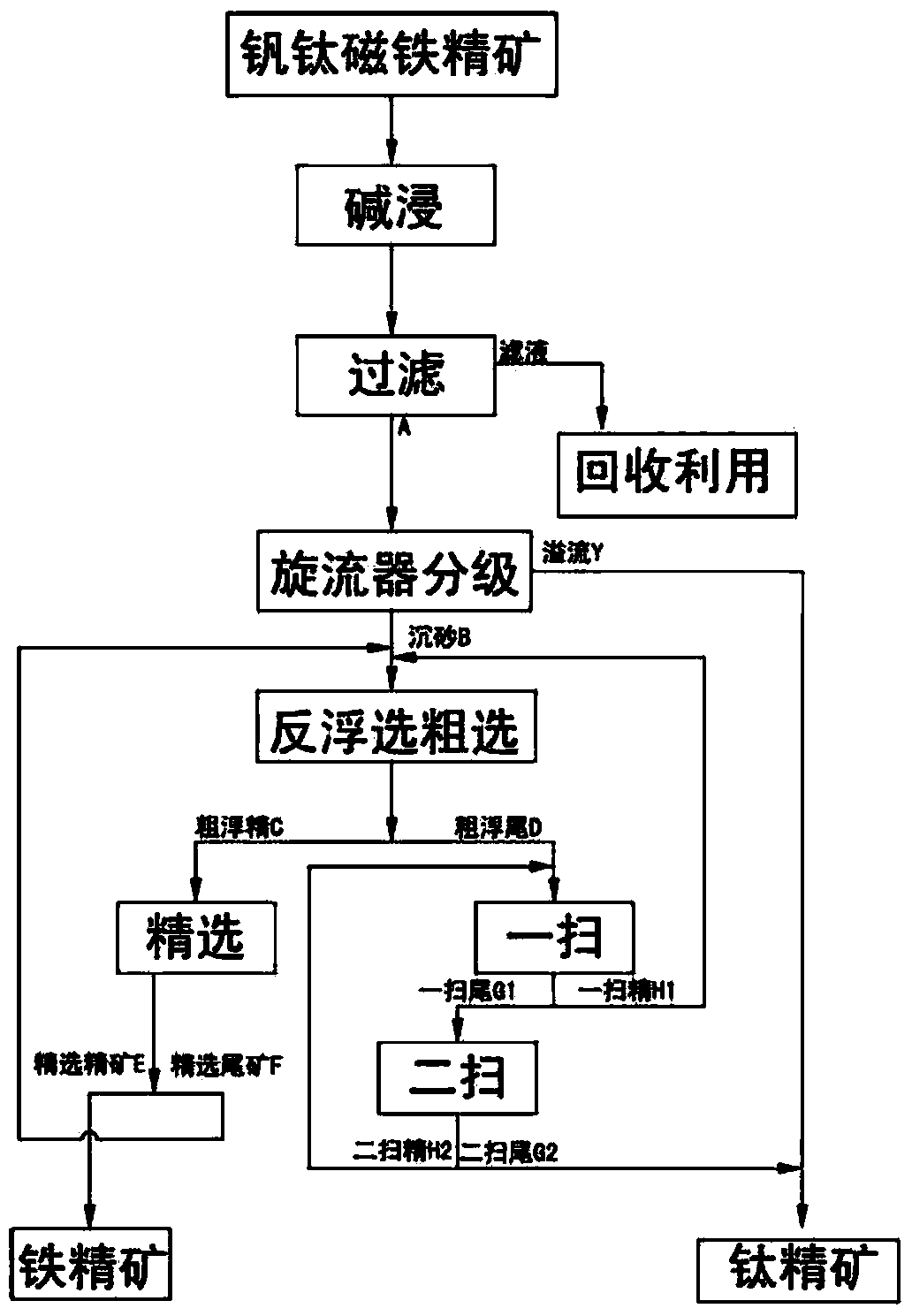

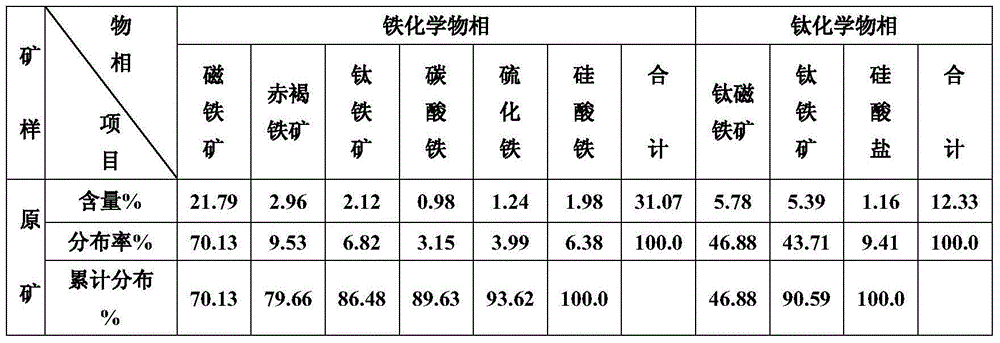

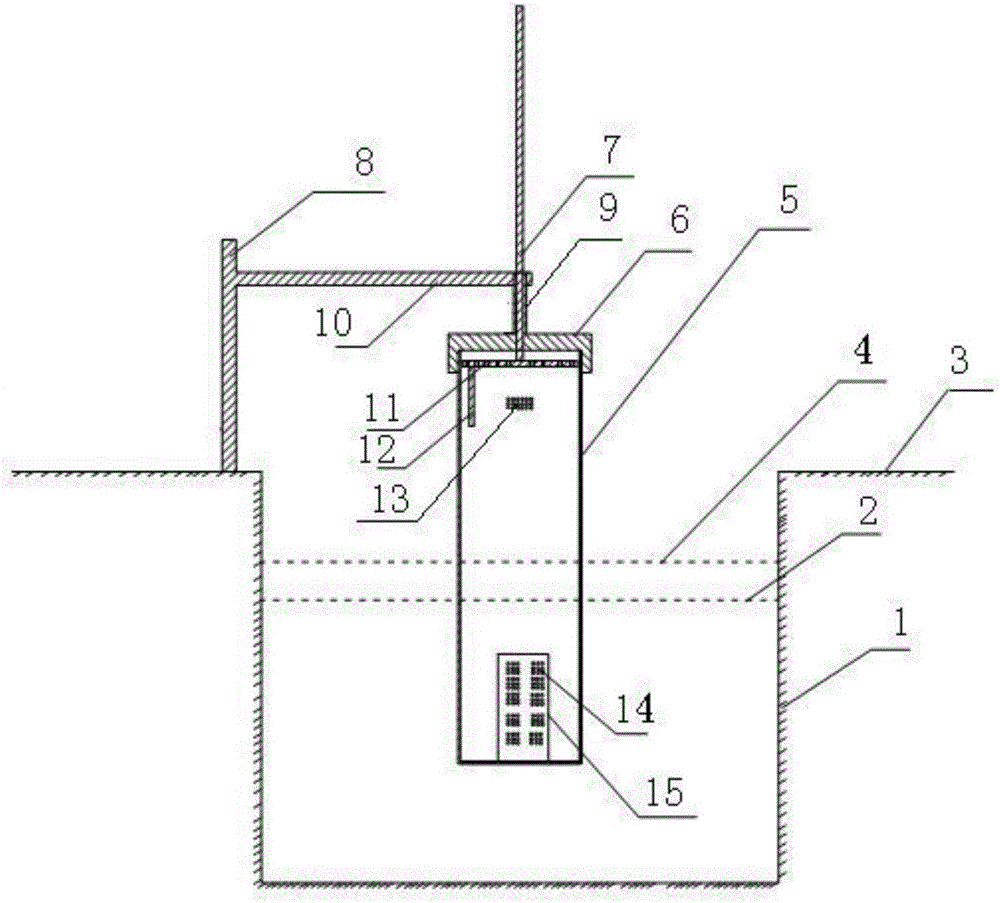

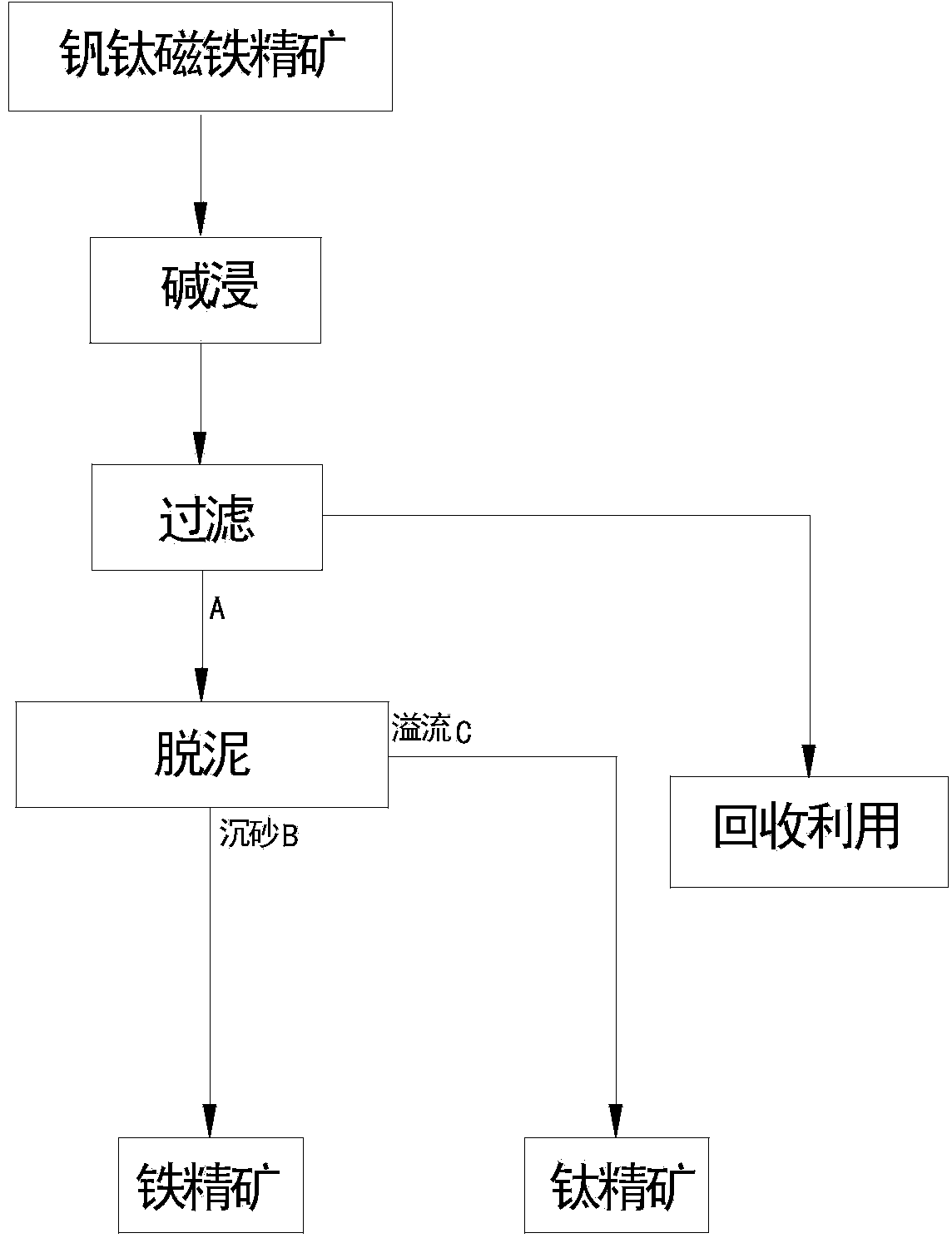

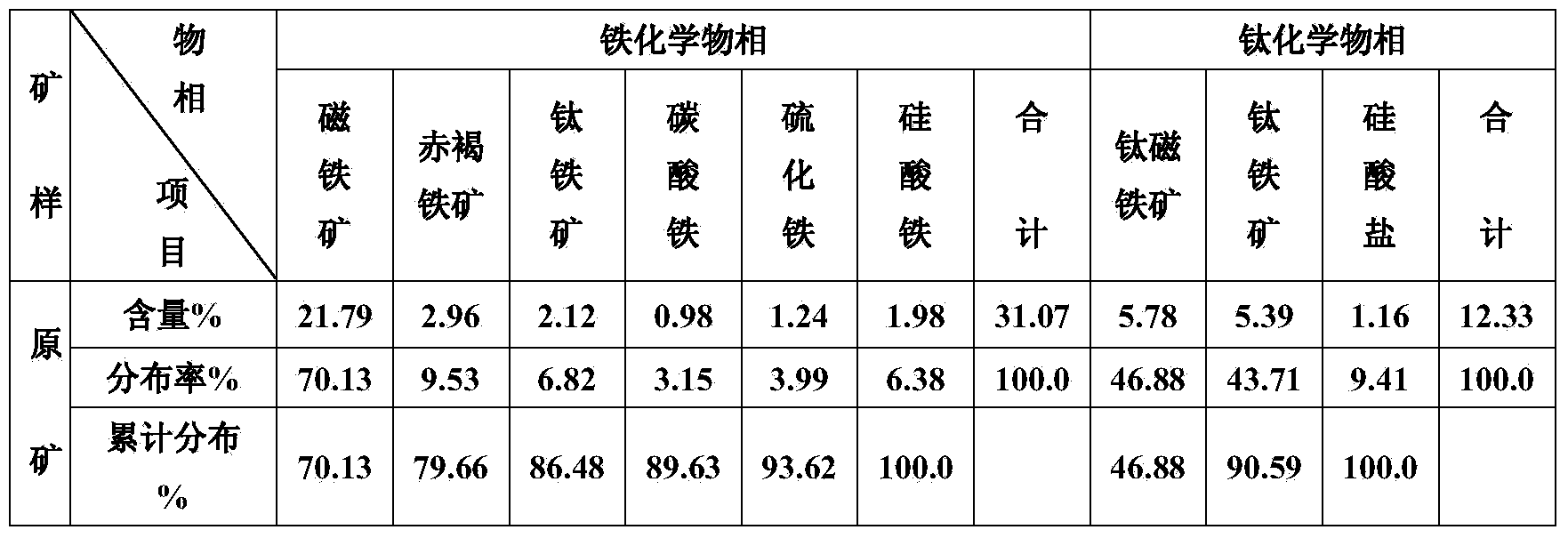

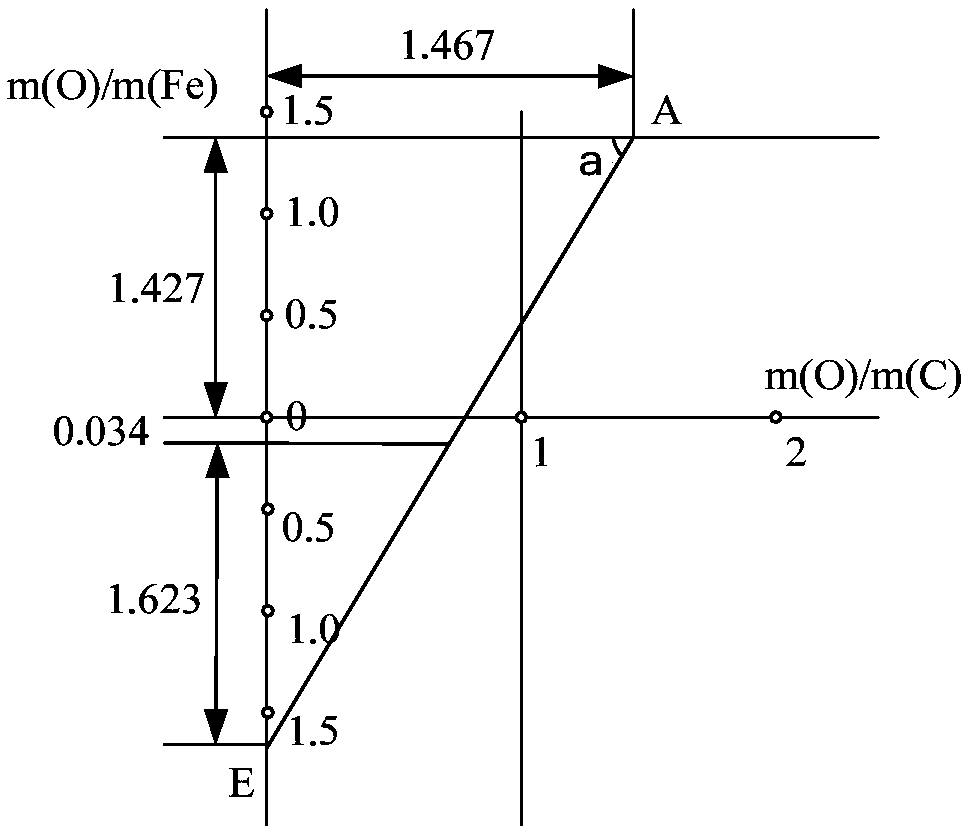

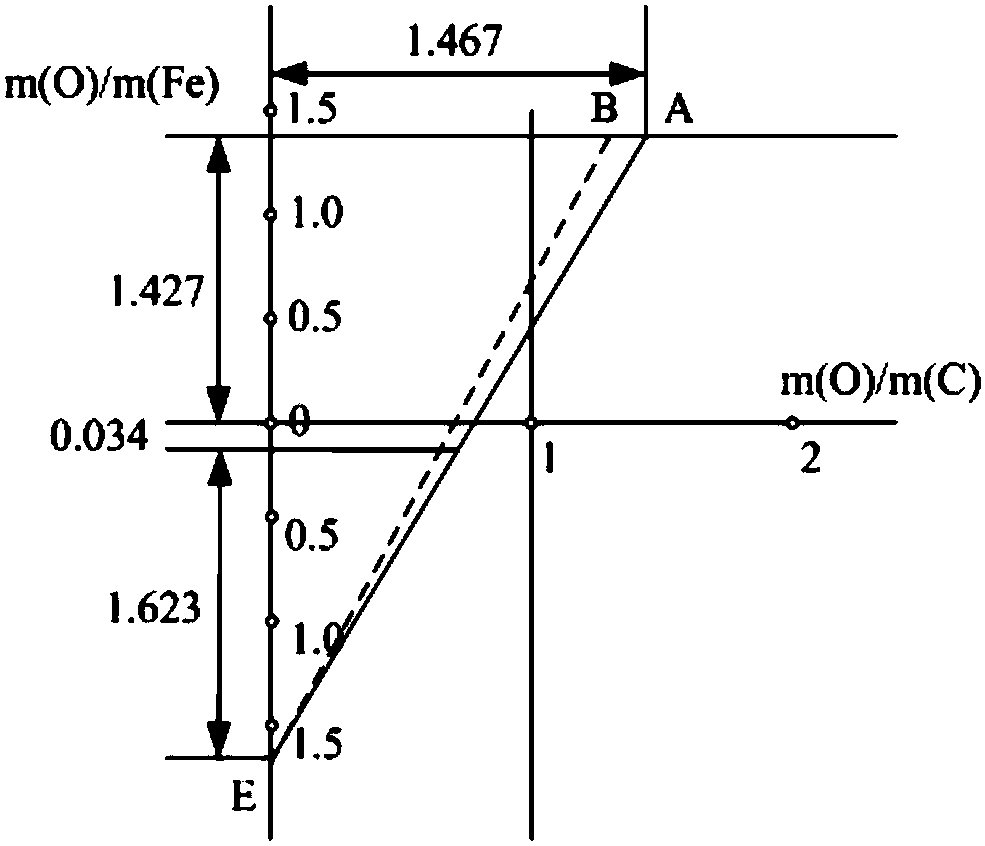

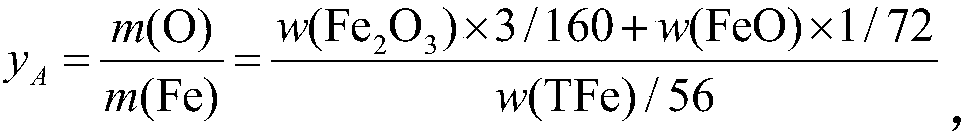

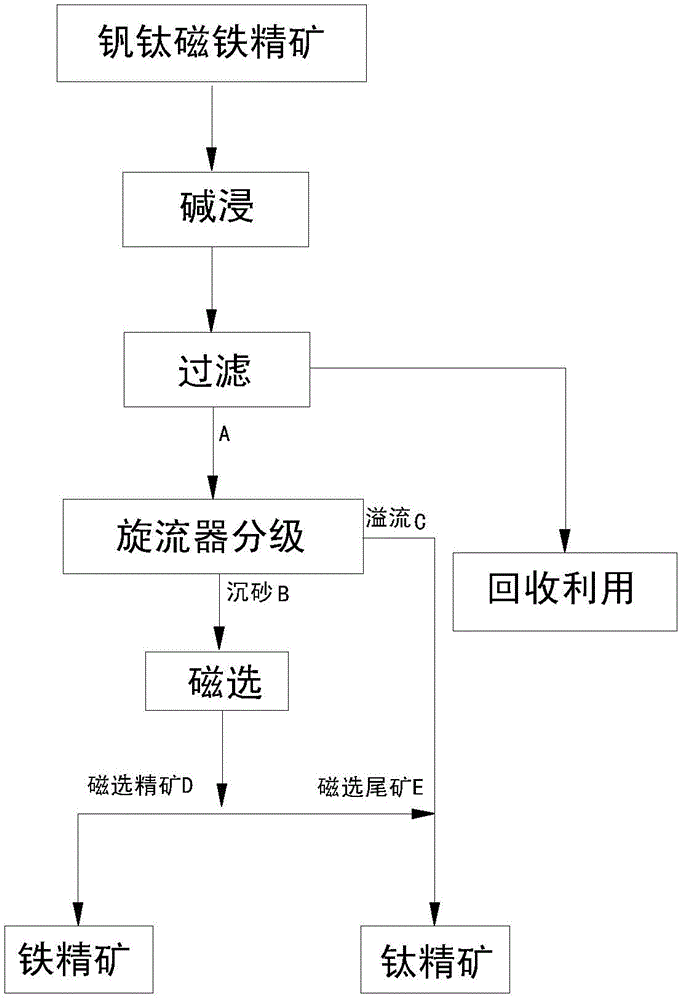

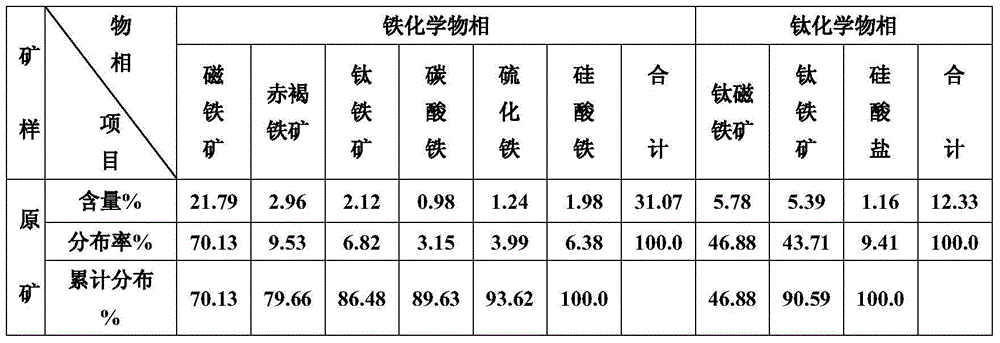

Vanadium-titanium magnetite concentrate recleaning method realized through alkaline leaching, classification and reverse flotation

The invention discloses a vanadium-titanium magnetite concentrate recleaning method realized through alkaline leaching, classification and reverse flotation. The method comprises the steps of placing vanadium-titanium magnetite concentrate in aqueous alkali with a mass concentration of 5%-52% for alkaline leaching reaction at a temperature between 280 DEG C and 370 DEG C for 0.5 h - 5 h and conducting filtering to obtain a filtrate and an alkaline leached filter cake A; adding water into A to form pulp with a mass concentration of 20%-25%, and feeding the pulp into a cyclone for classification to obtain effused flow Y and set sand B; adding water into the set sand B to obtain pulp with a mass concentration of 25%-30%, and conducting reverse flotation to obtain iron ore concentrate with the TFe content ranging from 65% to 69.5% and titanium concentrate with the TiO2 content ranging from 55% to 70%. The method has the advantages that efficient sorting of the vanadium-titanium magnetite concentrate is realized, alkali consumption is low, the content of impurities such as Al and Si entering a blast furnace is reduced, the content of detrimental impurities TiO2 and S is reduced especially, the utilization coefficient of the blast furnace is increased, blast furnace slag emission is reduced, the problems of high S content and severe pollution in the smelting process are solved, and the comprehensive utilization rate of titanium resources is increased.

