System and method for carrying out blast furnace ironmaking by using small-particle-size bituminous coals

A blast furnace ironmaking and small particle size technology, applied in the field of coal chemical industry, can solve the problems of low utilization rate of ironmaking heat, large amount of pulverized coal, shortage of pulverized coal resources, etc., so as to fully utilize energy, reduce ironmaking costs, alleviate the The effect of scarce resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

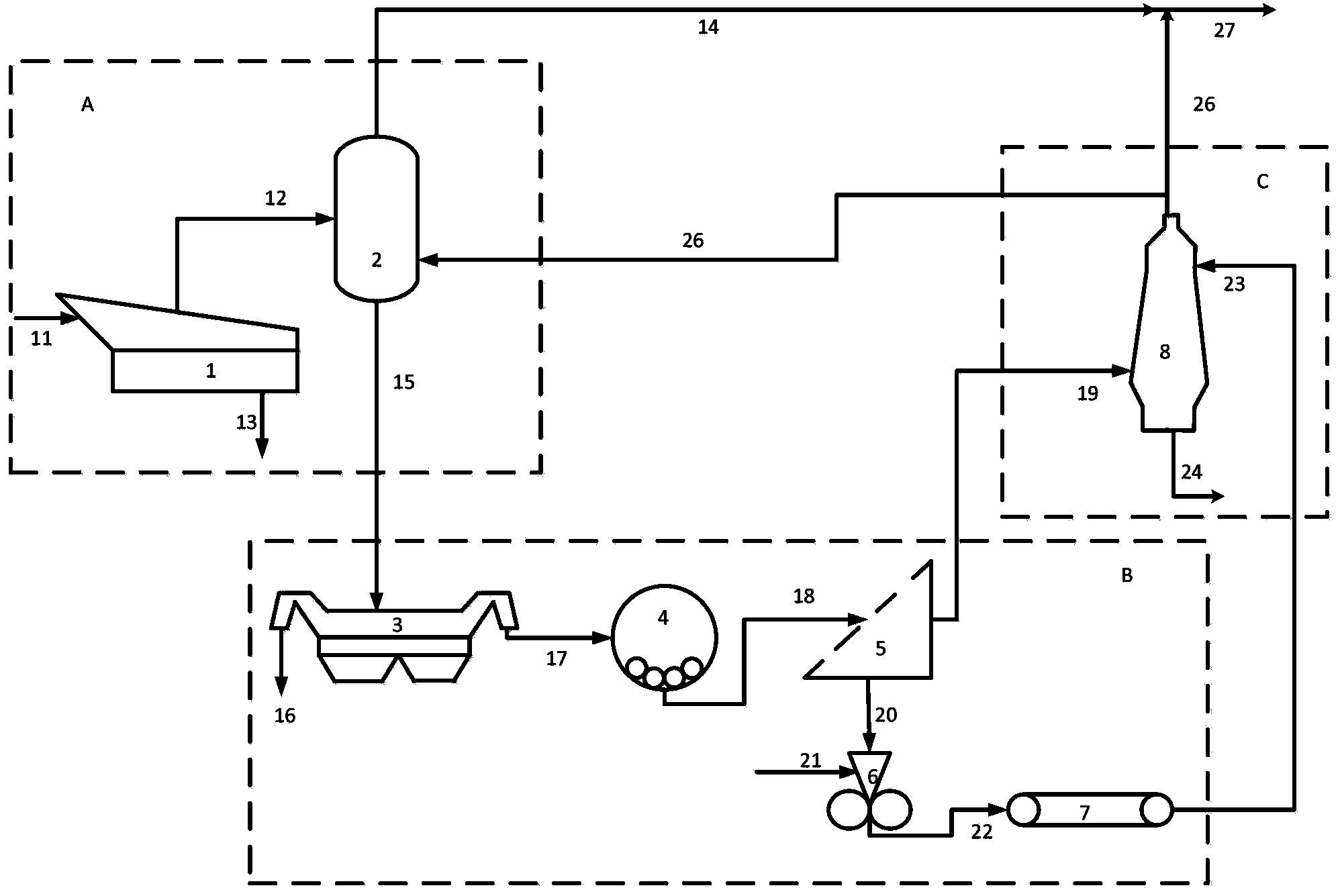

[0040] The pulverized coal of 0-6mm is sent to the compound dry separator for separation, and impurities such as ash in the coal are removed to obtain clean coal. Put the clean coal into the pyrolysis furnace, use the high-temperature flue gas from the blast furnace as the heat source, and control the temperature at 500-800°C to pyrolyze the clean coal in the pyrolysis furnace to obtain pyrolysis gas and pyrolysis Half focus. The calorific value of blast furnace flue gas is low, only 3500KJ / m 3 , not suitable for direct use as civil gas, and pyrolysis gas has a high calorific value, generally 16000-17000KJ / m 3, mix it with blast furnace flue gas in proportion, after further processing, the purified gas can be obtained, which can be used as civil gas or raw material gas for downstream chemical synthesis. The semi-coke discharged from the pyrolysis furnace is sent to the air-dense medium dry separator for sorting, and the ash is removed to obtain high-quality low-ash semi-coke...

Embodiment 2

[0042] The 6-20mm granular coal is sent to the compound dry separator for separation, and the ash and other impurities in the coal are removed to obtain clean coal. Put the clean coal into the pyrolysis furnace, use the high-temperature flue gas from the blast furnace, and control the temperature at 500-800°C to pyrolyze the clean coal in the pyrolysis furnace, which not only makes full use of the blast furnace flue gas In addition, carbon monoxide (about 25%), carbon dioxide (about 15%), hydrogen and other components in the blast furnace flue gas will also produce hydrogen-rich and oil-increasing effects on coal pyrolysis, which will significantly increase the yield of tar. The pyrolysis crude oil gas discharged from the pyrolysis furnace is processed to remove the dust to obtain tar and pyrolysis gas. The pyrolysis gas is purified and sent downstream for chemical synthesis, etc., and the tar can be used to extract phenols after further treatment. Classes, aromatics, etc., ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com