Owner:ANSTEEL GRP MINING CO LTD

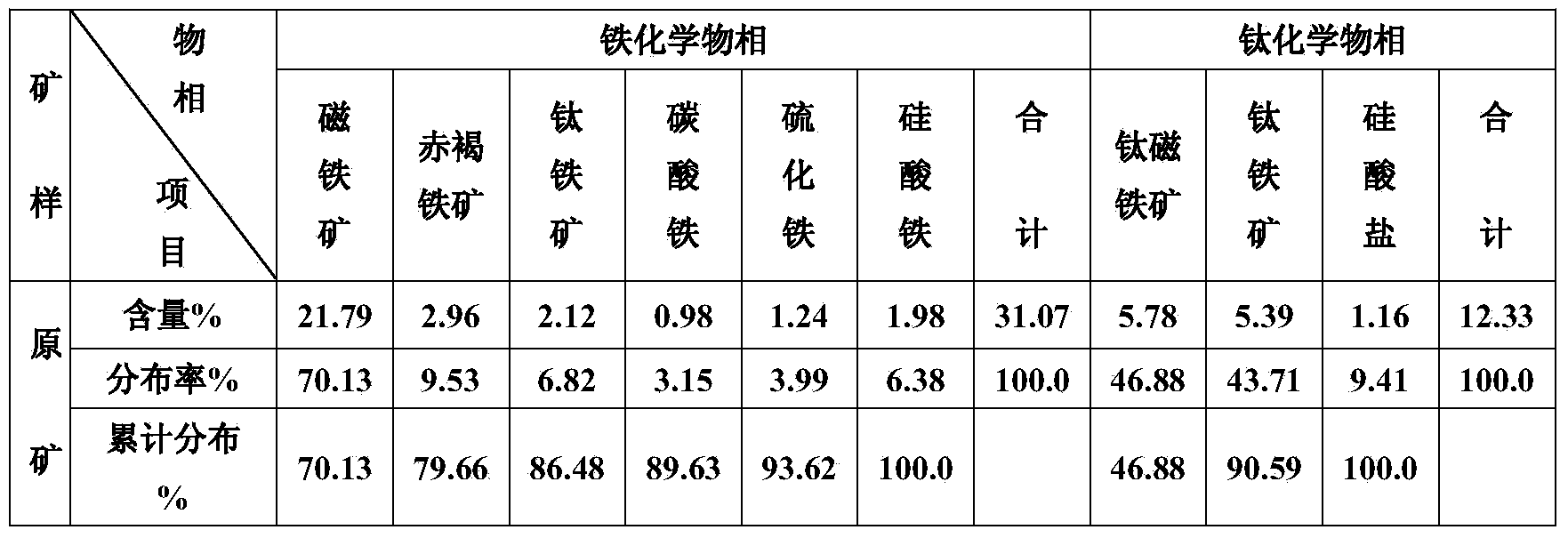

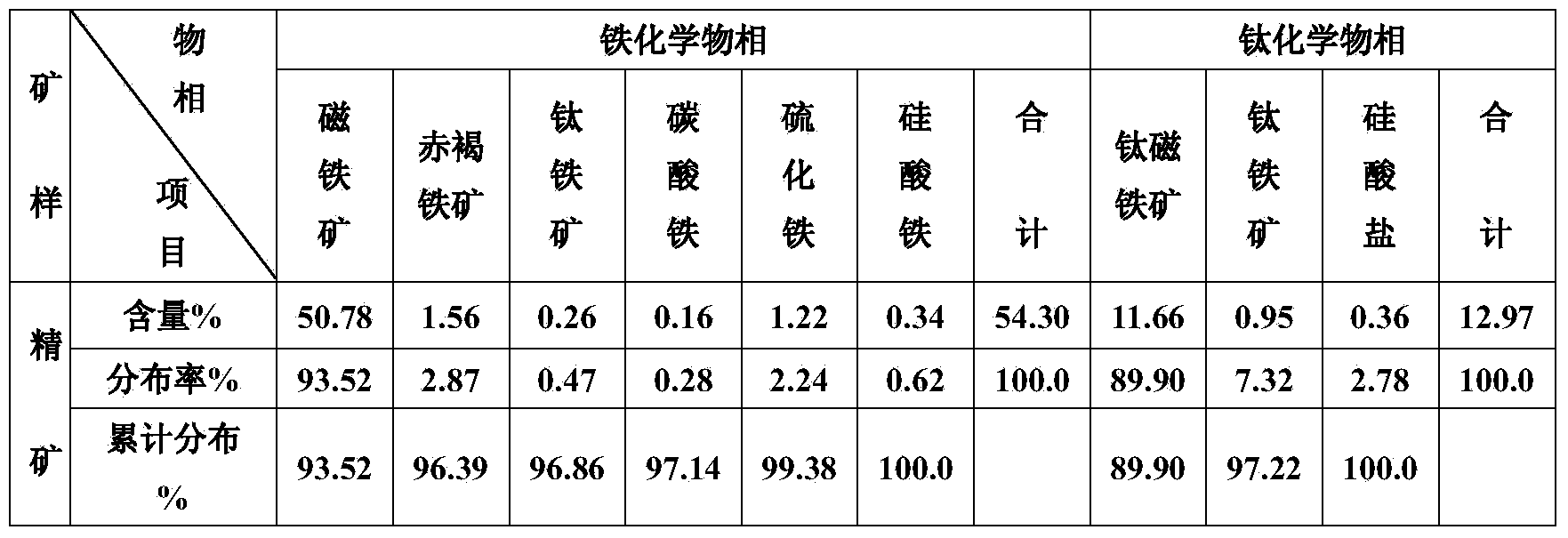

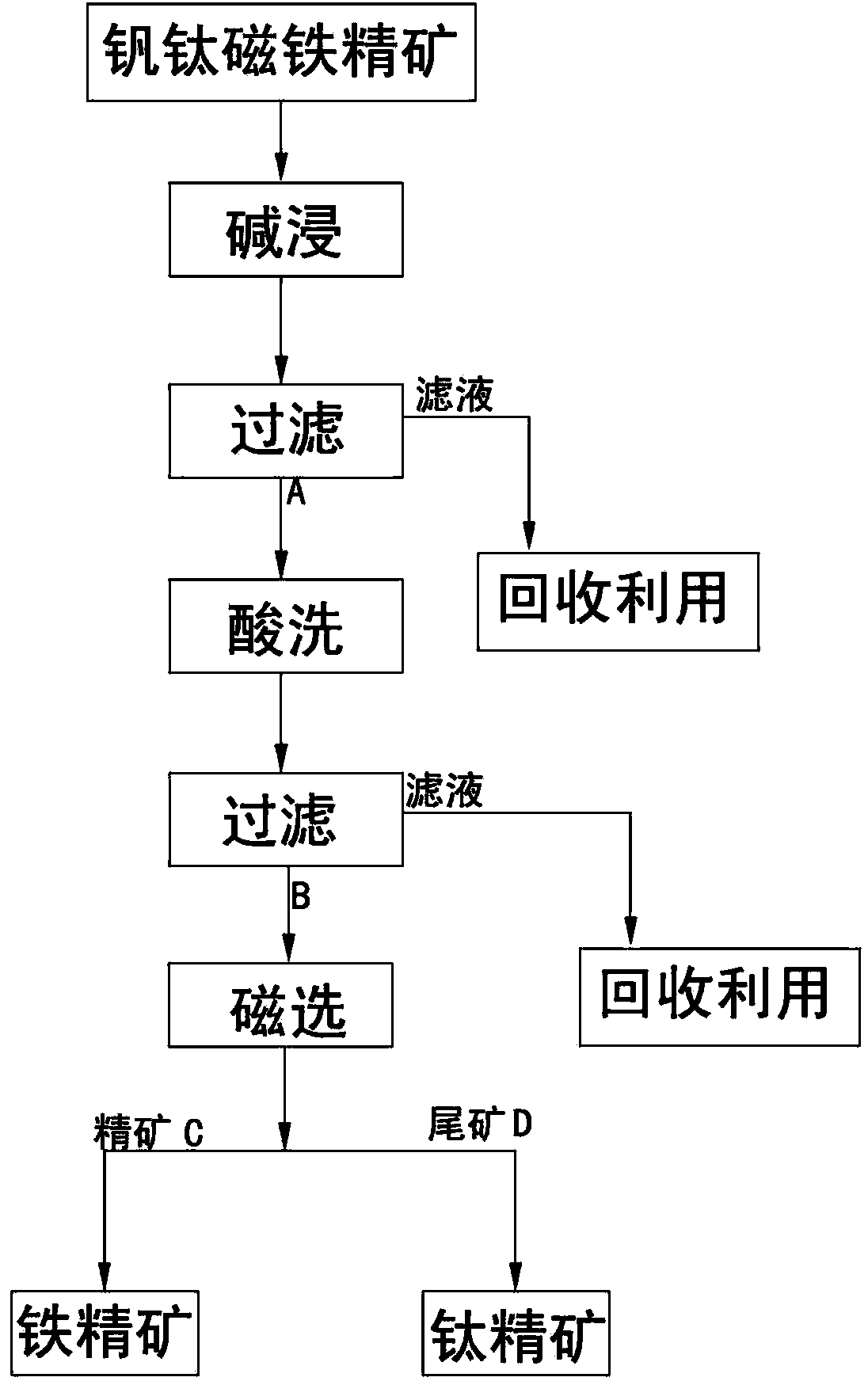

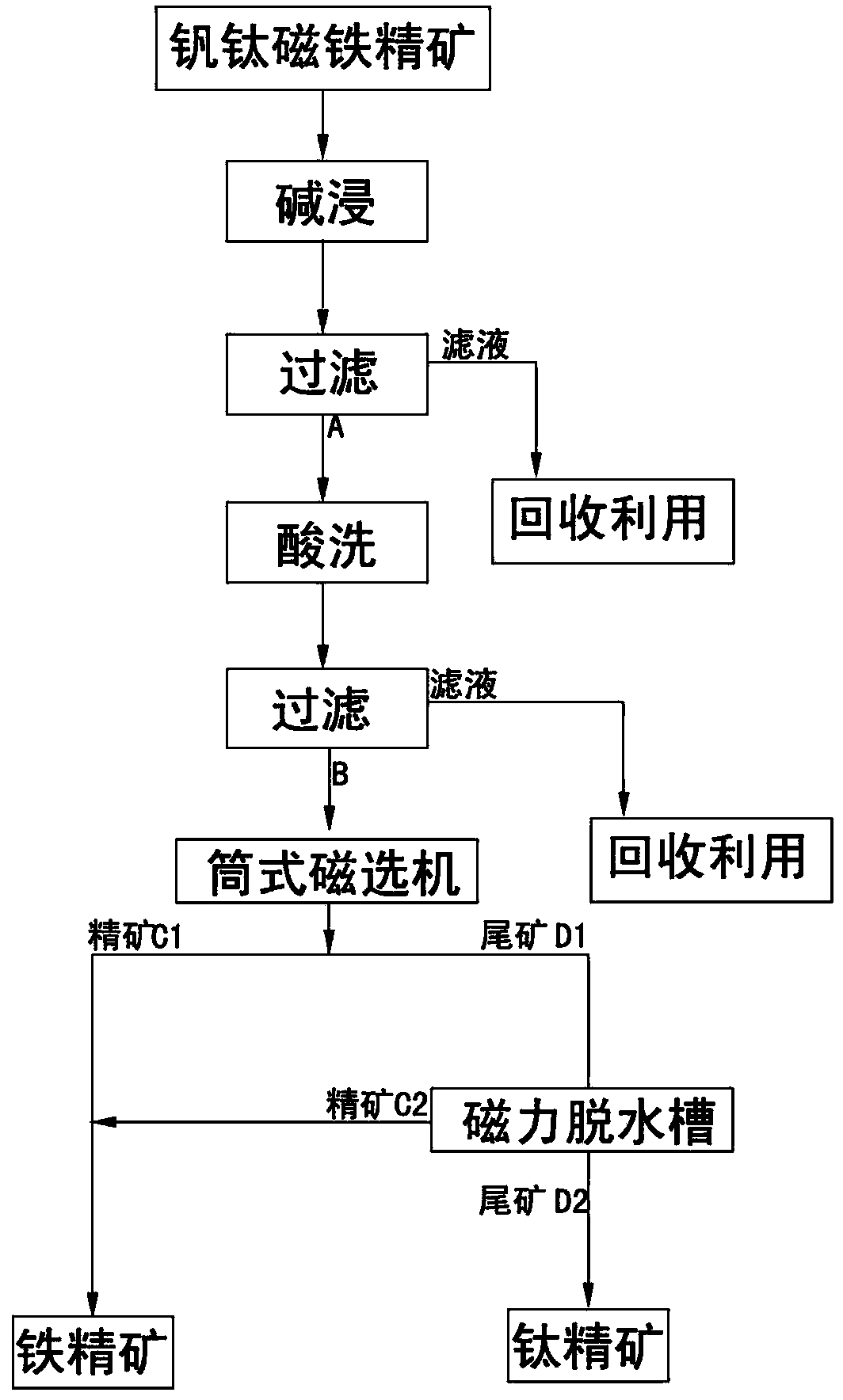

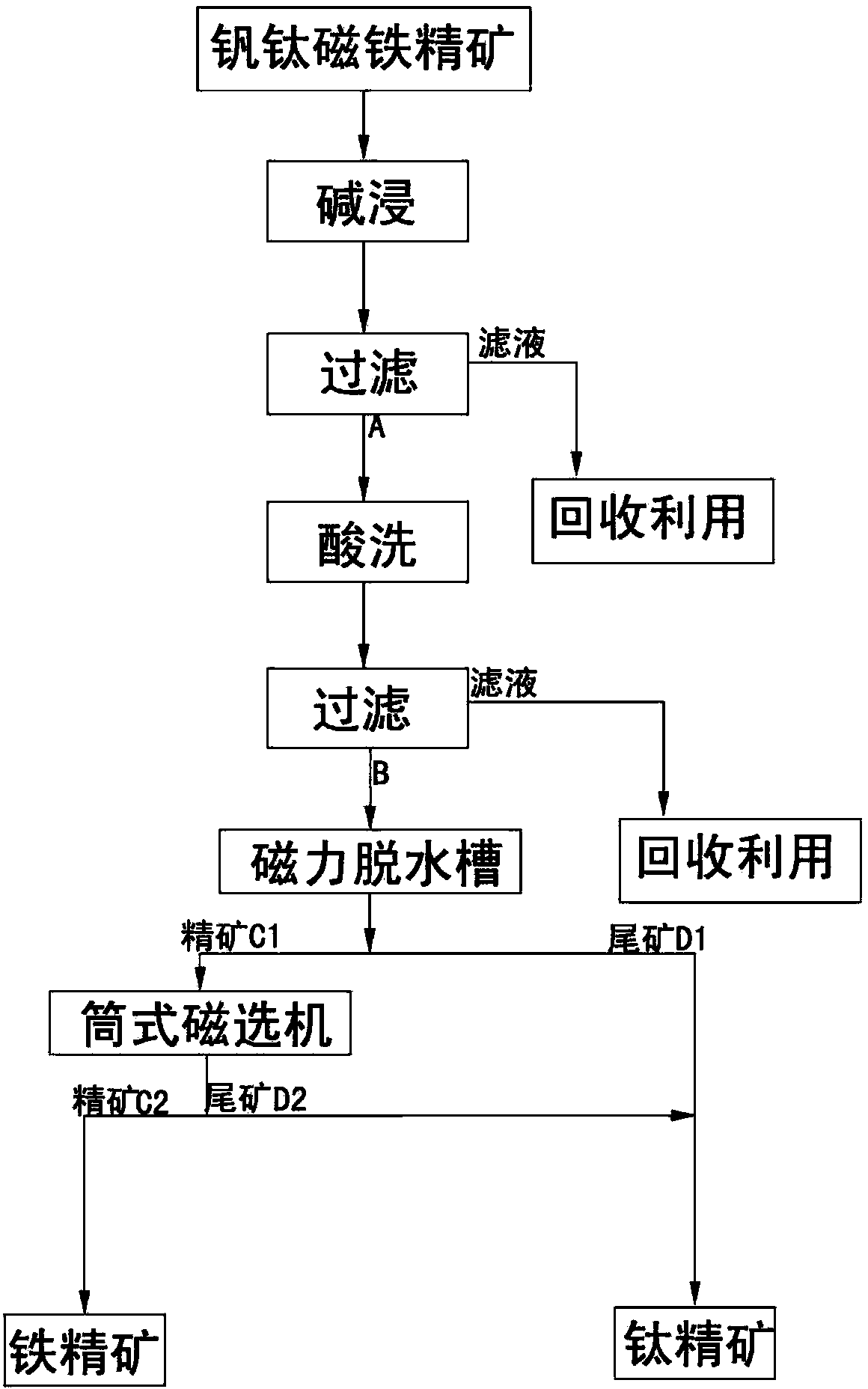

Method for re-concentrating vanadium-titanium magnetite concentrate through alkaline leaching, acid pickling and magnetic separation

The invention discloses a method for re-concentrating vanadium-titanium magnetite concentrate through alkaline leaching, acid pickling and magnetic separation. The method comprises the following steps: placing the vanadium-titanium magnetite concentrate in an alkali solution of which the mass concentration is 5-52% to be subjected to alkaline leaching reaction at the temperature of 280-370 DEG C for 0.5-5 hours, and filtering to obtain a filtrate and an alkaline leached filter cake A; preparing the filter cake A into ore pulp by adding water according to the fact that the mass ratio of solid to liquid is 1:(1-10), placing the ore pulp into an H2SO4 solution of which the mass concentration is 1-10% to be subjected to acid pickling at the temperature of 50-90 DEG C for 5-60 minutes, and filtering to obtain a filtrate and an acid picked filter cake B; preparing the filter cake B into ore pulp of which the mass concentration is 30-35% by adding water to be subjected to magnetic separation, so as to obtain iron ore concentrate of which the TFe content is 64-68% and titanium concentrate of which the TiO2 content is 40-60%. The method has the advantages that the vanadium-titanium magnetite concentrate can be efficiently sorted, the alkali consumption is low, the content of impurities such as Al and Si entering a blast furnace, especially the content of detrimental impurities such as TiO2 and S, is reduced, the utilization coefficient of the blast furnace is increased, the iron-making cost is reduced, the problem of high S content in the smelting process is solved, and the comprehensive utilization ratio of a titanium resource is increased at the same time.

Owner:ANSTEEL GRP MINING CO LTD

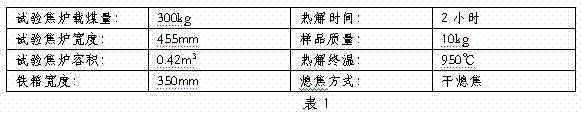

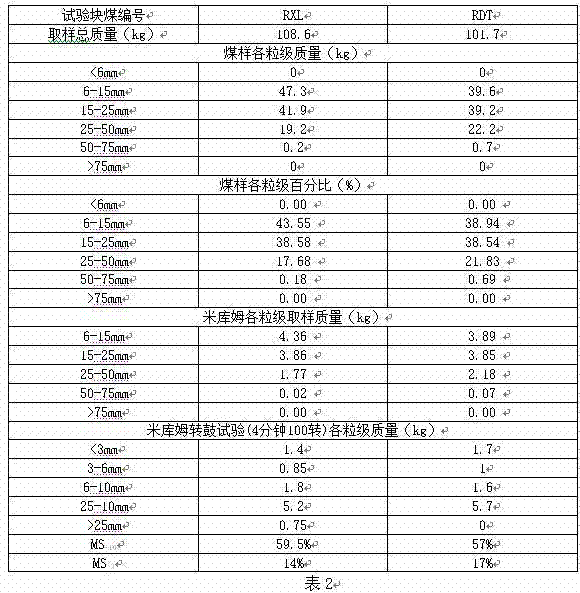

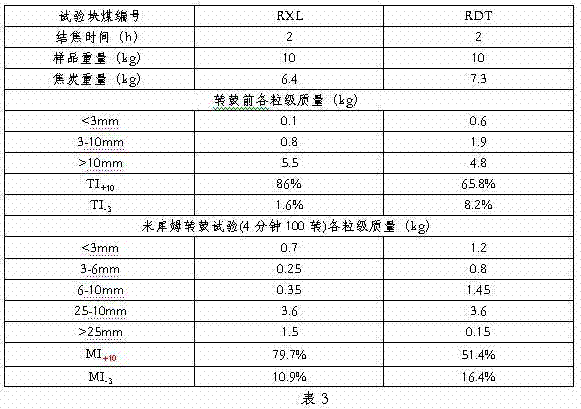

Lump coal pyrolysis experimental method for melting gasification furnace

ActiveCN102455308AAccurate and effective selectionReduce ironmaking costsCoke quenchingSpecial form destructive distillationCoal pyrolysisExperimental methods

The invention belongs to the field of test of lump coal properties and particularly relates to a lump coal property test method for a melting gasification furnace. A lump coal pyrolysis experimental method for the melting gasification furnace comprises three steps, namely lump coal mechanical strength experiment, lump coal coking characteristic experiment and lump coal semicoking strength experiment; a coal sample with the particle size of over 6 millimeters is used as a sample and prepared into 5 to 20 kilograms of samples; and a large-sized coking experiment coke furnace is used. In the lump coal pyrolysis experimental method for the melting gasification furnace, the experiment coke furnace, the sample and the process can better simulate states of lump coals in the melting gasification furnace, so that the problem of low discrimination of the conventional heat stability experiment can be solved; furthermore, the lump coal species for the melting gasification furnace, which are suitable for a COREX process can be selected accurately and effectively, the selection range of the lump coals for the COREX is expanded, and the iron-making cost of the COREX process is reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Super-thick material layer sintering method for dual-alkalinity complex sintered ore

The invention discloses a super-thick material layer sintering method for dual-alkalinity complex sintered ore. Two times of material distribution and two times of ignition are conducted, and a sintering mixture at the upper layer is different from a sintering mixture at a lower layer; the sintering mixture A is firstly added into a sintering trolley, the distribution thickness of the sintering mixture A is 600-800 mm, and the sintering mixture A with the alkalinity being 1.8-2.4 is subjected to down draft sintering through ignition of a first igniter; when the sintering trolley travels to the position where the distance between the sintering trolley and a first ignition system is one fifth to one half of the total length of a sintering machine, the sintering mixture B is added and distributed with the distribution thickness of 400-600 mm, and the sintering mixture B with the alkalinity being not higher than 0.5 is subjected to down draft sintering through ignition of a second igniter; and sintered ore at the upper layer and sintered ore at the lower layer are subjected to cooling uniform-mixing and screening uniform-mixing to form the complex sintered ore with the alkalinity being 1-1.4. By means of the super-thick material layer sintering method, the dual-alkalinity sintered ore can be produced through one-time sintering, the mixed sintered ore with the proper comprehensive alkalinity is formed after uniform mixing, and the sintering cost is lowered; and the number of pellets used for a blast furnace is reduced, and the ironmaking cost is lowered.

Owner:ANGANG STEEL CO LTD

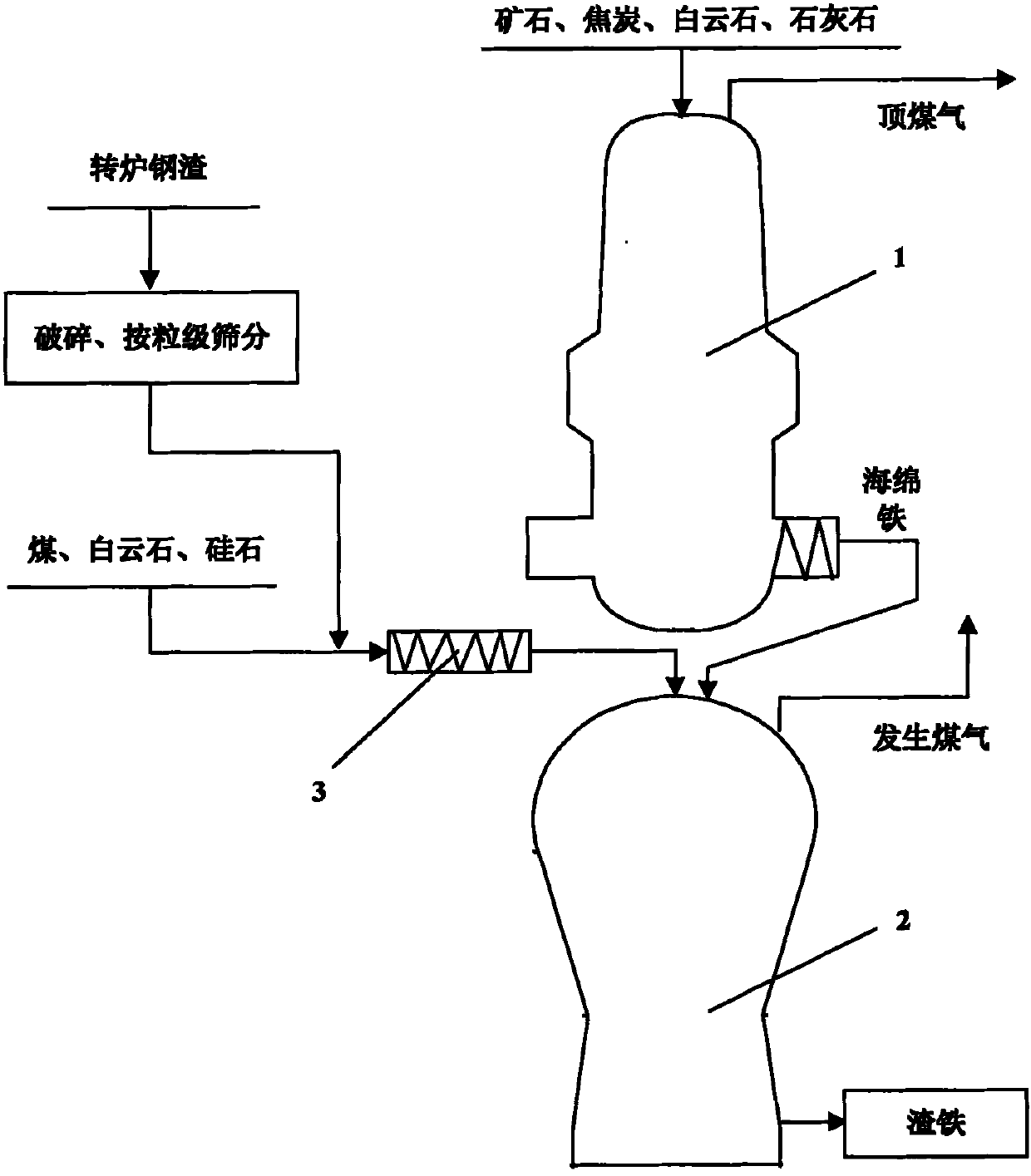

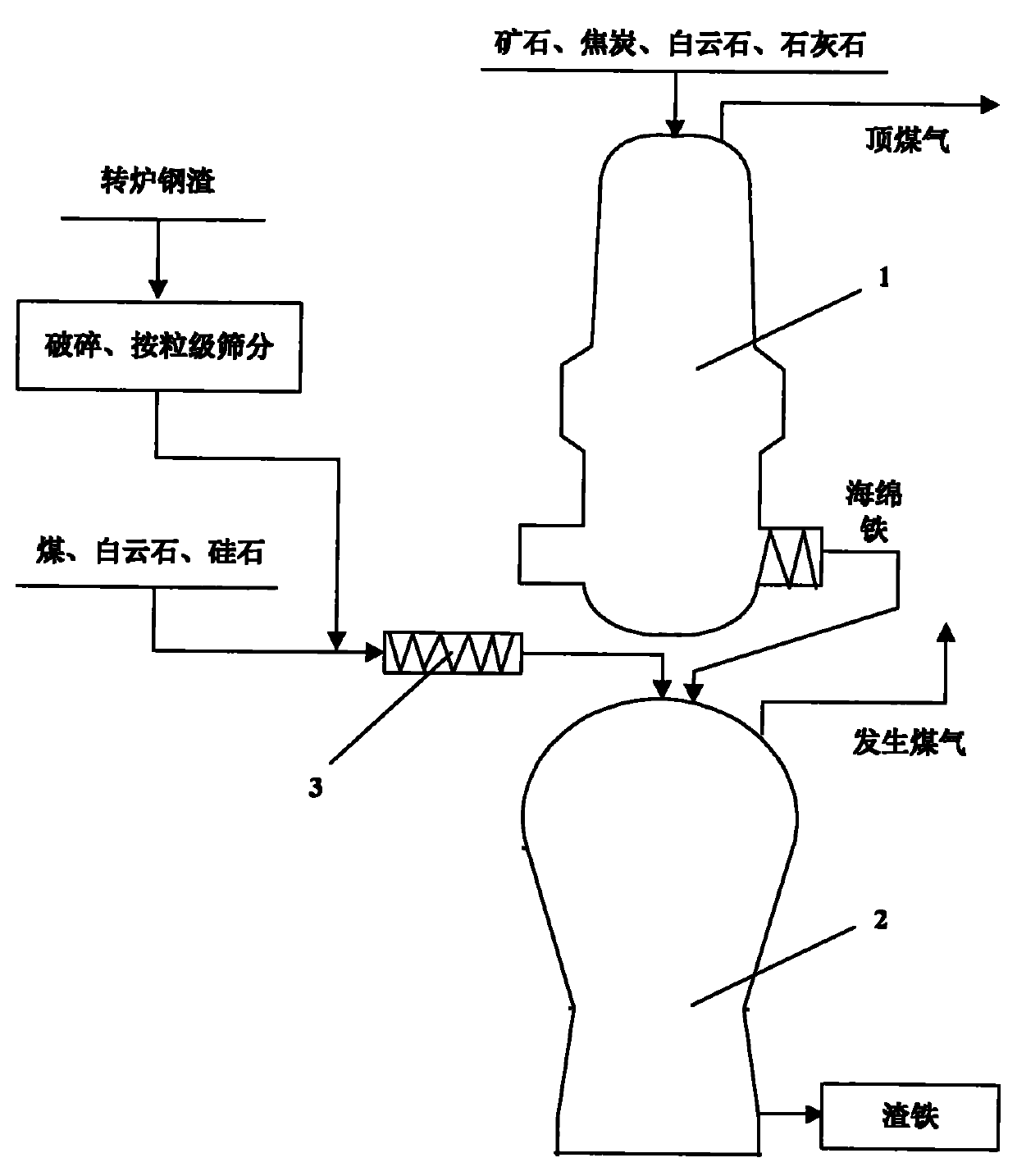

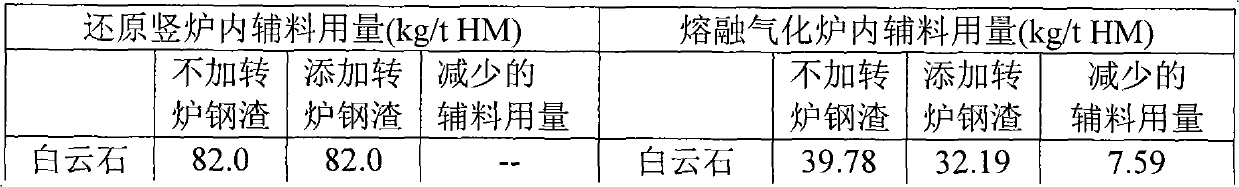

Method for recycling converter slags

ActiveCN102199677AReduce usageEnable recyclingRecycling and recovery technologiesProcess efficiency improvementSlagCrusher

The invention discloses a method for recycling converter slags, comprising the following steps: first, separating remainder iron blocks and shot iron from converter slags by magnetic separation, crushing remaining converter slags to particles with particle size of 0.01-25mm by a crusher, then, screening crushed converter slags according to different particle fractions, selecting converter slags with particle size of 8-25mm to mix with coal, dolomite and silica uniformly, transmitting the mixture into a COREX melter-gasifier via a belt conveyer for feed mixture. The crushed converter slags comprise 10-25wt% TFe, 30-60 wt% CaO, 4-15wt% MgO, 5-25wt% SiO2 and 0-2wt% P. According to the invention, the use of limestone, dolomite and silica in COREX process is reduced, the ironmaking cost is reduced, and discharge capacity of CO2 is also reduced. The method has the advantages of simple technology, low cost, and efficient utilization of industrial waste residues.

Owner:XINJIANG BAYI IRON & STEEL

Chemical additive for pulverized coal injection in blast furnace

InactiveCN1827783AReduce ironmaking costsReduce pollutionBlast furnace detailsFuel additivesCombustionGranularity

The invention relates to a chemical additive for pulverized coal injection in blast furnace, which is a powder form mixture having a grain size greater than 80 meshes, its constituents include (by weight percent) oxidizing agent 20-40%, catalyst 15-25%, combustion adjuvant 20-25%, and passivating agent 1-15%. The additive contains no harmful elements to iron-smelting, and can appreciably improve combustion behavior for the powdered coal.

Owner:刘虎生

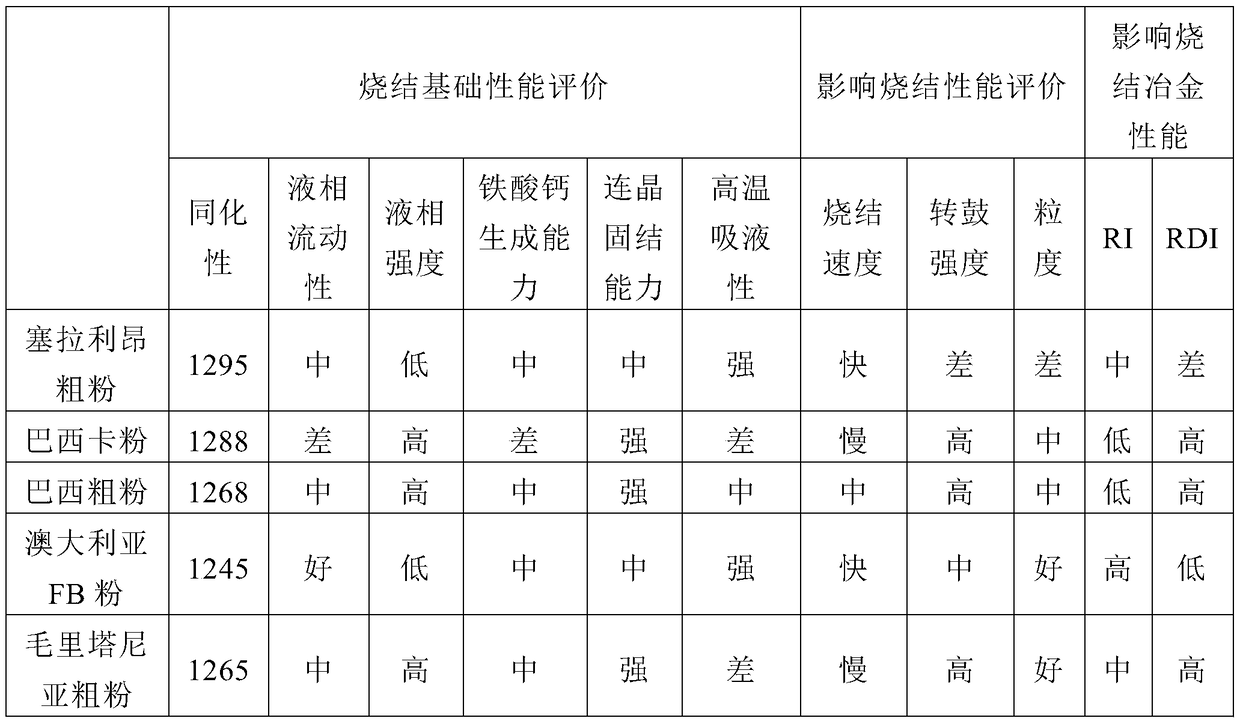

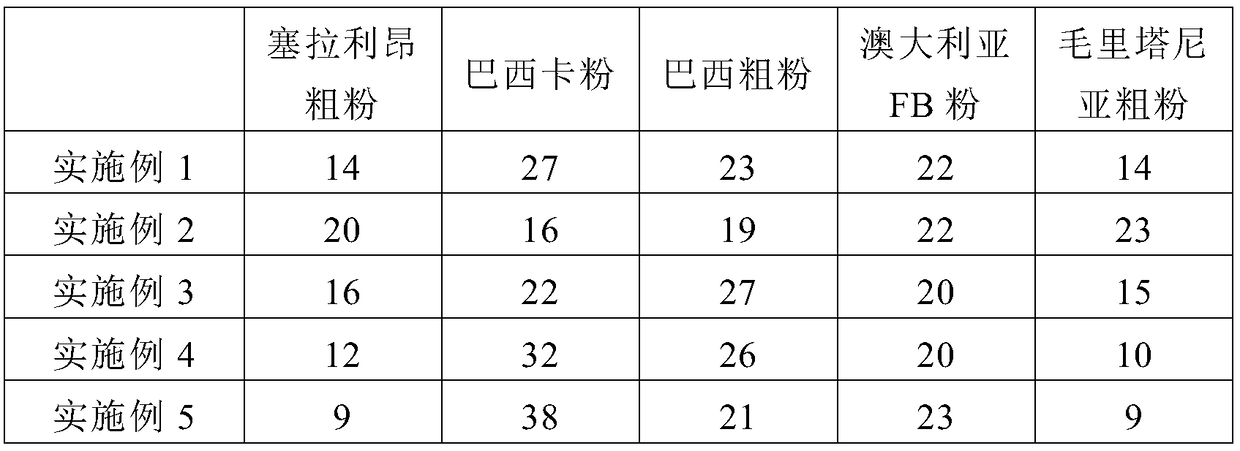

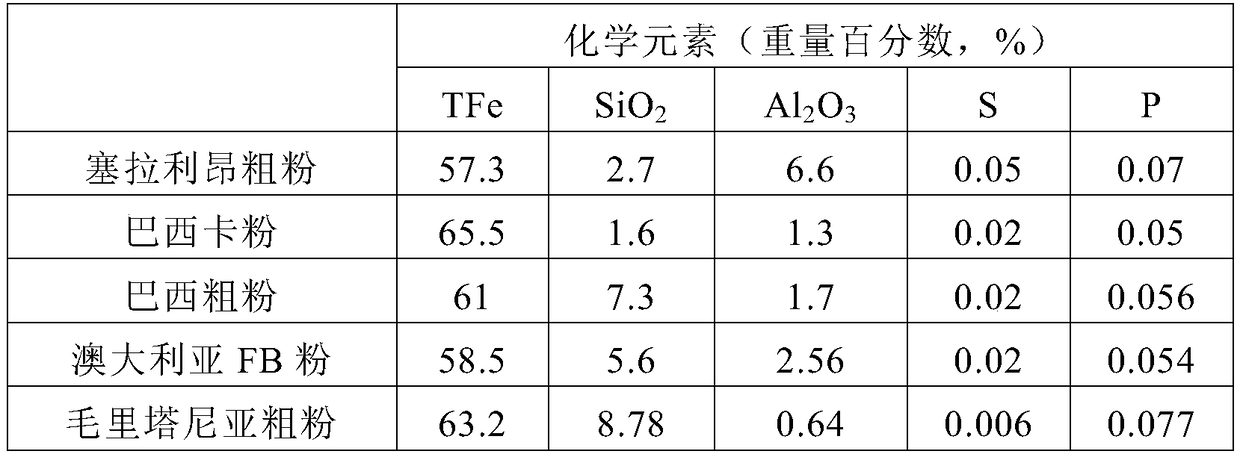

Iron ore well-blended powder with Sierra Leone coarse powder for reducing cost and improving efficiency

The invention discloses an iron ore well-blended powder with Sierra Leone coarse powder for reducing cost and improving efficiency. The iron ore well-blended powder includes, by weight, 8-25% of the Sierra Leone coarse powder, 15-40% of Brazilian Carajas sinter feed, 15-30% of Brazilian coarse iron ore powder, 15-25% of Australian FB powder, and 8-25% of Mauritania coarse powder. In the invention,the Sierra Leone coarse powder is successfully applied to sinter the well-blended ore; by matching proper iron ore, adverse factors, such as high content of Al2O3, high assimilation temperature and low liquid phase strength, of the Sierra Leone coarse powder, are overcome, thus guaranteeing the application effect of the Sierra Leone coarse powder.

Owner:上海慧安科技股份有限公司

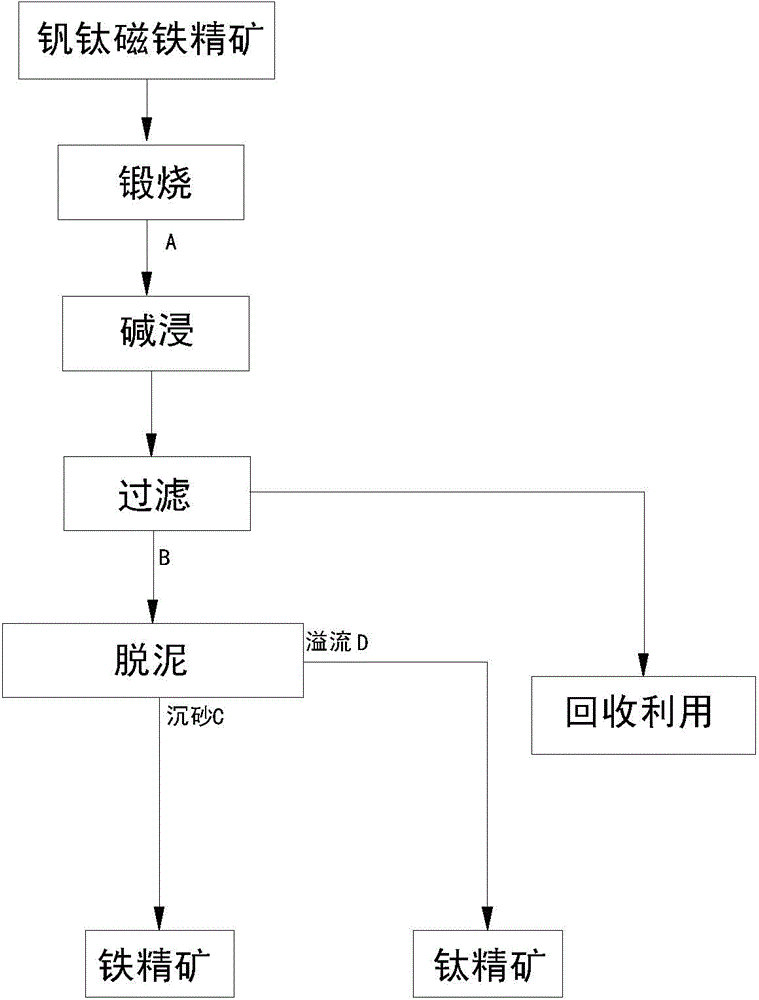

Method for recleaning vanadium-titanium magnetite concentrate by calcining, alkaline leaching and desliming

The invention discloses a method for recleaning vanadium-titanium magnetite concentrate by calcining, alkaline leaching and desliming. The method comprises the following steps: adding CaO into vanadium-titanium magnetite concentrate and calcining for 20-60 minutes at 800-1400 DEG C to form a calcined product A; and putting A in aqueous alkali, carrying out alkaline leaching reaction for 0.5-5 hours at 300-370 DEG C, and filtering to obtain a filtrate and a filtered alkaline leached filter cake B, and adding water into B to prepare pulp to be deslimed to obtain settled sands C and overflow D, wherein the settled sands C are the final iron ore concentrates with the TFe content range of 60-68% and the overflow D is the final titanium concentrate with the TiO2 content range of 40-50%. The method disclosed by the invention has the advantages that the consumption of NaOH or KOH is reduced, the vanadium-titanium magnetite concentrate is efficiently sorted, the alkaline consumption is low, the content of impurities such as Al and Si entering into a blast furnace is reduced, the utilization coefficient of the blast furnace is improved, the iron smelting cost is reduced, and the problem of severe pollution is solved; meanwhile, the comprehensive utilization ratio of titanium resources is improved.

Owner:ANSTEEL GRP MINING CO LTD

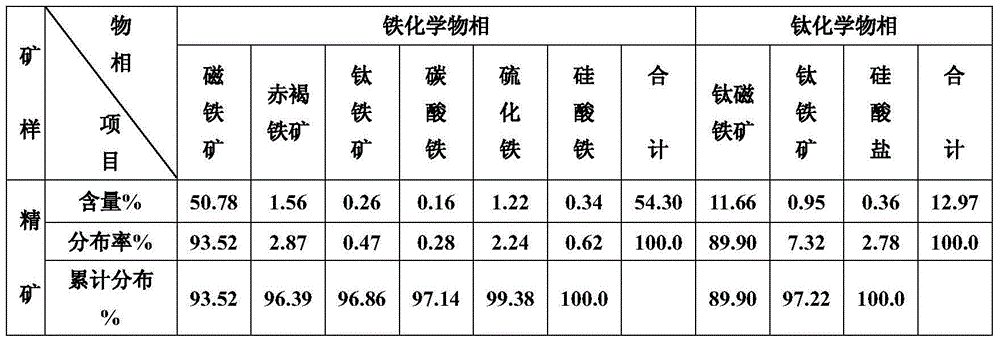

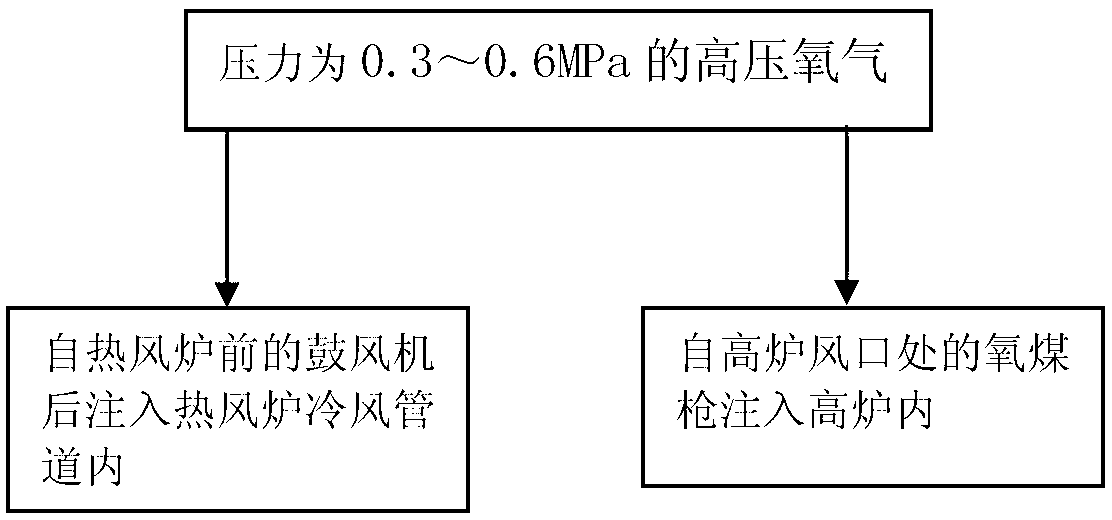

Method for supplying oxygen to blast furnace oxygen-enriched coal spray

InactiveCN103014205AIncrease productionEnsure safetyBlast furnace detailsCold airHigh pressure oxygen

The invention discloses a method for supplying oxygen to blast furnace oxygen-enriched coal spray. The method comprises the following steps of: a) supplying oxygen, namely supplying high-pressure oxygen of which the pressure is between 0.3 MPa to 0.6 MPa; and b) injecting the oxygen, namely dividing the high-pressure oxygen into two parts, injecting one part of the high-pressure oxygen into a cold air pipeline of a hot blast furnace from an air blower in front of the hot blast furnace, and injecting the other part of the high-pressure oxygen into a blast furnace from an oxygen-coal gun at a tuyere of the blast furnace. According to the method for supplying oxygen to the blast furnace oxygen-enriched coal spray, in order to ensure a high coal spray ratio of 200 to 300kg / t, an oxygen enrichment mode of injecting the high-pressure oxygen into the hot blast furnace from the air blower in front of the hot blast furnace and injecting the high-pressure oxygen into the blast furnace from the tuyere of the blast furnace is adopted, so that the coke consumption of the blast furnace is reduced and the iron-making cost is reduced under the condition that an oxygen supply system is safe and stable.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

Apparatus for simulating reaction of coke in blast furnace, and method thereof

ActiveCN106053758AGuaranteed uptimeAccurate measurementPreparing sample for investigationFuel testingEngineeringCantilever

The invention discloses an apparatus for simulating the reaction of coke in a blast furnace. The apparatus comprises a corundum box, a corundum sieve plate and a corundum rod; the corundum box is provided with first sieve pores and is fixed to the bottom of the corundum tube; the upper portion of the corundum tube is provided with second sieve pores, the top of the corundum tube is provided with a corundum cover, and the corundum cover is connected with a stand column through a cantilever; the cantilever is respectively connected with a cantilever elevating mechanism and a cantilever rotating mechanism; the corundum rod traverses through the corundum cover, stretch into the corundum tube, and is connected with the corundum sieve plate in the corundum tube, and a corundum brush is arranged at one side under the corundum sieve plate; and the corundum rod is respectively connected with a corundum rod elevating mechanism and a corundum rod rotating mechanism. The invention also provides a method for simulating the reaction of coke in the blast furnace. The method can really simulate the top-down cracking process of coke in the blast furnace in order to accurately determine the high temperature performances of the coke; and the apparatus can really simulate the reaction of coke in the lower portion of the blast furnace in order to accurate determine the high temperature performances of the coke.

Owner:武汉钢铁有限公司

Method for optimizing poor coal for blast furnace injection

InactiveCN1680607ALess investmentReduce pollutionBlast furnace detailsNational standardMaterials science

An optimizational process of lean coal for blast furnace blowing. Data after optimizational process is as follow. ash content, 9-12%; sulfur content,0.3-0.5%; fixed carbon, 75-87%; net calorific power, 27Mj / kj-30 Mj / kj; volatile fraction, 10-17%; explosiveness, 15mm-40mmh. All of them agree national standards.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV

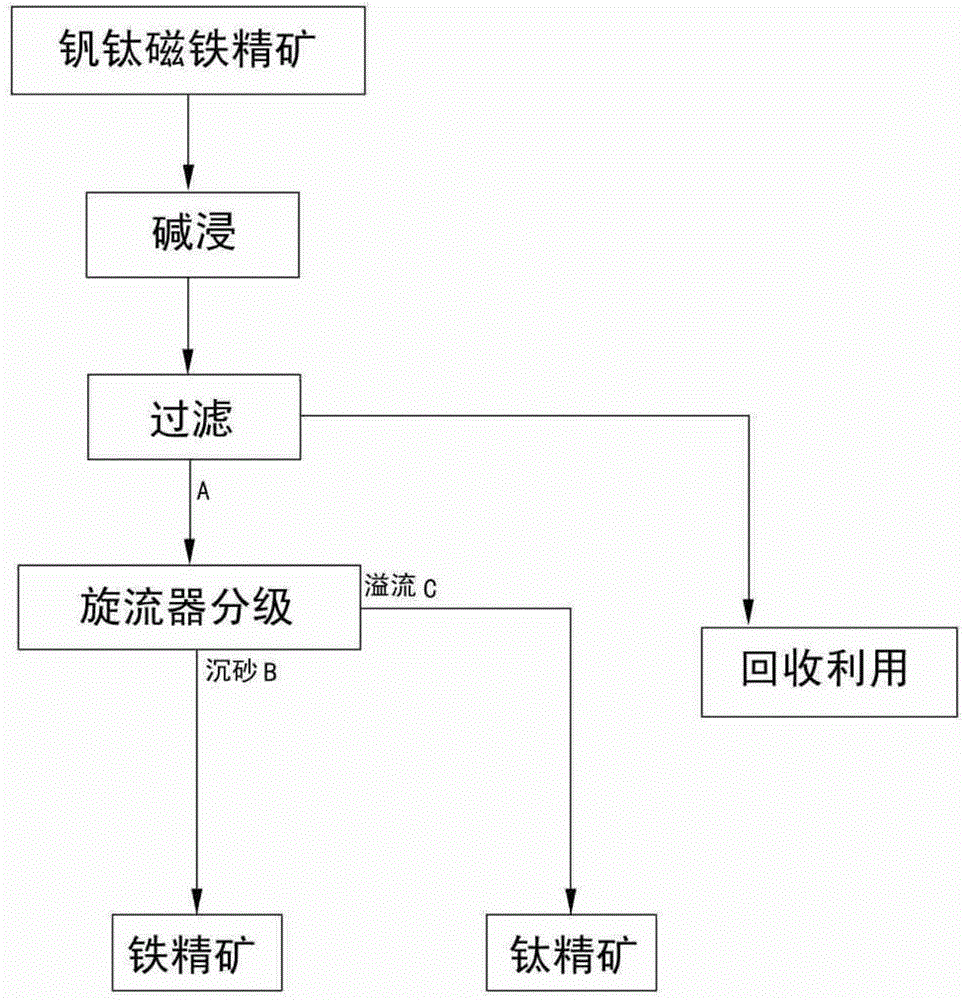

Method for recleaning vanadium titanium magnetite concentrate by using alkaline leaching and desliming

The invention discloses a method for recleaning vanadium titanium magnetite concentrate by using alkaline leaching and desliming. The method comprises the following steps: placing vanadium titanium magnetite concentrate into an alkaline solution with the mass concentration of 5-52%, performing alkaline leaching reaction for 0.5-5 hours at the temperature of 260-370 DEG C, and filtering to obtain a filtrate and an alkaline-leached filter cake A; adding water to the A to prepare A to ore slurry with the mass concentration of 21-15 % for performing desliming operation so as to obtain a sand setting B and an overflow C, wherein the sand setting B is a final iron concentrate with the TFe content of 60-68%, and the overflow C is a final titanium concentrate with the TiO2 content of 40-50%. The method has the advantages that the efficient separating of the vanadium titanium magnetite concentrate is realized; the alkali consumption is low; the contents of impurities such as Al and entering a blast furnace can be reduced, in particular the contents of harmful impurities such as TiO2 and S; the blast furnace utilization coefficient is increased; the blast furnace slag discharge capacity is reduced; the ironmaking cost is reduced; the problems of high S content and serious pollution in the smelting process can be solved; meanwhile, the comprehensive utilization of a titanium resource is improved.

Owner:ANSTEEL GRP MINING CO LTD

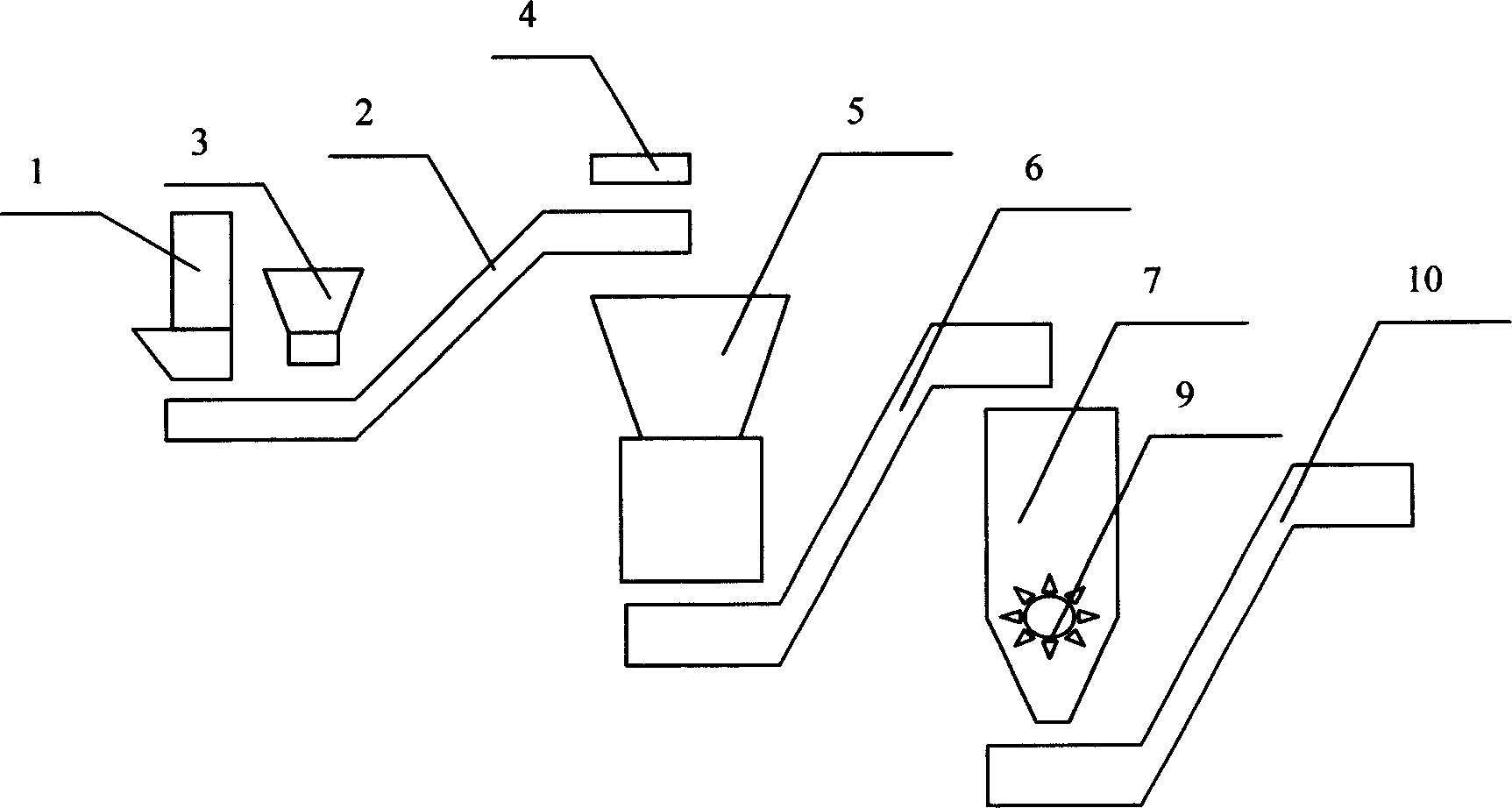

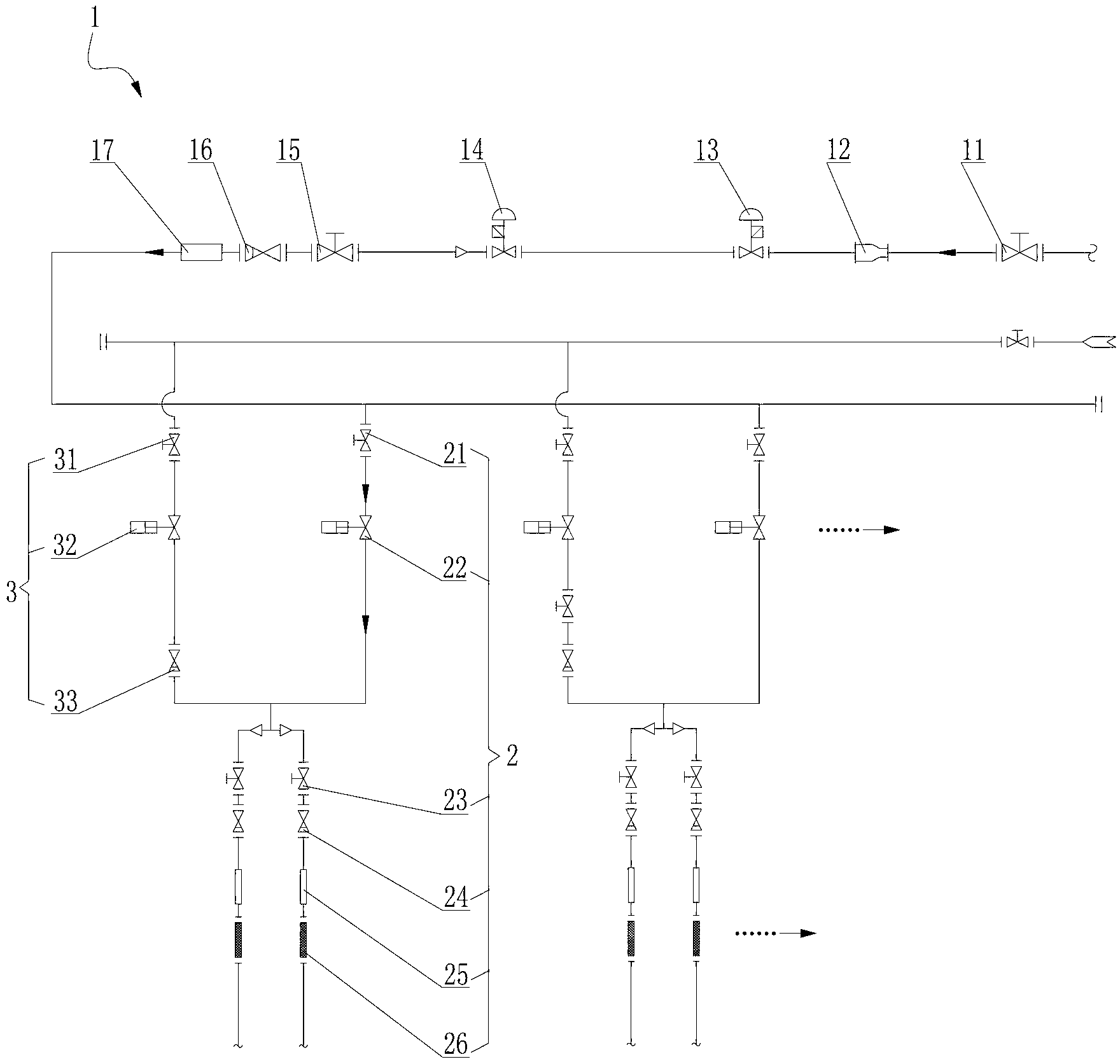

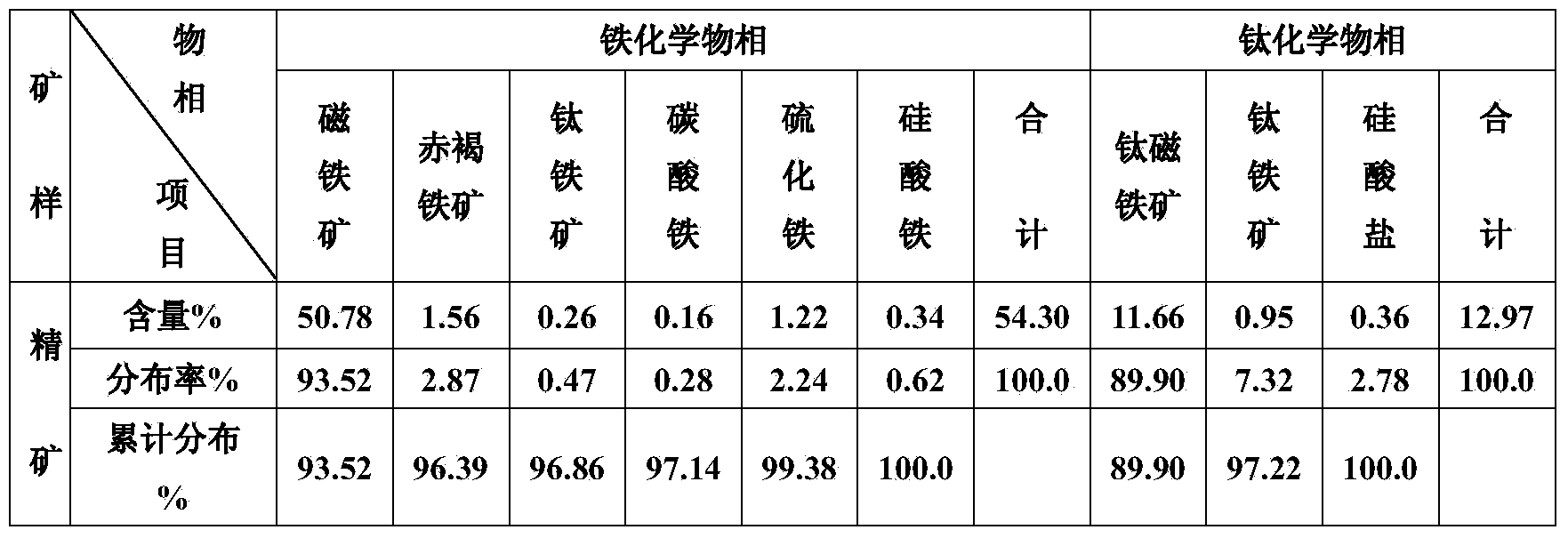

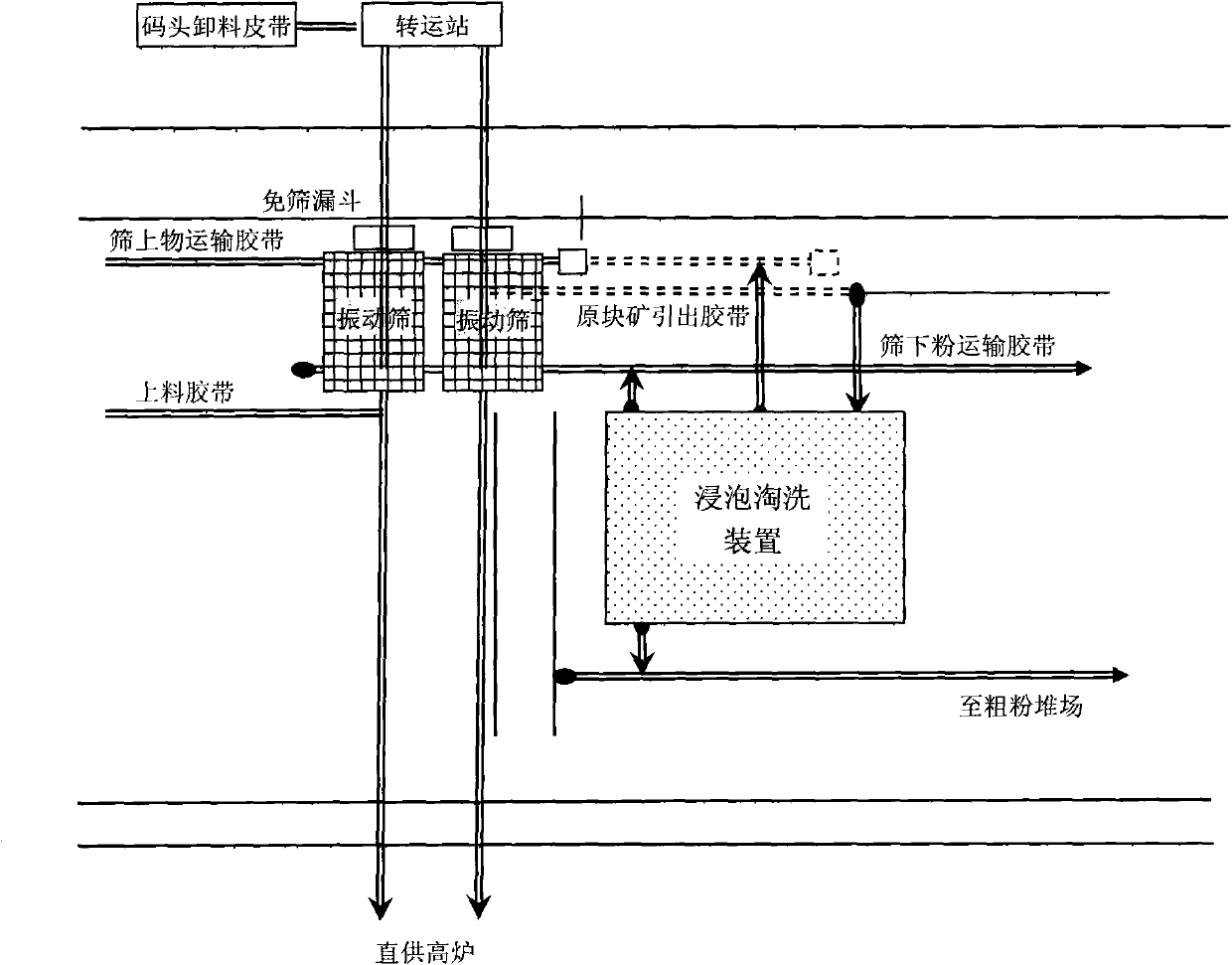

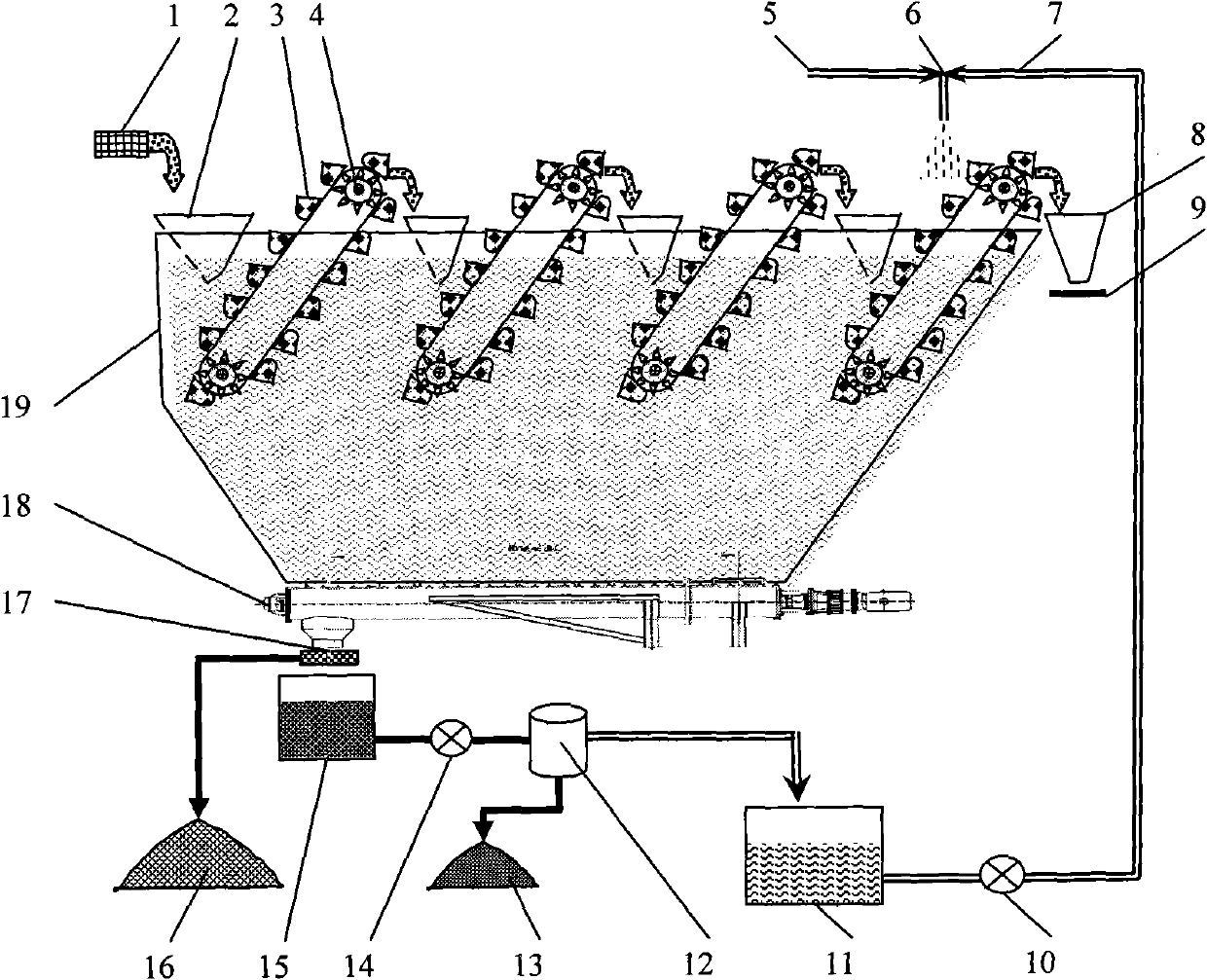

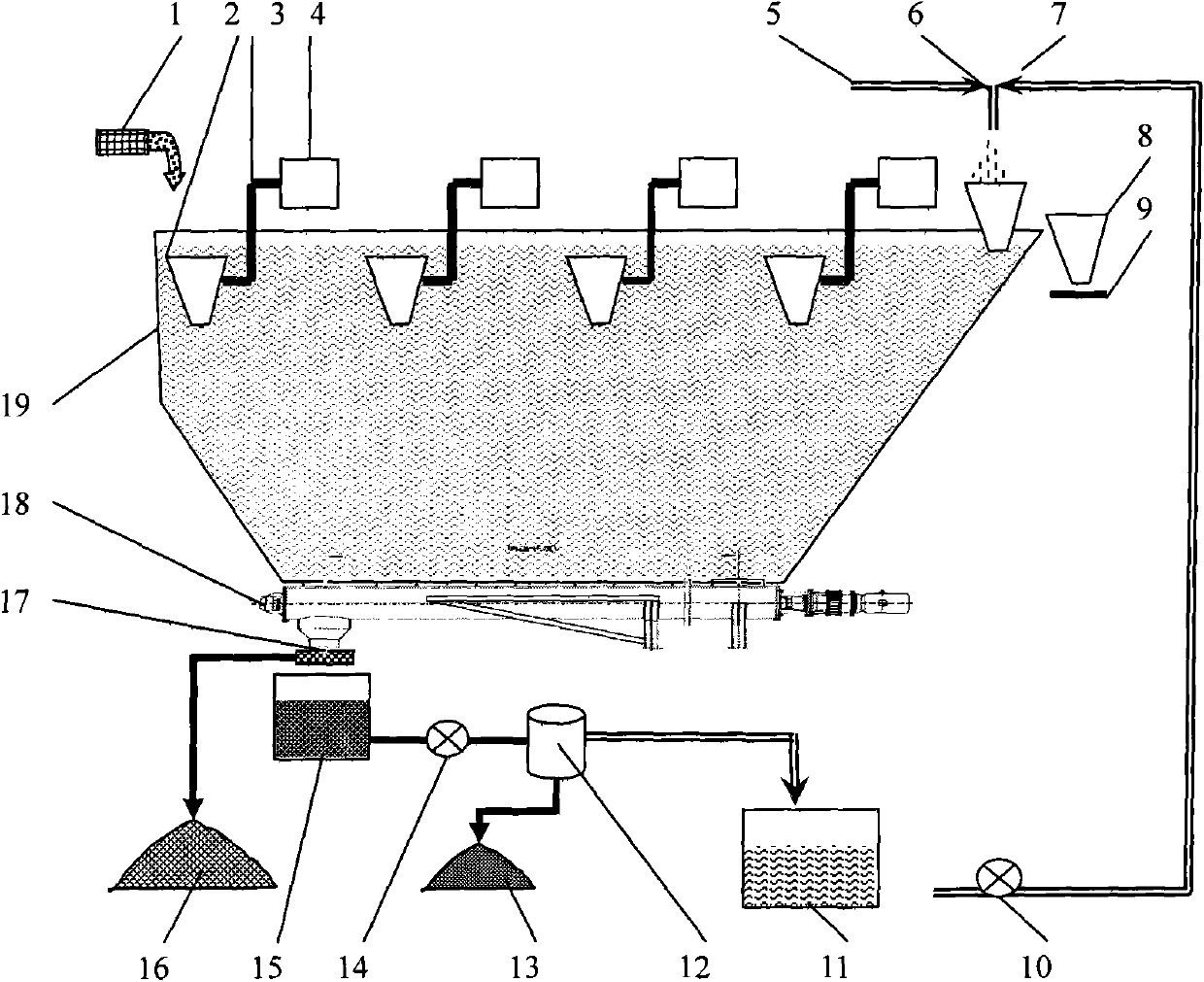

Powder containing lump ore conveying system

ActiveCN101992939AIncrease the proportion of furnaceReduce ironmaking costsCharge manipulationConveyor partsMoistureDelivery system

The invention discloses a powder containing lump ore conveying system, comprising a belt conveying system and a separating device. The invention is characterized in that powder containing lump ore is conveyed to a vibrating screen to be separated when moisture content is less than 4%, oversize product after screening is conveyed to a blast furnace, and screenings is subject to sintering; and powder containing lump ore is conveyed to a soaking and washing device to be separated when moisture content is more than 4. Net powder content of lump ore after being separated by the soaking and washingdevice can be reduced to about 3.5%, and screening efficiency meets the requirement of charging of blast furnace. Thus, even if in rainy season or moisture content of lump ore is high, lump ore whichcan be still used is charged, charging ratio of lump ore is improved, and blast furnace ironmaking cost is reduced.

Owner:MAANSHAN IRON & STEEL CO LTD

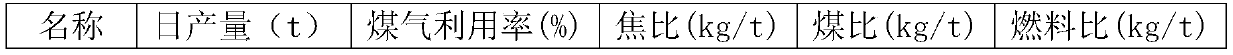

Establishment method for calculation method for influence of harmful elements on blast furnace fuel ratio

ActiveCN108197785AThe calculated value is accurateGood verifiabilityBlast furnace detailsResourcesBlast furnace smeltingZinc

The invention discloses an establishment method for a calculation method for the influence of harmful elements on a blast furnace fuel ratio, belongs to the field of new technology of ironmaking, andsolves the problem that iron ore with a high harmful element content. The method puts forward a concept of the influence of the harmful elements for the blast furnace fuel ratio on the basis of the periodic enrichment behaviors of harmful elements including alkali metal, zinc, lead and the lie. The influence rule of four common harmful elements Na, K, Zn and Pb of blast furnace smelting is determined, and a calculation method of the harmful elements for the blast furnace fuel ratio is established. Since the above technical scheme is adopted, the method can accurately calculate the influence degree of the harmful elements for the blast furnace fuel ratio, and has an important guidance meaning for iron and steel enterprises to evaluate ''economic furnace burden'' value. Meanwhile, for corresponding index revision, the method also can be used for calculating the influence of other harmful elements on the blast furnace fuel ratio.

Owner:UNIV OF SCI & TECH BEIJING

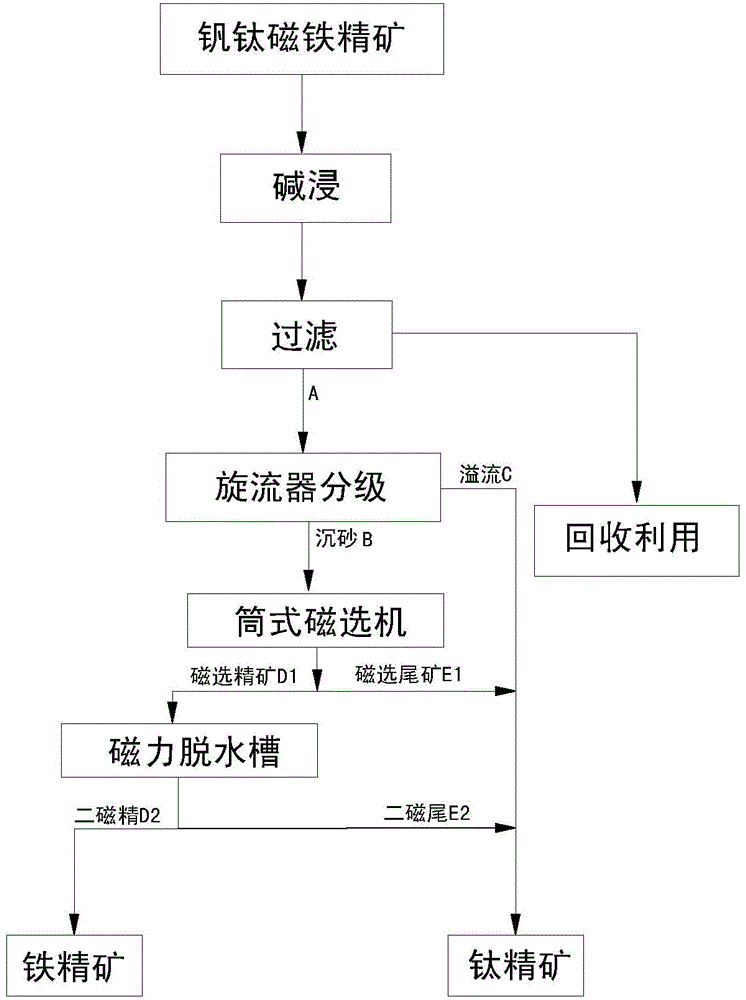

Method for recleaning of vanadium-titanium magnetite concentrate by using alkaline leaching, grading and magnetic separation

ActiveCN103949335AEfficient separationLow S contentMagnetic separationWet separationMagnetiteImpurity

The invention discloses a method for recleaning of a vanadium-titanium magnetite concentrate by using alkaline leaching, grading and magnetic separation. The method comprises the following steps of placing the vanadium-titanium magnetite concentrate into alkali solution with the mass concentration of 5-52%, reacting for 0.5-5 hours in an alkaline leaching mode at 280-370 DEG C, and filtering to obtain filtrate and an alkaline leaching filter cake A; adding water into A to make mine pulp with the mass concentration of 20-25% and feeding into a swirler for grading to obtain overflows and setting sand B; adding water into B to make mine pulp with the mass concentration of 30-36% and performing magnetic separation to obtain final iron ore concentrate with the TFe content range being 63-68% and final titanium concentrate with the TiO2 content range being 35-50%. The method has the advantages that the efficient separation for the vanadium-titanium magnetite concentrate is realized, the alkaline consumption is low, the contents of impurities such as Al and Si, particularly harmful impurities of TiO2 and S, which enter a blast furnace are reduced, the use coefficient of the blast furnace is improved, the discharge of blast furnace slag is reduced, the puddling cost is reduced, and the problems of high S content and severe pollution in the smelting process are solved; the comprehensive use rate of the titanium resources is improved.

Owner:ANSTEEL GRP MINING CO LTD

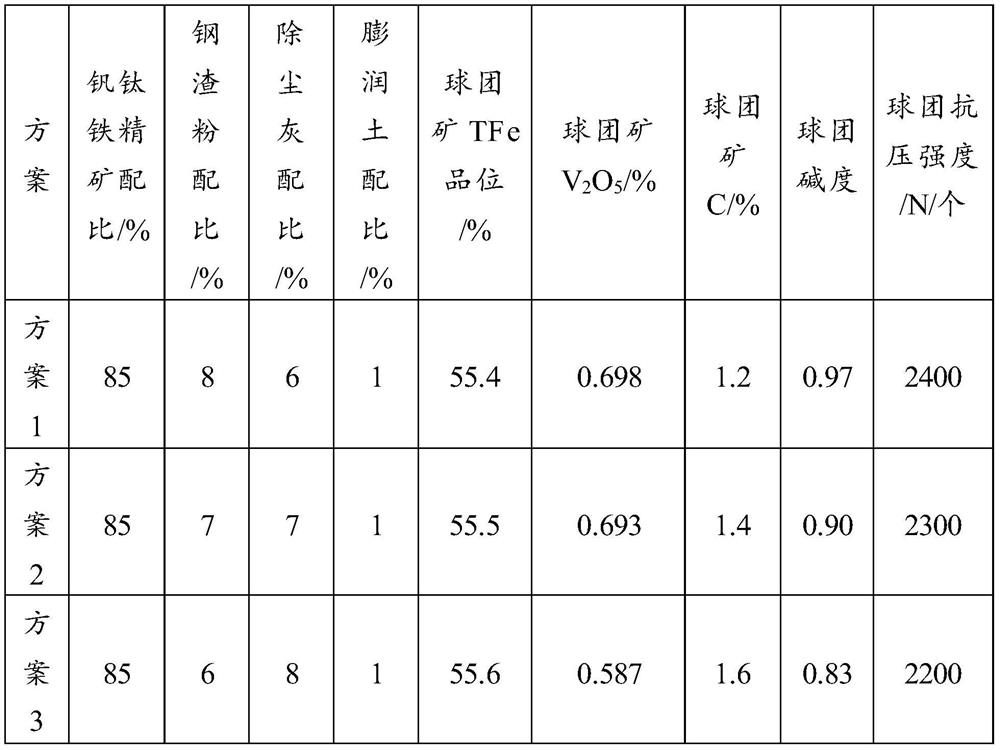

High-grade vanadium-titanium pellet and preparation method of high-grade vanadium-titanium pellet

The invention provides a high-grade vanadium-titanium pellet. The high-grade vanadium-titanium pellet is prepared from a high-grade vanadium-titanium-iron concentrate, steel slag powder, fly ash and bentonite. The invention further provides a preparation method of the high-grade vanadium-titanium pellet. According to the high-grade vanadium-titanium pellet, iron and carbon in iron-making fly ash and iron, CaO and V2O5 in steelmaking steel slag are utilized, reasonable utilization of secondary resources is achieved, a positive effect is achieved on reduction of an iron-making production cost, and actual production results show that the vanadium-titanium pellet contains 57%-60% of TFe, 8%-12% of TiO2 and 0.6%-0.9% of V2O5, and a roasted pellet compressive strength reaches 2,000-2,500 N / pellet.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

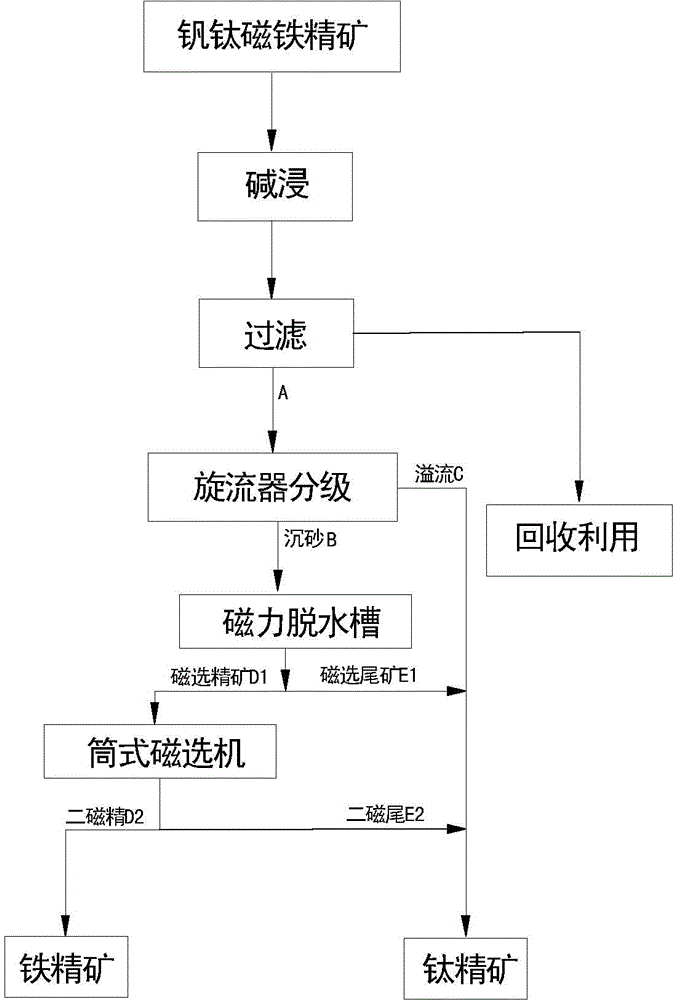

Method for recleaning vanadium-titanium magnetite concentrate by using alkaline leaching and grading

The invention discloses a method for recleaning vanadium-titanium magnetite concentrate by using alkaline leaching and grading. The method comprises the following steps: putting the vanadium-titanium magnetite concentrate in aqueous alkali with the mass concentration of 5-52%, carrying out alkaline leaching reaction at the temperature of 280-370 DEG C for 0.5-5 hours, and filtering so as to obtain filtrate and alkaline leaching filter cakes A; adding water to the alkaline leaching filter cakes A so as to prepare ore pulp with the mass concentration of 20%-25%, feeding the ore pulp into a hydrocyclone, and grading so as to respectively obtain iron ore concentrate with the TFe content of 60-68% and the titanium concentrate with the TiO2 content of 35-50%. The method has the advantages that the high-efficiency grading of the vanadium-titanium magnetite concentrate is realized, the alkali consumption is low, the content of impurities such as Al and Si entering a blast furnace is reduced, especially, the content of detrimental impurities such as TiO2 and S is reduced, the utilization coefficient of the blast furnace is increased, the discharge amount of blast furnace slag is reduced, the iron smelting cost is reduced, the problems of high S content and serious pollution in a smelting process are solved, and meanwhile, the compressive utilization rate of titanium resources is increased.

Owner:ANSTEEL GRP MINING CO LTD

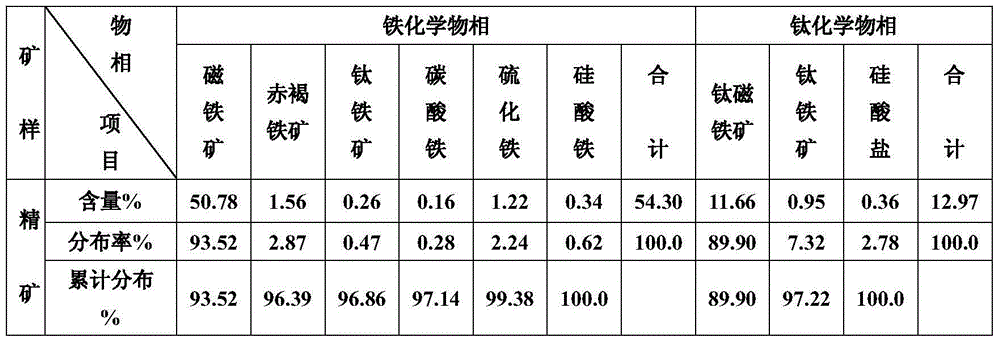

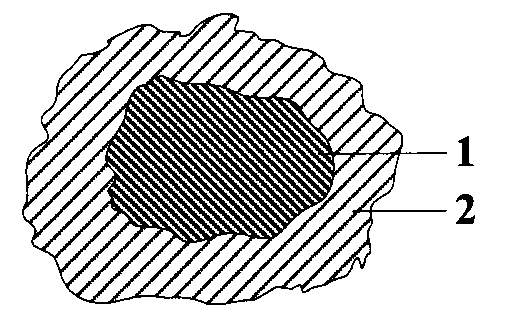

High-reactivity coke and manufacture method thereof

ActiveCN102719264BImprove responseHigh heat intensitySpecial form destructive distillationGranularityUltimate tensile strength

The invention provides high-reactivity coke and a manufacture method thereof, and the coke has an internal and external structure, wherein a core is prepared from blended coking coals and an external layer is prepared from high-volatile coals and blended coking coals through mixing. The method comprises: 1, blending coals; 2, preparing coal cores, comprising weighing 45% - 50% of coking coals, preparing the coal cores through crushing, binder addition, and ball-pressing, and sending into a soft asphalt spray room to spray asphalt to get the coal core; 3, processing external coking coals, comprising weighing 20% -25% of high-volatile coals, drying, crushing, screening and then sending particles with a grain size of less than 3 millimeters into a pre-mixer to evenly mix with 30% - 35% of coking coals; 4, preparing raw materials of finished products, comprising sending the external coking coals into a micro-swing mixing tank, and then putting in the coal cores to bond the external coking coals by mixing; 5, coking to get the finished coke. The high-reactivity cokes and manufacture method thereof are not only suitable for the present coke process to produce a high-reactivity and high-strength metallurgical coke with a low cost, but also can improve the operation of blast furnace production, thereby further reducing the ironmaking cost.

Owner:ANGANG STEEL CO LTD

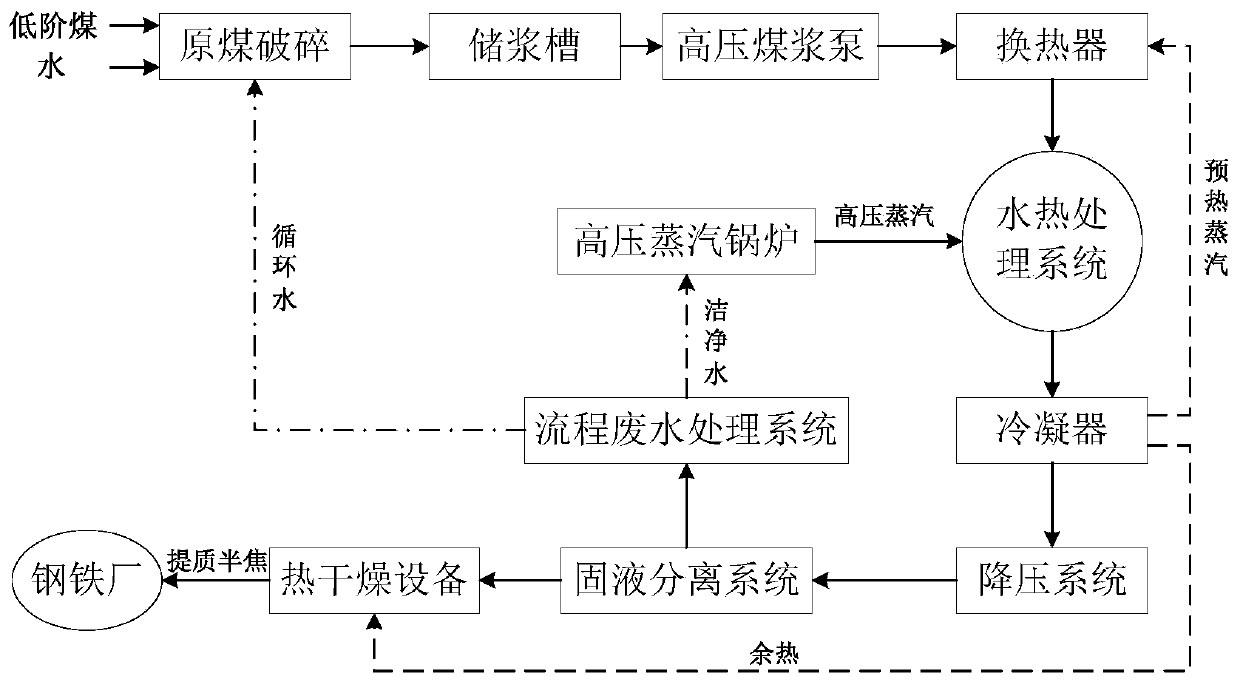

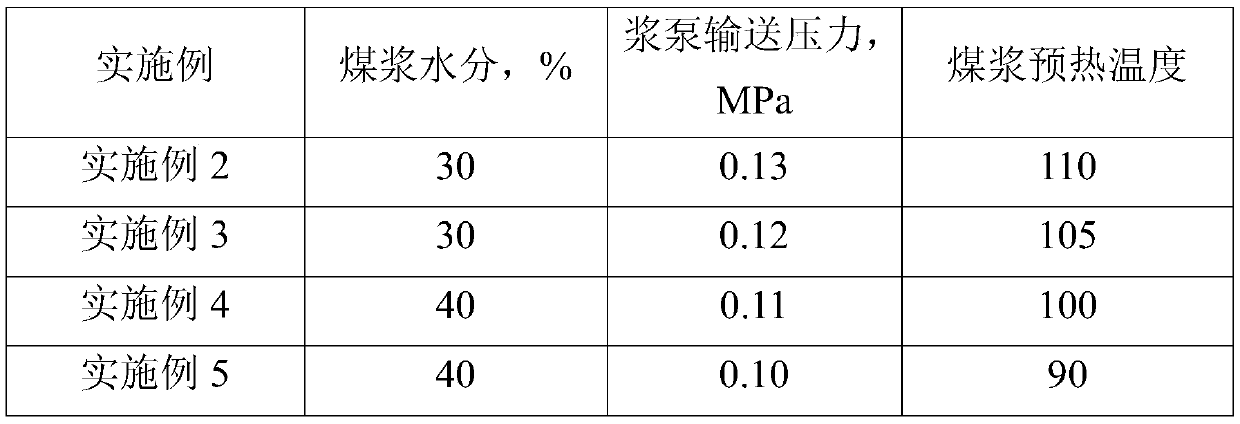

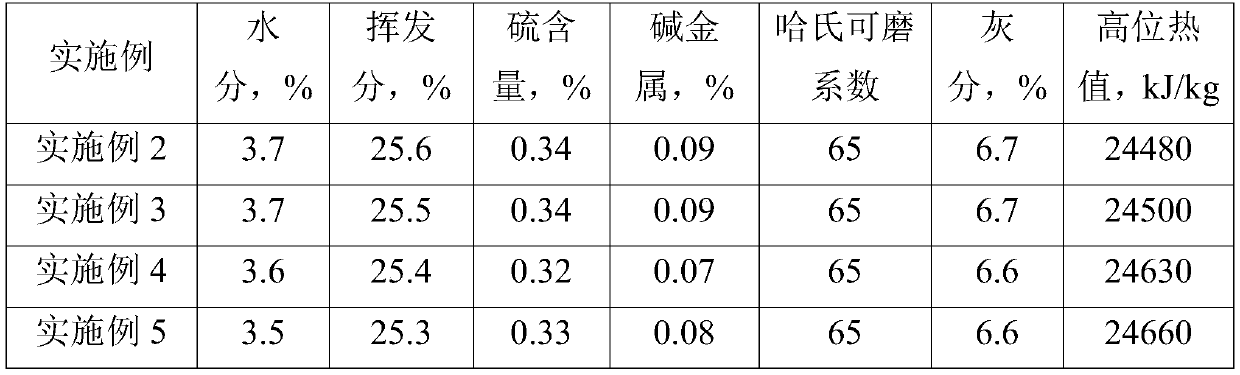

Method for preparing blast furnace blowing semicoke from low-rank coal based on high-pressure hydrothermal reaction

ActiveCN110982542ALow fixed carbon contentHigh fixed carbon contentEnergy inputSpecial form destructive distillationThermodynamicsProcess engineering

The invention relates to a treatment method for dehydrating and upgrading high-moisture and high-volatile low-rank coal, and discloses a method for preparing blast furnace blowing semicoke by upgrading low-rank coal based on a high-pressure hydrothermal reaction, wherein the method comprises four steps of low-rank coal pretreatment, high-pressure hydrothermal upgrading, waste heat recycling and upgraded semicoke dehydration and drying. According to the method, low-heat-value low-rank coal is converted into high-quality blast furnace blowing upgrading semicoke by utilizing a high-pressure hydrothermal reaction upgrading technology, wherein the moisture content of the semicoke air drying base is less than 6%, the volatile component content is less than 25%, the Hardgrove grind ability indexis greater than 60, the high-order heat generation value is greater than 24000 kJ / kg, soluble potassium salt, sodium salt and sulfate components in ash are dissolved out, the organic sulfur in coal iseffectively separated out, and the upgraded semicoke can meet the performance index requirements of coal for blast furnace blowing; and the method provided by the invention effectively solves the problems of high water content, high volatile component content, low heat value and high harmful element content of blast furnace blowing of low-rank coal, and provides a clean, efficient, low-energy-consumption and high-added-value low-rank coal upgrading utilization method.

Owner:UNIV OF SCI & TECH BEIJING

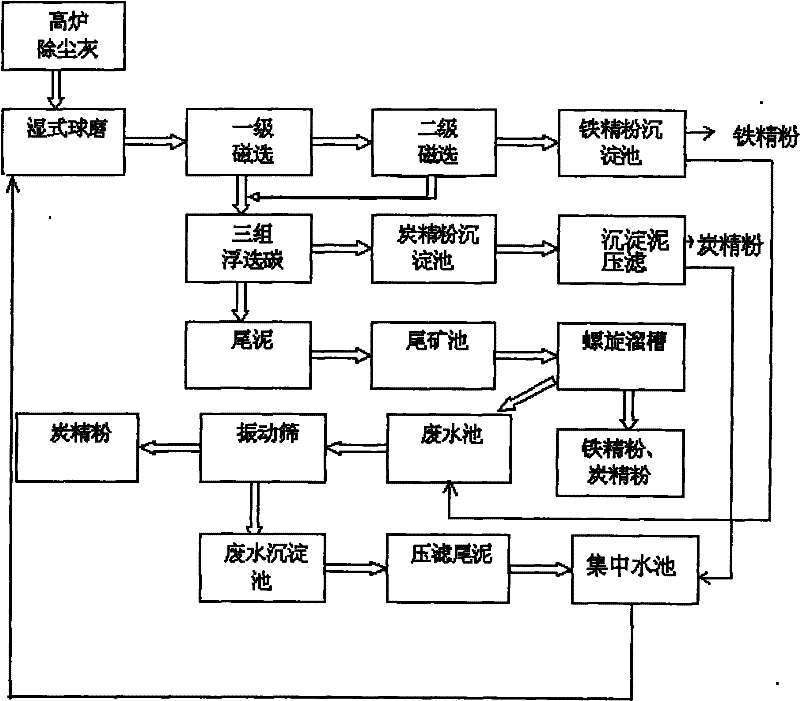

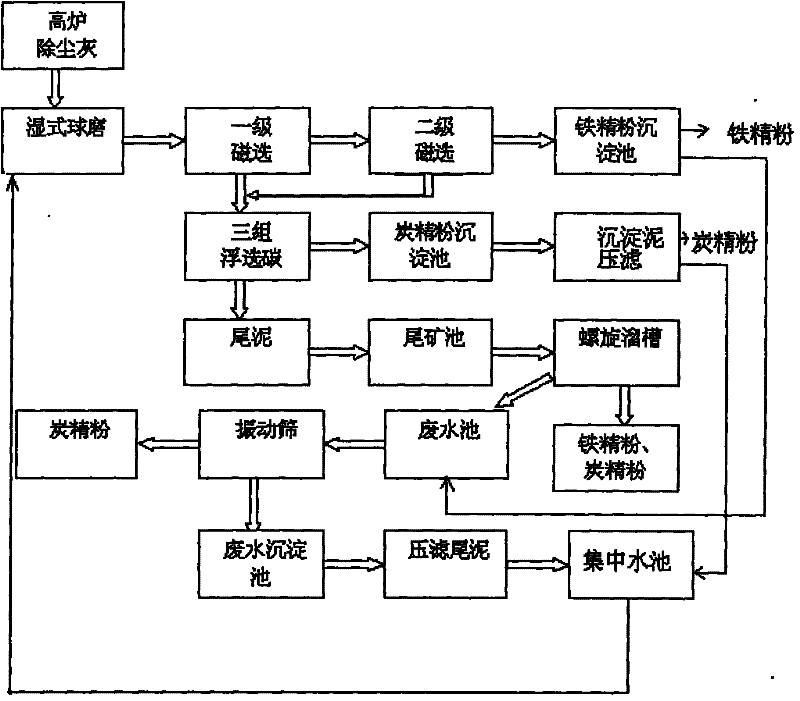

Comprehensive treatment method of blast furnace dedusting ash

InactiveCN101654717BReduce dosageLow costRecycling and recovery technologiesProcess efficiency improvementWaste treatmentPollution

The invention discloses a comprehensive treatment method of blast furnace dedusting ash, belonging to the technical field of the waste treatment. The method comprises the following steps: adding water in blast furnace dedusting ash for mixing, performing secondary magnetic separation, performing flotation, in the tailings treatment using a spiral chute to separate iron refined powder and carbon refined powder, screening to recycle the carbon refined powder in the wastewater which is obtained in the step of spiral chute ion-removing and performing filter pressing to the obtained wastewater forrecycling. The method can greatly increase the selection yield and grade of the iron refined powder and carbon refined powder, can also avoid to produce new pollution, protect the environment and recycle waste material.

Owner:山东泰山焦化有限公司

Using method of coke with different initial reaction temperatures in blast furnace

ActiveCN109706277AEasy to useImprove economic indicatorsBlast furnace detailsReaction temperatureEngineering

The invention discloses a using method of a coke with different initial reaction temperatures in a blast furnace.The using method comprises the following steps that 1, a coke initial reaction temperature is detected and obtained; 2, a production coke is divided into a first type of the coke and a second type of the coke; 3, material arrangement system of the blast furnace is remained unchanged, acoke material arrangement corner is divided into three parts: a center part, a middle part, and a edge part; and the second type of the coke is arranged in the middle part, and a mixing coke from thefirst type of the coke and the second type of the coke is arranged in the center part and the edge part; 4, using amount percentage by weight of the fist type of the coke in the mixing coke in the center part and the edge part is determined according to blast furnace capacity; 5, normal material arrangement is conducted; 6, when the blast furnace does not work well, using amount of the first typeof the coke in the center part and the edge part is adjusted; and 7, material arrangement is continued according to the adjusted scheme. The using method effectively solves the using problem of the coke with different initial reaction temperatures in the blast furnace, and provides reference for the application of the cokeinitial reaction temperature index in the blast furnace.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com